Patents

Literature

132results about How to "No need to remove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass fiber reinforcement wheat straw or rice straw composite material and preparation method thereof

The invention relates to a glass fiber reinforcement wheat straw or rice straw composite material and a preparation method thereof. The composite material comprises wheat straws or rice straws, glass fiber, polymer and additives, wherein the mass content of components except for the additives is 90%-100%, and the mass content of the additives is 0%-10%; the mass ratio of the wheat straws or rice straws to the glass fiber to the polymer except for the additives is 100:(10-40):(50-140). The glass fiber for reinforcement is chopped glass fiber strands with the length of 1cm-3cm. The glass fiber is directly or soaked, or treated directly or soaked and then subjected to surface coating so as to be used; the materials are directly mixed in the using process, and the mixing capability of materials can be reinforced by means of a solution or emulsion. The glass fiber is not subjected to strong shearing before hot pressing, thus keeping a good shape. The composite material prepared by adopting the method is high in strength, smooth in the surface, and uniform in performance; the preparation method is simple and efficient and strong in environment-friendliness.

Owner:JIUJIANG UNIVERSITY

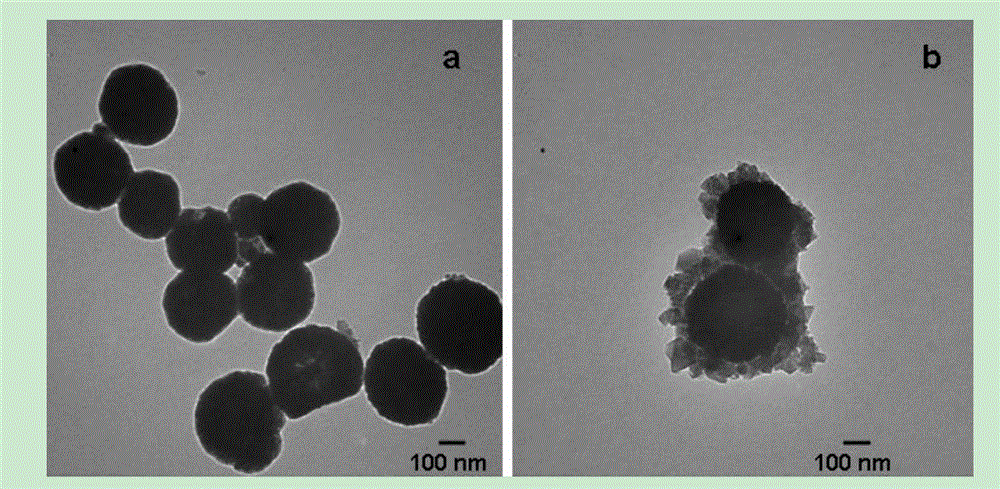

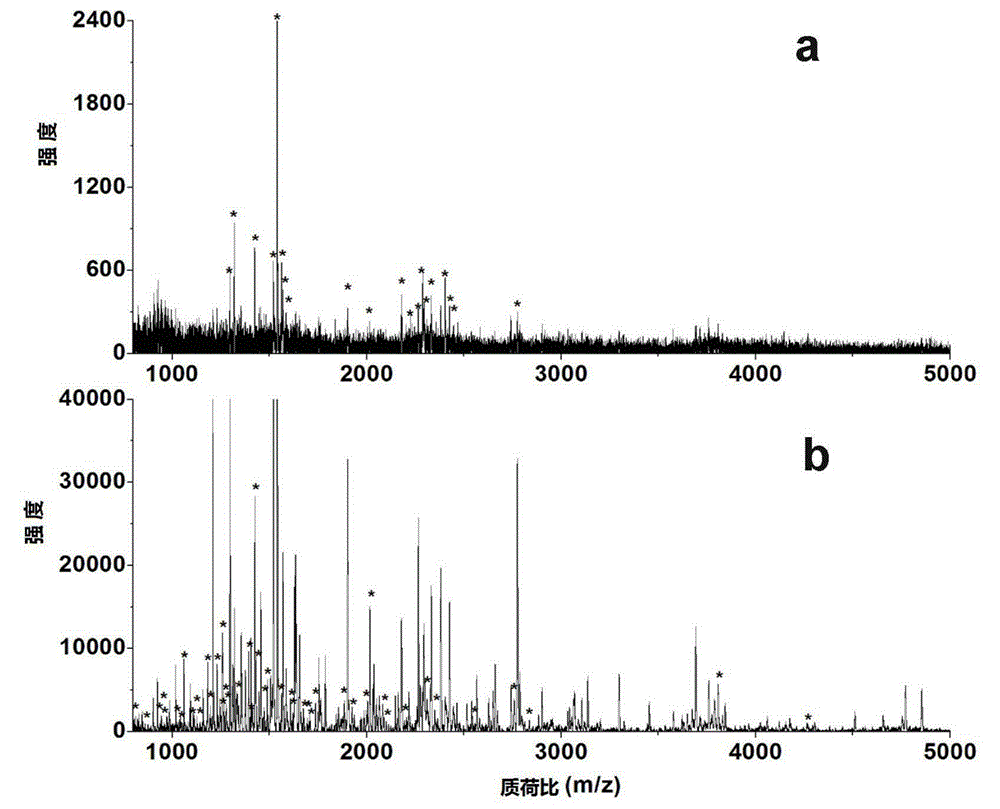

Preparation method and application of magnetic MIL-100 composite material

InactiveCN105203380ANo need to removeAvoid cumbersomePreparing sample for investigationAnalysis by material excitationCarbon layerSynthesis methods

The invention provides a preparation method and application of a magnetic MIL-100 composite material. The magnetic MIL-100 composite material is Fe3O4 / C@MIL-100, wherein the MIL-100 is a metal-organic framework material constructed by iron and trimesic acid. A synthesis method comprises the following steps: firstly, preparing a carbon layer clad magnetic microsphere and preparing the Fe3O4 / C@MIL-100 composite material. The prepared magnetic MIL-100 composite material is used for finding and detecting a blood serum biomarker. The preparation method and the application, provided by the invention, have the advantages that a carbon layer is ingeniously and uniformly clad on the surface of a high-quality Fe3O4 microsphere by the preparation method, and the Fe3O4 / C@MIL-100 composite material is prepared in situ by a one-pot method; the composite material has a magnetic separation property of magnetic nano particles and a size exclusion effect of MIL-101; and high-abundant protein does not need to be removed, and the composite material can be rapidly and efficiently suitable for finding and detecting the blood serum biomarker.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing polyether polyol by continuous process

The invention relates to a method for preparing unsaturated polyether polyols by utilizing a continuous method and a polymetallic cyanide complex as a ring opening polymerization catalyst of oxyalkylene. The method mainly resolves the problems exiting in prior art that the catalyst is only a bi-metallic catalyst and needs pre-activation, and the process is complicated and the conversion rate of monomer is relatively low. In the invention, the technical proposal which better resolves the problems is as follows: the polymetallic cyanide complex catalyst, an initiator and the oxyalkylene are continuously added in a reactor for preparing the unsaturated polyether polyols, and the polyether polyols obtained are continuously taken out of the reactor. The method is applied to the industrial preparation of polyether polyols by the continuous method.

Owner:CHINA PETROCHEMICAL CORP

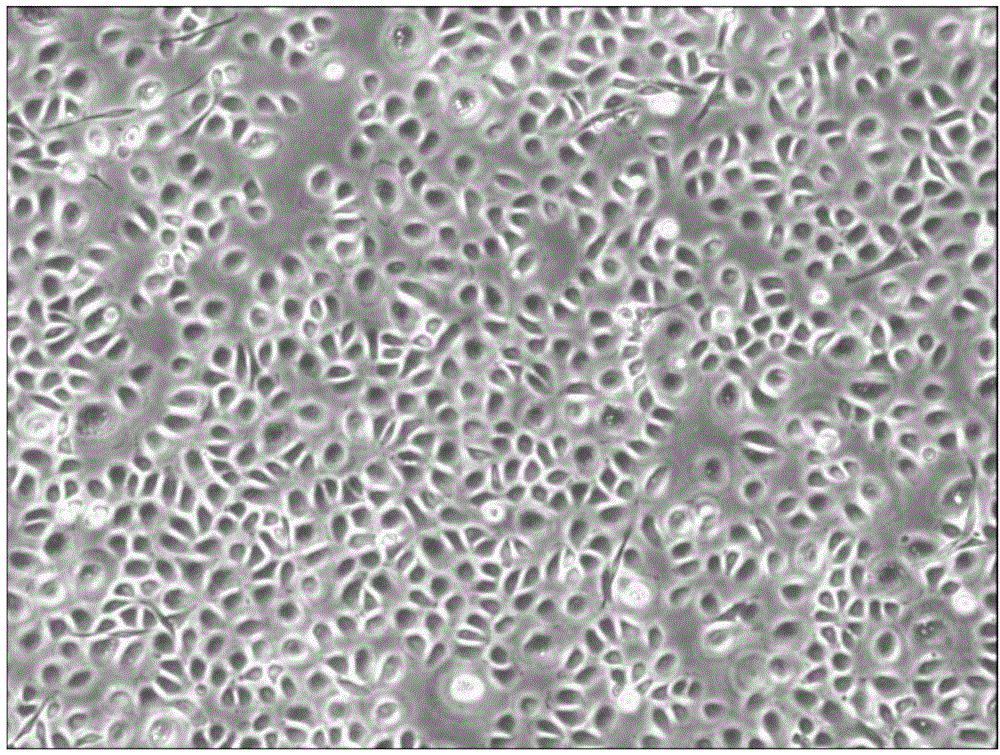

Novel method for in-vitro separated culture of human epidermal cells

ActiveCN104087551ANo need to removeTrained forVertebrate cellsArtificial cell constructsIn vitro digestionCuticle

The invention provides a novel method for the in-vitro separated culture of human epidermal cells. The method comprises the steps: taking normal human skin tissue containing epidermis and dermis, and carrying out in-vitro digestion and separation, so as to obtain the human epidermal cells; and then, carrying out in-vitro amplified culture on the epidermal cells. According to the method provided by the invention, fat is not required to be removed, and the epidermis and the dermis are not required to be separated; skin tissue taken by the method provided by the invention is all normal human skin tissue, including scalps with hair, tissue with fat and the like; the method is simple, convenient and fast, is not restricted to time and is applicable to the direct separation of different skin tissue, such as the scalps with hair and the tissue with fat; and an epidermal cell bank with relatively high activity can be established, so that the requirements on clinical transplantation are facilitated.

Owner:JINAN PANSHENG BIOTECH

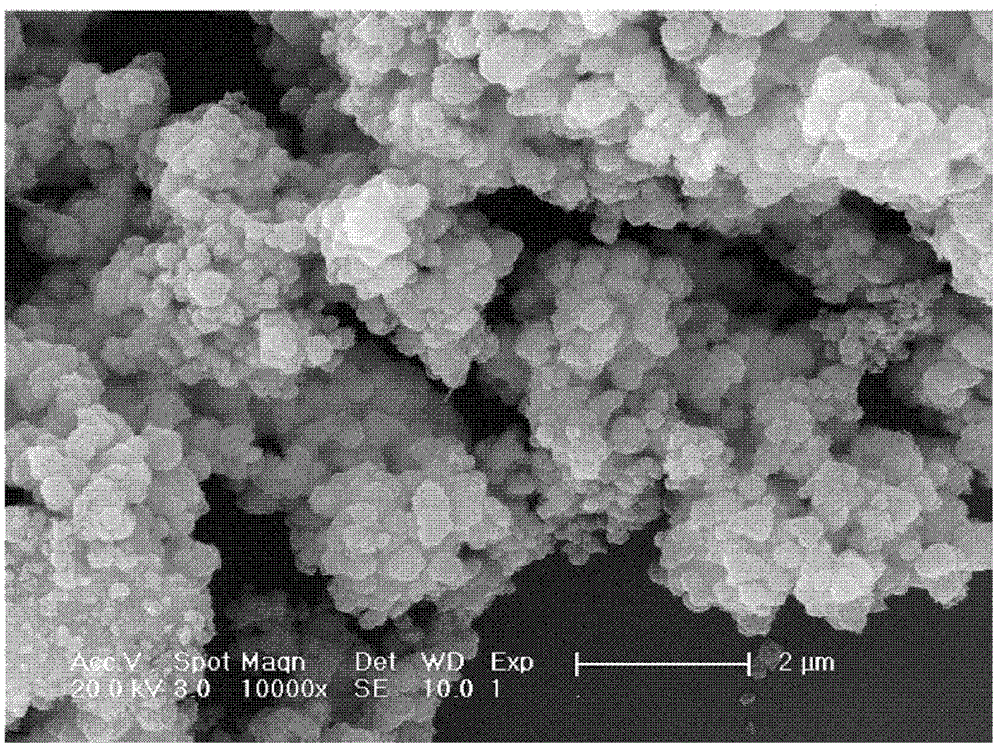

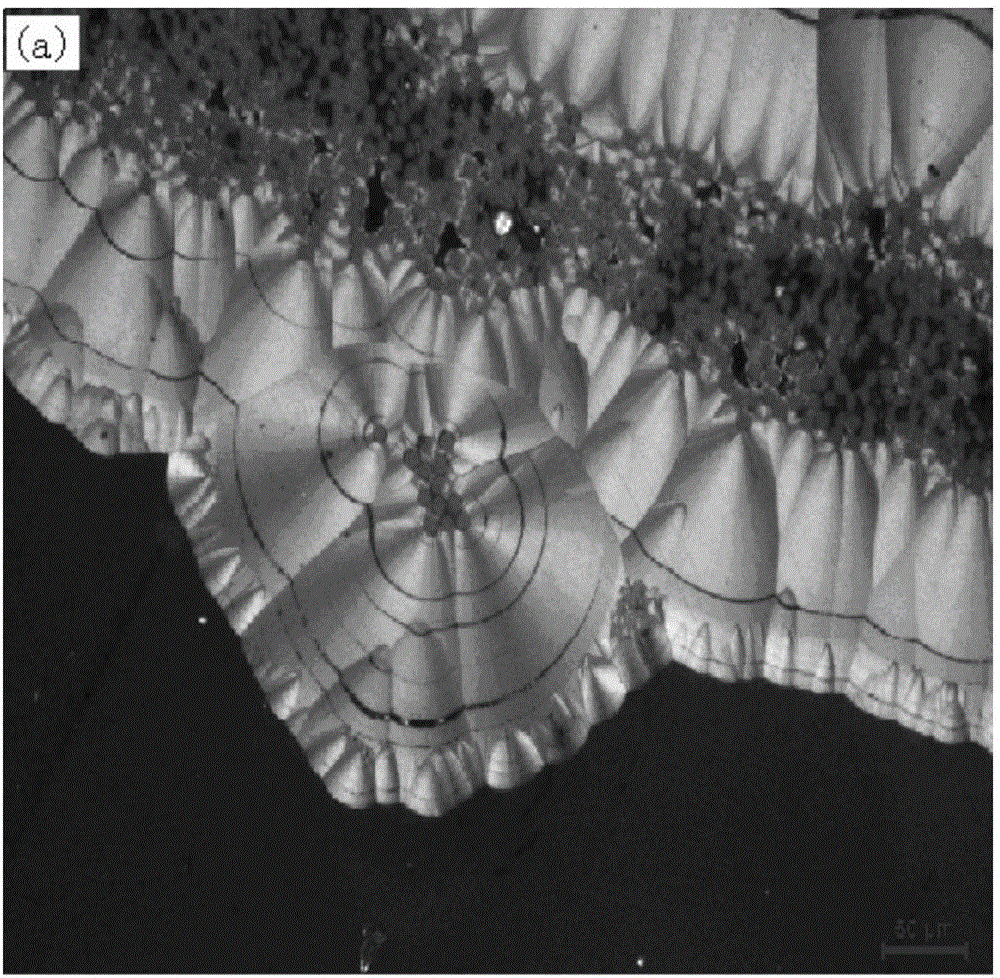

Mesoporous manganese dioxide material, preparation method thereof and supercapacitor

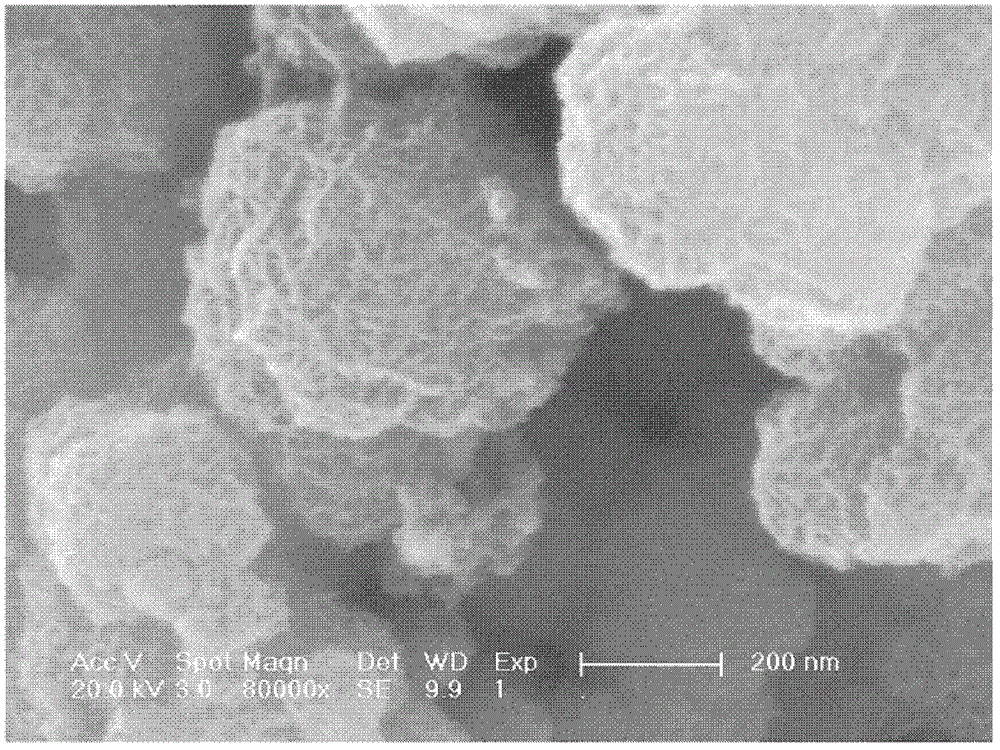

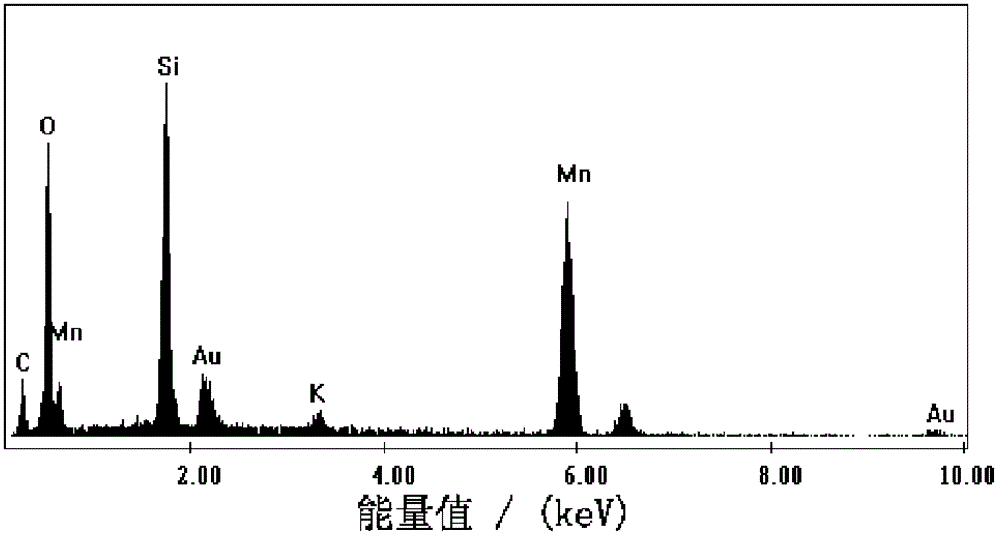

InactiveCN102795671AHigh BET specific surface areaExcellent electrochemical performanceElectrolytic capacitorsManganese oxides/hydroxidesPotassium permanganateAscorbic acid

The invention provides a mesoporous manganese dioxide material. Particle of the mesoporous manganese dioxide material is spherical-like, the surface of the particle is provided with mesopores and diamond-shaped bumps, the aperture of each mesopore is 5 to 30nm, and the specific surface area of the particle is 120 to 160 m<2> / g. The invention also provides a method for preparing the mesoporous manganese dioxide material. The method comprises the following steps of mixing a potassium permanganate solution and an ascorbic acid solution; and reacting to obtain the mesoporous manganese dioxide material under agitation, wherein the molar ratio of potassium permanganate to ascorbic acid is 10:(1-8). Besides, the invention provides a supercapacitor. The mesoporous manganese dioxide material has surface appearance similar to that of a walnut, the specific surface area, which is calculated by a brunauer-emmett-teller (BET) method, of the mesoporous manganese dioxide material is relatively large, and the supercapacitor has high electrochemical performance, particularly has relatively high unit specific surface area specific capacitance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

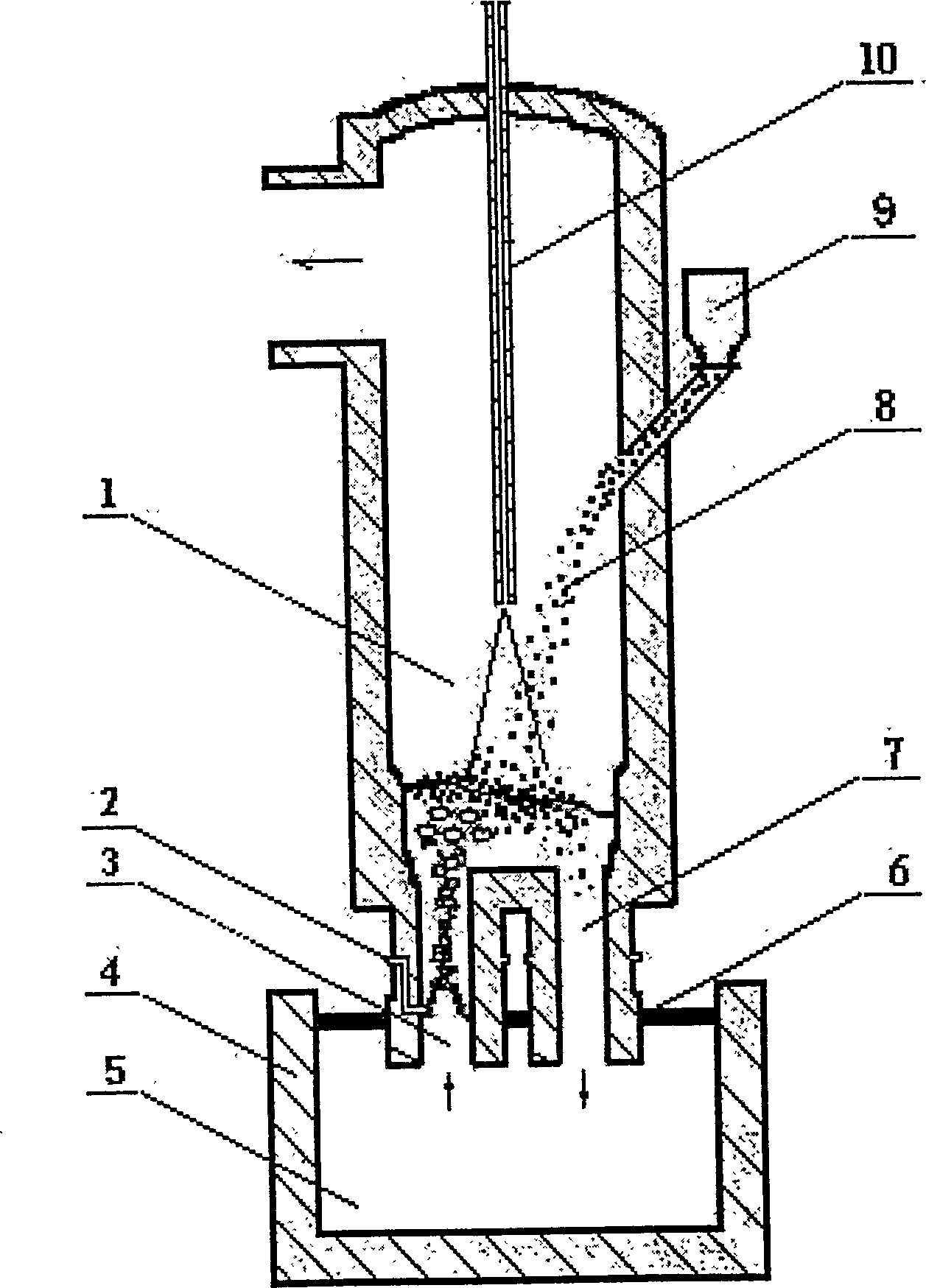

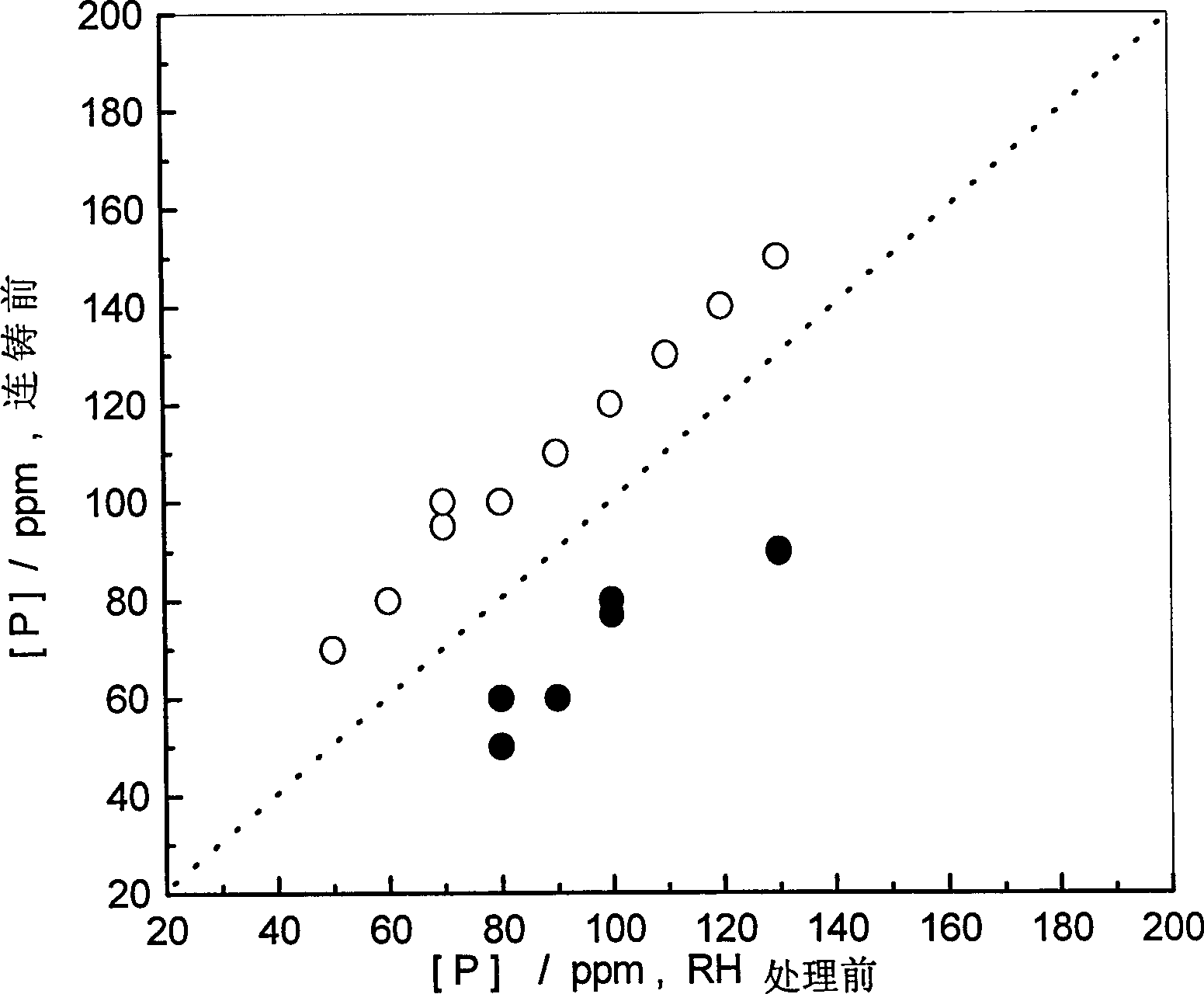

Vacuum treatment method of molten steel dephosphorus

A vacuum treatment method for dephosphorizing molten steel to produce low-phosphorus (or ultralow-phosphorus) weakly-deoxidized steel or other steel features that in the vacuum carbon-oxygen reactionphase, the oxygen or iron oxide needed by dephosphorizing reaction is added to the molten steel pool in a vacuum chamber while the lime blocks or powder is added for quickly dephosphorizing, and thismethod can also prevent rephosphorization from the steel ladle slag.

Owner:武钢集团有限公司

Micro-nano lignocellulose, preparation method and applications thereof

ActiveCN110055796ASolve processingSolve concentrationCellulose pulp after-treatment modificationMicro nanoCellulose

The invention provides micro-nano lignocellulose, a preparation method and applications thereof. The micro-nano lignocelluloses contain lignin structures; lignin is bonded with cellulose through hydrogen bonds and chemical bonds. The preparation method comprises following steps: a lignin containing cellulose raw material is dispersed in a hot urea aqueous solution so as to obtain a cellulose raw material dispersion liquid; mechanical pre-treatment is adopted for peeling and grinding so as to obtain a pre-treatment product; and the pre-treatment product is subjected to high pressure homogenizing using a high pressure homogenizer so as to obtain a micro-nano lignocelluloses dispersion liquid. According to the preparation method, removing of the lignin in the lignin containing cellulose raw material is not needed, the hot urea aqueous solution is combined with mechanical pre-treatment and high pressure homogenizing so as to prepare the product; the diameter of the obtained micro-nano lignocelluloses ranges from 5 to 180nm; the length / diameter ratio is 200 or larger; the lignin content ranges from 10 to 35wt%; micro-nano cellulose performance is improved; and the application prospect is promising.

Owner:山东省圣泉生物质石墨烯研究院

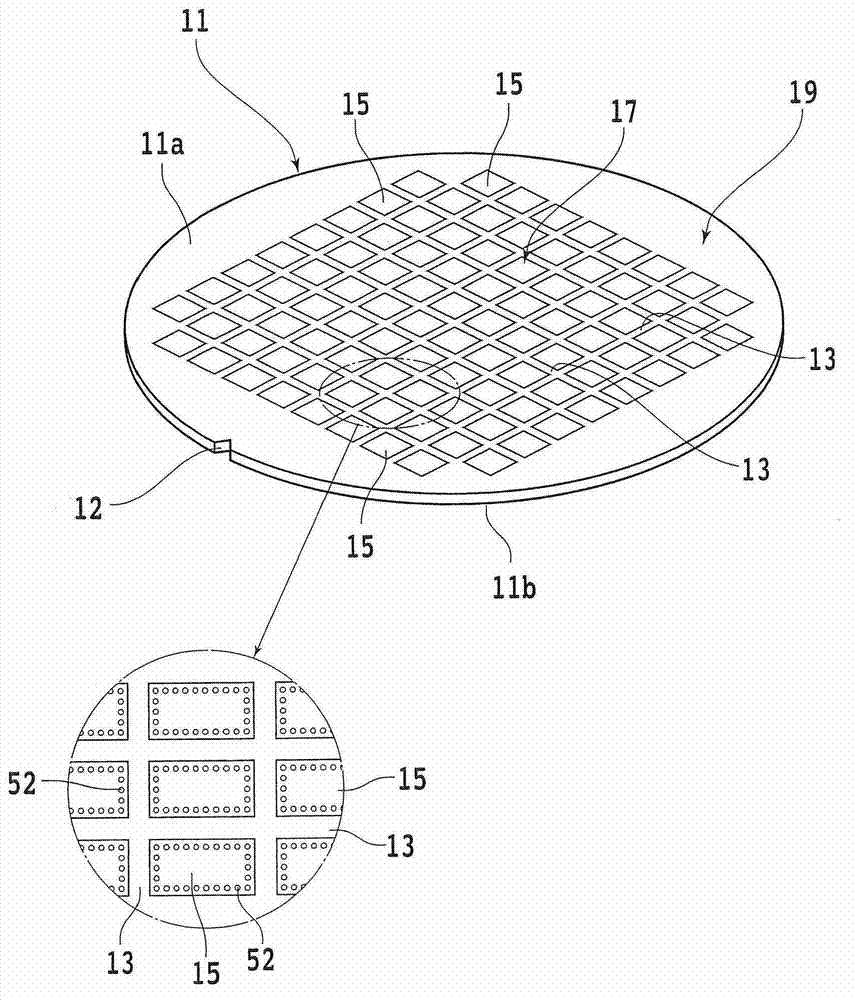

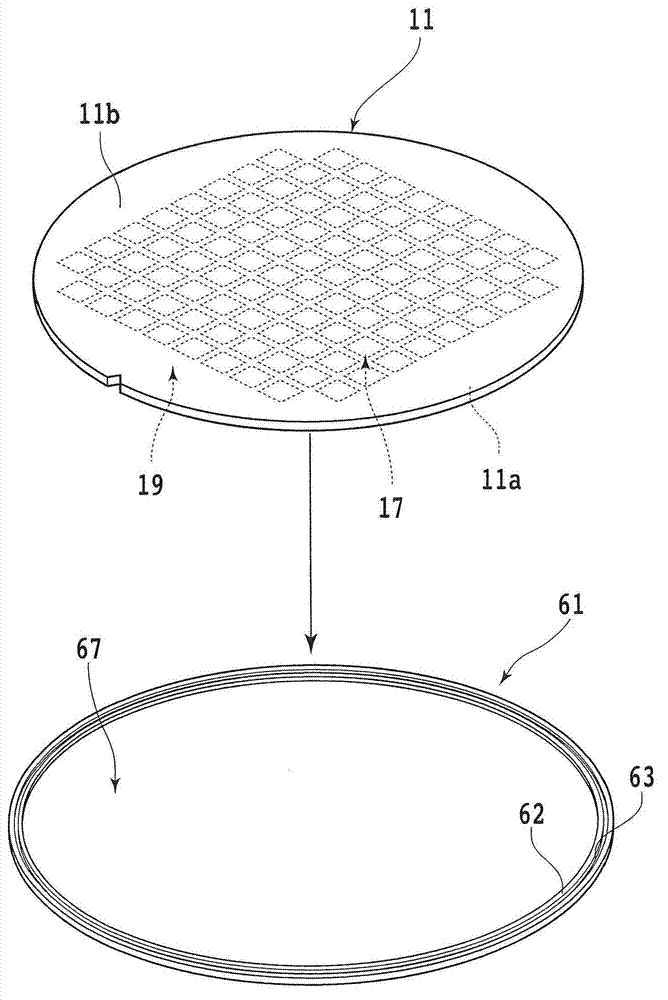

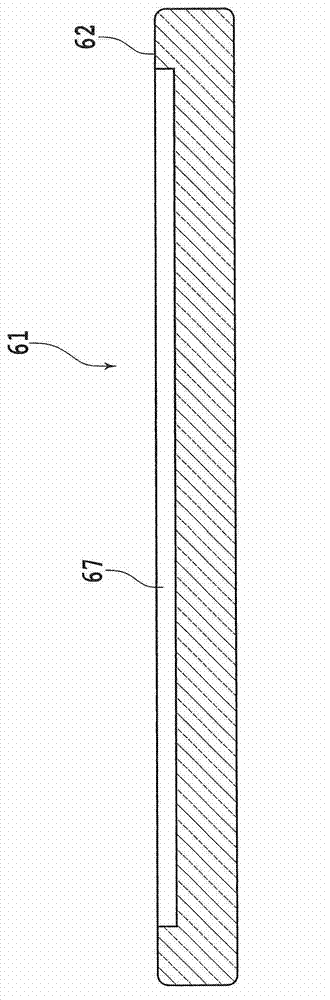

Processing method of device wafer with bump

ActiveCN103295948ADoes not produce unqualified adverse conditionsNo need to removeSemiconductor/solid-state device manufacturingAdhesiveEngineering

The invention provides a processing method of a device wafer with a bump. According to the invention, even the device wafer with the bump can be thinned and not damaged, and the devices will not be disqualified because of adhesion of the adhesive onto concave and convex parts formed by the bump. The processing method for a bump-included device wafer is characterized by including wafer so that the adhesive projects from the upper surface of an annular projection of the carrier wafer; a wafer attaching step of attaching and fixing the front side of the device wafer through the adhesive to the front side of the carrier wafer so as to accommodate bumps in a recess of the carrier wafer after performing the adhesive providing step; and a thickness reducing step of grinding or polishing the back side of the device wafer to reduce the thickness of the device wafer to a predetermined thickness after performing the wafer attaching step.

Owner:DISCO CORP

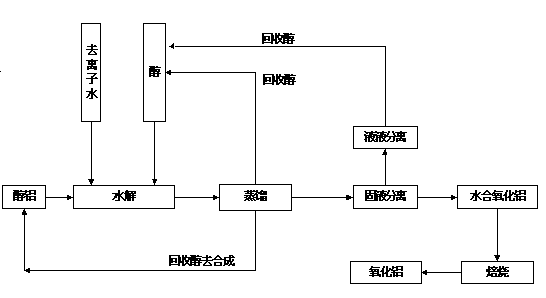

Preparation method for nanoscale alumina powder

InactiveCN102849762ANo need to removeEmission reductionNanotechnologyAluminium oxides/hydroxidesWastewaterSolvent

The invention relates to a preparation method for nanoscale alumina powder. The method includes allowing the reaction between aluminum powder and solvent n-hexanol to prepare an aluminum alkoxide compound, hydrolyzing, distilling, separating, and roasting to prepare nanoscale alumina powder product. The invention has no need for catalyst removal, has no need for large amount of water to wash away the impurities in the material, reduces the discharge of wastewater, reduces pollution and saves the production cost; in the production process, the used alcohol can be recycled (with recovery rate at 90%), to greatly reduce the production cost; and the product has low impurity content, large pore volume, large specific surface, and reasonable pore size distribution, and can be used as an industrial catalyst carrier.

Owner:YINGKOU HENGDA INDAL

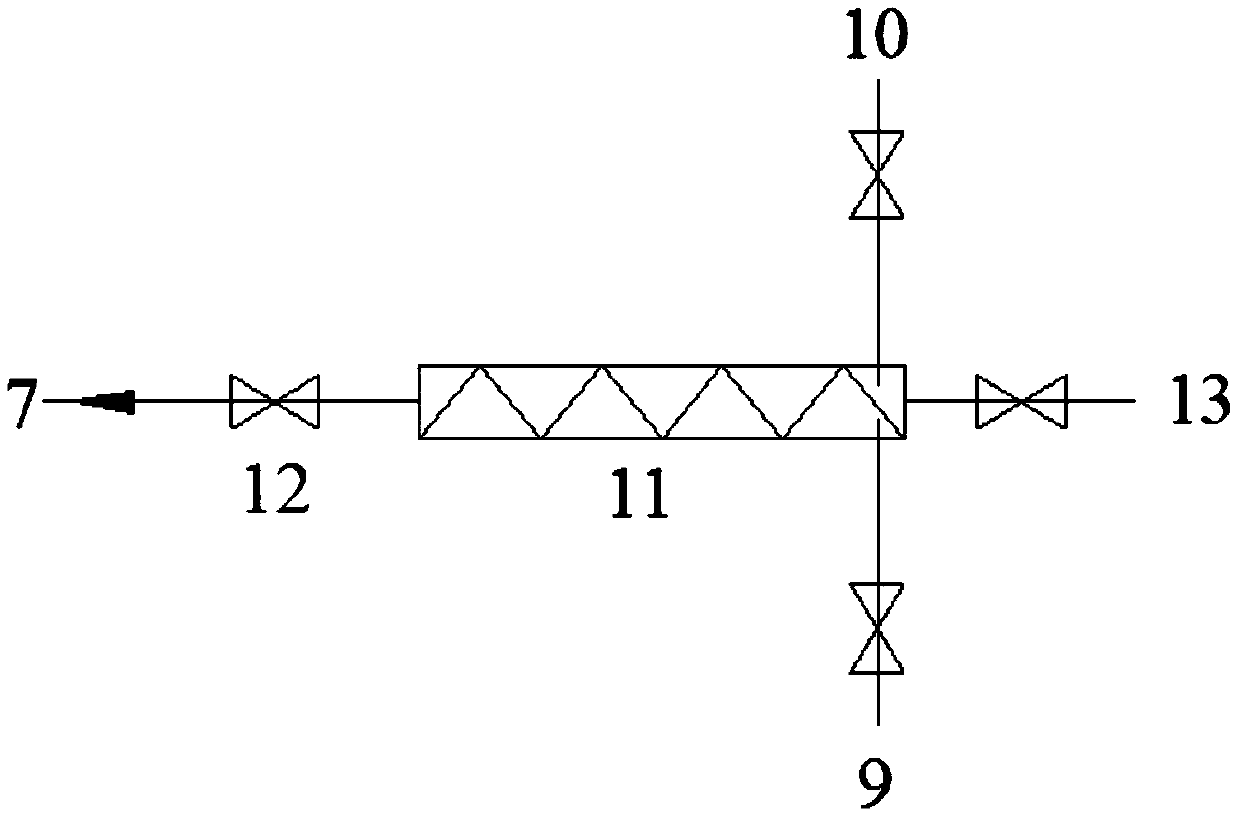

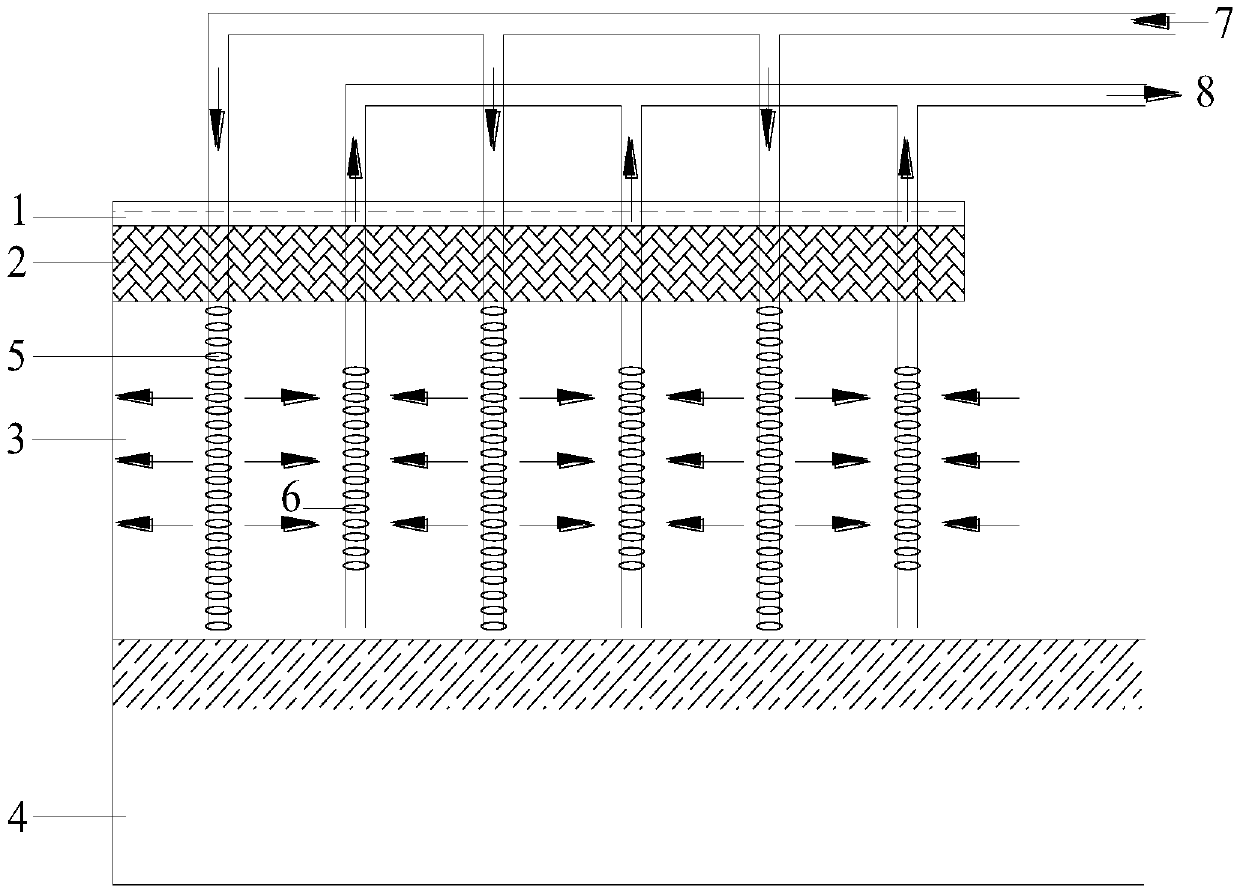

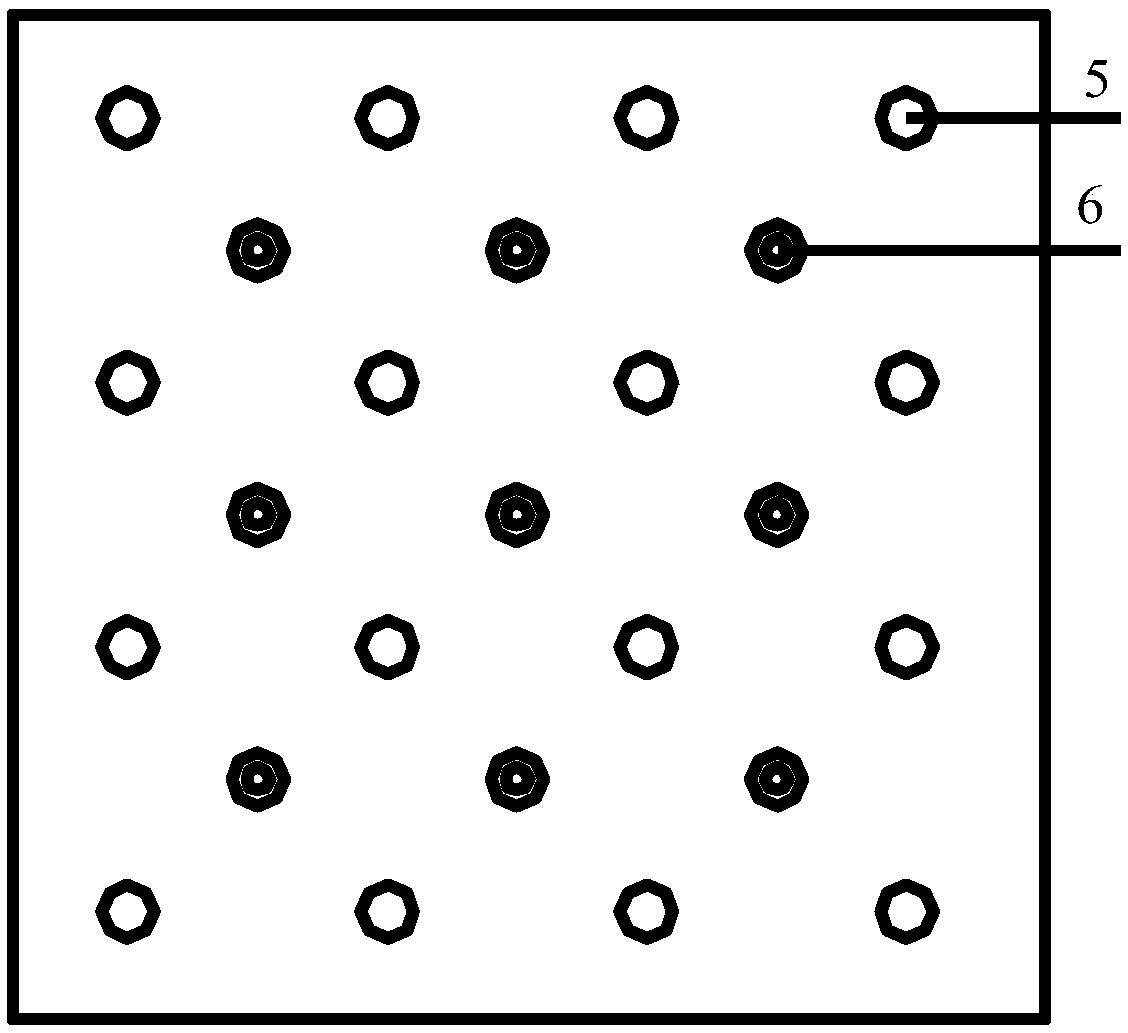

Method for removing farmland heavy metal pollution in situ through environment-friendly eluting agent

ActiveCN109675918AEasy to obtainSignificant environmental benefitsContaminated soil reclamationEngineeringPlastic film

The invention belongs to the technical field of farmland management, and particularly relates to a method for removing farmland heavy metal pollution in situ through an environment-friendly eluting agent. The method comprises the following steps: (1) a work cushion layer and a plastic film are sequentially arranged on mellow soil of farmland; (2) a pumping and injecting system is formed; (3) smallholes are evenly formed in the outer surface of the part, inserted into the mellow soil, of an eluting filter pipe; (4) small holes are evenly formed in the outer surface of the part, inserted into the mellow soil, of a vacuum collection filter tube; (5) the environment-friendly eluting agent is determined; (6) the well distance is determined according to the migration speed and the repair periodT of the environment-friendly eluting agent in the mellow soil; and (7) the environment-friendly eluting agent enters the mellow soil through the eluting filter pipe, through oxidation and complexingreactions between the environment-friendly eluting agent and the mellow soil, heavy metal in the mellow soil is transferred into a liquid phase, the heavy metal polluted farmland is repaired in situ,and an eluting solution is formed. The technical scheme has the beneficial effects that the treatment process is carried out in situ, polluted soil does not need to be removed, and operation is easyand convenient.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

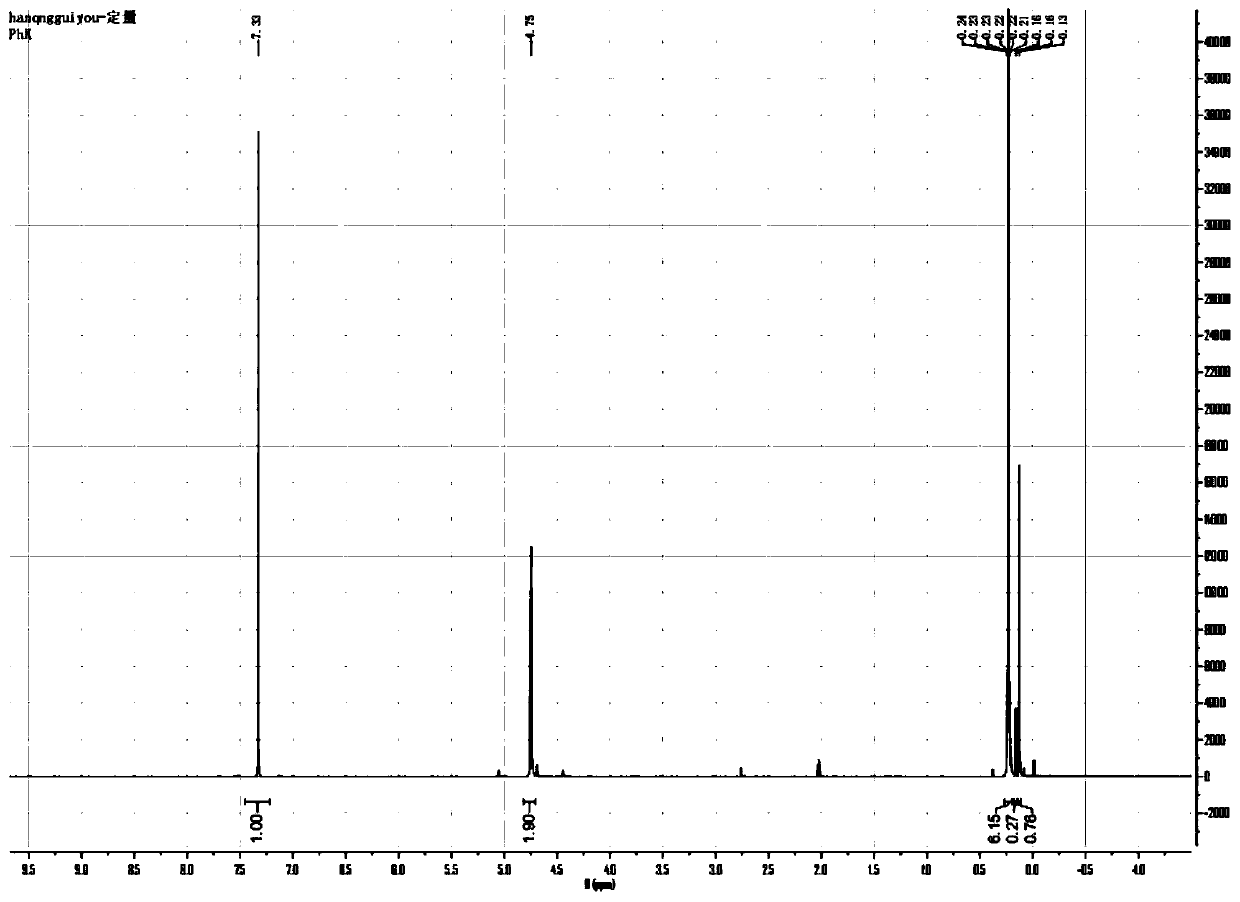

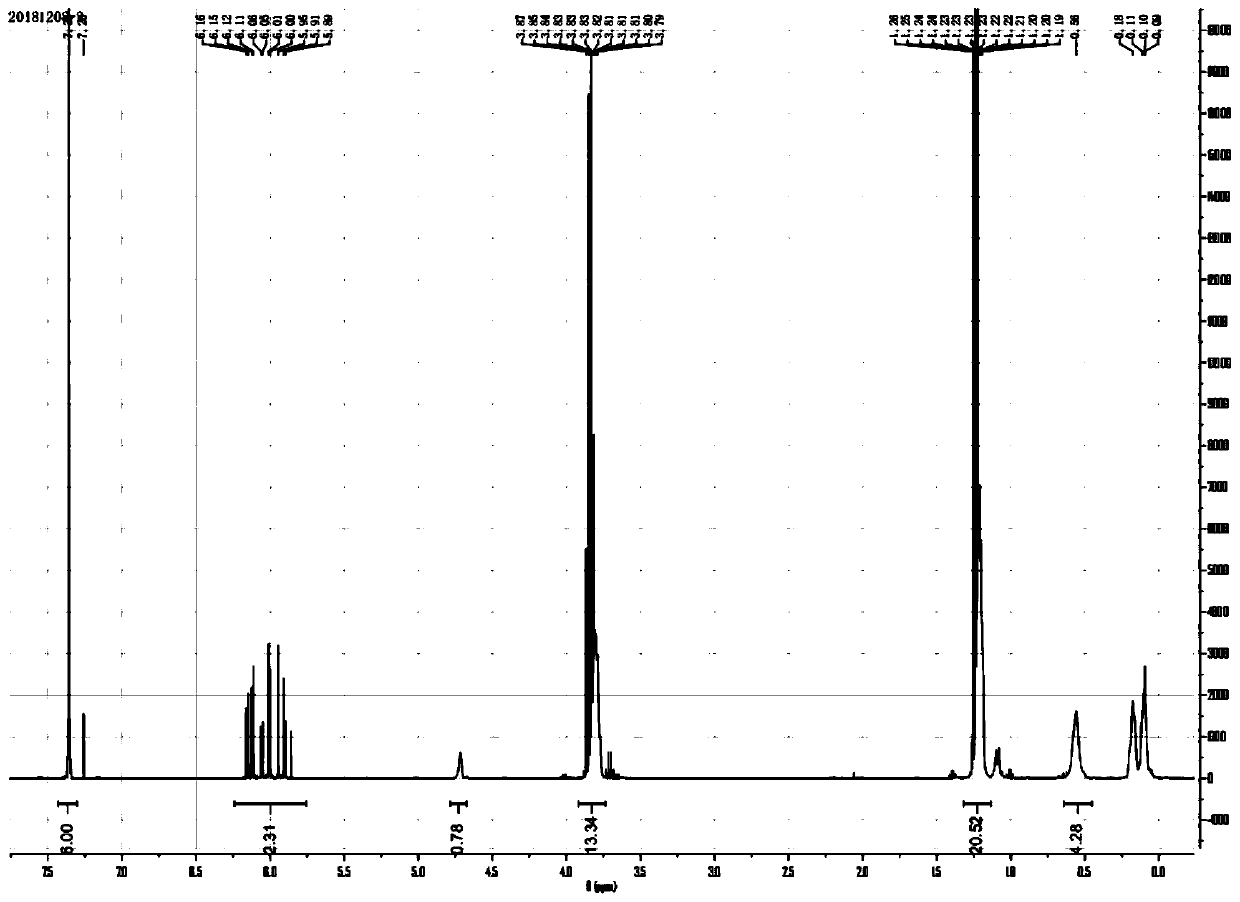

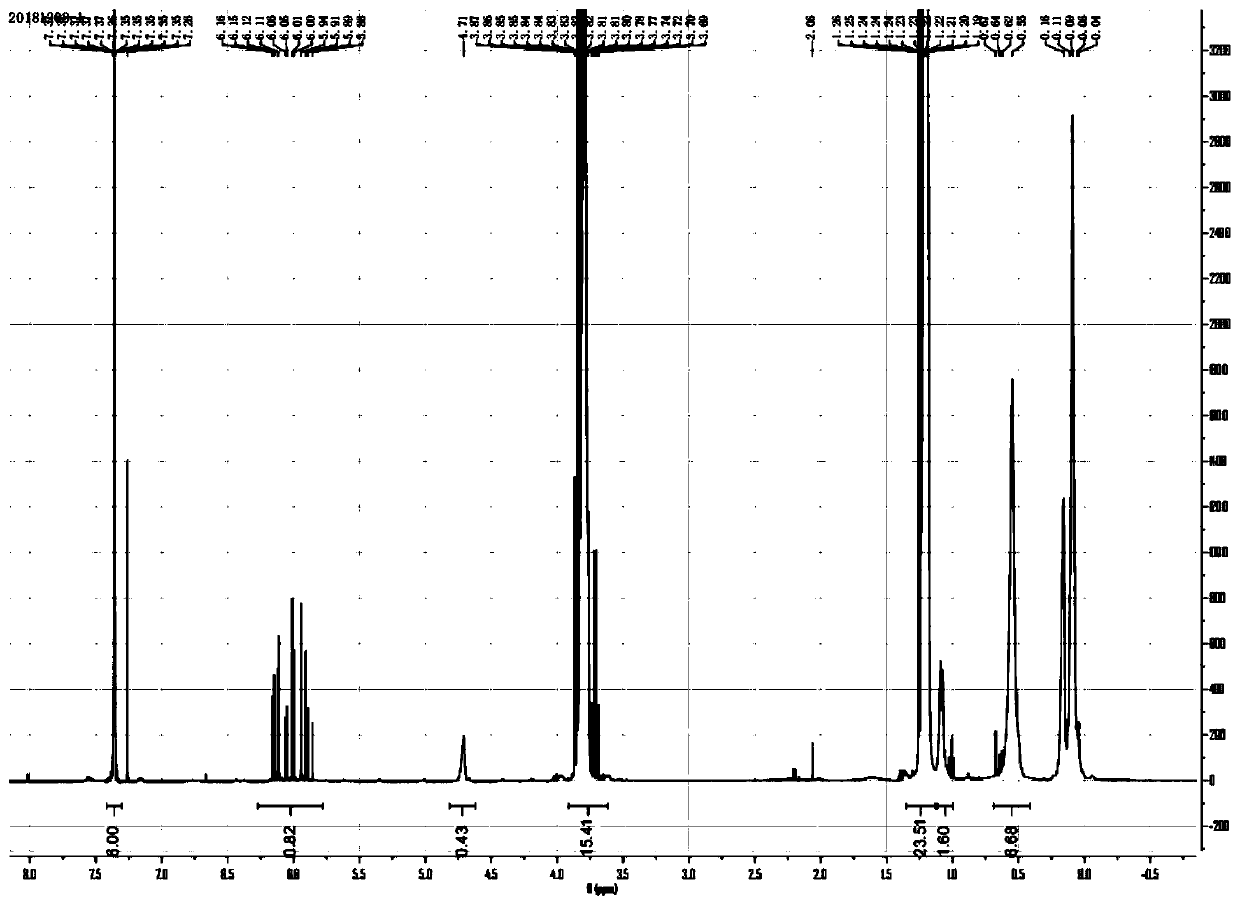

Vinyl siloxane grafted hydrogen-containing silicone oil and preparation method thereof

The invention discloses vinyl siloxane grafted hydrogen-containing silicone oil and a preparation method thereof, and belongs to the technical field of organic synthesis. The vinyl siloxane grafted hydrogen-containing silicone oil is provided, and modified hydrogen-containing silicone oil is obtained by an addition reaction of a C=C bond with a Si-H bond. The vinyl siloxane grafted hydrogen-containing silicone oil and the preparation method thereof are also provided, and the method comprises the following steps: first stirring hydrogen-containing silicone oil and performing slow heating; thensequentially adding a solid platinum-containing catalyst and vinyl siloxane, and carrying out a reaction at a constant temperature for a period of time; and finally performing cooling, and filtering out the platinum-containing solid catalyst to obtain the vinyl siloxane grafted hydrogen-containing silicone oil. In the preparation reaction system, preferably the platinum content accounts for 0.02-0.06% of the mass of the hydrogen-containing silicone oil, and preferably the molar ratio of the C=C bond in the vinyl siloxane to the Si-H bond in the hydrogen-containing silicone oil is (1-1.05):1; and the vinyl siloxane grafted hydrogen-containing silicone oil with high viscosity and low hydrogen content can be obtained under reactive solvent-free conditions.

Owner:GBXF SILICONES CO LTD

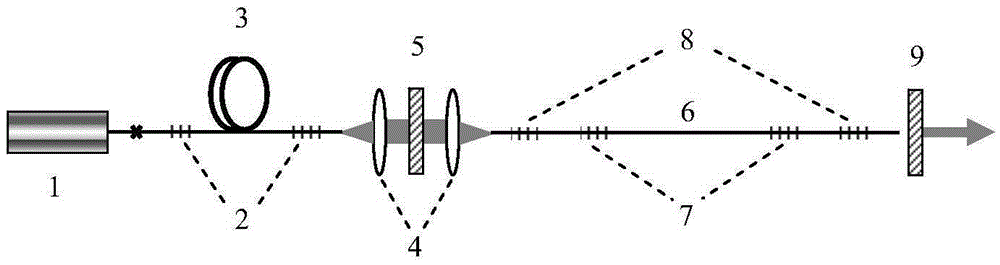

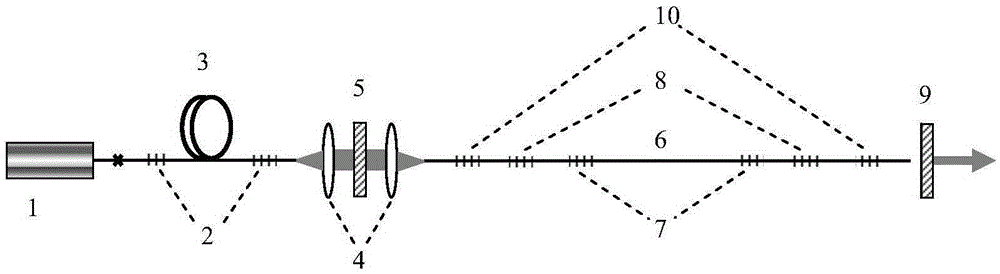

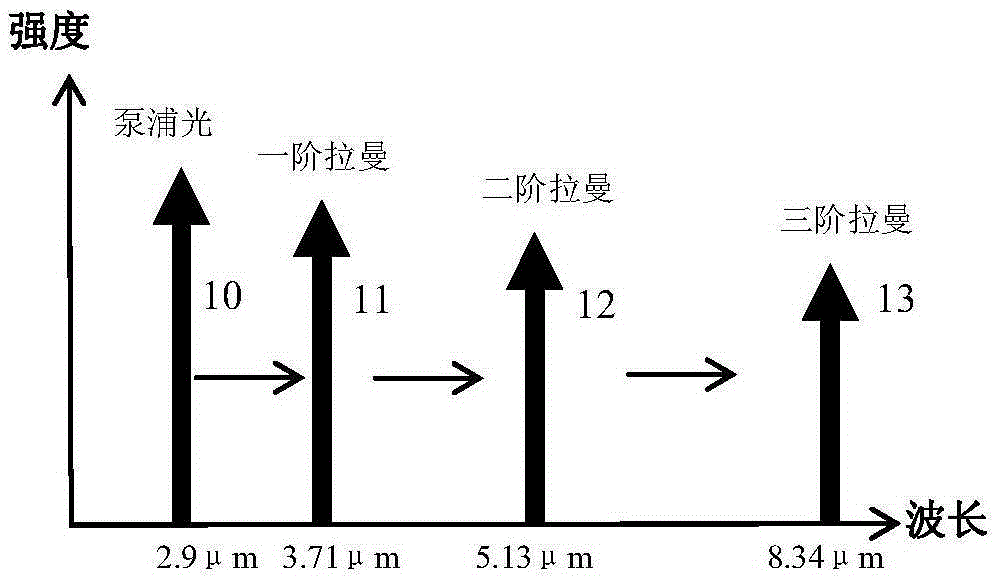

Tellurate fibre-based raman fibre laser device with mid-infrared band of over 5 microns

InactiveCN105406331AReduce complexityLow costLaser using scattering effectsActive medium shape and constructionGratingStimulate raman scattering

The invention discloses a tellurate fibre-based raman fibre laser device with a mid-infrared band of over 5 microns. The raman fibre laser device is characterized by comprising a tellurate fibre, wherein fibre bragg grating pairs for reflecting a first-order raman stokes signal and a second-order raman stokes signal are etched in regions close to two ends of the tellurate fibre; one end of the tellurate fibre is connected with a high-power erbium-doped fluoride fibre laser device; and output light of the high-power erbium-doped fluoride fibre laser device enters the tellurate fibre through an optical coupling system. The tellurate fibre disclosed by the invention has a large raman frequency shift and a large raman gain bandwidth; mid-infrared laser of which the output wavelength exceeds 5 microns is generated through first-order stimulated raman scattering and second-order stimulated raman scattering of the fibre; and a laser output of which the output wavelength exceeds 10 microns can be obtained through further expansion.

Owner:HEFEI UNIV OF TECH

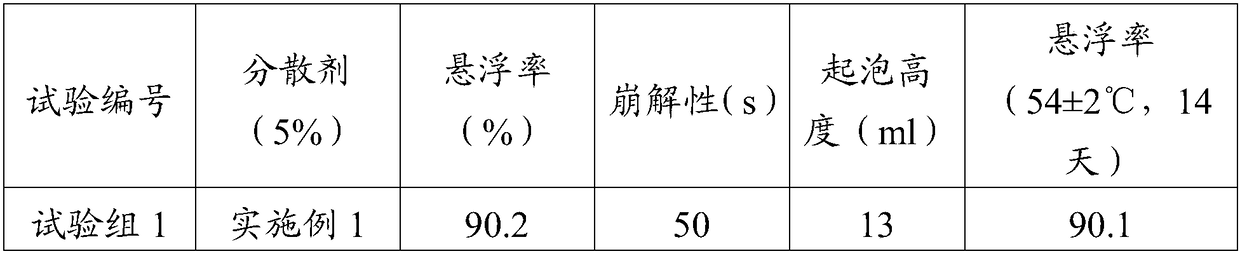

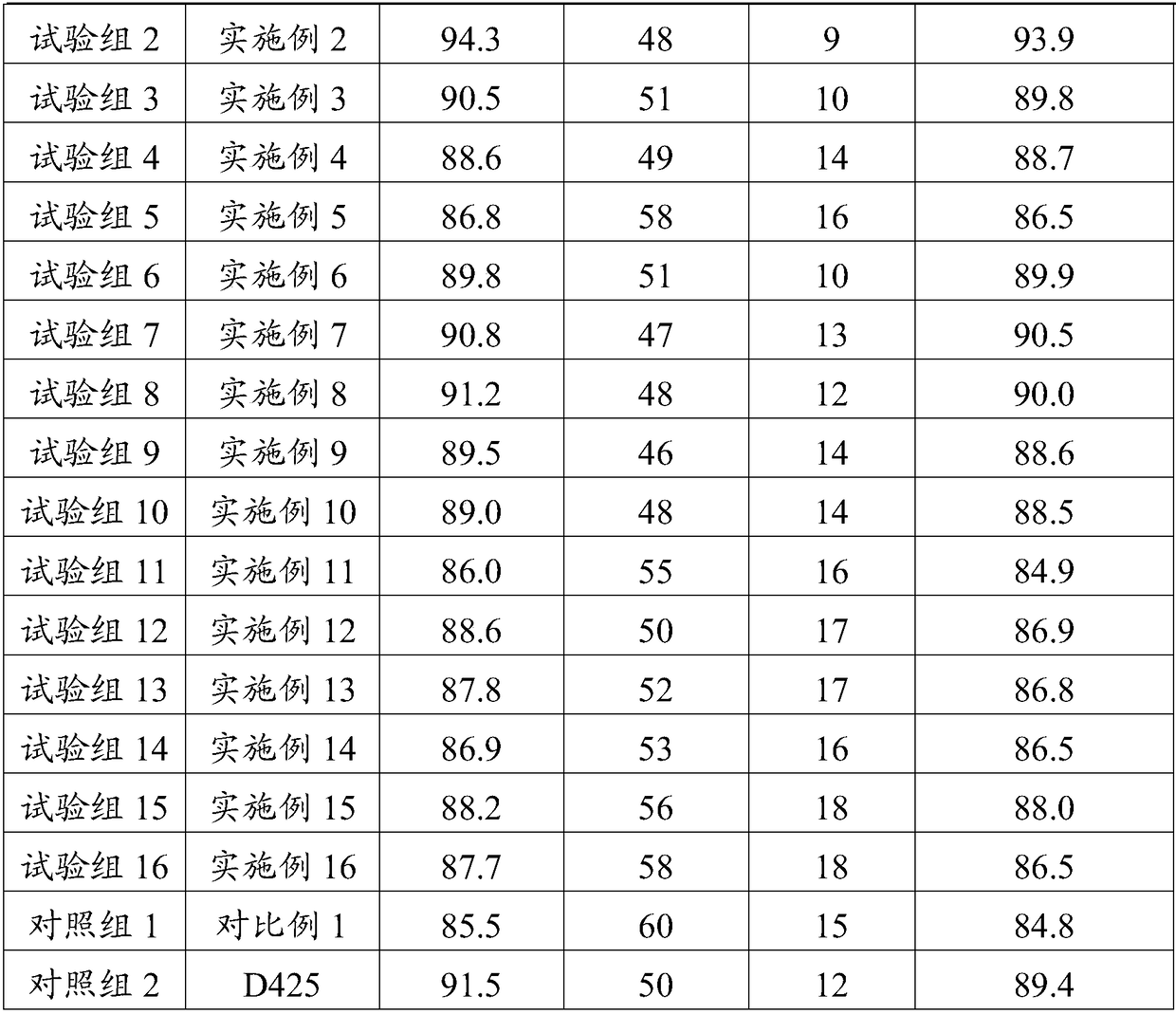

Preparation method and application of naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate

InactiveCN109020843AReduce dosageAvoid wastingBiocideSulfonic acids salts preparationSulfonateAlkyl transfer

The invention discloses a preparation method of a naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate. The preparation method comprises the following steps: firstly enabling naphthalene and an alkylation reagent to generate a mixed solution of naphthalene and alkyl naphthalene under the catalysis of sulfuric acid; then adding sulfuric acid into the mixed solution of naphthalene and alkyl naphthalene, and performing the sulfonation reaction; and adding formaldehyde, performing the one-pot condensation, and preparing thea naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate. By adopting the preparation method, the naphthalenesulfonic acid and alkyl naphthalene sulfonate do not need to be prepared independently, and the operation is simple; the wasteacid does not need to be removed, no acidic waste water is produced, and safety and environmental protection can be realized; and the prepared naphthalene sulfonate-alkyl naphthalene sulfonate-formaldehyde condensate is used as a dispersing agent to be applied to pesticide water dispersion granules or suspension, and has higher suspension rate and better heat storage stability.

Owner:江苏精禾界面科技有限公司

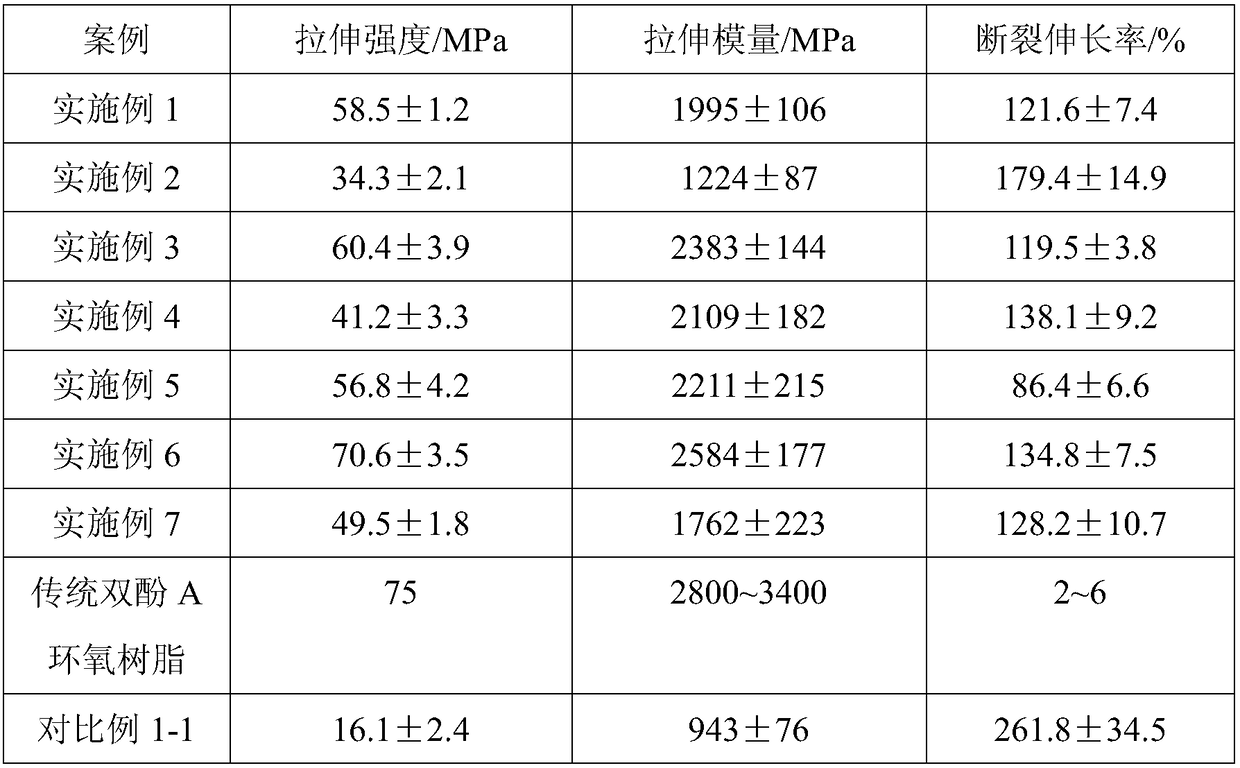

Method for preparing reversible crosslinked toughened epoxy resin through bulk click chemical reaction

The invention relates to a method for preparing thermoplastic toughened epoxy resin with a thermal reversible chemical crosslinking characteristic. The method comprises the steps as follows: 1) afterbifunctional epoxy resin and polyfunctional epoxy resin are mixed, the mixture and furfurylmercaptan are subjected to a click reaction, and an intermediate with a furan functional group as a terminalgroup is obtained, wherein the bifunctional epoxy resin is an epoxy monomer containing two epoxy groups and the polyfunctional epoxy resin is an epoxy monomer containing three or more epoxy groups; 2)the intermediate and a crosslinking agent containing a maleimide group are subjected to a Diels-Alder reaction to produce reversible crosslinked toughened epoxy resin. The defect that traditional curing epoxy resin is difficult to dissolve and melt is overcome. The thermoplastic reversible crosslinked toughened epoxy resin is recycled by use of Diels-Alder covalent bonds and can still keep performance of traditional epoxy resin, and the method is convenient and has industrial application prospects.

Owner:ZHEJIANG UNIV

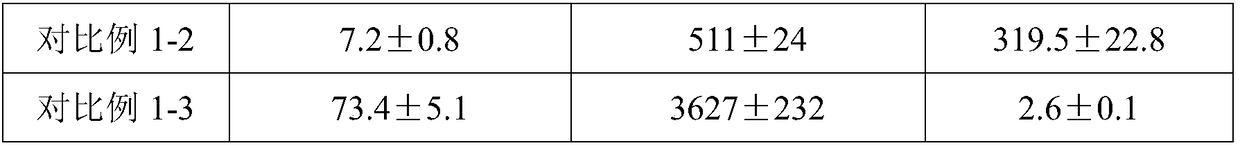

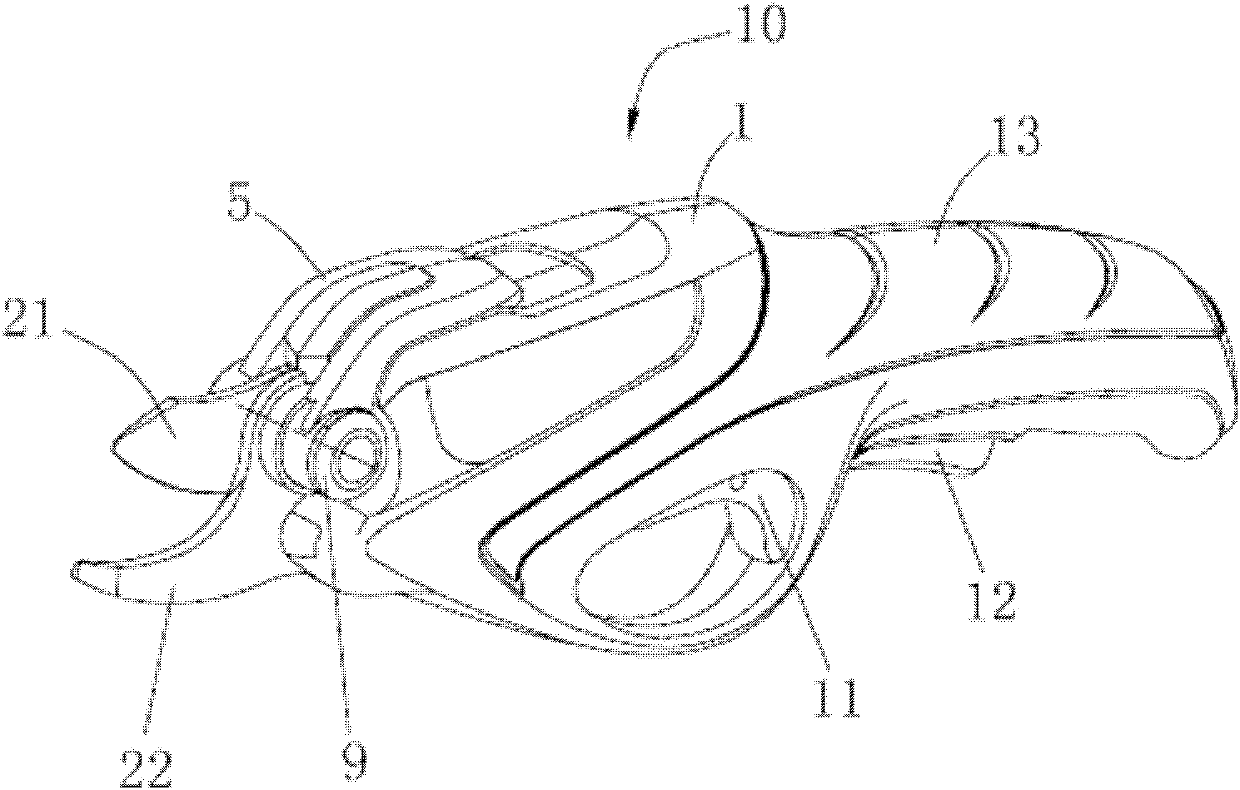

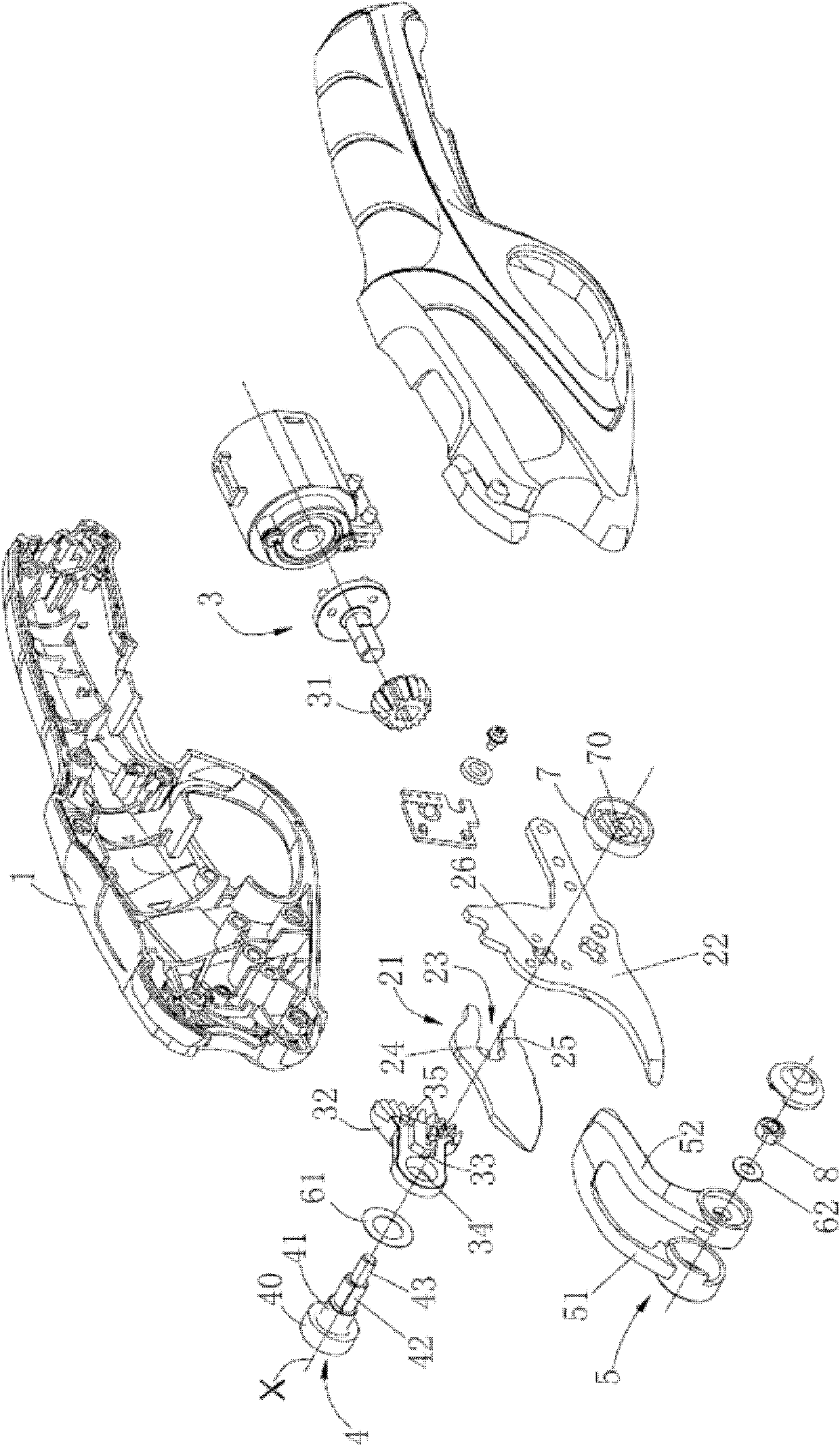

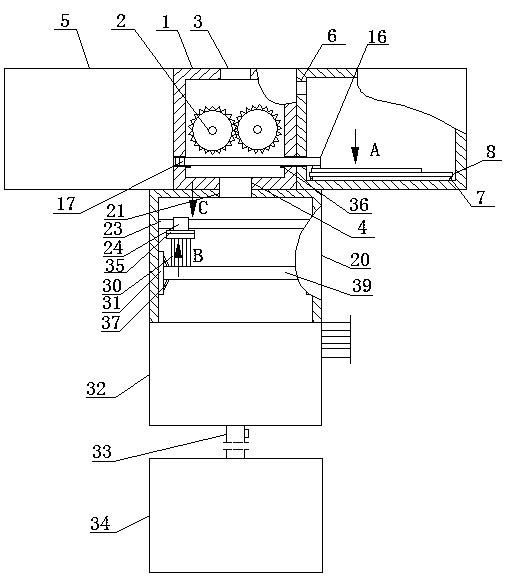

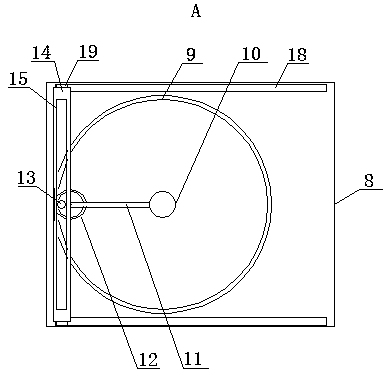

Electric pruning shears

ActiveCN102884948AEasy to replaceNo need to removeCuttersCutting implementsEngineeringMechanical engineering

The invention provides electric pruning shears. The pruning shears comprise a case, a motor and a transmission mechanism, wherein the motor is contained in the case; a movable blade and a fixed blade extend out from the front end of the case; the fixed blade is fixedly installed on the case; the movable blade is driven by the motor and is rotatablely connected on the fixed blade by a shaft; a slot is arranged on the movable blade and comprises a first slot and a second slot which are communicated with each other; the dimension of the first slot is greater than that of the second slot; the shaft comprises a first matching part and a second matching part; the shaft can move between a first position and a second position; in the first position, the first matching part is matched with the first slot and the movable blade is locked; and in the second position, the second matching part is matched with the first slot and the movable blade is loosened. Therefore, the movable blade can be replaced very simply and conveniently.

Owner:NANJING CHERVON IND

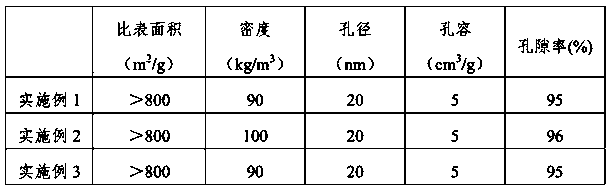

Method for preparing aerogel composite thermal insulation felt through normal pressure drying

The invention relates to a method for preparing an aerogel composite thermal insulation felt through normal pressure drying. The specific steps comprise: uniformly mixing a silicon source and deionized water to obtain a silicon-containing solution, uniformly mixing the silicon-containing solution, ethanol and an acidic catalyst, and stirring to obtain a sol; placing a composite material in a container, injecting the sol into the container loaded with the composite material, heating, and carrying out thermal insulation so as to wait gelation; placing the gel composite body obtained after the gelation into an acid alcoholization solution obtained by mixing anhydrous ethanol and sulfuric acid, heating, and carrying out thermal insulation; placing the gel composite body into a modified solution obtained by mixing a hydrophobic modifier and a solvent; and carrying out normal pressure drying on the modified gel composite body to obtain the aerogel composite thermal insulation felt material.According to the present invention, the technical scheme has advantages of low cost, less steps, less gel impurities, less energy consumption, simple equipment operation, and simple equipment maintenance.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

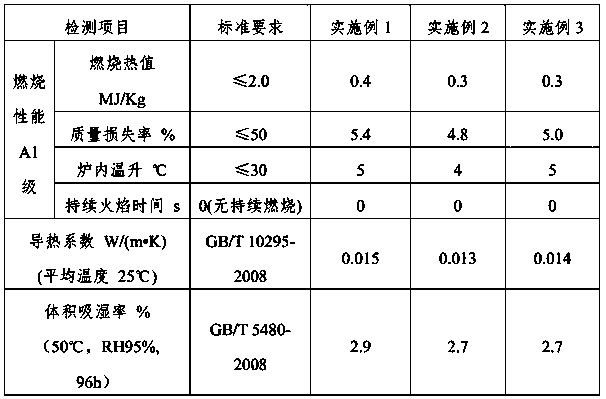

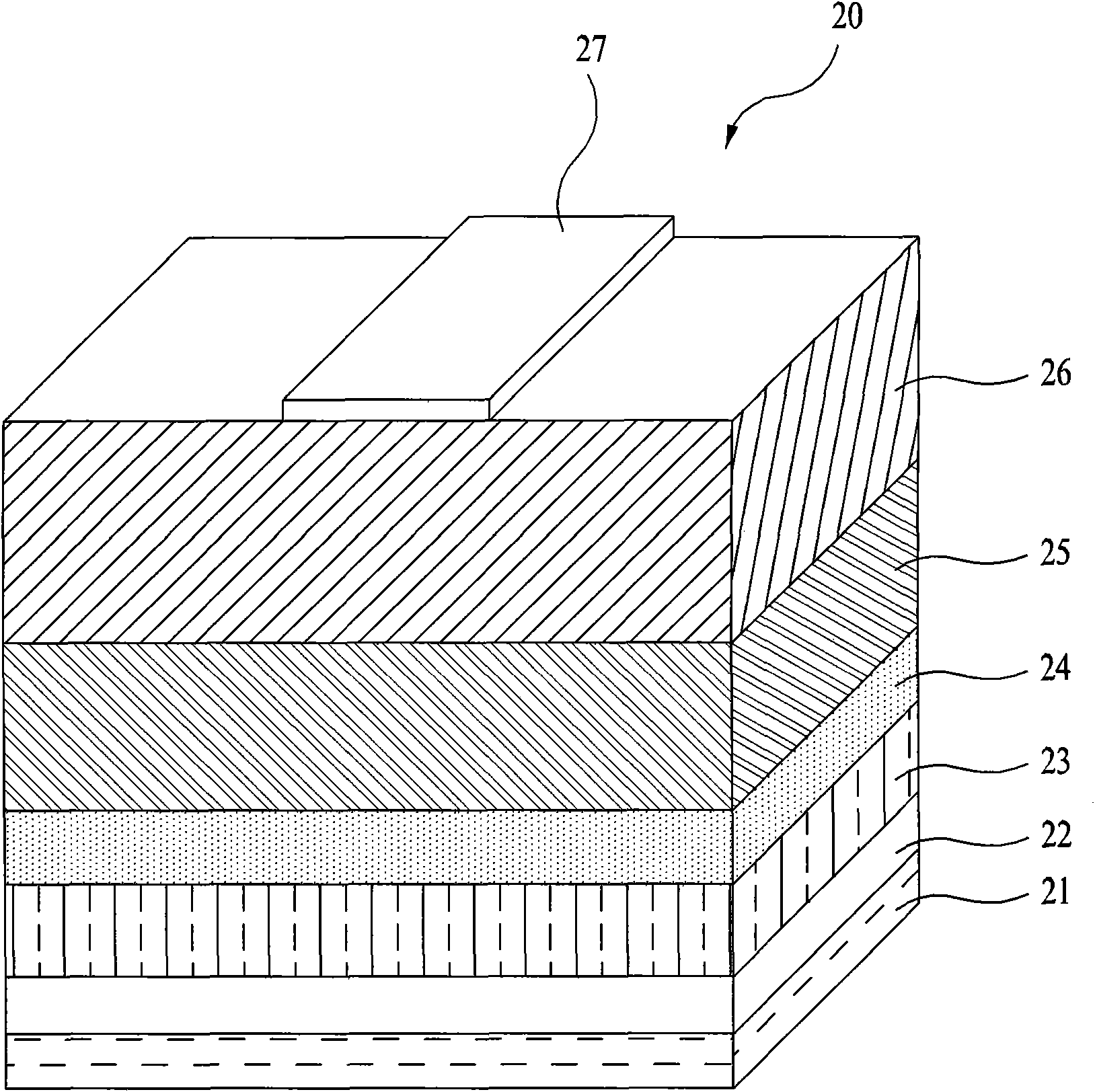

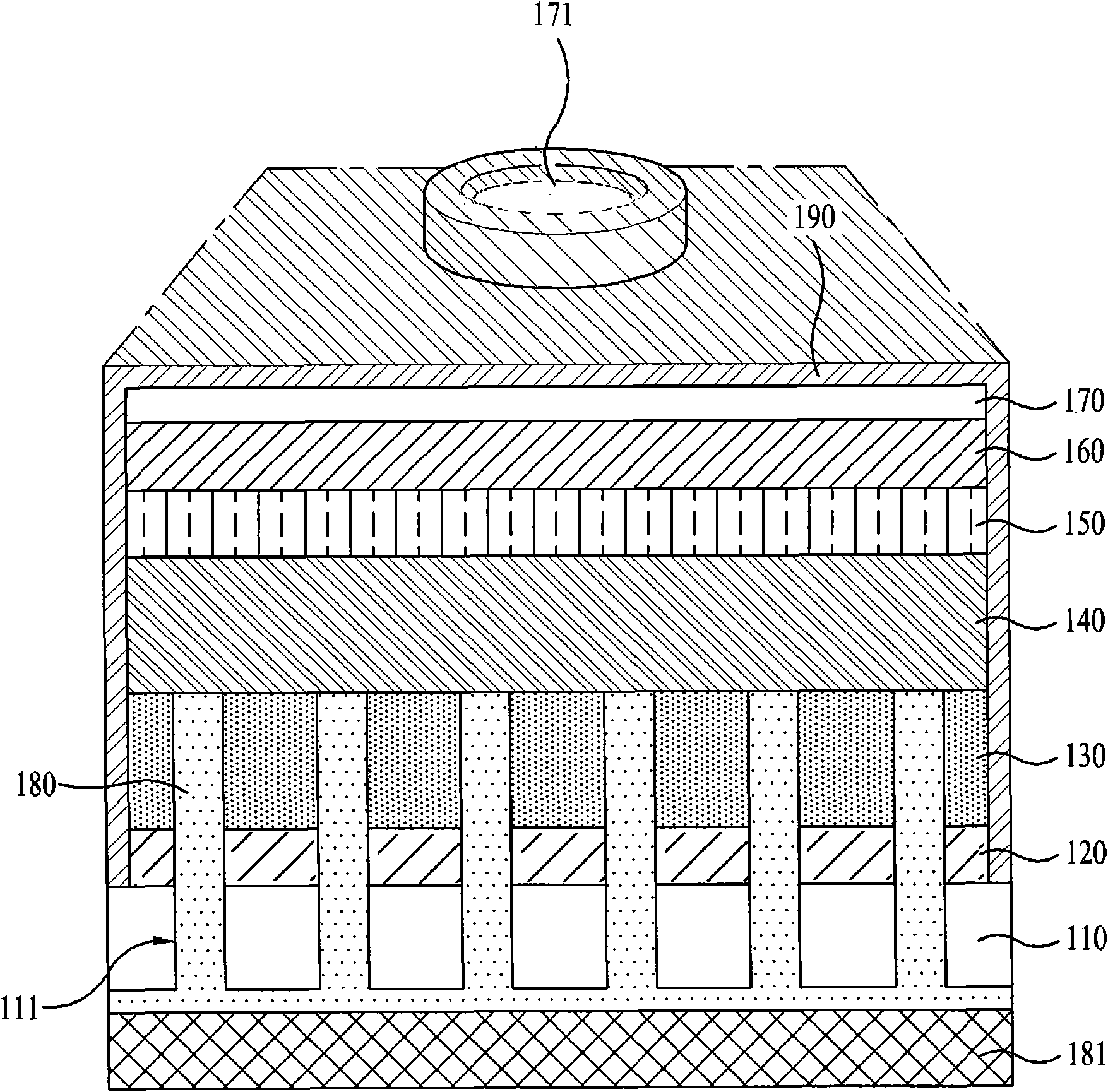

Vertical light emitting diode and manufacturing method of the same

The present invention relates to a vertical light emitting diode and a manufacturing method of the same. The vertical light emitting diode includes a substrate having a plurality of penetrating via-holes, a plurality of nitride semiconductor layers formed on the substrate, a first electrode formed on the plurality of nitride semiconductor layers, and a second electrode formed to fill the plurality of via-holes thereby contacting part of the plurality of nitride semiconductor layers.

Owner:LG DISPLAY CO LTD

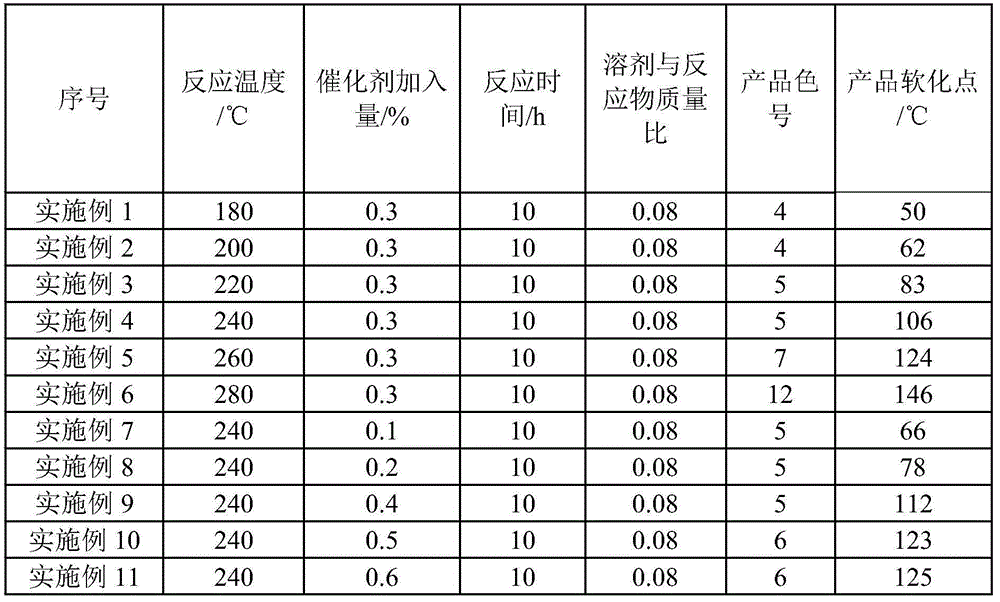

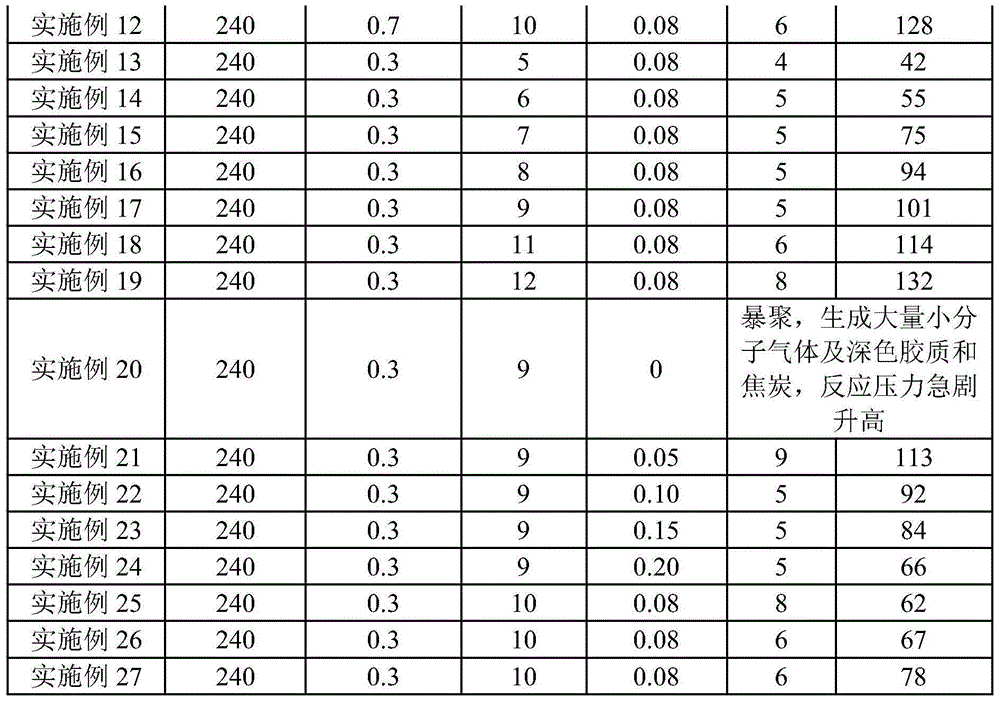

Method for reducing color number of cyclopentadiene petroleum resin

The invention discloses a method for reducing the color number of cyclopentadiene petroleum resin. A C5 olefin fraction is taken as a raw material and added to a high-pressure reactor together with a solvent and a catalyst, inert gas in fed to remove air, proper inert gas pressure is guaranteed, and the cyclopentadiene petroleum resin is prepared at a proper reaction temperature for a proper reaction time. On the premise that the performance of high-end products is met, the process is simple, the investment is low, the catalyst is not required to be removed, wastewater containing fluoride and the like cannot be produced, and the method has the characteristics of environment friendliness, high efficiency and good benefit.

Owner:沈阳 +1

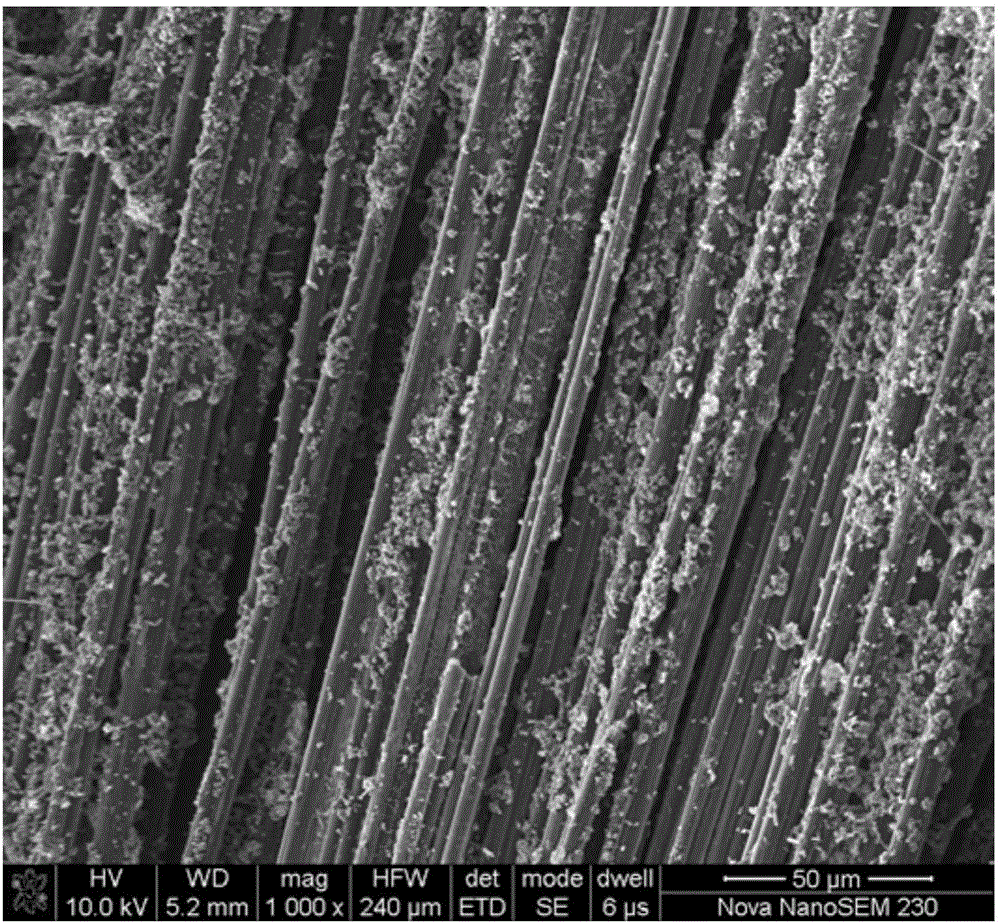

Compound interface layer modified C/C composite material as well as preparation method and application thereof

ActiveCN106830968AGood conditionSimple structureOther chemical processesCarbon fibersInterface layer

The invention relates to a compound interface layer modified C / C composite material as well as a preparation method and an application thereof, in particular to a carbon fiber / matrix carbon interface modified C / C composite material as well as a preparation method and an application thereof. The compound interface layer modified C / C composite material comprises carbon fibers, B-containing graphite layer, a SiC layer and a pyrolytic carbon layer, wherein the carbon fibers are coated with the B-containing graphite layer, the SiC layer is located between the B-containing graphite layer and the pyrolytic carbon layer, the B-containing graphite layer is coated with the SiC layer which is coated with the pyrolytic carbon layer, and the pyrolytic carbon layer contains graphite. The preparation method of the compound interface layer modified C / C composite material comprises the following steps: the carbon fibers dipped in boric acid aresubjected to first graphitization treatment, the treated carbon fibers are then coated with nano-SiC fibers, CVI densification is performed, and finally, graphitization treatment is performed once more. The composite material is reasonable in structural design, the preparation process is simple and easy to control, and the obtained product has excellent performance and is particularly applicable to friction materials.

Owner:CENT SOUTH UNIV

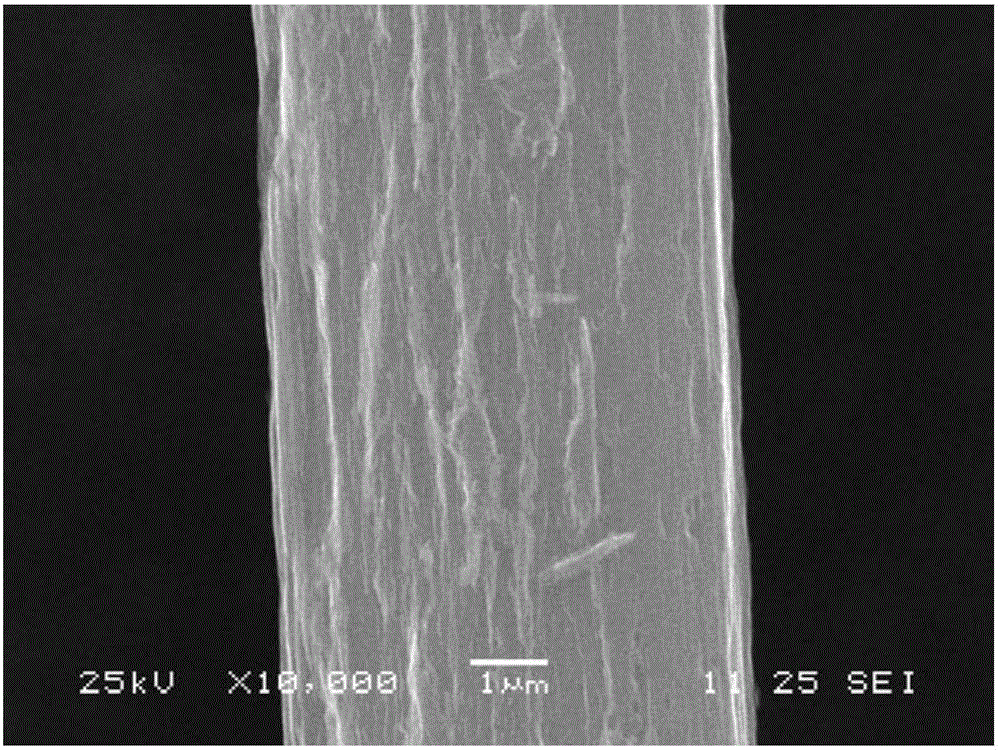

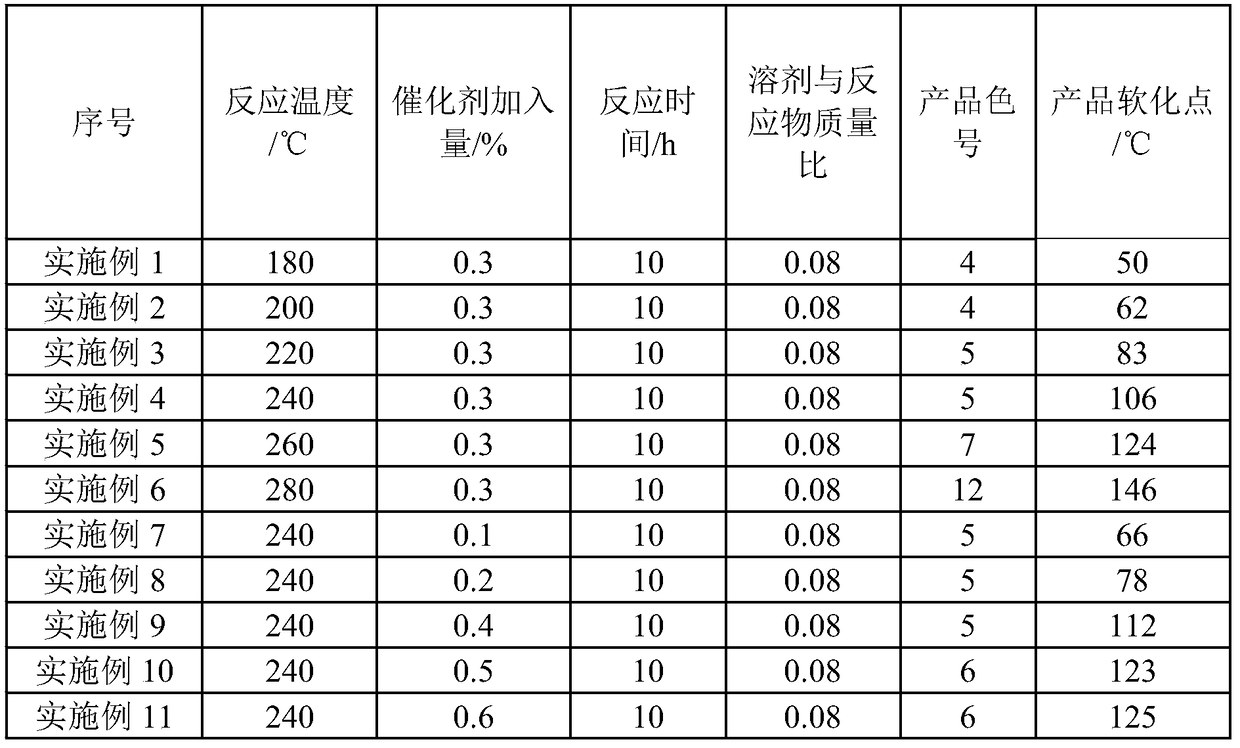

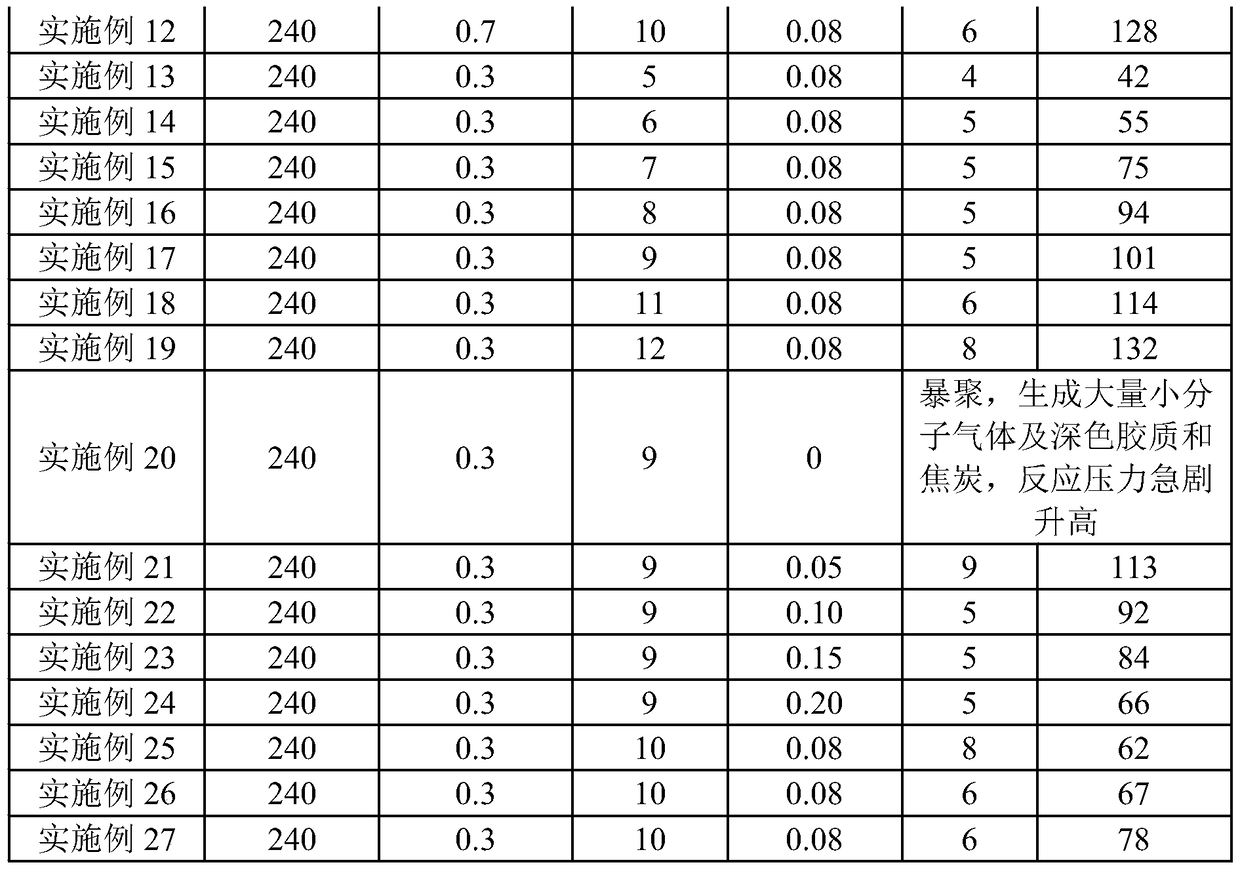

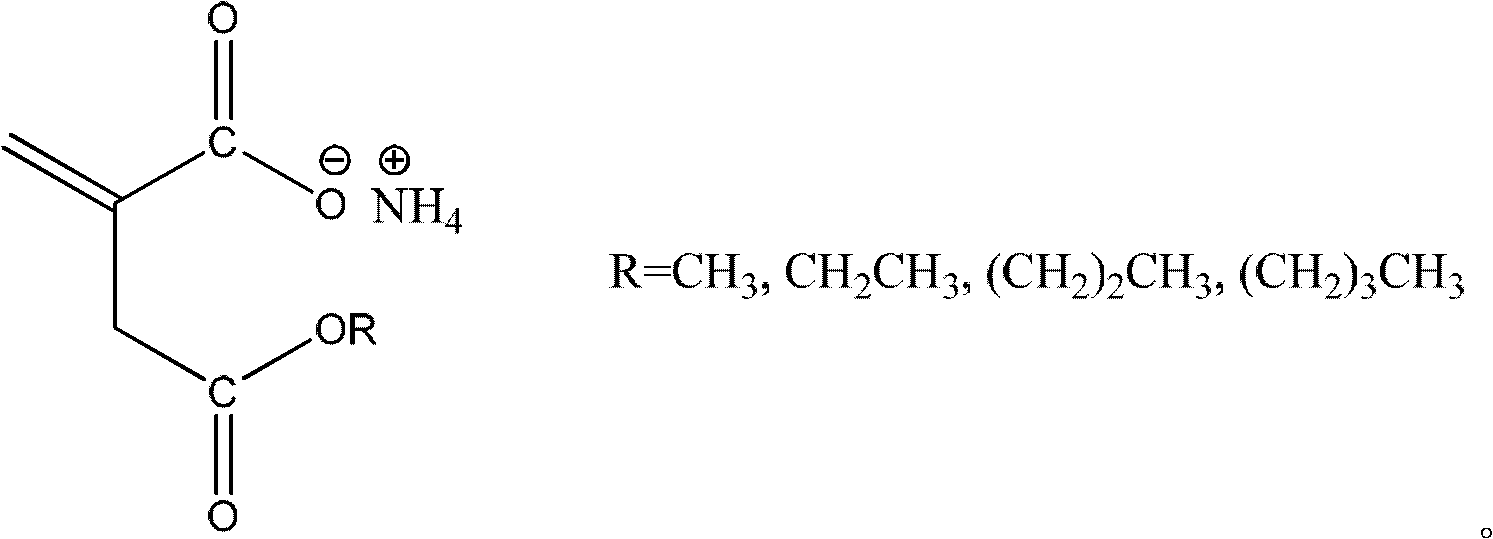

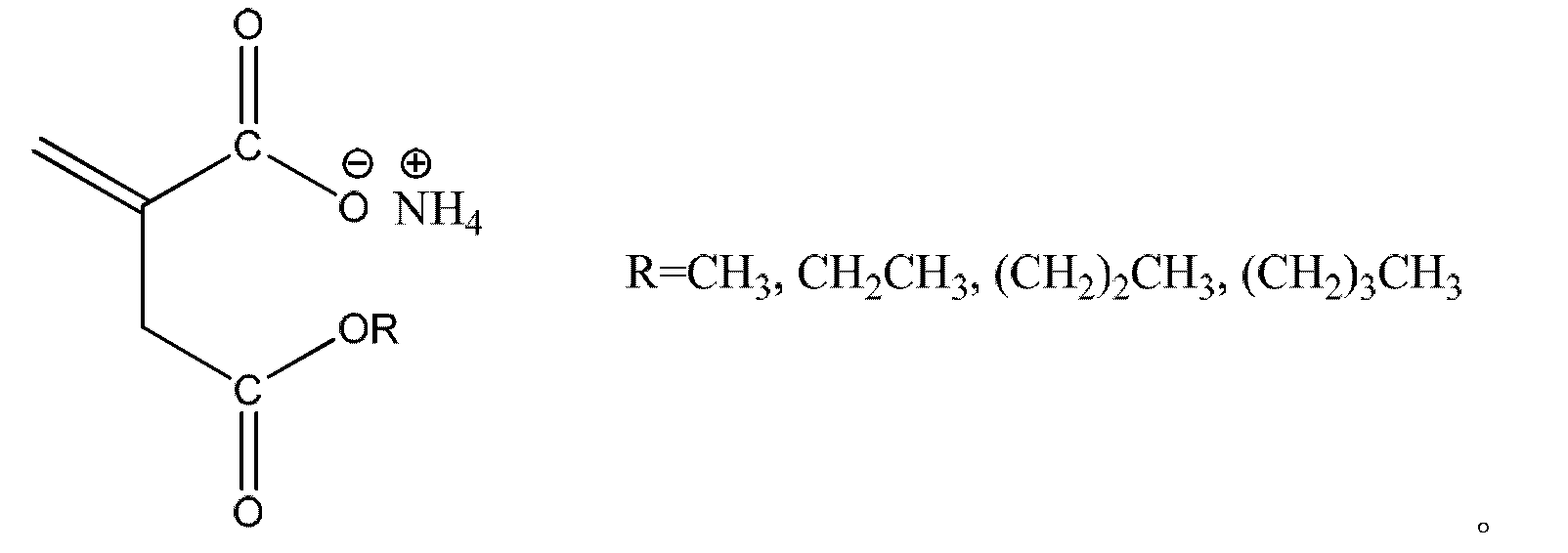

Preparation method of binary polyacrylonitrile carbon fiber precursor

InactiveCN103614800AReduce dosageImprove structural regularityFibre typesArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a preparation method of a binary polyacrylonitrile carbon fiber precursor. The method comprises the following steps: mixing acrylonitrile, a second comonomer beta-itaconic acid ester amide and a solvent in the presence of nitrogen, and adding an initiator; reacting for 22-38 hours under the condition of 35-75 DEG C, so as to obtain an acrylonitrile polymer; then filtering, taking off and defoaming, so as to prepare a spinning solution; spinning the spinning solution by virtue of a dry-jet wet process, stretching, oiling, drying, densifying, drawing by hot steam, and thermoforming, so as to obtain the binary polyacrylonitrile carbon fiber precursor. By adopting the preparation method, double functional group beta-itaconic acid ester amide is adopted as a comonomer, and a polyacrylonitrile macromolecule for the carbon fiber precursor is prepared by binary copolymerization and substituted ternary copolymerization. Thus, the dosage of the comonomer is reduced, meanwhile, the structural regularity of the polyacrylonitrile macromolecule is improved, and the prepared carbon fiber precursor is even in structure, small in fineness and high in strength.

Owner:DONGHUA UNIV

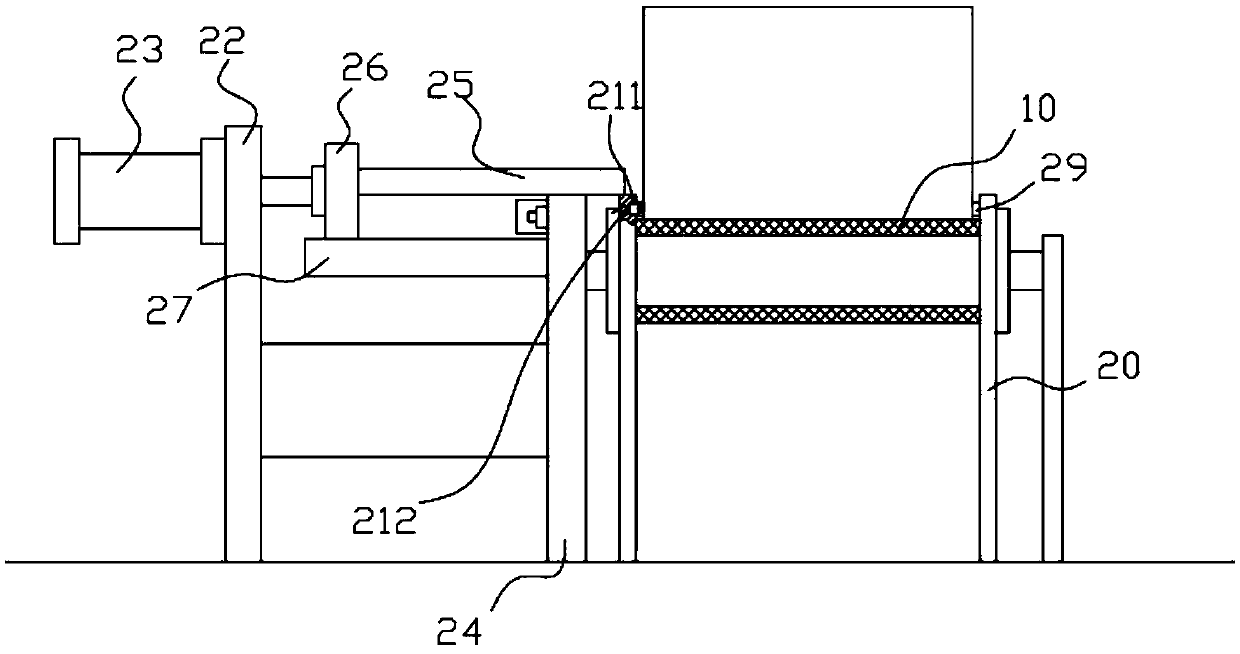

Adjustable packaging, conveying and limiting mechanism of corrugated paper boxes

The invention discloses an adjustable packaging, conveying and limiting mechanism of corrugated paper boxes. The adjustable packaging, conveying and limiting mechanism comprises a conveyor belt, wherein the two ends of the conveyor belt are tensioned on two transmission rollers; the two ends of the transmission rollers are hinged onto supporting legs; a driving motor is fixed on one supporting leg and drives the transmission rollers to rotate; limiting plates are fixed at the middle parts of the two sides of the conveyor belt; a plurality of arc-shaped convex blocks are uniformly distributed and fixed on opposite wall faces of the two limiting plates; a limiting frame is fixed at the rear part of one limiting plate; a pushing air cylinder is fixed on a rear plate of the limiting frame; a plurality of adjustable air cylinders are fixed on outer wall faces of two limiting inserting rods; push rods of the adjustable air cylinders penetrate through the limiting inserting rods and are fixed on corresponding clamping plates; and the two clamping plates are opposite to each other. The adjustable packaging, conveying and limiting mechanism can be used for positioning the corrugated paper boxes on the conveyor belt and can be adjusted according to the different corrugated paper boxes, so that the corrugated paper boxes can be conveniently and directly processed without being moved out in the following procedures, and furthermore, the effect is good and the efficiency is high.

Owner:海门市创豪工业设计有限公司

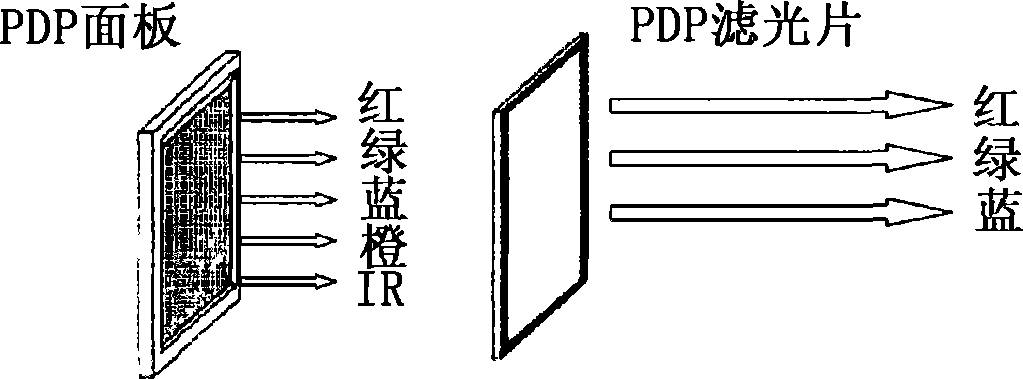

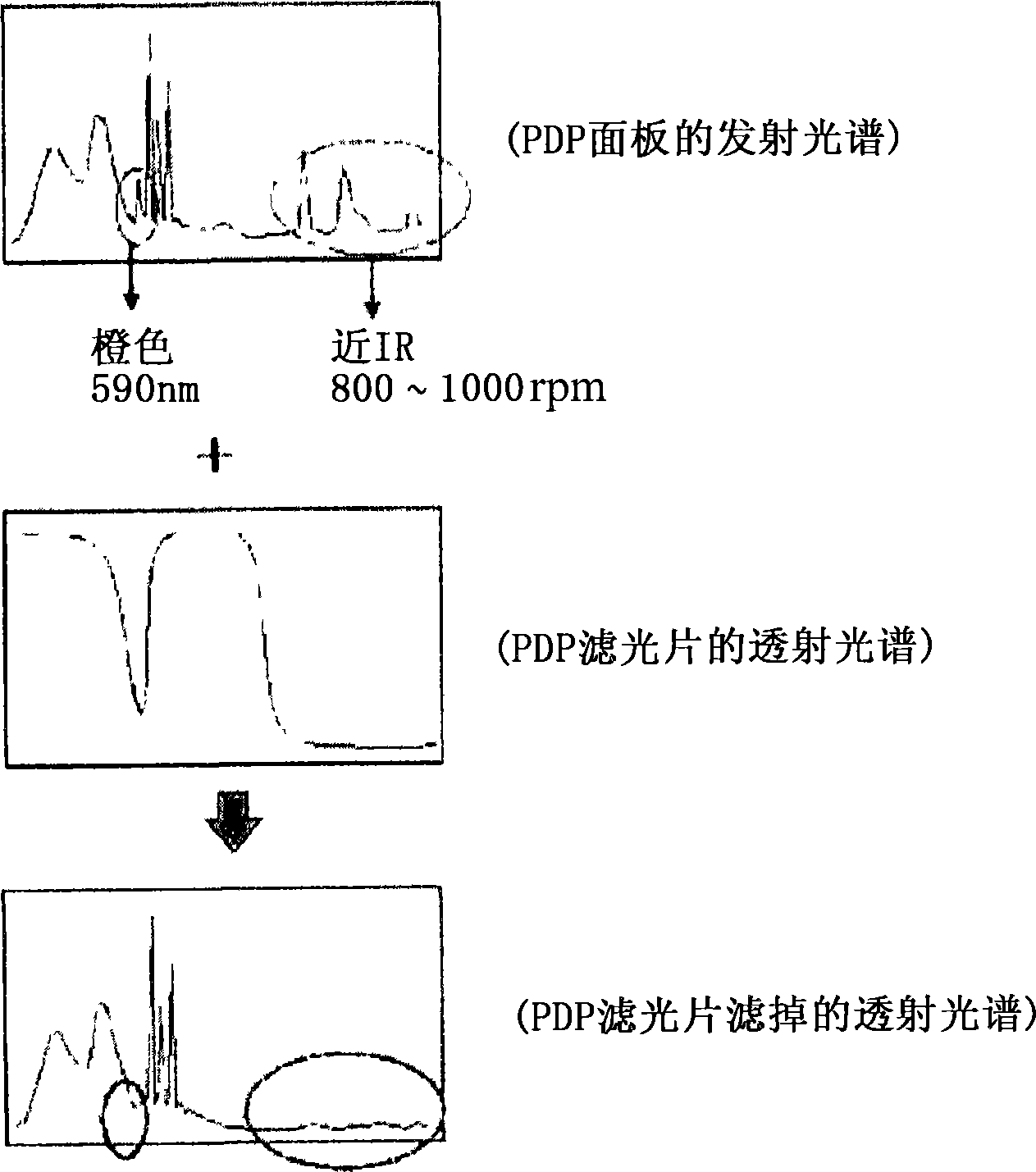

Film for PDP filter, PDP filter comprising the same and plasma display panel produced by using the PDP filter

InactiveCN1910723AReduce pollutionNo need to removeOptical/shielding coatings applicationCold-cathode tubesHigh humidityOrganic solvent

A film for a PDP filter including a binder resin composed of a styrene-acrylonitrile (SAN) copolymer, and a dye selected from the group consisting of a near infrared ray (NIR) absorbing dye, a Neon cut dye, a color control dye, and a mixture thereof is provided. The film for a PDP filter includes the SAN copolymer as a binder resin, and thus a change in transmittance is little under a high-temperature condition or a high-temperature and high-humidity condition, resulting in good durability and thermal stability and high transmittance in a visible light range. Further, since a general organic solvent can be used in the formation of the film, environmental pollution is reduced and the removal of a poisonous solvent is not required, thereby simplifying a process of forming the film.

Owner:LG CHEM LTD

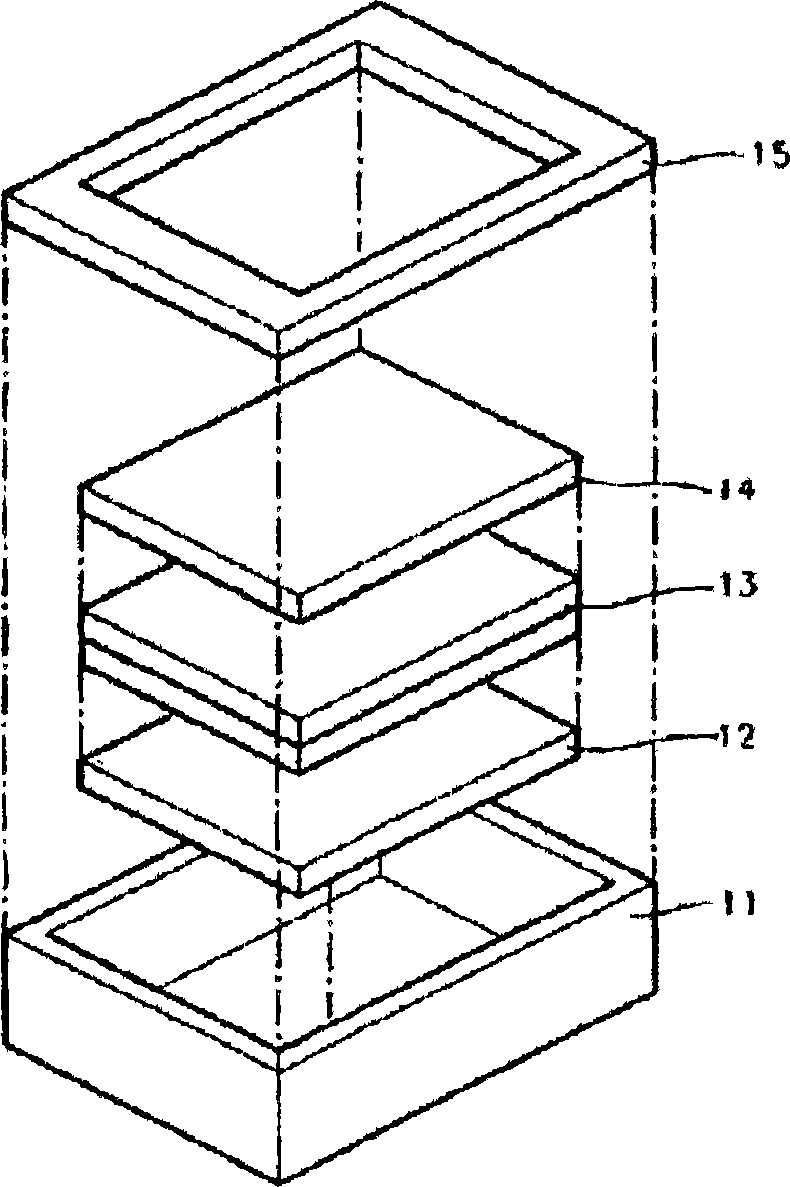

Prestressed concrete supporting pile wall

ActiveCN102605765AEasy to transportReduce shipping costsExcavationsBulkheads/pilesReinforced concretePre stress

The invention discloses a prestressed concrete supporting pile wall, which comprises a cement-soil wall consisting of a plurality of cement-soil stirring piles. The cement-soil wall is provided with an outwards protruded or staggered structure, prefabricated piles are continuously or intermittently inserted in the cement-soil stirring piles, each prefabricated pile comprises multiple sections of reinforced concrete members, a plurality of through holes are arranged on each reinforced concrete member along an axis direction, the reinforced concrete members of each prefabricated pile are serially connected together via an anti-bending rope penetrating through the through holes of the prefabricated pile, after being tensioned, each anti-bending rope is respectively fixedly connected with two ends of the corresponding prefabricated pile, and a reinforcing anti-shear plate is fixedly mounted at a joint of each two adjacent reinforced concrete members. Due to the mode, the prestressed concrete supporting pile wall not only guarantees safety and reliability of a foundation pit supporting structure, but also has a good economic benefit, is convenient in construction and low in influence to environments, and further meets requirements of foundation pit engineering construction.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

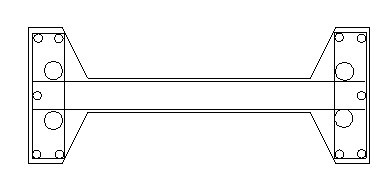

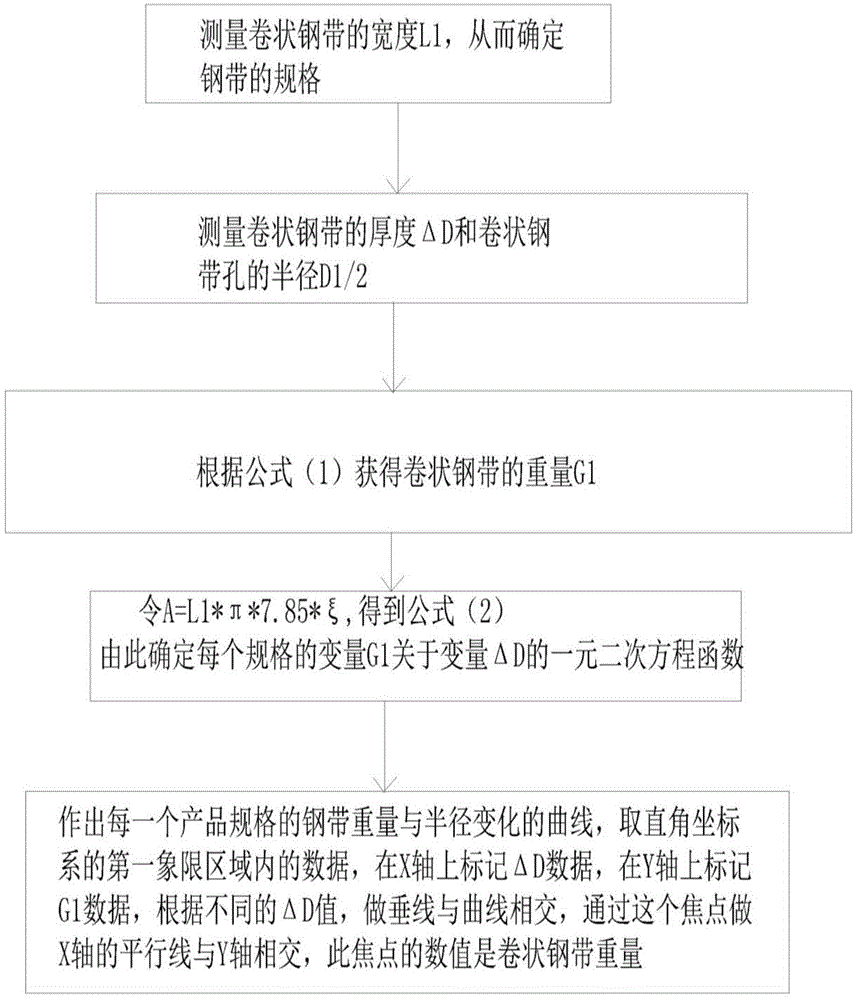

Coiled steel strip weight measuring and calculating method

InactiveCN104833285AAccurate weight calculationNo need to removeMechanical measuring arrangementsMetallurgyKeel

The invention relates to a coiled steel strip weight measuring and calculating method. With the method adopted, the weight of steel strips on a keel uncoiler can be calculated more accurately without dissembling the steel strips required. The method includes the following steps that: the width L1 of coiled steel strips is measured, and the specifications of the steel strips are determined; (2) the thickness deltaD of the coiled steel strips and the radius D1 / 2 of coiled steel strip holes are measured; (3) the weight G1 of the coiled steel strips is obtained according to G1=L1*PI*7.85*zeta*(D1*deltaD+deltaD2); (4) G1=A*(D1*deltaD+D2)=A*deltaD2+A*D1*deltaD is obtained, and a function of a variable G1 of steel strips of each specification relative to deltaD is determined; (5) curves indicating a situation that the weight of the steel strips of each product specification changes with the radius of the steel strips are drawn, and data in a first quadrant area are selected, and deltaD is marked on an X axis, and G1 is marked on a Y axis, and vertical lines are drawn according to different deltaD so as to intersect with the curves, parallel lines of the X axis, which pass through intersection points of the vertical lines and the curves, are drawn so as to intersect with the Y axis, and the intersection points of the parallel lines of the X axis and the Y axis are the weight of the coiled steep strips.

Owner:BEIJING NEW BUILDING MATERIALS PLC

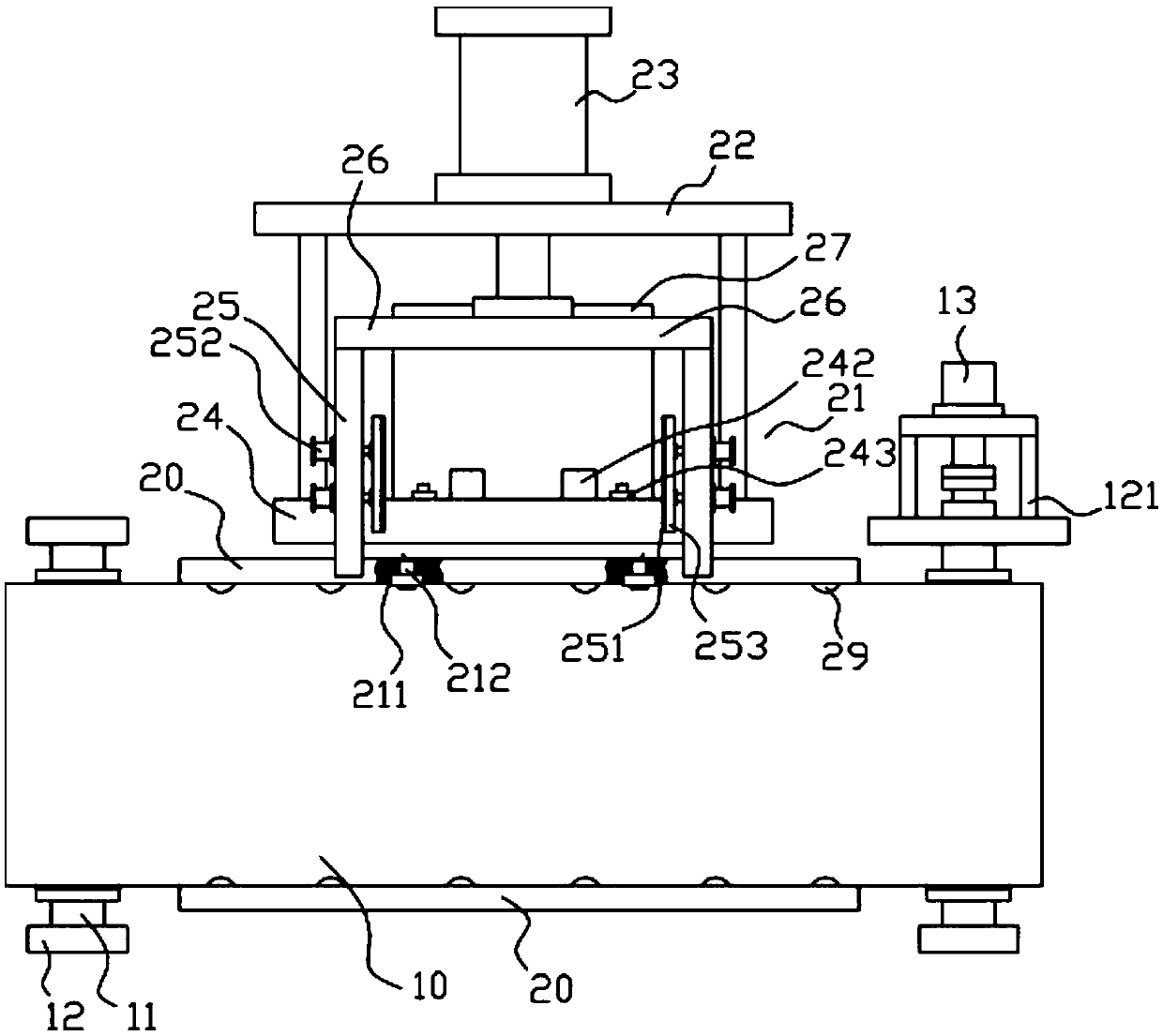

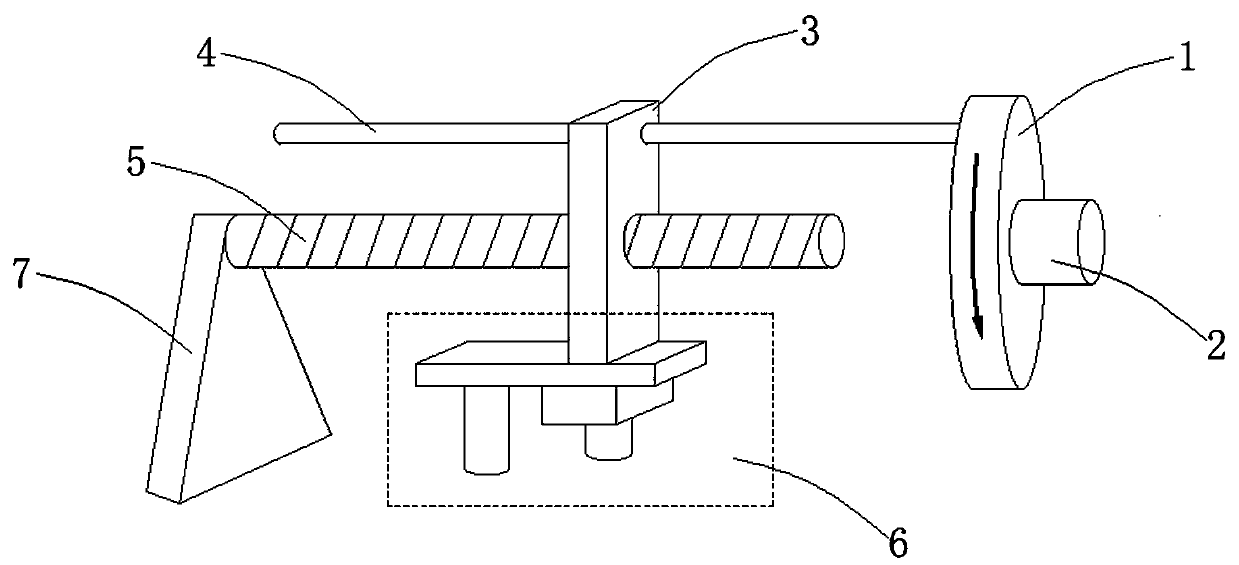

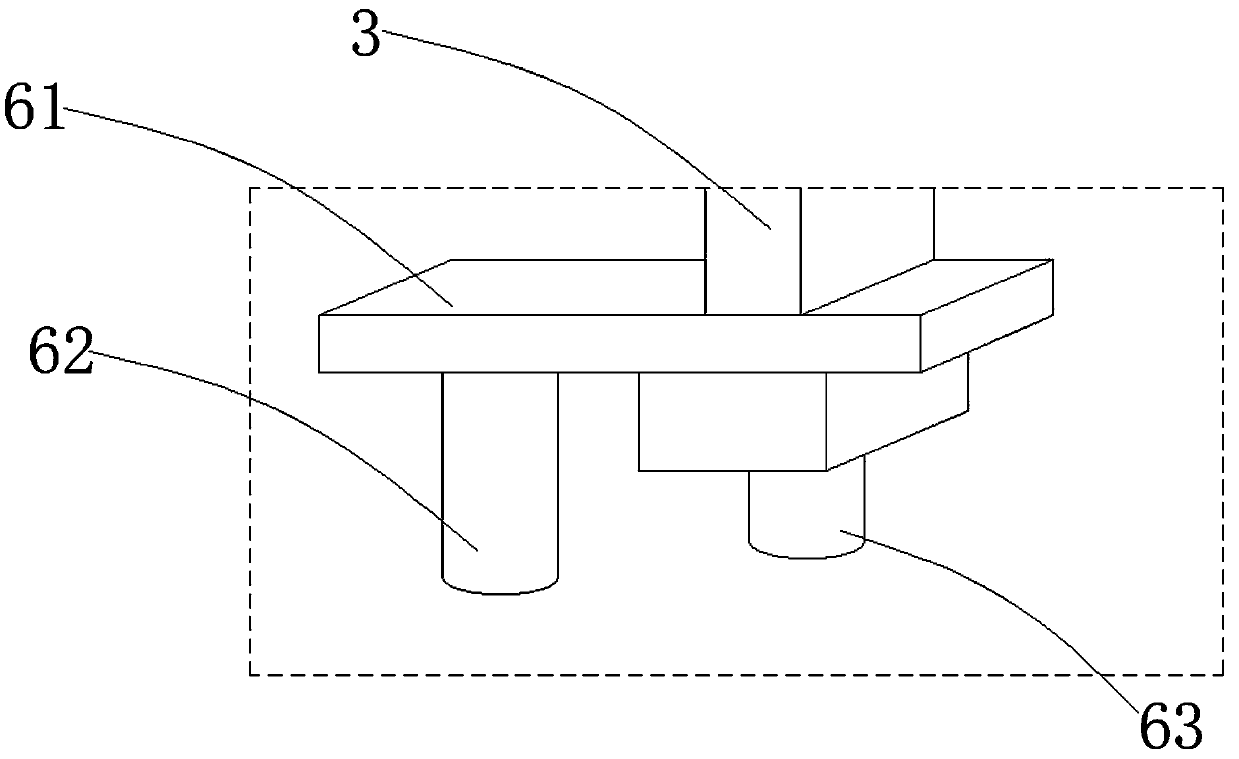

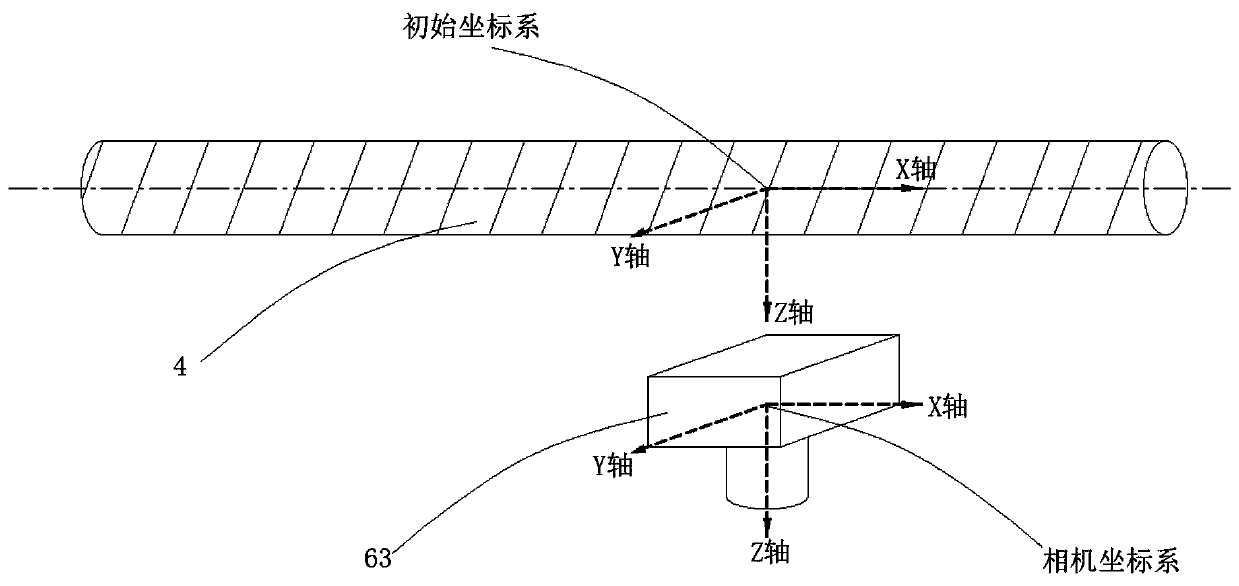

Automatic measuring device and method for inner wall of cavity part

The invention discloses an automatic measuring device for the inner wall of a cavity part. The device comprises a precession mechanism and a lead screw. The precession mechanism is in threaded connection with the lead screw, one end of the precession mechanism is provided with a driver, the other end of the precession mechanism is fixedly connected with a supporting frame, the driver can drive theprecession mechanism to rotate on the lead screw to move in an axial direction of the lead screw, and a vision measuring mechanism is arranged on the lower portion of the precession mechanism; and the driver is further provided with an encoder, and the encoder is electrically connected with the visual measuring mechanism. The specific method for measuring by using the measuring device comprises the following steps: step one, setting an initial coordinate system; step two, collecting images and calculating data; and step 3, carrying out data conversion. According to the measuring device and the measuring method, the lead screw serves as the positioning reference, mark points do not need to be pasted to the measured object in the measuring process, the mark points do not need to be removedafter measurement is completed, calculation of coordinate conversion is simplified, and three-dimensional measurement can be conducted on the inner wall of the cavity part without manual intervention.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

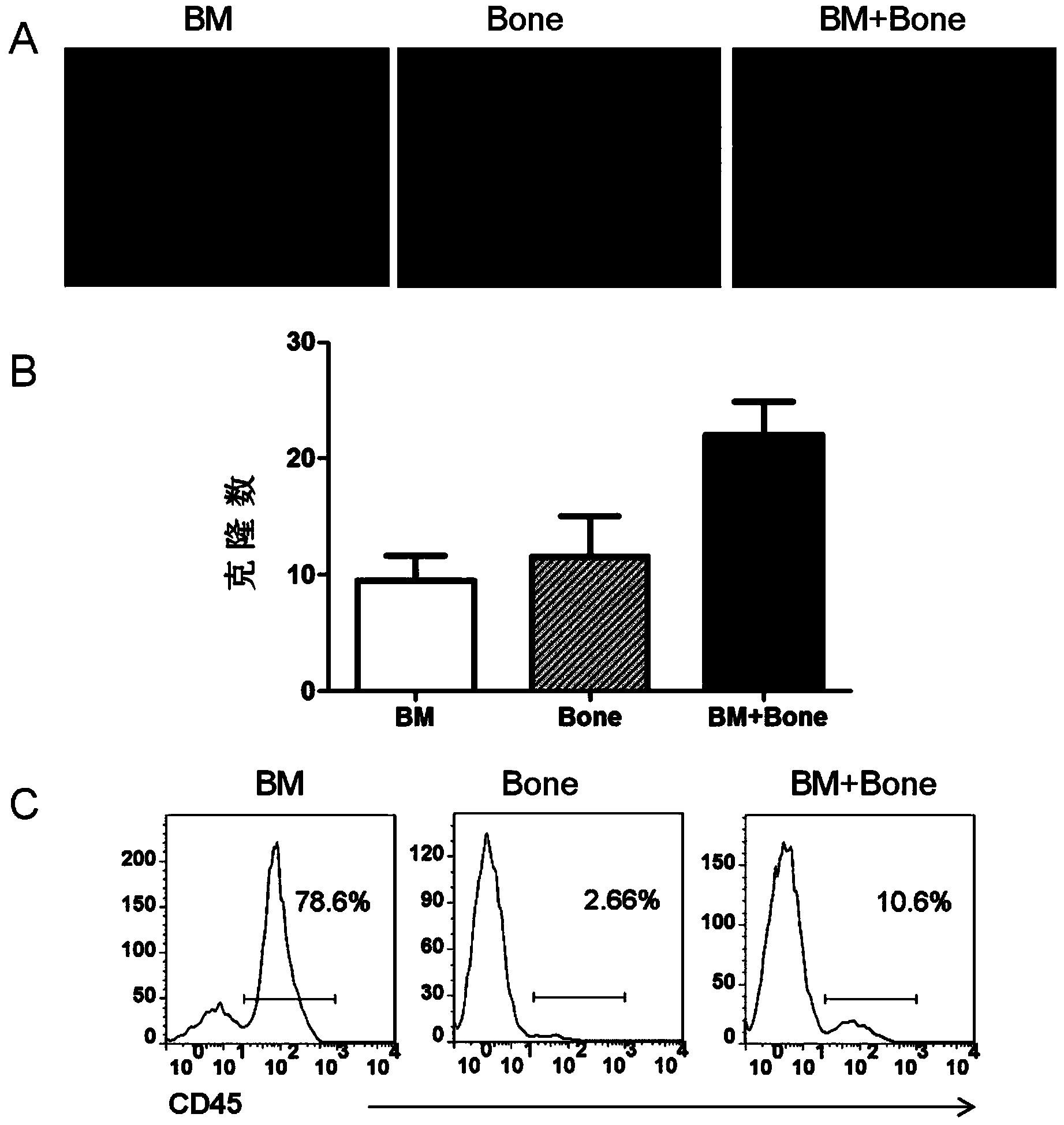

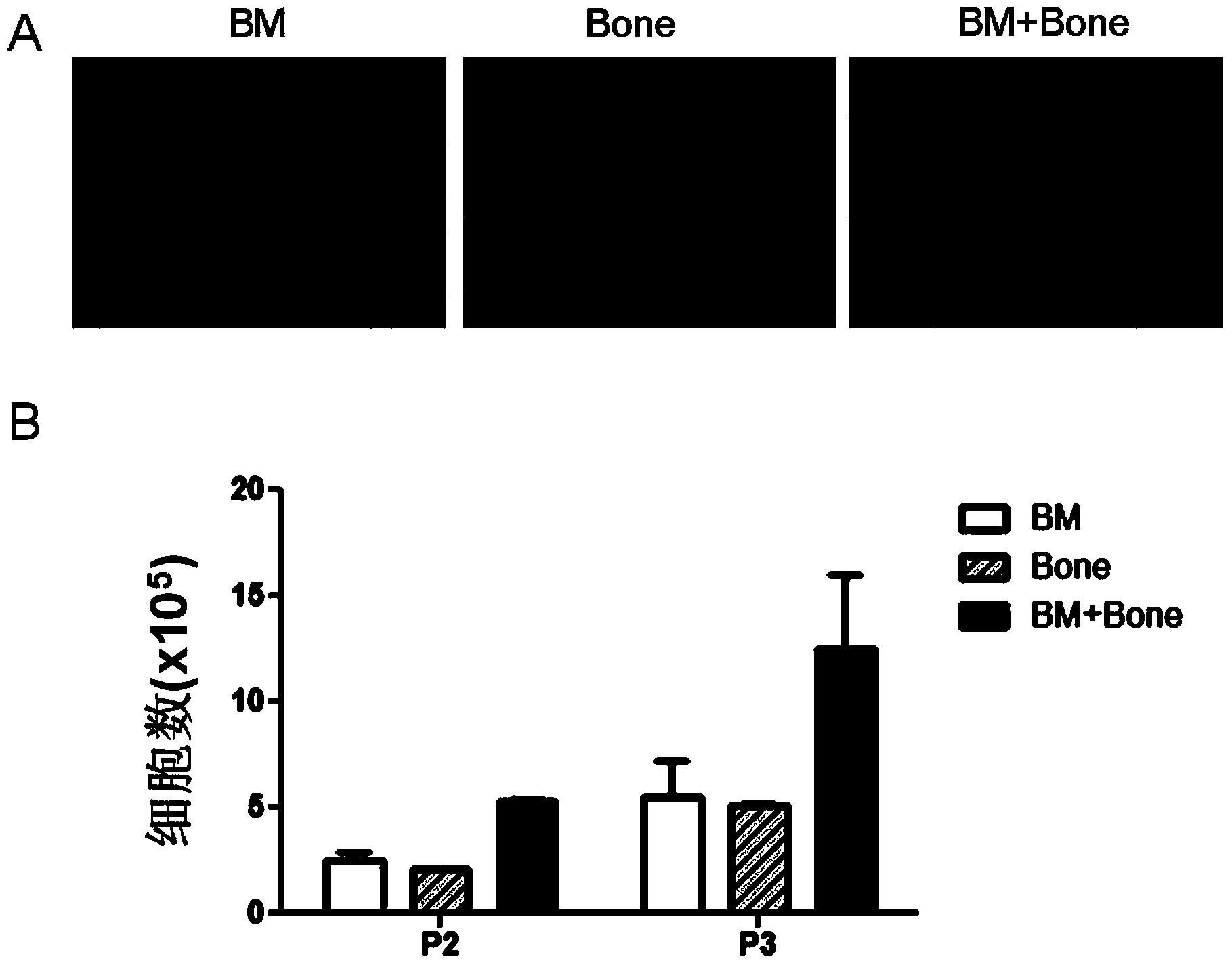

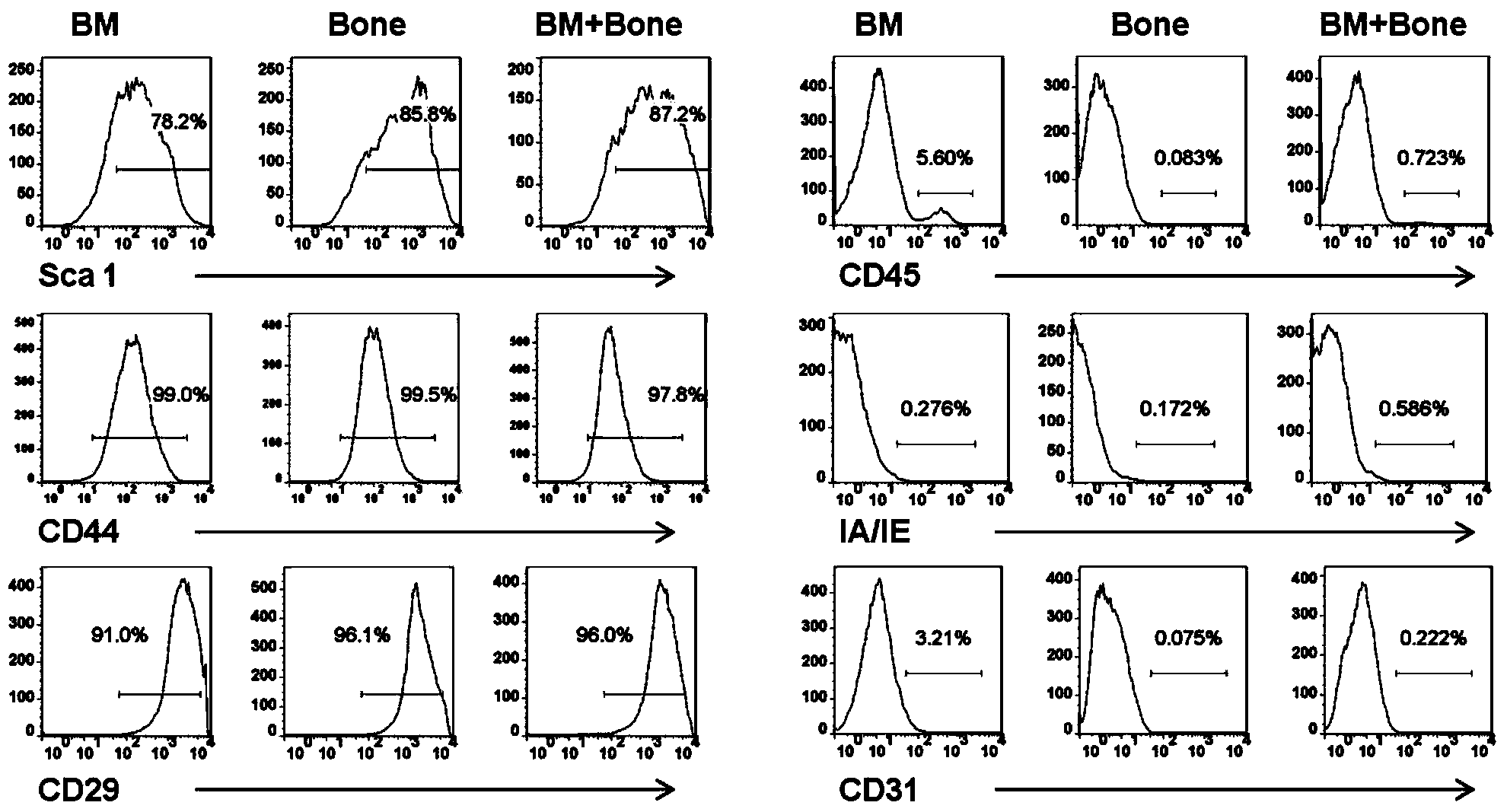

Method for separating and culturing animal bone marrow mesenchymal stem cell

ActiveCN103525761AAppeared earlyNo need to removeSkeletal/connective tissue cellsCell culture mediaSclerite

The invention discloses a method for separating and culturing an animal bone marrow mesenchymal stem cell (MSC). The method comprises the following steps: inoculating an inoculum into an animal cell culturing medium for primary culture, and subcultring cells obtained after the primary culture to obtain the animal MSC, wherein the inoculum is a precipitate obtained after centrifuging a long bone breaking liquid, and the long bone breaking liquid is a mixture obtained by breaking in-vitro animal long bones in a buffer solution to 0.5-2mm<3> particles. The method does not comprise a collagenase digestion step or an animal long bone marrow removal step. The method has the advantages of full utilization of the marrow and sclerite, simple processing, and obtaining of enough-quantity, good-growth-state and strong-proliferation-capability MSCs within a short time, and is a convenient, fast and efficient MSC separating and culturing method.

Owner:INST OF BASIC MEDICAL SCI ACAD OF MILITARY MEDICAL SCI OF PLA

Building waste brick-making production device

InactiveCN107718274ANo manual removal requiredNo need to removeMixing operation control apparatusPretreatment controlBrickArchitectural engineering

The invention relates to a building waste brick-making production device which comprises a first box body. Two horizontal crushing rods with power devices are arranged in the first box body, a first box body feeding opening is formed in the top end of the first box body, a first box body discharging opening is formed in the bottom end of the first box body, both sides of the first box body are fixedly provided with filtering boxes respectively, the opposite sides of the two filtering boxes are respectively provided with two openings, each opening is communicated with the interior of the firstbox body, and every two openings, arranged on the same side of the first box body, are disposed at the upper end and the lower end of the crushing stick respectively, a plurality of vertical lifting rods are fixedly arranged at the bottom end of each filtering box, and the top ends of the lifting rods in the same filtering box are connected through a supporting plate in a hinged mode. Building waste in the crushing process can be uninterruptedly filtered, so that the building waste reaches the required particle size and the brick-making production is carried out. Meanwhile, iron in the building waste does not need to be manually removed by the device, so that the labor intensity is reduced and the efficiency is improved.

Owner:XINYANG AGRI & FORESTRY UNIV

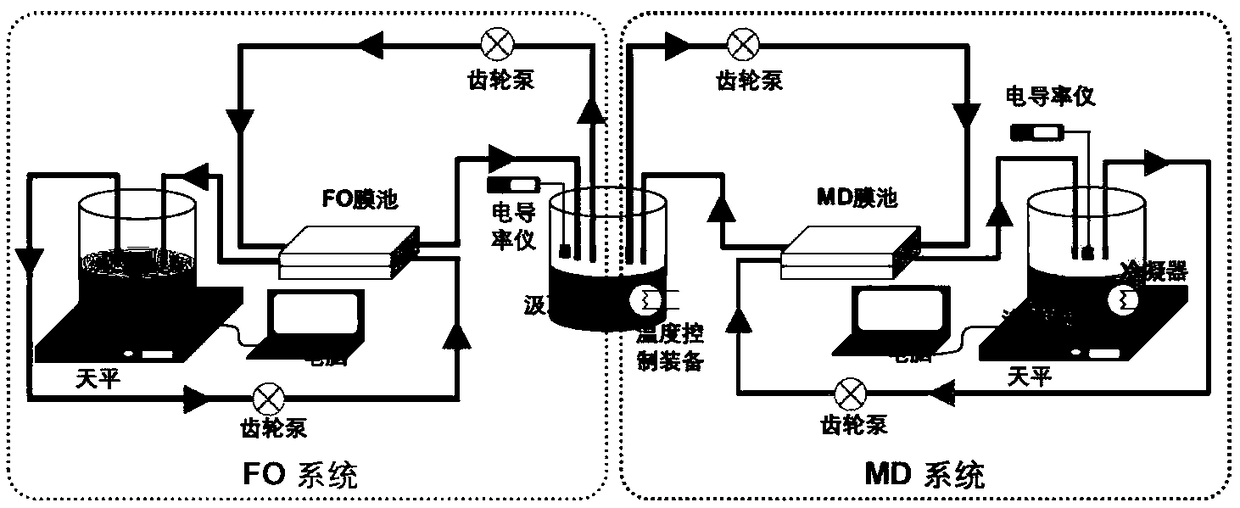

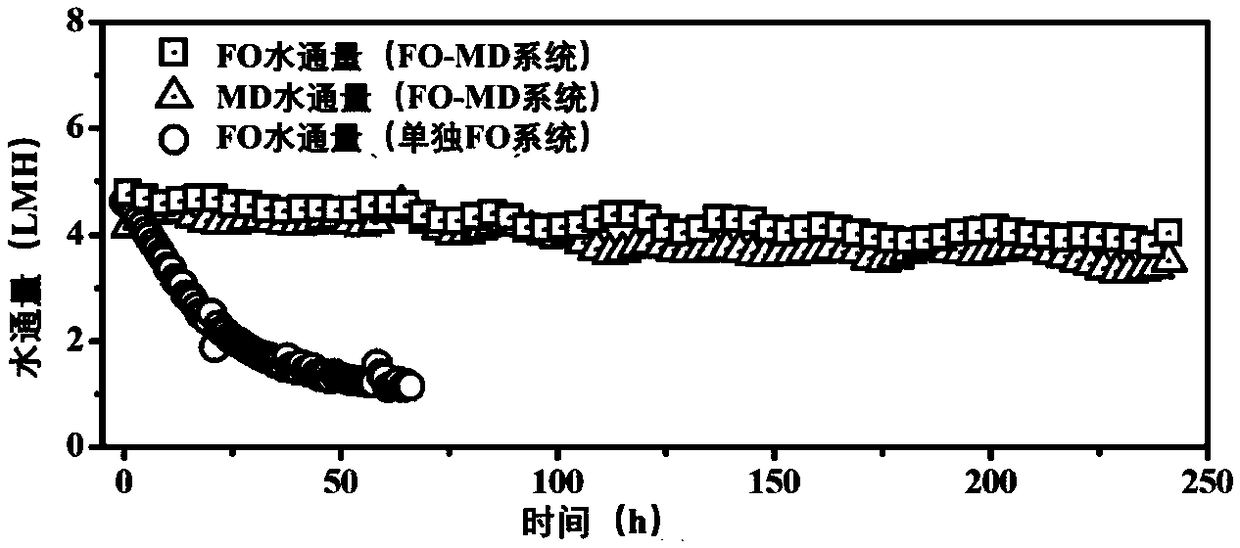

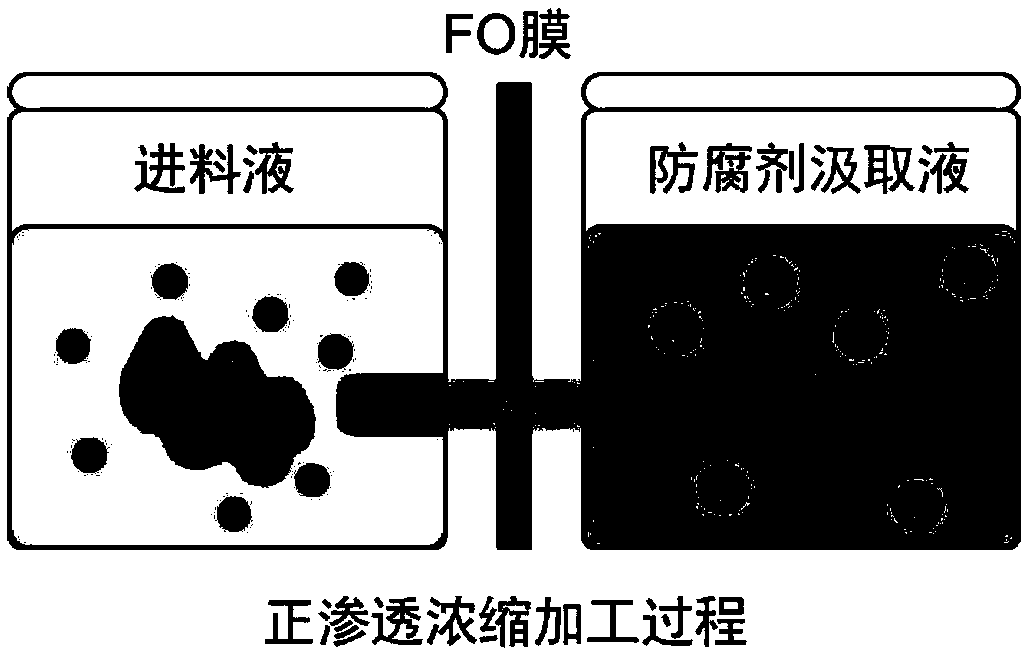

Application of positive infiltration technology using antiseptic as draw solution in product concentration

The invention discloses an application of a positive infiltration technology using an antiseptic as a draw solution in product concentration, which belongs to the technical field of food, chemical orpharmaceutical concentration processing. The technical scheme includes the application of the positive infiltration technology using the antiseptic as the draw solution in product concentration, specifically, the preservative is used as the draw solution, and the product is concentrated or separated by employing a positive osmosis system or a positive osmosis integrated system. The antiseptic is applied to the processing of food, chemical and pharmaceutical product, and solves the problem that the existing draw solution affects the product quality and easily causes membrane pollution. The antiseptic can be used as the draw solution to effectively inhibit the growth of microorganisms and reduce the risk of membrane pollution during the positive osmosis without affecting the quality of the product. At the same time, a draw solution solute entering the product through reverse osmosis can be used as an anti-corrosion additive, which cannot be required for being removed.

Owner:TIANJIN POLYTECHNIC UNIV

A method for reducing the color number of cyclopentadiene petroleum resin

The invention discloses a method for reducing the color number of cyclopentadiene petroleum resin. A C5 olefin fraction is taken as a raw material and added to a high-pressure reactor together with a solvent and a catalyst, inert gas in fed to remove air, proper inert gas pressure is guaranteed, and the cyclopentadiene petroleum resin is prepared at a proper reaction temperature for a proper reaction time. On the premise that the performance of high-end products is met, the process is simple, the investment is low, the catalyst is not required to be removed, wastewater containing fluoride and the like cannot be produced, and the method has the characteristics of environment friendliness, high efficiency and good benefit.

Owner:沈阳 +1

Method for preparing binary polyacrylonitrile-based carbon fiber protofilament

InactiveCN102605476AReduce dosageImprove structural regularityArtificial filament washing/dryingArtificial filament heat treatmentStructural regularityCarbon fibers

The invention relates to a method for preparing a binary polyacrylonitrile-based carbon fiber protofilament. The method comprises the following steps of: (1) performing copolymerization reaction on acrylonitrile and beta-ammonium itaconate for 10 to 30 hours at the temperature of between 50 and 70 DEG C by using dimethyl sulfoxide as a solvent and using azodiisobutyronitrile as an initiator, filtering, removing residual monomers, and defoaming to obtain a spinning solution; and (2) sequentially performing dry-spray wet spinning, drawing, oiling, drying densification, hot steam drawing and heat setting on the spinning solution, and thus obtaining the carbon fiber protofilament. By the method, the consumption of copolymerization monomers is reduced, and the structural regularity of polyacrylonitrile macromolecules is improved; and the prepared carbon fiber protofilament is uniform in structure, low in fineness and high in strength, and is suitable for preparing high-performance carbon fibers.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com