Patents

Literature

67 results about "Grubbs' catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

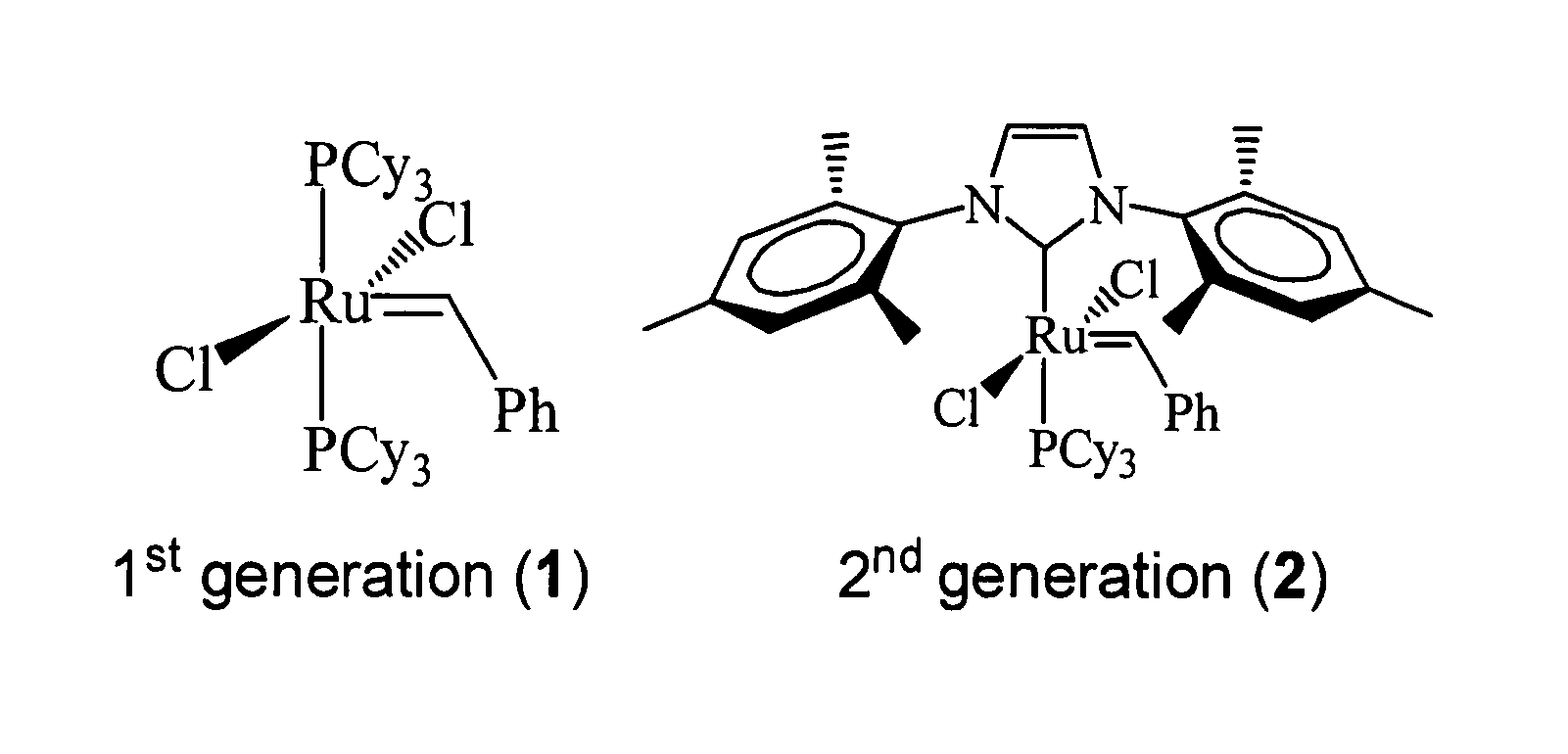

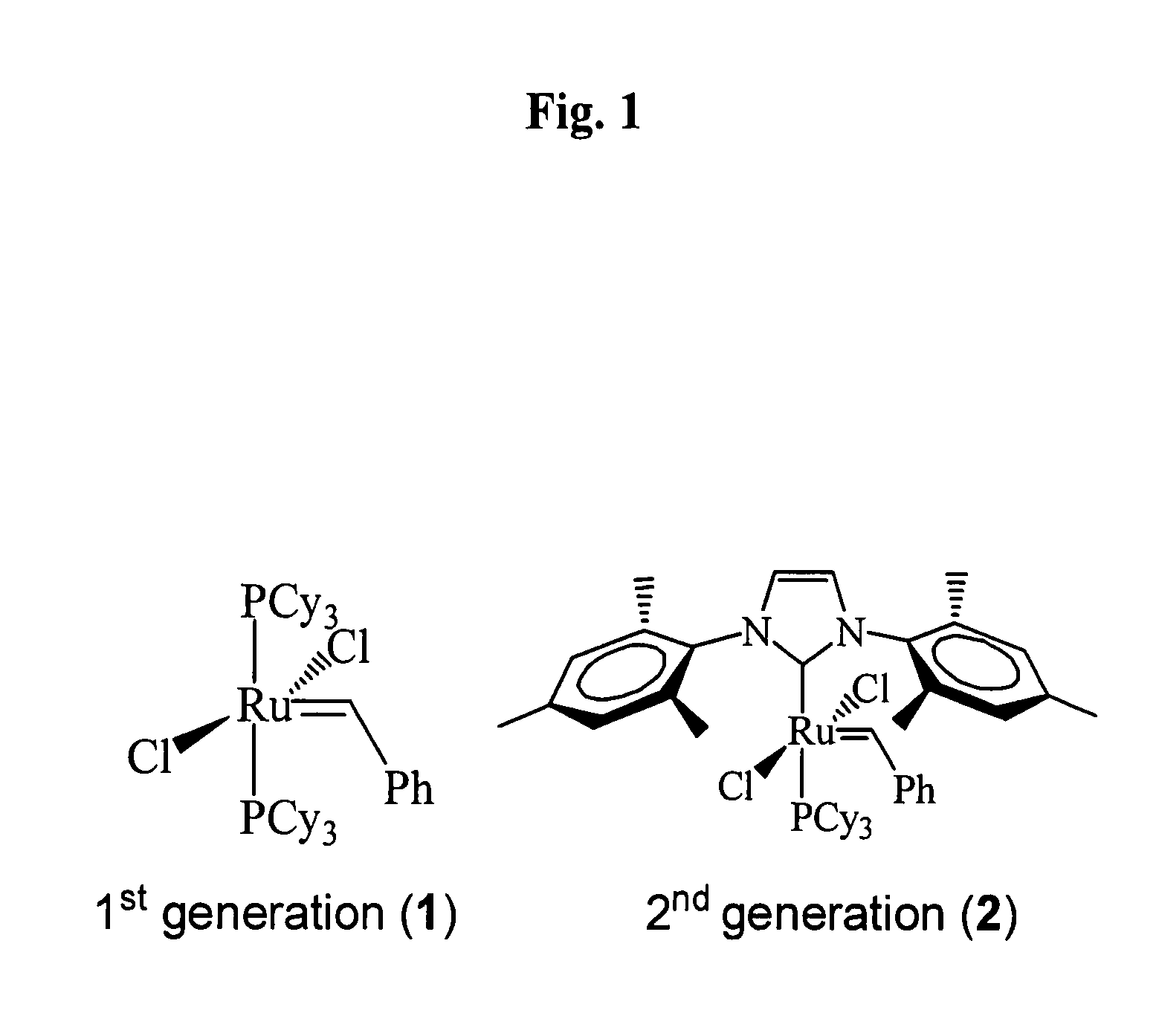

Grubbs catalysts are a series of transition metal carbene complexes used as catalysts for olefin metathesis. They are named after Robert H. Grubbs, the chemist who supervised their synthesis. Several generations of the catalyst have been developed. Grubbs catalysts tolerate many functional groups in the alkene substrates, are air-tolerant, and are compatible with a wide range of solvents. For these reasons, Grubbs catalysts have become popular in synthetic organic chemistry. Grubbs, together with Richard R. Schrock and Yves Chauvin, won the Nobel Prize in Chemistry in recognition of their contributions to the development of olefin metathesis.

Method of producing dicarboxylic acids

InactiveUS7534917B1Organic compound preparationCarboxylic acid esters preparationCarboxylic acidDouble bond

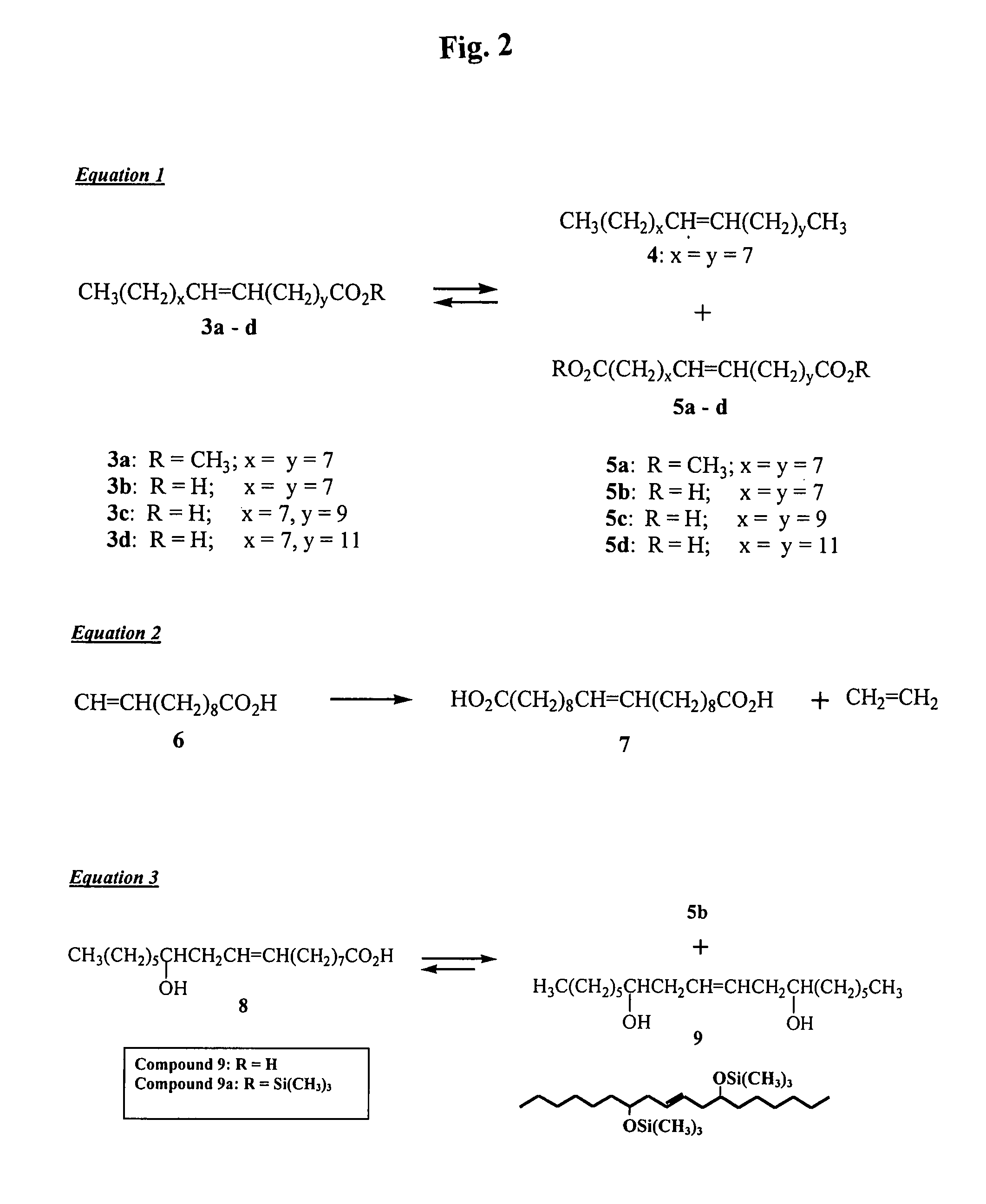

A method of producing dicarboxylic acids (e.g., α,ω dicarboxylic acids) by reacting a compound having a terminal COOH (e.g., unsaturated fatty acid such as oleic acid) and containing at least one carbon-carbon double bond with a second generation Grubbs catalyst in the absence of solvent to produce dicarboxylic acids. The method is conducted in an inert atmosphere (e.g., argon, nitrogen). The process also works well with mixed unsaturated fatty acids obtained from soybean, rapeseed, tall, and linseed oils.

Owner:US SEC AGRI

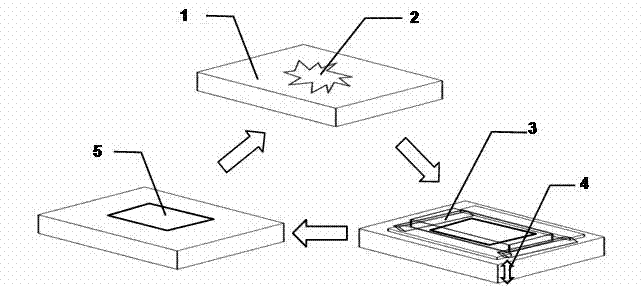

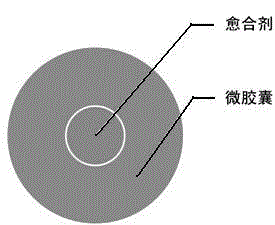

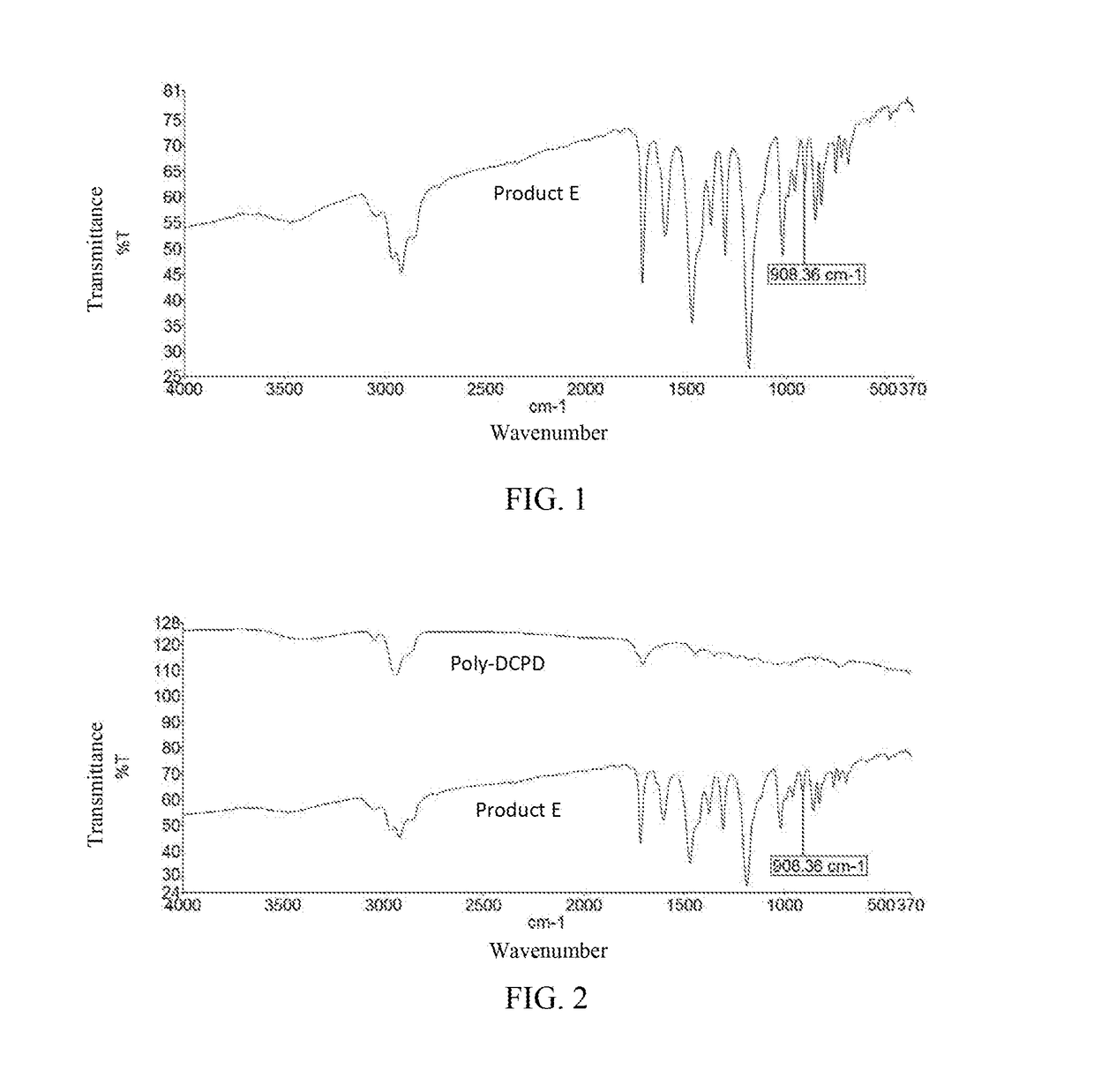

Self-healing epoxy powdery coating containing microcapsule and preparation method thereof

InactiveCN105038502AAvoid breakingPrevent peelingPowdery paintsEpoxy resin coatingsSelf-healingEpoxy

The present invention discloses a self-healing epoxy powdery coating containing microcapsule. The self-healing epoxy powdery coating containing microcapsule consists of the following components by weight: 5-15 parts of microcrack self-healing capsule, 2-4 parts of a Grubbs catalyst and 89-93 parts of epoxy powder resin matrix. The capsule wall of the self-healing microcapsule is theurea-formaldehyde resin prepared from urea and 37% formaldehyde solution in molar ratio of 0.5-0.6:1, and the capsule core is dicyclopentadiene by blending and high pressure electrostatic spraying. The housing capsule wall of the microcapsule is urea-formaldehyde resin; and the mass ratio of the inner capsule core to capsule wall is 5:1. When the coating cracks, the microcapsule ruptures, and dicyclopentadiene rapidly penetrates into the crazing and the met Grubbs catalyst to produce cross-linking, in order to achieve the purpose of repair. The invention prolongs the service life of the powdery coating and is applicable to novel industrial production.

Owner:南通南京大学材料工程技术研究院

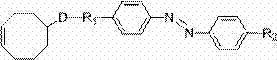

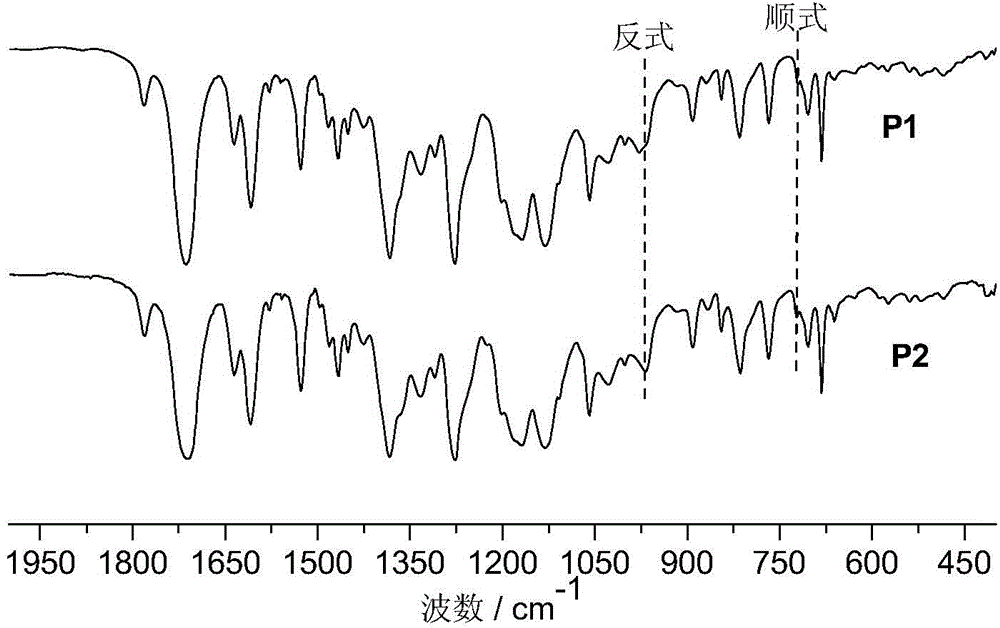

Side chained linear azobenzene liquid crystal polymer material and preparation method thereof

ActiveCN103087296AImprove photoresponse characteristicsProcessing size unlimitedLiquid crystal compositionsPlastic recyclingFiberCross-link

The invention belongs to the technical field of liquid crystal polymer materials, and particularly relates to a side chained linear azobenzene liquid crystal polymer material and a preparation method thereof. In the method, a novel liquid crystal polymer material using butadiene-ethylene-functional group substituted ethylene ternary alternative polymer as a main chain and the azobenzene derivative as a side chain structure is synthesized by using an open loop translocation polymerization method through using a 5-substituted cyclooctene (a substituent group is an azobenzene derivative) monomer in the presence of a Grubbs catalyst. According to the invention, the problem that the conventional azobenzene liquid crystal elastomer material is insoluble and is not molted so as not to be prepared by adopting a common machine shaping method. Under the condition of no cross-linked network structure, the side chained linear azobenzene liquid crystal polymer material has the rubber elasticity and good optical response characteristic; and the side chained linear azobenzene liquid crystal polymer material can machined to form liquid crystal polymer materials, such as films and fibers, after molten or dissolved without being limited in machining size and appearance and can be recycled for re-machine shaping after machine-shaping, and is a novel low-carbon and environment-friendly optical response liquid crystal polymer material.

Owner:FUDAN UNIV

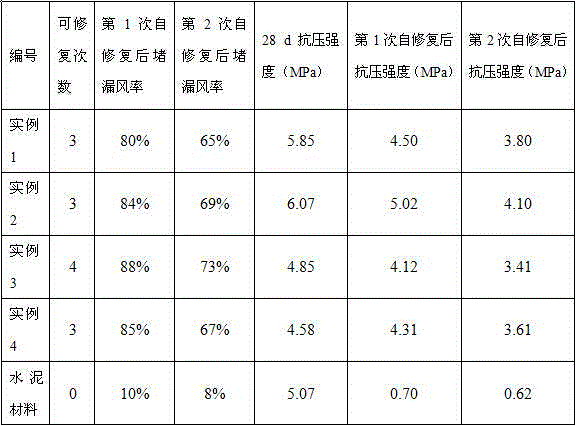

Bionic self-healing material for air leakage stoppage in coal mine

The invention relates to a bionic self-healing material for air leakage stoppage in a coal mine. The bionic self-healing material comprises a fast-setting expanding material, microcapsules containing a healing agent, and a catalyst, wherein the fast-setting expanding material comprises several of a cement clinker, coal ash, steel slag, mountain flour, salty mud, carbide slag, an expanding agent, a water reducing agent and sand, and each microcapsule is composed of a wall material (polymer resin) and a core material (the healing agent); the wall material of each microcapsule is at least one of urea resin, melamino-formaldehyde resin, melamine urea-formaldehyde resin and polyurethane, the healing agent is at least one of olefins containing double bonds, such as polyurethane prepolymer, isocyanate, phenolic resin, epoxy resin, styrene, acrylics and dicyclopentadiene (DCPD), and the catalyst is at least one of Grubbs catalyst, dibutyltin dilaurate and amines. The bionic self-healing material for air leakage stoppage in the coal mine disclosed by the invention has the advantages of being automatic in detection and healing, moderate in expansion, fast to set, good in conveying performance, strong in setting performance, green and environmentally friendly, and low in price.

Owner:胡相明

Cable insulation material with self-repairing function

InactiveCN106750829AImprove repairabilityPlastic/resin/waxes insulatorsLow-density polyethyleneAntioxidant

The invention discloses a cable insulation material with a self-repairing function. The cable insulation material is composed of the following components in parts by weight: 100 parts of low density polyethylene, 2-4 parts of vinyl trimethoxy silane, 0.08-0.2 part of tert-butyl peroxy-3,5,5-trimethylhexanoate, 0.4-1.2 parts of 1801 organic stearic acid, 1.5-4 parts of dibutyltin dilaurate, 1.5-4.5 parts of zinc oxide, 1.8-3.2 parts of 1010 antioxidants, 1-5 parts of microcapsules prepared by a urea resin coated dicyclopentadiene system and 0.02-0.03 part of a Grubbs catalyst. According to the cable insulation material with the self-repairing function disclosed by the invention, due to the effects of the microcapsules prepared by the urea resin coated dicyclopentadiene system and the Grubbs catalyst in the formula, a self-repairing crosslinked polyethylene cable insulation material in the invention has excellent performance of repairing electric tree defects.

Owner:CHONGQING UNIV

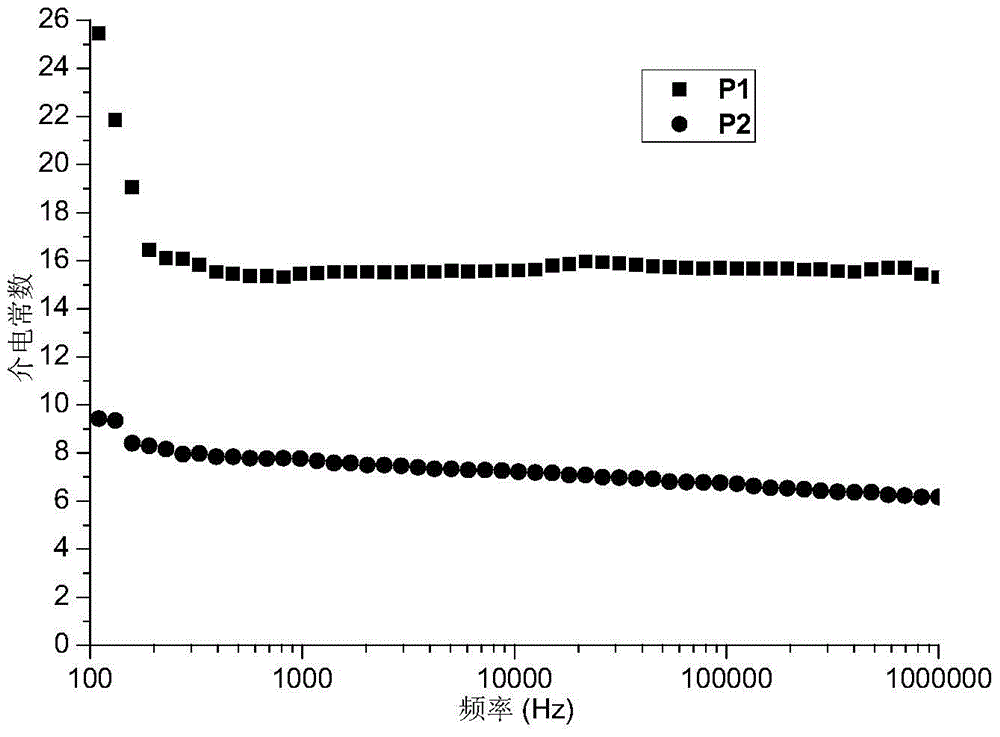

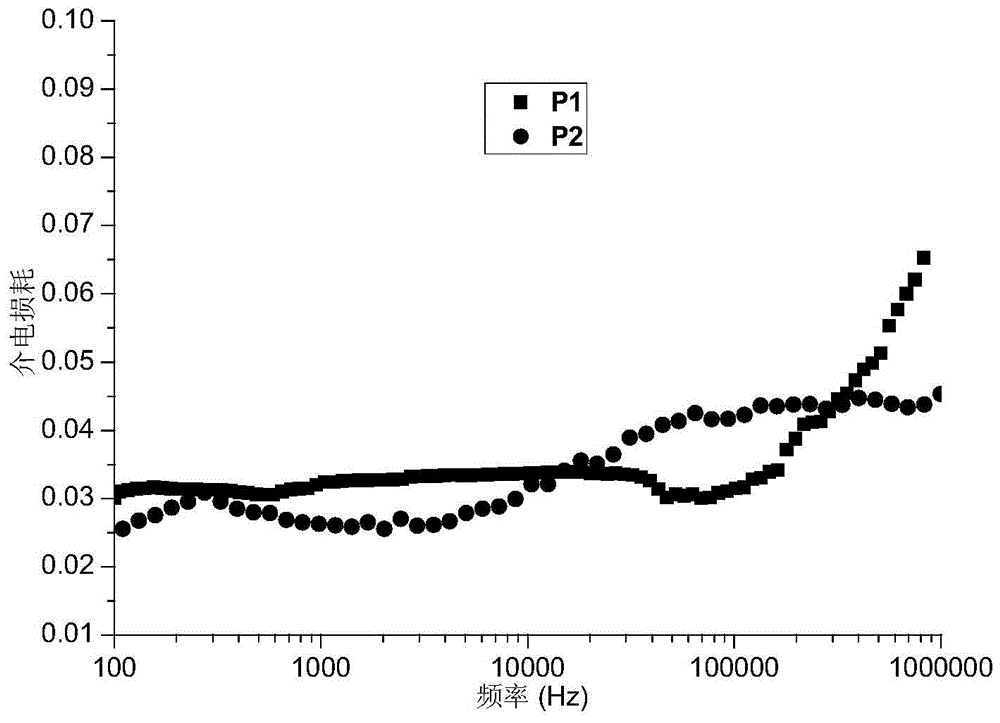

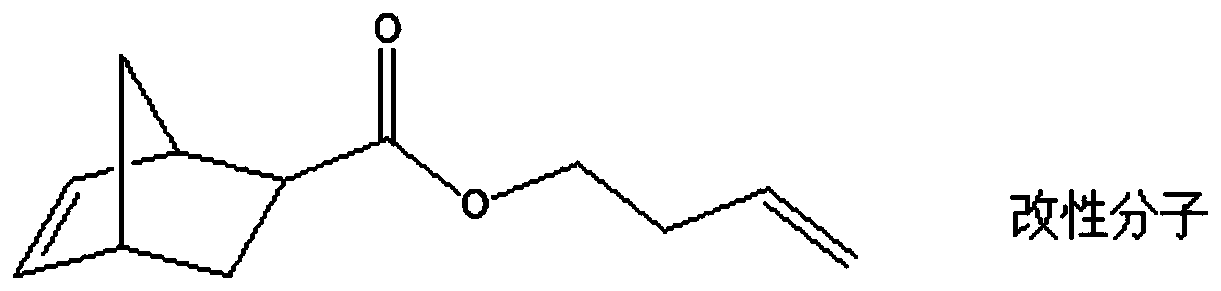

Cross-linkable high dielectric norbornene copolymer and norbornene cross-linked polymer and preparation methods thereof

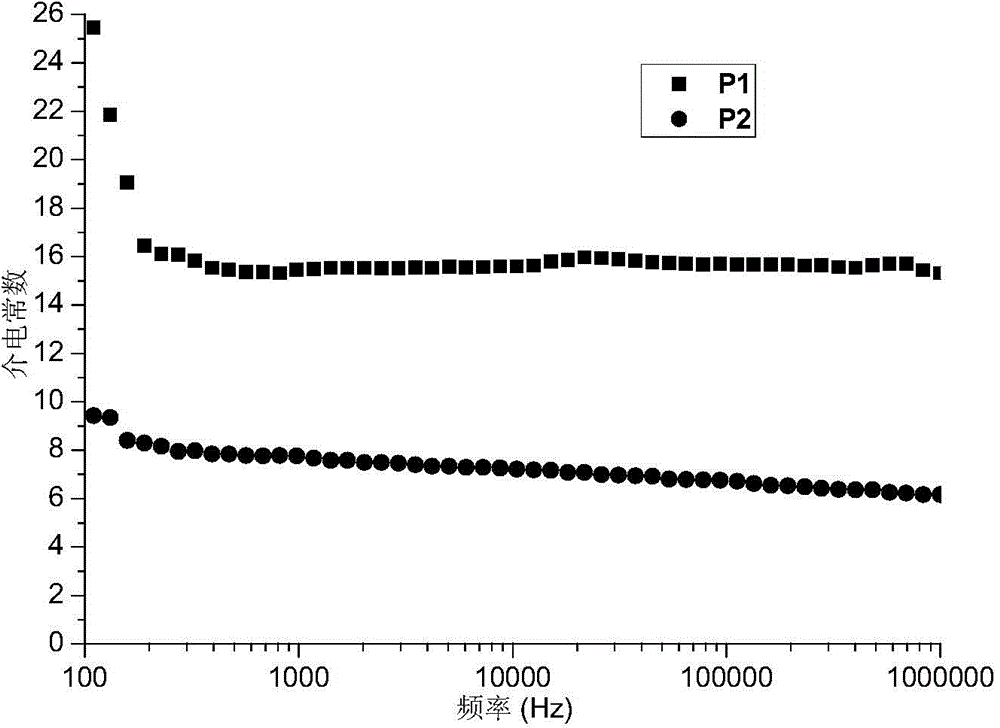

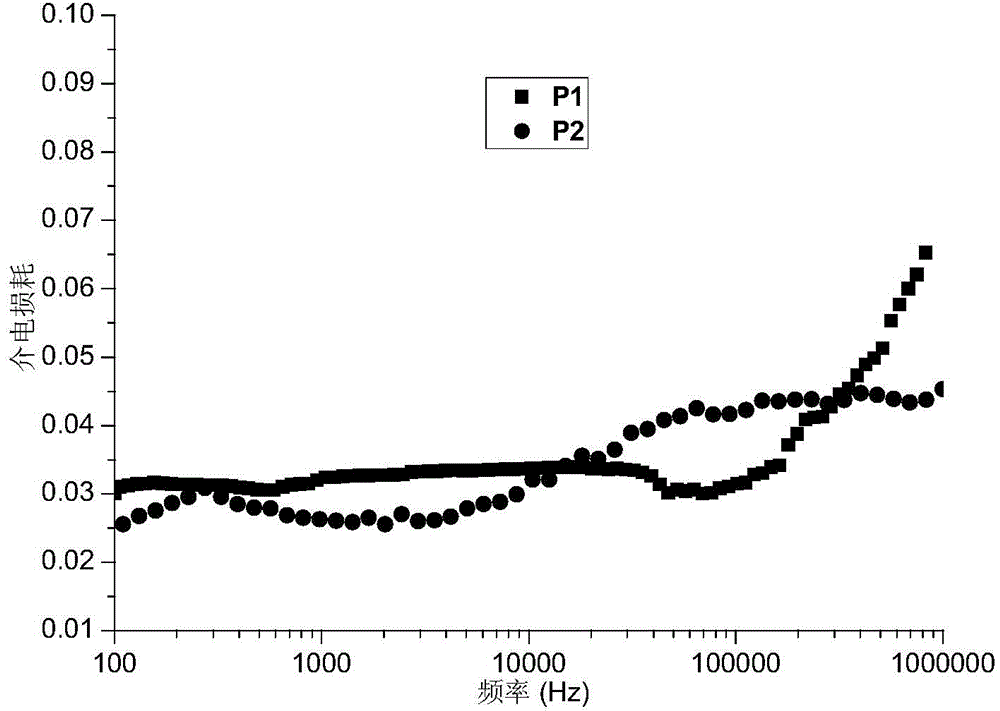

The invention provides a cross-linkable high dielectric norbornene copolymer. The cross-linkable high dielectric norbornene copolymer comprises a norbornene block copolymer which is formed by ring-opening metathesis polymerization of an endo-configuration norbornene monomer or an exo-configuration norbornene monomer and an exo-configuration oxa-norbornene monomer. The invention also provides a preparation method of the norbornene copolymer. According to the preparation method, the norbornene copolymer is obtained by ring-opening metathesis polymerization reaction of the endo-configuration norbornene monomer or the exo-configuration norbornene monomer and the exo-configuration oxa-norbornene monomer under the action of a Grubbs catalyst. The invention further provides a three-dimensional cross-linked network polymer formed by crosslinking of the norbornene copolymer and a preparation method thereof. The norbornene copolymer has a relatively high dielectric constant and very low dielectric loss. The preparation method of the norbornene copolymer is simple and practicable. The norbornene cross-linked polymer has relatively high dielectric constant and thermal stability, and the applied range of the norbornene crosslinked polymer in the field of thin-film capacitors is expanded.

Owner:EAST CHINA NORMAL UNIV

Self-healing material

The invention discloses a self-healing material which is mainly prepared from a porous material, paraffin, a polymer composite material, dicyclopentadiene liquid and a Grubbs' catalyst, wherein the polymer composite material is prepared from carbon, glass and resin. The porous material fully absorbs the dicyclopentadiene liquid, the porous material containing the dicyclopentadiene liquid is wrapped in the paraffin to be prepared into microcapsules, the microcapsules are doped into the polymer composite material containing the Grubbs' catalyst, and the self-healing material is obtained. The self-healing material has the advantages that cost is low, the manufacturing technology is simple, and the self-healing performance is remarkable.

Owner:CHONGQING LEHU TECH CO LTD

Self-repairing optical cable reinforced core containing microcapsules and preparation method

InactiveCN106896459AImprove the status quo that cannot be self-repairedFibre mechanical structuresPolyesterGrubbs' catalyst

The application discloses a self-repairing optical cable reinforced core containing microcapsules and a preparation method. The self-repairing reinforced chip is formed by mixing microcapsules, catalysts and an unsaturated polyester and covers an aramid fiber surface through a pultrusion process. The material of the reinforced core is aramid fibers, and the mass ratio of the microcapsules to the unsaturated polyester in the mixture is 5% to 15%; and shell capsule walls of the microcapsules are urea resins,inner capsule cores are dicyclopentadiene, and the mass ratios of the capsule cores to the capsule walls are 5:1. When the surface of the aramid fiber reinforced core cracks, the microcapsules are broken, dicyclopentadiene rapidly permeates crazing, and meets the Grubbs catalysts to produce cross-linking, thereby achieving the purpose of repairing. Thus the service life of an optical cable core is prolonged, and the self-repairing optical cable reinforced core is suitable for novel industrial production.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV +1

Method for preparing polyimide film with low surface energy

The invention discloses a method for preparing a polyimide film with low surface energy. The method comprises the following steps of reacting aromatic diamine containing a norbornene structure with aromatic tetracarboxylic acid dianhydride at room temperature, coating a film and baking to obtain polyimide film, and then in the presence of the Grubbs catalyst, initiating perfluoroalkyl esterification of norbornene by virtue of a surface initiated polymerization ring-opening metathesis polymerization method to prepare the polyimide film with low surface energy. The polyimide film with low surface energy prepared by the method has the characteristics of good film-forming property, optical transparency and heat resistance. The film can be used as anti-oil creeping, anti-fouling and self-cleaning materials.

Owner:甘肃中安瑞科科技有限公司

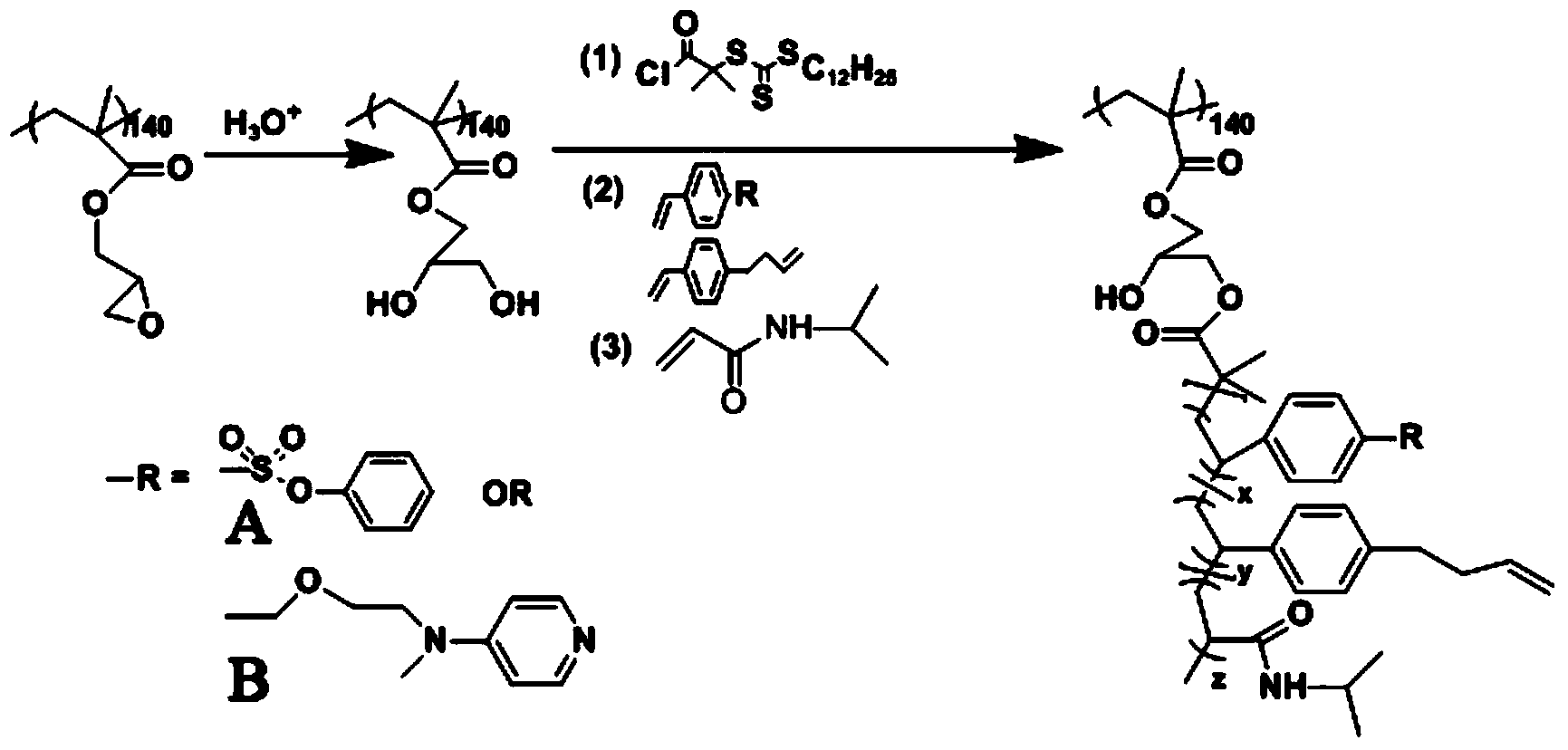

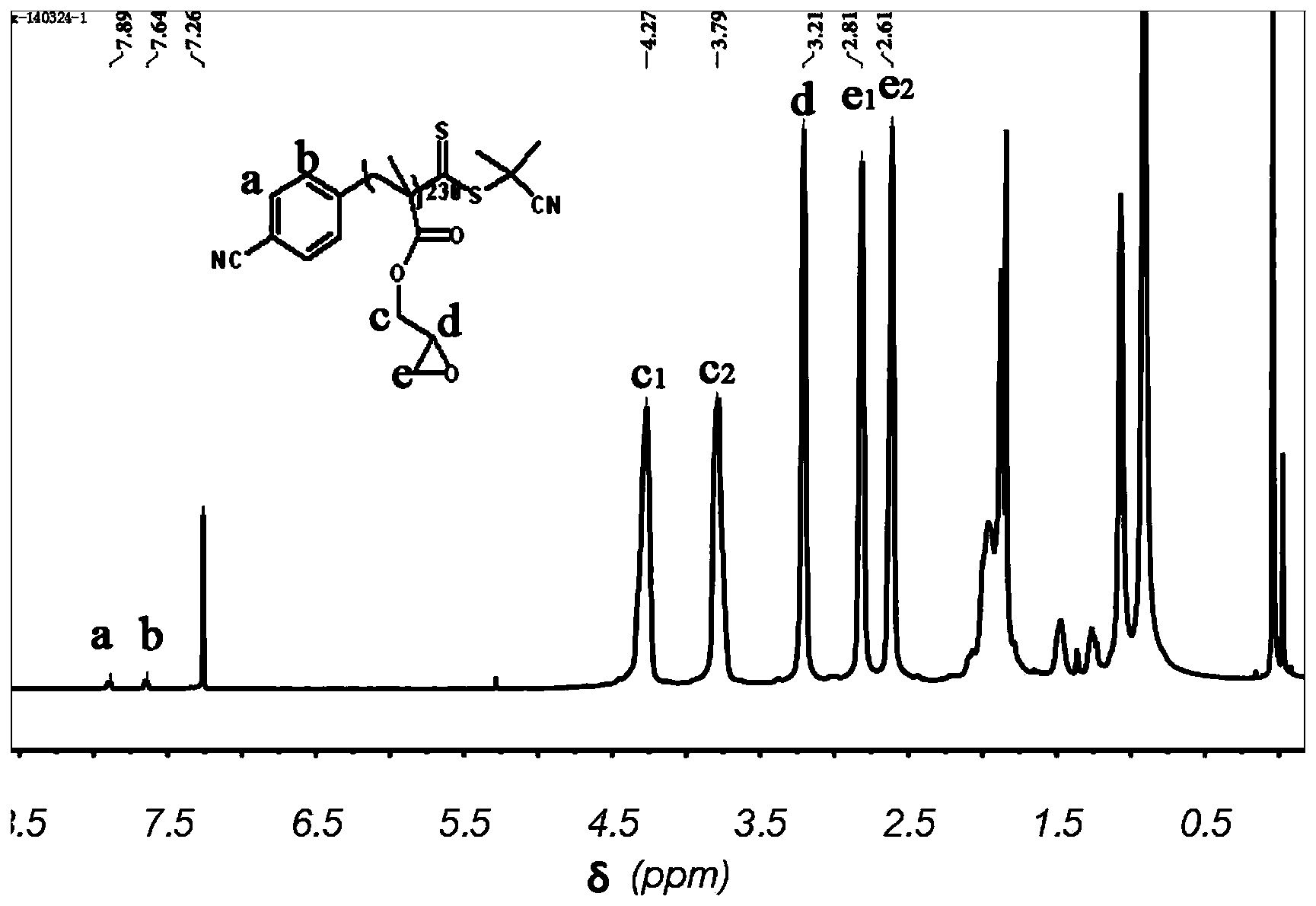

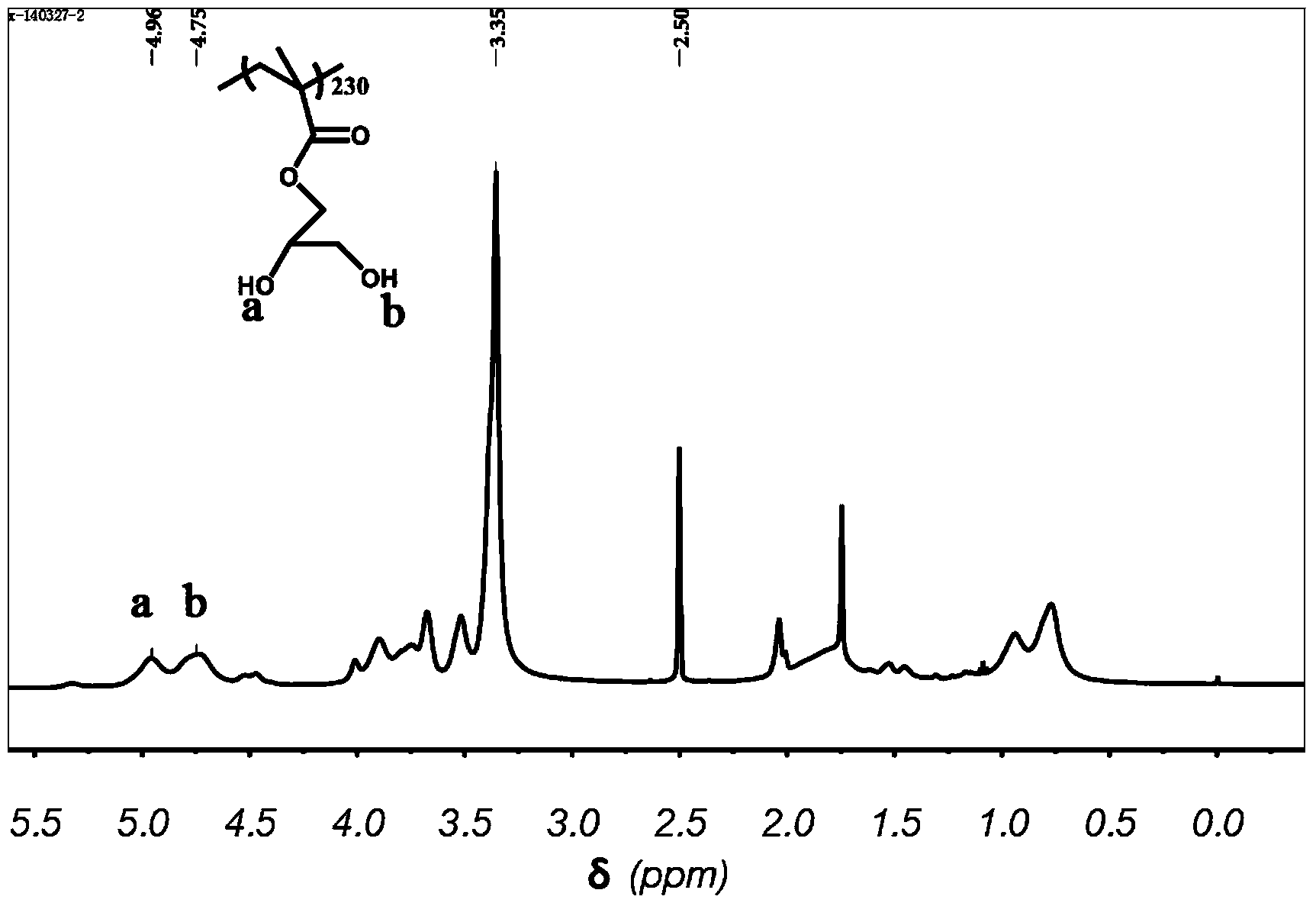

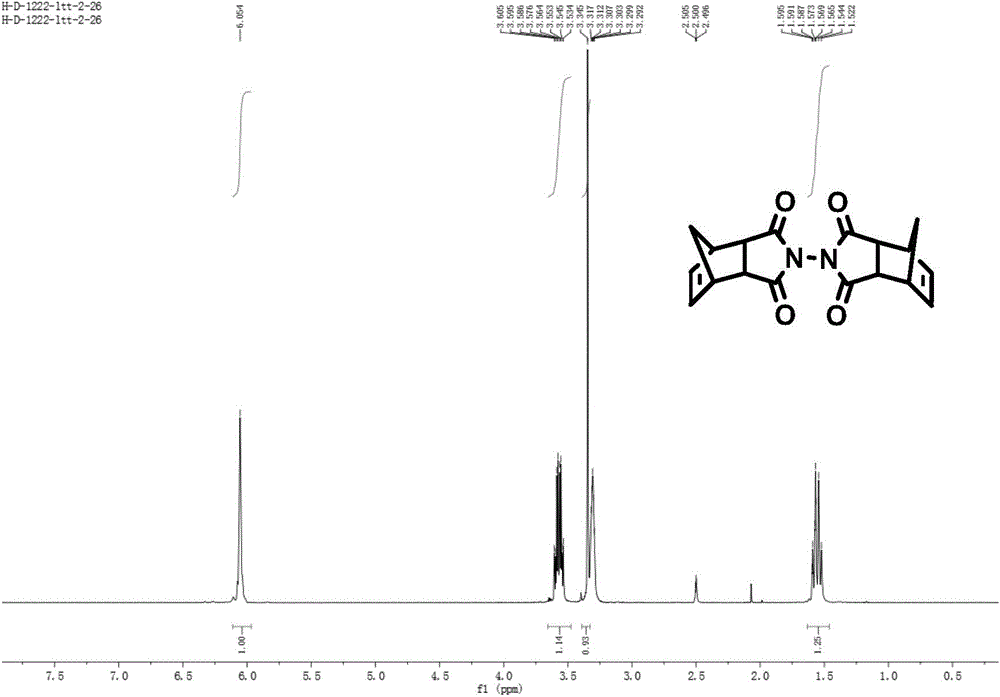

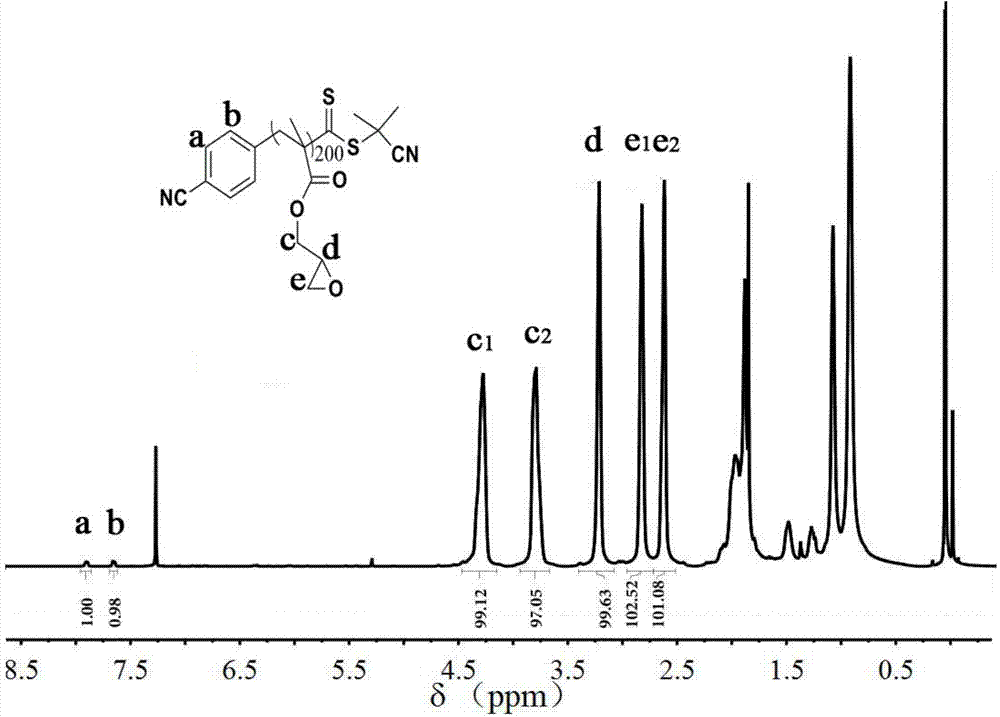

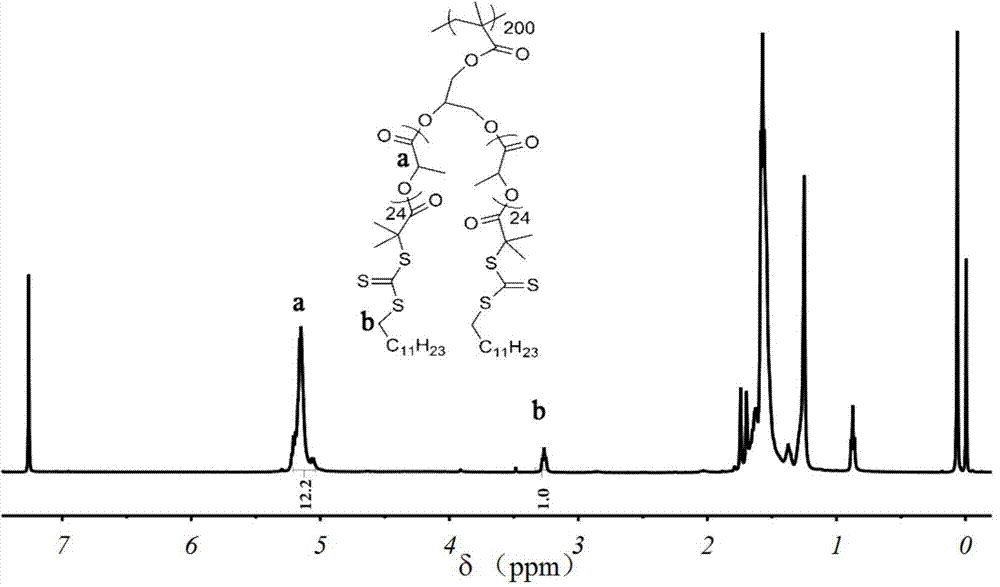

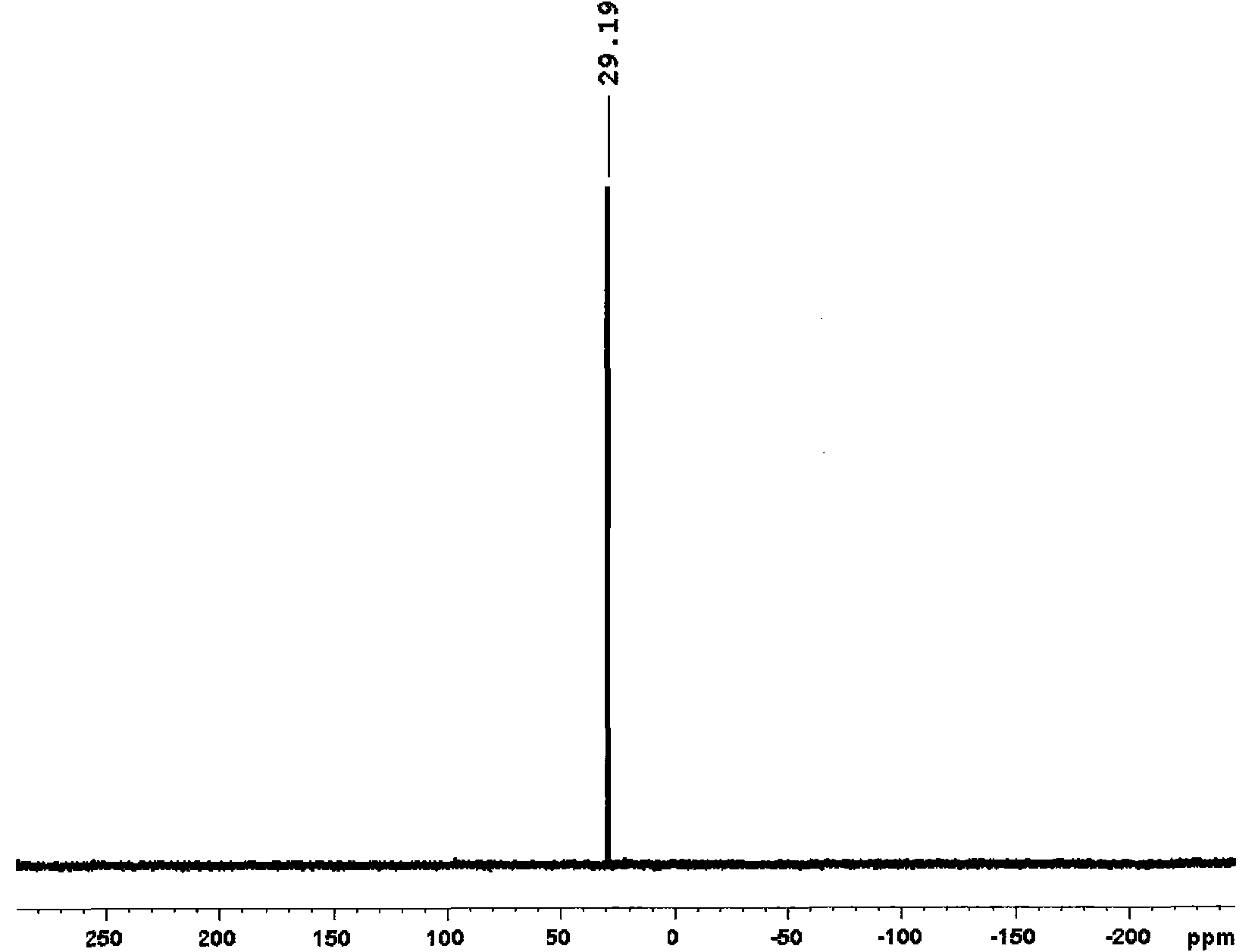

Polymer molecule brush supported catalyst as well as synthesis method and application of catalyst

InactiveCN104338555ACarboxylic acid nitrile preparationOrganic compound preparationCross-linkPolymer science

The invention discloses a polymer molecule brush supported catalyst described in a formula (I) and a synthesis method thereof. The synthesis method comprises the following steps: firstly synthesizing a polymer molecule brush precursor, crossing-linking the polymer molecule brush precursor by use of a Grubbs catalyst, then hydrolyzing and acidizing to obtain the polymer molecule brush supported catalyst. The invention also provides application of the polymer molecule brush supported catalyst in catalyzing cascade reaction. The polymer molecule brush supported catalyst has the advantages that molecule brushes act independently without influence with one another by virtue of the cross-linking within the molecule brushes and outer-layer high-density N-isopropyl acrylamide grafting, so that the catalytic efficiency is greatly improved.

Owner:EAST CHINA NORMAL UNIV

Norbornene imide heat-resistant polymer porous material and preparation method thereof

InactiveCN104877112AGuaranteed to proceed normallyEasy ring-opening metathesis polymerizationOrganic chemistryImideNorbornene anhydride

The invention provides a norbornene imide heat-resistant polymer porous material and its preparation method. The method comprises the following steps: Step 1, a norbornene imide monomeric compound is prepared from norbornene anhydride and a multi-element organic amine compound by a one-step method or a two-step method, and the norbornene imide monomeric compound is purified; Step 2, the purified product obtained from the step 1 is dissolved in an organic solvent b, temperature is maintained at minus 10-100 DEG C, a Grubbs catalyst is added to carry out a polymerization reaction at the reaction temperature of minus 10-120 DEG C for 5 minutes-2 weeks; and Step 3, aftertreatment is carried out to obtain the heat-resistant polymer porous material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Organic molecular cage loaded catalyst, synthesis method and application thereof

InactiveCN104759292AThe synthesis method is simpleRaw materials are easy to getCarboxylic acid nitrile preparationOrganic compound preparationChemical reactionSynthesis methods

The invention discloses an organic molecular cage loaded catalyst and a synthesis method thereof. The method includes: firstly synthesizing an organic molecular cage loaded catalyst precursor, then using a Grubbs catalyst to conduct catalytic crosslinking, and carrying out hydrolysis and azidation to synthesize an azide group containing organic molecular cage, and finally carrying out click chemical reaction to connect catalytic groups of different catalytic properties. The invention also puts forward application of the organic molecular cage loaded catalyst respectively in catalysis of oil soluble organic reaction in an aqueous solution, catalysis of ''one nest method'' tandem reaction, and Pd loaded load catalysis of Suzuki-Miyaura coupling reaction.

Owner:EAST CHINA NORMAL UNIV

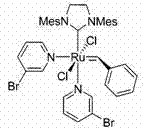

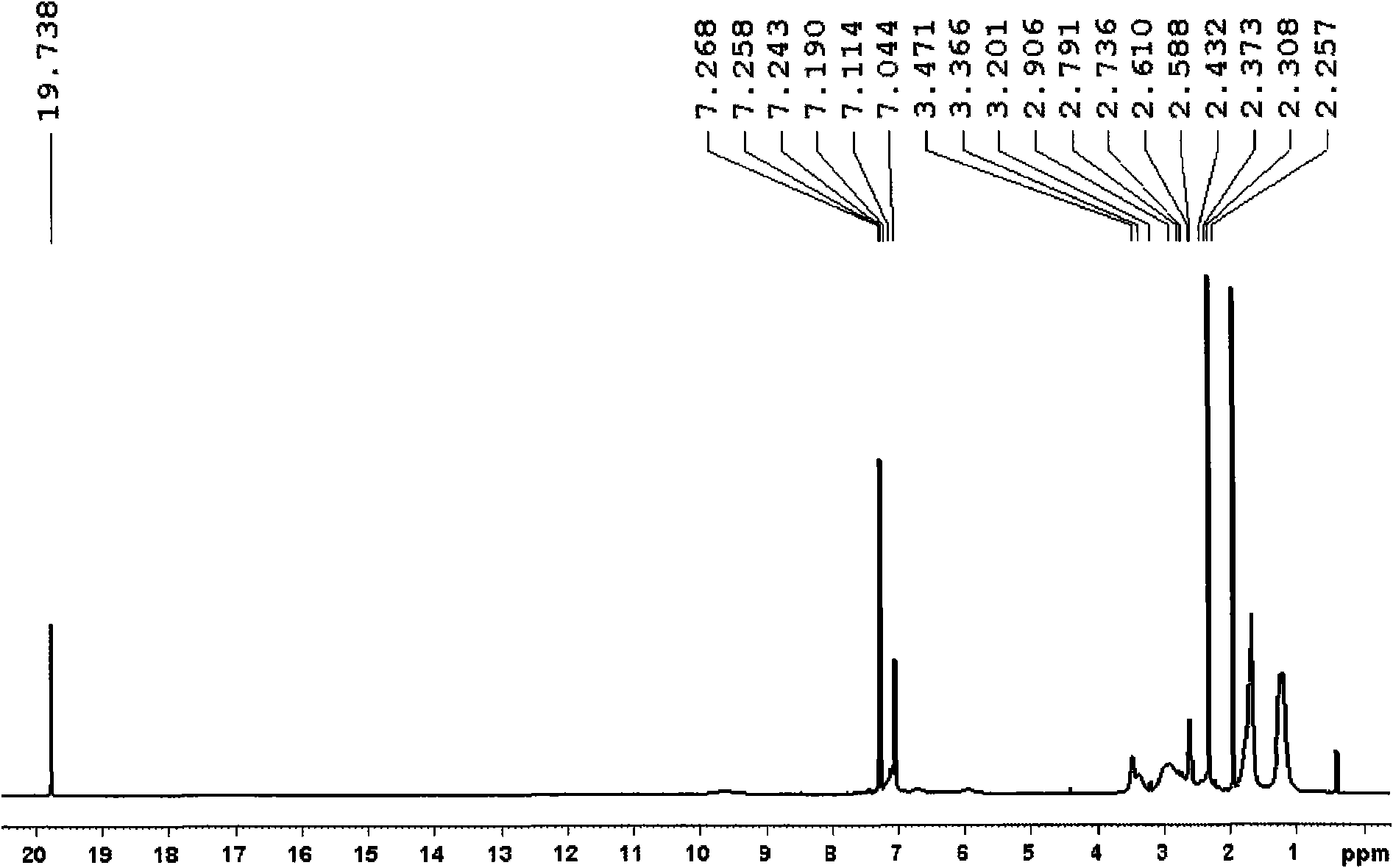

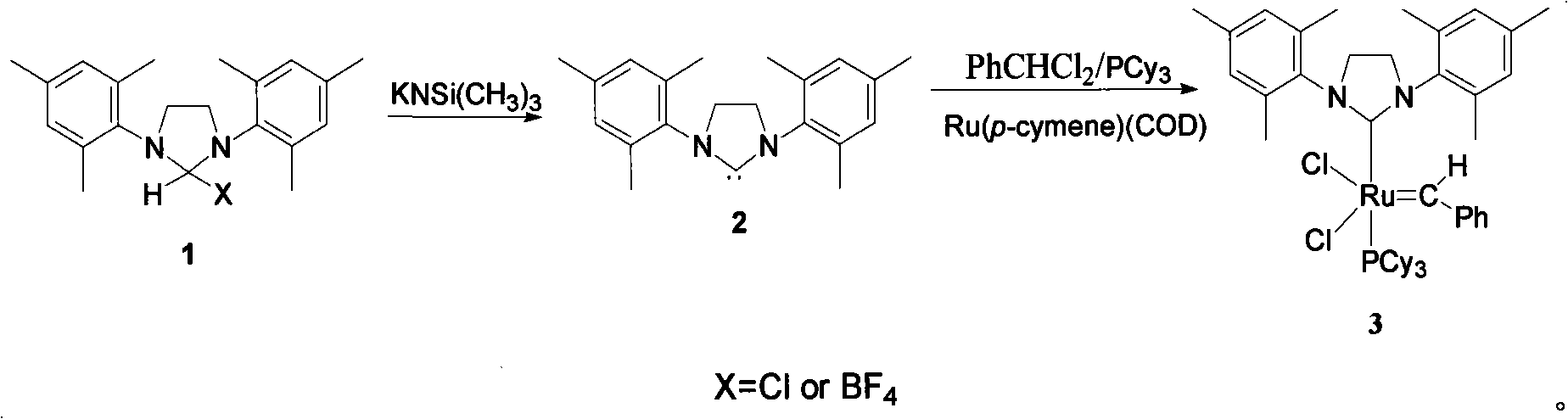

Method for synthesizing second generation Grubbs catalyst

InactiveCN101775043AEfficient synthesisSimple and safe operationOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsDecompositionCarbene

The invention discloses a method for synthesizing a second generation Grubbs catalyst, which relates to a catalyst, in particular to a metal carbine compound (H2IMes)(PCy3)(Cl)2Ru=CHPh(H2IMes is 1,3-di-(2,4,6-trimethylphenyl)imidazole alkyl, and PCy3 is tricyclohexyl phosphine) with favorable olefin double-decomposition catalytic activity, namely the second generation Grubbs catalyst. The method comprises the following step of reacting a zero valence ruthenium compound Ru(p-cymene)(COD)(p-cymene is paracymene, and COD is 1,5-cyclooctadiene) with PCy3, PhCHCL2 and a nitrogen heterocyclic carbine compound in toluene or other hydrocarbon solvents to obtain the second generation Grubbs catalyst. The invention has low cost and easy acquisition of used raw materials, simple and safe operation process, easy control and high yield and is particularly suitable for industrialized large production.

Owner:XIAMEN UNIV

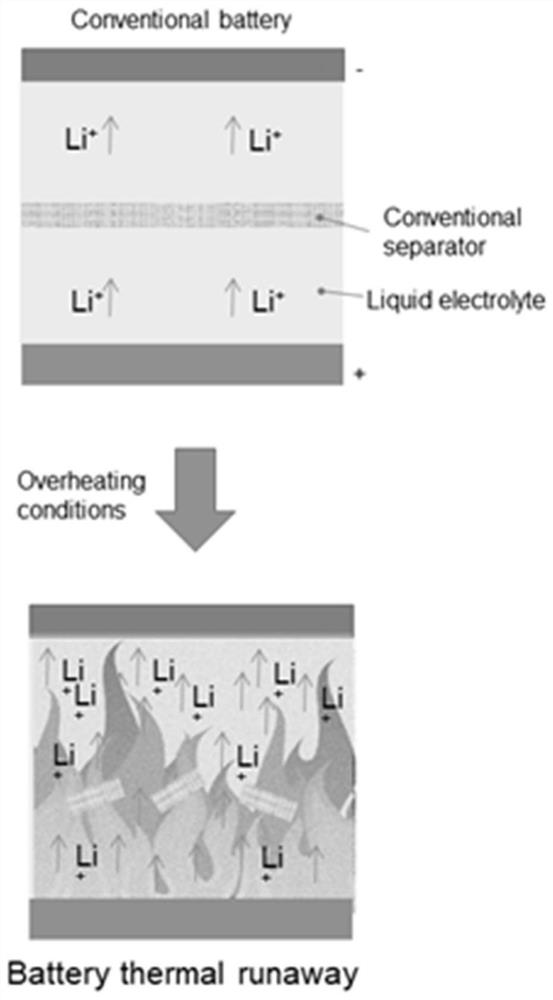

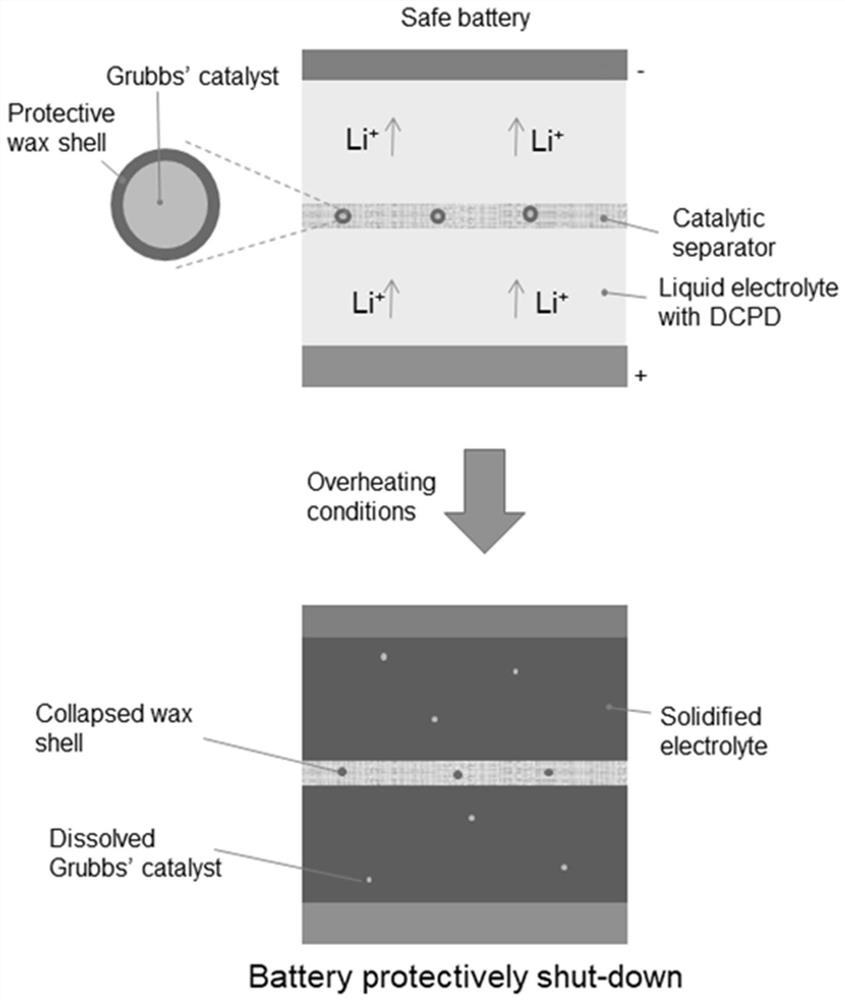

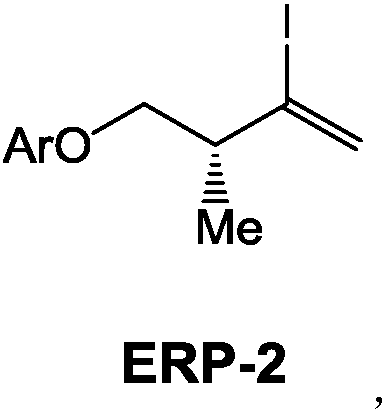

Lithium ion battery

PendingCN111933879AInhibit migrationEnsure safetyMaterial nanotechnologyFinal product manufacturePtru catalystChemical physics

The invention belongs to the field of batteries, and particularly relates to a lithium ion battery. The lithium ion battery comprises a positive electrode, a negative electrode, a diaphragm and electrolyte, the diaphragm comprises a base membrane and a coating formed on at least part of the surface of the base membrane, a coating material of the coating comprises core-shell structure microspheres,each core-shell structure microsphere comprises an inner core and an outer shell coating the inner core, the inner core comprises a Grubbs' catalyst, and the electrolyte comprises a polyfunctional monomer. The lithium ion battery provided by the invention can be used for efficiently and rapidly curing commercial liquid electrolyte under an overheating condition (such as 90 DEG C); therefore, further internal short circuit and thermal runaway of the lithium ion battery under an overheat condition are avoided, the safety of the lithium ion battery is guaranteed, and meanwhile, influence on theenergy density of the lithium ion battery is extremely small, so that the contradiction between the energy density and the safety of the lithium ion battery is overcome.

Owner:TSINGHUA UNIV +1

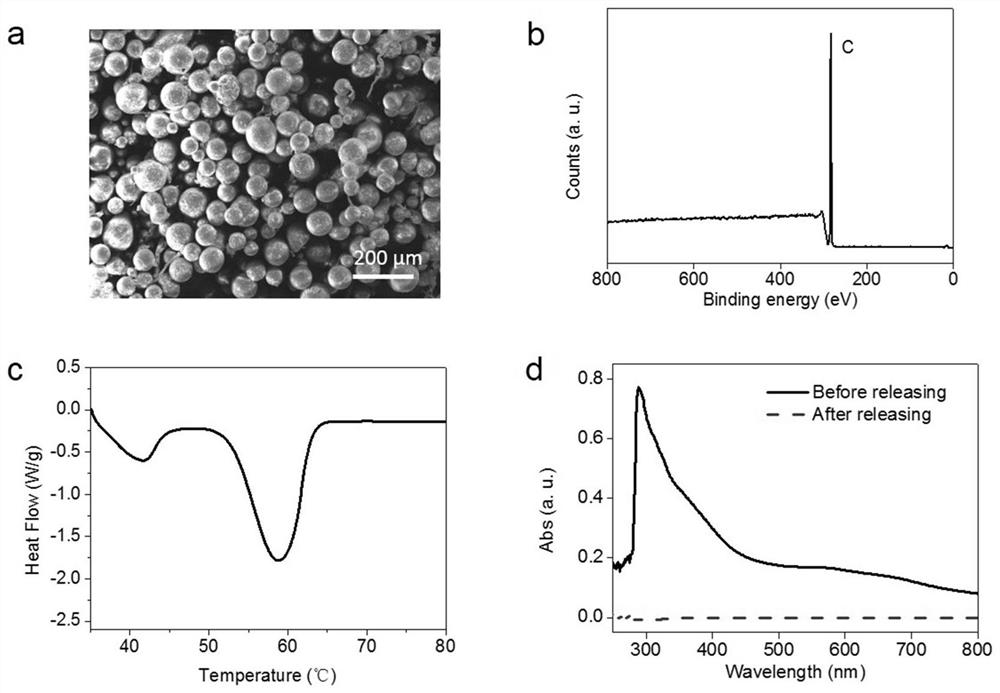

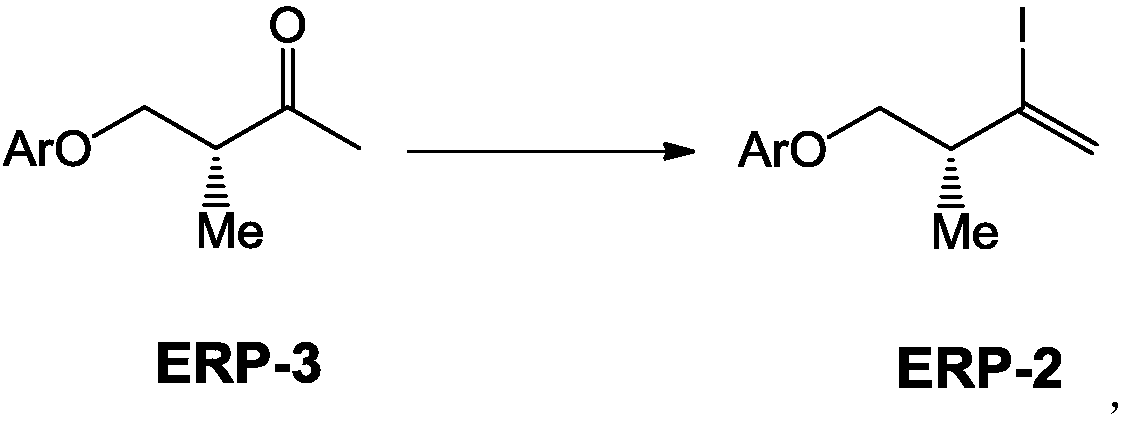

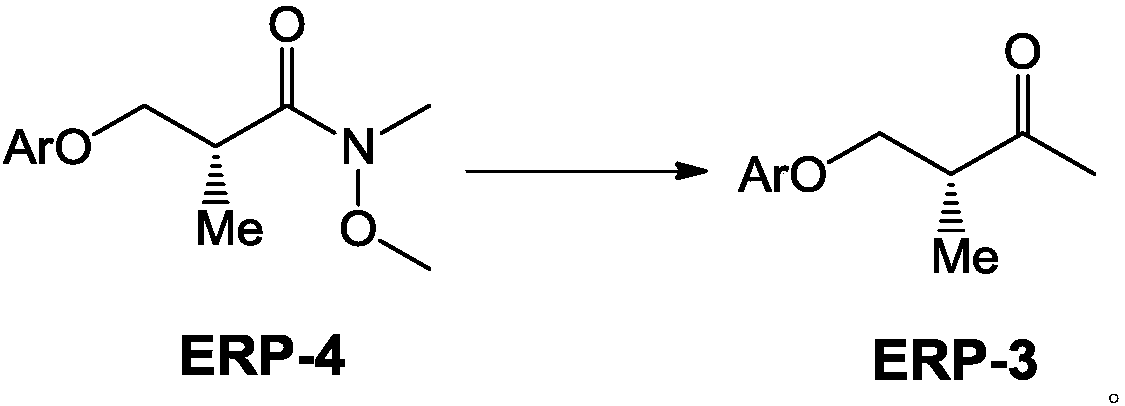

(3R)-2-iodo-4-benzyloxy-3-methyl-1-ene compound as well as preparation method and application thereof

InactiveCN110041160ANovel structureEasy to prepareOrganic compound preparationOrganic chemistry methodsIodineGrubbs' catalyst

The invention provides a (3R)-2-iodo-4-benzyloxy-3-methyl-1-ene compound as well as a preparation method and an application thereof, more particularly relates to a novel compound ERP-2 as well as a preparation method and an application thereof, also provides a novel preparation method of ERP ((3R)-2,4-diiodo-3-N-methyl butylamine-1-ene) and relates to use of the novel compound ERP-2. According tothe method, compared with the prior art, the yield and the quality of ERP-1 and ERP are notably increased when ERP-1 and ERP are prepared through the compound ERP-2, hazardous articles such as dimethylzinc or dimethyl aluminum are not required in the reaction process, expensive Hoveyda-Grubbs catalysts, Amano lipase PS-8000 and the like are not required, aftertreatment of a reaction is simple, theproduction cost is greatly saved, the production safety is improved, and the method is more suitable for industrial production.

Owner:NANTONG NUOTAI BIOLOGICAL PHARMA CO LTD

Crosslinkable high dielectric norbornene copolymer, norbornene crosslinked polymer and preparation method thereof

The invention provides a cross-linkable high dielectric norbornene copolymer. The cross-linkable high dielectric norbornene copolymer comprises a norbornene block copolymer which is formed by ring-opening metathesis polymerization of an endo-configuration norbornene monomer or an exo-configuration norbornene monomer and an exo-configuration oxa-norbornene monomer. The invention also provides a preparation method of the norbornene copolymer. According to the preparation method, the norbornene copolymer is obtained by ring-opening metathesis polymerization reaction of the endo-configuration norbornene monomer or the exo-configuration norbornene monomer and the exo-configuration oxa-norbornene monomer under the action of a Grubbs catalyst. The invention further provides a three-dimensional cross-linked network polymer formed by crosslinking of the norbornene copolymer and a preparation method thereof. The norbornene copolymer has a relatively high dielectric constant and very low dielectric loss. The preparation method of the norbornene copolymer is simple and practicable. The norbornene cross-linked polymer has relatively high dielectric constant and thermal stability, and the applied range of the norbornene crosslinked polymer in the field of thin-film capacitors is expanded.

Owner:EAST CHINA NORMAL UNIV

Cyclic trimetric polybutylene terephthalate preparation method

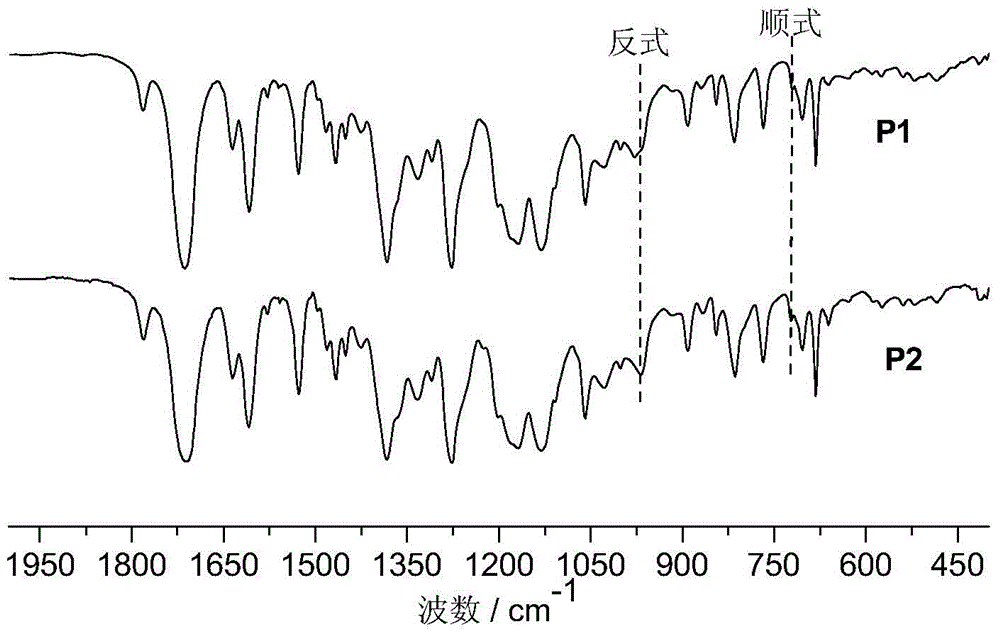

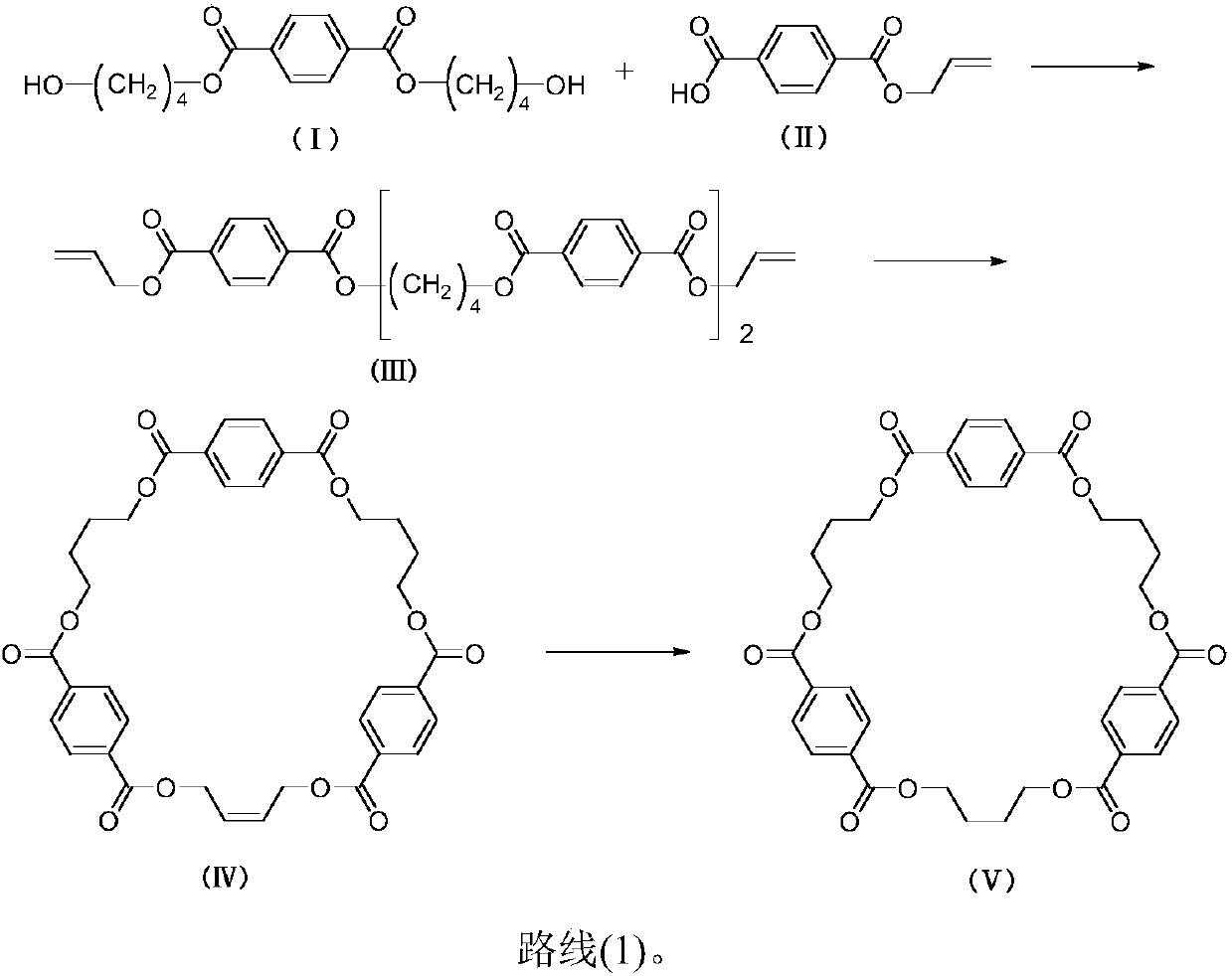

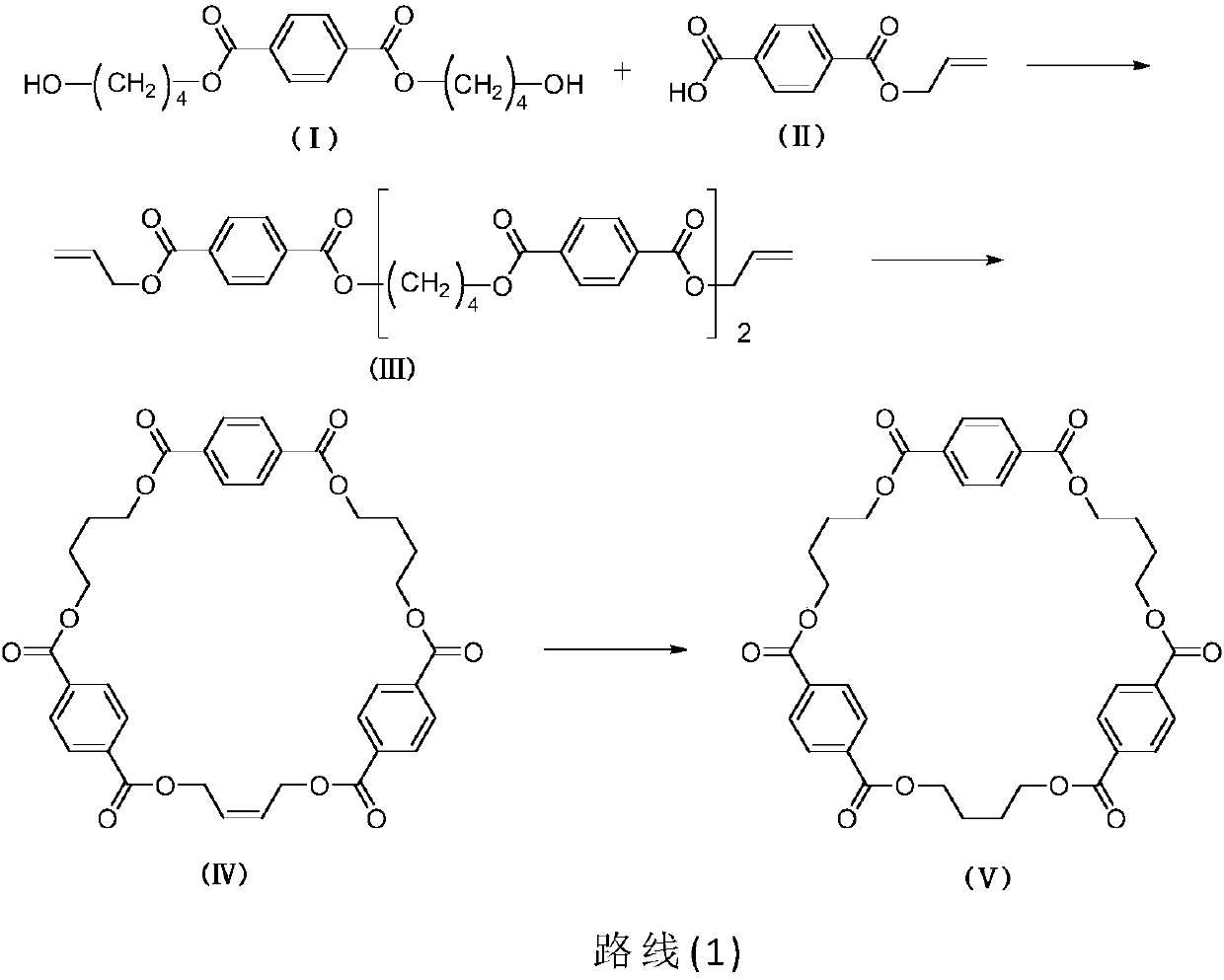

ActiveCN108047191AShort synthetic routeHigh yieldOrganic chemistryPolytetramethylene terephthalateBenzoic acid

The invention discloses a cyclic trimetric polybutylene terephthalate preparation method. The method comprises the steps: (a) preparing bis(4-(4-allyl terephthaloyl oxy)butyl)polyethylene terephthalate (III) from bis-(4-hydroxyl butyl)-polyethylene terephthalate (I) and 4-(allyloxy carbonyl)benzoic acid (II) under action of a condensing agent and an auxiliary reagent; (b) preparing cyclic trimetric polybutylene terephthalate precursor (IV) by ring closure of the bis(4-(4-allyl terephthaloyl oxy)butyl)polyethylene terephthalate (III) under the action of a Grubbs catalyst and lewis acid; (c) hydrogenating the cyclic trimetric polybutylene terephthalate precursor under the action of Pd / C to obtain cyclic trimetric polybutylene terephthalate (V). The preparation method disclosed by the invention has the advantages that the raw materials are cheap and easy to obtain, a synthesizing route is simple and short, a yield is high, and conditions are easy to control.(The formula is shown in the description.).

Owner:EAST CHINA NORMAL UNIV +1

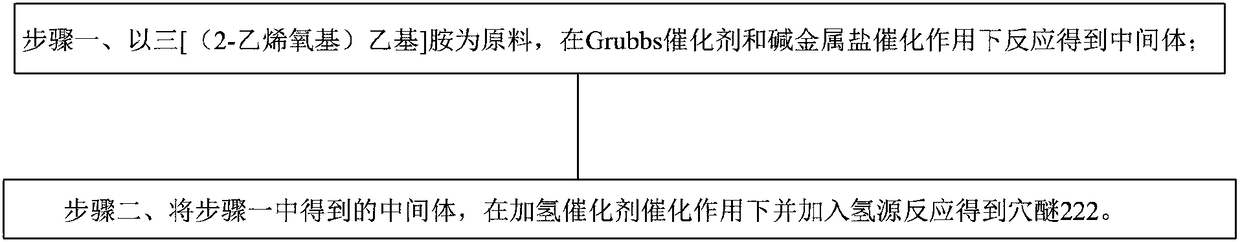

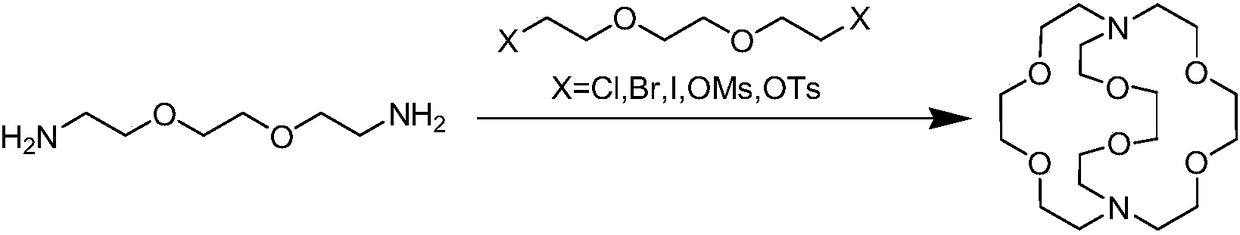

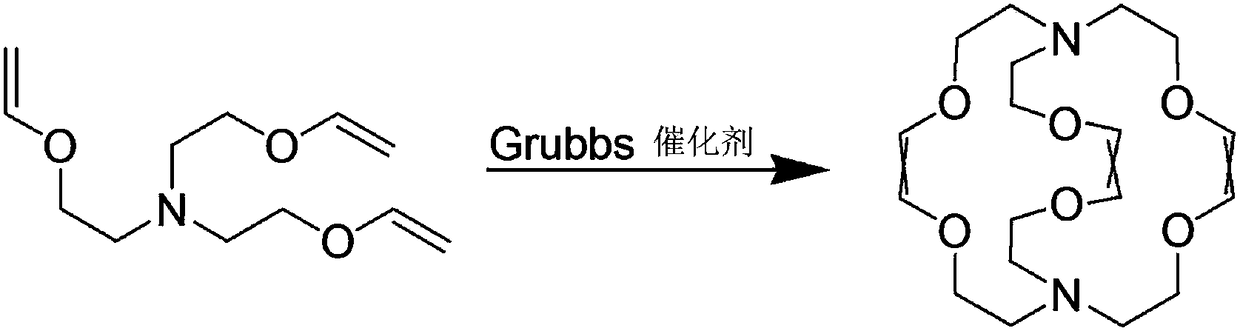

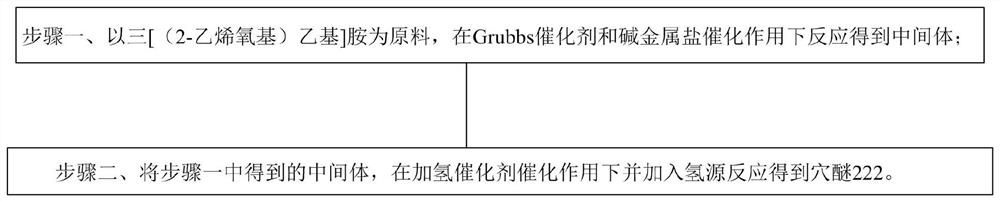

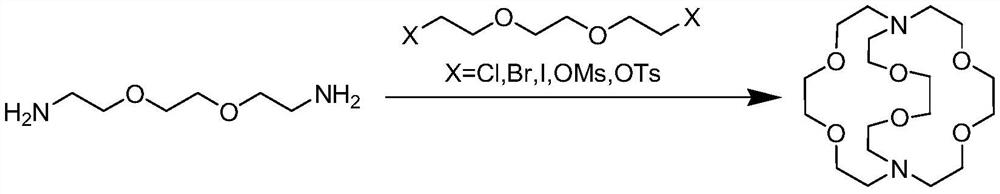

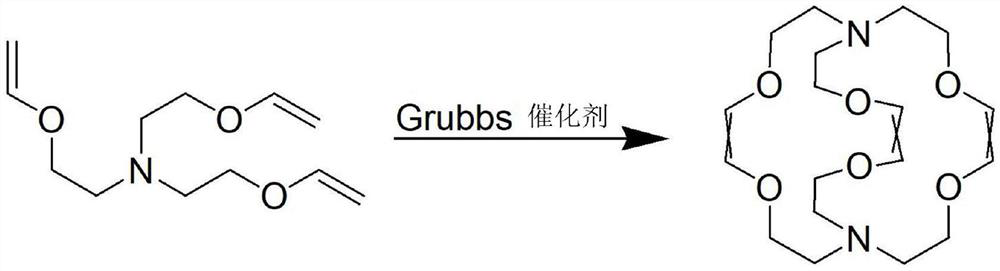

Process method for preparing cryptand 222

The invention discloses a process method for preparing cryptand 222. The process method comprises the following steps: 1, taking tris[(2-ethylnenoxy)ethyl]amine as a raw material, and reacting to obtain an intermediate under catalytic actions of a Grubbs catalyst and alkali metal salts; and 2, adding a hydrogen source into the intermediate obtained in the step 1 under the catalytic action of a hydrogenation catalyst, and reacting, thereby obtaining the cryptand 222. The process method disclosed by the invention has the beneficial effects of short synthesis period and high yield.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

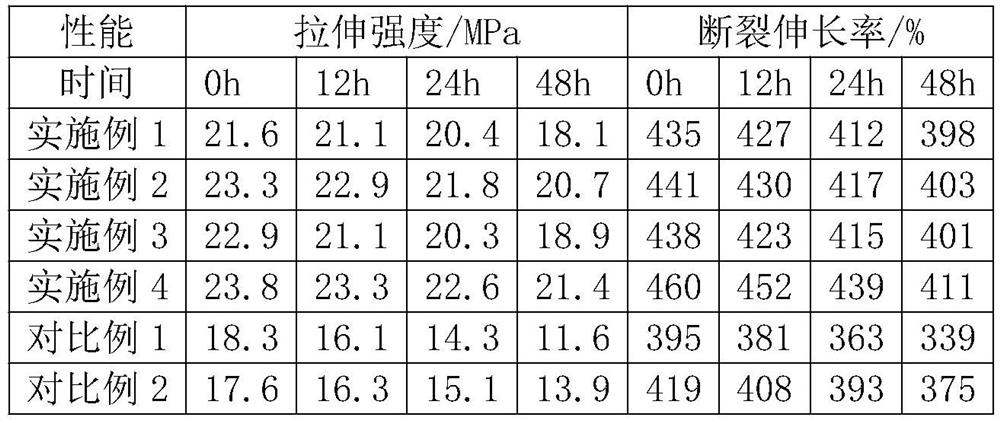

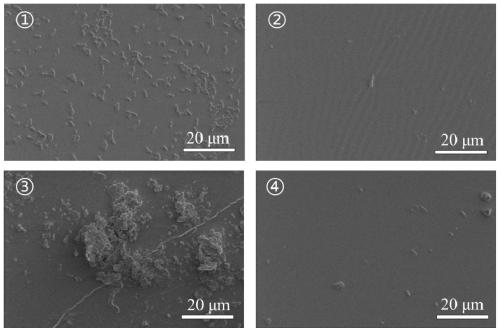

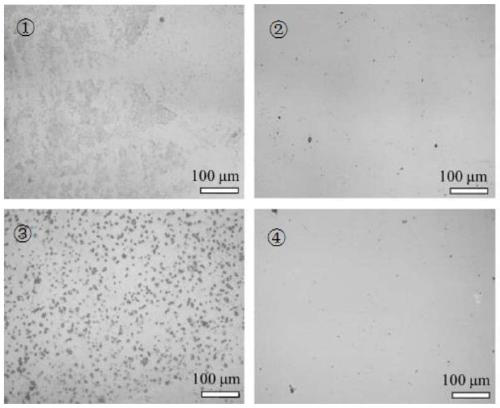

A kind of spray polyurea elastomer and preparation method thereof

ActiveCN113234385BWith automatic patching functionGood dispersionAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerFiber

The present invention relates to the technical field of spray-coated polyurea elastomer, and provides a spray-coated polyurea elastomer and a preparation method thereof. The preparation includes the following steps: step S100, preparing self-repairing microcapsules: using solid particle emulsifier, phenol, aldehyde, Prepare self-healing microcapsules by reacting deionized water, polyphenols, ammonium chloride, and dicyclopentadiene; step S200, preparing component A: polyetheramine, self-healing microcapsules, fiber filler, diethyltoluenediamine, The Grubb catalyst is mixed and stirred evenly; step S300, preparation of component B: mixing isocyanate and polyether polyol, and reacting to obtain an isocyanate prepolymer; step S400, preparation of sprayed polyurea elastomer: through a spraying machine, the components A and Component B is sprayed on the surface of the substrate at a volume ratio of 1:1, and reacted to obtain a sprayed polyurea elastomer. The sprayed polyurea elastomer provided by the invention has self-repair function, and has good mechanical properties and chemical corrosion resistance.

Owner:东营海瑞宝新材料有限公司

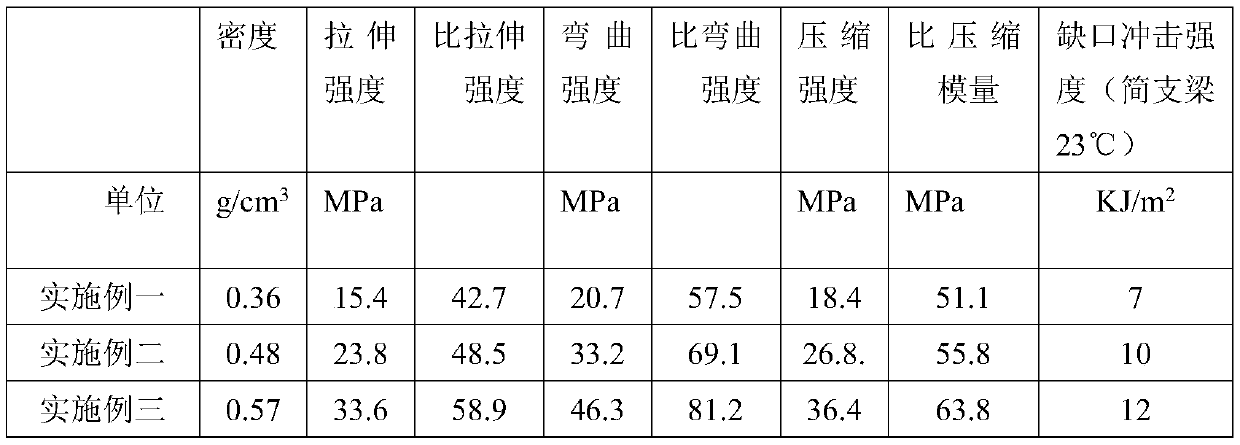

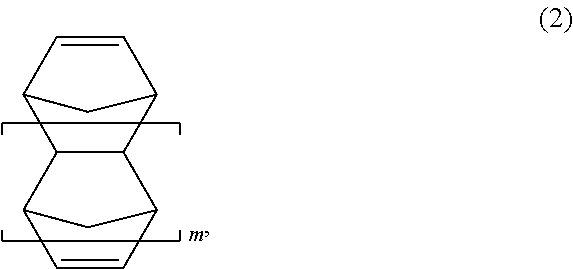

Novel porous foam material and preparation method thereof

The invention discloses a novel porous foam material and a preparation method thereof. The porous foam material comprises the following raw material components in parts by weight: 100 parts of dicyclopentadiene, 0.1-3 parts of an anti-aging agent, 0.1-3 parts of an ultraviolet absorbent, 0.2-5 parts of a tackifier, and a grubbs catalyst with the molar ratio of the grubbs catalyst to the dicyclopentadiene being 1 / 100000-1 / 500. The preparation method comprises the following steps: dissolving the anti-aging agent into dicyclopentadiene monomer at room temperature; dissolving the ultraviolet absorbent into the dicyclopentadiene monomer in the first step at room temperature; dissolving the tackifier into the dicyclopentadiene monomer obtained in the second step at room temperature; adding a certain proportion of catalyst solution into the dicyclopentadiene monomer; and pouring the obtained mixed solution into a mold, performing suction treatment for a period of time, carrying out vacuum insulation molding, cooling the molded product, and demolding the product to obtain the open-cell foam material. The obtained foam material has the properties of high strength, low density, heat insulation and sound insulation; the production process is simple, environment-friendly and convenient to operate.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD

Method for synthesizing 2H-azirine amide

The invention relates to a method for synthesizing 2H-azirine amide. 5-aminoisoxazole as a raw material is added to a reaction solvent, the Hoveyda-Grubbs Catalyst is then added, the materials are subjected to a catalytic reaction under green light illumination, the reaction solvent is removed from an obtained reaction liquid, the liquid is purified, and a product is obtained. The synthesis methodadopts quite mild required conditions and is green and high in yield, and the range of applicable substrates is wide, for example, various substituted phenyl groups, heterocyclic rings, olefins and alkanes can be adopted in the 2nd position of a three-membered ring of 2H-azirine amide, methyl, allyl, phenyl and 1-phenyl allyl groups can be adopted in the 3rd position, and arene, alkane or acyl substituted amine can be adopted for amide.

Owner:NANJING UNIV OF TECH

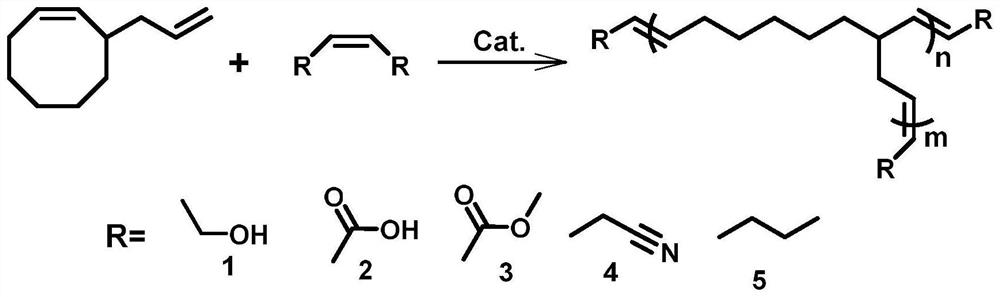

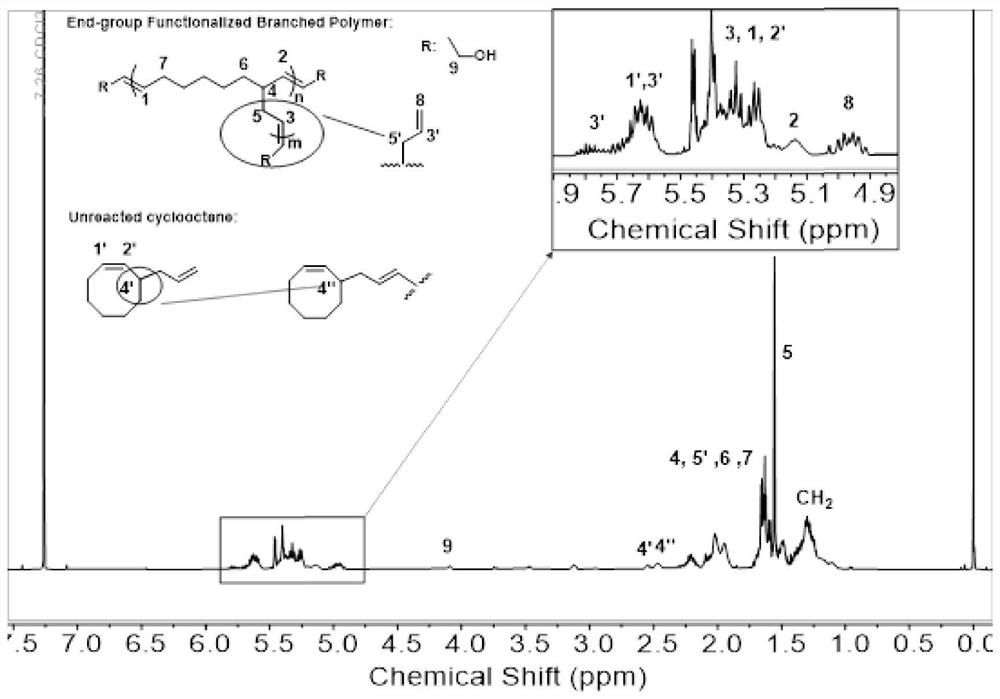

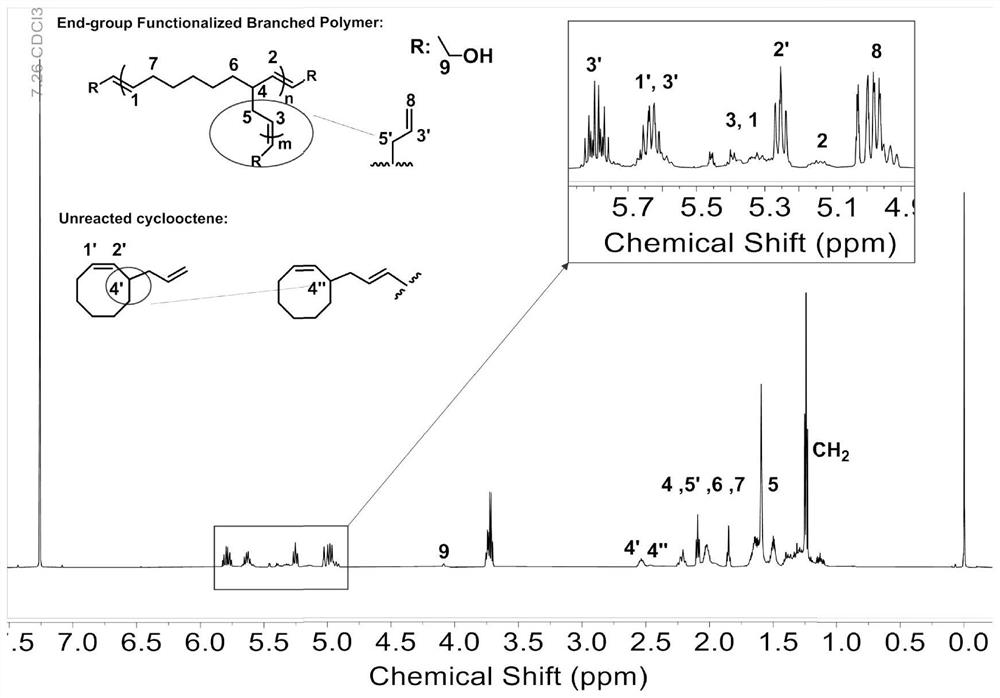

Preparation method of end group functionalized hyperbranched polyolefin

The invention relates to a preparation method of terminal group functionalized hyperbranched polyolefin. The preparation method comprises the following steps: taking 3-allyl-cyclooctene as a monomer, introducing a plurality of olefins with terminal functional groups as chain transfer agents, and directly obtaining end group functionalized polyolefin through simultaneous occurrence of ring-opening metathesis polymerization reaction and cross metathesis reaction in the presence of a plurality of Grubbs catalysts. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the preparation of hyperbranched polyolefin and the functionalization of the end group of the hyperbranched polyolefin can be simultaneously realized through a one-pot method; and the reaction conversion rate, the product structure, the type and number of end group units and the like are controlled by means of catalyst selection, monomer concentration change, chain transfer agent type and concentration change, reaction temperature and time control and the like.

Owner:上海零号源科技有限公司

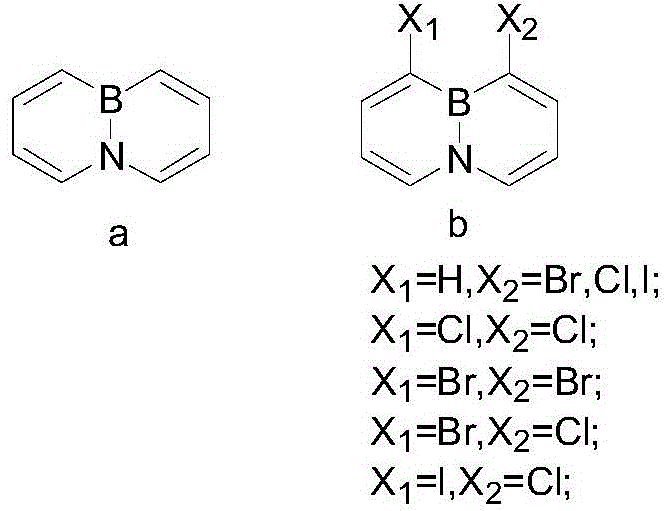

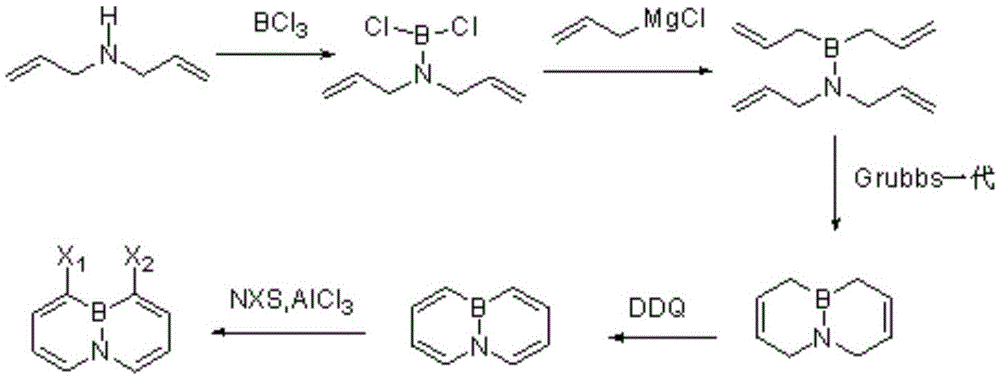

A method for synthesizing 4a, 8a-borazyridine and derivatives thereof

InactiveCN104098597BSources are cheap and readily availableMild reaction conditionsGroup 3/13 element organic compoundsSynthesis methodsBoron trichloride

The present invention relates to a kind of novel synthetic method of 4a, 8a borazine and derivatives thereof, and its synthetic steps comprise: (1) diallylamine reacts with boron trichloride at low temperature, generates diallyl Amino boron dichloride; (2) diallylamino boron dichloride reacts with allyl Grignard reagent at low temperature to generate diallylamino diallyl borane; (3) diallyl Aminodiallylborane uses Grubbs first-generation catalyst to trigger olefin metathesis into ring reaction; (4) the ring-forming product and dichlorodicyanobenzoquinone undergo dehydroaromatization reaction to generate 4a, 8a-borazepine Naphthalene; (5) 4a, 8a-borazine and halogenated succinimide undergo a halogenation reaction under Lewis acid catalysis to generate 4a, 8a-borazine derivatives substituted by halogen at the 4 / 5 position. The invention has simple steps, cheap and easy-to-obtain raw material sources, mild reaction conditions, less side reactions, and simple and efficient post-treatment process.

Owner:TONGJI UNIV

A kind of process for preparing cryptand 222

ActiveCN108117564BShort reaction cycleHigh yieldOrganic chemistryPtru catalystBiochemical engineering

The invention discloses a process method for preparing cryptand 222. The process method comprises the following steps: 1, taking tris[(2-ethylnenoxy)ethyl]amine as a raw material, and reacting to obtain an intermediate under catalytic actions of a Grubbs catalyst and alkali metal salts; and 2, adding a hydrogen source into the intermediate obtained in the step 1 under the catalytic action of a hydrogenation catalyst, and reacting, thereby obtaining the cryptand 222. The process method disclosed by the invention has the beneficial effects of short synthesis period and high yield.

Owner:SUZHOU BAILINGWEI HYPERFINE MATERIAL

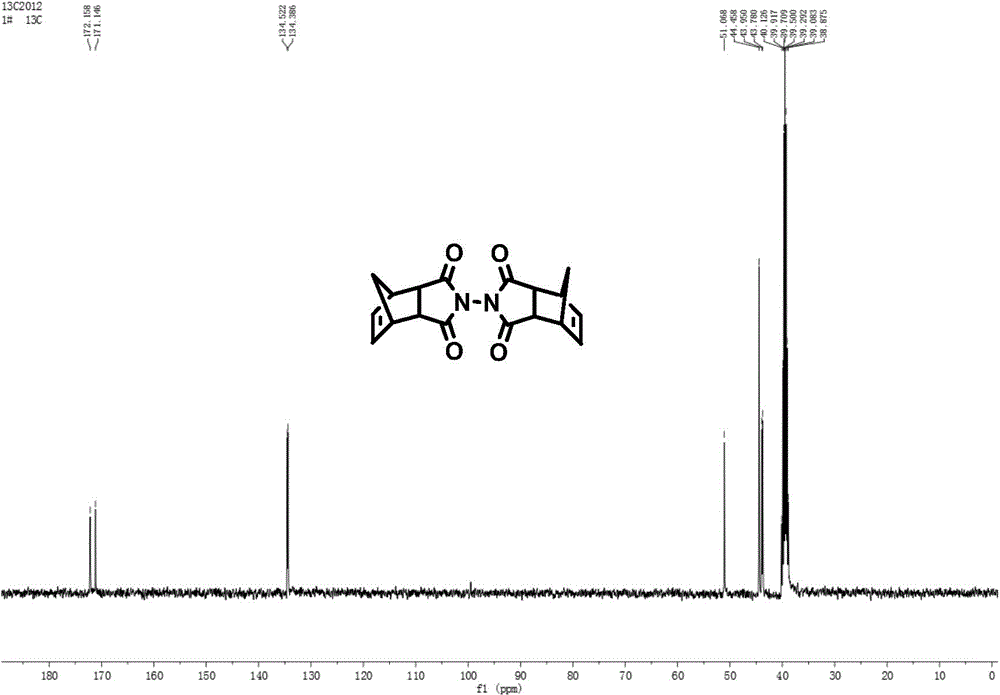

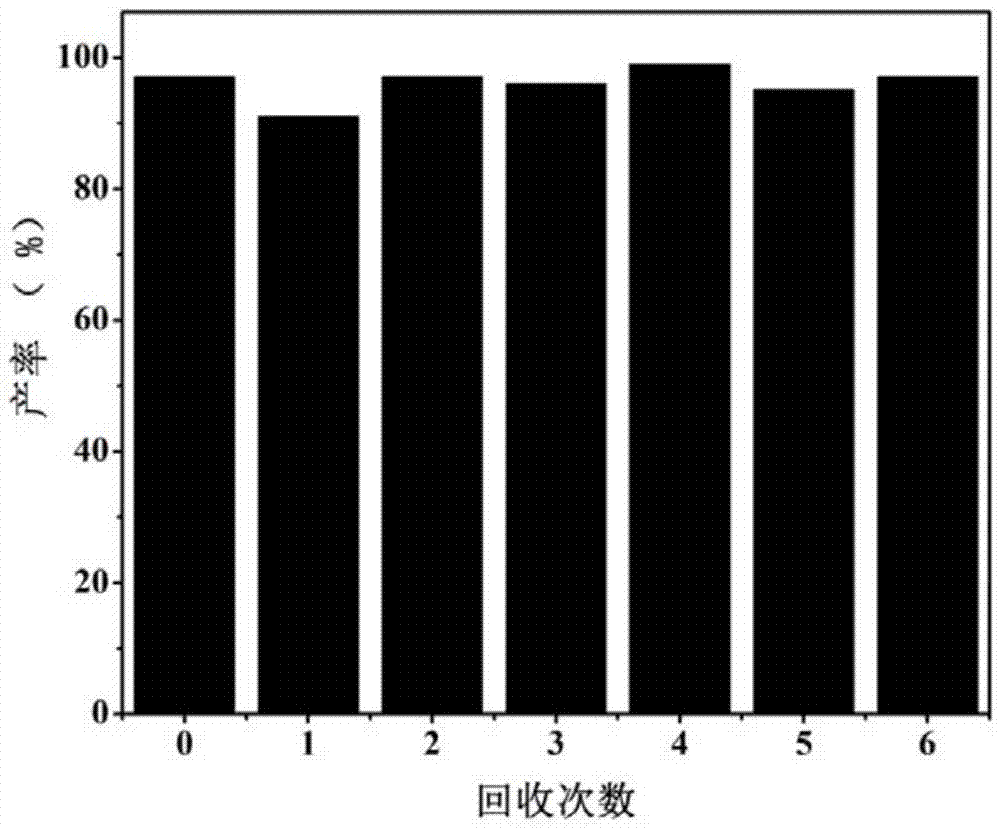

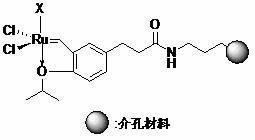

Preparation of loaded Grubbs catalyst and application of loaded Grubbs catalyst

InactiveCN102145304AReduce heavy metal pollutionReduce pollutionOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPropanoic acidOrganic synthesis

The invention discloses preparation of a loaded Grubbs catalyst and application of loaded Grubbs catalyst. The preparation is characterized in that: the catalyst is obtained by using the compound obtained by the amidation reaction of 3-3-ethenyl-4-isopropoxyphenyl-propionic acid as a loading precursor and then enabling the compound to carry out exchange complexation respectively with phenyl methylene-bistricyclohexylphosphine-dichlororuthenium or 1, 3-bis 2, 4, 6-trimethylphenyl-2-imidazolidinylidene-dichorobenzenemethylene-tricyclohexylphosphineruthenium; the catalyst is used for the olefin metathesis reaction of N,N-diallyl-4-methylbenzenesulfonamide and has quite strong catalytic activity. Compared with the prior art, the catalyst of the invention is simple in process and convenient in preparation, and can be recycled many times and keep excellent catalytic activity, thereby greatly reducing the heavy metal pollution caused by Grubbs type catalysts to the product of olefin metathesis reaction and developing a new way for green and environmentally-friendly organic synthetic chemistry.

Owner:EAST CHINA NORMAL UNIV

Spraying polyurea elastomer and preparation method thereof

ActiveCN113234385AWith automatic patching functionGood dispersionAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerFiber

The invention relates to the technical field of spraying polyurea elastomers, and provides a spraying polyurea elastomer and a preparation method thereof. The preparation method comprises the following steps that S100, preparation of self-repairing microcapsules: specifically, a solid particle emulsifier, phenol, aldehyde, deionized water, polyphenol, ammonium chloride and dicyclopentadiene react to prepare the self-repairing microcapsules; step S200, preparation of a component A: uniformly mixing and stirring polyether amine, self-repairing microcapsules, fiber filler, diethyltoluenediamine and a Grubbs catalyst; step S300, preparing a component B: mixing isocyanate and polyether polyol, and reacting to obtain an isocyanate prepolymer; step S400, preparing a spraying polyurea elastomer: spraying the component A and the component B on the surface of a base material according to the volume ratio of 1: 1 through a spraying machine, and reacting to obtain the spraying polyurea elastomer. The spraying polyurea elastomer has a self-repairing function and is good in mechanical property and chemical corrosion resistance.

Owner:东营海瑞宝新材料有限公司

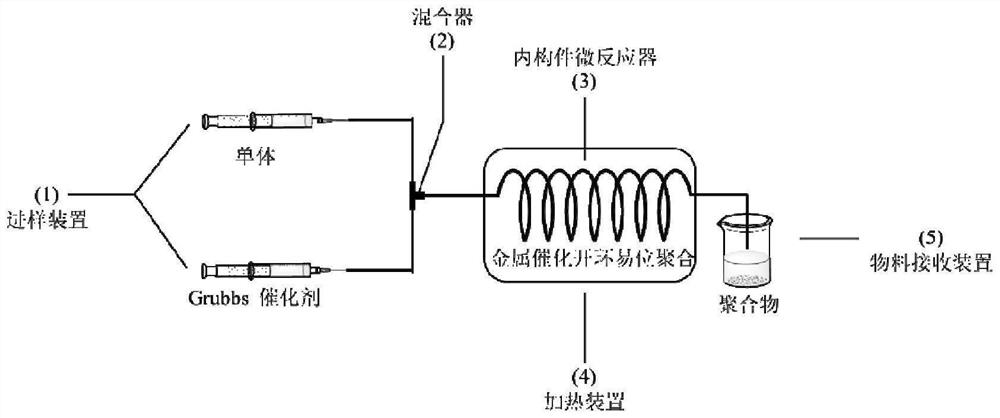

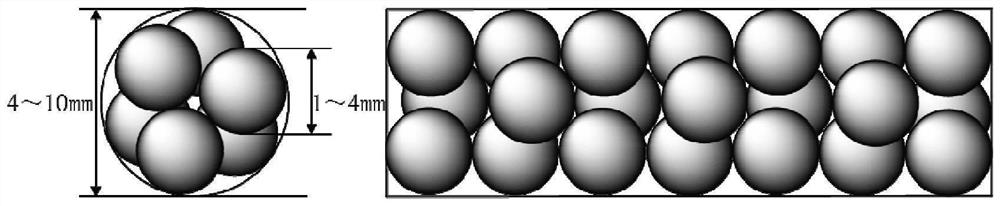

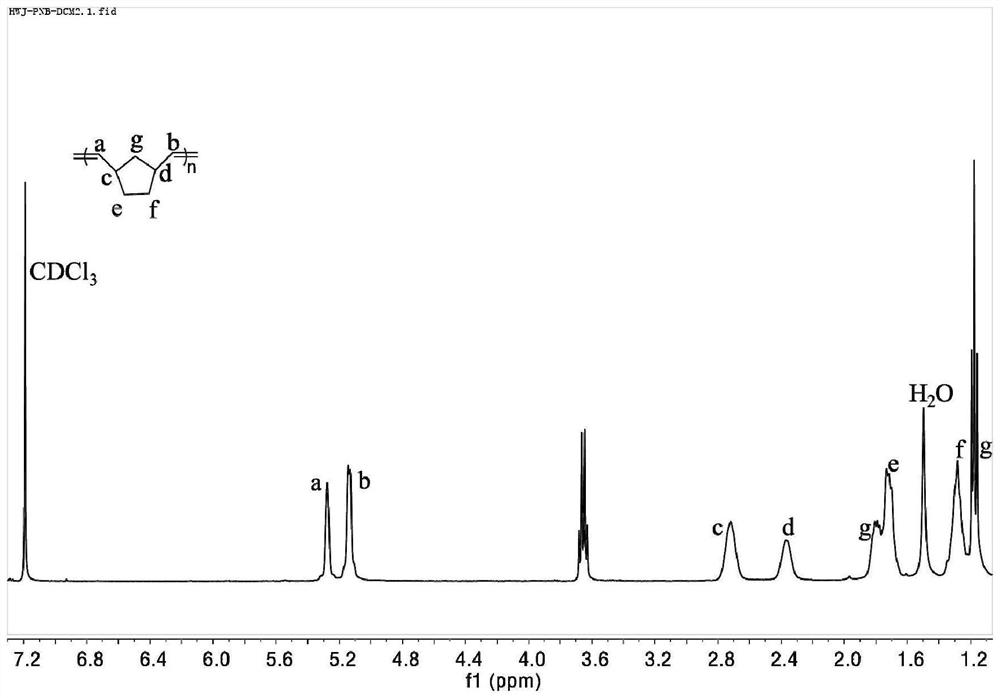

Method for preparing polyolefin through metal-catalyzed ring-opening metathesis polymerization

PendingCN114195986AEnhance heat and mass transferConvenient and efficient accessChemical/physical/physico-chemical microreactorsPolyolefinPtru catalyst

The invention discloses a method for preparing polyolefin by metal-catalyzed ring-opening metathesis polymerization, which comprises the following steps: (1) dissolving norbornene monomers in a solvent to prepare a monomer solution A; (2) dissolving a Grubbs catalyst in a solvent to prepare a catalyst solution B; and (3) in a microchannel reaction device, simultaneously pumping the monomer solution A and the catalyst solution B into a microreactor provided with a spherical internal component, reacting, collecting a reaction solution, separating and purifying to obtain polyolefin. According to the invention, the sphere is placed in the microreactor as an internal component, so that Poiseuille flow in the pipeline is effectively improved, the mass and heat transfer efficiency is improved, the polymerization rate is increased, the space-time control of the reaction in the pipeline is enhanced, and the high-molecular-weight narrow-distribution polyolefin is efficiently prepared. Meanwhile, a brand new thought is provided for polymerization reaction process control, and the method has important industrial application value.

Owner:NANJING ADVANCED BIOLOGICAL MATERIALS & PROCESS EQUIP INST CO LTD

Polyphenylene oxide prepolymer, method of making the same, resin composition and product made therefrom

ActiveUS20170342178A1High mechanical strengthSynthetic resin layered productsPrinted circuitsPolymer scienceNorbornene

Provided is a process of making a polyphenylene oxide prepolymer, comprising a step of reacting a reactive cycloolefin and a vinyl-containing polyphenylene oxide in the presence of a ruthenium catalyst. The reactive cycloolefin may be selected from dicyclopentadiene monomer, dicyclopentadiene oligomer, dicyclopentadiene polymer, norbornene monomer, norbornene oligomer, norbornene polymer, and a combination thereof; the vinyl-containing polyphenylene oxide may be selected from divinylbenzyl polyphenylene oxide resin, vinylbenzyl-modified polyphenylene oxide resin, methacrylic polyphenylene oxide resin, and a combination thereof; the ruthenium catalyst may be a Grubbs catalyst. Also provided are a polyphenylene oxide prepolymer made by the process, a resin composition containing the polyphenylene oxide prepolymer, and a product made from the resin composition.

Owner:ELITE MATERIAL

Amphoteric-polymer-based marine antifouling surface and preparation method thereof

InactiveCN109735230AHigh graft densityGood marine antifouling effectAntifouling/underwater paintsPaints with biocidesVolumetric Mass DensityGrubbs' catalyst

The invention belongs to the technical field of marine organism lossless protection, and particularly relates to an amphoteric-polymer-based marine antifouling surface and a preparation method thereof. The method includes the steps: designing and preparing a monomer of an amphoteric ion with a norbornene structure; initiating and grafting an amphoteric-polymer on the surface of modified polydimethylsiloxane by a surface initiation ring-opening metathesis polymerization method under catalyzing of a Grubbs catalyst to obtain the antifouling surface. The antifouling surface is simple and convenient to operate, the grafting density of an acquired polymer is high, and the antifouling surface has good marine antifouling effects.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN

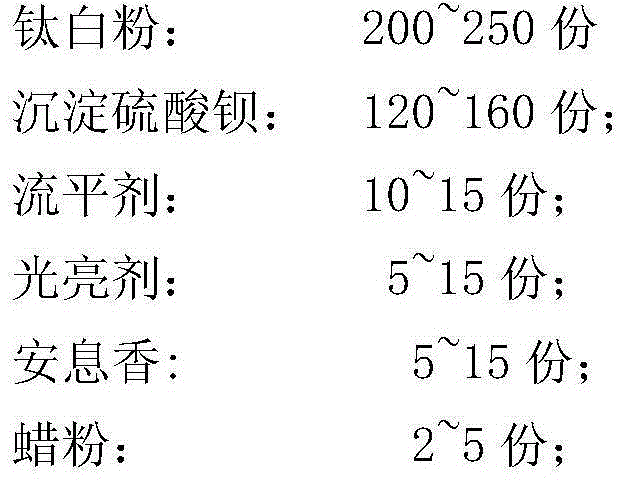

Self-repair powder coating applicable to aluminum material

The invention discloses a self-repair powder coating applicable to an aluminum material. The self-repair powder coating is used for electrostatic spraying preparation and application. The powder coating is prepared from, by weight, 450-650 parts of epoxy resin, 300-400 parts of pre-cipitated barium sulfate, 40-50 parts of a curing agent, 5-10 parts of a charge control agent, 20-30 parts of pigment and 40-60 parts of self-repair microcapsules with the catalysis effect. When the coating produces a microcrack, the microcapsules are broken, dicyclopentadiene will rapidly permeate into silver streaks, acts when encountering Grubbs catalyst to produce polymerization and crosslinking, and therefore the repair purpose is achieved. Accordingly, the service life of the powder coating is prolonged, and the self-repair powder coating is applicable to novel industrial production.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com