Patents

Literature

134results about How to "Low dielectric" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepreg applied for multi-layer board of printed electronic circuit

ActiveCN101220160ALow dielectricReduce residual stressSynthetic resin layered productsCircuit susbtrate materialsSolventFilling materials

The invention pertains to the technical field of the copper clad laminate, which more particularly relates to a prepreg applied to a printing circuit multilayer board. The prepreg comprises reinforced materials and resin composite, wherein, the reinforced materials is glass fiber paper, and according to part by weight, the formulation of the resin composite is as follows: 20 to 84 portions of resin, 0 to 35 portions of filling materials, 0.01 to 0.3 portions of curing accelerator and 10 to 45 portions of solvent; the resin composite solvent is soaked in the glass fiber paper for 1 to 5 minutes, and is put in a 140 to 200 DEG C oven for baking for 2 to 10 minutes; after the solvent is removed, the prepreg applied to multilayer PCB processing materials is obtained; white flake and spot problems of base materials during the manufacturing procedures of the multilayer PCB are prevented, problems of de-lamination, shrink resin, holes and crack of the resin and white flake, etc. that come up after the multilayer PCB goes through cold and hot impact are improved, and the prepreg has good reliability and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

Thermosetting Resin Composition and Application Thereof

InactiveUS20100240811A1Excellent dielectric propertiesIncrease thermal resistanceBiocideOrganic chemistryTetrabromobisphenol ASolvent

The present invention discloses a thermosetting resin composition including: a bi-functional or multi-functional epoxy resin, a SMA uses as a curing agent, an allyl phenol such as diallyl bisphenol A used as a co-curing agent and a toughening agent a low-bromine or high-bromine BPA epoxy resin or tetrabromobispheno A (TBBPA or TBBA) uses as a flame retardant agent, and an appropriate solvent. After the resin composition of the invention is cured, the resin composition has lower dielectric property and better thermal reliability and tenacity. A copper clad laminate made of an enhanced material such as glass fiber has lower dielectric constant (Dk) and loss tangent (Df), high Tg, high thermal decomposition temperature (Td), better tenacity and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs or applied as a molding resin material for contraction, automobile and air navigation.

Owner:ITEQ DONGGUAN +1

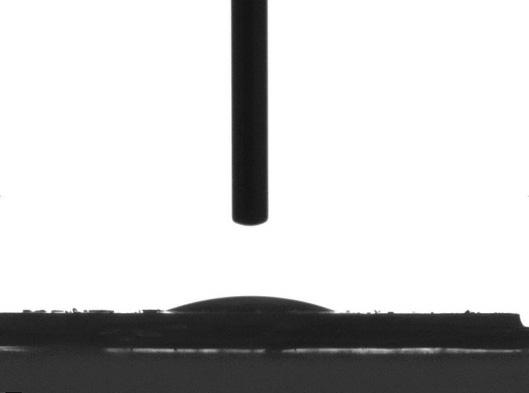

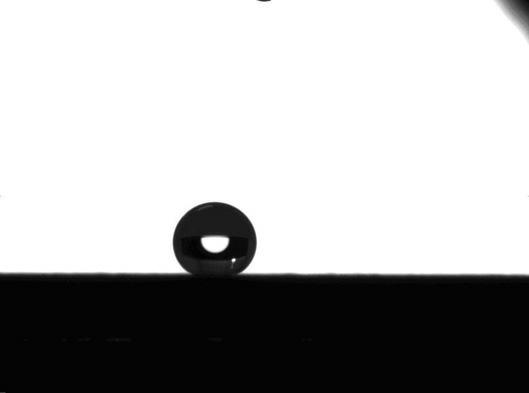

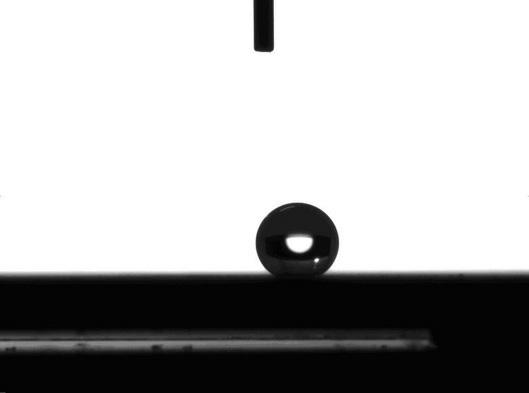

Preparation method for high-wave permeability super-hydrophobic moisture-proofing coating for antenna housing material

InactiveCN102492339AReduce porosityLow dielectricPretreated surfacesSpecial surfacesEpoxySilicon dioxide

The invention discloses a preparation method for high-wave permeability and super-hydrophobic moisture-proofing coating for an antenna housing material. The preparation method is characterized by comprising the following steps of: preparing hole-sealing emulsion; preparing super-hydrophobic moisture-proofing emulsion; coating the hole-sealing emulsion on the antenna housing material, surface-drying the film coating under a room temperature, and then curing the film coating under the temperature of 100 DEG C to 140 DEG C; cooling and immersing the film coating to the super-hydrophobic moisture-proofing emulsion; surface-drying the film coating under the room temperature, and curing the film coating under the temperature of 80 DEG C to 160 DEG C to acquire the high-wave permeability and super-hydrophobic moisture-proofing coating for the antenna housing material. Micron-level silicon dioxide and fluorine-containing polymer are used in the method to perform accumulating and hole-sealing;a micron surface structure with certain roughness is provided, and epoxy resin with good viscosity is added to the hole-sealed coating, so that the mechanical property of the hole-sealed coating is improved; a self-growth method is adopted for depositing micron-level fluorine-containing polymer, which is in-situ packaged by organic silicon resin and attached with hydrophobic nanometre silicon dioxide, to the surface of the hole-sealed coating, so that the high-wave permeability and super-hydrophobic moisture-proofing coating of the antenna housing material is prepared.

Owner:SOUTHWEAT UNIV OF SCI & TECH

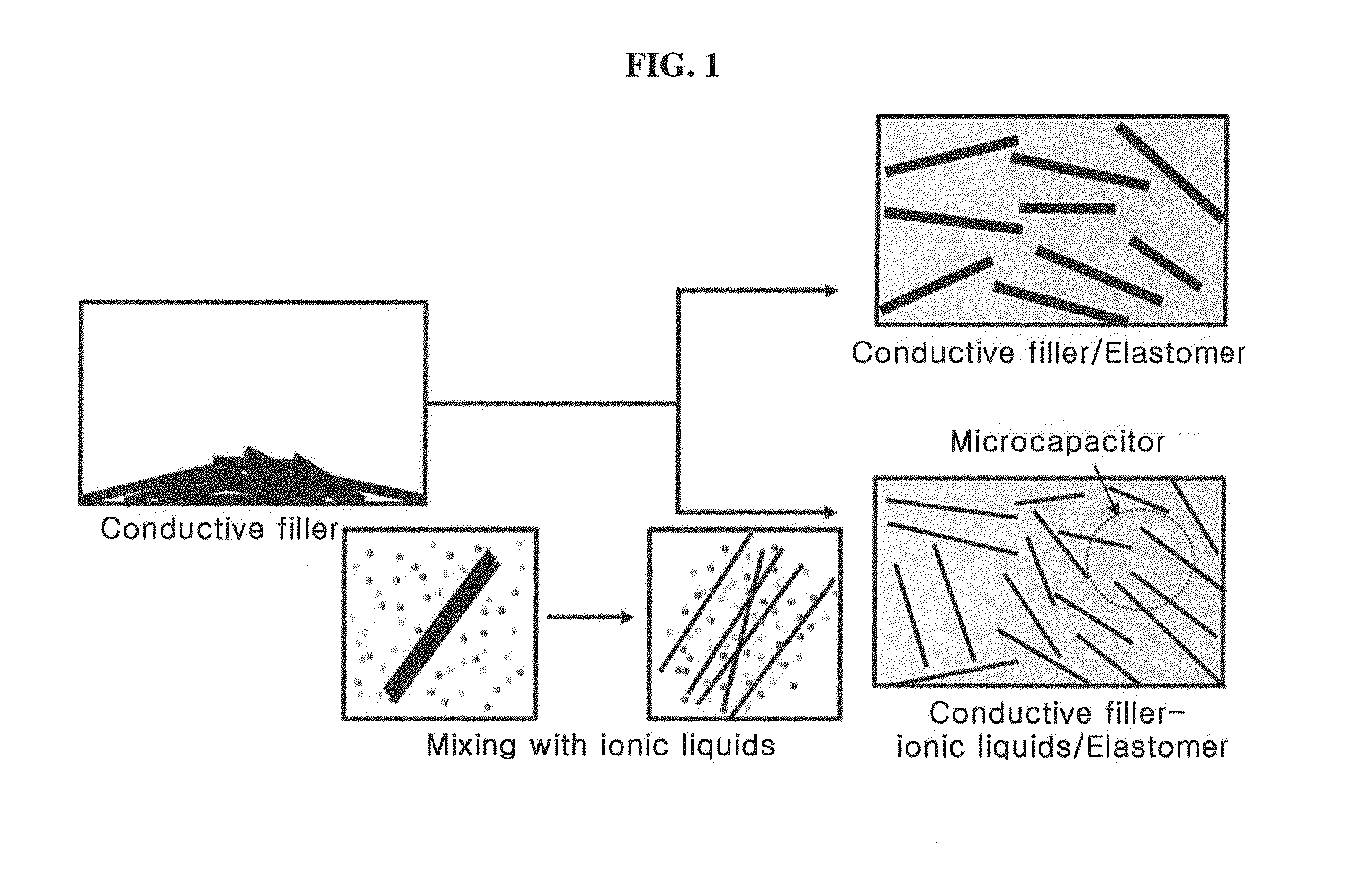

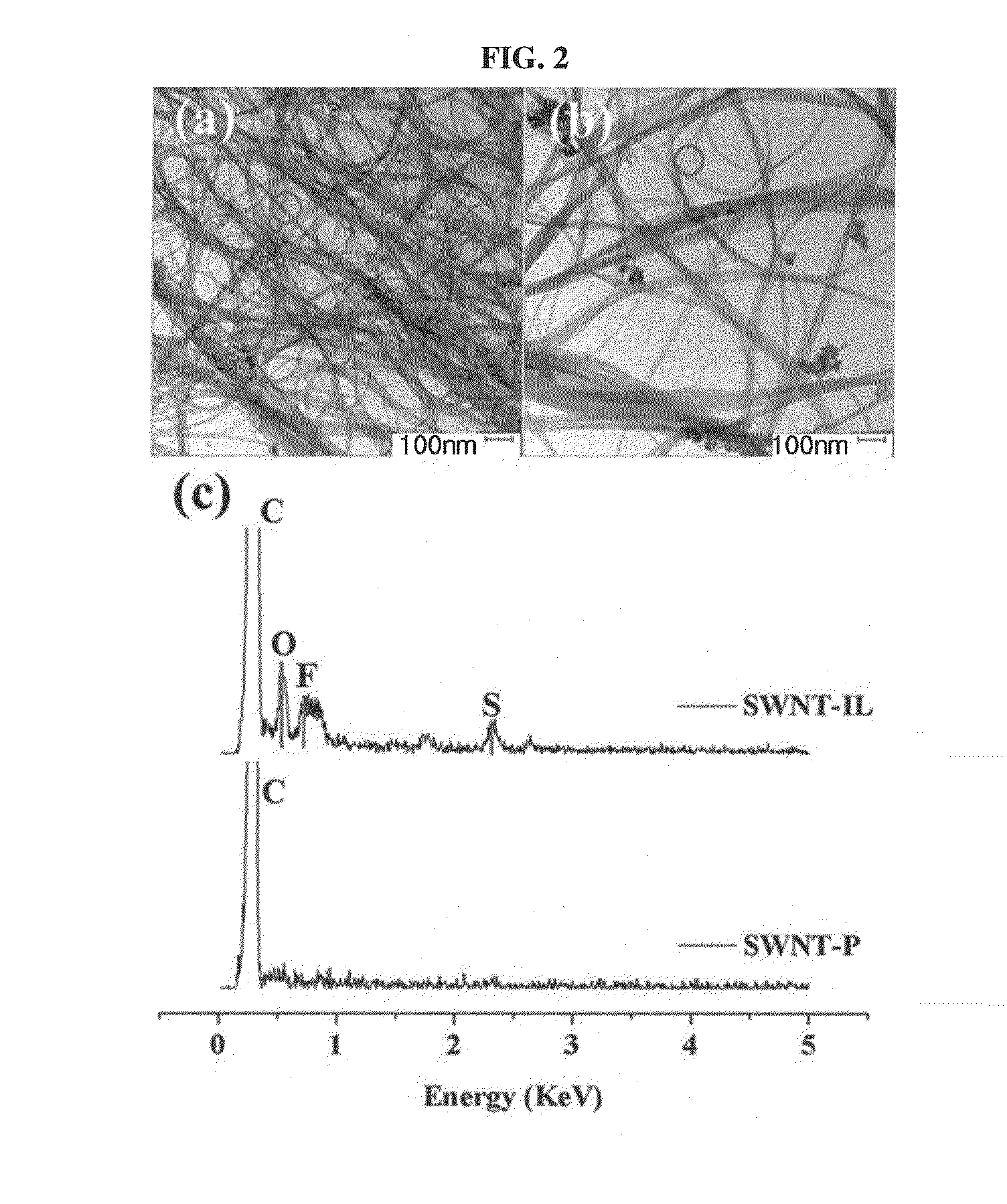

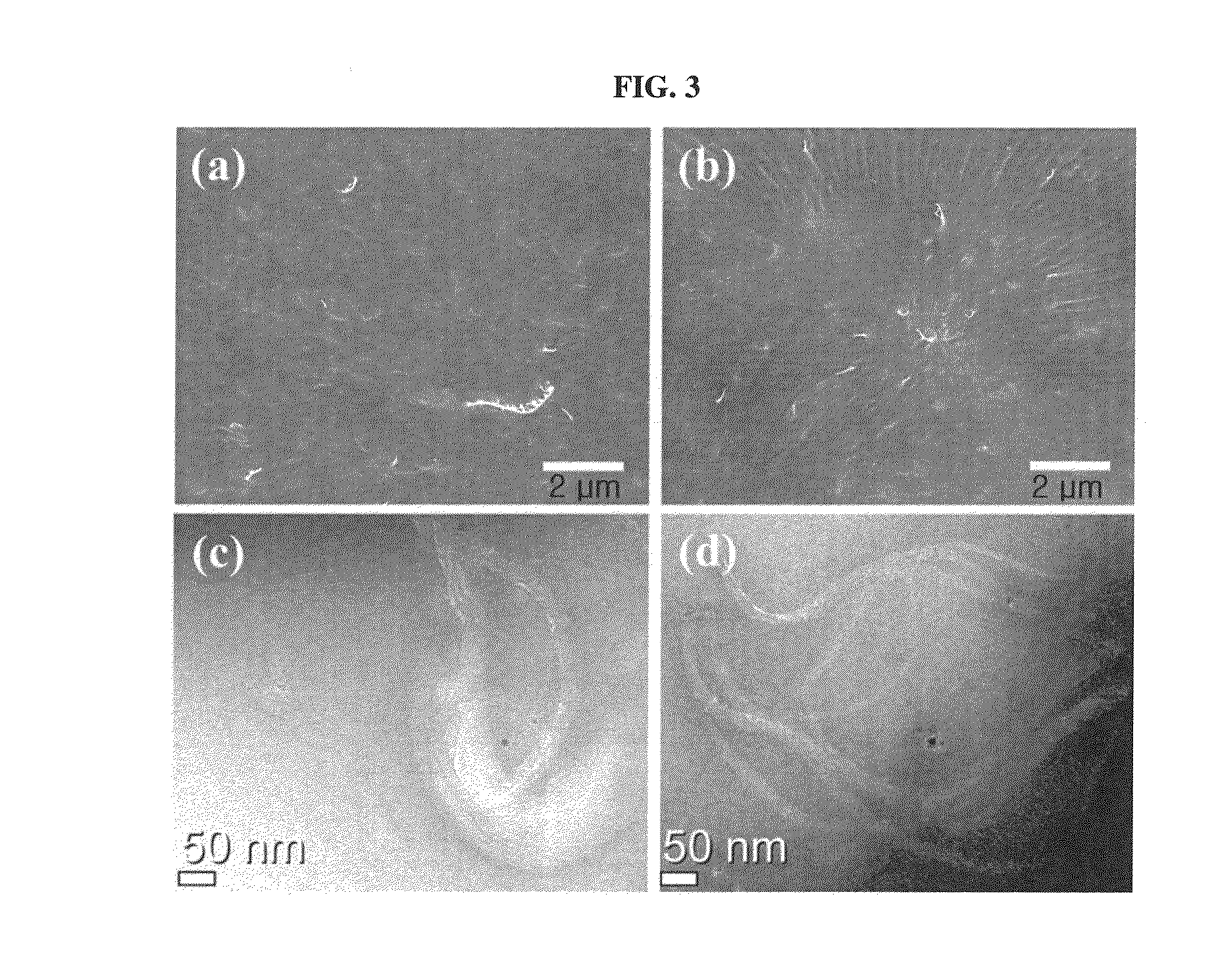

Elastomer composite with improved dielectric properties and production method thereof

ActiveUS20130310495A1Good dispersionHigh dielectric constantMaterial nanotechnologyInorganic insulatorsElastomer compositesConductive polymer

Disclosed is an elastomer-conductive filler composite with improved dielectric properties. The composite includes conductive fillers and an ionic liquid dispersing the conductive fillers. The ionic liquid is used as a dispersant to effectively enhance the dispersion of the conductive fillers, achieving a high dielectric constant and a low dielectric loss of the composite without deteriorating the physical properties of the conductive fillers. The use of the ionic liquid can reduce the number of processing steps and the presence of the conductive fillers at a low concentration in the composite can minimize deterioration of the physical properties of the elastomer. Further disclosed is a method for producing the composite.

Owner:KOREA INST OF SCI & TECH

Method for producing liquid crystal polymer molded article

InactiveUS20080048150A1Effectively and uniformly expressImprove thermal conductivityLiquid crystal compositionsPrinted circuit aspectsPolymer scienceLiquid crystal

A method for producing a molded article is provided, the method comprising the step of press-molding a resin composition comprising a filler and a powder of a liquid crystal polymer having a flow starting temperature of 280° C. or higher and an average particle size of 0.5 to 50 μm. In the molded article obtained by the method of the present invention, the functions provided by the filler, such as thermal conductivity and dielectric property, can be effectively and uniformly expressed.

Owner:SUMITOMO CHEM CO LTD

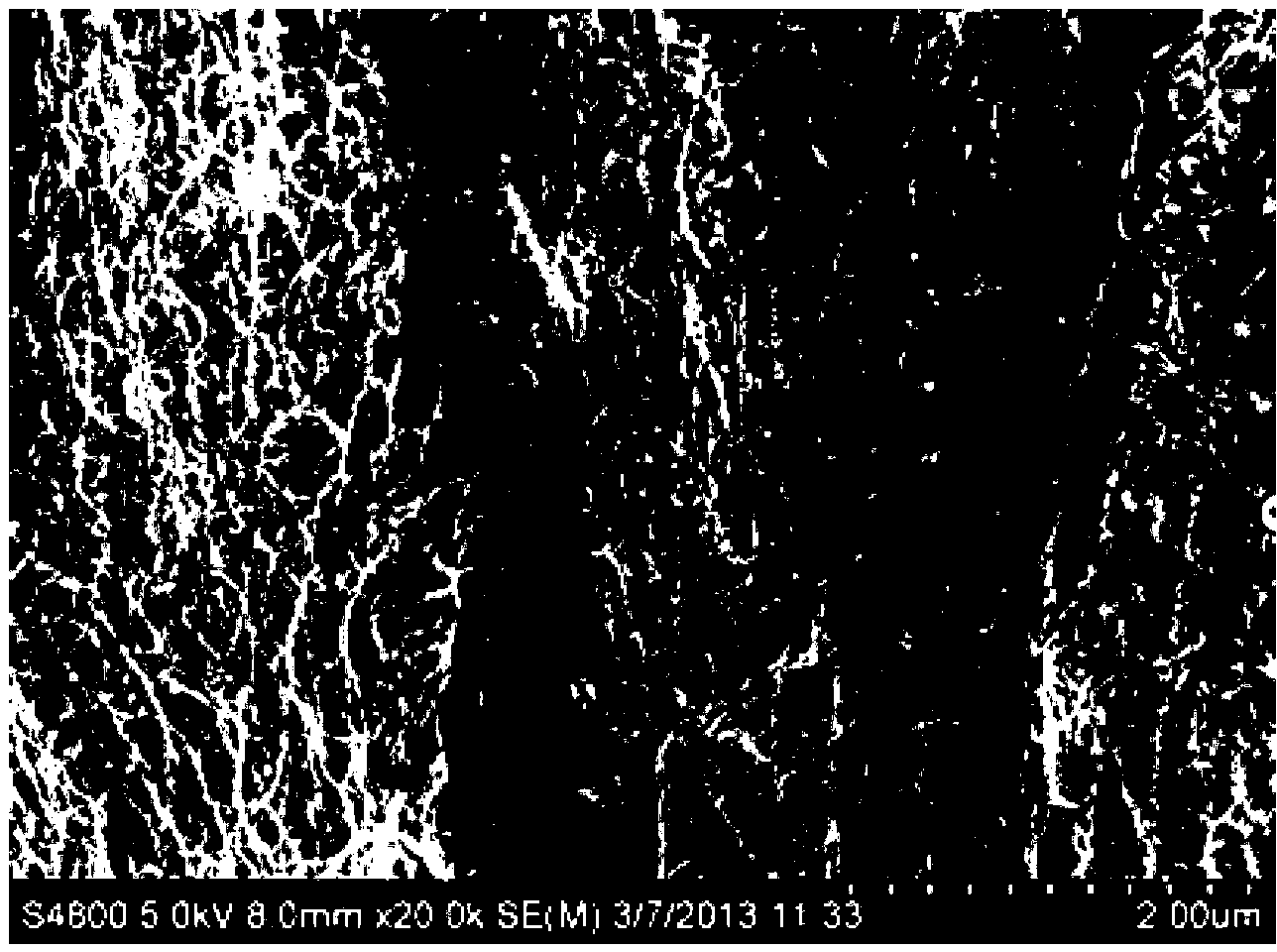

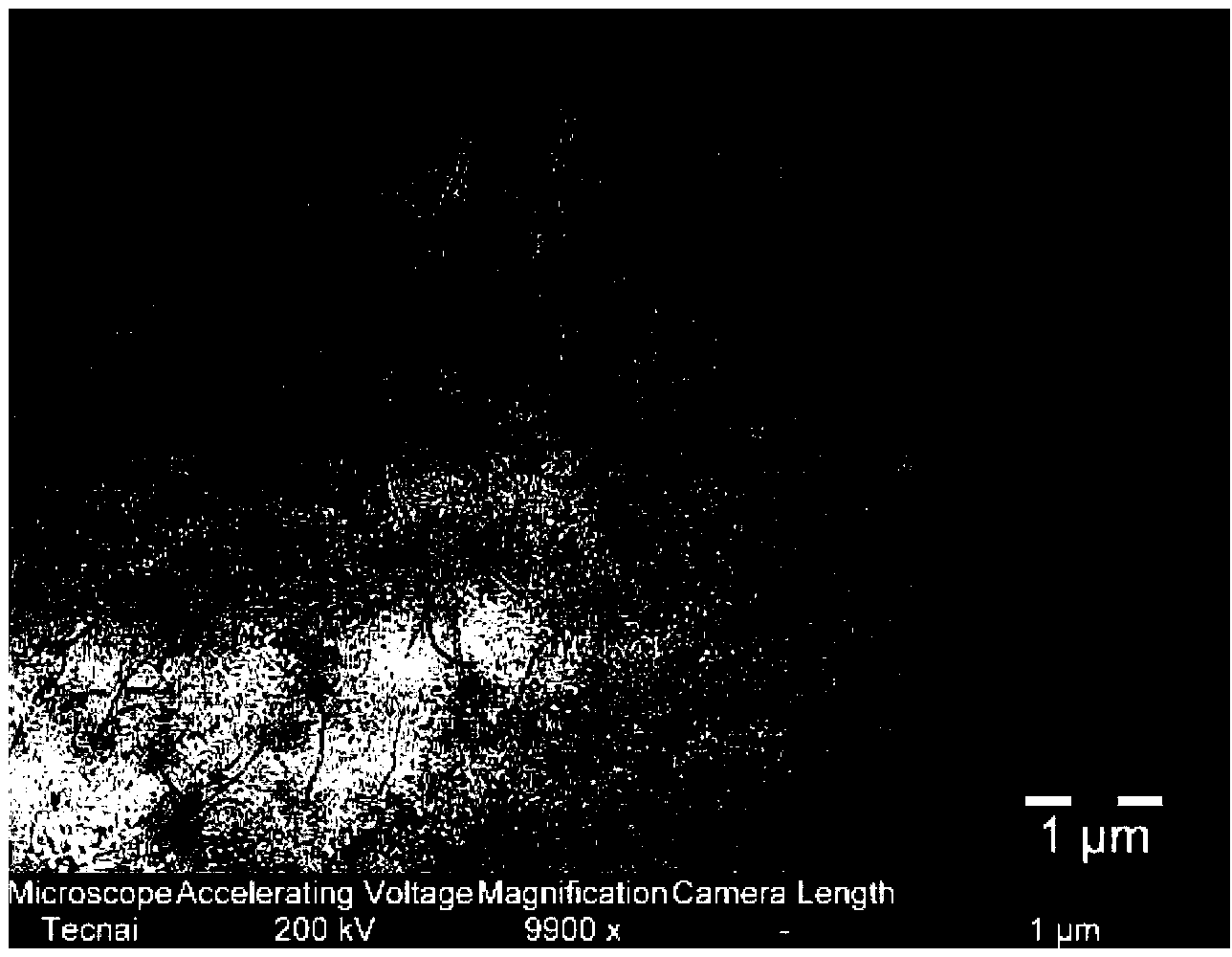

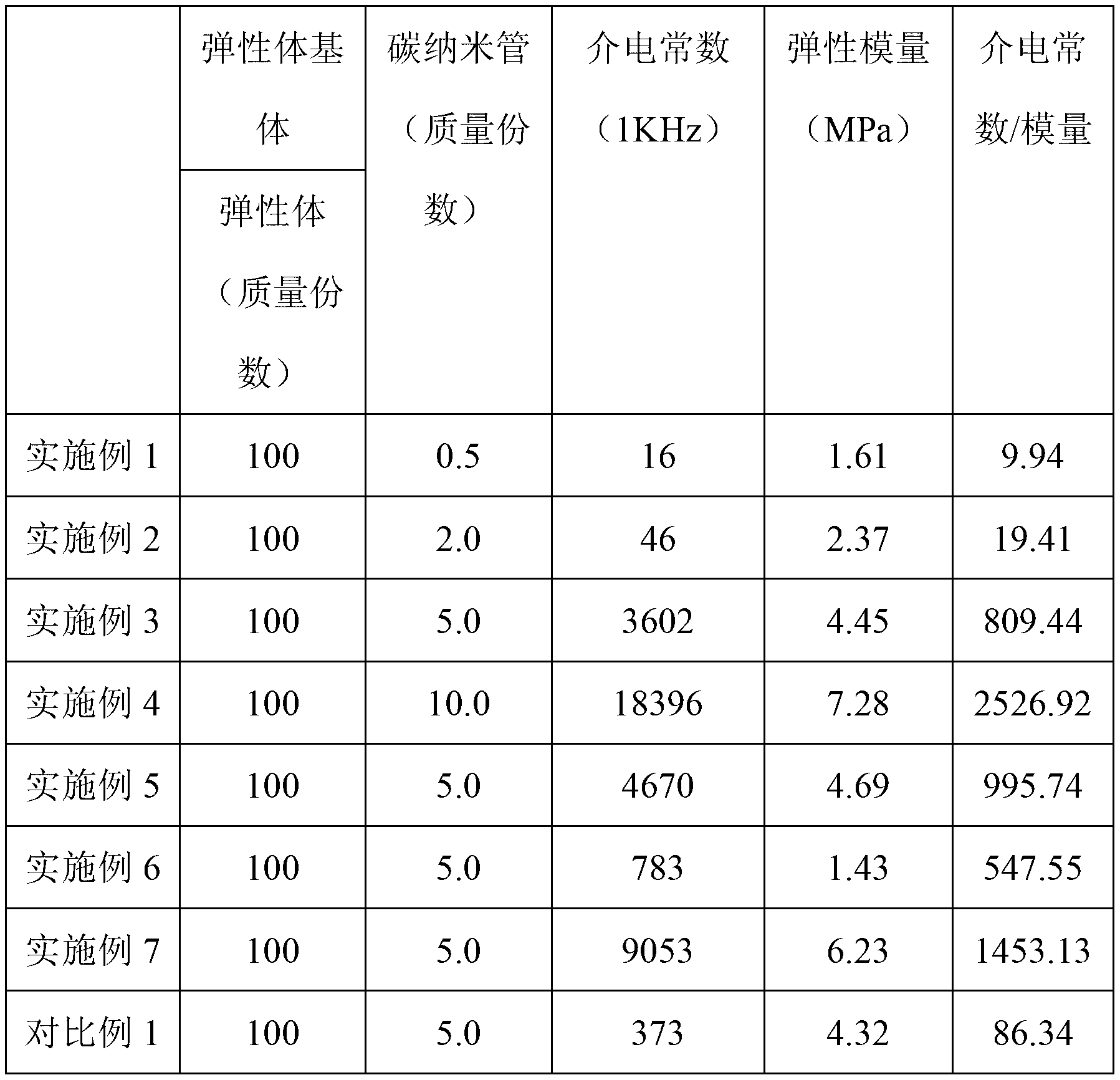

High-dielectric elastomer composite material with low content of carbon nanometer tubes and preparation method of composite material

ActiveCN103214707AHigh dielectric constantHigh dielectric constant/modulus ratioDielectricElastomer composites

The invention discloses a high-dielectric elastomer composite material with low content of carbon nanometer tubes and a preparation method of the composite material and belongs to an elastomer composite material. The high-dielectric elastomer composite material contains the following components in parts by weight: 100 parts of elastomers, 0.5-10 parts of array carbon tubes, 0 or 0.5-12 parts of a vulcanizing agent, and 0 or 1-7 parts of a vulcanizing-assisting agent, wherein when the elastomers are rubber matrixes, the vulcanizing agent and the vulcanizing-assisting agent are needed; and when the elastomers are thermoplastic elastomer matrixes, the vulcanizing agent and the vulcanizing-assisting agent are not needed. The composite material is prepared by a mechanical blending method. The composite material with good dispersing performance is obtained by means of adding the array carbon tubes with a one-dimensional orientation arrangement structure, the dielectric constant of the elastomer can be enhanced greatly under the condition of a low stuffing content, simultaneously the modulus of the elastomer is not increased remarkably and a high ratio value of dielectric constant / modulus is obtained.

Owner:BEIJING UNIV OF CHEM TECH

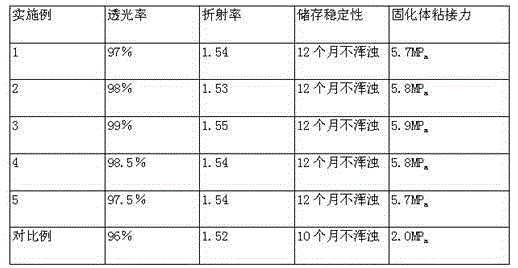

Packaging material for LED filament

InactiveCN105542693AImprove heat resistanceImprove compatibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesMaleic anhydrideTransmittance

The invention discloses a packaging material, specifically to a packaging material for an LED filament. The packaging material for the LED filament comprises red fluorescent powder and a cross-linking agent mixed with the red fluorescent powder. The cross-linking agent is prepared from the following raw materials by weight: 72 parts of epoxy resin, 18 to 22 parts of polyphenylene ether powder, 4 parts of methyl phenyl silicone oil, 0.2 to 0.4 part of nanometer zinc sulfide, 6 to 8 parts of transparent nanometer ceramic powder liquid with a mass concentration of 30 to 40%, 4 to 5 parts of nanometer titanium dioxide, 0.1 to 0.2 part of benzoyl peroxide, 0.4 to 0.5 part of maleic anhydride, 0.1 to 0.2 part of a silane coupling agent, 0.01 to 0.02 part of a chloroform antioxidant and 20 to 25 parts of a curing agent. The packaging material provided by the invention overcomes the technical defects of a small emergence angle and low light out-coupling efficiency and has improved transmittance and luminous intensity.

Owner:CHONGQING XINDE ELECTRONICS

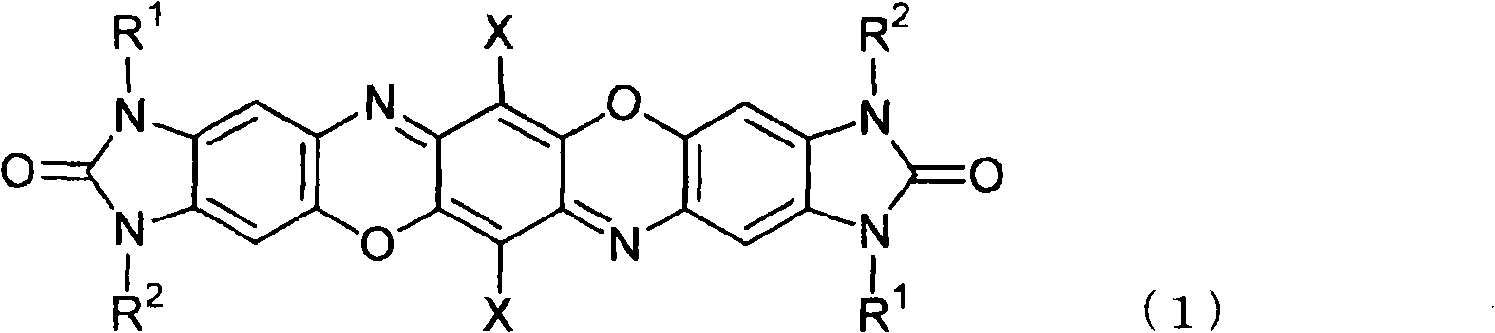

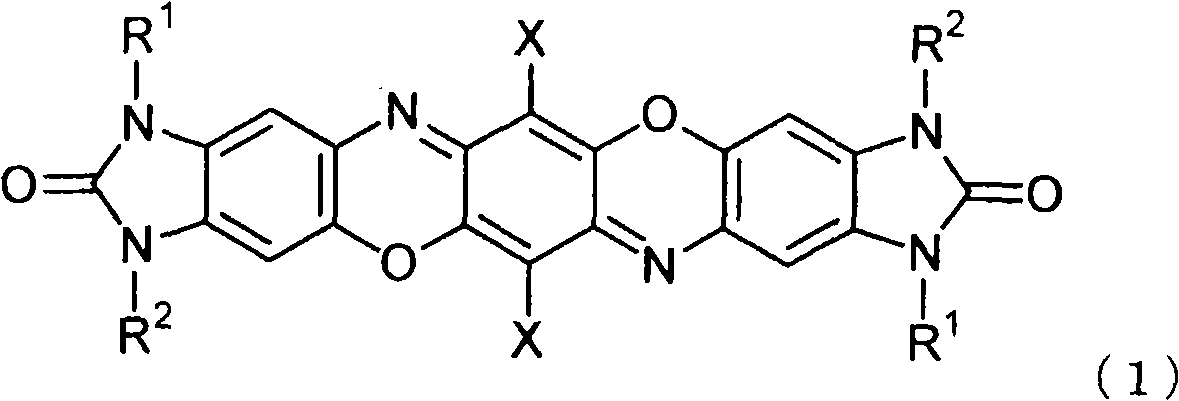

Lightproof composition and color filter

ActiveCN101266311AGood shading effectImprove insulation performanceOptical filtersAzo dyesSolid componentHydrogen atom

The aim of the invention is to supply a lightproof combination with high lightproof performance and excellent insulating ability and dispersible stability and a colour filter adopting the combination. The benzimidazolone dioxazine pigment expressed by general formula (1) is taken as the tinting material of the necessary components. In the solid content containing over 40wt% lightproof combination, the optical density of the solidified film, when the film thickness is over 2.0, (in the formula, R1 and R2 respectively and independently express a hydrogen atom or an alkyl with substituent, and X expresses a hydrogen atom or a halogen atom).

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

Bismuth sodium titanate series film material and preparing process thereof

InactiveCN1401611AImprove performanceHigh resistivityCeramic layered productsSodium titanateFilm material

A bismuth sodium titanate thin film series has a formula of (1-X)(Bi0.5Na0.5)TiO3+XMTiO3, where x=0-0.6 and M is chosen from Ba, Pb, Sr and Ca, and is prepared by metal-organic solution depositing method. Its advantages are proper electric conductivity in ferroelectric region, wide sinter temp range, and high storage and thermoelectric properties.

Owner:SHANDONG UNIV

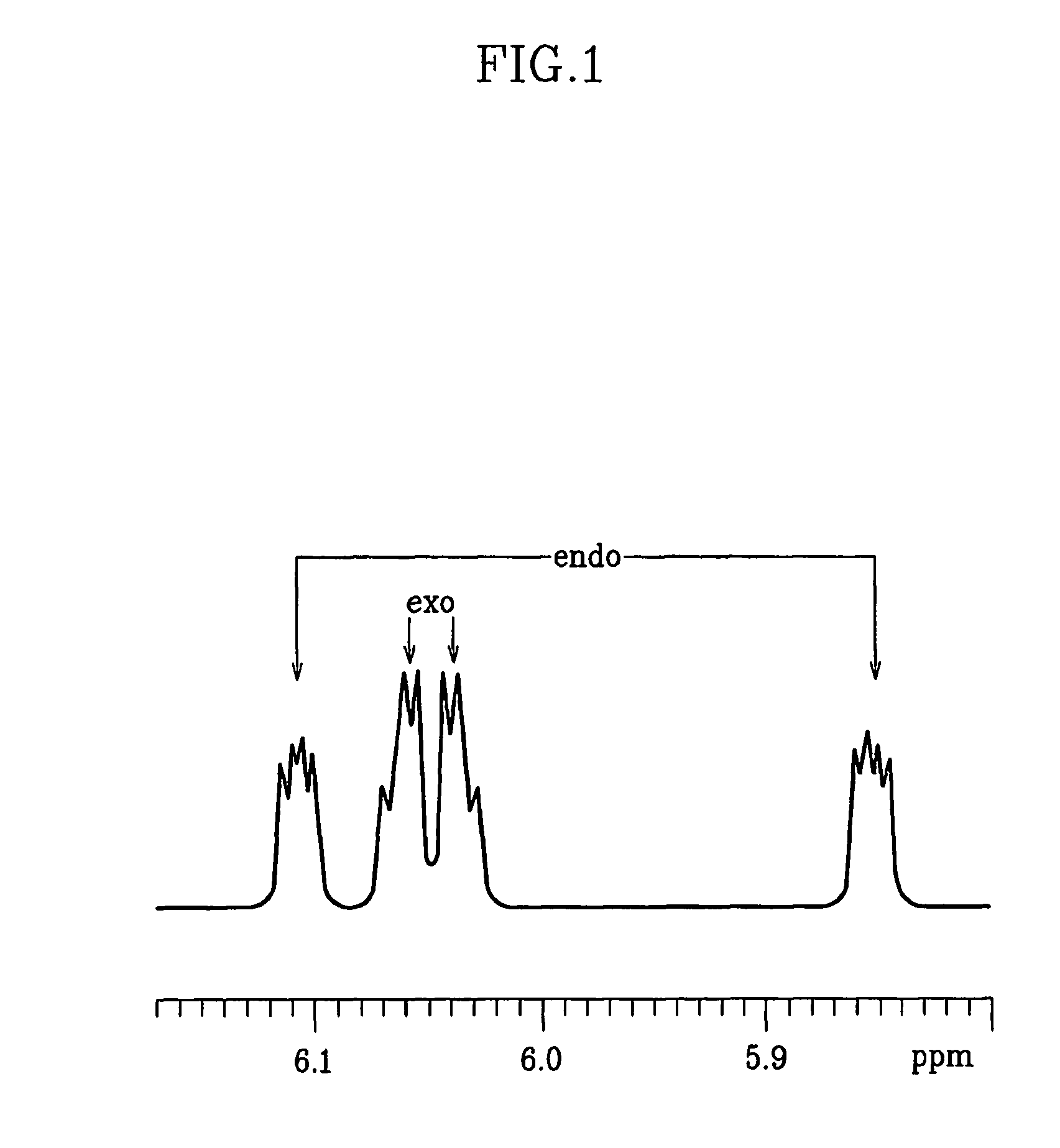

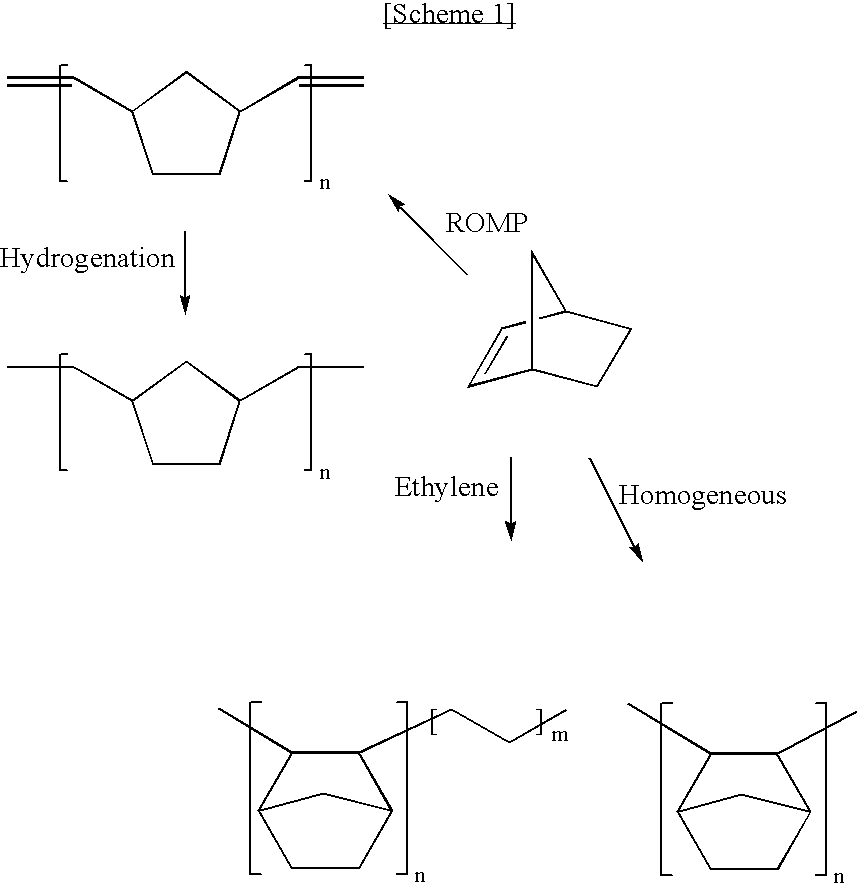

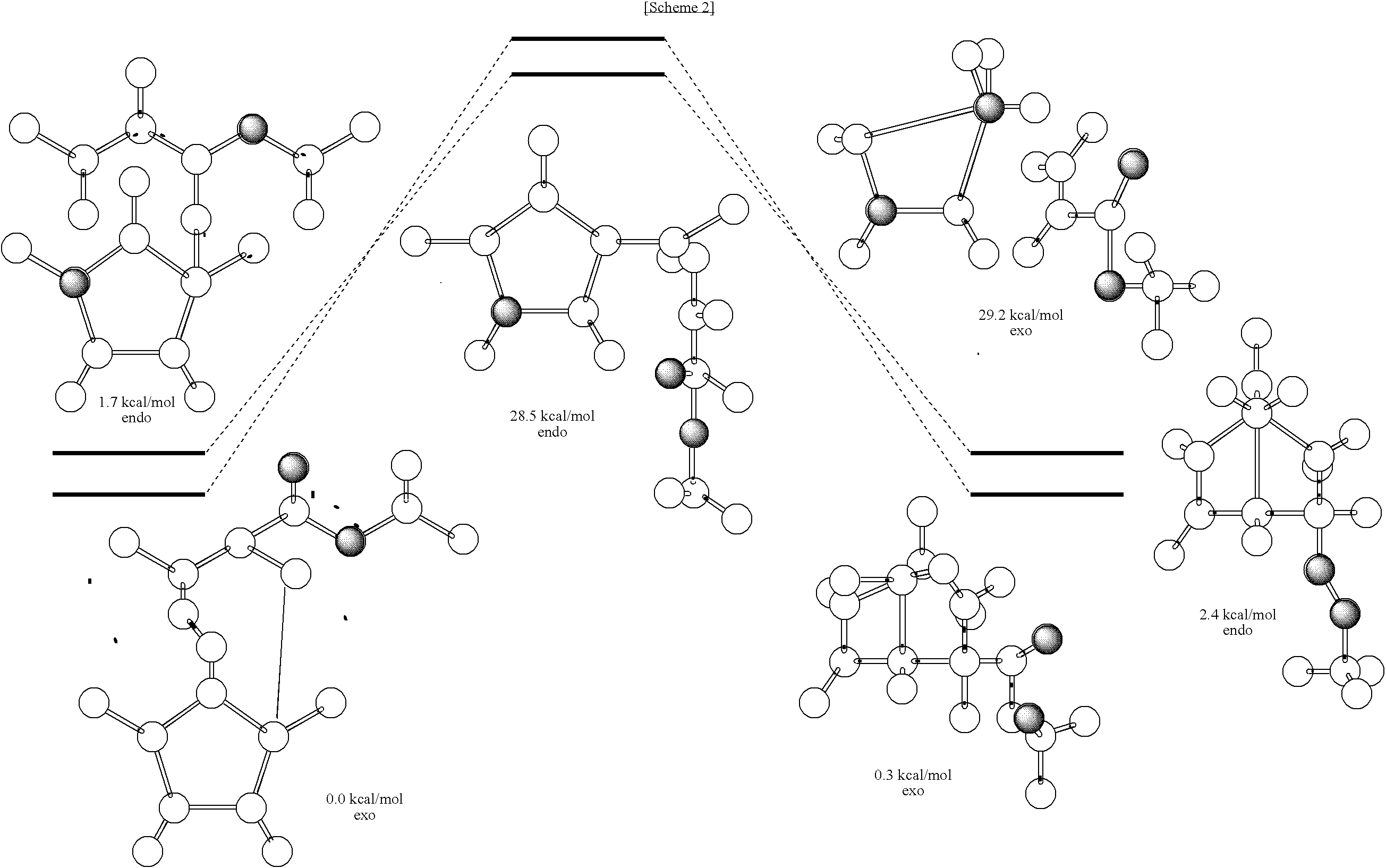

Nobonene-ester based addition polymer and method for preparing the same

InactiveUS7442752B2Low dielectricHigh glass transitionNon-linear opticsAddition polymerPolymer science

The present invention relates to a norbornene based addition polymer, and more particularly to an addition polymer of norbornene based monomers containing an ester group. The present invention provides a norbornene-ester based addition polymer having a molecular weight (Mn) larger than 20,000 and comprising a norbornene-ester based monomer comprising more than 50 mol % of exo norbornene-ester monomer as a repeating unit, a method for preparing the same, and an optically anisotropic film comprising the same. The norbornene-ester based addition polymer of the present invention is transparent, has a low dielectric constant, has good thermal stability and strength, leaves no unwanted materials when attached to metals or other polymers, and has good adhesivity, so that it can be used for optical films, retardation films, plastic substrate materials, transparent polymers such as POF or PCB, insulating materials, or insulating electronic devices such as PCB or insulating materials.

Owner:LG CHEM LTD

Modified PBO fiber/cyanate ester resin wave-transparent composite material and preparation method thereof

ActiveCN104761897AImprove bending strengthIncreased interlaminar shear strengthFibre typesFlexural strengthInterlaminar shear

The invention provides a modified PBO fiber / cyanate ester resin wave-transparent composite material and a preparation method thereof. A PBO fiber, high in strength and modulus and low in dielectric constant, is taken as a reinforcement, and a cyanate ester resin modified by an epoxy resin is taken as a substrate. The prepared modified PBO fiber / cyanate ester resin wave-transparent composite material not only is high in bending strength and interlaminar shear strength, but also has multiple characteristics of low dielectric constant and high temperature resistance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

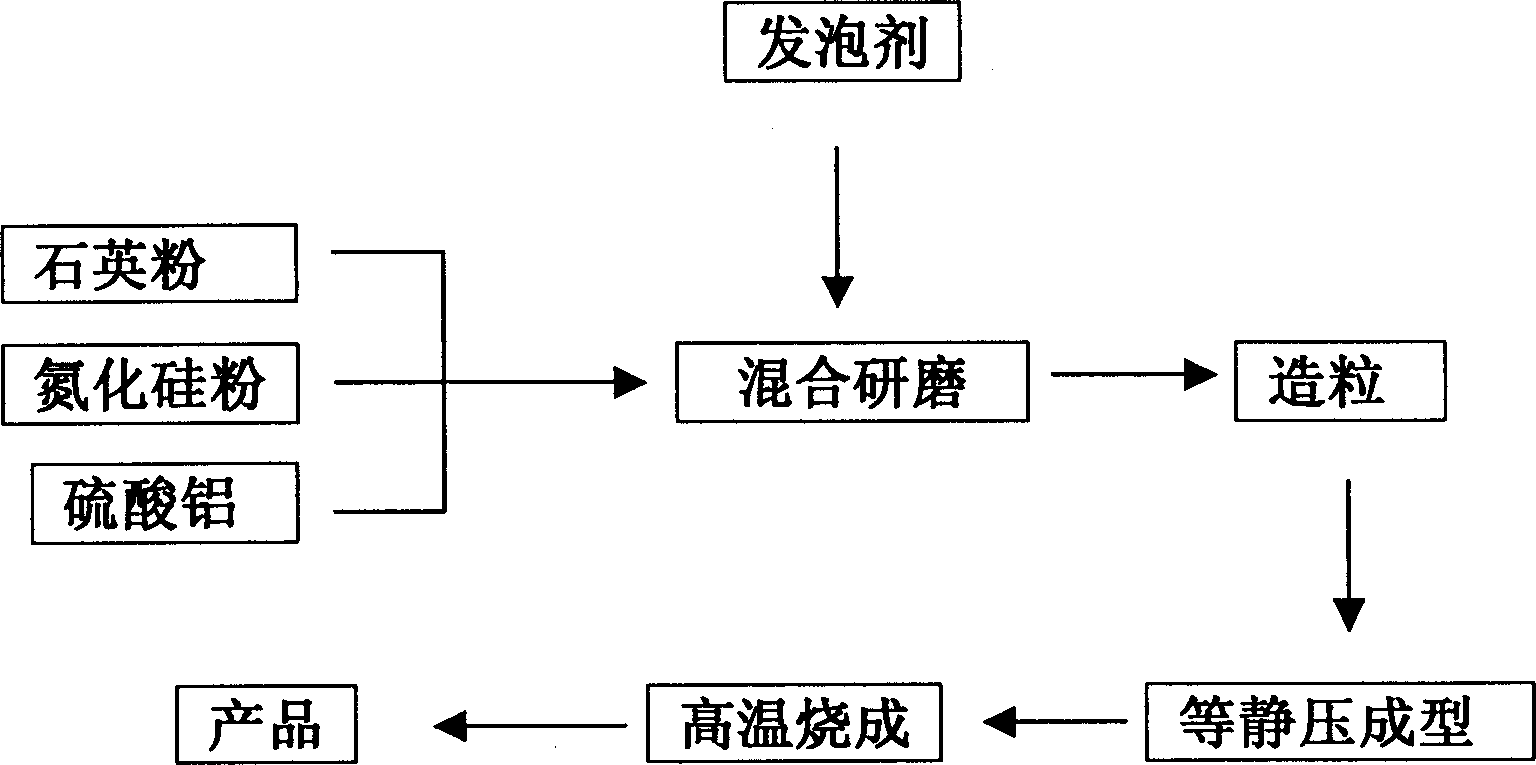

Low dielectric, wave-transparent porous ceramic material and preparation process thereof

ActiveCN1793014ALow dielectricLow dielectric constantPiezoelectric/electrostrictive/magnetostrictive devicesCeramicwareDielectricFoaming agent

The invention relates to a improved low dielectric, wave-passable multi-hole ceramic material and the manufacturing method. The weight proportion of the raw material is that quartz: aluminum phosphate: silicon nitride= (40-55): (40-55): (5-10), and 1-10% abio-liquid foaming agent. Pressing into mold after graining, the diameter is controlled to 60-90mm. The invention would satisfy application request, and it is easy to operate.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

Low-dielectric high-toughness reinforced PBT/PPO (polybutylene terephthalate/polyphenylene oxide) composition and preparation method thereof

InactiveCN109575528AExcellent dielectric propertiesImprove mechanical propertiesPolytetramethylene terephthalateGlass fiber

The invention relates to a low-dielectric high-toughness reinforced PBT / PPO (polybutylene terephthalate / polyphenylene oxide) composition and a preparation method thereof. The low-dielectric high-toughness reinforced PBT / PPO composition is made from, by weight, 45-85 parts of PBT and 15-55 parts of PPO, adding up to 100 parts, as well as 20-40 parts of glass fiber, 6-14 parts of a compatibilizer, 0.6-1 part of an antioxidant, 5-20 parts of polytetrafluoroethylene, 0.2-1 part of a plasticizer, 0.2-1 part of a silane coupling agent, wherein the weight ratio of the plasticizer to the silane coupling agent is 1:1 to 5:1. The PBT / PPO composition can meet the high requirements of the fields, such as electronic and electrical engineering, integrated circuit packaging and electromagnetic wave shielding, for dielectric properties, strength and toughness.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

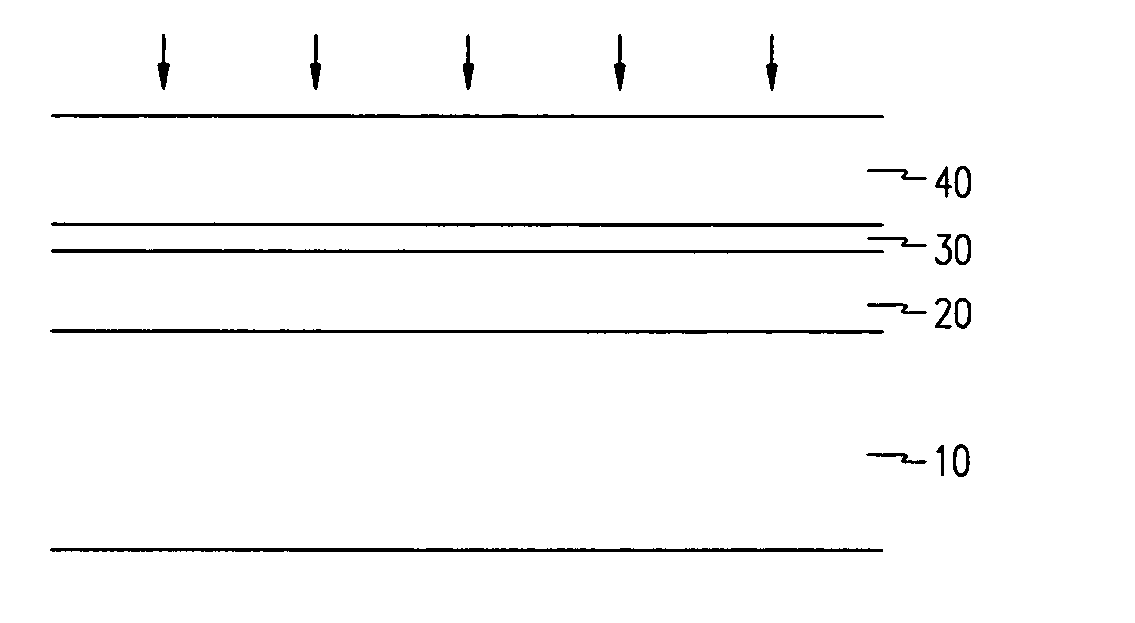

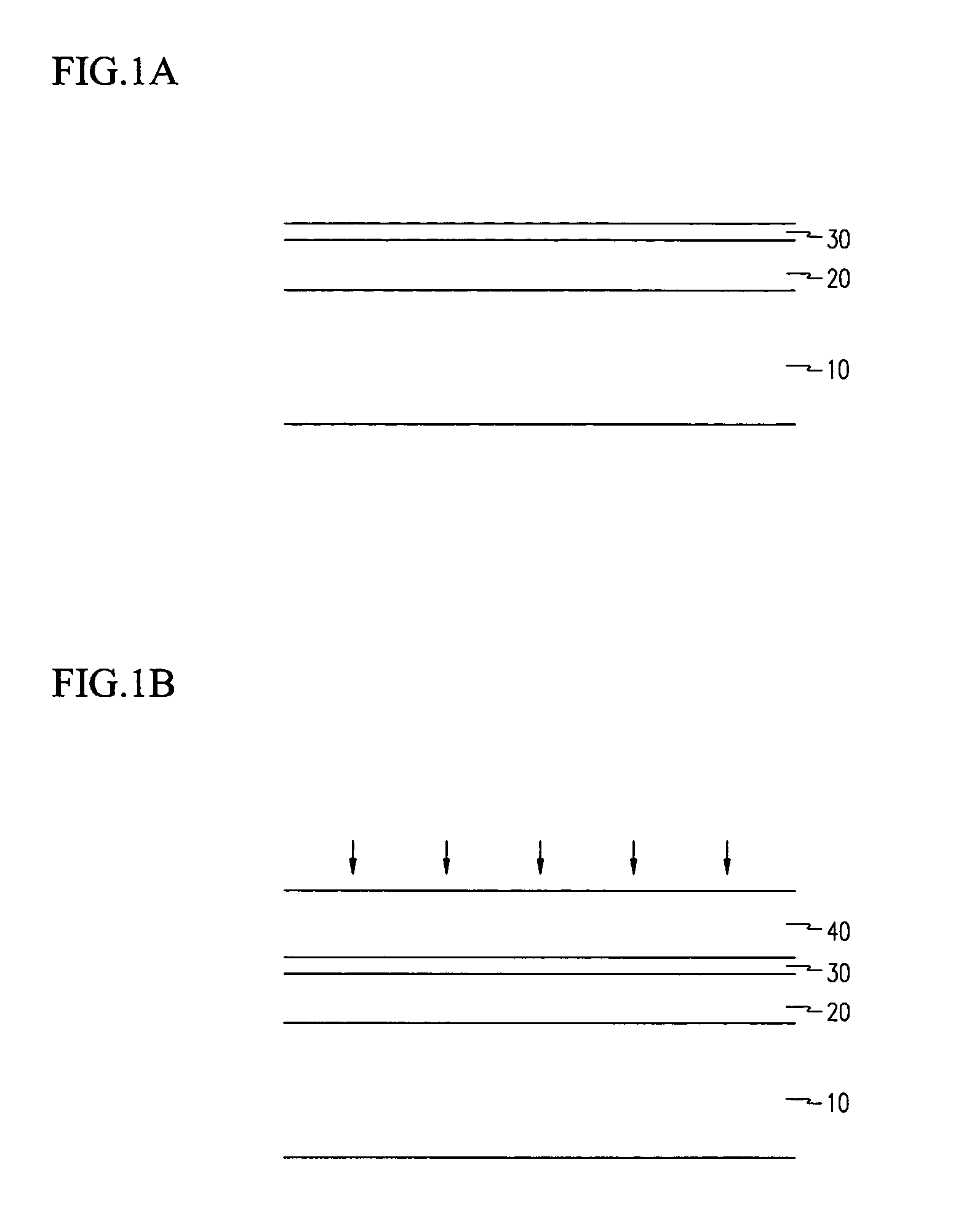

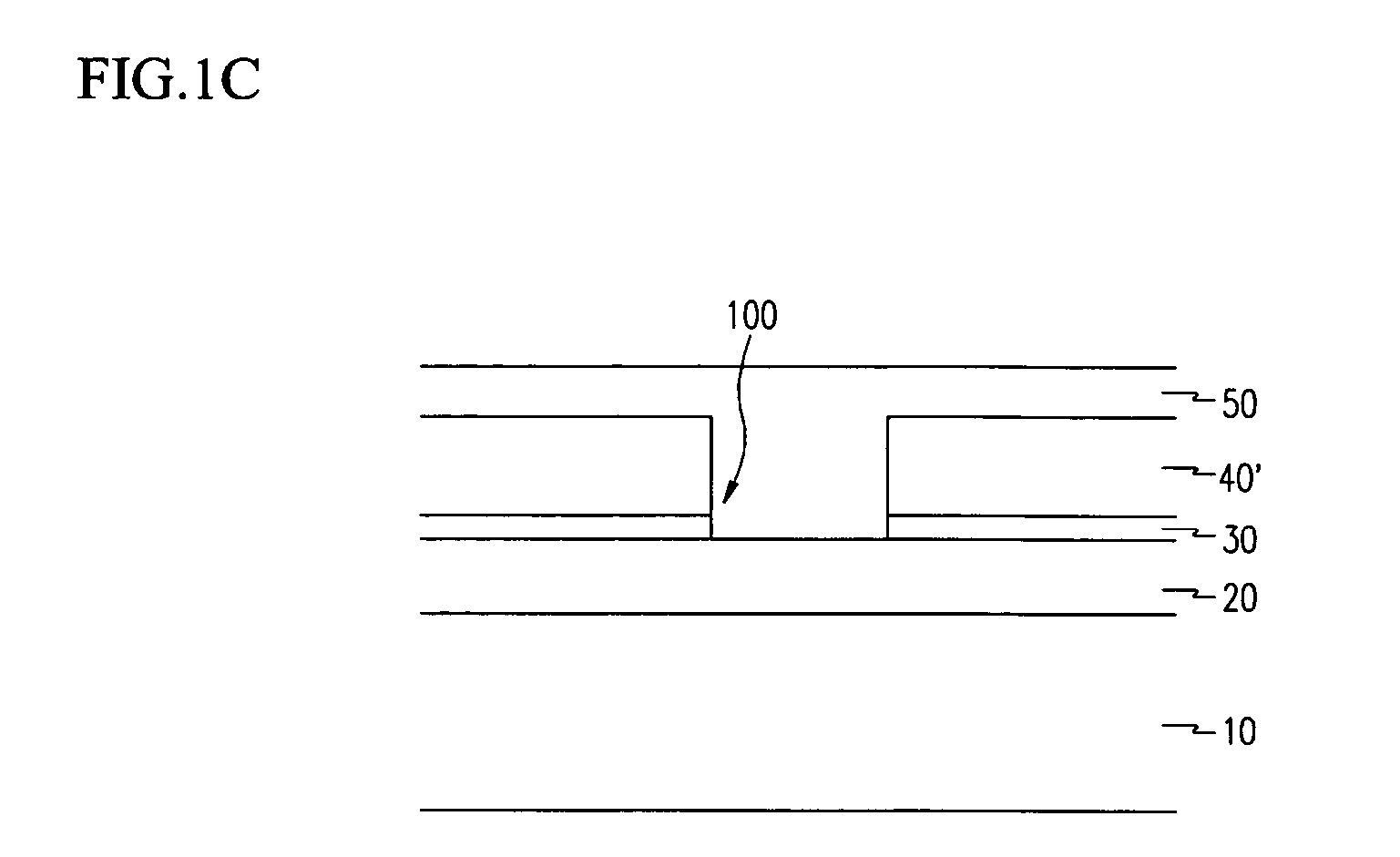

Method for manufacturing semiconductor device

ActiveUS20050255709A1Quality improvementLow dielectricSemiconductor/solid-state device manufacturingOxideRefractive index

High quality dielectric layers may be achieved without introducing excessive impurities when a semiconductor device is manufactured by a method that includes forming a lower wire layer on a structure above a semiconductor substrate, forming a silicon rich oxide layer having a refractive index of 0.45-1.55 on the lower wire layer and the structure, implanting carbon and oxygen (e.g., CO2) into the silicon rich oxide (SRO) layer, and forming an organosilicate glass layer by heat-treating the implanted SRO layer.

Owner:DONGBU ELECTRONICS CO LTD +1

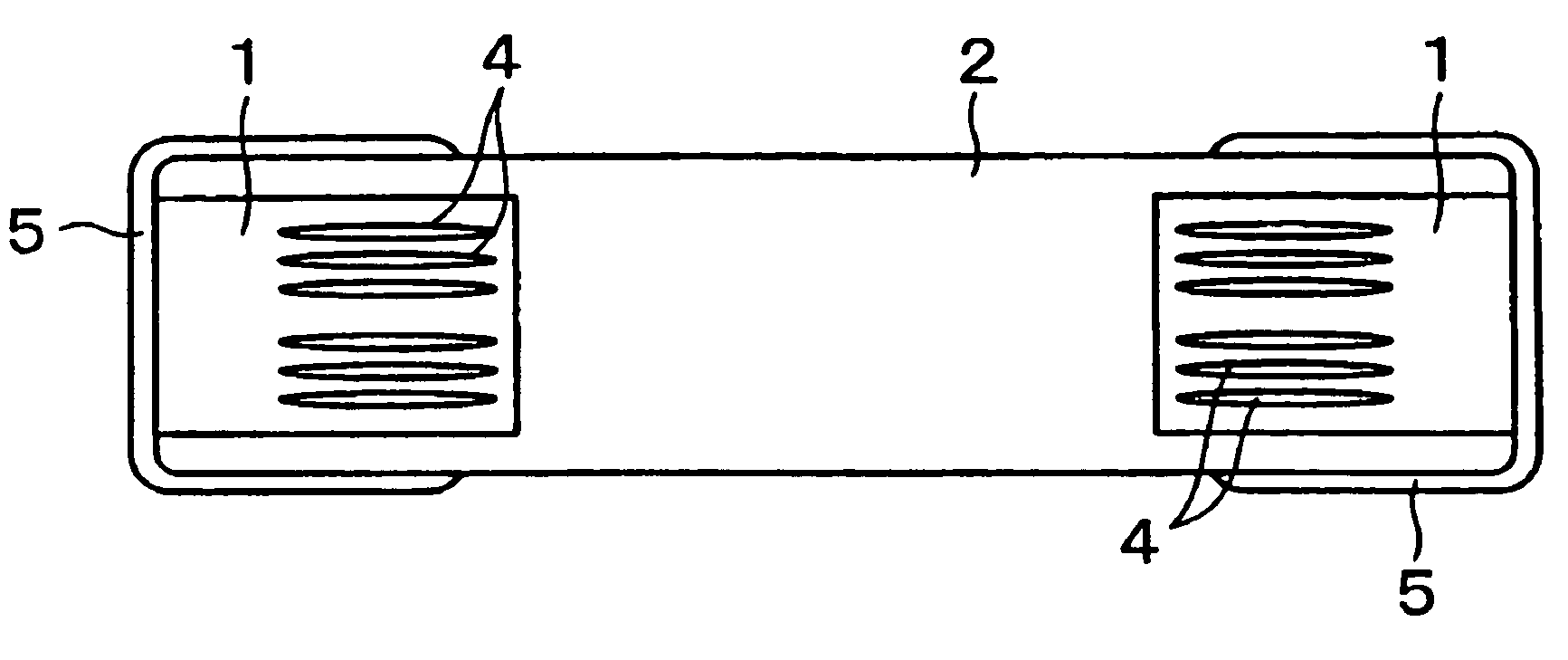

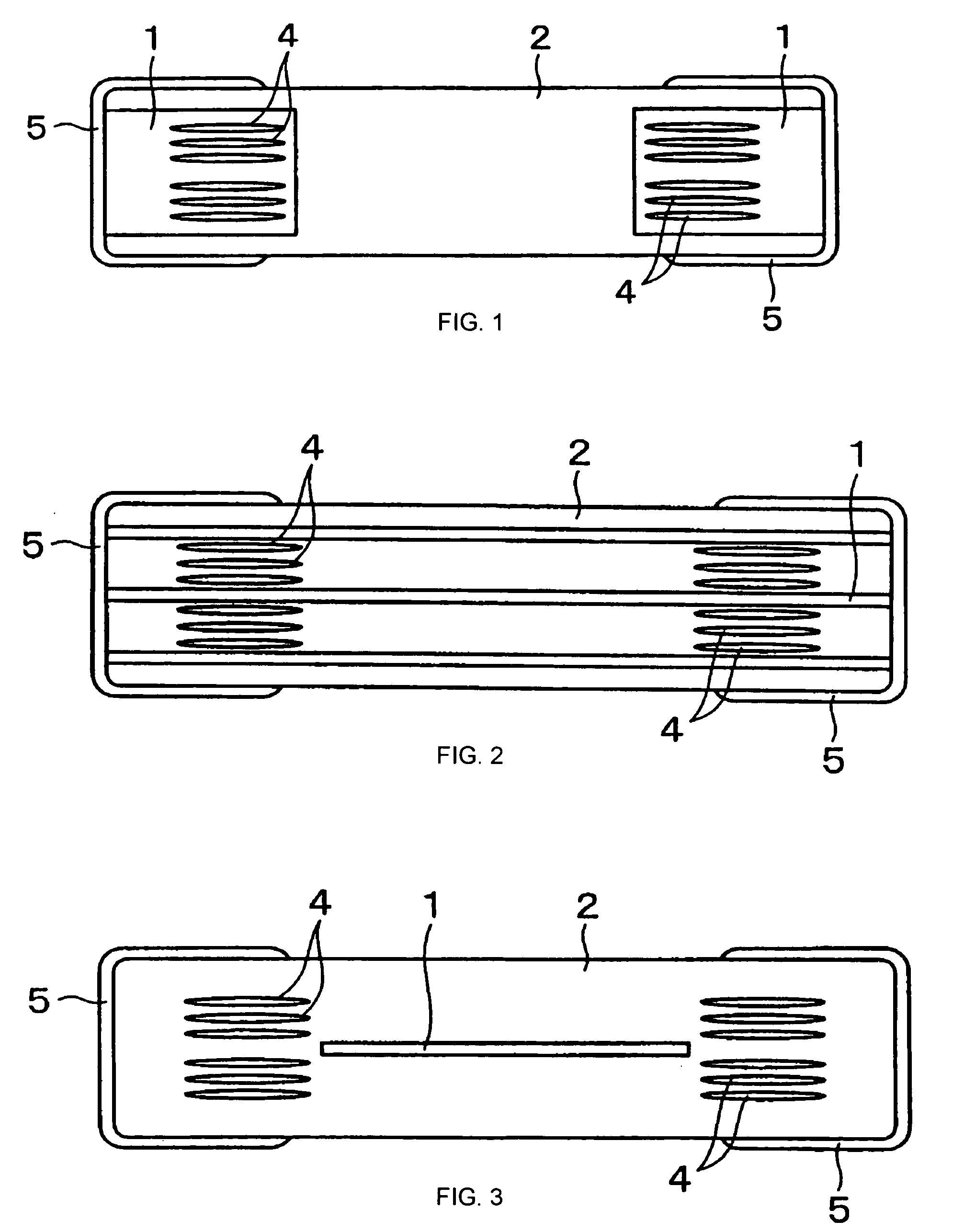

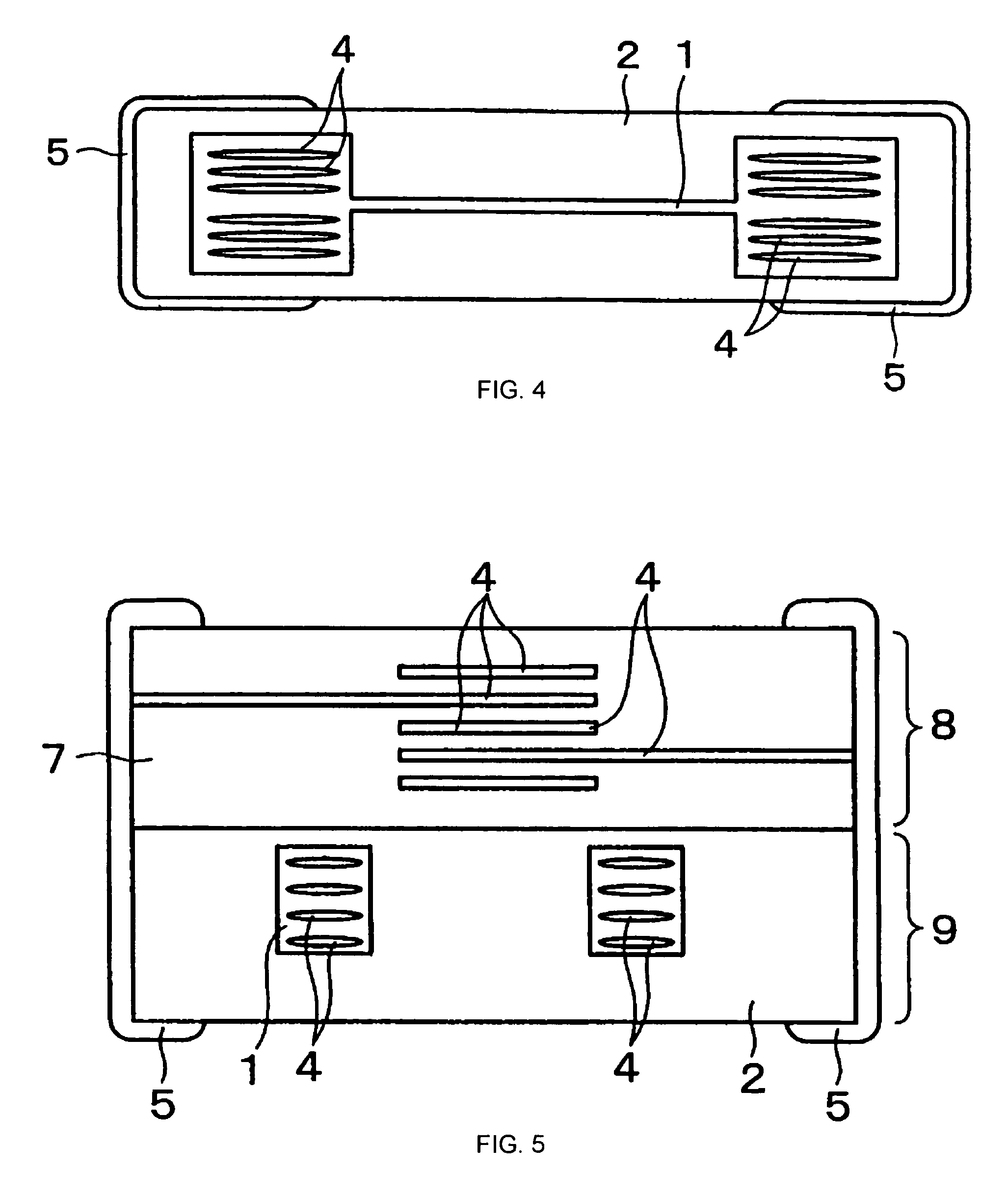

Electronic component

ActiveUS7034637B2Excellent co-sinterabilitySmall diffusionMultiple-port networksInductance with magnetic coreElectrical conductorElectronic component

An electronic component including a magnetic member comprising an iron oxide magnetic composition, a nonmagnetic member in contact with the magnetic member and including a glass ceramic composite composition, and an internal conductor portion disposed in at least one of the magnetic member and the nonmagnetic member. The glass ceramic composite composition includes crystallized glass as a main component, and quartz as a sub-component filler. The crystallized glass contains 25 percent by weight to 55 percent by weight of SiO2, 30 percent by weight to 55 percent by weight of MgO, 5 percent by weight to 30 percent by weight of Al2O3, and 0 percent by weight to 30 percent by weight of B2O3, and the content of the quartz is 5 percent by weight to 30 percent by weight relative to 100 percent by weight of the crystallized glass.

Owner:MURATA MFG CO LTD

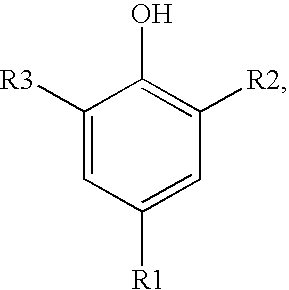

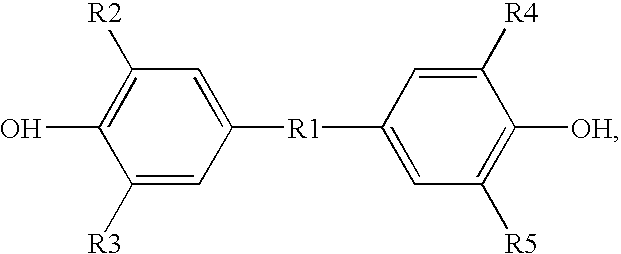

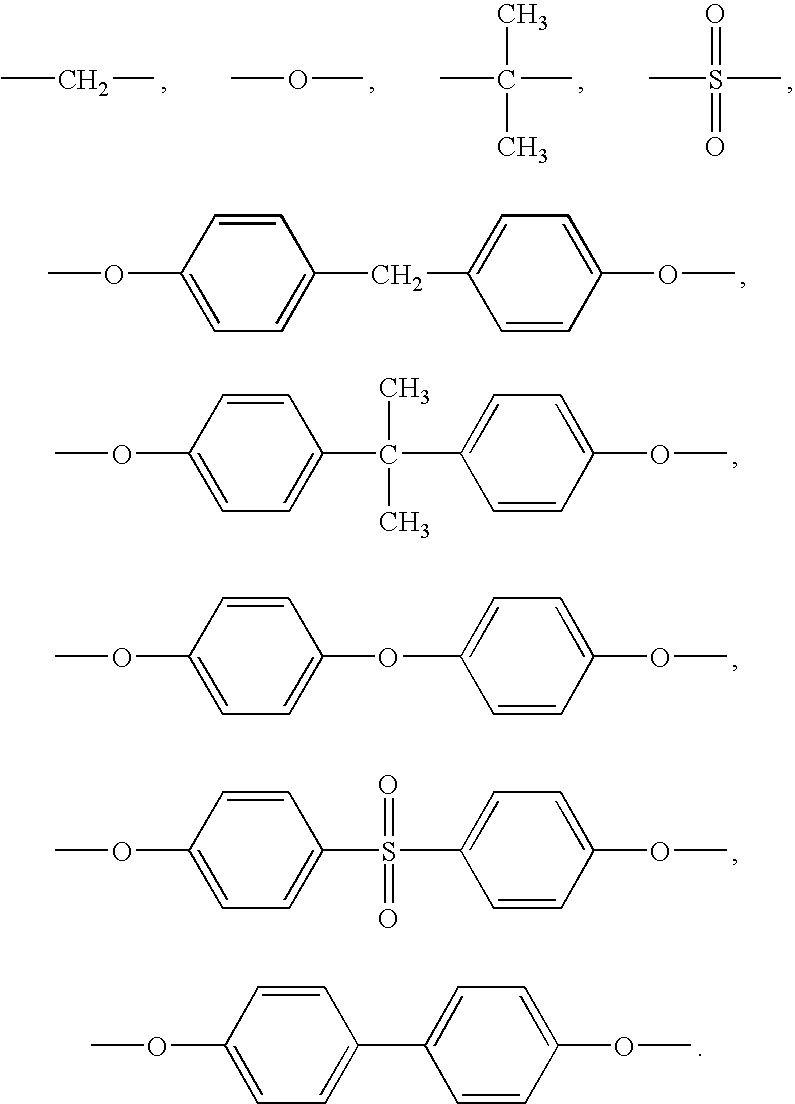

Preparation method of poly (arylene ether nitrile) resin low in dielectric constant and high in glass-transition temperature

The invention discloses a preparation method of a poly (arylene ether nitrile) resin low in dielectric constant and high in glass-transition temperature. The preparation method comprises following steps: potash and 2, 6-dichlorobenzonitrile are added into N-methyl pyrrolidone successively; a dihydric phenol and toluene are added successively, heating polymerization is carried out, evaporation is carried out to remove toluene, and cooling is carried out for precipitation of a solid material; washing is carried out to obtain a powder particle material; the powder particle material is dissolved in N-methyl pyrrolidone for purifying so as to obtain a purified sample; the purified sample is dissolved in N, N-dimethyl formamide, gauze filtering, tape casting film forming, and gradient heating are carried out to obtain poly (arylene ether nitrile) resin film. The preparation method is capable of increasing the glass-transition temperature and reducing the dielectric constant and loss of conventional poly (arylene ether nitrile), and satisfying basic using requirements of resin adopted in 5G high frequency base materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

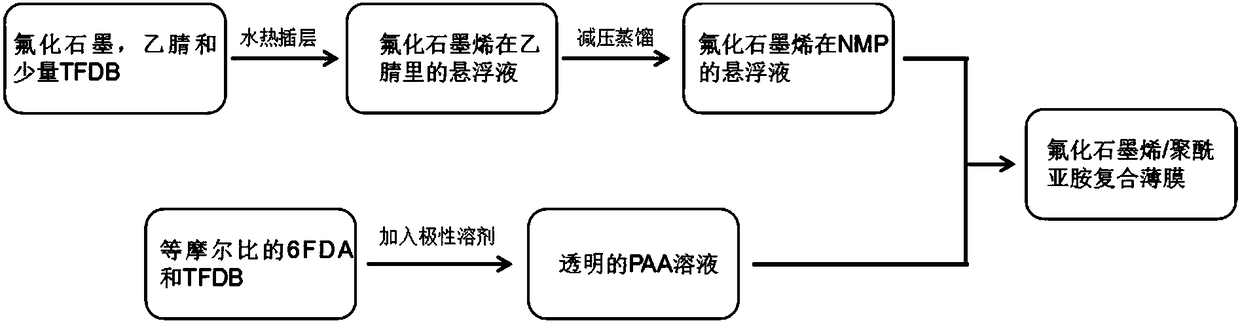

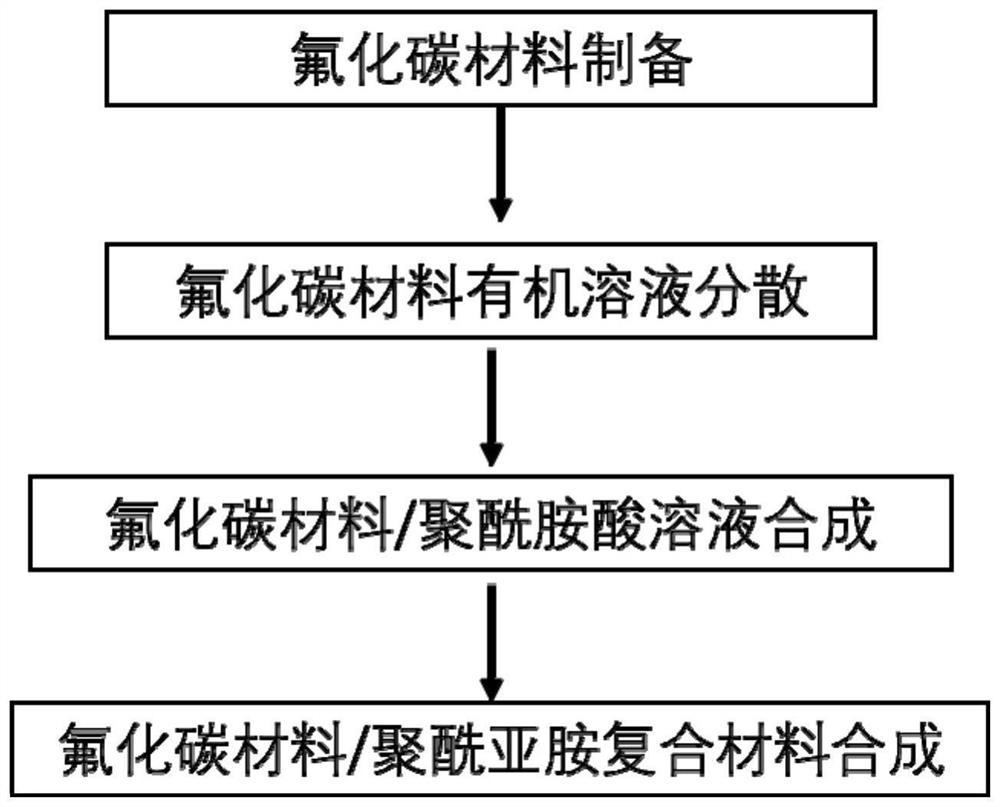

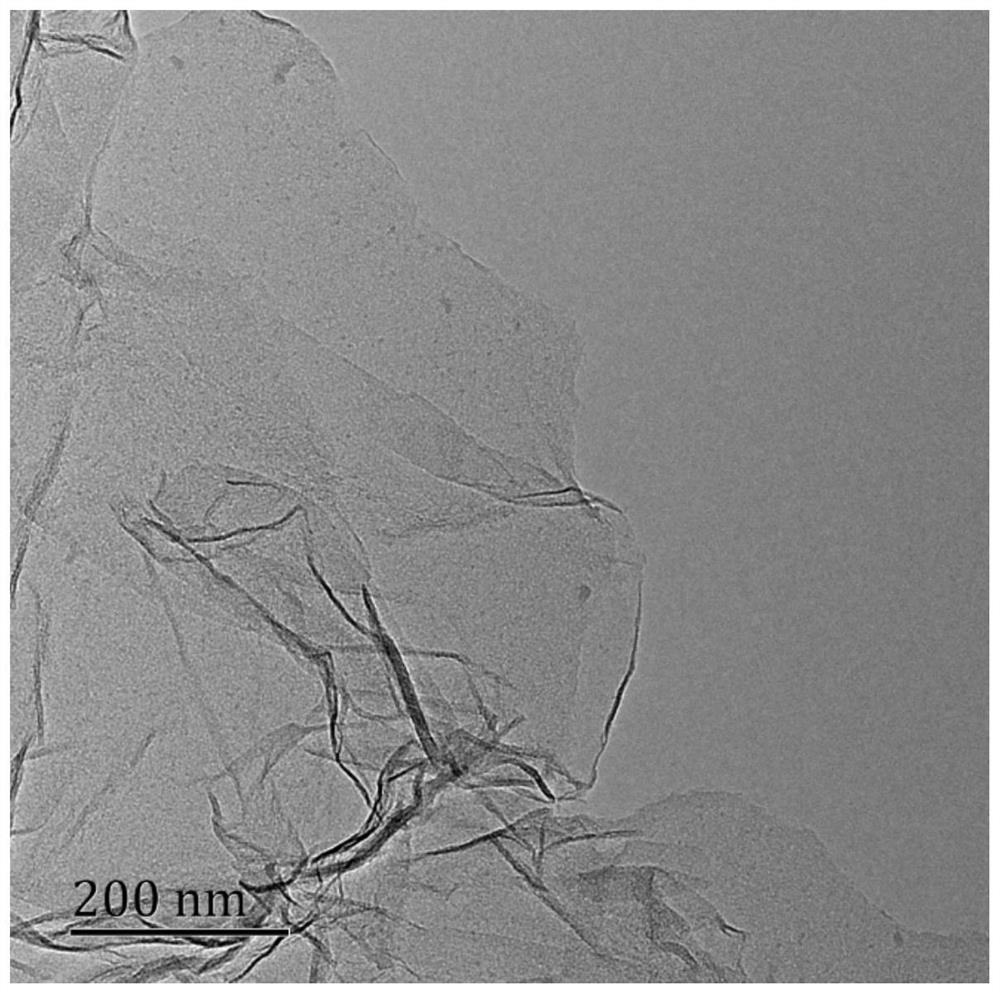

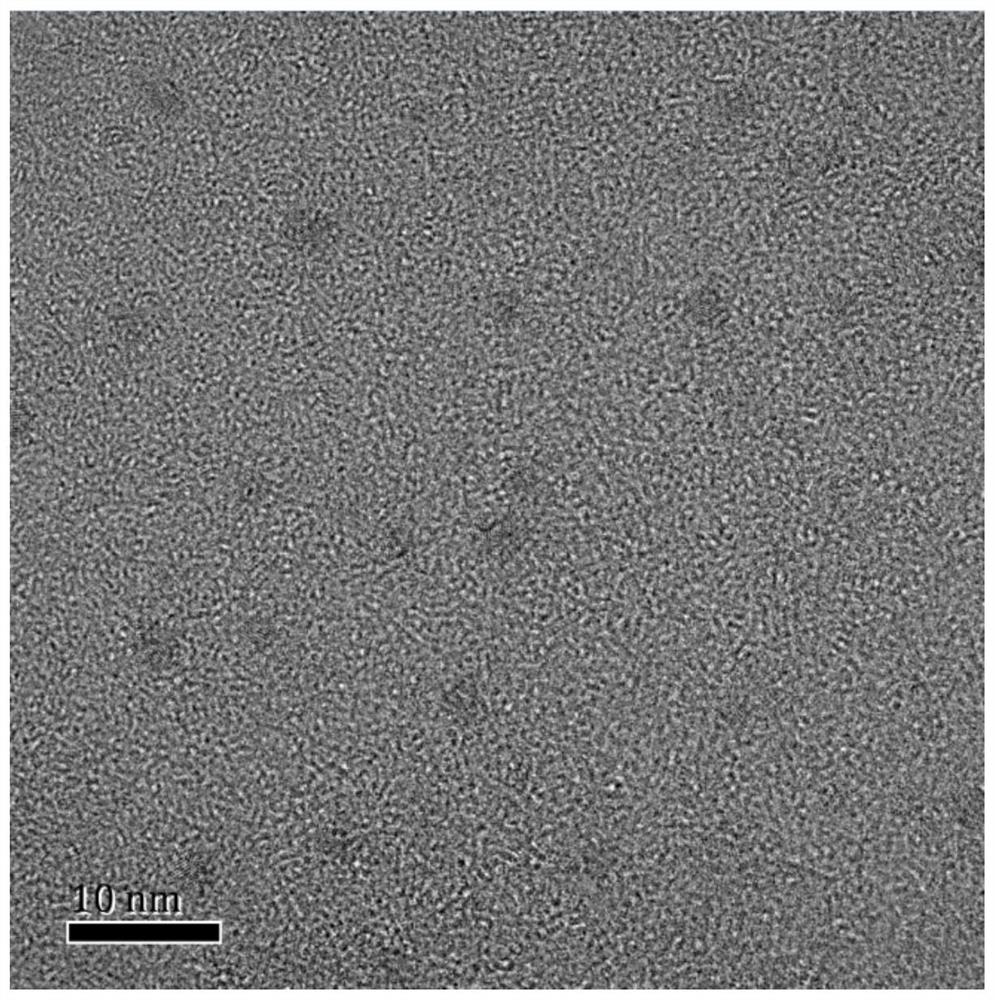

Preparation method of high light transmission and low dielectric fluorinated graphene/polyimide composite film

ActiveCN109251334AControllable equipmentDoes not affect the chemical structureComposite filmPolymer science

The invention discloses a preparation method of a high light transmission and low dielectric fluorinated graphene / polyimide composite film. The method is carried out according to the steps of: under an inert gas condition, adding an NMP suspension of fluorinated graphene into polyamide acid dropwise, and performing stirring continuously for 6-10h to obtain a mixed solution; subjecting the solutionto film coating and conducting thermal imidization, i.e. under an inert gas condition, conducting heat preservation at 80DEG C-300DEG C for 7-10h, thus obtaining the fluorinated graphene / polyimide composite film. The matrix raw material polyamide acid adopted by the invention is easily available, the preparation of fluorinated graphene is simple and controllable, and through thermal curing of fluorinated graphene and polyamide acid, compounding of polyimide and fluorinated graphene is realized. The fluorinated graphene / polyimide composite film obtained by the invention maintains the excellentproperties of polyimide, and also realizes low dielectric and high mechanical strength by compounding with fluorinated graphene.

Owner:TIANJIN UNIV

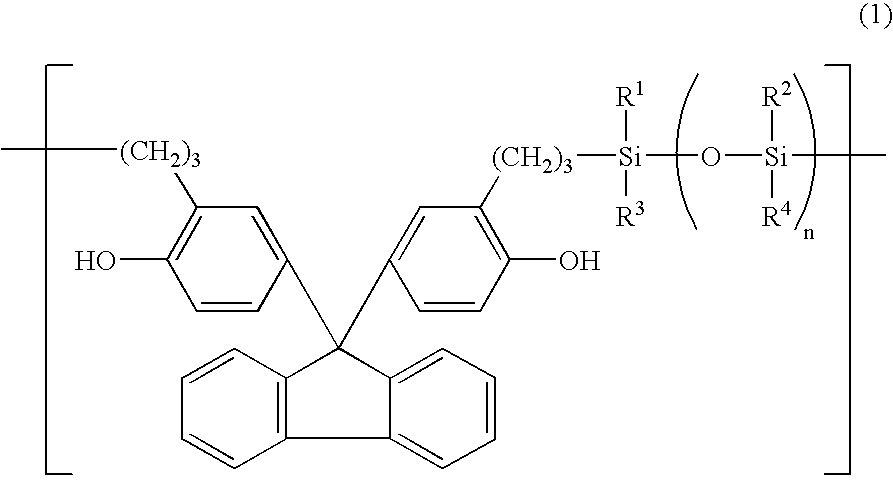

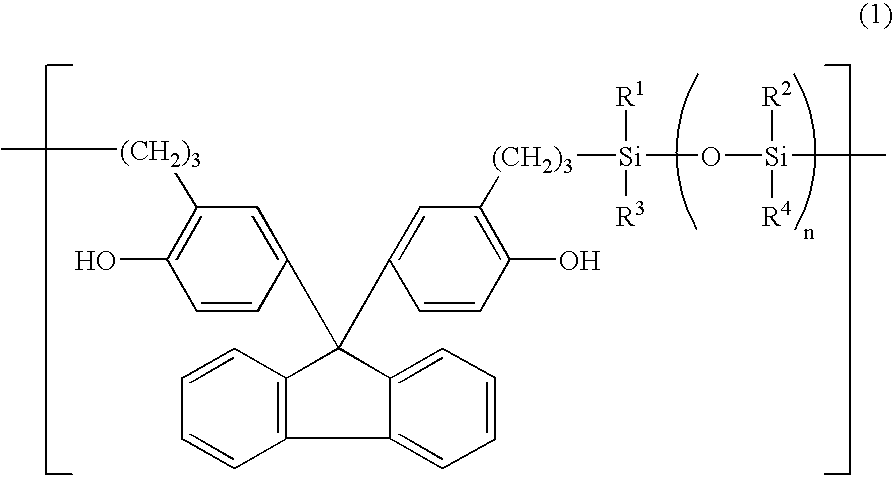

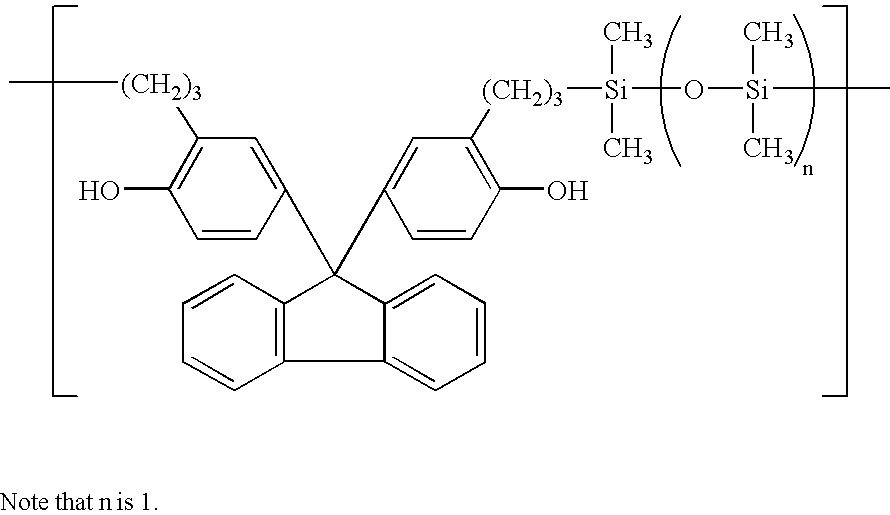

Epoxy resin compositions

An epoxy resin composition comprising (i) a compound having at least two epoxy groups in a molecule as a main component, (ii) a fluorene skeleton-bearing, silicone-modified phenolic resin as a curing agent, and (iii) an organophosphorus compound, amine compound or imidazole compound as a cure accelerator cures into an elastomeric product having a low elasticity, toughness and low dielectric properties.

Owner:SHIN ETSU CHEM IND CO LTD

Nanometer zinc borate-containing maleic anhydride-grafted polyphenyl ether modified epoxy resin composite used for LED packaging and preparation method thereof

The invention discloses a nanometer zinc borate-containing maleic anhydride-grafted polyphenyl ether modified epoxy resin composite used for LED packaging. The composite employs grafted polyphenyl ether to modify epoxy resin; a polyphenyl ether material obtained after grafting by raw materials like maleic anhydride and nanometer titanium dioxide maintains excellent low dielectric performance, low loss and high heat resistance and has improved compatibility with the epoxy resin, so the defects of the epoxy resin as a packaging material are effectively improved; and blended nanometer zinc borate and graphene oxide enable the composite to have improved electrical performance, better insulating properties and heat stability, flame retardation, water resistance and the like. The composite prepared in the invention has excellent mechanical properties and dielectric properties, long service life, economic performance and safety when used as an LED packaging material.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

Polyimide composite material and preparation method and application thereof

ActiveCN112029098AEasy to operateLow dielectricSemiconductor/solid-state device detailsSolid-state devicesImidePolymer science

The invention relates to a polyimide composite material and a preparation method and application thereof. The polyimide composite material comprises a polyimide matrix and a carbon fluoride material distributed in the polyimide matrix; the carbon fluoride material comprises any one or a combination of at least two of graphene fluoride with the plane size smaller than or equal to 10 [mu]m, fluorinated nano carbon black with the diameter smaller than or equal to 100 nm or fluorinated graphene quantum dots with the diameter smaller than or equal to 10 nm. The three carbon fluoride materials withspecific sizes are introduced into the polyimide matrix, so that the comprehensive performance of the polyimide can be effectively improved, and the polyimide has low dielectric constant, high light transmittance, low water absorption rate, high heat resistance and excellent mechanical properties.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

Laminated substrate

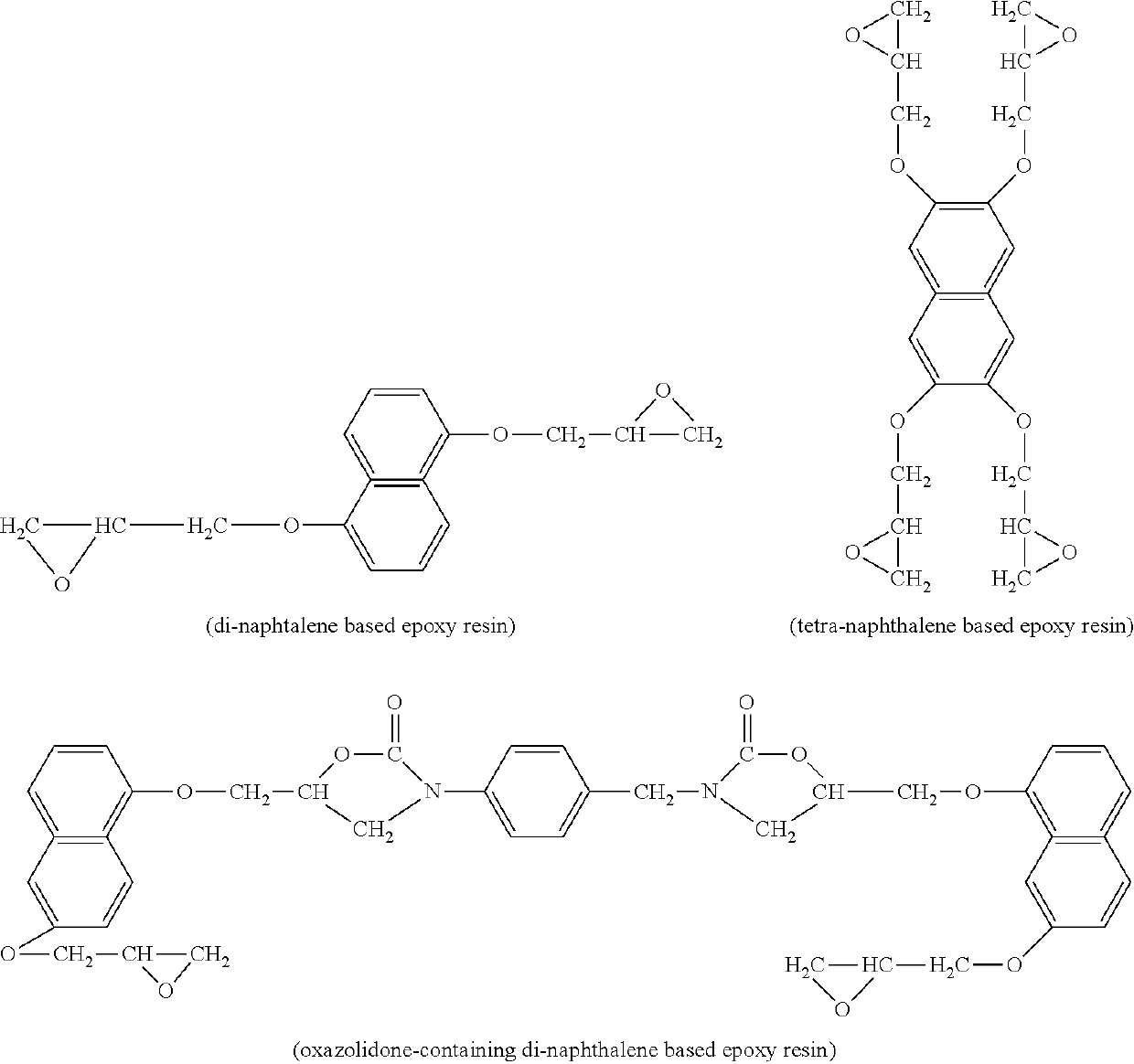

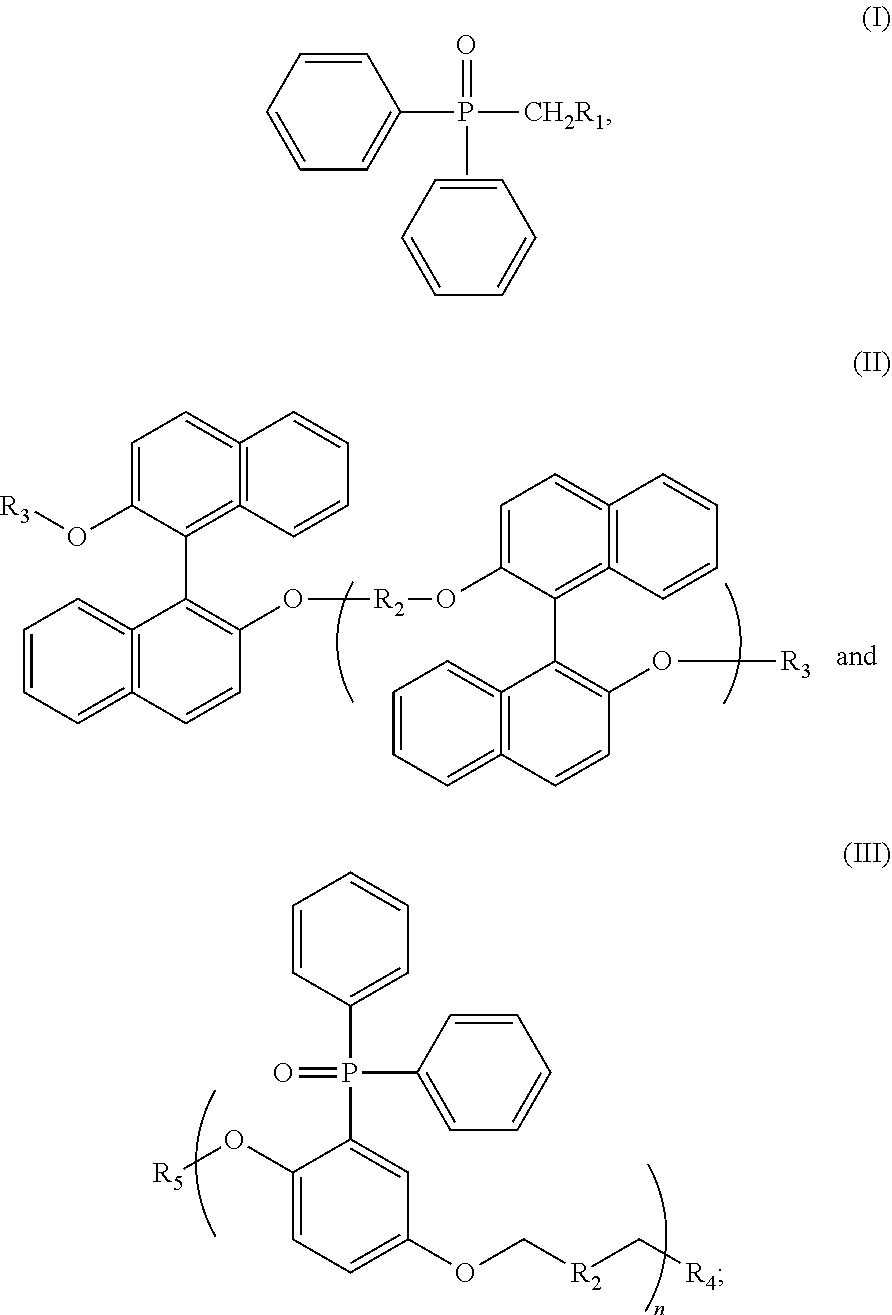

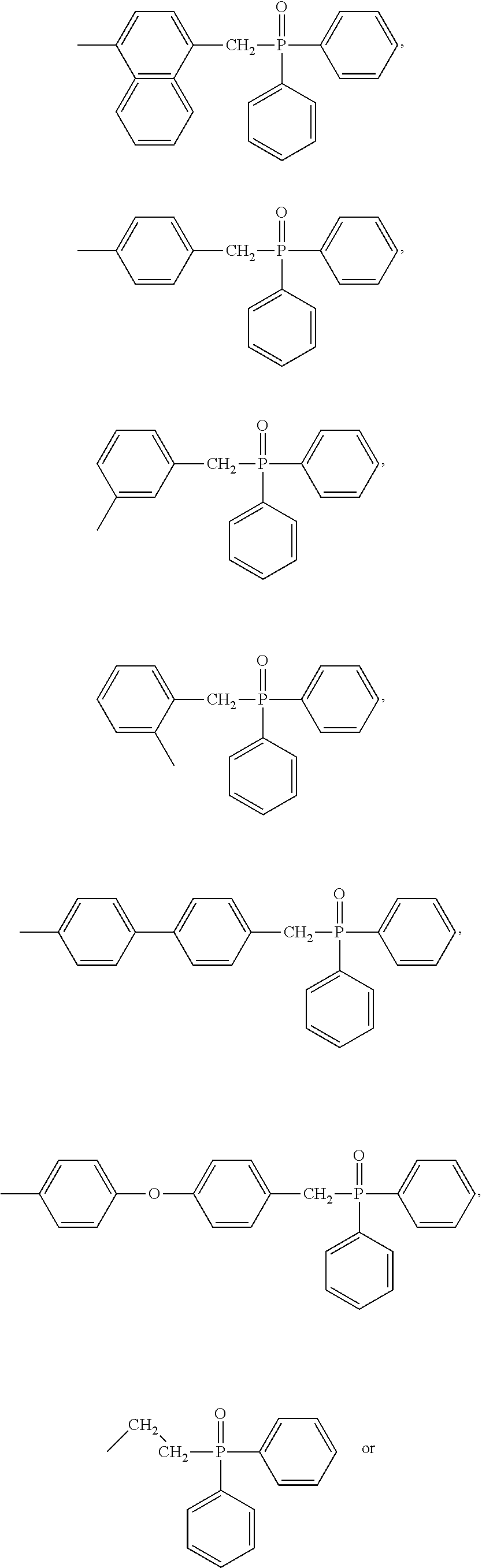

ActiveUS20190202168A1High glass transition temperatureLow dielectricPrinted circuit aspectsPrinted circuit manufactureLow dissipationHalogen

A laminated substrate including a halogen-free epoxy resin composition. The halogen-free epoxy resin composition includes 100 parts by weight of a halogen-free naphthalene type epoxy resin, 10 to 25 parts by weight of a DOPO modified curing agent, 25 to 45 parts by weight of a cyanate resin, 35 to 60 parts by weight of bismaleimide, 45 to 65 parts by weight of a non-DOPO flame retardant, and 0.5 to 15 parts by weight of a curing accelerator. The laminated substrate of the present disclosure includes a halogen-free epoxy resin composition which has the characteristic of high transition temperature, so that the halogen-free epoxy resin composition has low dielectric constant, low dissipation factor, high heat resistance and high storage modulus.

Owner:ITEQ CORP

Oxygen and water resistant maleic anhydride grafted polyphenyl ether modified epoxy resin composite material for LED packaging, and preparation method thereof

The invention discloses an oxygen and water resistant maleic anhydride grafted polyphenyl ether modified epoxy resin composite material for LED packaging. Epoxy resin is modified by grafted polyphenyl ether, polyphenyl ether grafted by maleic anhydride, nanometer organic montmorillonite and other raw materials maintains excellent performances of low dielectric property, low loss and high heat resistance, and the compatibility of the grafted polyphenyl ether and the epoxy resin is improved, so the defects of traditional epoxy resin as a packaging material are effectively improved; and the modified epoxy resin material prepared in the invention has excellent mechanical performances, and the unique structure of the nanometer organic montmorillonite makes the resin material be solidified and compact, so the composite material has good barrier ability to oxygen and water vapor, thereby the material is durable, and has the advantages of excellent mechanical and dielectric performances, high light and thermal ageing resistance, long service life, economy and durability as a packaging material.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

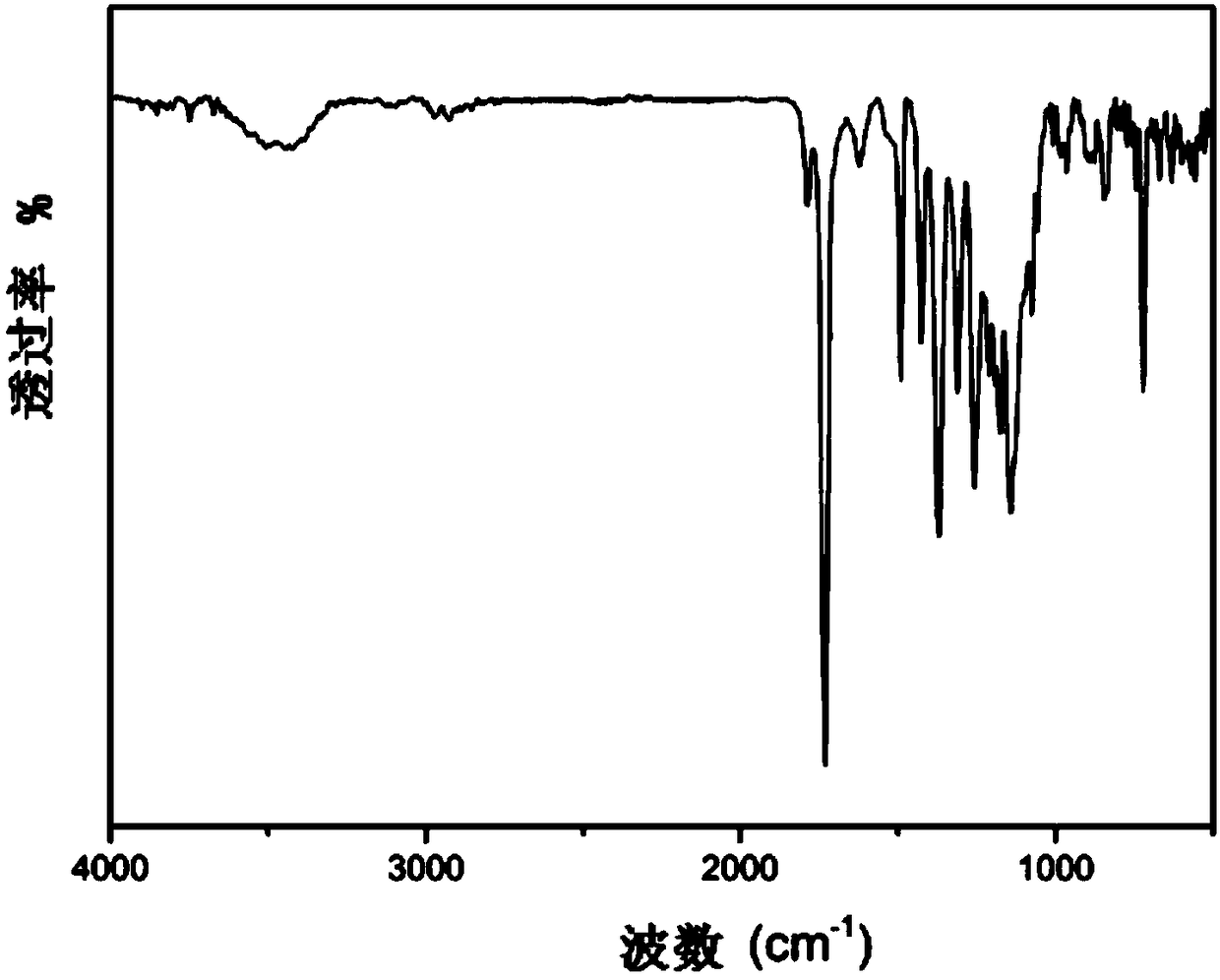

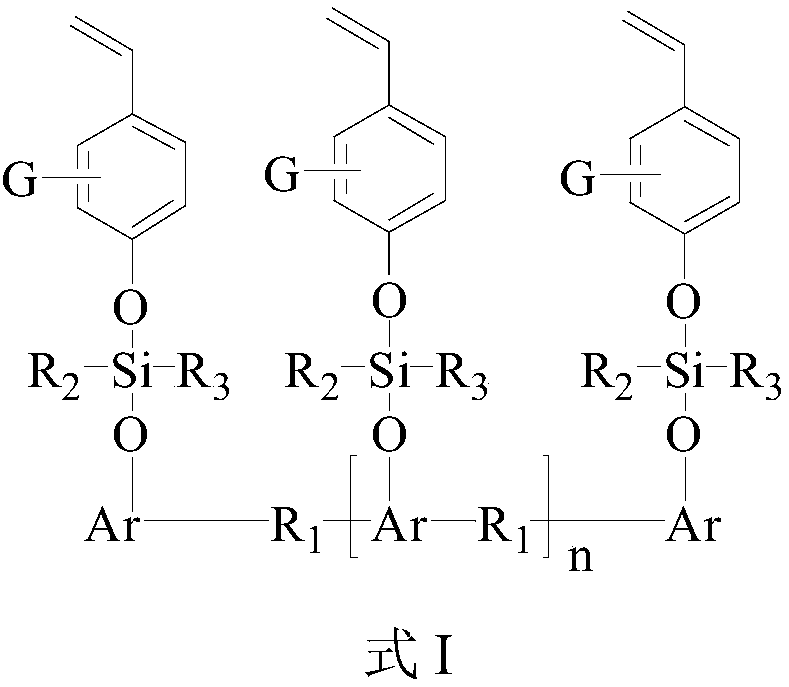

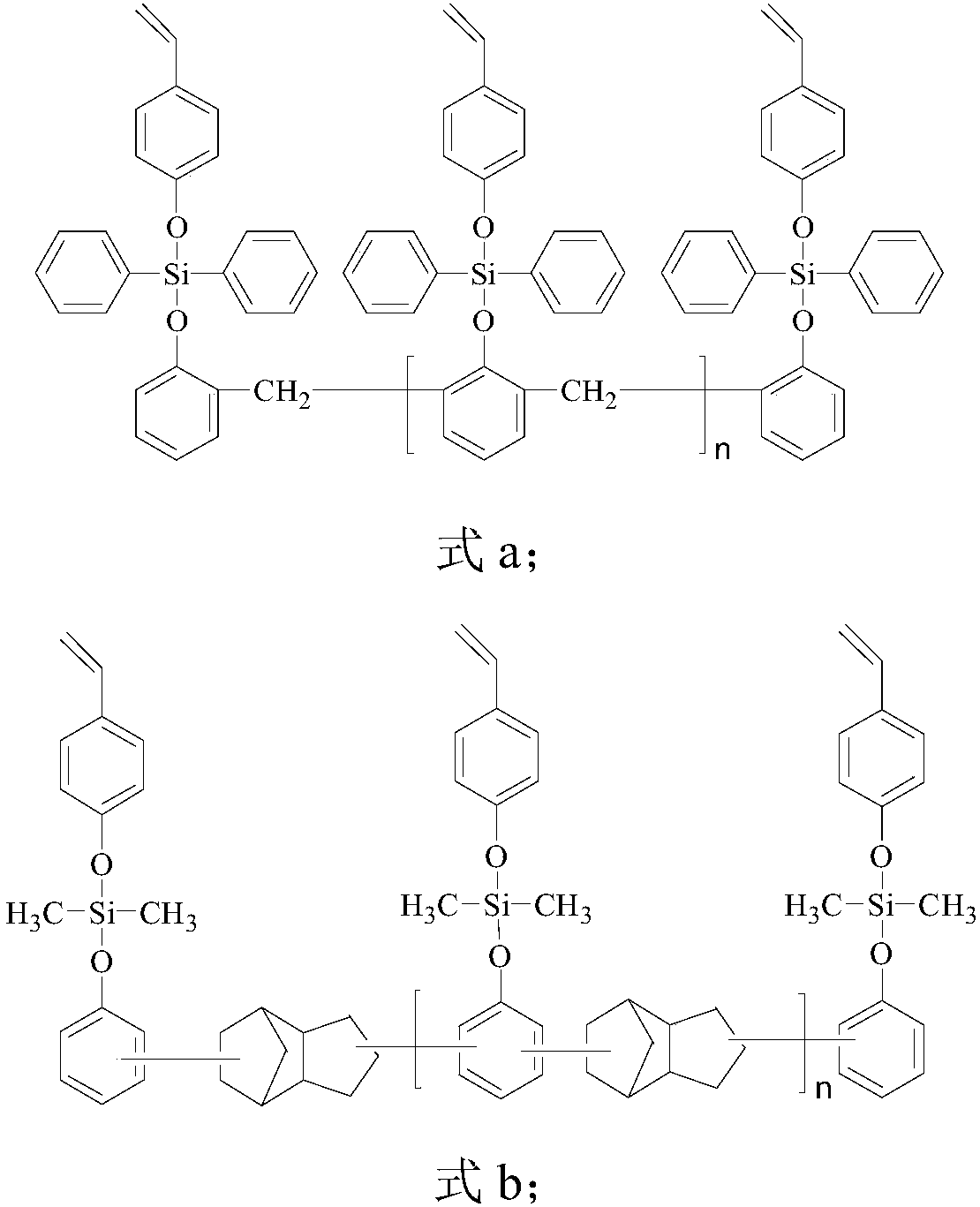

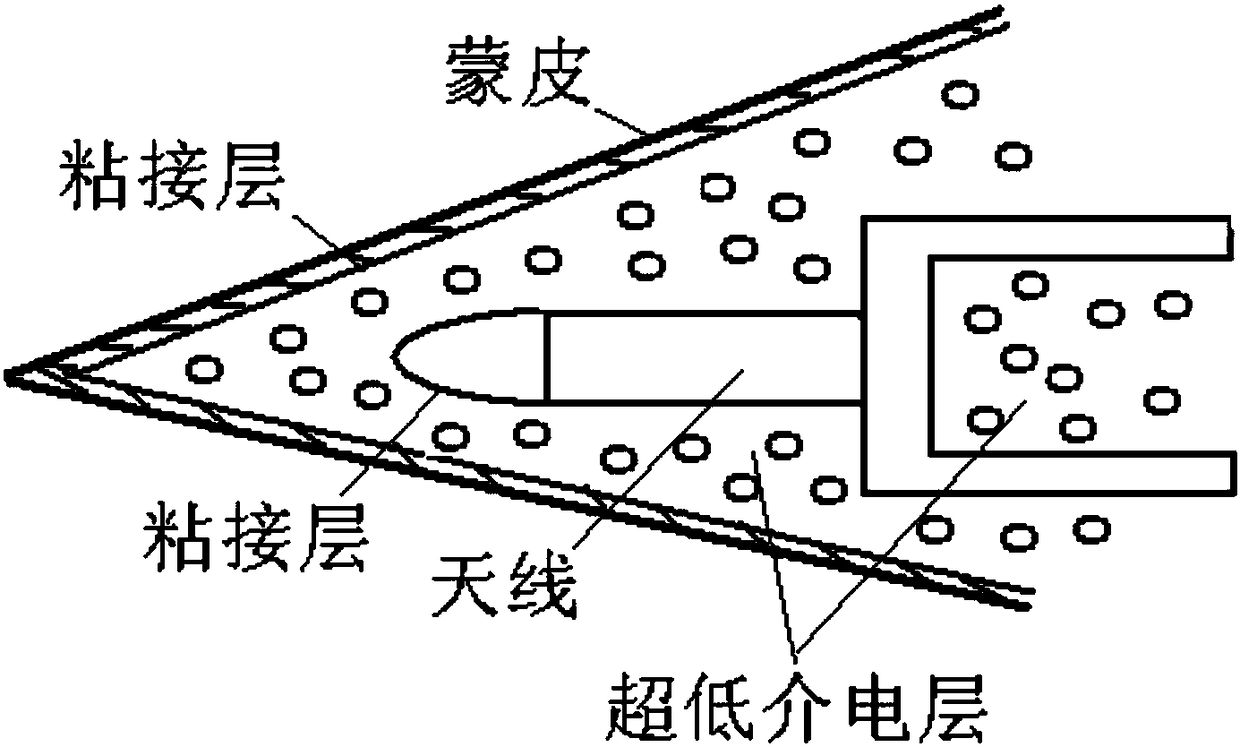

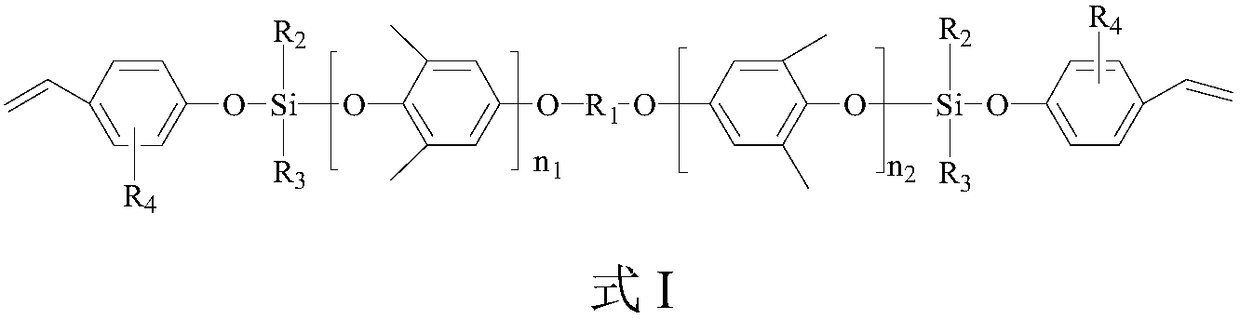

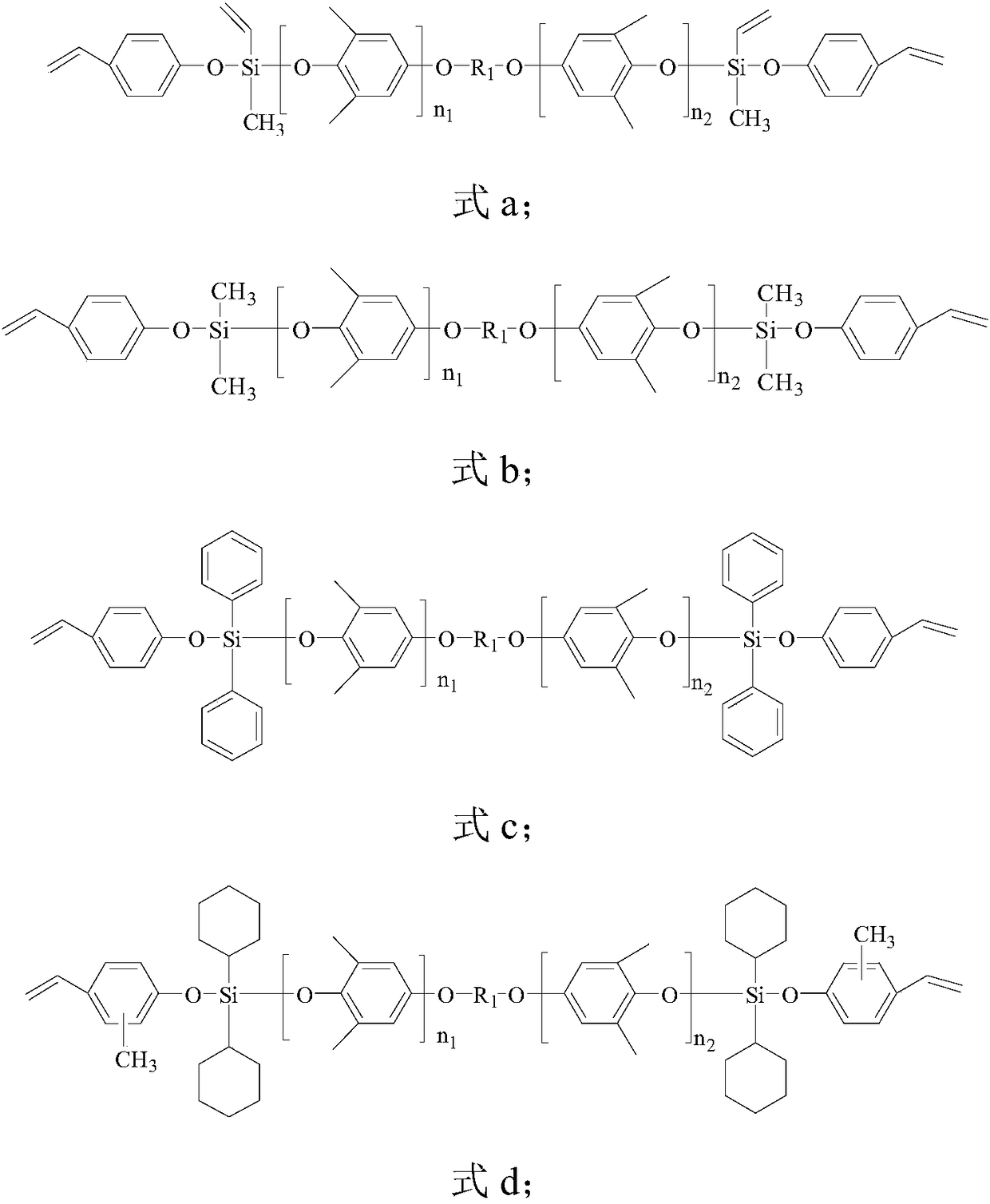

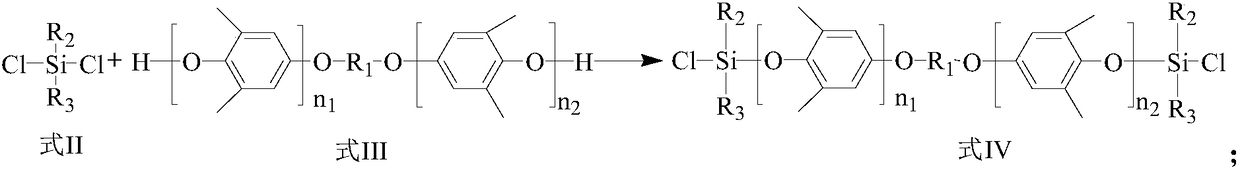

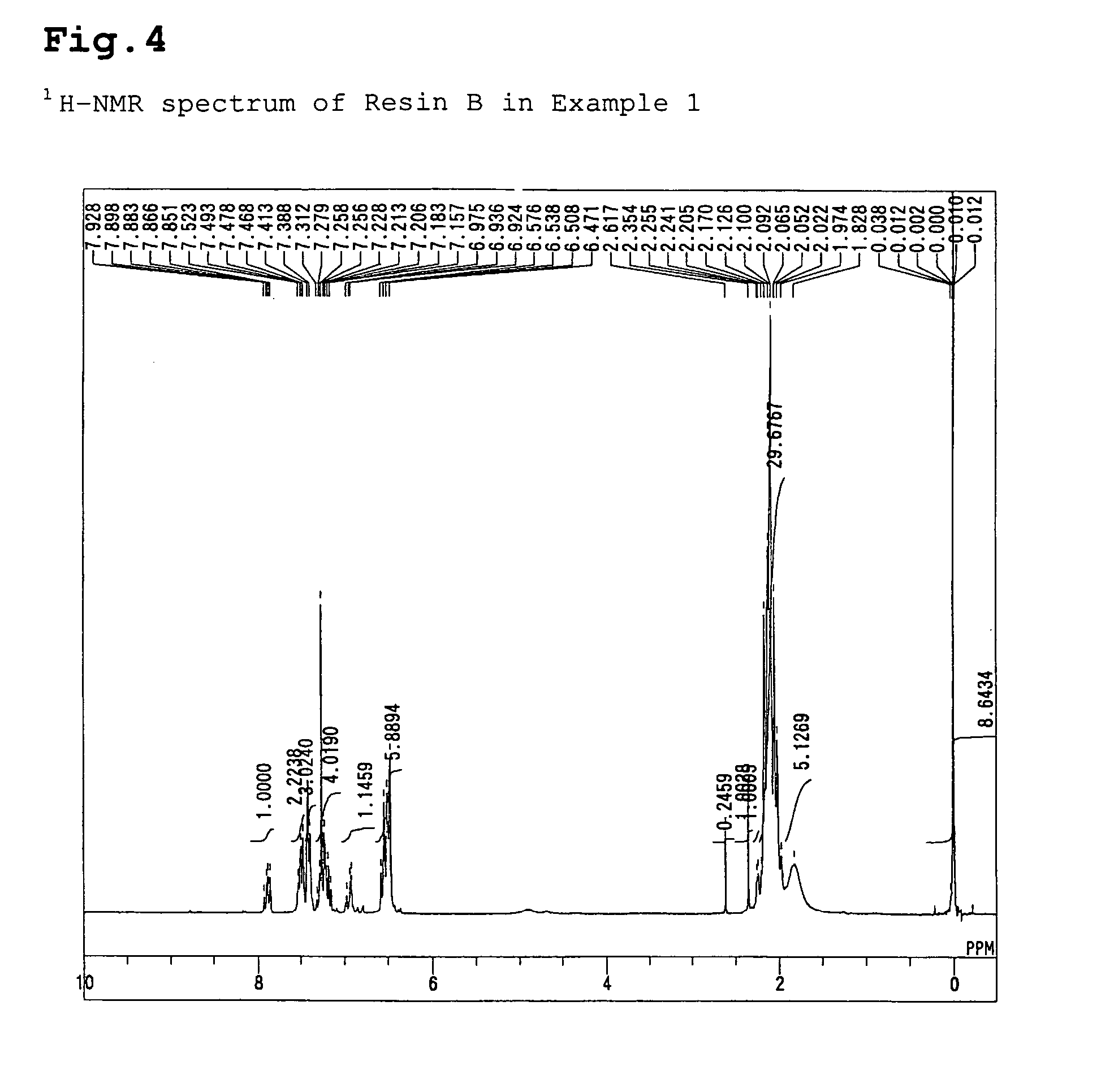

Styryl siloxy phenolic resin, and preparation method and application thereof

InactiveCN108148162ALow dielectricLow heat resistanceCircuit susbtrate materialsMetal layered productsAbsorption rateWeather resistance

The invention provides styryl siloxy phenolic resin, and a preparation method and application thereof. The styryl siloxy phenolic resin has a structure shown in a formula I. According to the method provided by the invention, a simpler synthetic method is utilized to introduce an unsaturated C=C double bond and a siloxy group into a side chain of phenolic resin, so that the resin simultaneously combines low dielectricity of double-bond curing and heat resistance, weather resistance, flame retardance, dielectric properties and a low water absorption rate of the siloxy group, greatly plays application advantages of the phenolic resin in a copper-clad laminate, and can provide excellent dielectric properties, heat and humidity resistance and heat resistance required for the high-frequency high-speed copper-clad laminate.

Owner:GUANGDONG SHENGYI SCI TECH

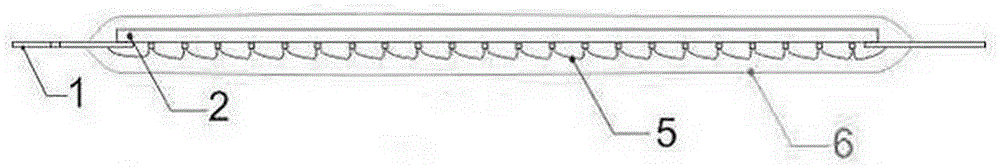

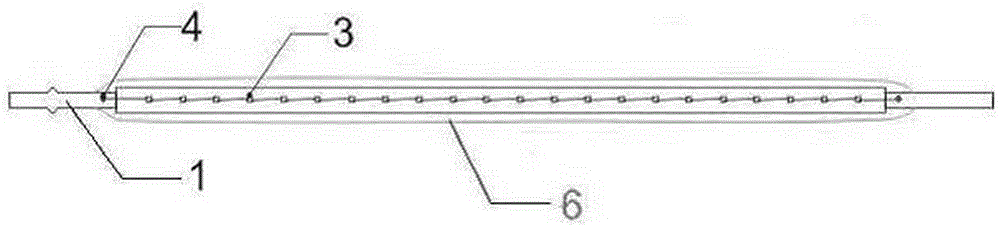

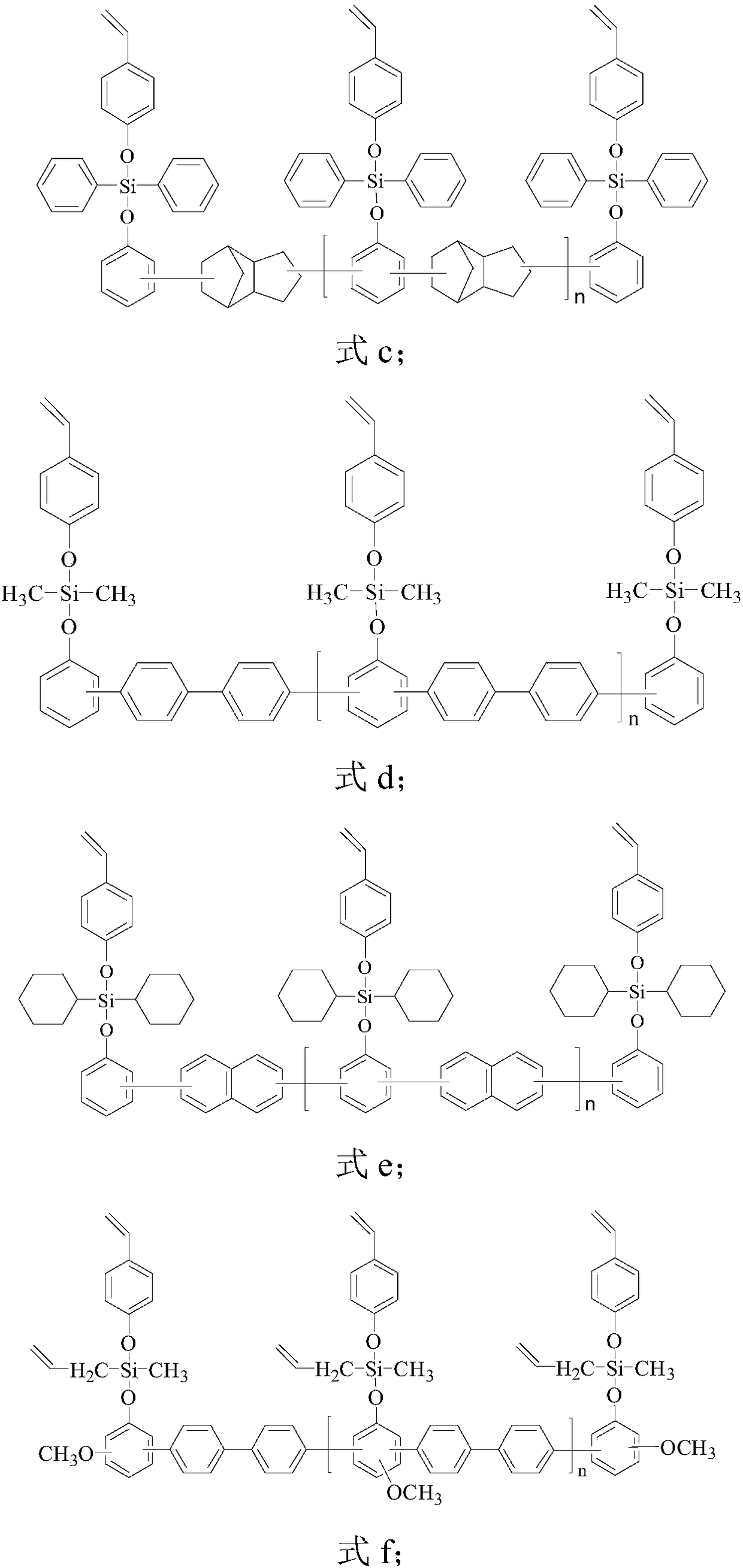

V-shaped radar radome structure and preparation method thereof

The invention provides a "V"-shaped radar radome structure and a preparation method thereof. The radome structure is obtained by co-curing of an antenna, a skin and a filling core layer, the skin andthe filling core layer are adhered by using an adhesive layer so as to form the radome, and the antenna and the filling core layer are adhered by using the adhesive layer and wrapped in the radome. The influence of multilayer reflection interference of the conventional interlayer radome surface can be weakened by the integral design of the radome and the antenna. Besides, compared with the multilayer skin core layer structure, only one skin is required, the wave permeability can be enhanced by the ultrathin skin design and the error of aiming can be greatly reduced. Meanwhile, the antenna pattern and phase consistency can be enhanced, and the problems of reduction of the wave permeability and pattern distortion under the broadband condition of the "V"-shaped radome can be solved, and the wave permeability, the pattern and the phase consistency of the "V"-shaped radome are enabled to meet the working requirements of the radar antenna.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

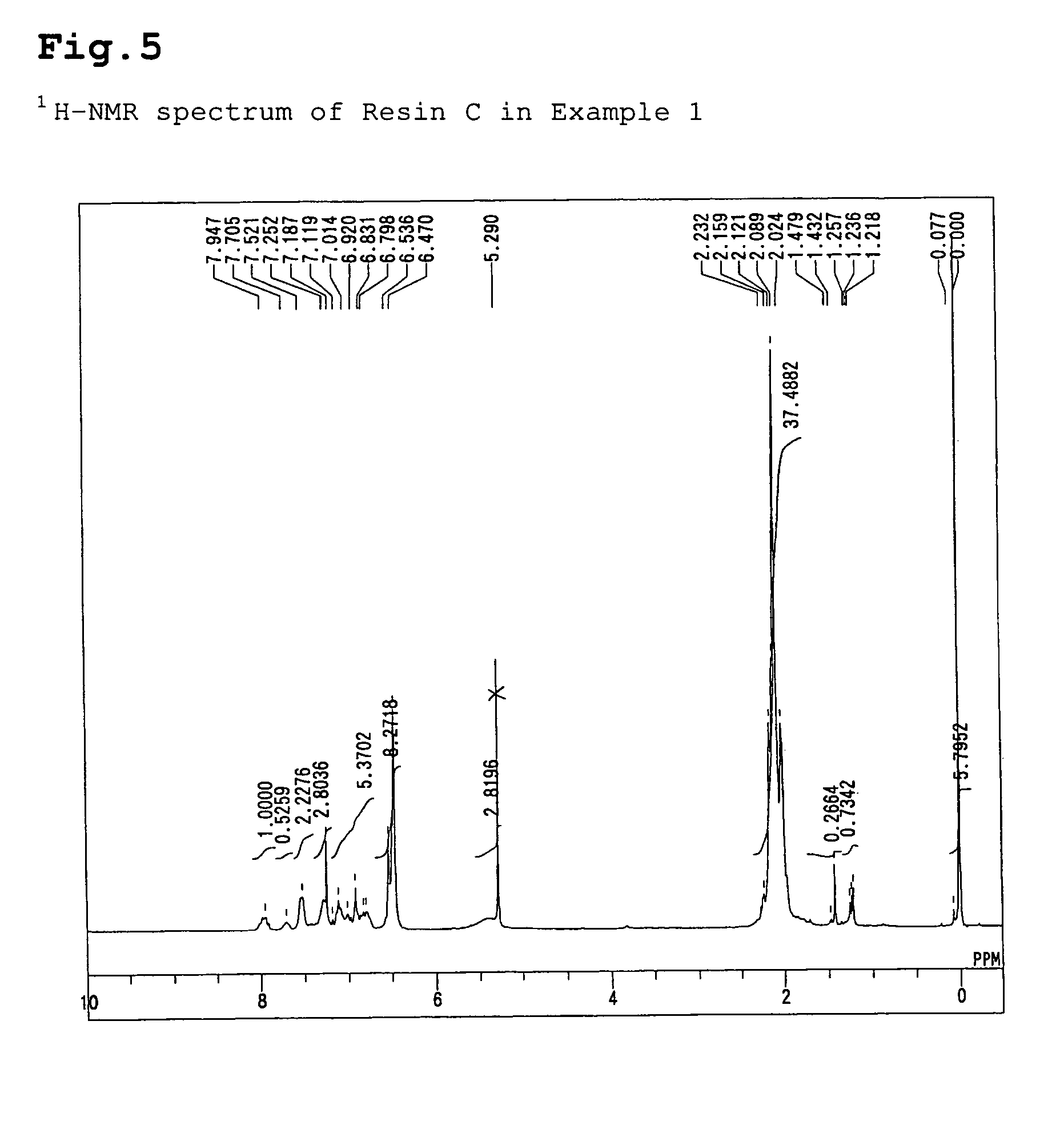

Styryl siloxy polyphenyl ether resin and preparation method and application thereof

ActiveCN108148196ALow dielectric propertiesExcellent dielectric propertiesPrinted circuit aspectsSynthetic resin layered productsPolymer scienceWeather resistance

The invention provides a styryl siloxy polyphenyl ether resin and a preparation method and application thereof. The styryl siloxy polyphenyl ether resin has a structure shown in the formula I. According to the invention, the styryl siloxy polyphenyl ether resin is obtained by introducing styryl groups and siloxy groups into polyphenyl ether end groups by using a relatively simple synthesis method.The resin combines the low dielectricity of cured styryl groups and the heat resistance, weather resistance, flame retardancy, dielectrical property and low water absorption rate of the siloxy groups, exerts the application advantages of polyphenyl ether resin in a copper clad plate, and can provide excellent dielectric property, moisture resistance, heat resistance and the like required by a high-frequency high-speed copper clad plate.

Owner:GUANGDONG SHENGYI SCI TECH

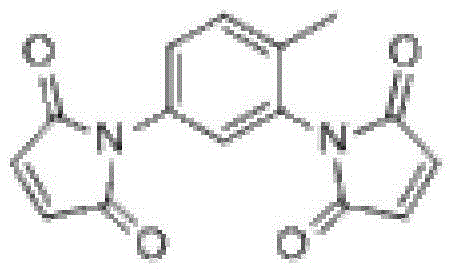

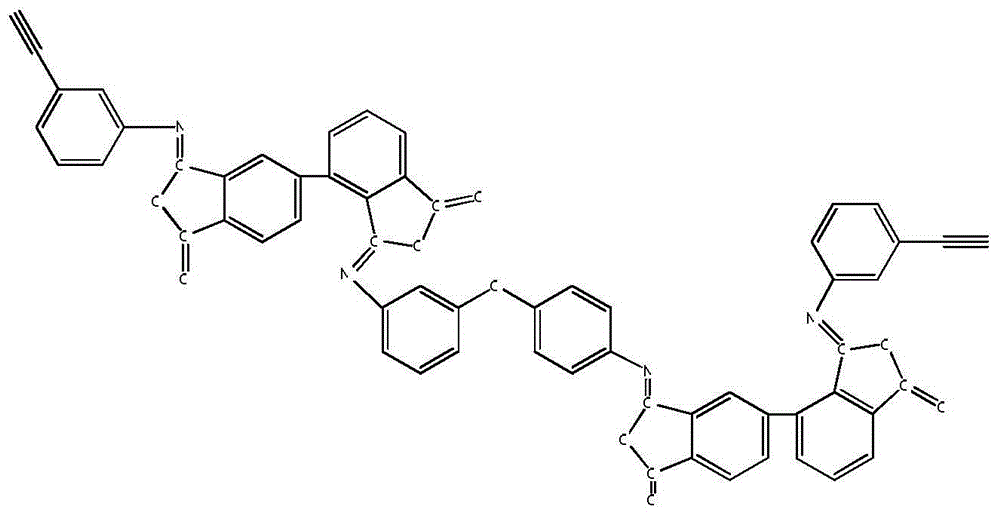

High-temperature-resistant honeycomb node adhesive and preparation method thereof

InactiveCN104479620AGood solubilityGood heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventCyanate ester

The invention discloses a high-temperature-resistant honeycomb node adhesive and a preparation method thereof and relates to an adhesive and a preparation method thereof. The high-temperature-resistant honeycomb node adhesive is used for solving the problem that the existing honeycomb node adhesive cannot meet the requirements on the manufacturing of polyimide paper honeycomb due to low temperature-resistant level and poor bonding compatibility. The adhesive is prepared from matrix resin, BMT type bismaleimide resin, phenolic cyanate ester, a co-polymerization modifier, a rubber elastomer toughening agent, inorganic nanometer filler and a solvent. The preparation method comprises the following steps: firstly, weighing; secondly, preparing toughening modified resin; thirdly, mechanically blending to obtain mixed rubber sheets; and fourthly, preparing uniform rubber liquid under stirring. The high-temperature-resistant honeycomb node adhesive is mainly applied in manufacturing aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance. The high-temperature-resistant honeycomb node adhesive prepared by the preparation method is used for the manufacturing of aerospace polyimide paper honeycomb and has the characteristics of high temperature resistance and good process performance.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

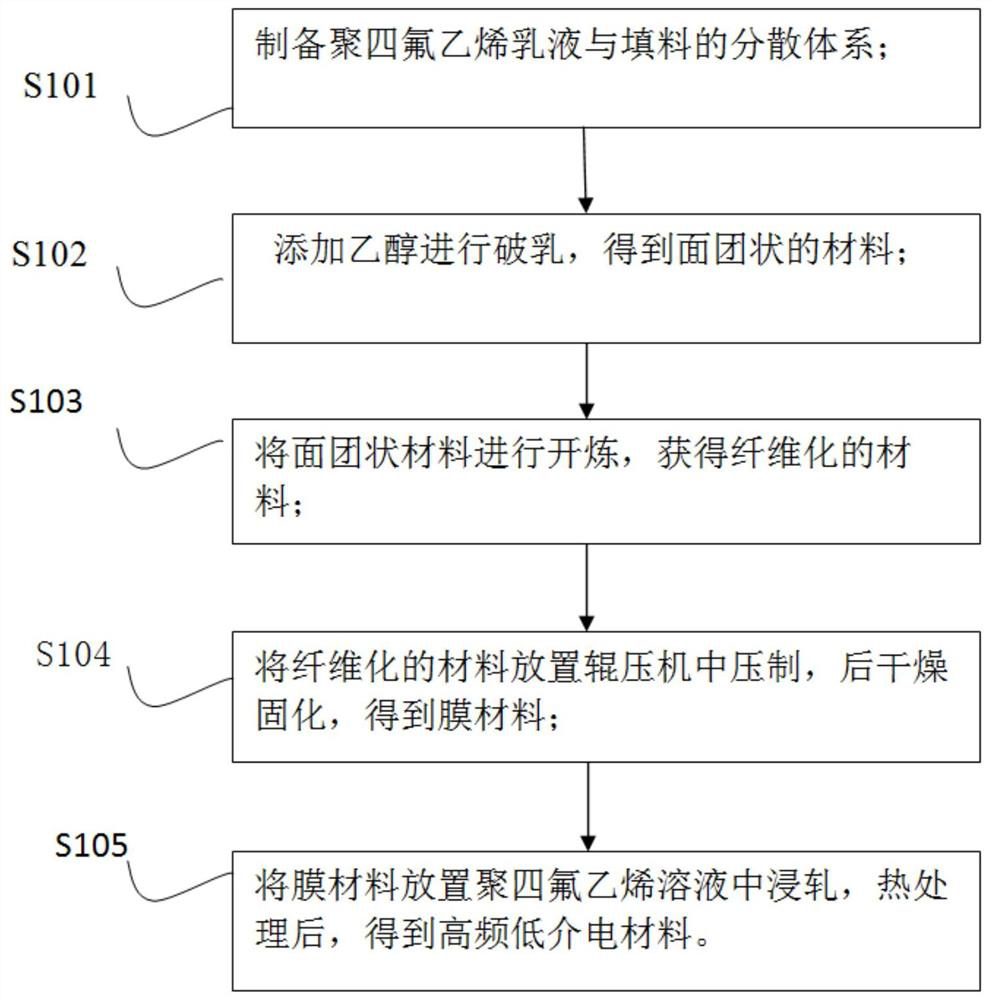

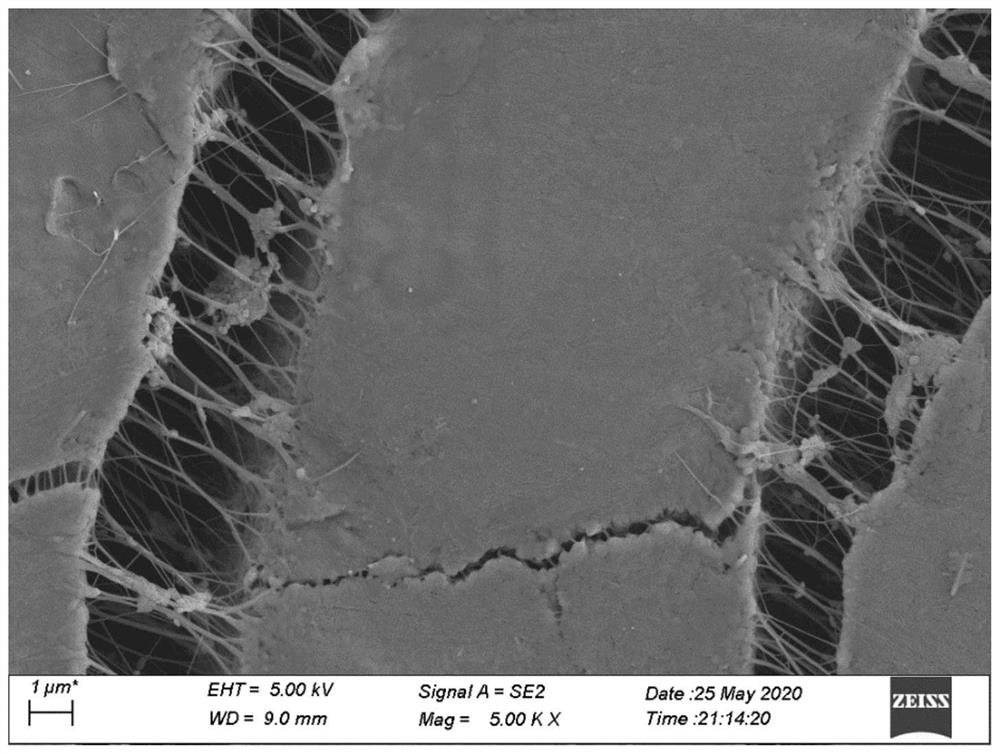

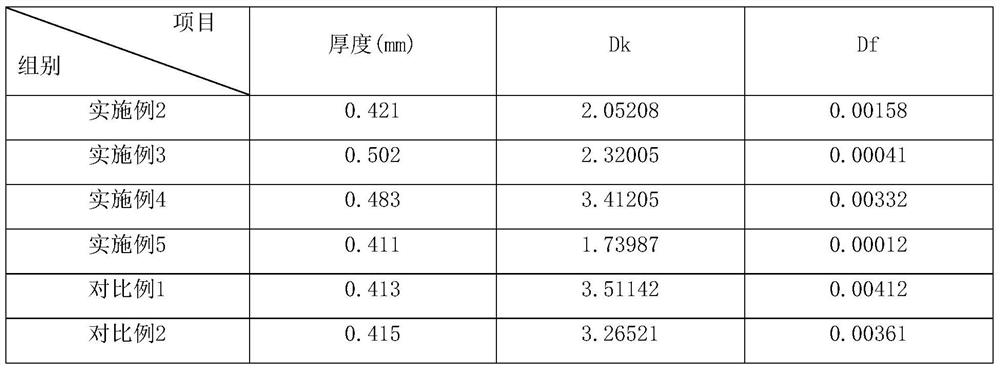

Preparation method of high-frequency low-dielectric material

The invention provides a preparation method of a high-frequency low-dielectric material. A dispersion system of a polytetrafluoroethylene emulsion and a filler is formed, the filler is fully dispersedin the polytetrafluoroethylene emulsion, ethanol is added for demulsification, then an open milling process is carried out, so that the system is fiberized, a material system with higher porosity isobtained, a film material is prepared through one-time forming of a roller press, and finally, the film material is impregnated in polytetrafluoroethylene emulsion to obtain a material with good strength, low dielectric and low water absorption, so that the material is applied to more fields. Generally, the problems that in the prior art, the dielectric property is poor, multi-layer stacking heating pressure is needed, the process is complex, and material application is limited can be effectively solved.

Owner:佛山(华南)新材料研究院

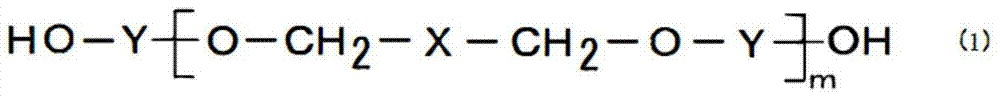

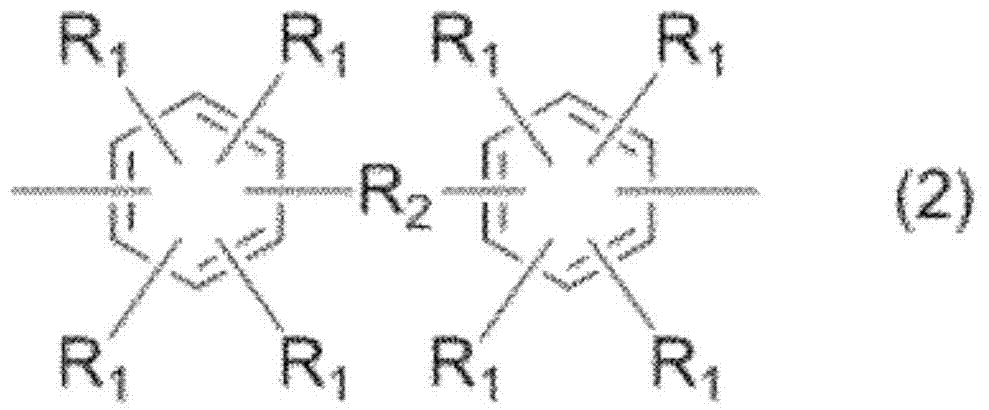

Epoxy resin composition and cured product thereof

ActiveCN104513359ALow dielectricImprove heat resistanceFilm/foil adhesivesSynthetic resin layered productsEpoxyHalogen

The invention provides an epoxy resin composition which has low medium property, high thermal resistance and excellent performance and is useful in overlaying, forming, casting, adhesion and other occasions, and a cured product of the epoxy resin composition. The invention relates to the epoxy resin composition and the cured product thereof. The epoxy resin composition contains an epoxy resin (A) represented in a formula (1) and a curing agent (B). In the formula (1), m is a number of repetition with the average value being 0<m<10; X and Y are selected from phenylene or naphthylene having hydroxy groups or halogen atoms which can serve as substituent group with the number of carbon atoms being 1 to 10, or at last one group in the groups represented in a formula (2), and can be the identical or different. In the formula (2), R1 represents a hydroxy group or a halogen atom having 1 to 10 hydrogen atoms or carbon atoms which can be the same or different; and R2 is a single bond or a bivalent group.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

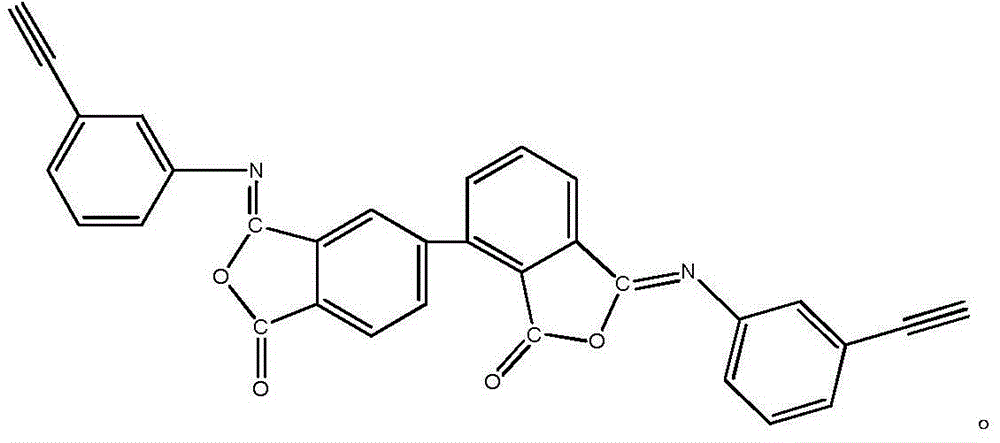

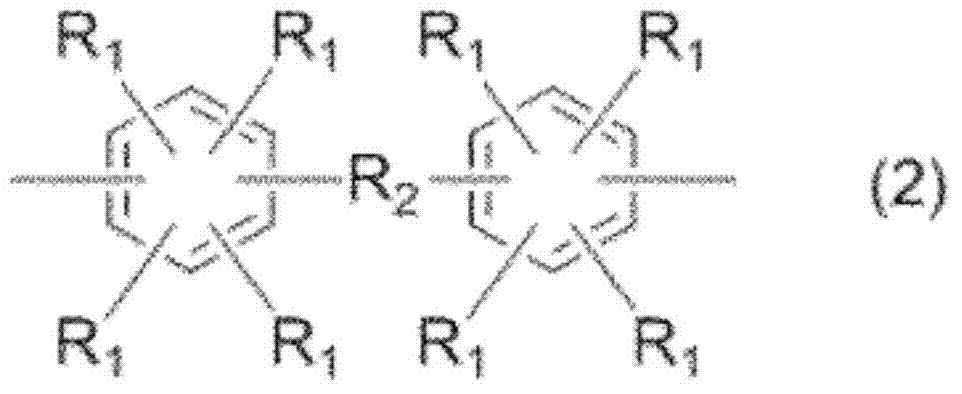

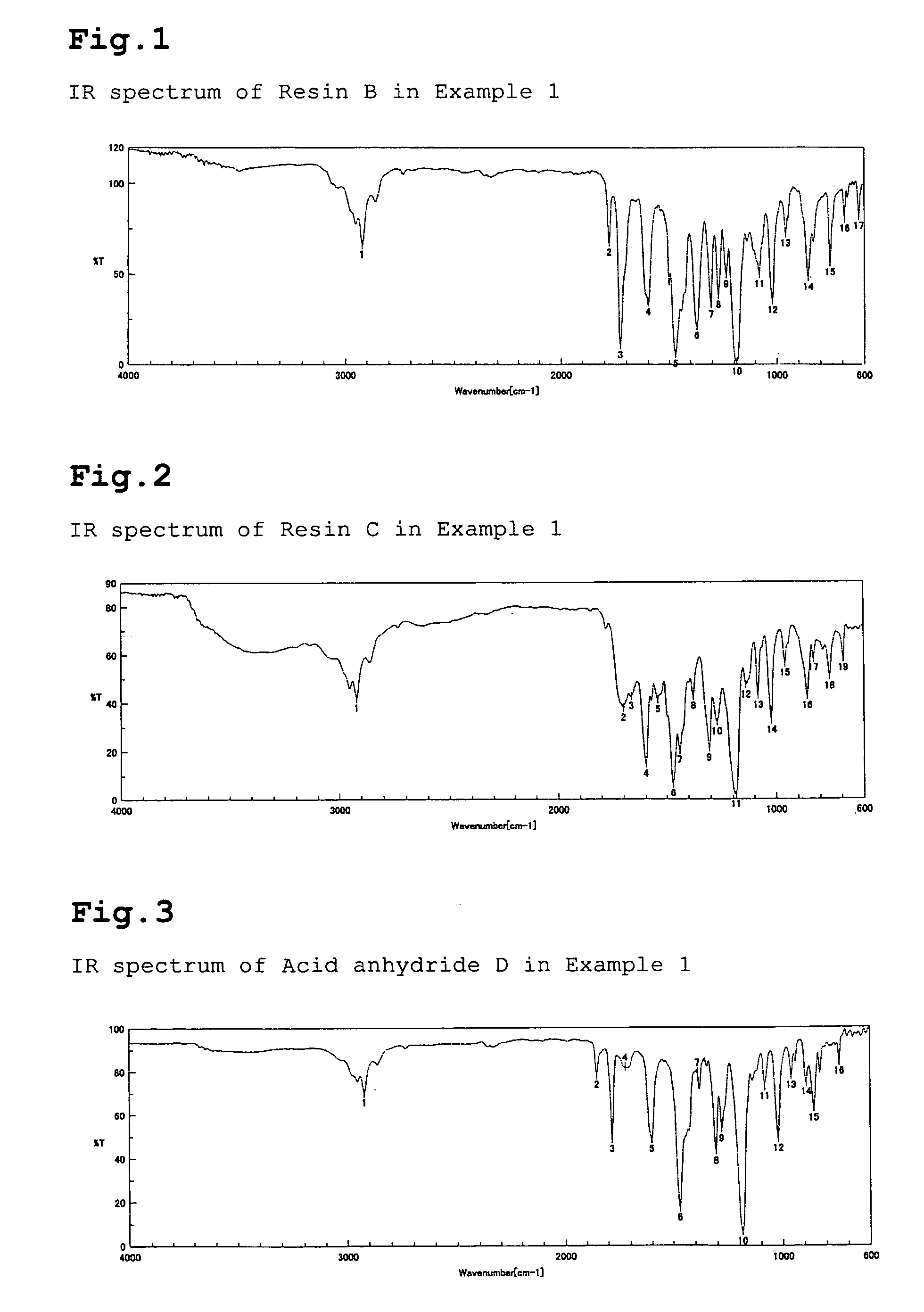

Acid anhydride and polyimide using the same

ActiveUS7193030B2Excellent in electric characteristic and moldabilityLoss tangentLiquid crystal compositionsOrganic chemistryOligomerEther

An acid anhydride of the formula (4), and a polyimide using the acid anhydride,wherein anhydrides are substituted at sites 3 or sites 4,which acid anhydride is obtained from, as a raw material, a bifunctional phenylene ether oligomer having a number average molecular weight of 500 to 3,000, represented by the formula (1).

Owner:MITSUBISHI GAS CHEM CO INC

Precursor composition for porous film and method for preparing the composition, porous film and method for preparing the porous film, and semiconductor device

InactiveUS20090053503A1Low dielectricLow refractive indexGroup 4/14 element organic compoundsLayered productsGas phaseRefractive index

A precursor composition for porous film comprising at least one member selected from the group consisting of compounds represented by the following general formulas: Si(OR1)4 and Ra(Si)(OR2)4-a (in the formulas, R1 represents a monovalent organic group; R represents a hydrogen atom, a fluorine atom or a monovalent organic group; R2 represents a monovalent organic group; a is an integer ranging from 1 to 3, provided that R, R1 and R2 may be the same or different); a heat decomposable organic compound capable of being thermally decomposed at a temperature of not less than 250° C.; and at least one element selected from the group consisting of elements each having a catalytic action, and organic solvent. A hydrophobic compound is subjected to a gas-phase polymerization reaction in the presence of a solution of this precursor composition to thus form a hydrophobic porous film having a low dielectric constant, a low refractive index and high mechanical strength. A semiconductor device prepared using the porous film.

Owner:ULVAC INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com