Patents

Literature

238results about How to "Improve charge and discharge cycle characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

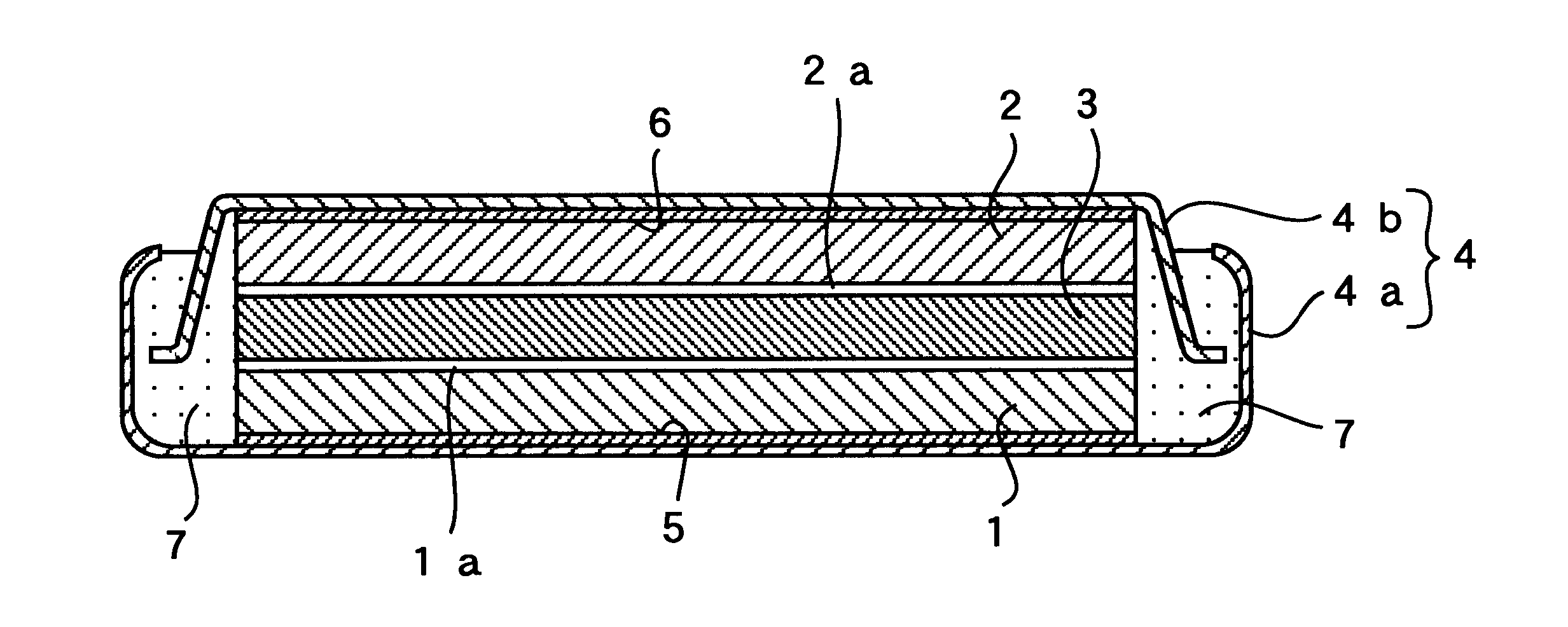

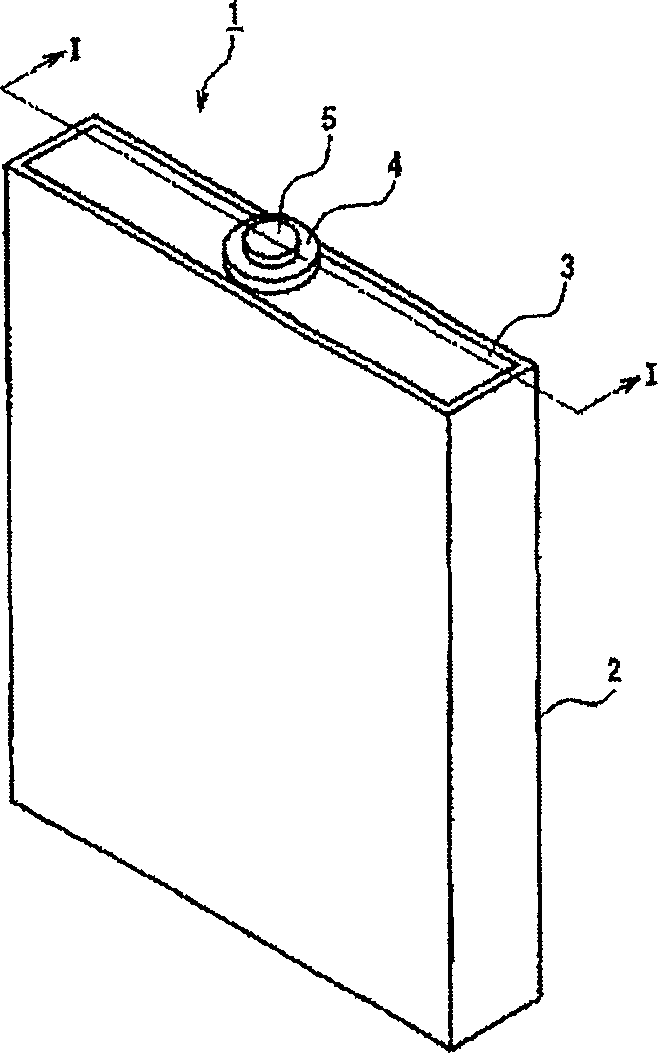

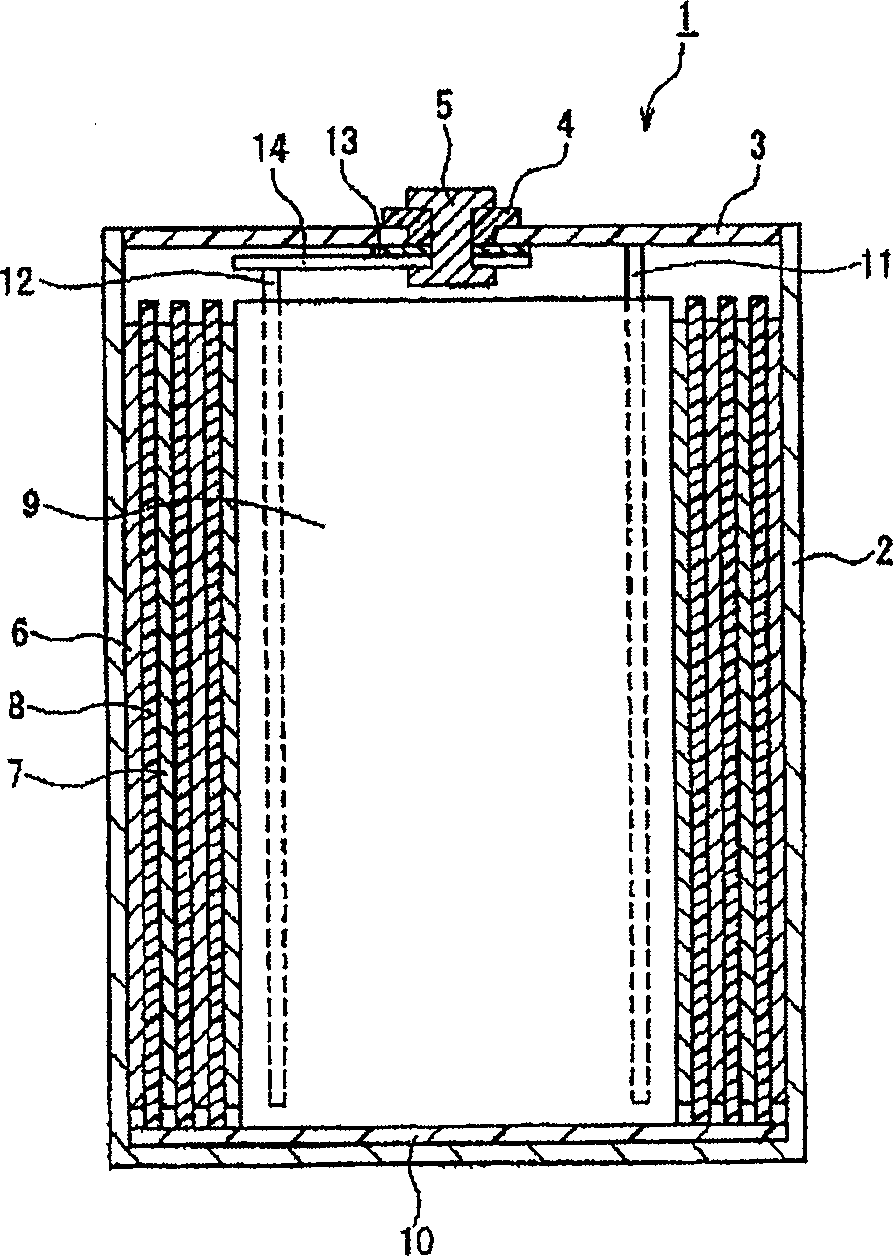

Electrode for rechargeable lithium battery and rechargeable lithium battery

InactiveUS7192673B1Improve charge and discharge cycle characteristicsInhibition formationElectrode manufacturing processesSmall-sized cells cases/jacketsAmorphous siliconMaterials science

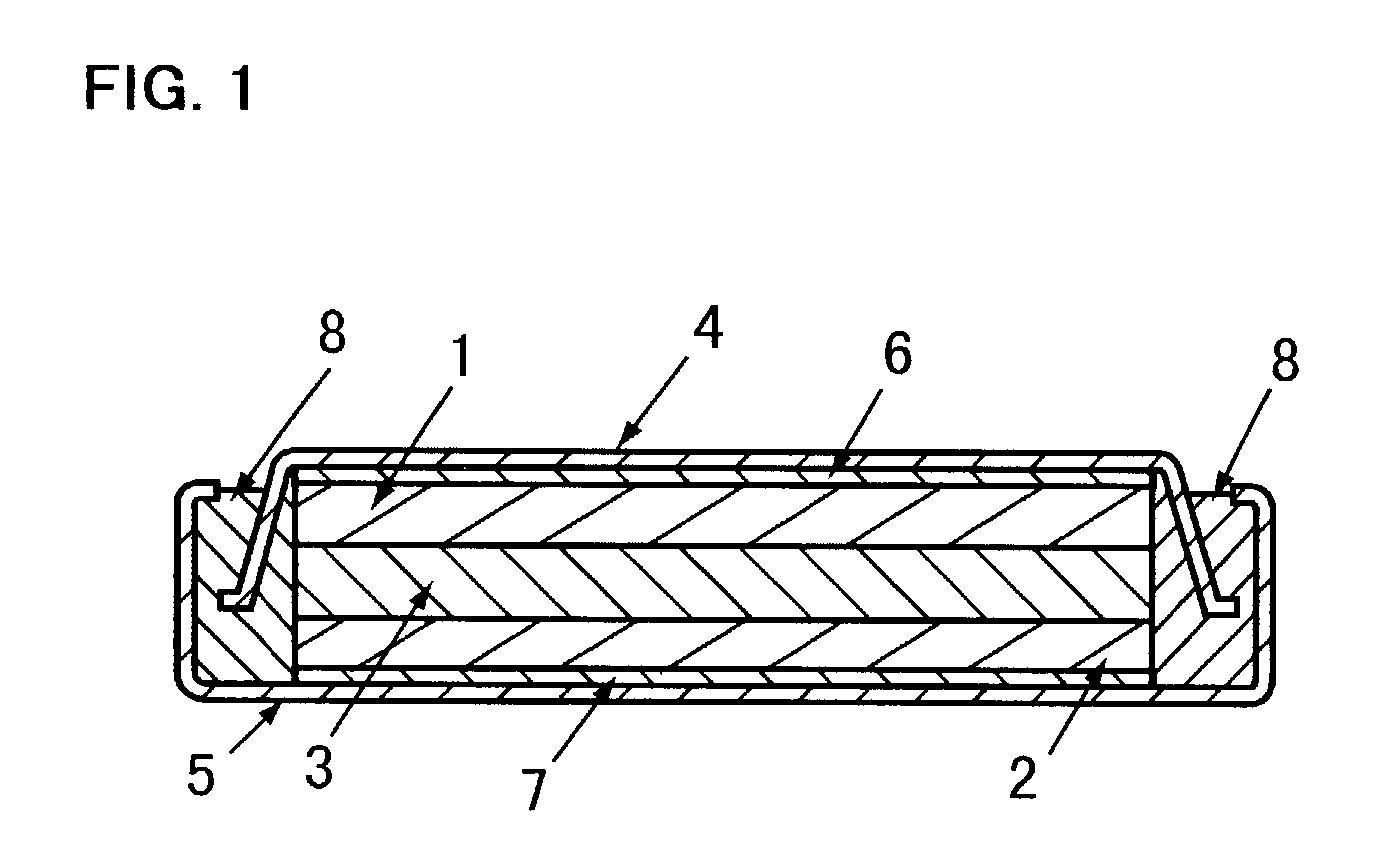

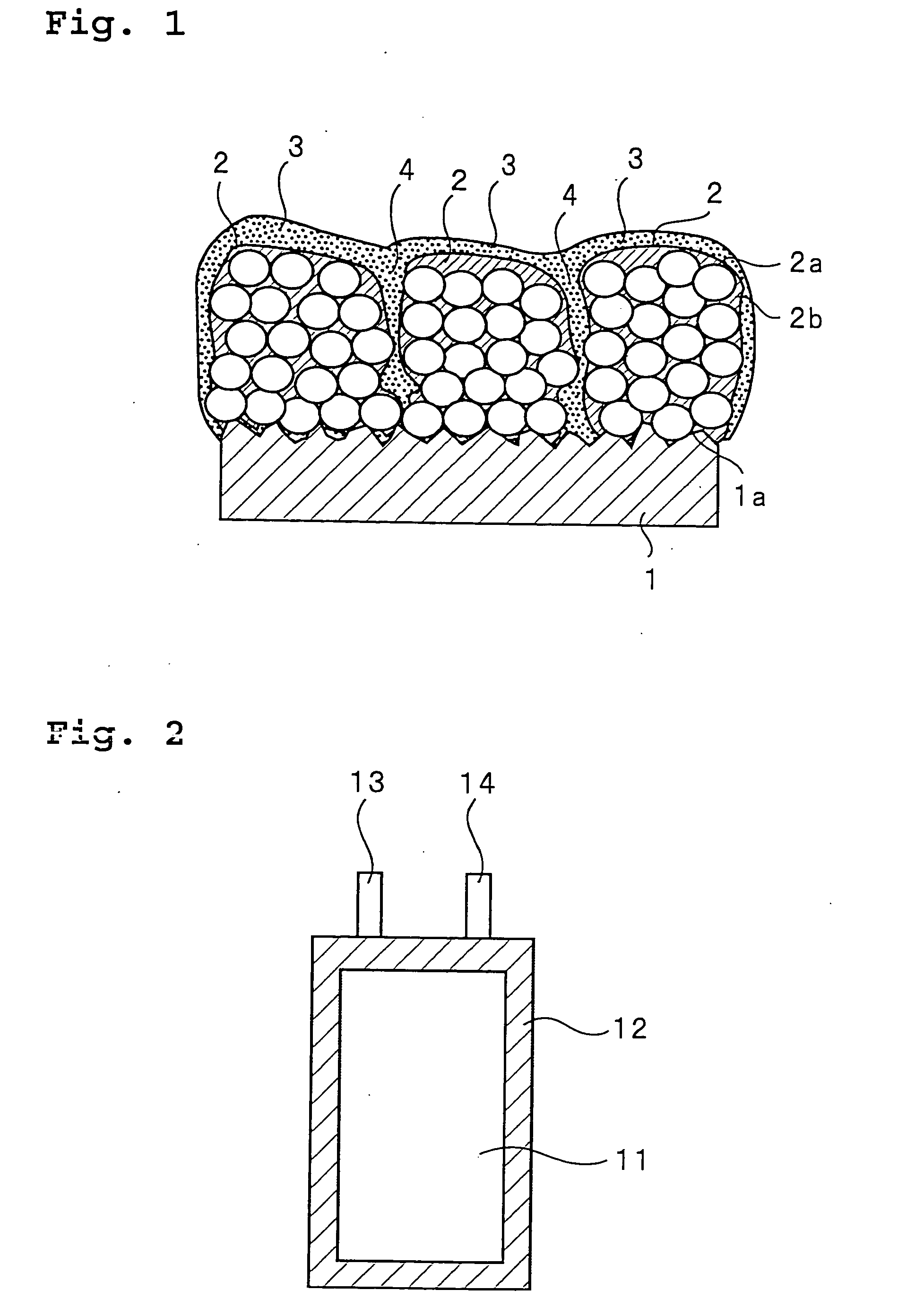

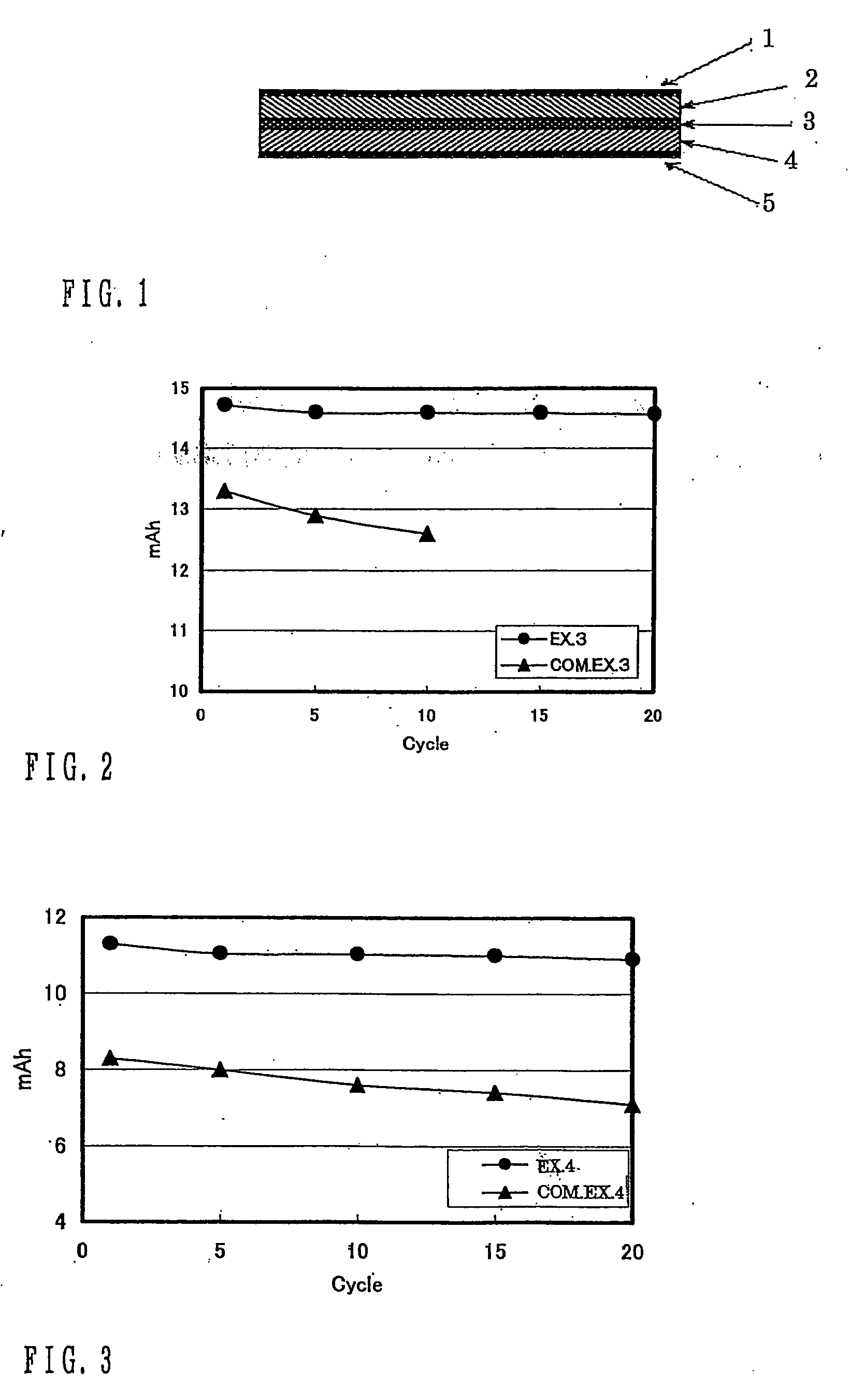

An electrode for a rechargeable lithium battery which includes a thin film composed of active material that expands and shrinks as it stores and releases lithium, e.g., a microcrystalline or amorphous silicon thin film, deposited on a current collector, characterized in that said current collector exhibits a tensile strength (=tensile strength (N / mm2) per sectional area of the current collector material×thickness (mm) of the current collector) of not less than 3.82 N / mm.

Owner:SANYO ELECTRIC CO LTD

Lithium ion conductive solid electrolyte and production process thereof

InactiveUS20070231704A1Increase battery capacitySimple and convenient manufactureSecondary cellsSolid electrolyte cellsPorosityLithium metal

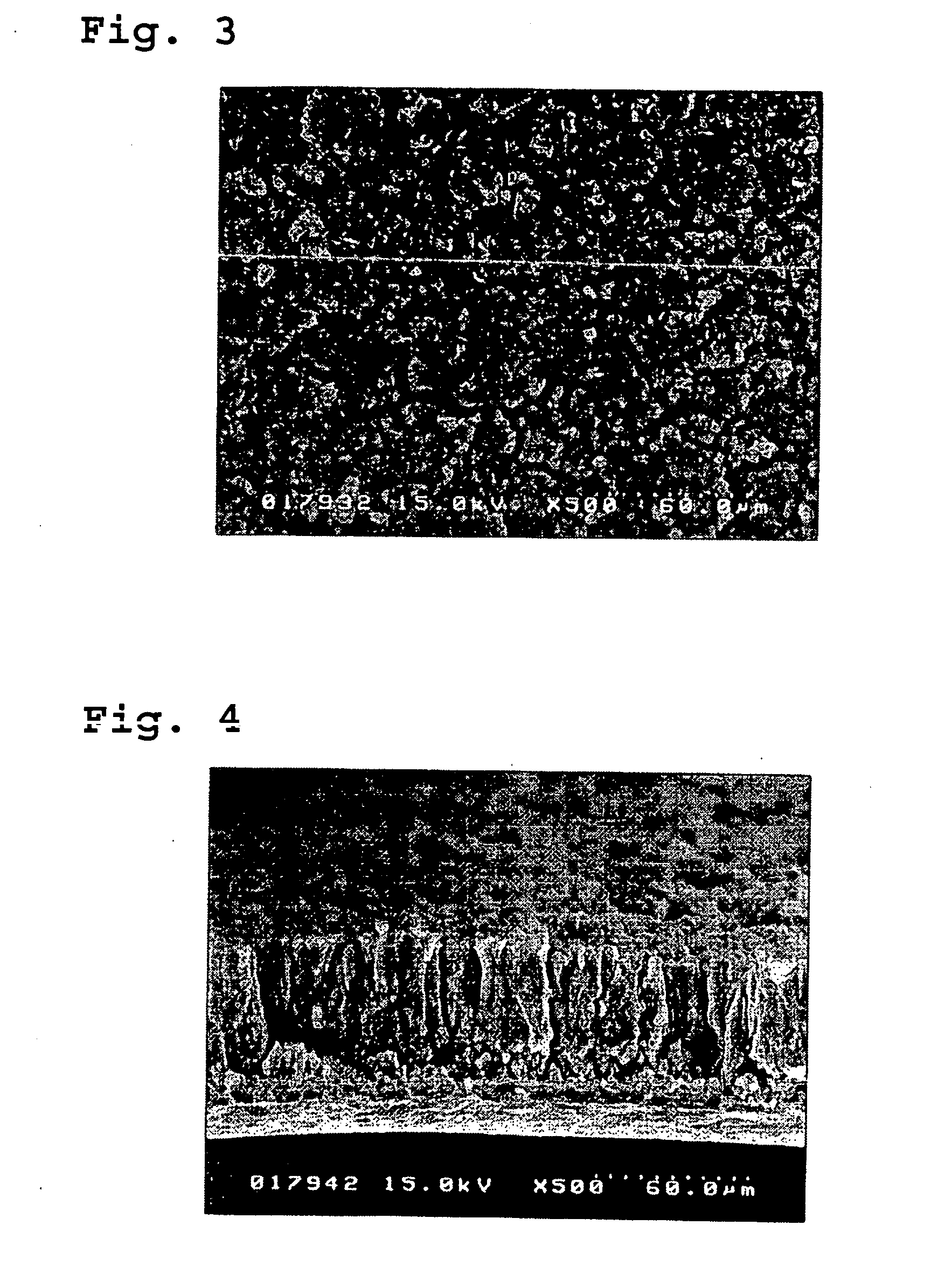

A lithium ion conductive solid electrolyte formed by sintering a molding product containing an inorganic powder and having a porosity of 10 vol % or less, which is obtained by preparing a molding product comprising an inorganic powder as a main ingredient and sintering the molding product after pressing and / or sintering the same while pressing, the lithium ion conductive solid electrolyte providing a solid electrolyte having high battery capacity without using a liquid electrolyte, usable stably for a long time and simple and convenient in manufacture and handling also in industrial manufacture in the application use of secondary lithium ion battery or primary lithium battery, a solid electrolyte having good charge / discharge cyclic characteristic in the application use of the secondary lithium ion battery a solid electrolyte with less water permeation and being safe when used for lithium metal-air battery in the application use of primary lithium battery, a manufacturing method of the solid electrolyte, and a secondary lithium ion battery and a primary lithium battery using the solid electrolyte.

Owner:OHARA

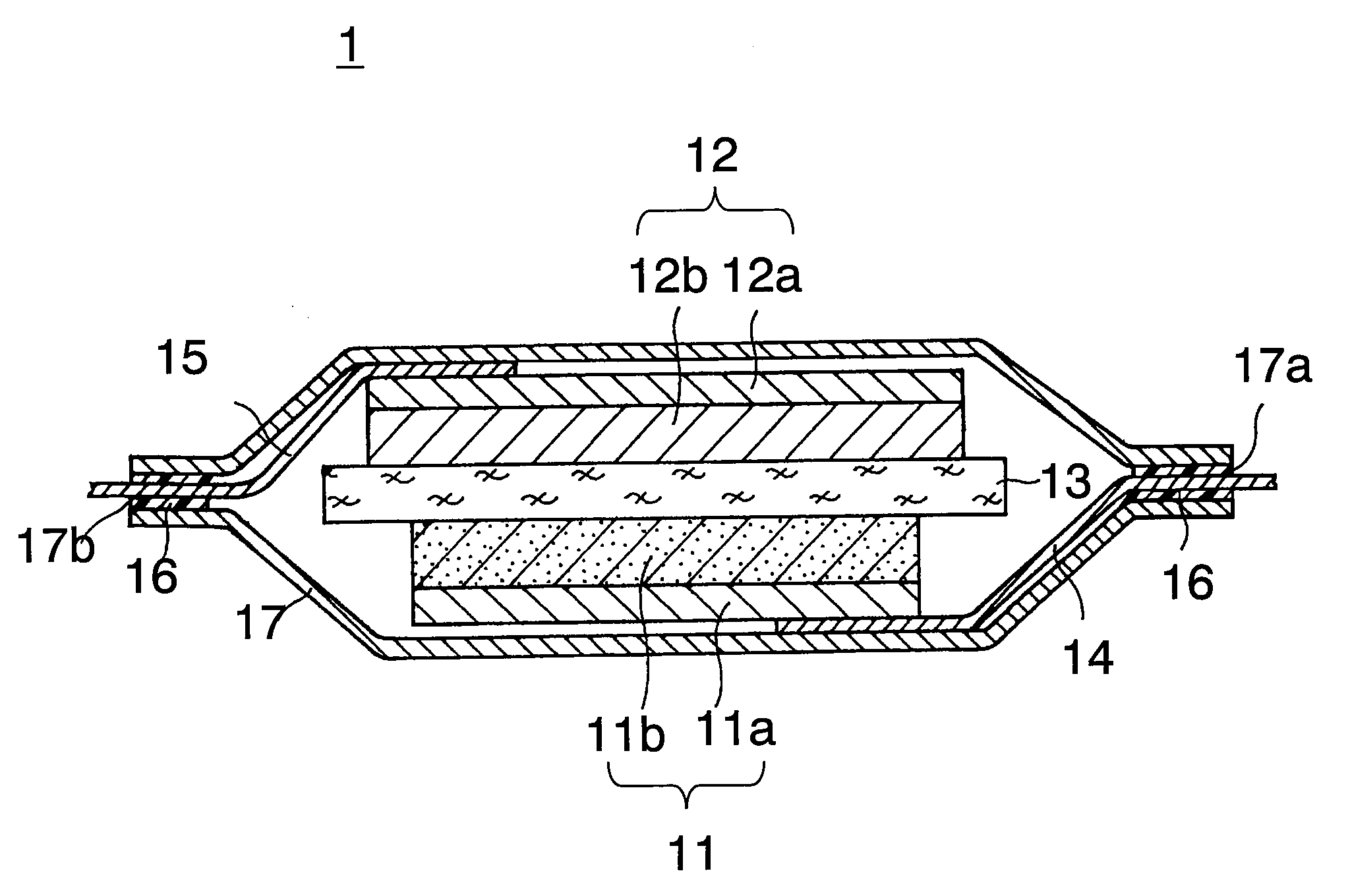

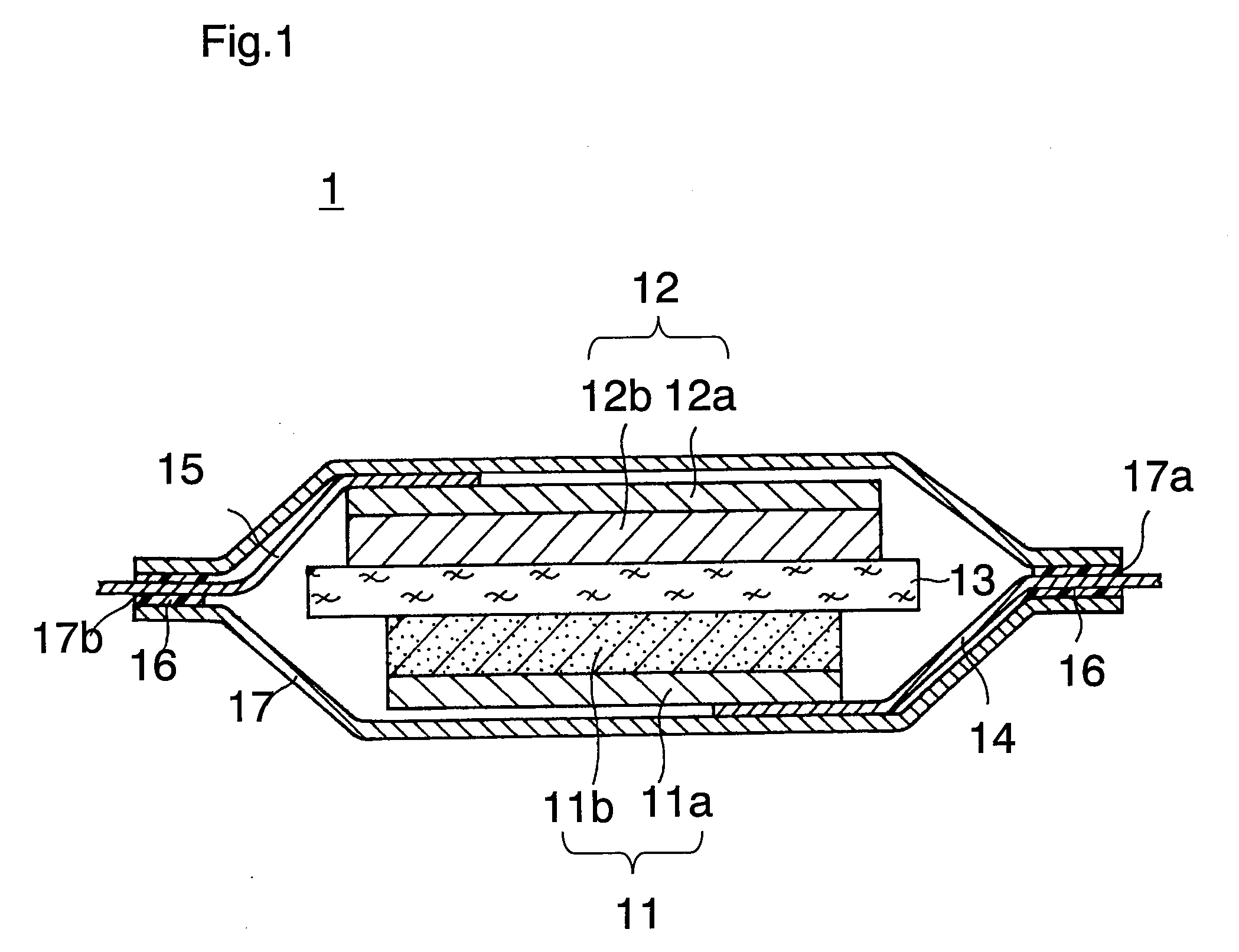

Lithium secondary battery and method for manufacturing thereof

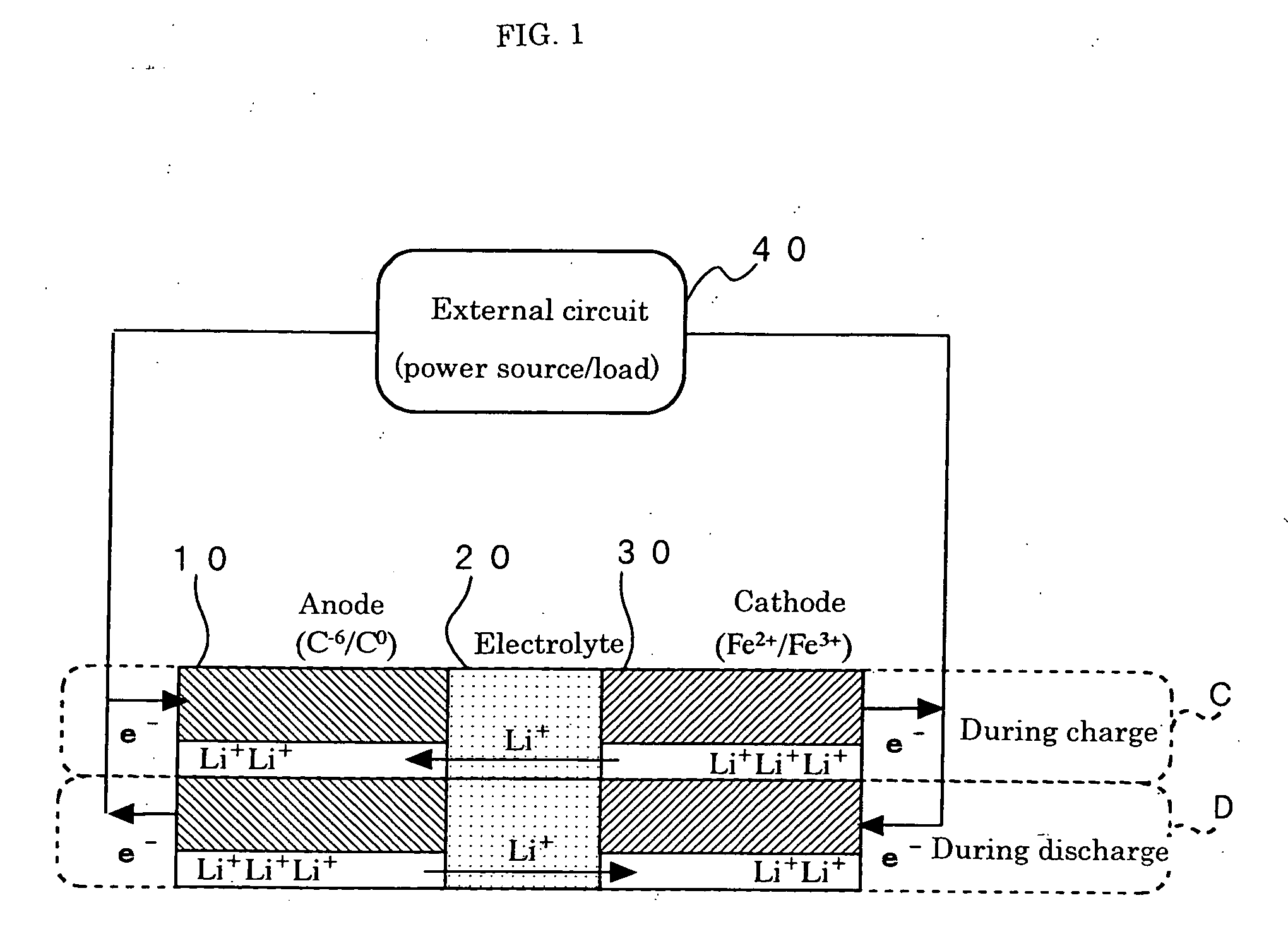

InactiveUS20040072067A1Increase currentExtended discharge cycleFinal product manufactureElectrode carriers/collectorsLithiumElectrochemistry

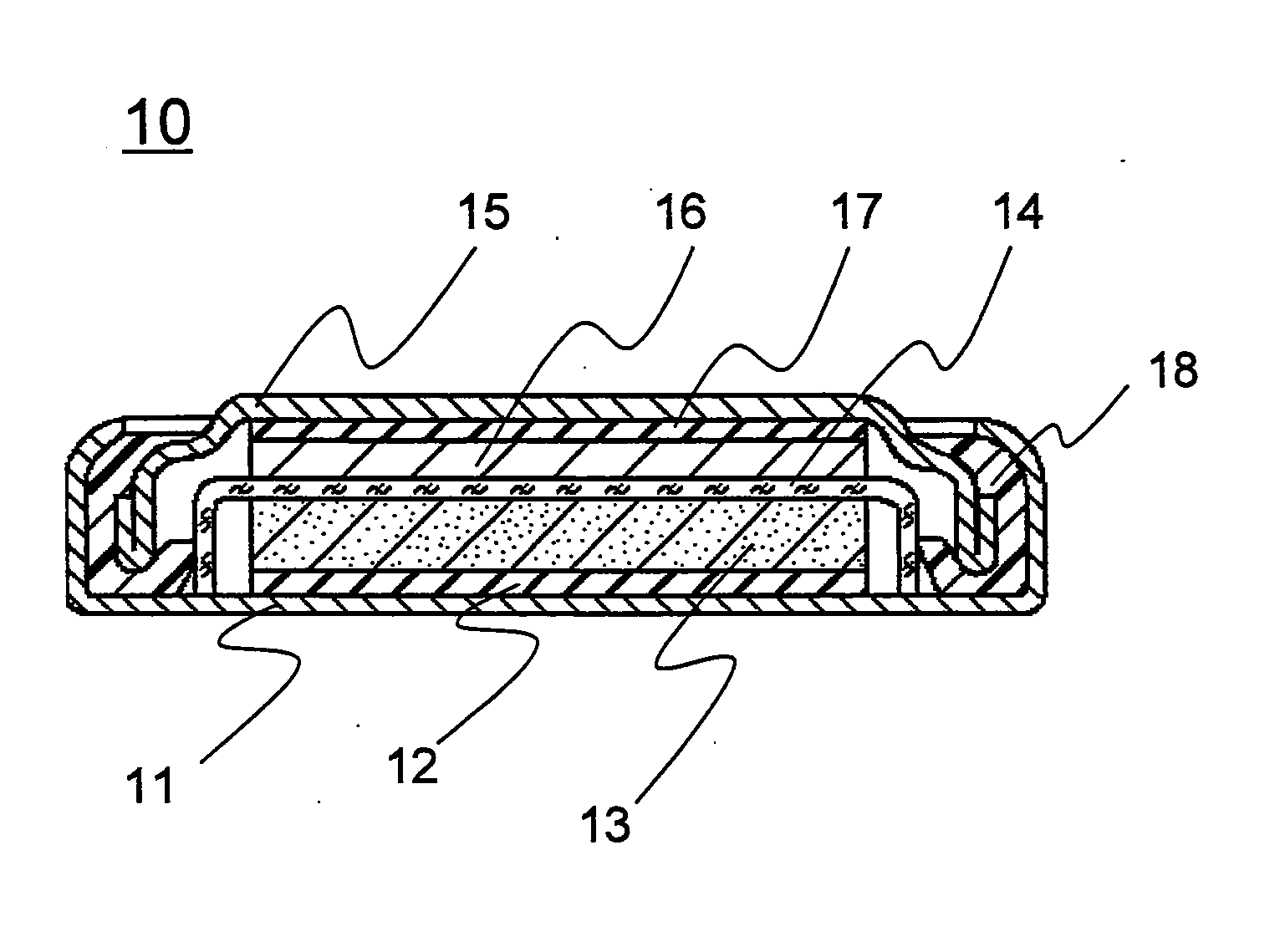

A lithium secondary battery comprising an electrode in which an active material layer which includes an active material that electrochemically occludes and releases lithium is formed on a current collector, wherein cracks are formed in the active material layer by occlusion and release of lithium ions and thereafter a solid electrolyte is formed in the cracks in the active material layer.

Owner:SANYO ELECTRIC CO LTD

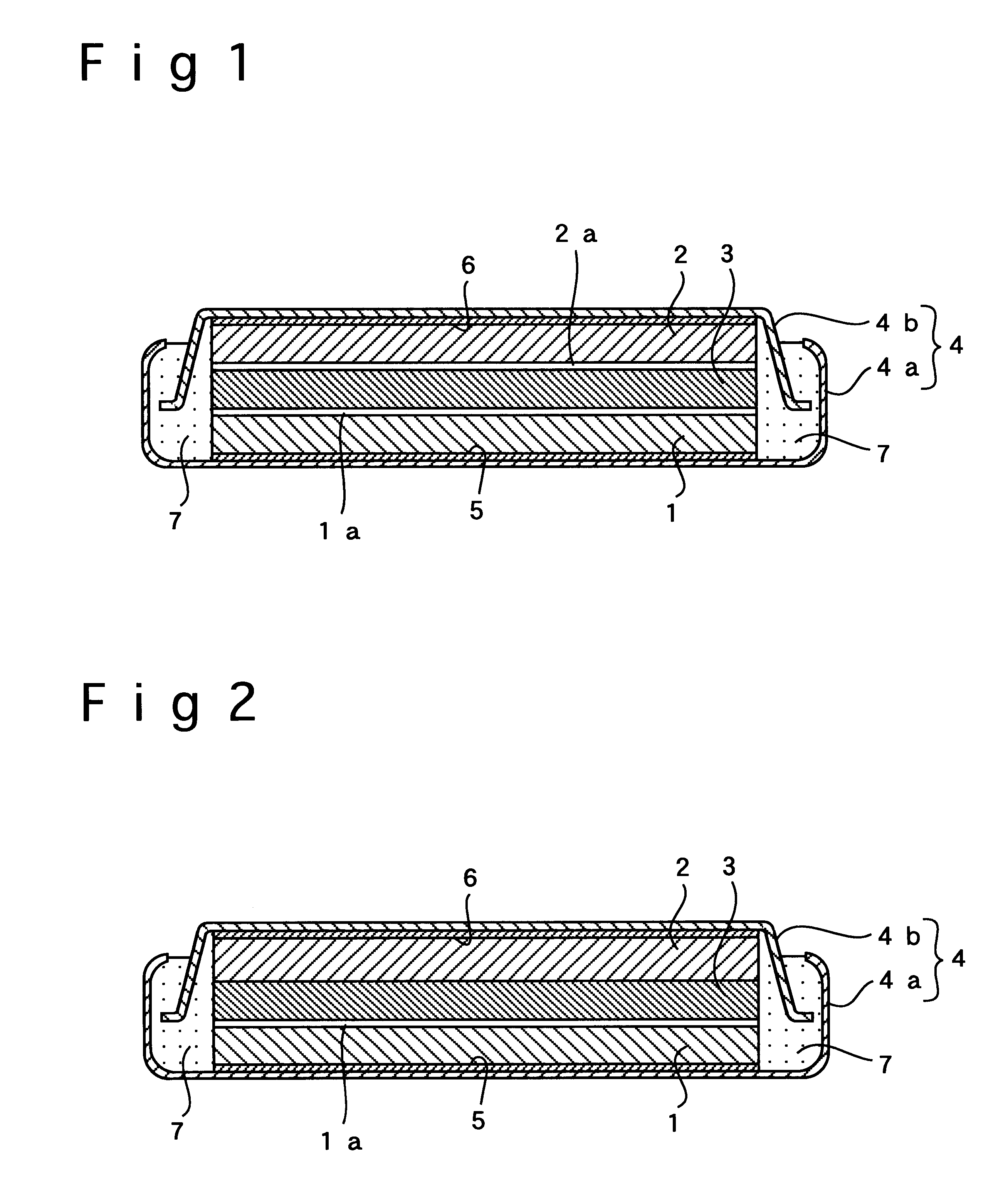

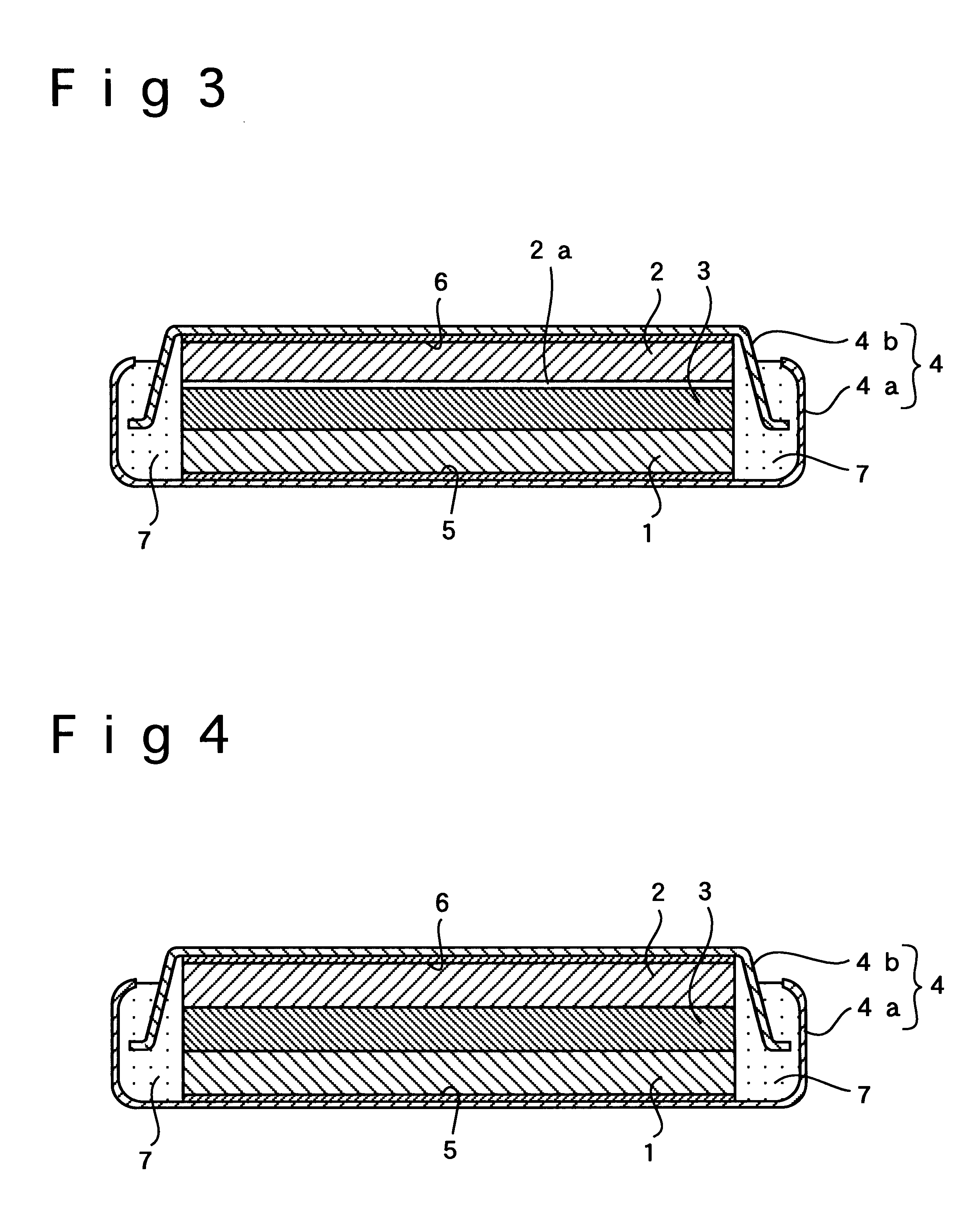

Electrode for rechargeable lithium battery and rechargeable lithium battery

InactiveUS7241533B1High charge and discharge capacityImprove charge and discharge cycle characteristicsElectrode manufacturing processesFinal product manufactureAmorphous siliconEngineering

An electrode for a rechargeable lithium battery characterized in that thin films of active material capable of lithium storage and release, i.e., microcrystalline or amorphous silicone thin films are deposited on opposite faces of a plate-form current collector.

Owner:SANYO ELECTRIC CO LTD

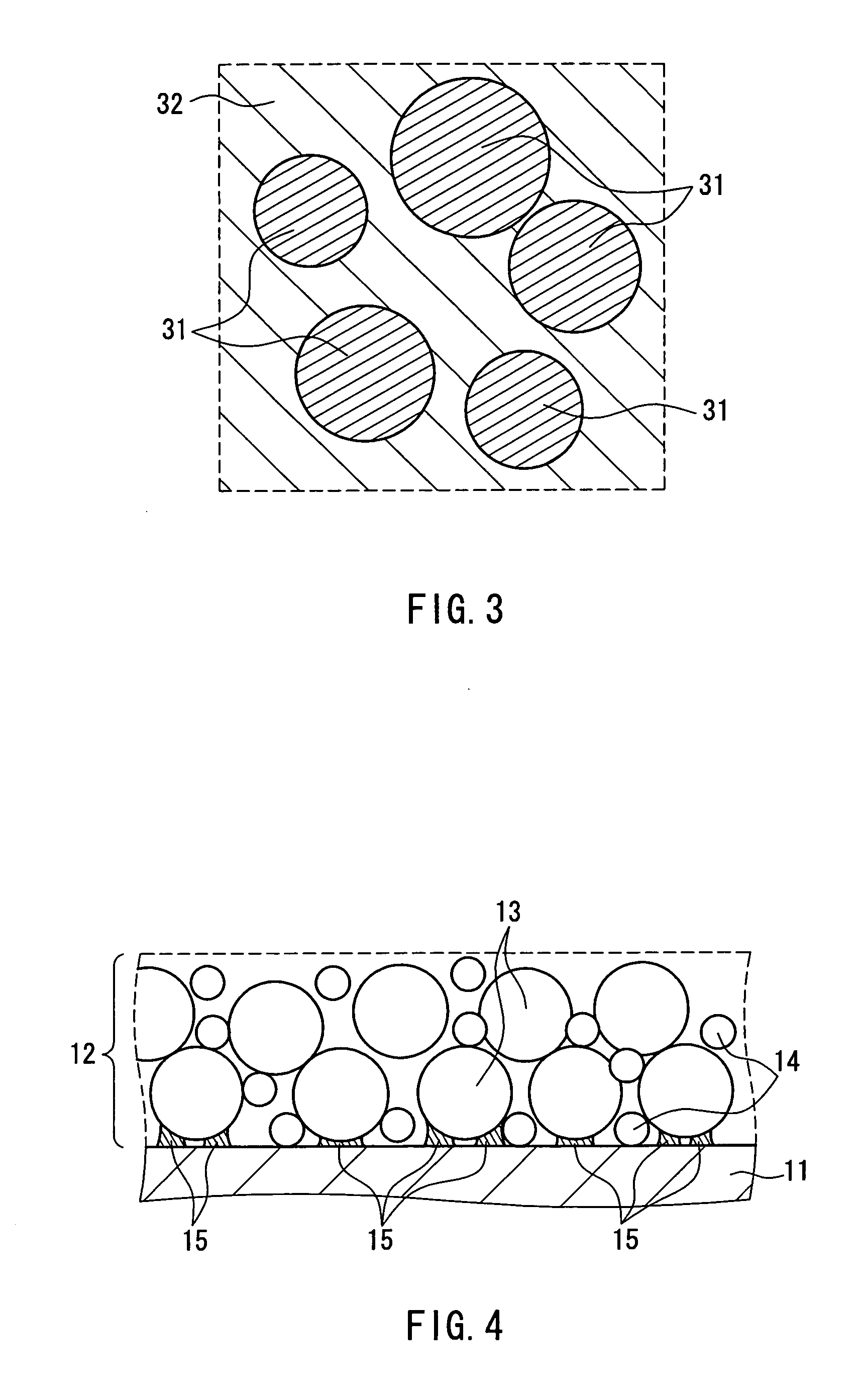

Nonaqueous electrolyte secondary battery and method for producing same

InactiveUS20060147800A1Conductivity is deterioratedImprove charge and discharge cycle characteristicsPrimary cellsElectrode carriers/collectorsLithiumEngineering

A nonaqueous electrolyte secondary battery with excellent charging / discharging cycle characteristics is provided, more specifically a nonaqueous electrolyte secondary battery in which deterioration of the conductivity of a negative electrode due to charging / discharging cycle is suppressed and a method for manufacturing the same are provided. The nonaqueous electrolyte secondary battery includes: a positive electrode and a negative electrode that are capable of reversibly absorbing and desorbing Li ions; and a nonaqueous electrolyte having lithium ion conductivity. The negative electrode includes a collector and active material particles that are disposed on a surface of the collector. The active material particles include Si and at least one element R selected from the group consisting of Sn, In, Ga, Pb and Bi. Metallic bond including the element R is formed between the active material particles.

Owner:PANASONIC CORP

Negative Electrode Material For Lithium Secondary Battery, Negative Electrode Using The Material, Lithium Secondary Battery Using The Negative Electrode, And Manufacturing Method Of Negative Electrode Material

InactiveUS20080113269A1Excellent discharge cycle characteristicSmall in irreversible capacityPrimary cellsElectrode carriers/collectorsLithiumSilicon oxide

In a negative electrode material for lithium secondary batteries, basic material particles include one of phase A having silicon as a main component, and a mixed phase of phase B including an intermetallic compound of a transition metal element and silicon and the phase A. The phase A or the mixed phase is microcrystalline or amorphous. A carbon material is adhered to surfaces of the basic material particles, and a film containing a silicon oxide is formed on remained surface portions.

Owner:PANASONIC CORP

Lithium Ion Secondary Battery and a Solid Electrolyte Therefof

InactiveUS20080268346A1Improve lithium ion conductivityImprove charge and discharge cycle characteristicsNon-metal conductorsHybrid capacitor electrolytesElectrolyteLithium

A solid electrolyte comprising powder of an inorganic substance comprising a lithium ion conductive crystal or powder of a lithium ion conductive glass-ceramic and an organic polymer added with an inorganic or organic lithium salt, and being free of an electrolytic solution. The organic polymer is a copolymer, a bridge structure or a mixture thereof of polyethylene oxide and other organic polymer or polymers. A lithium ion secondary battery comprises this solid electrolyte.

Owner:OHARA

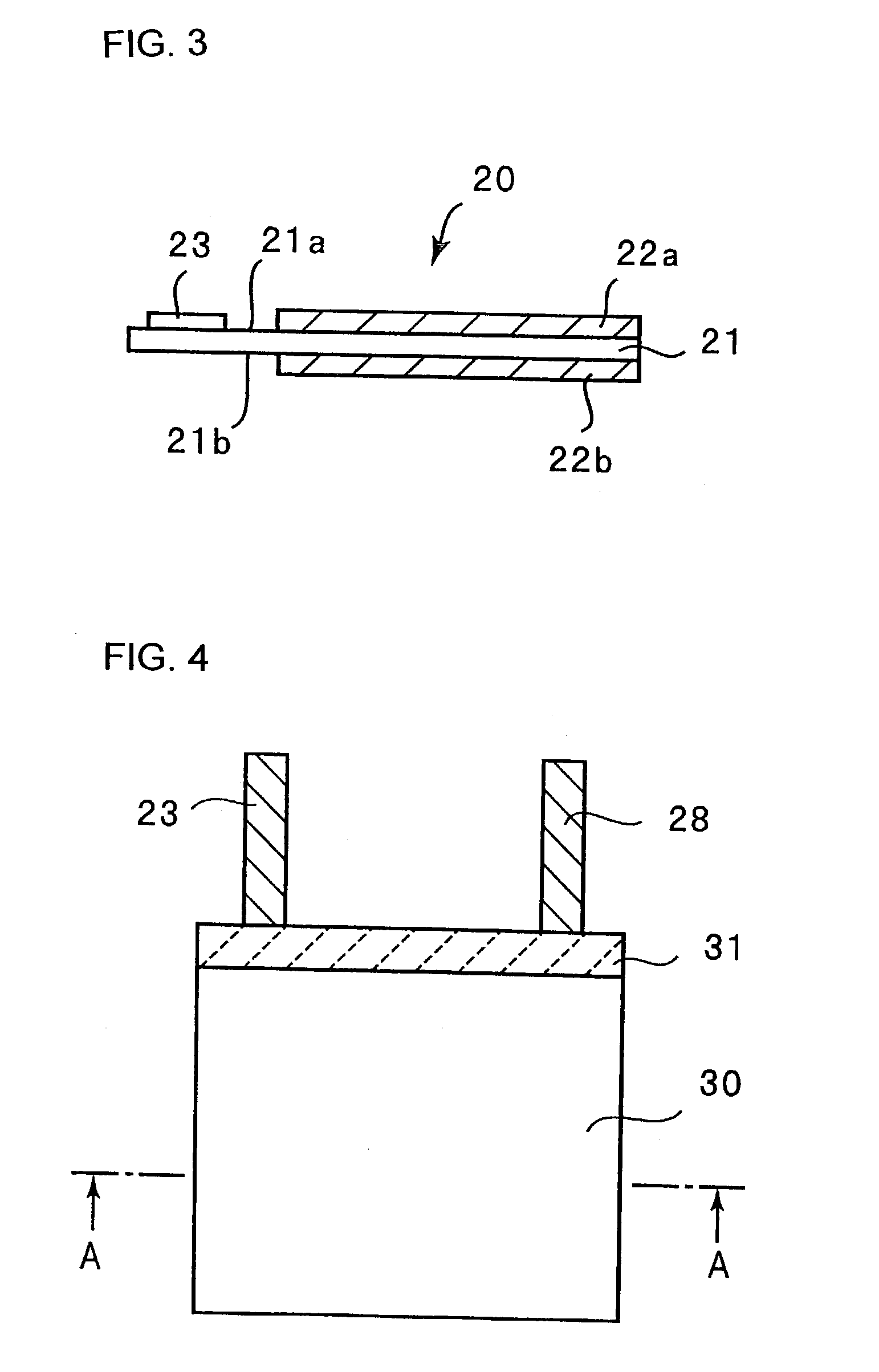

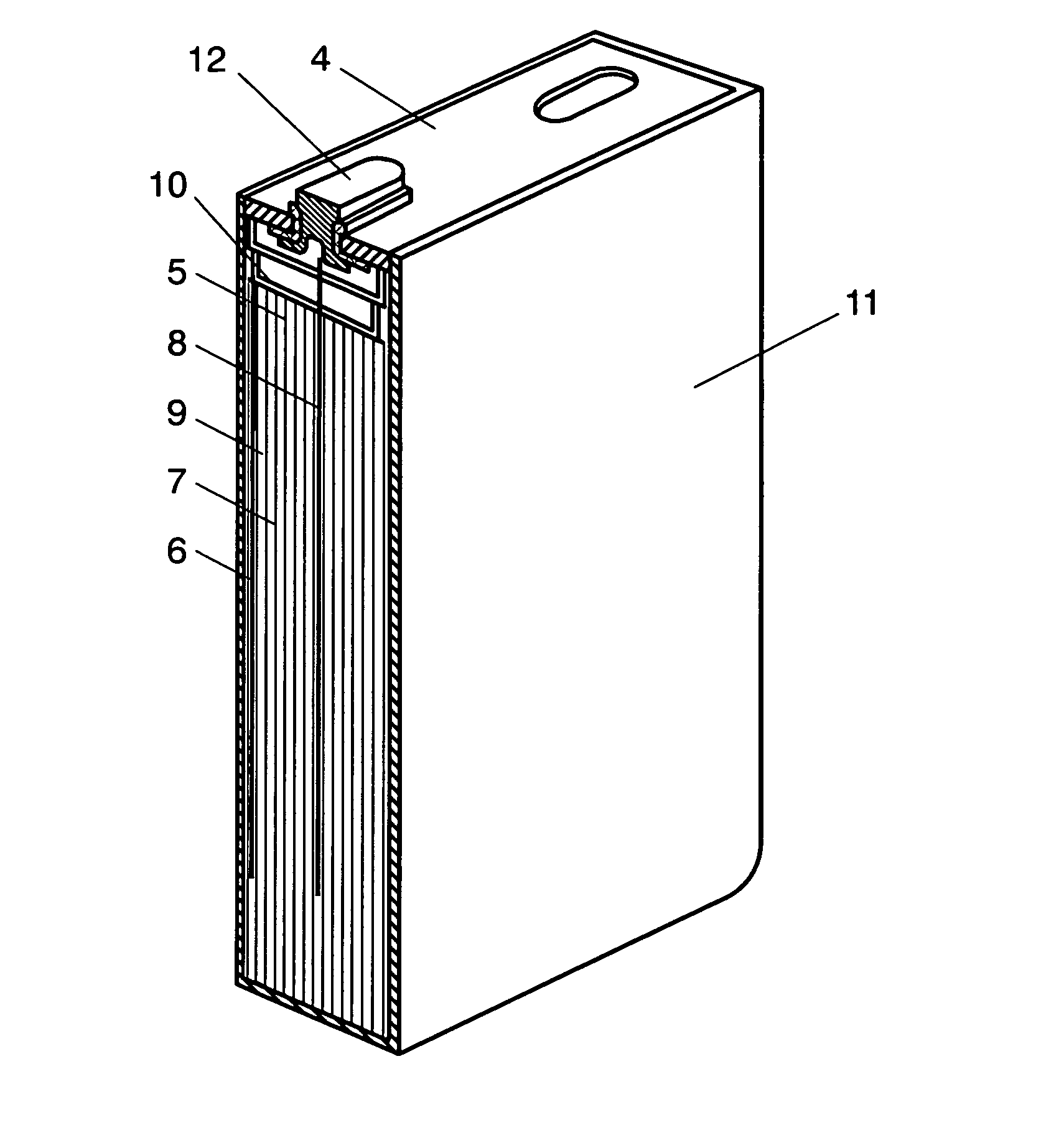

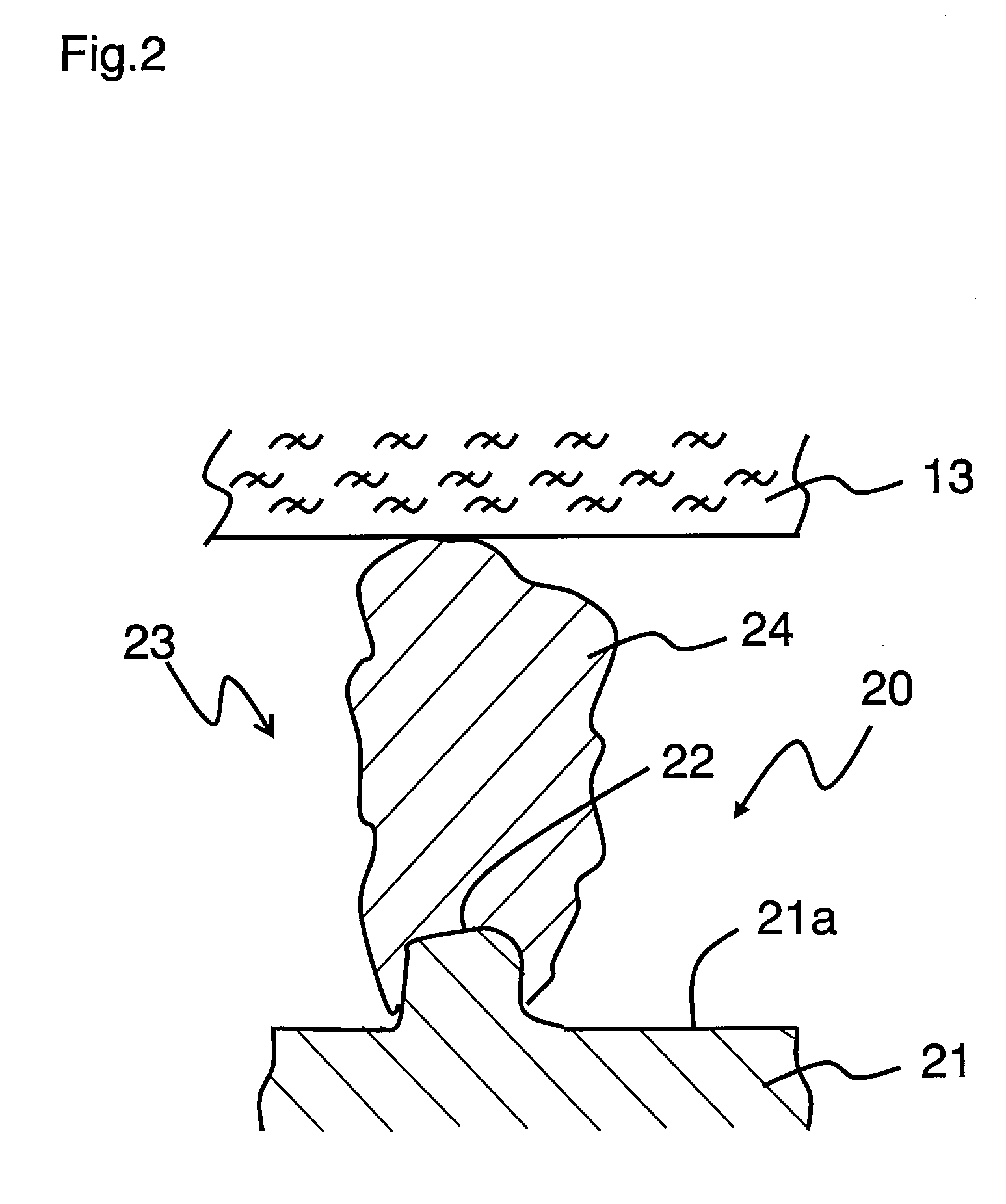

Negative electrode for lithium ion secondary battery and lithium ion secondary battery

InactiveUS20080213671A1Improve Coulombic efficiencyImprove lithium ion conductivityElectrode carriers/collectorsNegative electrodesLithiumHigh energy

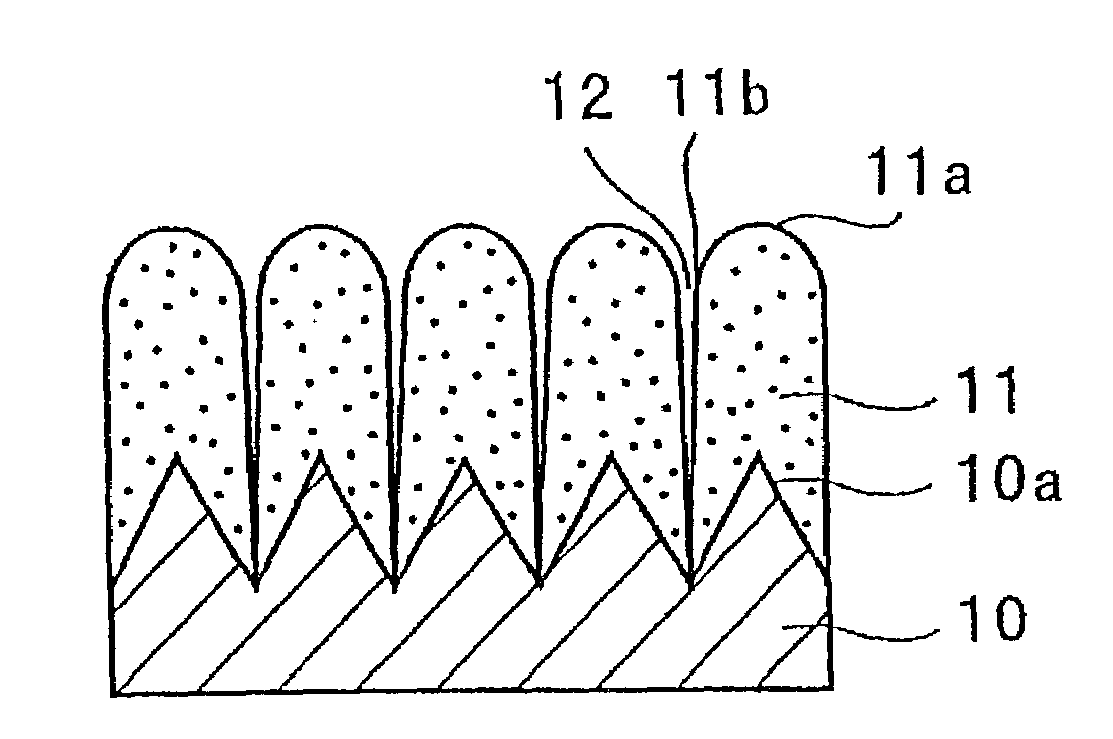

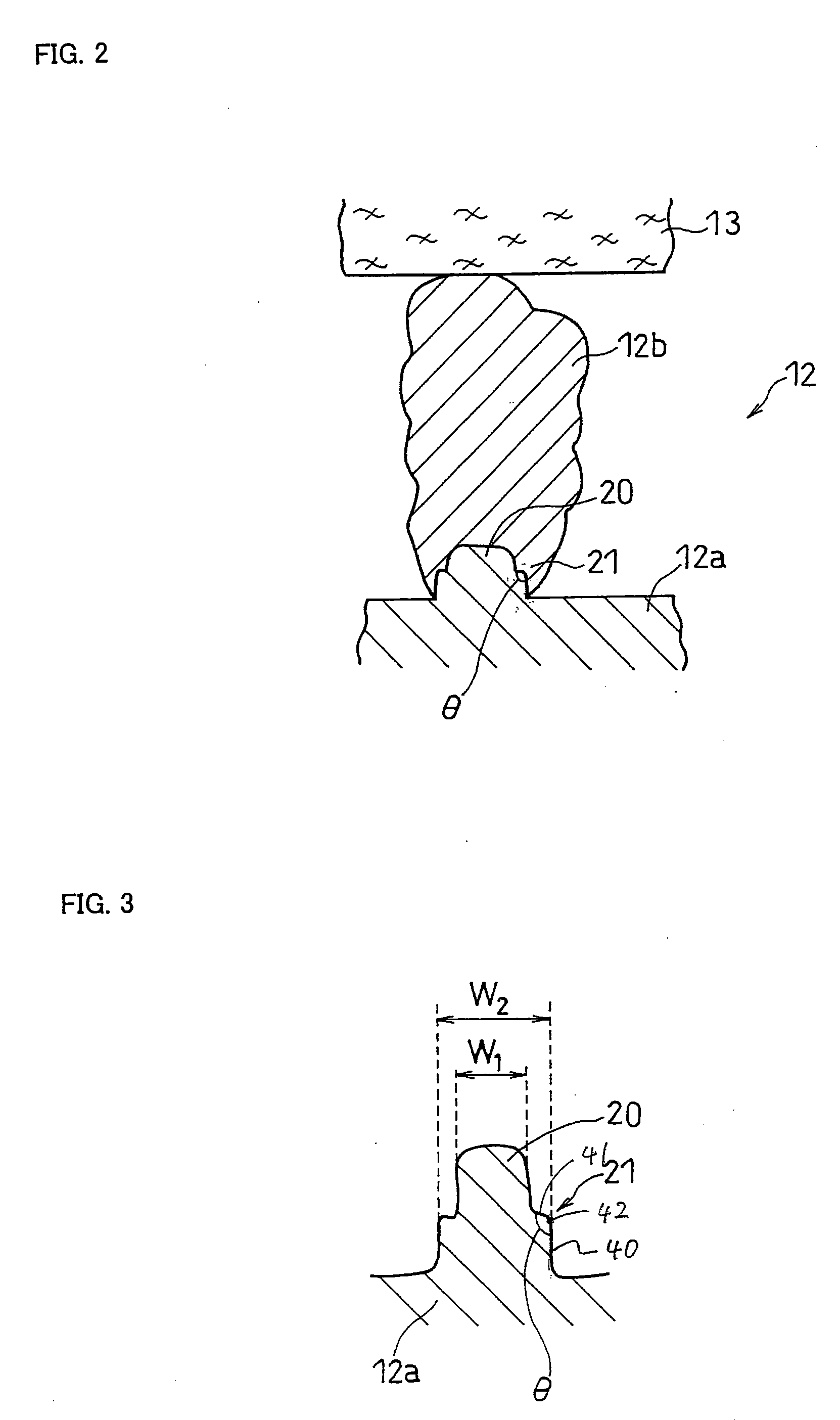

A negative electrode including a negative electrode current collector, first protrusions on a surface of the negative electrode current collector, a separation-stopping area on at least a part of a surface of each first protrusion, and a negative electrode active material layer including a negative electrode active material and formed on at least a top face of the first protrusion. This structure suppresses the separation of the negative electrode active material layer from the negative electrode current collector, the degradation of the current collecting ability, and the deformation of the negative electrode itself. A lithium ion secondary battery including this negative electrode has a high battery capacity, a high energy density, and an excellent charge / discharge cycle characteristic, and is capable of stably maintaining a high power over an extended period of time.

Owner:PANASONIC CORP

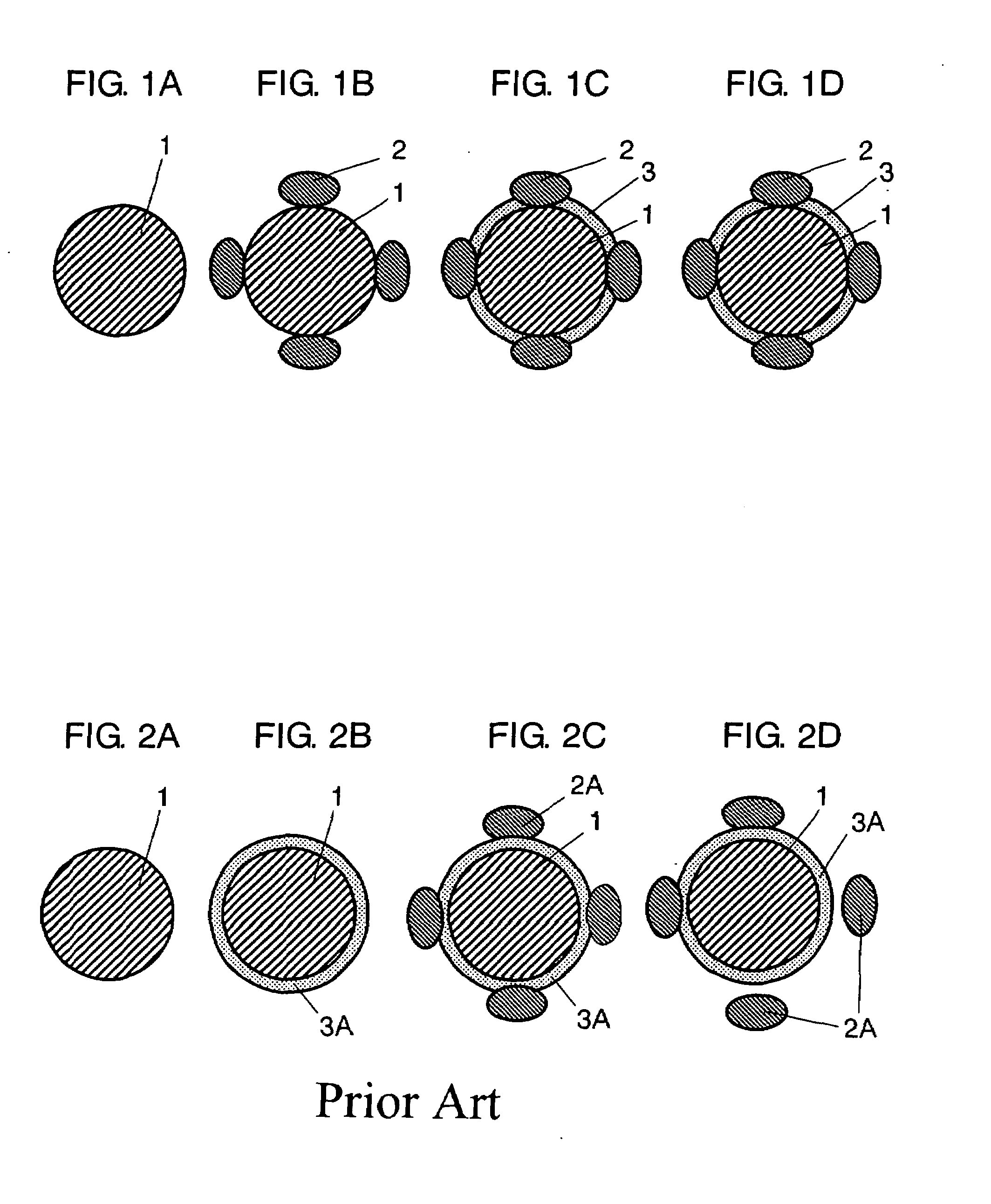

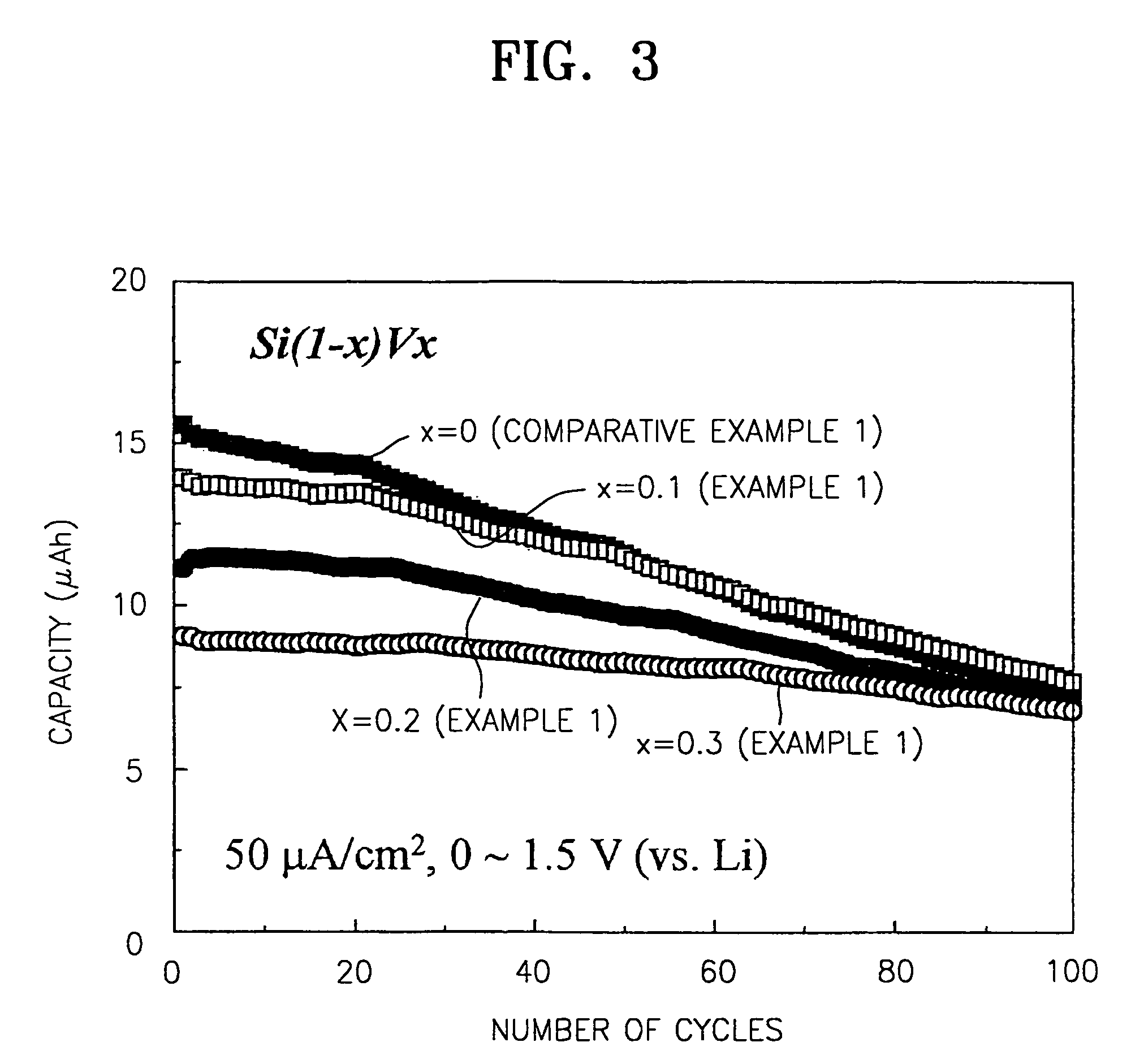

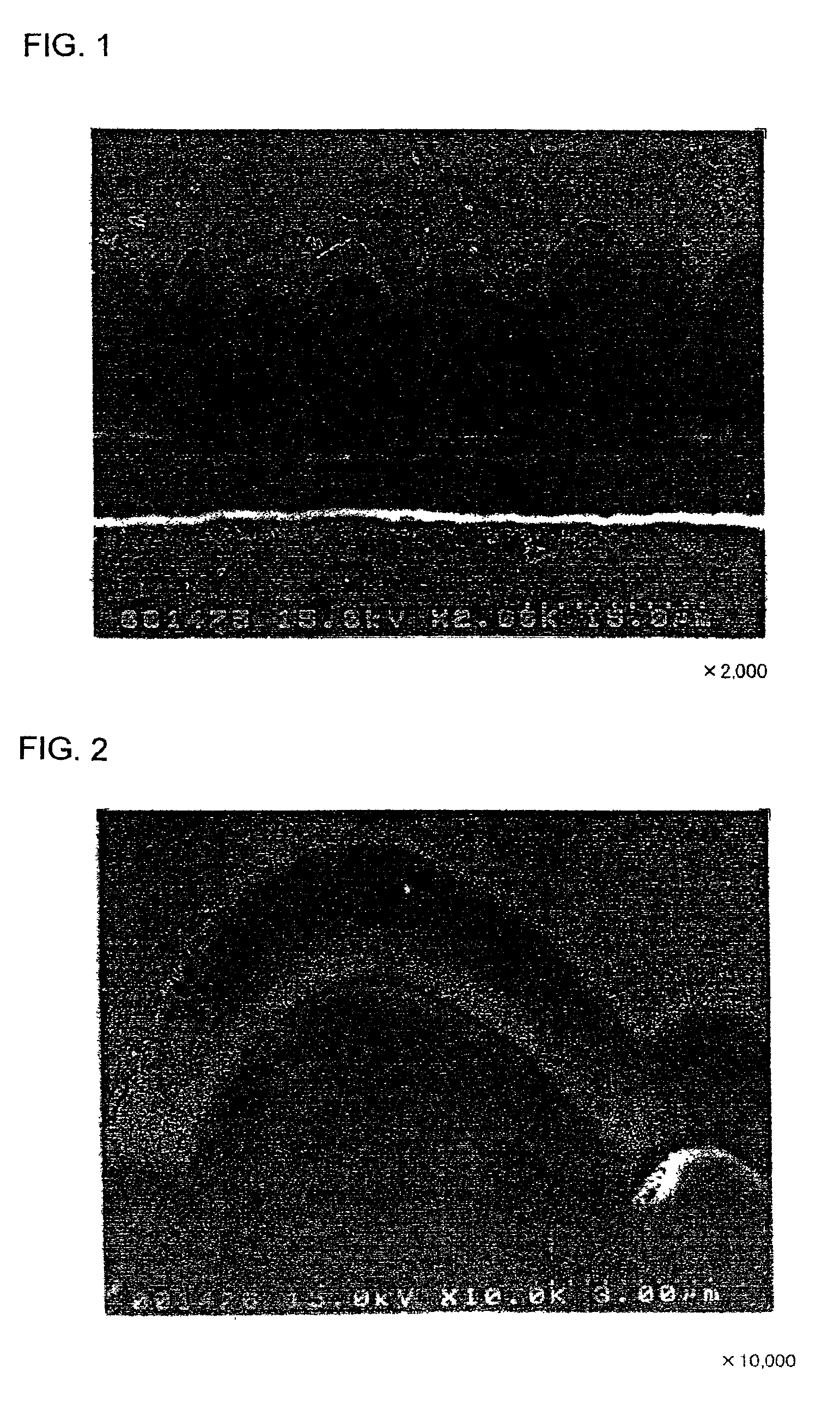

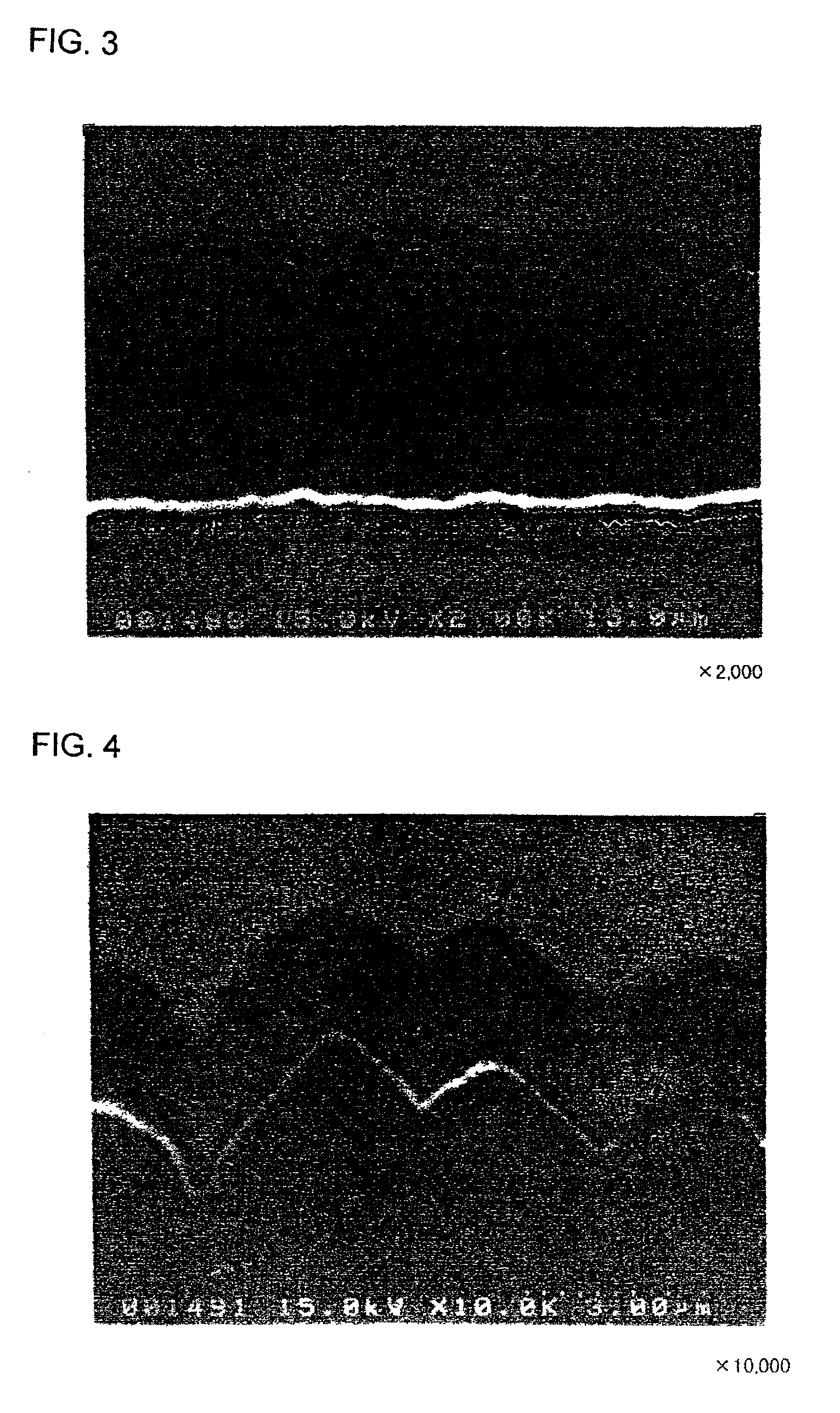

Method for improvement of performance of si thin film anode for lithium rechargeable battery

ActiveUS20070007239A1Improve featuresImprove the problemDecorative surface effectsElectrode carriers/collectorsLithiumElectrical battery

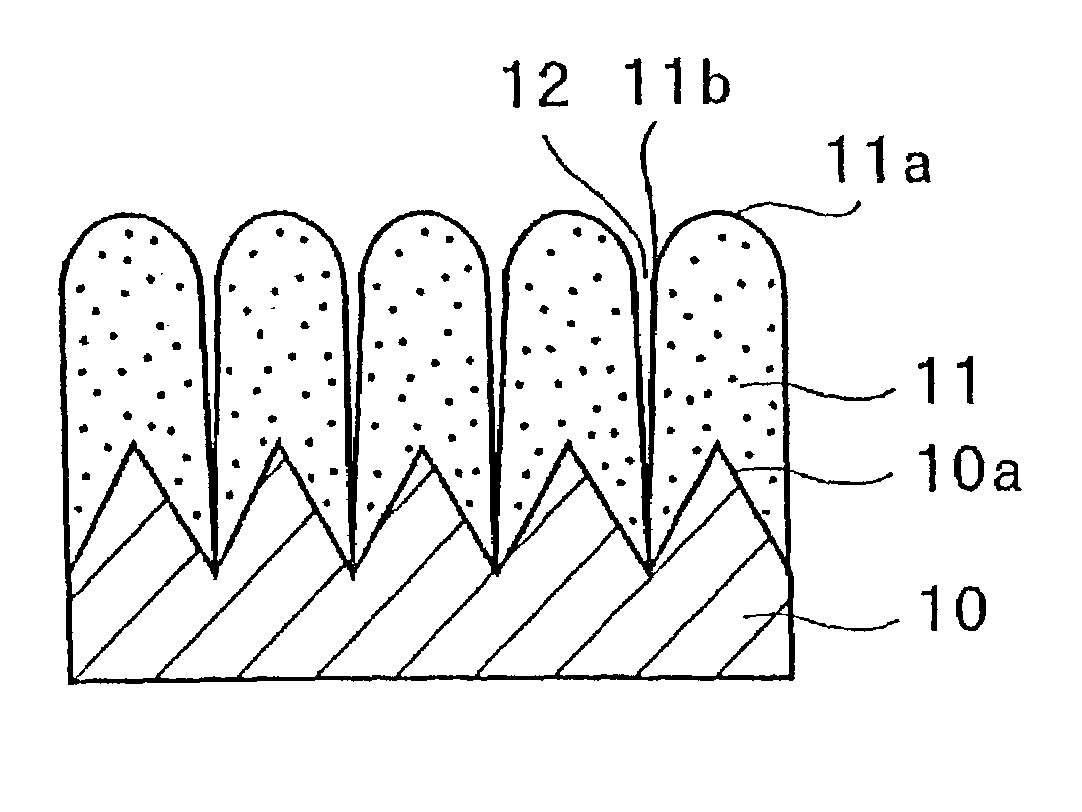

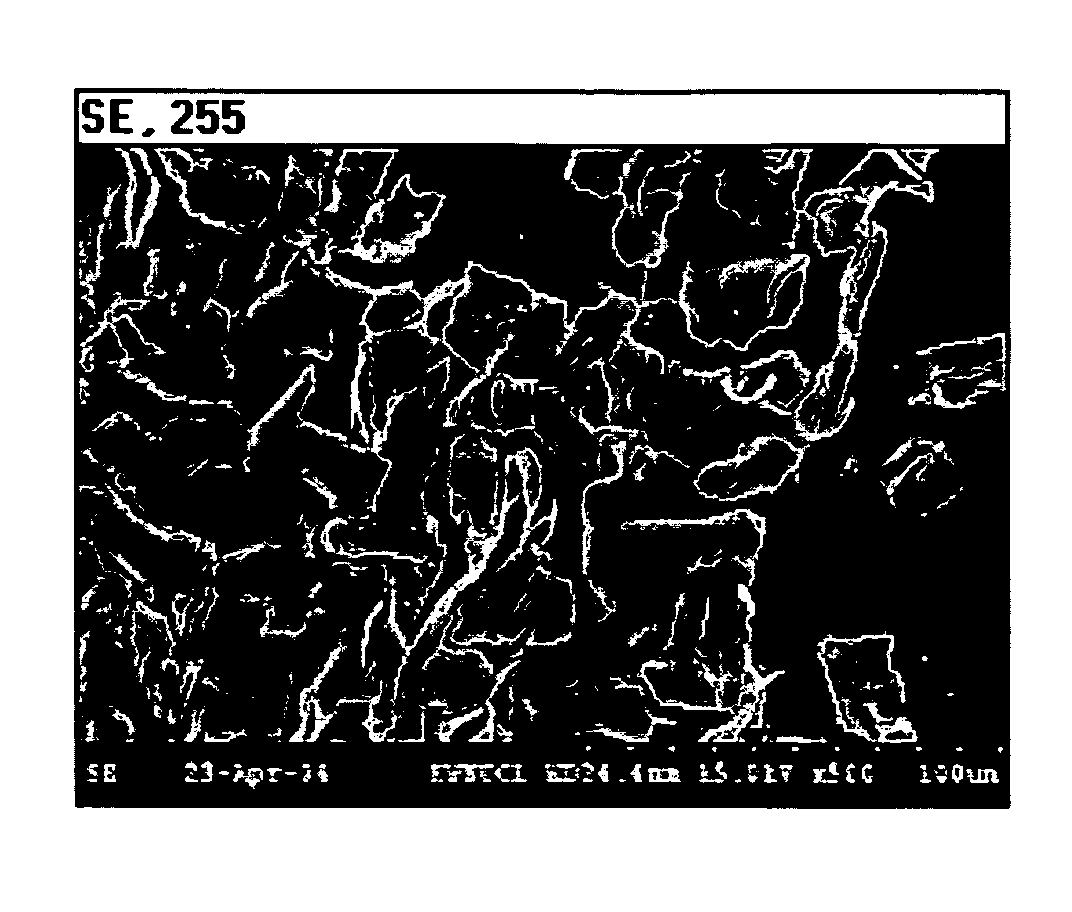

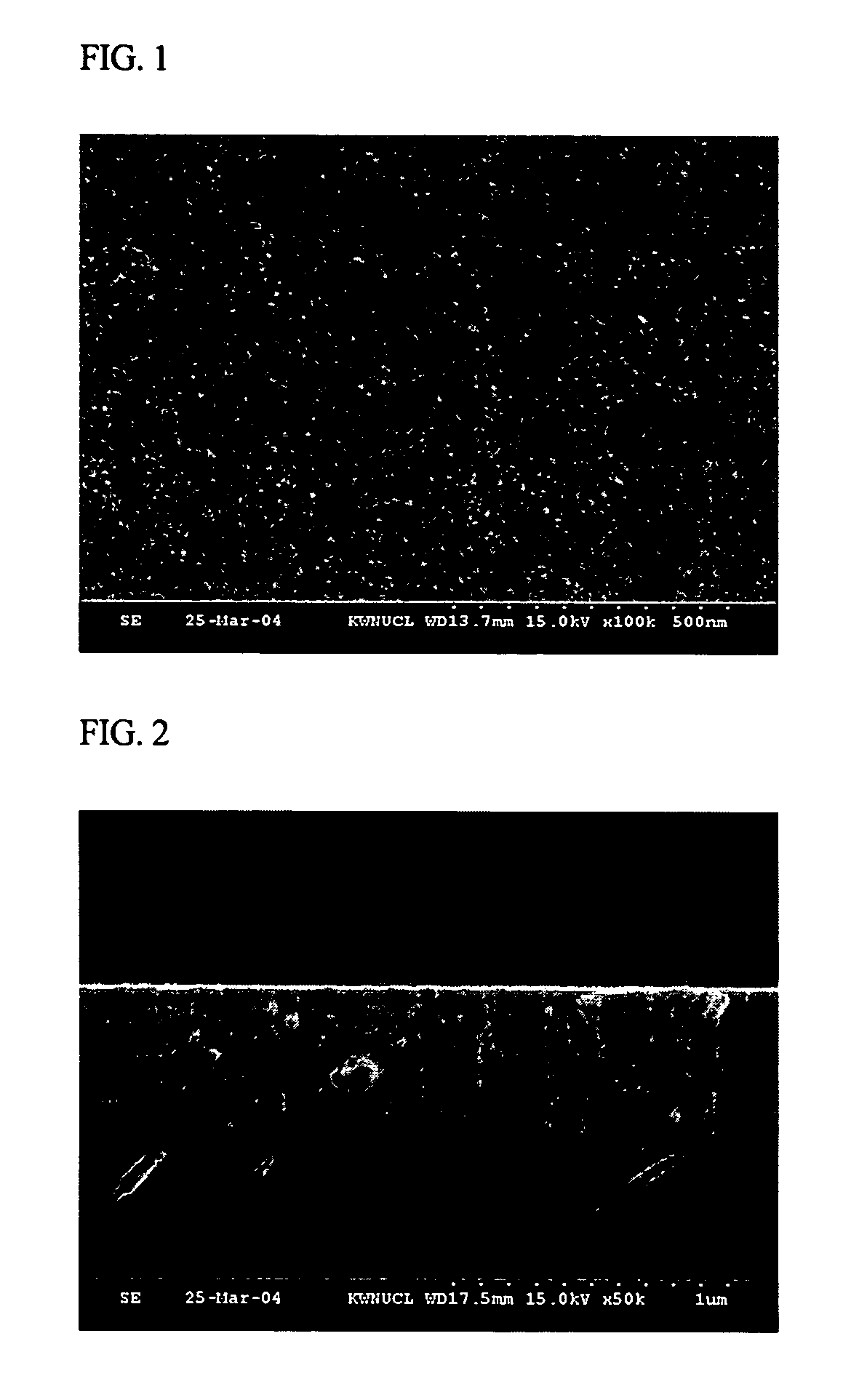

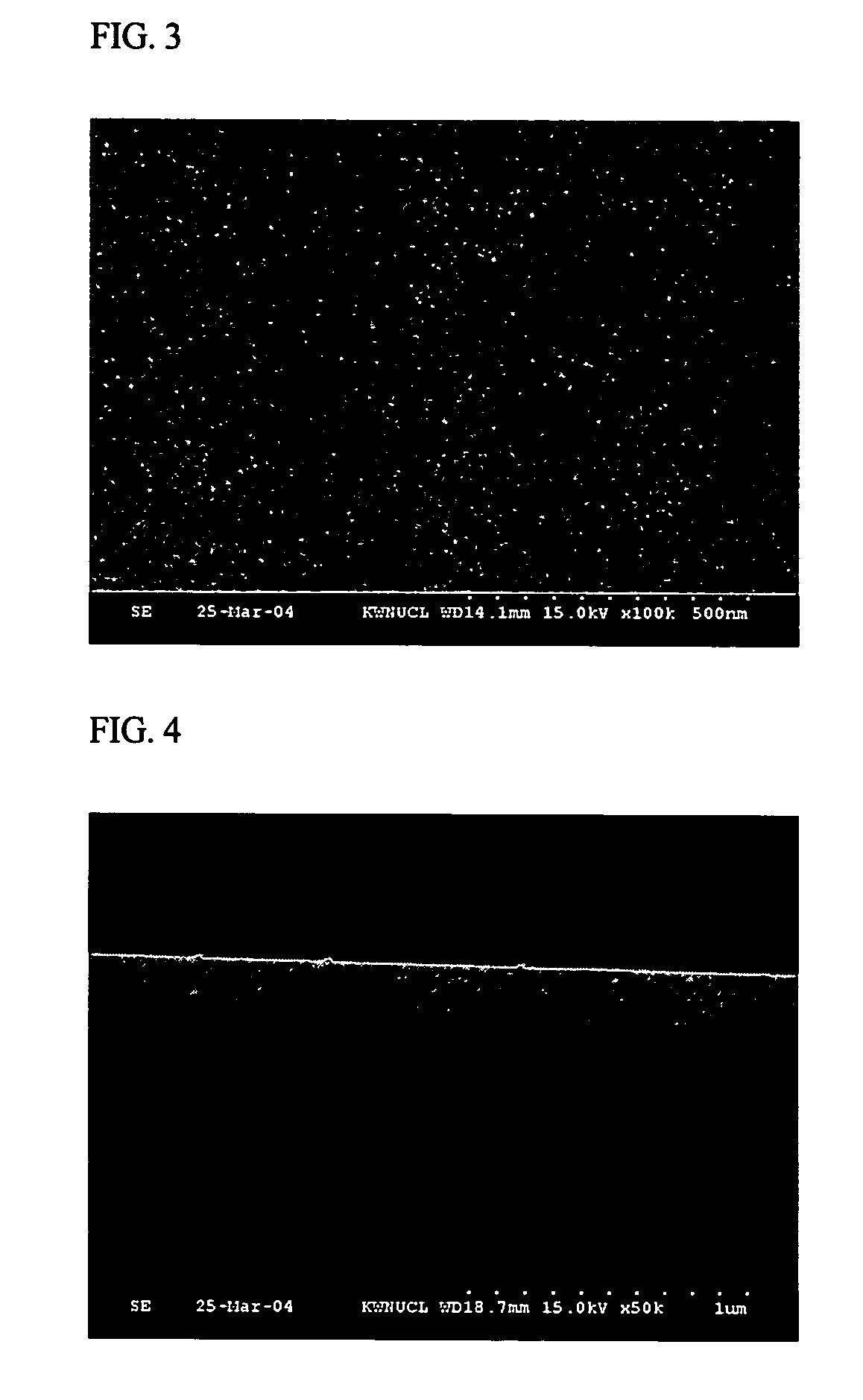

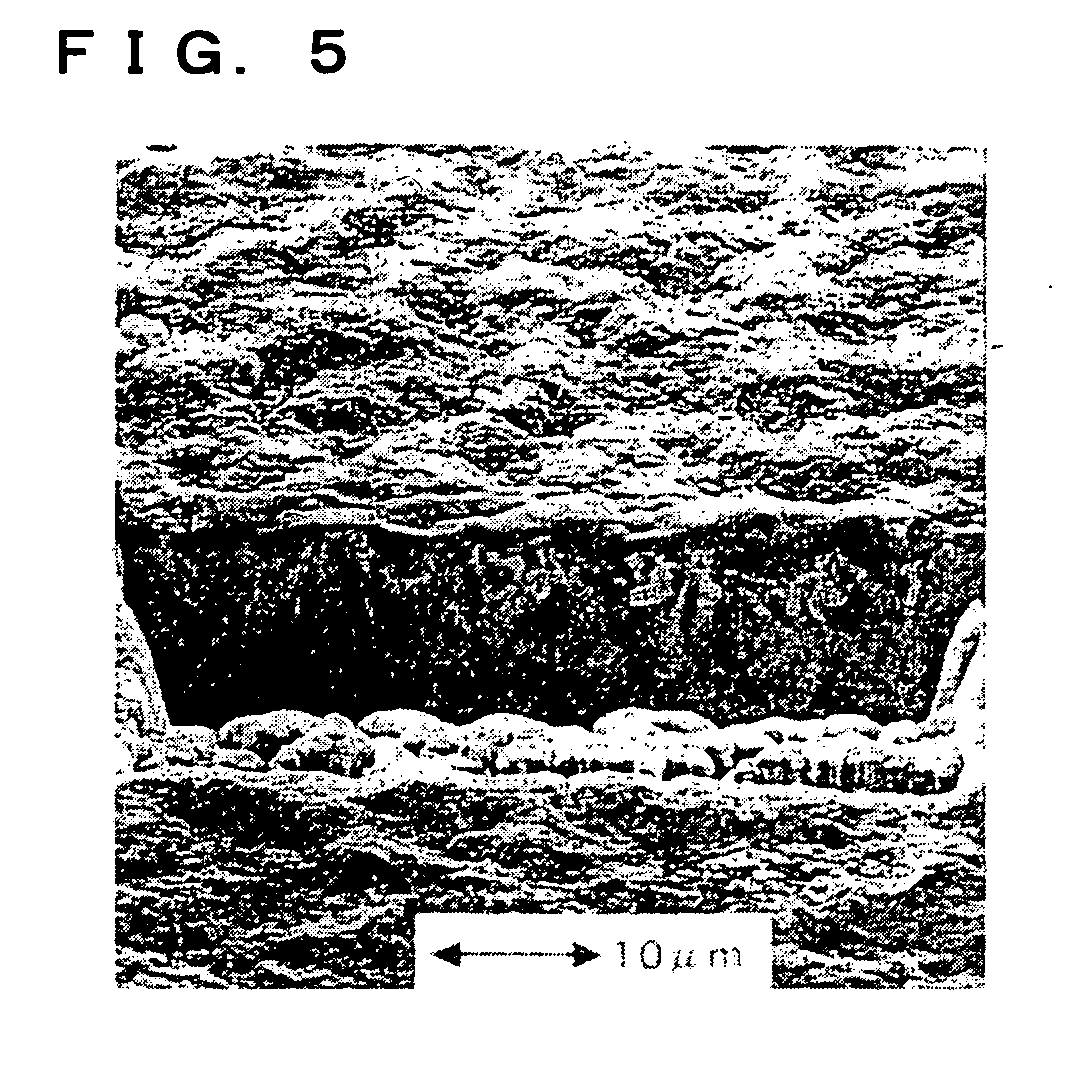

The present invention relates to a method for improving charge / discharge cycle characteristics of a lithium secondary battery using a Si based anode active material, the method comprising surface-treating a surface of an anode current collector to have specific morphology, and preferably vapor-depositing a silicon film, as the anode active material by sputtering under application of bias voltage to the surface-treated anode current collector, and / or disposing an adhesive layer between the surface-treated anode current collector and silicon film, so as to reinforce bondability between the anode current collector and active material, ultimately leading to improvement of charge / discharge characteristics of the battery.

Owner:LG ENERGY SOLUTION LTD

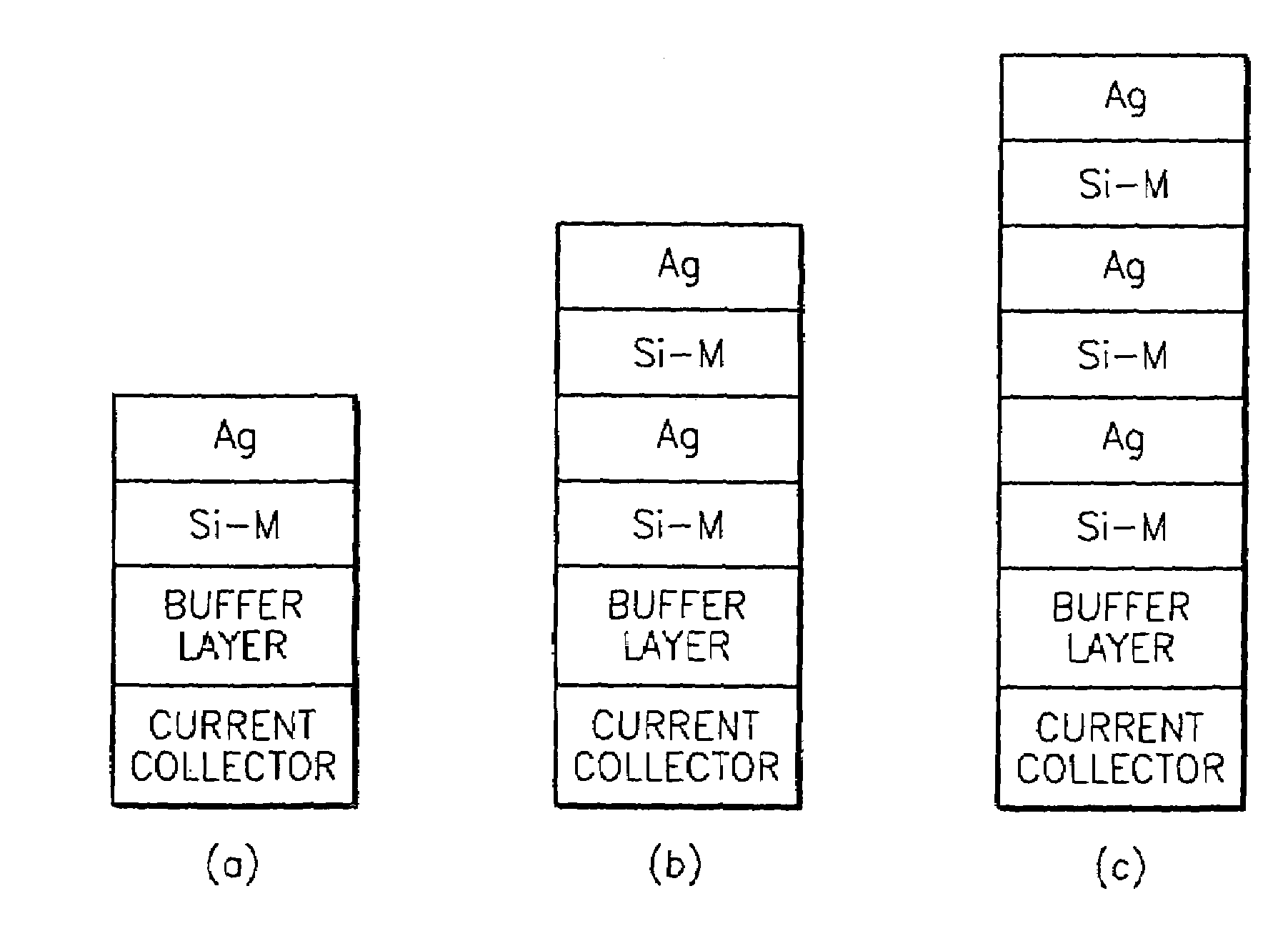

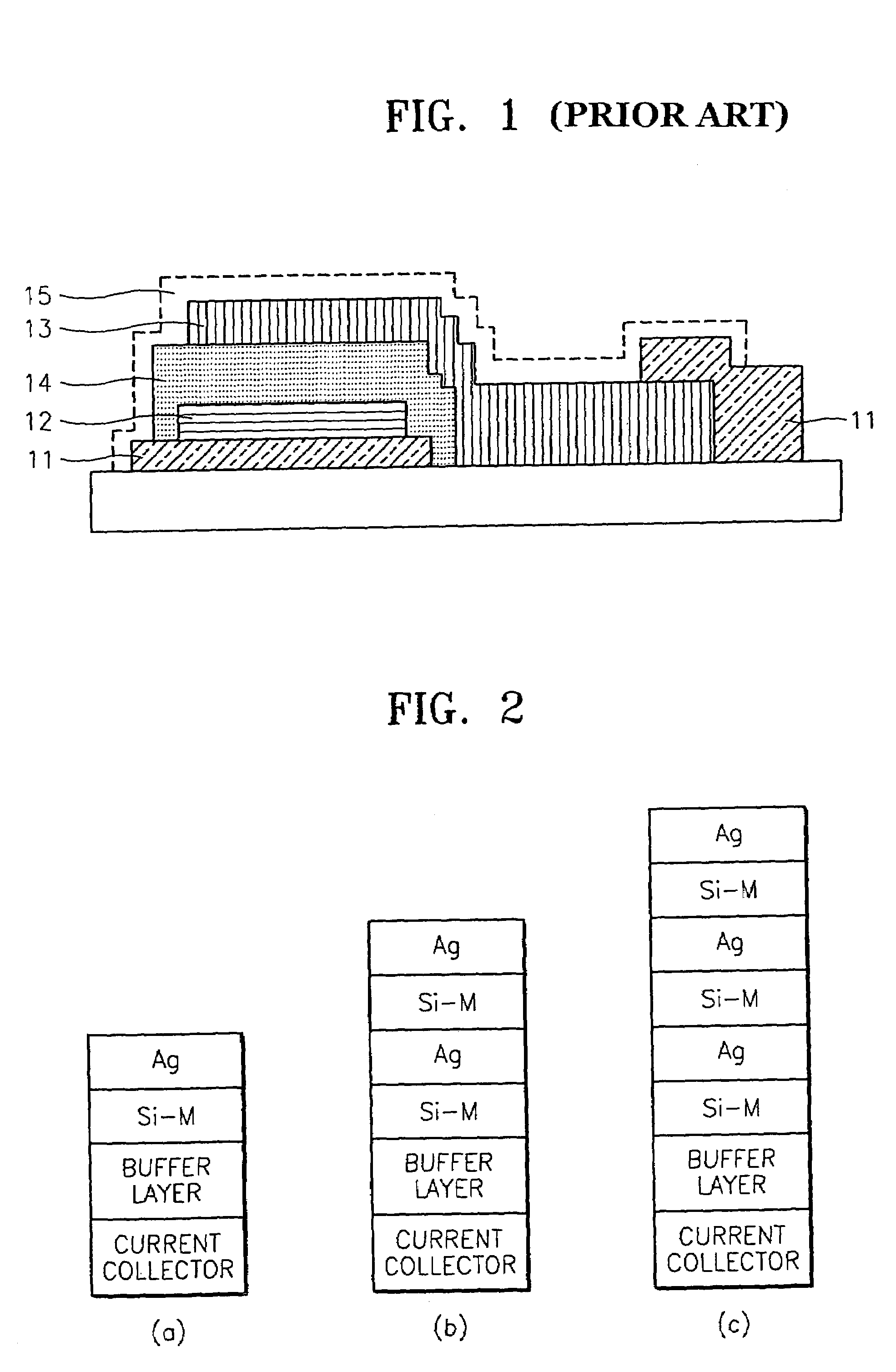

Method for manufacturing a multi-layered thin film for use as an anode in a lithium secondary battery

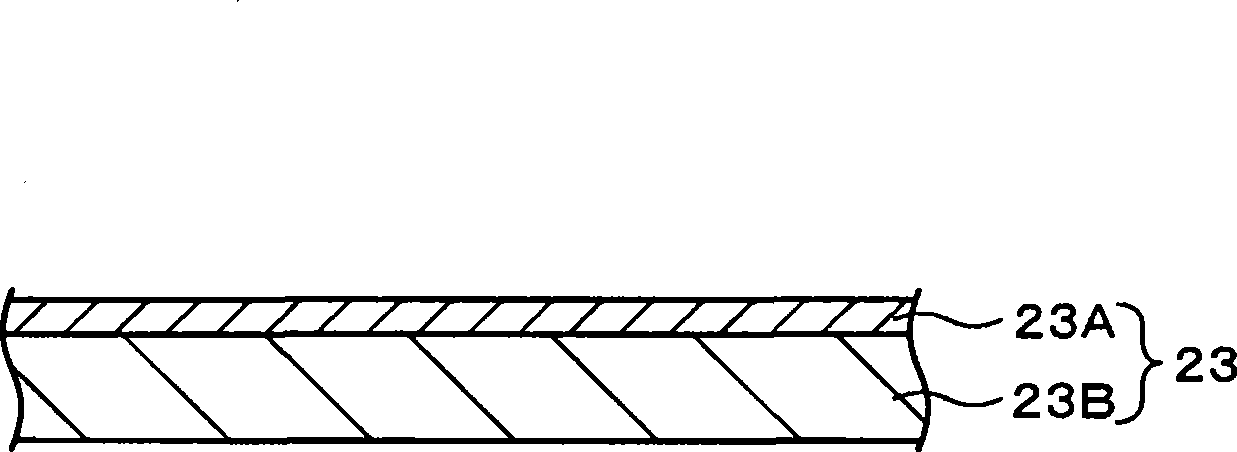

InactiveUS7316867B2Improve charge and discharge cycle characteristicsSilver accumulatorsFinal product manufactureMechanical stabilityLithium-ion battery

A thin film for an anode of a lithium secondary battery having a current collector and an anode active material layer formed thereon is provided. The anode active material layer is a multi-layered thin film formed by stacking a silver (Ag) layer and a silicon-metal (Si-M) layer having silicon dispersed in a base made from metal reacting with silicon while not reacting with lithium. The cycle characteristic of the thin film for an anode can be improved by suppressing the volumetric expansion and shrinkage of Si occurring during charging / discharging cycles. Thus, a lithium secondary battery with improved life characteristics by employing the thin film for an anode, which greatly improves the chemical, mechanical stability of the interface between an electrode and an electrolyte.

Owner:SAMSUNG SDI CO LTD

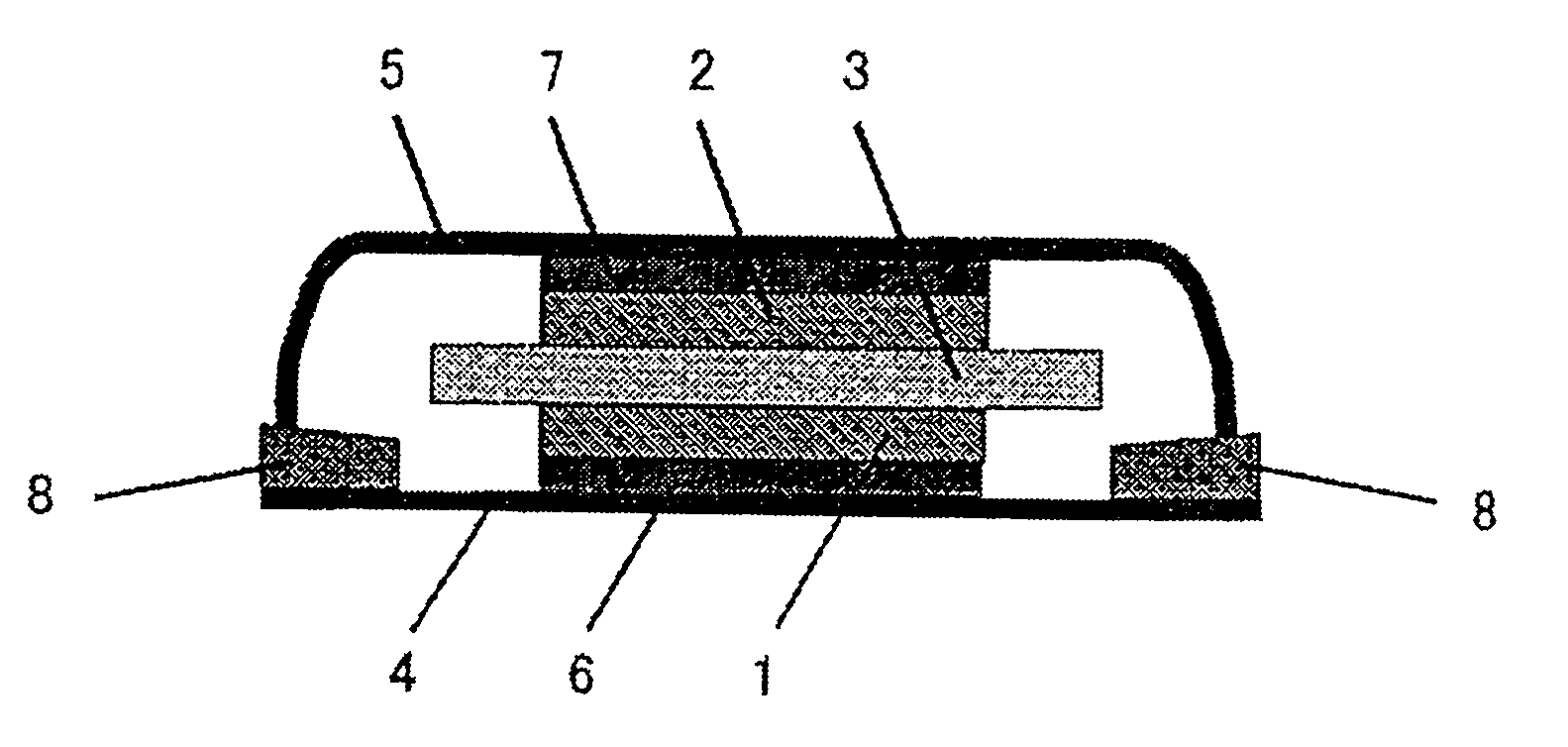

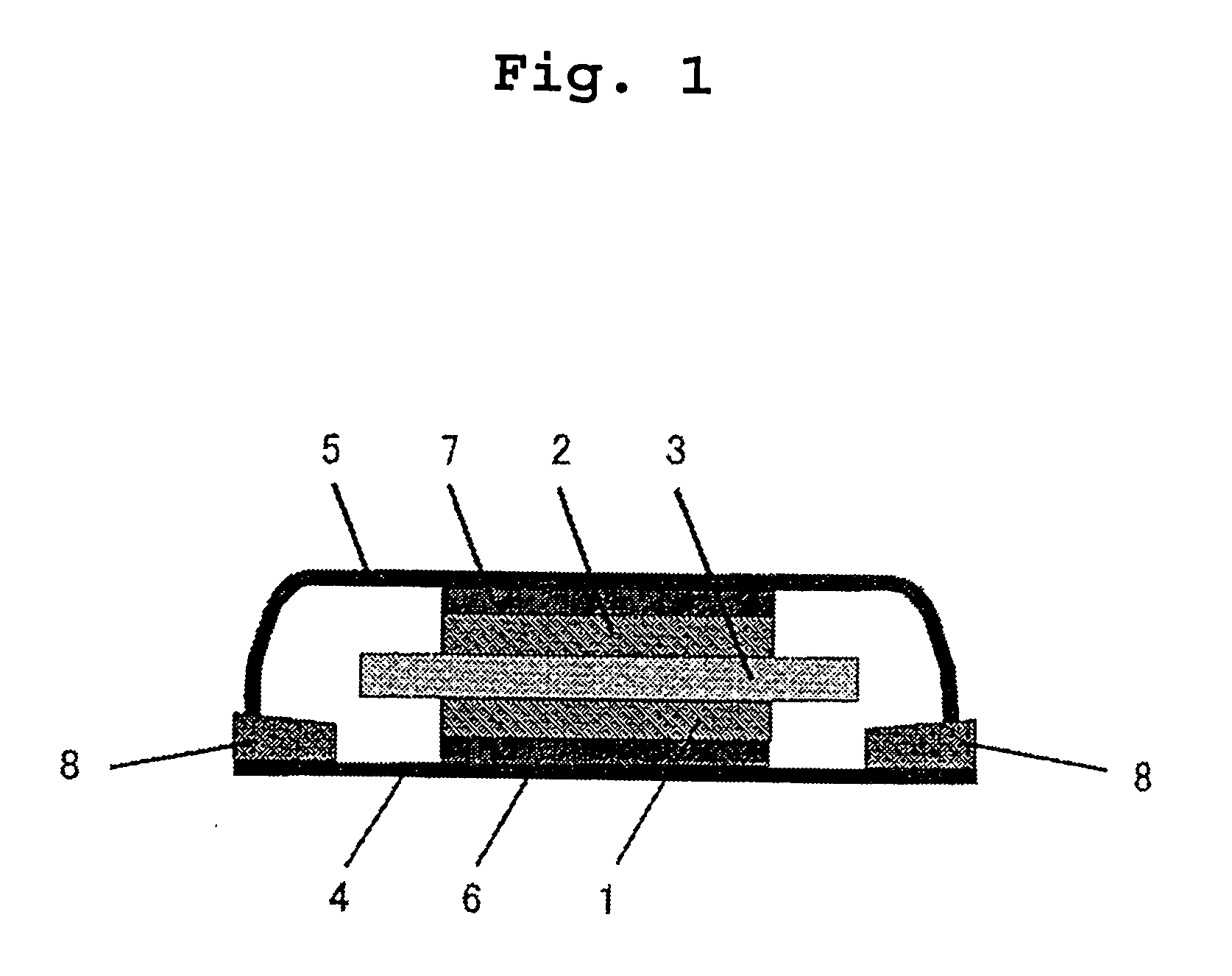

Polymer electrolyte batteries having improved electrode/electrolyte interface

InactiveUS6355379B1Improve ionic conductivityImprove charge and discharge cycle characteristicsSolid electrolytesOrganic electrolyte cellsPolymer electrolytesElectrolysis

In an inventive polymer electrolyte battery including a positive electrode, a negative electrode and a polymer electrolyte, at least one of the positive electrode and the negative electrode is formed with an inorganic amorphous solid electrolyte film at its interface with the polymer electrolyte.

Owner:GK BRIDGE 1

Cathode active material, cathode, and non-aqueous electrolyte secondary battery

ActiveCN101414680AImprove charge and discharge cycle characteristicsActive material electrodesLi-accumulatorsCapacitanceInternal resistance

The invention provides a cathode active material, a cathode, and a non-aqueous electrolyte secondary battery. The cathode active material has: a composite oxide particle containing at least lithium and one or a plurality of transition metals; and a coating layer provided on at least a part of the composite oxide particle. The coating layer contains at least one kind of element M differing from a main transition metal element A forming the composite oxide particle and selected from Groups 2 to 16 of the periodic table and a halogen element X. In the coating layer, the element M and the halogen element X exhibit different distribution states. It is, therefore, desirable to provide a cathode active material, a cathode, and a non-aqueous electrolyte secondary battery in which a large capacitance and excellent charge / discharge cycle characteristics are obtained and an increase in internal resistance can be suppressed.

Owner:MURATA MFG CO LTD

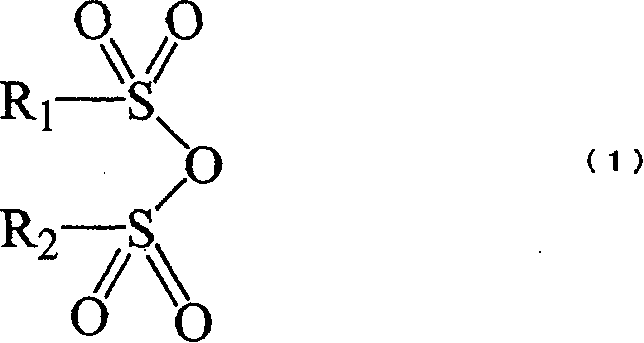

Non-aqueous electrolyte secondary battery

InactiveUS20080286657A1Improve charge and discharge cycle characteristicsLarge capacityAlkaline accumulatorsOrganic electrolyte cellsGraphiteSulfur containing

A non-aqueous electrolyte secondary battery is composed of a positive electrode containing a positive electrode active material capable of storing and releasing lithium ion, a negative electrode containing a negative electrode active material capable of storing and releasing lithium ion, and a non-aqueous electrolyte. The negative electrode active material contains a first material of a graphite material and a second material of a complex in which graphite material and silicon or silicon composite are coated with amorphous carbon material, and a cyclic carbonic acid ester derivative having fluoride atom and a sulfur-containing composite having cyclic structure are added to the non-aqueous electrolyte.

Owner:SANYO ELECTRIC CO LTD

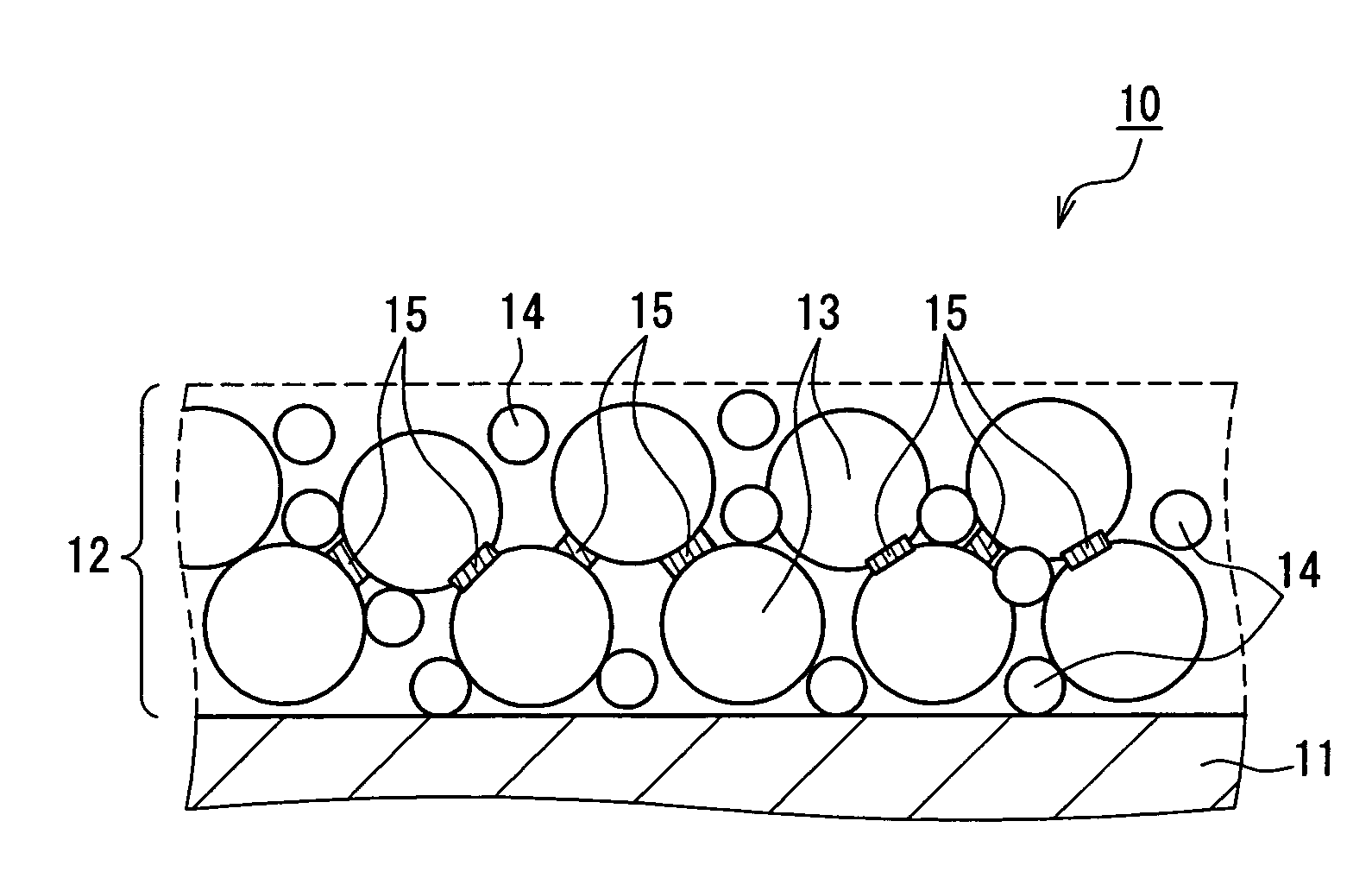

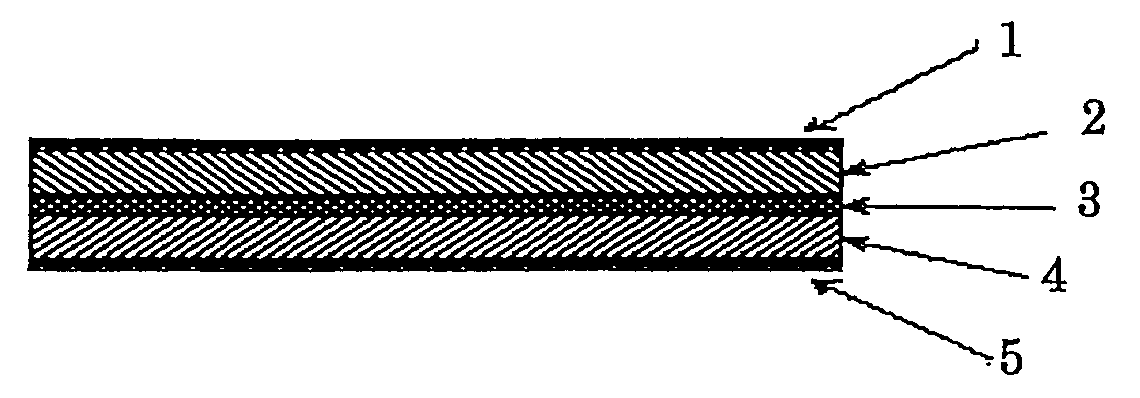

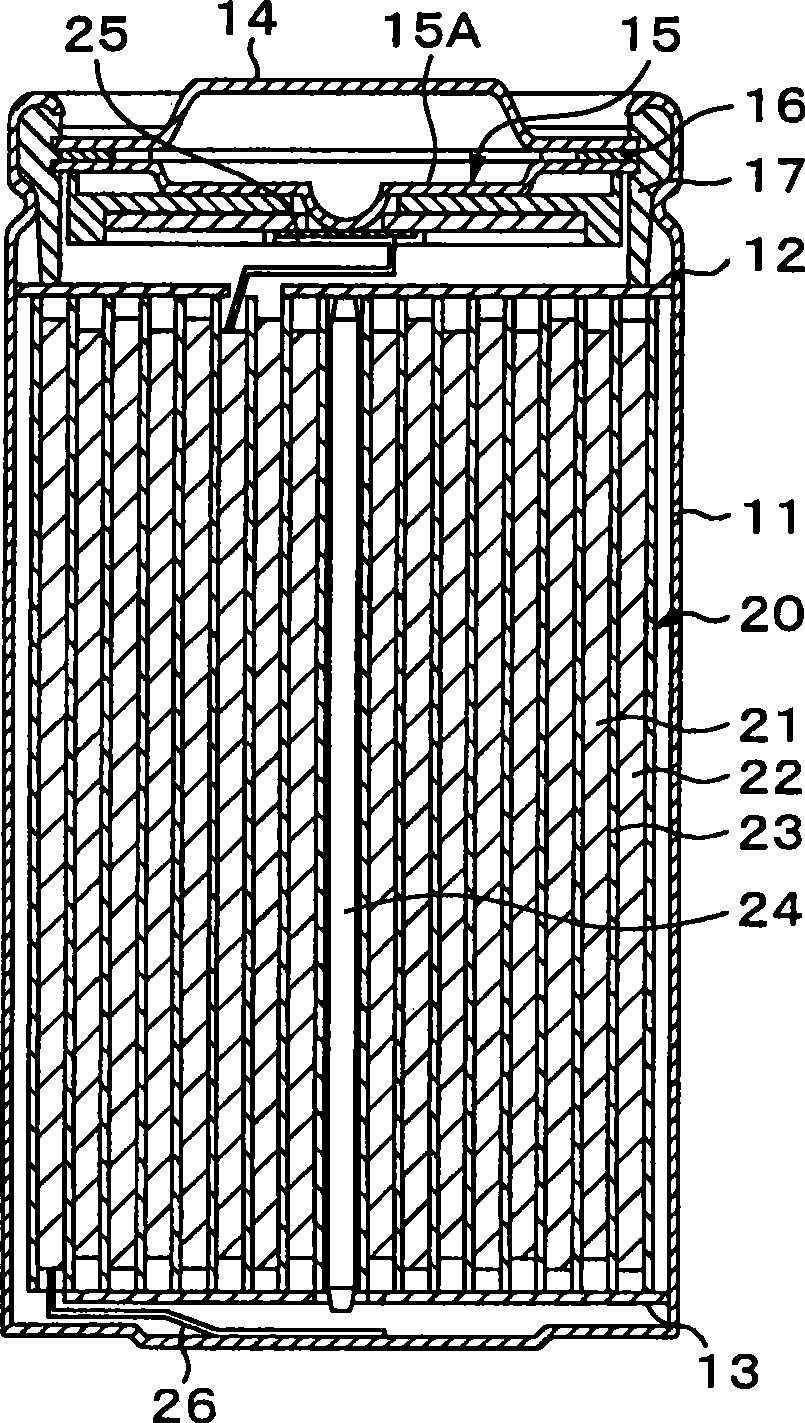

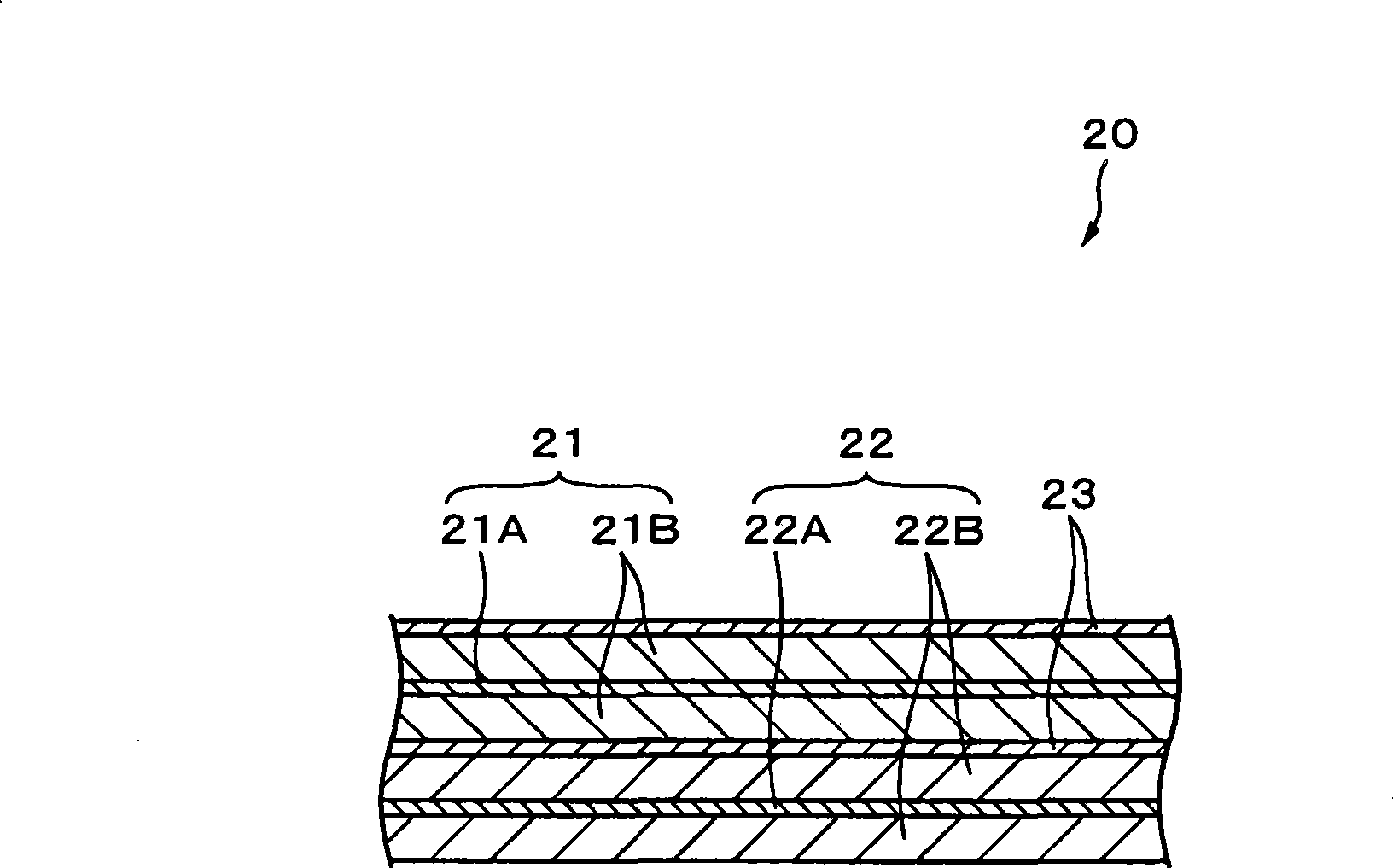

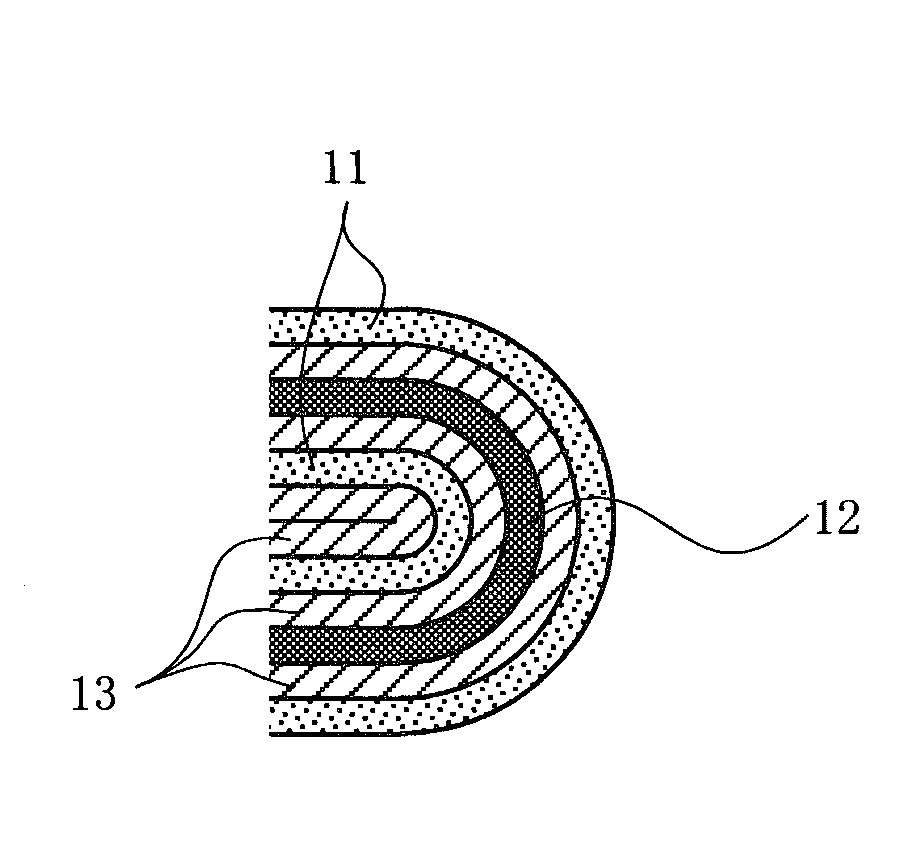

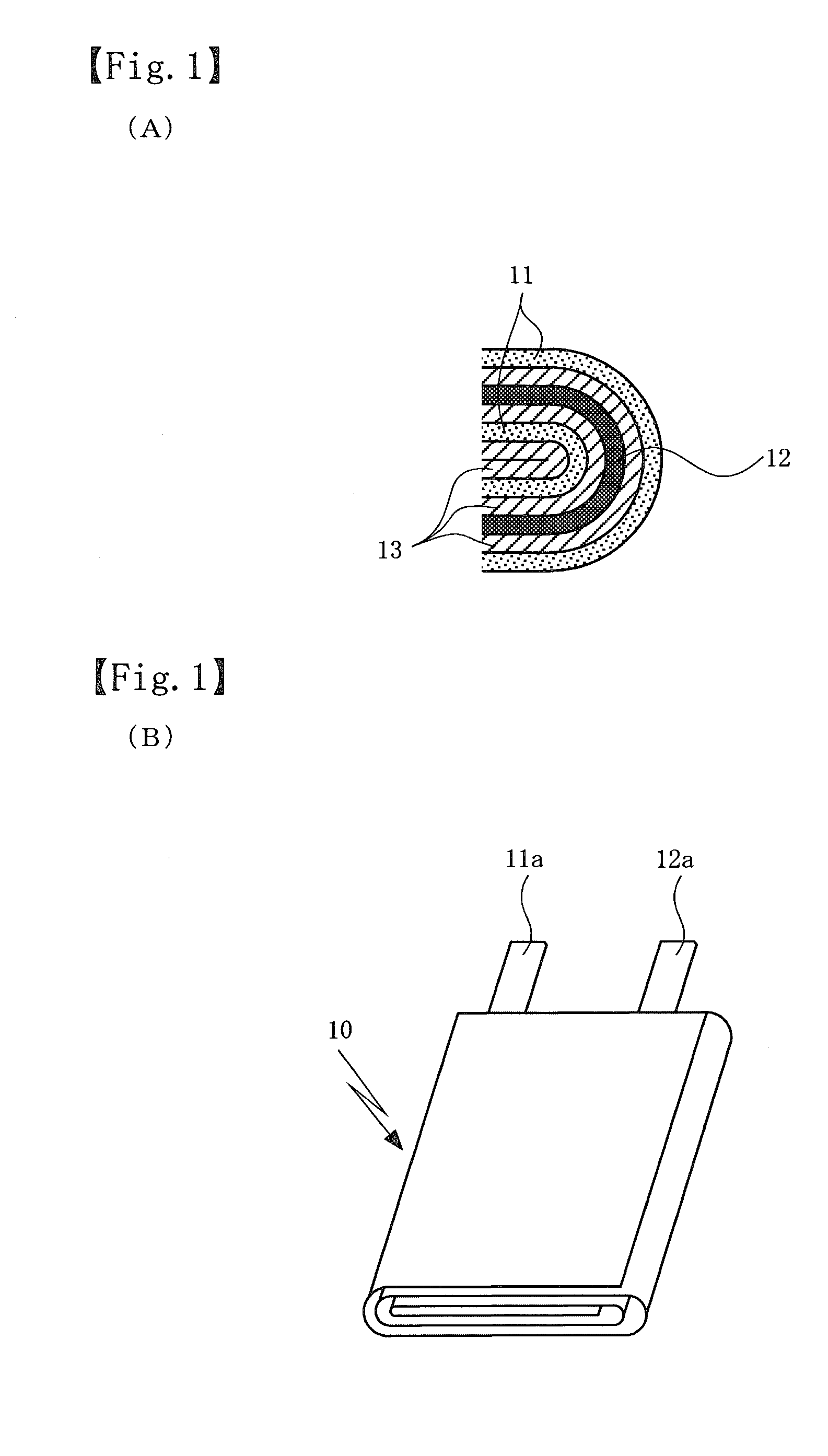

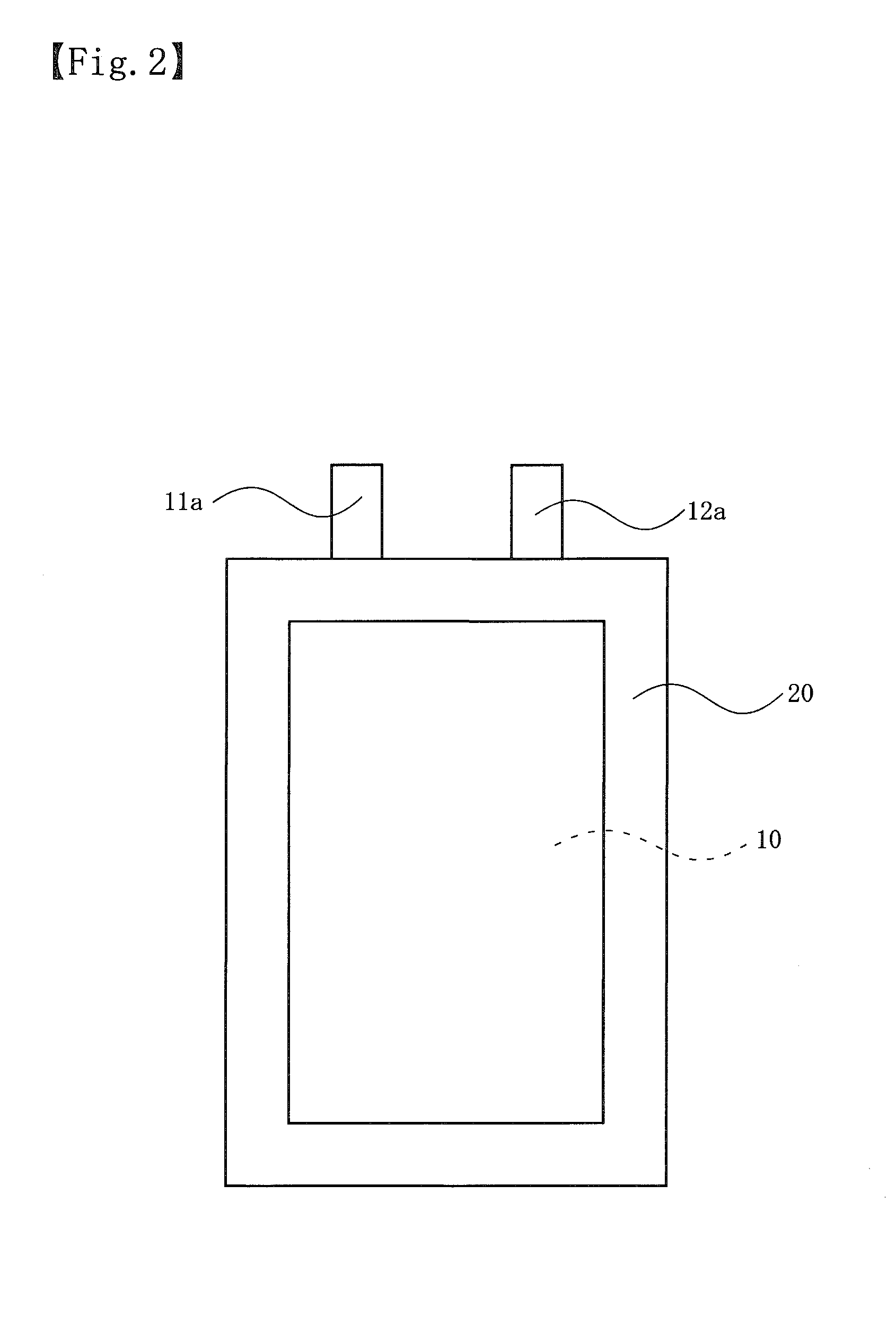

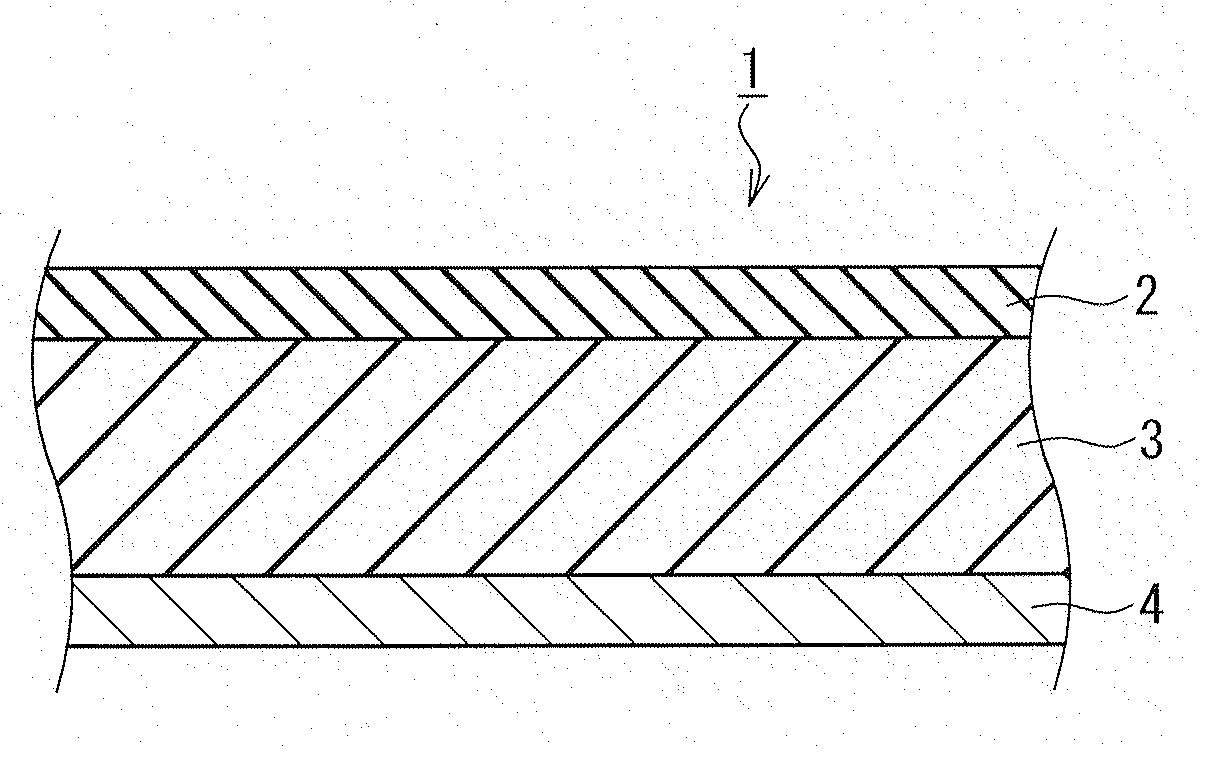

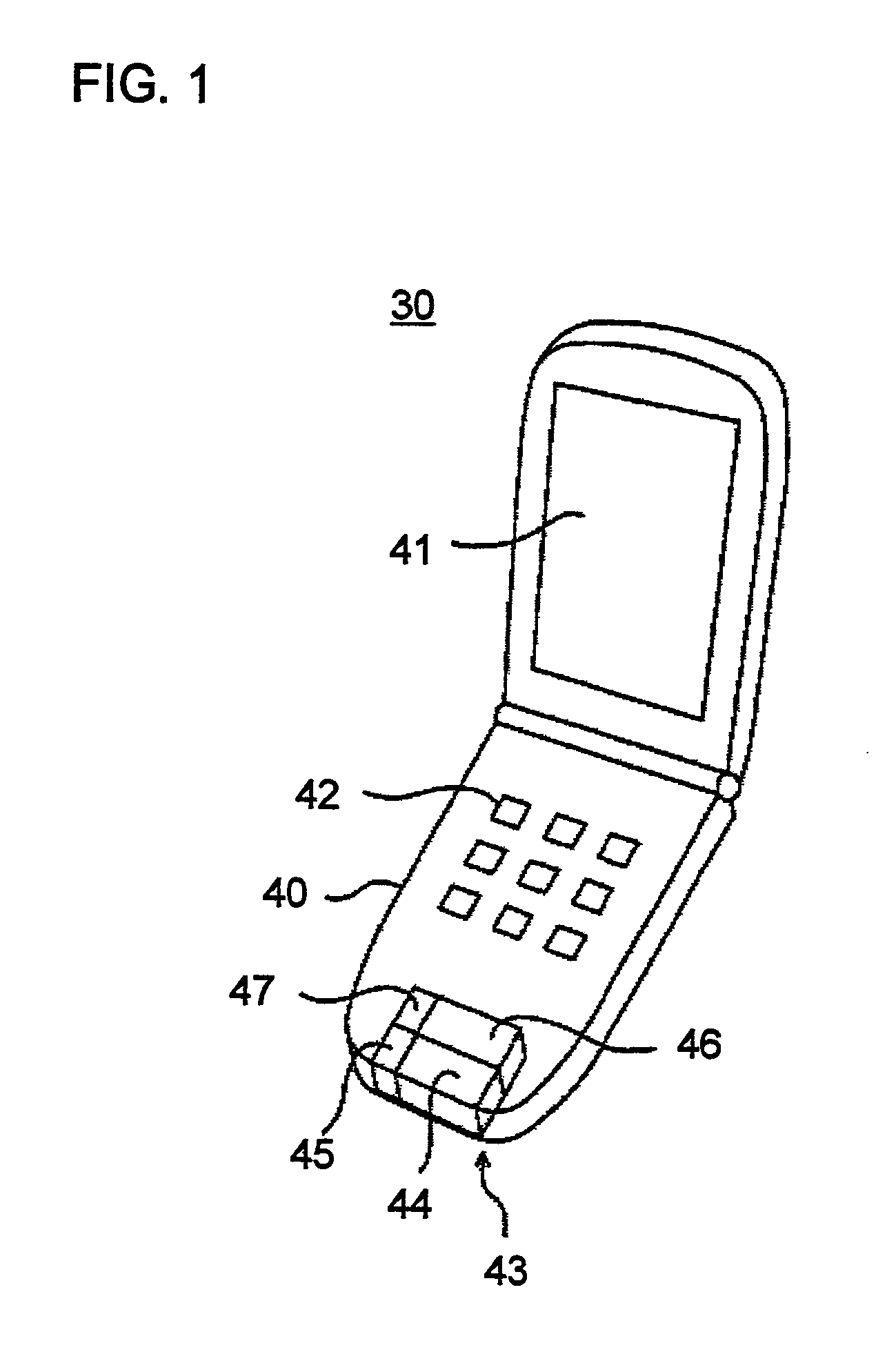

Negative electrode for lithium secondary battery, method for producing same, and lithium secondary battery comprising such negative electrode for lithium secondary battery

ActiveUS20090117472A1Improve charge and discharge cycle characteristicsHigh charge and discharge capacityElectrode manufacturing processesElectrode carriers/collectorsLithiumChemical composition

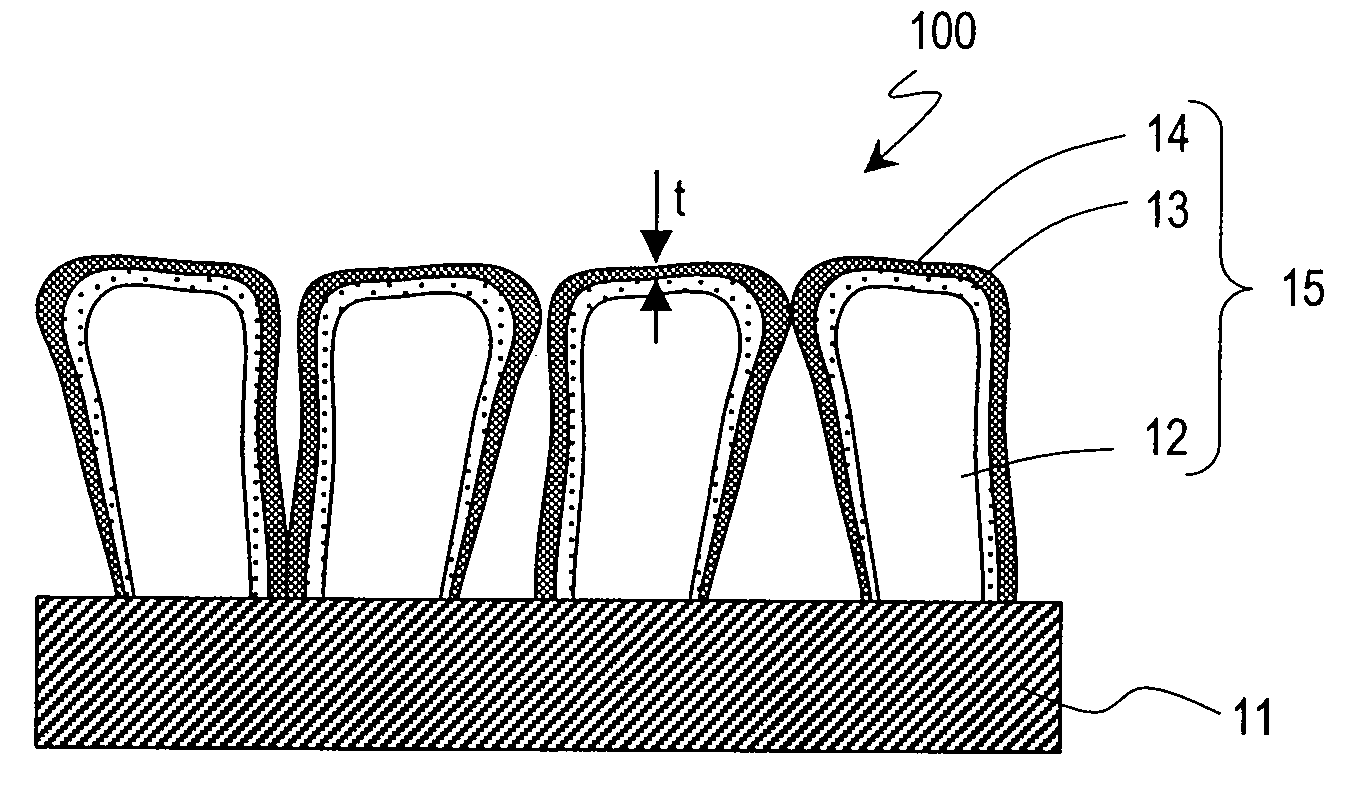

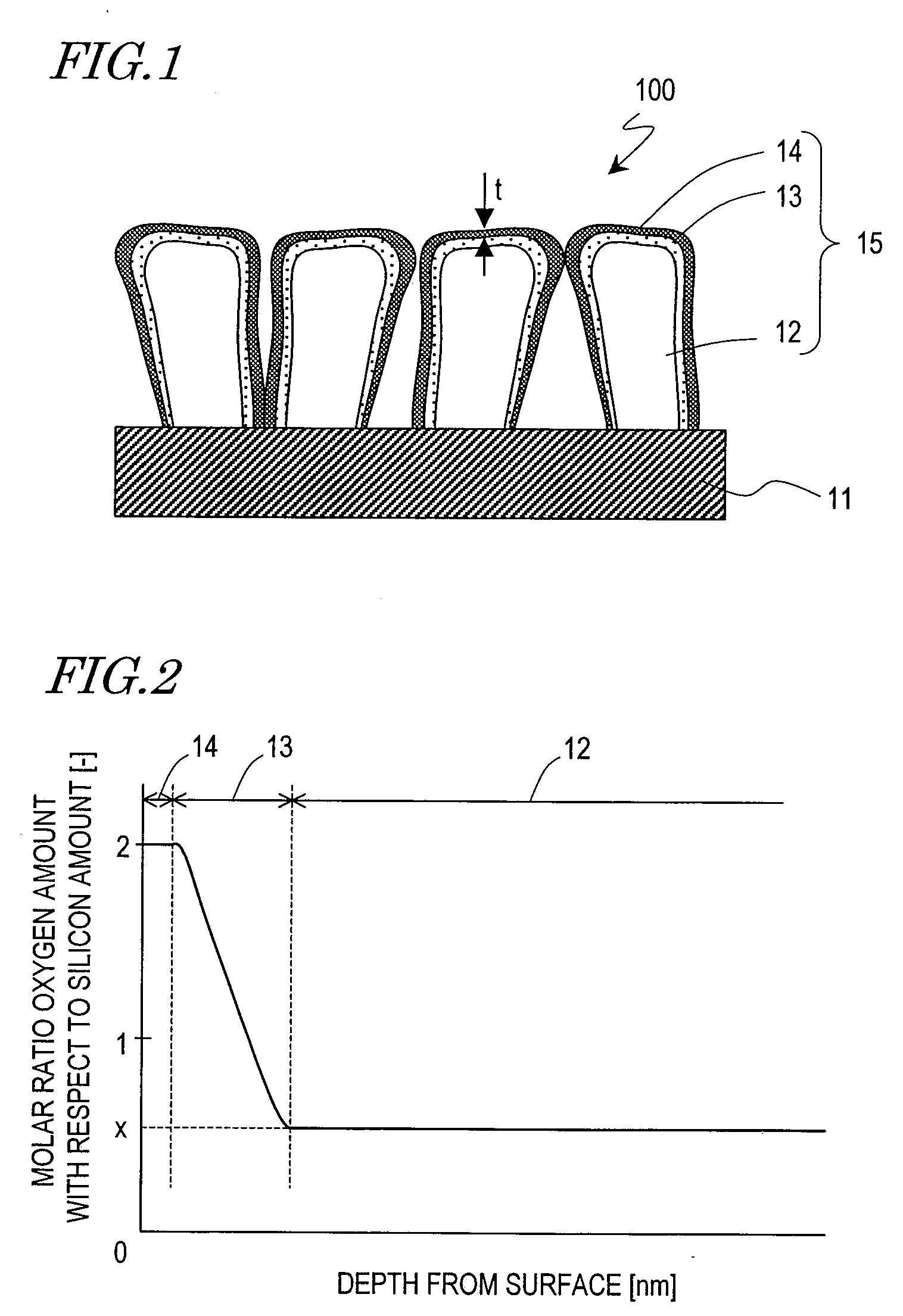

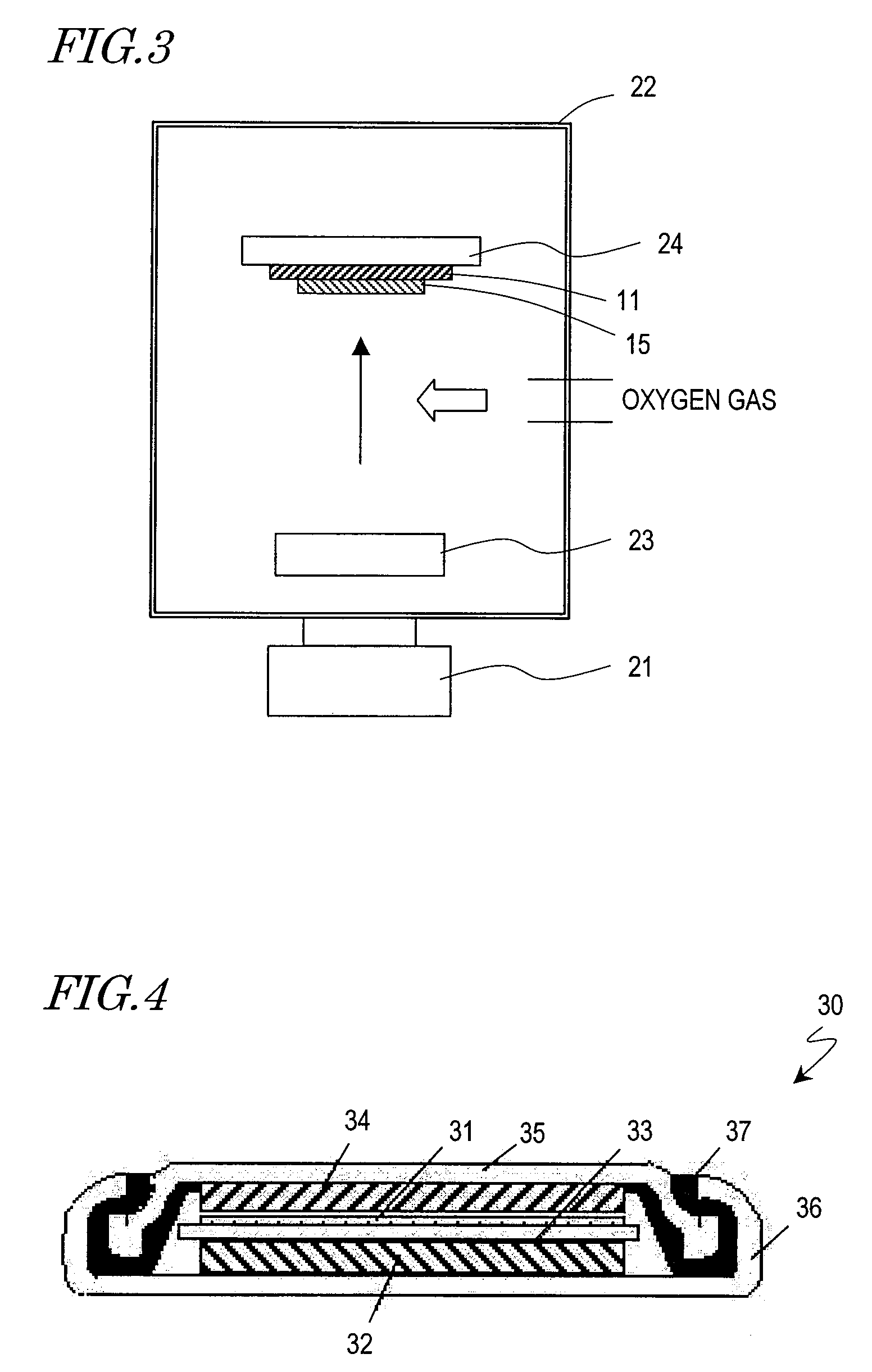

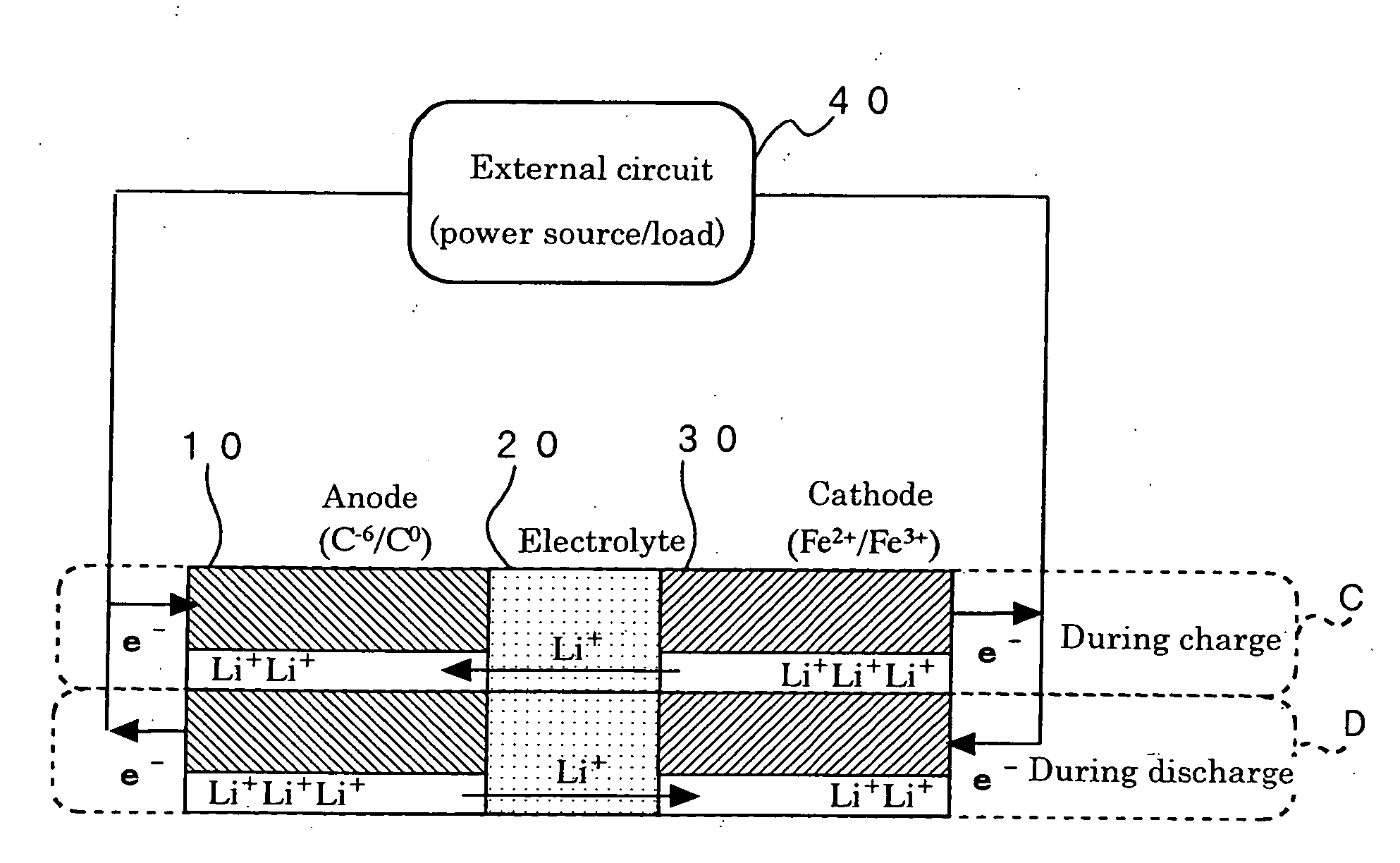

A negative electrode 100 for a lithium secondary battery includes: a current collector 11; a negative-electrode active material body 12 supported by the current collector 11, the negative-electrode active material body 12 having a chemical composition represented as SiOx (0.1≦x≦1.2); and a covering layer 14 formed on the negative-electrode active material body 12, the covering layer 14 having a chemical composition composed of silicon dioxide. The covering layer 12 has a thickness which is greater than 1 nm and no more than 10 nm.

Owner:PANASONIC CORP

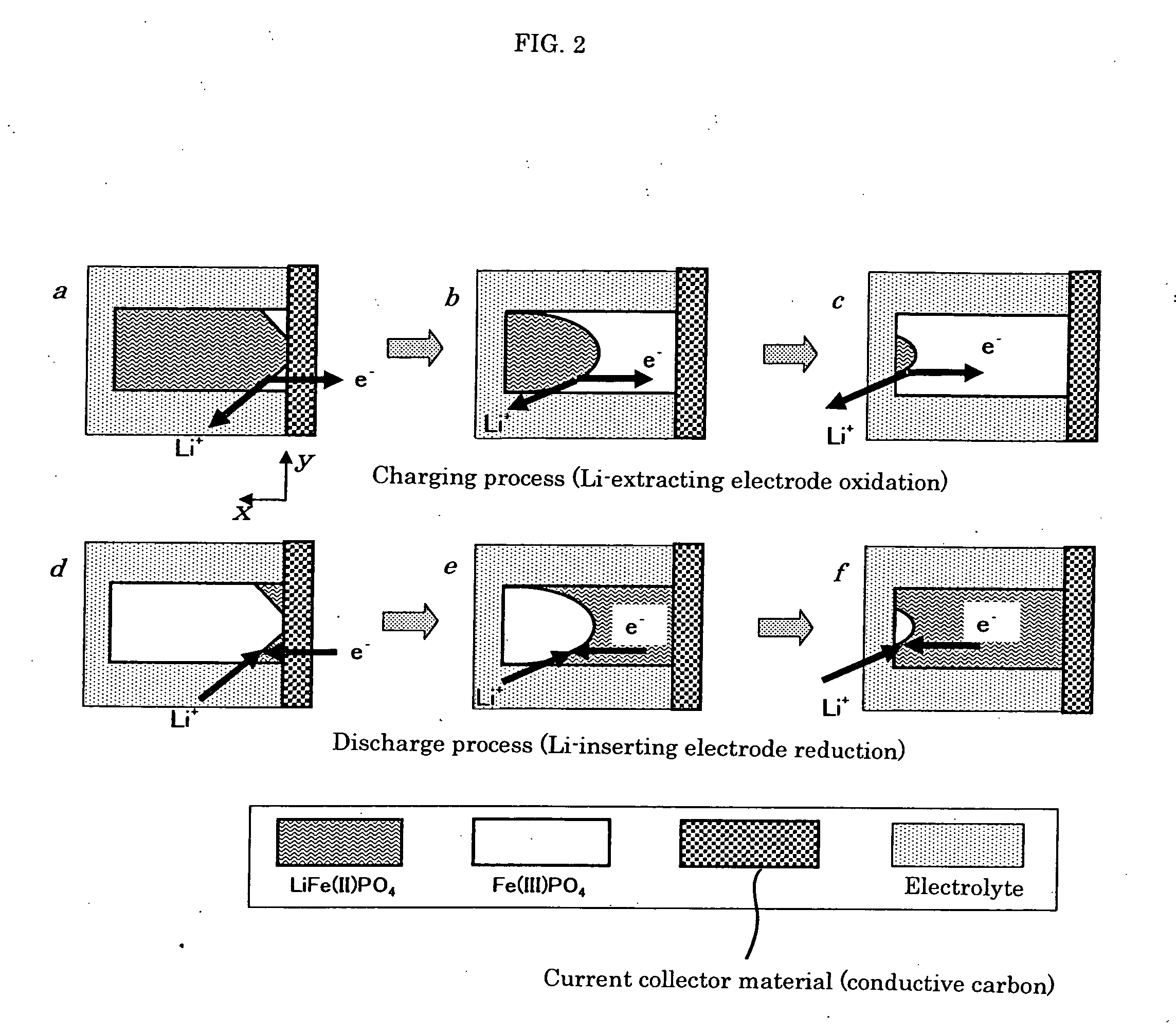

Cathode Material For Secondary Battery, Method For Producing Same, and Secondary Battery

InactiveUS20080138709A1Easy to getUniform depositionElectrode manufacturing processesNon-aqueous electrolyte accumulatorsCarbon depositPrimary component

A cathode material for a secondary battery containing a cathode active material represented by the general formula LinFePO4 (wherein n represents a number from 0 to 1) as a primary component and molybdenum (Mo), wherein the cathode active material LinFePO4 is composited with the Mo. In a preferred embodiment, the cathode material has conductive carbon deposited on the surface thereof.

Owner:MITSUI ENG & SHIPBUILD CO LTD +1

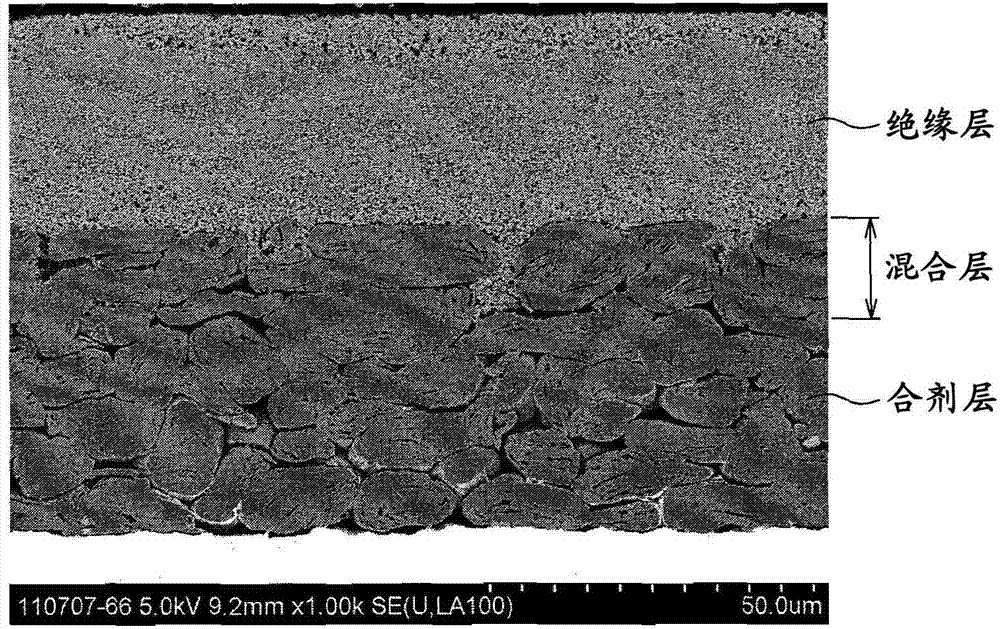

Electrode for nonaqueous secondary battery, nonaqueous secondary battery using the same, and method for producing electrode

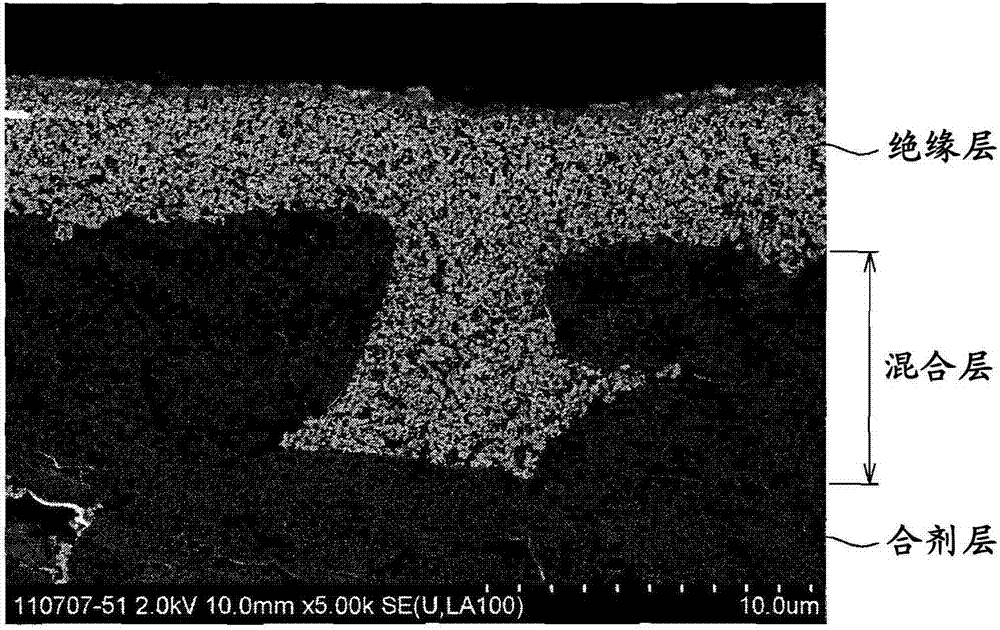

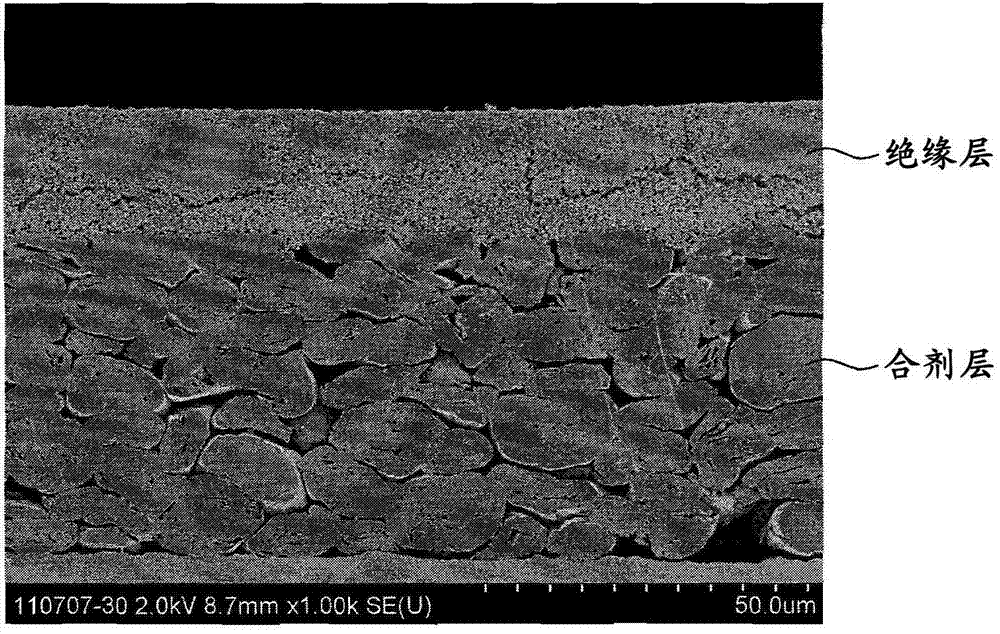

InactiveUS20100203392A1Large capacityImprove charge and discharge cycle characteristicsElectrode thermal treatmentNon-aqueous electrolyte accumulator electrodesPorous layerPolyamide-imide

The non aqueous secondary battery electrode of the present invention includes a mixture layer and a porous layer formed on the surface of the mixture layer. The mixture layer includes an electrode material expressed by the composition formula SiOx where x in the composition formula satisfies 0.5≦x≦1.5, a conductive material and at least one binder selected from the group consisting of polyimide, polyamideimide and polyamide. The porous layer includes an insulating material unreactive with Li.

Owner:HITACHI MAXELL ENERGY LTD

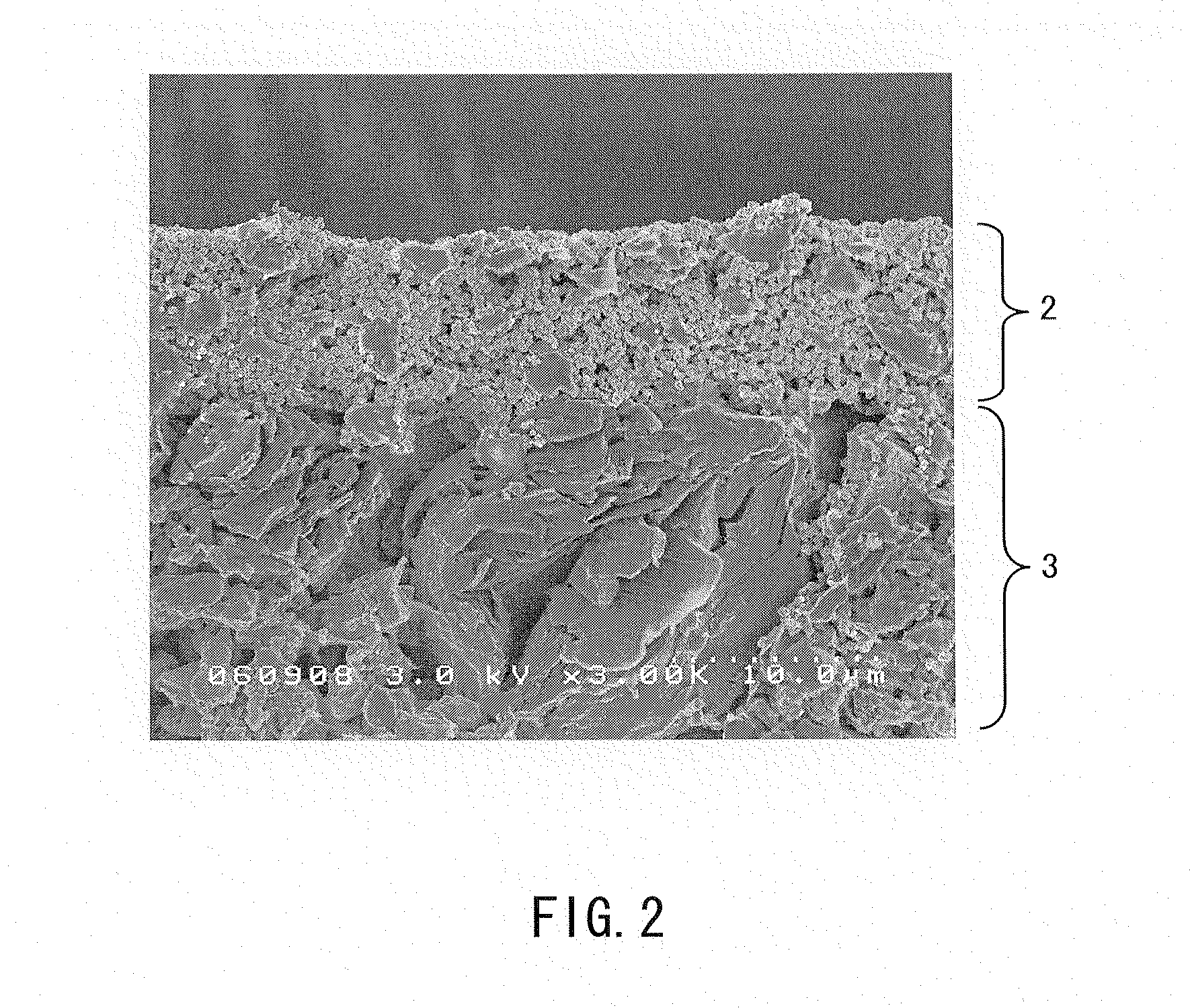

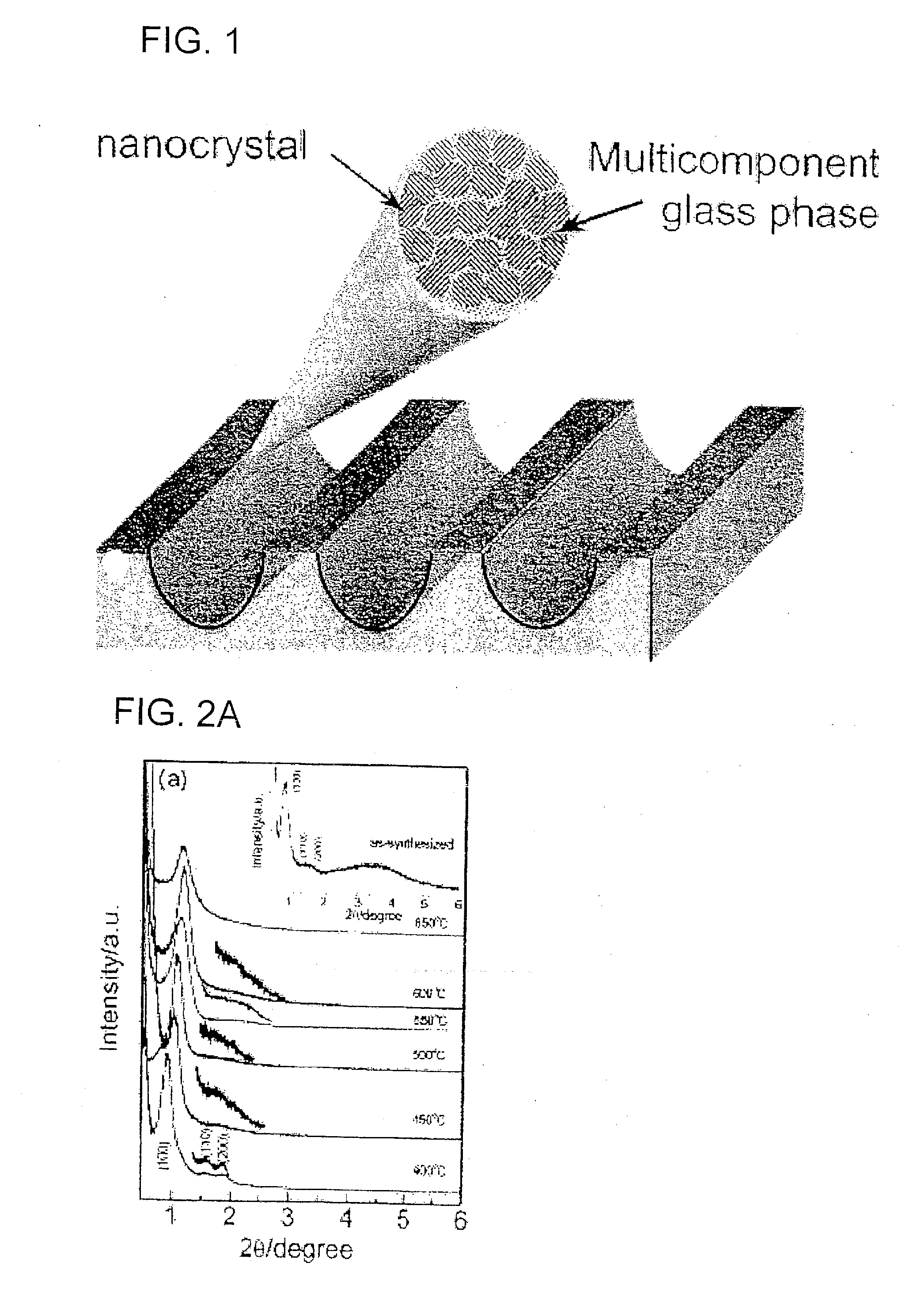

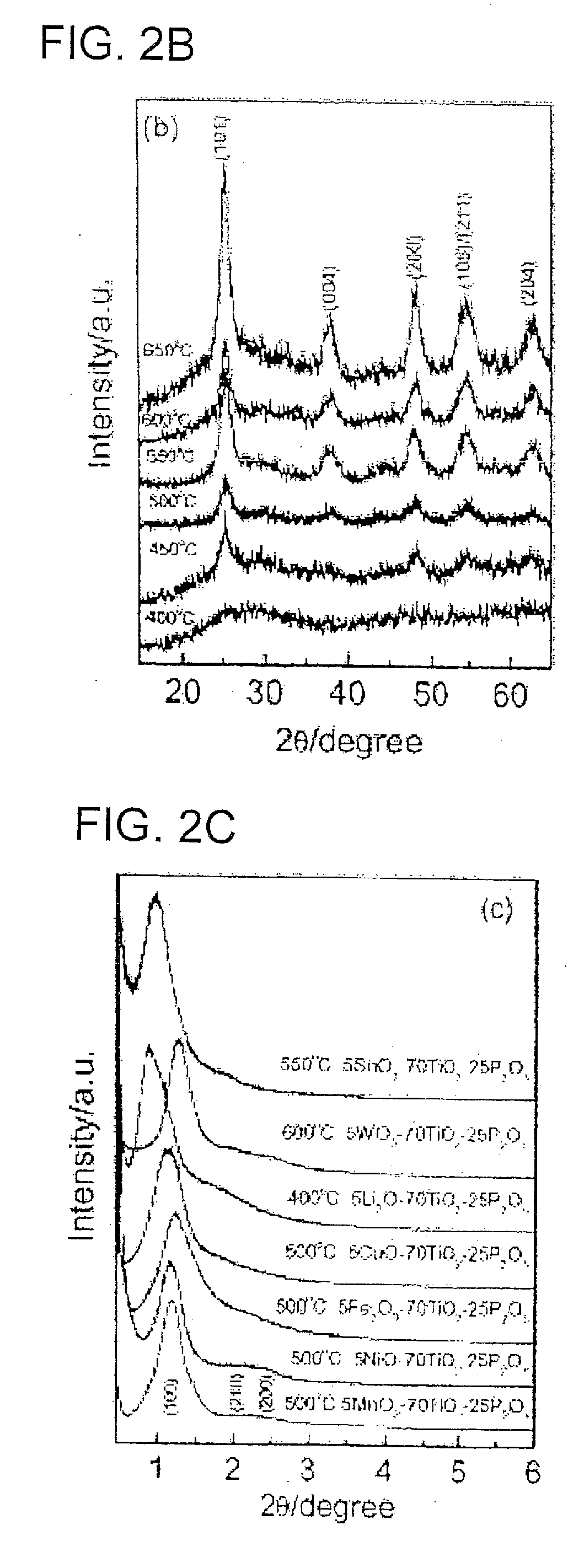

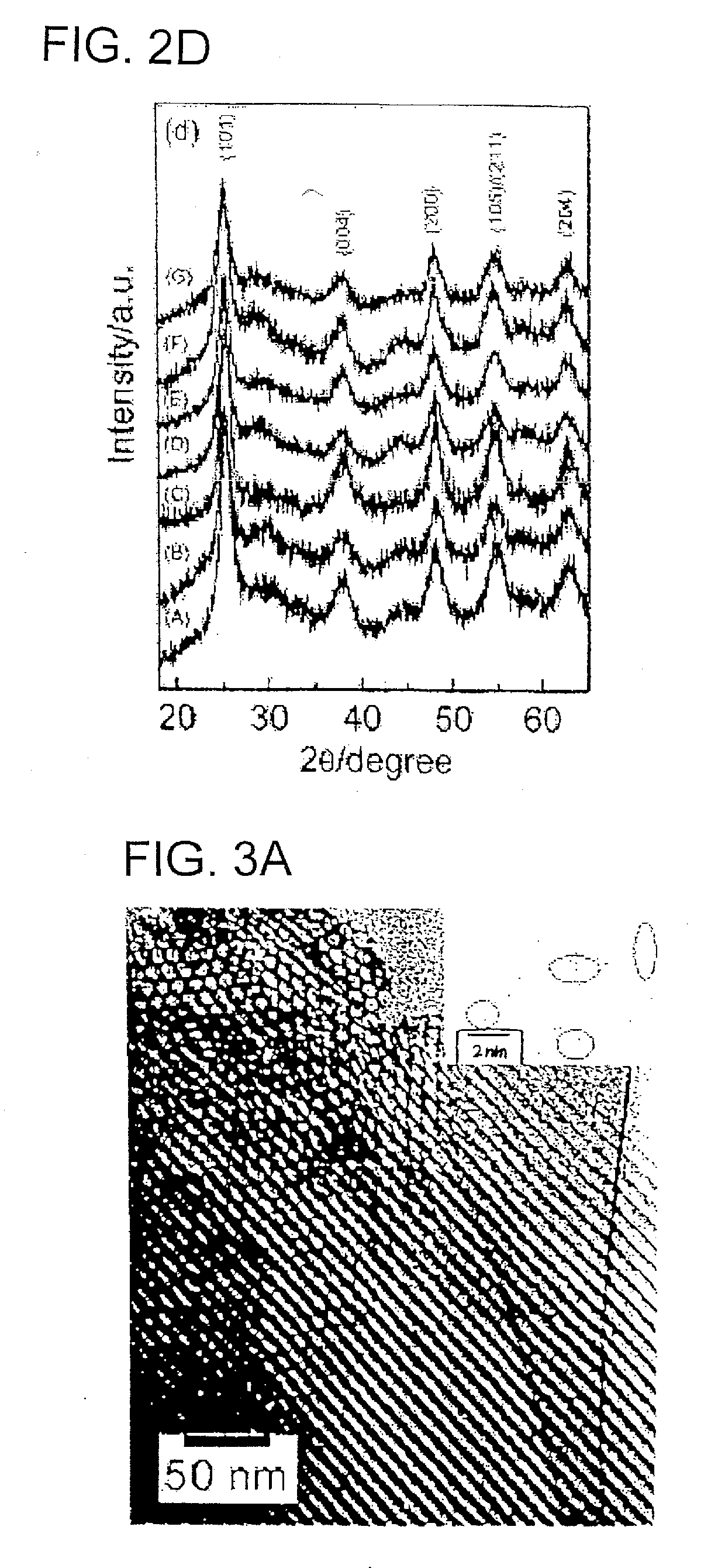

Nanocrystal oxide/glass composite mesoporous powder or thin film, process for producing the same, and utilizing the powder or thin film, various devices, secondary battery and lithium storing device

InactiveUS20070027015A1Simple methodLarge capacityPhosphorus oxidesMaterial nanotechnologyGlass compositesManufacturing technology

The present invention aims to realize (1) manufacture of a mesoporous composite powder or thin film composed of nanocrystalline metal oxide-glass having a three-dimensional structure with a large specific surface area, (2) construction of a porous structure framework with nanocrystalline metal oxide crystal and a slight amount of glass phase (SiO2 or P2O5, B2O3), (3) control of crystal growth of metal oxide with a slight amount of glass phase (SiO2 or P2O5, B2O3), (4) simplification of the manufacturing process, and (5) use thereof in manufacture of a lithium intercalation electric device, photocatalytic device, solar battery and energy storage device. Provided are a nanocrystal oxide-glass mesoporous composite powder or thin film having a three-dimensional structure with regularly arranged mesopores, and a secondary battery comprising the same.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Anodic carbon material for lithium secondary battery, lithium secondary battery anode, lithium secondary battery, and method for manufacturing anodic carbon material for lithium secondary battery

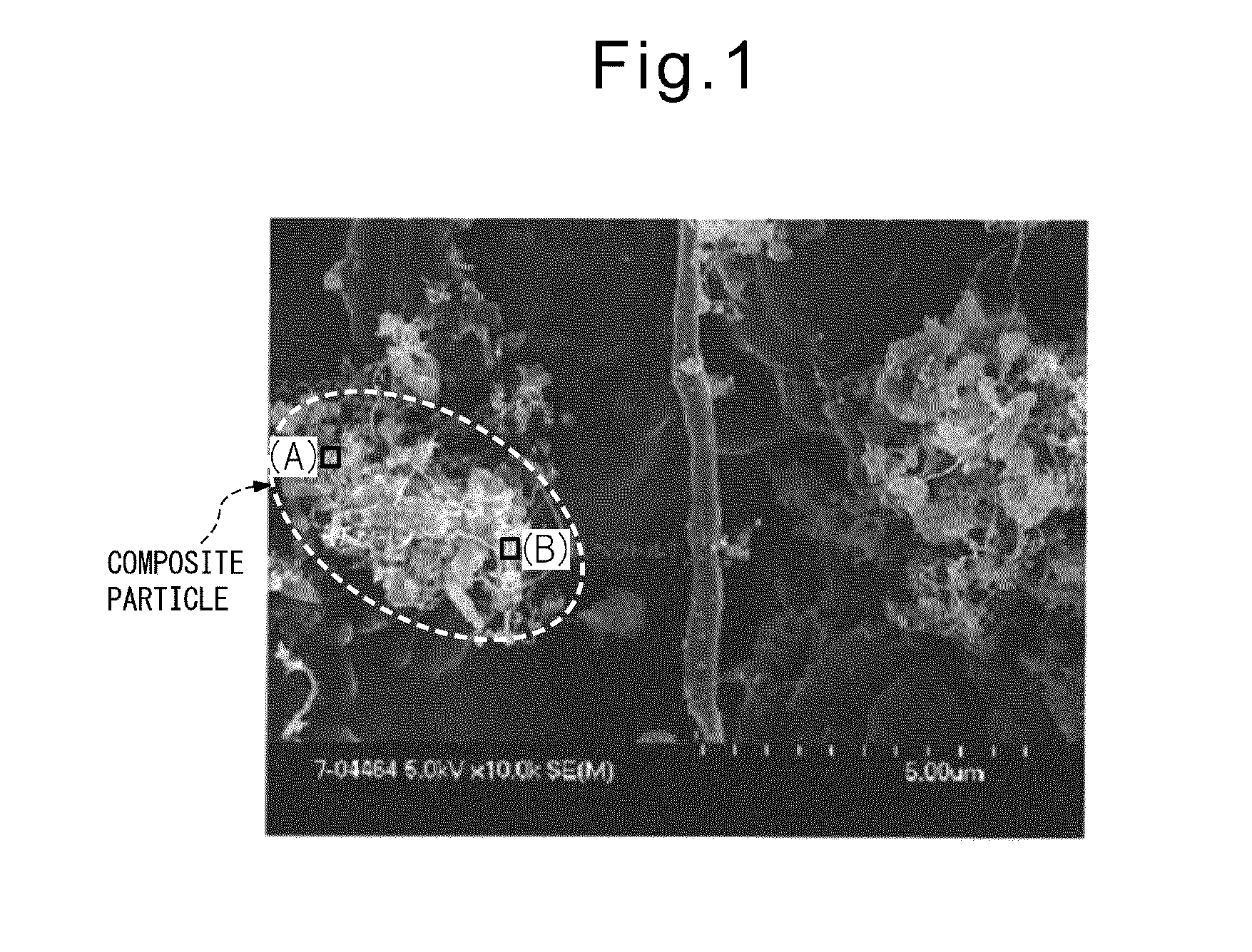

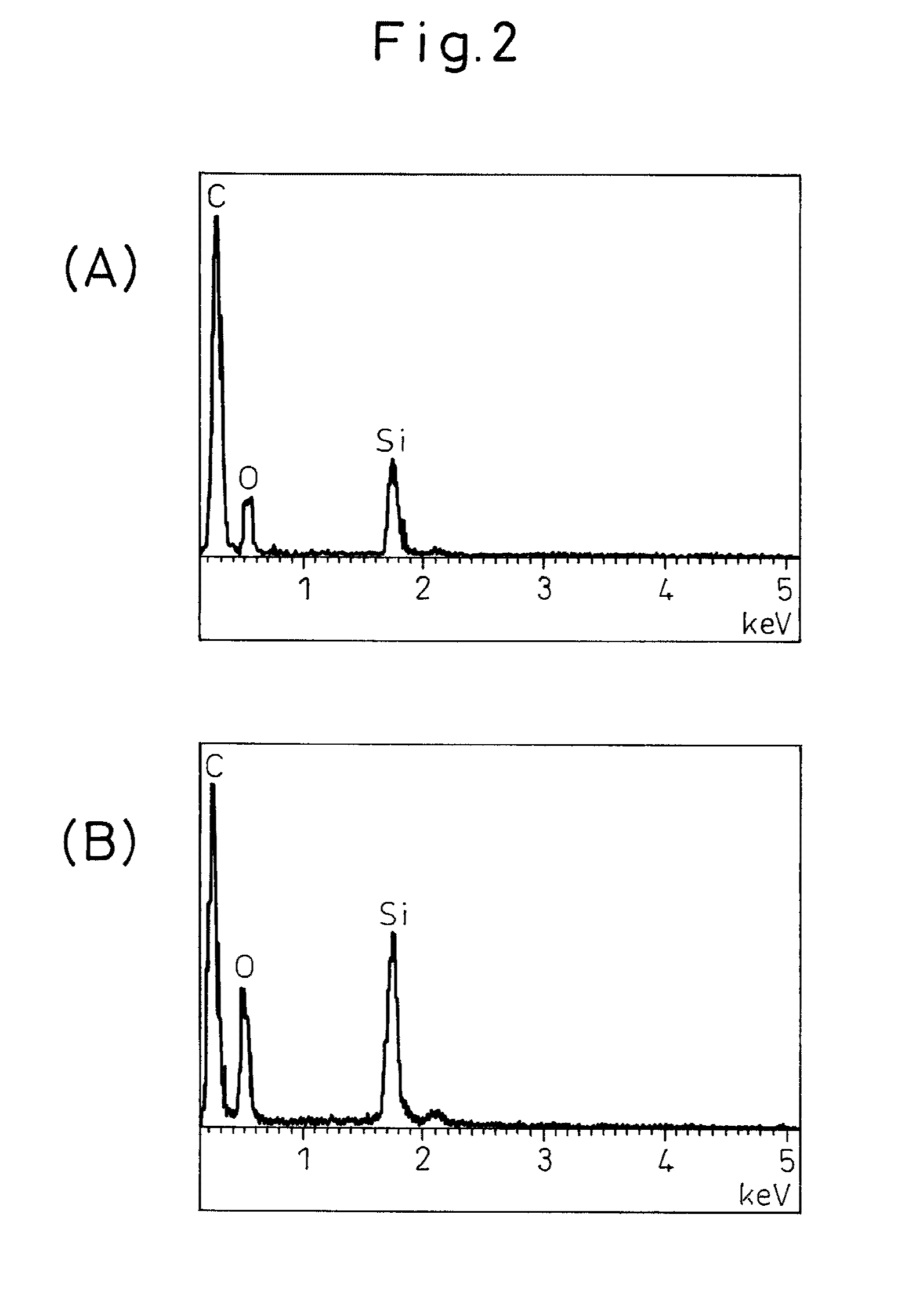

InactiveUS20110200874A1Improve charge and discharge cycle characteristicsAvoid conductivity dropMaterial nanotechnologyCarbon compoundsFiberNanofiber

The invention provides an anodic carbon material for a lithium secondary battery and a lithium secondary battery anode having excellent charge / discharge cycle characteristics, and a lithium secondary battery using the same. More specifically, an anodic carbon material for a lithium secondary battery according to the present invention comprises: composite particles composed of silicon-containing particles containing an alloy, oxide, nitride, or carbide of silicon capable of occluding and releasing lithium ions and a resinous carbon material enclosing the silicon-containing particles; and a network structure formed from nanofibers and / or nanotubes that bond to surfaces of the composite particles and that enclose the composite particles, and wherein: the network structure contains silicon.

Owner:SUMITOMO BAKELITE CO LTD

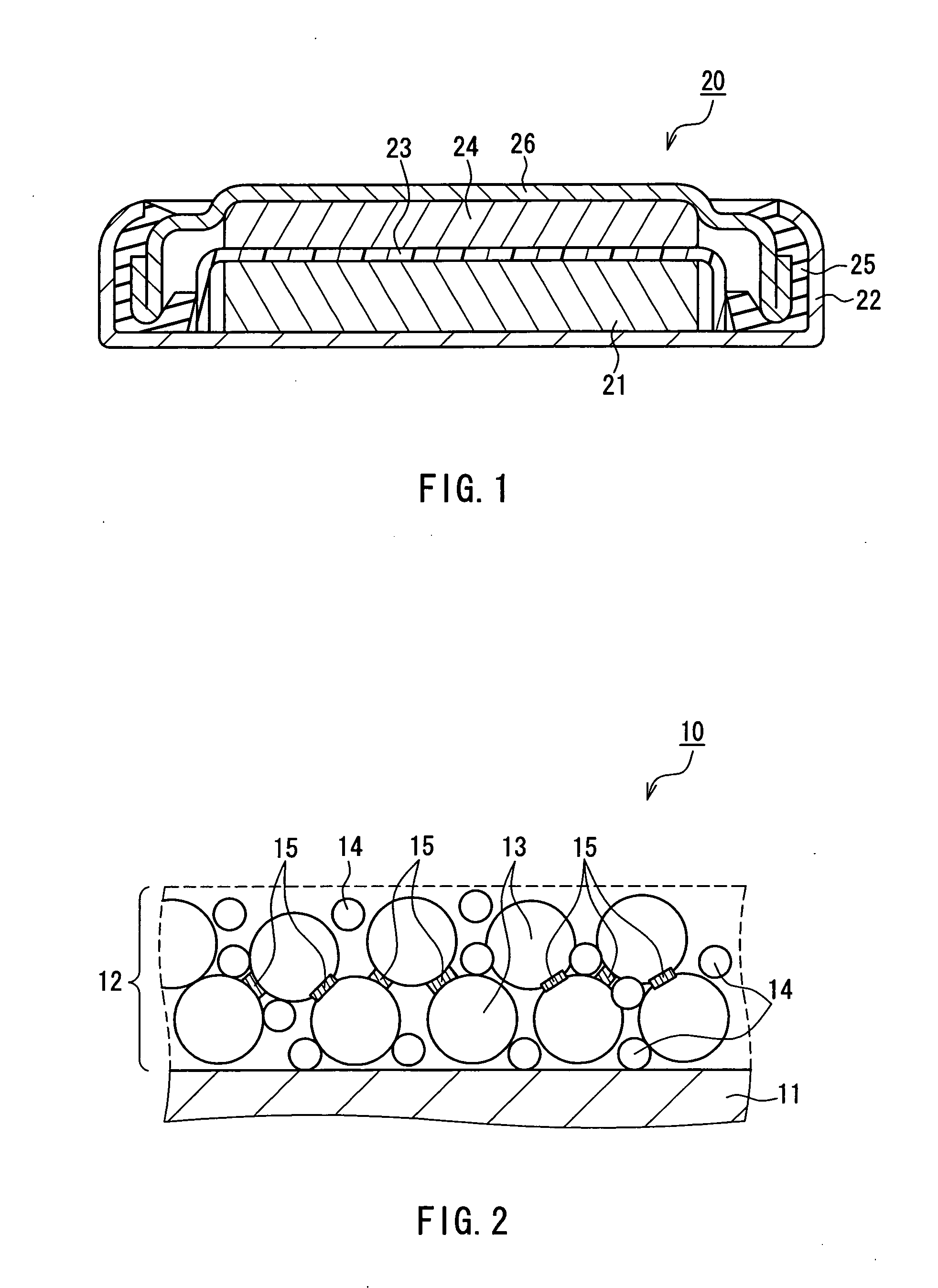

Electrode for lithium secondary battery and lithium secondary battery

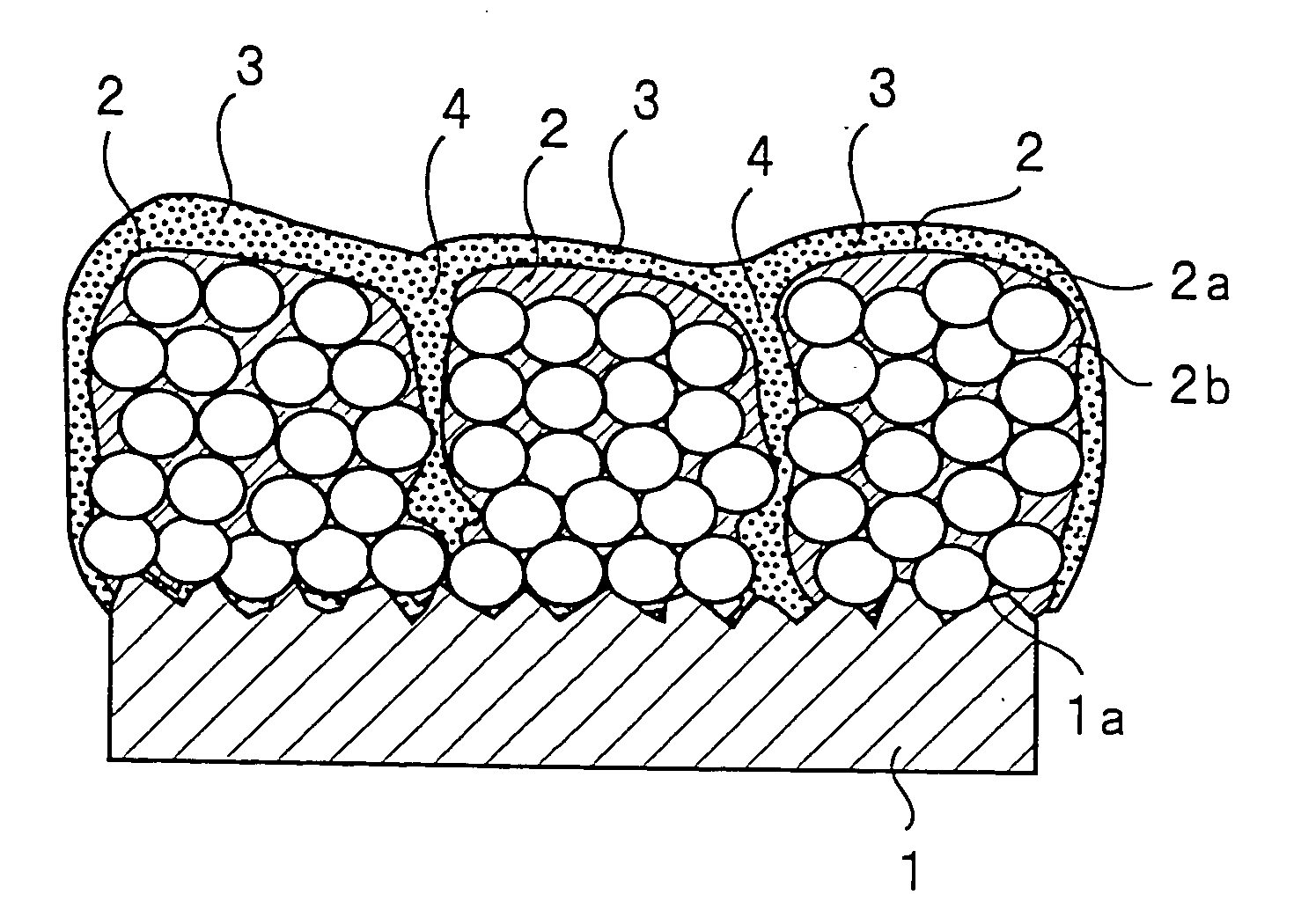

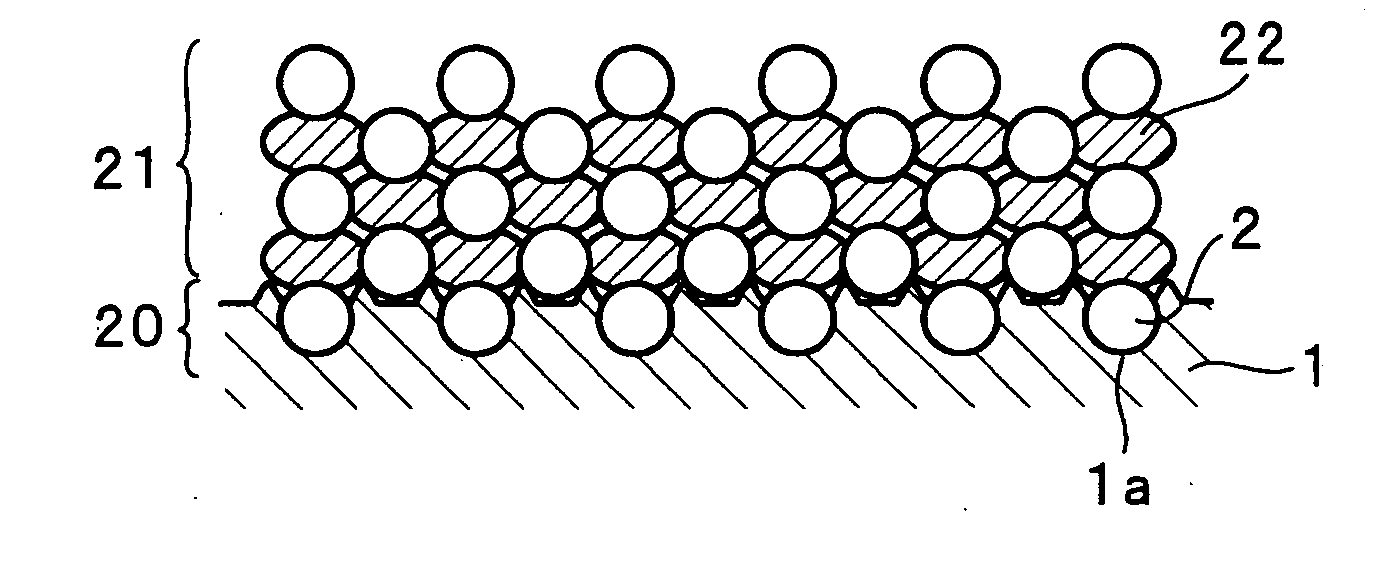

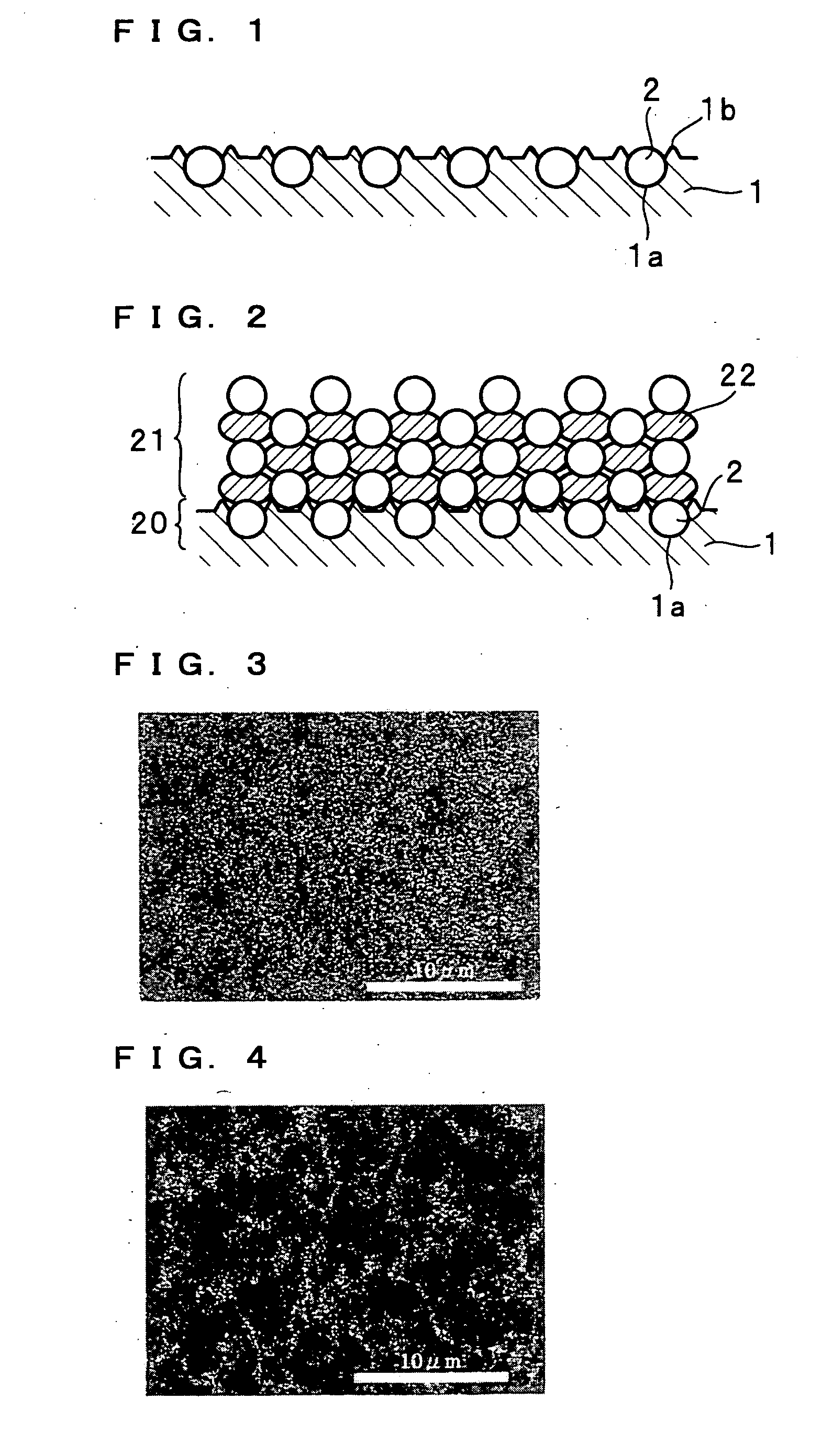

ActiveUS20060159997A1Increase volumetric energy densityImprove charge and discharge cycle characteristicsElectrode carriers/collectorsActive material electrodesLithiumEngineering

There is provided an electrode for a lithium secondary battery where particles, composed of an active material capable of occluding and releasing lithium, are arranged on a current collector, the active material particle being directly bonded to the surface of the current collector in a state where the bottom of the active material particle is imbedded in a concave portion formed on the surface of the current collector. A second particle layer may be provided on a first particle layer comprising the active material particles directly bonded to the surface of the current collector.

Owner:PANASONIC ENERGY CO LTD +1

Electrode active material for power storage device, power storage device, and elctronic and transport devices

ActiveUS20100196758A1Increase energy densityGood reversibilityAlkaline accumulatorsOrganic chemistryRedoxEngineering

An electrode active material for a power storage device of the invention includes a ketone compound that includes a ring structure in a molecule, the ring structure being a five-membered or seven-membered ring composed of atoms at least three adjacent ones of which are each bonded to a ketone group. The electrode active material for a power storage device of the invention has a high weight-energy density and good reversibility of oxidation-reduction reaction. The use of the electrode active material for a power storage device of the invention can provide a power storage device having a high capacity, a high voltage, and good charge / discharge cycle characteristics.

Owner:PANASONIC CORP

Non-aqueous electrolyte secondary battery

ActiveCN1877897AImprove securityImprove charge and discharge cycle characteristicsActive material electrodesLi-accumulatorsSulfonateSulfate

A non-aqueous secondary battery contains a positive electrode, a negative electrode, a separator and a non-aqueous electrolytic solution. The positive electrode contains a layered structure lithium-containing compound oxide, or a spinel lithium-containing compound oxide containing manganese as an active material. The non-aqueous electrolytic solution contains at least one additive selected from a sulfonic acid anhydride, a sulfonate ester derivative, a cyclic sulfate derivative and a cyclic sulfonate ester derivative, and a vinylene carbonate or a derivative of the vinylene carbonate.

Owner:MAXELL HLDG LTD

Electrode for non-aqueous electrolyte secondary battery, non-aqueous electrolyte secondary battery, and method for manufacturing the same

ActiveCN103311550AImprove load characteristicsImprove charge and discharge cycle characteristicsCell seperators/membranes/diaphragms/spacersFinal product manufactureCross-linkInorganic particle

The present invention relates to an electrode for a non-aqueous electrolyte secondary battery, a non-aqueous electrolyte secondary battery using the electrode, and a method for manufacturing the non-aqueous electrolyte secondary battery. The electrode for a non-aqueous electrolyte secondary battery includes a material mixture layer containing an active material and a porous insulating layer. The insulating layer is formed on the material mixture layer. The insulating layer contains a resin having a cross-linked structure and inorganic particles. A mixed layer that includes components of the insulating layer and components of the material mixture layer is provided at the interface between the insulating layer and the material mixture layer.

Owner:MAXELL HLDG LTD

Lithium ion secondary battery

InactiveUS20090117463A1Improve securityExcellent discharge cycle characteristicSecondary cellsNon-aqueous electrolyte accumulator electrodesLithiumAlloy

In a lithium ion secondary battery including a positive electrode, a negative electrode containing an alloy-based negative electrode active material, a separator, a positive electrode lead, a negative electrode lead, a gasket, and an outer case, the positive electrode is allowed to contain an oxygen deficient non-stoichiometric oxide, or an oxygen removing layer containing an oxygen deficient non-stoichiometric oxide is provided between the positive electrode and the separator. In a lithium ion secondary battery containing the alloy-based negative electrode active material, a reaction between oxygen generated in the positive electrode and the alloy-based negative electrode active material, and heat generation accompanying the reaction are prevented.

Owner:PANASONIC CORP

Negative electrode for lithium secondary battery, method for preparing negative electrode for lithium secondary battery and lithium secondary battery

InactiveUS20040062991A1Improve internal strengthImprove current collectabilityElectrode rolling/calenderingElectrode thermal treatmentLithiumSilicon alloy

A negative electrode for a lithium secondary battery obtained by sintering an active material layer on a current collector under a non-oxidizing atmosphere after the active material layer including primary particles of an active material containing silicon and / or a silicon alloy and a binder is formed on an electrically conductive metal foil as a current collector. A mean diameter of primary particles of the active material is less than 1 mum, the primary particles are dispersed uniformly in the active material layer, and the primary particles and the binder are uniformly mixed and distributed.

Owner:SANYO ELECTRIC CO LTD

Non-aqueous electrolyte secondary battery

InactiveUS20060199077A1Reduce oxidative decompositionIncrease charging voltageDrying solid materials without heatOrganic electrolyte cellsManganeseSolvent

A non-aqueous electrolyte secondary battery with excellent discharge cycle characteristics and a charging termination potential ranging from 4.4 to 4.6 V based on lithium, consisting of a positive electrode comprising a positive electrode active material, a negative electrode, and a non-aqueous electrolyte containing a non-aqueous solvent and an electrolyte salt, in which the positive electrode active material comprises a mixture of a lithium-cobalt composite oxide containing at least both zirconium and magnesium in LiCoO2, and a lithium-manganese-nickel composite oxide having a layered structure and containing at least both manganese and nickel, and the potential of the positive electrode active material ranges from 4.4 to 4.6 V based on lithium, and the non-aqueous electrolyte contains at least one of aromatic compounds selected from the group consisting at least of toluene derivatives, anisole derivatives, biphenyl, cyclohexyl benzene, tert-butyl benzene, tert-amyl benzene, and diphenyl ether.

Owner:SANYO ELECTRIC CO LTD

Electrode for lithium secondary battery and method for producing the same

InactiveUS6844113B2Improve charge and discharge cycle characteristicsGuaranteed generation effectElectrode carriers/collectorsNegative electrodesLithium-ion batteryMaterials science

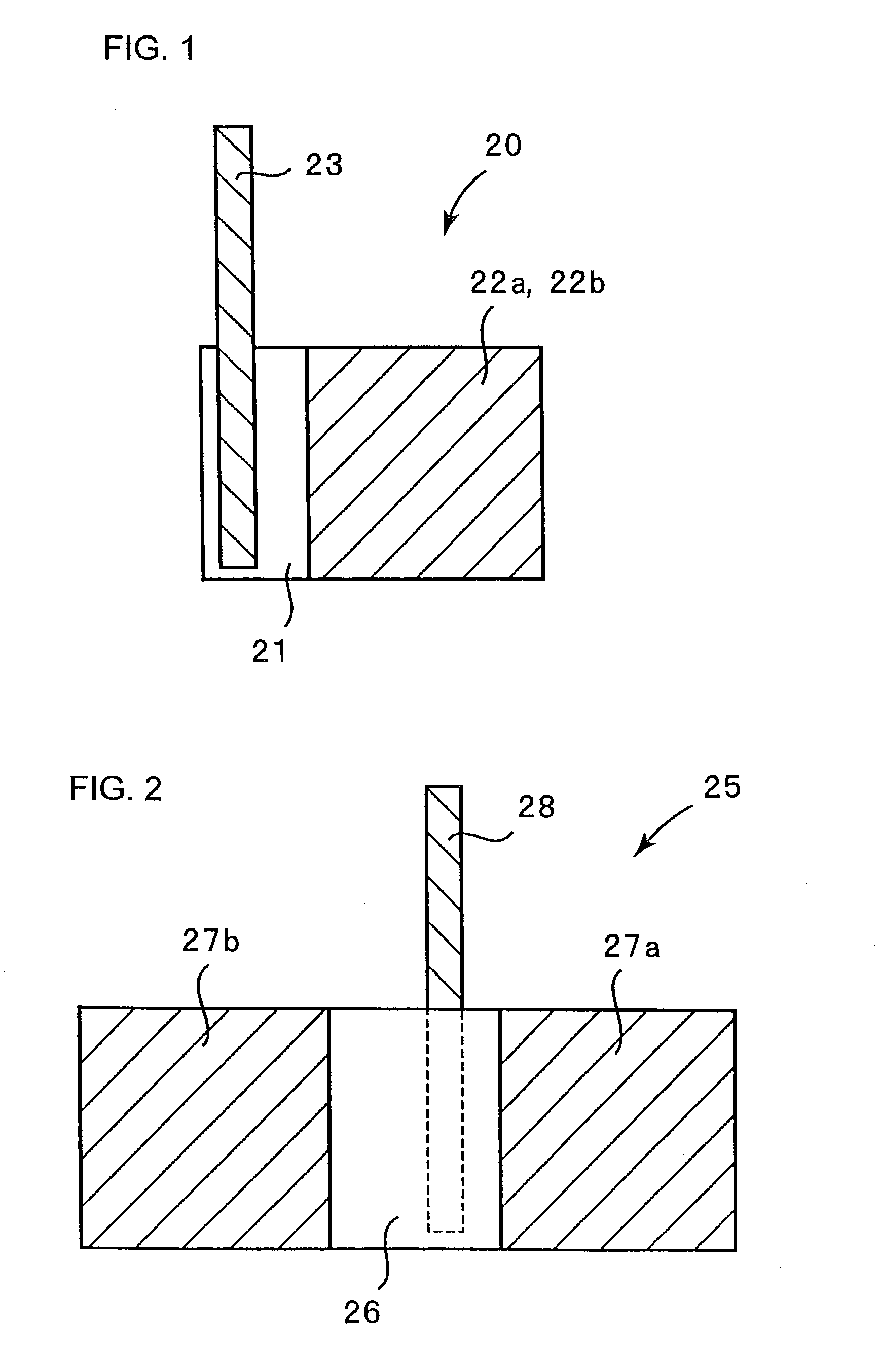

The electrode for a lithium secondary battery includes: a current collector; an interlayer containing Mo or W provided on the current collector; and a thin film composed of active material capable of lithium storage and release deposited on the interlayer.

Owner:SANYO ELECTRIC CO LTD

Electrode active material for power storage device and power storage device, and electronic equipment and transportation equipment

InactiveUS20110143197A1High energy densityHigh outputAlkaline accumulatorsOrganic chemistryKetonePower storage

An electrode active material for a power storage device of the invention includes an organic compound having, in the molecule, a plurality of electrode reaction sites and a linker site. The electrode reaction sites are residues of a 9,10-phenanthrenequinone compound that contributes to an electrochemical redox reaction. The linker site is disposed between the plurality of electrode reaction sites, does not contain any ketone group, and does not contribute to the electrochemical redox reaction. The electrode active material for a power storage device of the present invention is inhibited from being dissolved in an electrolyte and has a high energy density. By using the electrode active material, it is possible to obtain a power storage device having a high energy density and excellent charge / discharge cycle characteristics.

Owner:PANASONIC CORP

Lithium battery having effective performance

ActiveUS20050095507A1Improve charge and discharge cycle characteristicsLow-temperature discharging characteristicOrganic electrolyte cellsLi-accumulatorsSolventVinylene carbonate

A lithium battery which has an anode, a cathode having a compound capable of intercalating and deintercalating lithium, a separator interposed between the cathode and the anode, and an electrolyte solution having an electrolyte solute dissolved in a nonaqueous solvent. The nonaqueous solvent includes a mixed solvent containing 8 to 15% by volume of ethylene carbonate, 10 to 35% by volume of γ-butyrolactone, 35 to 65% by volume of at least one linear carbonate selected from the group consisting of dimethyl carbonate, diethyl carbonate, ethylmethyl carbonate, methylpropyl carbonate, ethylpropyl carbonate and methylbutyl carbonate and 8 to 15% by volume of fluorobenzene, and 0.5 to 9 parts by volume of vinylene carbonate based on 100 parts by volume of the mixed solvent. The nonaqueous solvent may further include 0.05 to 5 parts by volume of vinyl sulfone, isooxazole or a mixture thereof based on 100 parts by volume of the mixed solvent.

Owner:SAMSUNG SDI CO LTD

Method for manufacturing carbon material for lithium ion secondary batteries, carbon material for lithium ion secondary batteries, negative electrode active material for lithium ion secondary batteries, composition, carbon composite for negative electrode materials of lithium ion secondary batteries, negative electrode compound for lithium ion secondary batteries, negative electrode for lithium ion secondary batteries, and lithium ion secondary battery

InactiveUS20140166929A1Improve discharge capacityExtended discharge cycleSecondary cellsCarbon preparation/purificationSilica particleCarbon composites

There is provided a method for manufacturing the lithium ion secondary batteries includes a mixing step of mixing a phenol resin and a resin composition containing silica particles so as to obtain a mixture, a spraying step of spraying the mixture obtained in the mixing step so as to form liquid droplets, a first thermal treatment step of carrying out a first thermal treatment on the liquid droplets obtained in the spraying step so as to generate a carbon precursor, and a second thermal treatment step of carrying out a second thermal treatment, which is carried out at a higher temperature than the first thermal treatment, on the carbon precursor obtained in the first thermal treatment step so as to generate a carbon material containing carbon and silicon oxide represented by SiOx (0<X<2).

Owner:SUMITOMO BAKELITE CO LTD

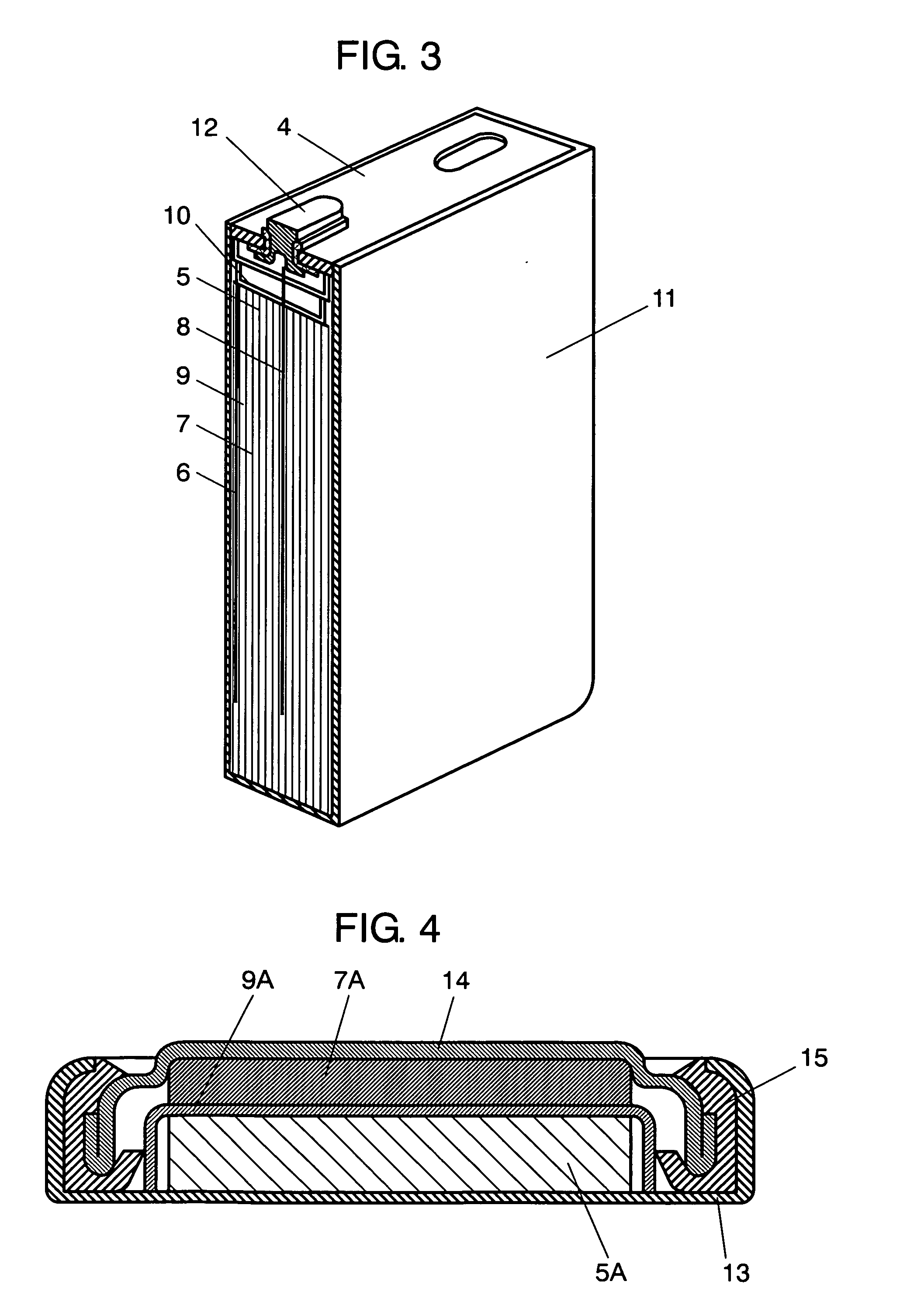

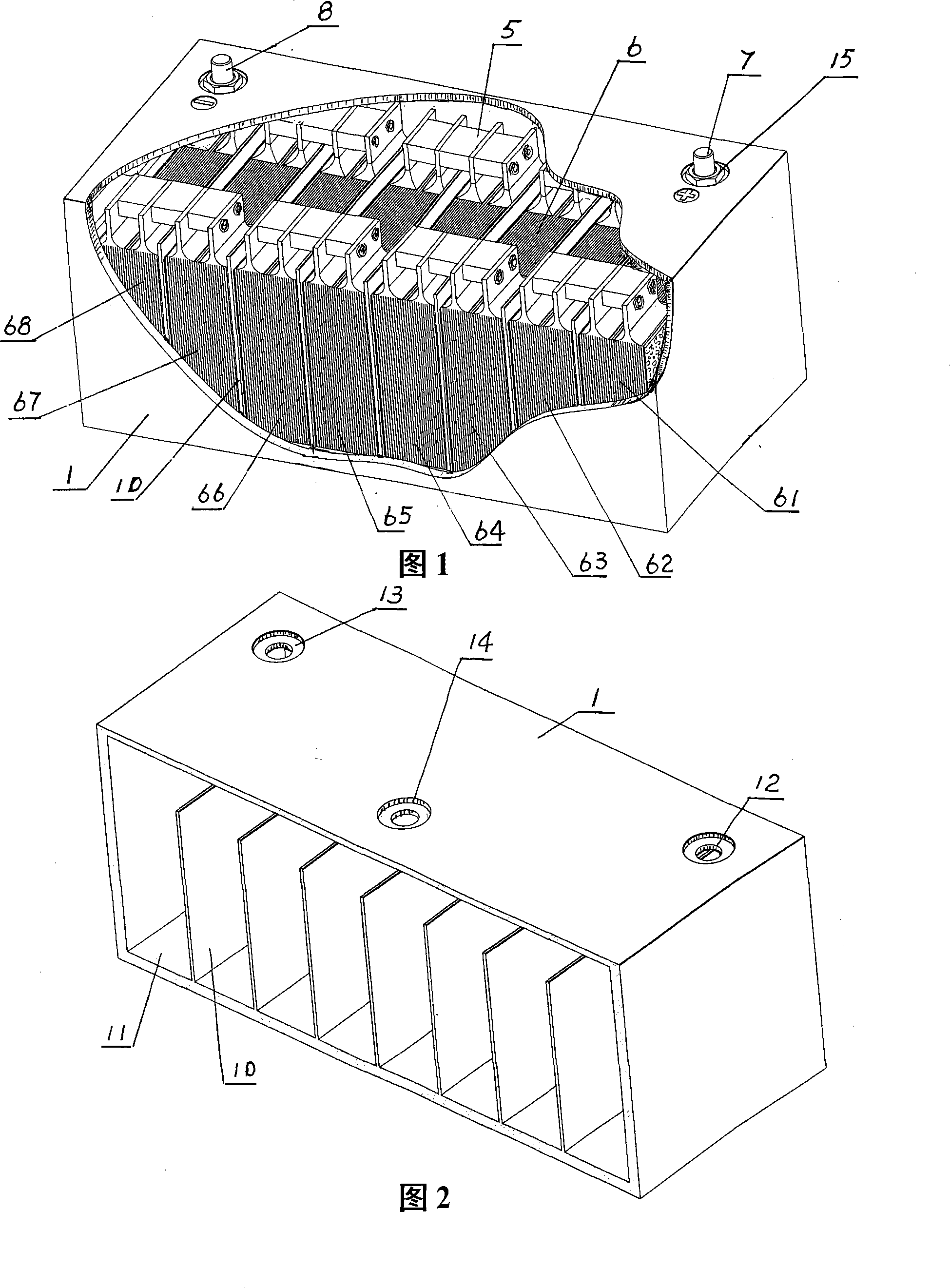

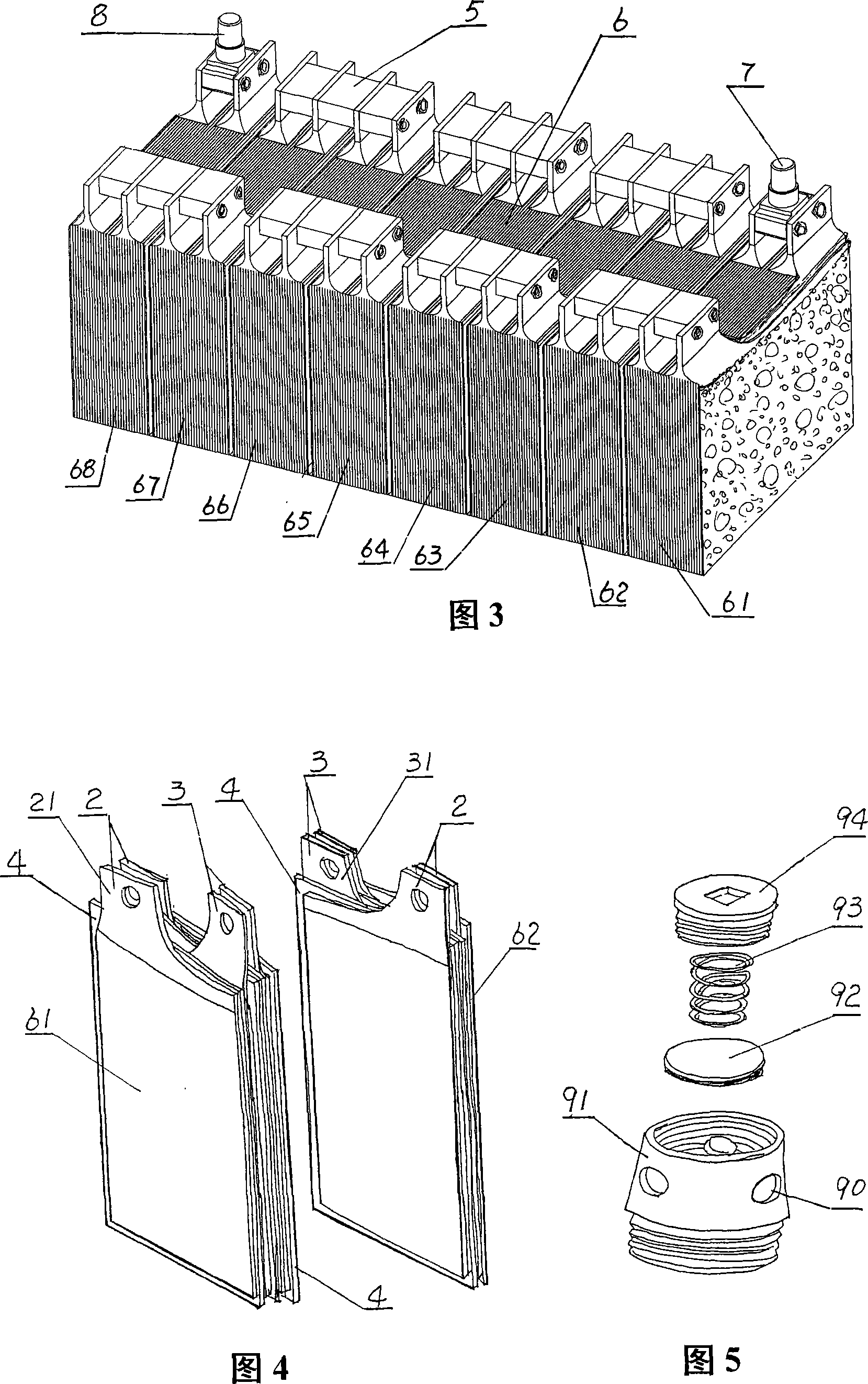

High voltage power type lithium ion chargeable battery

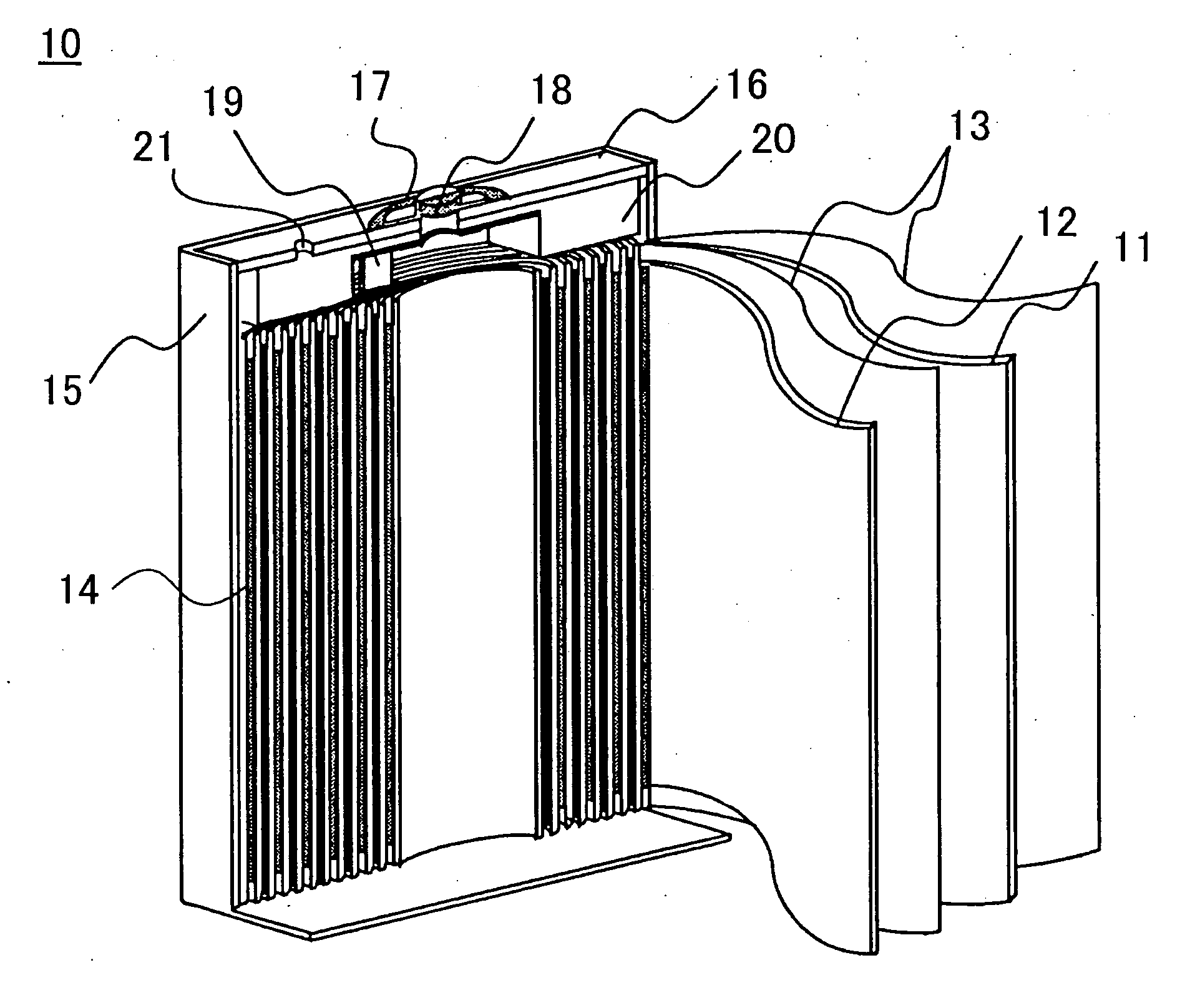

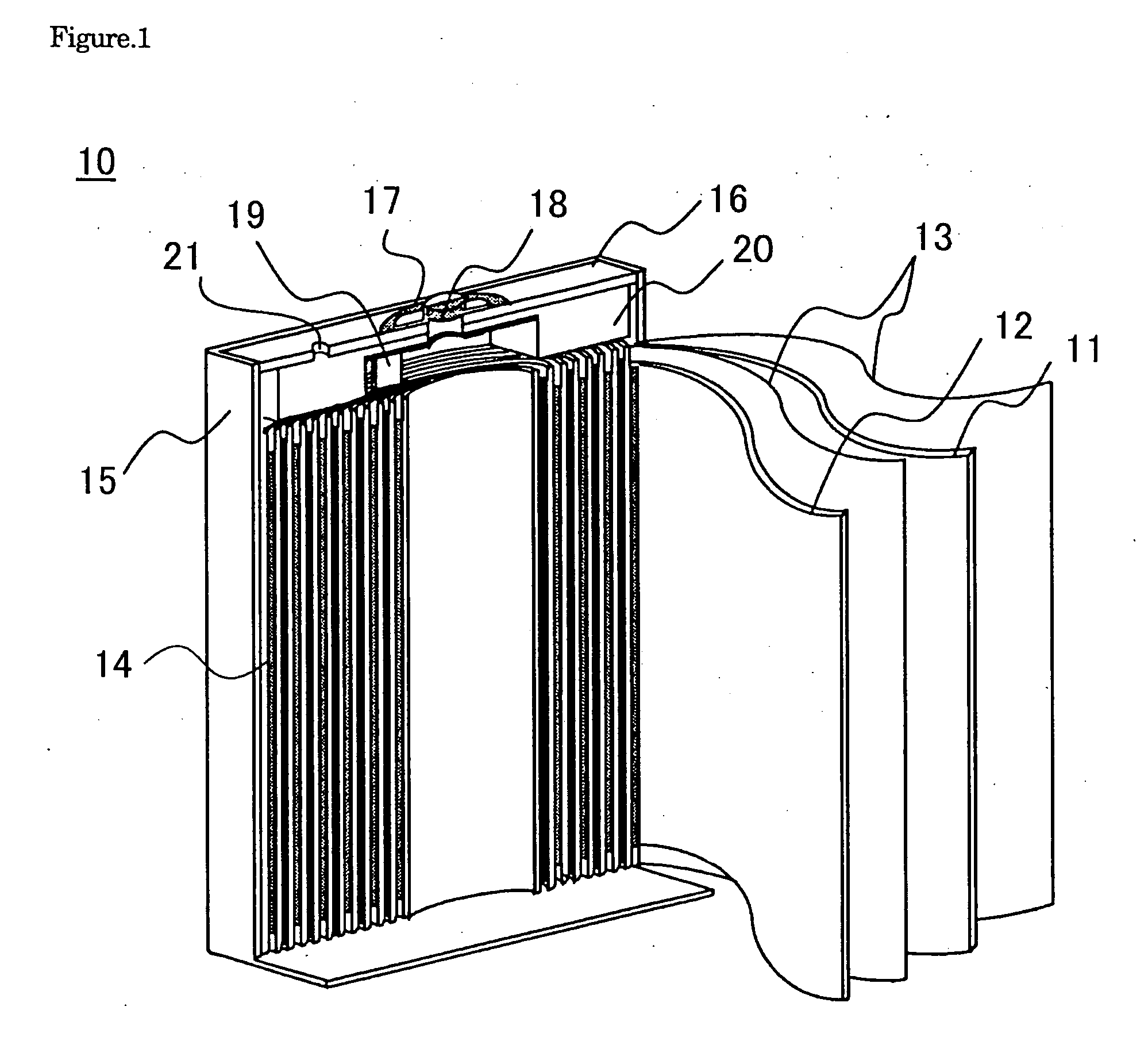

InactiveCN101141010ADesign scienceIngenious structureSmall-sized cells cases/jacketsVent arrangementsSodium-ion batteryEngineering

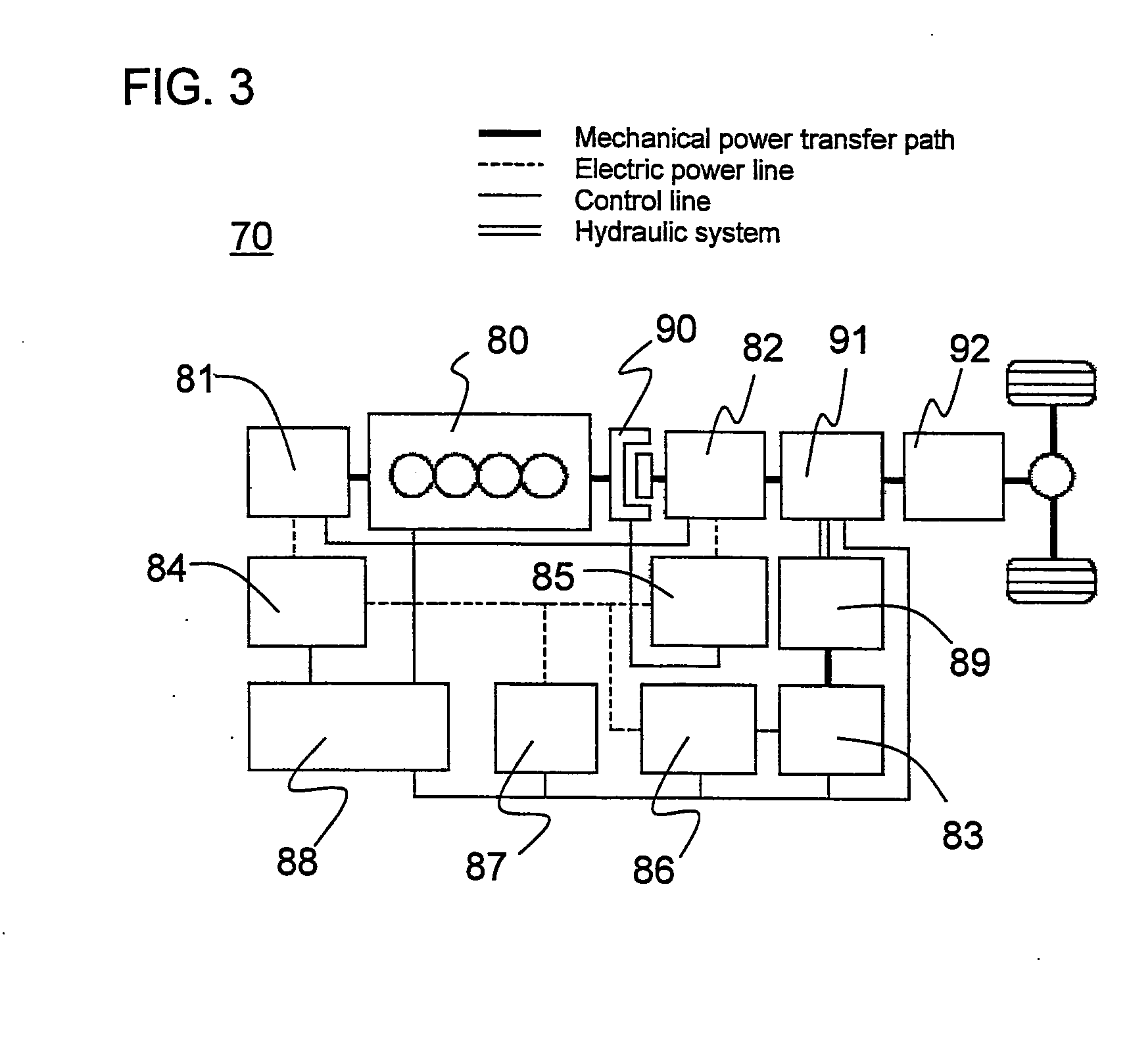

A high voltage dynamic lithium ion built-in battery is provided, which comprises a shell filled with electrolyte and at least two battery cells inside the shell. The positive and negative electrodes of each of the lithium ion battery cells are connected in series to form a battery cells body that will be wholly encapsulated into a shell. The invention is characterized in separately placing each of the said battery cells connected in series in each battery cell cabin. The invention is scientifically designed with refined and reasonable structure. Based on the characteristics of the invention, the said invention greatly improves its structure and lowers the possible damage due to the rise in temperature when using the battery. The structure can possibly increase the monomeric voltage of the lithium ion battery from 2.0V to hundreds of V, and brings better property of recharge cycles, meeting the requirement in various fields and under different loading conditions.

Owner:雷天电池技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com