Patents

Literature

45results about How to "Deterioration of battery performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonaqueous electrolytic solution type secondary battery

InactiveUS6919145B1Deterioration of battery performanceHigh viscosityElectrolytic capacitorsOrganic electrolyte cellsElectrolytic agentElectrical battery

A non-aqueous electrolyte secondary battery comprising a negative electrode, a positive electrode and an electrolyte having a lithium salt dissolved in a non-aqueous solvent characterized in that said non-aqueous solvent contains a vinylethylene carbonate compound represented by the general formula (I) in an amount of from 0.01 to 20% by weight is subject to minimized decomposition of the electrolyte and can provide a high capacity as well as exhibits excellent storage properties and cycle life performance. wherein R1, R2, R3, R4, R5 and R6 each independently represent a hydrogen atom or an alkyl group having 1 to 4 carbon atoms.

Owner:MITSUBISHI CHEM CORP

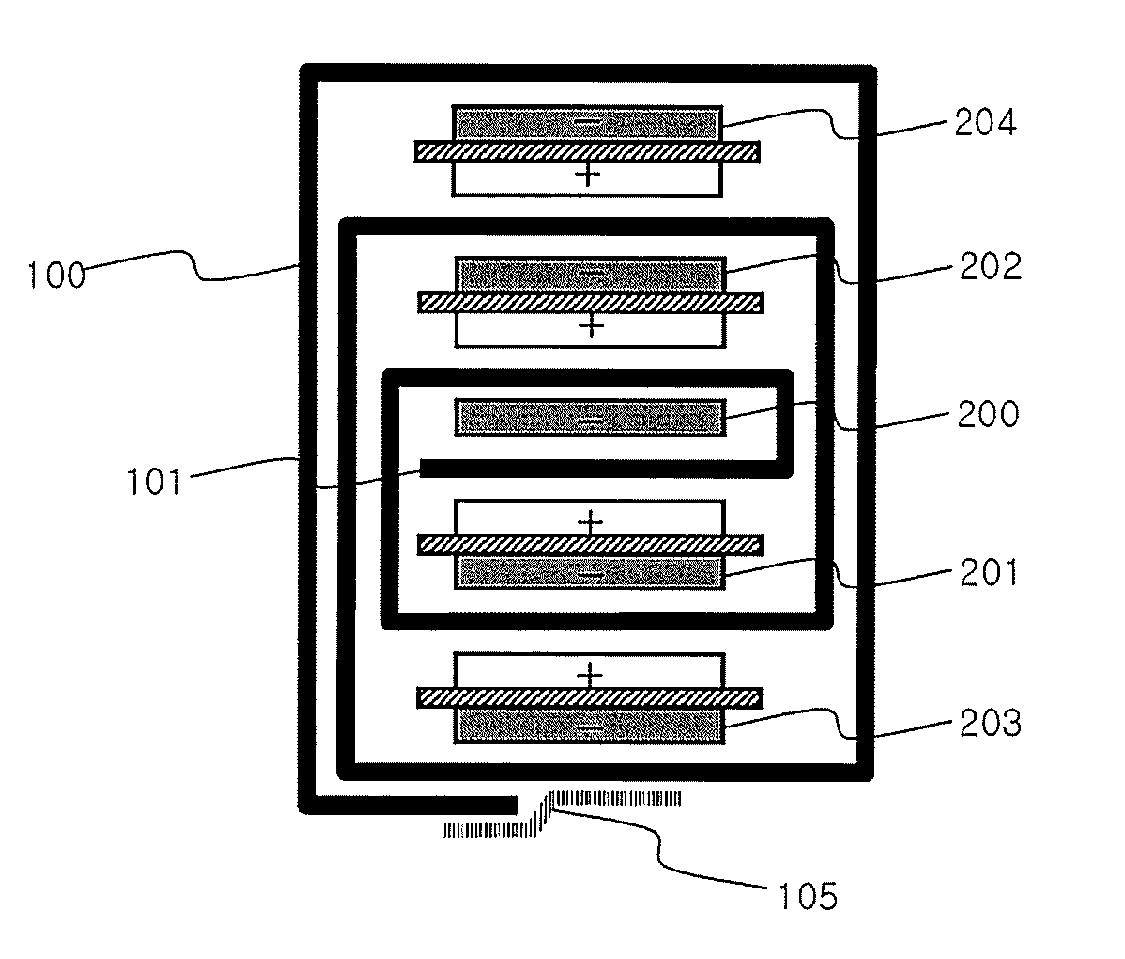

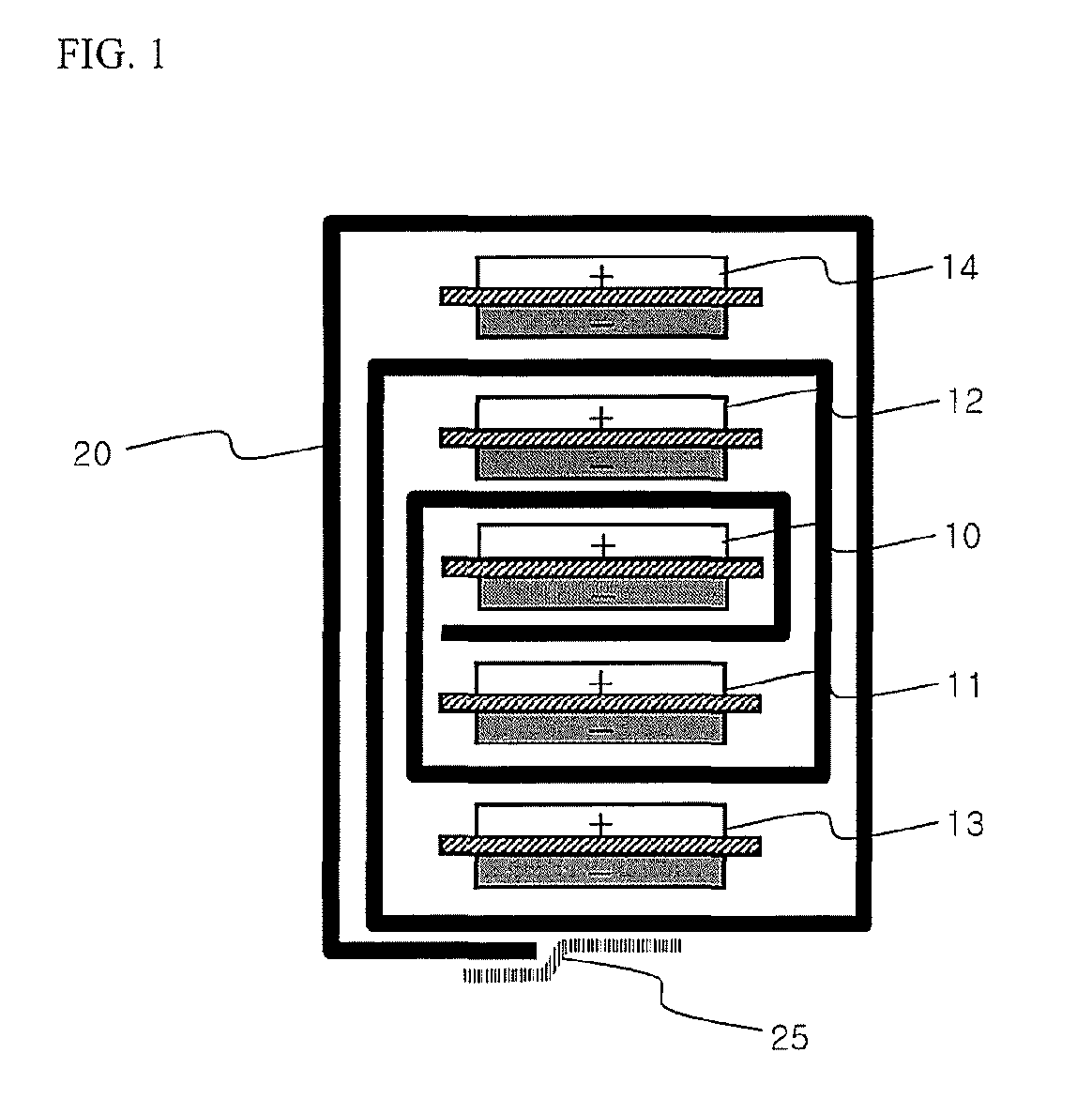

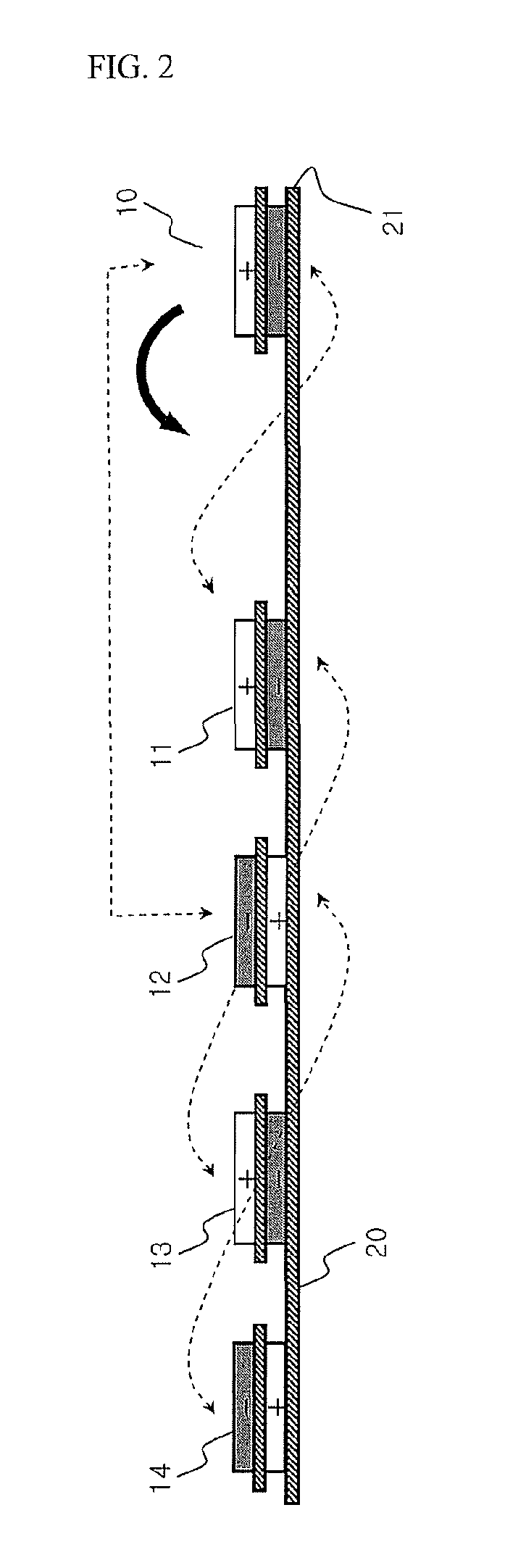

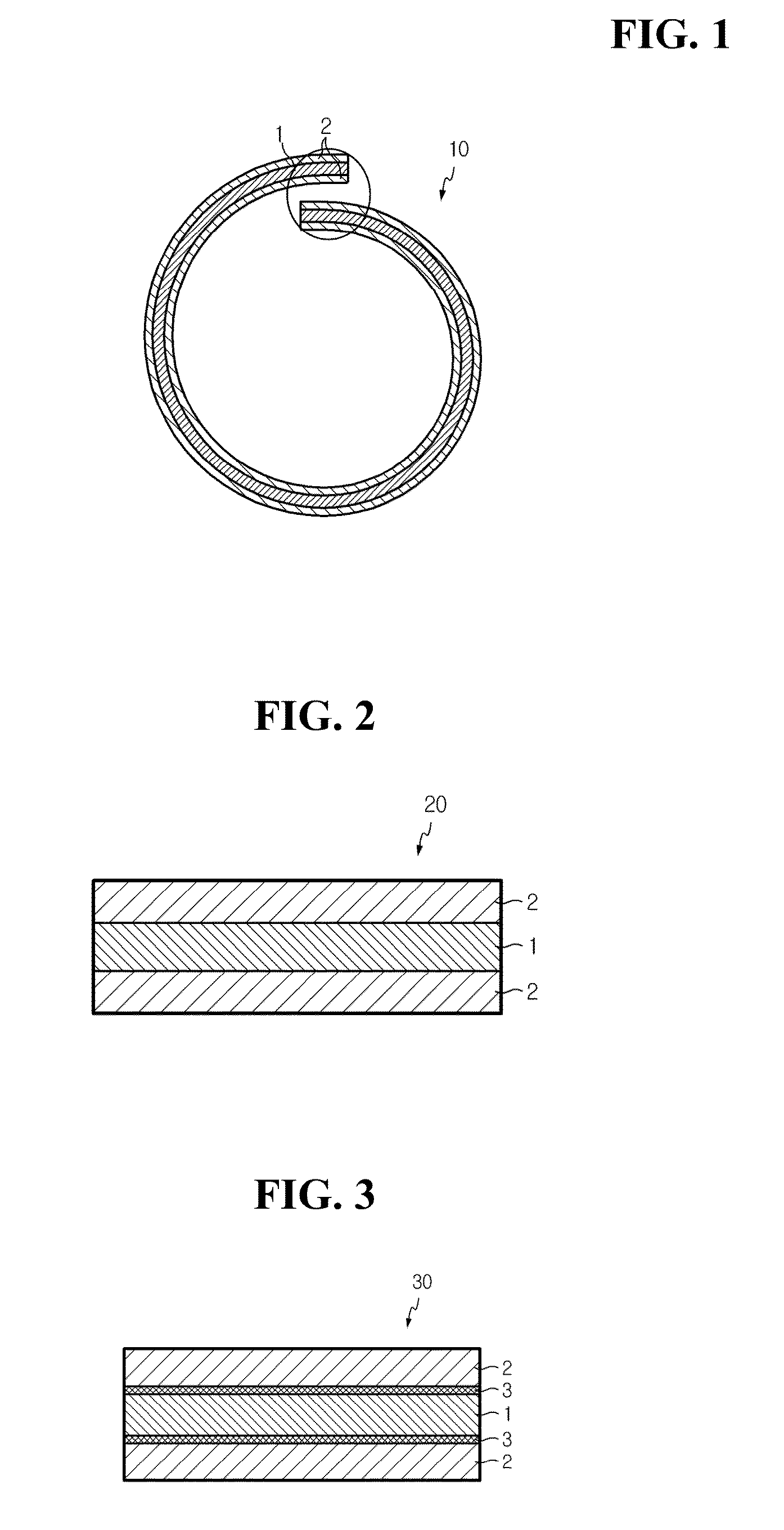

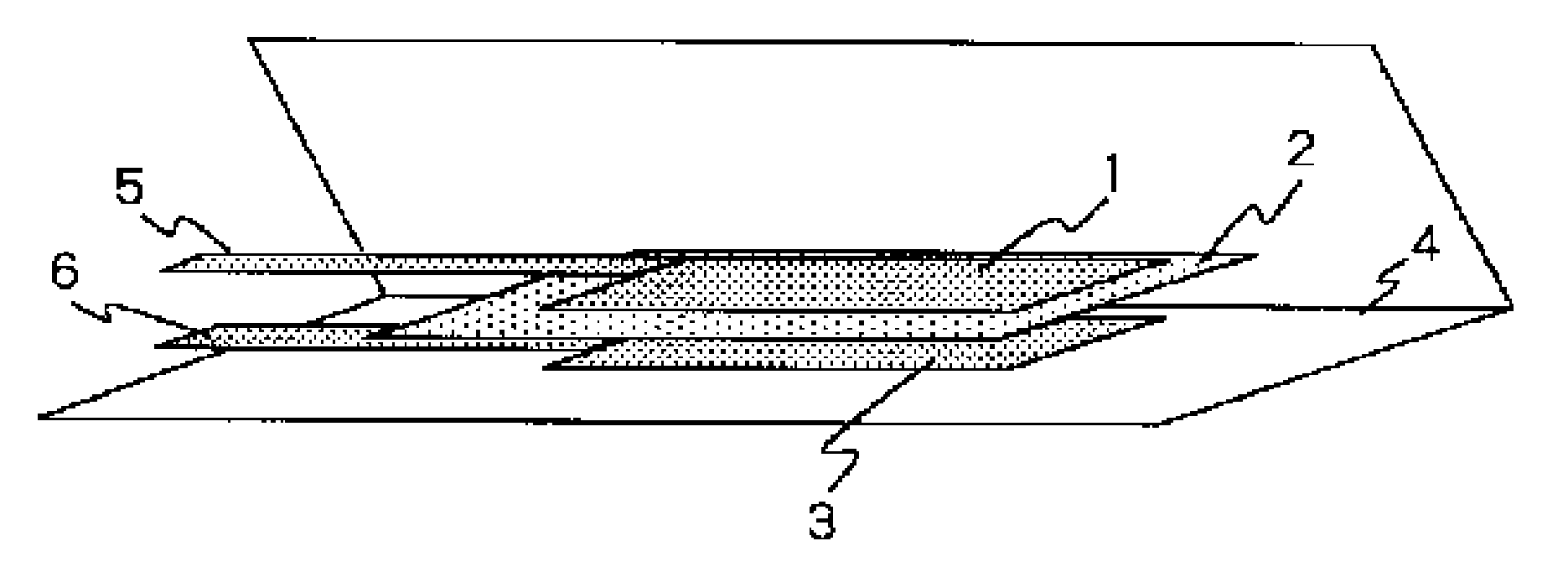

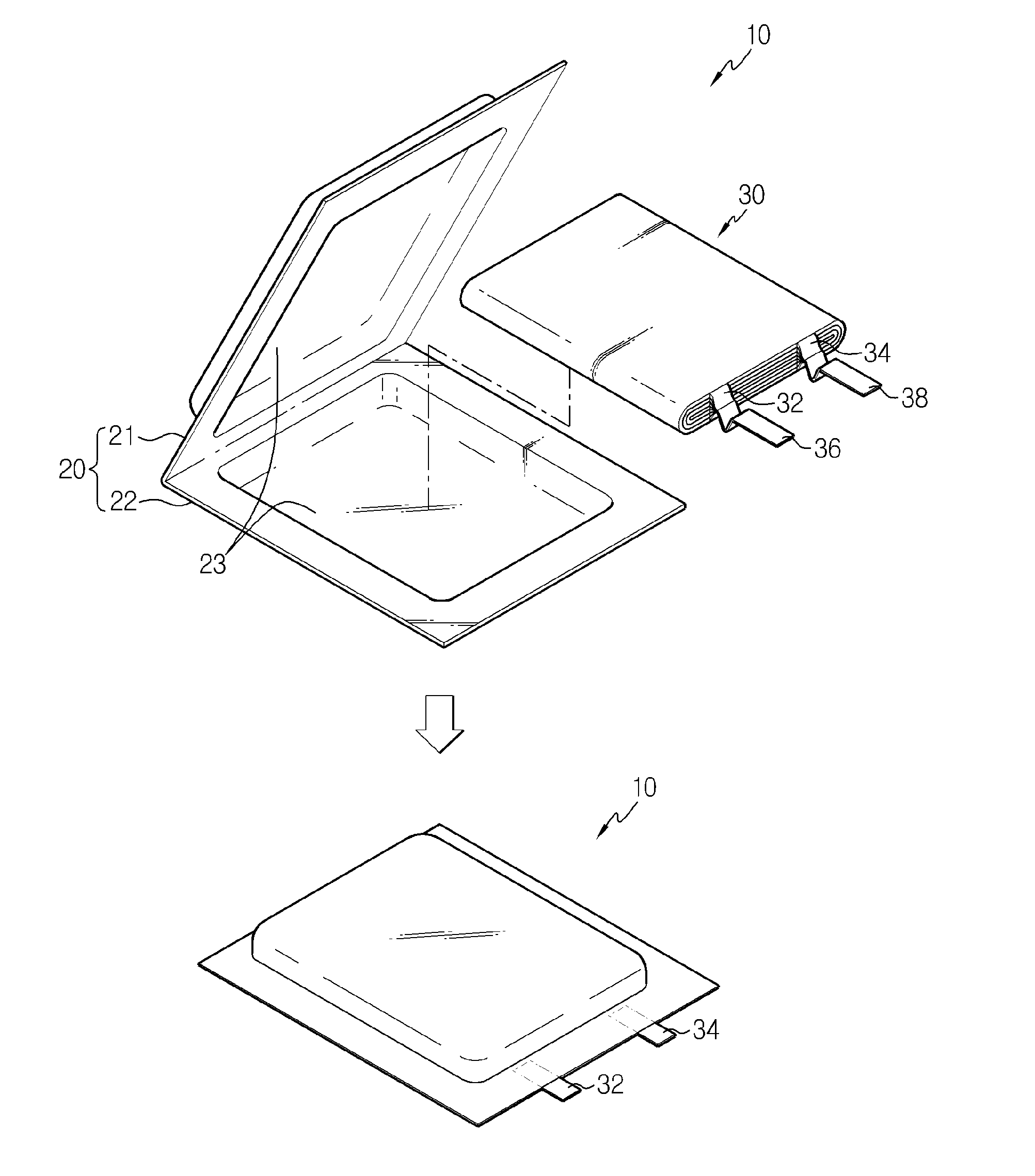

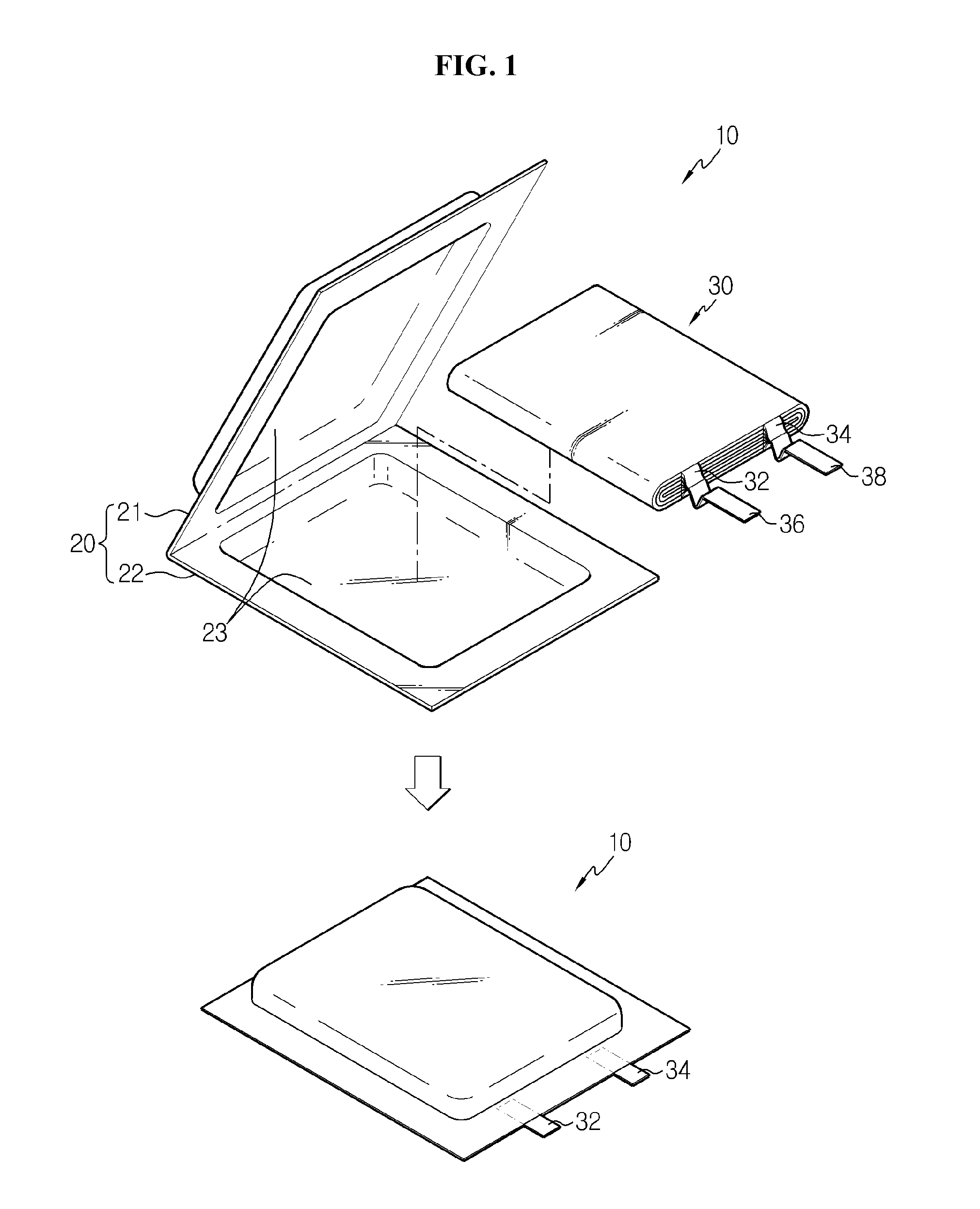

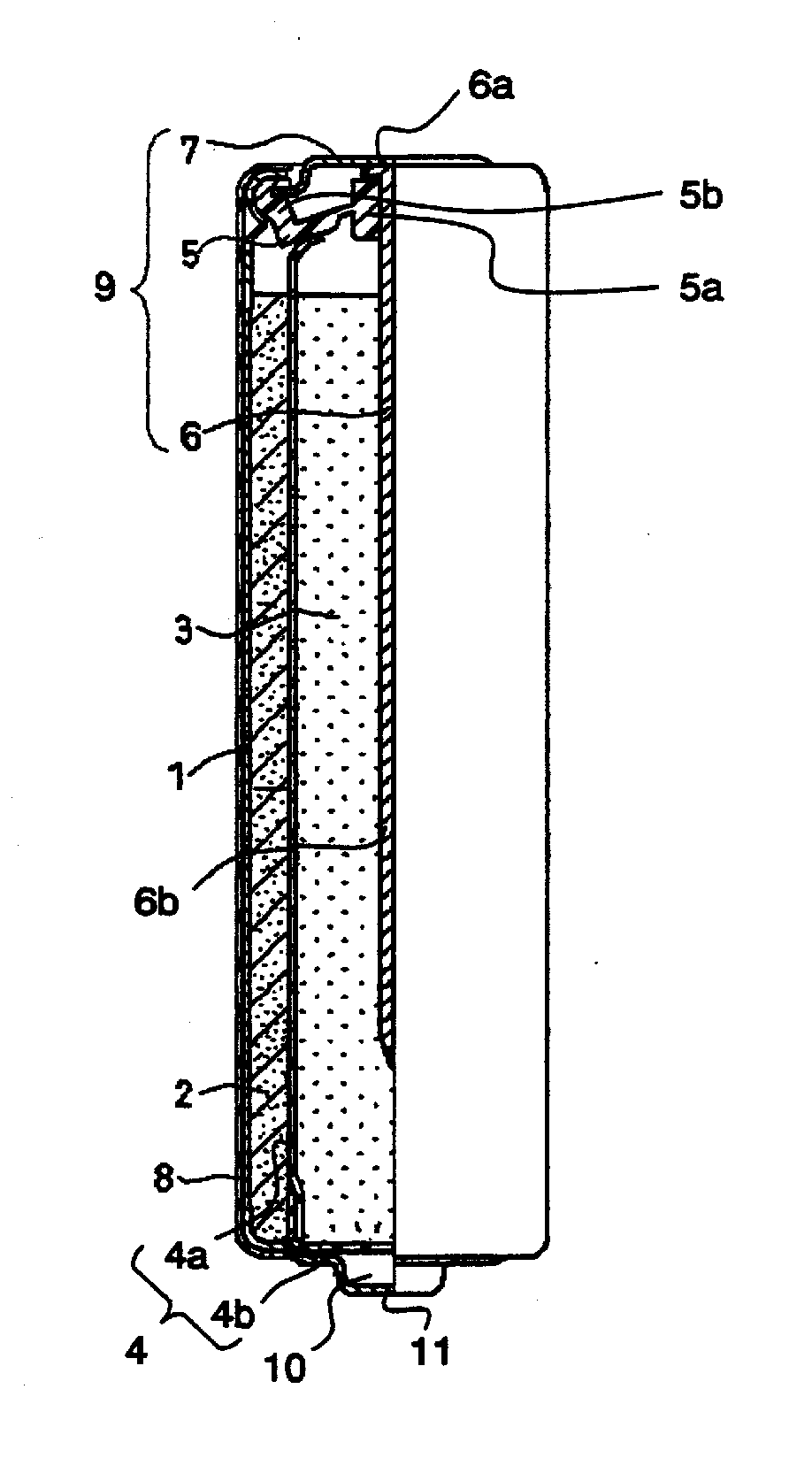

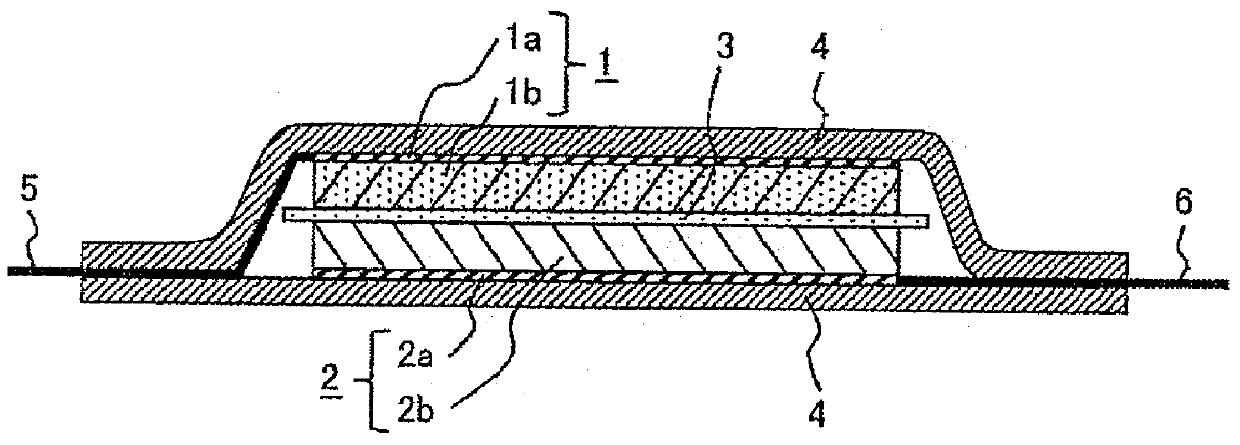

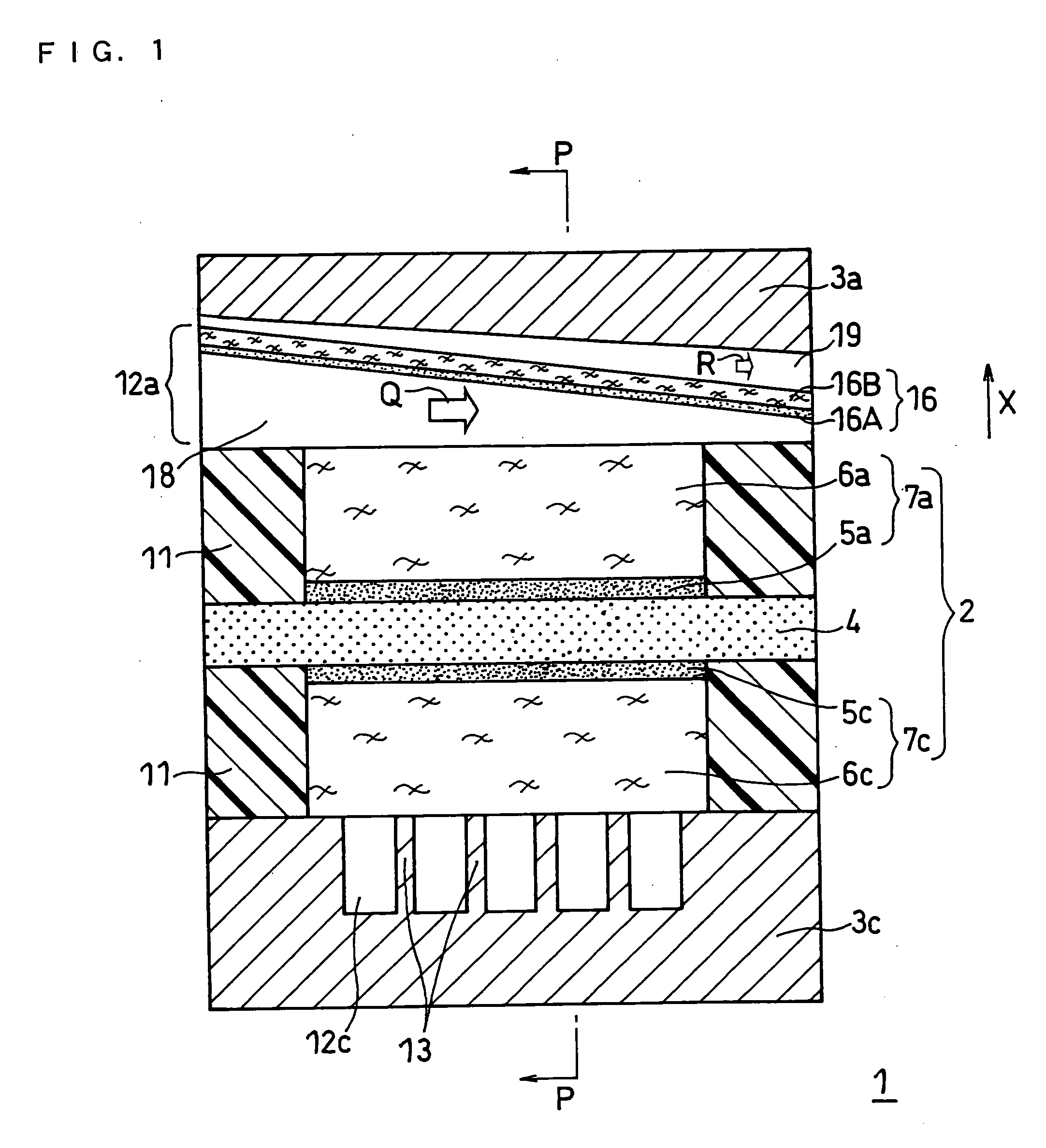

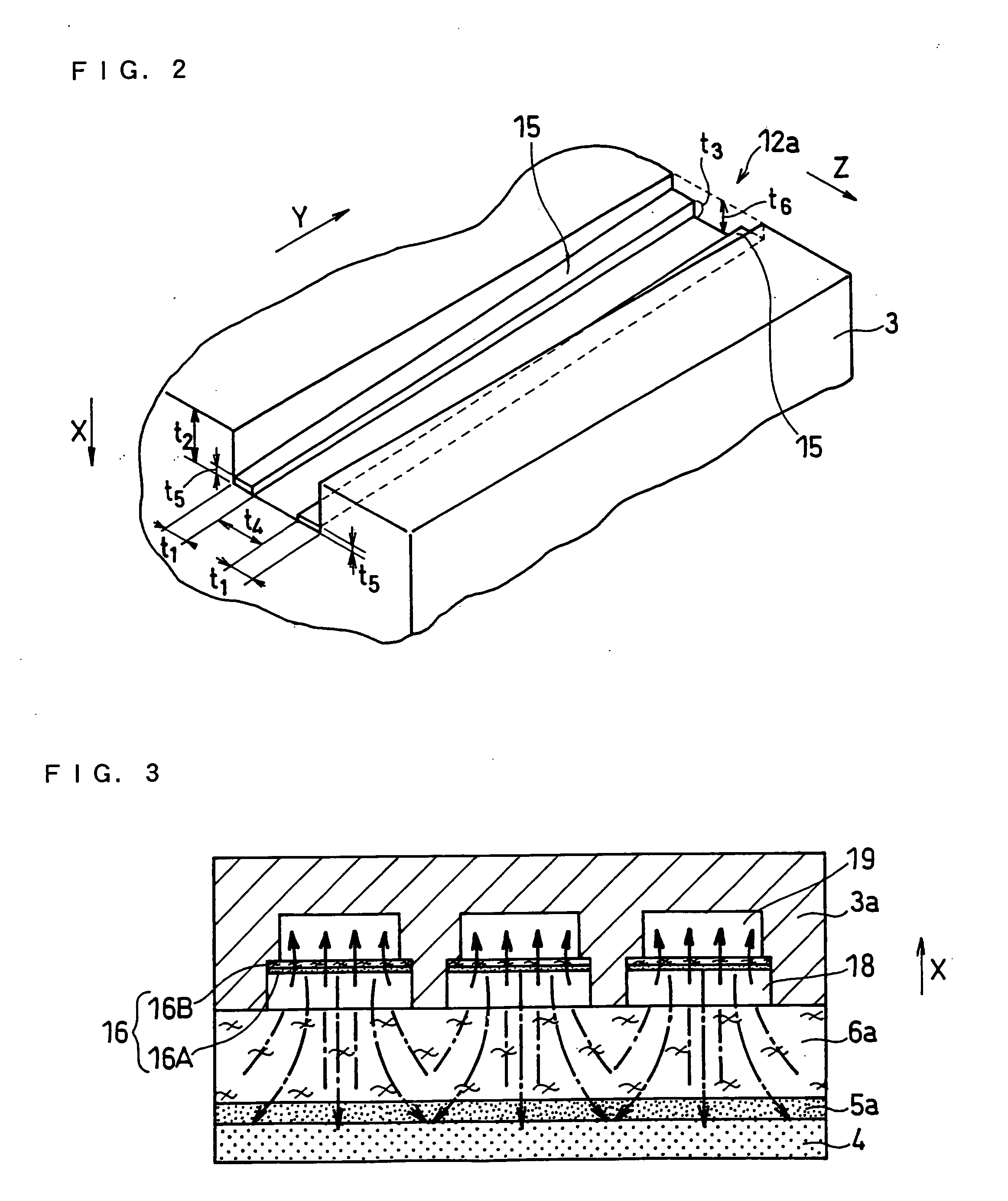

Stack/folding-typed electrode assembly and method for preparation of the same

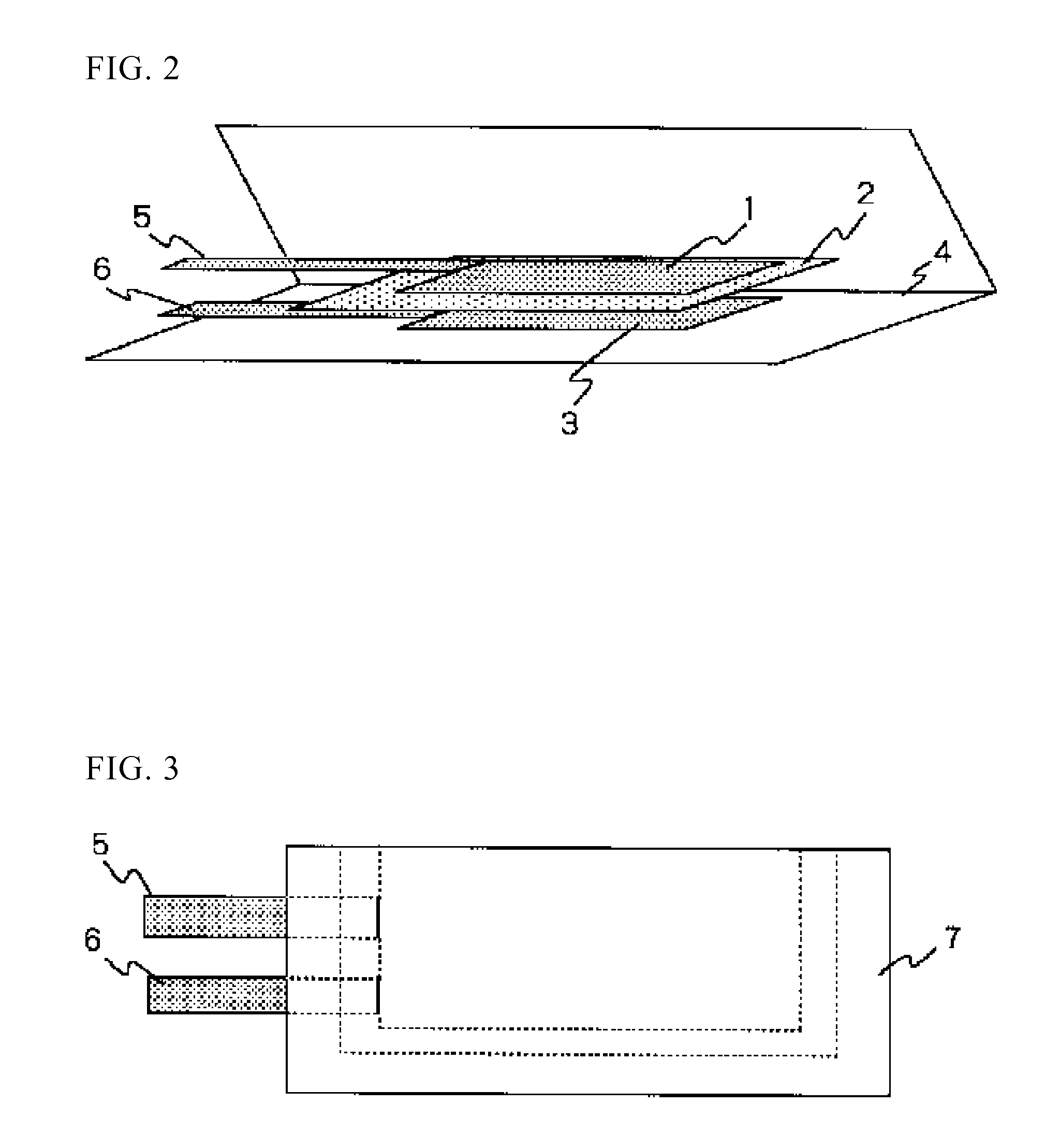

ActiveUS20110052964A1Simple manufacturing processImprove productivityCell seperators/membranes/diaphragms/spacersCurrent conducting connectionsProduction rateEngineering

Disclosed herein is an electrode assembly constructed in a structure in which a plurality of electrochemical cells, formed of full cells having a cathode / separator / anode structure, as basic units, are overlapped, and a continuous separator sheet is disposed between the overlapped electrochemical cells, wherein a unit electrode surrounded by the separator sheet is located at a middle of the overlapped electrochemical cells, which is a winding start point, and the full cells disposed above and below the unit electrode are symmetrical to each other about the unit electrode in the direction of electrodes of the full cells. The electrode assembly is manufactured with high productivity while the electrode assembly exhibits performance and safety equal to those of a conventional stack / folding type electrode assembly.

Owner:LG ENERGY SOLUTION LTD

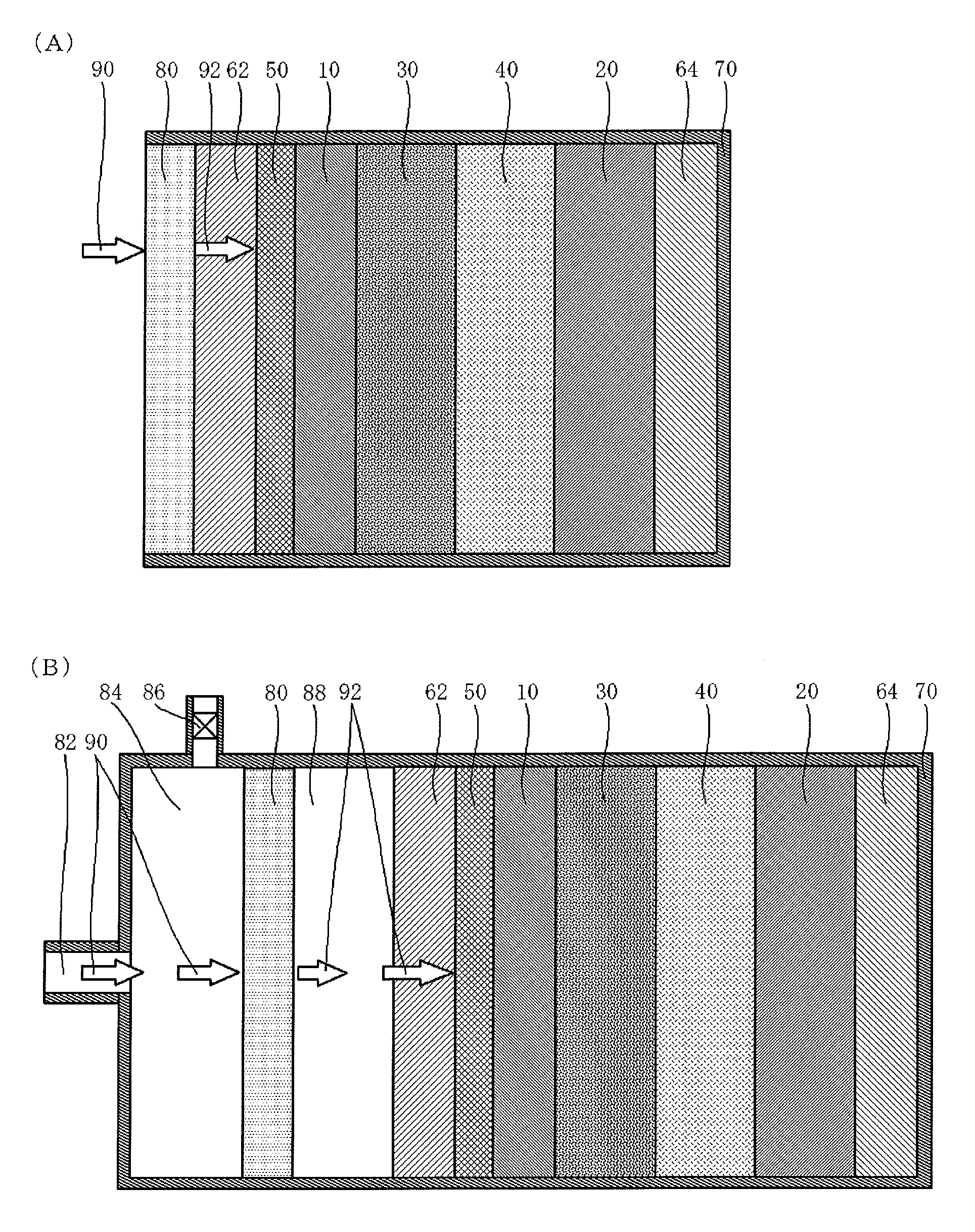

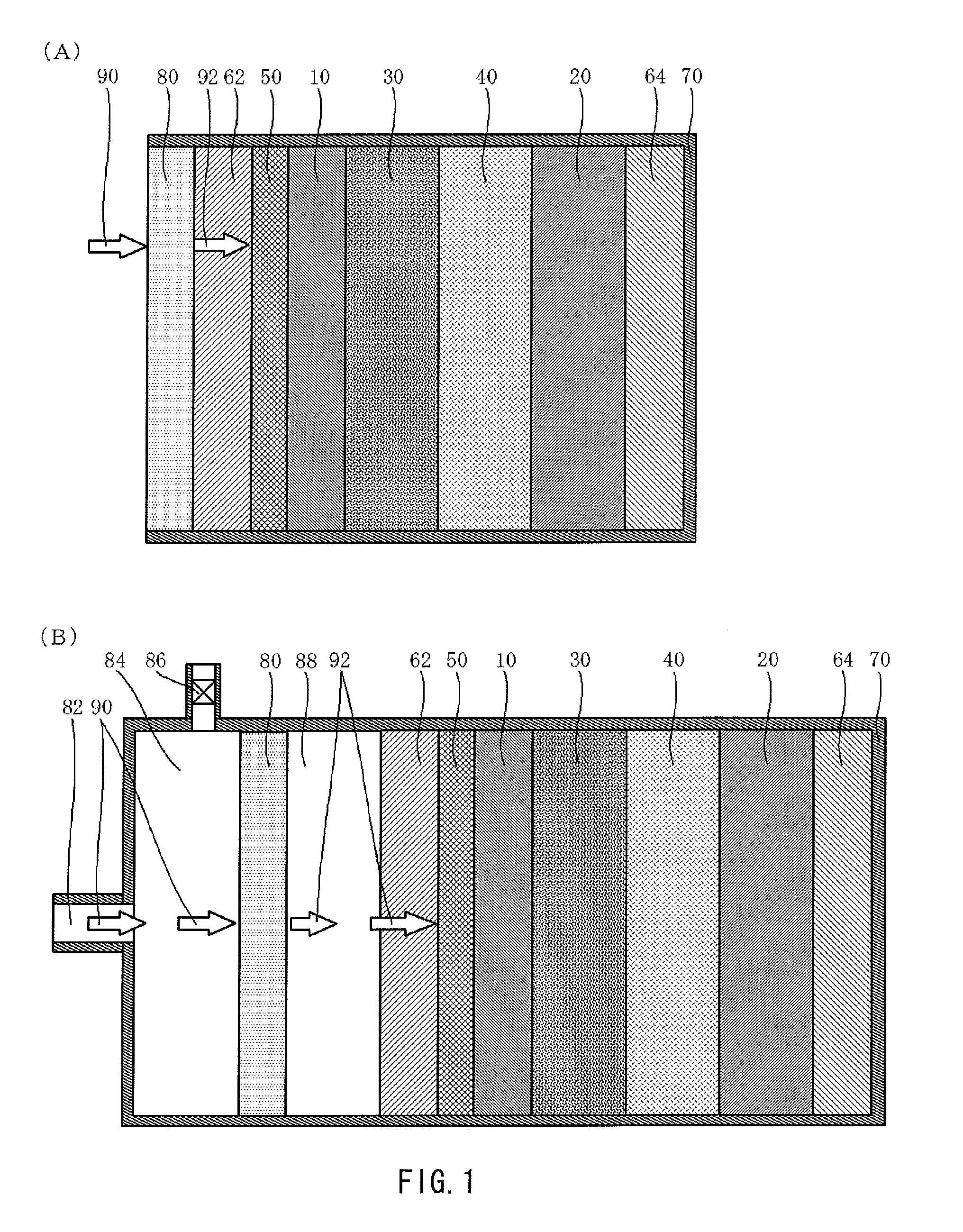

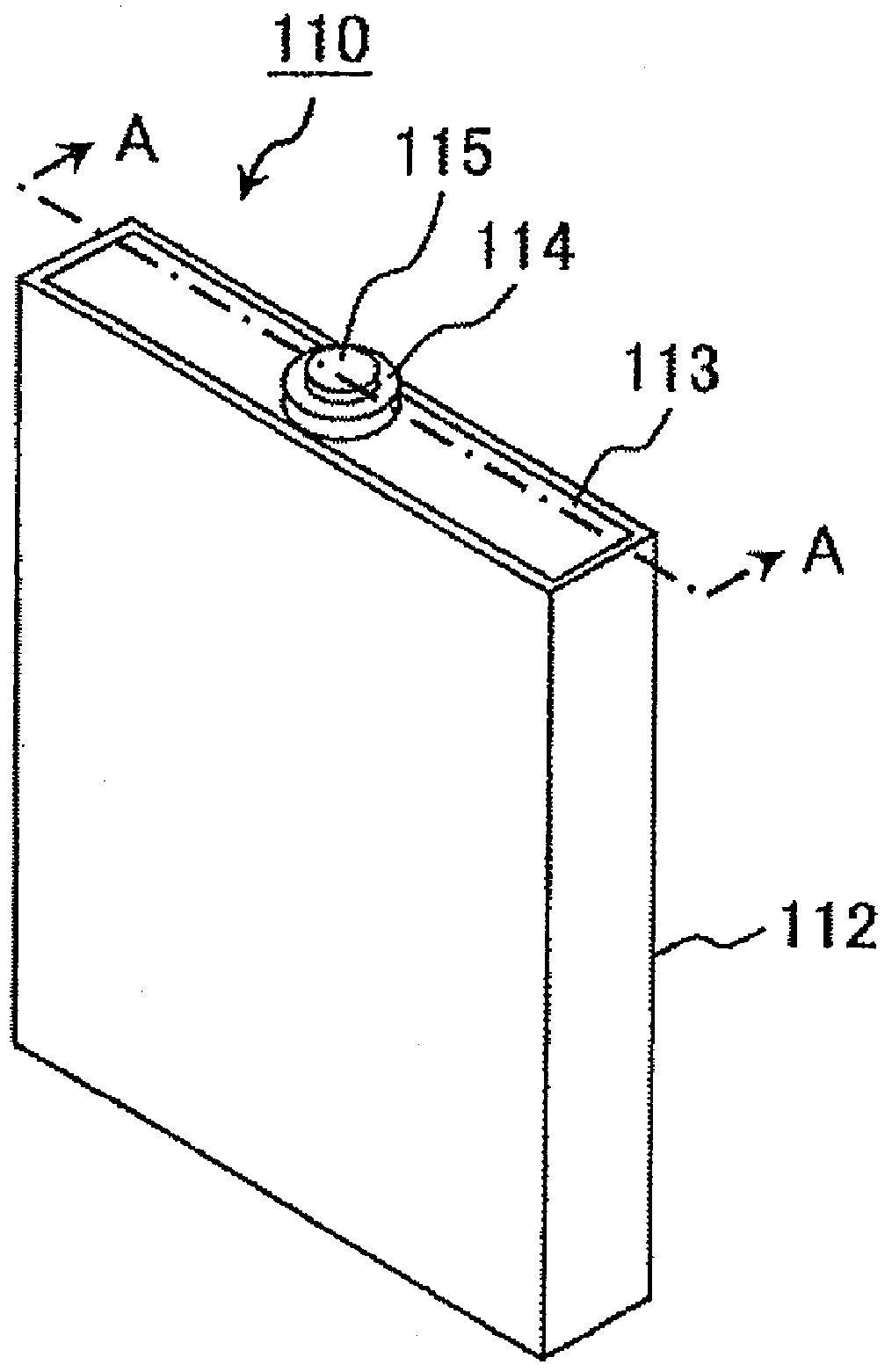

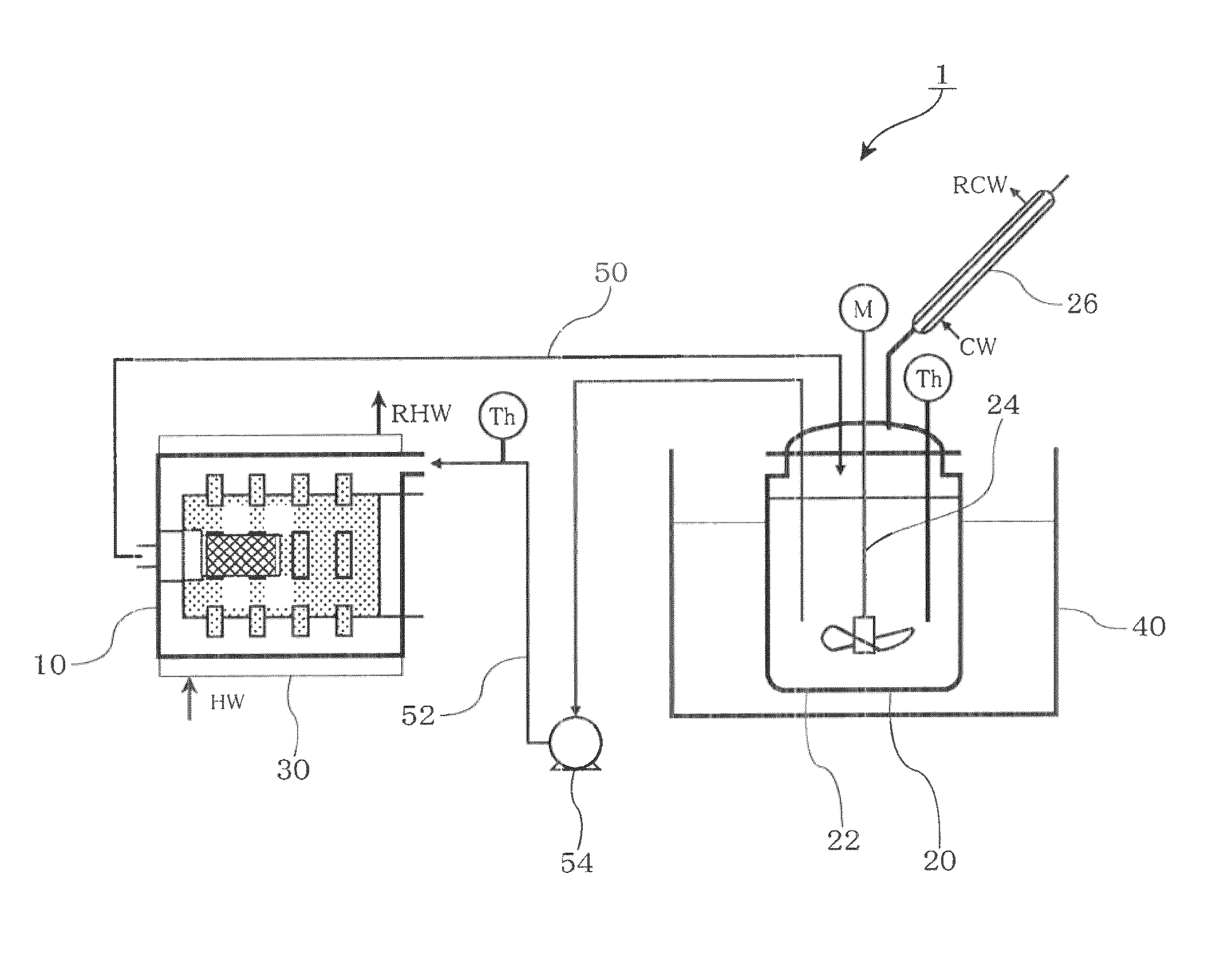

Lithium air battery

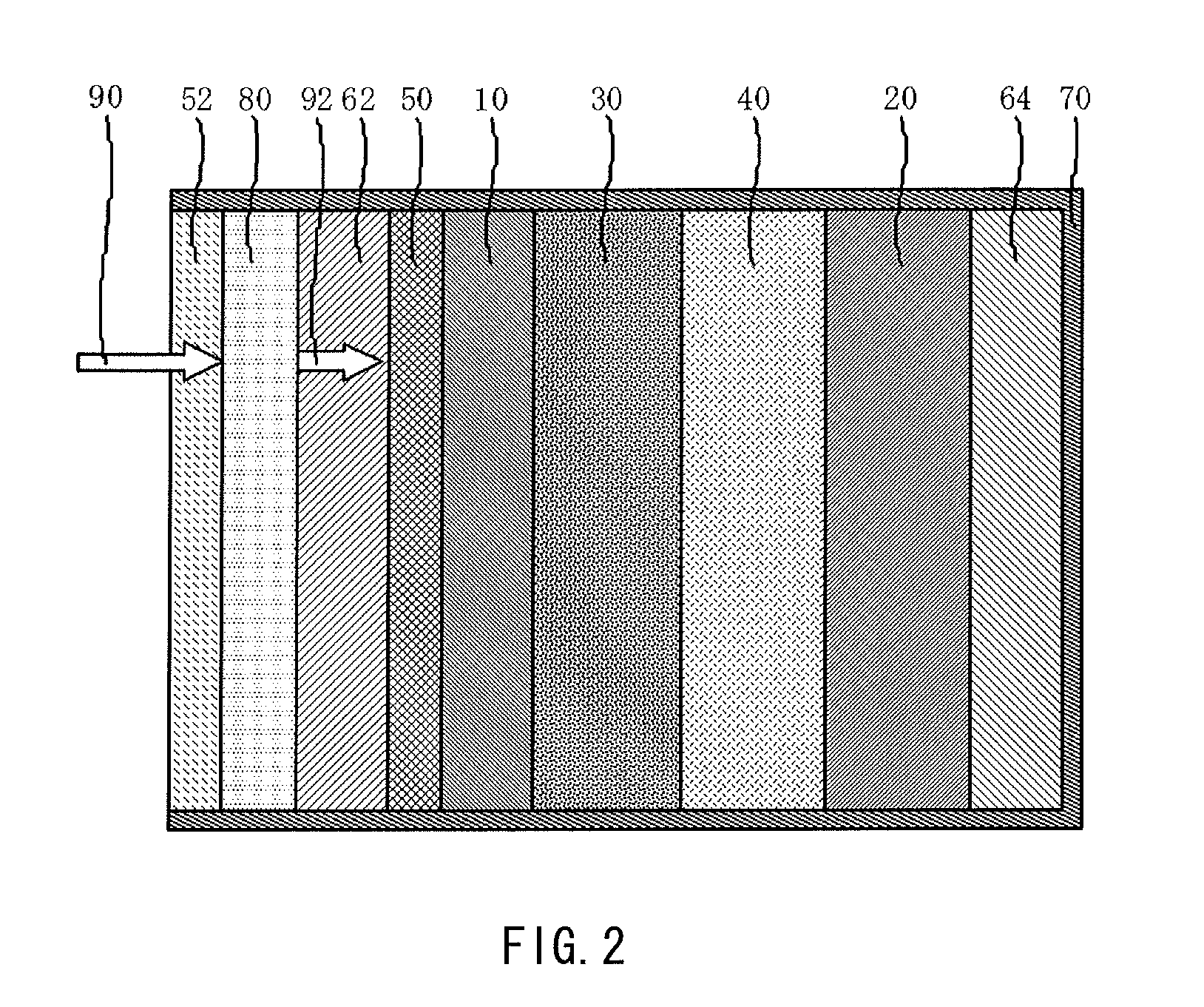

InactiveUS20120237838A1Little deteriorationIncrease battery outputFuel and primary cellsFuel and secondary cellsWater vaporLithium–air battery

A lithium air battery capable of being used for a long time with little deterioration due to influence by moisture in the air in which oxygen supply to a porous cathode is not inhibited by an air electrode current collector is provided. The lithium air battery includes an oxygen permselective film that is less likely to transmit moisture vapor and that selectively transmits oxygen, an oxygen chamber that stores oxygen, an air electrode current collector made of a porous material, a diffusion layer that is arranged between the air electrode current collector and a porous cathode and is made of a conductive material, the porous cathode containing a conductive material and a catalyst material, a separator that is less likely to pass moisture vapor, a nonaqueous electrolyte, an anode that extracts lithium ions, and an anode current collector. The lithium air battery may have a water-repellent layer.

Owner:SONY CORP

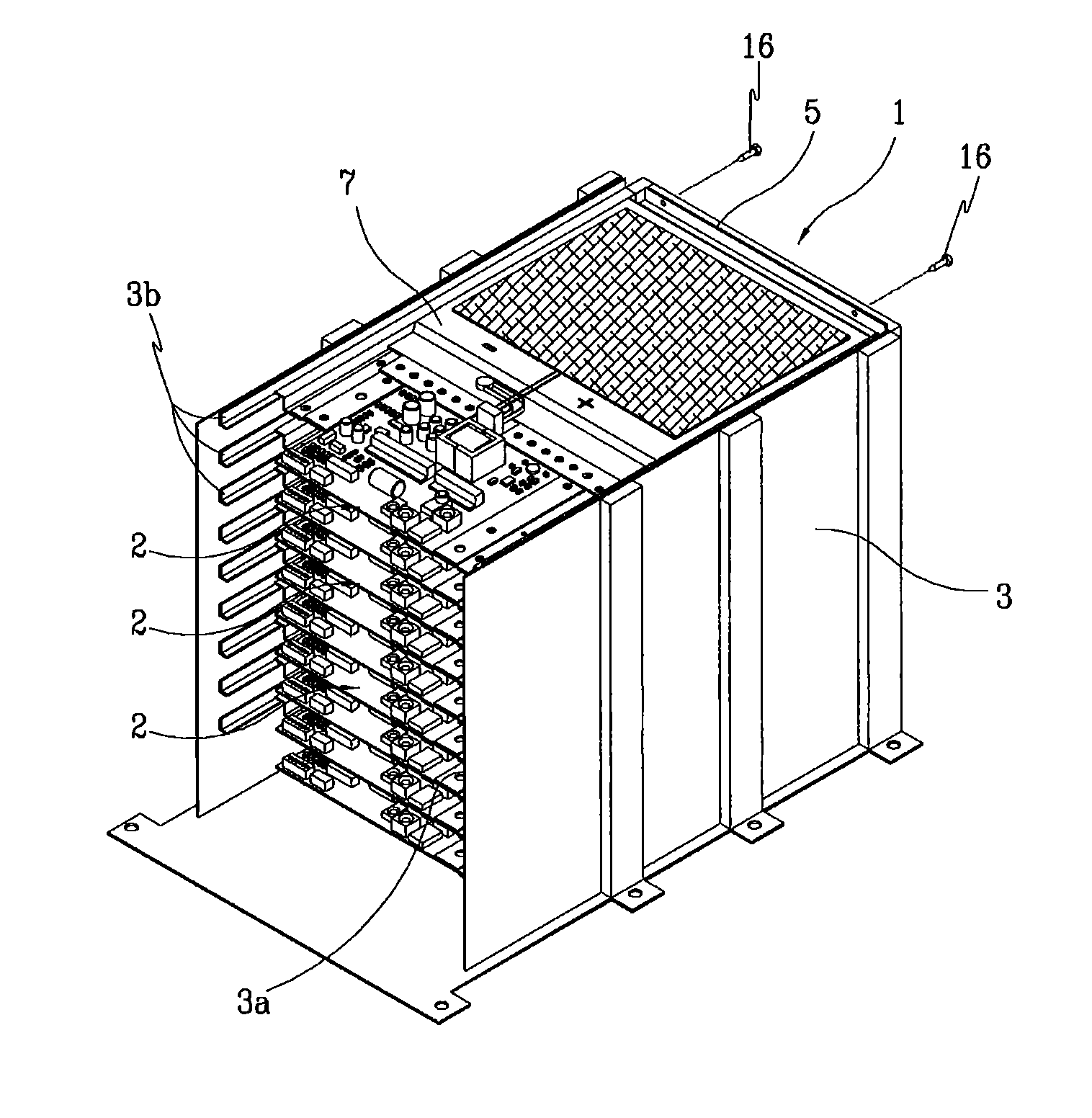

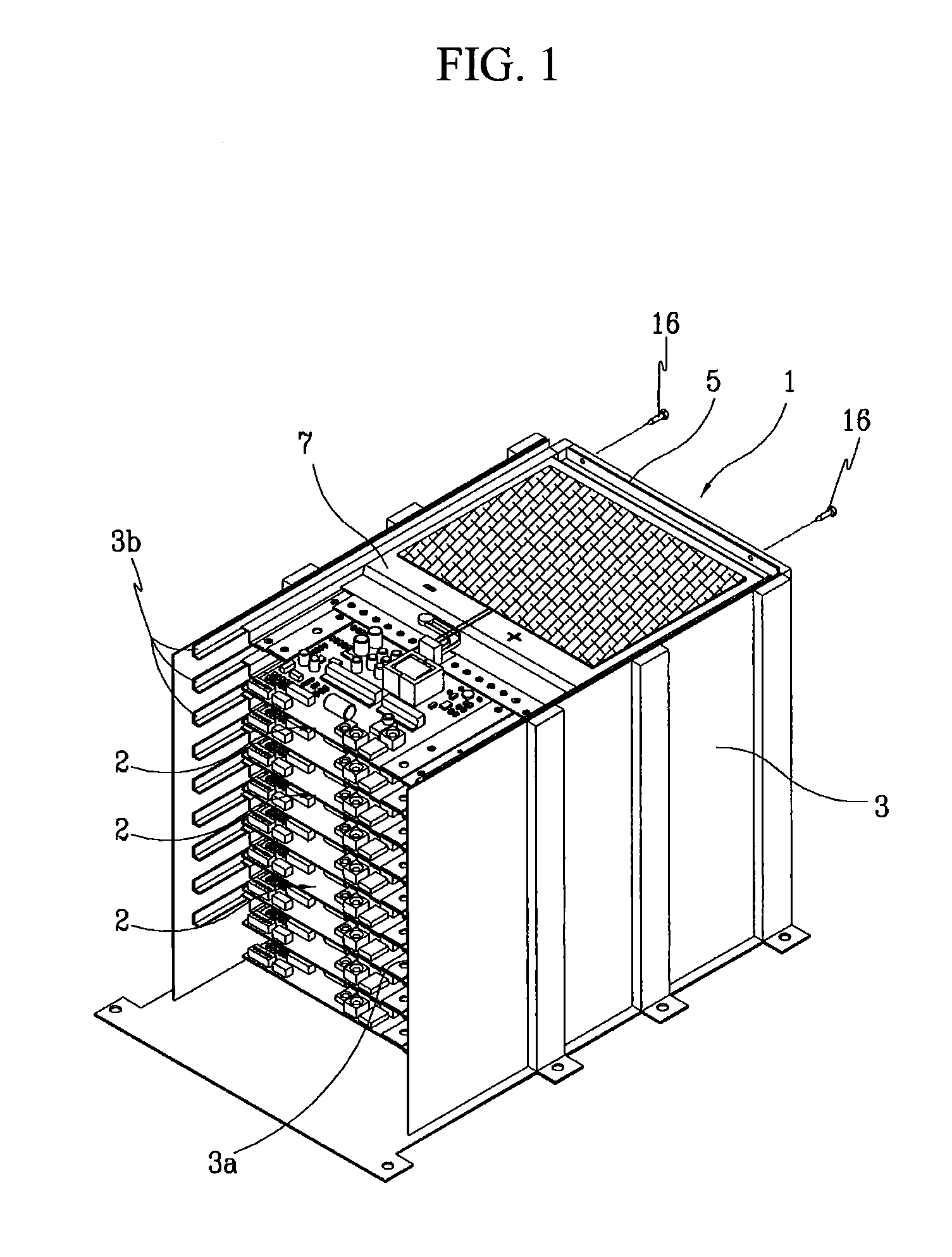

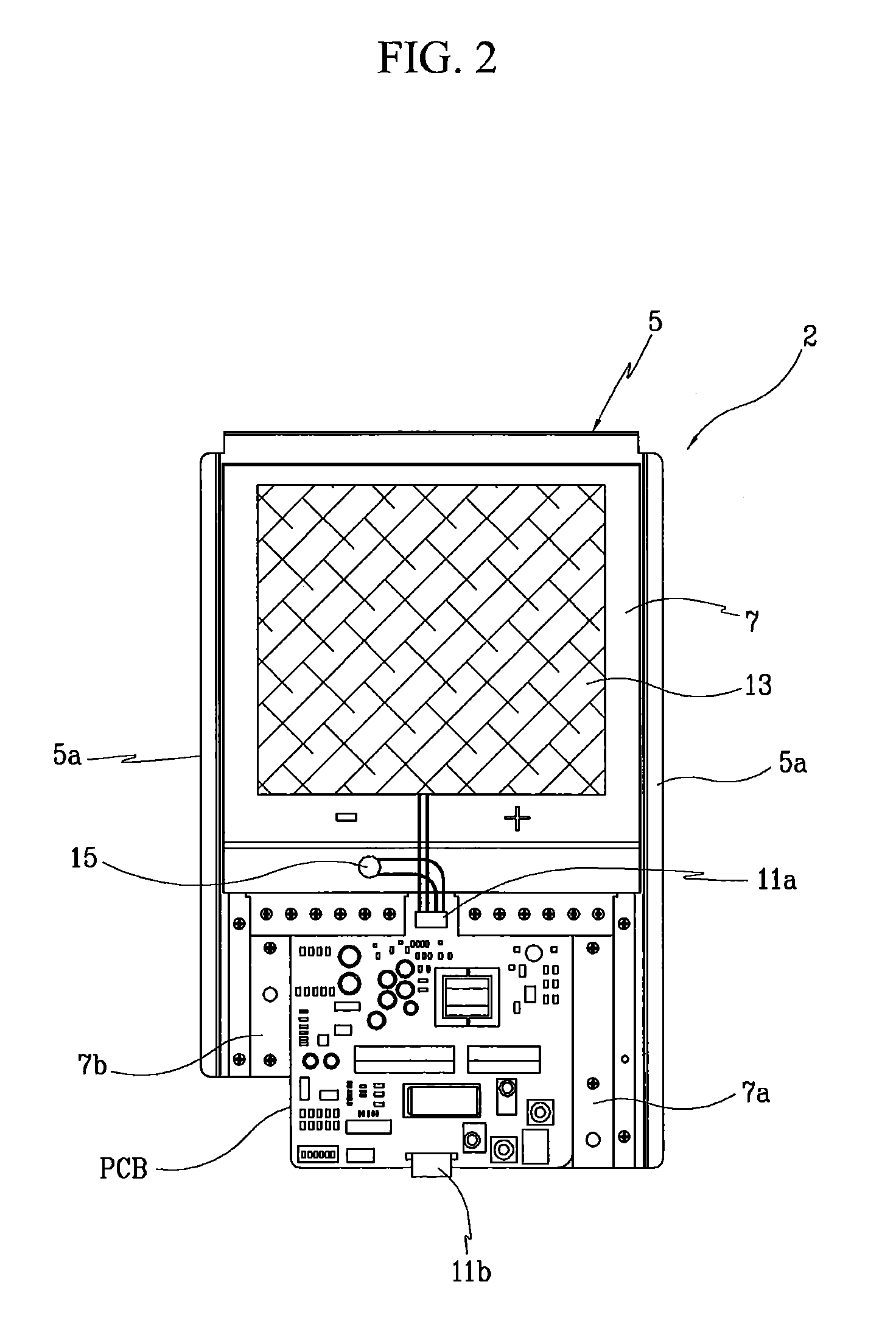

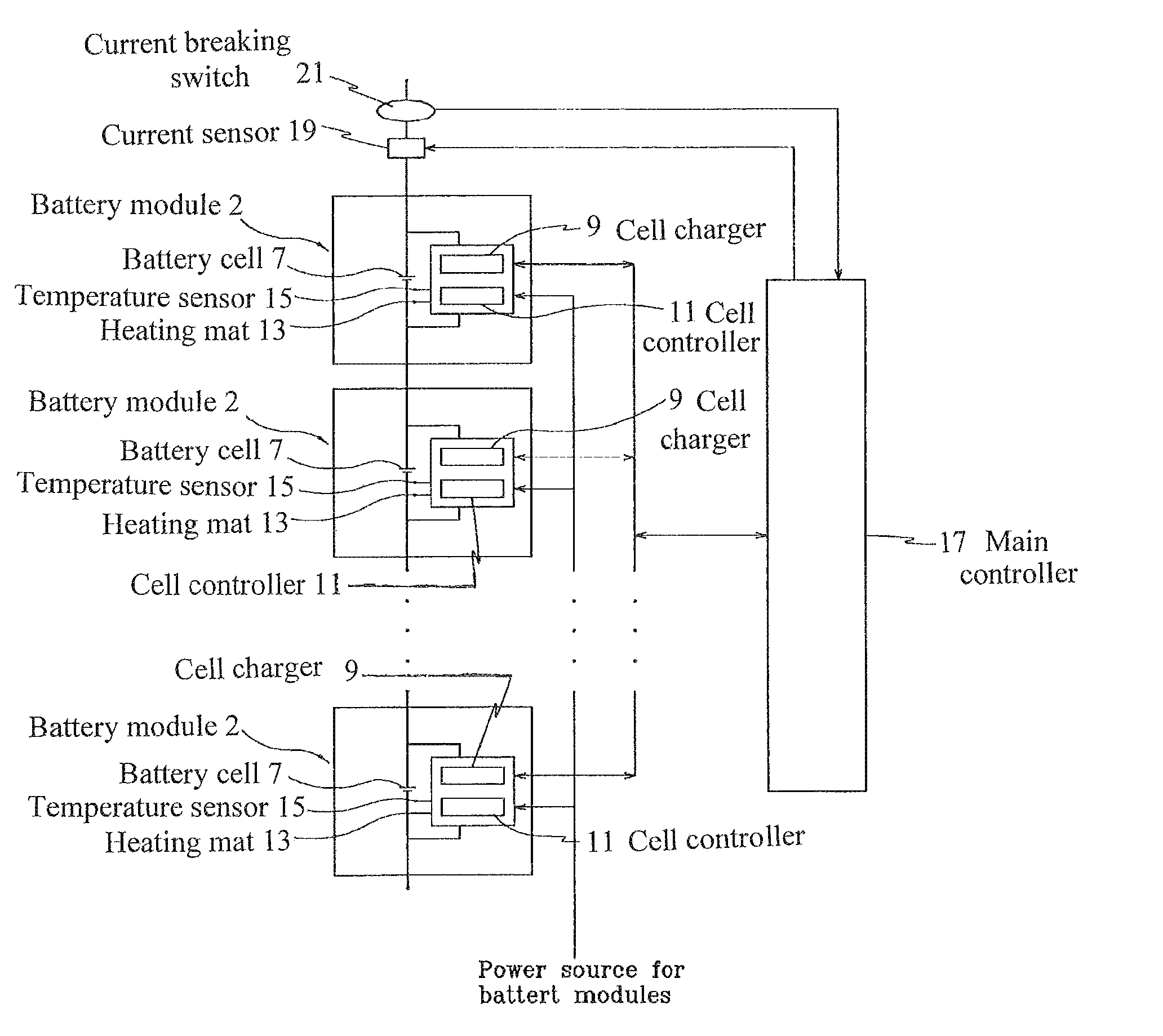

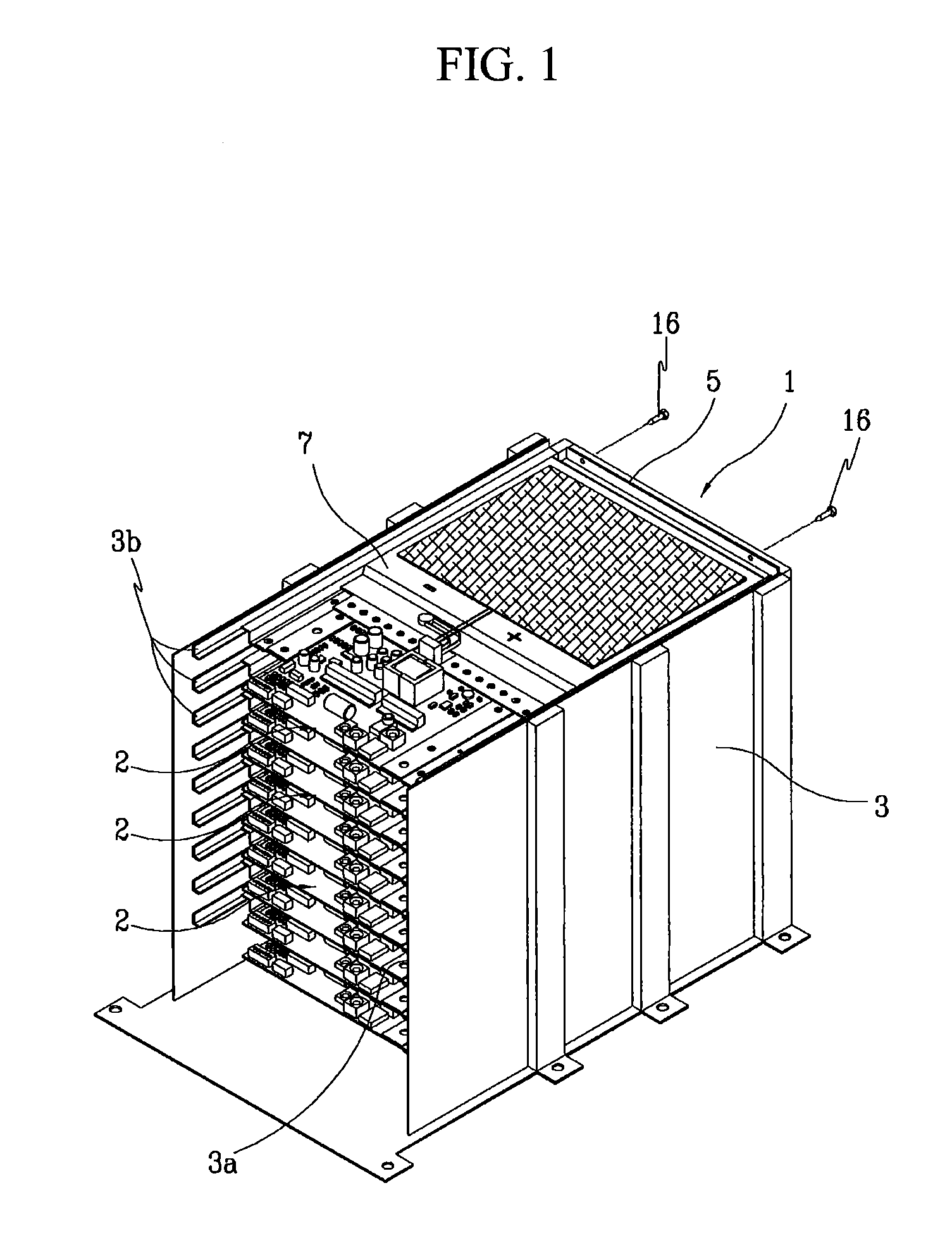

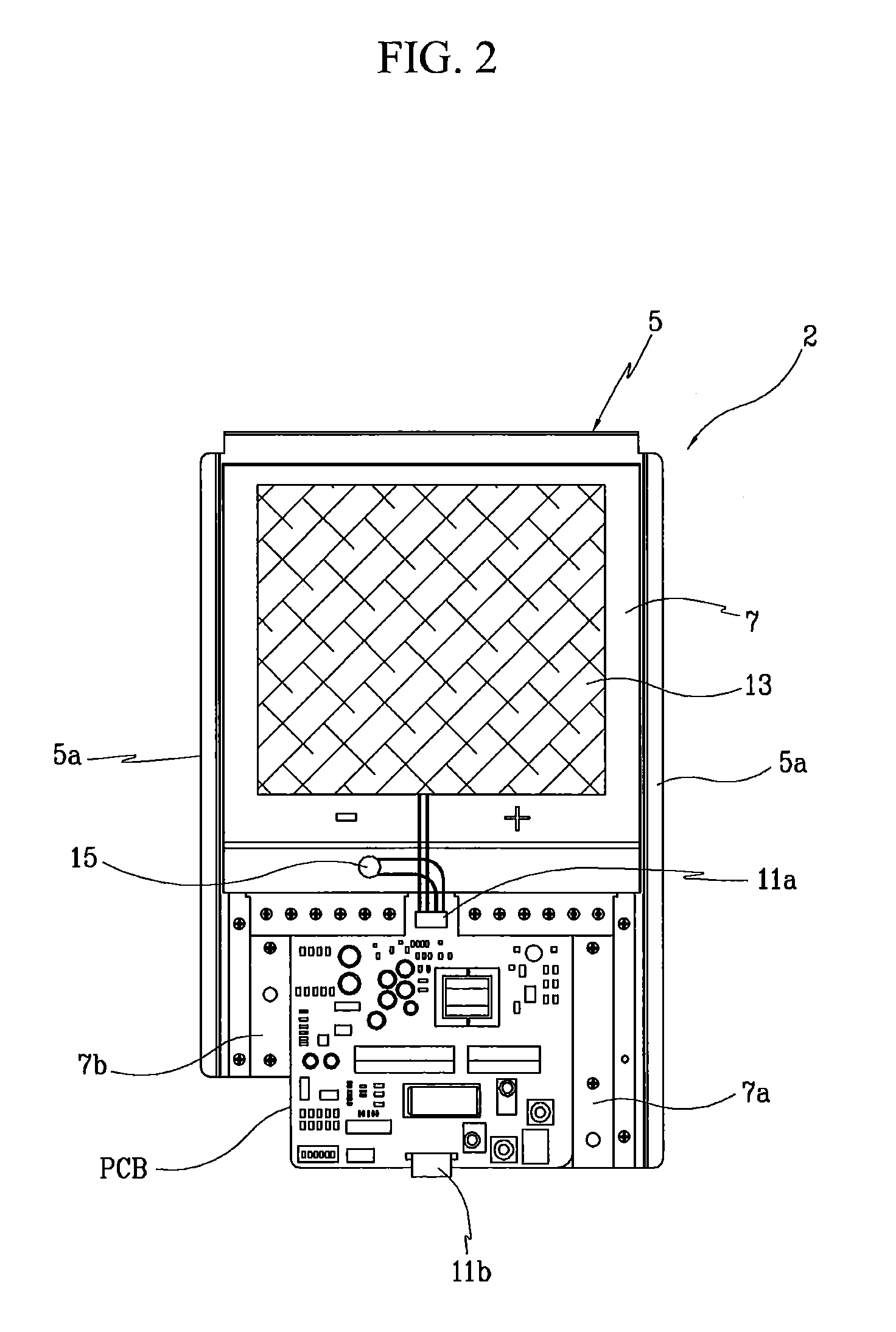

Battery pack and active cell balancing battery management system including the same

ActiveUS20120032638A1Deterioration of battery performanceShortened life-spanBatteries circuit arrangementsElectric devicesProduction rateSmart grid

The present invention discloses a battery pack which can be used for an electric vehicle, an Uninterrupted Power Supply (UPS), and a power supply for a smart grid and which can be easily manufactured and repaired and which is capable of improving productivity, the span of life, and performance, and a battery management system including the battery pack.The battery pack of the present invention comprises a casing in which a reception space is provided and battery modules coupled to the casing at regular intervals by fastening members so that the battery modules can be easily dismantled from the casing. Each of the battery modules includes a tray, a battery cell provided in the tray, a cell charger provided in the tray and configured to charge the battery cell, a cell controller provided in the tray and configured to control the cell charger, a heating mat coupled to the battery cell, and a temperature sensor provided in the tray and configured to sense a temperature of the battery cell.

Owner:TS NEXGEN CO LTD

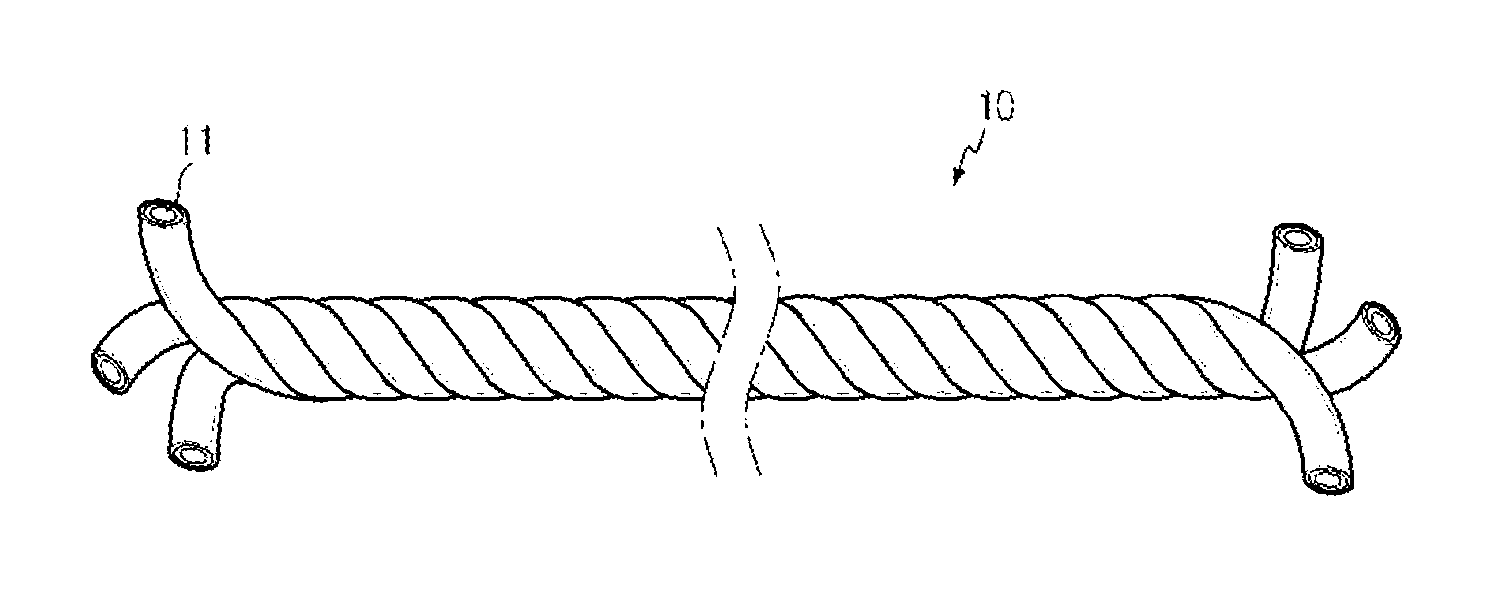

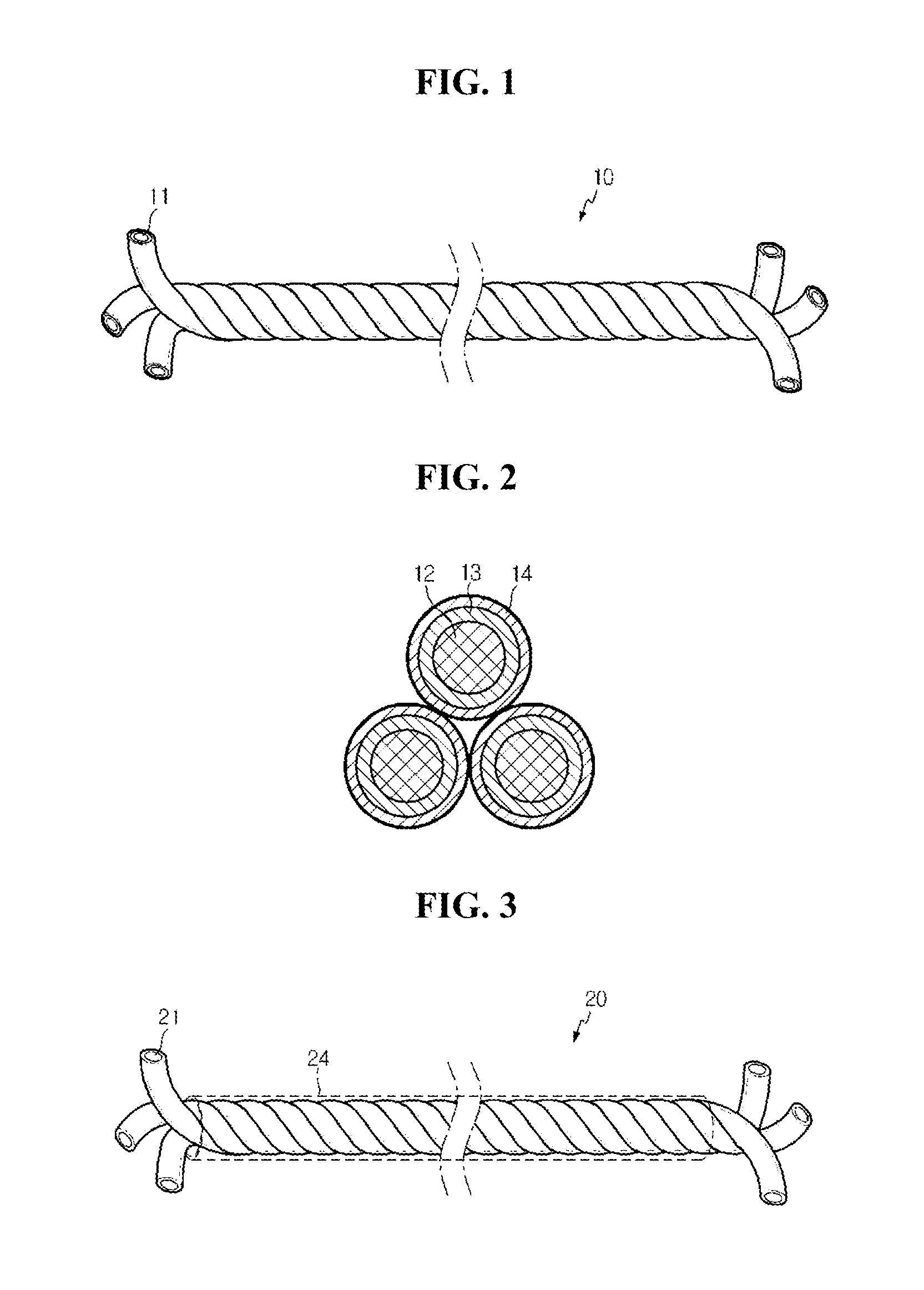

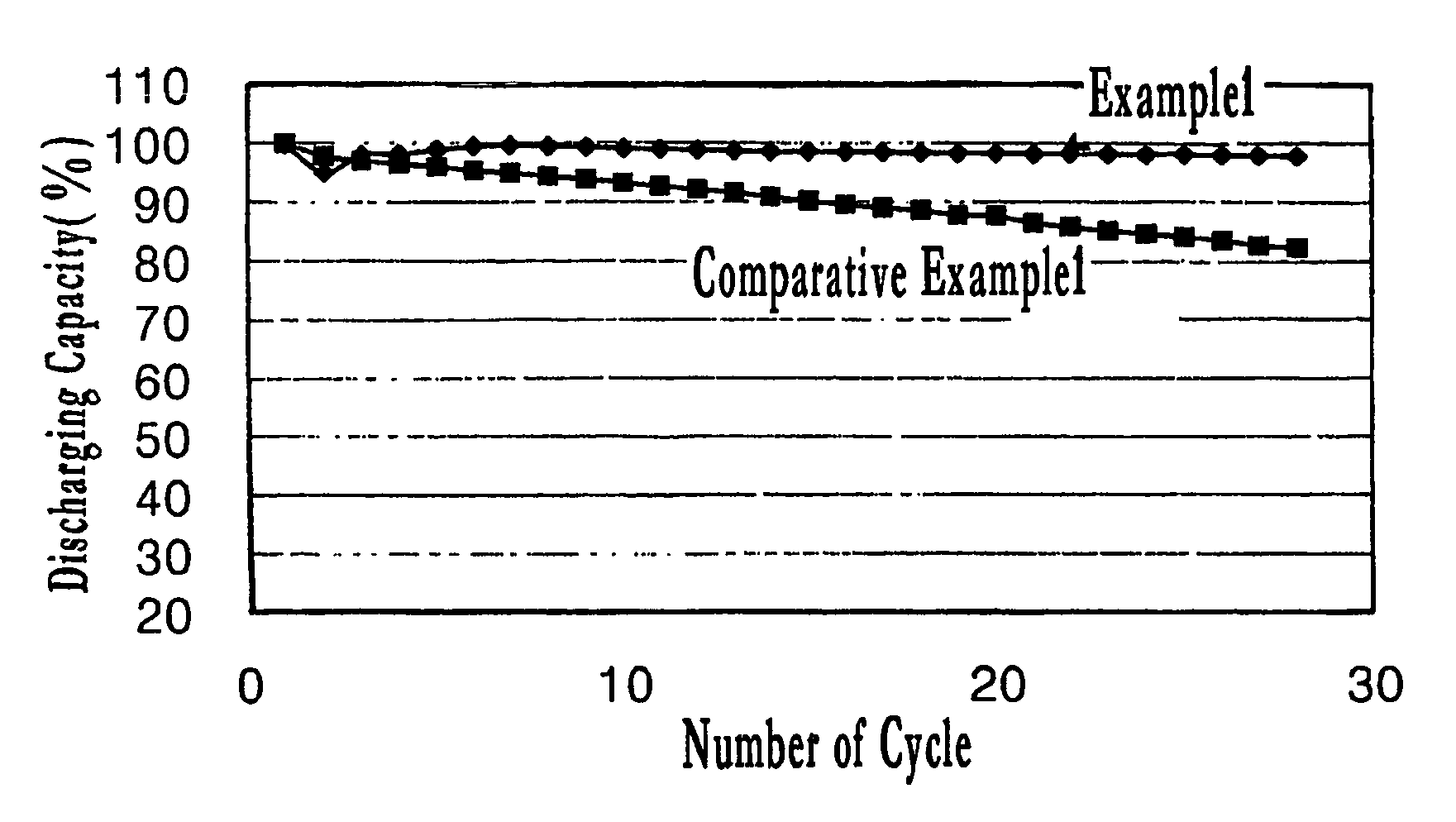

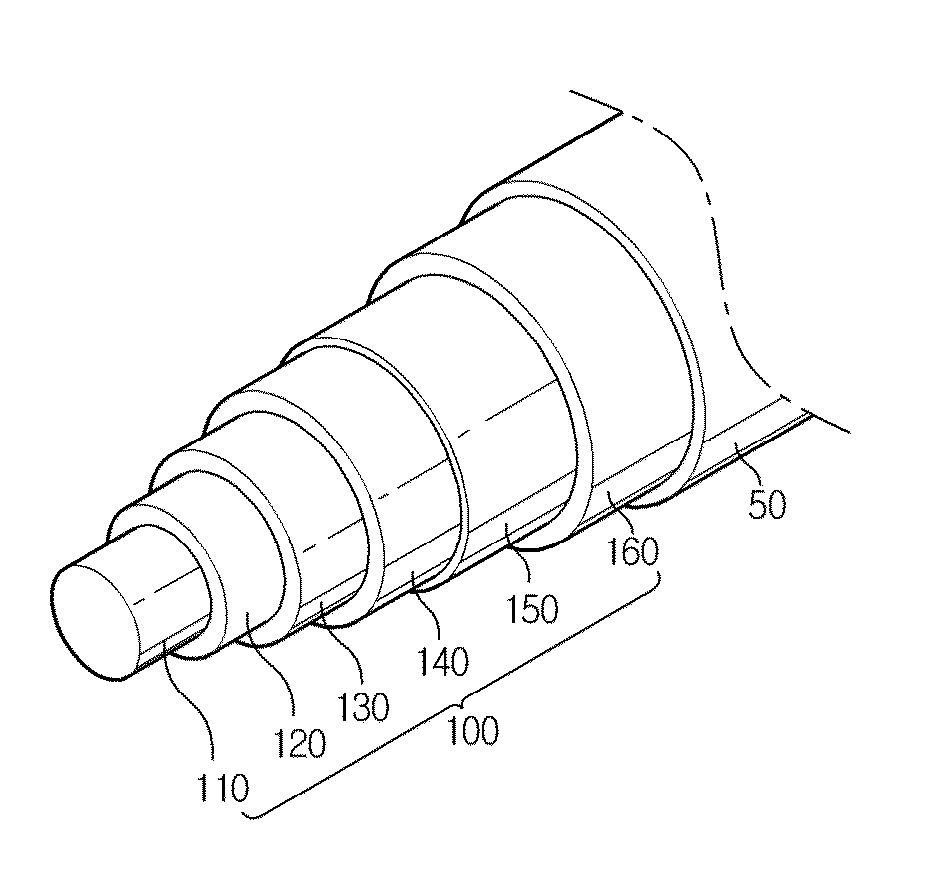

Anode for cable-type secondary battery and cable-type secondary battery comprising the same

ActiveUS20140234681A1Deterioration of battery performanceInhibit deteriorationSolid electrolytesFinal product manufacturePolymer resinPolymer chemistry

The present invention relates to an anode for a cable-type secondary battery, more specifically an anode for a cable-type secondary battery, comprising a spiral electrode consisting of at least two wire-type electrodes which are spirally twisted with each other, each of the wire-type electrodes comprising a wire-type current collector, an anode active material layer formed by coating on the outer surface of the wire-type current collector, and a polymer resin layer formed by coating on the outer surface of the anode active material layer; and a cable-type secondary battery comprising the anode. The anode for a cable-type secondary battery according to the present invention comprises a polymer resin layer formed by coating on the outer surface of an anode active material layer, thereby preventing the release of the anode active material layer from a wire-type current collector and eventually preventing the deterioration of battery performances.

Owner:LG ENERGY SOLUTION LTD

Electrode active materials for lithium secondary batteries, method for preparing the same, and lithium secondary batteries using the same

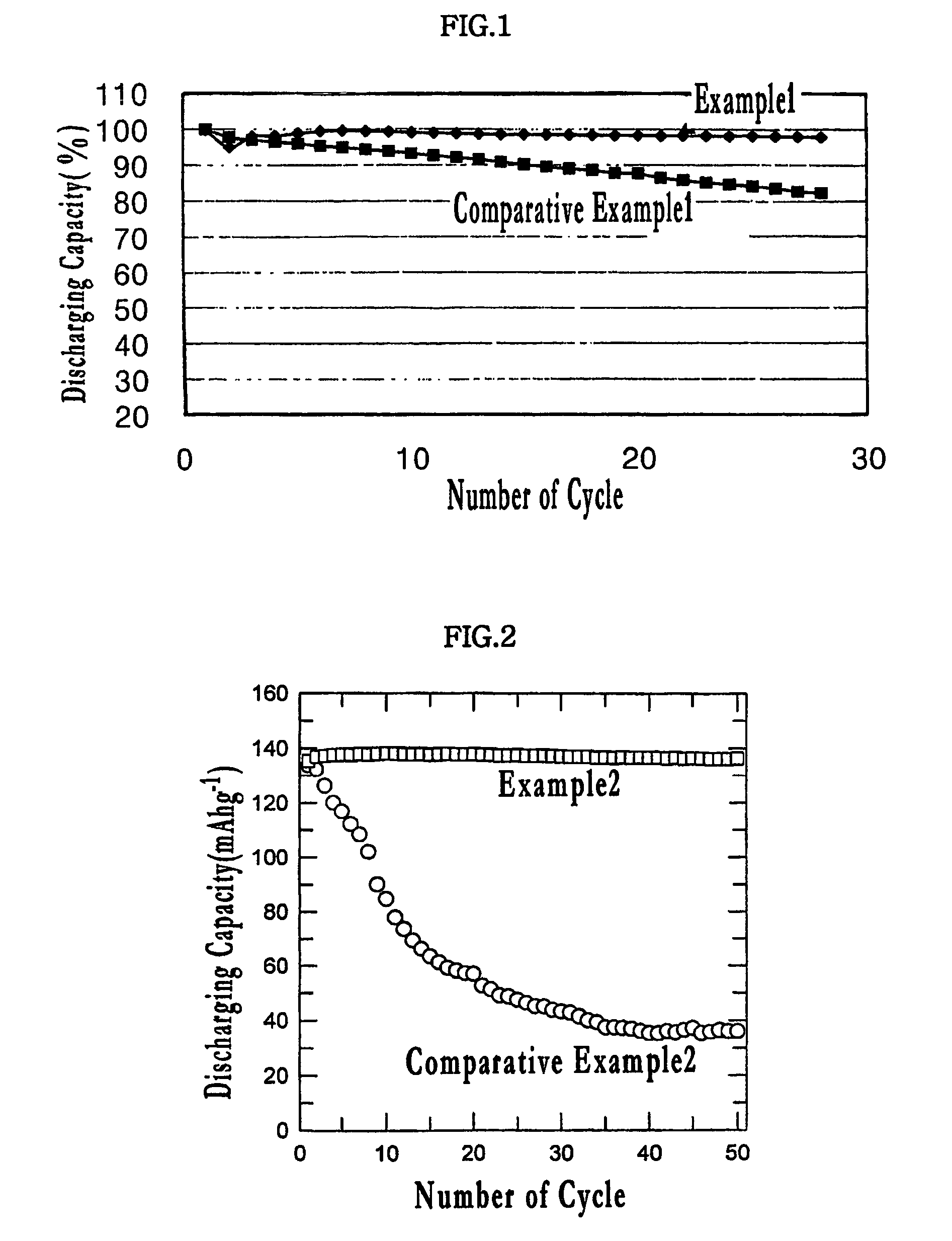

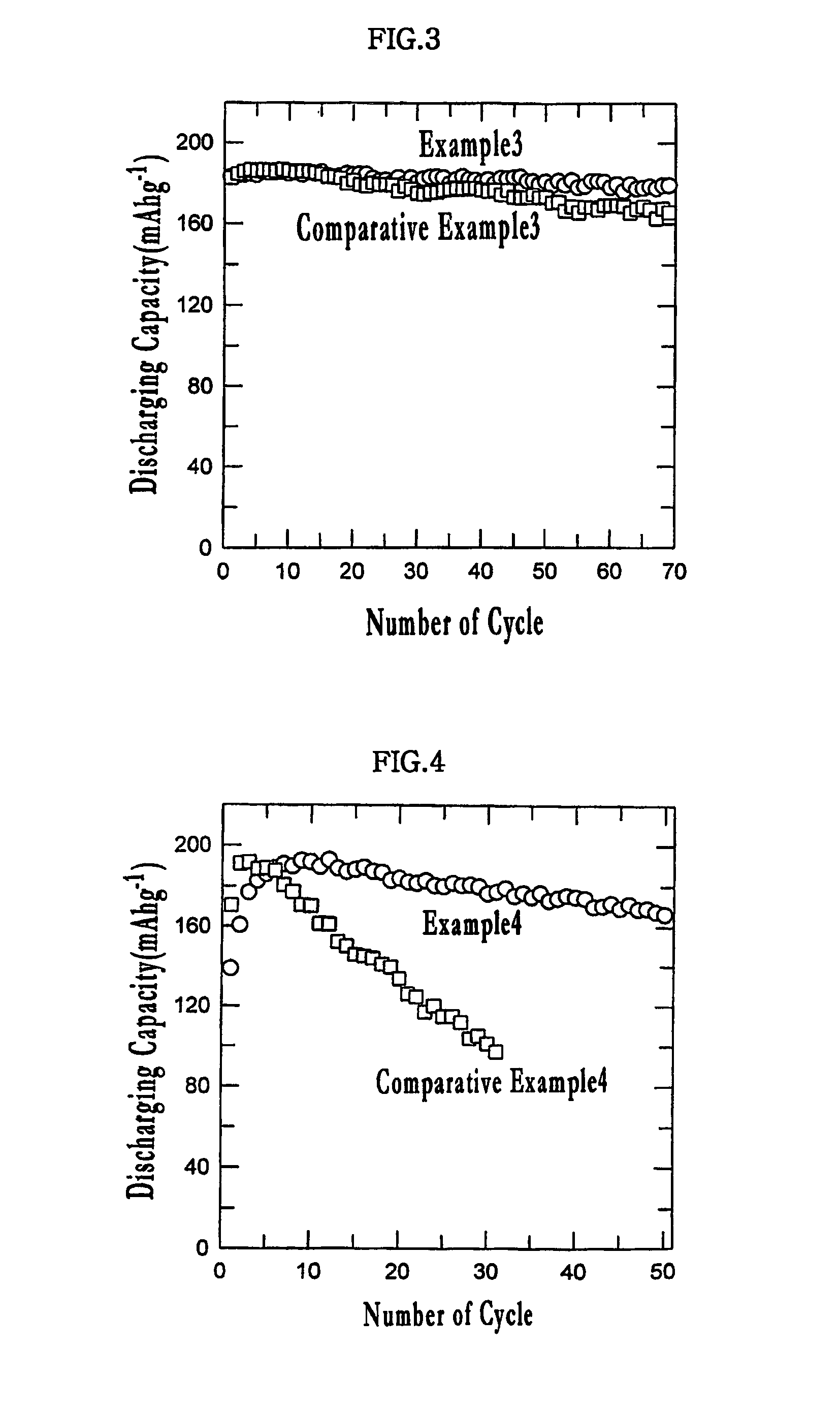

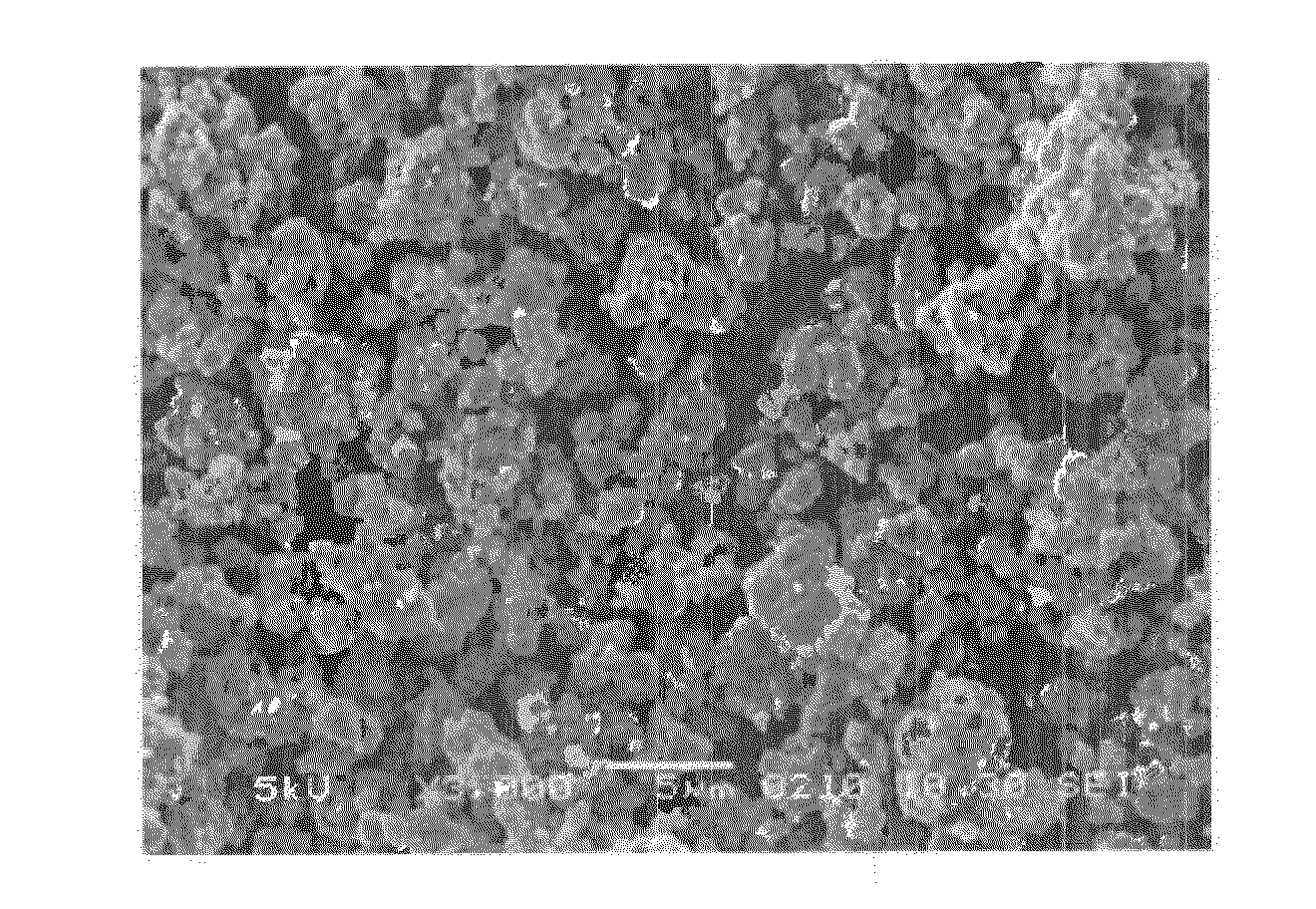

InactiveUS7674557B2Deterioration of battery performanceSuppress gas productionElectrode manufacturing processesNon-aqueous electrolyte accumulatorsLithiumAlkali metal oxide

An electrode active material further comprising an amphoteric compound, an alkali metal sulfide or an alkali metal oxide, and lithium secondary batteries using the electrode active material, are disclosed. The lithium secondary batteries neutralize acids generating around electrode active material so that it can inhibit the reduction in battery capacity. In addition, the lithium secondary batteries are excellent in its charge-discharge characteristics, cycle life and thermal stability. A method for preparing the electrode active material for lithium secondary batteries is also provided.

Owner:ENERCERAMIC

Electrolyte for lithium ion secondary battery and lithium ion secondary battery comprising the same

InactiveUS20140356734A1Avoid reactionImprove polymerizationCell electrodesOrganic electrolyte cellsLithiumOrganic solvent

An electrolyte for a lithium ion secondary battery and a lithium ion secondary battery including the same are provide. The electrolyte includes a non-aqueous organic solvent, a lithium salt which is dissolved in the non-aqueous solvent and a additive shown as general formula I. Wherein R1, R2 and R3 are each independently selected from H, alkyl group including from 1 to 12 carbon atoms, cycloalkyl group including from 3 to 8 carbon atoms and aromatic group including 6 to 12 carbon atoms; n represents an integer from 0 to 7. This additive in electrolyte can passivate cathode and anode effectively, restrain their reaction with electrolyte, reduce gases generation and battery's expansion in high temperature surrounding, provide as safety lithium ion secondary batteries.

Owner:NINGDE AMPEREX TECH

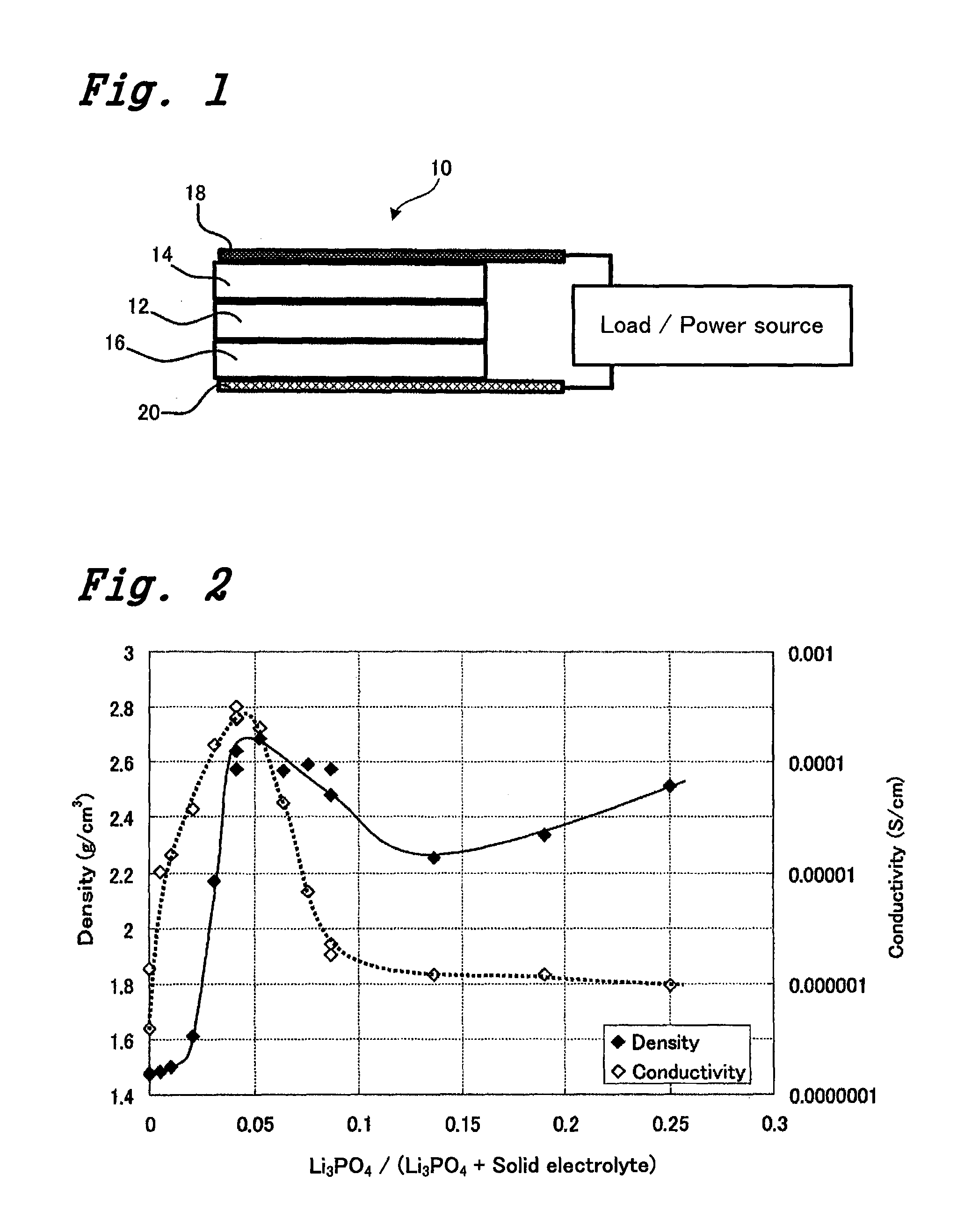

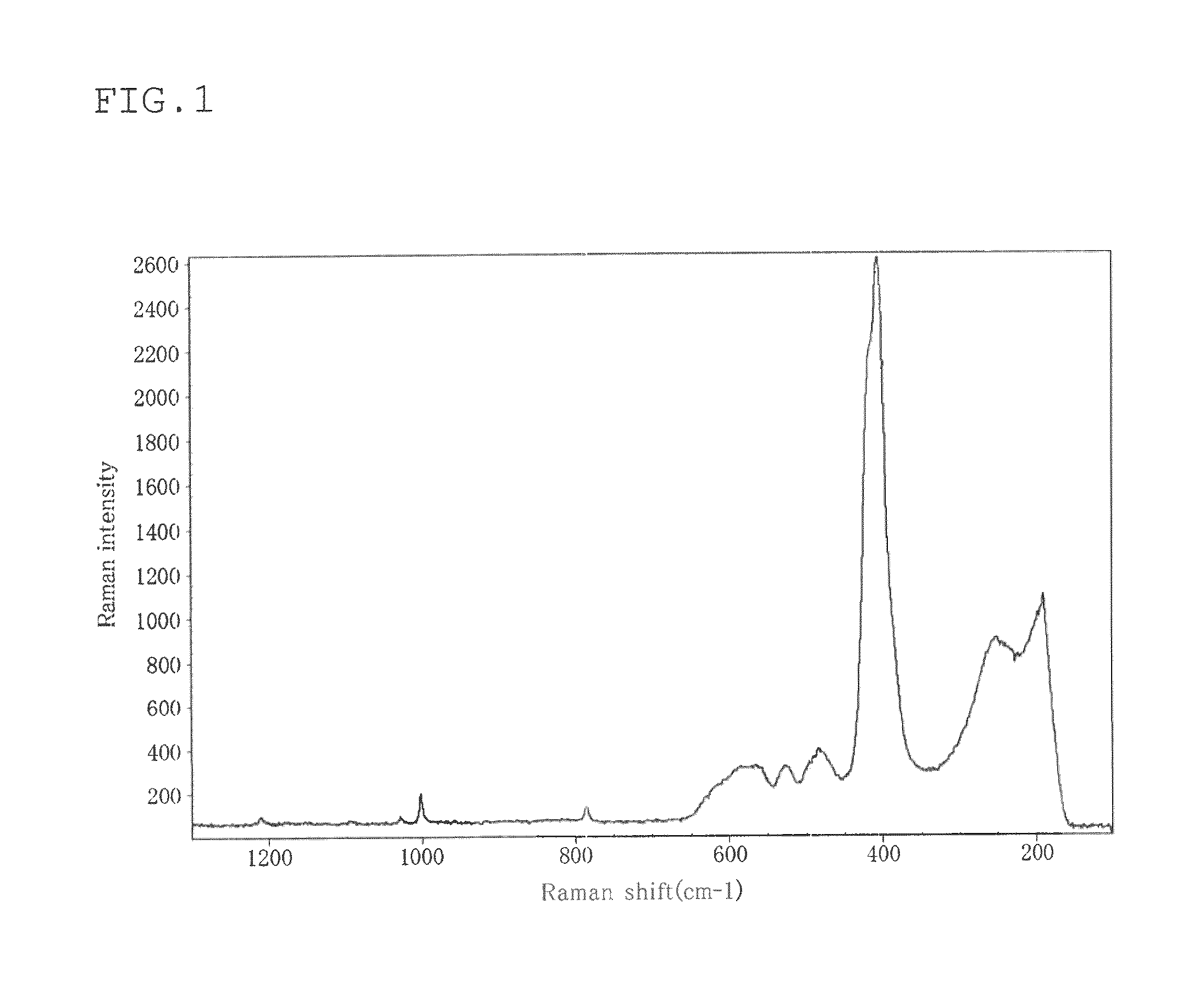

Glass comprising solid electrolyte particles and lithium battery

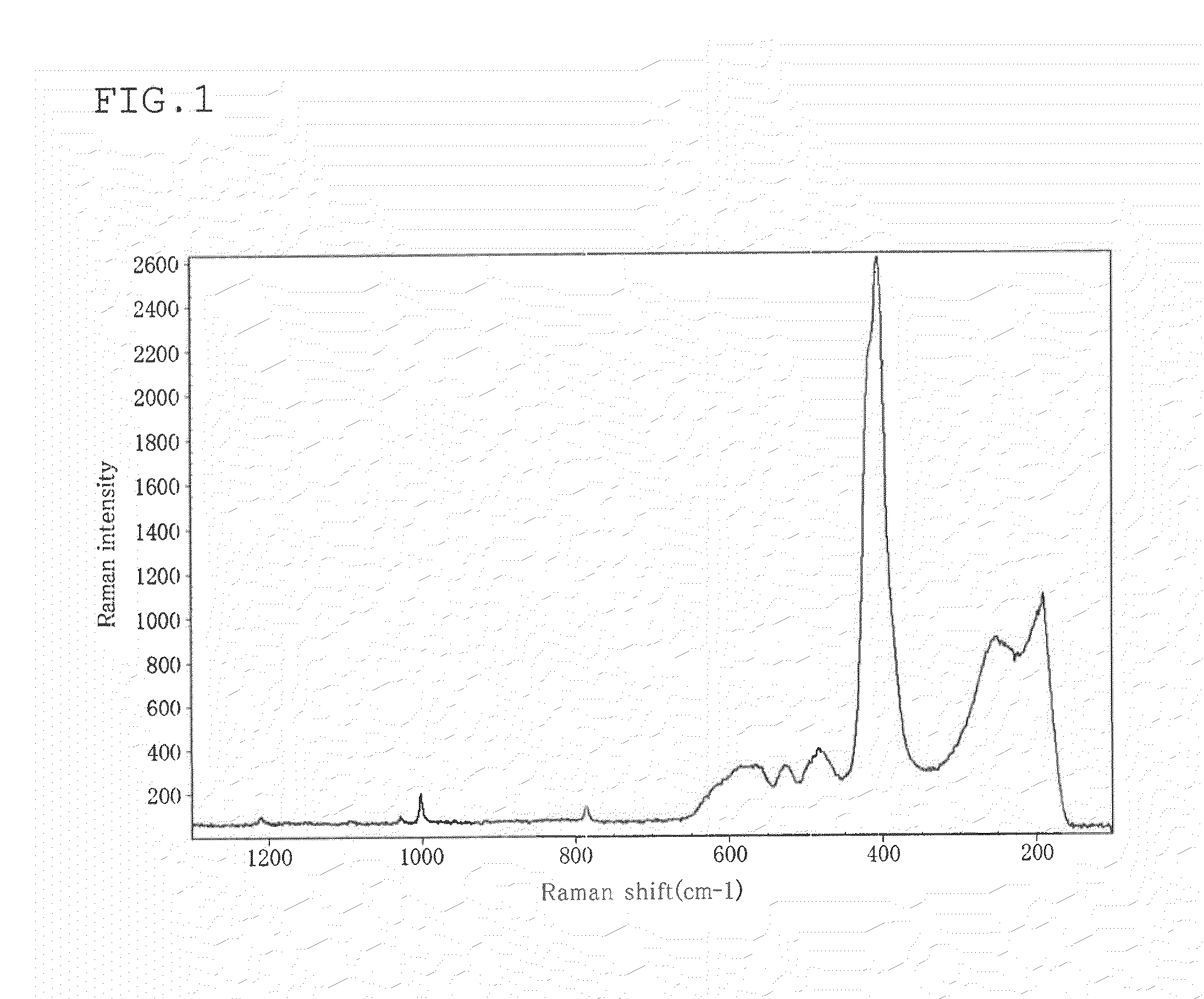

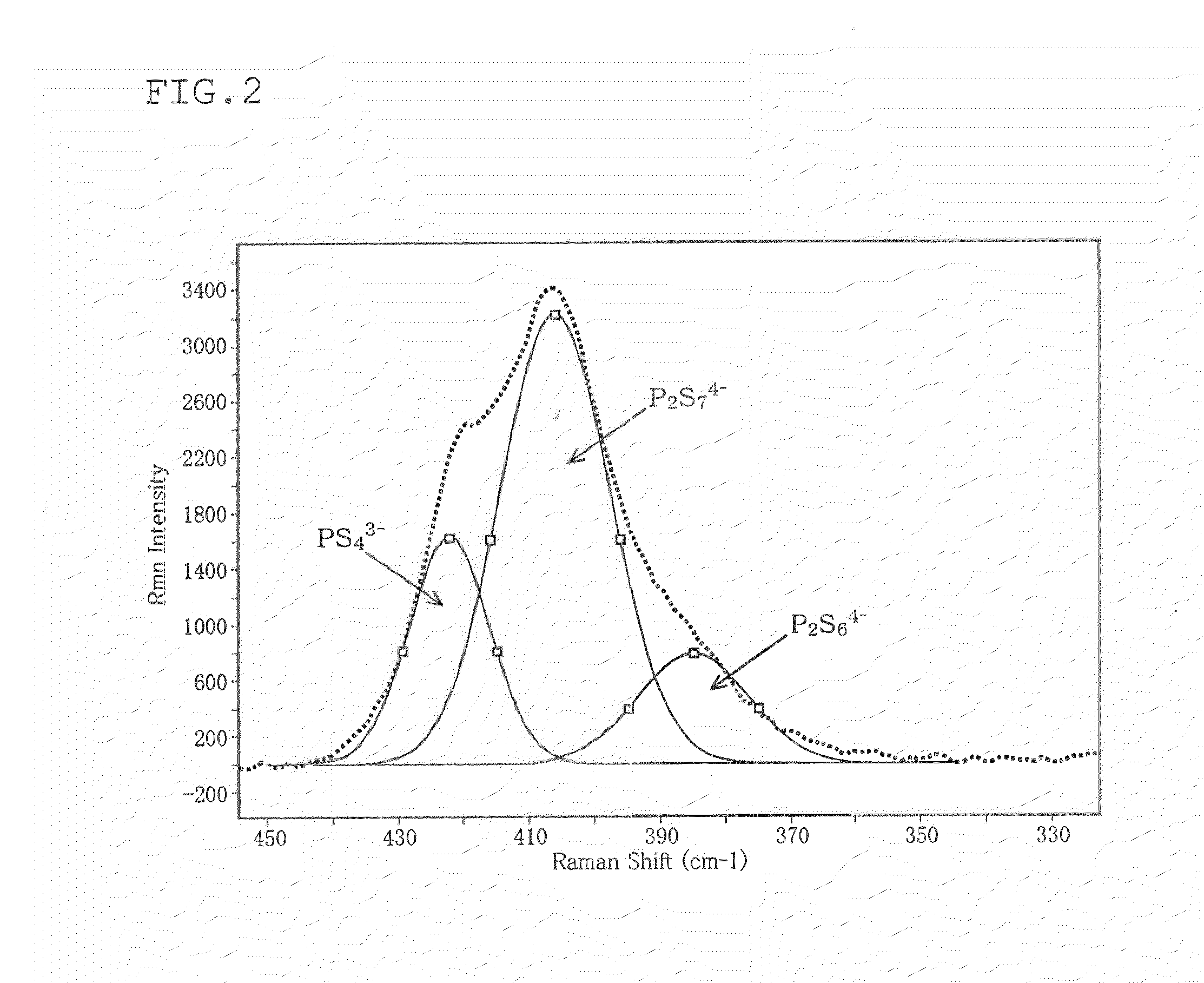

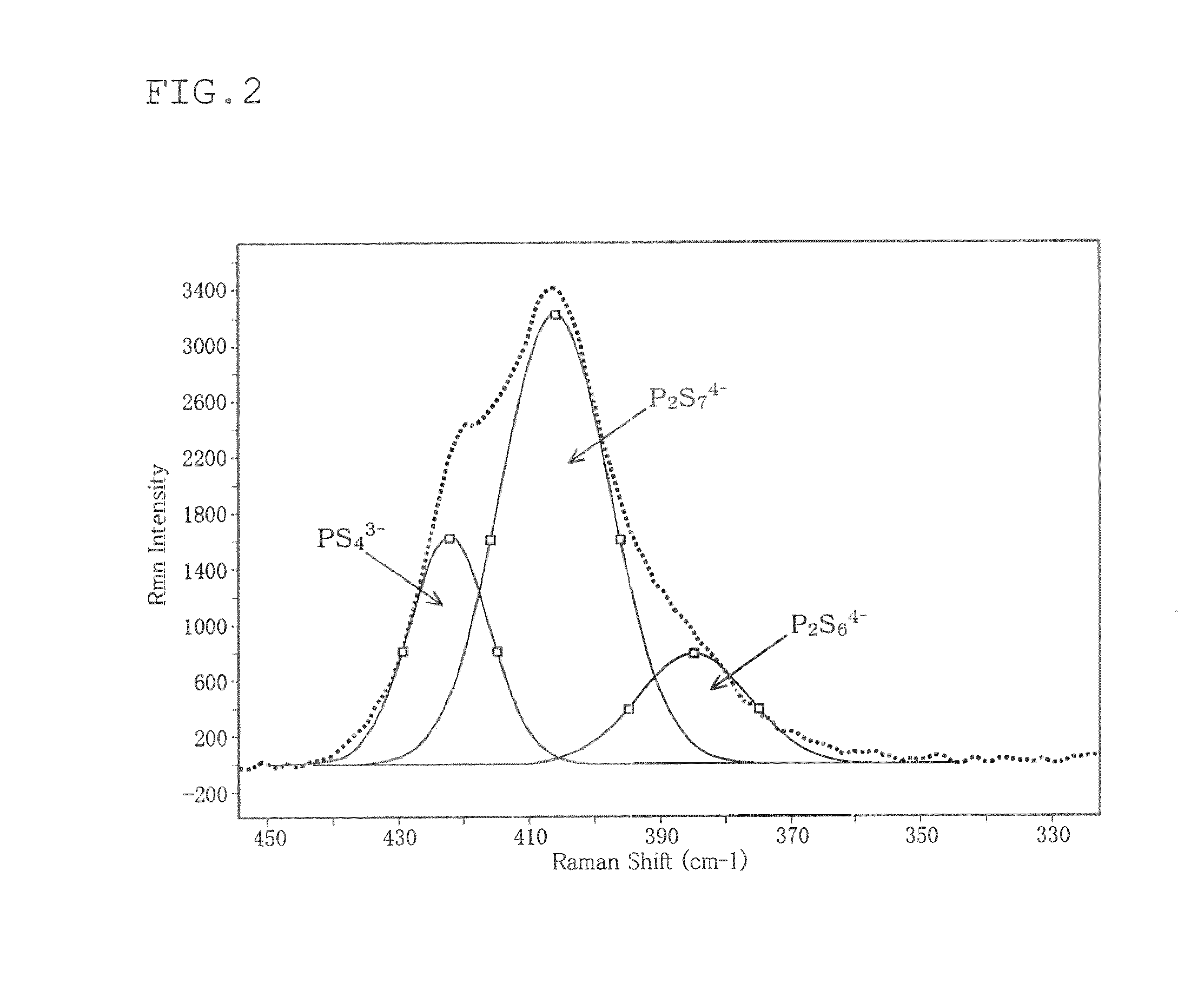

ActiveUS20120009484A1Deterioration of battery performanceStabilize battery performanceSolid electrolytesFinal product manufactureElectrolyteMaterials science

Glass includes an aggregate of solid electrolyte particles including Li, P, and S, wherein when a Raman spectrum of the glass is repeatedly measured and a peak at 330 to 450 cm−1 in each Raman spectrum is separated to waveforms of individual components, a standard deviation of a waveform area ratio of each component is less than 4.0.

Owner:IDEMITSU KOSAN CO LTD

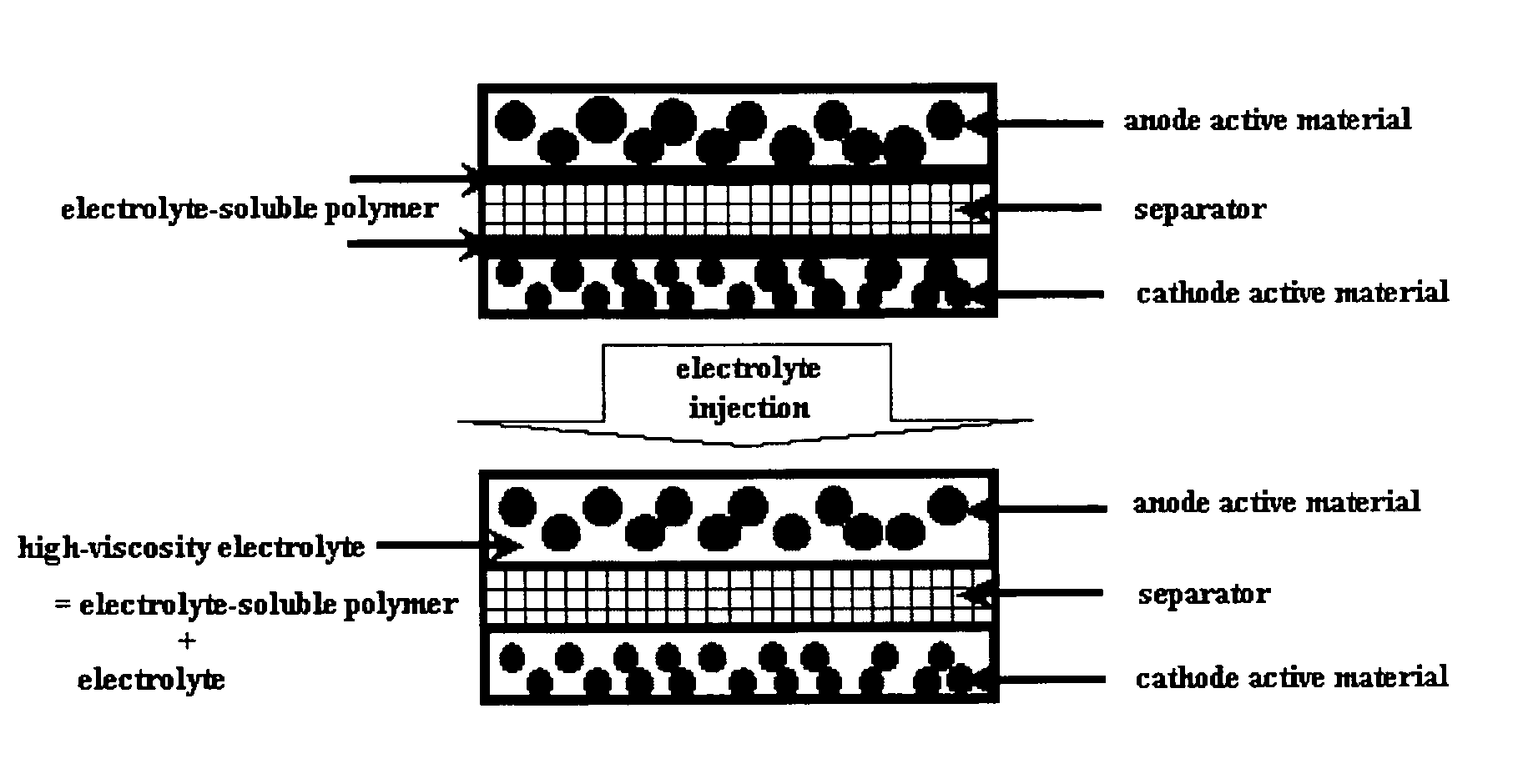

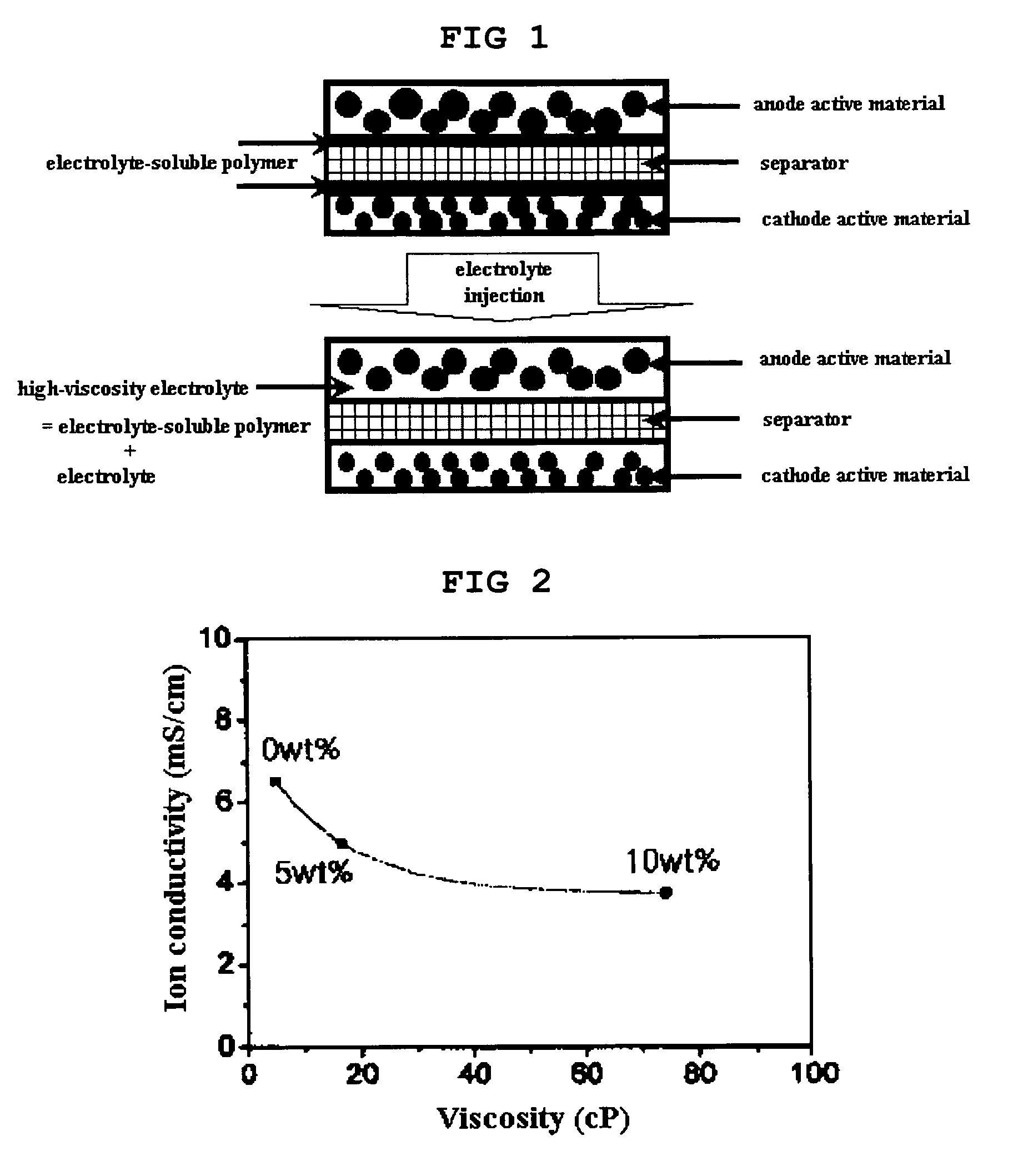

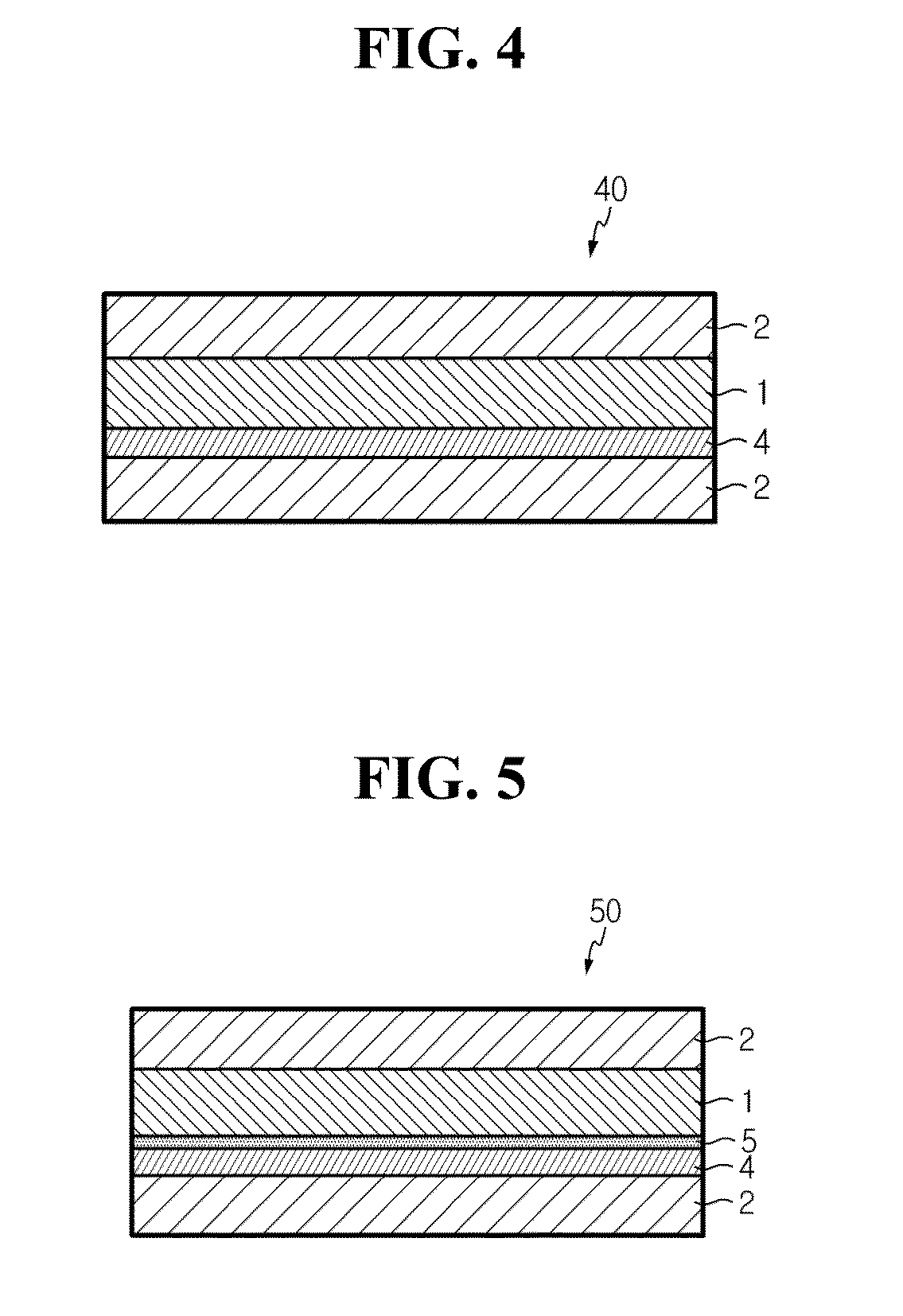

Seperator coated with electrolyte-miscible polymer and electrochemical device using the same

InactiveUS20070054184A1Improve battery safetyInhibit deteriorationCell seperators/membranes/diaphragms/spacersFinal product manufactureLithiumElectrochemistry

The present invention provides a separator in which an electrolyte-soluble polymer, which is soluble in liquid electrolyte, is coated on one or both surfaces of the separator, as well as an electrochemical device including the separator. Also, the present invention provides a method for producing an electrochemical device, comprising the steps of: (a) coating an electrolyte-soluble polymer, which is soluble in liquid electrolyte, on one or both surfaces of a separator; (b) interposing the separator produced in the step (a) between a cathode and an anode so as to assemble an electrochemical device; and (c) injecting a liquid electrolyte into the electrochemical device produced in the step (b). The electrochemical device, such as a lithium secondary battery, produced by the inventive method, has an improved safety while deterioration in the battery performance is minimized.

Owner:LG CHEM LTD

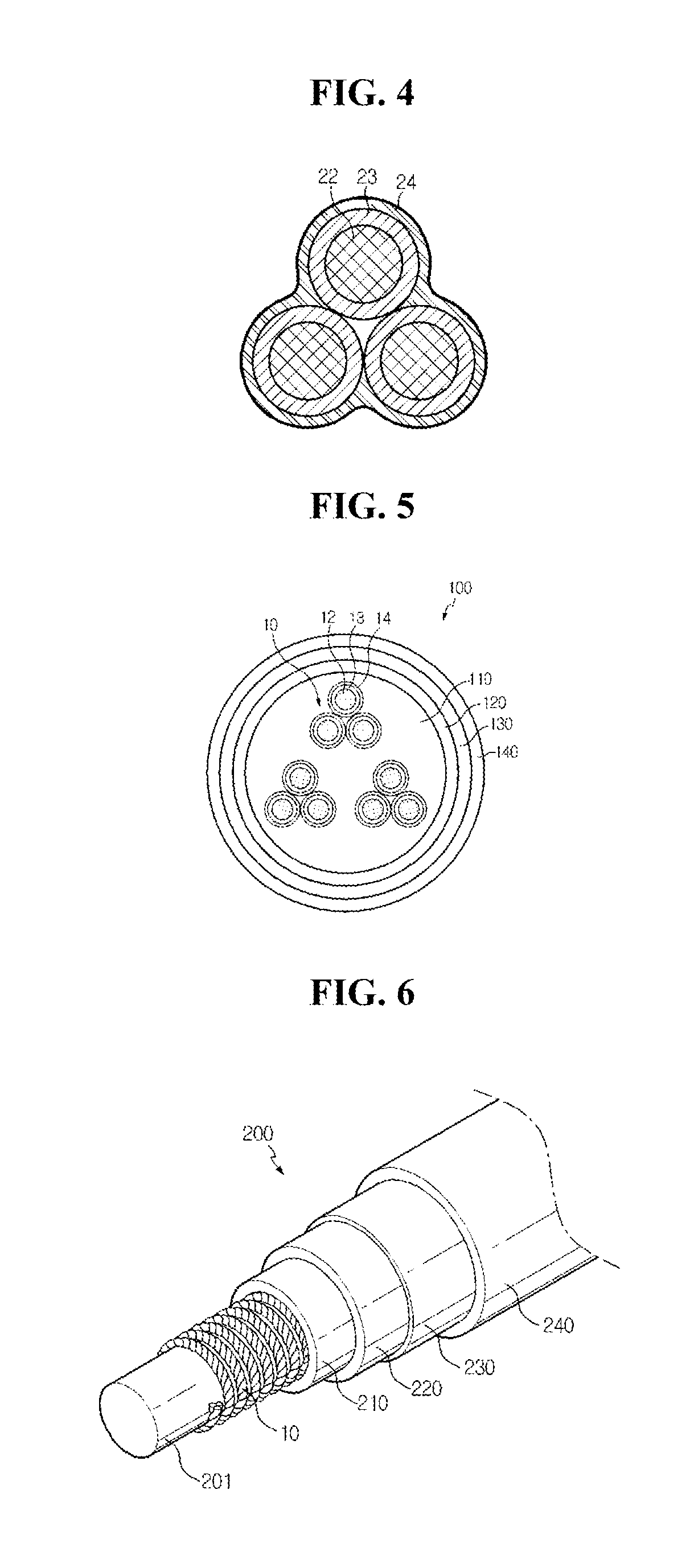

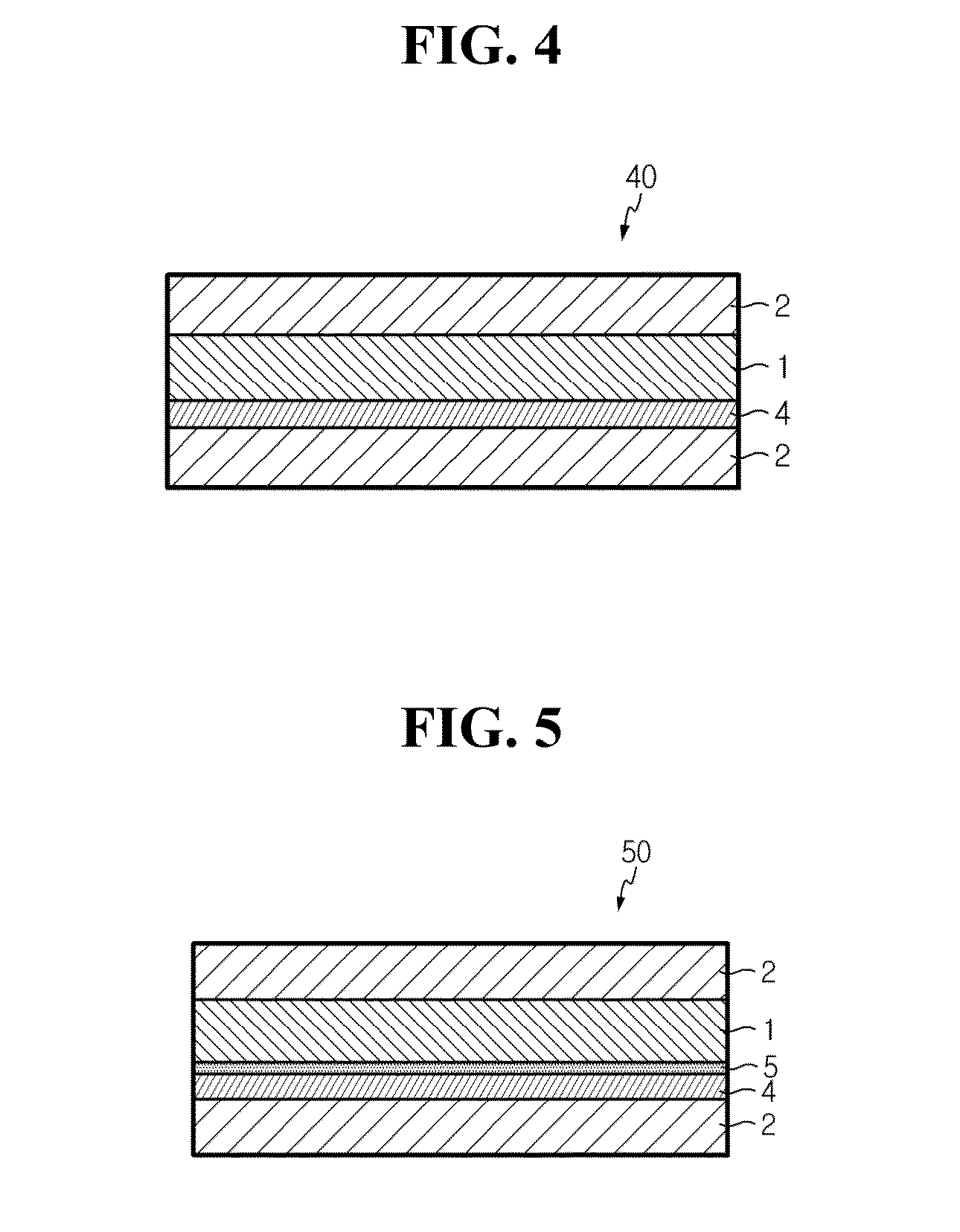

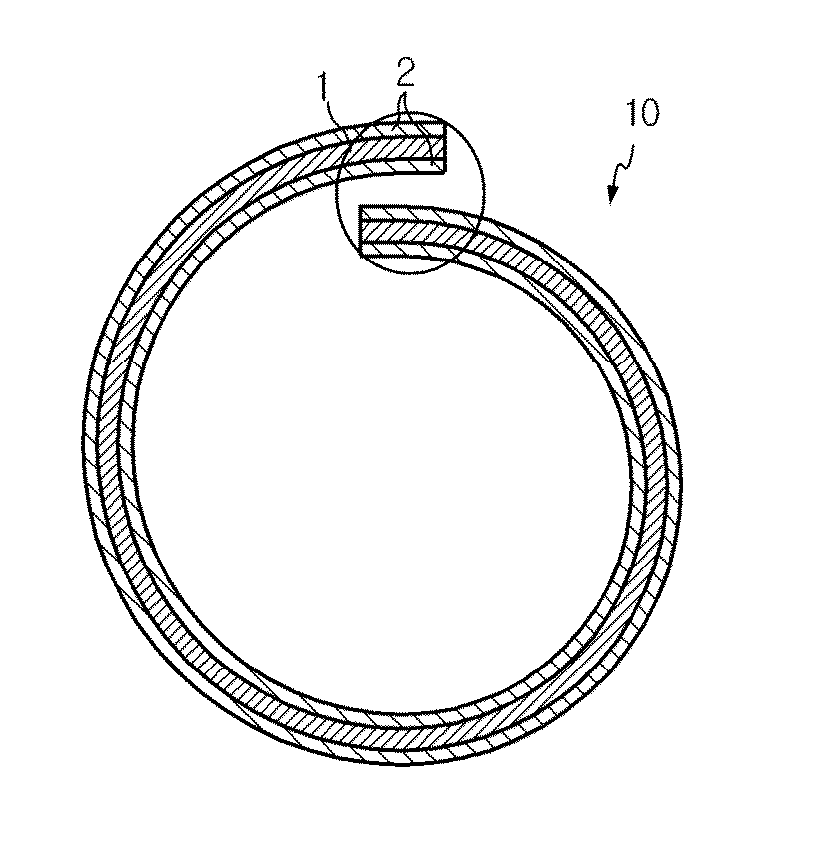

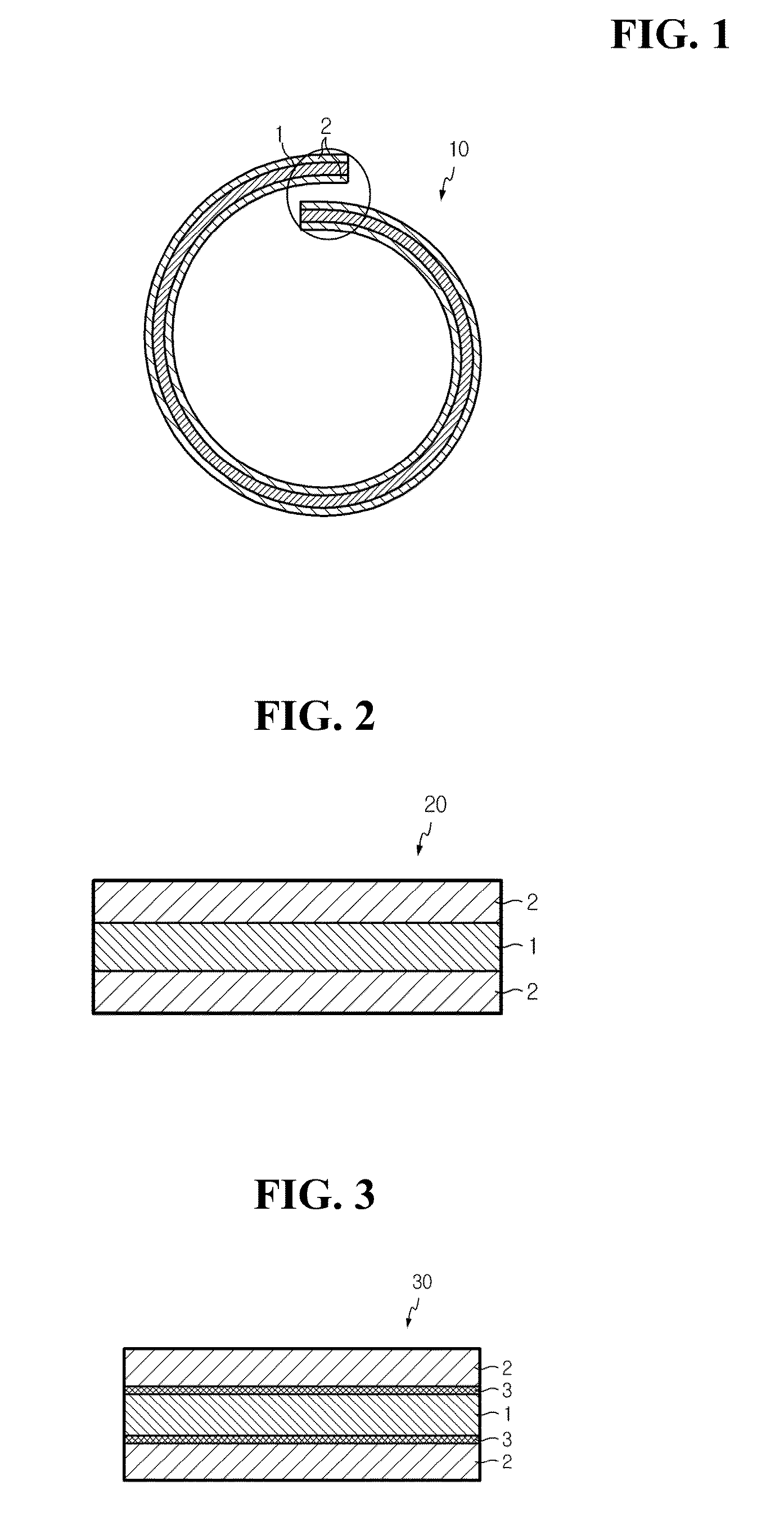

Packaging for cable-type secondary battery and cable-type secondary battery comprising the same

ActiveUS20140335391A1Avoid pollutionImprove life characteristicsFinal product manufactureElectrode carriers/collectorsEngineeringSealant

The present disclosure relates to a packaging for a cable-type secondary battery, surrounding an electrode assembly in the cable-type secondary battery, the packaging having a moisture-blocking layer comprising sealant polymer layers on both outer surfaces of a moisture-blocking film and a moisture-blocking film disposed between the sealant polymer layers, wherein the moisture-blocking layer is a tube form surrounding the electrode assembly, and the sealant polymer layers in both ends of the moisture-blocking layer are overlapped and adhered with each other in a predetermined part. The packaging according to the present disclosure can be used in a cable-type secondary battery to block moisture from being infiltrated into an electrode assembly, thereby improving the life characteristics of the battery and preventing the deterioration of battery performances.

Owner:LG ENERGY SOLUTION LTD

Battery pack and active cell balancing battery management system including the same

ActiveUS8872482B2Deterioration of battery performanceShortened life-spanBatteries circuit arrangementsElectric devicesProduction rateSmart grid

The present invention discloses a battery pack which can be used for an electric vehicle, an Uninterrupted Power Supply (UPS), and a power supply for a smart grid and which can be easily manufactured and repaired and which is capable of improving productivity, the span of life, and performance, and a battery management system including the battery pack.The battery pack of the present invention comprises a casing in which a reception space is provided and battery modules coupled to the casing at regular intervals by fastening members so that the battery modules can be easily dismantled from the casing. Each of the battery modules includes a tray, a battery cell provided in the tray, a cell charger provided in the tray and configured to charge the battery cell, a cell controller provided in the tray and configured to control the cell charger, a heating mat coupled to the battery cell, and a temperature sensor provided in the tray and configured to sense a temperature of the battery cell.

Owner:TS NEXGEN CO LTD

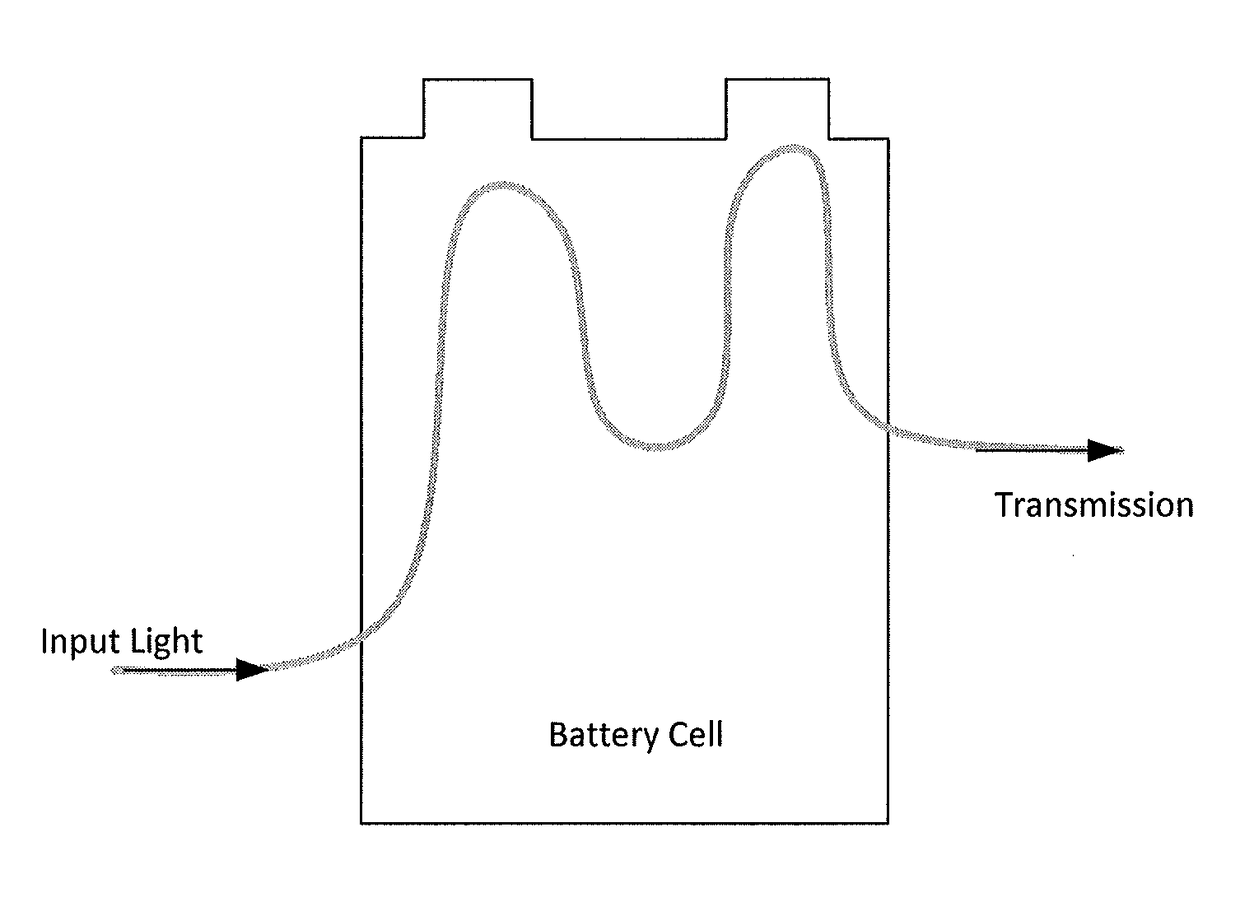

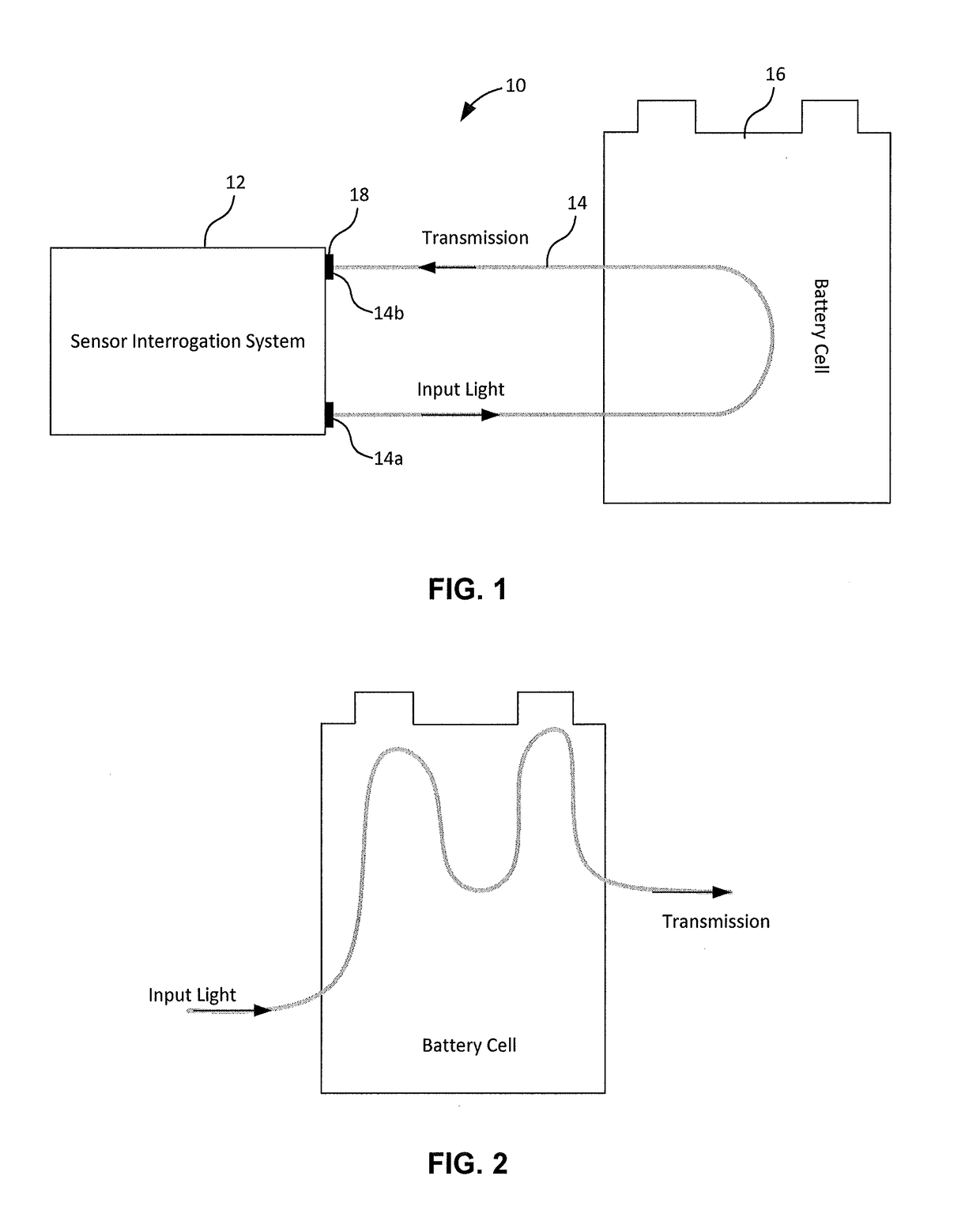

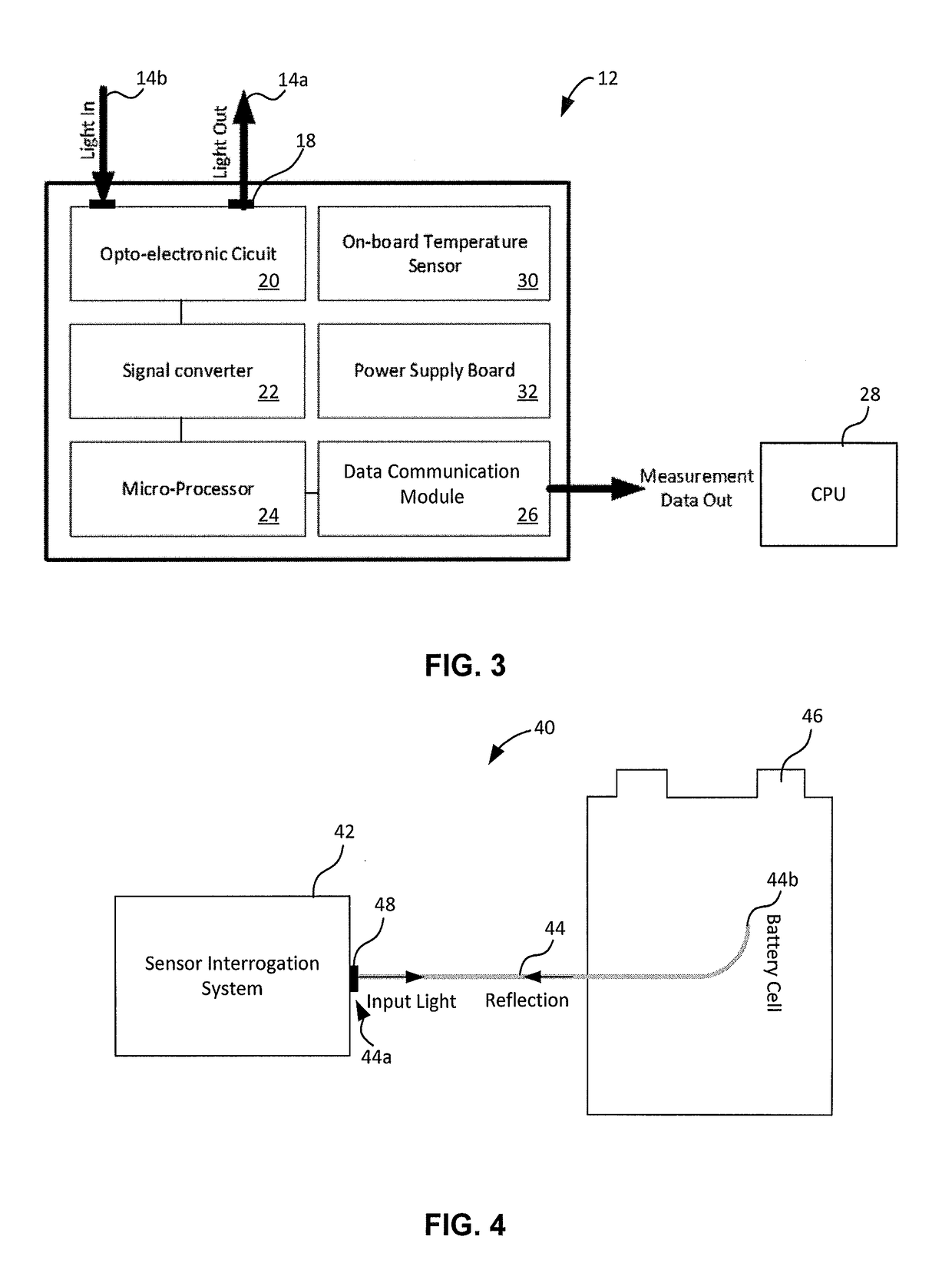

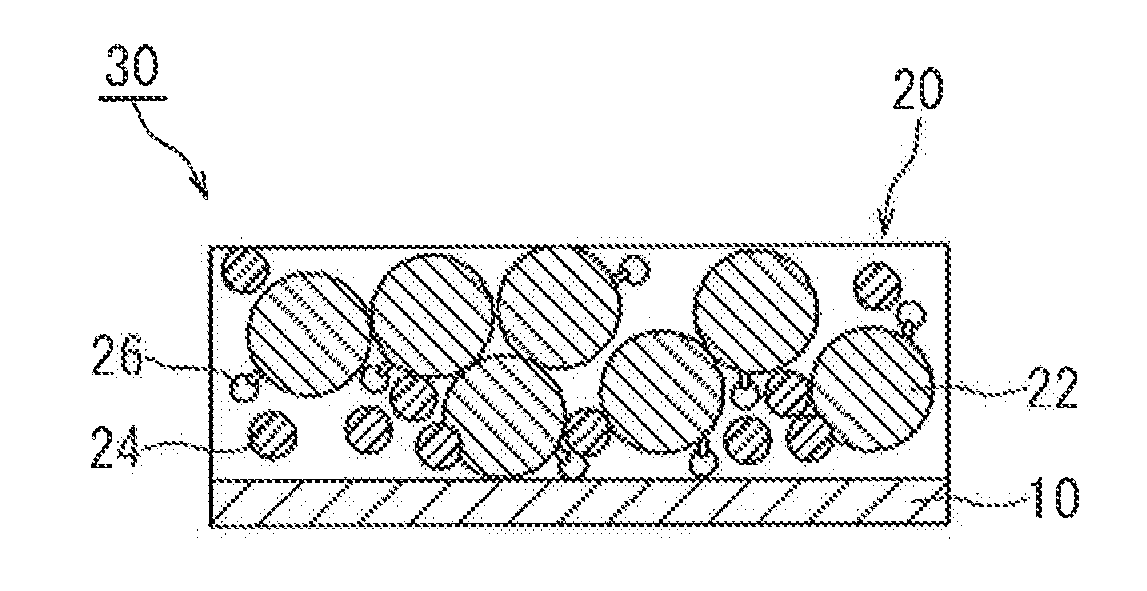

Method and apparatus for monitoring and determining energy storage device characteristics using fiber optics

InactiveUS20170131357A1Small form factorRobustness to corrosive environmentsElectrical testingSecondary cellsOptical fiber cableFiber

A system for monitoring characteristics of an energy storage device including the energy storage device, an optical fiber cable having a first end and a second end, the optical fiber cable embedded within the energy storage device, and a sensor interrogation system, the sensor interrogation system connected to at least one of the first end or second end of the optical fiber cable.

Owner:NIEVA PATRICIA +1

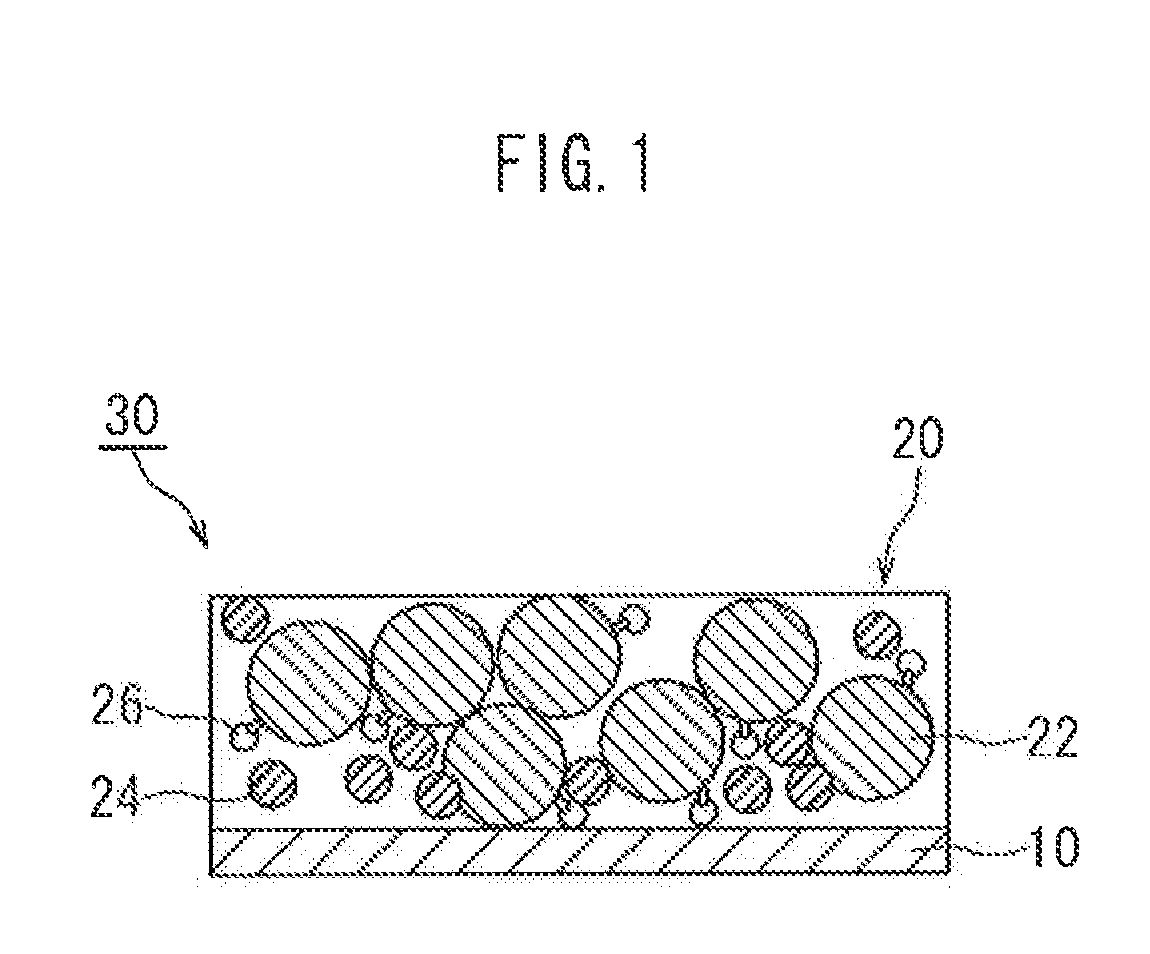

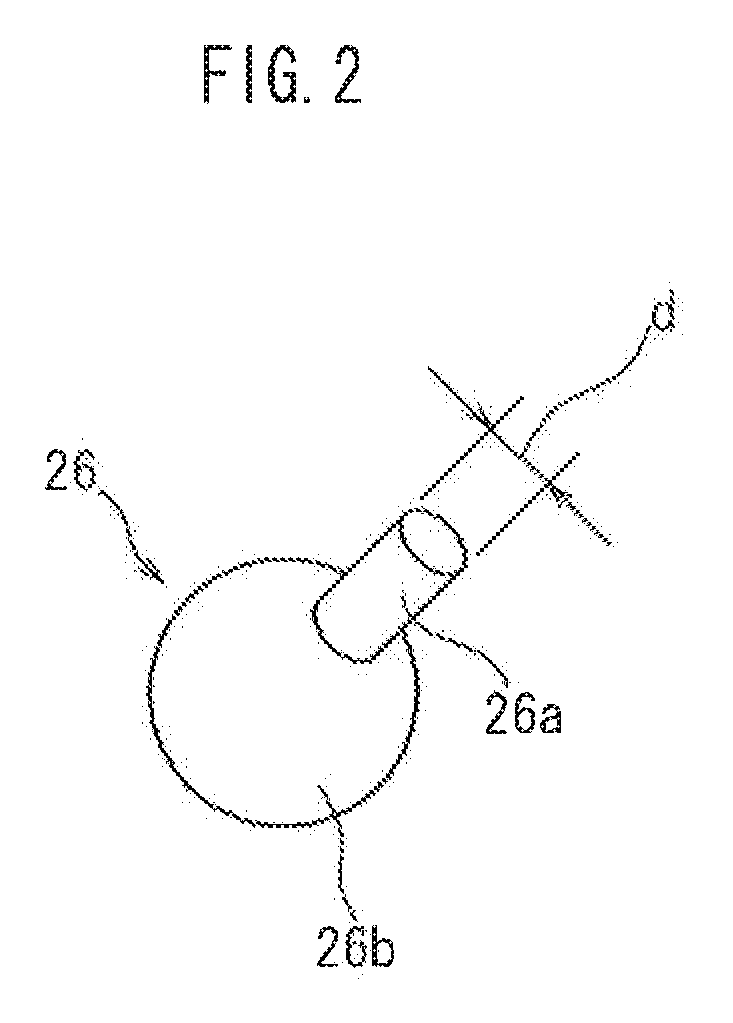

Method for producing battery electrode

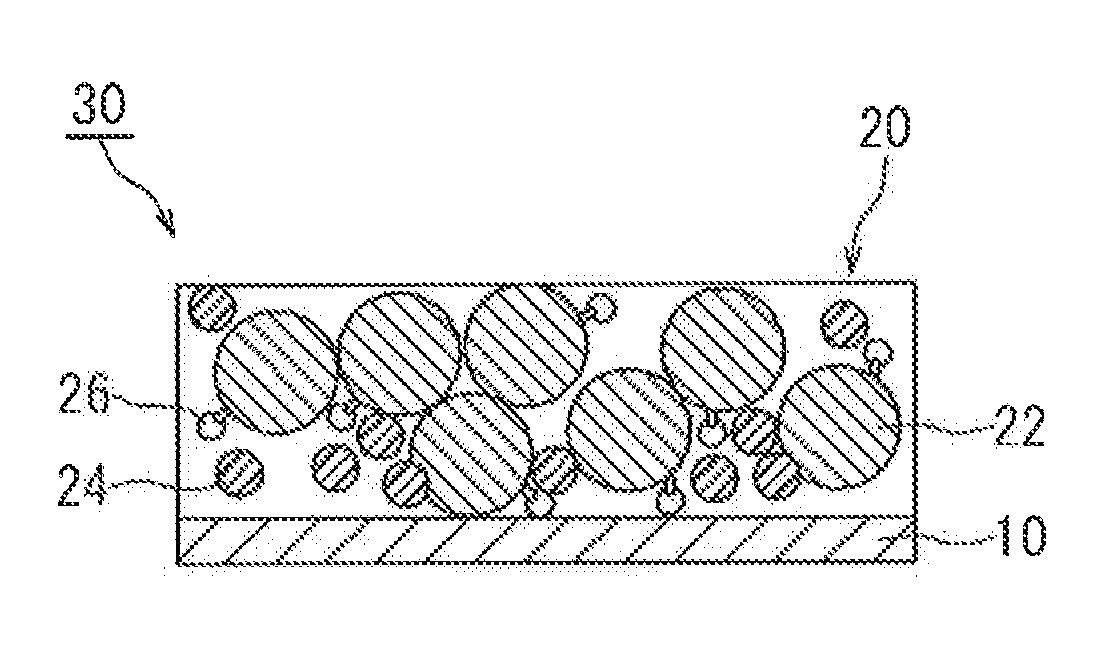

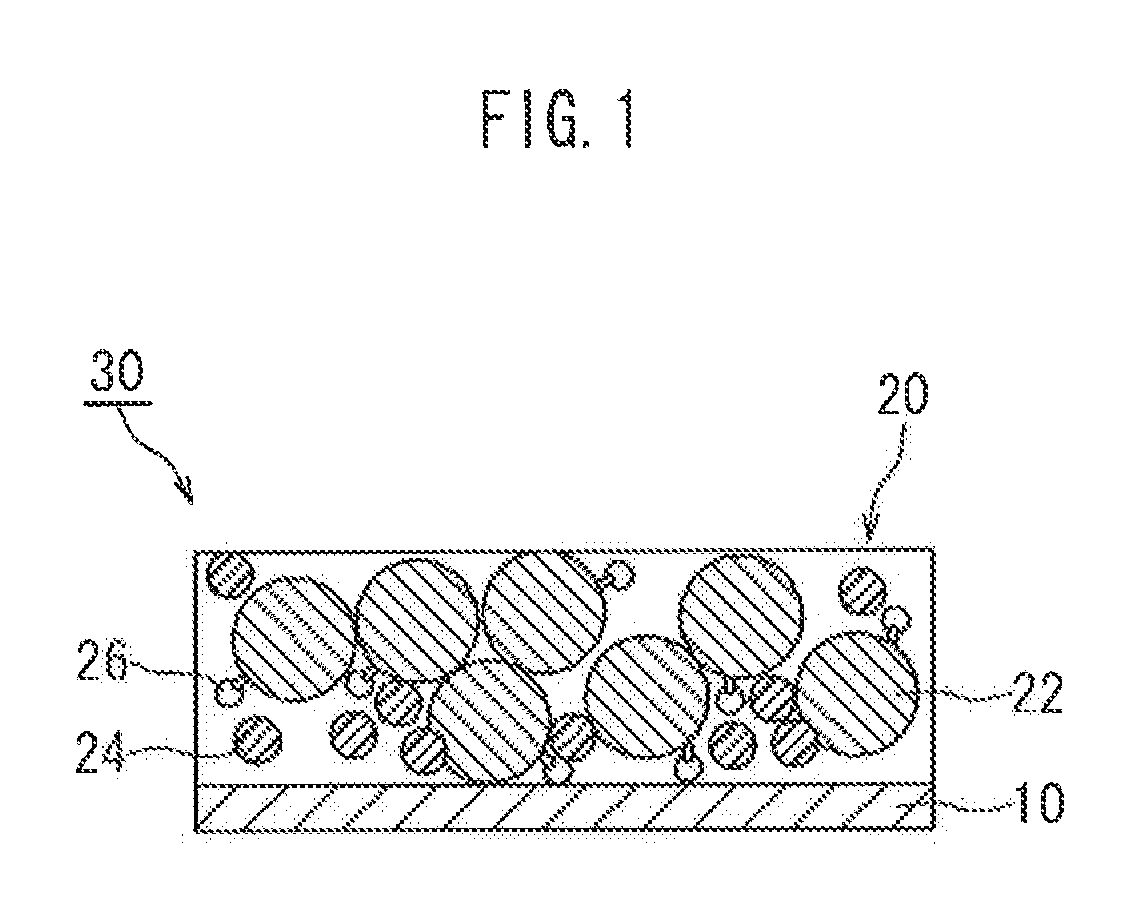

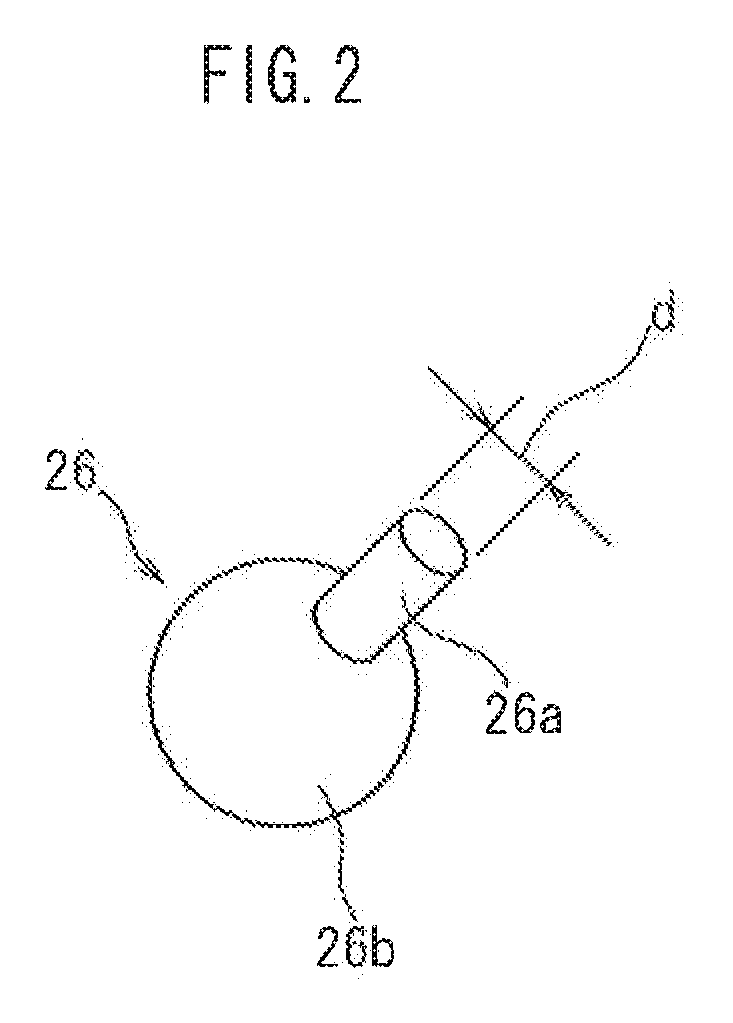

ActiveUS20130157130A1Deterioration of battery performanceImprove adhesionNon-aqueous electrolyte accumulatorsFinal product manufactureSolventCurrent collector

A main object of the present invention is to provide a method for producing a battery electrode that has excellent adhesion between a collector and an active material layer by suppressing a migration phenomenon. The method for producing a battery electrode of the present invention is a method for producing a battery electrode 30 that has a structure in which an active material layer 20 that includes an active material 22 is held on a collector 10. The method includes a step of applying, onto the collector 10, an active material layer forming paste that contains the active material 22 and polymer materials 24, 26 in a solvent; and a step of drying the applied paste coat material, to form thereby the active material layer 20 on the collector 10. Fibrillated polymer fibers 26 are used as at least one of the polymer materials 24, 26.

Owner:TOYOTA JIDOSHA KK

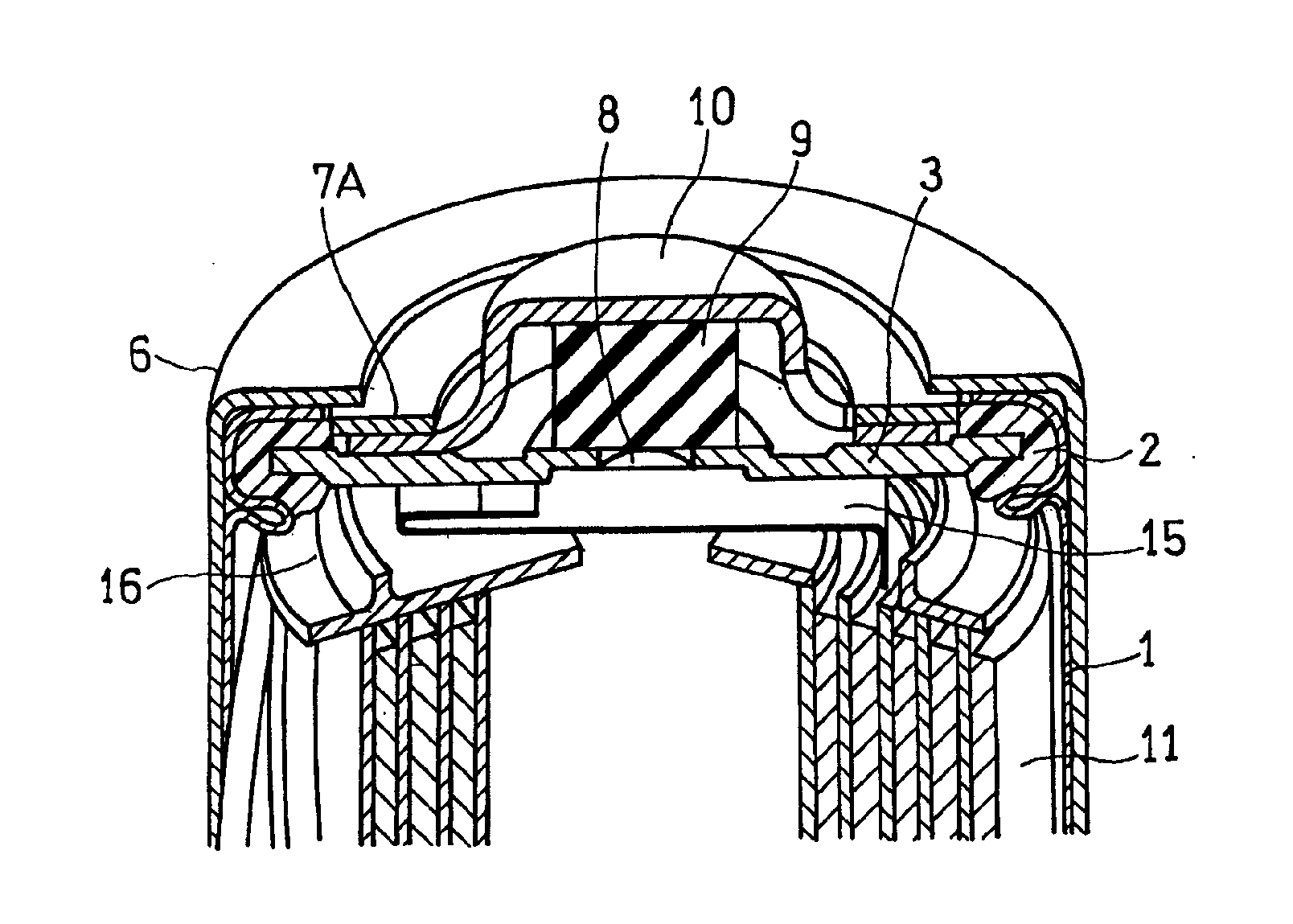

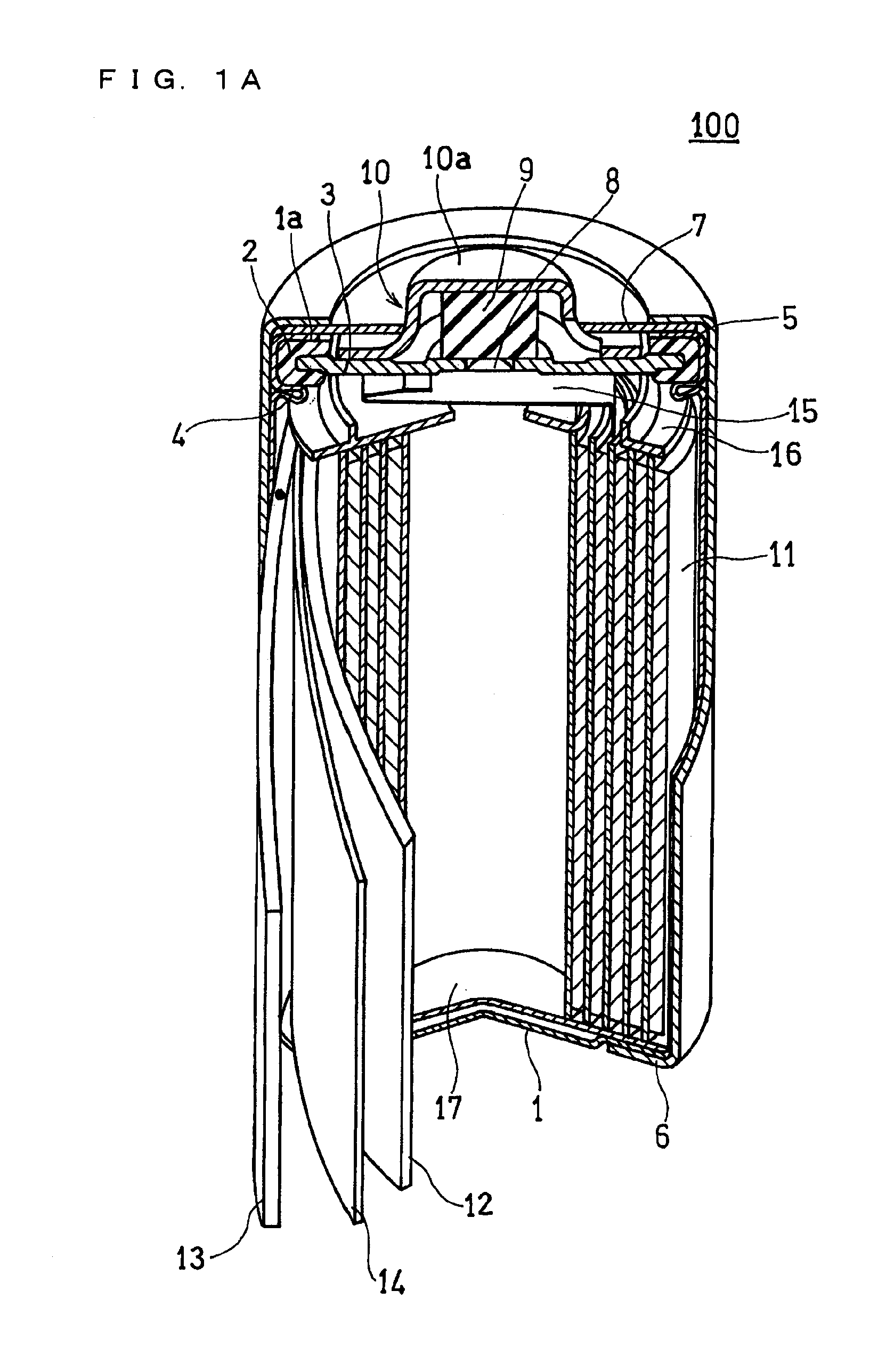

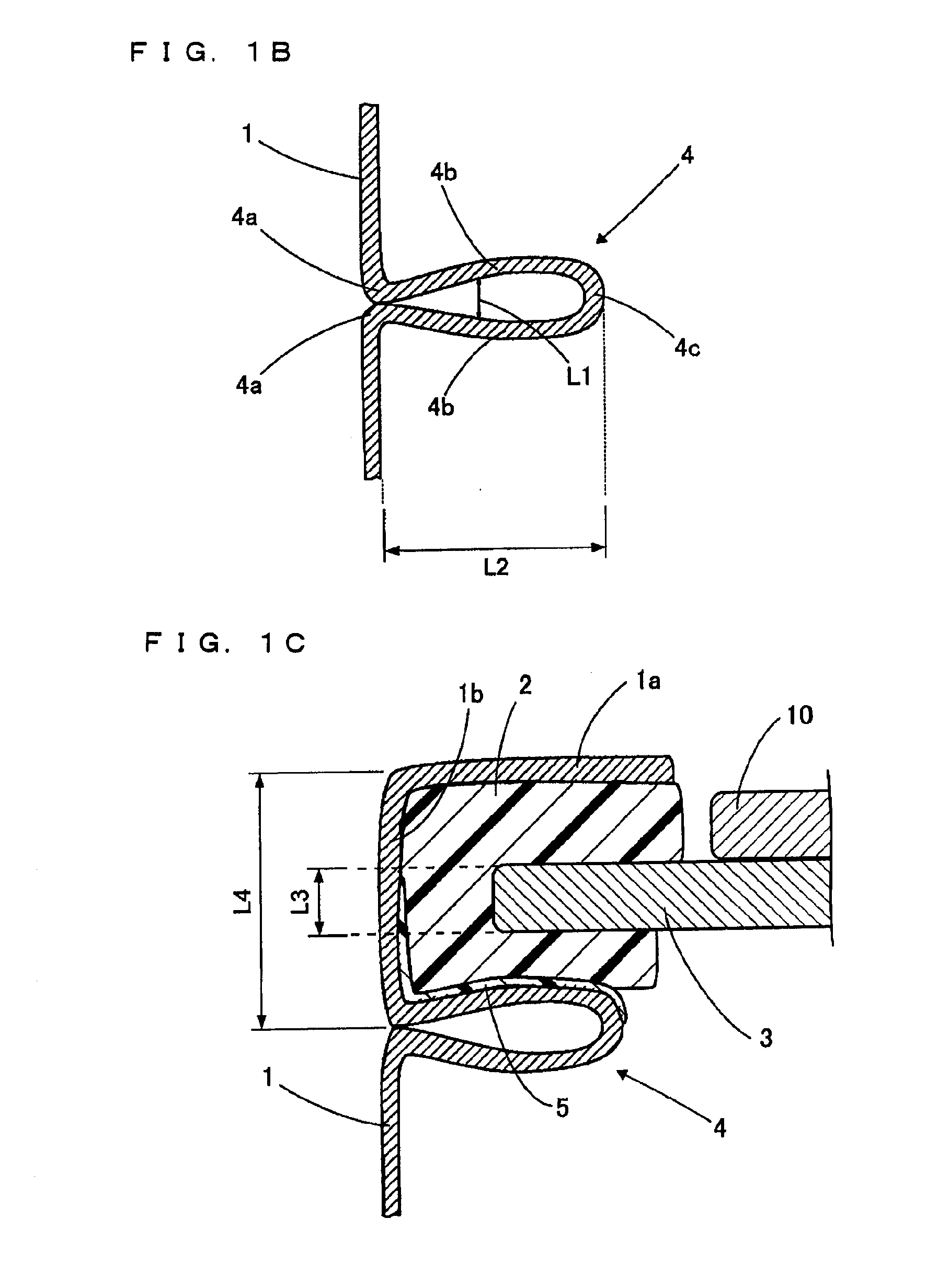

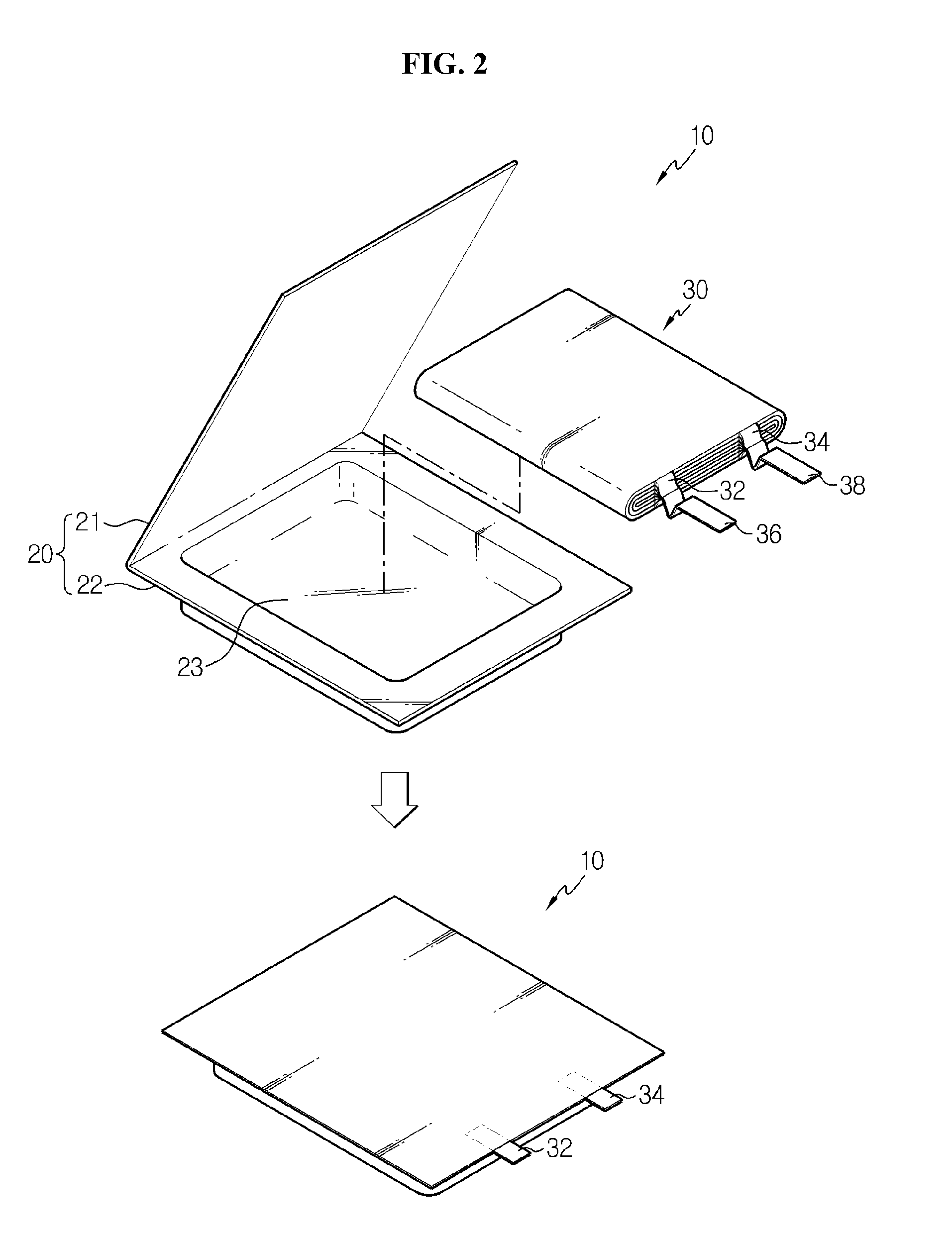

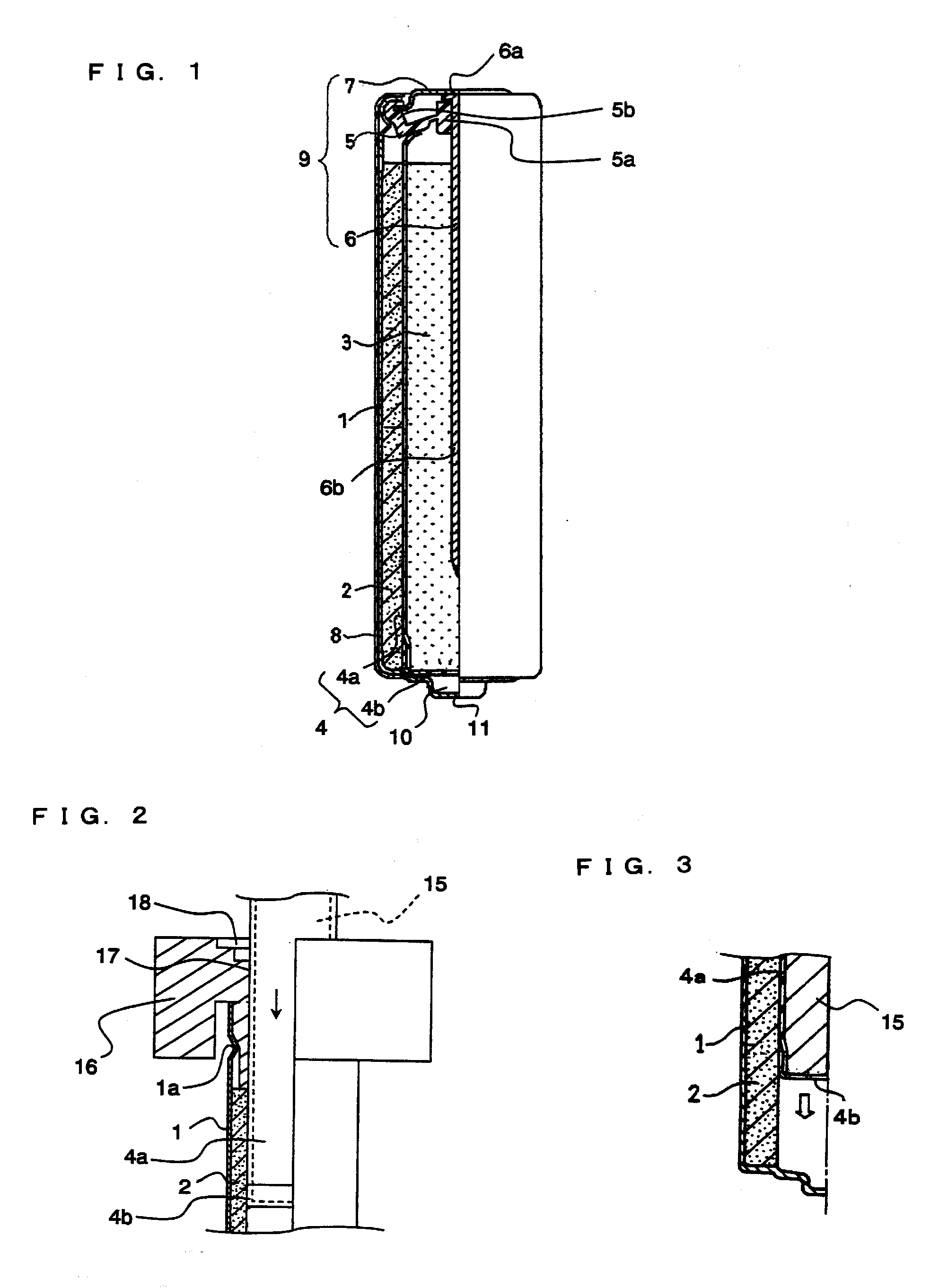

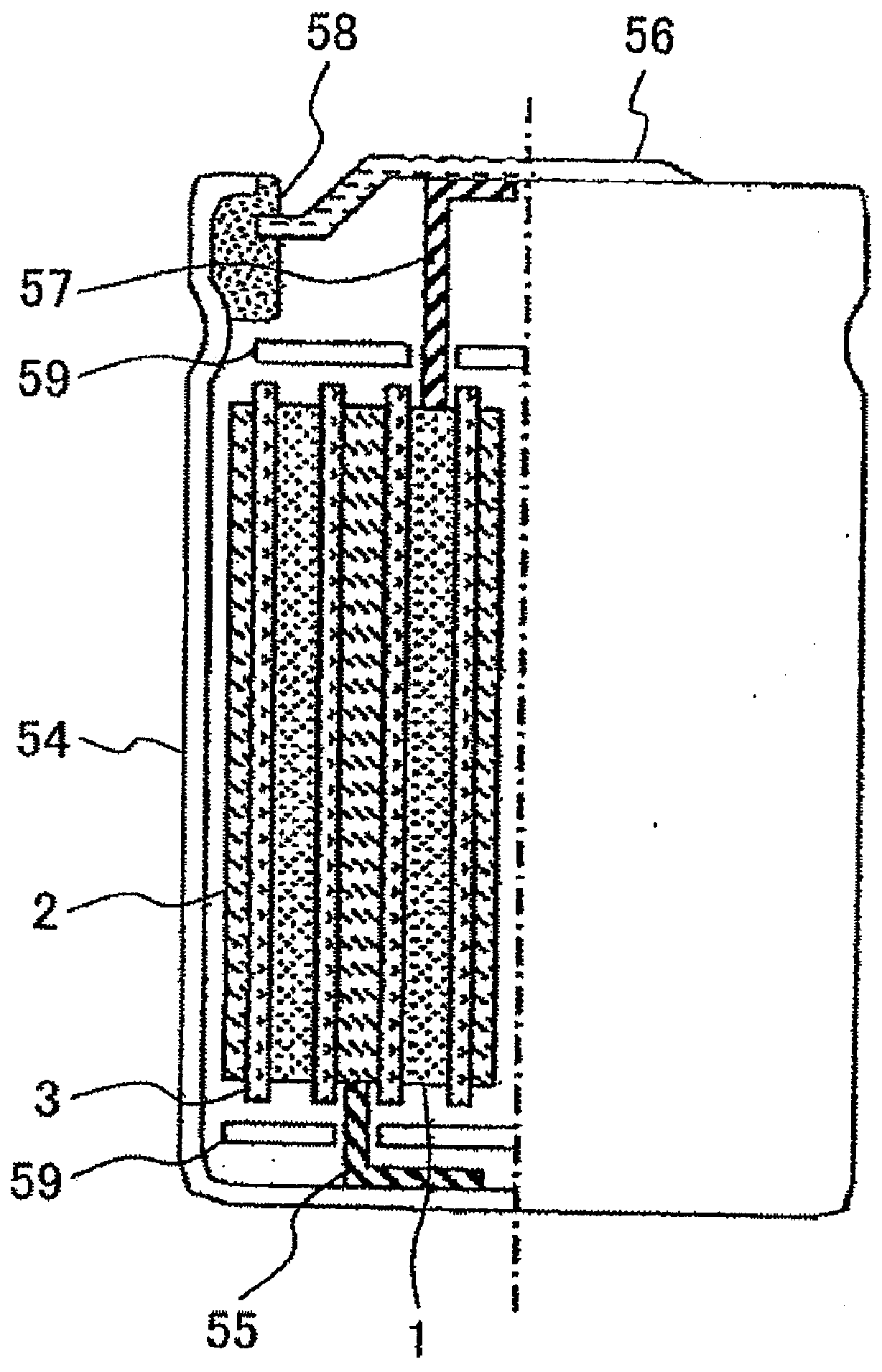

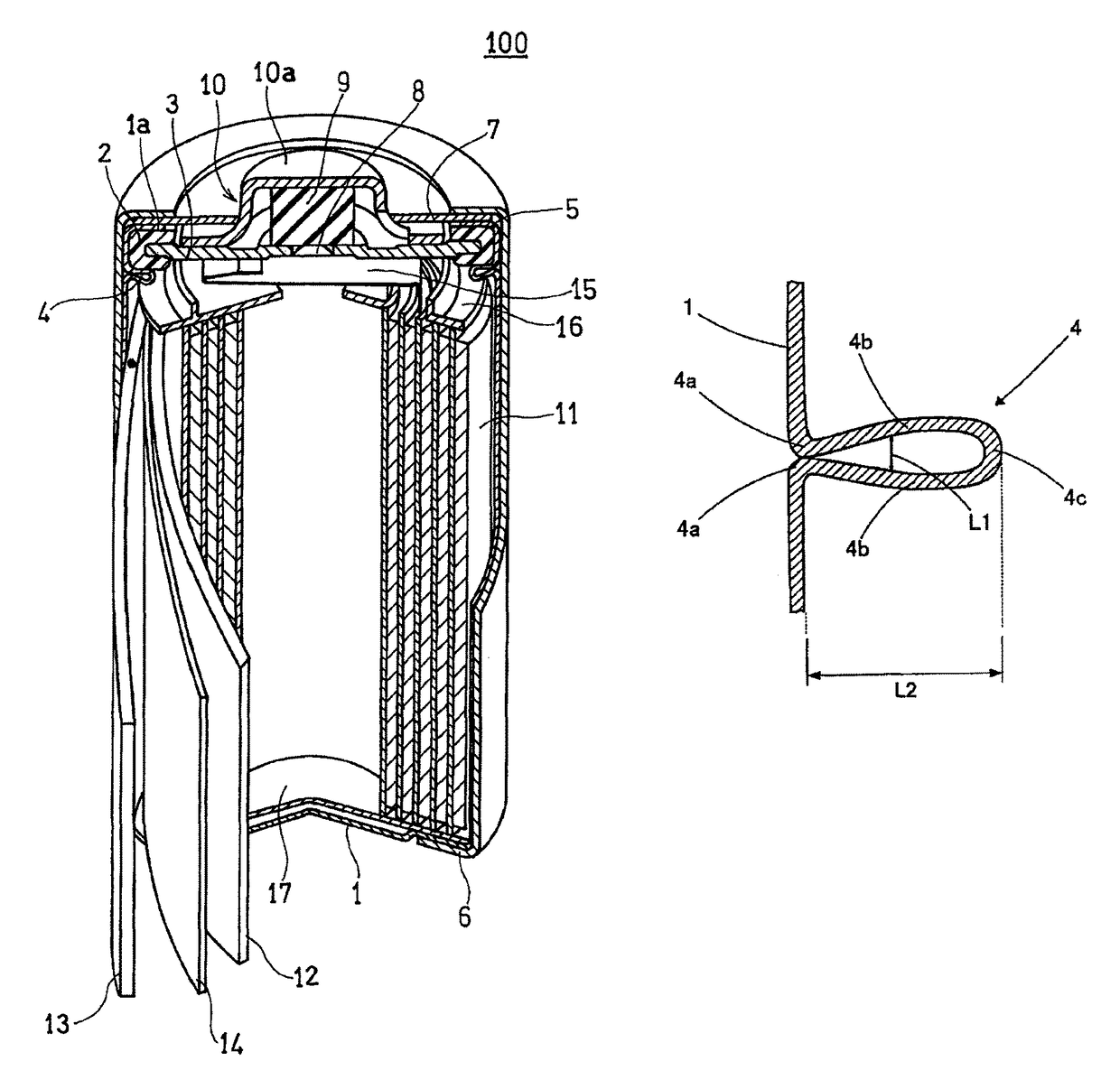

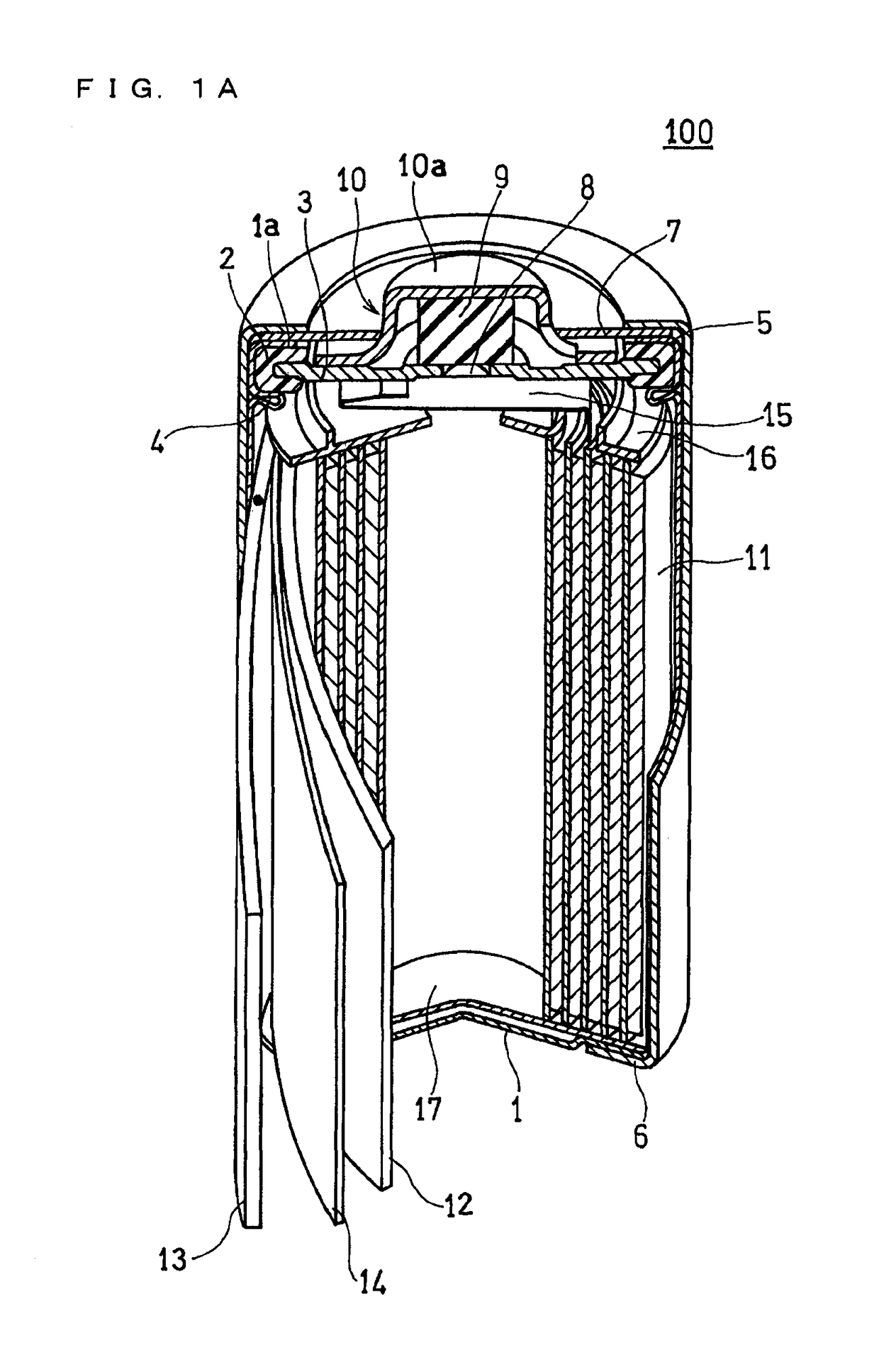

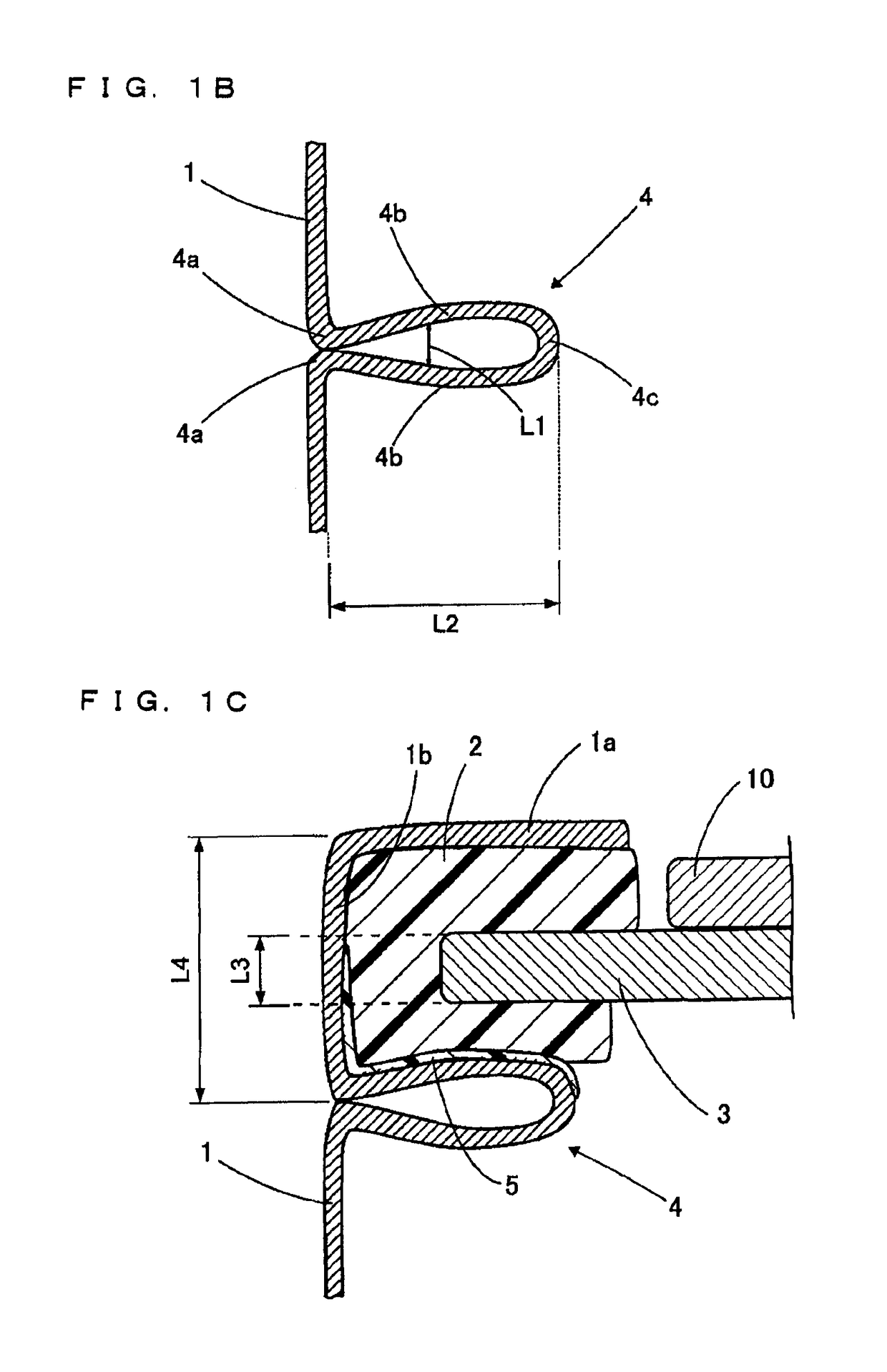

Cylindrical alkaline storage battery

ActiveUS20150024258A1Increase battery capacityDeterioration of battery performanceFinal product manufactureSmall-sized cells cases/jacketsRelative displacementEngineering

An alkaline storage battery includes: a cylindrical case having a side wall including an opening end portion and a bottom; a sealing plate; a gasket interposed between the sealing plate and the opening end portion; and a sealant between the gasket and the opening end portion. The side wall has an annular groove opened at an outer surface thereof, and an inwardly curl portion at the opening end portion. In at least part of the groove, the minimum width L1 is within 0.2 mm. The sealant includes a polyamide resin formed such that when two test-plate materials are bonded together at bonding faces facing each other via a bonding portion of the sealant, and moved in parallel with the bonding faces and in opposite directions to have a relative displacement within 0.5 to 5 mm, a stress at least 0.02 N / mm2 is applied to the bonding portion.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Lithium Ion Secondary Battery

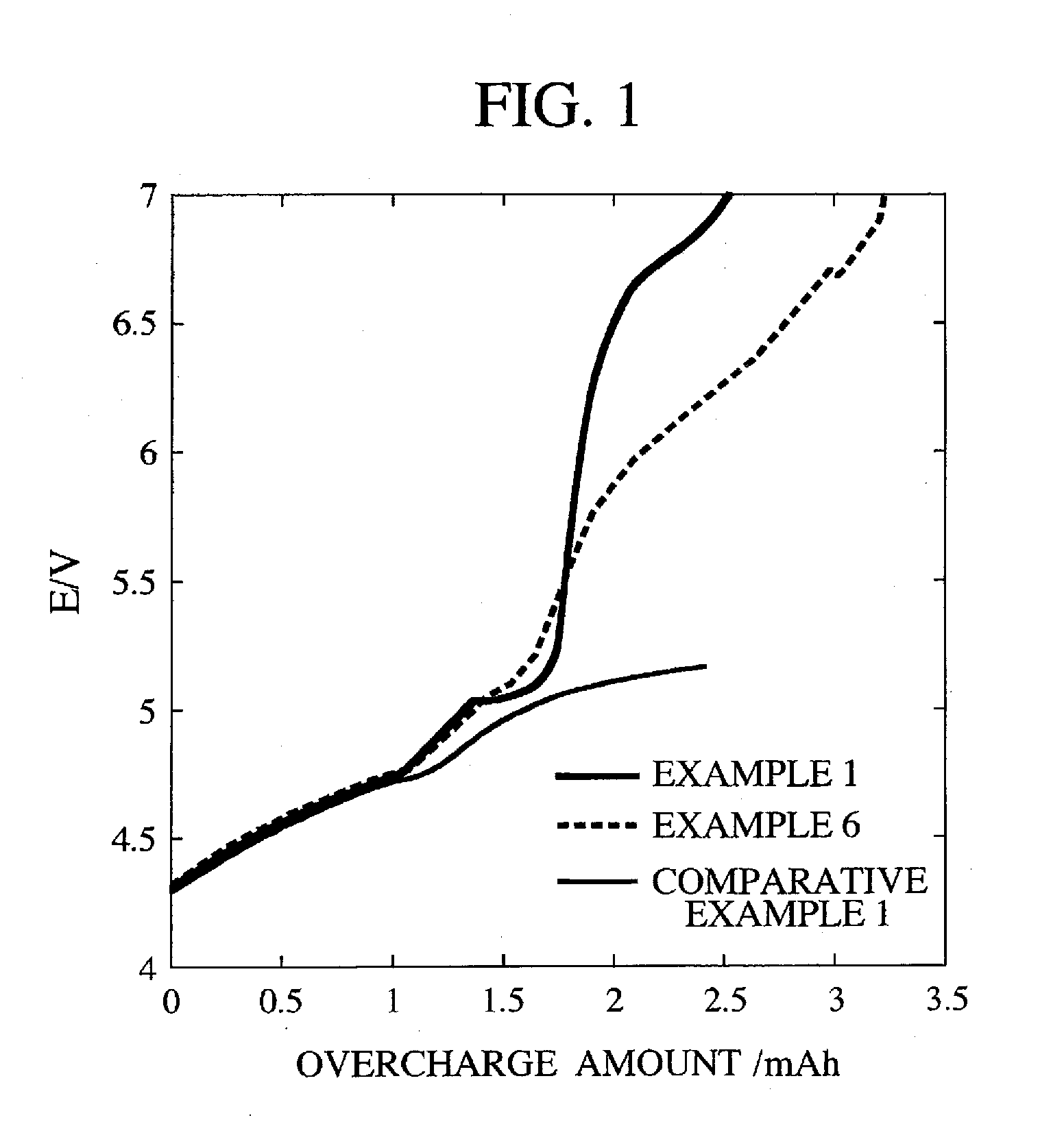

InactiveUS20100216029A1Deterioration of battery performance can be suppressedHigh affinitySolid electrolyte cellsSecondary cellsLithiumElectrode potential

An overcharge suppressing agent adapted to react when the positive electrode potential becomes higher, to increase the internal resistance of a battery during overcharge in an lithium ion secondary battery in which a positive electrode capable of occluding and releasing lithium and a negative electrode capable of occluding and releasing lithium are formed by way of an electrolyte. The electrolyte contains a polymerizable compound represented by the chemical formula (1-1) or the chemical formula (1-2):Z1-A Chemical formula (1-1)Z1-X-A Chemical formula (1-2)in which Z1 is a polymerizable functional group, X is a hydrocarbon group or an oxyalkylene group having 1 or more and 20 or less carbon atoms, and A is an aromatic functional group.

Owner:HITACHI LTD

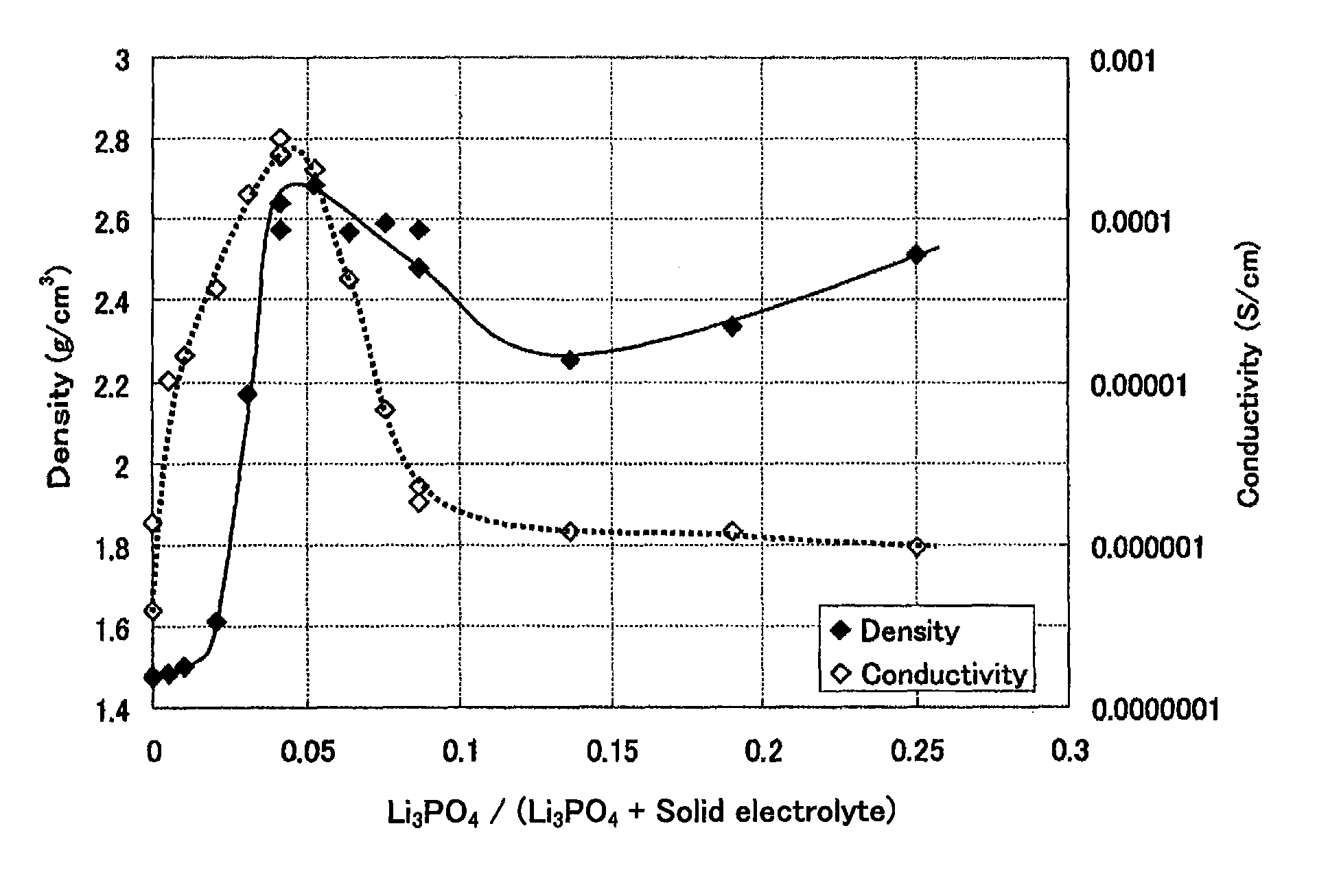

All solid state battery with densification additive

ActiveUS9266780B2Stable and high ionic conductivityDeteriorating battery propertyFinal product manufactureElectrode carriers/collectorsAll solid stateIon

An all solid state battery having high output performance and a manufacturing method thereof are provided. The all solid state battery of the present invention comprises a negative electrode layer, a positive electrode layer, and a solid electrolyte layer having a lithium ion conductivity. At least one layer of the solid electrolyte, the positive electrode layer, and the negative electrode layer includes a lithium ion conductive crystal and AxByOz (A is one or more selected from the group consisting of Al, Ti, Li, Ge, and Si. B is one or more selected from the group consisting of P, N, and C, wherein 1≦X≦4, 1≦Y≦5, and 1≦Z≦7). The solid electrolyte material to which a preferable sintering additive is added in a predetermined ratio is densified by firing at relatively low temperature in the manufacturing process. The ion conductivity thereof is also high.

Owner:OHARA

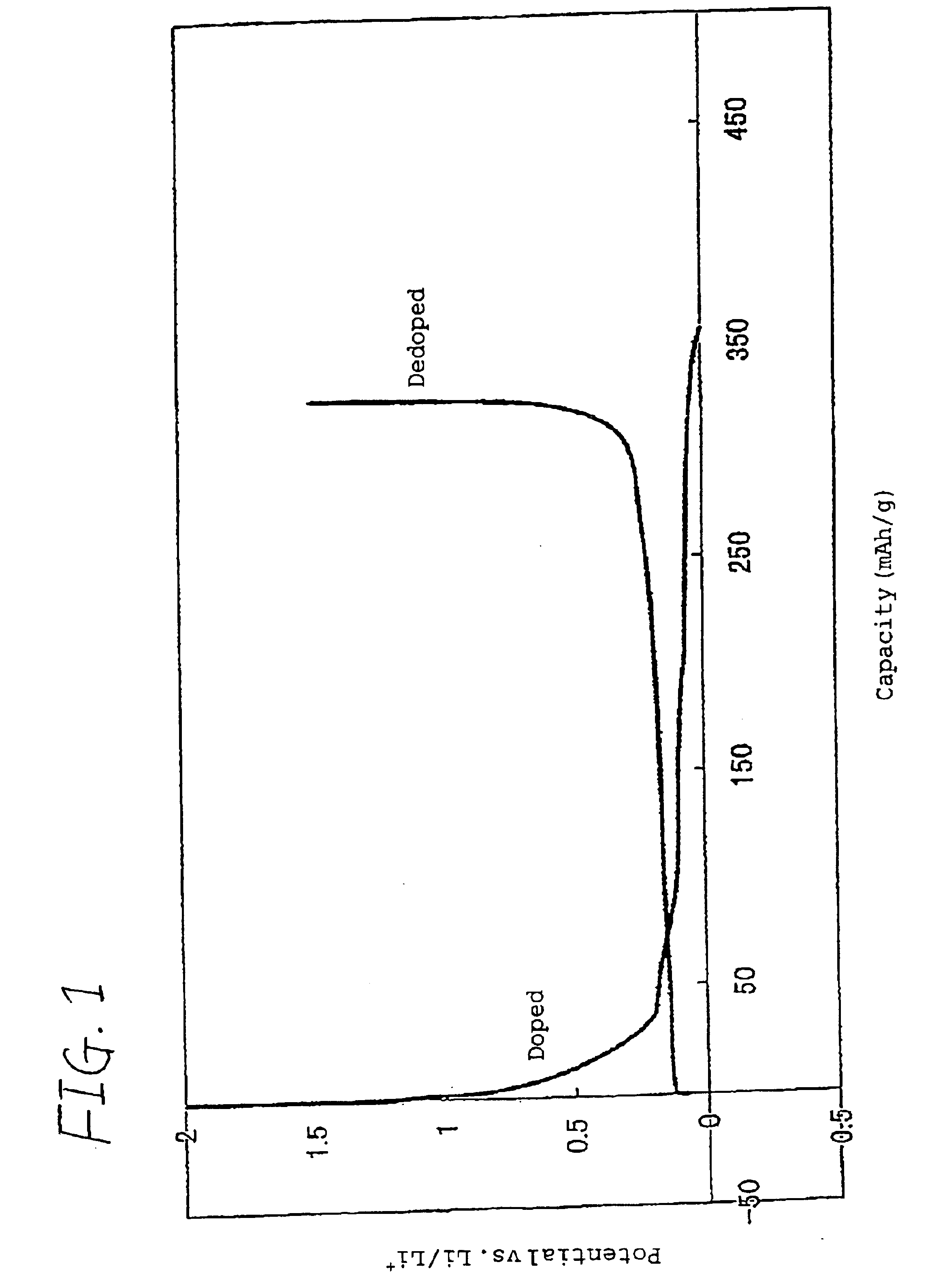

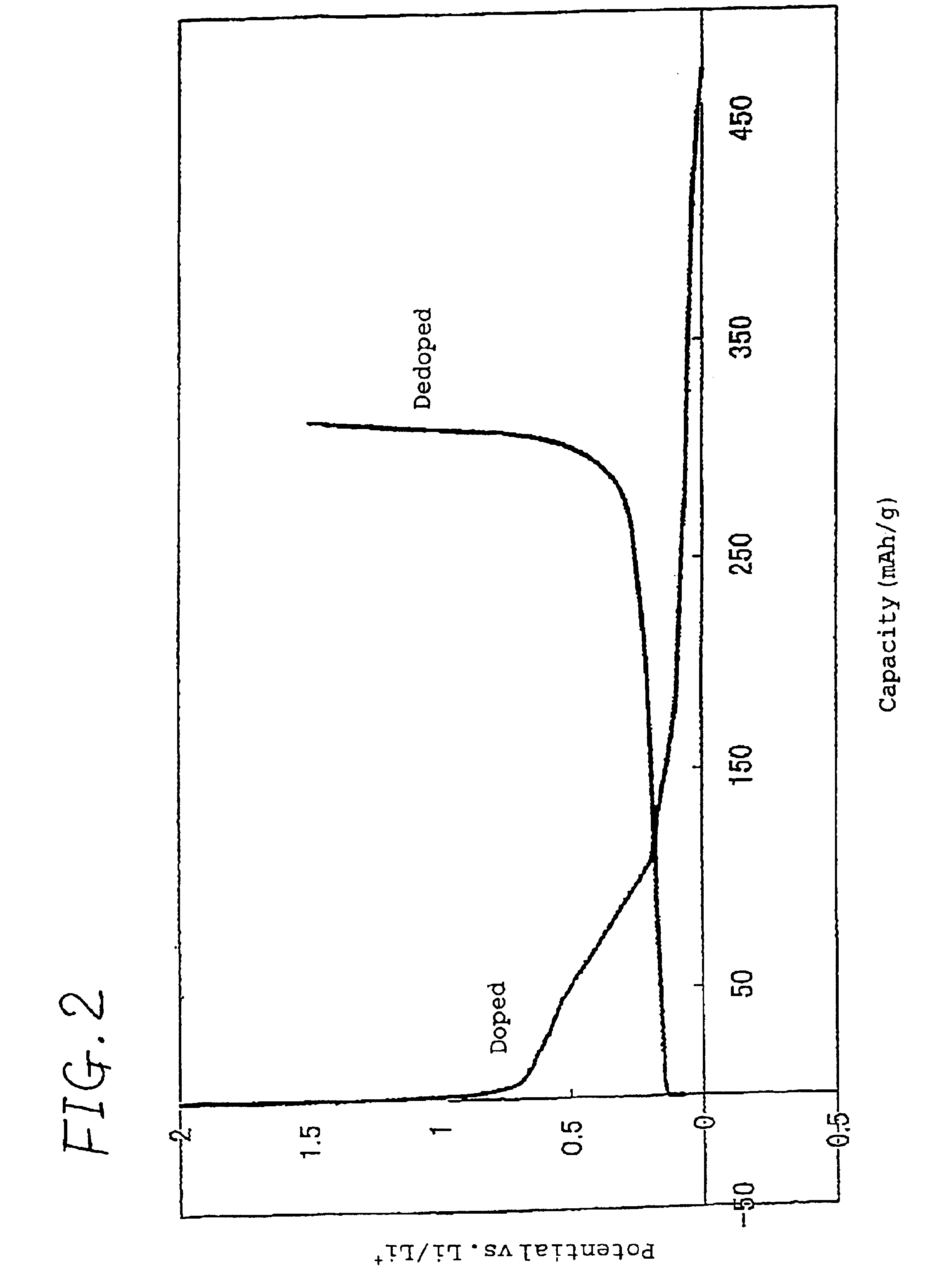

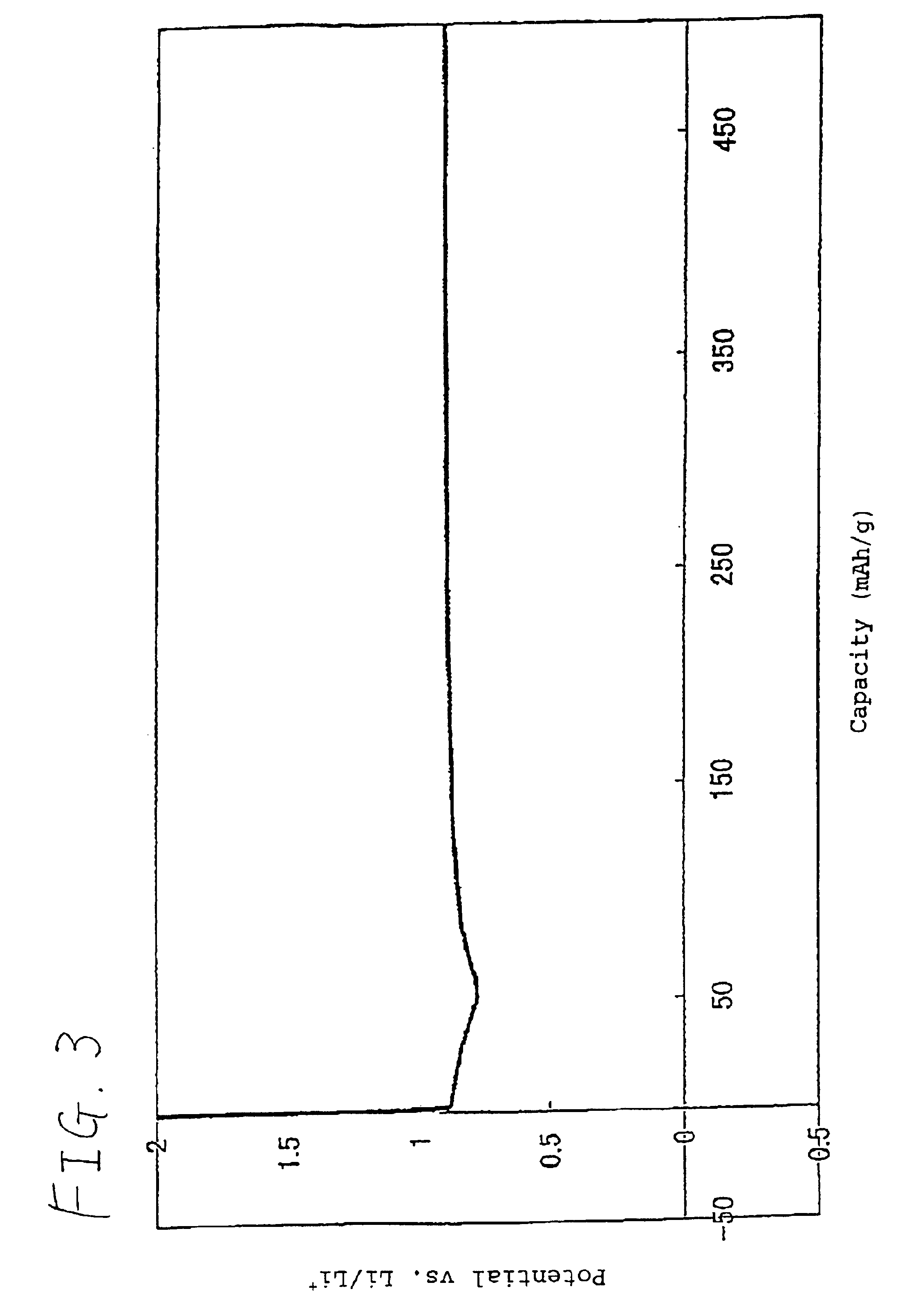

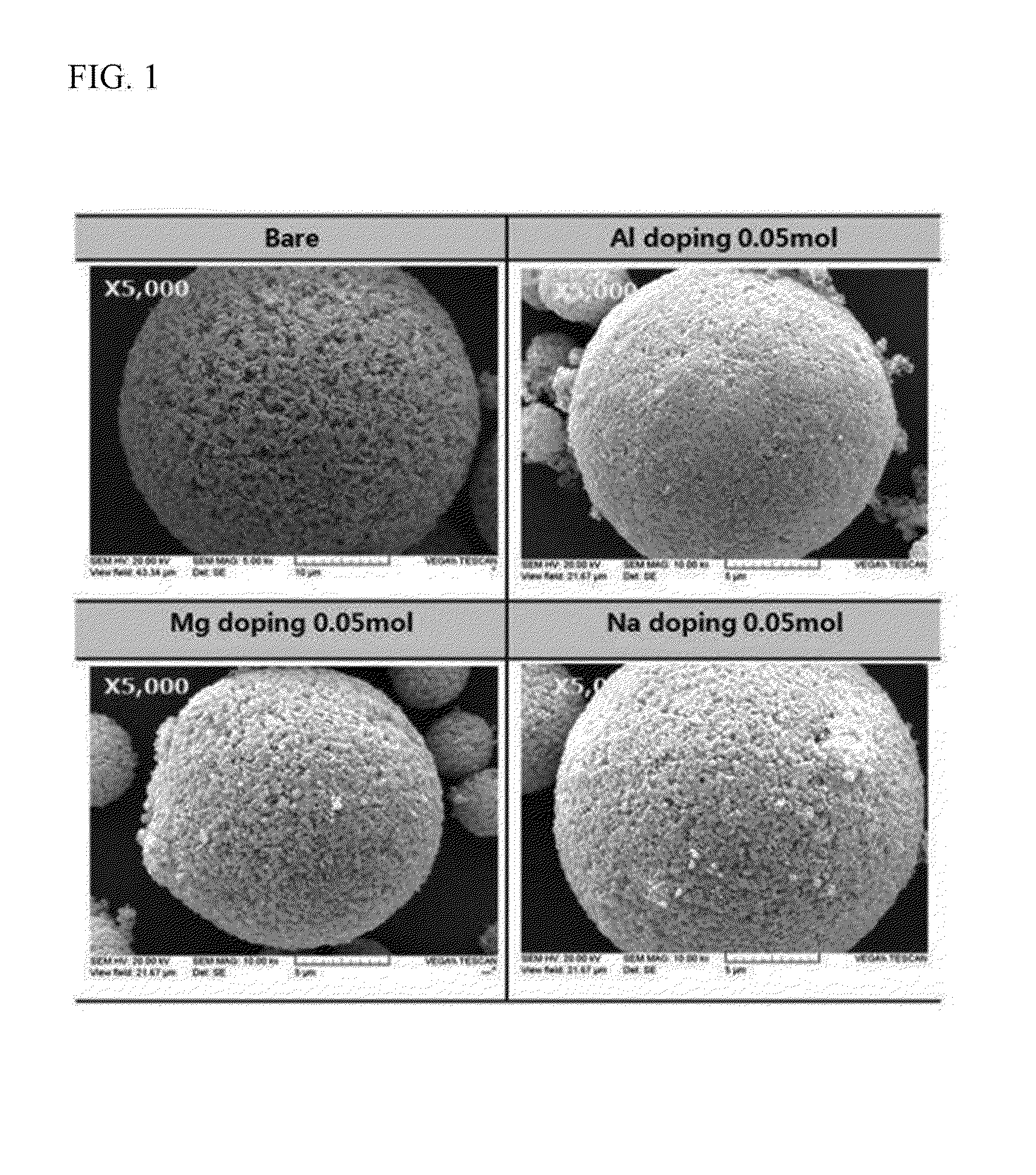

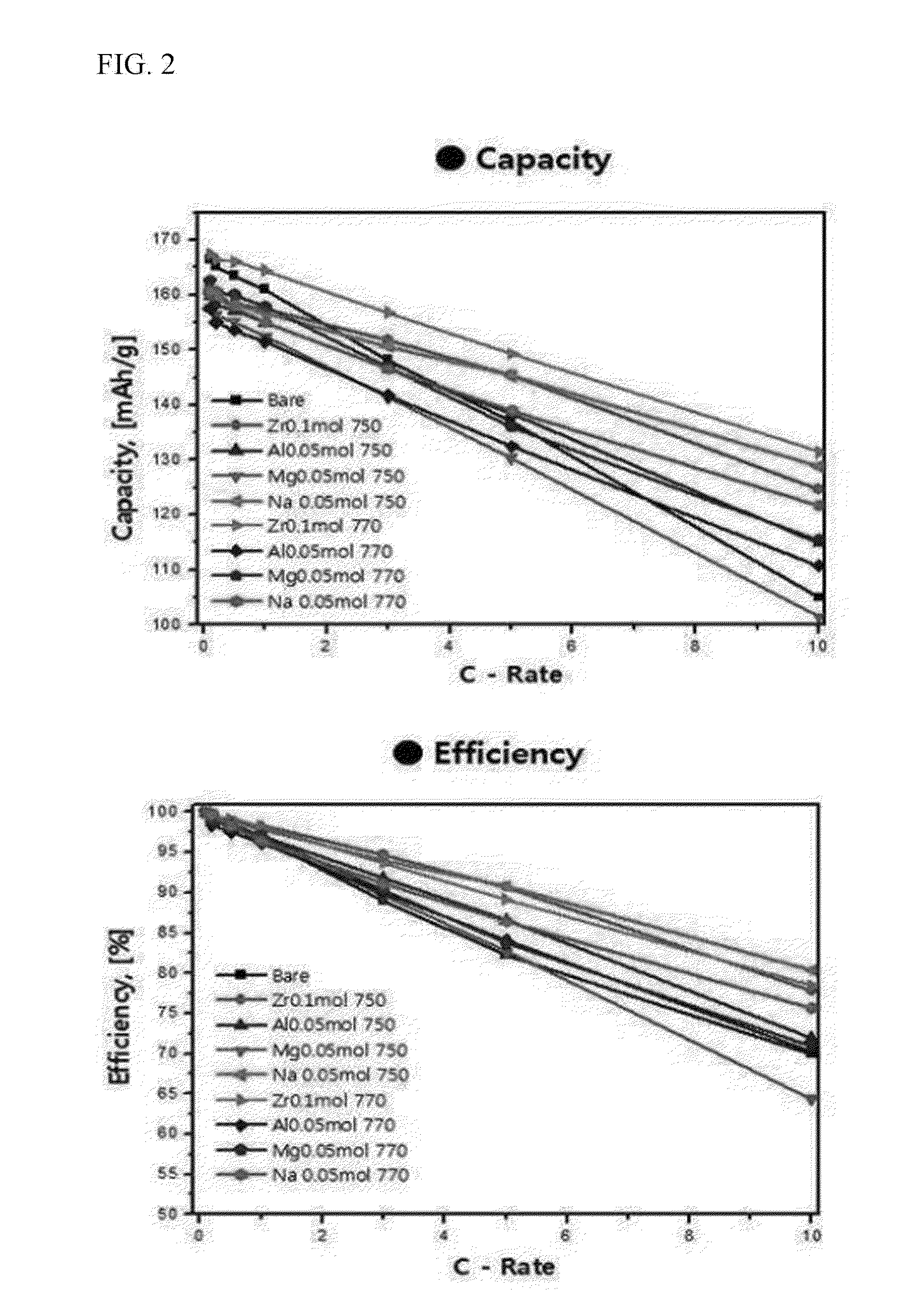

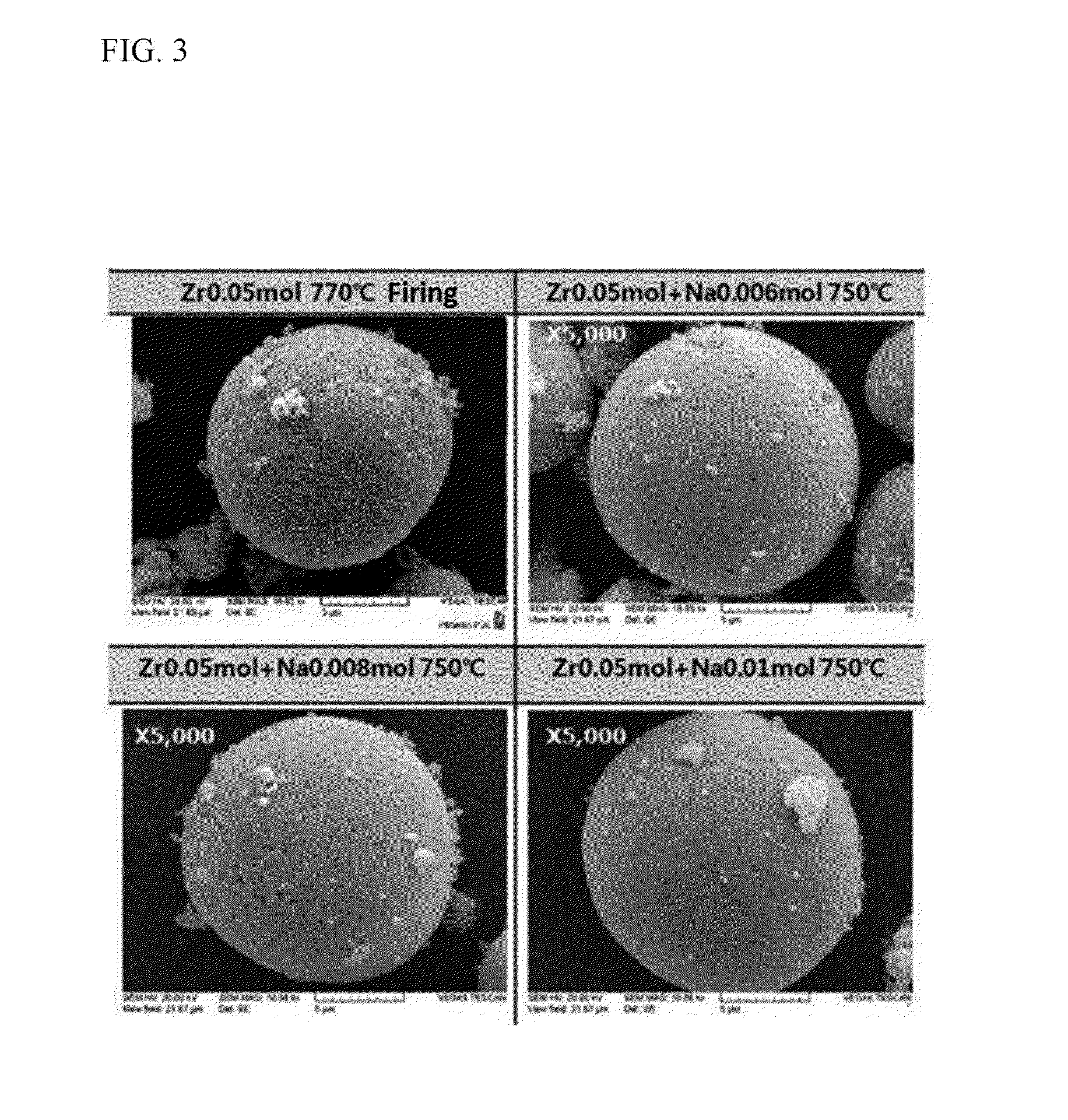

Manufacturing method of lithium-titanium composite oxide in which different metals are doped, and lithium-titanium composite oxide manufactured thereby in which different metals are doped

InactiveUS20160079594A1Increase battery capacity and crystallinityExcellent characteristicHeat treatmentsAlkali titanatesSolid phasesComposite oxide

Provided is a manufacturing method of a lithium-titanium composite oxide doped with different metals, solid-phase mixing after adjusting a mixing ratio of two kinds of different metals and pulverizing the same, and spray drying the same to adjust contents of impurities, and a lithium-titanium composite oxide doped with different metals manufactured therefrom. By doping two kinds of different metals on the surface of the lithium-titanium composite oxide after adjusting the ratio of the two different metals to be a desirable ratio, the contents of rutile-type titanium dioxide, anatase-type titanium dioxide and Li2TiO3 which have been included as impurities are reduced, thereby manufacturing titanium dioxide having excellent capacity characteristics and structural characteristics, and a battery including the titanium dioxide having excellent battery characteristics of high initial charge and discharge efficiency and rate capability.

Owner:POSCO CHEM +1

Method for producing battery electrode

ActiveUS8900747B2Improve adhesionDeterioration of battery performanceNon-aqueous electrolyte accumulatorsFinal product manufactureFiberEngineering

A main object of the present invention is to provide a method for producing a battery electrode that has excellent adhesion between a collector and an active material layer by suppressing a migration phenomenon. The method for producing a battery electrode of the present invention is a method for producing a battery electrode 30 that has a structure in which an active material layer 20 that includes an active material 22 is held on a collector 10. The method includes a step of applying, onto the collector 10, an active material layer forming paste that contains the active material 22 and polymer materials 24, 26 in a solvent; and a step of drying the applied paste coat material, to form thereby the active material layer 20 on the collector 10. Fibrillated polymer fibers 26 are used as at least one of the polymer materials 24, 26.

Owner:TOYOTA JIDOSHA KK

Electrolyte solution for non-aqueous electrolyte battery, and non-aqueous electrolyte battery using the same

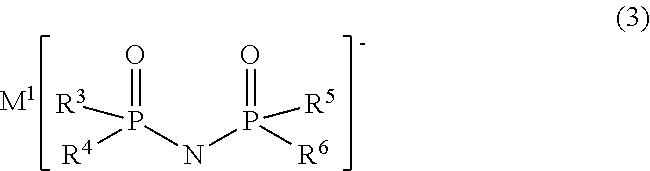

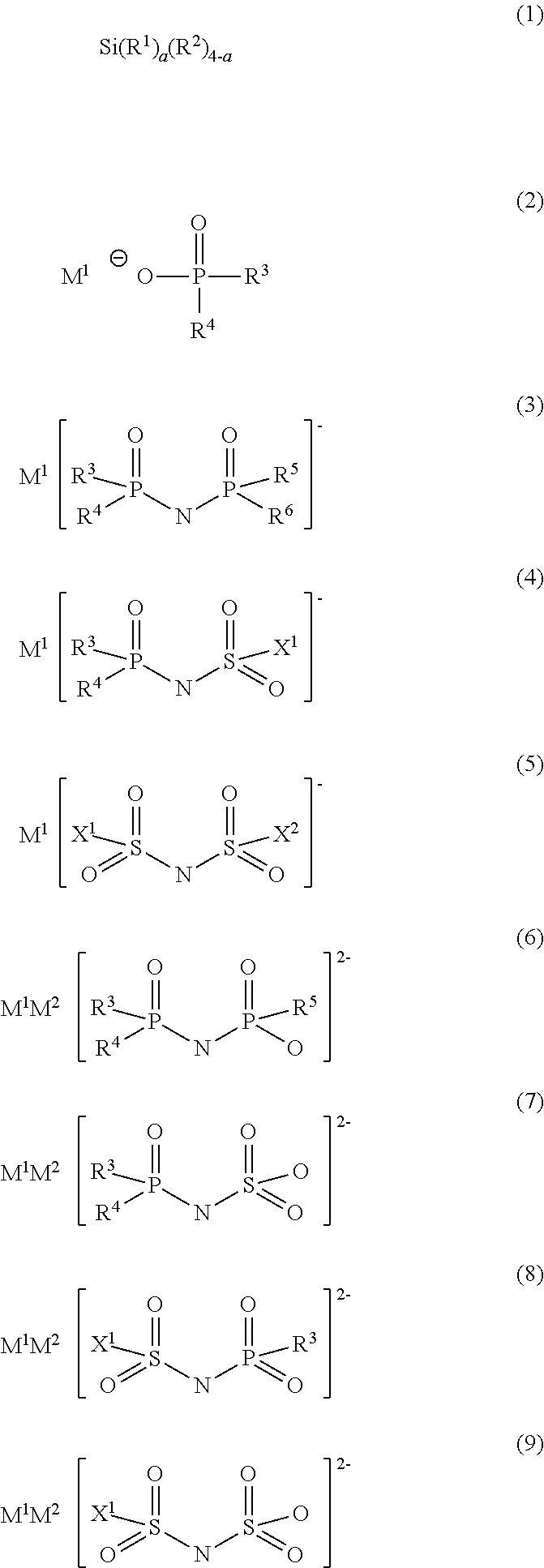

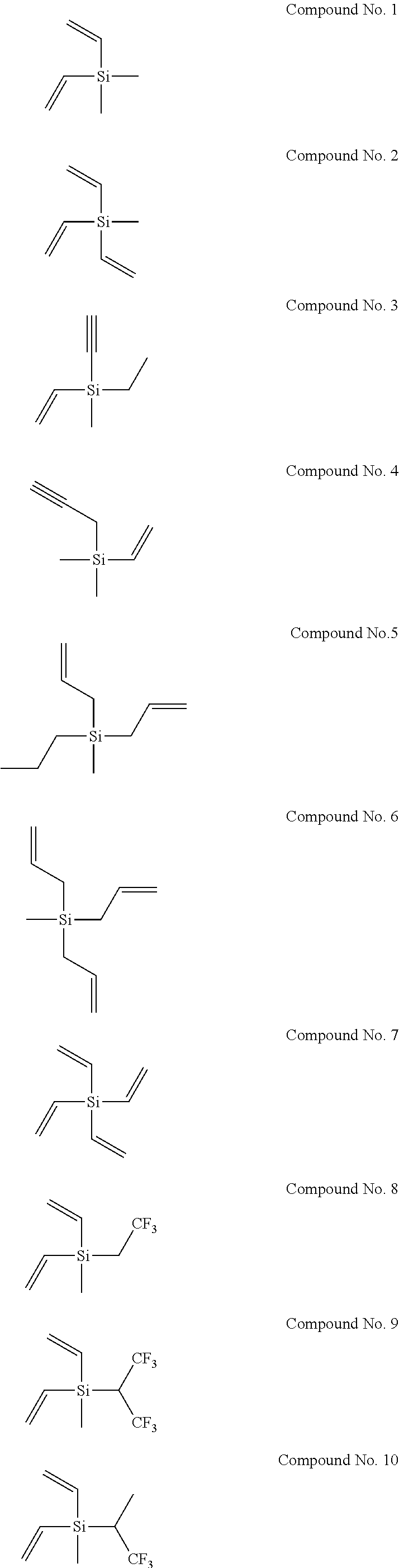

ActiveUS20180034103A1Increase discharge voltageExcellent low temperature output characteristicsGroup 4/14 element organic compoundsLi-accumulatorsSilane compoundsPhysical chemistry

The present invention provides an electrolyte solution for a non-aqueous electrolyte battery capable of an exerting high average discharge voltage and an excellent low-temperature output characteristic at −30° C. or lower and an excellent cycle characteristic and an excellent storage characteristic at high temperatures of 50° C. or higher, as well as a non-aqueous electrolyte battery containing the same. The present electrolyte solution comprises a non-aqueous solvent, a solute, at least one silane compound represented by the following general formula (1) as a first compound, and a fluorine-containing compound represented by the following general formula (3), for example, as a second compound.Si(R1)a(R2)4-a (1)

Owner:CENT GLASS CO LTD

Packaging for cable-type secondary battery and cable-type secondary battery comprising the same

ActiveUS9324978B2Avoid pollutionImprove life characteristicsFinal product manufactureSmall-sized cells cases/jacketsSealantMoisture

Owner:LG ENERGY SOLUTION LTD

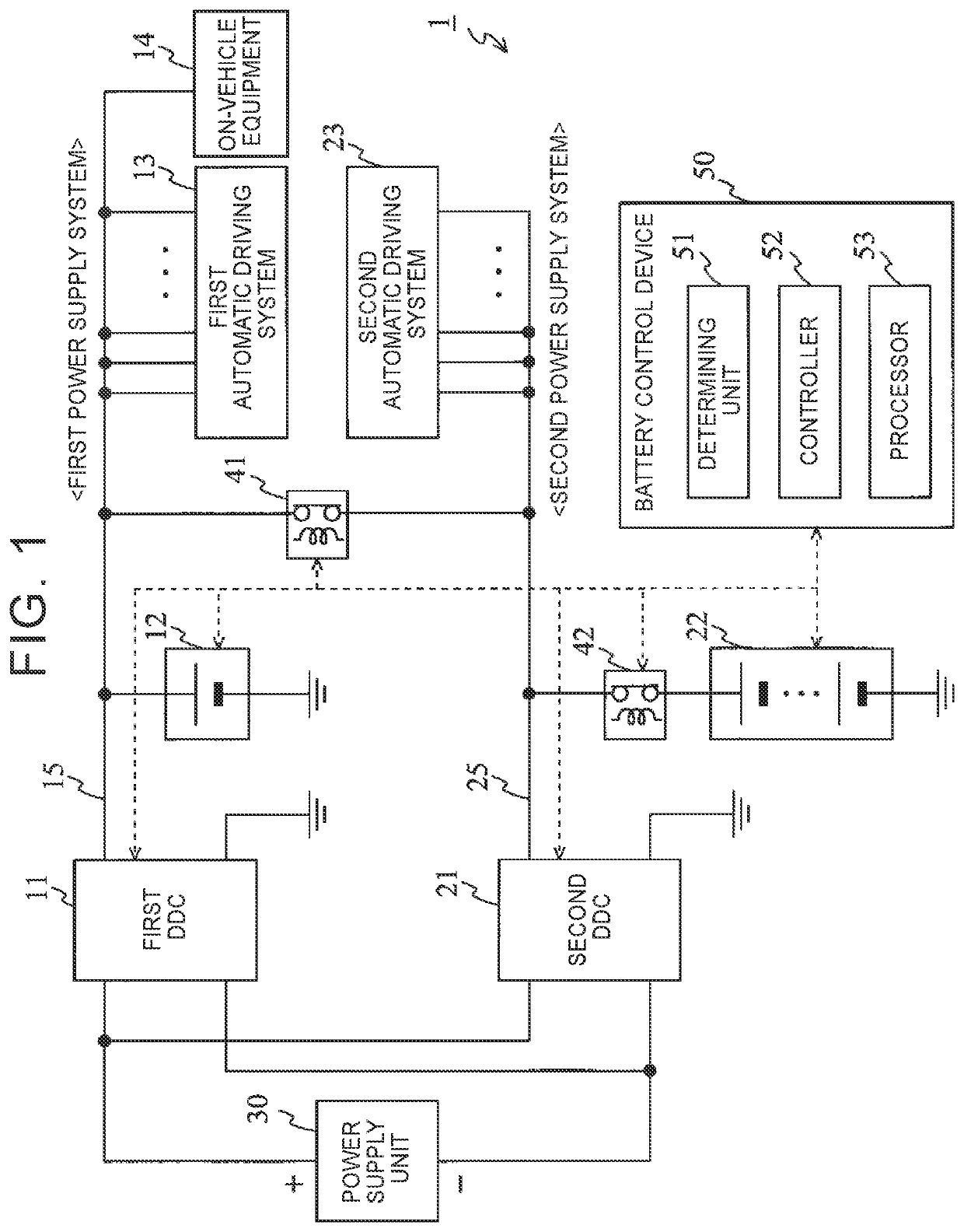

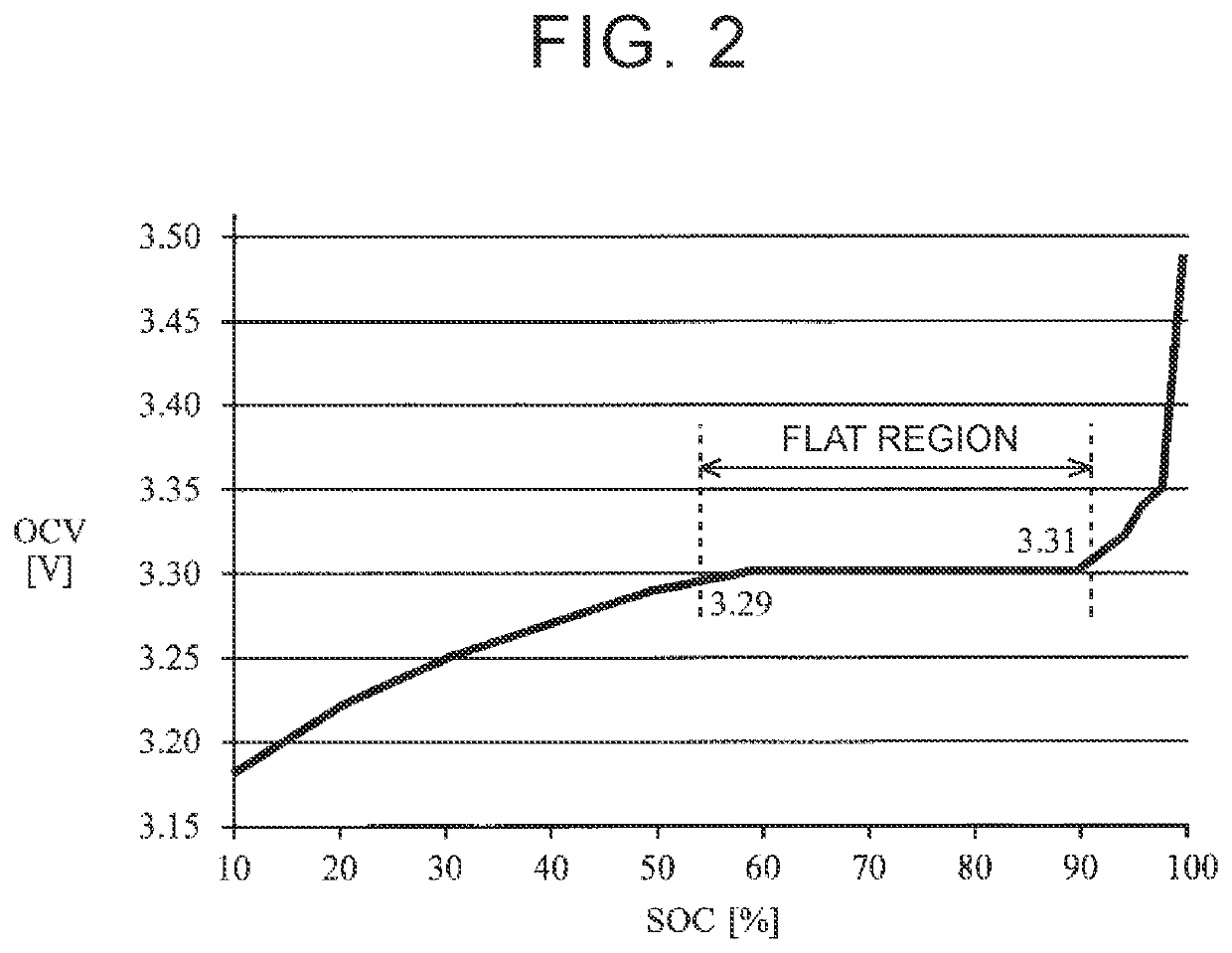

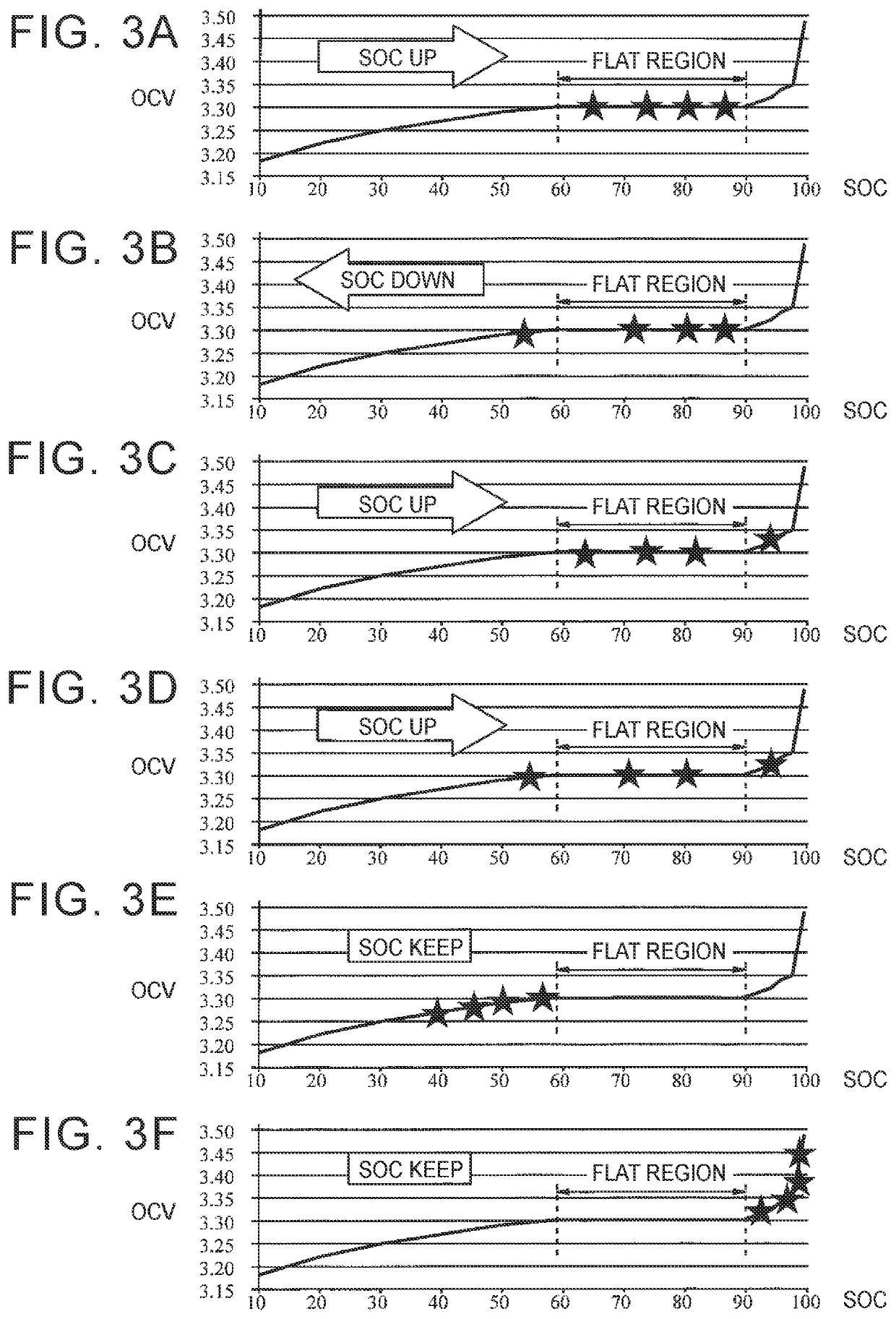

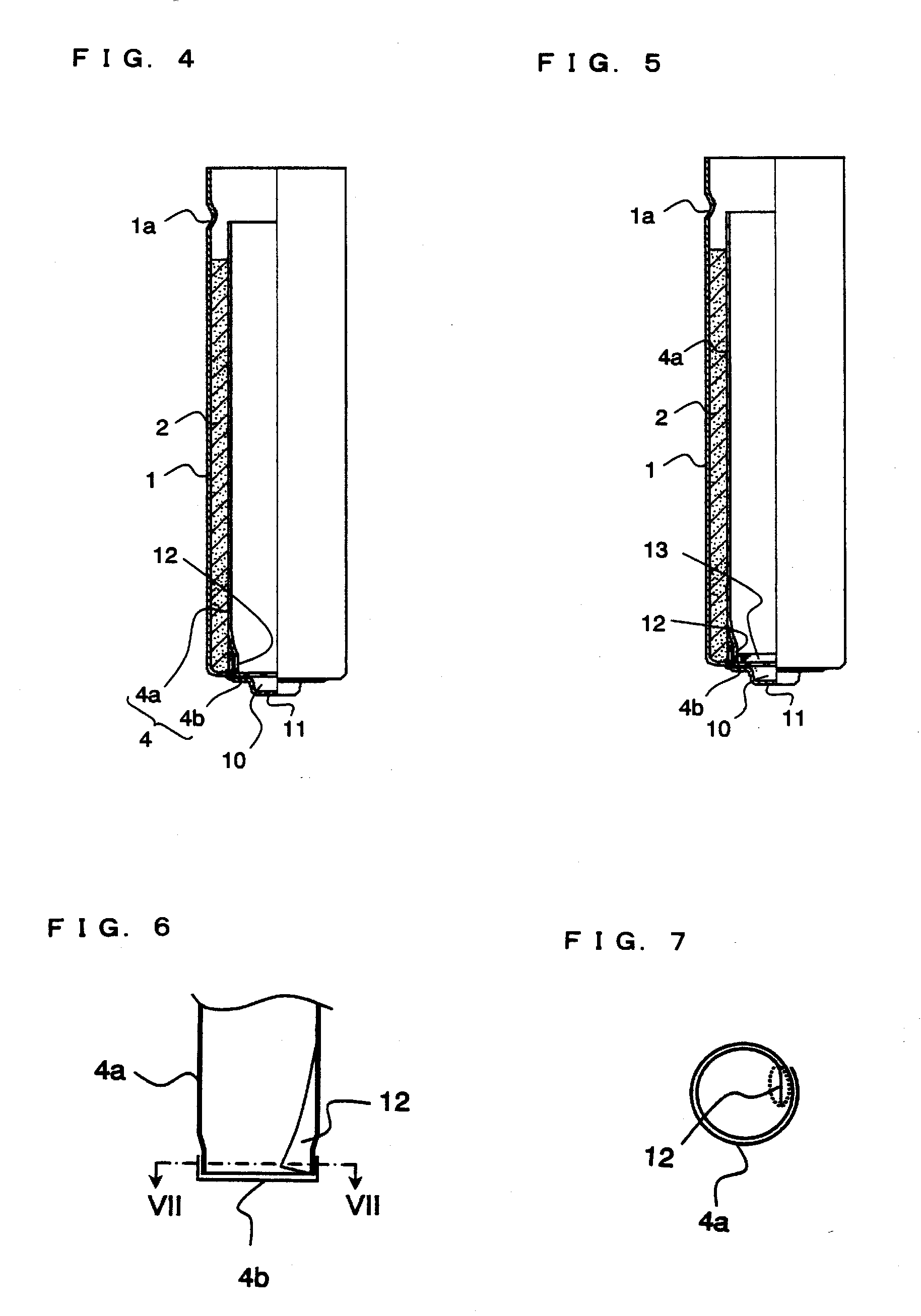

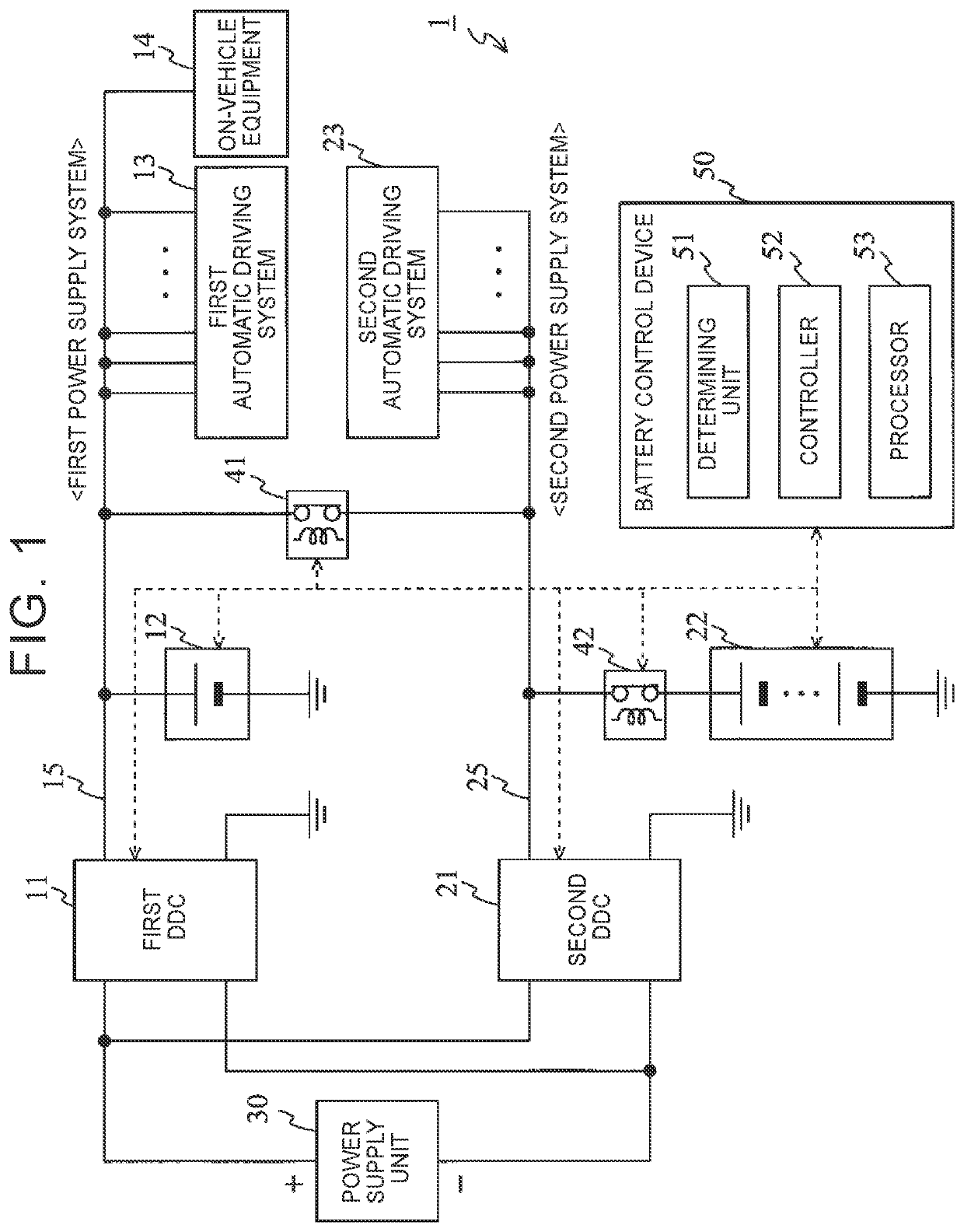

Battery control device

ActiveUS20200136399A1Increase opportunitiesAvoid performance degradationCharge equalisation circuitIndicating/monitoring circuitsControl engineeringControl theory

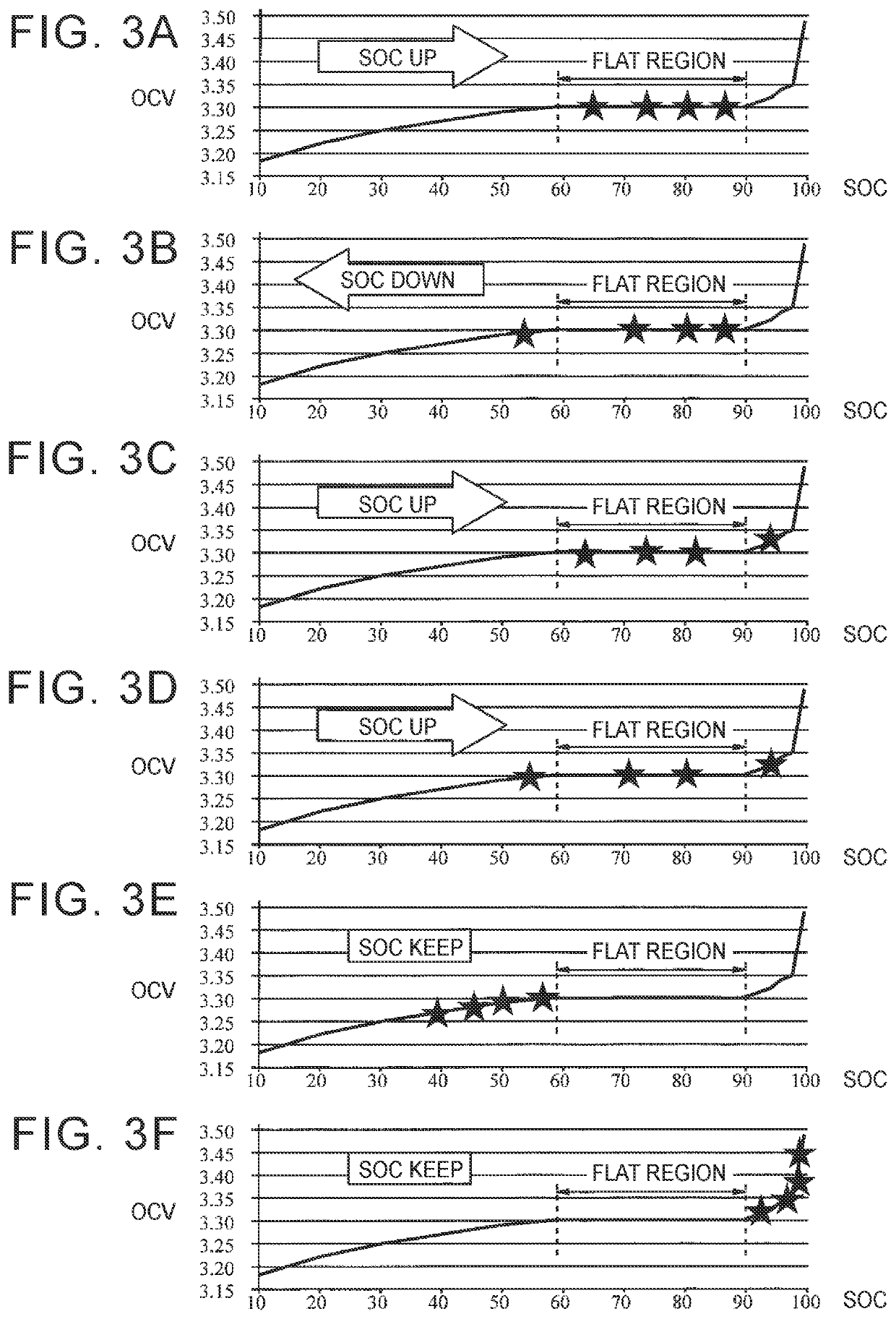

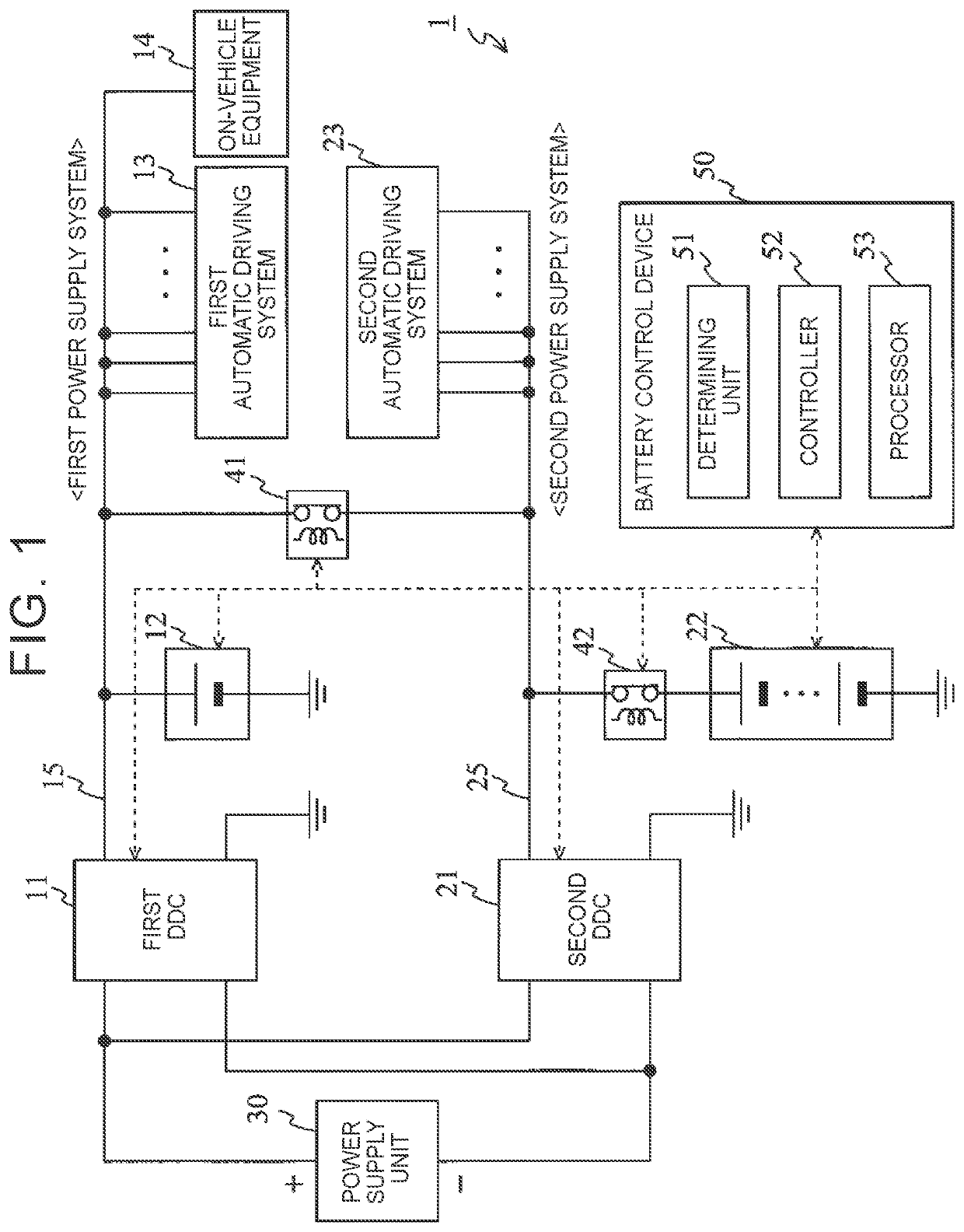

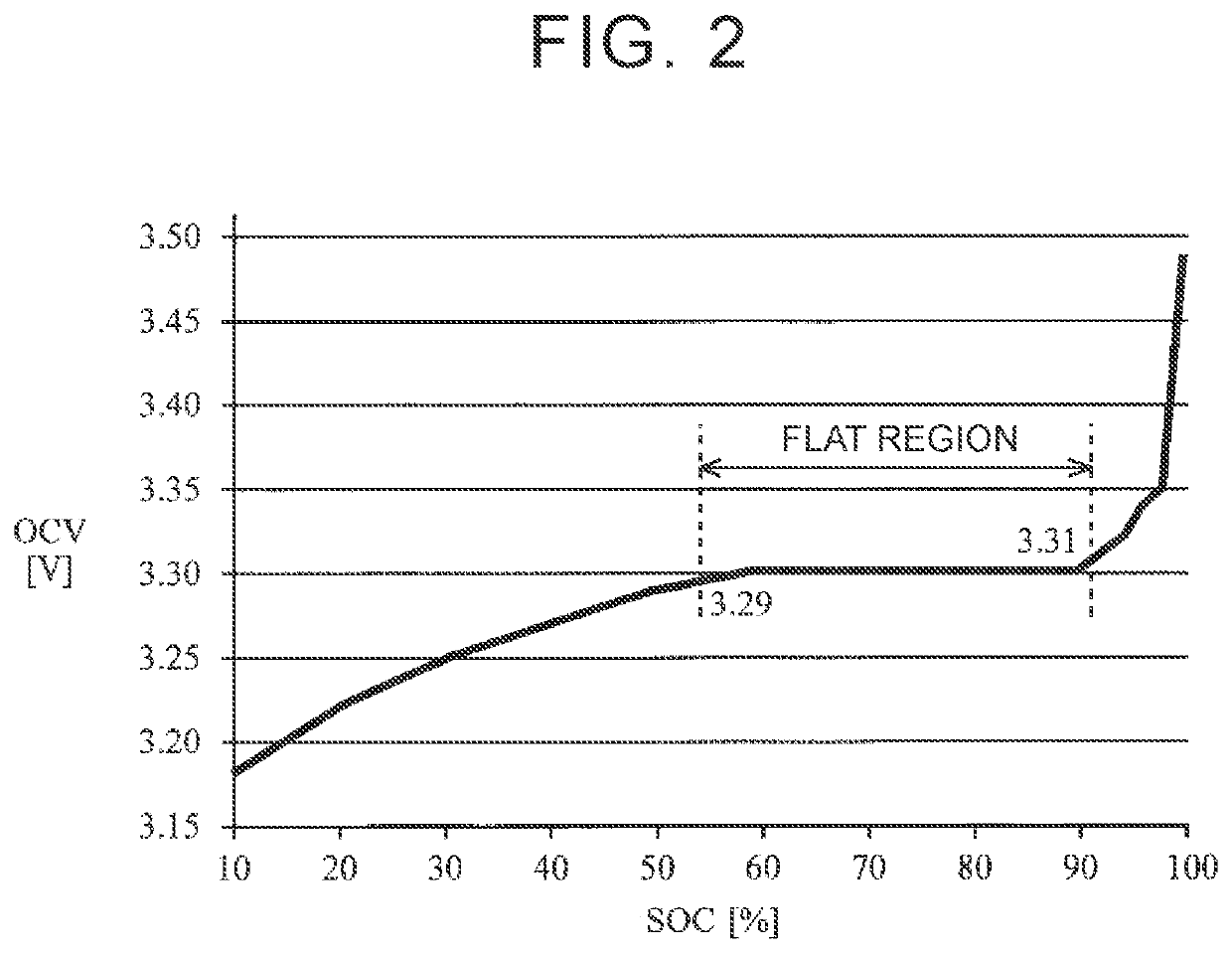

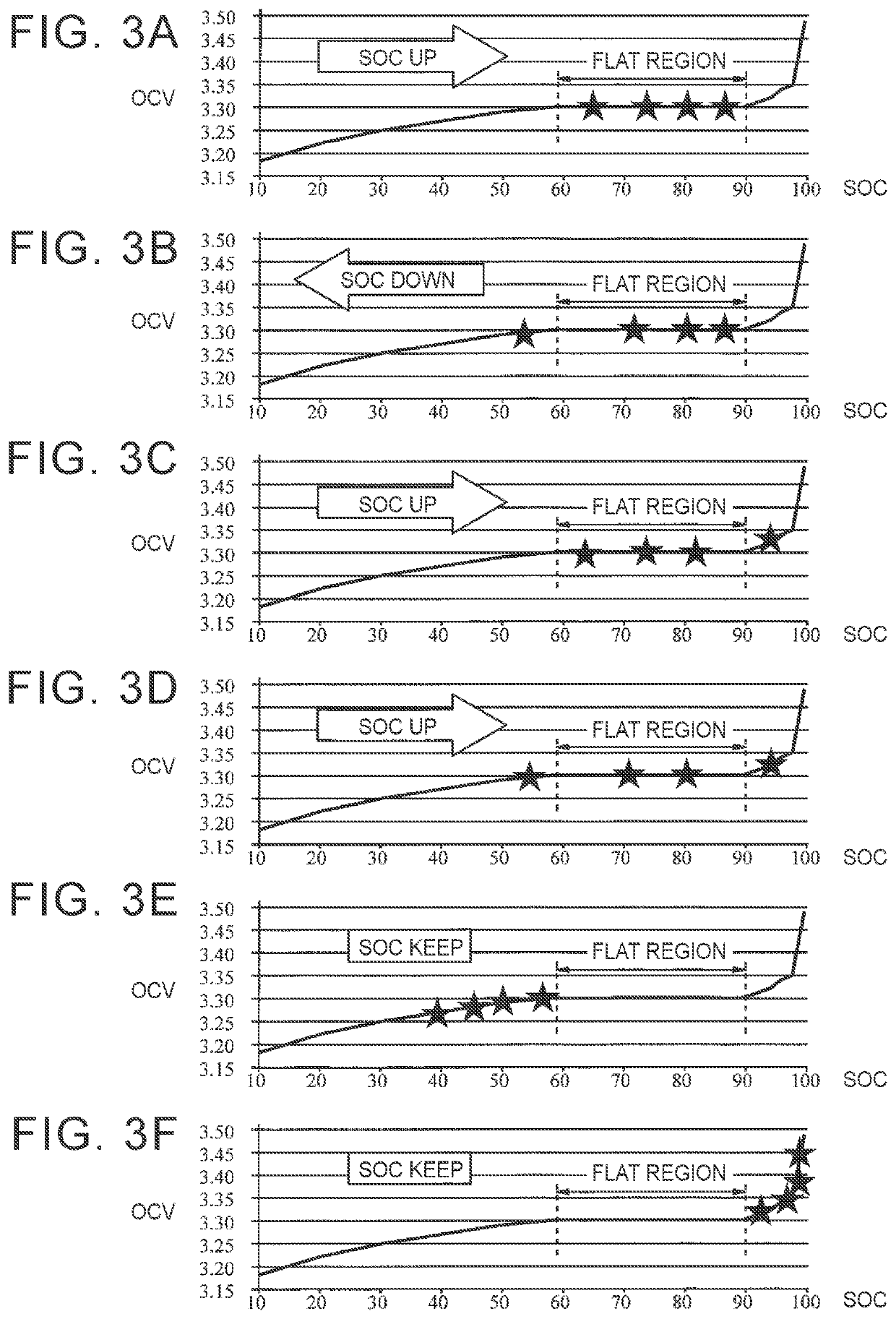

A battery control device that controls a battery assembly includes a first determining unit that determines whether a voltage difference between minimum and maximum values of OCVs of battery cells constituting the battery assembly and having an SOC-OCV characteristic curve including a flat region is equal to or larger than a predetermined voltage value, a second determining unit that determines whether the OCV of each battery cell is lower than a lower-limit voltage of the flat region, or is equal to or higher than the lower-limit voltage and lower than an upper-limit voltage, or is higher than the upper-limit voltage, a controller that executes control selected from SOC raising control, SOC lowering control, and SOC keeping control of the battery cells, based on determination results of the first and second determining units, and a processor that homogenizes the SOCs of the battery cells controlled by the controller.

Owner:TOYOTA JIDOSHA KK

Secondary battery of differential lead structure

InactiveUS20130130099A1Deterioration of battery performanceImprove degradation rateSmall-sized cells cases/jacketsElectrical batteryEngineering

Disclosed is a secondary battery of a differential lead structure including an electrode assembly including a cathode plate having a cathode tab, an anode plate having an anode tab, and a separator interposed between the cathode plate and the anode plate, a battery casing to receive the electrode assembly, a cathode lead electrically connected to the cathode tab, and an anode lead electrically connected to the anode tab and made of a different material from the cathode lead, wherein the cathode lead and the anode lead have a differential cross sectional area such that the lead having lower electrical conductivity has a larger cross sectional area than the other lead having higher electrical conductivity.

Owner:LG CHEM LTD

Method for producing alkaline primary battery

ActiveUS20120186074A1Sufficient amountResistance of battery does not increaseSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringElectrolytic agent

A method for producing an alkaline primary battery includes: (1) forming a cylindrical positive electrode having a hollow; (2) inserting a cylindrical separator with a bottom into the hollow of the positive electrode, the separator including: a wound cylindrical portion; and a bottom portion that is substantially U-shaped in cross-section, the bottom portion covering an opening of the cylindrical portion at a lower end thereof and having an upstanding portion that extends along a lower outer face of the cylindrical portion; and (3) injecting an electrolyte into the separator. The amount of the electrolyte injected into the separator in the step (3) is sufficient to impregnate the positive electrode and the separator and immerse a lower end of the cylindrical portion of the separator in the electrolyte remaining in the separator, thereby bringing the lower end of the cylindrical portion into contact with the upstanding portion.

Owner:PANASONIC CORP

Battery control device for homogenizing battery cells

ActiveUS11223212B2Reduce chanceVariations in the states of chargeCharge equalisation circuitIndicating/monitoring circuitsControl engineeringControl theory

A battery control device that controls a battery assembly includes a first determining unit that determines whether a voltage difference between minimum and maximum values of OCVs of battery cells constituting the battery assembly and having an SOC-OCV characteristic curve including a flat region is equal to or larger than a predetermined voltage value, a second determining unit that determines whether the OCV of each battery cell is lower than a lower-limit voltage of the flat region, or is equal to or higher than the lower-limit voltage and lower than an upper-limit voltage, or is higher than the upper-limit voltage, a controller that executes control selected from SOC raising control, SOC lowering control, and SOC keeping control of the battery cells, based on determination results of the first and second determining units, and a processor that homogenizes the SOCs of the battery cells controlled by the controller.

Owner:TOYOTA JIDOSHA KK

Battery control device for homogenizing battery cells

ActiveUS20220085621A1Reduce chanceVariations in the states of chargeCharge equalisation circuitElectric powerControl engineeringControl theory

A battery control device that controls a battery assembly includes a first determining unit that determines whether a voltage difference between minimum and maximum values of OCVs of battery cells constituting the battery assembly and having an SOC-OCV characteristic curve including a flat region is equal to or larger than a predetermined voltage value, a second determining unit that determines whether the OCV of each battery cell is lower than a lower-limit voltage of the flat region, or is equal to or higher than the lower-limit voltage and lower than an upper-limit voltage, or is higher than the upper-limit voltage, a controller that executes control selected from SOC raising control, SOC lowering control, and SOC keeping control of the battery cells, based on determination results of the first and second determining units, and a processor that homogenizes the SOCs of the battery cells controlled by the controller.

Owner:TOYOTA JIDOSHA KK

Slurry composition for coating secondary battery separator and secondary battery separator prepared using same

ActiveUS20200358064A1Good dispersionImprove adhesionSolid electrolytesCell seperators/membranes/diaphragms/spacersElectrical batteryPhysical chemistry

A slurry composition for coating a secondary battery separator, a separator prepared using the same, and a secondary battery including the separator, wherein the slurry composition includes a phenolic compound including two or more aromatic rings, inorganic particles, a binder, and a solvent.

Owner:LG ENERGY SOLUTION LTD

Lithium secondary battery

InactiveUS20120177980A1Reduce impactReduce conductivityCation exchanger materialsIon-exchanger regenerationLithiumHigh temperature storage

The gas generation and the decrease in battery capacity during high temperature storage of a lithium secondary battery are suppressed. The electrolyte contains a polymerizable compound or a polymer, the polymerizable compound contains a compound having an aromatic functional group and a polymerizable functional group and a compound having a complex-forming functional group forming a complex with a metal ion and a polymerizable functional group, and the polymer has the complex-forming functional group, the aromatic functional group and a residue of the polymerizable functional group.

Owner:HITACHI MAXELL ENERGY LTD

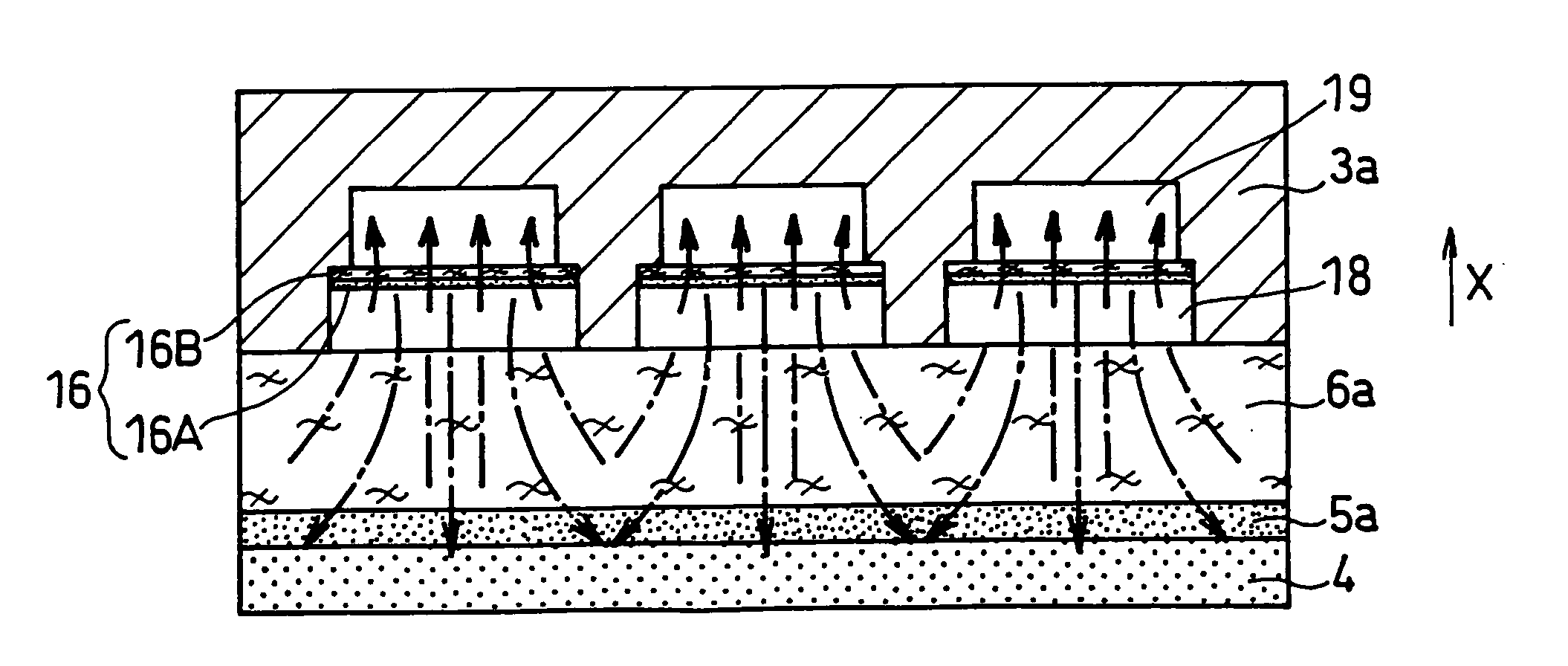

Direct methanol fuel cell

InactiveUS20060210863A1Smooth supplyMinimizing deteriorationSolid electrolytesFuel cell auxillariesFuel cellsEngineering

For give a direct methanol fuel cell which secures the fuel supply to the catalyst layer, reliably discharge generated carbon dioxide gas, and has excellent electricity generation ability, at least a portion of the anode side flow path is divided by a film having water-repellency and gas permeability to a first flow path portion positioned at the membrane electrode assembly side and a second flow path portion positioned at the bottom side of the anode side flow path where a fuel mainly flows in the first flow path portion and carbon dioxide mainly flows in the second flow path portion.

Owner:PANASONIC CORP

Glass comprising solid electrolyte particles and lithium battery

ActiveUS9051201B2Improve battery performanceImprove homogeneitySolid electrolytesFinal product manufactureElectrolyteMaterials science

Owner:IDEMITSU KOSAN CO LTD

Cylindrical alkaline storage battery

ActiveUS9627657B2Increase battery capacityDeterioration of battery performanceFinal product manufactureSmall-sized cells cases/jacketsRelative displacementEngineering

An alkaline storage battery includes: a cylindrical case having a side wall including an opening end portion and a bottom; a sealing plate; a gasket interposed between the sealing plate and the opening end portion; and a sealant between the gasket and the opening end portion. The side wall has an annular groove opened at an outer surface thereof, and an inwardly curl portion at the opening end portion. In at least part of the groove, the minimum width L1 is within 0.2 mm. The sealant includes a polyamide resin formed such that when two test-plate materials are bonded together at bonding faces facing each other via a bonding portion of the sealant, and moved in parallel with the bonding faces and in opposite directions to have a relative displacement within 0.5 to 5 mm, a stress at least 0.02 N / mm2 is applied to the bonding portion.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com