Patents

Literature

1032results about How to "High heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

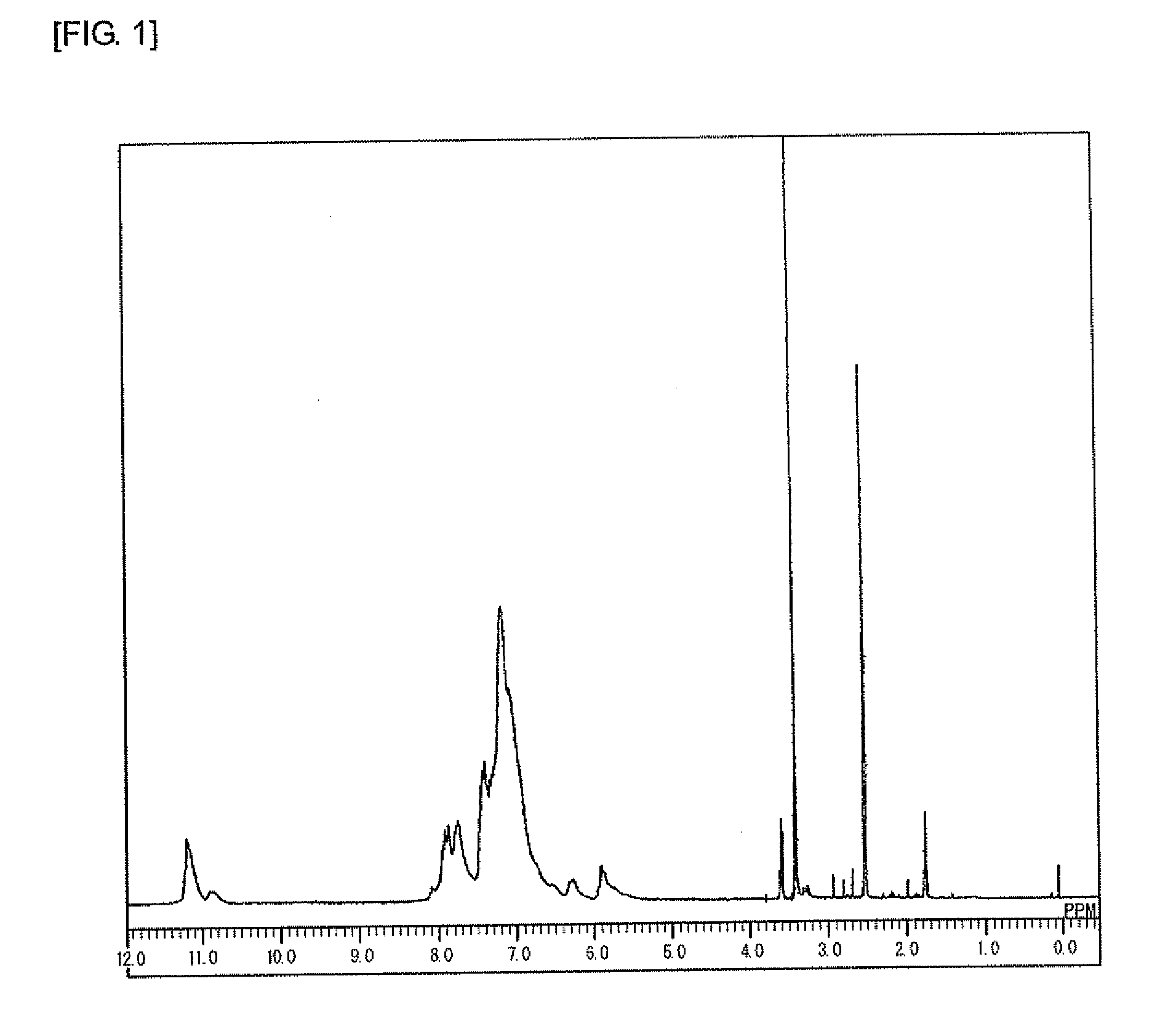

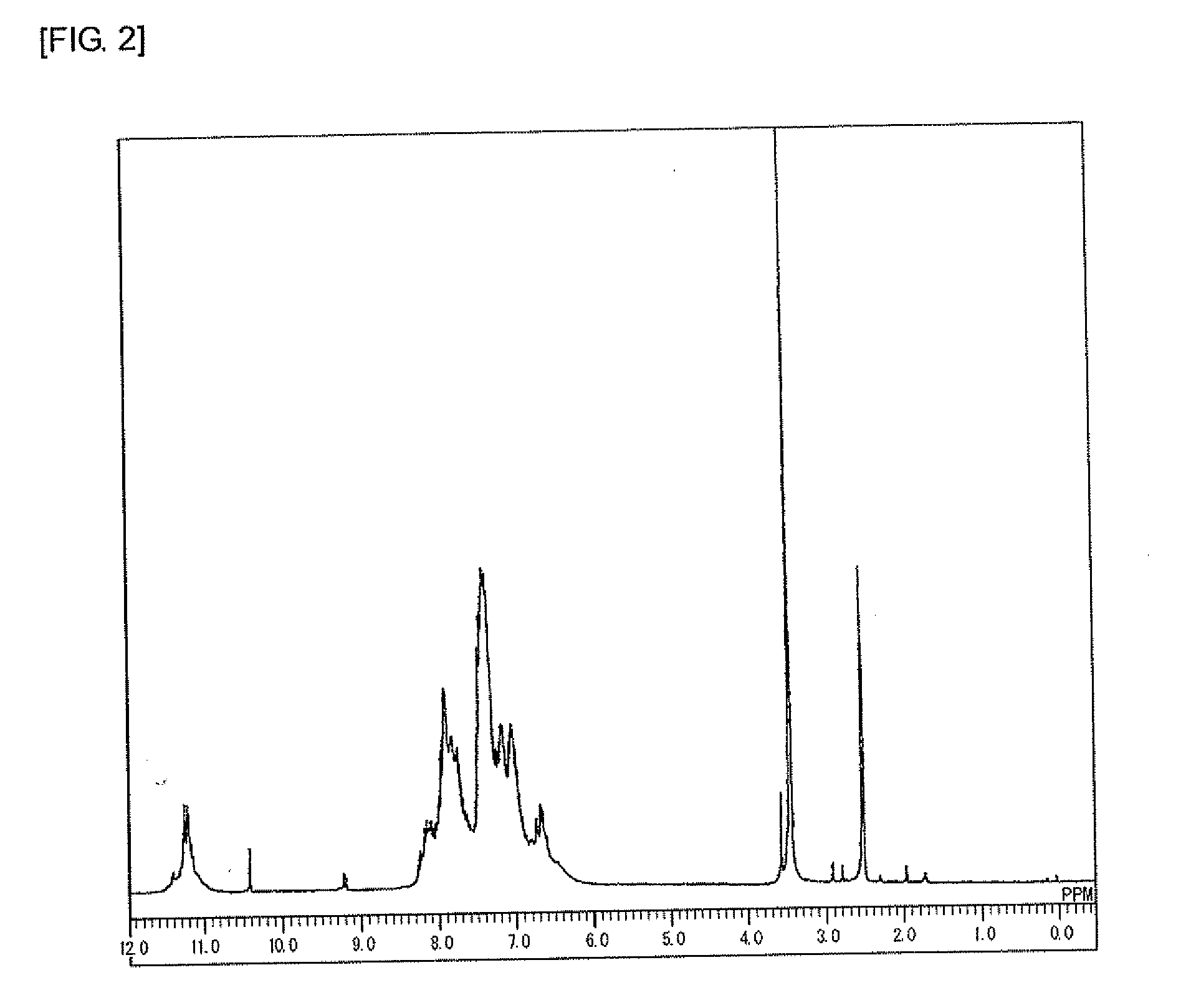

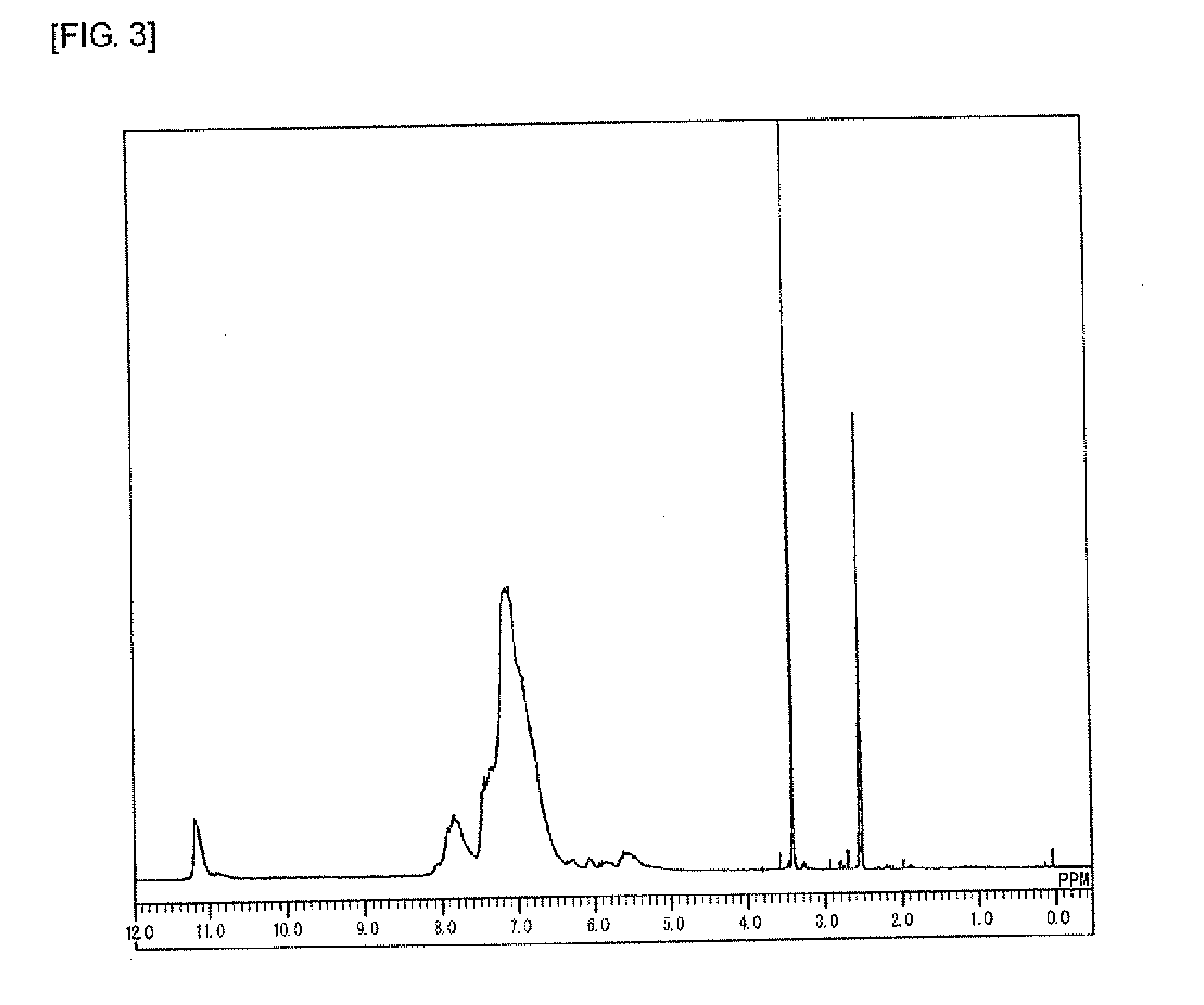

Material for organic electroluminescence device and organic electroluminescence device utilizing the same

ActiveUS20090017330A1High efficiencyHigh heat resistanceOrganic chemistryElectroluminescent light sourcesOrganic electroluminescenceChemistry

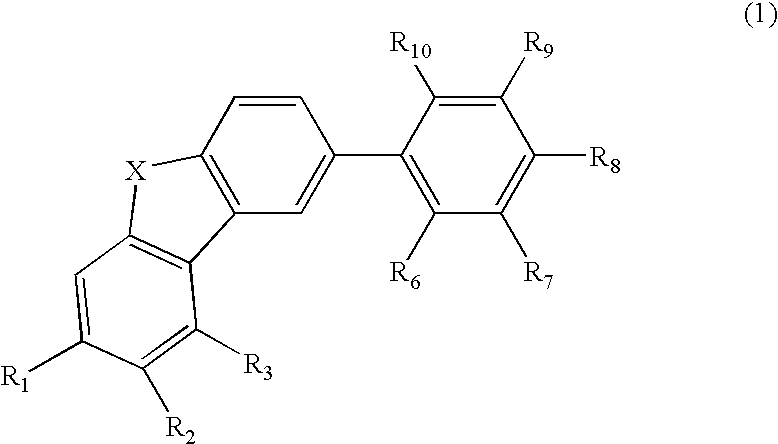

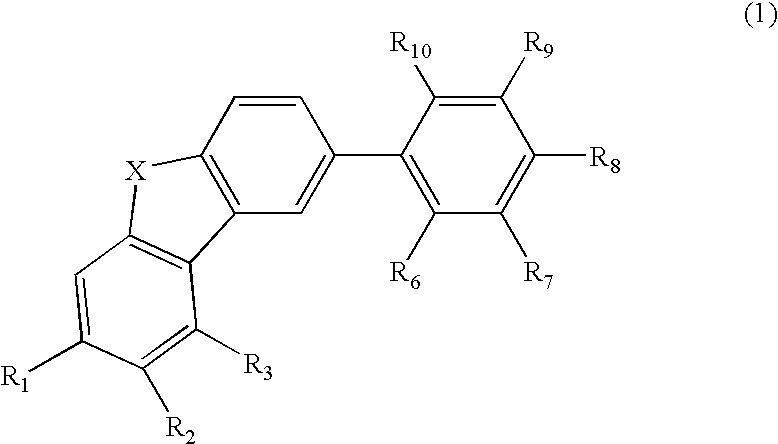

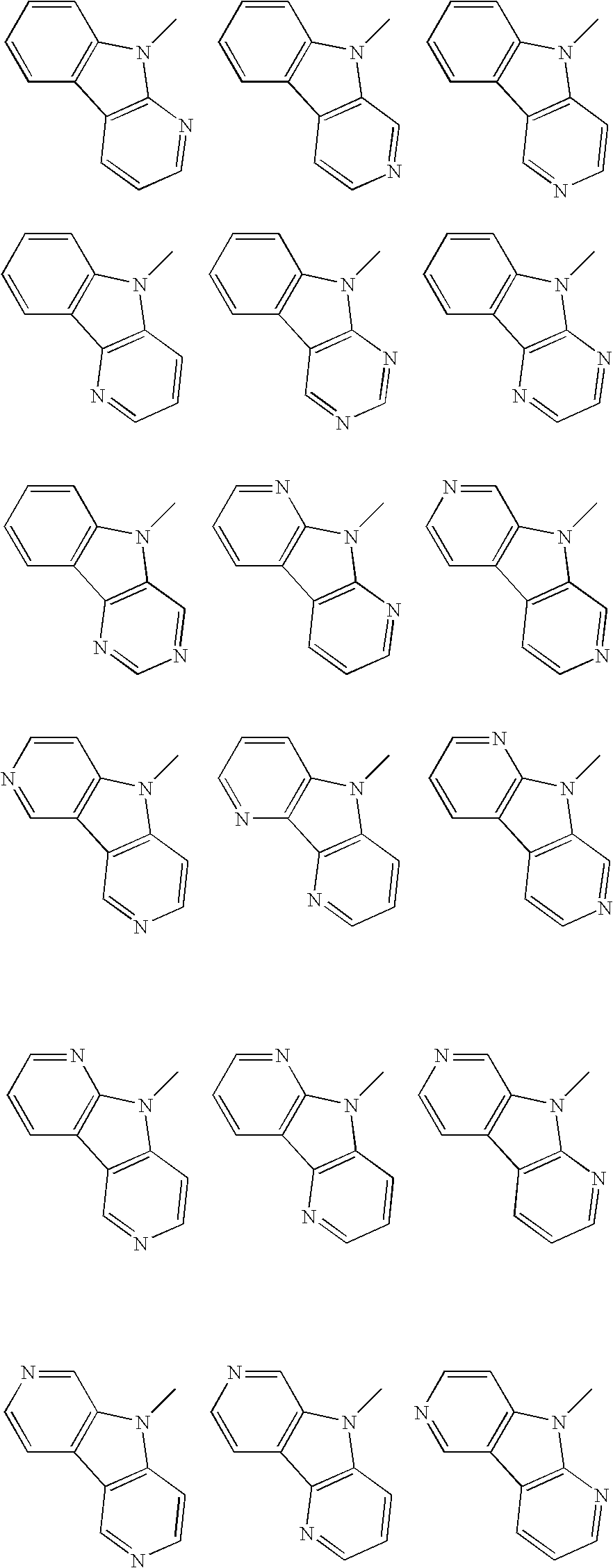

A material for organic electroluminescence devices of the invention which is for use in combination with at least one phosphorescent metal complex has a specific heterocyclic structure. The material for organic electroluminescence devices is used as a host material or a hole transporting material. An organic electroluminescence device having an anode, a cathode and an organic thin film layer having one or more layers which is interposed between the anode and cathode, in which at least one layer of the organic thin film layer contains the material for organic electroluminescence devices, has a high emitting efficiency, causes little pixel defects, is excellent in heat resistance, and shows a long lifetime.

Owner:IDEMITSU KOSAN CO LTD

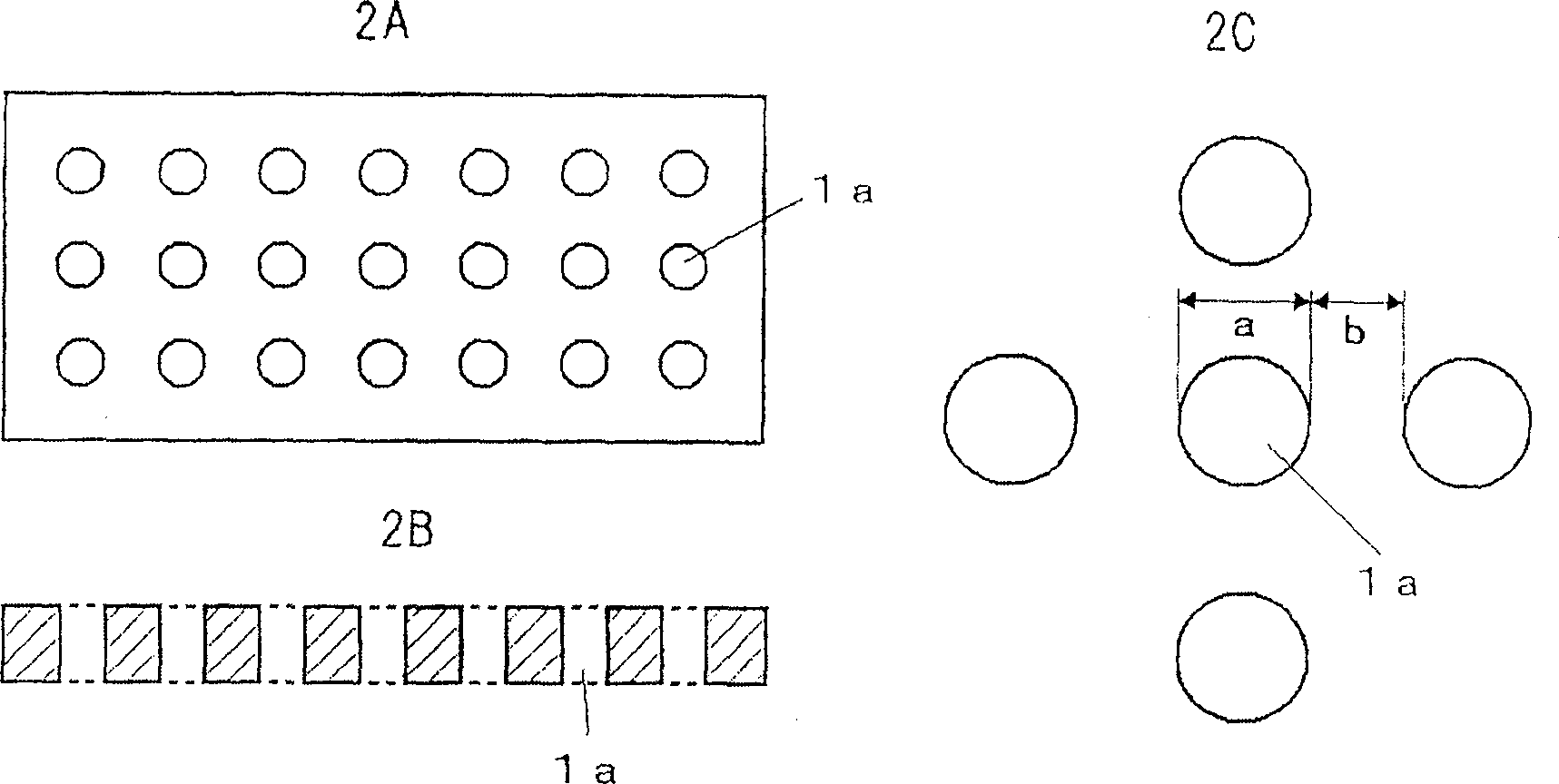

Heat-expandable microcapsules, process for producing the same, and method of utilizing the same

InactiveUS6235394B1High TgHigh heat-resistanceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHeat resistance

A heat-expandable microcapsule comprising a polymer shell formed by polymerizing (I) acrylonitrile, a main monomer component, (II) a monomer having carboxyl and (III) a monomer having groups reactive with the carboxyl of the monomer (II) and of a liquid having a boiling point lower than the softening point of the polymer and being encapsulated in the polymer shell. The heat-expandable microcapsules expand within high temperature range, 240° C. or above, and have heat-resistance.

Owner:MATSUMOTO YUSHI SEIYAKU

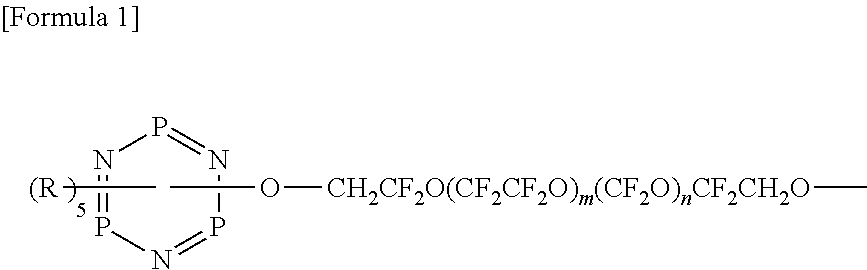

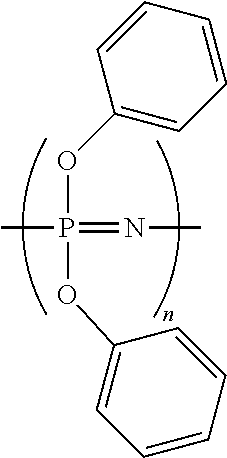

Lubricant for magnetic disk and magnetic disk

InactiveUS20120276417A1Improve heat resistanceHigh heat resistanceProtective coatings for layersMagnetic materials for record carriersHeat-assisted magnetic recordingPerfluoropolyether

A lubricant for a magnetic disk that is excellent in heat resistance and is suitably used in a magnetic disk to be mounted on a magnetic recording device of a thermally assisted magnetic recording system and a magnetic disk provided with a lubricant layer containing this lubricant. The lubricant for a magnetic disk contains a compound where perfluoropolyether groups each having a perfluoropolyether main chain in its structure and a phosphazene ring at an end are linked to each other through a linking group. The linking group is an aliphatic group or a phosphazene ring. In a magnetic disk having at least a magnetic recording layer, a protective layer, and a lubricant layer on a substrate, the lubricant layer contains the lubricant for a magnetic disk.

Owner:WESTERN DIGITAL TECH INC

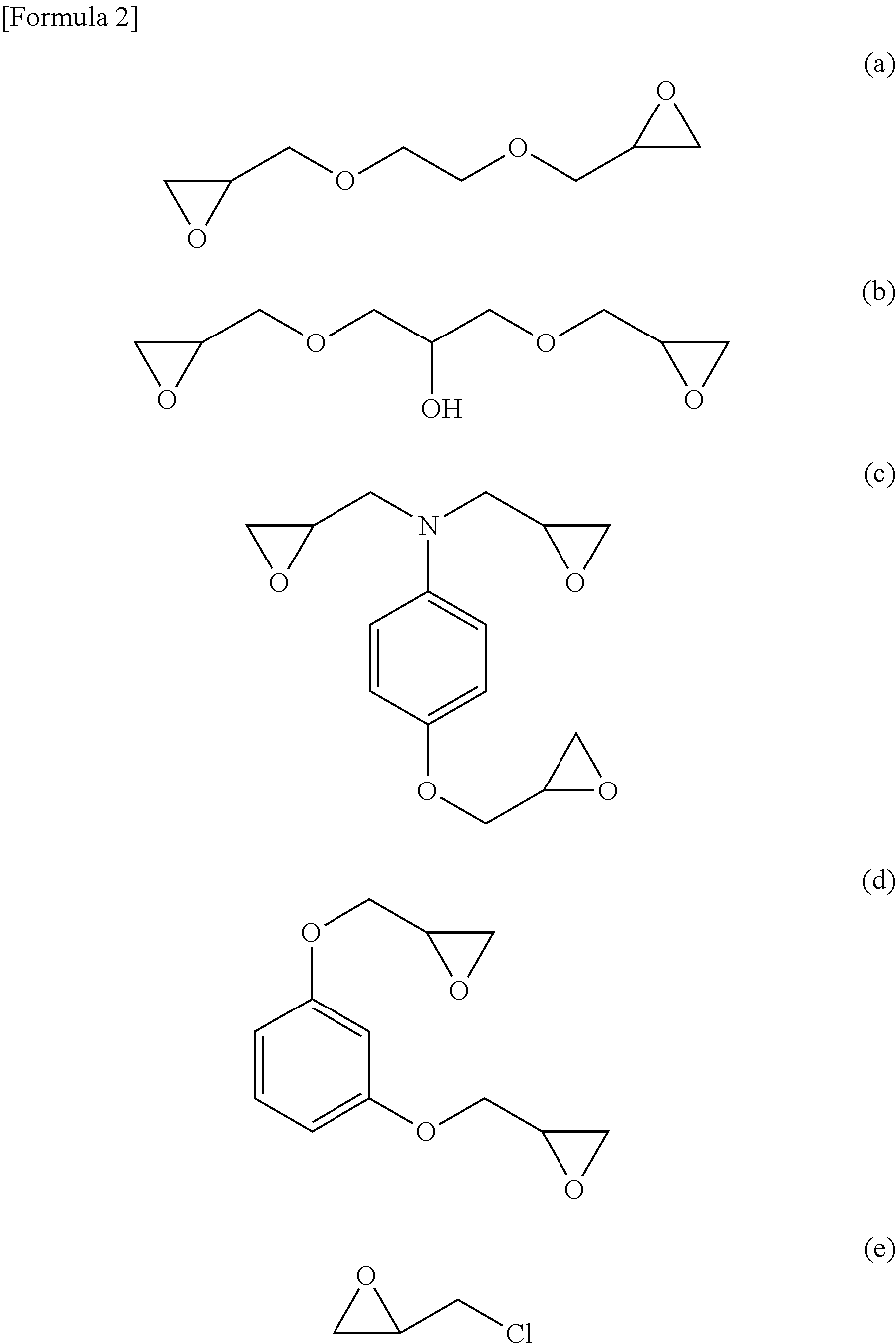

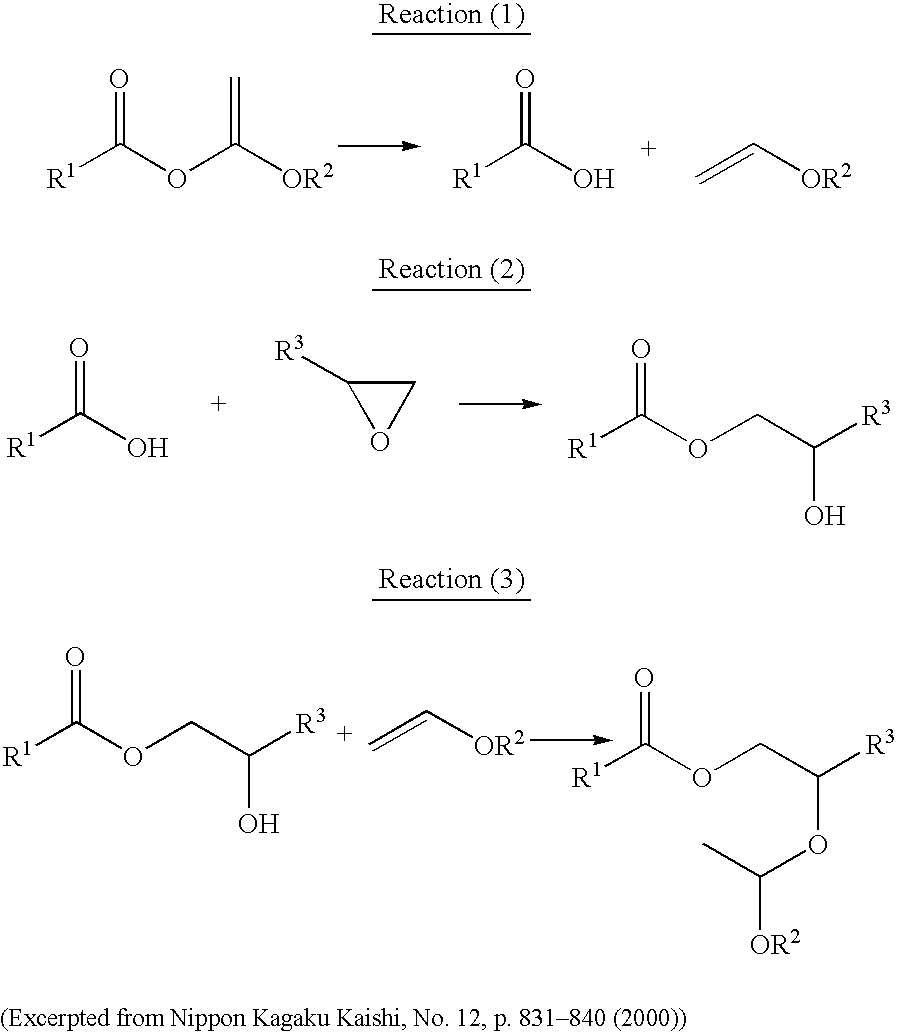

Volume type hologram recording photosensitive composition, volume type hologram recording medium using the same and method of producing volume type hologram

InactiveUS7018744B2Excellent optical characteristicHigh heat resistancePhotosensitive materialsRecord information storageRefractive index modulationChemistry

The present invention provides a volume type hologram recording photosensitive composition. A type (i) composition comprises one or more photopolymerizable compounds, a heat-curable compound and a heat-curing crosslinking agent, wherein the heat-curing crosslinking agent is a latent heat-curing crosslinking agent which is not reacted in an interference exposure process, is not reacted at the heating temperature used in a refractive index-modulation promoting process and becomes active at the heating temperature used in a heat-curing process. A type (ii) composition further comprises a binder resin beside the type (i) volume type composition.

Owner:DAI NIPPON PRINTING CO LTD

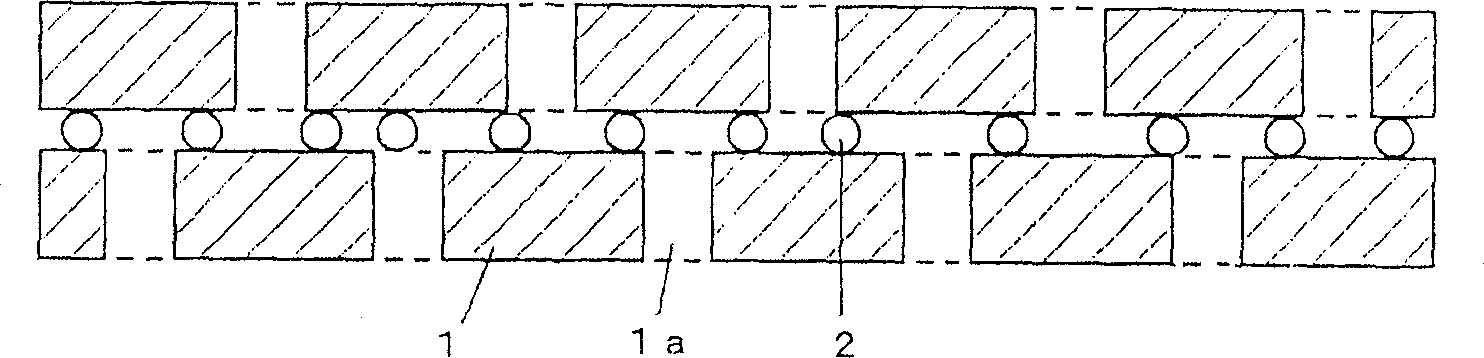

Prepreg and laminate

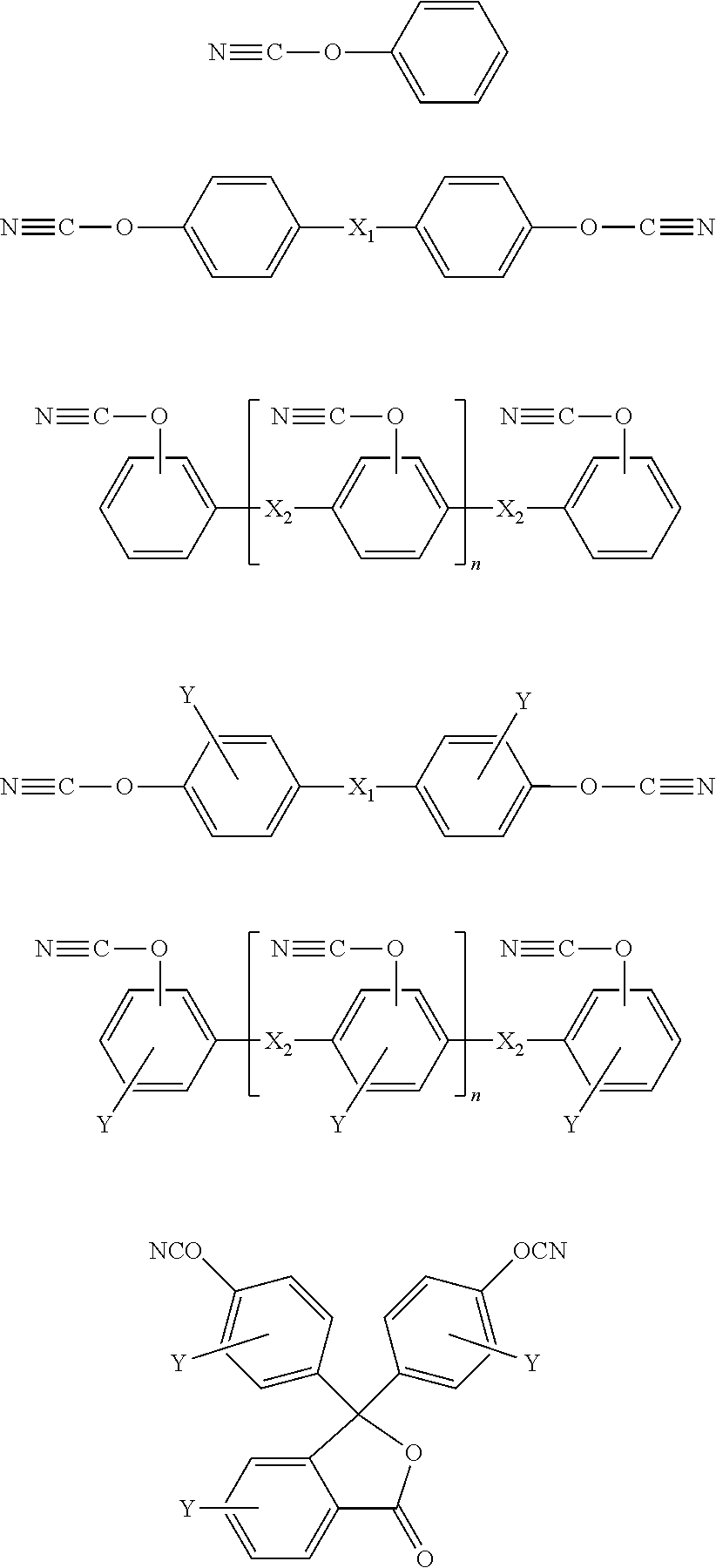

ActiveUS20090017316A1Improve flame retardant performanceImprove heat resistanceSpecial tyresElectrical equipmentThermal dilatationPolymer science

A prepreg for a printed wiring board, comprising a cyanate ester resin having a specific structure, a non-halogen epoxy resin, a silicone rubber powder as a rubber elasticity powder, an inorganic filler and a base material, which prepreg retains heat resistance owing to a stiff resin skeleton structure, has high-degree flame retardancy without the use of a halogen compound or a phosphorus compound as a flame retardant, and has a small thermal expansion coefficient in plane direction without using a large amount of inorganic filler, and a laminate comprising the above prepreg.

Owner:MITSUBISHI GAS CHEM CO INC

Adhesive polyethylene compositions and multi-layer laminated films using the same

InactiveUS6210765B1Improve adhesion strengthHigh heat sealing strength heatWrappers shrinkageShrinkage connectionsElastomerPolyamide

Disclosed is a specific adhesive polyethylene composition comprising [1] a modified ethylene / alpha-olefin copolymer resin or elastomer obtained by modifying a specific ethylene / alpha-olefin copolymer resin or elastomer, each of which comprises ethylene and an alpha-olefin of 3 to 20 carbon atoms, with an unsaturated carboxylic acid or anhydride, ester, amide, imide or metallic salt derivative of a unsaturated carboxylic acid thereof, [2] an unmodified ethylene / alpha-olefin copolymer resin and / or an unmodified ethylene / alpha-olefin copolymer elastomer and [3] a tackifier. Also disclosed is a multi-layer laminated film of 3 or more layers in which a layer of the above composition is interposed between an ethylene polymer layer and either a polyamide resin layer, an ethylene / vinyl alcohol copolymer layer or a layer of a mixture of polyamide resin and ethylene / vinyl alcohol copolymer. The adhesive polyethylene composition shows excellent adhesion strength to ethylene polymers, polyamide resins and ethylene / vinyl alcohol copolymers, high heat-sealing strength and heat resistance. The multi-layer laminated film shows excellent strength, heat resistance and gas barrier properties, and besides this film has heat shrinkability, so that the film is suitably used as a shrink film.

Owner:MITSUI CHEM INC

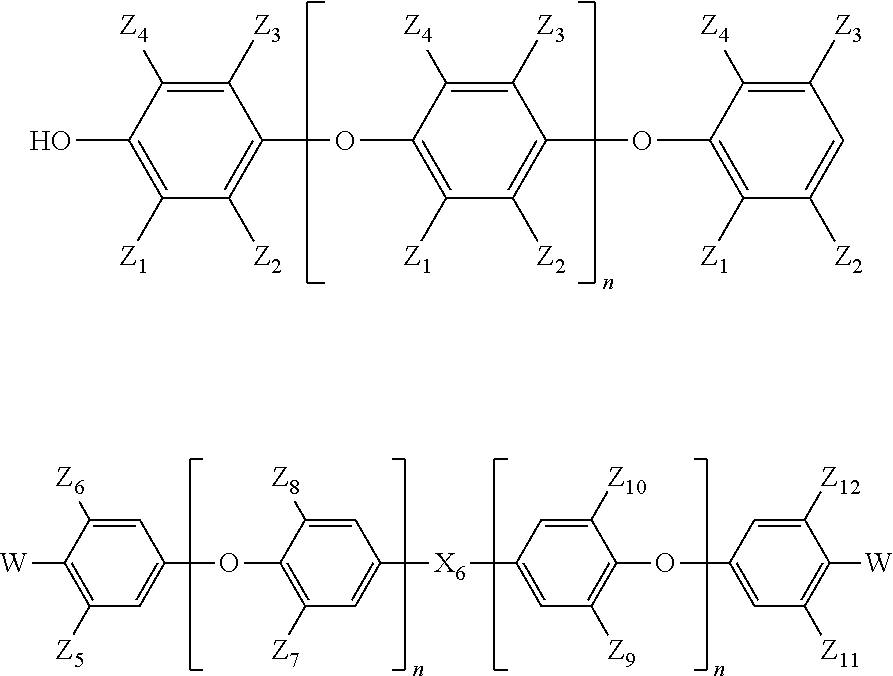

Halogen-free resin composition and copper clad laminate and printed circuit board using same

ActiveUS20130075138A1Low dissipation factorHigh heat resistancePrinted circuit aspectsSynthetic resin layered productsLow dissipationStyrene maleic anhydride

The halogen-free resin composition comprises (A)100 parts by weight of cyanate ester resin; (B) 5 to 50 parts by weight of styrene-maleic anhydride; (C) 5 to 100 parts by weight of polyphenylene oxide resin; (D) 5 to 100 parts by weight of maleimide; (E) 10 to 150 parts by weight of phosphazene; and (F) 10 to 1000 parts by weight of inorganic filler. By using specific components at specific proportions, the halogen-free resin composition of the invention offers the features of low dielectric constant, low dissipation factor, high heat resistance and high flame retardancy, and can be made into prepreg or resin film, and thereby used in copper clad laminate or printed circuit board.

Owner:ELITE MATERIAL

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

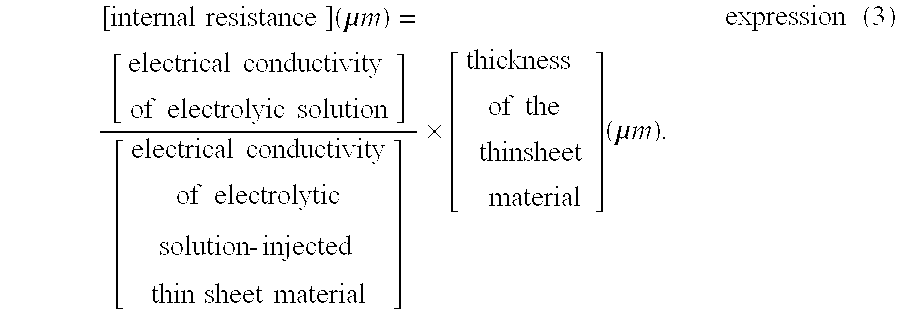

Aramid thin sheet material and electrical/electronic parts using the same

InactiveUS20070167101A1High strengthMaintain good propertiesHybrid capacitor separatorsPlastic/resin/waxes insulatorsInternal resistanceAramid

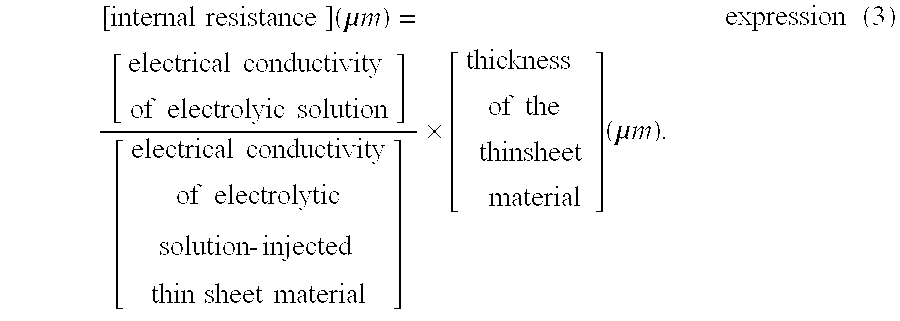

The invention provides an aramid thin sheet material comprising two components of aramid staple fibers and fibrillated aramid, or said two components and aramid fibrid, in particular, characterized by satisfying both of the following expressions (1) and (2): [internal resistance] (μm)≦250 (μm) expression (1) [Oken-type gas permeability] (sec / 100 cm3)≧0.5 (sec / 100 cm3) expression (2) wherein the [internal resistance] is a resistance value calculated by the following expression (3): [internal resistance ](μ m)=[electrical conductivity of electrolyic solution][electrical conductivityof electrolyticsolution-injected thin sheet material]×[thickness of the thinsheet material](μ m).expression (3)

Owner:DUPONT TEIJIN ADVANCED PAPERS JAPAN

Lithium ion secondary battery and solid electrolyte therefor

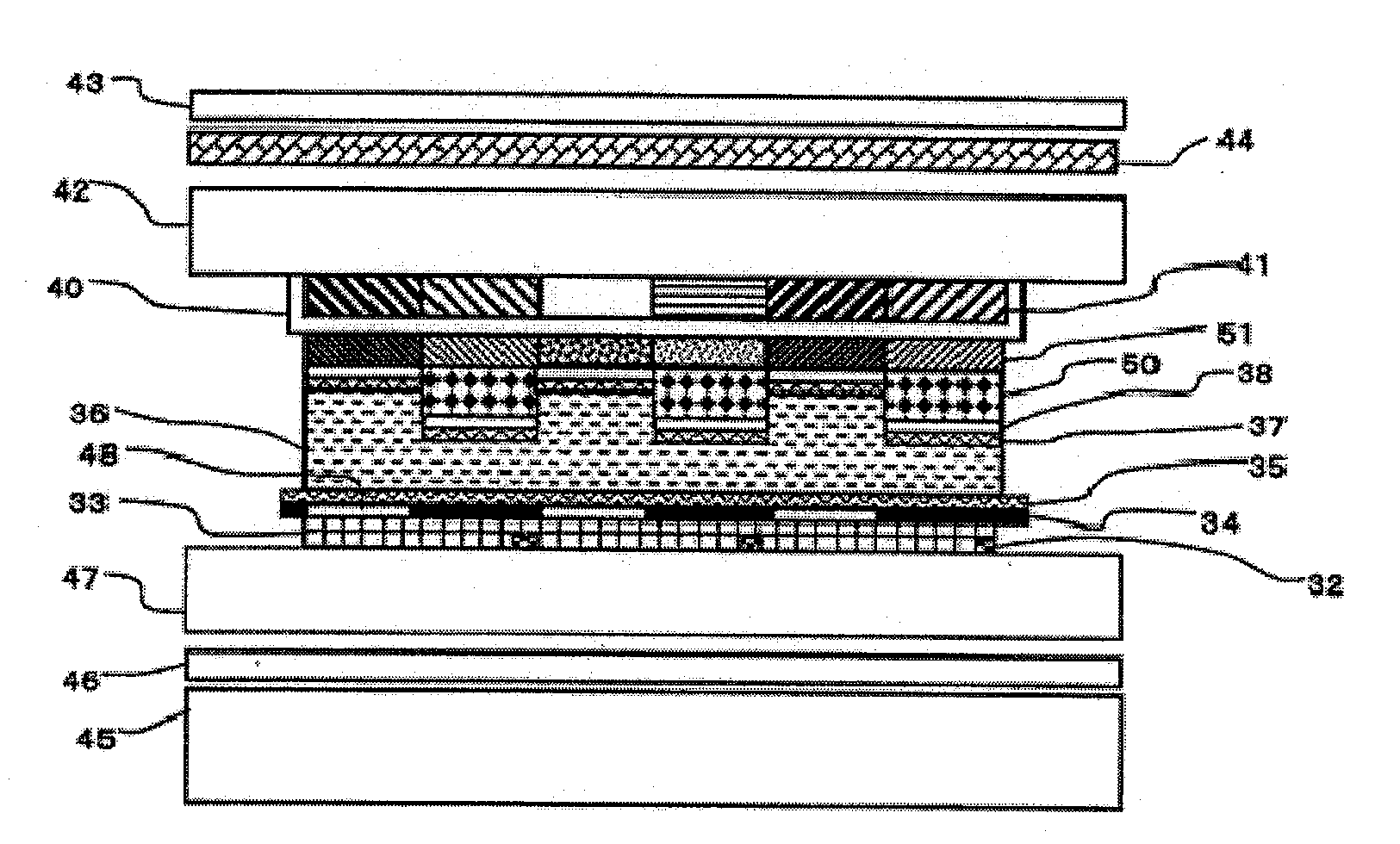

InactiveCN1925203AHigh outputReduce distanceNon-metal conductorsFinal product manufactureLithiumPhysical chemistry

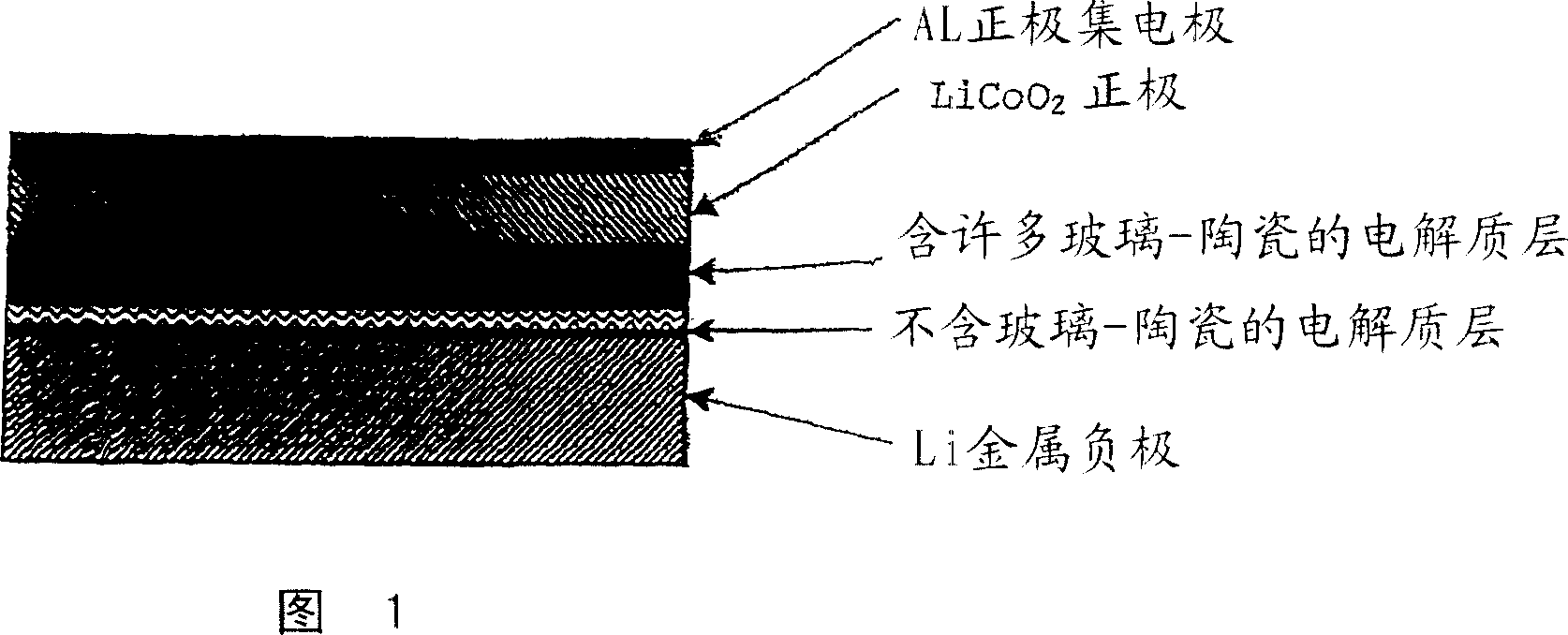

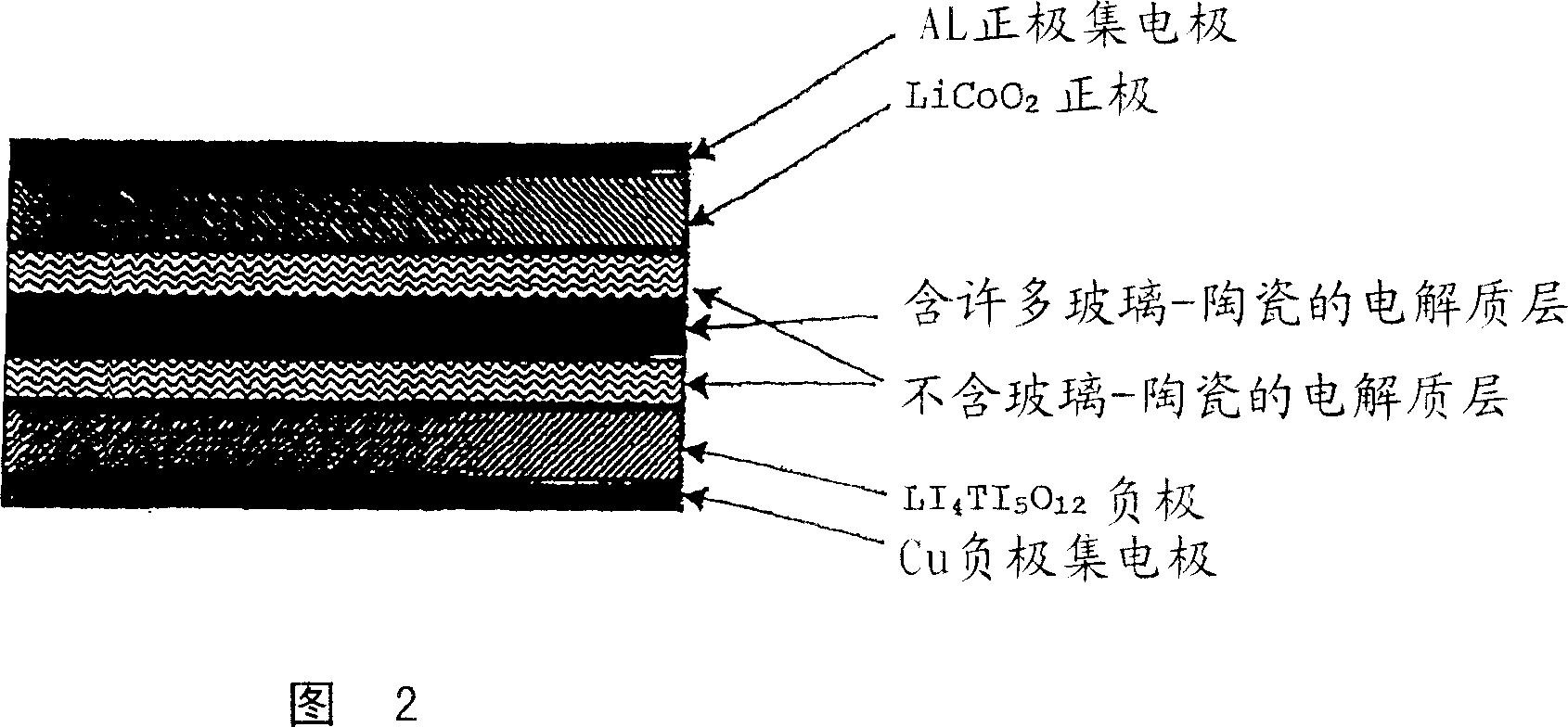

A solid electrolyte for a lithium ion secondary battery has a laminate of at least two layers. The thickest layer of the laminate comprises lithium ion conductive crystalline, preferably lithium ion conductive glass-ceramics having a predominant layer of Li 1+x+y (Al, Ga) x (Ti, Ge) 2-x Si y P 3-y O 12 where 0 x 1, 0 y 1. In a preferred embodiment, thickness of an electrolyte layer comprising the lithium ion conductive glass-ceramics is 150 m or below and thickness of an electrolyte layer which does not contain lithium ion conductive glass-ceramics or contains only a small amount of lithium ion conductive glass-ceramics is 50 m or below.

Owner:OHARA

Polylactic acid-based resin compositions, molded articles and process for producing the same

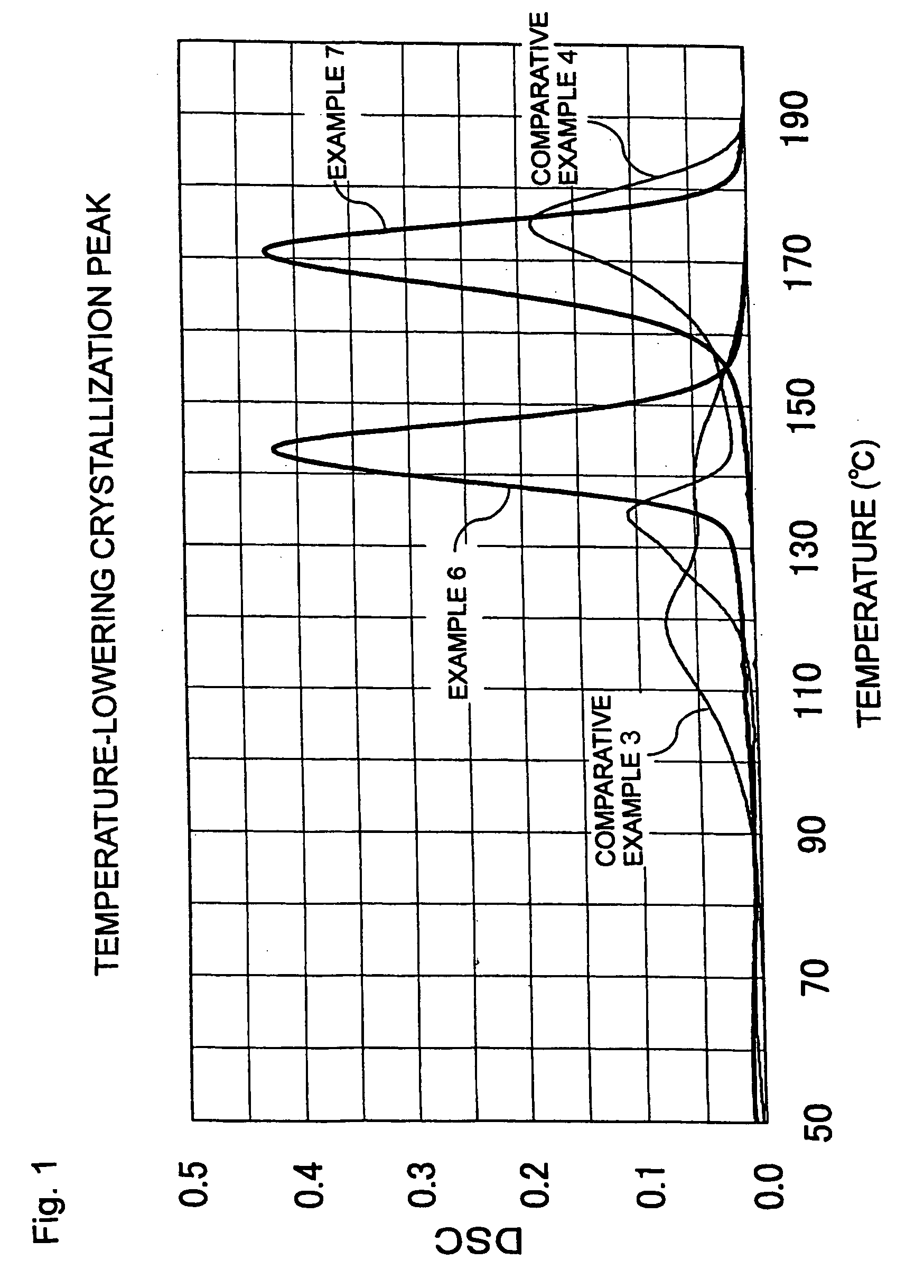

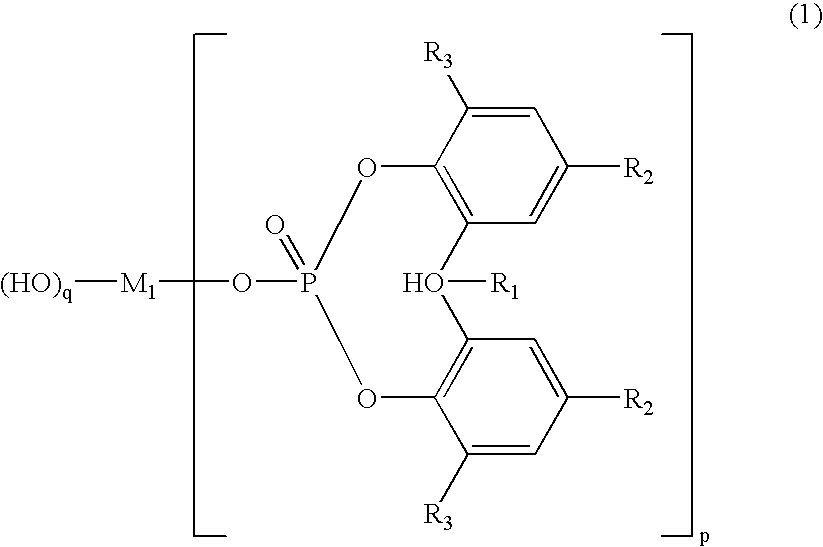

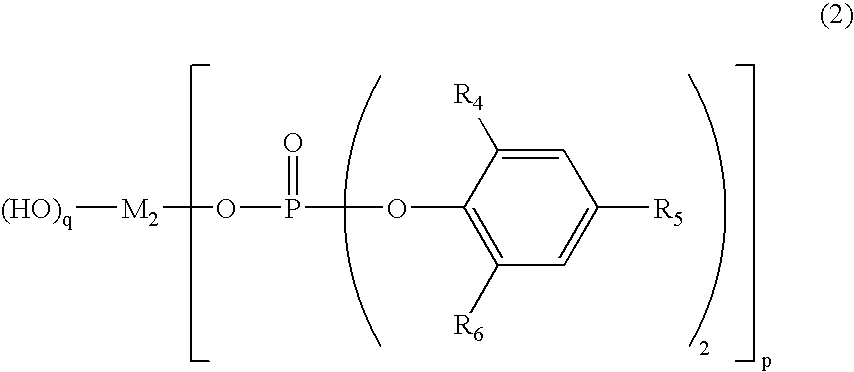

A polylactic acid-based resin composition is provided from which molded articles with a high heat resistance and high impact strength can be molded with improved moldability. Also provided is a heat-resistant polylactic acid-based resin molded article manufactured from the polylactic acid-based resin composition, as well as a process for manufacturing such a heat-resistant molded article. A polylactic acid-based resin composition comprising 0.01 to 5.0 parts by weight of a metal phosphate and 0.01 to 5.0 parts by weight of a basic inorganic aluminum compound, each serving as a nucleating agent, with respect to 100 parts by weight of a polylactic acid-based polymer. The polylactic acid-based resin composition is melted and filled a mold of a molding machine set in a temperature range of not more than the crystallization-initiating point nor less than the glass transition point, as measured by a differential scanning calorimeter (DSC), to be molded the composition under crystallizing.

Owner:ADEKA CORP +1

Electronic component separator and method for producing the same

ActiveCN1670989AImprove reliabilityImprove workabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:SUMITOMO CHEM CO LTD

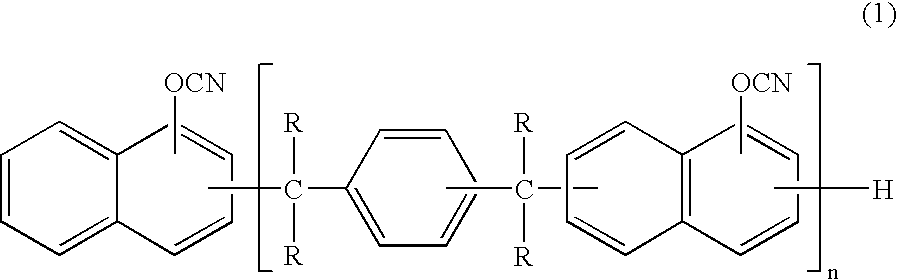

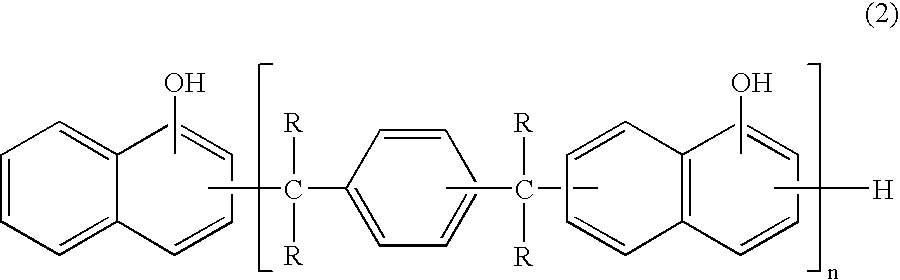

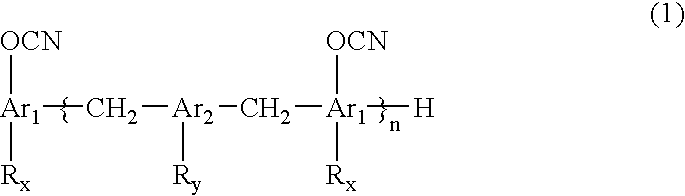

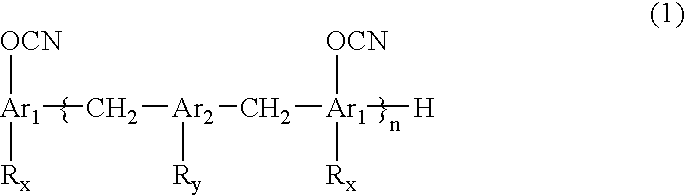

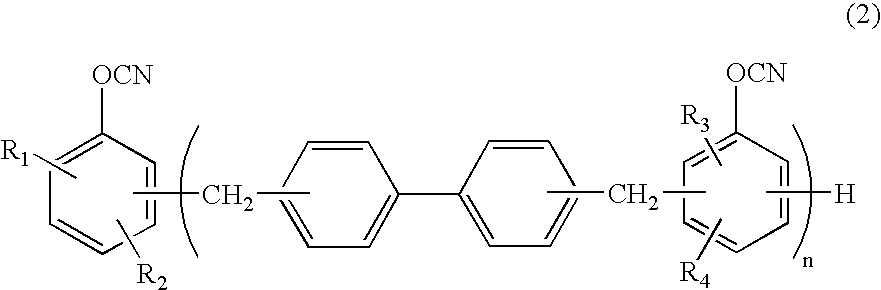

Novel cyanate ester compound, flame-retardant resin composition, and cured product thereof

InactiveUS20050182203A1Improve flame retardant performanceLow dielectric constantFireproof paintsInsulating substrate metal adhesion improvementArylHydrogen

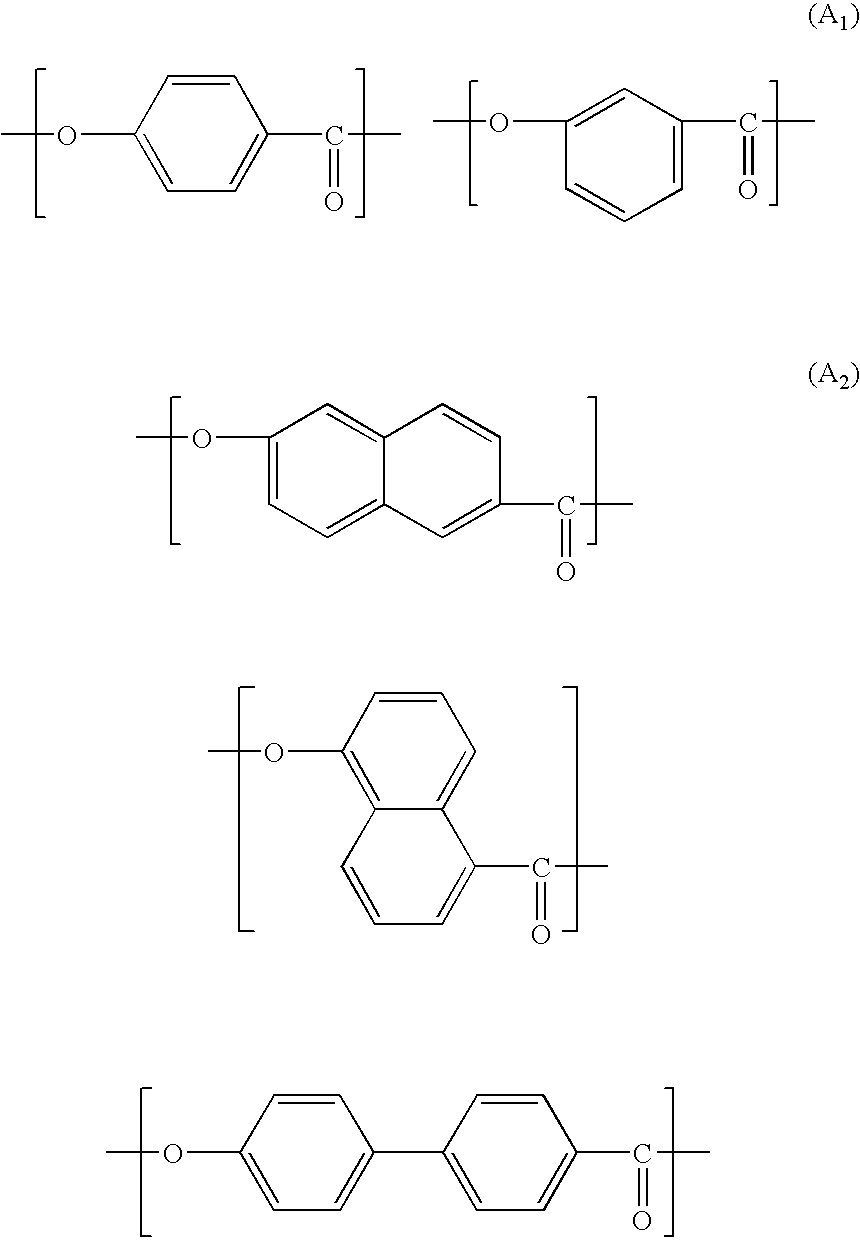

A cyanate ester compound represented by the formula (1), wherein Ar2 represents a phenylene group, a naphthylene group or a biphenylene group, Ar1 represents a naphthylene group or a biphenylene group when Ar2 is a phenylene group, or Ar1 represents a phenylene group, a naphthylene group or a biphenylene group when Ar2 is a naphthylene group or a biphenylene group, Rx represents all substituents of Ar1 each Rx is the same or different and represents hydrogen, an alkyl group or an aryl group, Ry represents all substituents of Ar2, each Ry is the same or different and represents hydrogen, an alkyl group or an aryl group, and n is an integer of 1 to 50.

Owner:MITSUBISHI GAS CHEM CO INC

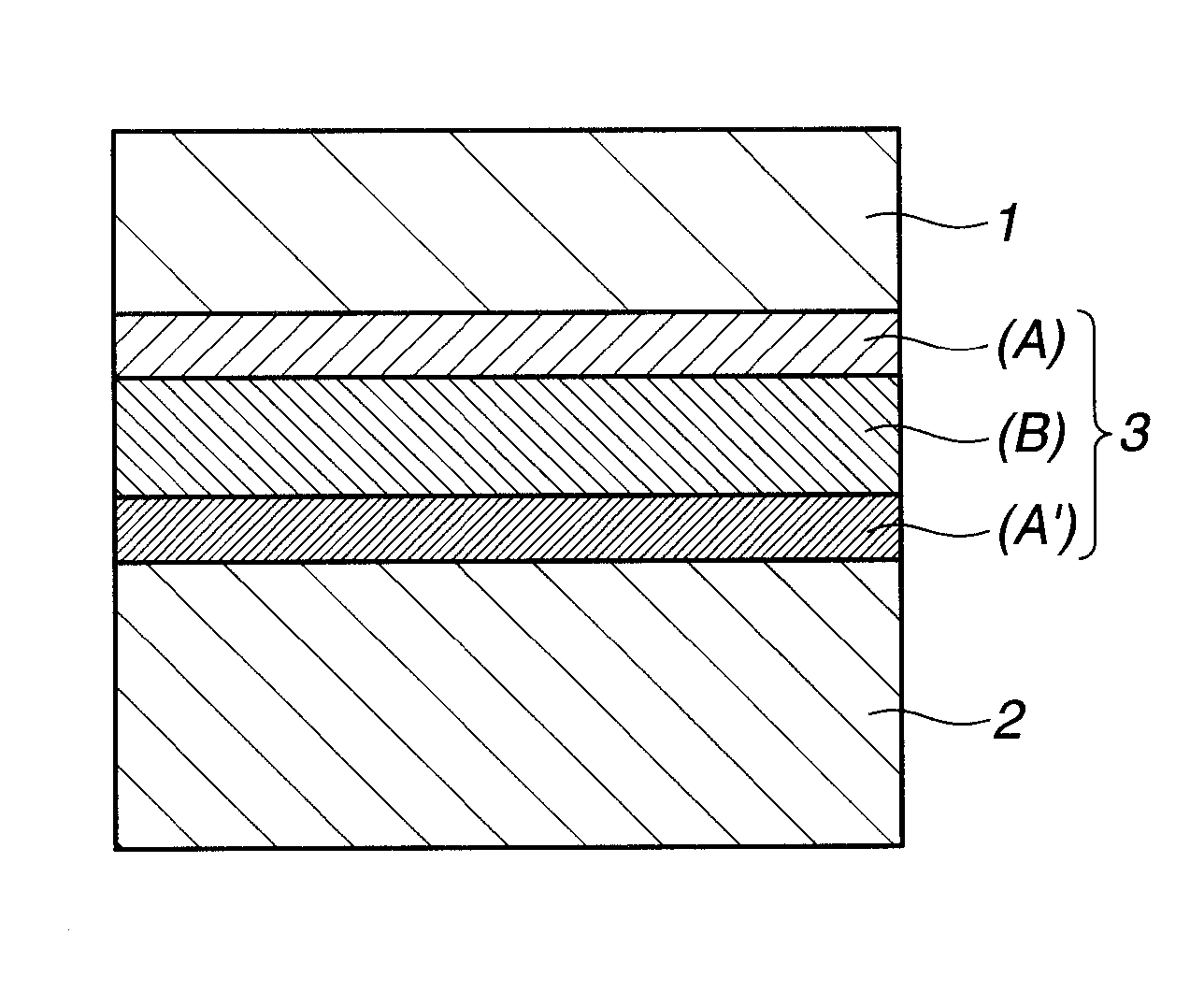

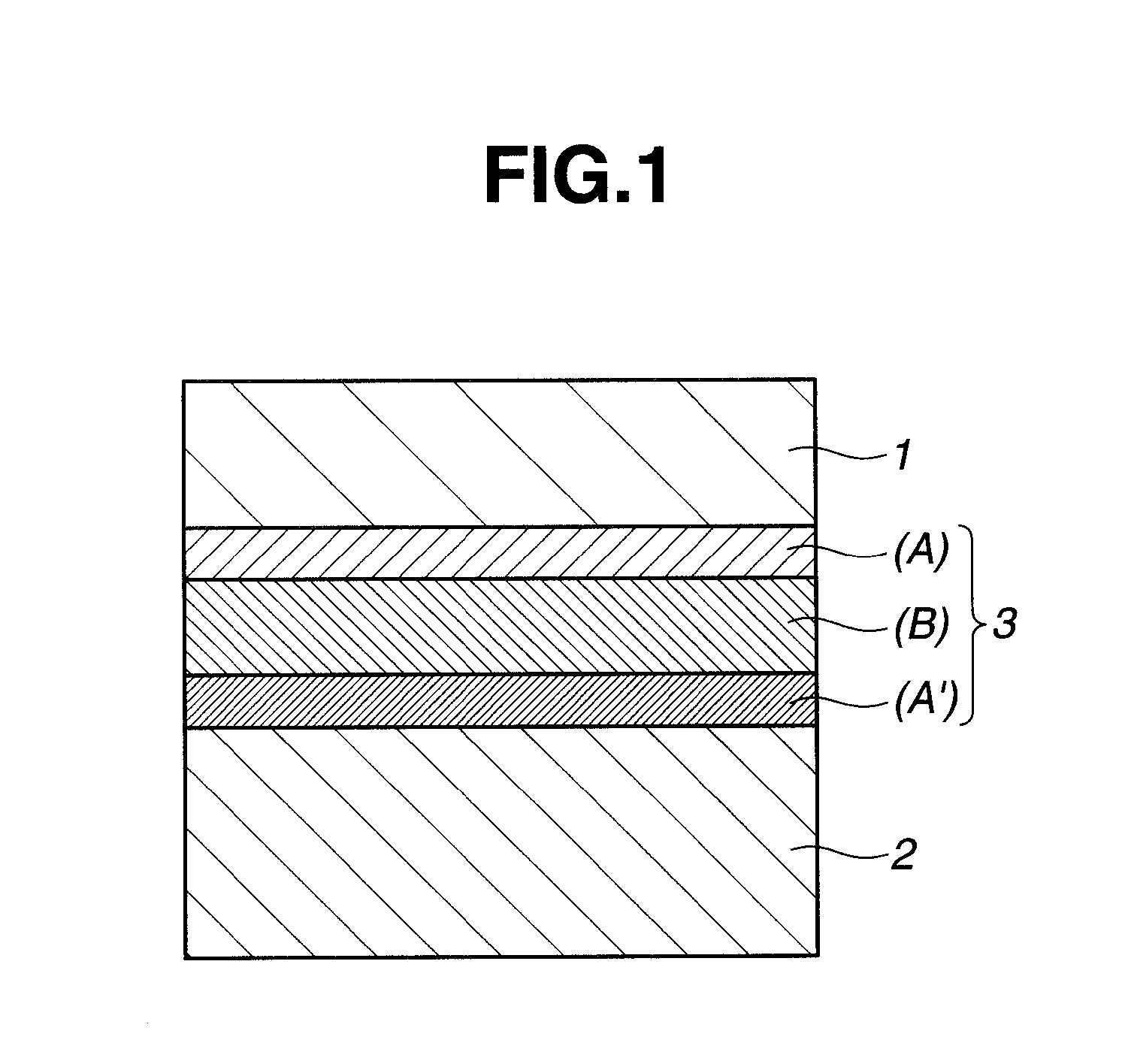

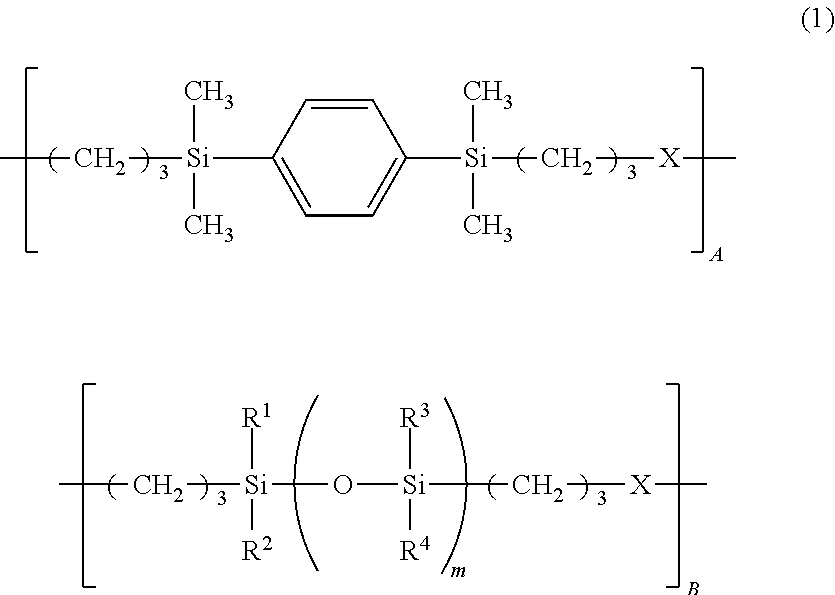

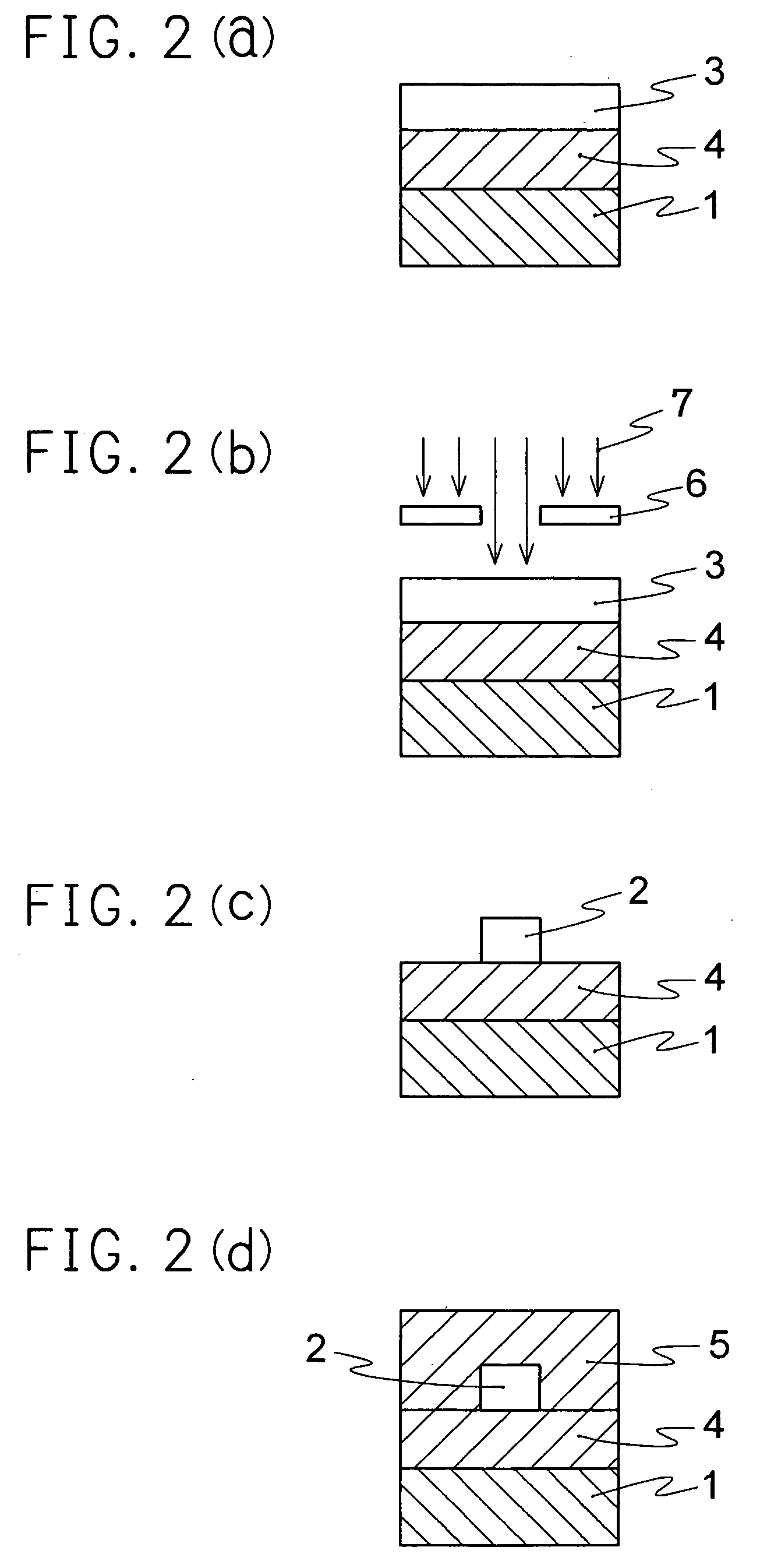

Wafer processing laminate, wafer processing member, temporary bonding arrangement, and thin wafer manufacturing method

ActiveUS20130108866A1Easy to manufactureEasy to disassembleLamination ancillary operationsFilm/foil adhesivesPolymer chemistrySiloxane

A wafer processing laminate is provided comprising a support, a temporary adhesive layer on the support, and a wafer laid on the temporary adhesive layer. The temporary adhesive layer has a trilayer structure consisting of a first bond layer (A) of thermoplastic organosiloxane polymer which is releasably bonded to the circuit-forming front surface of the wafer, a second bond layer (B) of thermosetting modified siloxane polymer which is laid on the first bond layer, and a third bond layer (A′) of thermoplastic organosiloxane polymer which is laid on the second bond layer and releasably bonded to the support.

Owner:SHIN ETSU CHEM IND CO LTD

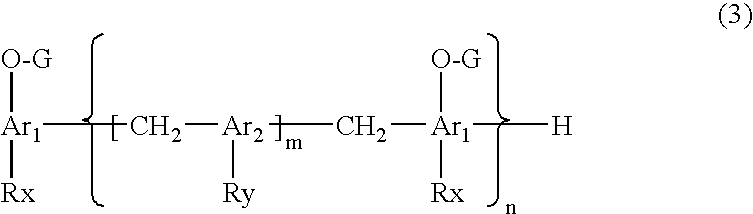

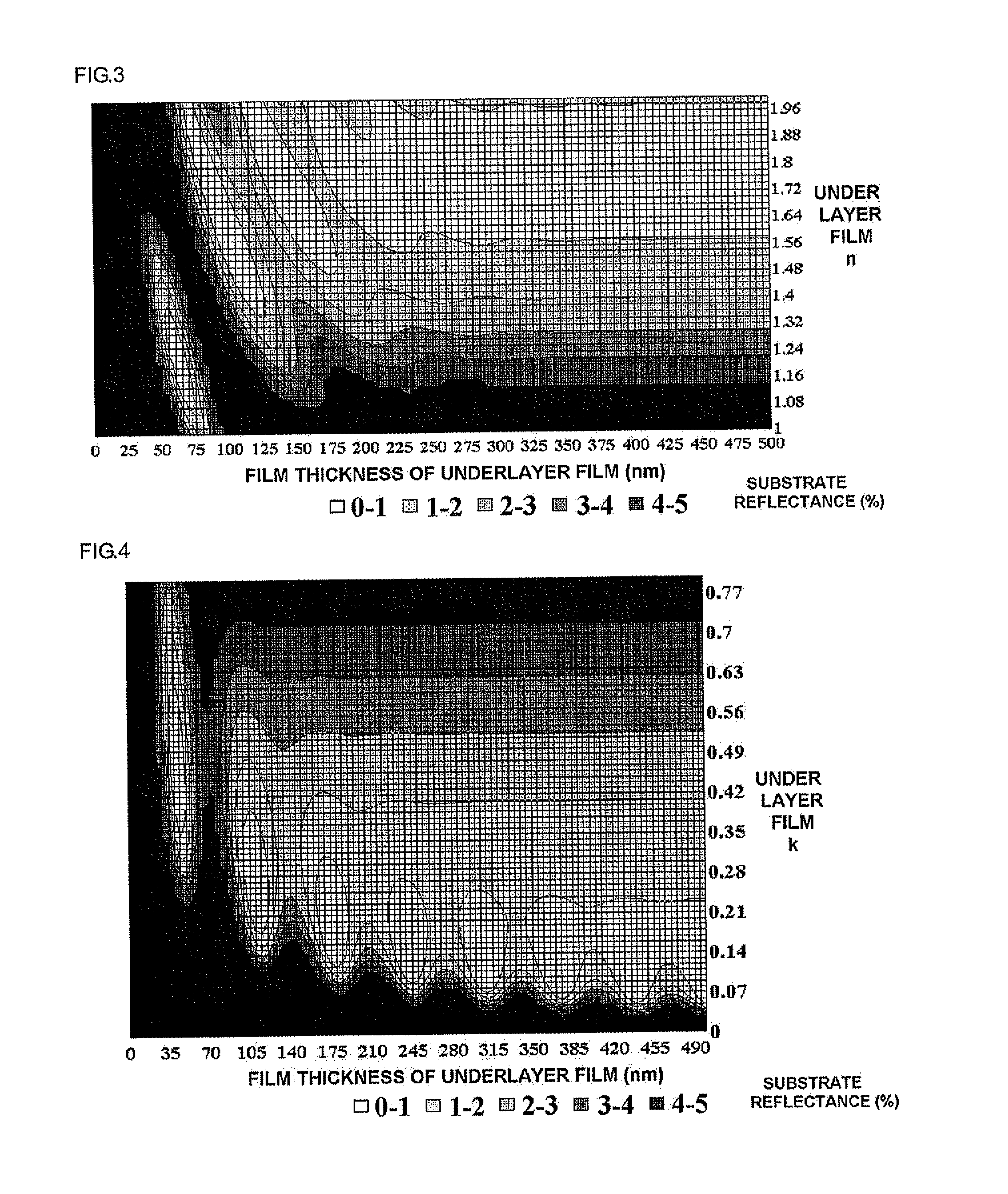

Carbazole novolak resin

ActiveUS20120077345A1Improve heat resistanceSuppress light reflectionSemiconductor/solid-state device manufacturingPhotosensitive material processingLithography processCarbazole

There is provided a resist underlayer film having heat resistance that is used for a lithography process in the production of semiconductor devices, and a high refractive index film having transparency that is used for an electronic device. A polymer comprising a unit structure of Formula (1):wherein each of R1, R2, R3, and R5 may be a hydrogen atom, R4 may be phenyl group or naphthyl group. A resist underlayer film forming composition comprising the polymer, and a resist underlayer film formed from the composition. A high refractive index film forming composition comprising the polymer, and a high refractive index film formed from the composition.

Owner:NISSAN CHEM IND LTD

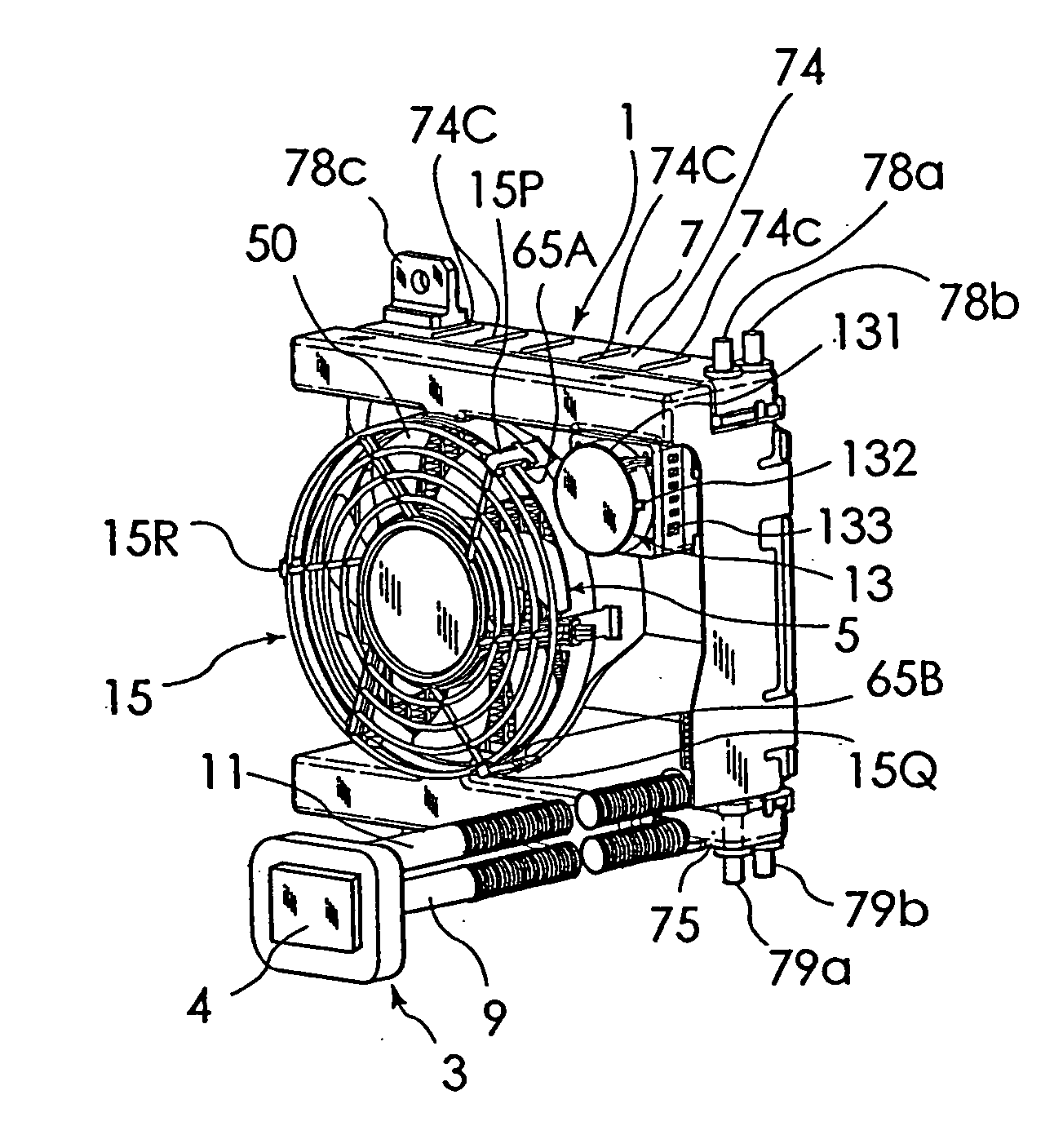

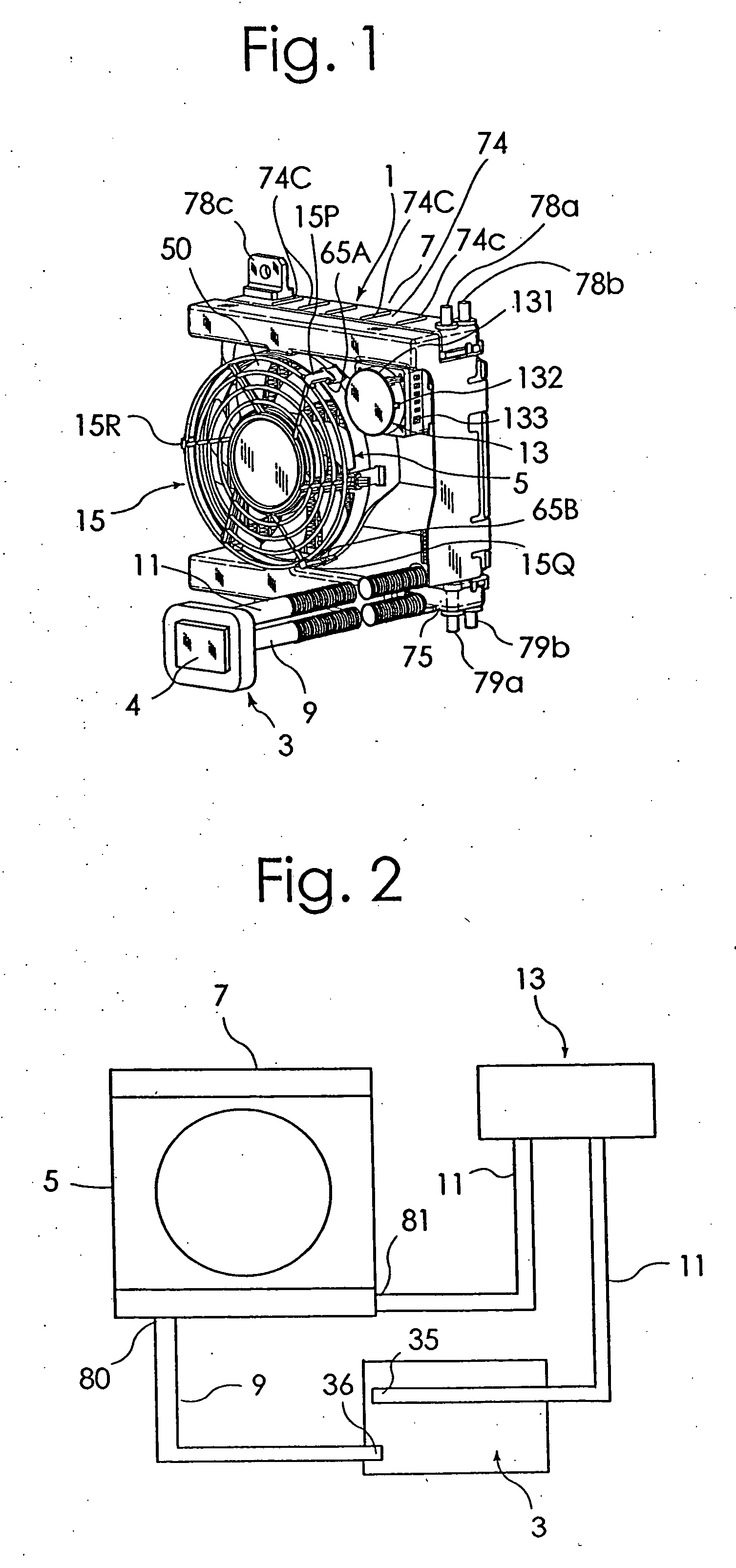

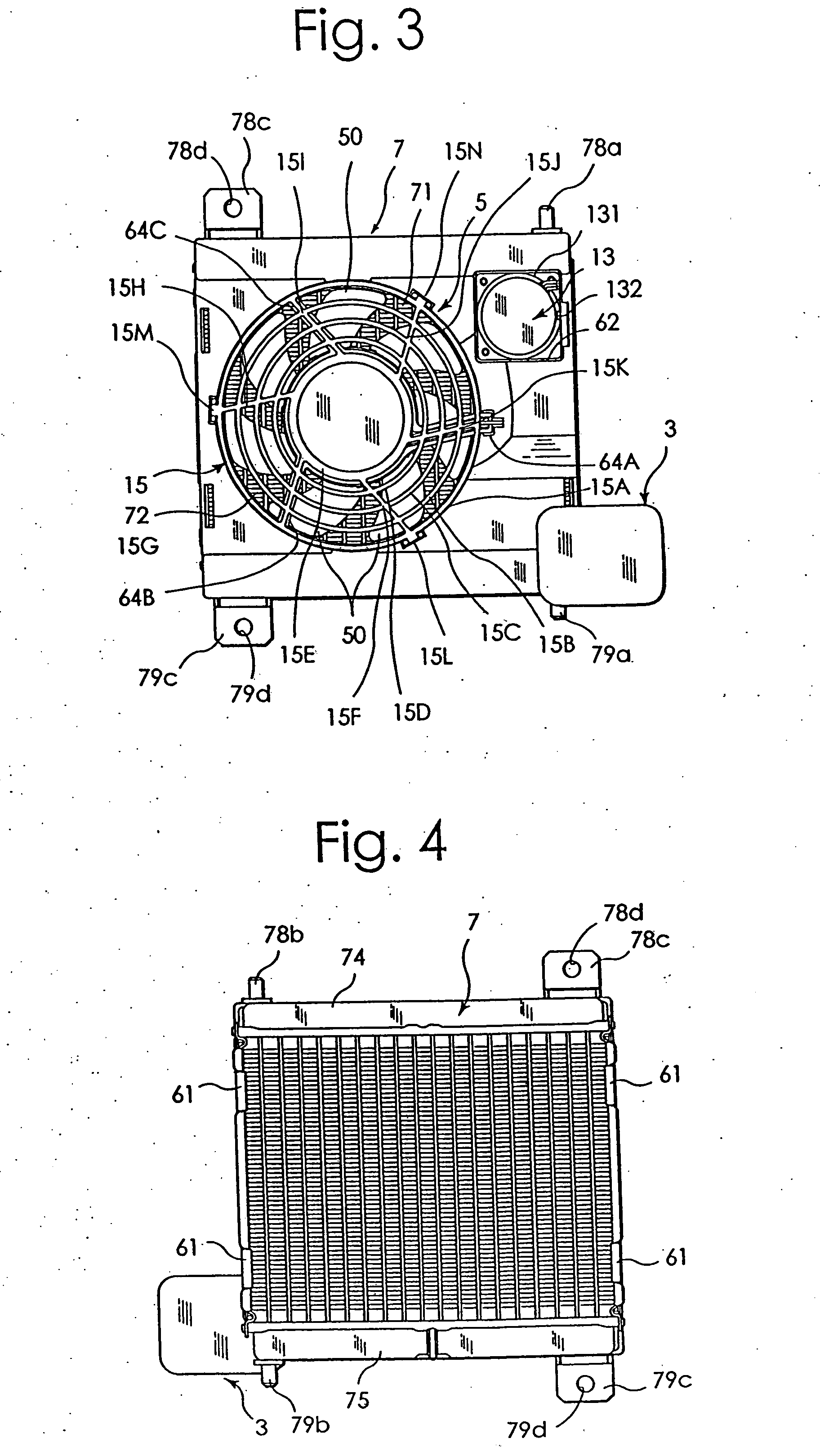

Electronic component cooling apparatus

ActiveUS20050168939A1Not to damageHigh mechanical strengthDomestic cooling apparatusDigital data processing detailsNuclear engineeringElectronic component

A small water-cooling type electronic component cooling apparatus is provided. The electronic component cooling apparatus comprises a so-called water-cooling heat sink 3 , a radiator 7 cooled by an electric fan 5 , first and second coolant paths 9, 11 for circulating a coolant between the heat sink 3 and the radiator 7 , and an electric pump 13 to supply a moving energy to the coolant. The electric pump 13 is arranged at a position facing the heat-radiating portion of the radiator 7.

Owner:SANYO DENKI CO LTD +1

Liquid crystalline polyester composition

InactiveUS7824572B2High heat resistanceReduce anisotropyLiquid crystal compositionsSynthetic resin layered productsPolyesterLiquid crystalline

The present invention provides a liquid crystalline polyester composition comprising a terphenyl and a liquid crystalline polyester, wherein the terphenyl substantially consists of p-terphenyl, and the p-terphenyl is contained in the composition in the amount of 0.3 to 15 parts by weight on the basis of 100 parts by weight of the liquid crystalline polyester. The liquid crystalline polyester composition has high flowability and low anisotropy, which can also suppress generation of gases when molded.

Owner:SUMITOMO CHEM CO LTD

Electroplating PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

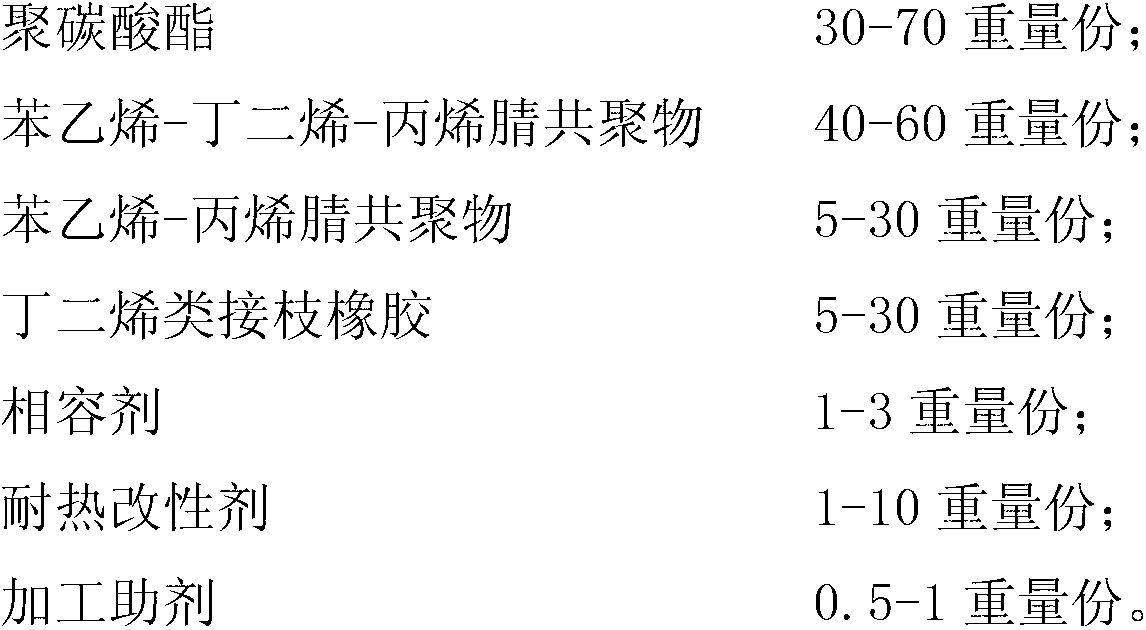

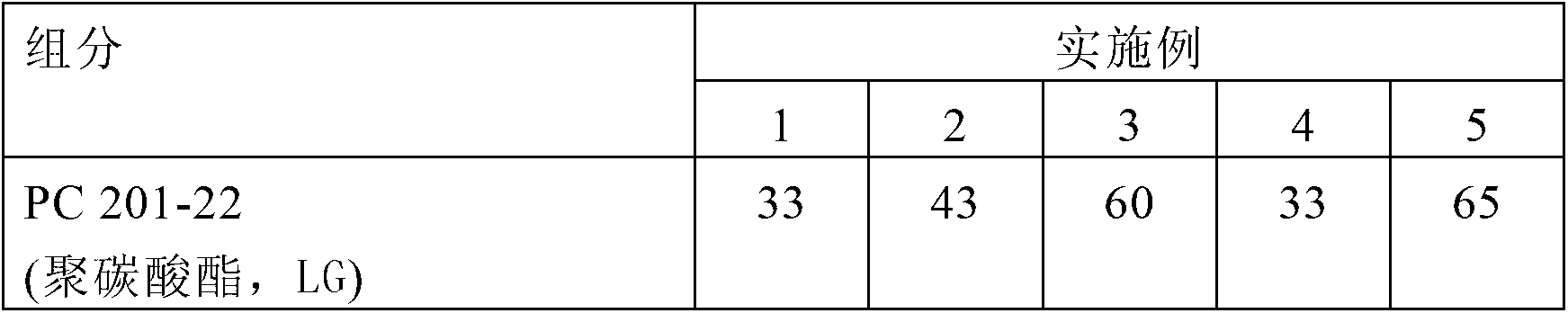

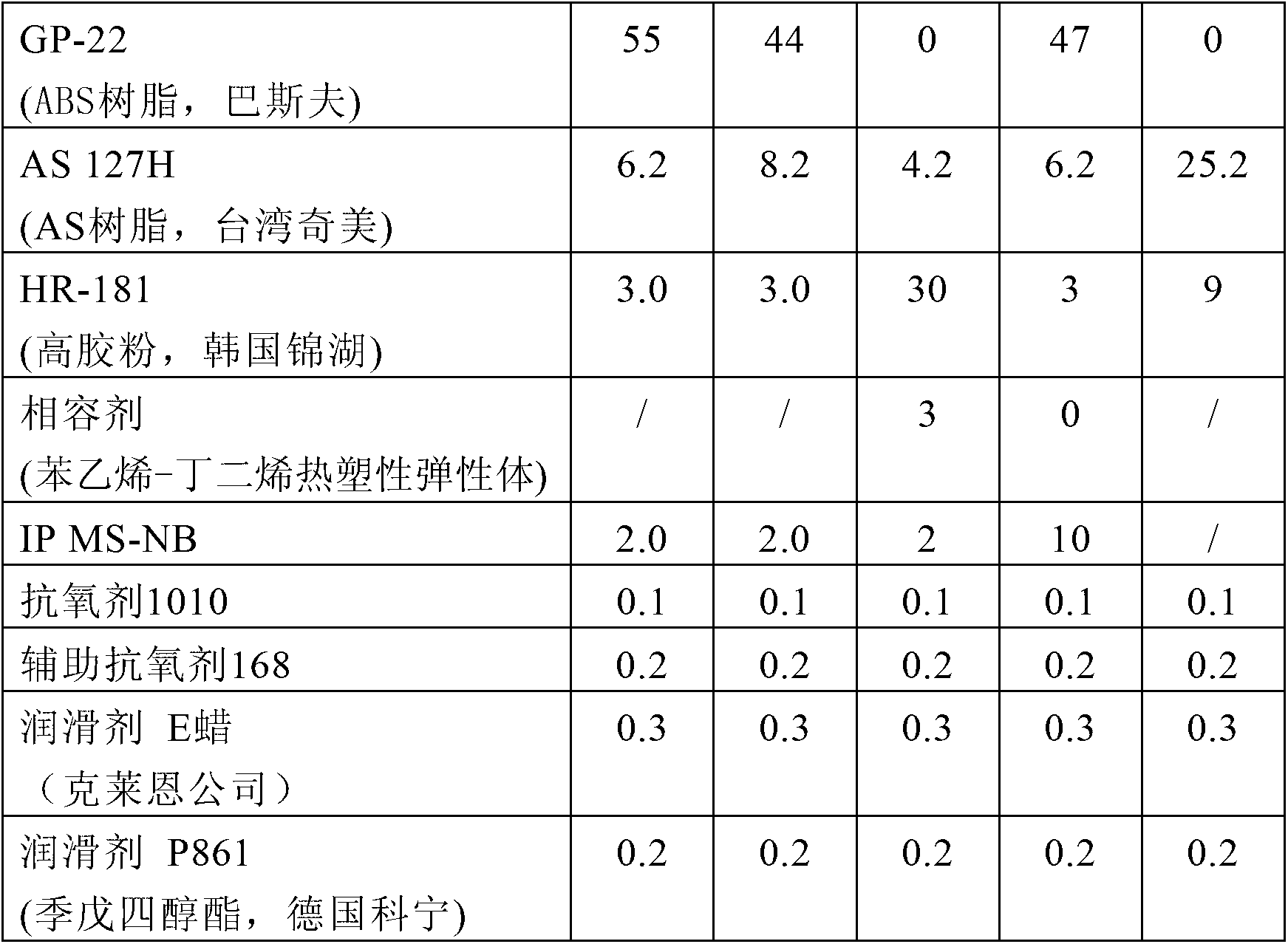

The invention provides an electroplating PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy material and a preparation method thereof. The electroplating PC / ABS alloy material comprises the following components in parts by weight: 30-70 parts of PC, 40-60 parts of ABS, 5-30 parts of styrene-acrylonitrile copolymer, 5-30 parts of butadiene graft rubber, 1-3 parts of compatilizer, 1-10 parts of heat-resistance modifier and 0.5-1 part of processing assistant. The alloy material provided by the invention has the advantages of favorable electroplating properties, excellent mechanical properties and favorable heat resistance, and can be used for designing automobile internal and external ornaments, including heat dissipation grids, door grips, vehicle logos, instrument panel decorating strips and the like.

Owner:中广核俊尔(上海)新材料有限公司

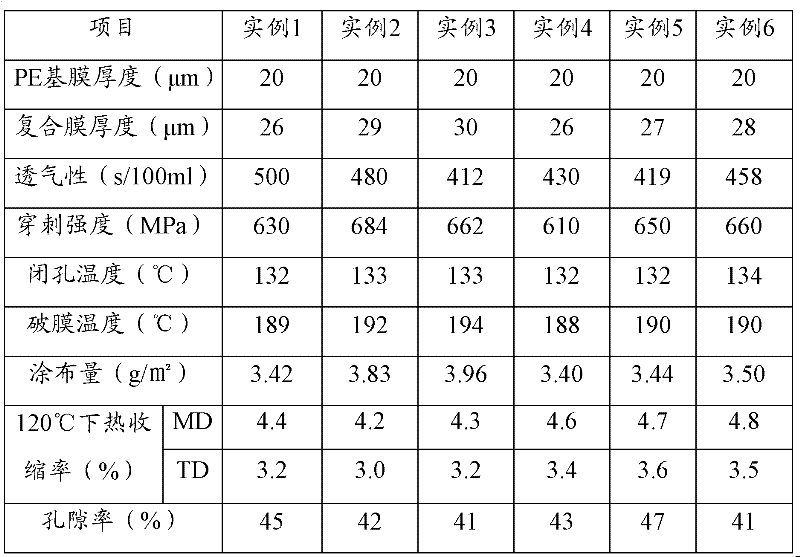

Lithium ion secondary battery porous multilayer diaphragm and manufacture method thereof

ActiveCN102394282AImprove heat resistanceHigh porosityCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPolyolefinHeat resistance

The invention relates to the technical field of lithium ion battery and specifically relates to a lithium ion secondary battery porous multilayer diaphragm and a manufacture method thereof. The porous multilayer diaphragm comprises a polyolefin porous membrane and at least one layer of heatproof coating layer coated on the polyolefin porous membrane; the heatproof coating layer comprises heatproof resin and inorganic insulating particles in a mass ratio of 1:0.5-5. The porous multilayer diaphragm prepared by steps of preparing coating liquid, coating, stretching and fixing has excellent heat resistance; the heatproof coating is also a film with micropore structure and enough high amount of porosity and heat resistance temperature; even a microporous base film is fused and ruptured, the coating can still maintain integrity thereof and obstruct direct contact of cell electrodes, so as to guarantee cell safety; the heatproof coating layer communicates with micropores of the microporous film of the matrix film layer to guarantee permeation performance of lithium ions.

Owner:河南惠强新能源材料科技股份有限公司

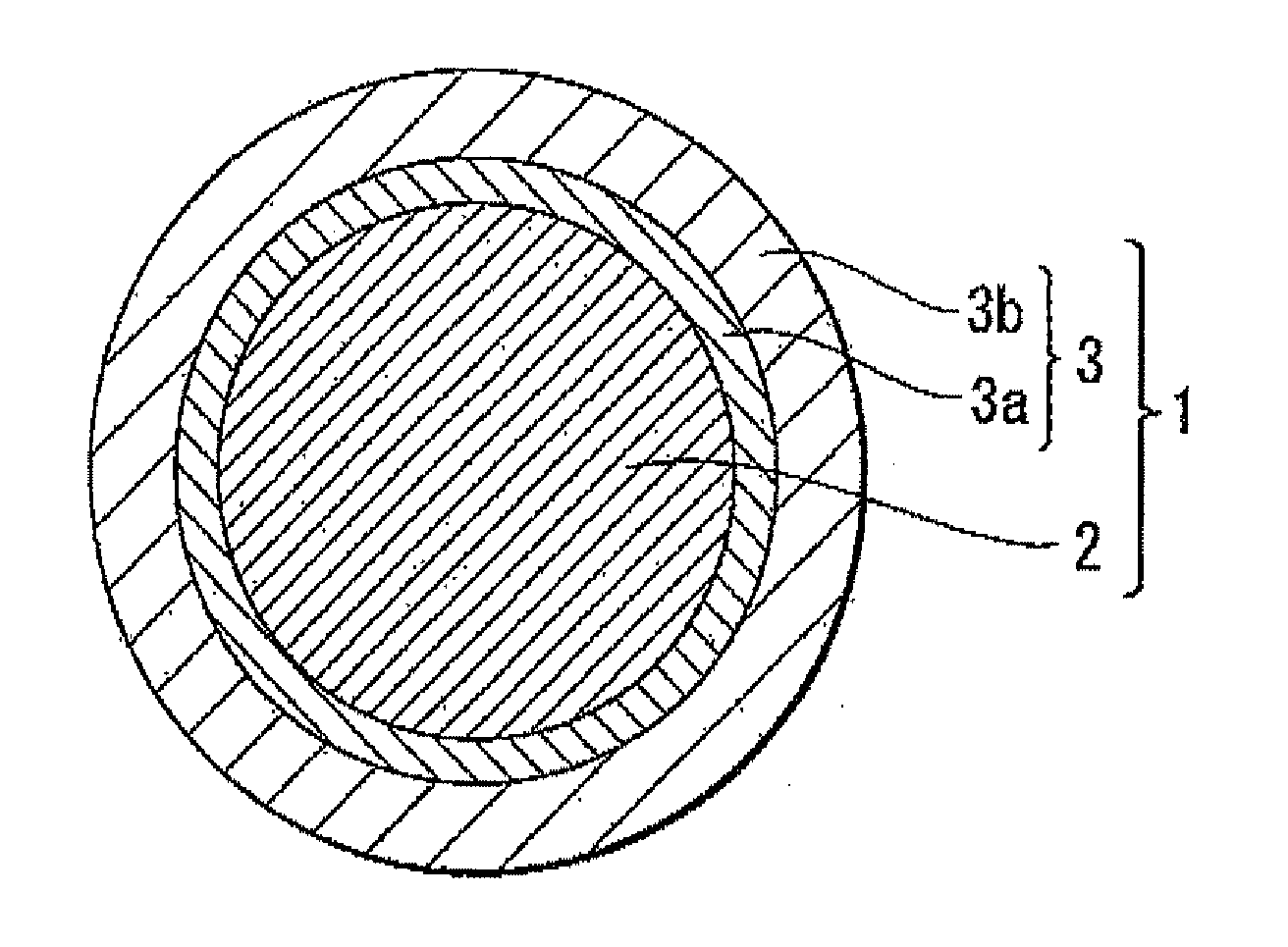

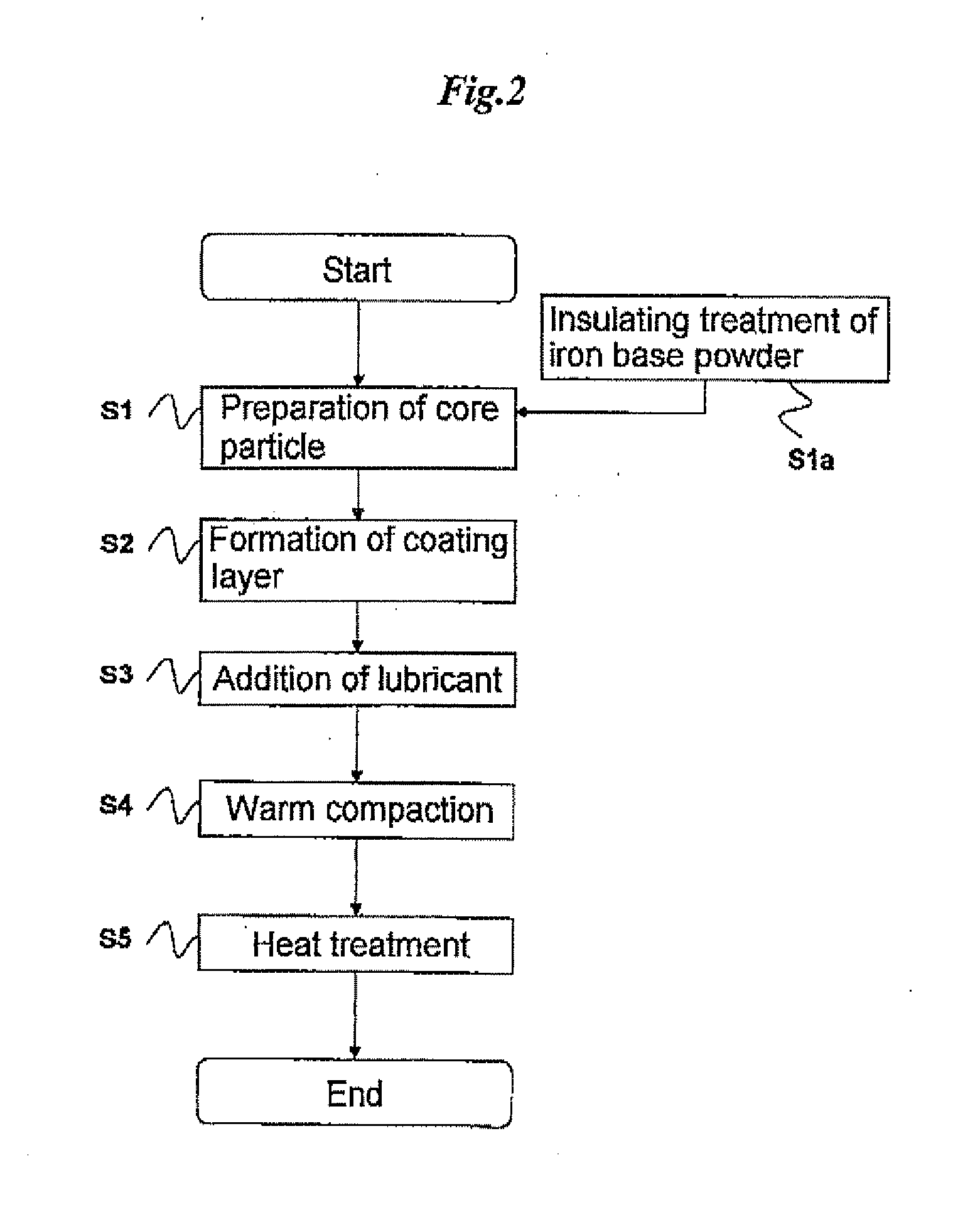

Powder magnetic core

ActiveUS20120082844A1High performanceHigh heat resistanceSynthetic resin layered productsMetal-working apparatusBrown iron oxideMagnetic core

A powder magnetic core having a high electrical resistivity and a high magnetic flux density, including at least a composite magnetic particle the composite magnetic particle including: a core particle containing iron as the main component; and an insulating passivation layer formed on the core particle, wherein: the insulating passivation layer at least has an inner layer formed on the core particle and the outermost layer formed on the inner layer; and the outermost layer contains iron oxide as the main component.

Owner:TDK CORPARATION

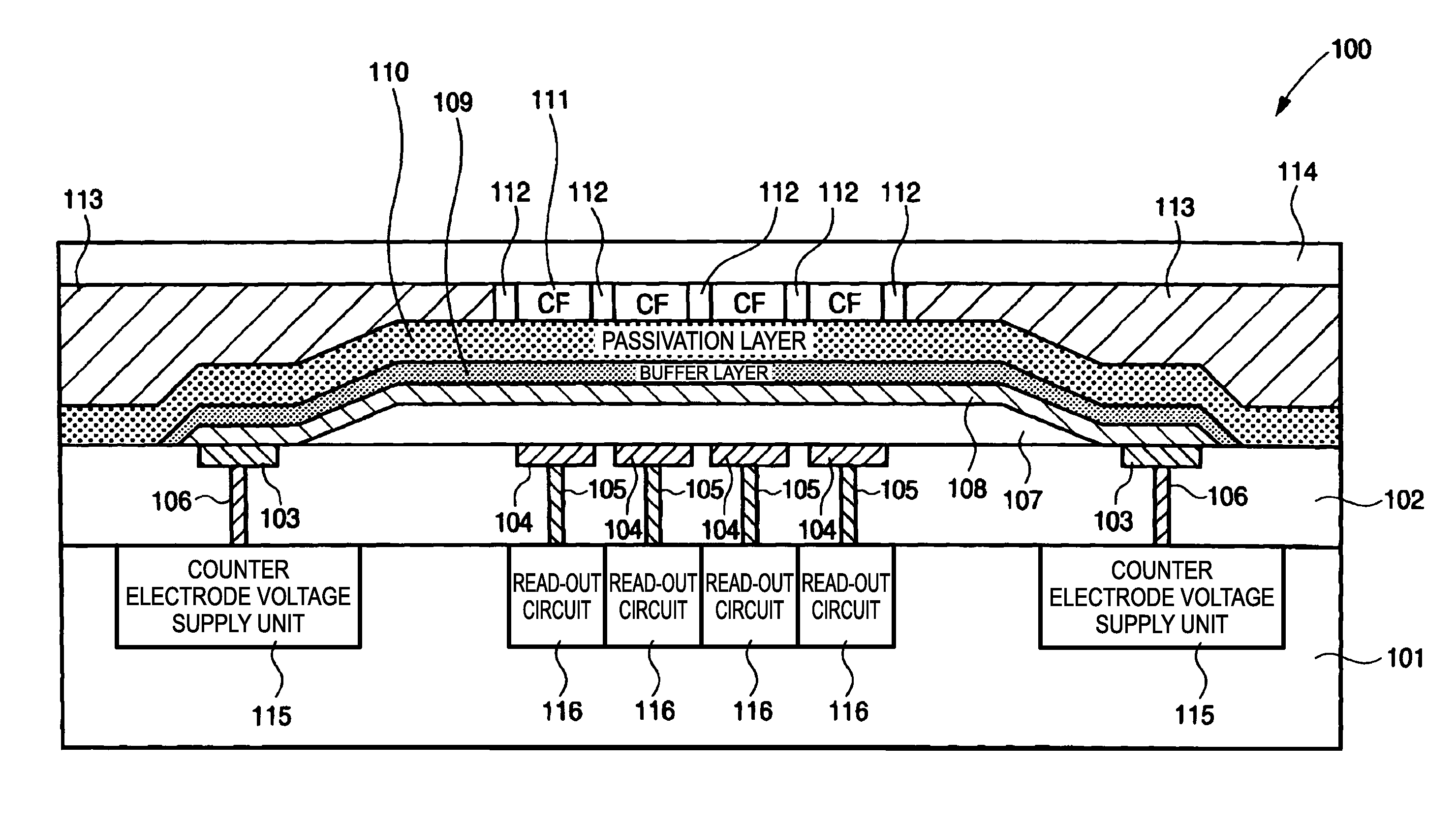

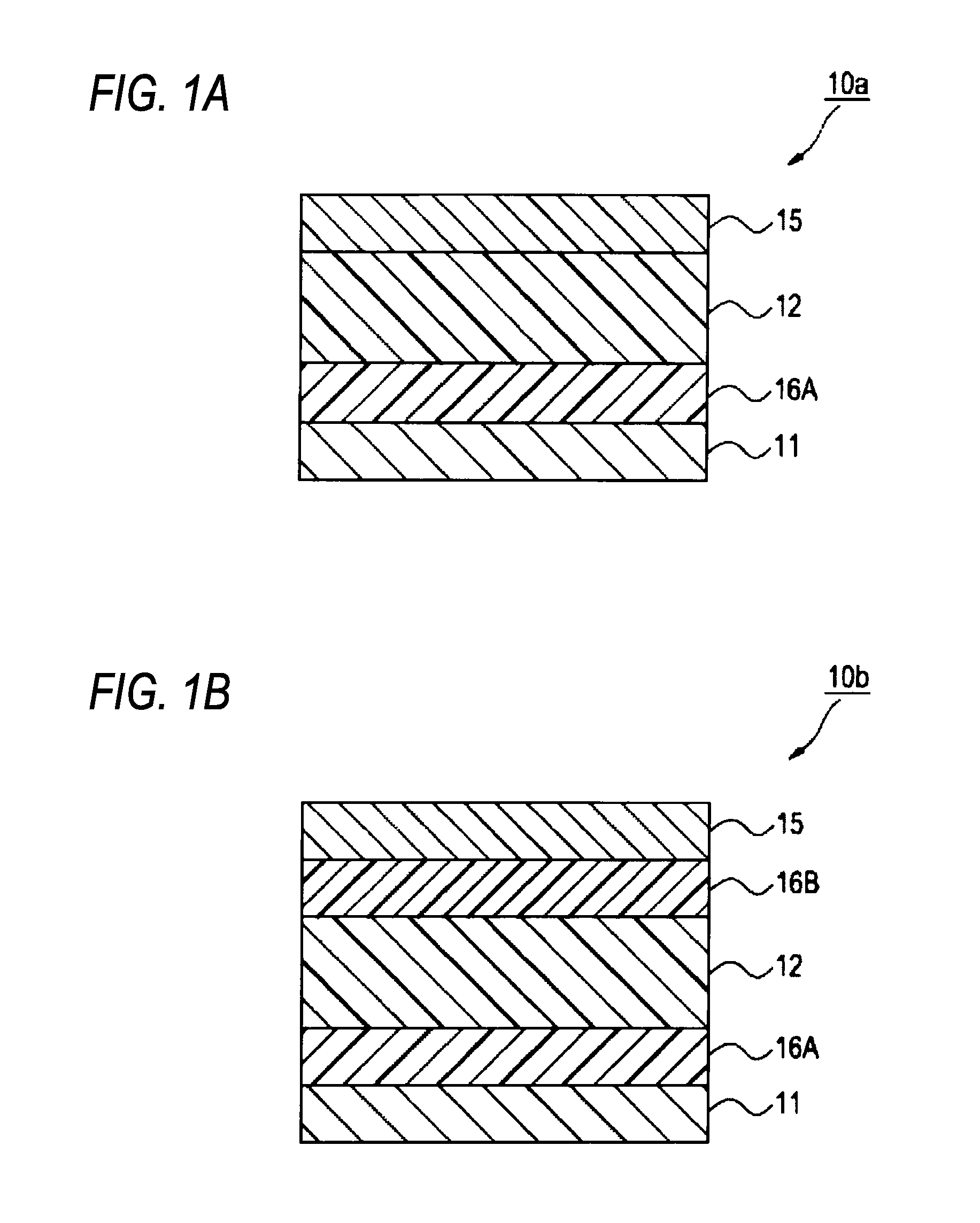

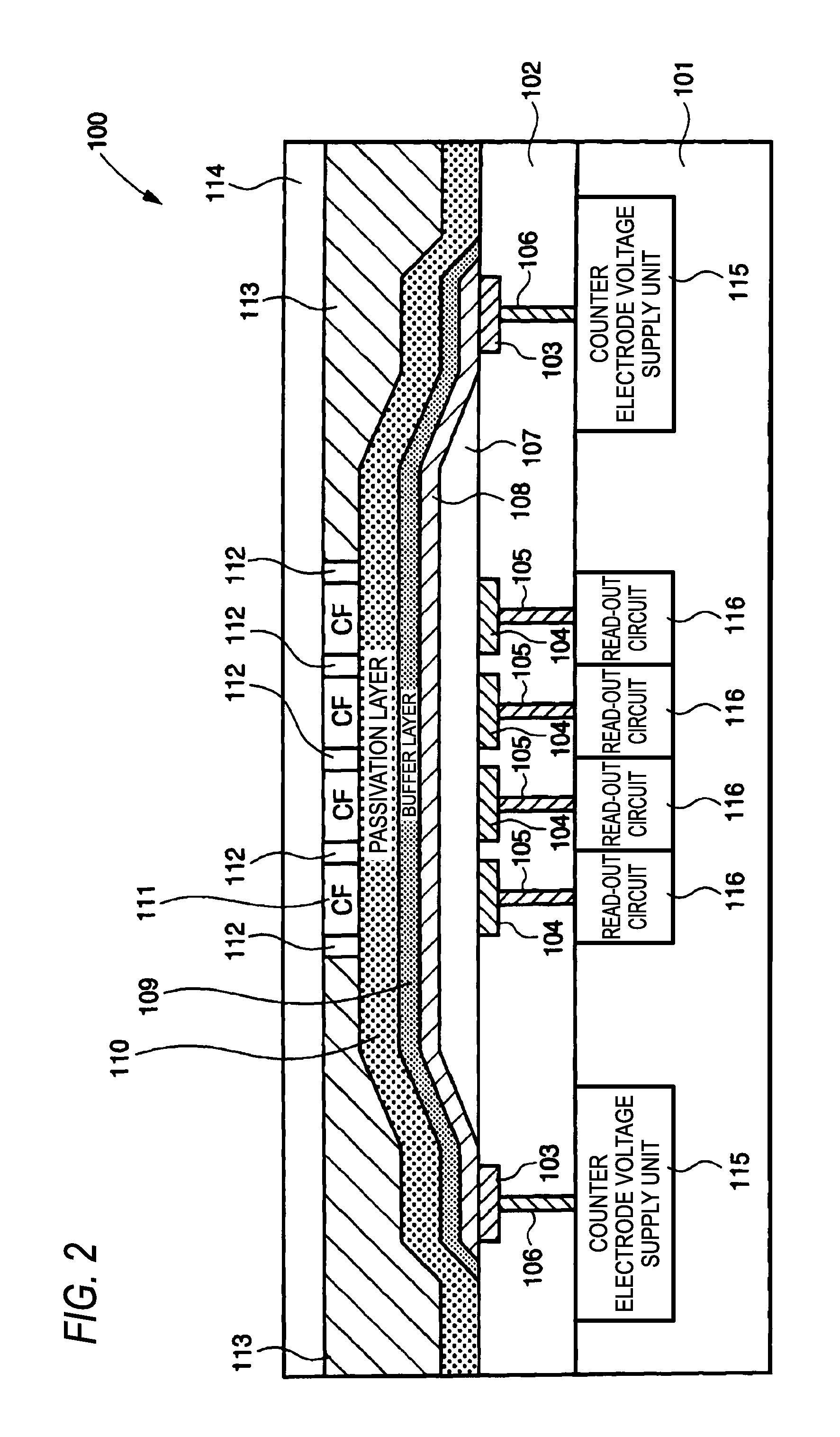

Photoelectric conversion material, film containing the material, photoelectric conversion device, method for preparing photoelectric conversion device, method for using photoelectric conversion device, photosensor and imaging device

ActiveUS20130181202A1Improve collection efficiencyHigh speed response propertyOrganic chemistryMethine/polymethine dyesDeposition temperatureExtinction

There is provided a compound represented by a specific formula, which has an absorption maximum at 400 nm or more and less than 720 nm in a UV-visible absorption spectrum, wherein a molar extinction coefficient is 10,000 mol−1·l·cm−1 or more at the absorption maximum wavelength, and a difference between a melting point and a deposition temperature (a melting point−a deposition temperature) is 31° C. or more.

Owner:FUJIFILM CORP

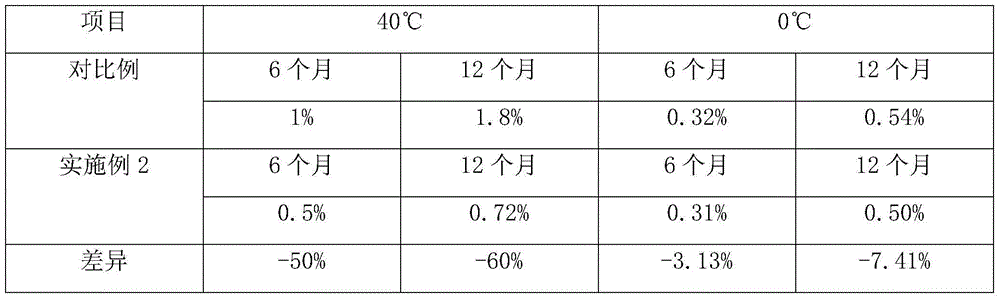

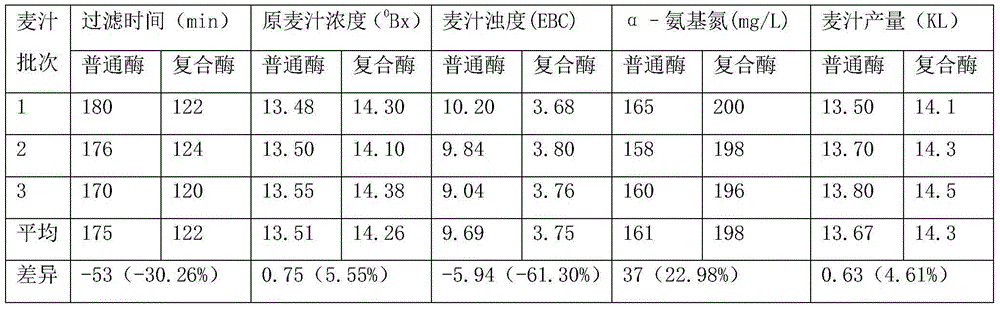

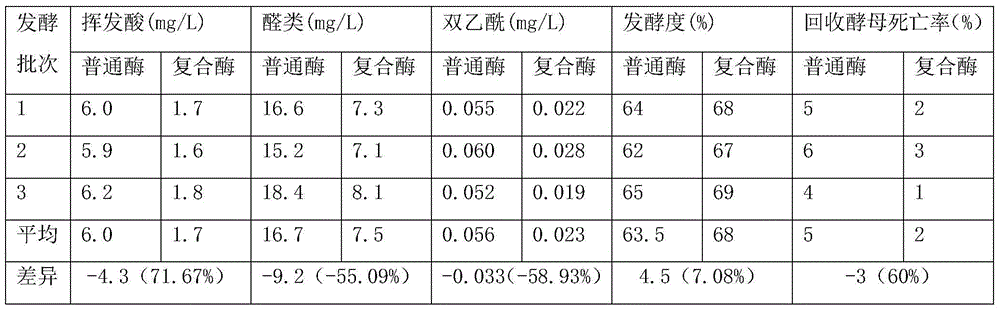

Fungal alpha-amylase-containing beer complex enzyme and preparation method thereof

ActiveCN104651335AEnsure food safetyIncrease profitOxidoreductasesGlycosylasesAntioxidantAlpha-amylase

The invention discloses a fungal alpha-amylase-containing beer complex enzyme and a preparation method thereof, belonging to the field of enzyme preparation processing. The high-activity fungal alpha-amylase and other food grade enzyme preparations, plant extracts, antioxidants, protective agents, activating agents and the like can be scientifically compounded by taking concentrated maltase and concentrated malt juice powder as main raw materials; the prepared beer complex enzyme is complete in proteases, high in enzyme activity, difficult to deactivate, mellow in malt aroma, and capable of providing abundant nitrogen source for malt juice, wherein the activity of fungal alpha-amylase in fermenting liquor during the preparation of fungal alpha-amylase is 17000-21000 U / mL. The complex enzyme can be stored for 12 months under the conditions of 0DEG C and 40DEG C, the single enzyme activity loss in the complex enzyme are respectively 0.50% and 0.72%, the enzyme deactivation caused by environment change, and inappropriate operation methods during packaging, storage, transportation, use and the like can be effectively prevented, especially the enzyme deactivation caused by high temperature can be prevented.

Owner:湖南新鸿鹰生物工程有限公司

Low-smoke bittern-free highly fire-proof elastic polyolefin electric cable material

InactiveCN101041731AGood flexibilityIncrease elasticityInsulated cablesInsulated conductorsBenzenePolyolefin

The invention discloses a low-smoke non-halogen high-flameproof elastic polyolefin wire and cable plastic, which comprises the following parts: 40-80% EVA elastics (ethene-vinyl acetate copolymer), 20-50% POE elastics (ethene-hexaethene copolymer), 5-15% EMA elastics (ethene-methyl acrylate copolymer), 30-70% magnesium hydroxide or aluminium hydroxide, 20-40% nanometer magnesium hydroxide, 0.1-0.6% DCP (peroxide diisopropyl benzene), wherein the hardness is not more than 85 A with strength not less than 9.0Mpa and extending rate not less than 150%; the flameproof property reaches UL1581 VW-1, which is excellent flexible macromolecular mixing material.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

Wood-plastic composite material and preparation method thereof

The invention belongs to the field of high-molecular material modified technology, and discloses a wood-plastic composite material and a preparation method thereof. The wood-plastic composite material is prepared by the following components of, by weight, 40-75 parts of a plastic substrate, 20-50 parts of wood powder and 5-10 parts of auxiliary agents. The preparation method of the wood-plastic composite material comprises the following steps of (1) mixing 20-50 parts of the wood powder, 40-75 parts of the plastic substrate and 5-10 parts of the auxiliary agents which are treated by silanization adequately, for 10-60 min; (2) extruding and granulating the uniform mixture obtained from the step (1) by using a double screw extruder, forming by introducing the obtained materials into an injection machine or flat-panel vulcanizing machine, or forming by introducing the uniform mixture obtained from the step (1) into the flat-panel vulcanizing machine. An inorganic layer is formed on the surface of the wood powder, thereby facilitating improving the interface bonding property between the inorganic layer and the plastic matrix, increasing heat resistant temperature of the wood powder and allowing the wood powder not to be decomposed in a processing process.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

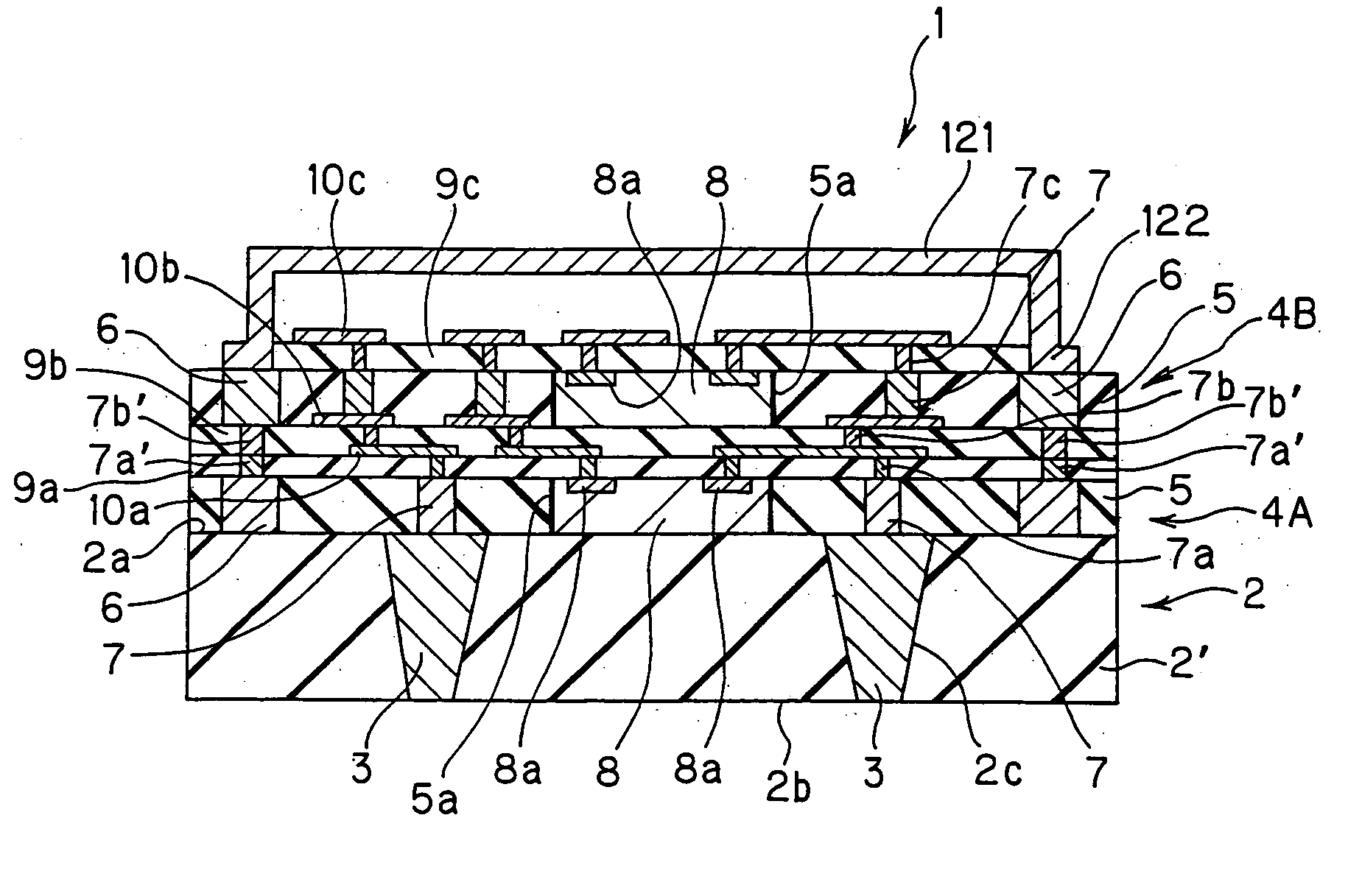

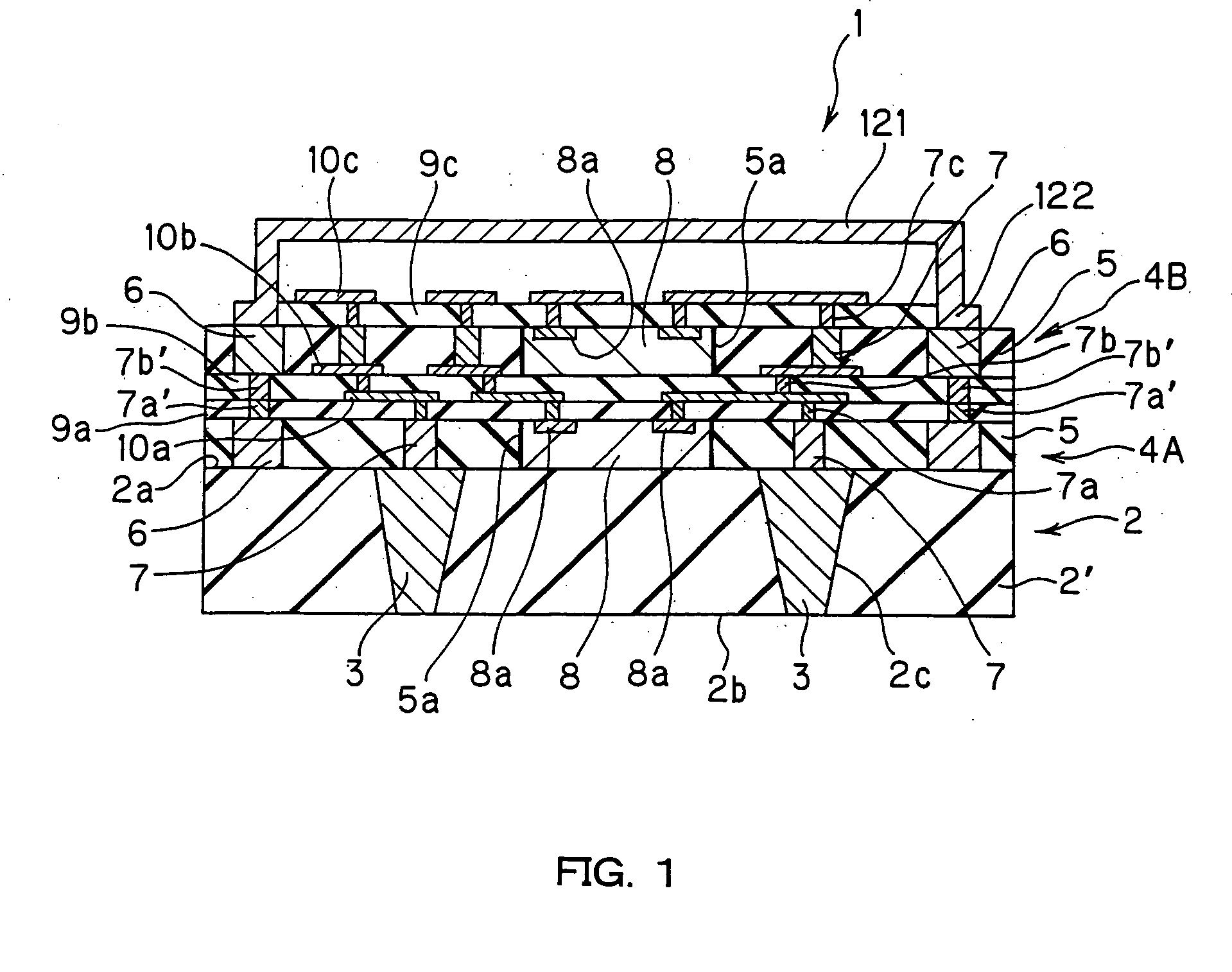

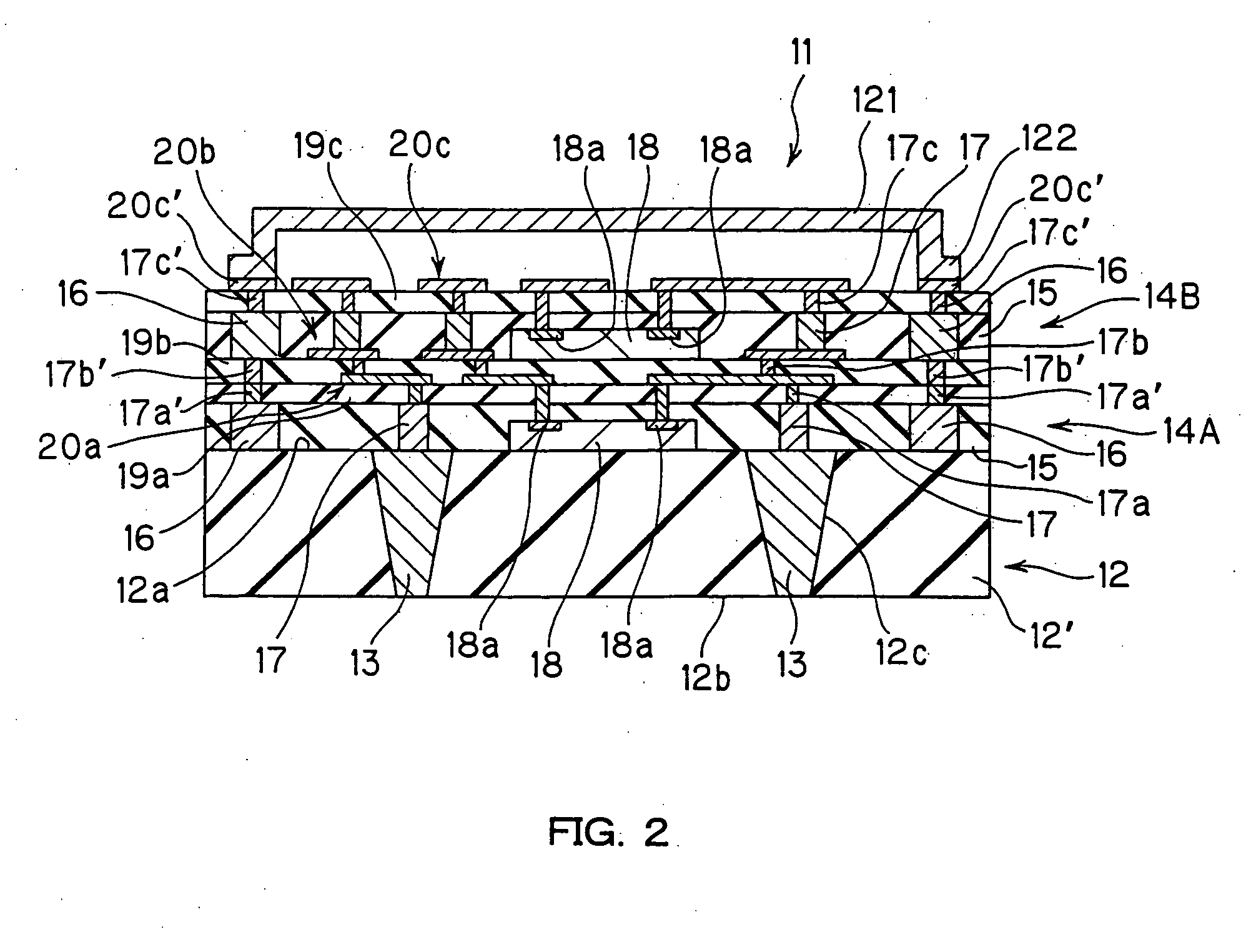

Electronic device and production method thereof

InactiveUS20050157477A1Reduce sizeHigh heat resistanceSemiconductor/solid-state device detailsSolid-state devicesFlangeHigh density

An object is to provide an electronic device of a multilayer structure with high density and high reliability that can be reduced in size while incorporating an electronic component therein, and further provide a production method for easily producing such an electronic device. An electronic device of the present invention includes wiring layers and electrically insulating layers stacked on a core board and establishes predetermined electrical conduction between the wiring layers through upper-lower side conducting vias provided in the electrically insulating layers. An electronic component incorporating layer formed by directly forming on a lower layer an insulating resin layer having a cutout portion for receiving an electronic component therein and upper-lower side conducting vias and by incorporating the electronic component in the cutout portion is provided at least between one of the wiring layers and one of the electrically insulating layers and / or between the core board and the electrically insulating layer. At least the uppermost-layer electronic component incorporating layer of electronic component incorporating layers has a metal frame body surrounding the electronic component and the upper-lower side conducting vias, and a metal cap having a flange portion fixed to the metal frame body of the uppermost-layer electronic component incorporating layer is provided.

Owner:DAI NIPPON PRINTING CO LTD

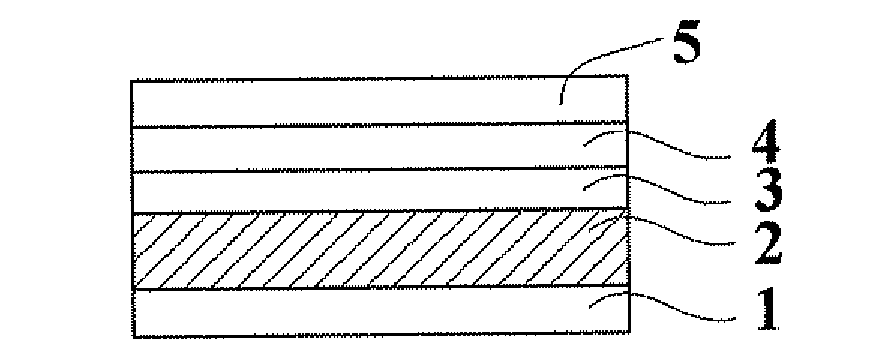

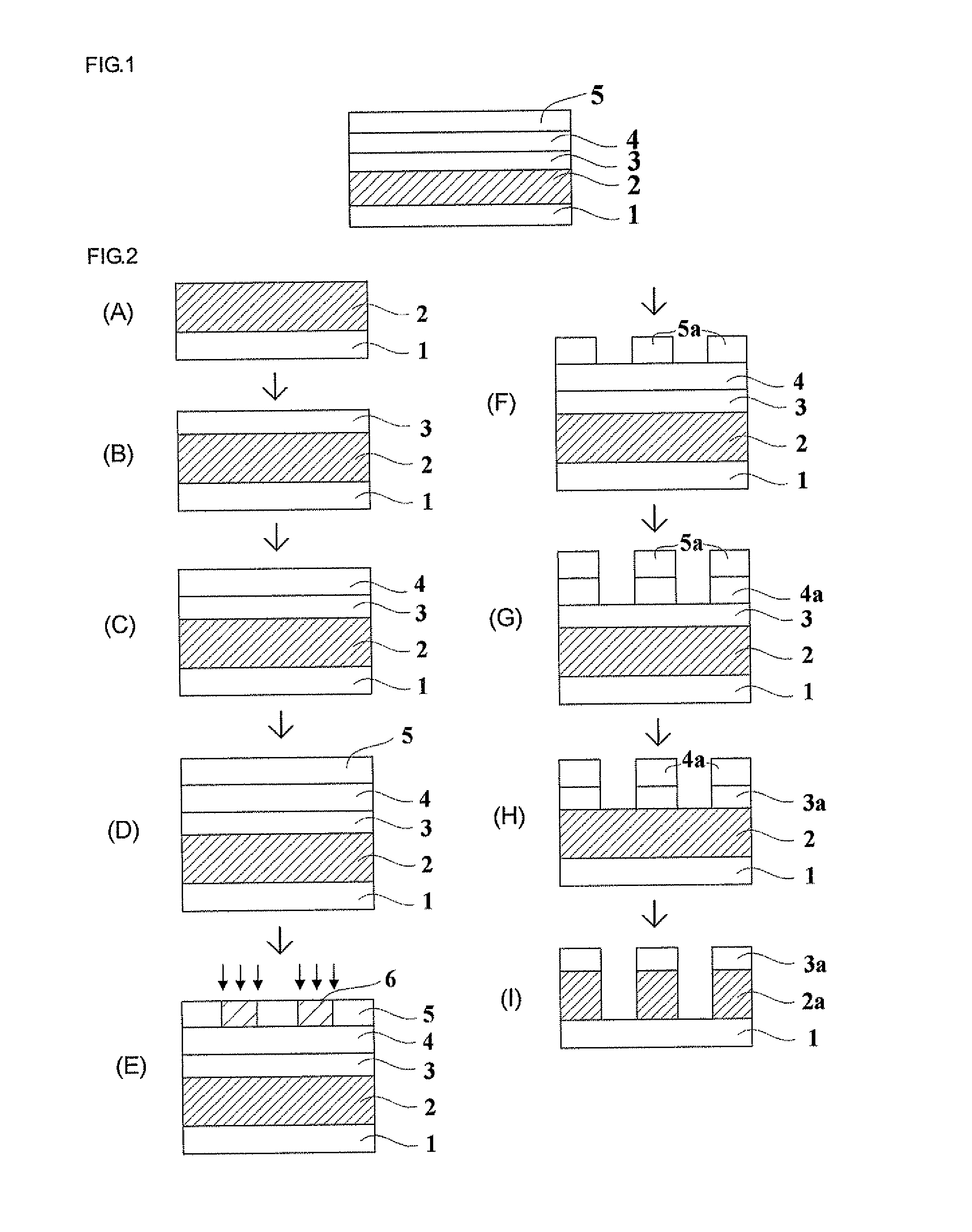

Resist underlayer film composition and patterning process using the same

ActiveUS20130087529A1Reduce reflectivityExcellent etch resistanceOrganic chemistryDecorative surface effectsResistHeat resistance

There is disclosed A resist underlayer film composition, the resist underlayer film composition contains a truxene compound having a substituted or an unsubstituted naphthol group as shown by the following general formula (1). There can be provided a resist underlayer film composition to form a resist underlayer film being capable of reducing reflectance and having high etching resistance, heat resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Retardation film based on optically aligned liquid crystalline polyimide and optical device

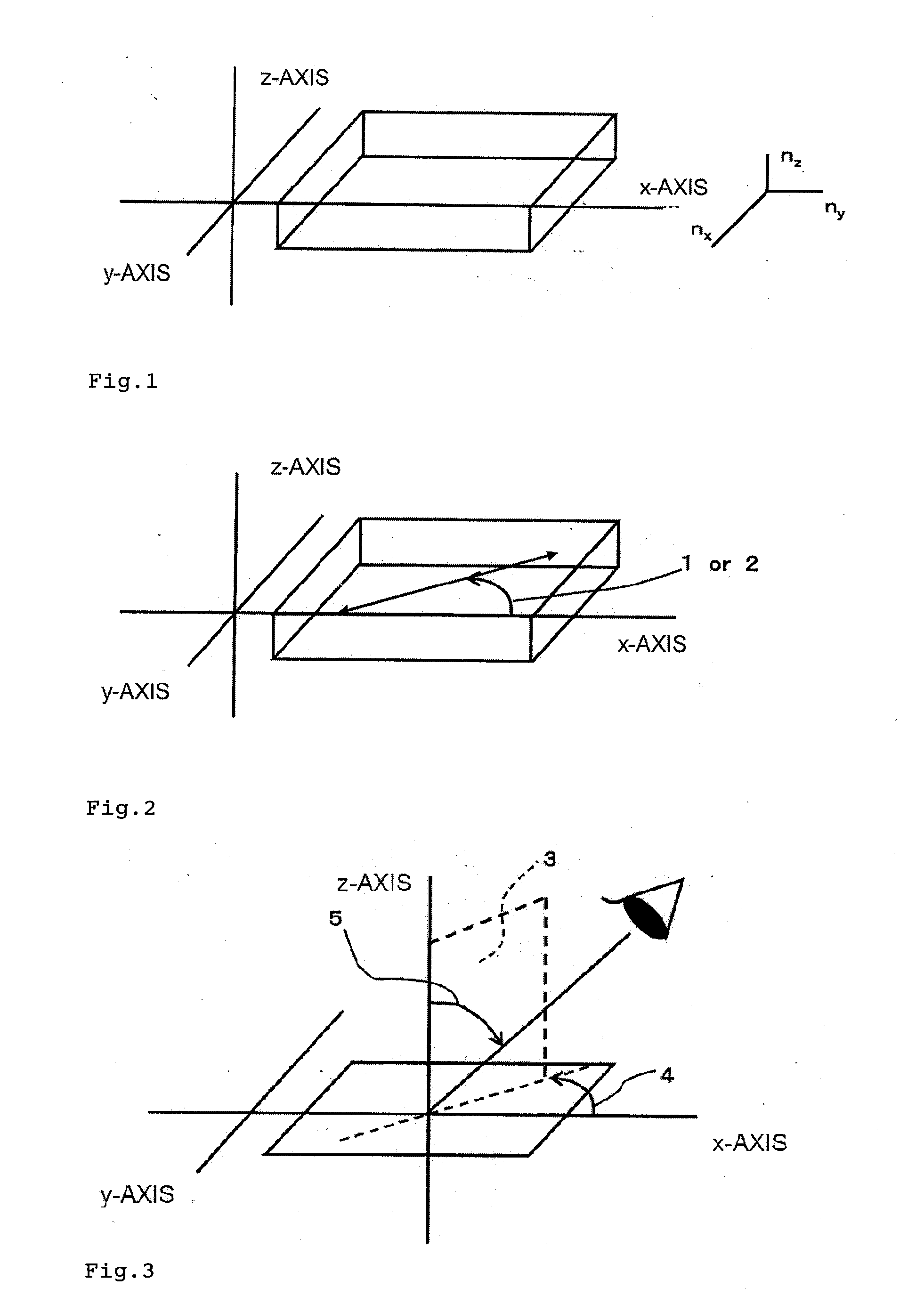

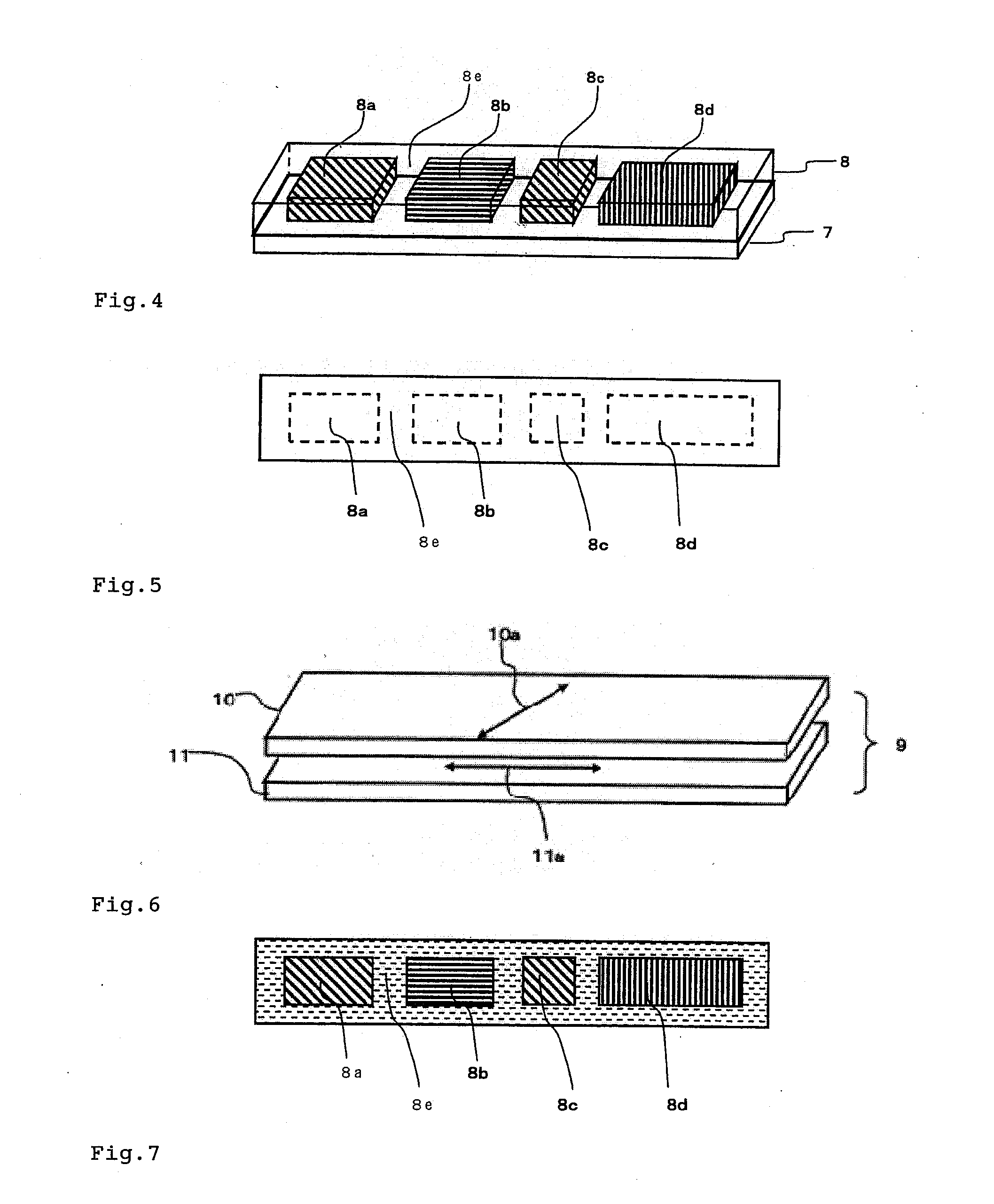

InactiveUS20120133871A1Improve heat resistanceReduce the numberNon-linear opticsOptical elementsLiquid crystallineLiquid-crystal display

Provided is a technology by which a retardation film in which regions different from each other in one or both of optical characteristics, i.e., an optical axis and a retardation are patterned can be produced with an additionally small load. The retardation film is formed of a liquid crystalline polyimide film having a photoreactive group. Further provided is an optical device and a liquid crystal display apparatus each having the retardation film.

Owner:JNC CORP +1

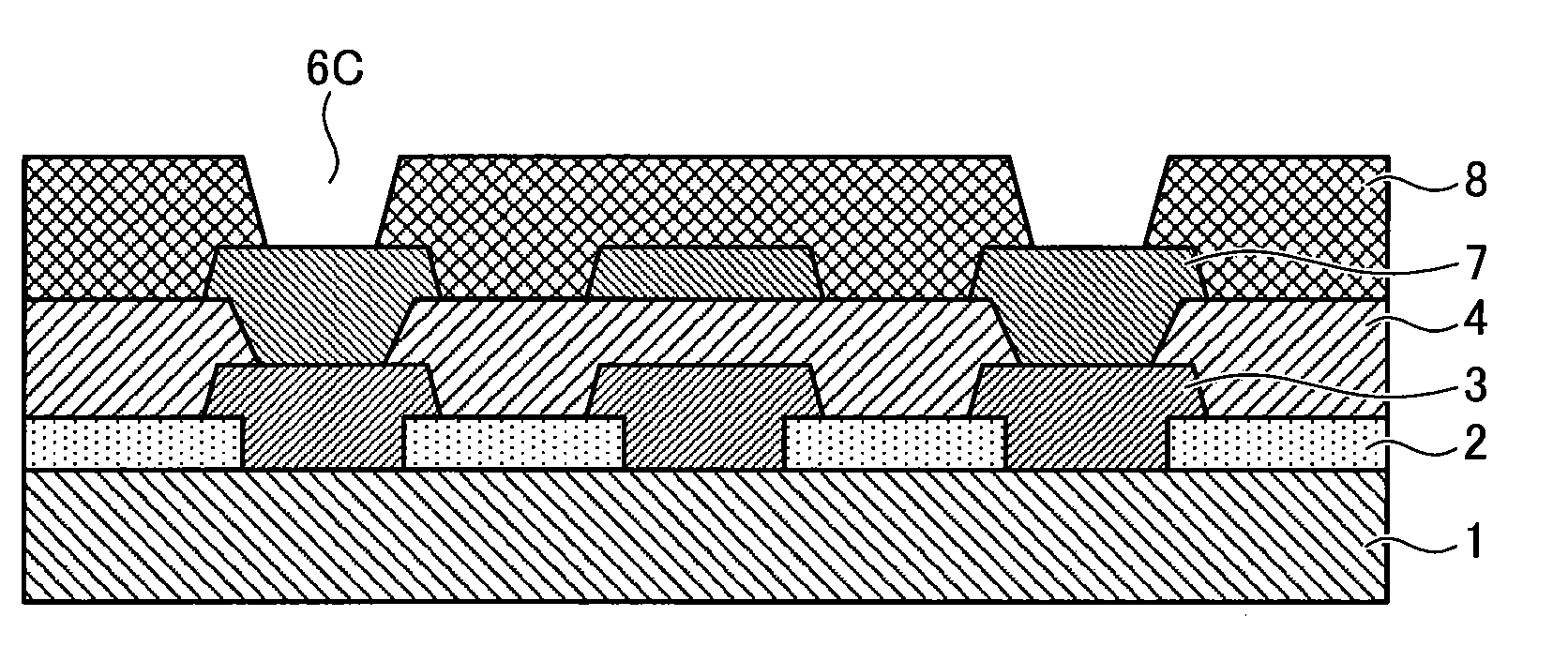

Photosensitive resin composition, process for producing patterned hardened film with use thereof and electronic part

ActiveUS20100092879A1Increase chanceFormed surelyPhotosensitive materialsSemiconductor/solid-state device manufacturingPhotosensitizerChain structure

To provide a photosensitive resin composition in which a hardened film obtained from the photosensitive resin composition has properties comparable to those of a film hardened at a high temperature, a method for manufacturing a patterned hardened film using the photosensitive resin composition, and an electronic part. The photosensitive resin composition includes (a) a polybenzoxazole precursor having a repeating unit represented by a general formula (I):wherein U and V represent a divalent organic group, and at least one of U and V is a group containing an aliphatic chain structure having 1 to 30 carbon atoms; (b) a photosensitizer; (c) a solvent; and (d) a crosslinking agent capable of causing crosslinking or polymerization by heating.

Owner:HITACHI CHEM DUPONT MICROSYSTEMS LTD

Transparent laminate, plastic lens for eyeglass and primer composition

InactiveUS20020159160A1Good weather resistanceImprove impact resistancePolyurea/polyurethane coatingsMountingsAnti-reflective coatingPolymer science

A novel primer composition which does not need to be thermally cured at a high temperature after it is applied to a plastic substrate and a transparent laminate, for example, a plastic lens for spectacles, which comprises the above primer composition and has high impact resistance and high heat resistance even when a transparent anti-reflection coat is formed. This transparent laminate comprises a transparent plastic substrate and a coating film formed on at least one side of the plastic substrate by applying and curing a liquid primer composition which comprises (A) a self-emulsifiable emulsion of a linear polyurethane having a pendant carboxylic acid group and no crosslinked structure between polymer chains, (B) a sol of an inorganic oxide having a hydrophobic group on the surface, and (C) a compound having 5 to 9 carbon atoms and at least one hydroxyl group and at least one oxygen atom other than an oxygen atom constituting a hydroxyl group in the molecule.

Owner:SDC TECHNOLOGIES INC

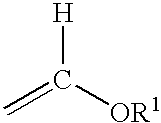

Optical material containing photocurable fluoropolymer and photocurable fluororesin composition

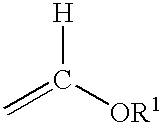

InactiveUS20050265685A1Improve heat resistanceLow refractive indexCoatingsOptical waveguide light guidePolymer scienceSide chain

There are provided various optical materials which contain a curable fluorine-containing polymer (I) having a number average molecular weight of from 500 to 1,000,000 and represented by the formula (1): MA (1) in which the structural unit M is a structural unit derived from a fluorine-containing organic group having crosslinkable cyclic ether structures in its side chain, the structural unit A is a structural unit derived from a monomer copolymerizable with the fluorine-containing ethylenic monomer for the structural unit represented by the formula (M), and the structural unit M and the structural unit A are contained in amounts of from 0.1 to 100% by mole and from 0 to 99.9% by mole, respectively, and further contain a photoacid generator (II). Those optical materials are suitable as materials for optical devices such as an optical waveguide and a sealing member and also as materials for display devices such as an antireflection film and are excellent in transparency in a near infrared region, resistance to moisture, heat resistance, etc. Also there are provided various members obtained by curing the optical materials.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com