Preparation method of high-frequency low-dielectric material

A low-dielectric material, high-frequency technology, applied in coatings and other directions, can solve problems such as poor dielectric properties, complex processes, and material application limitations, and achieve the effects of low dielectric constant, simple process, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

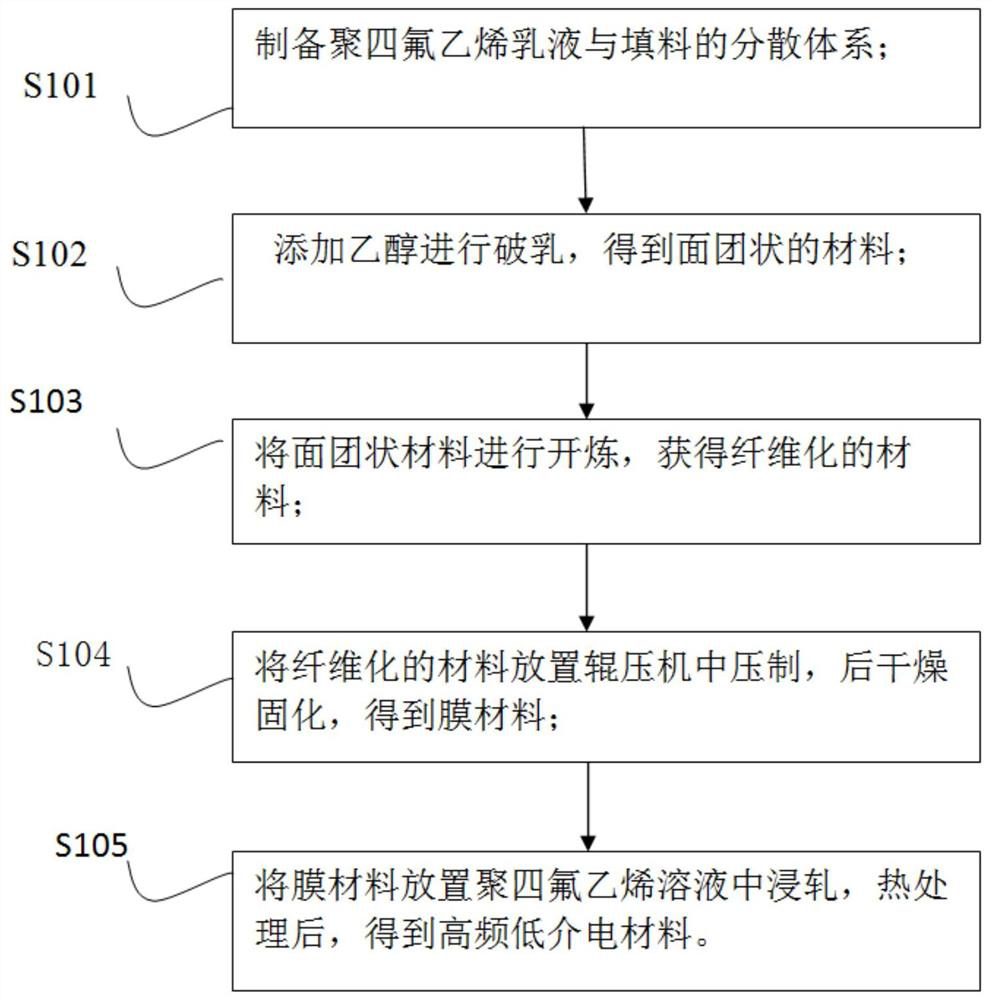

[0032] In this embodiment, a method for preparing a high-frequency low-dielectric material is provided, which includes the following steps:

[0033] S1. Weigh the polytetrafluoroethylene emulsion and the filler and add them to the disperser in turn, fully disperse and evenly obtain the dispersion system of the polytetrafluoroethylene emulsion and the filler, and in this embodiment, the conditions set in the disperser are: The stirring speed is 10-1000r / min, and the stirring time is 20-30min; according to the volume ratio, the addition ratio of the polytetrafluoroethylene emulsion and the filler is: 1:0.2-9; the filler is silicon micropowder, One or more of titanium dioxide and barium titanate;

[0034] S2. Add ethanol to the dispersion system of polytetrafluoroethylene emulsion and filler, continue to stir until described dispersion system demulsification, obtain the material that forms dough; The addition ratio of described polytetrafluoroethylene emulsion and described ethan...

Embodiment 2

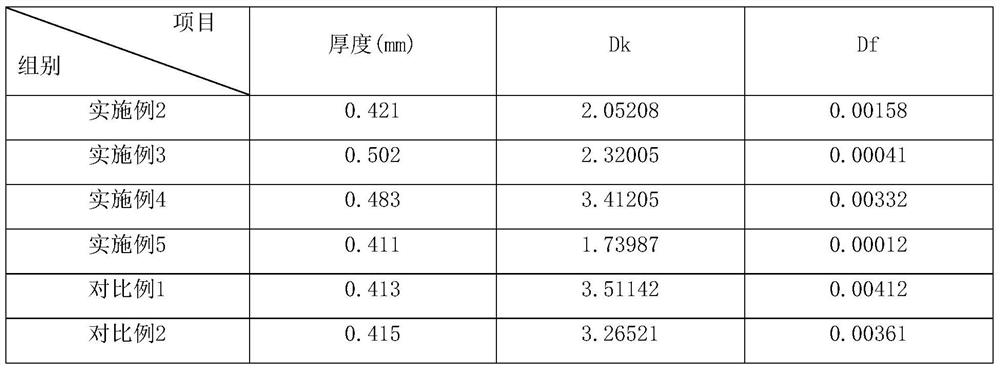

[0039] This embodiment should be understood as at least including all the features of the foregoing embodiments, and further explained on the basis of it, this embodiment provides a preparation method of a high-frequency low-dielectric material, as follows: Weigh 100g of polytetrafluoroethylene Emulsion, 25g of silicon micropowder with a particle size of 10 microns, was sequentially added to the disperser, dispersed at a rate of 500r / min for 10min, added ethanol, stirred continuously until all the emulsion was broken, and a dough-like material was obtained. Place the dough-like material at 40°C, start the mill, and adjust the temperature of the mill to 40°C for 5 minutes, and then roll it through the roller press, and the temperature of the roller press is 40°C. The pressure is 5MPa, and it is pressed into a sheet material at one time. The sheet material is placed at a temperature of 45°C for drying. Drying at 55°C, followed by heat treatment for 1 hour, the heat treatment tem...

Embodiment 3

[0041] This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further explained on the basis of it, this embodiment provides a preparation method of a high-frequency low-dielectric material, specifically as follows: Weigh 100 g of Polytetrafluoroethylene emulsion, 25g of silicon micropowder with a particle size of 3 microns, was sequentially added to the disperser, dispersed at a rate of 500r / min for 10min, added ethanol, stirred continuously until all the emulsions were broken, and a dough-like material was obtained. Place the dough-like material at 40°C, start the mill, and adjust the mill to 60°C for 15 minutes, and then roll it through a roller press with a temperature of 50°C and a pressure of 30MPa. Once pressed into a sheet material, place the sheet material at a temperature of 45°C for drying, place the dried sheet material in PTFE emulsion for one dip, and place it at a temperature of 55°C Drying under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com