Patents

Literature

587 results about "Rubber elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber elasticity, a well-known example of hyperelasticity, describes the mechanical behavior of many polymers, especially those with cross-links.

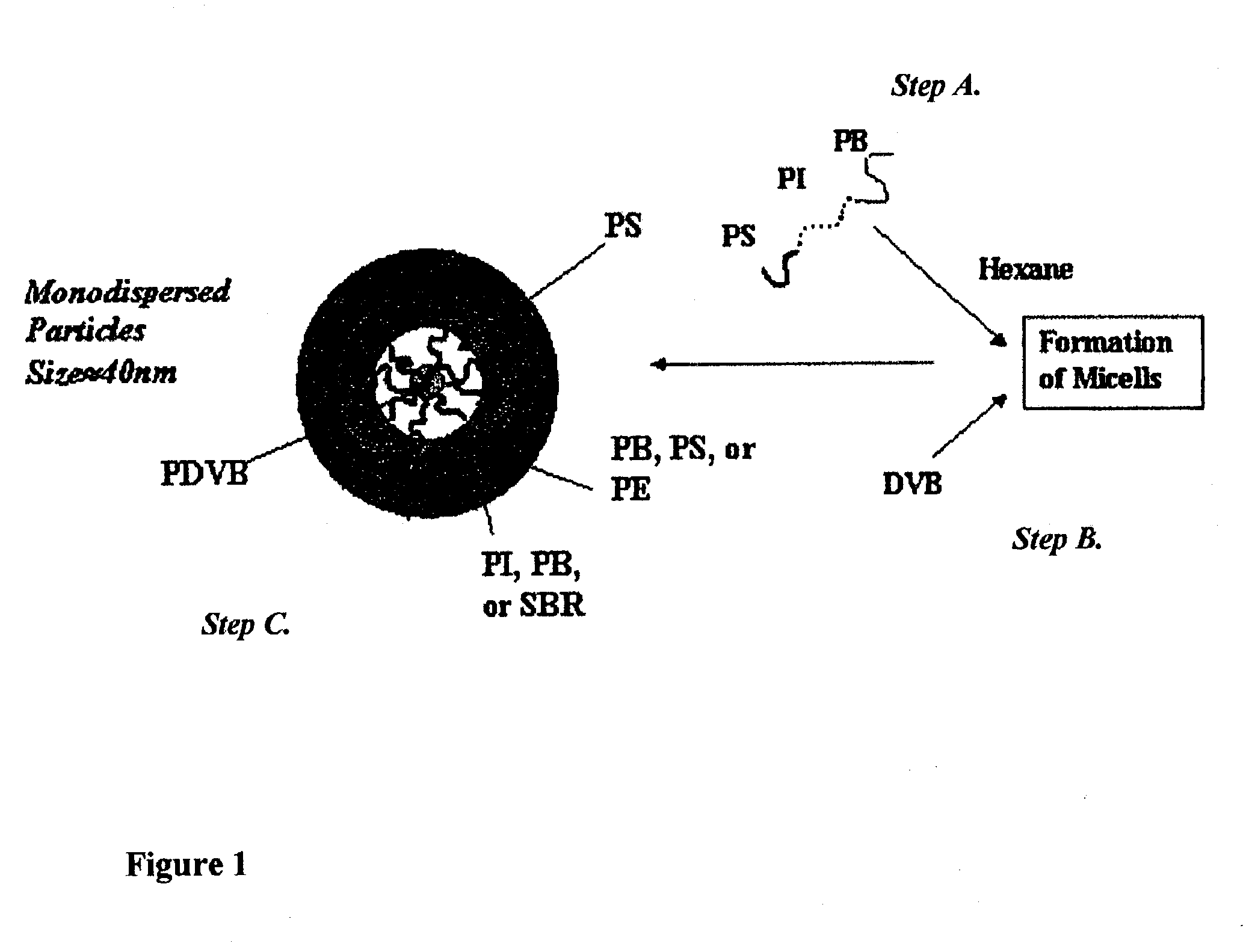

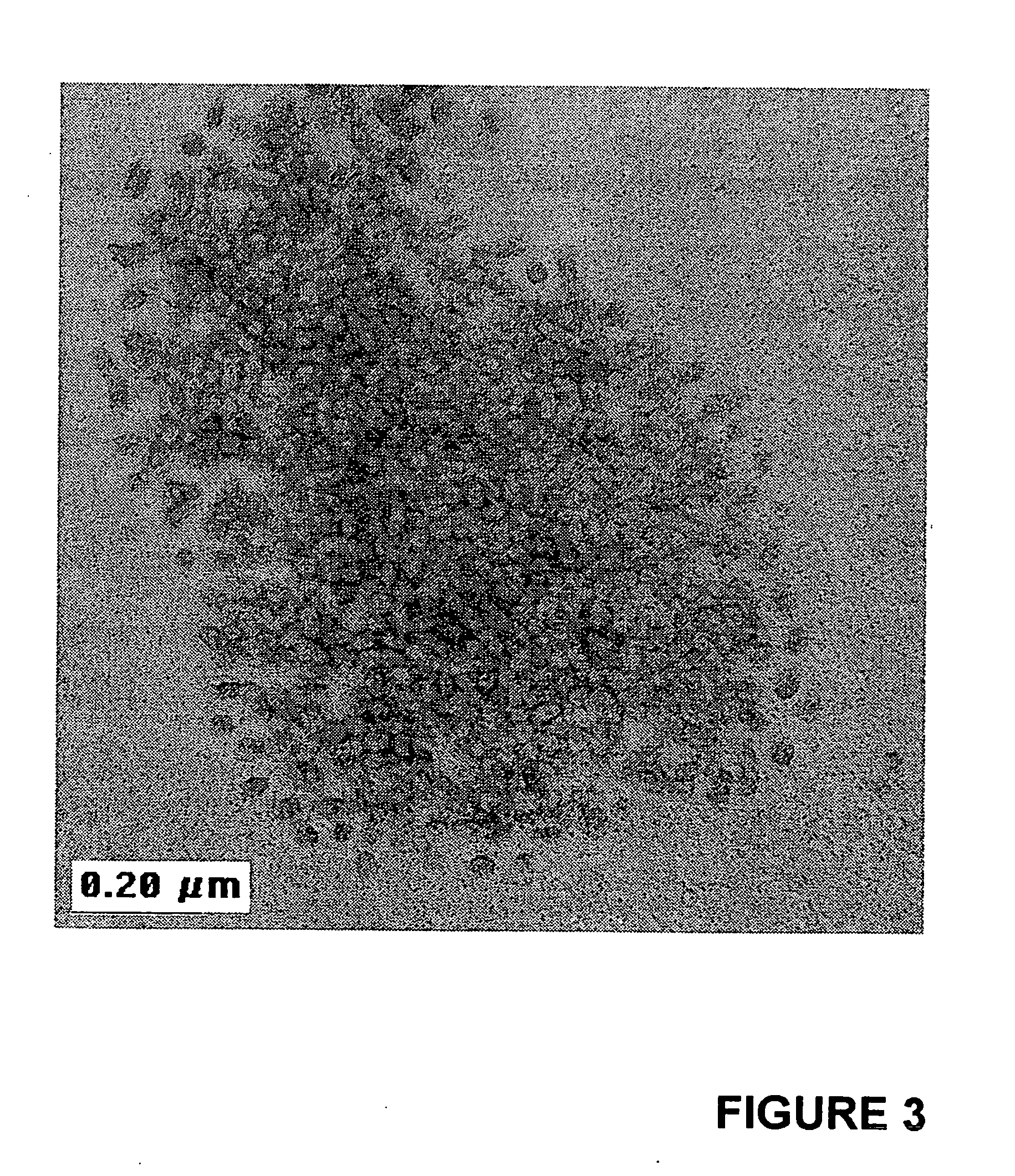

Multi-layer nano-particle preparation and applications

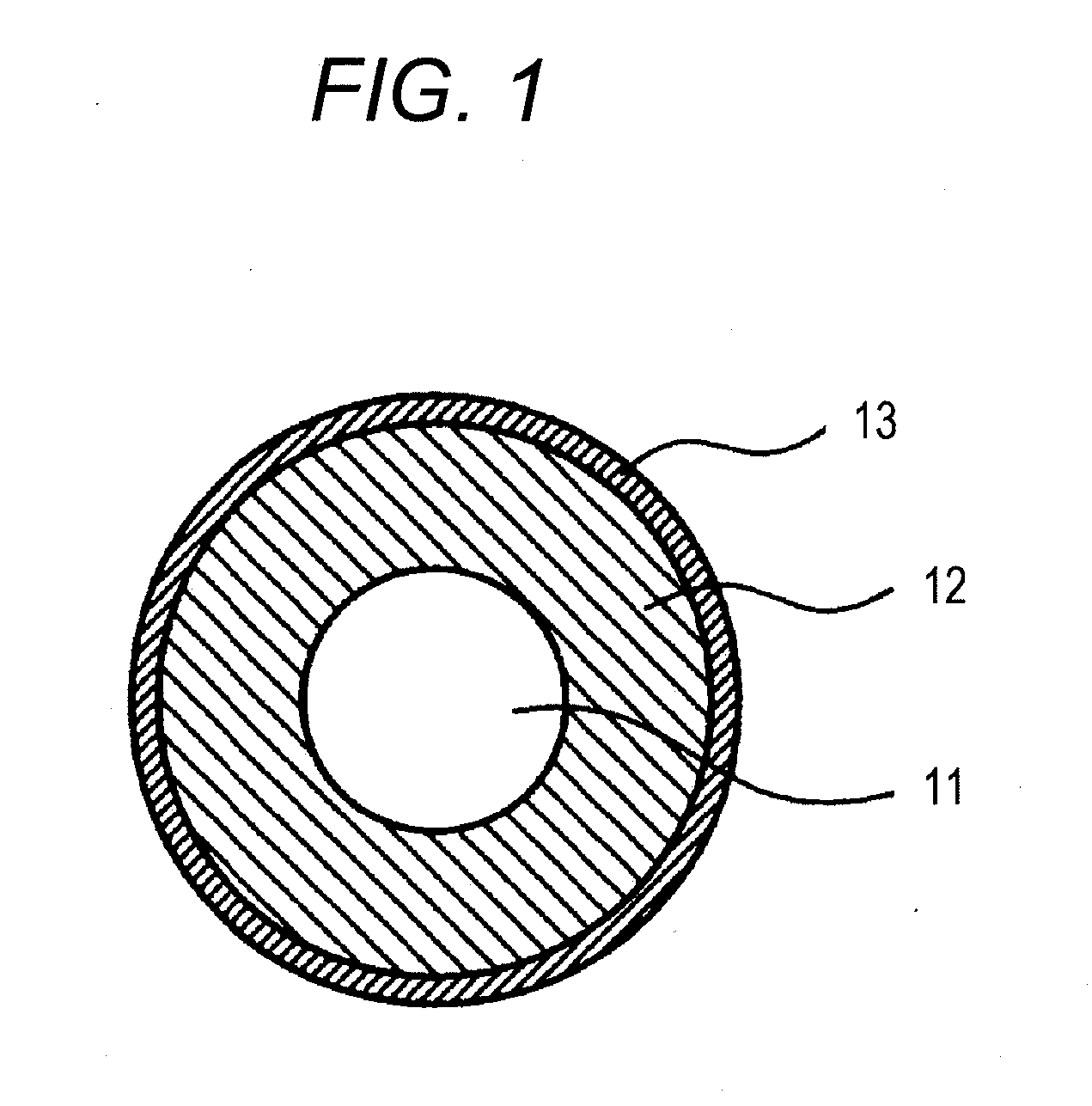

InactiveUS6872785B2Reduced shrinkage performanceImprove lagMaterial nanotechnologySpecial tyresThermoplasticElastomer

A multi-layer nano-particle composition including a polymer core and at least two additional layers is provided. The nano-particles have a mean average diameter less than about 100 nm. The nano-particles can be modified via, for example, hydrogenation or functionalization. The nano-particles can be advantageously incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE CORP

Prepreg and laminate

ActiveUS20090017316A1Improve flame retardant performanceImprove heat resistanceSpecial tyresElectrical equipmentThermal dilatationPolymer science

A prepreg for a printed wiring board, comprising a cyanate ester resin having a specific structure, a non-halogen epoxy resin, a silicone rubber powder as a rubber elasticity powder, an inorganic filler and a base material, which prepreg retains heat resistance owing to a stiff resin skeleton structure, has high-degree flame retardancy without the use of a halogen compound or a phosphorus compound as a flame retardant, and has a small thermal expansion coefficient in plane direction without using a large amount of inorganic filler, and a laminate comprising the above prepreg.

Owner:MITSUBISHI GAS CHEM CO INC

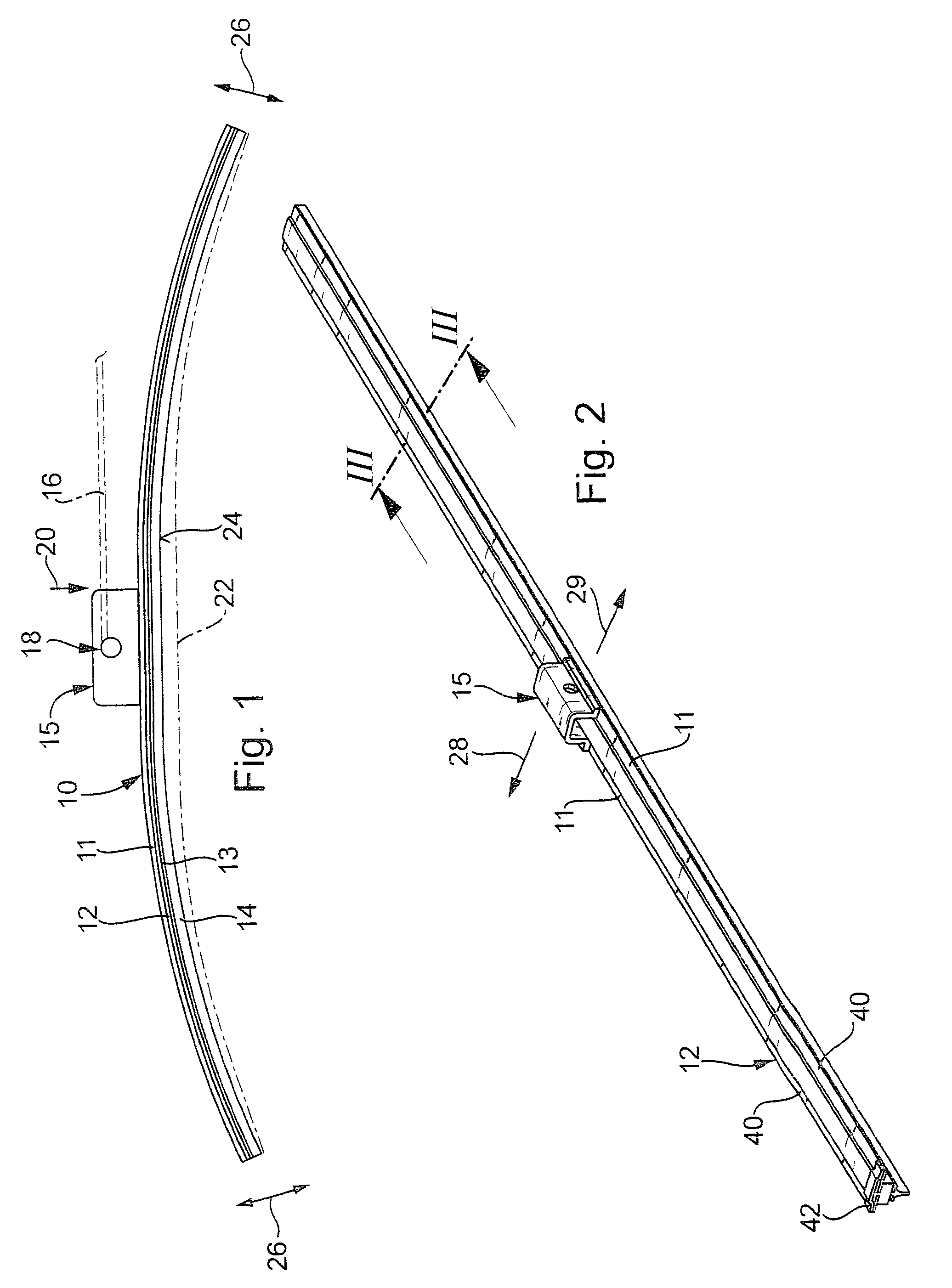

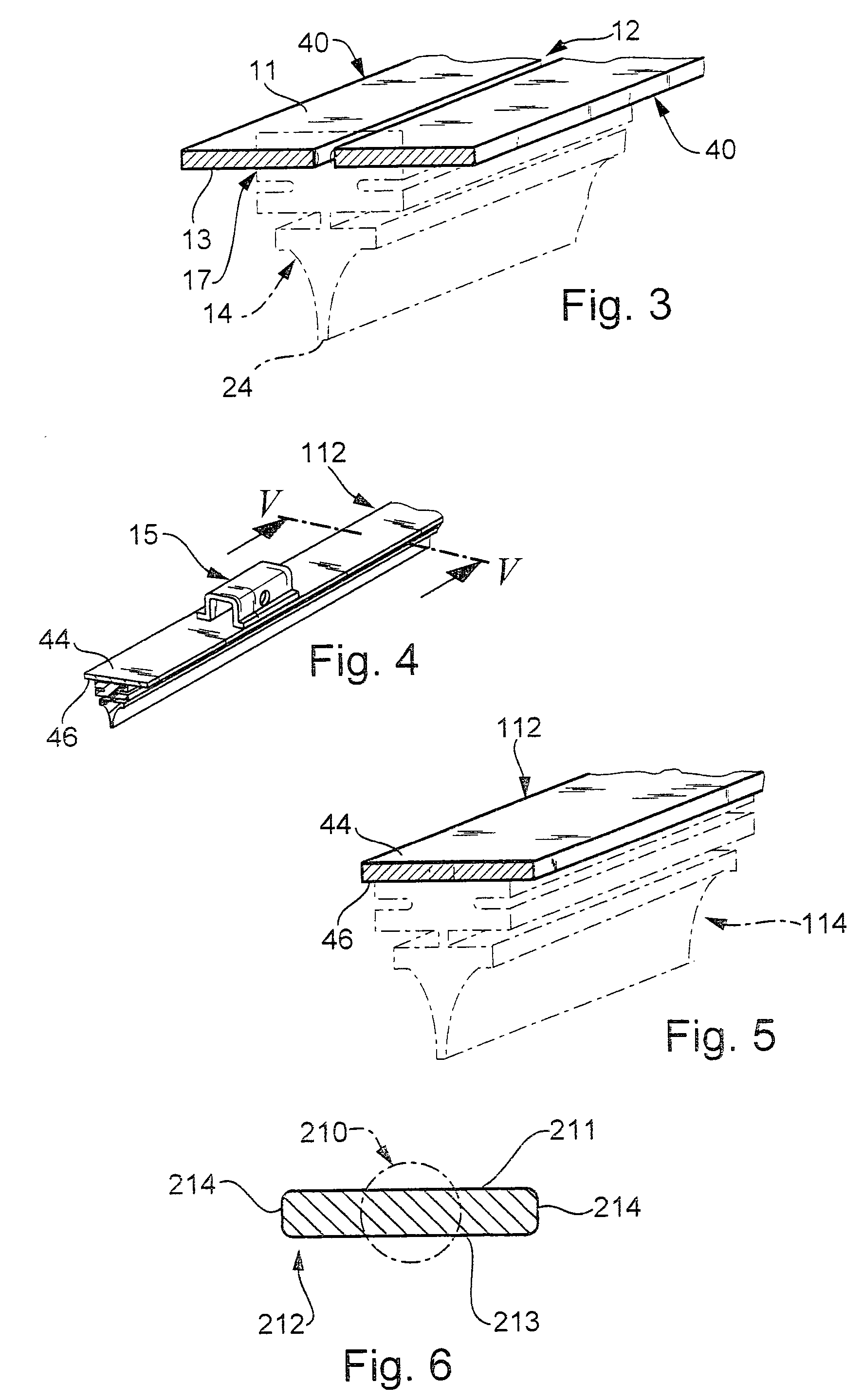

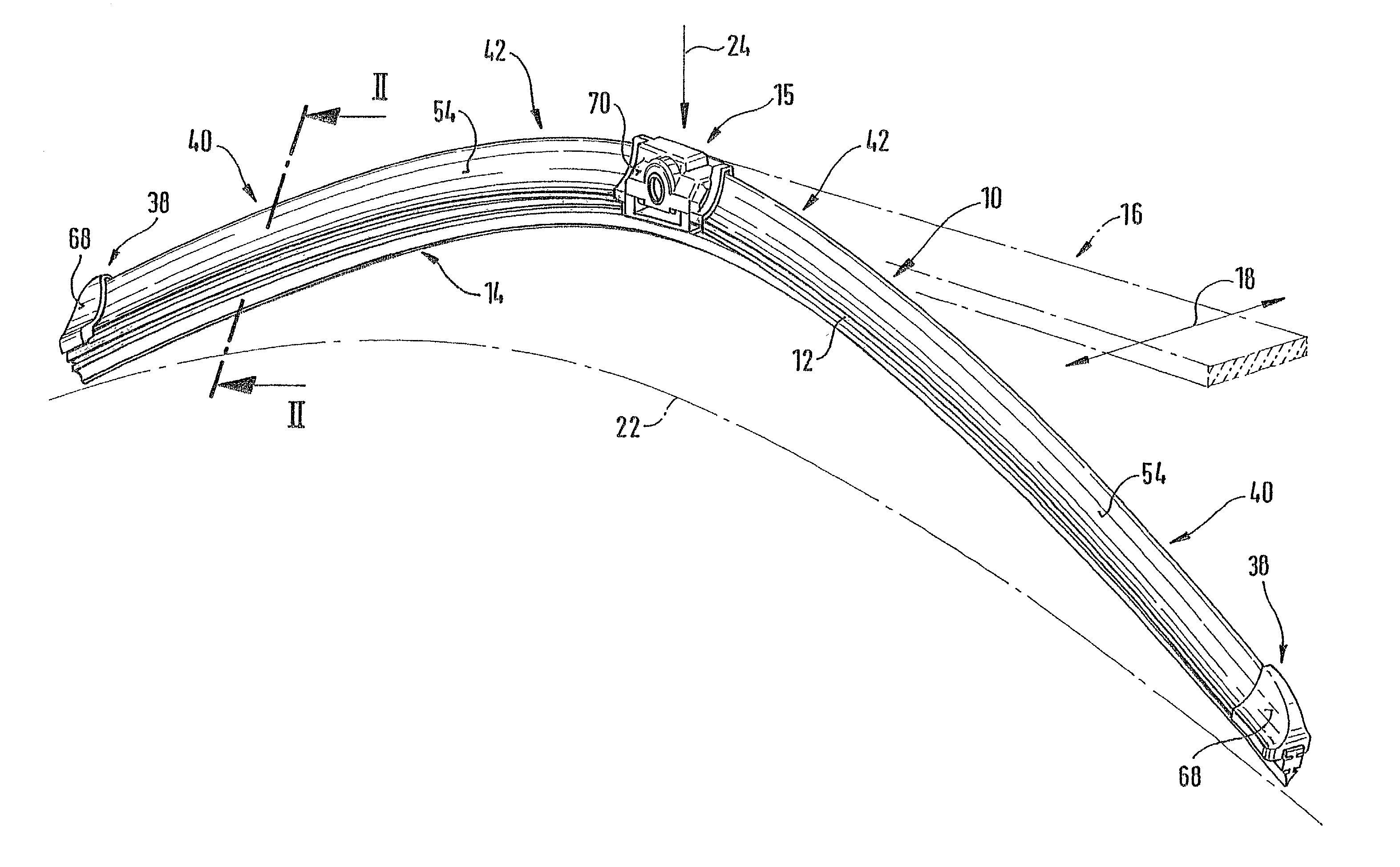

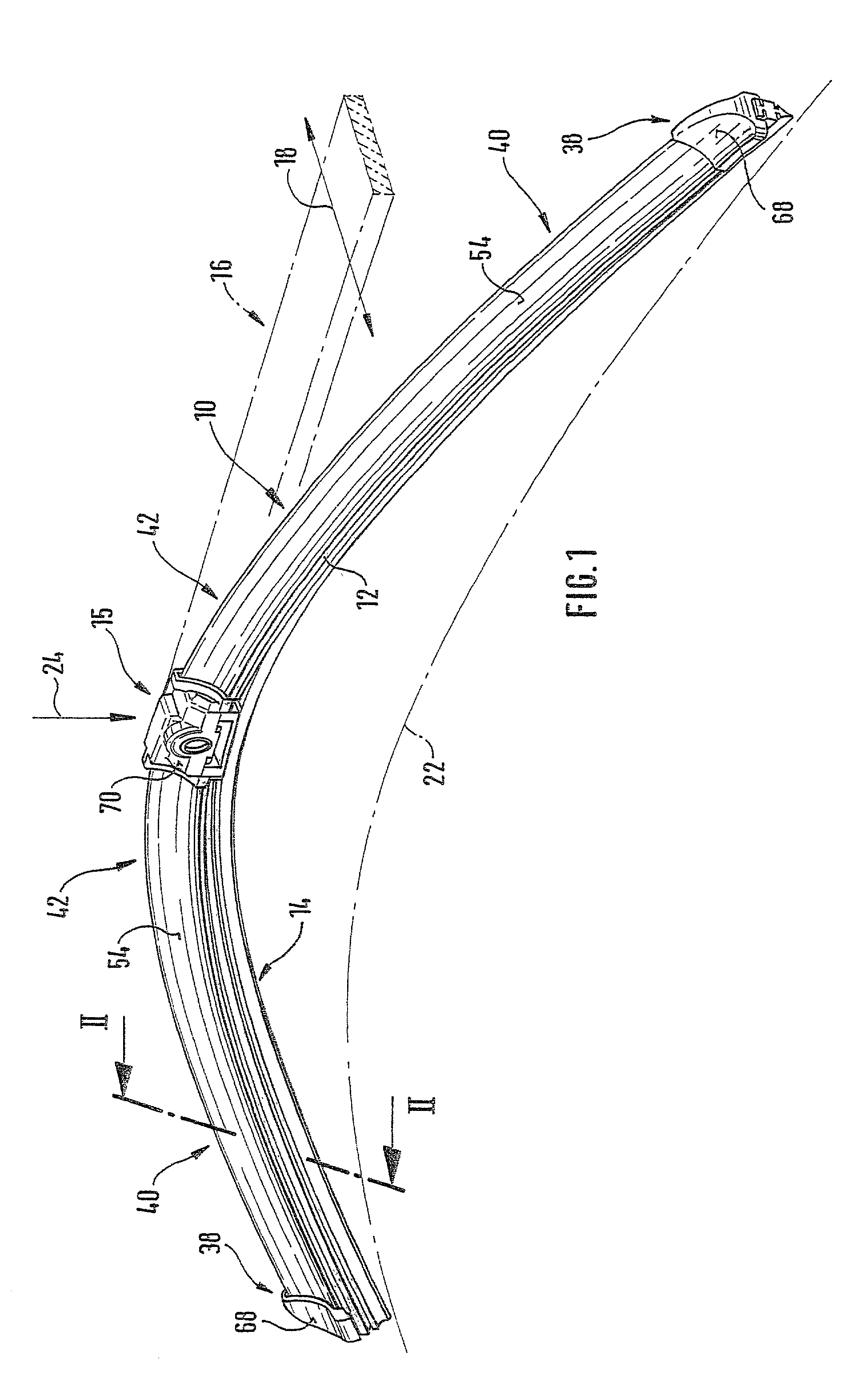

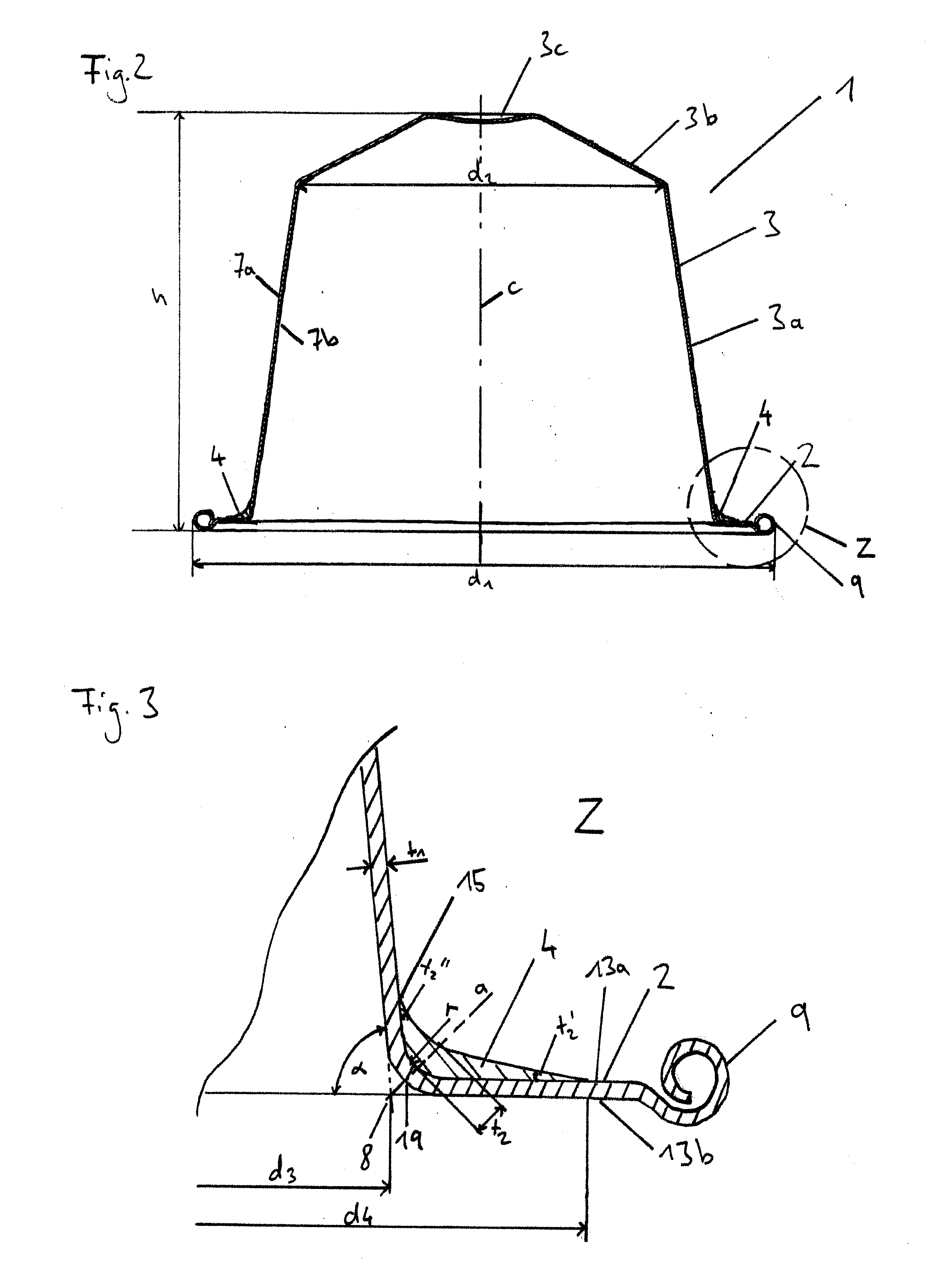

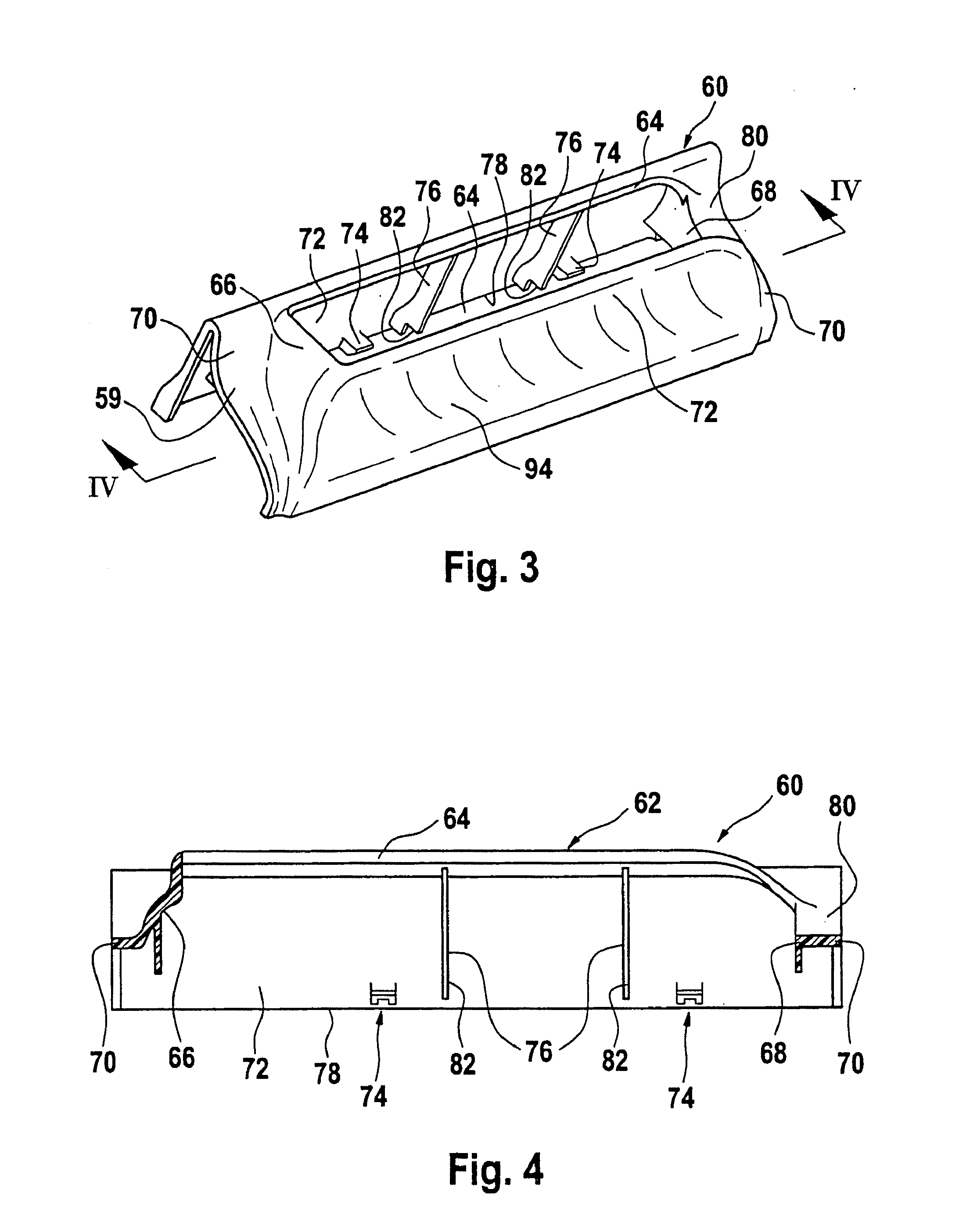

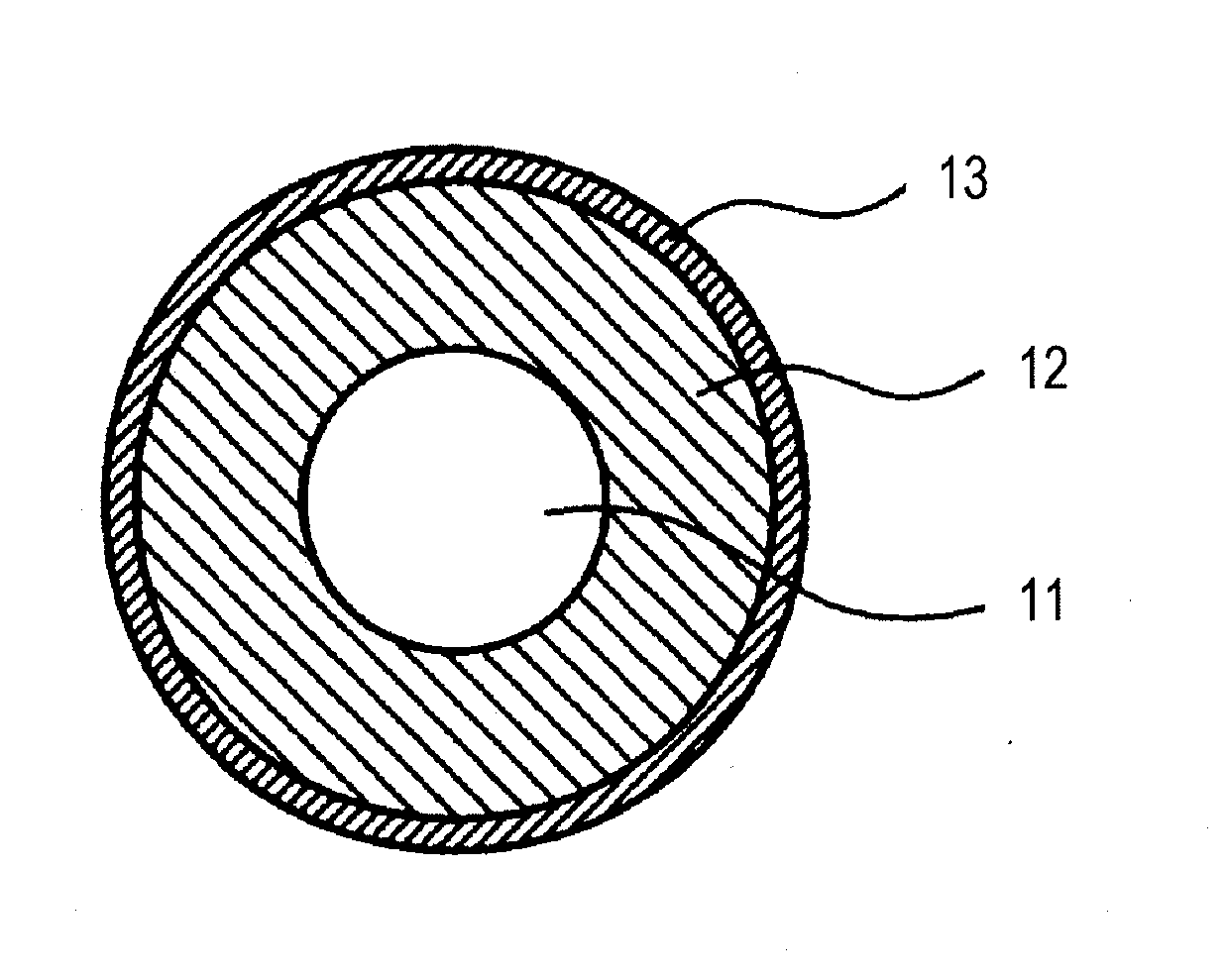

Wiper blade for cleaning glass panes, especially of motor vehicles, and method for the production of said wiper blade

InactiveUS20040025280A1Reduce adverse effectsImprove hardenabilityWindow cleanersVehicle cleaningMobile vehicleSulfur

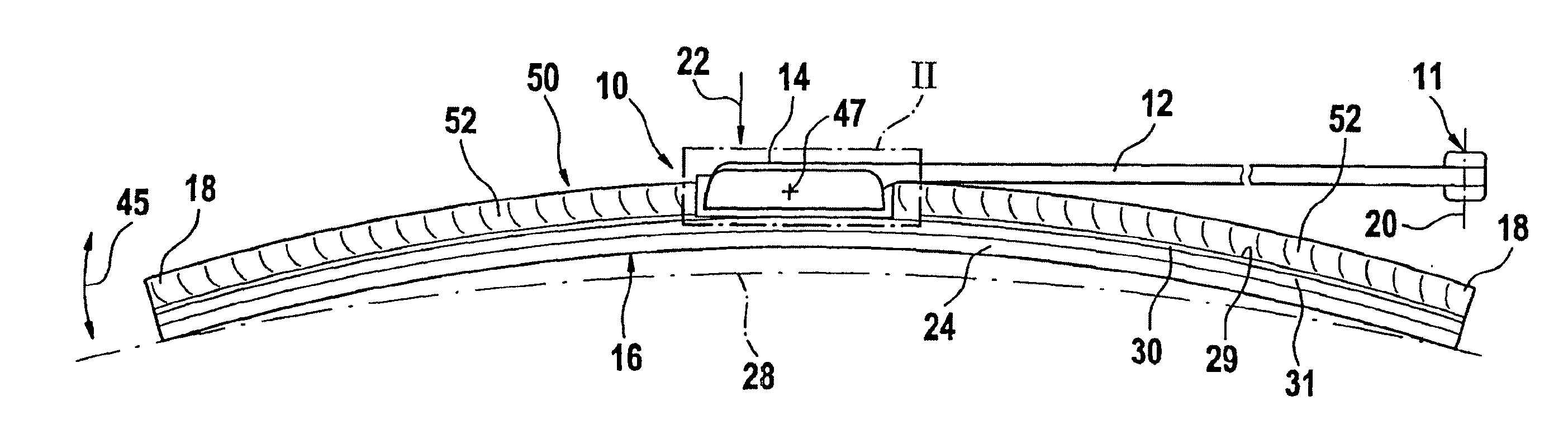

A wiper blade is proposed for cleaning windows, especially of motor vehicles, is proposed, which is provided with an elongated, rubber-elastic wiper strip that can be placed against the window, which wiper strip is disposed on the lower band face (13), oriented toward the window, of a bandlike-elongated support element (12) made from a spring-elastic steel, on whose other, upper band face (11) facing away from the middle, particularly in the middle portion of the support element, a device (15) for connecting the wiper blade to the free end, urged toward the window, of a driven wiper arm (16) guided on the motor vehicle is welded. It has proved particularly advantageous, in view of the demands made of the support element, if the support element is made from an alloyed quenched and tempered steel, which has the following alloy components: carbon (C), 0.18% to 0.36%; silicon (Si), 0.40% to 0.50 %; manganese (Mn), 1.10 % to 1.80%; phosphorus (P), 0.015% to 0.035%; and sulfur (S), 0.035% to 0.04%.

Owner:ROBERT BOSCH GMBH

Nano-particle preparation and applications

InactiveUS20050192408A1Super soft propertyHeat resistantMaterial nanotechnologyGlass/slag layered productsElastomerThermoplastic

A nano-particle composition including a poly(alkenylbenzene) core and a poly (conjugated diene) or a poly(alkylene) surface layer is provided. The nano-particles have a mean average diameter less than about 100 nm. The nano-particles can be modified via, for example, hydrogenation or functionalization. The nano-particles can advantageously be incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE FIRESTONE NORTH AMERICAN TIRE

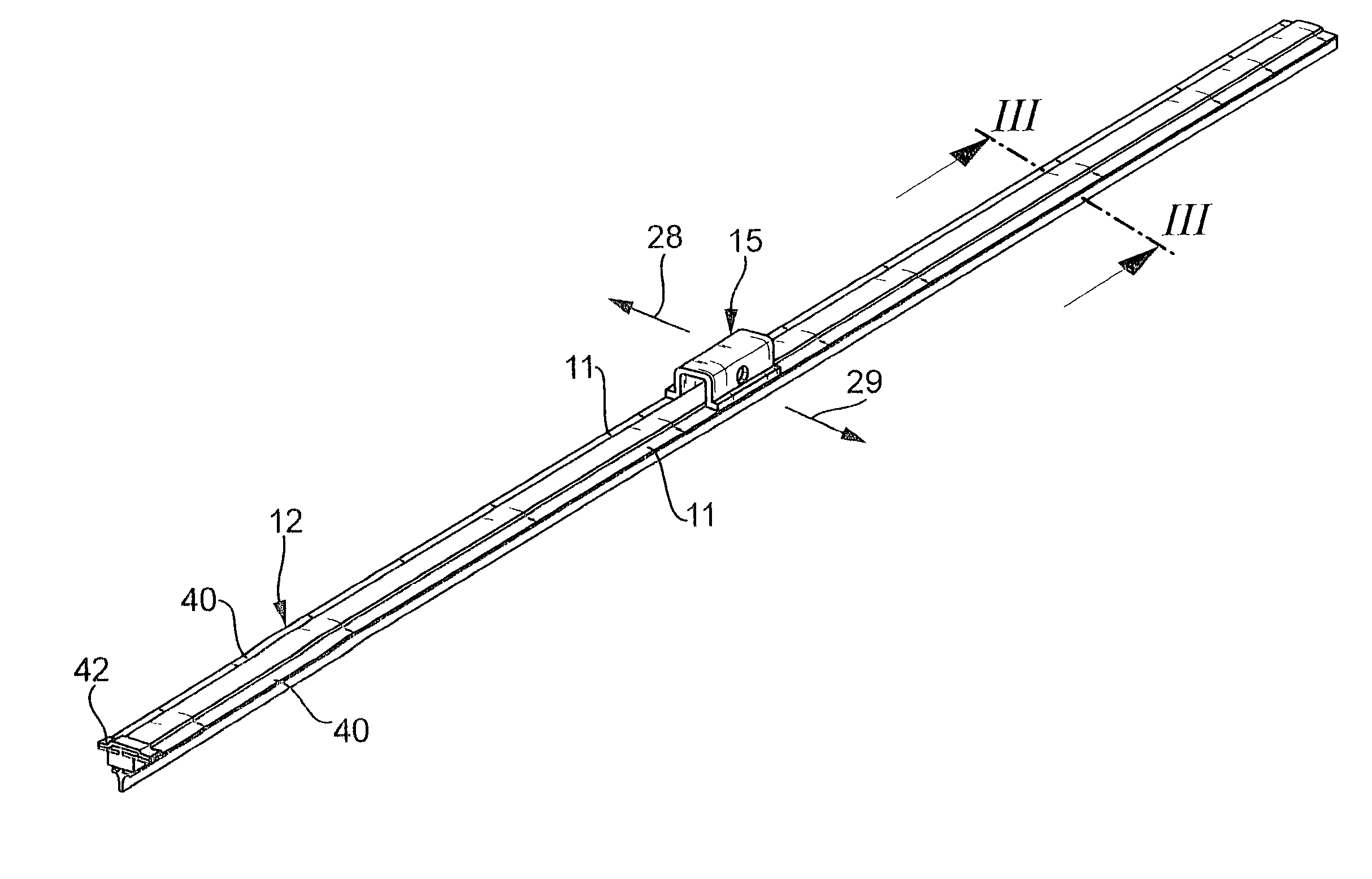

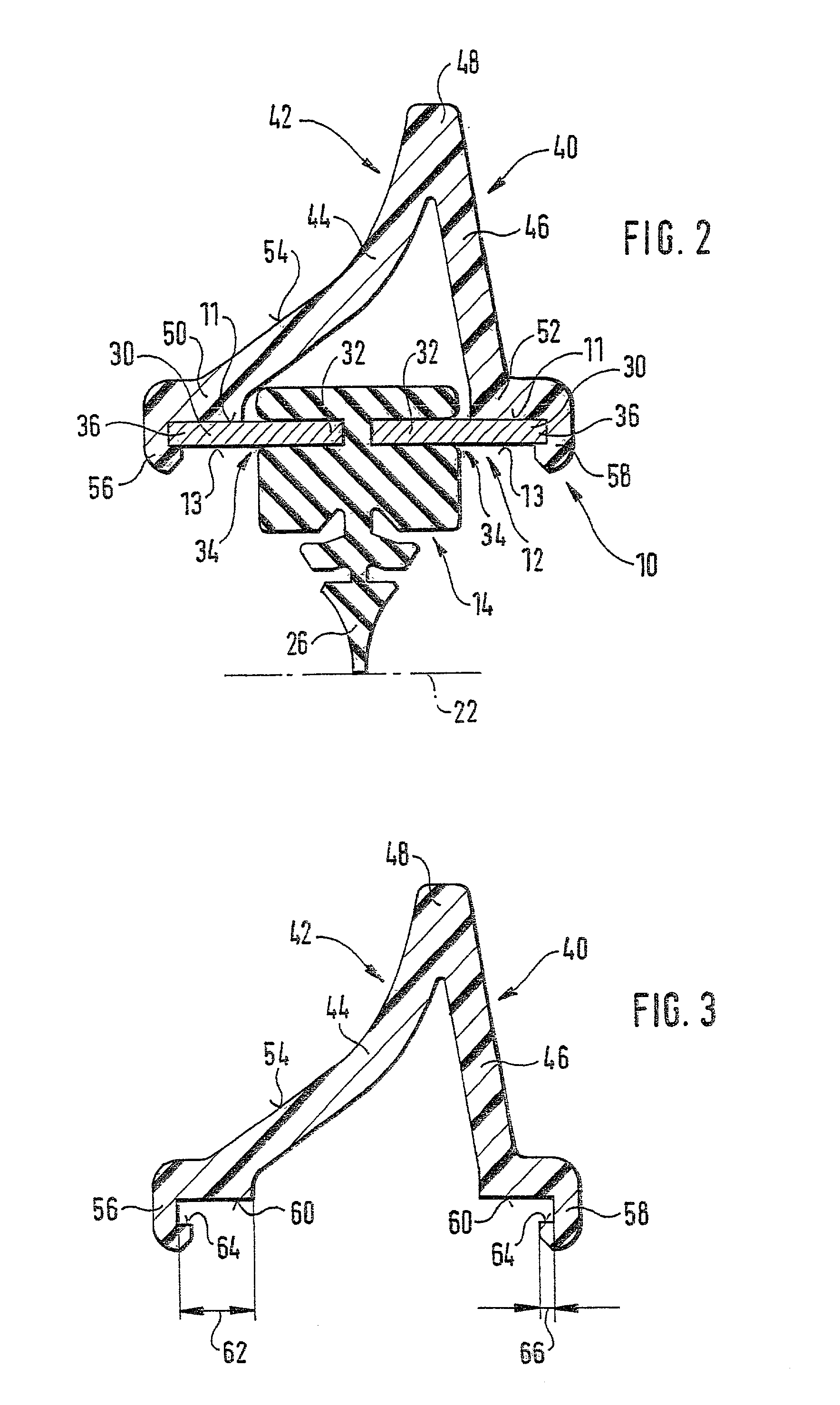

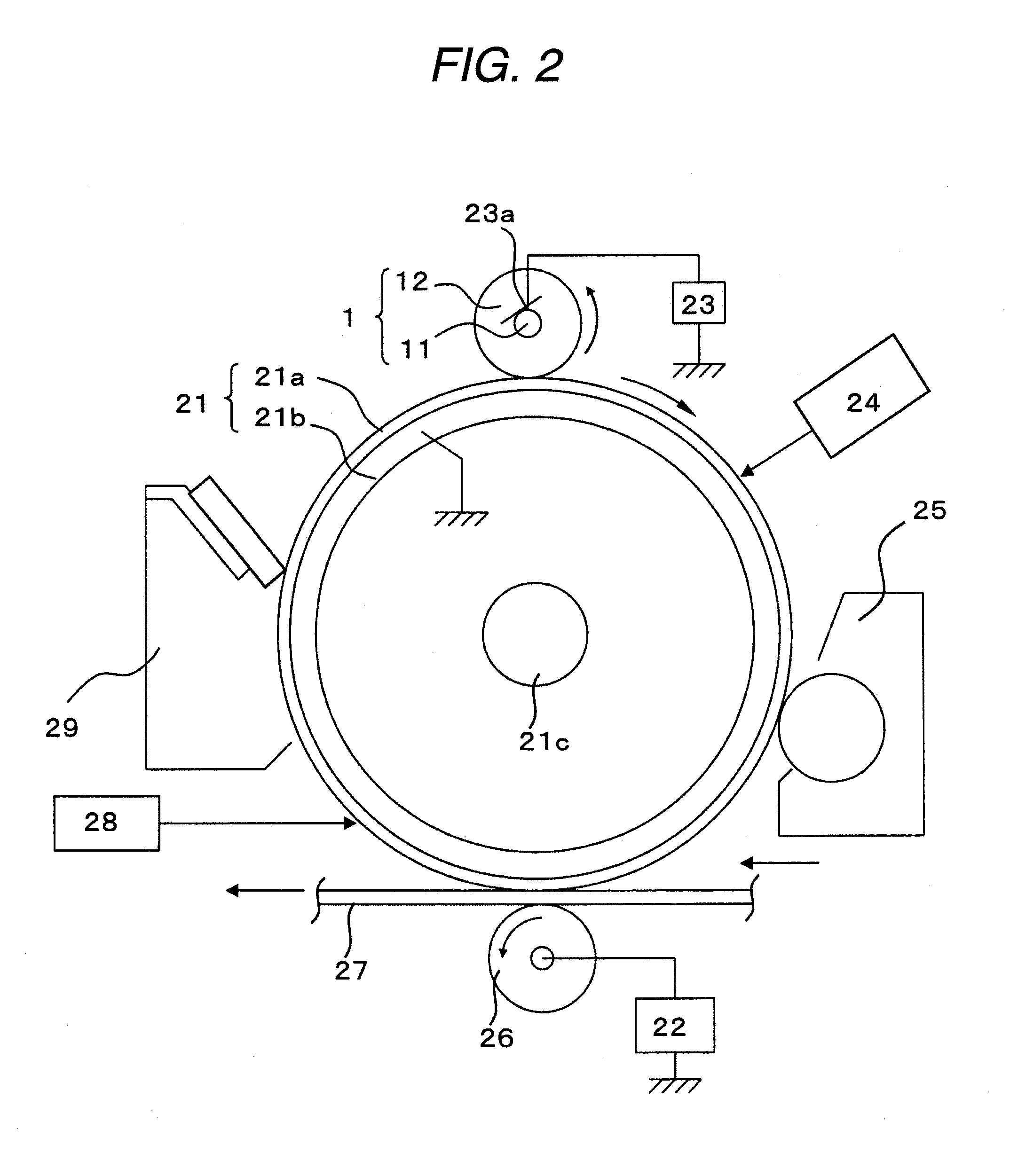

Wiper blade for cleaning screens in particular on motor vehicles

InactiveUS20020133897A1Reduce weightSave materialWindow cleanersVehicle cleaningCommon baseMobile vehicle

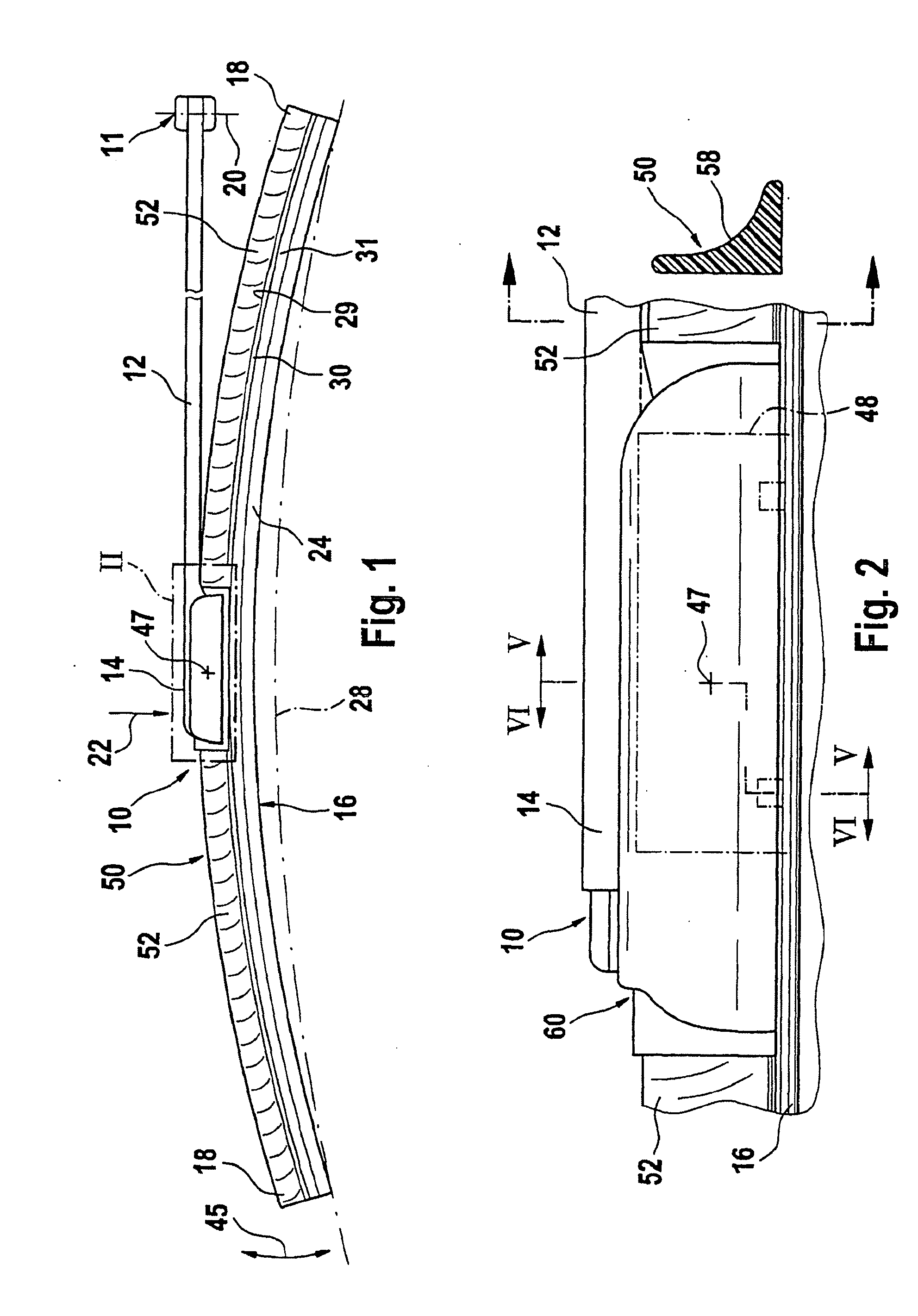

A wiper blade for cleaning motor vehicles is proposed, which is provided with a band-like, elongated, spring-elastic support element (12). The lower band surface (13) of the support element (12) oriented toward the window (22) has an elongated, rubber-elastic wiper strip (14), which can be placed against the window (22), disposed on it so that the longitudinal axes of these two parts are parallel and the upper band surface (11) of the support element (12) has a wind deflection strip (42) disposed on it, which extends in the longitudinal direction of the support element, is provided with an attack surface (54) oriented toward the main flow of the relative wind, and is comprised of an elastic material. A considerable weight savings for the wiper blade is achieved if the wind deflection strip (42, 142, or 242) has two diverging legs (44, 46), viewed in cross section, which are connected to each other at a common base (48) and whose free ends (50, 52) oriented toward the window (22) are supported on the wiper blade (10), and the attack surface (54) is embodied on the outside of the one leg (44).

Owner:ROBERT BOSCH CORP

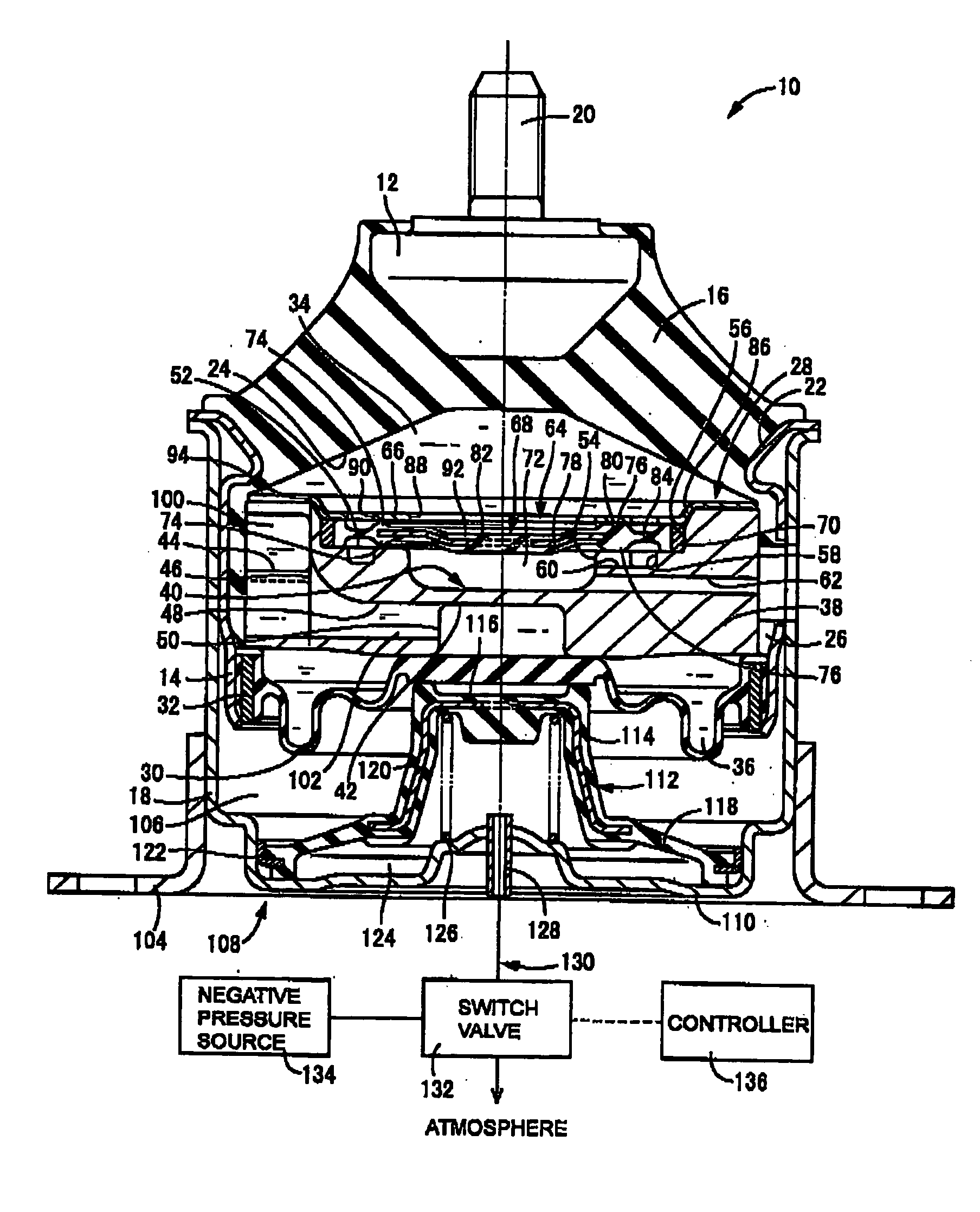

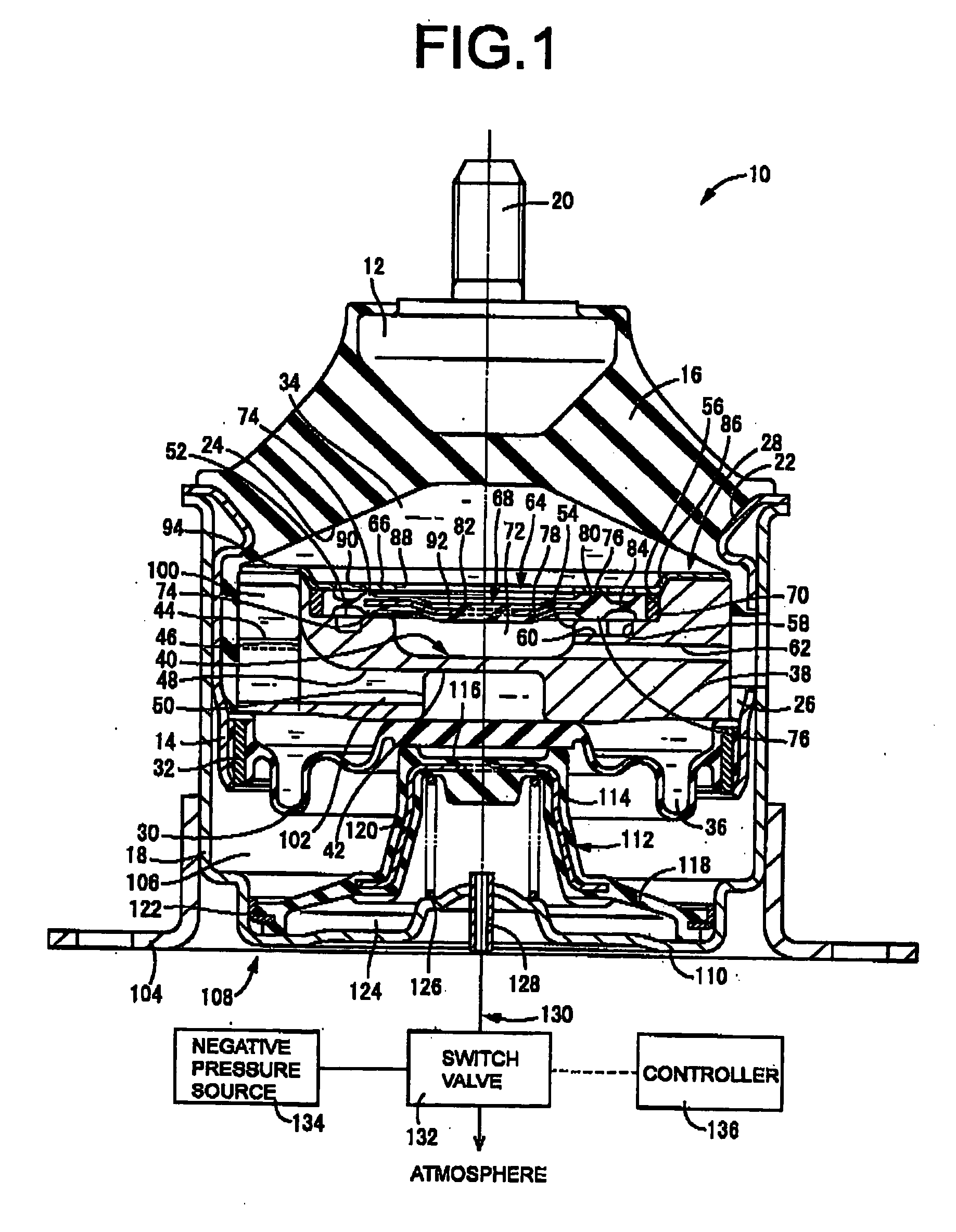

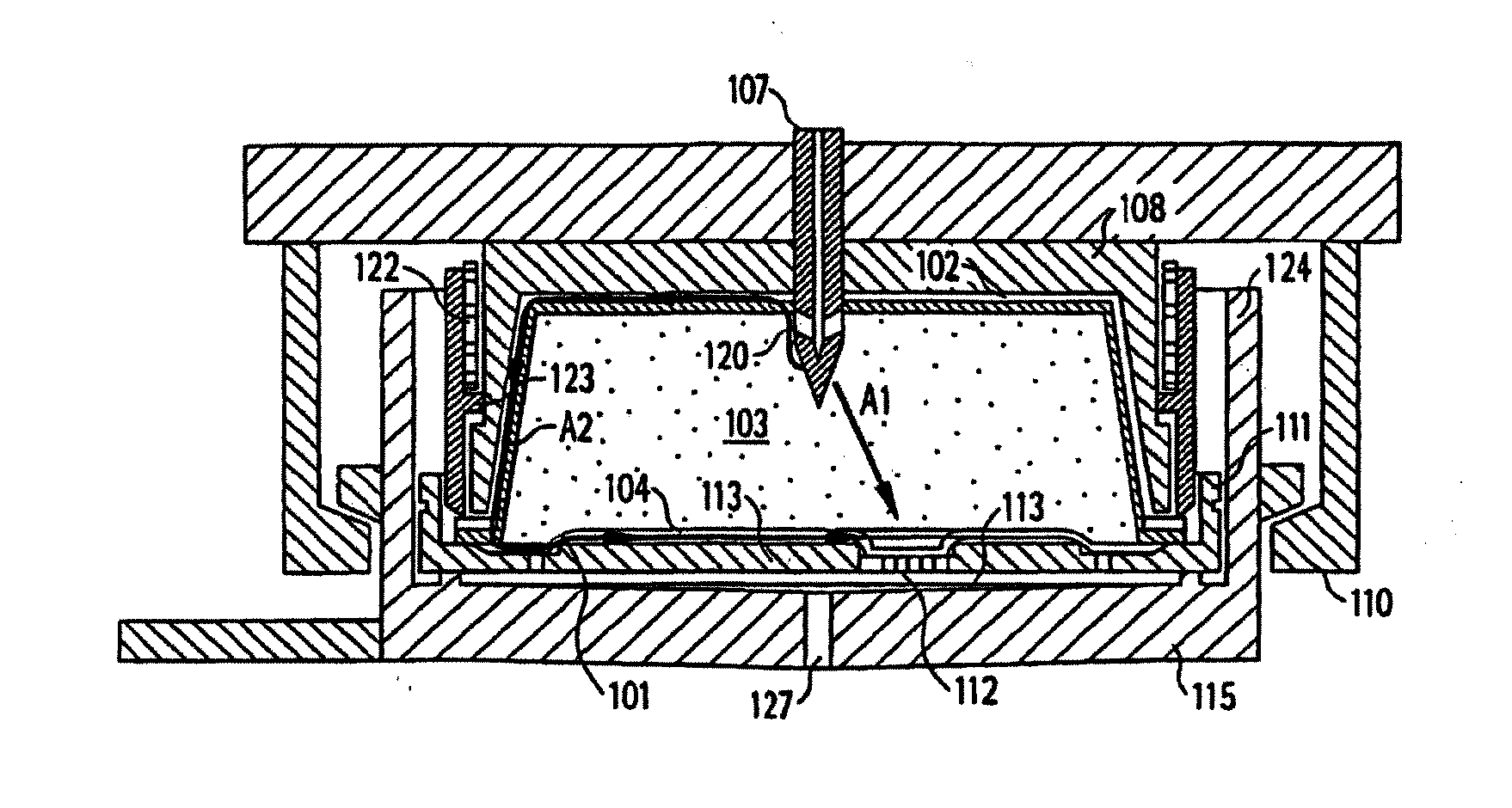

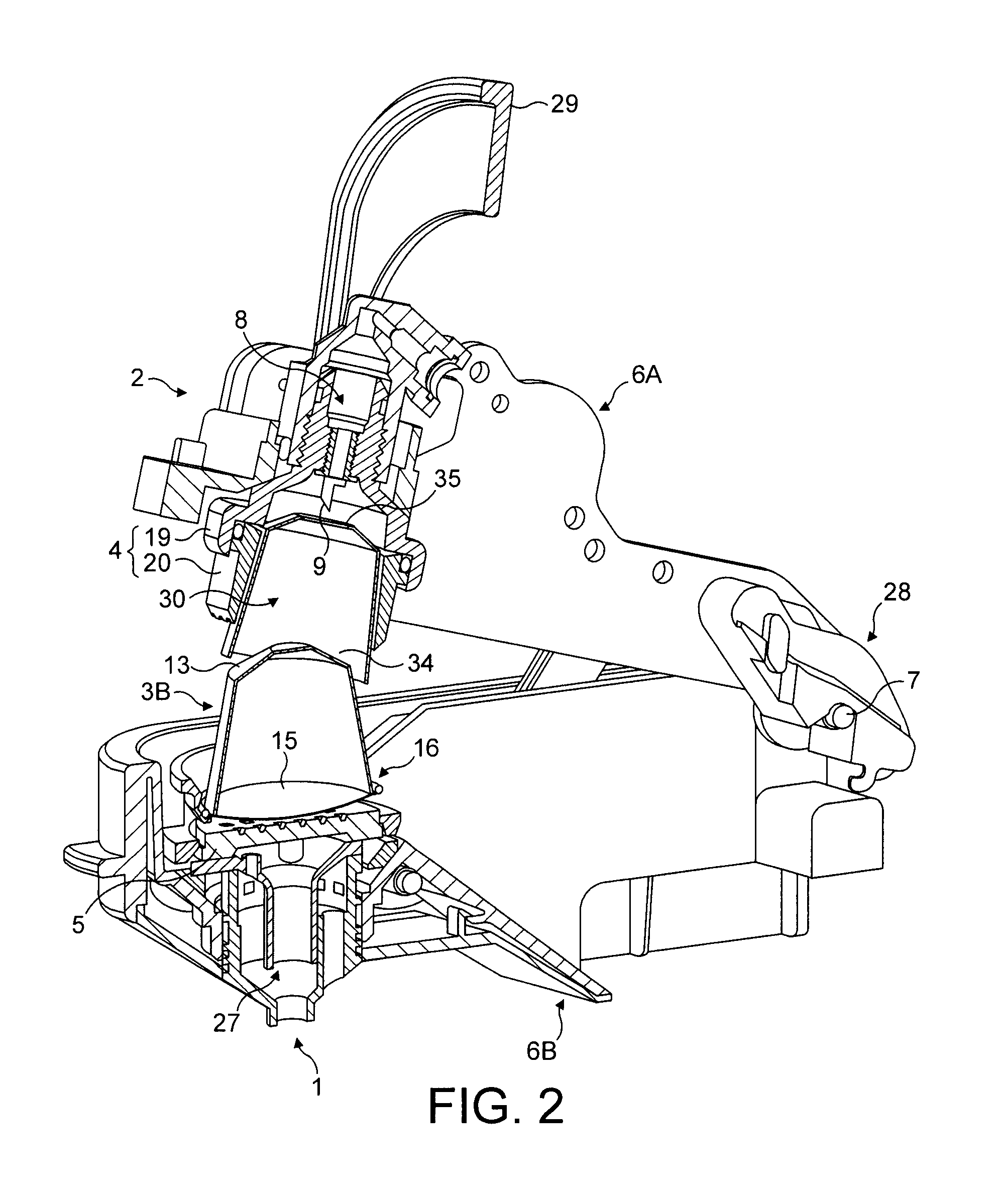

Pneumatically switchable type fluid-filled engine mount

ActiveUS20050258581A1Easy to moveGood vibration reduction effectPortable framesLiquid springsRubber elasticityMedium frequency

A fluid-filled engine mount, including: an elastic body connecting a first and a second mounting member; a pressure receiving chamber partially defined by the rubber elastic body; an equilibrium chamber partially defined by a flexible layer, a first orifice passage connecting between the pressure receiving and equilibrium chambers and tuned to a low frequency range, a second orifice passage connecting the both chambers and tuned to a medium frequency range; a valve member for opening / closing the second orifice passage and operated by a pneumatic actuator; a movable partition member including a rigid center movable plate portion and a readily deformable outer peripheral rubber film portion supported fluid-tightly by the second mount portion; and an intermediate equilibrium chamber formed opposing to the pressure receiving chamber with the movable partition member interposed therebetween.

Owner:SUMITOMO RIKO CO LTD

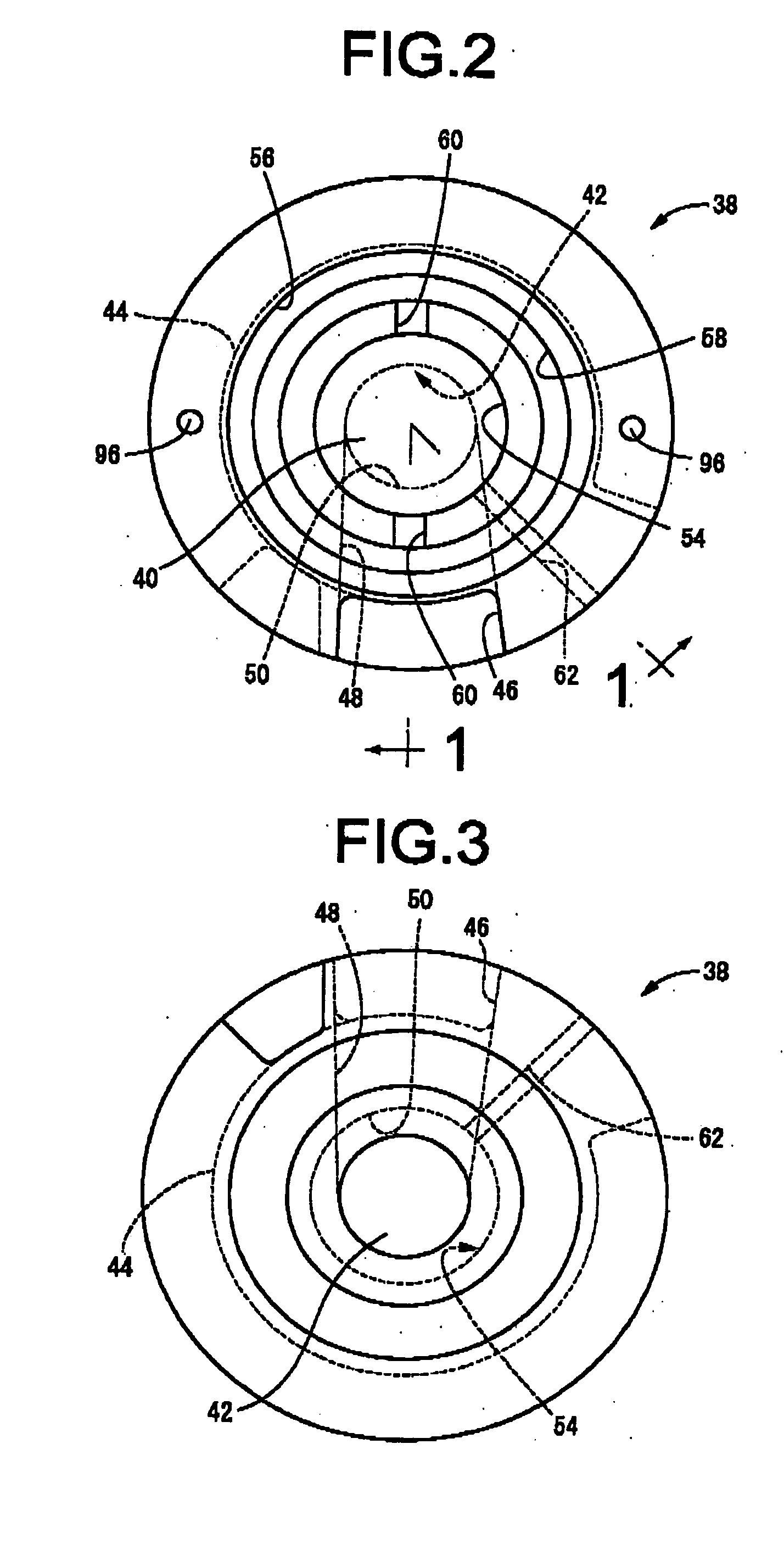

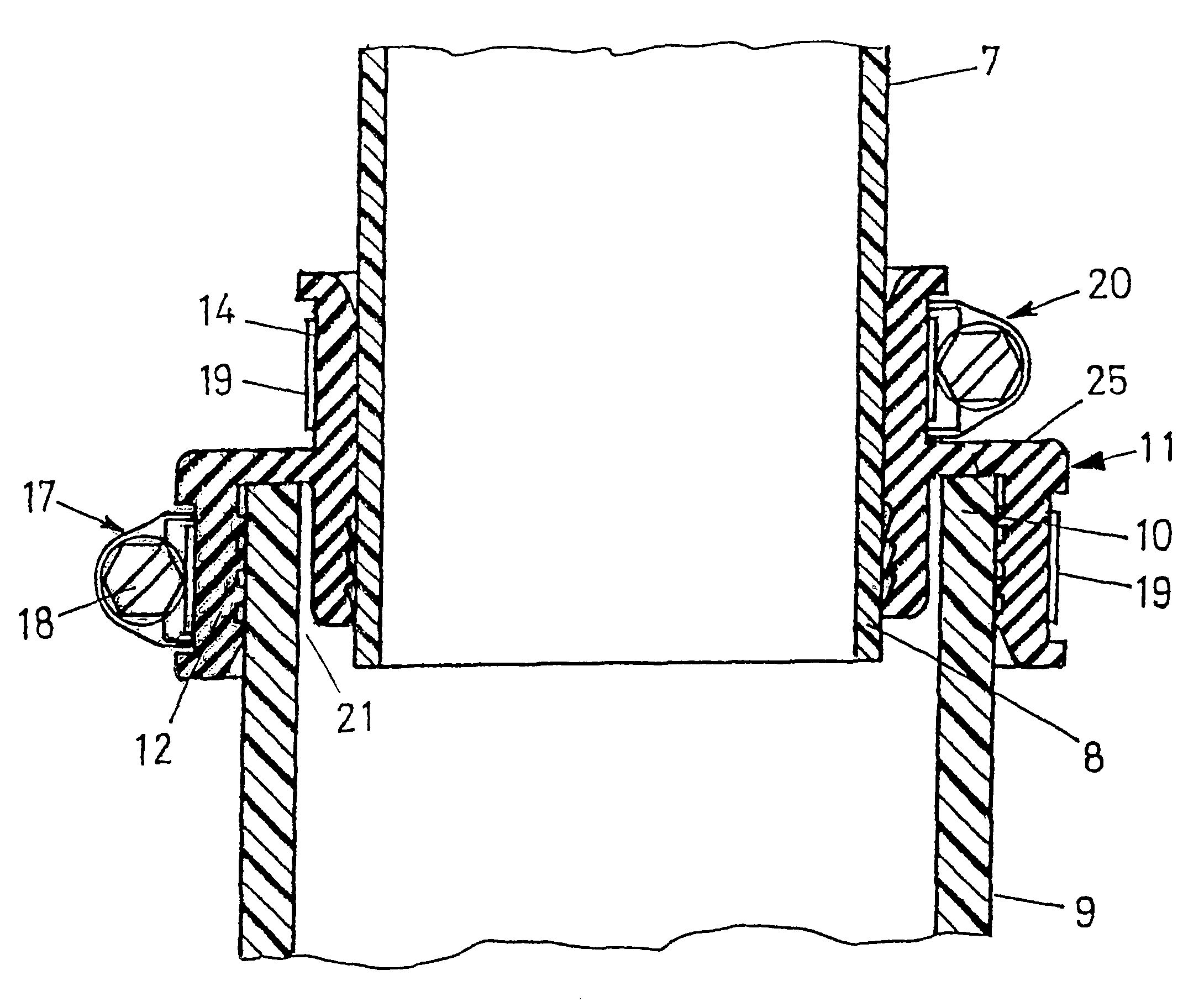

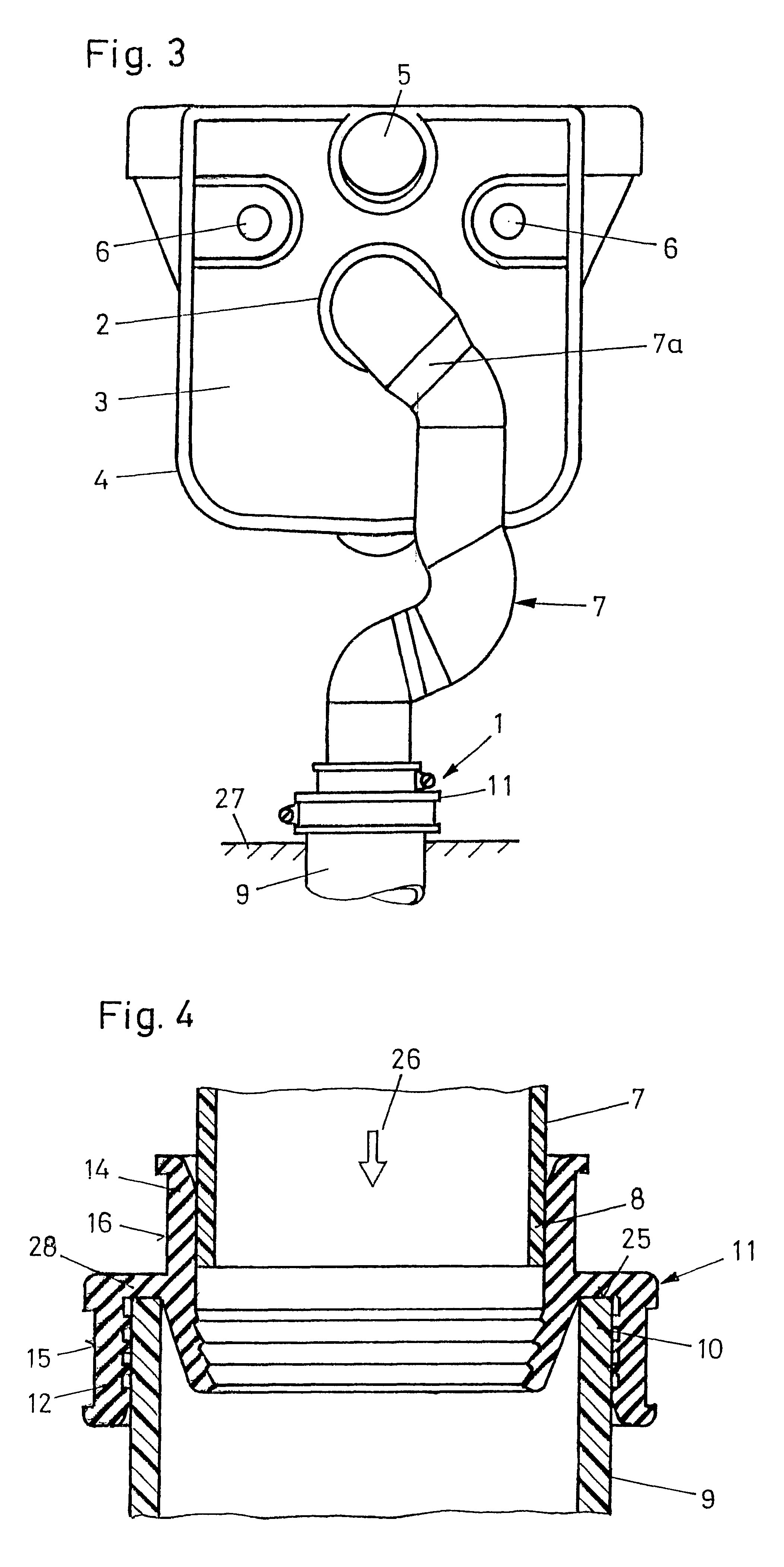

Connection between the intake end of a discharge pipe and the outlet end of a connection curve of a water toilet

InactiveUS6394505B1Improve sealingEasy to assembleSleeve/socket jointsWater closetsEngineeringMechanical engineering

A connection adapted to connect an intake end (10) of a discharge pipe (9) and an outlet end (8) of a connecting curve (7) of a water toilet, wherein the outlet end (8) projects concentrically into the intake end (10) of the discharge pipe (9), said connection comprising a rubber-elastic sealing collar (11), adapted to seal said outlet (8) and said intake end against one another, wherein the sealing collar (11) is h-shaped in a radial section, and has a first downwardly projecting region (12) adapted to tightly engage an outside of the intake end (10); a second downwardly projecting region (13) adapted to tightly engage an outside of the outlet end (8) and a upward-projecting region (14) adapted to tightly engage against the outside of the outlet end (8) of the connecting curve (7).

Owner:GEBERIT INT AG

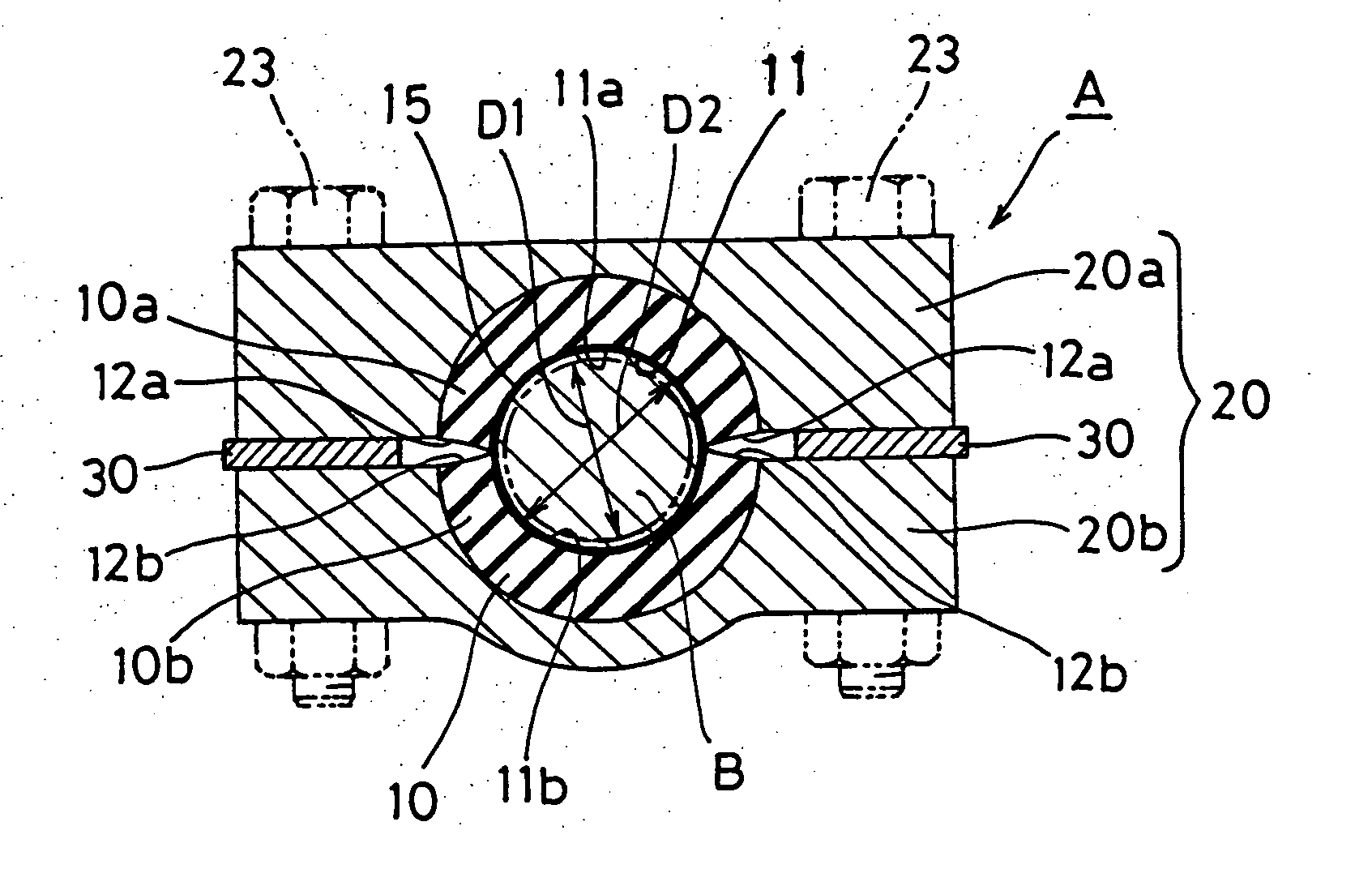

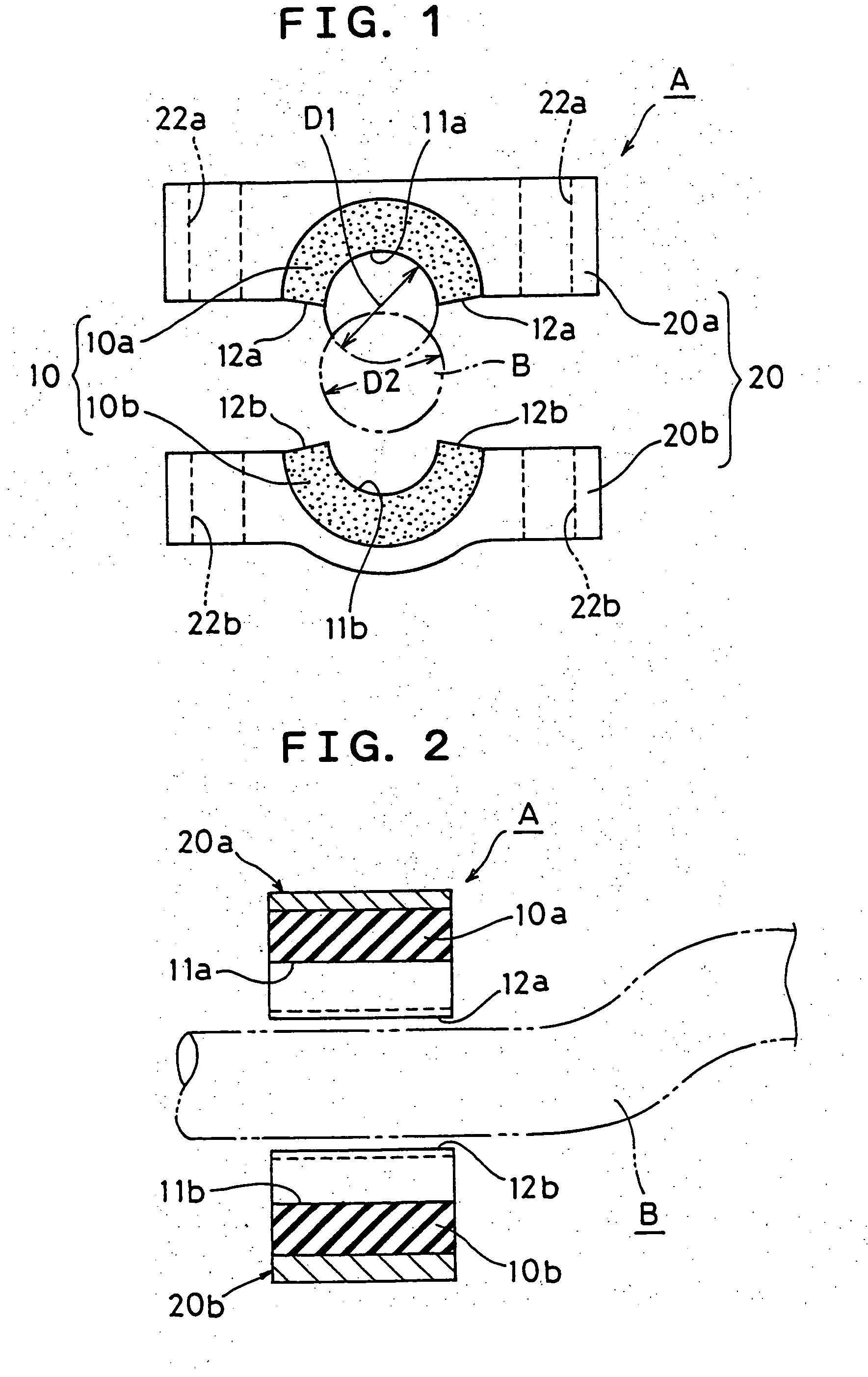

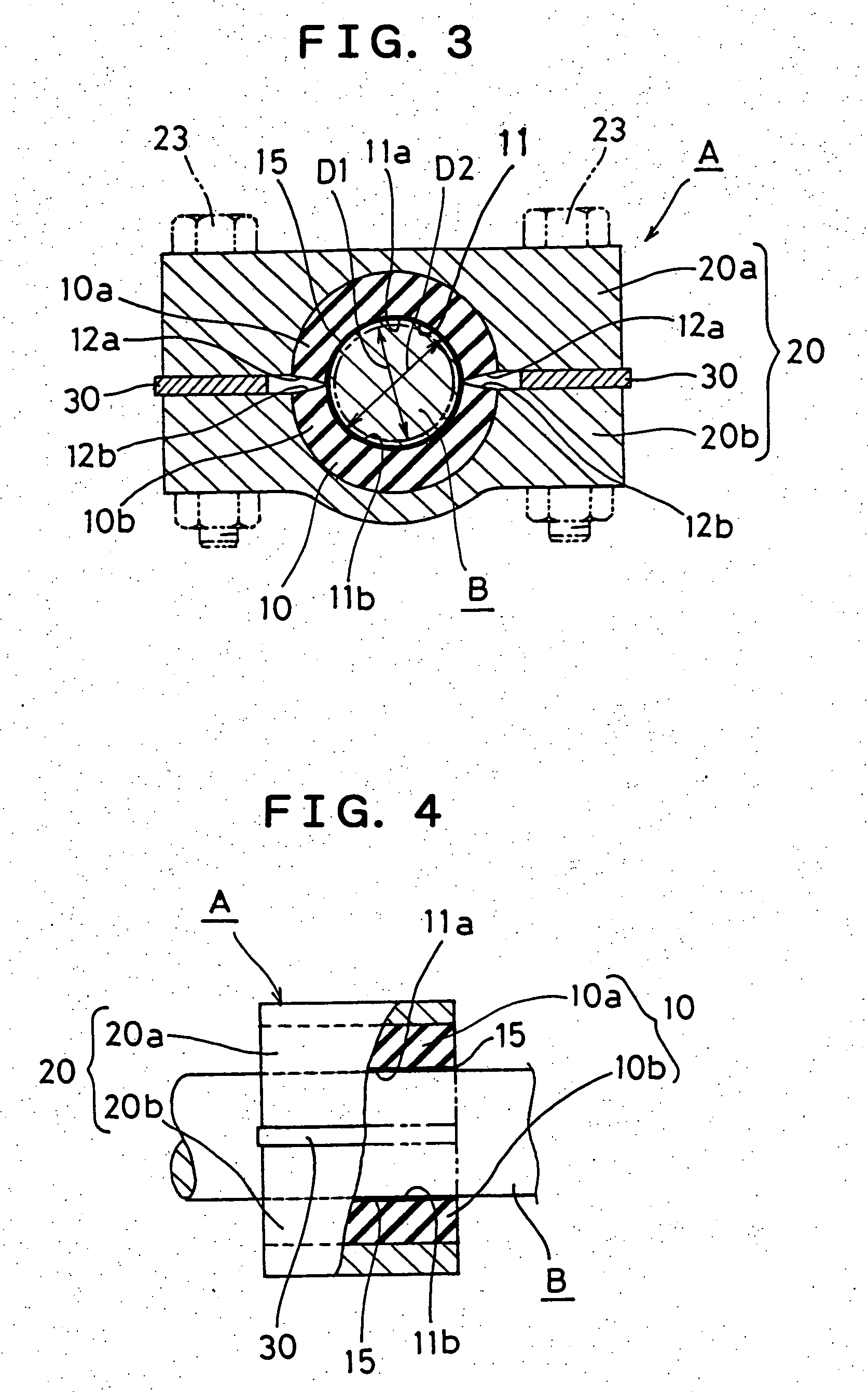

Vibration isolator and attachment method thereof

ActiveUS20060125165A1Avoid it happening againSteering stability can be satisfactorilyPortable framesStands/trestlesElastomerVulcanization

The invention is to permit a bushing main body of rubber elastomer to be adhered to a bar member while retaining a necessary contact pressure for adhering and after adhering, to permit a further compressive force to be imparted. The bushing main body (10) having a bore (11), through which the bar member (B) passes, and a bracket (20) holding the former are longitudinally split into two, respectively, the resulting split rubber bodies (10a)(10b) are vulcanization bonded to inner peripheral surfaces of the resulting half bracket members (20a)(20b). The inside diameter (D1) of both split rubber bodies as molded is made smaller than the outside diameter (D2) of the bar member, and inner peripheral surfaces (11a)(11b) at the bore are formed to be eccentric on mutually opposite sides. While pinching the bar member by both split rubber bodies, both half bracket members interposing a spacer (30) are locked together to compress the split rubber bodies thereby to adhere the peripheral surfaces at the bore to the outer peripheral surface of the bar member, and after the spacer is removed, both half members are locked so as to butt contact with each other thereby further compressing both split rubber bodies in mutually opposing directions.

Owner:TOYO TIRE & RUBBER CO LTD

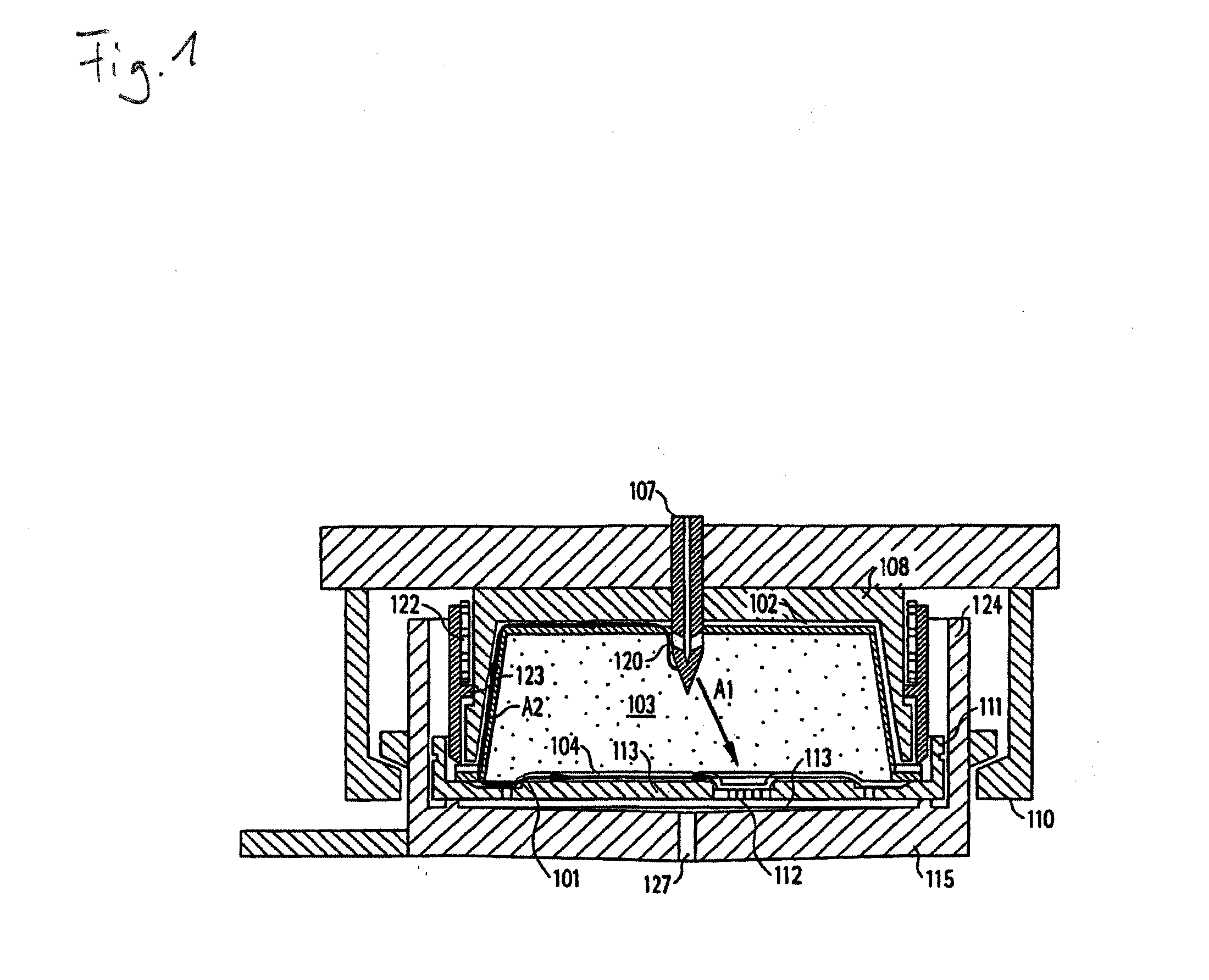

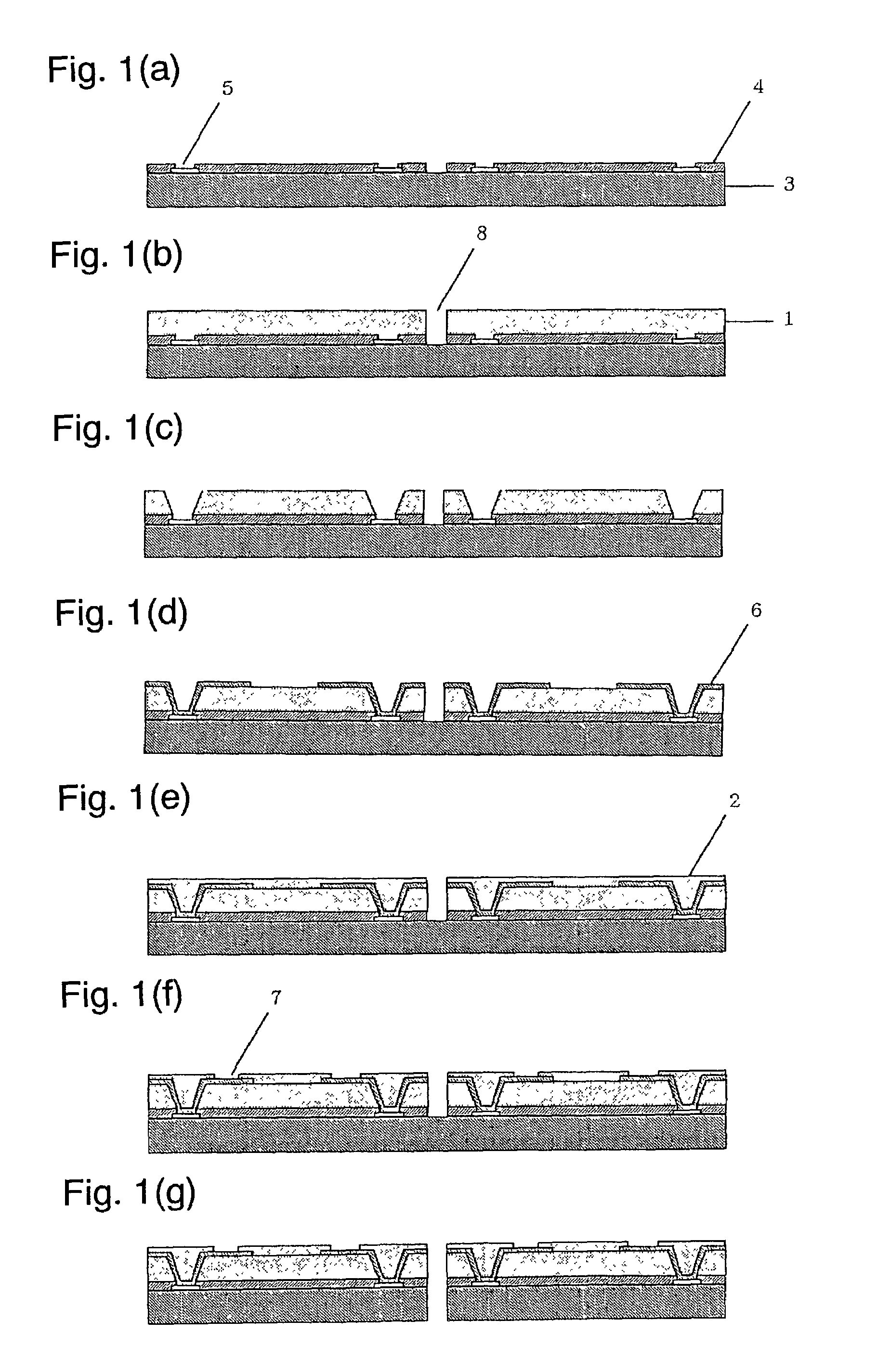

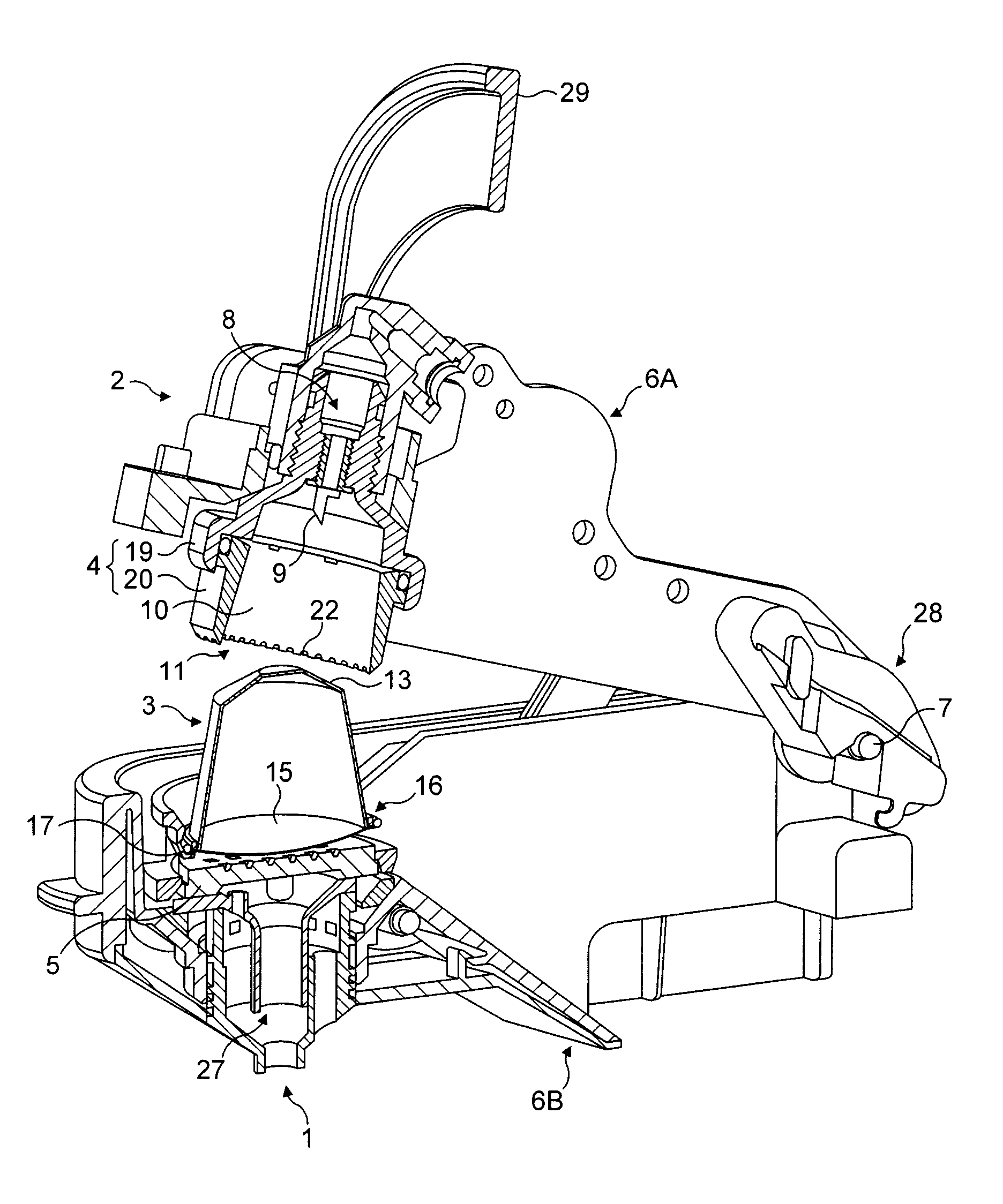

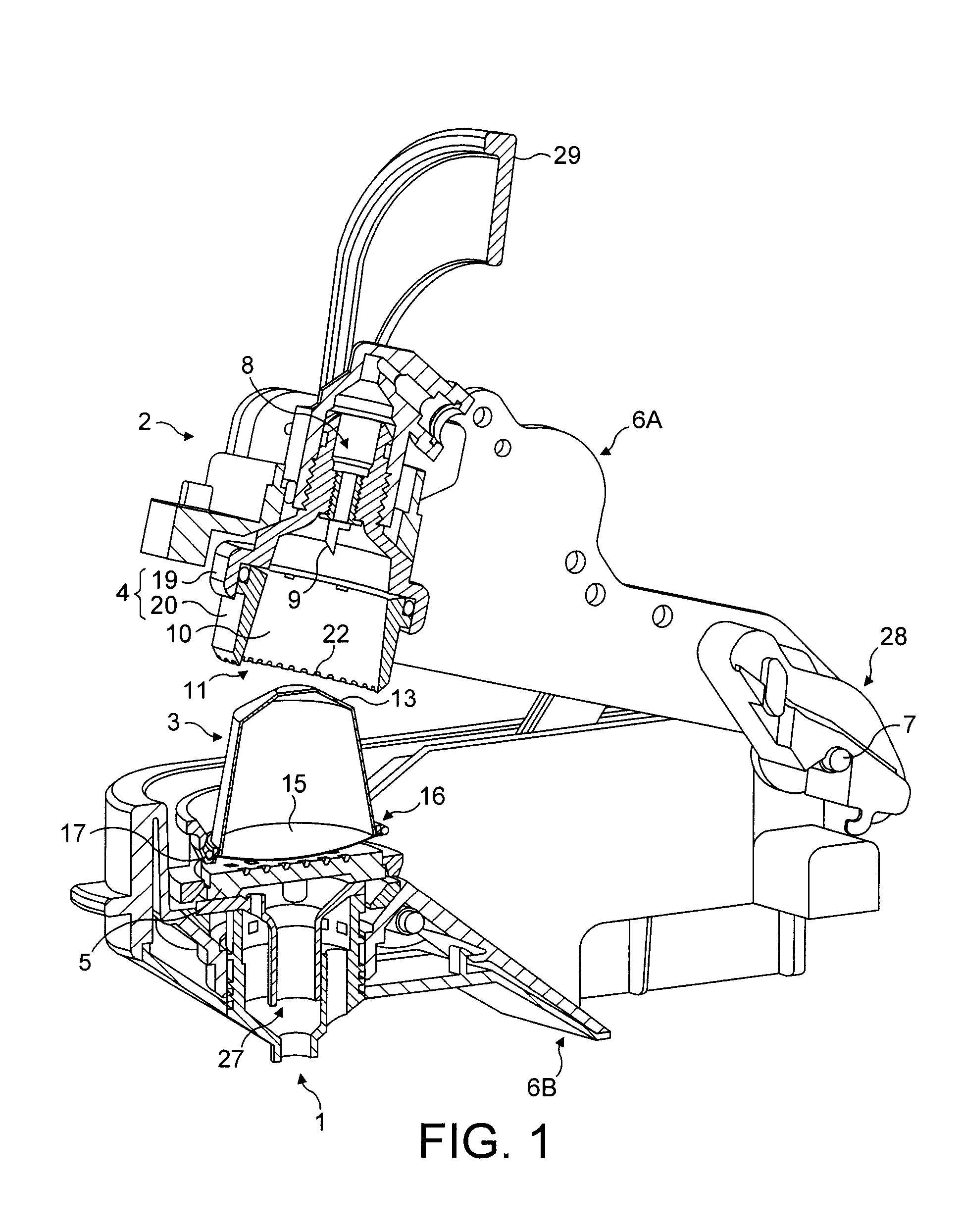

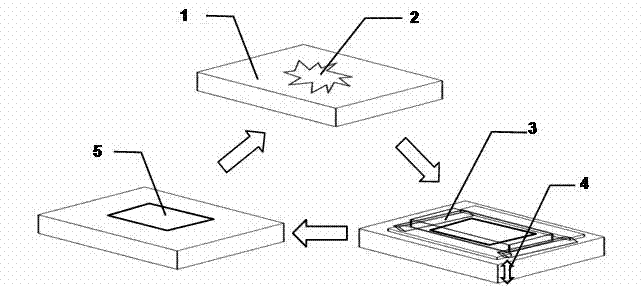

Method for applying a liquid seal rubber to a capsule

ActiveUS20110259204A1Effective interactionAccurately and conveniently placedEngine sealsClosure with auxillary devicesPolymer scienceRubber elasticity

The present invention proposes a method for providing a rubber-elastic sealing member onto a capsule (1) intended for producing a beverage in a beverage production device, wherein the capsule has a body portion (3) having a side wall (3a) and a flange-like rim portion (2), wherein the rim portion (2) extends from the side wall (3a) of the body portion (3), the method comprising the steps of:—applying an uncured sealing composition (4) in a liquid or viscous state onto the rim portion (2) of the capsule (1),—heating said applied sealing composition (4) such that the sealing composition at least partially migrates towards the side wall (3a) until it reaches the side wall, and—curing the sealing composition (4) after the migration towards the side wall (3a).

Owner:SOC DES PROD NESTLE SA

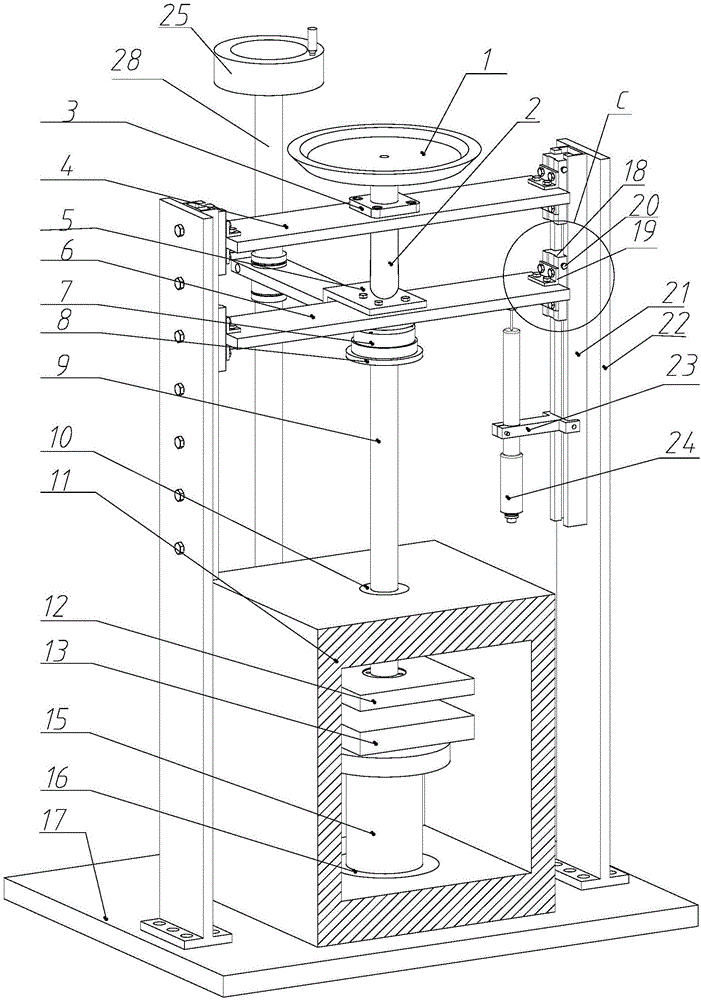

Apparatus for high-temperature creep test and stress relaxation test of rubber elastomer

ActiveCN106124337ALess volatilityThe data result is accurateMaterial strength using tensile/compressive forcesElastomerTemperature control

The invention relates to an apparatus for a high-temperature creep test and a stress relaxation test of a rubber elastomer. A stress loading part is positioned right above a temperature control part; a clamp comprises an upper pressing plate and a lower pressing plate which correspond to each other in the vertical direction, wherein the upper pressing plate is horizontally suspended in a high-temperature test box by virtue of a connecting rod, and the lower pressing plate is movably installed in the high-temperature test box; an upper crossbeam is positioned above a lower crossbeam; two ends of the upper crossbeam are fixed on a side plate, and two ends of the lower crossbeam are fixed on the side plate by virtue of a slide apparatus which can slide up and down along the side plate and can be positioned; a straight shaft vertically penetrates through the upper crossbeam, the upper end of the straight shaft is fixedly provided with a weight disc, and the lower end of the straight shaft pushes against the upper surface of the lower crossbeam; a pressure sensor is connected with a connecting rod penetrating through the top of the high-temperature test box; a displacement sensor is fixed on the side plate; and a drive part comprises a ball screw pair consisting of a ball screw and a bearing, the bearing is installed on a base, the ball screw is engaged with the bearing, and the ball screw is detachably connected with the lower crossbeam by virtue of a fixed bracket.

Owner:ZHEJIANG UNIV OF TECH

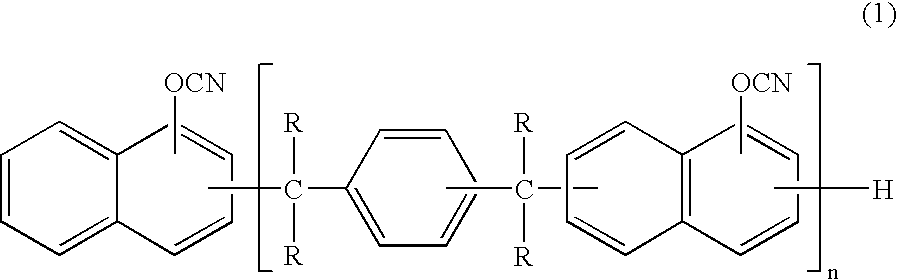

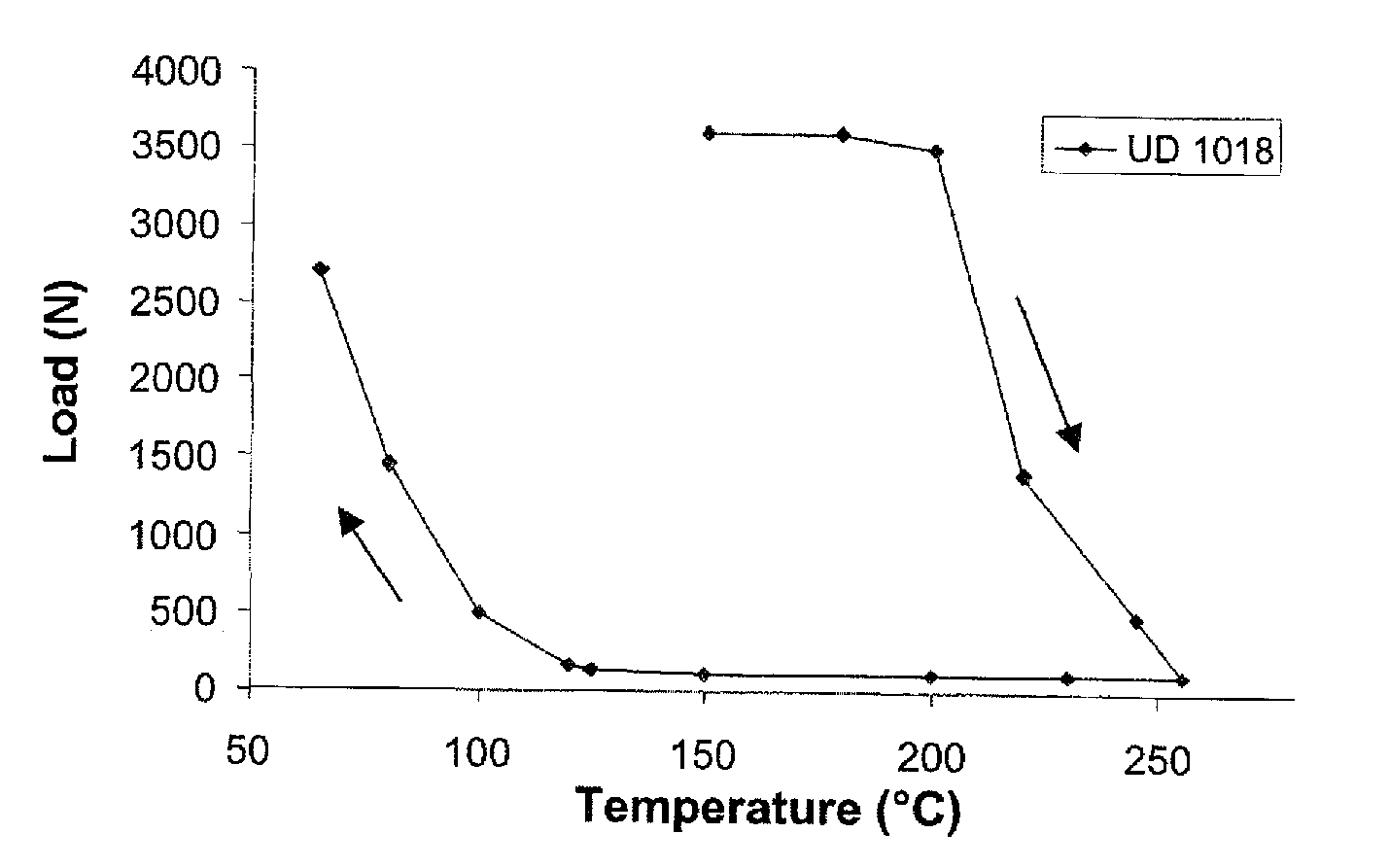

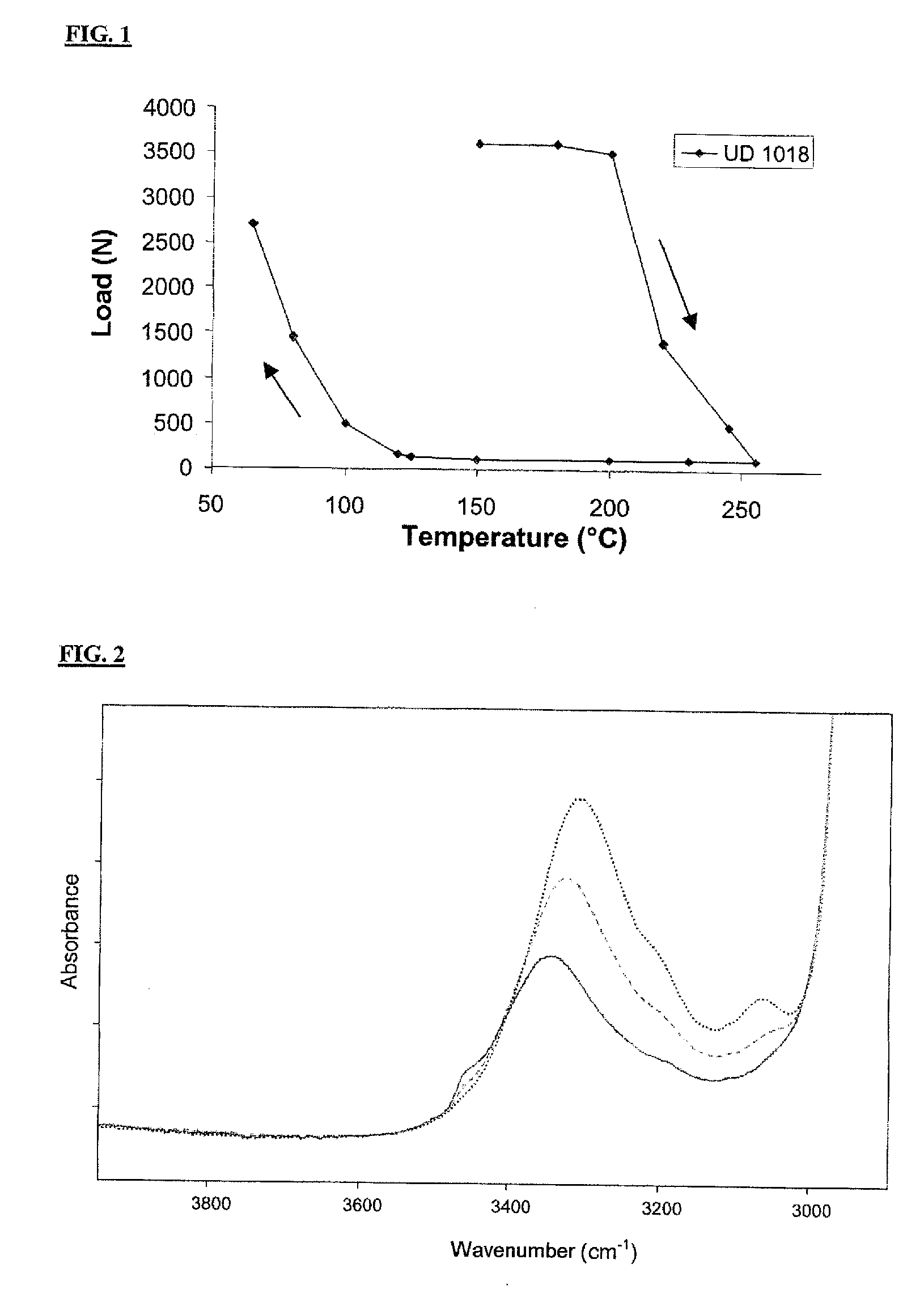

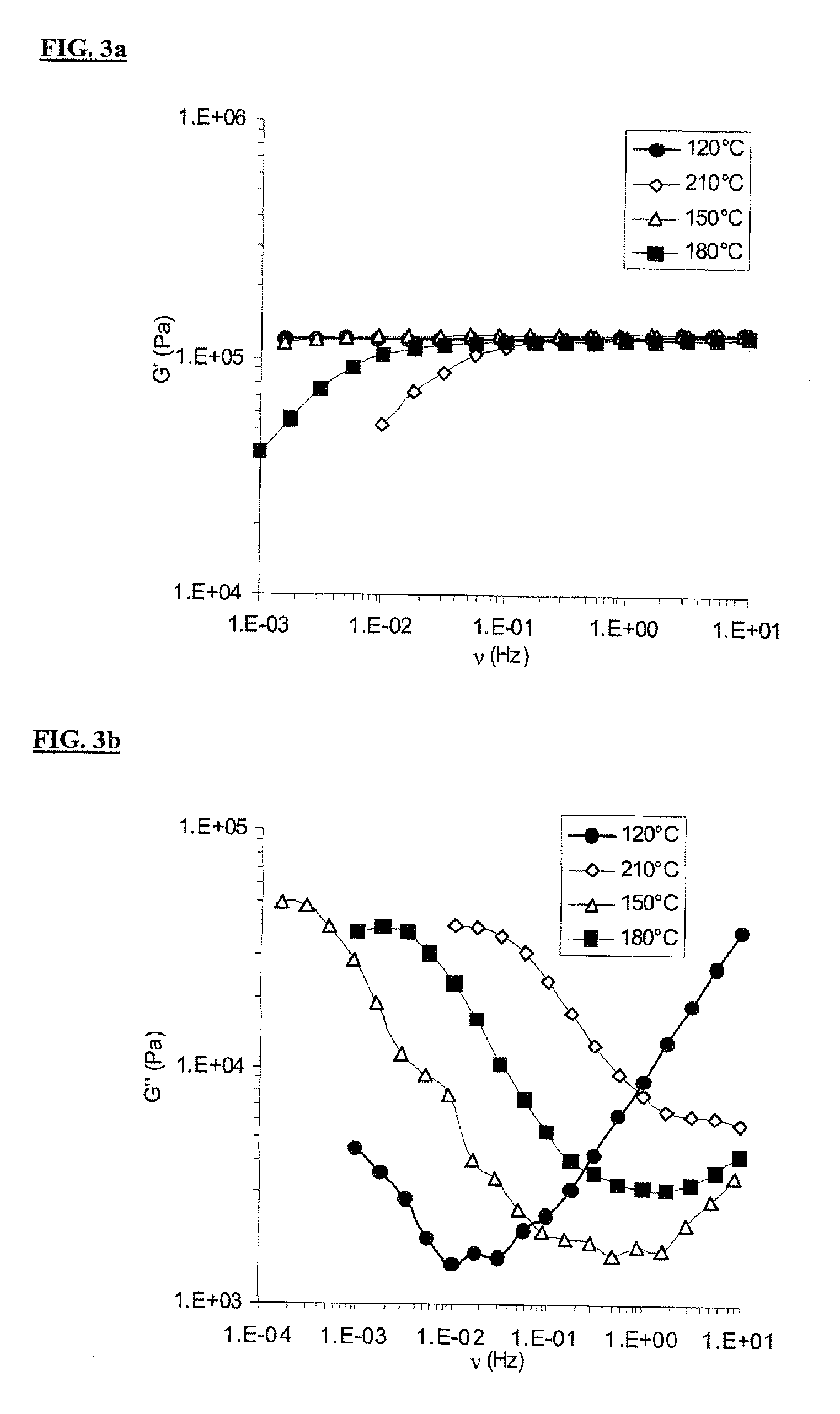

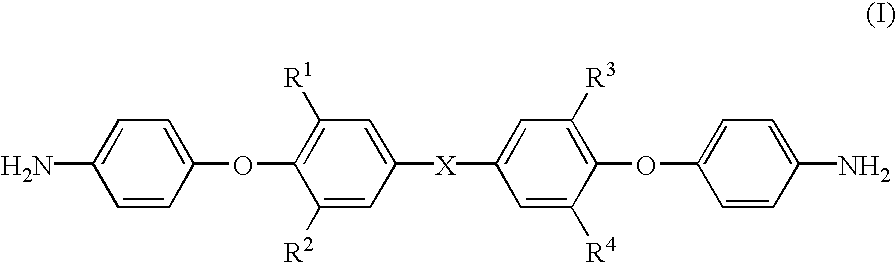

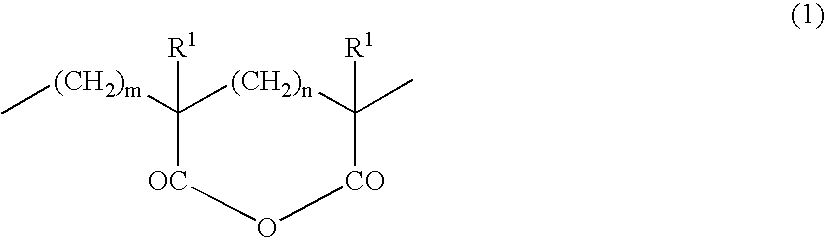

Elastic materials

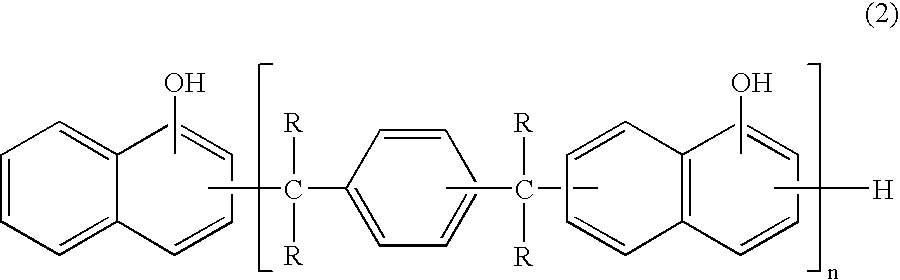

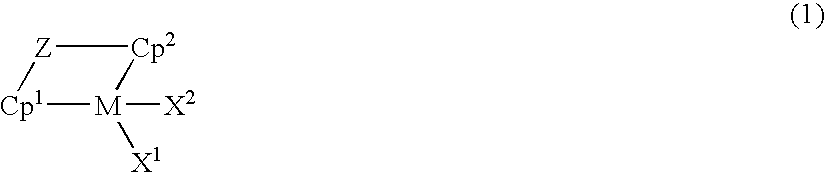

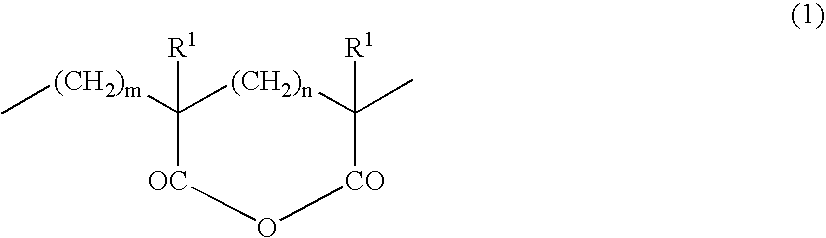

The present invention relates to materials exhibiting the property of rubbery elasticity, consisting of molecules with a mass of between 9 and 9000 g / mol, all or some of the molecules having at least three groups (also referred to as “associative groups”) capable of associating via non-covalent interactions.Although consisting of small non-polymerized molecules that are not chemically crosslinked, this material exhibits properties of rubbery elasticity. According to an embodiment of the invention, this material exhibits rubbery elasticity at ambient temperature. Above a certain temperature, the material flows like a simple liquid. The material is thermoreversible, i.e. after cooling, the material again exhibits the property of rubbery elasticity. This material is self-repairing and potentially recyclable, which is never the case with a chemically crosslinked elastomer.According to an embodiment of the invention, the molecules constituting the material of the invention bear associative groups of formula (1) below:in which A denotes oxygen, sulphur or NH; the carbon atoms of formula (1) can be substituted. Preferably, A denotes oxygen. Advantageously, the material comprises (i) molecules having at least 3 associative groups, and (ii) molecules having a single associative group.Advantageously, the molecules are obtained from fatty acid derivatives.

Owner:ARKEMA FRANCE SA

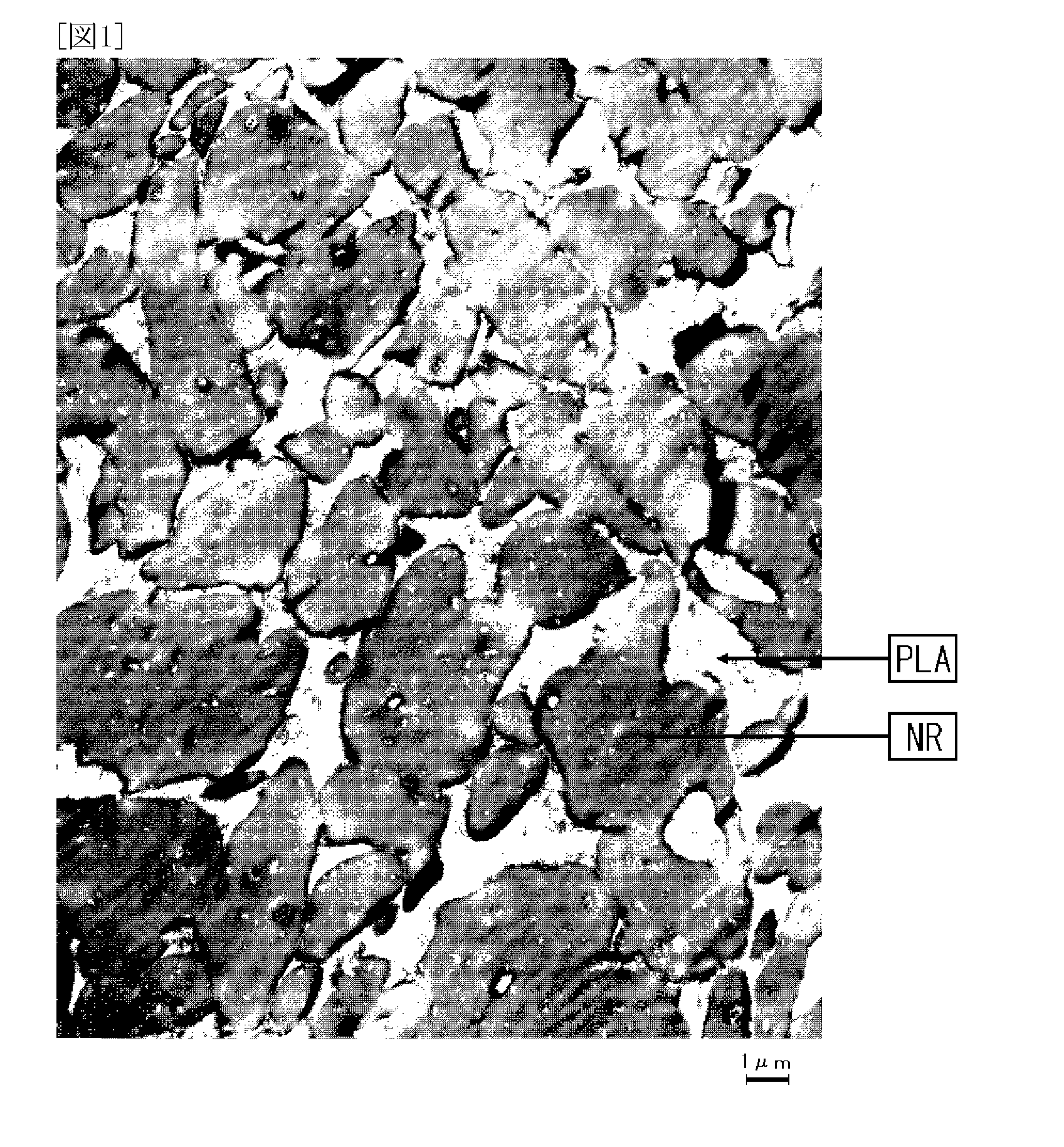

Thermoplastic elastomer composition

An object of the present invention is to provide: a thermoplastic elastomer composition, which is accompanied by less environmental burden, and which has flexibility, rubber elasticity, formability and recyclability; and a molded product obtained using the same. The present invention is directed to a thermoplastic elastomer composition comprising a thermoplastic resin (A) derived from a non-petroleum source, and at least one rubber (B) selected from a natural rubber, a diene polymer rubber, an olefin polymer rubber, an acrylic rubber and a silicone rubber, the thermoplastic elastomer composition being obtained by allowing the rubber (B) to be dynamically crosslinked with a crosslinking agent (C) in the presence of the thermoplastic resin (A). Preferred (A) is a polylactic acid, or a poly(3-hydroxybutyrate), and preferred (B) is a natural rubber.

Owner:KANEKA CORP

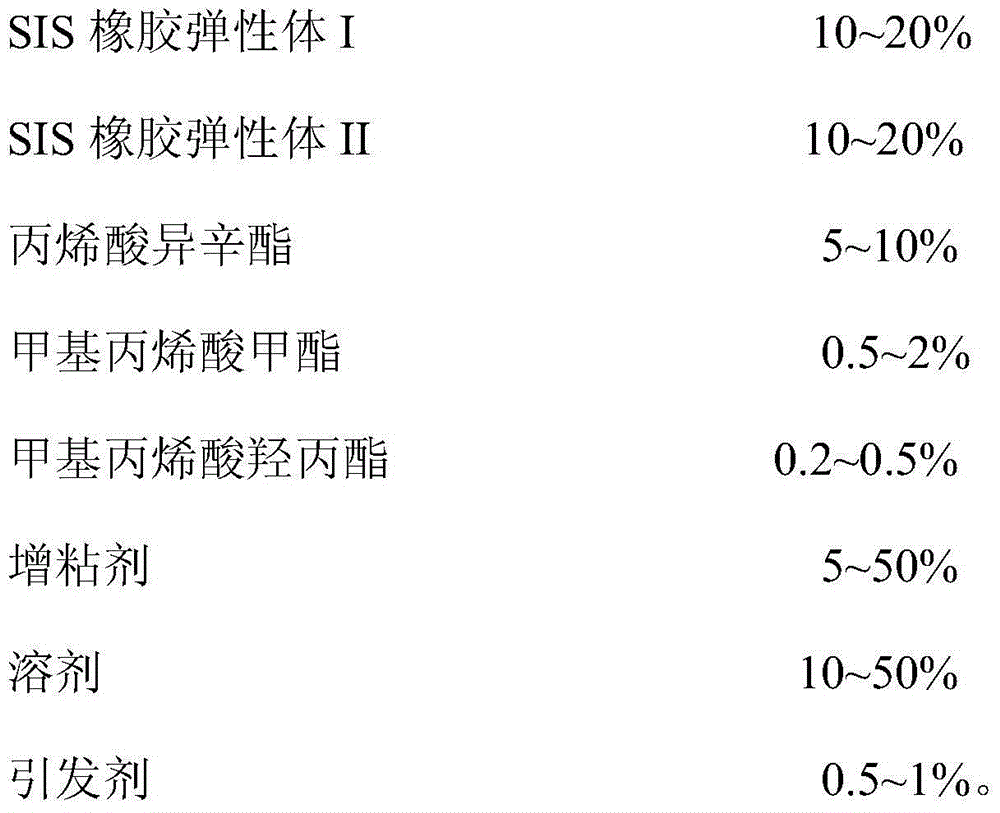

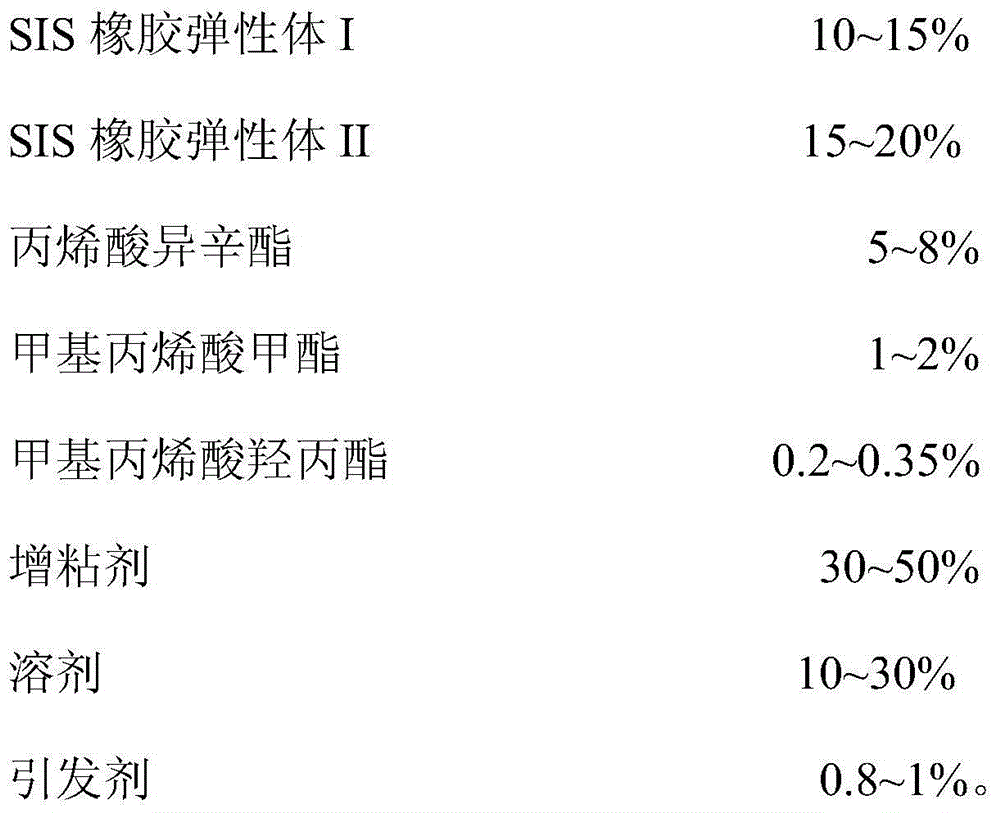

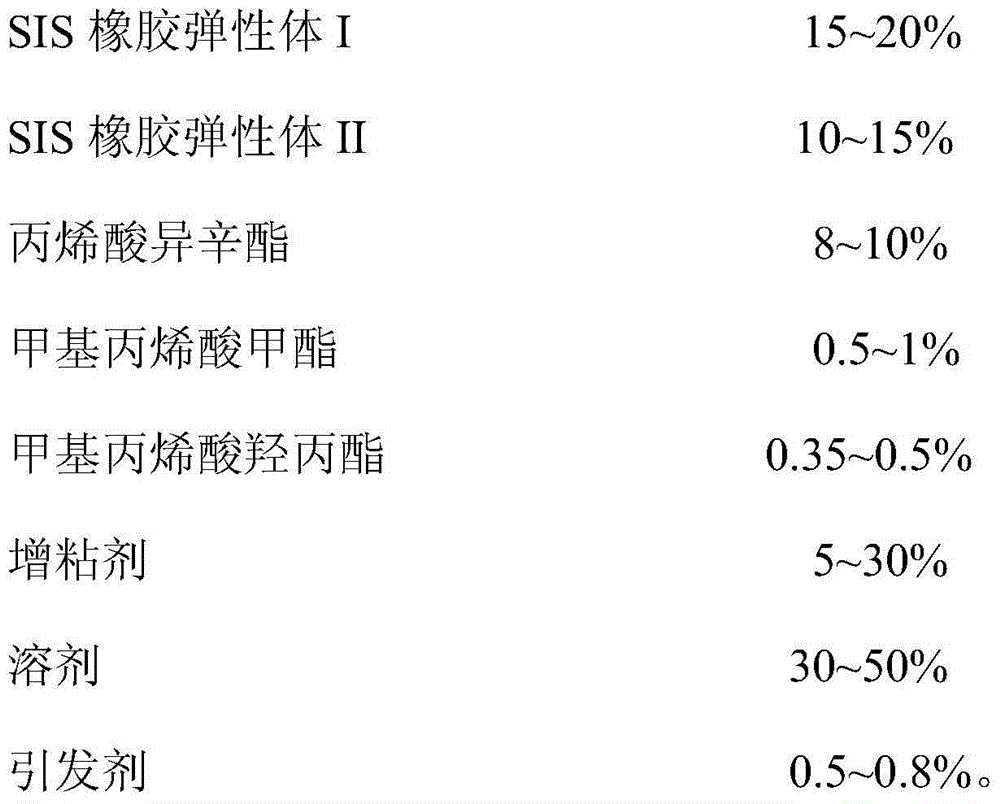

Acrylic acid modified hot-melt pressure-sensitive adhesive for bearing adhesive tape and preparation method of acrylic acid modified hot-melt pressure-sensitive adhesive

The invention relates to an acrylic acid modified hot-melt pressure-sensitive adhesive for a bearing adhesive tape. The acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following raw materials in percentage by weight: 10-20 percent of an SIS rubber elastomer I, 10-20 percent of an SIS rubber elastomer II, 5-10 percent of 2-ethylhexyl acrylate, 0.5-2 percent of methyl methacrylate, 0.2-0.5 percent of hydroxypropyl methacrylate, 5-50 percent of a tackifier, 10-50 percent of a solvent, and 0.5-1 percent of an initiator. The acrylic acid modified hot-melt pressure-sensitive adhesive is high in cohesion, high in adhesion stress, high in ageing resistance, strong in adhesive force on a substrate, and wide in application range. A preparation method of the acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following steps: the materials are weighed: the SIS rubber elastomer I, the SIS rubber elastomer II and a solvent account for the total amount of the solvent are added in a first reaction kettle, and 2-ethylhexyl acrylate, methyl methacrylate, hydroxypropyl methacrylate, the initiator and the rest of the solvent are added in a second reaction kettle to form a mixed solution; the mixed solution is slowly added in the first reaction kettle; the tackifier is added in the first reaction kettle, and the solvent is distilled out; the materials are discharged in heating, and the finished product is obtained. The preparation method is simple in process, and high in the production efficiency and yield.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

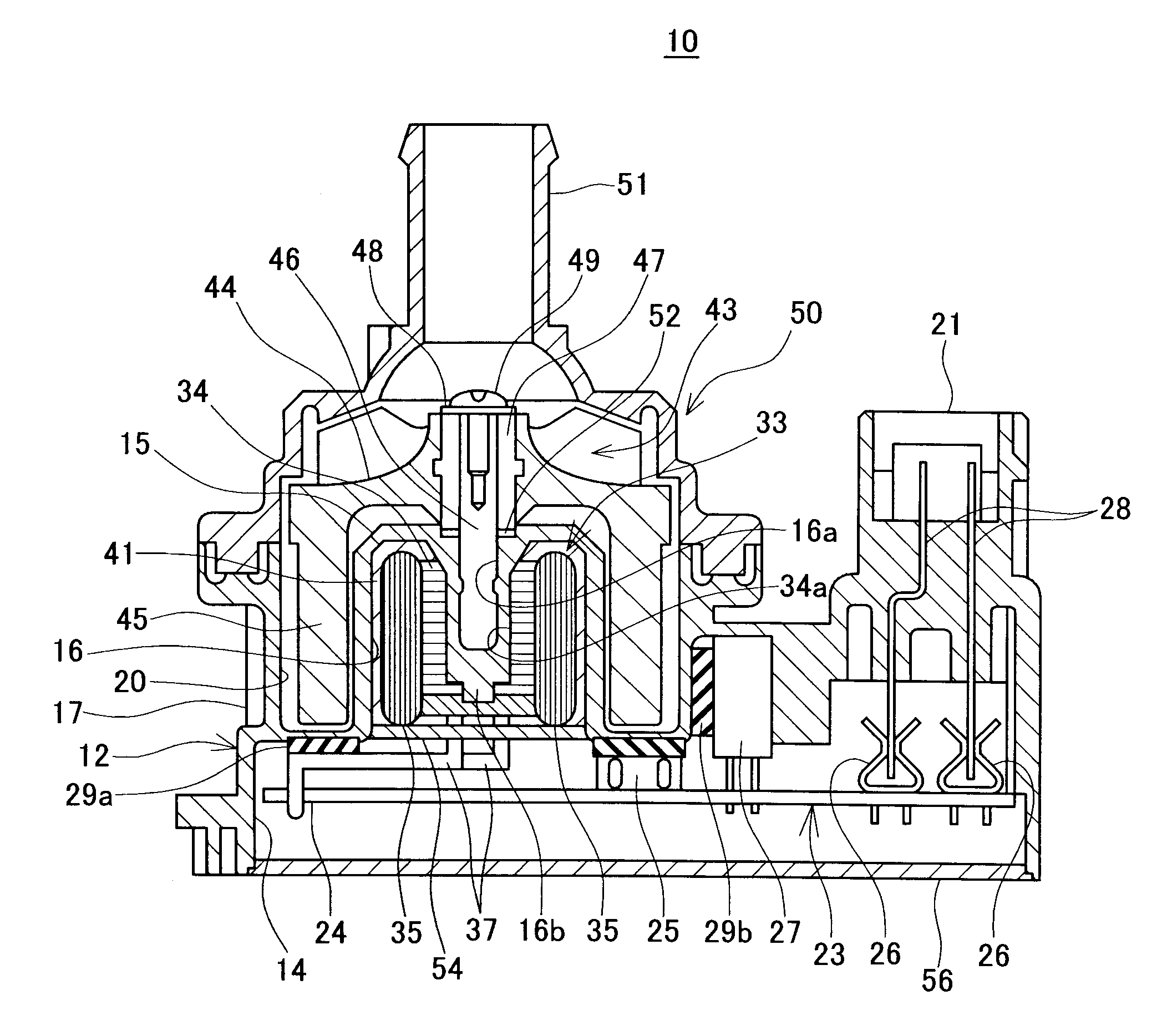

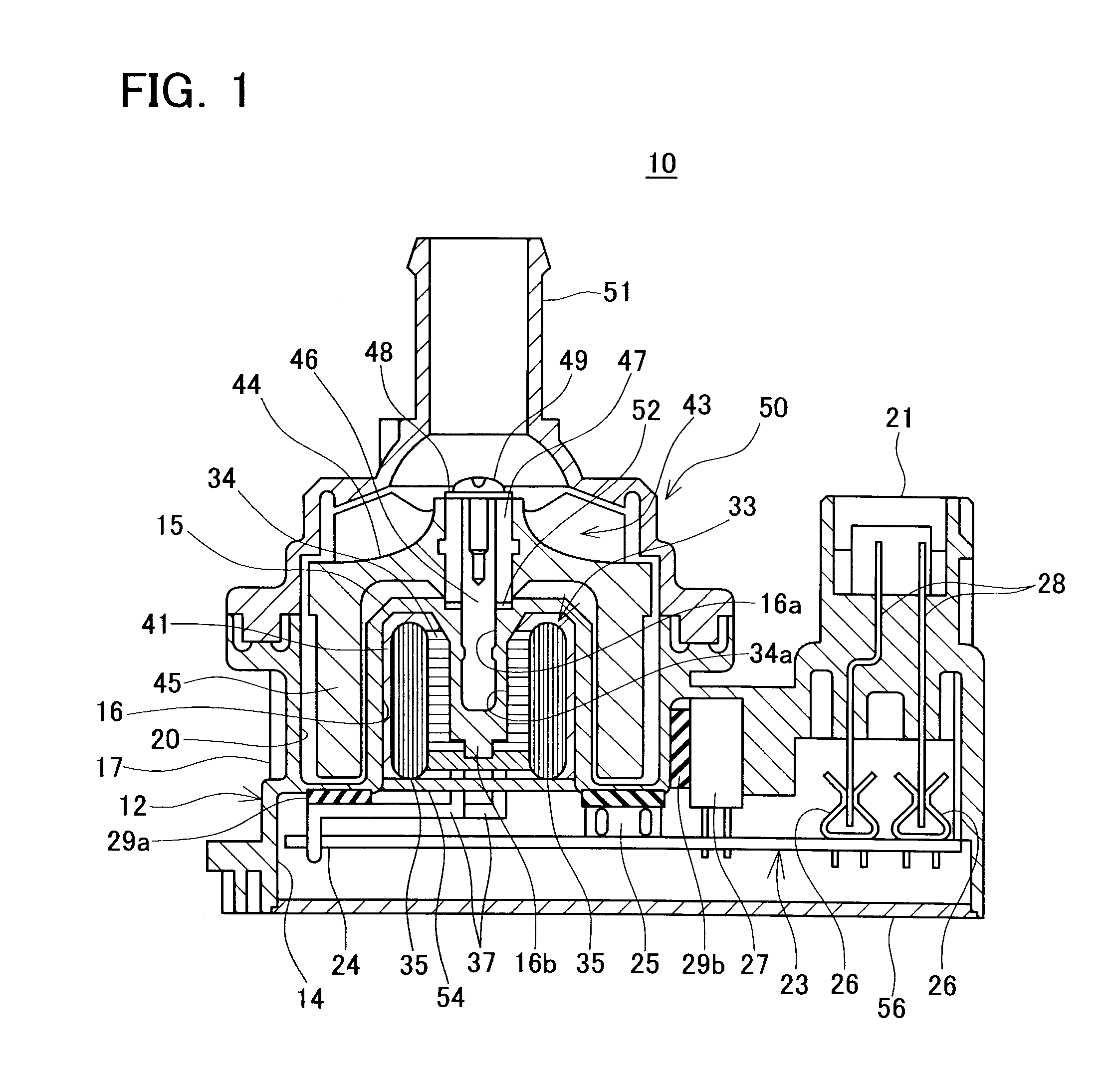

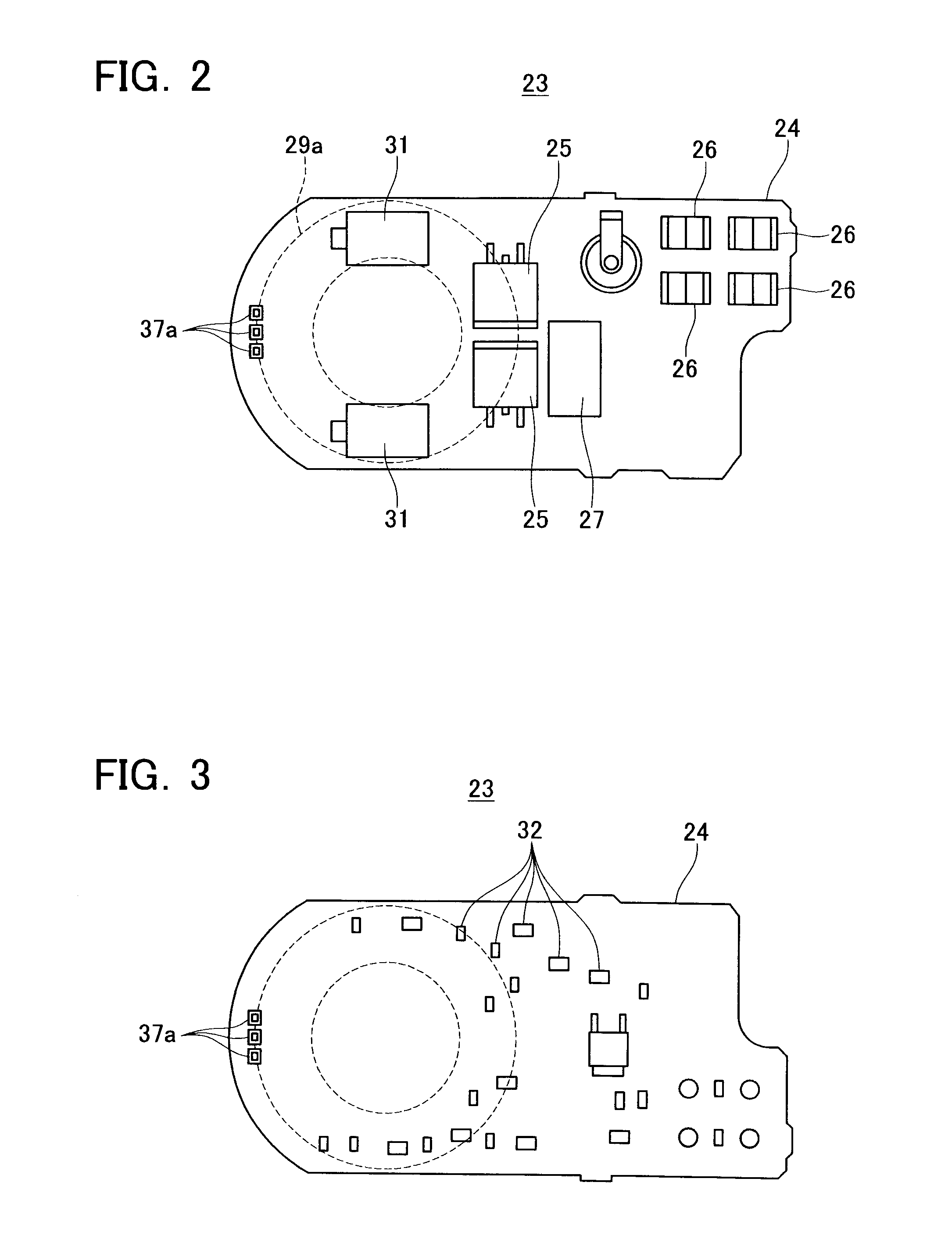

Fluid pump

InactiveUS20080118380A1Efficiently cooling semiconductor deviceReduce vibrationPump componentsPiston pumpsImpellerPump chamber

Fluid pump (10) comprises a casing provided with a partition separating a pump chamber and a housing chamber. Impeller (43) is disposed within the pump chamber. Stator (33), semiconductor device (25), terminal (37), and sheet member (29a) are disposed within the housing chamber. Terminal (37) electrically connects the semiconductor device to the stator. Sheet member (29a) may have rubber elasticity. Preferably, the sheet member has s a first plane surface, which makes contact in a planar manner with the semiconductor device, and a second plane surface which makes contact in a planar manner with the partition of the casing.

Owner:AISAN IND CO LTD

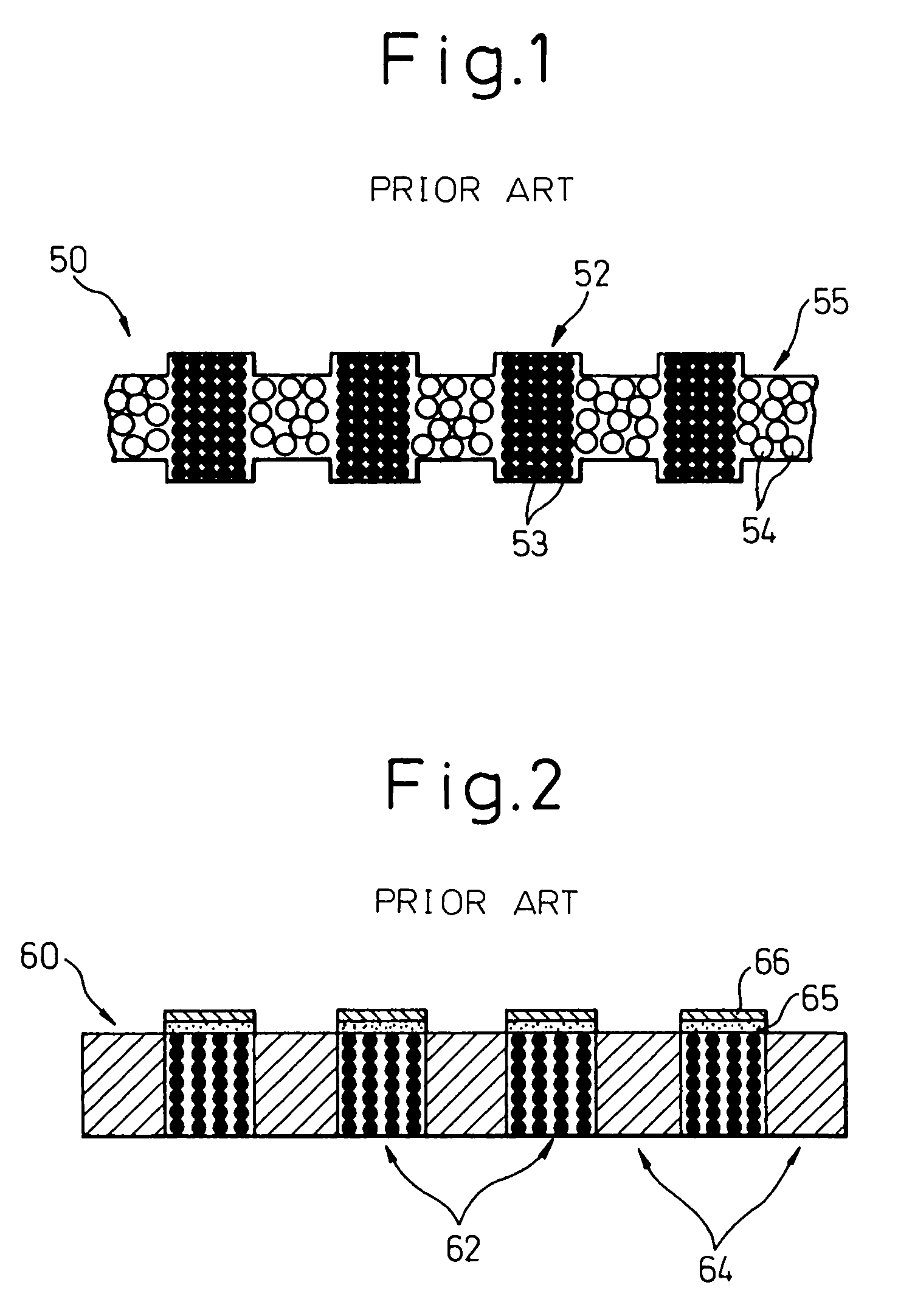

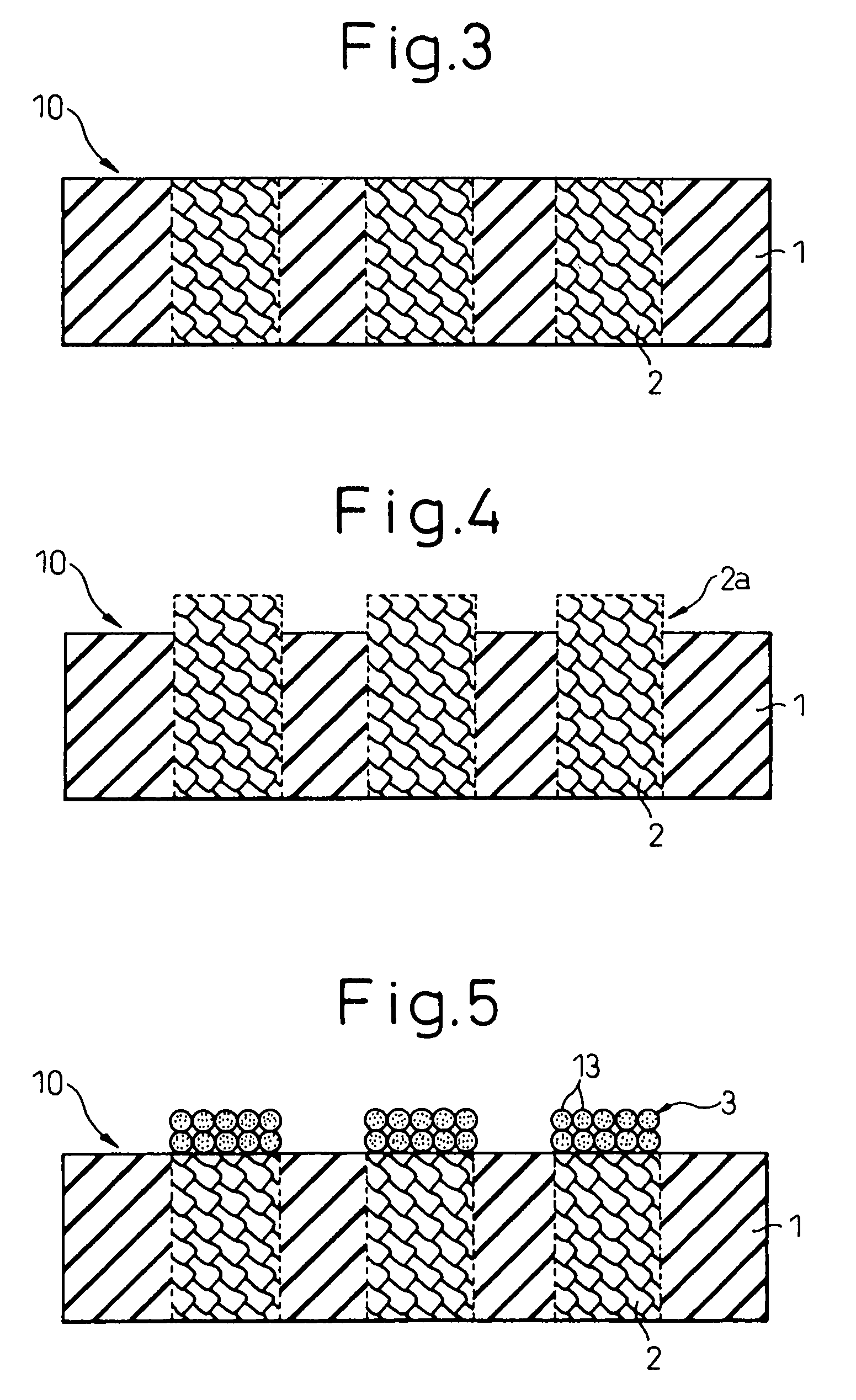

Anisotropic conductive sheet, production process, contact structure, electronic device and inspection apparatus for operation test

InactiveUS7267559B2Life span is longSimple processCoupling device connectionsNon-insulated conductorsElectricitySurface layer

An anisotropic conductive sheet comprising an insulating base material and a plurality of conductive passages embedded at predetermined positions in the insulating base material, penetrating the insulating base material in the thickness direction. The conductive passage comprises a matrix consisting of non-silicone material or silicone material having rubber elasticity, the matrix material being filled into through-holes formed at a predetermined position in the base material and then hardened, and a conductive filler dispersed in the matrix at an amount capable of exhibiting conductivity at all times. A surface layer of conductive material is capable of functioning as a contact and ensuring an electrical connection by piercing a surface layer of an opponent when the surface layer is used as a contact, such as a layer of fine conductive particles is further provided on at least one of the end faces of the conductive passage. An anisotropic conductive sheet of the present invention can be advantageously used in an electronic device or inspection apparatus, used for an operation test, as a contactor.

Owner:FUJITSU LTD

Room temperature-curable organopolysiloxane compositions

InactiveUS20070088123A1High bonding strengthGood rubber elasticitySynthetic resin layered productsCellulosic plastic layered productsPolymer scienceRubber elasticity

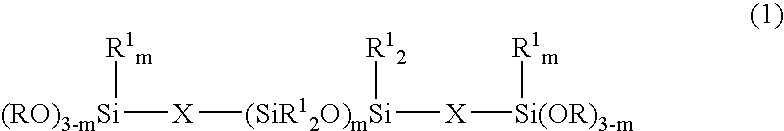

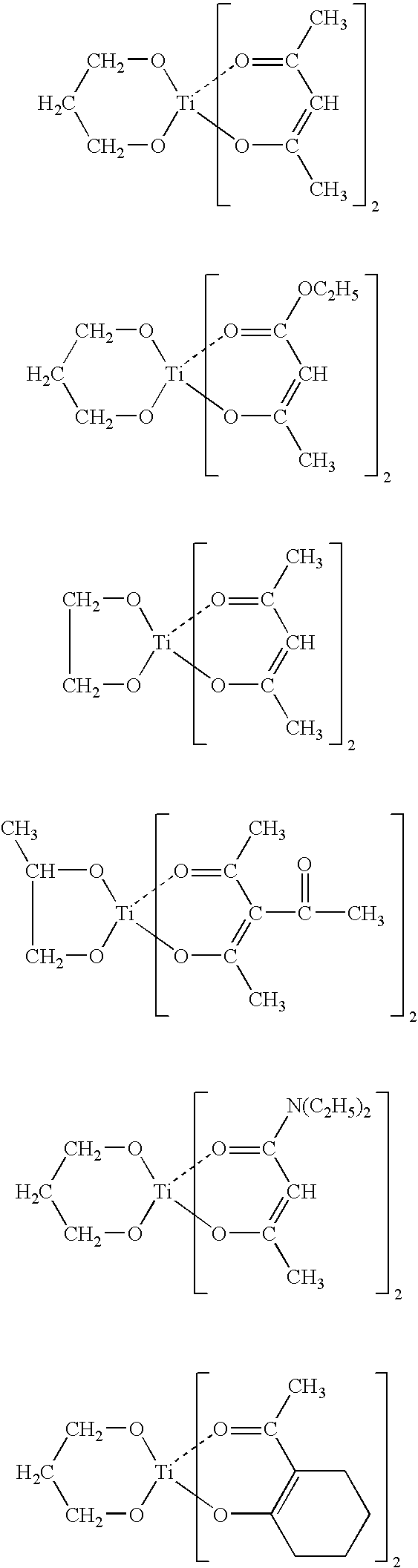

A RTV organopolysiloxane composition comprising (A) an organopolysiloxane containing at least two Si—OH or organoxy radicals and having a viscosity of at least 500 mPa-s at 25° C., (B) an organosilane containing at least two organoxy radicals, (C) an organotin catalyst, and (D) an Si—OH radical-containing organopolysiloxane having a viscosity of up to 300 mPa-s at 25° C. It has shelf stability and discoloration resistance in the uncured state and exhibits rubber elasticity and adhesion in the cured state.

Owner:SHIN ETSU CHEM IND CO LTD

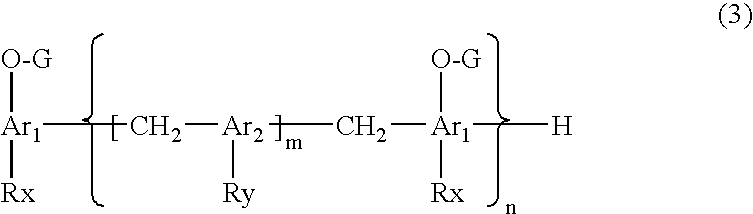

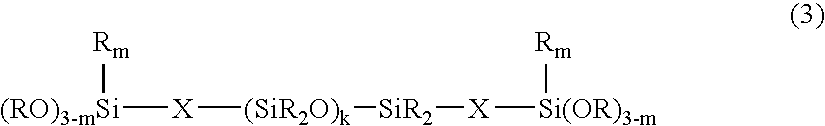

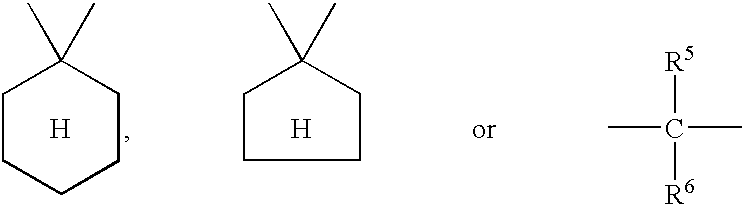

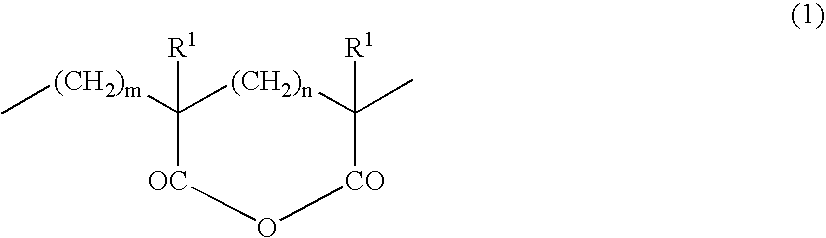

Room temperature-curable organopolysiloxane composition

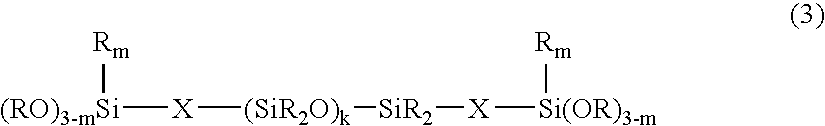

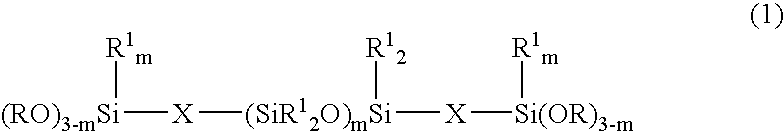

A room temperature-curable polyorganosiloxane composition is provided. The composition comprises(A) 100 parts by weight of a polyorganosiloxane represented by the following general formula (1):wherein R is a monovalent hydrocarbon group containing 1 to 5 carbon atoms, R1 is independently a substituted or unsubstituted monovalent hydrocarbon group containing 1 to 10 carbon atoms; n is an integer of at least 10; X is oxygen atom or an alkylene group containing 2 to 5 carbon atoms, and m is independently an integer of 0 or 1; or a mixture of such polyorganosiloxane,(B) 0.1 to 50 parts by weight of a partial hydrolysate of an organosilicon compound having at least 3 hydrolyzable groups bonded to silicon atom in one molecule;(C) 1 to 500 parts by weight of at least one filler,(D) 0.01 to 10 parts by weight of a curing catalyst, and(E) 0.1 to 10 parts by weight of a silane coupling agent.The present invention is capable of forming a rubber elastomer which exhibits excellent adhesion to resins whose adhesion has been difficult, for example, polyimide resin.

Owner:SHIN ETSU CHEM IND CO LTD

Environment-friendly and decorative nail-free glue and preparation method thereof

ActiveCN103484043AReduce contentNo pollution in the processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention belongs to environment-friendly and decorative glue, particularly relates to environment-friendly and decorative nail-free glue and a preparation method thereof. The environment-friendly and decorative nail-free glue comprises the following components: 5.0 to 20.0 percent of rubber elastomers, 10.0 to 30.0 percent of tackifying resin, 15.0 to 35.0 percent of reinforcing fillers, 2.0 to 8.0 percent of a thixotropic agent, 10.0 to 40.0 percent of a solvent and 0.1 to 1.0 percent of anti-oxidant; the preparation method of the environment-friendly and decorative nail-free glue comprises the following steps: putting the solvent into a high-speed stirrer, sequentially adding the rubber elastomers and the tackifying resin after a stirrer is started, stirring for 2 to 8 hours until all materials are dissolved to be a uniform liquid, then slowly adding the enhancing fillers and stirring uniformly so as to prepare a flowable slurry mixture, then adding the thixotropic agent and the anti-oxidant, and stirring uniformly so as to prepare the environment-friendly and decorative nail-free glue. The environment-friendly and decorative glue provided by the invention is environmental-friendly, is convenient to use, has high product bonding intensity and is excellent in durability.

Owner:GLEIHOW NEW MATERIALS CO LTD

Alpha-Olefin-Based Polymer Composition, Molded Product Formed From the Composition, and Novel Polymer

ActiveUS20070225431A1Excellently balanced in flexibilityExcellently balanced in rubber elasticityRubber elasticityHeat resistance

A composition having excellent transparency, flexibility, rubber elasticity, thermal resistance, impact resistance, abrasion resistance and the like, a composition having excellent rigidity and impact resistance as well as excellently balanced in whitening resistance, abrasion resistance and heat sealability, and a composition having excellent rubbery properties, thermal resistance, abrasion resistance and flexibility are provided. A composition comprising a specific propylene•α-olefin copolymer for which, in a signal chart measured by 13C-NMR and predetermined such that the peak present at the highest magnetic field among the signals originating from CH (methine) of the constituent unit derived from an α-olefin having 4 to 20 carbon atoms is to be at 34.4 ppm, an absorption intensity A at about 22.0 to 20.9 ppm and an absorption intensity B at about 19.0 to 20.6 ppm satisfy the following relational expressions (i) and (ii) with respect to an absorption intensity C at about 19.0 to 22.0 ppm, which is assignable to propylene methyl: (A / C)×100≦8 (i), and (B / C)×100≧60 (ii), a molded product thereof, and the α-olefin-based copolymer are provided.

Owner:MITSUI CHEM INC

Wiper lever with a driven wiper arm and a wiper blade

InactiveUS20080034530A1Noise is generatedAvoid problemsWindow cleanersVehicle cleaningRubber elasticityControl theory

Wiper lever (10) with a driven wiper arm (12) and a wiper blade (16) linked to it for cleaning windows, particularly those of motor vehicles, which is provided with a band-like, long-stretched-out, elastic supporting element (30), which features, on its lower band surface facing the window, a long-stretched-out, rubber elastic wiper strip (24) that can be applied to it, on whose upper band surface (29), particularly in the longitudinal middle area of the supporting element (30), a coupling part (32) is situated and wind deflector strip partial sections (52) extending to the ends of the supporting element are arranged on both sides of the coupling part (32). An especially harmonic transition between the wiper blade (16) and the wiper arm (12) is achieved in the area of the joint (46, 47) connecting these two wiper lever parts if the wiper lever (10) is provided with a cap (60) to cover the connection area between the wiper blade (16) and the wiper arm (12).

Owner:ROBERT BOSCH CORP

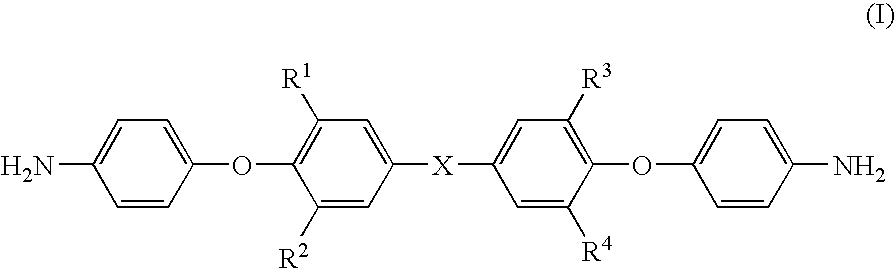

Resin composition, heat-resistant resin paste and semiconductor device using them and method for manufacture thereof

InactiveUS7061081B2Non-fibrous pulp additionElectric ignition installationLiquid stateRubber elasticity

There are disclosed a resin composition comprising (A) a heat-resistant resin soluble in a solvent at room temperature, (B) a heat-resistant resin which is insoluble in a solvent at room temperature but becomes soluble by heating, and (C) a solvent; a heat-resistant resin paste further containing (D) particles or liquid state material D showing rubber elasticity; and a semiconductor device using the same and a method for producing the same.

Owner:HITACHI CHEM CO LTD

Thermoplastic elastomer composition and molded article thereof

InactiveUS20060276592A1Superior in rubber elasticity (compression set)High mechanical strengthSpecial tyresRubber elasticityThermoplastic elastomer

According to the present invention, there are provided a thermoplastic elastomer composition which includes (A1) an ethylene•α-olefin-based copolymer or (X) an oil-extended rubber, (B) a crystalline polyethylene type resin, (C) a first hydrogenated block copolymer, and (D) a second hydrogenated block copolymer, and may further includes (E1) a mineral oil type softening agent; and a molded article thereof. The thermoplastic elastomer composition and the molded article are superior in rubber elasticity (compression set), mechanical strength and moldability and, when containing a mineral oil type softening agent, is low in oil bleeding.

Owner:JSR CORPORATIOON

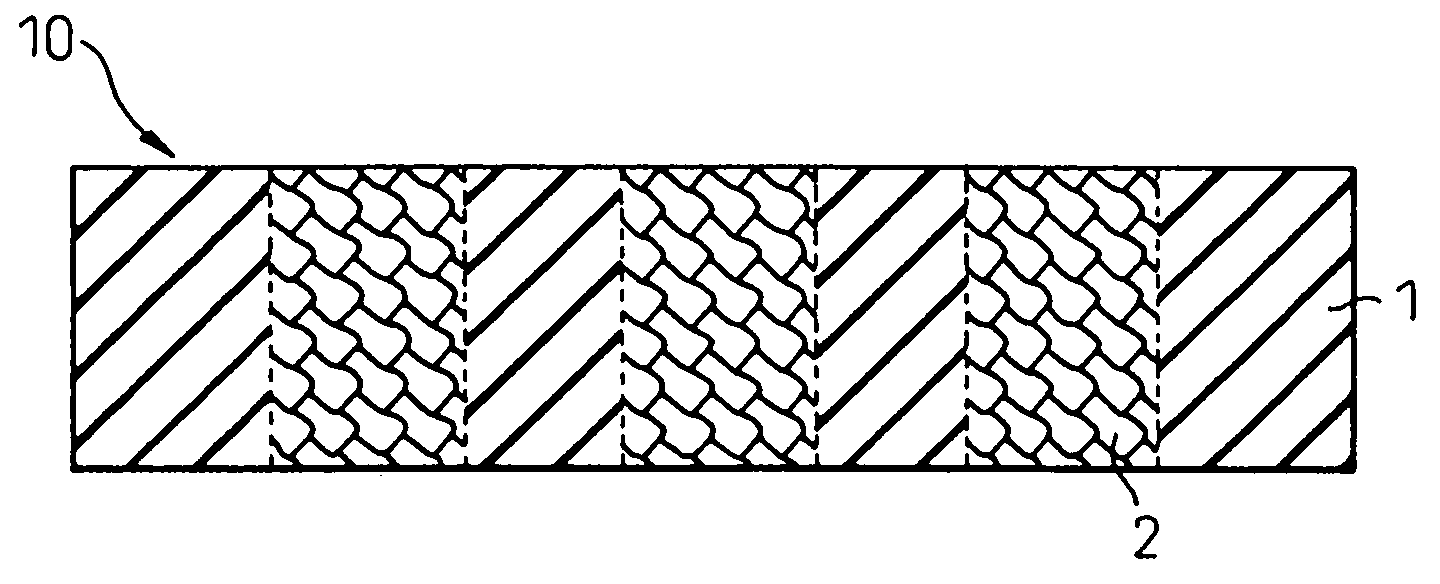

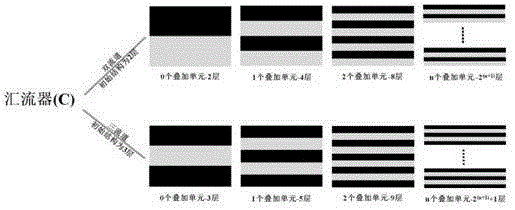

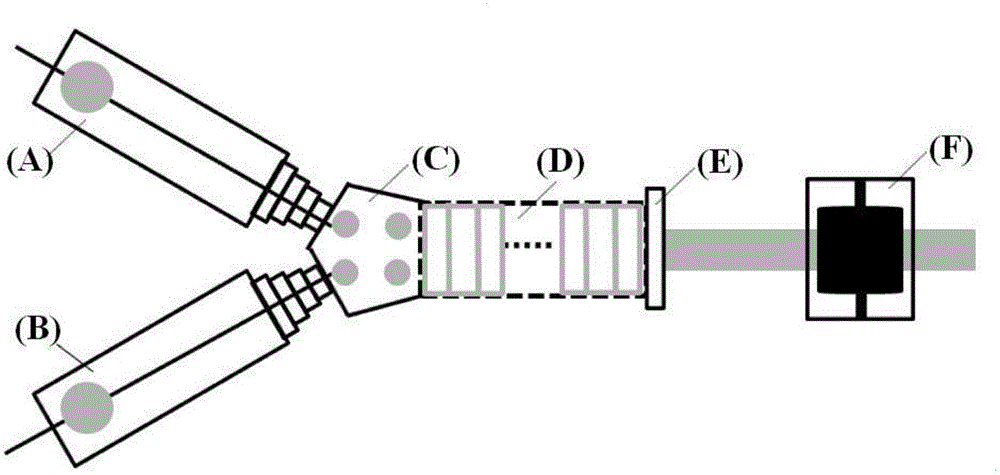

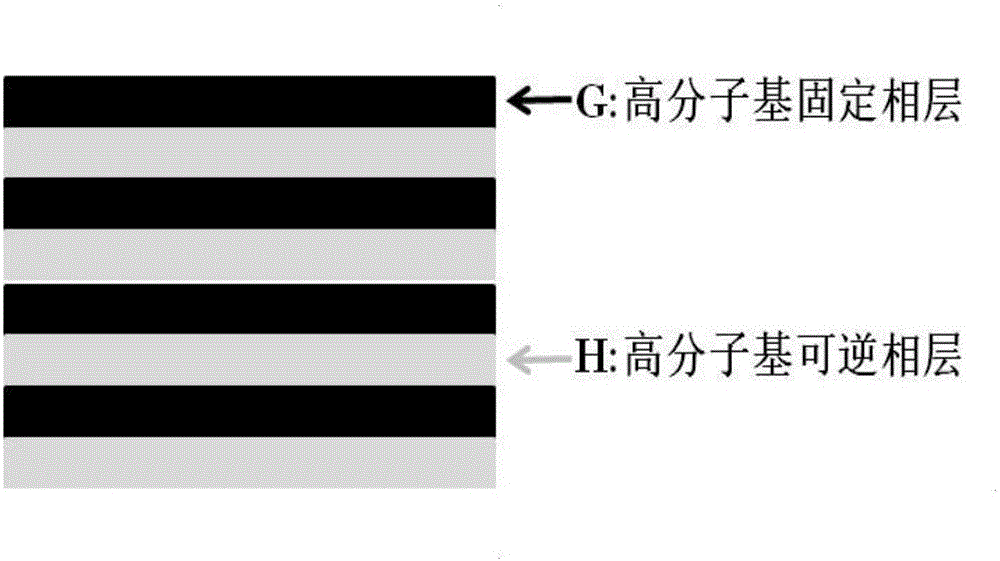

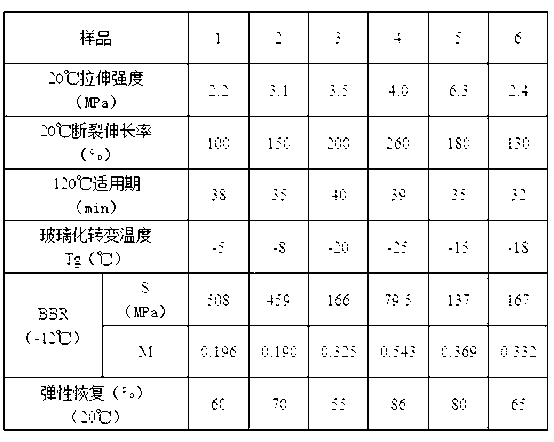

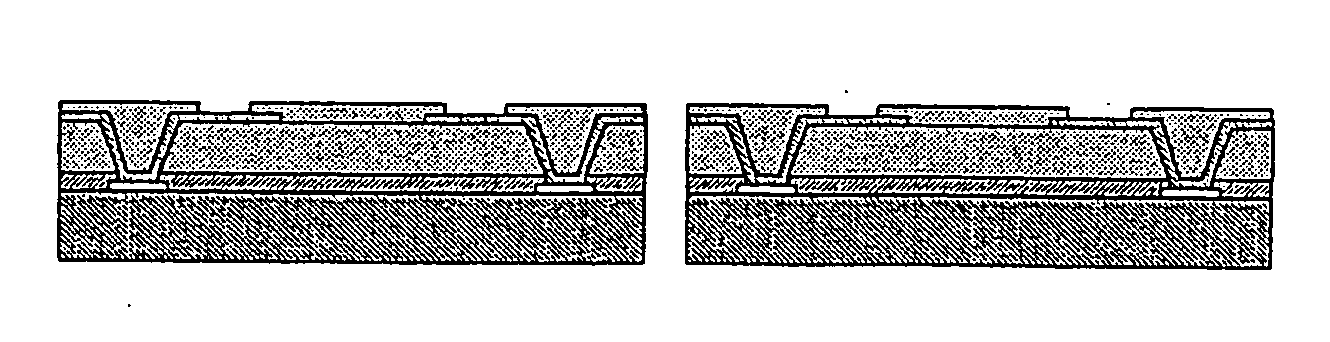

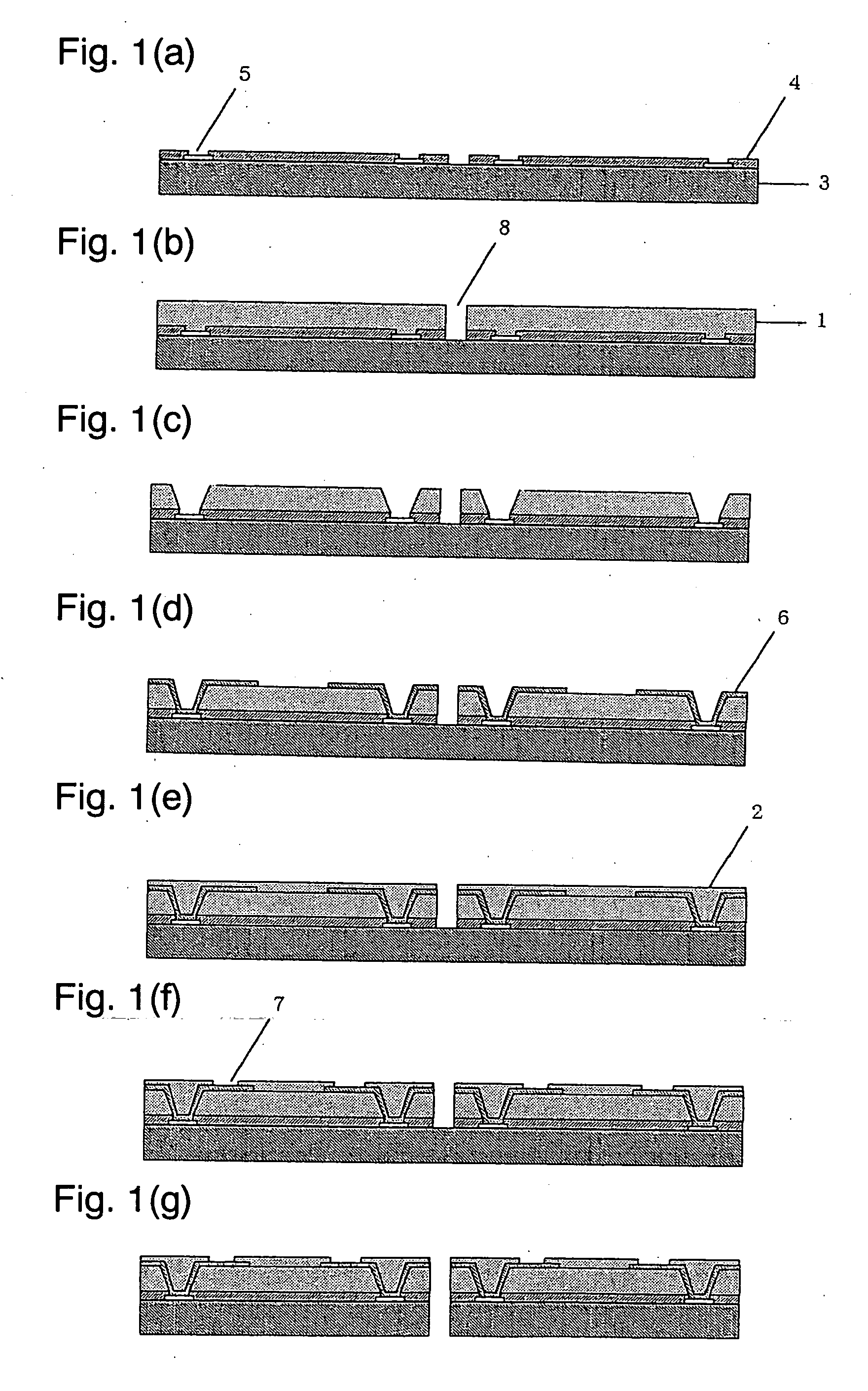

Preparation method of novel polymer-based multilayer shape memory material

ActiveCN106379011AExcellent shape memory performanceEasy to fixSynthetic resin layered productsRubber layered productsPolymer scienceRubber elasticity

The invention discloses a preparation method of a novel polymer-based multilayer shape memory material. The multilayer shape memory material prepared through the preparation method is formed by a polymer-based fixed phase layer and a polymer-based revertible phase layer, and has a two phase alternate multilayer bicontinuous structure, wherein the polymer-based fixed phase layer is a polymer having rubber elasticity at room temperature, and the polymer-based revertible phase layer is a polymer having obvious melt transition or glass transition in the heating process. The multilayer material deforms at a melting point or a glass transition temperature or above, then is cooled to room temperature in order to obtain a temporary shape, and then is heated to the melting point or the glass transition temperature or above in order to recover to an initial shape. The polymer-based multilayer shape memory material prepared through the preparation method has the advantages of controllable layer quantity, layer thickness and layer structure, adjustable raw material formula, excellent shape memory performance, commercial raw materials, and low production cost; and the preparation method has the advantages of simplicity, high production efficiency, and realization of continuous batch production.

Owner:SICHUAN UNIV

Conductive rubber elastic material, charging member and electrophotographic apparatus

ActiveUS20120224887A1Improve charging effectEasy to changeNon-metal conductorsConductive materialRubber materialPolymer science

A conductive rubber elastic material is stably provided which can produce a charging member that may less vary in electrical resistance even with changes in applied voltage, promises uniform electrical properties, has charge characteristics not affected by changes in environments such as temperature and humidity, and enables a charging object member such as a photosensitive member to be kept from being contaminated. It is a conductive rubber elastic material which contains a matrix containing at least one ionically conductive rubber selected from the group consisting of epichlorohydrin rubber, epichlorohydrin-ethylene oxide rubber, epichlorohydrin-ethylene oxide-allyl glycidyl ether rubber, acrylonitrile-butadiene rubber and a hydrogenated product of acrylonitrile-butadiene rubber and domains composed of an electronically conductive rubber material containing i) a rubber having a butadiene skeleton and ii) carbon black, and the rubber having a butadiene skeleton is modified at a molecular terminal thereof with a specific atomic group.

Owner:CANON KK

Sealing adapter for a beverage extraction system suitable for preparing a beverage from cartridges

InactiveUS20110200725A1Improve sealingReduce riskBeverage vesselsFood shapingAdditive ingredientEngineering

Cartridge sealing adapter (30, 300, 304, 305, 306,330,50, 74) intended to be used in an extraction system for preparing a beverage from a cartridge using fluid injected under pressure and comprising a dished body (14) containing beverage ingredients to be extracted, a beverage delivery foil (15) closing the dished body which can be perforated under the effect of the pressure of fluid within the cartridge, wherein the cartridge sealing adapter is designed for providing a sealing engagement between the extraction system and a cartridge with at least one sealing portion intended to be interposed between a surface of the extraction system and the cartridge. The cartridge adapter can be a rubber-elastic material positioned in solid state or, alternatively as a liquid or viscous material.

Owner:NESTEC SA

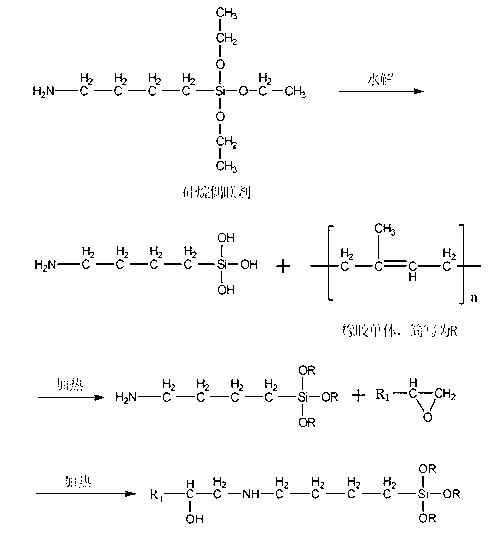

Epoxy glue powder asphalt material and preparation method thereof

InactiveCN102796387AGood compatibilityGood flexibility at low temperatureBuilding insulationsElastomerFirming agent

The invention relates to an epoxy glue powder asphalt material and a preparation method thereof. A macromolecular curing agent, a rubber elastomer, a plasticizer and the like are used for improving the flexibility of the cured epoxy resin so as to improve the low-temperature performance of the epoxy resin curing material, but the epoxy asphalt is easy to separate caused by low compatibility of the macromolecular compound, the rubber elastomer and the asphalt. The preparation method comprises the following steps: soaking rubber particles into the hydrolysate of a silane coupling agent to obtain a surface and interface activated rubber particle curing agent, adding into the matrix asphalt, cutting, cooling, adding modified asphalt, plasticizer, aliphatic dibasic acid, dimer acid or alkyd resin and fatty acid anhydride and obtaining an epoxy asphalt component B under the action of a shearing and emulsifying machine; and mixing and stirring the epoxy asphalt component A namely the epoxy resin and the epoxy asphalt component B to obtain the activated rubber particle modified epoxy asphalt material. According to the invention, the low-temperature flexibility of the epoxy asphalt is obviously improved; and a large amount of activated rubber particles are added, so the cost of the epoxy asphalt is greatly reduced.

Owner:黄卫 +2

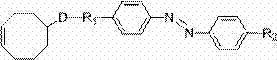

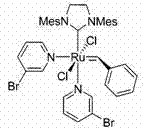

Side chained linear azobenzene liquid crystal polymer material and preparation method thereof

ActiveCN103087296AImprove photoresponse characteristicsProcessing size unlimitedLiquid crystal compositionsPlastic recyclingFiberCross-link

The invention belongs to the technical field of liquid crystal polymer materials, and particularly relates to a side chained linear azobenzene liquid crystal polymer material and a preparation method thereof. In the method, a novel liquid crystal polymer material using butadiene-ethylene-functional group substituted ethylene ternary alternative polymer as a main chain and the azobenzene derivative as a side chain structure is synthesized by using an open loop translocation polymerization method through using a 5-substituted cyclooctene (a substituent group is an azobenzene derivative) monomer in the presence of a Grubbs catalyst. According to the invention, the problem that the conventional azobenzene liquid crystal elastomer material is insoluble and is not molted so as not to be prepared by adopting a common machine shaping method. Under the condition of no cross-linked network structure, the side chained linear azobenzene liquid crystal polymer material has the rubber elasticity and good optical response characteristic; and the side chained linear azobenzene liquid crystal polymer material can machined to form liquid crystal polymer materials, such as films and fibers, after molten or dissolved without being limited in machining size and appearance and can be recycled for re-machine shaping after machine-shaping, and is a novel low-carbon and environment-friendly optical response liquid crystal polymer material.

Owner:FUDAN UNIV

Thermoplastic Elastomer Composition

InactiveUS20080227905A1Improve balanceGood rubber elasticityFilm/foil adhesivesElastomerPolymer science

The object of the present invention is to provide a thermoplastic elastomer composition having a good balance between the hardness and the mechanical strength, exhibiting superior rubber elasticity, high-temperature creep characteristics and formability in a wide range of temperature, and having oil resistance and heat resistance. The thermoplastic elastomer composition comprises (A) (meth)acrylic block copolymer; (B) a compound containing at least two amino groups in its molecule; and (C) a thermoplastic resin. The (meth)acrylic block copolymer (A) comprises (A1) a (meth)acrylic copolymer block and (A2) an acrylic copolymer block. A1 least one of the polymer blocks has at least one acid anhydride group. The (meth)acrylic block copolymer (A) and the compound (B) are dynamically vulcanized in the thermoplastic resin (C).

Owner:KANEKA CORP

Resin composition, heat-resistant resin paste and semiconductor device using these and method of preparing the same

InactiveUS20060180908A1Semiconductor/solid-state device detailsSolid-state devicesPolymer scienceRubber elasticity

Owner:RESONAC CORPORATION

Rubber mixture with improved abrasion

ActiveUS20090306267A1Improve grinding effectImprove performanceSpecial tyresGranular deliveryElastomerVulcanization

A rubber mixture with improved abrasion with improved abrasion performance, in particular for pneumatic tires, has the following composition: from 30 to 100 phr of at least one diene rubber; from 0.1 to 10 phr of at least one vulcanization accelerator selected from the group consisting of: thiazole accelerators, mercapto accelerators, sulfenamide accelerators, guanidine accelerators, thiuram accelerators, dithiocarbamate accelerators, amine accelerators, thioureas, and / or other accelerators; and a vulcanization system of sulfur comprising elemental sulfur, sulfur donor and silane between 0.25 and 0.08 moles per 100 parts by weight of the rubber elastometer, whereby the free sulfur contributes in the range of 0 to 70%, the sulfur donor contributes in the range of 5 to 30%, and the silane contributes in the range of 20 to 95%.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com