Application of positive infiltration technology using antiseptic as draw solution in product concentration

A forward osmosis and preservative technology, which is applied in the application field of forward osmosis technology in product concentration, can solve the problems of forward osmosis membrane pollution, affecting food flavor, and high reverse osmosis volume, so as to inhibit the growth of microorganisms and reduce the risk of membrane pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

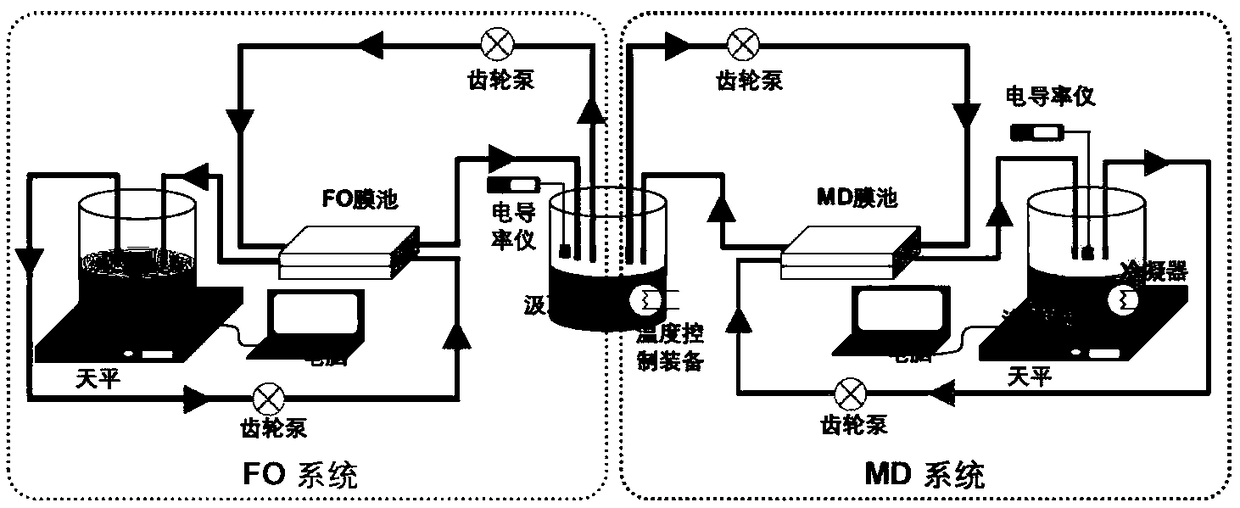

[0042] Such as figure 1 As shown, the FO system is equipped with a membrane element of a forward osmosis membrane, a feed liquid circulation system located on one side of the forward osmosis membrane and a draw liquid circulation system located on the other side of the forward osmosis membrane, and the MD system includes a distillation The membrane element of the membrane, the cold side water circulation system on one side of the distillation membrane and the draw liquid circulation system on the other side of the distillation membrane.

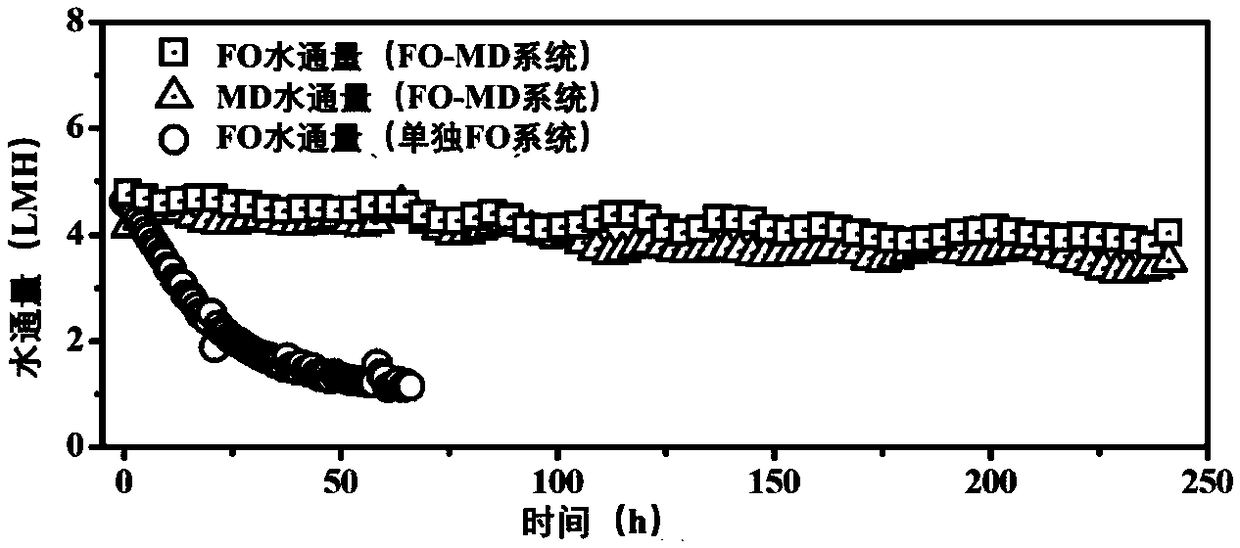

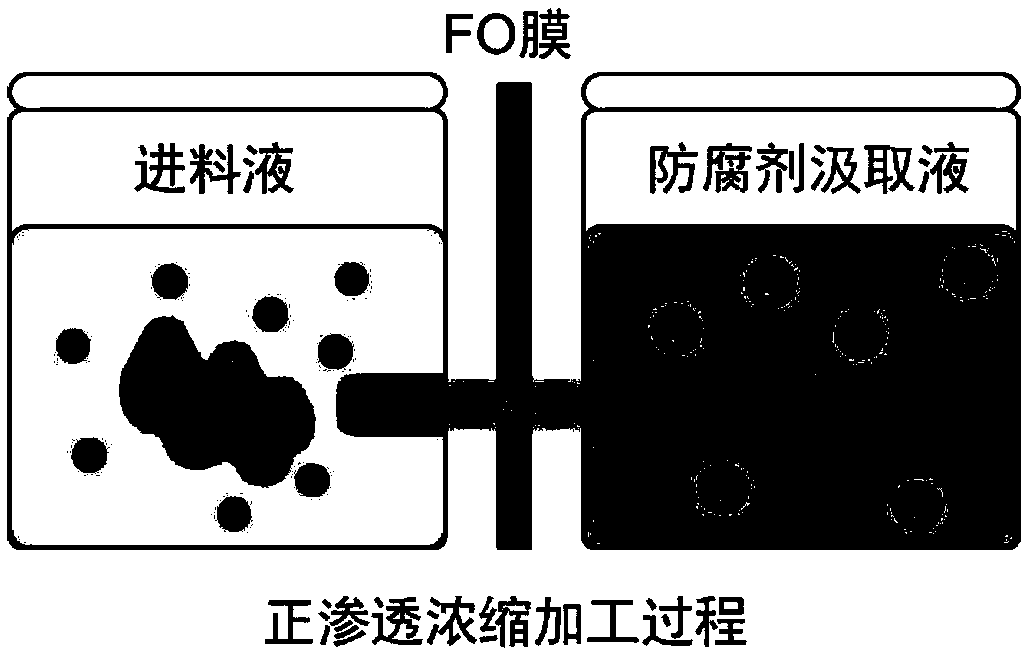

[0043] The thin film composite forward osmosis membrane based on polysulfone substrate and the nanofiber hydrophobic membrane were gently installed into the membrane elements of the FO system and the membrane elements of the MD system respectively, and the potassium sorbate solution with a concentration of 2mol / L was used as the draw solution to open the FO system. Two gear pumps on both sides of the forward osmosis membrane of the system, ad...

Embodiment 2

[0046] The application method of the forward osmosis technology of the preservative as the drawing solution in product concentration is the same as in Example 1, the difference is that the lemon juice is concentrated with the sodium ascorbate solution of 2mol / L as the drawing solution, and the forward osmosis Water flux data for concentrated lemon juice such as Figure 5 shown.

Embodiment 3

[0048] The application method of the forward osmosis technology of the preservative as the drawing solution in product concentration is the same as in Example 1, the difference is that the lemon juice is concentrated with 2mol / L sodium nitrite solution as the drawing solution, and the forward osmosis concentrates the lemon juice The water flux data such as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com