Clamping manipulator for tobacco dedicated charging basket

A manipulator and bucket technology, applied in the field of manipulators, can solve the problems of inconvenient cleaning of pipelines, waste of raw materials, high labor intensity, etc., and achieve the effects of eliminating the quality accident of artificially sending wrong materials, improving the sanitary environment, and reducing the consumption of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

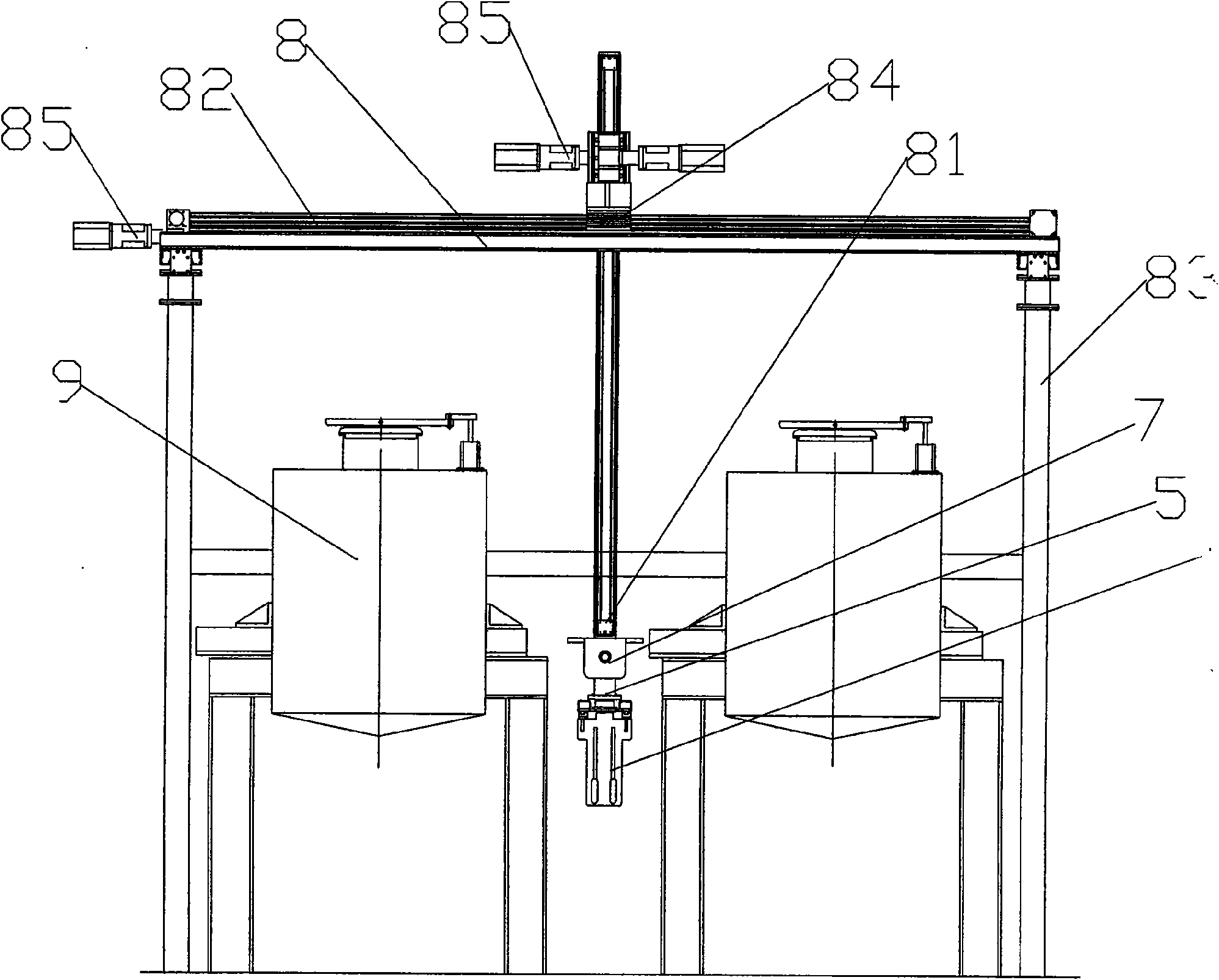

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

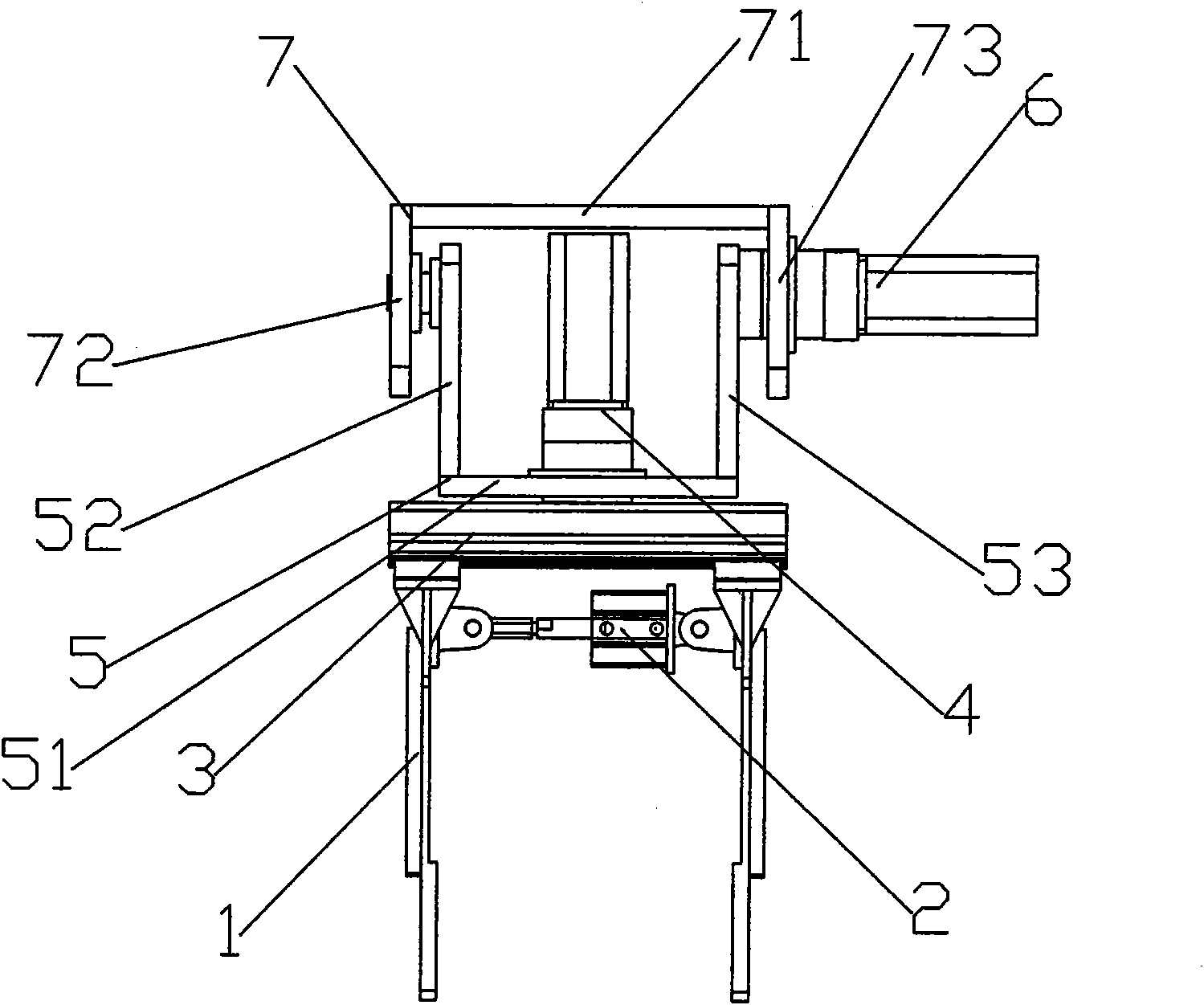

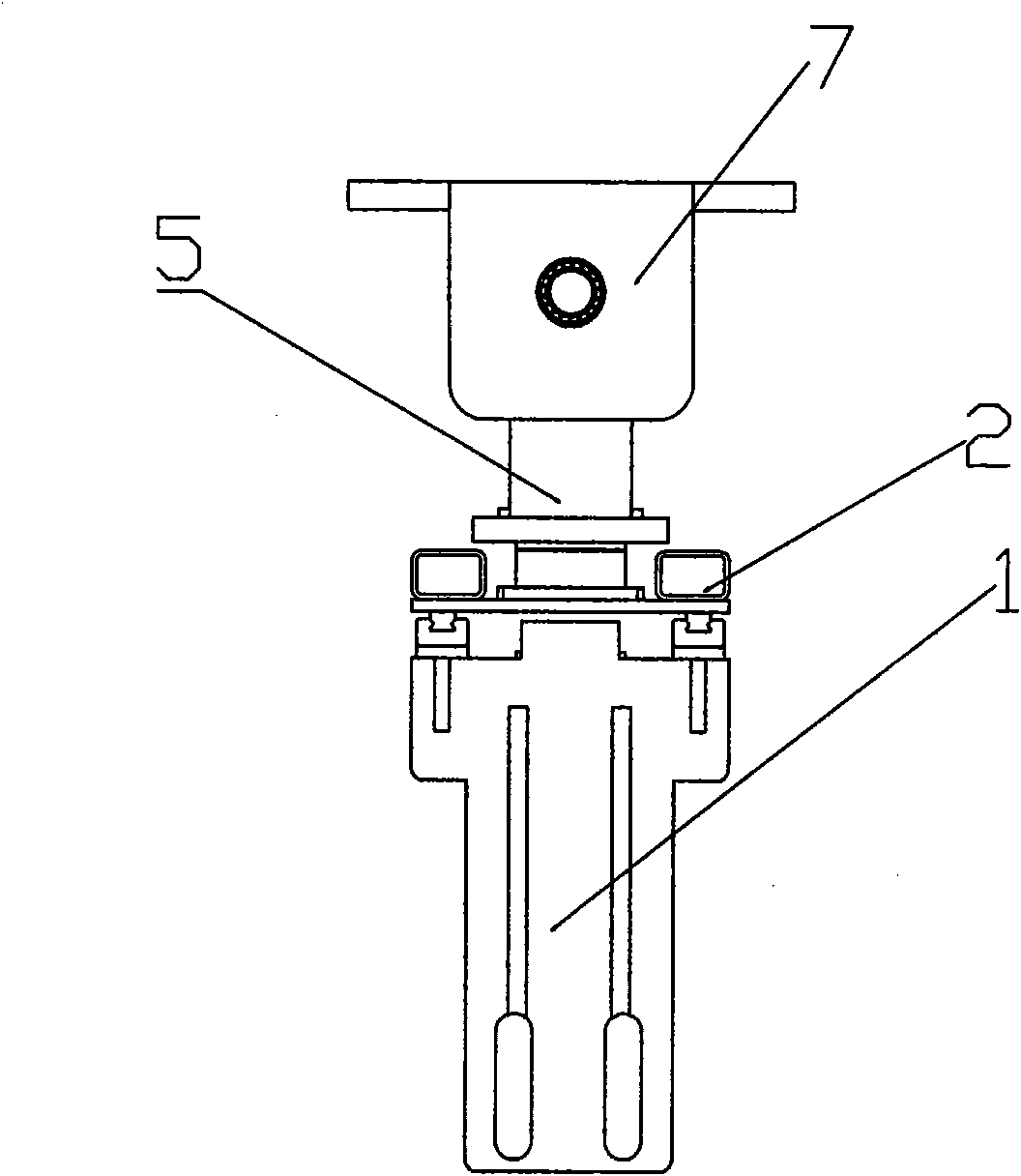

[0014] like figure 1 , 2 As shown, the tobacco-specific barrel holding and clamping manipulator includes a clamping claw, and the clamping claw includes a claw guide rail 3 and two clamping claw pieces 1, and the two clamping claw pieces 1 and the claw guide rail 3 connection, two clamping claw pieces 1 are connected by a cylinder 2, and the cylinder 2 reciprocatingly expands and contracts to drive the clamping claw piece 1 to slide back and forth on the claw guide rail 3.

[0015] A rotary servo motor 4 is arranged above the hand claw guide rail 3, and the rotary servo motor 4 is fixed on the first motor support base 5. The first motor support base 5 includes a first horizontal plate 51, a first vertical plate 52 and a second vertical plate 53, the first vertical plate 52, the second vertical plate 53 are vertically connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com