Non-aqueous electrolyte secondary battery

A non-aqueous electrolyte, secondary battery technology, used in non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

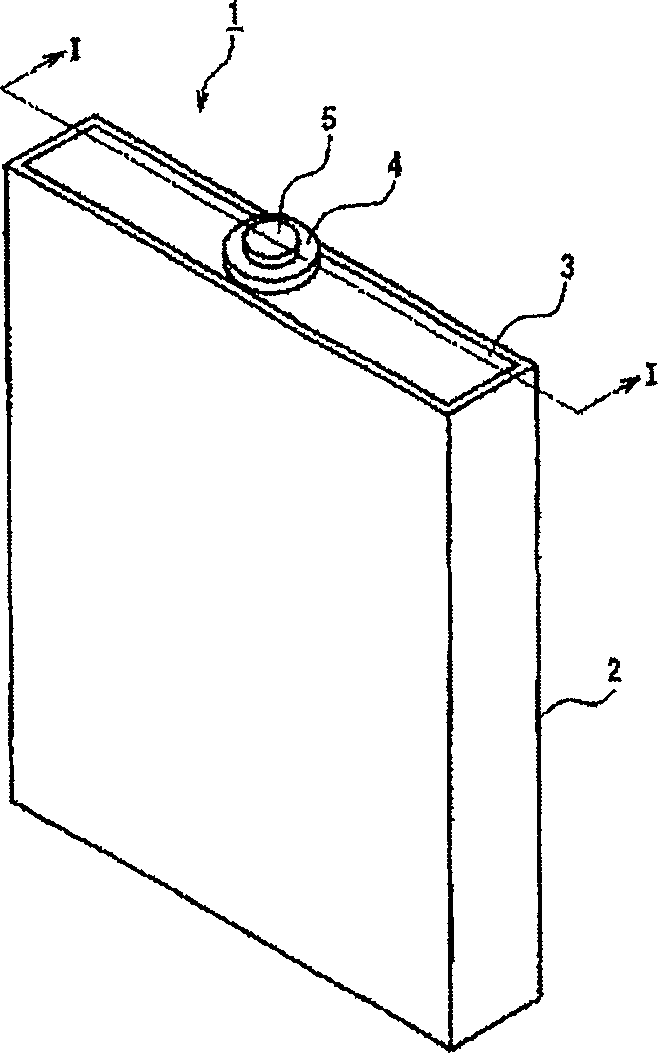

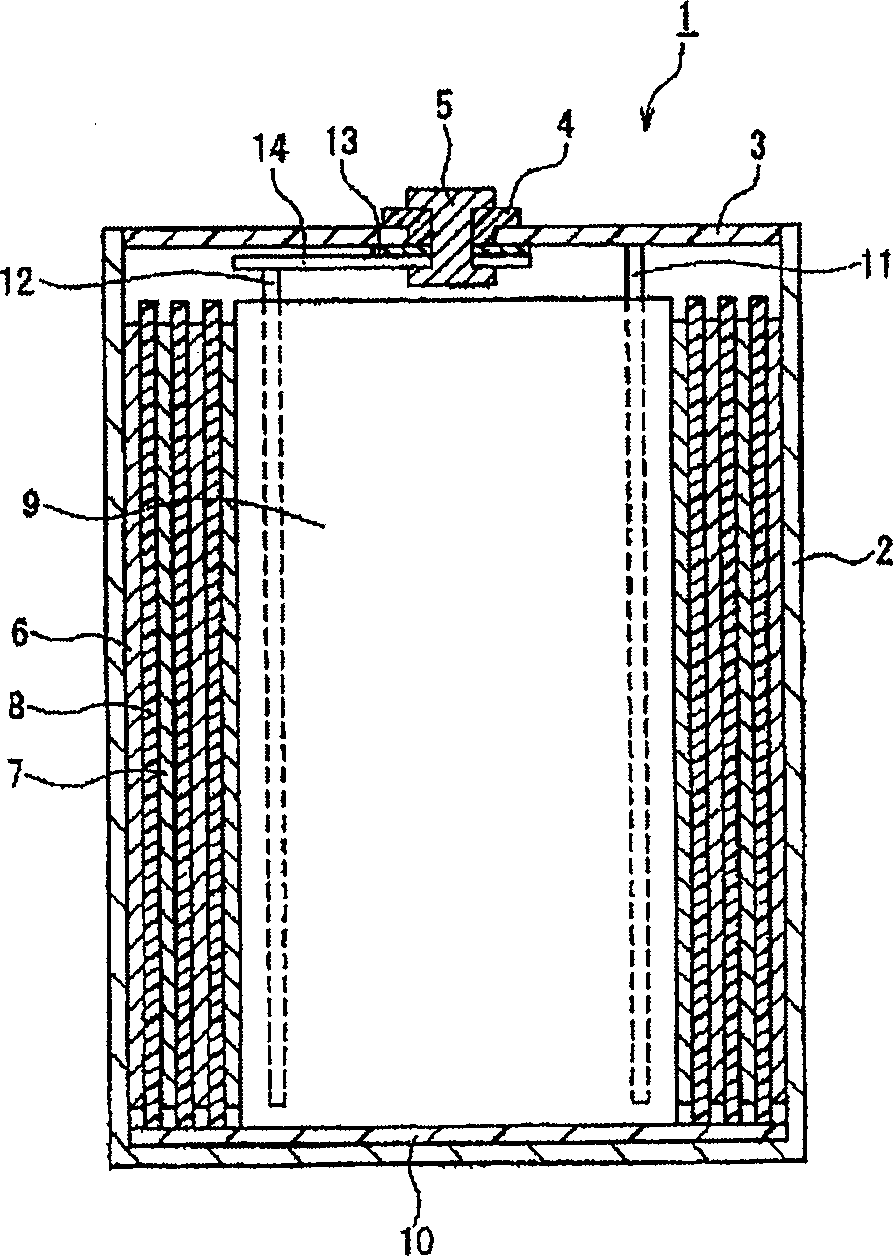

[0080] Fabricate the electrodes and prepare the non-aqueous electrolyte as follows, making and figure 1 and figure 2 A non-aqueous electrolyte secondary battery of the same configuration as shown.

[0081]

[0082] The positive electrode was fabricated as described below. First, in Li as a layered lithium-manganese composite oxide 1.02 Ni 1 / 3 mn 1 / 3 co 1 / 3 o 2 (Positive electrode active material) In 94 mass parts, mix the carbon black of 3 mass parts as conductive auxiliary agent, add the solution that 3 mass parts of polyvinylidene fluoride is dissolved in NMP to this mixture, mix and make the slurry containing positive electrode mixture , so that it passes through a 70-mesh sieve to remove the part with large particle size. The slurry containing the positive electrode mixture is evenly coated on both sides of the positive electrode collector formed by aluminum foil with a thickness of 15 μm, and after drying, it is compressed and molded by a roller extruder. After ...

Embodiment 2~6

[0091] Instead of 1,2-propanediol sulfate, ethylene glycol sulfate (Example 2), 1,3-Propanediol sulfate (Example 3), 1 , 3-propane sultone (Example 4), 1,2-Propane sultone (Example 5), 1,4-Butane sultone (Example 6), in addition, with Example 1 was operated in the same manner to prepare a non-aqueous electrolyte. Except having used these nonaqueous electrolyte solutions, it carried out similarly to Example 1, and produced the nonaqueous electrolyte solution secondary battery.

Embodiment 7~13

[0093] A nonaqueous electrolytic solution was prepared in the same manner as in Example 1, except that the amount of 1,3-propane sultone added to the total mass of the nonaqueous electrolytic solution was changed as shown in Table 3. Except having used these nonaqueous electrolyte solutions, it carried out similarly to Example 1, and produced the nonaqueous electrolyte solution secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com