Patents

Literature

3803results about "Large-sized cells cases/jackets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

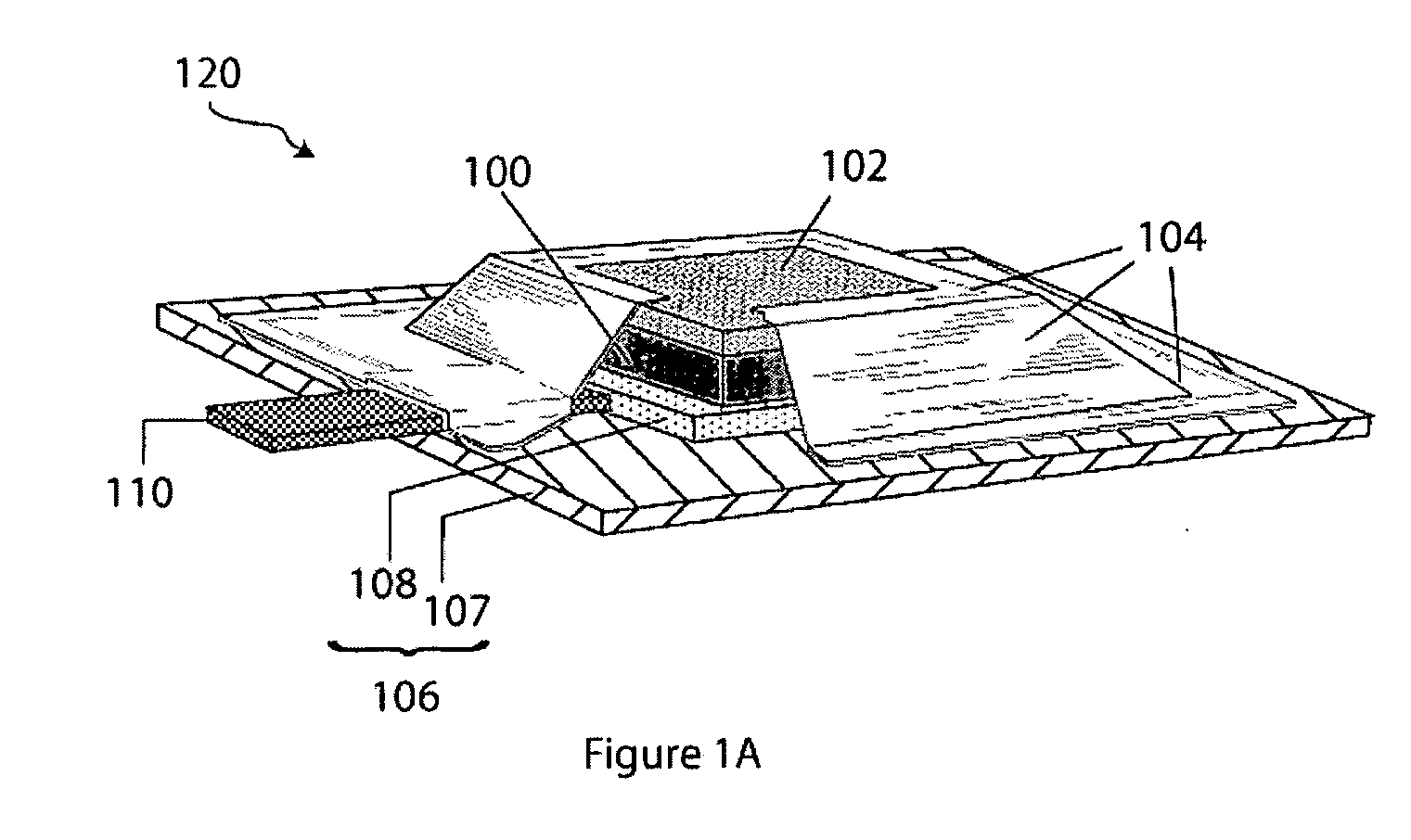

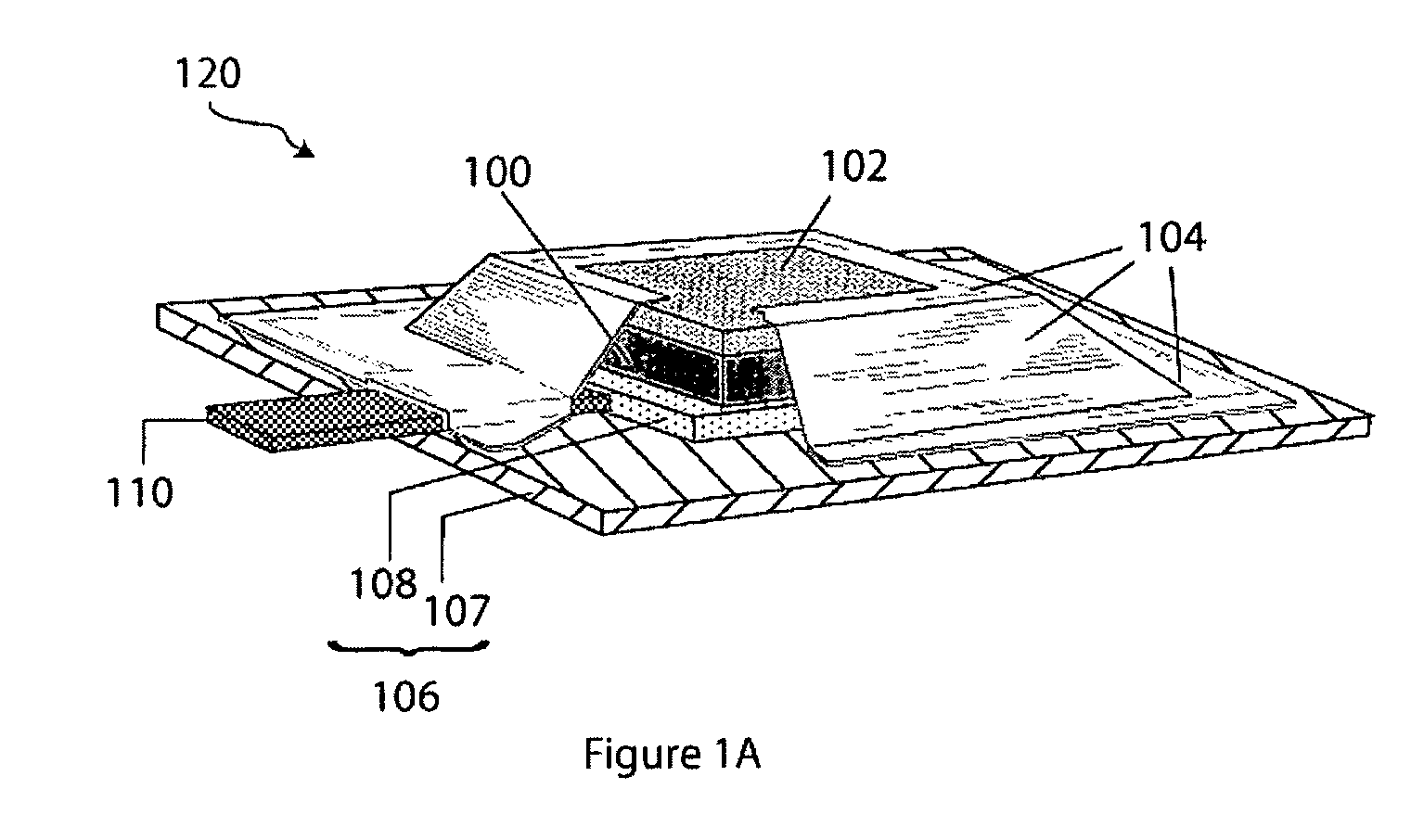

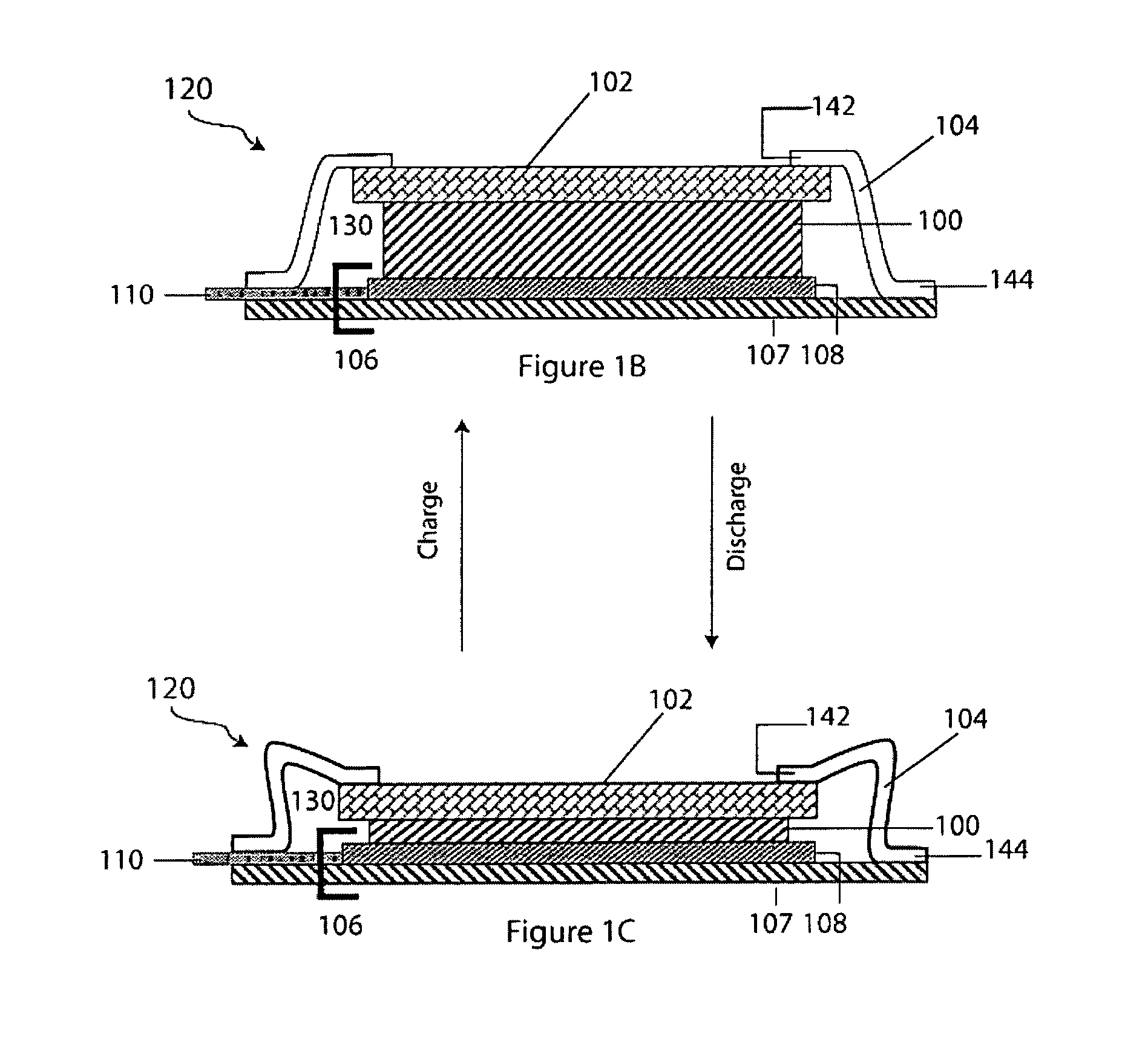

Design and construction of non-rectangular batteries

ActiveUS20120015236A1Facilitate efficient use of spaceEasy to carry and useFinal product manufactureSmall-sized cells cases/jacketsEngineeringBattery cell

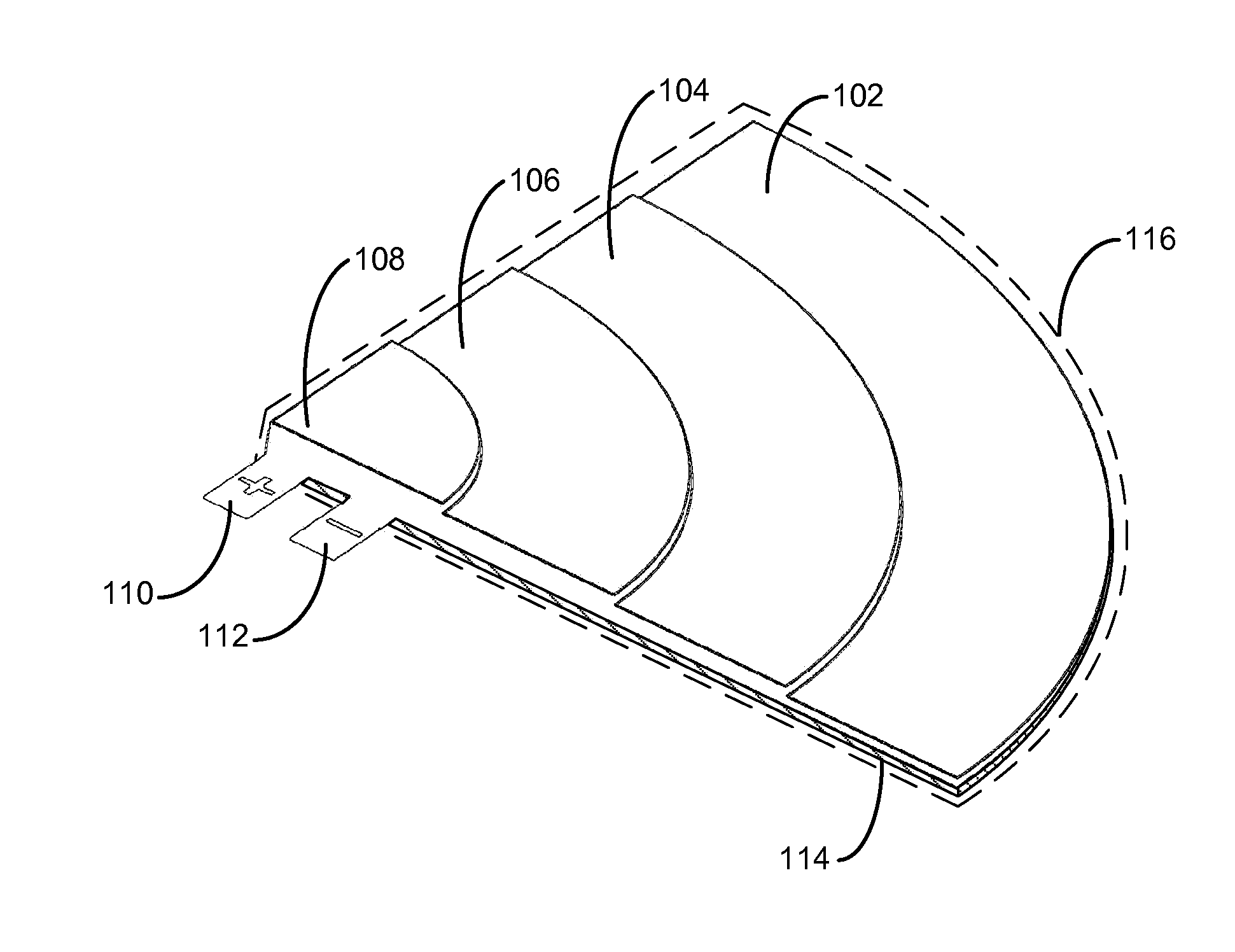

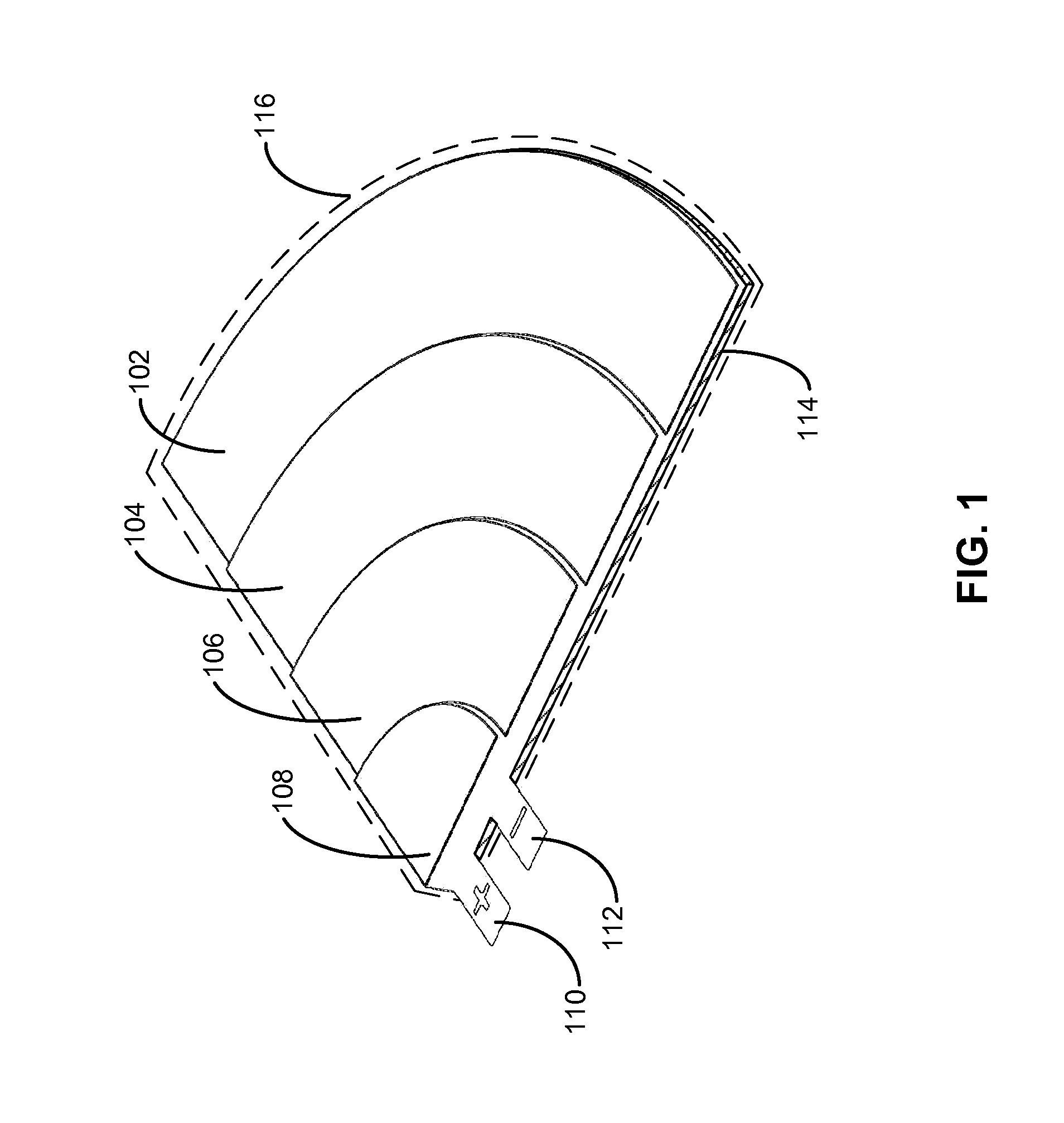

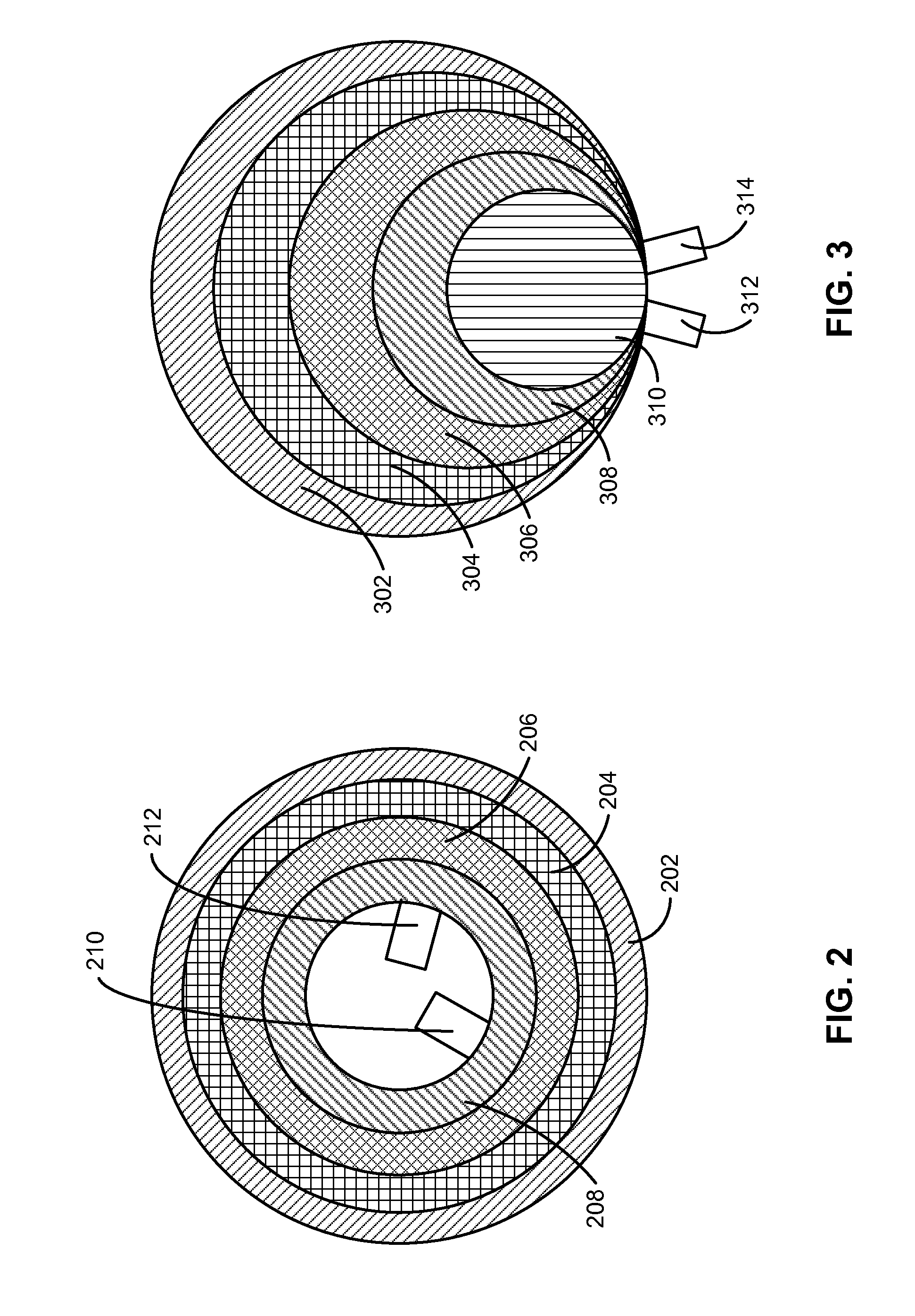

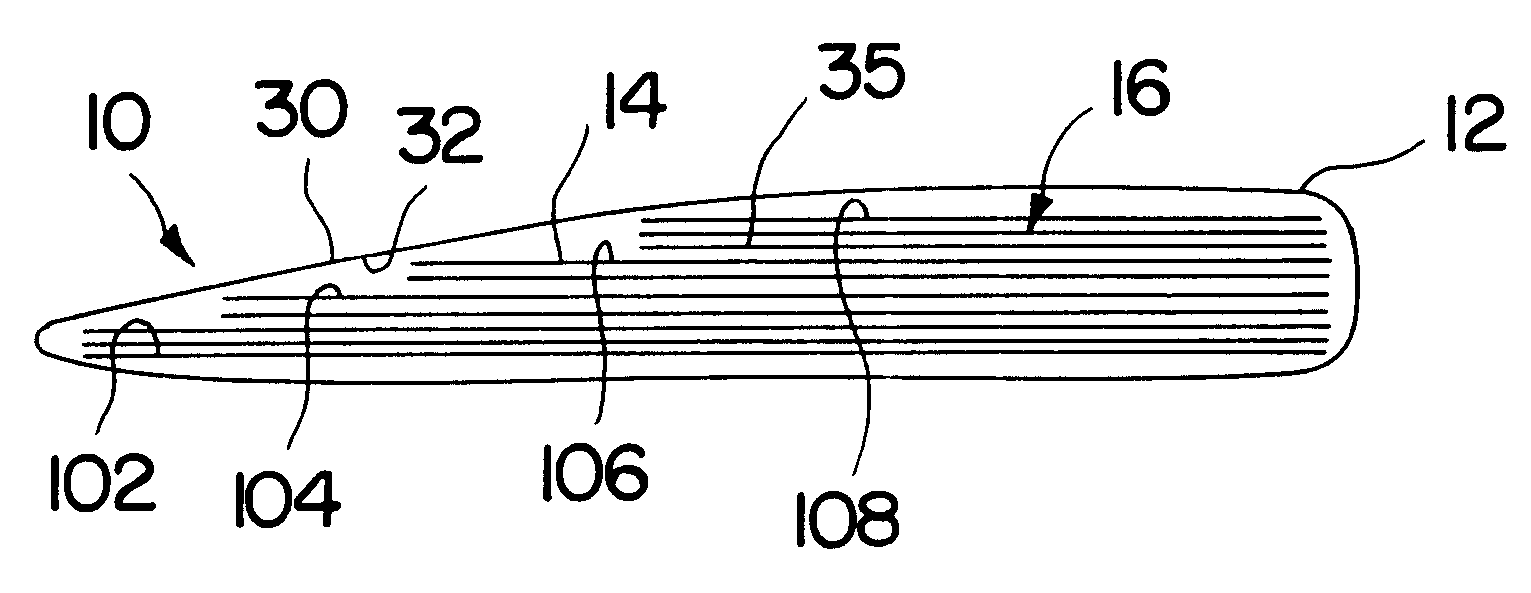

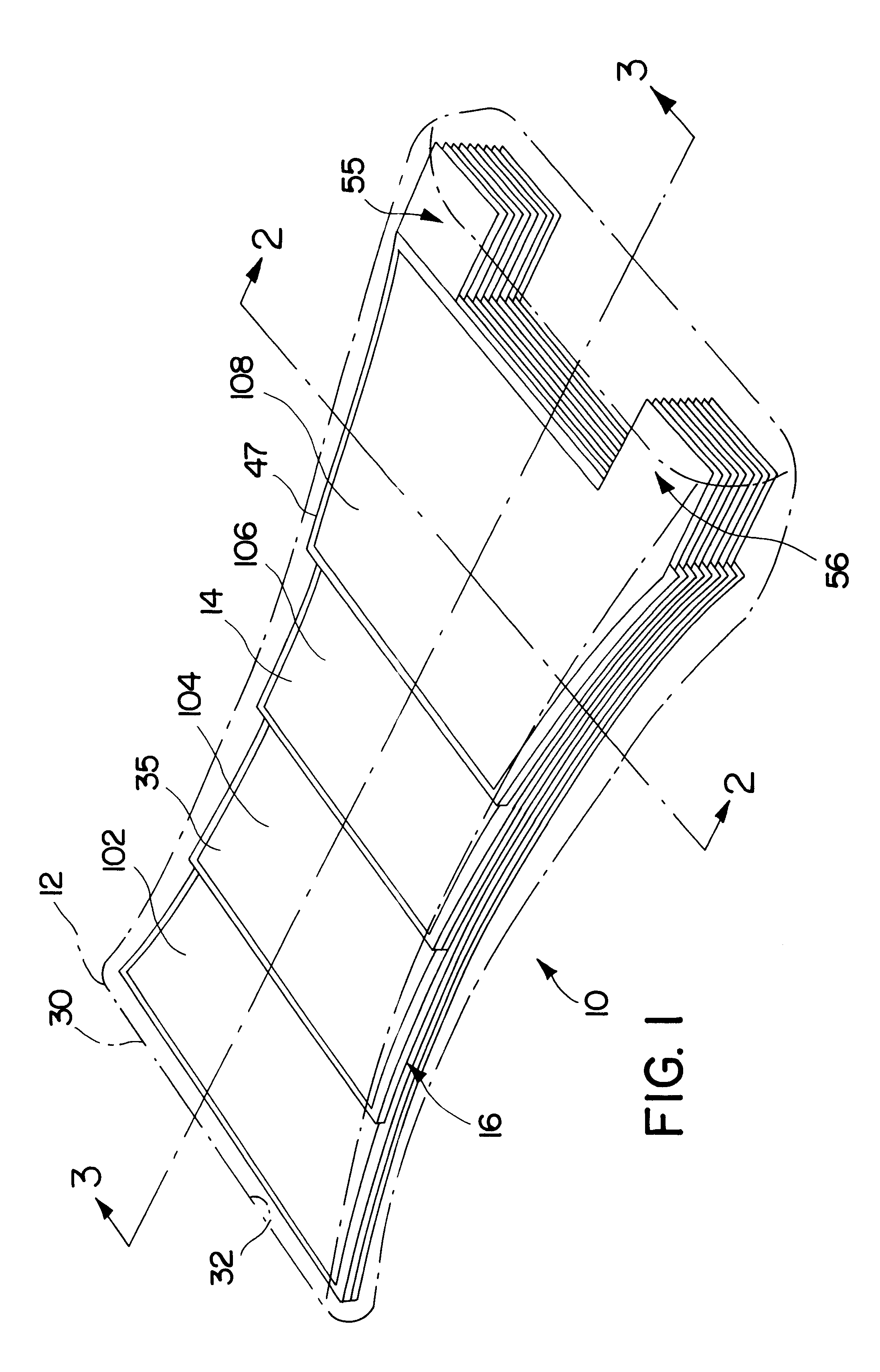

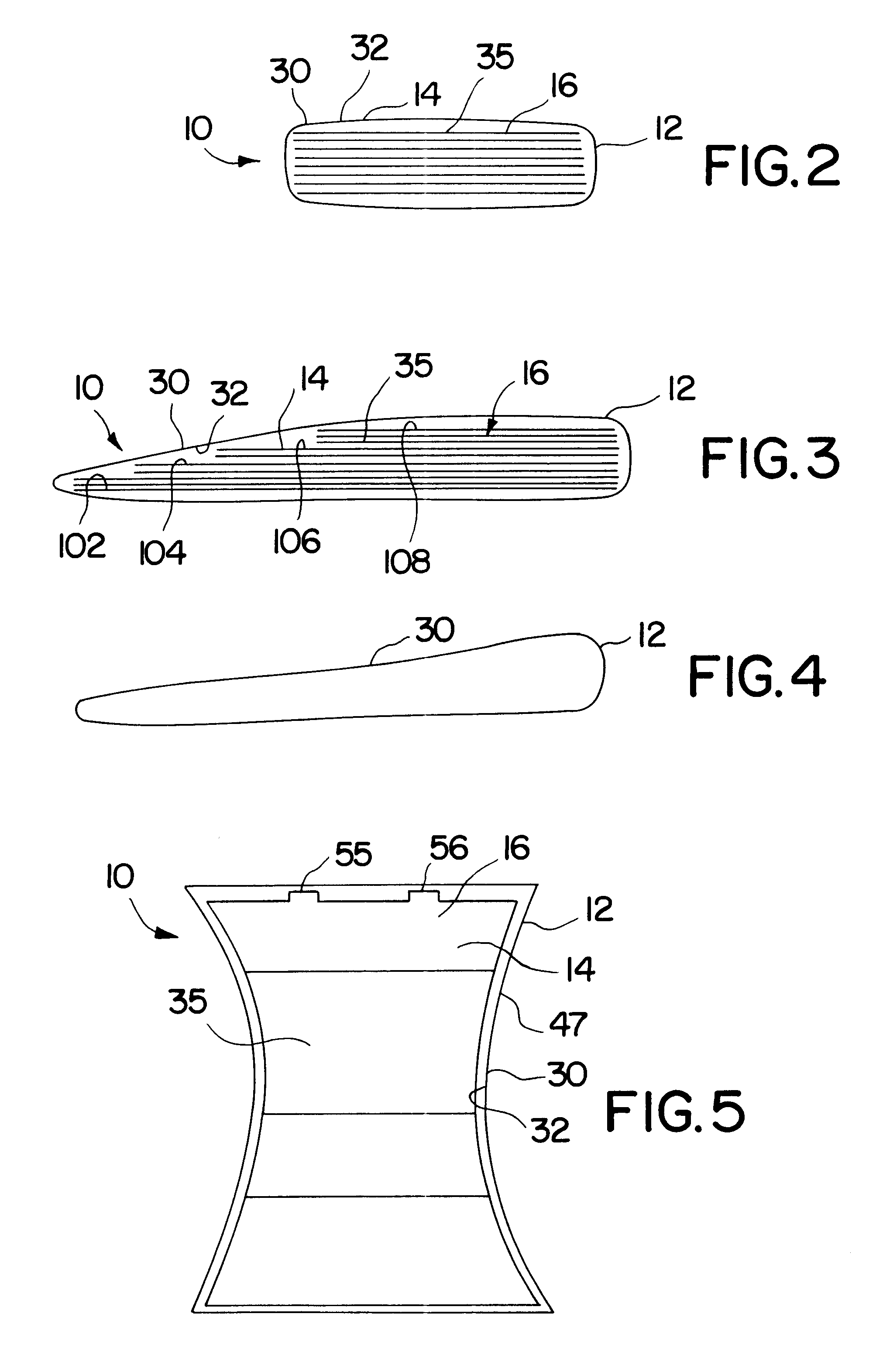

The disclosed embodiments relate to a battery cell which includes a set of electrode sheets of different dimensions arranged in a stacked configuration to facilitate efficient use of space inside a portable electronic device. For example, the electrode sheets may be arranged in the stacked configuration to accommodate a shape of the portable electronic device. The stacked configuration may be based on a non-rectangular battery design such as a toroidal design, an L-shaped design, a triangular design, a pie-shaped design, a cone-shaped design, and / or a pyramidal design.

Owner:APPLE INC

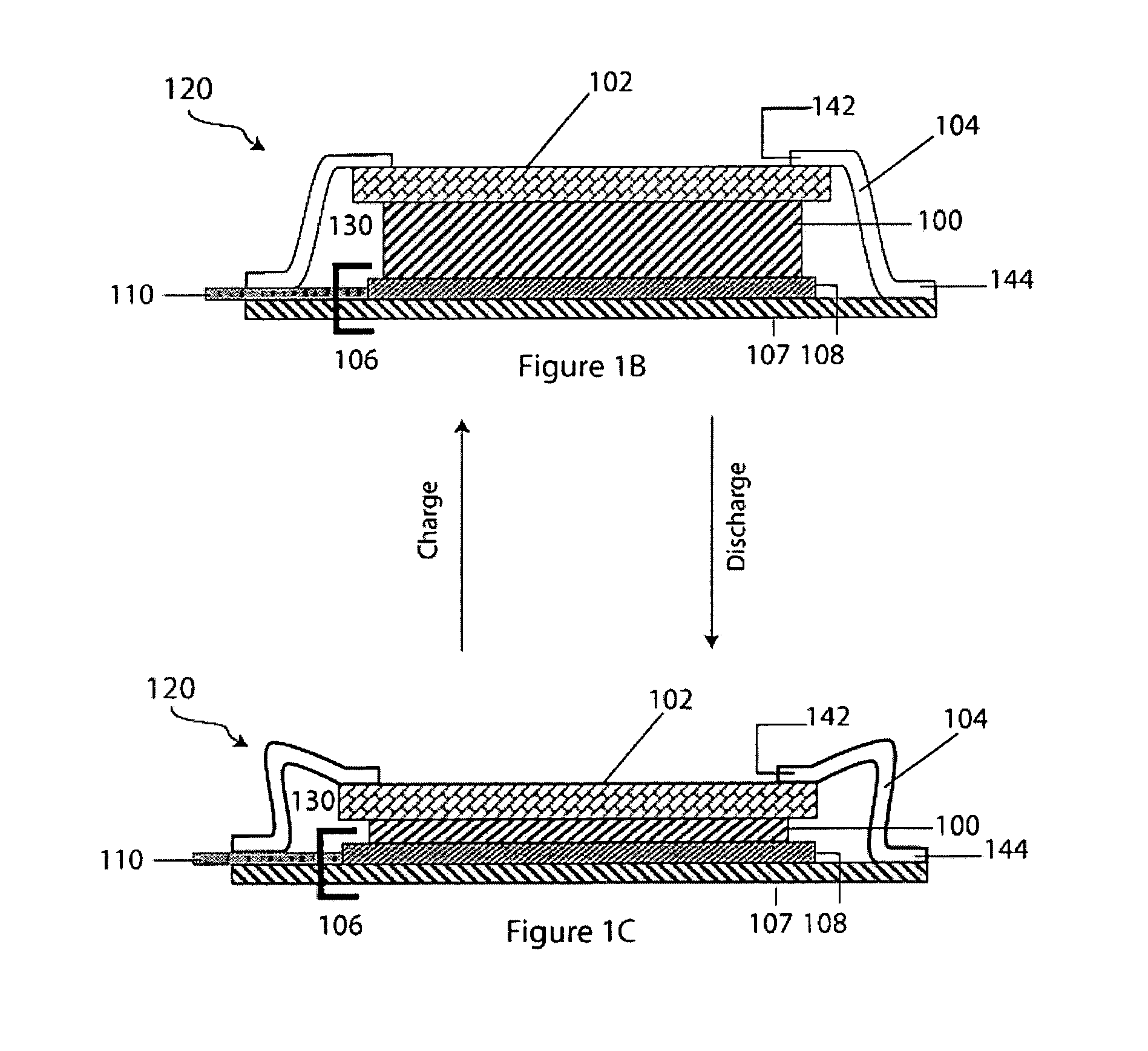

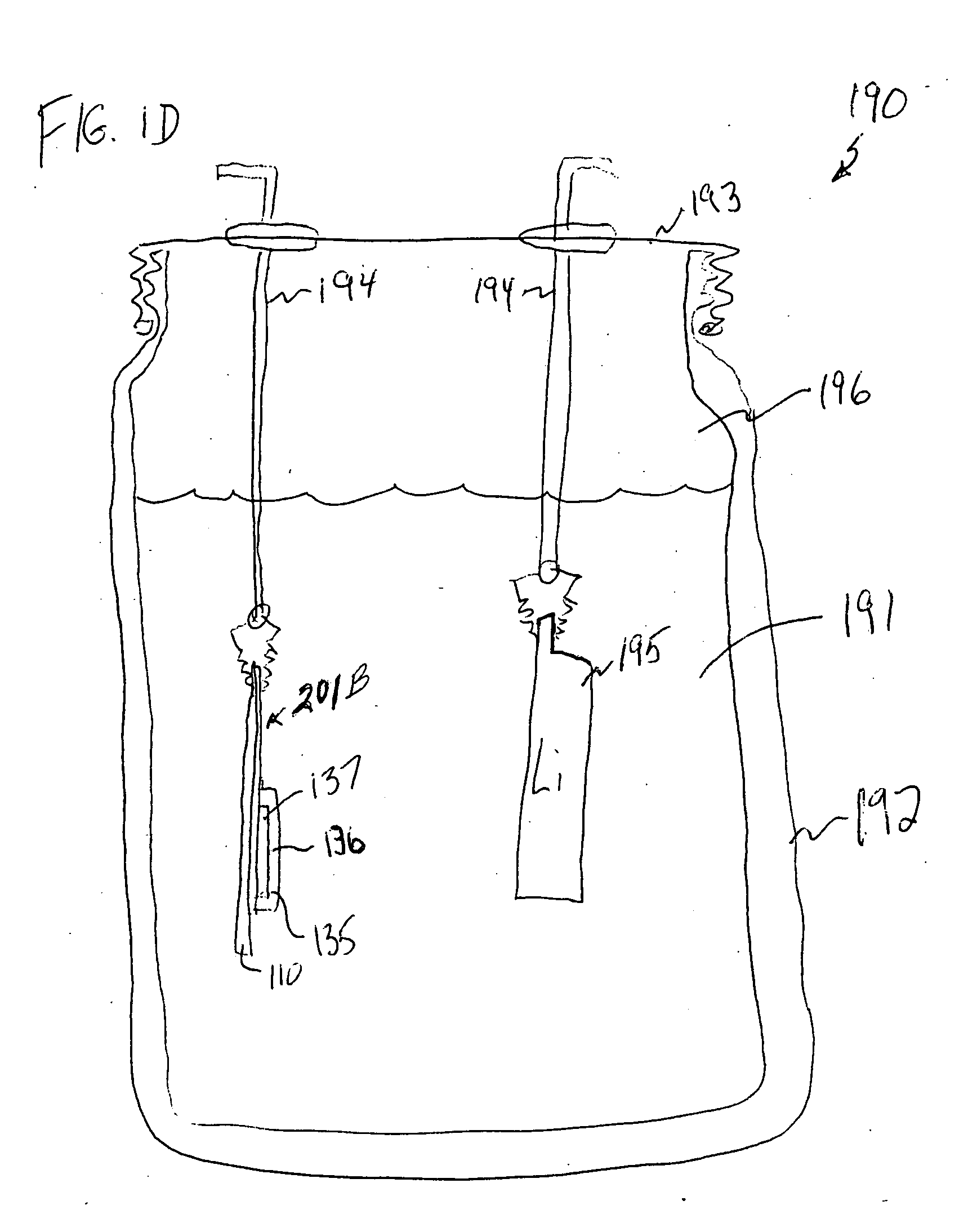

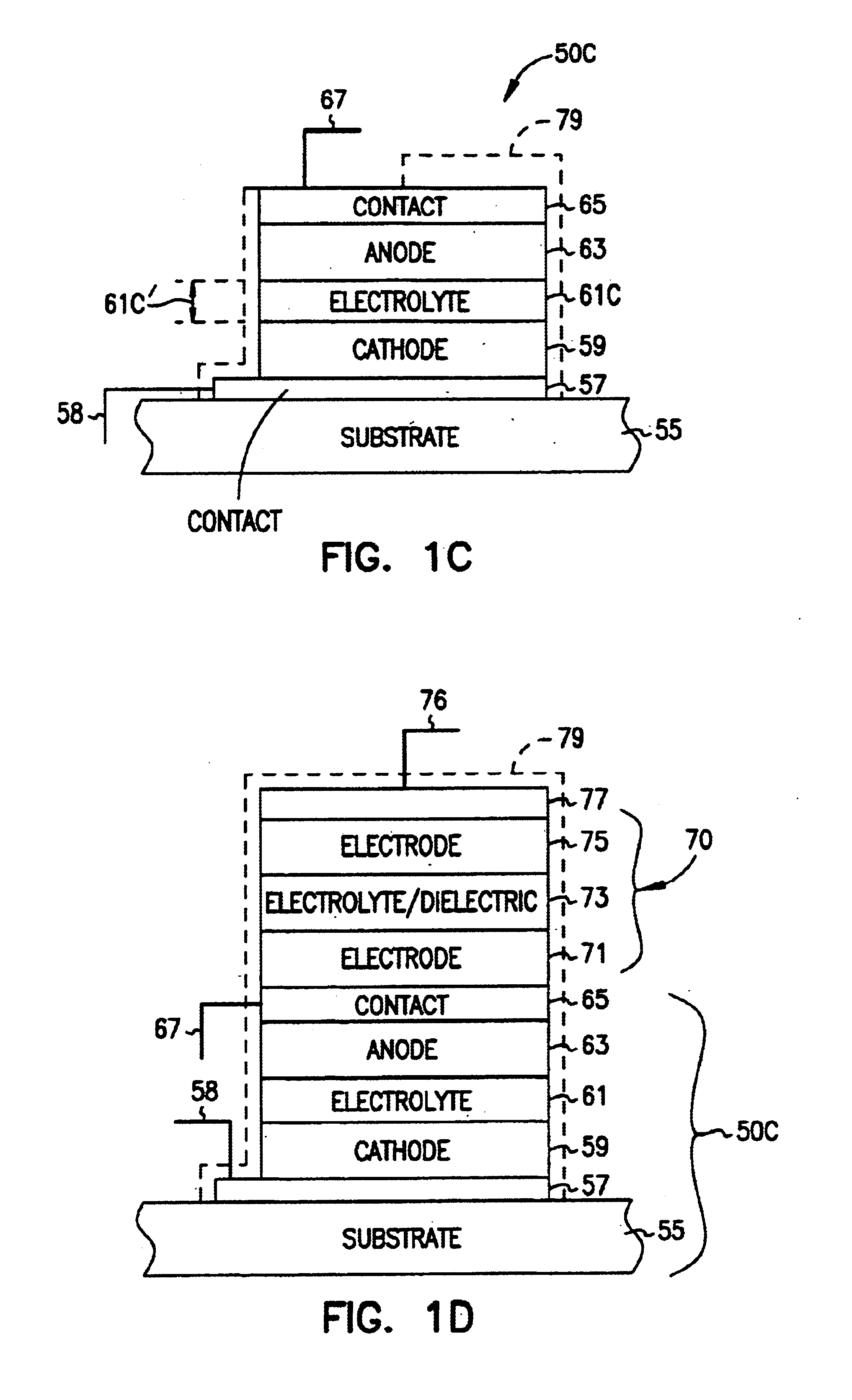

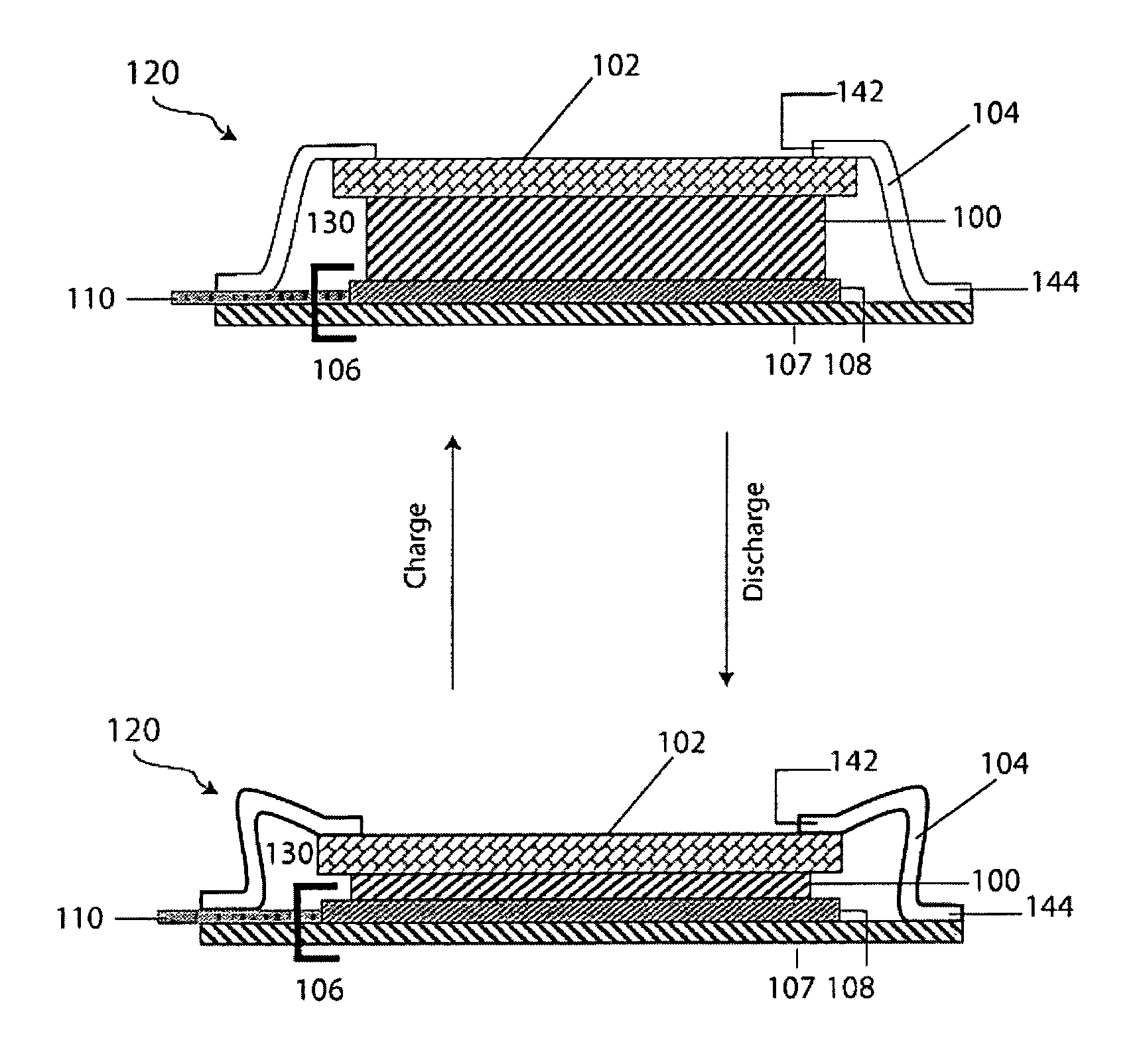

Compliant seal structures for protected active metal anodes

ActiveUS20070037058A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Electrode for rechargeable lithium battery and rechargeable lithium battery

InactiveUS7192673B1Improve charge and discharge cycle characteristicsInhibition formationElectrode manufacturing processesSmall-sized cells cases/jacketsAmorphous siliconMaterials science

An electrode for a rechargeable lithium battery which includes a thin film composed of active material that expands and shrinks as it stores and releases lithium, e.g., a microcrystalline or amorphous silicon thin film, deposited on a current collector, characterized in that said current collector exhibits a tensile strength (=tensile strength (N / mm2) per sectional area of the current collector material×thickness (mm) of the current collector) of not less than 3.82 N / mm.

Owner:SANYO ELECTRIC CO LTD

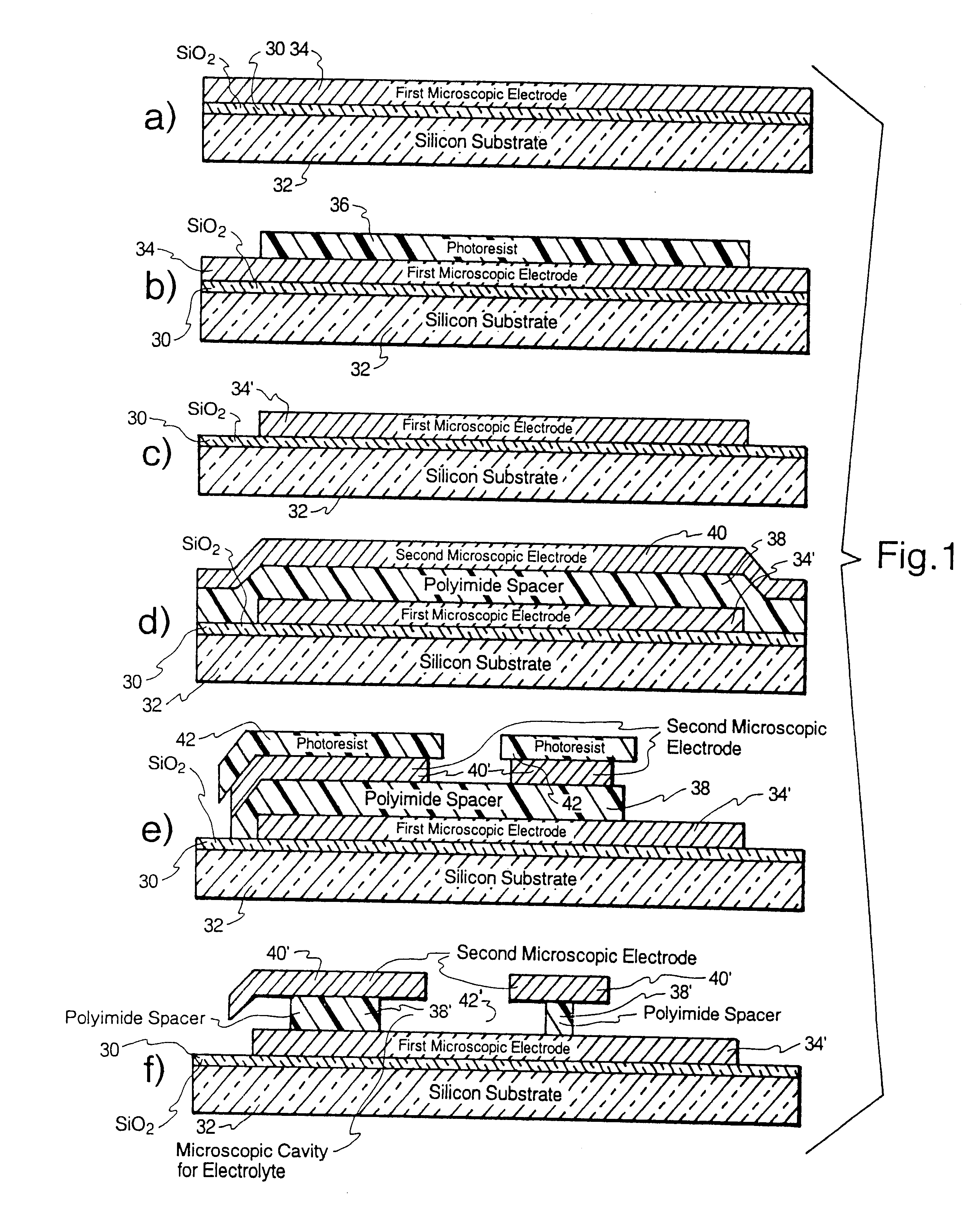

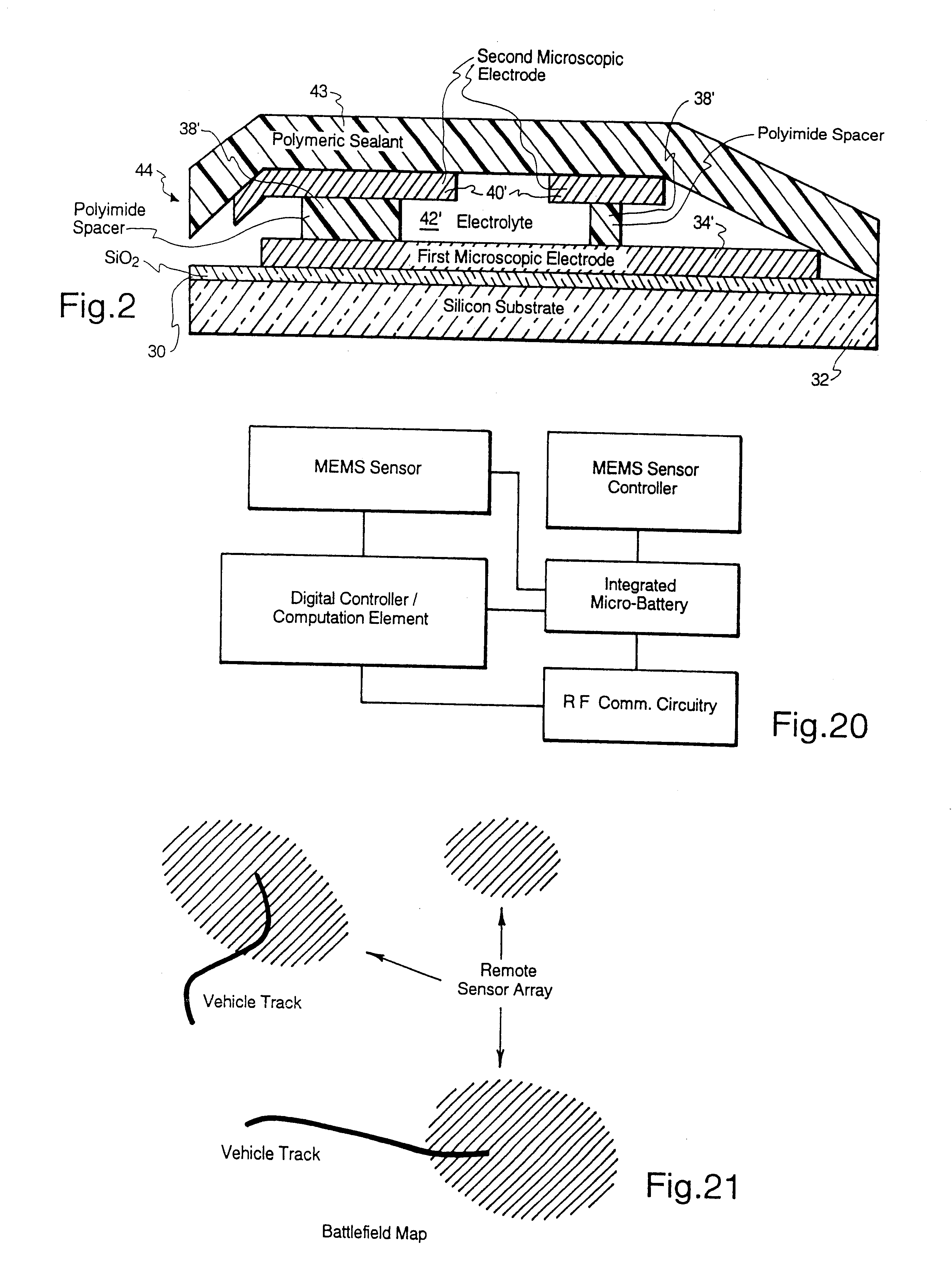

Microscopic batteries for MEMS systems

InactiveUS6610440B1Reduce power lossIncrease powerBatteries circuit arrangementsFinal product manufactureElectricityMicrofabrication

Microscopic batteries, integratable or integrated with microelectromechanical systems or other microscopic circuits, including a MEMS microcircuit, and methods of microfabrication of such microscopic batteries are disclosed, among which comprise closed system microscopic batteries for internal storage of electricity using interval reactants only, which comprise microscopic electrodes, electrolyte and reservoir for the electrolyte.

Owner:BIPOLAR TECH

Three dimensional free form battery apparatus

A battery apparatus comprising a casing, at least two stacked lithium ion cells a member for maximizing the utilization of the casing and a member for precluding inadvertent deformation of the casing. The casing includes a non-uniform inner periphery. Each of at least two stacked lithium ion cells is positioned within the casing. The utilization maximizing member maximizes the utilization of the inner periphery of the casing by facilitating the independent shaping of each of the at least two stacked lithium ion cells to confirm to the inner periphery. As a result, the shape of one cell does not limit or dictate the shape of any other cell. The deformation precluding member is associated with each of the at least two lithium ion cells, and, substantially precludes inadvertent deformation of the casing by the at least two lithium ion cells, during cell cycling and storage. The invention further includes a process for fabricating a battery apparatus.

Owner:MITSUBISHI CHEM CORP

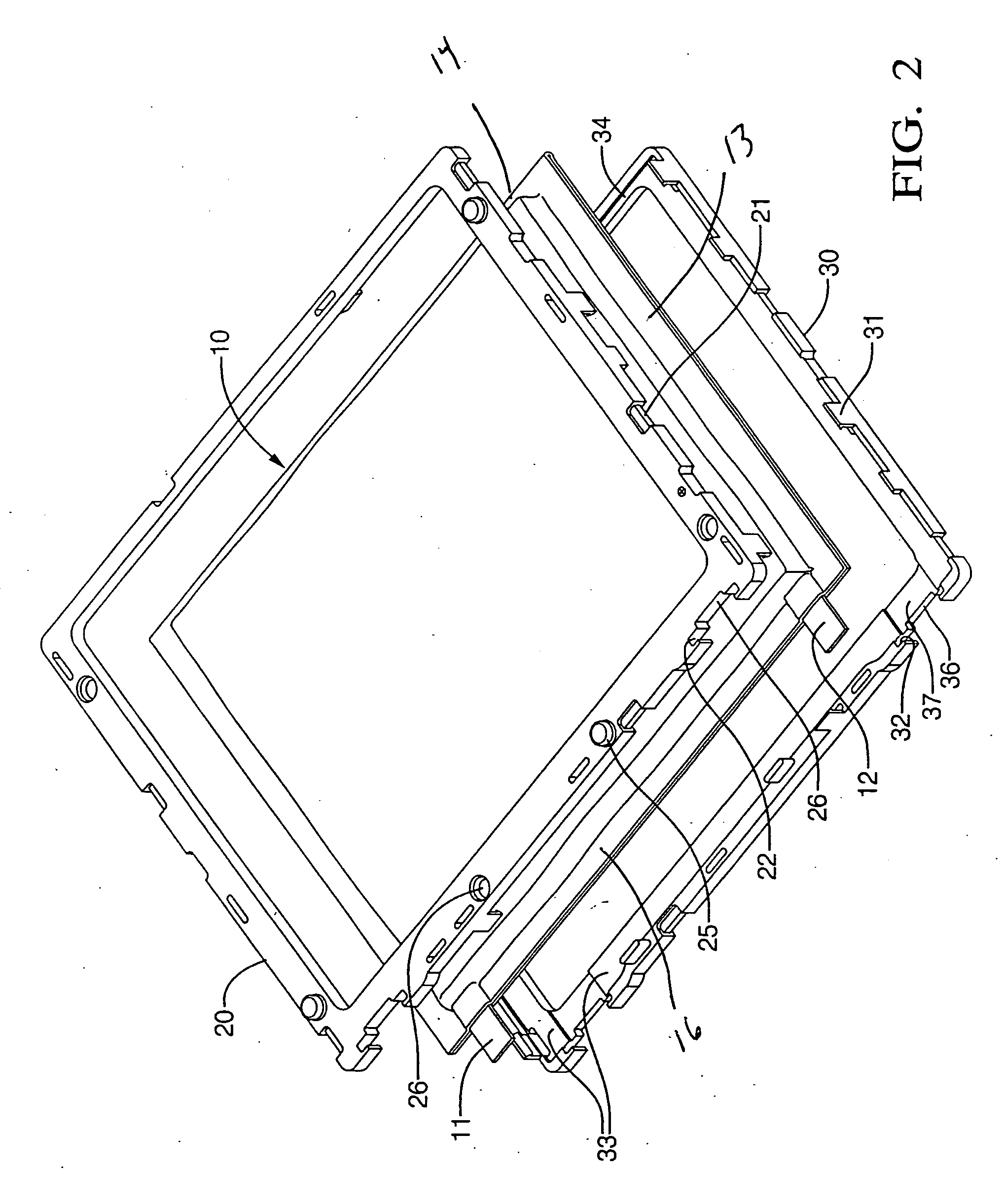

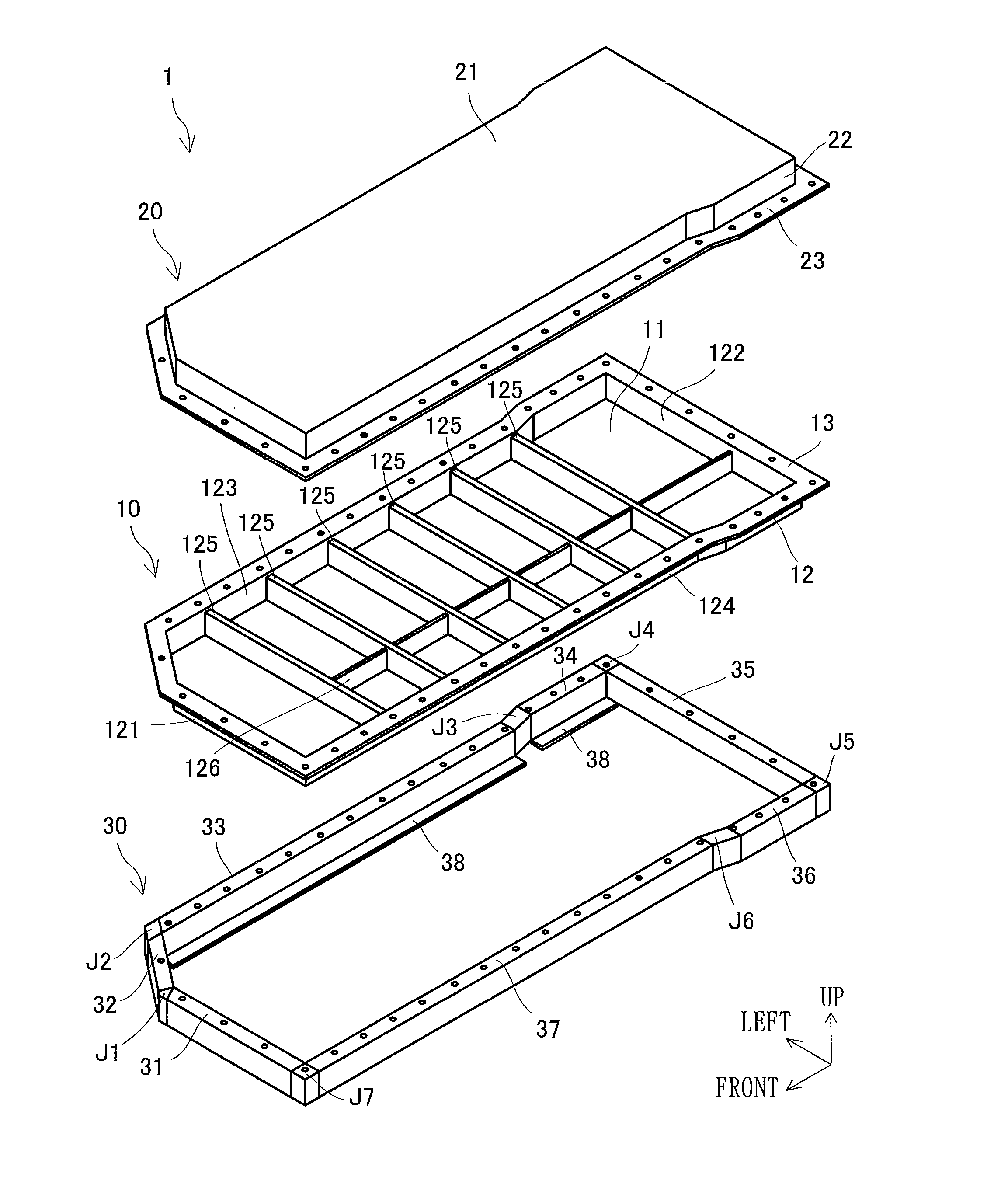

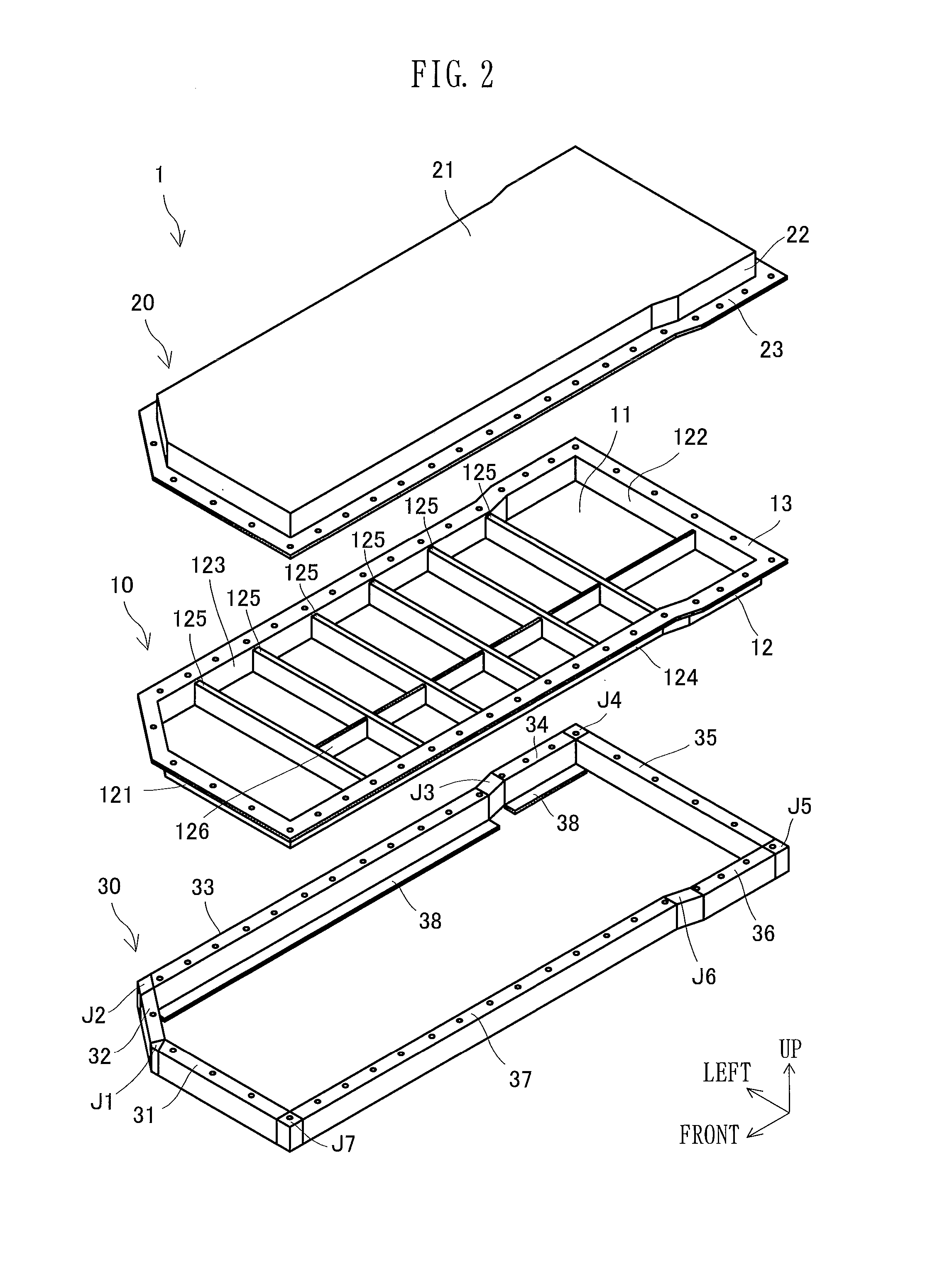

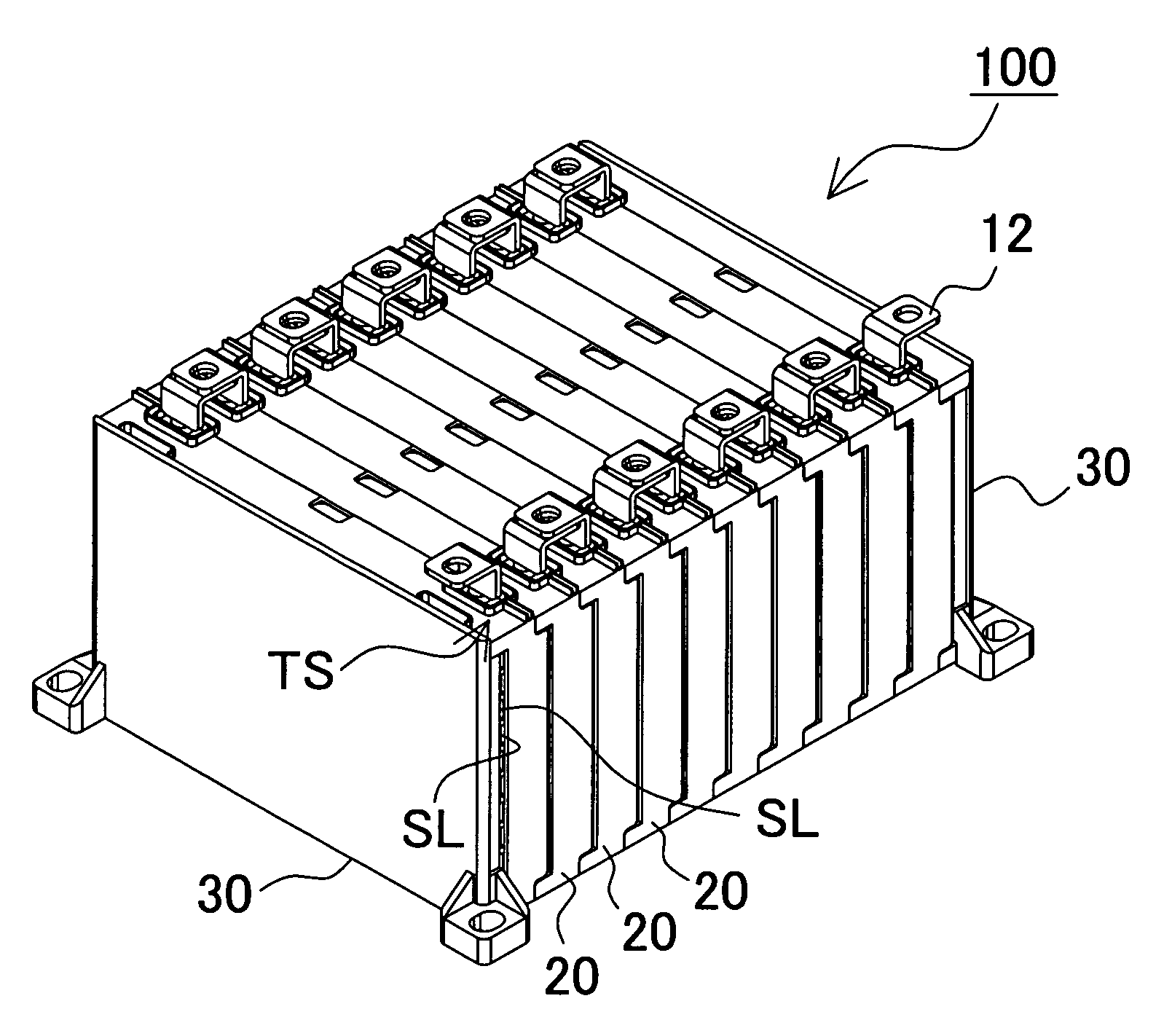

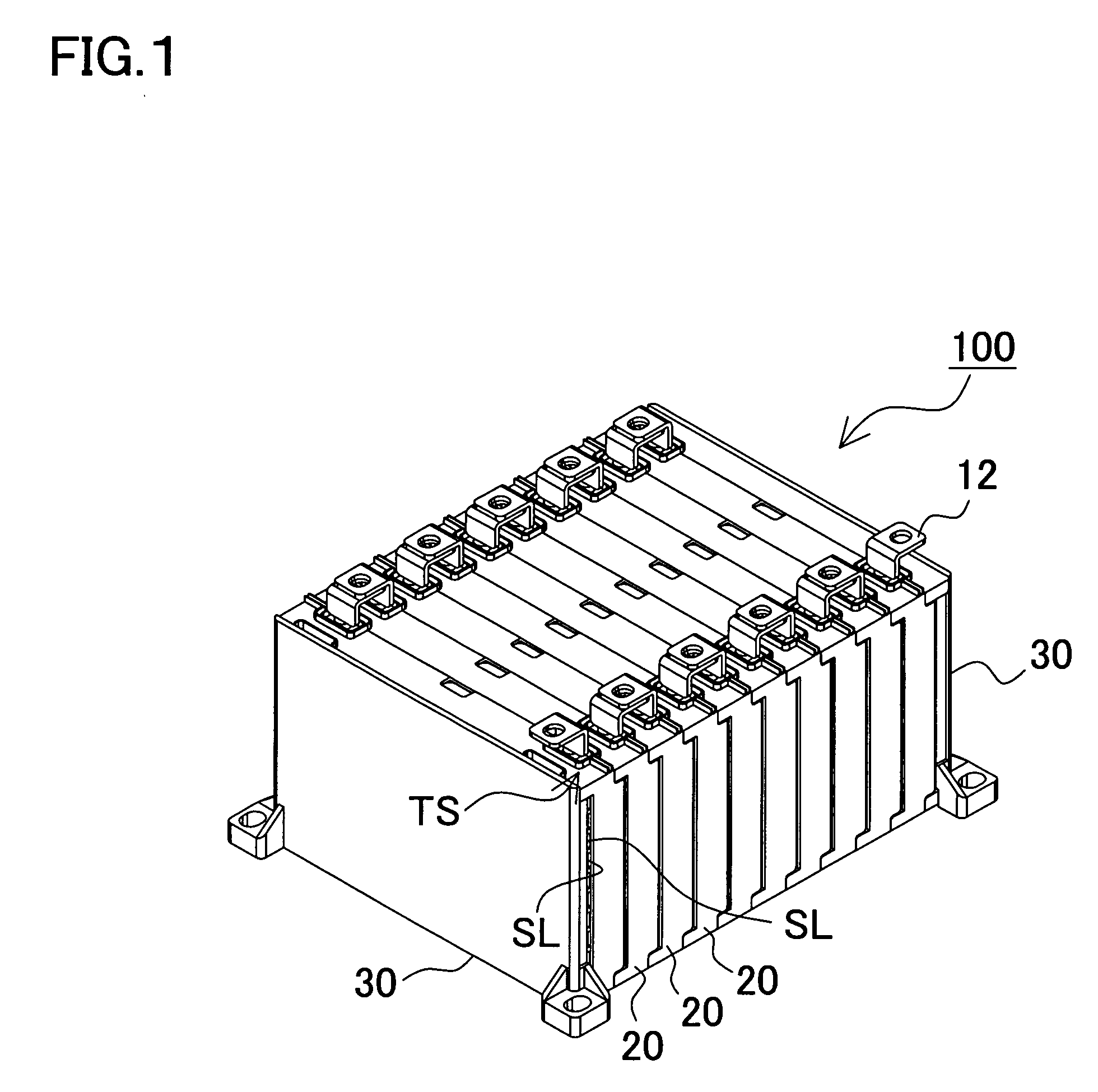

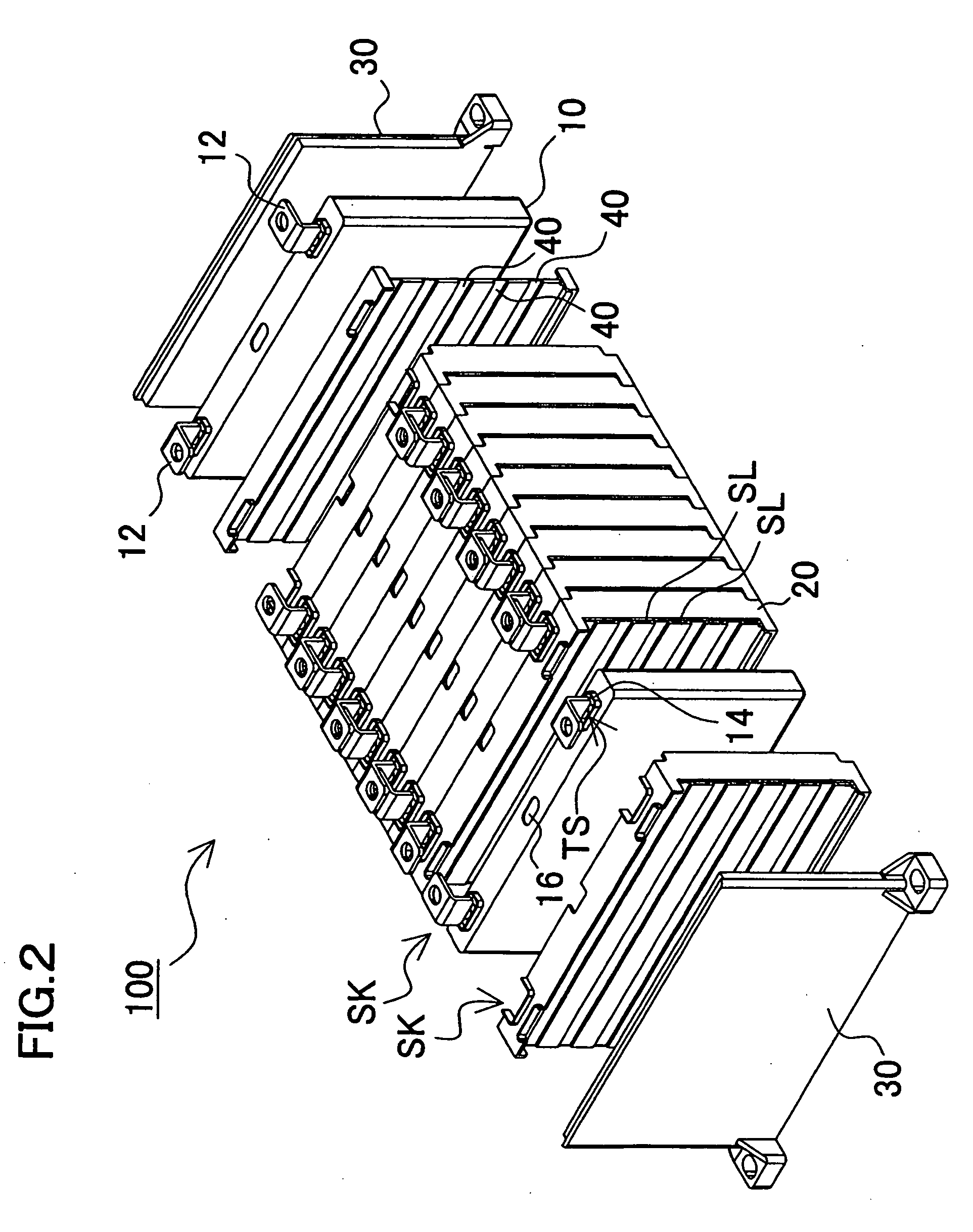

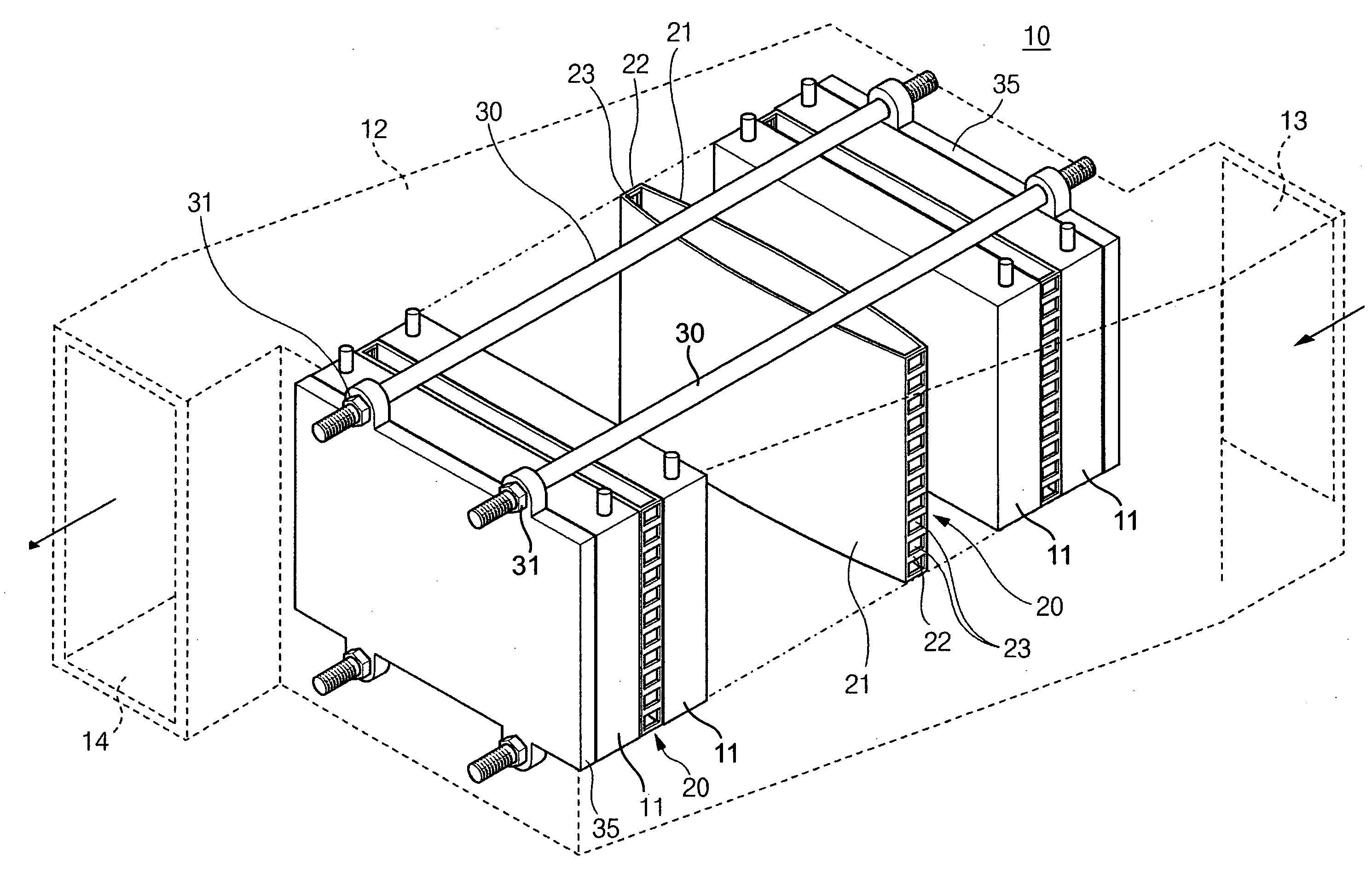

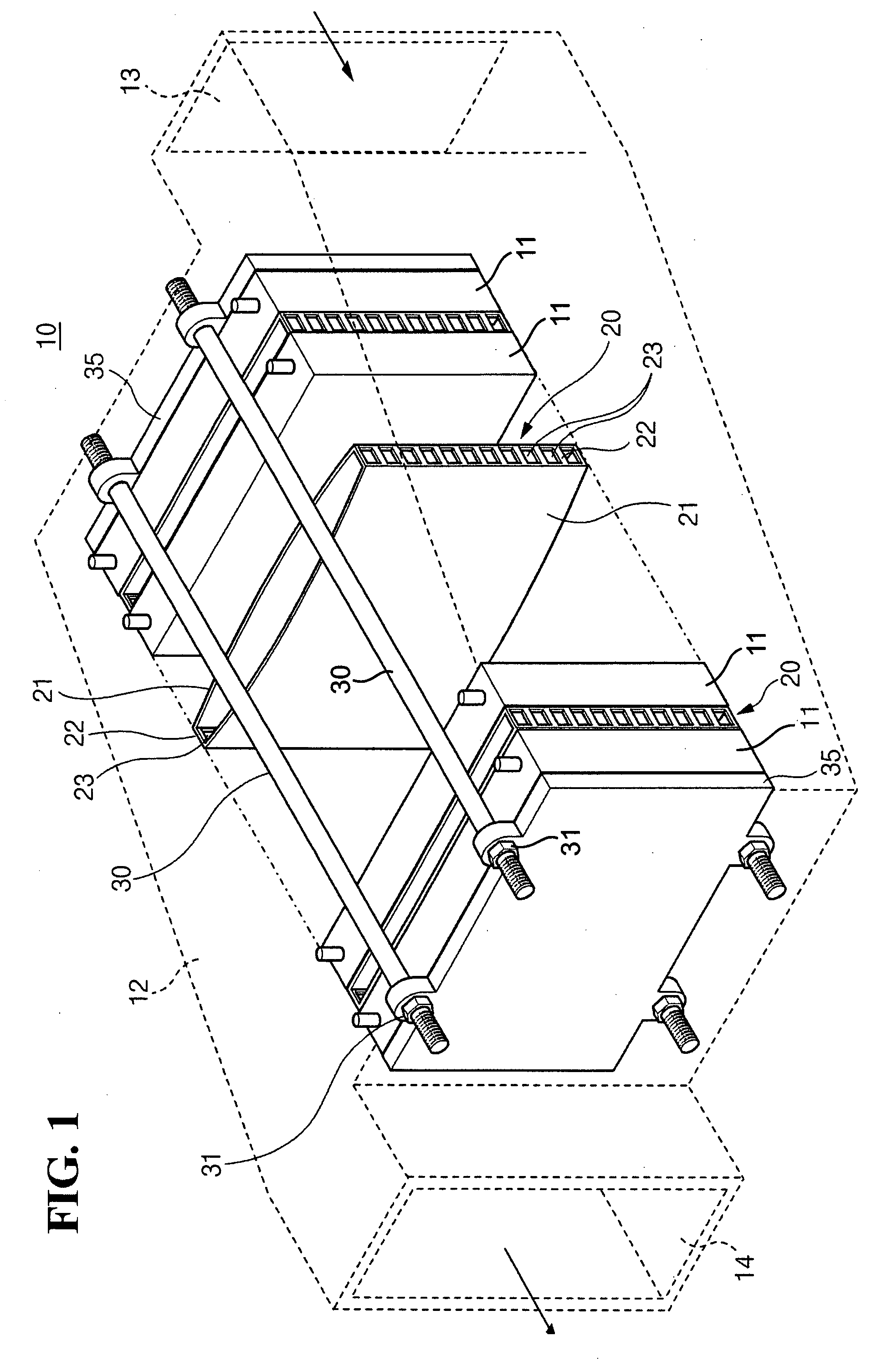

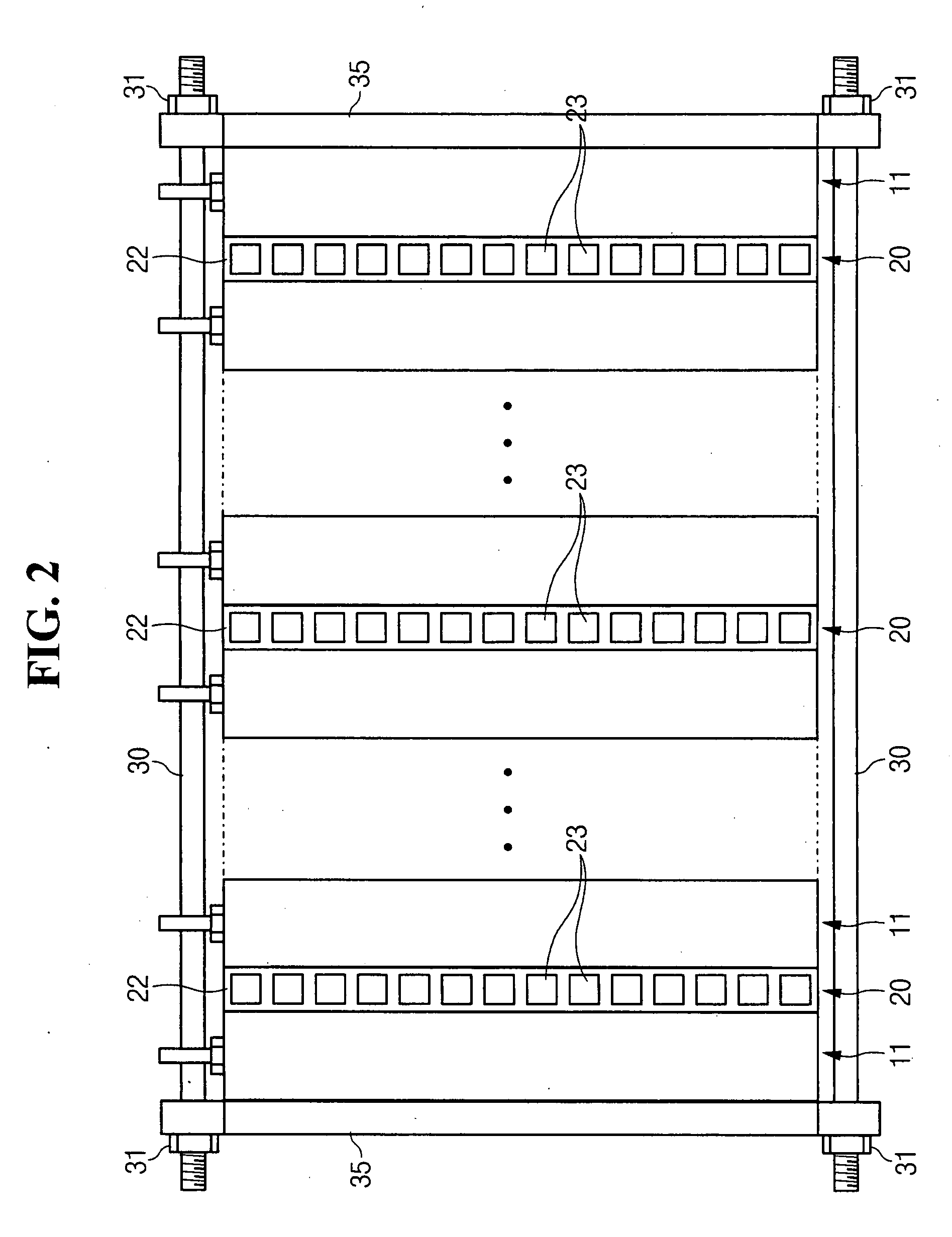

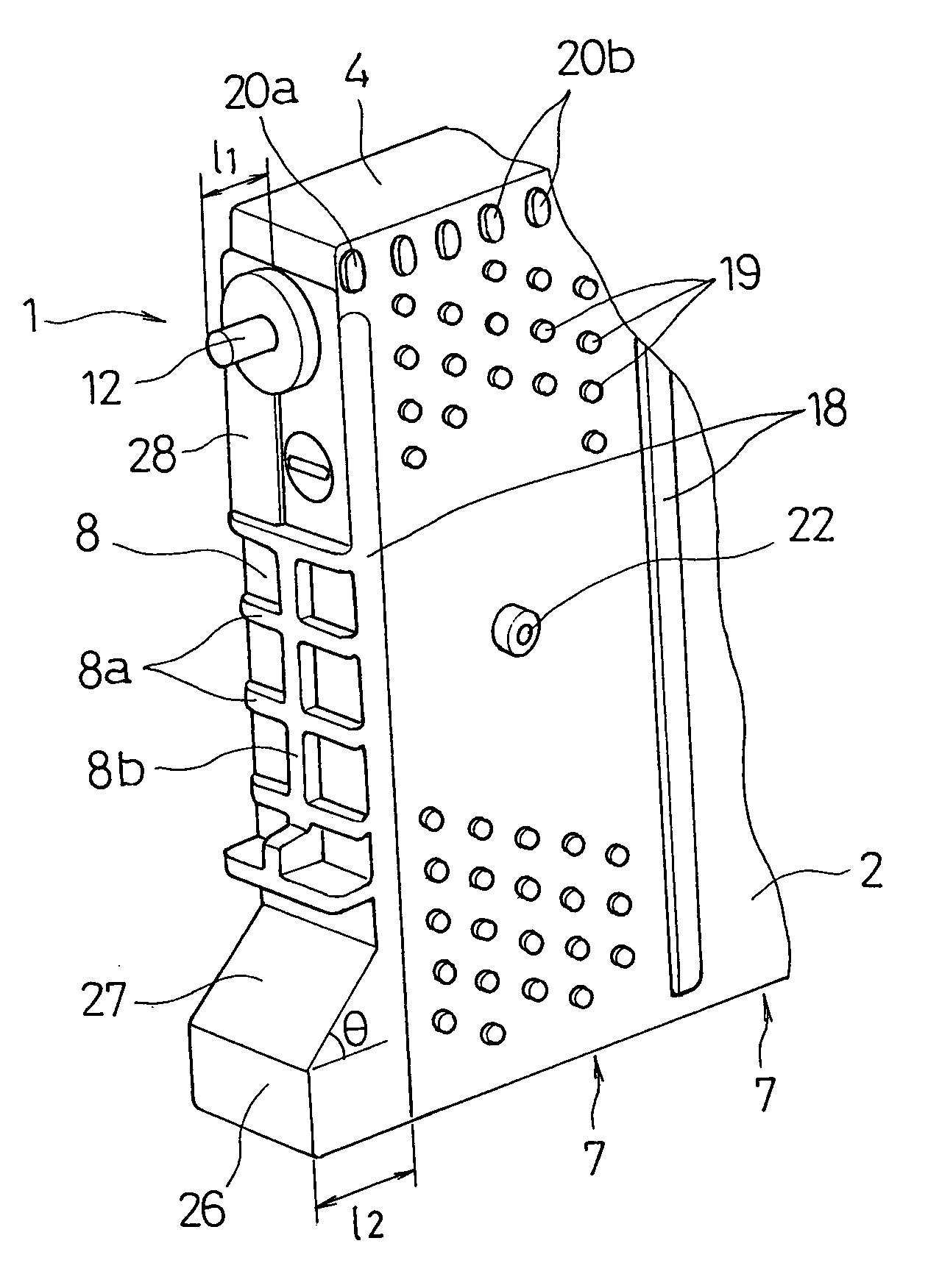

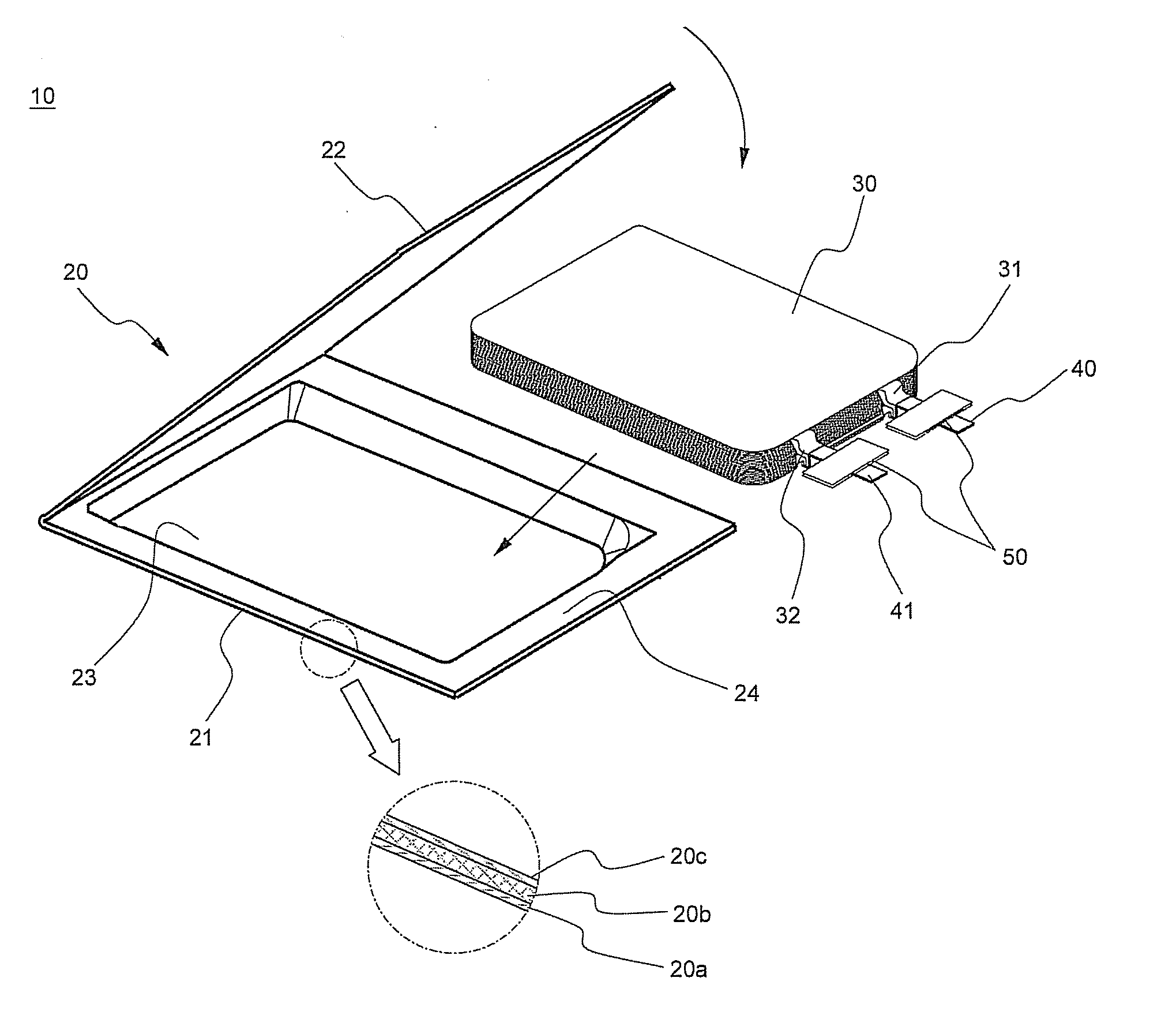

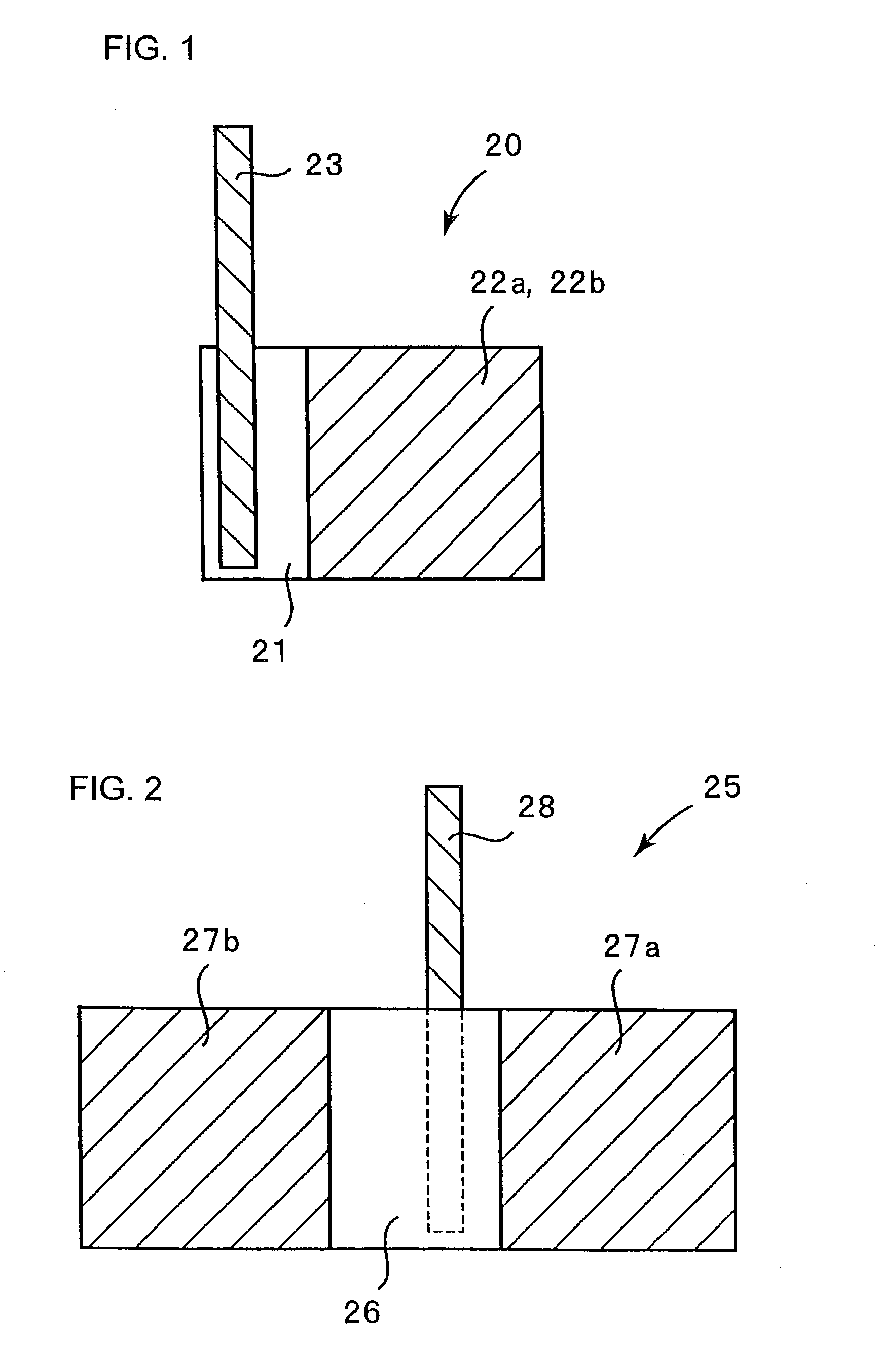

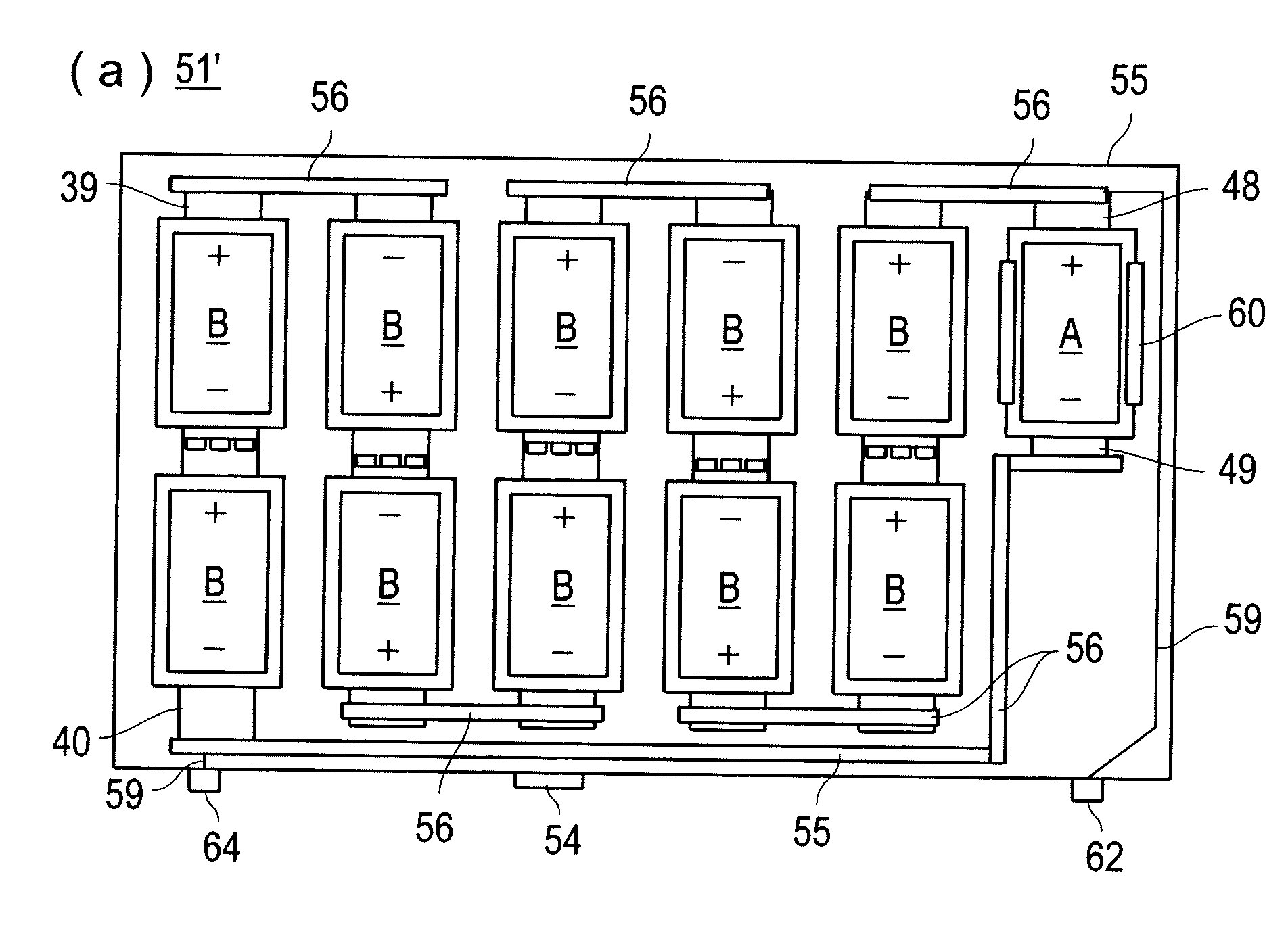

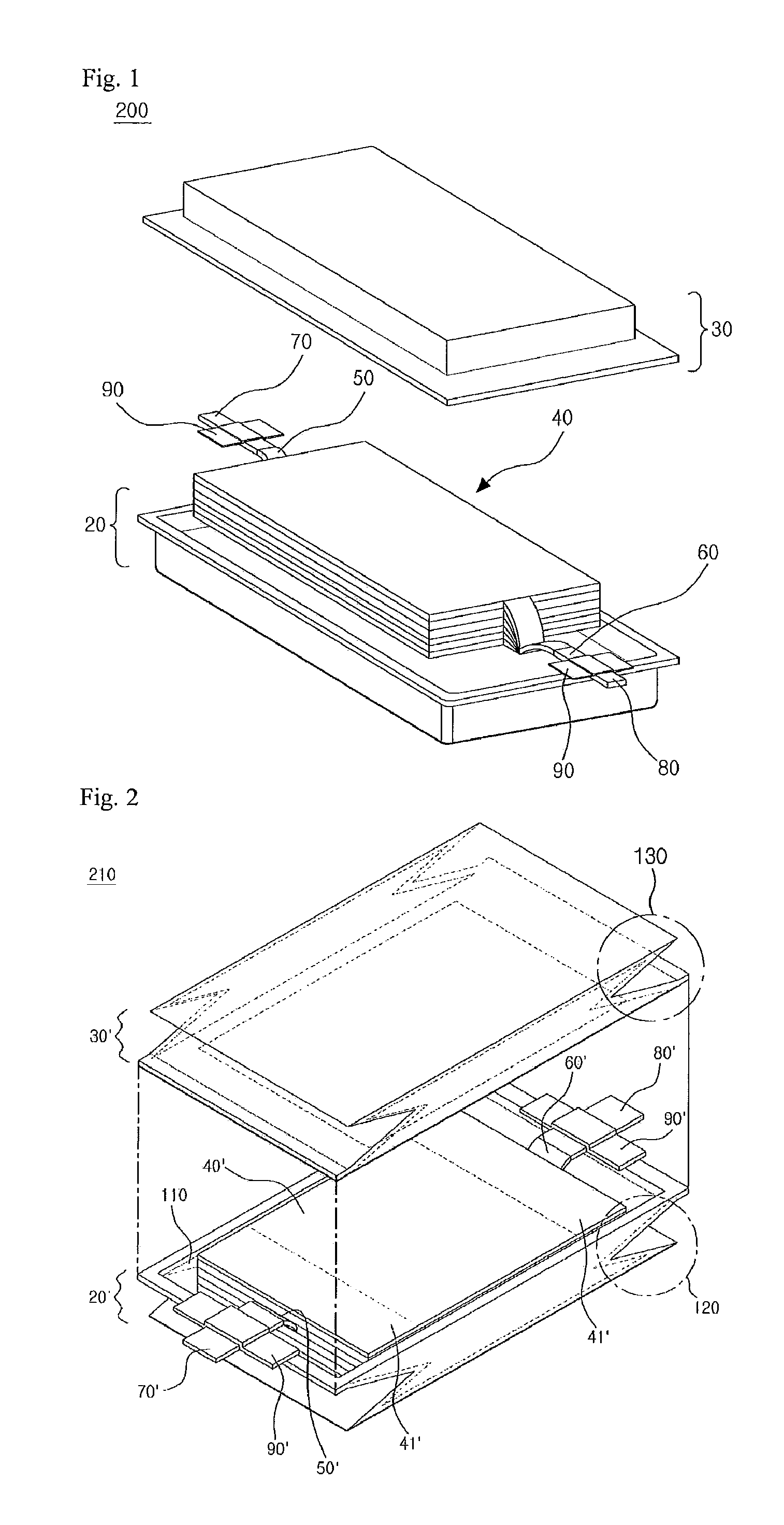

Apparatus and method for securing battery cell packs

ActiveUS20060234119A1Facilitate electrically connectingFacilitate mechanically connectingFinal product manufactureSmall-sized cells cases/jacketsEdge surfaceBattery cell

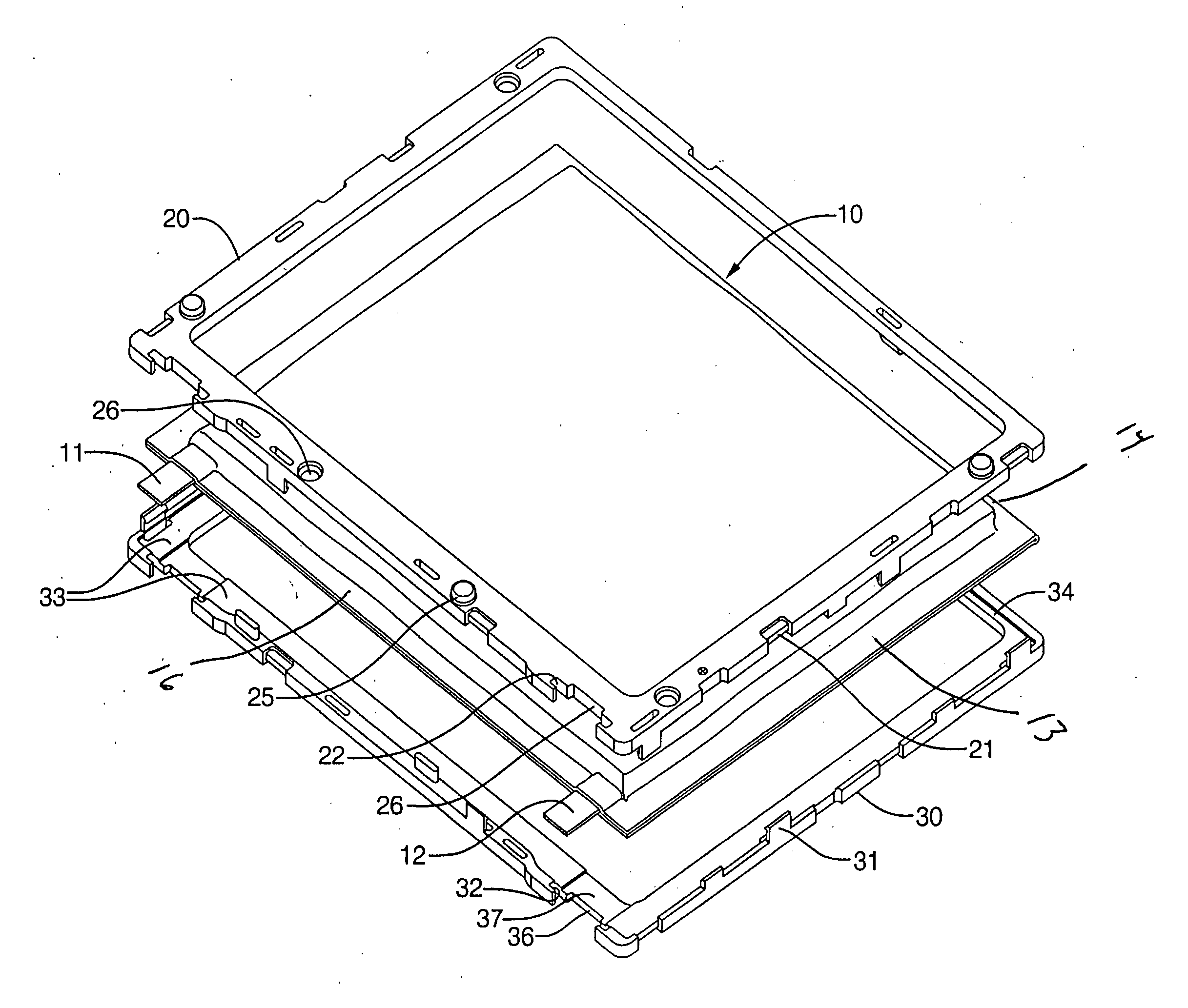

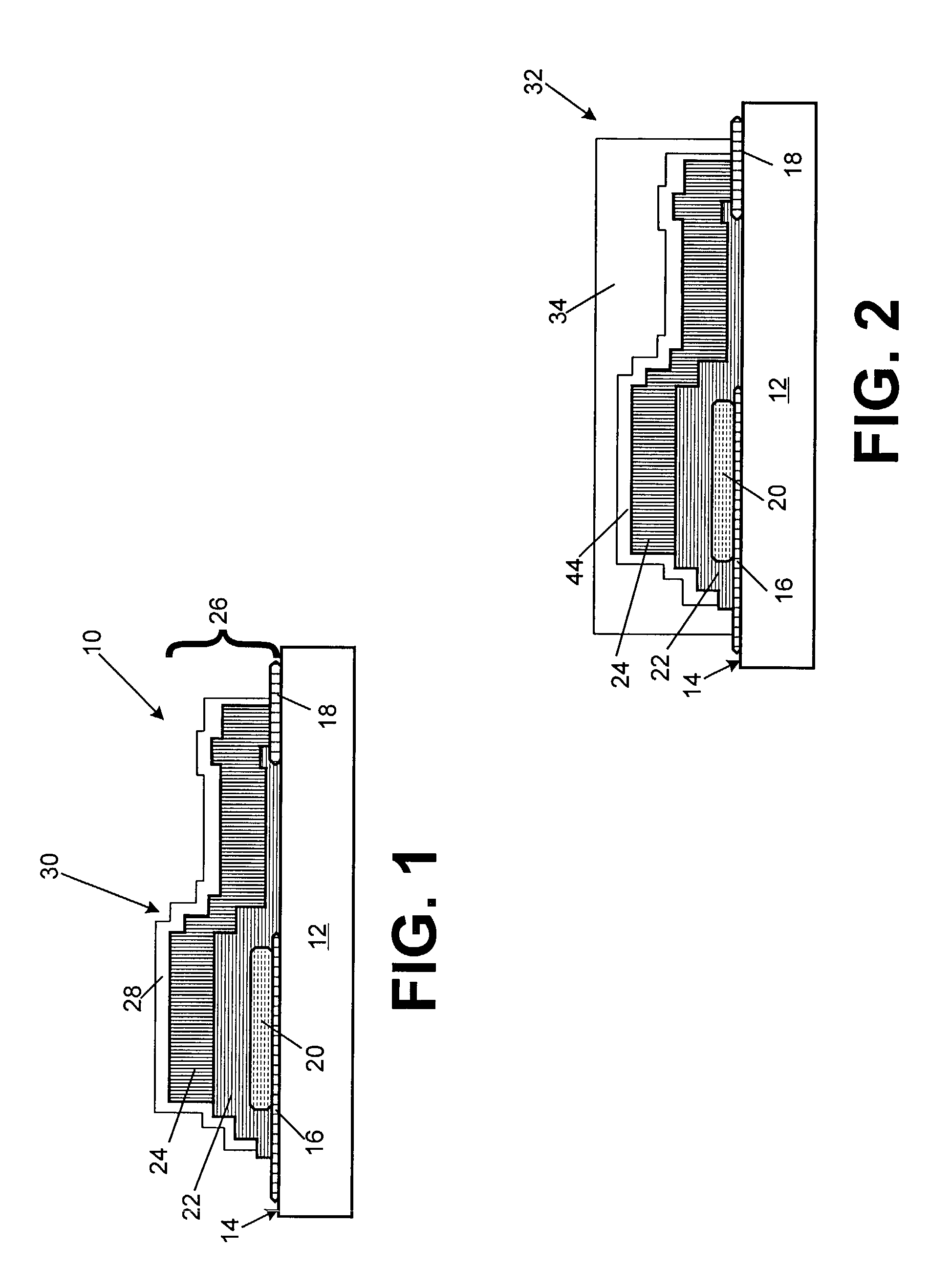

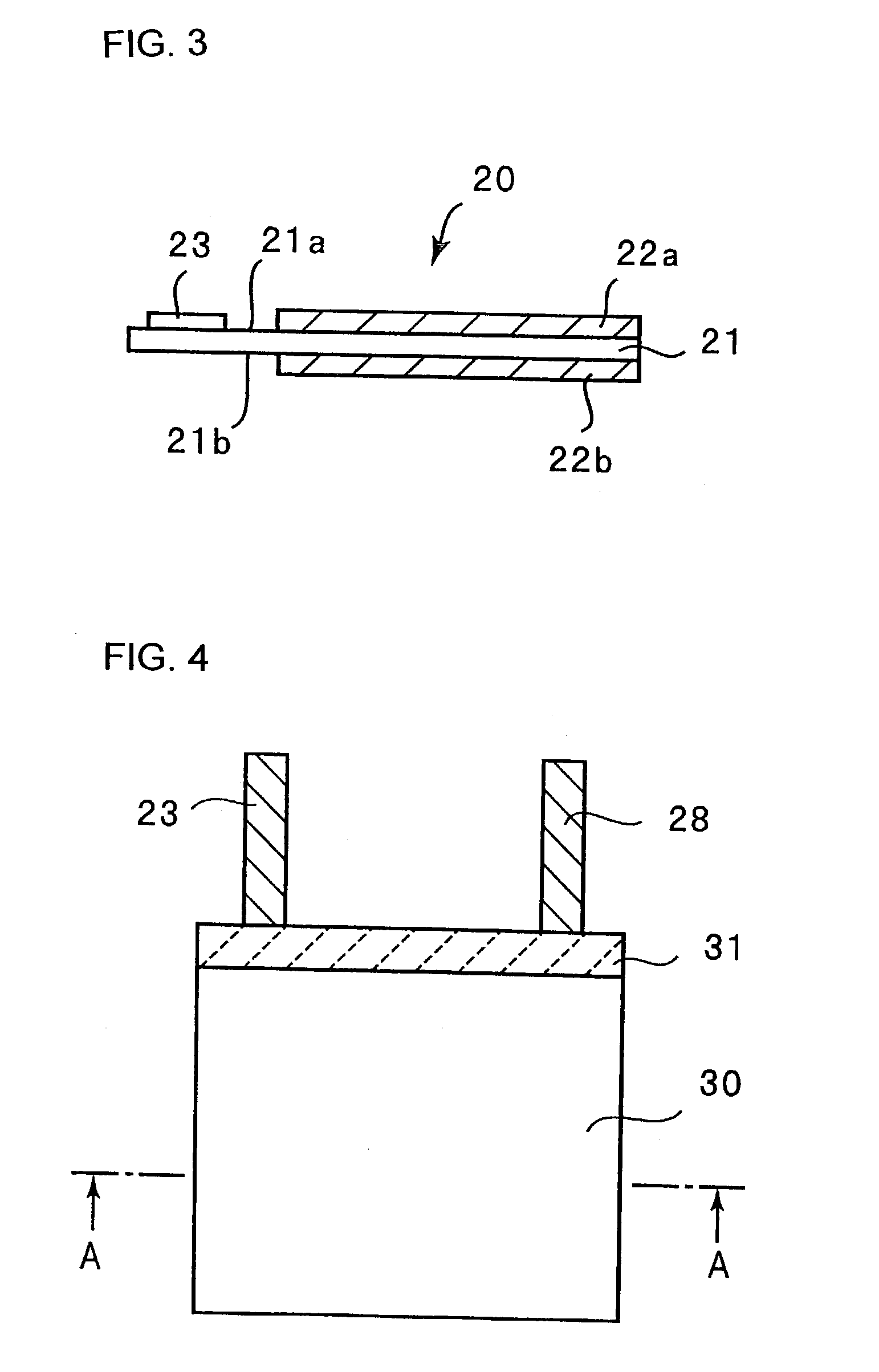

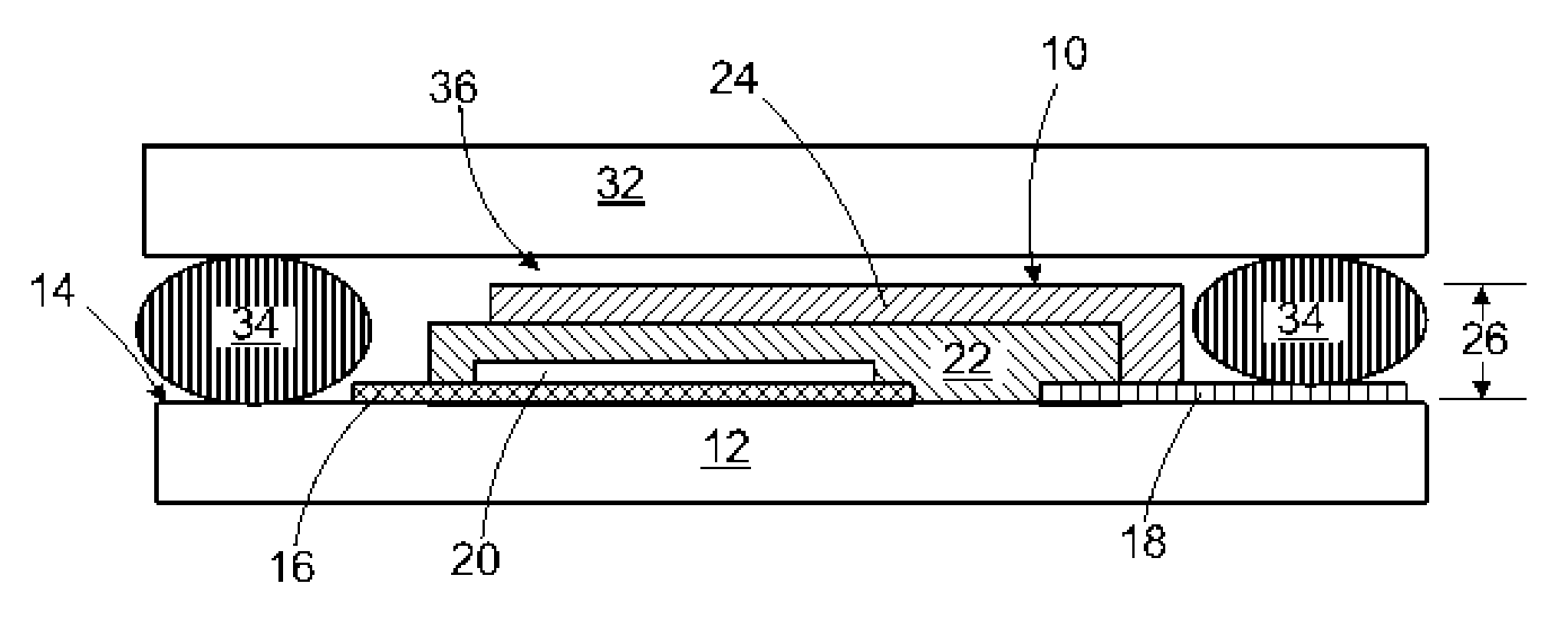

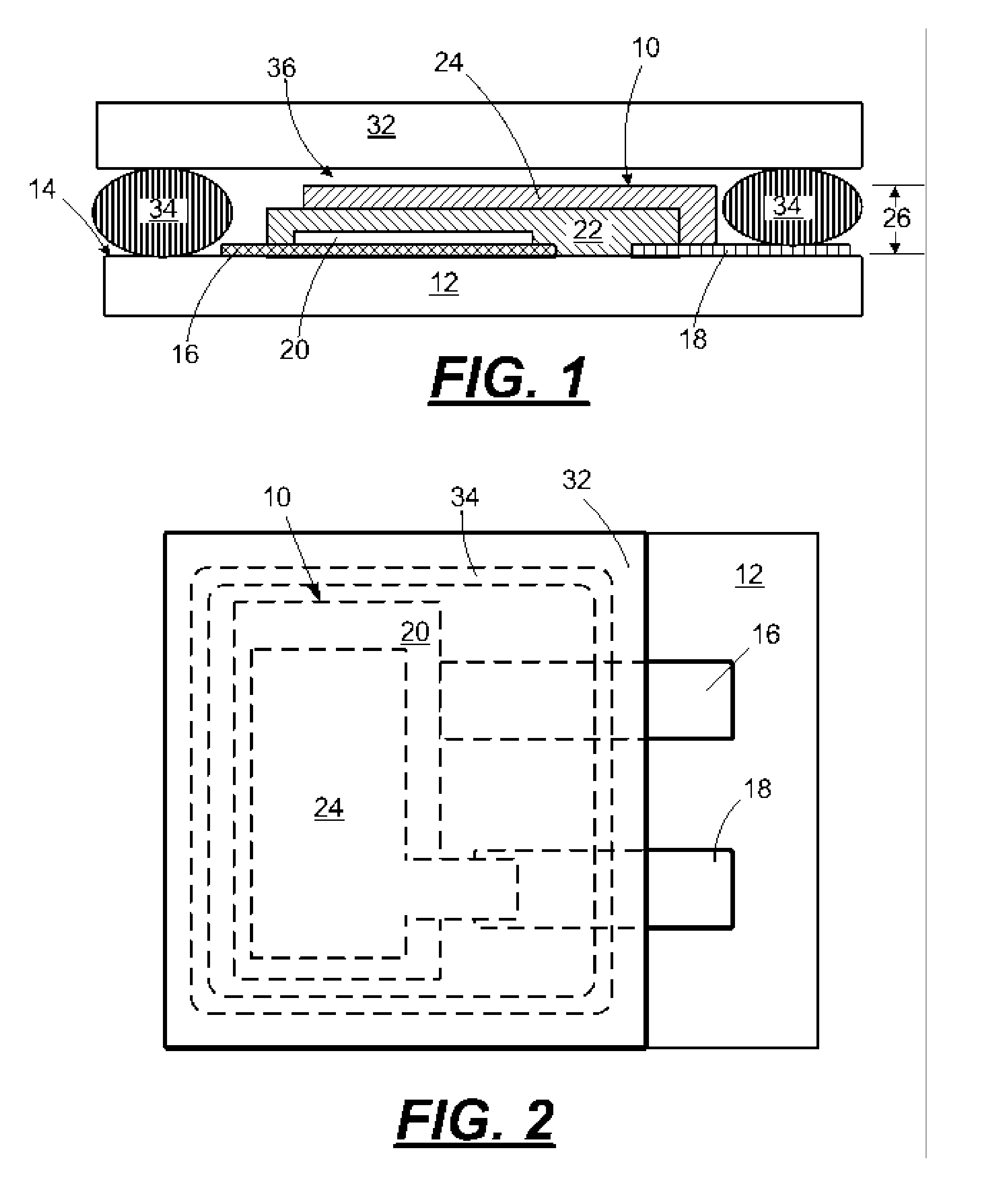

A framed lithium battery cell group includes a first frame member (20) and a second frame member (30). The frame members are locked together, clamping the lithium battery cell pack (10) on the seal edge surfaces (13, 16), thereby providing structural rigidity and protection from damage due to handling and vibration. Each of the frame members (20, 30) has multiple pins (25) and sockets (26) on the side opposite the clamping surface (33) to facilitate aligning and stacking multiple lithium battery cell pack and frame assemblies to form a lithium battery cell group (50). Each of the frame members (20, 30) include a buss bar capture feature (22, 32) having a bus bar (40) inserted therein for electrically connecting all of the terminals for a given lithium battery pack group to the buss bar (40).

Owner:ENERDEL

Electrode for use in lithium battery and rechargeable lithium battery

InactiveUS7235330B1High charge and discharge capacityImprove featuresElectrode manufacturing processesSmall-sized cells cases/jacketsAmorphous siliconSurface roughness

Owner:SANYO ELECTRIC CO LTD

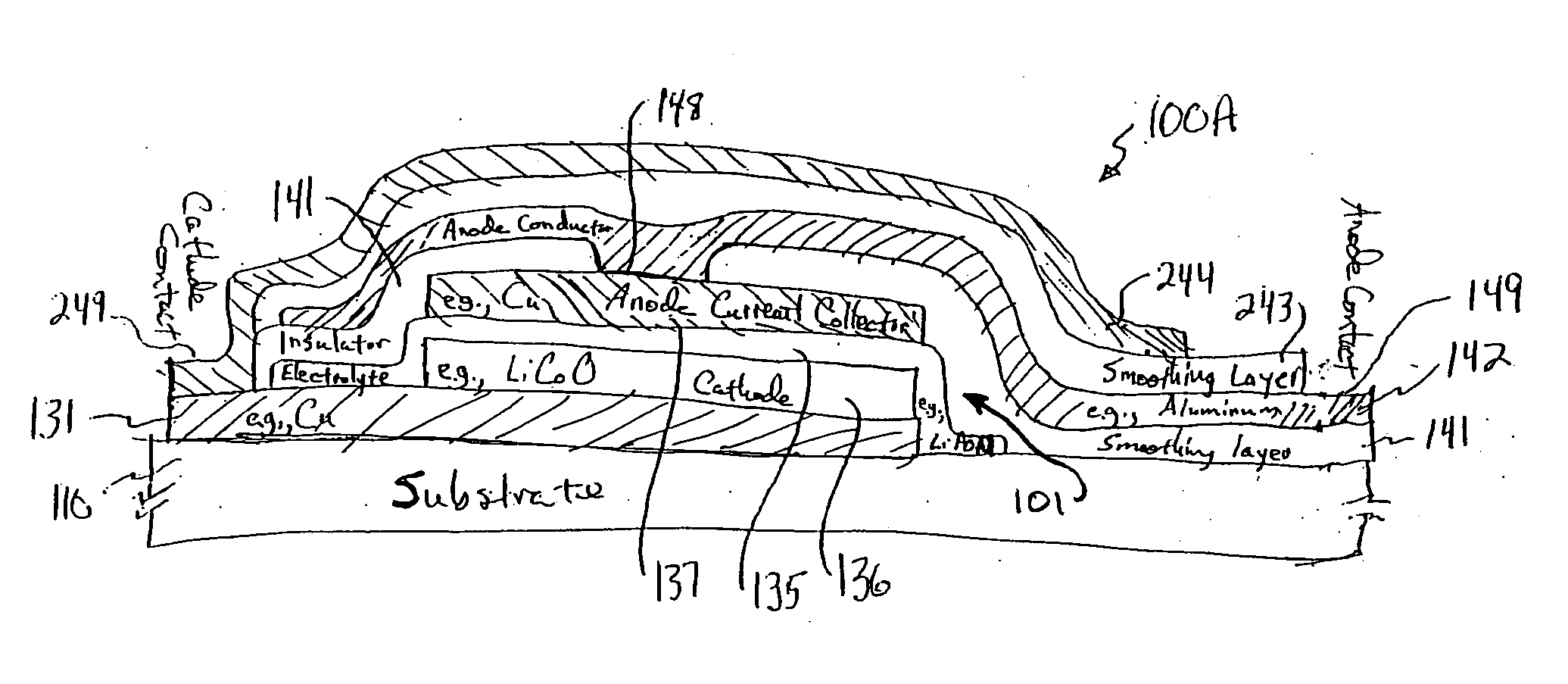

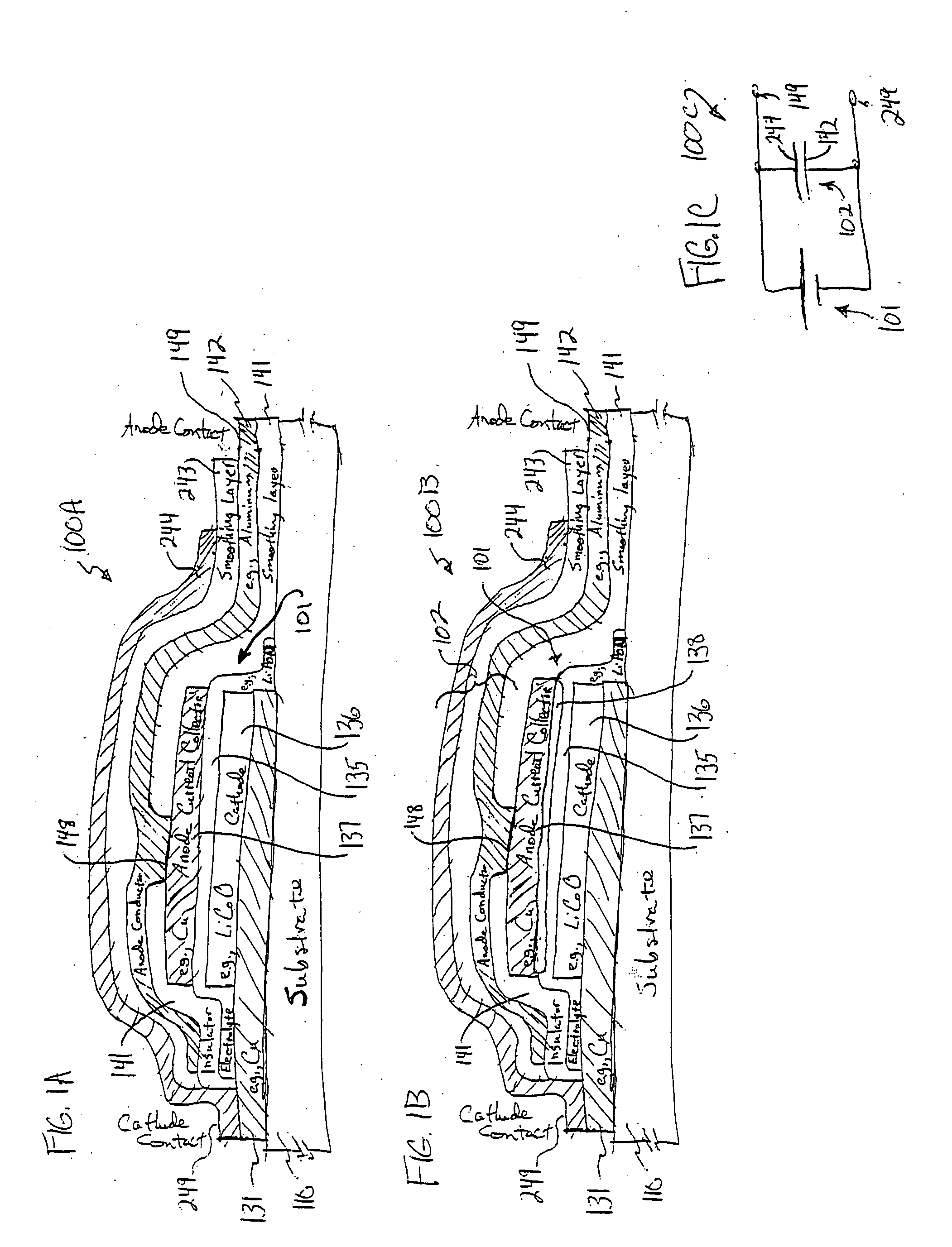

Long life thin film battery and method therefor

InactiveUS6994933B1Extend battery lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsOxygen fluxSurface roughness

A thin film battery including an anode layer, a cathode layer and a solid electrolyte layer. The battery also includes, a planarization layer applied to the thin film battery. The planarization layer has a surface roughness of no more than about 1.0 nanometers root mean square and a flatness no larger than about 0.005 cm / inch. A barrier layer is applied to the planarization layer. The barrier layer is provided by one or more layers of material selected from the group consisting of polymeric materials, metals and ceramic materials. The planarization layer and barrier layer are sufficient to reduce oxygen flux through the barrier layer to the anode layer to no more than about 1.6 μmol / m2-day, and H2O flux through the barrier layer to the anode layer to less than about 3.3 μmol / m2-day thereby improving the life of the thin film battery.

Owner:OAK RIDGE MICRO ENERGY

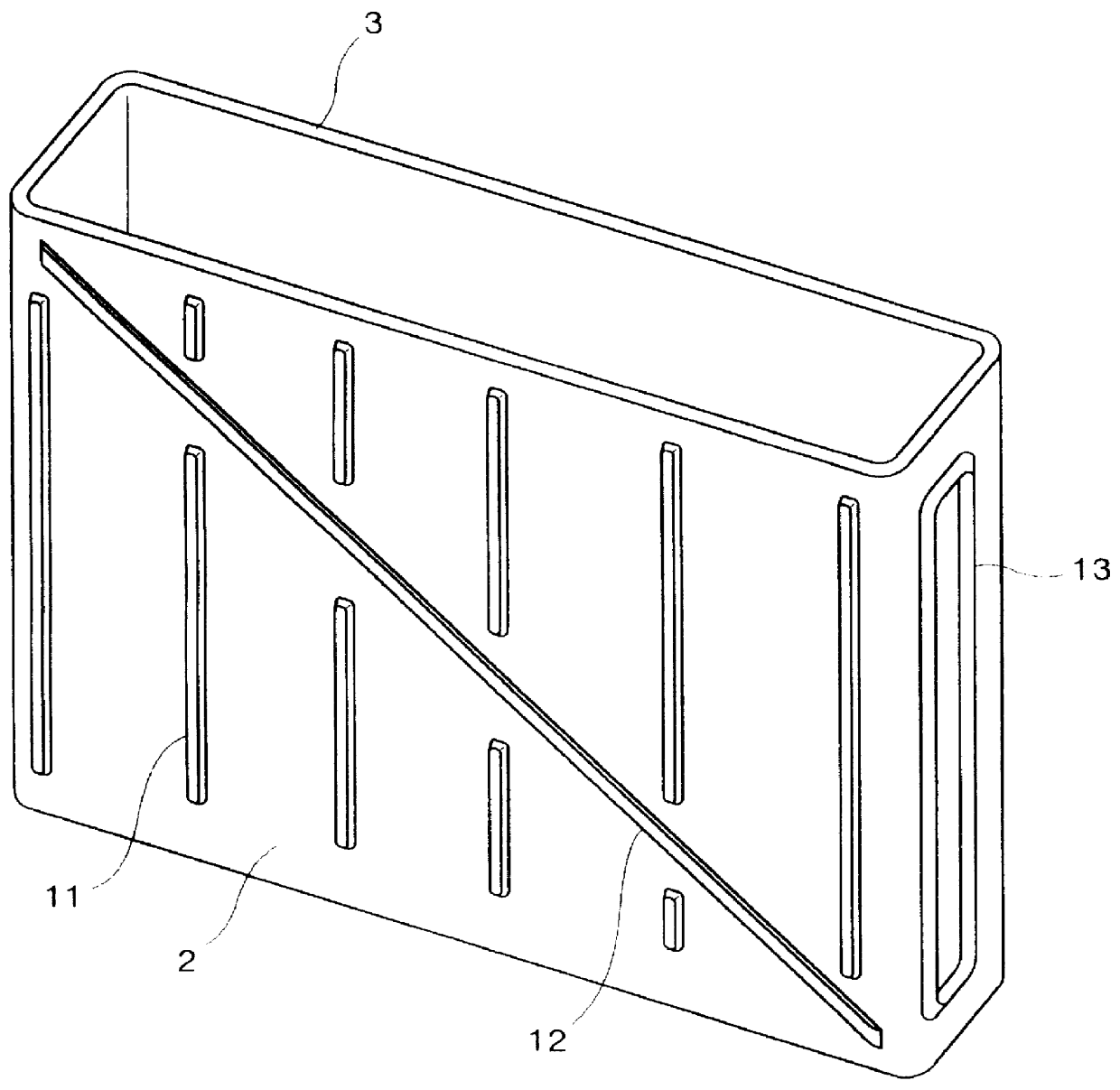

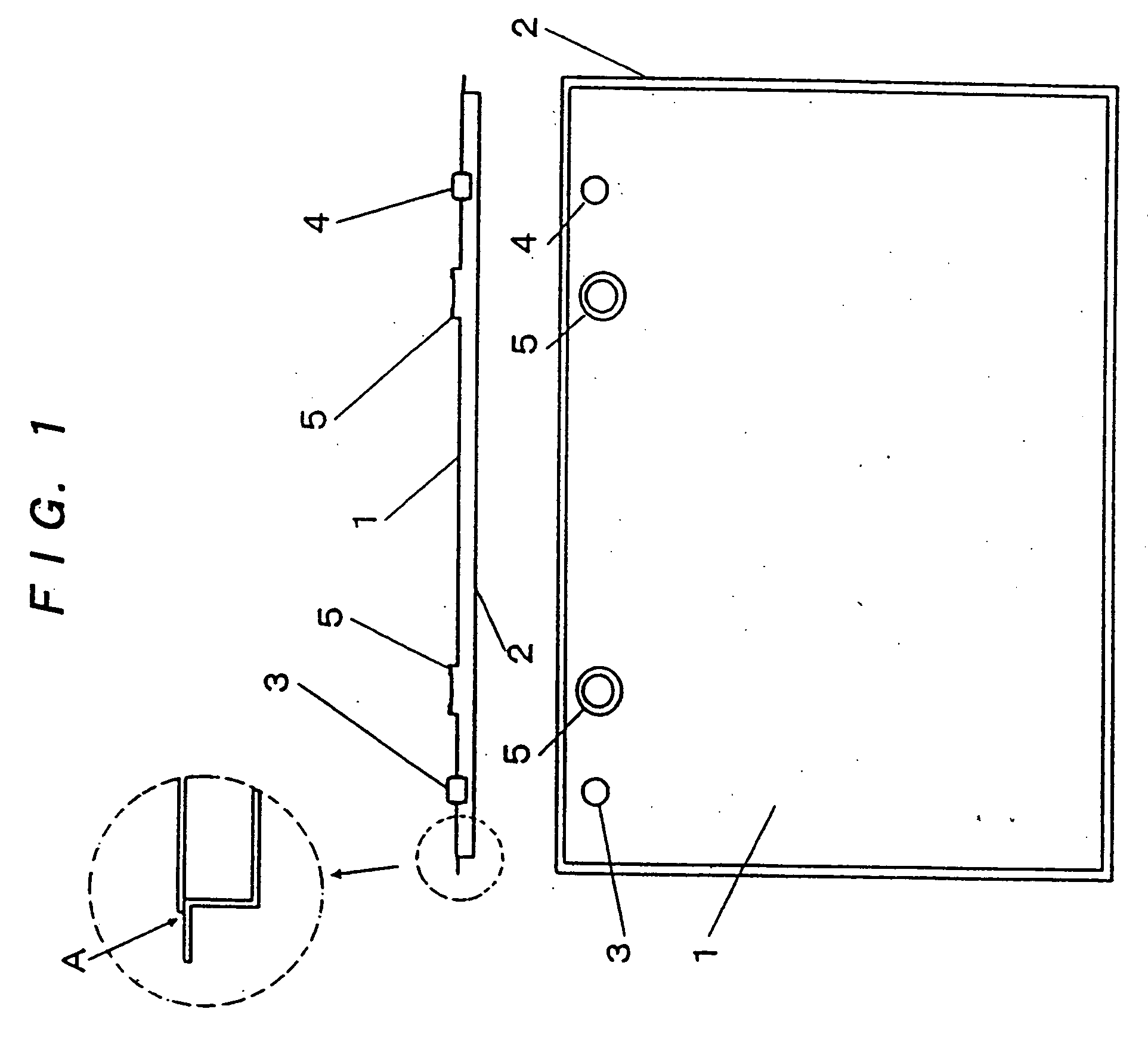

Battery case

ActiveUS20110143179A1Good effectRigidity be retainedSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringFlange

A battery case comprises: a battery tray formed from a resin, the battery tray having a bottom wall on which batteries are mounted, and a peripheral side wall which surrounds the periphery of the bottom wall; and a battery cover which covers the battery tray. A flange portion is provided on the upper surface of the peripheral side wall, and a metallic housing-shaped frame is provided beside the outer wall of the battery tray. The flange portion and the battery cover are fixed onto the upper surface of the metallic housing-shaped frame by fastening members.

Owner:MITSUBISHI MOTORS CORP

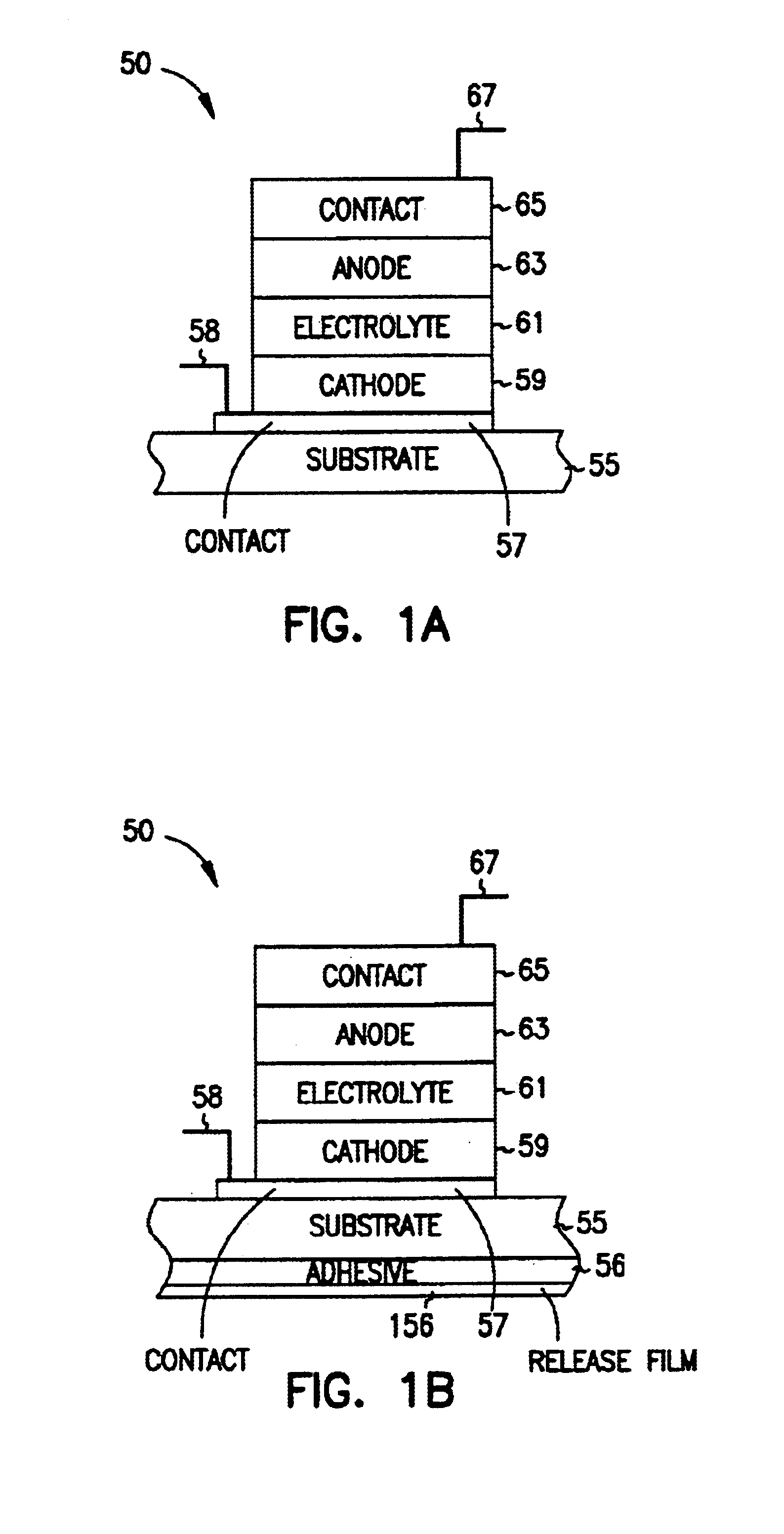

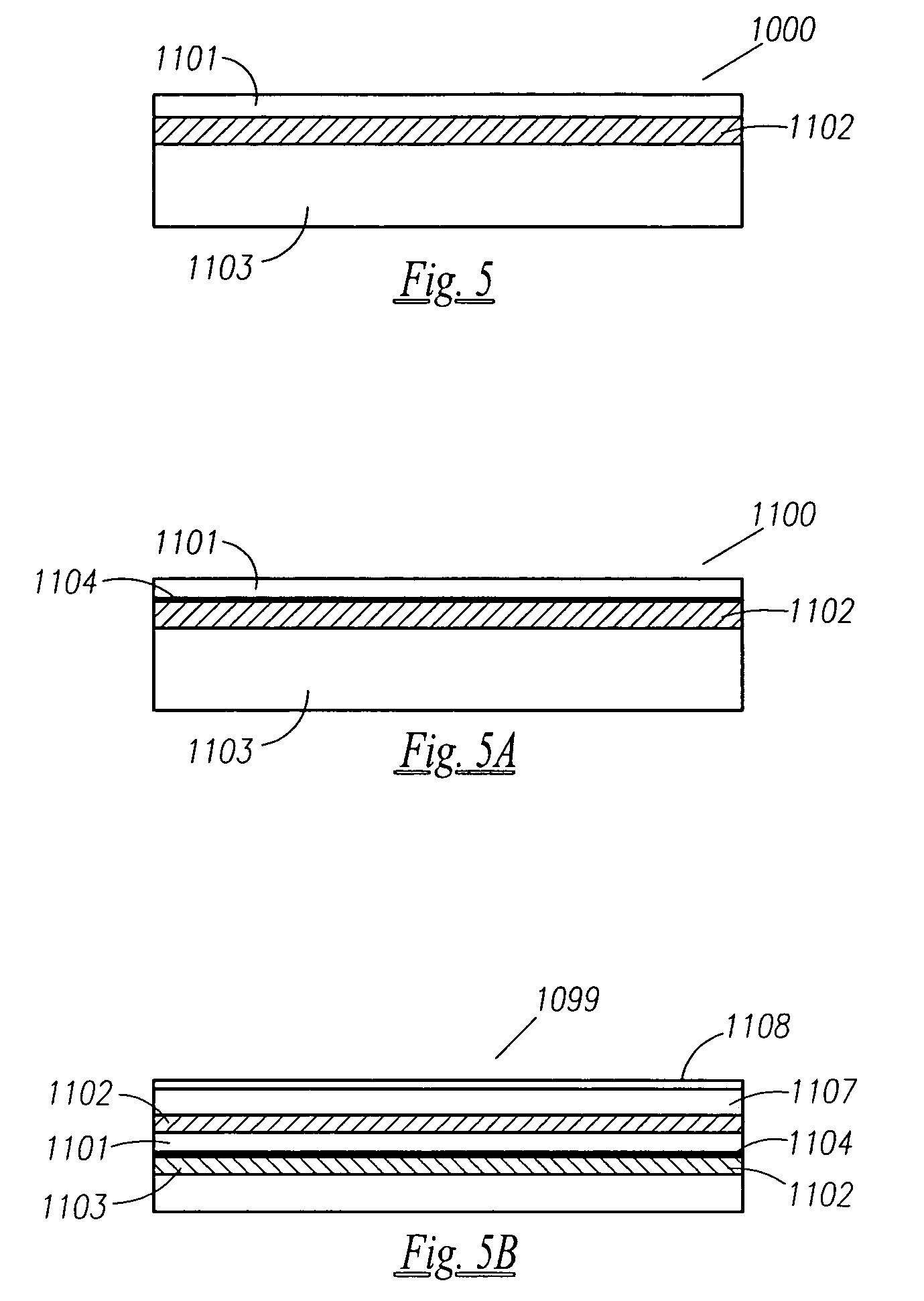

Layered barrier structure having one or more definable layers and method

InactiveUS20050147877A1Reduce transmissionLow rateFuel and primary cellsElectrode manufacturing processesDielectricLithium compound

A system provides an environmental barrier also useful for providing a circuit, for example, one having a thin-film battery such as one that includes lithium or lithium compounds connected to an electronic circuit. An environmental barrier is deposited as alternating layers, at least one of the layers providing a smoothing, planarizing, and / or leveling physical-configuration function, and at least one other layer providing a diffusion-barrier function. The layer providing the physical-configuration function may include a photoresist, a photodefinable, an energy-definable, and / or a maskable layer. The physical-configuration layer may also be a dielectric. A layered structure, including a plurality of pairs of layers, each pair including a physical configuration layer and a barrier layer with low gas-transmission rates, may be used in reducing gas transmission rate to beyond currently detectable levels.

Owner:CYMBET CORP

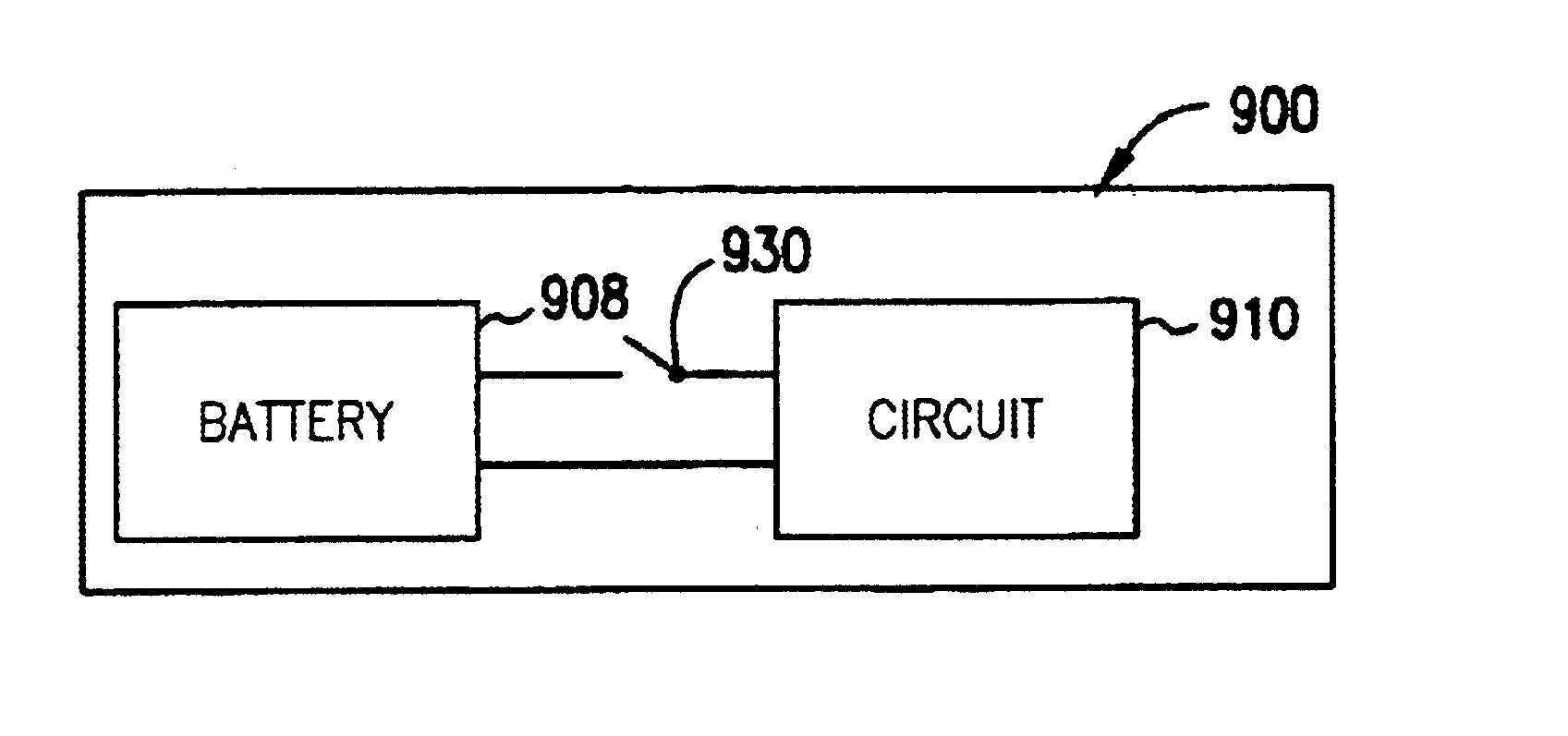

Solid state activity-activated battery device and method

InactiveUS6906436B2Sufficient energy storageBatteries circuit arrangementsFinal product manufactureEngineeringElectron

A system includes a thin-film battery and an activity-activated switch. The system is placed on a substrate with an adhesive backing. In some embodiments, the substrate is flexible. Also formed on the substrate is an electrical circuit that includes electronics. The activity-activated switch places the thin-film battery in electrical communication with the circuit and electronics. The battery and the circuit are formed on the substrate and may be comprised of one or a plurality of deposited layers.

Owner:CYMBET CORP

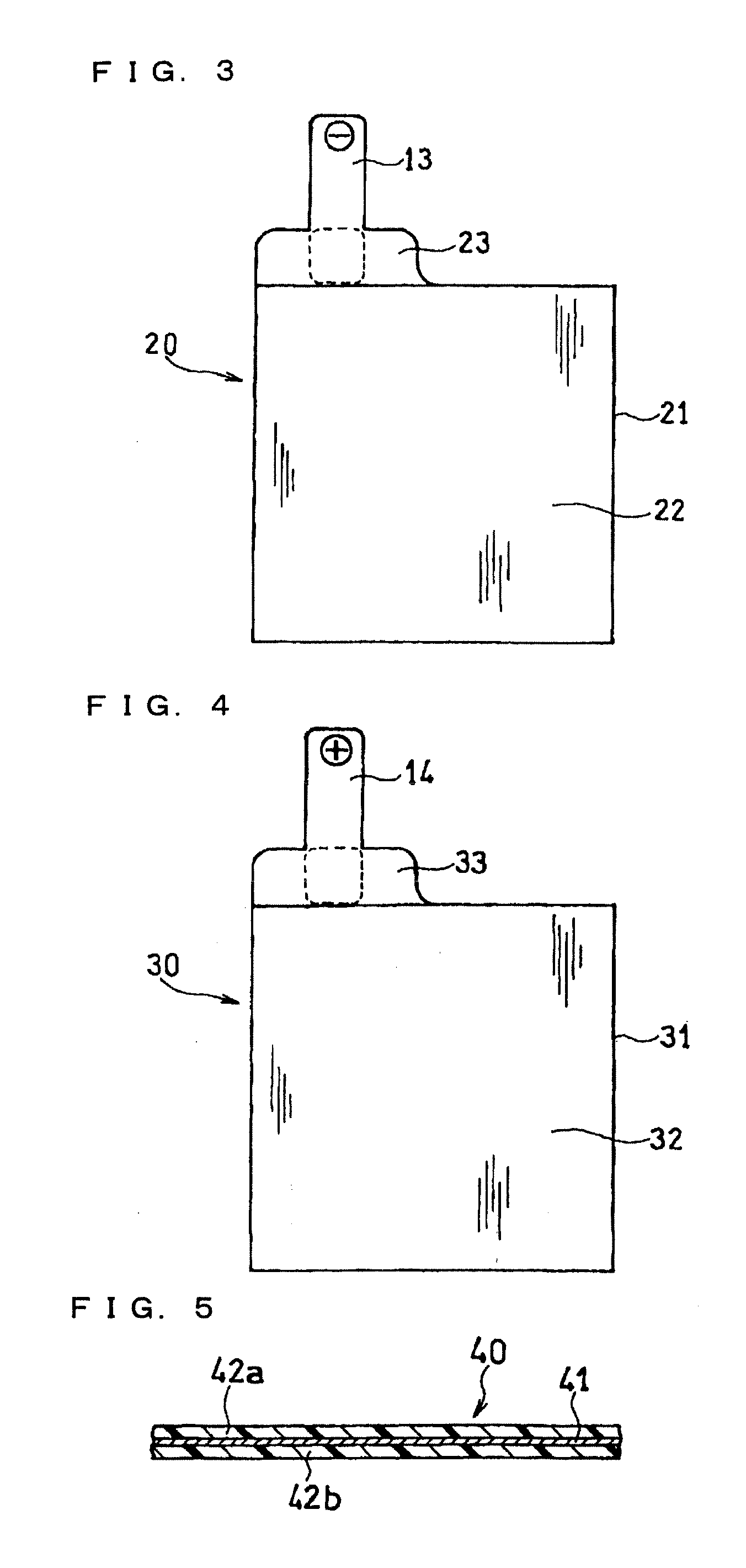

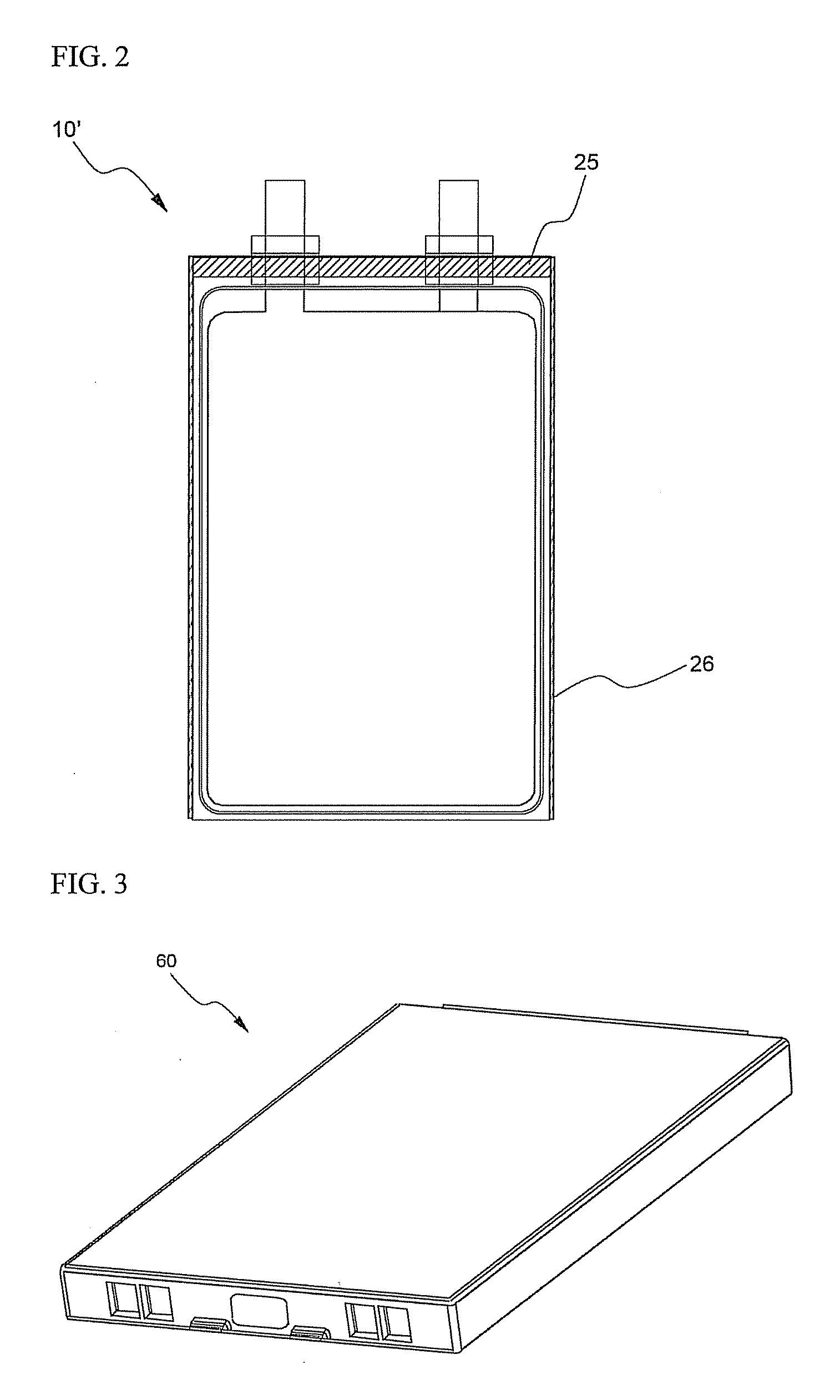

Battery pack

In a battery pack having a plurality of battery cells 10 connected in series and / or parallel, the battery pack is provided with a plurality of battery cells 10 each encased in a rectangular external case, and a plurality of separators 20 with electrical and heat insulating properties covering the outside of each battery cell external case excluding electrode terminals 12. Each separator 20 is disposed to intervene between adjacent battery cells 10 putting the external cases of those battery cells 10 in contact with both sides of the separator 20. With the external case of each battery cell 10 covered by separators 20 while exposing electrode terminals 12, those electrode terminals 12 are connected together. As a result, excluding required regions, battery cells 10 can be enclosed and unintended events such as short circuits can be effectively prevented.

Owner:SANYO ELECTRIC CO LTD

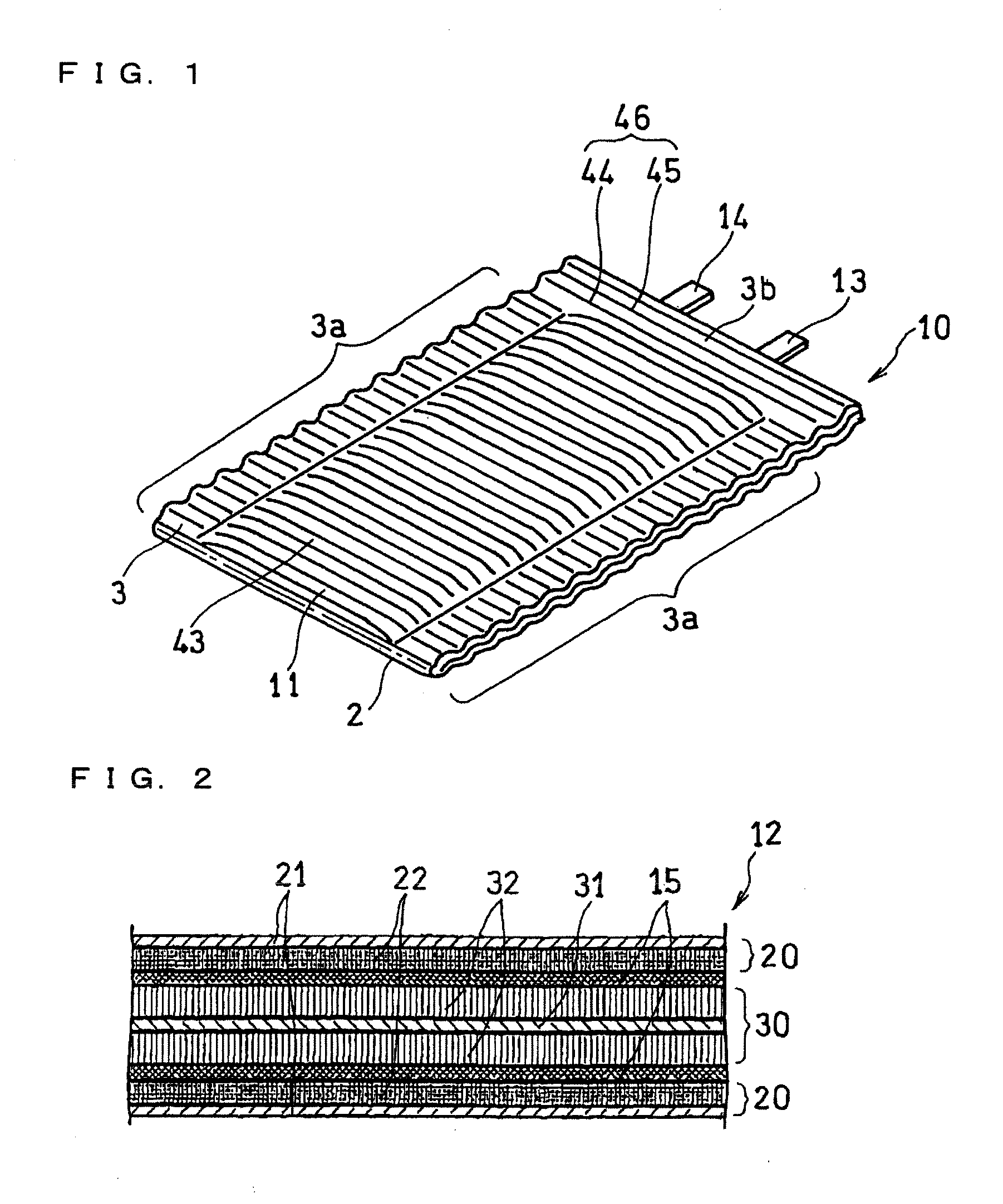

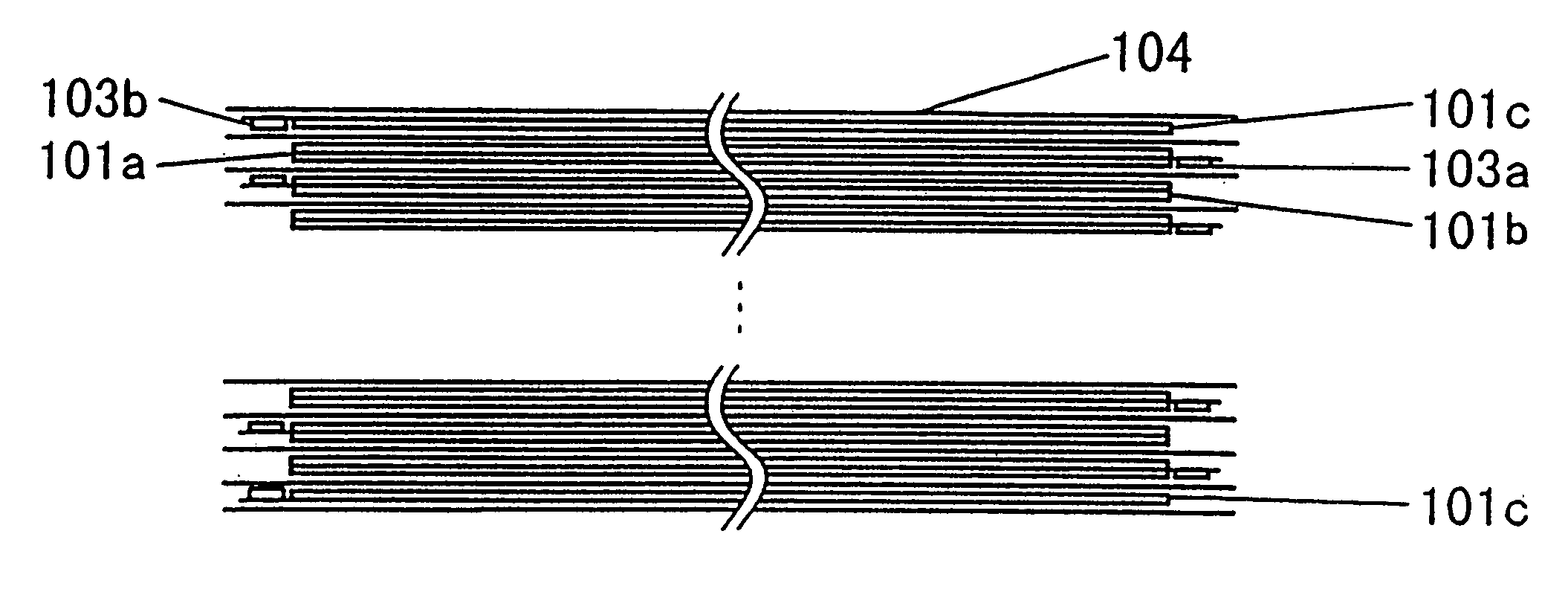

Thin-film batteries with soft and hard electrolyte layers and method

InactiveUS20070015060A1Improve environmental resistanceInhibition formationFinal product manufactureConductive materialLithium metalPolymer gel

A method and apparatus for making thin-film batteries having composite multi-layered electrolytes with soft electrolyte between hard electrolyte covering the negative and / or positive electrode, and the resulting batteries. In some embodiments, foil-core cathode sheets each having a cathode material (e.g., LiCoO2) covered by a hard electrolyte on both sides, and foil-core anode sheets having an anode material (e.g., lithium metal) covered by a hard electrolyte on both sides, are laminated using a soft (e.g., polymer gel) electrolyte sandwiched between alternating cathode and anode sheets. A hard glass-like electrolyte layer obtains a smooth hard positive-electrode lithium-metal layer upon charging, but when very thin, have randomly spaced pinholes / defects. When the hard layers are formed on both the positive and negative electrodes, one electrode's dendrite-short-causing defects on are not aligned with the other electrode's defects. The soft electrolyte layer both conducts ions across the gap between hard electrolyte layers and fills pinholes.

Owner:CYMBET CORP

Resin composition and resin composition for secondary battery jar

InactiveUS6045883ASave resourcesProtect environmentSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsPolypropyleneEther

PCT No. PCT / JP96 / 01794 Sec. 371 Date Dec. 8, 1997 Sec. 102(e) Date Dec. 8, 1997 PCT Filed Jun. 28, 1996 PCT Pub. No. WO97 / 01600 PCT Pub. Date Jan. 16, 1997A resin composition comprising a polypropylene resin, a polyphenylene ether resin and a compatibility agent wherein dispersion particles comprising the polyphenylene ether resin (b) are dispersed in a matrix comprising the polypropylene resin (a), a minor diameter of the dispersion particles is 2 mu m or less, and the ratio of major diameter / minor diameter is 1-10.

Owner:ASAHI KASEI KK

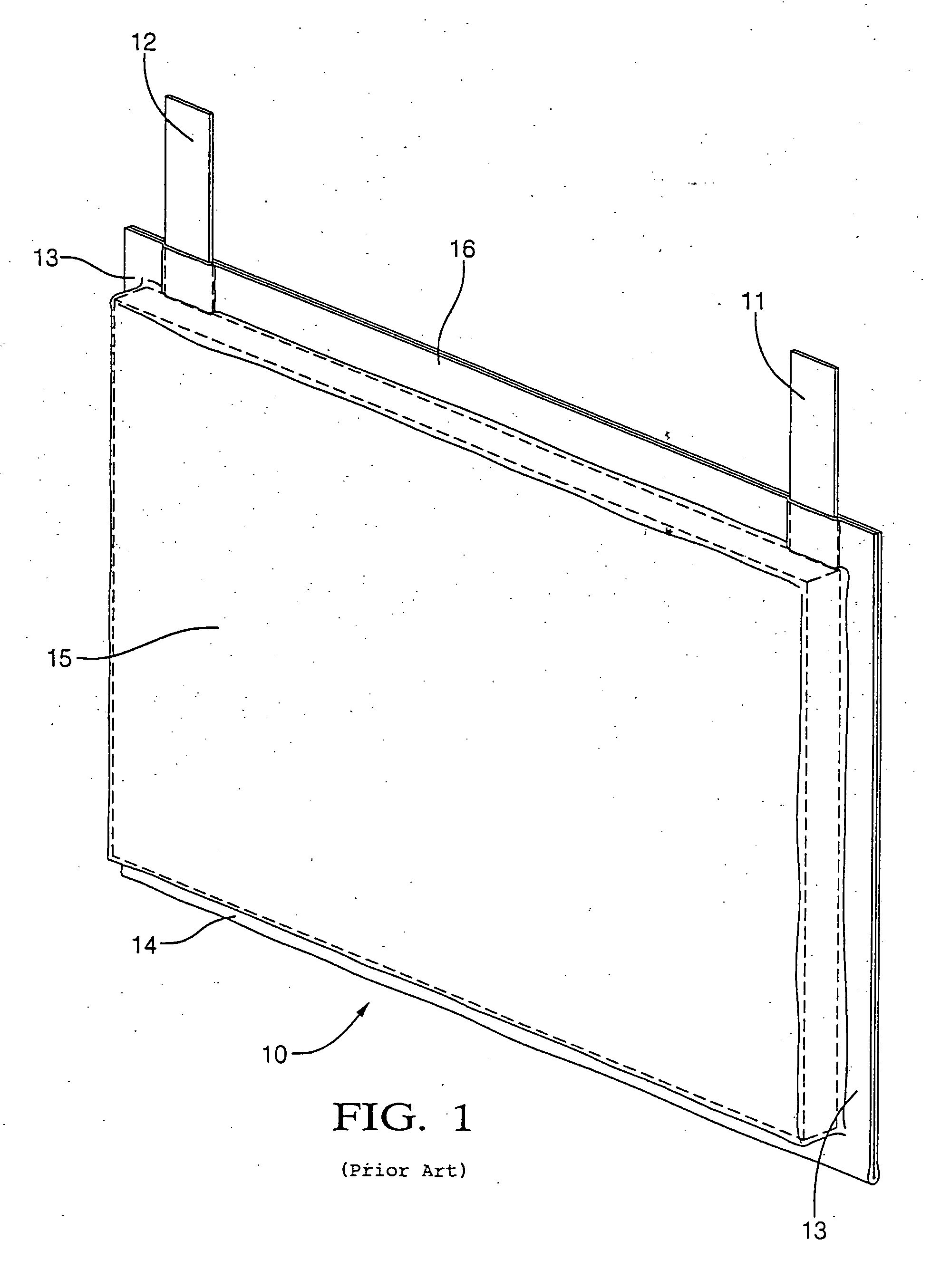

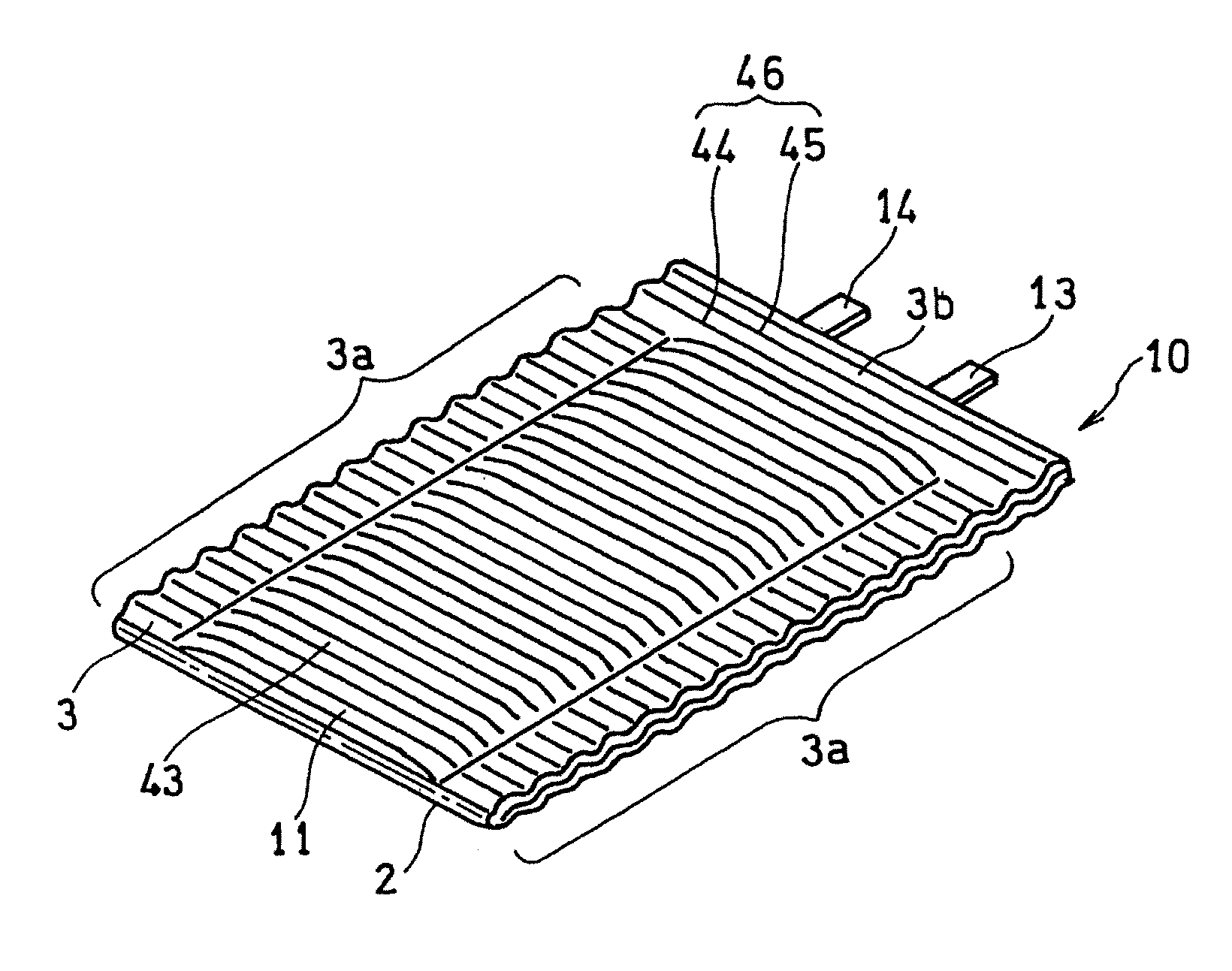

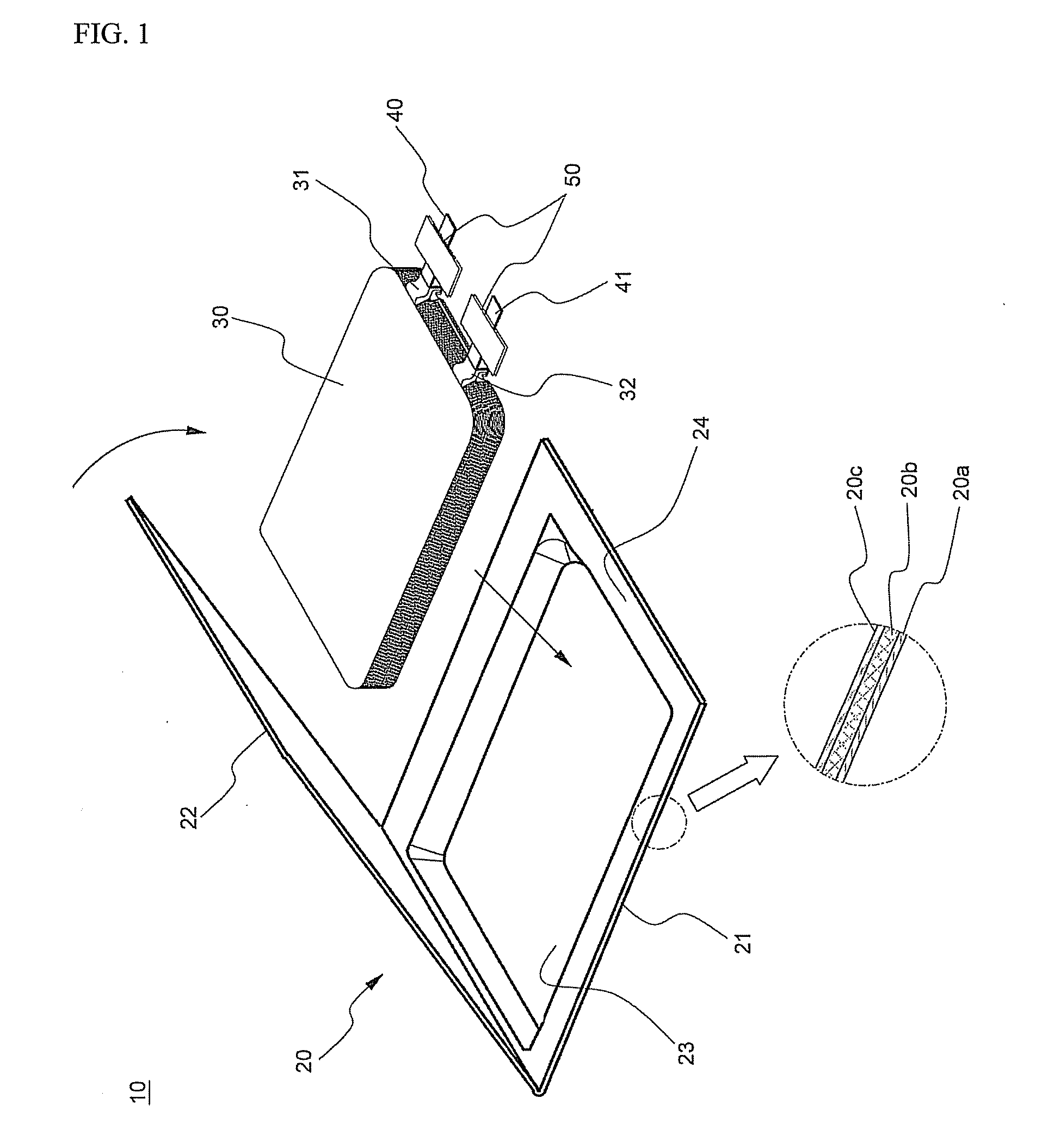

Flexible battery and method for producing the same

InactiveUS20130101884A1Impart high flexibilityImproves sealing reliabilityFinal product manufactureSmall-sized cells cases/jacketsEngineeringFlexible battery

Disclosed is a flexible battery including a sheet-like electrode group, an electrolyte, and a housing with flexibility enclosing the electrode group and electrolyte. The housing includes a film material folded into two in which the electrode group is inserted. The film material has two facing portions respectively facing two principal surfaces of the electrode group, a fold line which is between the two facing portions and along which the film material is folded, and two bonding margins respectively set around the two facing portions. The two bonding margins are bonded to each other into a bonded portion. At least the two facing portions of the film material are formed in a corrugated shape having a plurality of ridge and valley lines arranged in parallel to each other. The ridge lines in one of the two facing portions are overlapped with the valley lines in the other. The fold line is parallel to the ridge and valley lines.

Owner:PANASONIC CORP

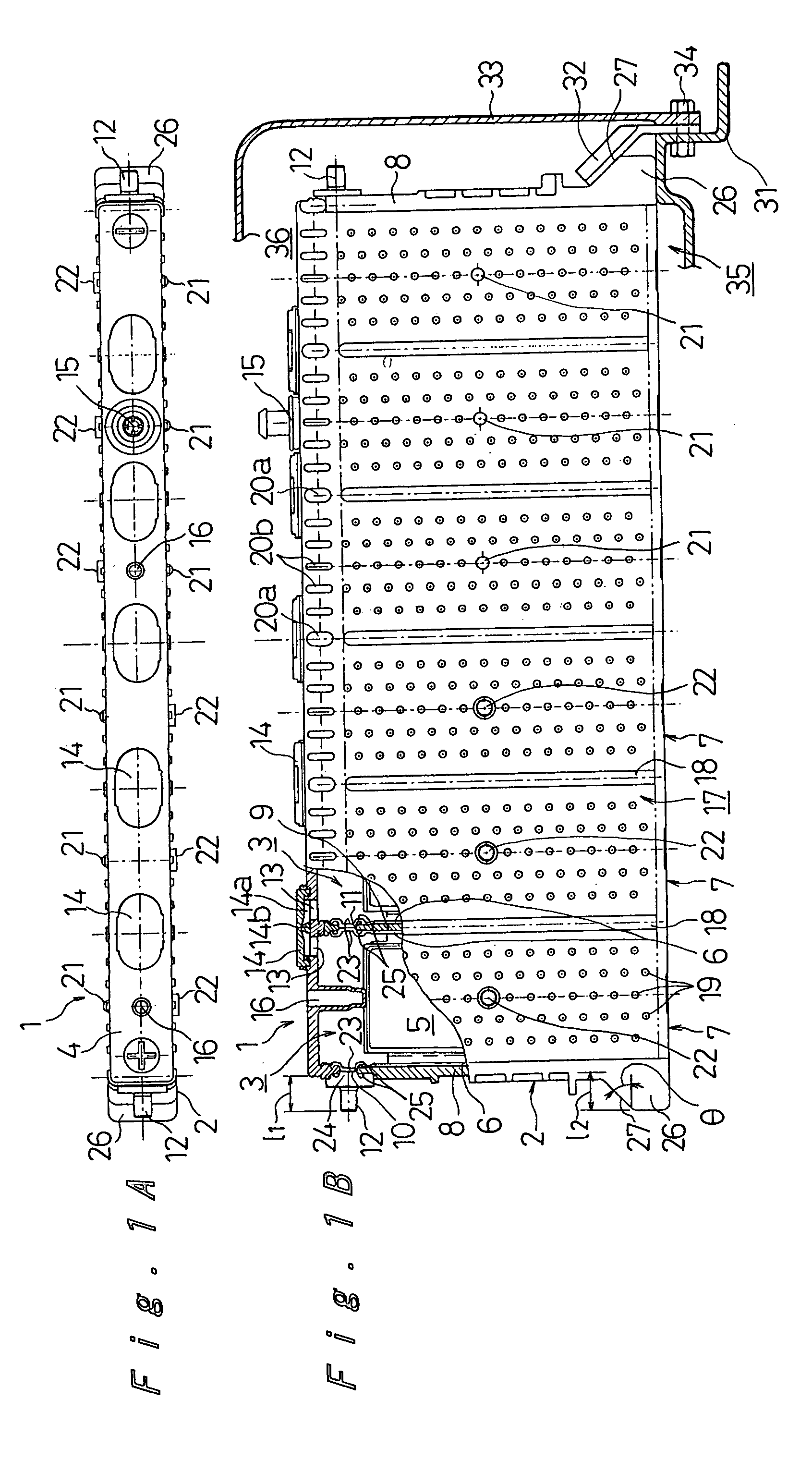

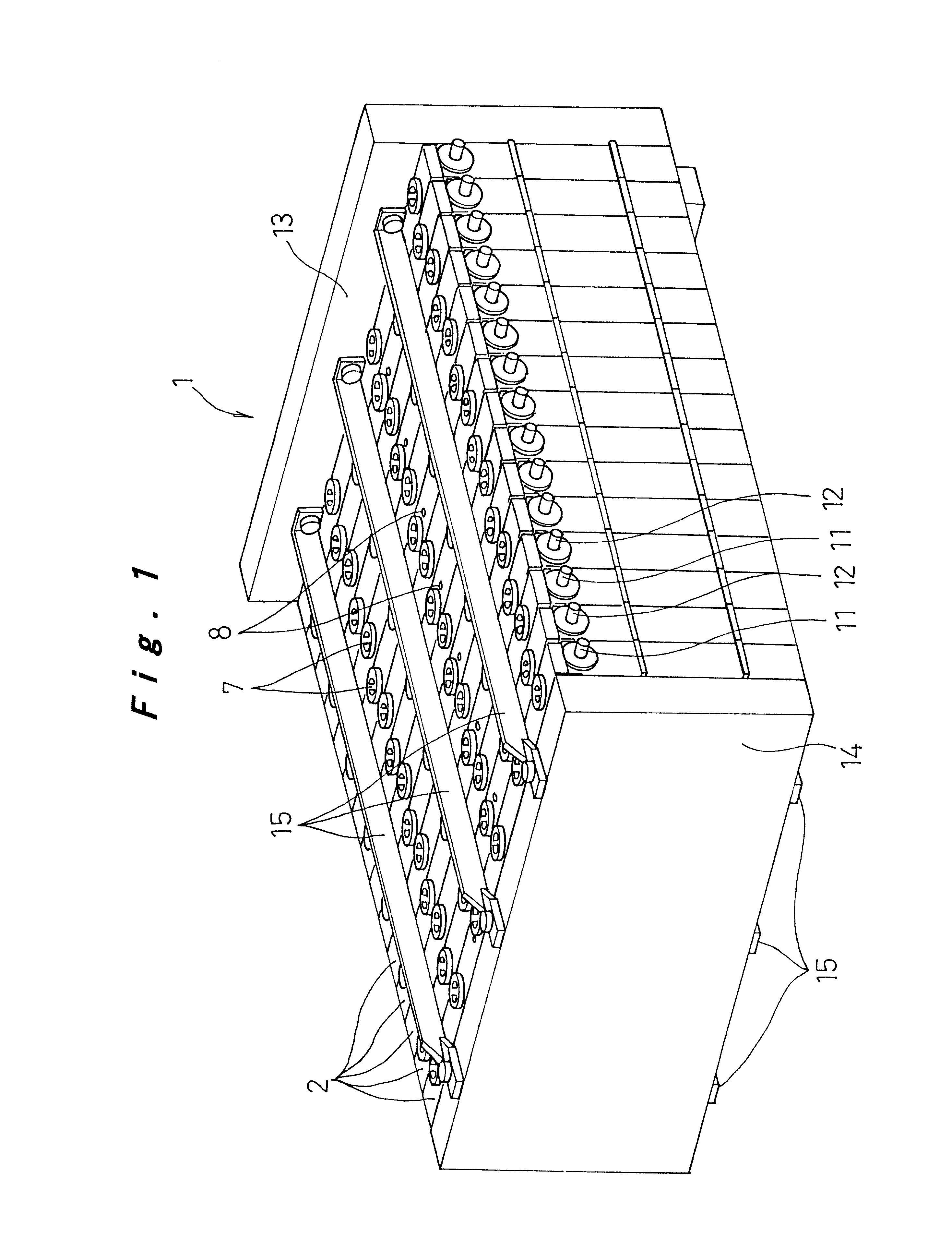

Battery module

InactiveUS20070285051A1Improved contact characteristicsIncrease contactBatteries circuit arrangementsLarge-sized flat cells/batteriesEngineeringElectrical and Electronics engineering

A battery module includes a plurality of unit batteries and barriers which are interposed between the unit batteries. The barriers have front surfaces which contact the unit batteries and which are curved to bend elastically. The barriers have side surfaces which interconnect the front surfaces, and which have pathways through which a heat transfer medium flows. Connecting rods and nuts interconnect end plates of the battery module so as to press the unit batteries and the barriers together.

Owner:SAMSUNG SDI CO LTD

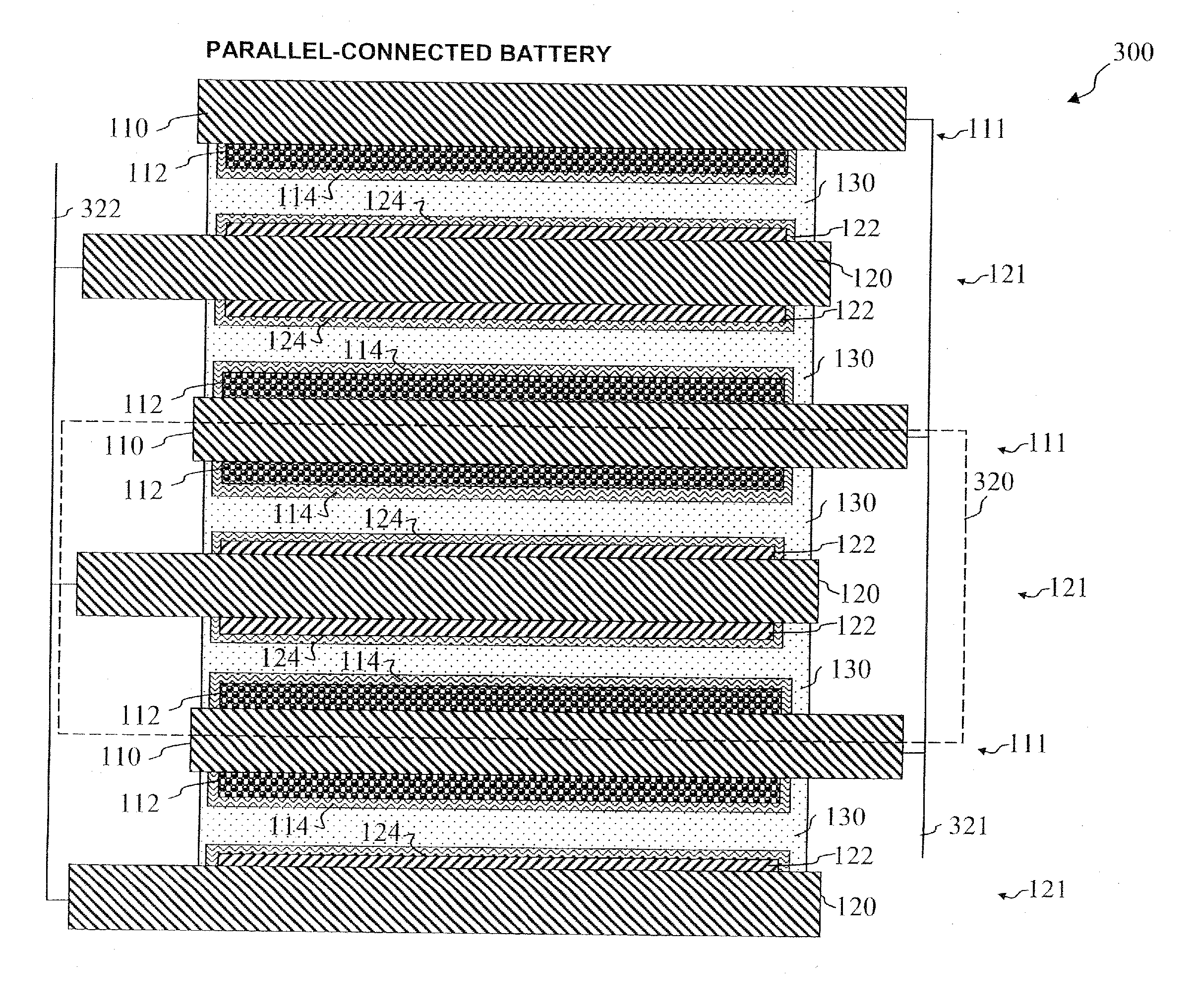

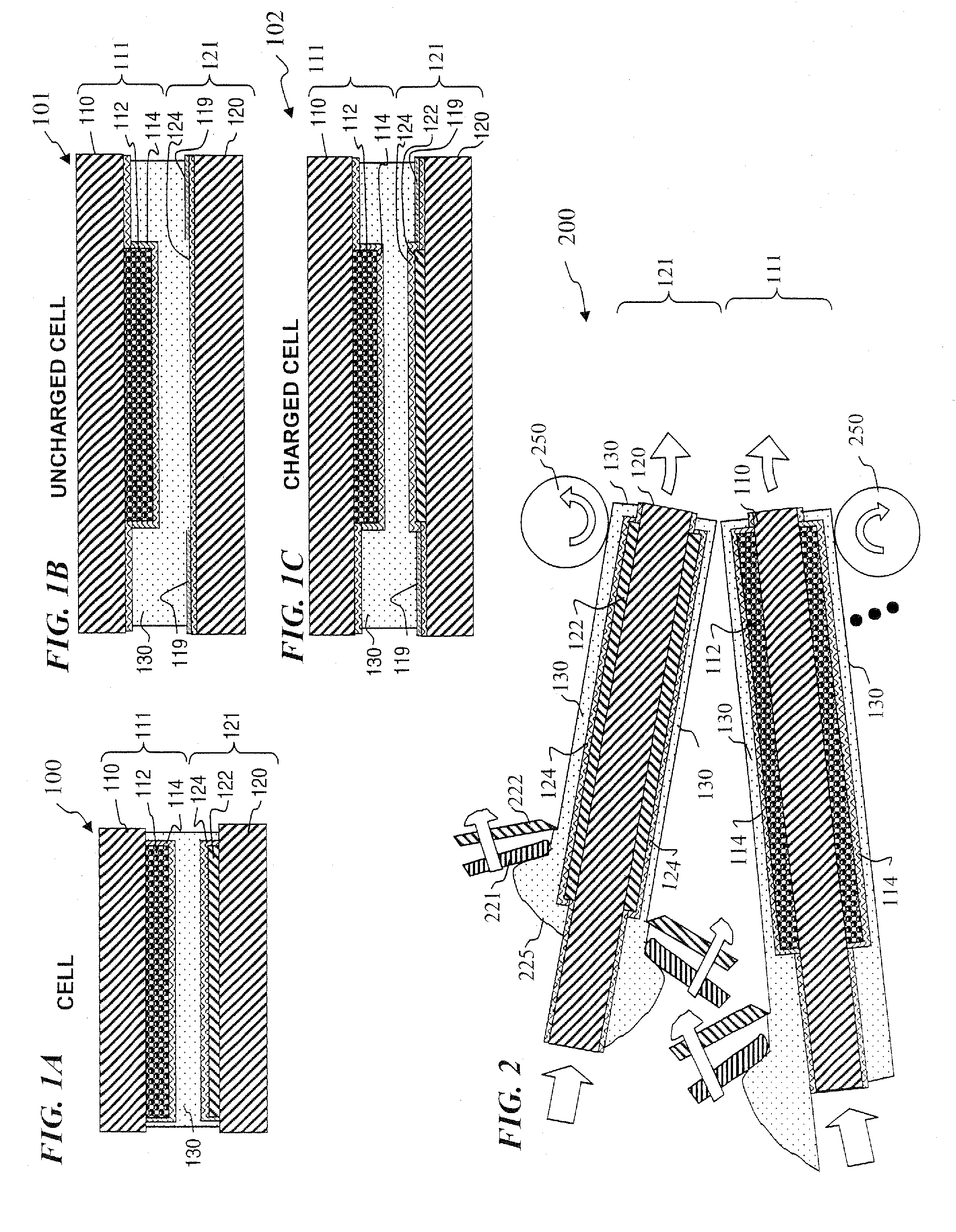

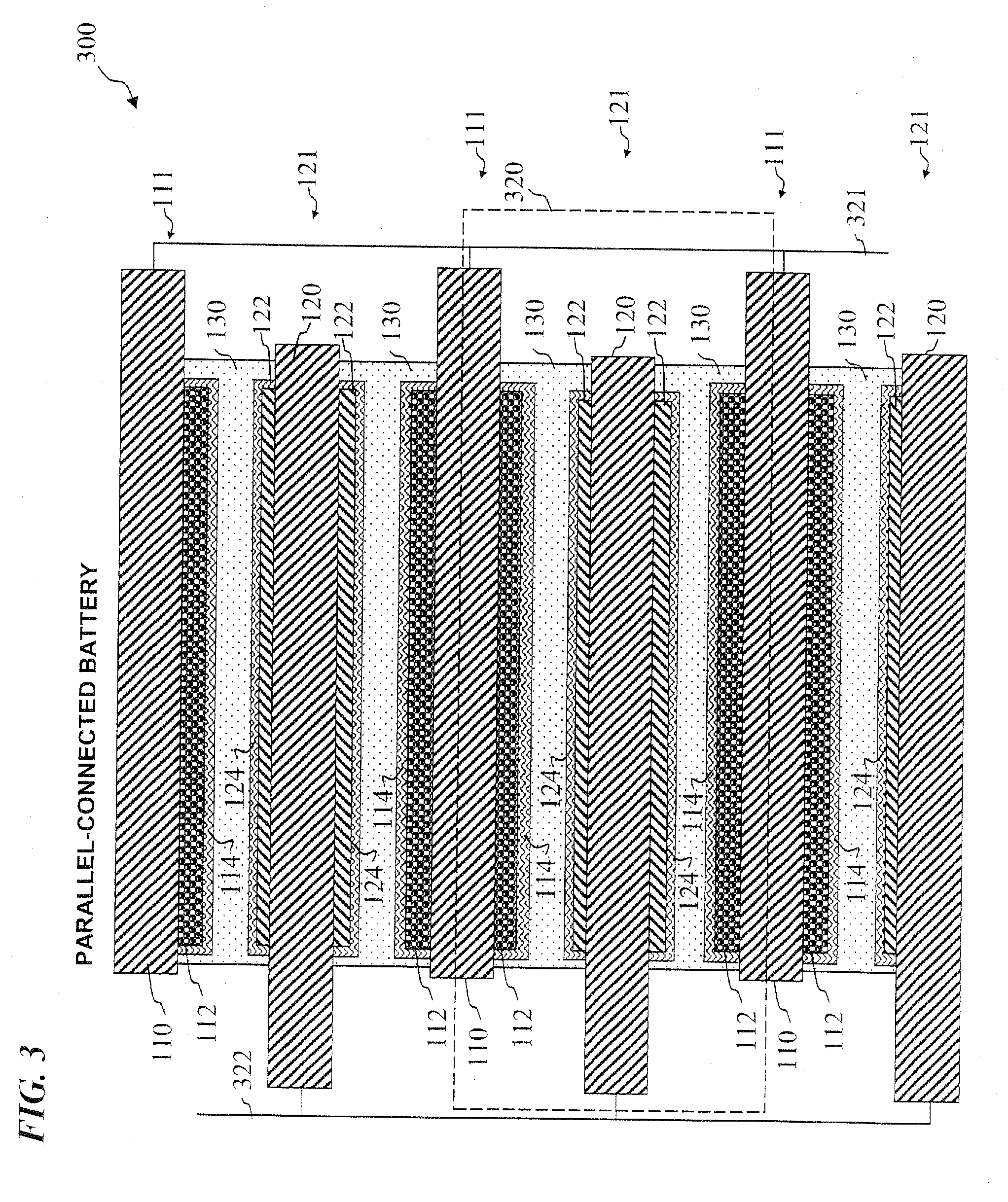

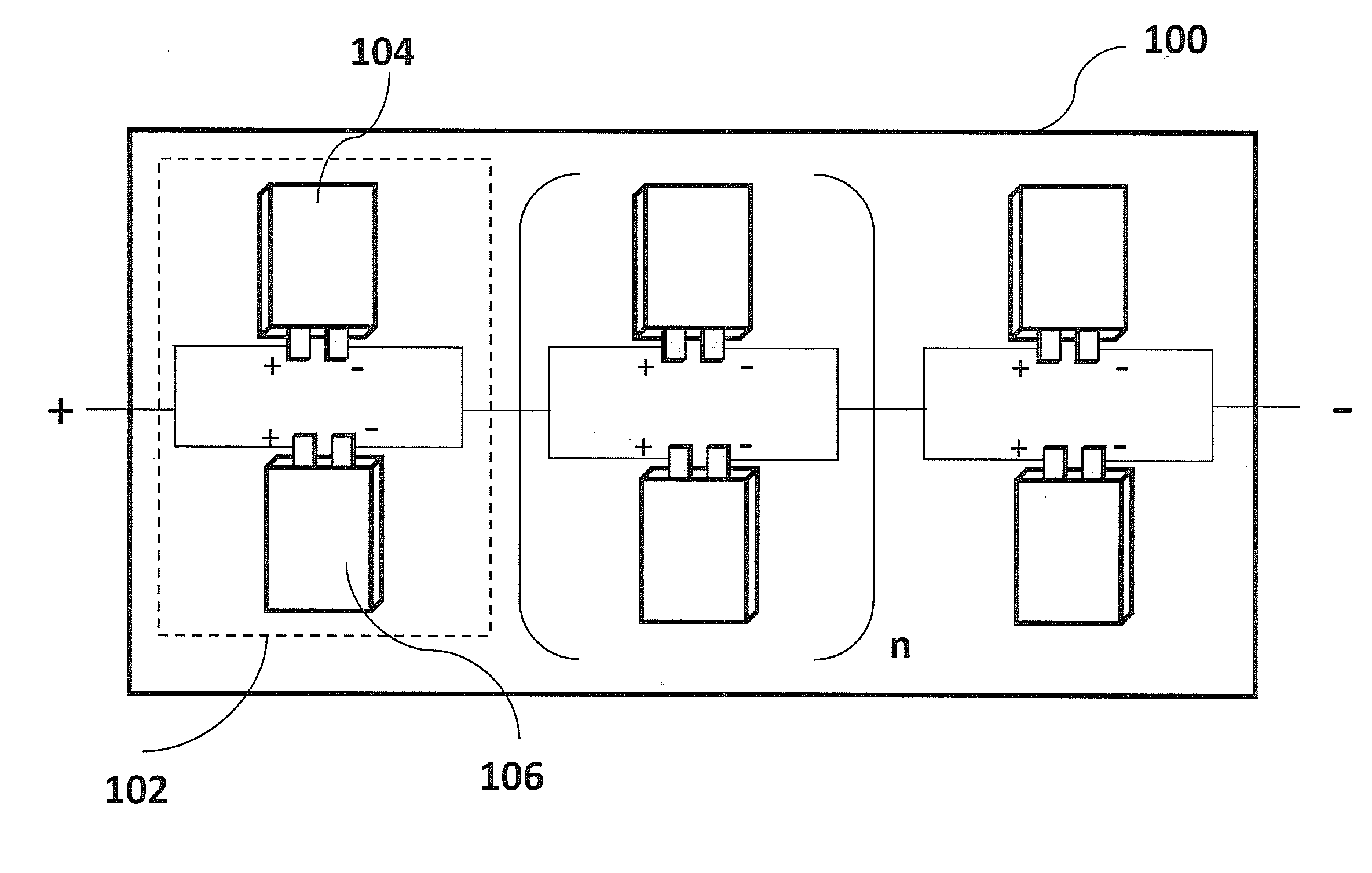

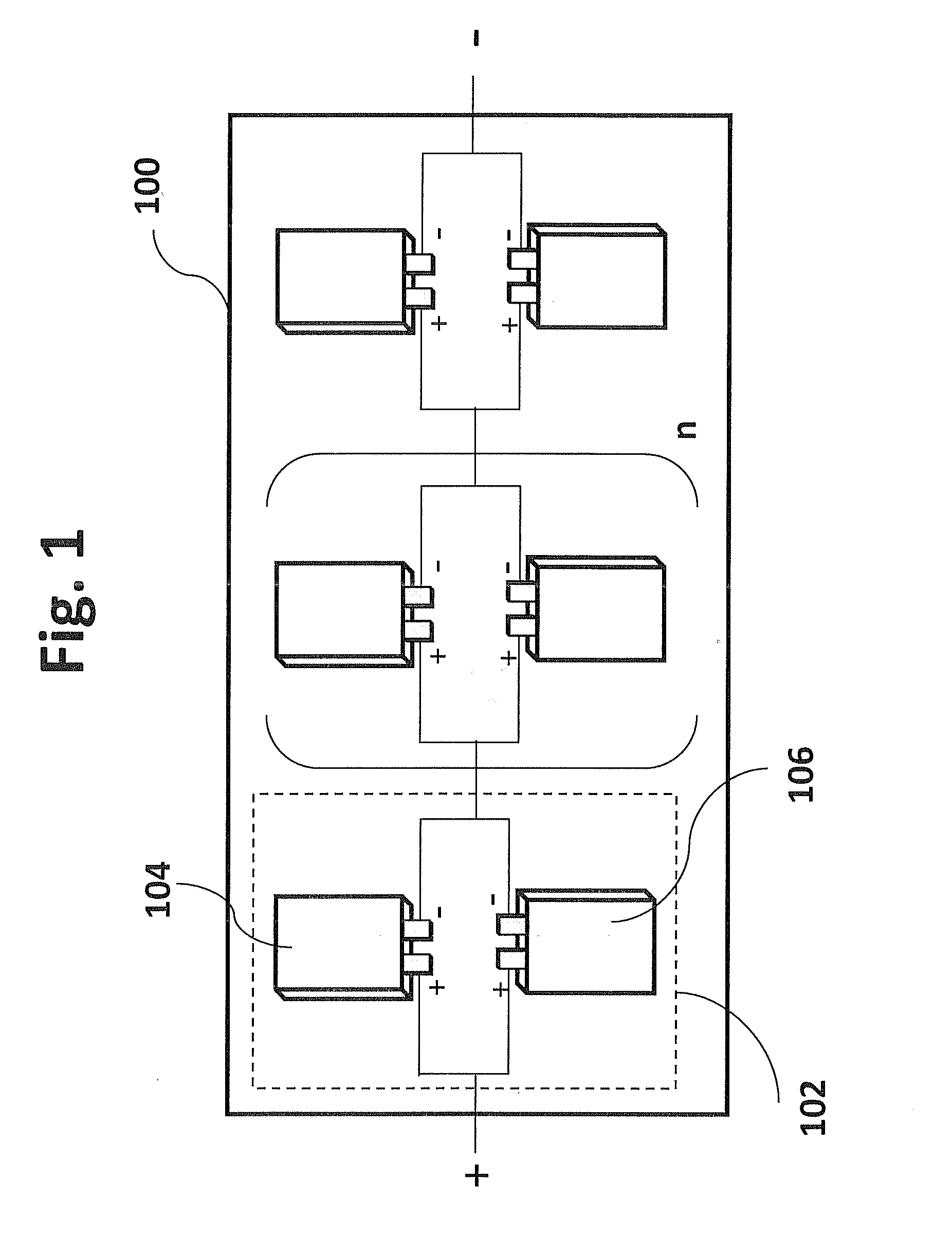

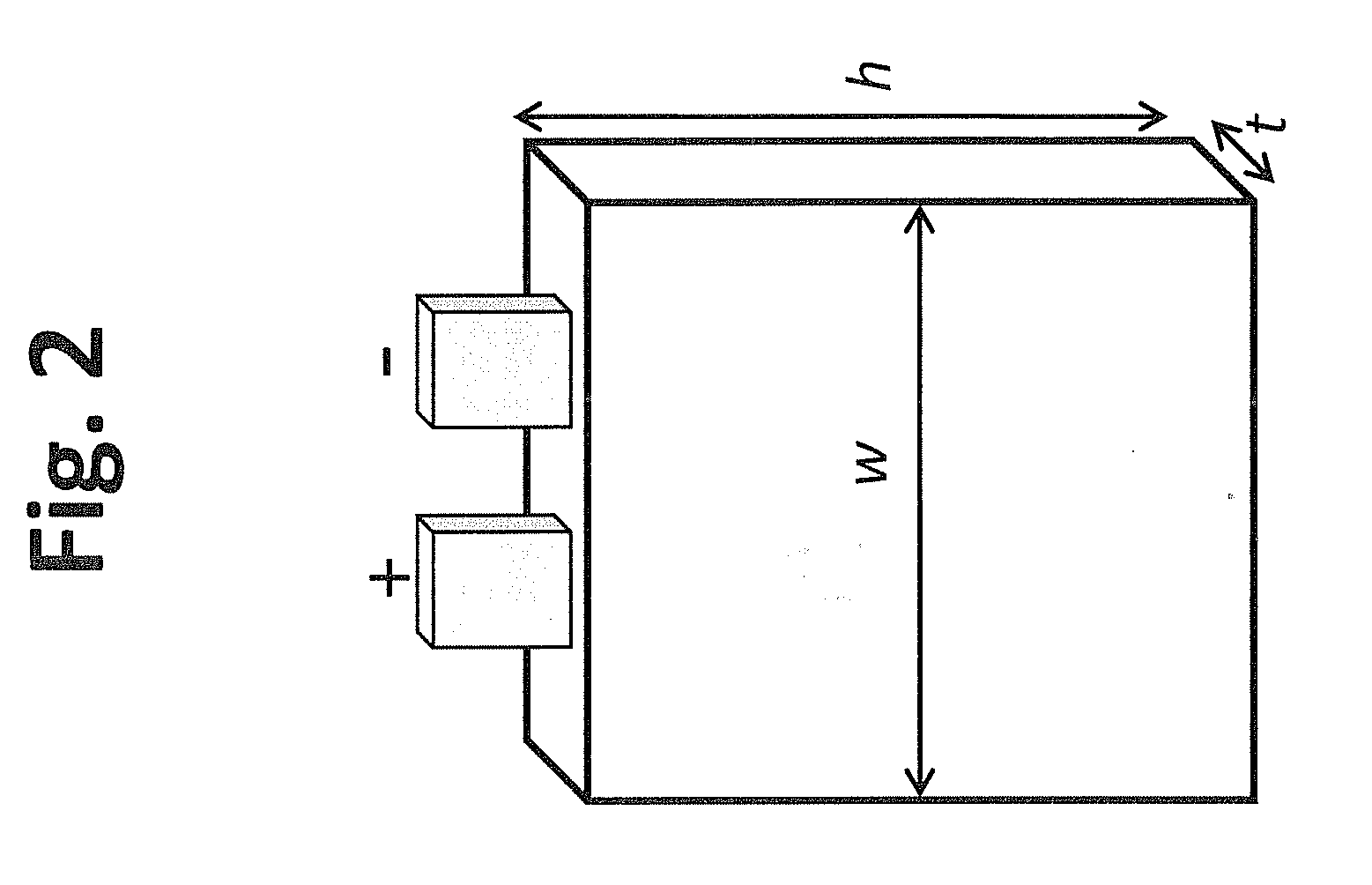

Battery Packs for Vehicles and High Capacity Pouch Secondary Batteries for Incorporation into Compact Battery Packs

High performance battery packs are described especially for use in electric vehicles and plug-in hybrid electric vehicles. Based on high energy lithium ion battery designs, the battery packs can have pairs of parallel connected batteries to supply an energy capacity at full discharge of at least about 40 kilowatt-hours or in alternative embodiments a set of all series connected batteries that can produce at full discharge at least about 15 kilowatt-hours. In some embodiments, lithium rich positive electrode active materials can be used to faun the batteries in which the material comprises a composition approximately represented by a formula xLi2M′O3.(1−x)LiMO2 with x from about 0.05 to about 0.8.

Owner:IONBLOX INC

Structure for electrode terminals of battery module

InactiveUS6982131B1Compact structurePrimary cell to battery groupingLarge-sized flat cells/batteriesElectrical and Electronics engineeringHorizontal ribs

On the opposite end walls of a flat, prismatic battery case of a battery module where electrode terminals are attached, protruding components are formed such as to protrude further than the electrode terminals. Terminal holes are formed in the end walls in which the electrode terminals are fitted, and the thickness of the end walls of the integral battery case in the vicinity of the terminal holes is not the same on both sides of each of the terminal holes. Also, one or a plurality of vertical and horizontal ribs are formed on the end walls between the electrode terminals and the protruding components. Further, a sealing structure is included for a battery.

Owner:PANASONIC CORP +1

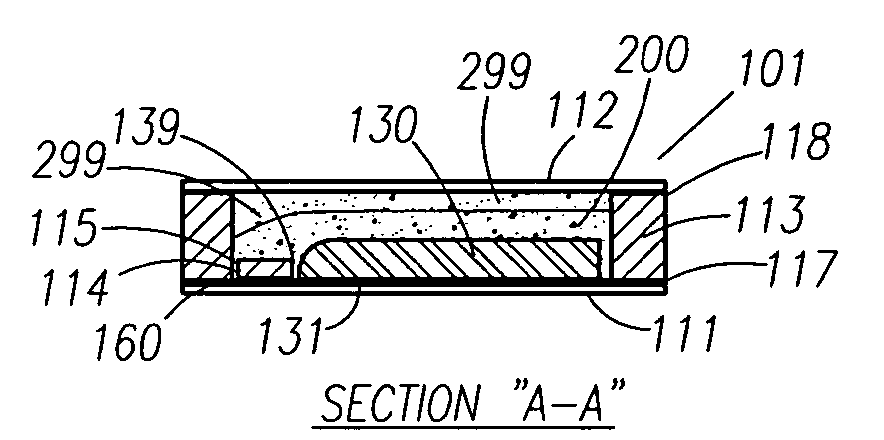

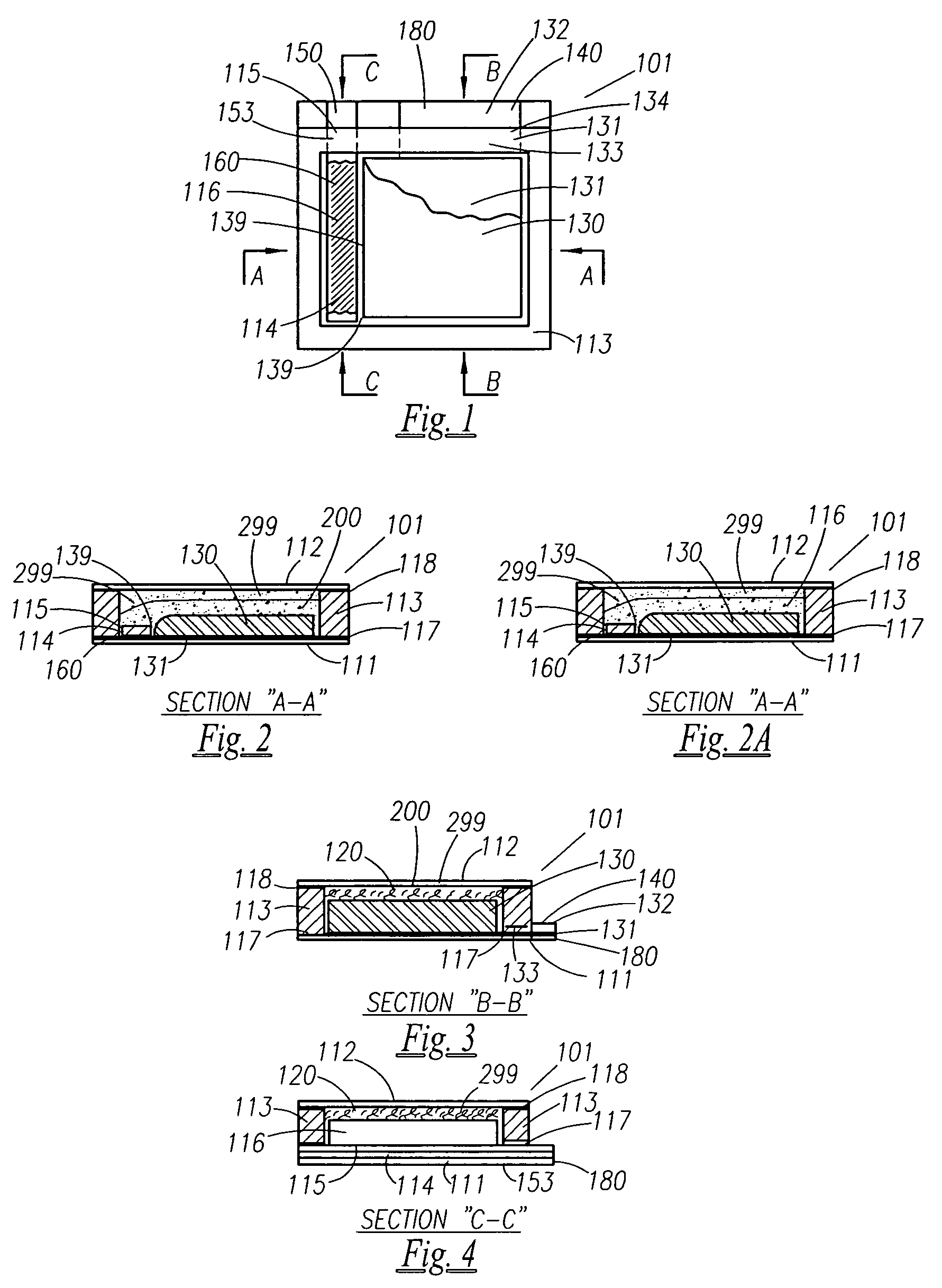

Thin printable electrochemical cell utilizing a "picture frame" and methods of making the same

A thin printed flexible electrochemical cell, and its method of manufacture, using a “picture frame” structure sealed, for example, with a high moisture and oxygen barrier polymer film and featuring, for example, a printed cathode deposited on an optional, highly conductive carbon printed cathode collector with a printed or a foil strip anode placed adjacent to the cathode. A viscous or gelled electrolyte is dispensed and / or printed in the cell, and a top laminate can then be sealed onto the picture frame. Such a construction could allow the entire cell to be made on a printing press, for example, as well as gives the opportunity to integrate the battery directly with an electronic application, for example.

Owner:BLUE SPARK INNOVATIONS LLC

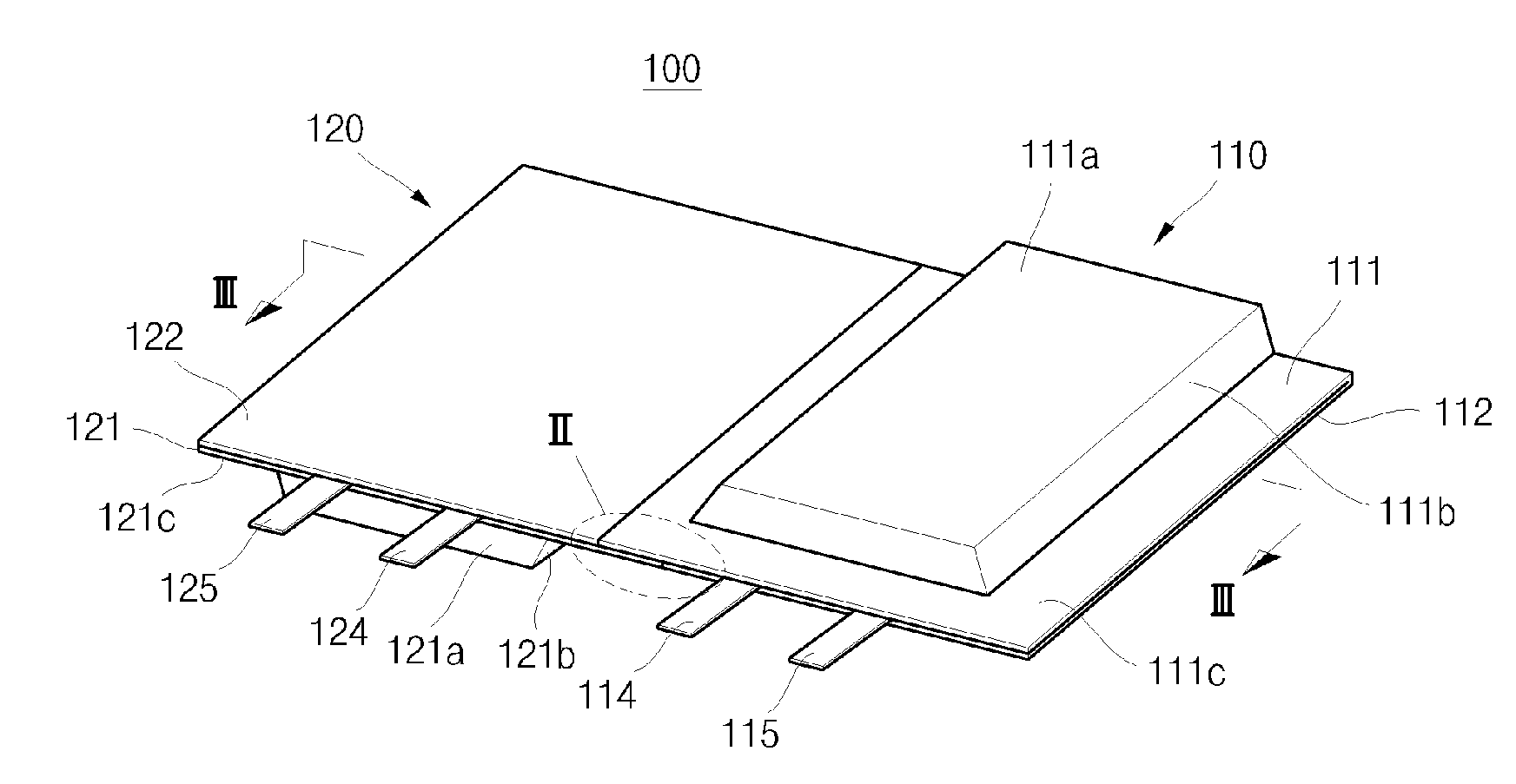

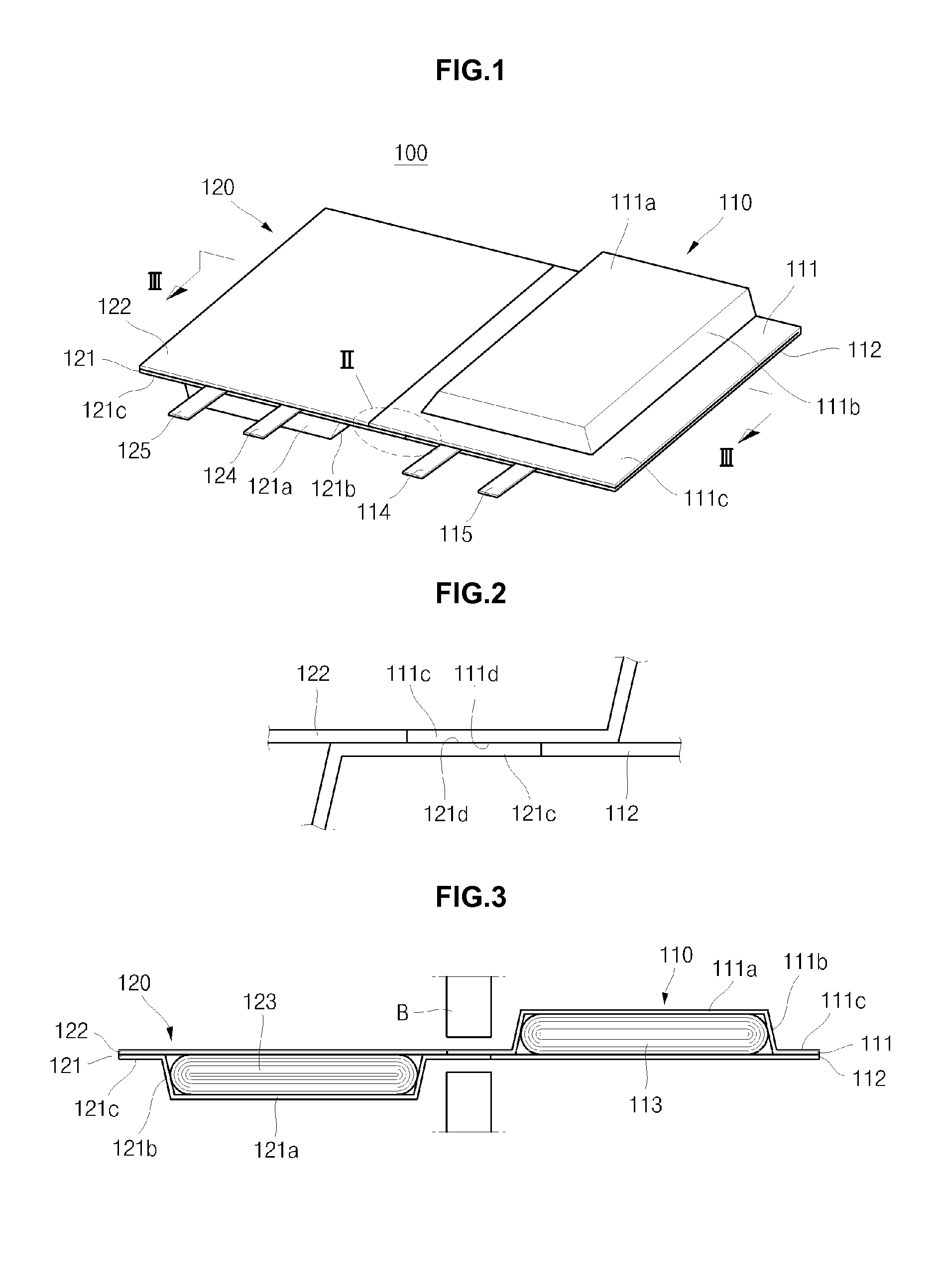

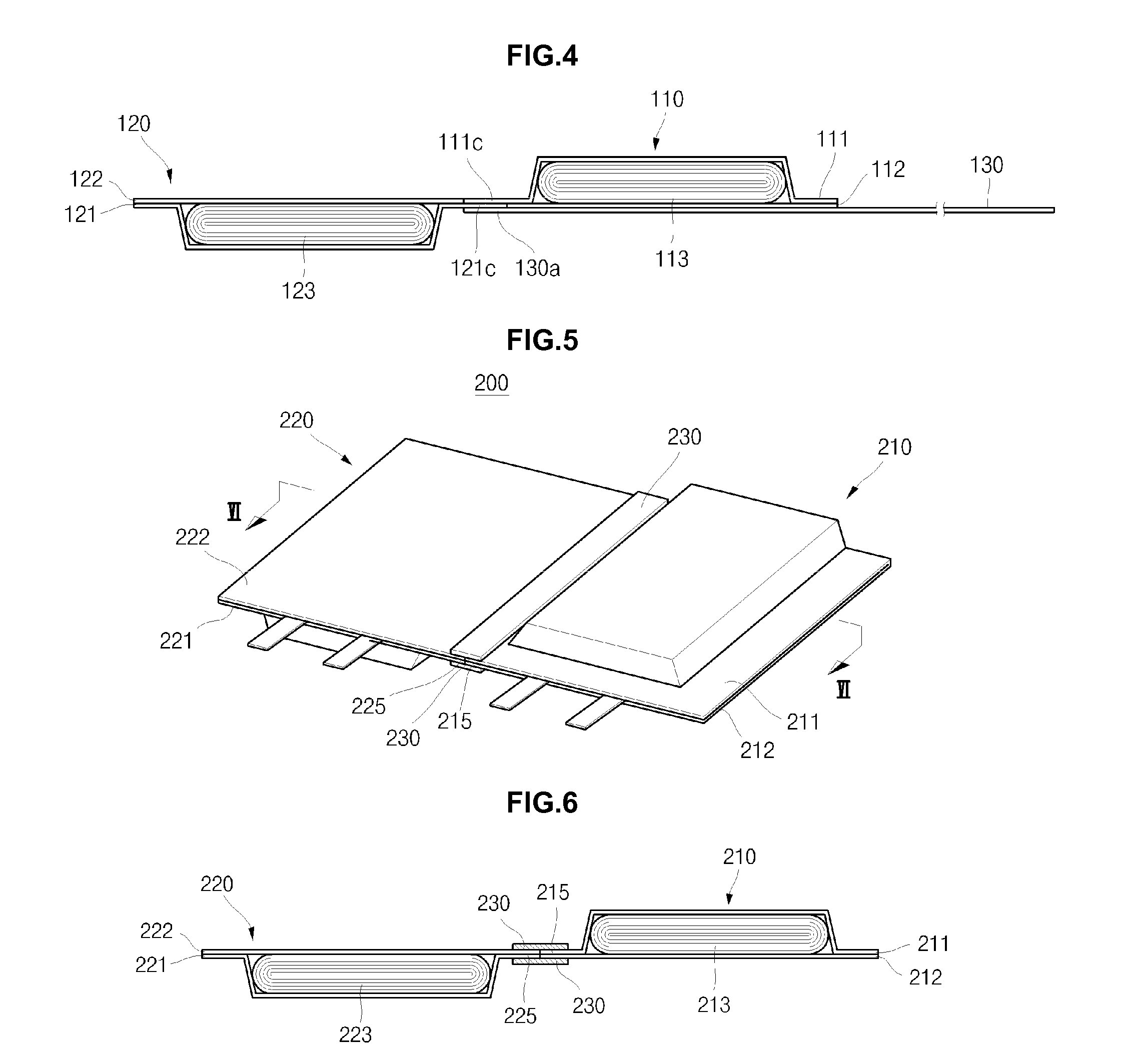

Small battery pack employing PCM on side sealing part

InactiveUS20070264535A1Enhanced couplingAvoid introducingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringHigh intensity

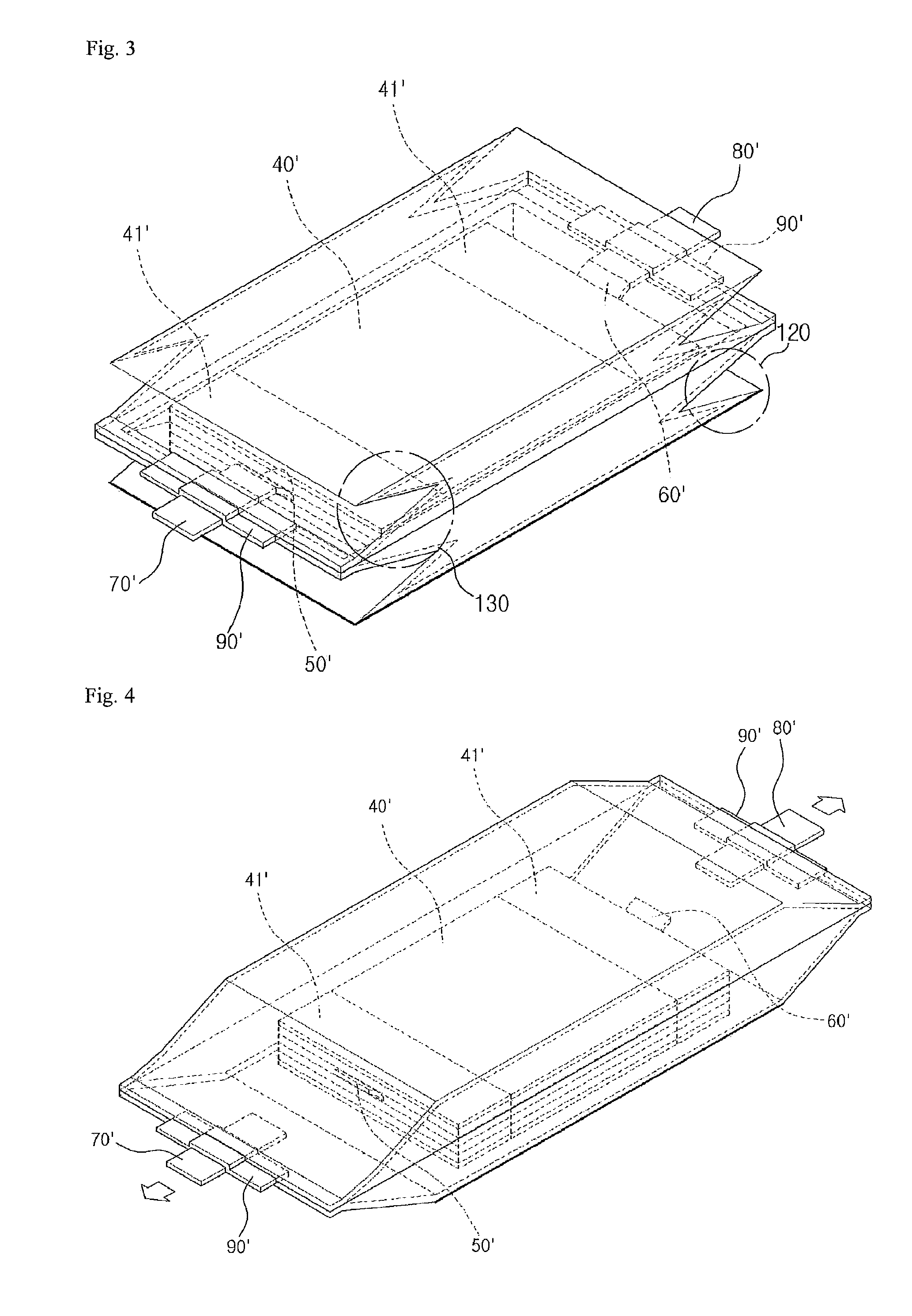

Disclosed herein is a battery pack constructed such that a battery case, in which an electrode assembly is mounted, is made of a laminate sheet having high strength, side sealing parts of the battery case are formed in a specific shape, and a protection circuit module (PCM) is located in the inner space of at least one of the side sealing parts. The side sealing parts in themselves are used as a structure to decide the external shape of the battery pack, and, at the same time, are used as spaces for mounting the PCM therein. Consequently, it is possible to construct the battery pack without using additional pack sheathing members, to simplify the assembly process of the battery pack, and to manufacture the battery pack in a thinner and more compact structure with the reduced manufacturing costs. Furthermore, the PCM is located at either side of the battery cell while the PCM is spaced apart from electrode terminals. Consequently, the battery pack exhibits high safety against external impacts, such as dropping of the battery pack.

Owner:LG CHEM LTD

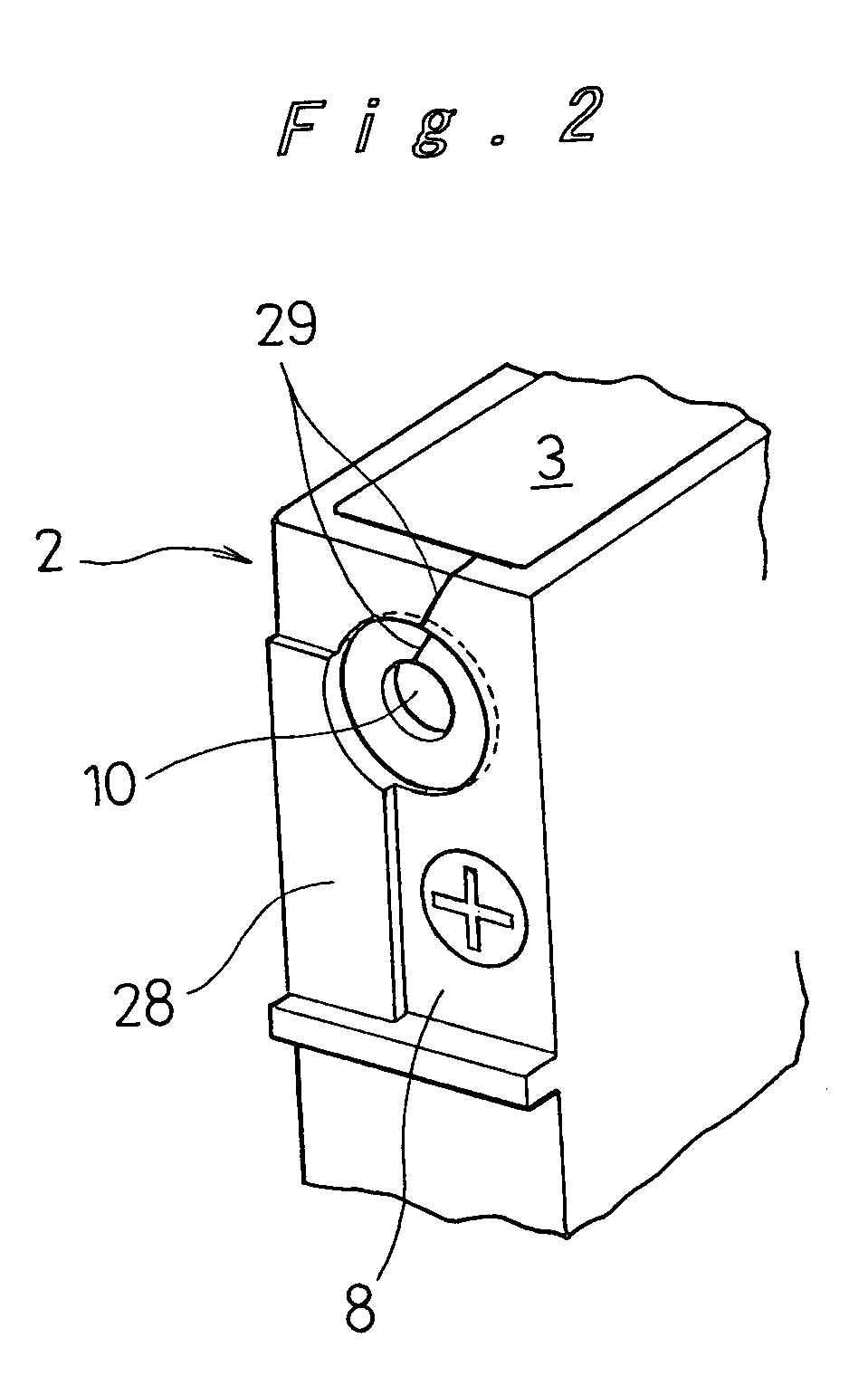

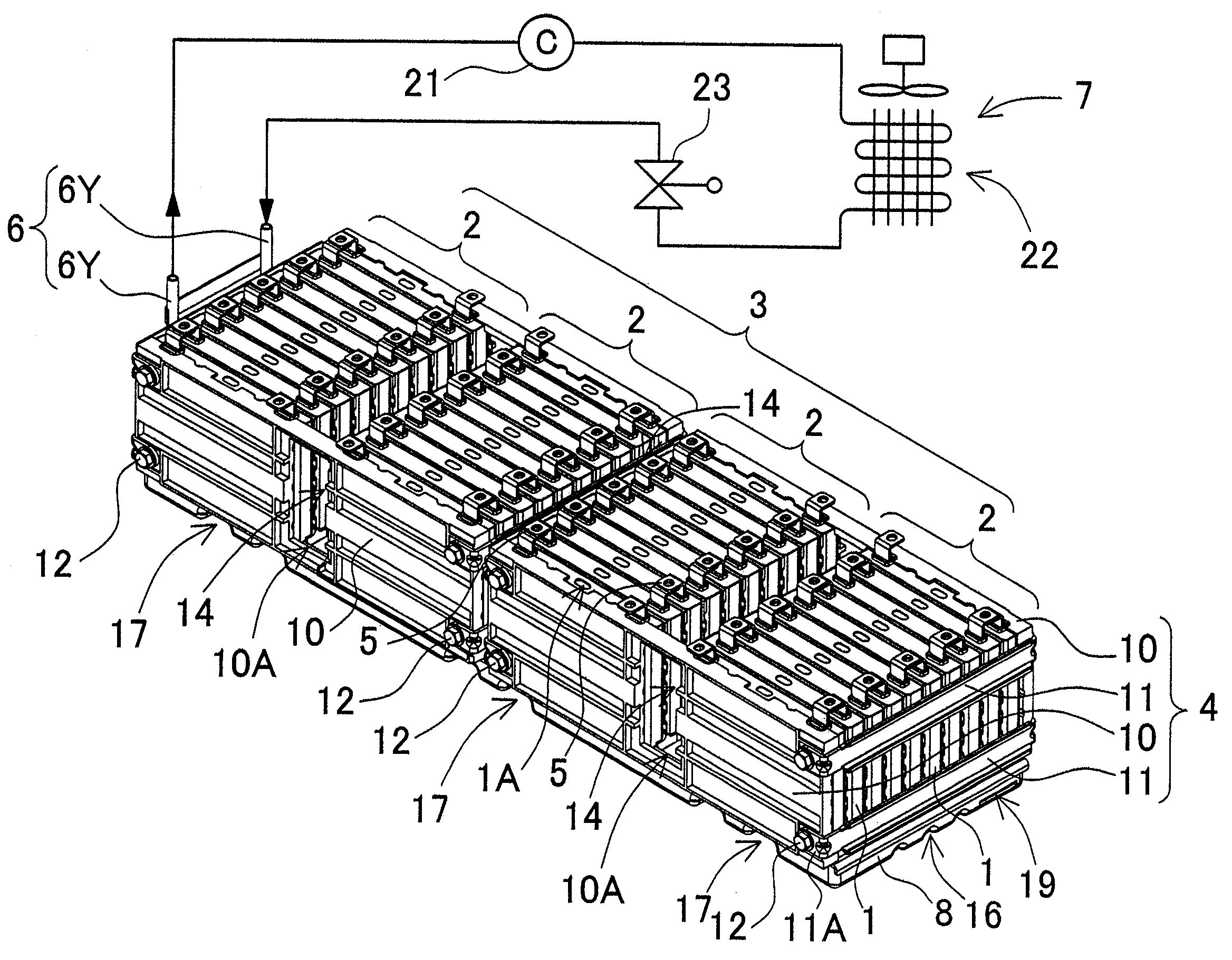

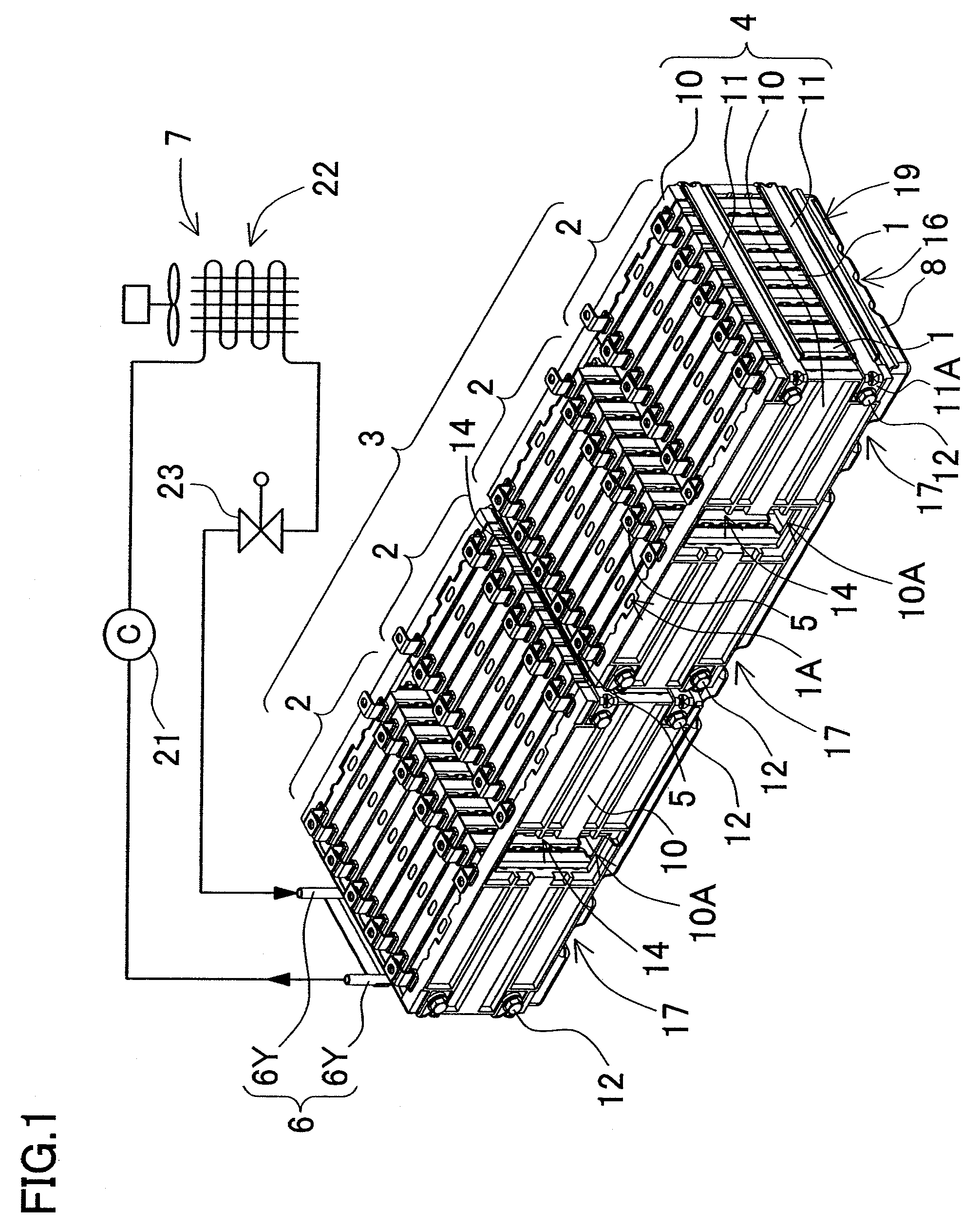

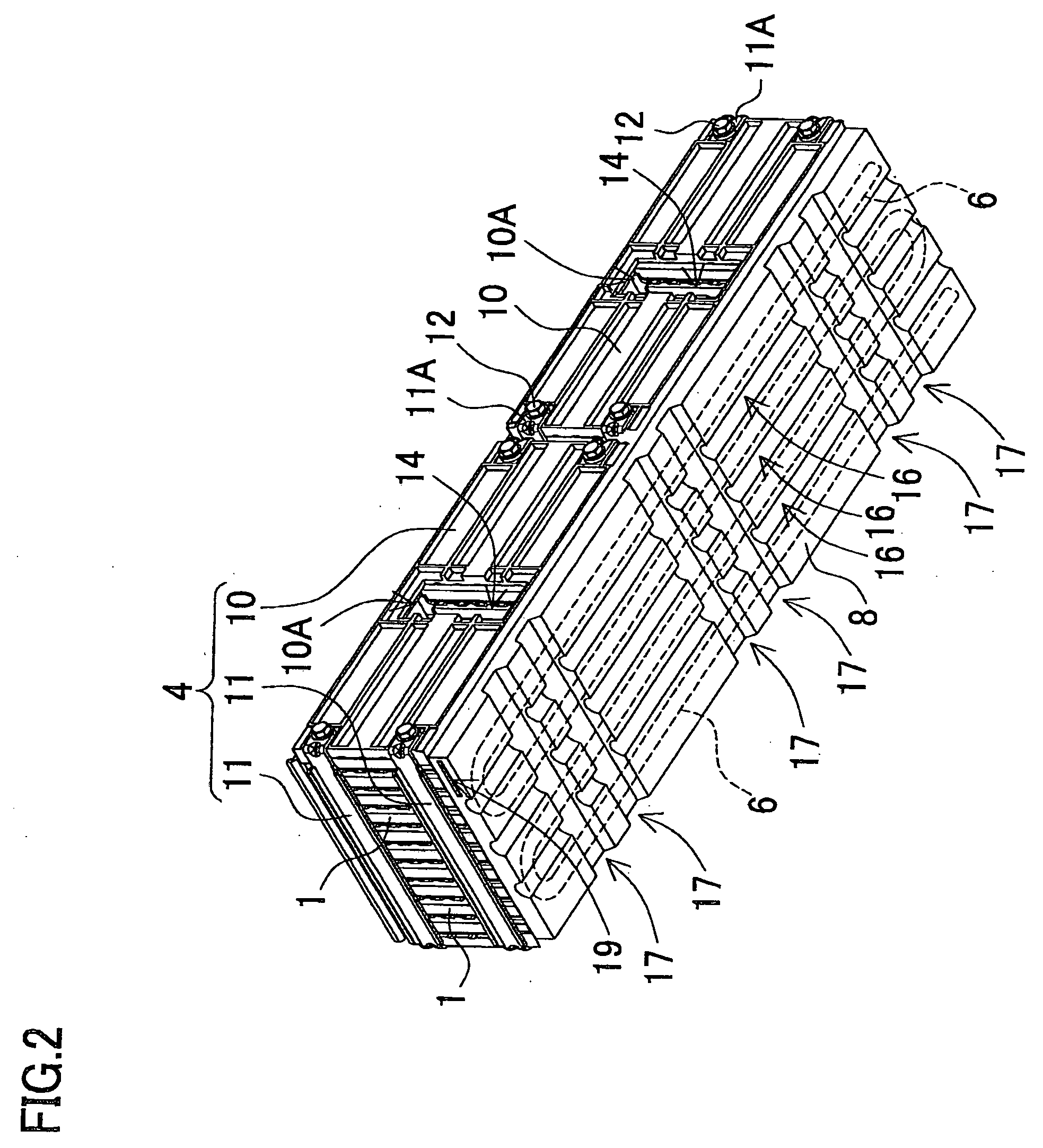

Battery system cooled via coolant

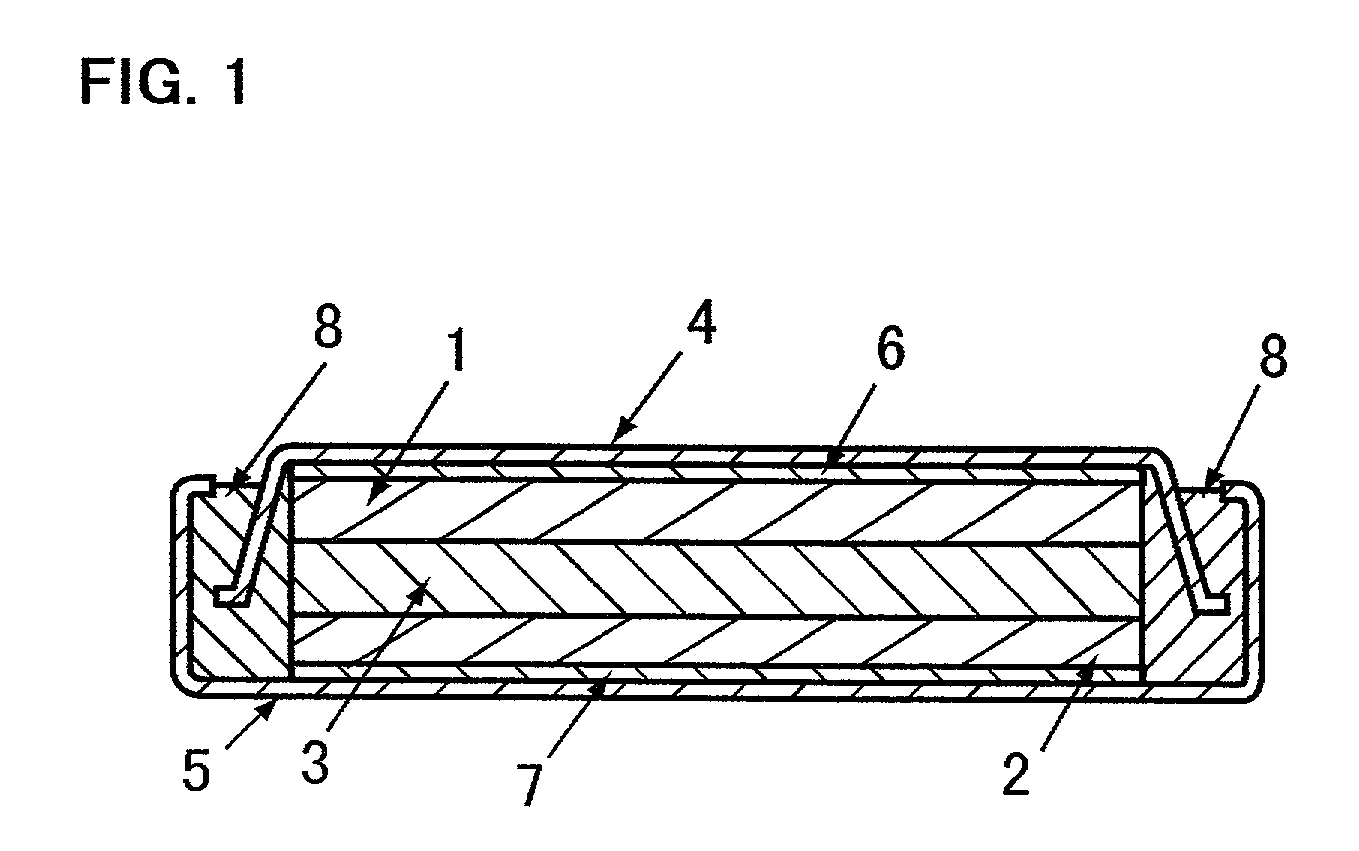

InactiveUS20090142628A1Increase contact areaImprove cooling effectSmall-sized cells cases/jacketsCell temperature controlThermal contactCooling pipe

The battery system cooled via coolant has a battery block 3 with a plurality of rectangular batteries 1 retained in a stacked configuration by a battery holder 4; a cooling plate 8 disposed in thermal contact with the bottom surface of the battery block 3 and having a hollow region 18 inside; cooling pipe 6 disposed inside the hollow region 18 of the cooling plate 8; and a coolant supply device 7 to supply coolant to the cooling pipe 6. The hollow cooling plate 8 has a surface plate 8A that makes thermal contact with the bottom surface of the battery block 3, and cooling pipe 6 is disposed within the hollow region 18 in contact with the inside of the surface plate 8A. Further, the cooling plate 8 hollow region 18 is filled with plastic foam 9.

Owner:SANYO ELECTRIC CO LTD

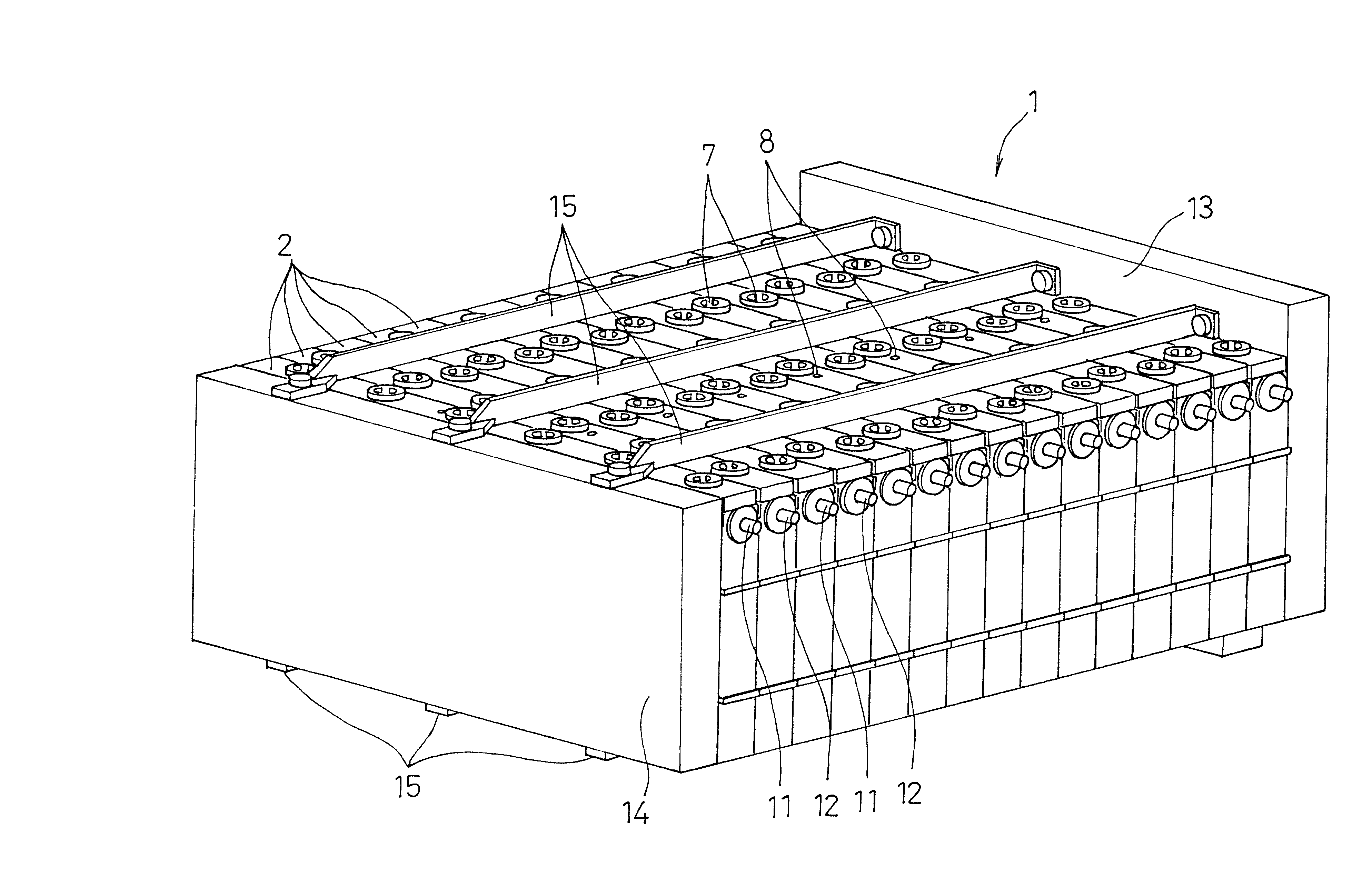

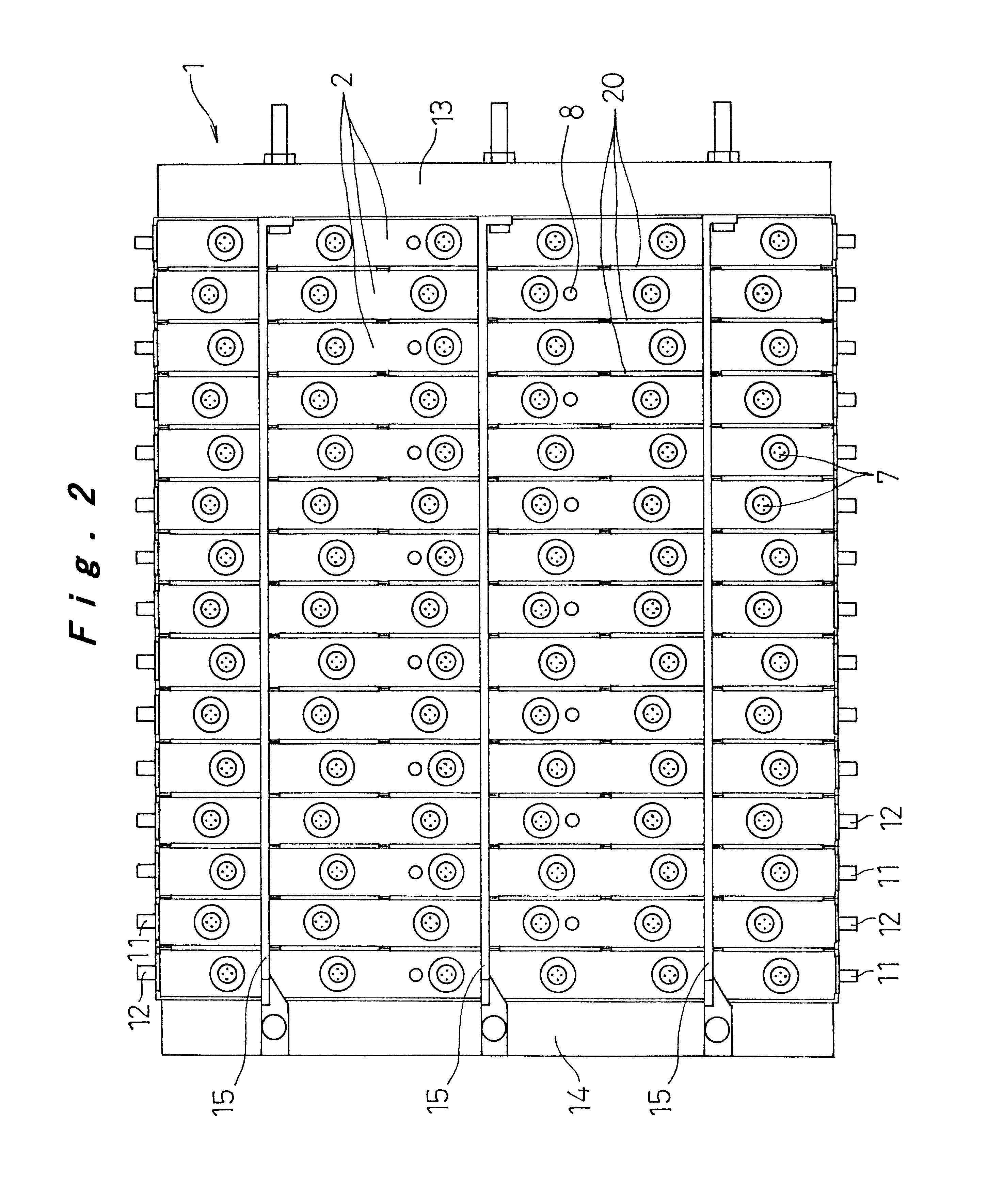

Battery pack

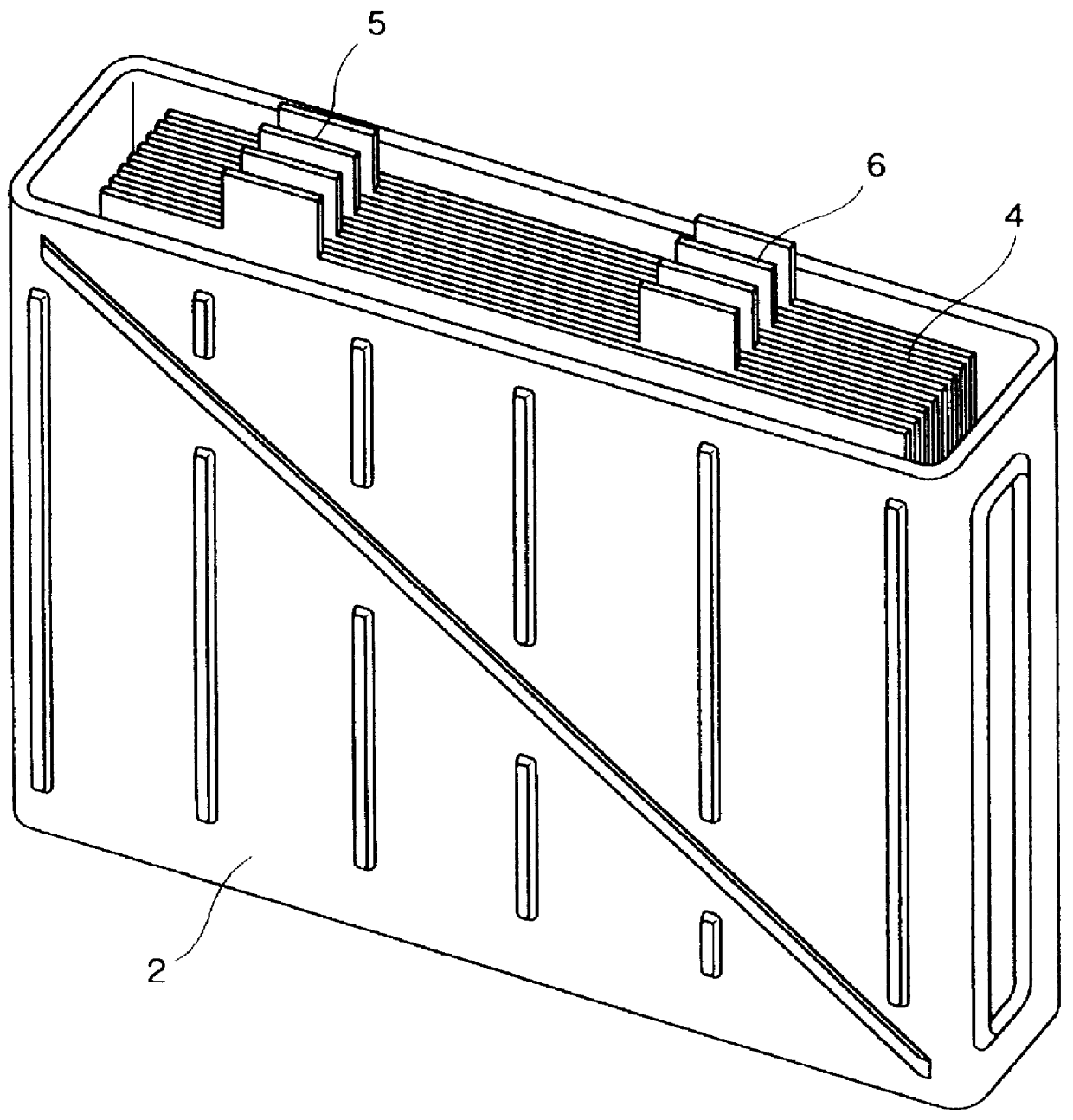

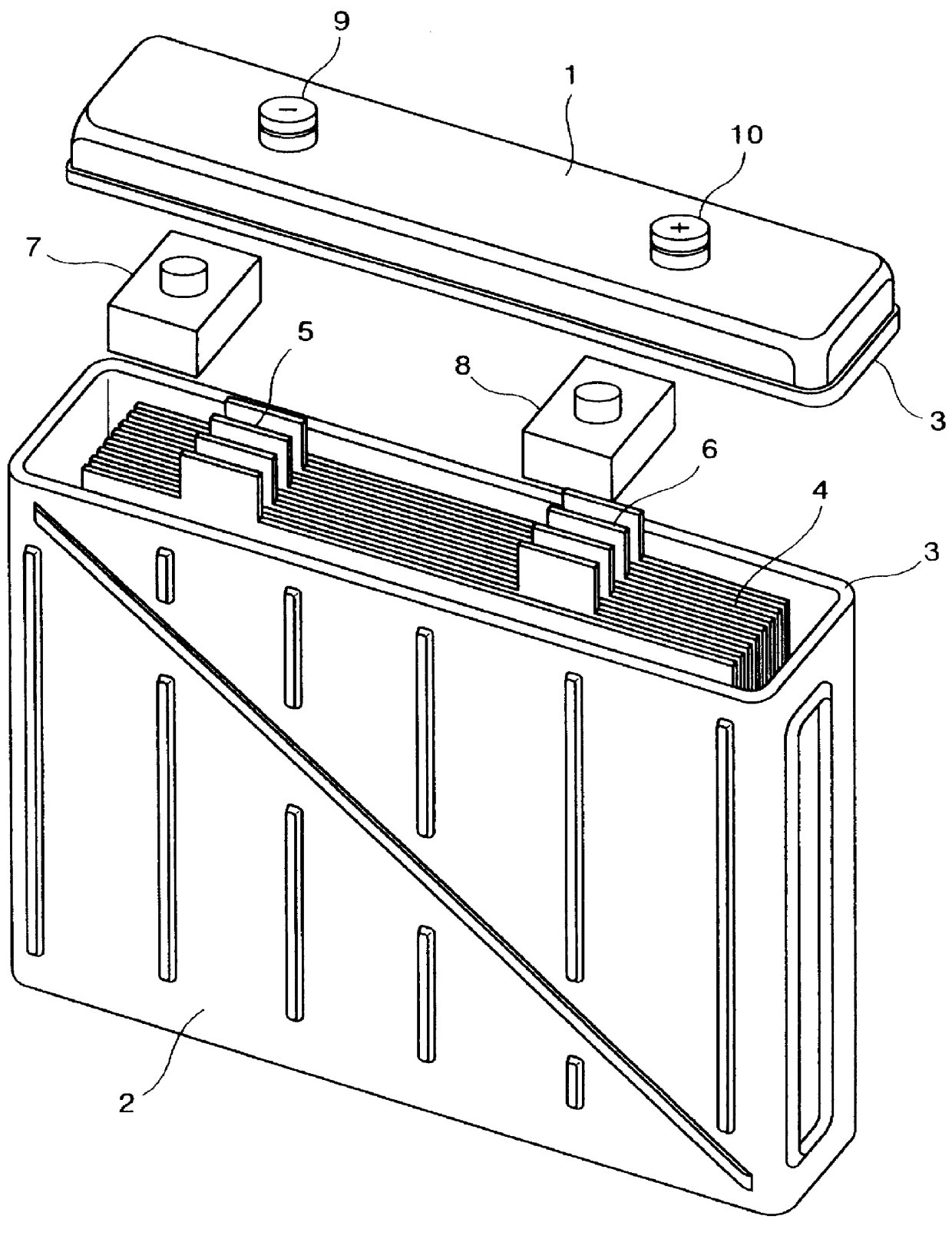

InactiveUS6569561B1Large-sized flat cells/batteriesFinal product manufactureBattery packElectrical and Electronics engineering

A battery module is constructed of an integral battery case which is constituted by forming a plurality of prismatic cell cases into a unitized body, wherein positive electrode plates and negative electrode plates laminated alternately upon one another with intervening separators are respectively accommodated in each of the cell cases, thereby constituting a plurality of cells, these cells being electrically connected in series. A plurality of such battery modules are arranged in a direction in which the electrode plates within each cell are laminated in a condition with coolant passages formed between the battery modules, and bound tightly together with end plates arranged at both ends in the direction of adjacent arrangement of the battery modules.

Owner:PANASONIC CORP +1

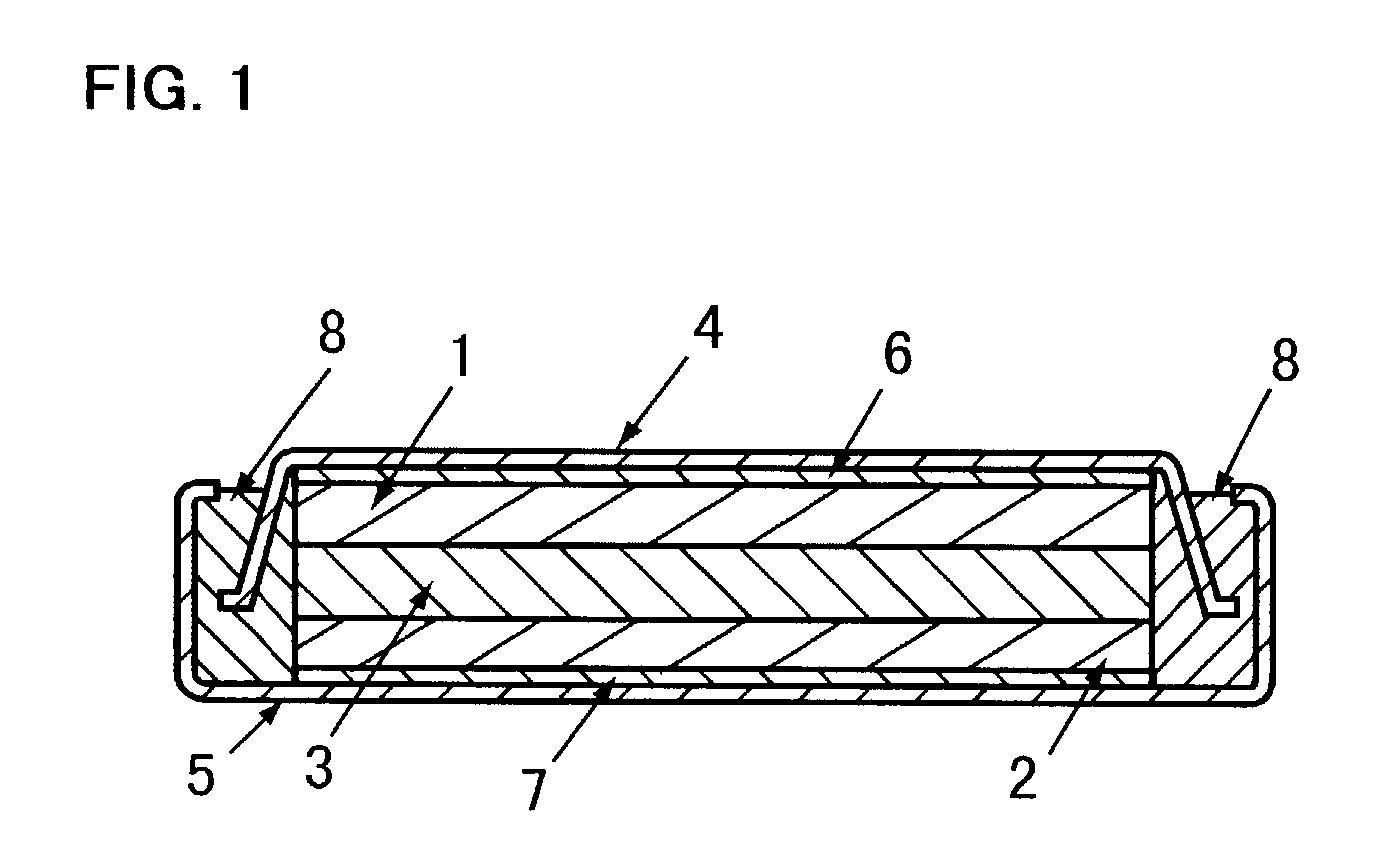

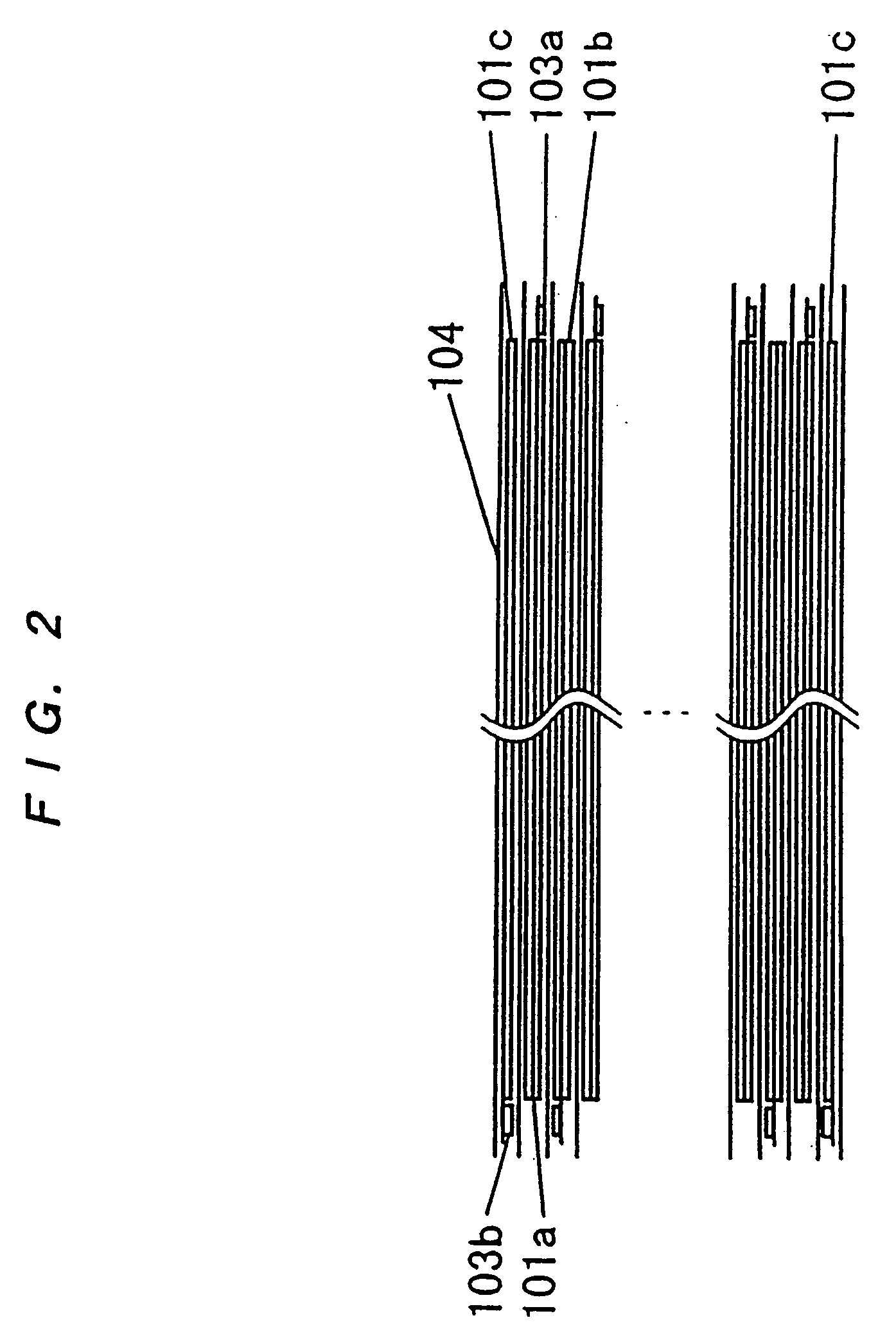

Electrode for rechargeable lithium battery and rechargeable lithium battery

InactiveUS7241533B1High charge and discharge capacityImprove charge and discharge cycle characteristicsElectrode manufacturing processesFinal product manufactureAmorphous siliconEngineering

An electrode for a rechargeable lithium battery characterized in that thin films of active material capable of lithium storage and release, i.e., microcrystalline or amorphous silicone thin films are deposited on opposite faces of a plate-form current collector.

Owner:SANYO ELECTRIC CO LTD

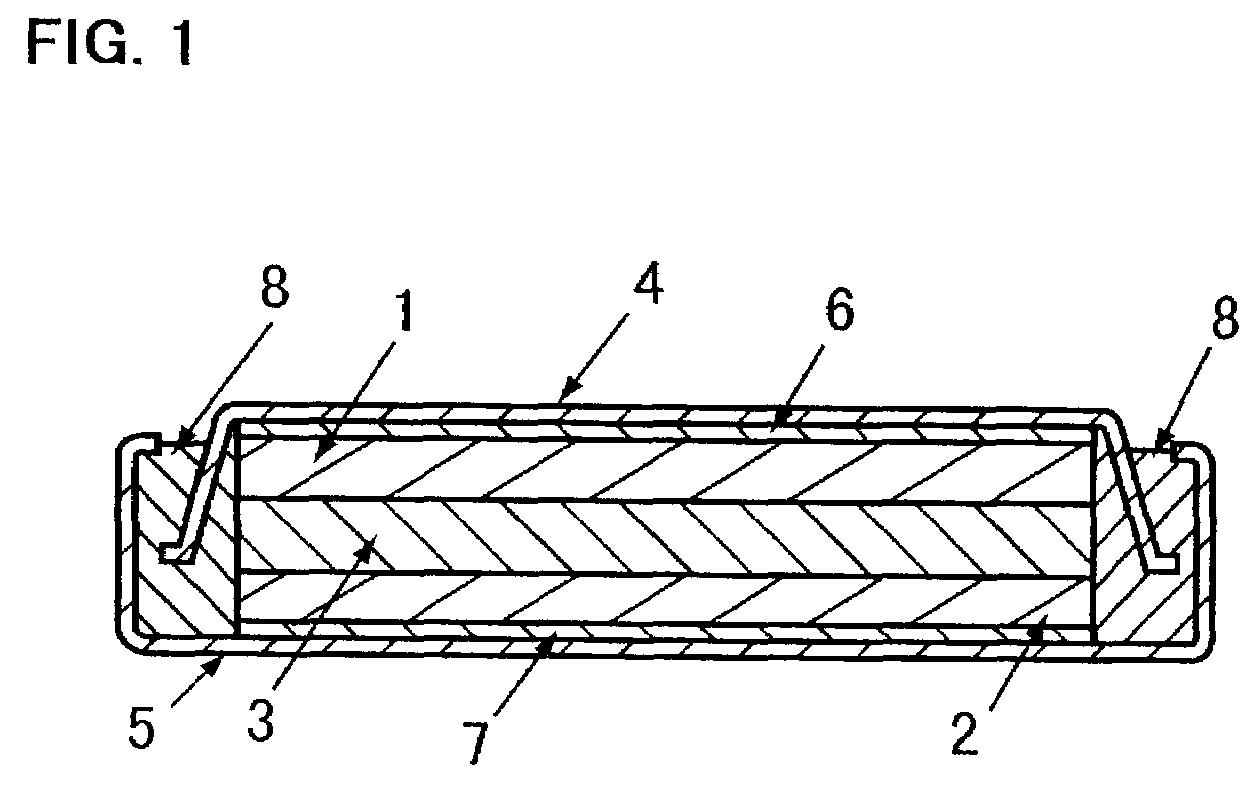

Long life thin film battery and method therefor

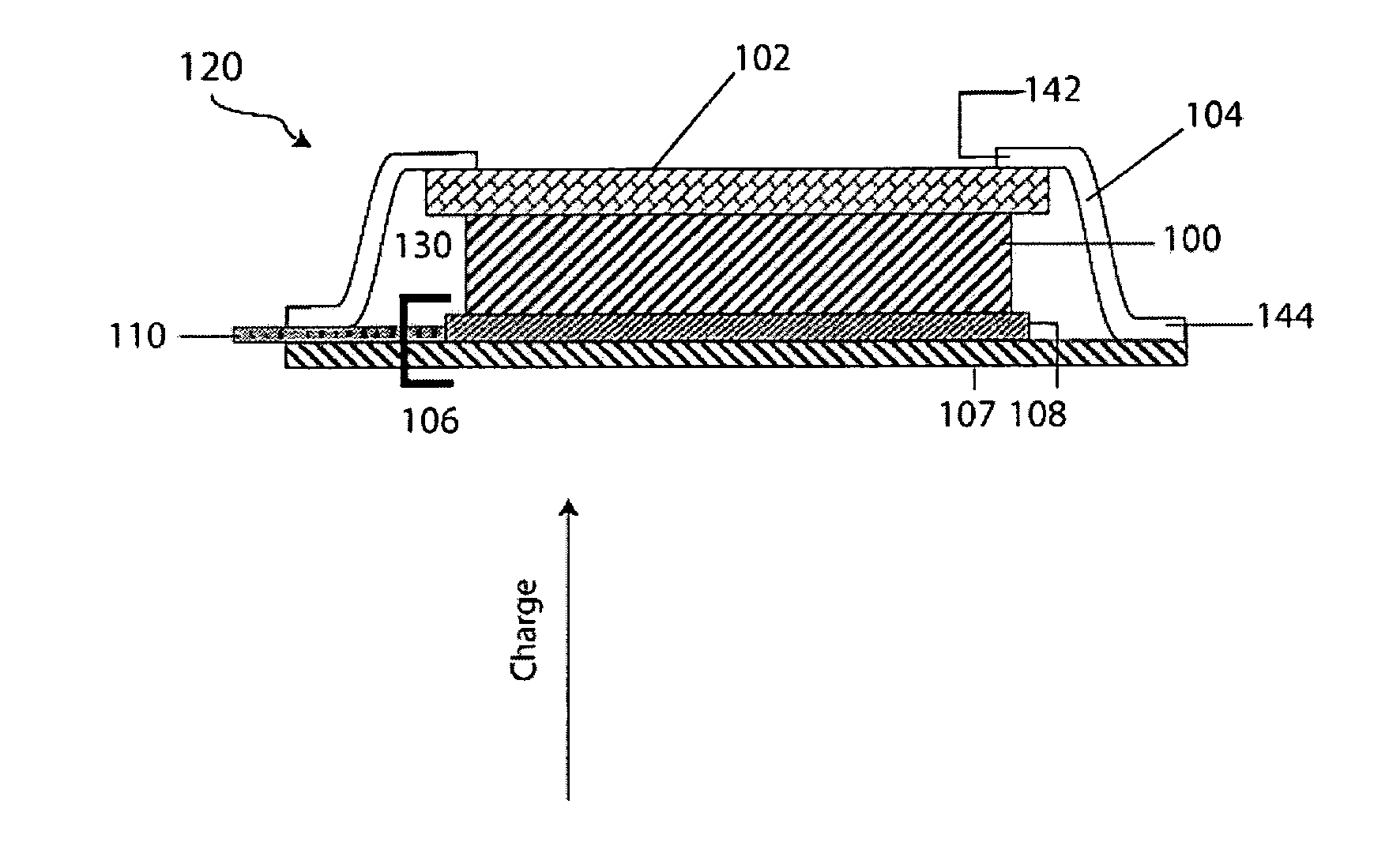

InactiveUS20080003492A1Improve air tightnessIncrease costSolid electrolytesFinal product manufactureEngineeringThin film rechargeable lithium battery

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure.

Owner:OAK RIDGE MICRO ENERGY

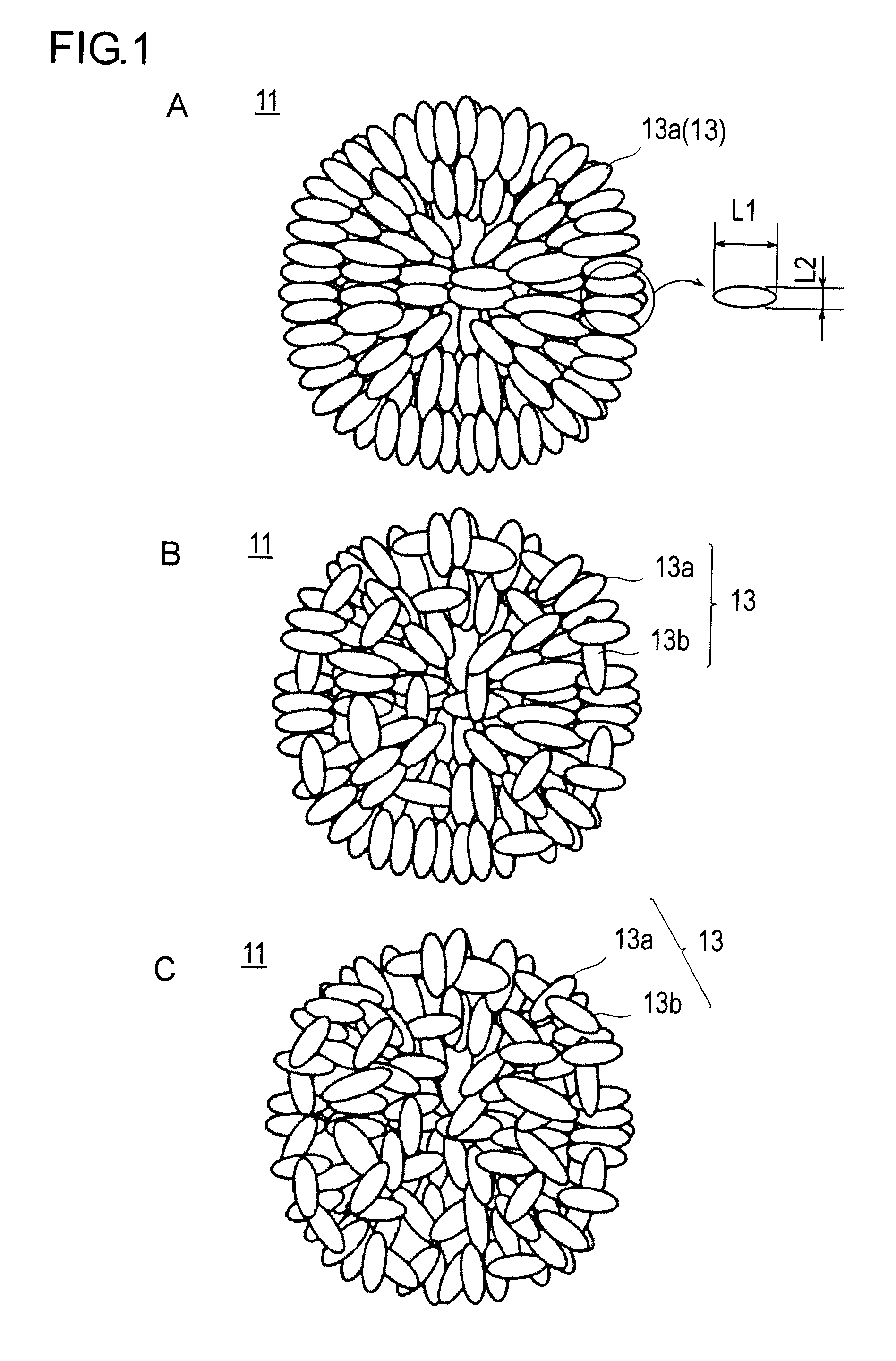

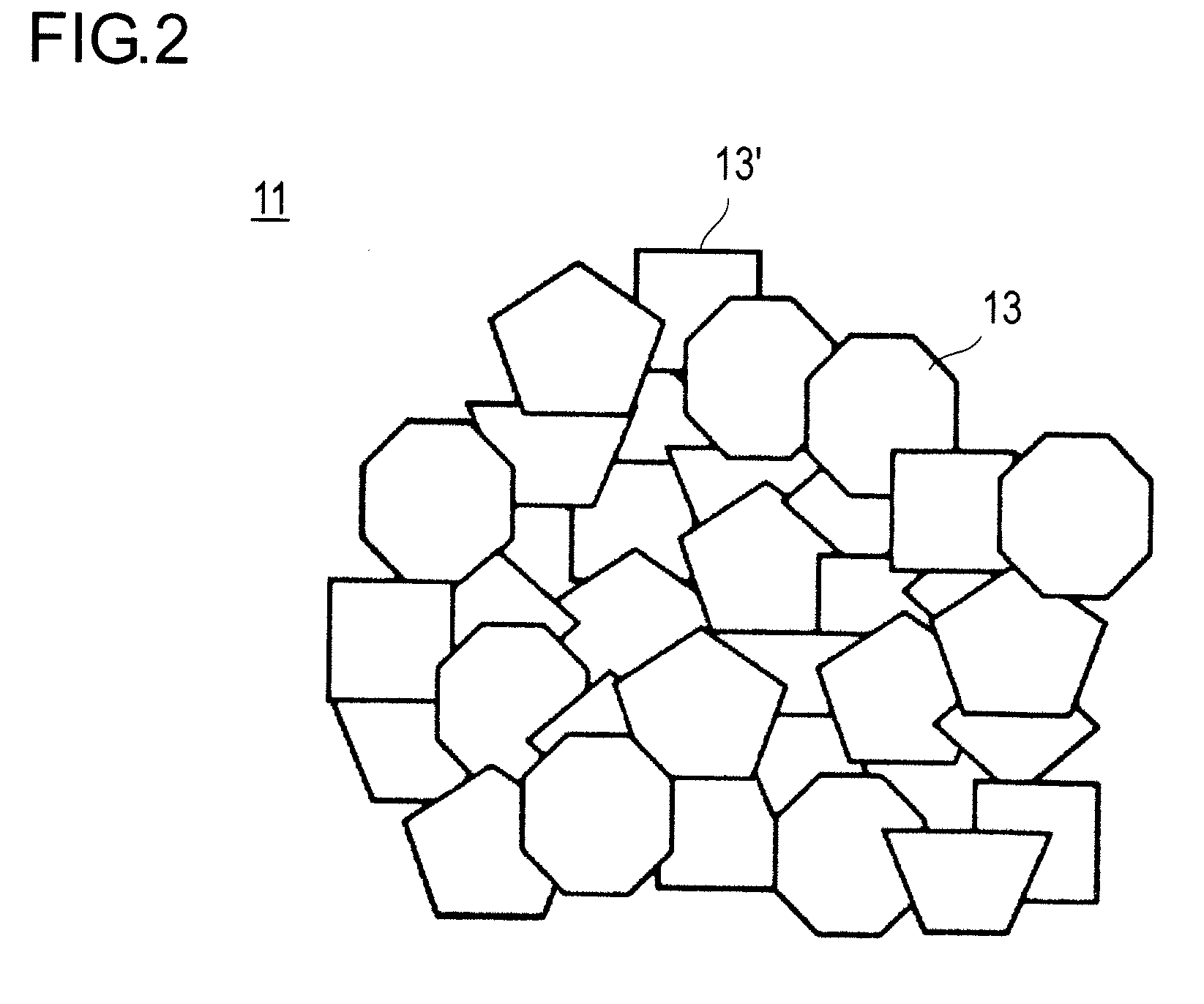

Positive electrode material for lithium ion battery with nonaqueous electrolyte, and battery using the same

ActiveUS20090029253A1Increase output powerAvoid crackingSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsLithium-ion batteryComposite oxide

An object of the present invention is to provide a positive electrode material for non-aqueous electrolyte lithium-ion battery which capable of discharging high output power and inhibiting cracking of secondary particle in the cyclic endurance at a high temperature. The above object can be attained by a positive electrode material for non-aqueous electrolyte lithium-ion battery of the present invention, characterized in that said material comprises secondary particles composed of primary particles of lithium nickel composite oxide containing the primary particles having different aspect ratios, and that at least a part of said primary particles having different aspect ratios are arranged so as to make the longitudinal direction (the long side direction) thereof oriented toward the center of the secondary particle.

Owner:ENVISION AESC JAPAN LTD +1

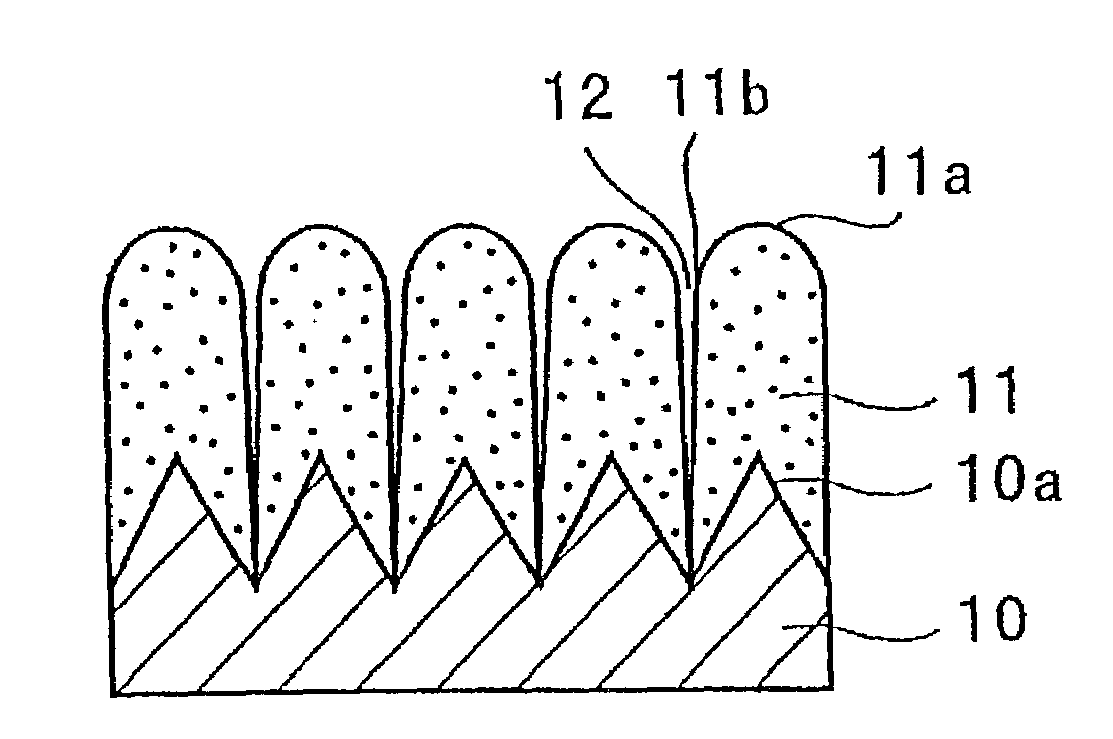

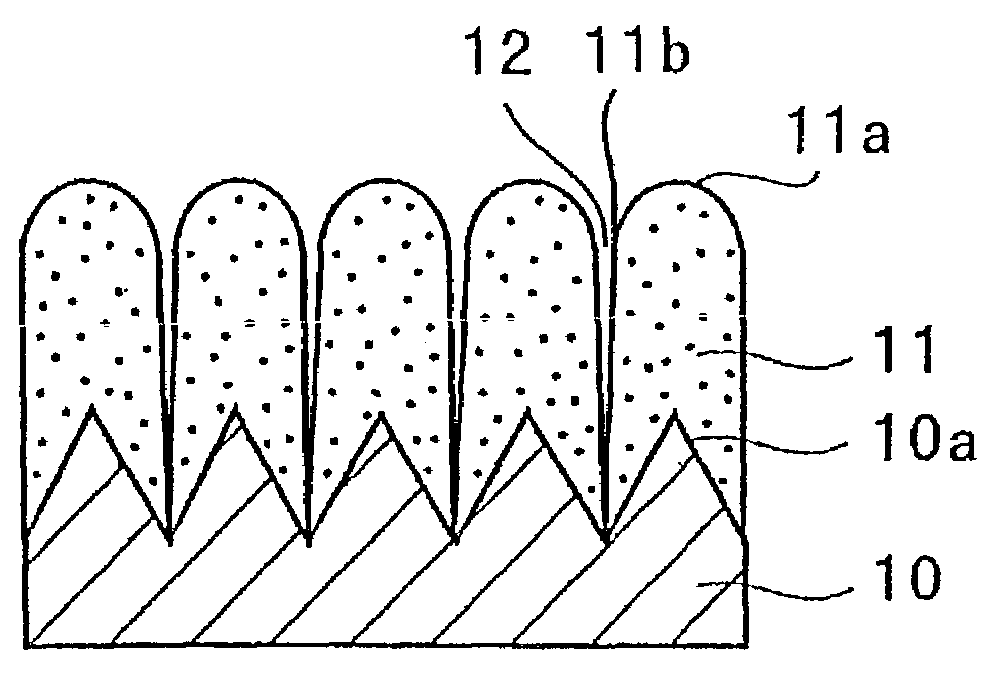

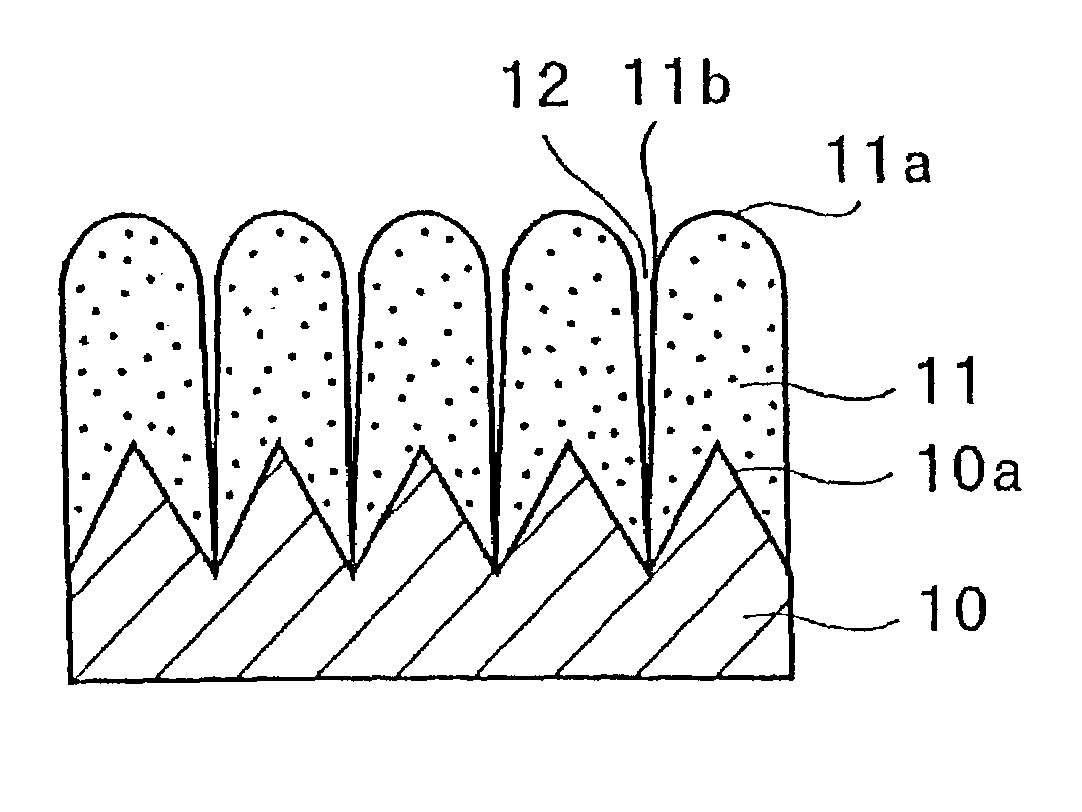

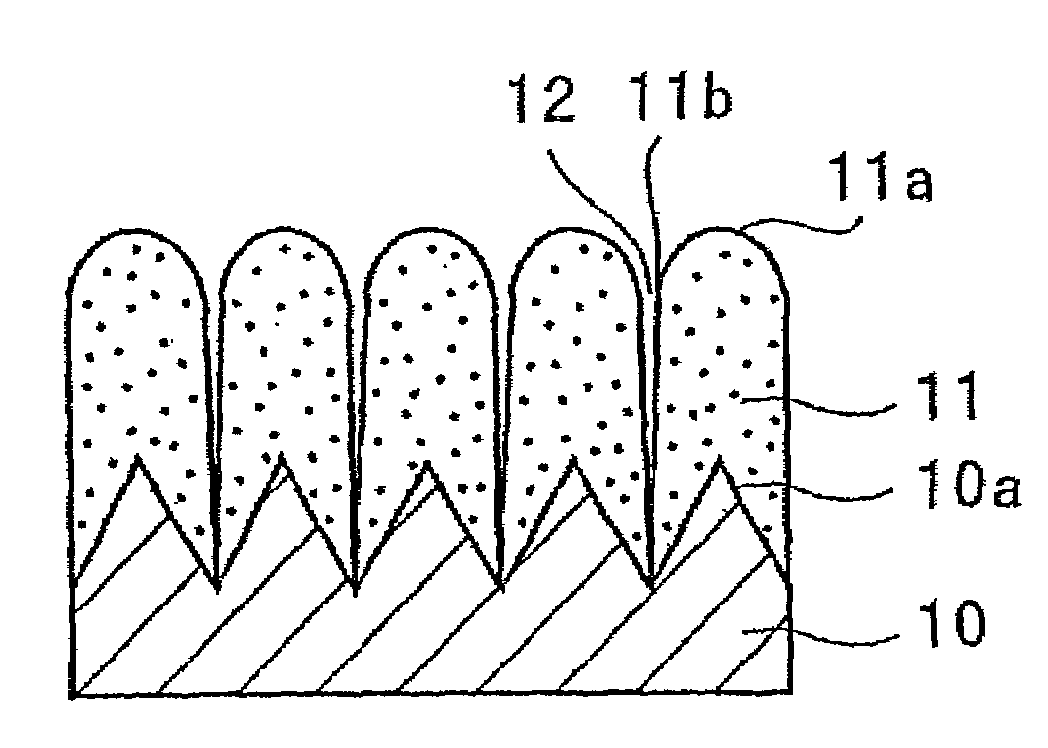

Electrode for use in lithium battery and rechargeable lithium battery

InactiveUS7195842B1High charge and discharge capacityImprove featuresElectrode manufacturing processesSmall-sized cells cases/jacketsPhysical chemistryAmorphous silicon

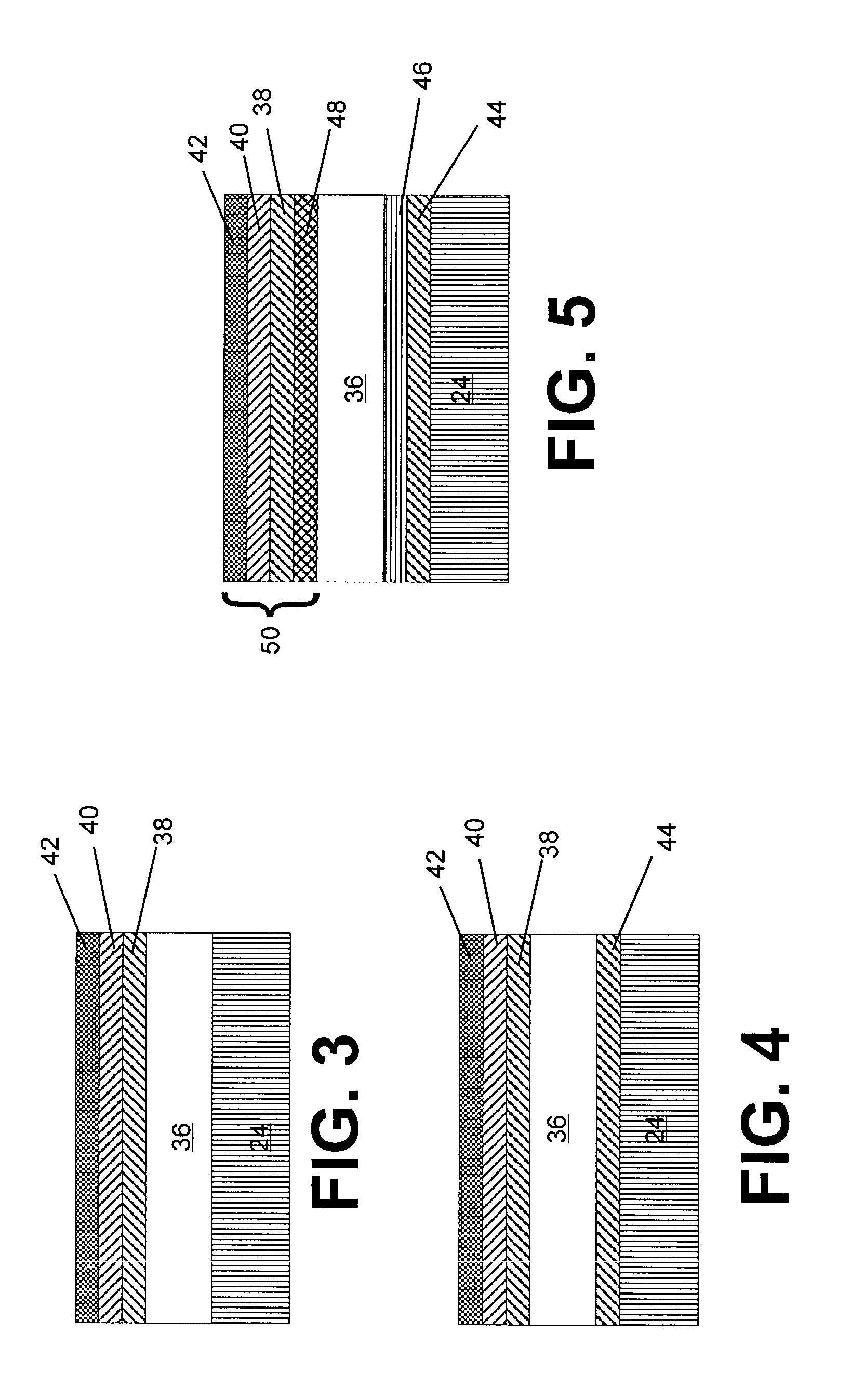

In an electrode for a lithium battery having a lithium storing and releasing active thin film provided on a current collector, such as a microcrystalline or amorphous silicon thin film, the electrode is characterized in that the thin film is divided into columns by gaps formed therein in a manner to extend in its thickness direction and that the columnar portions are at their bottoms adhered to the current collector.

Owner:SANYO ELECTRIC CO LTD

Pouch having improved safety, pouch-type secondary battery including the same, and medium-to-large battery pack

InactiveUS20120040235A1Cutting off electric currentTotal current dropPrimary cell to battery groupingSolid electrolytesManufacturing cost reductionInternal pressure

Provided are a pouch-type secondary battery having improved safety, and a battery pack including the pouch-type secondary battery. When inner pressure of a pouch is increased by an overdischarge, the pouch is deformed to separate electrode leads from electrode tabs. When the secondary battery is manufactured, an additional material or device is unnecessary. In addition, since the pouch-type secondary battery fundamentally cuts off electric current when gas is generated therein, the service life and safety of the secondary battery can be significantly improved, and the manufacturing costs and the weight thereof can be reduced. Furthermore, the shape of the secondary battery can be easily modified.

Owner:LG CHEM LTD

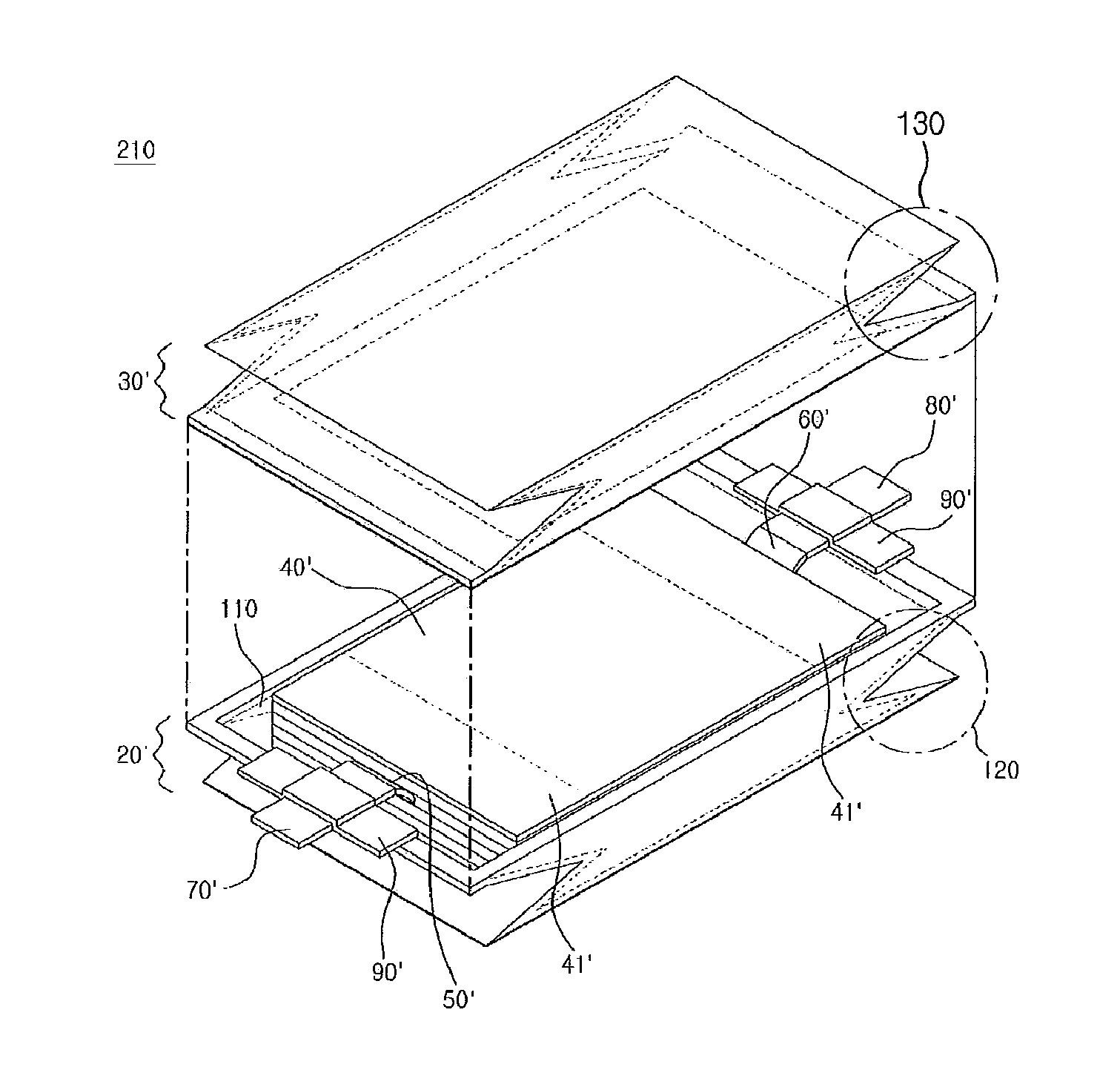

Pouch type battery pack

InactiveUS20090023057A1Avoid damageImprove cooling effectLarge-sized flat cells/batteriesFinal product manufactureEngineeringThermal radiation

A pouch type battery pack, including: a first pouch battery and a second pouch battery adjacent to the first pouch battery, wherein the first and second pouch batteries are combined by bonding an edge of the first pouch battery and an edge of the second pouch battery to each other. Accordingly, the bare cell can be separated without being damaged when the pouch battery is separated from the battery pack. Furthermore, the heat radiation performance is improved by including a heat radiation member between the two pouch batteries when the pouch batteries are stacked.

Owner:SAMSUNG SDI CO LTD

Compliant seal structures for protected active metal anodes

ActiveUS7824806B2Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesTectorial membraneOptoelectronics

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Non-aqueous secondary battery and its control method

InactiveUS20040048152A1Improve featuresOptimize the stack structureLarge-sized flat cells/batteriesFinal product manufactureEngineeringEnergy storage

The invention provides a non-aqueous secondary battery having positive and negative electrodes and non-aqueous electrolyte containing lithium salt which has an energy capacity of 30 Wh or more, a volume energy density of 180 Wh / l or higher, which battery has a flat shape and is superior in heat radiation characteristic, used safely and particularly preferably used for a energy storage system. The invention also provides a control method of the secondary battery.

Owner:KRI INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com