Patents

Literature

356 results about "Acrylic coating" patented technology

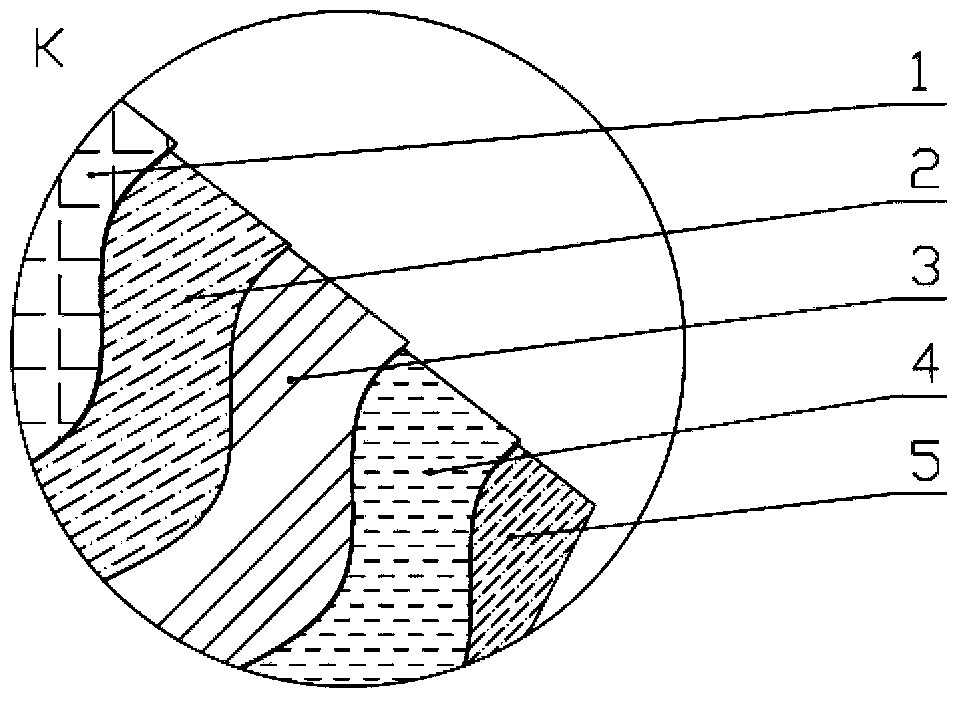

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based acrylic acid top-coat

The present invention relates to a water-based acrylic coating which is produced by grinding, dispersing and other processes after the base material of water-based acrylic emulsion is mixed with pigment, filler, additives, co-solvents and water. The water-based acrylic coating of the invention has the same finishing effect as the oiliness acrylic coating and the glossiness can reach forty percent. The water-based acrylic coating shows good water-resistance in the early stage, which passes the water-sealing test. In addition, secure and convenient in application, the water-based acrylic coating has no pollution to the environment and is harmless to the workers. Suitable for high-pressure airless spraying, the water-based acrylic coating has high operation efficiency. The thickness of a single coating layer is thirty to one hundred micron and no more coating layer is needed as no sagging or cracking can be found in a single coating layer. The water-based acrylic coating can not only be used for the decoration and protection of the outer surface of a container, but also can be widely used as antirust for the iron and steel parts of transportation means like automobiles, trains and ships; of structures like bridges, towers, doors and windows; and of facilities like tanks and pipes.

Owner:WEIXIN ENVIRONMENTAL PROTECTION COATING SHENZHEN

Long-acting water-soluble and environmentally-friendly steel structural protective coating

ActiveCN103450719AImprove adhesionHigh reactivityAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceAcrylic coating

The invention provides a long-acting water-soluble and environmentally-friendly steel structural protective coating. The long-acting water-soluble and environmentally-friendly steel structural protective coating is characterized in that a water-soluble inorganic zinc silicate coating is used as a primer of the protective coating; a water-soluble silicon-acrylic coating is used as an intermediate coating; a water-soluble fluorocarbon coating serves as a top coating; the water-soluble inorganic zinc silicate coating comprises the raw materials of high-modulus potassium silicate inorganic nanometer resin and synthesized organic polymer emulsion, wherein the high-modulus potassium silicate inorganic nanometer resin has the modulus of 5.3 to 6.2, and the particle diameter is 5 to 20nm; the synthesized organic polymer emulsion is composed of one or a plurality of water-soluble styrene-acrylic emulsion, water-soluble pure acrylic emulsion, water-soluble silicone acrylic emulsion, water-soluble fluorocarbon emulsion and water-soluble fluoro-silicon emulsion; and the water-soluble silicon-acrylic coating comprises the raw material of a silicon-acrylic matrix, wherein the silicon-acrylic matrix is one of a mixture of silicone acrylic emulsion and pure acrylic emulsion, the mixture of silicone acrylic emulsion and styrene-acrylic emulsion, and silicone acrylic emulsion. By adopting the long-acting water-soluble and environmentally-friendly steel structural protective coating, the corrosion resistance and weather resistance of the protective coating are obviously improved; the corrosion resisting effect can last for 20 years; and the weather resistance lasts for more than 20 years.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Flexible luminescent paints

InactiveUS20100283007A1Easy to optimizeIncrease flexibilityLuminescent paintsLuminescent compositionsPolymer sciencePhotoluminescence

Flexible luminescent paints are prepared from physical blends of hybrid epoxy acrylic resins, cementicious acrylic resins and optionally pure acrylic coating resins together with monopropylene glycol, suspension additives, rheological additives and photoluminescent pigments. The luminescent paints exhibit bright, even and long-lasting photoluminescent afterglow, excellent flexibility in both thin and thick layers, and are suitable for spraying, brushing, rolling and screen printing. Optional fluorescent pigments may be utilized to give daylight coloration and up-convert the photoluminescent emissions to the fluorescent emissions color.

Owner:ROBINSON JOHN RUSSELL

Ultraviolet cured coating system

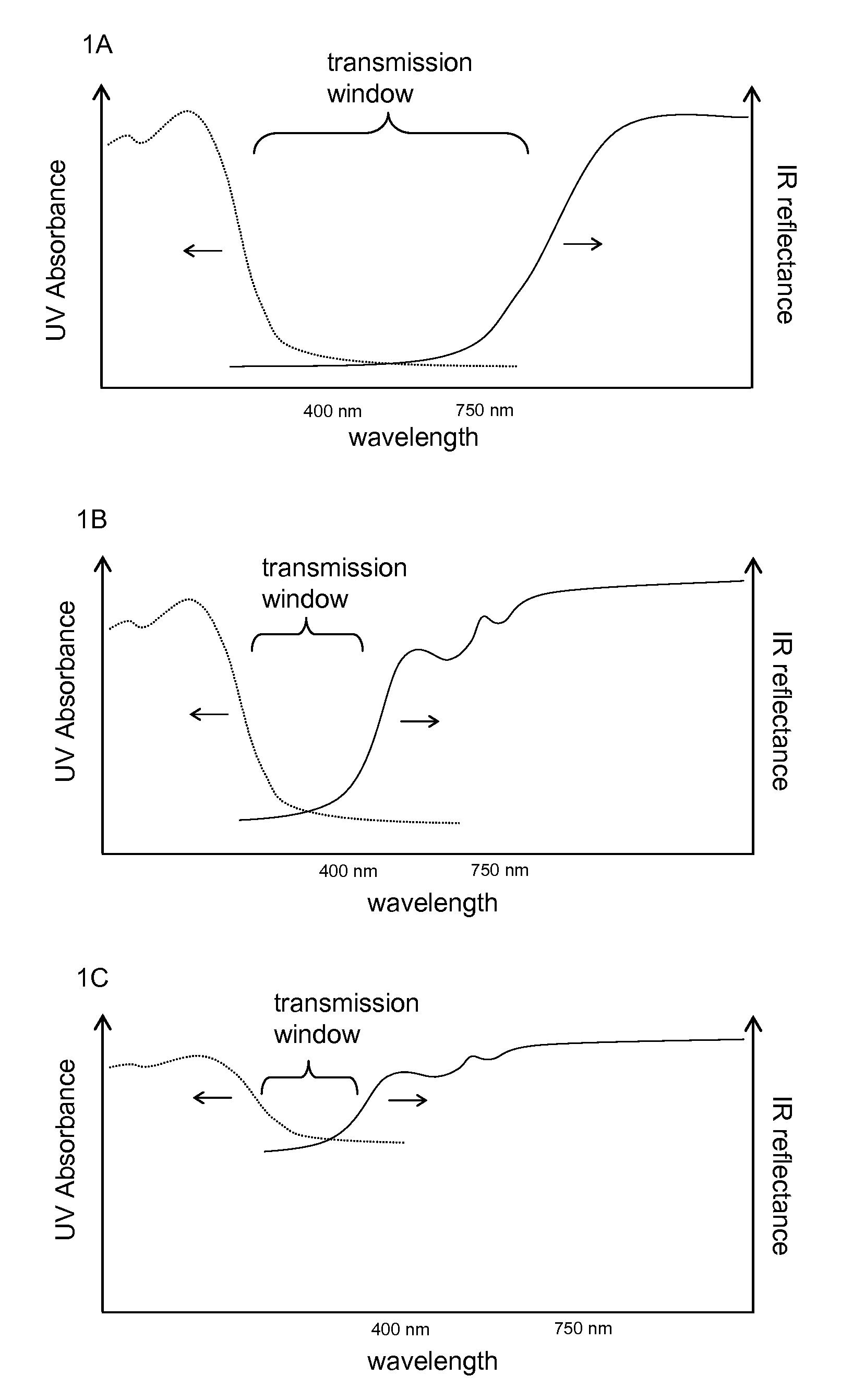

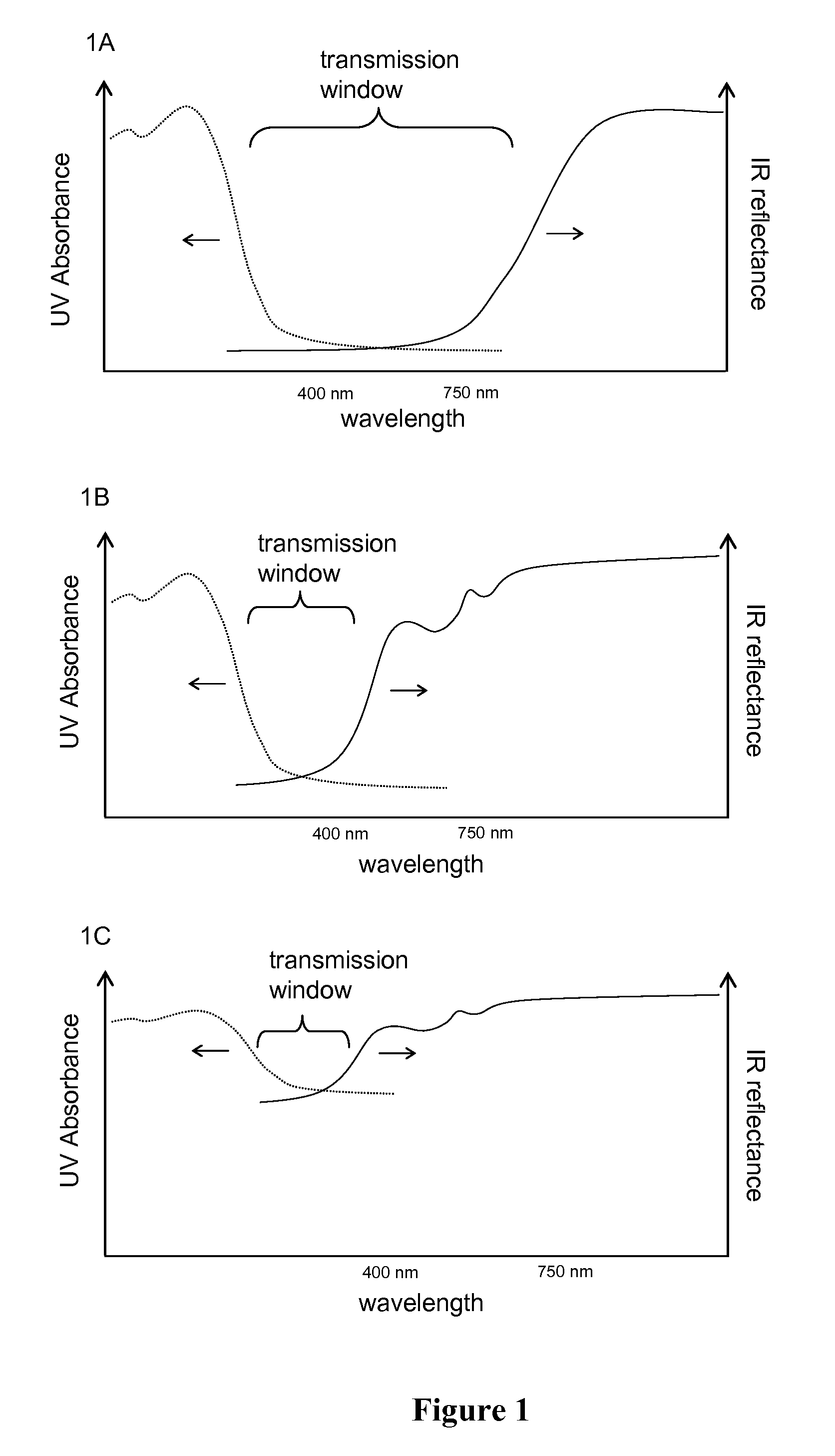

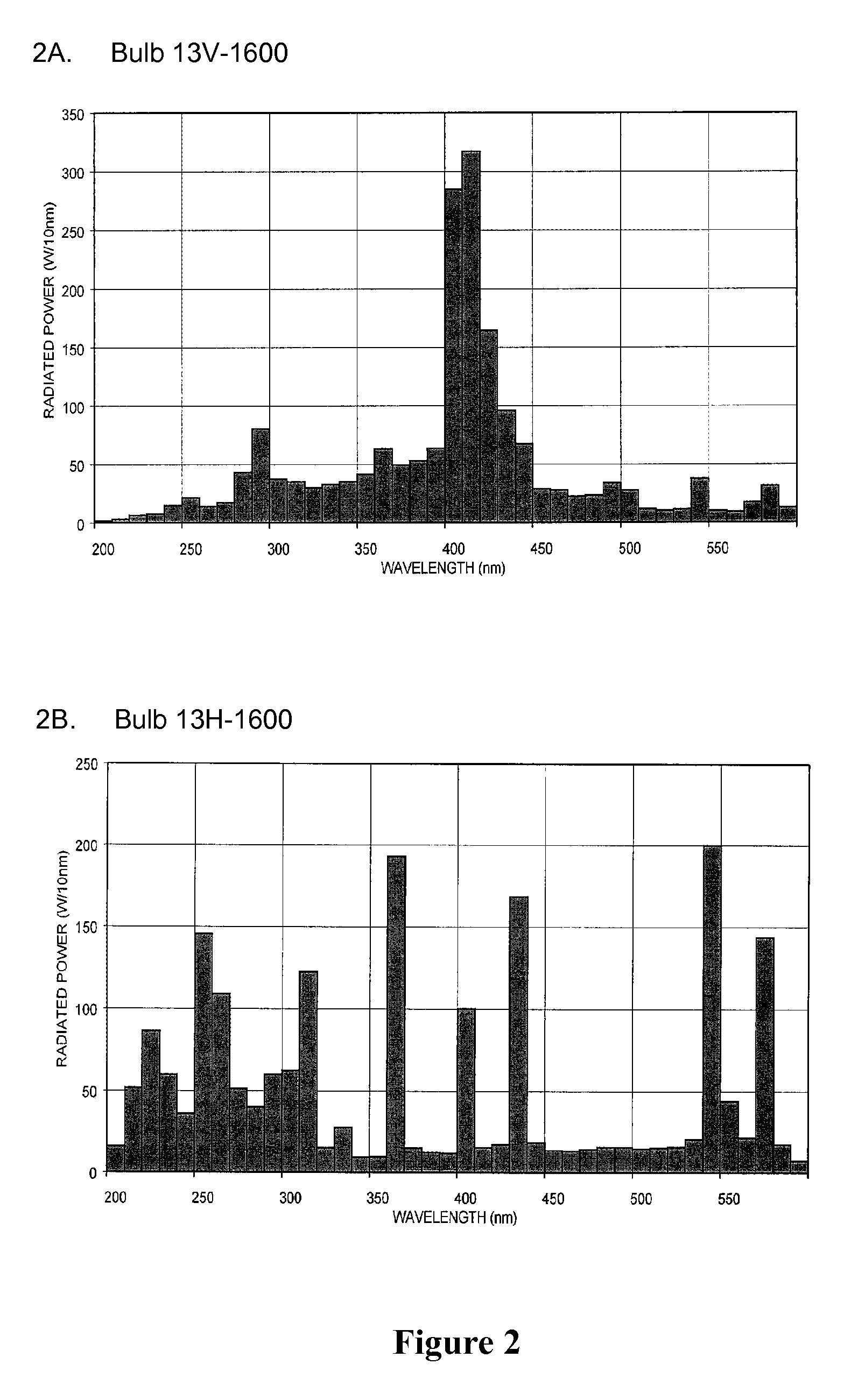

InactiveUS20090188559A1Weather resistantReduce surface temperatureMixing methodsPhotovoltaicsUV curingCoating system

The present invention is directed to ultraviolet cured coating compositions. More specifically, the present invention is directed to urethane / acrylic coating compositions that contain additives for the absorption of ultraviolet radiation and the reflection of infrared radiation and which are UV cured.

Owner:BUILDING SOLUTIONS IP

Ultra-discharging water-soluble fluor-silicon-acrylic coatings with nano particles

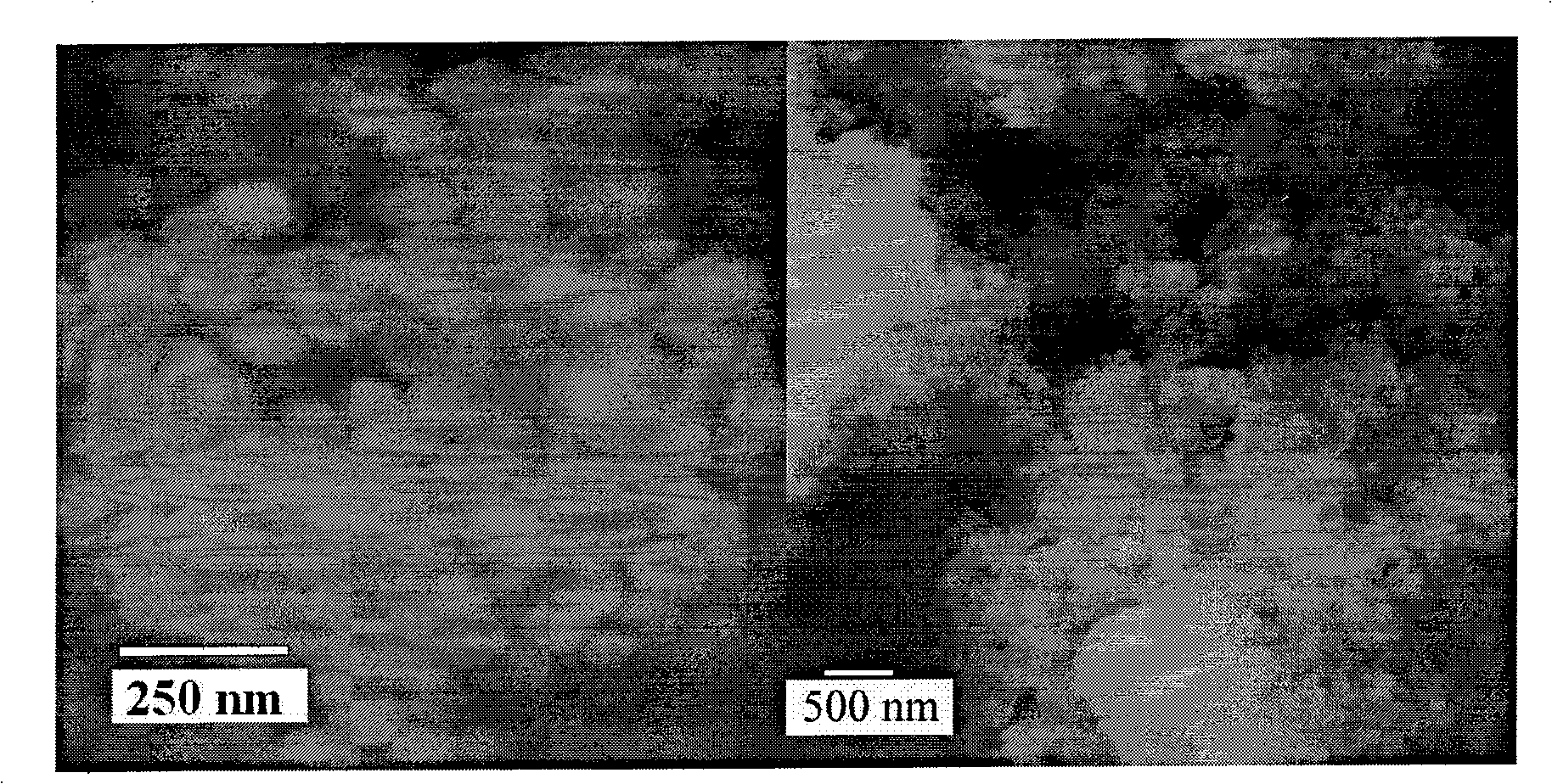

InactiveCN101307210AWide variety of sourcesInexpensive and easy to obtainEmulsion paintsMechanical propertyNuclear chemistry

The invention discloses a super-hydrophobic water fluorine silicone / acrylic paint containing nanoparticles. The paint is prepared by mixing the compositions by weight percentage: 30 to 65 percent of water, 10 to 40 percent of silicone-acrylate emulsion, 10 to 40 percent of water fluoro-polymer emulsion, 1 to 10 percent of nano-meter oxid particles, 1 to 15 percent of inorganic hole compound and a small quantity of inorganic acid used for adjusting the pH value. The invention also discloses a super-hydrophobic water fluorine silicone / acrylic coating prepared by the paint. The water static wrapping angle of the coating is more than 150 degrees and a rolling angle is lower than 5 degrees. The coating prepared by the paint has the advantages of super-hydrophobicity, excellent mechanical property and easy process, etc. and has the self-cleaning function similar to a lotus leaf.

Owner:胡硕

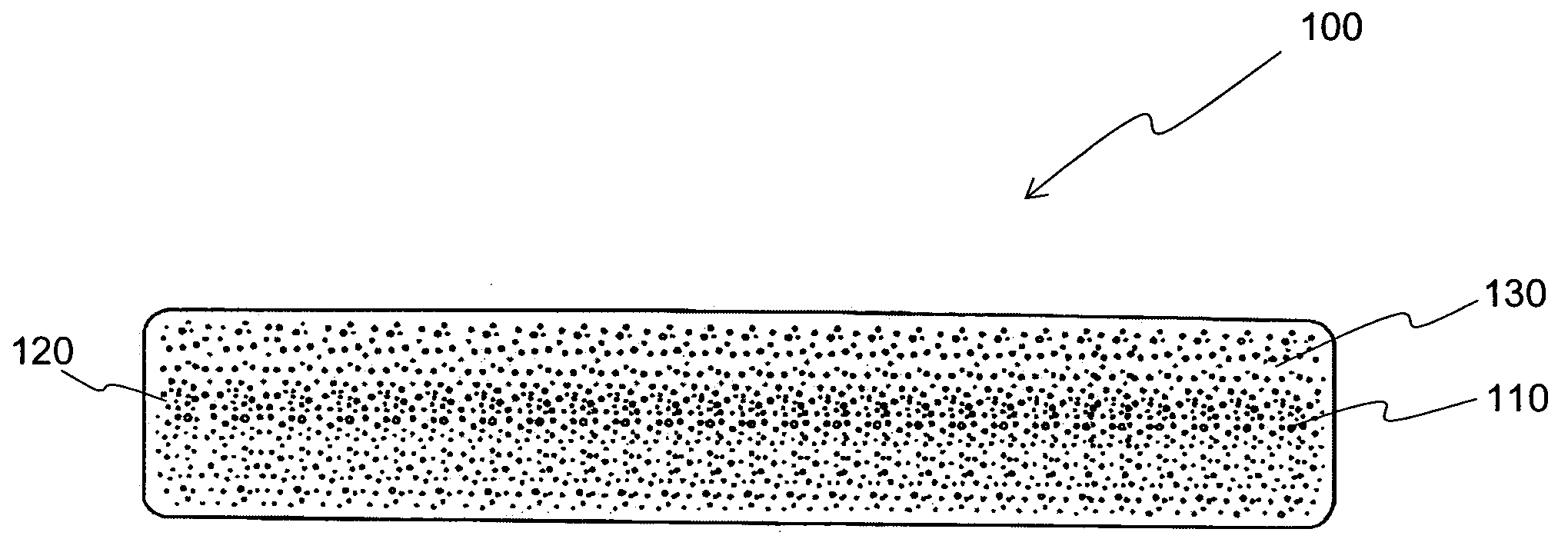

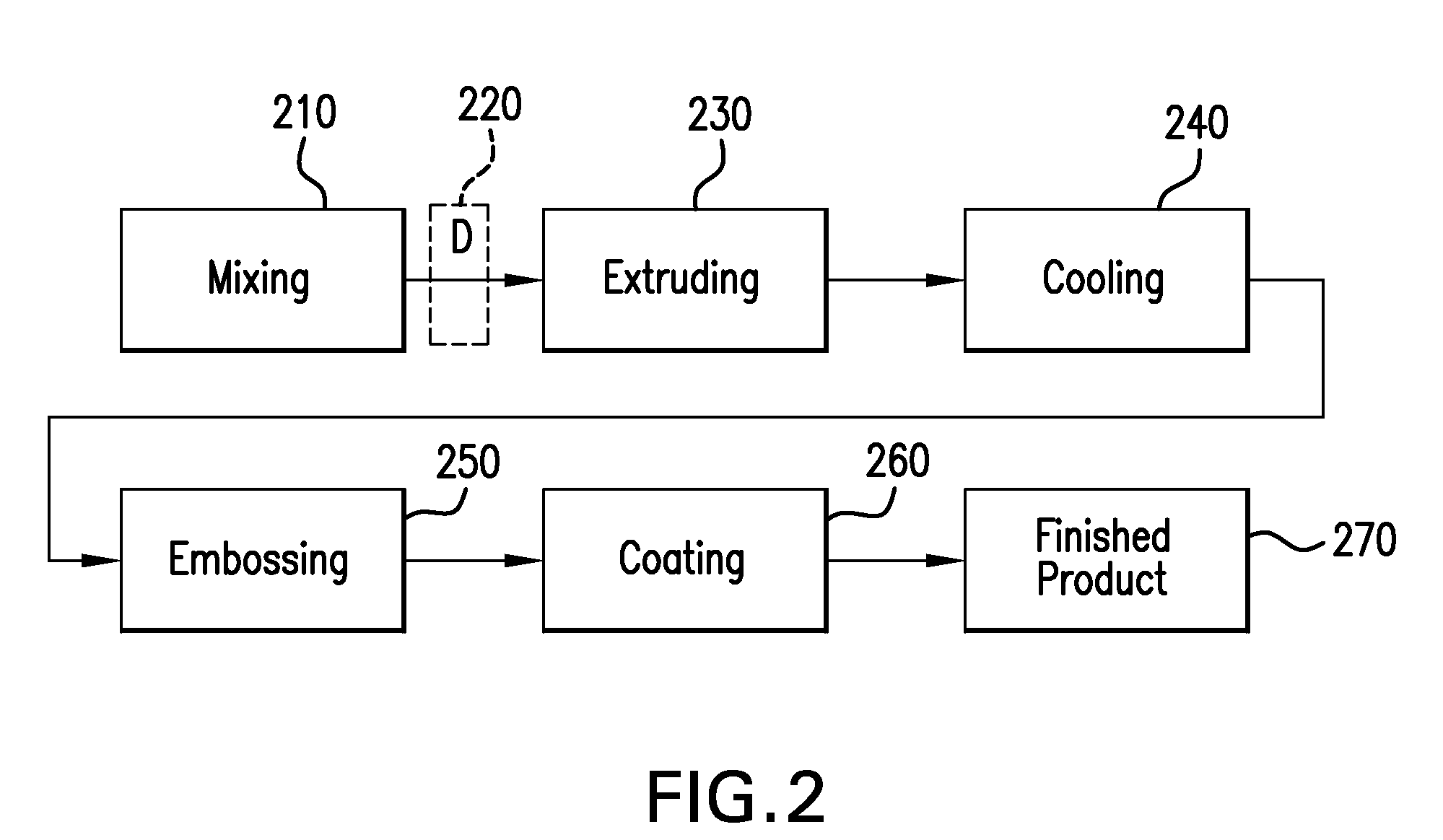

Composite building material and method for making composite building material

InactiveUS20080193740A1Prevent degradationAvoid insufficient temperatureLayered productsPretreated surfacesFoaming agentProcedure Agents

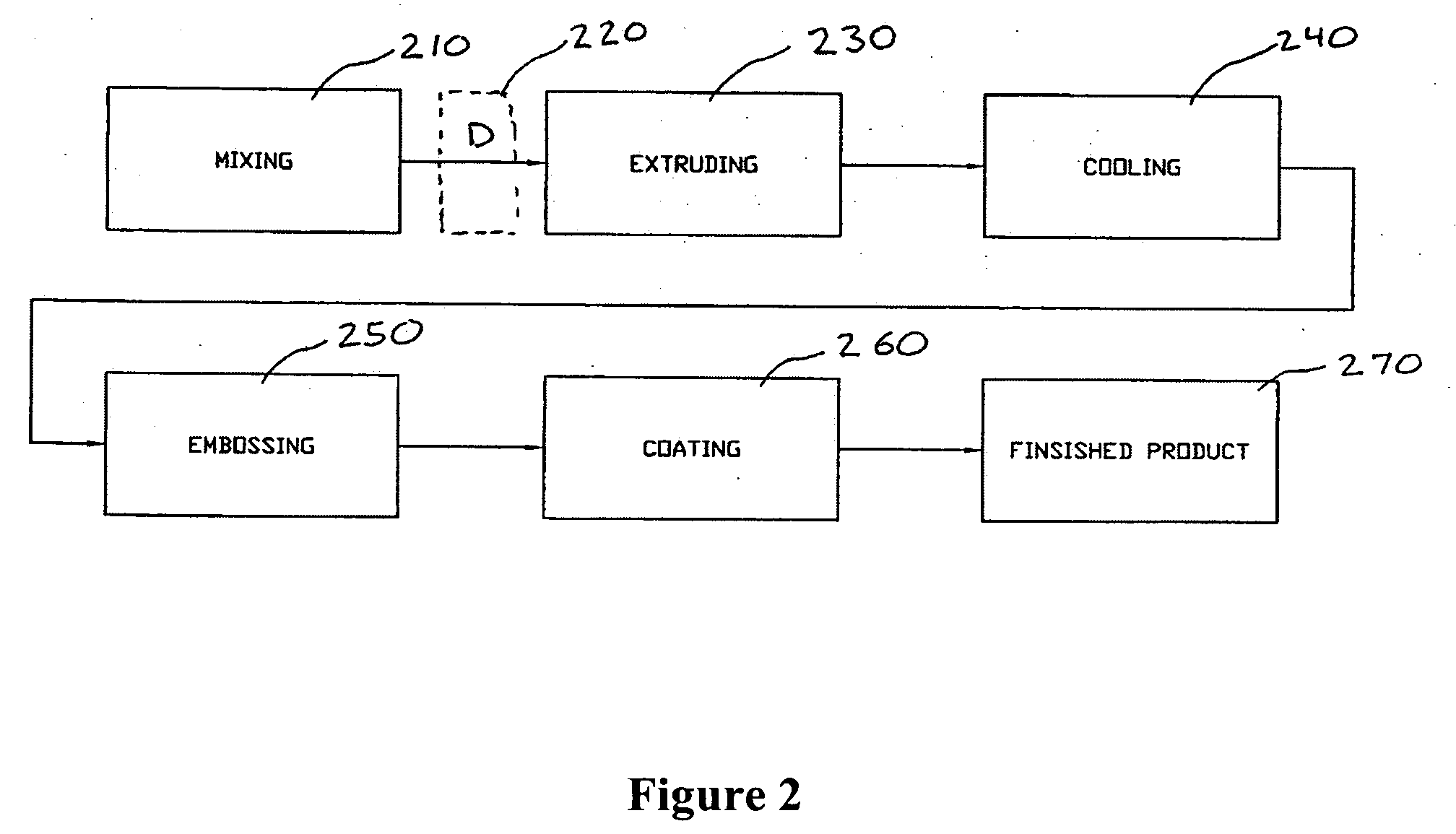

A composite building material and a method for its manufacture are provided. The method comprises the steps of: providing a foamable mixture comprising a polymeric matrix material, a filler, a processing aid, one or more lubricants, a thermal stabilizer, and a blowing agent; foaming said foamable mixture to form a foamed composite substrate; optionally embossing the substrate; and coating the substrate with a polyurethane / acrylic coating to form the composite building material, wherein the polyurethane / acrylic coating is keyed chemically and / or physically to the foamed composite substrate.

Owner:FIBER COMPOSITES

Manufacture process of imitation stainless steel metal drawbench film

InactiveCN102642439AIncrease the dyne coefficientHigh fastnessLamination ancillary operationsSynthetic resin layered productsPolyesterAcrylic coating

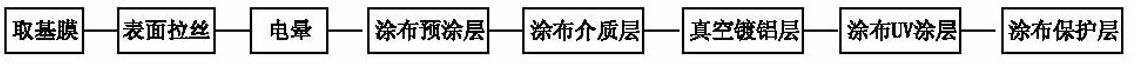

The invention discloses a manufacture process of an imitation stainless steel metal drawbench film, which comprises the following steps: 1 taking a base film which is a polyester (PET) film; 2 conducting surface drawbench and surface polishing one surface of the base film; 3 conducting surface corona and conducting corona processing on two surfaces of the base film, 4 conducting precoat coating and conducting network roller coating on the surface of the base film receiving surface drawbench and corona processing through methyl methacrylate coating, 5 conducting media layer coating and conducting network roller coating on a precoat through acrylic coating, 6 conducting vacuum aluminizing on the media layer, 7 conducting ultraviolet (UV) coating coating and conducting network roller coating on one face of the base film without surface drawbench through colored translucent UV coating, and 8 conducting protection layer coating and preventing an aluminizing layer from being oxidized. The manufacture process improves product structure firmness, and ensures optimum using effects of products. The products can show different gloss effects from dumb light to high light, thereby meeting requirements for environment protection.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Acrylic coating powders comprising hydrophobic particles and powder coatings therefrom having improved filiform corrosion resistance

ActiveUS20090192247A1Improved filiformSolve the lack of resistanceAnti-corrosive paintsPowdery paintsAlloy substrateAcrylic coating

The present invention provides coating powder compositions for making filiform corrosion resistant coatings, the compositions comprising particles or agglomerates which include, intimately mixed, each of one or more thermosetting acrylic copolymer, one or more crosslinker for the acrylic copolymer and one or more hydrophobic submicron particle additive, wherein the hydrophobic submicron particle additive comprises from 0.01 to 1.5 wt. %, based on the total weight of the coating powder. The hydrophobic submicron particle additive comprises a submicron inorganic oxide, e.g. fume silica or a metal oxide, and one or more organosilicon compound, e.g. polydimethylsiloxane. In addition, the invention provides filiform corrosion resistant clear coat or tinted clear coat powder coatings on metal, e.g. aluminum wheels or forged alloy substrates.

Owner:AKZO NOBEL COATINGS INT BV

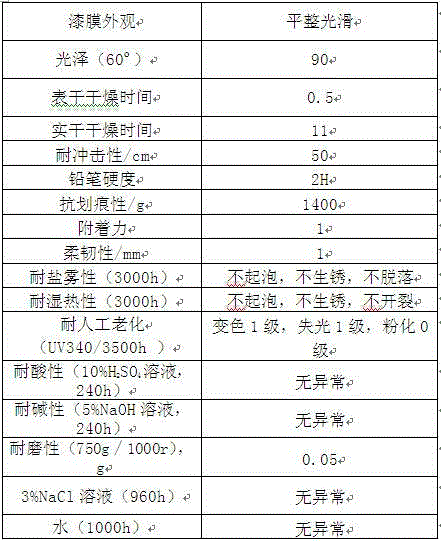

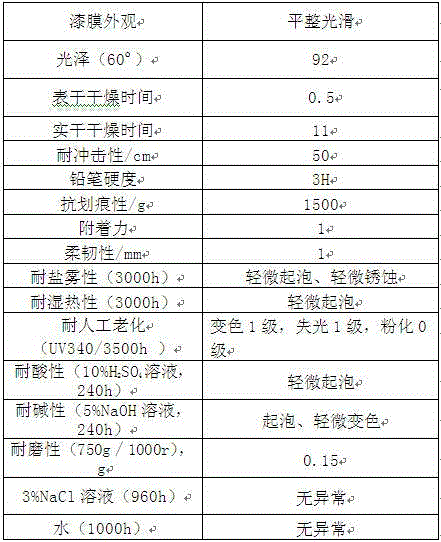

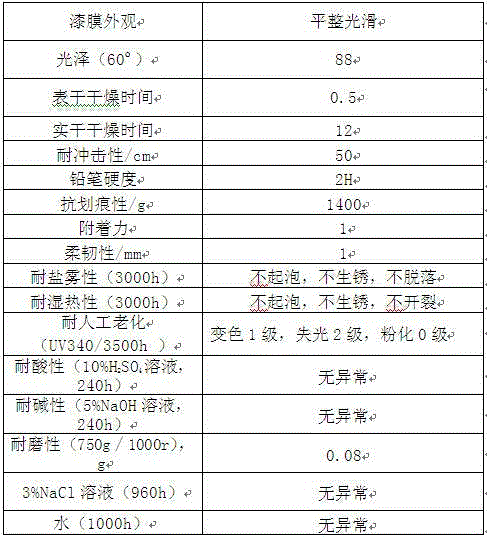

Organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating and preparation method thereof

ActiveCN104673039ALow priceGood alkali resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinAcrylic coating

The invention discloses an acrylic coating and a preparation method thereof, and particularly relates to an organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating and a preparation method thereof. The invention provides the organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating which has free TDI content less than 0.15% after blended, is capable of reducing the pollution hazard on the environment and has preferable film-forming property and a preparation method thereof, aiming at overcoming the defects of the prior art. The organic-silicon organic-fluorine modified acrylic heavy anti-corrosion coating comprises the following components in parts by weight: 40-60 parts of fluorine-silicon modified acrylic resin, 0.2-0.5 part of dispersing agents, 10-20 parts of pigments, 10-20 parts of fillers, 0.2-0.5 part of defoaming agents, 0.2-0.5 part of levelling agents, 10-15 parts of solvents and 8-14 parts of aliphatic polyurethane curing agents, wherein the proportion sum is 100 parts.

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

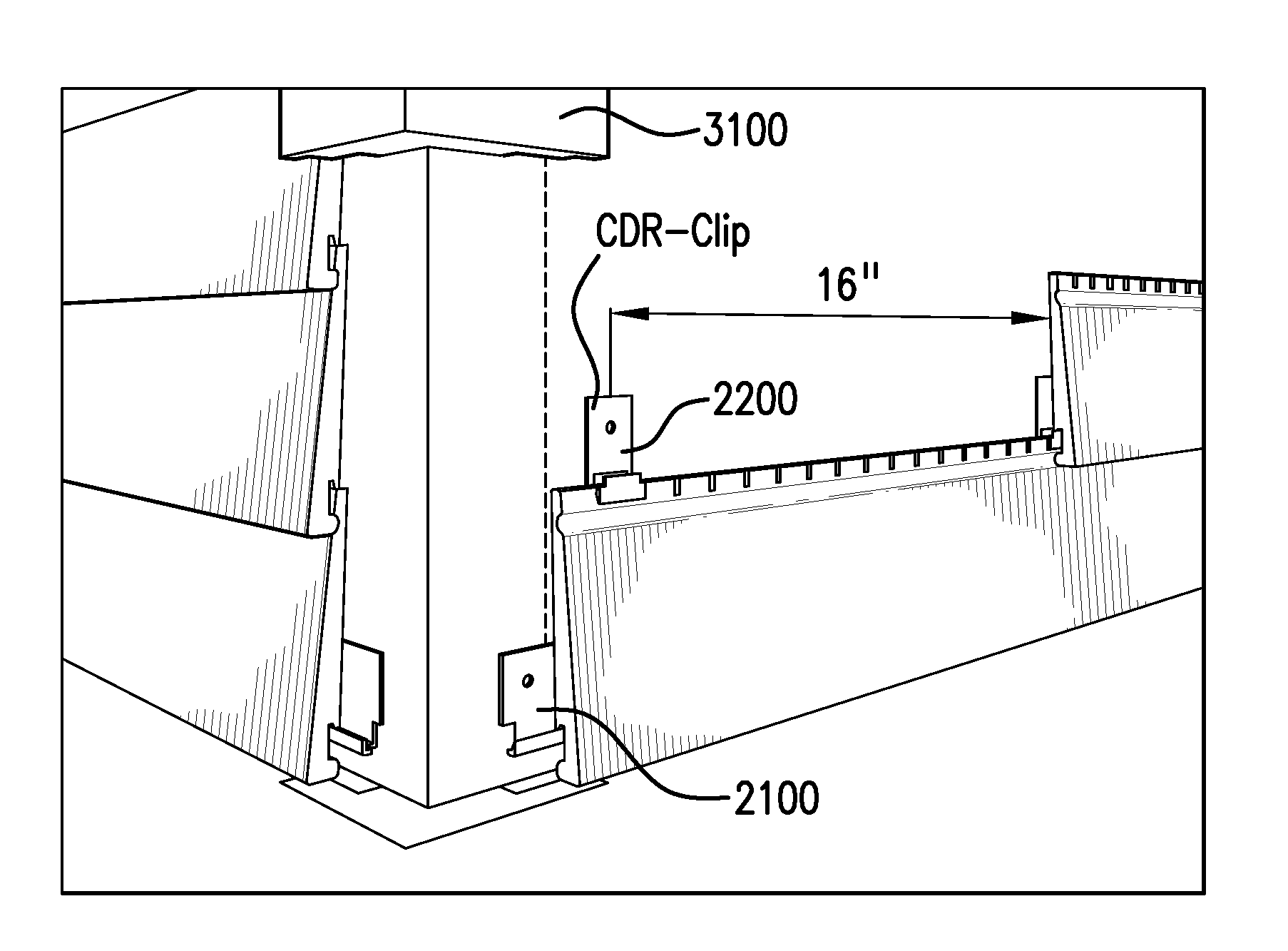

Siding containing composite building material and siding clip

InactiveUS20100132295A1Prevent substrate deteriorationReduce the temperatureRoof covering using tiles/slatesCovering/liningsAcrylic coatingPigment

Siding including composite building material and a siding clip are provided. The panel has male and female interlocking elements and may be formed from a composite building material having a foamed substrate having a foamed inner core and a dense integral skin, wherein the foamed substrate includes a polymer matrix and a reinforcing filler, and a urethane / acrylic coating applied to the foamed substrate at the front face of the siding panel, wherein the coating includes an IR-reflective pigment, wherein the urethane / acrylic coating is chemically and / or physically bound to the substrate.

Owner:FIBER COMPOSITES

Hydroxy acrylic resin dispersoid and waterborne coating prepared from same

InactiveCN107722186ASimple and fast operationReduce energy consumptionAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinLacquer

The invention relates to a hydroxy acrylic resin dispersoid and a waterborne coating prepared from the same. Resin is obtained by two-step polymerization, amine is added to perform neutralization, andwater is added to disperse the resin to obtain the stably stored hydroxy acrylic resin dispersoid with a core-shell structure. Two steps include: first, preparing a hydrophobic portion by free radical solution polymerization; second, preparing a hydrophilic portion by free radical solution polymerization. The hydroxy acrylic resin dispersoid has the core-shell layered structure and has the advantages of high solid content, low viscosity and the like. The two-component waterborne acrylic coating prepared by the method can combine the advantages of an acrylic coating and a polyurethane coating,has excellent physical performance, chemical performance and appearance performance, has the advantages of high paint film crosslinking density and hardness, good toughness and chemical medium resistance, high drying speed, capability of drying at room temperature and the like, and is widely applied to priming paint, finishing paint and priming and finishing combined paint of various engineeringmachinery and automobiles.

Owner:CHANGZHOU HUAKE POLYMERS

Manufacture method of plastics parts for vehicle or cladding parts

InactiveCN101357509ASolve efficiency problemsSolve environmental problemsDomestic articlesGlass fiberAcrylonitrile

The invention discloses a method for manufacturing plastic parts or covering parts, which comprises the two parts of sheet material plastic-absorption molding and reaction injection molding, wherein, the sheet material plastic-absorption molding includes that plastic-absorption molding is carried out on acrylonitrile-butadiene-styrene / acrylic coating exemption sheet material, polypropylene sheet material, polyvinyl chloride sheet material, poly carbon ester sheet material, polythene sheet material, nylon sheet material or acrylonitrile-butadiene-styrene sheet material for manufacturing the finished plastic-absorption products; the reaction injection molding includes that the mixed reactant of polyurethane and glass fibre bunch is poured on the internal surface of the finished plastic-absorption products, the dies are assembled, after complete reaction, the plastic part or covering part used on vehicles is manufactured. The method has the advantages of being suitable for mass production and low harm to environment and human body.

Owner:叶欣

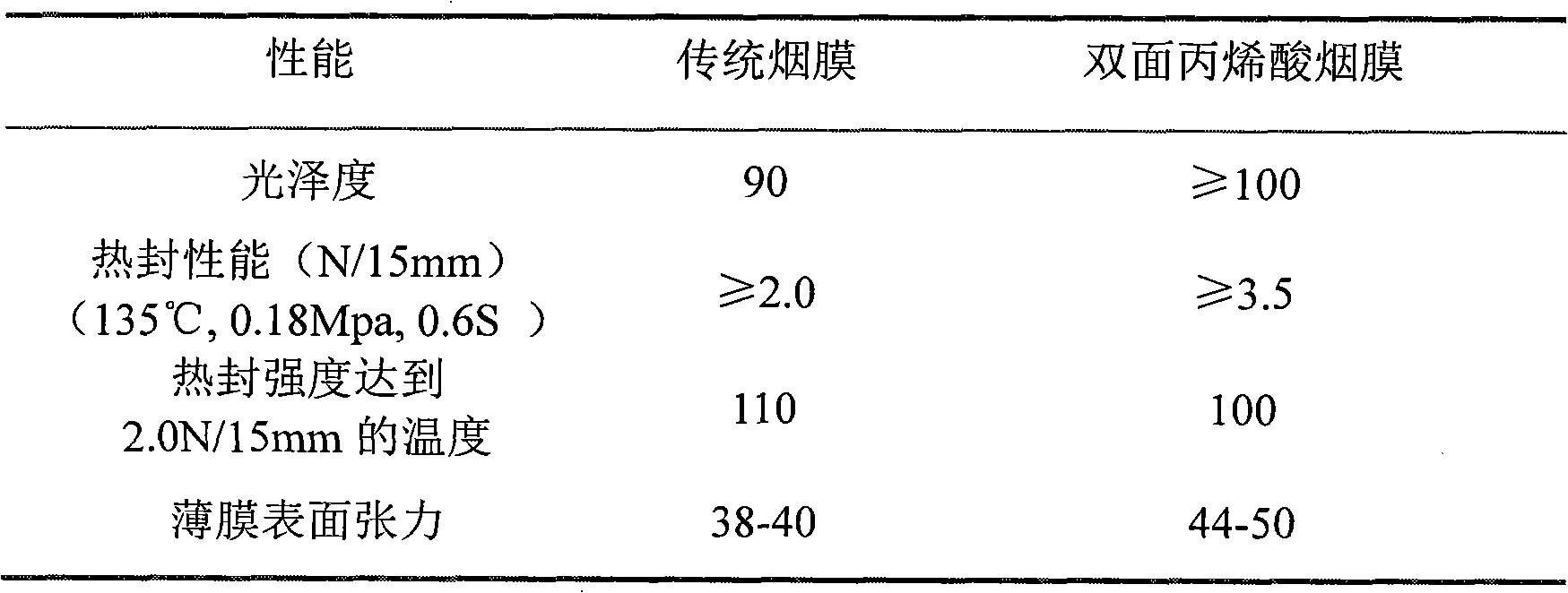

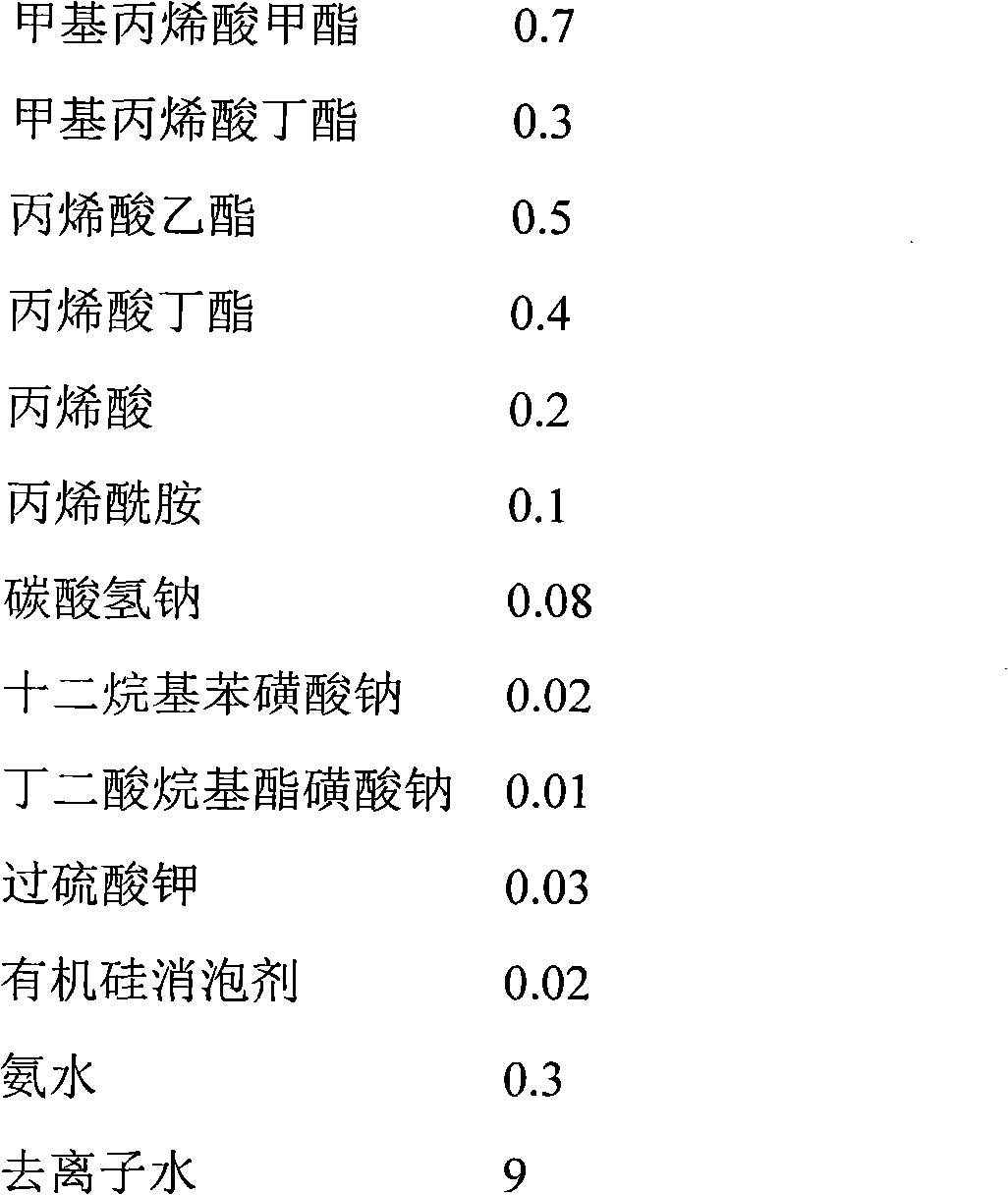

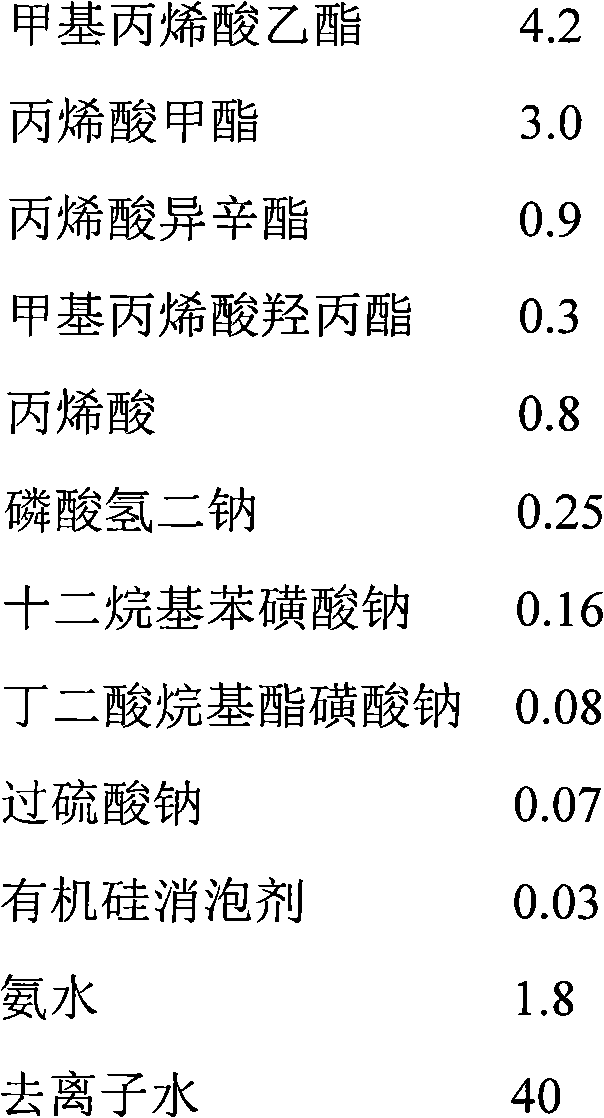

High thermal-sealing type acrylic coating special for cigarette film and preparation method thereof

InactiveCN102649892AImprove mechanical stabilityGood storage stabilityCoatingsSal ammoniacAcrylic coating

The invention provides a high thermal-sealing type acrylic coating special for a cigarette film and a preparation method thereof. The coating comprises the following raw materials by weight percent: 8-10% of metacrylic acid ester, 7-9% of acrylic ester, 1-5% of crosslinking monomer, 0.5-2% of emulsifying agent, 0.1-0.4% of initiator, 0.1-1% of buffering agent, 0.05-0.2% of defoaming agent, 2-4% of ammonia water and 75-82% of de-ionizing water. The high thermal-sealing type acrylic coating has high thermal sealing property, high glossing degree and excellent printing property, and is widely suitable for the coating of the cigarette film.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

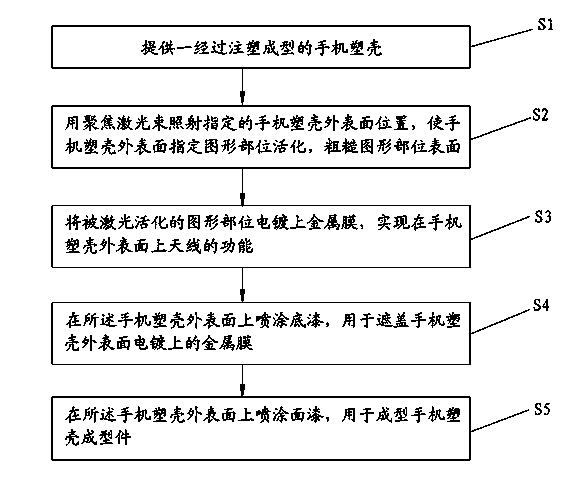

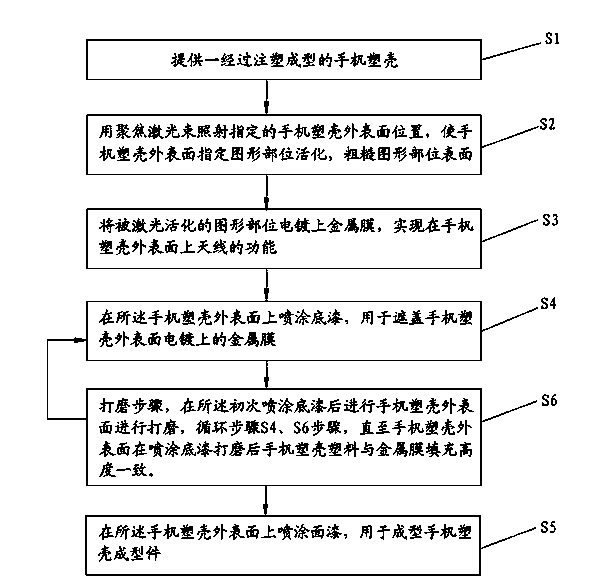

Spraying process for laser-direct-structuring (LDS) antenna on outside surface of mobile phone plastic shell

The invention discloses a spraying process for a laser-direct-structuring (LDS) antenna on an outside surface of a mobile phone plastic shell. The spraying process comprises the following steps of providing the mobile phone plastic shell of injection molding; irradiating the specified position of the outside surface of the mobile phone plastic shell by using a focused laser beam to activate the specified graph part of the outside surface of the mobile phone plastic shell, and roughing the surface of the graph part; electroplating the graph part activated by laser with a metal film; spraying undercoat to be used for covering the electroplated metal film on the outside surface of the mobile phone plastic shell; and spraying finishing coat to be used for forming a formed part of the mobile phone plastic shell. The primary spraying thickness of the undercoat is 40-60mum, the spraying thickness of the finishing coat is 10-20mum, the undercoat is acrylic coating, and the finishing coat is ultraviolet (UV) coating. According to the spraying process for the LDS antenna on the outside surface of the mobile phone plastic shell disclosed by the invention, the height difference between the LDS antenna and the mobile phone plastic shell is effectively handled during the manufacturing process of a normal mobile phone plastic shell, and therefore, not only is the using function of the LDS antenna satisfied but also the appearance surface of the mobile phone plastic shell is not influenced. Meanwhile, a manufacturing process is simple and is good in effect.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

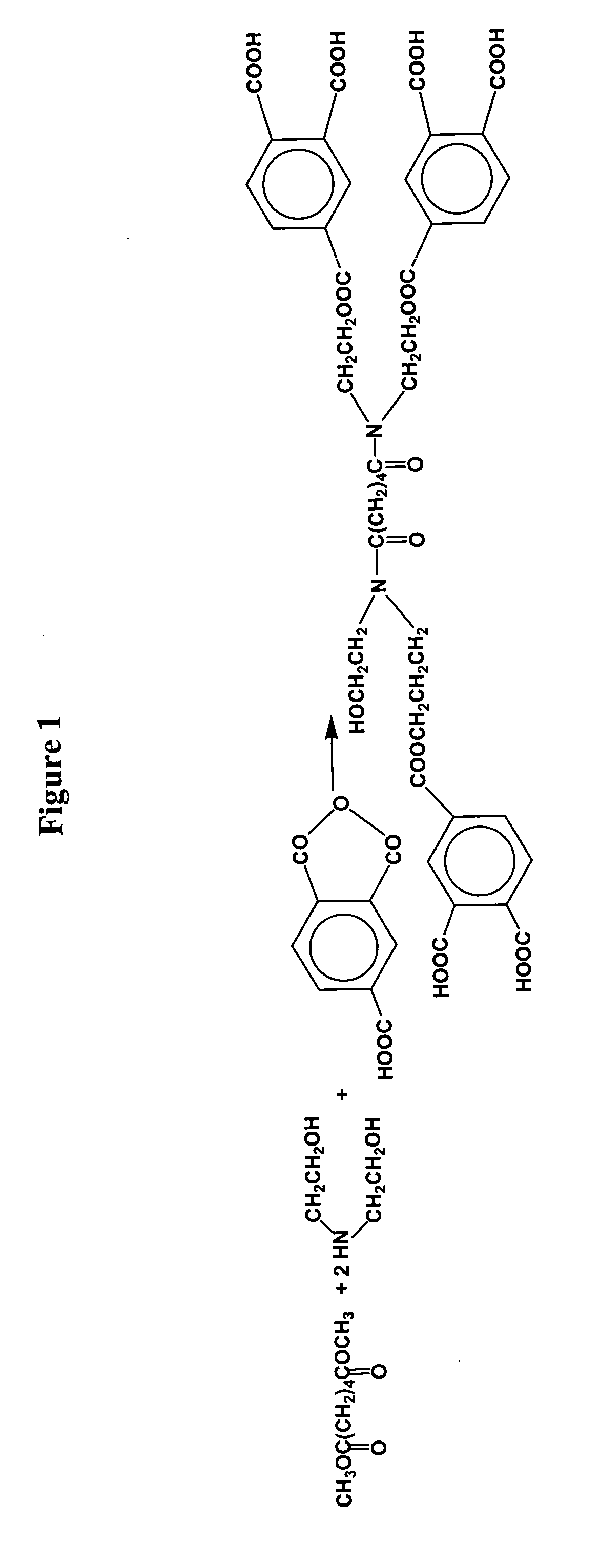

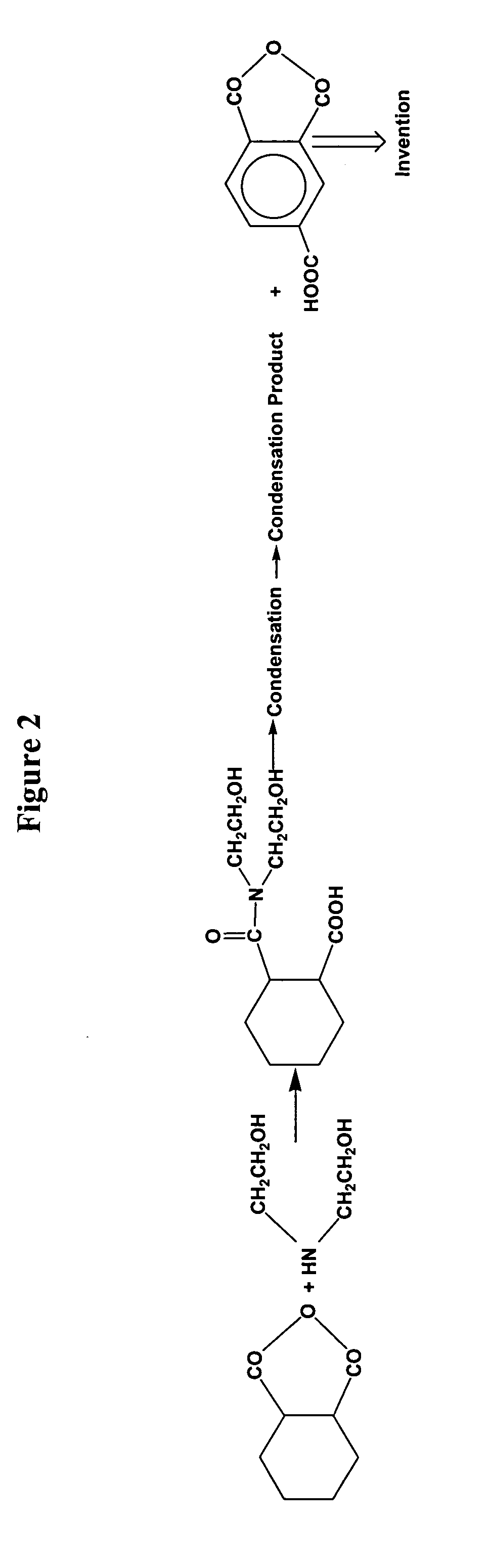

Coating matting agent comprising amide condensation product

InactiveUS20050288450A1Reduce glossImprove adhesionSynthetic resin layered productsPolyamide coatingsEpoxyPolyester

The compounds of this invention are suitable matting agents for coatings. The compounds are amide-containing condensation products optionally comprising at least one β-hydroxyalkylamide functional group and, for example, are prepared from monomeric amides, oligomeric polyamides or polymeric polyamides bearing β-hydroxyalkylamide groups by reacting the hydroxyalkylamide bearing amide with another compound such that at least one reactive functional group other than β-hydroxyalkylamide is also present on the condensation product, and further such that 50% or more of the terminal β-hydroxyalkylamide functionality has been reacted or converted to groups containing terminal carboxylic acid groups or other reactive groups including, but not limited to, groups reactive with polymers and crosslinkers suitable for preparing epoxy, epoxy-polyester, polyester, polyester acrylic, polyester-primid, polyurethane or acrylic coatings. Other embodiments of the invention comprise the combination of the aforementioned condensation product with inorganic solids such as silicas and aluminas, and / or matte activators.

Owner:FLETCHER TIM

Extra-weather-resistant waterborne environment-protective resin and preparation technology thereof

According to the invention, methyl methacrylate (MMA), butyl acrylate (BA), ethyl acrylate (EA), acrylic acid (AA) and methacrylic acid (MAA) and trifluoroethyl methacrylate (TFEMA), vinyltriethoxysilane (KH-151) and styrene (ST) and other functional monomers are used as comonomers; benzoyl peroxide (BPO) is used as a chain initiator, a solution polymerization method is used, and a free radical polymerization is carried out through a special process to synthesize organic fluorine-silicon modified waterborne acrylic resin with excellent performance. The resin is extra-weather-resistant, is applied to a water-based acrylic coating, and has advantages of good gloss retention, exterior durability, good pollution resistance and the like. By the use of the resin, water resistance, solvent resistance and heat resistance of a water-based acrylic resin coating can be improved, and hardness and shock resistance of a paint film can be enhanced. As a coating with superior performance, the product has a wide application prospect.

Owner:沈阳宣伯新材料科技有限公司

Two-component water-based hydroxyl acrylic coating

InactiveCN105368287AImprove adhesionStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a two-component water-based hydroxyl acrylic coating composed of a component A and a component B, wherein the weight ratio of the component A to the component B is 1 to (1-3). The component A comprises the raw materials in parts by weight: 40-80 parts of modified hydroxyl acrylic resin, 5-20 parts of water-based hydroxyl fluorosilicone acrylic resin, 5-15 parts of a water-based nano alumina dispersion body, 5-10 parts of a water-based nano silica dispersion body, 2-6 parts of ethylene glycol monoethyl ether acetate, 1-3 parts of a levelling agent BYK306, 0.2-0.8 part of a catalyst dibutyltin dilaurate, and 1-5 parts of xylene. The component B comprises the raw materials in parts by weight: 10-20 parts of a hexamethylene diisocyanate trimer, 1-5 parts of HDI biuret, and 20-30 parts of a diluent. The two-component water-based hydroxyl acrylic coating has good water resistance and excellent corrosion resistance.

Owner:ANHUI JINDUN PAINT

Modified acrylic coating concrete anti-corrosion method

InactiveCN105369904APrevent agingImprove anti-corrosion performanceCovering/liningsBridge erection/assemblyAcrylic resinAcrylic coating

The invention discloses a modified acrylic coating concrete anti-corrosion method, which comprises the following steps of coating test; scaffold erection; concrete cleaning; concrete grinding; concrete repair leveling; acrylic resin seal primer coating and brushing; acrylic resin finish paint coating and brushing; and maintenance. The modified acrylic coating concrete anti-corrosion method has the advantages that the spraying and coating is convenient and fast; the coating is compact and firm; acrylic resin seal primer and finish paint are used, so that a powerful protective barrier is formed on the concrete surface; water and carbon dioxide are effectively blocked; concrete aging and internal steel bar corrosion are effectively prevented; and the anti-corrosion performance of concrete is greatly improved.

Owner:CHINA MCC17 GRP

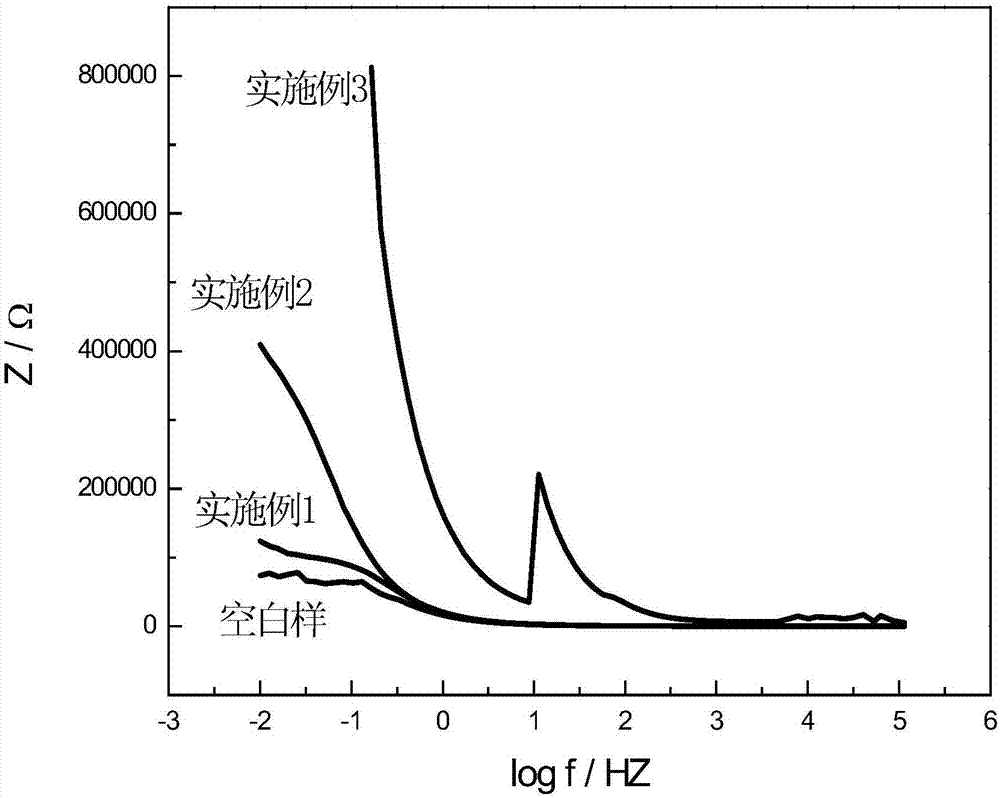

Graphene oxide modified aqueous acrylic acid functional coating and preparation method thereof

The invention relates to the technical field of functional coatings, and in particular relates to a graphene oxide modified aqueous acrylic acid functional coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: 5-15 parts of a functionalized graphene dispersion liquid, 20-45 parts of an aqueous acrylic emulsion, 5-25 parts of pigments and filler, 1-5 parts of a dispersant, 1-5 parts of a defoamer, 5-25 parts of water and 1-5 parts of a PH regulator. By compounding resin and functionalized graphene oxide physically to modify the aqueous acrylic coating, the corrosion resistance of the aqueous acrylic coating is enhanced effectively. In addition, by adding methacrylamide and vinyl acetate functional modifying monomers, phenyl, amide bases and ester groups are introduced to the acrylic resin, so that the performance of the acrylic emulsion is promoted.

Owner:FOSHAN UNIVERSITY

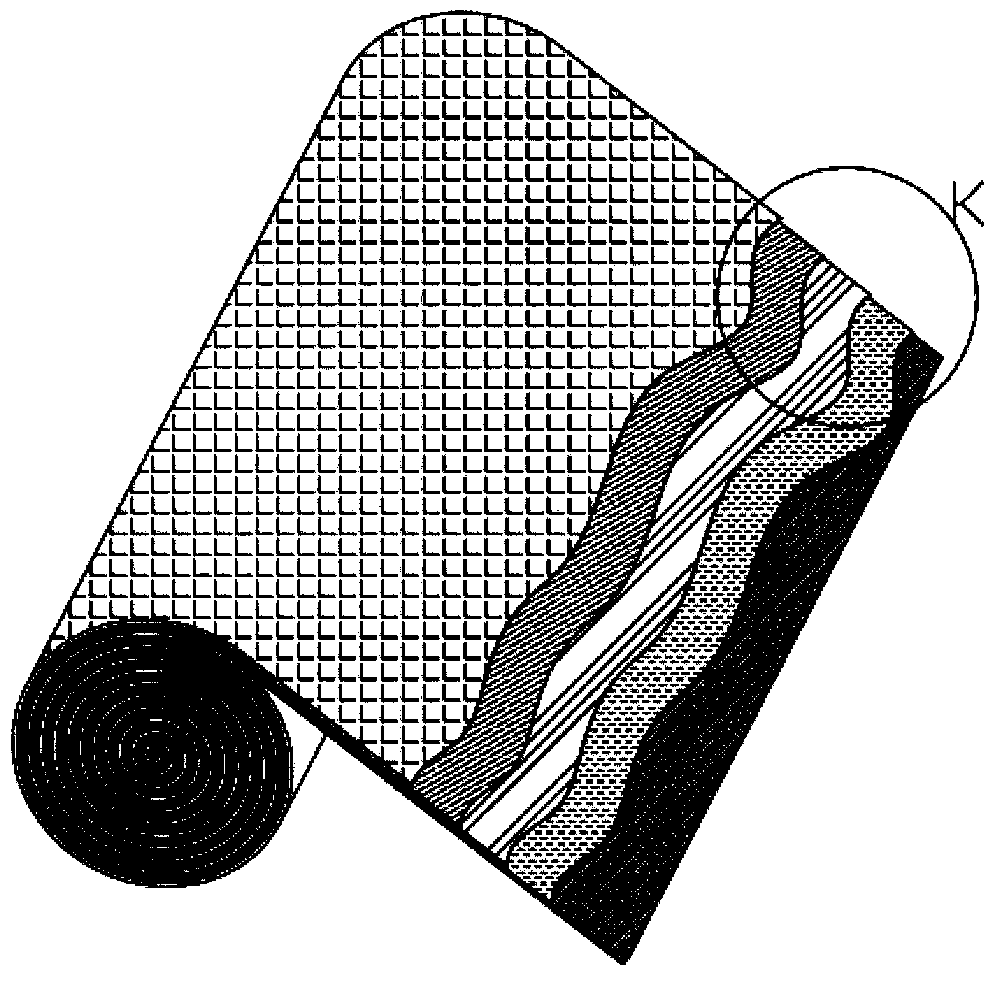

Photovoltaic waterproof coiled material for roof and preparation method for photovoltaic waterproof coiled material

ActiveCN103410276ADoes not affect appearanceHigh roof area utilizationRoof covering using slabs/sheetsRoof covering using tiles/slatesPolyesterFluoropolymer

The invention discloses a photovoltaic waterproof coiled material for a roof. The photovoltaic waterproof coiled material is in a layered structure and comprises a waterproof coiled material base material, a flexible membrane photovoltaic battery assembly, a membrane layer and a coating layer sequentially from inside to outside. The invention also discloses a method for preparing the photovoltaic waterproof coiled material for the roof. The method comprises the steps of (1) preparing the waterproof coiled material base material: cleaning one side of the surface of the waterproof coiled material base material for standby application; (2) preparing the photovoltaic battery assembly: coating the front face of the flexible membrane photovoltaic battery assembly which is provided with the surface packaged by a fluorine-containing TPT polyester membrane or an ethylene-tetrafluoroethylene copolymer membrane with a nanoscale silicone acrylic coating or a nanoscaleperfluorocarbon coating; (3) performing combining and packaging: performing stacking in the sequence of the flexible membrane photovoltaic battery assembly, a Sika single-component high-modulus polyurethane sealant and the waterproof coiled material base material, and performing roll pressing and laminating machine vacuum pumping, so that layers of elements are bonded closely, and a product is obtained. The preparation method is simple, low in cost, multiple in option of substrates and suitable for large-scale industrial production.

Owner:新大运防水科技(唐山)有限公司

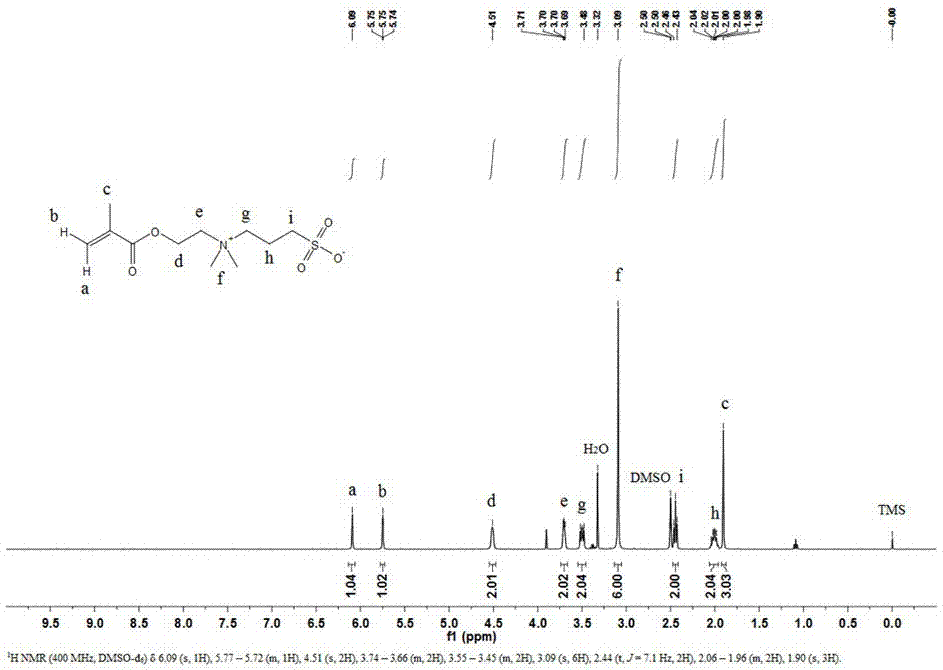

Reversible self-repair antibacterial acrylic coating and preparation and self-repair methods

ActiveCN106928797AReversible self-healingAntibacterialAntifouling/underwater paintsPaints with biocidesMethacrylateBetaine

The invention discloses a reversible self-repair antibacterial acrylic coating and preparation and self-repair methods. The preparation method comprises the steps of adding methyl methacrylate, butyl acrylate, sulfonyl betaine methacrylate and acetoacetoxy methacrylate gylcol ester into an alcohol solvent, and performing free radical polymerization under the initiation of azodiisobutyronitrile to obtain linear acrylic resin; and dissolving the linear acrylic resin and amino-containing hyperbranched polysiloxane into the alcohol solvent, coating the surface of a base material, and drying, thus obtaining the reversible self-repair antibacterial acrylic coating. Efficient and mild repair of the coating is realized by using the characteristic of reversible reaction of vinylogous urethane bonds at room temperature and amino rich at the terminal of the hyperbranched polysiloxane, and the acrylic coating is endowed with excellent antibacterial property by the safe, nontoxic and non-specific sulfonyl betaine. The product has good applicability and strong practicability; the preparation method has the characteristics of wide raw material source, simple process and environment friendliness.

Owner:SUZHOU UNIV

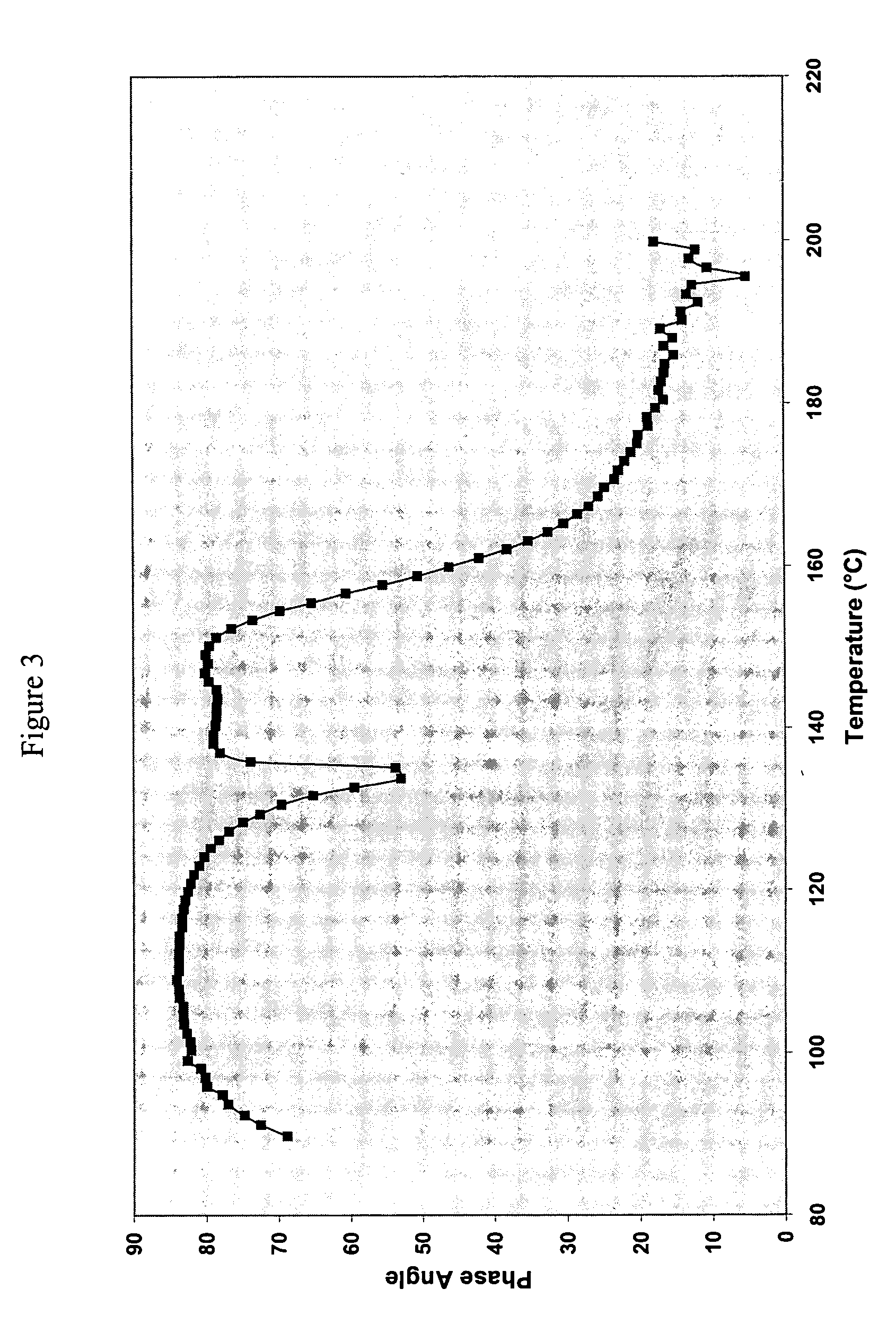

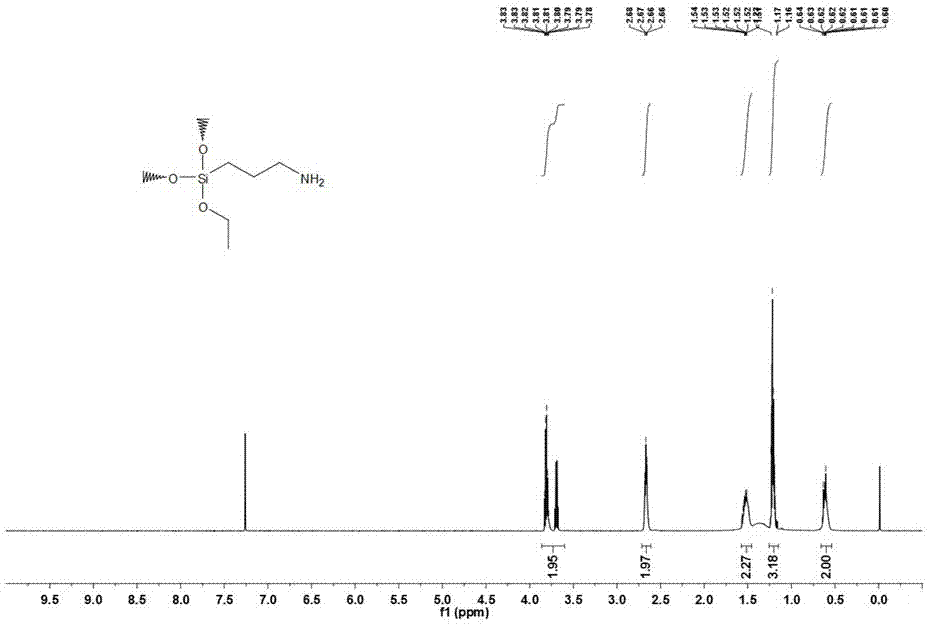

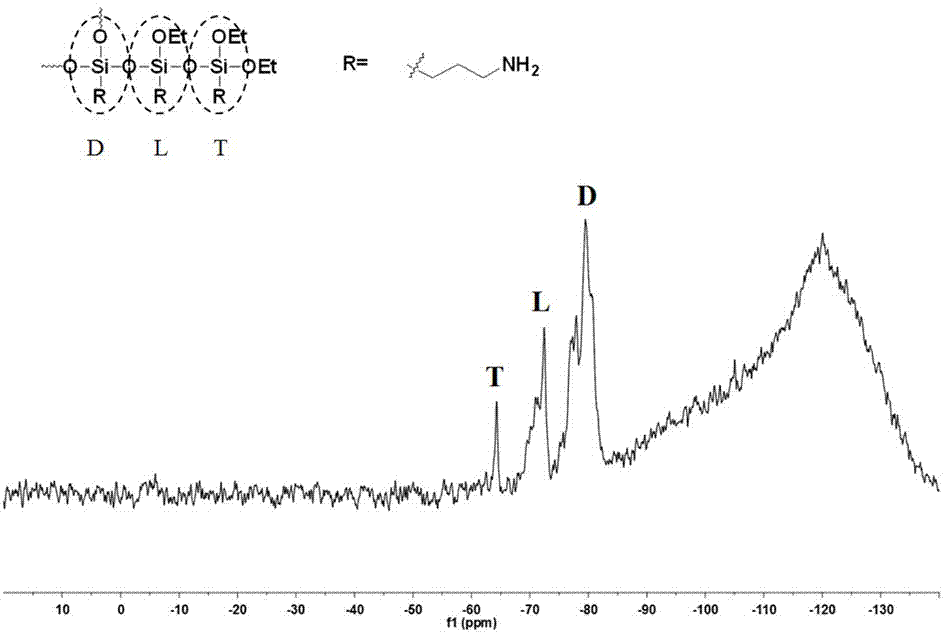

Moisture cure non-isocyanate acrylic coatings

An ambient temperature curing coating composition comprising the crosslinked reaction product of:(a) an amino-functional compound, wherein the amino-functional compound is a bis-silylamine of general formula:(R2)b(R1Y)aSi-Q1-NH-Q2-(NH-Q3)n-Si(YR1)a(R2)b wherein n≧0, a=3−b, b=0,1,2 and wherein each Y is independently a heteroatom, selected from O, N; if Y is N, then the valency of Y is 2; if Y is O, then the valency of Y is 1; each R1 is independently a monovalent radical (e.g., hydrogen, hydrocarbon including but not limited to alkyl (linear or brached), cycloalkyl, aryl, allyl, or aralkyl. Preferably, R1 is an alkyl of 1–10 carbon atoms. Each R1 may be the same or different; R2 is a monovalent radical, and can include heteroatoms (e.g., oxygen, nitrogen, sulfur) not directly bonded to the silicon atom, including but not limited to, alkyl (linear or branched), cycloalkyl, aryl, allyl, or aralkyl. Each R2 may be the same or different. Q1, Q2, Q3 is a divalent bridging group, including but not limited to an alkylene, but preferably is a C1–C12 alkylene, and can be branched or cyclic; each Q can be the same or different; and(b) an acrylic polymer having pendant alkoxysilane and optionally epoxy groups.The invention can be further crosslinked with reactive polysiloxanes.

Owner:SHERWIN WILLIAM COMPANY THE

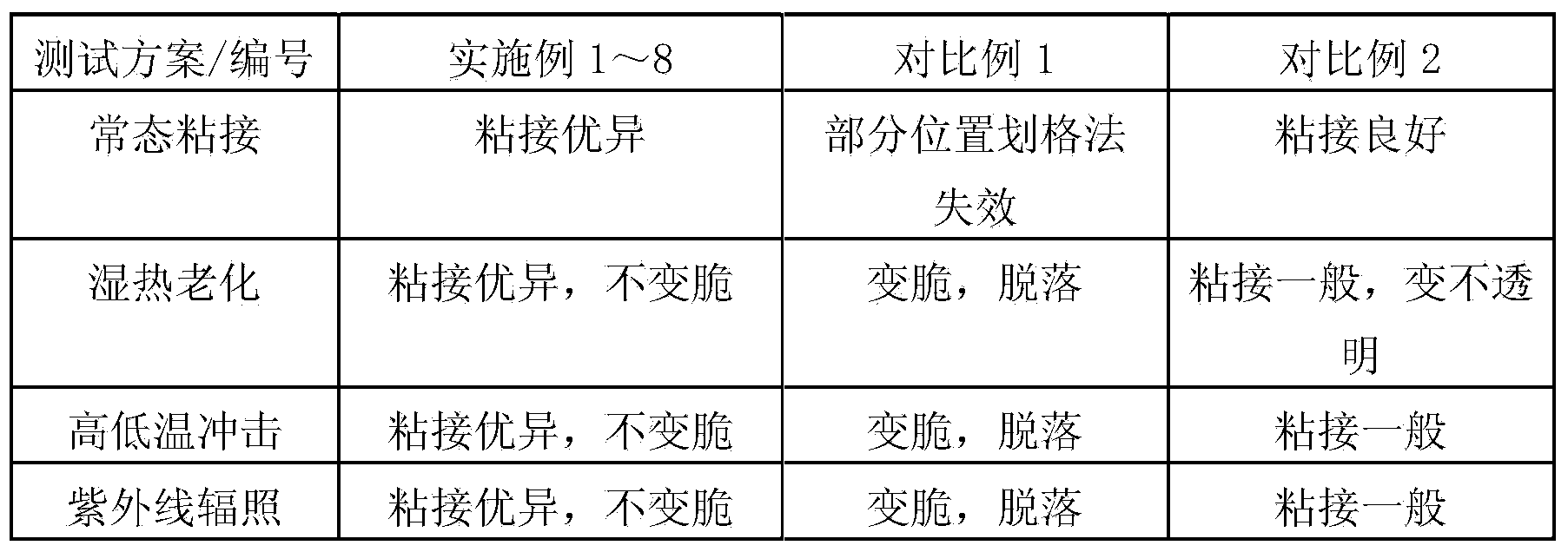

Method for improving adhesion property and prolonging service life of acrylic coating

The invention discloses a method for improving the adhesion property and prolonging service life of acrylic coating. The method comprises the steps of: adding organic titanium compound into the acrylic coating, wherein the organic titanium compound content is 0.05-3% of the weight of the acrylic coating; adding organosilicon tackifier which has Si-H, Si-CH3 obtained through substituting -H by CH3, or Si-C2H5 obtained through substituting -H by -C2H5, epoxy group or alkoxy group in the molecular structure, wherein the organosilicon tackifier content is 0.05-5% of the weight of the acrylic coating; adding a water removing agent into the acrylic coating, wherein the water removing agent content is 0.1-5% of weight of the acrylic coating. The method has the advantages that the performances of normal adhesion, wet-heat adhesion and adhesion after high / low-temperature impact of the acrylic coating to glass, plastic, metal and other substrates are improved, and meanwhile, the weather ability and hydrophobicity of the coating are also improved, the moisture transmittance of the coating is reduced, and the service life of the coating is prolonged.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

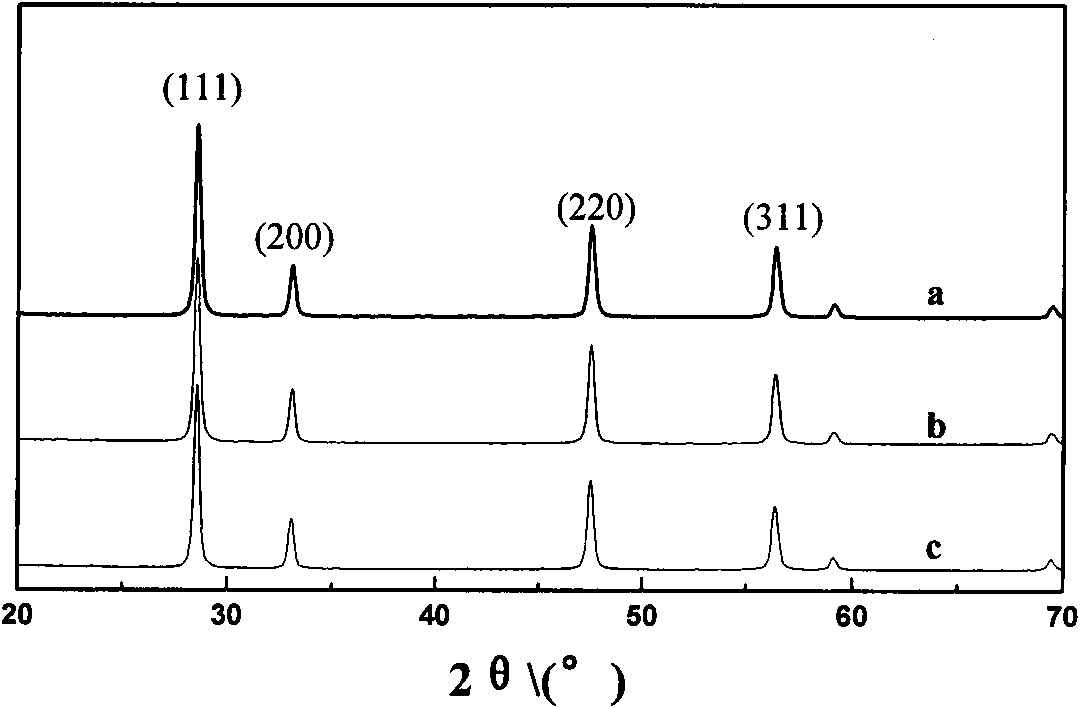

UV resistant agent used for acrylic coating and preparation method and application thereof

ActiveCN101629033AReduce oxidation catalytic activityImproves UV resistanceCoatingsSurface finishAcrylic coating

The invention discloses a UV resistant agent used for acrylic coating and a preparation method and an application thereof. The UV resistant agent is obtained by that nanometer CeO2 doped with Ca is prepared with a carboxymethocel ultrasound assisted method, then SiO2 is adopted to coat, and surface finish is performed by silane coupling agent. The UV resistant agent of the invention is suitable for UV aging protection of acrylic coating; when adding amount is 3%, ultraviolet screening efficiency is 94.5%; the penetration ratio in a visible light zone is kept above 71%, which is obviously higher than that of ZnO and TiO2, so that the UV resistant agent can serve as an excellent UV resistant agent which can be used on various coatings exposing in outdoor environment for prolonging the service life of the coating.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

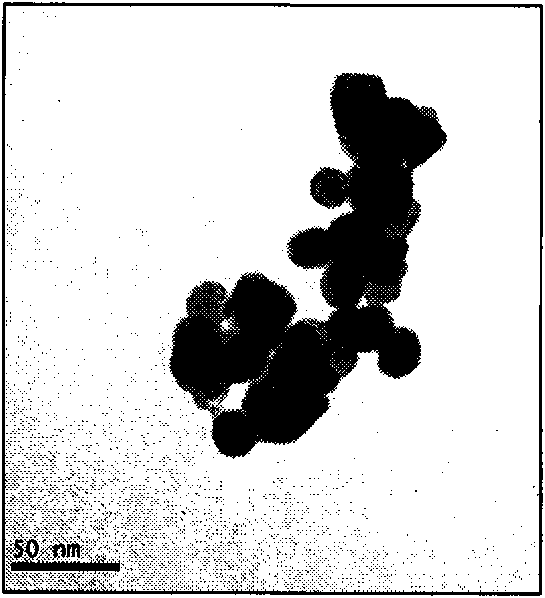

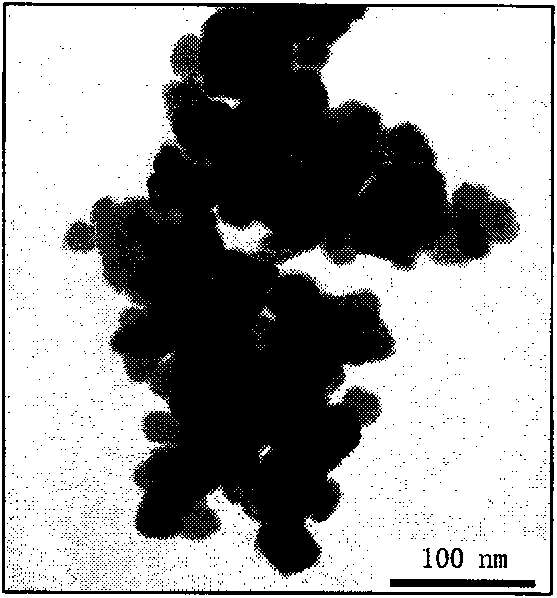

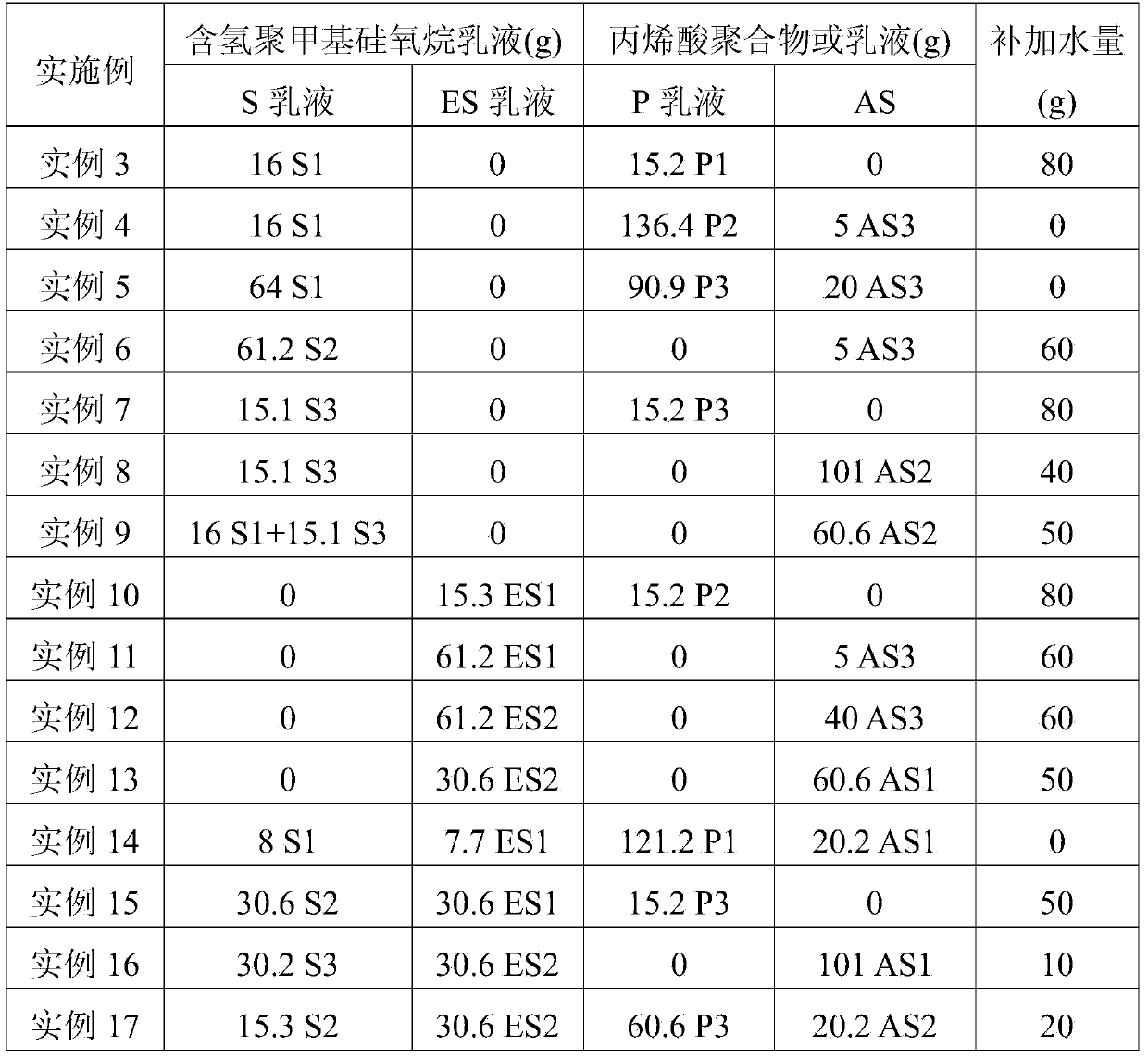

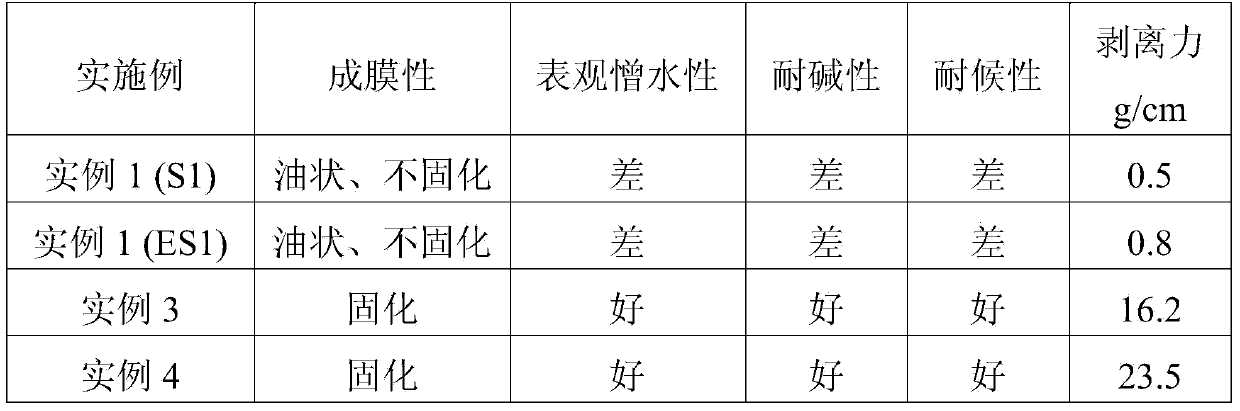

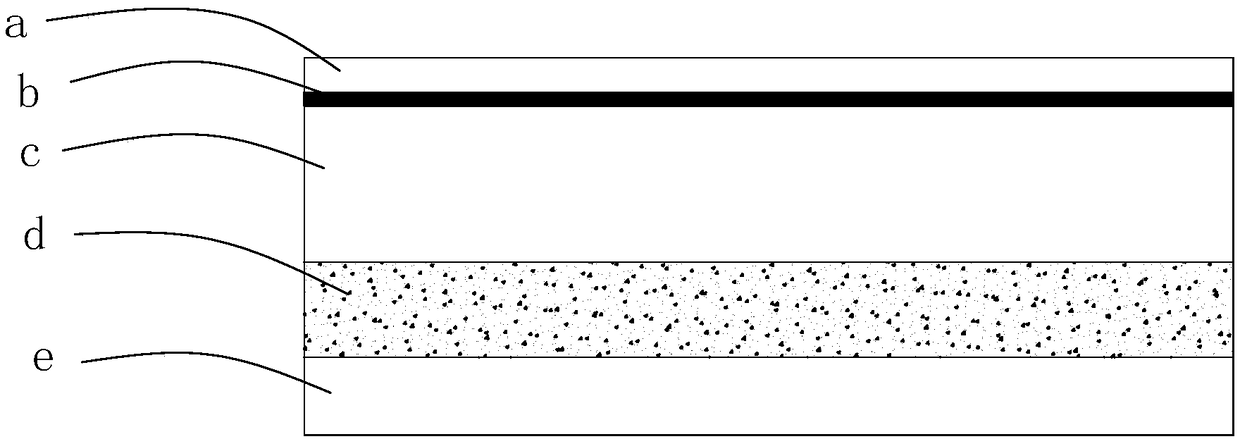

Acrylic organosilicone water-emulsion coating as well as preparation method and application for same

The invention belongs to the technical field of acrylic coatings, and discloses an acrylic organosilicone water-emulsion coating as well as a preparation method and an application for the same. The acrylic organosilicone water-emulsion coating comprises the following components in the following parts by weight: 100 parts of water, 0.1-4 parts of an emulsifier, 5-20 parts of liquid hydrogen-containing polymethyl siloxane, and 5-50 parts of acrylic polymers. The organosilicone content of the acrylic organosilicone water-emulsion coating disclosed by the invention is up to more than 10% in the polymers, organosilicone and the acrylic polymers are compounded in a wide range, and curing film-forming is performed at a room temperature. The preparation process disclosed by the invention is simple, and the obtained emulsion is good in stability; and after curing film-forming, the acrylic organosilicone water-emulsion coating is good in mechanical performance (wherein the hardness can be up to 3 H), excellent in waterproof and hydrophobic performances, acid-base resistance, weather resistance, and adhesive force (which can be up to 2.5 MPa), and proper in peel strength (which can be up to 23 g / cm).

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

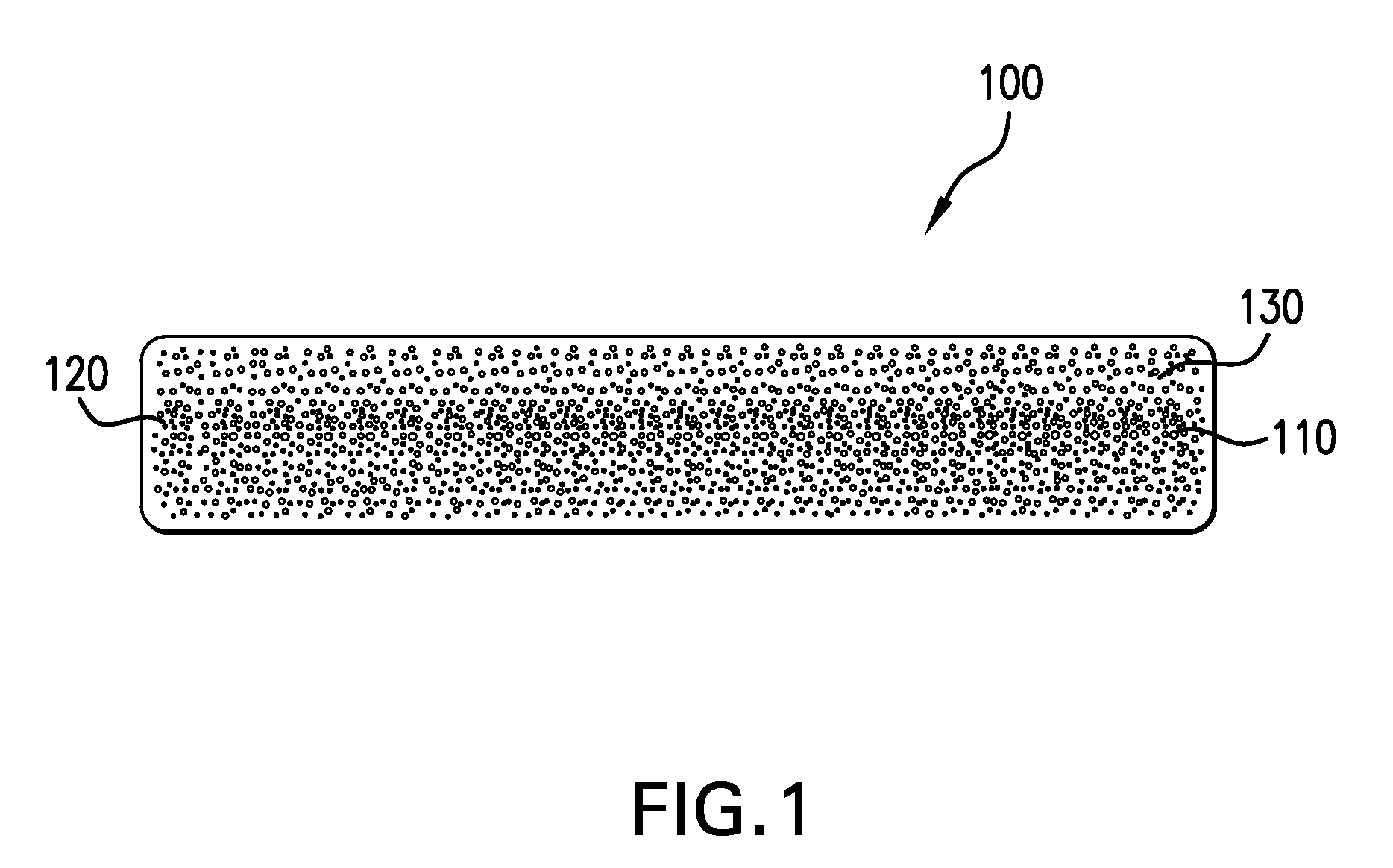

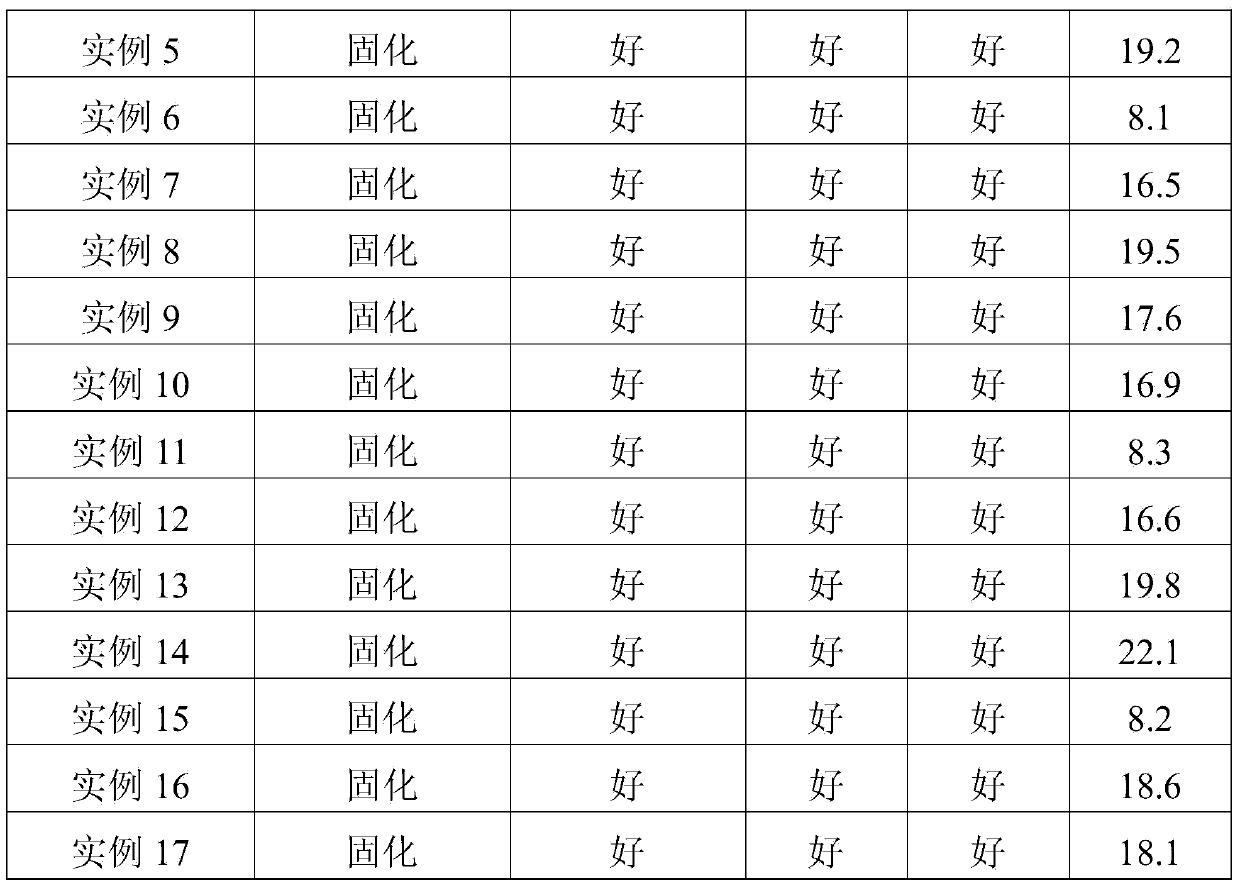

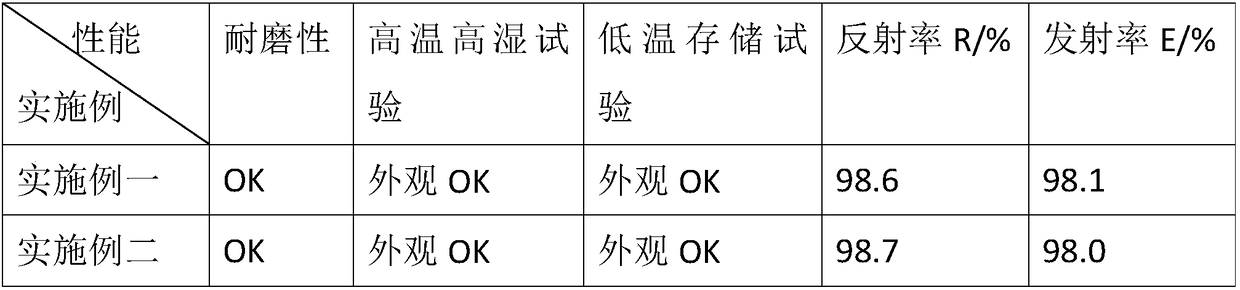

Reflective radiation refrigeration film

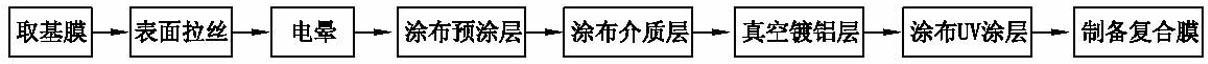

PendingCN109135599ASimple manufacturing methodLow costFilm/foil adhesivesRadiation-absorbing paintsPolyesterPolyethylene terephthalate glycol

The invention discloses a reflective radiation refrigeration film which comprises a coating layer, a metal layer, a transparent PET (polyethylene terephthalate) layer, adhesives and a release protective film which are sequentially arranged. The coating layer comprises organic acrylic coatings and micro-spheres, the micro-spheres are one of SiC, SiO2, TiO2, BaSO4 and CaCO3, the metal layer is deposited on the transparent PET layer by a magnetron sputtering method, and the ratios of the thicknesses of all the layers to the total thickness of the radiation refrigeration film include 2%-10% of thecoating layer, 0.01%-0.1% of the metal layer, 14.9%-87.99% of transparent PET, 5%-40% of the adhesives and 5%-35% of the release protective film. The micro-spheres with the particle size of 1-15 micrometers are randomly inlaid into polymethyl methacrylate coatings to prepare the film with the thickness of 50-150 micrometers. The film is simple and easy in preparation method, low in cost and goodin radiation refrigeration effect.

Owner:宁波瑞凌辐射制冷科技有限公司

Modified fly ash with surface coated with SiO2 and preparation method and use thereof

ActiveCN104403401AProtect the porous structureGood heat insulationSolid waste managementCoatingsPolymer scienceThermal insulation

The invention belongs to the technical field of inorganic powder surface modification, and in particular relates to modified fly ash with surface coated with SiO2 and a preparation method and use thereof, the method is as follows: Step 1) fly ash iron removal, step 2) capillary adsorption paraffin, step 3) coating of the surface with SiO2, the water absorption rate of the modified fly ash prepared by the method is 20%-22%, the whiteness is 20-30, the near infrared reflectivity is 60-80%, the coefficient of thermal conductivity is less than 0.25W / M.K; and the modified fly ash prepared by the method has good barrier thermal insulation and reflective thermal insulation performances. A thermal insulation coating prepared from the modified fly ash has excellent thermal insulating property, can be used in epoxy floor coatings, acrylic coatings for exterior wall, casting coatings and the like, and is free of the color and the construction problems, and high in added value.

Owner:SHAANXI UNIV OF TECH

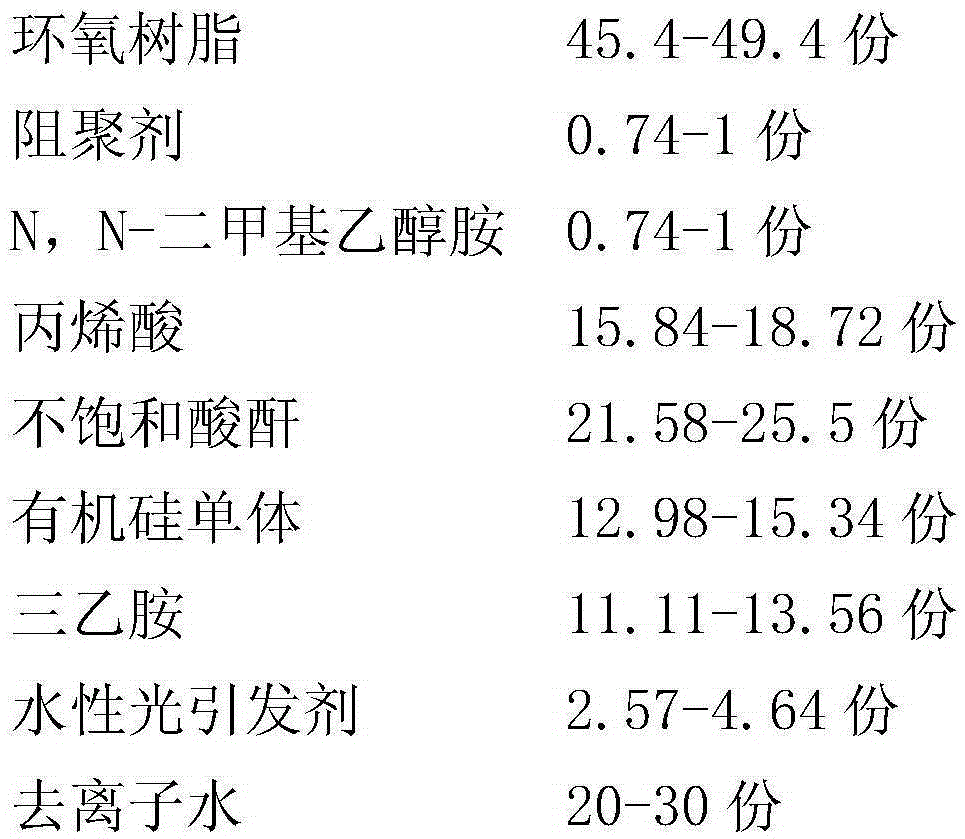

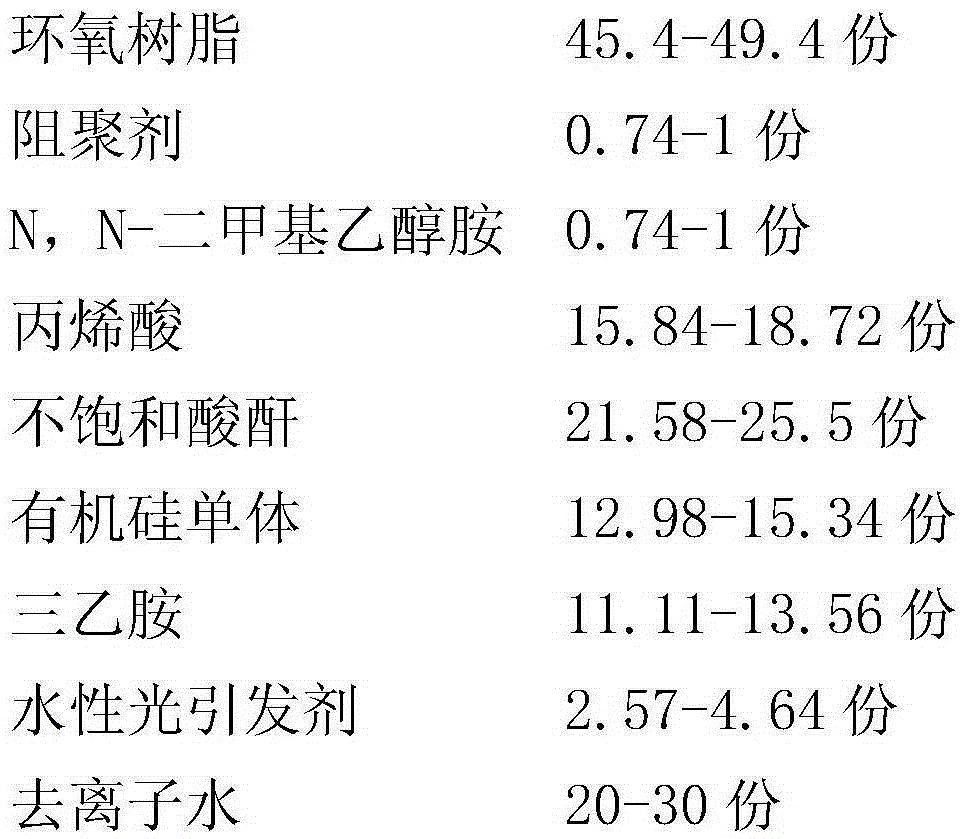

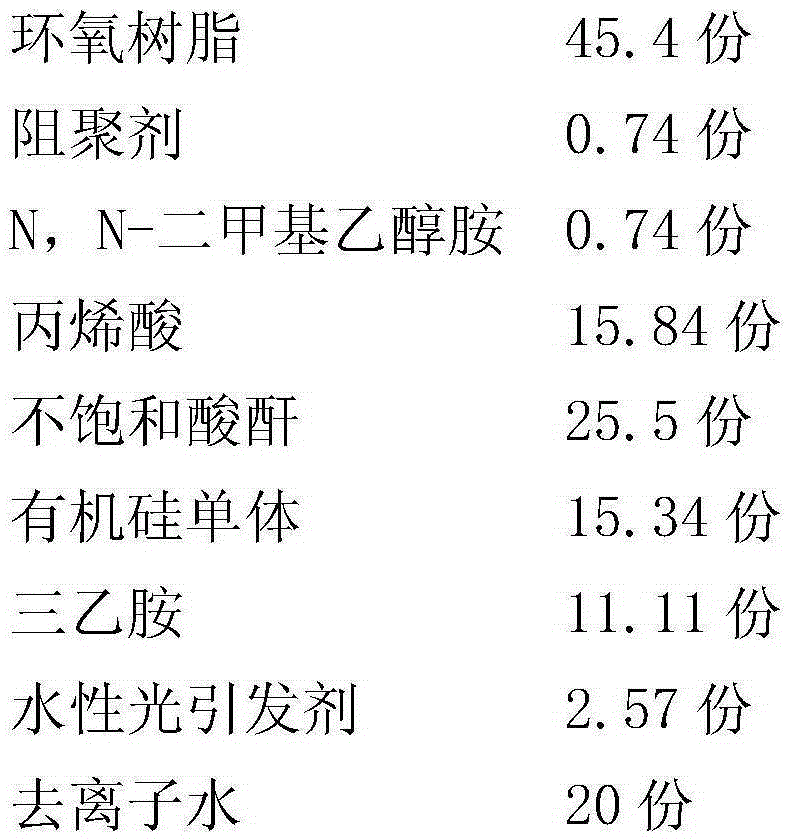

Organosilicon modified waterborne photo-curing epoxy-acrylic coating and preparation method thereof

The invention relates to an organosilicon modified waterborne photo-curing epoxy-acrylic coating prepared from the following components in parts by weight: 45.4-49.4 parts of epoxy resin, 0.74-1 part of a polymerization inhibitor, 0.74-1 part of N,N-dimethyl ethanolamine, 15.84-18.72 parts of acrylic acid, 21.58-25.5 parts of unsaturated acid anhydride, 12.98-15.34 parts of an organosilicon monomer, 11.11-13.56 parts of triethylamine, 2.57-4.64 parts of a waterborne light initiator, and 20-30 parts of deionized water. The organosilicon modified waterborne photo-curing epoxy acrylate prepolymer is a true zero-VOC waterborne photo-curing prepolymer, and has the advantages of high crosslinking degree, good water resistance, high hardness, good adhesive force, high pendulum hardness and good flexibility.

Owner:SKSHU PAINT

Cultured stone heat-insulation and decoration integrated plate and production technology thereof

The invention relates to a cultured stone heat-insulation and decoration integrated plate and a production technology thereof. The cultured stone heat-insulation and decoration integrated plate is made of the following raw materials: 42.5 silicate cement, coal ash, quartz sand, re-dispersible emulsion powder, hydroxypropyl methyl cellulose, warm water with the temperature of 35-40 DEG C, polypropylene fibers, ceramic powder, naphthalene-based superplasticizer, polyphenyl granules, closed primer and silicon-acrylic coatings. The production technology comprises the following steps of preparation of a heat-insulation layer, preparation of a surface layer, injection molding and plate making, and surface decoration. The cultured stone heat-insulation and decoration integrated plate which is produced by using the formula and the technology not only has a quite high decoration effect, but also has high heat-insulation performance.

Owner:高广银

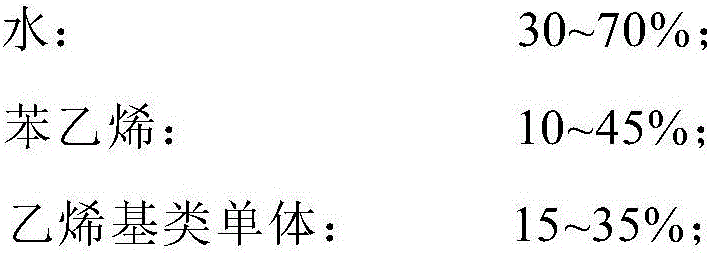

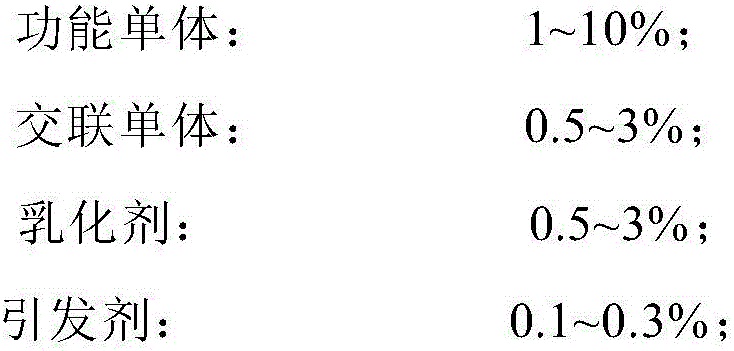

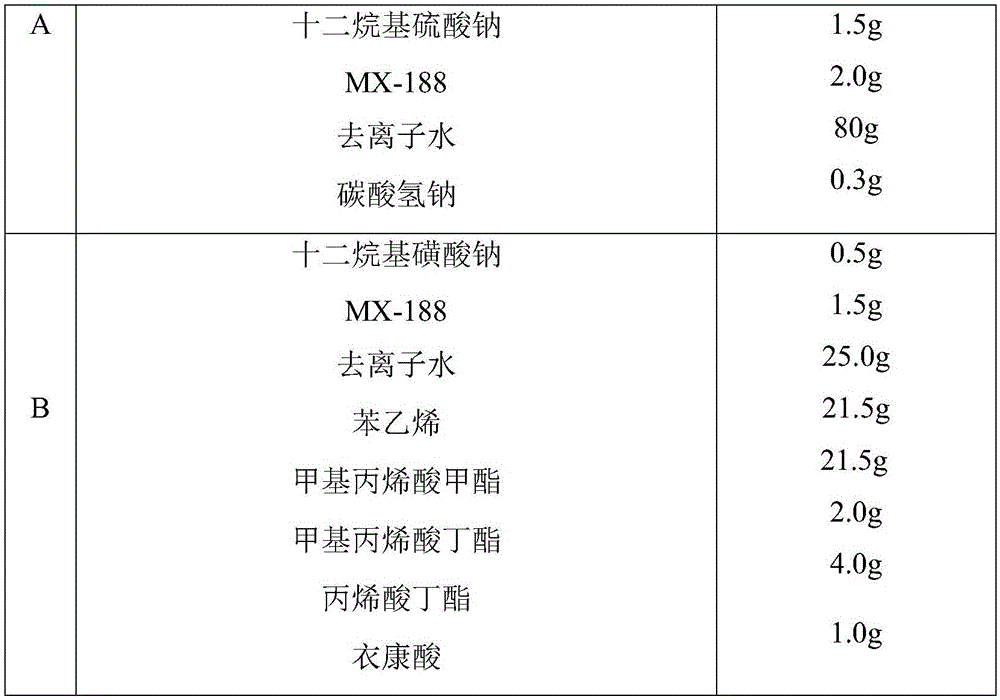

Room temperature self-crosslinking acrylic emulsion and a preparation method thereof

InactiveCN106117407AIncrease stickinessNo problems with cross-linking to release aldehydesInksFunctional monomerPolymer science

The invention provides a room temperature self-crosslinking acrylic emulsion and a preparation method thereof. The acrylic emulsion comprises the following components: water, styrene, vinyl monomer, a functional monomer, a crosslinking monomer, an emulsifier and an initiator. The preparation method comprises the following steps: preparing a monomer pre-emulsion 1, preparing a monomer pre-emulsion 2, mixing a pH buffering agent, an emulsifier, an initiator and water, adding part of the monomer pre-emulsion 1, reacting, adding the residual monomer pre-emulsion 1 and the residual initiator, reacting, and adding the crosslinking monomer to obtain product. The water-soluble acrylic coating does not need any film forming auxiliary or cosolvent addition for film forming. The coating can effectively hinder the movement of small molecules or small alcohols, and can be added in high-content common alcohol solvent. The waterborne acrylic emulsion as a main film-forming material endows the aqueous ink with high adhesion and dry formed film, and can satisfy the physical properties of waterborne ink.

Owner:SHANGHAI WEIKAI CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com