Preparation method of polydicyclopentadiene/rubber in-situ polymerization blending composite material

A technology for polydicyclopentadiene and dicyclopentadiene, which is applied in the field of polydicyclopentadiene/rubber in-situ polymerization and blending composite material preparation, can solve the problems of no polydicyclopentadiene production technology and materials, and achieves The effect of high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Under the condition of 50±10°C, 0.1% by mass percentage of styrene-butadiene rubber is dissolved in dicyclopentadiene with a purity of more than 98% and a mass percentage of 99.9%, and the dicyclopentadiene-styrene-butadiene rubber solution is obtained after uniform stirring. The obtained dicyclopentadiene styrene-butadiene rubber solution is subjected to degassing reaction and then protected with an inert gas for use.

[0032] Under nitrogen protection, 20 kg of dicyclopentadiene styrene-butadiene rubber solution (40 kg in total, containing 0.04 kg of styrene-butadiene rubber) was added to feed tank A and feed tank B of the reaction injection molding machine respectively. Because the catalyst of this system is easy to lose activity when it encounters water vapor and air, the whole system must be sealed and protected by inert gas.

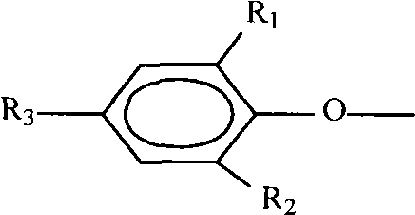

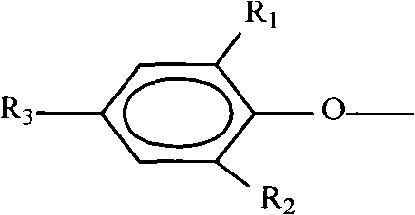

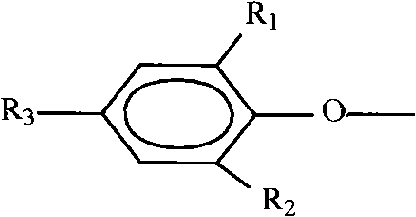

[0033] Add 0.0002 kg of tert-butyl hydroperoxide (1% of the contained rubber mass) and 0.107 kg of bis[2,6 di-tert-butyl-4-methylphenoxy] t...

Embodiment 2

[0038]Under the condition of 50±10°C, dissolve styrene-butadiene rubber with a mass percentage of 1% in dicyclopentadiene with a purity of more than 98% and a mass percentage of 99%, and stir evenly to obtain a dicyclopentadiene-styrene-butadiene rubber solution. The obtained dicyclopentadiene styrene-butadiene rubber solution is degassed and then protected with inert gas for use.

[0039] Under nitrogen protection, 20 kg of dicyclopentadiene styrene-butadiene rubber solution (40 kg in total, containing 0.4 kg of styrene-butadiene rubber) was added to feed tank A and feed tank B of the reaction injection molding machine respectively. Because the catalyst of this system is easy to lose activity when it encounters water vapor and air, the whole system must be sealed and protected by inert gas.

[0040] Add 0.005 kg of tert-butyl hydroperoxide (2.5% of the contained styrene-butadiene rubber mass) and 0.106 kg of bis[2,6 di-tert-butyl-4-methylphenoxy] dichloride in A material tank...

Embodiment 3

[0045] Under the condition of 50 DEG C, 10 mass percent of styrene-butadiene rubber is dissolved in dicyclopentadiene with a purity of more than 98 percent and a mass percent of 90 percent, and the dicyclopentadiene-styrene-butadiene rubber solution is obtained after uniform stirring. The obtained dicyclopentadiene styrene-butadiene rubber solution is degassed and then protected with inert gas for use.

[0046] Under nitrogen protection, 20 kg of dicyclopentadiene styrene-butadiene rubber solution (40 kg in total, containing 4 kg of styrene-butadiene rubber) was added to feed tank A and feed tank B of the reaction injection molding machine respectively.

[0047] Add 0.1 kg of tert-butyl hydroperoxide (5% of the contained styrene-butadiene rubber mass) and 0.096 kg of bis[2,6-di-tert-butyl-4-methylphenoxy] dichloride in A material tank Tungsten catalyst (1 / 2000 of the molar number of dicyclopentadiene added).

[0048] Add 0.656 kg of diethylaluminum chloride (40 times the mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com