A method for reducing the color number of cyclopentadiene petroleum resin

A technology of petroleum resin and cyclopentadiene, which is applied in the field of reducing the color number of cyclopentadiene petroleum resin, can solve the problems of high price, low benefit, and low product color number, and achieve simple process, low investment and good benefit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

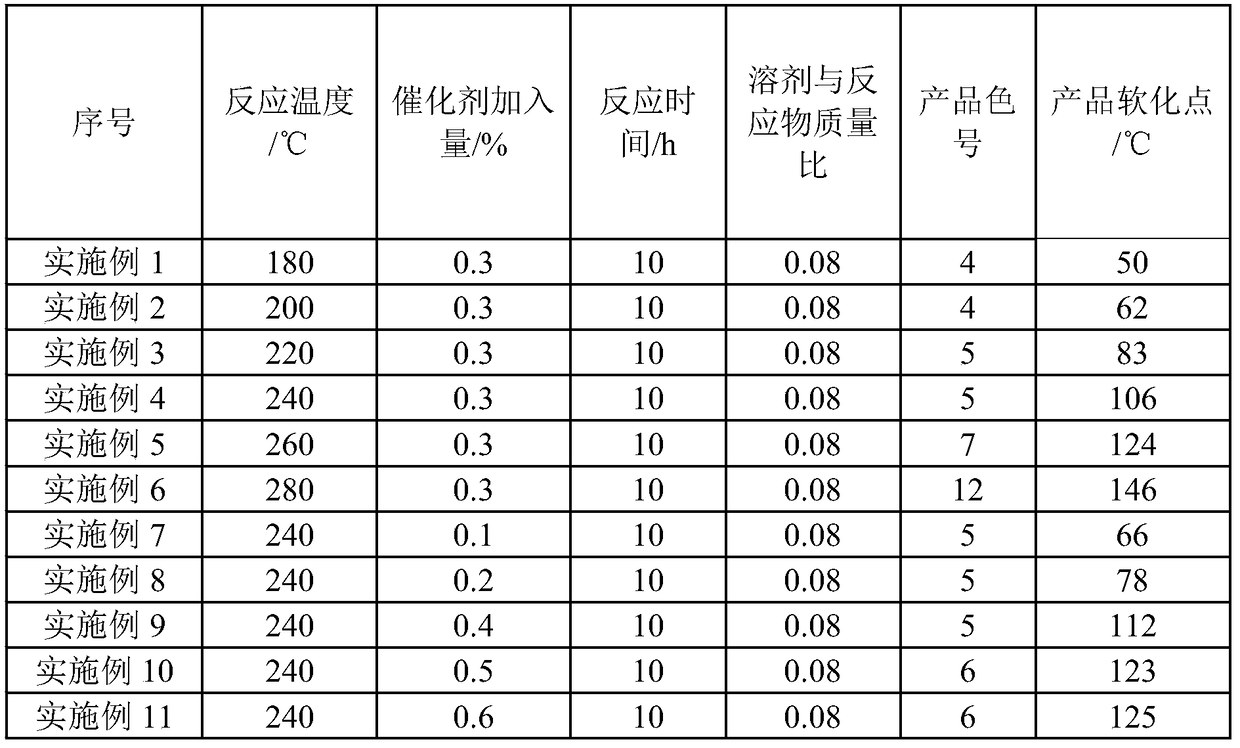

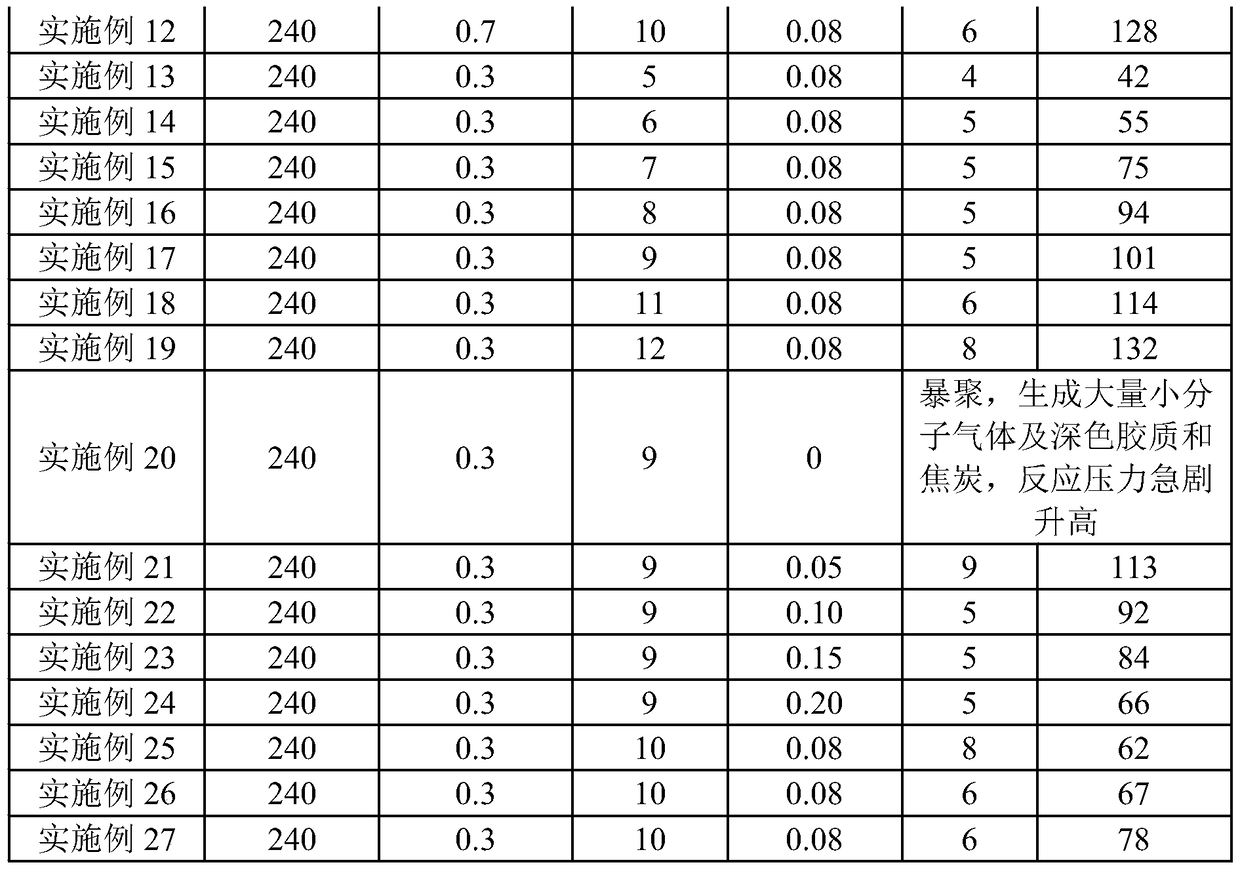

Examples

Embodiment 1

[0015] 1. Take 3g of composite catalyst, 80g of solvent, and 1000g of C5 into the reaction device, and stir for 20 minutes; the catalyst is composed of azobisisobutyronitrile, dicumyl peroxide, 2,5-dimethyl-2,5 -Bis(tert-butylperoxy)hexane, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol, tris[2,4-di-tert-butylphenyl ] Phosphite, β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, calcium stearate, zinc stearate by mass ratio 1:2:1: 0.5:1:0.5:0.3:0.2 mixed.

[0016] 2. Keep stirring, pass the inert gas for 10 minutes, seal the reaction device, and keep the inert gas pressure of 0.1MPa.

[0017] 3. React at 180°C for 10 hours, then cool down to 60°C.

[0018] 4. Distill the reaction materials to remove the solvent and oligomers, and the bottom of the kettle is the product.

[0019] 5. Analyze product data, mainly for color number and softening point.

Embodiment 2

[0021] Same as Example 1, the difference is that the reaction temperature is 200°C as shown in Table 1.

Embodiment 3

[0023] Same as Example 1, the difference is that the reaction temperature is 220°C as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com