Hard oxidation method for aluminum alloy of rotary compression disc of air conditioning compressor

An air-conditioning compressor, rotary compression technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of corrosion and dissolution, the existence of oxide film, and the inability of current density and heat to remove the oxide film in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

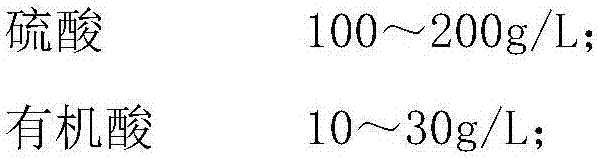

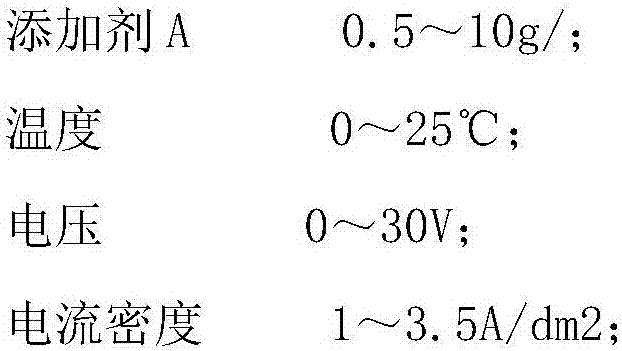

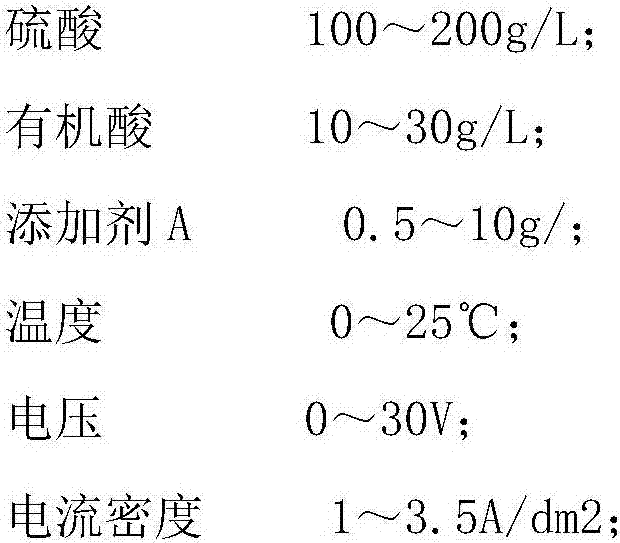

[0018] Preparation of anodic oxidation electrolyte: first add about 70% pure water to the electrolytic cell, then add 150g / L concentrated sulfuric acid, add the remaining pure water to the scale line and stir evenly to obtain a sulfuric acid aqueous solution with a temperature of about 60°C , take out part of the sulfuric acid solution for additive preparation, and continue to add 15g / L oxalic acid to the rest and stir to dissolve. Take 1000ml sulfuric acid aqueous solution, put 40g sodium molybdate, 20g sodium phosphate and 20g sodium tellurate quickly at about 60°C and stir to dissolve to obtain additive solution. In the mixed solution of sulfuric acid and oxalic acid, add the additive solution of 20~50ml / L, preferably 25ml / L, and stir evenly.

[0019] The electrolytic tank is equipped with an overflow tank and a cooling pipe, and the bottom of the tank is equipped with an air pipe. During electrolysis, the water pump is turned on to overflow the electrolyte and the heat gen...

Embodiment 2

[0022] In this embodiment, the preparation of the electrolytic solution for anodic oxidation: first add about 70% pure water in the electrolytic cell, then add 180g / L concentrated sulfuric acid, supplement the remaining pure water to the scale line and stir to obtain the sulfuric acid aqueous solution The temperature is about 60°C, take out part of the sulfuric acid solution for additive preparation, and continue to add 20g / L oxalic acid to the rest and stir to dissolve. Take 1000ml of sulfuric acid aqueous solution, quickly add 40g of sodium molybdate, 20g of sodium phosphate and 20g of sodium tellurate at about 60°C and stir to dissolve to obtain an additive solution. In the mixed solution of sulfuric acid and oxalic acid, add 20-50ml / L additive solution, preferably 25ml / L, and stir evenly.

[0023] The electrolytic tank is equipped with an overflow tank and a cooling pipe, and the bottom of the tank is equipped with an air pipe. During electrolysis, the water pump is turned...

Embodiment 3

[0026] In the present embodiment, the preparation of the electrolytic solution of anodic oxidation: first add about 70% pure water in the electrolytic cell, then add the concentrated sulfuric acid of 150g / L, replenish the remaining pure water to the scale line and stir the obtained sulfuric acid aqueous solution The temperature is about 60°C, take out part of the sulfuric acid solution for additive preparation, and continue to add 20g / L oxalic acid to the rest and stir to dissolve. Take 1000ml of sulfuric acid aqueous solution, quickly add 40g of sodium molybdate, 20g of sodium phosphate and 20g of sodium tellurate at about 60°C and stir to dissolve to obtain an additive solution. In the mixed solution of sulfuric acid and oxalic acid, add 20-50ml / L additive solution, preferably 25ml / L, and stir evenly.

[0027] The electrolytic tank is equipped with an overflow tank and a cooling pipe, and the bottom of the tank is equipped with an air pipe. During electrolysis, the water pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com