Prestressed concrete supporting pile wall

A technology for supporting pile walls and concrete, applied in sheet pile walls, construction, excavation, etc., can solve the problems of large amount of steel bars and concrete in cast-in-situ piles, high transportation and leasing costs of section steel, and increased use cost of section steel, etc., to achieve Good economic benefits, enhanced bending stiffness and lateral movement resistance, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0034] see Figure 1 to Figure 4 , the embodiment of the present invention includes:

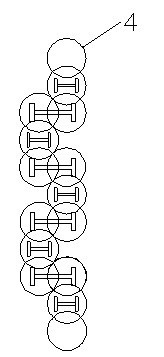

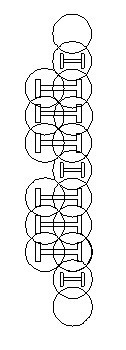

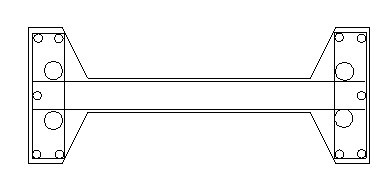

[0035] A prestressed concrete supporting pile wall, comprising: a cement-soil wall composed of several cement-soil mixing piles 4, the cement-soil wall has a convex or staggered structure, and the cement-soil mixing pile 4 is continuous Or prefabricated piles are inserted at intervals.

[0036] The cement-soil mixing pile 4 is constructed by a three-axis cement-soil mixing pile construction machine, and three cement-soil mixing piles 4 interlocking are processed each time, which are respectively the front pile, the middle pile and the rear pile, forming a ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com