Patents

Literature

169 results about "Polydicyclopentadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

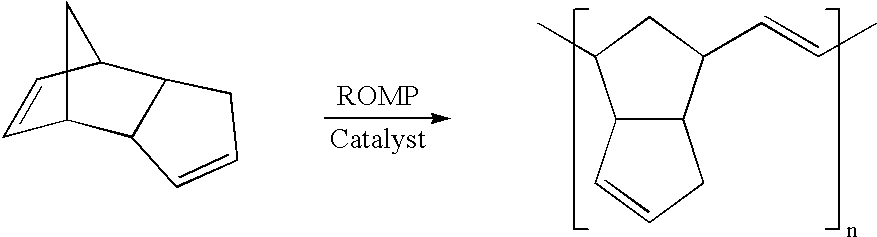

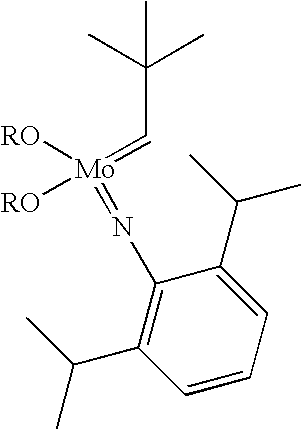

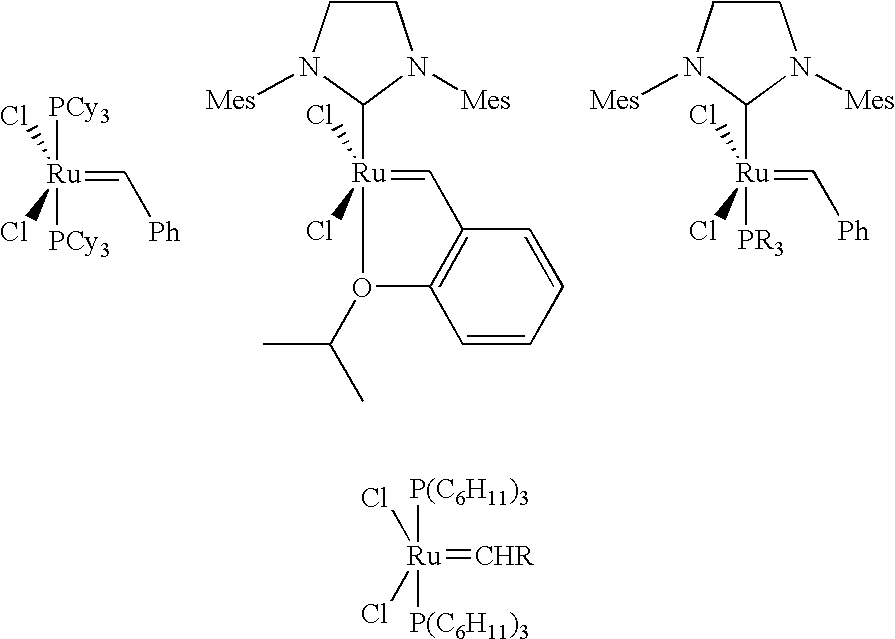

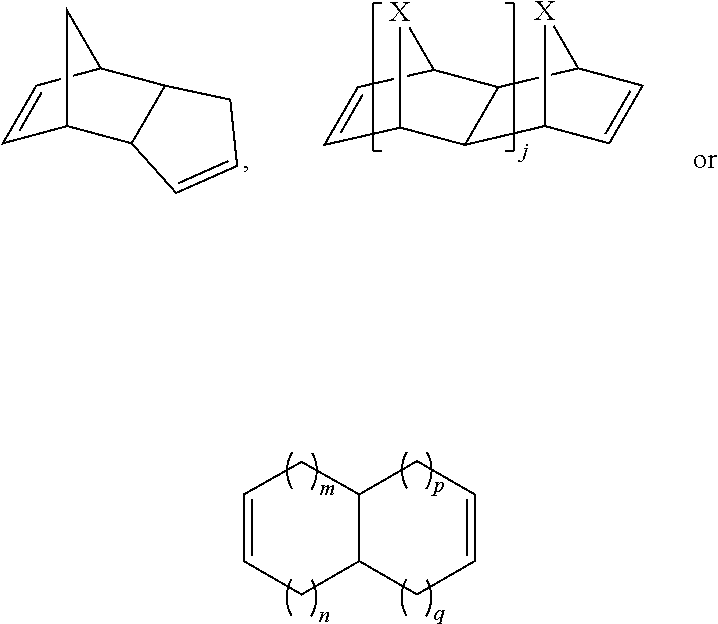

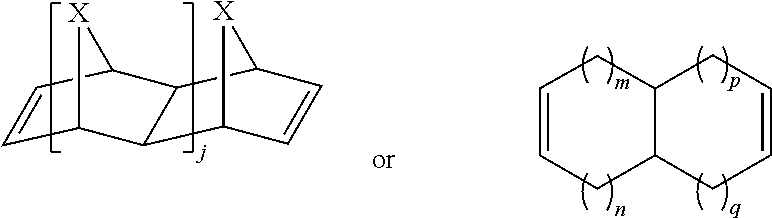

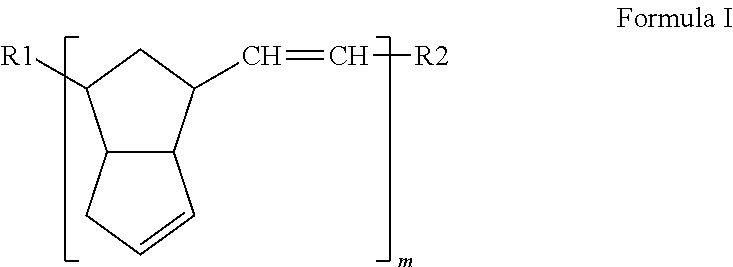

Polydicyclopentadiene (PDCPD) is a polymer which is formed through ring opening metathesis polymerisation (ROMP) of dicyclopentadiene (DCPD). The difference between the various systems lies in the type of catalyst used to create the polymer, but the final polymer properties are similar.

Polydicyclopentadiene composite material and preparation method thereof

The invention discloses a polydicyclopentadiene composite material, which consists of the following components in percentage by weight: 0.1 to 2 percent of inorganic nano filler, 0 to 5 percent of auxiliary polymer particles and the balance of polydicyclopentadiene and inevitable impurities, wherein the inorganic nano filler is nano inorganic salt, nano oxide, nano carbide or nano sulfide containing Si, Al, Ca, Zn, Ti, Zr or Mo metal or carbon-containing nonmetallic nano compound; and the auxiliary polymer particles are particles of polyethylene, polytetrafluoroethylene or polyamide, the particle diameter of which is 0.5 to 15 microns. The inorganic nano material and the auxiliary polymer particles are blended into the polydicyclopentadiene to prepare the polydicyclopentadiene composite material; and the abrasion resistance of the nano composite material is improved at the same time of improving the modulus and the impact strength, and the erosion and abrasion resistance of the nano composite material can reach 5 to 9 times that of low-chromium cast iron.

Owner:HENAN UNIV OF SCI & TECH

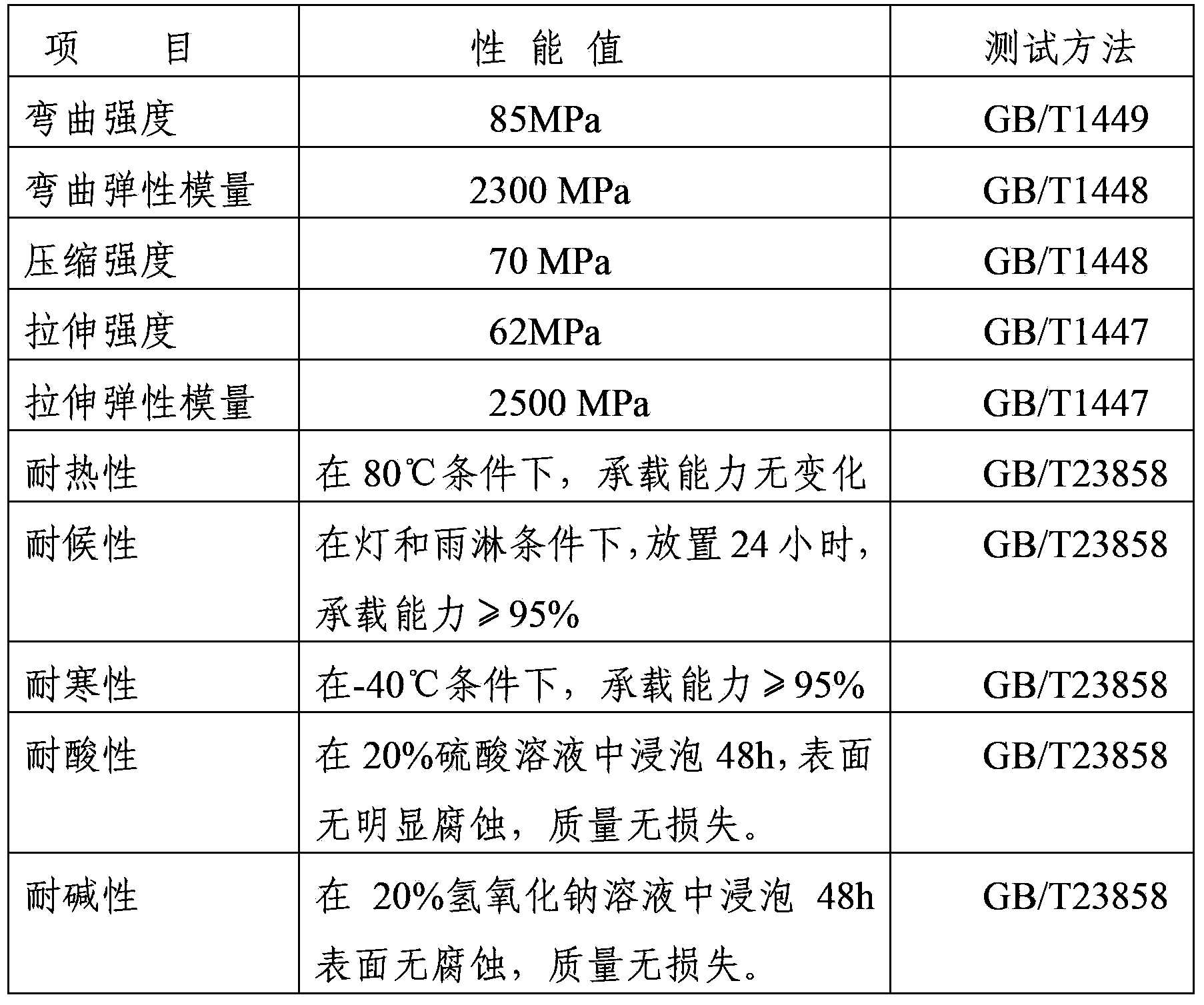

Polydicyclopentadiene composite material and single material reaction injection molding technology thereof

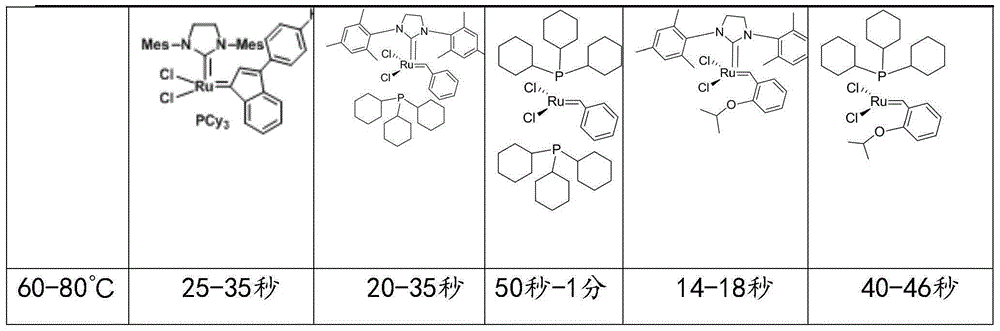

The invention discloses a formula of a polydicyclopentadiene (PDCPD) composite material and a single material reaction injection molding (RIM) technology thereof. The composite material is prepared from 35-65% of dicyclopentadiene, 1-15% of copolymers, 10-51% of functional filler, 0.01-0.1% of polymerization regulator, 1-5% of antiaging agents, 1-3% of cosolvent and 0.01-0.1% of curing agent, and the curing agent is a ruthenium-carbine catalyst. The single material reaction injection molding technological method includes the steps that the formula materials are mixed and evenly dispersed and form mixed slurry with a curing agent solution, and the mixed slurry is injected into a molding mold at the speed of 10-100 ml / s with the temperature kept below 30 DEG C; the mold is heated to 60 DEG C-80 DEG C, curing is carried out fast within one minute, and then demolding is carried out. The PDCPD composite material is good in mechanical property, the curing time is short, and the process is simple.

Owner:克琴新材料科技(上海)有限公司

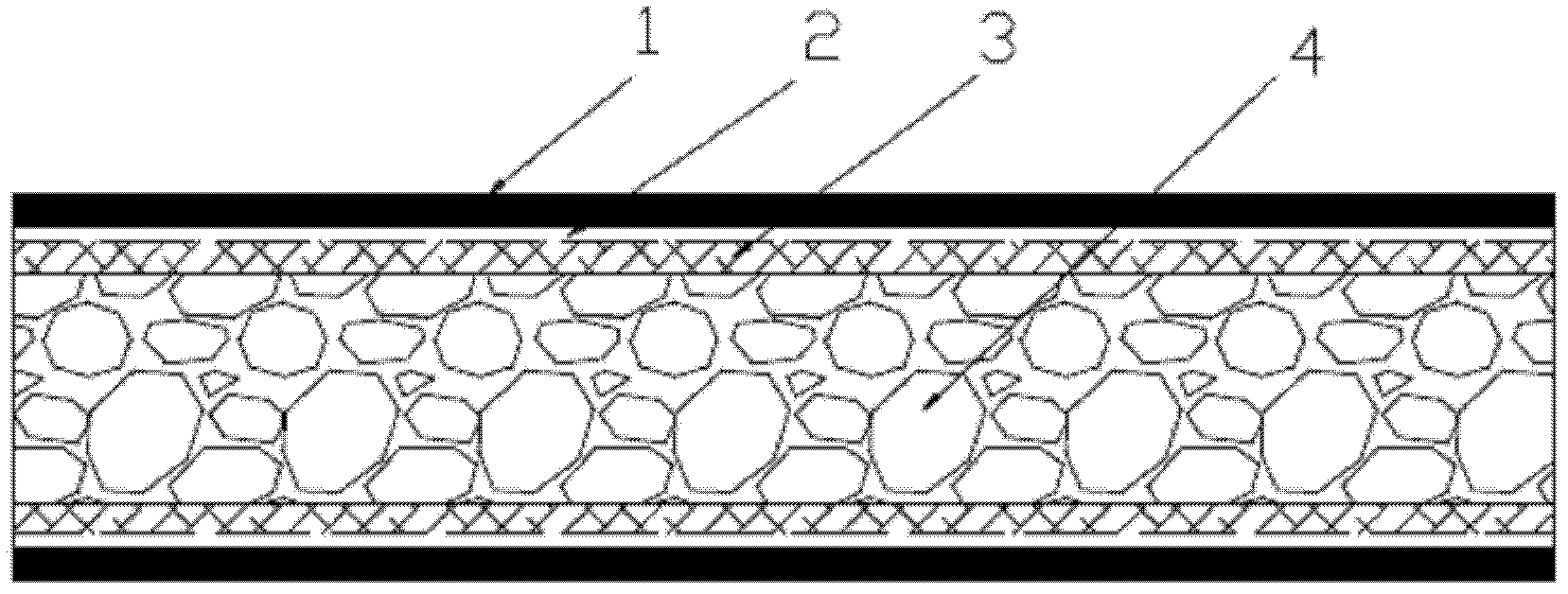

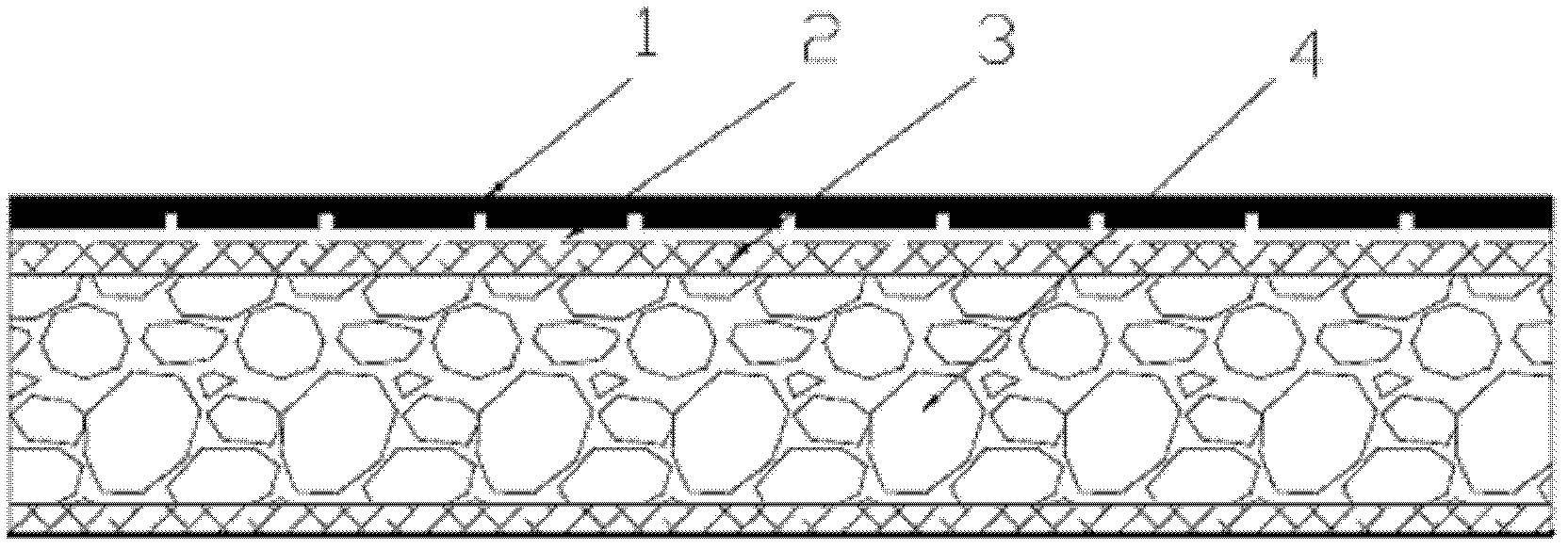

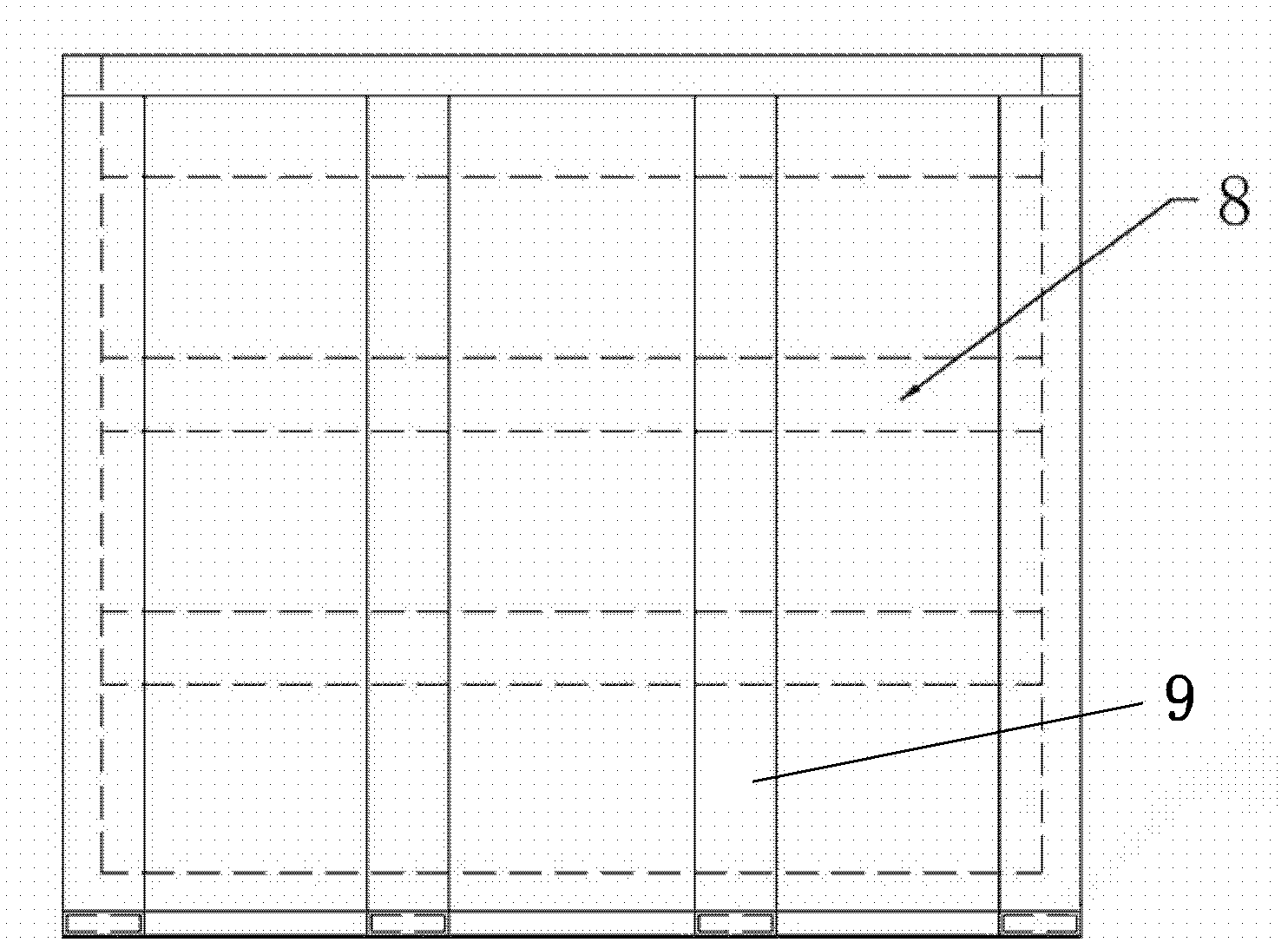

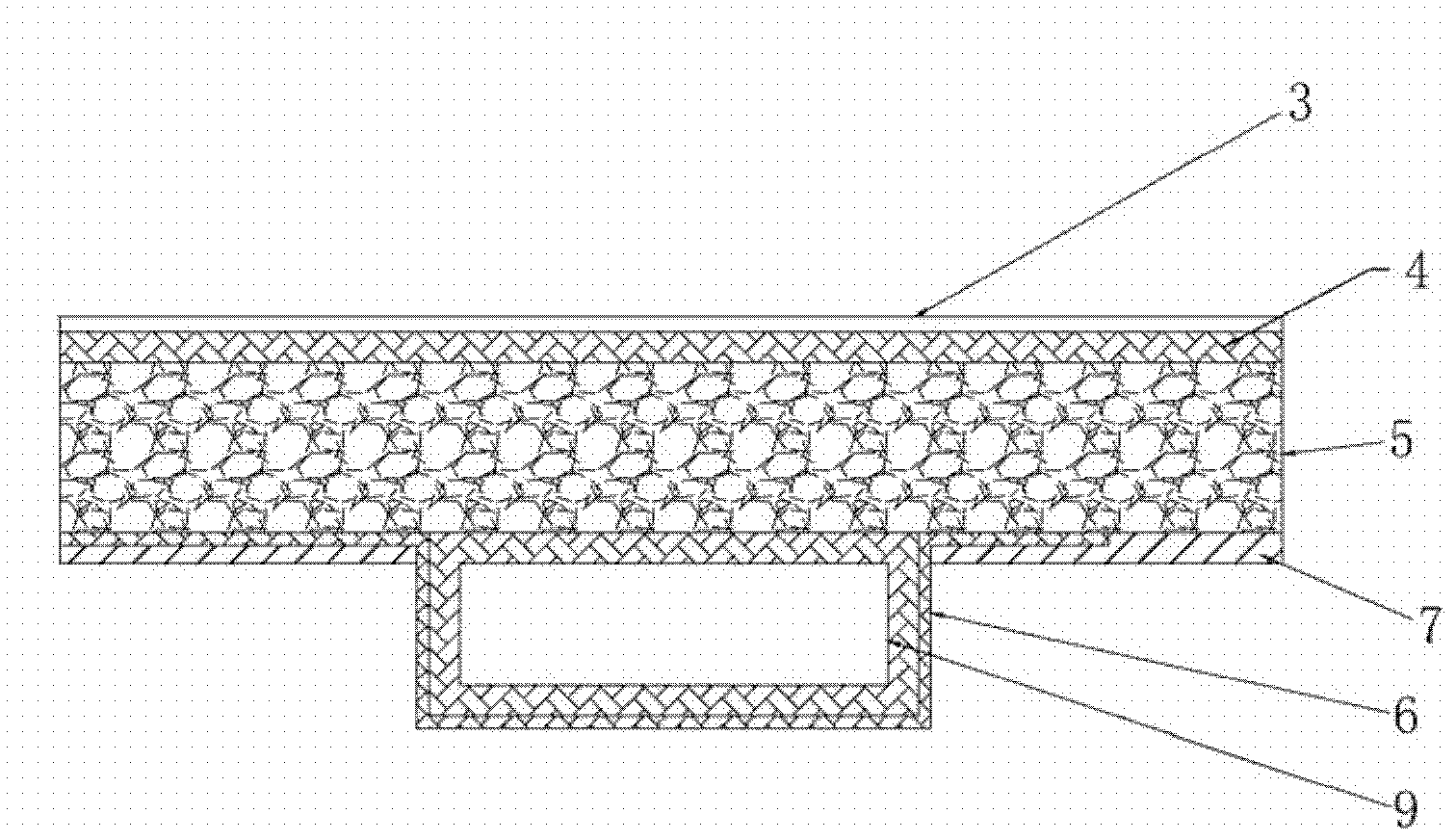

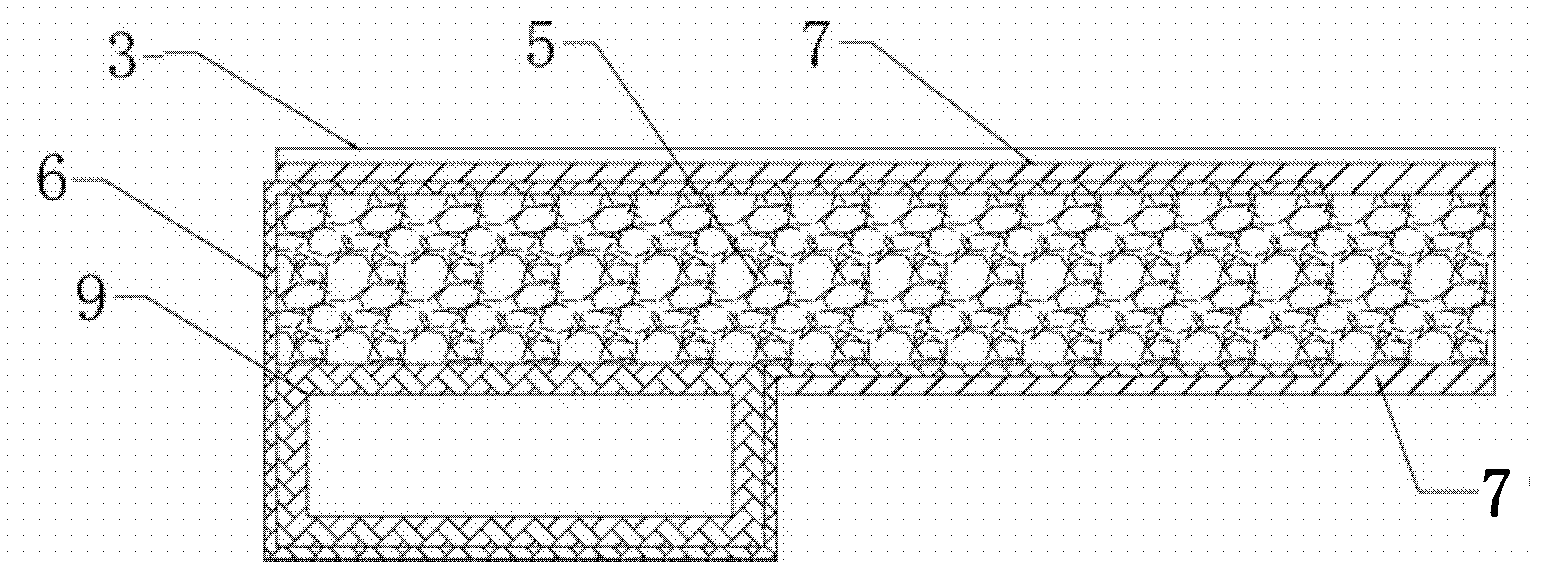

Composite material plate, preparation method and use of composite material plate

InactiveCN103009728AIncrease stiffnessSolve wear resistanceSynthetic resin layered productsLaminationWear resistancePolydicyclopentadiene

The invention relates to a composite material plate. The composite material plate comprises a sandwich layer, two covering layers coating the outer surface of the sandwich layer, and a polydicyclopentadiene layer arranged on the outer surface of at least one of the covering layers. The invention also relates to a preparation method and a use of the composite material plate. According to the composite material plate, outside of a fiber reinforced material is coated by the polydicyclopentadiene layer, so that the problem that a conventional fiber reinforced resin-based composite material is easily suffered from layering failure and is poor in abrasive resistance when being subjected to an impact load is solved. The composite material plate can be widely applied to loading or load-bearing components on mine, railway and road transportation heavy vehicles and goods hoppers. The composite material plate material can be obtained through a reaction injection molding process combined with a vacuum auxiliary molding process, and is suitable for industrial production.

Owner:蓝星环境工程有限公司

Preparation method of polydicyclopentadiene/rubber in-situ polymerization blending composite material

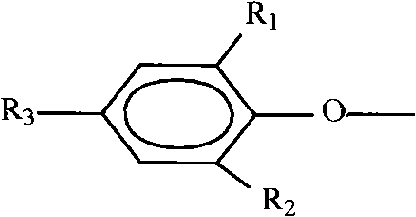

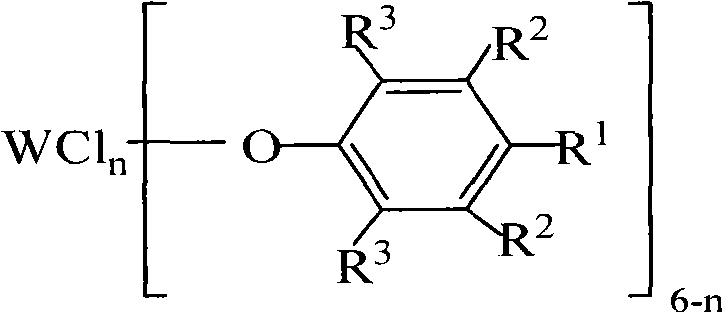

The invention provides a preparation method of a polydicyclopentadiene / rubber in-situ polymerization blending composite material. The method comprises the following steps: dissolving the rubber into the polydicyclopentadiene, taking the aryloxy-tungsten complexes as main catalyst and the alkyl aluminium as cocatalyst, utilizing reaction injection molding technology to prepare the polydicyclopentadiene / rubber blending composite material by in-situ polymerization blending, due to the introduction of the rubber, the polydicyclopentadiene material has high toughness, thus enlarging the application field thereof. By adopting the reaction injection molding method, a high performance polydicyclopentadiene composite material can be prepared simply and effectively. The prepared polydicyclopentadiene / rubber in-situ polymerization blending composite material has higher impact resistant performance of which the impact strength can reach 200-400J / m.

Owner:HENAN UNIV OF SCI & TECH

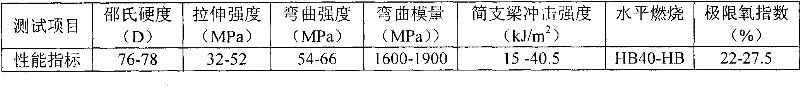

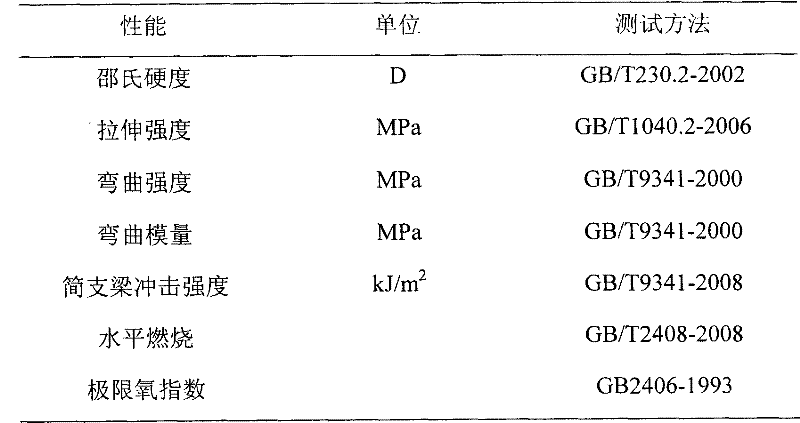

Flame-retardant polydicyclopentadiene composition, and thermosetting material and preparation method thereof

The invention discloses a flame-retardant polydicyclopentadiene composition, and a thermosetting material and a preparation method thereof. The composition comprises a dicyclopentadiene monomer, a catalyst, and moderate-low molecular weight bromide polymer capable of being dissolved in monomer dicyclopentadiene, and also can comprise other cycloolefins capable of being copolymerized with dicyclopentadiene, a synergistic flame retardant, a flame retardant synergist, other aids and the like. A main flame retardant in the composition can be dissolved in the monomer dicyclopentadiene, and is small in dosage and good in flame retardant effect. The composition can be prepared into the thermosetting material according to a reaction injection molding process, and the material has good comprehensive performance.

Owner:LIMING RES INST OF CHEM IND

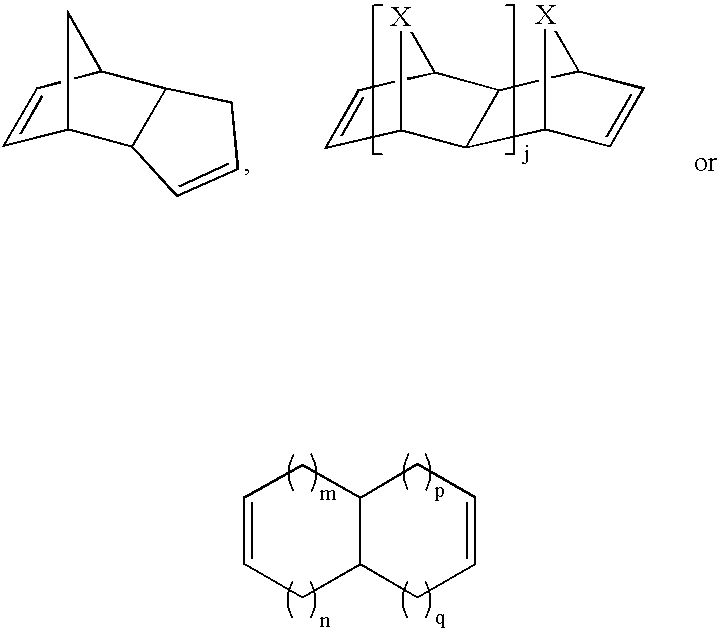

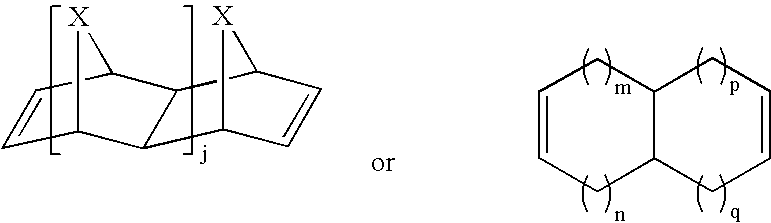

Method for preparing poly(dicyclopentadiene)

Crosslinked polydicyclopentadiene polymer and copolymer are made by first forming a thermoplastic polymeric intermediate in a ring-opening metathesis polymerization (ROMP), and then crosslinking the intermediate in a melt-processing or solution processing step. The formation of the intermediate permits facile removal of residual monomer, which leads to a reduction in odor and improvement in physical properties. Crosslinking can be achieved using various crosslinking strategies, including further ROMP reactions, addition polymerization of residual double bonds, addition of a crosslinking agent or introduction of functional groups.

Owner:DOW GLOBAL TECH LLC

Halogen-free flame-retardant dicyclopentadiene material and preparation method thereof

ActiveCN101792505AImprove appearance qualityImprove mechanical propertiesPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPhosphateAluminium hydroxide

The invention discloses a halogen-free flame-retardant dicyclopentadiene material and a preparation method thereof. The material consists of polydicyclopentadiene, flame retardant, modifier and catalyst, wherein the flame retardant is silane coupling agent, titanate coupling agent, aluminium zirconate coupling agent, organic chromium coupling agent, higher fatty acid and salt thereof, phosphate, unsaturated organic acid or organic ammonium salt modified aluminium hydroxide. The preparation method prepares the flame-retardant material by using reaction injection moulding. The oxygen index of the obtained material is 22 to 26 percent, and the horizontal combustion test can reach HB level; and the bending strength is 40 to 45MPa, the bending modulus is 1,400 to 1,700MPa, the tensile strength is 34 to 37MPa, the impact strength is 26-80kJ / m<2>, and the hardness is 74 to 76 Shaw D. The material does not contain halogen flame retardant, and has high flame-retardant performance and high mechanical property.

Owner:LIMING RES INST OF CHEM IND

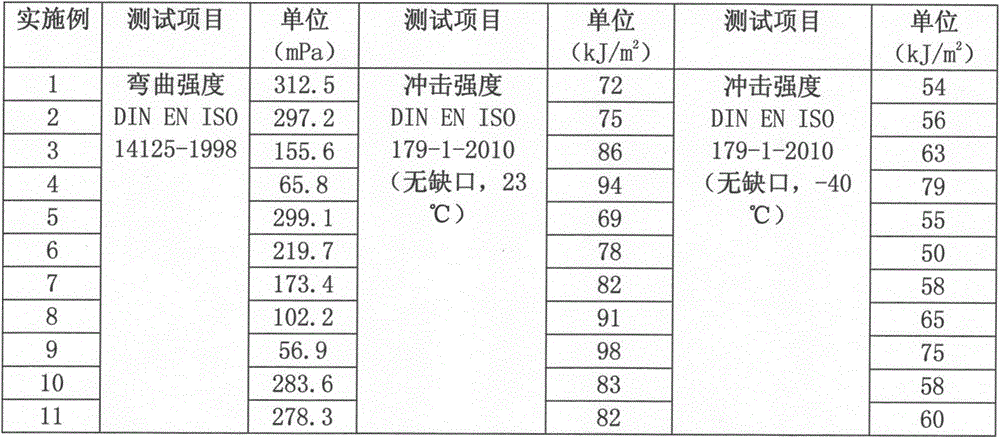

Polydicyclopentadiene composite material and preparation method thereof

The invention discloses a polydicyclopentadiene composite material and a preparation method thereof, which belongs to the technical field of the forming of macromolecular material. The composite material mainly consists of raw materials such as polydicyclopentadiene, main catalyst and auxiliary catalyst in the ratio of (2000-4000): 1: (15-40), wherein the main catalyst is di[2,6 tert-butyl-4-methyl phenoxyl] dichloride tungsten, and the auxiliary catalyst is aluminium diethyl monochloride or triethyl aluminum. The polydicyclopentadiene composite material is excellent in comprehensive mechanical property, high in across measure and high in low-temperature impacting strength, the bending-resistant modulus is more than 1500MPa, the minimal notch impact strength is not less than 100J / , and the impact strength is maintained stable at the temperature of minus 40 to 115 DEG C. After being compounded with inorganic filler, the enhanced polydicyclopentadiene composite material is excellent in the comprehensive mechanical property on the basis of maintaining the original performance, the bending-resistant modulus can reach more than 2500MPa, and the hardness can be doubled.

Owner:长春三友智造科技发展有限公司

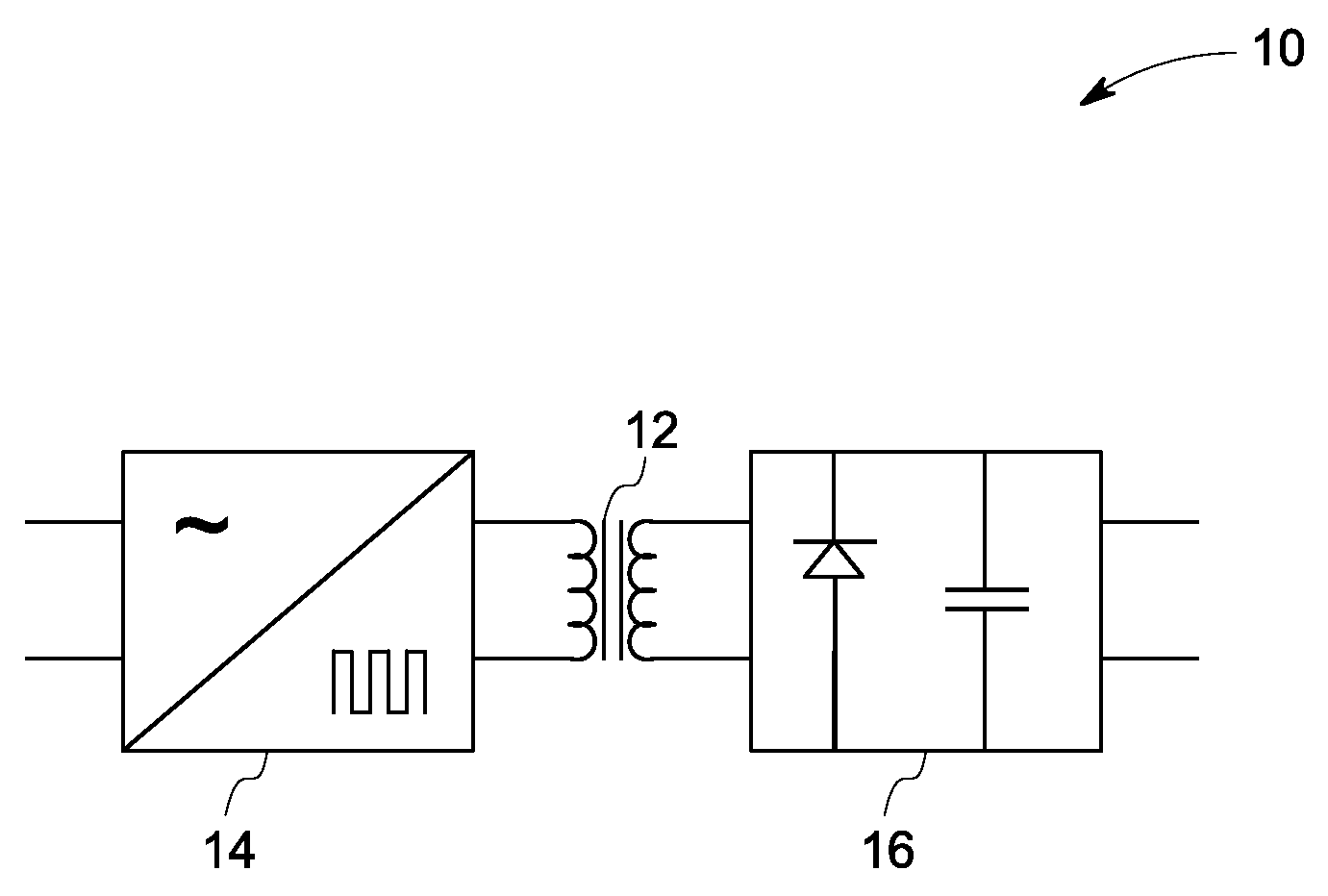

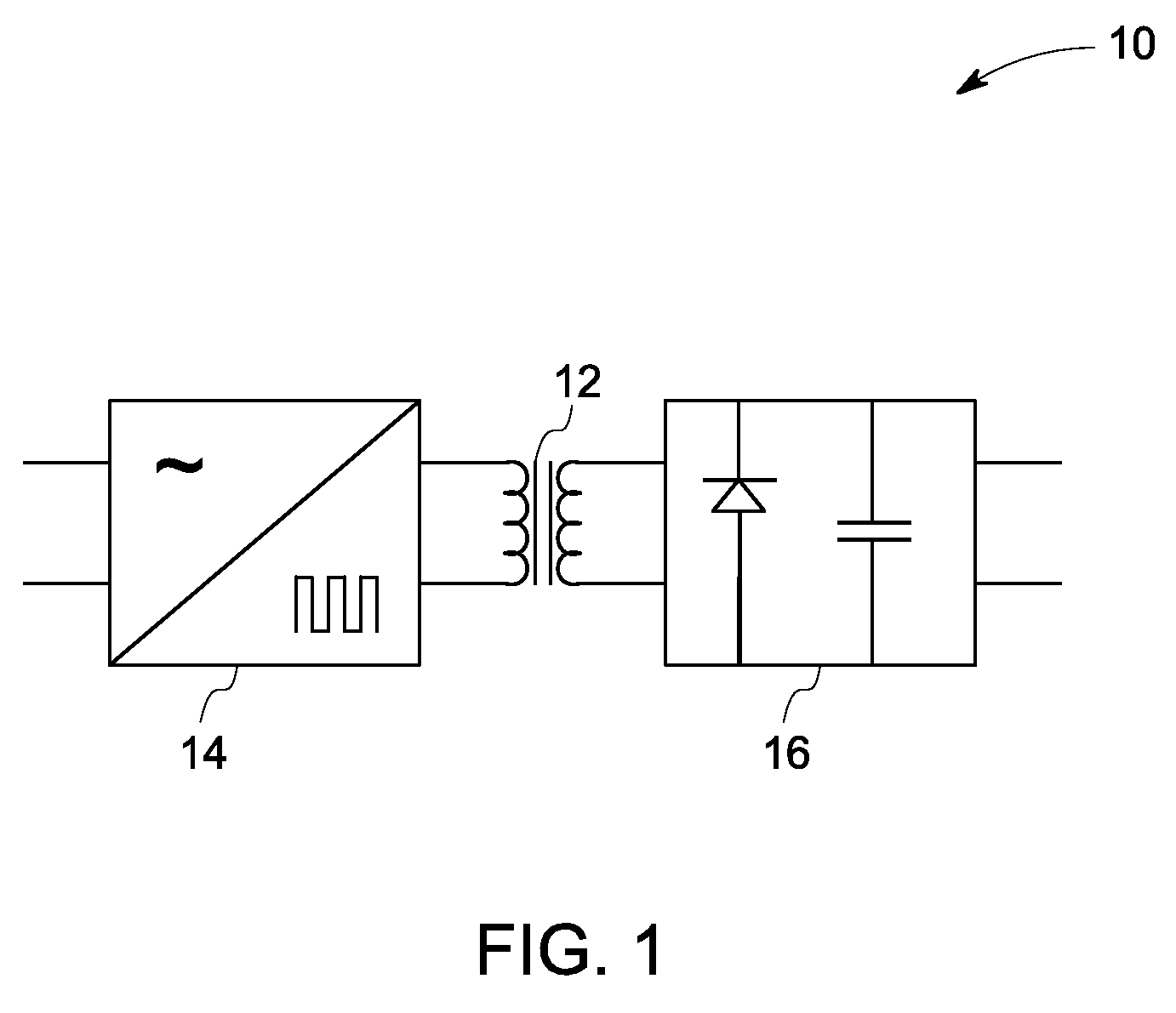

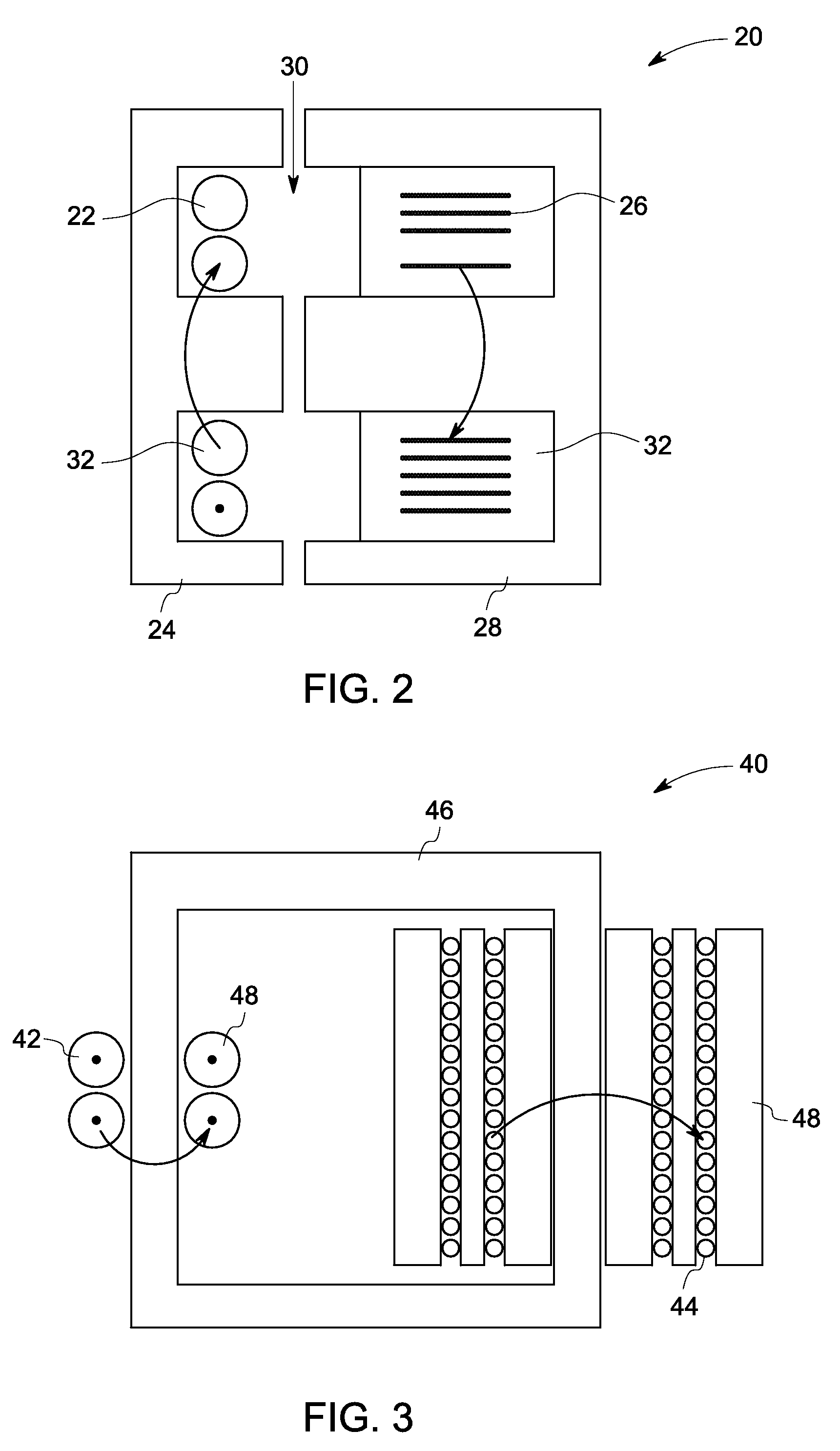

Electrical energy transformation apparatus

InactiveUS20100148903A1Transformers/inductances casingsOrganic-compounds/hydrides/coordination-complexes catalystsFrequency changerLow voltage

In one aspect, the present invention provides a high voltage-high frequency electrical energy transformation apparatus comprising a frequency inverter capable of converting 60 Hz electrical energy into 40-100 KHz electrical energy; and a voltage transformer. The voltage transformer comprises a transformer housing; at least one soft magnetic core; a low voltage primary winding and a high voltage secondary winding; and a solid insulating material comprising polydicyclopentadiene. The solid insulating material is in contact with the high voltage secondary winding.

Owner:GENERAL ELECTRIC CO

Fiber-reinforced polydicyclopentadiene composite material and preparation method thereof

The invention discloses a fiber-reinforced polydicyclopentadiene composite material which is prepared by blending and polymerizing the following raw materials in percentage by weight: 95-99.99% of dicyclopentadiene and 0.01-5% of fiber, wherein the fiber is carbon fiber grey yarn or aramid fiber grey yarn. The carbon fiber grey yarn and the aramid fiber grey yarn used as reinforcing materials are blended and polymerized with the dicyclopentadiene to prepare the fiber-reinforced polydicyclopentadiene composite material; the addition of a small amount of fiber grey yarn can obviously enhance the impact strength and tensile strength of the polydicyclopentadiene material; and compared with the single polydicyclopentadiene material, the impact strength is enhanced from 100J / m to 180-350J / m, and the tensile strength is enhanced from 25 MPa to 30-35 MPa.

Owner:NORTH HUAJIN CHEM IND CO LTD

Polydicyclopentadiene/ethylene copolymer in-situ polymerization blend composite and preparation method thereof

The invention discloses a polydicyclopentadiene / ethylene copolymer in-situ polymerization blend composite and a preparation method thereof, and the blend composite is formed by carrying out polymerization and blending on mixed solution of an ethylene copolymer and dicyclopentadiene, the ethylene copolymer is a copolymer of ethylene and olefin containing less than 8 carbon atoms, acrylic alkyl ester or acetic acid olefin ester, wherein the content of the ethylene is 80-95%. The invention simultaneously discloses a preparation method of the blend composite. The polydicyclopentadiene / ethylene copolymer in-situ polymerization blend composite is fully dissolved and uniformly mixed with the ethylene copolymer before the polymerization of the dicyclopentadiene, the dicyclopentadiene is polymerized under the common action of a tungsten catalyst and alkyl aluminum, and the blending with the ethylene copolymer is realized while carrying out the polymerization, thereby obtaining a semi-interpenetrating network type polymer composite which is blended with the ethylene copolymer, improving the impact strength of the material from the original 100J / m which is not blended with the ethylene copolymer to 150-300L / m, and leading the blend composite to have high toughness.

Owner:HENAN UNIV OF SCI & TECH

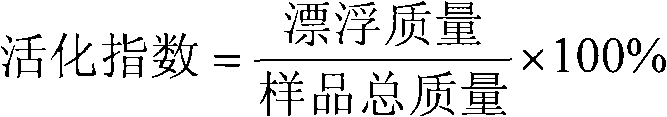

Dicyclopentadiene and carbon fiber cloth composite manhole cover and manufacturing method thereof

ActiveCN104250330AHigh strengthIncrease stiffnessArtificial islandsUnderwater structuresFiberHeat resistance

The invention discloses a dicyclopentadiene (DCPD) and carbon fiber cloth composite manhole cover and a manufacturing method thereof. According to the manufacturing method, a component A and a component B are adopted, are mixed through an injection machine mixing head according to the weight ratio of 1:1 and then are injected into a manhole cover mold pre-placed and fixed with carbon fiber cloth subjected to surface treatment, polymerization reaction and molding processes are preformed in the manhole cover mold, and thus the polydicyclopentadiene and carbon fiber cloth composite manhole cover is obtained; the component A comprises dicyclopentadiene and a main catalyst; the component B comprises dicyclopentadiene and an activating agent. With adopting of the reaction injection molding processing method, the processing process adopts one-time molding, the processing flow is greatly reduced, and the processing speed is improved; with adopting of dicyclopentadiene and the carbon fiber cloth as the materials, the manhole cover strength and rigidity are obviously improved, the manhole cover has the advantages of abrasion resistance, corrosion resistance, excellent rigidity, excellent impact strength, wide applicable temperature range and good heat resistance, and the service life is prolonged.

Owner:北京蓝星清洗有限公司

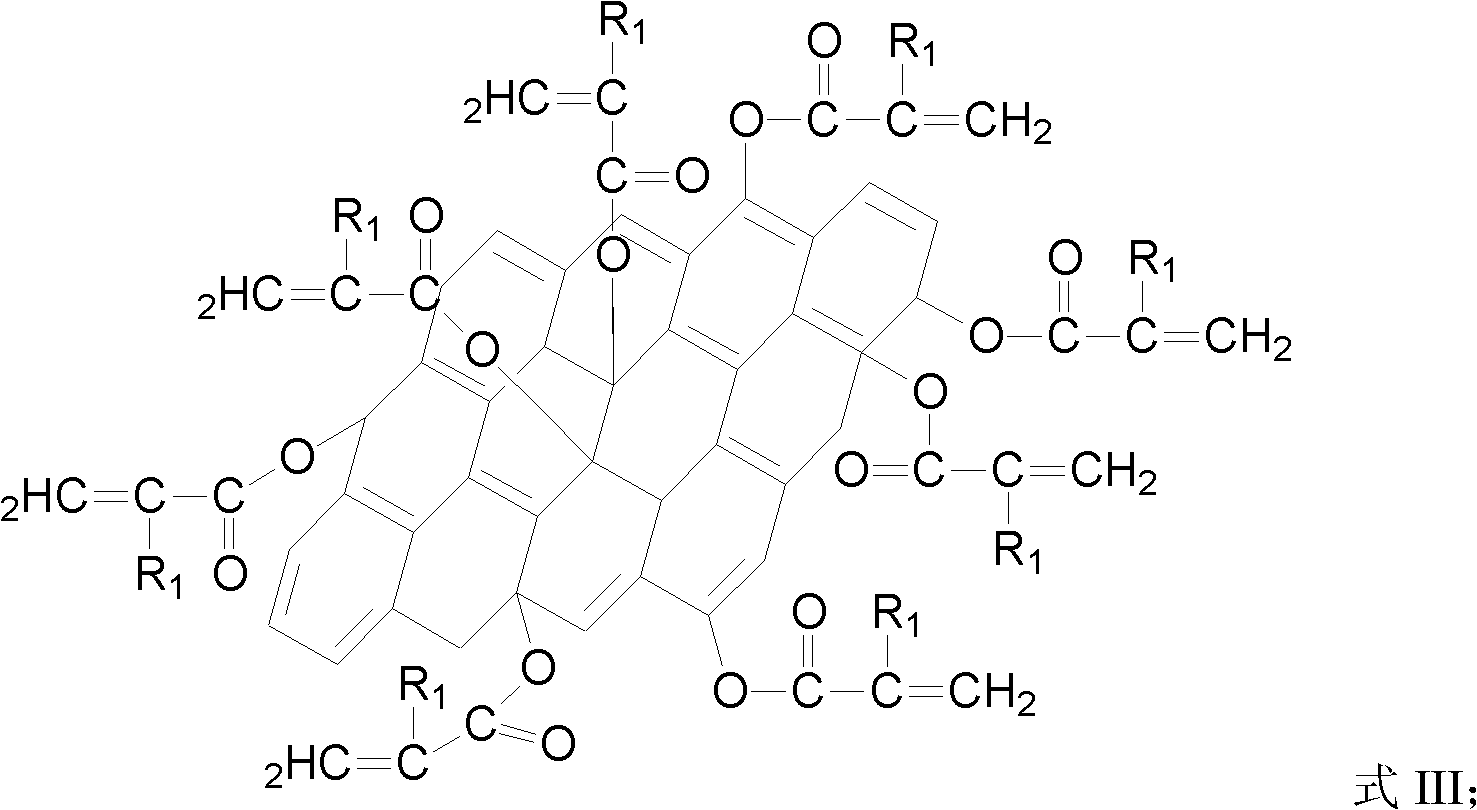

Modified graphene reinforced polydicyclopentadiene composite material and preparation method thereof

The invention discloses modified graphene reinforced polydicyclopentadiene composite material, which is obtained by blending and polymerizing the following main raw materials by weight: 95 to 99.9 parts of dicyclopentadiene, and 0.1 to 5 parts of modified graphene, wherein the modified graphene is modified graphene connected with acrylic units on the surface. Compared with polydicyclopentadiene material which is not reinforced by the modified graphene, the impact strength of the composite material provided by the invention is improved from 100J / m to 200-320J / m, the tensile strength is improved from 25MPa to 31-35MPa. And the addition amount of the modified graphene is very small (less than 5%), thus improving the toughness and strength with low cost of preparation.

Owner:HENAN UNIV OF SCI & TECH

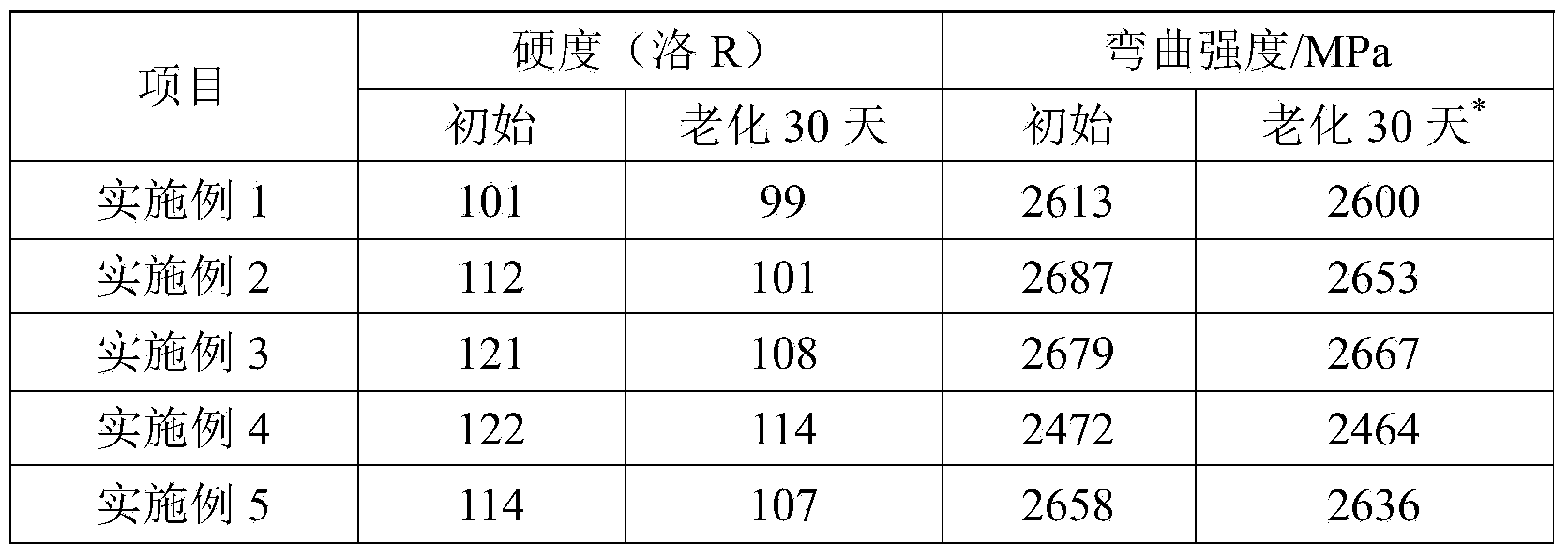

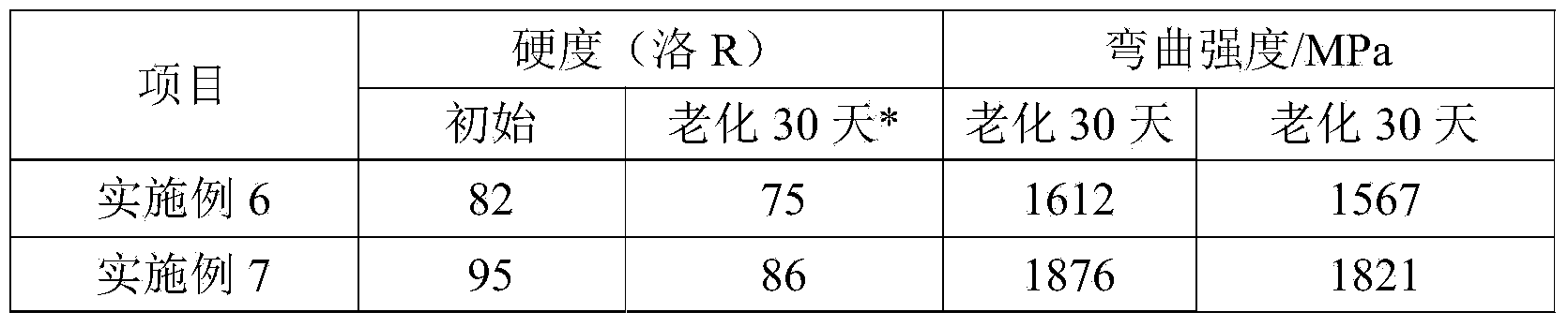

Multicolor ageing-resistant spraying-free polydicyclopentadiene composite material, and preparation method and application thereof

InactiveCN106243279AColorfulAnti-aging and long service lifeBuilding insulationsAging resistanceCarbene

The invention discloses a multicolor ageing-resistant spraying-free polydicyclopentadiene composite material, and a preparation method and an application thereof. Raw materials for preparing the composite material comprise 35-65% of dicyclopentadiene, 1-15% of a copolymer, 10-35% of a functional filler, 0.05-5% of environmentally-friendly color paste or high-mesh toner, and 0.01-0.1% of a ruthenium carbene catalyst. The material is integrally formed after high-efficiency dissolution of the environmentally-friendly color paste or the high-mesh toner with dicyclopentadiene, full mixing of the obtained material with other ingredients, reaction of the obtained mixture with a curing agent, and injection molding polymerization. The spraying-free polydicyclopentadiene composite material has the advantages of brilliant color, ageing resistance, long life, superior mechanical performances, and simple repairing of minimal scratches, and the preparation method is simple.

Owner:SHANGHAI COACHCHEM TECH

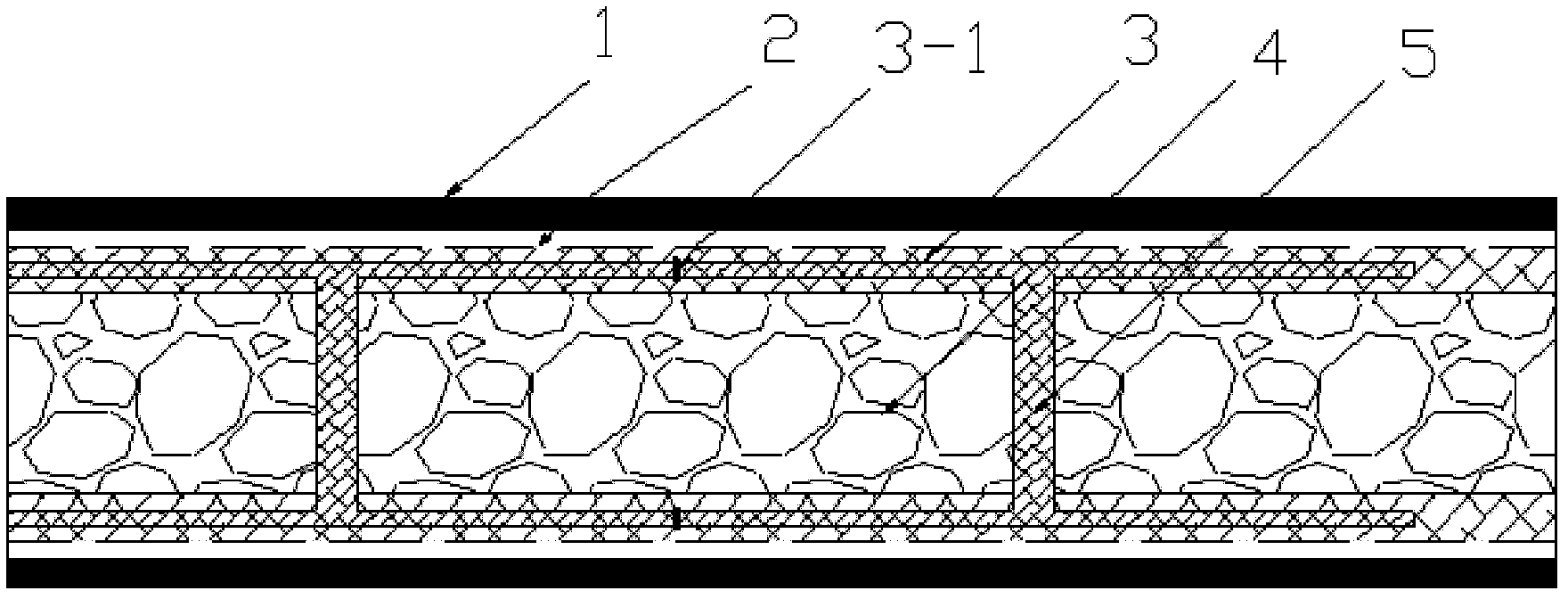

Composite board and preparation method thereof, and dumper compartment

InactiveCN103010316AAddressing Layered FailuresSolve wear resistanceSynthetic resin layered productsWood layered productsEngineeringPolydicyclopentadiene

The invention discloses a composite board which comprises two skin layers, wherein an intermediate layer is formed between the two skin layers and an inner stiffening beam is arranged between the two skin layers, a core material is filled in the intermediate layer, an outer stiffening beam is arranged between the core material and at least one skin layer, and a polydicyclopentadiene layer is arranged outside the at least one skin layer. The invention also discloses a preparation method of the composite board. The invention further discloses a dumper compartment comprising the composite board. The dumper compartment has the characteristics of strong bearing capacity, remarkable weight reducing effect, oil consumption saving, carbon dioxide emission reducing, long service life and the like.

Owner:蓝星环境工程有限公司

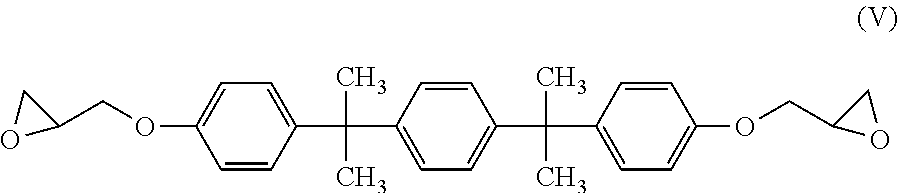

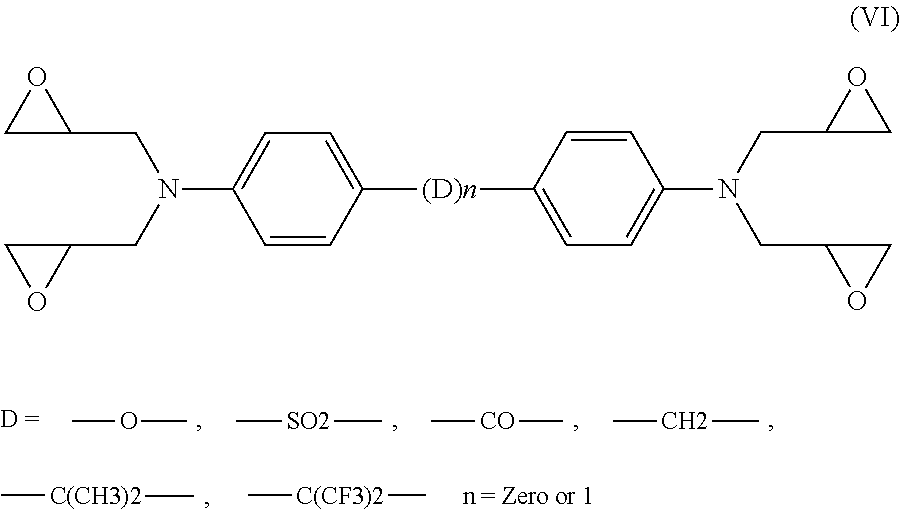

Electrical insulation system

InactiveUS20130203897A1Good dispersionSimple mixing methodMaterial nanotechnologyPlastic/resin/waxes insulatorsPolytetramethylene terephthalateEpoxy

Electrical insulation system with improved electrical breakdown strength, including a hardened polymer component having incorporated therein a filler material and a nano-scale sized filler material. The hardened polymer component is selected from epoxy resin compositions, polyesters, polyamides, polybutylene terephthalate, polyurethanes and polydicyclo-pentadiene. The filler material has an average particle size within the range of 1 μm-500 μm, and is present in a quantity within the range of 40%-65% by weight, calculated to the total weight of the insulation system. The nano-scale sized filler material is a pretreated nano-scale sized filler material, having been produced by a sol-gel process. The nano-scale sized filler material is present within the electrical insulation system in an amount of about 1%-20% by weight, calculated to the weight of the filler material present in the electrical insulation system.

Owner:ABB RES LTD

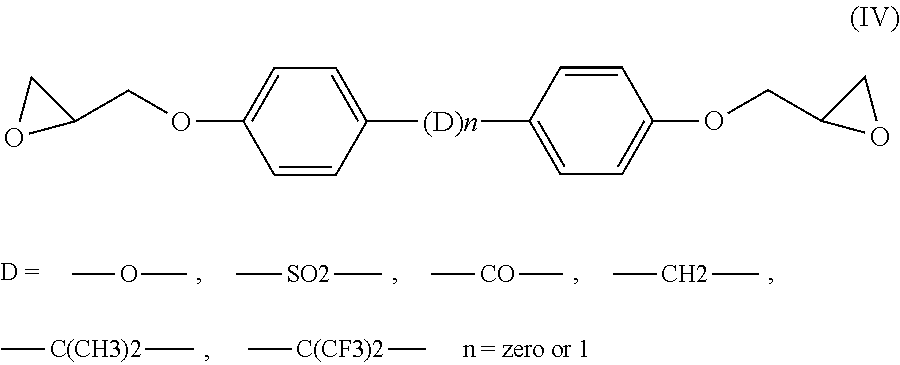

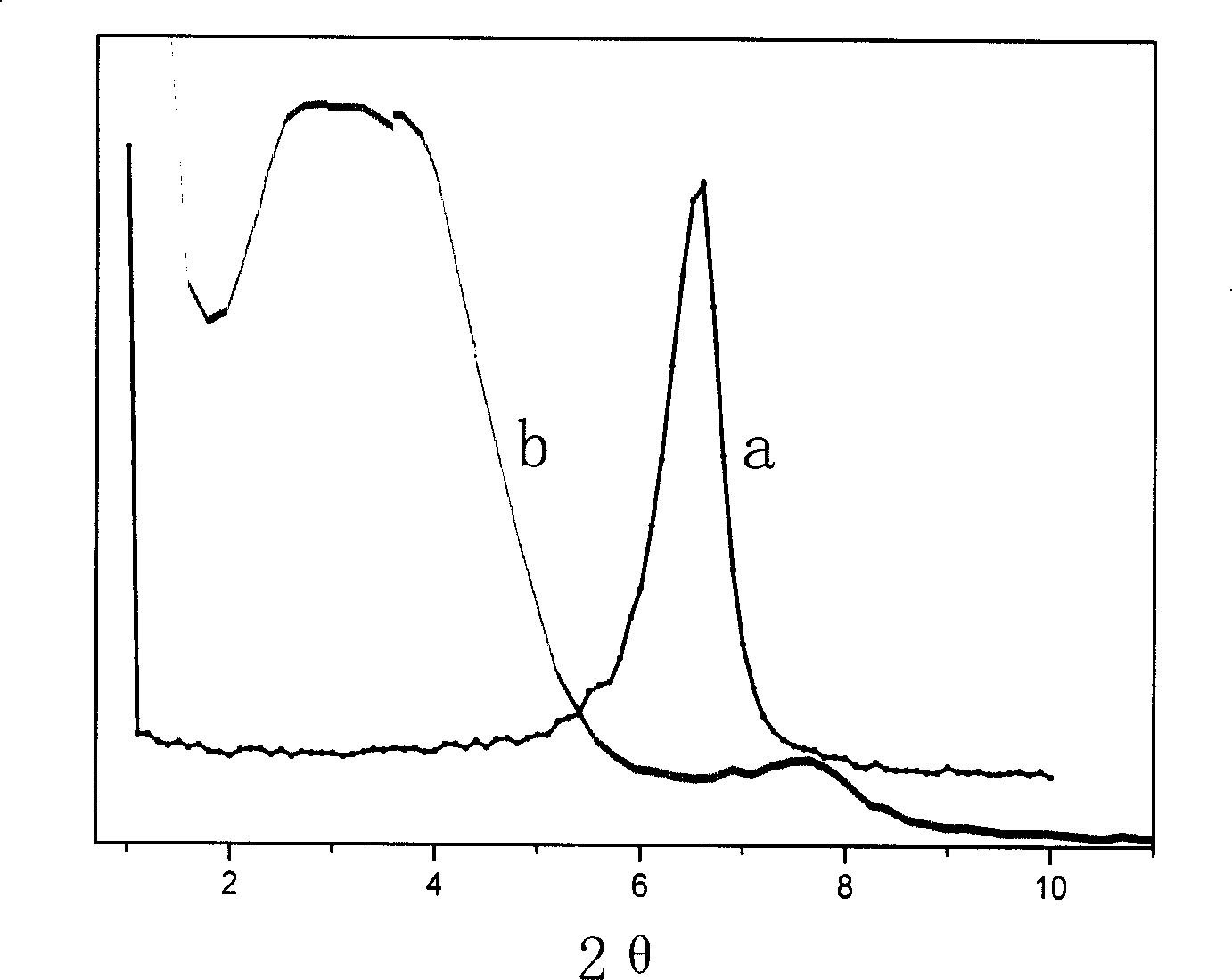

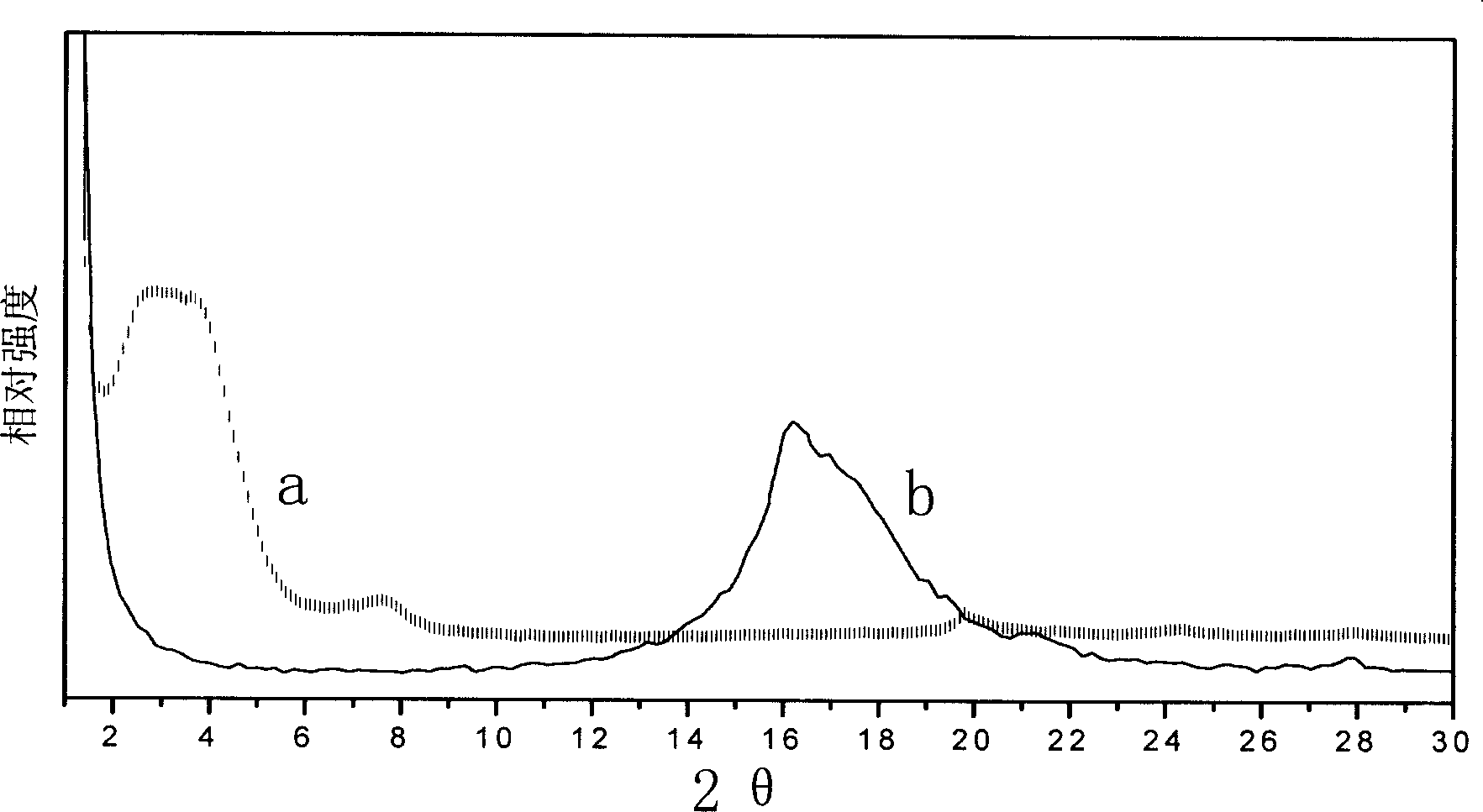

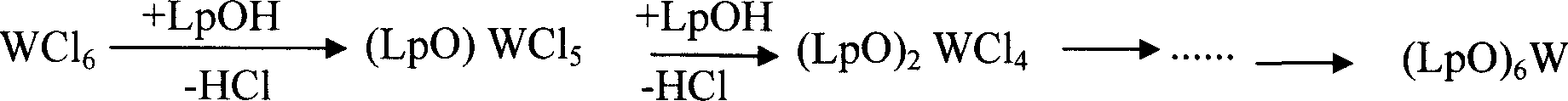

Preparation of polydicyclopentadiene/montmorillonite nano composite material

The invention discloses a preparation method of the poly-dicyclopentadiene / montmorillonite nanocomposites. The support catalysts is prepared through the complex compound compounded by the compound with hydroxide radical and the tungsten hexachloride attaching to the organic montmorillonite, and the complex compound comprises the paratert-butyl phenol, quadruple ((Beta-(3, 5-tert-butyl -4- hydroxy phenyl) monoprop) pentaerythritol ester or 2-hydroxy-4-n-octyloxybenzophenone, etc. The polymerization of the dicyclopentadiene is catalysed through the in situ polymerization model by the catalyst, the interlayer spacing is increased when the dicyclopentadiene monomer polymerizing in the interlayer of the montmorillonite, the interlayer of the montmorillonite is peeled by the heat produced in the reaction, the peeled interlayer of the montmorillonite is scattered in the poly-dicyclopentadiene, and the poly-dicyclopentadiene / montmorillonite Nanocomposites is produced, and then a model is prepared by the reaction injection molding method. The composites are showed with nanocomposites structure through the X-ray diffractogram.

Owner:HENAN UNIV OF SCI & TECH

Microporous polycyclopentadiene-based aerogels

Microporous polyolefin and microporous polydicyclopentadiene (polyDCPD) based aerogels and methods for preparing and using the same are provided. The aerogels are produced by forming a polymer gel structure within a solvent from a olefin or dicyclopentadiene monomer via Ring Opening Metathesis Polymerization (ROMP) reactions, followed by supercritical drying to remove the solvent from the aerogel. Other aerogels are prepared by sequentially (1) mixing at least one dicyclopentadiene monomer, at least one solvent at least one catalyst and at least one inorganic and / or organic reinforcing material, (2) gelling the mixture, (3) aging, and (4) supercritical drying. Aerogels provided herein are inexpensive to prepare, possess desirable thermal, mechanical, acoustic, chemical, and physical properties and are hydrophobic. The aerogels provided herein are suitable for use in various applications, including but not limited to thermal and acoustic insulation, radiation shielding, and vibrational damping applications.

Owner:ASPEN AEROGELS INC

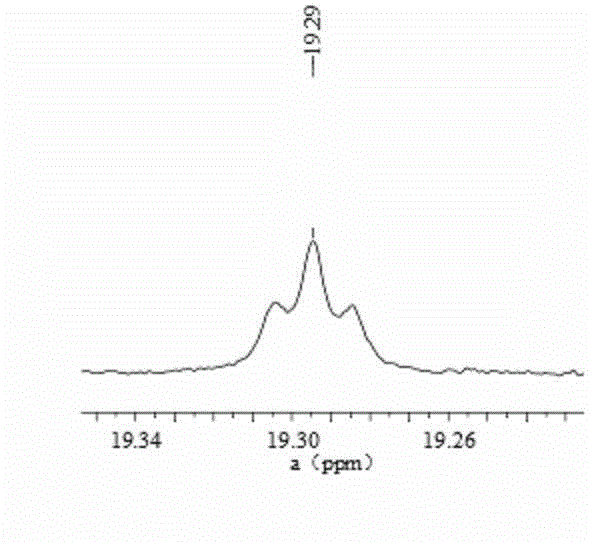

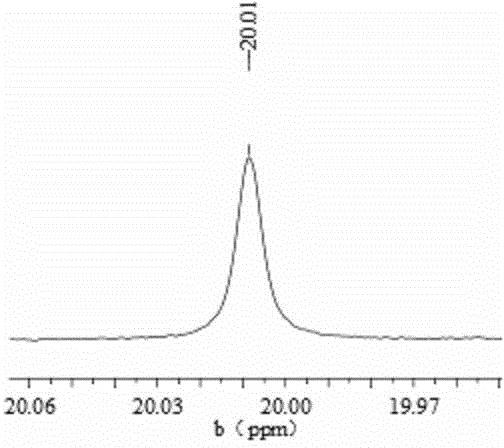

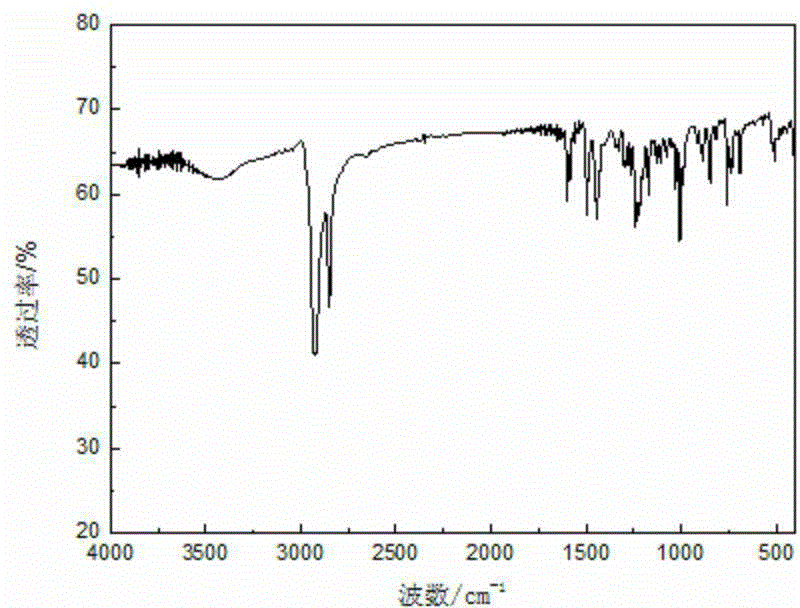

Preparation method and application of ruthenium-carbene catalyst

InactiveCN104558049AReasonable useSimple equipmentRuthenium organic compoundsPolymer sciencePtru catalyst

The invention discloses a preparation method and application of a ruthenium-carbene catalyst. According to the invention, a ruthenium-carbene complex is prepared by a method of olefin metathesis, the device and technology used for preparation are simple, only two-step reaction is needed, the cost is lower, and the production rate can reach 95%. According to the invention, the ruthenium-carbene complex is used as a catalyst for a ring-opening metathesis polymerization reaction of dicyclopentadiene so as to prepare polydicyclopentadiene. The activity of the ring-opening metathesis polymerization reaction is high, the transformation rate to the polymerization of the dicyclopentadiene is 99.8%, the reaction condition is moderate, high temperature and high pressure are not needed, resources are reasonably utilized, the reaction has no bad influence on the environment, and therefore, the method disclosed by the invention is a green process route, and is suitable for industrial popularization.

Owner:CHANGCHUN UNIV OF TECH

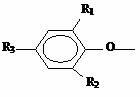

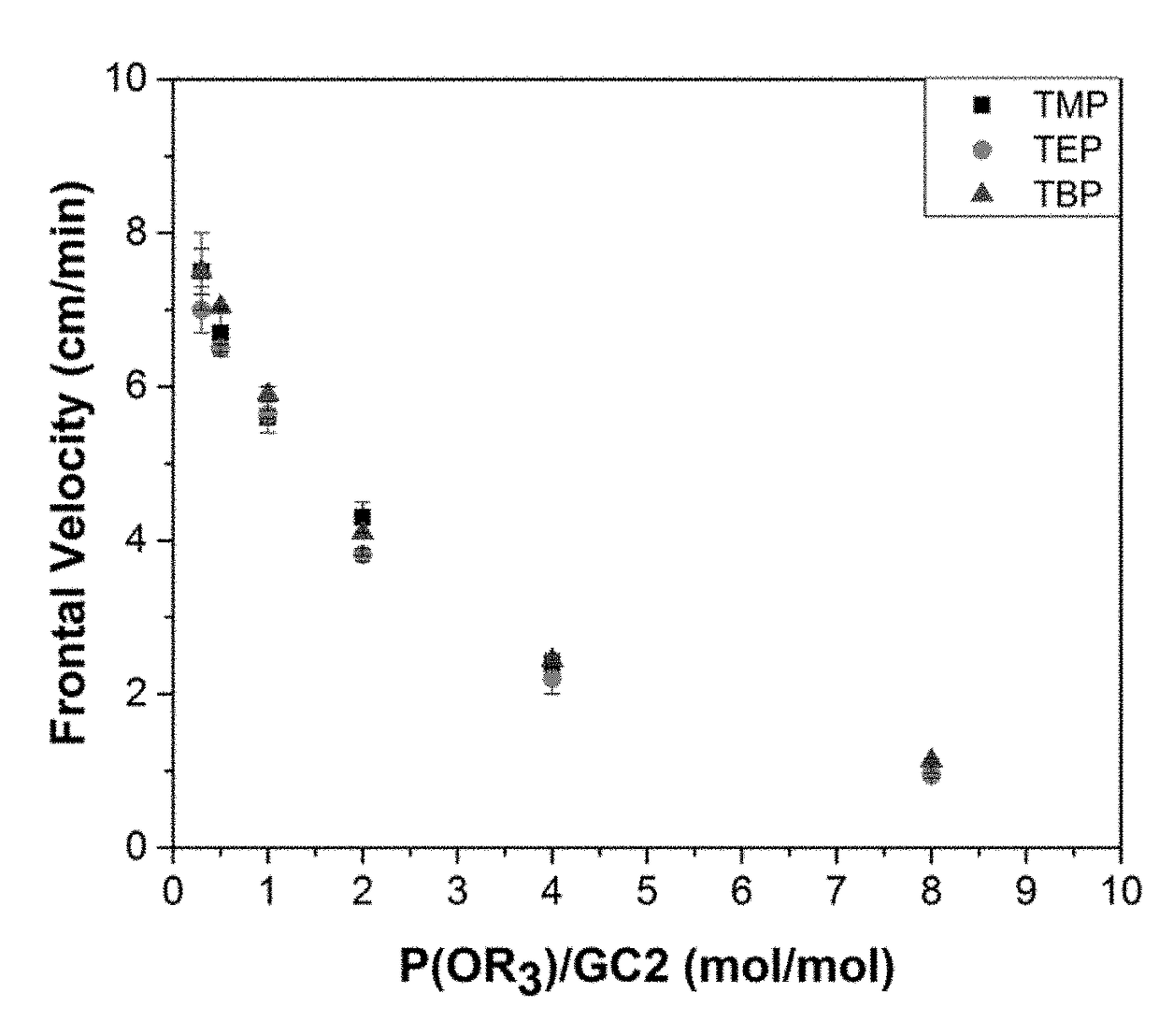

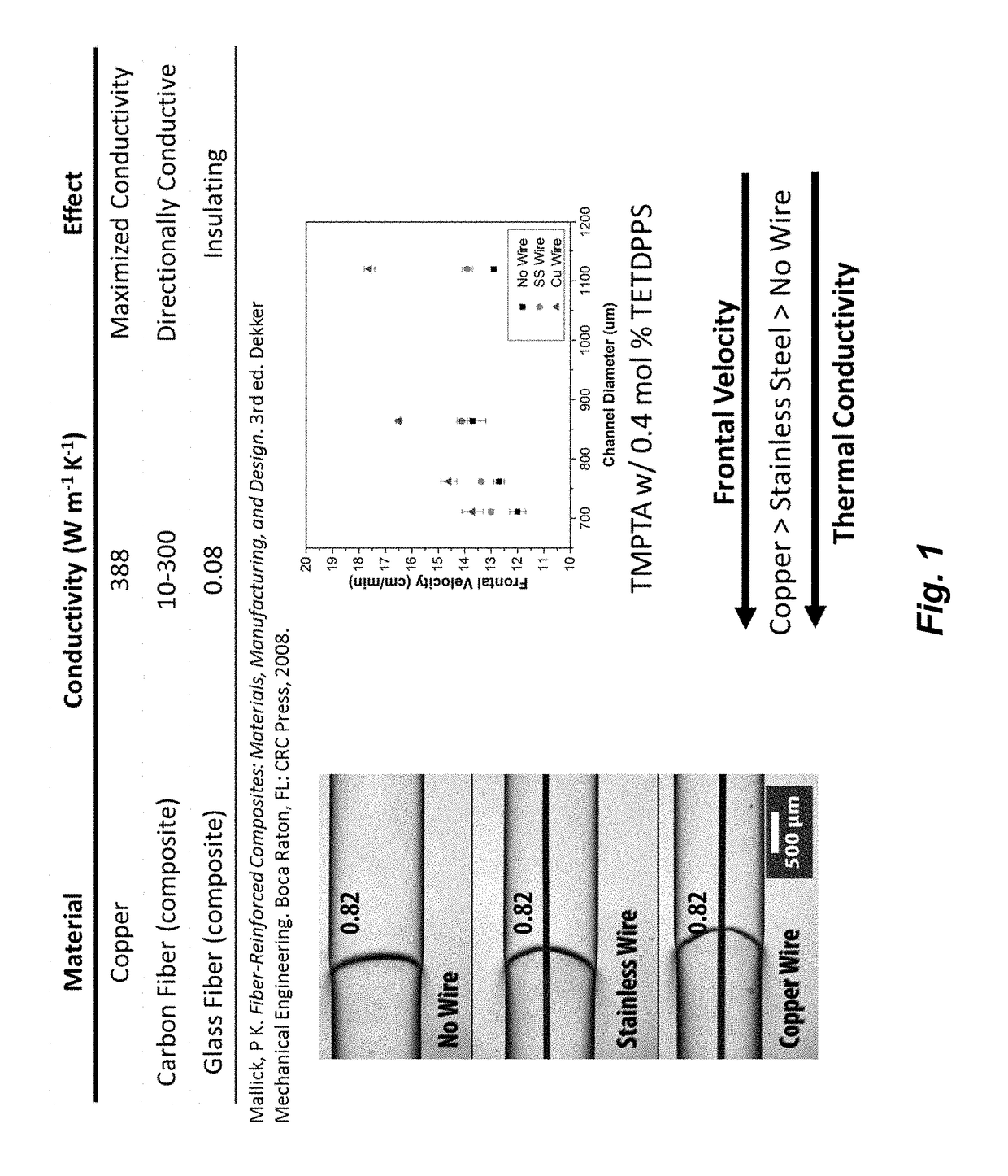

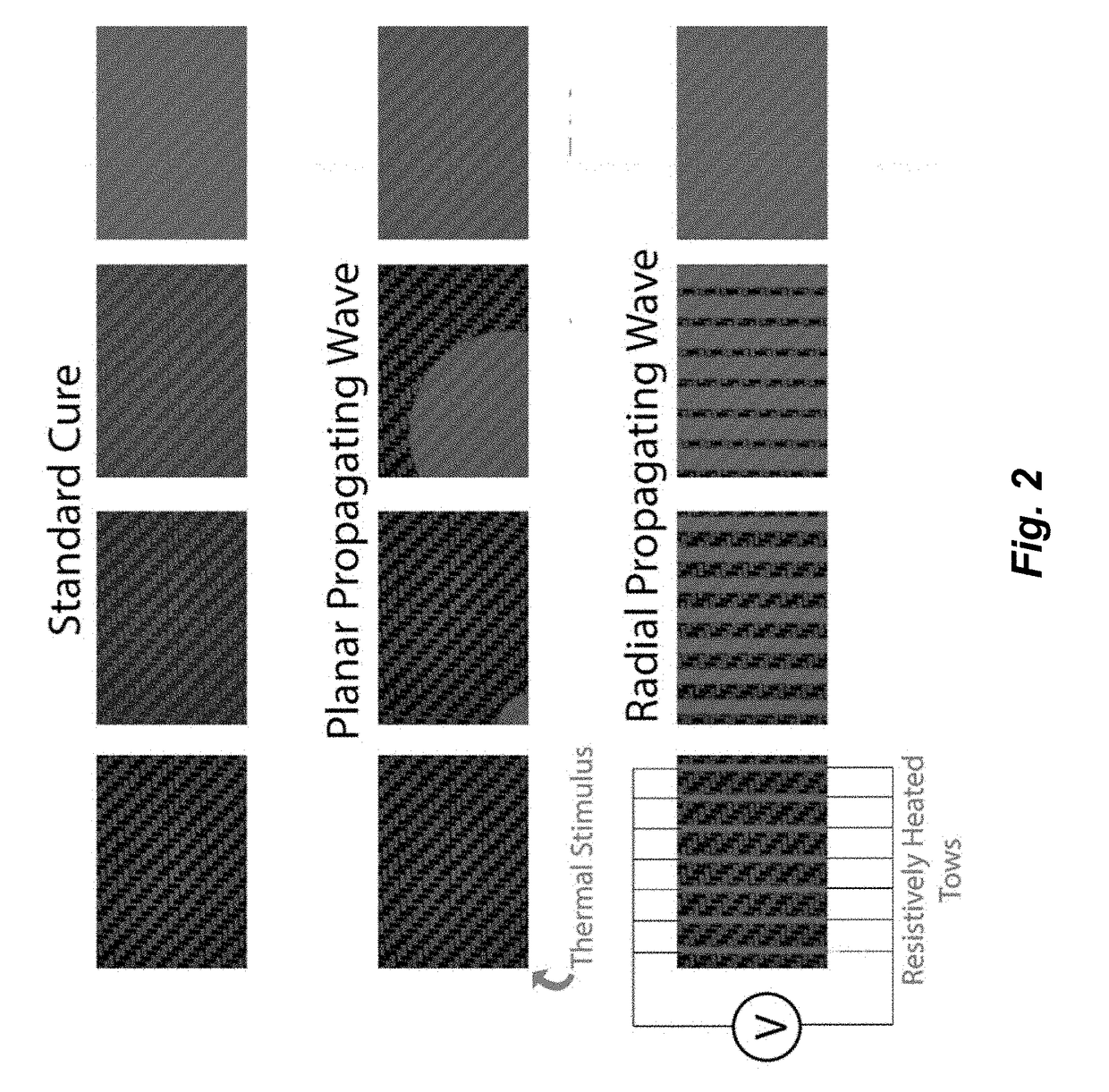

Frontal polymerization for fiber-reinforced composites

ActiveUS20180230642A1Extended validity periodExtended gel timeFibre treatmentWoven fabricsFiber-reinforced compositePolydicyclopentadiene

Polydicyclopentadiene (PDCPD) is a polymer of growing importance in industrial applications. Frontal ring-opening metathesis polymerization (FROMP) offers a means to rapidly cure PDCPD with minimal input energy owing to a propagating reaction wave sustained by the exothermic polymerization. The disclosure provides methods for the rapid fabrication of fiber reinforced composites that is less restrictive and more energy efficient than conventional methods.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

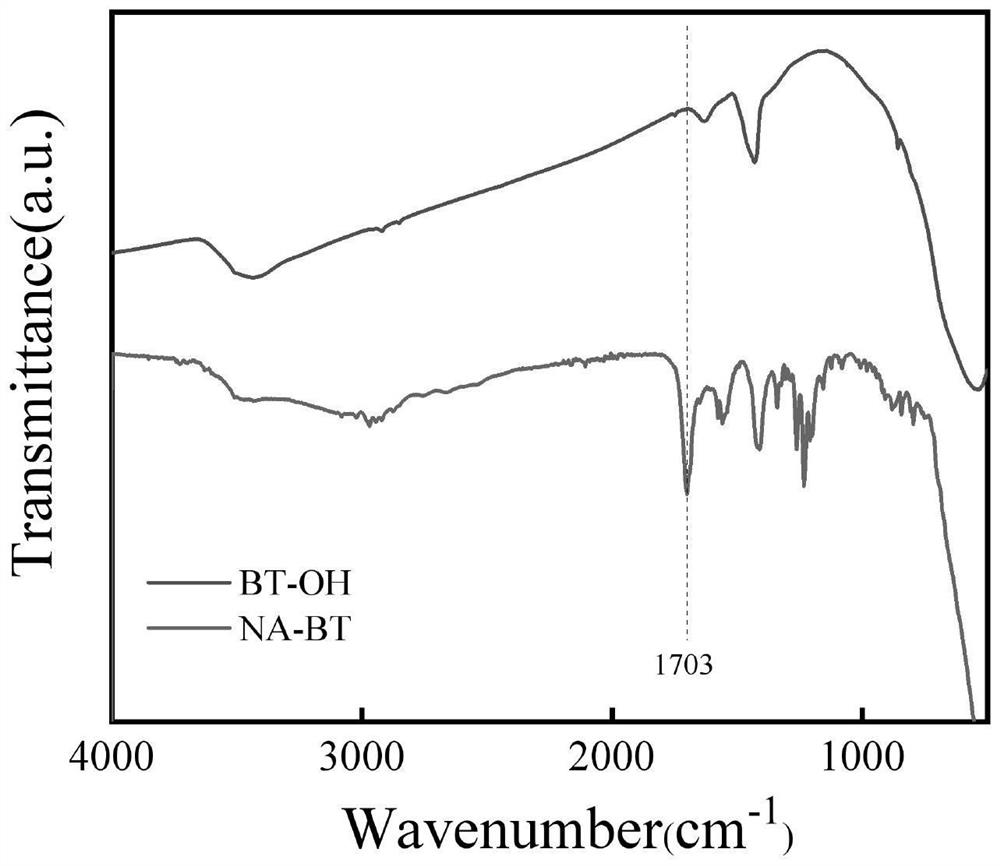

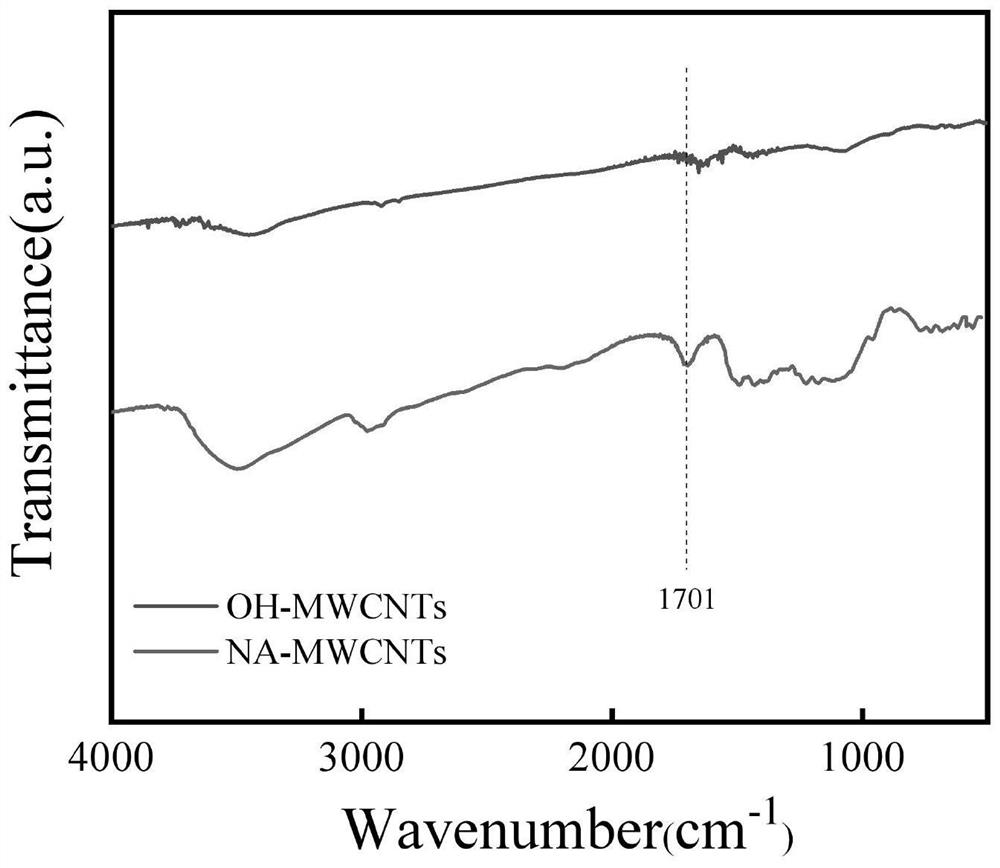

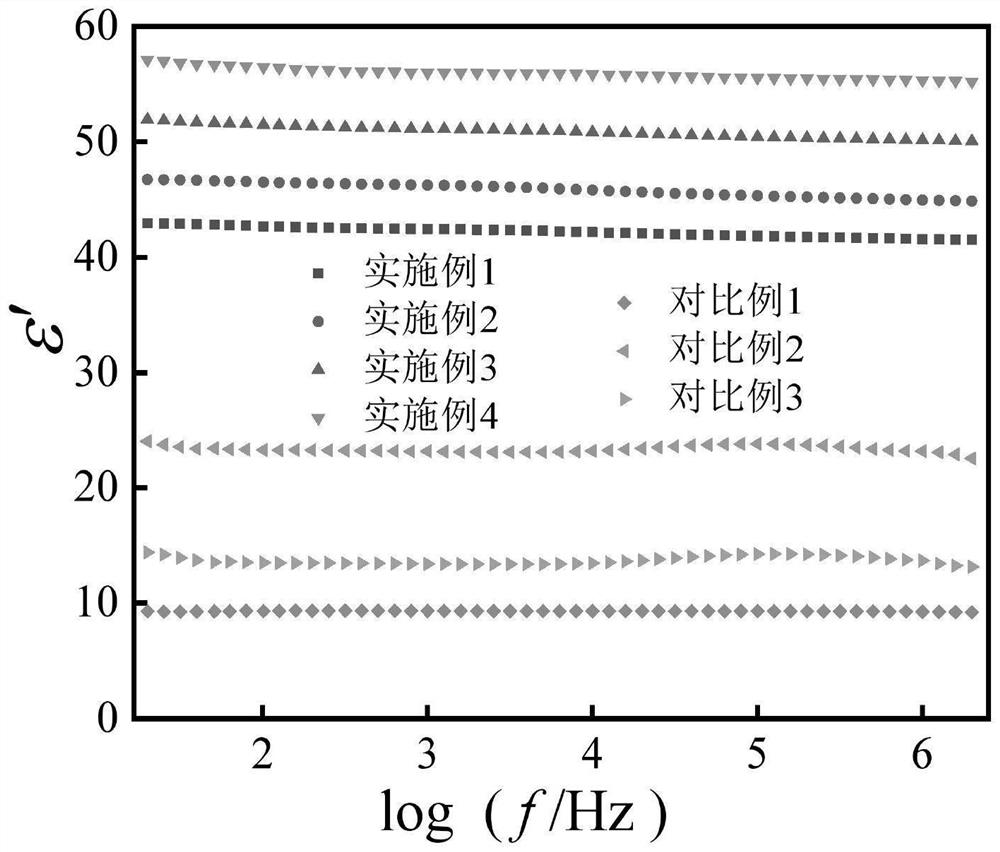

Multi-walled carbon nanotube/barium titanate/polydicyclopentadiene composite material based on front-end ring-opening metathesis polymerization and preparation method thereof

The invention discloses an MWCNTs / barium titanate / PDCPD composite material based on front-end ring-opening metathesis polymerization and a preparation method thereof. The PDCPD composite material is prepared from the following raw materials: dicyclopentadiene, 5-ethylidene-2-norbornene, a norbornene dianhydride grafted carbon nanotube, norbornene dianhydride grafted barium titanate, a catalyst and an inhibitor, wherein the mass fraction of the dicyclopentadiene and the 5-ethylidene-2-norbornene is 84.58%- 92.76%; the mass fraction of the catalyst is 0.06-0.07%; and the mass fraction of the inhibitor is 0.18-0.35%. Under the conditions of room temperature and 100Hz frequency, the dielectric constant of the prepared composite material exceeds 40, the dielectric loss is as low as 0.08, the glass transition temperature exceeds 160 DEG C, and the composite material has excellent thermal stability and mechanical properties. Meanwhile, processing equipment and a forming process for preparing the material are simple, the energy consumption in the processing process is low, the efficiency is high, the operation is easy, and the application of the PDCPD material in a severe environment is effectively expanded.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Microporous polydicyclopendiene-based aerogels

Microporous polyolefin and microporous polydicyclopentadiene (polyDCPD) based aerogels and methods for preparing and using the same are provided. The aerogels are produced by forming a polymer gel structure within a solvent from a olefin or dicyclopentadiene monomer via Ring Opening Metathesis Polymerization (ROMP) reactions, followed by supercritical drying to remove the solvent from the aerogel. Other aerogels are prepared by sequentially (1) mixing at least one dicyclopentadiene monomer, at least one solvent at least one catalyst and at least one inorganic and / or organic reinforcing material, (2) gelling the mixture, (3) aging, and (4) supercritical drying. Aerogels provided herein are inexpensive to prepare, possess desirable thermal, mechanical, acoustic, chemical, and physical properties and are hydrophobic. The aerogels provided herein are suitable for use in various applications, including but not limited to thermal and acoustic insulation, radiation shielding, and vibrational damping applications.

Owner:ASPEN AEROGELS INC

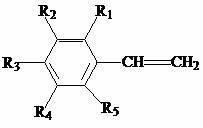

Polydicyclopentadiene/polystyrene interpenetrating polymer network and preparation method thereof

ActiveCN102558731APromote aggregationMake up tensile strengthHeat deflection temperaturePolymer science

The invention discloses a polydicyclopentadiene / polystyrene interpenetrating polymer network and a preparation method thereof. A compound material is formed through simultaneous polymerization of polymeric monomers in part by weight: 60 to 99 part of dicyclopentadiene, 1 to 40 parts of styrene or benzene ring substitution styrene and 0.01 to 10 parts of divinylbenzene, wherein a substitution group in the benzene ring substitution styrene is an alkyl substitution group with halogen or carbon number ranging from 1 to 6; dicyclopentadiene is polymerized by a ring-opening translocation catalytic body; and styrene and divinylbenzene are polymerized by a free radical. Heat generated by ring-opening polymerization of polydicyclopentadiene causes the polymerization of styrene to form an interpenetrating polymer network type compound material taking polydicyclopentadiene as a first network and polystyrene as a second network, as compared with the single polydicyclopentadiene material, the tensile strength is improved by 3 to 15%, the heat distortion temperature is increased by 5 to 13 DEG C, the polymerization conversion rate of the polydicyclopentadiene is increased from 97.2% to 99.5%, and the styrene adopting halogen can enhance the flame retardance of the material.

Owner:HENAN UNIV OF SCI & TECH

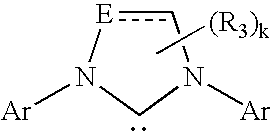

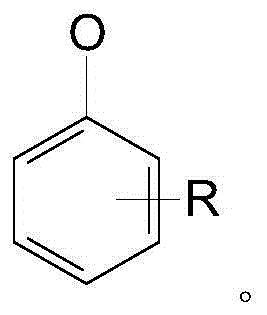

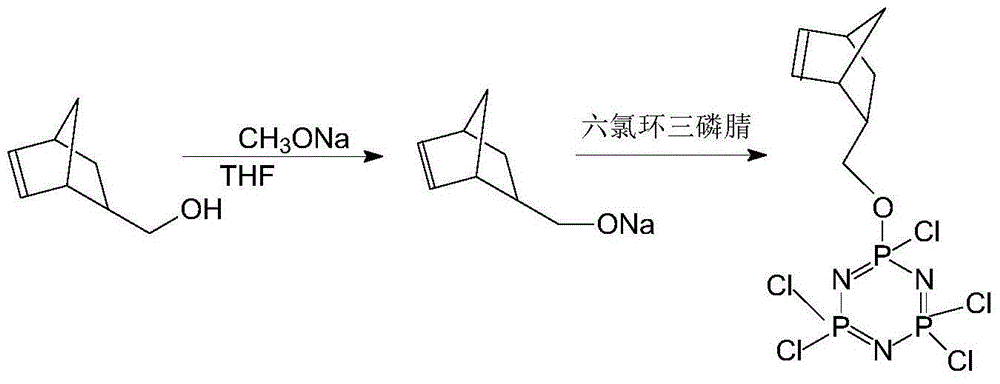

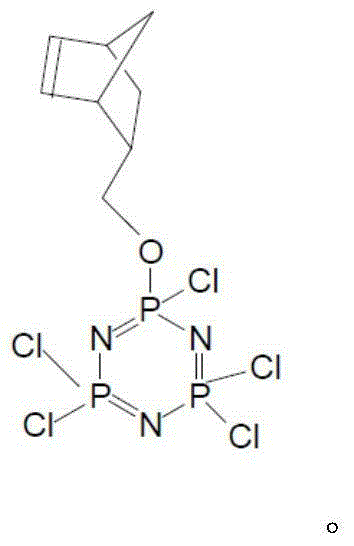

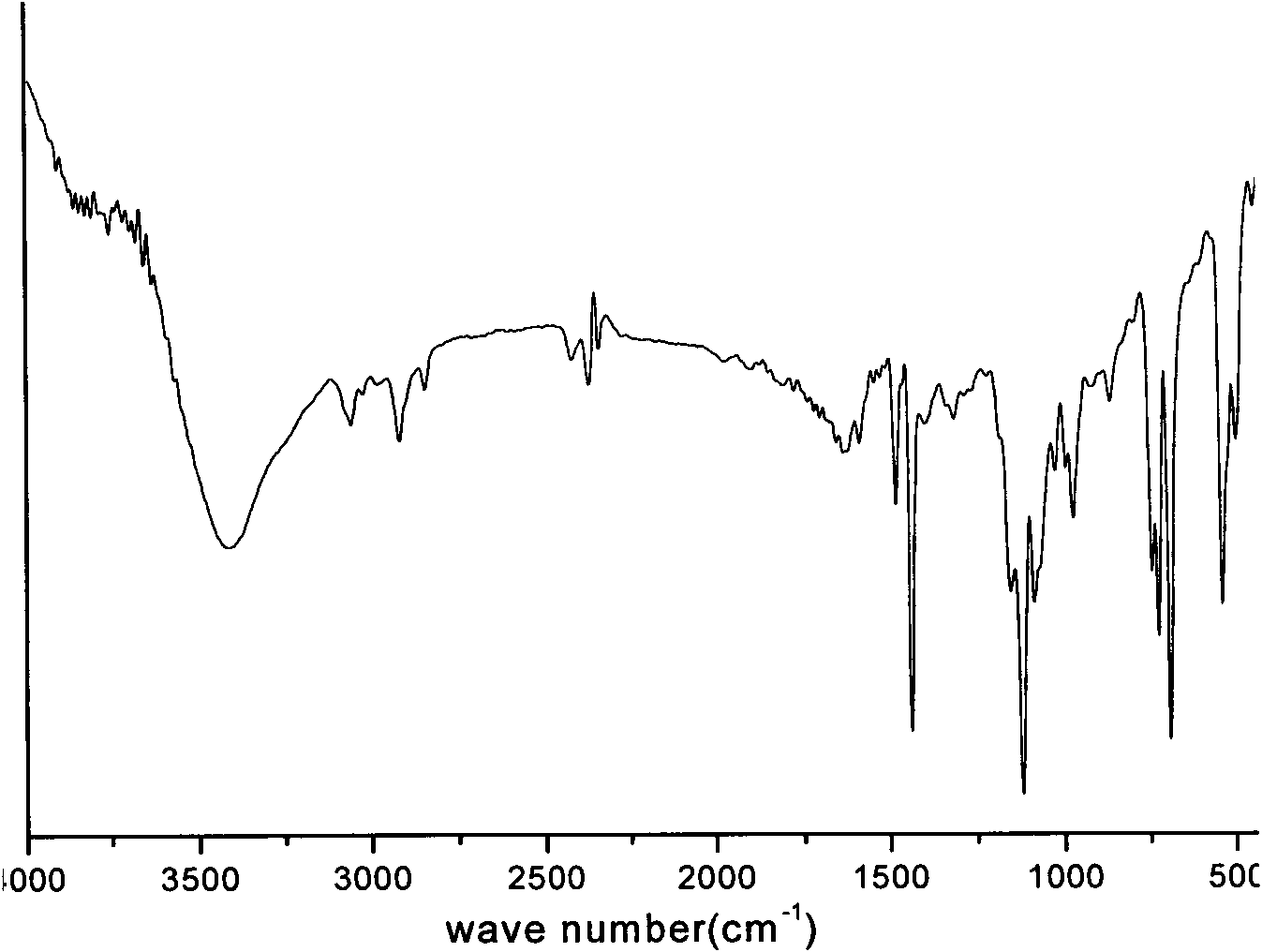

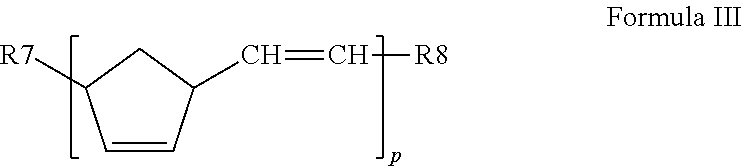

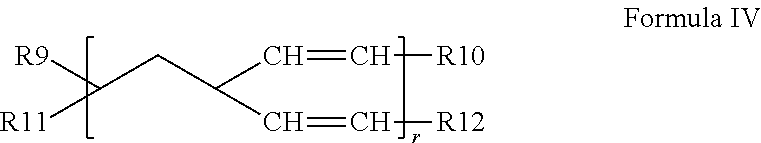

Flame retardant, preparation method as well as modified polydicyclopentadiene and preparation method

ActiveCN104592301AImprove flame retardant performanceGood compatibilityGroup 5/15 element organic compoundsPolymer scienceNorbornene

The invention discloses a flame retardant, a preparation method as well as modified polydicyclopentadiene and a preparation method and belongs to the technical field of flame retardant materials. According to the flame retardant disclosed by the invention, by taking a phosphonitrilic chloride trimer as a matrix which is connected with a norbornene methanol group, the flame retardant has a good co-dissolving and co-polymerizing characteristic with dicyclopentadiene for modifying dicyclopentadiene. The invention discloses the flame retardant modified polydicyclopentadiene material which is blended and polymerized by dicyclopentadiene and the flame retardant, wherein the flame retardant is 3-15% by mass of dicyclopentadiene. By using mono-norborneol methoxyl cyclotriphosphazene pentachloride as the flame retardant, compared with a pure polydicyclopentadiene material, a few flame retardant is added to obviously improve the flame retardant performance of polydicyclopentadiene and meanwhile, the mechanical property is not reduced. The preparation method disclosed by the invention is simple in craft process, easy to control and realize, and suitable for industrialized popularization and application.

Owner:常州巨德新材料有限公司

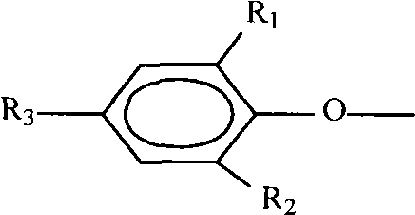

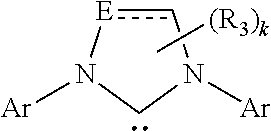

Organophosphorus based tungsten complex and preparation method and application thereof

ActiveCN101659678ALower reaction conditionsLow priceGroup 6/16 element organic compoundsWater vaporTriphenylphosphine oxide

The invention discloses an organophosphorus based tungsten complex which is bidentate chloride of triphenylphosphine or triphenylphosphine oxide of tungsten. Phenyl in the triphenylphosphine or triphenylphosphine oxide may be alkyl substituted phenyl and the number of the alkyl substituents can be 1-3. The invention also discloses a preparation method of the organophosphorus based tungsten complex and application of the organophosphorus based tungsten complex in synthesizing polydicyclopentadiene. Under the action of organophosphorus ligands, the tungsten complex of the invention has higher catalytic activity in synthesizing polydicyclopentadiene, has high chemical stability and is insensitive to air and water vapors, thus lowering the reaction conditions for synthesizing polydicyclopentadiene. In addition, the raw materials adopted by the organophosphorus based tungsten complex prepared by the invention are low in price and the preparation method is simple; therefore, the tungsten complex is low in preparation cost and has good popularization and application prospect.

Owner:NORTH HUAJIN CHEM IND CO LTD

Polydicyclopentadiene/high-polymer elastomer IPN (interpenetrating polymer network) high-polymer alloy material and preparation method thereof

The invention discloses a polydicyclopentadiene / high-polymer elastomer IPN (interpenetrating polymer network) high-polymer alloy material and a preparation method thereof. The high-polymer alloy material is an interpenetrating network structure formed by the polydicyclopentadiene-formed molecular chain network and the elastomer. The preparation method comprises the following steps: dissolving the elastomer in a dicyclopentadiene liquid; and adding a catalyst into the elastomer dicyclopentadiene solution, injecting the mixed solution into a mold, and curing by reaction. The high-polymer elastomer is completely dissolved to form the uniform continuous phase, and the elastomer also forms the network structure while the dicyclopentadiene molecular chain forms the network structure, thereby forming the dicyclopentadiene-elastomer-interpenetrating IPN high-polymer alloy material. The high-polymer alloy material has the rigidity of the dicyclopentadiene, and also has favorable toughness.

Owner:广东东杰新材料有限公司

Silicon dioxide/polydicyclopentadiene composite and preparation method thereof

The invention relates to a thermosetting polymer-based composite, in particular to a silicon dioxide / polydicyclopentadiene composite, and a preparation method thereof. The composite is prepared through reaction of raw compositions and is characterized by comprising dicyclopentadiene, silicon dioxide and a catalyst, silicon dioxide accounts for 0.05-20 parts by weight and the catalyst accounts for 0.003-0.6 part by weight when dicyclopentadiene accounts for 100 parts by weight, the silicon dioxide contains nonpolar groups, and the catalyst is first-generation Grubbs catalyst or second-generation Grubbs catalyst. Compared with the prior art, the silicon dioxide / polydicyclopentadiene composite prepared has high strength and toughness; the preparation method is simple to perform, low in cost, high in efficiency, and easy to use in industrial production.

Owner:NINGBO UNIV

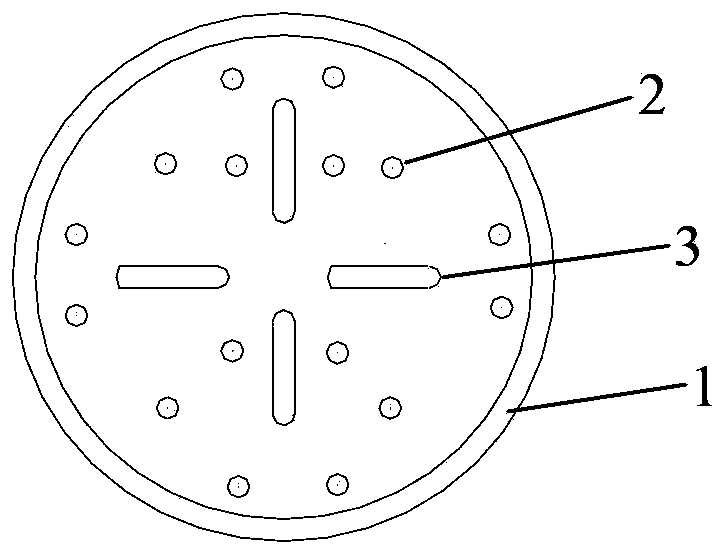

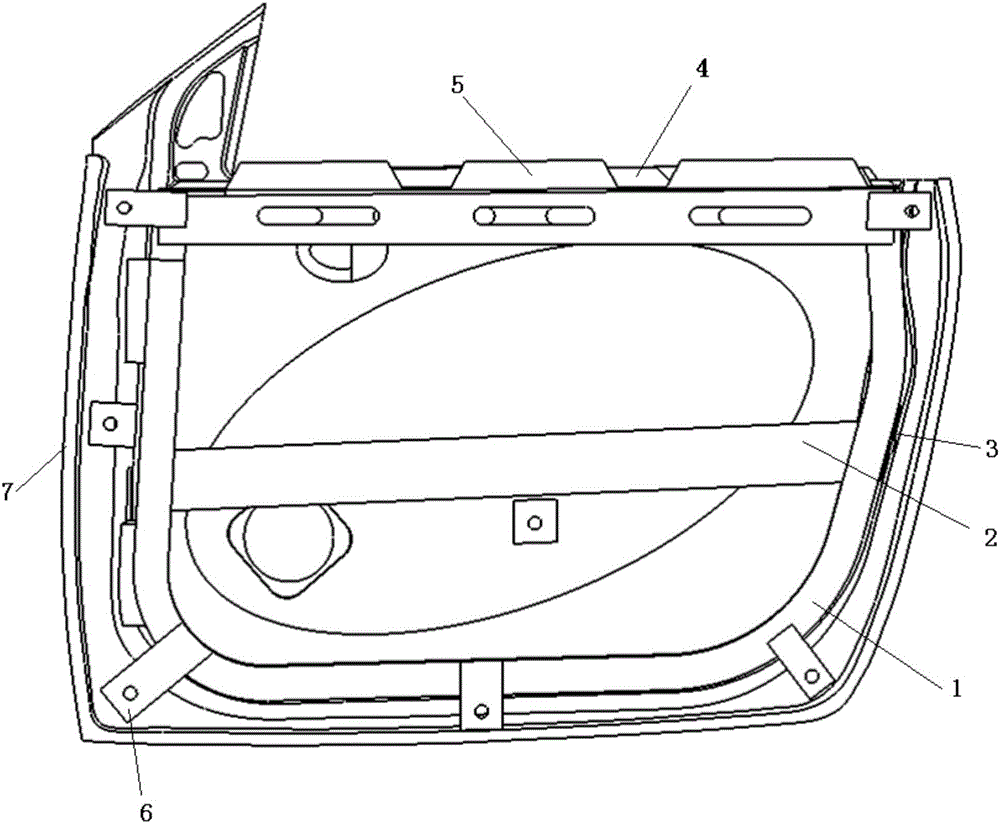

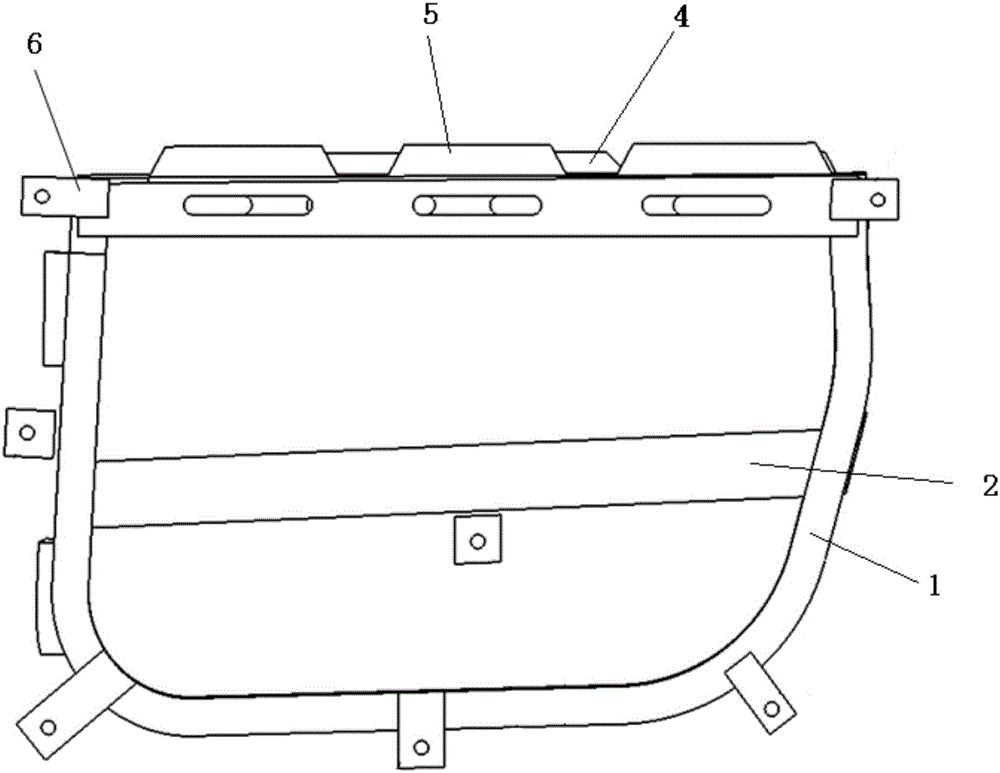

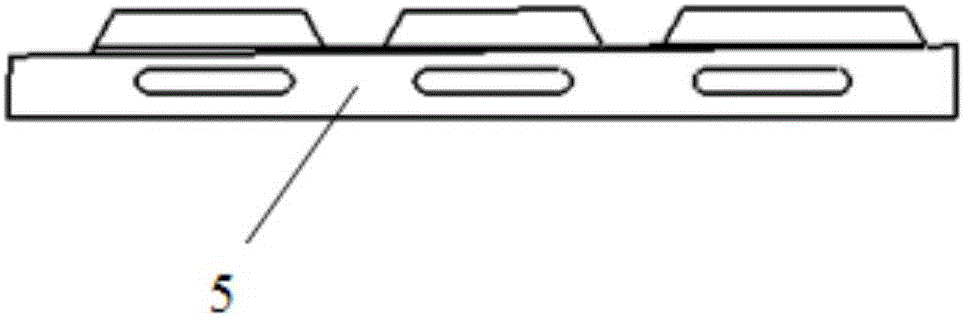

Safety door structure made of PDCPD (Polydicyclopentadiene) material

InactiveCN106004369AMeet the strength and rigidity requirementsTo achieve the purpose of lightweightDoorsEnergy absorptionEngineering

Owner:SOUTH CHINA UNIV OF TECH

Microporous polyolefin-based aerogels

Microporous polyolefin and microporous polydicyclopentadiene (polyDCPD) based aerogels and methods for preparing and using the same are provided. The aerogels are produced by forming a polymer gel structure within a solvent from a olefin or dicyclopentadiene monomer via Ring Opening Metathesis Polymerization (ROMP) reactions, followed by supercritical drying to remove the solvent from the aerogel. Other aerogels are prepared by sequentially (1) mixing at least one dicyclopentadiene monomer, at least one solvent at least one catalyst and at least one inorganic and / or organic reinforcing material, (2) gelling the mixture, (3) aging, and (4) supercritical drying. Aerogels provided herein are inexpensive to prepare, possess desirable thermal, mechanical, acoustic, chemical, and physical properties and are hydrophobic. The aerogels provided herein are suitable for use in various applications, including but not limited to thermal and acoustic insulation, radiation shielding, and vibrational damping applications.

Owner:ASPEN AEROGELS INC

Polydicyclopentadiene building template material and its preparation method

InactiveCN102827318AHigh impact strengthHigh tensile strengthForming/stuttering elementsGlass fiberUltimate tensile strength

The invention discloses a polydicyclopentadiene building template material. The polydicyclopentadiene building template material is obtained through blending polymerization of 80-99.99wt% of dicyclopentadiene and 0.01-20wt% of a glass fiber. The polydicyclopentadiene building template material selects the glass fiber as a reinforcement material to undergo blending polymerization with the dicyclopentadiene to synthesize the composite material, so the impact strength and the tensile strength of the polydicyclopentadiene material can be substantially improved only through adding a small amount of the glass fiber. The impact strength of the composite material is improved to 180-350J / m from original 100J / m of the single polydicyclopentadiene material, and the tensile strength of the composite material is improved to 30-35MPa from original 25MPa of the single polydicyclopentadiene material. The polydicyclopentadiene building template material enables building templates to be 1 / 6-1 / 7 lighter than templates prepared from steel, has the advantages of no rust generation, no deformation, and non-affinity with the building surface, and simultaneously overcomes the shortages of easy water absorption, easy mildewing, low strength and short service life of bamboo templates.

Owner:洛阳智颢工程塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com