Thin stone or thin brick veneer wall system and clips therefor

a thin brick veneer and wall system technology, applied in the direction of walls, coverings/linings, building components, etc., can solve the problems of veneer walls of great weight, affecting and requiring a skilled masonry contractor, so as to prevent the clip from deflecting or collapsing, strengthen the clip, and add to the overall strength of the wall system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

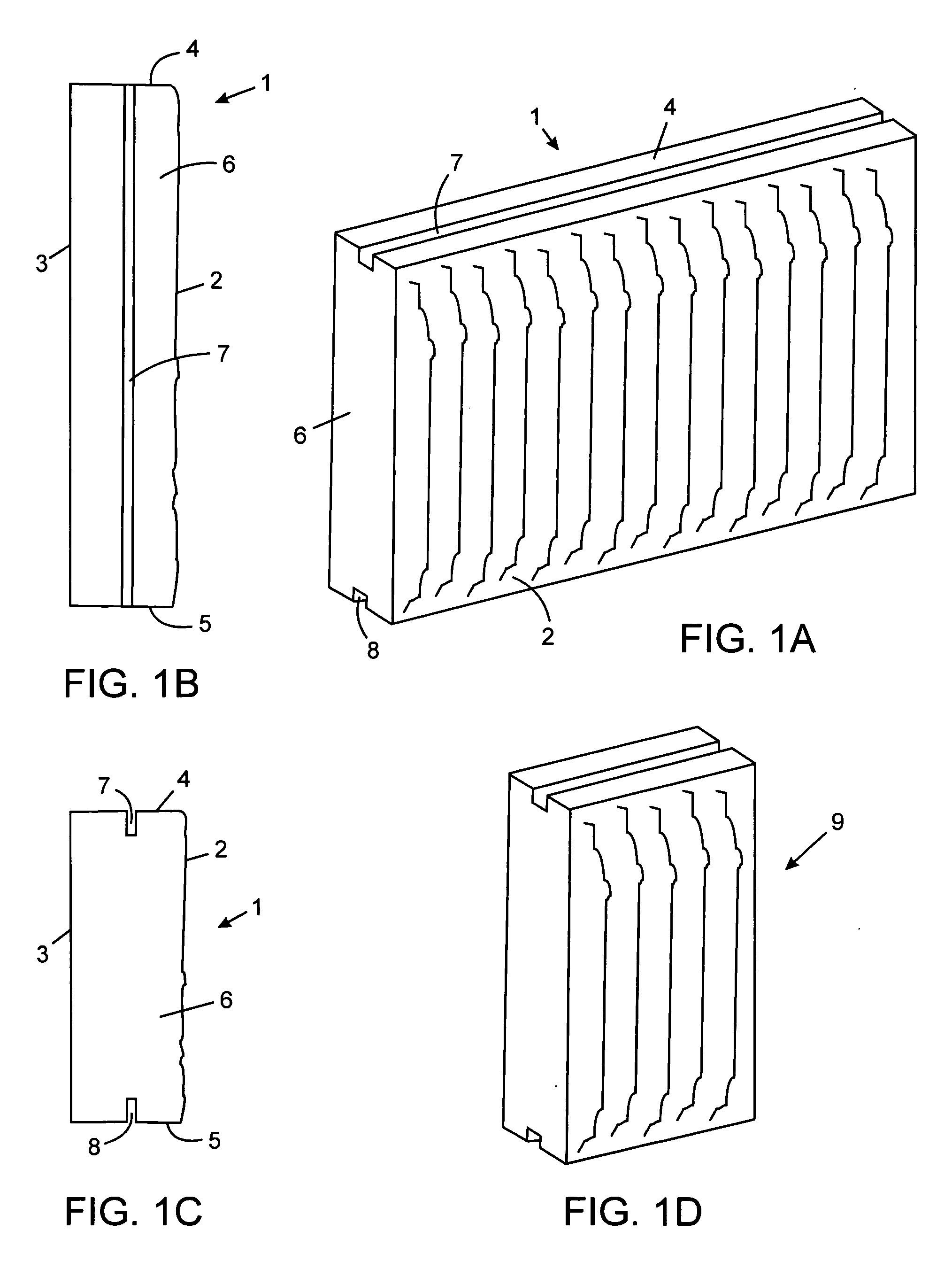

[0062] Referring to FIGS. 1A-1D, thin stone facing element 1 comprises front face 2, rear face 3, upper edge 4, lower edge 5 and two side edges 6. Groove 7 in the upper edge runs the entire length of the stone facing element from one side to the other side. Groove 8 in the lower edge runs the entire length of the stone facing element from one side to the other side. The front face of the stone facing element is dressed for aesthetic appeal since the front face presents outwardly when mounted in a veneer wall. Stone facing element 1 is 15.5 inches long by 7.5 inches in height. Stone facing element 9 depicted in FIG. 1D is the same as stone facing element 1 except that stone facing element 9 is only 5.0 inches long. Stone facing elements 1 and 9 may be used together in a thin stone veneer wall, and together with other sized stone facing elements if desired, to provide a more random appearance to the veneer wall.

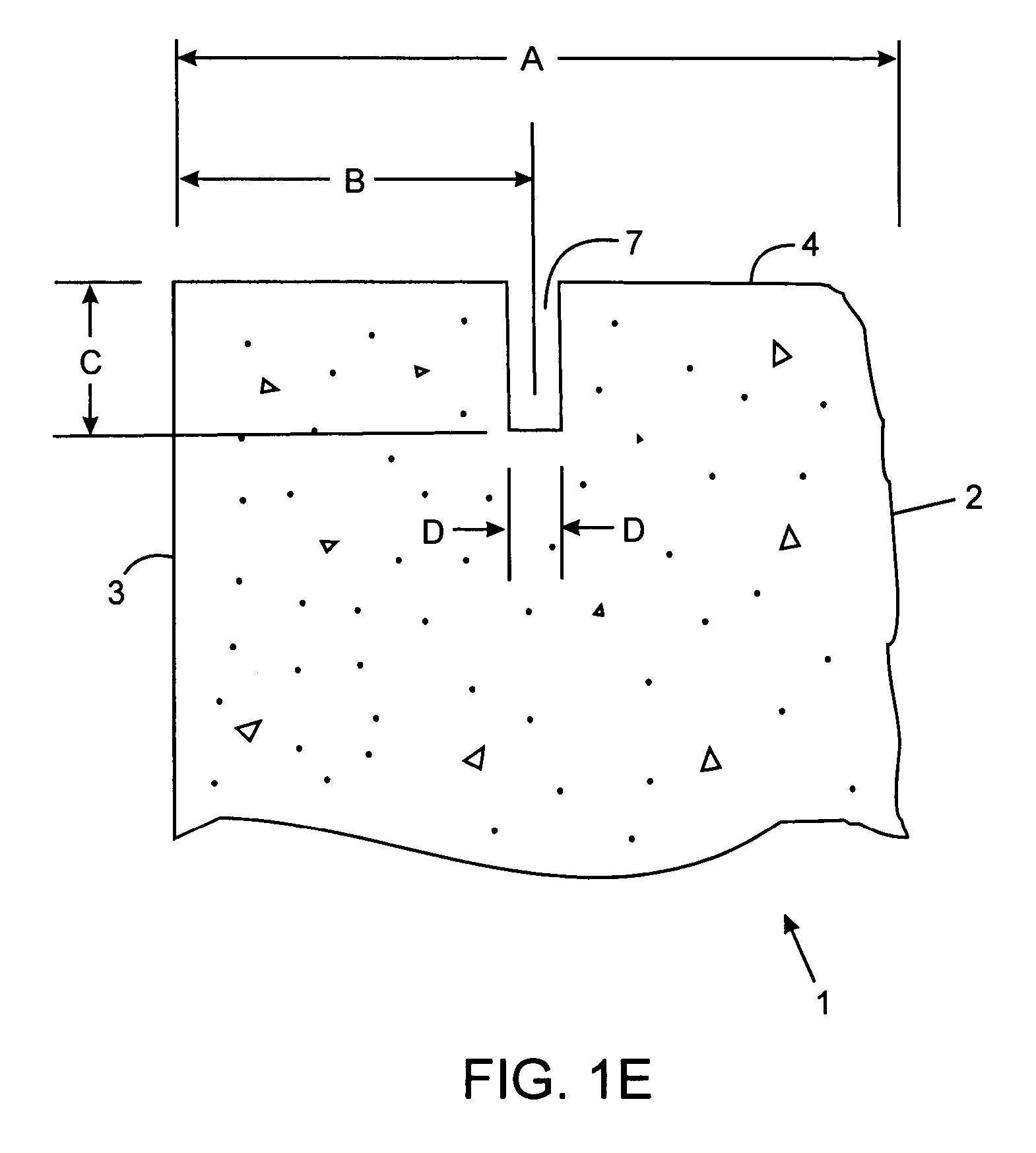

[0063] Referring specifically to FIG. 1E, an enlarged portion of the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com