Patents

Literature

224 results about "Acrylic paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

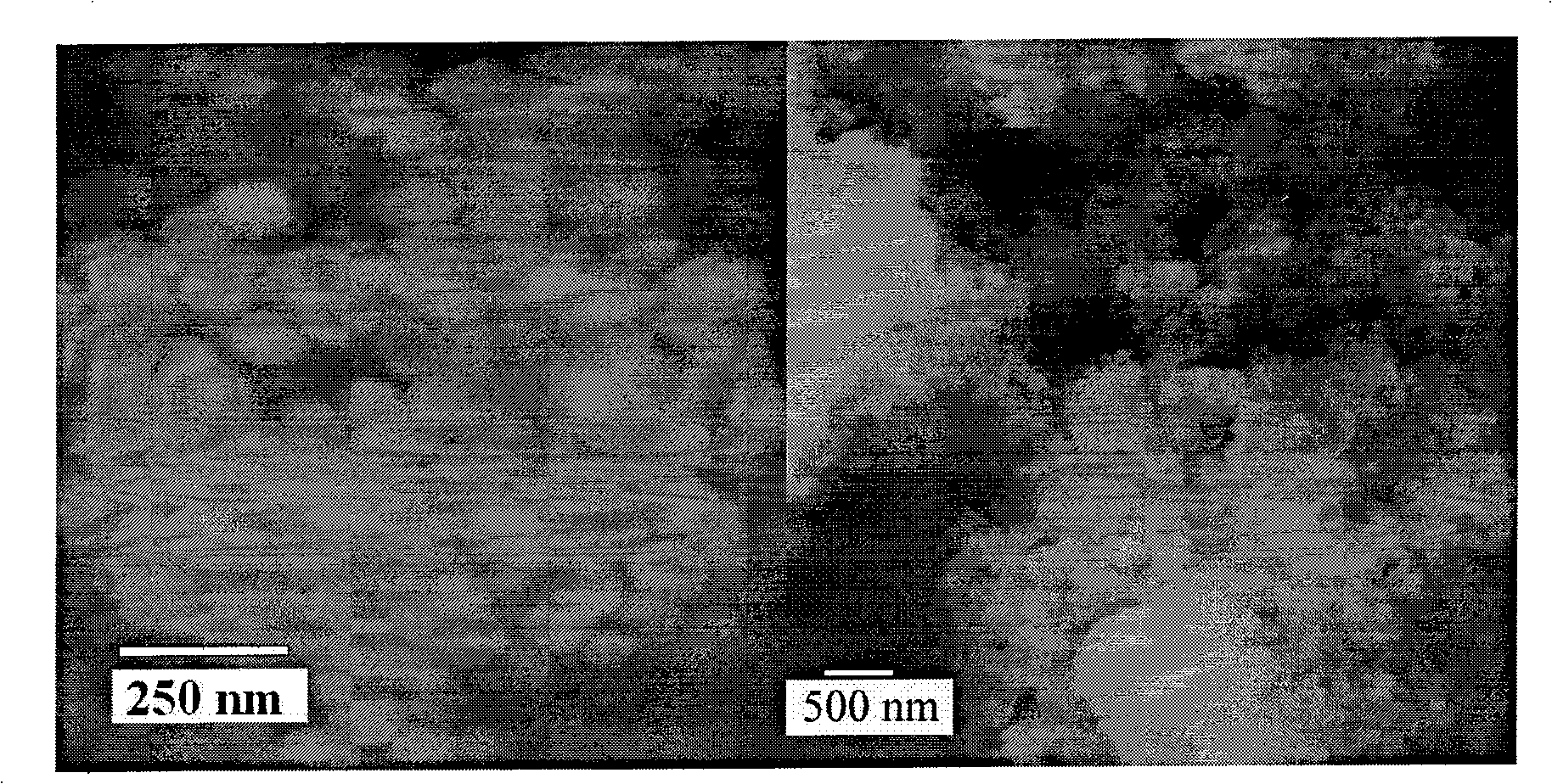

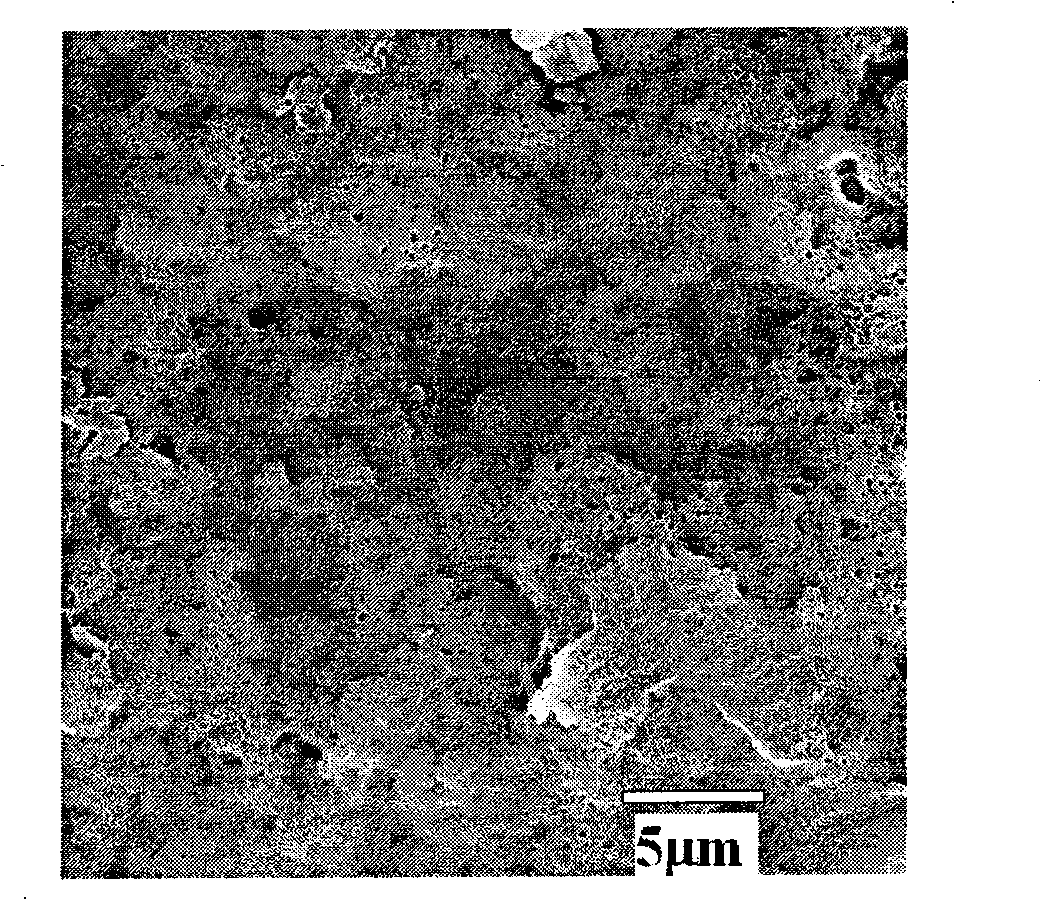

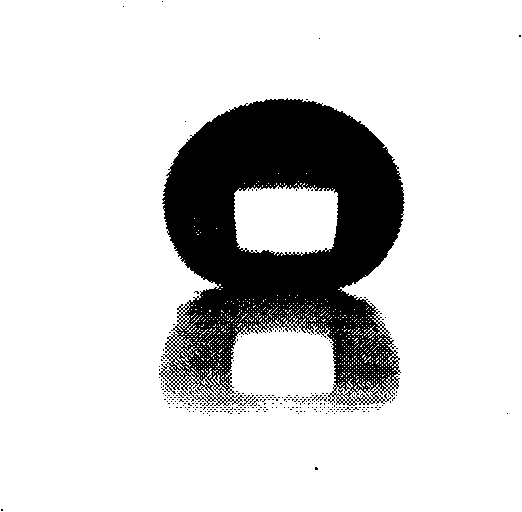

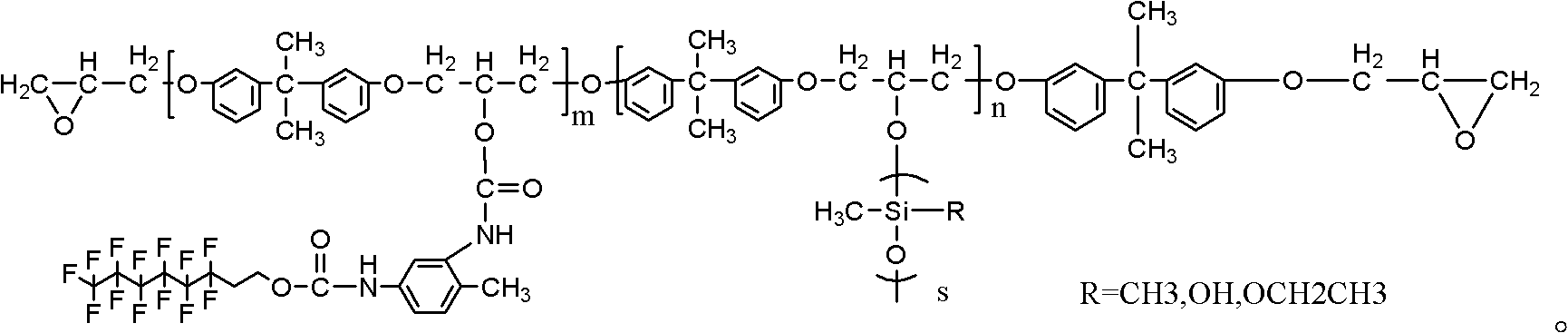

Ultra-discharging water-soluble fluor-silicon-acrylic coatings with nano particles

InactiveCN101307210AWide variety of sourcesInexpensive and easy to obtainEmulsion paintsMechanical propertyNuclear chemistry

The invention discloses a super-hydrophobic water fluorine silicone / acrylic paint containing nanoparticles. The paint is prepared by mixing the compositions by weight percentage: 30 to 65 percent of water, 10 to 40 percent of silicone-acrylate emulsion, 10 to 40 percent of water fluoro-polymer emulsion, 1 to 10 percent of nano-meter oxid particles, 1 to 15 percent of inorganic hole compound and a small quantity of inorganic acid used for adjusting the pH value. The invention also discloses a super-hydrophobic water fluorine silicone / acrylic coating prepared by the paint. The water static wrapping angle of the coating is more than 150 degrees and a rolling angle is lower than 5 degrees. The coating prepared by the paint has the advantages of super-hydrophobicity, excellent mechanical property and easy process, etc. and has the self-cleaning function similar to a lotus leaf.

Owner:胡硕

High-voltage power transmission line ice-covering-proof paint and preparation method thereof

InactiveCN102146249AImprove thermal conductivityImprove hydrophobicityEpoxy resin coatingsTransformerLow temperature curing

The invention discloses high-voltage power transmission line ice-covering-proof paint and a preparation method thereof. The preparation method comprises the following steps: using toluene diisocynate, tridecafluoro-octanol, butyl acetate, organosilicon modified epoxy resin, epoxy resin curing agent, organic solvent, nanographite and carbon nanotubes as raw materials to react and ensure that long-carbon-chain fluoro-alcohol is grafted in the molecular chain of epoxy resin, and adding nanographite and carbon nanotubes in the modified epoxy resin to prepare the paint with good hydrophobicity and thermal conductivity. The paint is mainly used in the coating of the high-voltage power transmission line and the coatings of equipment such as the insulator and the transformer case; and the paint has high coating adhesion, is ice-covering-proof and environmental friendly, has the advantages of corrosion resistance, ultraviolet resistance and aging resistance, and no pollution. Compared with the traditional acrylic paint, the paint has the advantages of simple preparation technology and excellent room temperature curing performance and low temperature curing performance, and is convenient to construct and operate.

Owner:甘肃省电力公司检修公司 +1

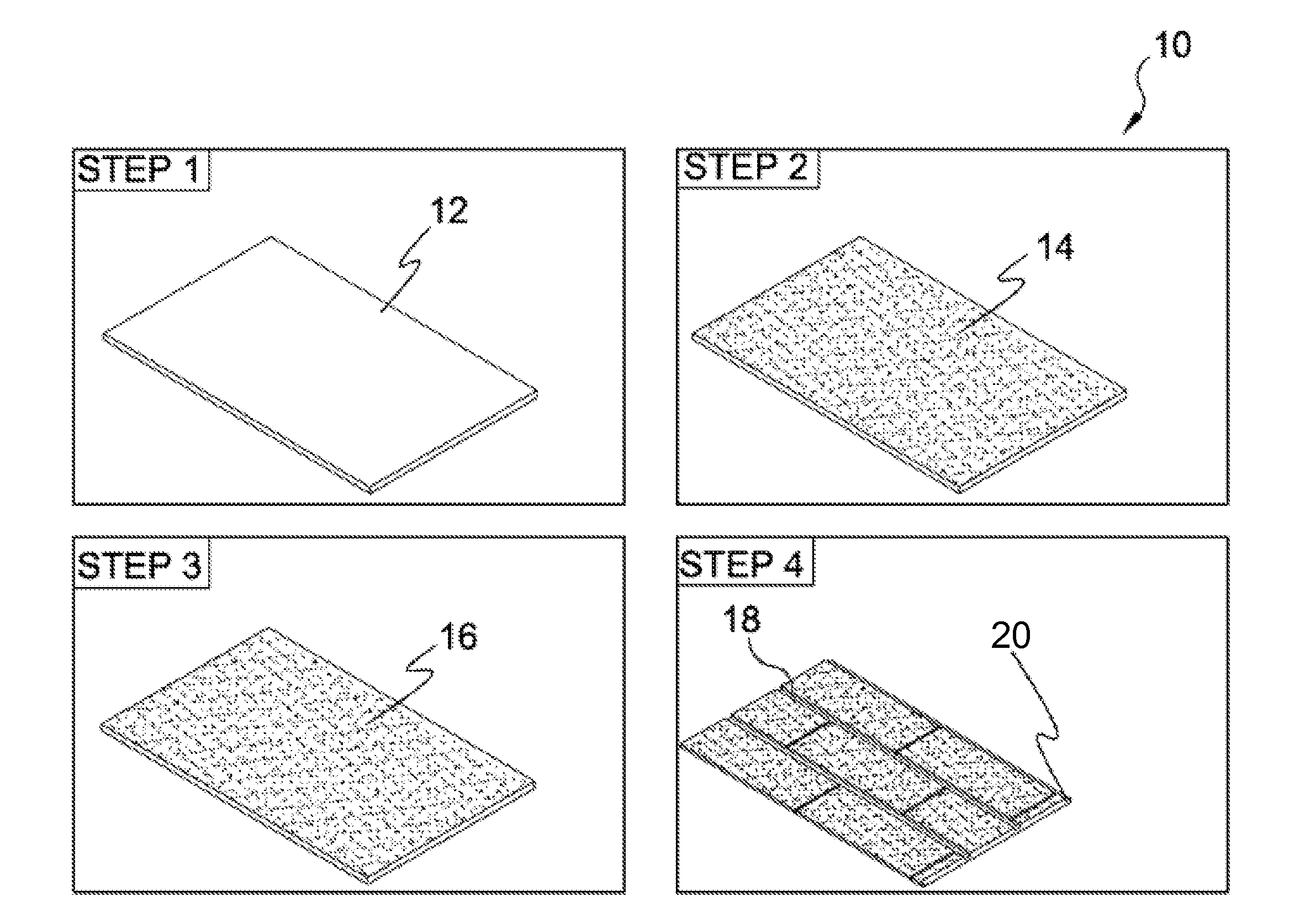

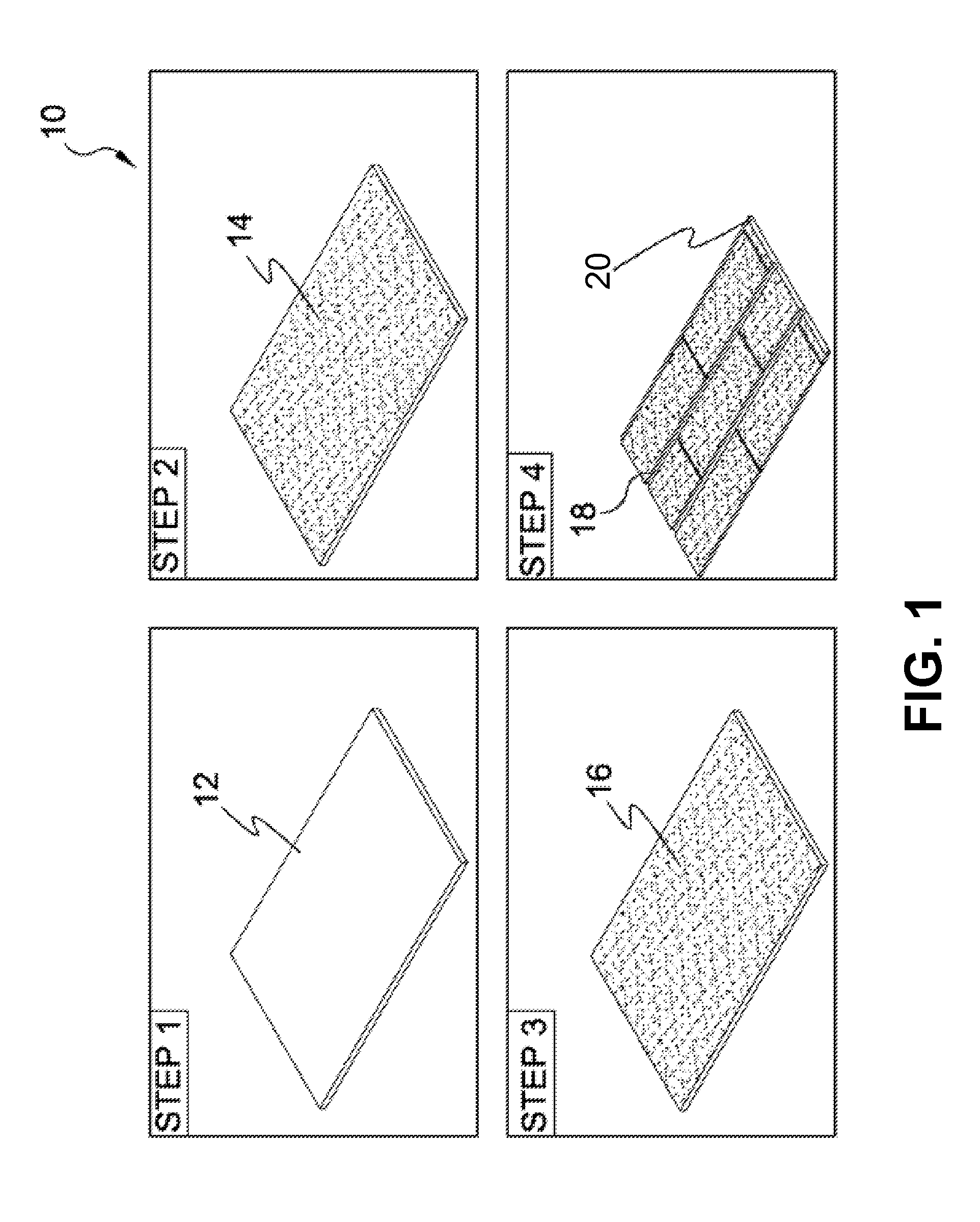

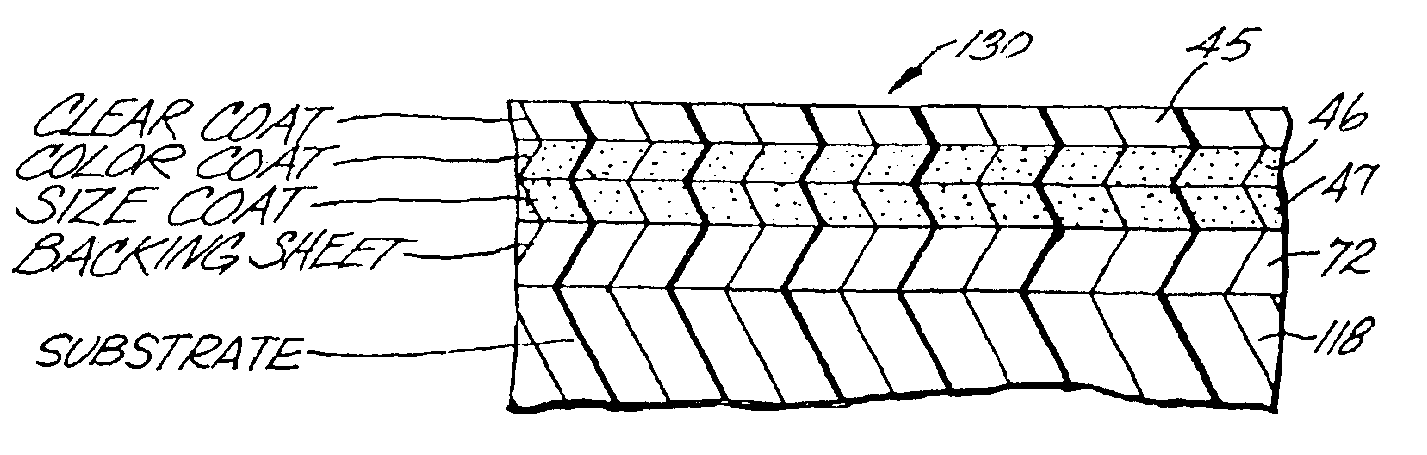

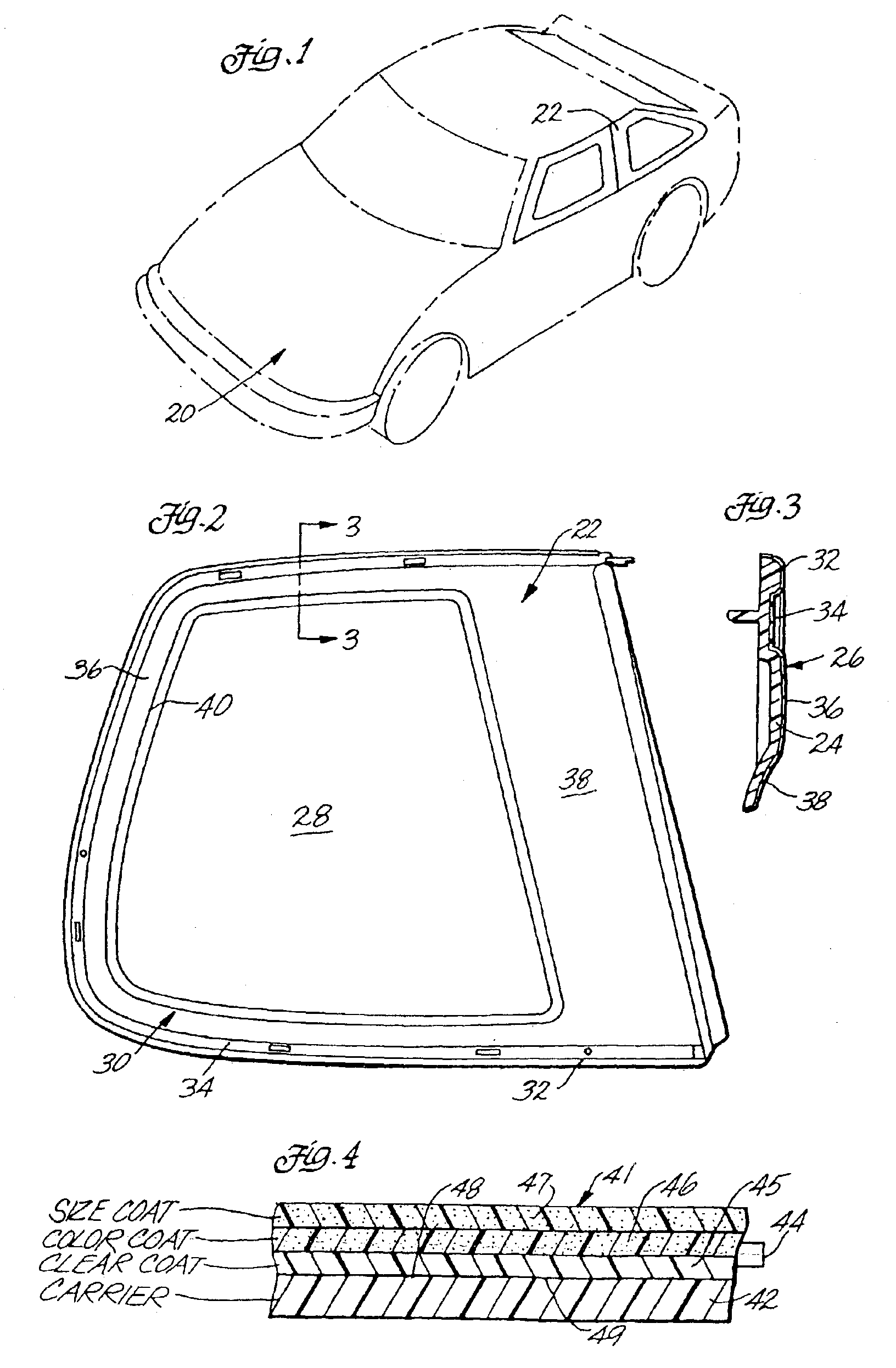

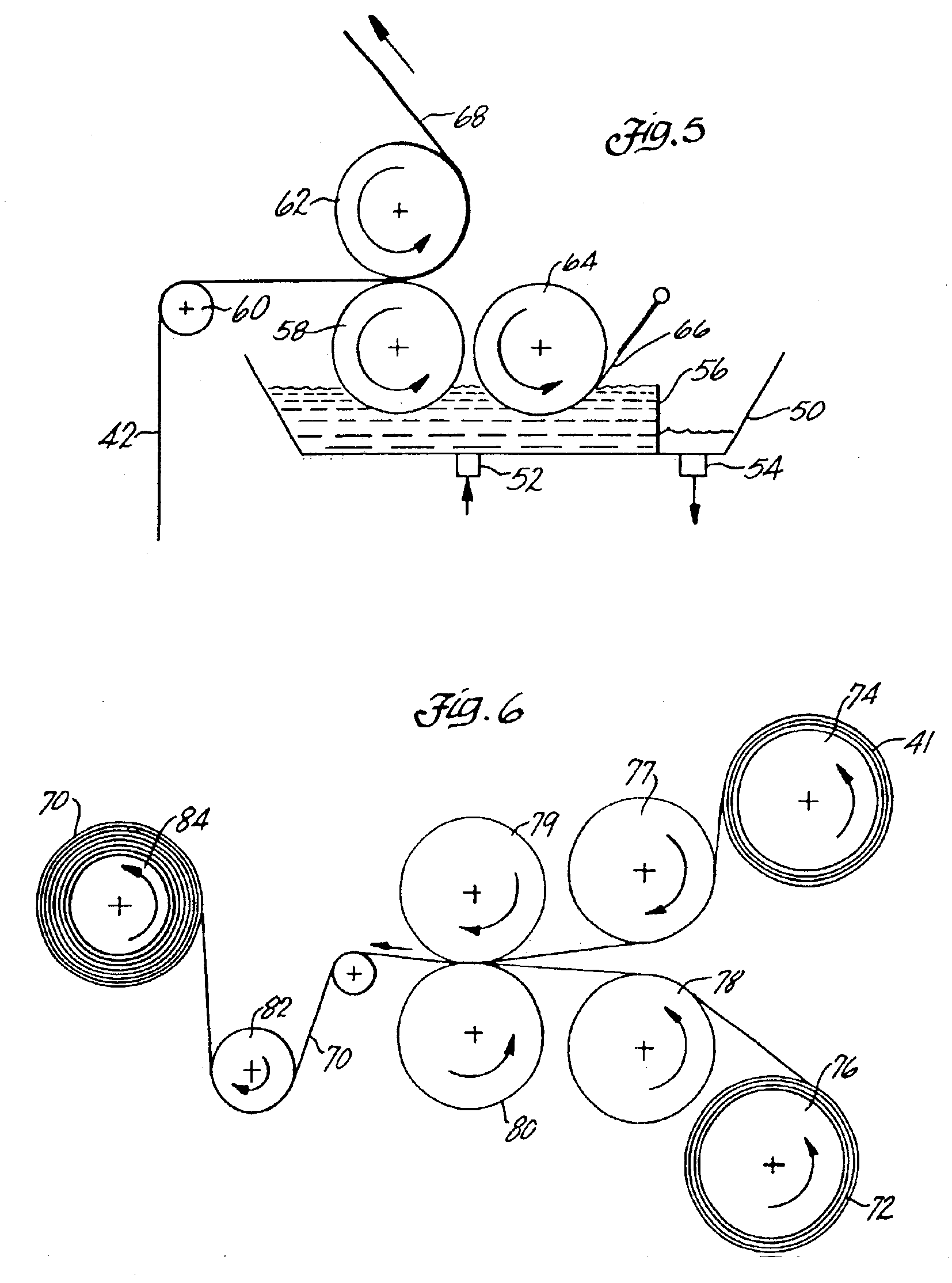

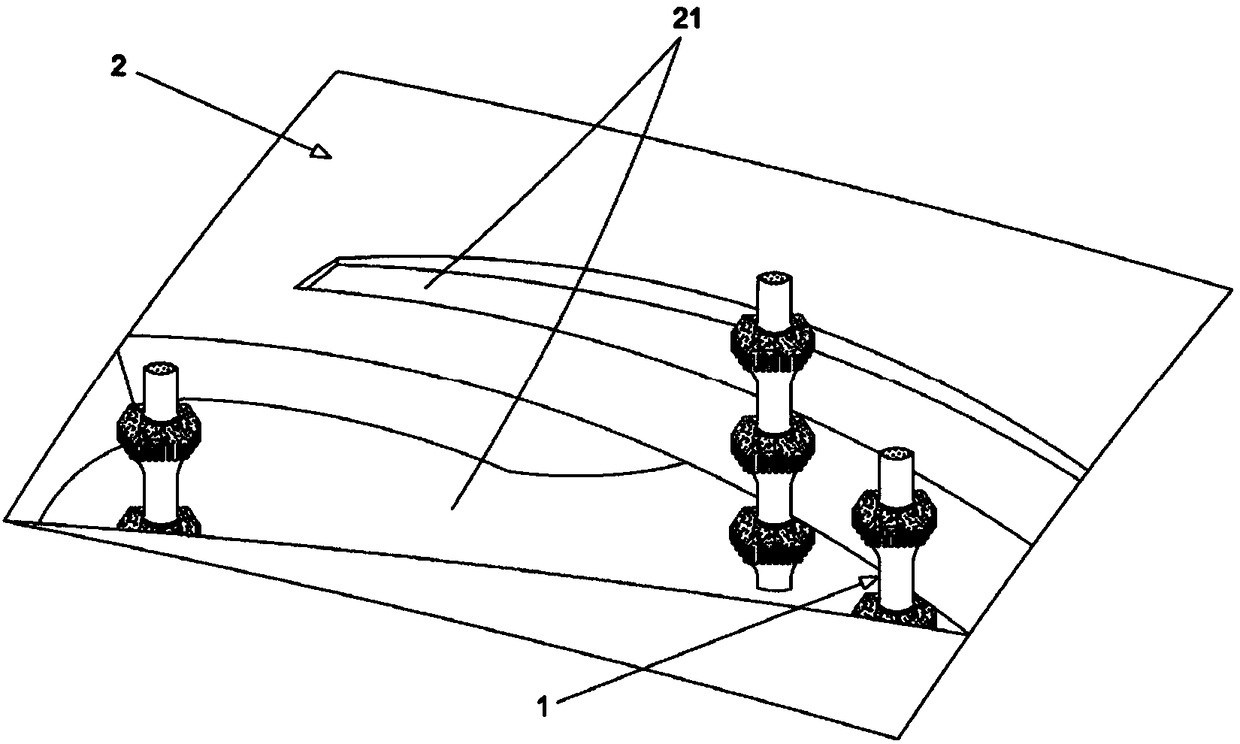

Dry paint transfer process and product

InactiveUS6838130B1Sufficient level of resistanceSufficient elongationLiquid surface applicatorsElectrical controlShell moldingLacquer

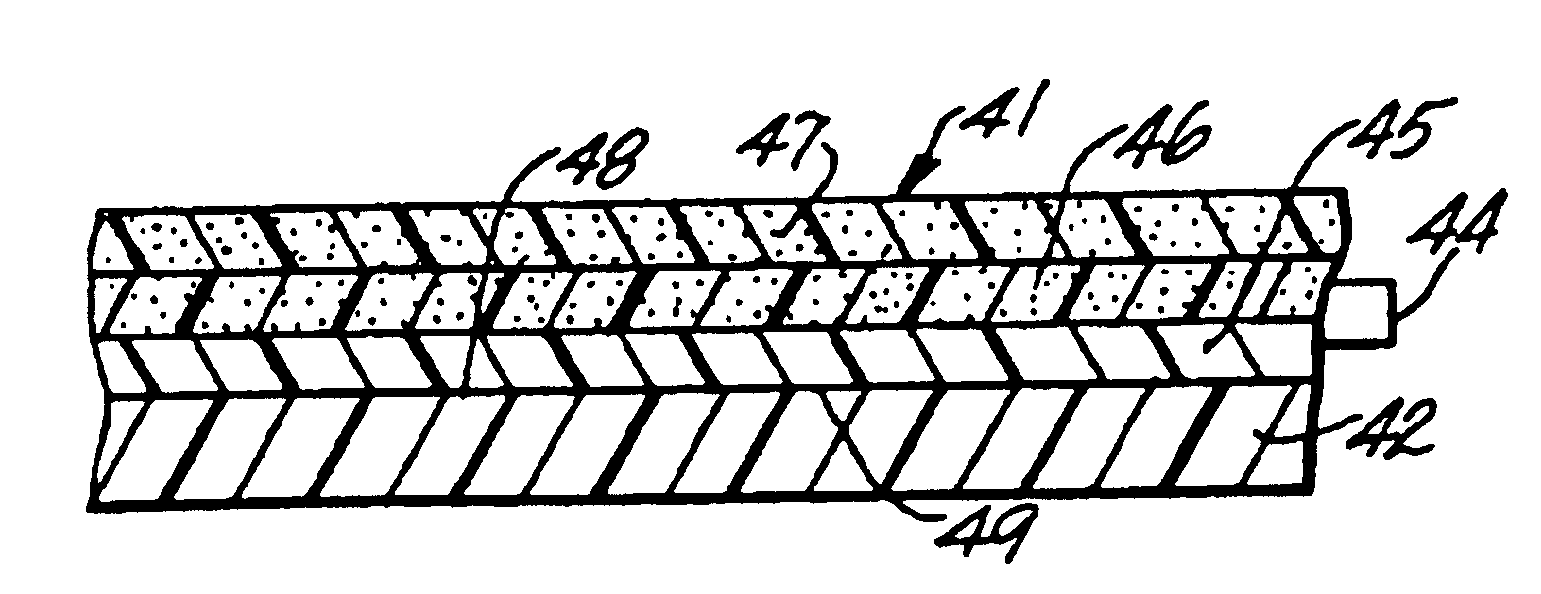

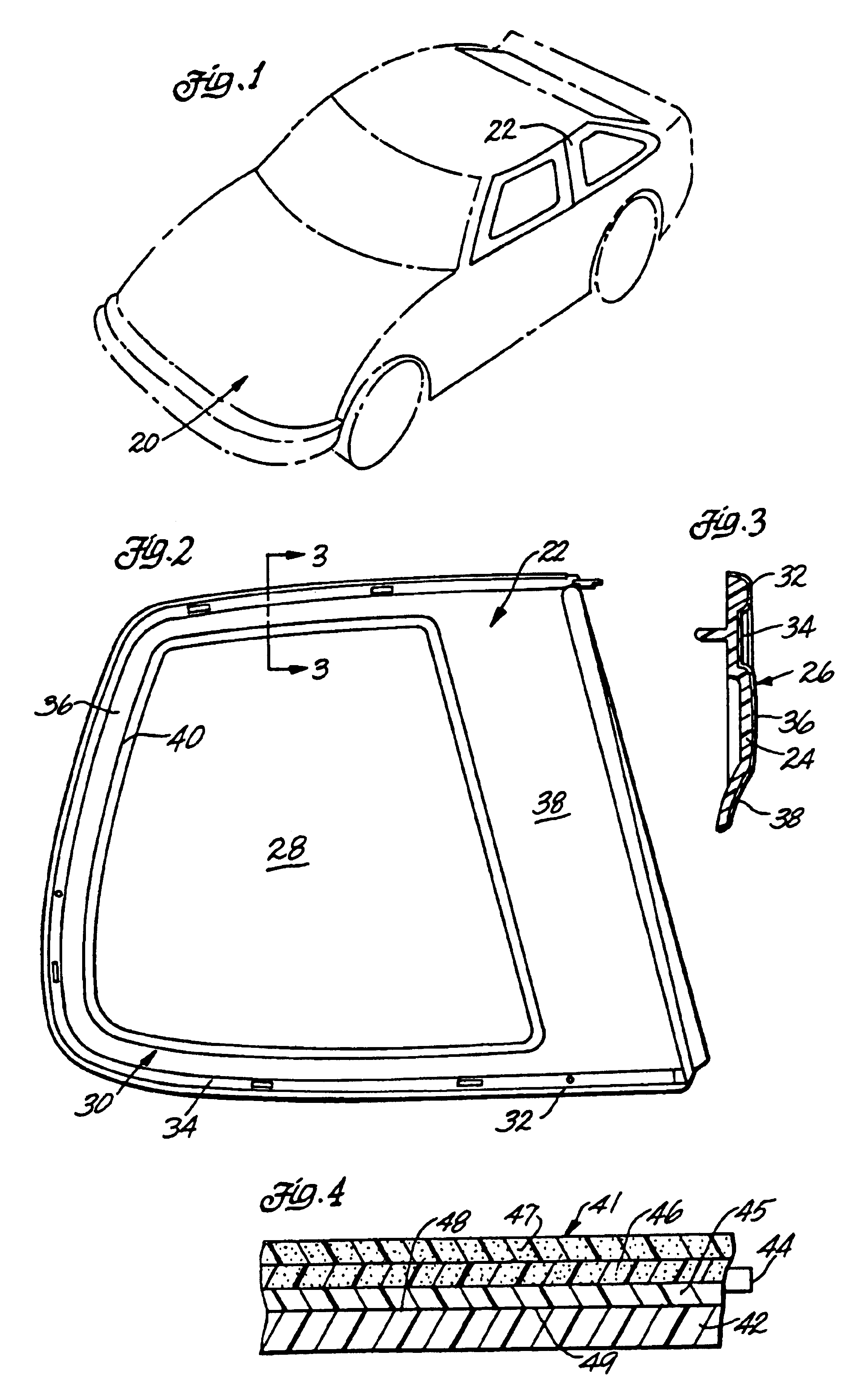

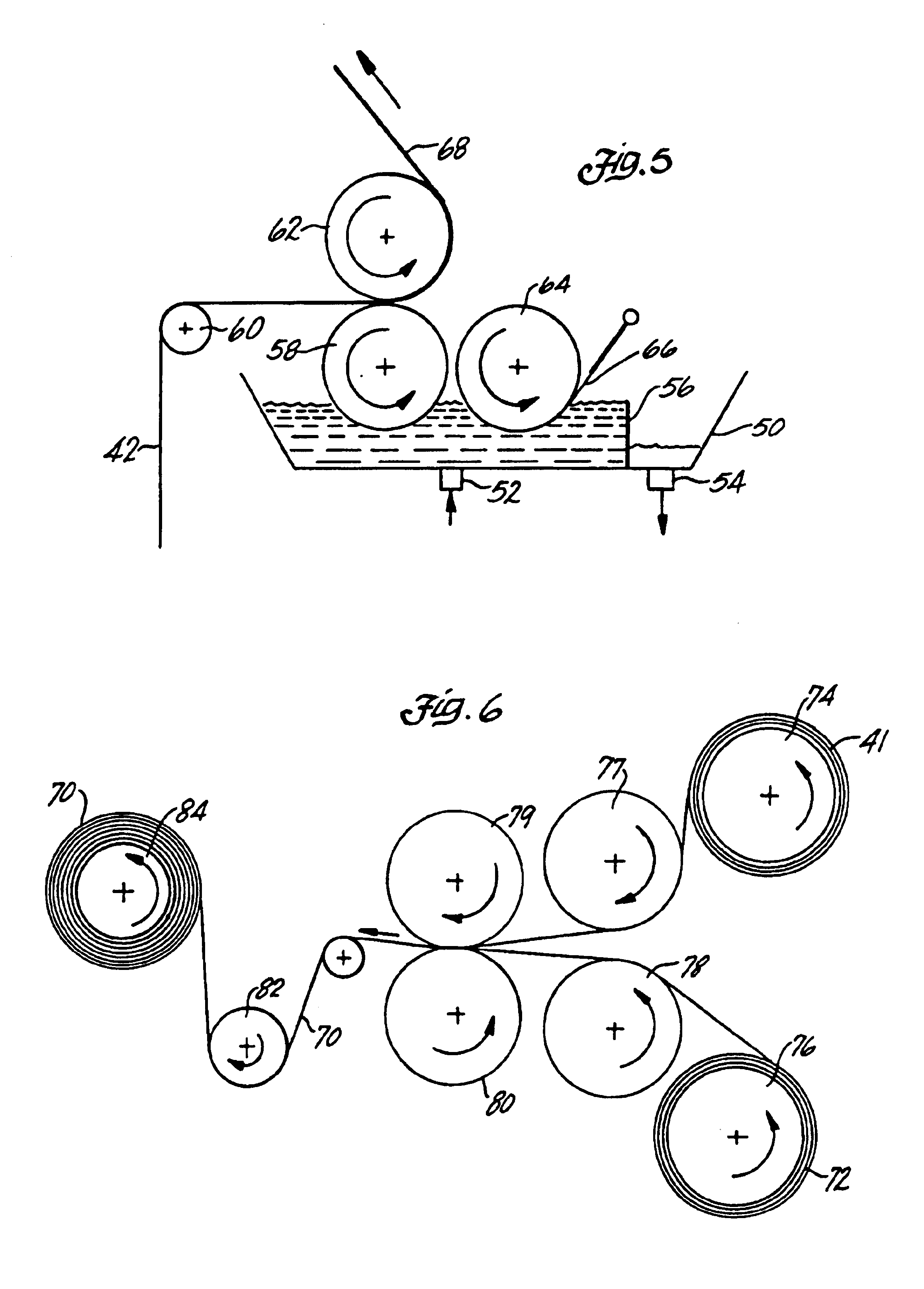

An automotive quality paint coat (44) is laminated to the exterior surface of a molded plastic car body member or panel (118). In one embodiment, the paint coat (44) includes an exterior clear coat (45) above a color coat (46). During processing, the clear coat (45) and color coat (46) are each coated on a temporary flexible casting sheet (42) and dried. A high gloss surface is transferred to the clear coat (45) from the casting sheet (42). The paint coat (44) is then transferred from the casting sheet (42) to a thin, semi-flexible thermoformable plastic backing sheet (72) by dry paint transfer-laminating techniques. The resulting laminate (70) is thermoformed into a complex three-dimensional shape of the car body member or panel. The preformed laminate (116) is then bonded to an underlying plastic substrate material, by injection-cladding techniques, for example, to form the finished article. The paint coat (44) has sufficient elongation to retain exterior automotive appearance and durability properties during thermoforming without deglossing. The backing sheet (72) absorbs defects in the substrate material so the paint coat retains its appearance and durability properties during the injection-cladding step. The finished article comprises a high gloss, defect-free paint coat on the exterior of a molded plastic car body member or panel. Solution-form polyvinylidene fluoride / acrylic paint systems have remarkably high combined gloss and distinctiveness-of-image levels, together with durability properties required for exterior automotive use.

Owner:CCL LABEL INC

Ultraviolet light solidifying paint containing POSS and its preparation method

InactiveCN1718656ASimple processCoating film cures quicklyPolyurea/polyurethane coatingsPolyolDiluent

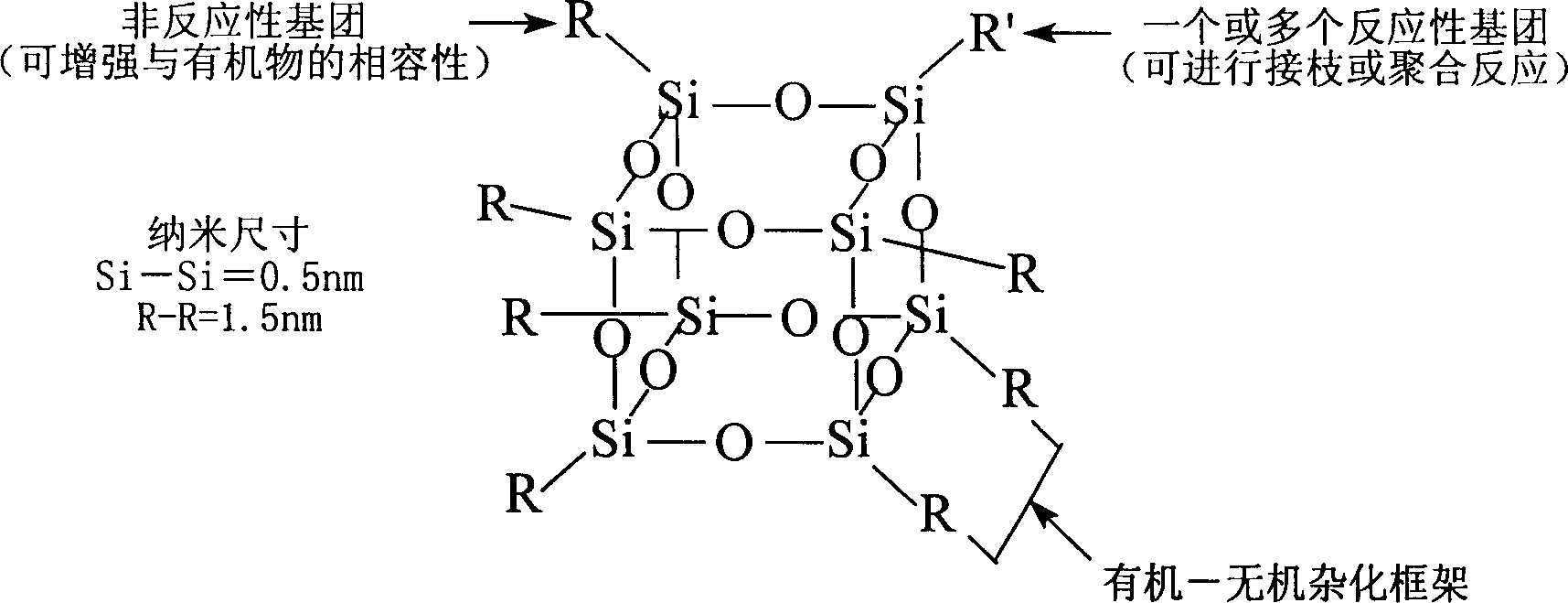

An ultraviolet solidified paint containing POSS is prepared through preparing the POSS with double bond from organic siloxane, proportionally mixing diisocyanate, polyol, catalyst and active diluent, stirring, heating while reacting to obtain the PUA prepolymer containing POSS, mixing it with catalyst, optical trigger, active diluent and other assistants, and stirring.

Owner:TONGJI UNIV

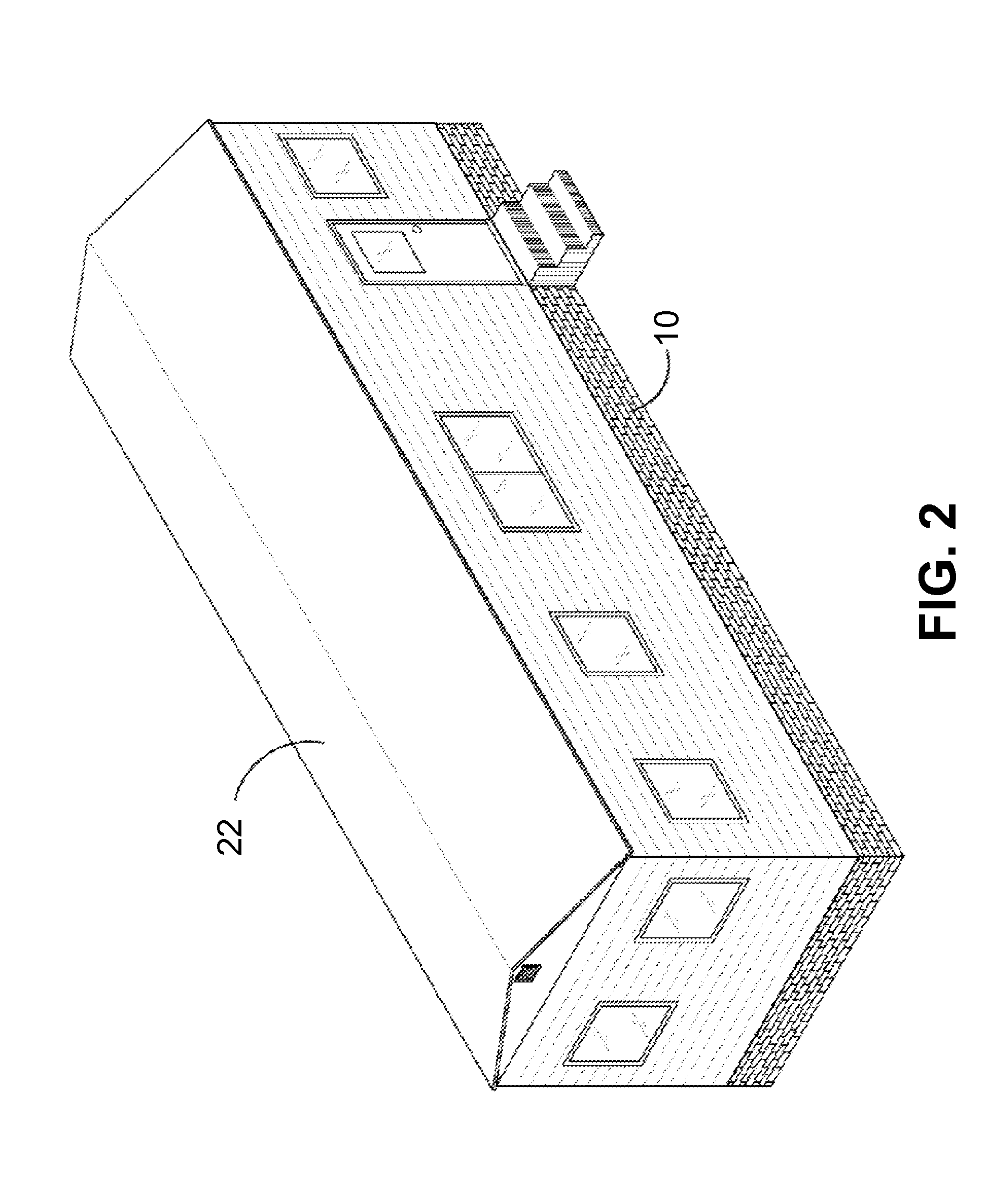

Building Panel

A building panel including a magnesium oxide board having a front surface and back surface, wherein the front surface of the magnesium oxide board displays a pattern of cuts, wherein the front surface of said magnesium oxide board is covered by an acrylic paint and sand mixture, wherein the pattern of cuts are grouted, wherein the first end of said magnesium oxide board includes at least one male engaging member and the second end includes at least one female recess. A method of making a faux brick building panel and a faux rock building panel are also disclosed.

Owner:QUICK BRICK MFG

Dry paint transfer-lamination process for making high DOI automotive body panels

InactiveUS6966962B2Sufficient level of resistanceSufficient elongationLiquid surface applicatorsElectrical controlShell moldingLacquer

Owner:CCL LABEL INC

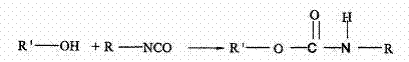

Preparation method of hydroxy-polyacrylate aqueous dispersion and waterborne paint containing hydroxy-polyacrylate aqueous dispersion

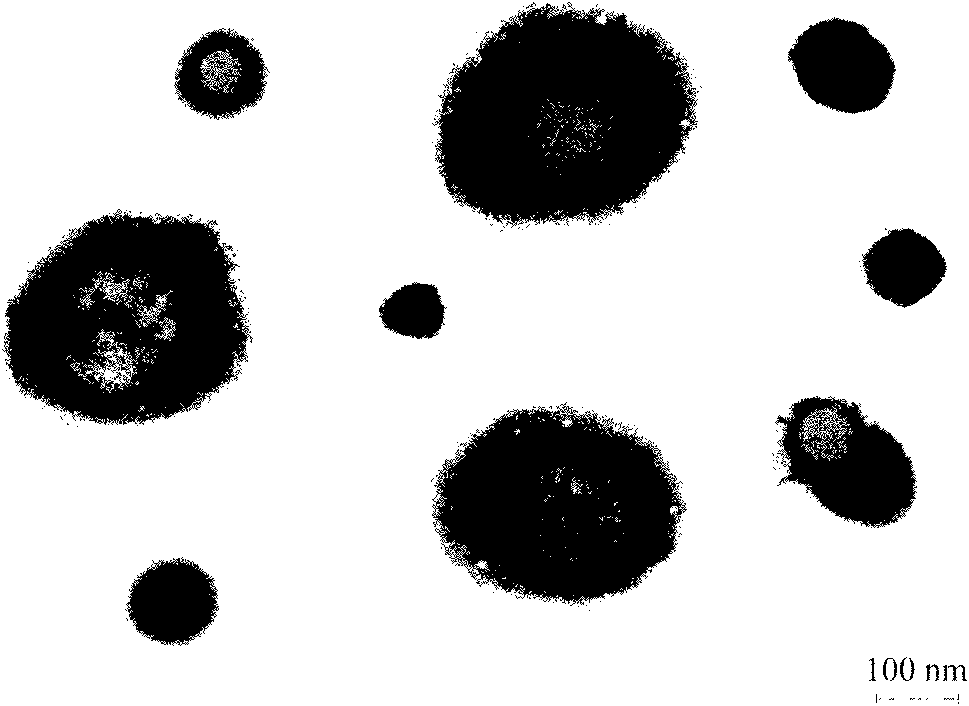

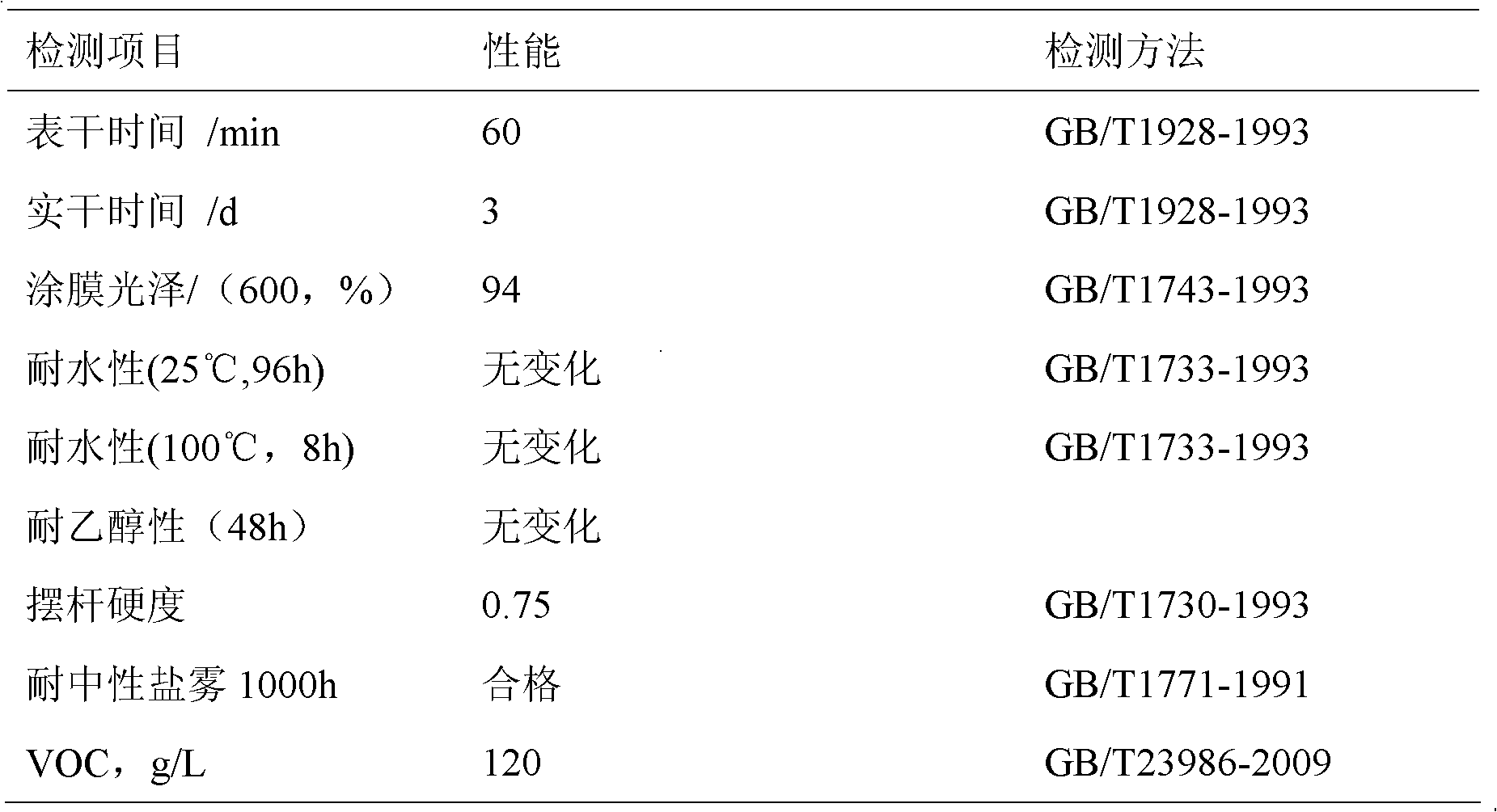

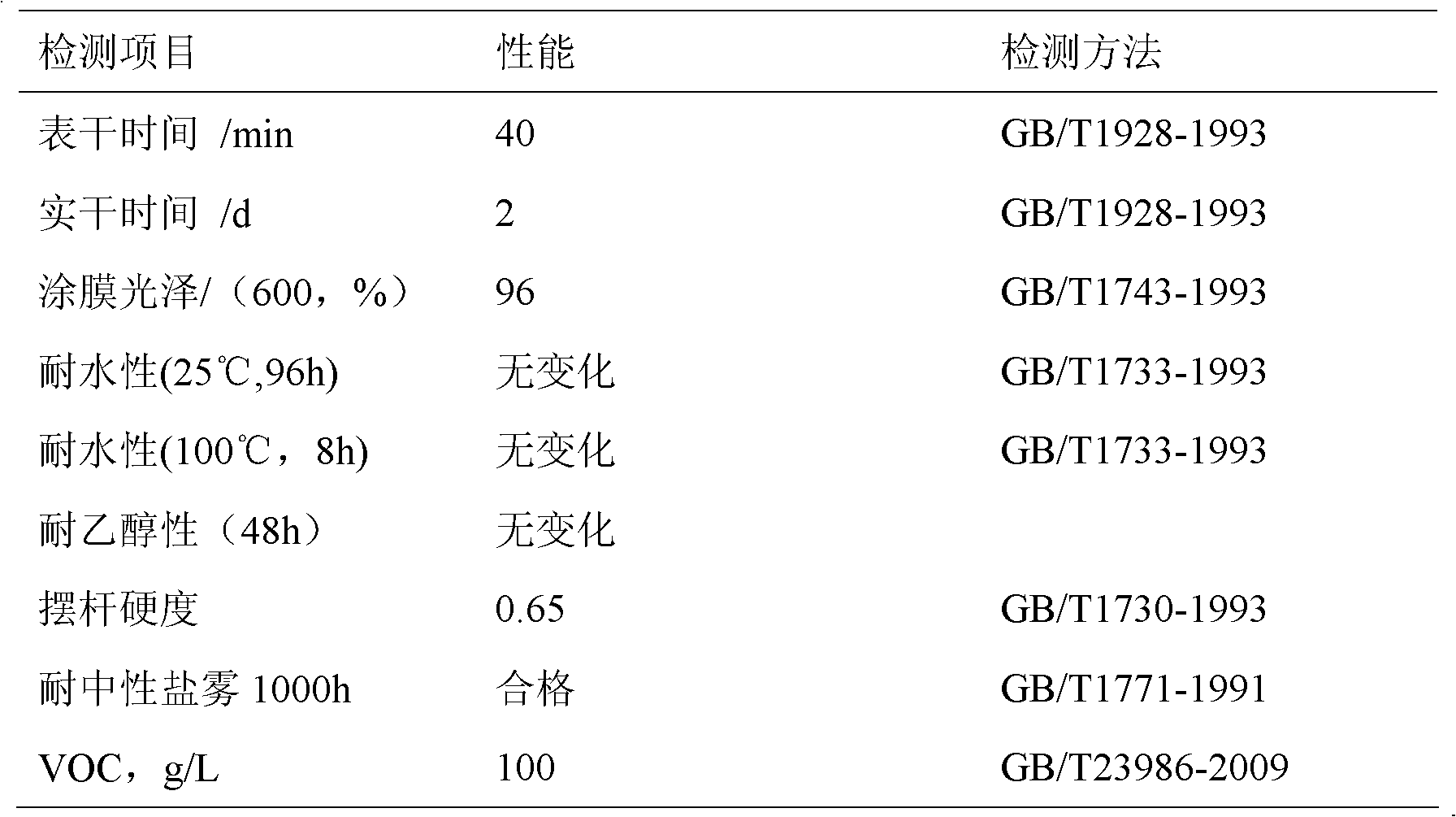

The invention relates to a preparation method of hydroxy-polyacrylate aqueous dispersion, belonging to the field of the organic polymer compound. The method comprises the following steps: (1) mixing hydroxy-polyacrylate with carboxylate and hydroxy-polyacrylate without carboxylate in a weight ratio of 1:0.1-3, adding deionized water which is 1-10 times of hydroxy-polyacrylate with carboxylate by weight to emulsify; and (2) distilling to removing solvent and ensure that the solid content is 40-70%, and adjusting the pH value to 6-8 to obtain the hydroxy-polyacrylate aqueous dispersion. The aqueous dispersion prepared by the method has high solid content and a core-shell structure; the film-forming property of the two-component waterborne acrylate paint can be increased, the fullness of the film can be improved; and the aqueous dispersion has excellent dispersibility to isocyanate curing agent and good compatibility with the curing agent and the luster and decoration performance of the film can be increased. The hydroxy-polyacrylate aqueous dispersion prepared by the method of the invention can be used to prepare the two-component waterborne acrylic paint.

Owner:SOUTH CHINA UNIV OF TECH +1

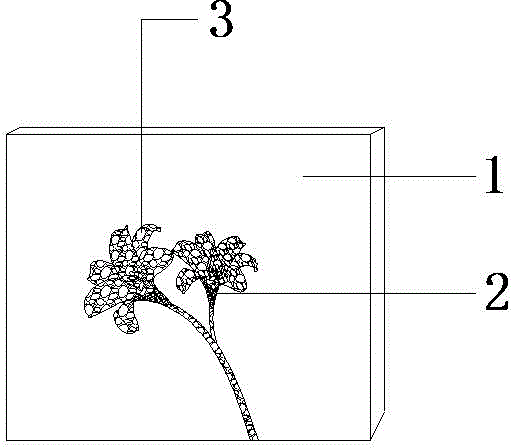

Water absorbent canvas coating and manufacture method thereof

The invention relates to a water absorbent canvas coating which is characterized in that the water absorbent canvas coating is manufactured by the following materials in percentage by weight: 30 to 33water, 18 to 23 polyacrylic emulsion, 8 to 13 polyvinyl alcohol, 12 to 15 titanium pigment, 10 to 12 talcum powder, 7 to 10 light calcium carbonate, 7 to 10 heavy calcium carbonate, 2 to 4 silica white, 0.3 to 0.4 dispersant, 0.2 to 0.3 anti-foaming agent, and 1 to 2 thickening agent; and the canvas provided with the coating is particularly applicable to acrylic painting, the coating which is identical with acrylic paints ensures that the paints is very firmly bound with the canvas, and the acrylic paints can be used for being adjusted to water color effect and poster color effect on the canvas according to the requirements, to ensure that the color tolerance of the acrylic paints is better and the expressive force is stronger.

Owner:WUXI PHOENIX ARTIST MATERIALS

Waterborne single-component thermoplastic plastic paint and production method and construction method thereof

ActiveCN102146243AAvoid long-term contactReduce pollutionCoatingsSpecial surfacesPolymethyl methacrylatePolycarbonate

The invention provides waterborne single-component thermoplastic plastic paint and a production method and construction method thereof. The plastic paint is suitable for the coating of plastic cabinet prepared from ABS (Acrylonitrile Butadiene Styrene), PS (poly styrene), HIPS (High Impact Polystyrene), PC (polycarbonate), PMMA (polymethyl methacrylate) and the like, has good adaptability to the surface of the material and also has good adhesive force, thus the adhesive force problem of the waterborne paint on the plastic substrate can be solved. A waterborne system is adopted for the paint mainly adopts, the production and using processes are safe; and water is used as diluent, and the paint has the advantages of low toxicity, low pollution, extremely low volatile organic compound (VOC) emission and the like and meets various laws and regulations on environmental protection. Meanwhile, the paint can use different color pastes for coloring; and the paint has better decorative propertyon the substrate while the properties can not be affected. Compared with the common solvent thermoplastic acrylic paint, the paint only uses a small amount of low-toxicity alcohol ether type organic solvent, thus the influence on the plastic substrate is extremely small; and the paint film has bright colour, full appearance effect and good performances.

Owner:深圳市嘉卓成科技发展有限公司

Treatment method for wood surface defects

InactiveCN102632528AWon't fall offPromote infiltrationIrregularity removal devicesPolymer scienceAdhesive

The invention provides a treatment method for wood surface defects. The treatment method comprises the following steps: (1) cleaning up wood surface defect parts; (2) spraying or wetting the peripheries of the defect parts by using alcohol, an acrylic paint or an adhesive; (3) coating the defect parts by directly using the acrylic paint / the isocyanate adhesive or firstly filling in repairing putty and then coating by using the acrylic paint / the isocyanate adhesive; (4) carrying out indoor natural surface drying for over 3 hours or after baking for 20-120 minutes at the temperature of 30-80 DEG C for complete curing, carrying out light sand treatment on the surface for painting to enable the adhesive or paint to evenly penetrate into the defects so as to achieve a better bonding effect, and ensure that the defect parts cannot crack again in the using process of a repaired wood board, and the acrylic paint and the isocyanate adhesive do not have volatility, thus not polluting the environment and being environmentally-friendly.

Owner:GUANGDONG YIHUA TIMBER IND

Fire retardant type UV light solidifying polyurethane acrylic acid paint and its preparation method

InactiveCN1718657AFully curedFast curingFireproof paintsPolyurea/polyurethane coatingsDiluentDouble bond

A flame-retarding ultraviolet solidified polyurethane-acrylic acid paint is prepared through proportionally mixing the modified diphenylmethane diisocyanate, modified polyol with double bond and containing melamine-phenolic resin, catalyst and active diluent, stirring, heating while reacting to obtain the prepolymer, mixing it with catalyst, optical trigger, active diluent and other assistants, and stirring.

Owner:TONGJI UNIV

Thermoplastic acrylic paint

The present invention discloses one kind of thermoplastic acrylic paint comprising thermoplastic acrylate resin, pigment, assistant and solvent. The process of producing the thermoplastic acrylic paint includes the following steps: mixing and dispersing thermoplastic acrylate resin, pigment and dispersant in certain weight proportion in a high speed dispersing machine; grinding the mixture in a sand mill to reach required fineness; adding defoaming agent, leveling agent and solvent and stirring in the high speed dispersing machine to obtain the thermoplastic acrylic paint. Compared with common paint, the thermoplastic acrylic paint has the advantages of use convenience, high weather resistance, low cost and high adhesion.

Owner:郎需东

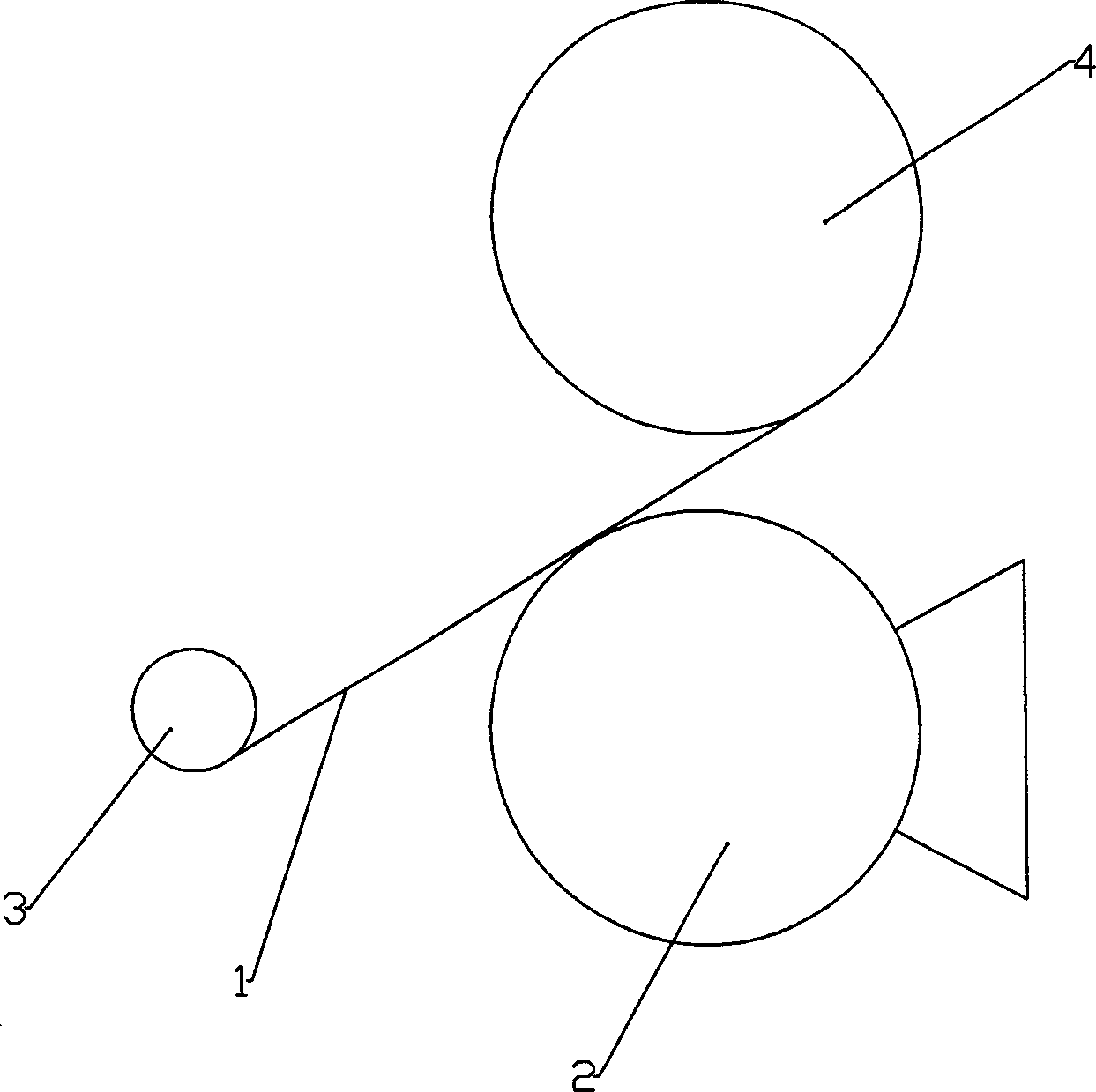

Acrylic acid coating film and its manufacturing method

ActiveCN1686712AGood low temperature heat sealabilityHigh heat sealing strengthLayered productsEmulsionSoftened water

An acrylic acid coated film is composed of a substrate layer, a coated acrylic paint layer and a sandwich layer between the first two layers. Its preparing process includes such steps as preparing acrylic paint from acrylic emulsion, softened water, smoothing agent and detackifier, coating it on the substrate and baking.

Owner:HAINAN SHINER IND

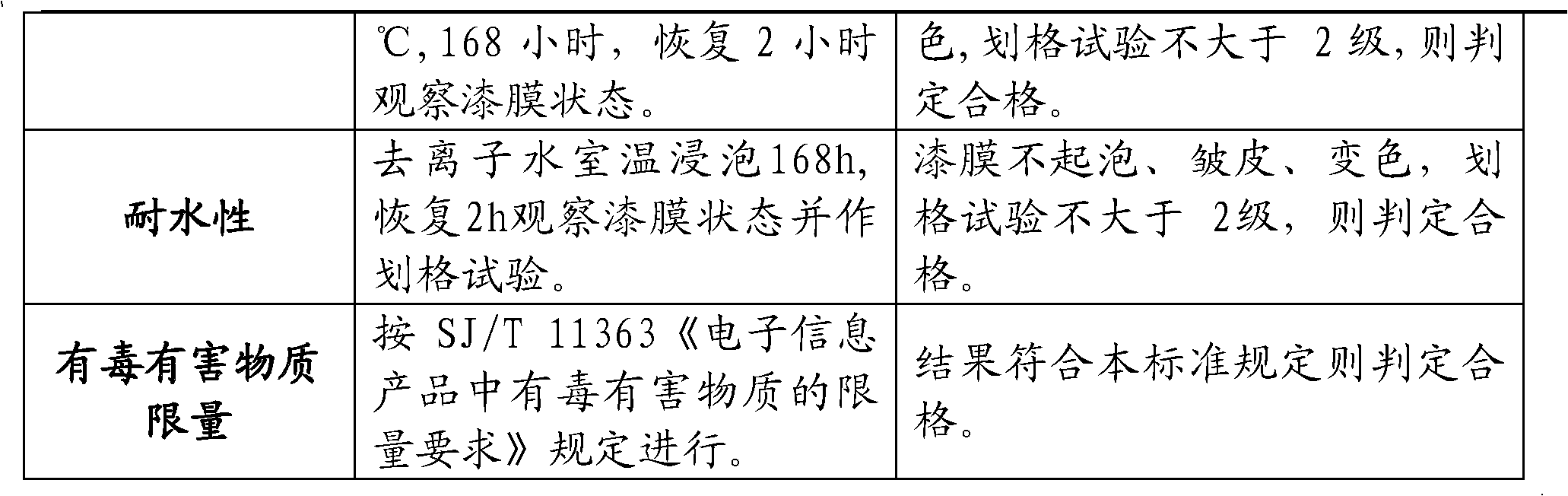

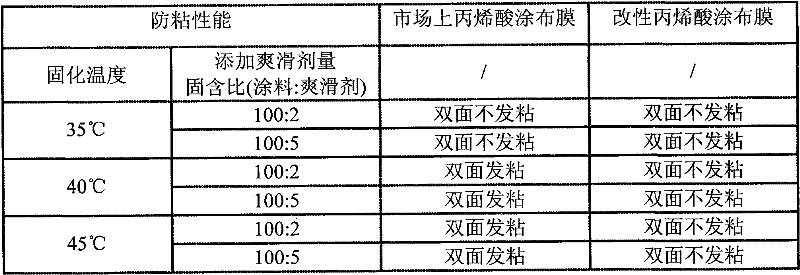

Anti-sticking acrylic acid paint for coating and preparation method thereof

InactiveCN102352163AImprove mechanical stabilityGood storage stabilityCoatingsCross-linkHigh humidity

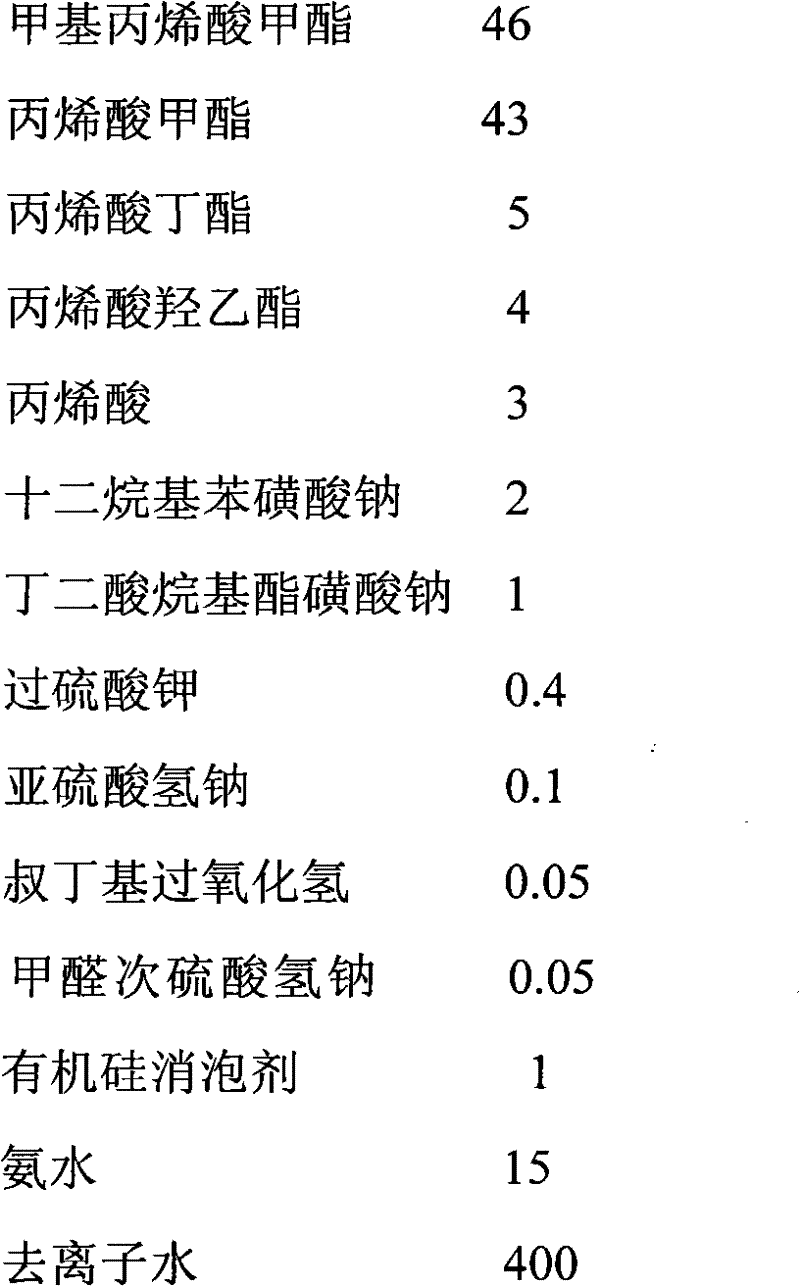

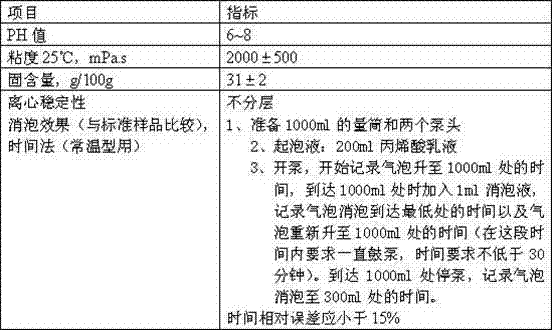

The invention relates to anti-sticking acrylic acid paint for coating and a preparation method thereof. The paint comprises the following ingredients in percentage by weight: 8 to 11 percent of methacrylate, 6 to 10 percent of acrylic ester, 0.4 to 2 percent of hydroxyethyl acrylate, 0.4 to 2 percent of acrylic acid, 0.05 to 0.6 percent of emulsifying agents, 0.02 to 0.18 percent of oxidation type initiators, 0.005 to 0.12 percent of reducing type initiators, 0.01 to 0.2 percent of defoaming agents, 1 to 5 percent of ammonia water and 76 to 84 percent of deionized water. In the acrylic ester polymerization process, and the functional cross linking monomers are added, so the heat cross linking effect is carried out in the coating curing process of the paint for enhancing the anti-sticking effect of the coating film in high-humidity environment. In addition, through the reasonable use of the emulsifying agents and the initiators in a polymerization system, the integral performance of the acrylic paint can also be improved. A proper emulsifying system, the initiators, monomers and processes are adopted for preparing the acrylic acid paint for coating with the ideal anti-sticking effect, and simultaneously, the original performance such as good heat sealing performance, high glossiness and the like is maintained. The paint is stable and has good coating adaptability, the process is simple, the cost is low, and the paint is suitable for industrial production.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Art acrylic paints containing nano-pigment and method for manufacturing same

InactiveCN101225250AImprove color qualityColorful and brightArtist's paintsHyaluronic acid coatingsSilicon dioxideSizing

The invention relates to art acrylic paints with nano-pigment and the preparation method, belonging to technical field of painting things, which is characterized in that the hydroxyethylcellulose and the chitosan are put into distilled water first and then the sodium benzoate, the nano-graining paste and the polyacrylic acid latex are added in. Then the powdered paint or lithopone hydrated silicon dioxide, glycerin and ethanol are added in and then blended evenly. The preparation method first disperses the nano-pigment into the bond and then adds the powdered paint to blend evenly, so can expel most air on the surface of the common pigment grain and grinds by a three-roller mill, and then disaggregates the large grain and small gobbet of the sizing agent by shearing force, extrusion force and grinding force. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of improving the service performance and reducing the economic cost and also has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

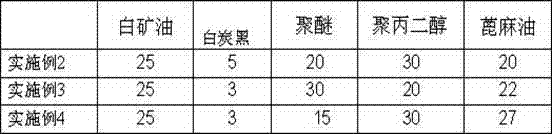

Preparation method of non-silicon defoaming agent

The invention discloses a preparation method of a non-silicon defoaming agent. The method is characterized in that the method comprises the steps that: first, a factice is prepared, wherein materials are blended according to a weight ratio that white mineral oil to white carbon black to polyether to polyether polyol to castor oil is 10-25:2-5:15-25:10-20:10-25; the materials are added into a reaction vessel provided with stirring blades, a motor and a heating system, and are well mixed under a room temperature; discharging can be carried out after 1h of stirring; 80 parts of the prepared factice, 20 parts of self-emulsifying silicone oil, 20 parts of tributyl phosphate, and 10 parts of a mixed emulsifier are well mixed by stirring; 280 parts of water is added such that the mixture is subjected to phase inversion; after phase inversion is completed, 16 parts of a thickening agent is added for regulating the viscosity to 1500-2000CS; and discharging and packaging are carried out. The preparation method is simple, production cost is low, and produced product is environment-friendly and has no pollution. Various performance indicators of the product are good. The non-silicon defoaming agent is suitable to be used in defoaming and foaming-inhibiting of water-based acrylic paints.

Owner:佛山市华联有机硅有限公司

Graphene-based waterborne acrylic paint and preparation method thereof

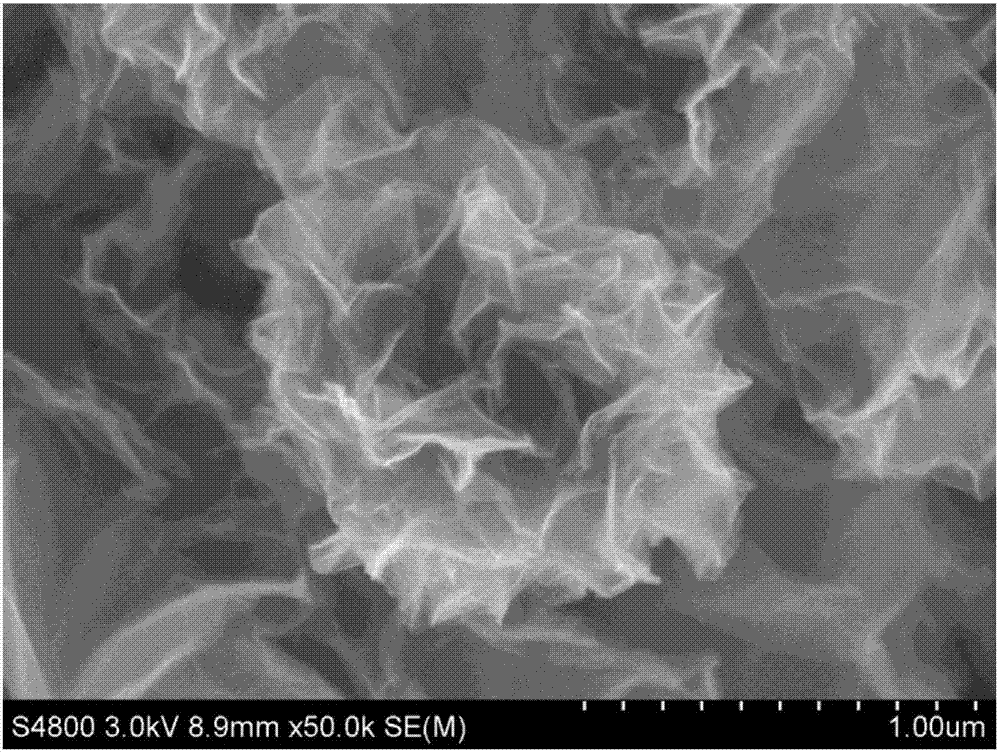

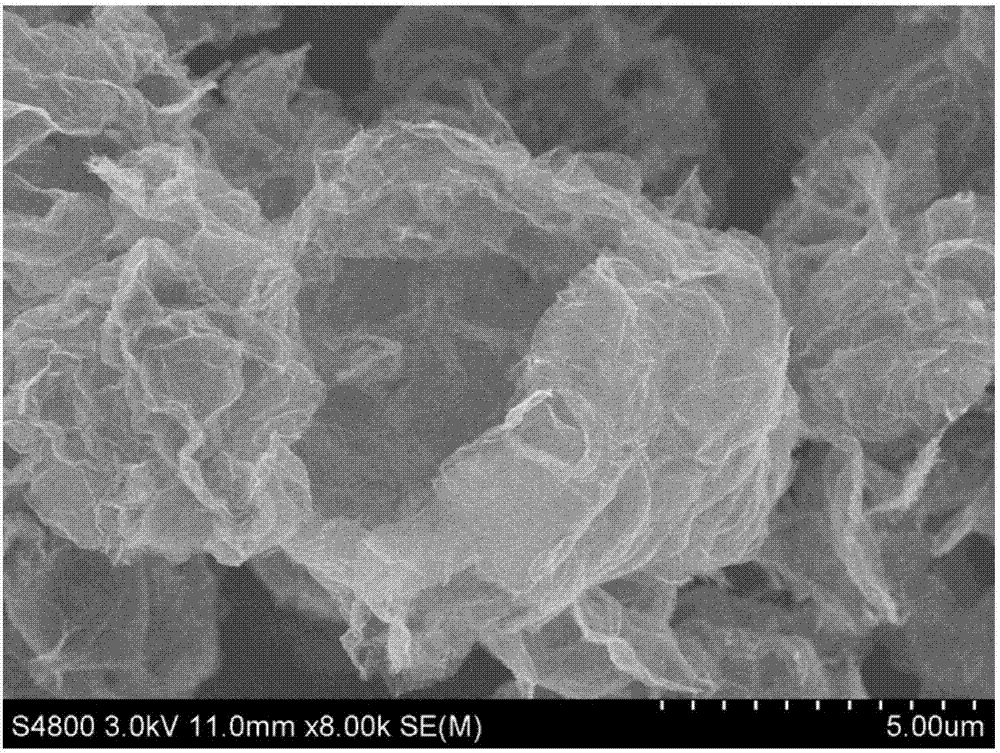

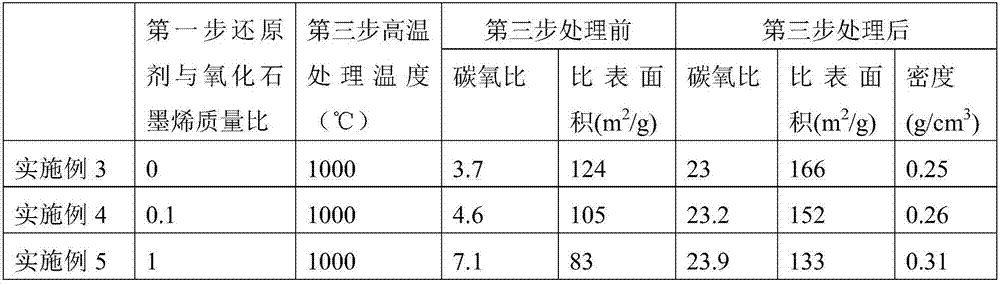

ActiveCN106987188ASimple structureCompact structureAntifouling/underwater paintsPaints with biocidesEmulsionAcrylic resin

The invention discloses a graphene-based waterborne acrylic paint and a preparation method thereof. The paint is prepared by mixing the following raw materials in parts by weight: 100 parts of an acrylic resin emulsion, 0.1-1 part of spitball graphene microspheres, 30-60 parts of an inorganic filler, 9-12 parts of an assistant and 10-20 parts of water. The spitball graphene microspheres with good mechanical property and elasticity can be obtained through spray drying and two-step method reduction. The spitball graphene microspheres are capable of effectively absorbing shock after being added to the paint, so that the abrasive resistance of a coating is improved and the chemical corrosion resistance can be improved. The spitball graphene microspheres have a unique microstructure, so that graphene can be effectively prevented from being stacked, the phenomena of aggregation and precipitation of the graphene in the paint are avoided and the overall stability of the paint is greatly improved.

Owner:HANGZHOU GAOXI TECH CO LTD

Water-based acrylic paint for composite paperboards and preparation method thereof

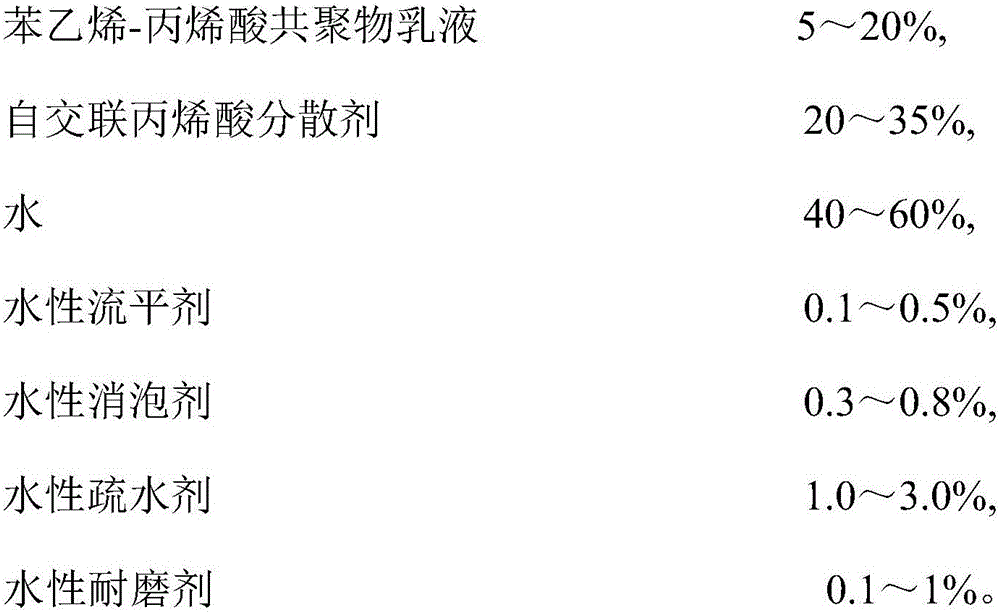

InactiveCN106835834AGood film formingImprove compactnessCoatingsCoatings without pigmentsWater basedEmulsion

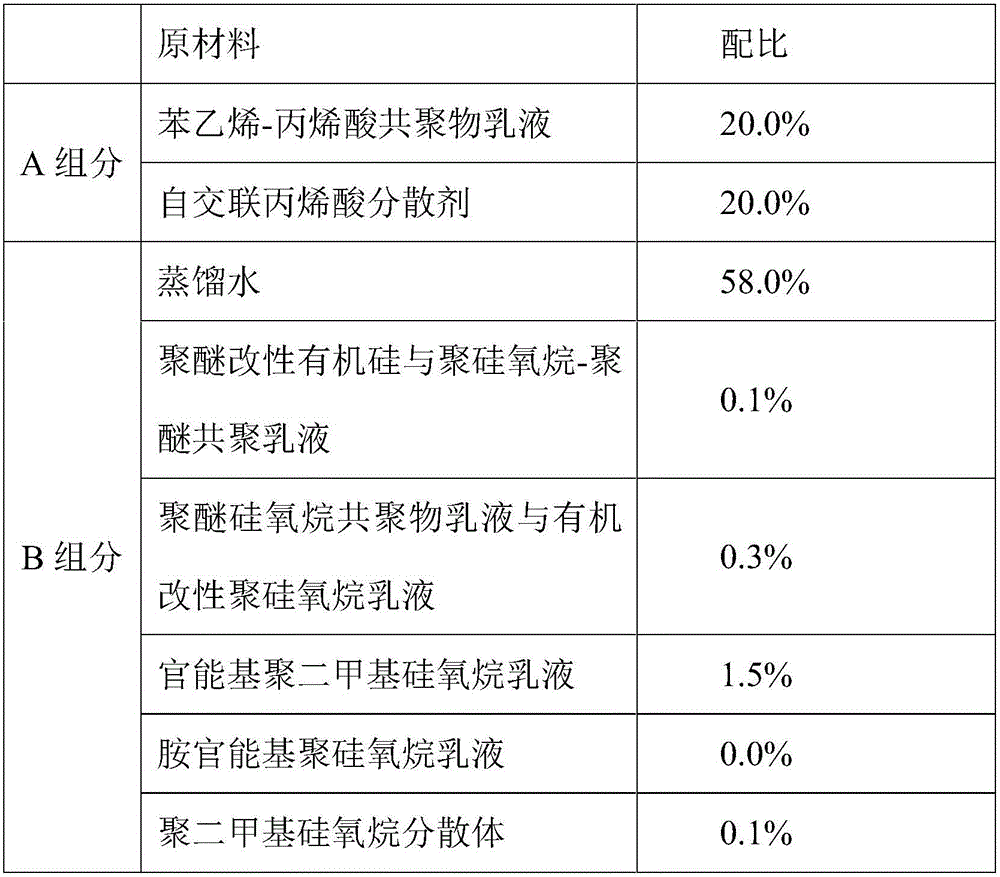

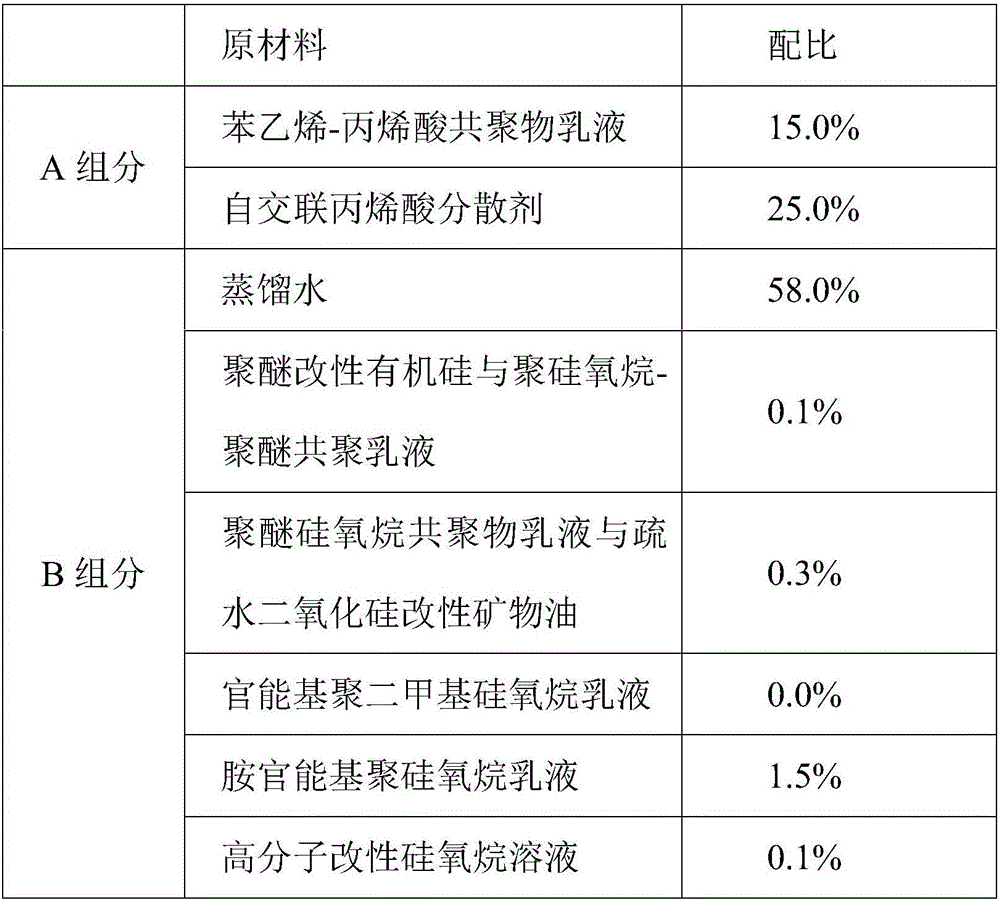

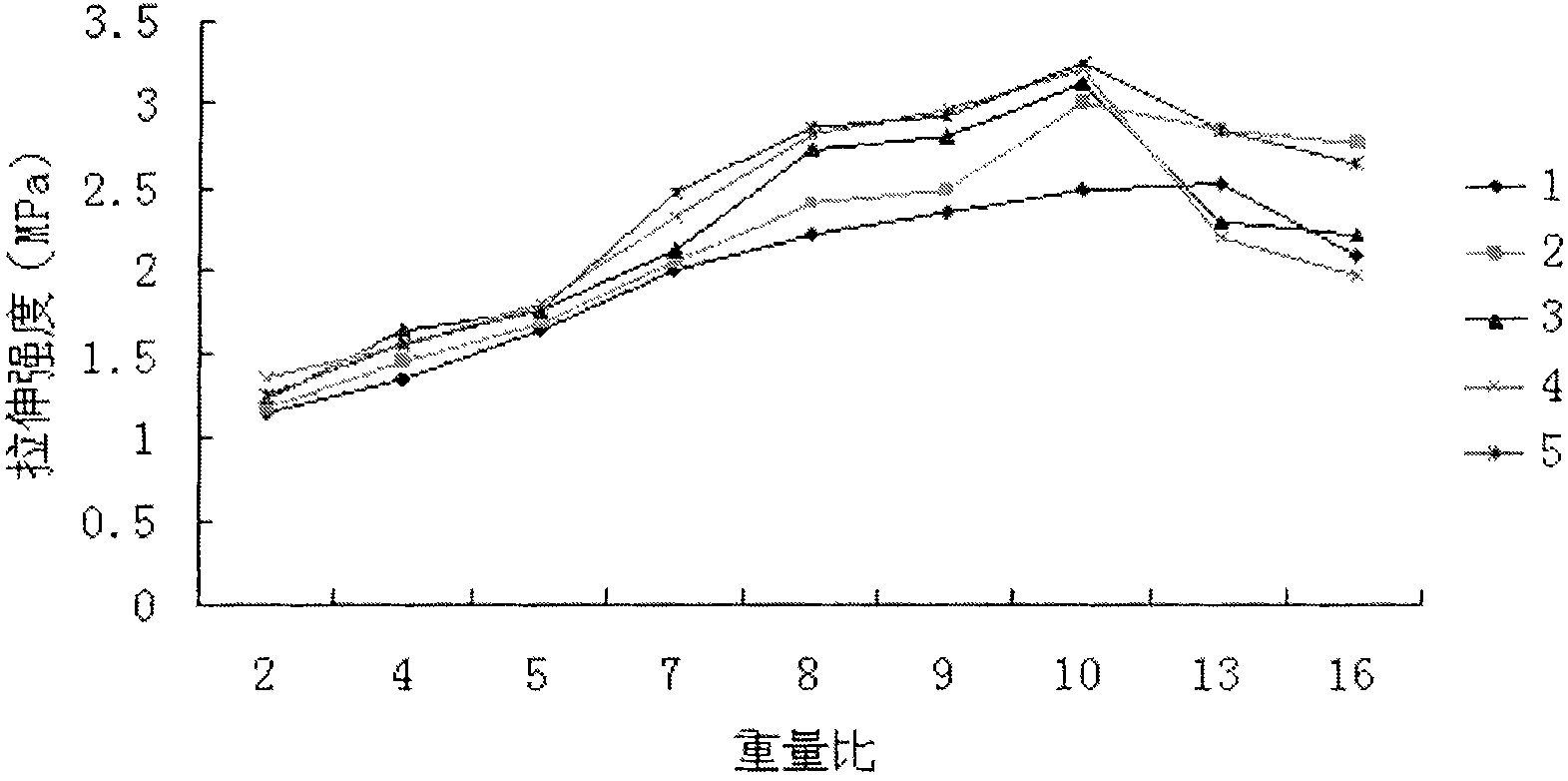

The invention discloses a water-based acrylic paint for composite paperboards. The technical scheme is as follows: the water-based acrylic paint for composite paperboards comprises the following components in percentage by weight: 5-20% of styrene-acrylic acid copolymer emulsion, 20-35% of self-crosslinked acrylic acid dispersing agent, 40-60% of water, 0.1-0.5% of water-based leveling agent, 0.3-0.8% of water-based defoaming agent, 1.0-3.0% of water-based hydrophobing agent and 0.1-1% of water-based anti-wear agent. The water-based acrylic paint for composite paperboards can well balance the moisture in the paperboard, keep the paperboard flat and prevent the paperboard from warping, curling and the like, has certain smoothness, and is coated on the back surface of the composite paperboard. The invention also discloses a preparation method of the water-based acrylic paint for composite paperboards.

Owner:ZHONGSHAN BOHAI SPECIAL CHEM CO LTD

Self-thickening pure acrylic latex used in art paints, and preparation method thereof

ActiveCN102399344AImprove thixotropyImprove rheologyArtist's paintsDyeing processEmulsionPolymer science

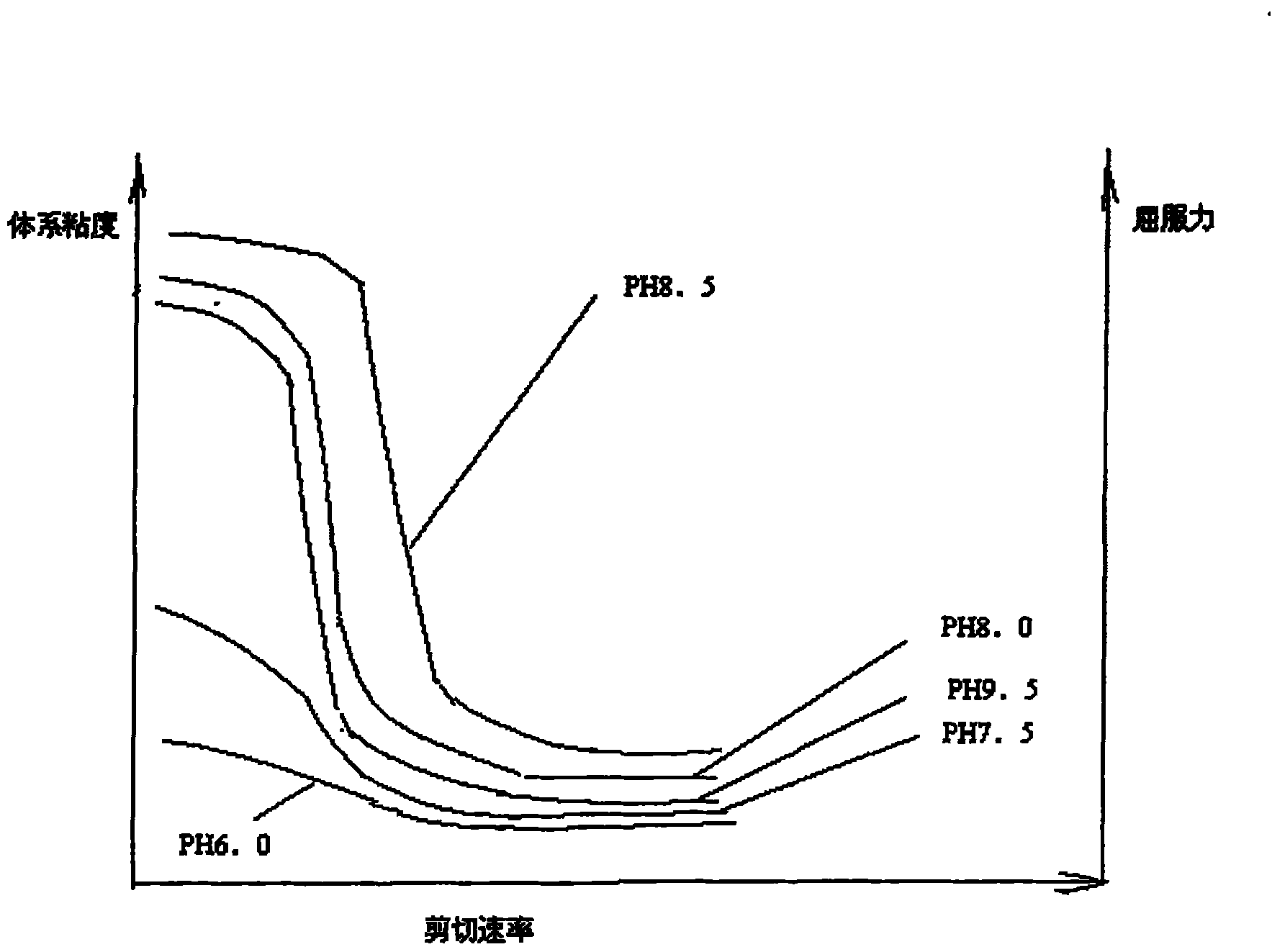

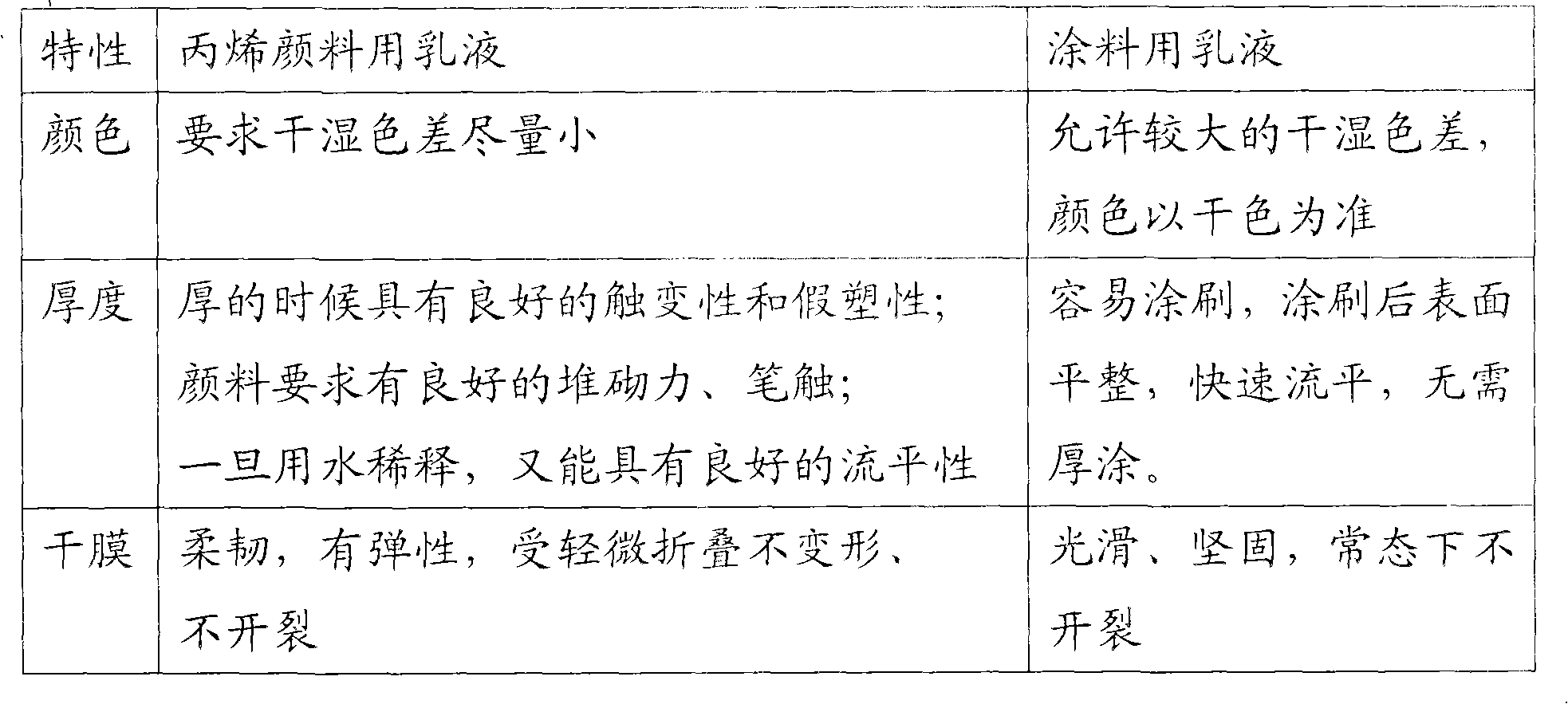

The invention provides a self-thickening pure acrylic latex used in art paints, and a preparation method thereof. The self-thickening pure acrylic latex is prepared from 45-55% of water, 40-48% of polymerizing monomers, 0.2-1.8% of a functional cross-linking agent, 2-10% of an emulsifier, and 0.2-1% of an initiator. The pure acrylic latex is obtained through polymerization. Specifically, under a temperature of 74 to 85 DEG C, the polymerizing monomers are used in polymerization, and a partial cross-linking reaction is carried out, such that an emulsion, which is the pure acrylic latex, is obtained. The polymer contains hydrophilic carboxy. Major molecular structures of the polymer are linearly distributed. The pure acrylic latex is a green and environment-friendly product, and is mainly used as adhesives and functional film-forming substrates in acrylic paints and engraving paints. The pure acrylic latex provided by the invention is characterized in high adhesive force, excellent tensile strength, good accumulation capacity, high yield strength, high pseudo-plasticity, high aging resistance and high light resistance.

Owner:宁波康大美术画材集团股份有限公司

Decorative thermoplastic acrylic paint

The invention relates to ornamental thermoplastic crylic acid paint, which is made up of base material, pigment, assistant and solvent, mentioned base material is thermoplastic acroid resin whose character is changed by saturated fatty acid, its viscosity is 800-2000 mPa.s, molecule of the resin contains saturated fatty acid radical which is about 5-30% of resin weight, at the same time it also contains tertiary carbonate which is about 5-20% of resin weight, each element of the paint and their weight proportion is as follows: base material (counted by solid) 100, pigment 3-90 assistant 0.3-2, solvent 145-160. It applies to be used as ornamental face-paint for metals and plastics, the build, glossiness and resistance to element is excellent, the storing is stable.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

Anti-cracking agent for water-borne acrylic paint and coating compositions

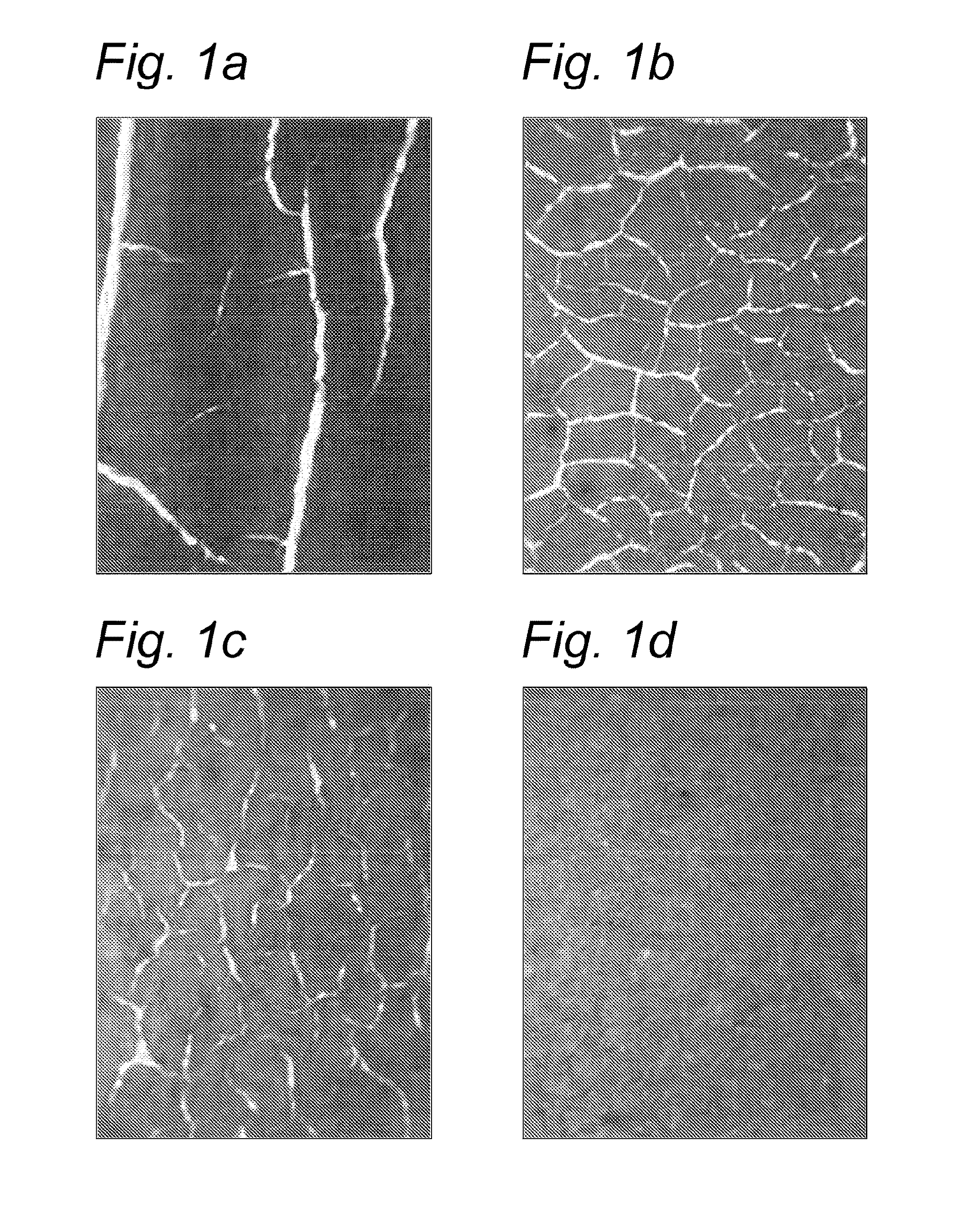

InactiveUS20150191612A1Highly beneficial rheological behaviourSignificant viscosity of compositionNon-fibrous pulp additionPulp properties modificationFiberNanofiber

This invention relates to water-borne acrylic paints and coatings, especially to agents that can be used to reduce the amount of VOCs to yield satisfactory paints or coatings. It has been found that cellulose based particles, which comprise cell wall material and their networks of cellulose based fibers and nanofibrils can be used to accomplish a reduction in VOCs and at the same time increase hardness and lower cracking of the dried acrylic paints and coatings. It is assumed that the organization of the cellulose fibrils, as it exists in the parenchymal cell walls, is at least partly retained in the cellulose based particles of the invention, even though part of the pectin and hemicellulose is removed there from.

Owner:KONINK COOPERATIE COSUN U A

Silicon acrylic paint

The invention provides a slicone modified coating synthesized by reactive emulsifying agent especially used for high-grade exterior wall paint, wherein the pigment of the coating employs titanium dioxide powder, talcum powder and barium sulfate, the flowing deformation auxiliary agent employs gaseous phase silicon dioxide, the levelling agent employs propylene glycol, and the thickening agent employs polyacrylates. The coating is prepared by the color paste method.

Owner:SUN YAT SEN UNIV

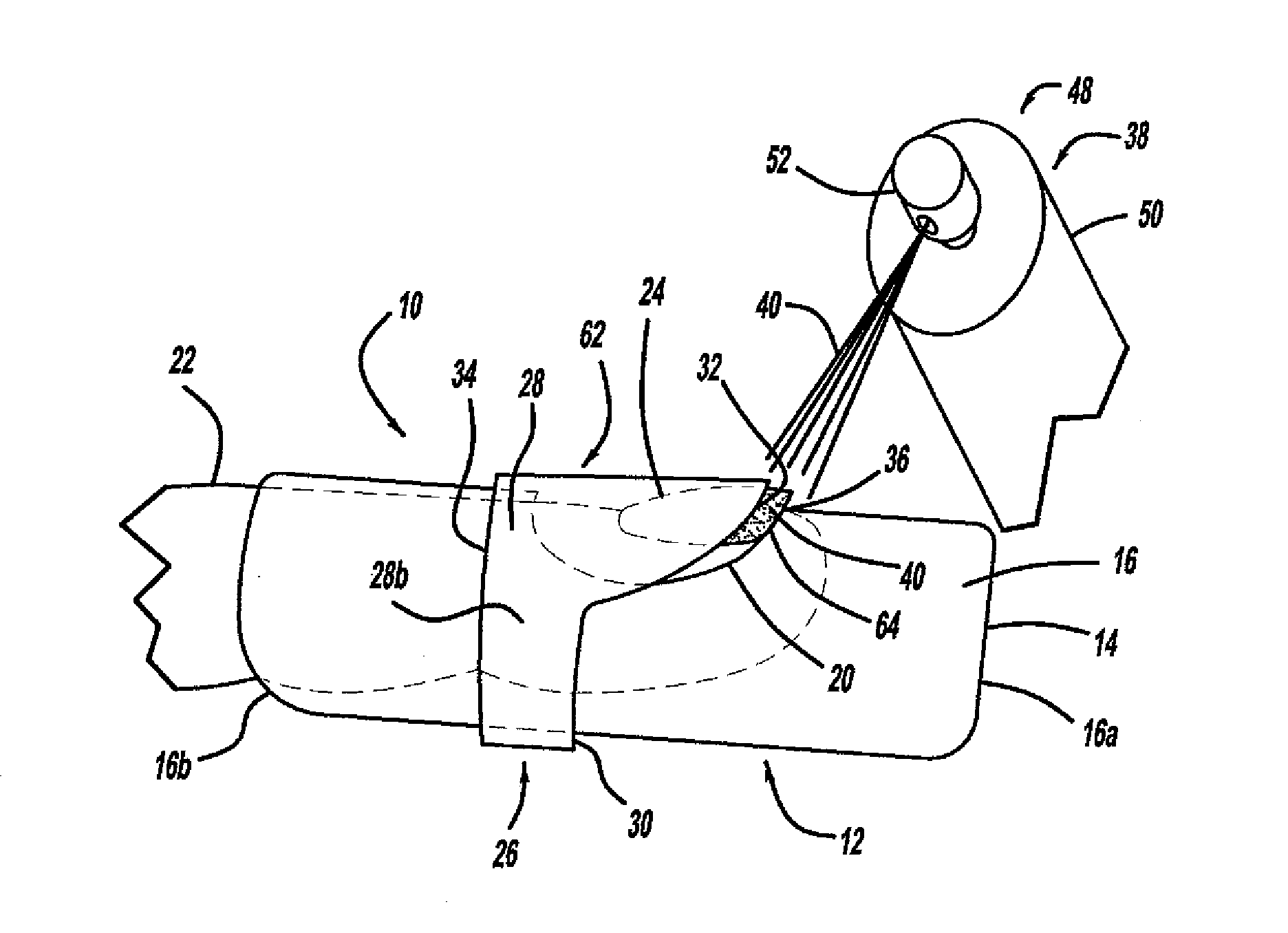

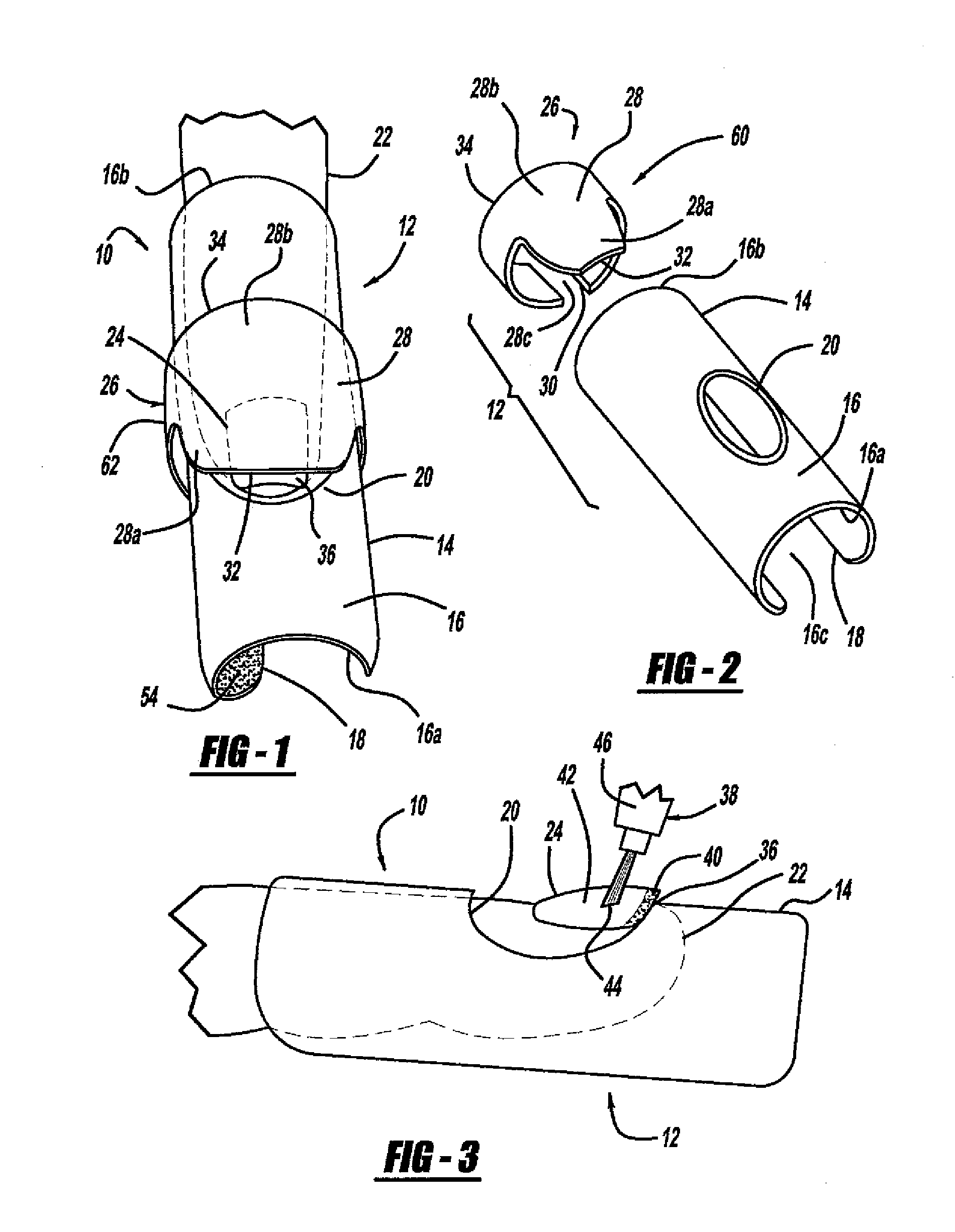

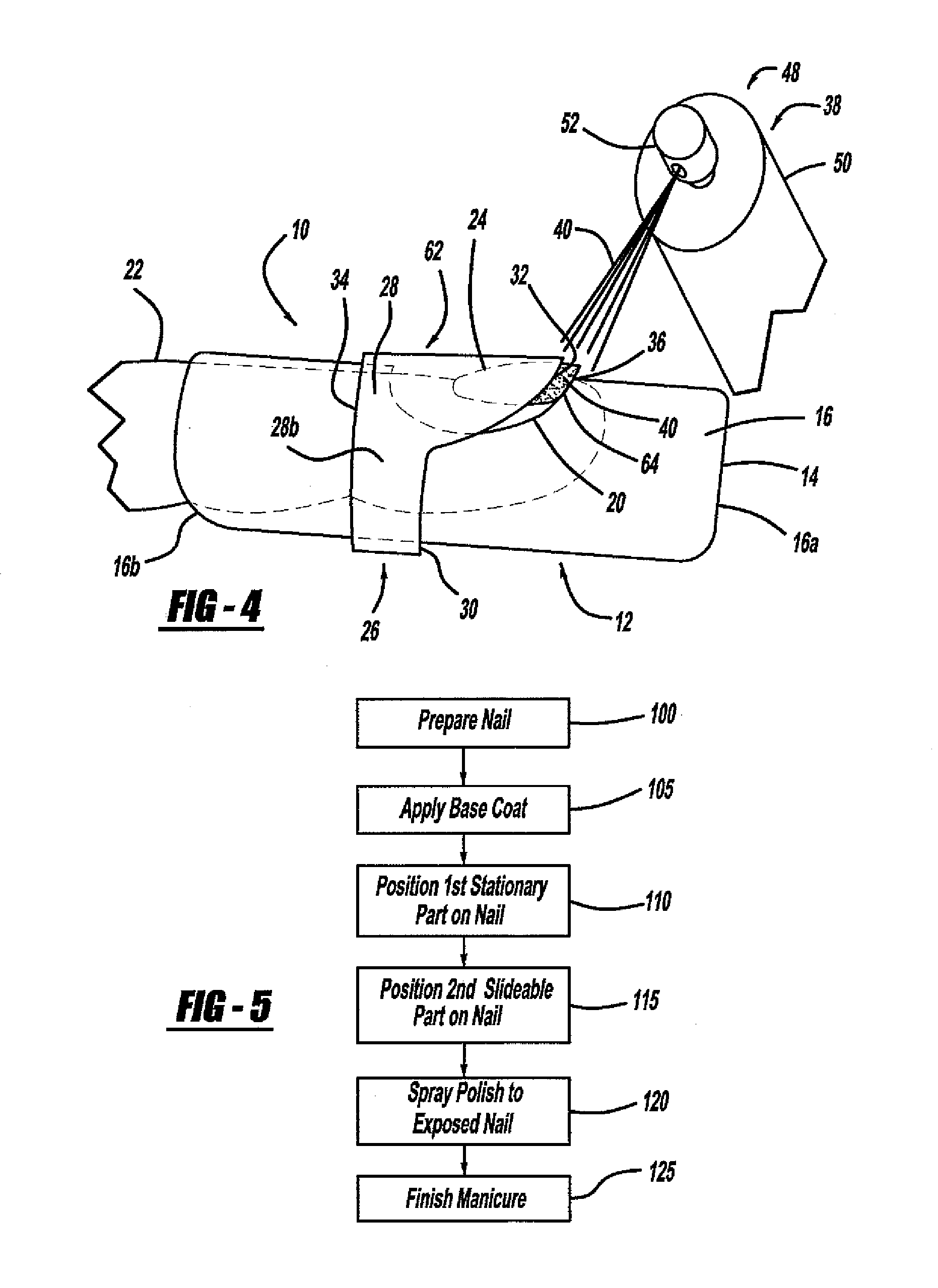

System, method and apparatus for self-applying a french manicure

InactiveUS20100313904A1Easy to useThe result is moreCurling devicesManicure/pedicureWater basedEngineering

A system and method for self-applying a French manicure using an adjustable form includes positioning a base member over a user's finger so that the nail is located within a nail receiving opening. An outer edge of a shield member wall is positioned at a position relative to the nail receiving opening to expose the tip of the nail. A first paint type is applied to the exposed nail tip using an applicator means. The first paint type is a water-based, non-toxic acrylic paint and the applicator means atomizes the paint to apply a plurality of droplets to the exposed nail. The shield member is repositioned relative to the nail receiving opening to expose the entire nail surface. A second enamel nail paint type is applied to the exposed nail surface to seal the first paint type.

Owner:GARINGER TAMMY

Manufacturing process of car hood

ActiveCN104874982AImprove antioxidant capacityImprove high temperature resistanceSuperstructure subunitsNumerical controlManufacturing technology

The invention discloses a manufacturing process of a car hood, and relates to the field of car manufacturing. The manufacturing process comprises the following steps: (1) blanking, (2) stretch forming, (3) trimming and punching, (4) deburring, (5) welding, (6) grinding, (7) painting, (8) baking, (9) polishing and waxing, and (10) coating. According to the manufacturing process, an outer cover plate and an inner cover plate similar in shape are designed to use the same blanking die for blanking so as to reduce the production cost; a compound die with trimming and punching functions is adopted to reduce the steps and improve the production efficiency; a numerical control automatic resistance spot welding machine is used for welding the hood, so that the welding efficiency and accuracy are improved; an acrylic paint is used for repeatedly spraying the hood for three times, so that the paint layer has strong adhesive force and good heat resistance; the coating processing is used to improve the oxidation, high temperature and scratch resistances of the hood paint.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Bi-component polyurethane coating with low infrared emissivity and preparation method thereof

ActiveCN102732145AImprove performanceLow emissivityPolyurea/polyurethane coatingsEmissivityMelamine formaldehyde

The invention discloses a bi-component polyurethane coating with low infrared emissivity and a preparation method thereof, relating to coatings with low infrared emissivity. The bi-component polyurethane coating with low infrared emissivity is prepared from the following raw materials by weight: 91.7 of hydroxy acrylic resin, 8.3 of terpolycyantoamino-formaldehyde resin, 5 to 15 of floatable flake aluminum powder, 13.7 to 16.7 of titanium dioxide, 75 of acrylic paint thinner, 1.55 of a levelling agent, 1.55 of an antifoaming agent and 33.3 of an HDI biuret curing agent. The bi-component polyurethane coating prepared in the invention has a good color, good flowing performance and good infrared stealth performance; usage amount of metal powder in the coating is substantially reduced; and the coating has excellent comprehensive properties and is a low-infrared-emissivity coating satisfying practical needs.

Owner:ZHONGBEI UNIV

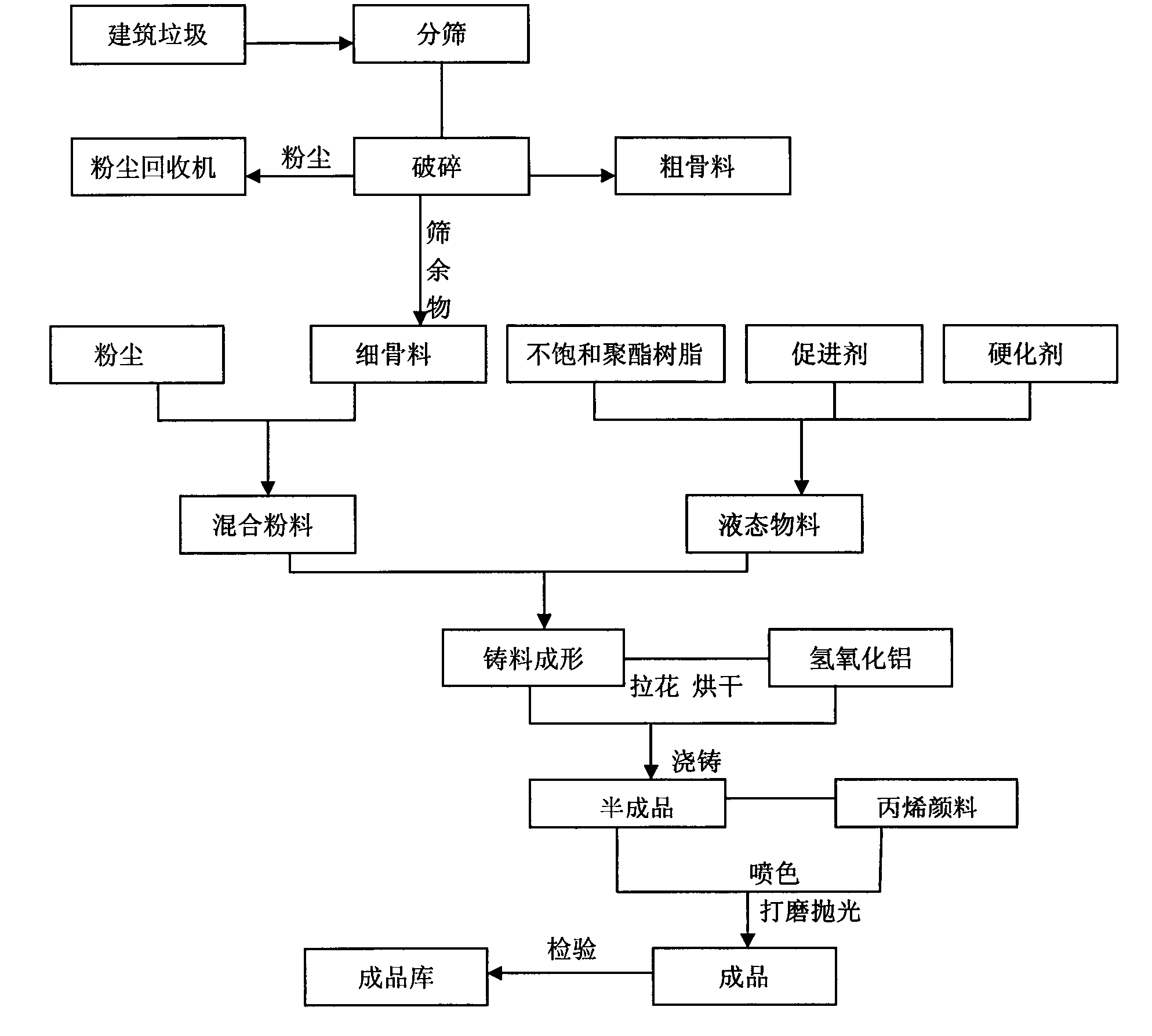

Construction waste recycled artificial marble and preparation method thereof

InactiveCN102838321AAddressing the threat of scarcitySolve social problems such as environmental pollutionSolid waste managementArchitectural engineeringAcrylic paint

The invention relates to a construction waste recycled artificial marble and also relate to a preparation method of the construction waste recycled artificial marble. The construction waste recycled artificial marble comprises the following components by weight: 30-70% of construction waste dust, 10-50% of construction waste recycled fine aggregate, 10-40% of unsaturated polyester resin, 2-15% of accelerant, 0.5-4% of curing agent, 0.3-4% of acrylic paint and 0.2-4% of aluminum hydroxide. The preparation method of the construction waste recycled artificial marble comprises the steps as follows: mixing; forming by pouring, pulling and drying; coloring and drying; grinding and polishing; checking quality; and warehousing finished products. According to the construction waste recycled artificial marble, a problem of resource scarcity of natural marble is solved, and remarkable social and environmental benefits are obtained; and according to the preparation method of the construction waste recycled artificial marble, the process is advanced, the technology is mature, the resources are recycled, and requirements of national recycling economy development are met.

Owner:QINGDAO GREEN SAIL RECYCLED BUILDING MATERIALS

Acrylic paint

The invention discloses an acrylic paint. The acrylic paint comprises, by weight, 30-60 parts of hydroxy acrylic resin, 20-30 parts of an aqueous acrylic resin, 10-15 parts of talcum powder, 10-20 parts of stearic acid, 10-15 parts of a pigment, 1-3 parts of iron rust, 5-10 parts of titanium dioxide and 10-15 parts of deionized water. The acrylic paint uses deionized water as a dispersion medium, and the addition of an organic solvent is not needed, so the pollution to the environment is reduced, and resource saving can be realized. An aqueous acrylic polyurethane finish made according to the above composition formula in the invention has very strong adhesion on various substrates, and a coat obtained by using the finish has the advantages of high hardness, good water resistance, good weather resistance, good chemical resistance and high wear resistance. The acrylic paint has wide uses, can be used as terrace and floor paints, a metal antirust paint and a ship paint, and can also be used for the anticorrosion of automobile light industrial products and the inner walls of drinking water cylinders.

Owner:QINGDAO XUANWEI COATING MATERIAL

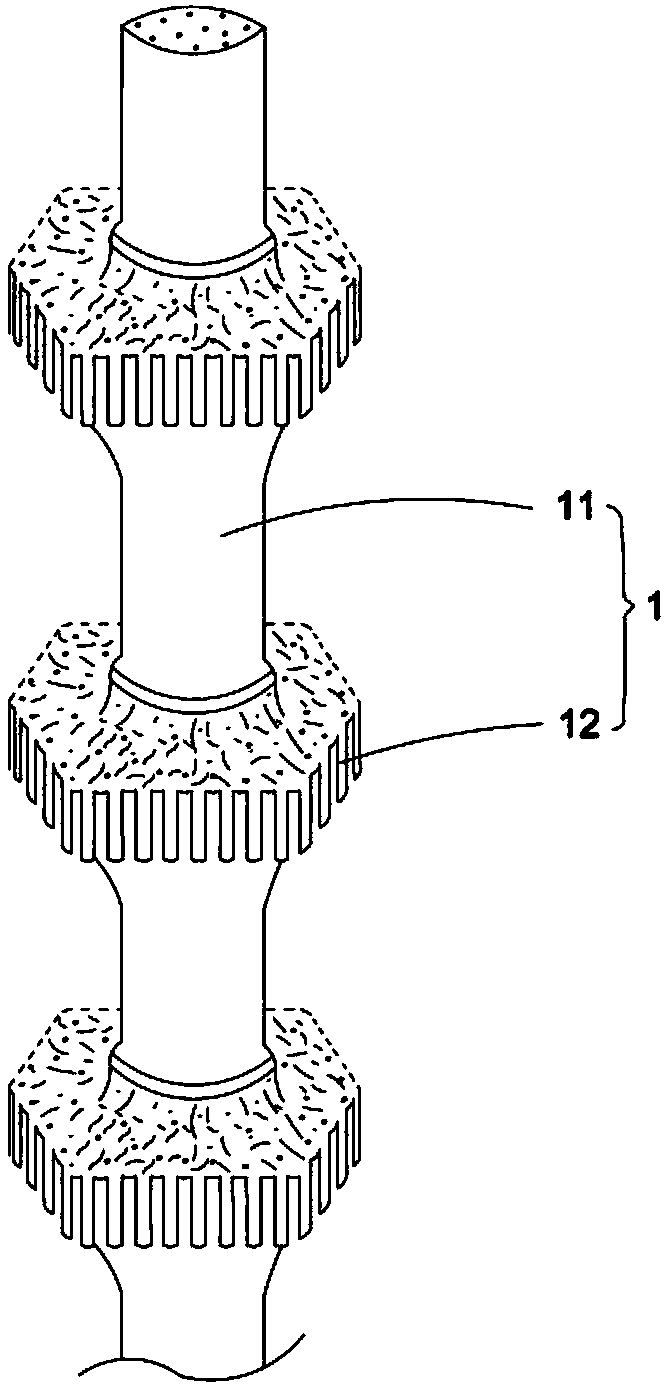

Furniture wood board surface metallic paint spraying method

InactiveCN108480166AImprove adhesionPrevent disengagementPretreated surfacesCoatingsTouch sensationAcrylic paint

The invention provides a furniture wood board surface metallic paint spraying method. The furniture wood board surface metallic paint spraying method comprises the following steps that mixed priming paint is prepared, specifically, 0.1-0.5% of shish-kebab-structure polymer is added into acrylic paint, and uniform mixing is conducted; mixed finish paint is prepared, specifically, 10-20% of metal powder is added into the acrylic paint, and uniform mixing is conducted; primary polishing is conducted, specifically, the surface of a wood board is polished through a polishing machine, and thus, thesurface of the wood board is smooth; the priming paint is sprayed, specifically, the mixed priming paint is sprayed onto the surface of the wood board through a spraying technology, leveling is conducted, and after baking, a priming paint layer which is 25-40 [mu]m thick is formed; secondary polishing is conducted, specifically, the surface of the priming paint layer is polished through fine sandpaper so as to be smooth; and the finish paint is sprayed, specifically, the mixed finish paint adheres to the priming paint layer through the spraying technology, leveling is conducted, and after baking, a finish paint layer which is 100-120 [mu]m thick is formed. After metallic finish paint is sprayed onto the surface of furniture, the surface of furniture has metallic luster, the paint surface is high in stereoscopic impression and smooth when being touched with a hand, and the good visual effect and touch sensation are achieved.

Owner:GUANGDONG HULUBAO CULTURE TECH CO LTD

Anticorrosive epoxy acrylic paint

InactiveCN1389530AOvercome the disadvantage of water resistance dropOvercome the disadvantage of easy bleedingAnti-corrosive paintsEpoxyAcid value

The invention relates to epoxy crylic acid anti-corrosino paint, it is made up of base material, pigment, solvent and dispersant, the resin used as base material is epoxy acroid resin which contains silica alkyl and high strength polar radicel, acid value of the resin is 3-8, epoxy equivalent is 0.02-0.50, under 25 deg.C and 50% solid shares, the viscosity of the resin is 400-1500 mPa.s, the content of epoxy in molecular is 2-10%, the content of silica alkyl is 0.3-3.5%, the content of high strength polar radicel is 2-10%; What used as pigment is compound antirust pigment which is made up of chemical antirust pigment and physical antirust pigment, the weight proportion of each element in the paint is as follows: base material (counted by solid) 20-25, pigment 28-40, solvent 40-45, dispersant 0.4-6, it can be used as primer.

Owner:JIANGSU RONGCHANG NEW MATERIAL TECH

Antique jade simulation mosaic pasting decorative picture

InactiveCN104527311AColorful and beautifulGood collection valueDecorative surface effectsSpecial ornamental structuresEngineeringAcrylic paint

The invention relates to an antique jade simulation mosaic pasting decorative picture. A canvas in a shape is manufactured, a line drawing is drawn on the canvas, acrylic paint is used for filling color, then crystal leftover materials of various colors are selected for being cut, ground and polished to be crystal stones of different sizes, and according to the colors needed by the drawn line drawing, the ground and polished crystal stones are pasted to the corresponding colors of the line drawing by transparent adhesive tape.

Owner:王旭东

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com