Patents

Literature

135 results about "Tellurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry tellurate is a compound containing an oxyanion of tellurium where tellurium has an oxidation number of +6. In the naming of inorganic compounds it is a suffix that indicates a polyatomic anion with a central tellurium atom.

Leadless tellurate low melting glass used as cementation phase in electronic slurry

The leadless tellurate low melting glass is used as binder phase for preparing electron paste. Said glass is mixed with functional powder to produce composite powder, which is then dispersed in organic solution to prepare thick paste, i.e. electron paste, used for making various kinds of electron devices. Said low melting glass, during sintering, melts-out and takes effect of adhering. The sintering temperature is between 350-600deg.C when making electron device. The components of the glass are (mass percentages): TeO2 10-90%,V2O5 0-40%,SiO2 0-5%,B2O3 0-5%,ZnO 0-10%,Bi2O3 0-20%,Sb2O3 0-8%,Al2O3 0-4%,SnO2 0-6%,Ag2O 0-10%,BaO 0-5%,MgO+CaO 0-5%.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

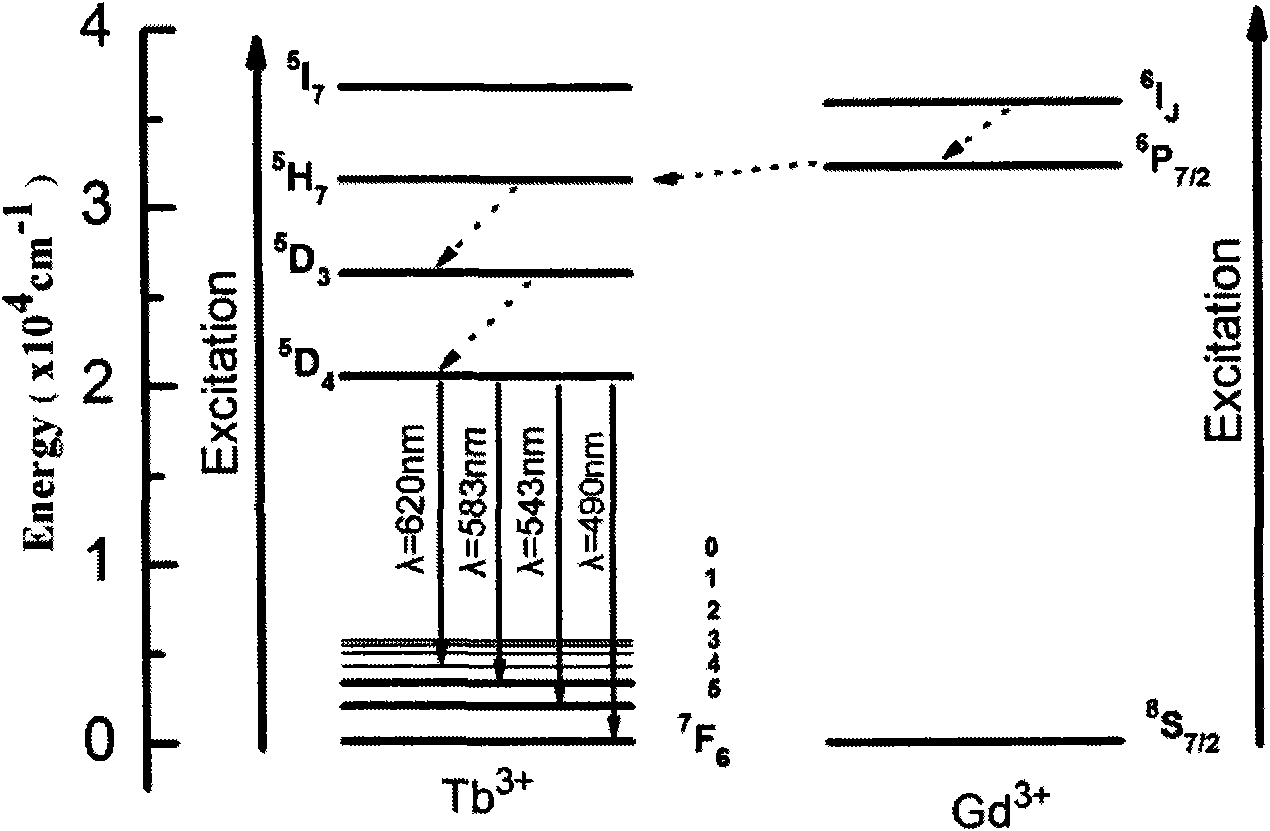

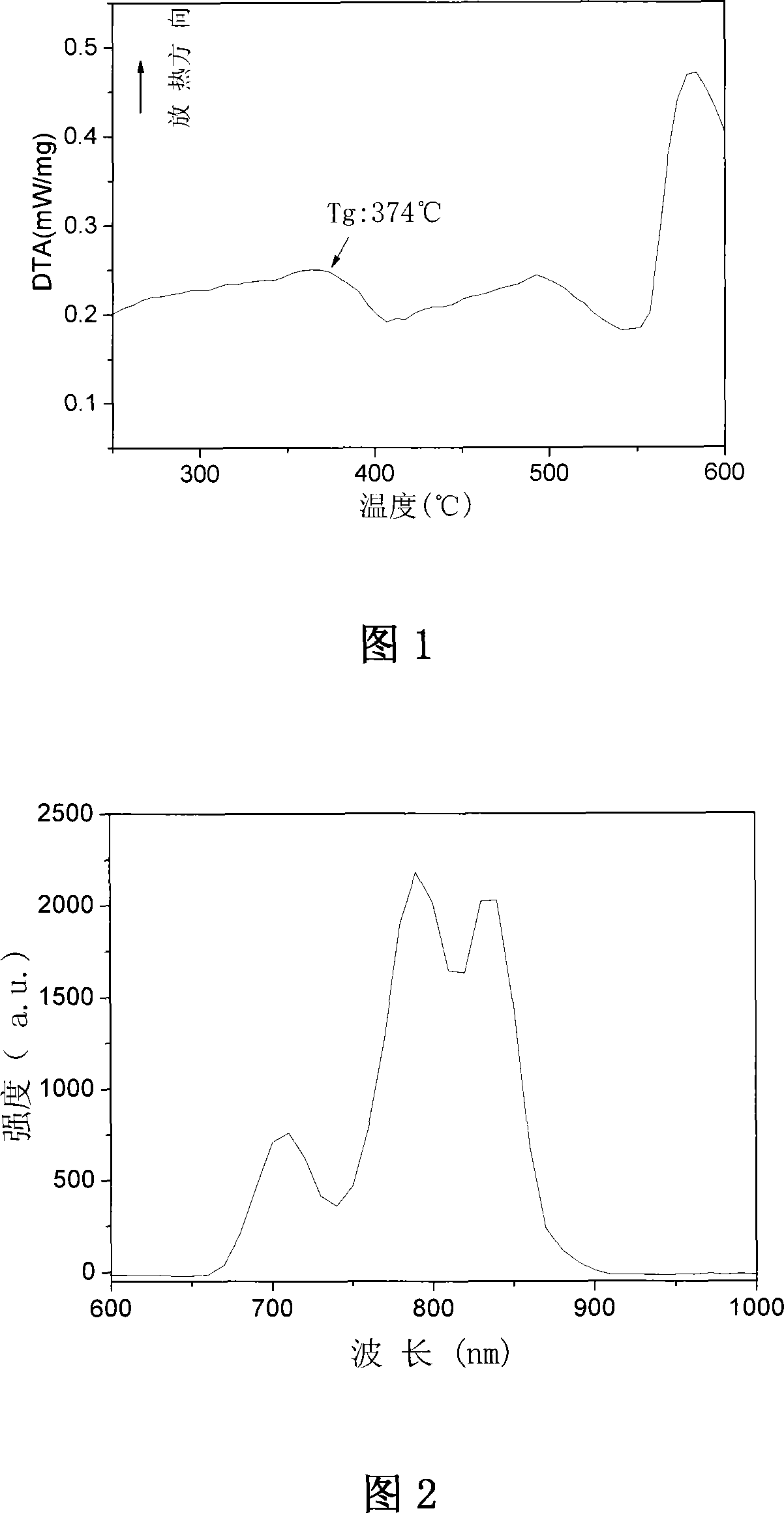

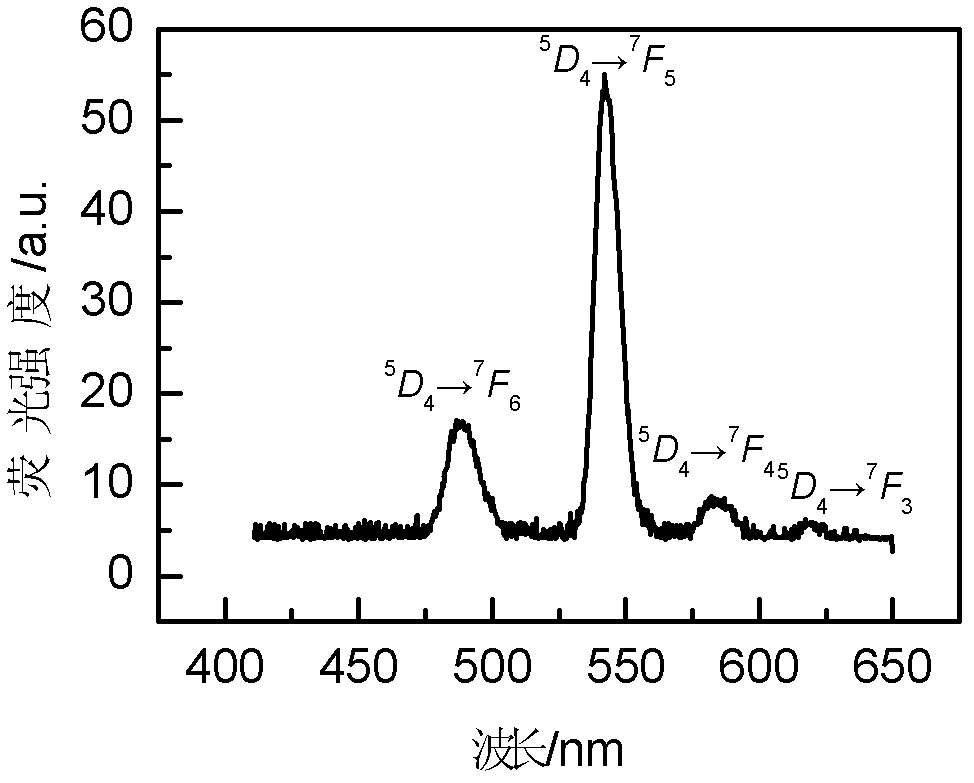

Rare-earth doped oxyfluoride tellurate scintillation glass and preparation method thereof

The invention discloses rare-earth doped oxyfluoride tellurate scintillation glass and a preparation method thereof. Raw materials TeO2, PbF2, BaF2 and Gd2O3 of the scintillation glass are high-density compounds, so the obtained oxyfluoride tellurate glass has high density, and the density can reach over 6g / cm<3>. Compared with the traditional scintillation glass containing the raw materials PbO, Bi2O3 and the like according to the raw material formula, the scintillation glass of the invention has high short wavelength blue-violet light transmittance and avoids self absorption of the glass; wide wave band also can transmit visible light; the Gd2O3 raw material contained in the scintillation glass can sensitize the luminescence of rare-earth ions such as Tb3+, Ce3+ and the like and greatly improves the output of scintillation light; therefore, the scintillation glass has the advantages of high density, strong scintillation light emission and output, wide wave band and good short wavelength transmission performance. The preparation method for the scintillation glass is simple and has low production cost.

Owner:NINGBO UNIV

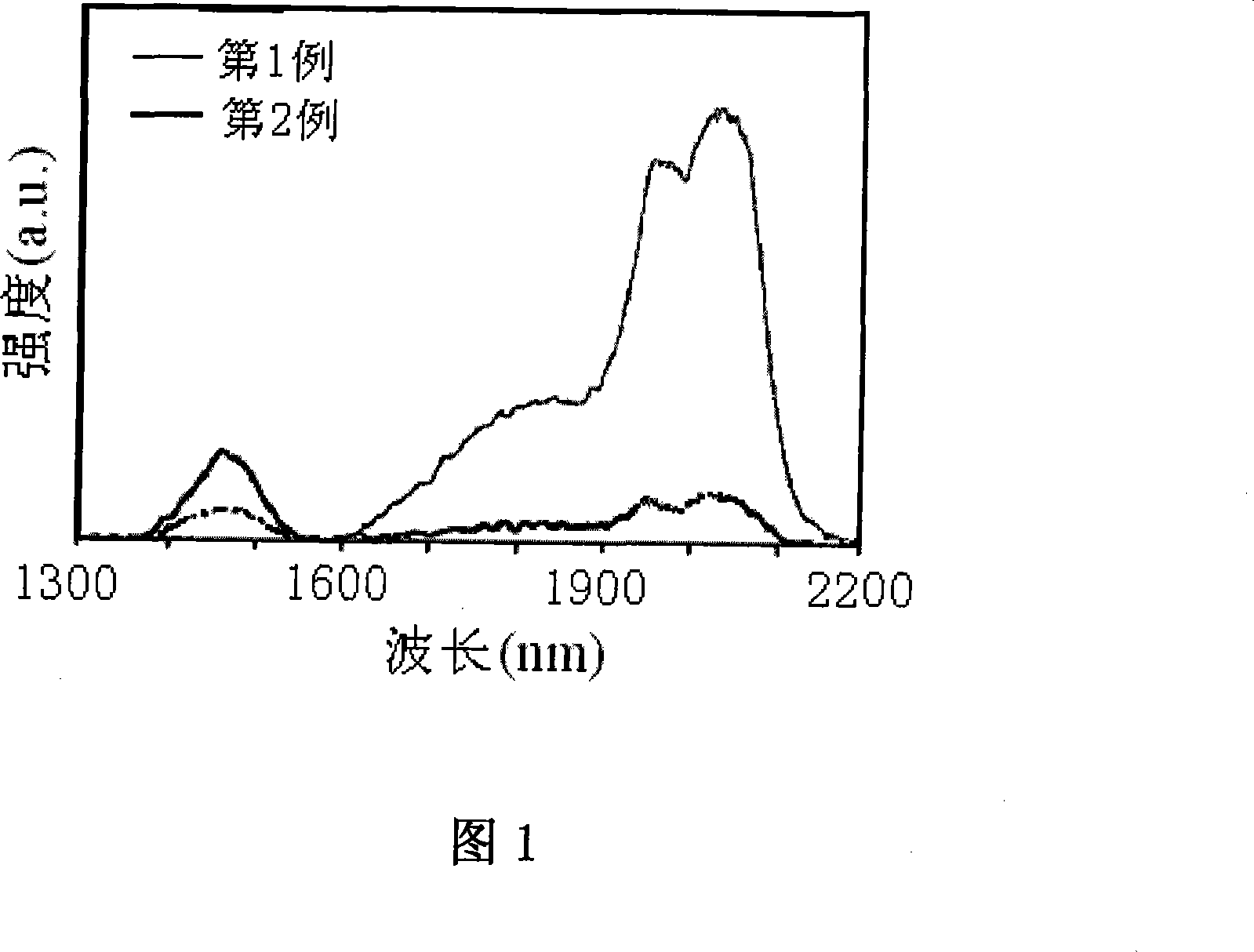

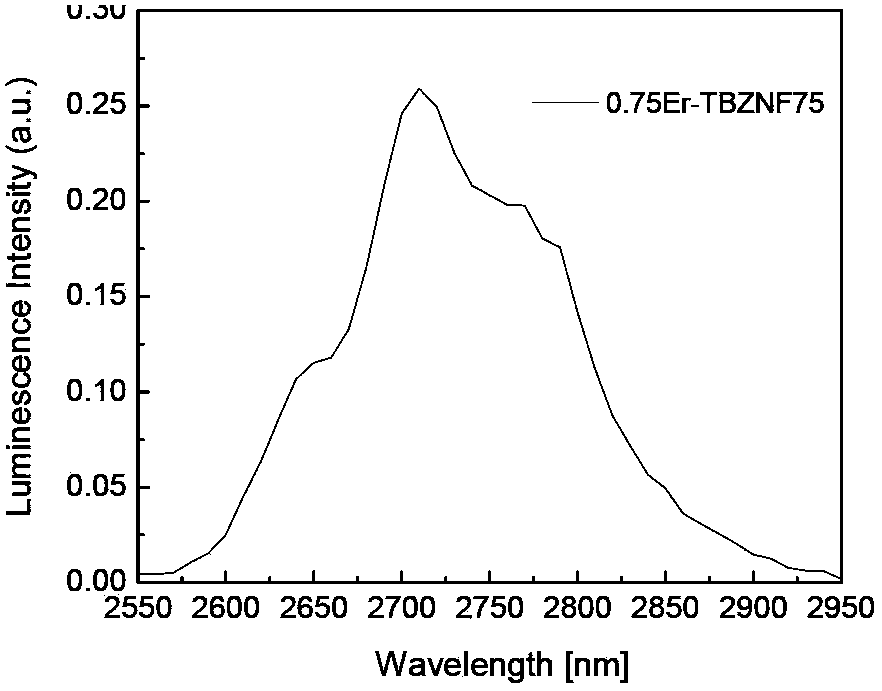

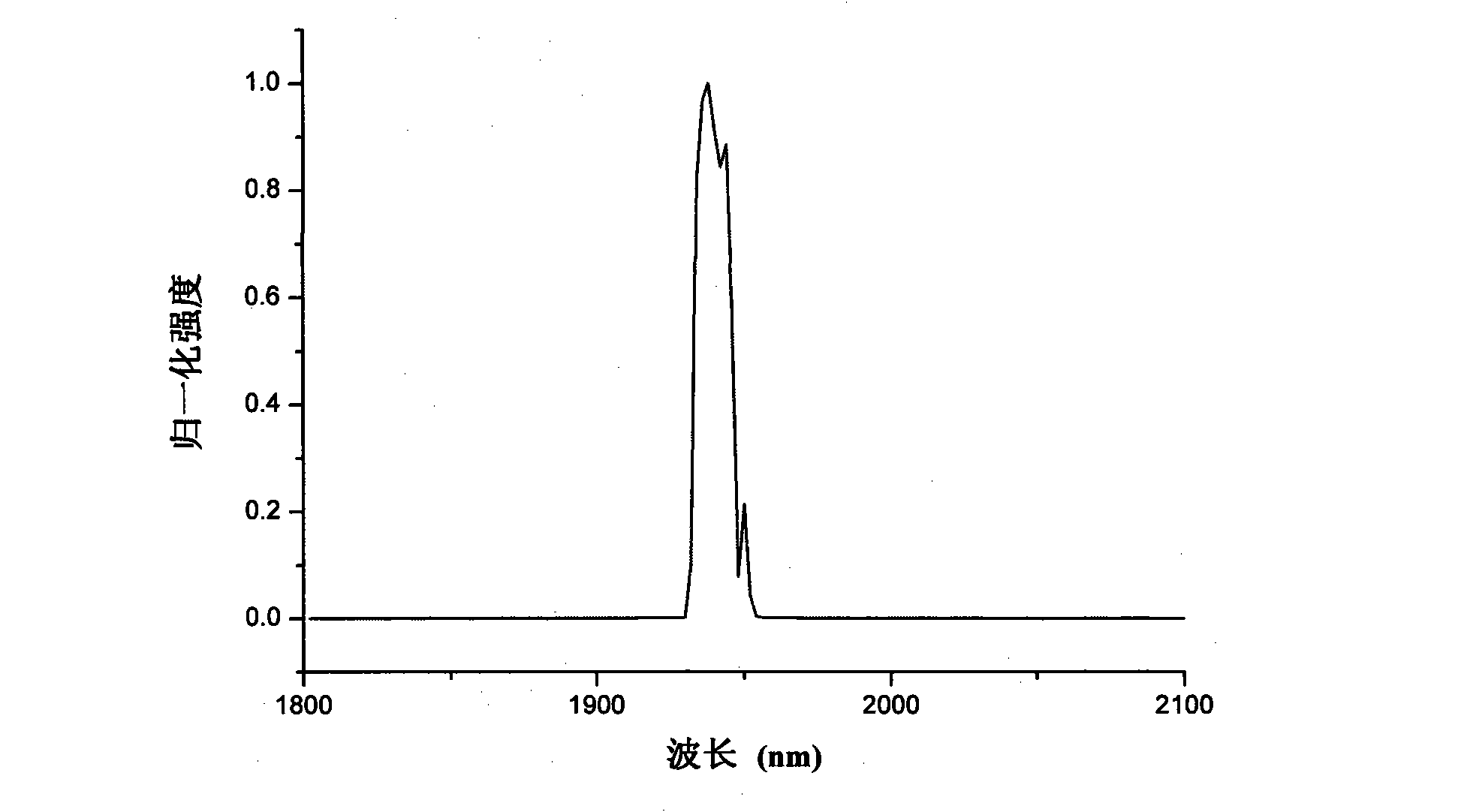

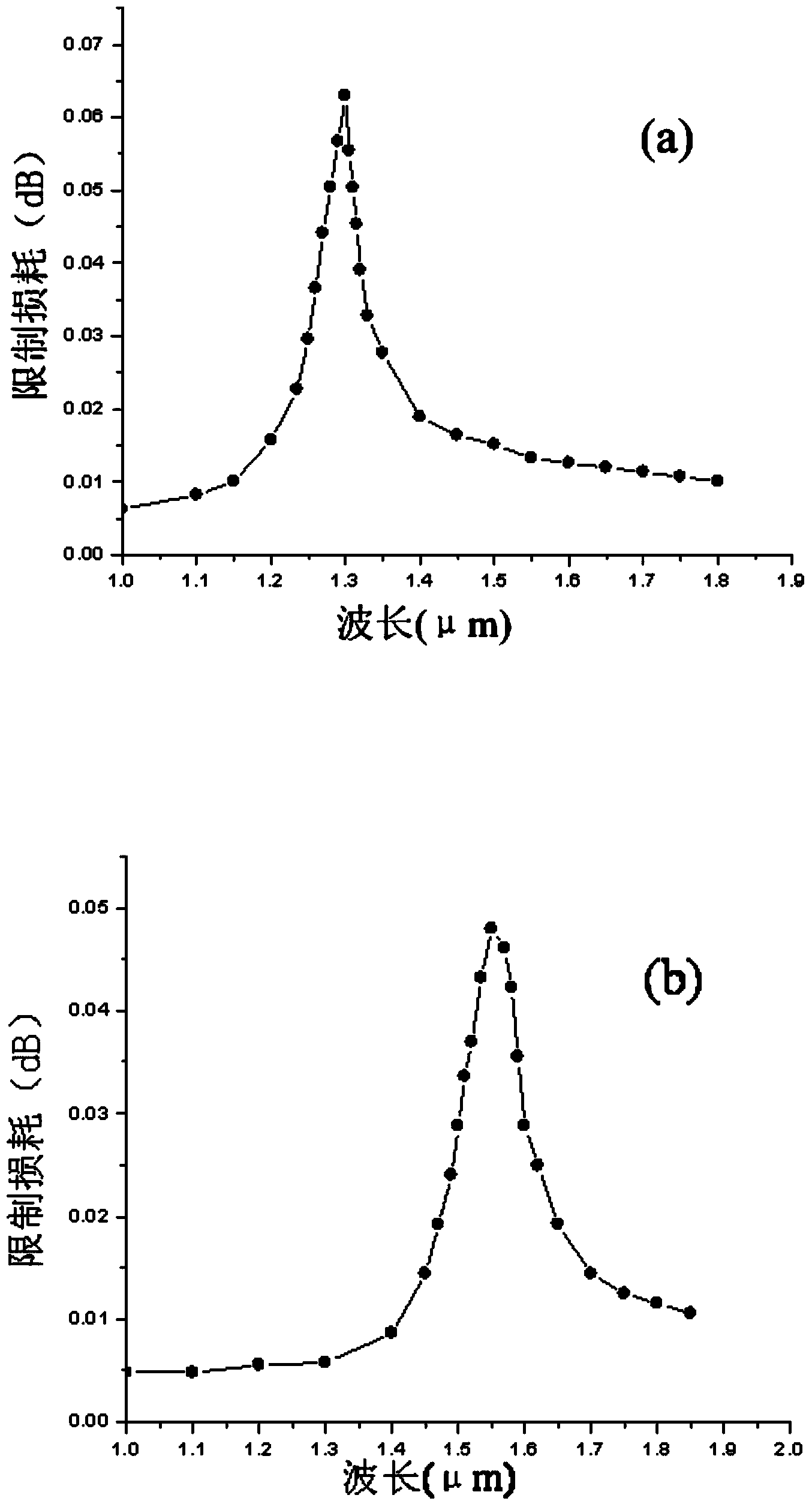

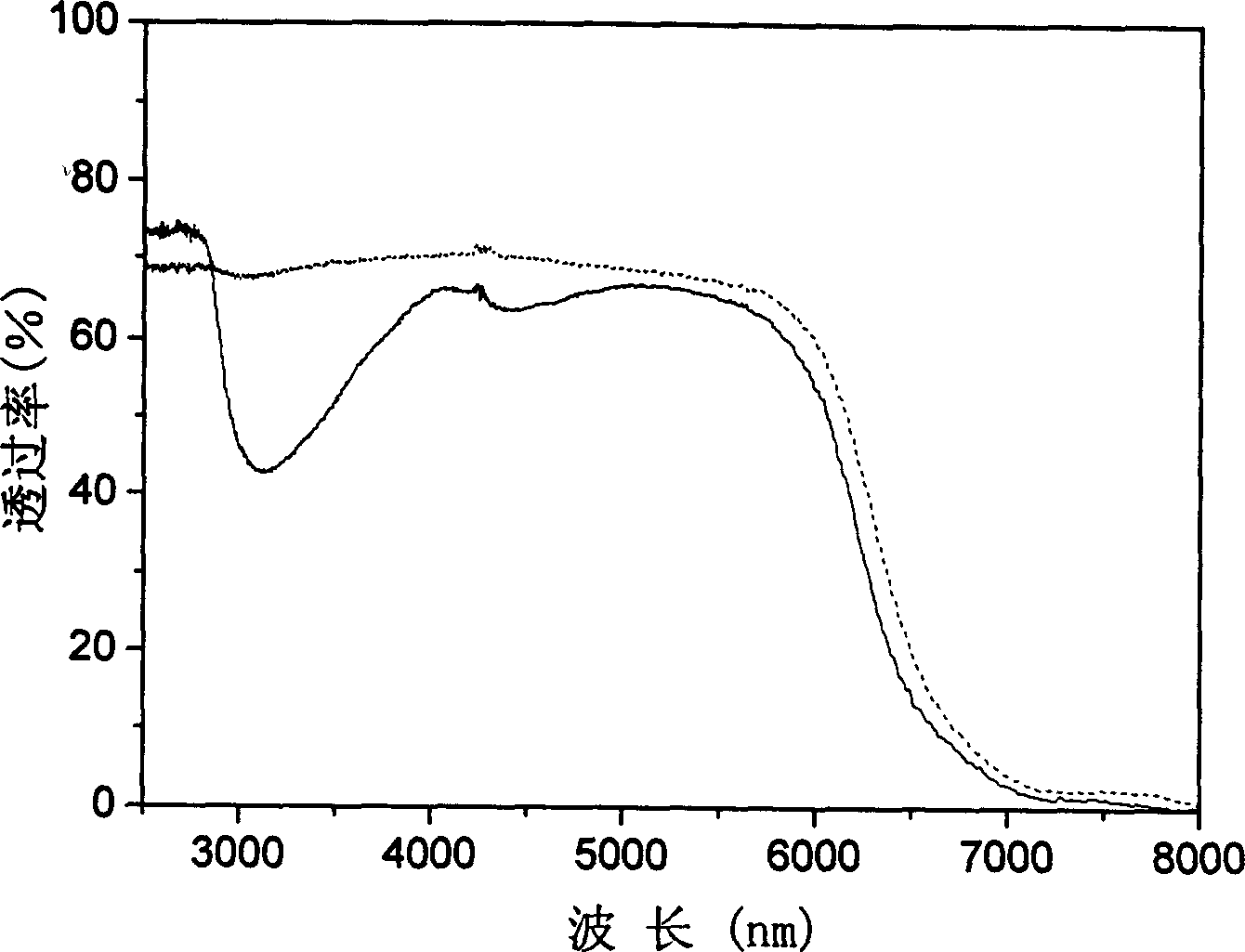

2ª–m band light-emitting oxyhalide tellurite glasses

The invention relates to a piece of luminous oxyhalide tellurate glass with 2 Mum wave band, the glass compositions and mole percentages are as follows: TeO2: 40-85, PbO: 0-15; PbF2 plus ZnF2: 5-30; ZnO: 0-15; GeO2: 0-10; Nb2O5: 0-10; WO3: 0-10; Li2O plus Na2O plus K2O: 3-10; Tm2O3 plus Ho2O3 plus Er2O3 plus Yb2O3: 2-7, wherein, at least one of the Tm2O3 and the Ho2O3 is not equal to zero. The glass is prepared through a common melting method. The oxyhalide tellurate glass of the invention has the advantages of high infrared transmittance, transparence, no crystallization, no bubbles and stripes, excellent pinhole test, high luminous efficiency at the 2 Mum wave band, etc. The preparation technique is simple, can be operated easily and has lower cost. The materials of the invention are applicable to infrared laser optical lenses at the 2 Mum wave band or infrared special fiber matrix materials at the 2 Mum wave band.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

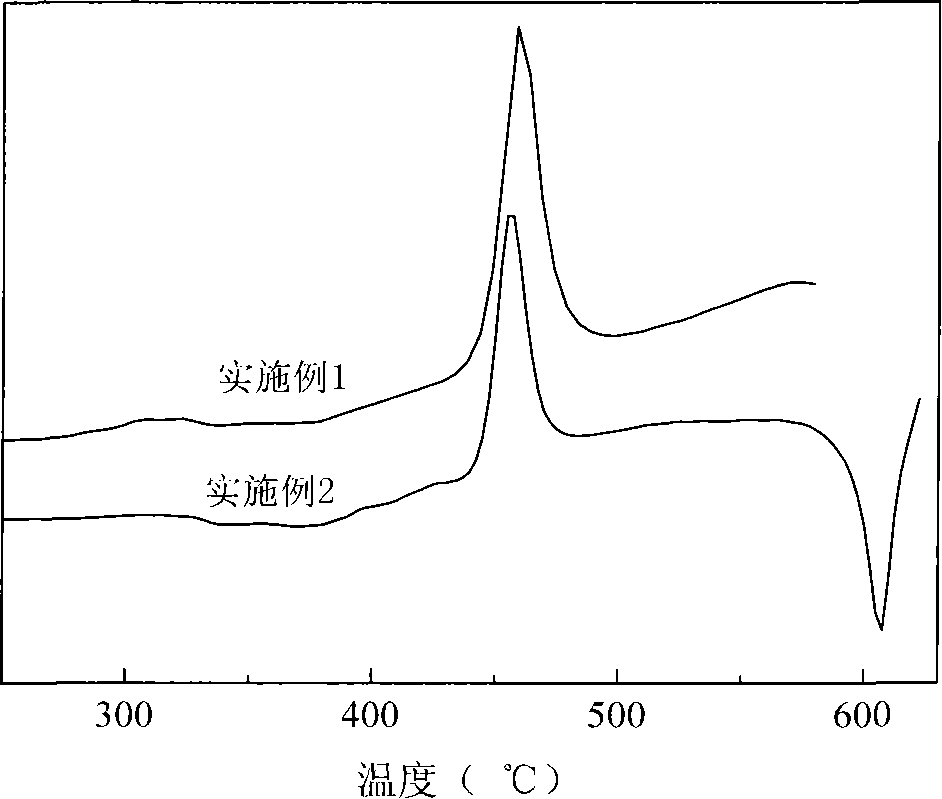

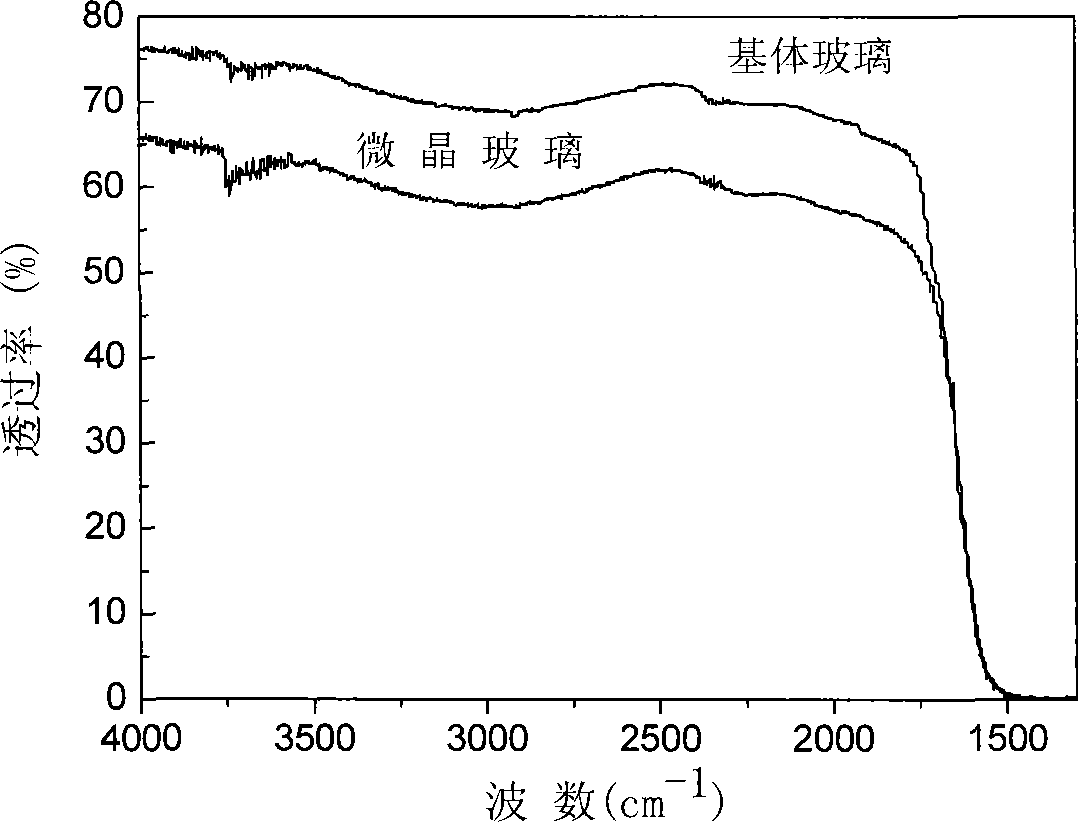

Rear earth doping oxygen-fluorine tellurate microcrystalline glass and preparation method thereof

The present invention relates to a rare earth doping oxyfluoride tellurite nucleated glass and the preparing method thereof, and the mol percentage of the nucleated glass is as follows: TeO2: 68-73%, ZnO: 15-18%, ZnF2: 7-10%, RF3(R is a rare earth element): 3-5%. The preparing method is firstly preparing oxyfluoride tellurite glass with a melting method, then through an accurate heat processing technique the substrate glass is heat treated for crystallization to obtain a transparent oxyfluoride tellurite nucleated glass. The prepared oxyfluoride tellurite nucleated glass is excellent and has excellent infrared transmitting property and the dimension of the crystal phase in the nucleated glass is tens in nano-scale. The preparing method of the nucleated glass of the invention is simple relatively, comparing with the fluoride glass the stability of the glass is better and the heat treating blooming process can be controlled more easily. The nucleated glass is suitable for applying in the optical window material of the mid-infrared waveband, and is used for high intensity upper converting luminous material.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

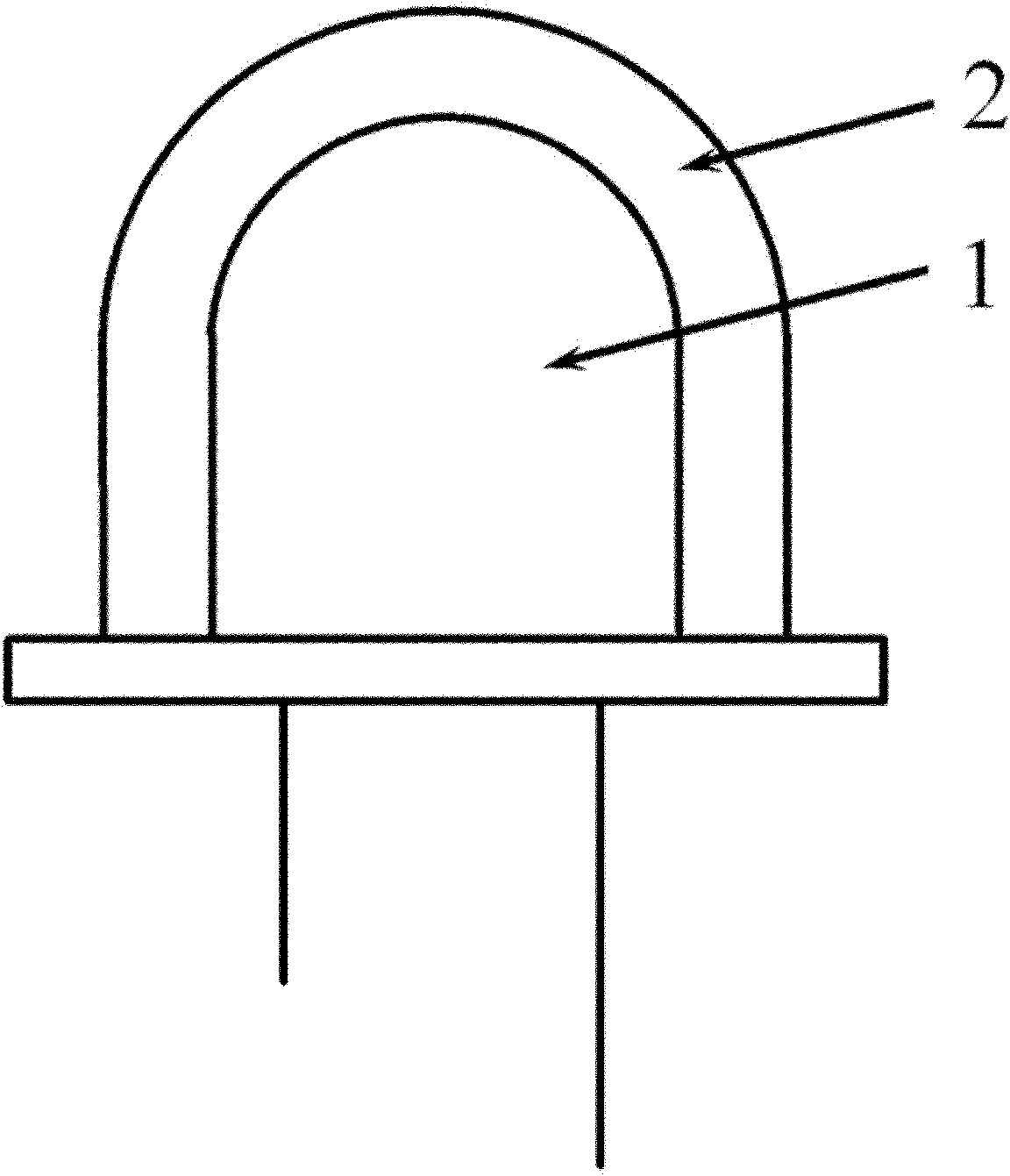

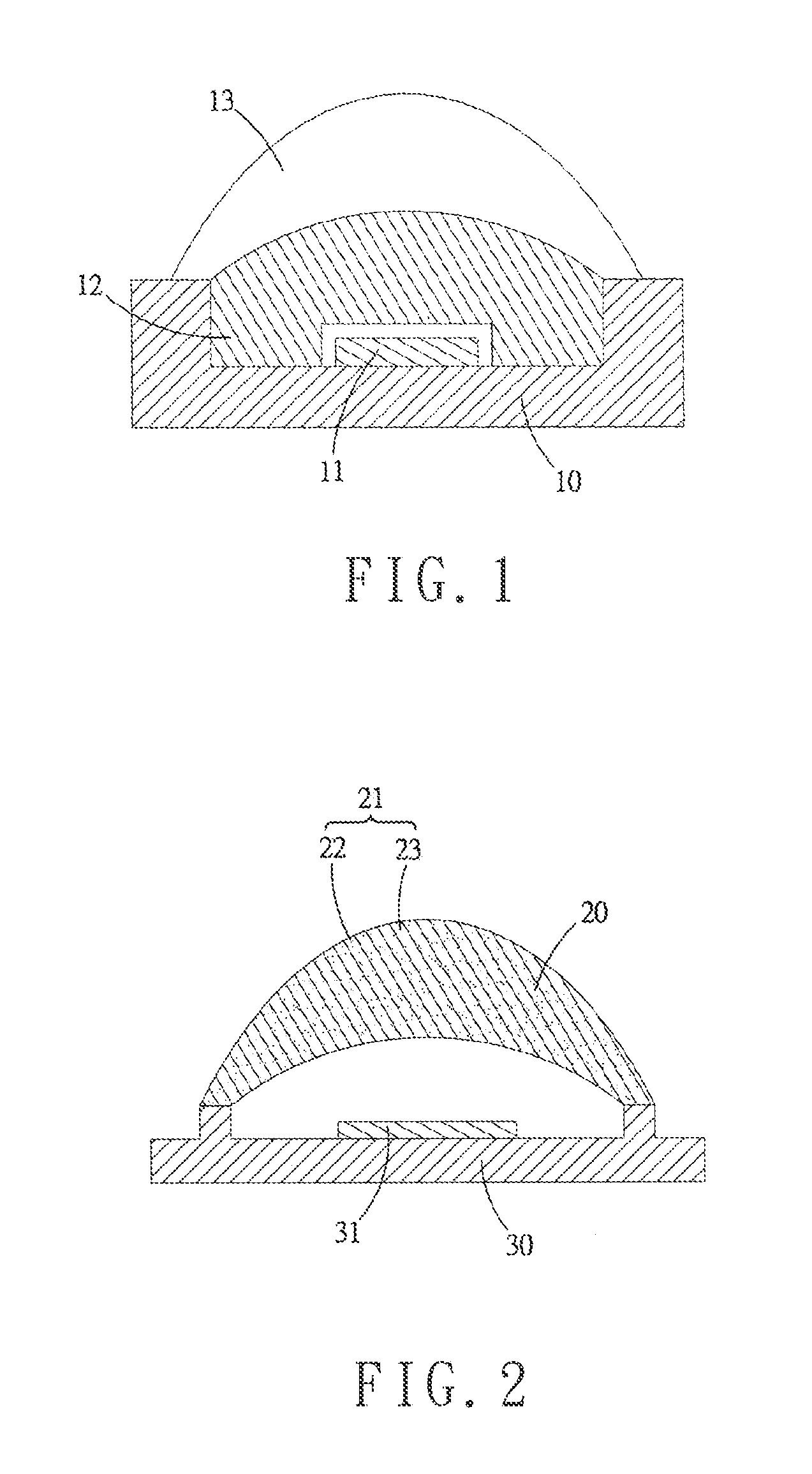

White LED light source and manufacturing method of phosphor thereof

InactiveCN102121591AIncrease varietyRare earth ion doping concentration is highElectric lightingGas discharge lamp usageFluorescenceTellurate

The invention discloses a white LED light source and a manufacturing method of a phosphor thereof. The light source comprises a blue LED and a phosphor, wherein the phosphor is a rare-earth ion doped glass body containing metal nano particles. In the invention, germinate and borate or tellurate are used as matrixes, AgNO3 is used as a raw material, silver is added into glass; the growth of metal silver nano particles is realized through a heat treatment process; Eu<3+>, Sm<3+> or Pr<3+> is used as a red emitting and doping center, and Tb<3+>, Er<3+> or Ho<3+> is used as a green emitting and doping center; and the ions are singly doped or jointly doped into a glass matrix to match with the blue LED chip to emit out white light. In the invention, a single glass phosphor is used for replacing a traditional white LED fluorescent powder and a packaging material, thus the packaging process can be simplified; the ageing problem of a white LED device can be solved, and the stability of the device can be improved; and the excitation efficiency of rare-earth ions can be improved so as to realize high-brightness fluorescence-emission.

Owner:DALIAN MARITIME UNIVERSITY

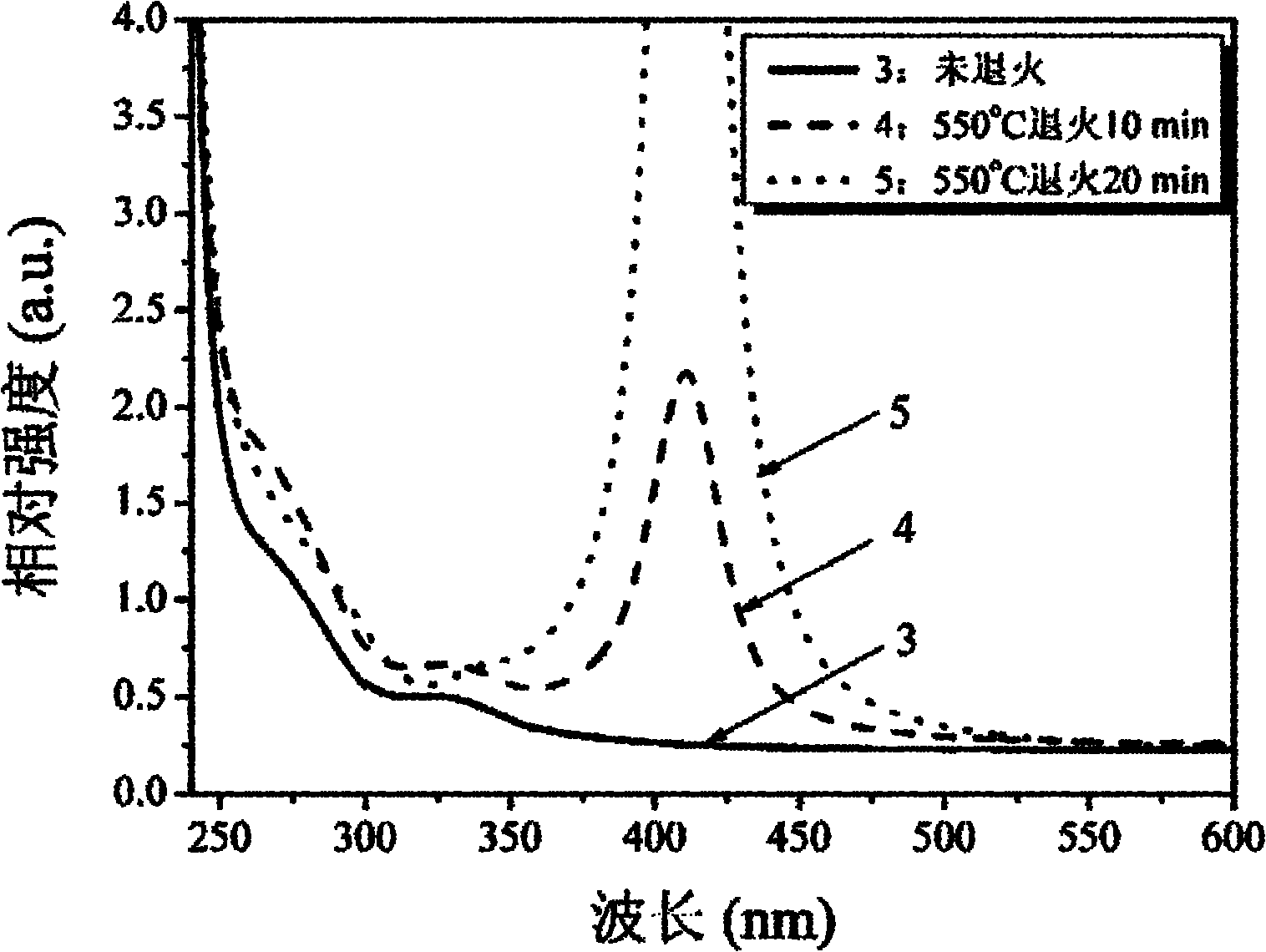

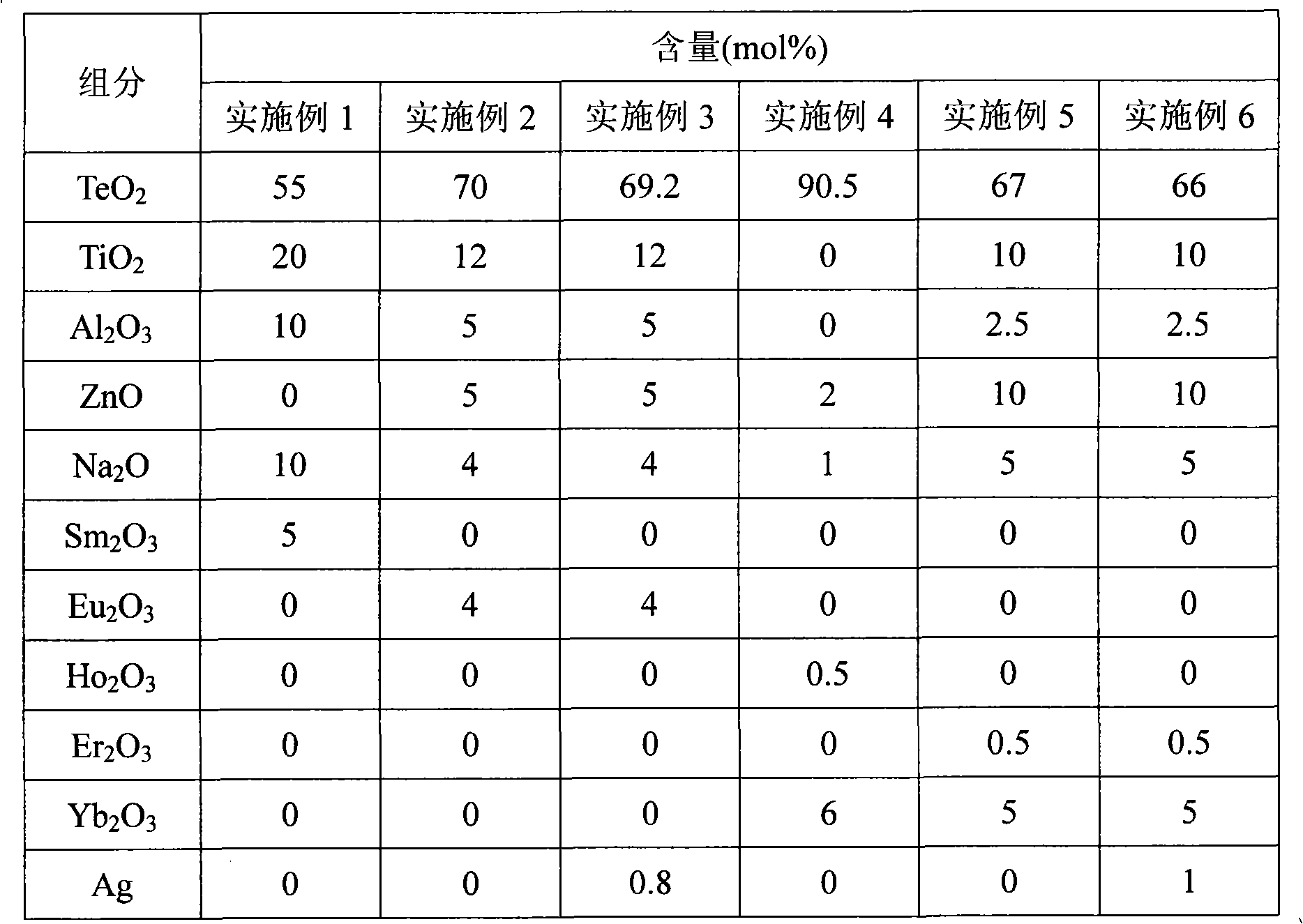

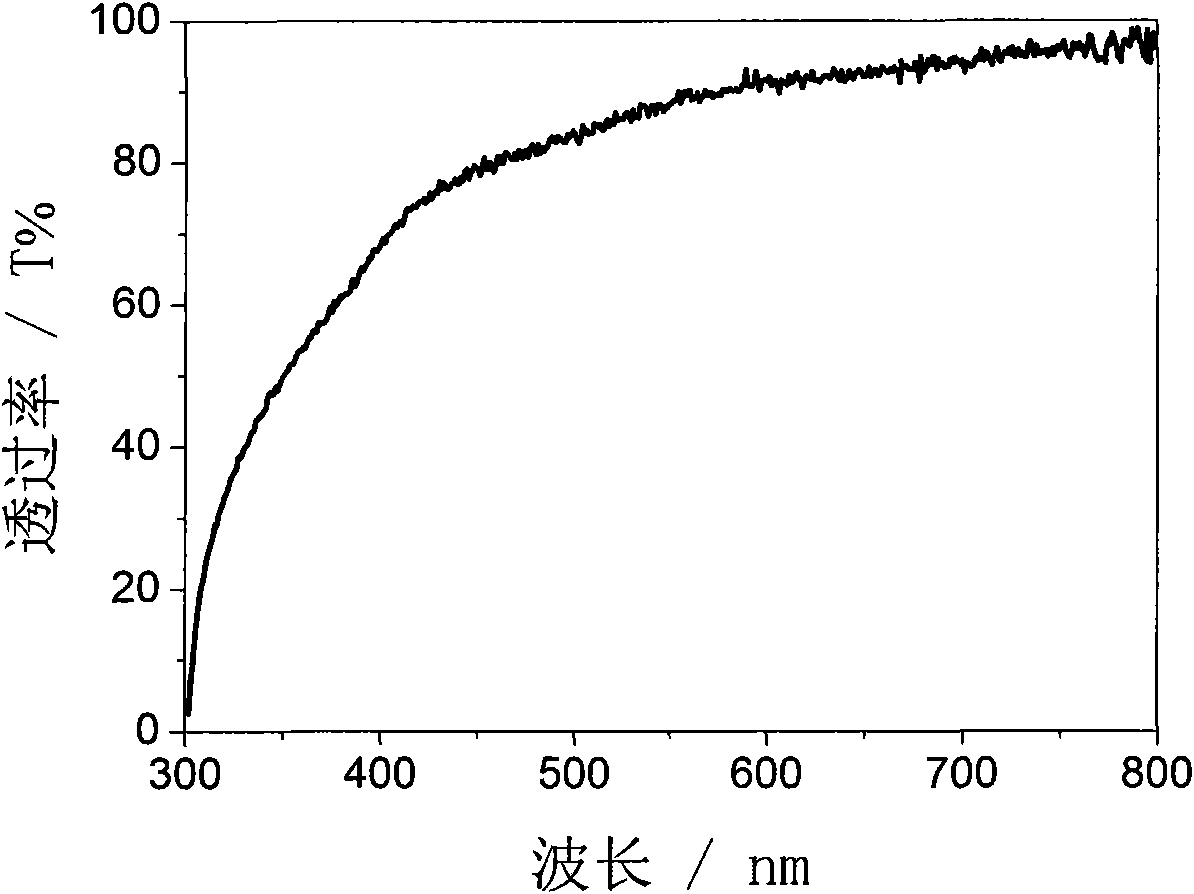

Nanocrystal reinforced rare earth doped tellurate luminous film material and preparation method thereof

InactiveCN101812299AStrong designabilityControllable microstructureLuminescent compositionsRare-earth elementFluorescence

The invention belongs to the technical field of photoelectron information, particularly relating to a nanocrystal reinforced rare earth doped tellurate luminous film material and a preparation method thereof. The tellurate luminous film material comprises the following components: 50-95 mol% of TeO2, 0-20 mol% of TiO2, 0-10 mol% of Al2O3, 0-30 mol% of ZnO, 1-10 mol% of Na2O, 1-10 mol% of Re2O3 and 0-30 mol% of M, wherein Re is rare earth element and is one or a plurality of Pr, Nd, Sm, Eu, Tb, Ho, Er, Tm and Yb, and M is noble metal element and is one or a plurality of Ag, Au and CU. The tellurate luminous film material utilizes organic alkoxide or inorganic salt of the components through a non-hydrolysis sol-gelation method, and the tellurate luminous film material is prepared on the optical glass substrate according to the composition range and certain technical condition. The invention has simple preparation method and low cost, and the obtained film material is even and transparent, and fluorescent output can be greatly enhanced by laser pump excitation. The film material can be used in the fields, such as optical information record, display, treatment and the like.

Owner:TONGJI UNIV

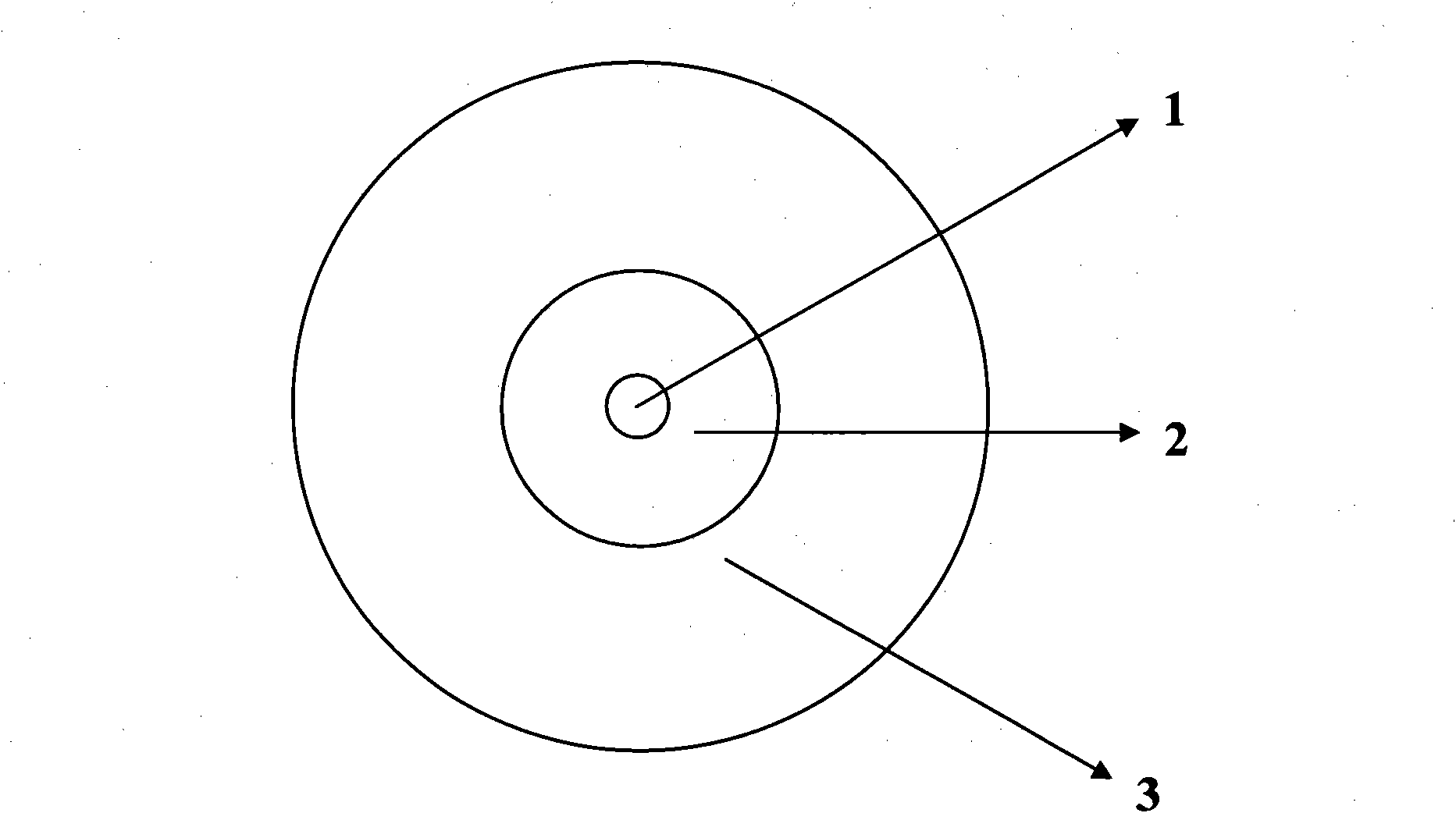

Yb3+ doped tellurate glass doubly coated fiber and preparing method thereof

InactiveCN1603871ADrawing process is simpleLow costGlass making apparatusOptical waveguide light guideTellurateRefractive index

It is a tellurate glass double-layer fiber mixed with Yb#+[3+] and its process method, which uses tellurate glass system as fiber core material of the fiber and uses tellurate glass system with matching refractive index, expansion index and intenerate temperature with the core material as inner layer. The method is the following: to choose matchable fiber core and inner layer glass materials; to melt them; to process pre-made bar to form core composite; finally to do fiber pulling to plastic package layer coating and fixing to make the double-layer fiber.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

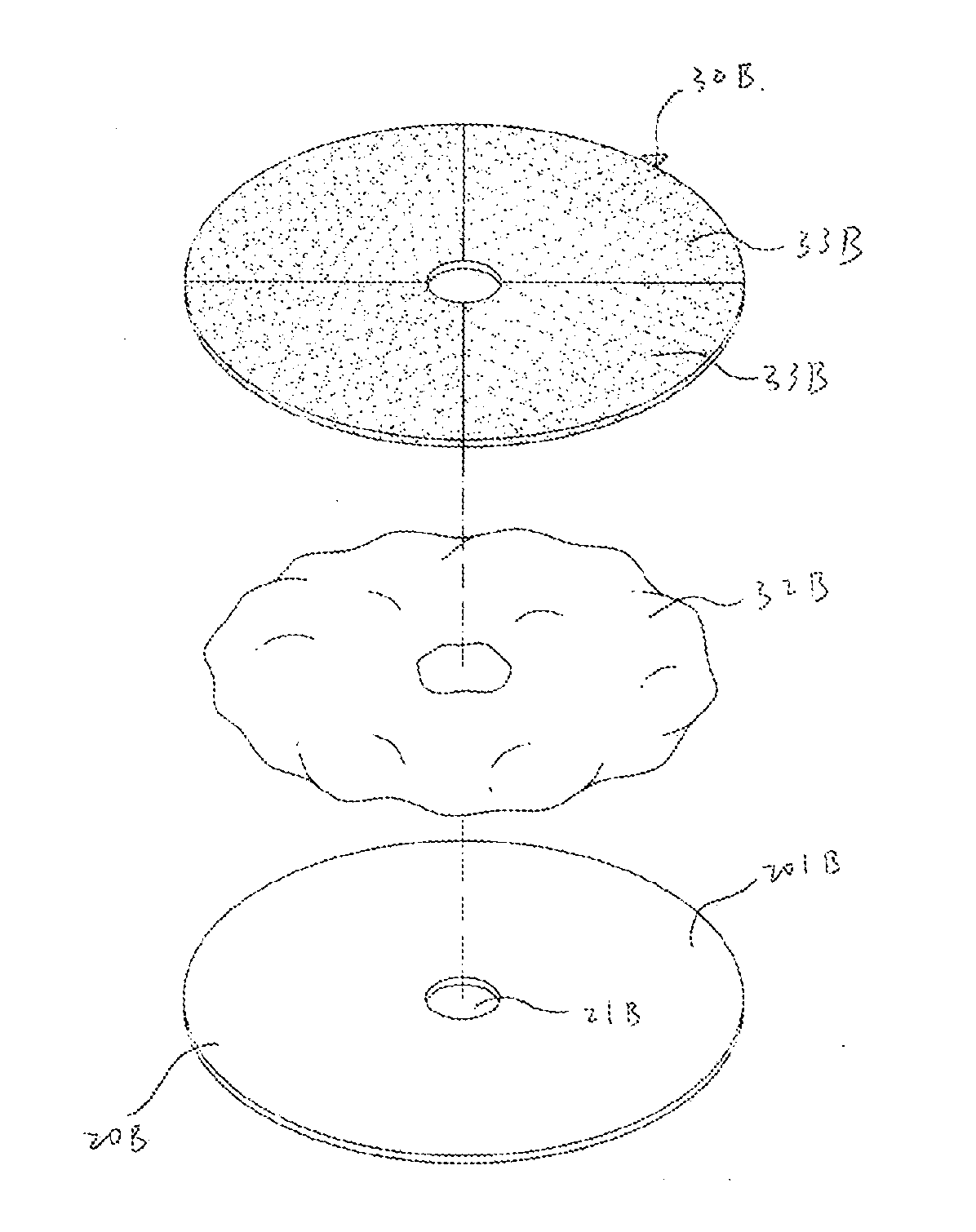

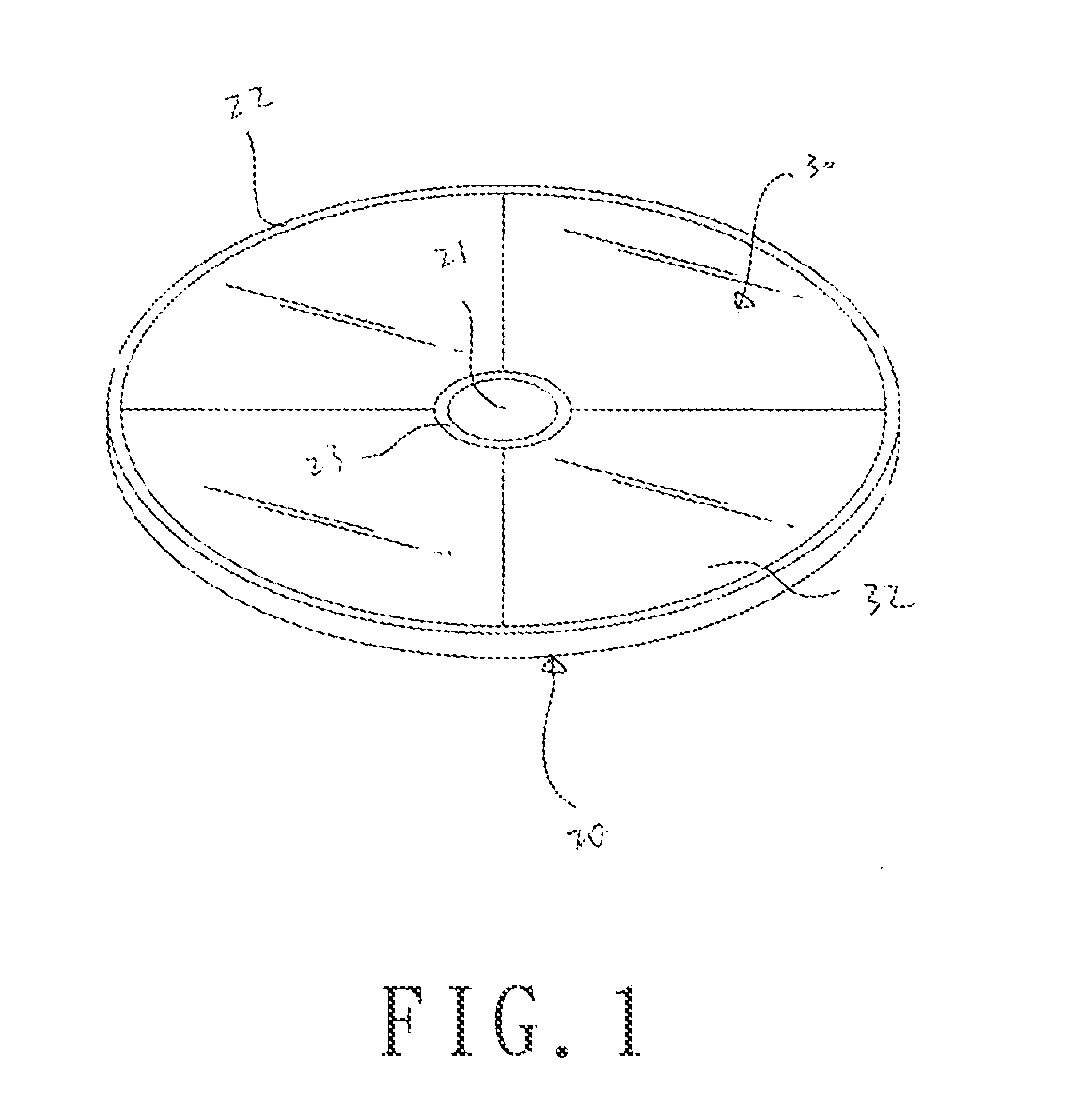

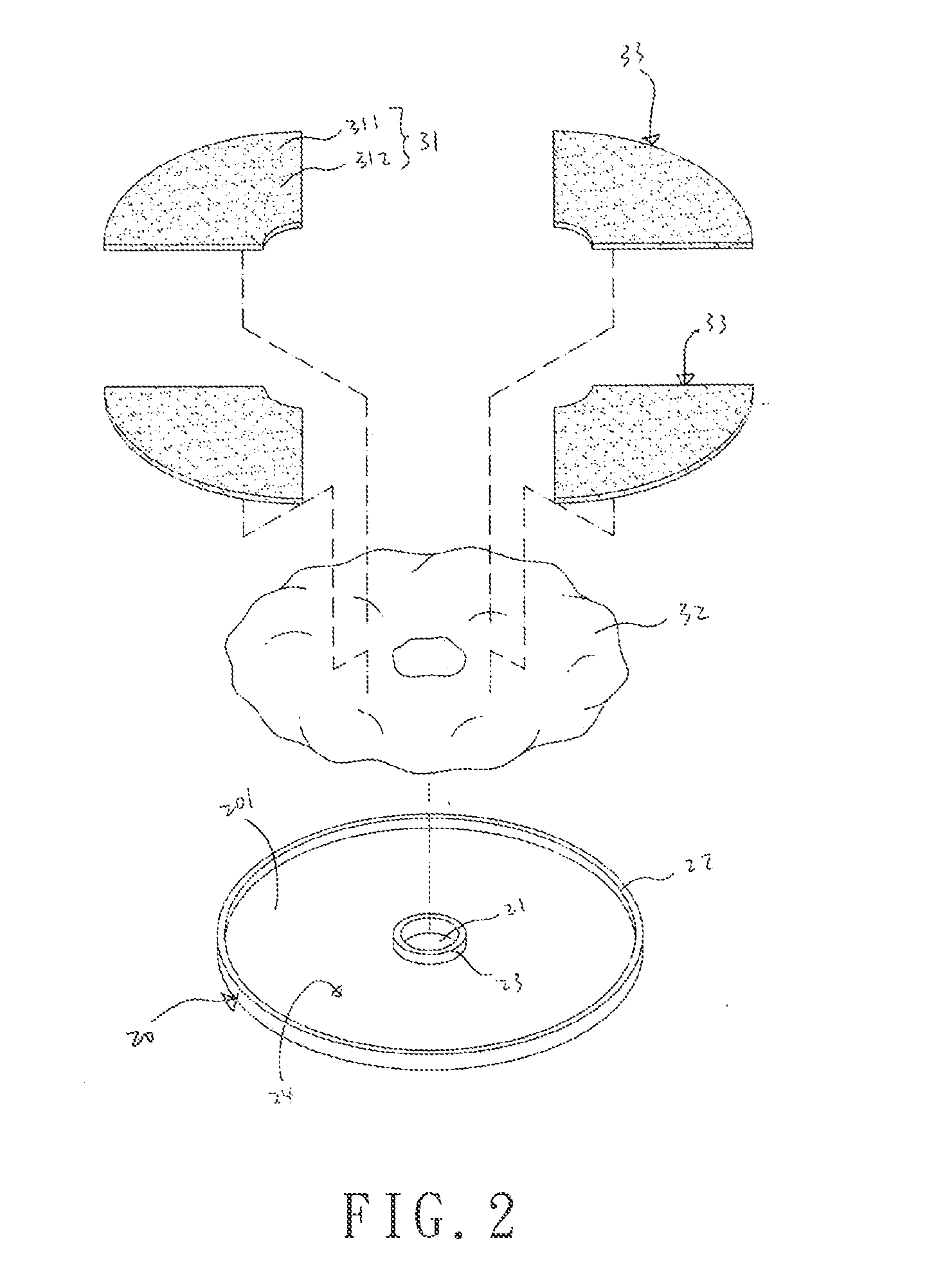

Glass phosphor color wheel and methods for producing the same

InactiveUS20160139401A1Extended service lifeHigh temperature resistanceGlass drawing apparatusGlass forming apparatusAluminateTellurate

A glass phosphor color wheel includes a wheel body made of a glass phosphor formed by sintering a glass material and fluorescent powder. The fluorescent powder is a fluorescent material selected from the group consisting of yttrium aluminum garnet, nitride, silicate, aluminate, and oxynitride. The glass material is selected from the group consisting of a silicate system, a phosphor system, a borate system, and a tellurate system. A method for producing a glass phosphor color wheel includes concentrically placing an inner tube into an outer tube. The glass material and the fluorescent powder are placed between the outer and inner tubes and are formed into a wheel body. In another method, the glass material and the fluorescent powder are sintered at a temperature of 500-1000° C. to form at least one glass phosphor color block that is subsequently coupled to a substrate to form a glass phosphor color wheel.

Owner:TAIWAN COLOR OPTICS

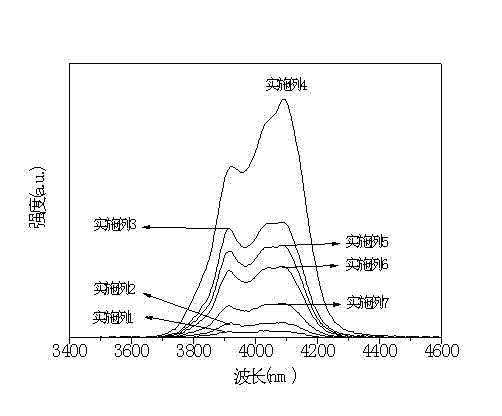

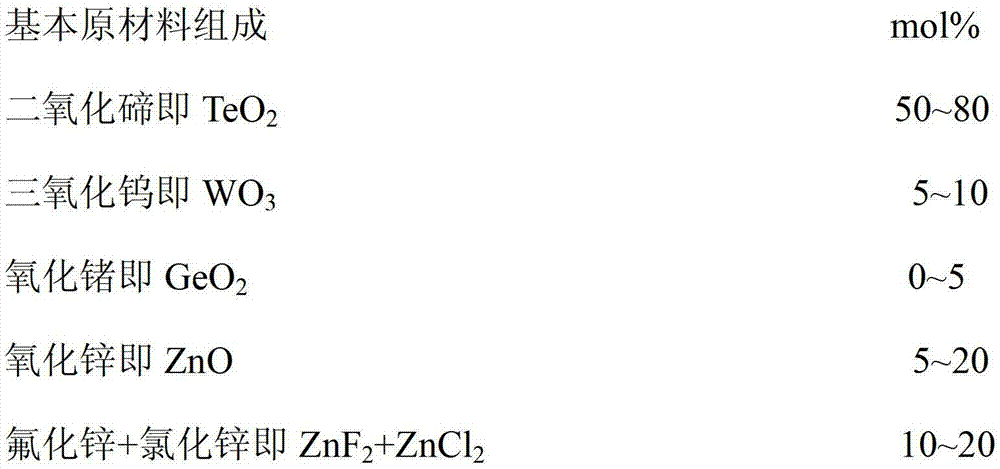

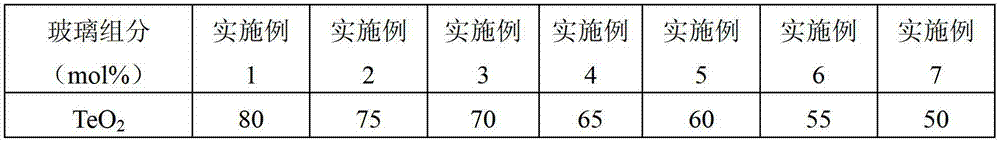

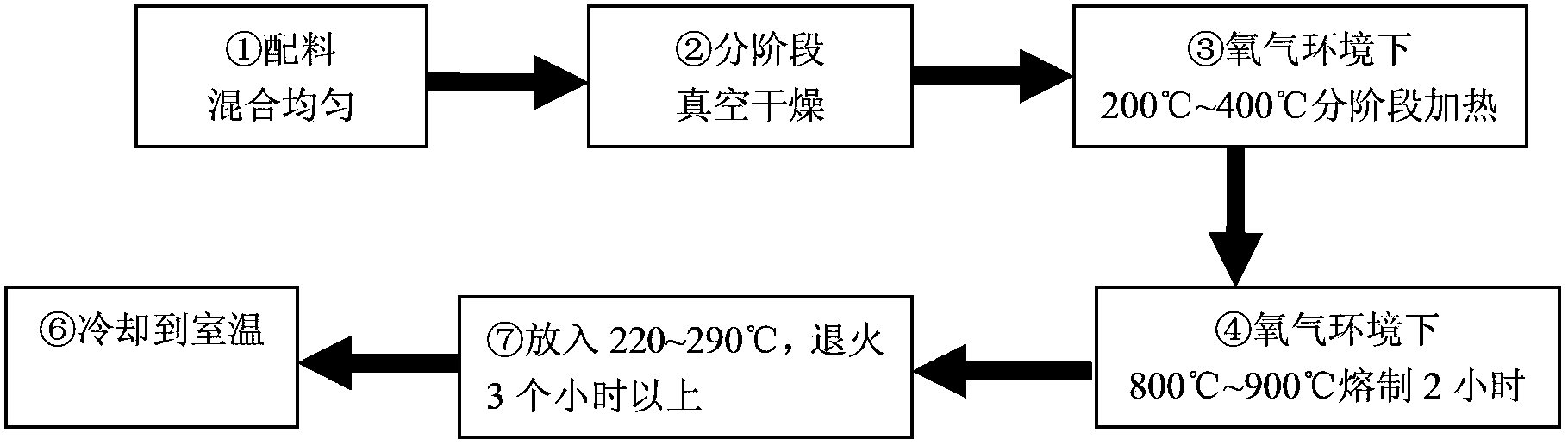

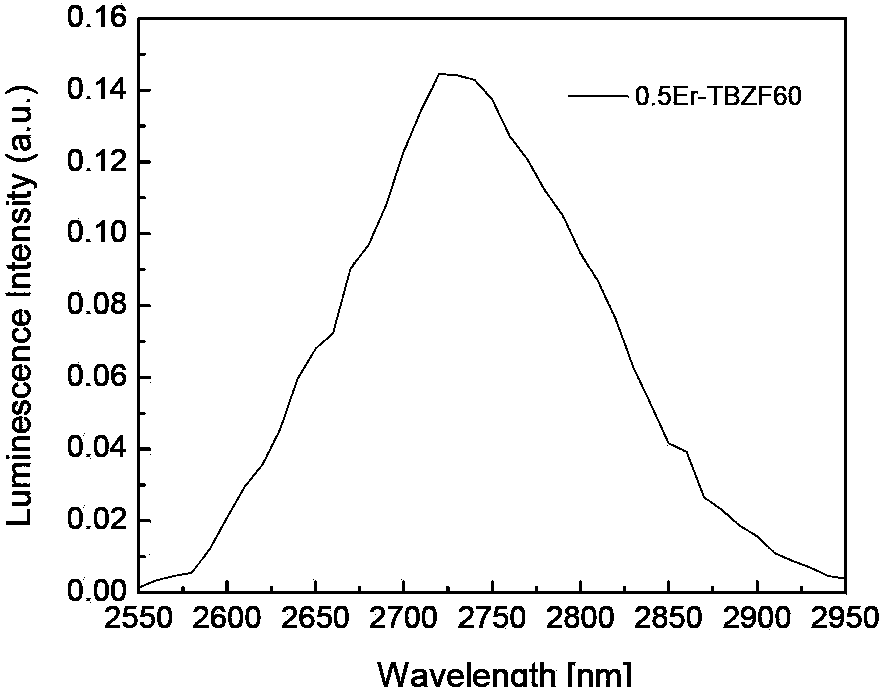

Method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m

The invention relates to the technical field of intermediate infrared rare earth doped luminescent glass application, and aims at solving the technical problem of providing a method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m. The glass is good in glass forming property, high in infrared light transmission rate, good in luminescence property and beneficial to output of fluorescence and laser of 4 mu m. The oxygen fluorine chlorine tellurate glass prepared by using a fusion method is tellurate glass which contains zinc fluoride and zinc chloride, and due to the appropriate amount of contains zinc fluoride and zinc chloride, the hydroxyl content and the phonon energy in the system are greatly reduced, so that the forming capability of the glass is effectively improved, the doping amount of rare earth ions is increased, and the fluorescence service lives of the rare earth ions are prolonged. By adopting the doping amount of the external doping rare earth ions, namely, Ho<3+> and Yb<3+>, the pumping efficiency of 980nm is greatly improved, and tests show that the oxygen fluorine chlorine tellurate glass has remarkable fluorescence output at 4 mu m.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

Intermediate infrared anhydrous fluorine tellurate laser glass and preparation method thereof

The invention relates to intermediate infrared anhydrous fluorine tellurate laser glass and a preparation method thereof. The intermediate infrared anhydrous fluorine tellurate laser glass is prepared from 50-85 mol percent of TeO2, 5-45 mol percent of ZnF2 or BaF2, 0-20 mol percent of ZnO, 0-20 mol percent of sodium ion compound or potassium ion compound and 0.1-2 mass percent of erbium ion compound. The invention provides the intermediate infrared anhydrous fluorine tellurate laser glass which can generate strong intermediate infrared luminescence and is expected to be applied to medicine, bioindustry and economic construction, as well as a preparation method of the intermediate infrared anhydrous fluorine tellurate laser glass.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

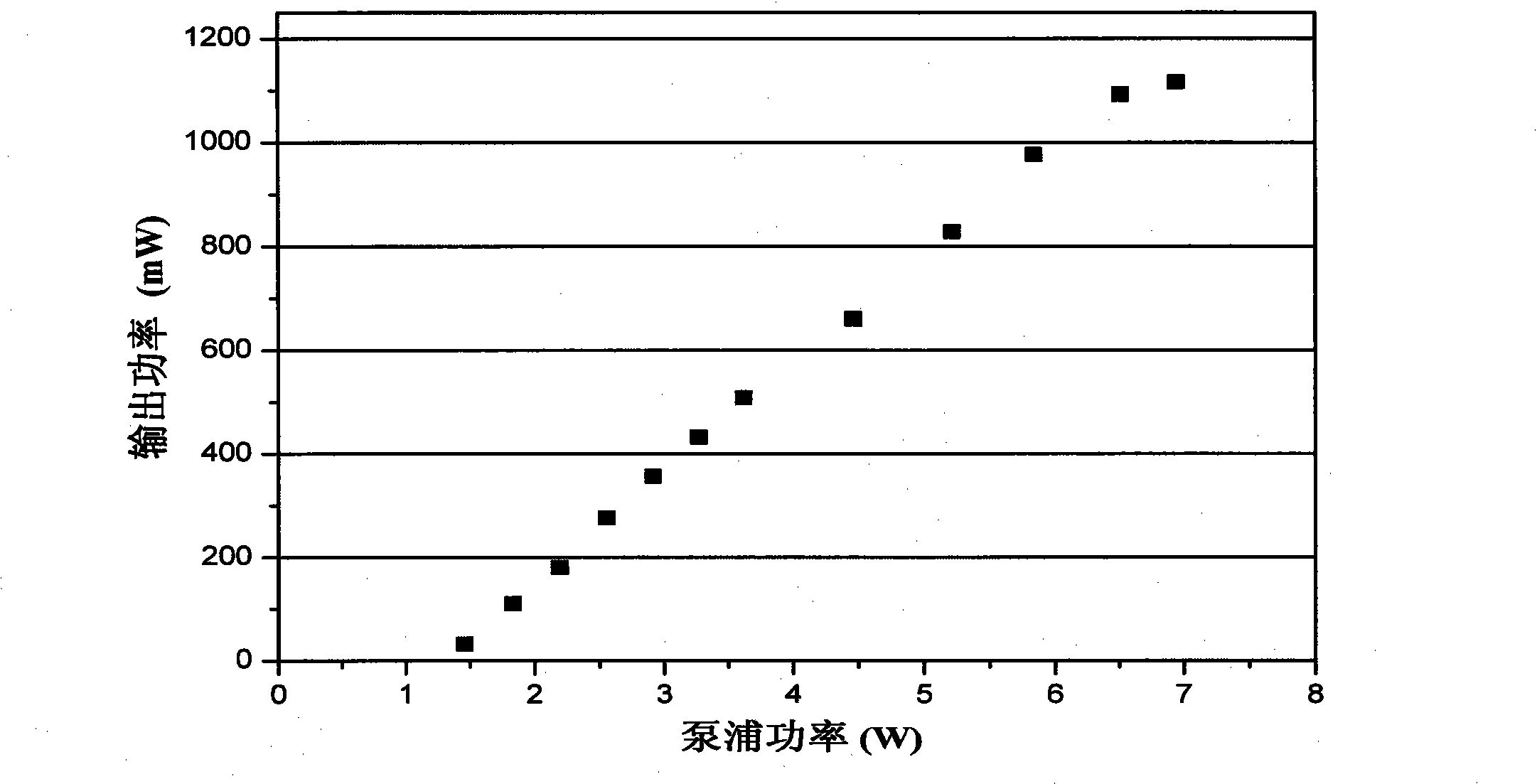

Thulium-doped tellurate glass doubly-clad optical fiber and preparation method thereof

ActiveCN101923189ALarge unit length gainLarge length gainOptical fibre with multilayer core/claddingFiberTellurate

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

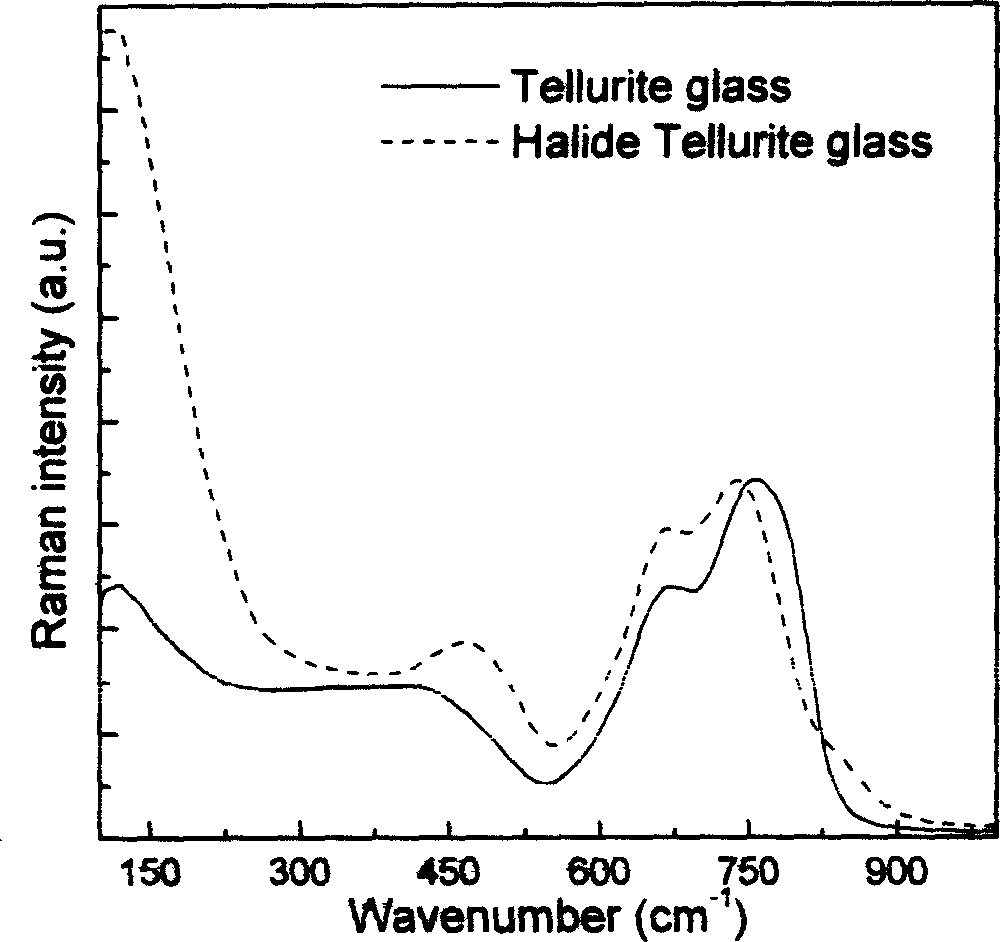

Tellurate glass and method for producing the same

InactiveCN101219857AHigh densityHigh refractive indexPot furnacesGlass furnace apparatusFiberMetallurgy

The invention tellurate glass and a preparation method is disclosed, among which the basic compositions of the glass are 65-85 mol percent of TeO2, 0-20 mol percent PbO, 2-8 mol percent of PbF2, 0-10 mol percent of Bi2O3, 0-15 mol percent Nb2O5. , Being prepared through a common melting method. In the melting process, preparation technologies like stirring, putting into dry nitrogen and clarification are adopted to ensure that [OH-] mass in the glass compositions can be effectively removed. The glass material is characterized by good materialization stability, favorable fiber-forming, high third-order nonlinear susceptibility, small dispersion slope and so on; the preparation process has simple and easy operation and low cost. The invention is applicable to use optical fiber matrix material in super short pulser source of optical communication.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

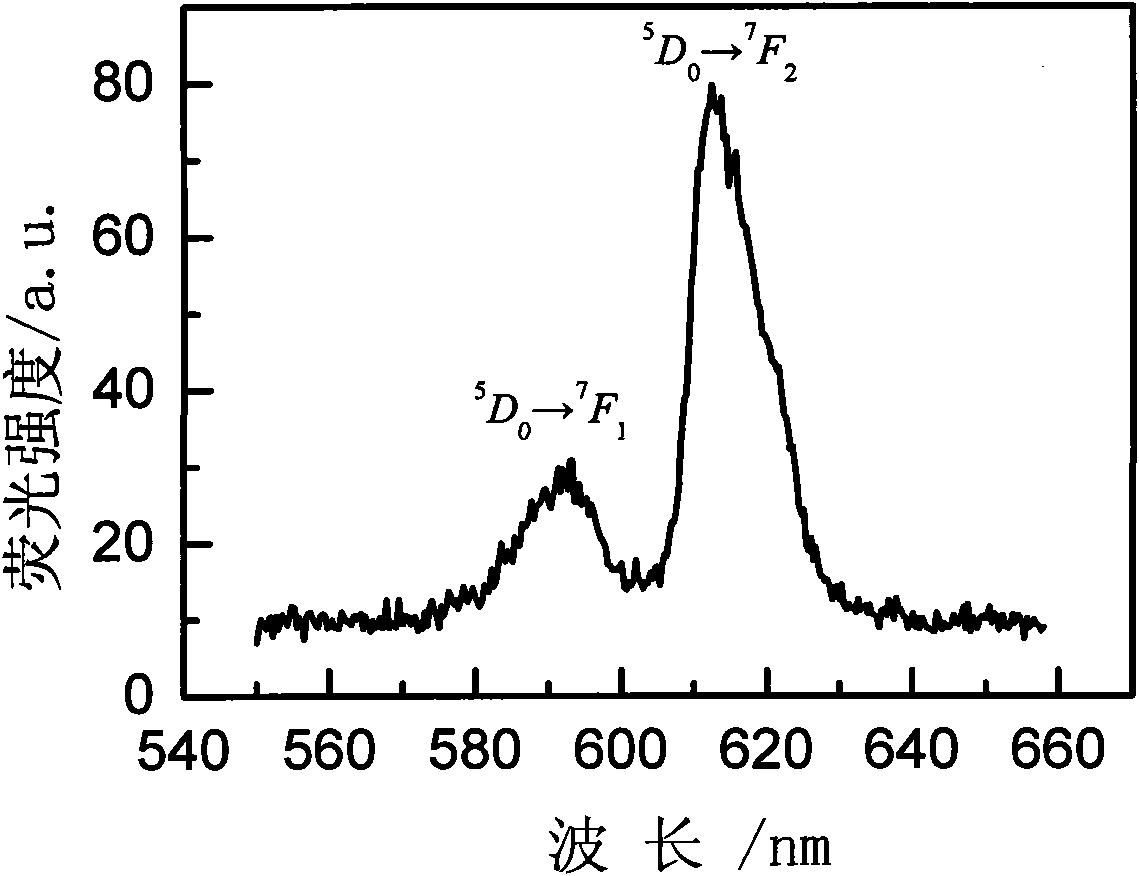

Rare earth doped oxyfluoride tellurite scintillation glass and preparation method thereof

The invention discloses rare earth doped oxyfluoride tellurite scintillation glass and a preparation method thereof. The scintillation glass and the preparation method have the following advantages: the raw materials of the scintillation glass, such as TeO2, PbF2, BaF2 and Gd2O3, are all high-density compounds, so the obtained oxyfluoride tellurite glass has density higher than 6g / cm<3>; compared with the traditional scintillation glass containing such raw materials as PbO and Bi2O3, the scintillation glass containing the above raw materials has higher short wavelength blue and violet light transmittance, so self-absorption of the scintillation glass is avoided and visible light can transmit the glass even the wave band is wider; and the scintillation glass contains Gd2O3, and luminescence of sensitized Tb3<+>, Ce3<+> and other rare earth ions greatly improves flare light output. Therefore, the scintillation glass has the advantages of high density, strong flare light luminescence output, wider wave band and good short wavelength transmittance; and the preparation method of the scintillation glass is simple and is lower in production cost.

Owner:江西璞晶新材料股份有限公司

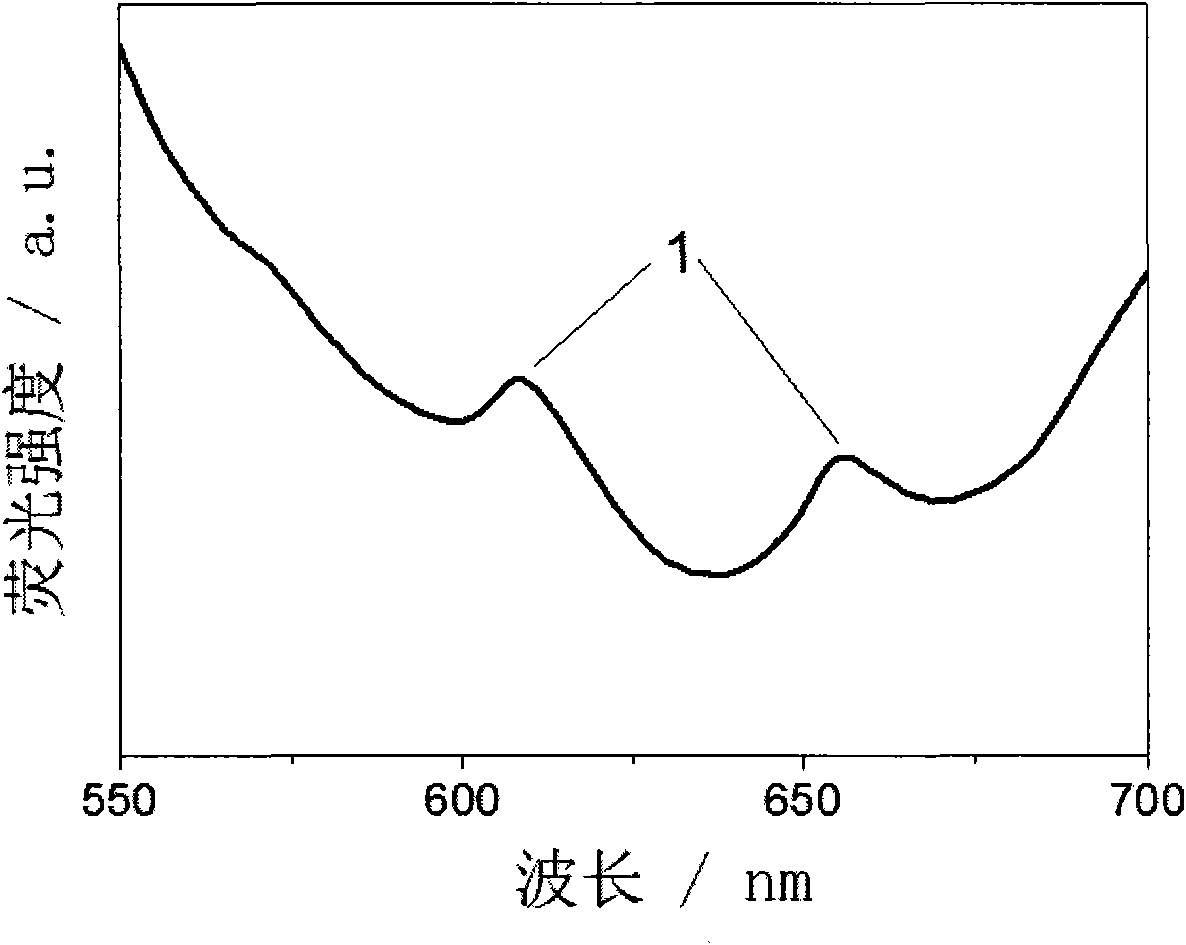

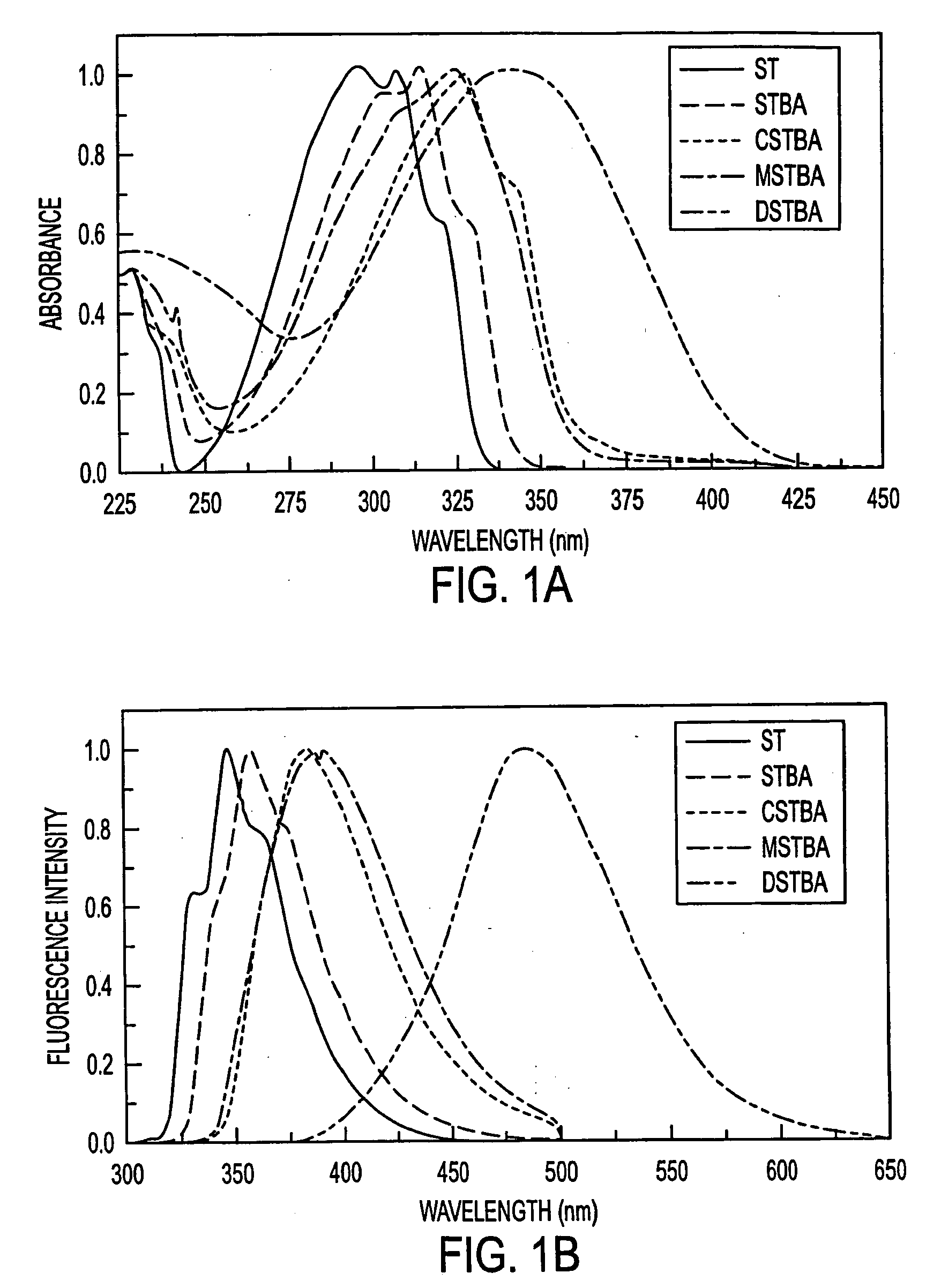

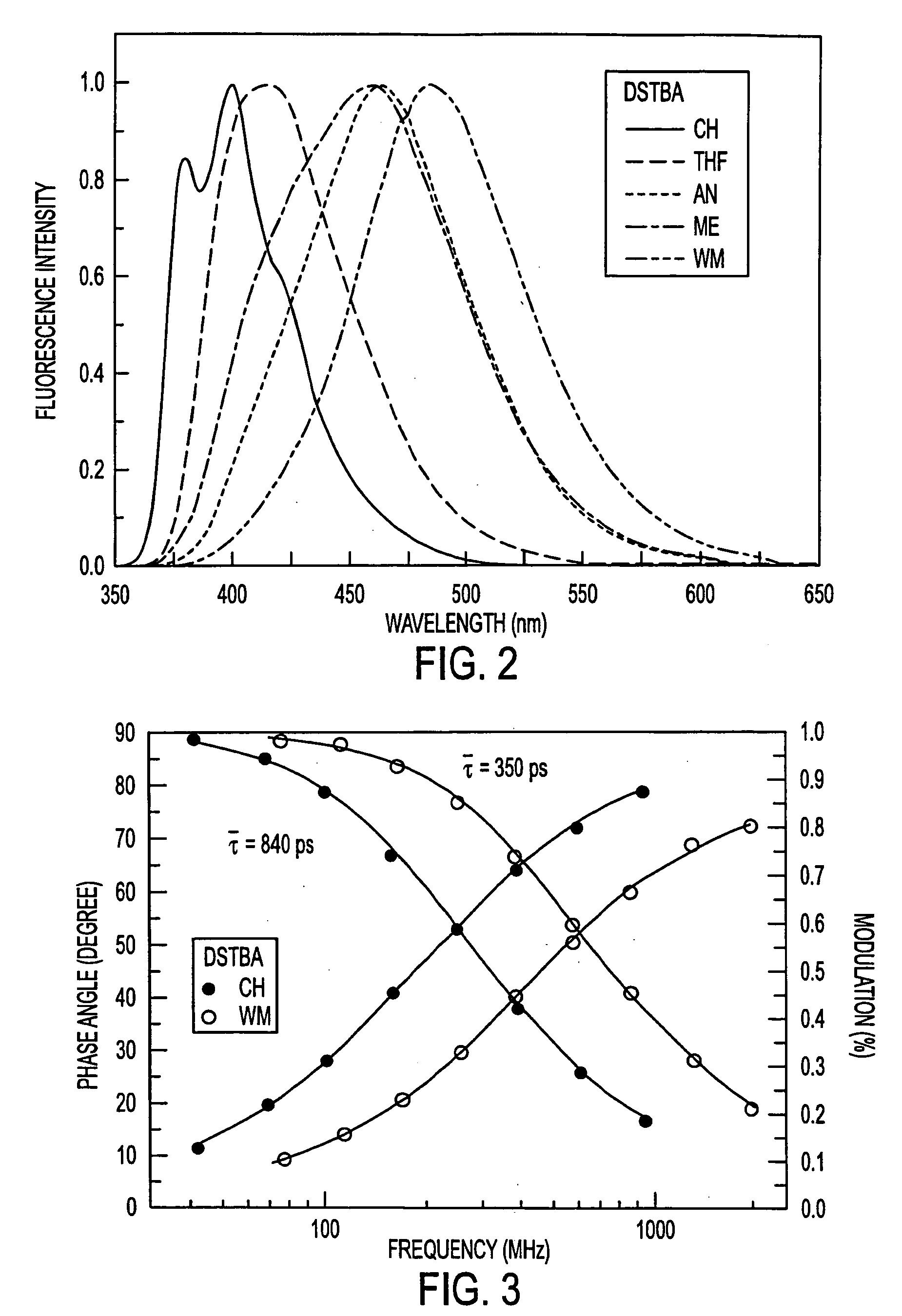

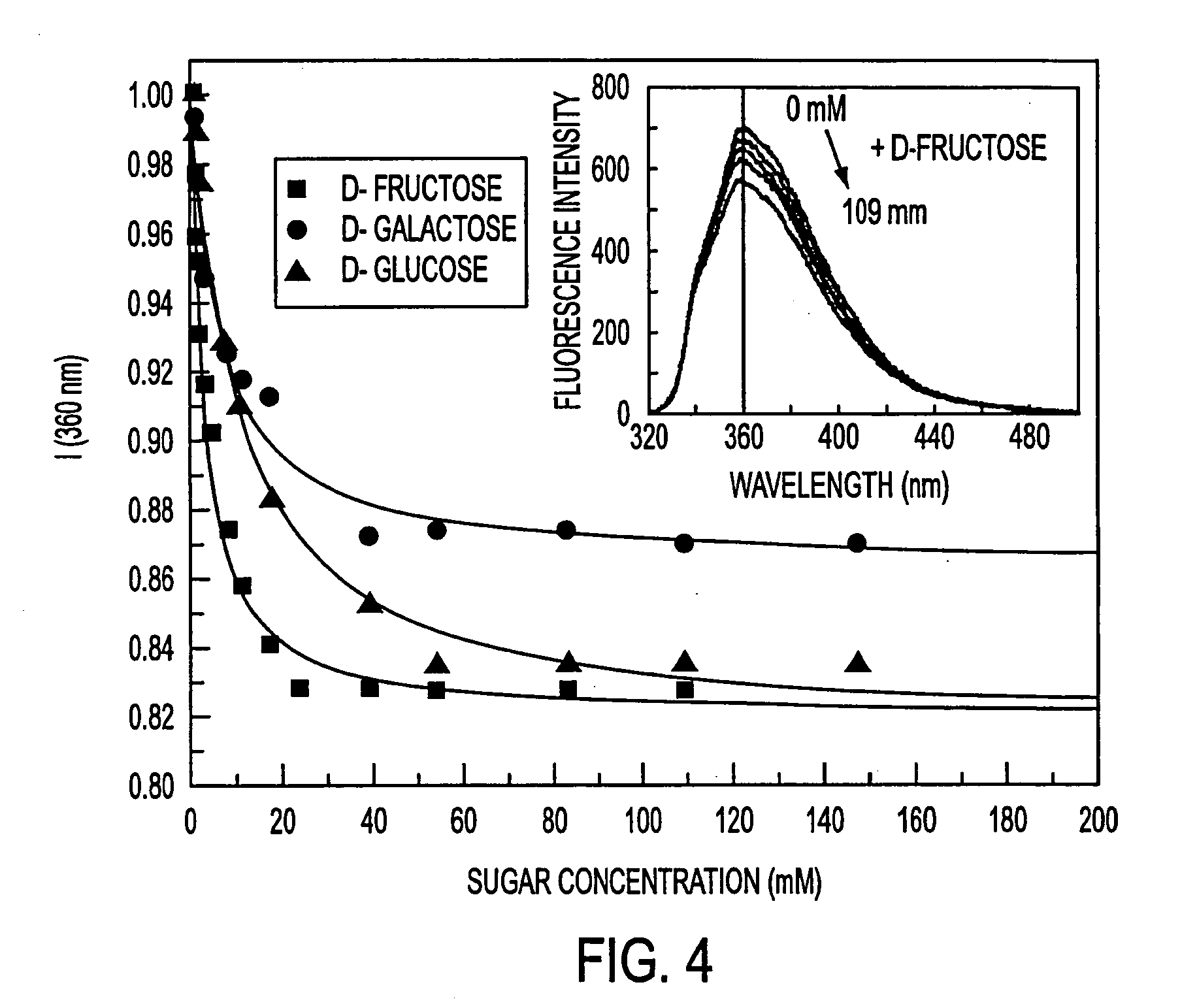

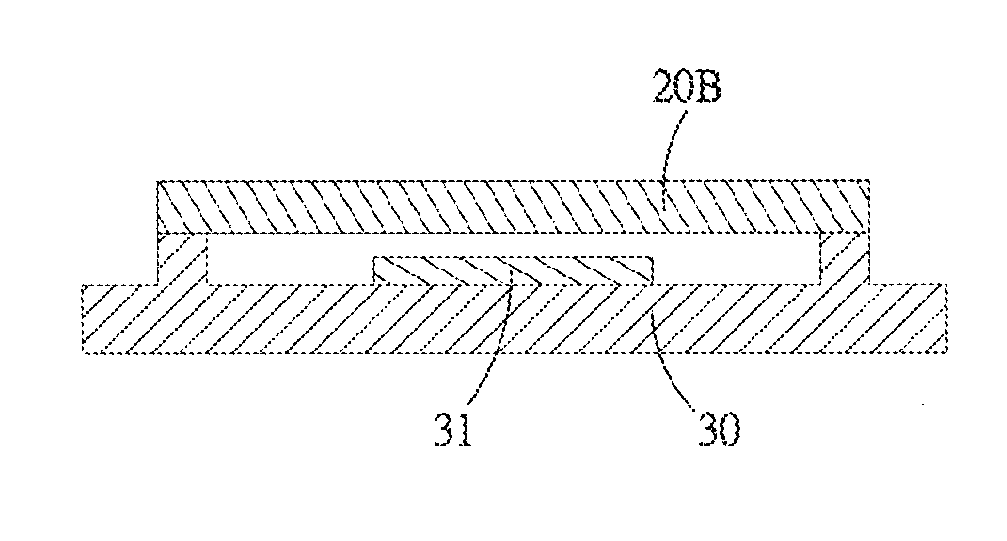

Fluorescent probes for saccharrides

The spectroscopic and photophysical properties of fluorescent probes comprising donor-acceptor derivatives comprising the boric acid group or a derivative of boric acid, B(OH)3 (or borate ion, BO(OH)2−1), arsenious acid, H3 AsO3 (or arsenite ion, H2AsO3−1), telluric acid, H6TeO6 (or tellurate ion, H5 TeO6−1) or germanic acid, Ge(OH)6 (or germanate ion, GeO(OH)3−1) are described. Method of using said probes are also provided.

Owner:LAKOWICZ JOSEPH R +1

Method for producing a low temperature glass phosphor lens and a lens produced by the same

InactiveUS20160139300A1Less easily to ageStable structureGlass shaping apparatusLuminescent compositionsTelluratePhosphor

A method for producing a low temperature glass phosphor lens includes dry mixing a glass material and fluorescent powder to form a powdery or particulate mixture. The mixture is grinded to a diameter of 15-20 μm, obtaining uniformly mixed glass fluorescent powder. The glass fluorescent powder is hot pressed into a glass phosphor at a temperature of 500-1000° C. The glass phosphor is grinded and polished into a lens. The fluorescent powder can be a fluorescent material selected from the group consisting of yttrium aluminum garnet, nitride, and silicate. The glass material can be selected from the group consisting of a silicate system, a phosphor system, a borate system, and a tellurate system. The glass phosphor includes characteristics of both of glass and fluorescence. The glass phosphor can keep efficiency under the high heat generated by the chip of an LED.

Owner:TAIWAN COLOR OPTICS

Oxygen-fluorine tellurate glass and preparation method thereof

InactiveCN1541964AHigh possibilityGreat practicabilityGlass shaping apparatusElectric furnaceFiberTellurate

The present invention is oxide-fluoride-tellurate glass with excellent heat stability and its preparation. The oxide-fluoride-tellurate glass has molar material composition of 70TeO2.(20-x)BaO.xBaF2.(10-y)La2O3.yLaF3, where x is 0-20 and y is 0-10. The oxide-fluoride-tellurate glass is prepared through melting process, is transparent a has no recrystallization. The oxide-fluoride-tellurate glass of the present invention has high heat stability and may be excellent glass substrate material for RE ion doped fiber.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

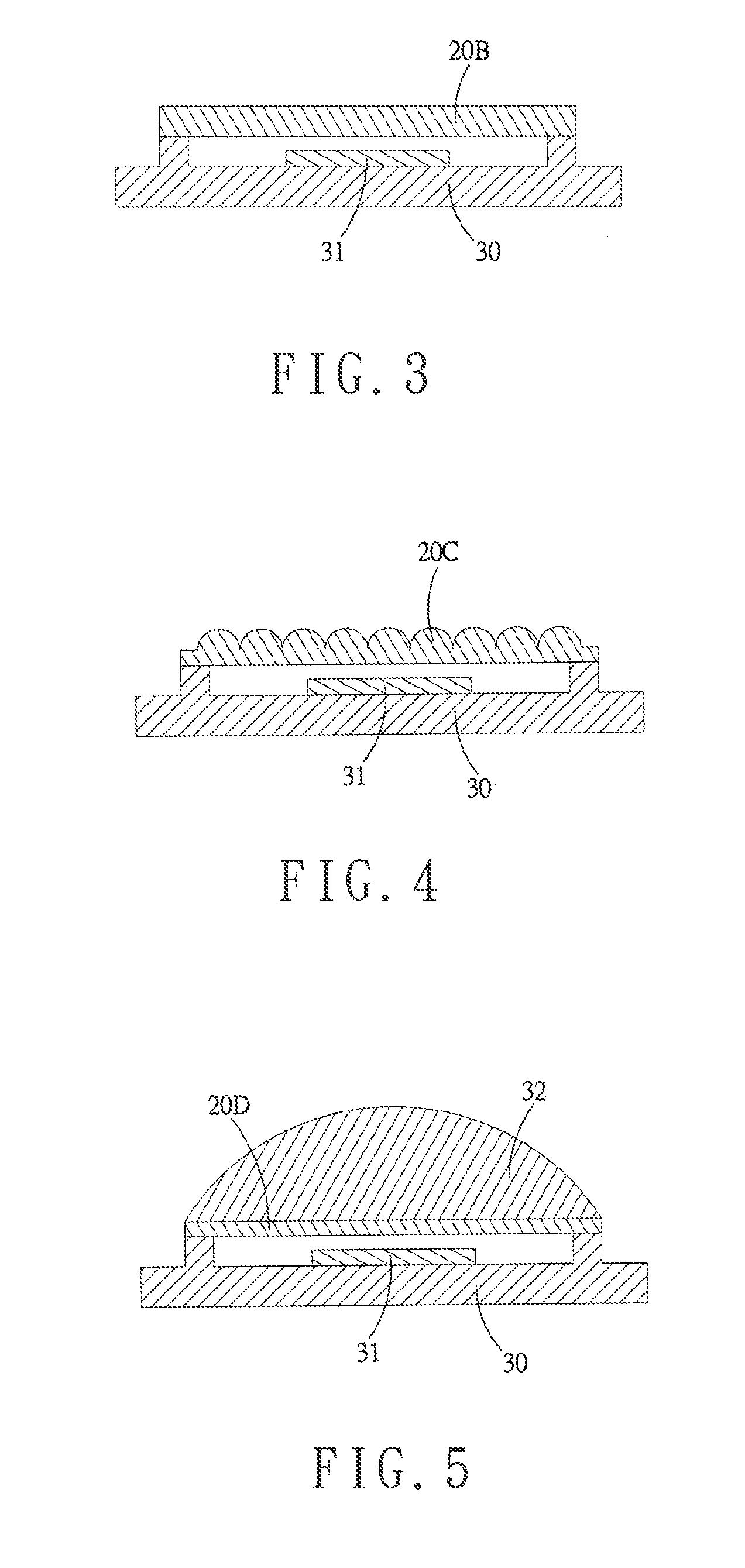

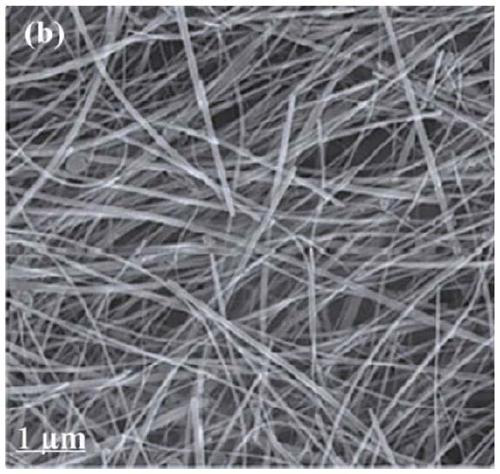

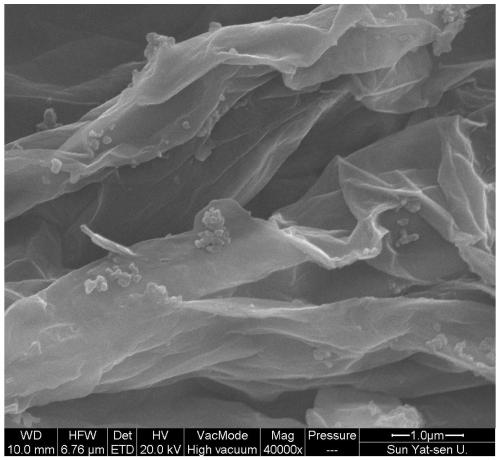

Semi-metal material Te nanowire/graphene hydrogel composite material as well as preparation method and application thereof

ActiveCN110449169AEasy to operateHas photocatalytic bactericidal propertiesBiocidePhysical/chemical process catalystsNanowireTellurate

The invention discloses a semi-metal material, namely a Te nanowire / graphene hydrogel composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: adding ammonium hydroxide and a reducing agent, namely a hydrazine hydrate solution, into a water solution of sodium tellurate and polyvinylpyrrolidone, performing uniform mixing, performing a hydrothermal synthesis reaction, performing cooling to room temperature, separating a reaction product so as to obtain precipitate, washing the precipitate to be neutral, performing drying and grinding so as to obtain Te nanowires, adding a graphene oxide suspension, performing uniform mixing, performing a hydrothermal synthesis reaction, removing excessive graphene oxide and Te nanowireswhich are not tightly compounded, and performing freeze drying, so as to obtain the composite material. The Te nanowire / graphene hydrogel composite material disclosed by the invention is simple in preparation method, has photocatalysis sterilization and photo-thermal conversion performance, thermocatalytic sterilization can be promoted through a photo-thermal synergetic function, the inactivationratio is 70-100%, no chemical reagent is additionally used, and the problem of secondary pollution of a byproduct of a conventional sterilization technique can be effectively solved.

Owner:SUN YAT SEN UNIV

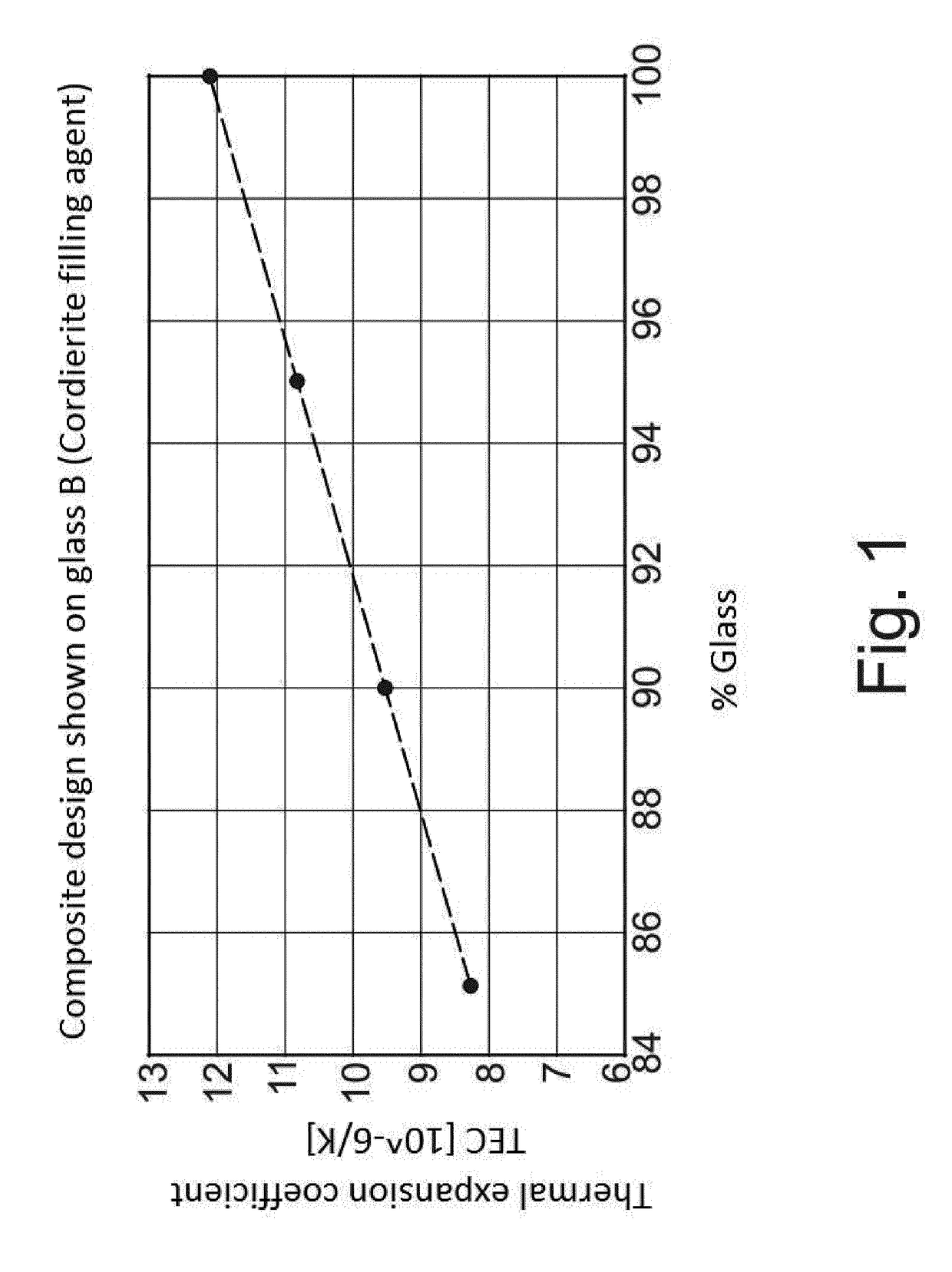

Tellurate Joining Glass Having Processing Temperatures Less Than Or Equal To 420°C

ActiveUS20170243995A1Simple designReduce weightClimate change adaptationWindows/door improvementTellurateGlass sheet

The present invention relates to a glass, in particular a glass for the joining of glass panes for the production of vacuum insulating glasses at processing temperatures ≦420° C., to the corresponding composite glass, and to the corresponding glass paste. Moreover, the present invention relates to a vacuum insulating glass produced using the glass paste according to the invention, to the production process thereof, and to the use of the inventive glass and / or composite glass, and glass paste. The glass according to the invention is characterized in that it comprises the following components, in units of mol-%: V2O5 5-58 mol-%,Te02 40-90 mol-%, and at least one oxide selected from ZnO 38-52 mol-%, or Al2O3 1-25 mol %, or MoO3 1-10 mol-%, or WO3 1-10 mol-%, or a combination thereof.

Owner:FERRO GMBH

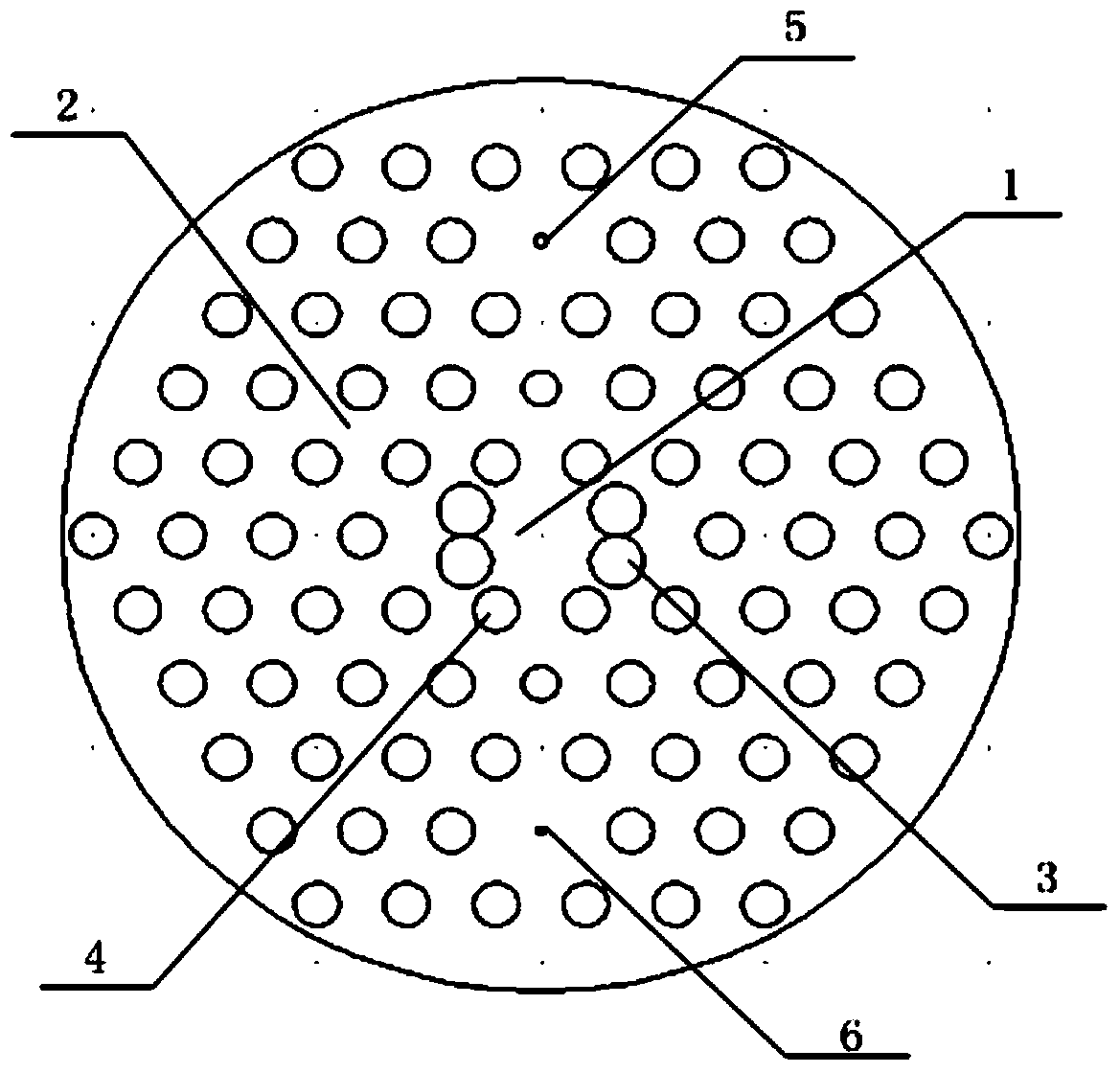

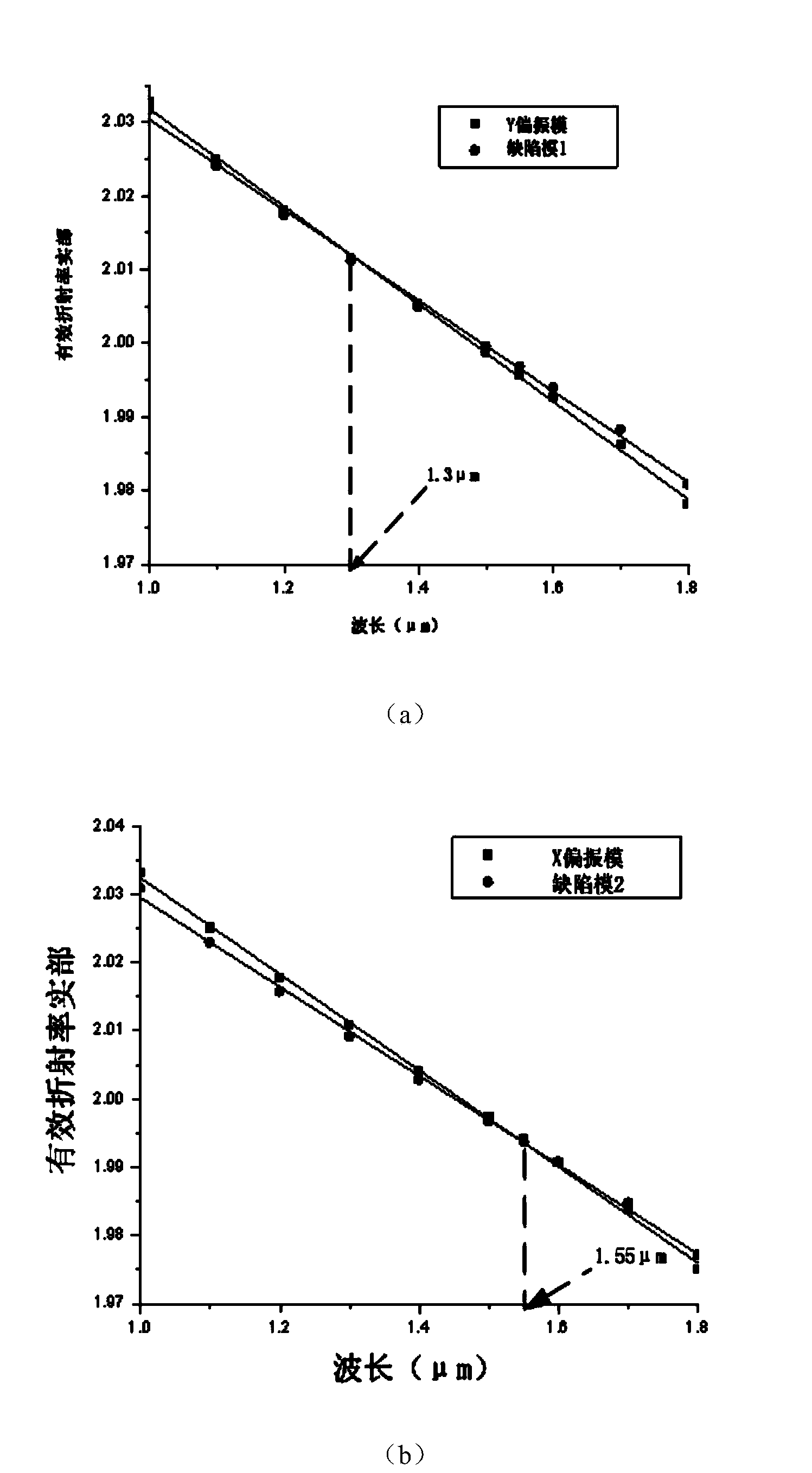

Single-core photonic crystal fiber polarization splitter

InactiveCN104297837ASimple structureImprove spectroscopic effectCladded optical fibreOptical waveguide light guideFiberTellurate

A photonic crystal fiber polarization splitter is composed of a fiber core and a wrapping layer, wherein the refractive index of the wrapping layer is smaller than that of the fiber core, the background material of the wrapping layer is tellurate, four round air holes a and four round air holes b in the center of the wrapping layer jointly form a fiber core area, the round air holes a are arranged in two rows, the two round air holes a in each row are tangential, the fiber core is encircled by the wrapping layer, the wrapping layer is formed by round air holes b which have the same diameters and are arranged periodically in a regular hexagon mode, the total number of the layers of the round air holes b which are periodically arranged is five, and a small round air hole c and a small round air hole d are formed in the outer side of the wrapping layer and located at the positions symmetrical about the fiber core. The photonic crystal fiber polarization splitter has the advantages that zinc telluride serves as the background material of the polarization splitter, the polarization splitter is simple in structure, good in beam splitting effect and easy to manufacture; the small air holes are formed in the outer side of the wrapping layer to form defects, a defect mode is generated so that the defect mode is coupled to a fiber core mode, and the purpose that light is propagated in the orthogonal direction to be split is achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for preparing high-purity tellurium by using tellurium dioxide

InactiveCN102874772ASimple production processReduce dosageElemental selenium/telluriumTellurateEthylic acid

The invention relates to a method for preparing high-purity tellurium by using tellurium dioxide. According to the technical scheme, the method comprises the following steps of: dissolving the tellurium dioxide by using NaOH, regulating the pH value of the dissolved tellurium dioxide to 13, stirring for 3h, filtering, adding a Na2S solution into a filtrate, detecting an end point by using lead acetate test paper, stirring for 2h to remove foreign ions, and filtering; adding a hydrogen dioxide solution into a sodium tellurite solution, stirring for 4h in an ice-water bath to generate a sodium tellurate precipitate, filtering, washing by using absolute ethanol, and drying to obtain sodium tellurate; dissolving the sodium tellurate in 6 mol / L hydrochloric acid, heating to 75 DEG C, introducing sulfur dioxide gas to generate tellurium, and filtering; and stirring at the temperature of 60 DEG C for 1h in the 2 mol / L hydrochloric acid, filtering, washing by using second boiling water until the acidity is not acid, and drying to obtain high-purity tellurium. By the method, the yield of the tellurium can reach 70.12 percent, and the product purity of the tellurium is more than 99.99 percent.

Owner:LIAONING UNIVERSITY

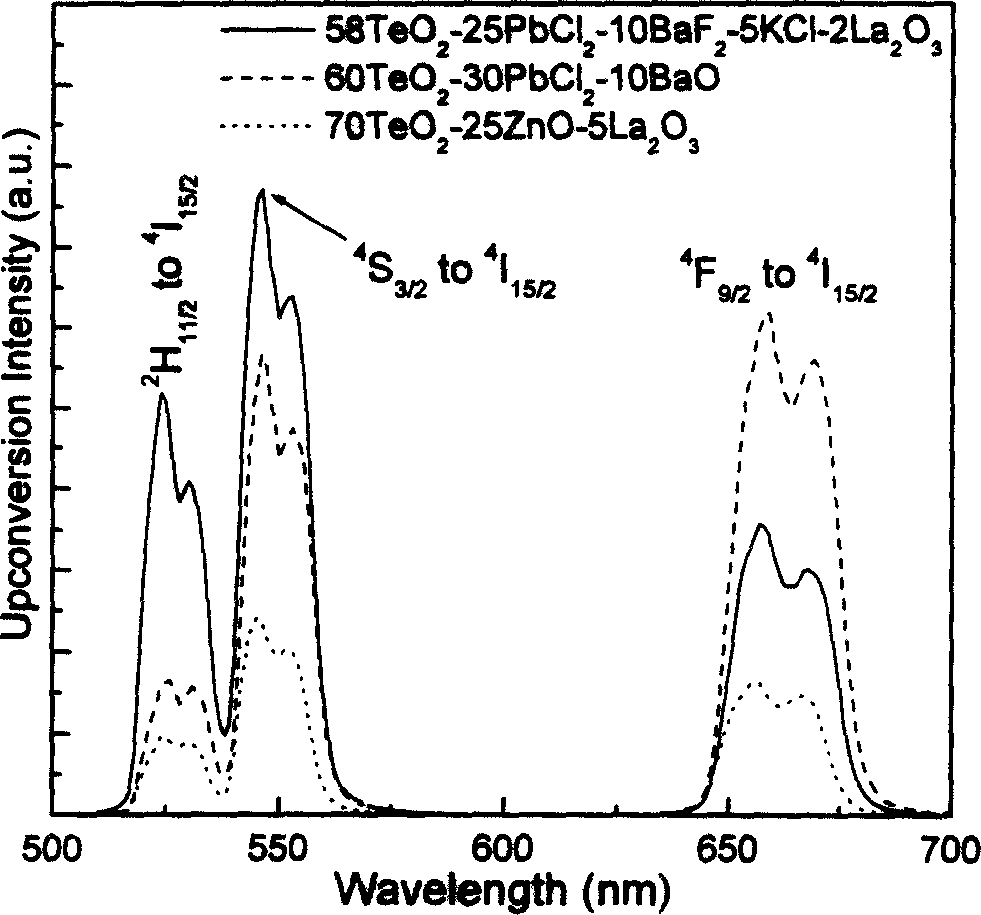

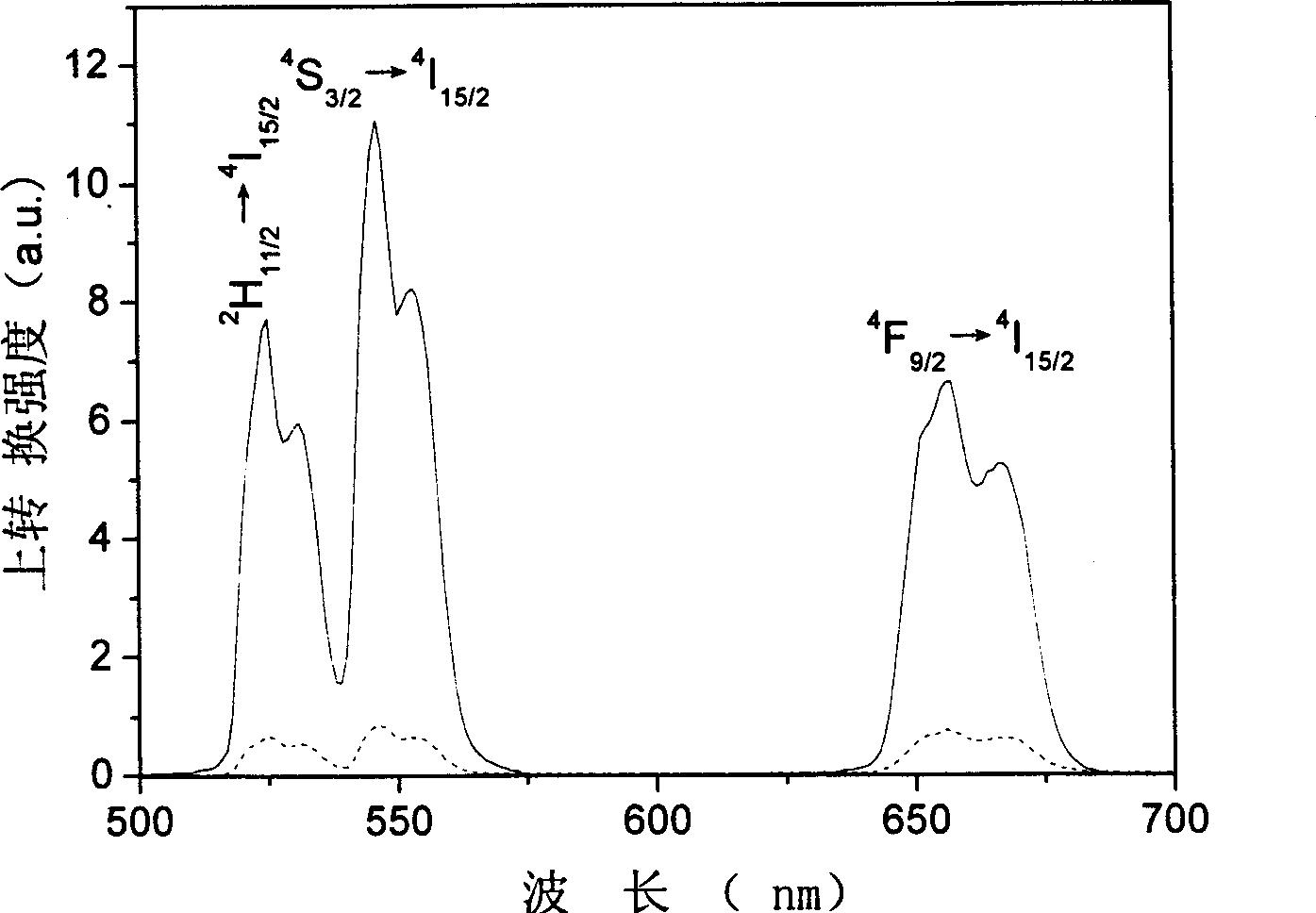

Luminous glass conversion of oxyhalogen tellurate

InactiveCN1559946AImprove stabilityIncrease the intensity of upconversion luminescenceUpconversion luminescenceTellurate

The invention is an oxyhalogen tellurate upconversion light-emitting, and its characteristic: its components and component contents (mol%) as follows: TeO2 58-80, PbF2 + PbCl2 10-30, BaO + BaF2 0-10, XY (X = Na and K; Y = F and Cl) 0-10, ZnO + ZnBr2 0-10; La2O + Al2O3 0-5, and Yb2O3 + Er2O3 1-4.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

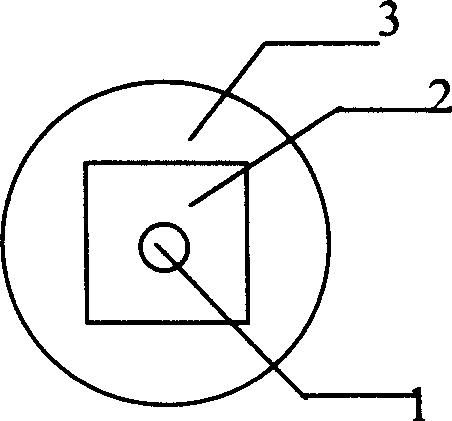

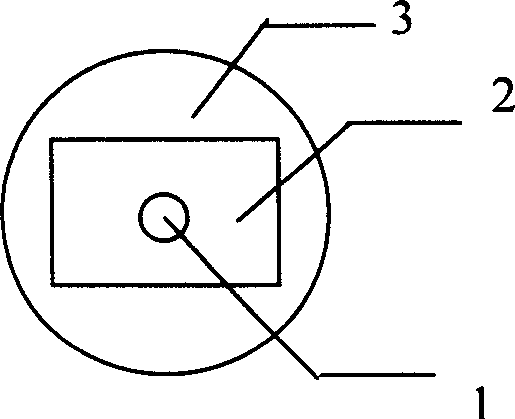

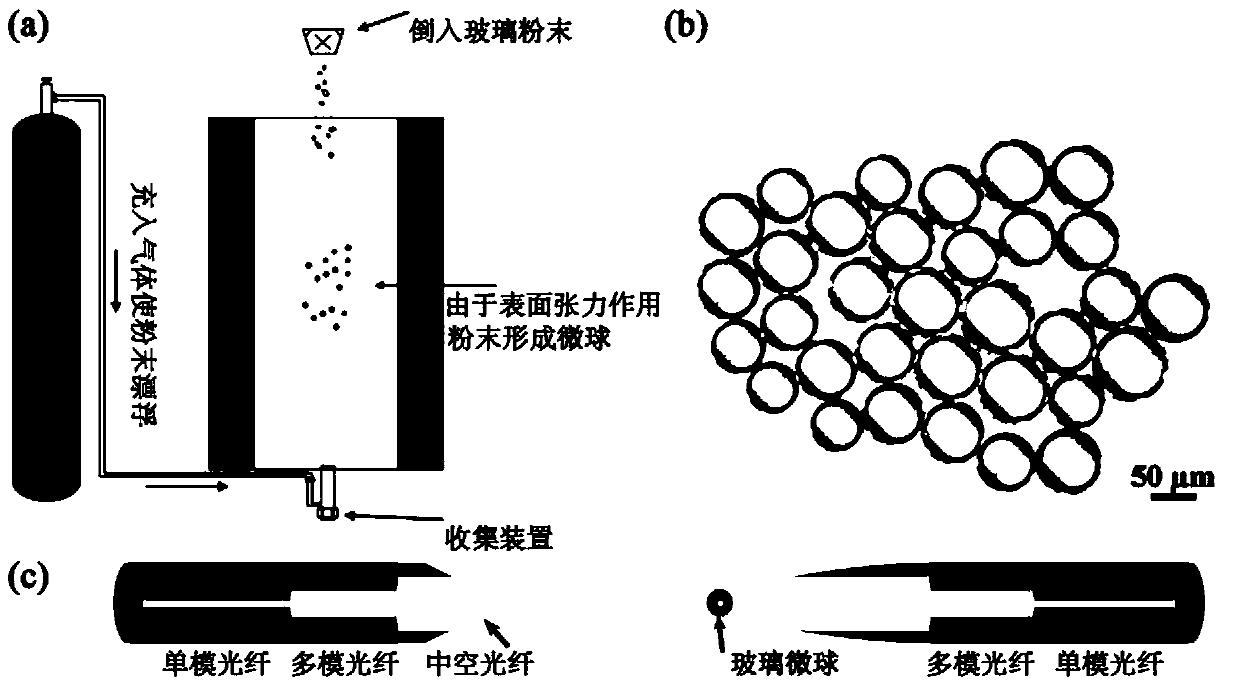

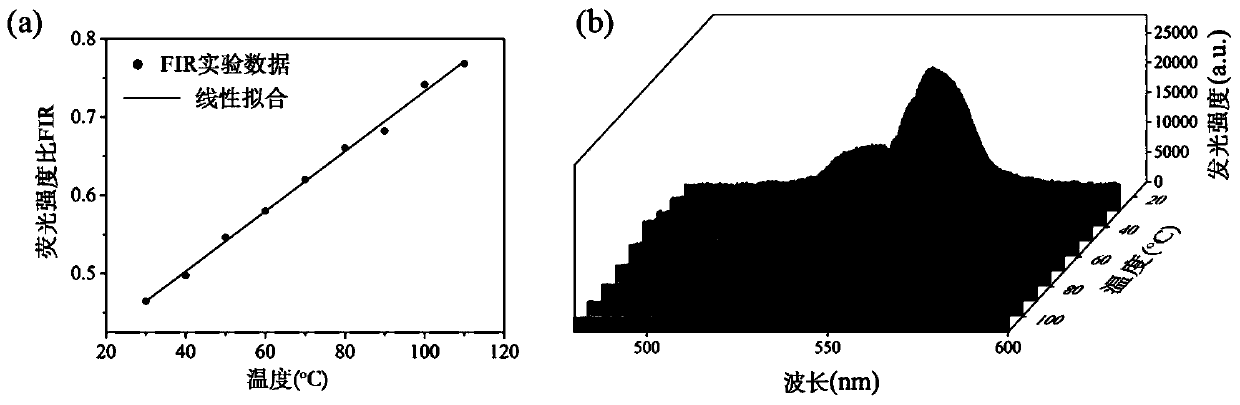

Temperature sensor capable of conversion fluorescent radiation and manufacturing method thereof

InactiveCN109827678ACompact structureEasy to makeThermometers using physical/chemical changesActive medium shape and constructionMicrosphereTellurate

The invention relates to a temperature sensor capable of conversion fluorescent radiation and a manufacturing method thereof and belongs to the field of solid lasers. The structure of the sensor is asingle-mode optical fiber-multimode optical fiber-suspended three-core hollow special optical fiber-multimode optical fiber-single-mode optical fiber structure; the sensor specifically includes a single-mode optical fiber, a multimode optical fiber, a suspended three-core hollow special optical fiber, and erbium ytterbium co-doped tellurate glass microspheres; the erbium ytterbium co-doped tellurate glass microspheres are built in the three-core hollow special optical fiber; and the middle portion of the suspended three-core hollow special optical fiber forms a tapered waist through fused tapering. According to the temperature sensor of the invention, a structural advantage that air holes exist inside the hollow optical fiber is utilized to naturally encapsulate the microspheres inside theoptical fiber, and therefore, the coupling excitation of microsphere resonator inside the optical fiber is realized without additional operation required; the special optical fiber prepared by the method is provided with a built-in gain microsphere photonic integrated device, and therefore, the special optical fiber achieves strong up-conversion fluorescence radiation under the excitation of pumplight, and exhibits high temperature sensing performance.

Owner:HARBIN ENG UNIV

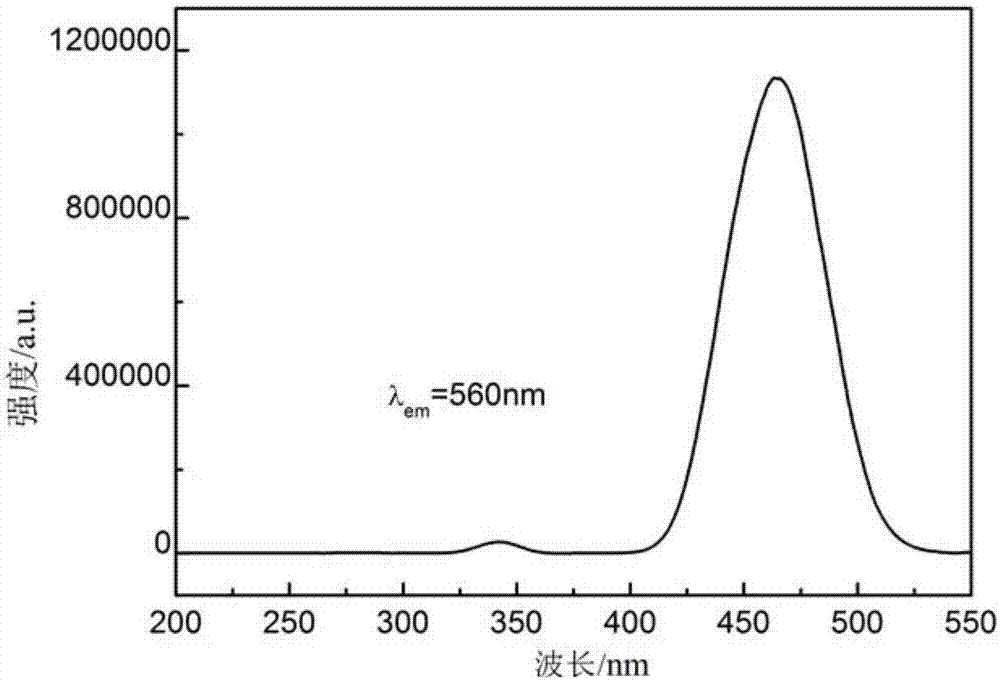

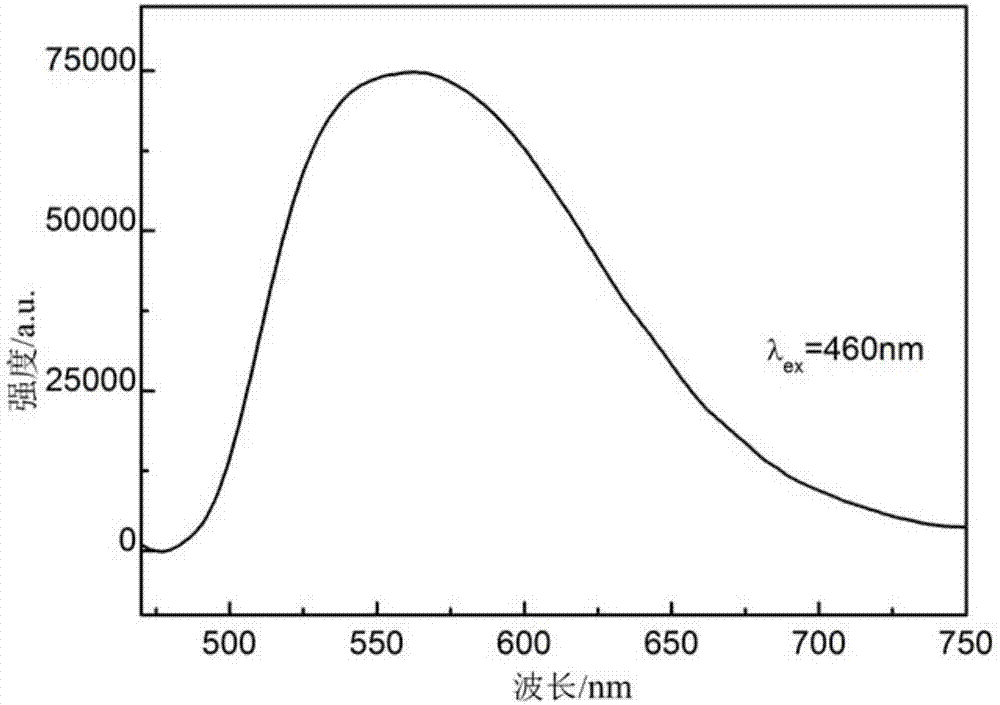

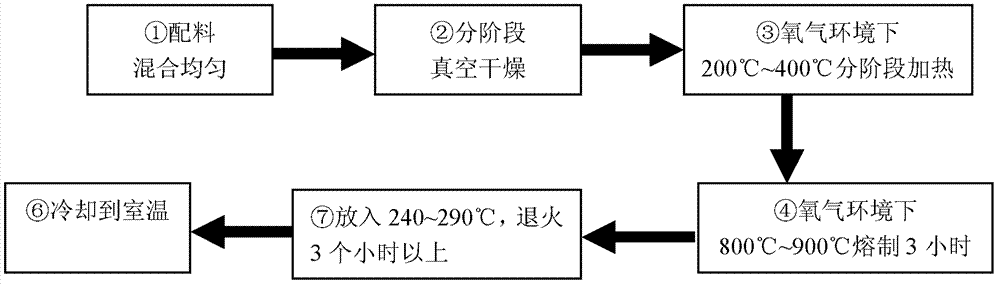

Preparation method of tellurate transparent fluorescent glass for LED (light emitting diode) illumination

The invention discloses a preparation method of tellurate transparent fluorescent glass for LED (light emitting diode) illumination. The preparation method comprises the following steps: (1) sufficiently mixing frit with YAG fluorescent powder in a mortar, and grinding to obtain a fluorescent glass mixture, wherein the frit consists of TeO2, Na2CO3, H3BO3 and ZnO; (2) pouring the fluorescent glassmixture into a crucible, and sintering in a muffle furnace to obtain molten frit; (3) annealing the molten frit; (4) cooling to room temperature to obtain transparent fluorescent glass. The fluorescent glass prepared in the invention has the advantages of stable chemical performance, high transparency, good radiating effect and excellent optical performance, and is ground, polished and cut into acertain size and is encapsulated on an LED blue-light chip to emit white light.

Owner:SHANGHAI INST OF TECH +1

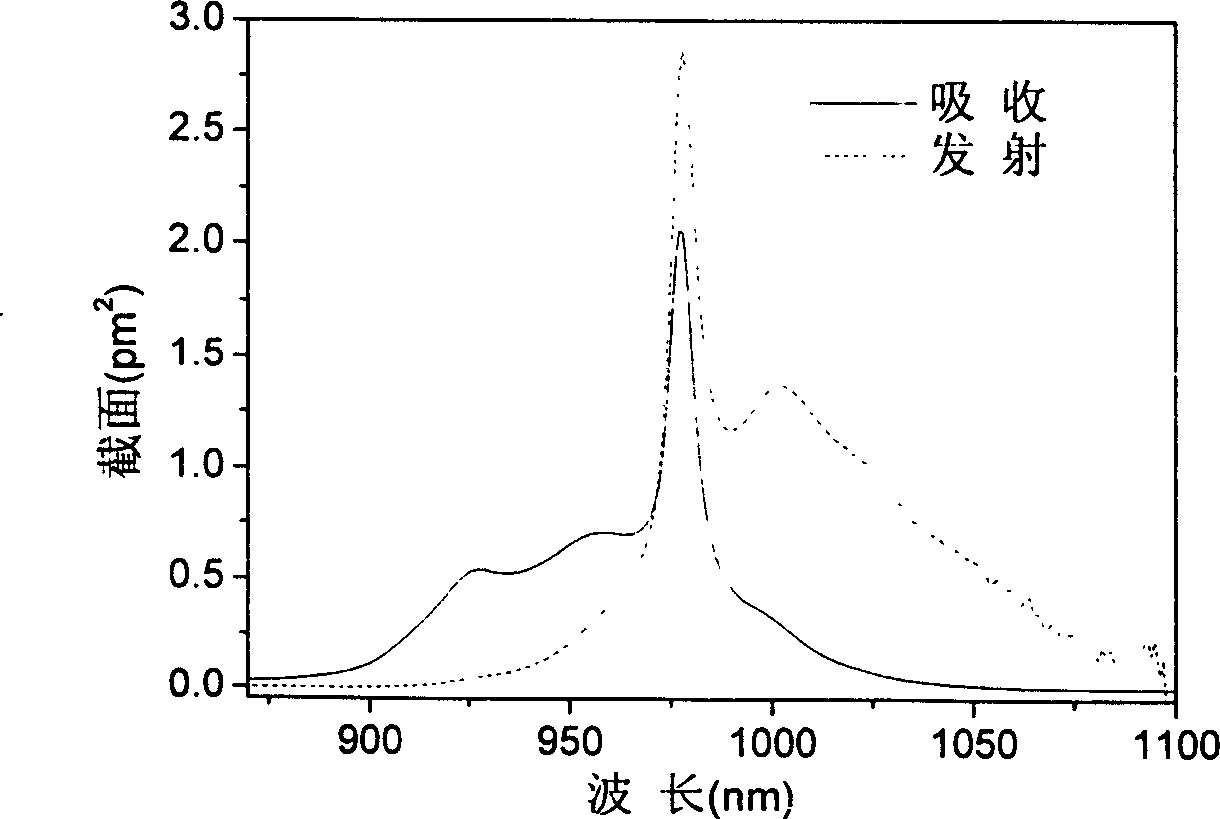

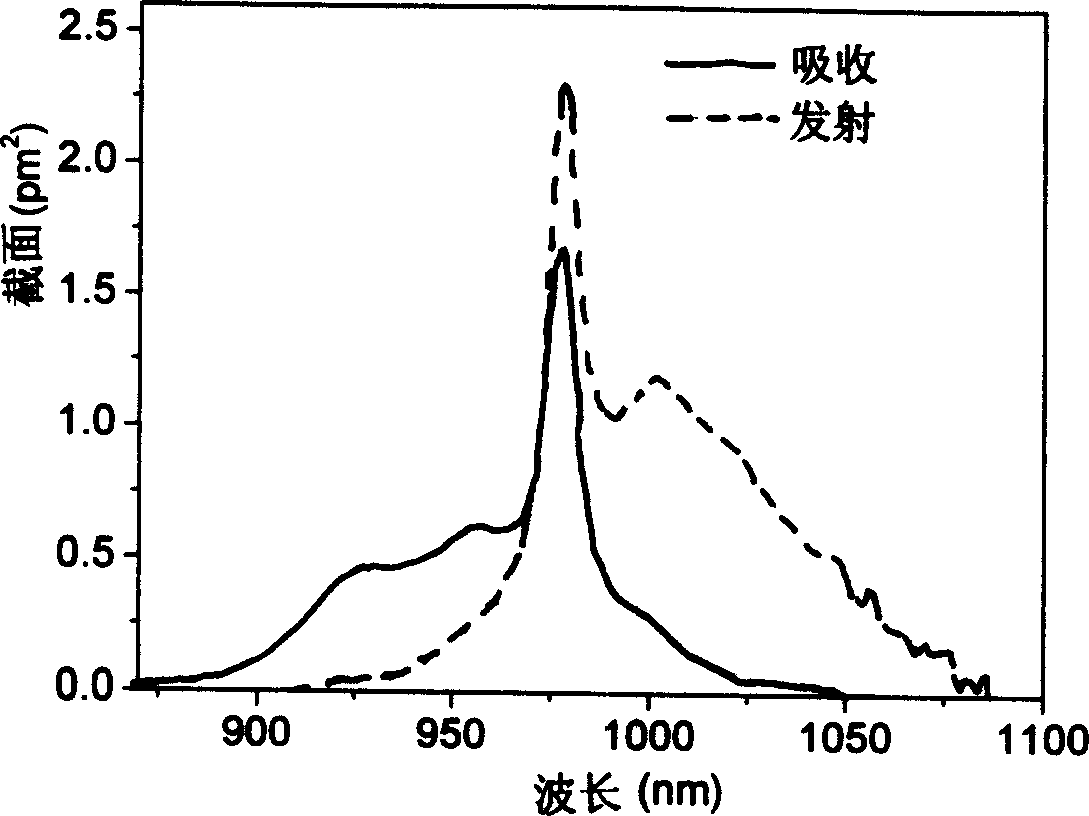

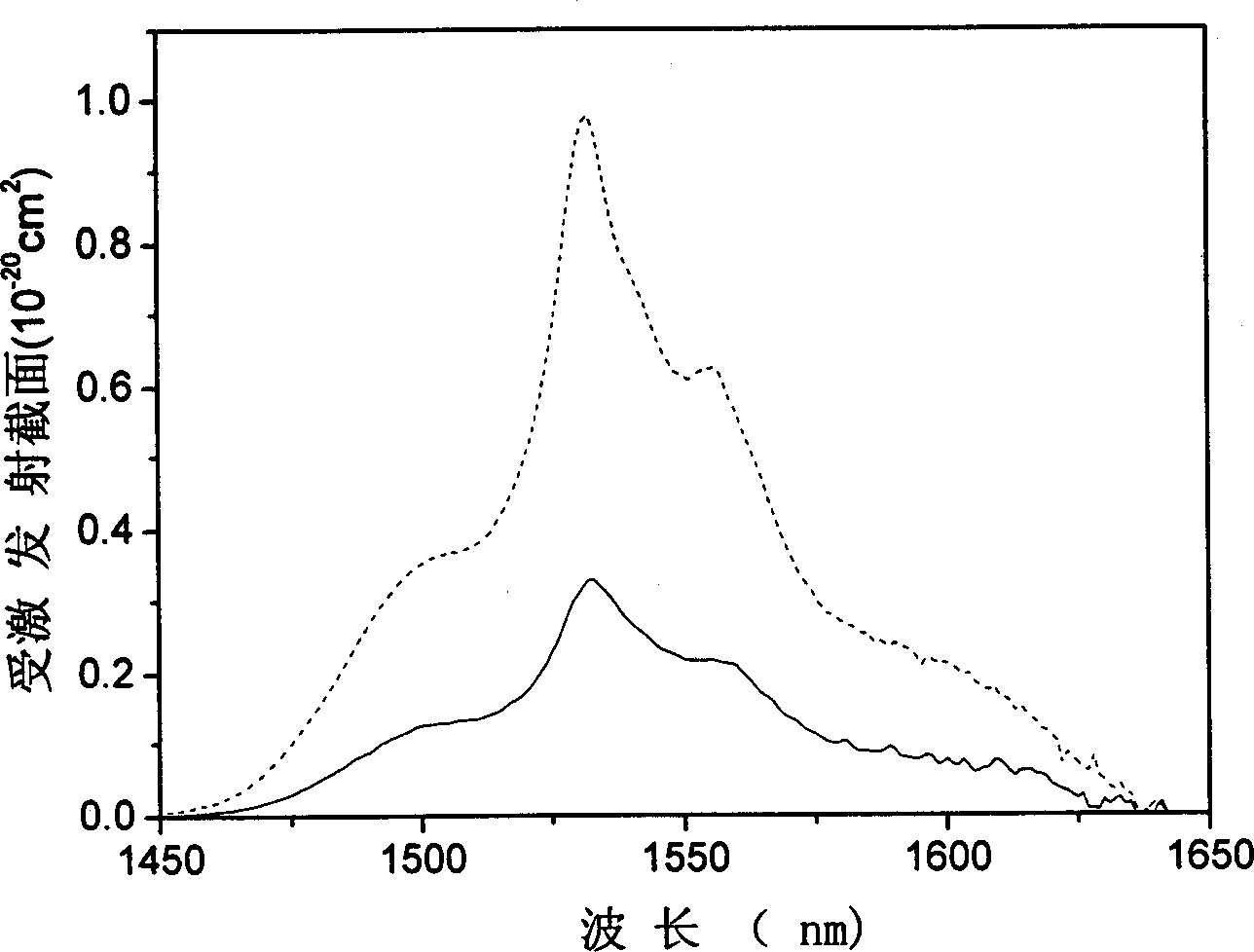

Yb3+ blended tellurate glass and its preparing method

InactiveCN1587138AGood anti-devitrification performanceMeet practical requirementsLine widthFluorescence

The present invention is Yb3+ doped tellurate glass and its preparation process. The glass consists of TeO2 60-80 mol%, ZnO 5-15 mol%, WO3 0-25 mol%, La2O3 0-4.5 mol%, Na2O3 0-5 mol%, K2O 0-5 mol%, and Yb2O3 0.5-5 mol%. It is prepared through smelting process, and is colorless, transparent, no defitrification, good in transparency loss resisting performance and excellent in physical and chemical performance. The semiconductor light source pump test of 940 nm band proves its stimulated emission cross section as high as 0.35 sq pm and effective fluorescent line width as high assemble 80 nm. Compared with available technology, the glass of the present invention has the advantages of simple preparation process, high heat stability, great absorption and stimulated emission cross section and wide fluorescent line width. The glass material may be used in high power pulse adjustable laser, micro solid fiber laser, etc.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Yb3+/Ce3+/Er3+ codoped oxychloro tellurate glass and its preparation method

The present invention relates to an Yb(3+) / Ce(3+) / Er(3+) codoped oxychlorinated tellurate glass and its preparation method. Said glass composition contains: (by mol%) 50-80 TeO2, 5-35 BiCl3, 5-20 GeO2, 3-5 Na2O, 1-3 La2O3, 2-5 Yb2O3, 0.5-0.8 Ce2O3 and 0.5-1 Er2O3. Said tellurate glass prepared by means of melting process is transparent, has high resistance to devitrification and good physical and chemical properties. Said glass can be extensively used in the optical fibre amplifier system.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

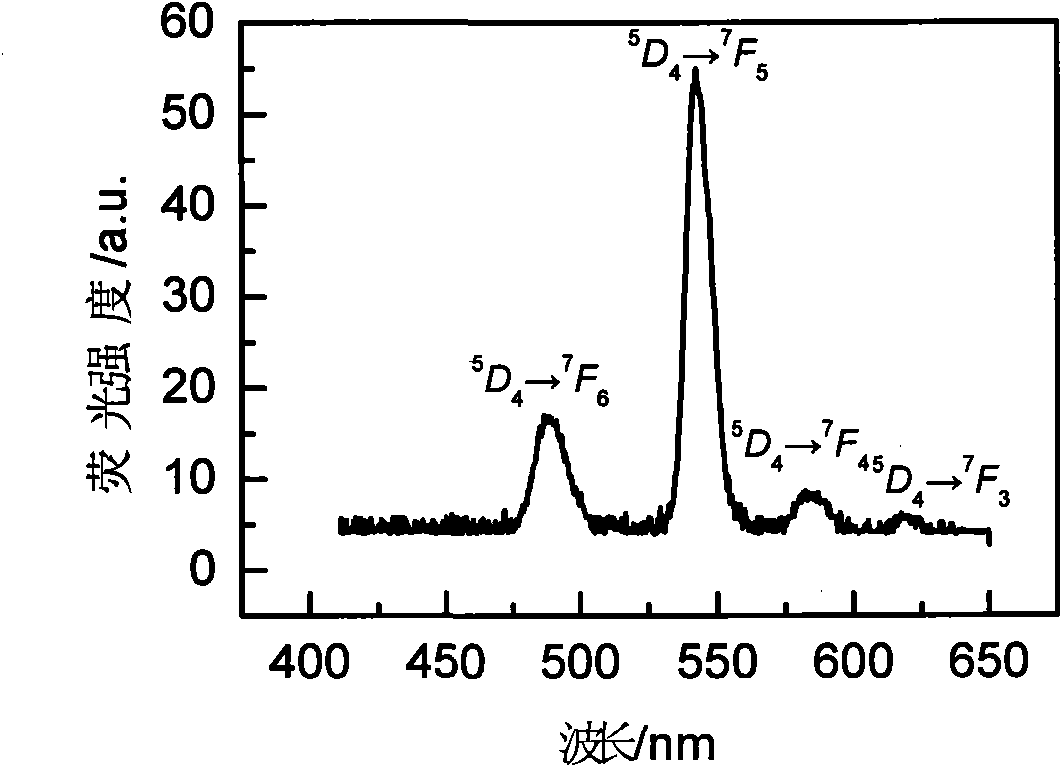

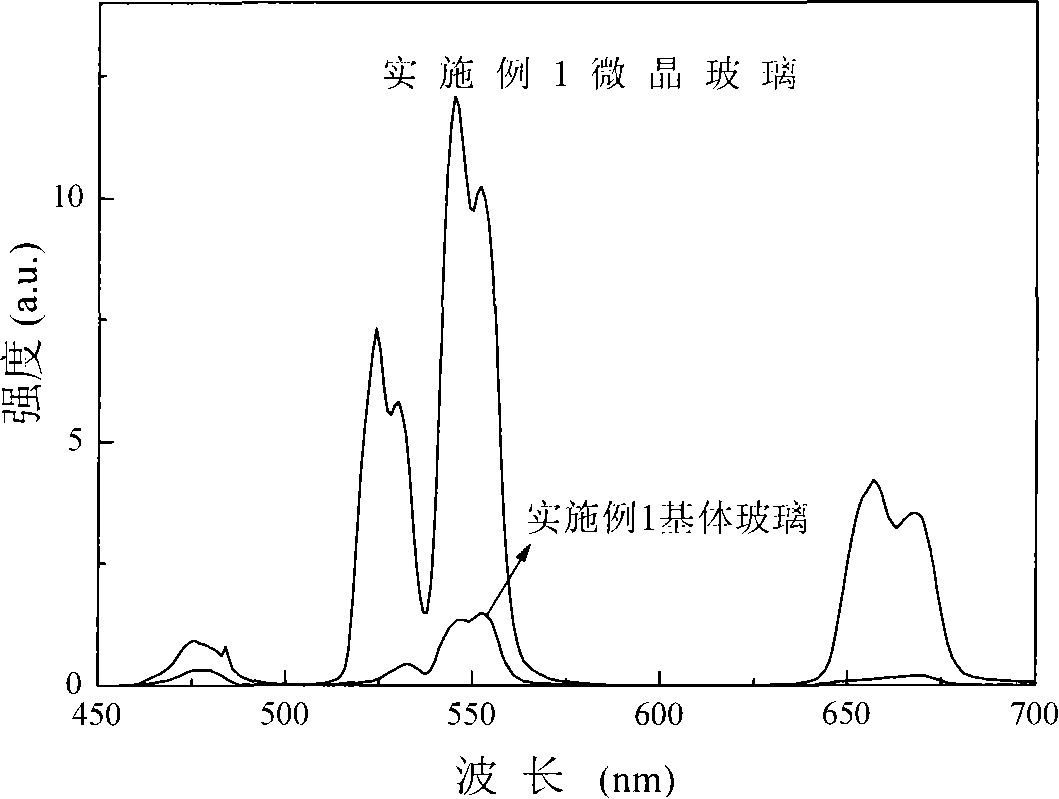

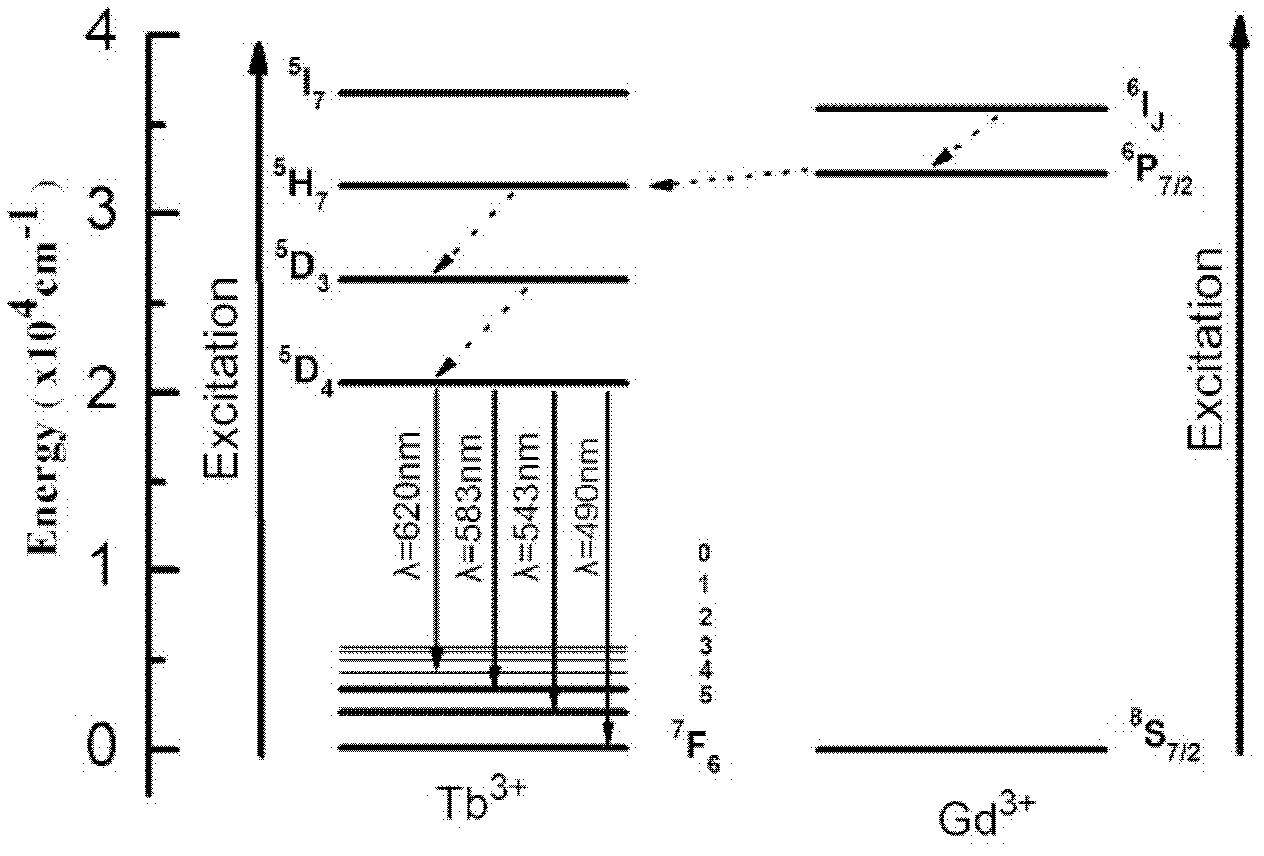

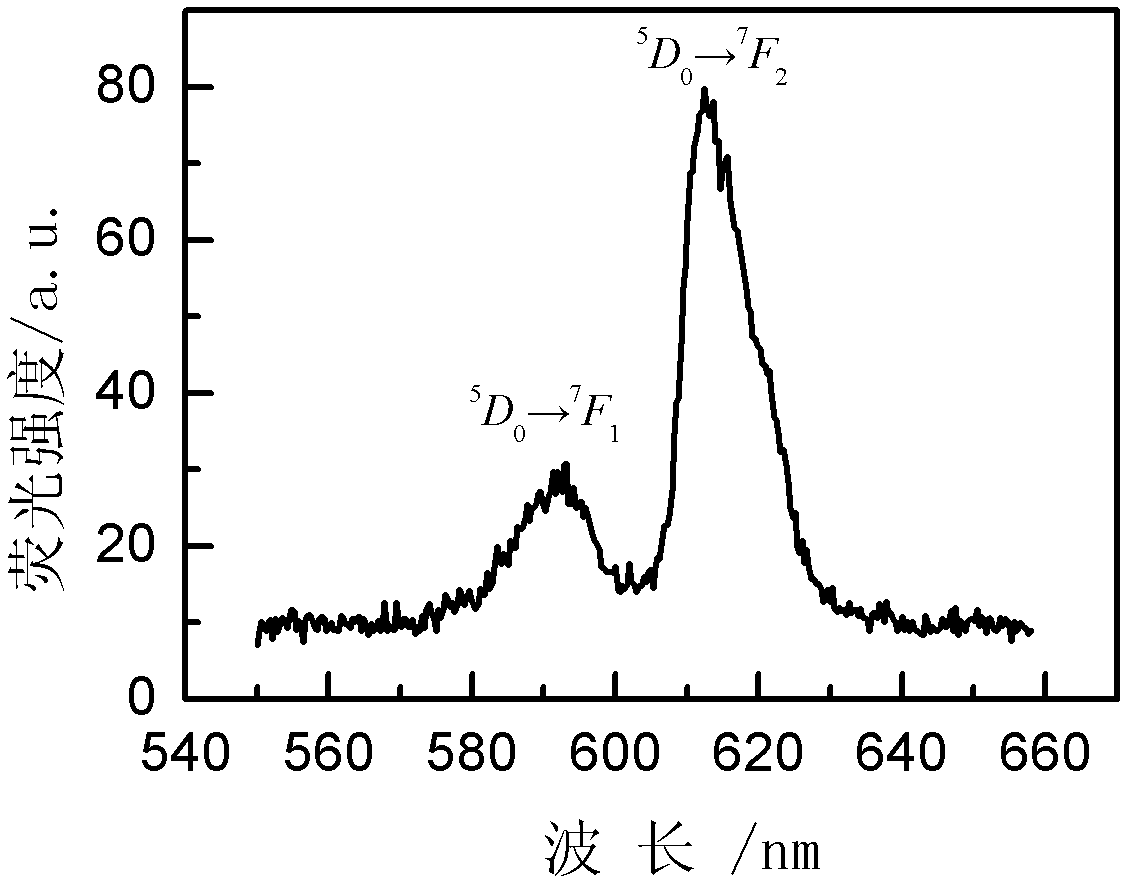

Green-light-emitting tellurate glass and preparation method thereof

The invention relates to green-light-emitting tellurate glass and a preparation method thereof. The green-light-emitting tellurate glass is prepared from 65-90mol% of TeO2, 5-25mol% of ZnO, 3-20mol% of Na2O, a ytterbium ionic compound with mass percent concentration of 2-8% and a terbium ionic compound with the mass percent concentration of 1-4%. The invention provides a tellurate glass matrix which can emit intense and visible green light and can be doped with massive rare earth ions, green-light-emitting tellurate glass with a simple and feasible preparation process and a preparation method of the green-light-emitting tellurate glass.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

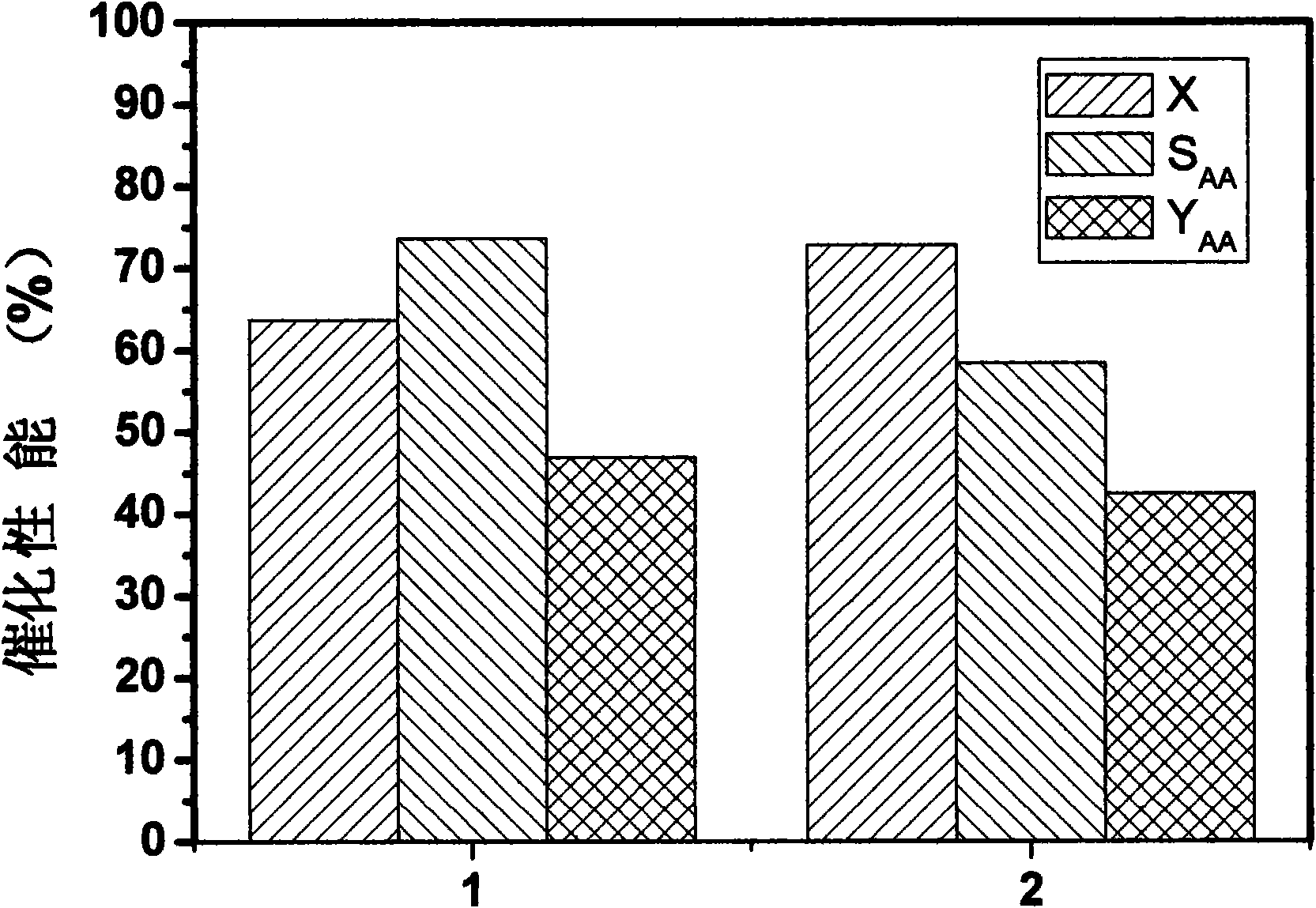

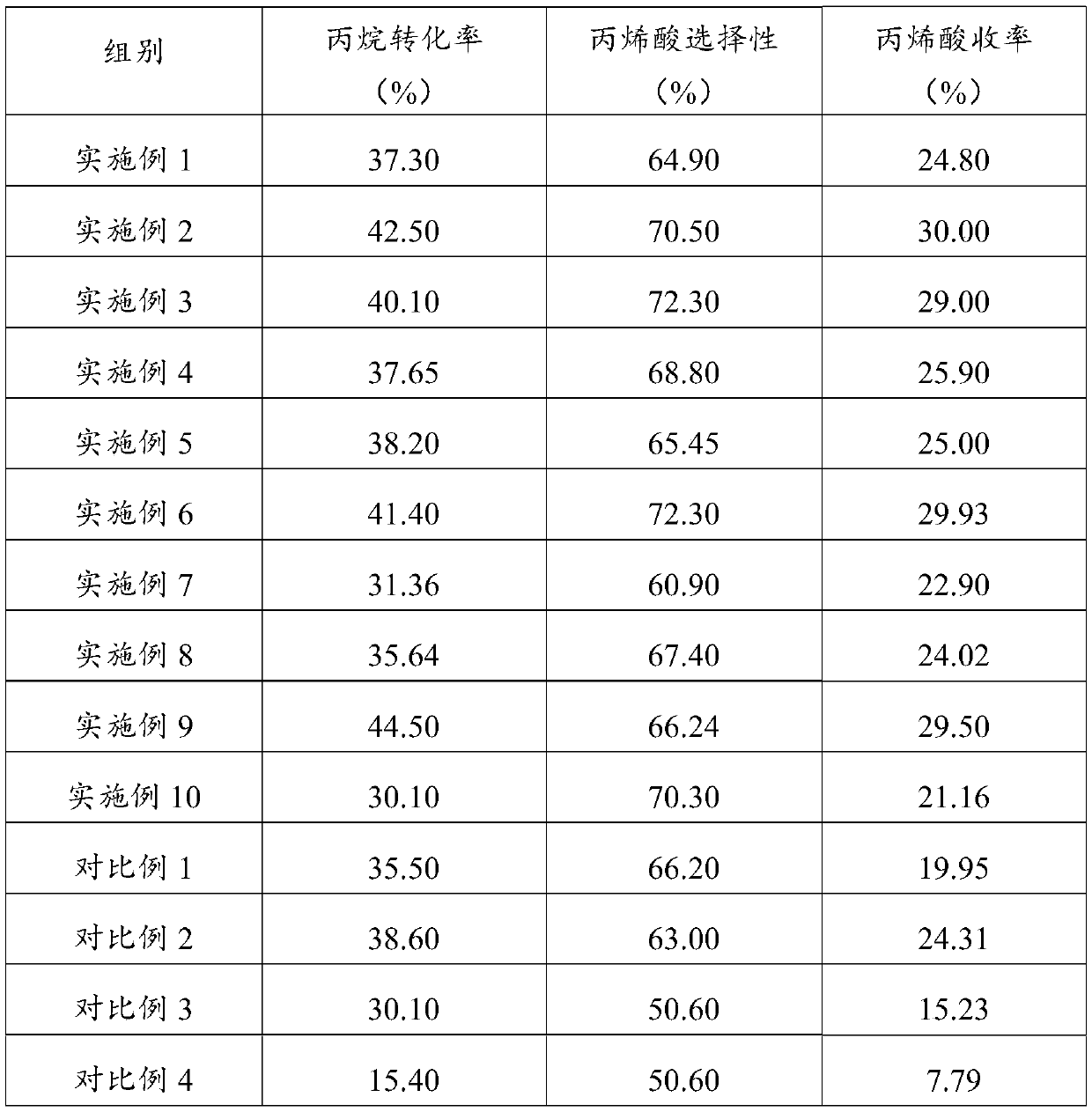

Method for preparing catalyst used in selective oxo-synthesis of crylic acid from propane

InactiveCN101628232AHigh selectivityHigh yieldOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsTellurateFiltration

The invention provides a method for preparing catalyst used in selective oxo-synthesis of crylic acid from propane. The method comprises the following steps: adopting ammonium molybdate, vanadyl sulfate, hydrogen tellurate and niobium oxalate as raw materials, wherein the molar ratio of active components in form of Mo, V. Te and Nb is 1:0.2-1.0:0.2-1.0:0.1-0.5; mixing the ammonium molybdate, the vanadyl sulfate, the hydrogen tellurate and the niobium oxalate in a ratio to prepare mixed solution, putting the mixed solution into a stainless steel reaction kettle with polyfluortetraethylene lining, and placing the resulting product in an oven for in-situ aging; and taking the aged product out and subjecting the aged product to suction filtration, drying, baking and crushing to prepare the catalyst. Mo-V-Te-Nb-O catalyst prepared by adopting an in-situ hydrothermal synthesis method has high activity and product selectivity in the reaction for selective oxo-synthesis of the crylic acid from the propane with propane conversion rate equal to 63.7 percent, crylic acid selectivity equal to 73.6 percent and yield equal to 46.9 percent; moreover, the preparation method has ideal repeatability and simple synthesis process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method and application of Mo-V-Te-Nb-O catalyst

InactiveCN109569668AHigh catalytic activityEasy to handleOrganic compound preparationHeterogenous catalyst chemical elementsNiobiumTellurium compounds

The invention provides a preparation method and application of an Mo-V-Te-Nb-O catalyst, and relates to the technical field of catalysts. Compared with an existing process in which tellurate is takenas a tellurium source, the preparation method, in which reducing metal tellurium obtained by reducing a high-valent tellurium compound by a reducing agent is taken as a tellurium source and then is mixed with and reacts with a molybdenum source, a vanadium source and a niobium source before drying and calculating to obtain the Mo-V-Te-Nb-O catalyst, has the advantages that the Mo-V-Te-Nb-O catalyst obtained by the preparation method has high catalytic activity; the reducing agent used in the preparation process is stable and easy to operate, has no toxic effect on experimenters and the environment, and is inexpensive and suitable for industrial scale. The Mo-V-Te-Nb-O catalyst prepared by the preparation method is applied to reactions of producing acrylic acid through dimethylmethane oxidation.

Owner:SHANDONG YUHUANG CHEM CO LTD

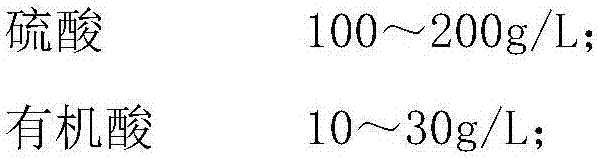

Hard oxidation method for aluminum alloy of rotary compression disc of air conditioning compressor

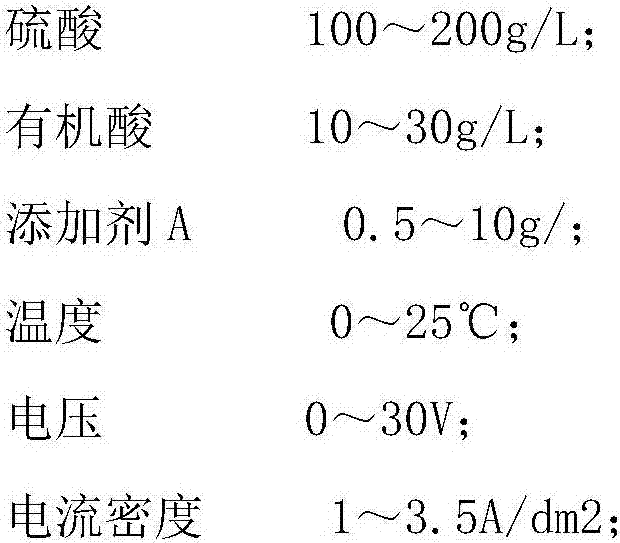

The invention discloses a hard oxidation method for an aluminum alloy of a rotary compression disc of an air conditioning compressor. The method comprises the steps that pretreatment is carried out, specifically, the aluminum alloy is sequentially subjected to oil removing, water washing, alkali etching, water washing, bright dipping and water washing pretreatment; anodic oxidation is carried out, specifically, the pretreated aluminum alloy serves as an anode, a lead plate serves as a cathode, anodic oxidation is carried out in an electrolyte, and a power supply is powered on by adopting a direct-current pulse superposition mode, wherein the electrolyte for anode oxidation is composed of 100-200g / L of sulfuric acid, 10-30g / L of organic acid and 0.5-10g / L of an additive A, the temperature is 0-25 DEG C, the voltage is 0-30V, the current density is 1-3.5A / dm2, and the additive A is a mixture of molybdate, phosphate and tellurite which are mixed according to the mass ratio of 2-3:1:1; and an aluminum alloy workpiece subjected to anodic oxidation is soaked and sealed through a hole sealing agent. The method has the advantages that an aluminum alloy hard oxidation film has higher thickness and hardness, and the phenomenon of burning loss of an oxide layer can be avoided.

Owner:江苏昊科汽车空调有限公司

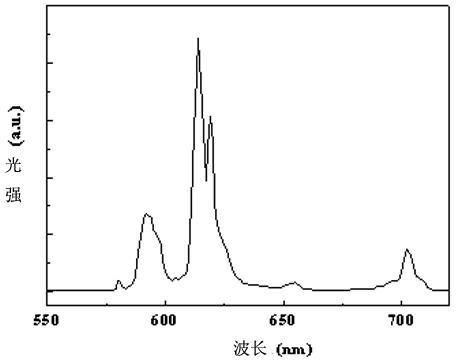

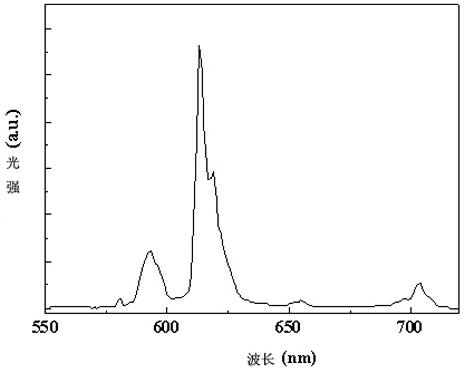

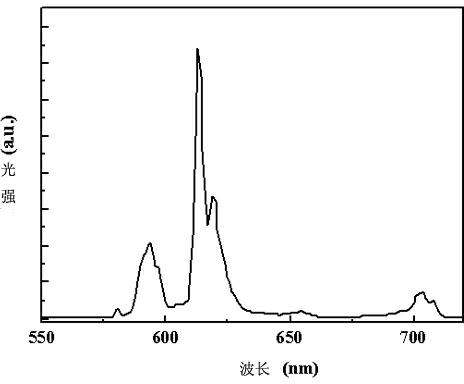

Red fluorescent powder for light-emitting diode (LED) and preparation method for red fluorescent powder

ActiveCN102690660AImprove energy conversion efficiencyExcellent luminous propertiesGas discharge lamp usageLuminescent compositionsTellurateRed fluorescence

The invention discloses red fluorescent powder for a light-emitting diode (LED). The red fluorescent powder is trivalent europium activated calcium tellurate fluorescent powder, and has the chemical expression formula of (Ca1-2xEuxAx)TeO3, wherein A refers to at least one of Li, Na and K; and x is more than 0 and less than 0.5. The invention discloses a preparation method for the red fluorescent powder. The preparation method comprises the following steps: uniformly mixing and grinding simple substances, compounds or corresponding salts of Ca, Te and Eu and compounds or corresponding salts of A, roasting at high temperature, crushing, cleaning to remove impurities, drying and processing. The fluorescent powder has the characteristics of wide wavelength exciting range, high efficiency, stability and the like; and the preparation method is simple, pollution-free and low in cost. The fluorescent powder can be widely applied to purple, ultraviolet or blue light-emitting diode (LED) chips for manufacturing white LEDs.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com