Extrusion/reaction injection molding system

a technology of injection molding and extrusion, which is applied in the direction of dough shaping, hollow wall objects, explosives, etc., can solve the problems of time-consuming and costly, and achieve the effect of high volume parts and economical ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

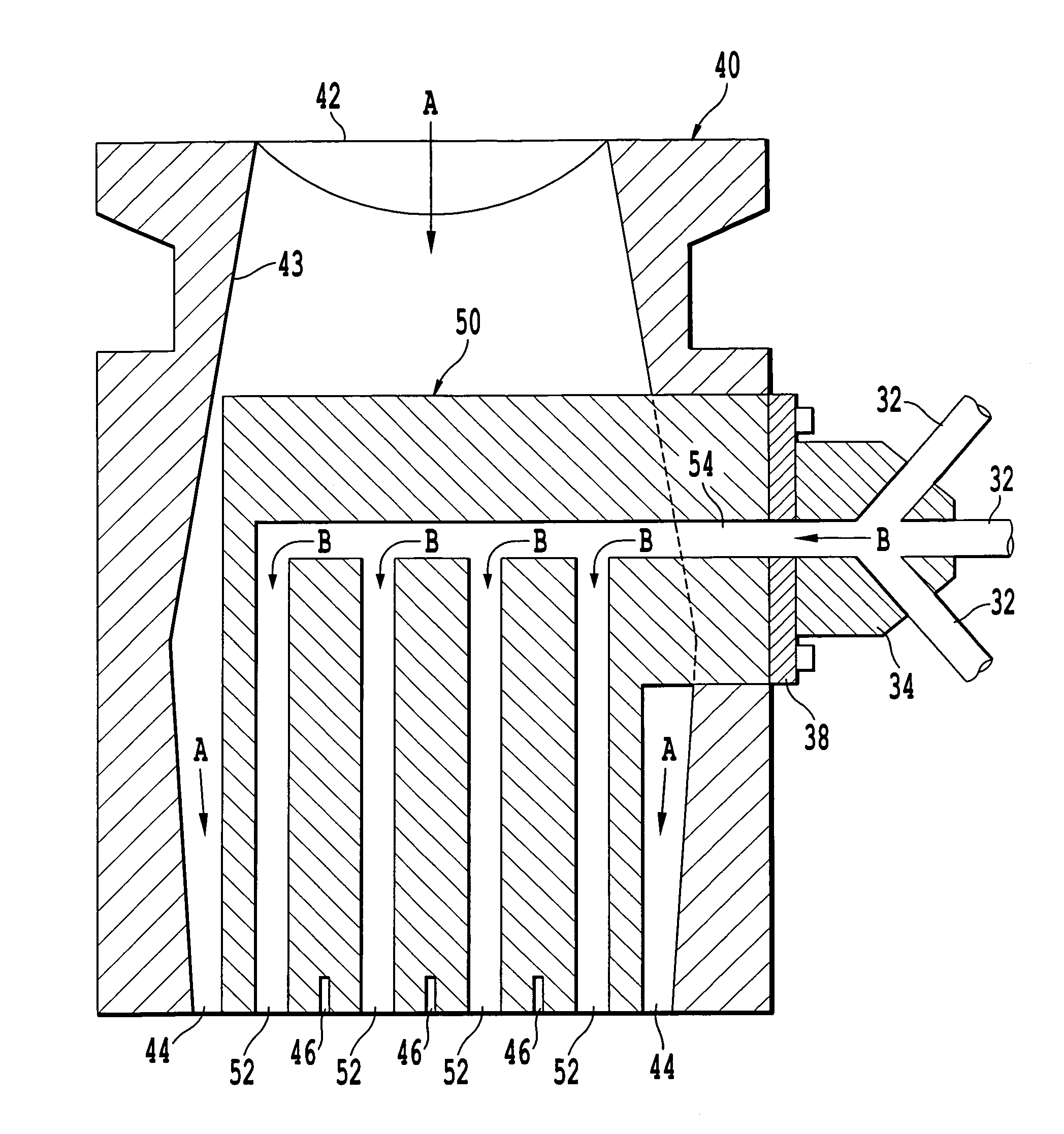

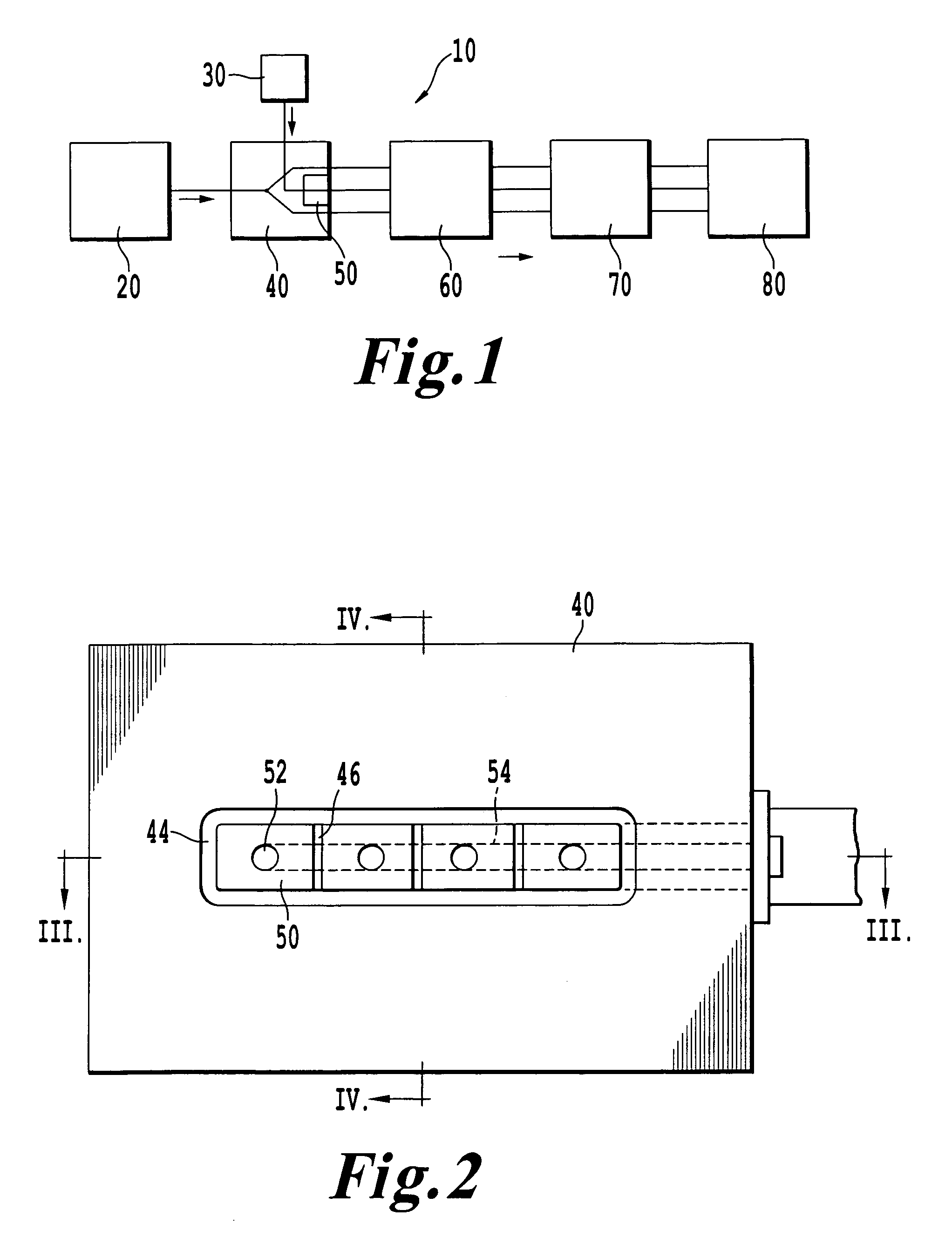

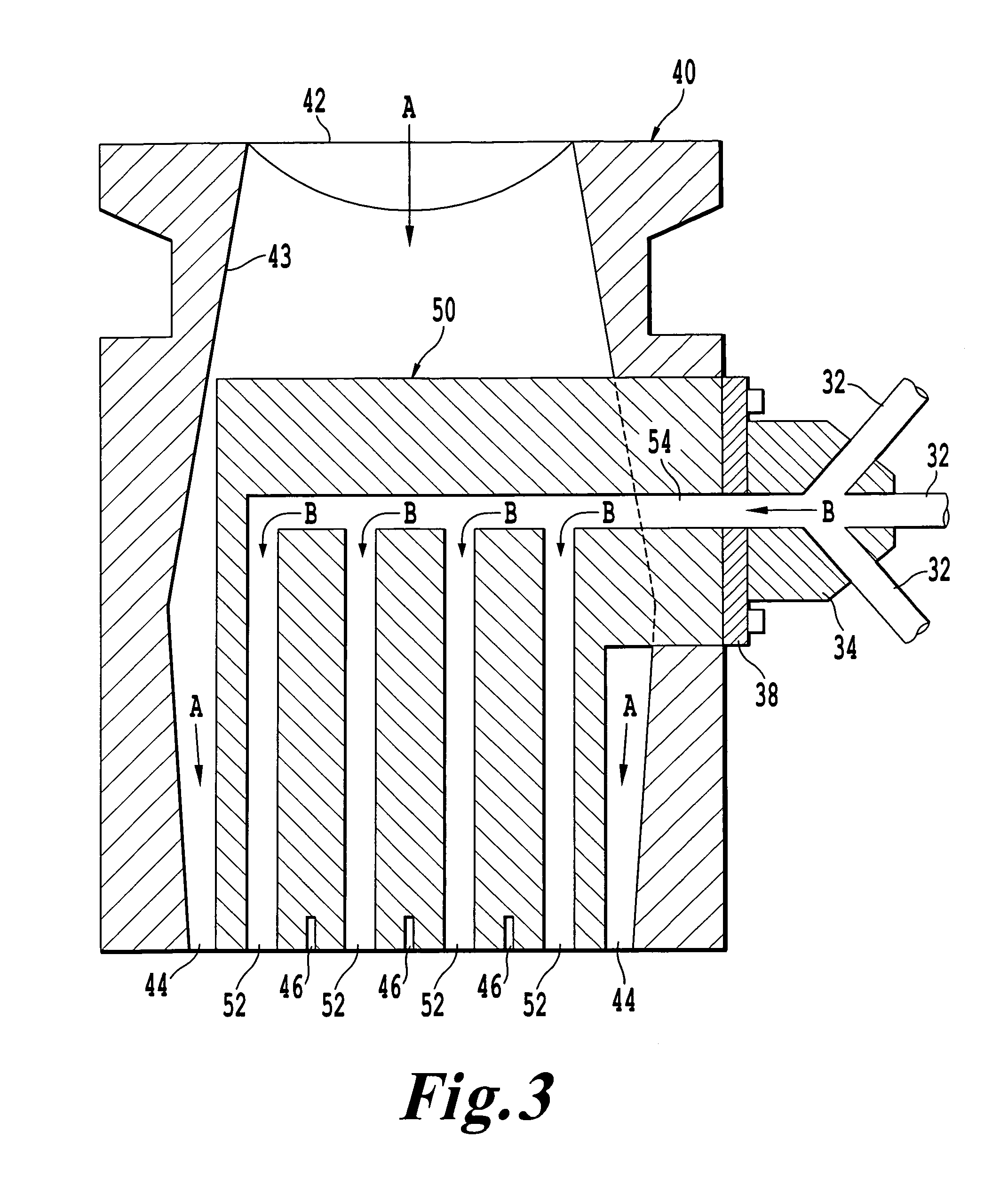

[0025]Embodiments of the present invention will be described hereinafter with reference to the accompanying drawings. In the following description, the constituent elements having substantially the same function and arrangement are denoted by the same reference numerals, and repetitive descriptions will be made only when necessary.

[0026]As mentioned above, the present invention relates to a combined extrusion and reaction injection molding system and method which combines the benefits of the two types of molding processes. More specifically, the invention combines extrusion molding technology with reaction injection molding (RIM) technology to produce molded articles that heave, for example, a rigid polyvinylchloride (PVC) exterior shell and a firm, lightweight polyurethane (PUR) inner core.

[0027]A known benefit of polyurethane is the high strength to weight ratio of the material. Polyurethane is also desirable because of its ability to duplicate parts, such as wood moldings and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com