Novel porous foam material and preparation method thereof

A foaming material and a new technology, applied in the field of foamed plastics, can solve the problems of complex preparation process, poor solubility of foaming agent, high price, etc., and achieve the effect of simple production process, environmental protection process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

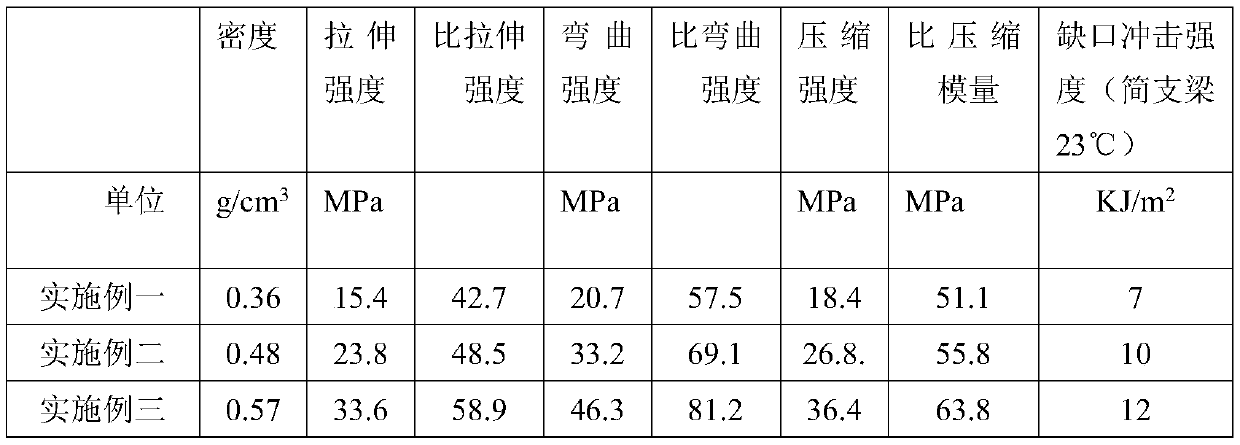

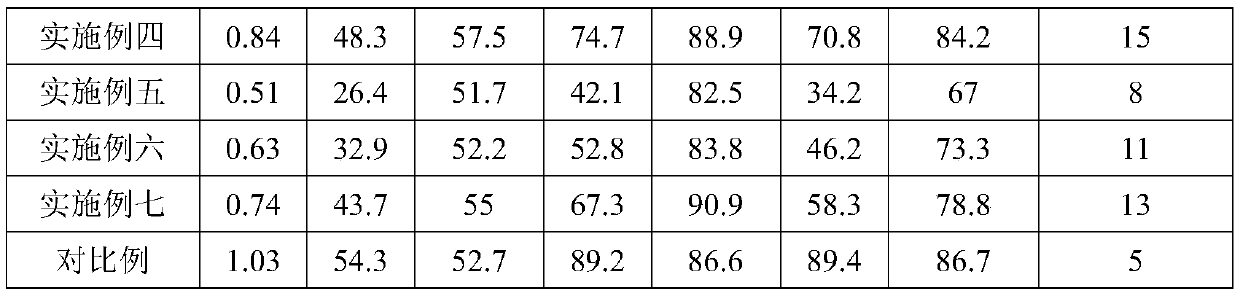

Embodiment 1

[0030] A novel open-cell foaming material and preparation method thereof: dissolve 1% 2,6-di-tert-butyl-4-methylphenol into 1000 mL of dicyclopentadiene monomer, stir for 5 minutes, and dissolve 2,6 - Dissolve 1% UV-531 in the monomer of di-tert-butyl-4-methylphenol, stir for 4min, dissolve in the monomer of 2,6-di-tert-butyl-4-methylphenol and UV-531 Dissolve 1% styrene-butadiene rubber, add 1 / 10000g rubbs catalyst solution (dissolved in dichloromethane or toluene solution), stir evenly for 2 minutes; pour into 50 ℃ mold, extract vacuum, react for 30 minutes, keep warm for 10 minutes, cool and demould Open-cell foamed PDCPD materials are available.

Embodiment 2

[0032] A novel open-cell foaming material and a preparation method thereof. Dissolve 0.5% bis(3,5-di-tert-butyl-4-hydroxyphenyl) sulfide in 1000 mL of dicyclopentadiene monomer, stir for 5 min, Dissolve 1% UV-326 into the monomer dissolved with bis(3,5-di-tert-butyl-4-hydroxyphenyl) sulfide, stir for 3 min, and dissolve in bis(3,5-di-tert-butyl- Dissolve 2% styrene-butadiene rubber into the monomer of 4-hydroxyphenyl) sulfide and UV-326, stir for 9min, add 1 / 10000grubbs catalyst solution (dissolved in dichloromethane or toluene solution), stir evenly for 3min; pour Put it into a mold at 50°C, extract the vacuum, react for 30 minutes, keep it for 10 minutes, and then cool and demold to obtain an open-cell foamed PDCPD material.

Embodiment 3

[0034] A novel open-cell foaming material and a preparation method thereof. Dissolve 0.5% 2,6-di-tert-butyl-4-methylphenol in 1000mL of dicyclopentadiene monomer, stir for 4min, and dissolve 2,6 - Dissolve 2% UV-326 in the monomer of di-tert-butyl-4-methylphenol, stir for 5min, dissolve in the monomer of 2,6-di-tert-butyl-4-methylphenol and UV-326 Dissolve 3% styrene-butadiene rubber in the medium, stir for 8min, add 1 / 10000grubbs catalyst solution (dissolved in dichloromethane or toluene solution), stir evenly for 3min; pour into a 50°C mold, extract vacuum, react for 30min, keep warm for 10min and then cool The open-cell foamed PDCPD material can be obtained by demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com