Patents

Literature

227 results about "Reaction injection molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reaction injection molding (RIM) is similar to injection molding except thermosetting polymers are used, which requires a curing reaction to occur within the mold. Common items made via RIM include automotive bumpers, air spoilers, and fenders.

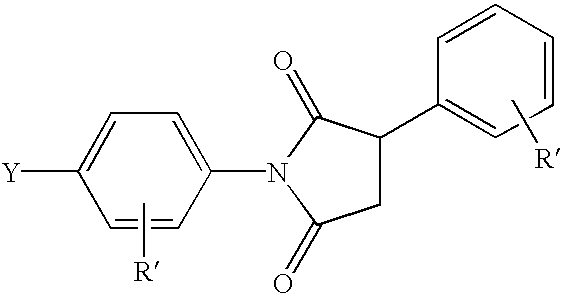

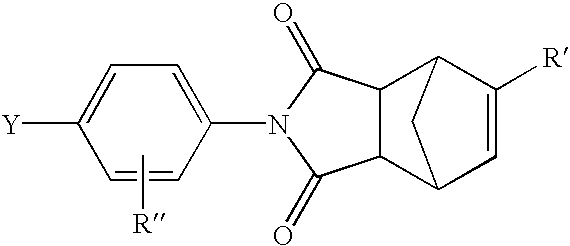

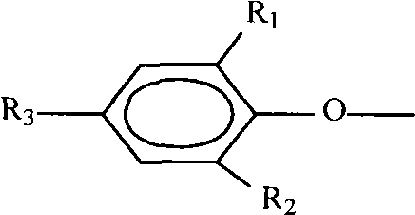

Liquid crystalline thermosets from ester, ester-imide, and ester-amide oligomers

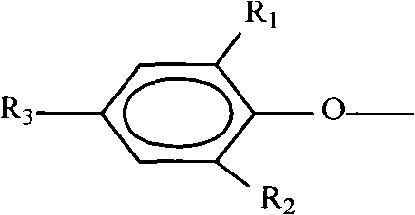

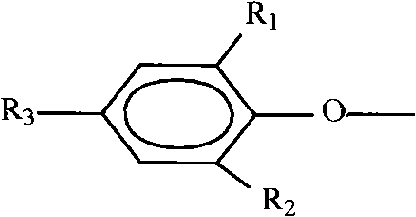

InactiveUS6939940B2Low viscosityLow dielectric constantLiquid crystal compositionsLiquid crystallineEnd-group

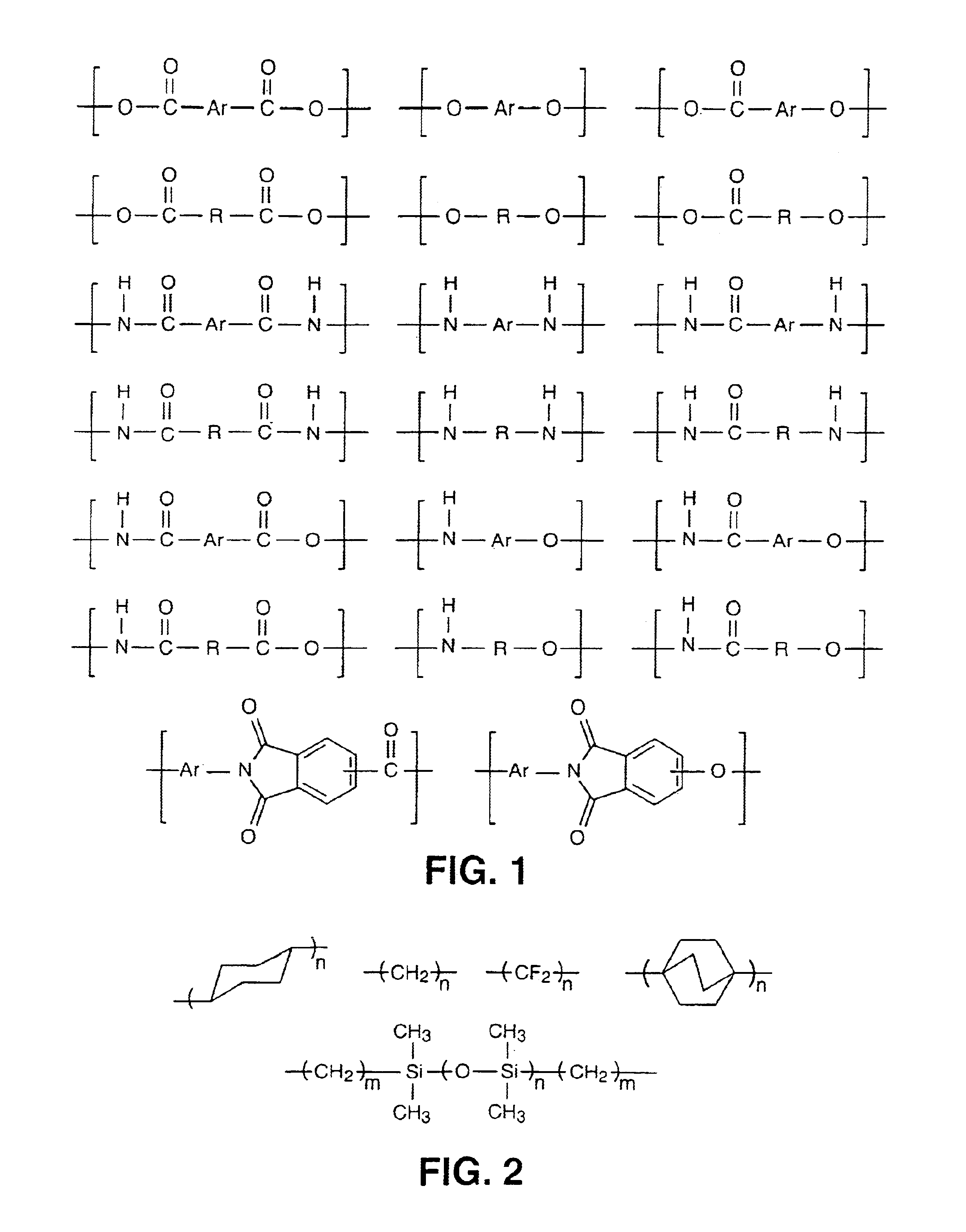

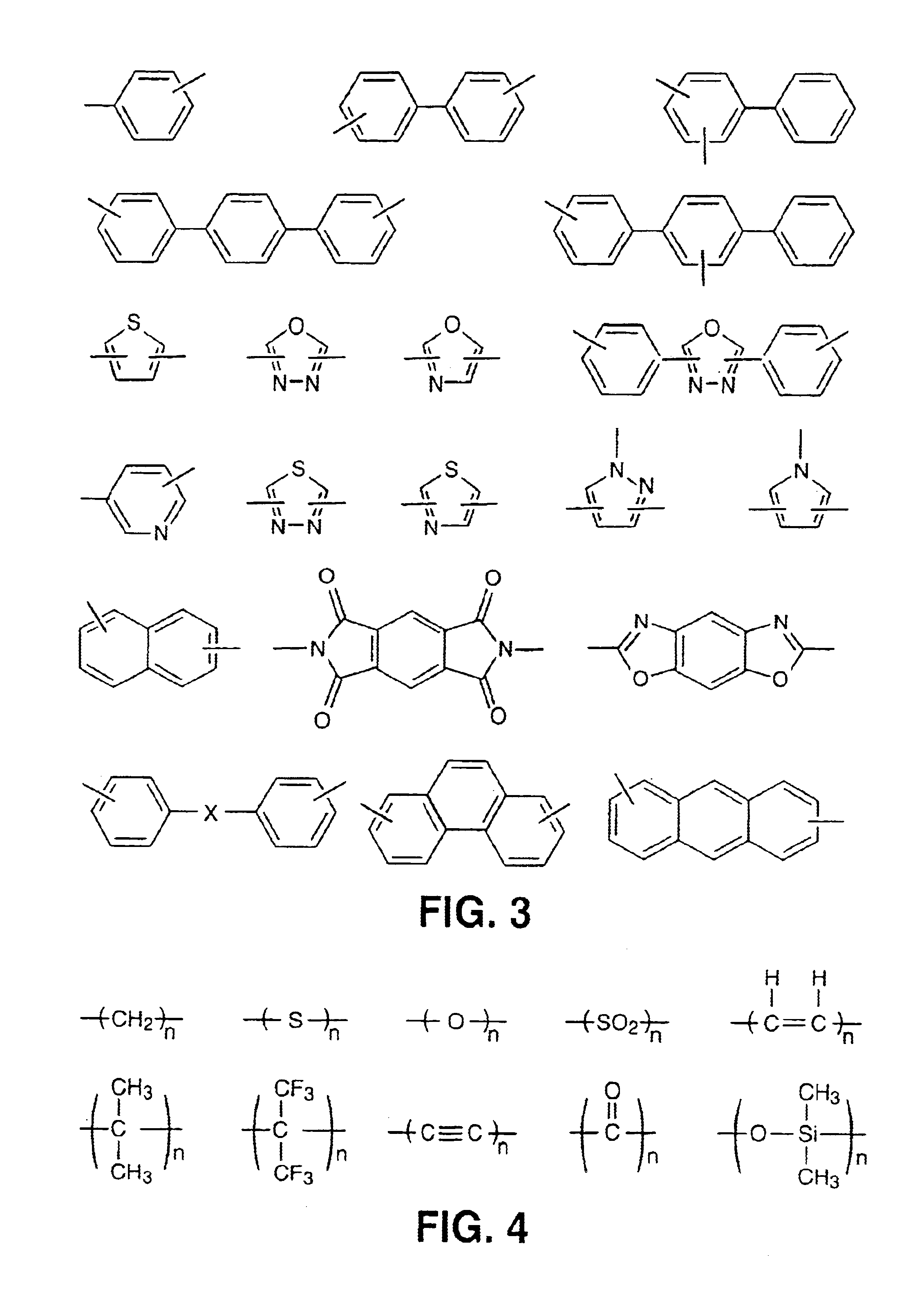

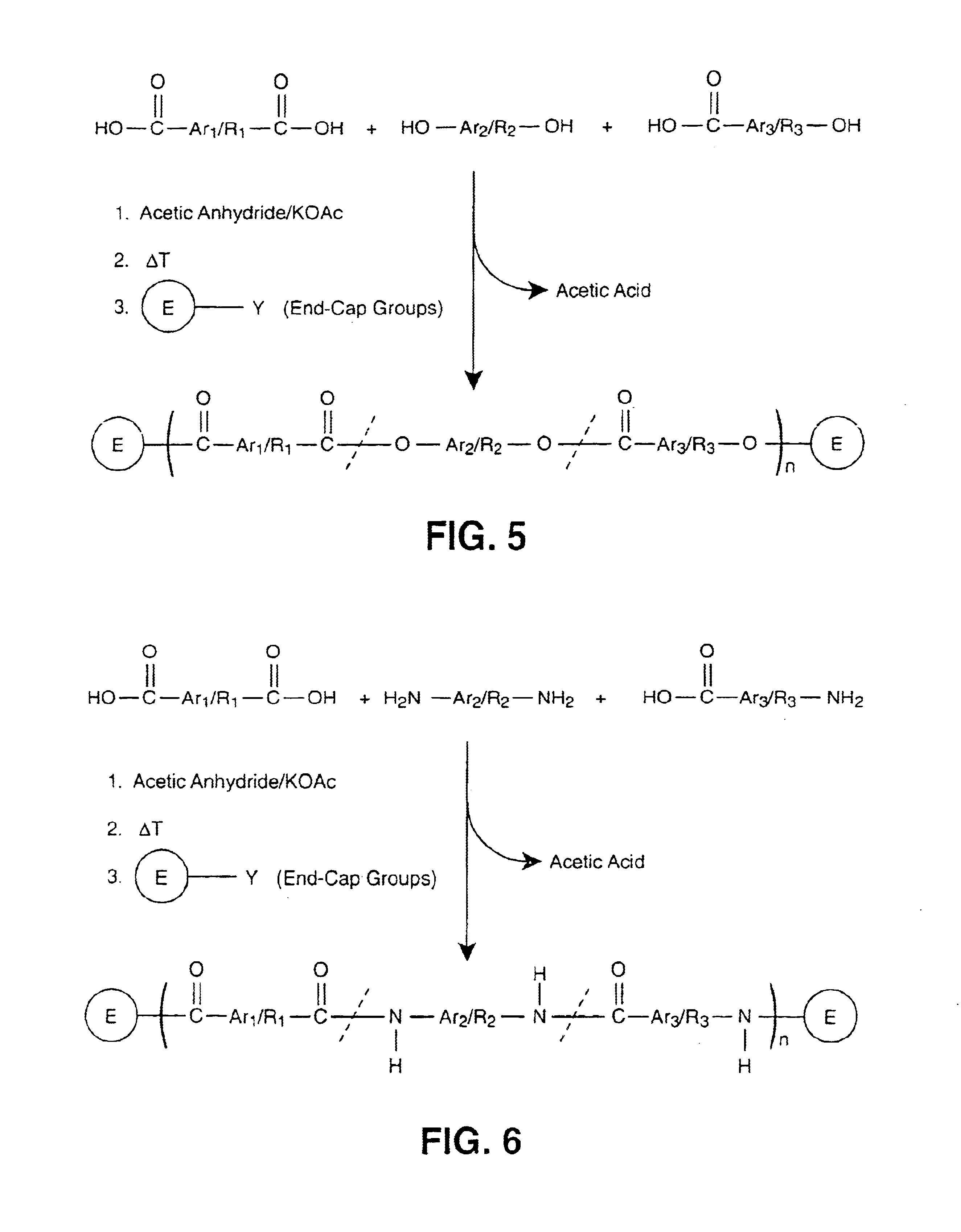

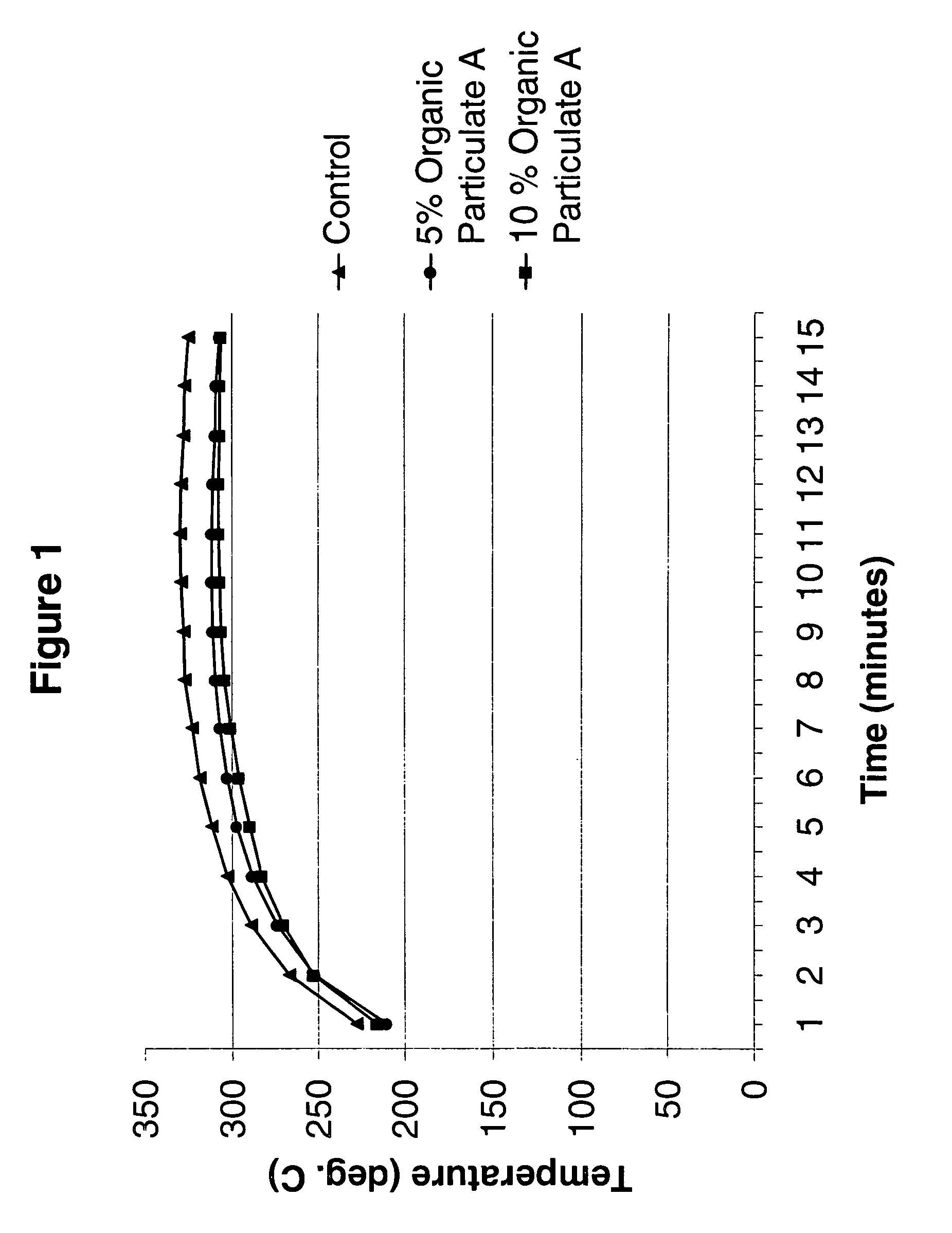

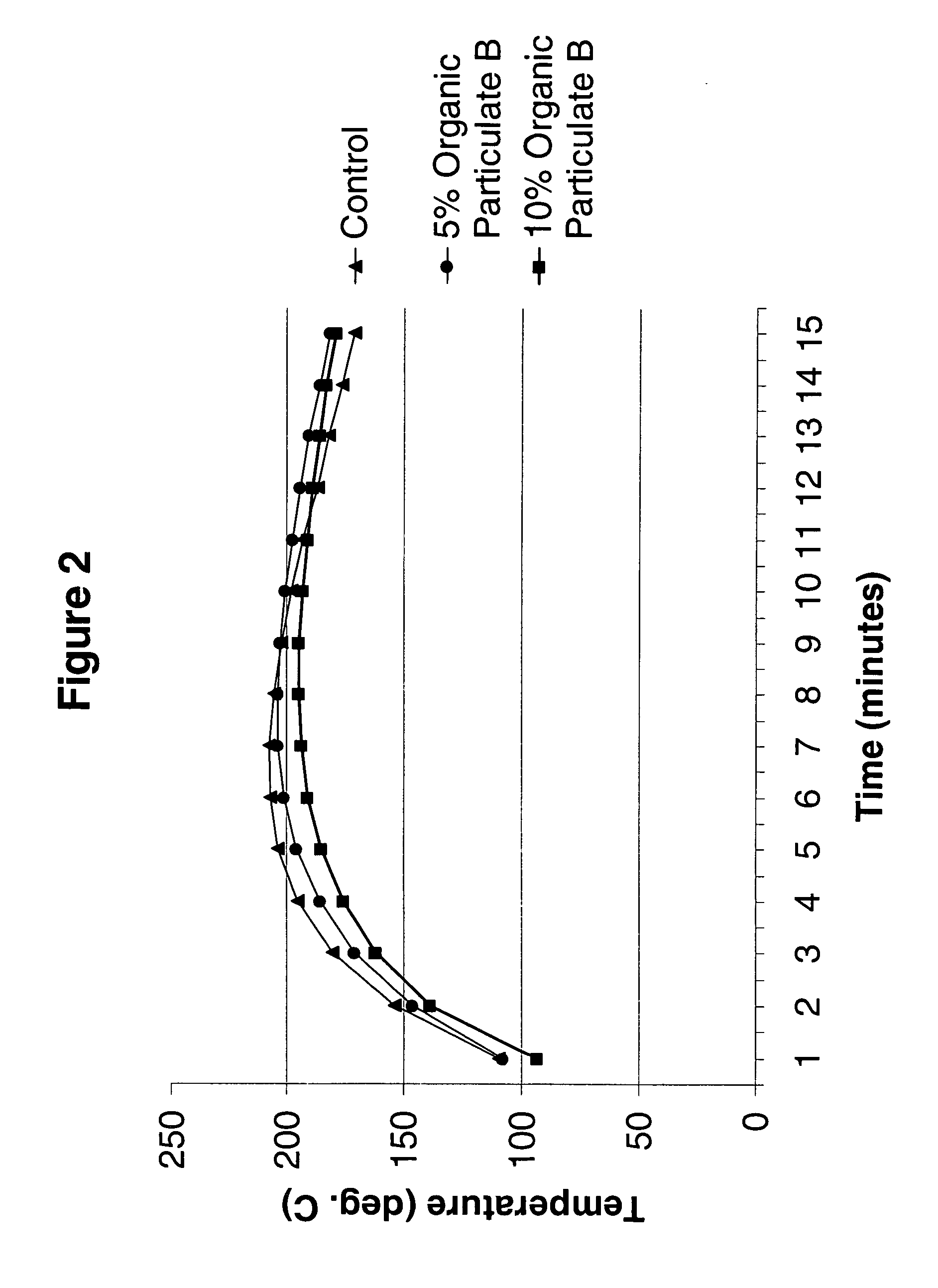

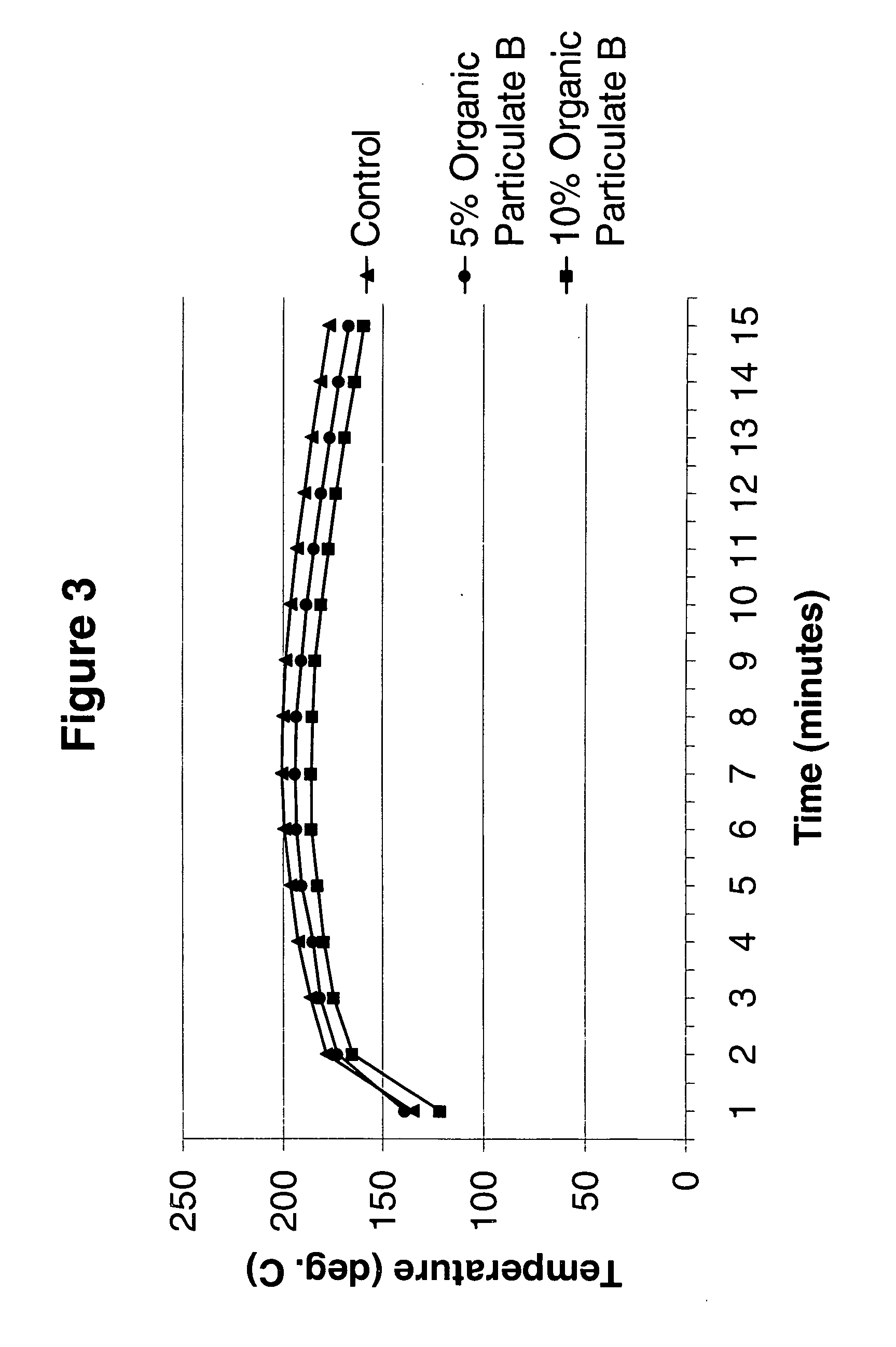

Main chain thermotropic liquid crystal esters, ester-imides, and ester-amides were prepared from AA, BB, and AB type monomeric materials and were end-capped with phenylacetylene, phenylmaleimide, or nadimide reactive end-groups. The resulting reactive end-capped liquid crystal oligomers exhibit a variety of improved and preferred physical properties. The end-capped liquid crystal oligomers are thermotropic and have, preferably, molecular weights in the range of approximately 1000-15,000 grams per mole. The end-capped liquid crystal oligomers have broad liquid crystalline melting ranges and exhibit high melt stability and very low melt viscosities at accessible temperatures. The end-capped liquid crystal oligomers are stable for up to an hour in the melt phase. These properties make the end-capped liquid crystal oligomers highly processable by a variety of melt process shape forming and blending techniques including film extrusion, fiber spinning, reactive injection molding (RIM), resin transfer molding (RTM), resin film injection (RFI), powder molding, pultrusion, injection molding, blow molding, plasma spraying and thermo-forming. Once processed and shaped, the end-capped liquid crystal oligomers were heated to further polymerize and form liquid crystalline thermosets (LCT). The fully cured products are rubbers above their glass transition temperatures. The resulting thermosets display many properties that are superior to their non-end-capped high molecular weight analogs.

Owner:NASA

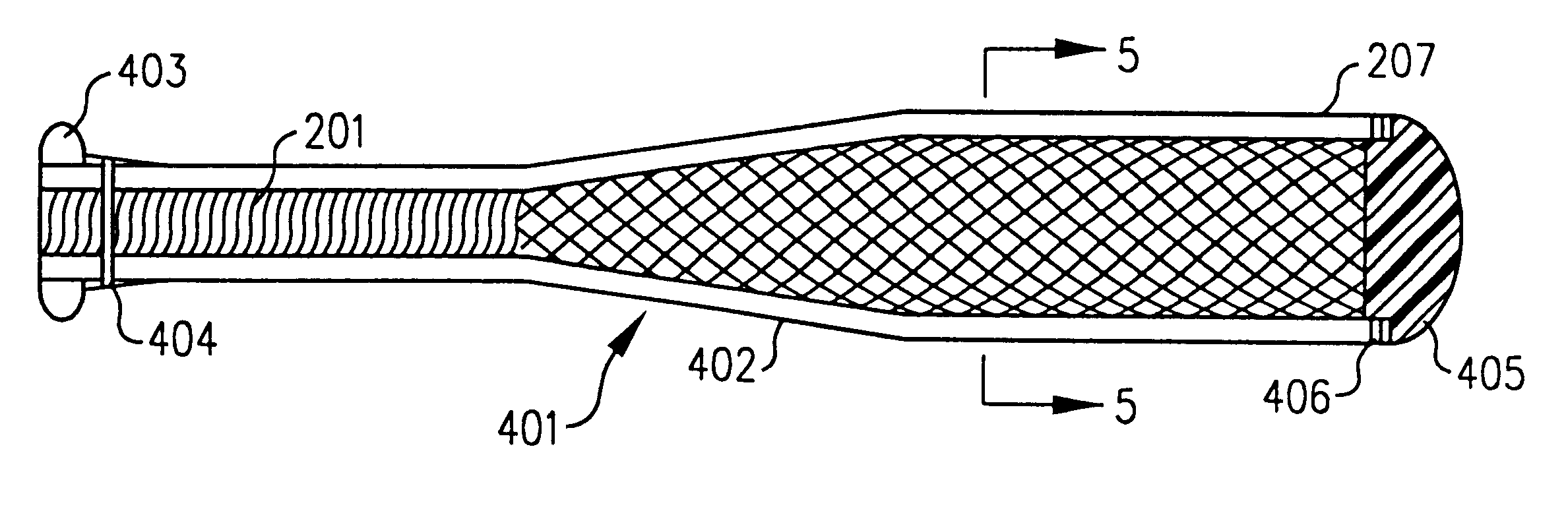

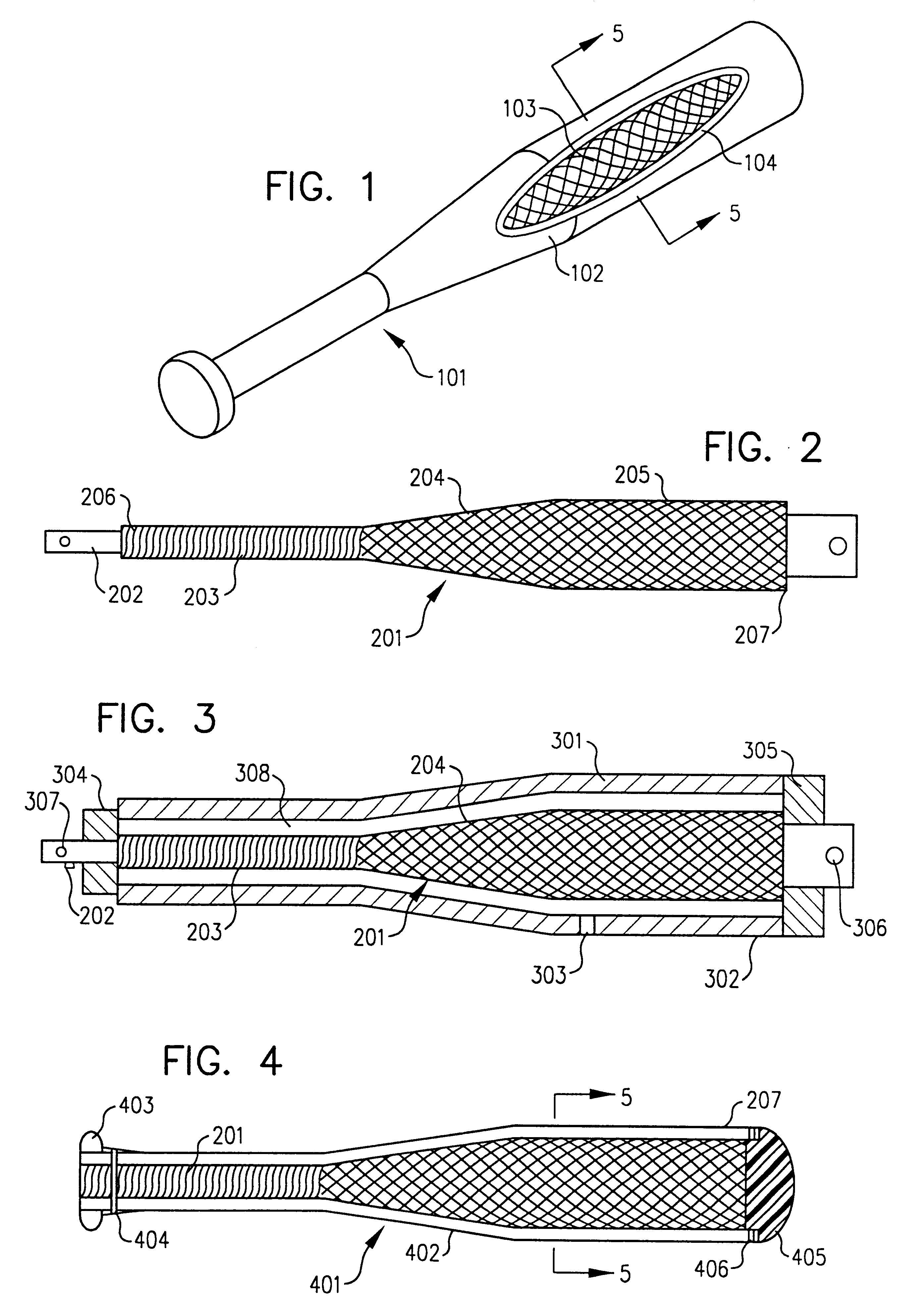

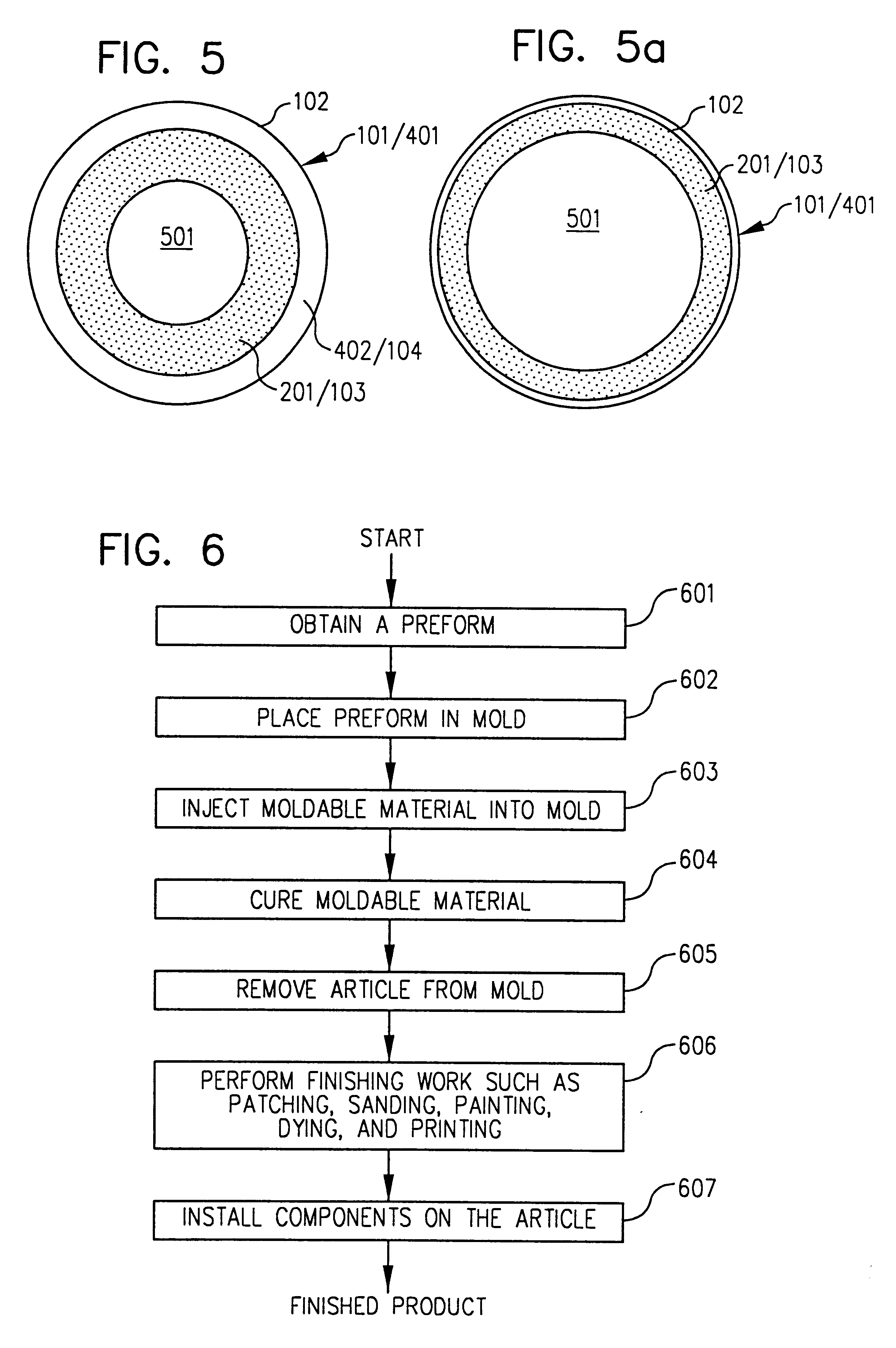

Fiber reinforced molded products and processes

A method for manufacturing elongate articles such as baseball bats, paddles, oars, hockey sticks, generic tubing and other articles and articles including molded material molded about a preform. The preferred method includes manufacturing a filament wound preform and reaction injection molding material about the preform to result in a finished article. The preferred baseball bat includes an elongate filament wound preform about which a quantity of urethane foam is molded.

Owner:ADVANCED COMPOSITES

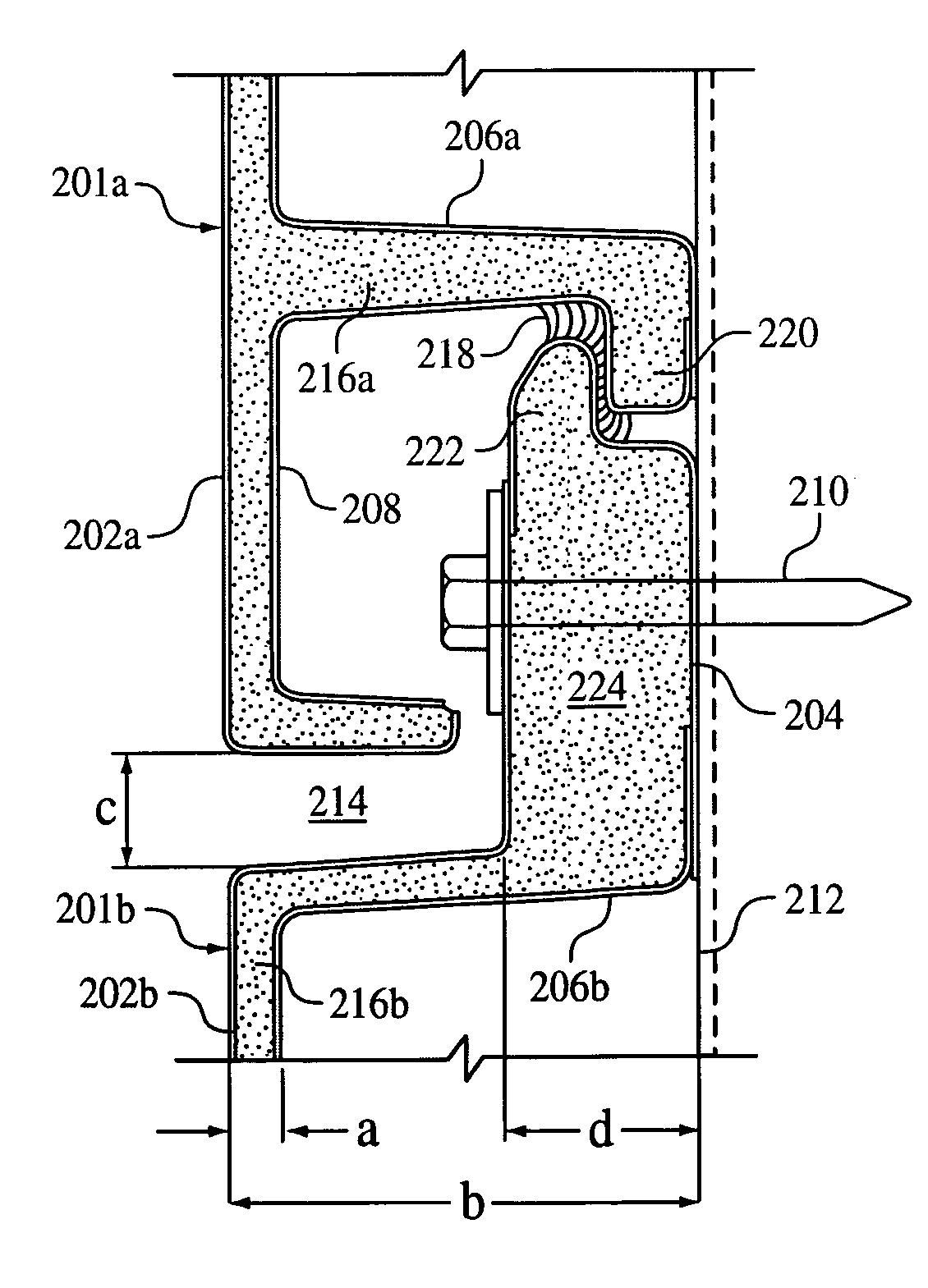

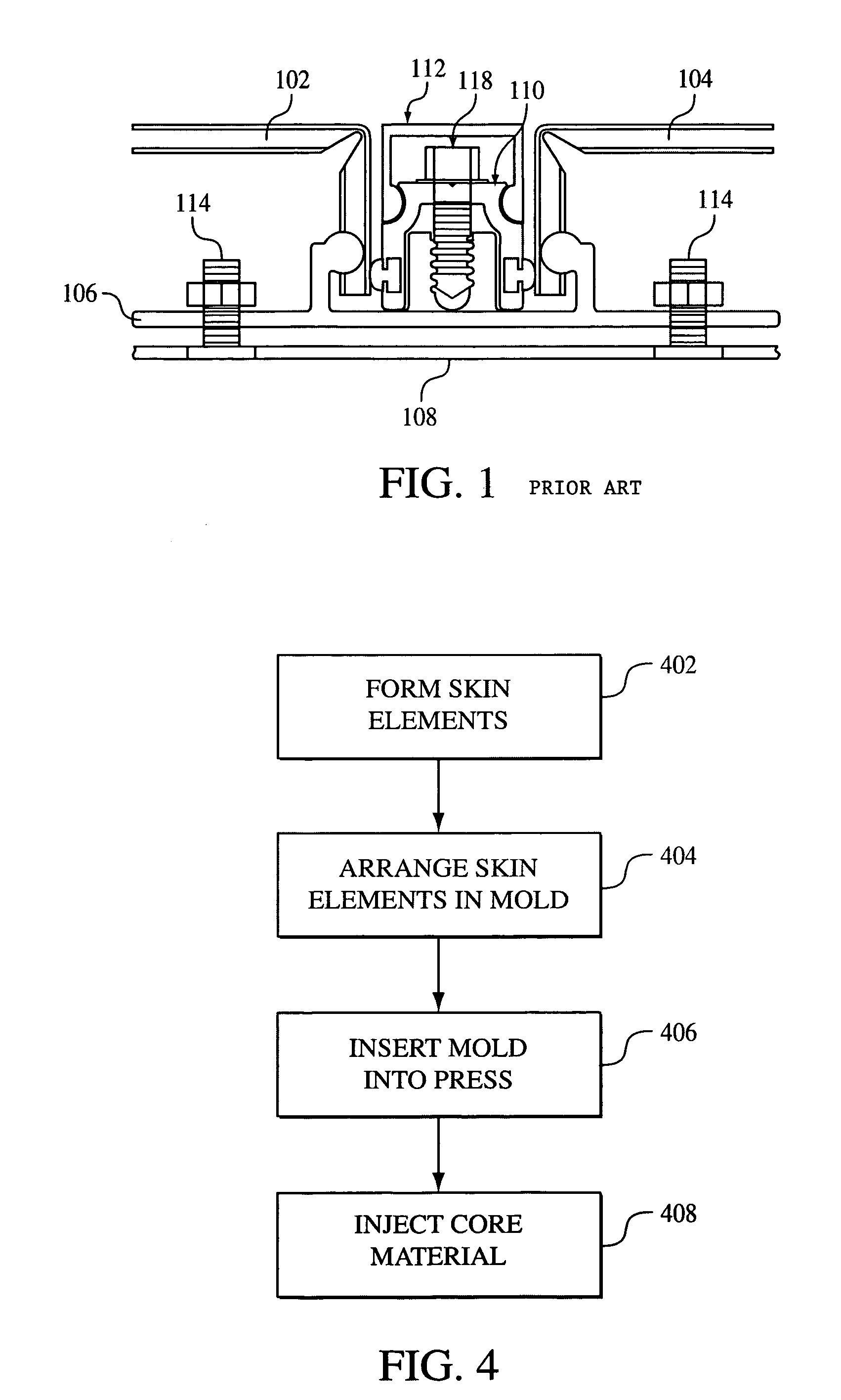

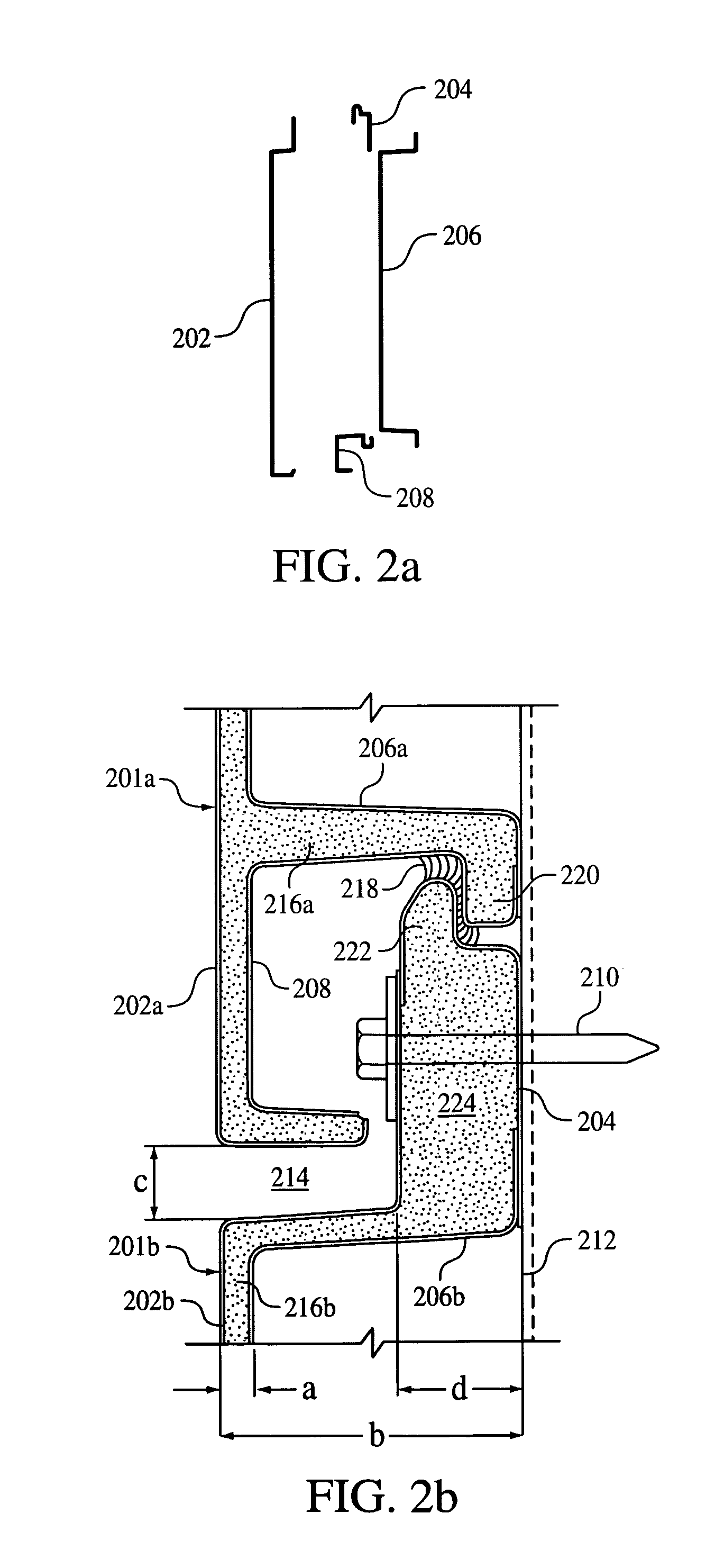

Features for thin composite architectural panels

InactiveUS7007433B2Altering coloringAltering other visual featureCovering/liningsWallsInterconnectionComposite plate

Thin composite panels with interconnection schemes that are unitized with the panels, i.e., formed integrally and substantially simultaneously with the panels. Further contemplated is the application of an injection molding technique, such as reaction injection molding, in establishing a foam or polymeric core between laminates in thin composite panels. Additionally contemplated is the use of interchangeable laminate components in affording the capability of altering the coloring or other visual features of a reveal in a panel or panels.

Owner:CENTRIA

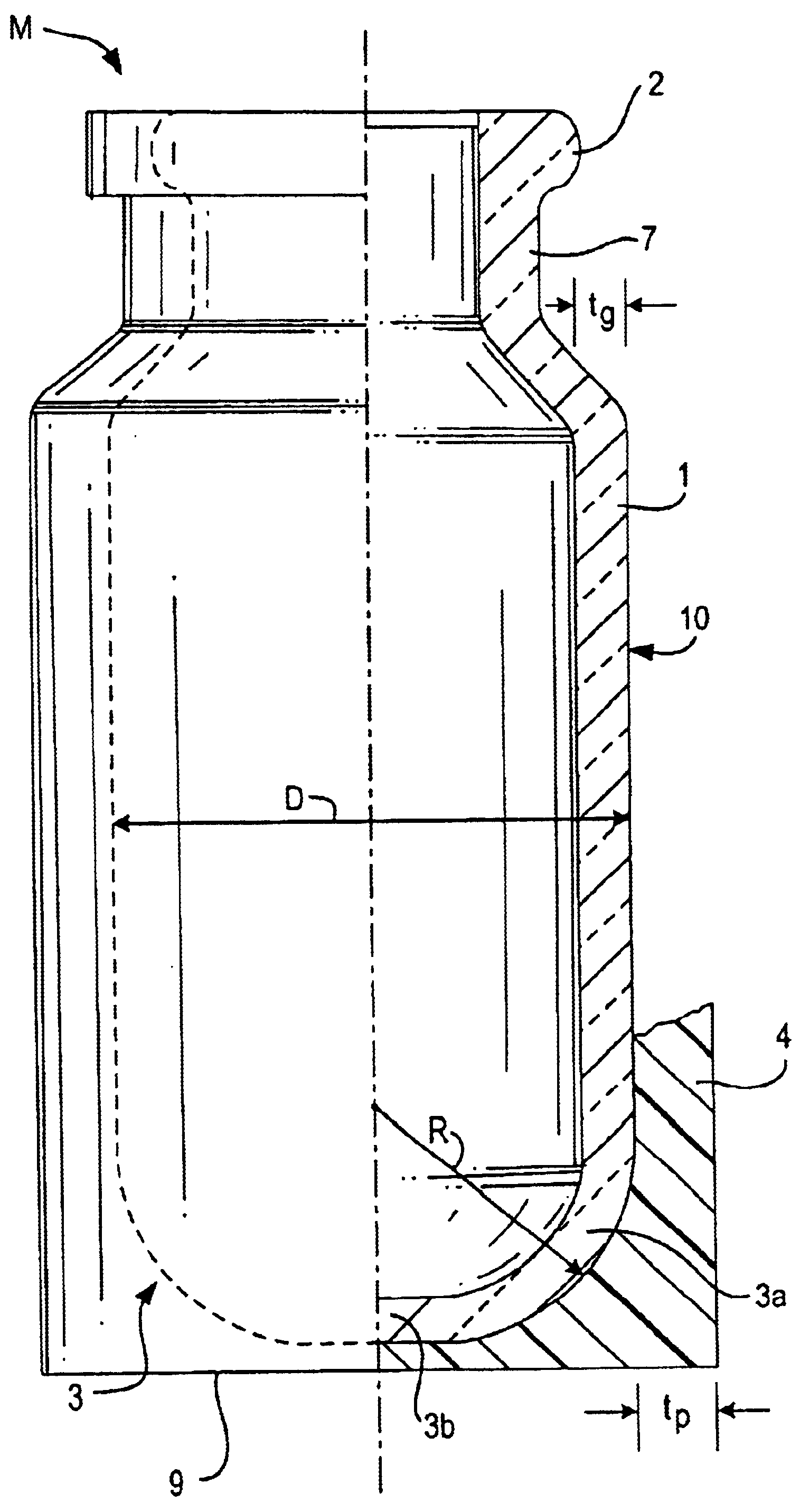

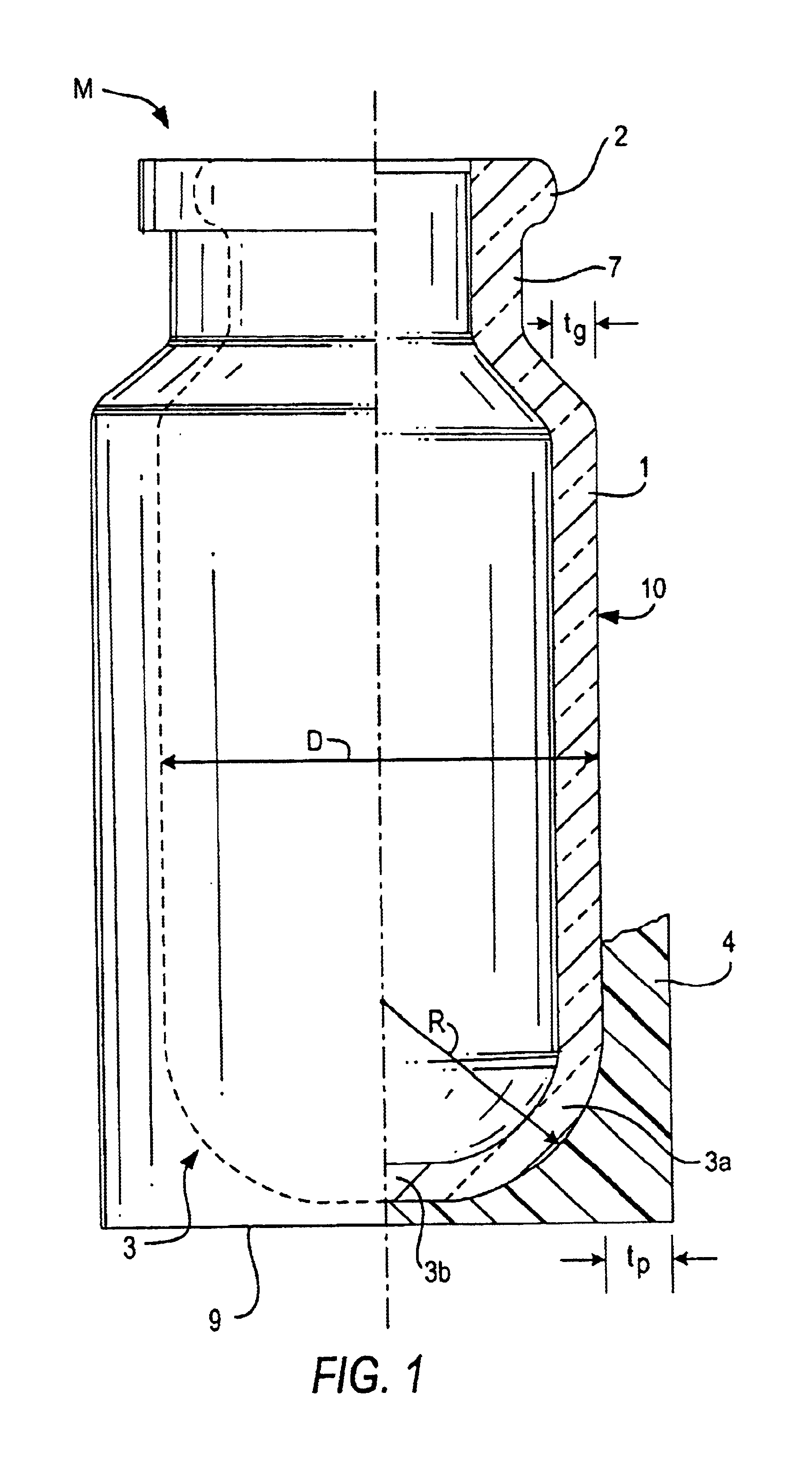

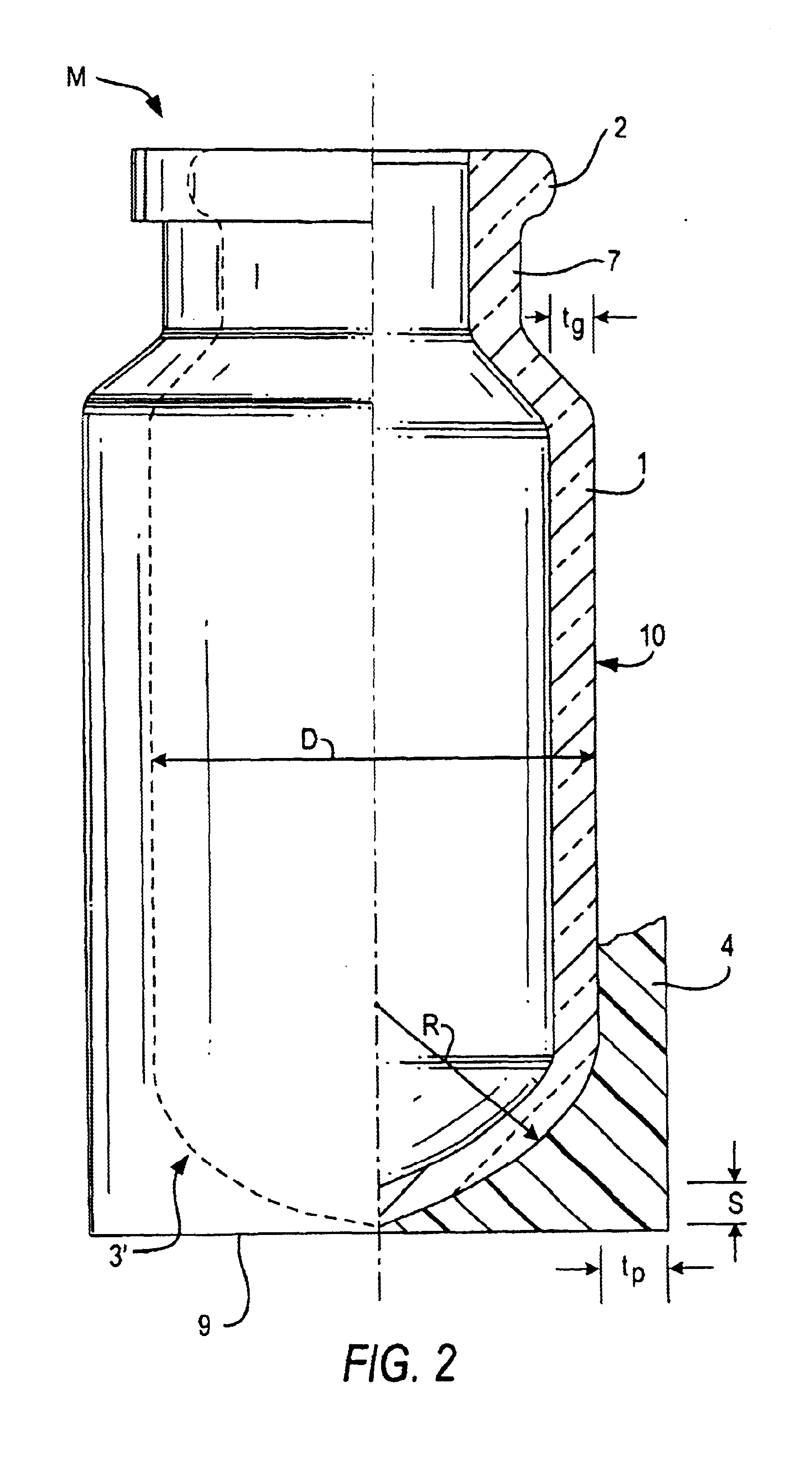

Closeable glass container comprising a plastic coating applied by injection molding and method for the production thereof

InactiveUS6866158B1Reduce wasteProduce some attenuationBottlesNon-pressured vesselsEngineeringBottle

The container is a glass bottle (10) encased with a plastic coating (4) from its base section (3) to a sealing rim (2) around its mouth (M) in order to protect against shattering or explosive failure. The glass bottle, preferably a glass inlet, is fillable under pressure with a sprayable medically active substance and a propellant and provided with a delivery element attached to the sealing rim. To facilitate lower injection molding temperatures and pressures and to permit autoclaving at high temperatures the glass bottle with the plastic coating (4) is made by a method which includes injecting at least one reactively cross-linkable plastic capable of being heat-softened into a mold surrounding the glass bottle and forming the plastic coating (4) by a reaction injection molding (RIM) method.

Owner:SCHOTT AG

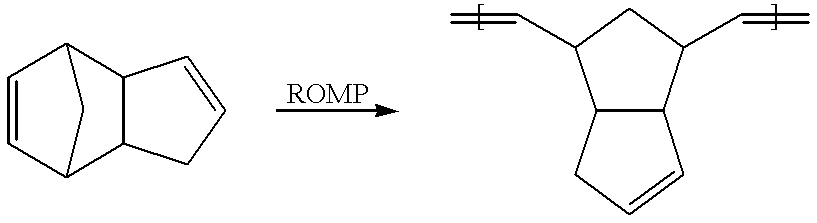

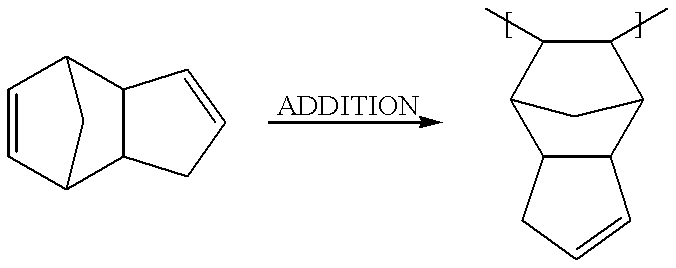

Mold addition polymerization of norbornene-type monomers using group 10 metal complexes

InactiveUS6350832B1Increase displacementMore efficient in polymerizing polycyclic olefinsCoatingsThermoplasticPolymer science

A catalyst system and a process for the bulk addition polymerization or of polycyclic olefins, such as norbornene, methylnorbornene, ethylnorbornene, butylnorbornene or hexylnorbornene, 1,2,3,4,4a,5,8,8a-octahydro-1,4:5,8-dimethanonapthalene, 5,5'-(1,2-ethanediyl)bisbicyclo[2.2.1]hept-2-ene, and 1,4,4a,4b,5,8,8a,8b-octahydro-1,4:5,8-dimethanobiphenylene are disclosed. The catalyst includes an organonickel or organopalladium transition metal procatalyst and an activator compound. Polymerization can be carried out in a reaction injection molding process to yield thermoplastic and thermoset molded polymeric articles possessing high glass transition temperatures.

Owner:SUMITOMO BAKELITE CO LTD

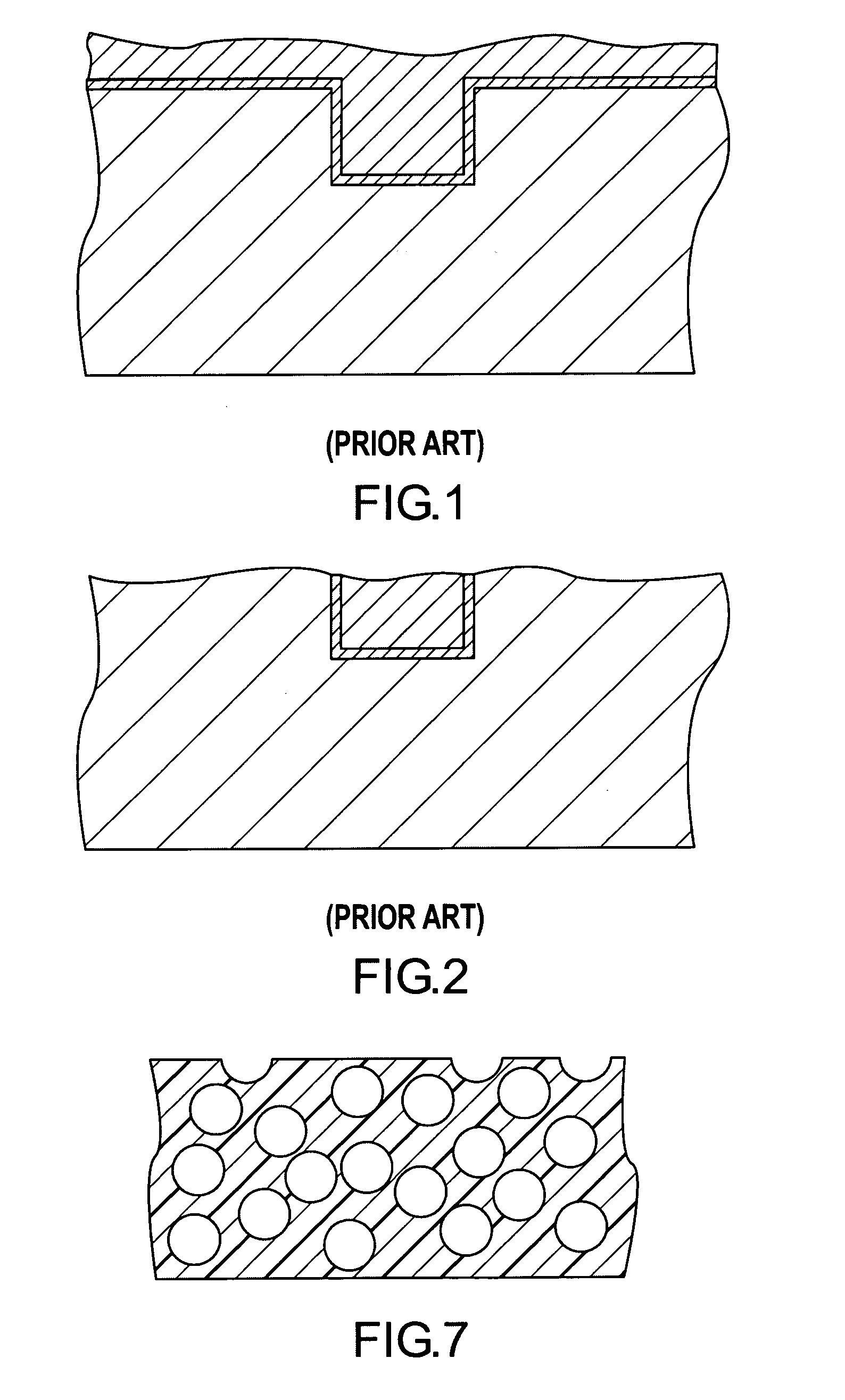

Method for manufacturing auxiliary gas-adding polyurethae/polyurethane-urea polishing pad

InactiveUS20040021243A1Improve accuracyImprove flatnessFlexible-parts wheelsLapping toolsHydrogenPolythiol resin

A method for manufacturing a PU (polyurethane) polishing pad is provided. Resins containing active hydrogen functional groups such as polyol resins, polyamine resins, and polythiol resins, and polyisocyanate resins containing -NCO functional groups are mixed to form a foamed PU polishing pad with excellent polishing properties by reaction injection-molding under high pressure, low temperature and auxiliary gas-adding. The PU polishing pad in accompany with an abrasive slurry can be widely used to polish high-level products such as wafers and optical glass.

Owner:IV TECH CO LTD

Polishing pad and method of making same

InactiveUS6986705B2Control UniformityUniform sizeSemiconductor/solid-state device manufacturingFlexible-parts wheelsShell moldingMaterials science

Owner:RIMPAD TECH

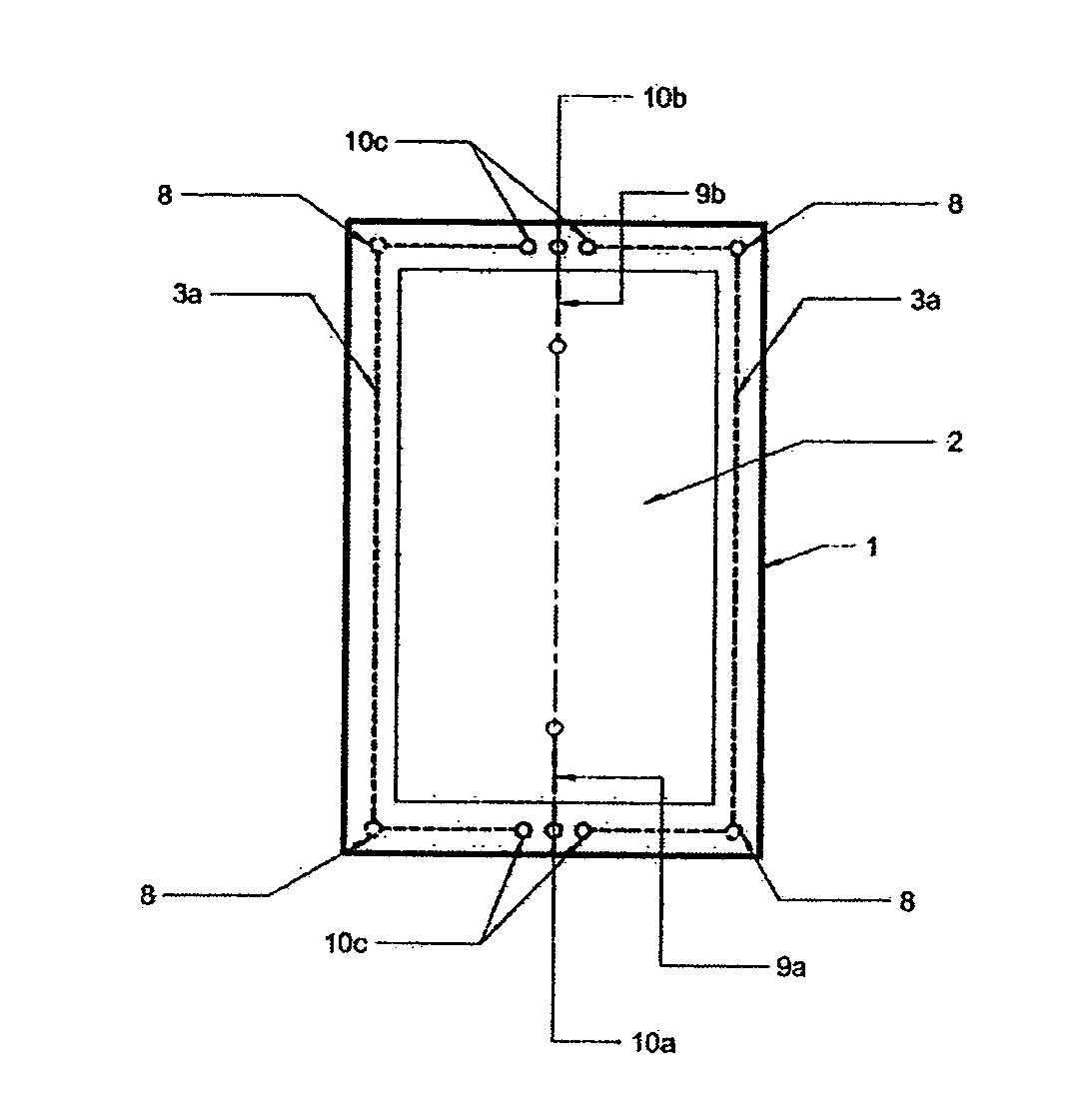

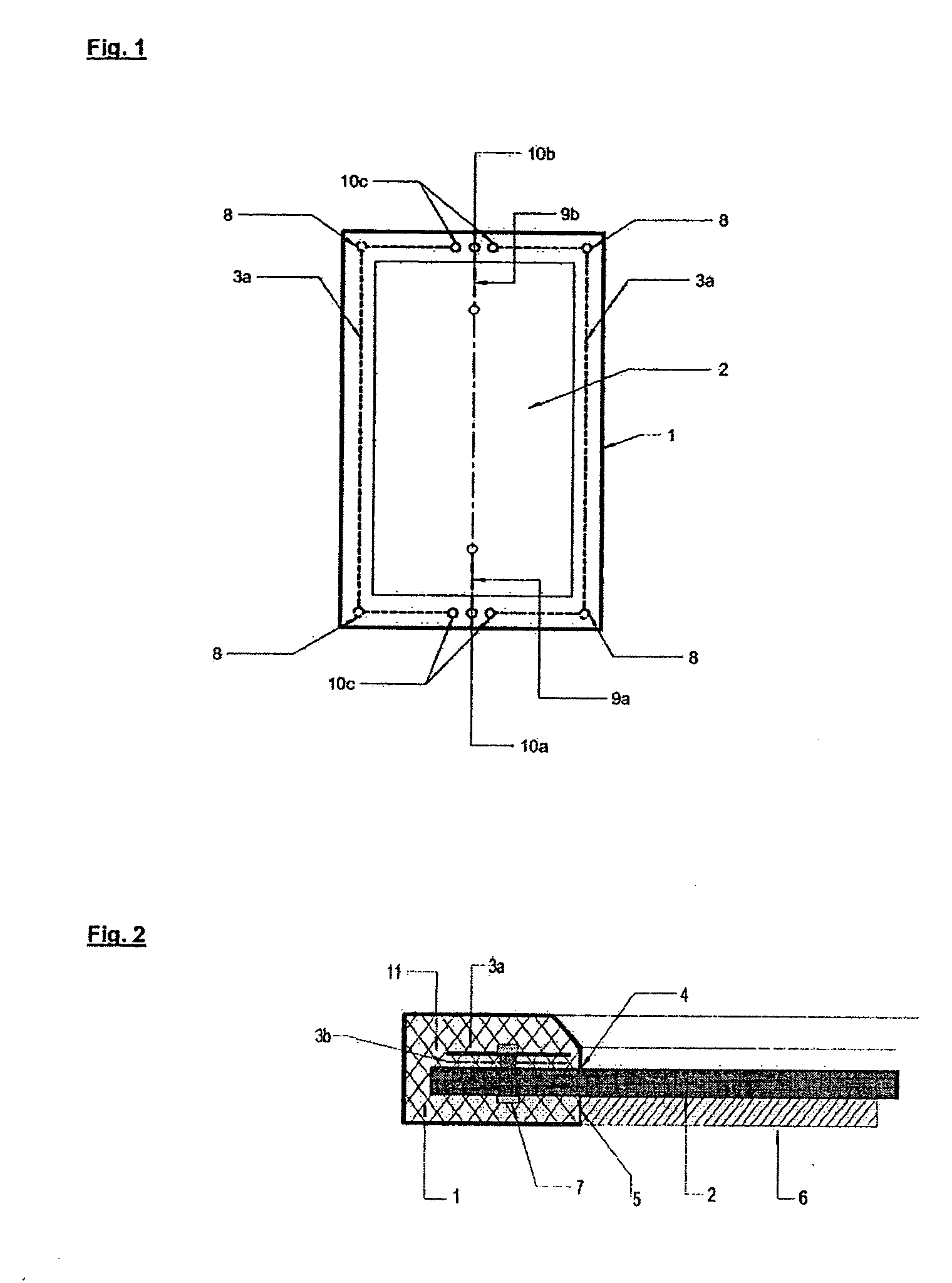

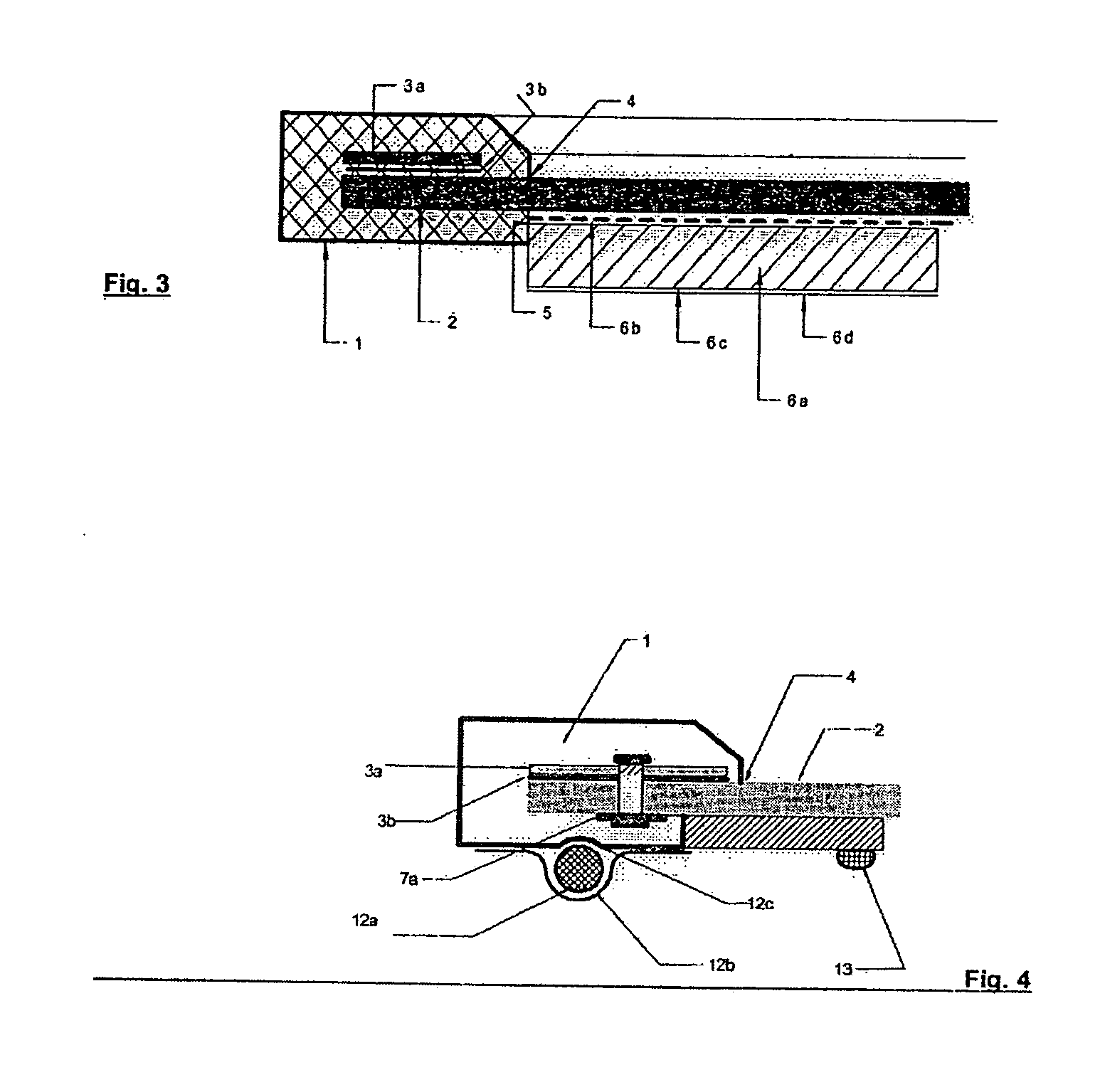

Flexible solar power module with a current lead integrated in the frame

The invention refers to a non-glass and flexible solar power module and the method for its manufacture where the module is provided with a circumferential and flexible frame having integrated through-wiring and socket parts, which are formed face-side into the frame, for module interconnection by means of plug-in connectors. The solar module is thoroughly and completely sealed off on its rear side and has a full-surface smooth texture which is established by the insertion of a thin flexible panel, preferably made of plastic, together with the laminate into the form for the manufacture of the frame by means of RIM (reaction injection moulding). The modules are mounted on the building, preferably by means of bonding / cementing to practically any random roof materials, as well as to curved surfaces and without a backward cable lead.

Owner:BAYER MATERIALSCIENCE AG

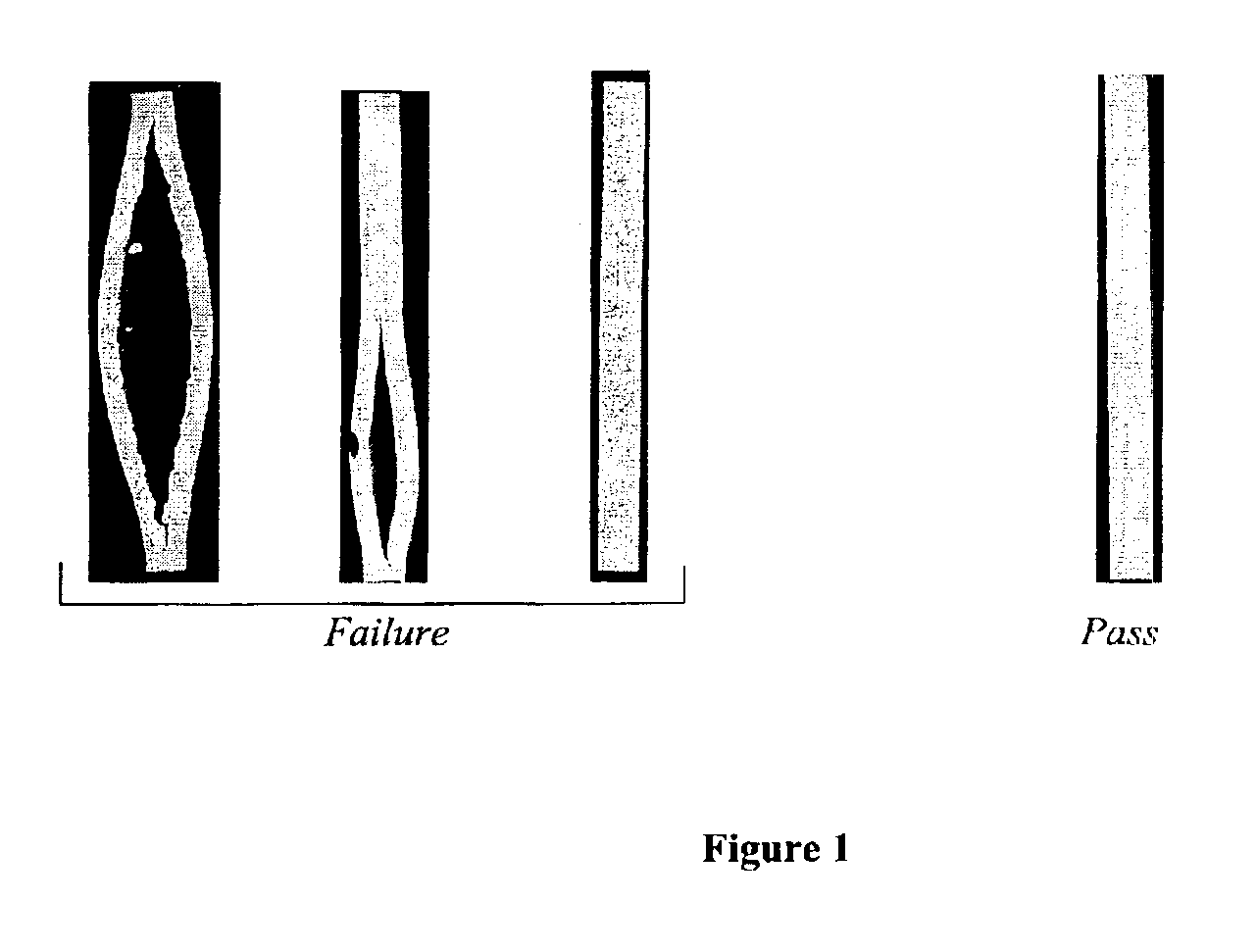

Molded foam articles prepared with reduced mold residence time and improved quality

Foamed molded articles produced by reaction injection molding (RIM) are provided. The molded articles are formed by reaction of a polyisocyanate component with an isocyanate reactive component in a mold using a blowing agent. The molded articles are preferably composites formed in the presence of a fibrous reinforcing material. The foamed articles are characterized by relatively short minimum mold residence times, and can thereby be produced more economically than prior art composites. The foamed articles are further characterized by a reduction in physical defects, such as splits and voids.

Owner:HUNTSMAN INT LLC +1

Solid polyurethane compositions, infrastucture repair and geo-stabilization processes

Owner:BAYER MATERIALSCIENCE AG

Fibers treated with polymerization compounds and fiber reinforced composites made therefrom

InactiveUS20110045275A1Group 4/14 element organic compoundsMolecular sieve catalystsFiber-reinforced compositePolymer chemistry

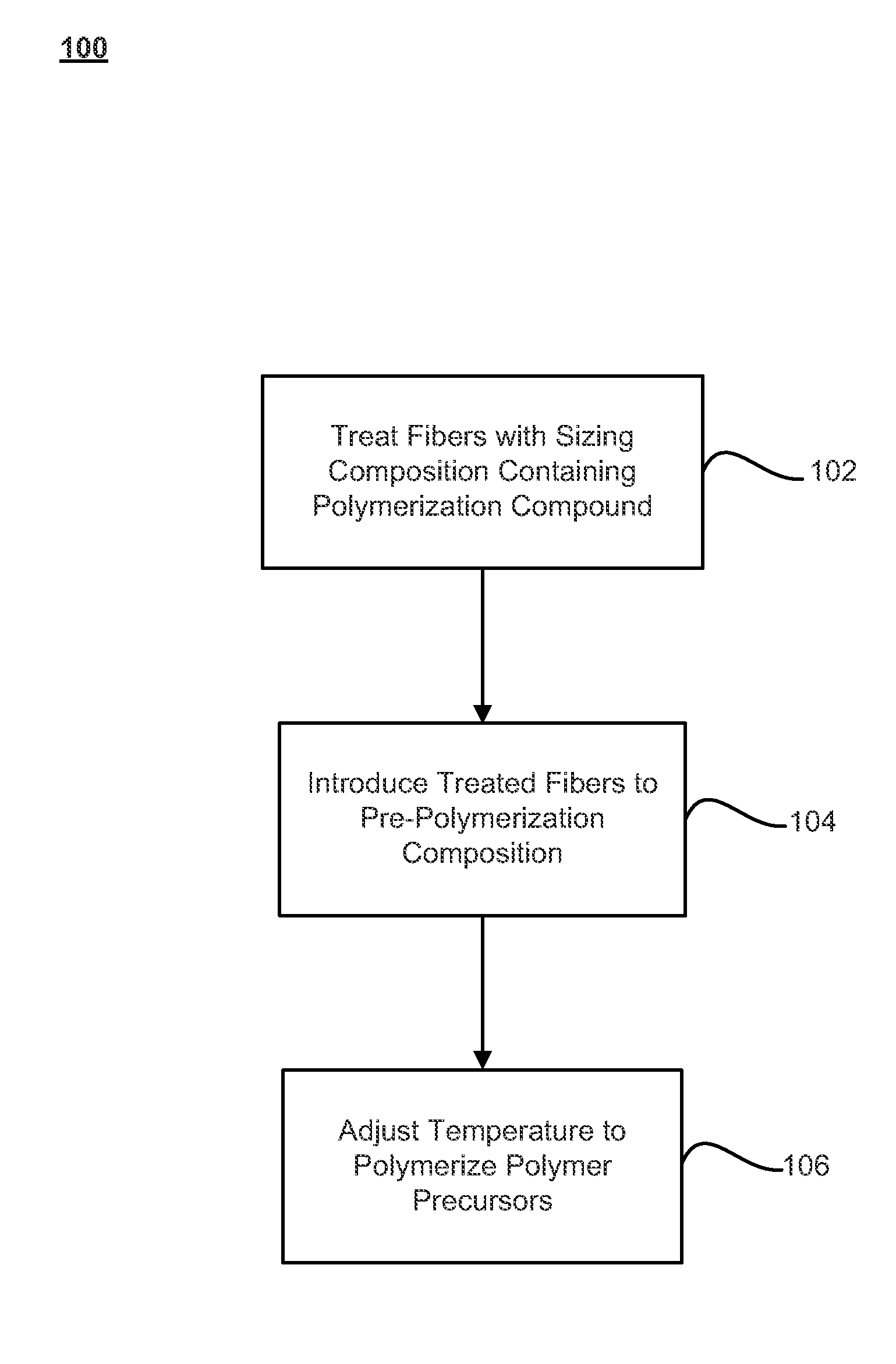

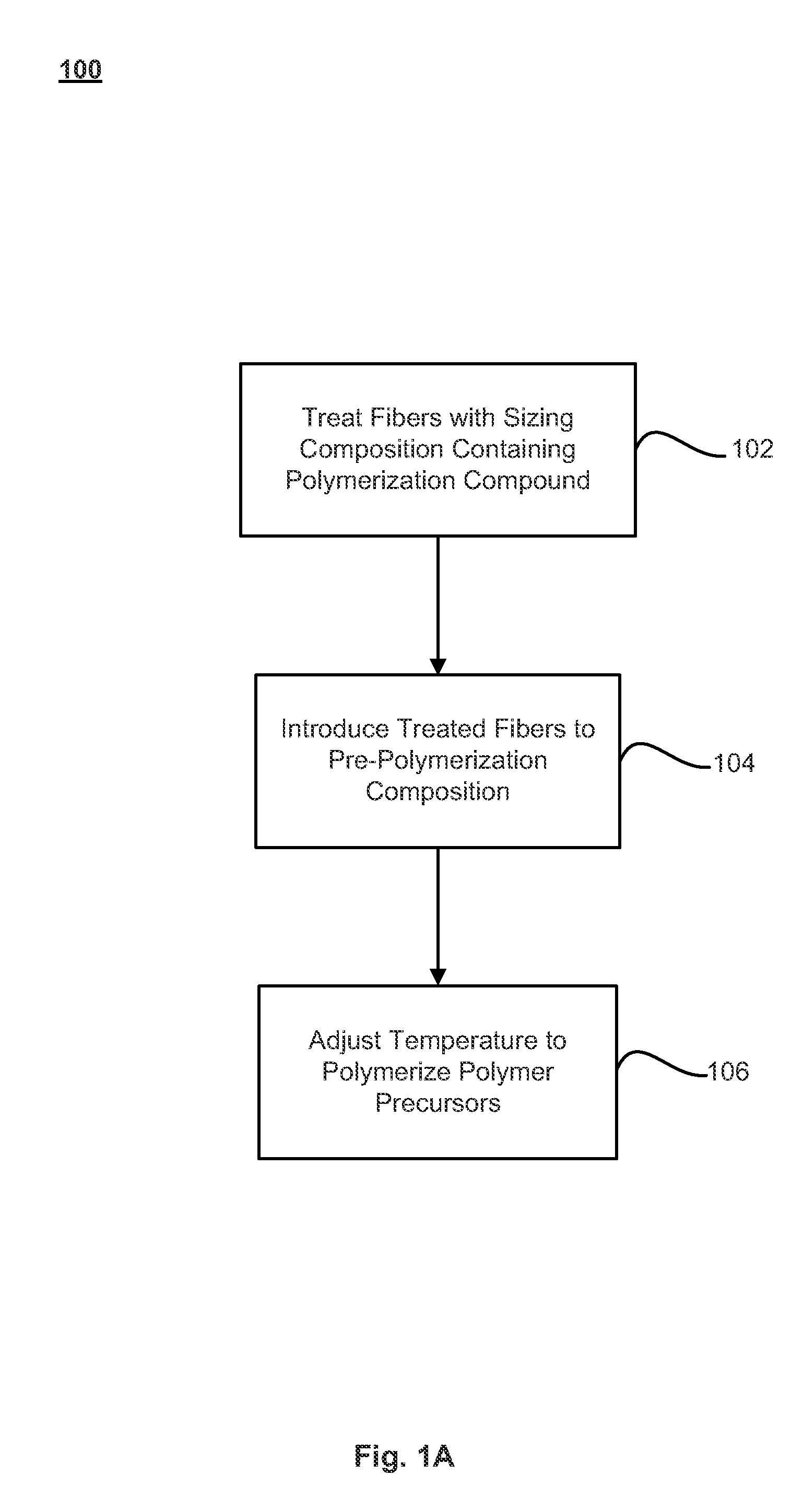

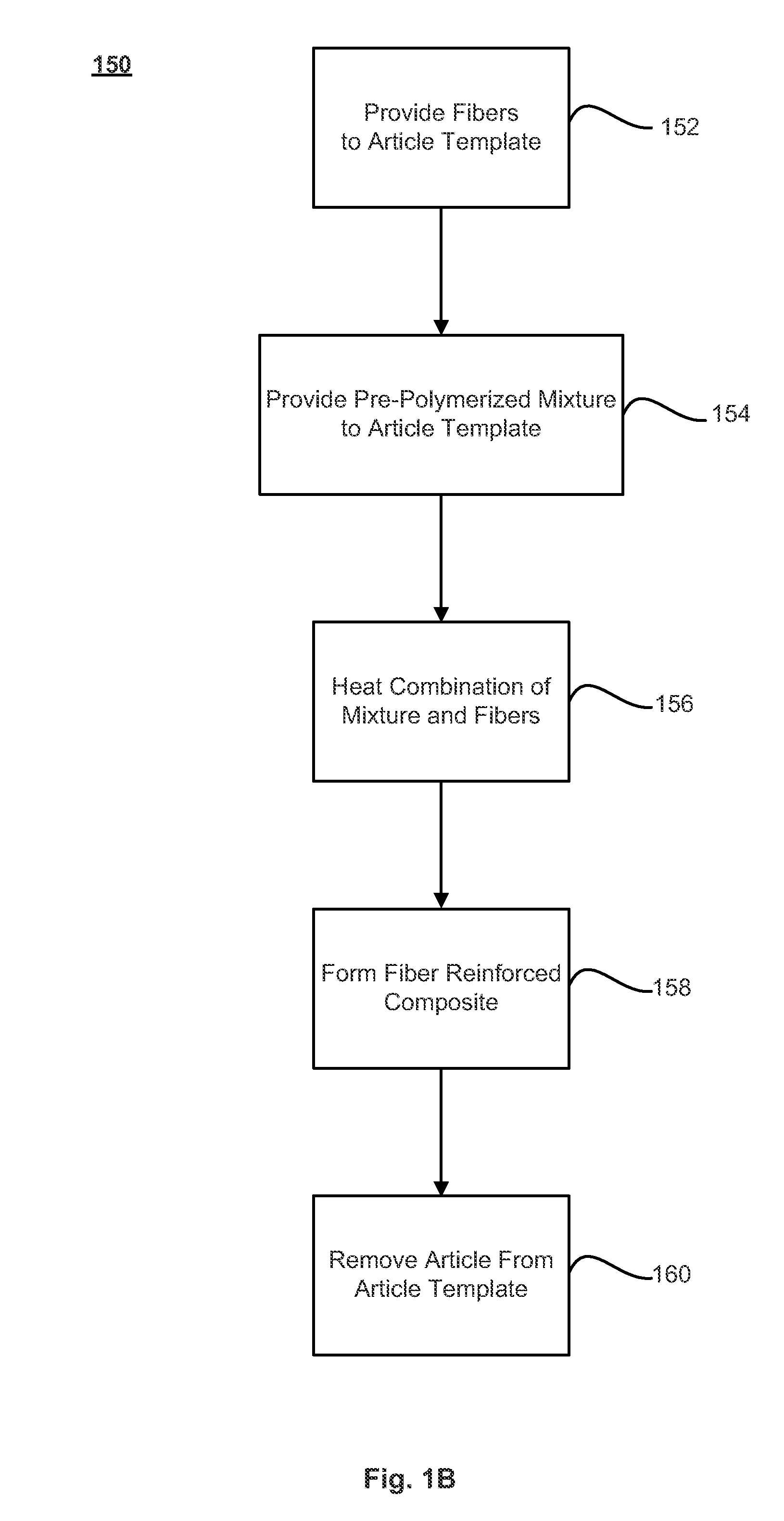

Methods of making fiber reinforced composite articles are described. The methods may include treating fibers with a sizing composition that includes a polymerization compound, and introducing the treated fibers to a pre-polymerized composition. The combination of the treated fibers and pre-polymerized composition may then undergo a temperature adjustment to a polymerization temperature at which the pre-polymerized composition polymerizes into a plastic around the fibers to form the fiber-reinforced composite article. Techniques for introducing the treated fibers to the pre-polymerized composition may include pultrusion, filament winding, reactive injection molding (RIM), structural reactive injection molding (SRIM), resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM), long fiber injection (LFI), sheet molding compound (SMC) molding, bulk molding compound (BMC) molding, a spray-up application, and / or a hand lay-up application, among other techniques.

Owner:TADEPALLI RAJAPPA +3

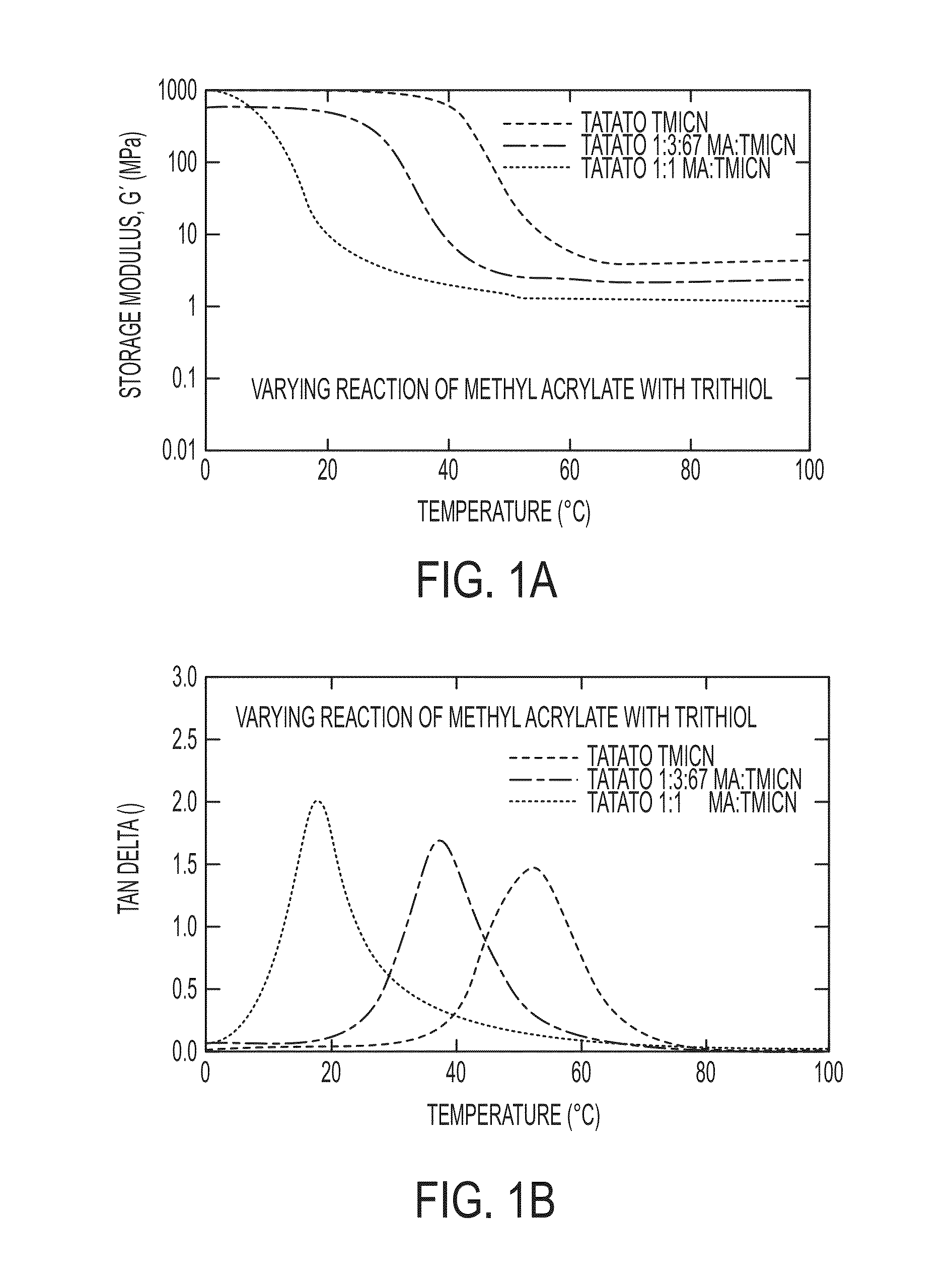

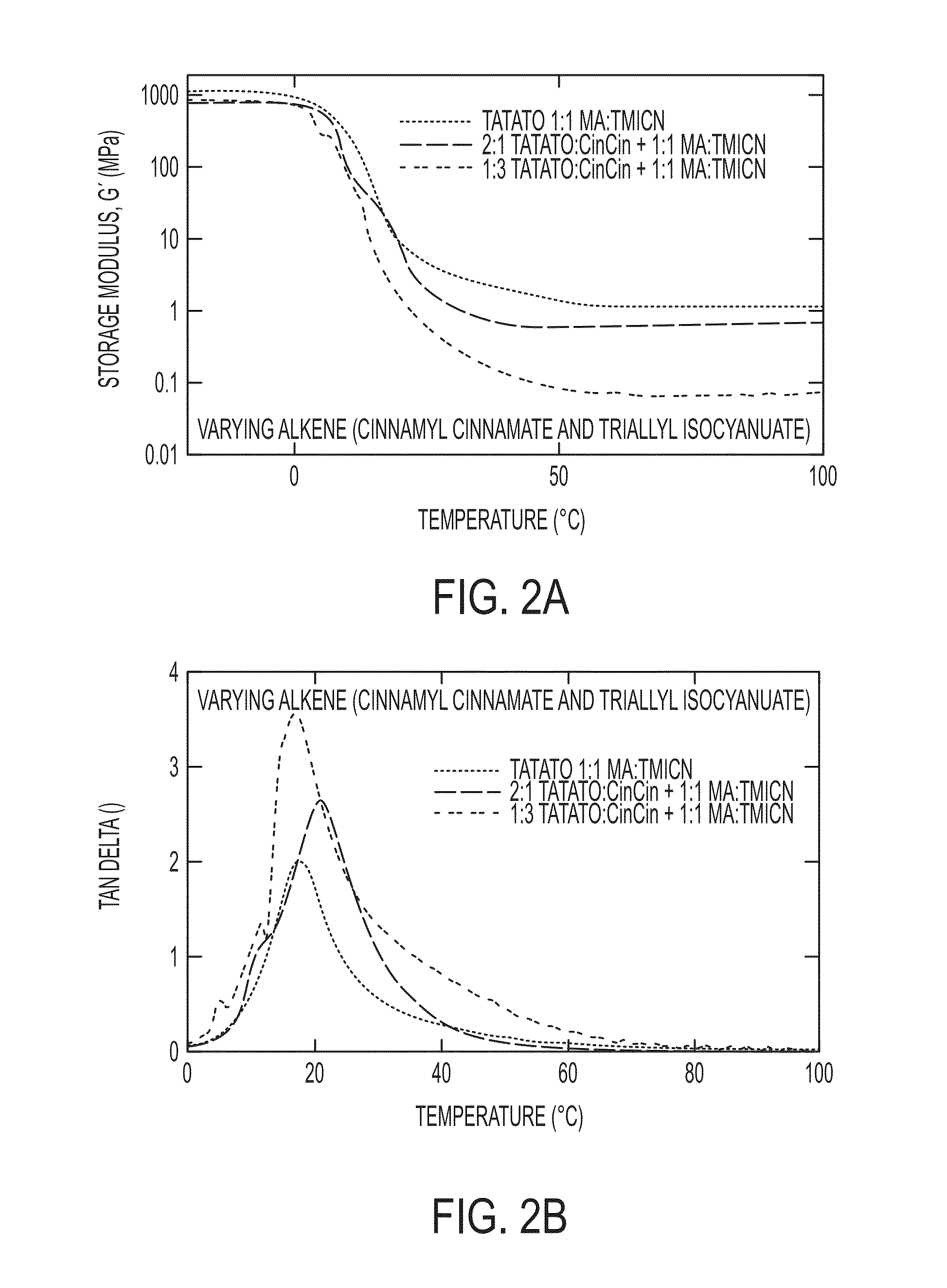

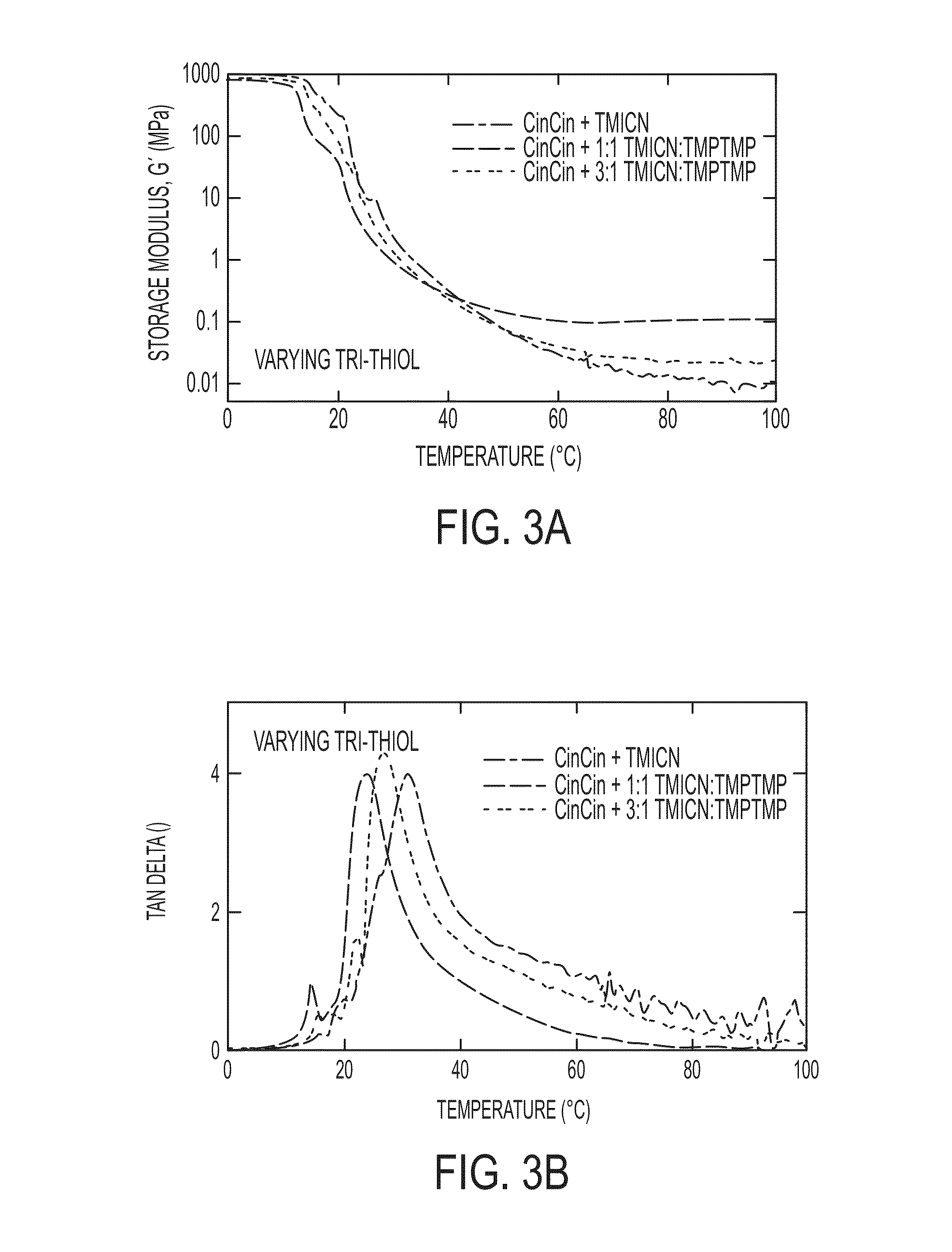

Softening materials based on thiol-ene copolymers

Embodiments of the invention are directed to softening amorphous polymeric materials based on a combination of thiol, acrylate, ene and epoxy monomers. These materials can soften to the modulus of tissue, have a sharp transition and are highly tunable. The materials have a glassy modulus of 1-7 GPa and exhibit a rubbery plateau in modulus that can range from 100 MPa down to as low as 0.03 MPa, which is at or below the modulus of tissue. They have potential uses as materials for near net shape processing such as casting, stereolithography, reaction injection molding, fused deposition molding and various other forms of 3D printing.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

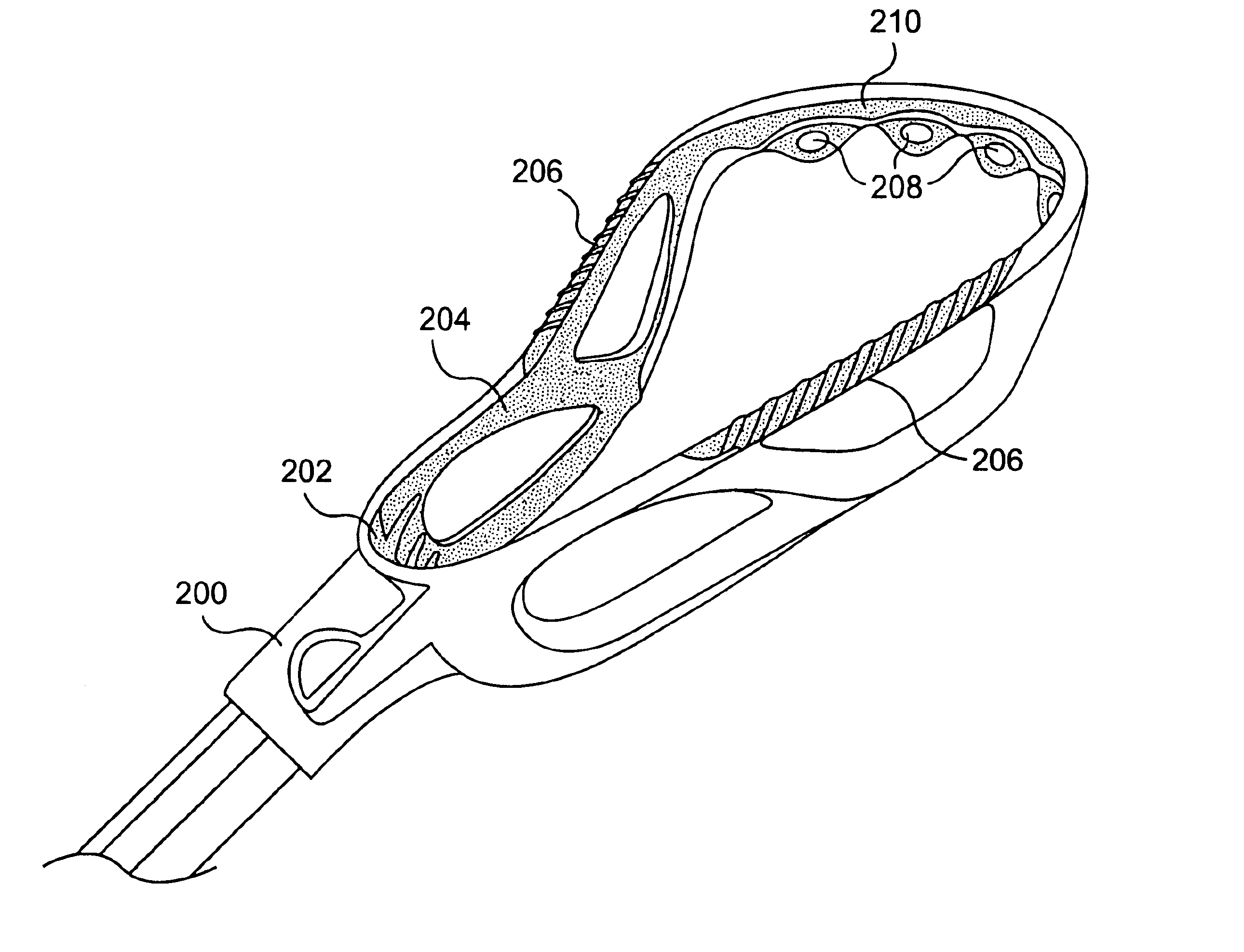

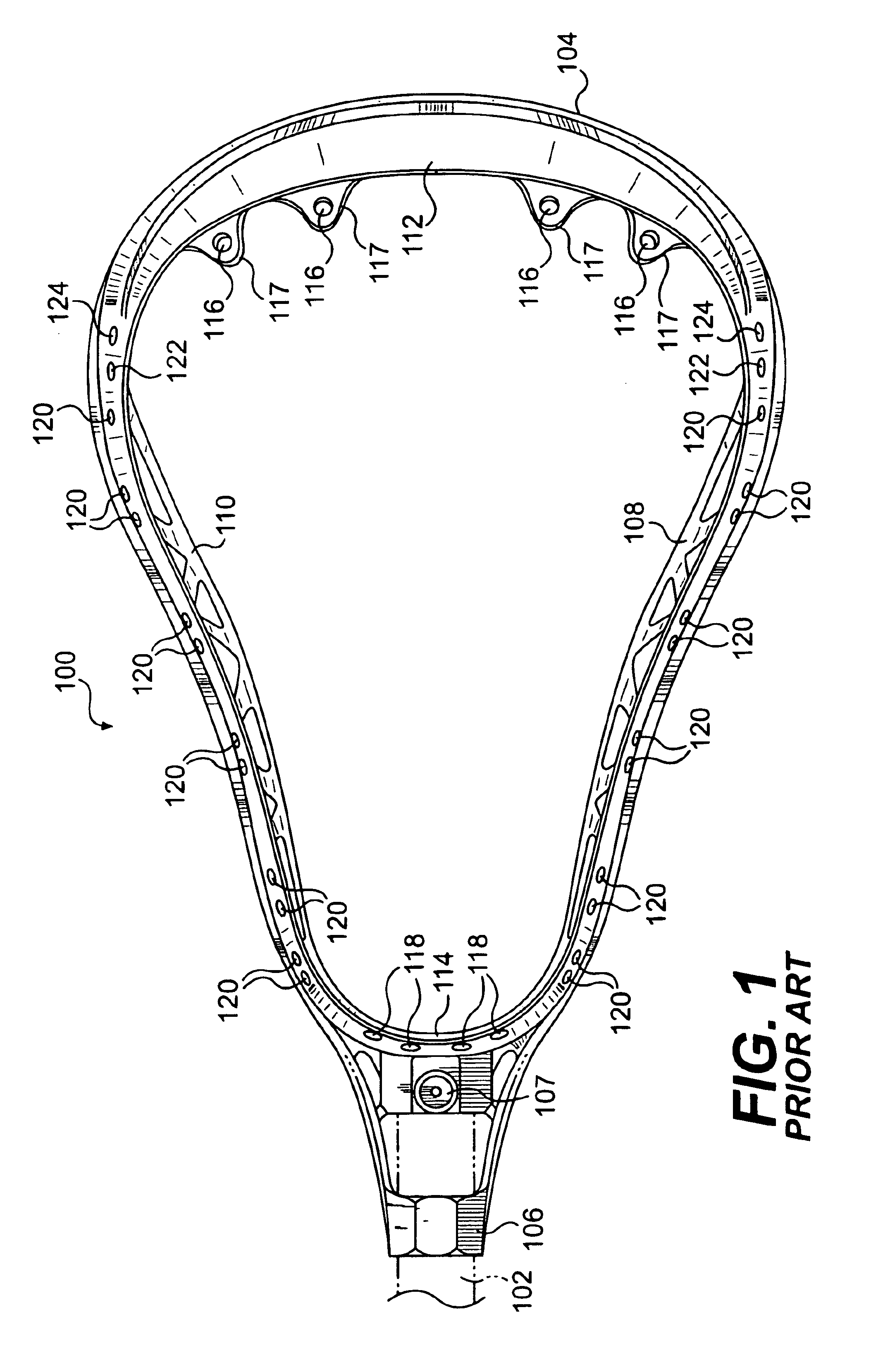

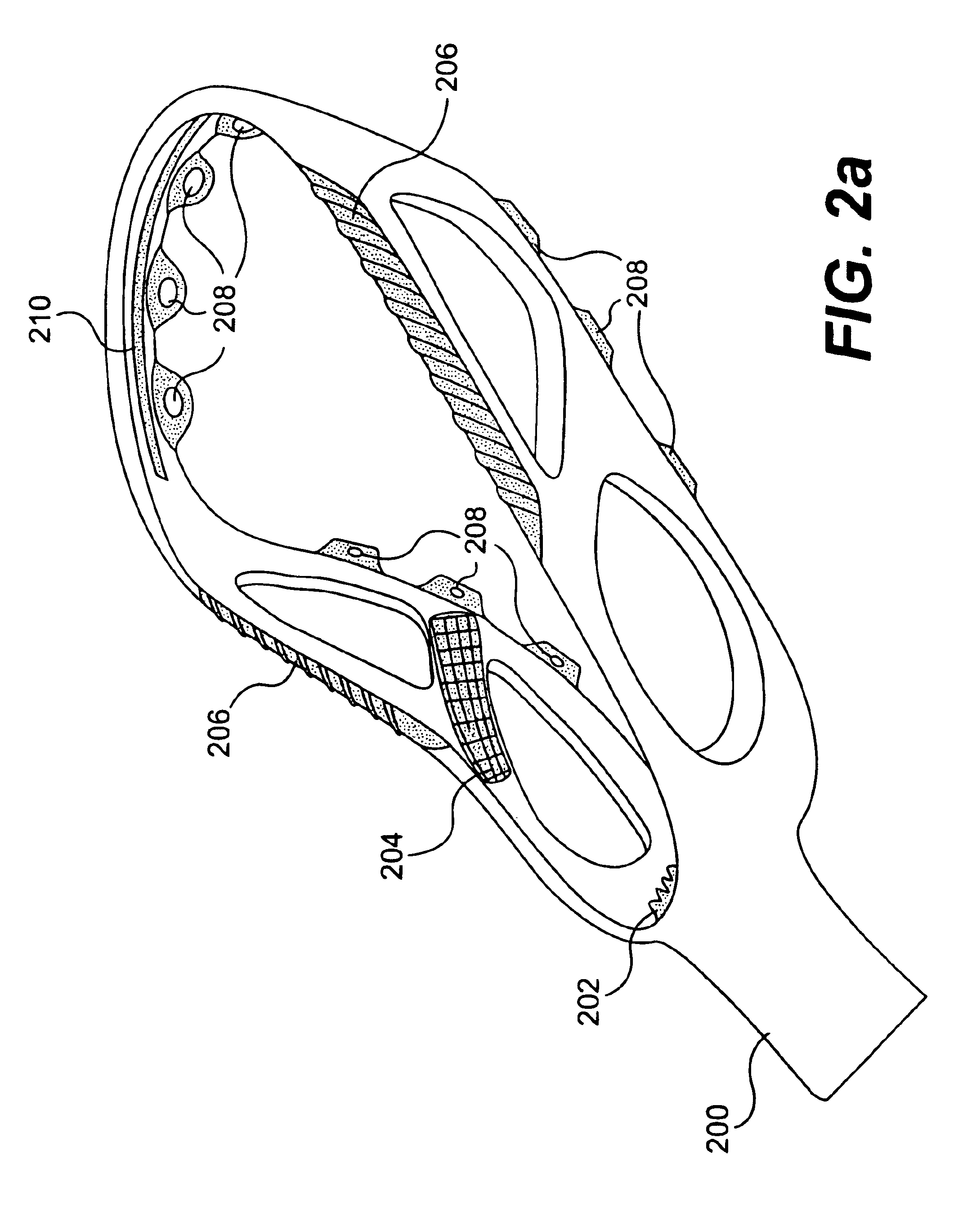

Multi-component lacrosse stick head

InactiveUS6910976B2Improve ball controlMinimize injuryThrow gamesBall sportsInterference fitSpherical form

A multi-component lacrosse stick head, made of at least two materials, including a base lacrosse head structure of one material and one or more overlays made of one or more other materials strategically located on the base structure. The base structure and overlays provide particular performance characteristics for the lacrosse head. An embodiment of the invention includes a base lacrosse head structure, and at least one of a ball stop overlay, a sidewall overlay, an edge overlay, a thread opening overlay, and a scoop overlay. The overlays are affixed to the base lacrosse head structure by, for example, insert molding, over molding, reaction injection molding, spray application, rotational molding, dual extrusion, casting, or an interference fit.

Owner:WM T BURNETT IP

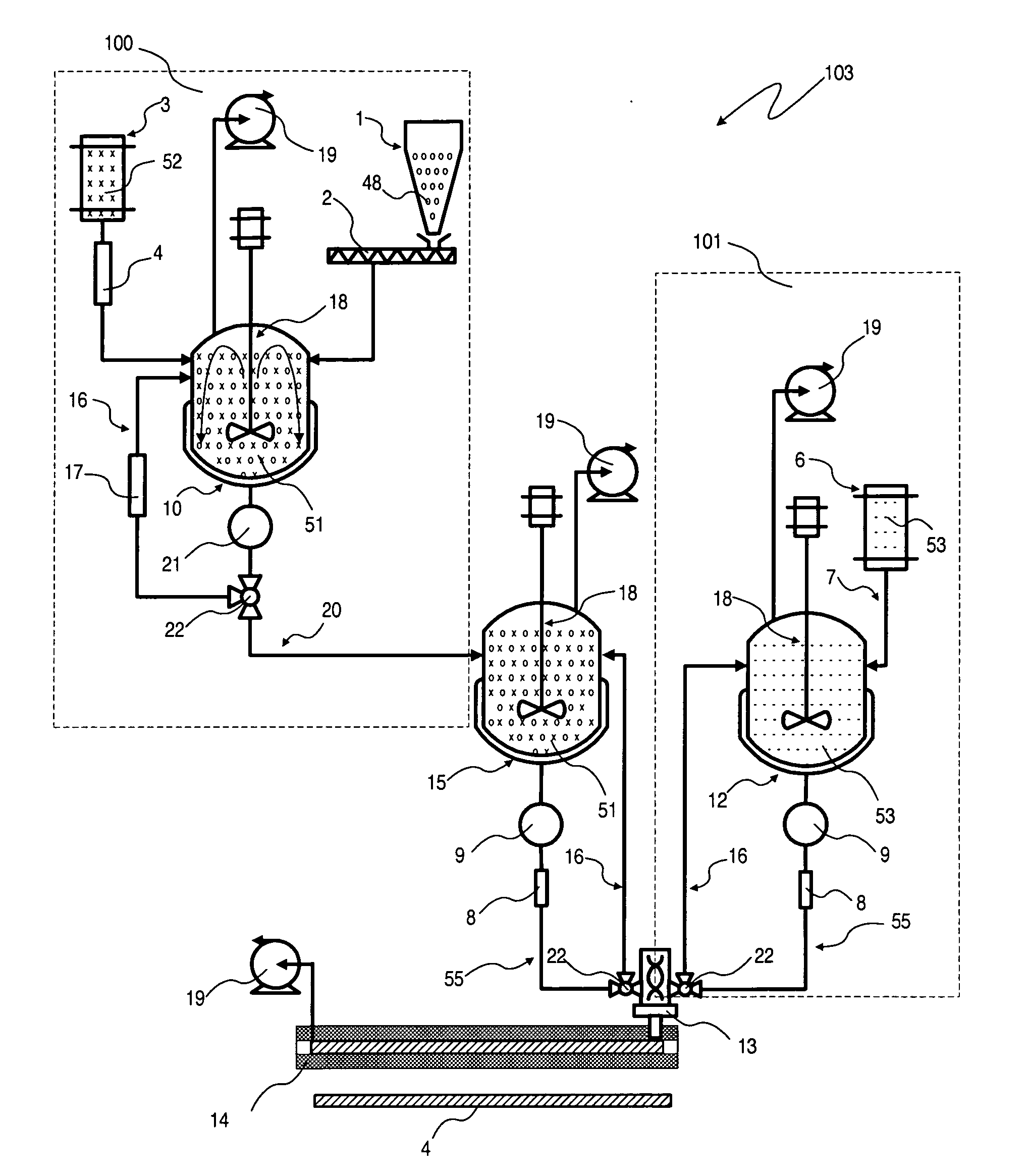

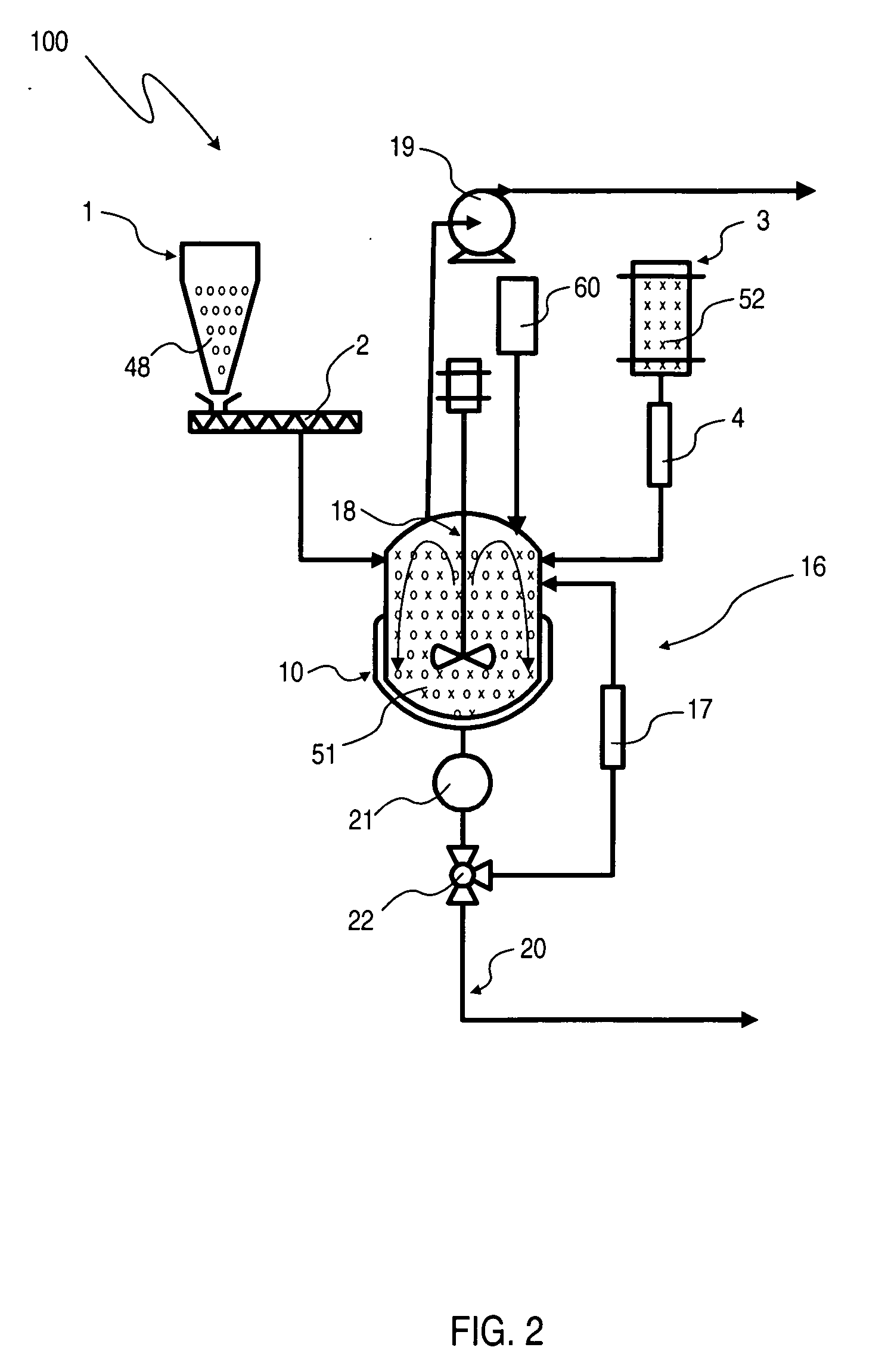

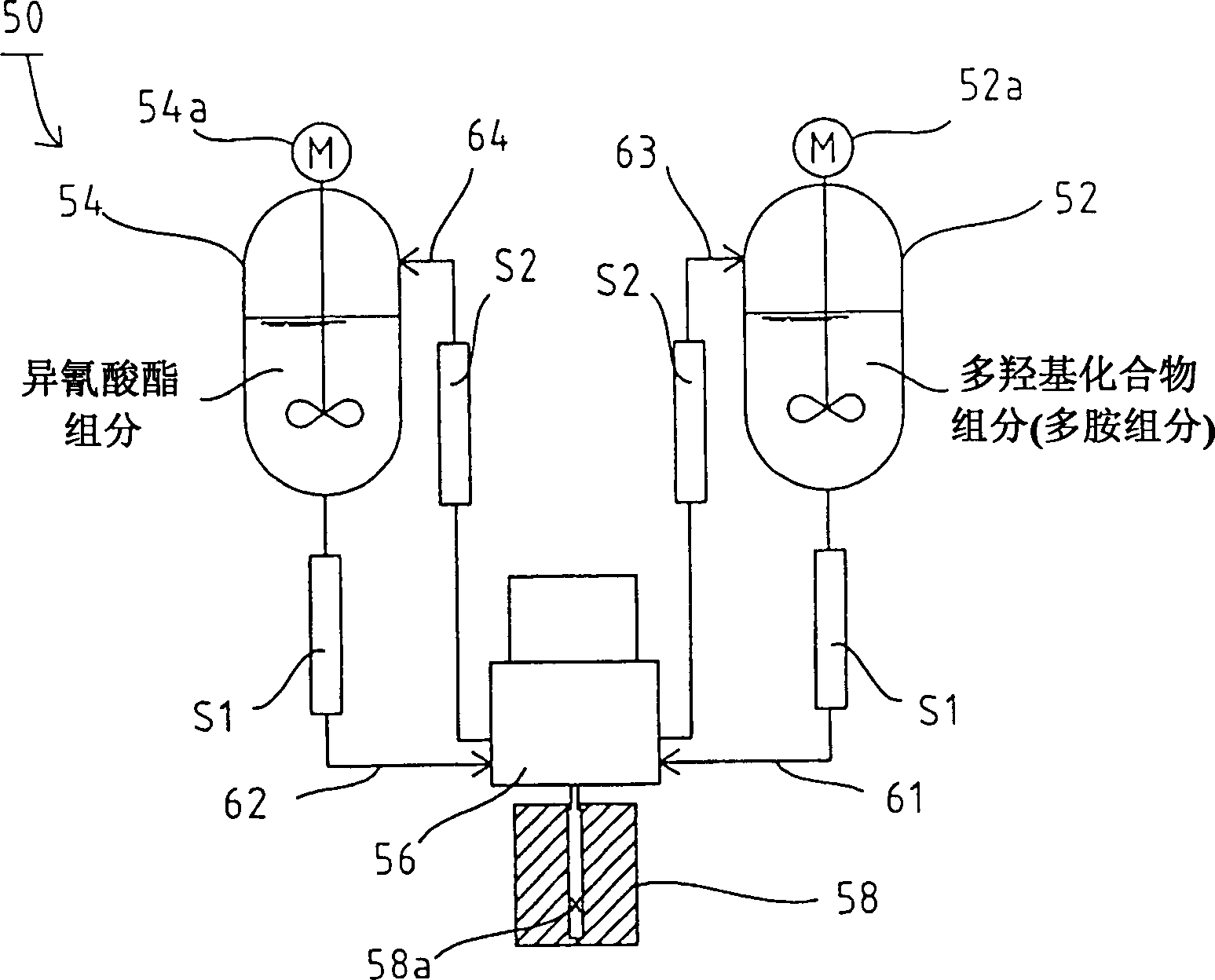

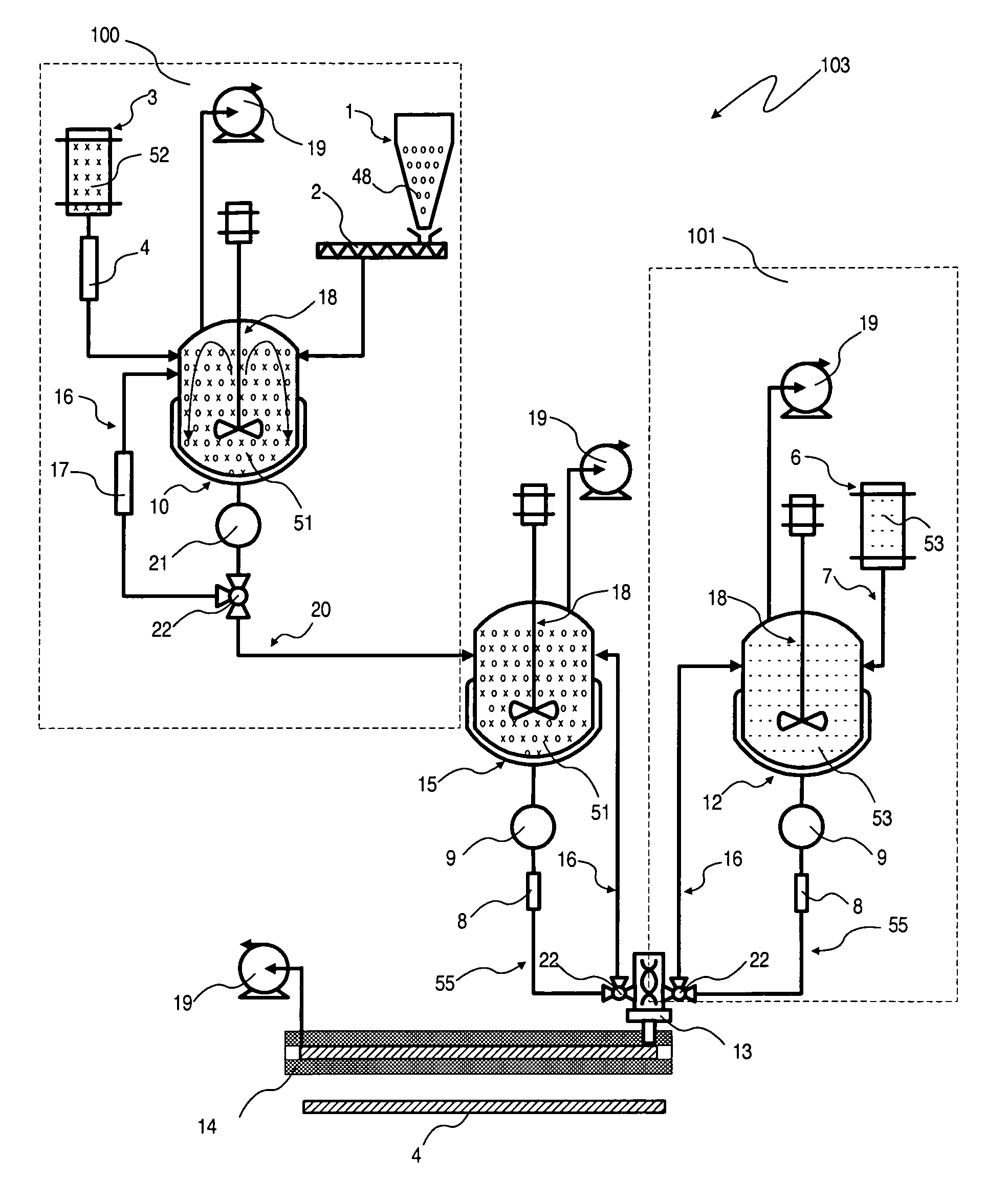

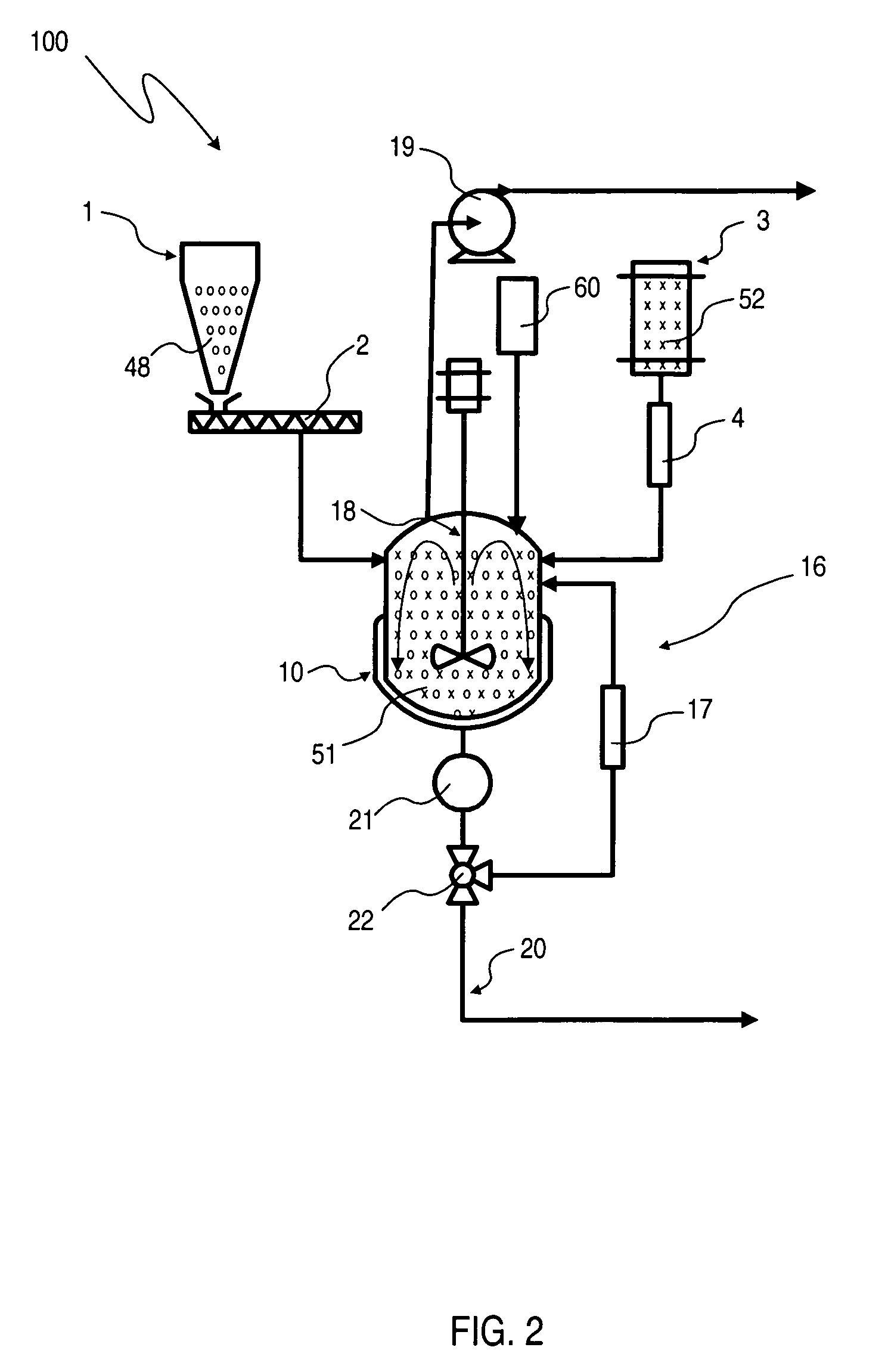

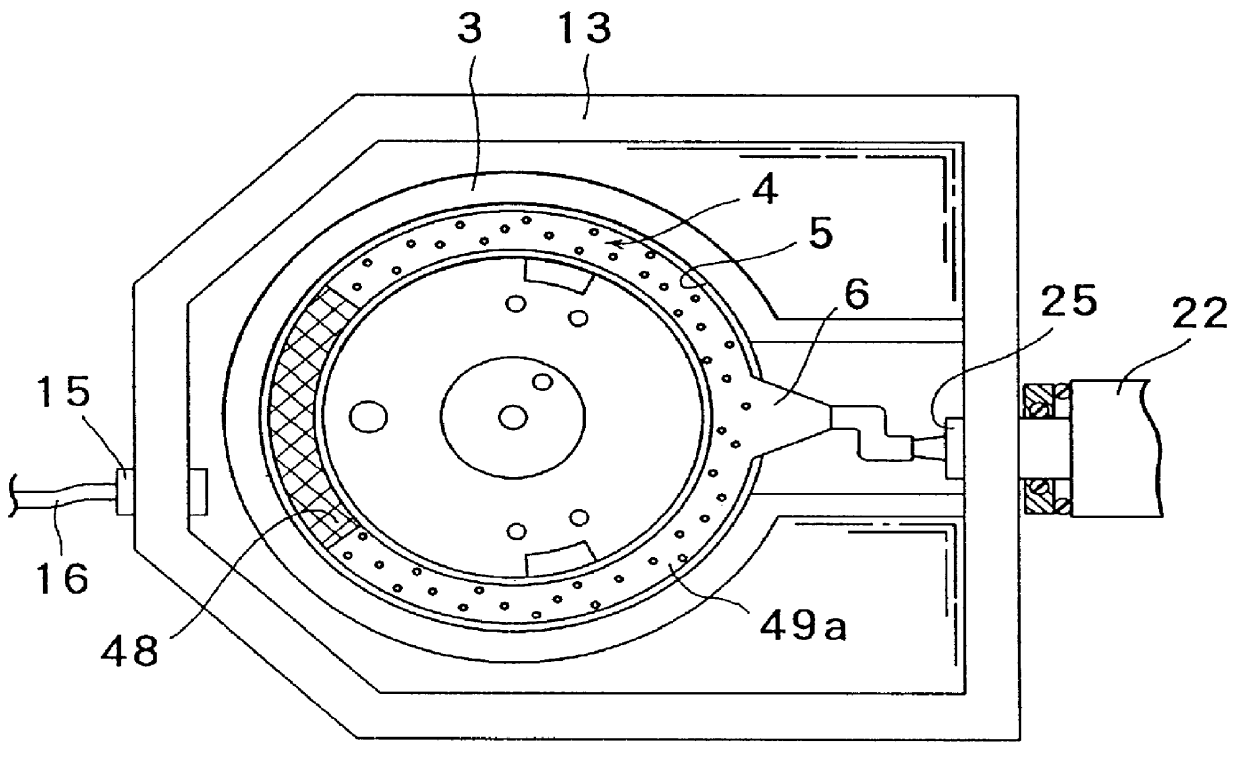

Apparatus for forming a porous reaction injection molded chemical mechanical polishing pad

The present invention provides an apparatus for forming a chemical mechanical polishing pad, comprising a tank with polymeric materials, a storage silo with microspheres, a isocyanate storage tank with isocyanates and a premix prep tank for forming a pre-mixture of the polymeric materials and the microspheres. The invention further provides a premix run tank for storing the pre-mixture, a mixer for forming a mixture of the pre-mixture and the isocyanates, a closed mold for reaction-injection molding the mixture and a vacuum for degassing at least one of the tank, isocyanate storage tank or the mold.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

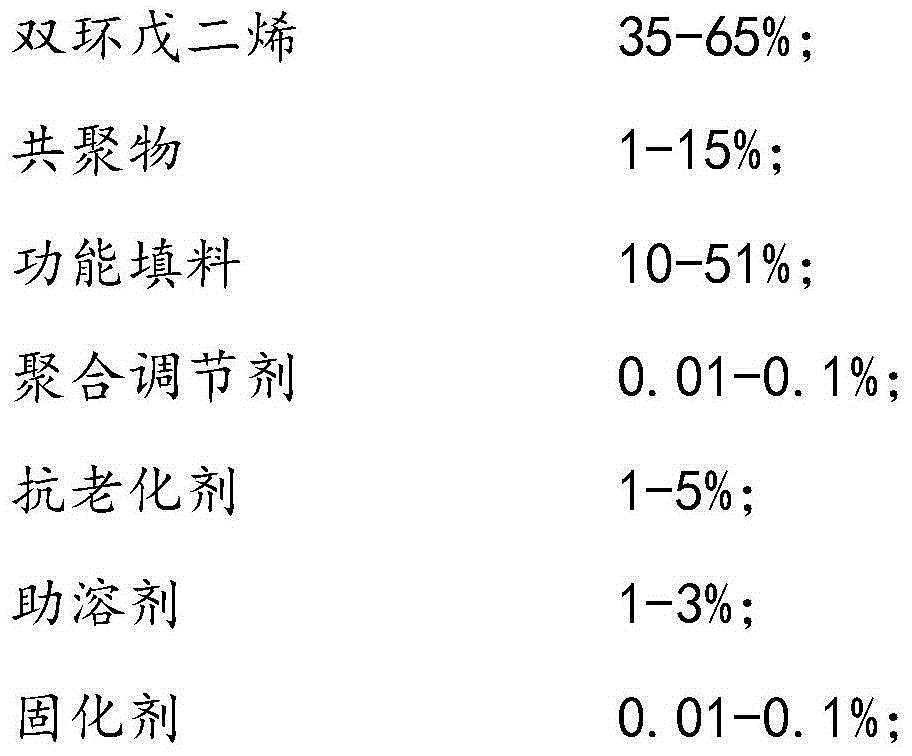

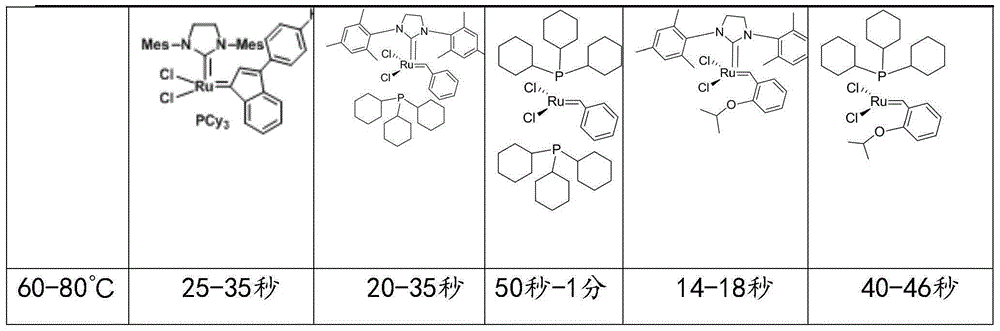

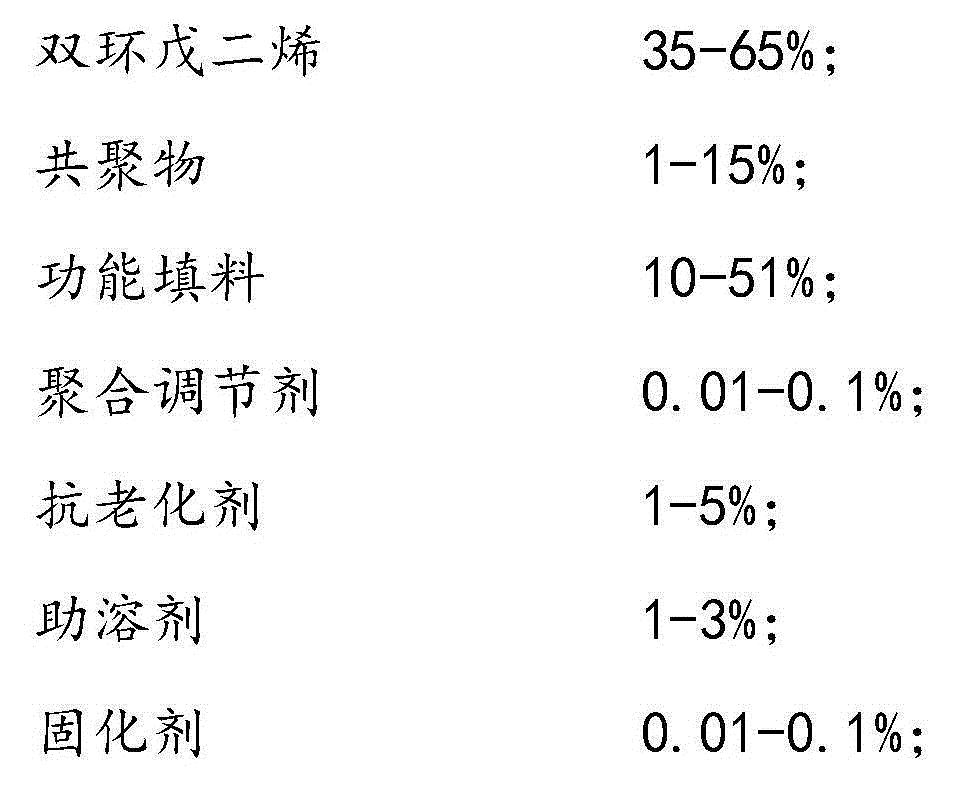

Polydicyclopentadiene composite material and single material reaction injection molding technology thereof

The invention discloses a formula of a polydicyclopentadiene (PDCPD) composite material and a single material reaction injection molding (RIM) technology thereof. The composite material is prepared from 35-65% of dicyclopentadiene, 1-15% of copolymers, 10-51% of functional filler, 0.01-0.1% of polymerization regulator, 1-5% of antiaging agents, 1-3% of cosolvent and 0.01-0.1% of curing agent, and the curing agent is a ruthenium-carbine catalyst. The single material reaction injection molding technological method includes the steps that the formula materials are mixed and evenly dispersed and form mixed slurry with a curing agent solution, and the mixed slurry is injected into a molding mold at the speed of 10-100 ml / s with the temperature kept below 30 DEG C; the mold is heated to 60 DEG C-80 DEG C, curing is carried out fast within one minute, and then demolding is carried out. The PDCPD composite material is good in mechanical property, the curing time is short, and the process is simple.

Owner:克琴新材料科技(上海)有限公司

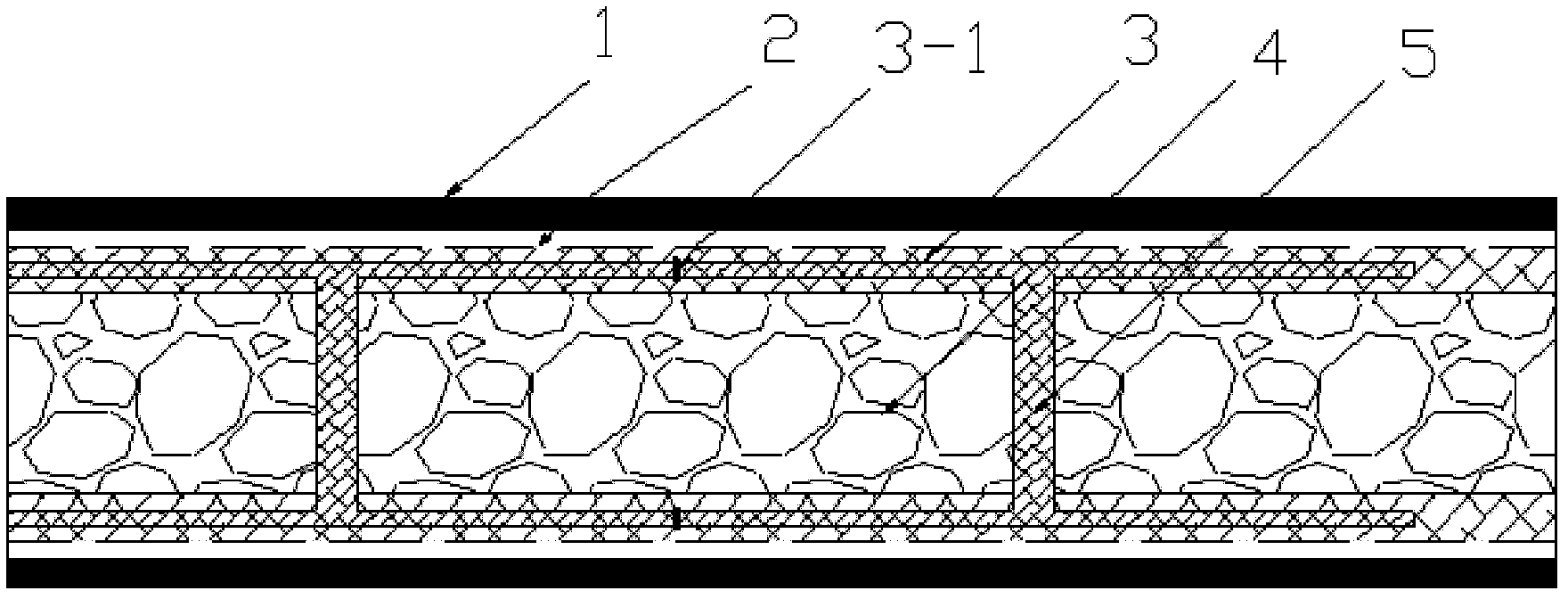

Fiber-reinforced modified-reaction injection-molding nylon sheet and preparation method thereof

ActiveCN101525433AGuaranteed continuityThe upper and lower surfaces are flatFlat articlesCarbon fibersPolymer science

The invention relates to a fiber-reinforced modified-reaction injection-molding nylon sheet and a preparation method thereof, belonging to the field of composite material preparation. An amide monomer is used as a basal raw material; a catalyst, an auxiliary catalyst, an auxiliary antioxidant, a stabilizing agent, a surface conditioning agent, and the like are added; and the materials are injected into a high-temperature mold cavity with preset fibers by an RIM and thermally pressed and molded to prepare the reinforced modified-reaction injection-molding nylon sheet. The prepared sheet comprises the following ingredients by mass percentage: 30 to 95 of amide monomer, 3 to 70 of fiber, 0.01 to 2 of catalyst, 0.01 to 10 of auxiliary catalyst, 0.1 to 2 of antioxidant, 0.1 to 2 of stabilizing agent and 0.1 to 1 of surface conditioning agent, wherein the amide monomer is caprolactam or dodecalactam, the fiber is one of glass fiber, carbon fiber or aramid fiber and is in the form of fiber cloth, short-cut fiber or compound fiber. Compared with common reaction injection nylon and monomer cast nylon sheets, the reaction injection-molding nylon sheet has stronger carrying capability, low manufacture cost and easy popularization and application.

Owner:株洲时代工程塑料科技有限责任公司

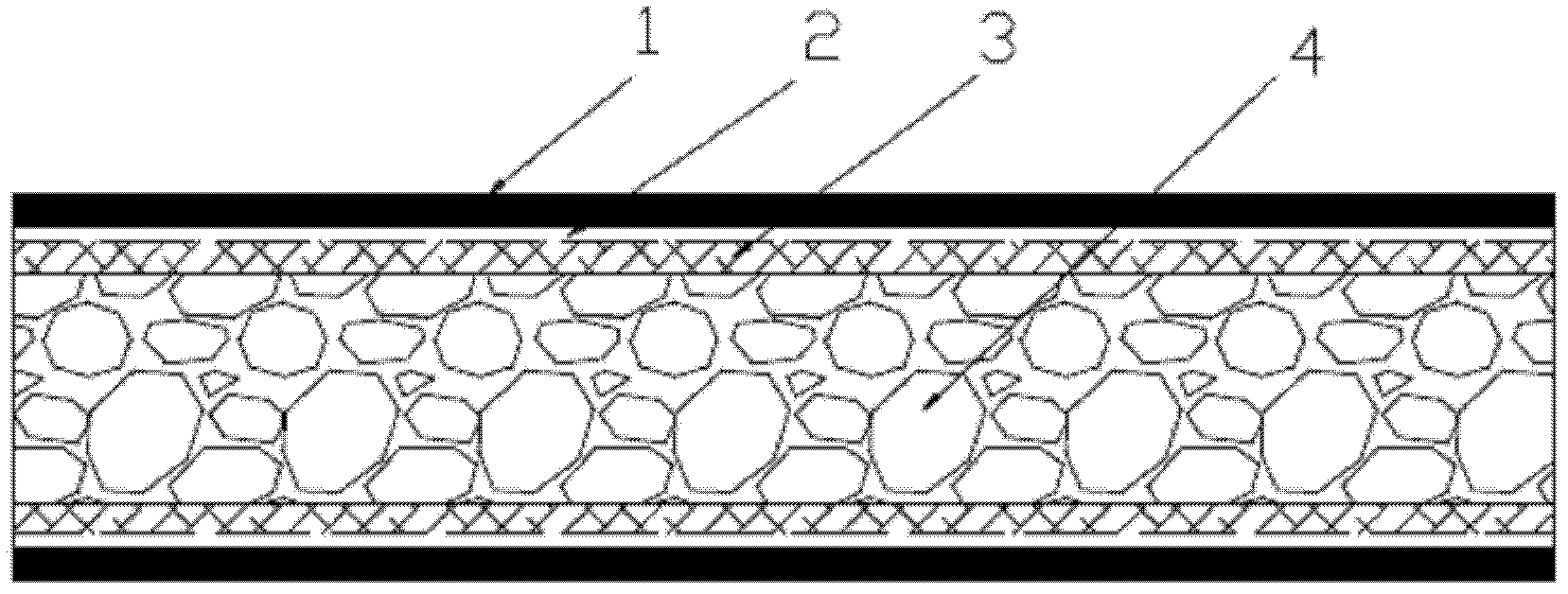

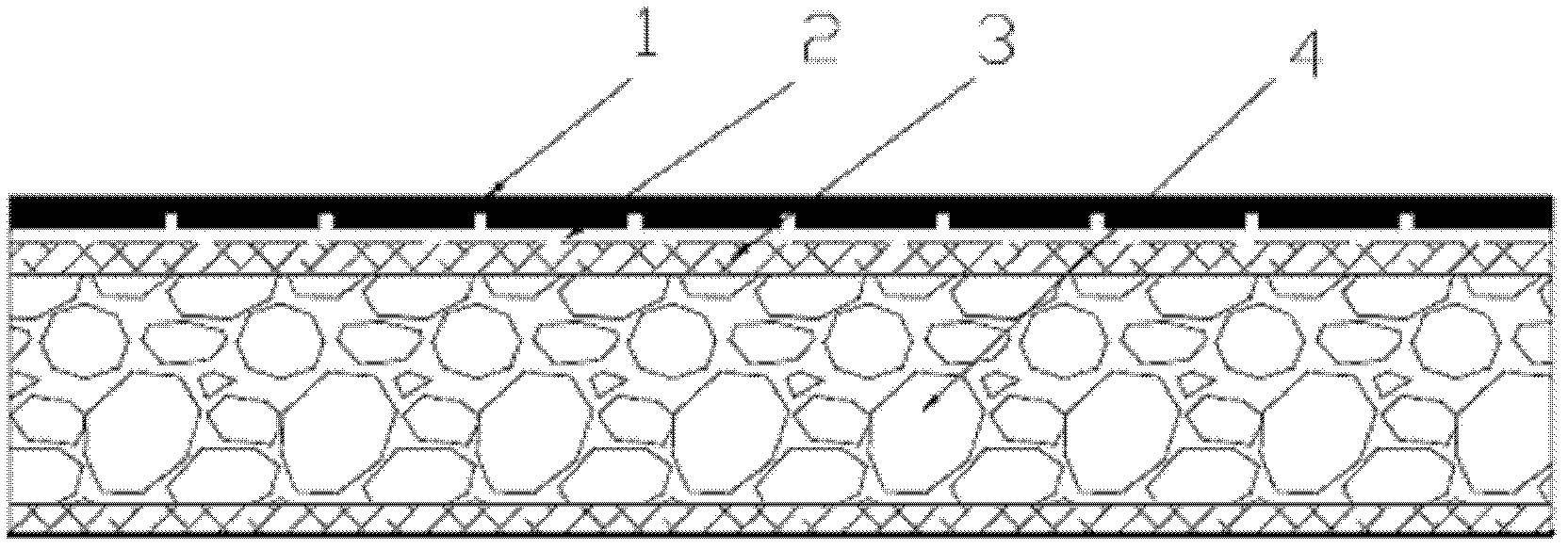

Composite material plate, preparation method and use of composite material plate

InactiveCN103009728AIncrease stiffnessSolve wear resistanceSynthetic resin layered productsLaminationWear resistancePolydicyclopentadiene

The invention relates to a composite material plate. The composite material plate comprises a sandwich layer, two covering layers coating the outer surface of the sandwich layer, and a polydicyclopentadiene layer arranged on the outer surface of at least one of the covering layers. The invention also relates to a preparation method and a use of the composite material plate. According to the composite material plate, outside of a fiber reinforced material is coated by the polydicyclopentadiene layer, so that the problem that a conventional fiber reinforced resin-based composite material is easily suffered from layering failure and is poor in abrasive resistance when being subjected to an impact load is solved. The composite material plate can be widely applied to loading or load-bearing components on mine, railway and road transportation heavy vehicles and goods hoppers. The composite material plate material can be obtained through a reaction injection molding process combined with a vacuum auxiliary molding process, and is suitable for industrial production.

Owner:蓝星环境工程有限公司

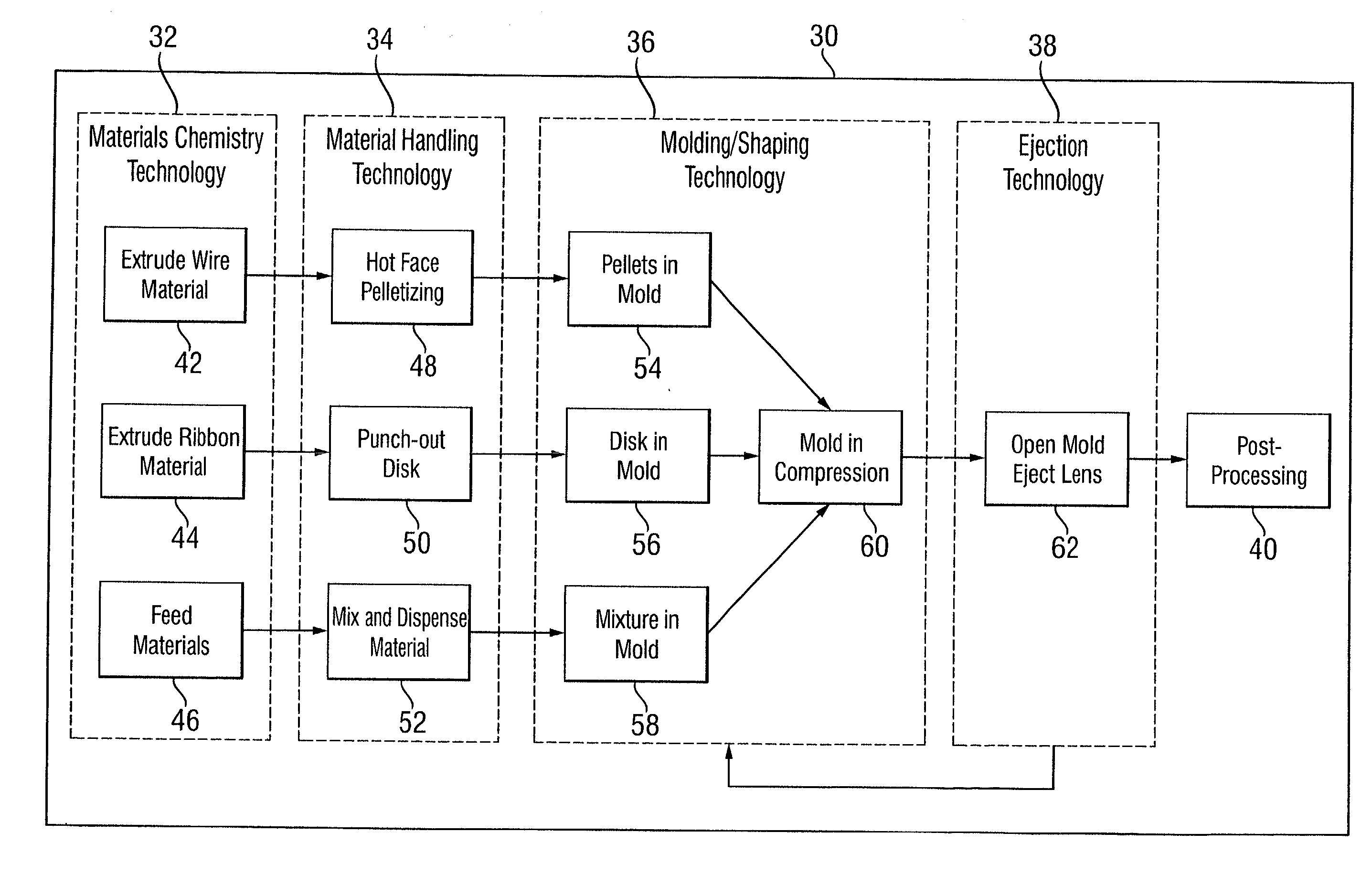

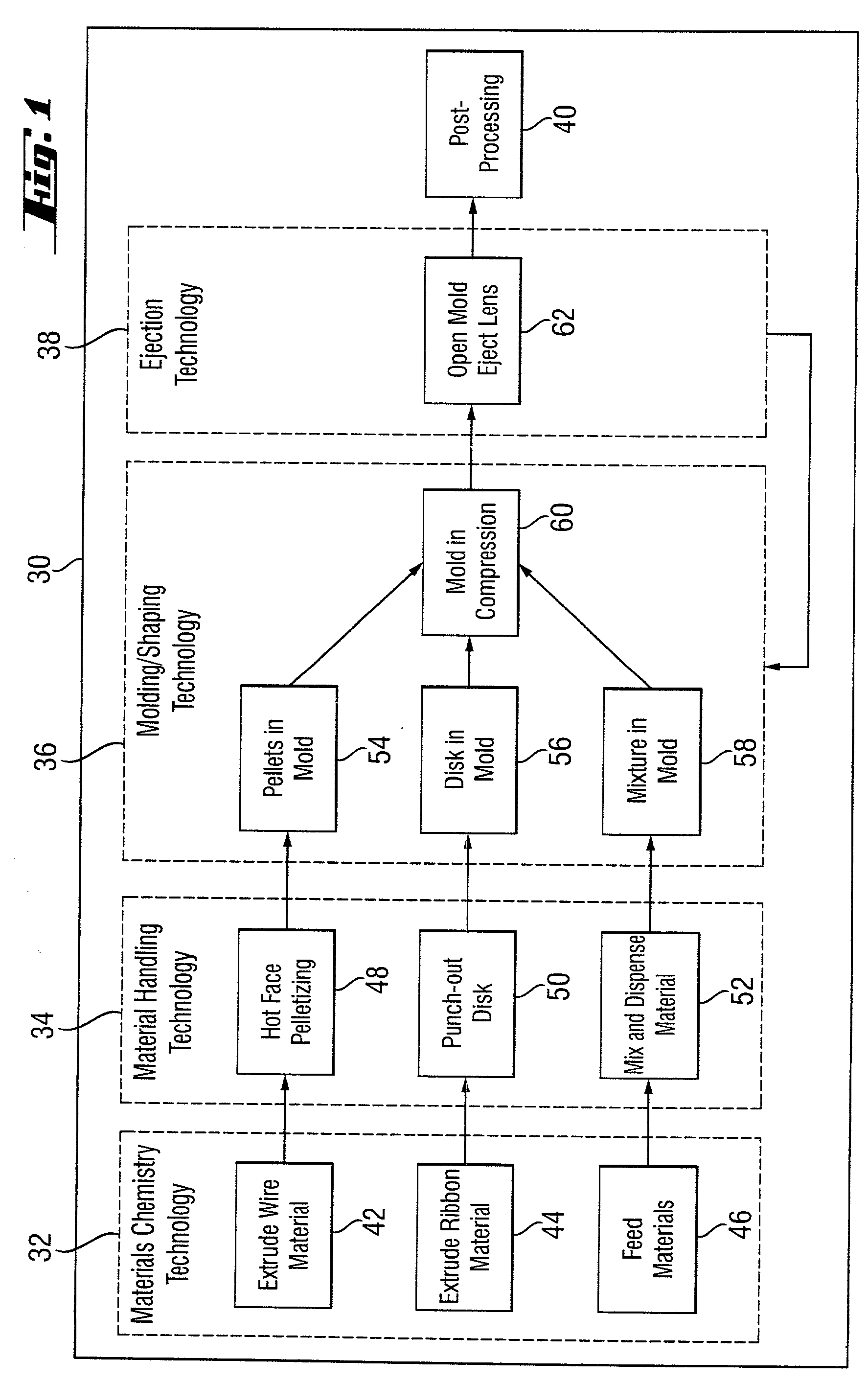

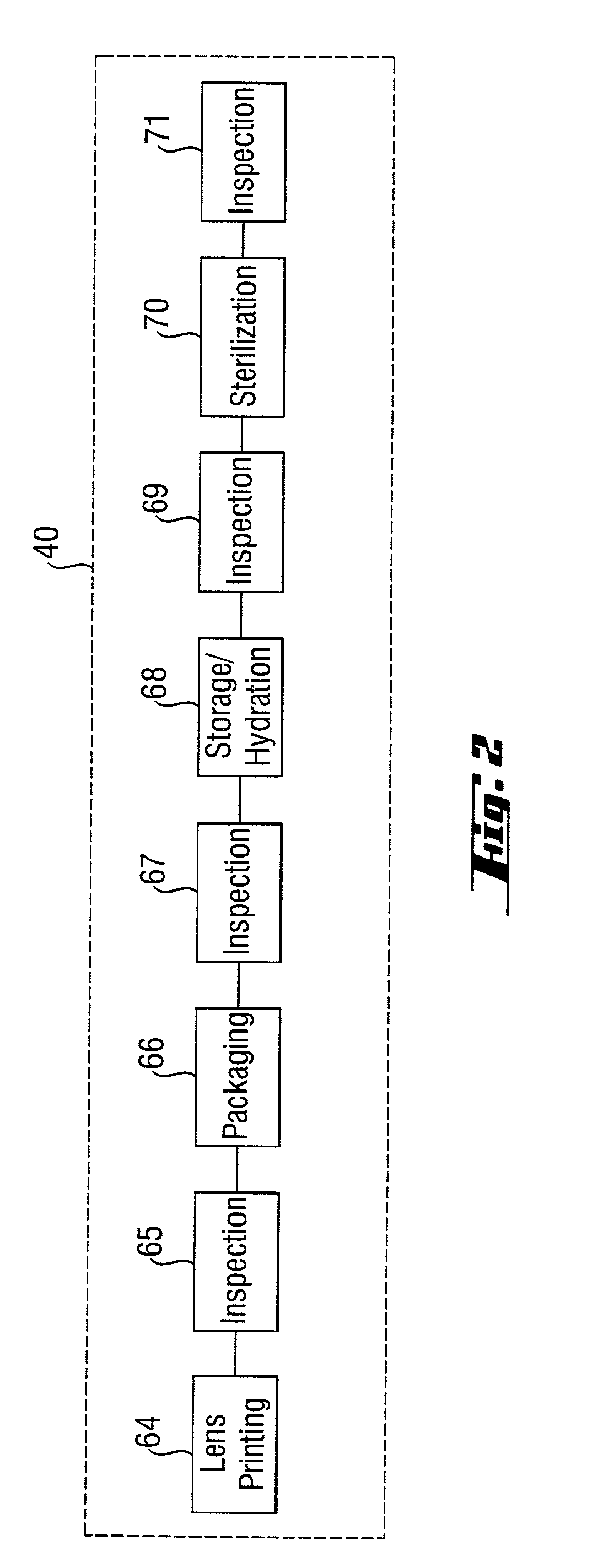

Lens manufacturing process

InactiveUS20020153623A1Suitable for processingImprove automationOptical articlesOptical partsCompression moldingThermoforming

A process for manufacturing ophthalmic lenses is described. This process has several phases, including raw material processing, material metering and dispensing, the material shaping, and ejection / de-molding. The material-shaping phase can utilize various molding processes including compression molding, thermoforming, reaction injection molding, or injection molding. The process allows re-use of the shaping molds / dies and can be automated.

Owner:NOVARTIS AG

Grinding pad

InactiveCN1407606AGrinding fitSemiconductor/solid-state device manufacturingFlexible-parts wheelsSemiconductor materialsMetallurgy

Owner:ROGERS INOAC CORP

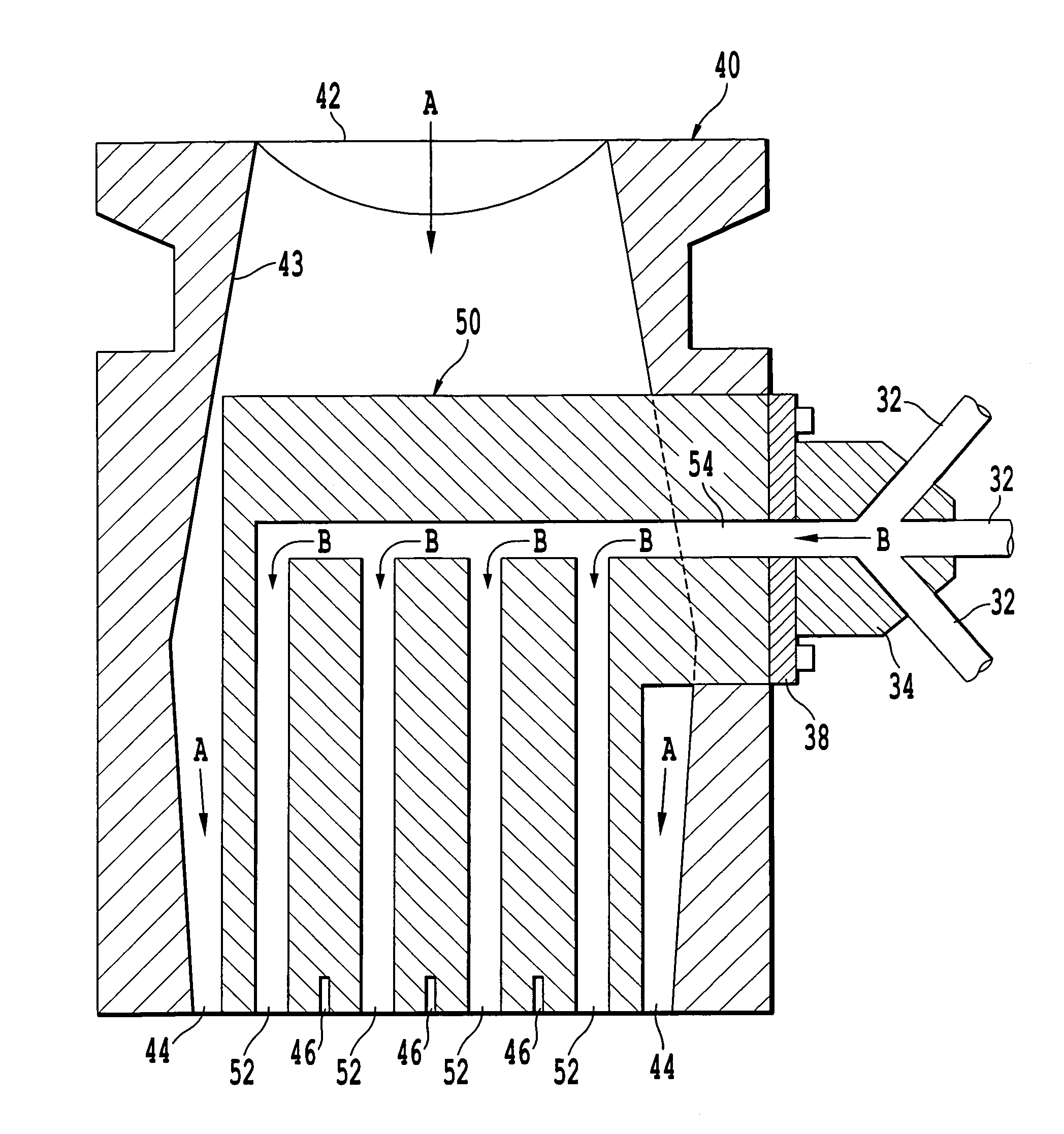

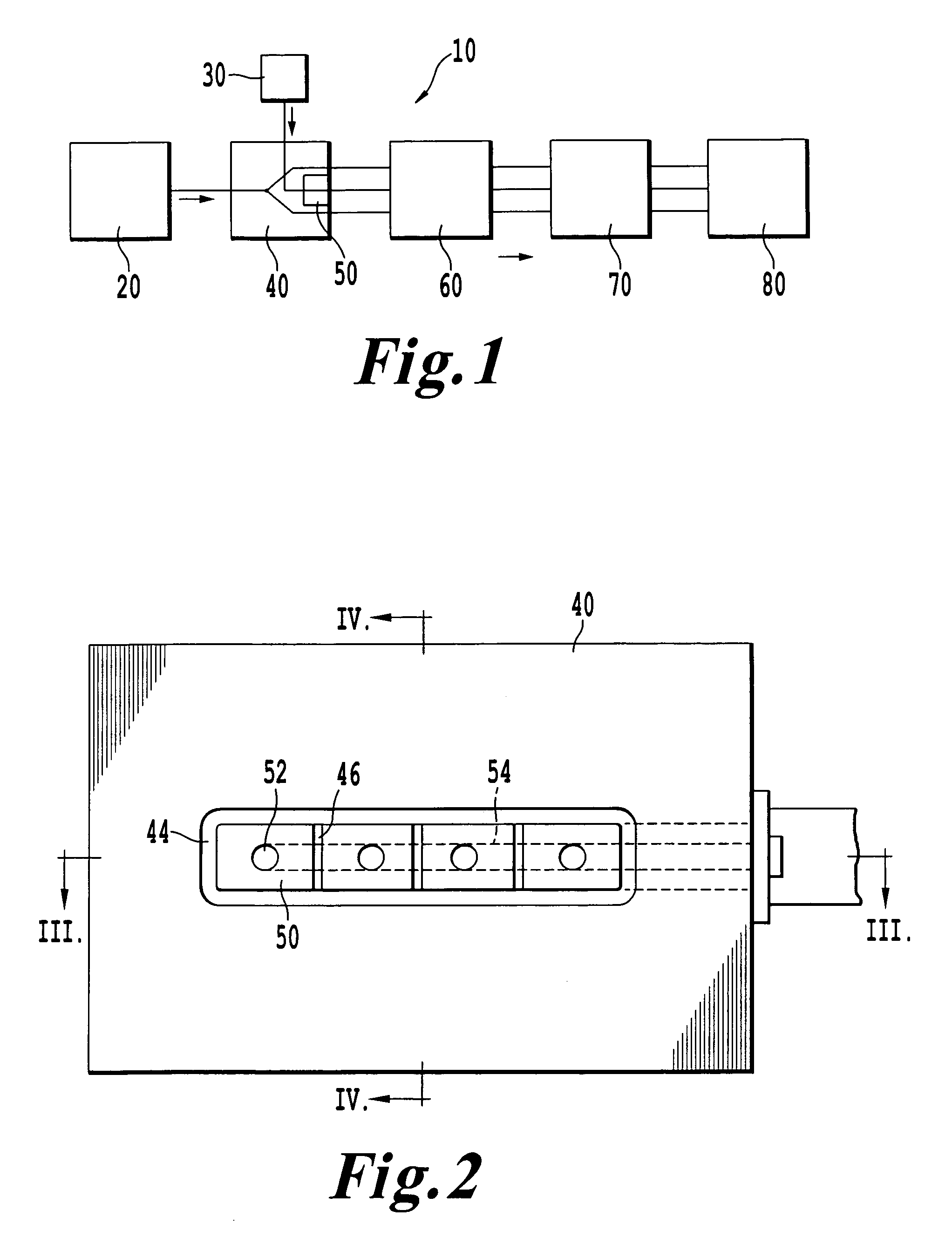

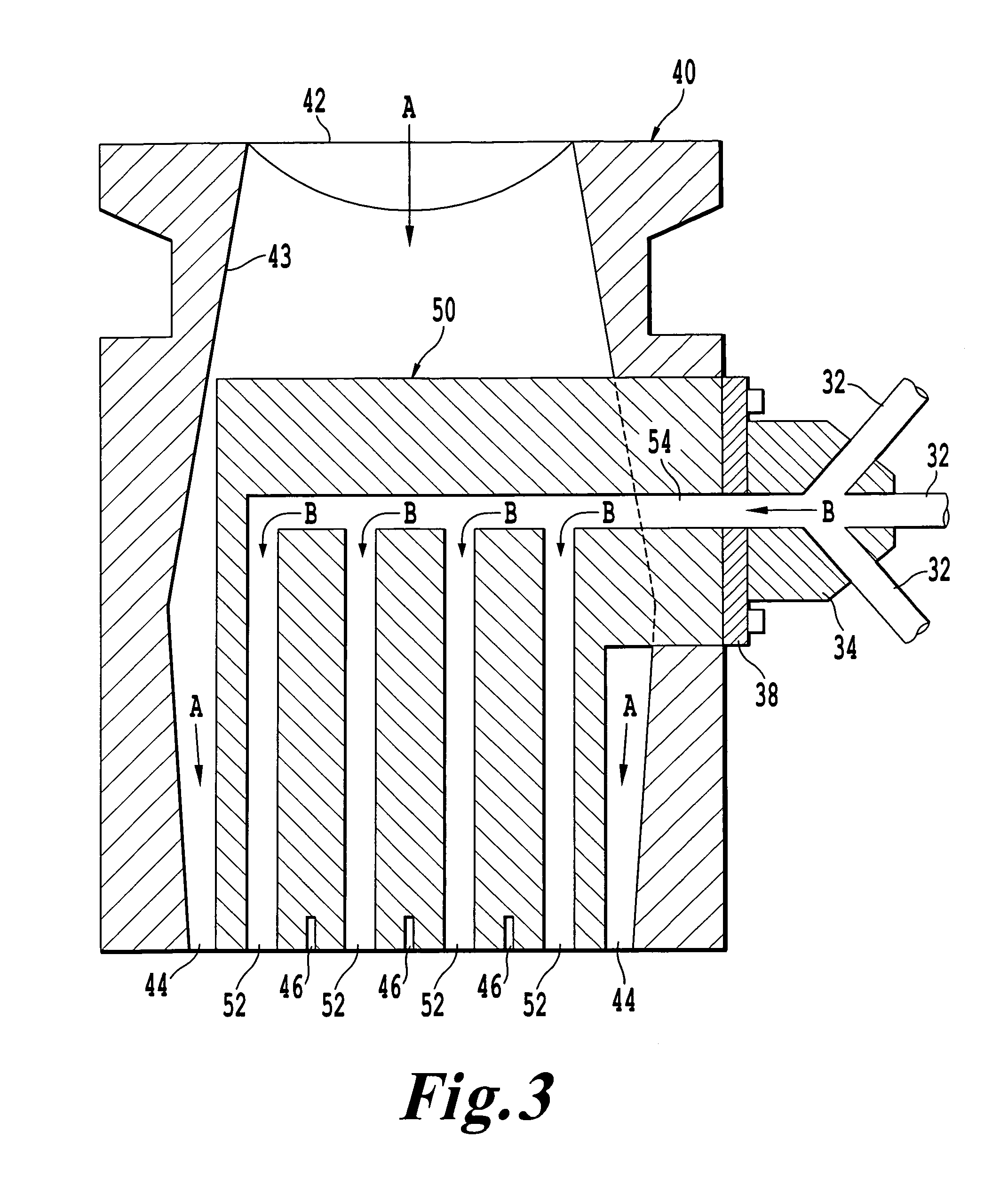

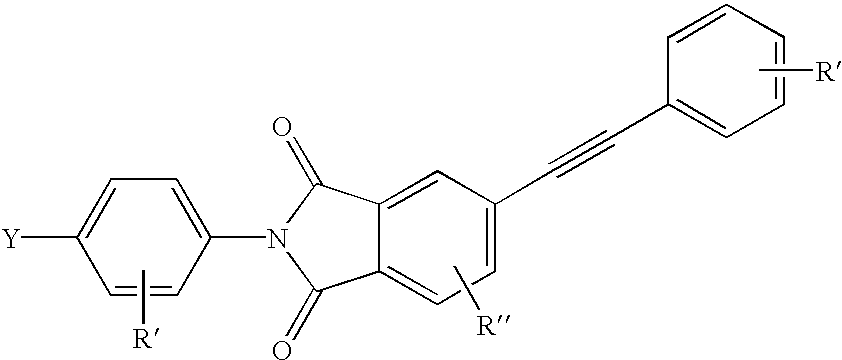

Extrusion/reaction injection molding system

InactiveUS7281917B2Increase volumeEconomical rateConfectionerySynthetic resin layered productsEngineeringBiomedical engineering

A method of manufacturing an extruded part having an exterior shell and a core foam material. The method includes extruding the exterior shell from an extrusion die, and reaction injection molding the core foam material within an interior of the exterior shell using a distribution block having a plurality of orifices configured to inject the core foam material within the interior of the exterior shell. The orifices are configured to evenly distribute the core foam material throughout the interior of the exterior shell. the method can be used to form an exterior shell having a plurality of internal chambers, where the orifices of the distribution block are configured to inject core foam material within the plurality of internal chambers.

Owner:PATWIN PLASTICS

Liquid crystalline thermosets from ester, ester-imide, and ester-amide oligomers

InactiveUS20020132933A1Good physical propertiesLiquid crystal compositionsLiquid crystallineEnd-group

Main chain thermotropic liquid crystal esters, ester-imides, and ester-amides were prepared from AA, BB, and AB type monomeric materials and were end-capped with phenylacetylene, phenylmaleimide, or nadimide reactive end-groups. The resulting reactive end-capped liquid crystal oligomers exhibit a variety of improved and preferred physical properties. The end-capped liquid crystal oligomers are thermotropic and have, preferably, molecular weights in the range of approximately 1000-15,000 grams per mole. The end-capped liquid crystal oligomers have broad liquid crystalline melting ranges and exhibit high melt stability and very low melt viscosities at accessible temperatures. The end-capped liquid crystal oligomers are stable for up to an hour in the melt phase. These properties make the end-capped liquid crystal oligomers highly processable by a variety of melt process shape forming and blending techniques including film extrusion, fiber spinning, reactive injection molding (RIM), resin transfer molding (RTM), resin film injection (RFI), powder molding, pultrusion, injection molding, blow molding, plasma spraying and thermo-forming. Once processed and shaped, the end-capped liquid crystal oligomers were heated to further polymerize and form liquid crystalline thermosets (LCT). The fully cured products are rubbers above their glass transition temperatures. The resulting thermosets display many properties that are superior to their non-end-capped high molecular weight analogs.

Owner:NASA

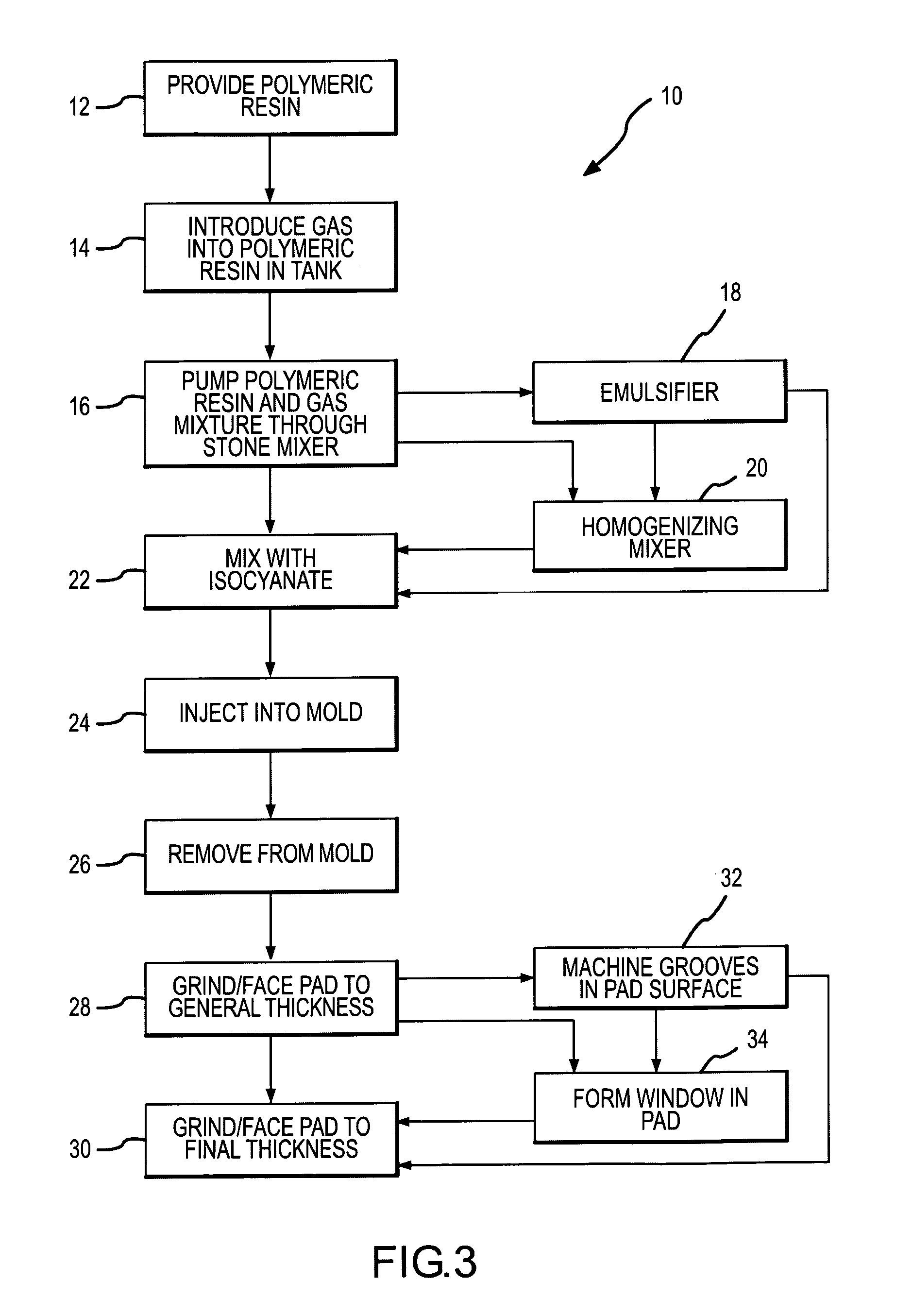

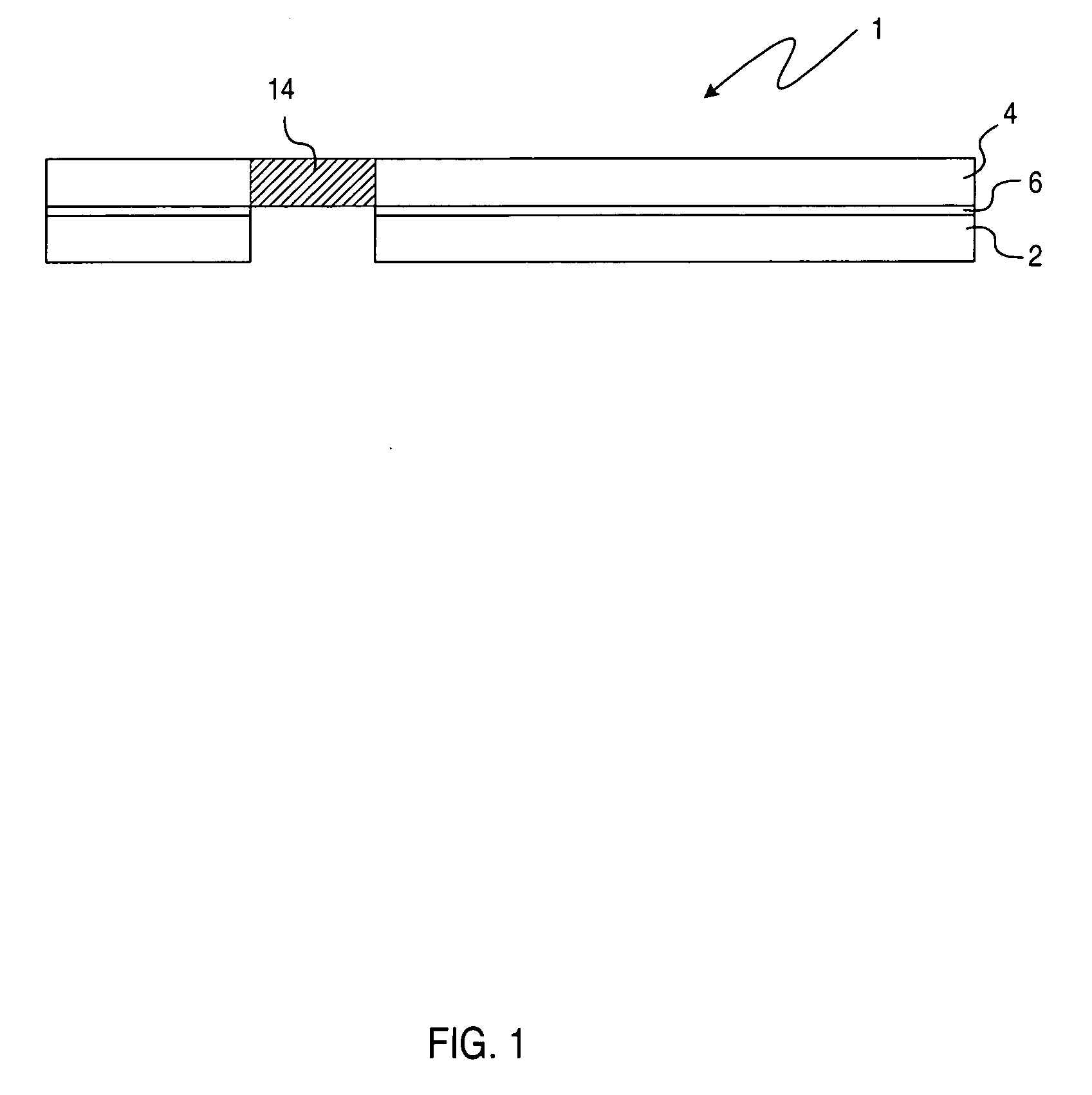

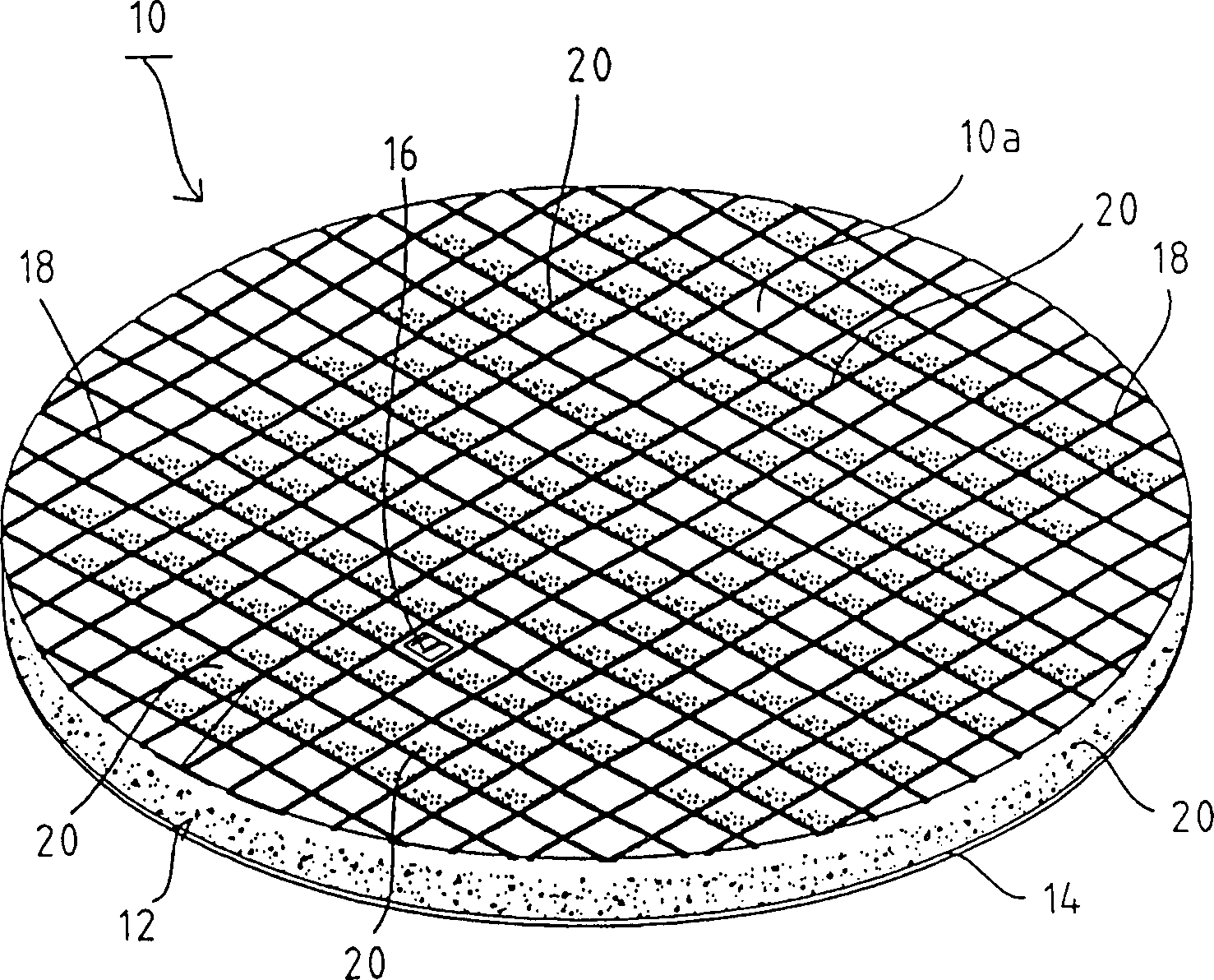

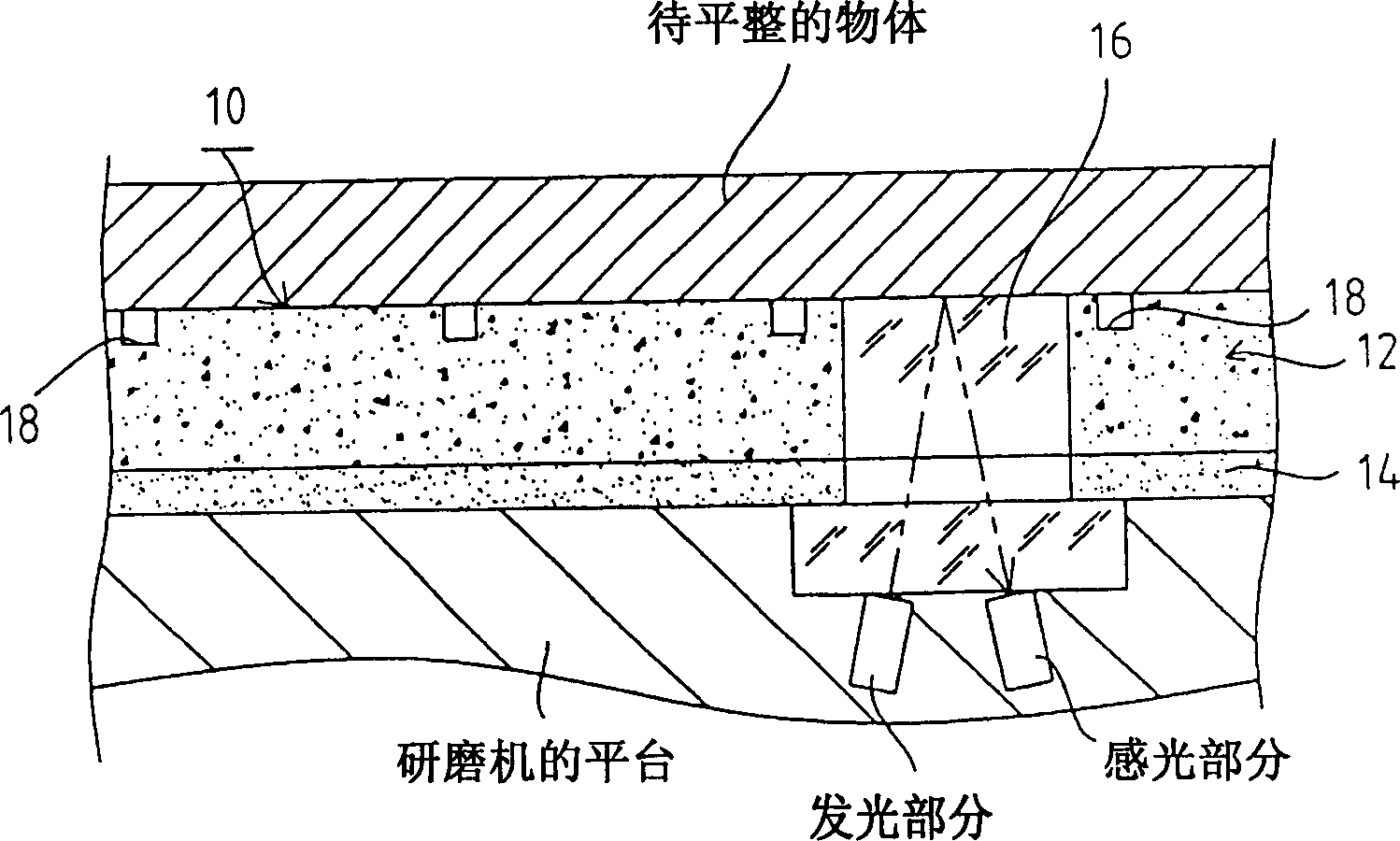

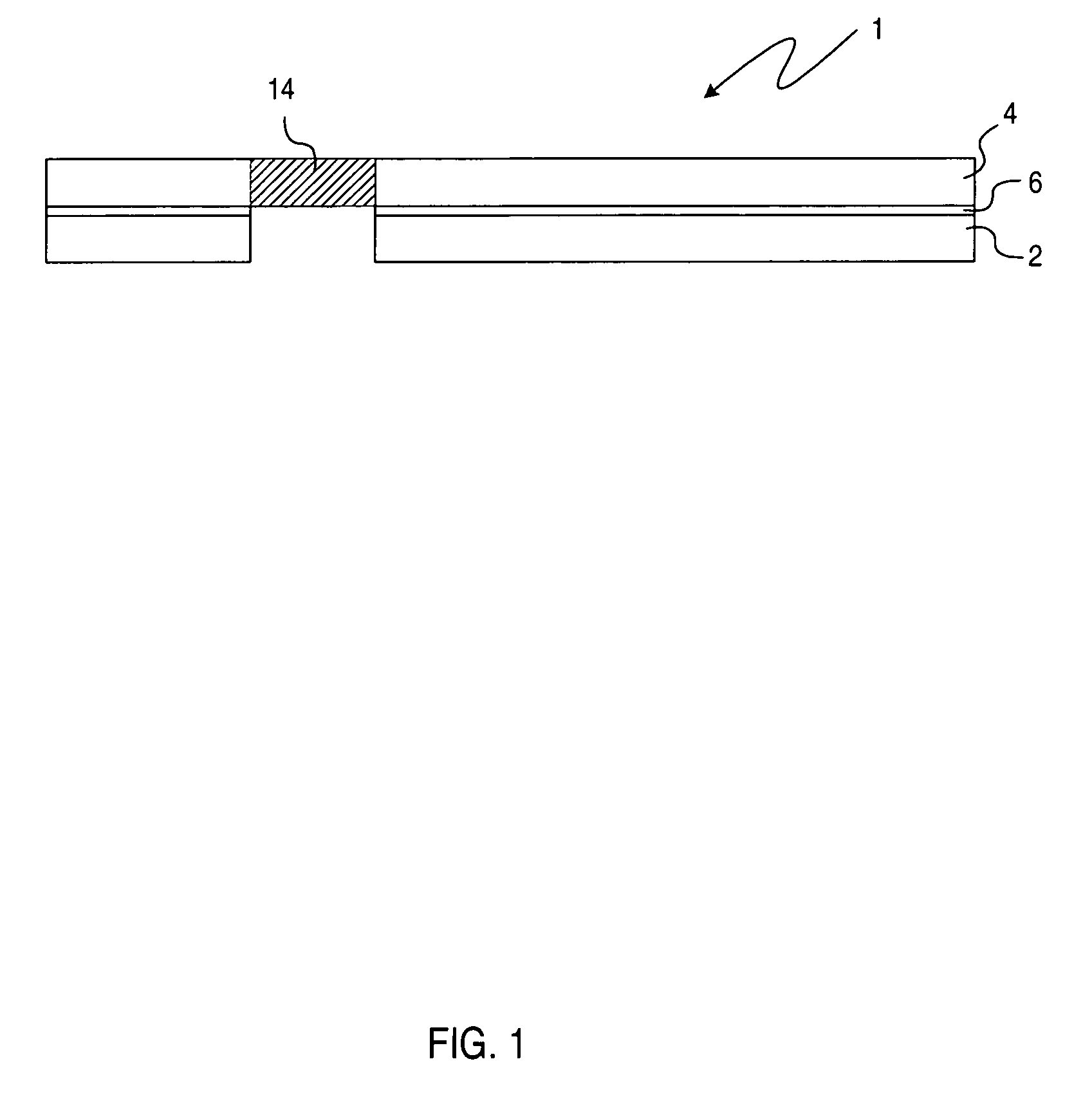

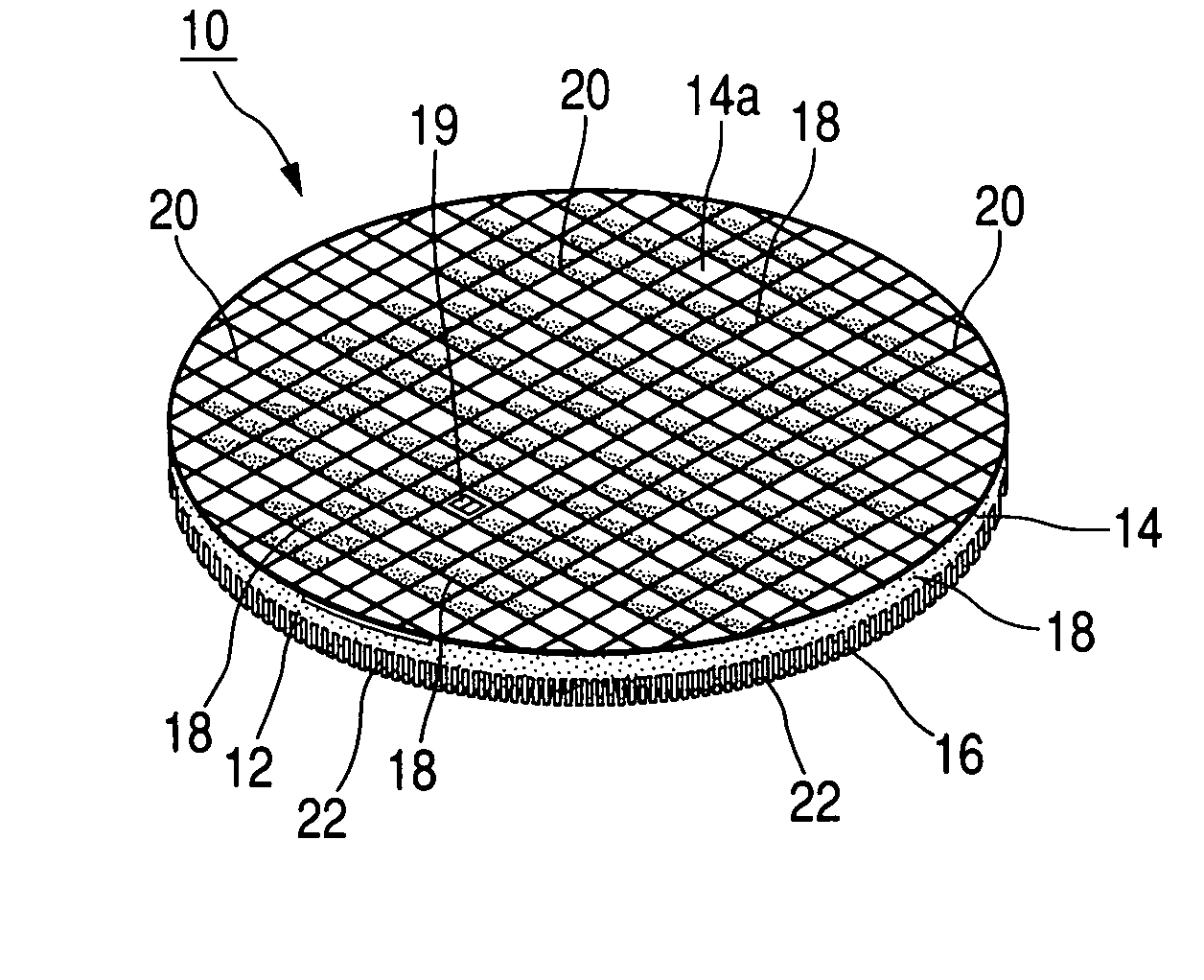

Polishing pad

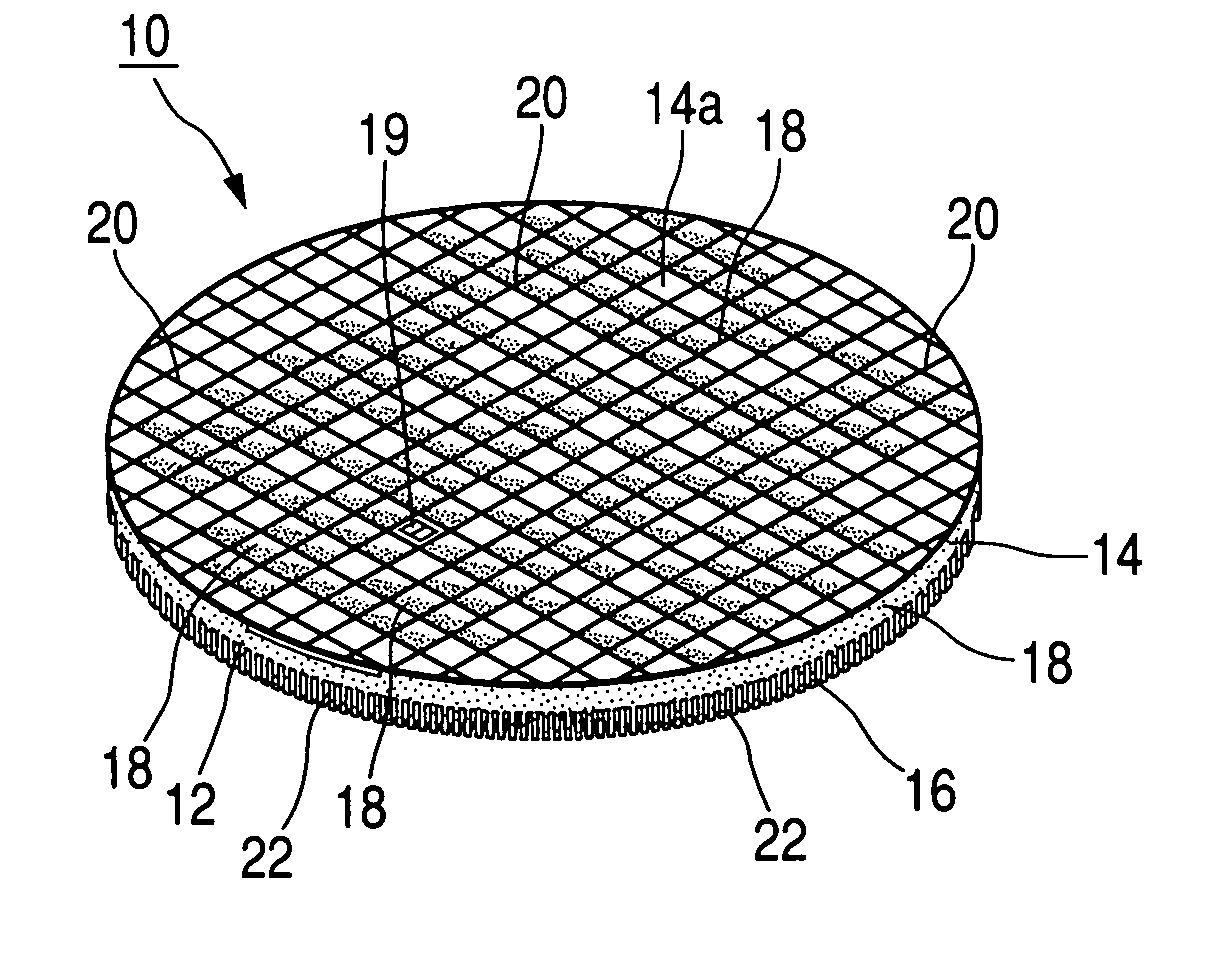

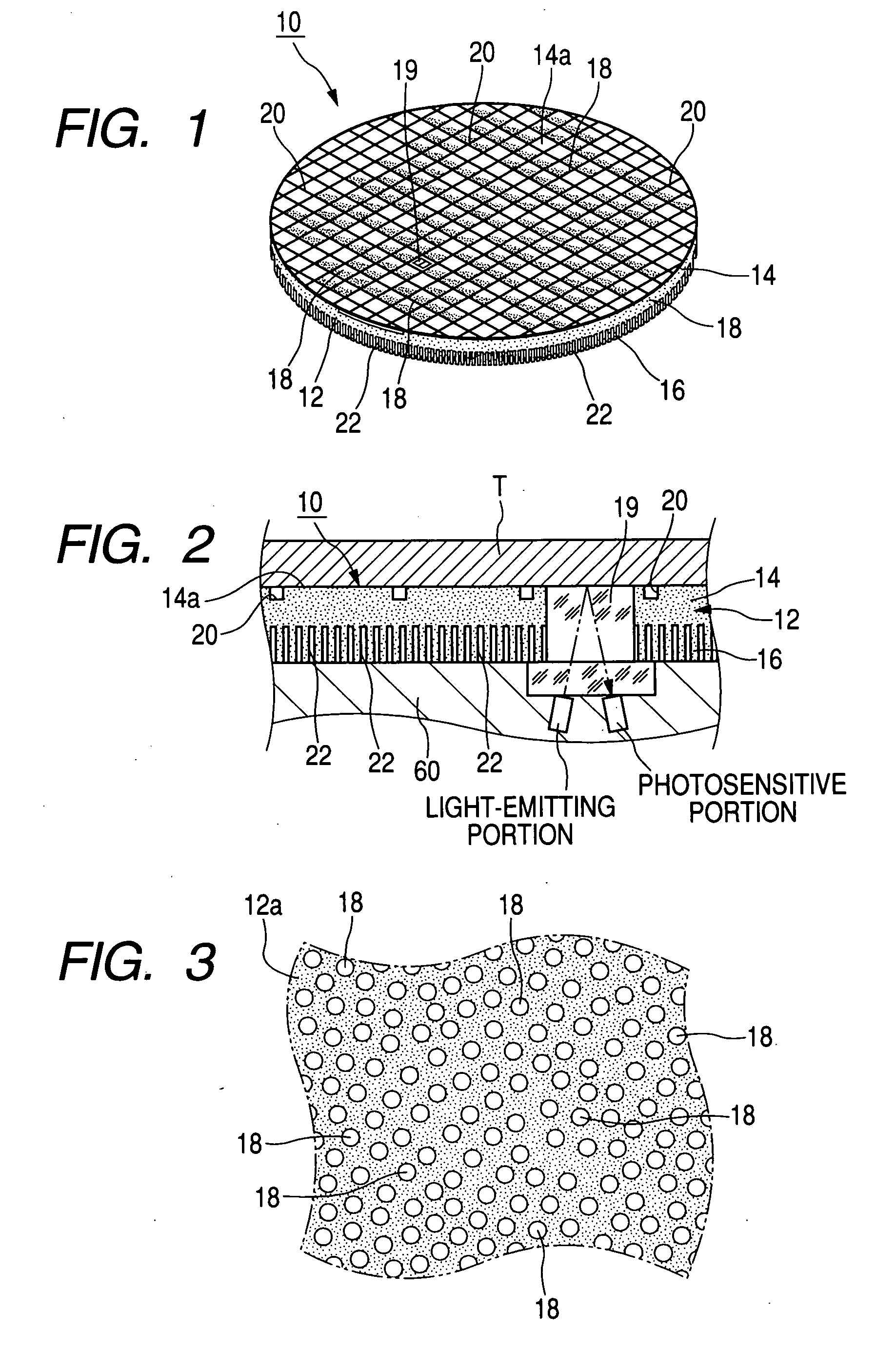

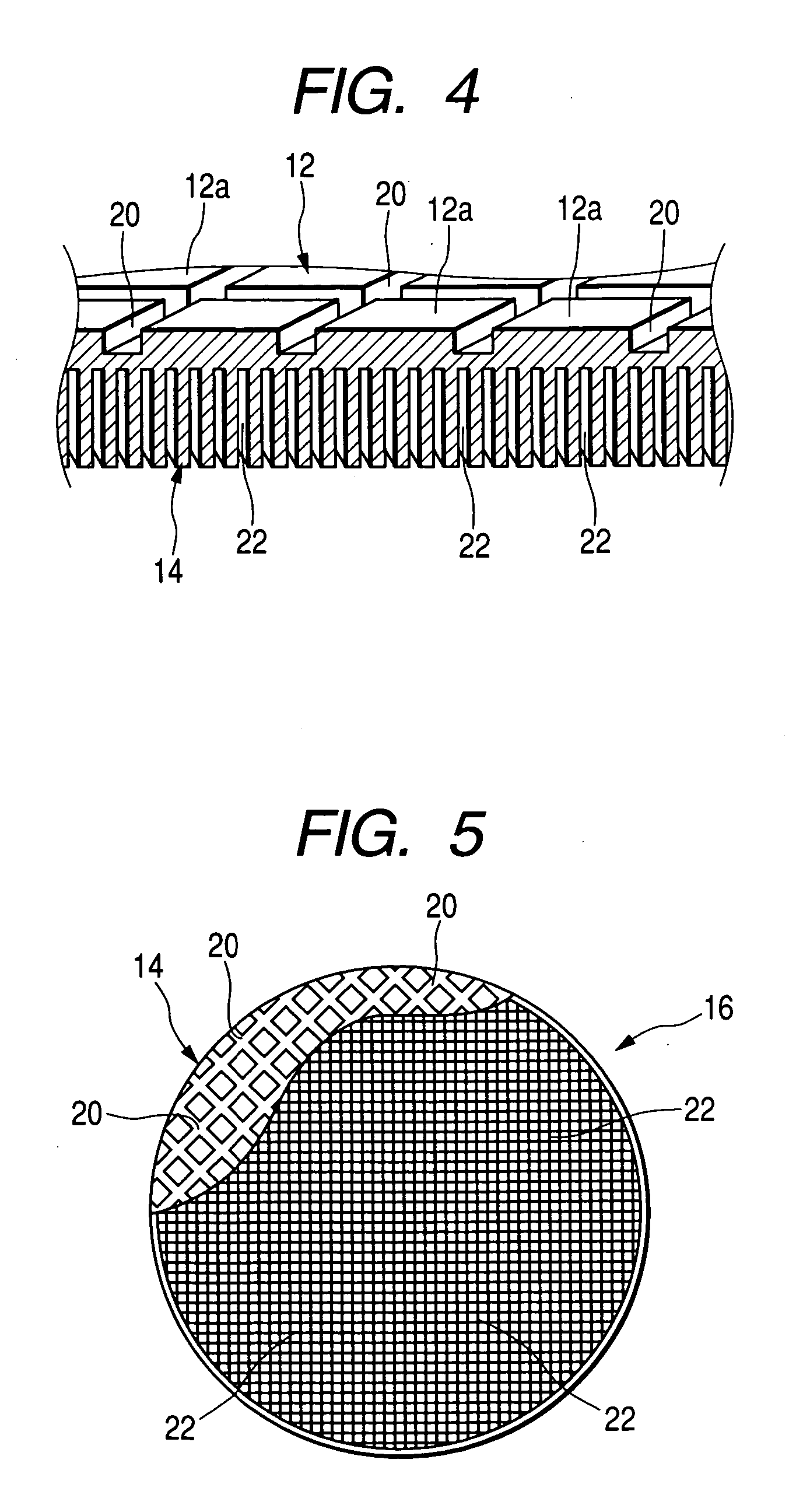

InactiveUS20060178099A1Excellent step height reductionImprove in-plane uniformityAbrasion apparatusLapping toolsIn planeSemiconductor materials

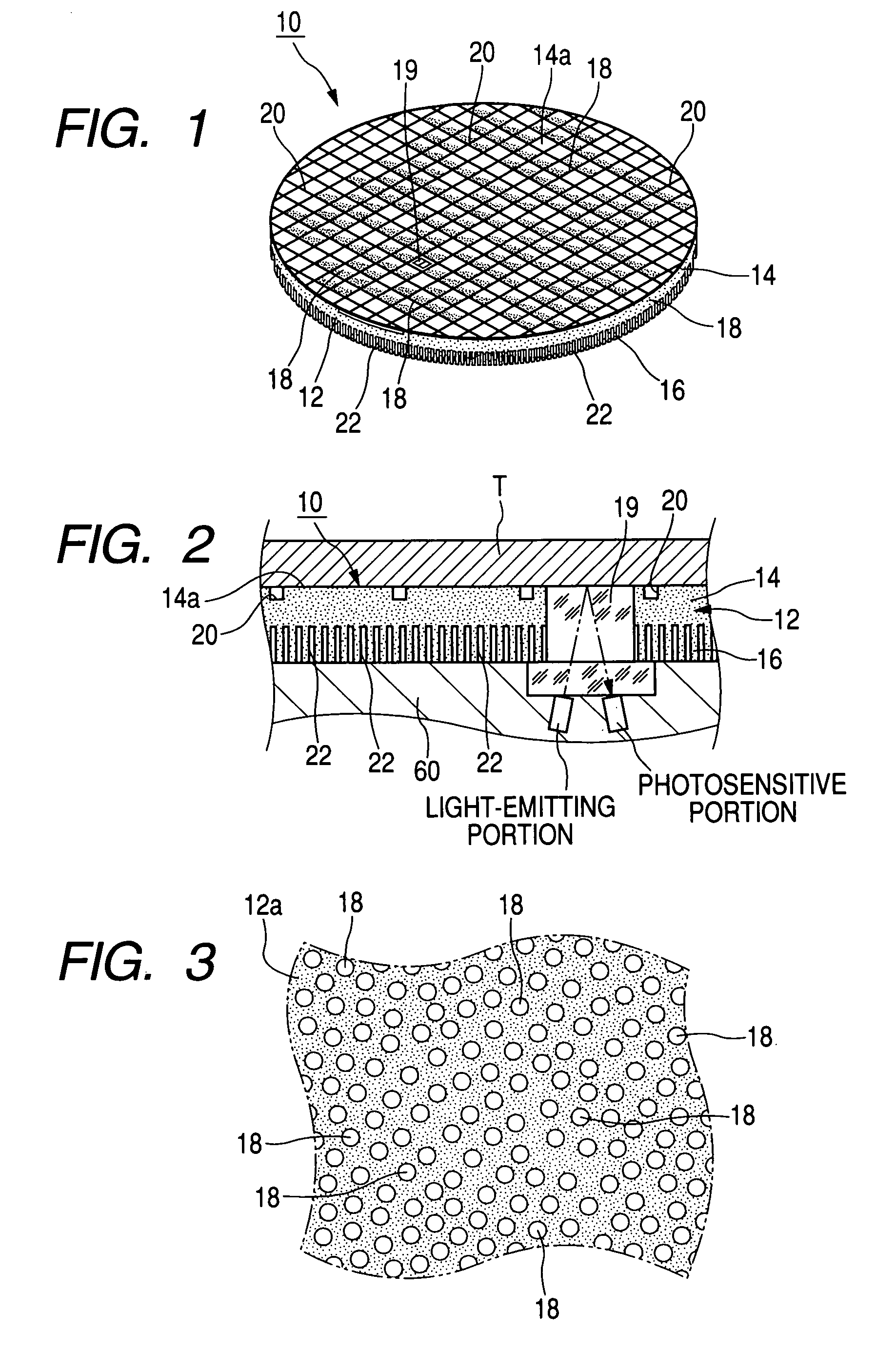

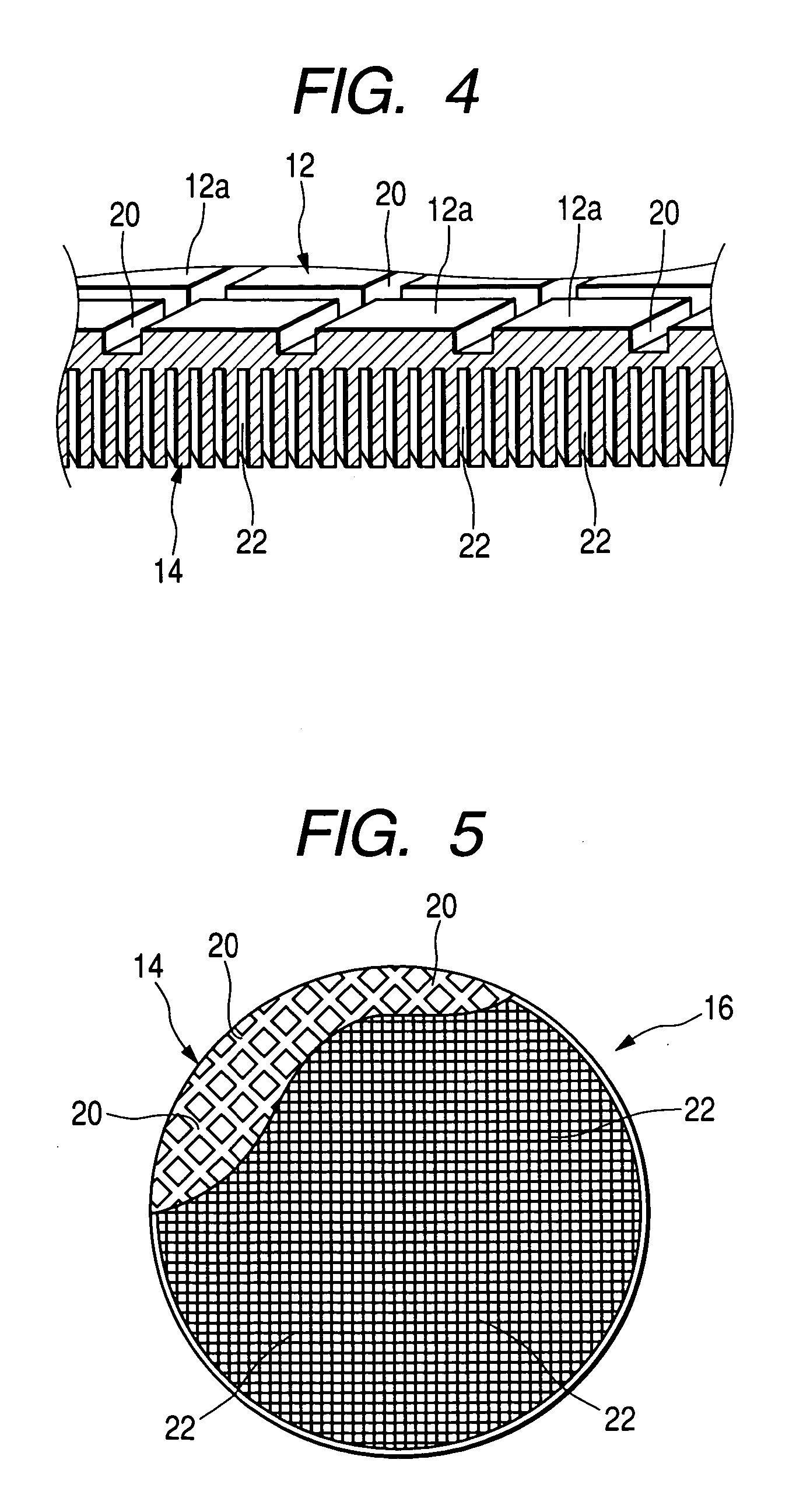

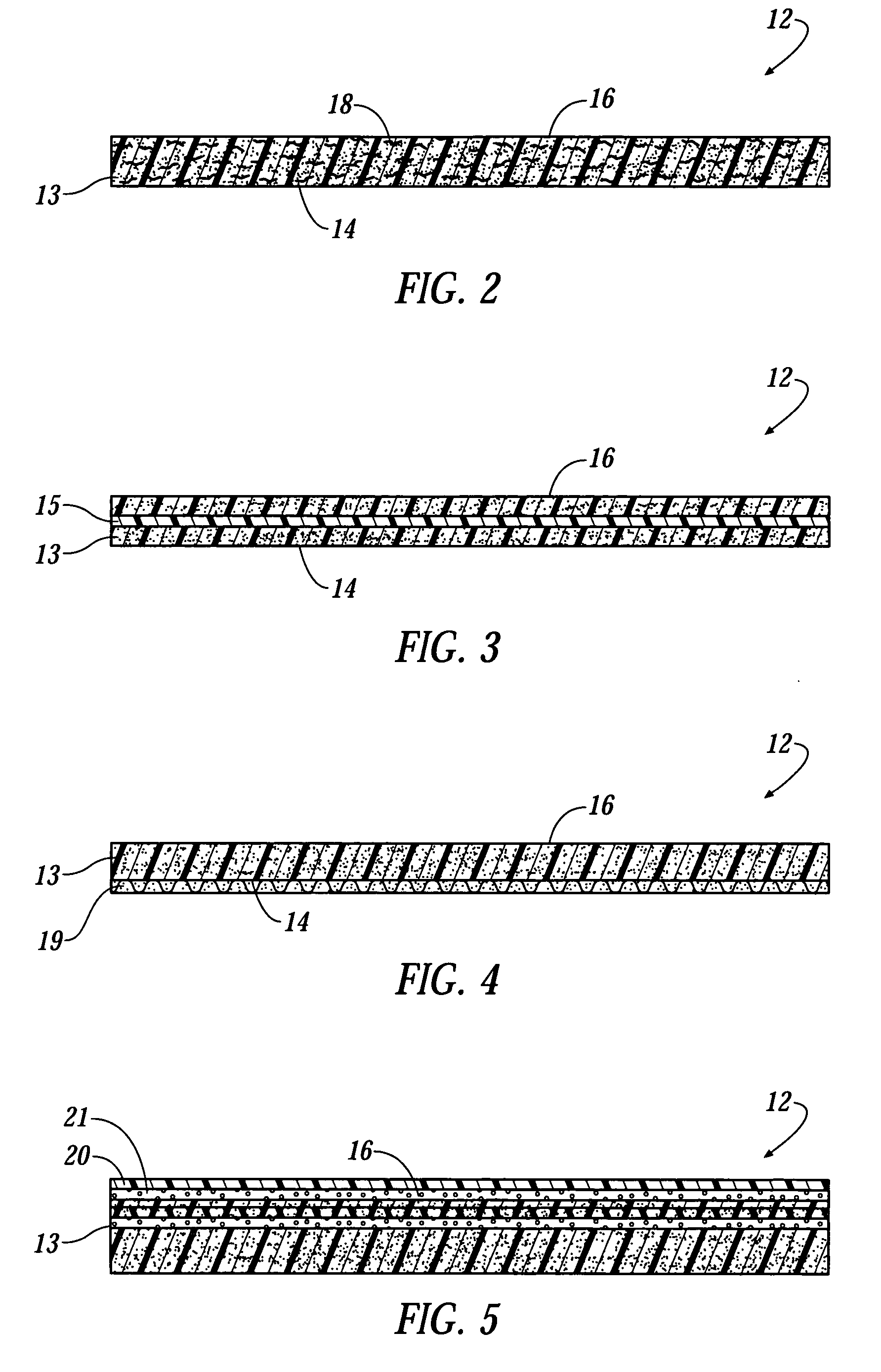

A single-layered polishing pad suitable for chemical mechanical polishing (CMP) of semiconductor wafers, etc., which attains excellent step height reduction and in-plane uniformity and is integrally molded by reaction injection molding, is provided. The polishing pad is a polyurethane-based foam 12 having a desired shape, as obtained by molding a gas-dissolved raw material having an inert gas dissolved under pressure in a polyurethane-base resin raw material by a reaction injection molding method, and includes a polishing region 14 having a polishing surface 14a suitable for polishing semi-conductor materials, etc. and having a Shore D hardness in the range of from 40 to 80 and a stress reduction region 16 which is present in the side opposing to the polishing surface 14a and which, when provided with a stress adjusting portion 22 of a desired pattern, is set up so as to have an amount of deflection, as applied with a load of 0.05 MPa, of 10 μm or more.

Owner:INOAC CORP +1

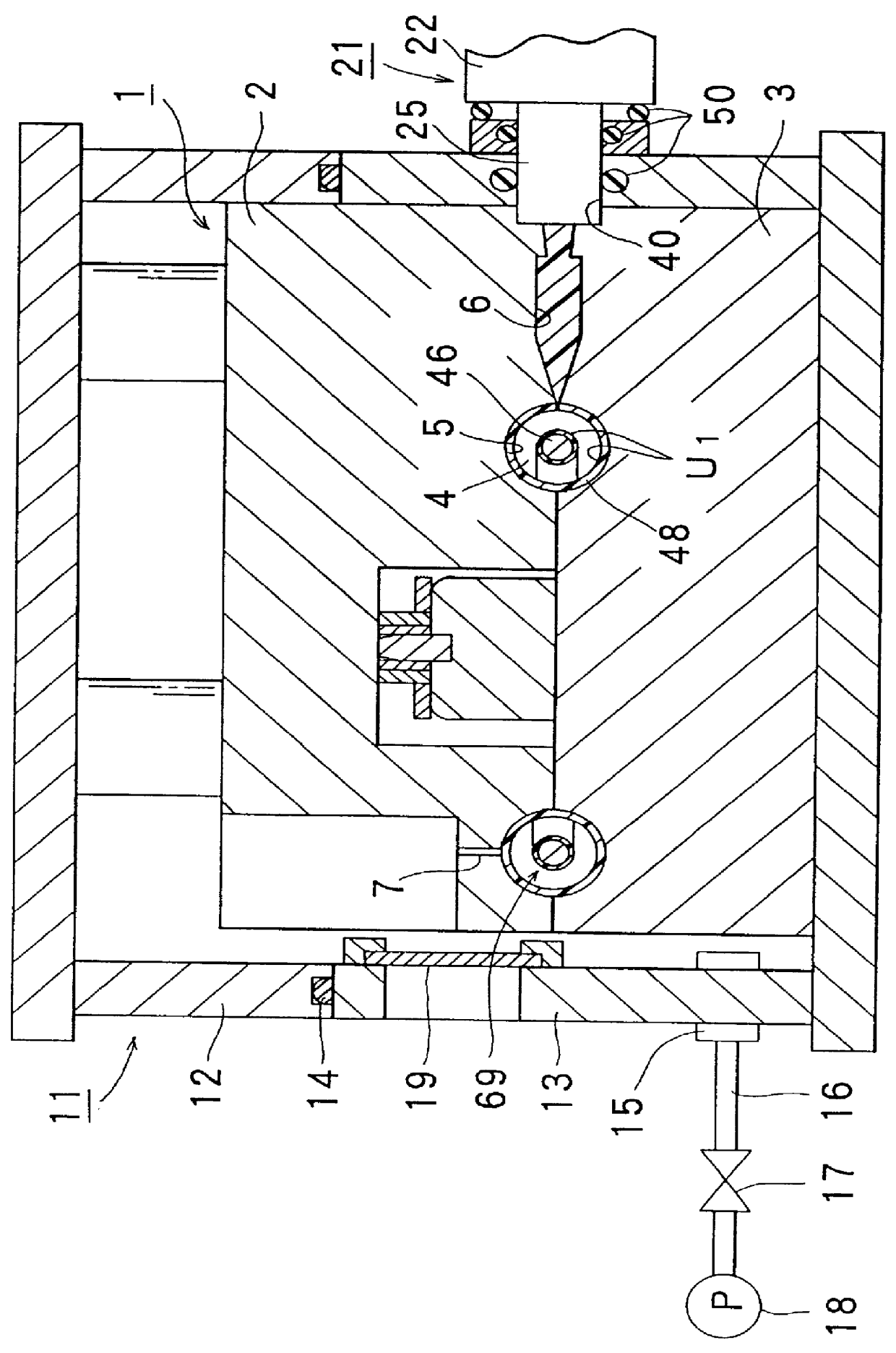

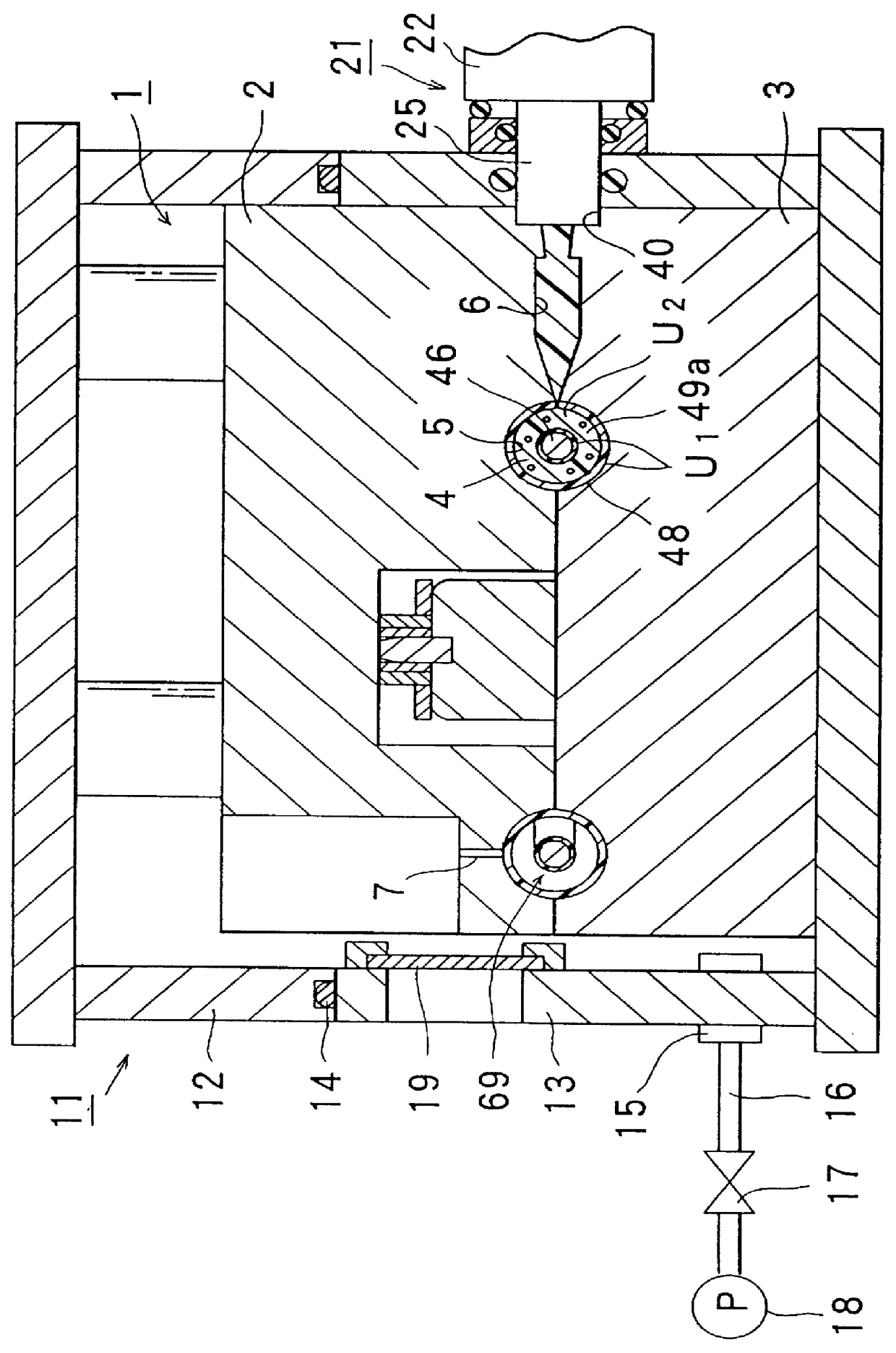

Apparatus for forming a porous reaction injection molded chemical mechanical polishing pad

The present invention provides an apparatus for forming a chemical mechanical polishing pad, comprising a tank with polymeric materials, a storage silo with microspheres, a isocyanate storage tank with isocyanates and a premix prep tank for forming a pre-mixture of the polymeric materials and the microspheres. The invention further provides a premix run tank for storing the pre-mixture, a mixer for forming a mixture of the pre-mixture and the isocyanates, a closed mold for reaction-injection molding the mixture and a vacuum for degassing at least one of the tank, isocyanate storage tank or the mold.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Polishing pad

InactiveUS7261625B2Convenient heightImprove uniformityAbrasion apparatusLapping toolsIn planeProduct gas

A single-layered polishing pad suitable for chemical mechanical polishing (CMP) of semiconductor wafers, etc., which attains excellent step height reduction and in-plane uniformity and is integrally molded by reaction injection molding, is provided. The polishing pad is a polyurethane-based foam 12 having a desired shape, as obtained by molding a gas-dissolved raw material having an inert gas dissolved under pressure in a polyurethane-base resin raw material by a reaction injection molding method, and includes a polishing region 14 having a polishing surface 14a suitable for polishing semi-conductor materials, etc. and having a Shore D hardness in the range of from 40 to 80 and a stress reduction region 16 which is present in the side opposing to the polishing surface 14a and which, when provided with a stress adjusting portion 22 of a desired pattern, is set up so as to have an amount of deflection, as applied with a load of 0.05 MPa, of 10 μm or more.

Owner:INOAC CORP +1

Polyurethane elastomer for automobile glass encapsulation and preparation method thereof

The invention discloses a polyurethane elastomer for automobile glass encapsulation and a preparation method thereof. The elastomer is prepared from isocyanate component A and polyhydric alcohols component B with a reaction injection moulding process, wherein the density is larger than 1000kg / cubic meter, and the index number of the isocyanate is 90 to 120, the component A is NCO-capped prepolymer with NCO % being 18 to 28 %, and is the reaction product of aromatic diisocyanate and polyhydric alcohols with low molecular weight; the component B comprises at least 60 percent of polyether polyol with the molecular weight of 1000 to 10000, 1 to 20 percent of arylamine, 0 to 20 percent of alcohol, and 0.2 to 0.5 percent of composite catalyst, and also comprises an antioxidant, a light stabilizer and color paste. The polyurethane elastomer of the invention has excellent mechanical capacity and moderate aging resistant performance, and is applicable to the glass encapsulation with various specifications, especially to the large, ultrathin or complex product.

Owner:南京汇科高分子材料有限公司

Reactive injection molding process for manufacturing a two-colored molded polyurethane products

Owner:TOYODA GOSEI CO LTD

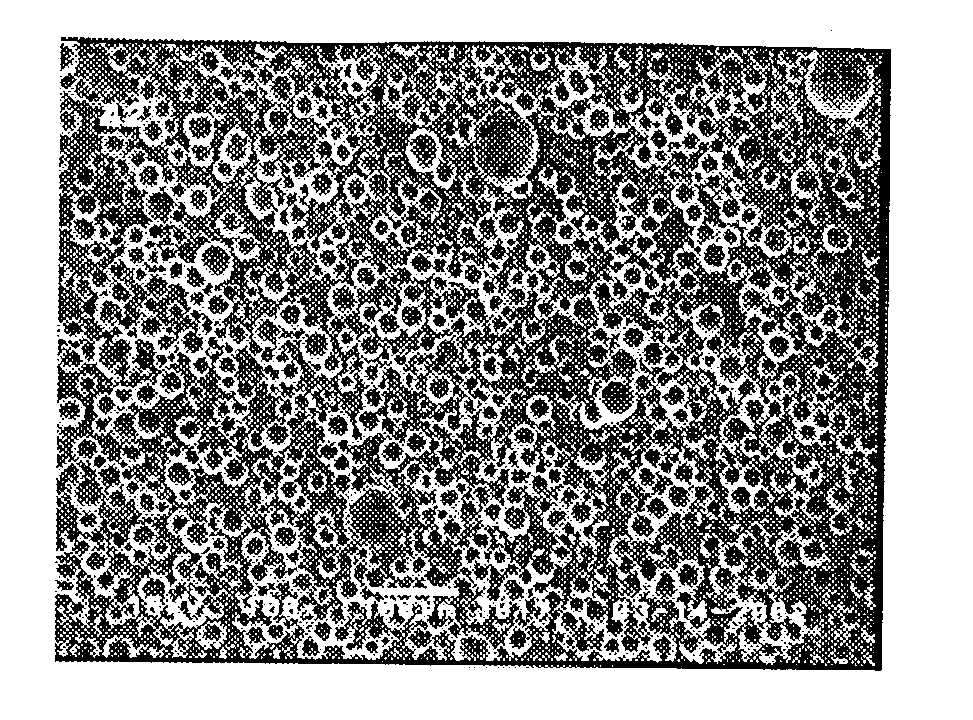

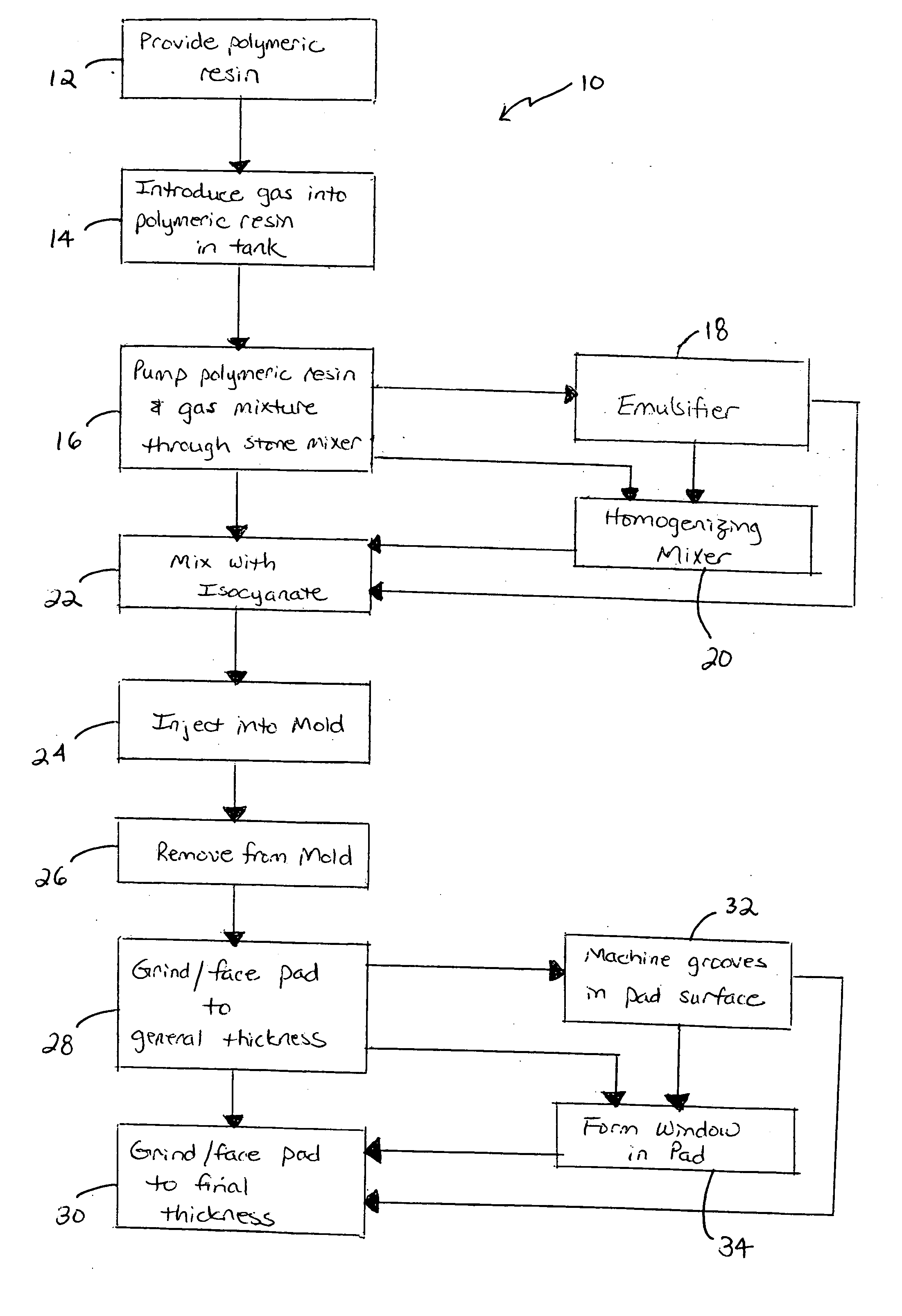

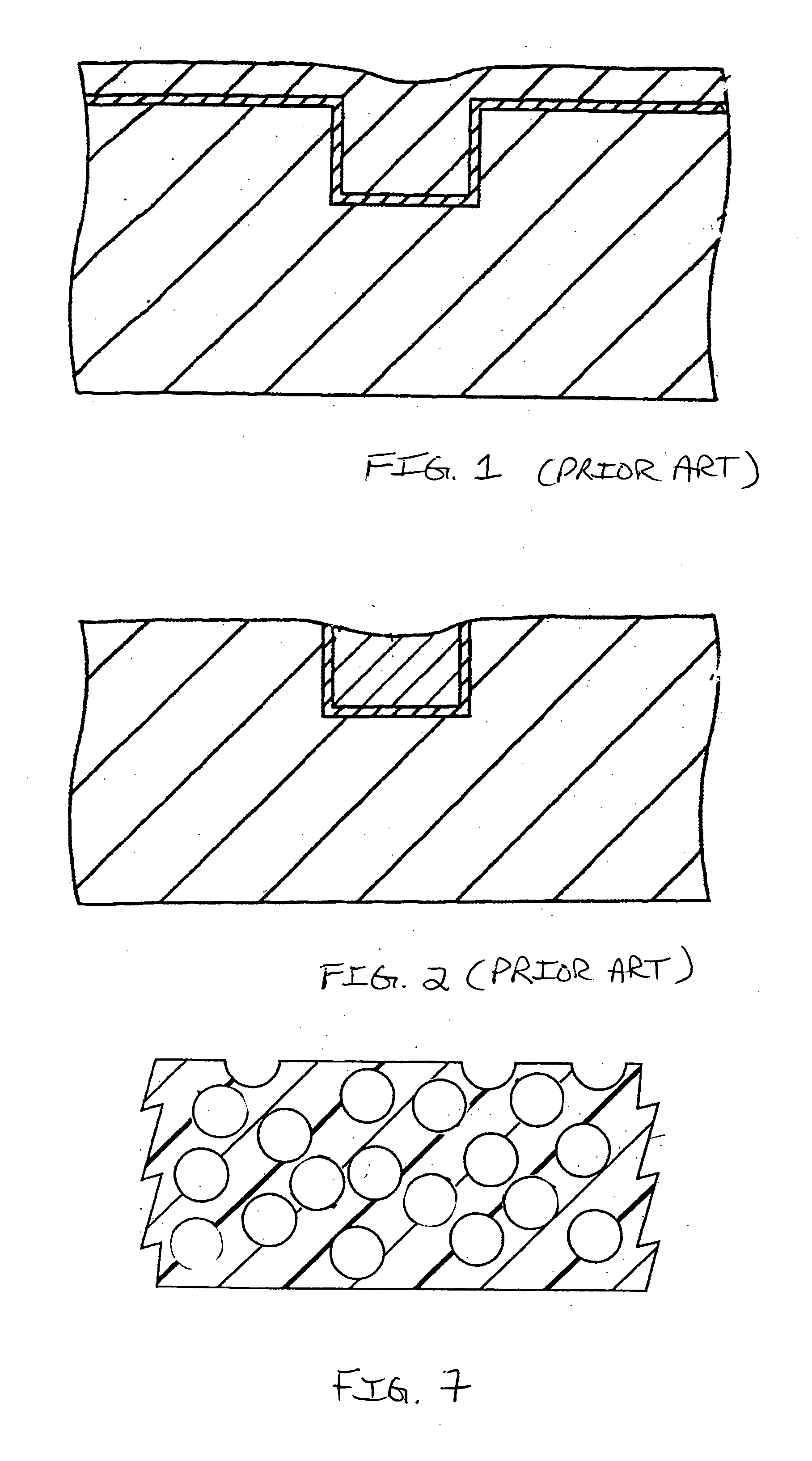

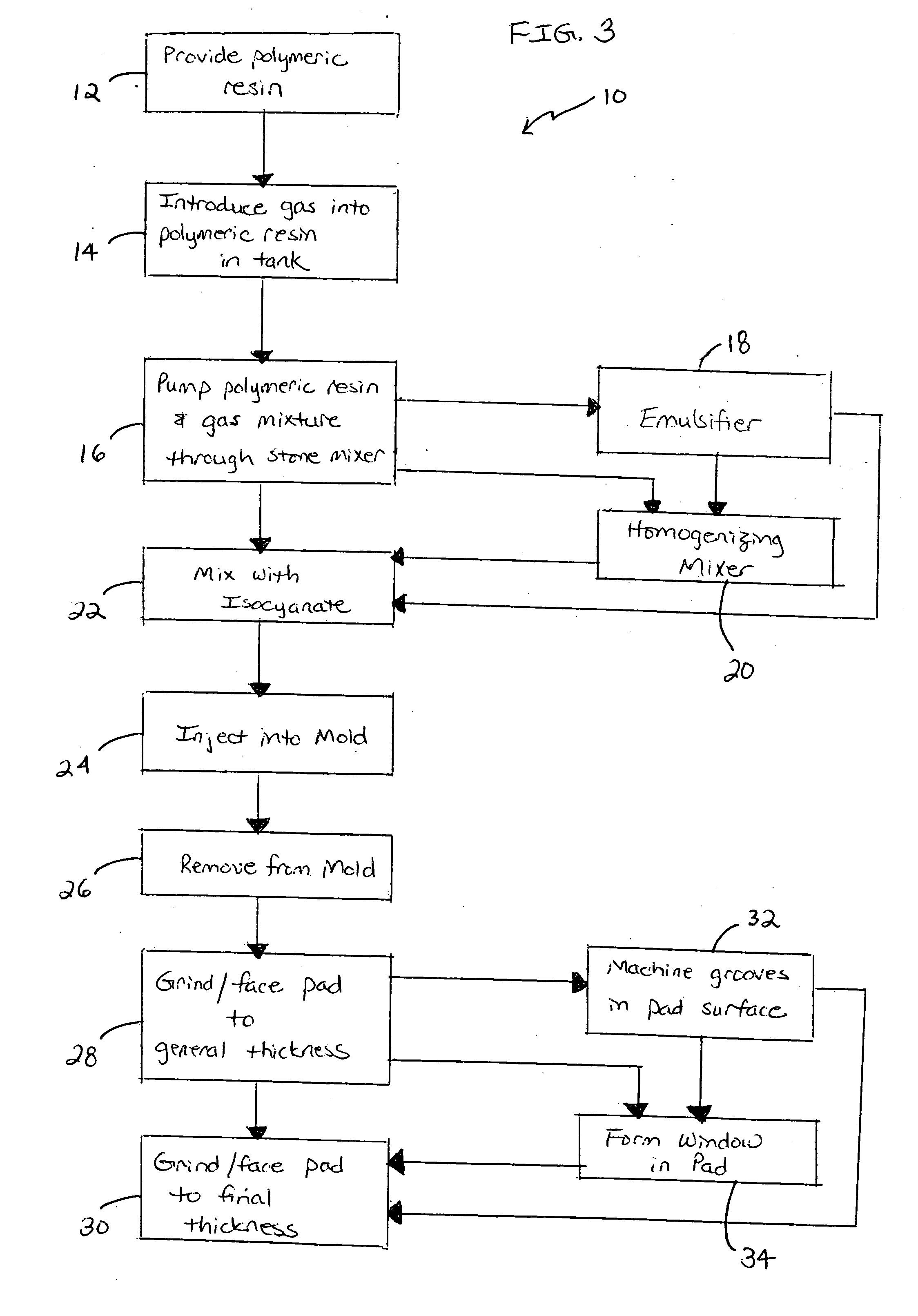

Polishing pad and method of making same

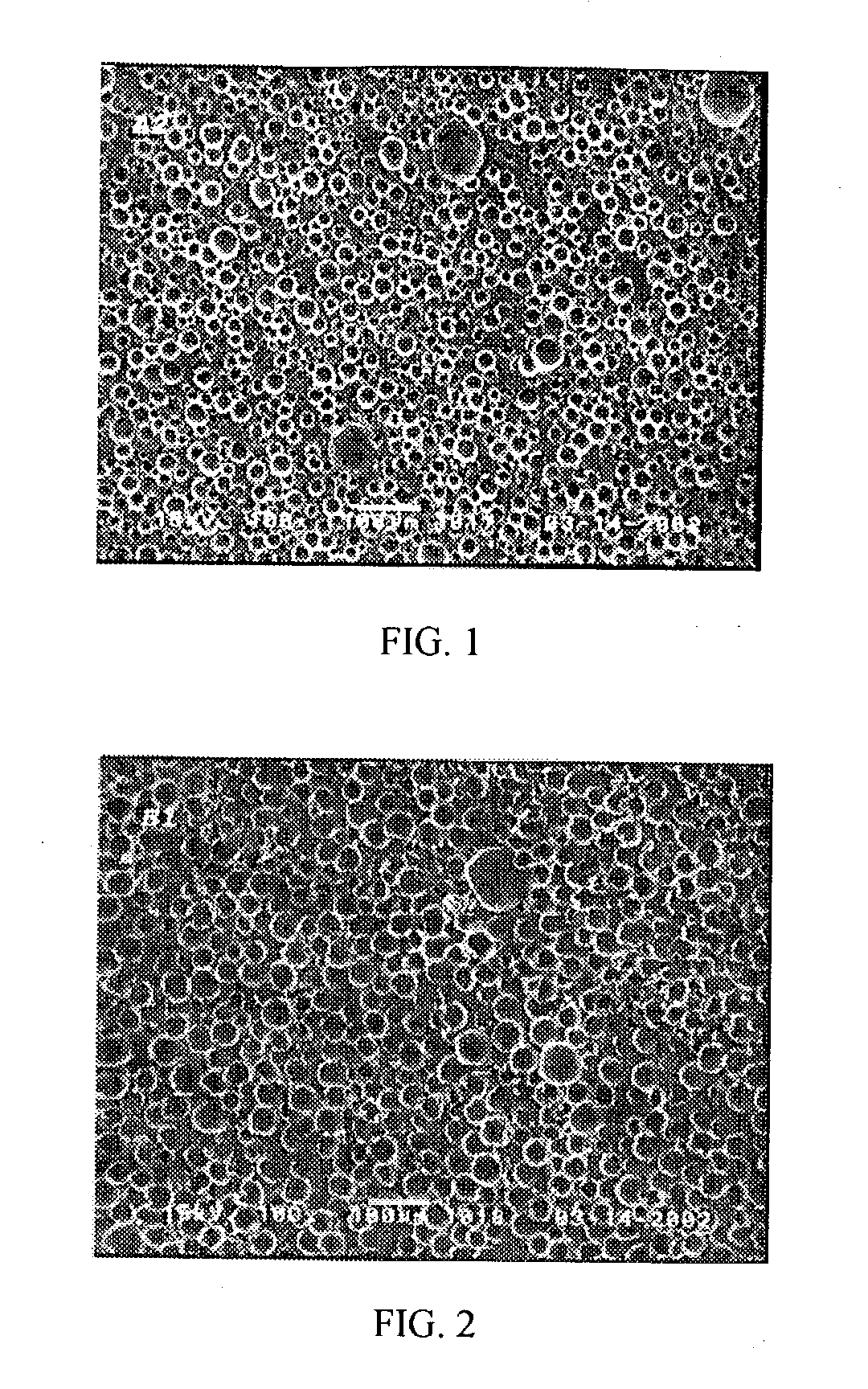

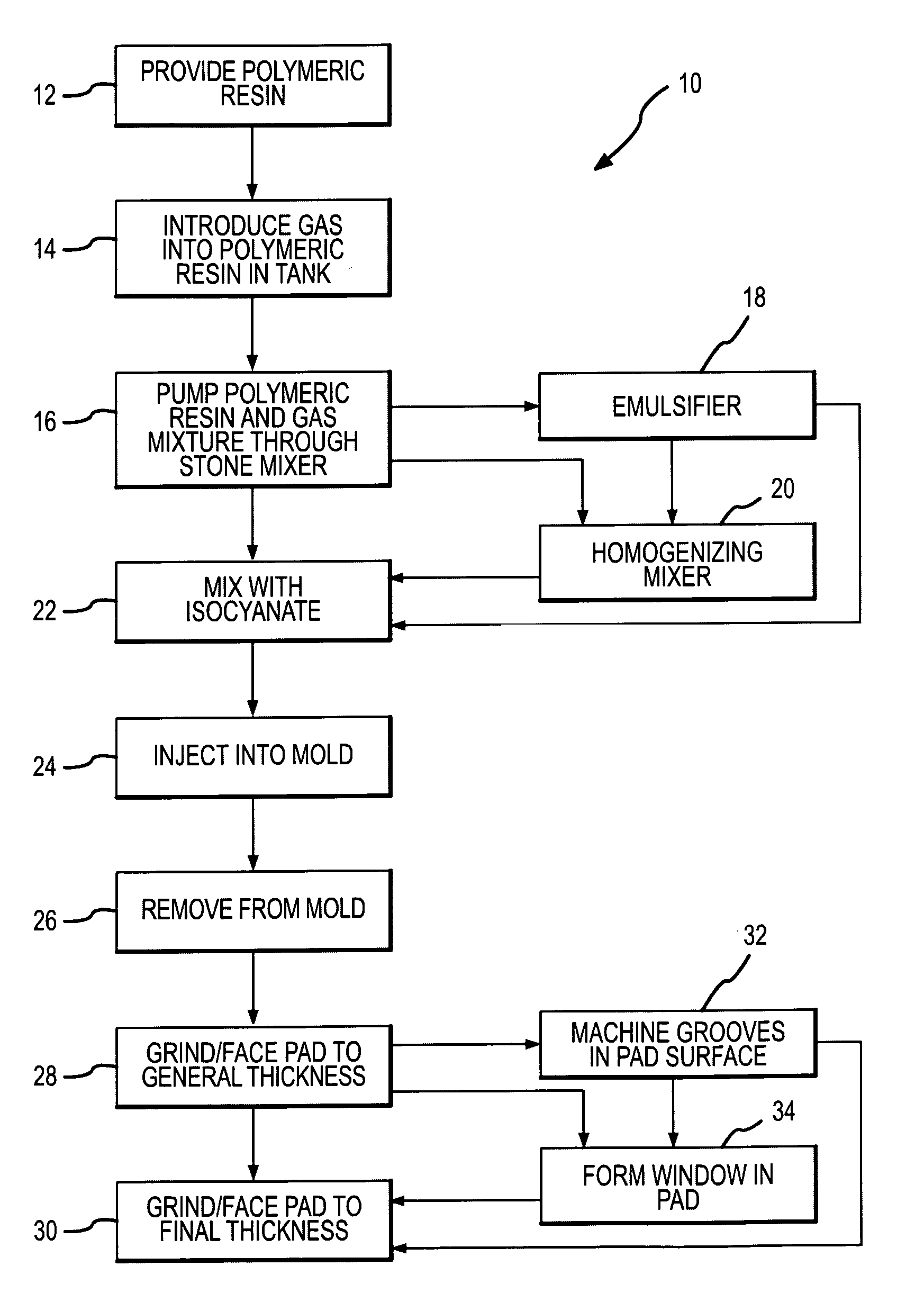

InactiveUS20050218548A1Control microcellular sizeControl UniformitySemiconductor/solid-state device manufacturingLapping machinesGas bubbleReaction injection molding

An article or polishing pad for altering a surface of a work piece includes a polymer matrix created by reaction injection molding of size controlled gas bubbles within a polyurethane matrix. The proposed liquid urethane precursor is first injected into an actuated mold and cured. The molded product is then removed from the mold and double side faced or ground to form a single thin polishing pad comprising a single layer of homogeneous material.

Owner:RIMPAD TECH

Acoustical panel assembly

InactiveUS20060013417A1Polymeric diaphragmsTransducer casings/cabinets/supportsSynthetic materialsTransducer

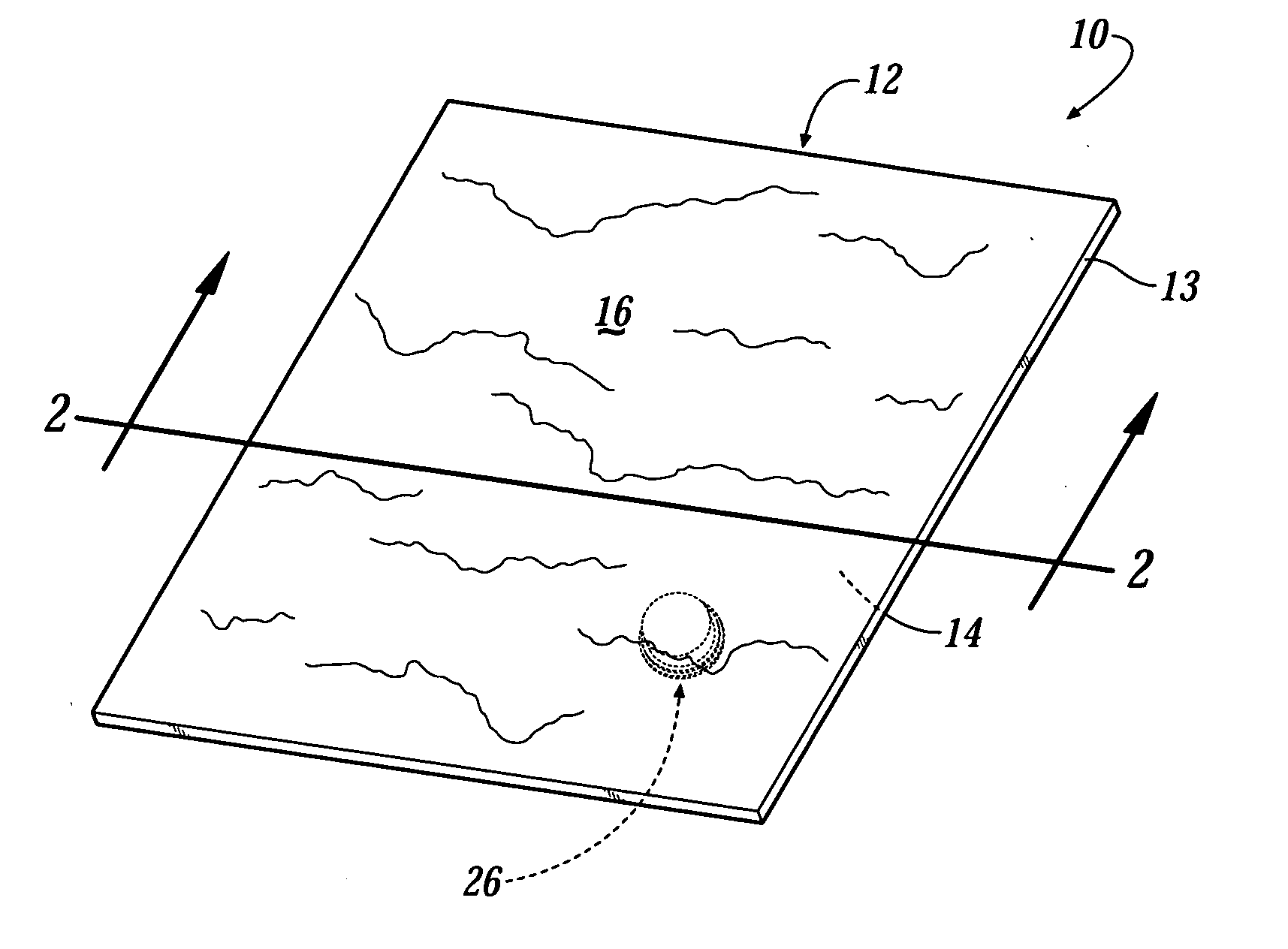

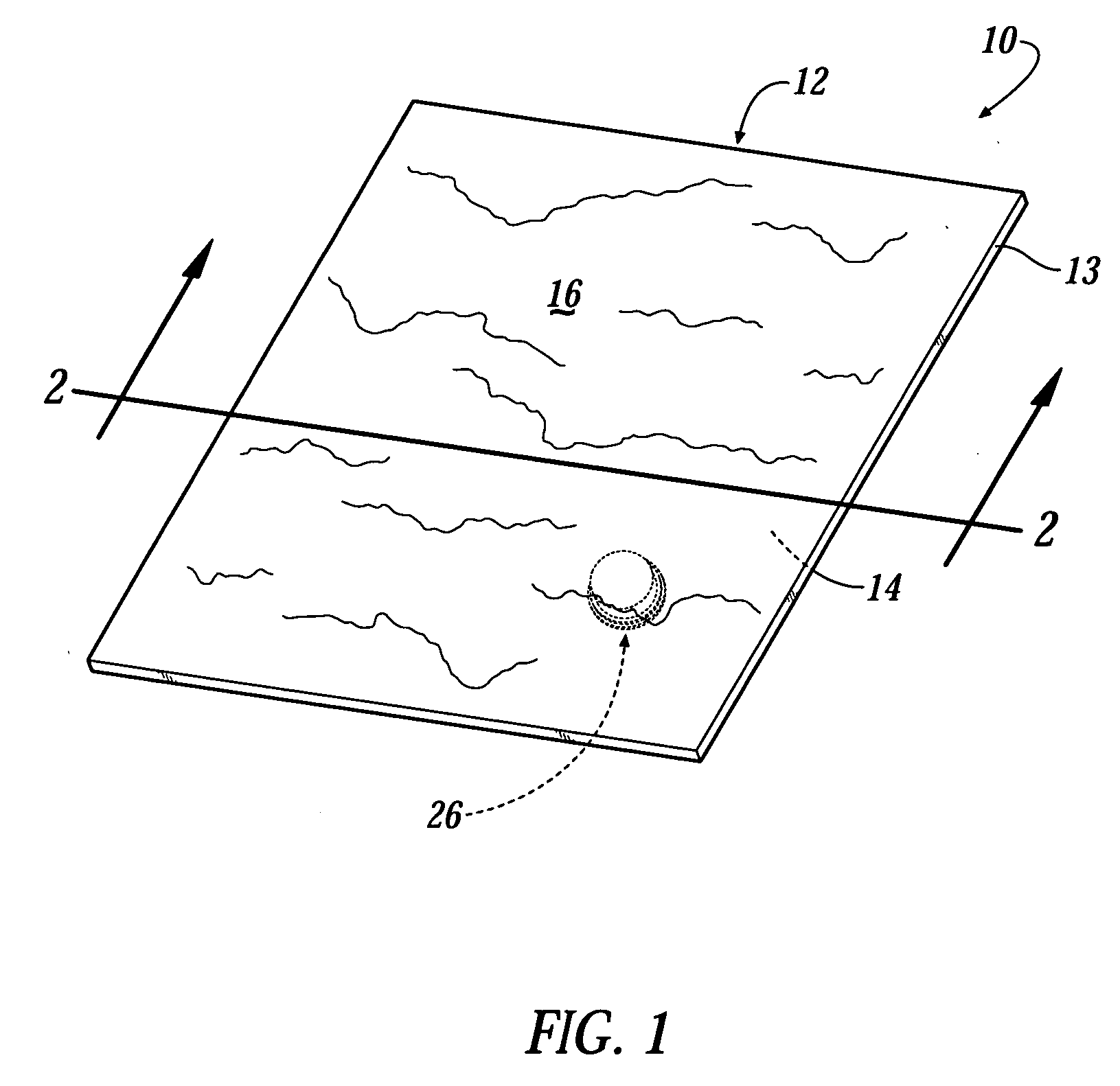

An acoustical panel assembly (10) includes a panel (12) having a core (13) made of synthetic material and an acoustical device (26) mounted to an exterior surface (14, 16) of the panel (12). The panel (12) may include an integrally formed attachment member (24) for mounting the acoustic device (26), such as a loudspeaker, an exciter, a piezoelectric transducer, or the like, directly to the panel (12) without the need of a separate mounting member. Alternatively, the acoustic device (26) may be mounted directly to the panel (12) without the use of the attachment member (24). The panel (12) can be formed by a reaction injection molding (RIM) process, a reinforced reaction injection molding (RRIM) process, or a structural reaction injection molding (SRIM) process.

Owner:INTIER AUTOMOTIVE INC

Manufacture method of plastics parts for vehicle or cladding parts

InactiveCN101357509ASolve efficiency problemsSolve environmental problemsDomestic articlesGlass fiberAcrylonitrile

The invention discloses a method for manufacturing plastic parts or covering parts, which comprises the two parts of sheet material plastic-absorption molding and reaction injection molding, wherein, the sheet material plastic-absorption molding includes that plastic-absorption molding is carried out on acrylonitrile-butadiene-styrene / acrylic coating exemption sheet material, polypropylene sheet material, polyvinyl chloride sheet material, poly carbon ester sheet material, polythene sheet material, nylon sheet material or acrylonitrile-butadiene-styrene sheet material for manufacturing the finished plastic-absorption products; the reaction injection molding includes that the mixed reactant of polyurethane and glass fibre bunch is poured on the internal surface of the finished plastic-absorption products, the dies are assembled, after complete reaction, the plastic part or covering part used on vehicles is manufactured. The method has the advantages of being suitable for mass production and low harm to environment and human body.

Owner:叶欣

Preparation method of polydicyclopentadiene/rubber in-situ polymerization blending composite material

The invention provides a preparation method of a polydicyclopentadiene / rubber in-situ polymerization blending composite material. The method comprises the following steps: dissolving the rubber into the polydicyclopentadiene, taking the aryloxy-tungsten complexes as main catalyst and the alkyl aluminium as cocatalyst, utilizing reaction injection molding technology to prepare the polydicyclopentadiene / rubber blending composite material by in-situ polymerization blending, due to the introduction of the rubber, the polydicyclopentadiene material has high toughness, thus enlarging the application field thereof. By adopting the reaction injection molding method, a high performance polydicyclopentadiene composite material can be prepared simply and effectively. The prepared polydicyclopentadiene / rubber in-situ polymerization blending composite material has higher impact resistant performance of which the impact strength can reach 200-400J / m.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com