Water-based acrylic paint for composite paperboards and preparation method thereof

A water-based acrylic and composite card technology, applied in paper coating, papermaking, coating, etc., can solve the problems affecting the effect of packaging paper products, composite cardboard moisture imbalance, affecting paper flatness, etc., to achieve superior water retention performance and excellent printing Good adaptability and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

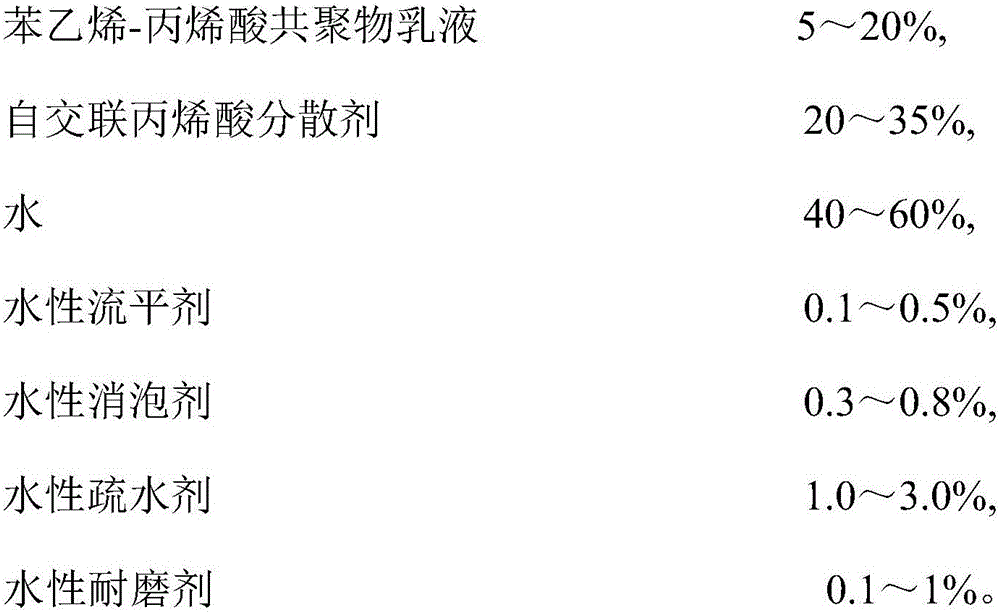

[0034] A water-based acrylic paint for composite cardboard, consisting of the following components by weight:

[0035]

[0036] The preparation method of this kind of composite cardboard water-based acrylic paint is as follows:

[0037] 1) Configure component A: add styrene-acrylic acid copolymer emulsion and self-crosslinking acrylic acid dispersant to the dispersion tank according to the formula ratio, and stir at 250 rpm for 10 minutes;

[0038] 2) Configuration B component: deionized water, polysiloxane-polyether copolymer emulsion, polyether siloxane copolymer emulsion, functional polydimethylsiloxane emulsion, amine functional polysiloxane emulsion 1. Add the polydimethylsiloxane dispersion into the mixing tank respectively, and stir for 15 minutes at a speed of 350 rpm;

[0039] 3) Mixing: pump the uniformly stirred component B into the dispersion tank, mix with component A, and stir at 250 rpm for 10 minutes;

[0040] 4) Filtration and purification packaging: remo...

Embodiment 2

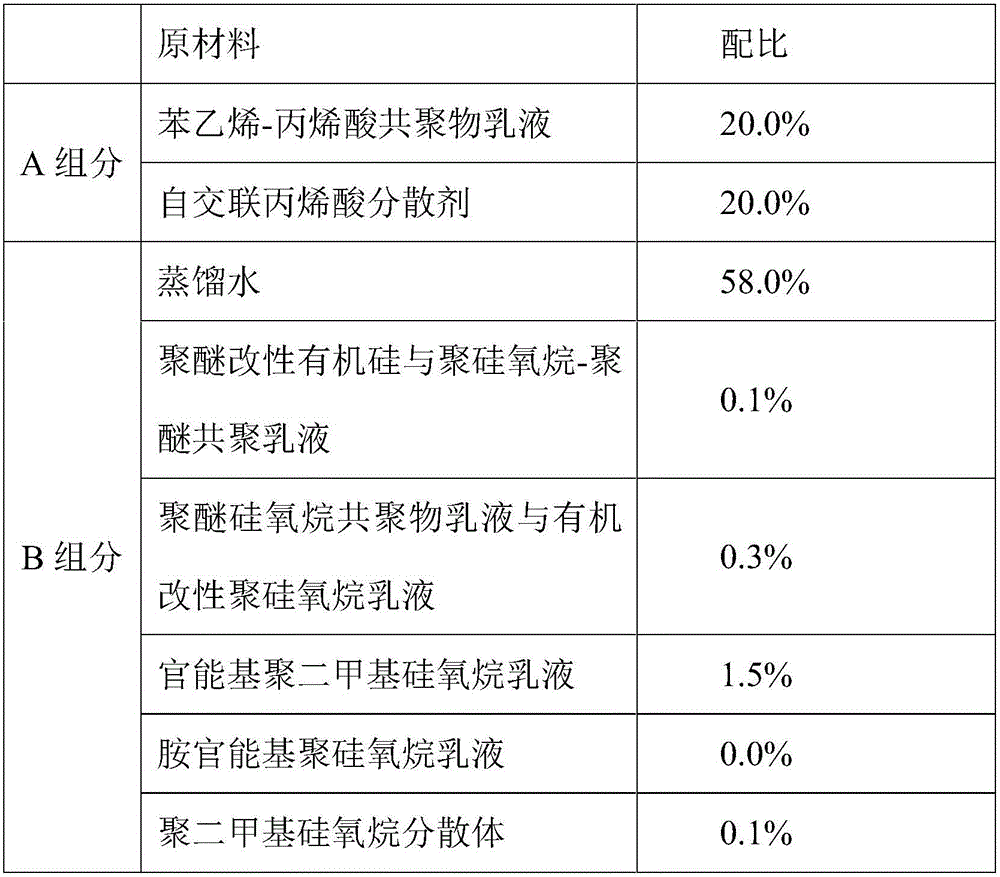

[0042] A water-based acrylic paint for composite cardboard, consisting of the following components by weight:

[0043]

[0044] The preparation method of this kind of composite cardboard water-based acrylic paint is as follows:

[0045] 1) Configure component A: add styrene-acrylic acid copolymer emulsion and self-crosslinking acrylic acid dispersant to the dispersion tank according to the formula ratio, and stir at 250 rpm for 15 minutes;

[0046] 2) Configuration B component: deionized water, polysiloxane-polyether copolymer emulsion, polyether siloxane copolymer emulsion, functional polydimethylsiloxane emulsion, amine functional polysiloxane emulsion 1. Add the polydimethylsiloxane dispersion into the mixing tank respectively, and stir for 20 minutes at a speed of 400 rpm;

[0047] 3) Mixing: pump the uniformly stirred component B into the dispersion tank, mix with component A, and stir at 250 rpm for 15 minutes;

[0048] 4) Filtration and purification packaging: remo...

Embodiment 3

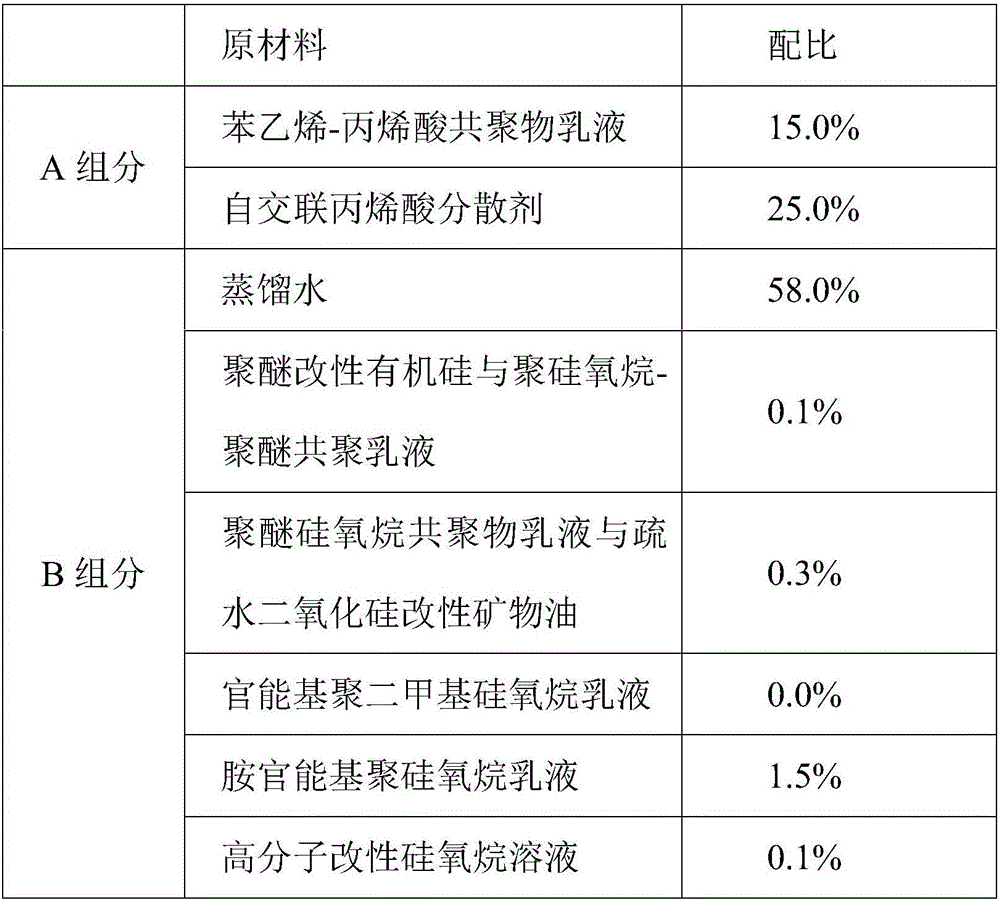

[0050] A water-based acrylic paint for composite cardboard, consisting of the following components by weight:

[0051]

[0052] The preparation method of this kind of composite cardboard water-based acrylic paint is as follows:

[0053] 1) Configure component A: add styrene-acrylic acid copolymer emulsion and self-crosslinking acrylic acid dispersant to the dispersion tank according to the formula ratio, and stir at 300 rpm for 15 minutes;

[0054] 2) Configuration B component: deionized water, polysiloxane-polyether copolymer emulsion, polyether siloxane copolymer emulsion, functional polydimethylsiloxane emulsion, amine functional polysiloxane emulsion 1. Add the polydimethylsiloxane dispersion into the mixing tank respectively, and stir for 20 minutes at a speed of 450 rpm;

[0055] 3) Mixing: Pump the evenly stirred component B into the dispersion tank, mix with component A, and stir at 300 rpm for 15 minutes;

[0056] 4) Filtration and purification packaging: remove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Minimum film forming temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com