Method for improving adhesion property and prolonging service life of acrylic coating

An acrylic and adhesive technology, applied in coatings and other directions, can solve the problems of affecting the mechanical properties of products, loss of safety glass, degumming, etc. The effect of weather resistance and hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

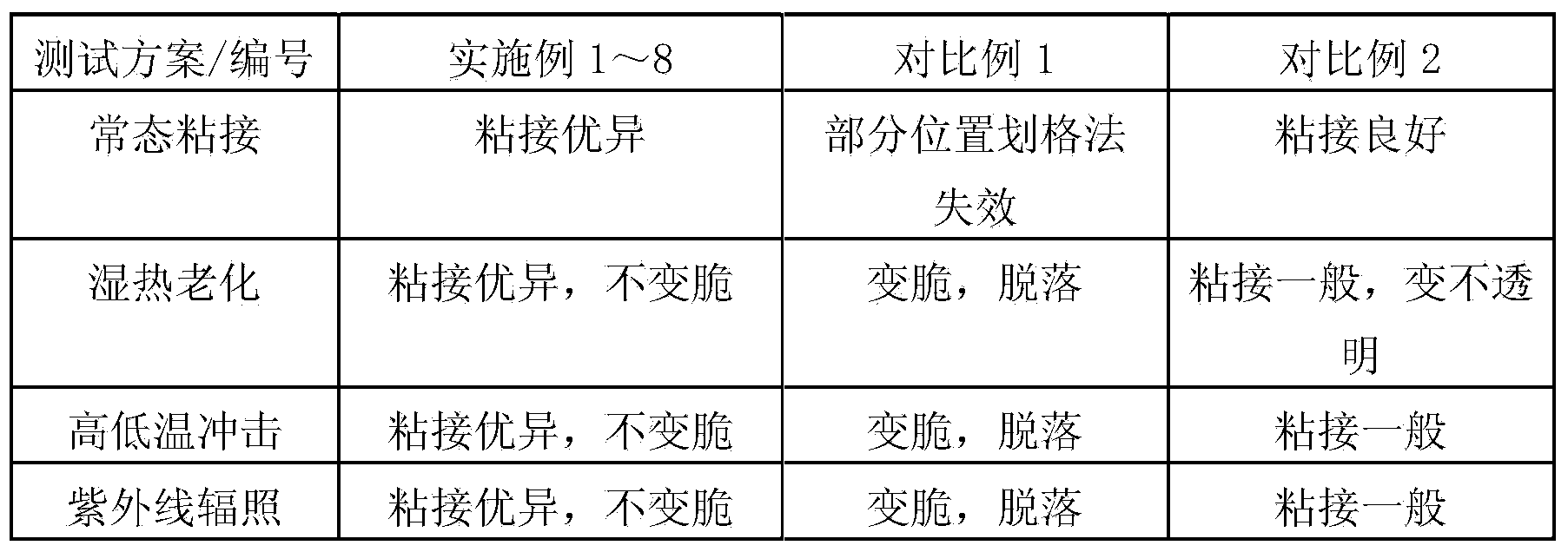

Examples

Embodiment 1

[0036] Curing conditions: coated on glass, plastic and other substrates, cured at 25°C for 7 days, the same as the following examples.

[0037] The organic titanium compound used in this embodiment is isopropyl titanate, which can also be used in butyl titanate, polybutyl titanate, tetraisooctyl titanate, tetraethoxytitanium, and n-propyl titanate. One or more mixtures are substituted. A mixture of isopropyl titanate and the above-mentioned substances can also be used instead of isopropyl titanate in this embodiment. The amount of the organic titanium compound is 0.05-3% of the mass of the final acrylic paint. The content of organic titanium compound in this embodiment is 3%.

[0038] The tackifier 1# used in this example belongs to tetracyclic methylhydrogen cyclosiloxane containing 1 Si-H and 3 trimethoxy groups. The organosilicon tackifier in this embodiment can also adopt tetracyclome methylcyclosiloxane, pentacyclome methylcyclosiloxane, pentacyclome methylhydro...

Embodiment 2

[0041] components

[0042] In this embodiment, butyl titanate is used as an organic titanium compound to be added to the raw material of acrylic paint, and tackifier 2# is used. The tackifier 2# belongs to a tetracyclic ring containing 3 Si-H and 1 trimethoxy Bulk methylhydrocyclosiloxane and methyltriethoxysilane were used as water remover. The organotitanium compound, tackifier and water remover can also be replaced by the same substances listed in Example 1, and the following examples are also available. The dosage of each substance in this embodiment is shown in the table of this embodiment.

Embodiment 3

[0044] components

[0045] polybutyl titanate

[0046] The organotitanium compound, tackifier and water remover used in this embodiment are shown in the table, wherein tackifier 3# belongs to tetracyclic methylhydrogen cyclosiloxane containing 3 Si-H and 1 epoxy group .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com