Patents

Literature

497results about "Terminal applying apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

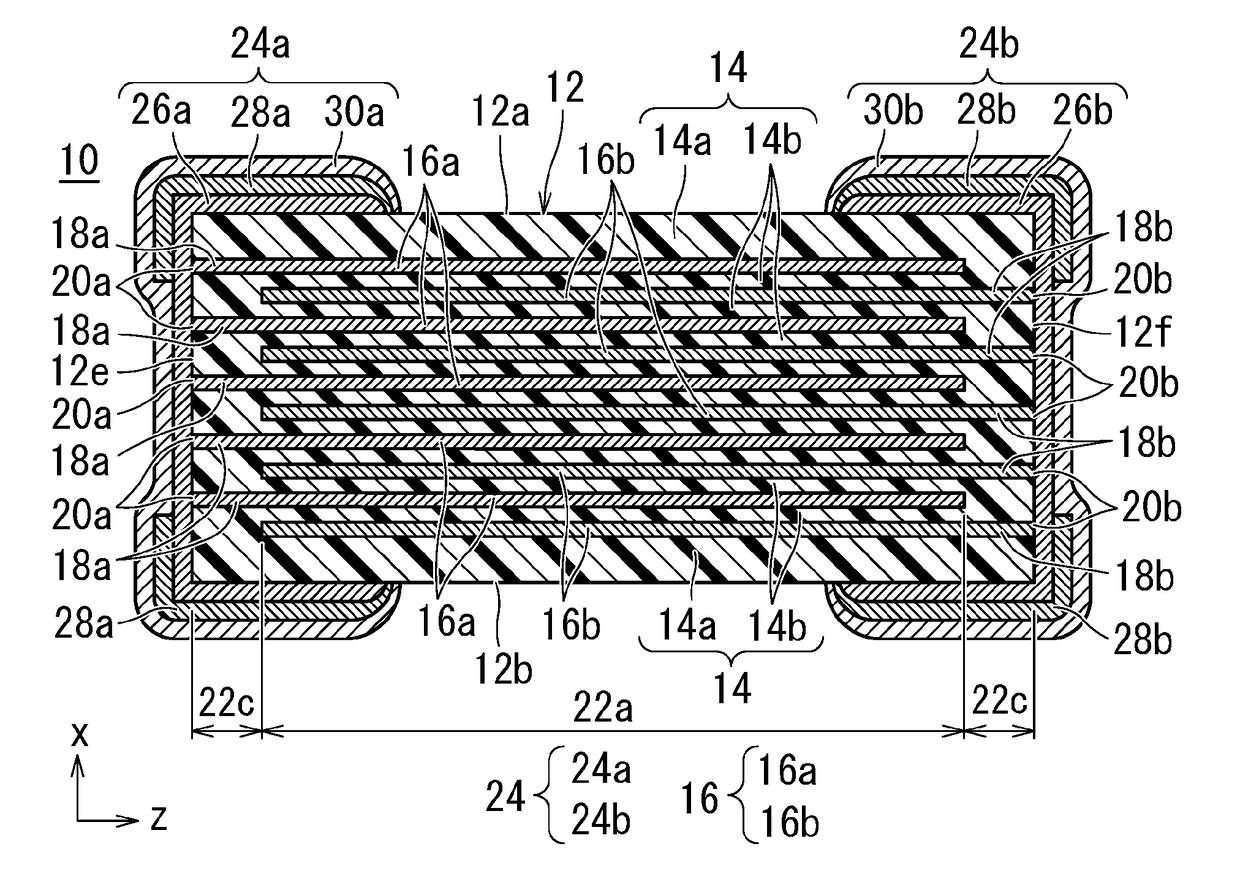

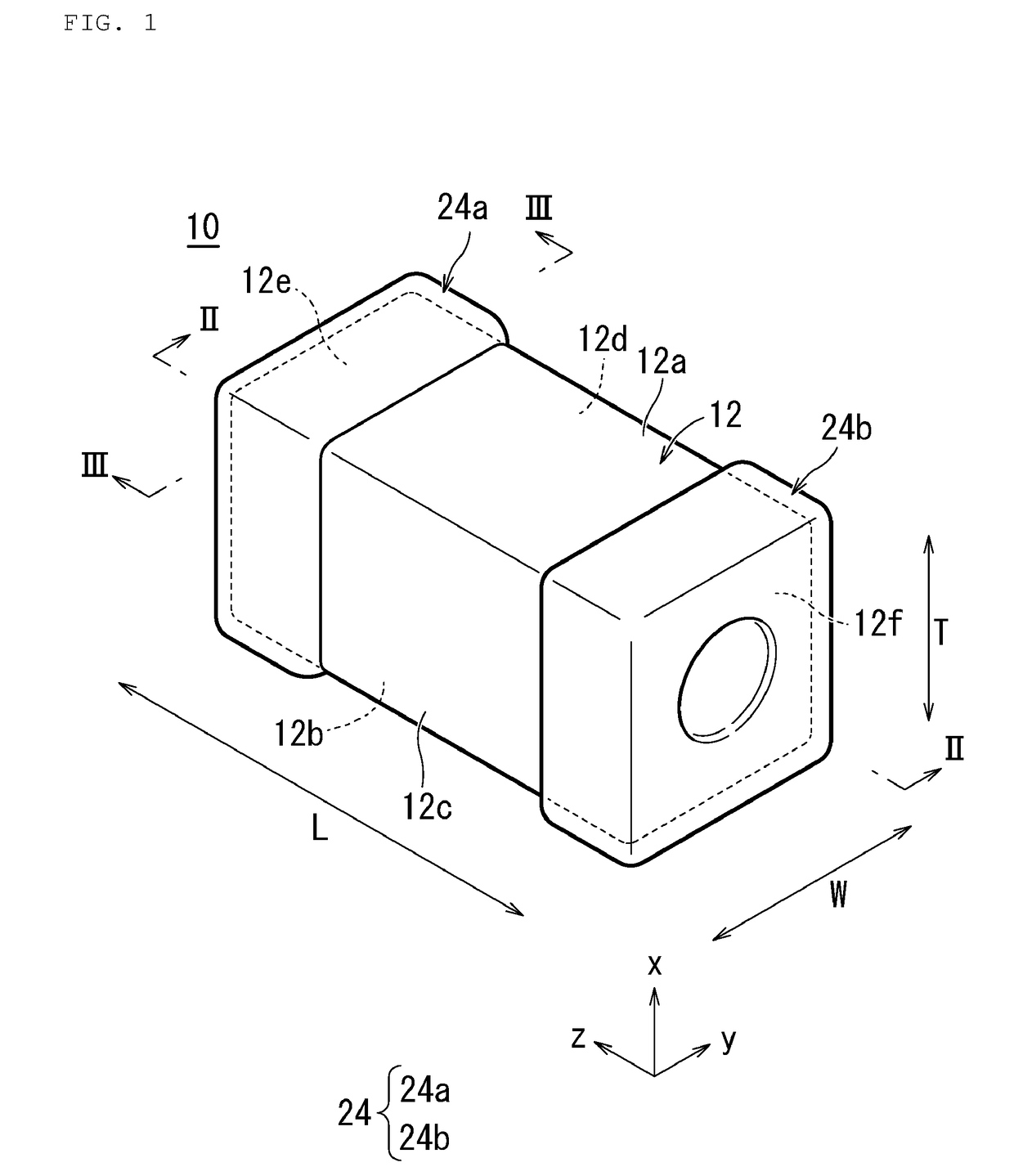

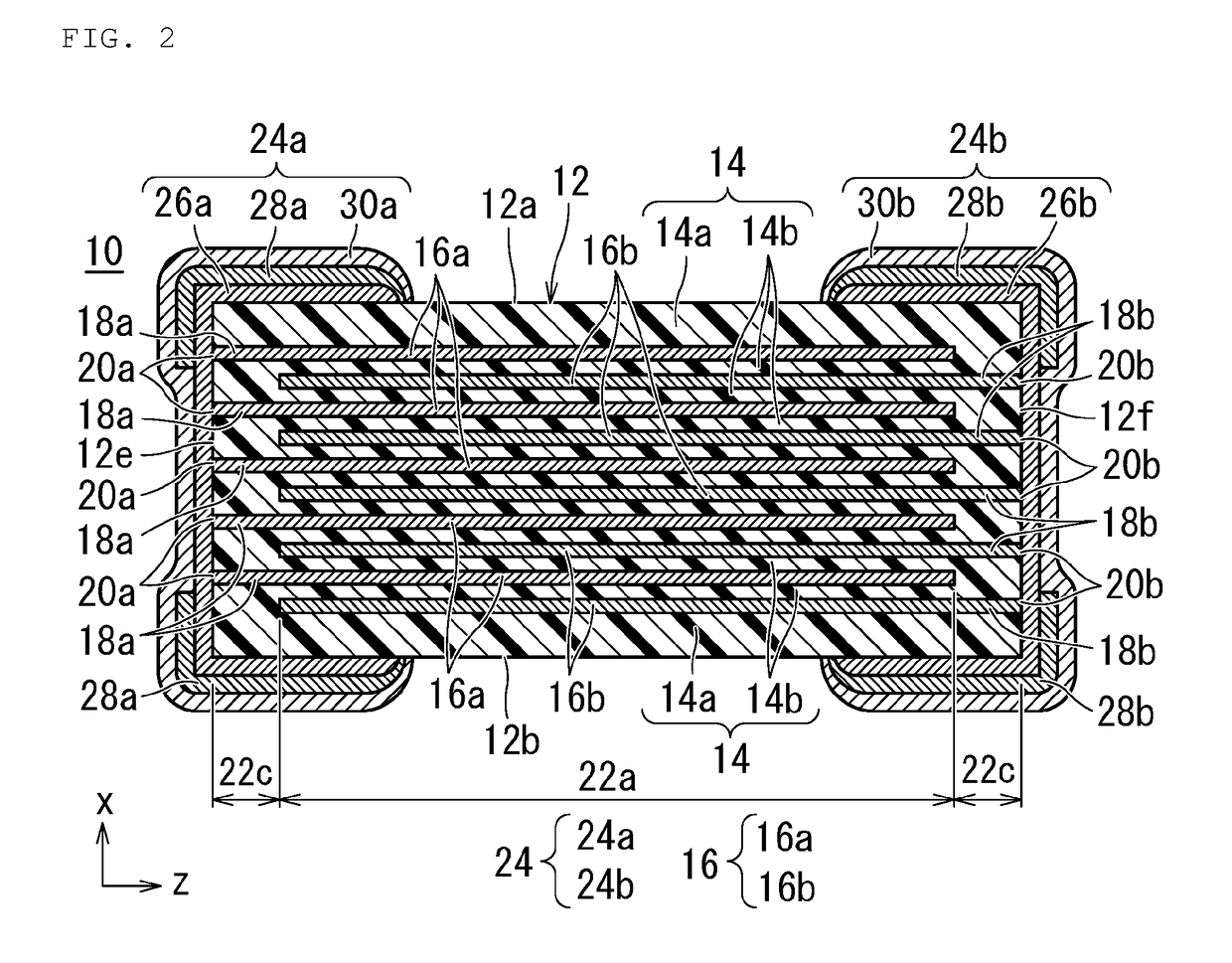

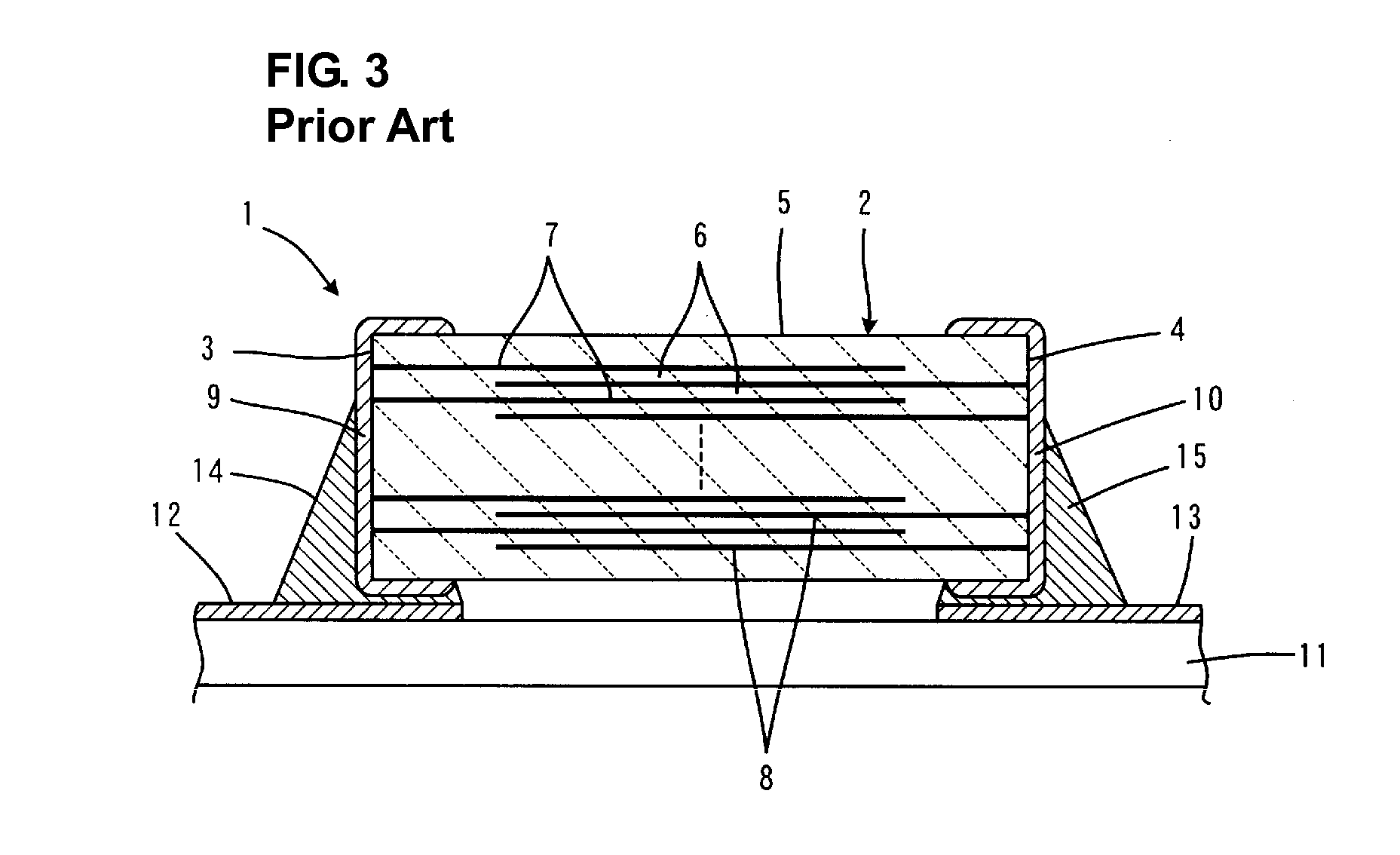

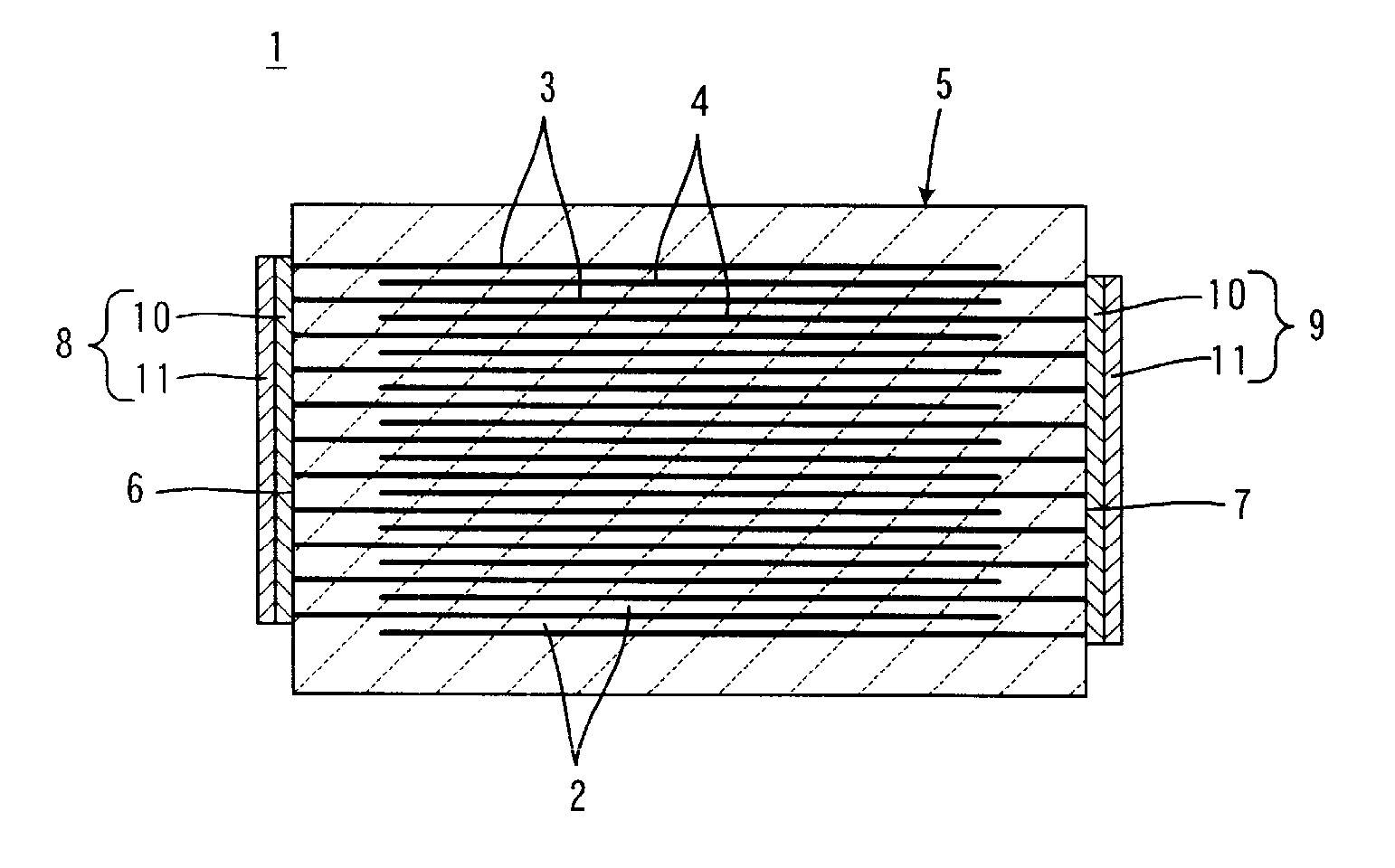

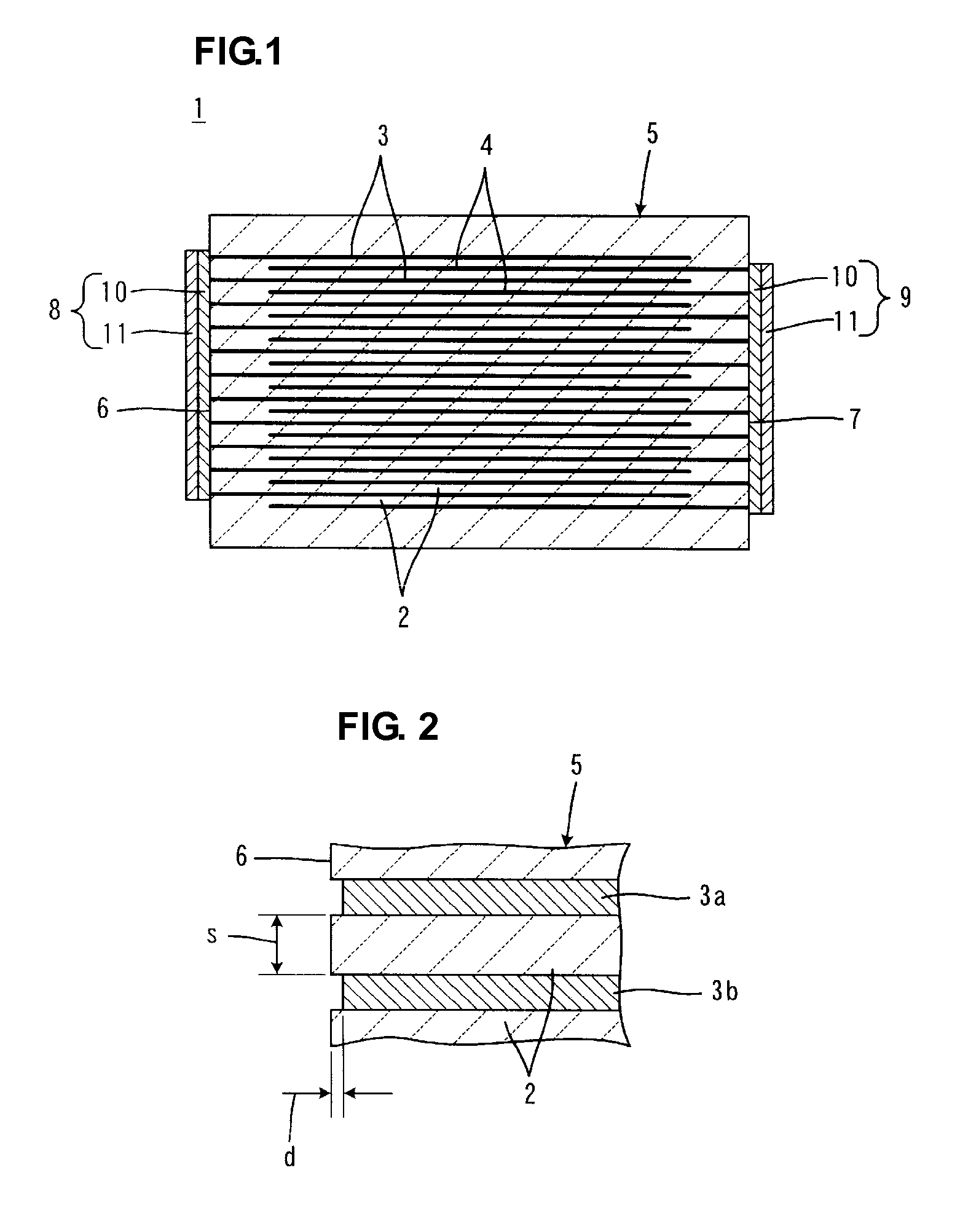

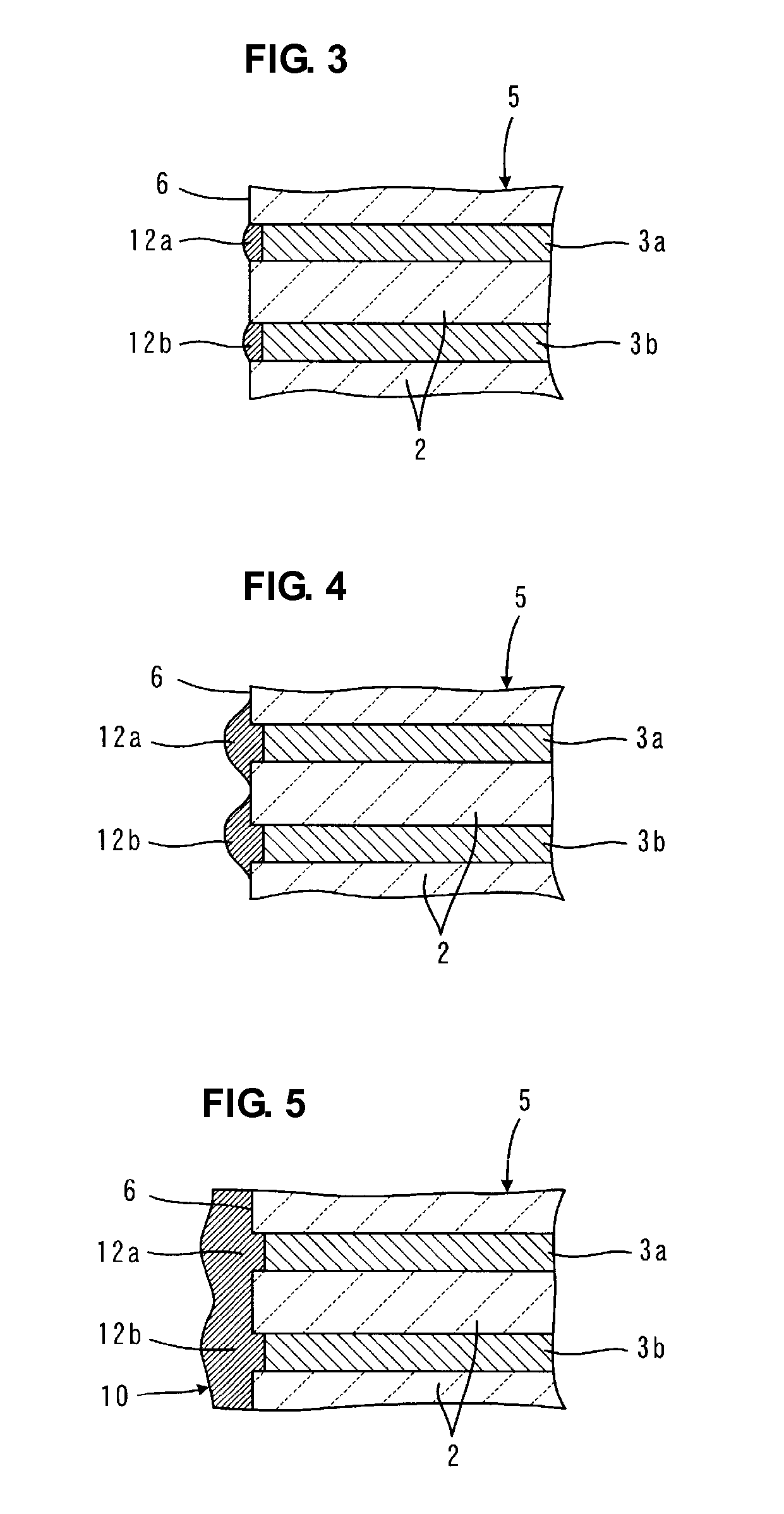

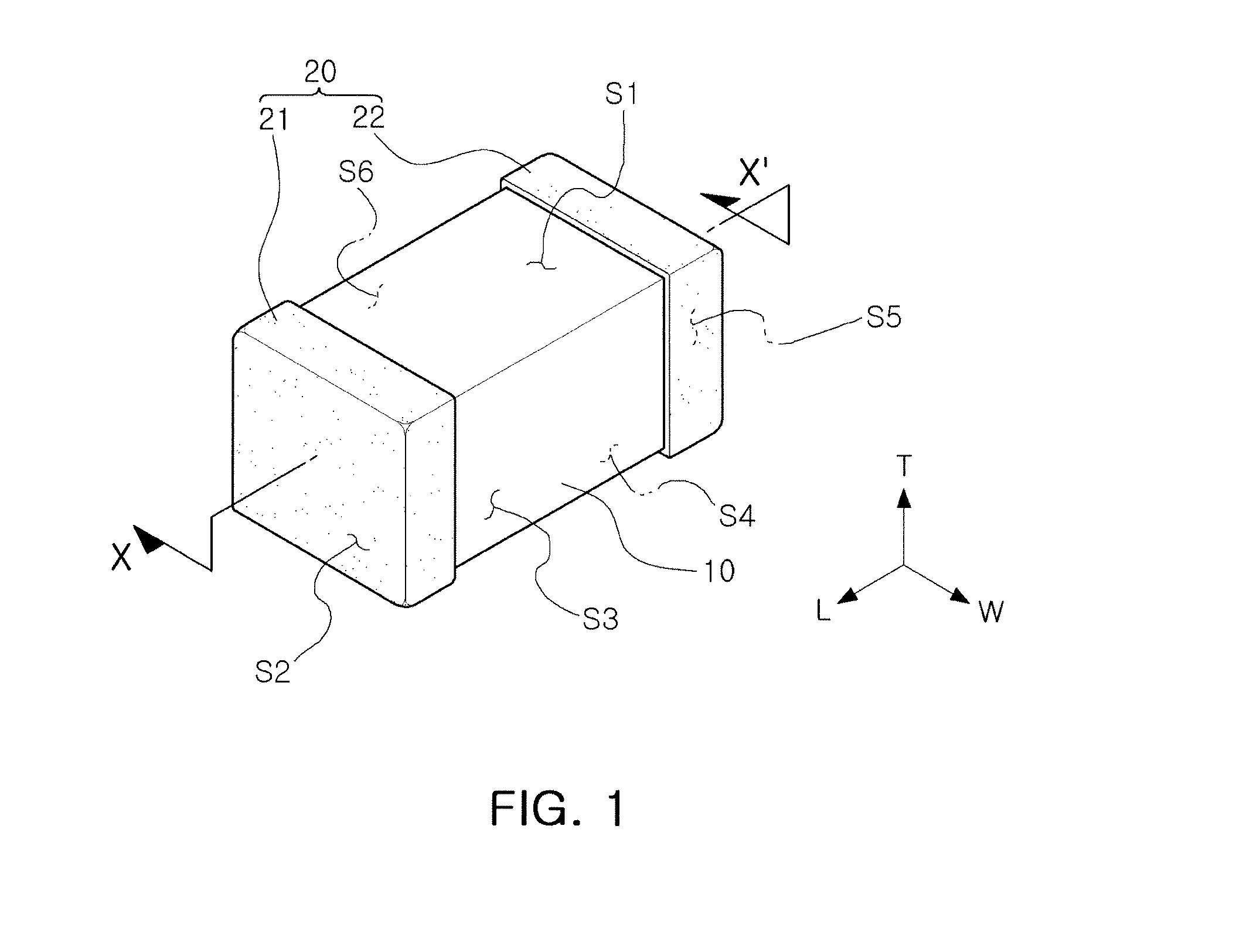

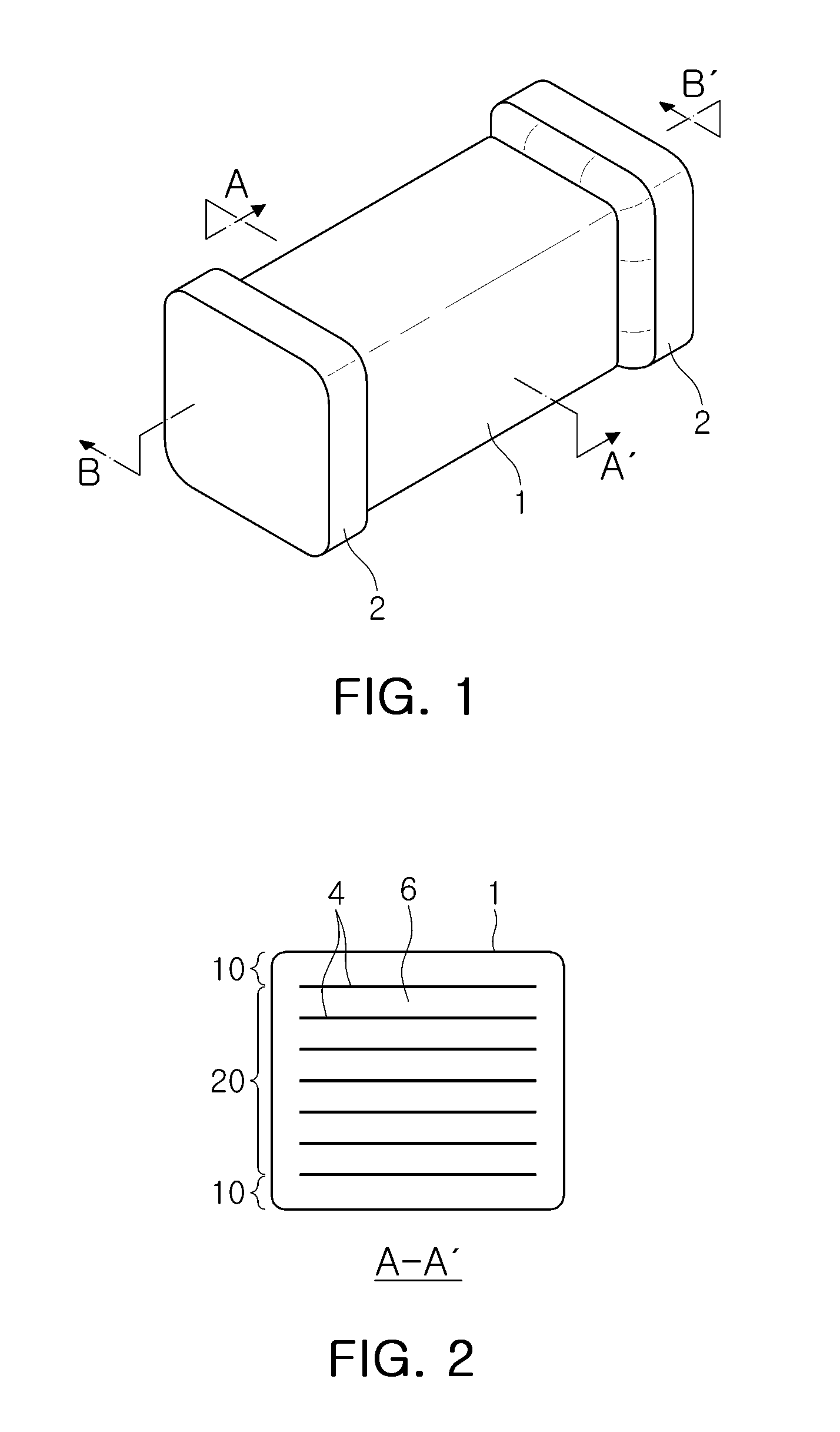

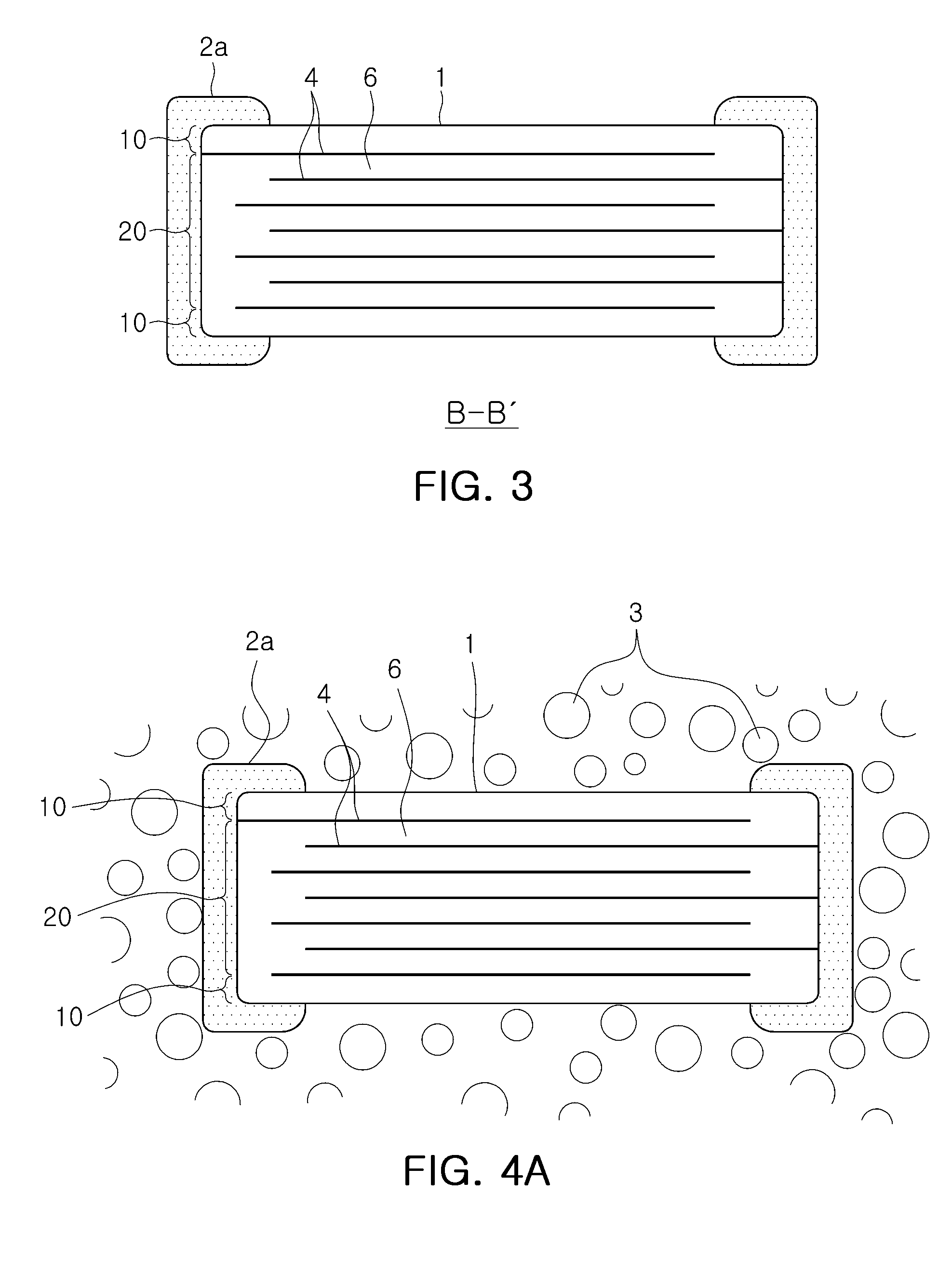

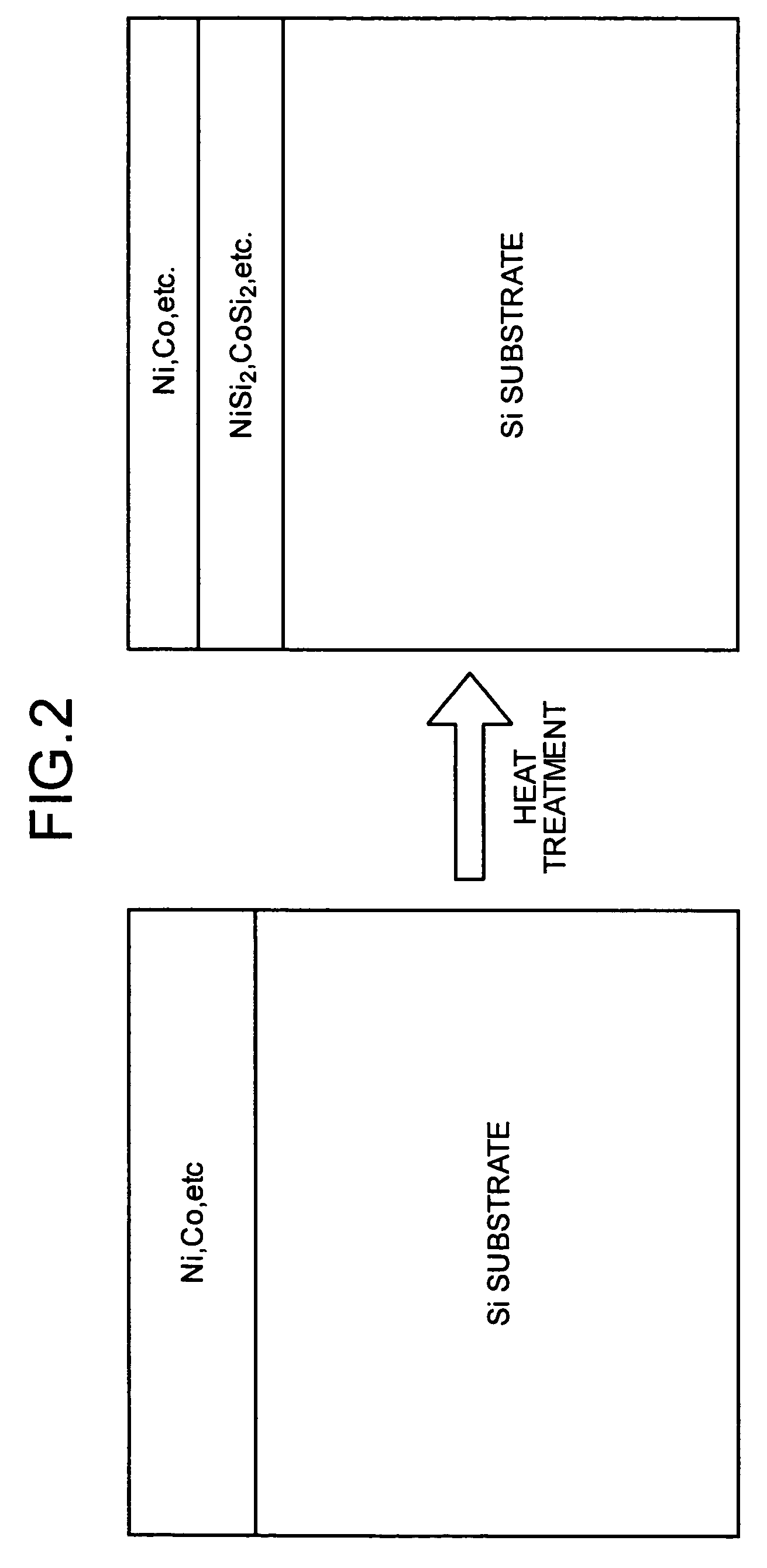

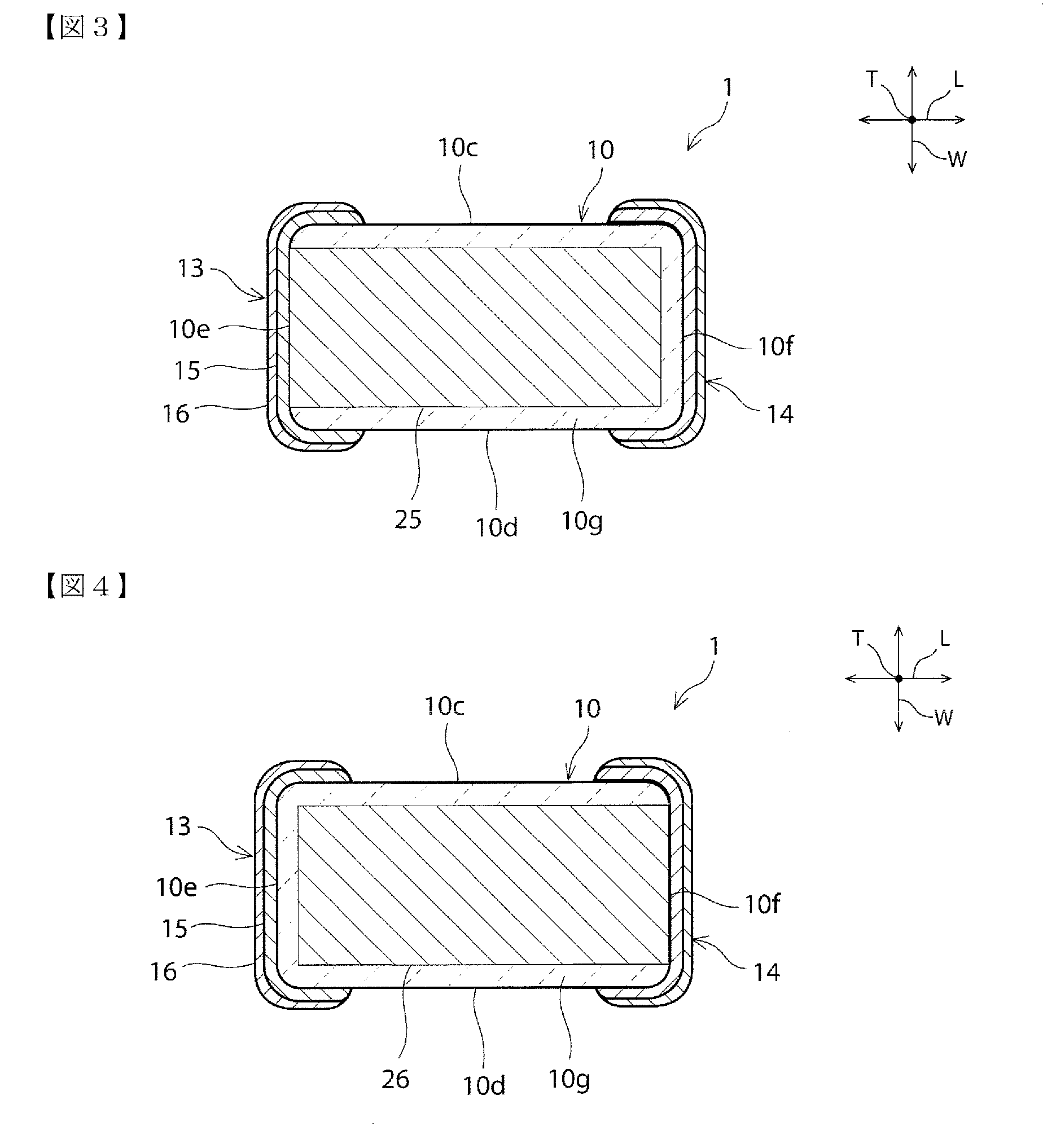

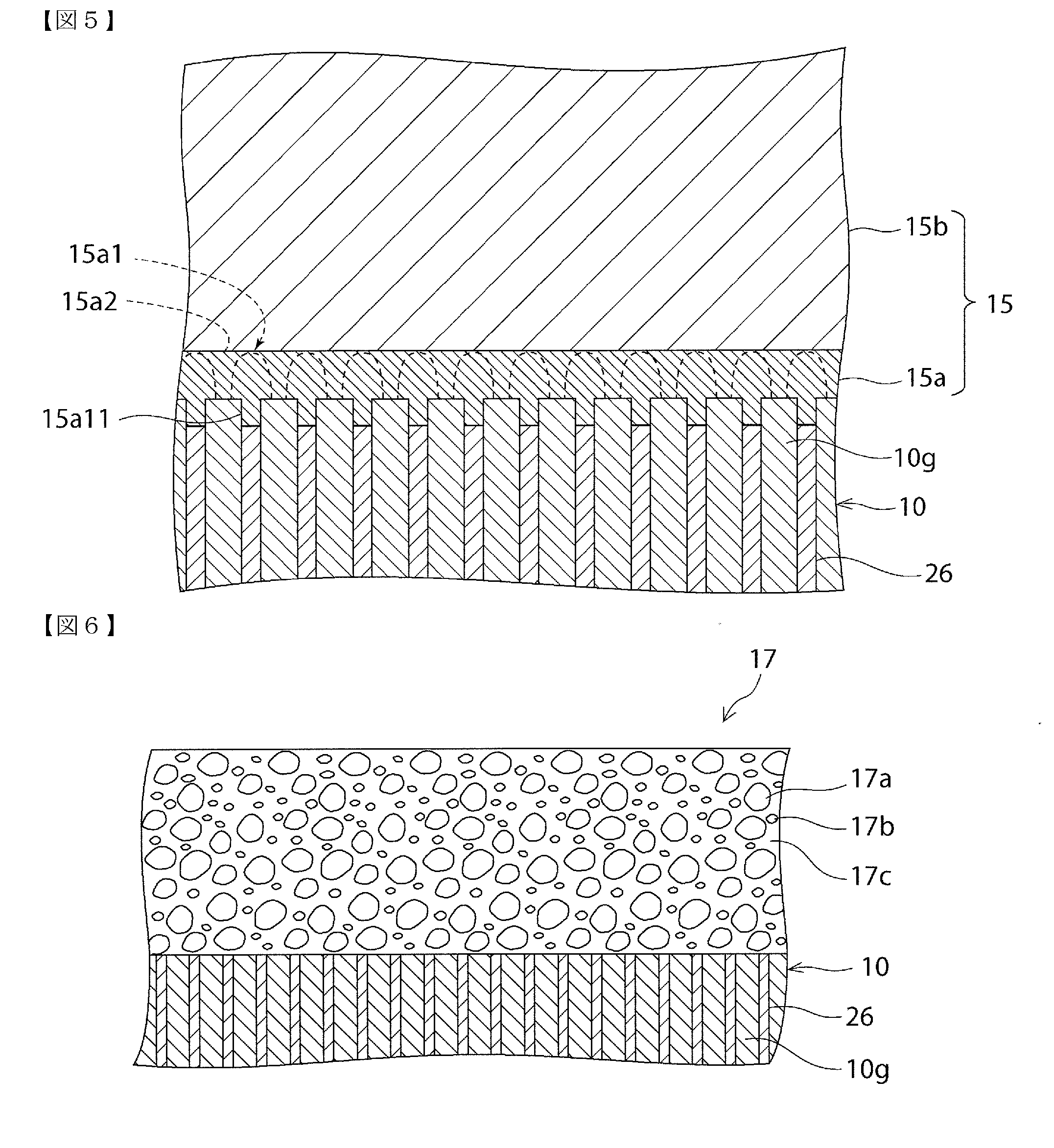

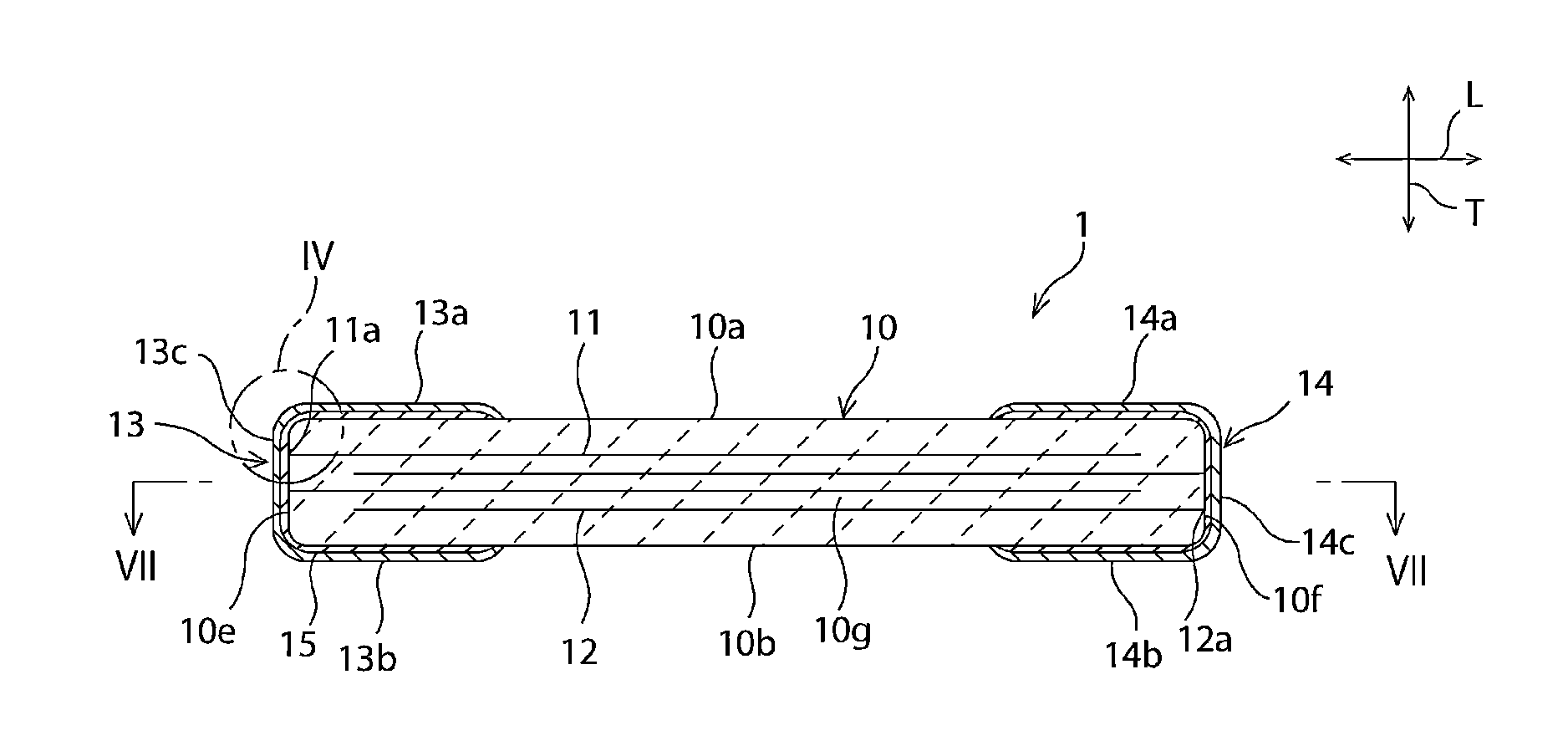

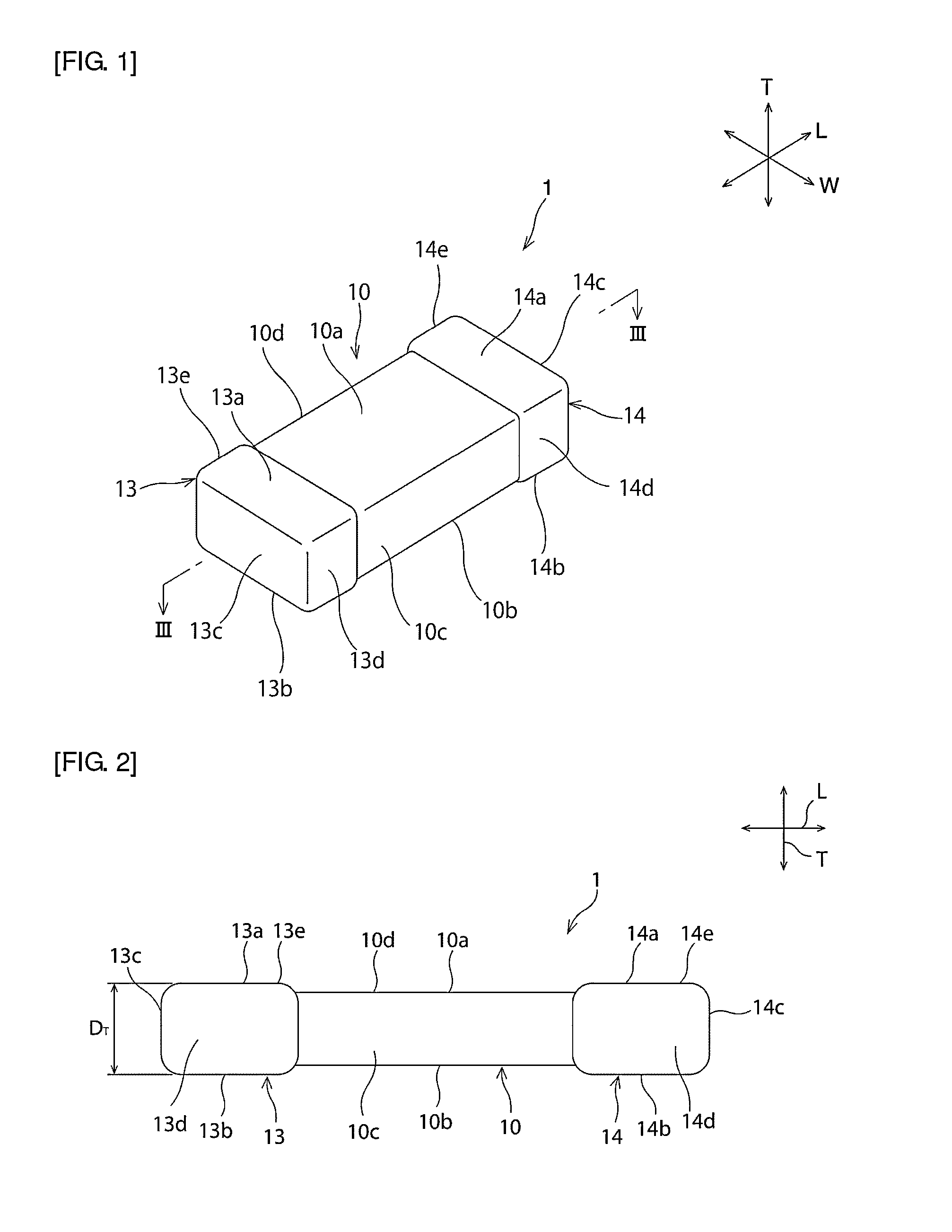

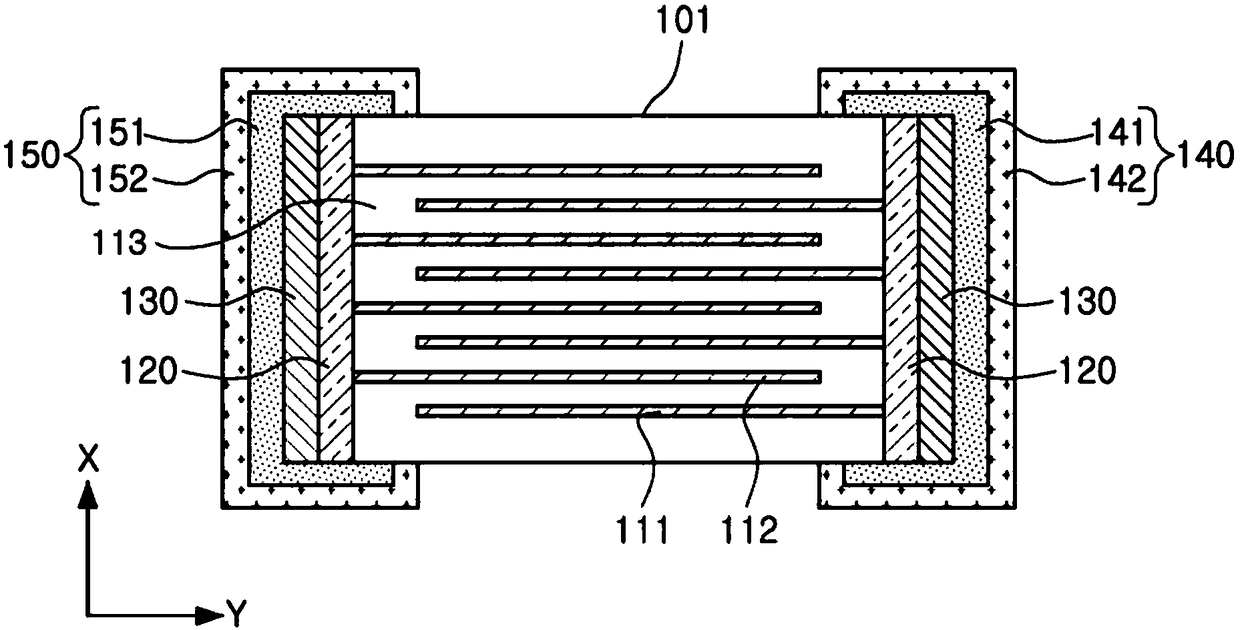

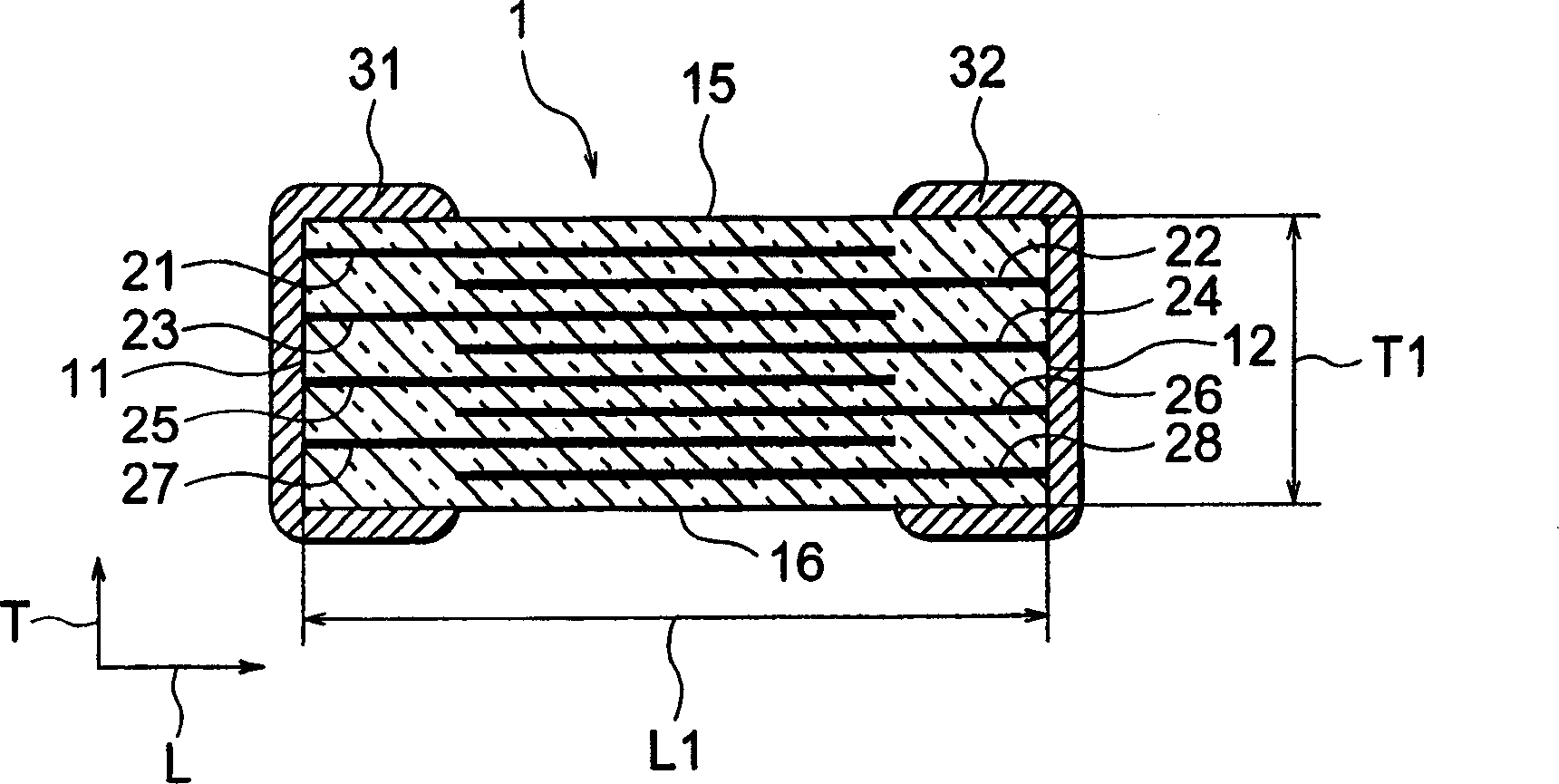

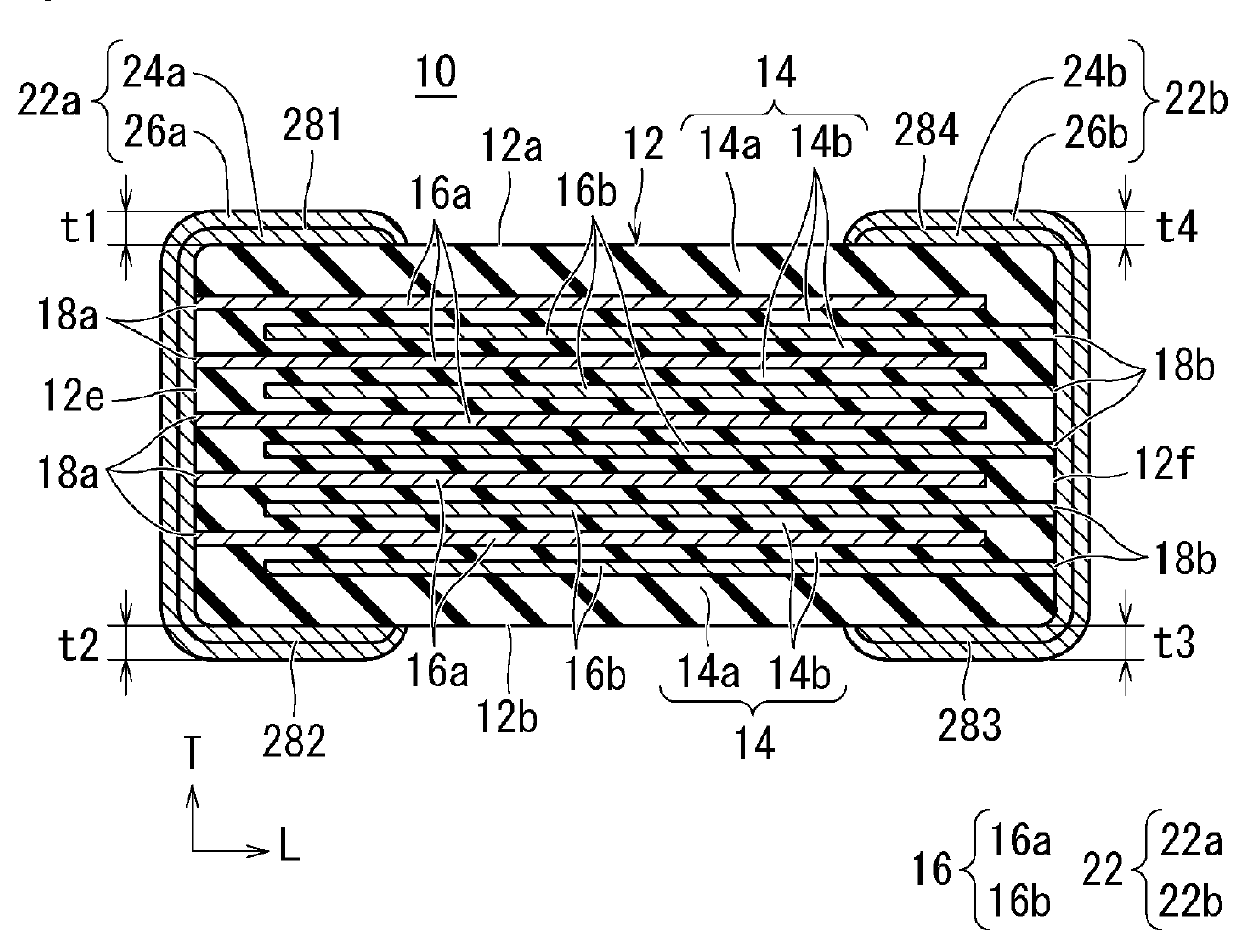

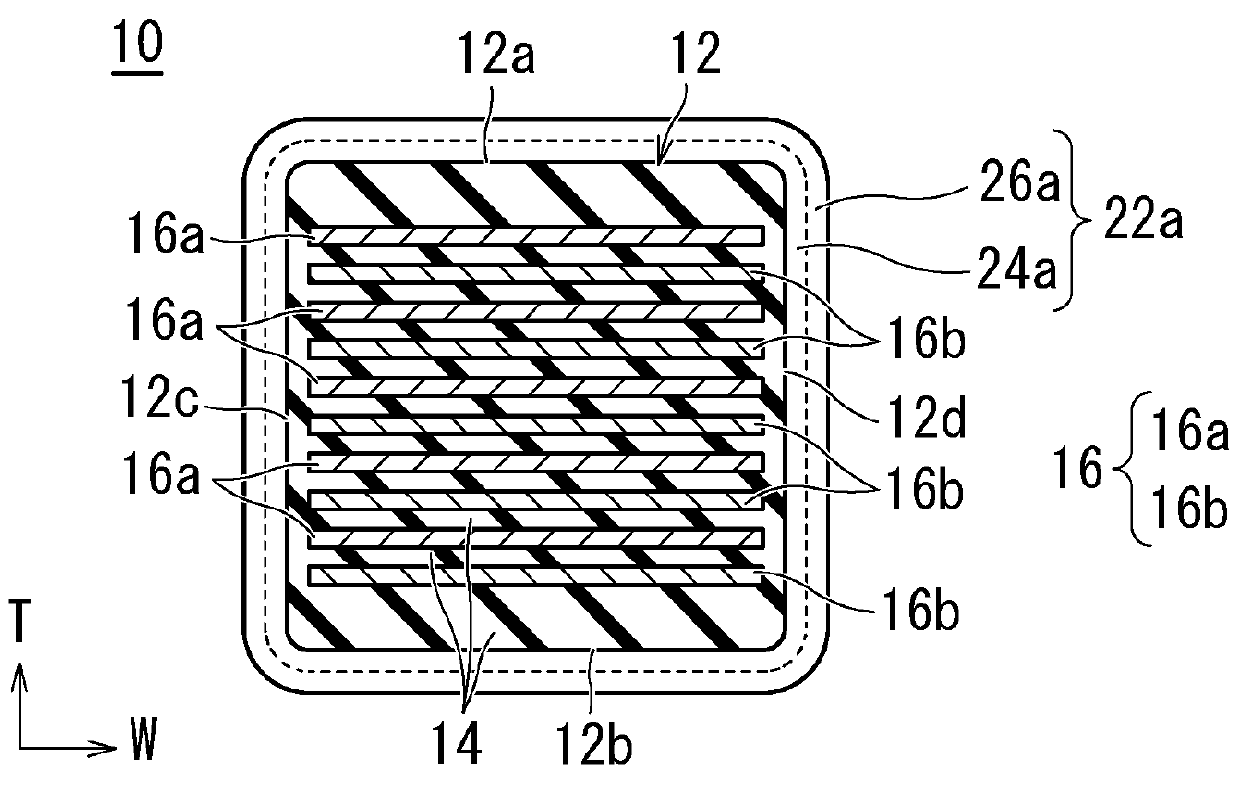

Multilayer ceramic capacitor

ActiveUS20180174753A1Reduce and prevent increaseCrack can be prevented and reducedFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorMaterials science

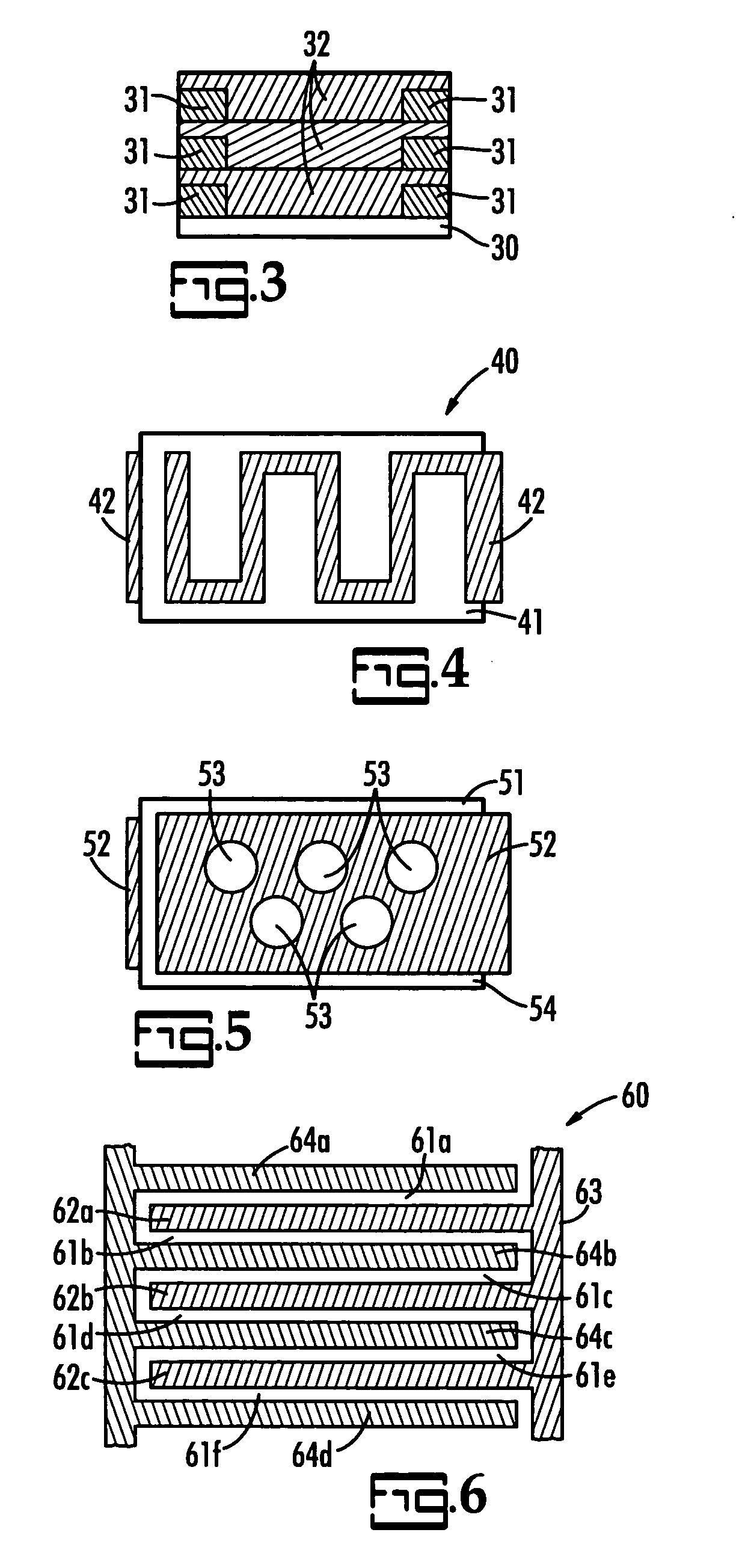

A multilayer ceramic capacitor includes a laminate and first and second external electrodes that each include first and second underlying electrode layers, first and second conductive resin layers, and first and second plating layers. The first underlying electrode layer includes a portion not covered with the first conductive resin layer on an end surface of the laminate, and the first plating layer is disposed on a surface of the portion of the first underlying electrode layer. The second underlying electrode layer includes a portion not covered with the second conductive resin layer on an end surface of the laminate, and the second plating layer is disposed on a surface of the portion of the second underlying electrode layer.

Owner:MURATA MFG CO LTD

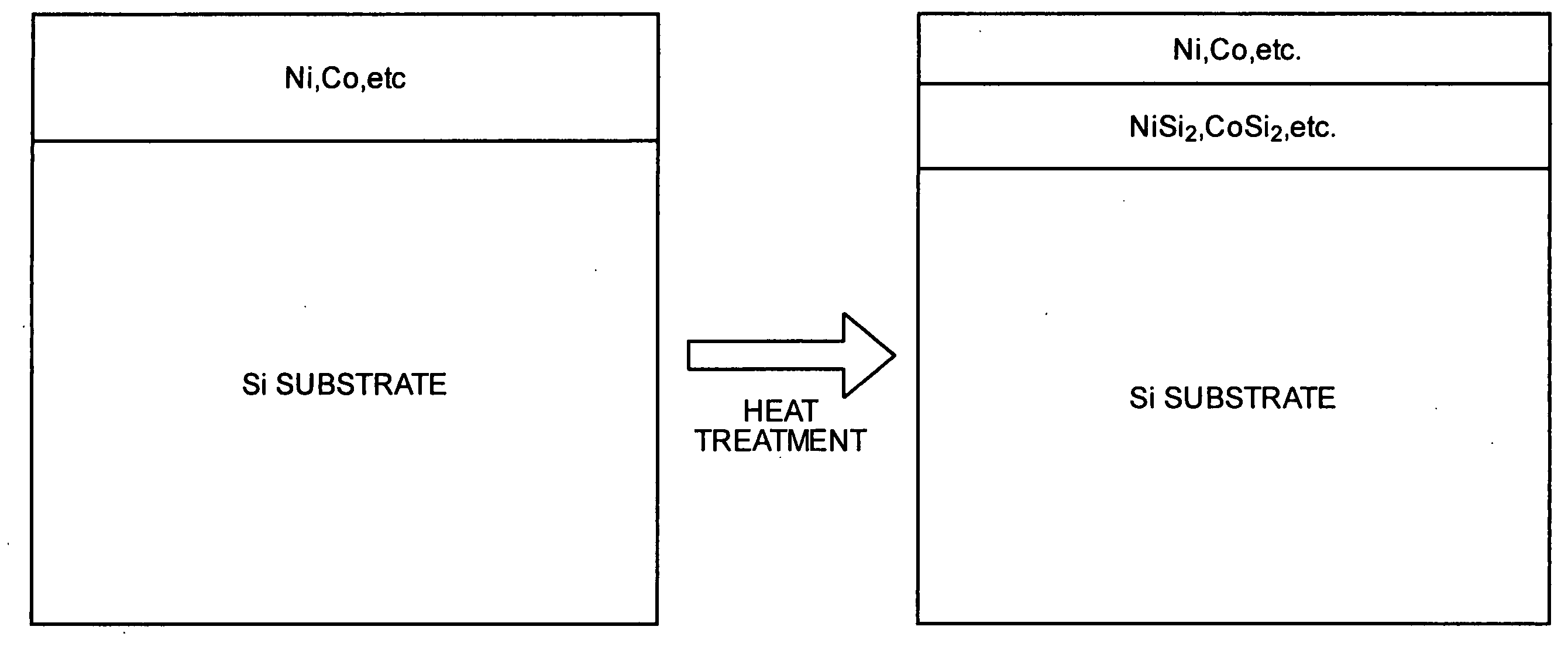

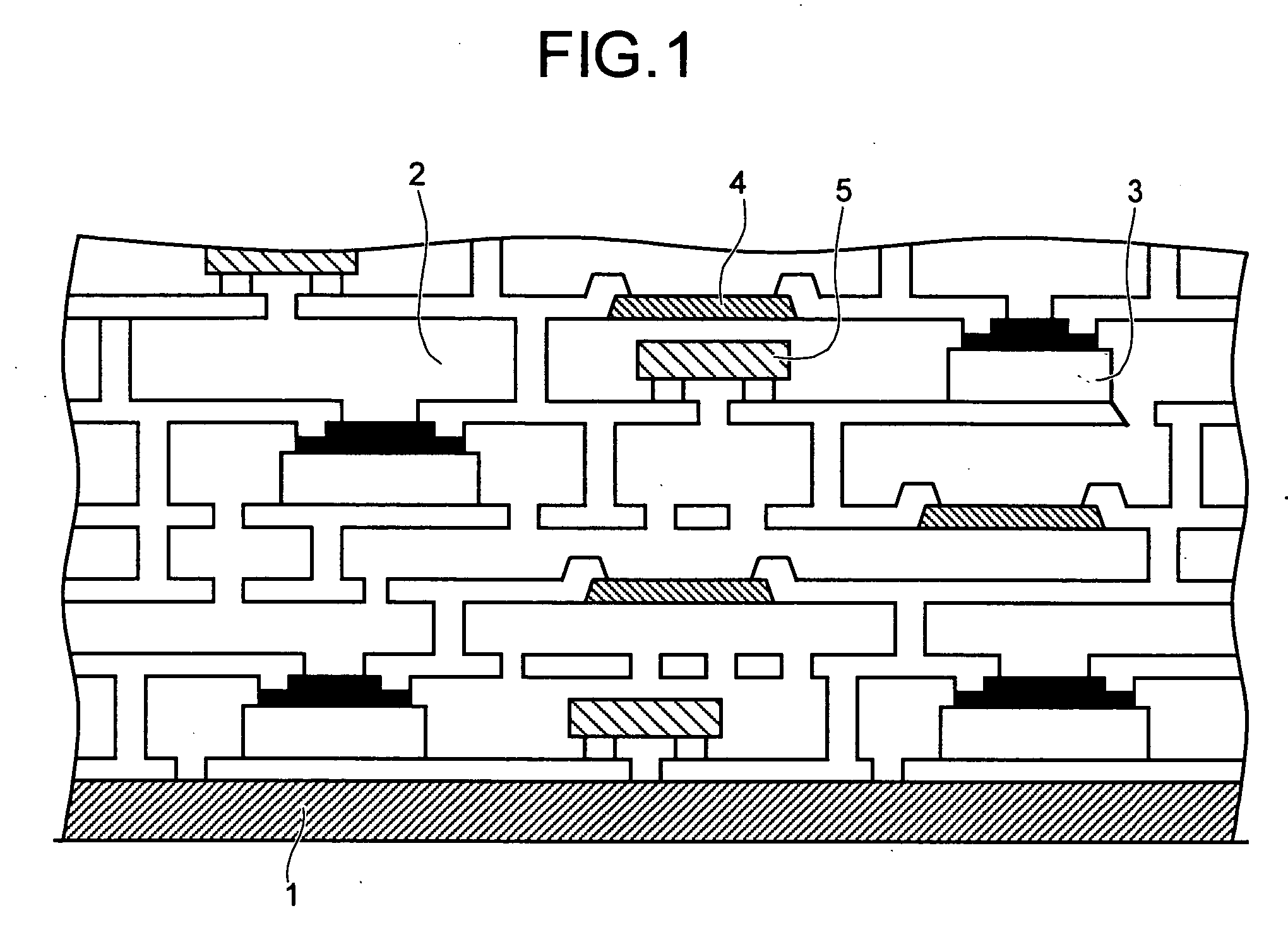

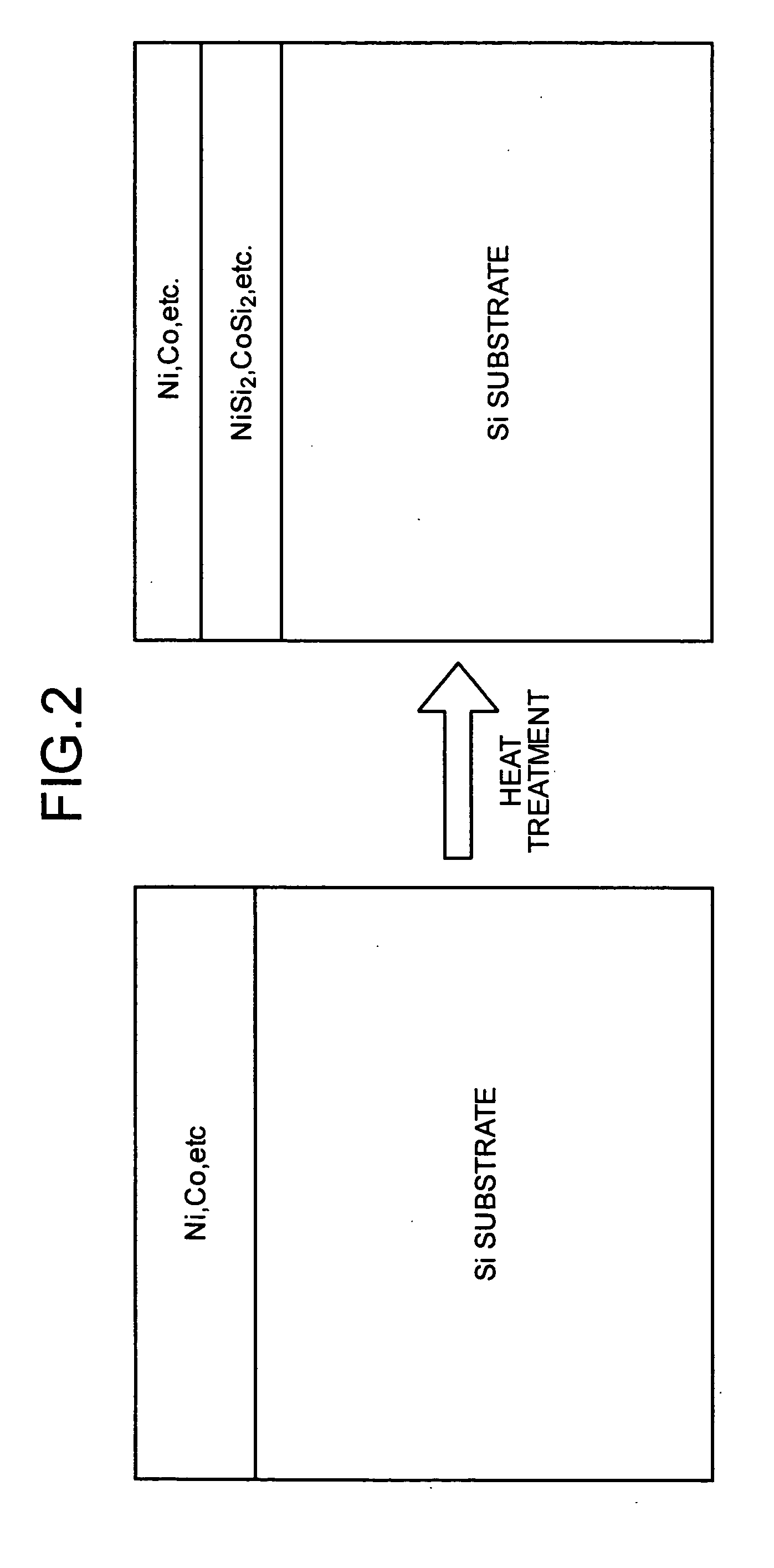

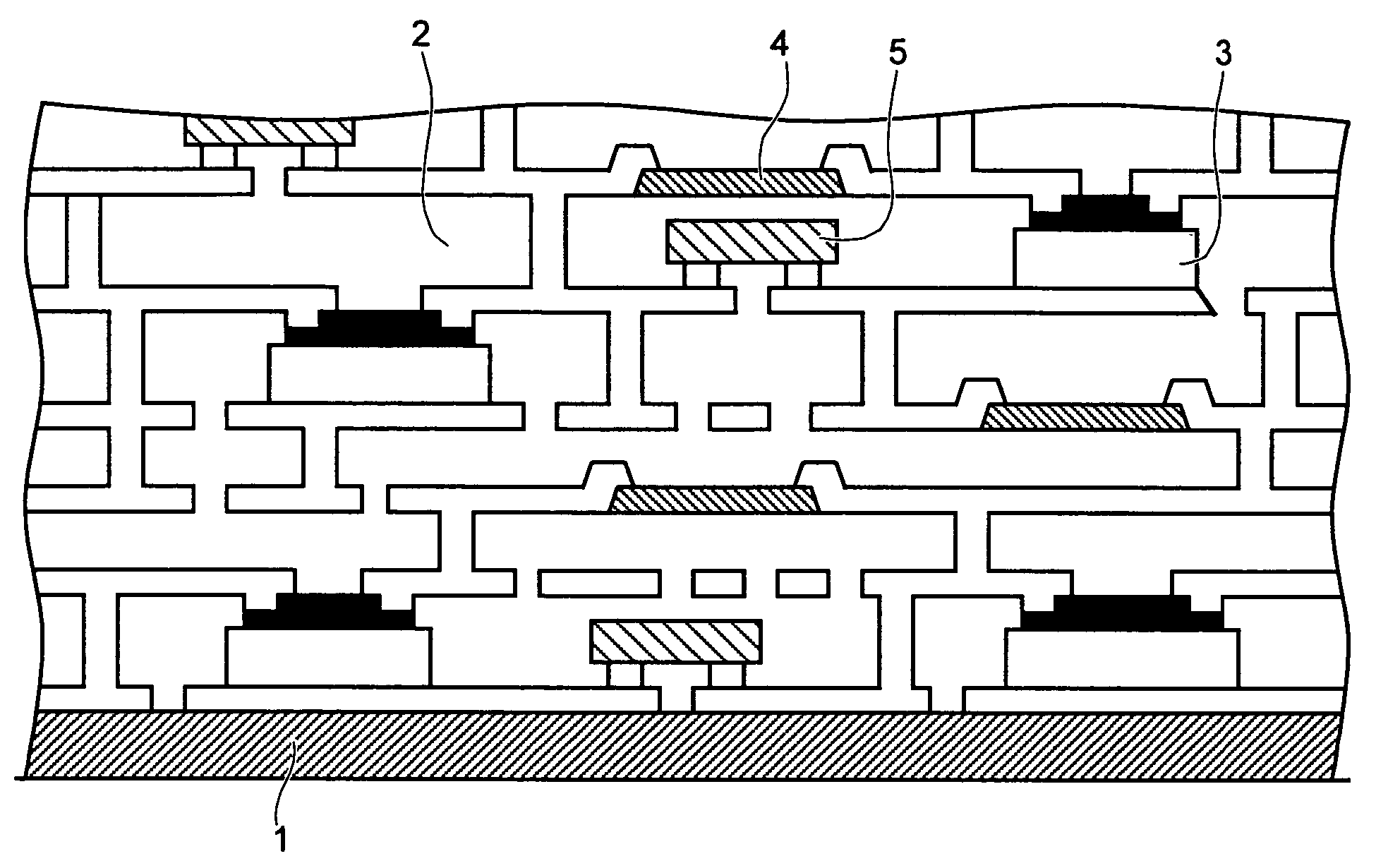

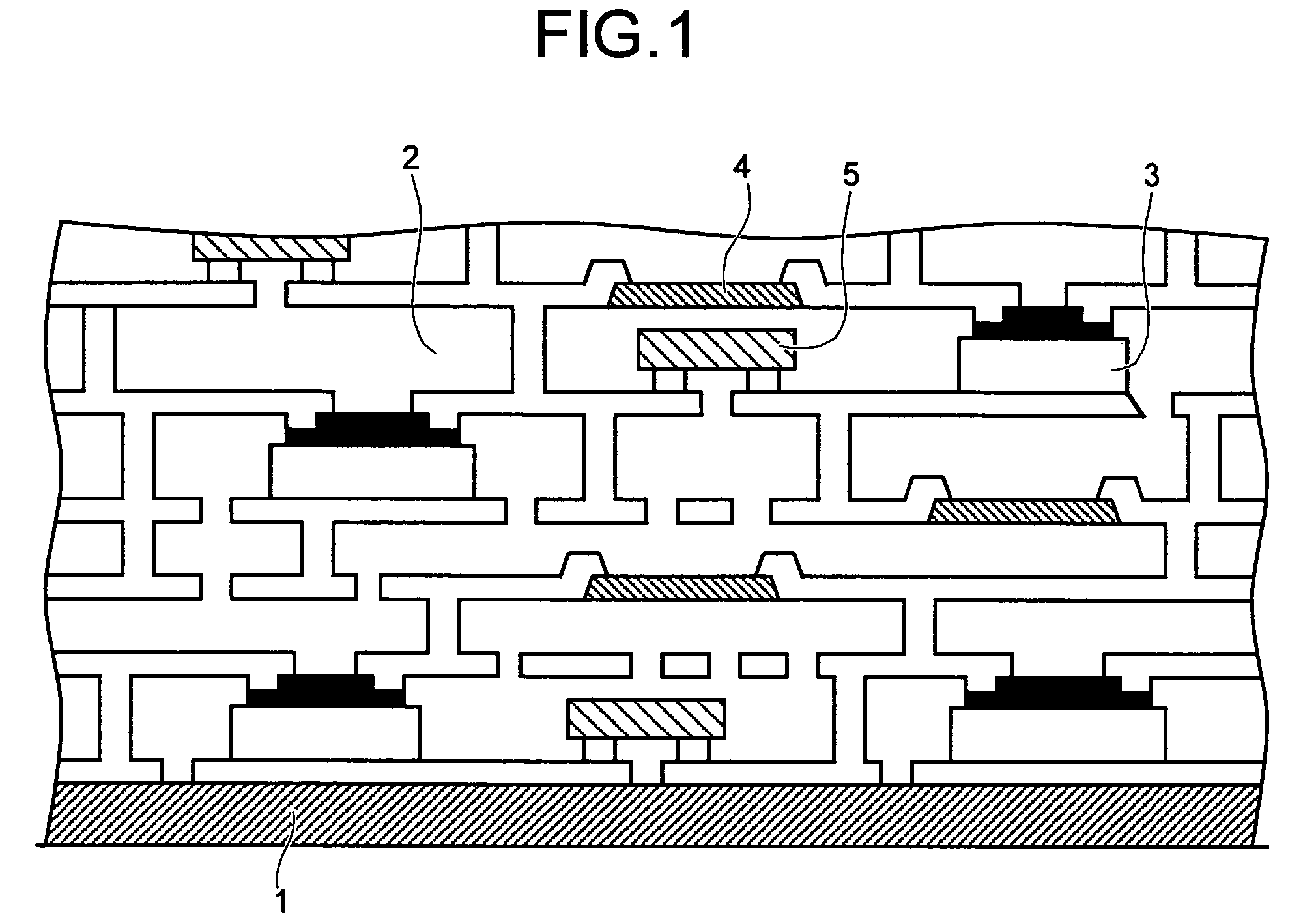

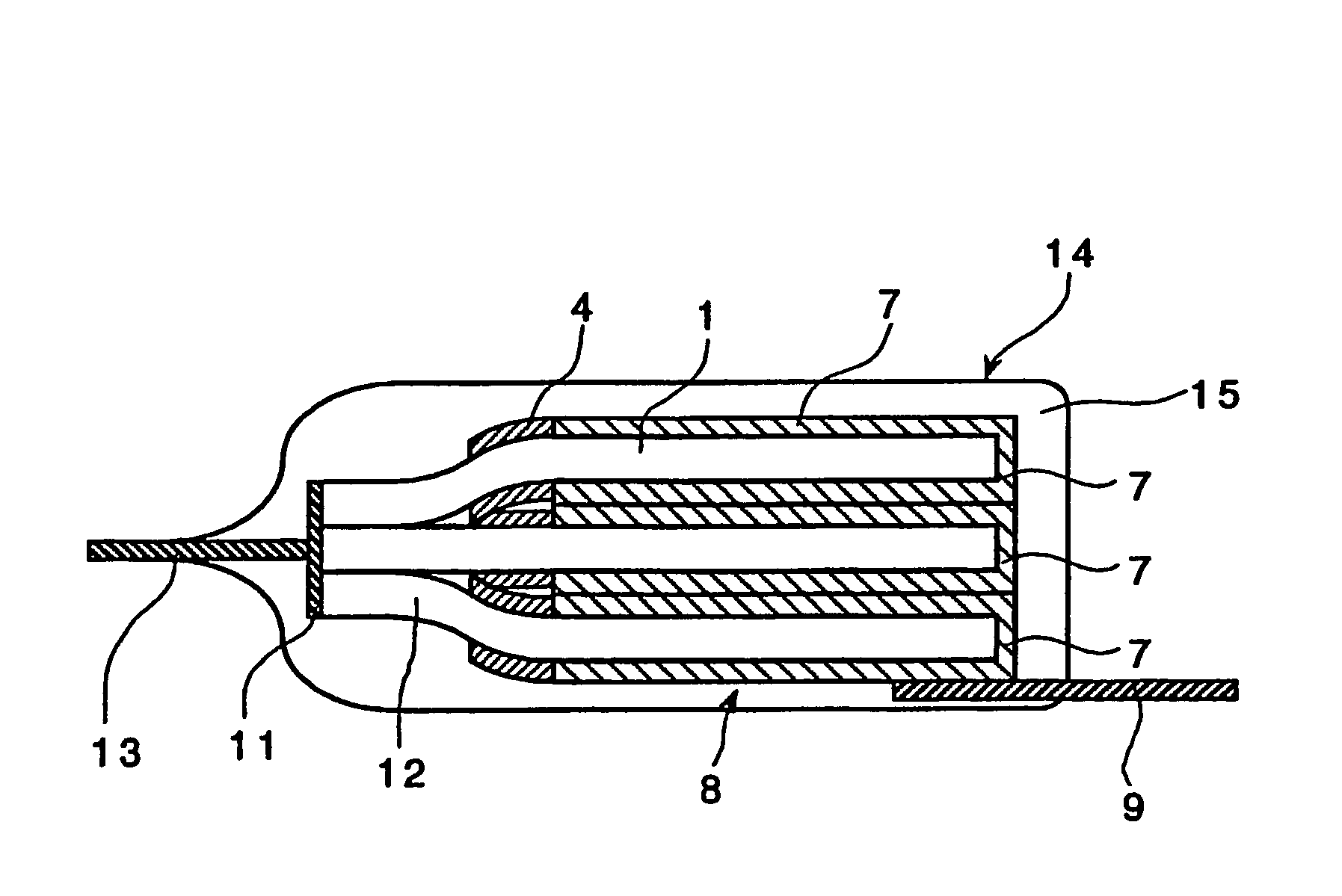

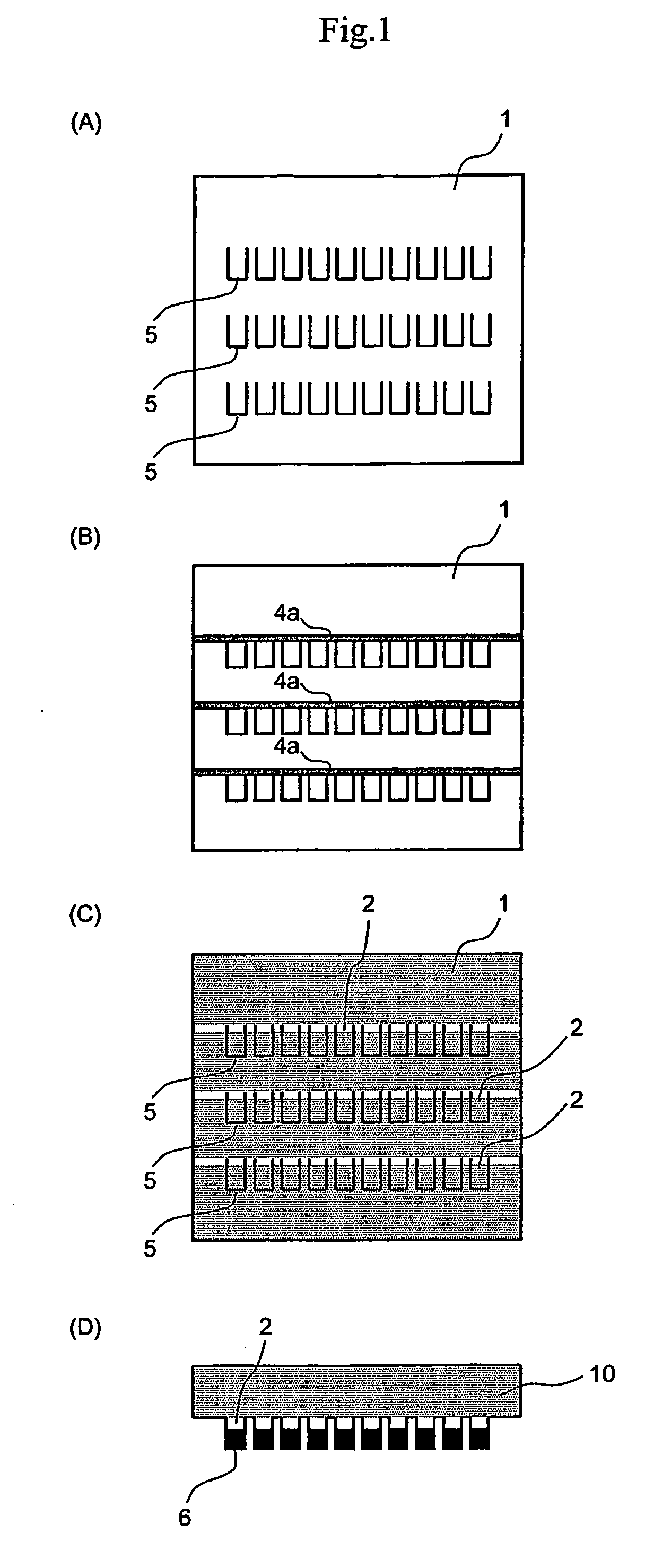

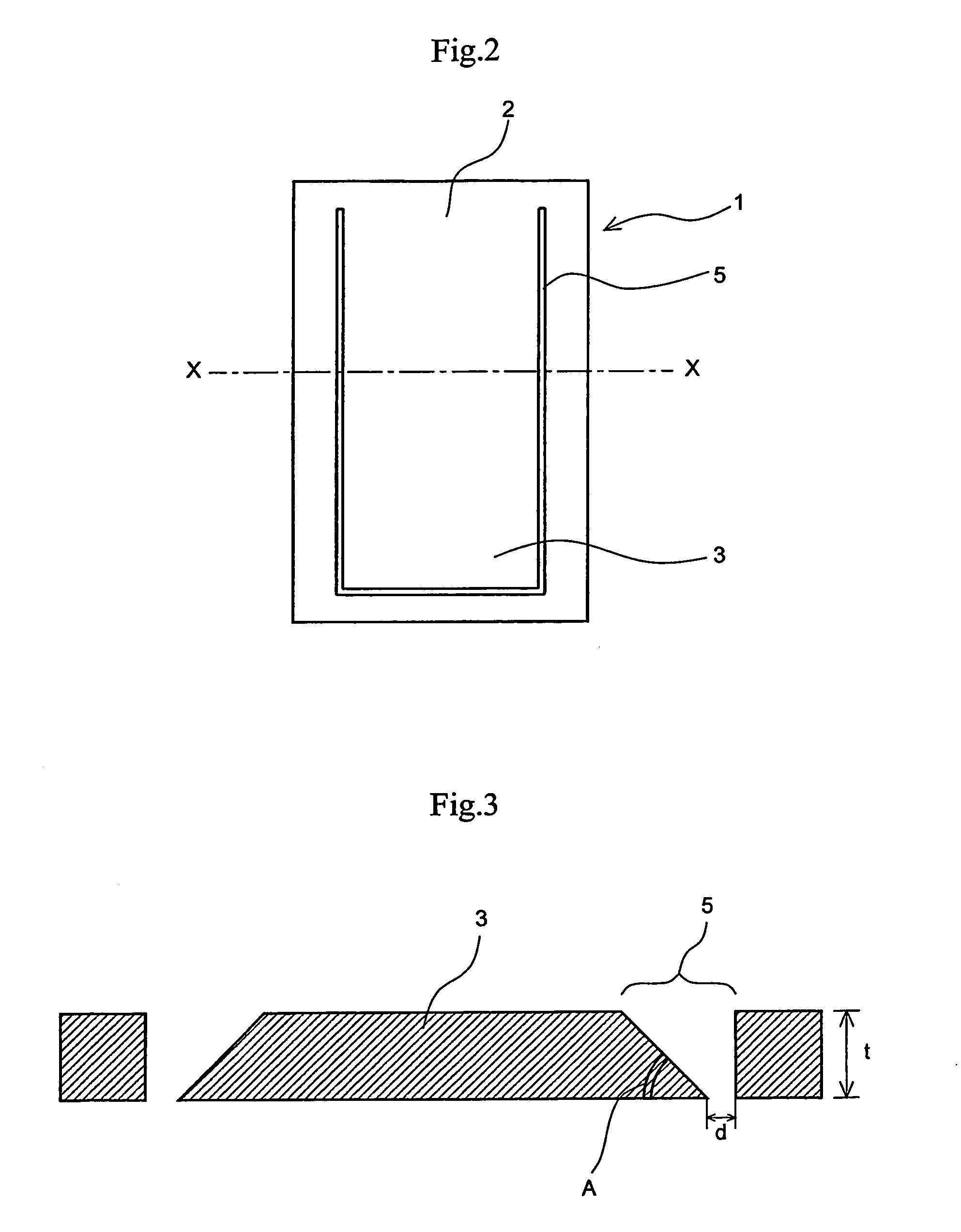

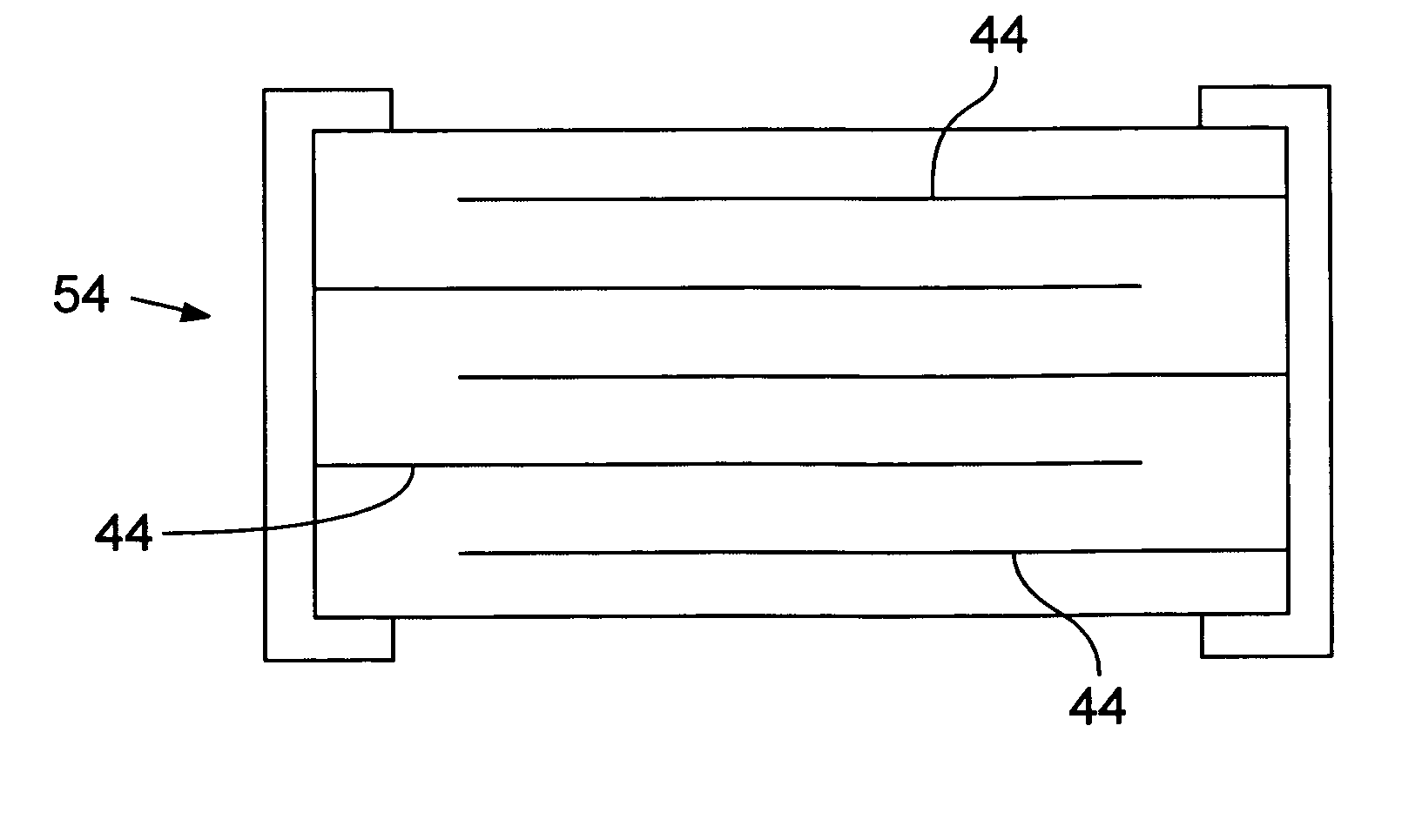

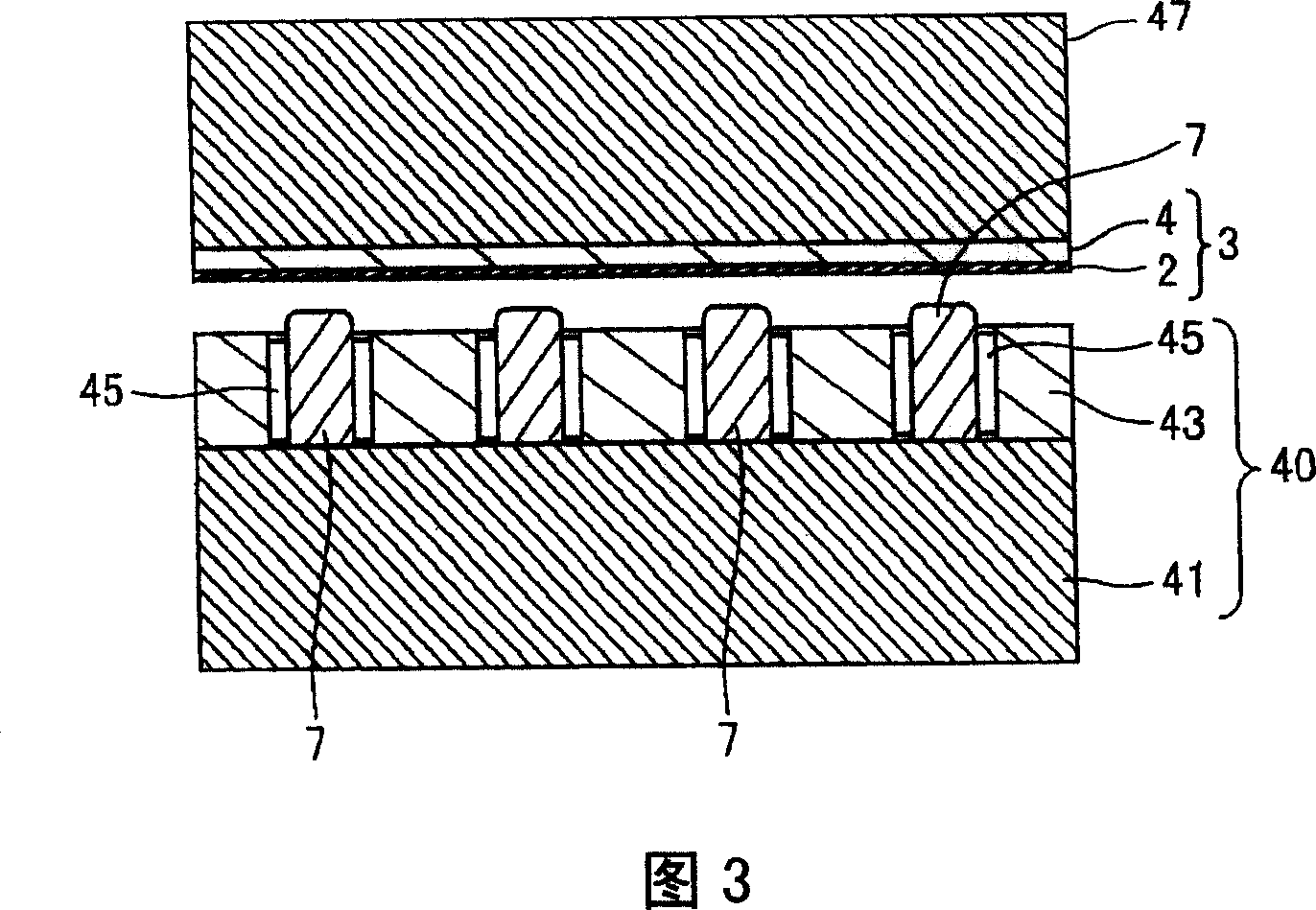

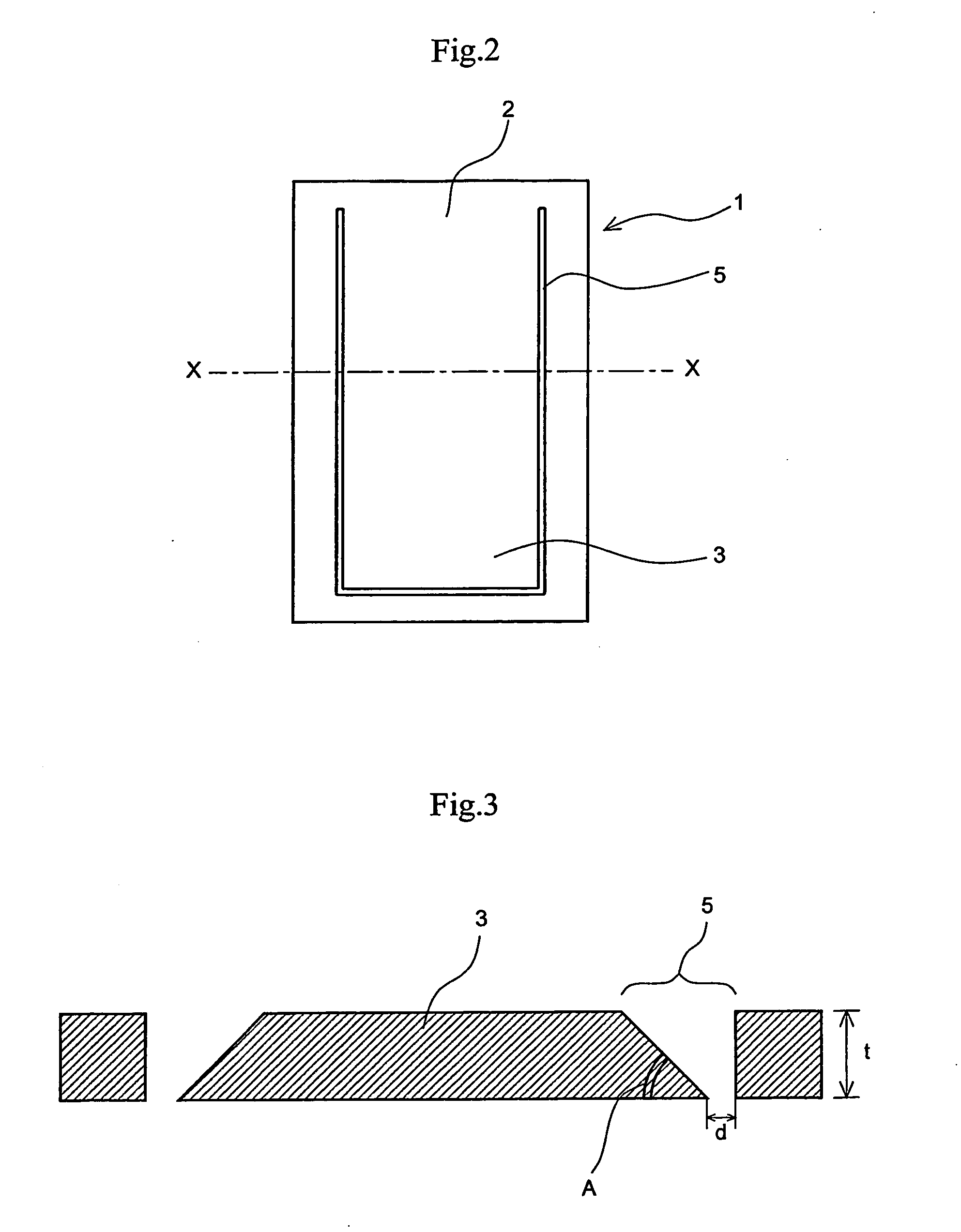

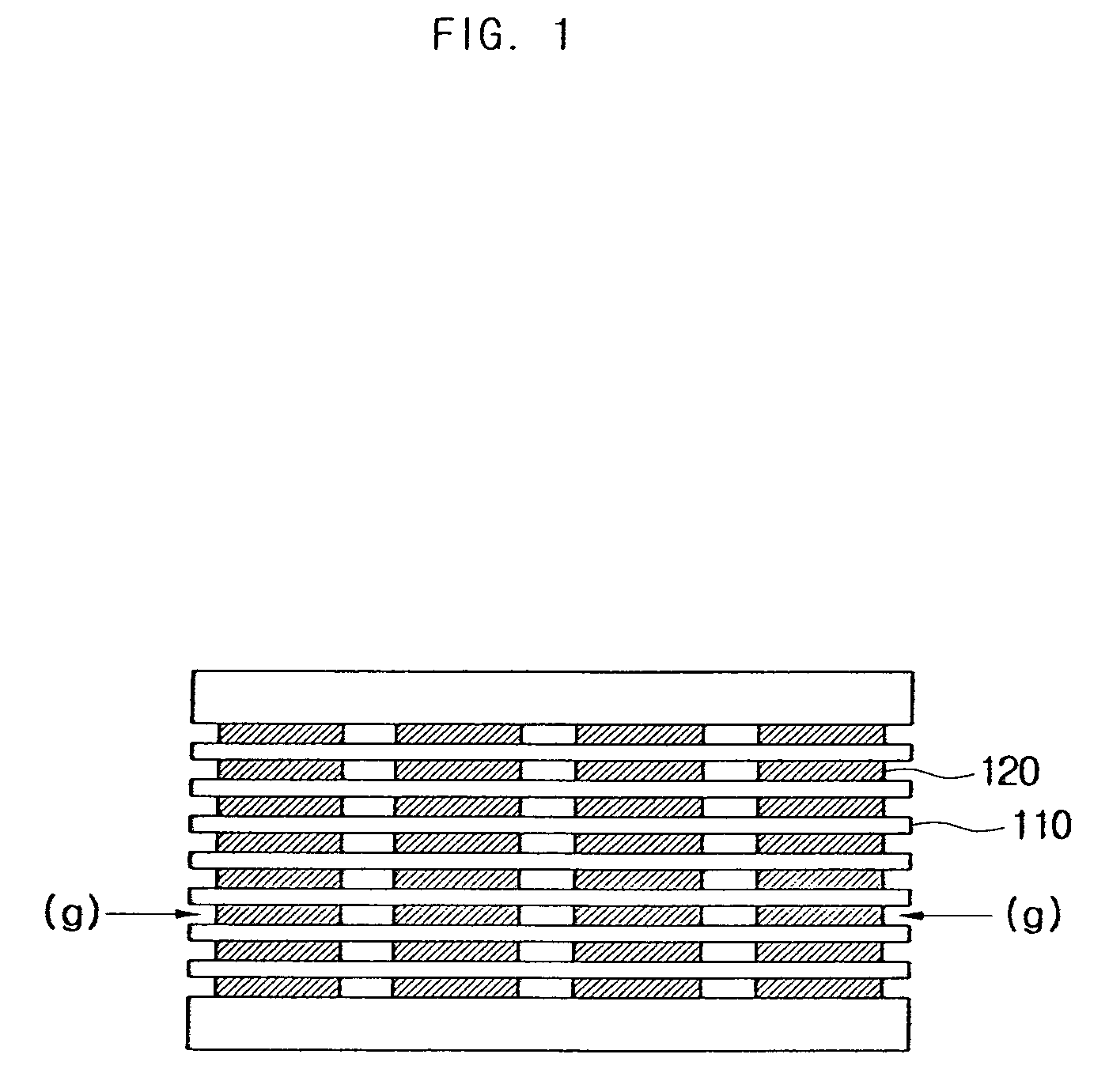

Thin film capacitor, high-density packaging substrate incorporating thin film capacitor, and method for manufacturing thin-film capacitor

InactiveUS20050111162A1Sufficient capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFilm capacitor

A capacitor capable of being incorporated into a packaging substrate, characterized in that the capacitor comprises a high-dielectric-constant layer, and an upper electrode layer and a lower electrode layer sandwiching the high-dielectric-constant layer from the upper side and the lower side. A packaging substrate containing the capacitor, and a method for producing the same are also provided.

Owner:WASEDA UNIV +2

Ceramic electronic component and method for manufacturing the same

ActiveUS20090040688A1Prevent surface oxidationReduce the valueFixed capacitor dielectricStacked capacitorsStress concentrationElectronic component

In a ceramic electronic component, an electrically conductive resin layer is arranged to cover a thick film layer and to extend beyond the end of the thick film layer by at least about 100 μm and a plating layer is arranged to cover the electrically conductive resin layer except a region having a dimension of at least about 50 μm and extending along the end of the electrically conductive resin layer. Consequently, the concentration of the stress is reduced.

Owner:MURATA MFG CO LTD

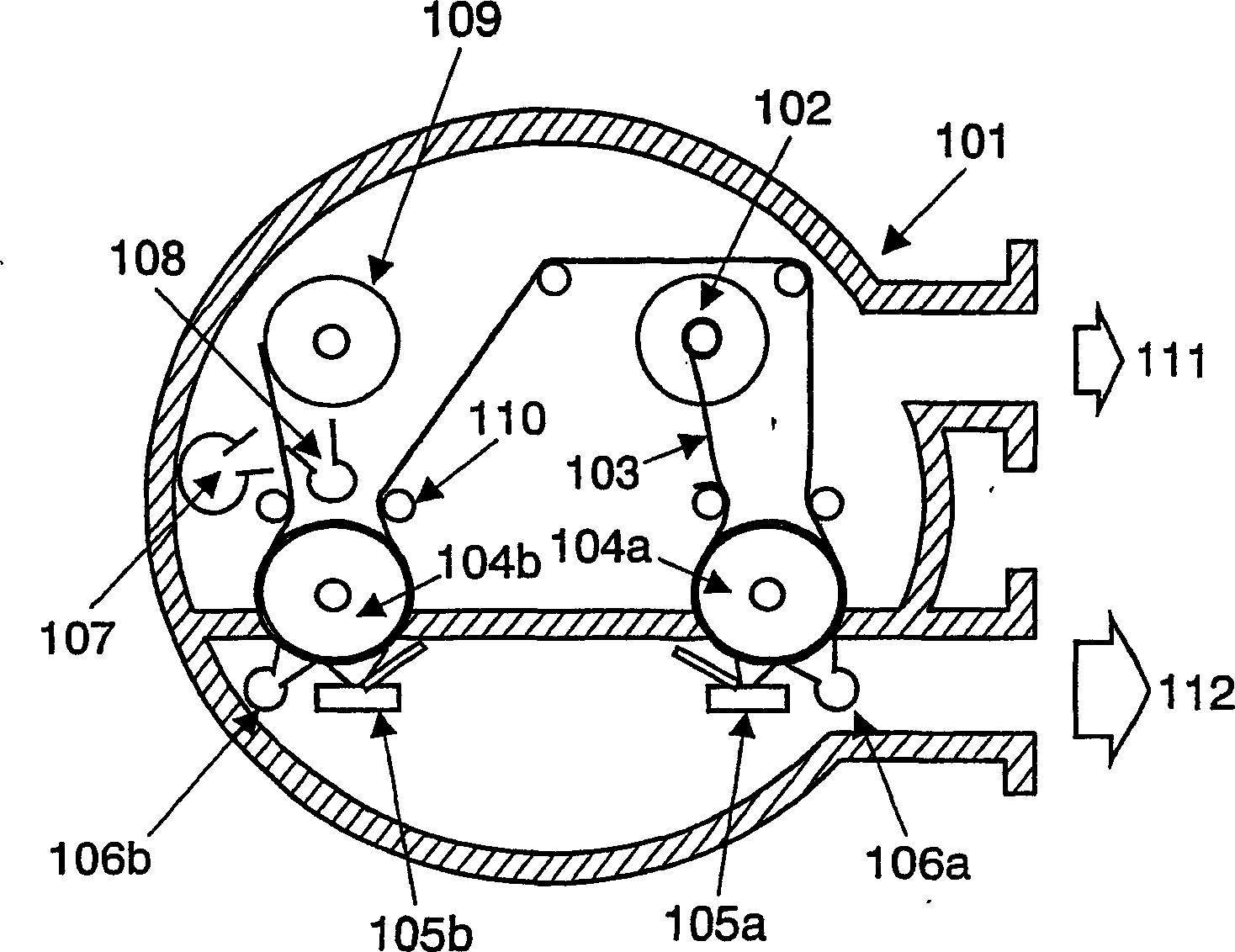

Method of manufacturing multilayer electronic component

InactiveUS20080145551A1Increase the effective volume ratioImprove reliabilityFixed capacitor dielectricStacked capacitorsElectronic componentElectrochemistry

An electroless plating step for forming external electrodes includes preparing a plating solution including a reducing agent and metal ions having a more electochemically positive deposition potential than the oxidation-reduction potential of the reducing agent, placing a laminate for a multilayer electronic component together with a conductive medium having catalytic activity for an oxidation reaction of the reducing agent in a vessel, and stirring the laminate and the conductive medium in the plating solution by rotation, shaking, inclination, or vibration. Electroless plating proceeds to connect each other plating deposits deposited on the ends of a plurality of internal electrodes.

Owner:MURATA MFG CO LTD

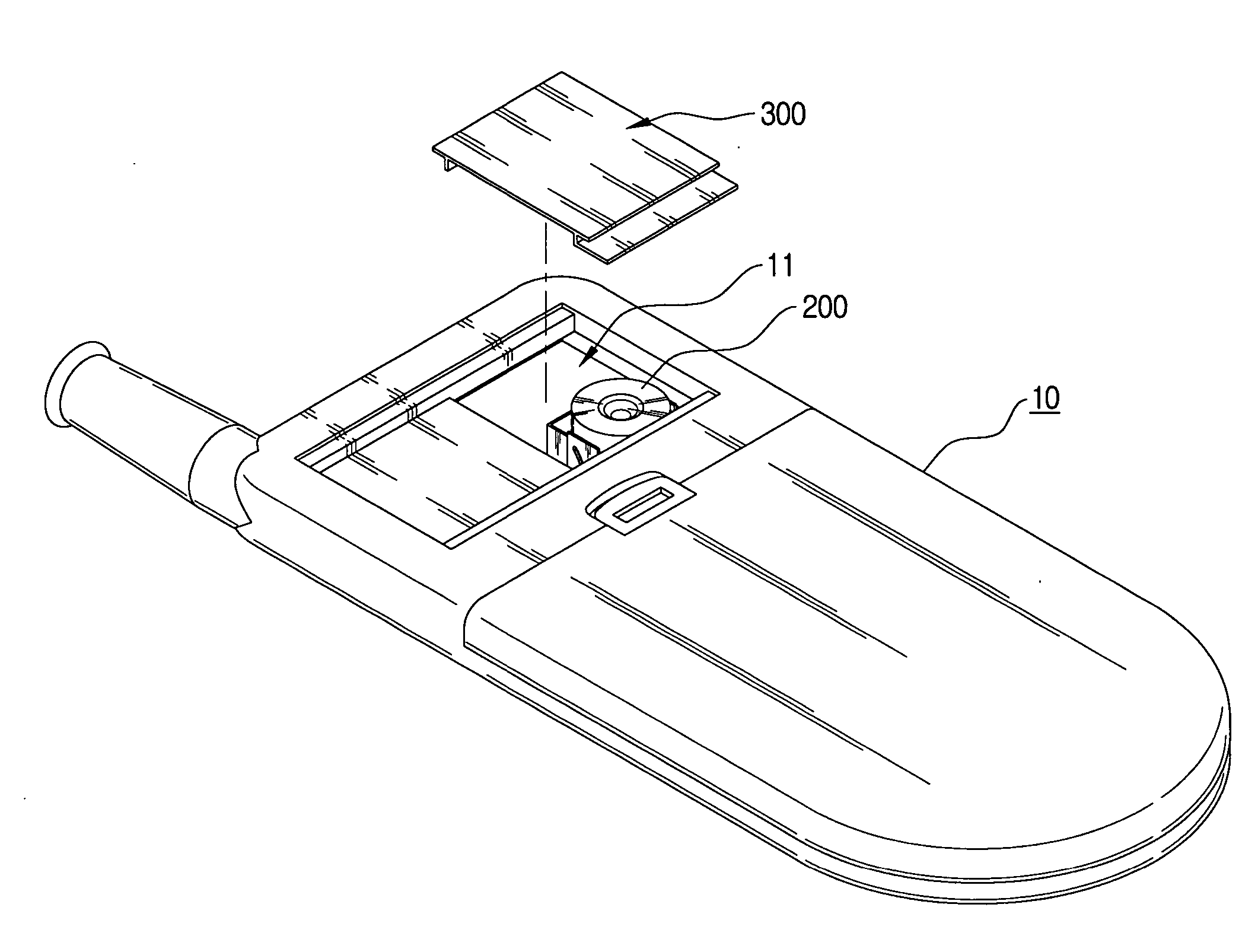

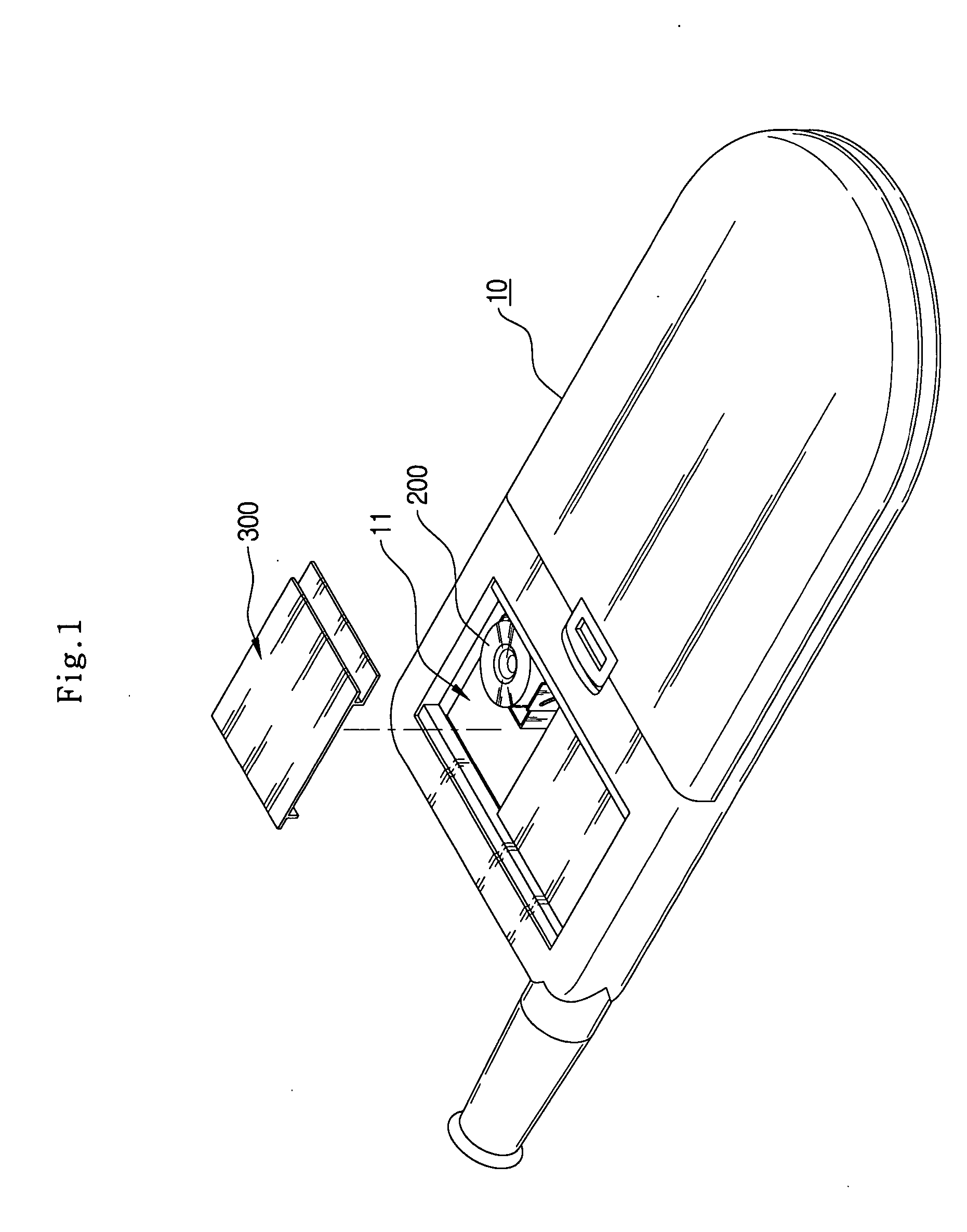

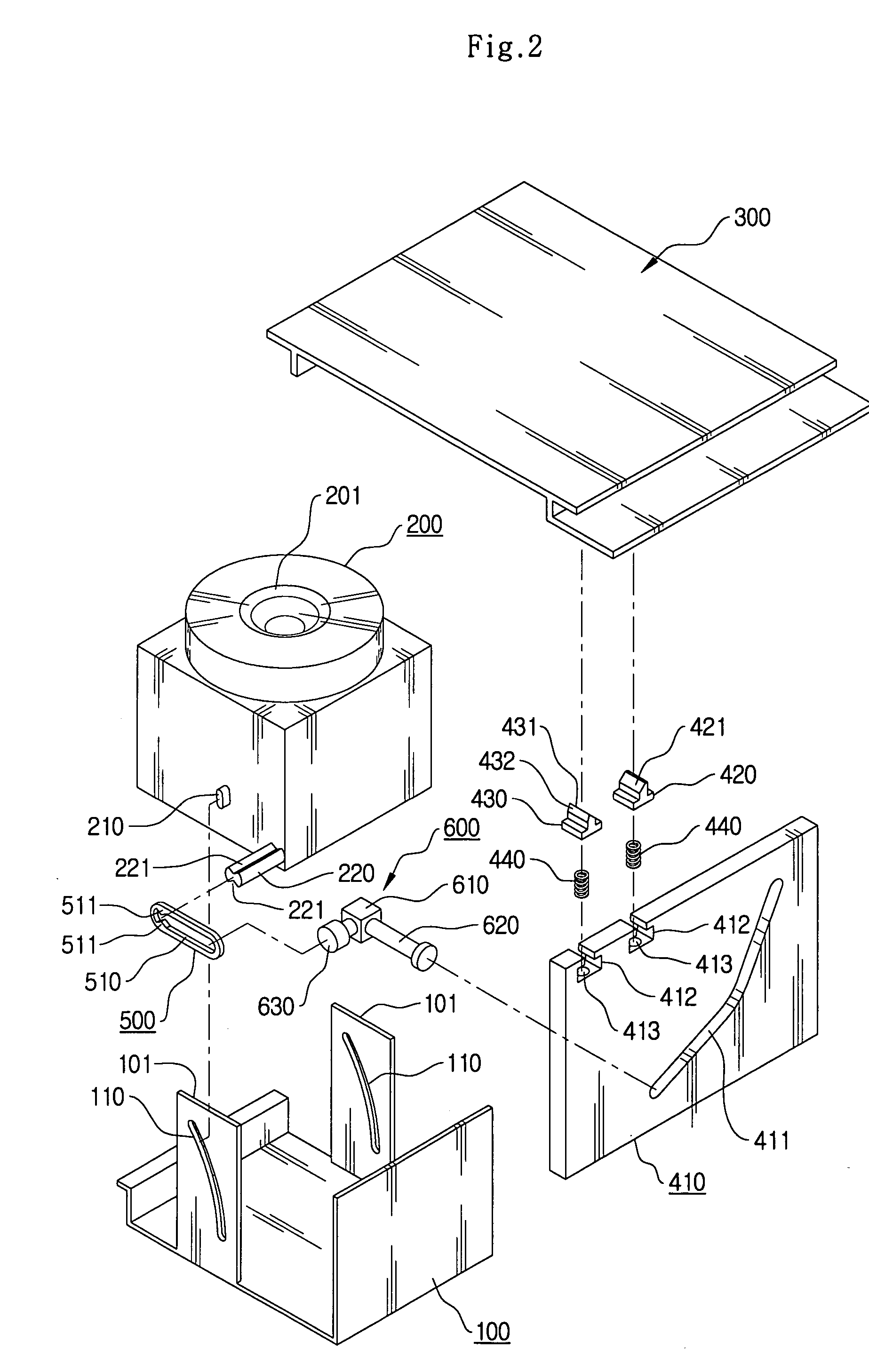

Mobile communication terminal having selectively exposed camera

A mobile communication terminal has a body, a camera installed in a receiving space formed in the body so as to be pivotally moved up and down, a door installed on an outer surface of the body so as to be slidingly moved to open and close an opening of the receiving space, and a cam plate installed in the body as to be slidingly moved in association with the movement of the door to pivotally move the camera. In the mobile communication terminal, when users open the door, the cam plate is linearly moved in association with the movement of the door to pivotally move the camera upward, so that the camera is popped out from the terminal through the opening of the receiving space.

Owner:CURITEL COMM

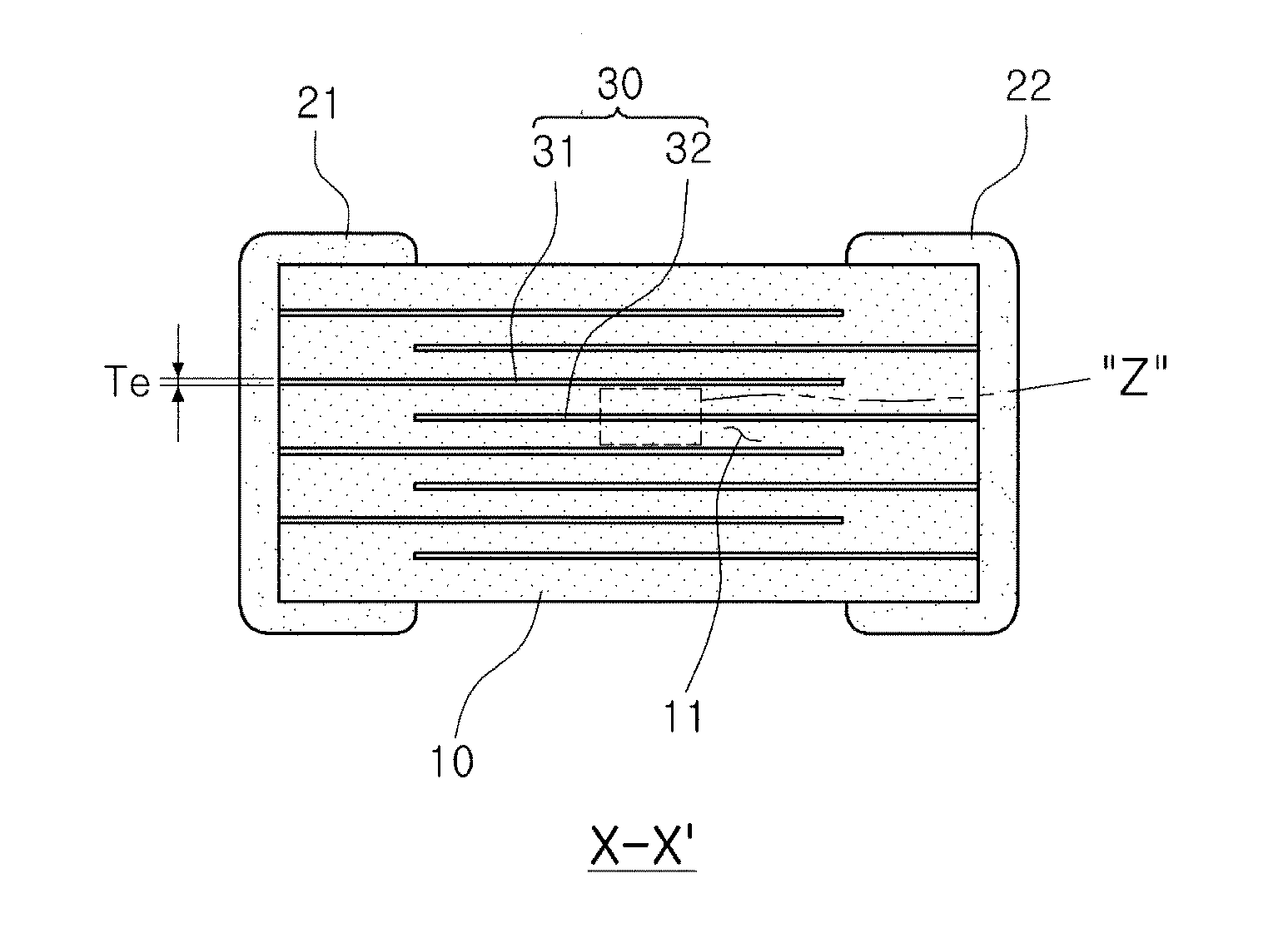

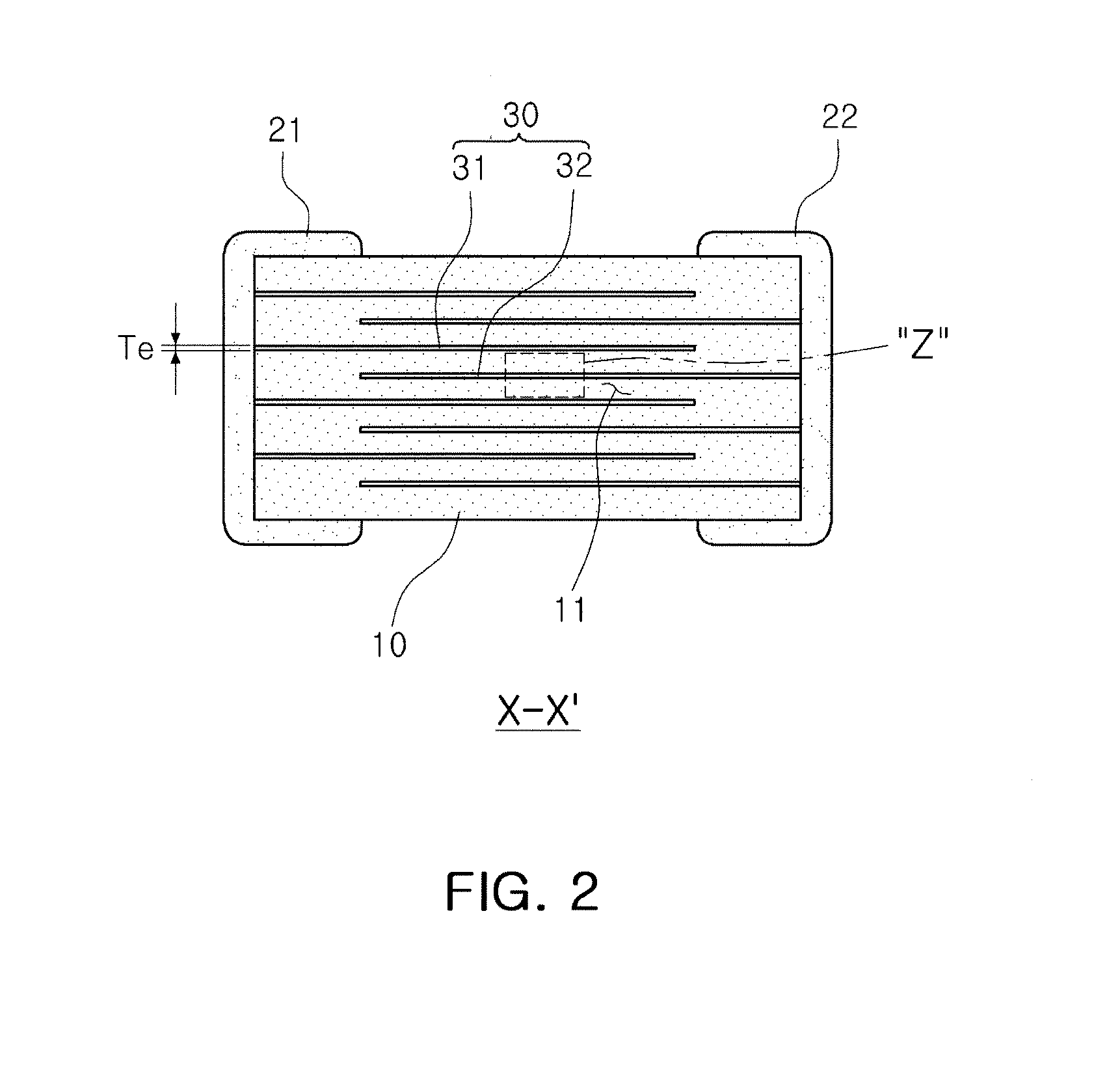

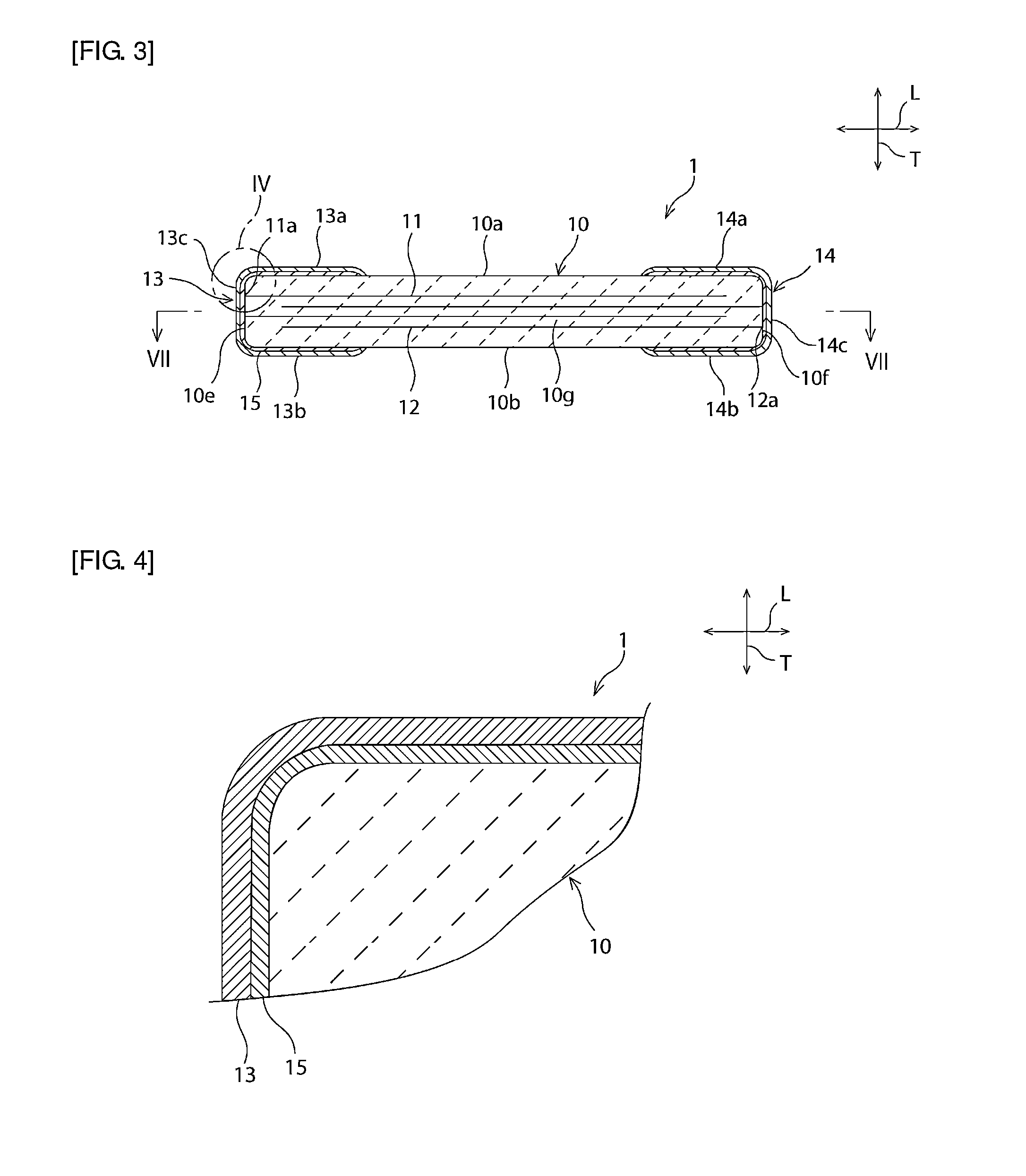

Multilayer ceramic electronic component and method of manufacturing the same

ActiveUS20130286539A1Avoid insulation breakdownAvoid crackingFixed capacitor electrodesFixed capacitor dielectricMaximum diameterMetallurgy

There is provided a multilayer ceramic electronic component, including: a ceramic body; and internal electrodes formed inside the ceramic body and having a plurality of non-electrode regions, wherein, on a cross-section taken in length and thickness directions of the ceramic body, when a thickness of the internal electrode is denoted by Te, a continuity of the internal electrode is denoted by C, an area of the internal electrode is denoted by Ae, an area of the plurality of non-electrode regions is denoted by Ao, and a maximum diameter of the non-electrode region having the maximum diameter among the plurality of non-electrode regions is denoted by Pmax, 0.1 μm≦Te≦0.5 μm, 1.1%≦Ao / Ae≦3.2%, Pmax≦120 nm, and 95%≦C≦99.5% are satisfied.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

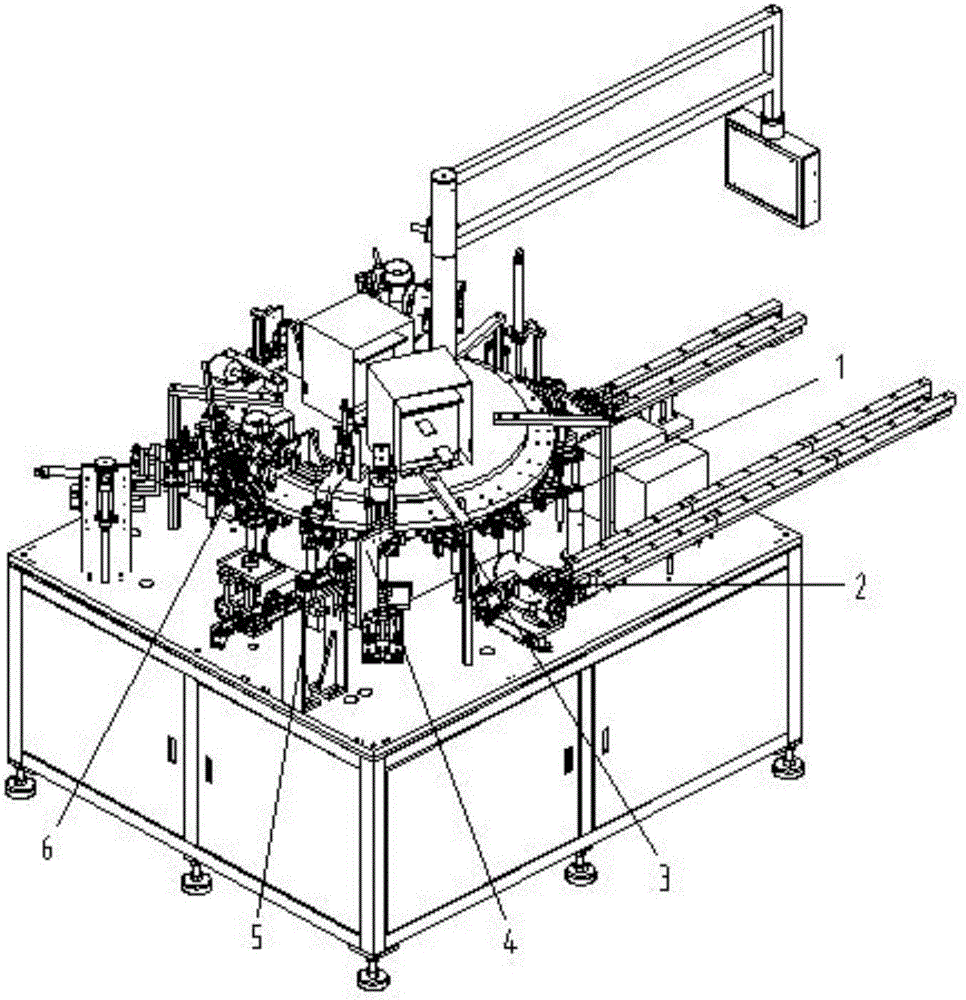

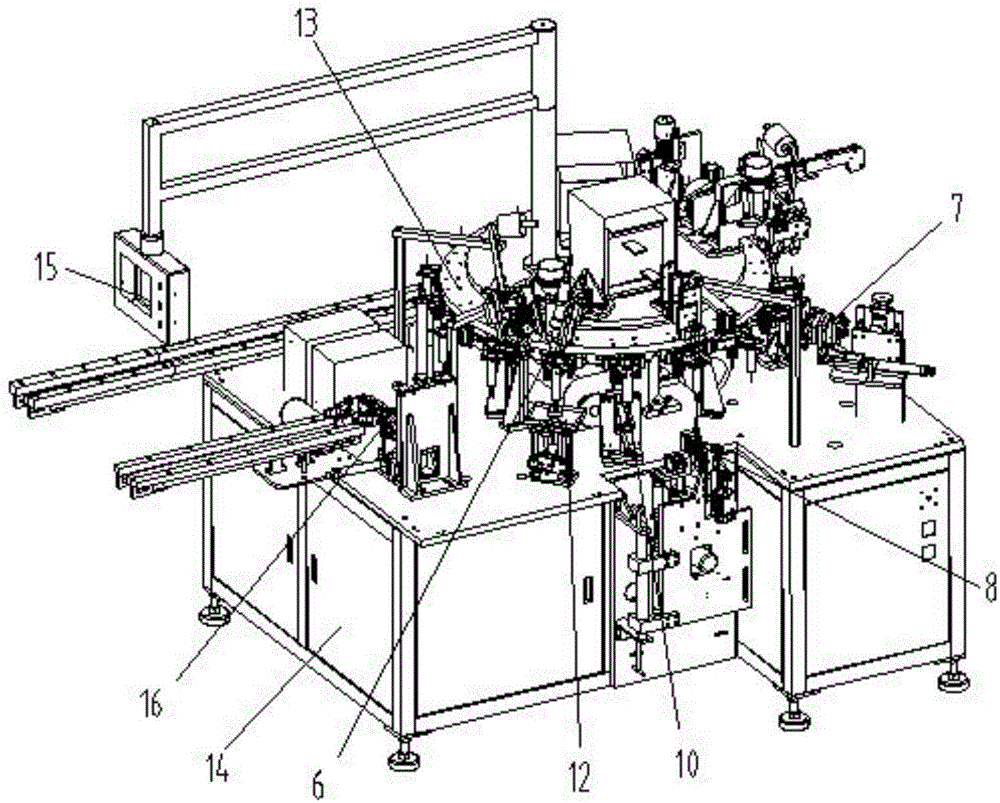

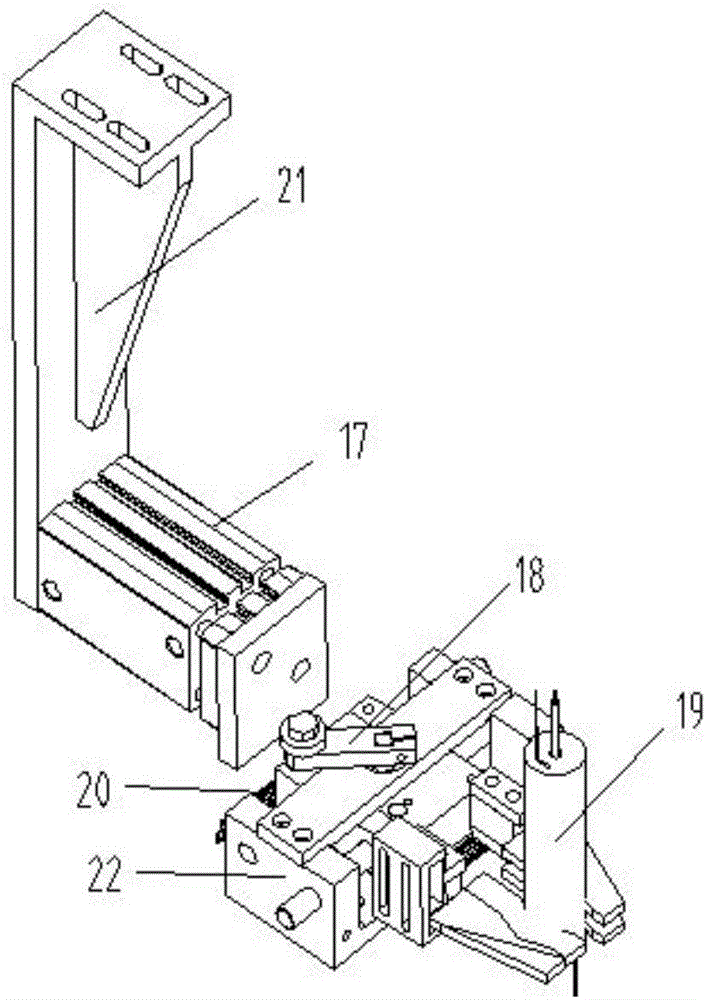

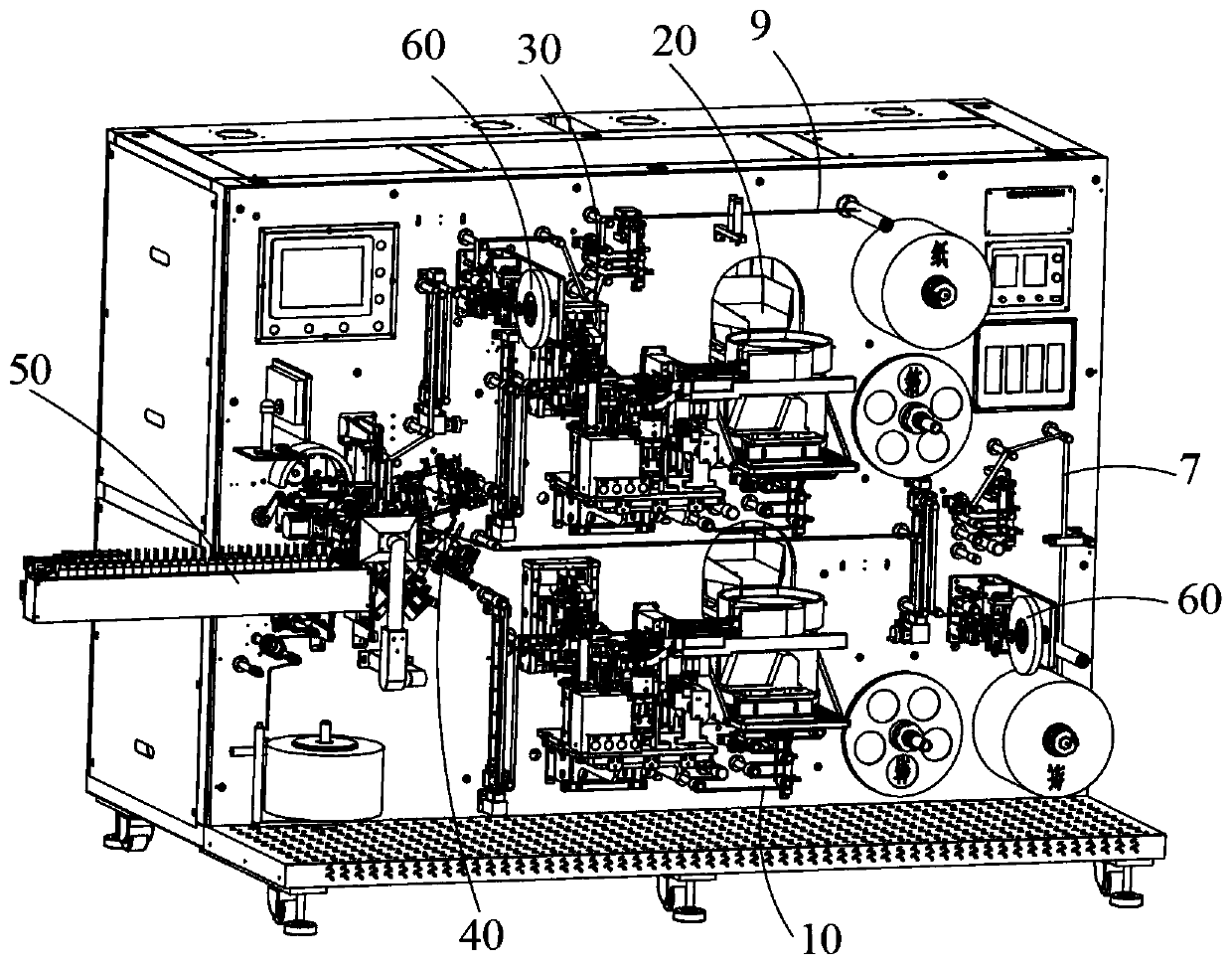

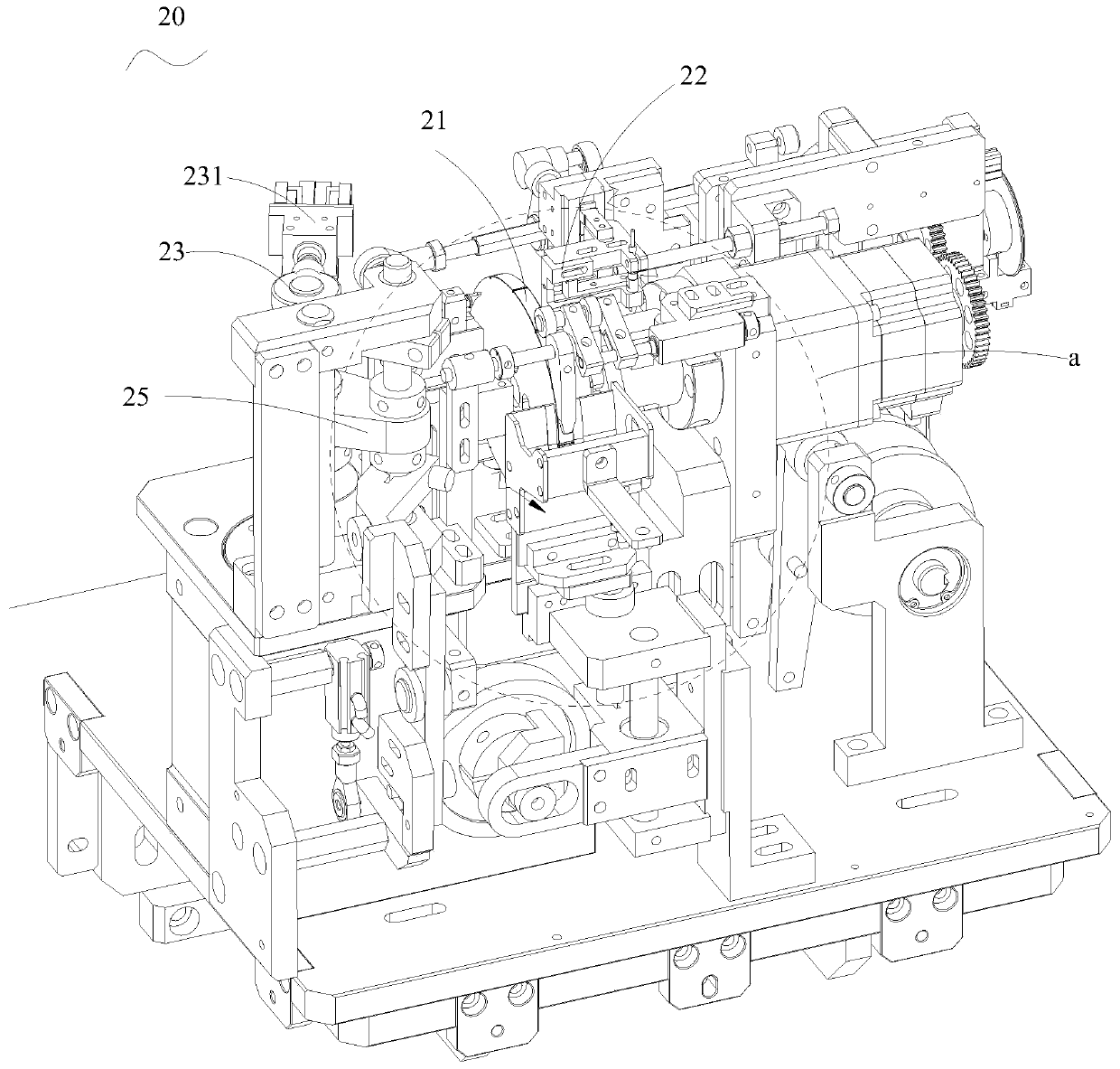

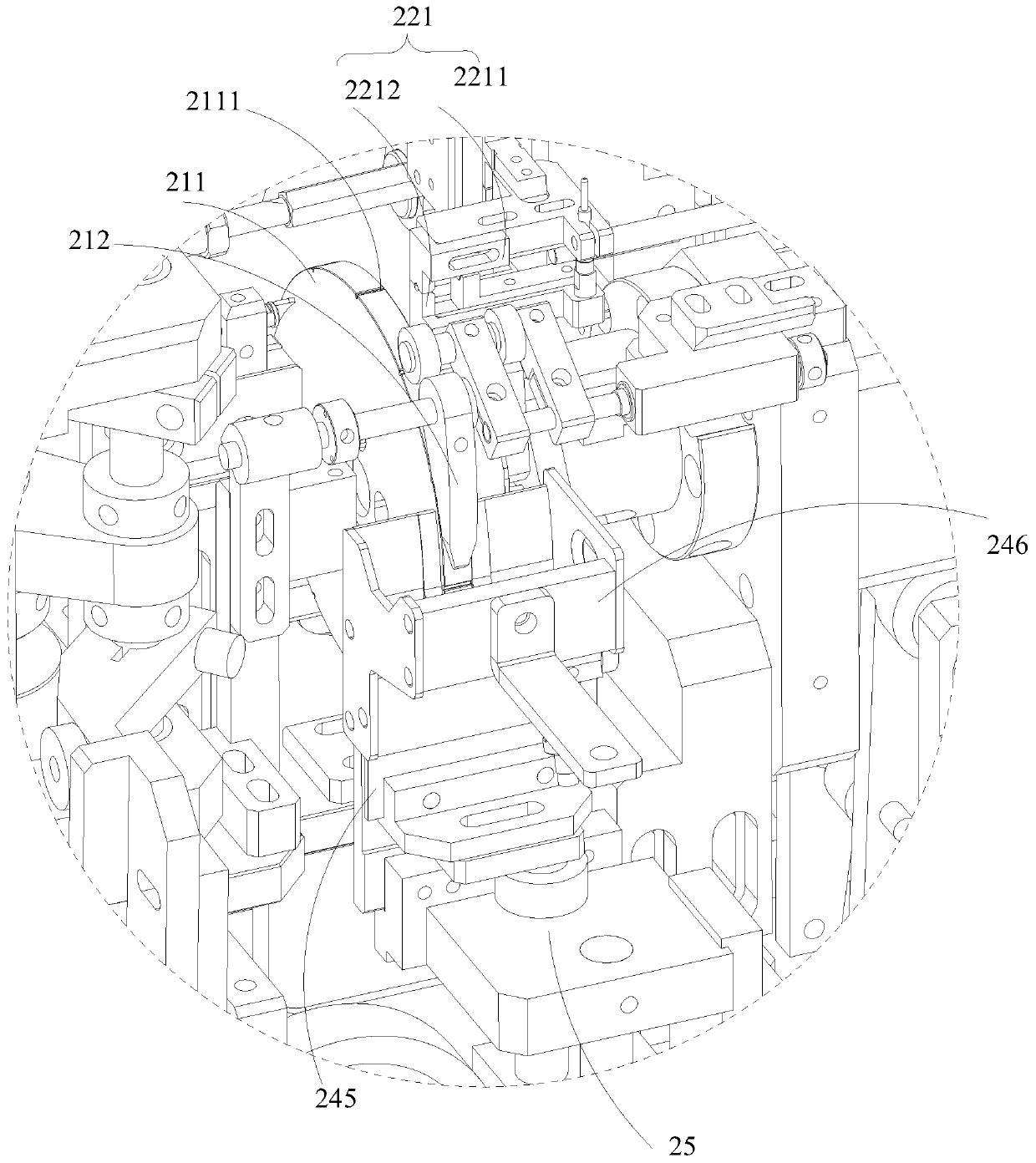

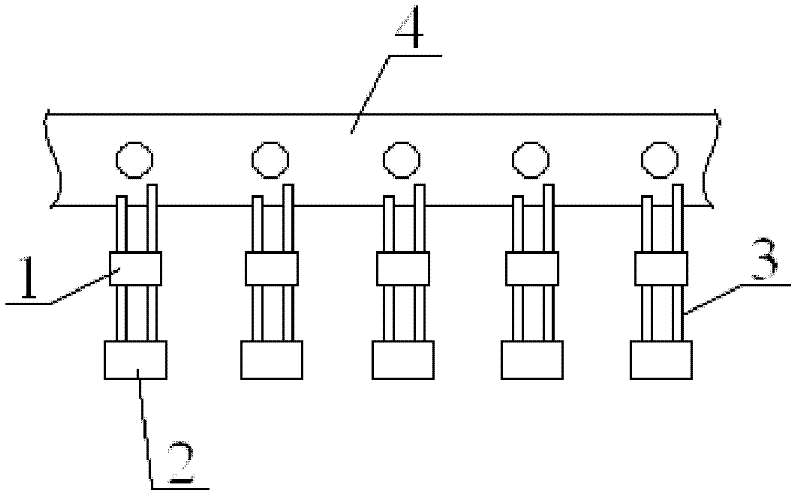

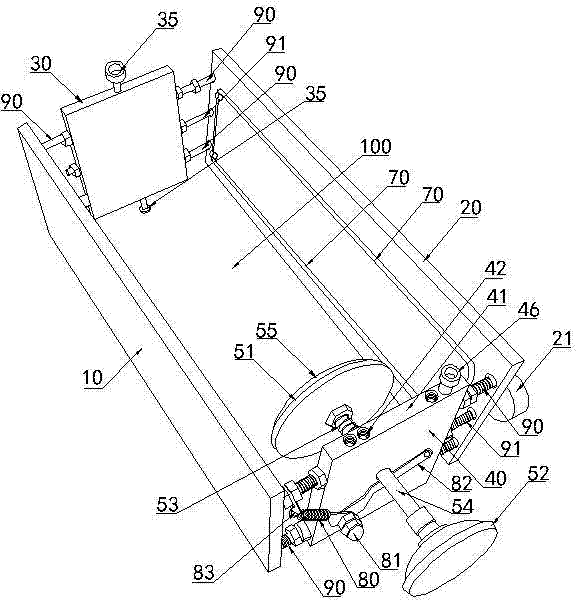

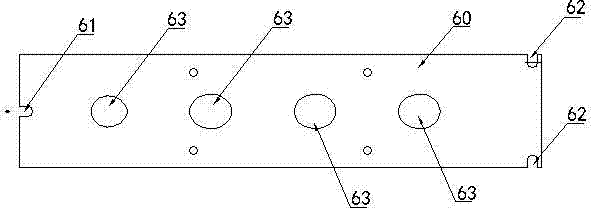

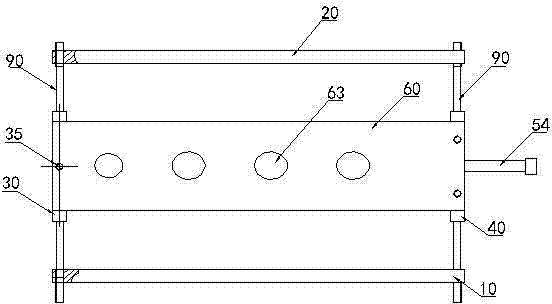

Automatic assembly machine of round capacitor

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

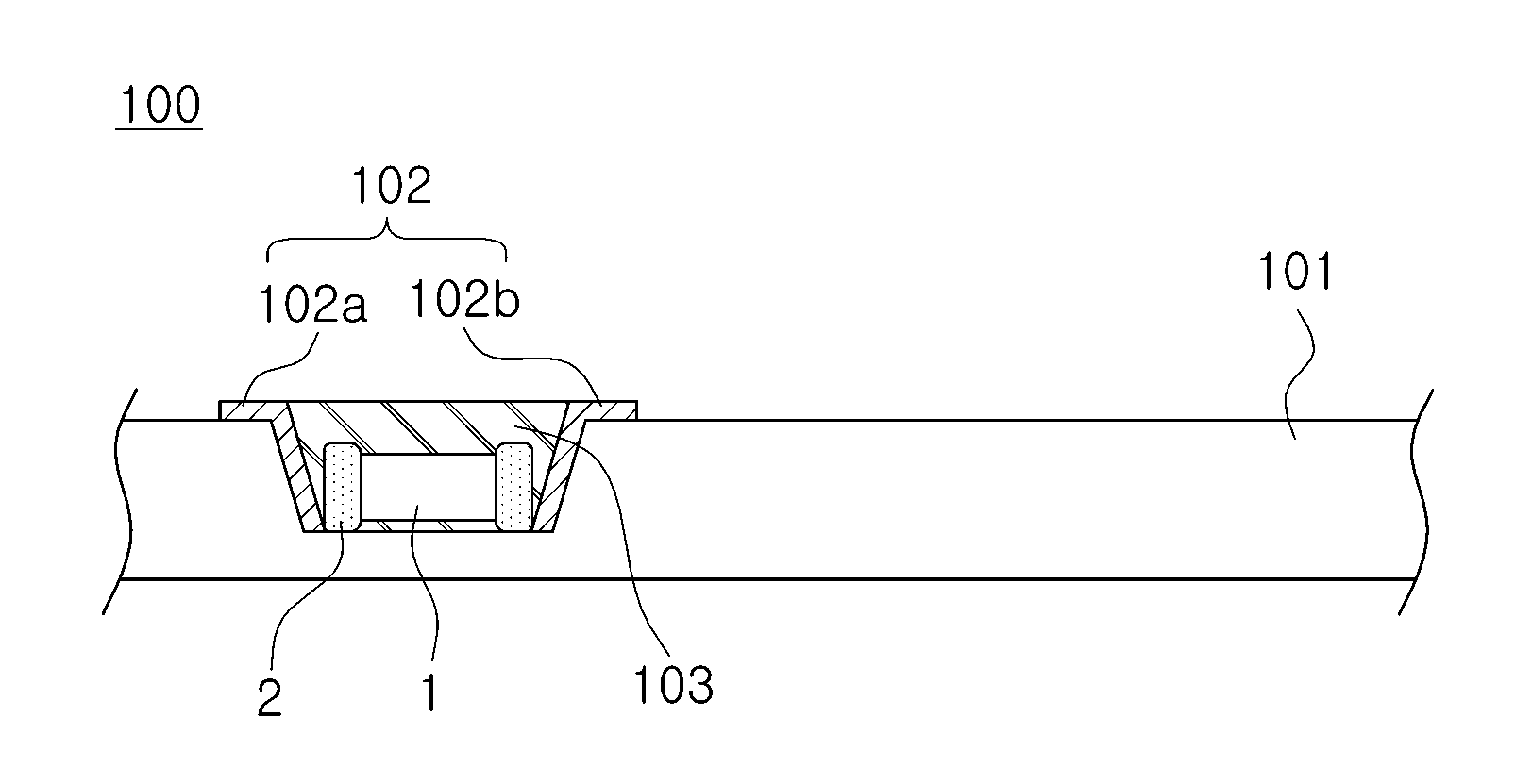

Multilayer ceramic capacitor, printed circuit board including the same, methods of manufacturing thereof

InactiveUS20110266040A1Avoid crackingStable capacitancePrinted circuit assemblingFixed capacitor electrodesCeramic capacitorPrinted circuit board

There are provided a multilayer ceramic capacitor, a printed circuit board including the same, a method of manufacturing the multilayer ceramic capacitor, and a method of manufacturing the printed circuit board. The method of manufacturing a multilayer ceramic capacitor includes: preparing a capacitor body on which external electrode material layers are formed, dry polishing the capacitor body such that surfaces of the external electrode material layers are smooth and compact, and forming plating layers on the surfaces of the external electrode material layers in order to form external electrodes. Therefore, the surface smoothness, compactness, and uniformity of an external electrode plating layer can be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Thin film capacitor, high-density packaging substrate incorporating thin film capacitor, and method for manufacturing thin-film capacitor

InactiveUS7196898B2Sufficient capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingHigh densityEngineering

A capacitor capable of being incorporated into a packaging substrate, which capacitor includes a high-dielectric-constant layer, and an upper electrode layer and a lower electrode layer sandwiching the high-dielectric-constant layer from the upper side and the lower side. A packaging substrate containing the capacitor, and a method for producing the same are also provided.

Owner:WASEDA UNIV +2

Ceramic electronic component and manufacturing method thereof

ActiveUS20130107421A1Improve moisture resistanceFixed capacitor electrodesFixed capacitor dielectricElectronic componentMaterials science

A ceramic body includes an inner electrode disposed inside the ceramic body and in which an end portion of the inner electrode extends to a surface of the ceramic body. An electrode layer is formed on the surface of the ceramic body so as to cover the end portion of the inner electrode, the electrode layer including a resin, a first metal filler that contains a first metal component, and a second metal filler that contains a second metal component having a higher melting point than the first metal component. A step of heating the electrode layer is performed to form an electrode including a metal layer that is located on the surface of the ceramic body and that includes the first and second metal components and a metal contained in the inner electrode.

Owner:MURATA MFG CO LTD

Ceramic electronic component and method for producing the same

ActiveUS20130201601A1Improve moisture resistanceSmall thicknessStacked capacitorsCoatingsMetallurgyElectronic component

A ceramic electronic component includes a ceramic body, a glass coating layer, and an electrode terminal. The ceramic body includes a plurality of internal electrodes whose ends are exposed on the surface of the ceramic body. The glass coating layer covers a portion of the ceramic body on which the internal electrodes are exposed. The electrode terminal is provided directly on the glass coating layer. The electrode terminal includes a plating film. The glass coating layer is made of a glass medium in which metal powder particles are dispersed. The metal powder particles define conduction paths that electrically connect the internal electrodes with the electrode terminal.

Owner:MURATA MFG CO LTD

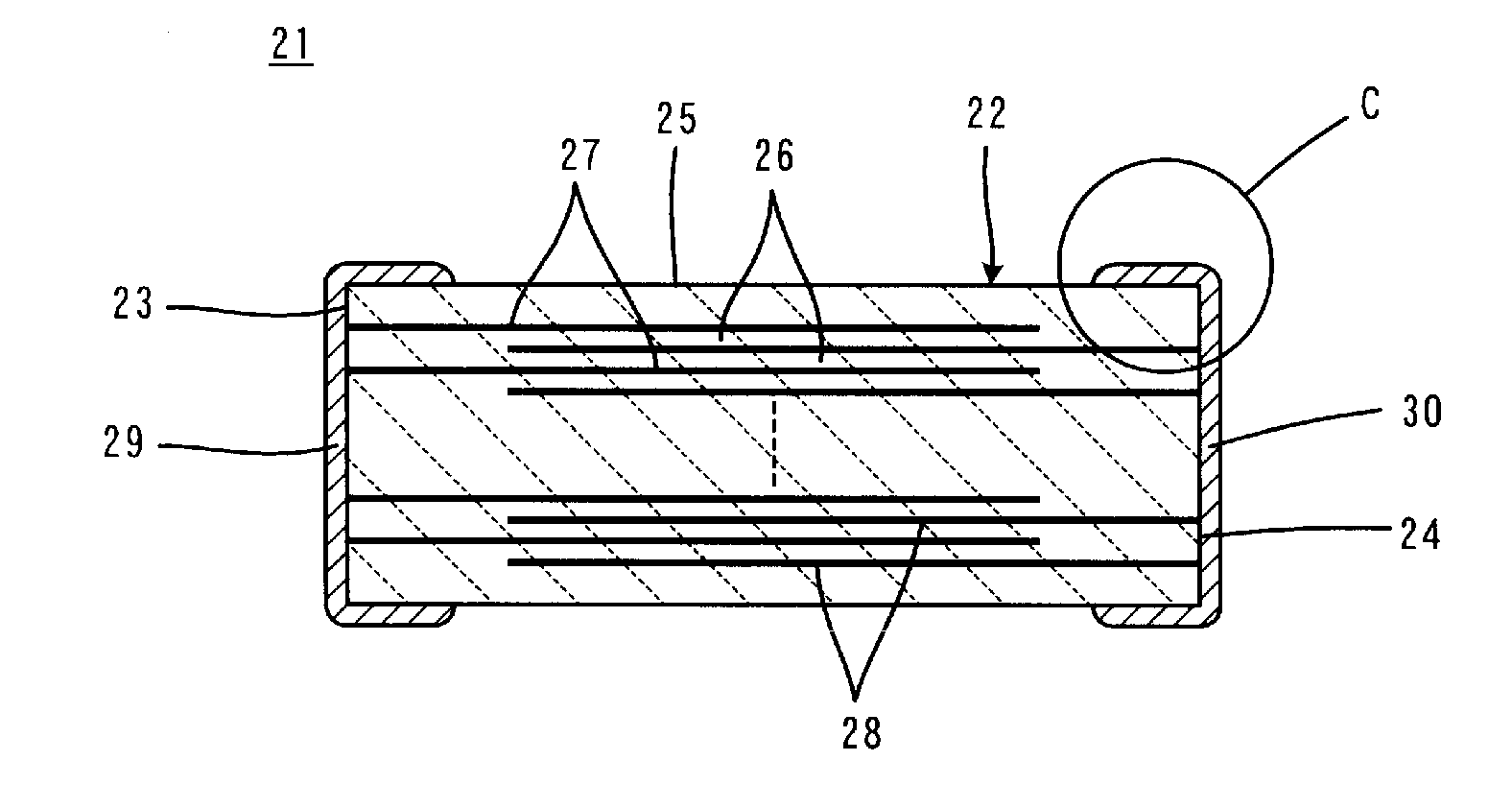

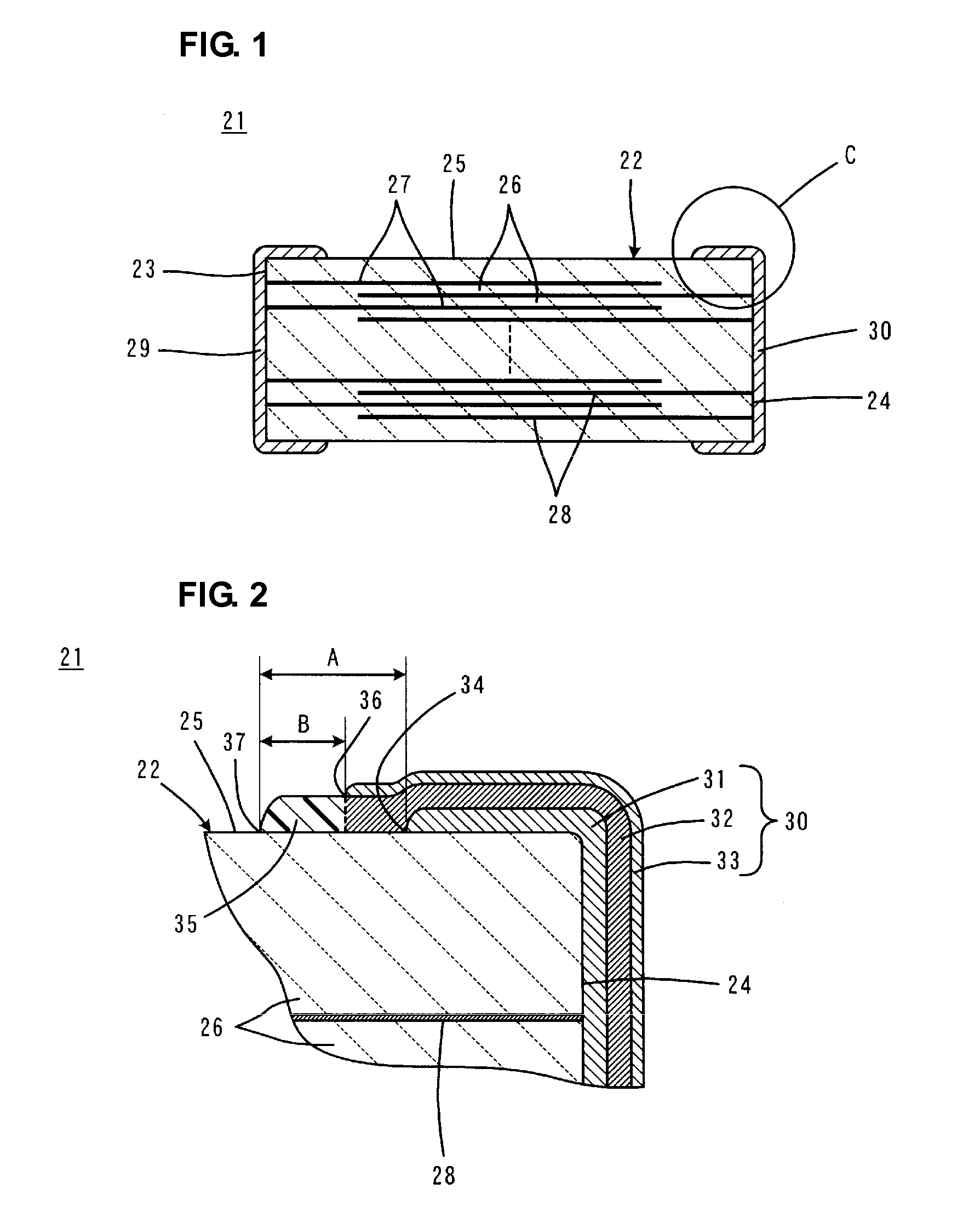

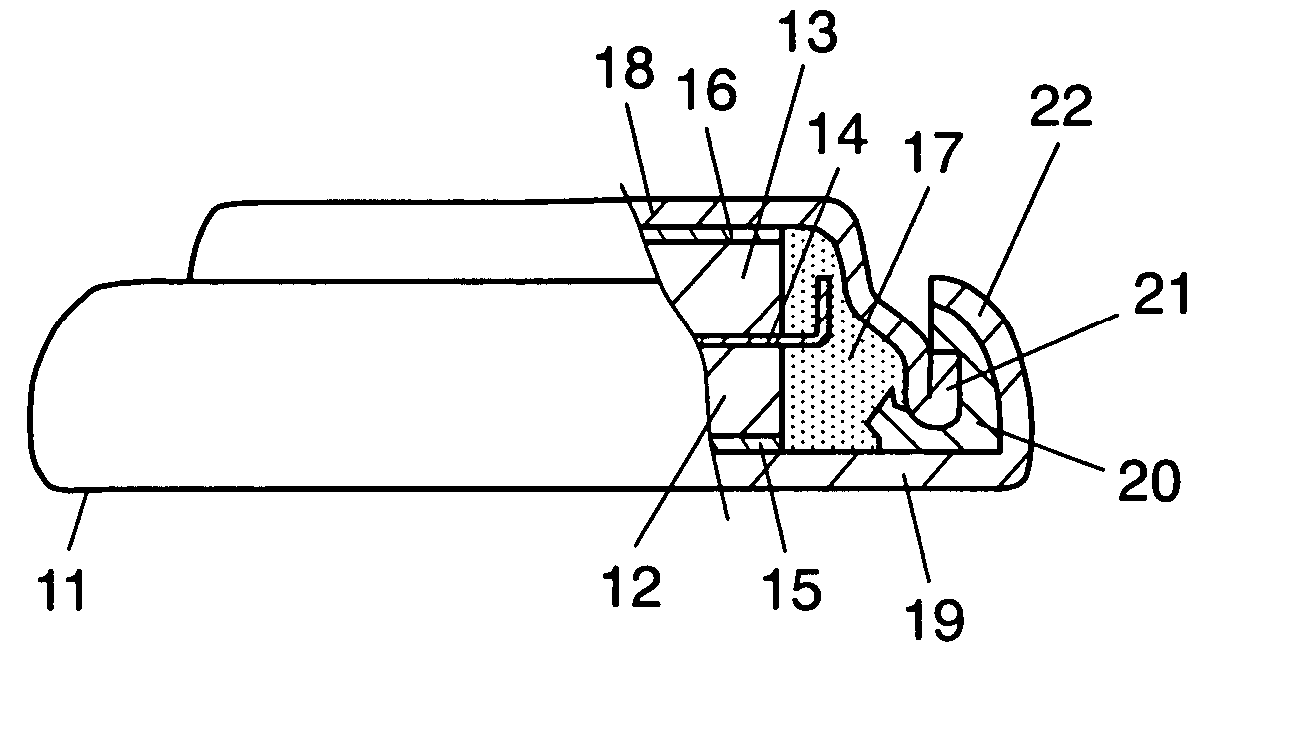

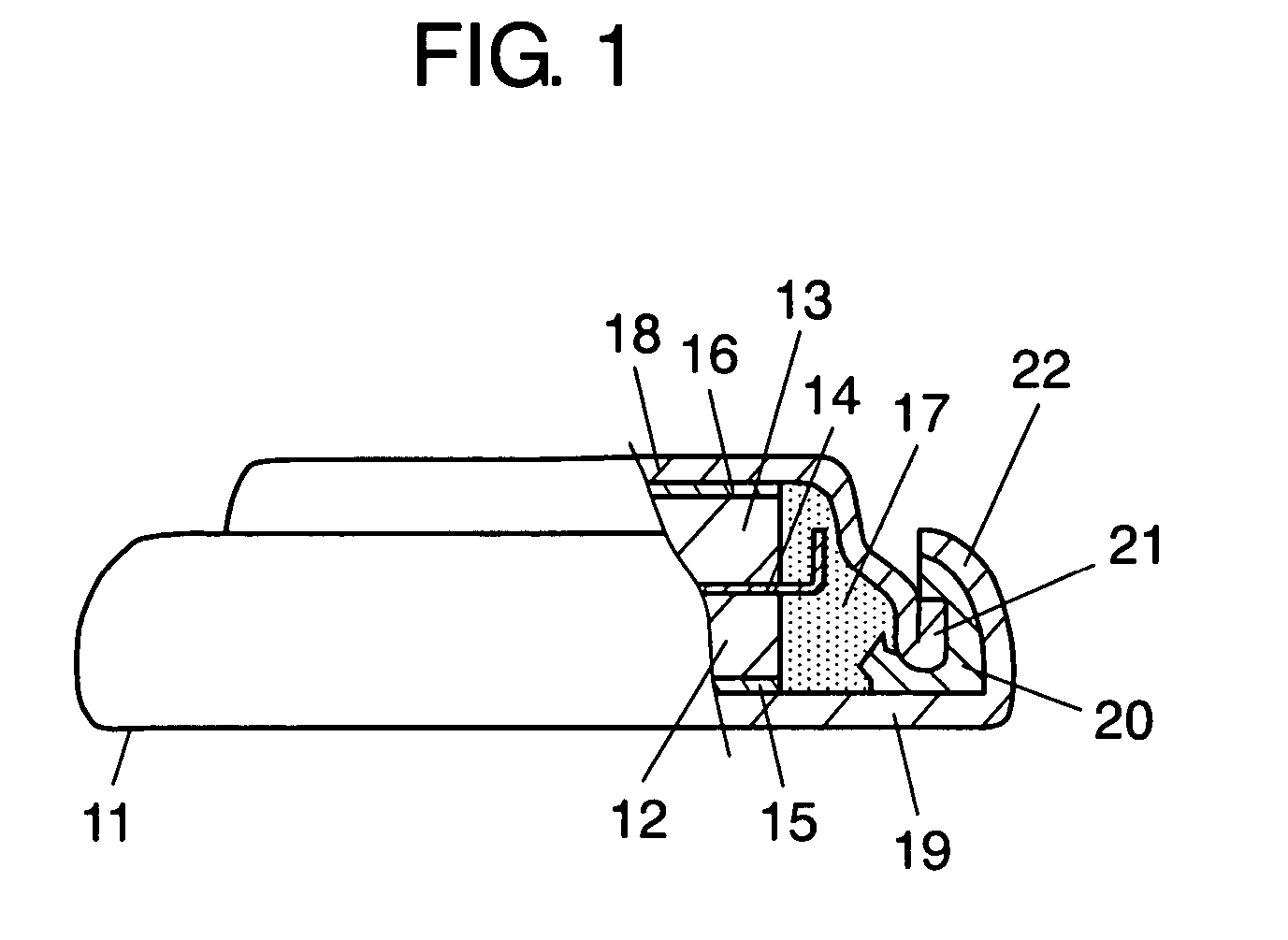

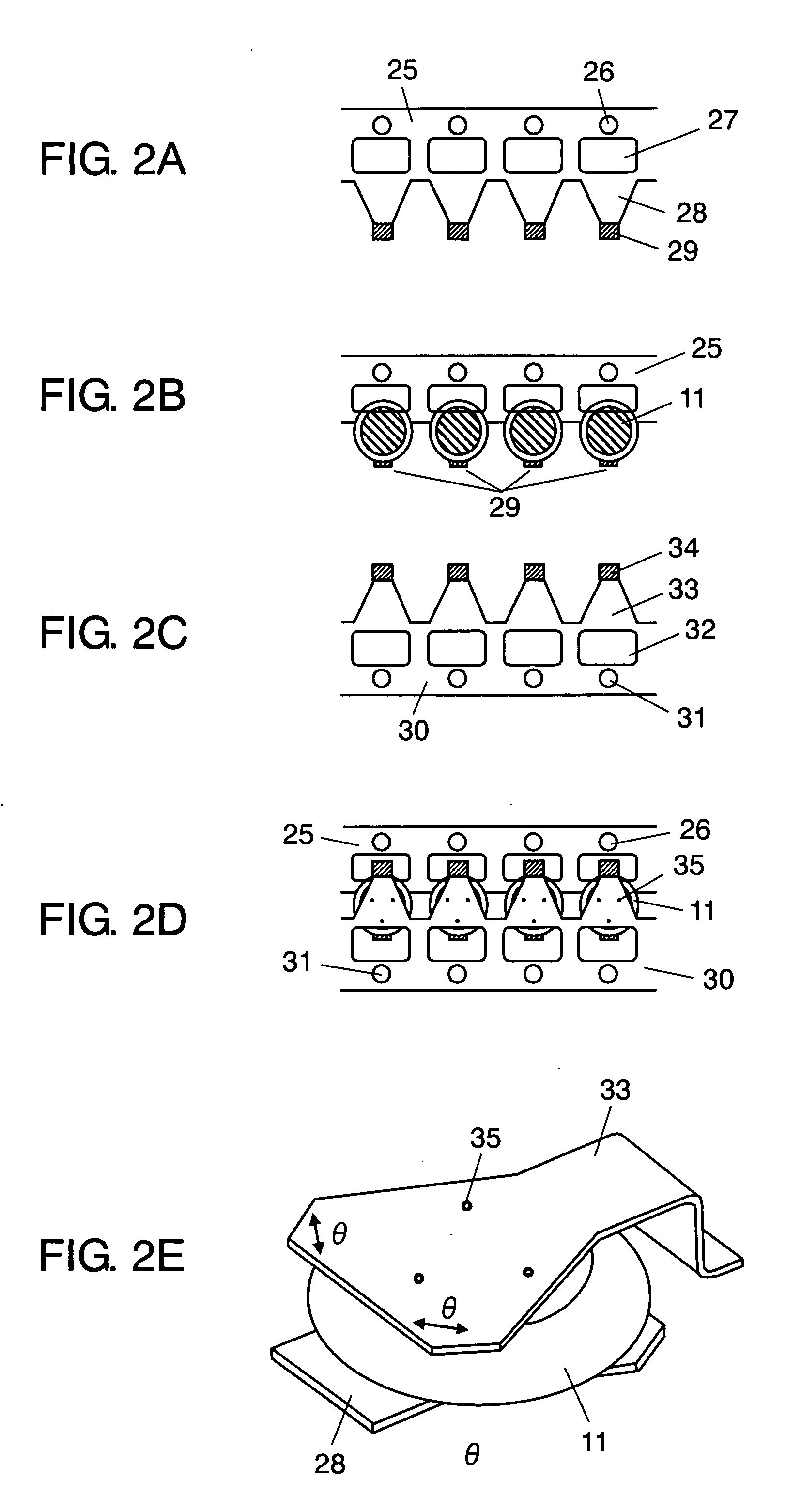

Method Of Producing A Coin-Type Electrochemical Element And A Coin-Type Electrochemical Element

InactiveUS20080089011A1Minimize mounting areaExcellently produced maintaining reliabilityCapacitor terminalsSmall-sized cells cases/jacketsEngineeringElectric double-layer capacitor

A coin-type electrochemical element enabling the external lead terminal portions to be accurately and reliably attached to a first lid portion and to a second lid portion of the coin-type electrochemical element, and a method of its production. Coin-type electric double layer capacitor (11) includes first lid portion (19) and second lid portion (18). External lead terminal portions (28) and (33) having a nearly triangular shape are separately connected to the outer surfaces of the lid portions. Upon providing external lead terminal portions (28) and (33) having the triangular shape, welded portion (35) is allowed to have an increased area enabling the coin-type electrochemical element of even a small size to be accurately and reliably welded and making it possible to provide the coin-type electrochemical element having excellent reliability.

Owner:PANASONIC CORP

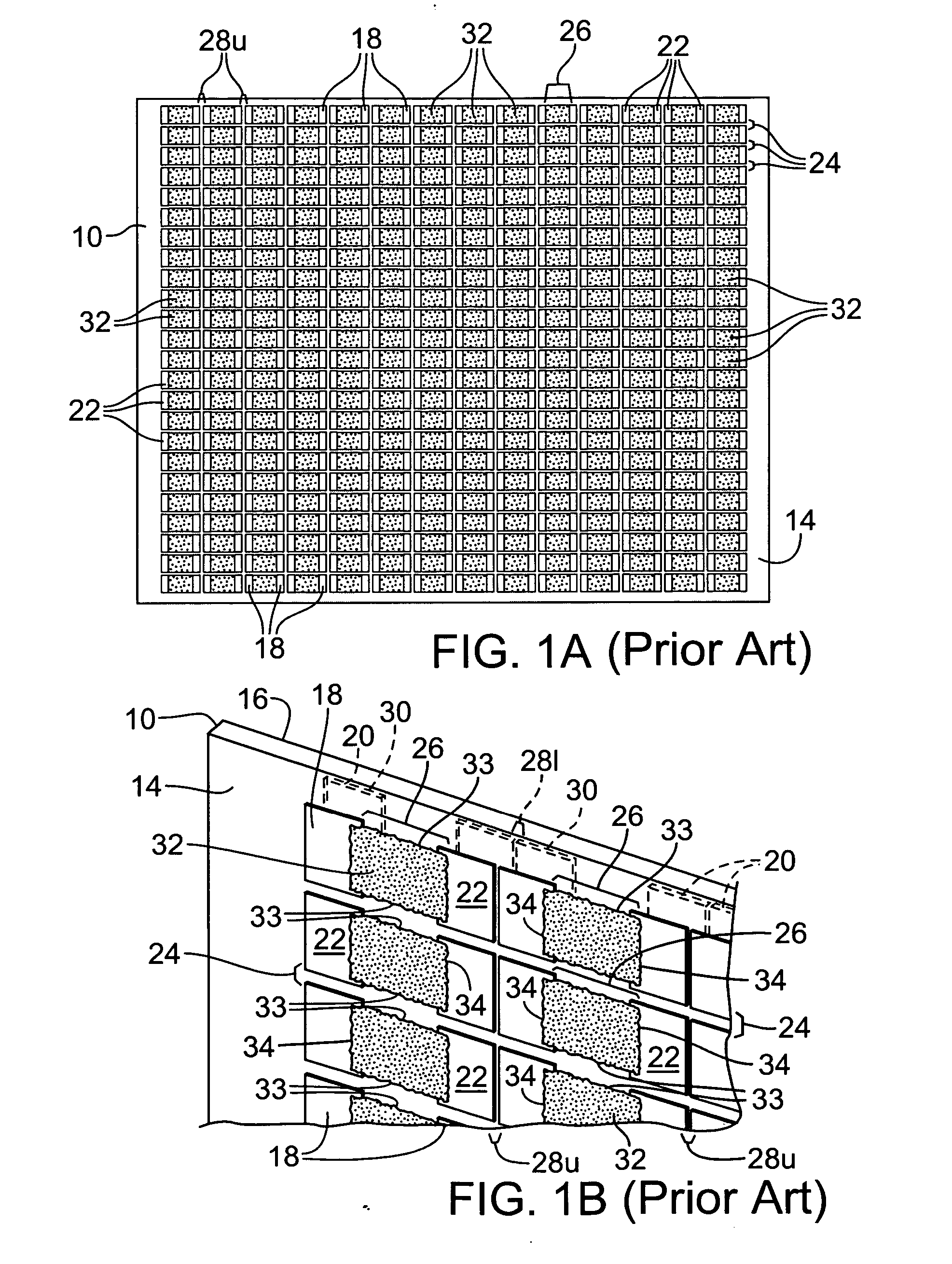

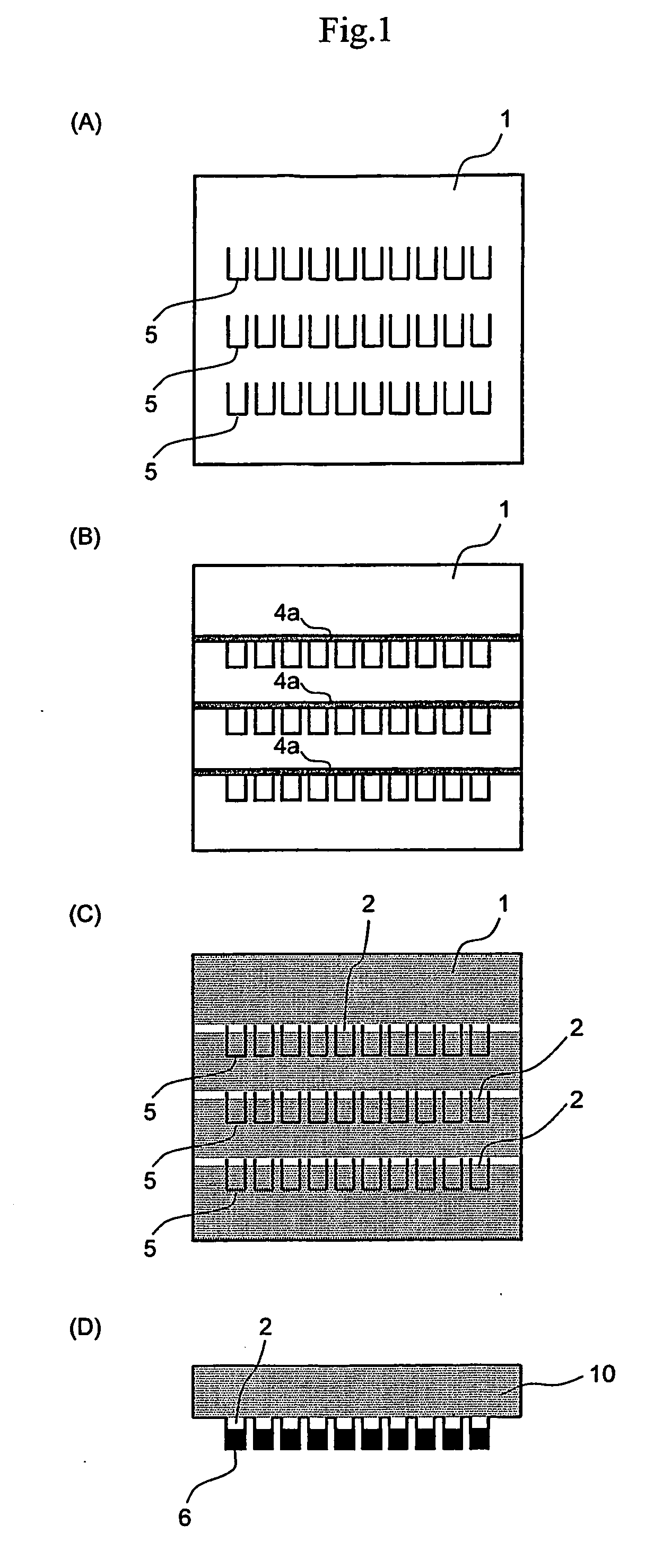

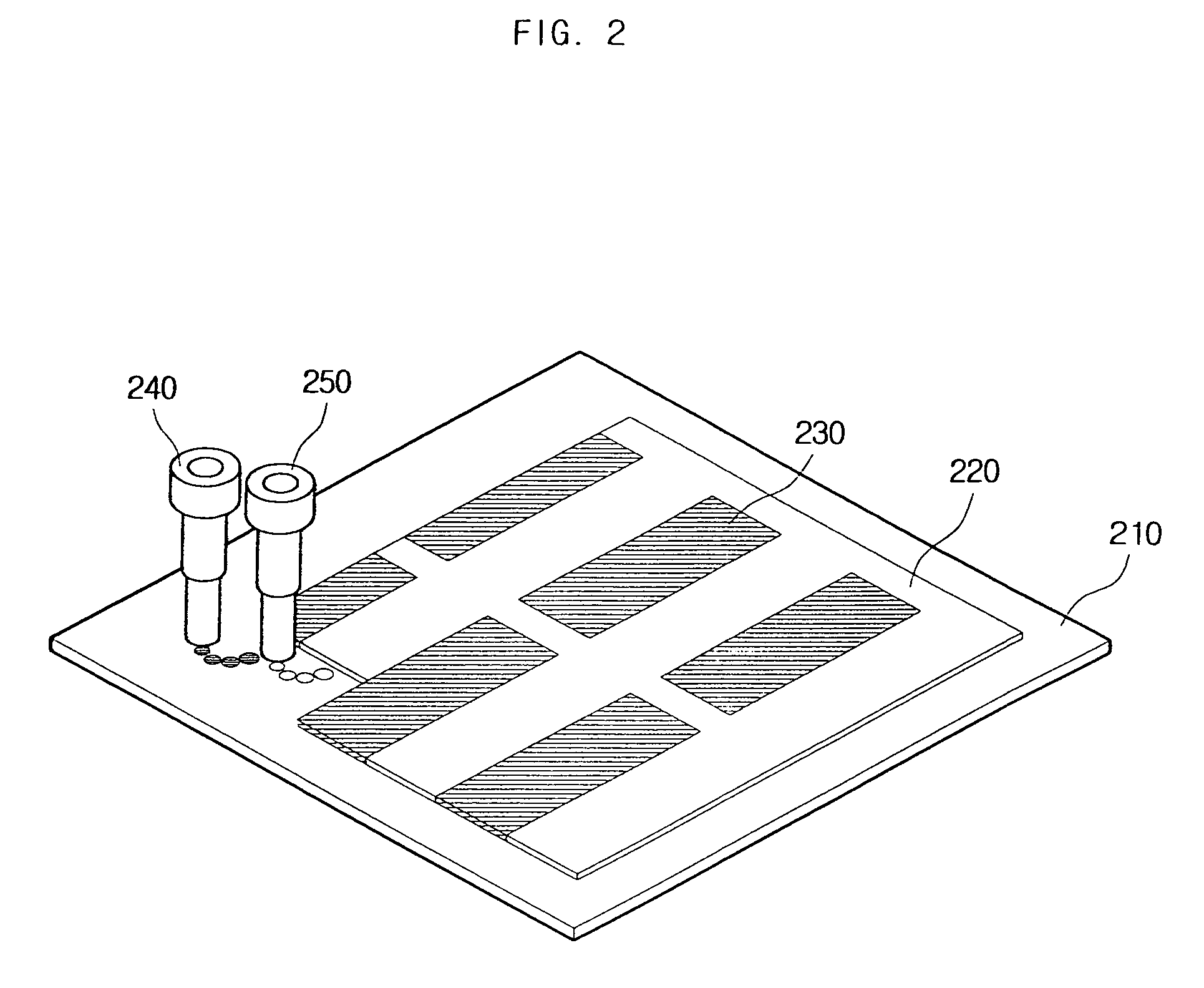

Process for manufacture of ceramic capacitors using ink jet printing

InactiveUS20080026136A1Minimal distortionAccurately and consistently appliedFixed capacitor dielectricStacked capacitorsMetallurgyCeramic capacitor

A process for forming a multilayer ceramic device. The device includes forming a ceramic precursor layer followed by ink jet printing in alternating order an electrode precursor in a predetermined pattern on the ceramic precursor layer to form an electrode and a ceramic ink on the electrode. The ceramic precursor is then sintered.

Owner:KEMET ELECTRONICS CORP

Metal foil for capacitor, solid electrolytic capacitor using the foil and production methods of the foil and the capacitor

A metal foil for capacitor element is produced through a process including steps of etching and ten electrochemically forming a metal foil after making cut lines each in a shape of a capacitor element with at least a part of a portion predetermined to be an anode-leading-out-part left uncut. The step of etching the foil is preferably performed with the anode-leading-out-parts being protected by protective material. Solid electrolytic capacitor elements prepared by using the metal foil have narrow variation in capacitance.

Owner:MURATA MFG CO LTD

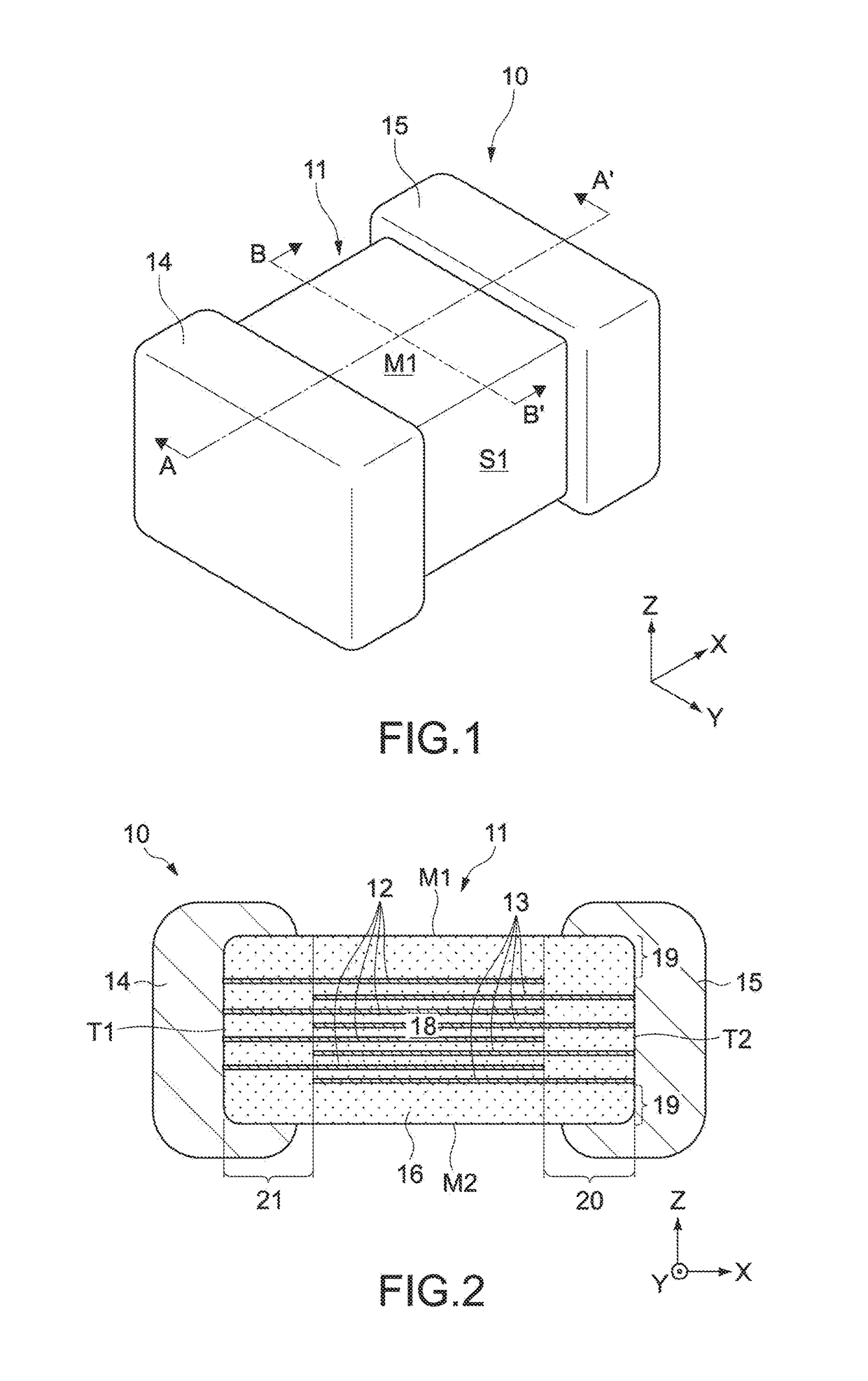

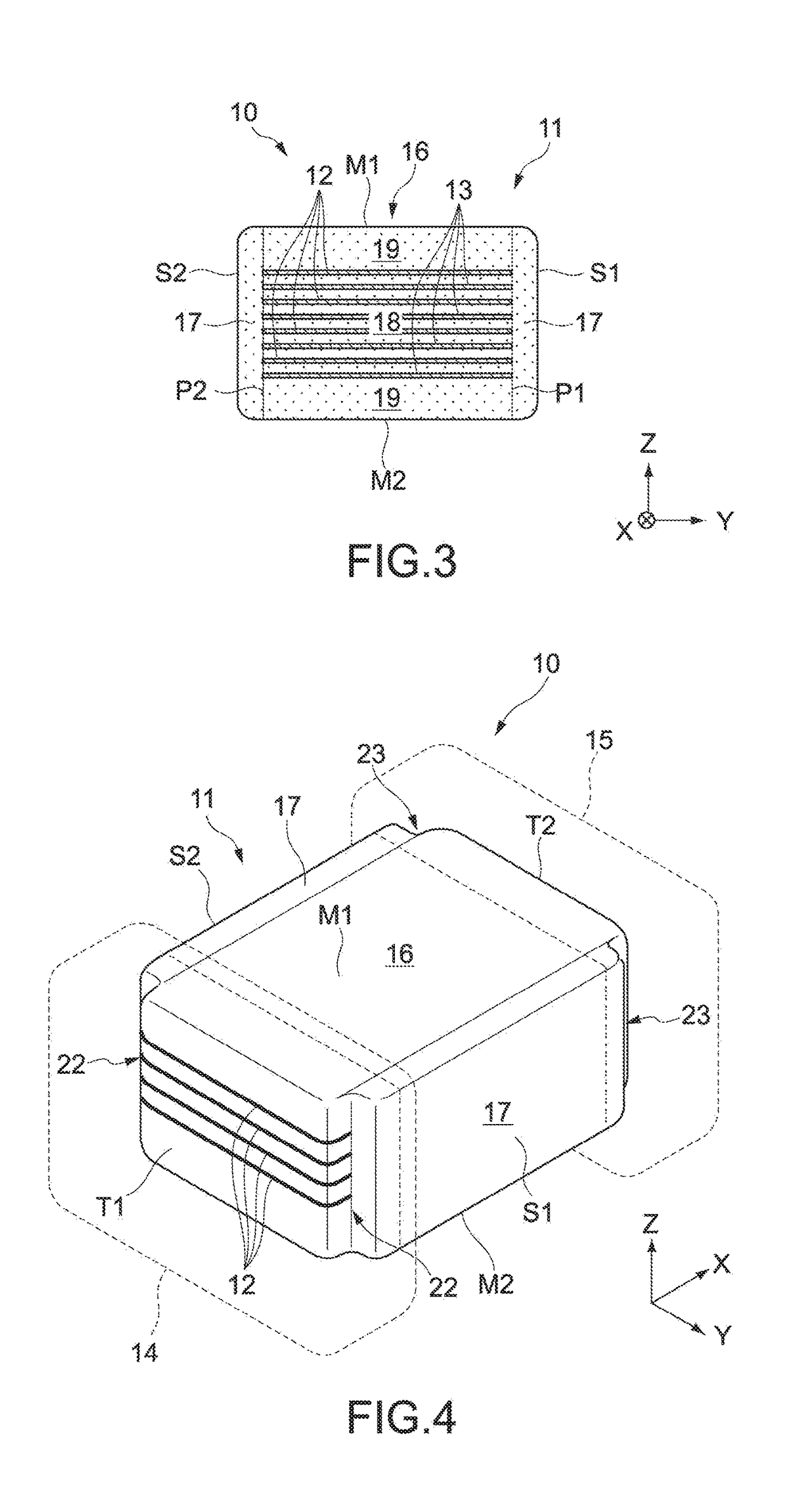

Capacitor Component and method for manufacturing same

The invention provides a capacitor component and a method for manufacturing same. The capacitor component includes a body having a first surface and a second surface opposing each other and includinga multilayer structure in which a plurality of dielectric layers are stacked and first and second internal electrodes are alternately disposed with respective dielectric layers interposed therebetweenand exposed to the first surface and the second surface, respectively, first and second metal layers covering the first surface and the second surface and connected to the first and second internal electrodes, respectively, first and second ceramic layers covering the first and second metal layers, and first and second external electrodes covering the first and second ceramic layers and connectedto the first and second metal layers to be electrically connected to the first and second internal electrodes, respectively.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method of forming passive electronic components on a substrate by direct write technique using shaped uniform laser beam

InactiveUS20060261924A1Sufficient accuracySolve the lack of precisionResistor chip manufactureThin/thick film capacitorElectrical resistance and conductanceConductive materials

A method of using a laser to achieve direct patterning of resistive or electrically conductive materials in the fabrication of miniature electronic components entails aligning with a patterned array-carrying major surface a laser beam that has a sufficient spot size and energy distribution to remove selected portions of resistive or conductive material that has been applied to the substrate. The major surface carrying the resistive or conductive material and the laser beam are moved relative to each other such that the laser beam ablates, or otherwise removes, selected portions of the resistive or conductive material. Thus preferred embodiments of the method form an array of multiple, mutually spaced-apart resistive or conductive material regions whose side and end margins have improved dimensional precision.

Owner:ELECTRO SCI IND INC

Method of making, apparatus, and article of manufacture for an ultracapacitor electrode termination contact interface

An ultracapacitor electrode termination contact interface adapted for use in an energy storage device is disclosed. The disclosed apparatus and article of manufacture function to lower equivalent series resistance of the ultracapacitor electrode termination contact interface. In one embodiment of the present teachings, an ultracapacitor electrode termination contact interface, adapted to increase reliability and manufacturing yield of such devices is disclosed.

Owner:TESLA INC

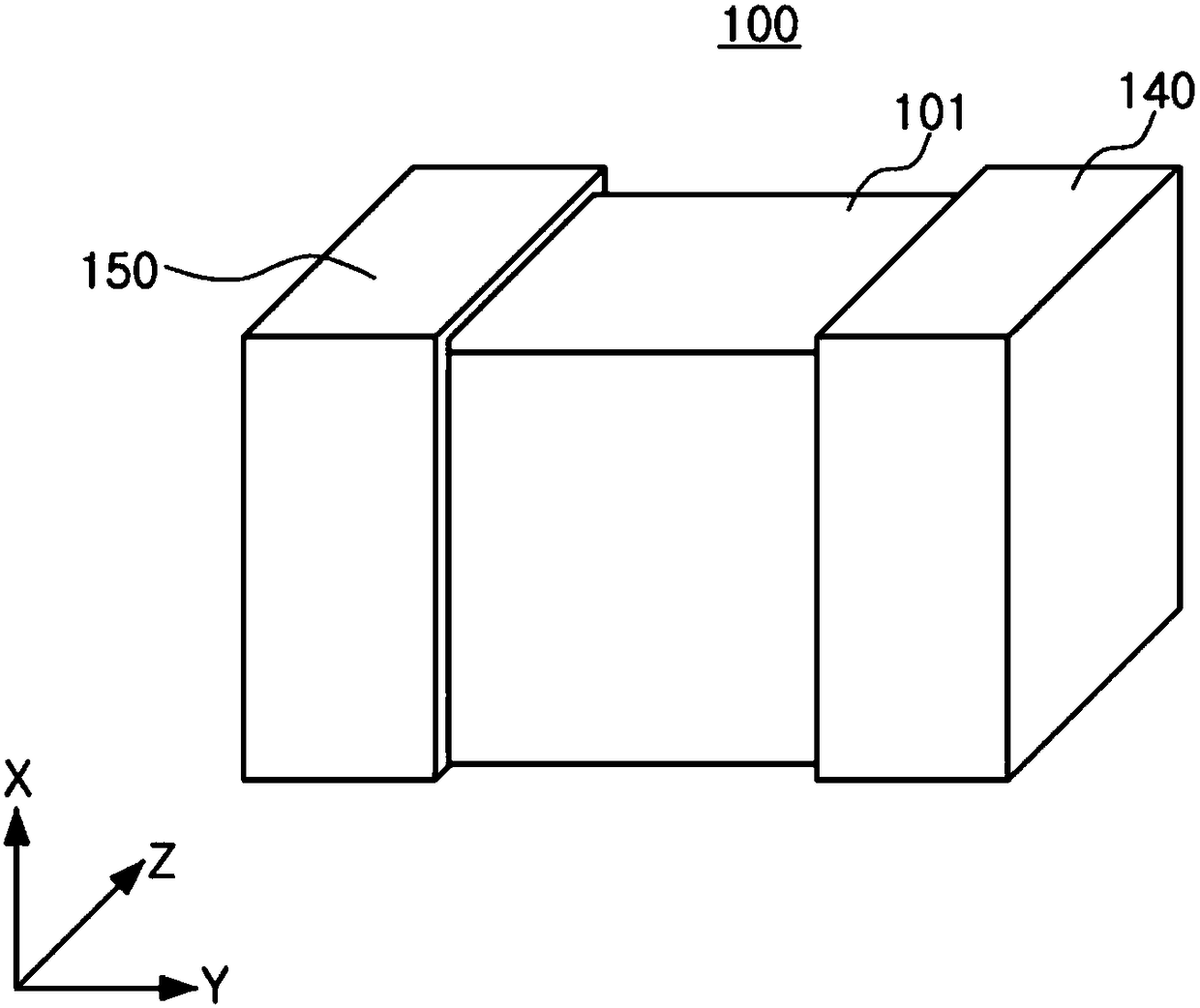

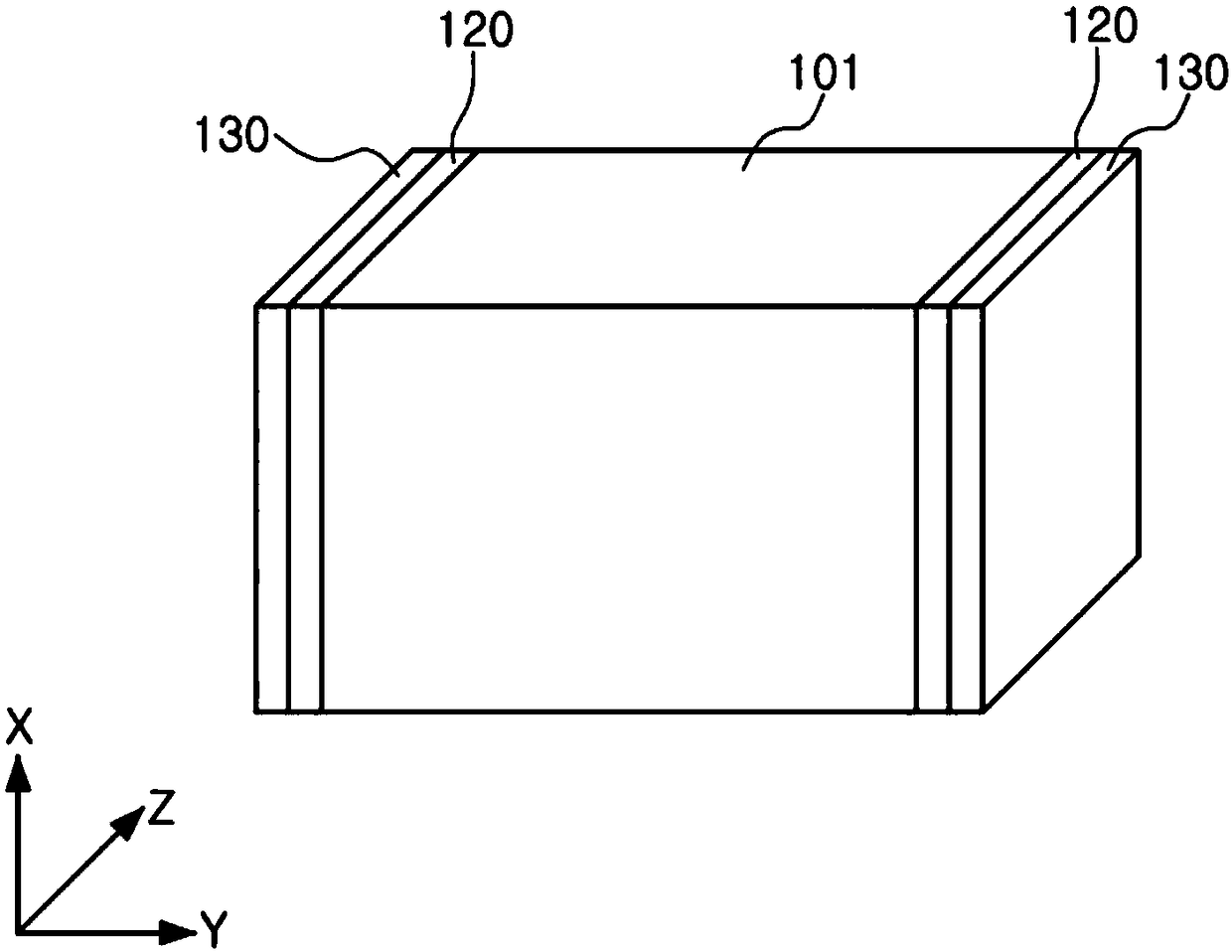

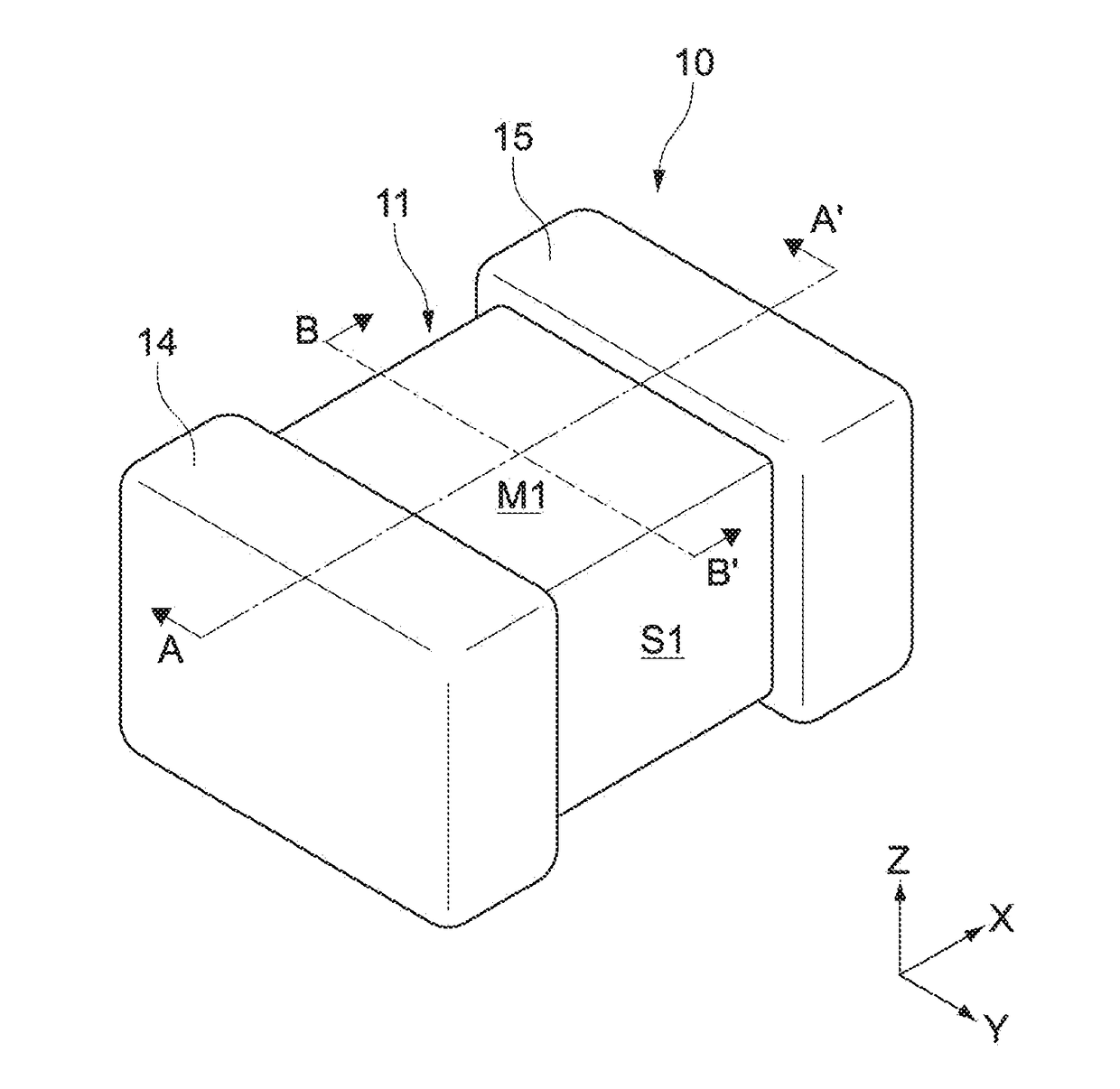

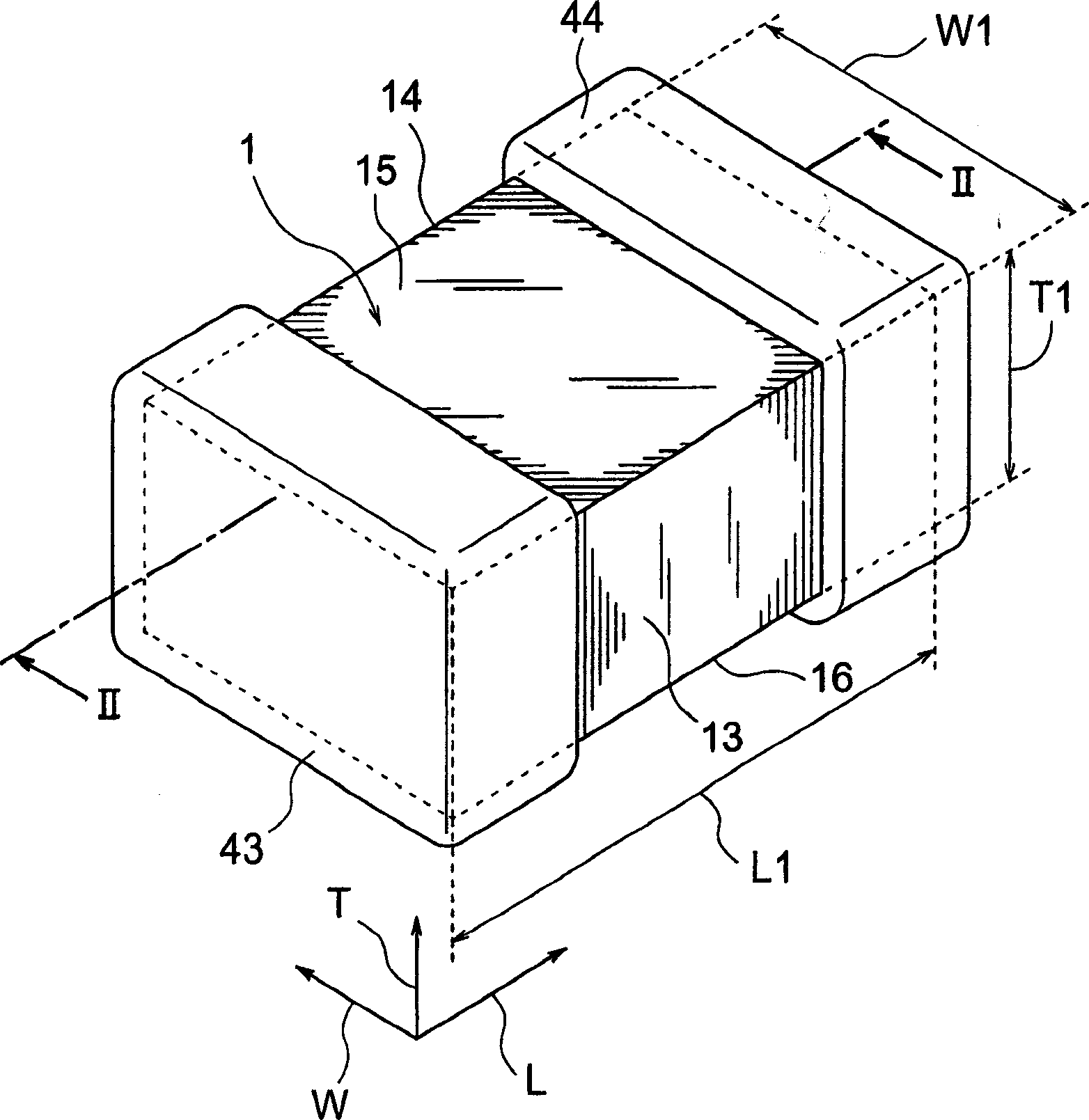

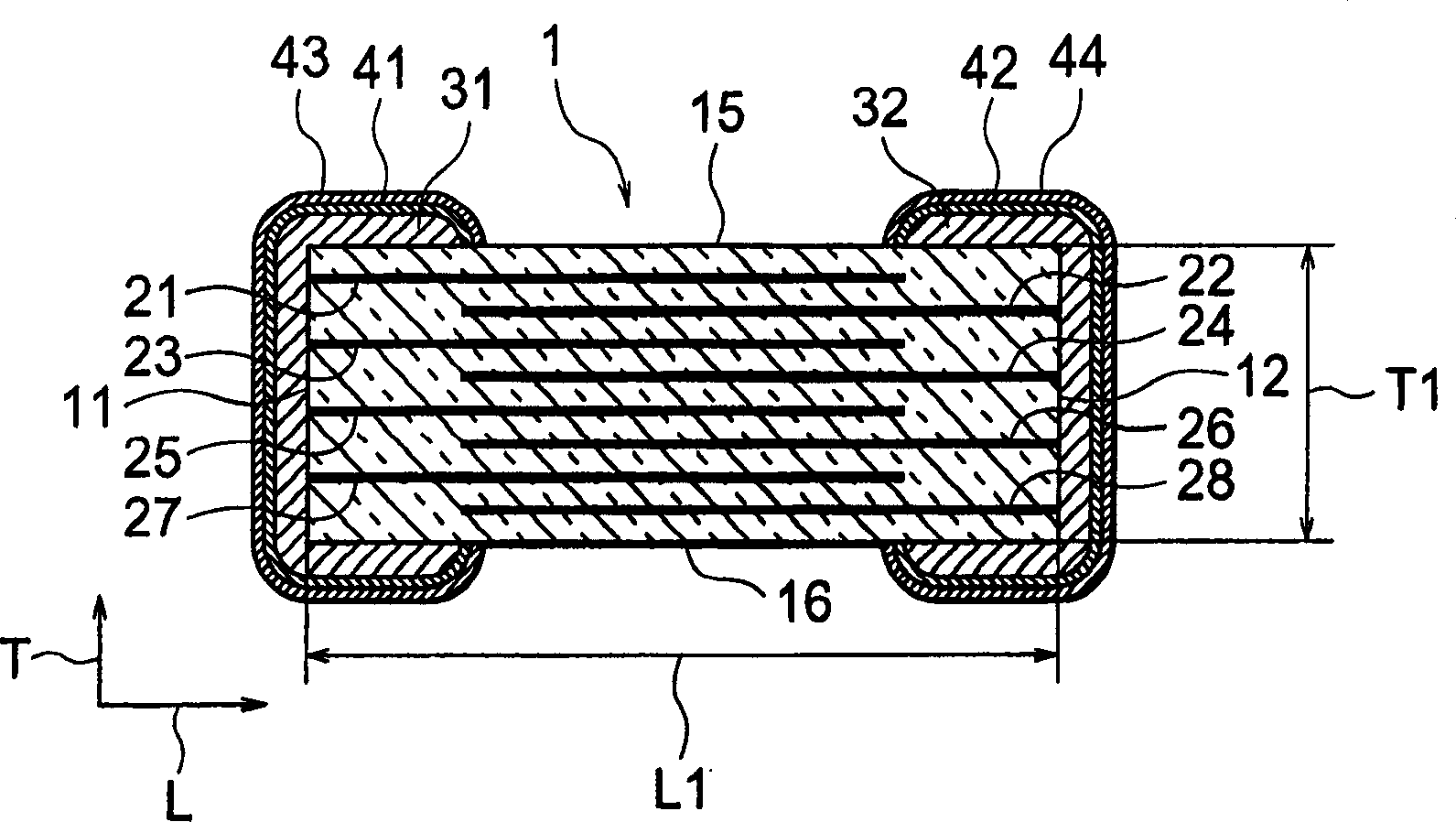

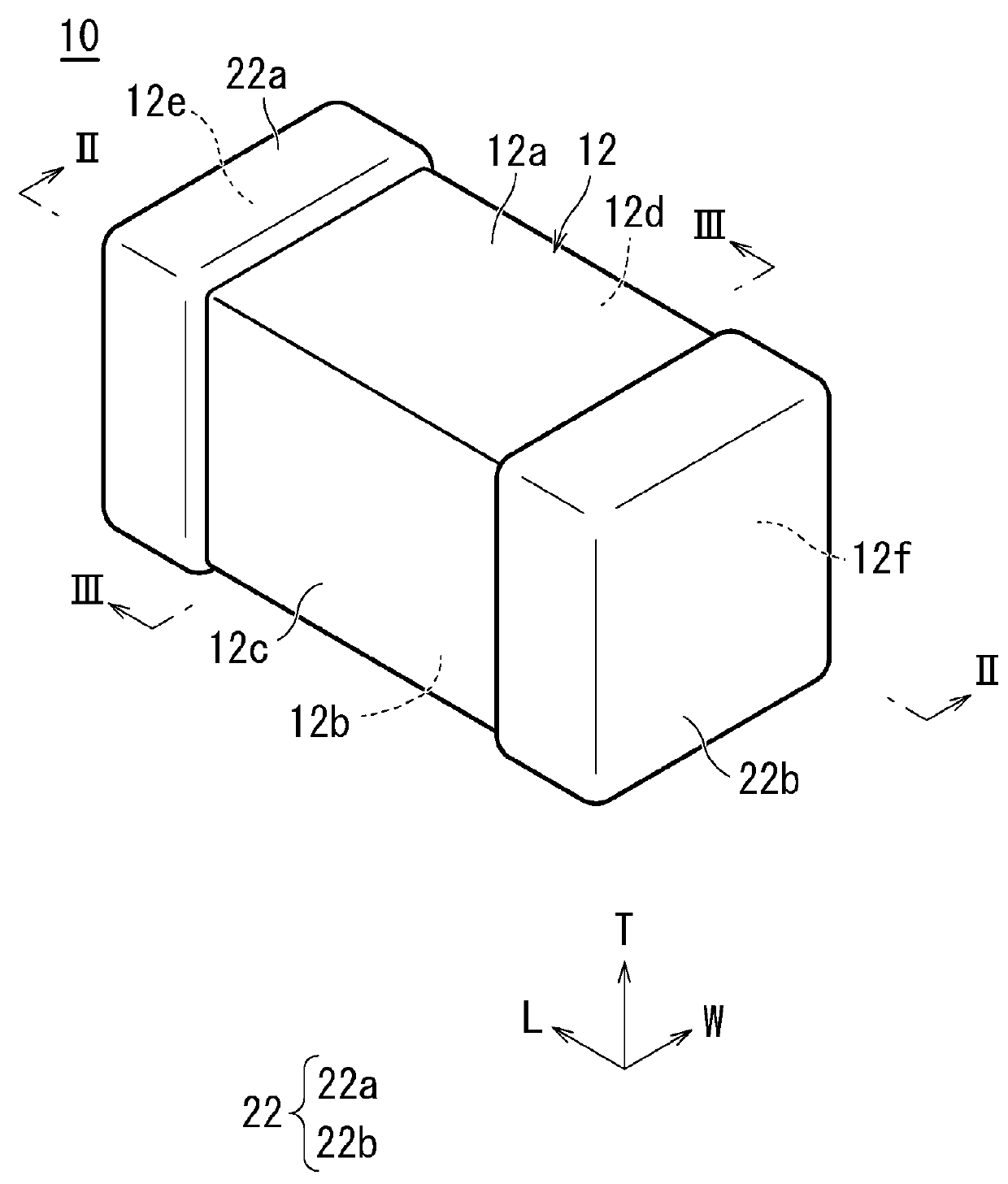

Multi-Layer Ceramic Capacitor and Method of Producing the Same

ActiveUS20170301471A1Well formedImprove connection strengthFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorBiomedical engineering

A multi-layer ceramic capacitor includes: a body, a first external electrode, and a second external electrode. The body includes a first end surface and a second end surface that face each other, a side surface that extends between the first end surface and the second end surface, a first recess that extends along a first ridge of the first end surface and the side surface, a second recess that extends along a second ridge of the second end surface and the side surface, a first internal electrode that is drawn to the first end surface and the first recess, and a second internal electrode that faces the first internal electrode and is drawn to the second end surface and the second recess. The first external electrode covers the body from the first end surface. The second external electrode covers the body from the second end surface.

Owner:TAIYO YUDEN KK

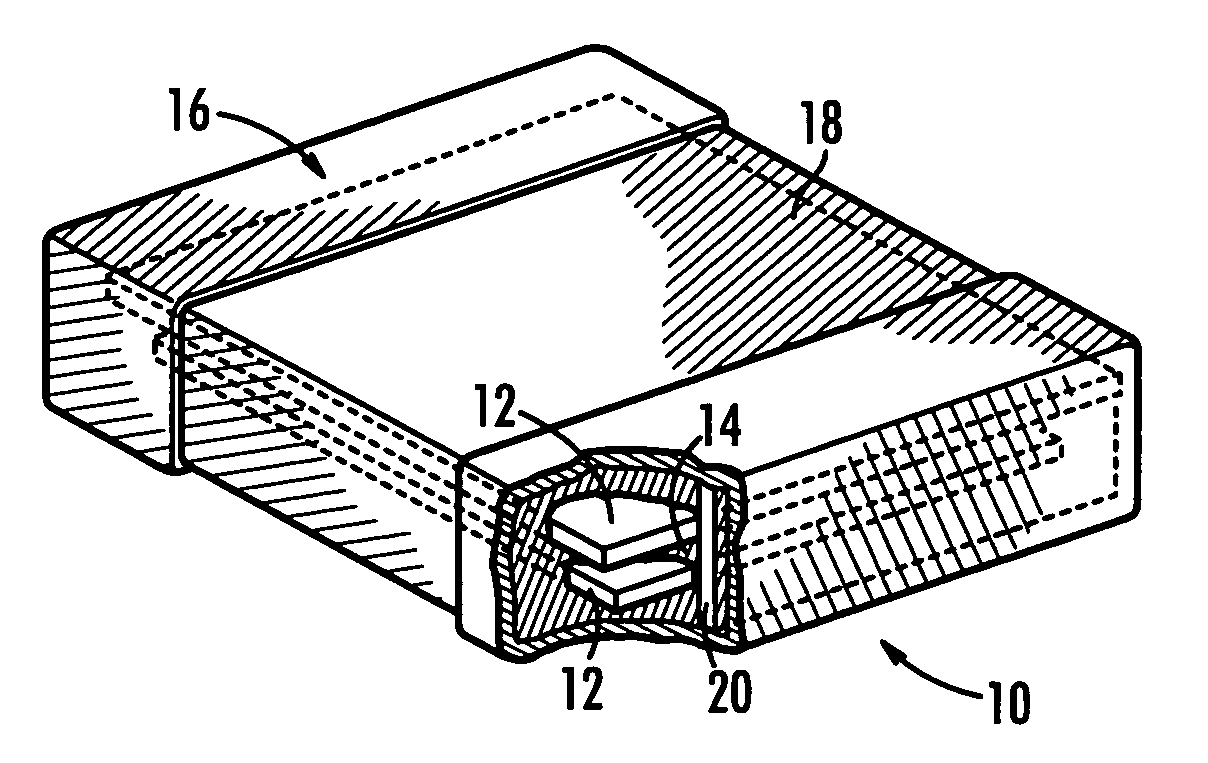

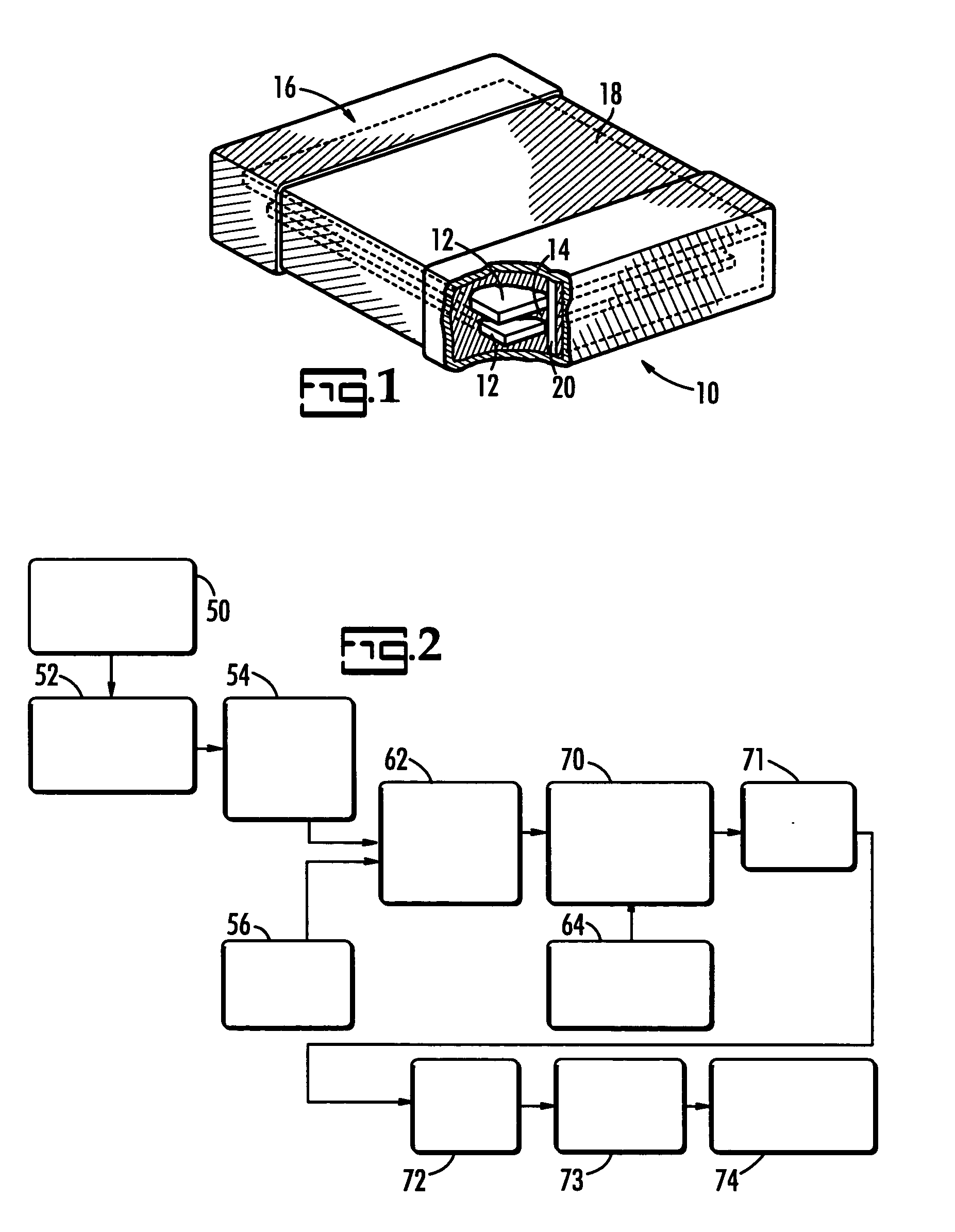

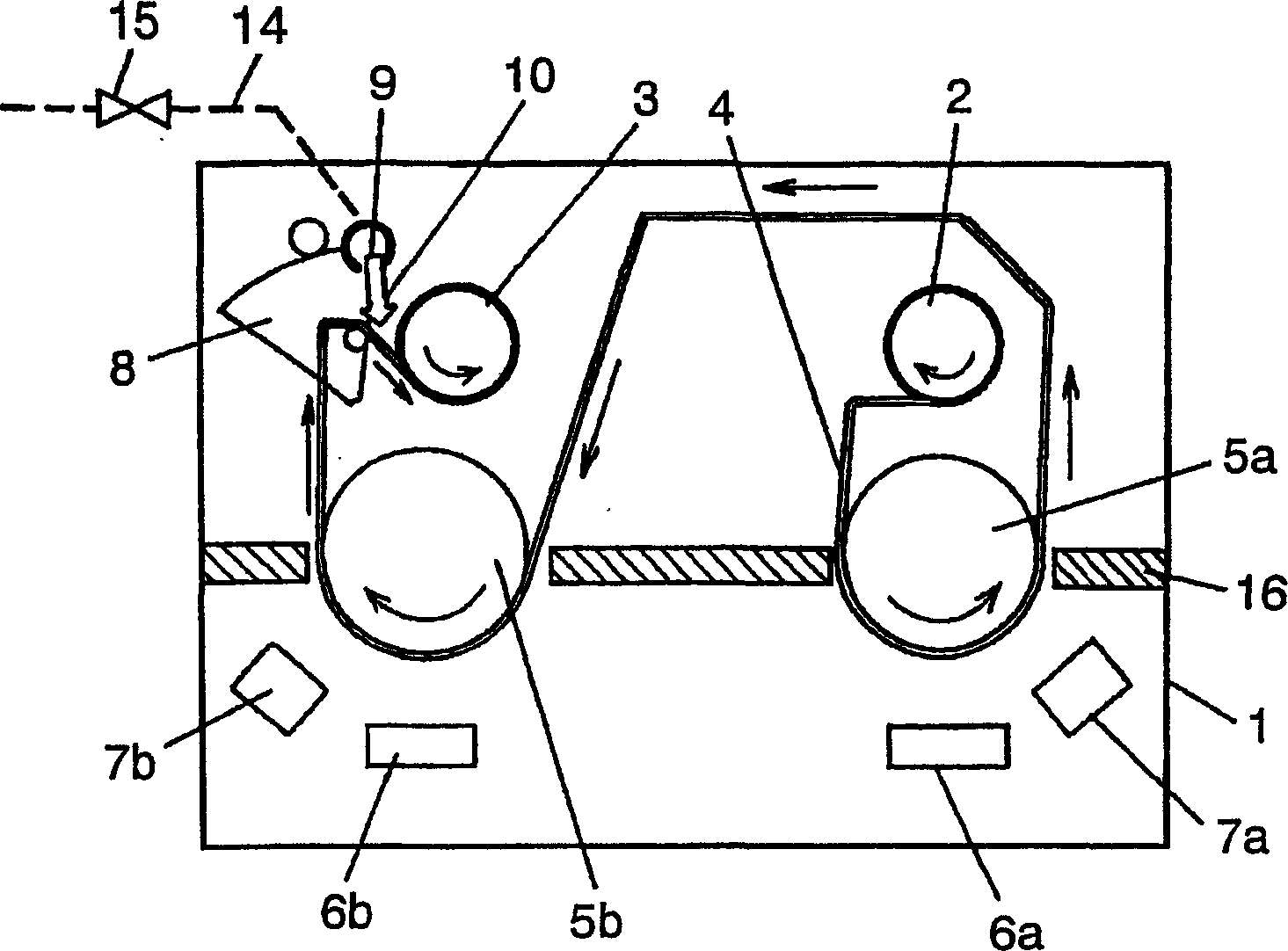

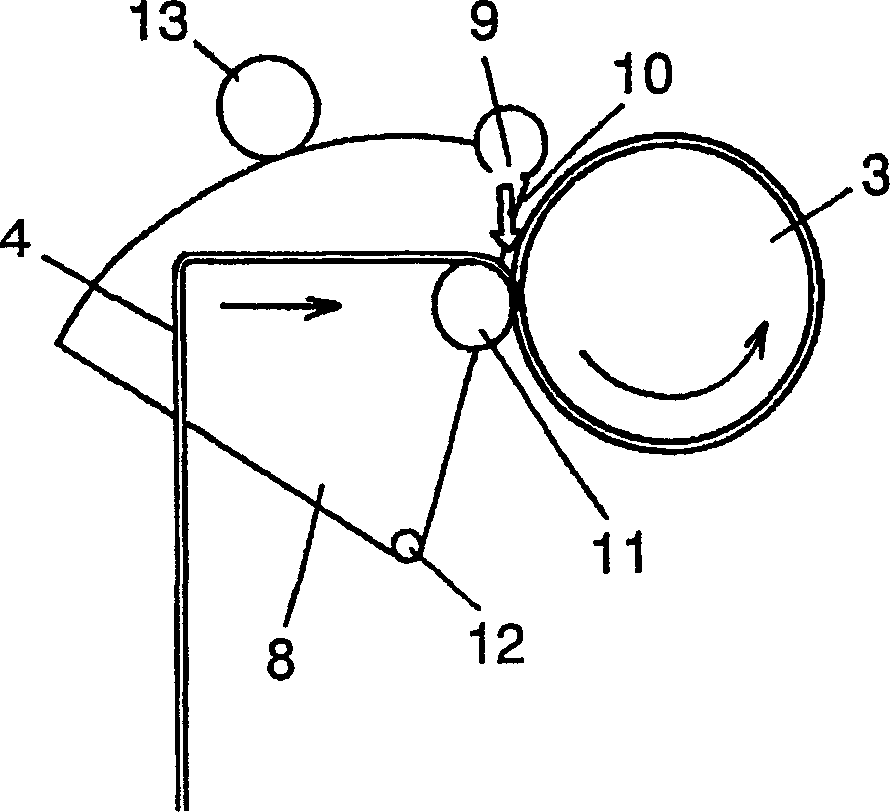

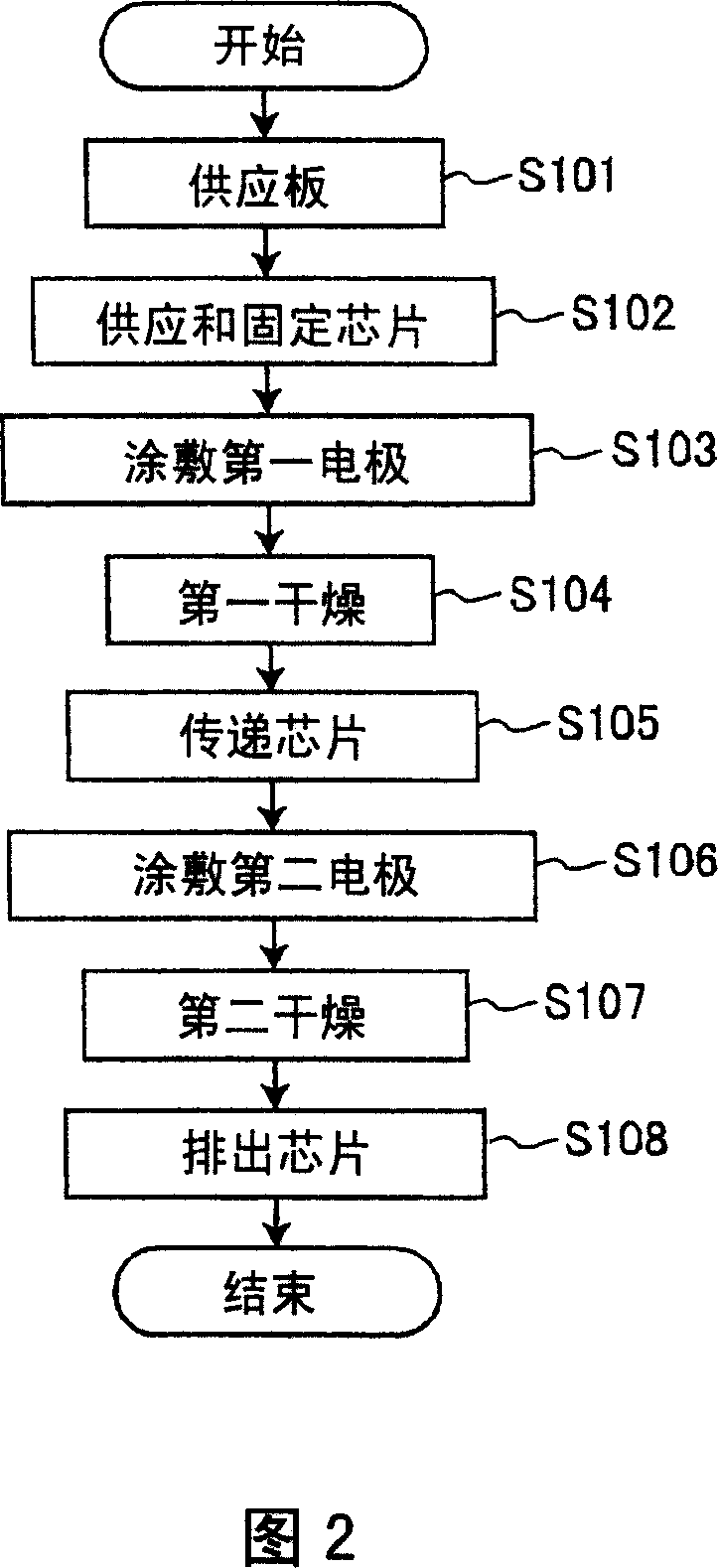

Ceramic electronic part, coating method and device

InactiveCN1444239AEfficient productionLess prone to the Manhattan phenomenonPrinted circuit assemblingLiquid surface applicatorsMetallurgyCeramic capacitor

A ceramic capacitor having a ceramic body and terminal electrodes, the ceramic body being substantially a rectangular parallelopiped in shape, the terminal electrodes being provided at the two ends of the ceramic body in the length direction, each terminal electrode being provided to cover one end face of the ceramic body in the length direction, part of the two surfaces in the width direction, and part of the two surfaces in the thickness direction, wherein, when the length of the ceramic body is L1 and the maximum lengths of the terminal electrodes at the two surfaces of the ceramic body in the width direction are L3 and L4, 0<=|(L4-L3| / L1<=0.0227 is satisfied. One surface among the two surfaces of the ceramic body in the width direction is the paste introduction side in the roller coating, while the other surface is the paste escape side in the roller coating.

Owner:TDK CORPARATION

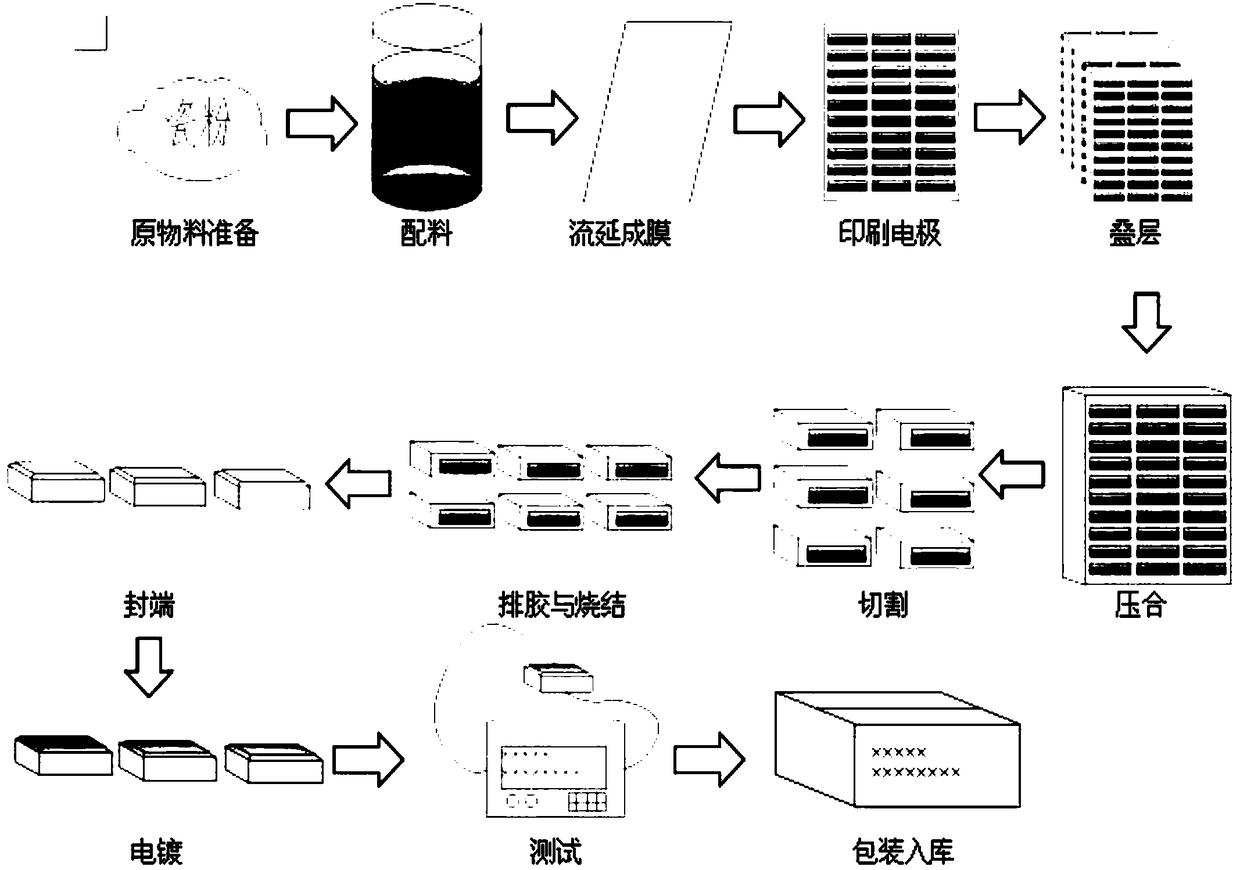

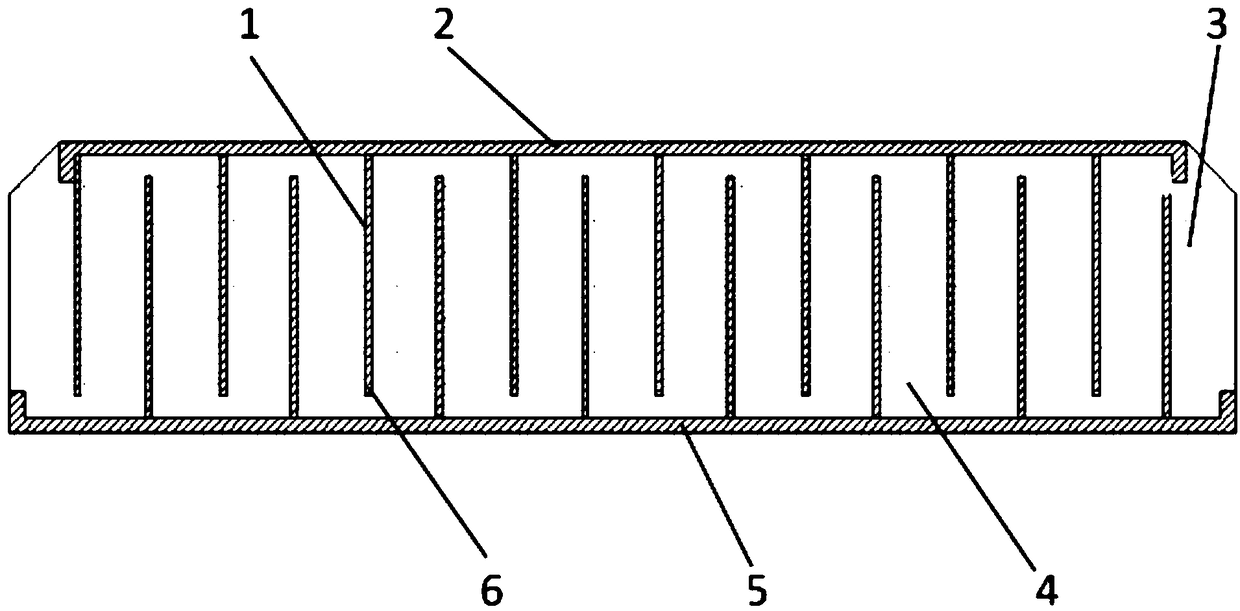

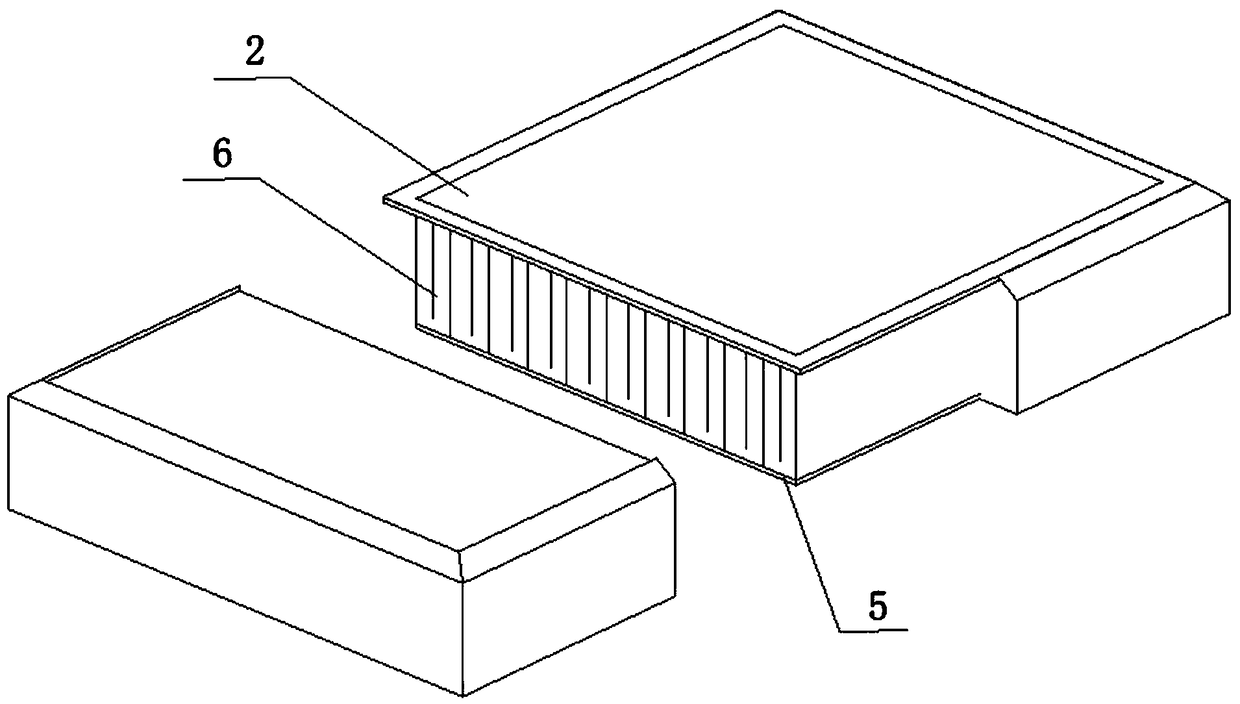

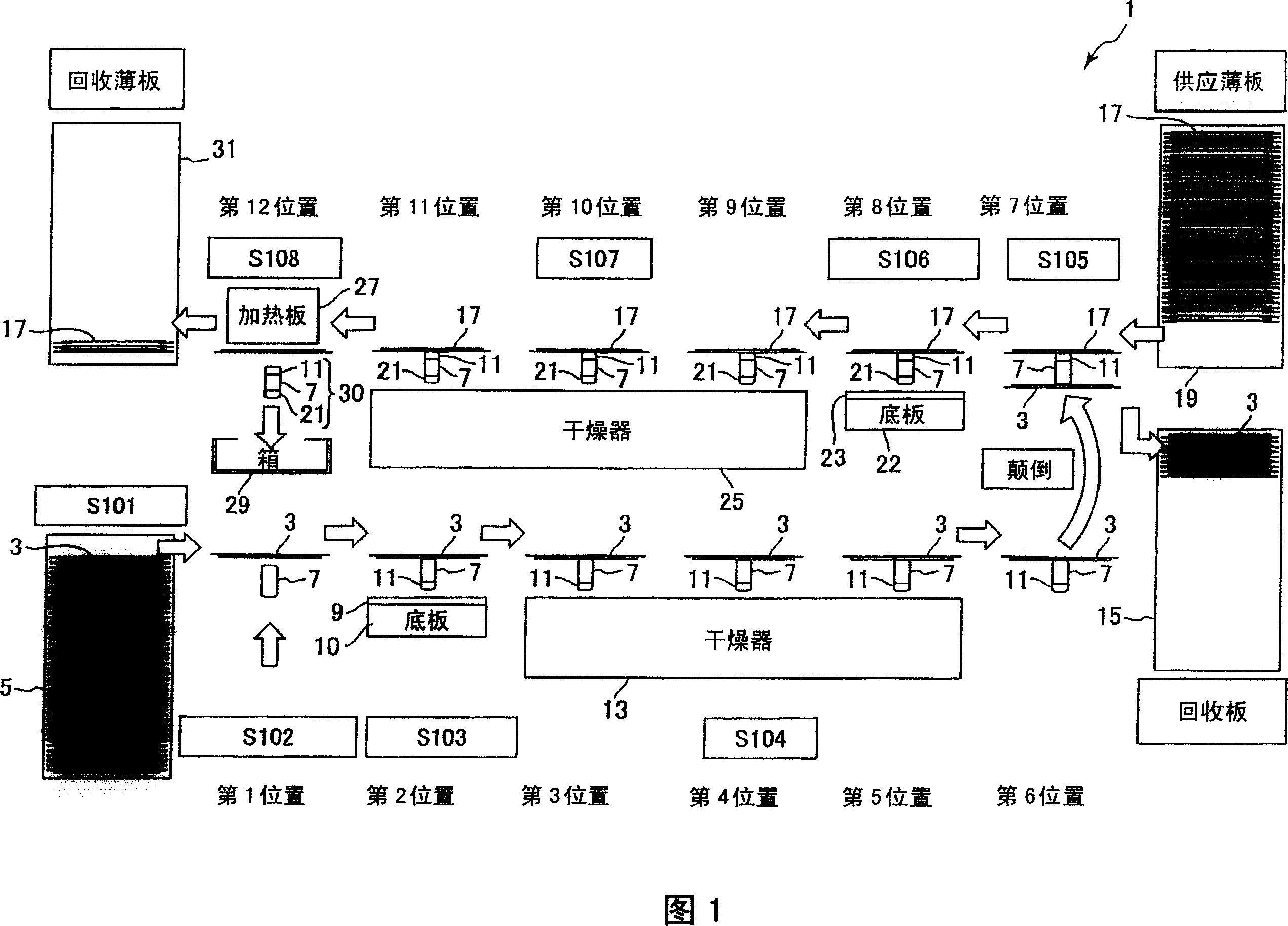

Manufacturing process of vertical ceramic patch capacitor and capacitor product of vertical ceramic patch capacitor

InactiveCN108281283AChange shapeChange electrode directionFixed capacitor electrodesFixed capacitor dielectricCapacitanceMaterials preparation

The invention discloses a manufacturing process of a vertical ceramic patch capacitor and a capacitor product of the vertical ceramic patch capacitor, and belongs to the technical field of microelectronics. The process comprises the steps of material preparation, in which raw materials are mixed according to a proportion; coating, in which a layer of uniform paste thin film is formed from paste bya coating machine; printing, in which internal electrode paste is printed onto a ceramic film by a screen printing plate according to the process requirement; lamination, in which the printed ceramicfilms are laminated to form green blank having different layers; lamination, in which the green blank is loaded in a lamination bag; cutting, in which the laminated large green blank is cut to relatively small blanks; gluing, in which the cut blank blocks are glued; sintering, in which the green blank is sintered to form a ceramic body; chamfering, corners of the product of the capacitor sinteredto form ceramic are chamfered; sealing, in which the product is sealed to form the ceramic body; and sintering, in which the ceramic body is sintered to form the ceramic capacitor. The purpose of changing the shape of the capacitor and the electrode direction is achieved by changing an electrode printing method, a cutting method and a coating process, so that the installation and the applicationof a capacitor in a flat package component can be adapted.

Owner:SHANDONG DIYI ELECTRONICS SCI & TECH

Mfg. method of double-sided metallization film and metallization film capacitor using same

InactiveCN1463450ALess laborNo increase in tanδFixed capacitor electrodesVacuum evaporation coatingPolymer scienceOxygen

Owner:PANASONIC CORP

Method and device for forming external electrodes in electronic chip component

ActiveCN101047069AHighly stable product qualityIncrease production capacityResistor chip manufactureFixed capacitor electrodesConductive pasteAdhesive

Owner:TDK CORPARATION

Metal foil for capacitor, solid electrolytic capactor using the foil and production methods of the foil and the capacitor

ActiveUS20060046417A1Stable capacitanceReduce leakage currentSolid electrolytic capacitorsLiquid electrolytic capacitorsCapacitanceElectrolysis

A metal foil for capacitor element is produced through a process comprising steps of etching and then electrochemically forming a metal foil after making cut lines each in a shape of a capacitor element with at least a part of a portion predetermined to be an anode-leading-out-part left uncut. The step of etching the foil is preferably performed with the anode-leading-out-parts being protected by protective material. Solid electrolytic capacitor elements prepared by using the metal foil have narrow variation in capacitance.

Owner:MURATA MFG CO LTD

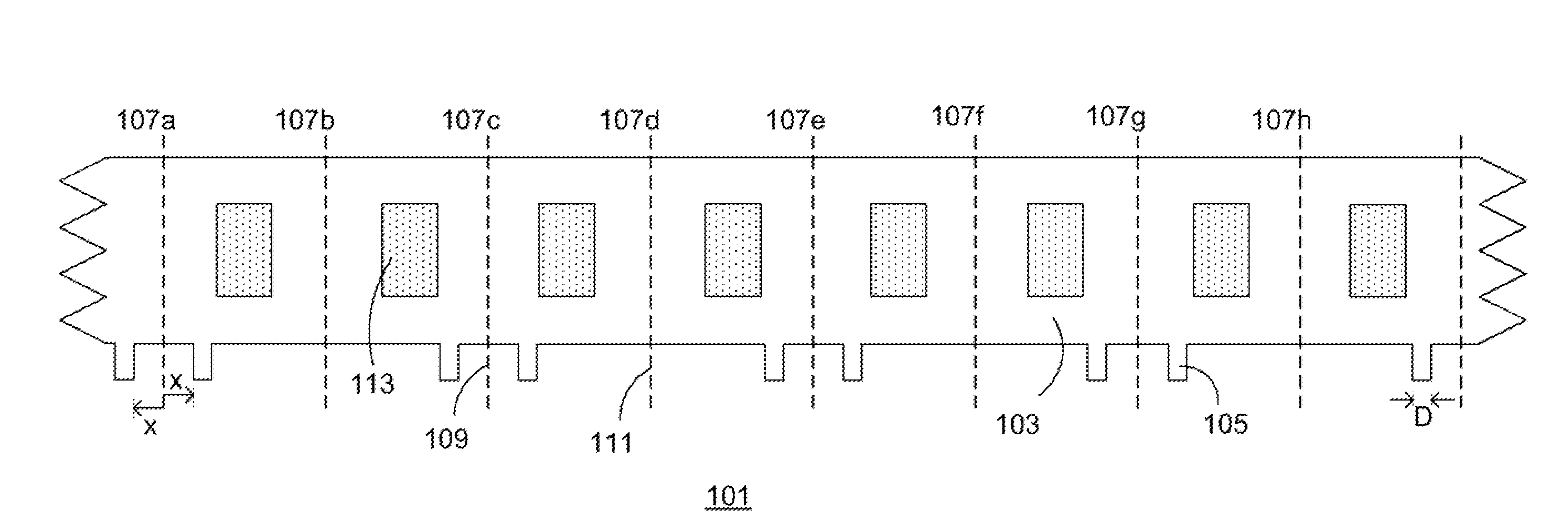

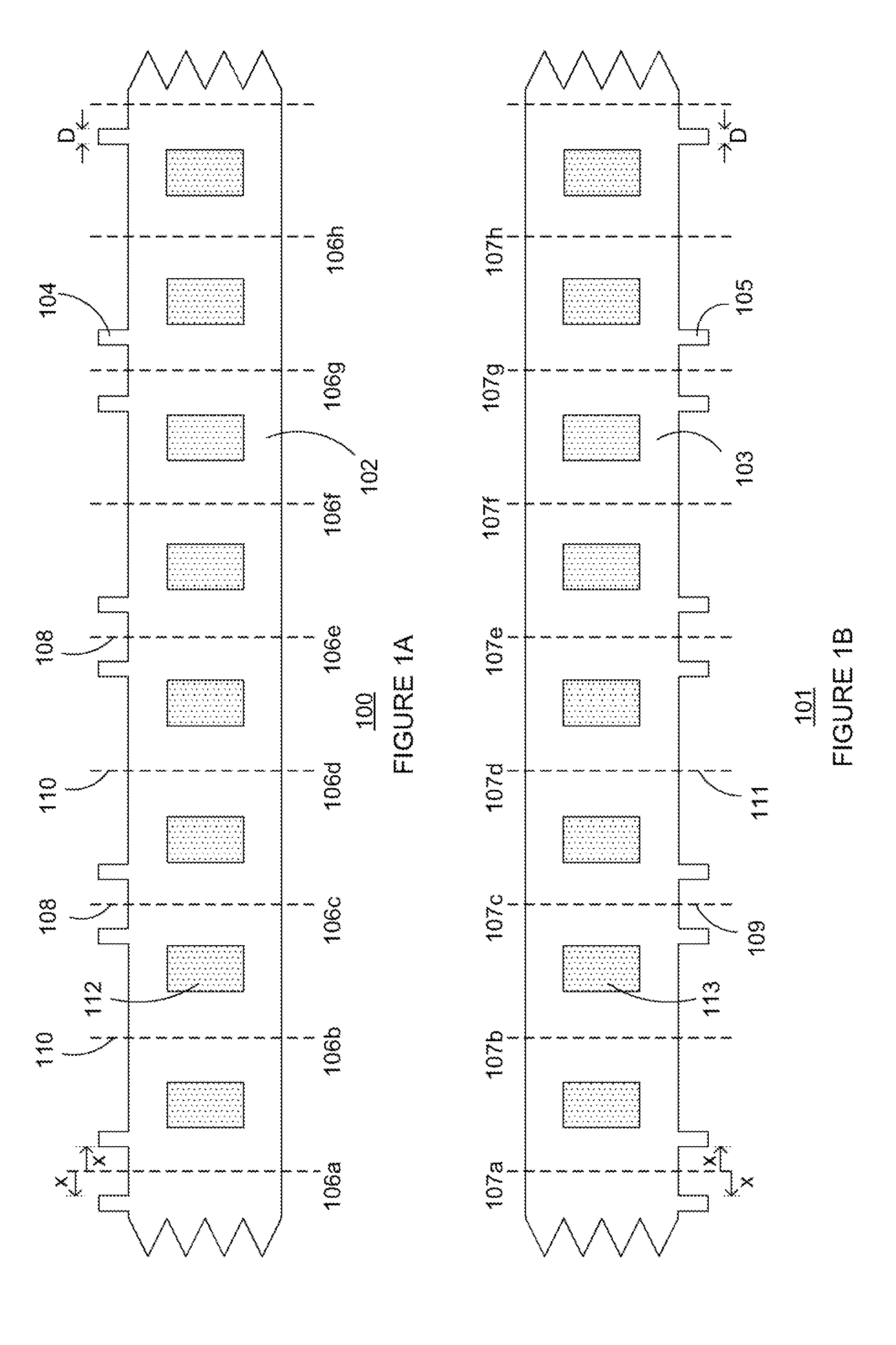

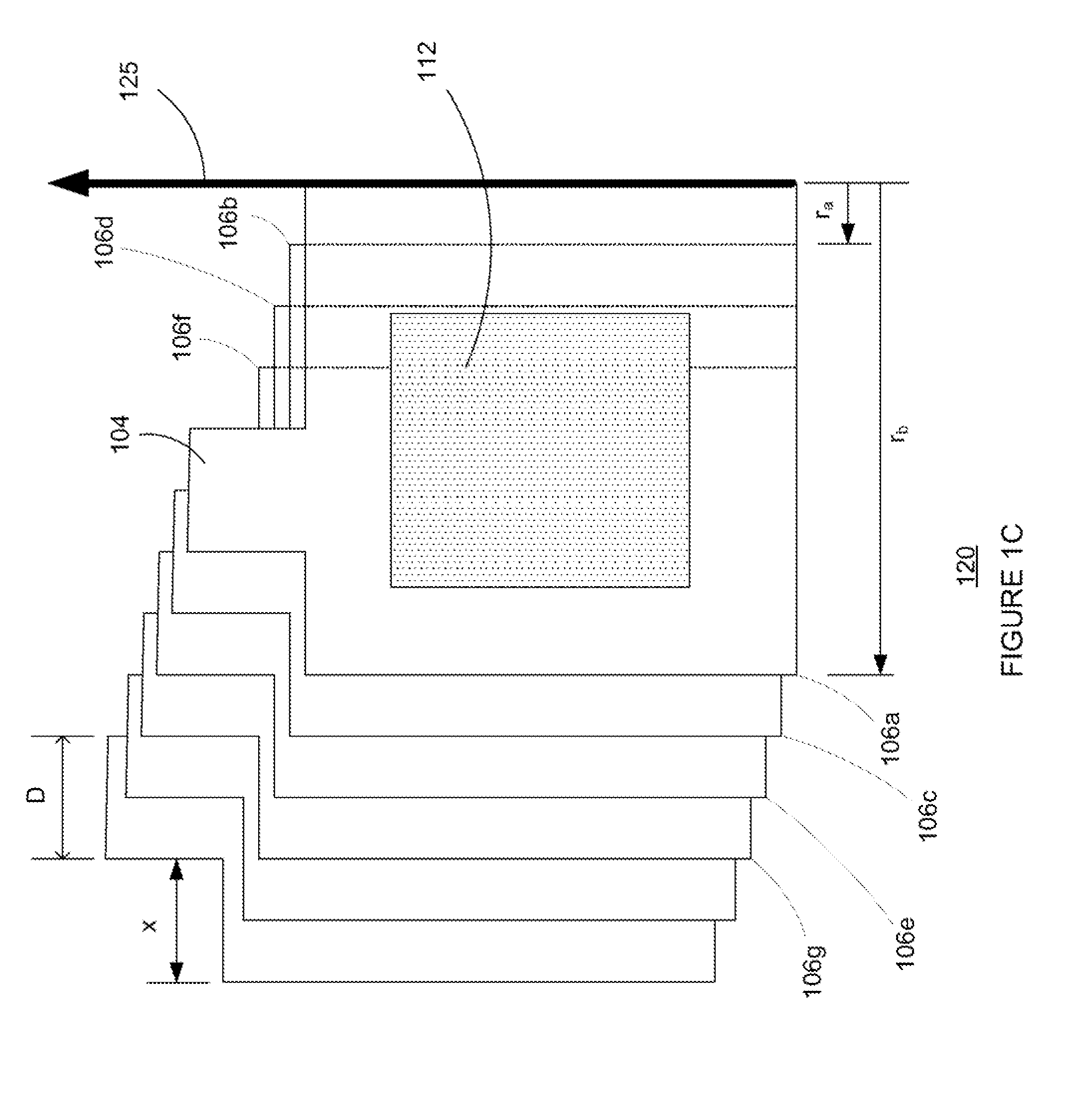

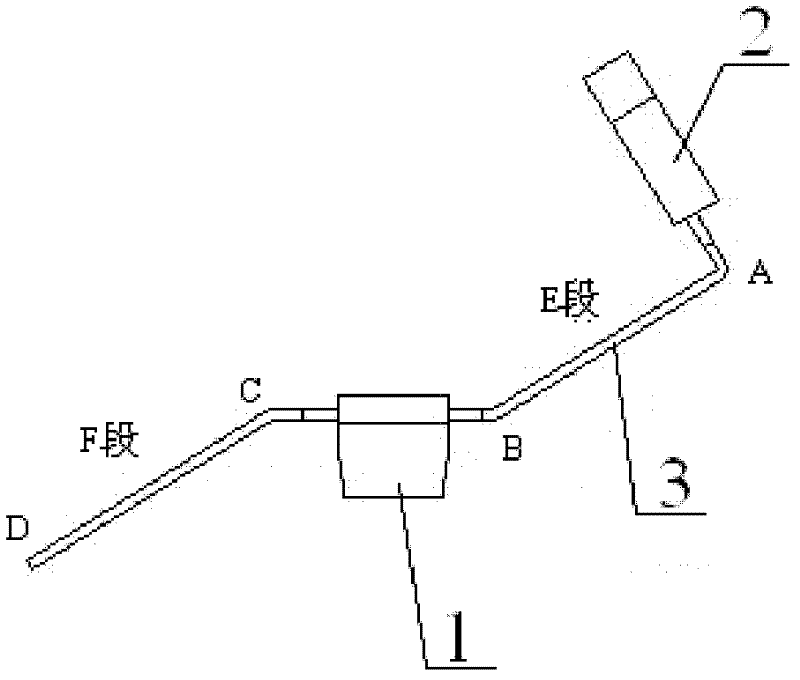

Fully automatic nailing and winding integrated machine

ActiveCN110140189AAvoid errorsImprove hole position accuracyWinding capacitor machinesTerminal applying apparatusWinding machineEngineering

The invention relates to the technical field of capacitor preparation, in particular to a fully automatic nailing and winding integrated machine. The automatic nailing and winding integrated machine comprises a foil conveying mechanism, a needle conveying mechanism, a nailing mechanism, a winding mechanism and a cutting mechanism, and the nailing mechanism only needs to move the mold assembly to be movable in the first direction And the movement of the molds on the mold assembly in the second direction can complete the nailing of the guide pins and the foil strips without changing the positionof the foil strips, omitting the foil-rolling wheel, and avoiding the foil-feeding wheel during the transmission process The error caused by the change of the tension improves the precision of the hole position of the first nailing hole and the second nailing hole, ensures the quality of the nailing, and improves the yield of the automatic nailing and winding machine.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

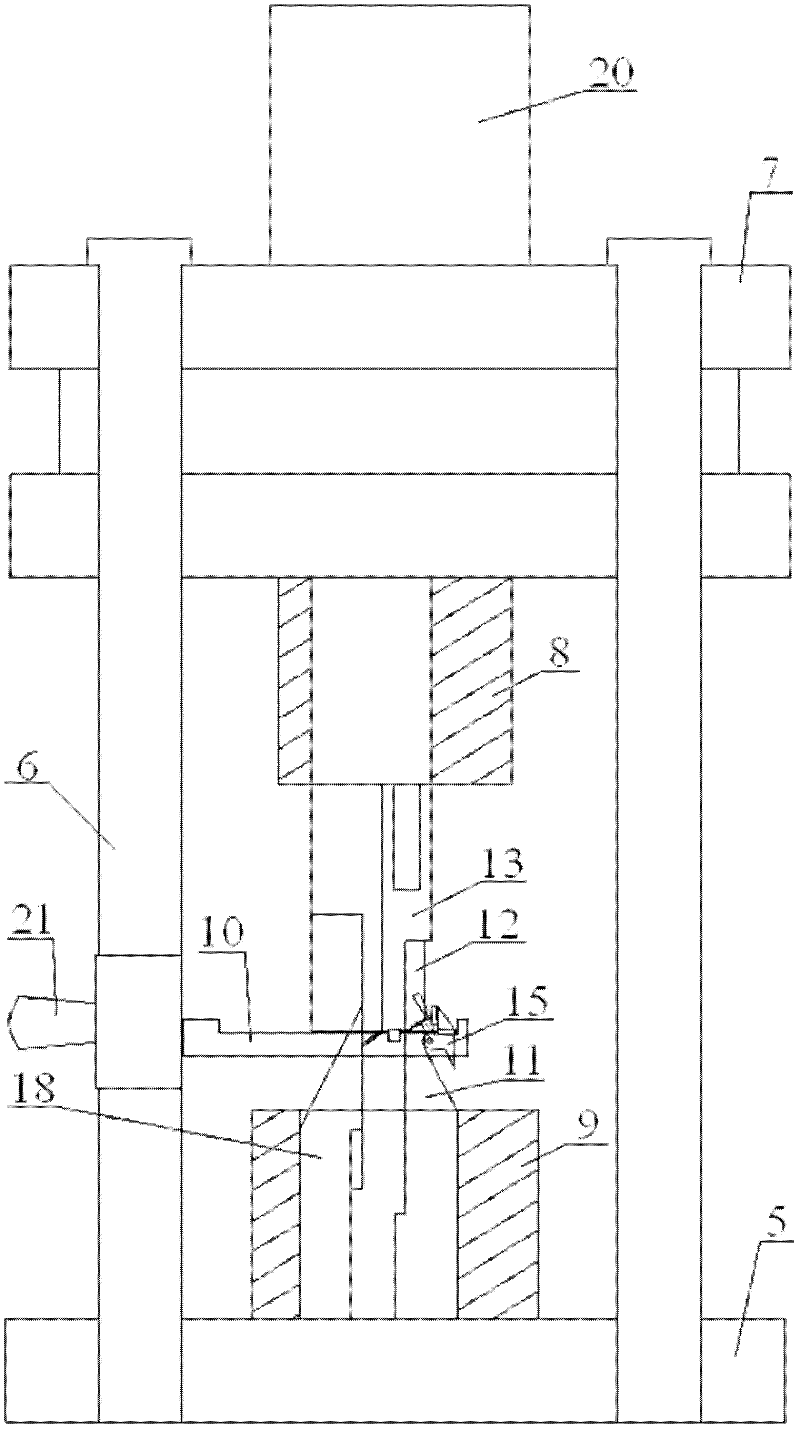

Hall chip forming tool

InactiveCN102641972AEasy to increase the possibility of deformationIncrease the itineraryTerminal applying apparatusMetal working apparatusCapacitanceEngineering

The invention discloses a Hall chip forming tool comprising an upper die holder, a lower die holder, a plurality of guide pillars and a feeding guide slot, wherein the upper die holder and the lower die holder are respectively provided with an upper die block assembly and a lower die block assembly; the upper die block assembly comprises an upper die fixing block, an upper blade and an upper die pressing block; the lower die block assembly comprises a lower die fixing block, a lower blade, a lower die pressing block and a lower die forming block; the end of the lower die fixing block is provided with a hinge and a cam, and the cam is right positioned under the hinge to be matched with the hinge; and the upper die holder is provided with an air cylinder, and a piston rod of the air cylinder is fixedly connected to the upper surface of the upper die holder. The Hall chip forming tool disclosed by the invention adopts a once fixation and multi-forming mode so as to avoid the damage to a chip part and a capacitor part. The structure of the Hall chip forming tool is once fixed by adopting a spring buffering method so as to prevent a Hall chip pin from being pressed to be transformed. In addition, the Hall chip forming tool disclosed by the invention adopts a hinge structure to assist 90 DEG forming, so that the production efficiency is enhanced.

Owner:安徽睿联测控技术有限公司

Array type multi-layer ceramic capacitor and production method thereof

InactiveUS7593214B2Improve adhesionMultiple fixed capacitorsFixed capacitor electrodesDielectricCeramic capacitor

A method of producing an array type multi-layer ceramic capacitor is disclosed, comprising: forming dielectric films, forming dielectric sheets on which internal electrodes and interelectrode dielectrics formed on the same plane as the internal electrodes are printed simultaneously by spraying ink intended for internal electrodes and ink intended for dielectrics onto the dielectric film via a plurality of inkjet printer heads, stacking and compressing the dielectric sheets, cutting the stacked dielectric sheet to include a plurality of internal electrodes on the same plane as the dielectric sheet, and sintering the cut dielectric sheets. The array type multi-layer ceramic capacitor according to the invention can solve the problem of interlayer gaps by printing the dielectrics and internal electrodes simultaneously, and can solve the contact problem by printing the internal electrode and the external electrode as a single body.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for manufacturing multilayer ceramic capacitor

ActiveUS20180108483A1Increase ratingsRelieve pressureFixed capacitor electrodesFixed capacitor dielectricConductive pasteCeramic capacitor

A method for manufacturing a multilayer ceramic capacitor includes preparing a green multilayer body including a stack of dielectric sheets printed with inner electrodes, coating the green multilayer body with a conductive paste that is connected to the inner electrodes, and firing the conductive paste and the green multilayer body at the same time, wherein a rate of temperature increase from about 800° C. to about 1,100° C. during the firing is about 15° C. per minute or more.

Owner:MURATA MFG CO LTD

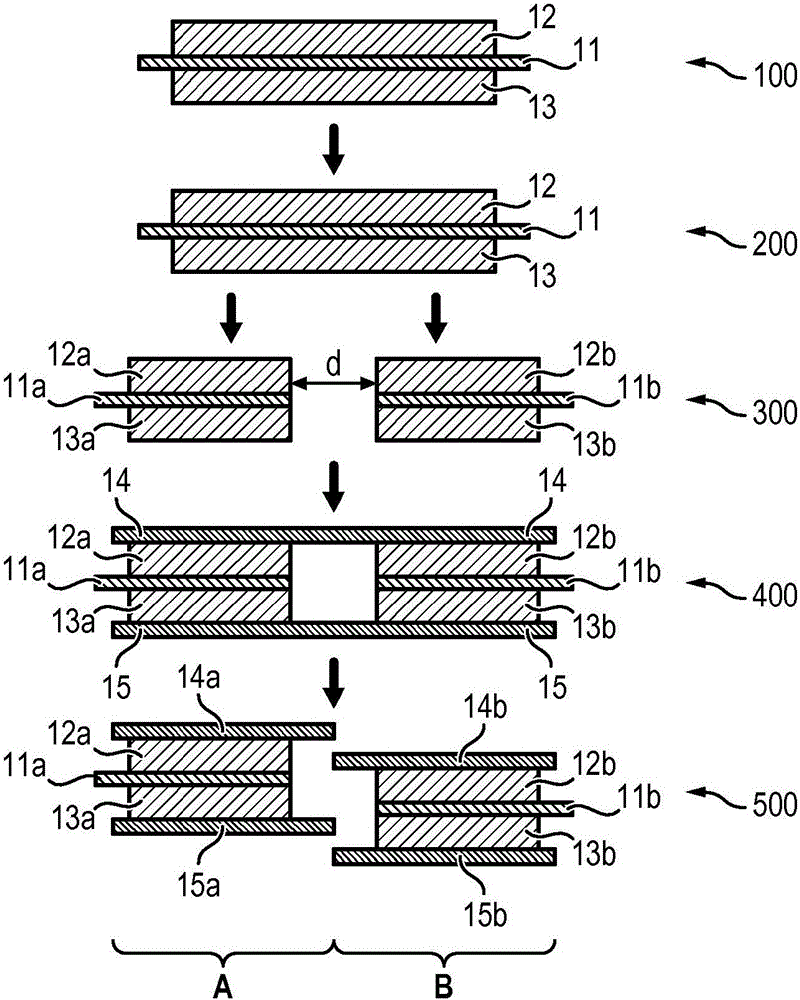

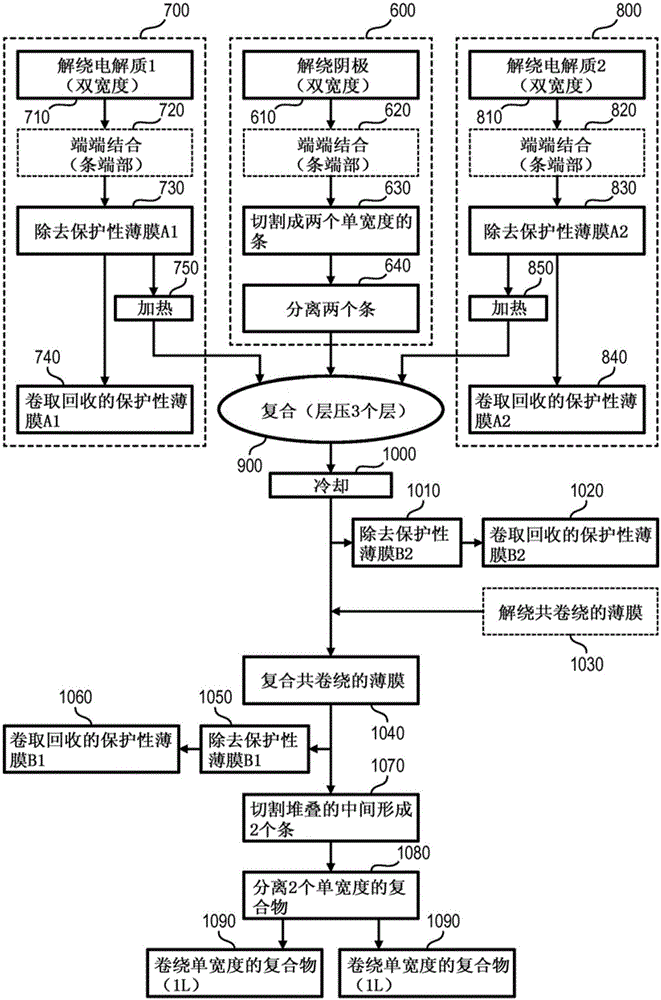

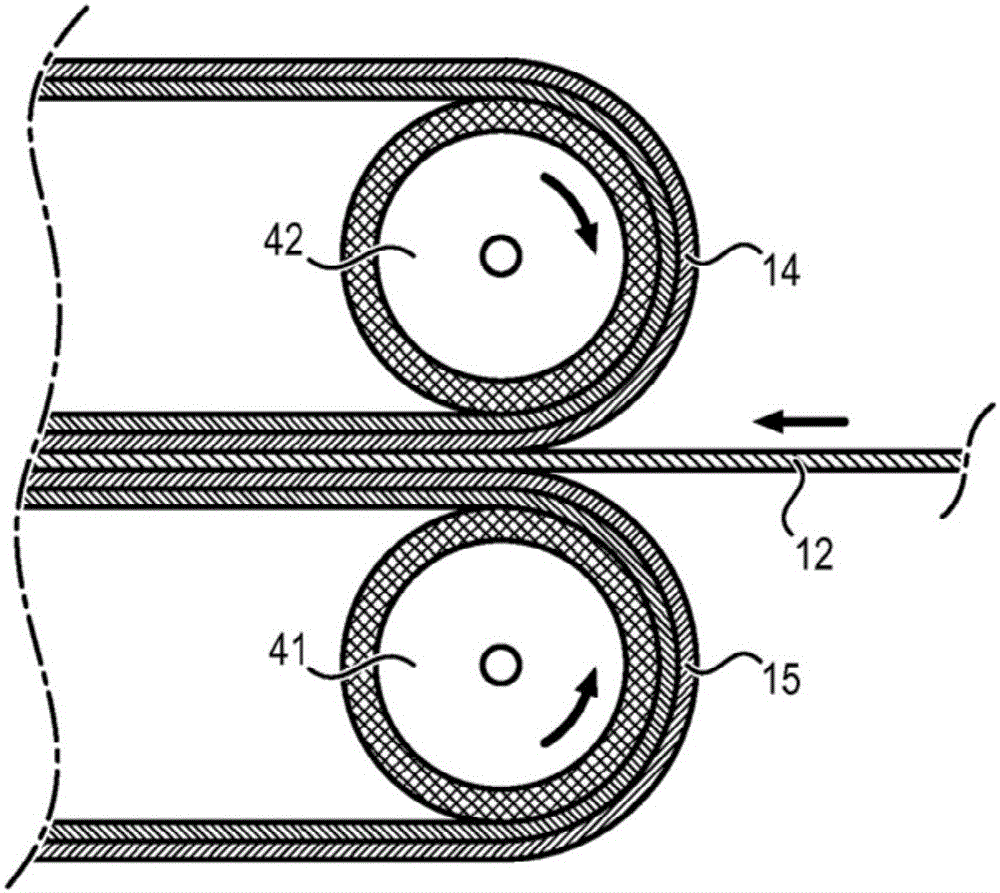

Device for separating at least two adjacent strands of material and system including such device

InactiveCN105164036AImproved bonding qualityElectrode manufacturing processesAssembling battery machinesClassical mechanicsStructural engineering

The invention relates to a device (30) for separating at least two strands of material (12a, 12b) from the cutting of a strip of material moving continuously, characterized in that the device includes a spreader (32, 33) for spreading the strands of material apart in a transverse direction (v) extending in the movement plane (P2) of the strands of material, perpendicularly to the movement direction of said strands of material.

Owner:BLUE SOLUTIONS

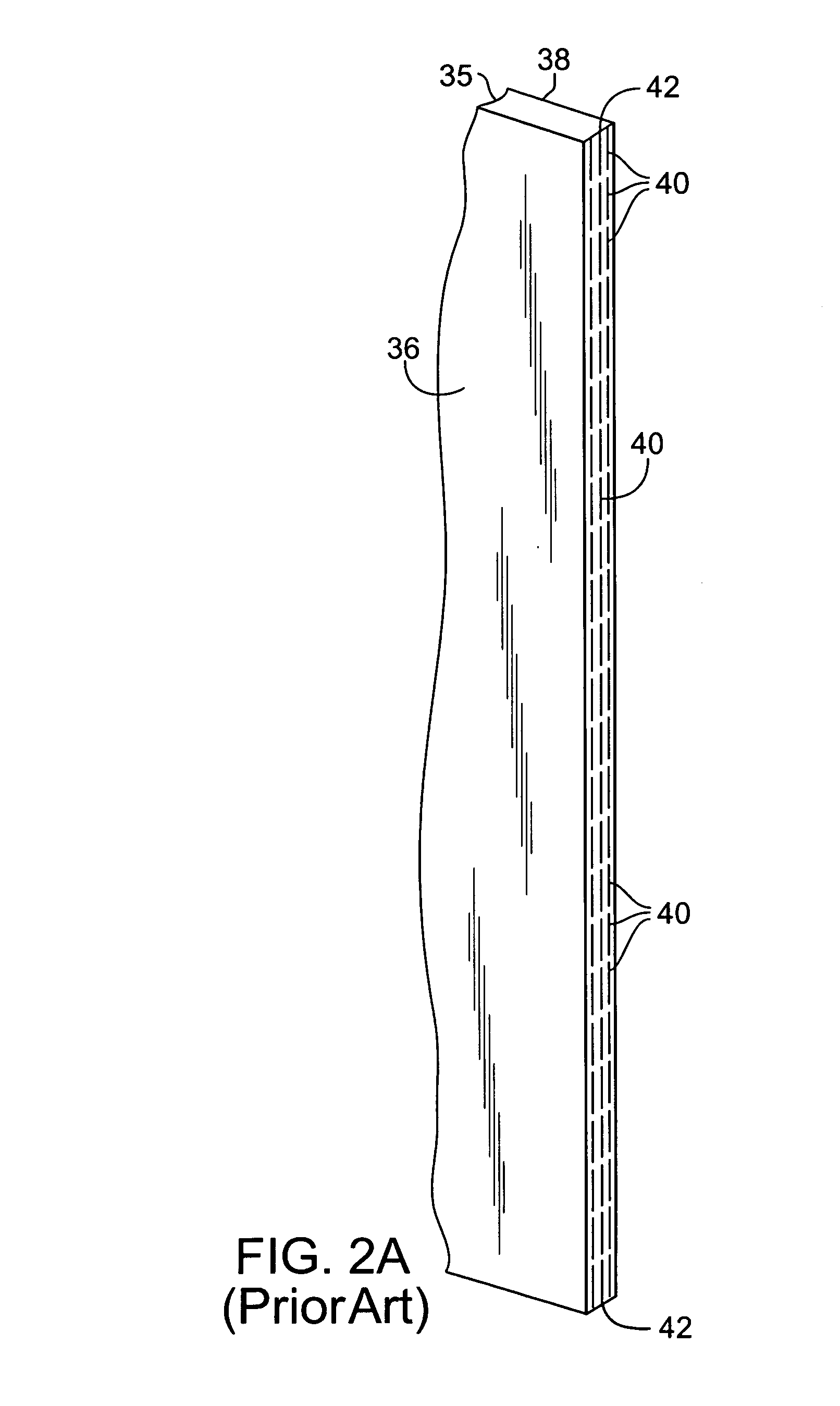

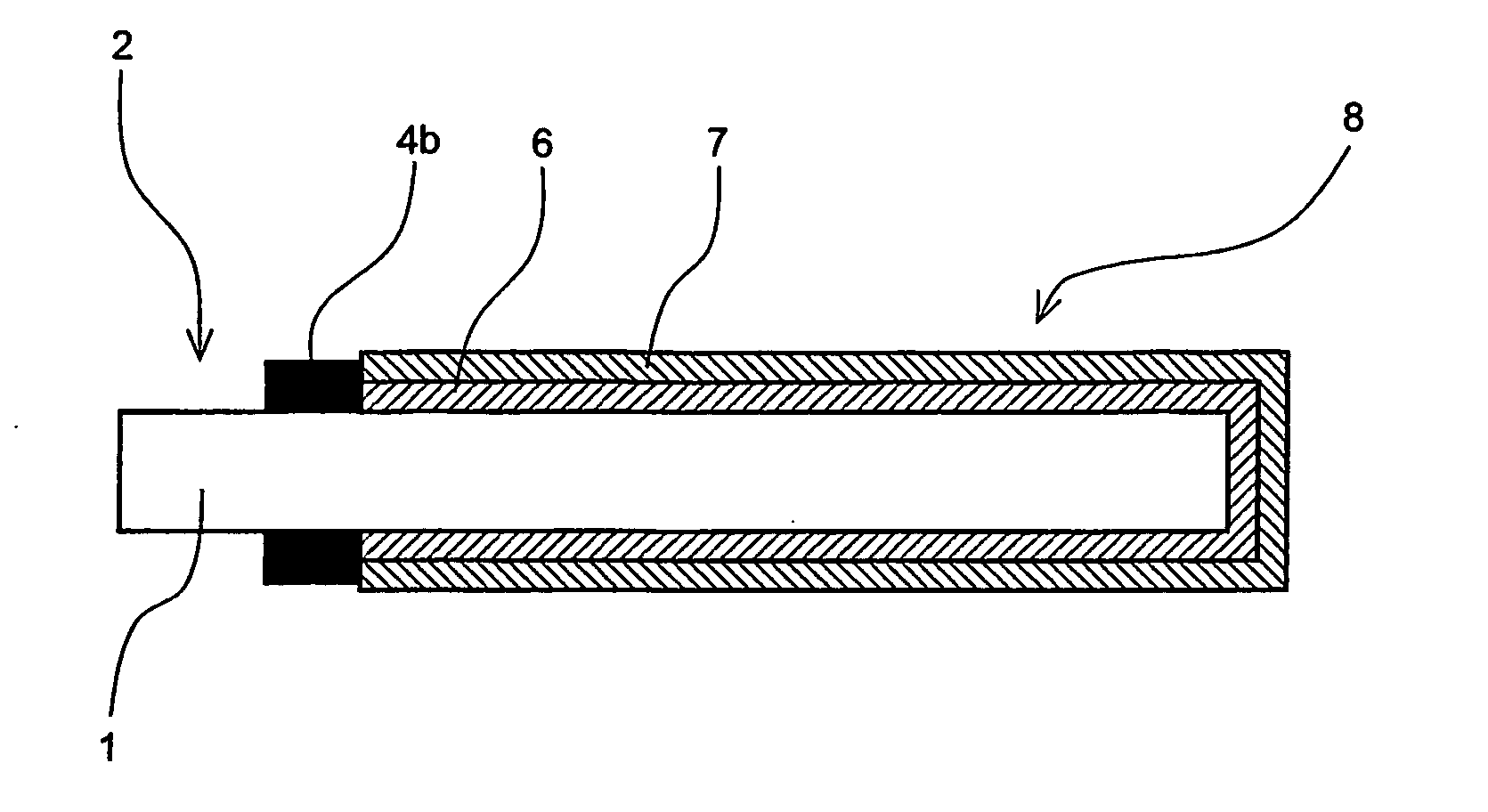

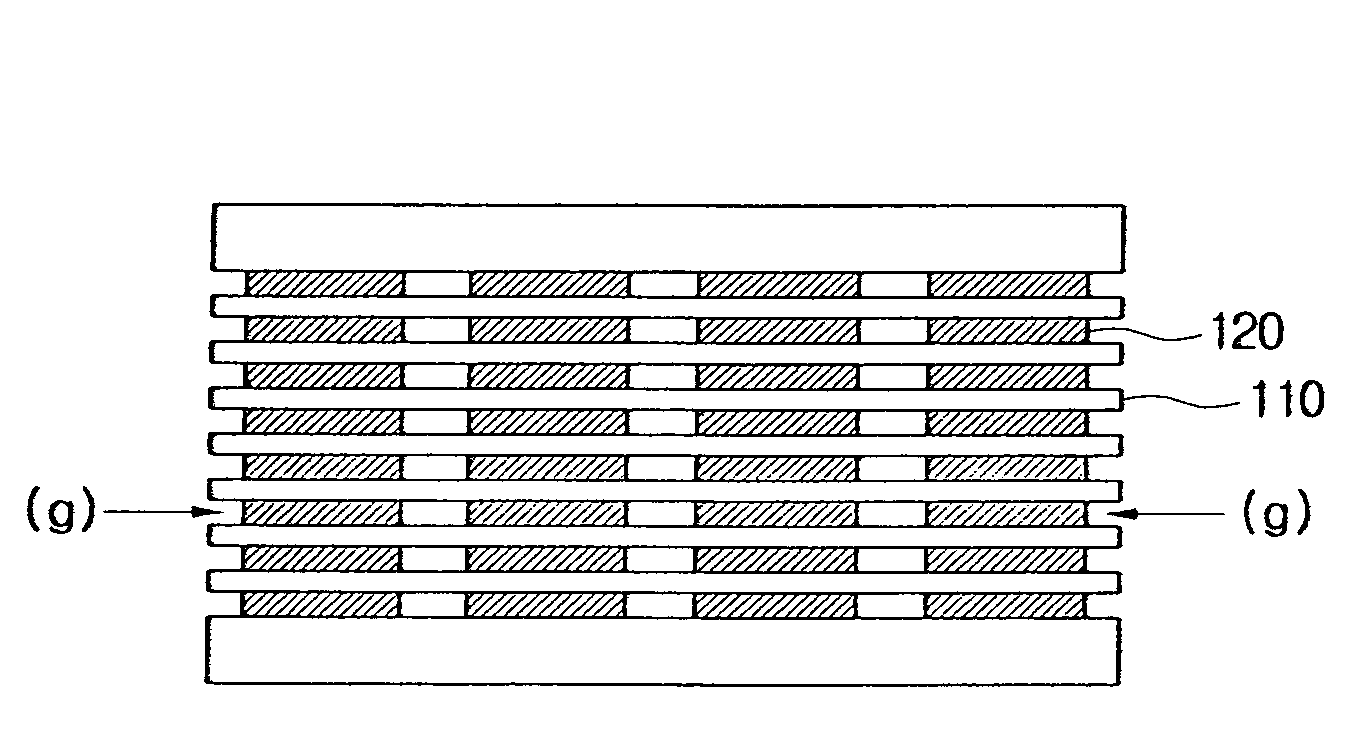

Electric chemical capacitor, and method and apparatus for manufacturing electrode for electric chemical capacitor

ActiveUS7251122B2Prevent peelingShort-circuit of preventedClosuresLiquid electrolytic capacitorsOptoelectronicsElectrochemistry

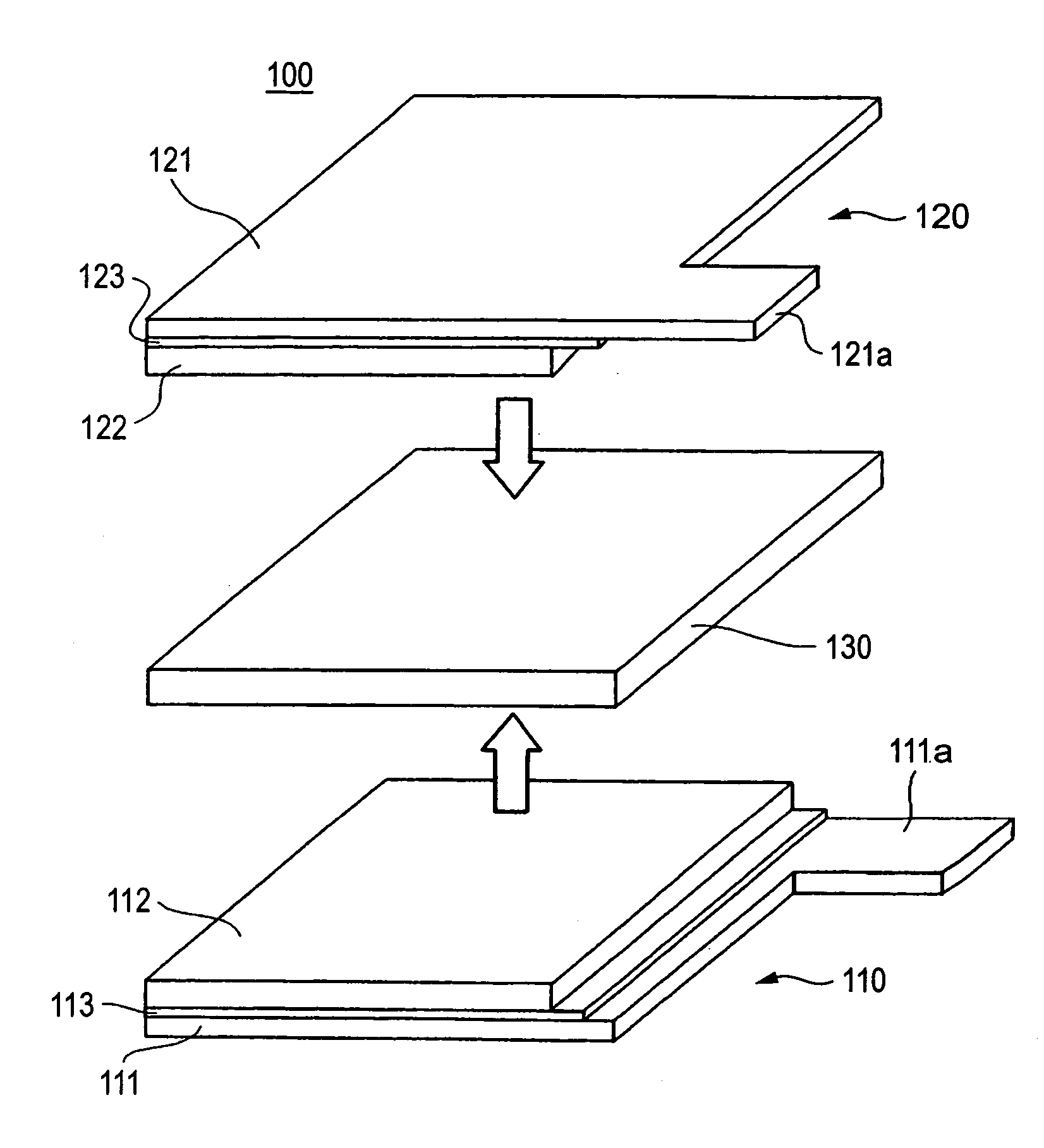

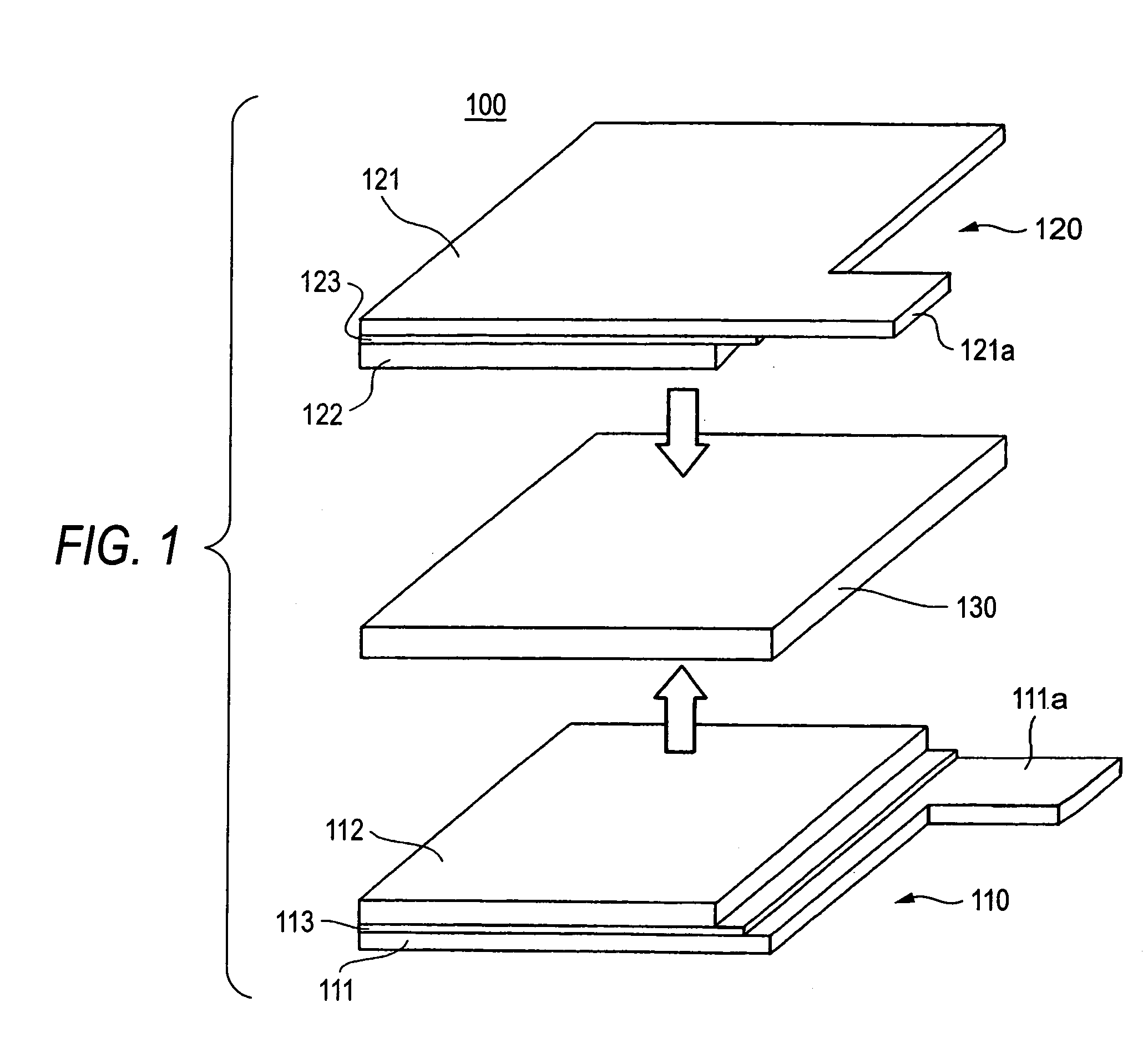

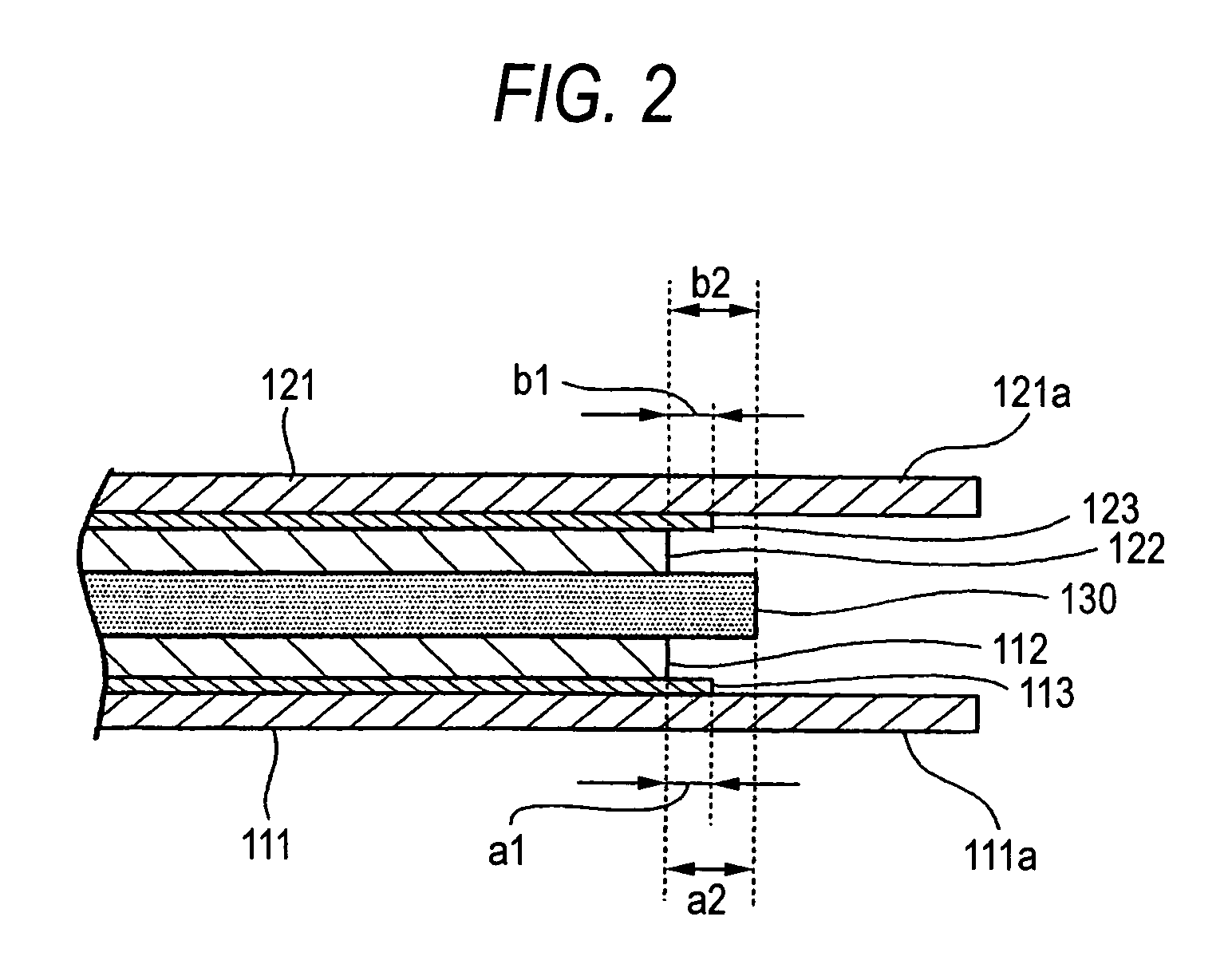

An electric chemical capacitor includes first and second electrodes each including a collector 111, 121, a polarized electrode layer 112, 122 and an undercoat layer 113, 123 for bonding the collector and the polarized electrode layer with each other, and a separator put between the first and second electrodes so that the polarized electrode layers 112 and 122 face each other, wherein an end portion of each undercoat layer 113, 123 is located in the same position as or on the outer side of an end portion of the corresponding polarized electrode layer 112, 122, and located on the inner side of an end portion of the separator 130. Thus, the polarized electrode layers can be prevented from peeling from the collector. Further, the undercoat layers can be prevented from abutting against each other, and the undercoat layer of one electrode and the collector of the other electrode can be prevented from abutting against each other.

Owner:TDK CORPARATION

Welding and locating device of capacitor

ActiveCN103692127AImprove insulation performanceImprove production safetyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringStructural engineering

The invention discloses a welding and locating device of a capacitor. The welding and locating device comprises a locating and welding pressing plate and two side wall clamping plates, wherein the two side wall clamping plates are arranged in a length direction, two end heads of the two side wall clamping plates are respectively provided with an end head baffle plate, the upper and the lower end surfaces of the front end head baffle plate and the rear end head baffle plate are respectively provided with a locating and locking post, the rear end head baffle plate is provided with an end head clamping and adjusting structure in the length direction of the welding and locating device, the end head clamping and adjusting structure comprises an inner clamping piece which is arranged at the inner side of the rear end head baffle plate and a clamping and adjusting operation handle which is arranged at the outer side of the rear end head baffle plat, a clamping and adjusting connecting rod is connected between the inner clamping piece and the clamping and adjusting operation handle, and a clamping and adjusting spring is sleeved on the clamping and adjusting connecting rod between the inner clamping piece and the rear end head baffle plate. The welding and locating device disclosed by the invention has the advantages that a capacitor bank which needs to be located and welded can be freely and flexibly adjusted and clamped in the length direction and the width direction, quick and effective locating and welding operation can be carried out, the welding efficiency is high, and the labor intensity and the difficulty of production operation are reduced.

Owner:宁波新容电器科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com