Integrative simulation system of production plan of steel making, continuous casting and hot rolling

A production planning and simulation system technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of difficulty in ensuring the integration of three-zone production plans, lack of flexibility, and short preparation cycles, and improve planning efficiency. , reduce work intensity, optimize the effect of production implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

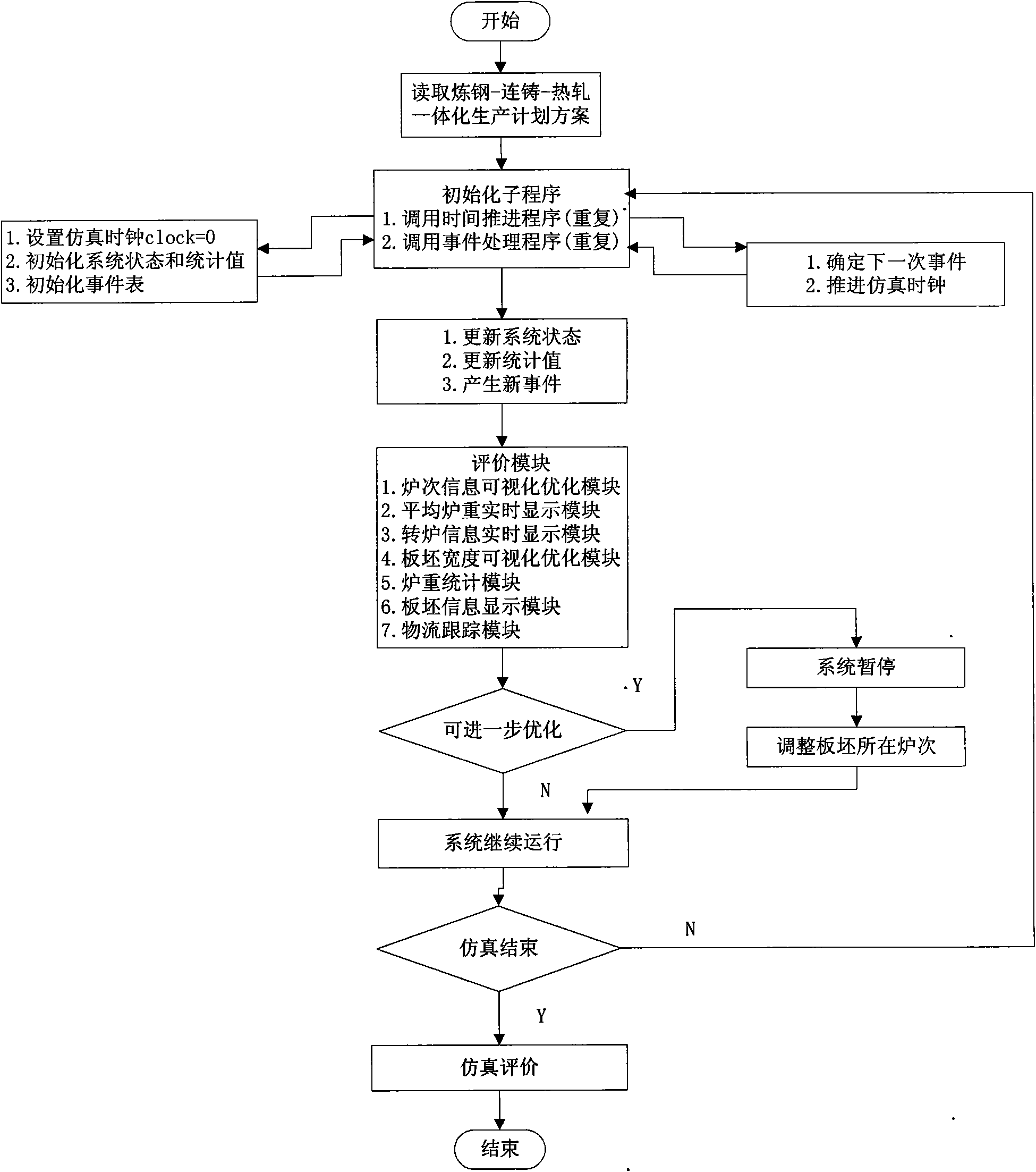

[0040] The present invention is further described in conjunction with accompanying drawing:

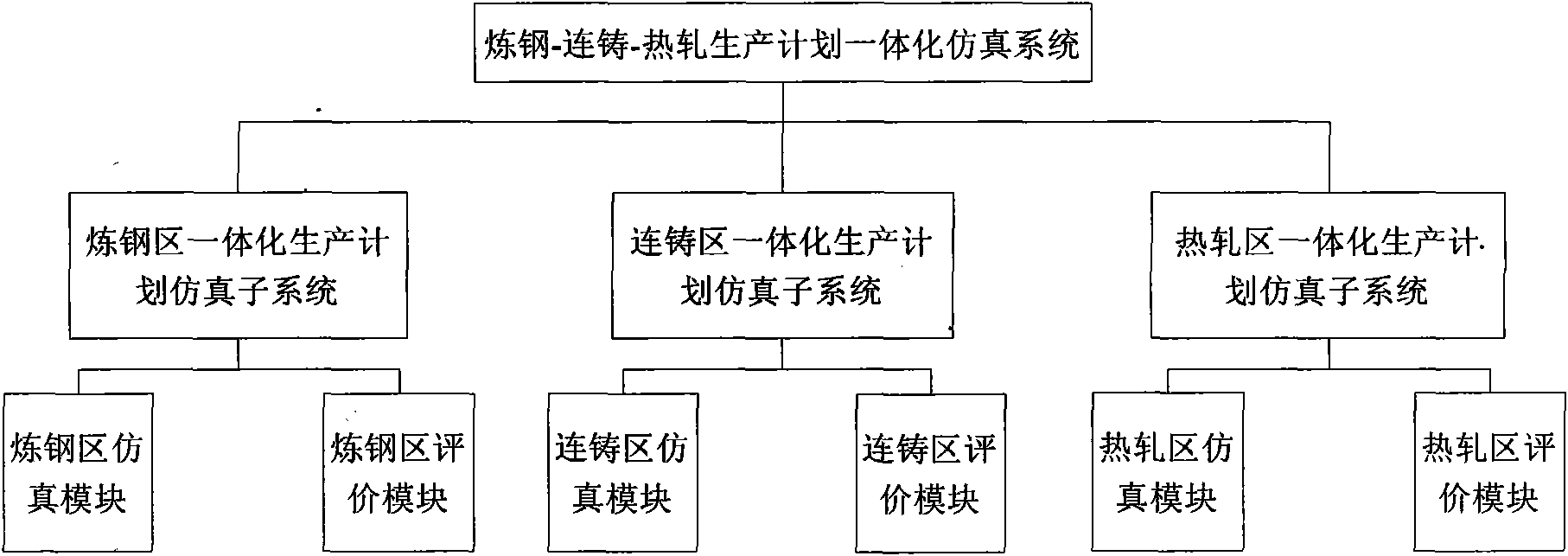

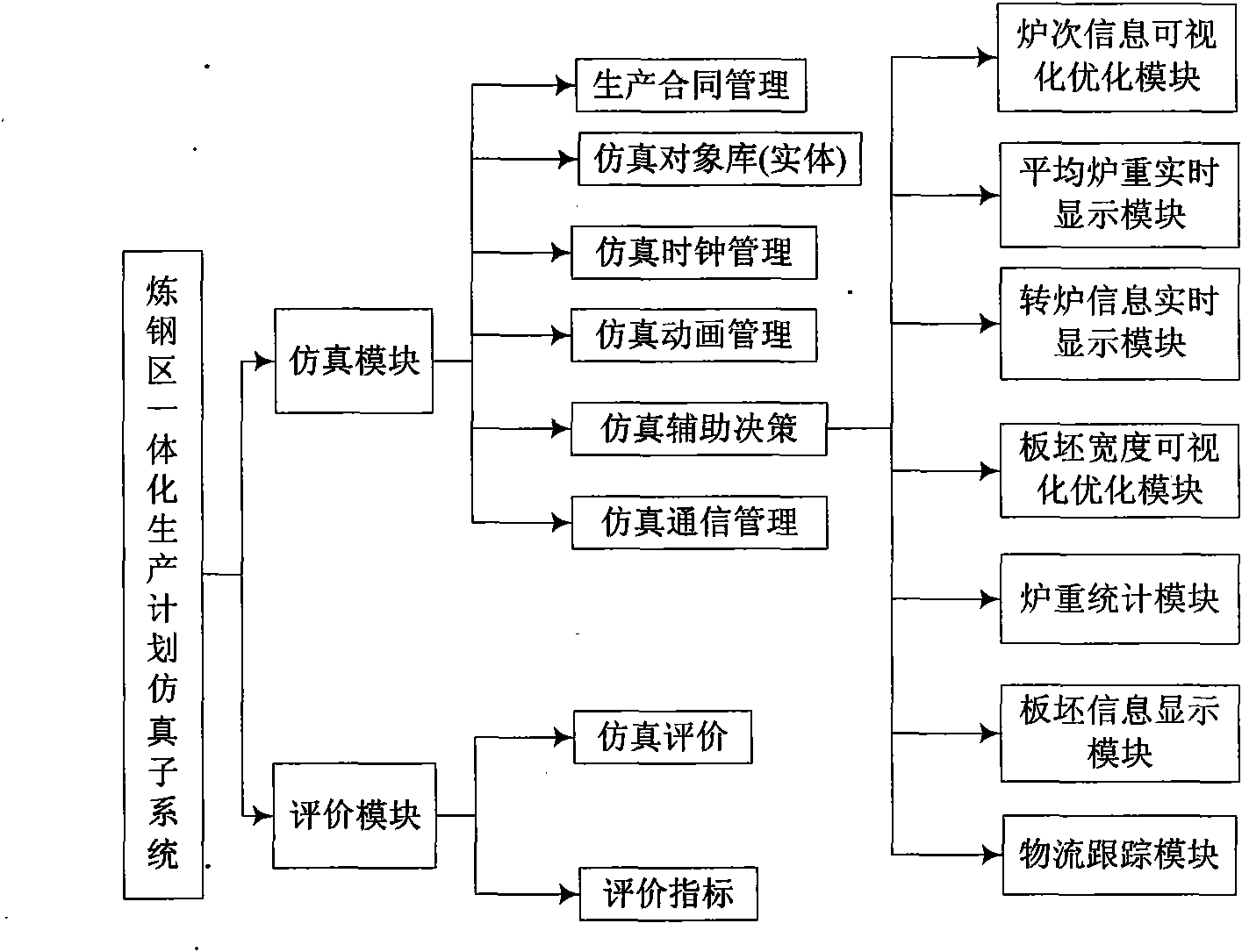

[0041]The steelmaking-continuous casting-hot rolling production plan integrated simulation system of the present invention is based on the flexsim software platform, including three steelmaking area plan simulation subsystems, continuous casting area plan simulation subsystems, and hot rolling area plan simulation subsystems The system realizes the integration of the three areas through the socket communication mechanism. For each subsystem, the corresponding planner integrates expert experience with the system to carry out dynamic human-computer interaction to realize the dynamic optimization of the plan. At the same time, the 3D simulation of the integrated production process of steelmaking-continuous casting-hot rolling has been realized.

[0042] The steelmaking-continuous casting-hot rolling integrated production planning simulation system mainly includes the integrated producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com