Aramid thin sheet material and electrical/electronic parts using the same

a technology of aramid thin sheets and electrical/electronic parts, which is applied in the direction of cell components, plastic/resin/waxes insulators, cell components, etc., can solve the problems of not fully meeting the recent demands for capacitors or batteries of still higher capacity and power output required for electric cars, and achieve excellent electrolyte-retaining function, increase strength, excellent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 and 2

(Preparation of Aramid Thin Sheet Material)

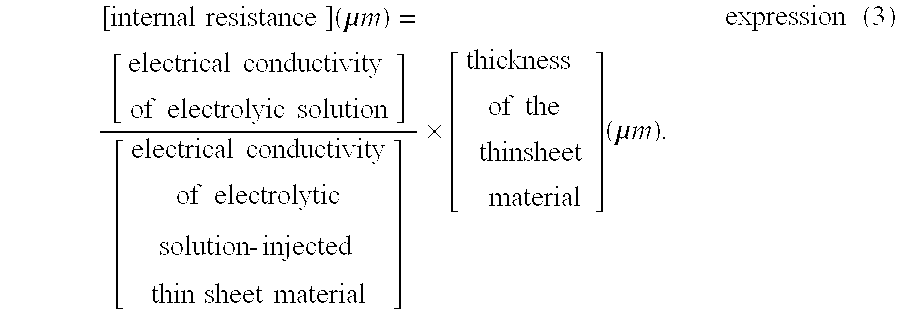

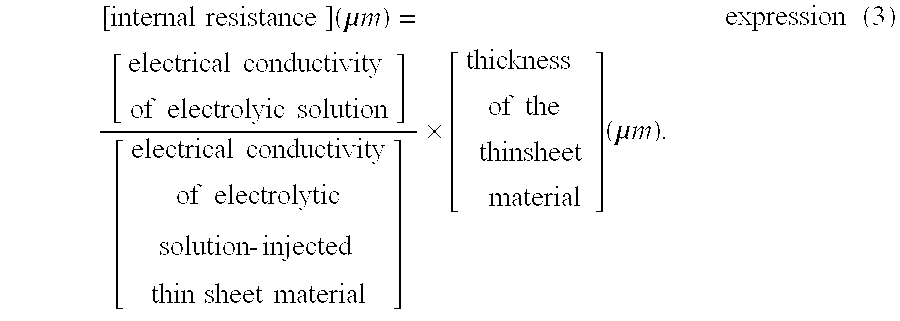

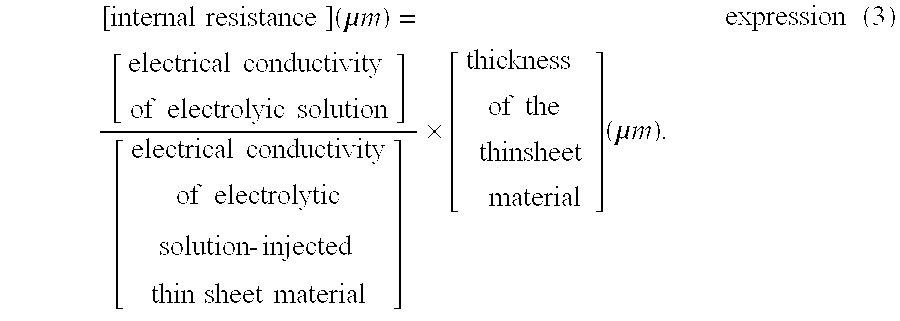

[0067] Each of the aramid fibrid, aramid staple fibers and fibrillated aramid prepared in the foregoing manner was dispersed in water to form a slurry. Those slurries were mixed to make the blend ratios of the aramid fibrid, aramid staple fibers and fibrillated aramid the values as indicated in Table 1, to form sheet-formed products with TAPPI sheet machine (cross-sectional area=325 cm2). The products were then given a hot-press processing with metallic calendar rolls at a temperature of 330° C. and linear pressure of 100 kg / cm to provide thin sheet materials.

[0068] Main parameter values of thus obtained aramid thin sheet materials were as shown in Table 1.

TABLE 1Physical PropertyUnitExample 1Example 2Composition of starting materialwt %Aramid fibrid01Aramid staple fiber5049Fibrillated aramid5050Basis weightg / m224.524.4Thicknessμm5147Densityg / cm30.480.52Electrical conductivitymS / cm1.371.04Internal resistanceμm186245Gas permeabilitysec / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical fiber length measuring apparatus | aaaaa | aaaaa |

| weight-average fiber length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com