Mfg. method of double-sided metallization film and metallization film capacitor using same

A technology of metallized film and manufacturing method, which is applied in the direction of capacitors, capacitor manufacturing, and wire-wound capacitors, and can solve problems such as tan delta deterioration, reduced withstand voltage, and weak adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

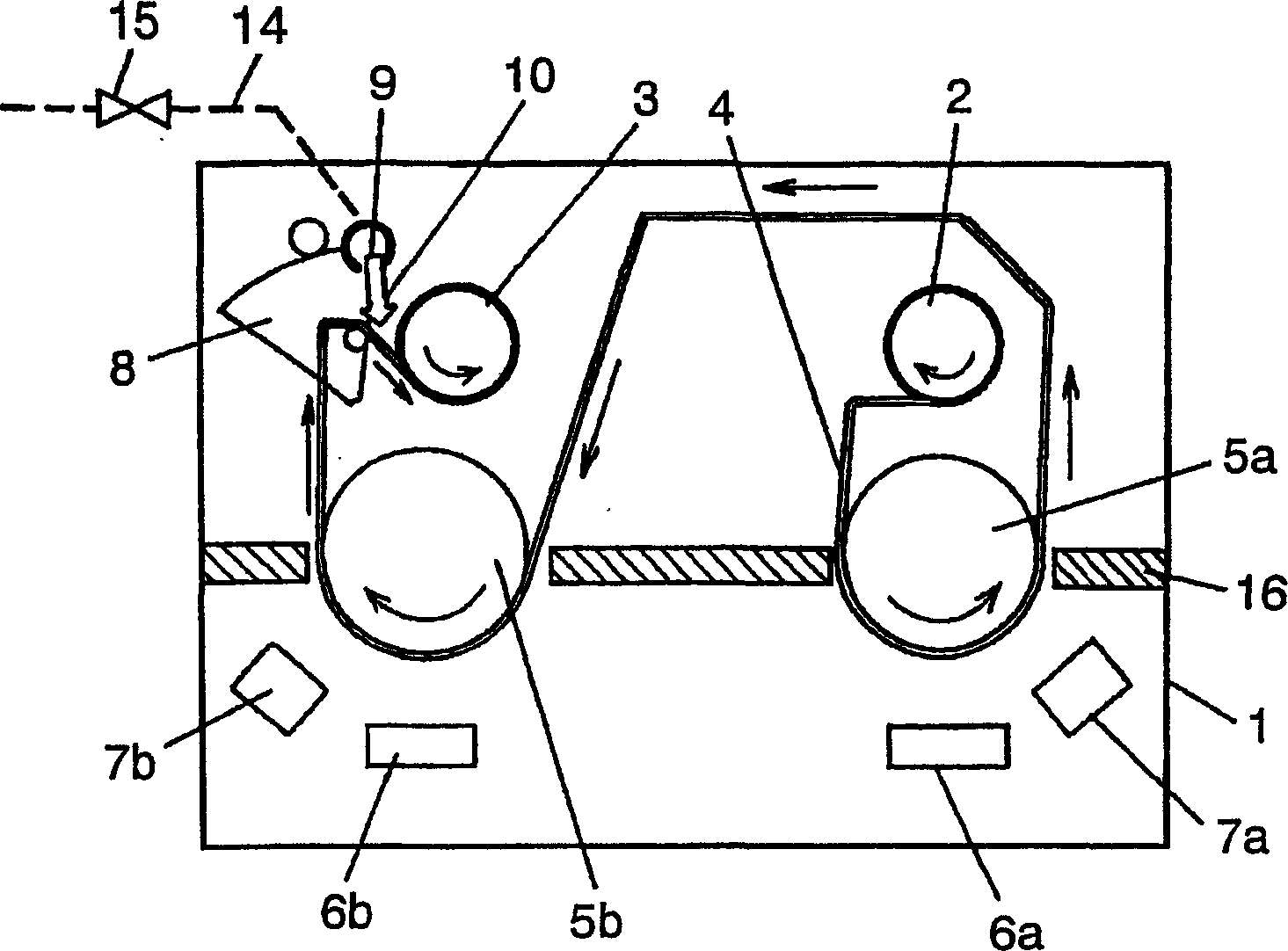

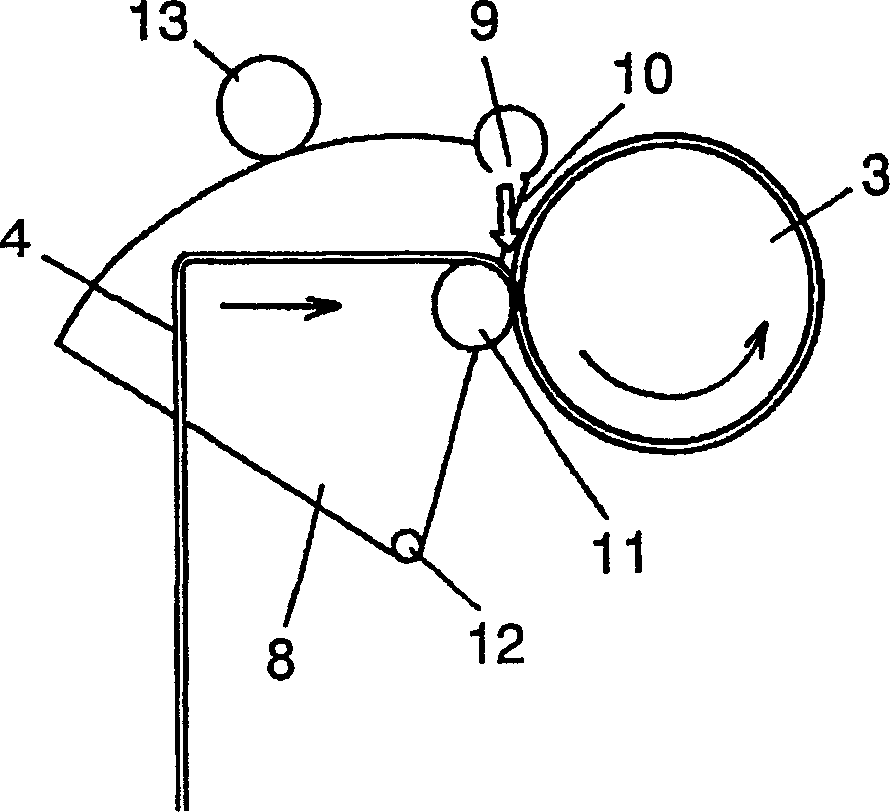

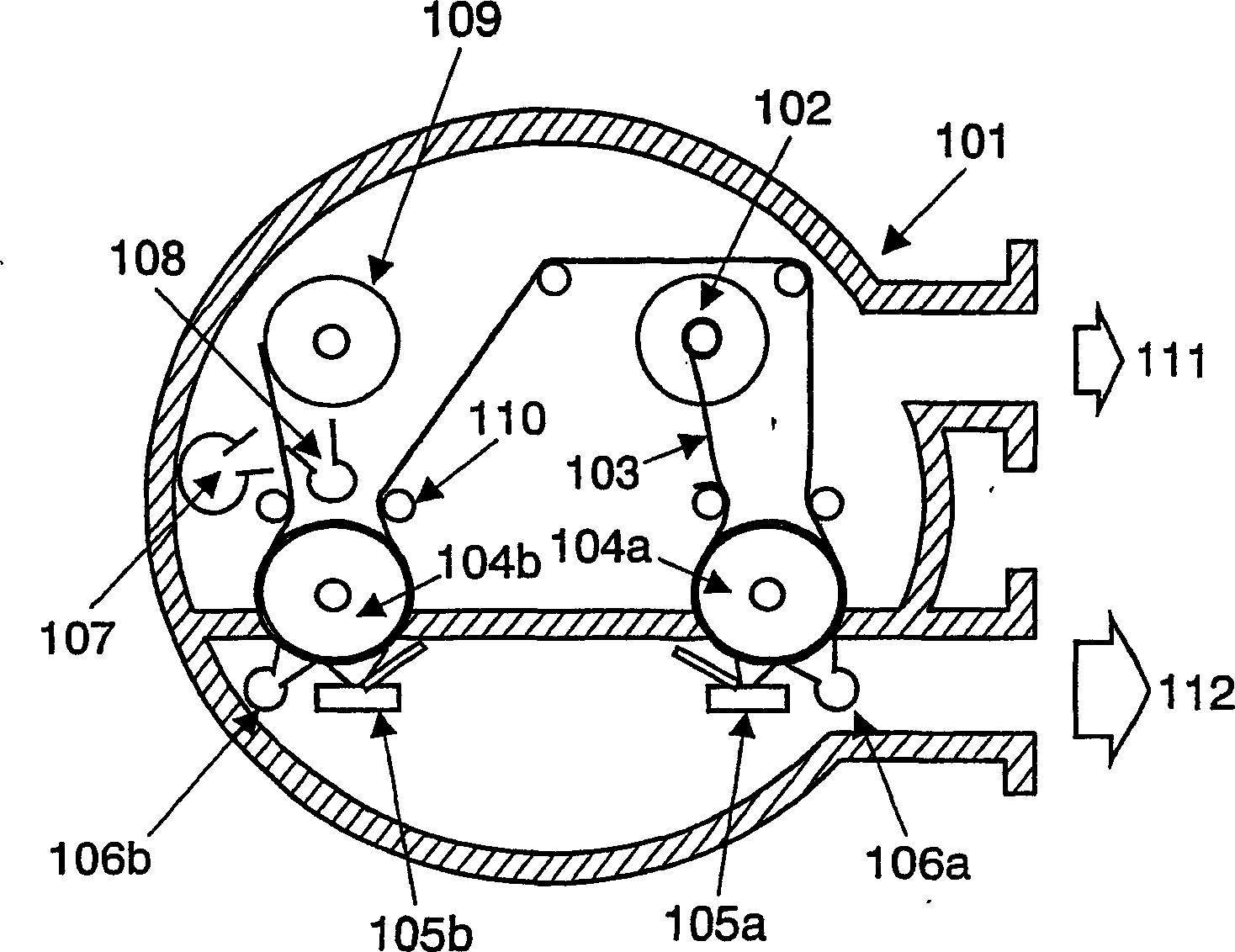

[0033] Refer below figure 1 , figure 2 and Figure 11 An example in which a PP film is used as an insulating film in Embodiment 1 of the present invention will be described.

[0034] figure 1 In the process, the PP film 4 is rolled up with the raw material roll 2 installed inside the coating machine 1, and the inlet-side vapor deposition is formed on one side of the PP film 4 by the inlet-side aluminum evaporation source 6a and the zinc evaporation source 7a in the inlet-side cooling tank 5a. Metal. Next, an output-side vapor-deposited metal is formed on the reverse surface of the PP film 4 by the output-side aluminum evaporation source 6 b and the zinc evaporation source 7 b in the output-side cooling tank 5 b. In addition, in order to prevent the gas and moisture adsorbed on the PP film 4 in the raw material roll 2 from causing the vacuum near the evaporation sources 5a, 5b, 6a, and 6b to deteriorate, a partition 16 is provided to separate the evaporation chamber. . ...

Embodiment 1-2

[0042] Embodiment 1-2: vapor-deposit the mixture of zinc and aluminum on both sides of PP film 4, according to figure 1 The method shown blows air and rolls into a product roll 3 .

Embodiment 1-3

[0043] Embodiment 1-3: vapor-deposit the mixture of zinc and aluminum on both sides of PP film 4, according to figure 1 The process shown blows oxygen and rolls into a product roll 3 .

[0044] Next, after the product roll 3 is taken out from the coating machine, samples are taken while rolling up the vapor-deposited PP film 32 on both sides of the outermost peripheral part and the innermost peripheral part of the product roll 3, and the deposited film is observed with a 50-fold transmission microscope. The peeling condition of the metal 31 was taken and photographed. The photograph was digitally processed with a computer, and the percentage of the peeled portion of the vapor-deposited metal 31 was obtained by binarizing the peeled and non-peeled portions of the vapor-deposited metal 31 . In addition, for the sake of comparison, the following samples were produced using the double-sided vapor-deposited PP film of the prior art, and the peeling ratio was determined.

[0045]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com