Patents

Literature

516results about How to "Improve preparation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulp for lithium ionic cell electrode and manufacturing method thereof

ActiveCN101393978AEasy to useReduce dosageElectrode manufacturing processesActive material electrodesAdhesiveColloid

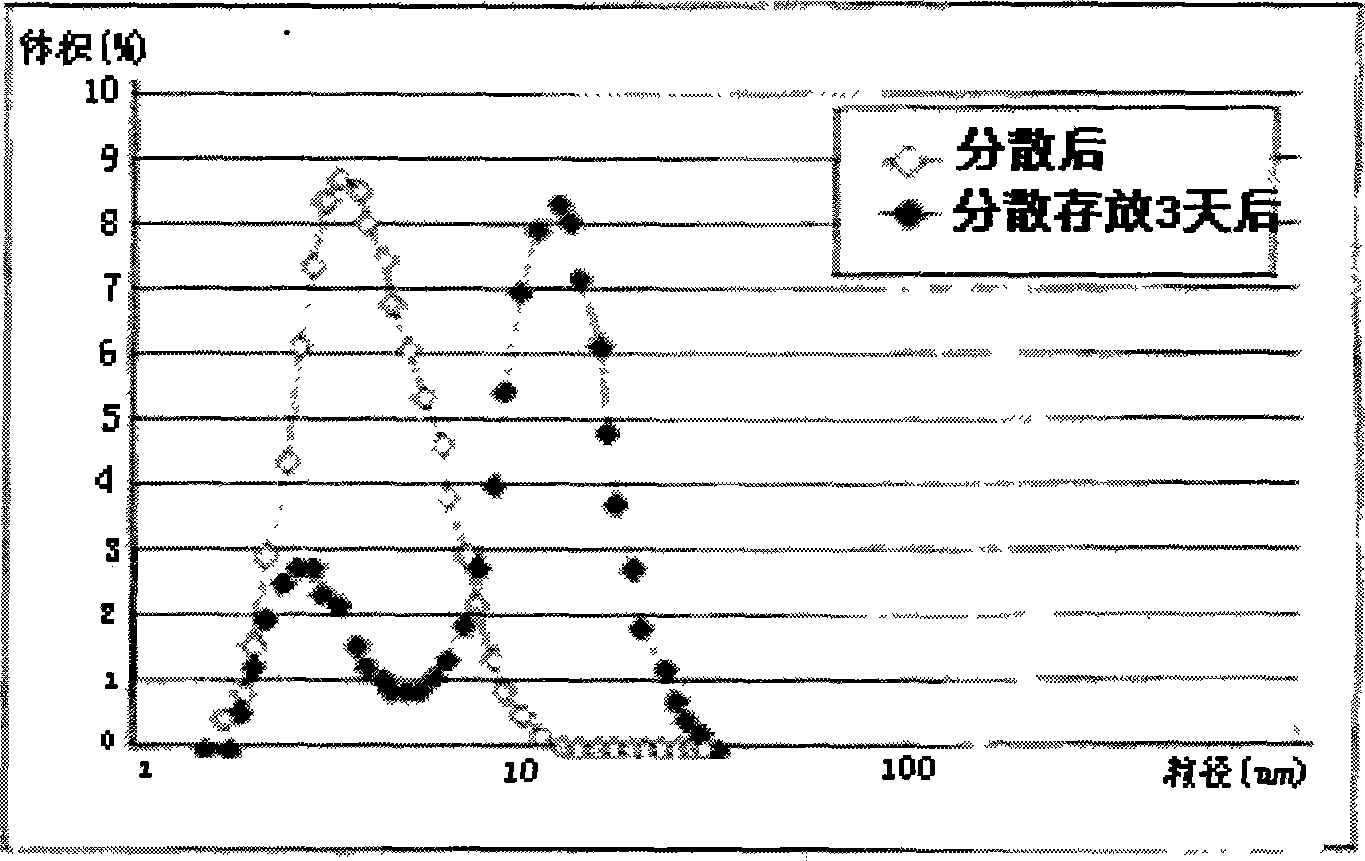

A sizing material for electrodes of a lithium ion battery mainly comprises an active material, a conductive agent, an adhesive and a solvent, and is characterized in that the distribution ratio of the active material, the conductive agent, the adhesive and the solvent is 100 : 0-4 : 1-7 : 35-100. The preparation process thereof comprises the following steps: 1) mixing the adhesive with partial solvent to prepare a glue body with the viscosity of 1 to 10 percent; 2) mixing the conductive agent weighed according to the distribution ratio with the glue body prepared in the step 1) and stirring to form a conductive glue; 3) mixing the active material and the rest solvent weighed according to the distribution ratio with the conductive glue and stirring to form a premixed sizing material; 4) introducing the premixed sizing material into a dispersion machine rotating at a high speed to conduct dispersion; 5) cooling and vacuumizing the dispersed sizing material to form the sizing material for the electrodes of the lithium ion battery. The sizing material has the better use performance, and the preparation method thereof solves the defect in the traditional mixture that the layering of the conductive agent is easily caused by a larger density difference when the conductive agent is mixed with the active material and the like, thereby ensuring the uniform distribution of each ingredient of the sizing material.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Identification method of machining characteristics of complex parts of airplane

InactiveCN101763069AShorten the manufacturing cycleReduce workloadProgramme controlComputer controlNumerical controlCharacteristic type

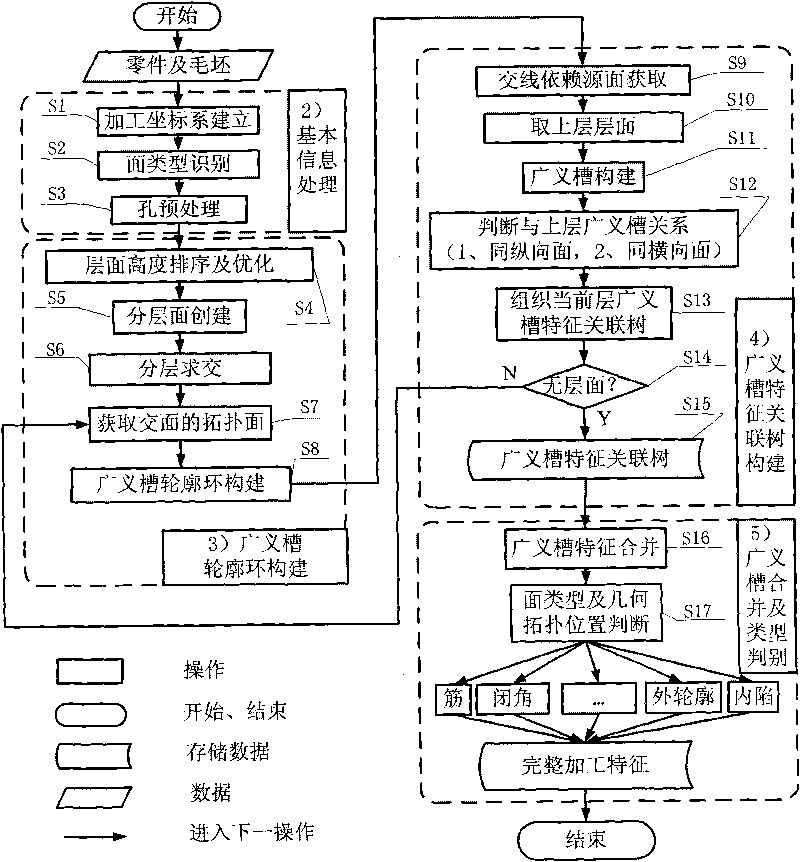

The invention provides an identification method of the machining characteristics of complex parts of an airplane, which comprises steps of: firstly, setting a machining coordinate system, identifying a machining surface and preprocessing a hole to complete basic information process; secondly, layering and intersecting to obtain intersecting line rings in each layer of intersecting result and relationships among the intersecting line rings to complete the construction of outline rings of generalized grooves; building the generalized grooves according to the outlines of the generalized grooves and the source surface depended by the intersecting lines; building the characteristics relevance tree of the generalized grooves according to the lengthways relationship of the outlines of the generalized grooves; and emerging the generalized grooves and identifying the characteristics types to complete the identification of the machining characteristics of a whole part. The method has the characteristics of high identification accuracy rate, high speed and small space usage, and the like; can be used for designing and developing systems for programming the complex parts of the airplane by means of intelligent numerical control, analyzing a machining technical scheme, and automatically generating blanks, and the like; and has good application foreground.

Owner:SHENYANG AIRCRAFT CORP +1

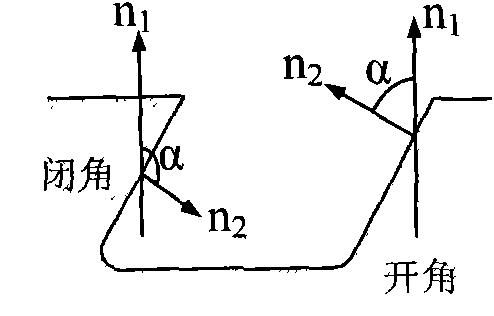

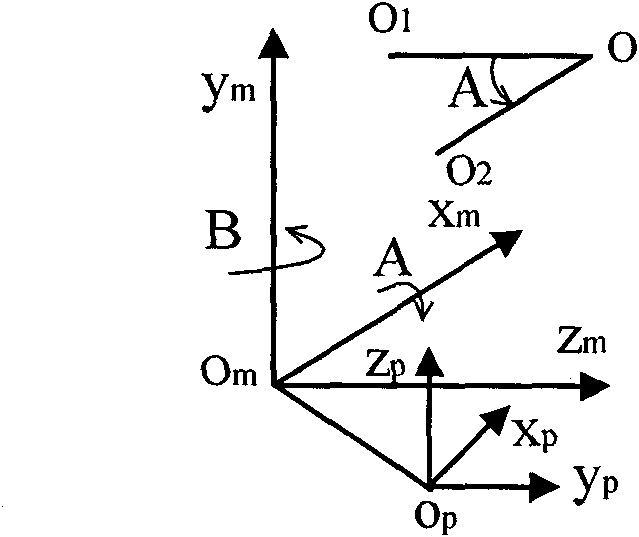

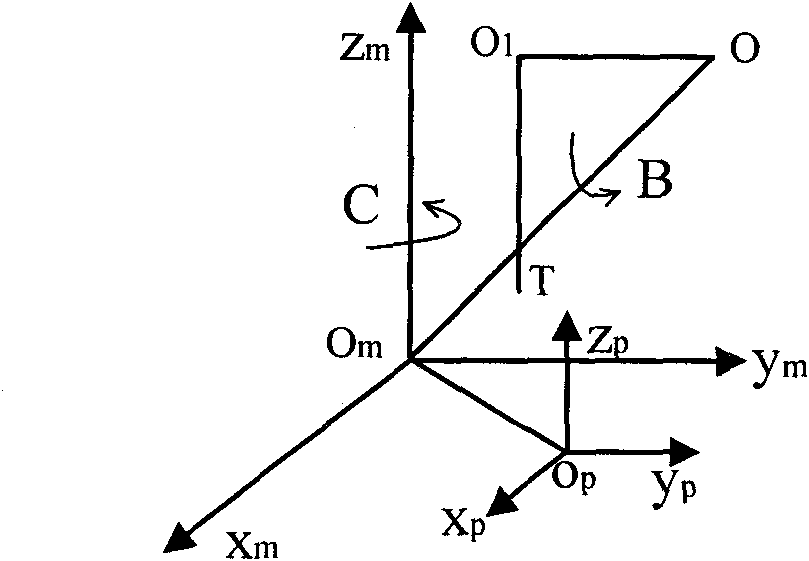

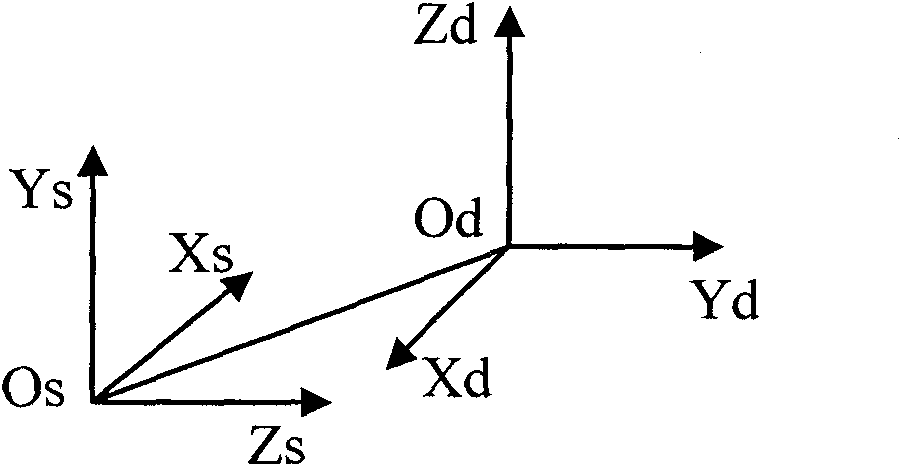

Five-coordinate numerical control machining cutter path changing method

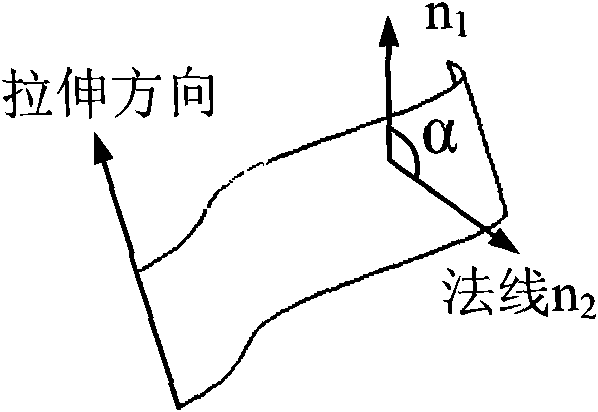

InactiveCN101859126AKeep optimization resultsImprove preparation efficiencyNumerical controlNumerical controlWorkload

The invention relates to a five-coordinate numerical control machining cutter path changing method, which comprises the following steps: firstly establishing a table of device data before and after change, then constructing post-processing methods of the two devices for each machine tool before and after the change between a cutter path described in a cutter position document and a machining cutter path based on the characteristics of the devices, carrying out inverse computation on the input machining cutter paths to obtain a linear shaft programming cutter position point, necessarily constructing an anti-tracking rotation processing method, constructing a corresponding relationship between coordinate systems of the devices before and after the change, constructing a method for mutually changing the machining cutter paths between the two machine tools based on the corresponding relationship between the coordinate systems, and finishing the change of the machining cutter paths based on the constructed method for changing the machining cutter paths of the machine tools. The method improves the preparation efficiency of the machining cutter paths in the process of changing components / devices, and reduces the workload.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

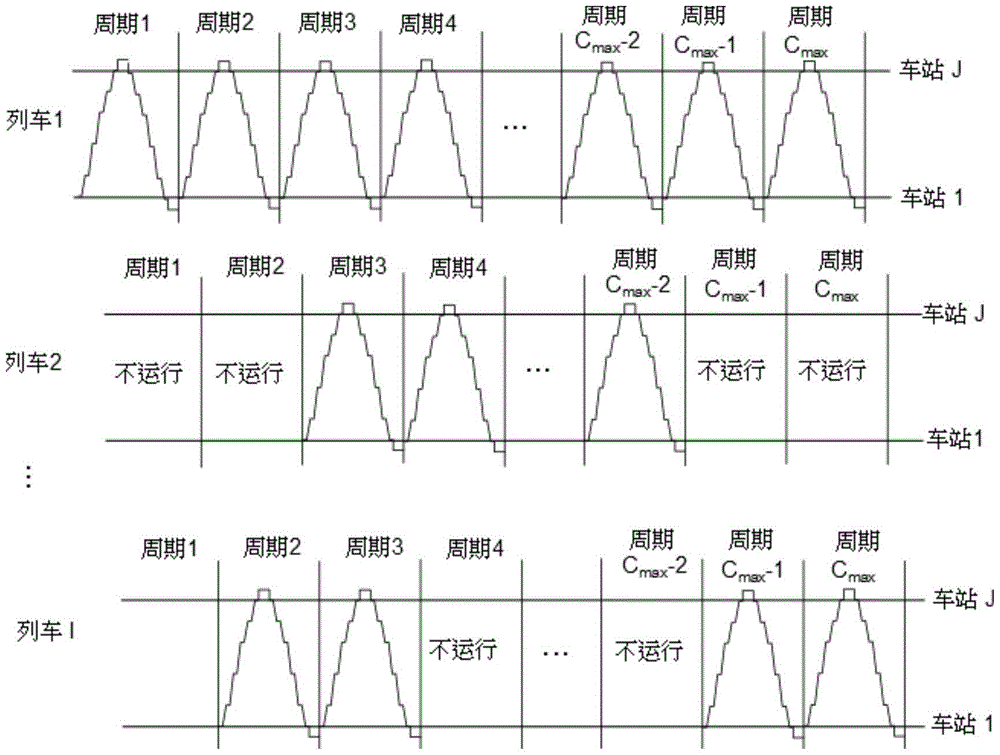

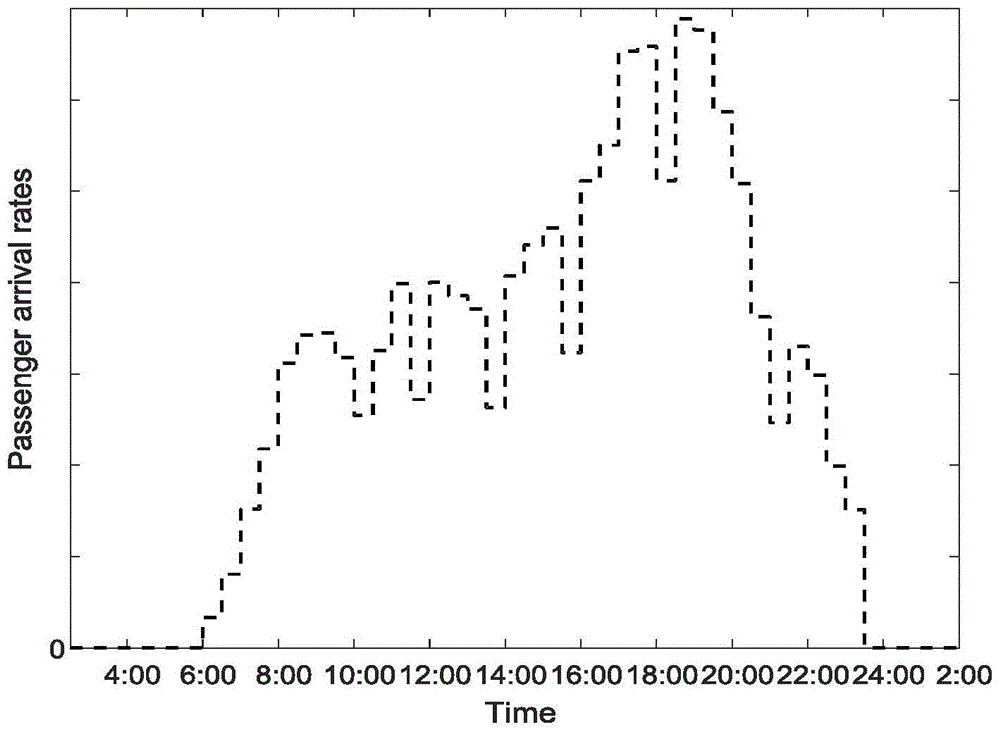

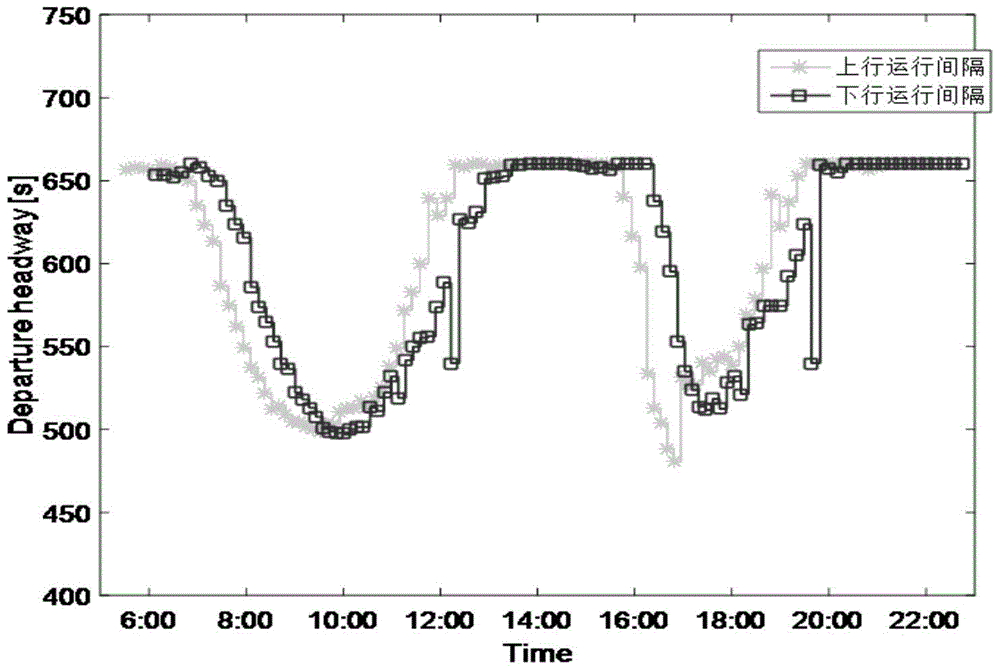

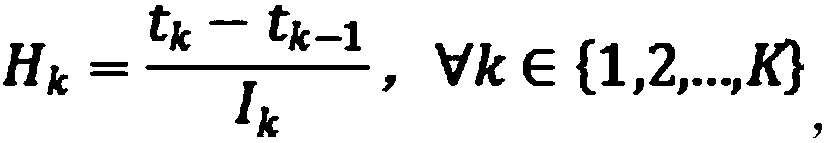

Automatic compilation method for passenger flow demand based train working diagram

ActiveCN105740556AGuaranteed feasibilityReduce operating costsSpecial data processing applicationsSimulationOperational cost reduction

An embodiment of the invention provides an automatic compilation method for a passenger flow demand based train working diagram. The method mainly comprises the steps of establishing a train working diagram optimization model according to basic parameters and passenger flow information, wherein the train working diagram optimization model includes a train cyclic working model, a train arrival and departure moment calculation model, a train sequential constraint model, a train load factor calculation model and a target function model; and solving the train working diagram optimization model by adopting a dual-layer planning algorithm combining a heuristic algorithm with nonlinear planning to obtain the passenger flow demand based train working diagram. According to the embodiment of the invention, high and low-peak time periods and corresponding intervals do not need to be pre-specified and the train working interval is automatically changed along with the passenger flow demand; and the automatically compiled train working diagram can meet constraint conditions of turn-back time, an available vehicle number, a load factor and the like, the feasibility of the working diagram is ensured, and on the premise of meeting the passenger flow demand, the operation cost is reduced and the working diagram compilation efficiency can be greatly improved.

Owner:BEIJING JIAOTONG UNIV

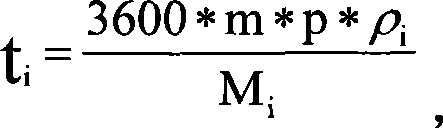

Method for implementing auto making city rail train diagram

InactiveCN101388050ARun Interval BalanceImprove preparation efficiencySpecial data processing applicationsEngineeringTerminal time

The invention relates to a method for realizing automatically compiling train working diagrams of the urban rail train, which comprises configuring basic parameters required by compilation, configuring ideal running intervals of each time period in one day, adjusting ranges of the time periods, determining starting time and terminal time of each running line, pre-connecting the running lines, regulating the starting point according to the number of rolling stock, compiling running lines of entering / exiting the garage of the train, and then diagramming a train working diagram. Compared with the prior art, the method has the advantages that, by regulating the time periods into integral multiple of the running intervals, the balance of diagramming transient running line of the peak hours and the non-peak hours is guaranteed, further, the compiling software is enabled to automatically diagram urban rail train working diagrams with balanced running intervals and capability of furthest meeting requirements of passenger flow in various time periods under restriction of conditions of the number of rolling stock, reentrant time, reentrant mode and the like, thereby significantly increasing the compiling efficiency of train working diagrams to be adaptable to requirements of train working diagram regulation along with variation of passenger flow, technical equipments and transport organizing methods.

Owner:CASCO SIGNAL

Inner wall spraying robot system and inner wall spraying method

ActiveCN101602034AEasy to movePrecise positioningLiquid surface applicatorsSpraying apparatusEngineeringControl theory

The invention discloses an inner wall spraying robot system and an inner wall spraying method. The system comprises a robot and an air cushion transport vehicle, wherein the robot is used for finishing the spraying work; the robot comprises a spray gun, a crank arm, a telescopic arm and a base, which are connected in turn; the sum of freedom degrees of the spray gun, the crank arm, the telescopic arm and the base is not less than 6; and the robot is arranged on the air cushion transport vehicle, the air cushion transport vehicle comprises an air bag positioned at the bottom thereof, and the air bag is used for floating the air cushion transport vehicle so as to coarsely position the system before the system enters a working area. The technical proposal of the invention realizes spraying work for the inner wall of a special-shaped long and narrow pipeline through multi-redundant freedom degree design for the robot, and improves the efficiency of preparation work before the spraying work.

Owner:TSINGHUA UNIV +1

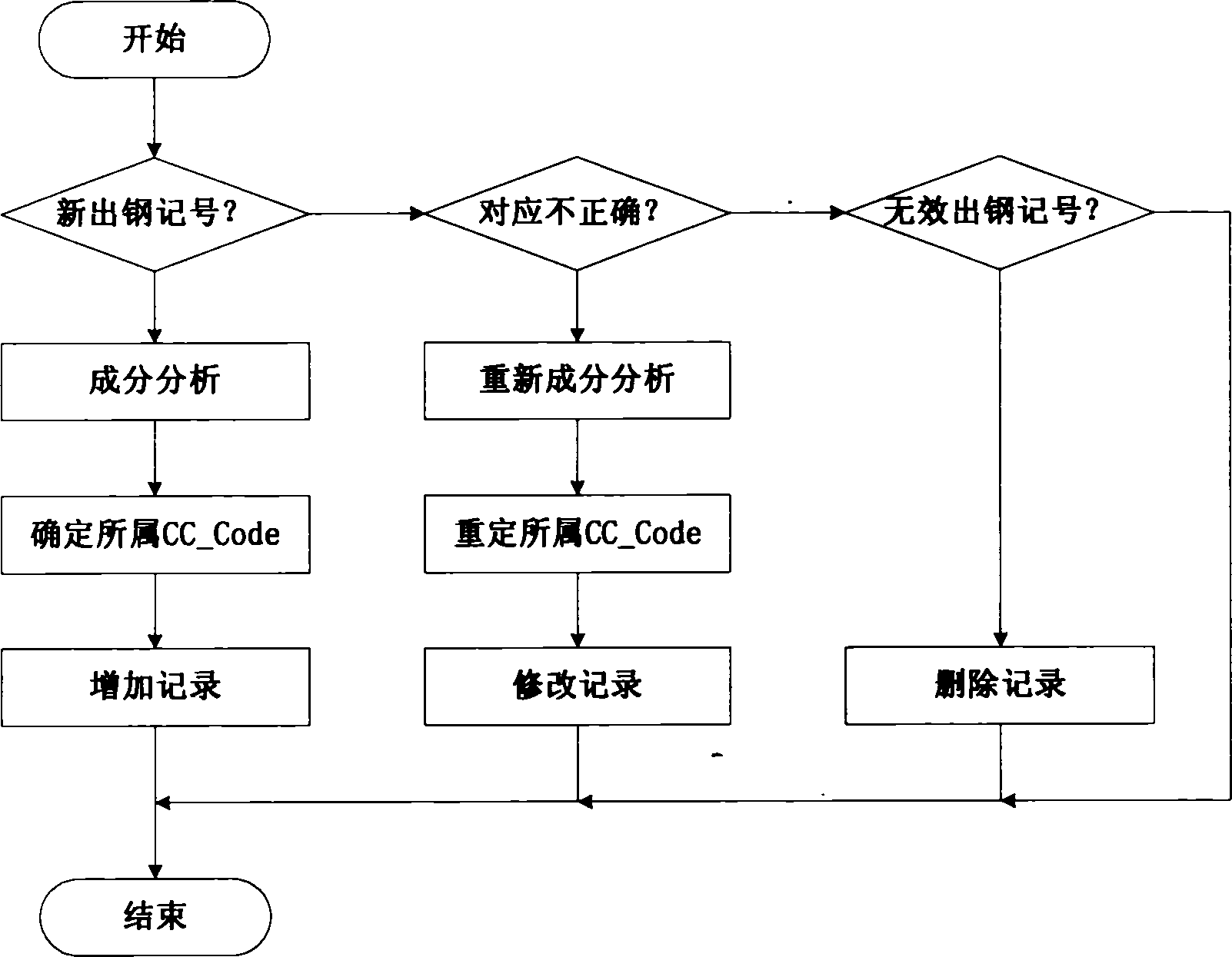

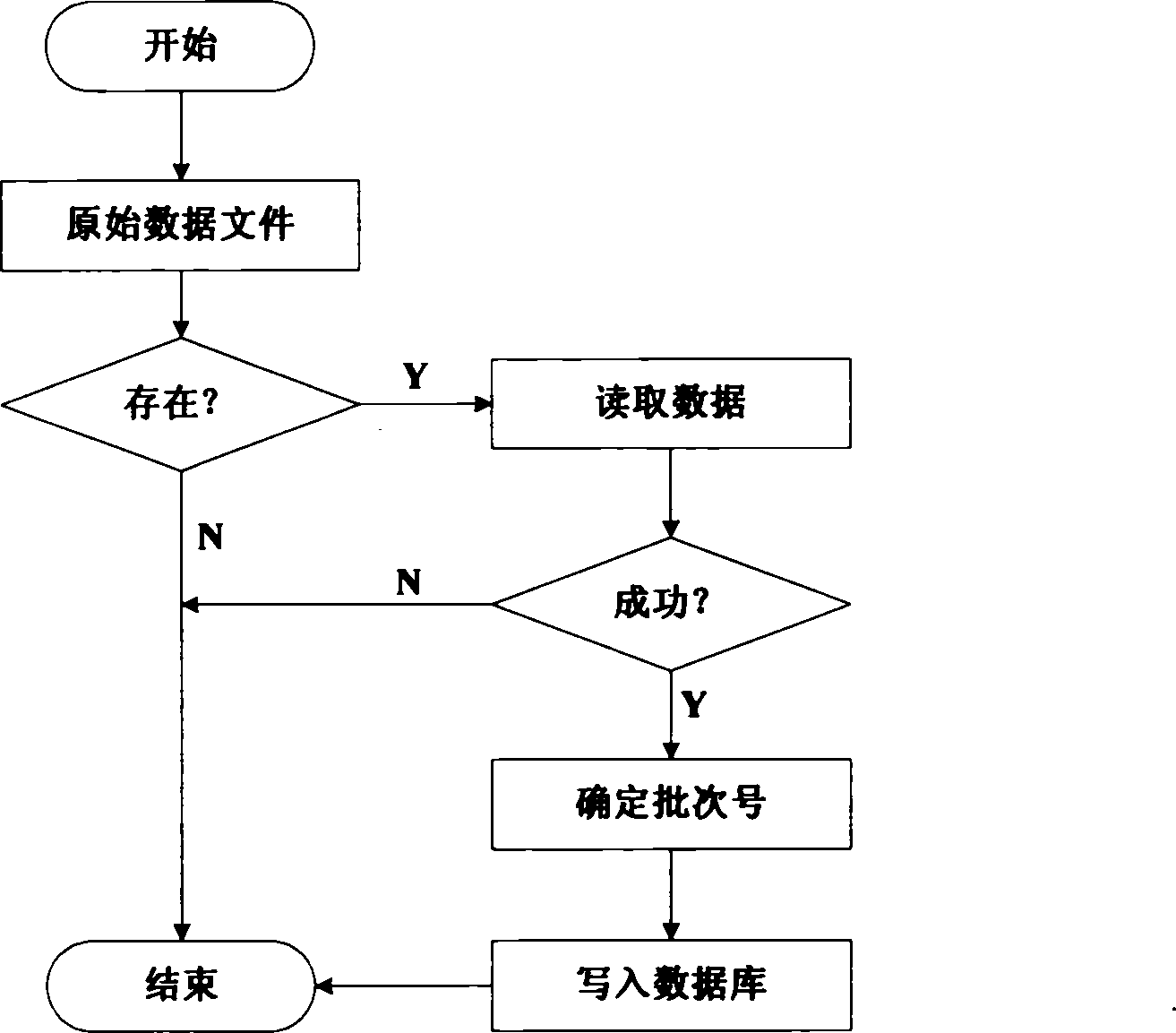

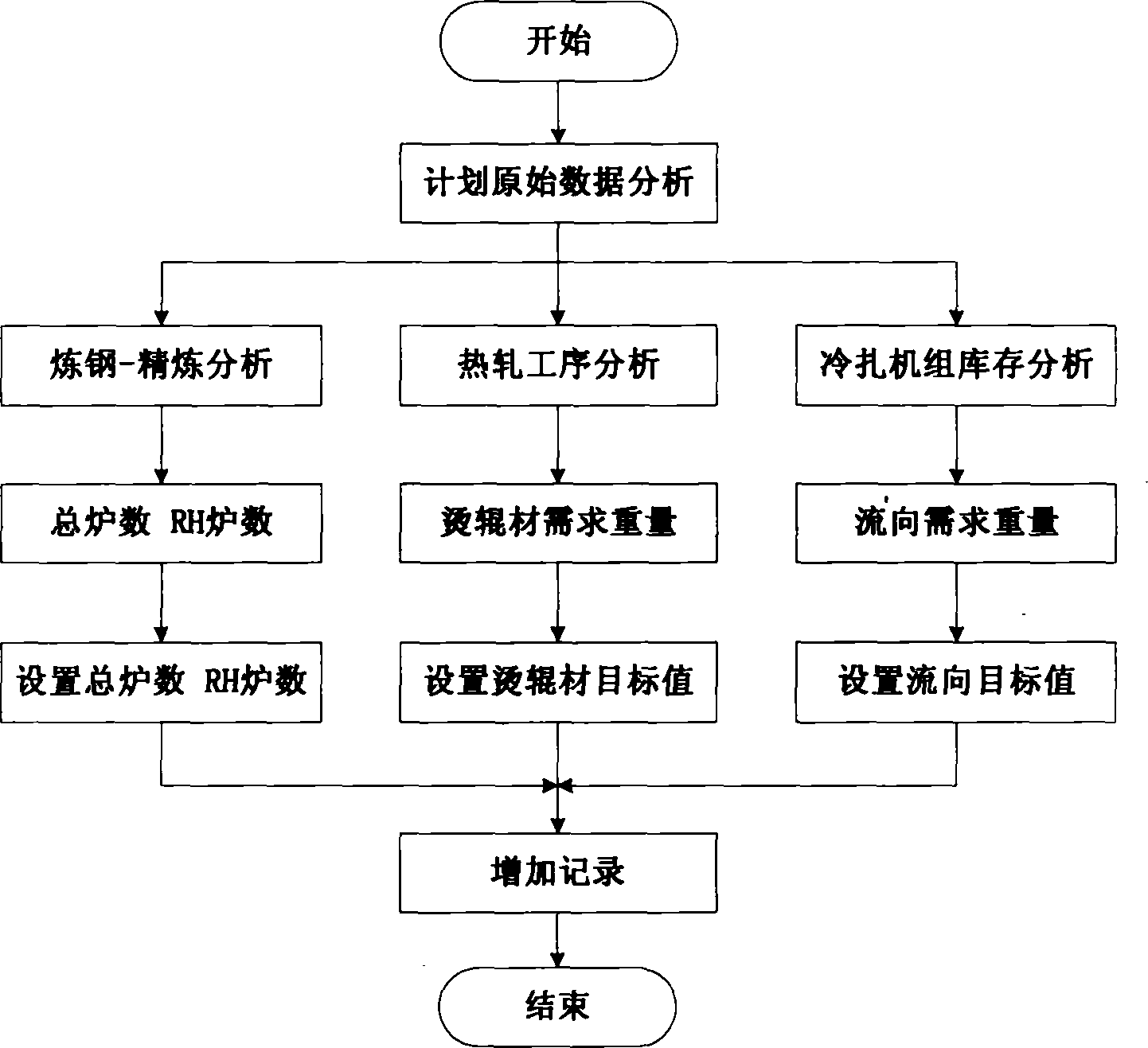

Steelmaking-continuous casting tundish batch plan method and system

The invention relates to a steel-smelting-continuous casting middle pack batch plan and relative system, wherein said system comprises arc static parameter setting module, original data download module, batch plan demand setting module, model algorism parameter setting module, middle pack batch plan automatic generating module, plan index stat display module, plan result stat display module, producing plan artificial adjusting module, and producing plan upload module. And said method uses middle pack batch plan math model, uses two-stage multi nearby field forbidden search algorism, to fix how the furnace time is batched into the middle pack to realize multi-furnace continuous casting, to maximize the casting number, and reduce the cost. The invention can improve the plan efficiency, reduce labor density, improve plan quality and optimize production.

Owner:NORTHEASTERN UNIV

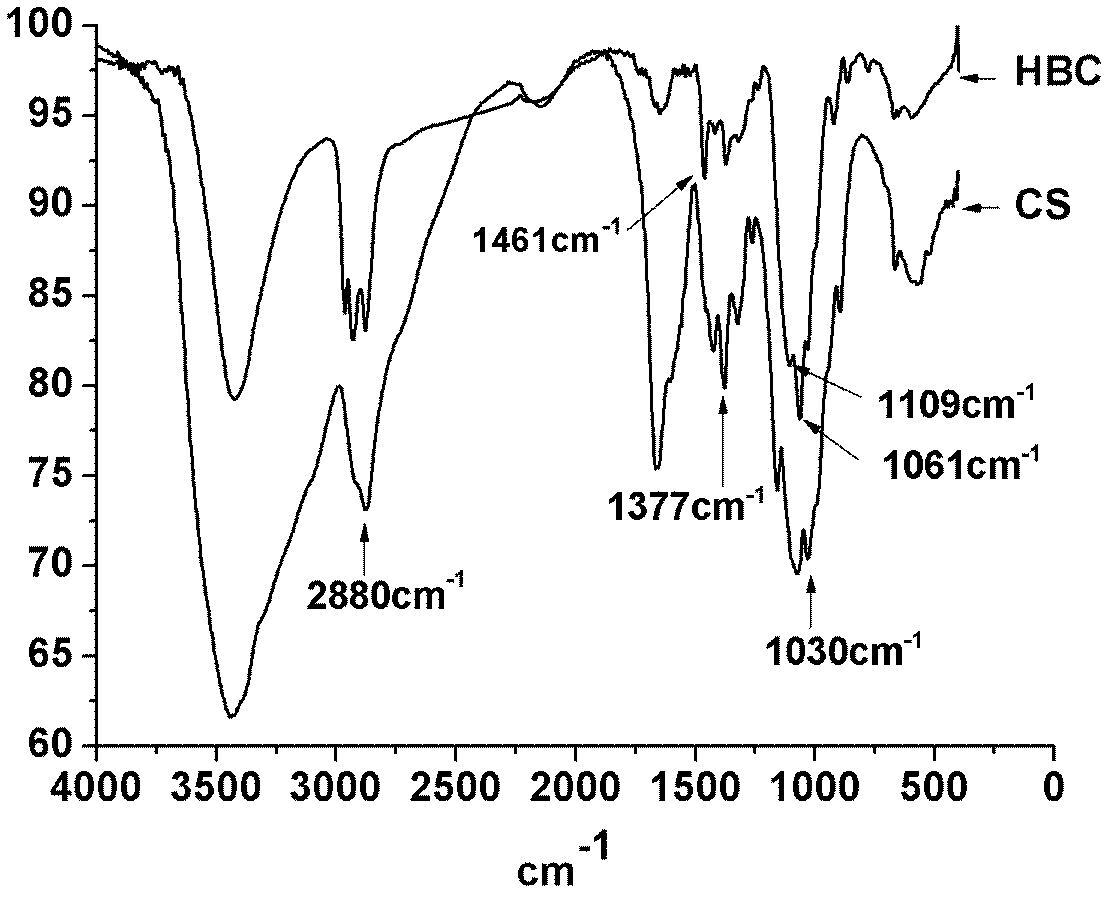

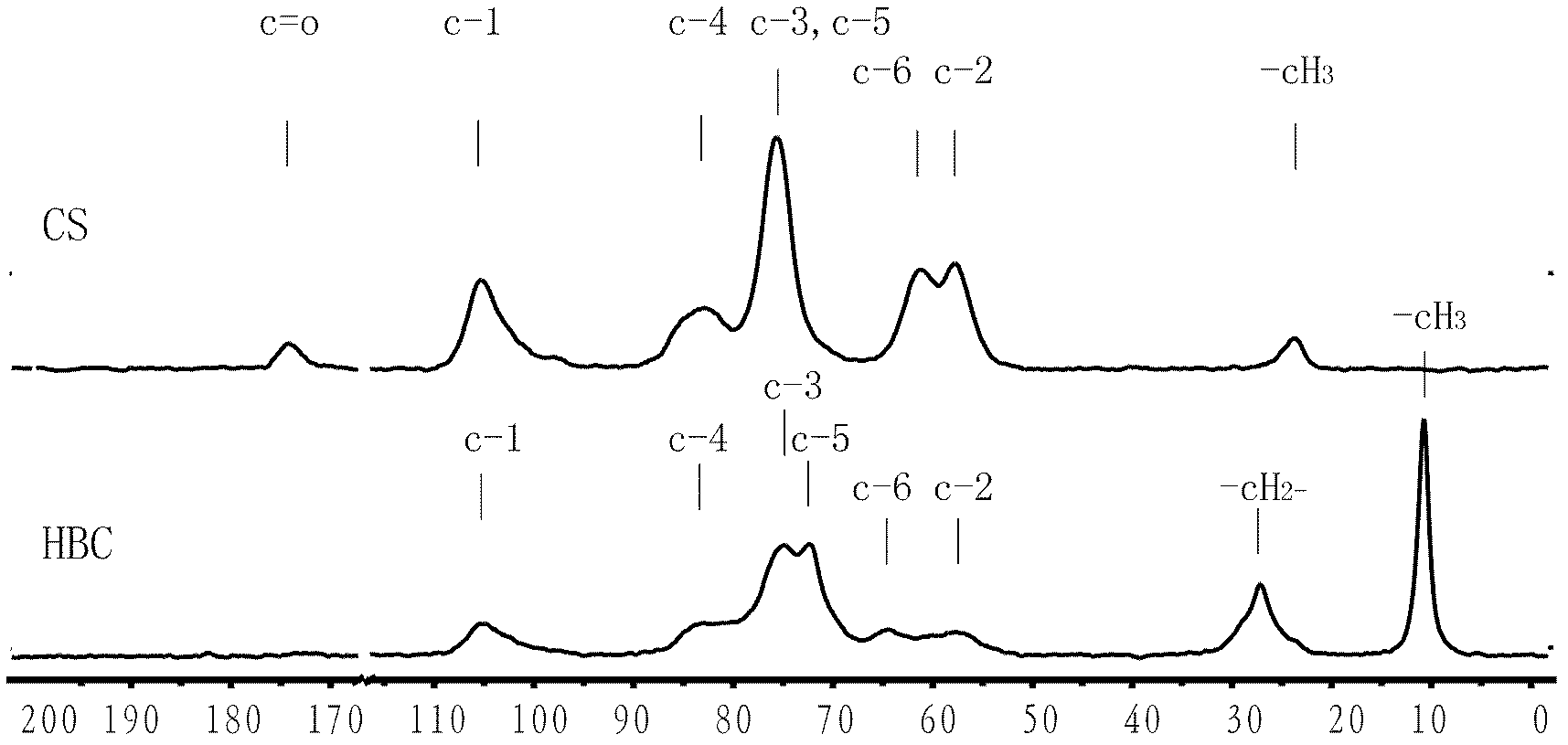

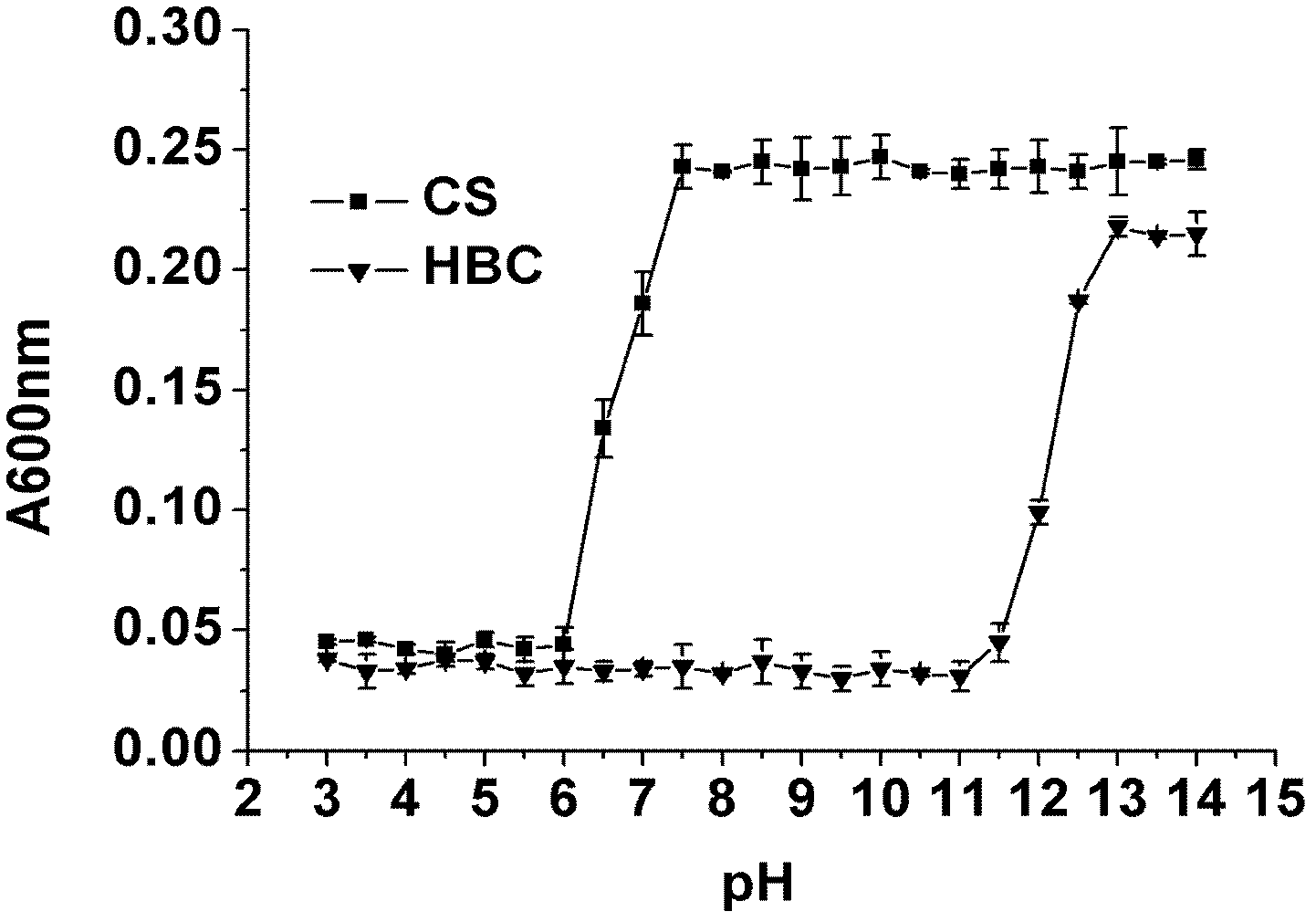

A kind of preparation method of chitosan hydroxybutyl derivative

ActiveCN102276756AShort preparation cycleImprove preparation efficiencyMicrowave - actionChitosan derivative

The invention relates to a preparation method of a chitosan hydroxybutyl derivative. Chitosan is used as a raw material; 1,2-epoxybutane is used as an etherifying agent; the hydroxybutyl modification of the chitosan is performed in an isopropanol aqueous solution dispersion system under microwave action with controlled reaction temperature and time; a chitosan derivative, hydroxybutyl chitosan, is successfully prepared; the preparation period is greatly shortened, and the preparation efficiency is increased. During the reaction, the hydroxybutyl modification of the chitosan is performed orderly under the microwave action and with controlled reaction temperature and time, which shortens the preparation period. The product has a wider pH dissolution range, and has a soluble property in weakacid, neutral, and weak alkaline aqueous solutions, that is to say, the limitation that chitosan is only soluble in acids or acid solutions is improved; the aqueous solution of the product has temperature sensitivity, can be transformed between an aqueous solution and hydrogel by adjusting the temperature; and the product is widely applicable to fields of biomedicine, tissue engineering, pharmaceutical carriers, chemical engineering, food, cosmetics, etc.

Owner:惠众国际医疗器械(北京)有限公司

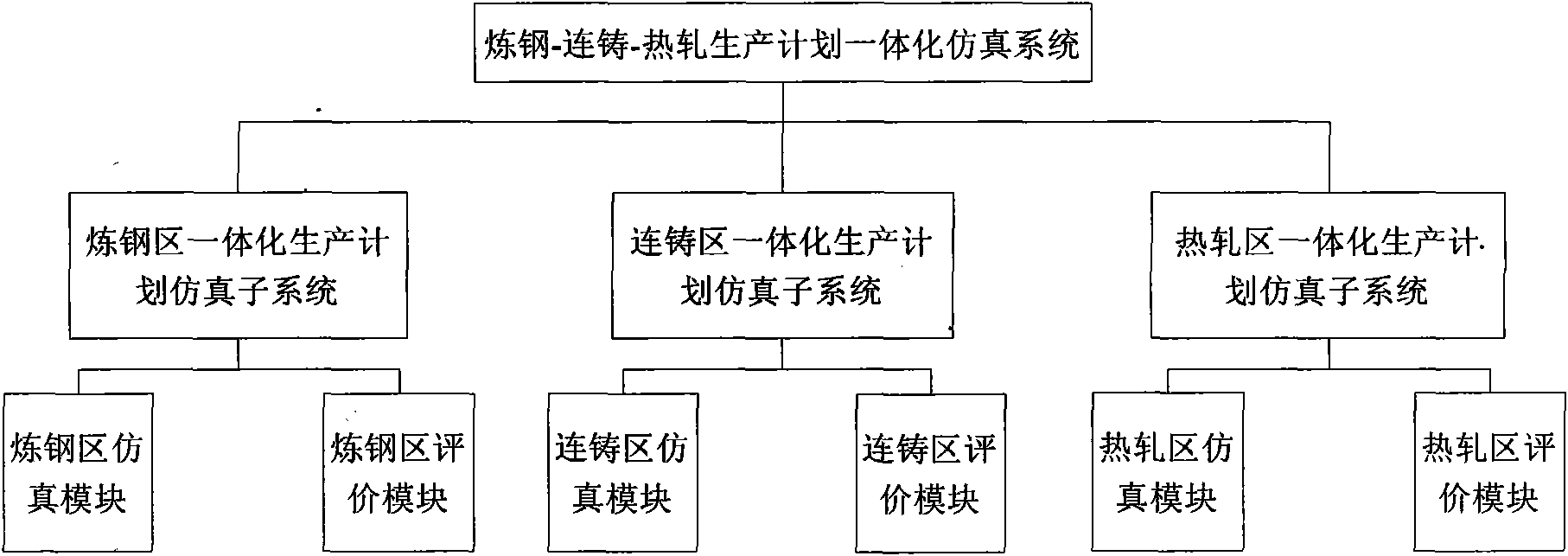

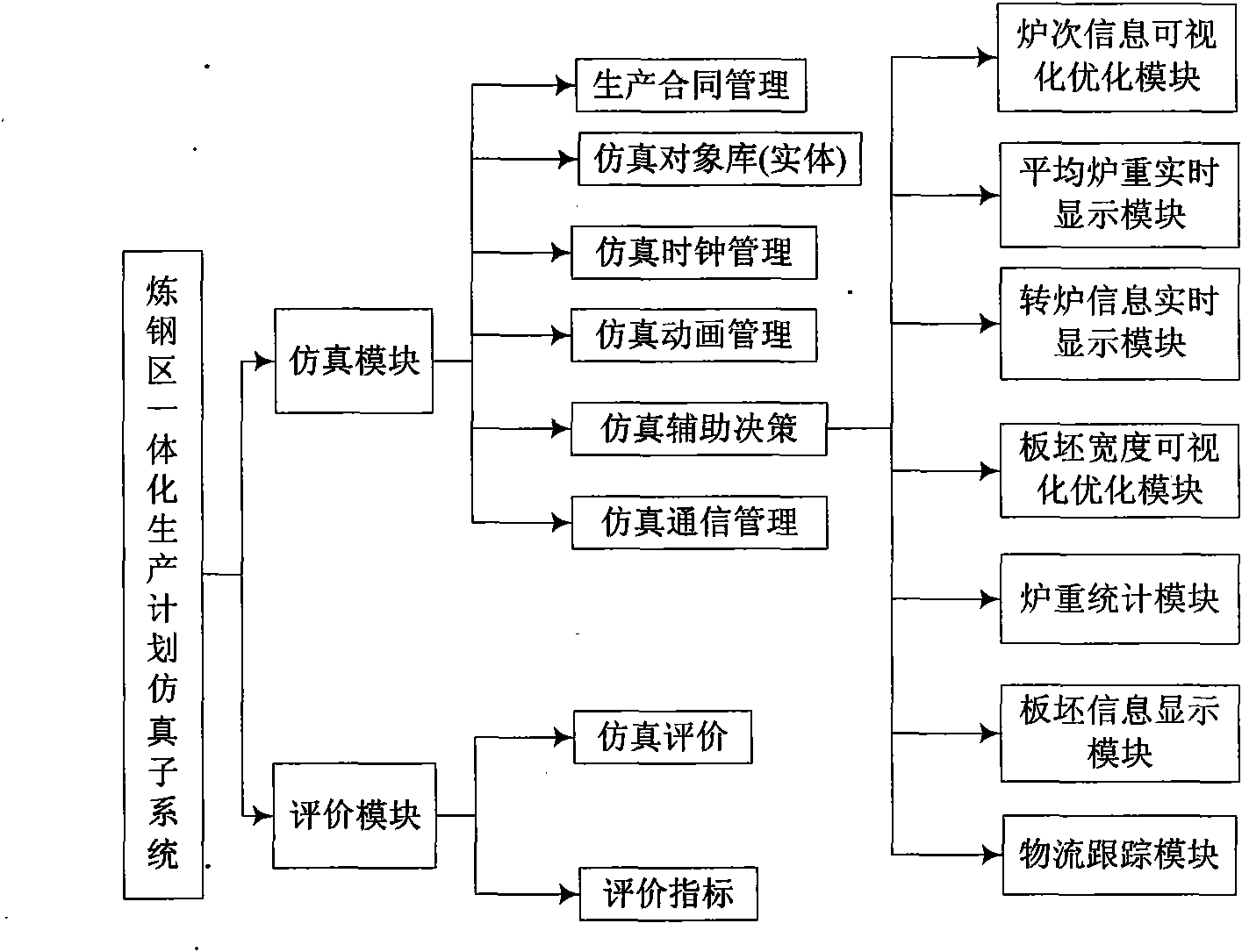

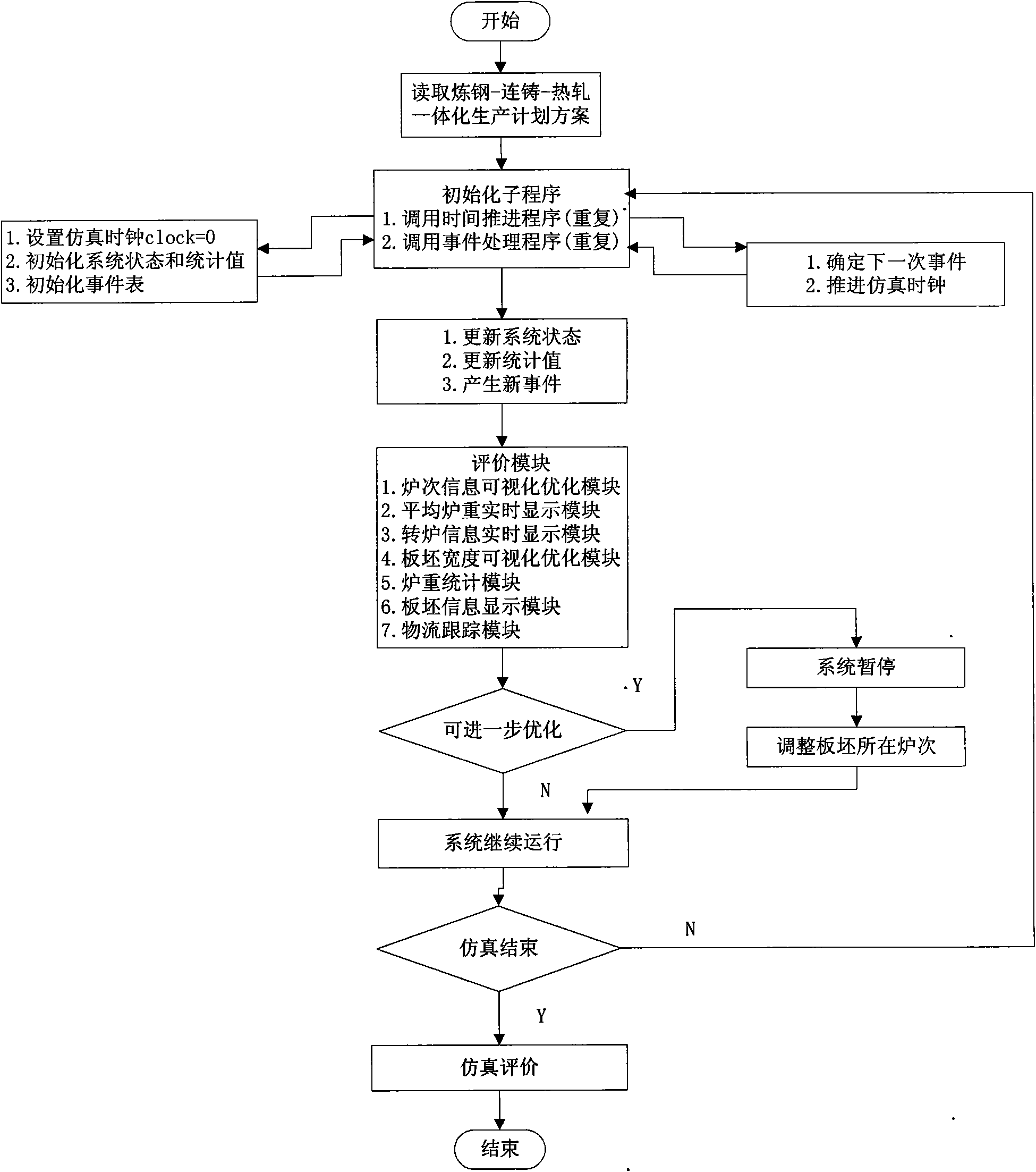

Integrative simulation system of production plan of steel making, continuous casting and hot rolling

InactiveCN101604145AImprove preparation efficiencyQuality improvementSimulator controlMaterials scienceContinuous casting

The invention relates to a simulation system of an integrative production plan of steel making, continuous casting and hot rolling, belonging to the technical fields of manufacture and automatization and comprising an integrative production plan simulation subsystem of a steel making area, an integrative production plan simulation subsystem of a continuous casting area and an integrative production plan simulation subsystem of a hot rolling area, wherein a simulation module of the steel making area reads a production plan scheme of the steel making area and simulates and imitates an actual production procedure of the steel making area in the process of steel making, a simulation module of the continuous casting area reads a production plan scheme of the continuous casting area and is used for simulating and showing an actual production procedure of the continuous casting area in the process of steel making, and a simulation module of the production procedure of the hot rolling area reads a production plan scheme of the hot rolling area, comprises a subjection relationship of a temporary entity equipment plate blank and each equipment and simulates an actual production procedure of the hot rolling area in the process of steel making. The invention simulates the integrative production process of the production plan of steel making, continuous casting and hot rolling, enhances the quality of planning and optimizes the production execution.

Owner:NORTHEASTERN UNIV

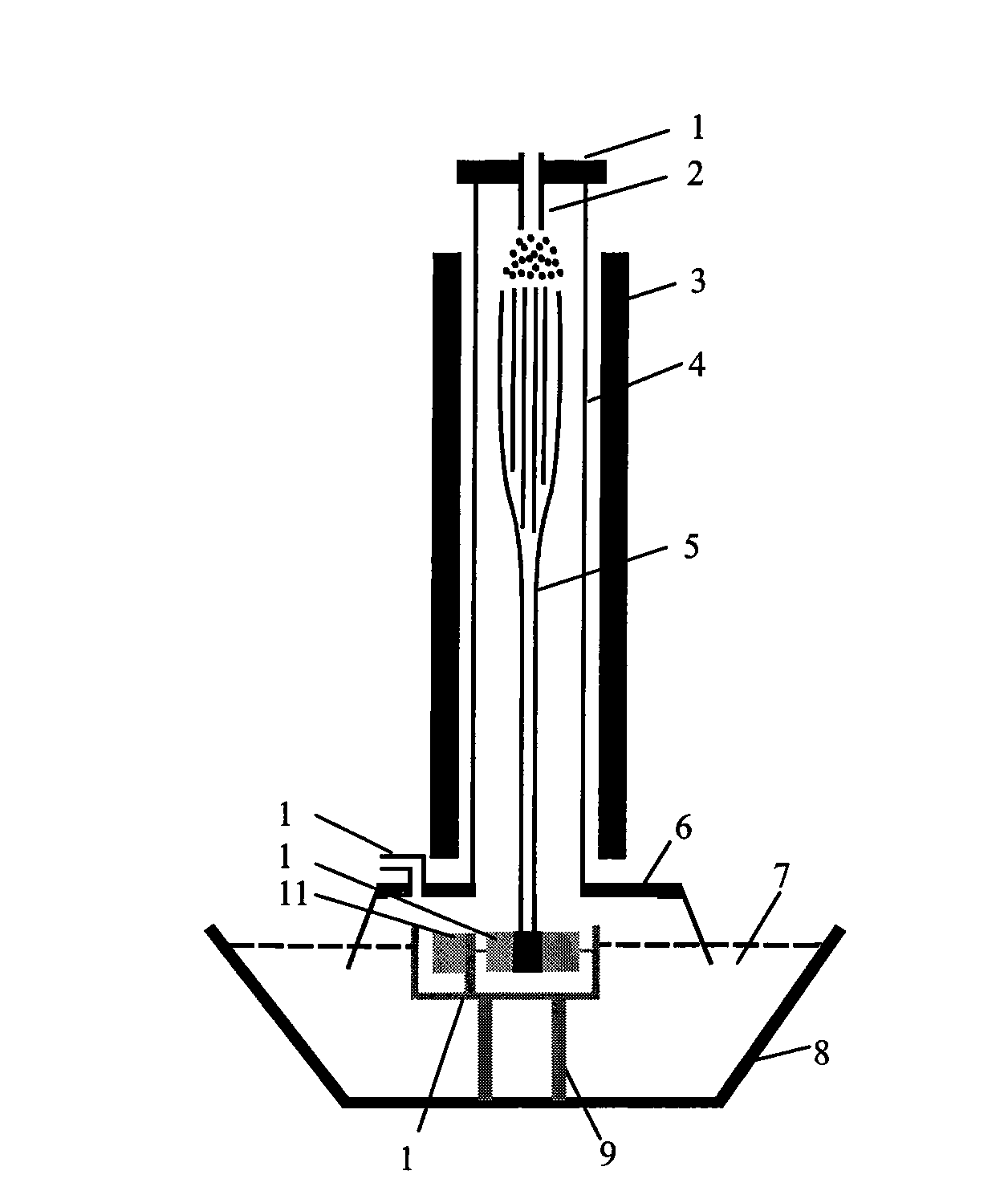

Method and device for preparing carbon nanotube film

InactiveCN101665247AImprove preparation efficiencyThe reaction equipment is simpleElectrically conductiveTube furnace

The invention relates to a method and a device for preparing a continuous transparent conductive carbon nanotube film. In the device, a water tank is connected with a quartz tube in a tubular furnacevia water seal chemical vapor reaction; a spindle shaft of a spindle film is installed on a seal water surface and rotates driven by a motor; the spindle shaft and the motor can be mounted in a smalltrough or on a bracket of the water surface; the mixed solution of ethanol, ferrocene and thiofuran are injected in a carrier gasflow of H2 with the speed of 200-4000ml / min to react at a high temperature of 900-1600 DEG C; the tubular continuous carbon nanotube film synthesized by reaction is spinned by the spindle shaft, and the spinned carbon nanotube film can be resolved; the size of the carbontube film is correlated to the size of the reactor, and the size of the carbon tube film can be adjusted by adjusting the reaction parameter as for special reactors; and the continuous transparent conductive carbon nanotube film of different structures can be prepared by altering the chemical mixture ratio of the reacted solution. The invention ensures that the continuous transparent conductive carbon nanotube film can be prepared in one step, has high preparation efficiency and simple reaction devices, and is suitable for large-scale production of carbon nanotube films.

Owner:TIANJIN UNIV

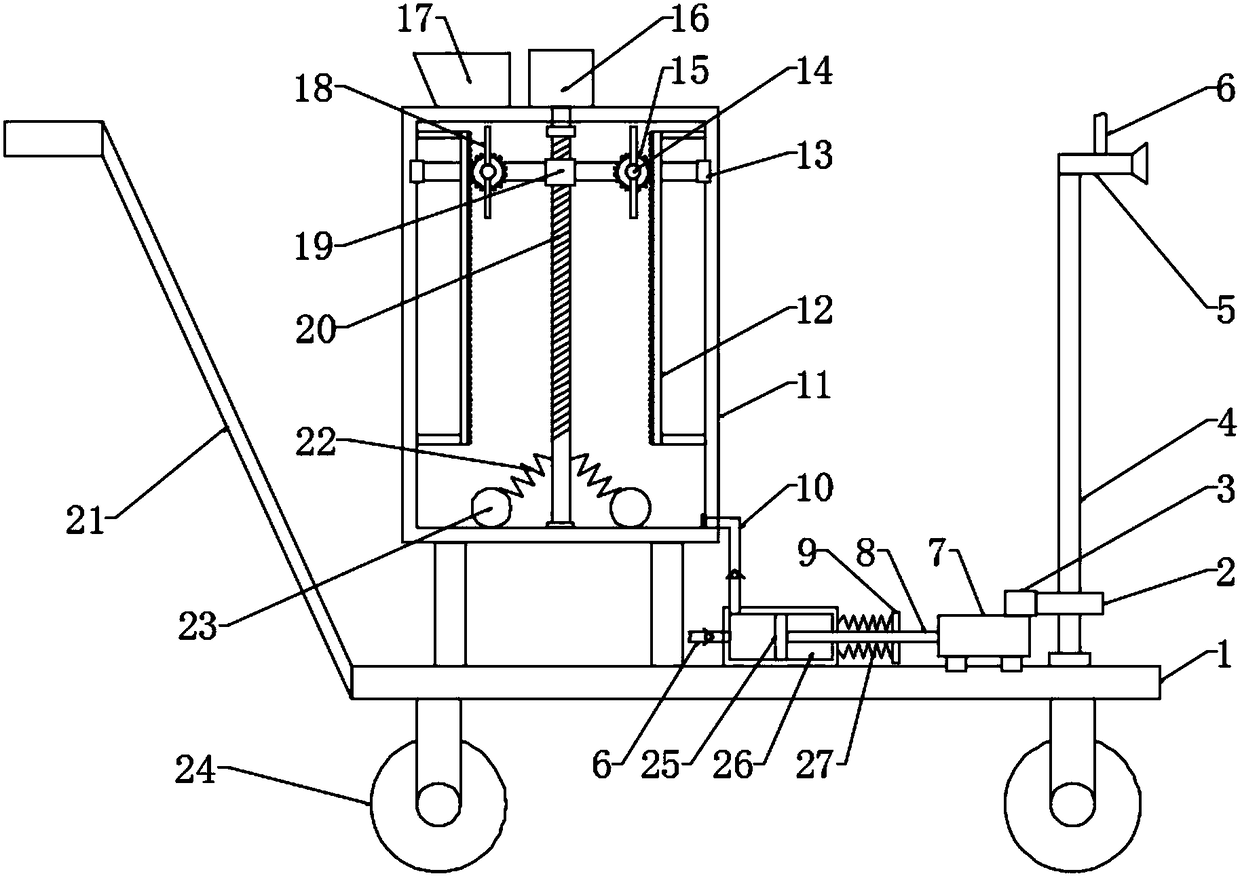

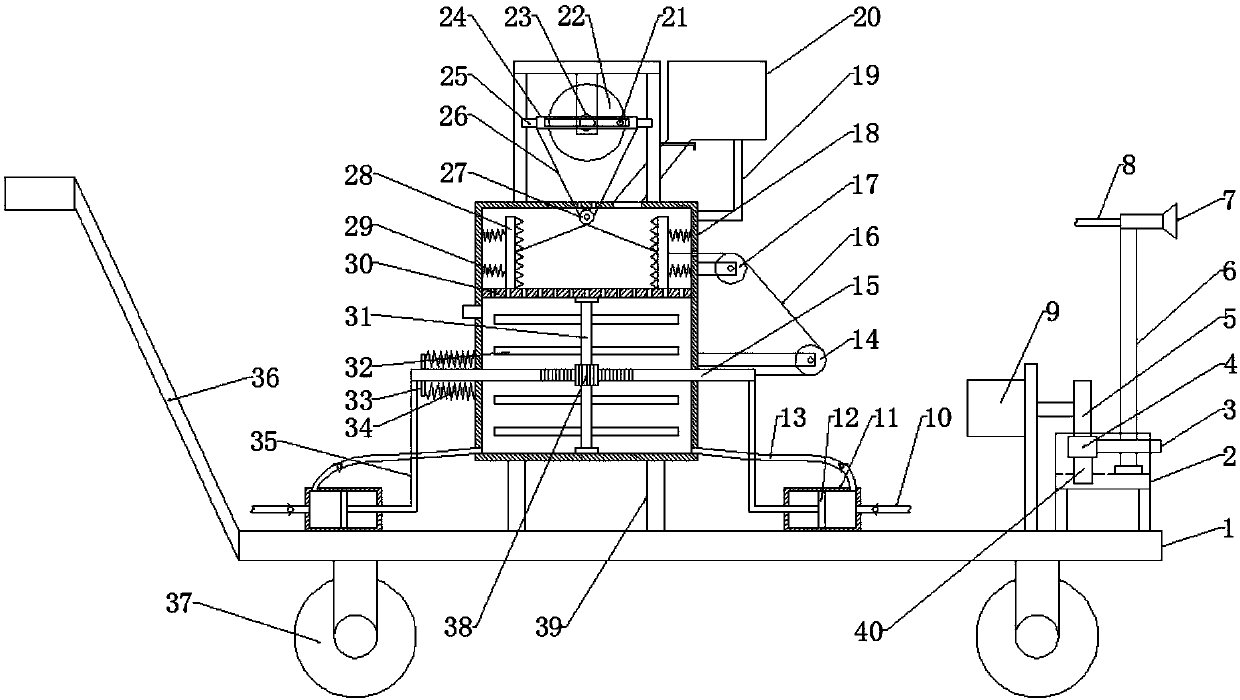

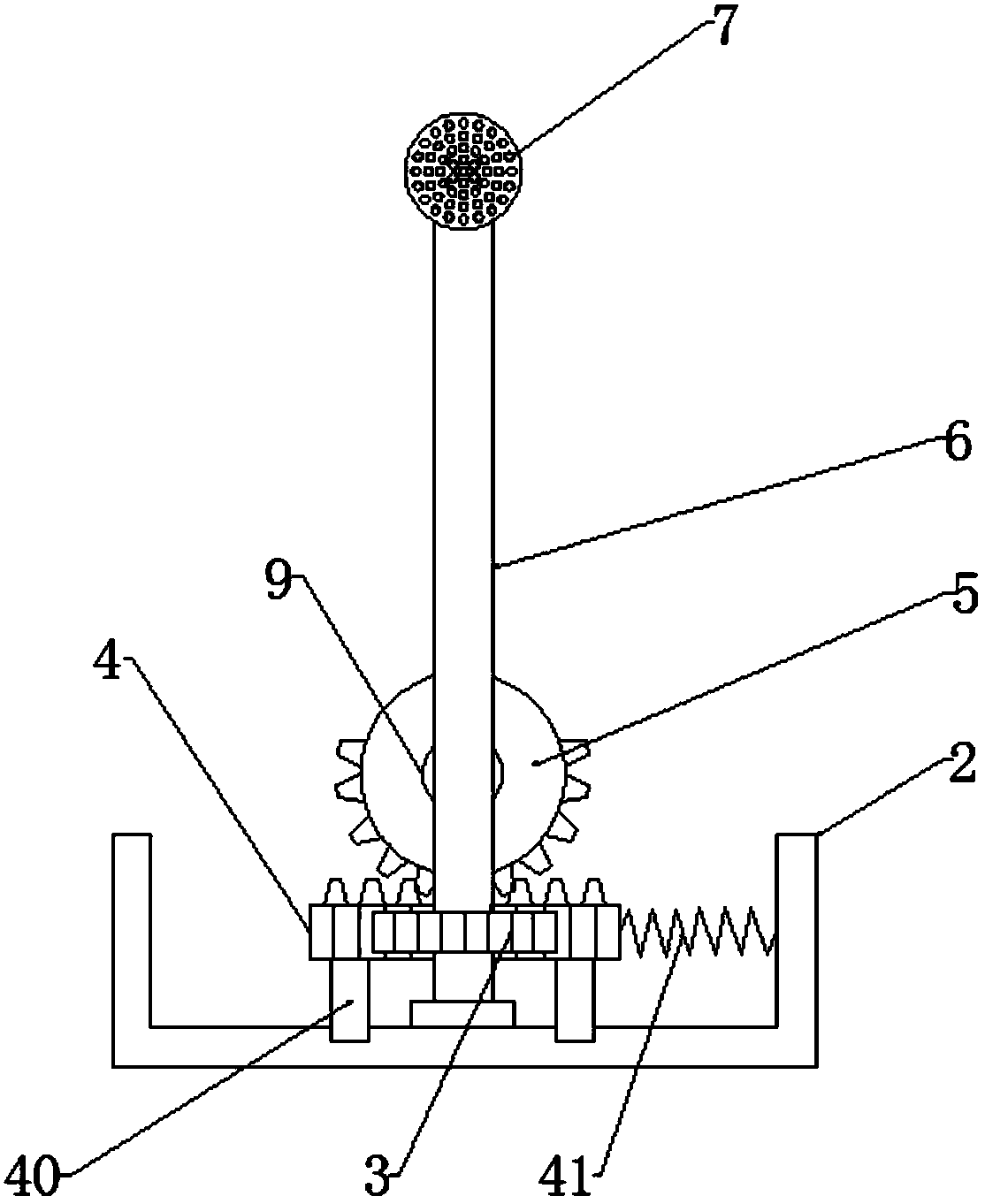

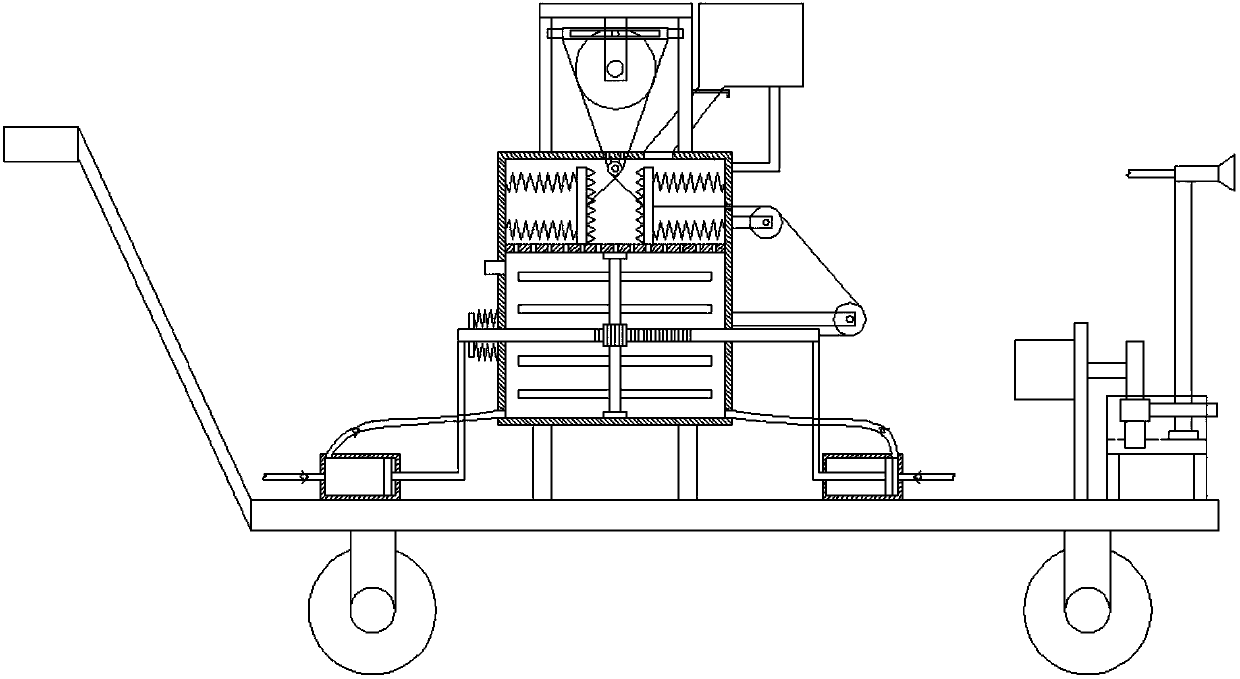

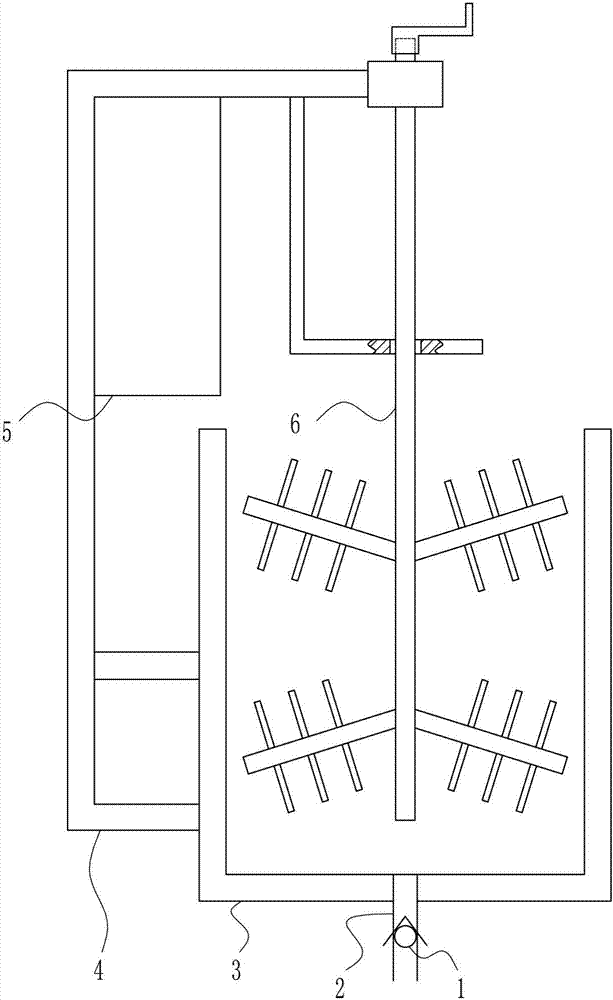

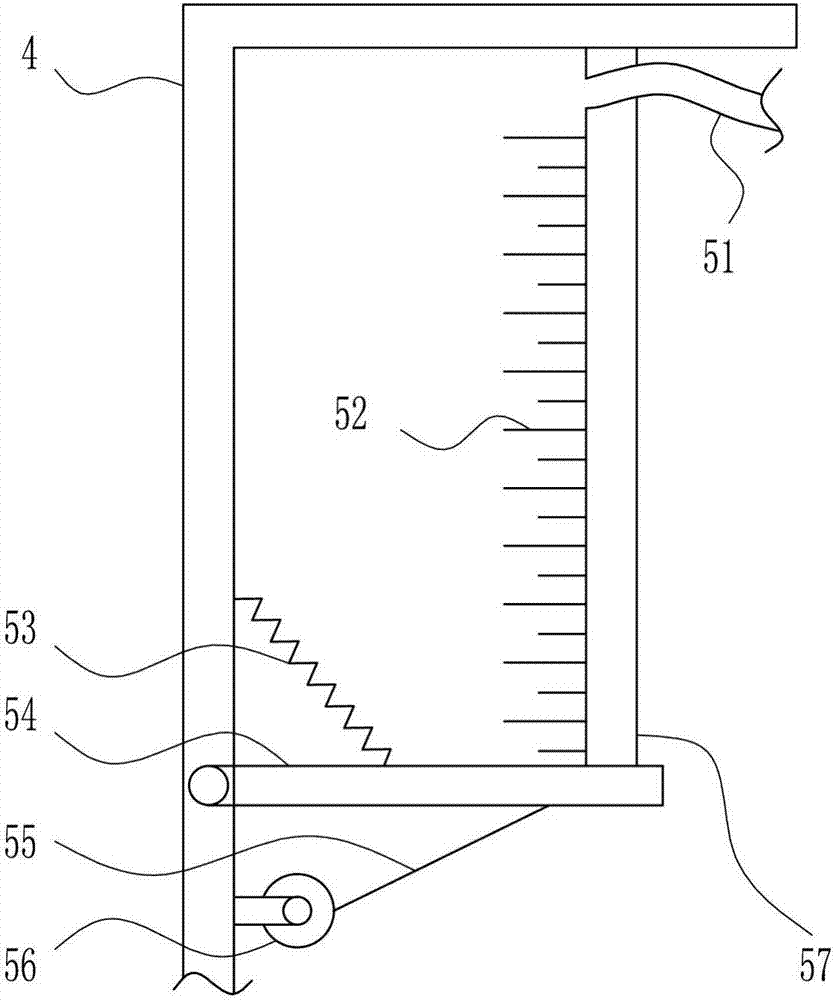

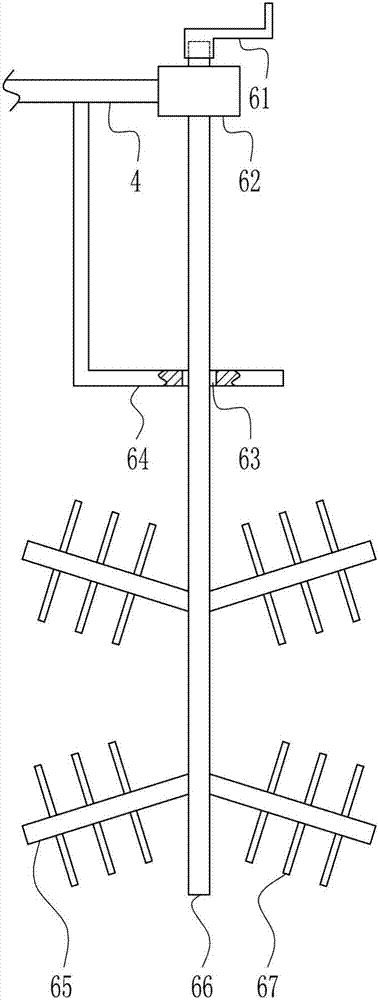

Garden greening efficient watering and fertilization integrated device

InactiveCN108077036AStir wellImprove preparation efficiencyShaking/oscillating/vibrating mixersTransportation and packagingSprayerGear wheel

The invention discloses a garden greening efficient watering and fertilization integrated device which comprises a bottom plate, a water and fertilizer box, a motor, a threaded rod, a sleeve, a firstrotating shaft, a first gear, a first rack, a stirring rod, a first spring, a grinding ball, a movable cam, a cylinder, a piston rod, a second spring, a pulley, another movable cam, an electric push rod, a second rotating shaft, a sprayer, a second gear and a second rack. By coordination of the motor, the sleeve, the threaded rod, the first gear, the first rack, the first spring and the grinding ball, the stirring rod is driven to vertically move and continuously rotate, water and solid fertilizers are sufficiently stirred, so that the solid fertilizers are more effectively dissolved in the water, and the preparation efficiency of water and fertilizer solution is improved. By coordination of the electric push rod, the movable cams, the piston rod, the cylinder, the pulley, a piston and thesecond spring, the sprayer is driven to continuously rotate forwards and reversely, spraying range is widened, and working efficiency is improved.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

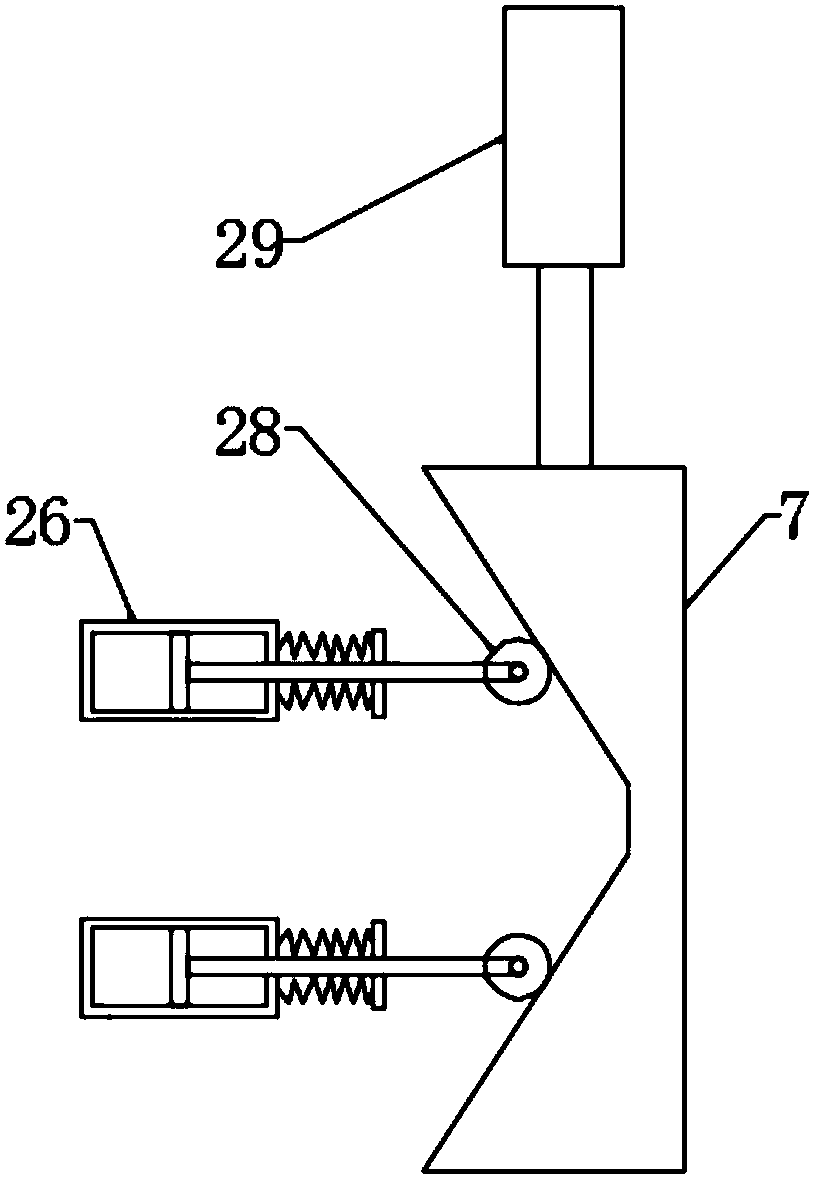

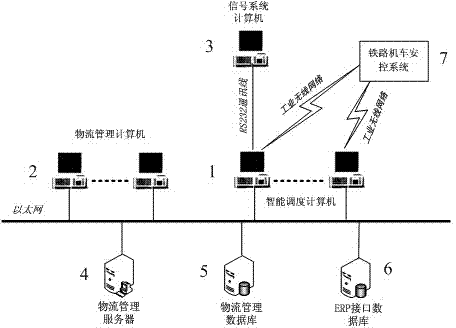

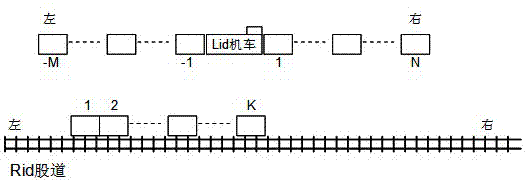

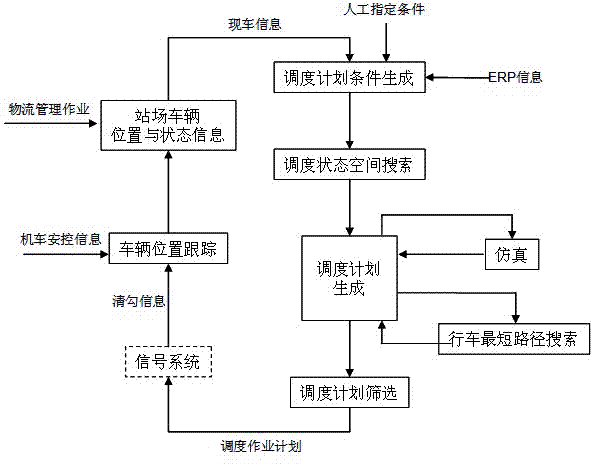

Dispatching plan generating method of industrial railway logistics intelligent dispatching system

ActiveCN103366262AGuaranteed preparation qualityFully automatedLogisticsRail transportationSignalling system

The invention relates to an industrial railway intelligent dispatching system and a dispatching plan generating method thereof. The system comprises an intelligent dispatching computer, a logistics management computer, a signal system computer, a logistics management server, a logistics management database, an ERP (Enterprise Resource Planning) interface database and a railway locomotive security system, and functional modules comprise four parts, i.e. a dispatching plan condition generating module, a dispatching state spatial search module, a dispatching plan generating module and a dispatching plan screening module. The intelligent dispatching computer, the logistics management computer, the logistics management server, the logistics management database and the ERP interface database are mutually communicated through the Ethernet, RS232 communication is adopted between the intelligent dispatching computer and the signal system computer, and the intelligent dispatching computer and the railway locomotive security system are communicated through an industrial wireless network. The industrial railway intelligent dispatching system and the dispatching plan generating method can realize intelligent dispatching on trains in an industrial railway transportational process.

Owner:HEFEI GOCOM INFORMATION &TECH CO LTD

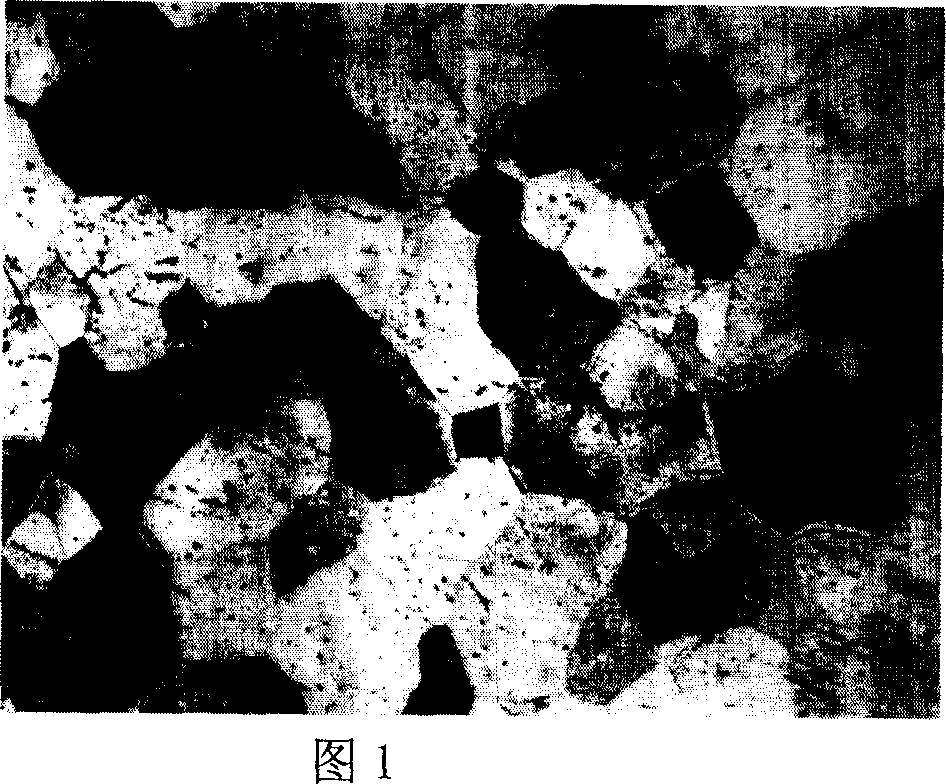

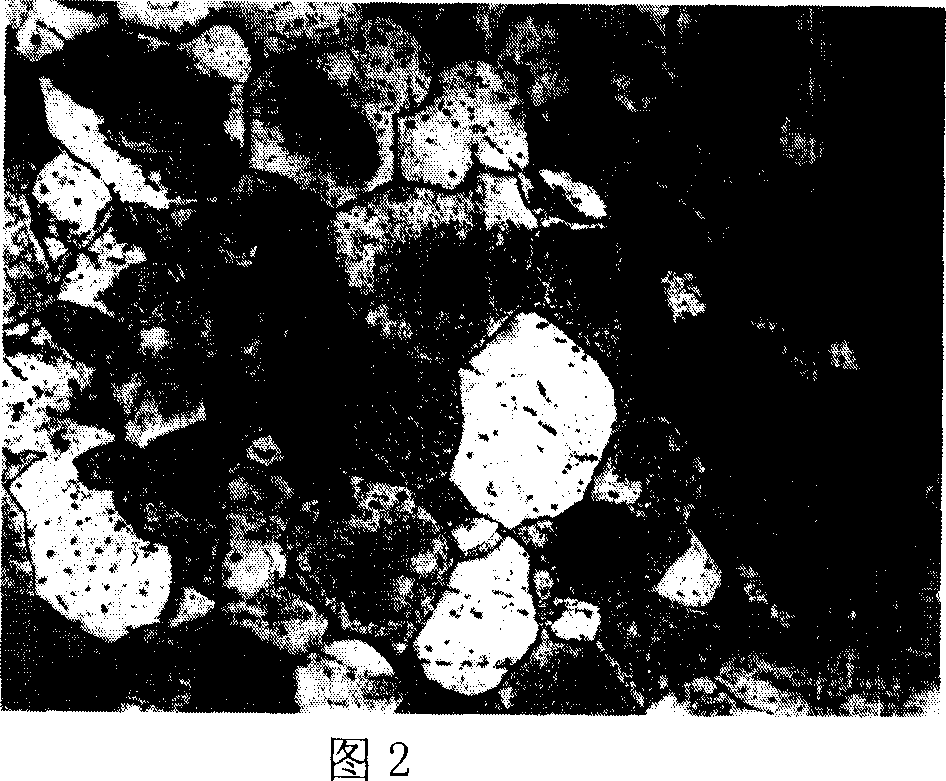

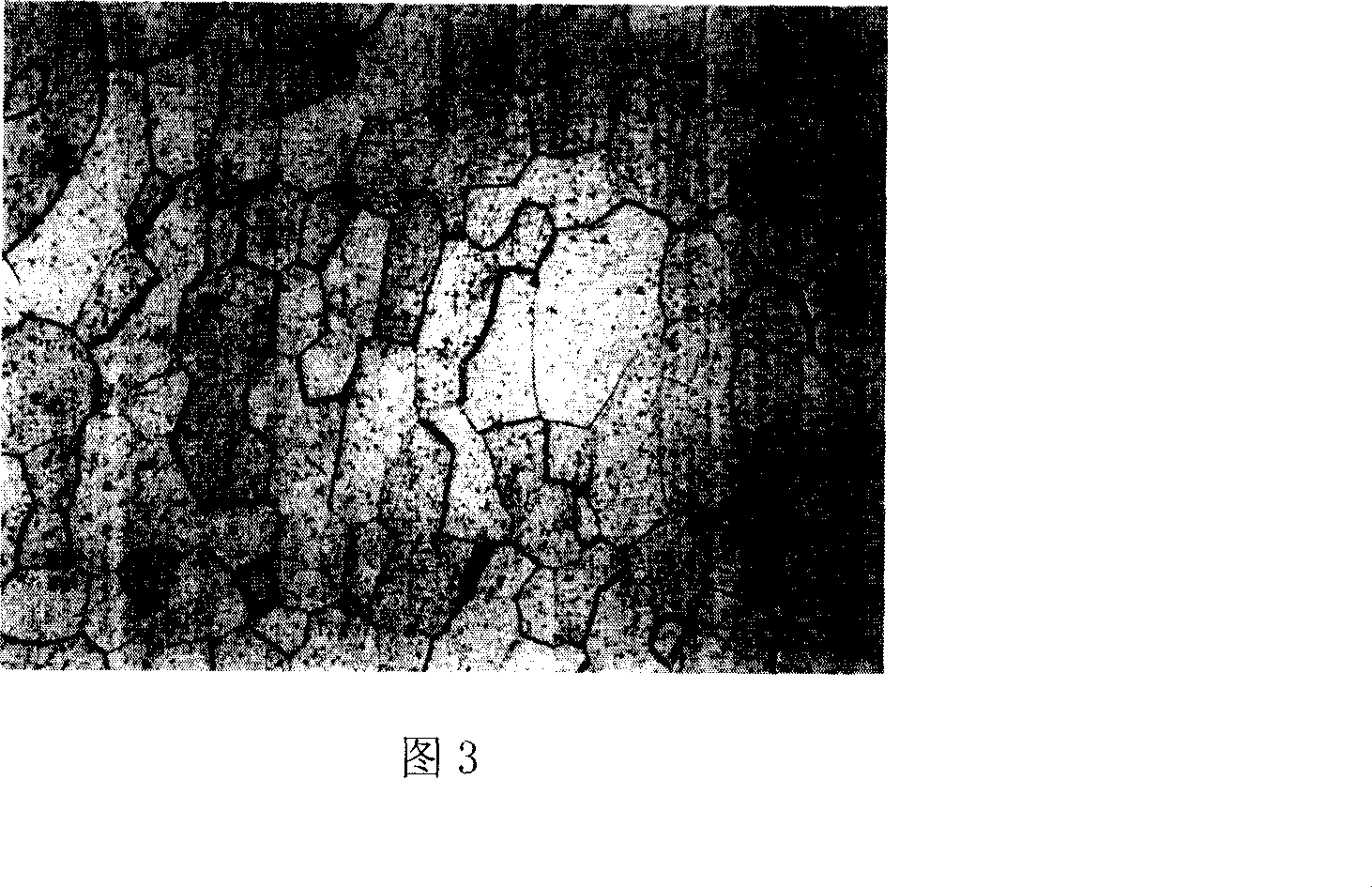

Method for preparing Al-Si-Cu-based alloy metallographic sample and displaying tissue thereof

InactiveCN1967197AImprove preparation efficiencyReduce labor intensityPreparing sample for investigationSilk clothEtching

Preparation of Al-Si-Cu alloy metallography sample and display organize method, it includes the following steps: a. rough grinding: using size reduction water sandpapers in turn, the samples are accomplished at least two times water polished, and after each sandpaper changing rotate 90 degree, until eliminating the scratch of the previous process, and before sandpaper changing, the samples are cleaned with water; b. electrolytic polishing: using the electrolytic polishing machine, polish at least two times, and after each time, rinse and cool with water; c. flannel polishing: samples polish on the single direction with the polishing pasted silk cloth; d. chemical etching: the etchant is dropped on the sample surface, eroded using wipe-mop method. Compared with the existing technologies, the advantages of the invention is to take electrolytic polishing and flannel polishing at the same time, combining chemical corrosion, optimized selecting the etchant of HF:HCl:H2O=2:3:18, to successful prepare metallographic examination samples. It is a high efficiency for sample preparation, low labor intensity, and it is the technology to obtain a very clear and integrity crystal boundary.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Feed for the moulting period of young pigeons

InactiveCN102273552ADecreased palatabilityImprove palatabilityAnimal feeding stuffSesamum orientaleAnimal science

The invention provides a feed for the moulting period of young pigeons, which is composed of the following raw materials (weight ratio): 18-22% of corn, 22-25% of peas, 3-5% of mung beans, 8-12% of barley, wheat 7-10%, rapeseed 8-12%, sesame 8-10%, sunflower 6-8%, yellow sand 4-6%, salt 2-3%, binder 0.5-1%, appropriate amount of green feed. As a further improvement, by adding green feed rich in vitamins and trace elements, it is nutritious and disease-resistant, and can also provide water for young pigeons. The invention is characterized by good palatability, comprehensive nutrition, obvious health care and disease prevention functions, simple operation and good palatability. And improve the nutritional value and deliciousness of meat pigeons.

Owner:赵建芸

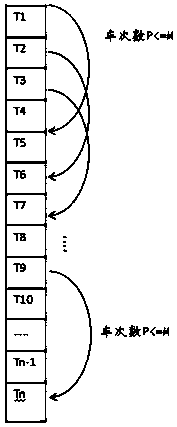

Automatic compilation method of train working diagram based on underbody duplexing

ActiveCN107284480AImprove preparation efficiencyGuaranteed feasibilityInternal combustion piston enginesRailway traffic control systemsReturn timeOperational cost reduction

The embodiment of the invention provides an automatic compilation method of a train working diagram based on underbody duplexing, and relates to the technical field of train running control. The automatic compilation method includes steps of configuring basic parameters for compiling the train running diagram; configuring a train operation plan according to the basic parameters; building up an optimal model of the train working diagram according to the basic parameters and the train operation plan; applying a mixed integer linear planning algorithm to solve the optimal model of the train working diagram, and acquiring the train working diagram based on the number of the underbody in operation. The method improves the compilation efficiency of the working diagram; the automatically compiled train working diagram can meet the returning time, safety interval, train order, underbody use, and other restriction conditions, guarantee the feasibility of the working diagram, reduce the operation cost, and decrease the passenger waiting time; besides, the method can meet the demand of frequent adjustment of the train working diagram under a refined management of an urban rail system.

Owner:BEIJING JIAOTONG UNIV

Efficient watering and fertilization device for agriculture

InactiveCN107580847AIncrease profitImprove preparation efficiencyPressurised distribution of liquid fertiliserGear wheelAgricultural engineering

The invention discloses an efficient watering and fertilization device for agriculture. The device comprises a base plate, a box, a first motor, a disc, a movable rod, a fertilizer hopper, a crushingplate, a first spring, a first haulage rope, a second haulage rope, a first tooth bar, a second spring, a first rotating shaft, a first gear, an agitator arm, spraying mechanisms and a fertilization mechanism. With the arrangement of the first motor, the disc, the movable rod, the first haulage rope and the crushing plate, a solid granular fertilizer is repeatedly crushed, and then the solid fertilizer is better dissolved in water and utilization rate of the fertilizer is raised. With the arrangement of the second haulage rope, the first tooth bar, the first gear, the second spring, the firstrotating shaft and the agitator arm for cooperation, the agitator arm rotates in the forward and reverse directions such that water and the fertilizer are better integrated and fertilizer water preparation efficiency is raised. With the arrangement of two spraying mechanisms, continuous spraying is realized. With the arrangement of the fertilization mechanism, a nozzle can rotate a certain angle in both forward and reverse directions such that spraying range is widened, fertilization efficiency is raised and labor of workers is reduced.

Owner:临泉县生产力促进中心

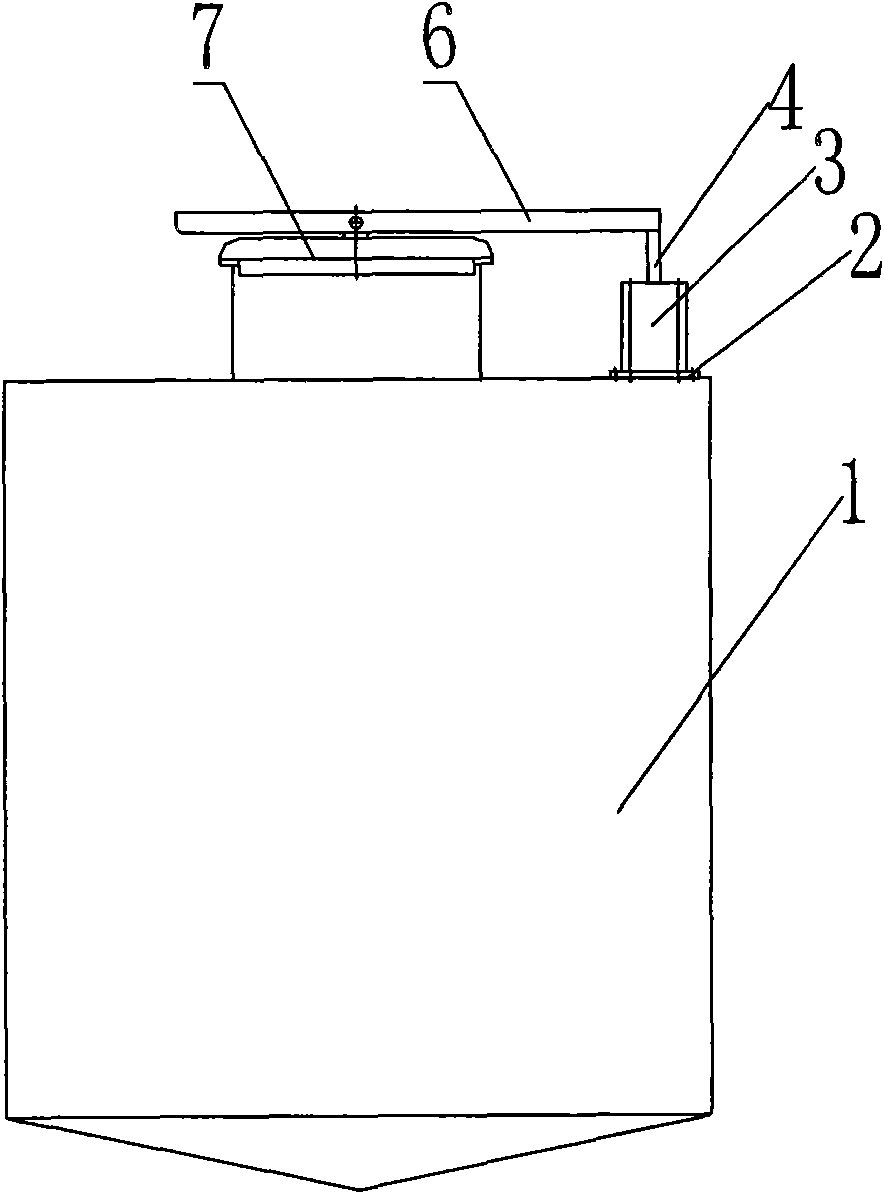

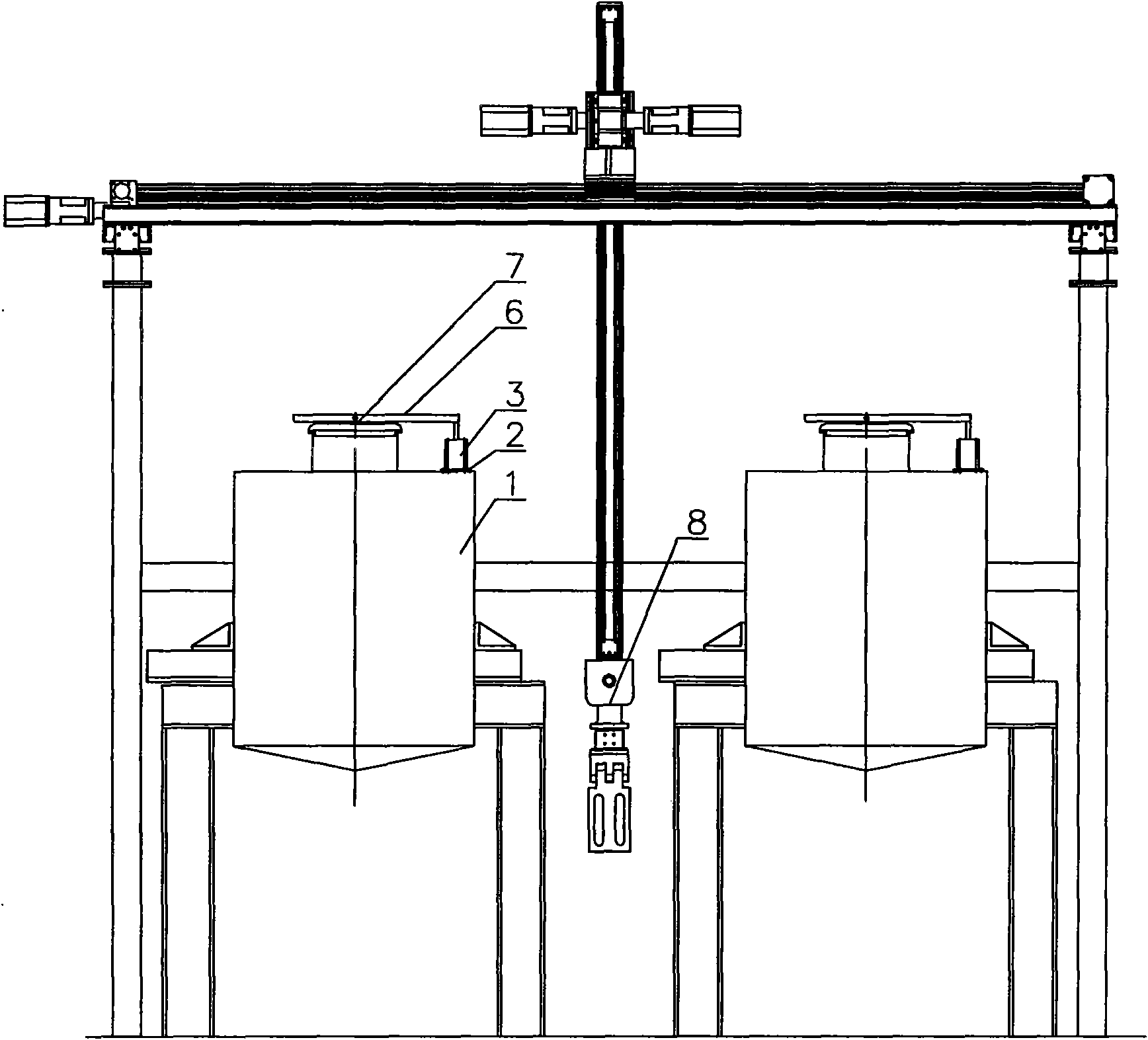

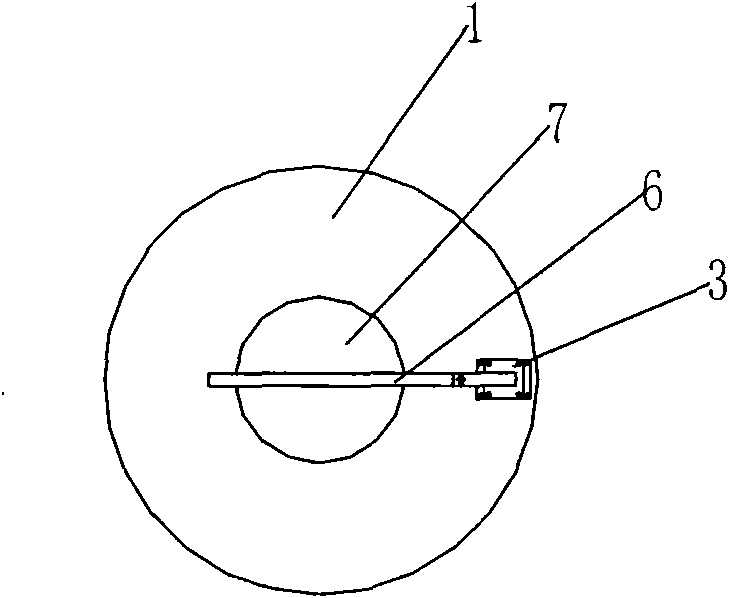

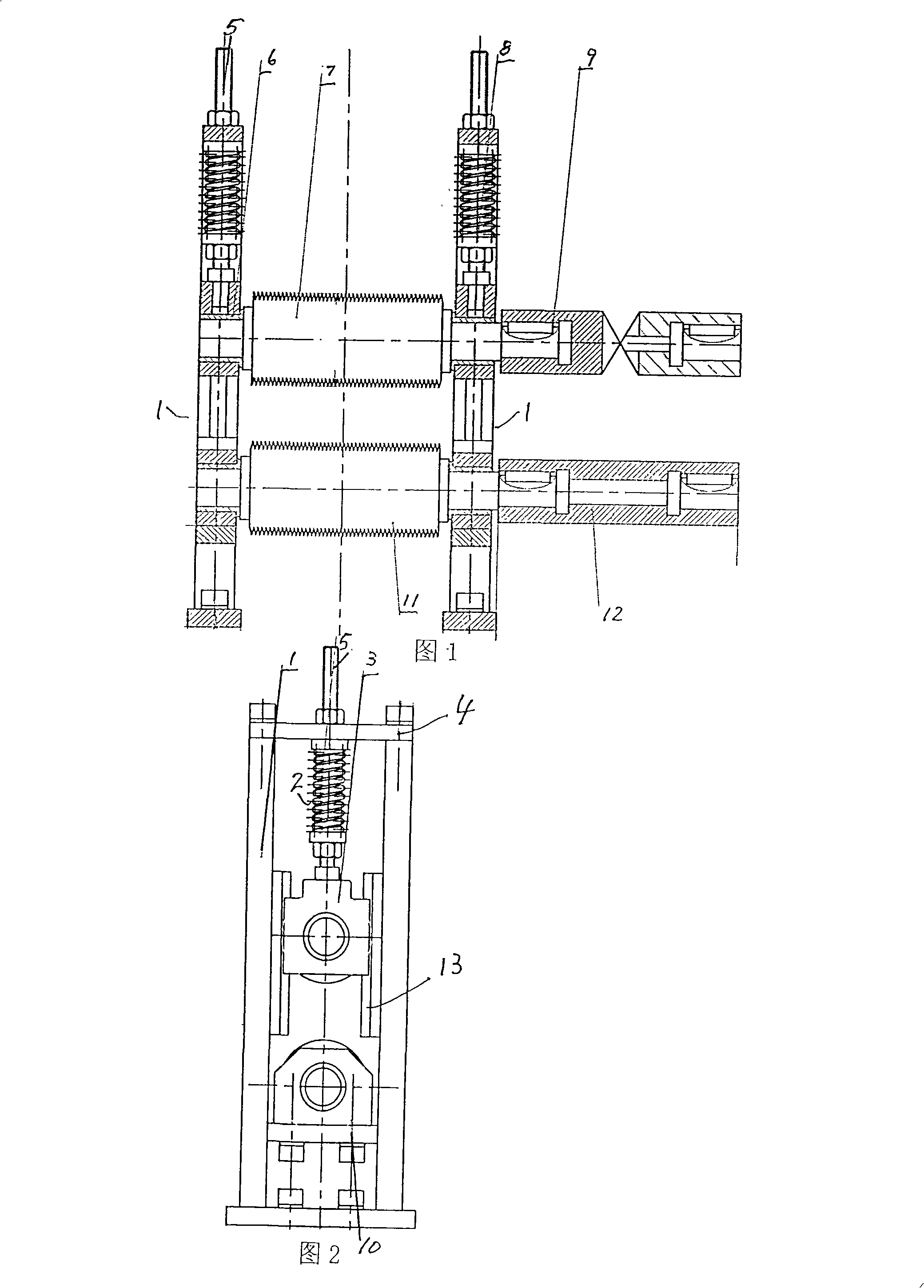

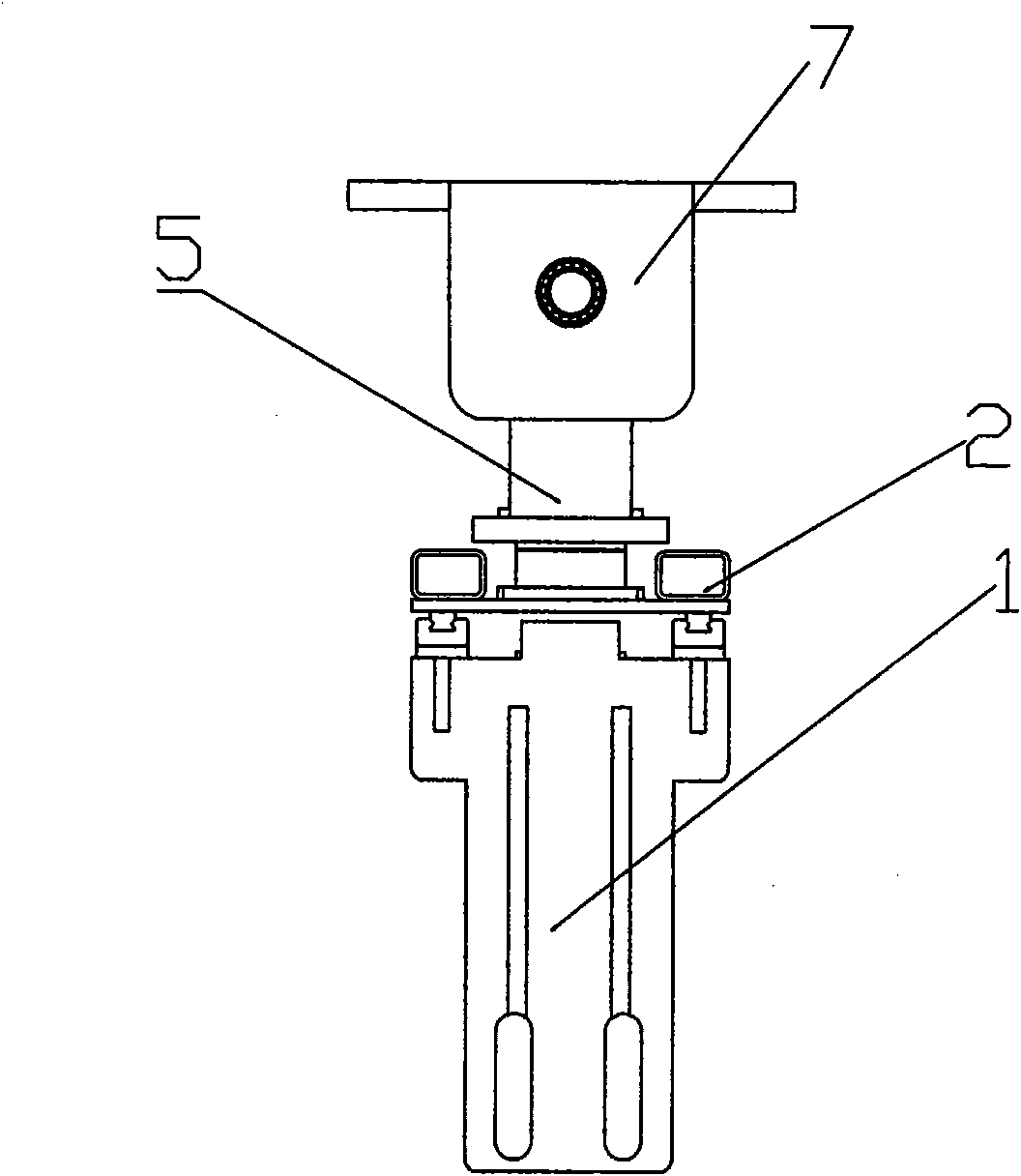

Automatic uncovering device of tobacco dedicated charging bucket

The invention discloses an automatic uncovering device of a tobacco dedicated charging bucket, comprising a charging bucket and a rectilinear swinging combined cylinder, wherein the top of the charging bucket is provided with an opening, and the opening is provided with a bucket cover; the rectilinear swinging combined cylinder is fixed on the charging bucket, and the piston rod of the rectilinearswinging combined cylinder faces upwards; and the piston rod is connected with the bucket cover via a batten connecting bar. In the scheme, the rectilinear swinging combined cylinder is connected with the bucket cover of the charging bucket, thus driving the bucket cover of the charging bucket to carry out lifting and rotating combination movement; thus the invention can open and close the bucketcover of the charging bucket, realizes the automation of opening and closing the bucket cover of the charging bucket and satisfies the production automation requirement of a full-automatic sugar kitchen system.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

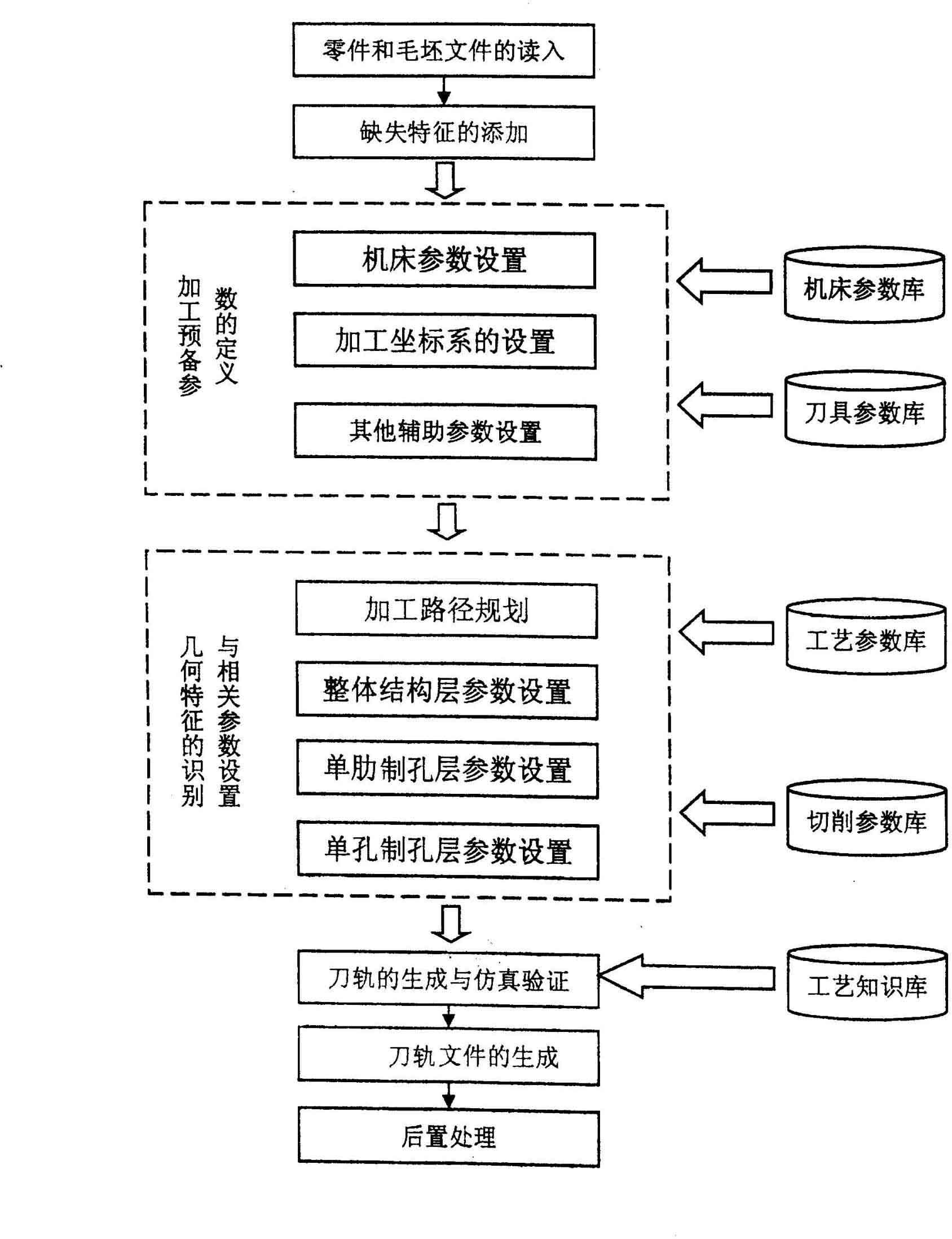

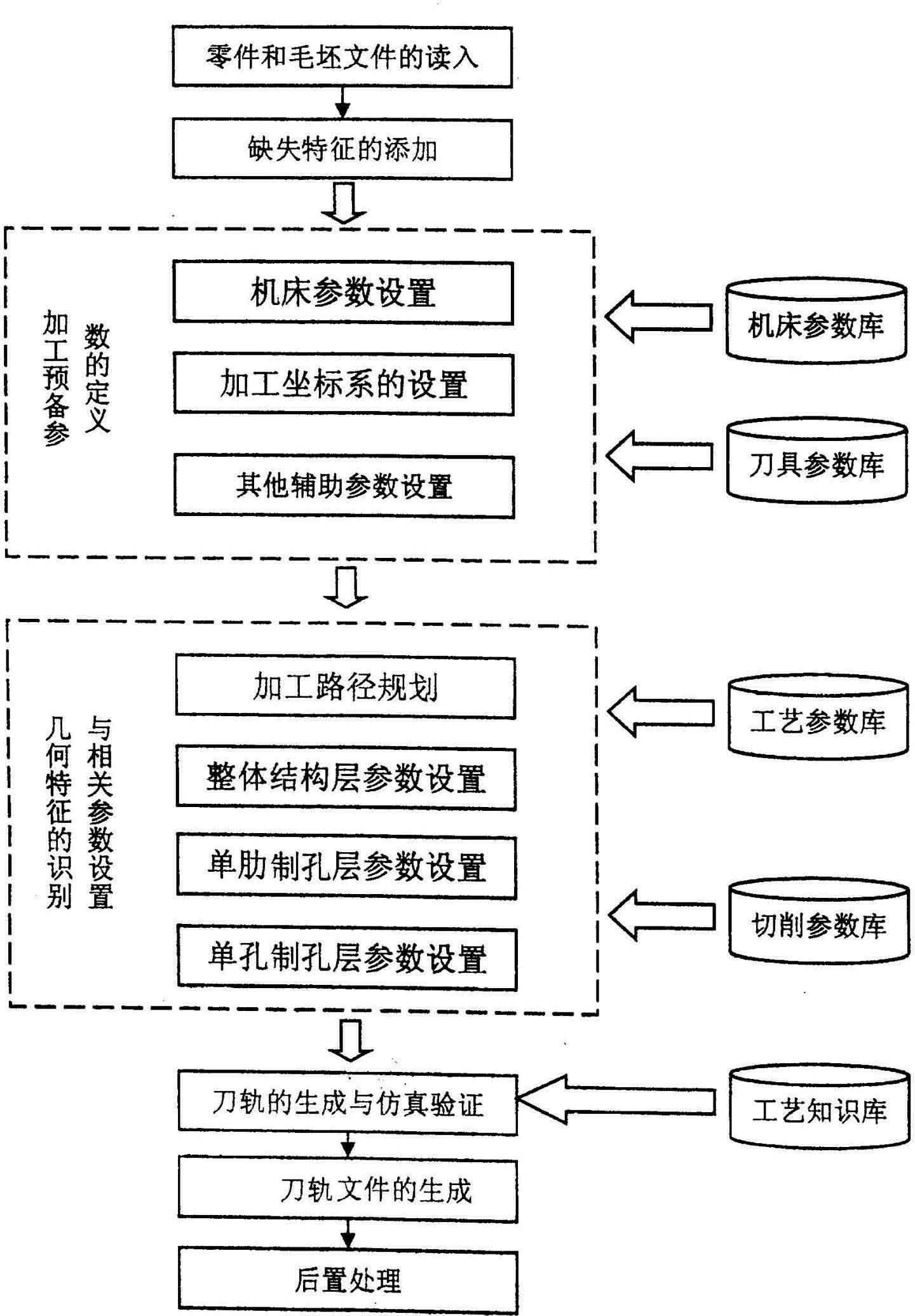

Multilayer numerical control programming method for flexible hole formation on large-scale wing part

ActiveCN102591261ARealize data sharingAchieve integrationProgramme controlComputer controlNumerical controlPath generation

The invention relates to a multilayer numerical control programming method for flexible hole formation on a large-scale wing part. The multilayer numerical control programming method includes the steps as follows: (1) reading part and blank documents; (2) adding missing features, that is, generating needed hole position information in a digital model; (3) extracting related information in a machine tool parameter library and a cutter parameter library, performing definition of machining preparation parameters, that is, setting machine tool parameters, setting a machining coordinate system and setting other auxiliary parameters; (4) extracting related information in a technological parameter library and a cutting parameter library, performing geometrical characteristic recognition and related parameter setting, namely, machining path planning and parameter setting; (5) extracting related information in a technological knowledge library, and performing cutter path generation and simulation verification; (6) generating a cutter path document; and (7) postprocessing. The system is used in the process of flexible hole formation on a wing, can finish skin and rib drilling and dimple programming work in one step, effectively improves the programming efficiency, and meanwhile improves the auxiliary hole position precision.

Owner:SHENYANG AIRCRAFT CORP

Processing method for homogeneous and natural texture-forming bamboo plywood

InactiveCN101342714ALow costImprove preparation efficiencyOther plywood/veneer working apparatusCane mechanical workingSurface layerPresent method

The invention relates to method for processing bamboo plywood which is homogeneous and forms natural texture; the processing method solves the disadvantages of low productivity, bad levelness of the product surface, uneven product intensity, easy deformation, low strength and narrow application field with the present method. The method includes the following steps that saw bamboo into tubes of proper length and cleave the tubes into slices of proper width and then remove the layers of green color and yellow color; cleave the bamboo slices into thin strips of proper thickness and weave the strips in parallel with wire to form a bamboo curtain and the thickness difference of strips used for the same curtain should be within 1mm; dry and size the curtain and then dry for the second time; pile the curtain on the board of a hot-press layer by layer to form plate blank; the included angle of two neighboring layers is acute or right one and the surface layer or / and the bottom layer consist(s) of one to four bamboo curtains with included angles of zero degree between all strips in the pattern of one to four layers; the plate blank is hot pressed and trimmed to obtain the homogeneous bamboo plywood.

Owner:李和麟

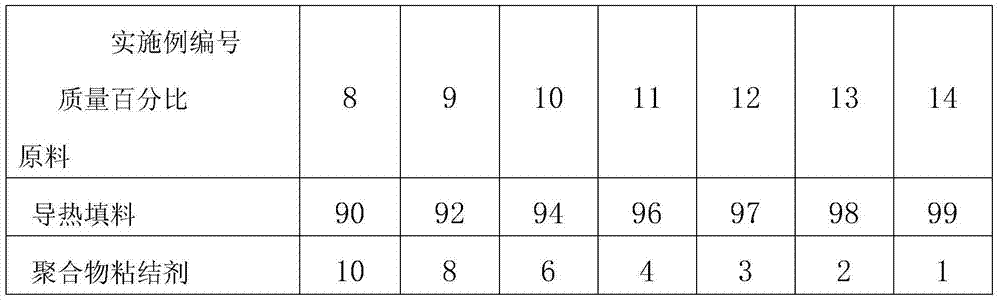

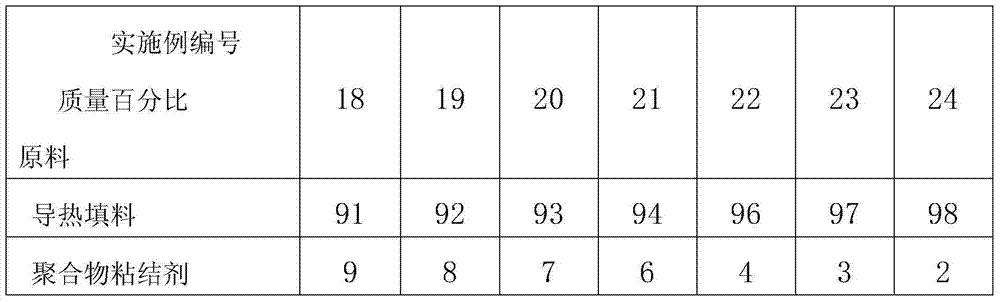

Heat conductive composite material with high volume fraction and preparation method thereof

InactiveCN104119627AImprove preparation efficiencyExcellent mechanical properties and thermal conductivityHeat-exchange elementsFlat panel displayHot press

The invention discloses a heat conductive composite material with a high volume fraction. The composite material is characterized by being composed of a heat conductive filling material, which is irregularly stacked to form a heat conductive network and accounts for 90 to 99% of the total weight of the composite material, and a polymer adhesive, which is dispersed in the cavities in the heat conductive network and accounts for 1 to 10% of the total weight of the composite material, wherein the heat conductive filling material is high heat conductive carbon-base micro nano powder. The moulded products can be prepared through the steps of direct mixing and hot press molding, and the preparation efficiency is high. The preparation of the composite material is simple and convenient. Moreover the content of the high heat conductive carbon-base micro nano powder filling material is high, so the composite material can meet the realistic requirements on massive production. The prepared heat conductive composite material has an excellent heat conductive performance and mechanical properties, also has a certain electric conductive performance, and can be used in fields like 3D printing materials, notebook, large power LED luminescence, panel display, digital camera, and mobile communication products and related compact and high-speed electronic elements.

Owner:SOUTHWEAT UNIV OF SCI & TECH

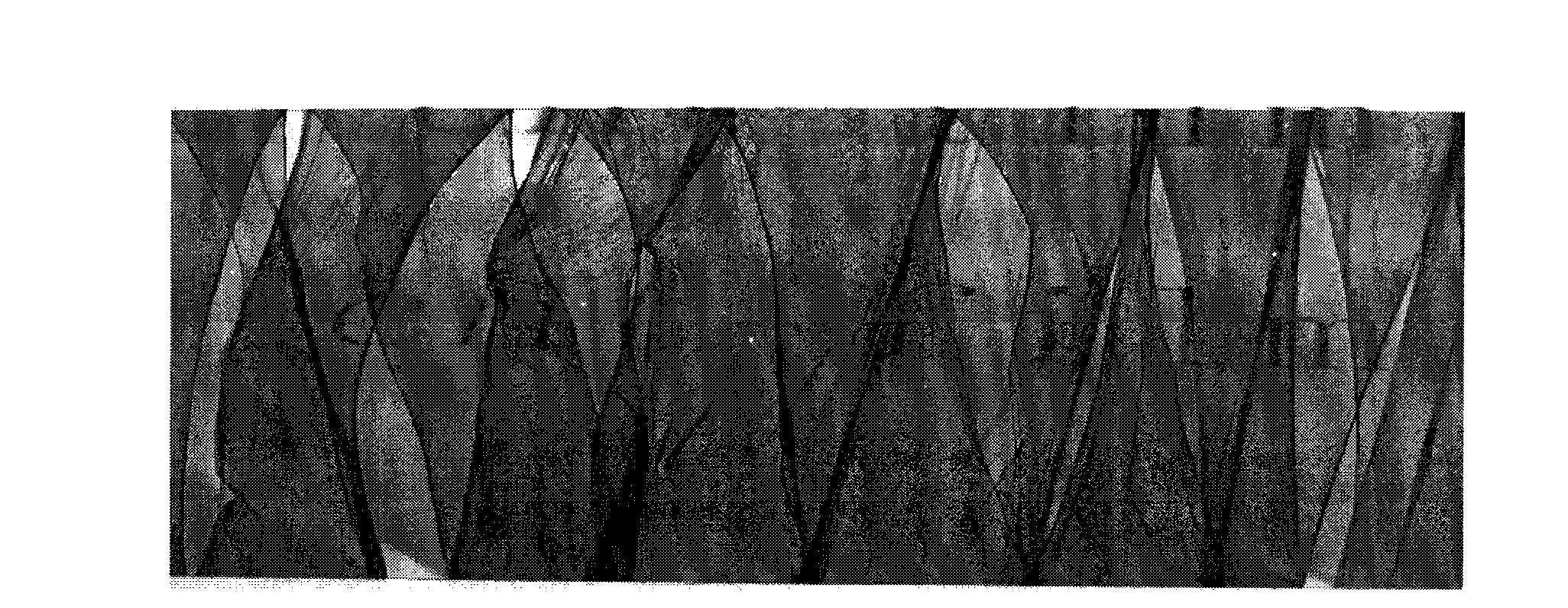

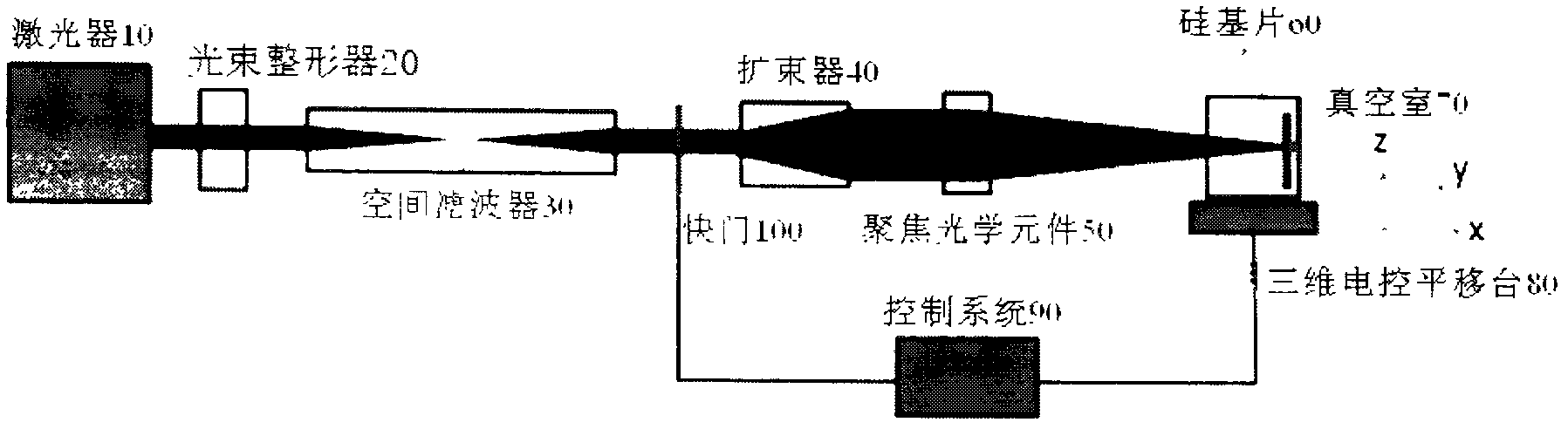

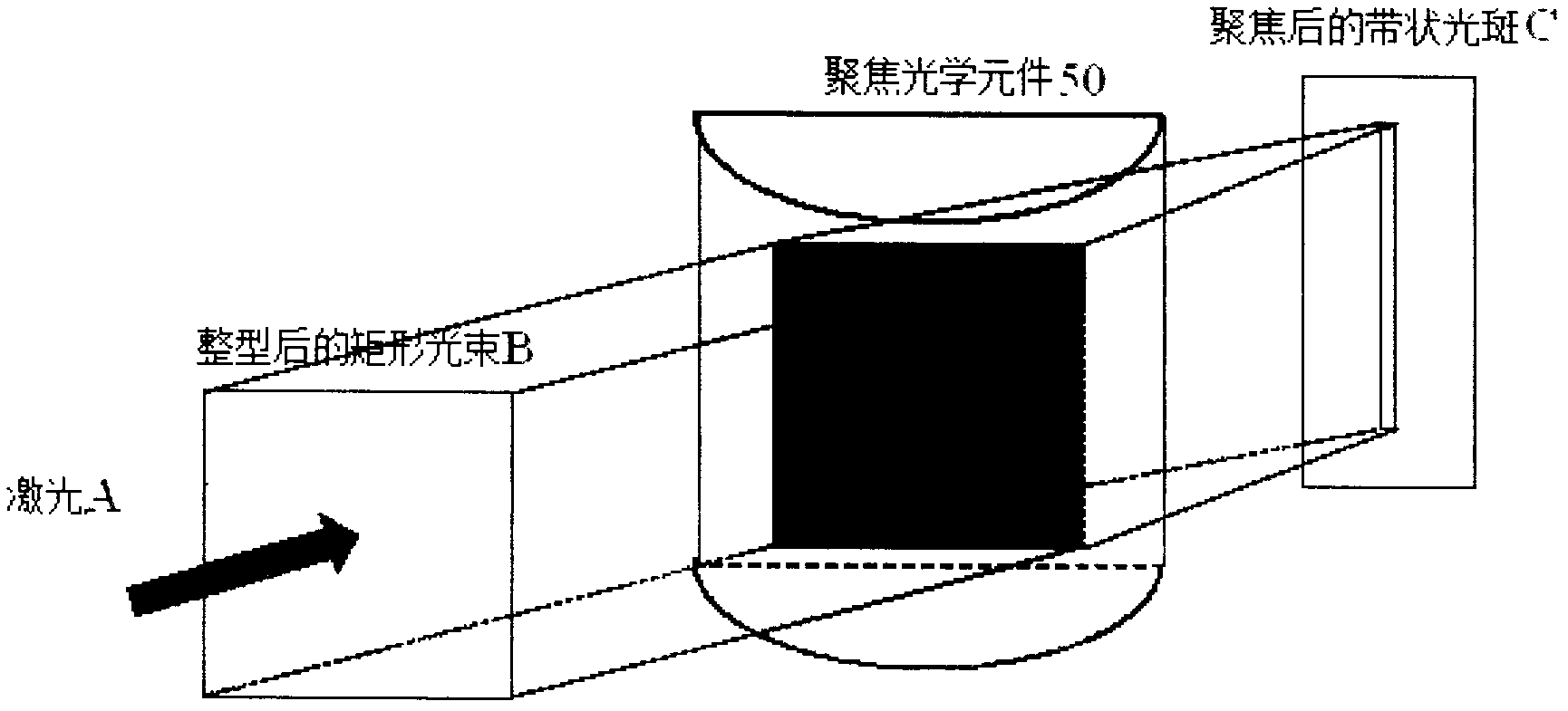

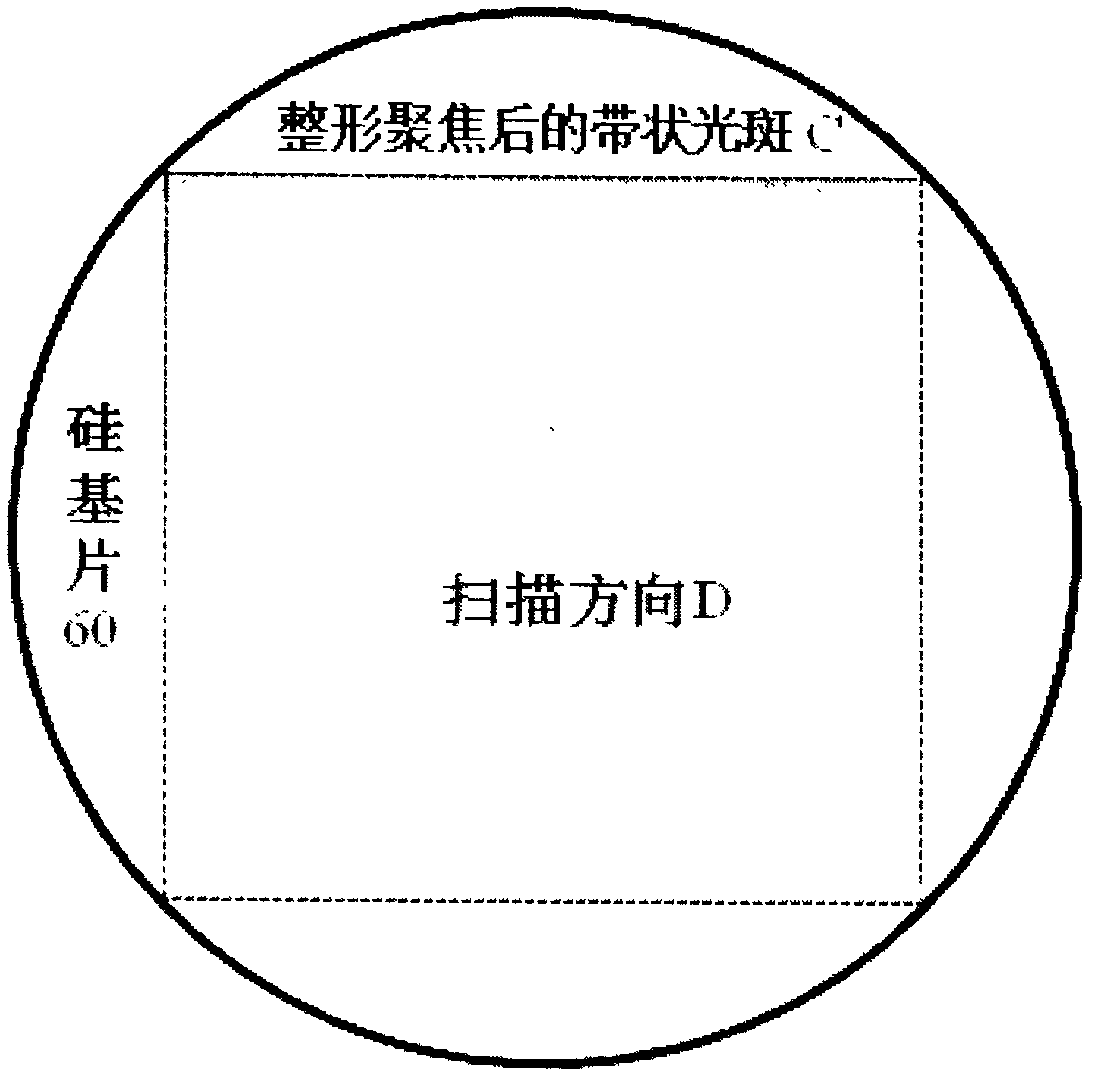

Method for rapidly preparing large-area and uniform black silicon material, and device thereof

InactiveCN102321921AImprove preparation efficiencyGood uniformityAfter-treatment detailsDiffusion/dopingMicrostructureLaser beams

The present invention discloses a method for rapidly preparing a large-area and uniform black silicon material through pulsed laser grating type scanning, and a device thereof. The method comprises the following steps: 1, placing a silicon substrate in a black silicon preparing environment; 2, shaping laser beams, converging the laser beams into a strip light spot to irradiate a surface of the silicon substrate; 3, adopting the laser to carry out grating type scanning for the surface of the silicon substrate, growing a microstructure on the surface of the silicon substrate to form the black silicon. With the method and the device provided by the present invention, the black silicon can be directly prepared on the 2 inch silicon substrate, 4 inch silicon substrate, or larger silicon substrate through the one-time scanning, the surface microstructure of the prepared black silicon has good uniformity, and the method can meet the actual requirements of mass production.

Owner:SOUTHWEAT UNIV OF SCI & TECH

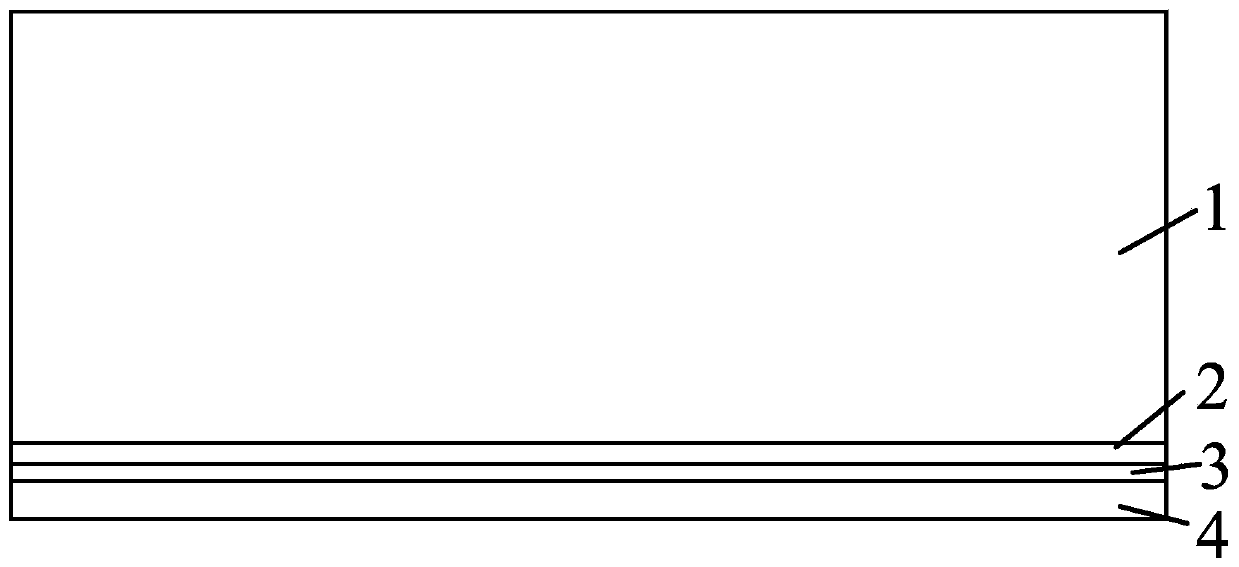

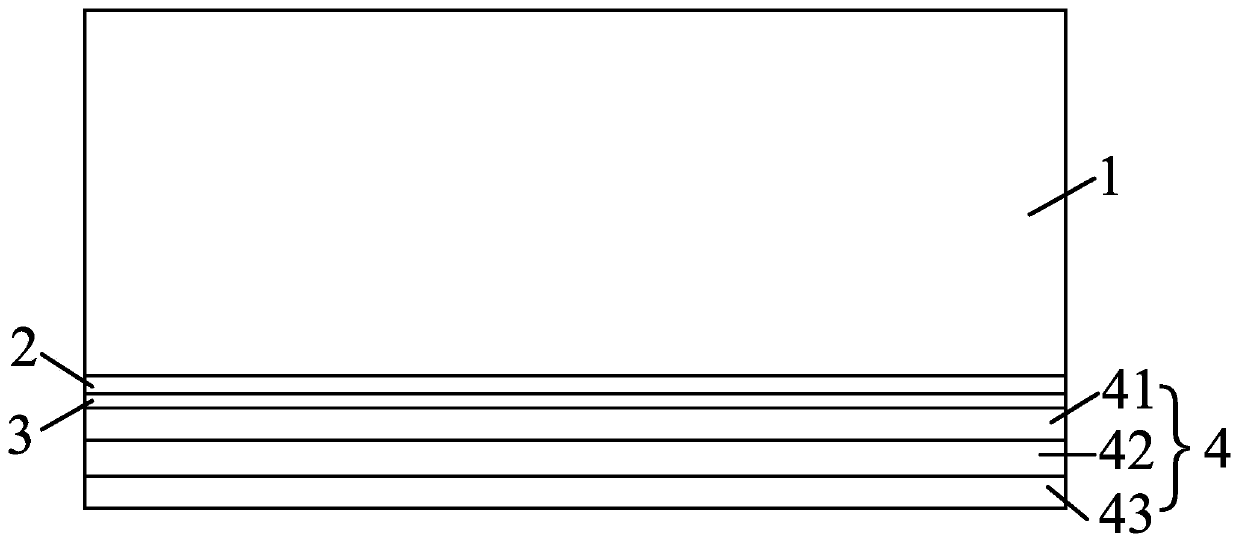

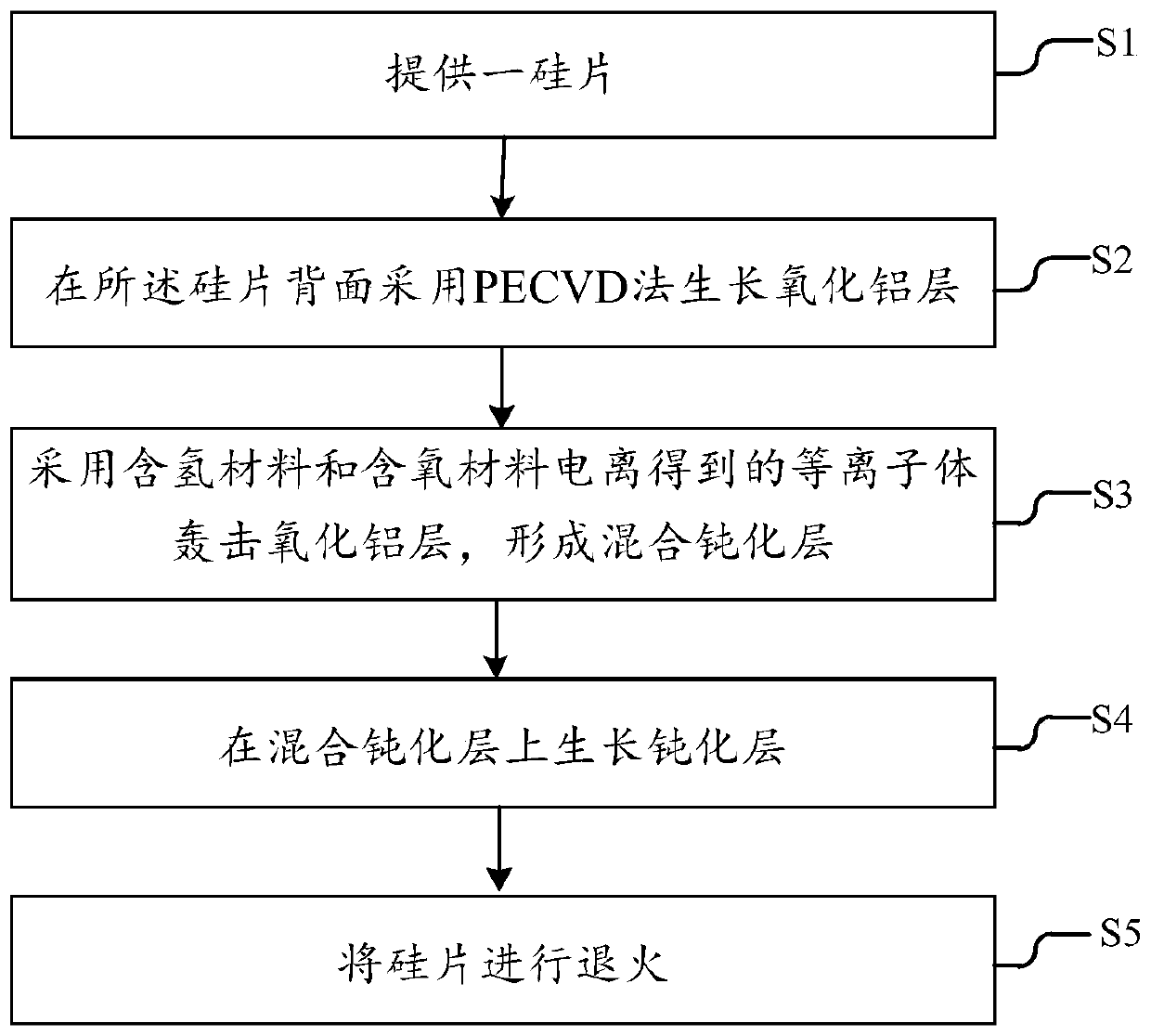

Solar cell laminated passivation structure, preparation method thereof and cell

PendingCN110491949AIncrease productivityImprove preparation efficiencyFinal product manufactureChemical vapor deposition coatingSolar cellAluminium oxide

The invention discloses a solar cell laminated passivation structure. The laminated passivation structure comprises a silicon wafer, and an aluminum oxide layer, a mixed passivation layer and a passivation layer which are sequentially arranged on the back surface of the silicon wafer, wherein the aluminum oxide layer is formed through a PECVD method; and the mixed passivation layer is formed by bombarding the aluminum oxide layer by plasmas obtained by ionizing a hydrogen-containing material. The invention also discloses a laminated passivation solar cell which comprises the solar cell laminated passivation structure. By implementing the method, dangling bonds on the back surface of the silicon wafer can be effectively removed, the surface state is reduced, and the efficiency of the solarcell is improved.

Owner:CENTROTHEM PHOTOVOLTAICS AG +1

Processing method for burrs of bamboo canes used for bamboo weaving

InactiveCN105291225AIncrease elasticityReduce harmWood treatment detailsReed/straw treatmentRoom temperatureEngineering

The invention relates to a processing method for burrs of bamboo canes used for bamboo weaving. The processing method comprises the following steps that 1 the split bamboo canes are placed into conditioning fluid to be soaked for 1-1.5 hours, the bamboo canes are turned over once every 10-15 min, and the temperature of the conditioning fluid is maintained at 50-55 DEG C, so that part of the conditioning fluid is absorbed by the bamboo canes; 2 the bamboo canes which are soaked already in the step 1 are fished out, the moisture on the surfaces of the bamboo canes is drained off, then the bamboo canes are sent to refrigeration equipment and frozen continuously for 2-2.5 hours in the refrigeration equipment at the temperature of minus 5-10 DEG C, and the bamboo canes are taken out and placed at room temperature for half a day; 3 the bamboo canes in the step 2 are placed in the blazing sun for 2-3 days, and if possible, the bamboo canes can be sent into baking equipment to be baked till the moisture content of the bamboo canes is within 20%; 4 the bamboo canes in the step 3 are placed into the conditioning fluid again to be soaked for 1 hour, then the bamboo canes are taken out, the moisture of the bamboo canes is drained off, and the bamboo canes are sent to the refrigeration equipment and frozen in the refrigeration equipment at the temperature of minus 4-6 DEG C for 1 hour; and 5 the bamboo canes already frozen in the step 4 are wiped back and forth twice with gauze so that the burrs on the surface can be removed, the problem that hands are pricked cannot occur, and the bamboo canes can be used for weaving products.

Owner:界首市祥雨竹编专业合作社

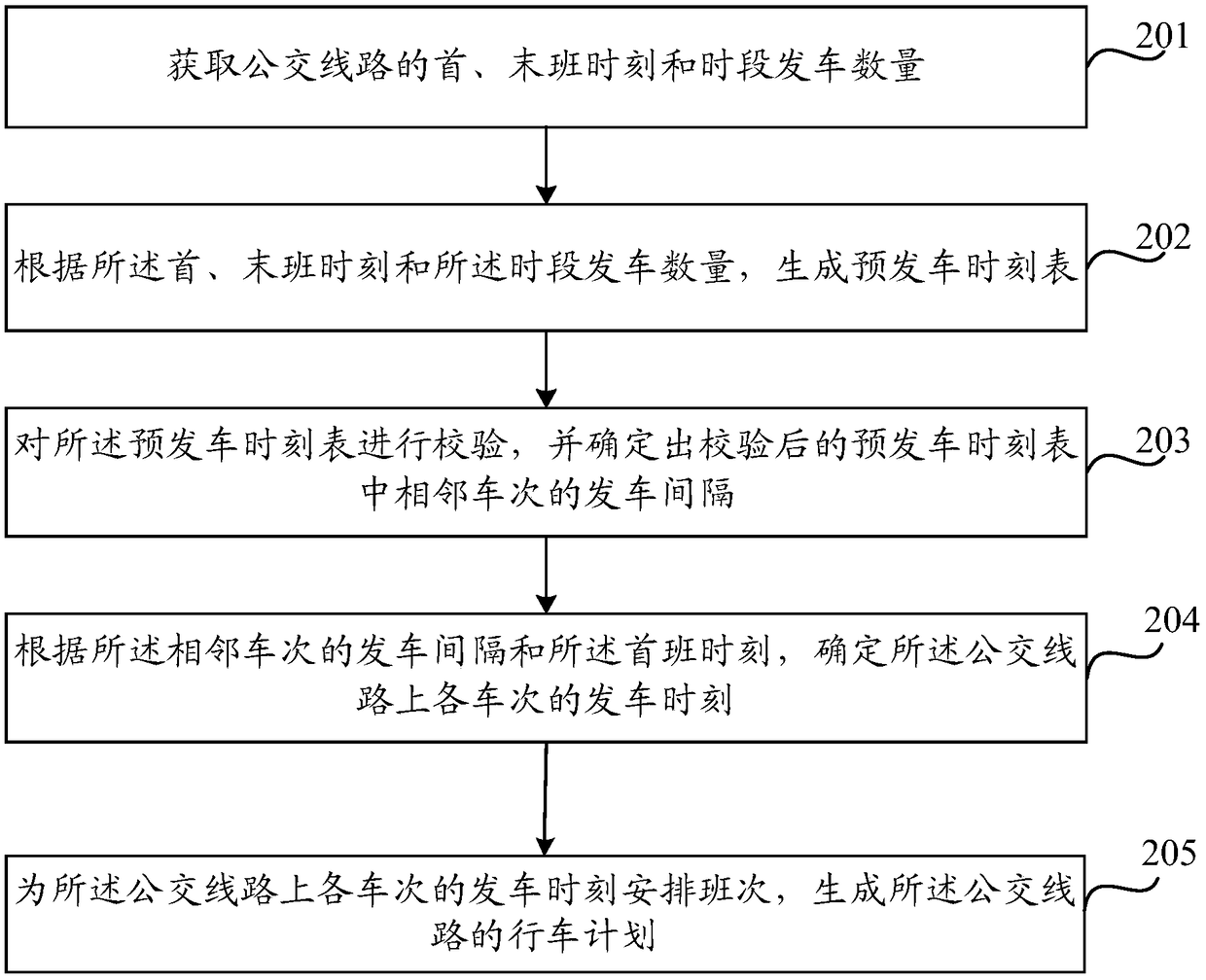

Public-transport line vehicle-driving plan generation method and device

InactiveCN108734353AImprove preparation efficiencyImprove matchRoad vehicles traffic controlForecastingEngineeringVehicle driving

The invention discloses a public-transport line vehicle-driving plan generation method and device. The method includes: obtaining first and last shift moments and time interval vehicle departure quantity; generating an expected vehicle departure schedule according to the first and last shift moments and the time interval vehicle departure quantity; verifying the expected vehicle departure schedule, and determining vehicle departure intervals of adjacent vehicles in the expected vehicle departure schedule after verification; determining vehicle departure moments of all vehicles on a public-transport line according to the vehicle departure intervals of the adjacent vehicles and the first and last shift moments; and scheduling shifts for the vehicle departure moments of all the vehicles on the public-transport line, and generating a vehicle-driving plan of the public-transport line. The vehicle-driving plan can be automatically generated on the basis of the first and last shift moments and the time interval vehicle departure quantity, efficiency of vehicle-driving plan compilation is improved, a matching degree of the vehicle-driving plan and an actual line situation is increased, a satisfaction degree of taking public transport for travel is increased, and a utilization rate of public-transport resources is increased.

Owner:QINGDAO HISENSE TRANS TECH

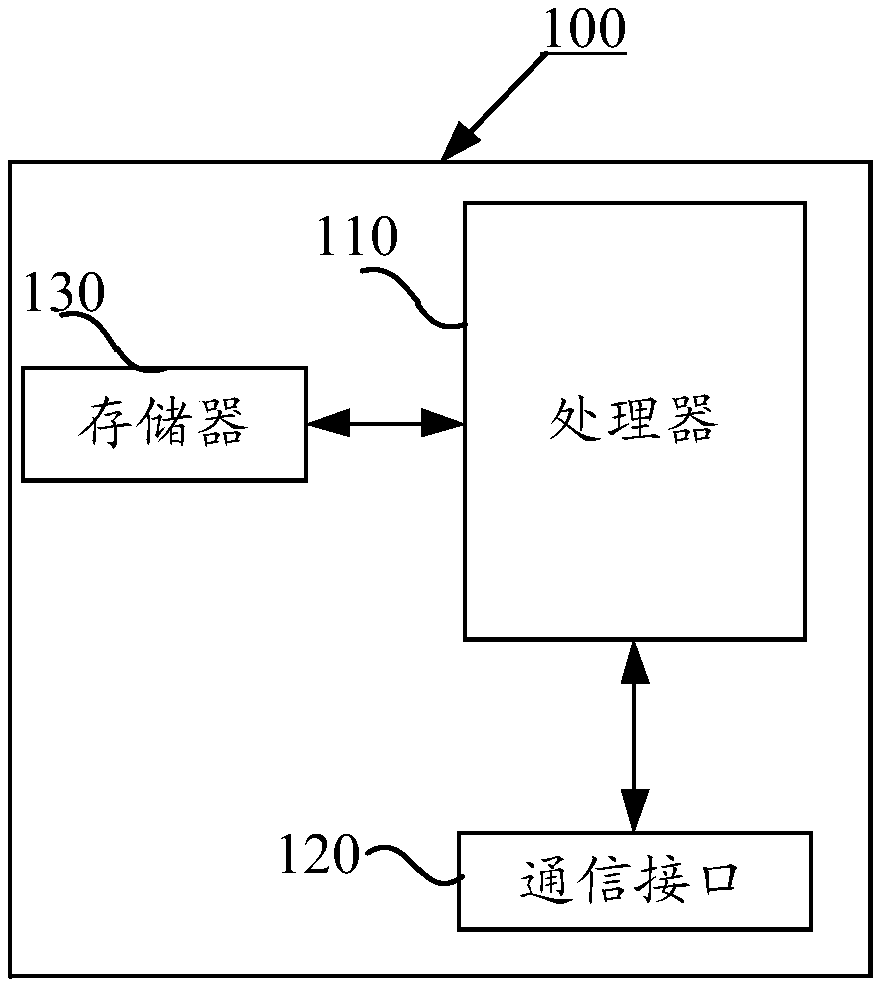

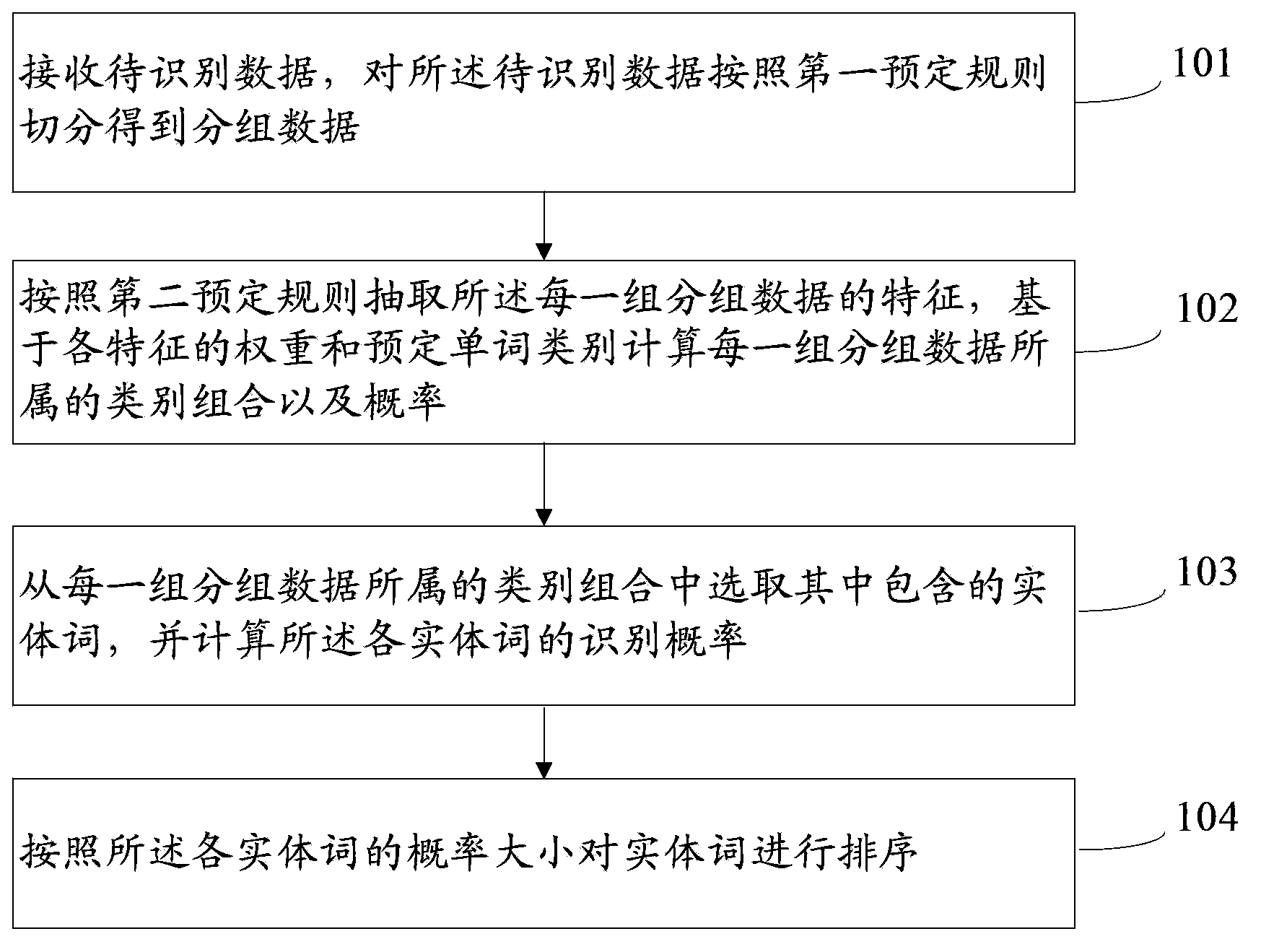

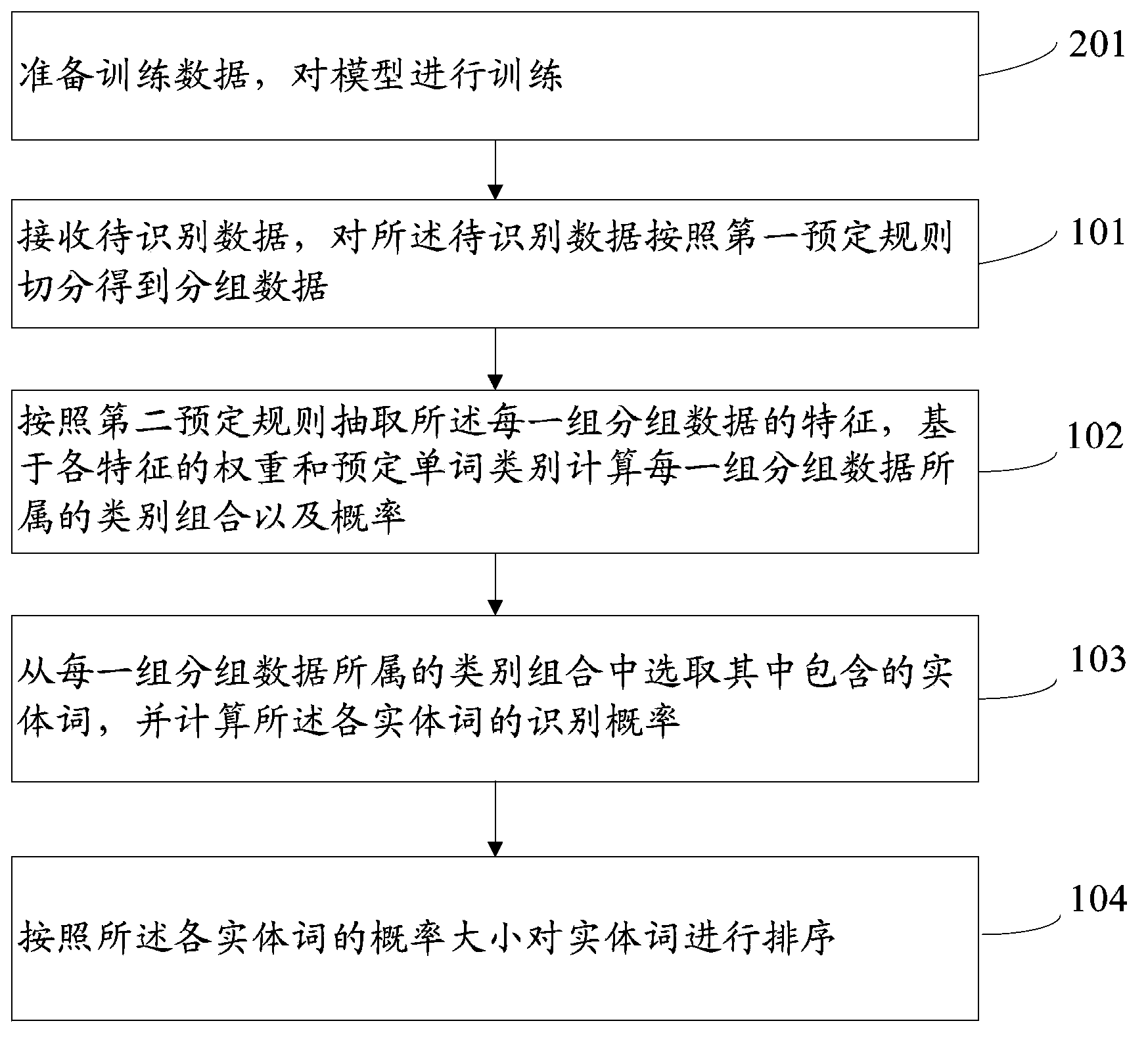

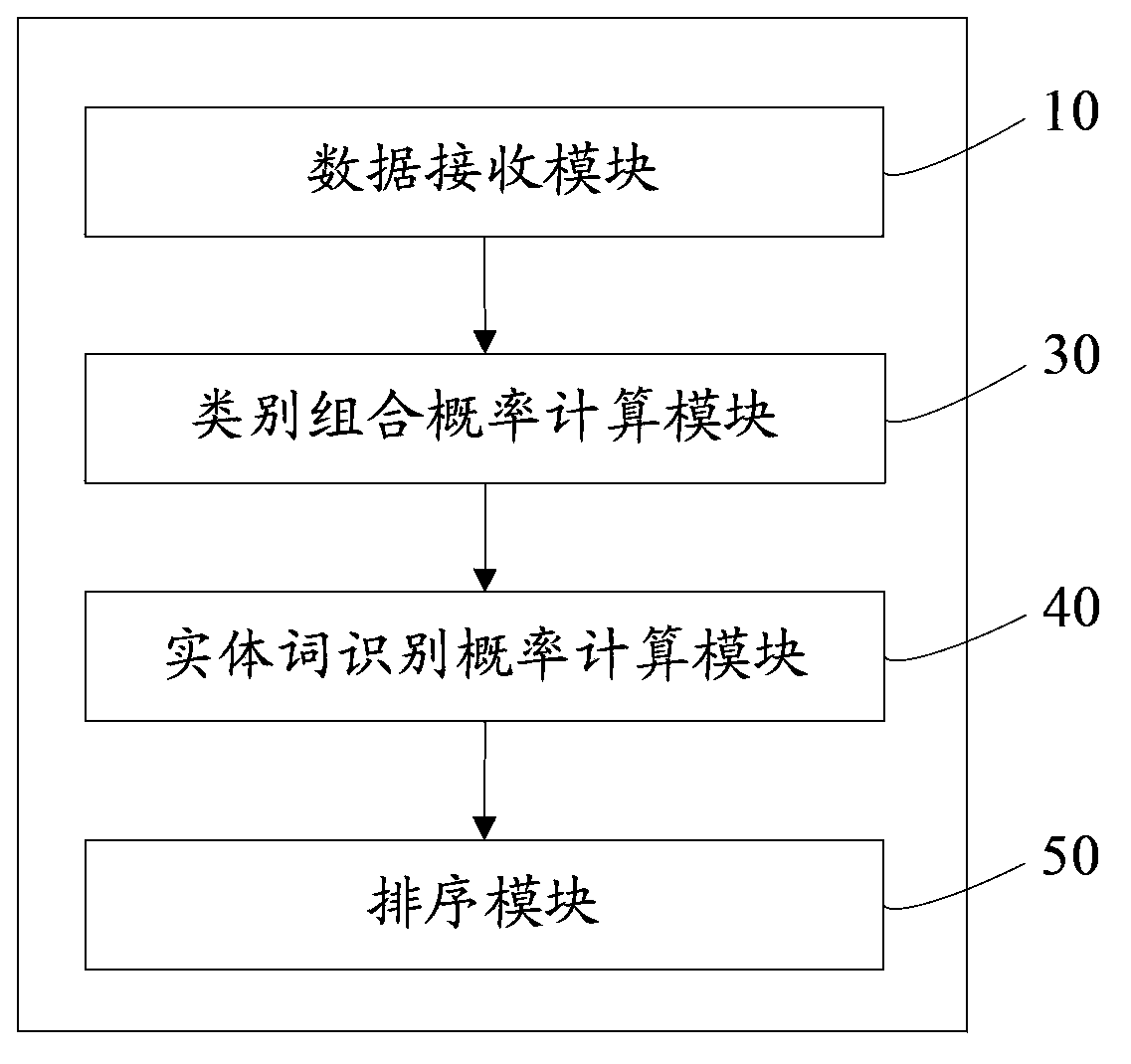

Method and device for identifying entity words

ActiveCN103678336AQuick identificationTimely updateNatural language data processingSpecial data processing applicationsIdentification deviceData mining

Owner:ALIBABA GRP HLDG LTD

Dye preparing device for leather dyeing

InactiveCN106890597AGood mixing effectEvenly preparedRotary stirring mixersTransportation and packagingSolventDyeing

The invention relates to dye preparing devices, in particular to a dye preparing device for leather dyeing. The dye preparing device comprises a one-way valve, a water discharge pipe, a preparing box, a support, a preparing device, a stirring device and the like, wherein the preparing device and the stirring device are arranged at the top of the support, the preparing device is located on the left of the stirring device, the preparing box is connected to the right end of the lower portion of the support, the water discharge pipe is connected to the middle of the bottom of the preparing box, and the one-way valve is arranged on the water discharge pipe. The dye preparing device has the advantages that a preparing solvent can be measured precisely, a prepared dye solution is even and fine and smooth, the dye solution is high in homogenizing degree and is evenly mixed, and high preparing efficiency and preparing accuracy are achieved.

Owner:翁帆安

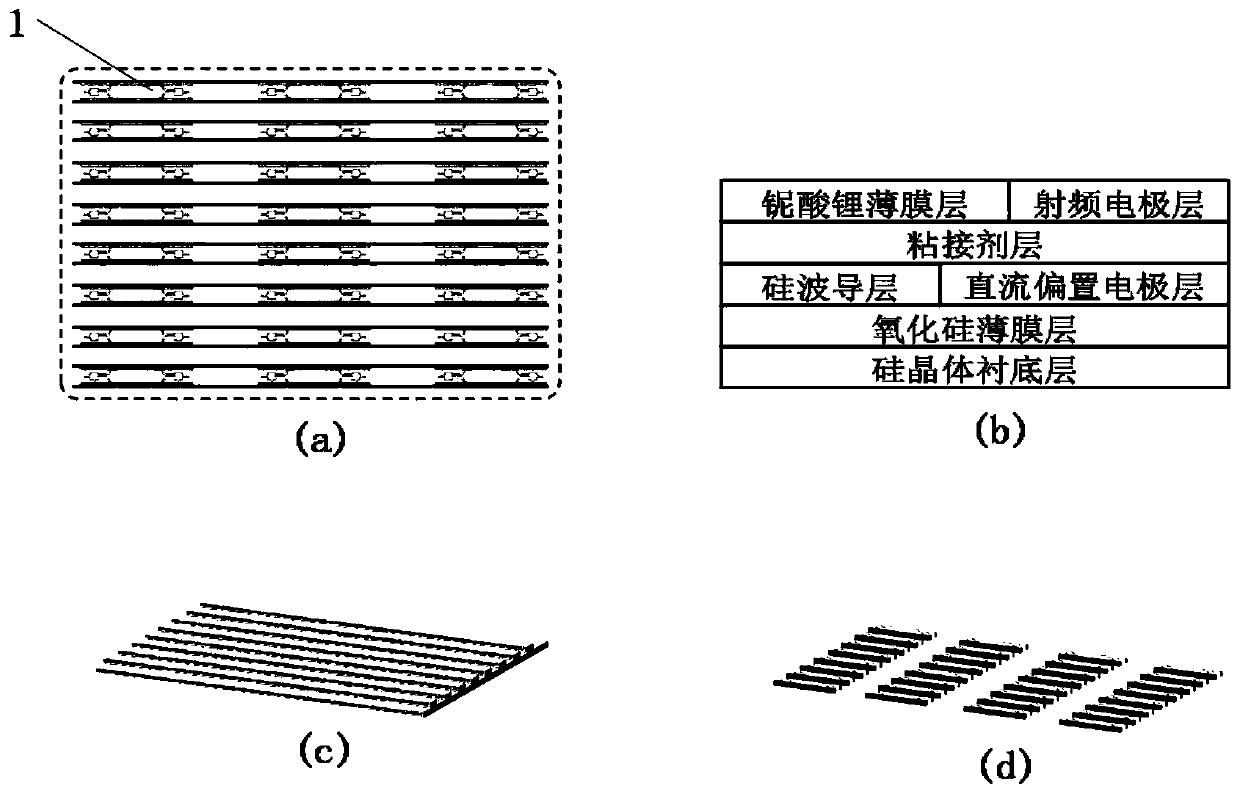

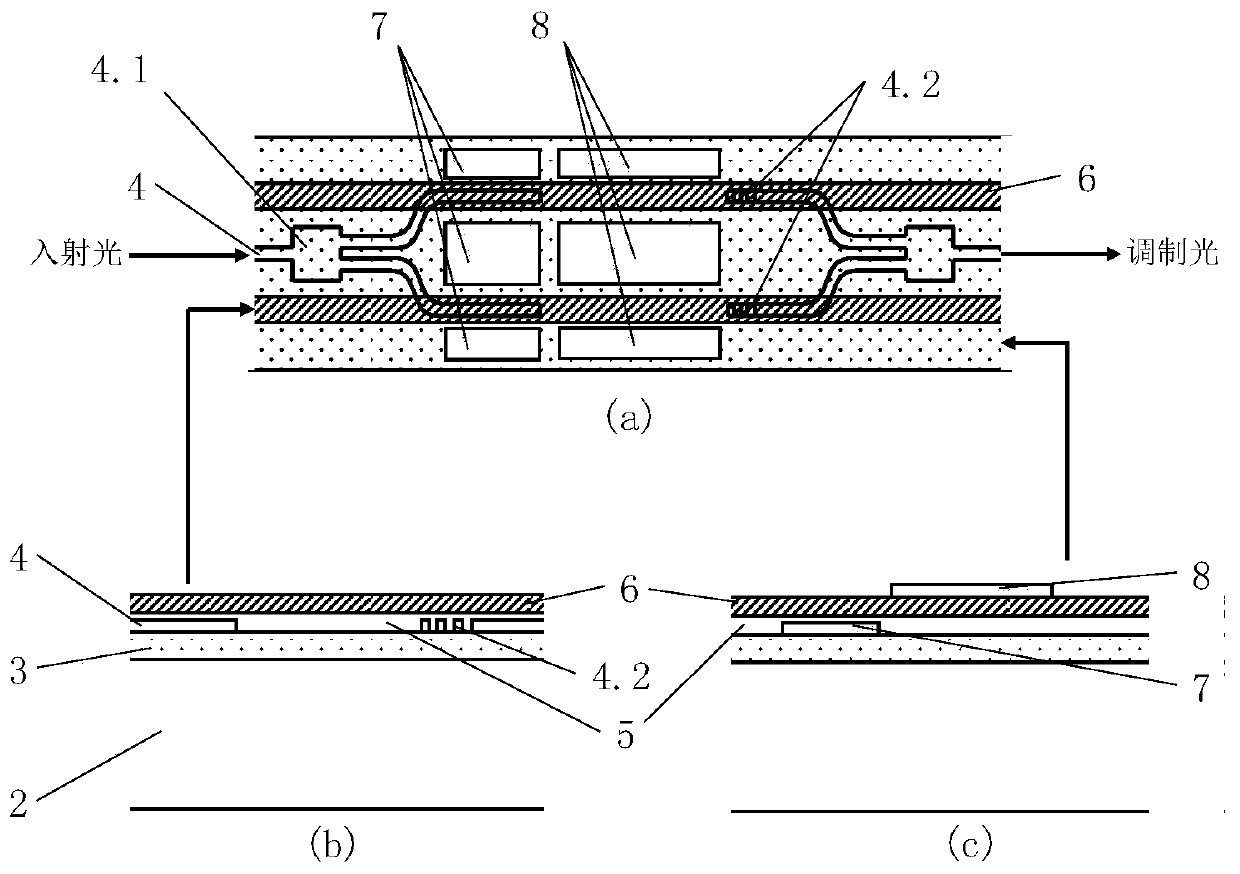

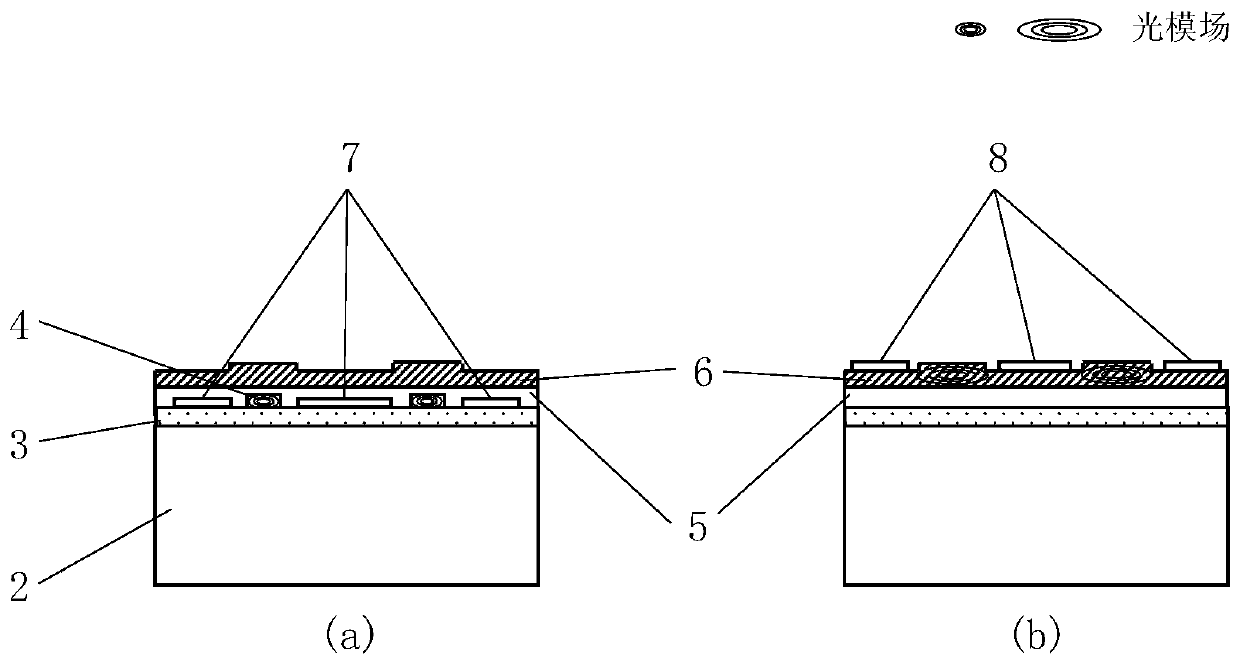

Method for integrating silicon-based lithium niobate thin film electro-optic modulator arrays

ActiveCN110161625AGuarantee functional availability and stabilityImprove preparation efficiencyOptical waveguide light guideNon-linear opticsProcess errorLithium niobate crystal

The object of the present invention is to provide a method for integrating large-scale silicon-based lithium niobate thin film electro-optic modulator arrays in view of the deficiencies of the prior art. By using the method, the preparation process difficulty of the lithium niobate crystal layers is reduced, the precision requirement for the bonding of lithium niobate and silicon is reduced, and the preparation and bonding of the large-scale array-type lithium niobate crystal layers can be simultaneously completed at one time, so that production efficiency of the lithium-based lithium niobatethin film electro-optic modulator arrays is greatly improved; by structurally designing and optimizing the silicon crystal layer, the light can be naturally alternated and mutually transmitted in thesilicon waveguide and the lithium niobate waveguide, so that a high-performance lithium niobate film electro-optic modulation effect is achieved; and in addition, the advantages of standardized silicon-based integration technology maturity are used in the method, and the complex chip preparation process is concentrated on the silicon crystal layer, so that the process error in the chip fabricationprocess can be reduced, and performance stability of the entire silicon-based lithium niobate film electro-optic modulator array is ensured.

Owner:交芯科(上海)智能科技有限公司

Health-care pigeon feed

InactiveCN101438763AImprove palatabilityMeet nutritional needsAnimal feeding stuffAccessory food factorsAnimal scienceSodium Bentonite

The invention discloses a health care pigeon feed which is prepared by the following raw materials according to the mixture ratio (weight ratio): 37-46 percent of corn, 18-27 percent of pea, 7-11 percent of bean cake, 2-4 percent of fish meal, 1-5 percent of hemp seed, 8-12 percent of red soil, 3-5 percent of bentonite, 9-13 percent of yellow sand, 2-4 percent of common salt, 0.5-3.5 percent of Chinese herbal medicine containing Chinese caterpillar fungus and 0.5-1 percent of binding agent. As the further improvement, the preferred Chinese herbal medicine containing Chinese caterpillar fungus is the mixture of the Chinese caterpillar fungus, Chinese gentian, liquorice root and common andrographis herb, and the best weight percentage of the four is 2: 1: 1: 1. The health care pigeon feed is characterized by good palatability, comprehensive nutrition, obvious functions of health care and disease prevention, simple operation and good palatability.

Owner:王华如

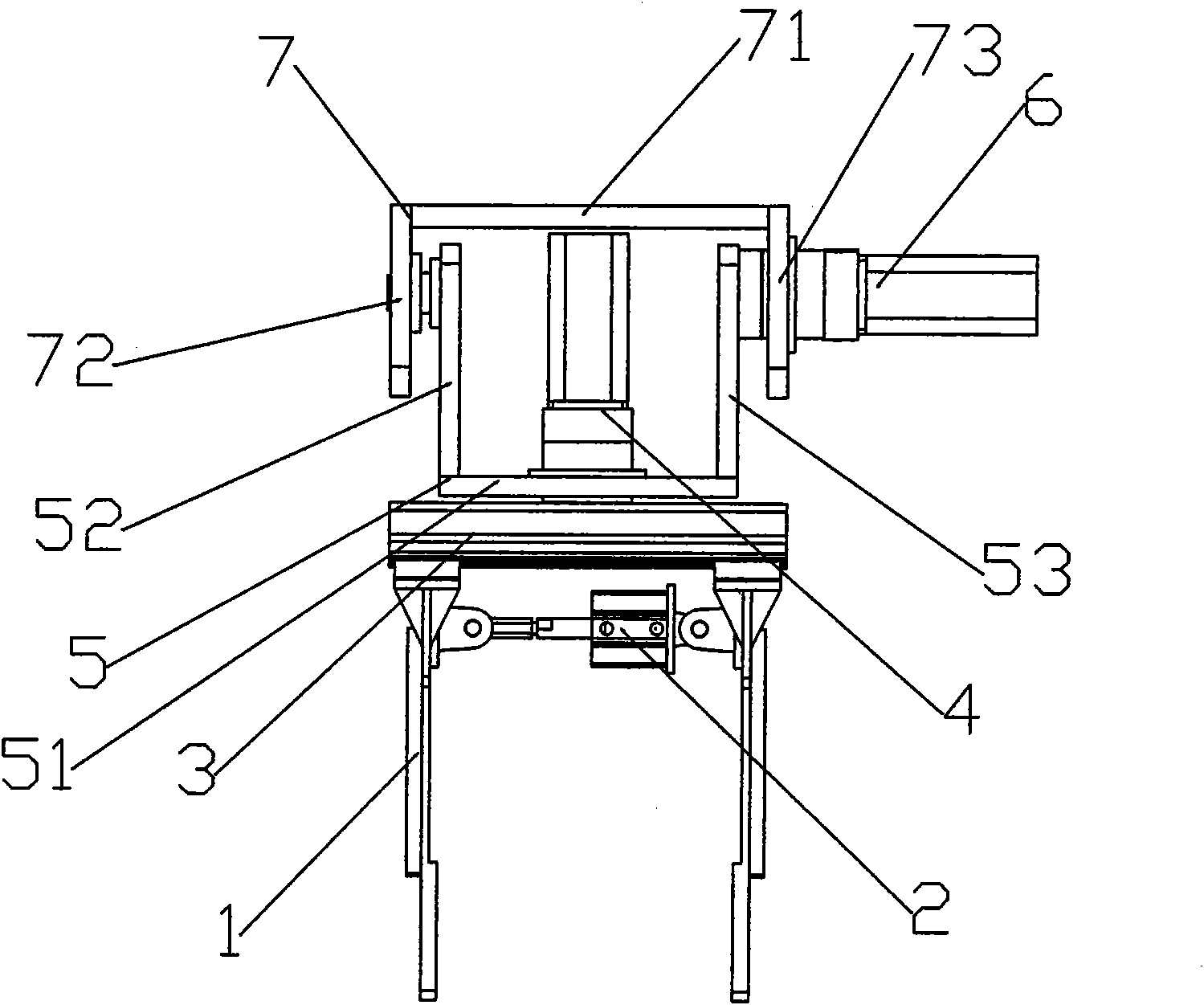

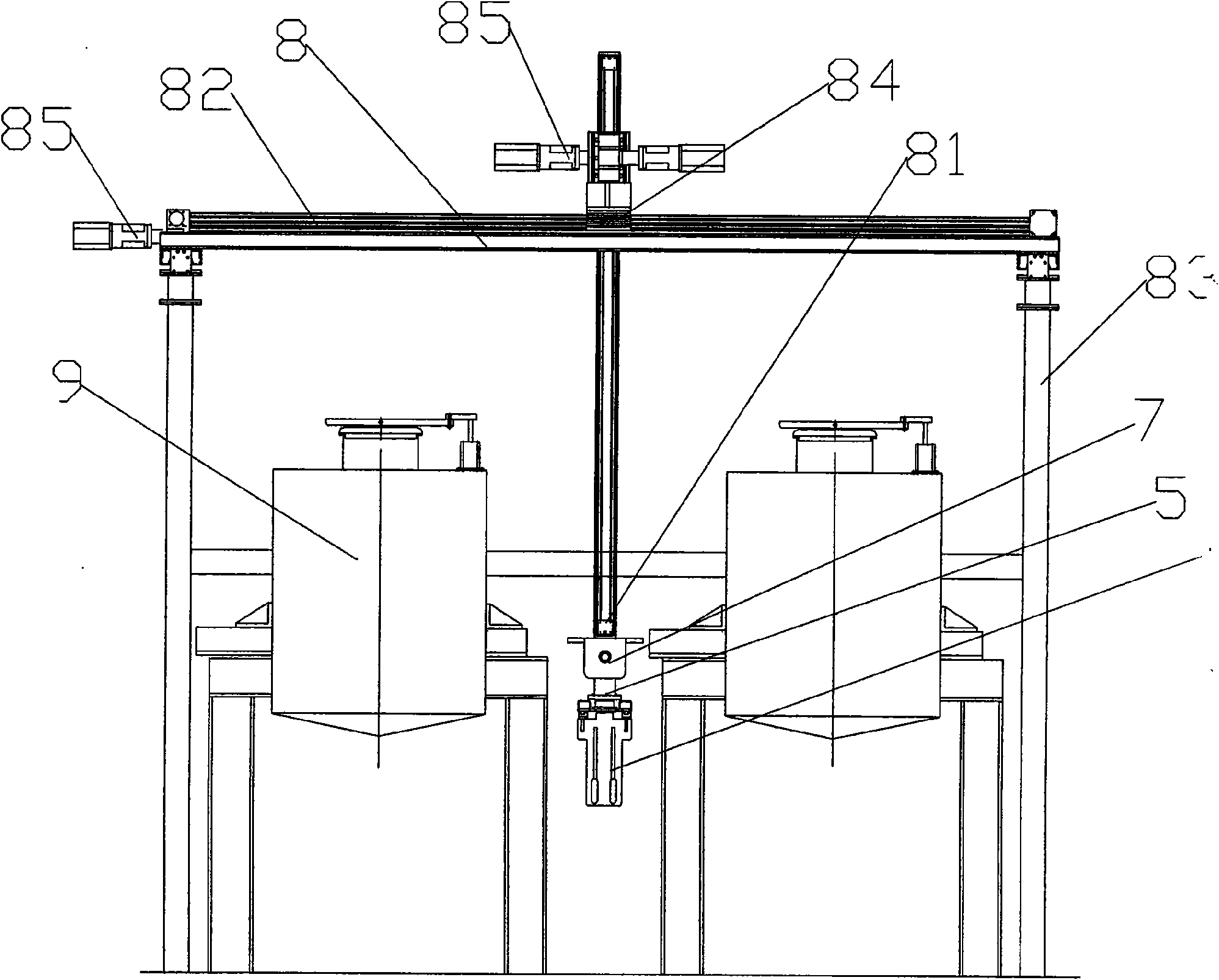

Clamping manipulator for tobacco dedicated charging basket

ActiveCN101670577AAchieve releaseRealize the clamping effectTobacco preparationManipulatorRectangular coordinatesEngineering

The invention discloses a clamping manipulator for a tobacco dedicated charging basket, comprising a paw guide rail, two paw clamping sheets, a rotary servo motor, a swinging servo motor and a three-dimensional rectangular coordinate robot, wherein two paw clamping sheets can slide along with the paw guide rail and are mutually connected via a cylinder; the rotary servo motor is fixed on the supporting seat of a first motor and can drive the paw guide rail to rotate; the swinging servo motor is fixed on the supporting seat of a second motor and can drive the supporting seat of the first motorto rotate; and the three-dimensional rectangular coordinate robot is connected with the supporting seat of the second motor. The scheme controls clamping, dumping, shaking, transporting and releasingof the charging basket by the clamping paw by controlling the components of the cylinder, the servo motor, the rectangular coordinate robot and the like, thus realizing automation control, improving feed liquor preparing efficiency, avoiding quality accident of artificially missending material, lowering raw material consumption and worker labor intensity to the utmost, and improving workshop sanitary environment.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

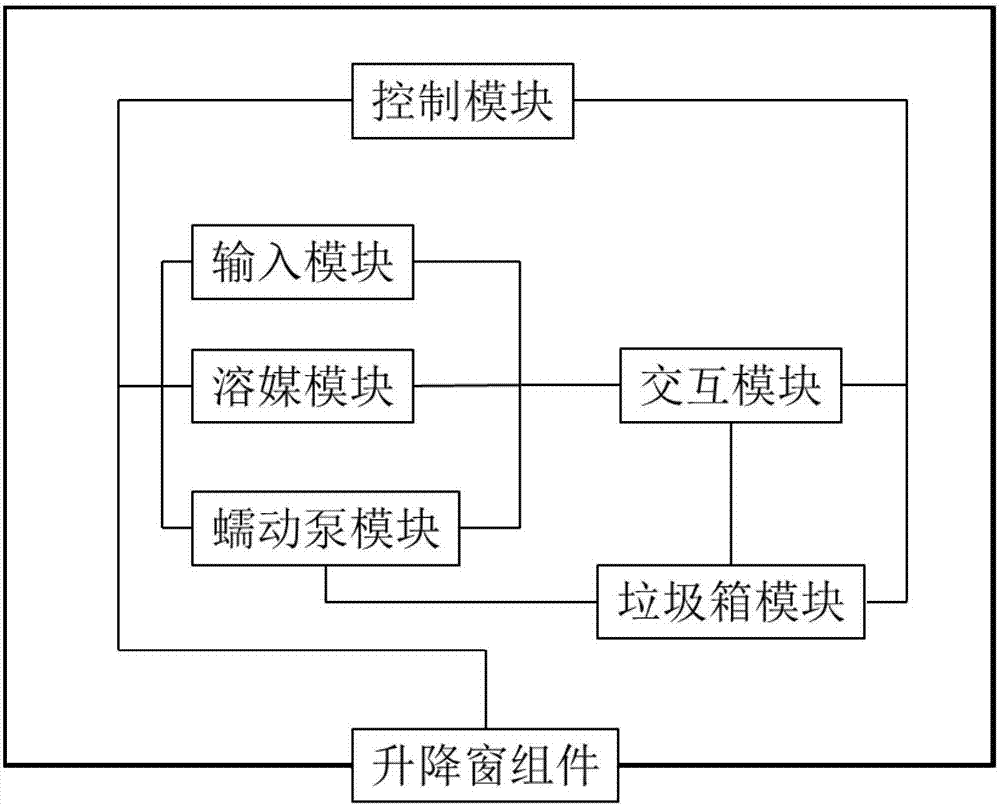

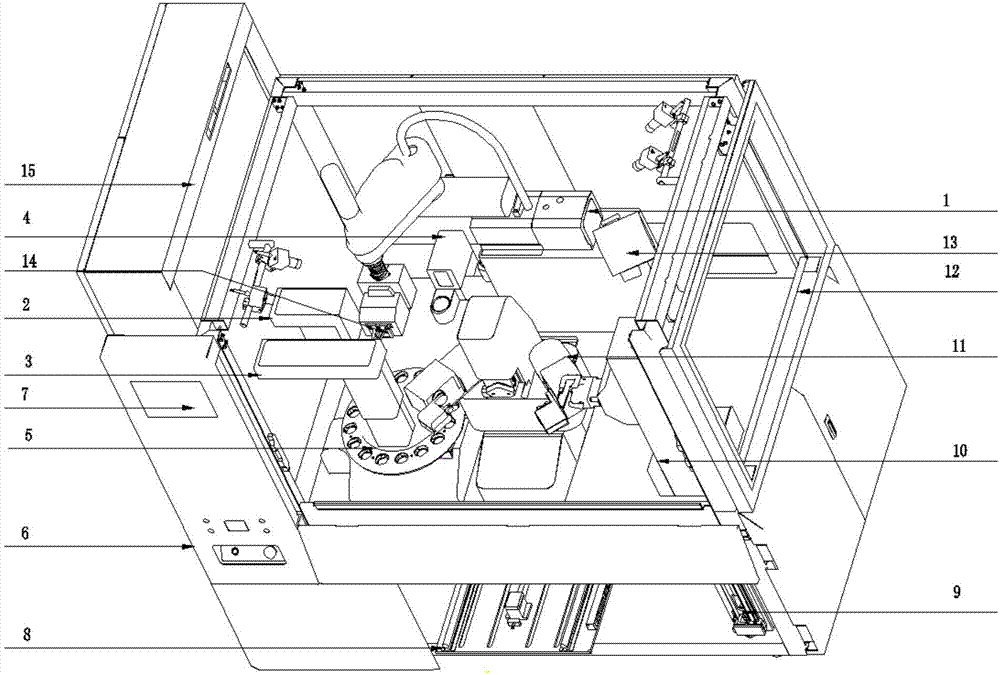

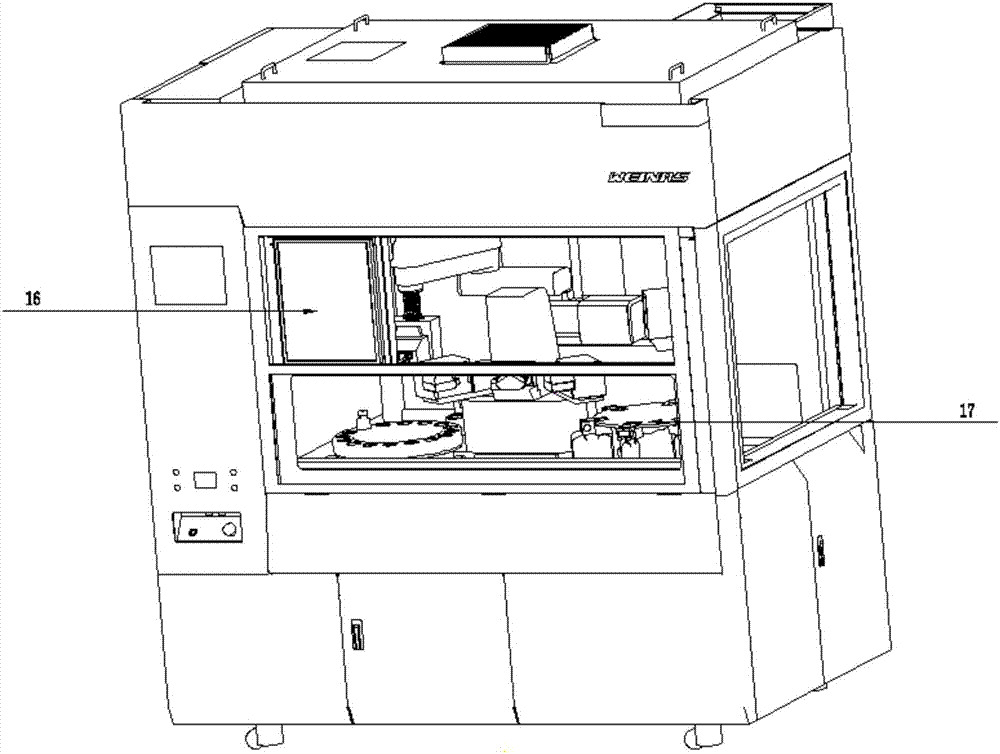

Automatic medicine dispensing device

InactiveCN107149886ARealize automatic liquid injectionSafe handlingShaking/oscillating/vibrating mixersDissolving systemsPeristaltic pumpPenicillin

The invention discloses an automatic medicine dispensing device, which comprises a control module, an input module, an interaction module, a solvent module, a peristaltic pump module, a waste bin module and a lifting window component, wherein the input module, the interaction module, the solvent module and the peristaltic pump module are arranged in a medicine dispensing cavity located in the upper part of the automatic medicine dispensing device; the waste bin module and the lifting window component are arranged in a supporting cavity located below the medicine dispensing cavity. Through the automatic medicine dispensing cavity provided by the invention, the liquid injection on a penicillin bottle, the dissolution of a medication in the penicillin bottle and the suction of a liquid medicine can be automatically realized; after the medicine dispensation is completed, waste medicine bottle and needling instrument are discarded into the waste bin; therefore, the whole medicine dispensing process is automatically completed with high efficiency; meanwhile, the pollution of the liquid medicine, which is easily brought during manual operation, can be avoided; the safety is improved; a medical worker is also prevented from injuries from edge tools of the medication and the broken medicine bottle or a needle head and the like during the medicine dispensation.

Owner:SHENZHEN CITY WEIBANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com