Preparation method of high light transmission and low dielectric fluorinated graphene/polyimide composite film

A technology of fluorinated graphene and polyimide, which is applied in the field of preparation of high light transmittance and low dielectric fluorinated graphene/polyimide composite films, can solve the problems of decreased light transmittance, limitation, etc. High mechanical strength, low dielectric, simple and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

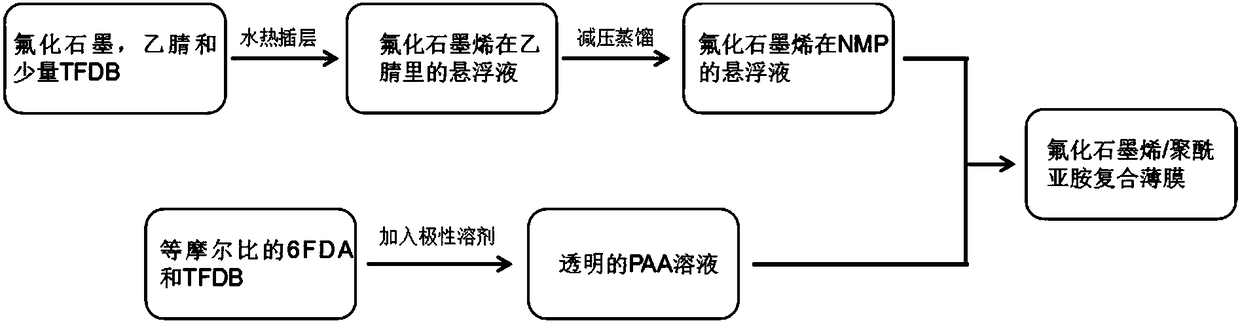

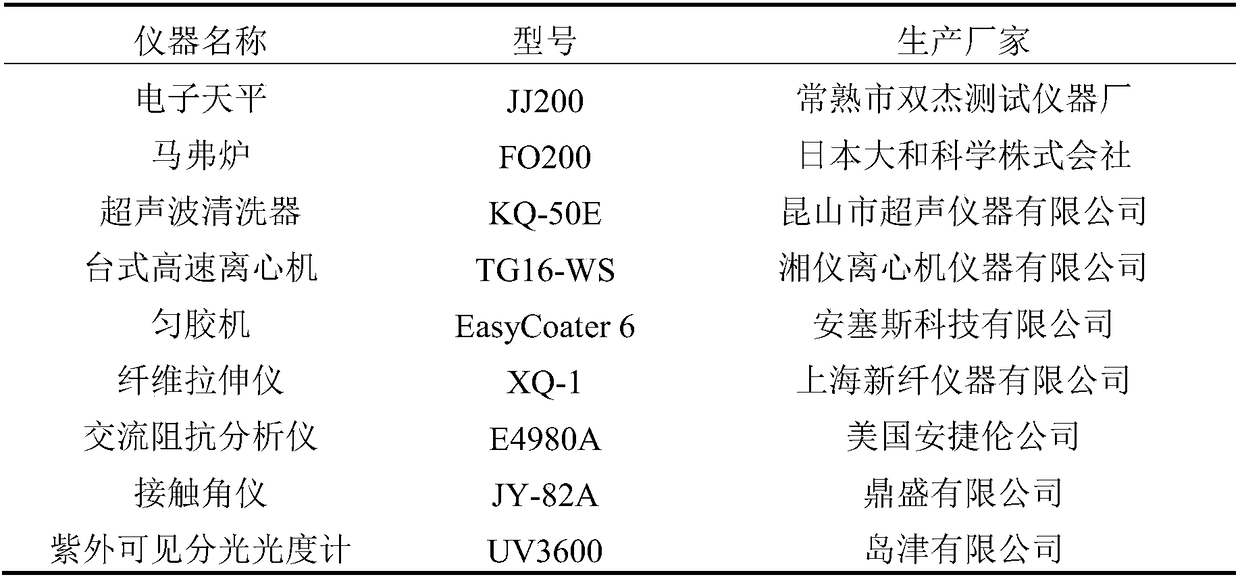

[0038] A method for preparing high light transmittance and low dielectric fluorinated graphene / polyimide composite film is carried out according to the following steps:

[0039] Step 1. Prepare the NMP suspension of fluorinated graphene: add fluorinated graphite to the solvent to obtain a fluorinated graphite suspension with a concentration of 1 mg / ml; then add diamine monomer to the fluorinated graphite suspension and place it in a sealed container The reaction kettle is hydrothermally intercalated at 85°C for 6 hours. After the hydrothermal intercalation reaction, ultrasonic peeling is performed for 25 hours. After centrifugation, the upper suspension is taken (the upper suspension is a solvent with fluorinated graphene), and the suspension Add 20 mL of NMP to the solution and distill under reduced pressure; where the solvent is acetonitrile, and the mass ratio of diamine monomer to fluorinated graphite is 1:10;

[0040] Step 2. Under the protection of inert gas, slowly add the N...

Embodiment 2

[0045] A method for preparing high light transmittance and low dielectric fluorinated graphene / polyimide composite film is carried out according to the following steps:

[0046] Step 1. Prepare the NMP suspension of fluorinated graphene: add fluorinated graphite to the solvent to obtain a fluorinated graphite suspension with a concentration of 1.5 mg / ml; then add diamine monomer to the fluorinated graphite suspension and place In a closed reactor, the hydrothermal intercalation reaction was conducted at 85°C for 8 hours. After the hydrothermal intercalation reaction, ultrasonic peeling was performed for 30 hours. After centrifugation, the upper suspension was taken (the upper suspension is a solvent suspended in fluorinated graphene), and Add 20 mL of NMP to the suspension and distill under reduced pressure; where the solvent is acetonitrile, and the mass ratio of diamine monomer to fluorinated graphite is 1:10;

[0047] Step 2. Under the protection of inert gas, slowly add the NMP...

Embodiment 3

[0052] A method for preparing high light transmittance and low dielectric fluorinated graphene / polyimide composite film is carried out according to the following steps:

[0053] Step 1. Prepare the NMP suspension of fluorinated graphene: add fluorinated graphite to the solvent to obtain a fluorinated graphite suspension with a concentration of 2mg / ml; then add diamine monomer to the fluorinated graphite suspension and place it in an airtight The reaction kettle is hydrothermally intercalated at 85°C for 6 hours. After the hydrothermal intercalation reaction, ultrasonic peeling is performed for 48 hours. After centrifugation, the upper suspension is taken (the upper suspension is a solvent with fluorinated graphene), and the suspension Add 20mL NMP to the solution and distill under reduced pressure; where the solvent is acetonitrile, and the mass ratio of diamine monomer to fluorinated graphite is 1:15;

[0054] Step 2. Under the protection of inert gas, slowly add the NMP suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com