Preparation process of self-sharpening metallic bond diamond abrasive layer

A metal bond and preparation process technology, applied in the field of abrasive tool processing, can solve the problems of difficult control of self-sharpening of finished products, increased manufacturing process difficulty, complex material composition, etc., and achieve the effects of low cost, convenient operation and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

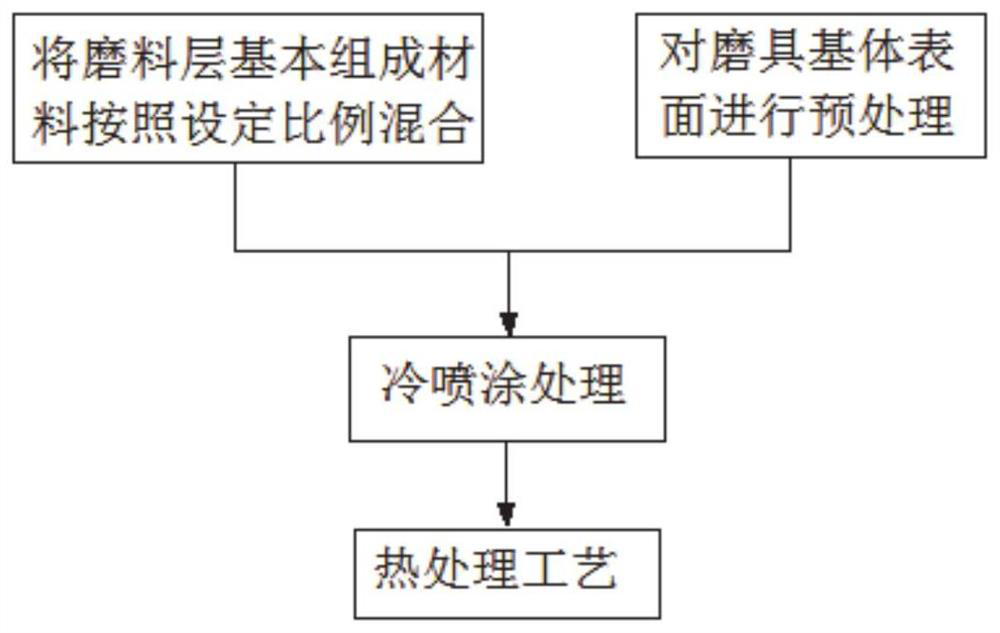

[0033] The present embodiment provides a kind of self-sharpening metal bond diamond abrasive layer preparation process, such as figure 1 shown, including:

[0034] Mix the basic constituent materials of the abrasive layer according to the set ratio;

[0035] Pretreat the surface of the abrasive tool substrate to obtain a good interface and promote the combination with the abrasive layer;

[0036] Spray the mixed material on the surface of the pretreated abrasive tool substrate by cold spraying to form an abrasive layer;

[0037] Controlling the gap and pore content of the hard and brittle intermetallic compounds formed in the abrasive layer through the heat treatment process to obtain a controllable self-sharpening abrasive layer.

[0038] Further, the basic constituent materials of the abrasive layer include diamond micropowder, high-purity Ni powder and high-purity Al powder, and the mass ratio of each component is: 20-50% of diamond, 30-50% of high-purity Ni powder, and 3...

Embodiment 2

[0053] The preparation process of the self-sharpening metal bond diamond abrasive layer of the present embodiment comprises the following steps:

[0054] Step 1. Mix the basic constituent materials of the abrasive layer according to the set ratio:

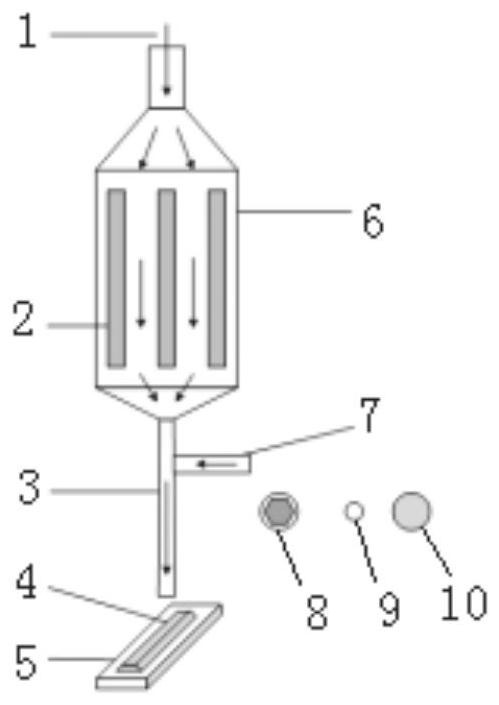

[0055] The basic composition material of the abrasive layer is a mixture of high-purity Ni powder 9, high-purity Al powder 10, and core-shell diamond micropowder 8, wherein the high-purity Ni powder 9 has an electrolytic irregular shape and is nearly spherical on the whole, 5-10 μm; High-purity Al powder 10 is prepared by gas atomization, spherical particles, 13-30 μm; core-shell diamond powder 8 has a diamond abrasive grain size of W28, 20-38 μm, and two layers are plated on its surface by chemical plating technology Metal, the middle layer is Ti, the weight gain ratio is 5%, the outermost layer is Ni, the weight gain ratio is 100%, and the coating thickness is 2.6-5.0 μm.

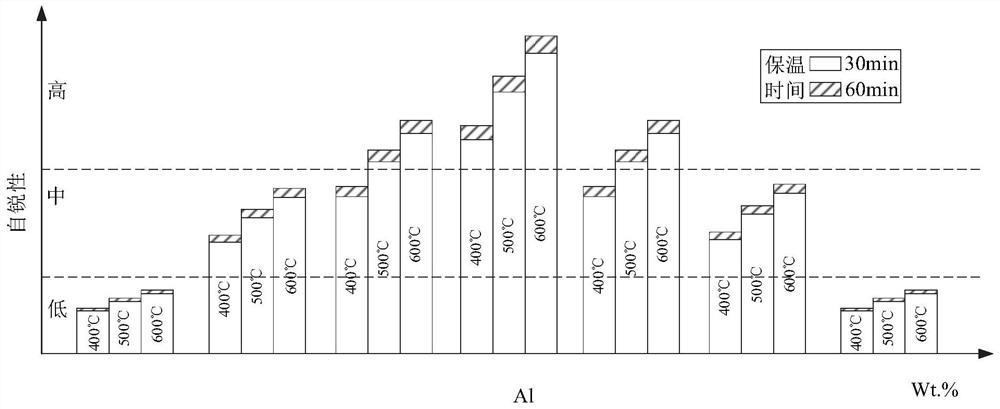

[0056] In order to achieve a higher degree of self-shar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com