Patents

Literature

280 results about "Metallised film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallised films (or metalized films) are polymer films coated with a thin layer of metal, usually aluminium. They offer the glossy metallic appearance of an aluminium foil at a reduced weight and cost. Metallised films are widely used for decorative purposes and food packaging, and also for specialty applications including insulation and electronics. Its burning caused the crash of Swissair Flight 111 in 1998 that killed 229 people.

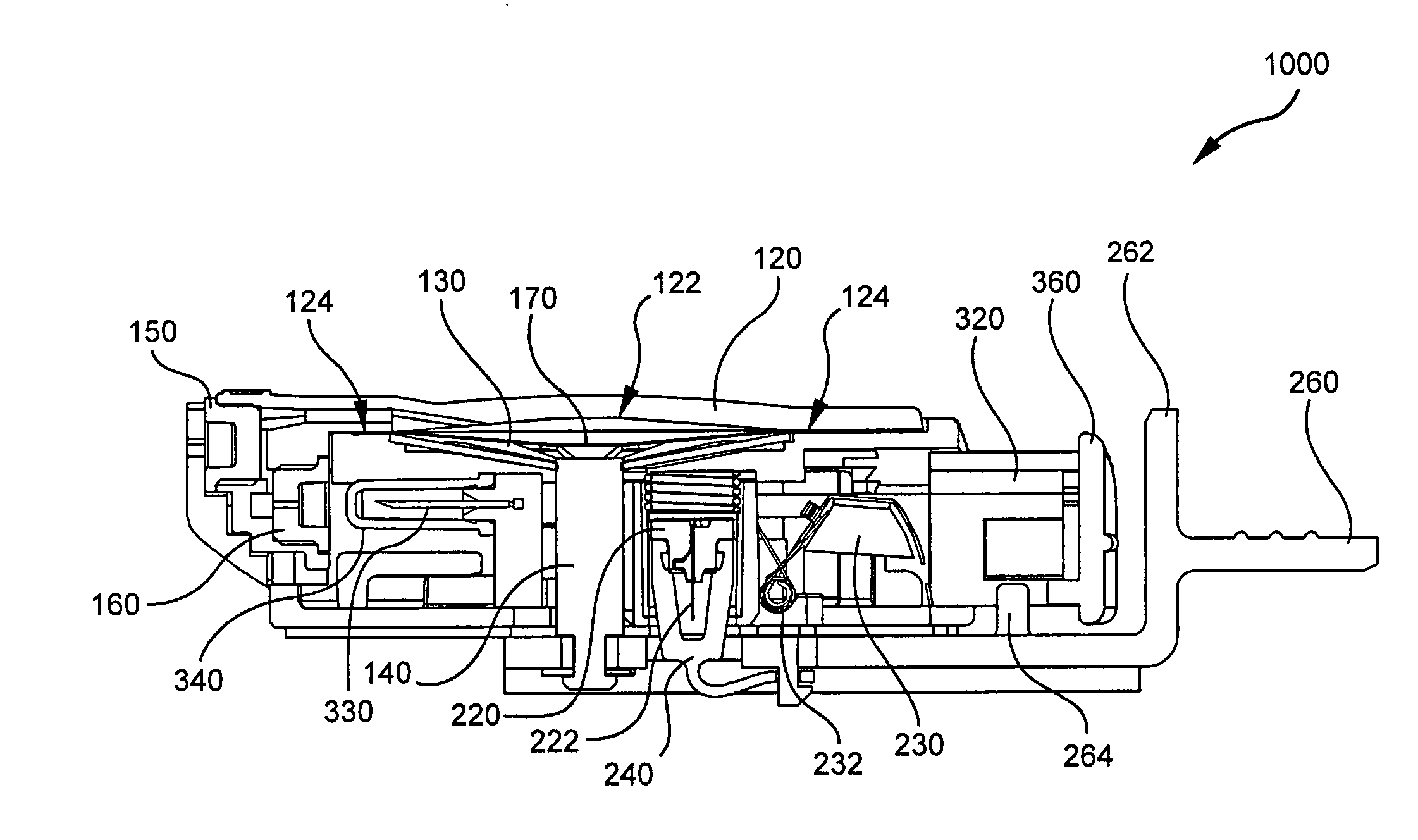

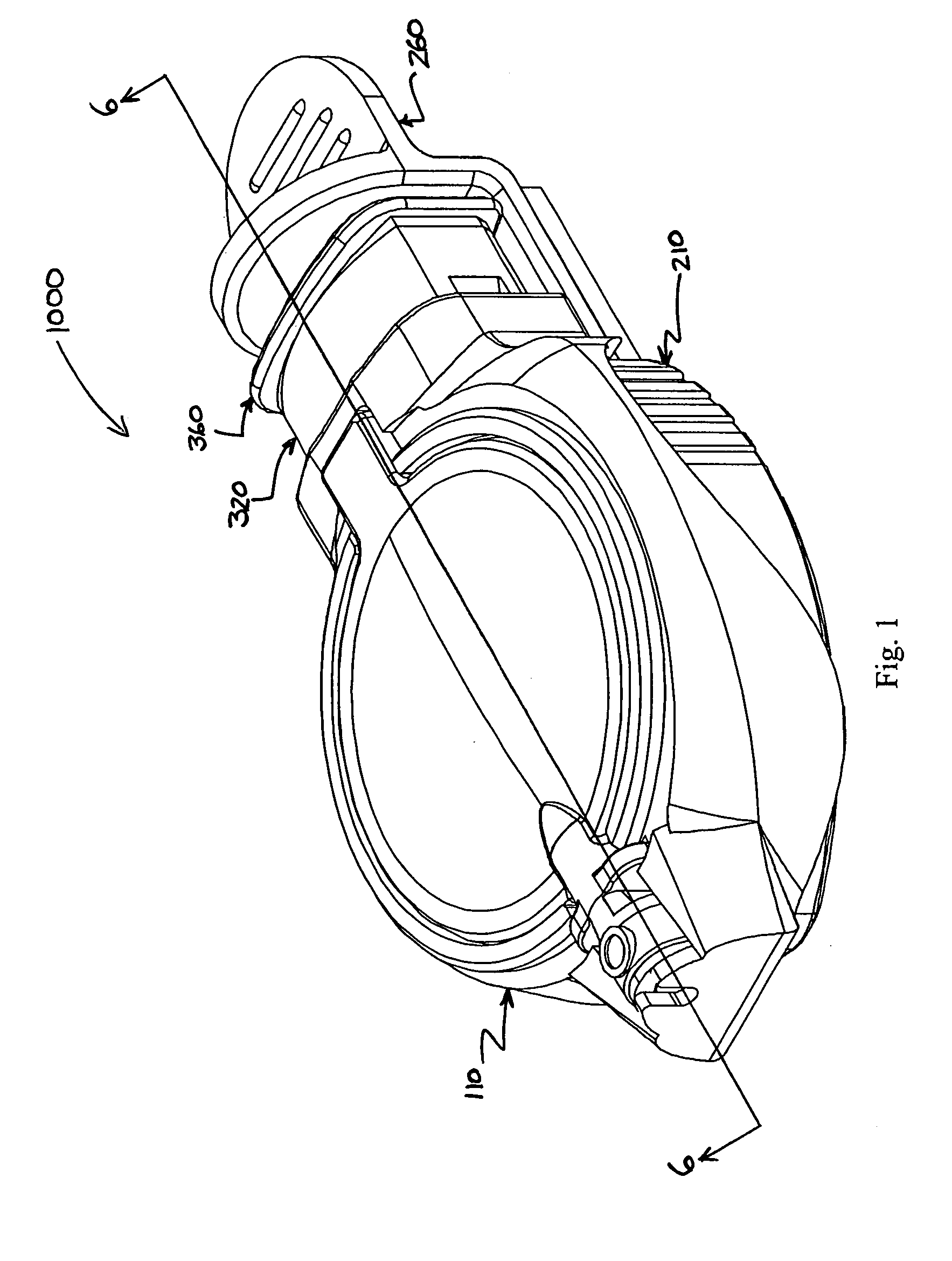

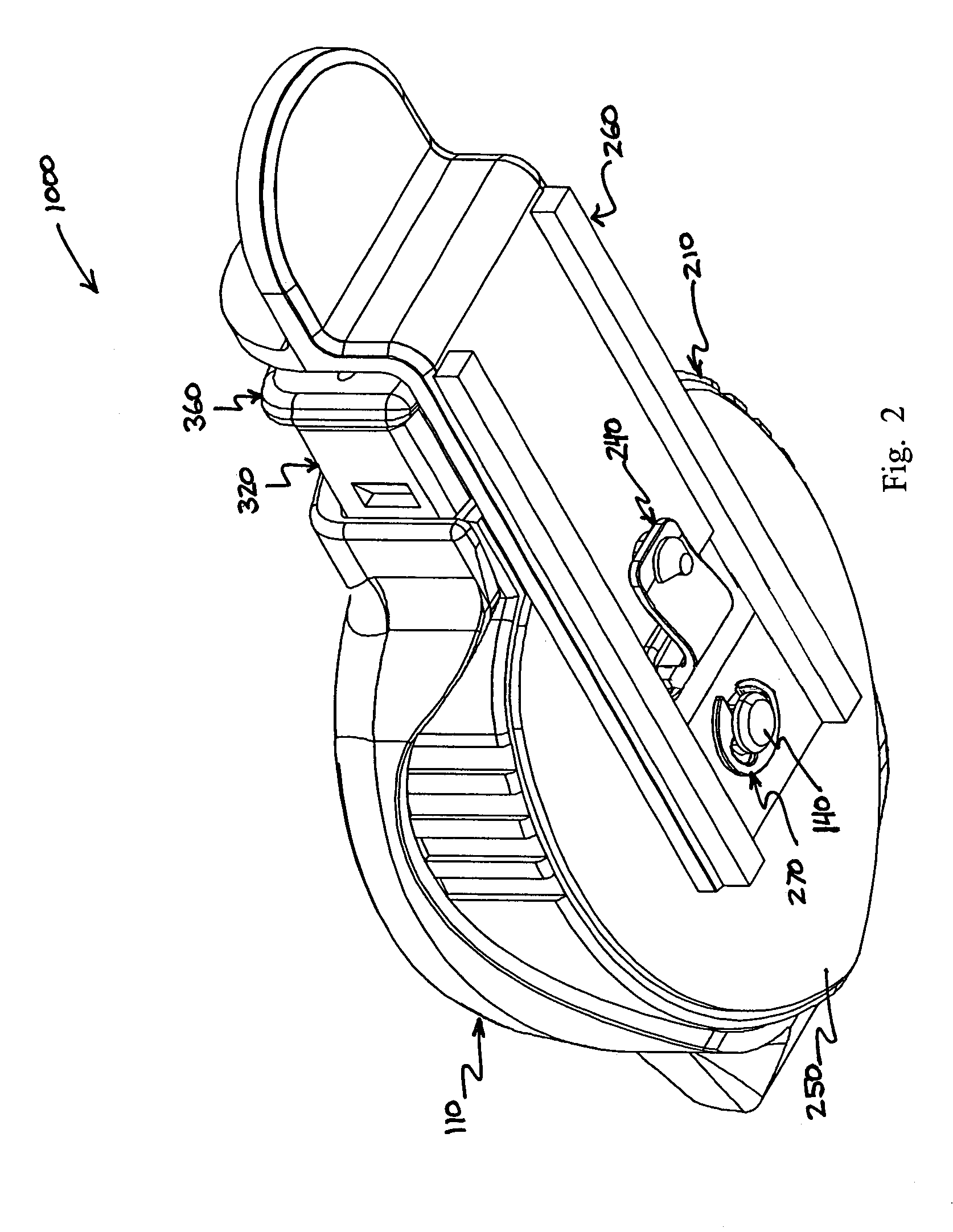

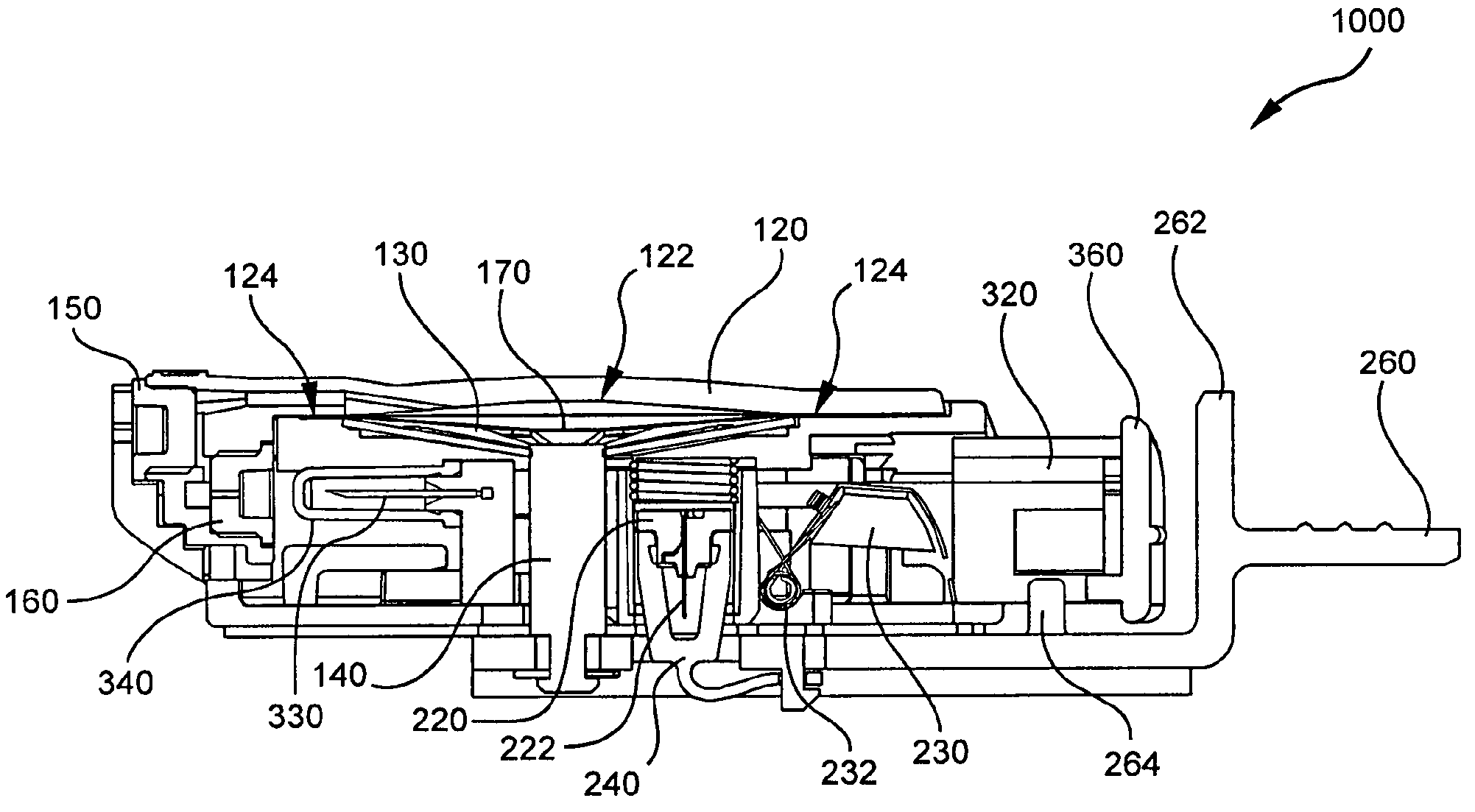

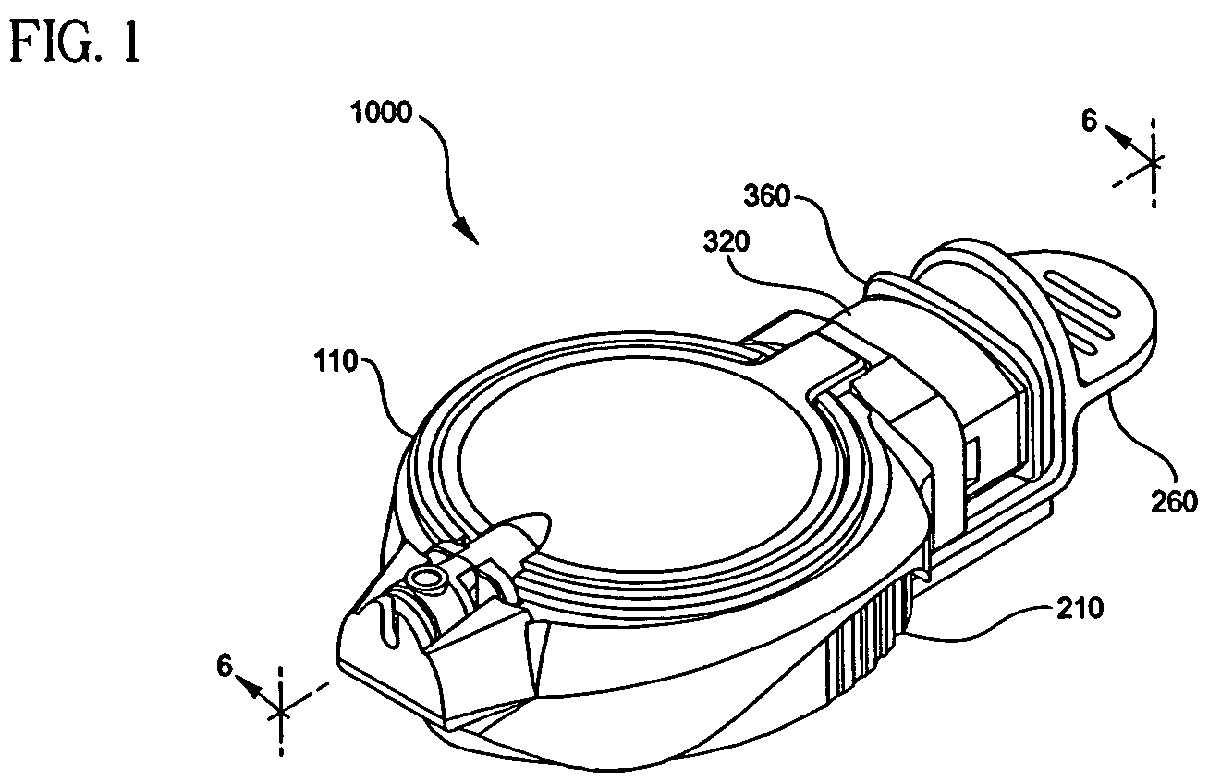

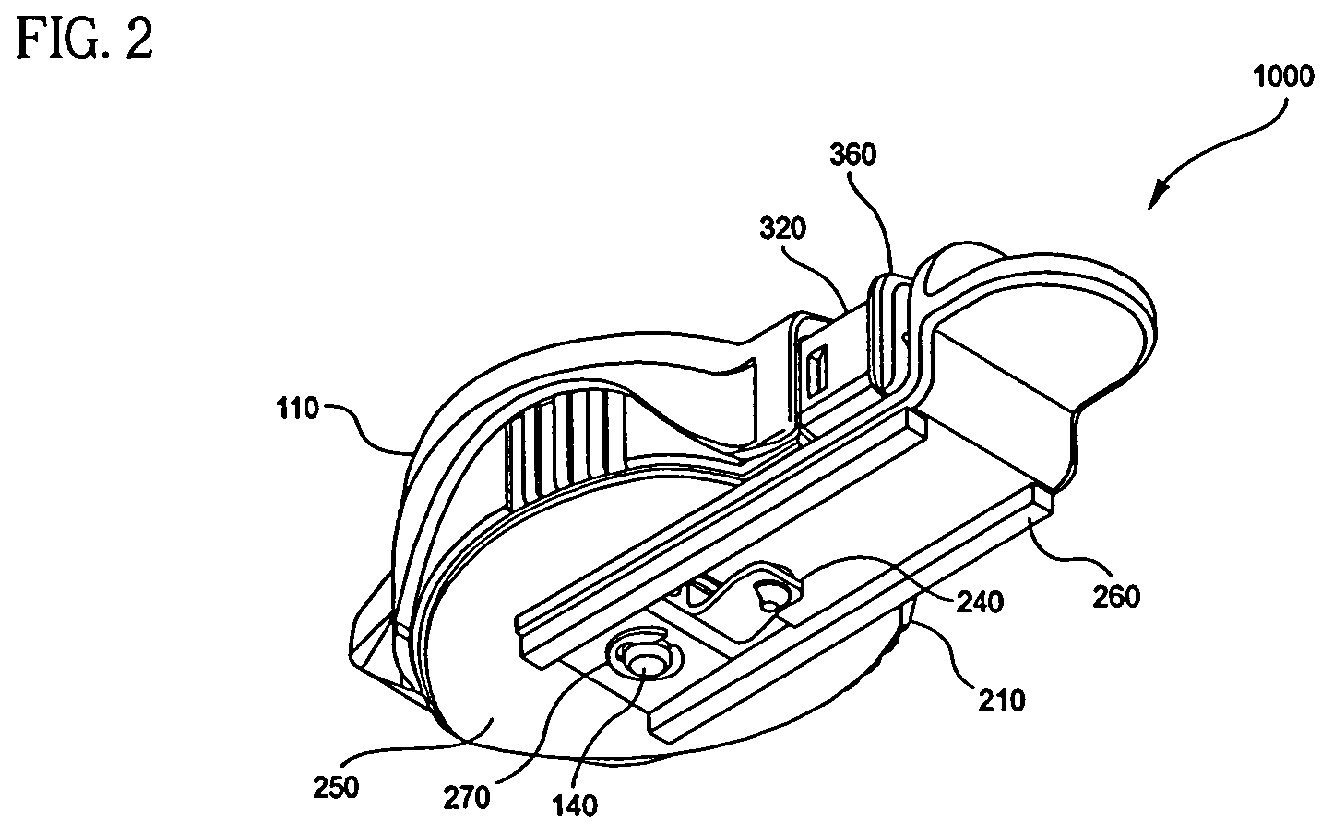

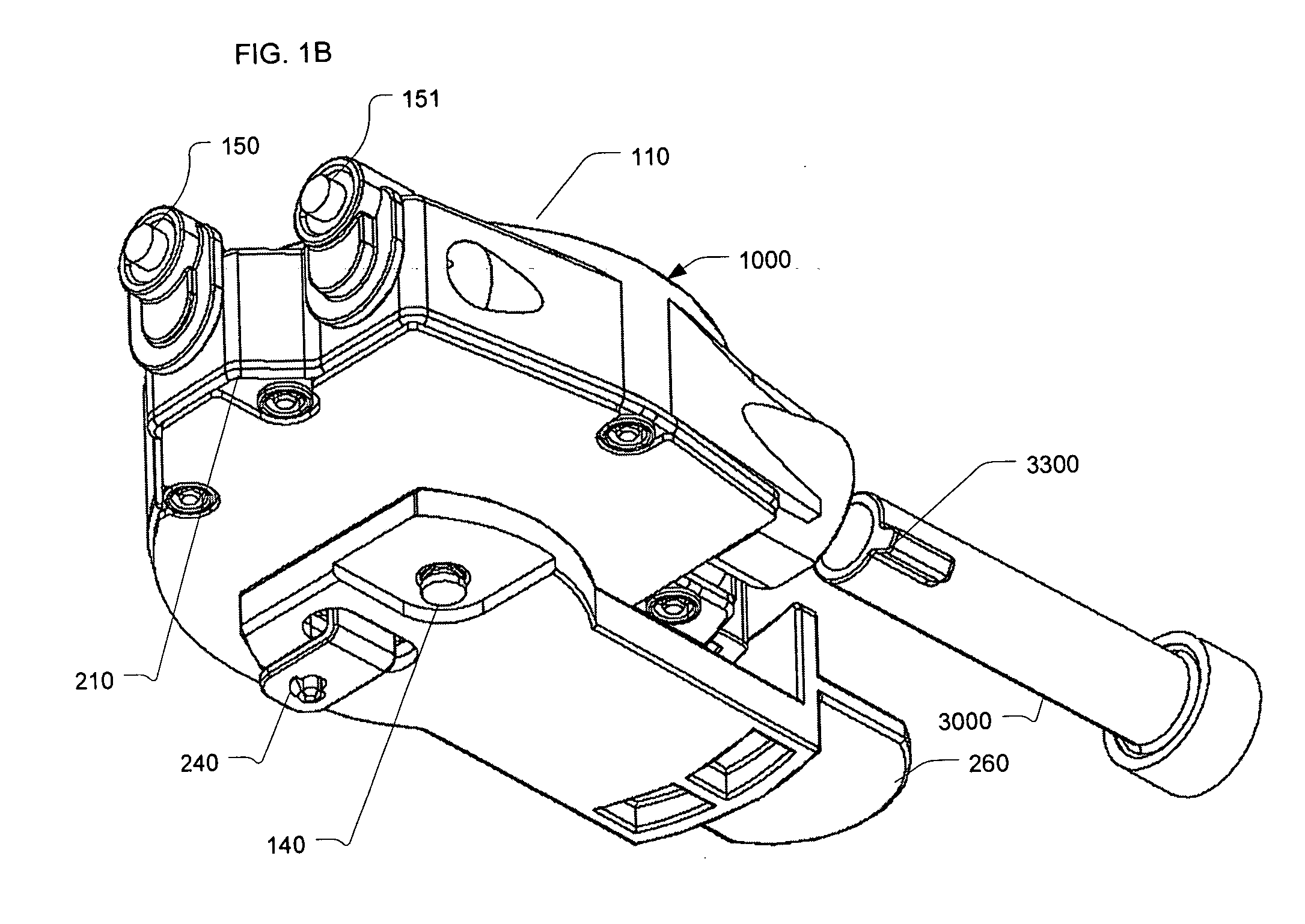

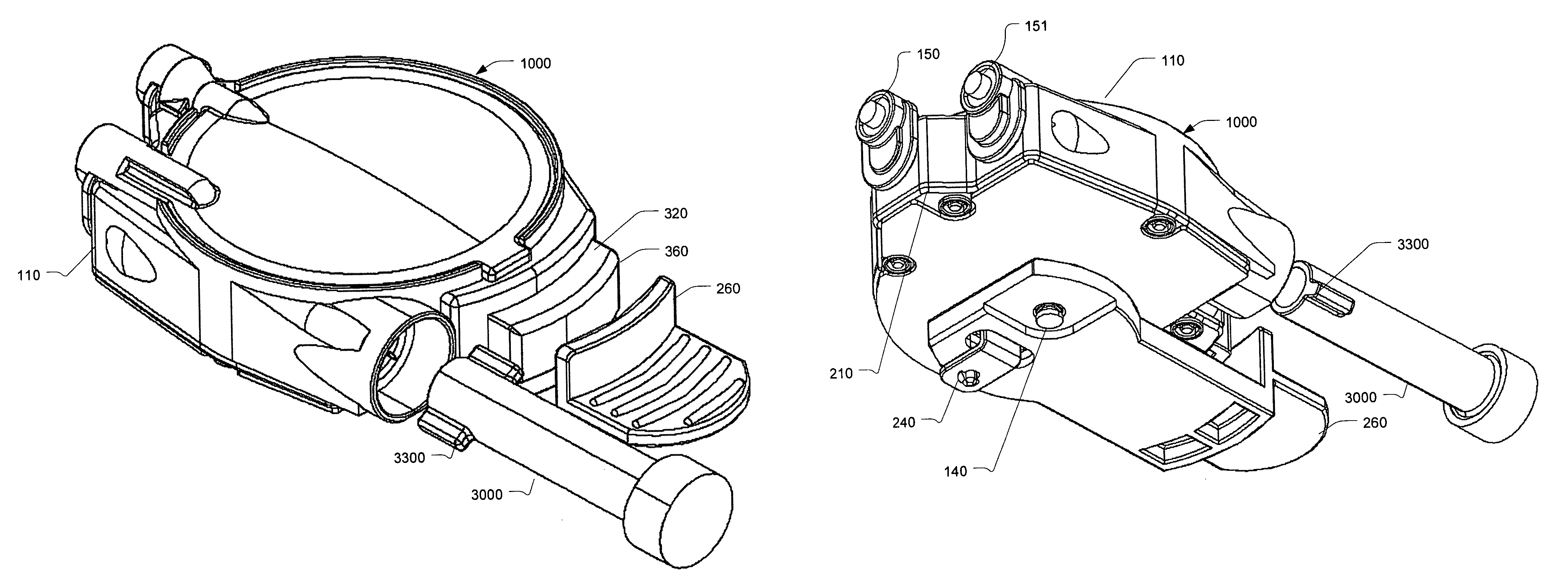

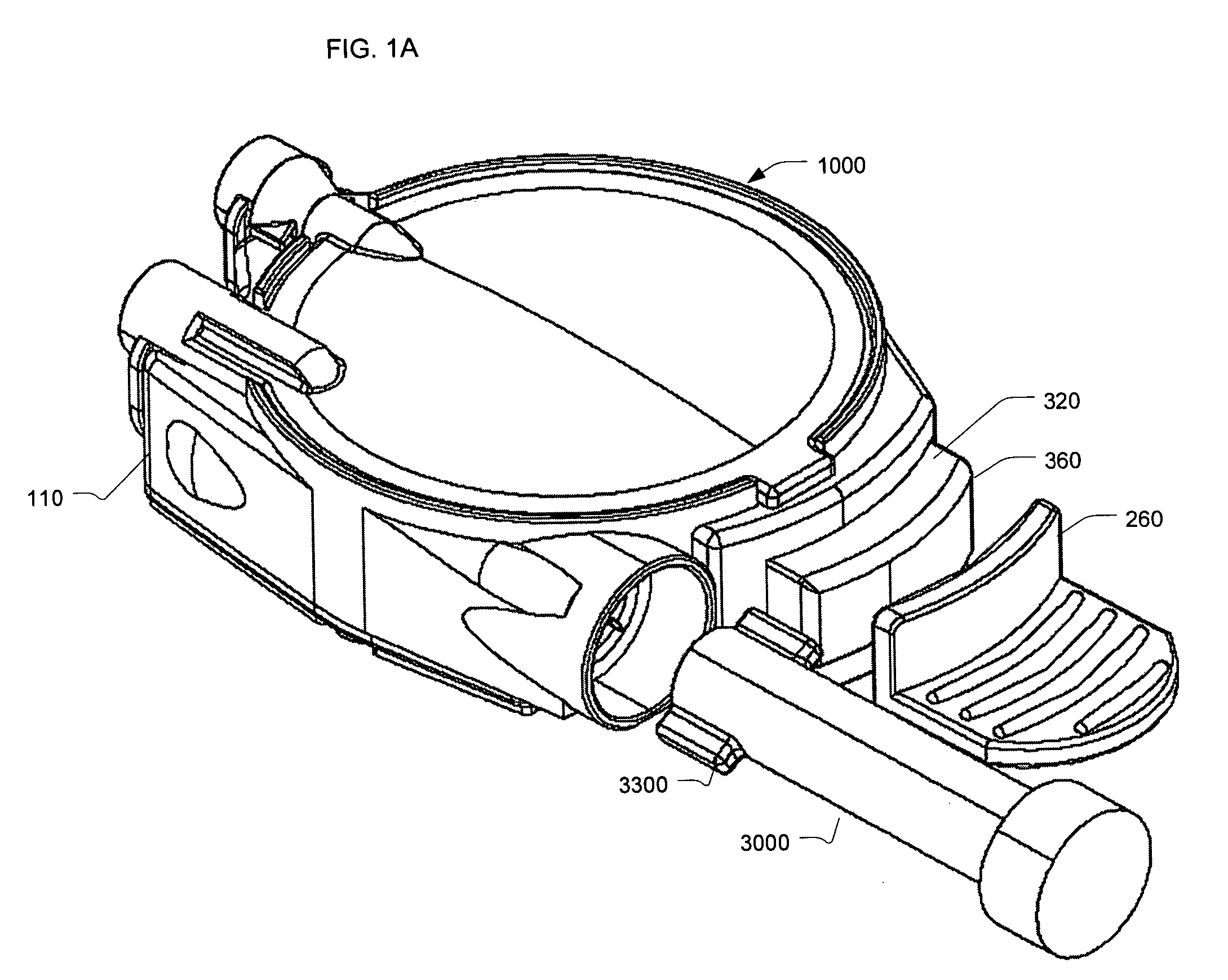

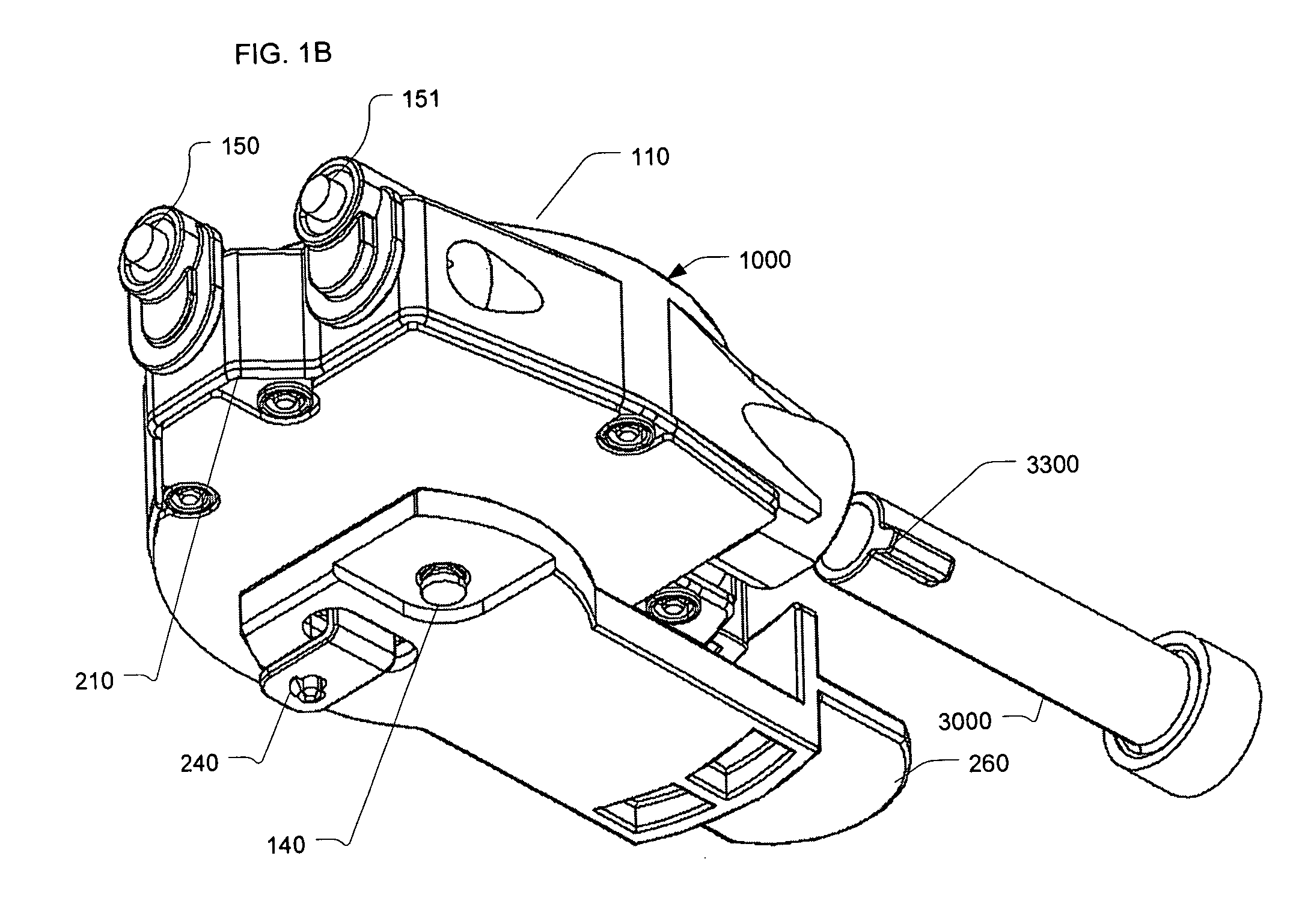

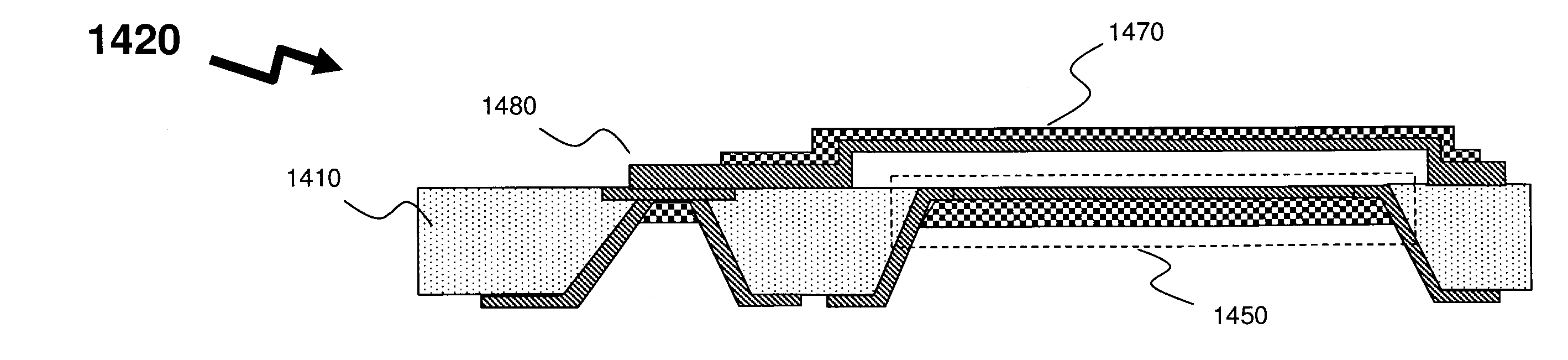

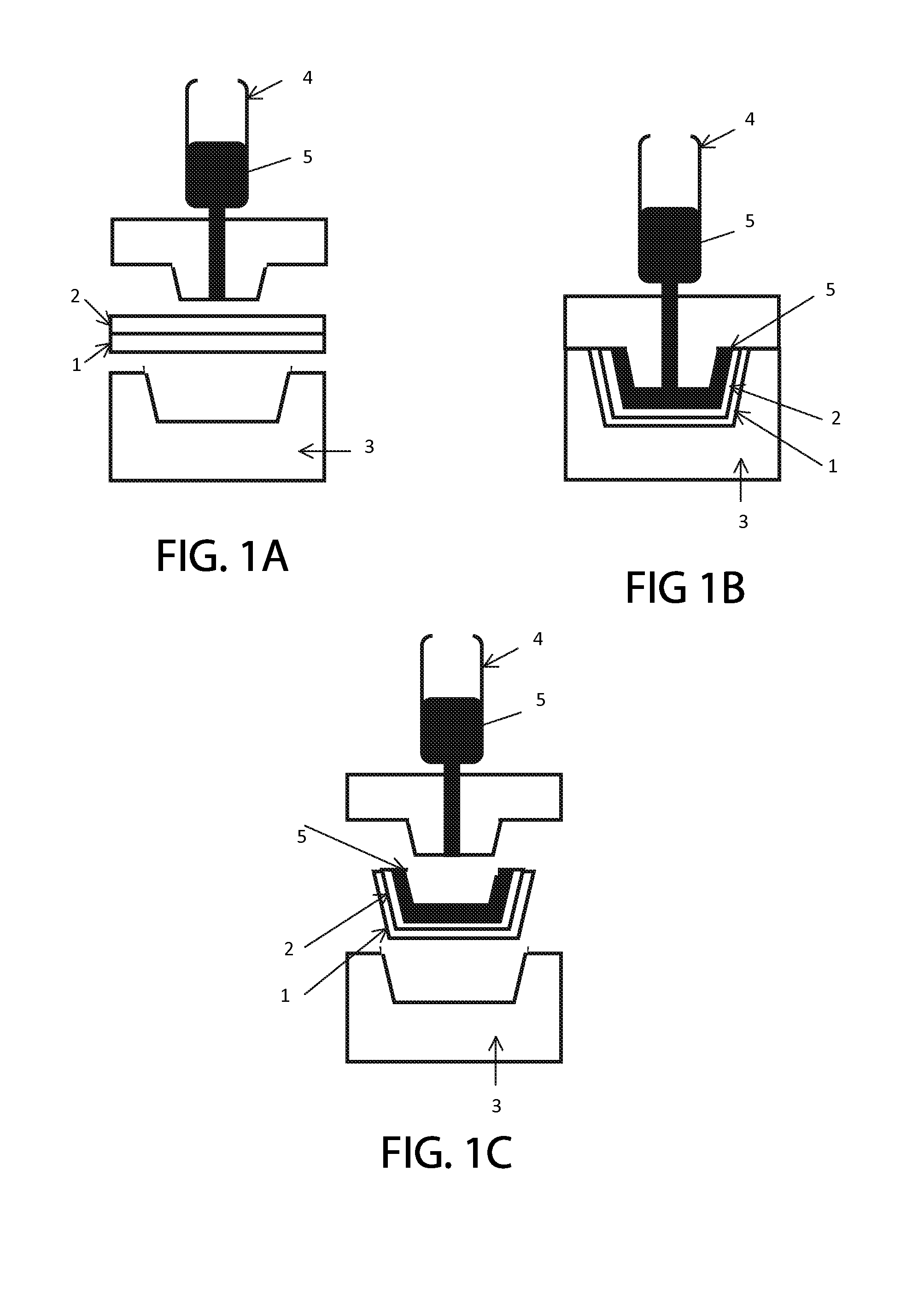

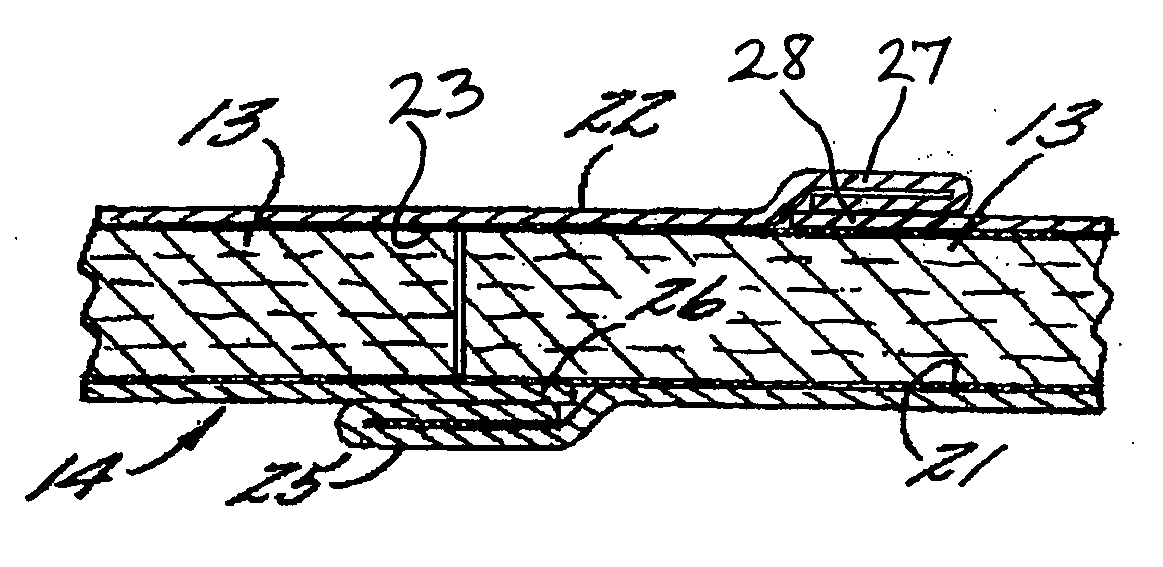

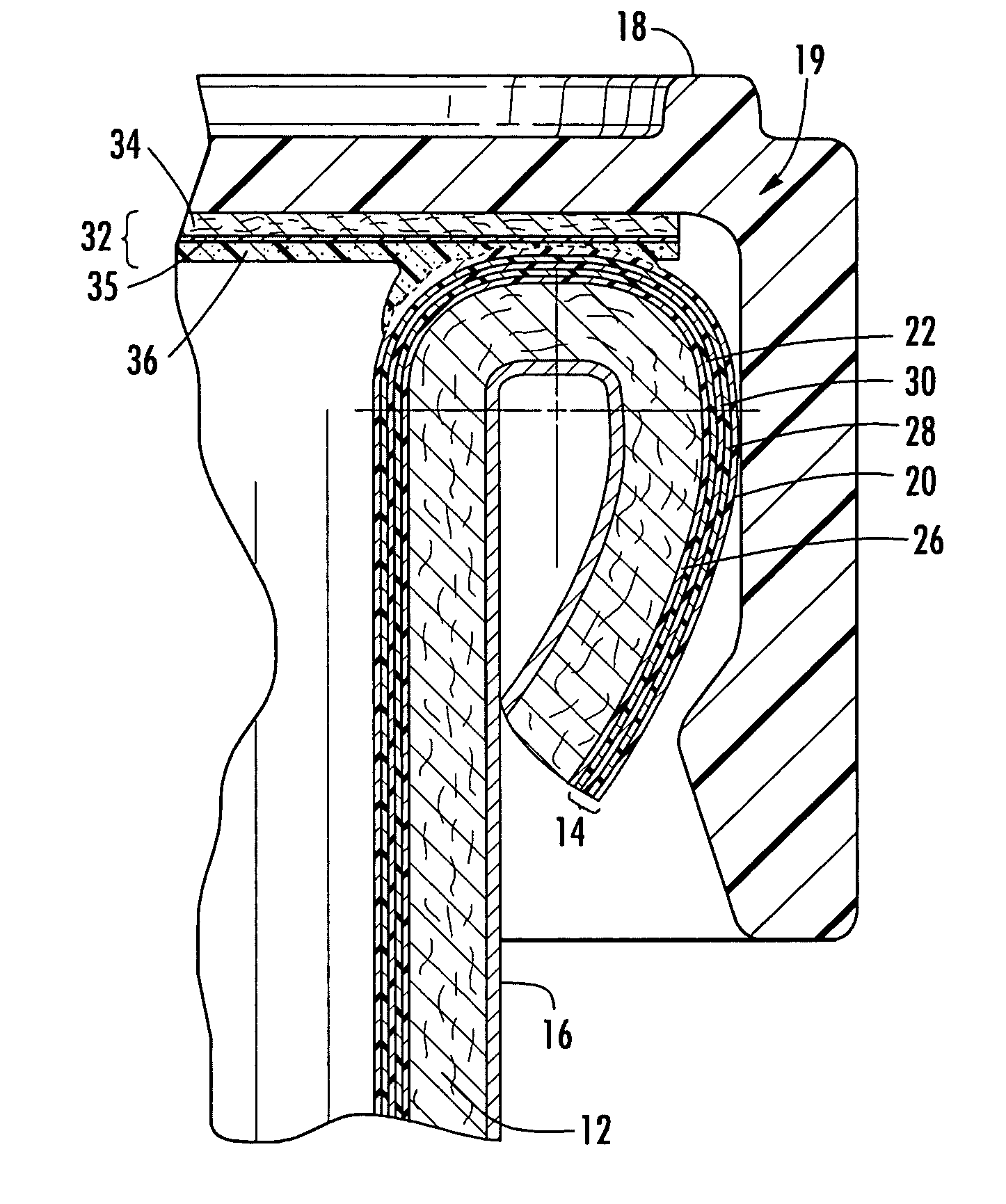

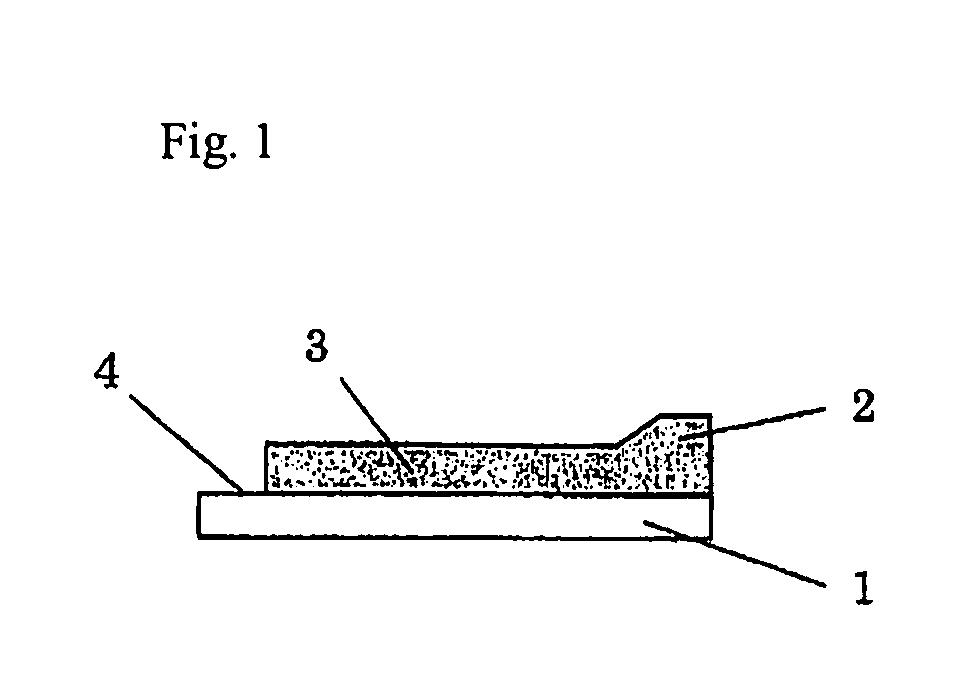

Patch-like infusion device

ActiveUS7250037B2Avoid accidental activationFacilitates self-injectionAutomatic syringesMedical devicesSkin surfaceInfusion set

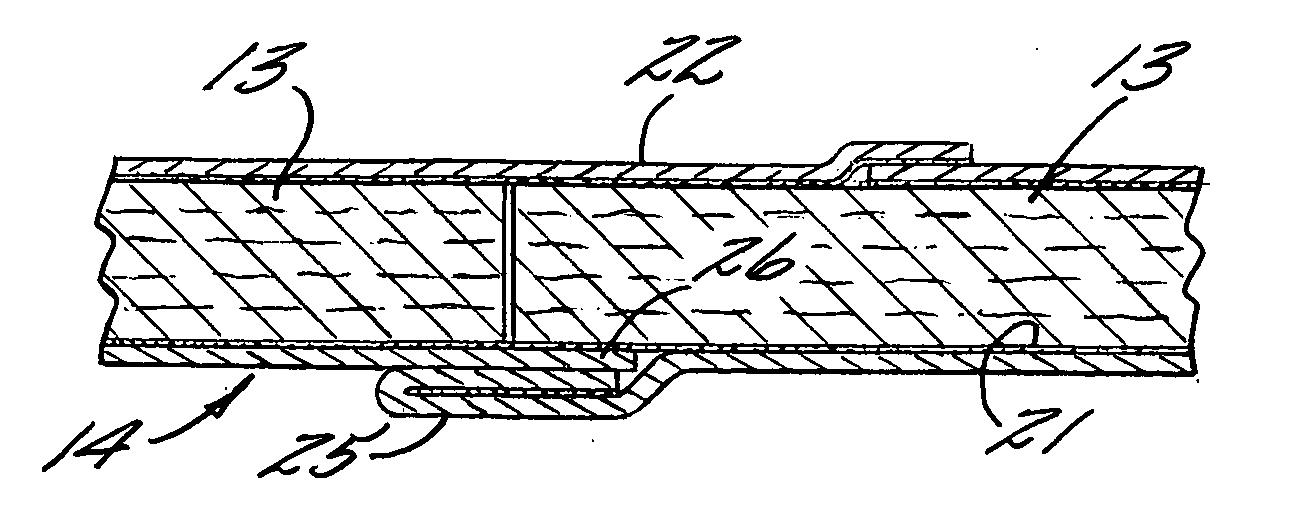

A system and method for a patch-like, self-contained substance infusion device which provides one or more substantially hidden patient needles which can be placed in fluid communication with a fluid reservoir subassembly that includes a rigid bladder portion used in conjunction with a non-distensible bladder film, such as a metallized film. Simple removal of an interlock allows a disk, or Belleville spring assembly to apply an essentially even and constant pressure to the contents of the fluid reservoir assembly, and allows the device to then be attached to a skin surface via an adhesive contact surface. A push button activation assembly is provided which can then be used to release and seat one or more spring-loaded patient needles into the skin surface, and establish a fluid communication path between the patient needles and the pressurized fluid reservoir contents thereby delivering an infusion into the skin.

Owner:BECTON DICKINSON & CO

Patch-like infusion device

InactiveUS7678079B2Conveniently worn against skinAutomatic syringesMedical devicesSkin surfaceCombined use

Owner:BECTON DICKINSON & CO

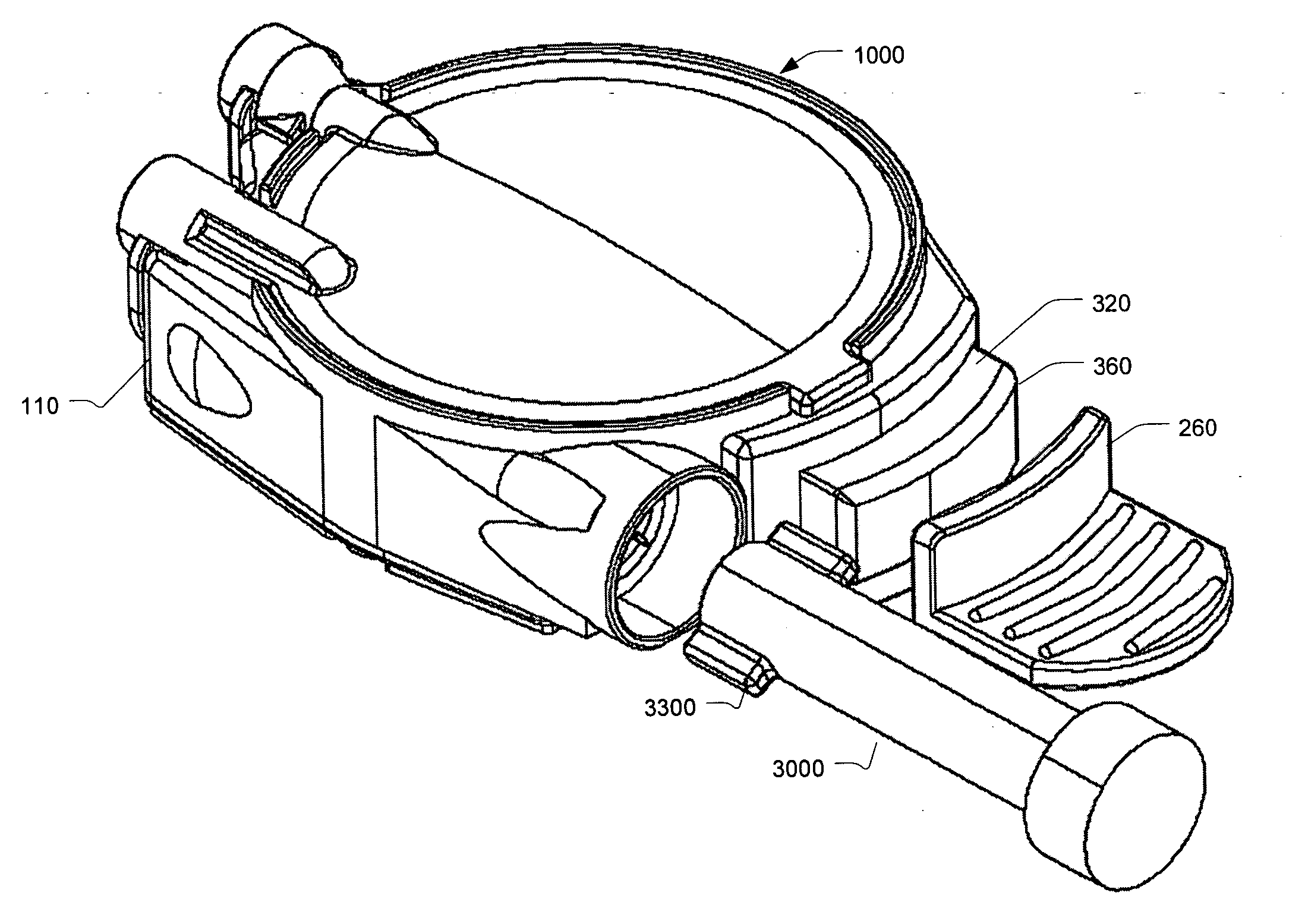

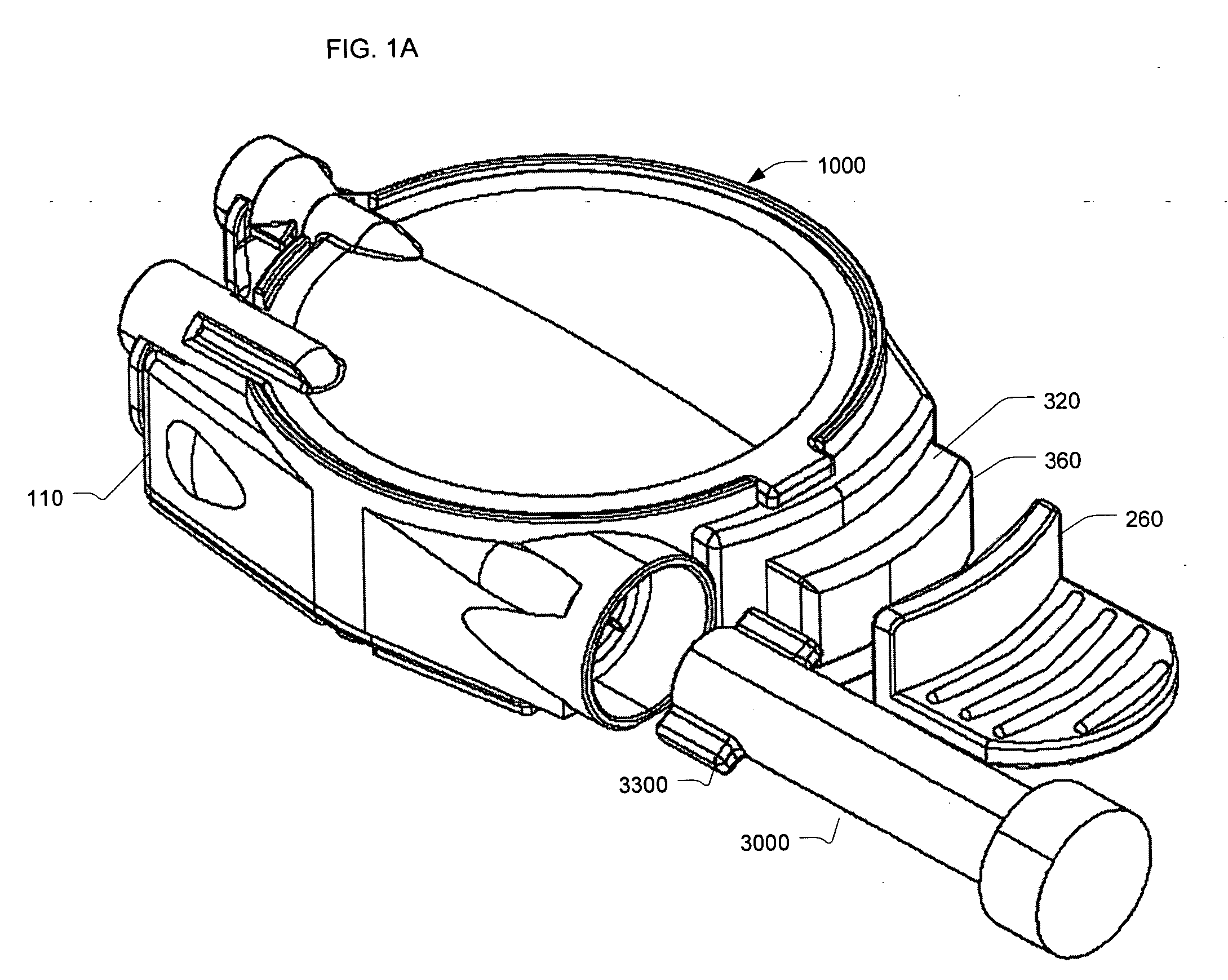

Reconstituting infusion device

ActiveUS20060106346A1Easy to handleEfficient storageAutomatic syringesMedical devicesSkin surfaceInfusion set

A system and method for a patch-like, self-contained multi-component substance infusion device which provides one or more substantially hidden patient needles which can be placed in fluid communication with a fluid reservoir assembly that includes a rigid bladder portion used in conjunction with a non-distensible bladder film, such as a metallized film. The device can be attached to a skin surface via an adhesive contact and a pressurization system provides a pressure to the contents of a fluid reservoir assembly. Improvements to dry powdered formulations for reconstitution for preferred use in the device are also disclosed.

Owner:BECTON DICKINSON & CO

Reconstituting infusion device

ActiveUS7981076B2Easy to handleEfficient storageAutomatic syringesMedical devicesMedicineSkin surface

A system and method for a patch-like, self-contained multi-component substance infusion device which provides one or more substantially hidden patient needles which can be placed in fluid communication with a fluid reservoir assembly that includes a rigid bladder portion used in conjunction with a non-distensible bladder film, such as a metallized film. The device can be attached to a skin surface via an adhesive contact and a pressurization system provides a pressure to the contents of a fluid reservoir assembly. Improvements to dry powdered formulations for reconstitution for preferred use in the device are also disclosed.

Owner:BECTON DICKINSON & CO

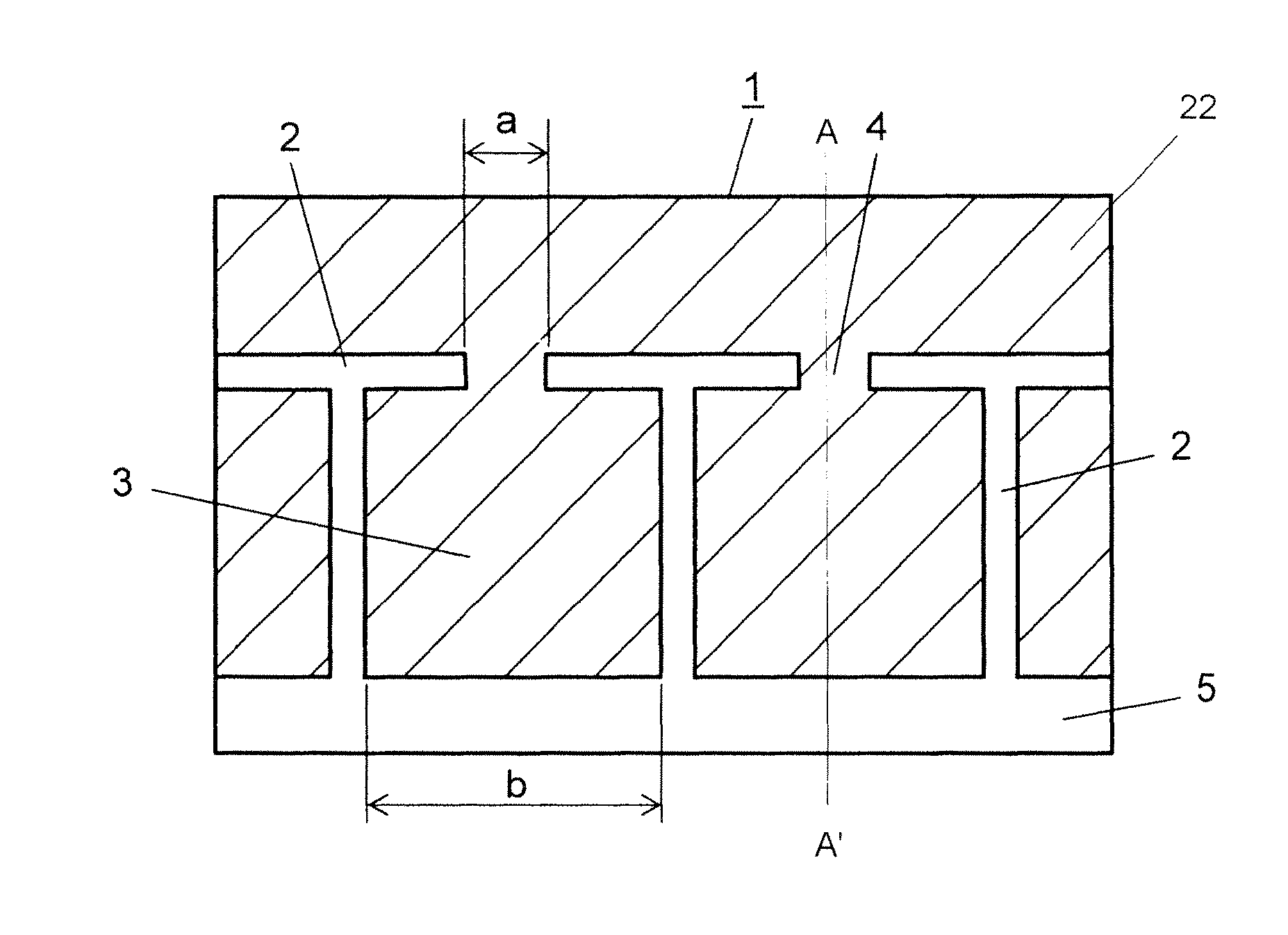

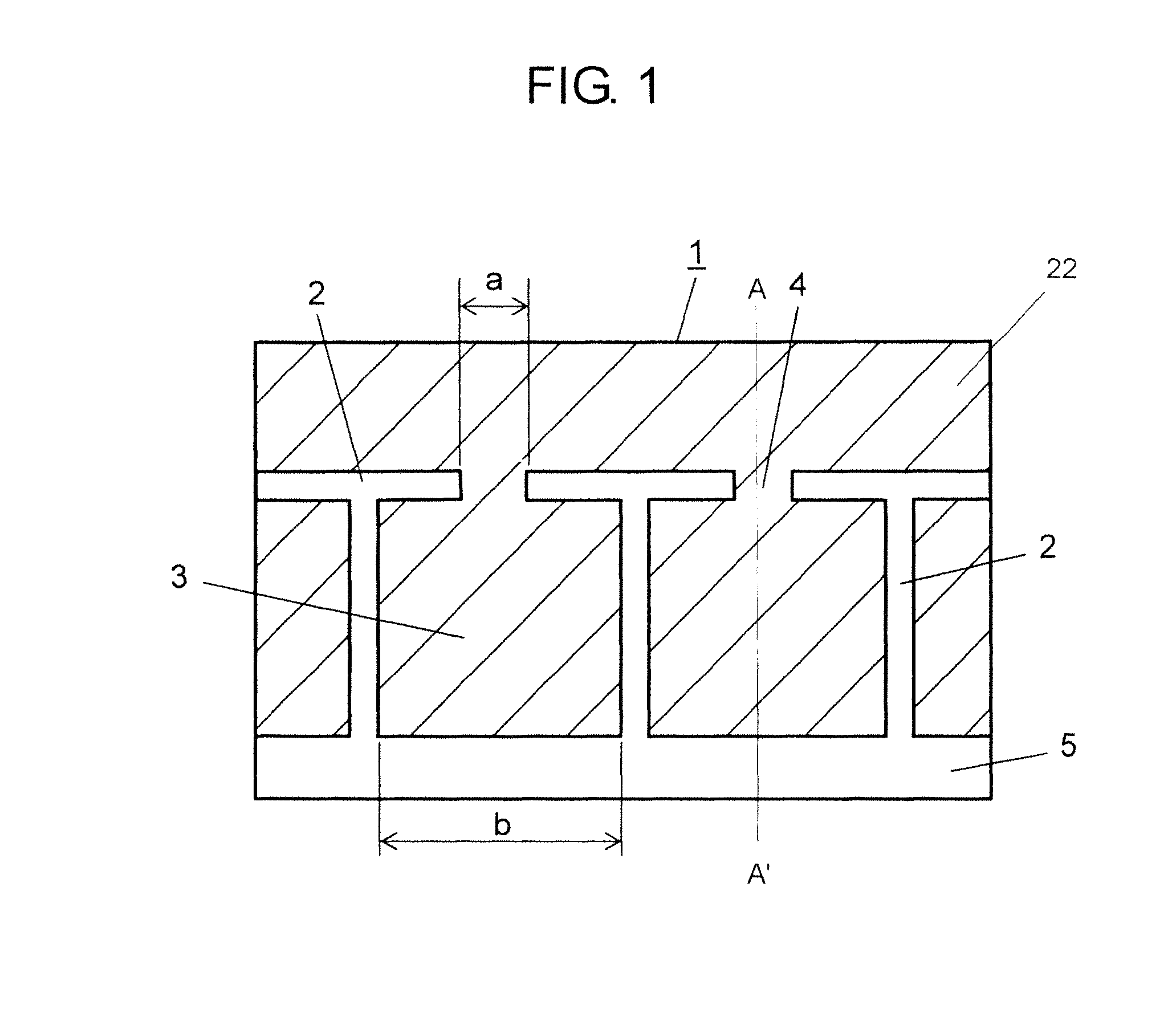

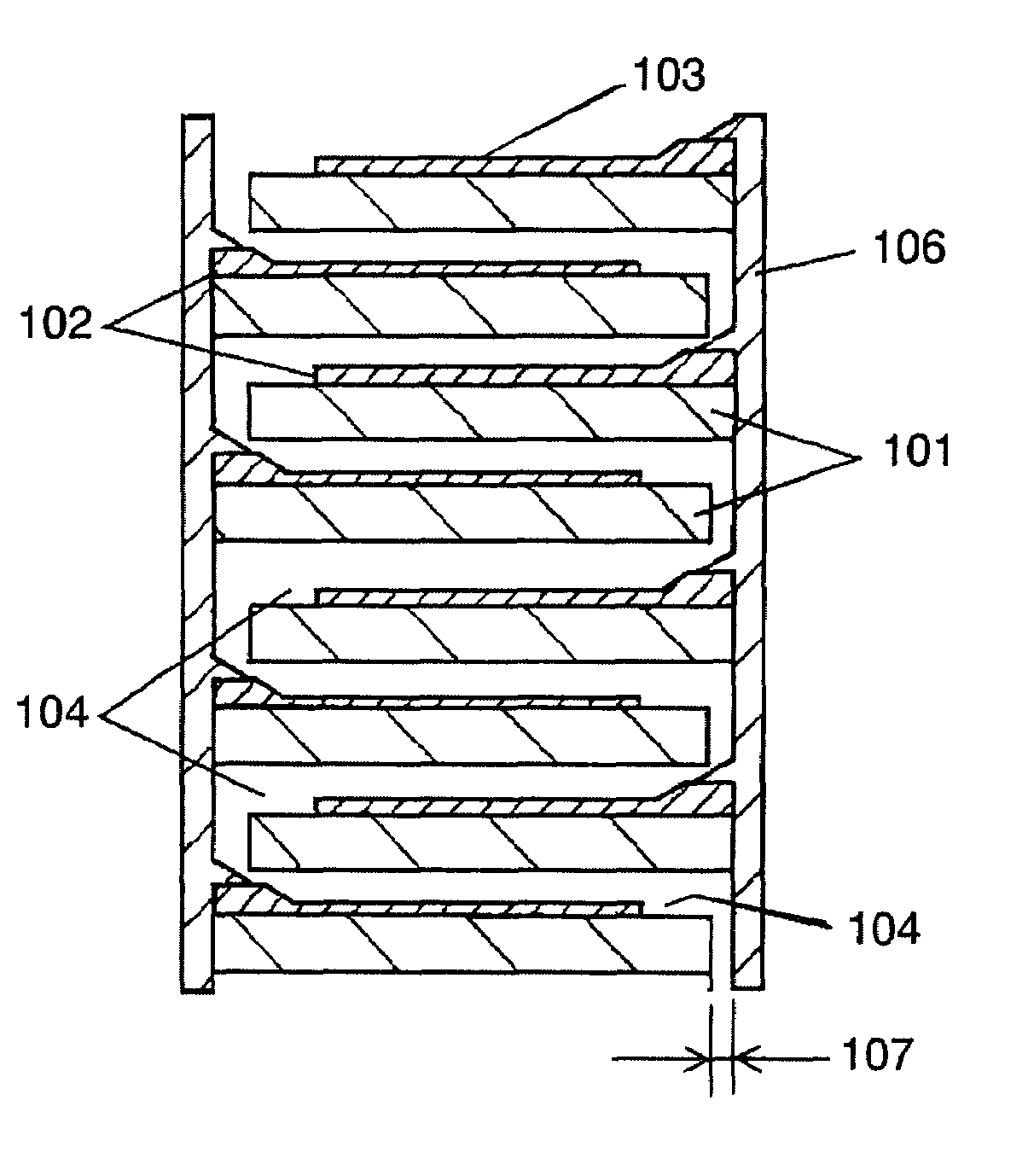

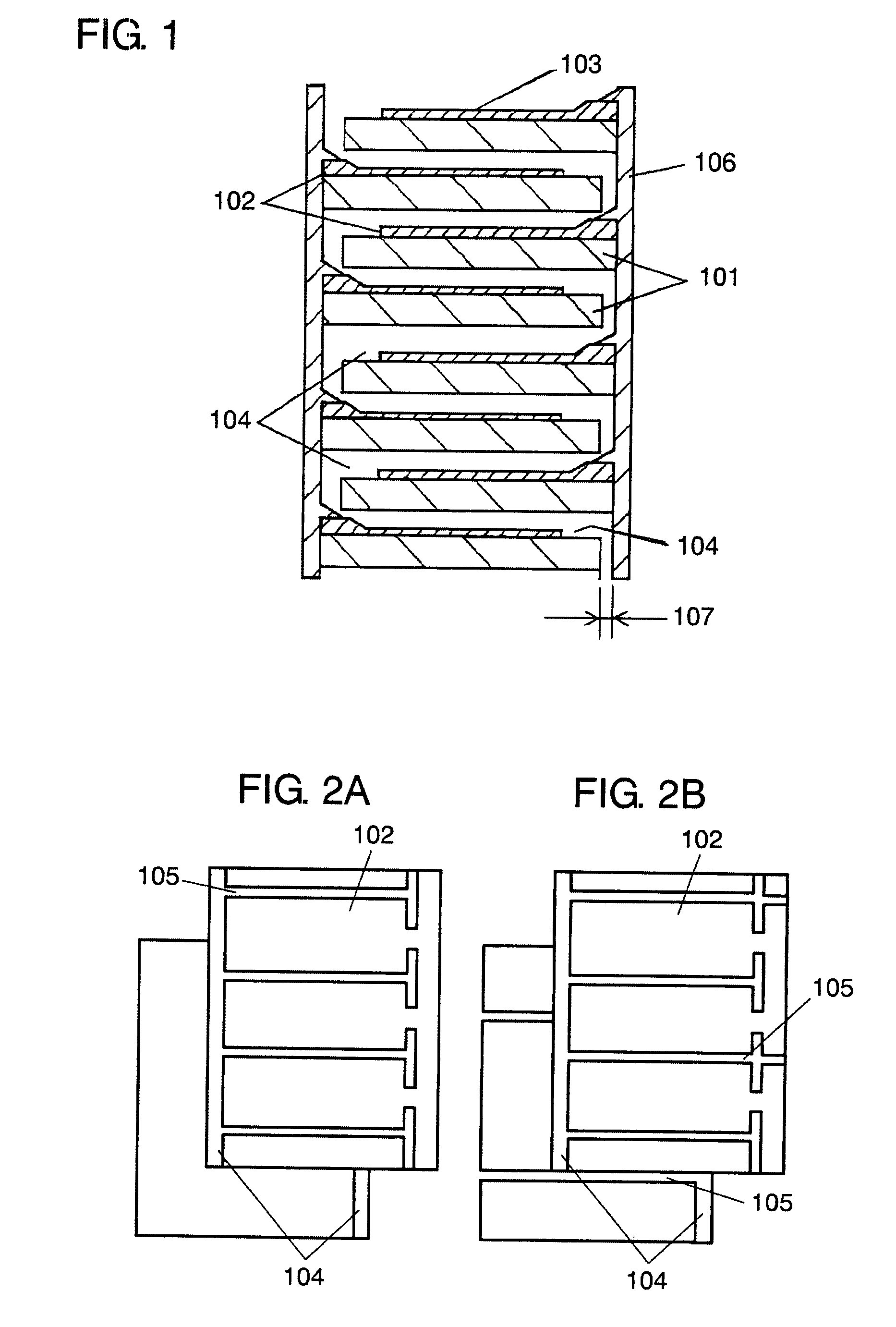

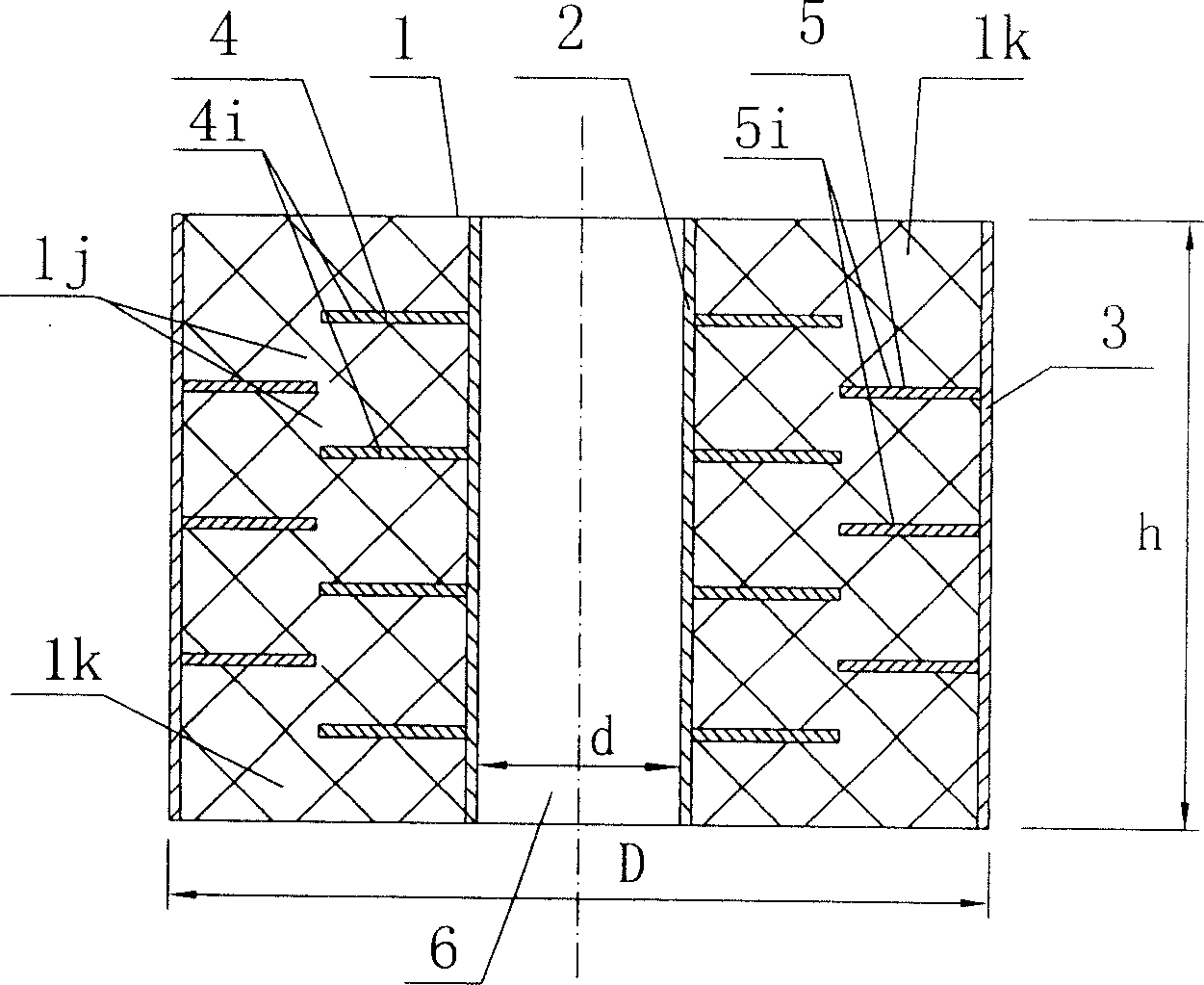

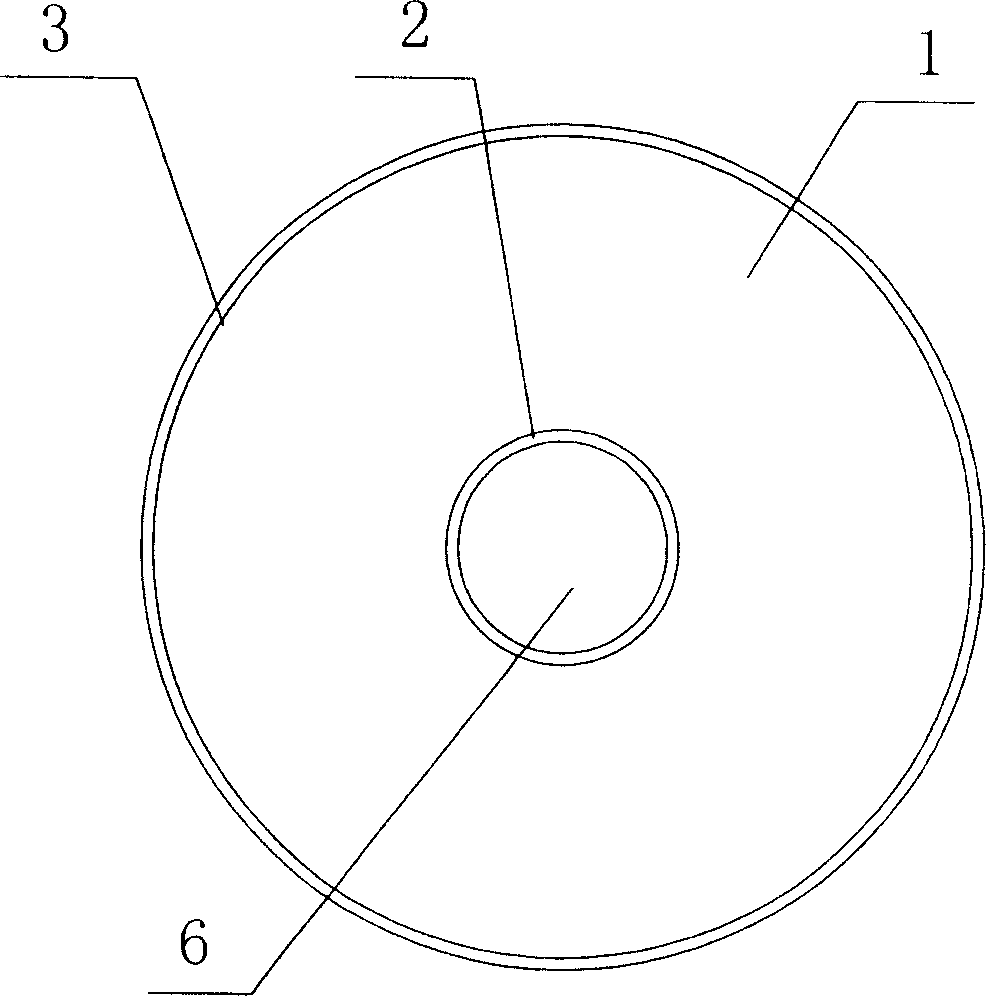

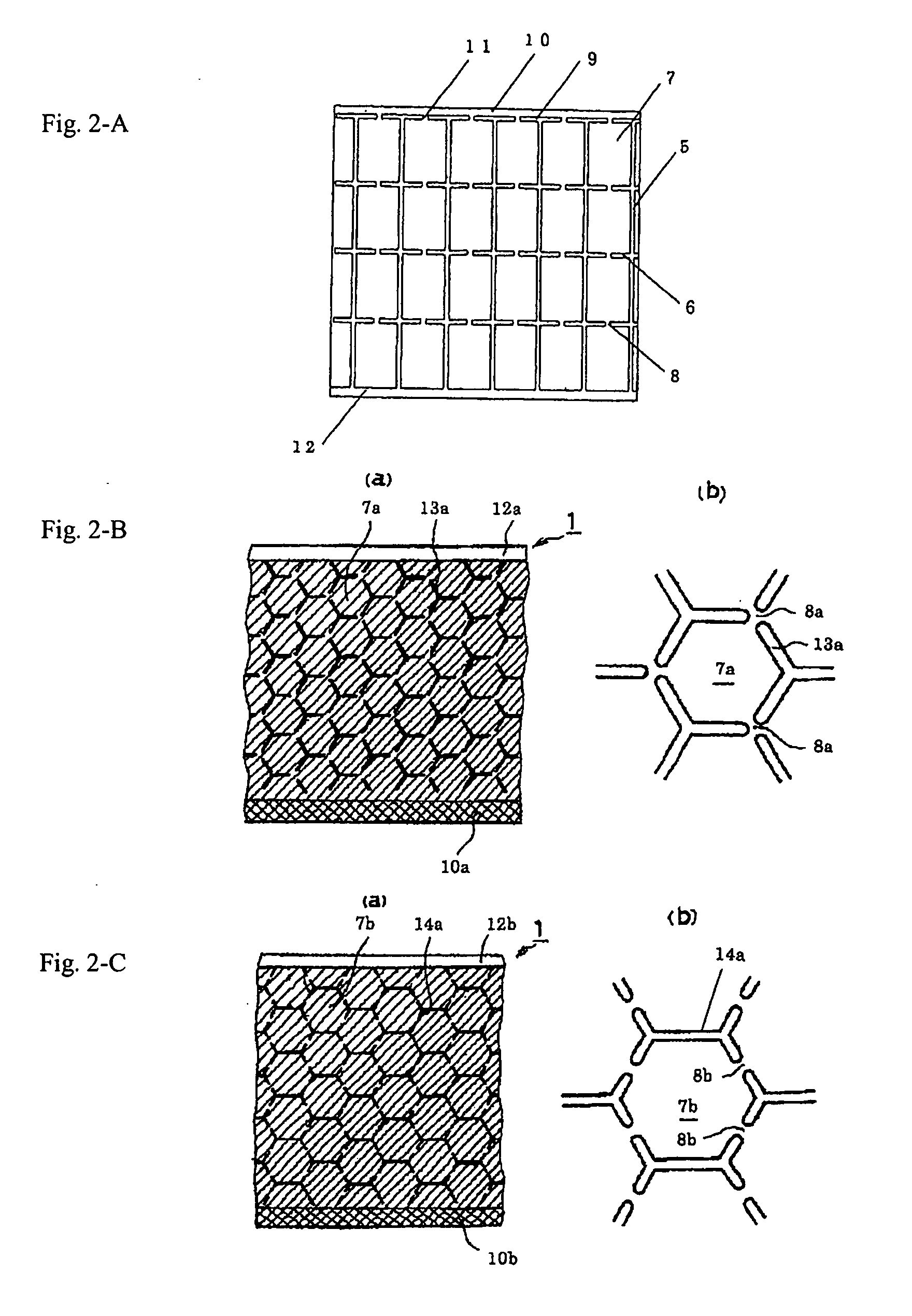

Metallization film capacitor having divided electrode with fuse

InactiveUS8310802B2Improve heat resistanceImprove pressure resistanceFixed capacitor electrodesThin/thick film capacitorHeat resistancePass rate

A metallization film capacitor that achieves both high heat resistance and high withstand voltage at the same time. A metal-deposited electrode is formed on a PEN film in each of a pair of metalized films. These metalized films are wound such that the metal-deposited electrodes face each other via the dielectric film in between. A metalized contact electrode is formed on both end faces of these wound metalized films to configure the metallization film capacitor. A divisional electrode is provided on the metal-deposited electrode. In addition, a fuse is coupled to this divisional electrode for providing a self-maintaining function. Pass rate a / b of a deposition pattern is set to 4.0 or smaller, where ‘a’ is the fuse width, and ‘b’ is the length of the divisional electrode in a lengthwise direction of the metalized films.

Owner:PANASONIC CORP

Low Temperature Wafer Level Processing for MEMS Devices

ActiveUS20110027930A1Impedence networksSemiconductor/solid-state device detailsLow temperature depositionEngineering

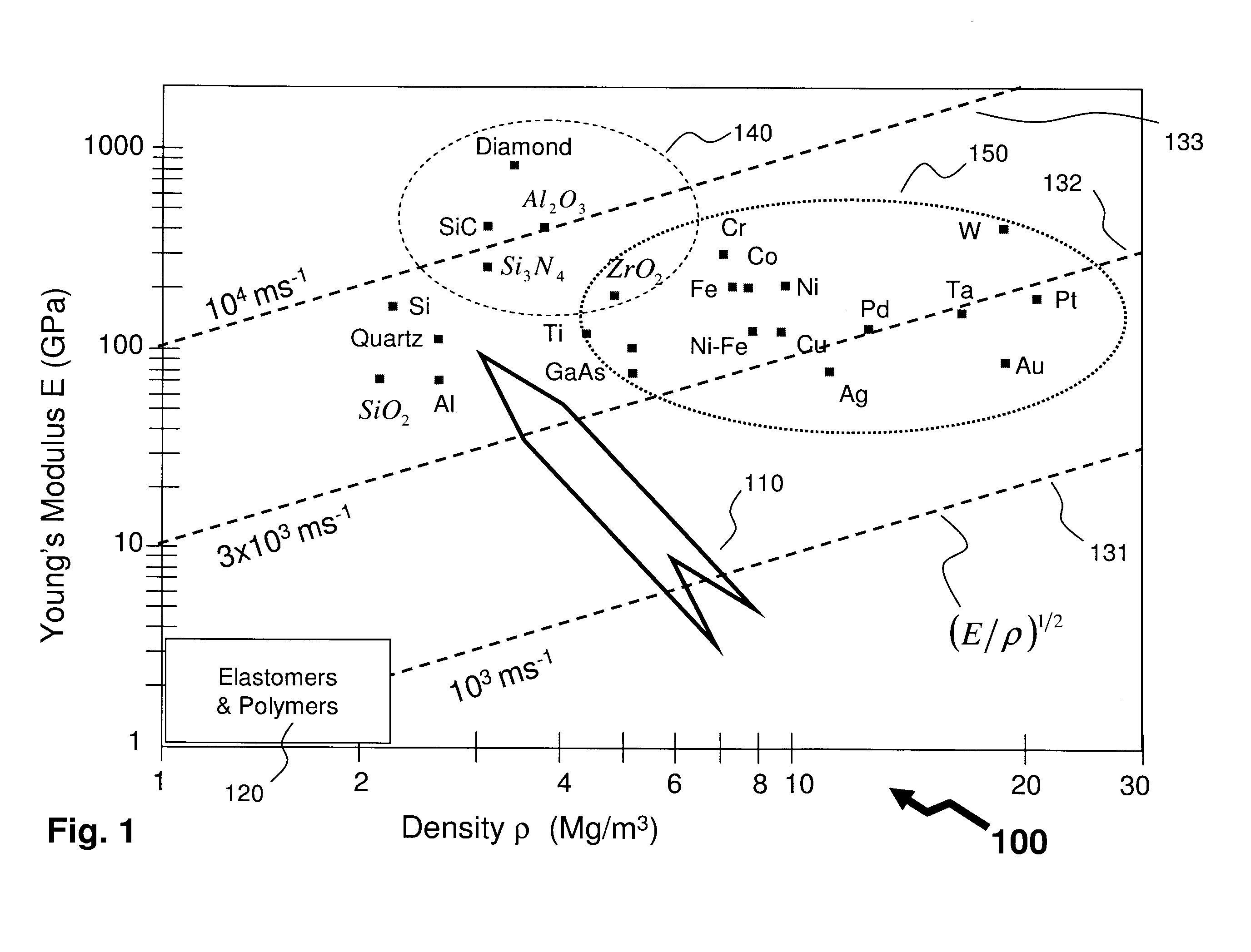

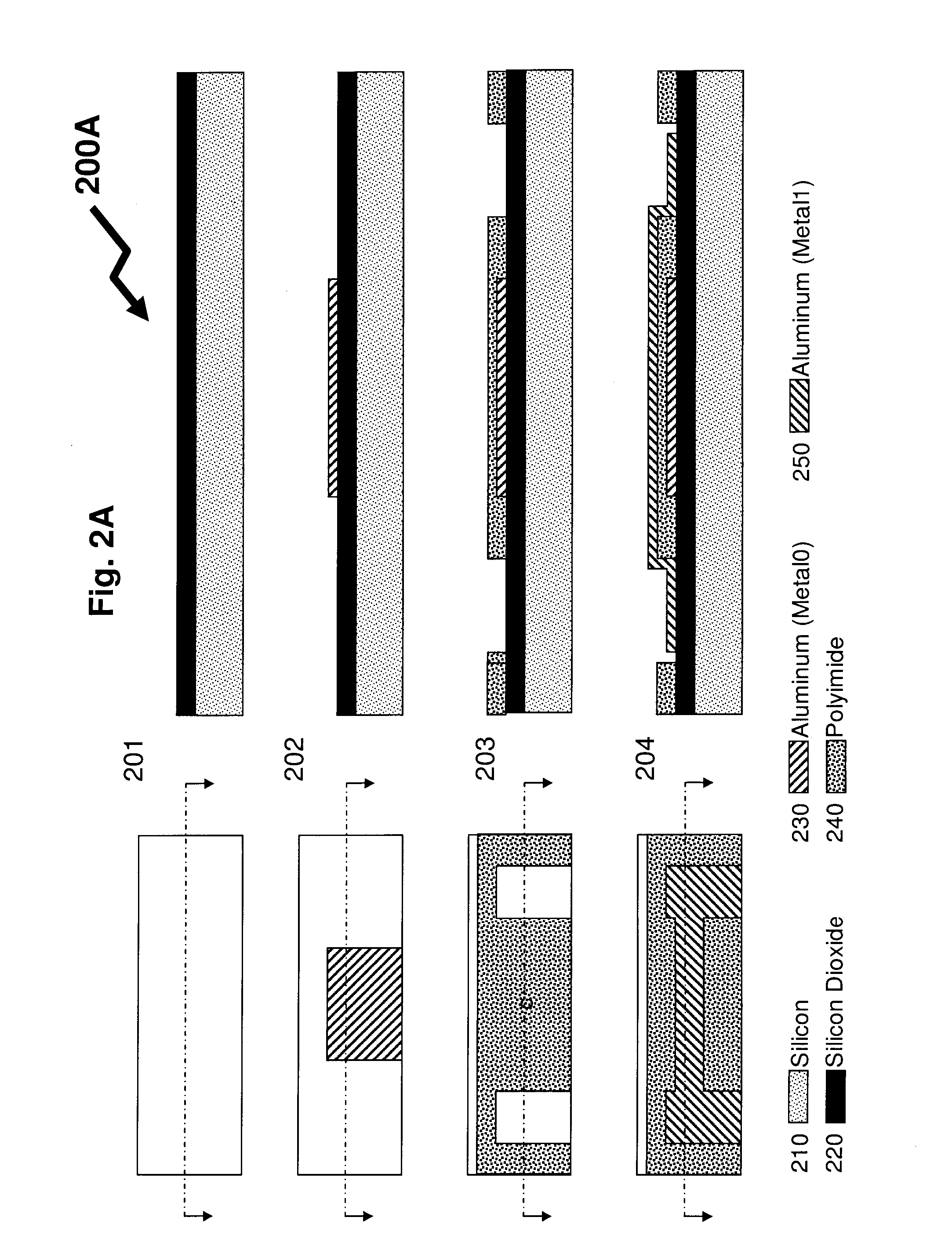

Microelectromechanical systems (MEMS) are small integrated devices or systems that combine electrical and mechanical components. It would be beneficial for such MEMS devices to be integrated with silicon CMOS electronics and packaged in controlled environments and support industry standard mounting interconnections such as solder bump through the provisioning of through-wafer via-based electrical interconnections. However, the fragile nature of the MEMS devices, the requirement for vacuum, hermetic sealing, and stresses placed on metallization membranes are not present in packaging conventional CMOS electronics. Accordingly there is provided a means of reinforcing the through-wafer vias for such integrated MEMS-CMOS circuits by in filling a predetermined portion of the through-wafer electrical vias with low temperature deposited ceramic materials which are deposited at temperatures below 350° C., and potentially to below 250° C., thereby allowing the re-inforcing ceramic to be deposited after fabrication of the CMOS electronics.

Owner:MCGILL UNIV

High barrier metallized film with mirror-like appearance

InactiveUS6844077B2Improved gas propertyImproved moisture barrier propertyFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyolefin

A metallized, multi-layer film is disclosed that comprises at least a polyolefin layer, a tie layer, and a metallized lactic acid polymer layer to yield a final film having improved moisture and gas barrier, optical, and mechanical properties.

Owner:EXXONMOBIL CORP (US)

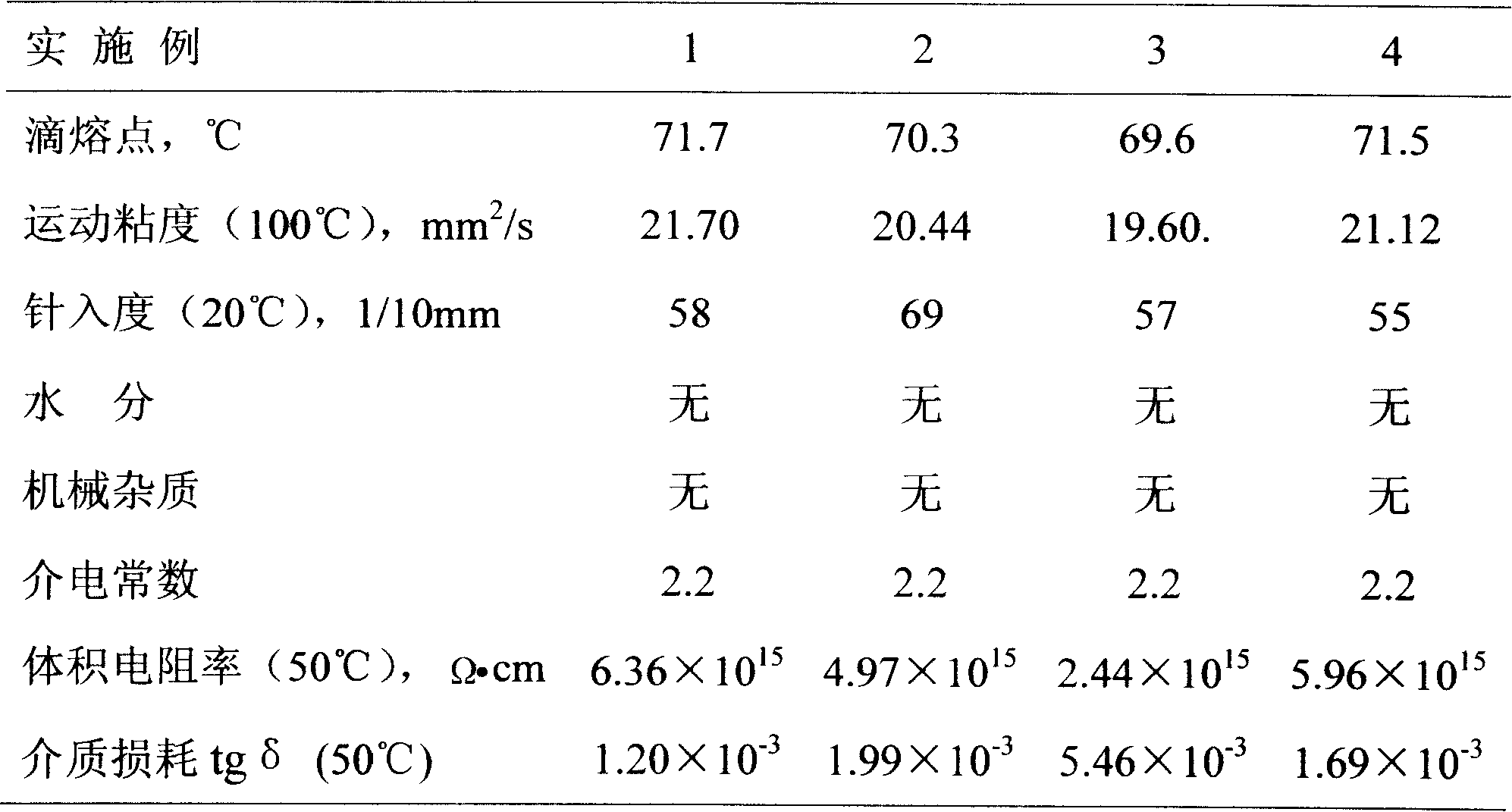

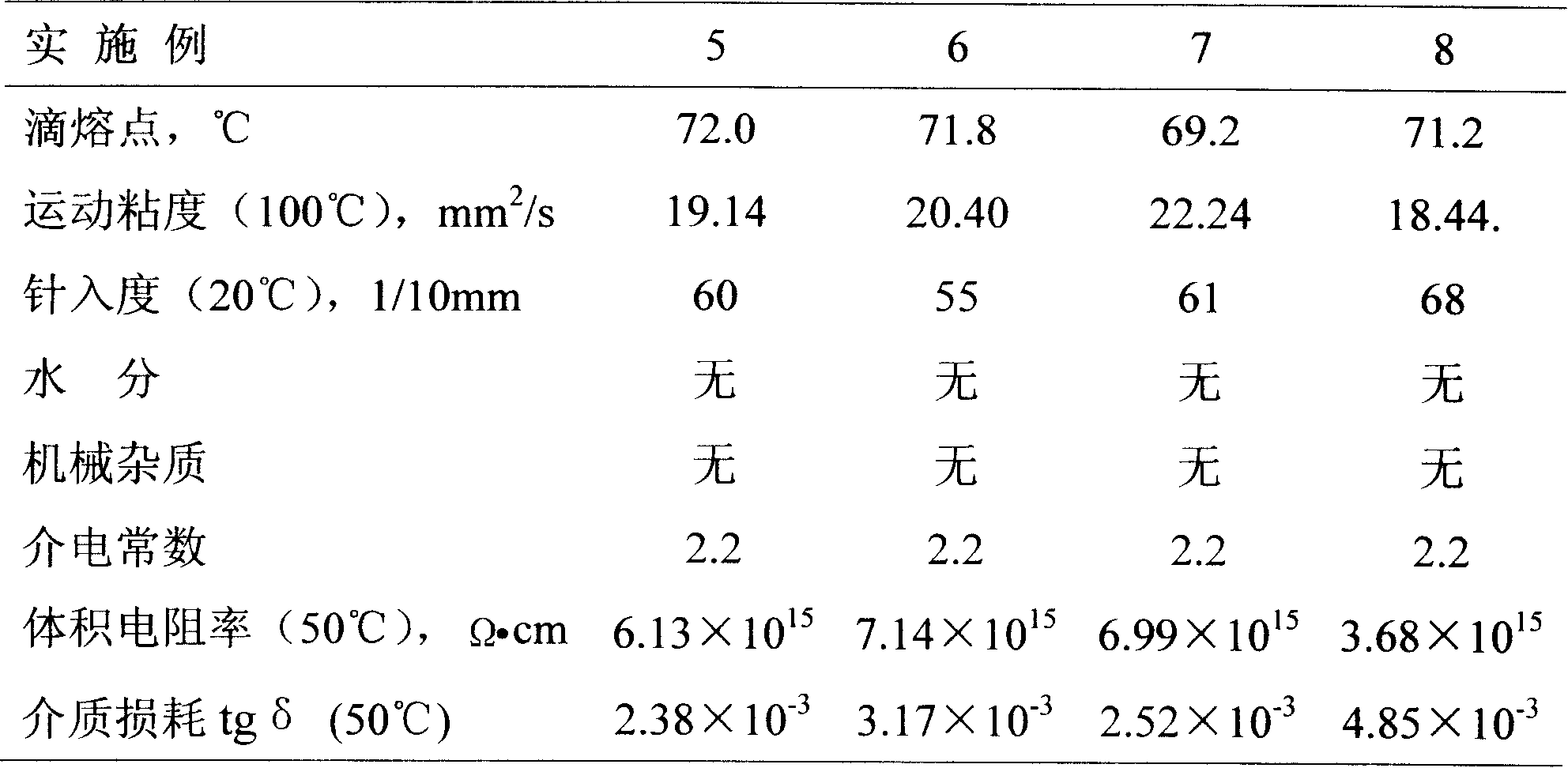

Metallized membrane capacitance embedding wax

InactiveCN101173158AExcellent electrical performanceImprove moisture resistanceOther chemical processesFixed capacitor housing/encapsulationCapacitanceLow voltage

The invention relates to a potting wax composition for metalized film capacitors, which comprises petroleum wax, synthetic wax, malthene and a tackiffer. The invention provides a potting wax composition for metalized film capacitors with suitable properties, and the defect of prior art that no special product exists in the field is made up. The invention is suitable for the potting of low voltage self-recover metalized polypropylene film power capacitors, CBB series capacitors and other metalized film capacitors. The invention has the advantages of good electrical properties, good moistureproof property, good fluidity, good heat resistant, good cold tolerance, suitable physical and chemical properties and processing property, innocuity, no corrosion, no impurity, and other advantages.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of metalized film of induction cooker capacitor

ActiveCN103112169AImprove performanceGood removal effectVacuum evaporation coatingSputtering coatingMetallised filmRejection rate

The invention relates to the field of preparation of a capacitor, and in particular relates to a preparation method of a metalized film of an induction cooker capacitor. The preparation method comprises the following steps of: selection and preparation of raw materials, extruding a melt through an extruder, cooling the melt through a chilling roller and an air shower, drawing the melt in a vertical direction, drawing the melt in a transverse direction, testing the thickness of the drawn melt, performing procedures of trimming and corona treatment, rolling, time sequence treatment, slicing, and vacuum-evaporating the metalized film. Through the steps, the prepared metalized film is comparatively high in performance, comparatively low in rejection rate, low in cost and high in current carrying capability.

Owner:NINGBO GREAT SOUTHEAST WAN XIANG SCI & TECH

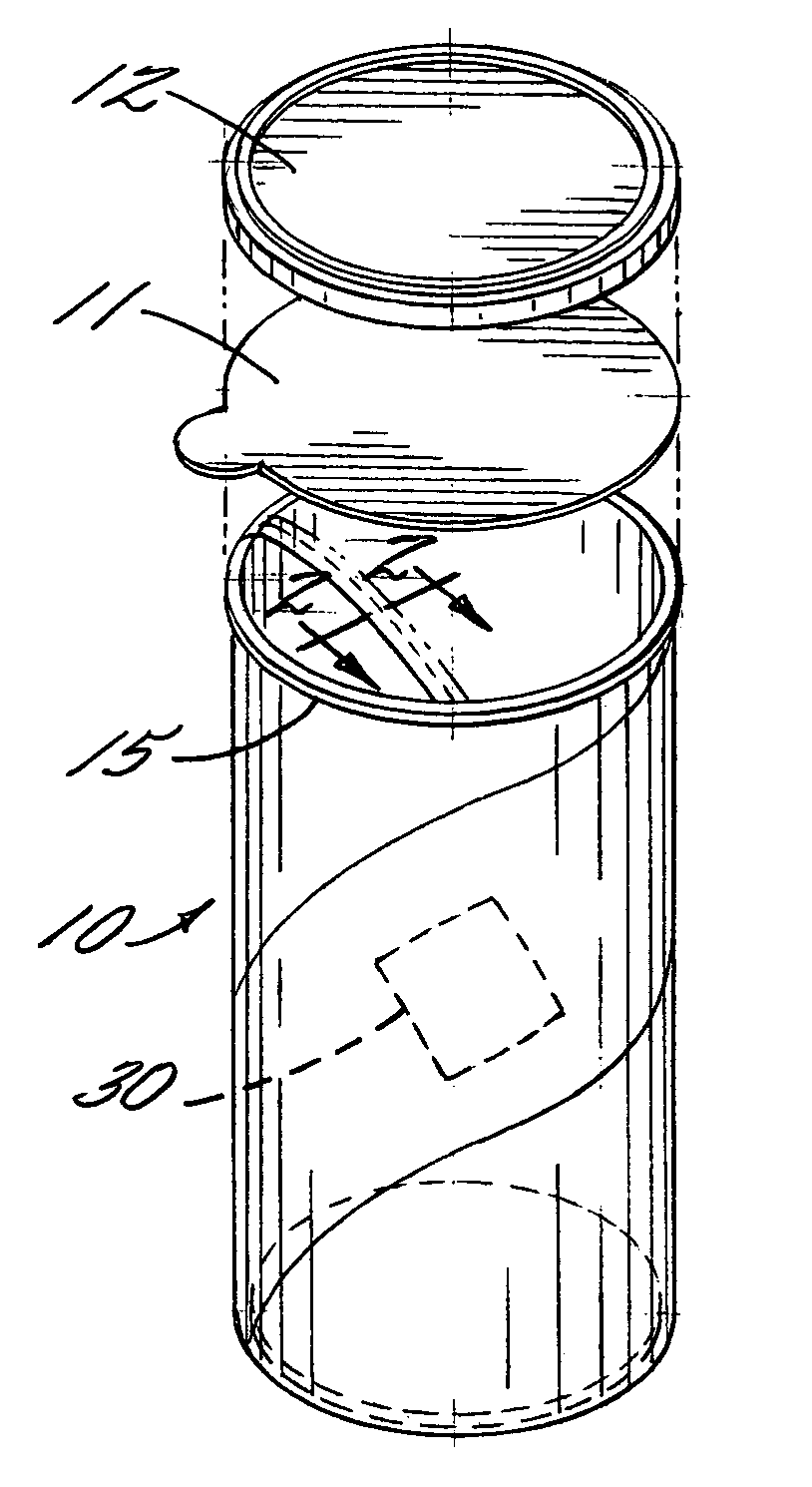

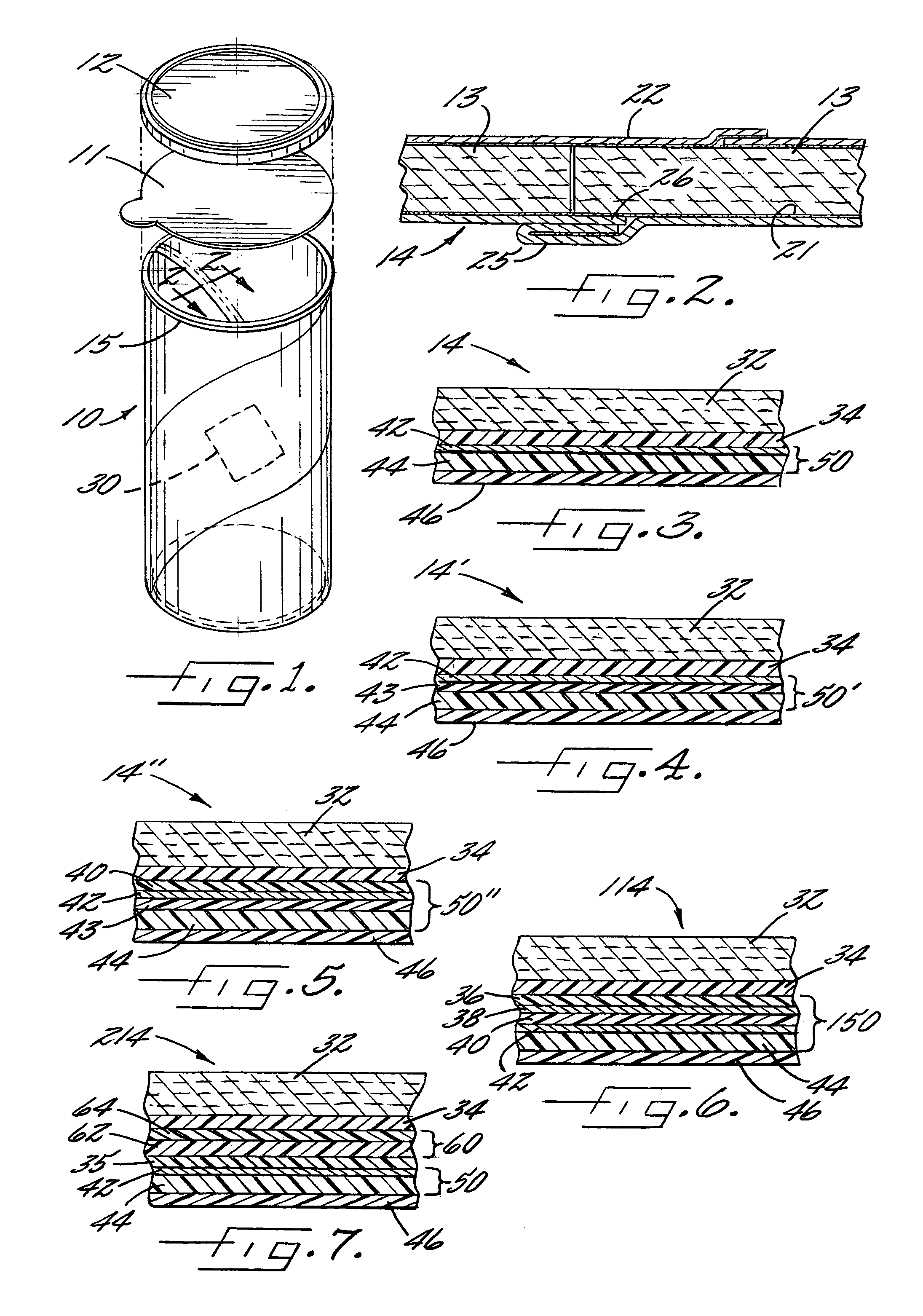

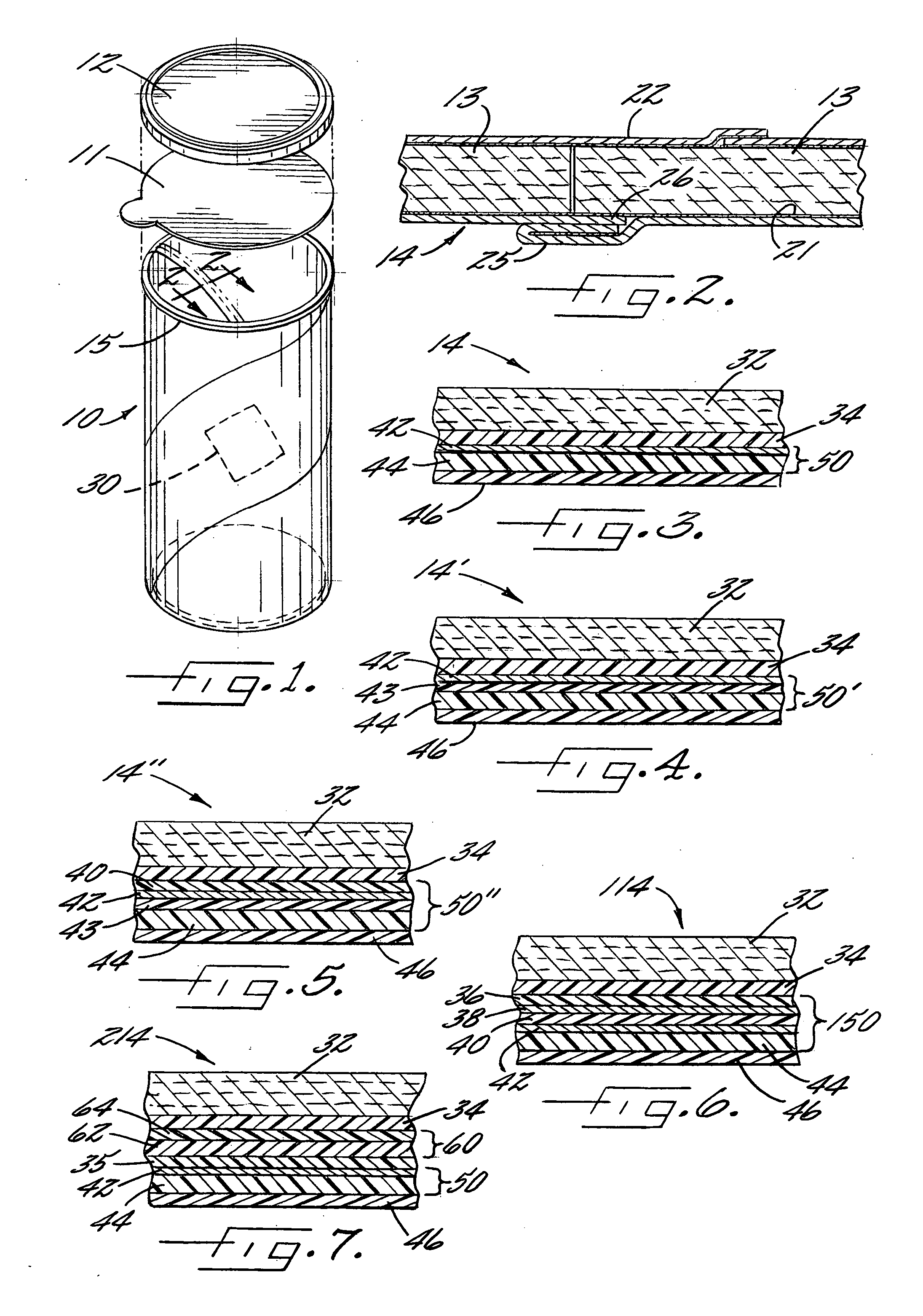

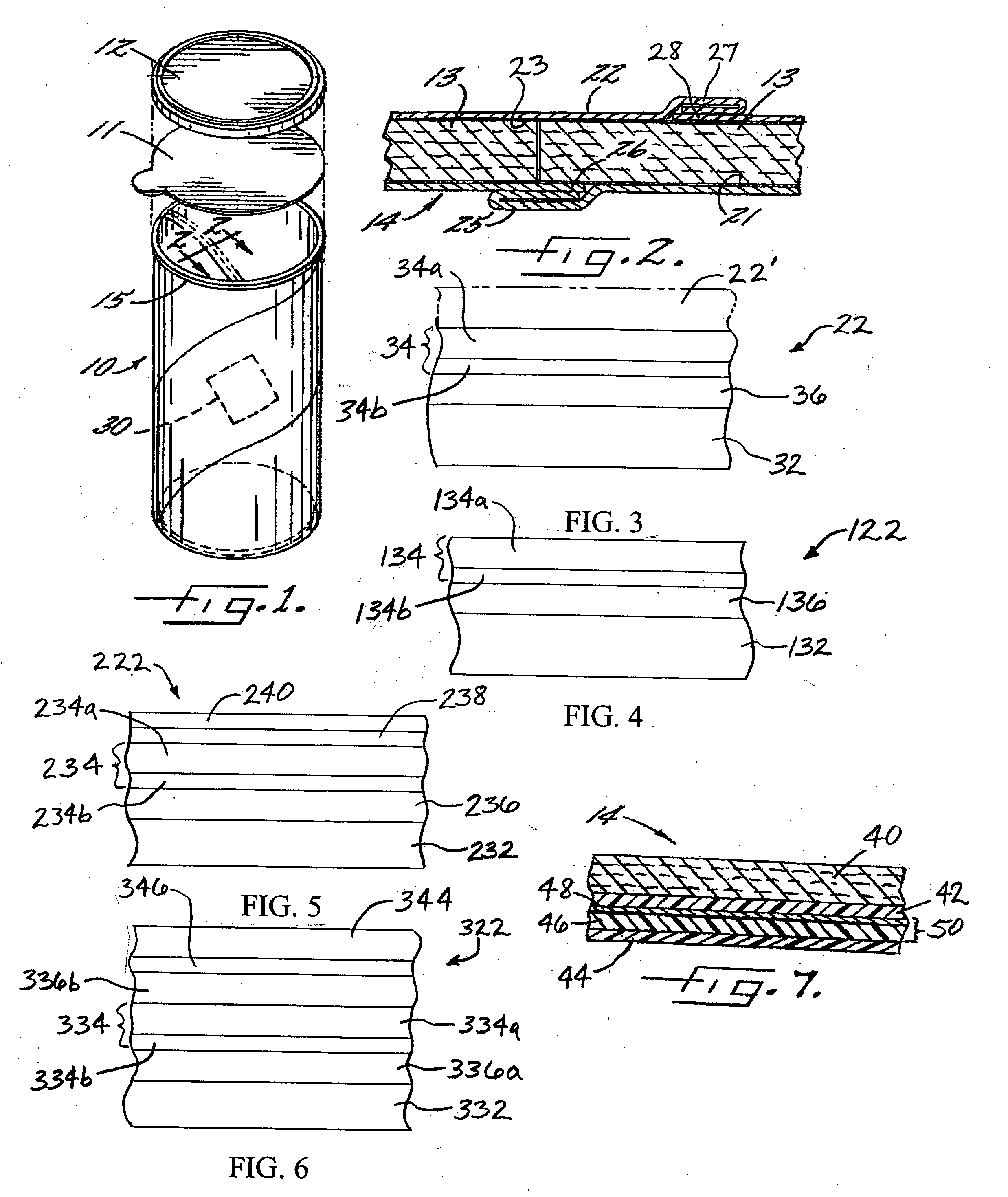

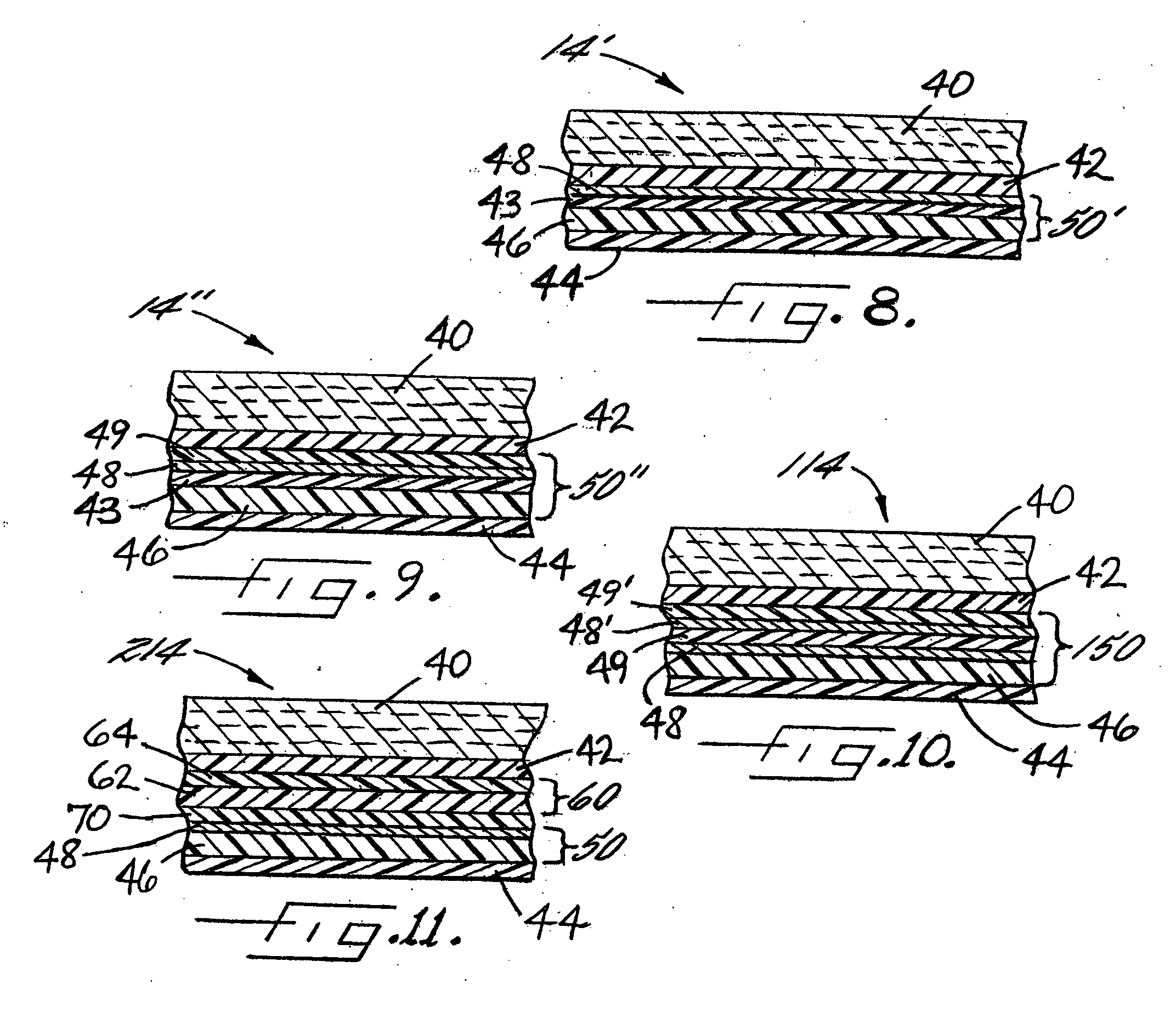

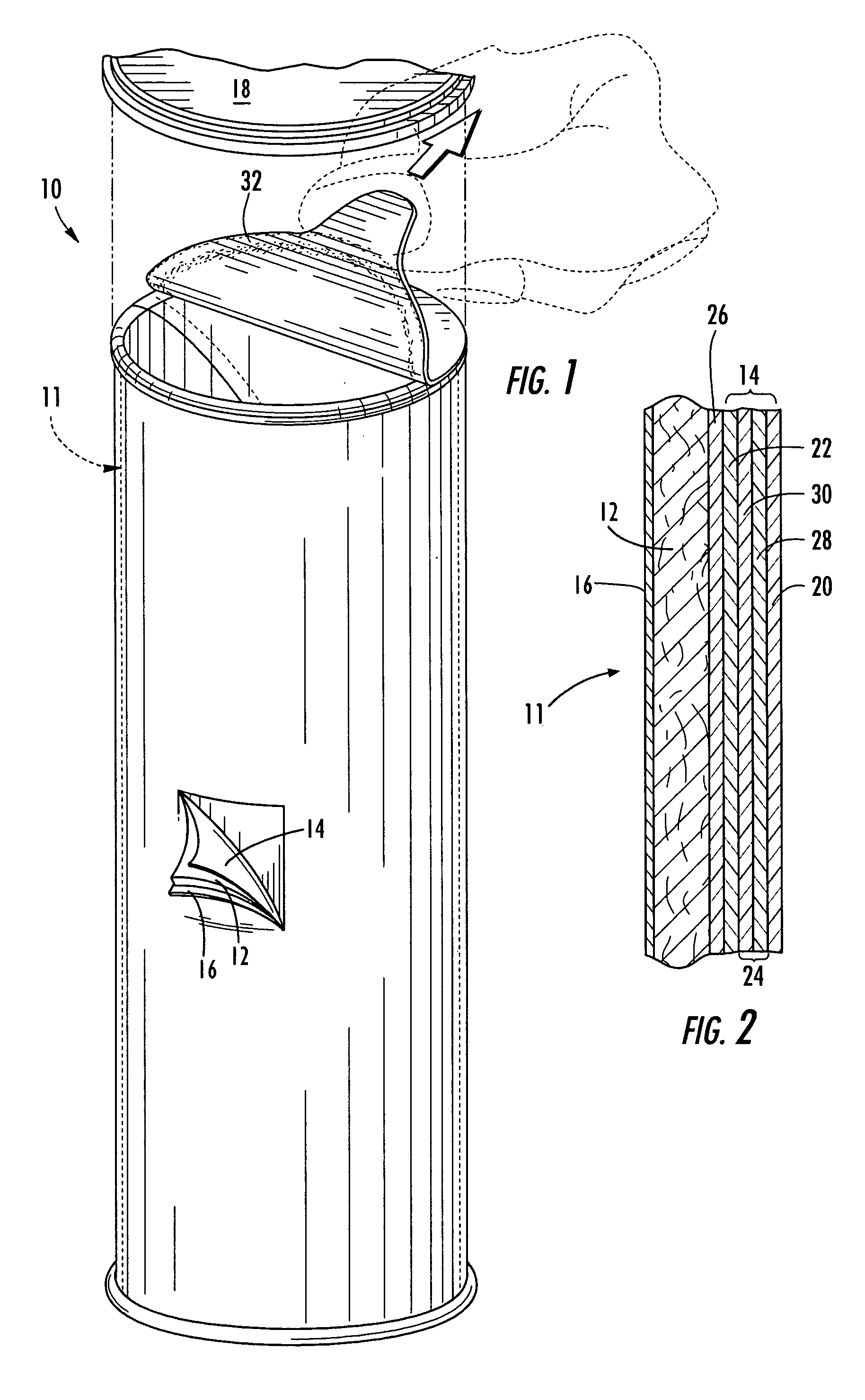

Composite container with RFID device and high-barrier liner

ActiveUS7112356B2Improve uniformity and continuityImprove barrier propertiesEnvelopes/bags making machineryContainer decorationsCardboardEngineering

A high-barrier liner for a composite container that is compatible with the use of RFID devices in the container includes a paper layer having an outer surface for attachment to an inner paperboard surface of a body wall of the container, and a metallized film attached to the inner surface of the paper layer, the metallized film comprising a polymer film substrate having a vapor-deposited layer of metal applied to one surface of the substrate. The liner also includes a heat seal layer disposed on an opposite side of the metallized film from the paper layer and forming an innermost surface of the liner. The metallized film can include a metallization-promoting material coated onto the substrate prior to metallization to improve the uniformity and continuity of the metal layer. The metal layer of the metallized film can have a protective coating applied over it.

Owner:SONOCO DEV INC

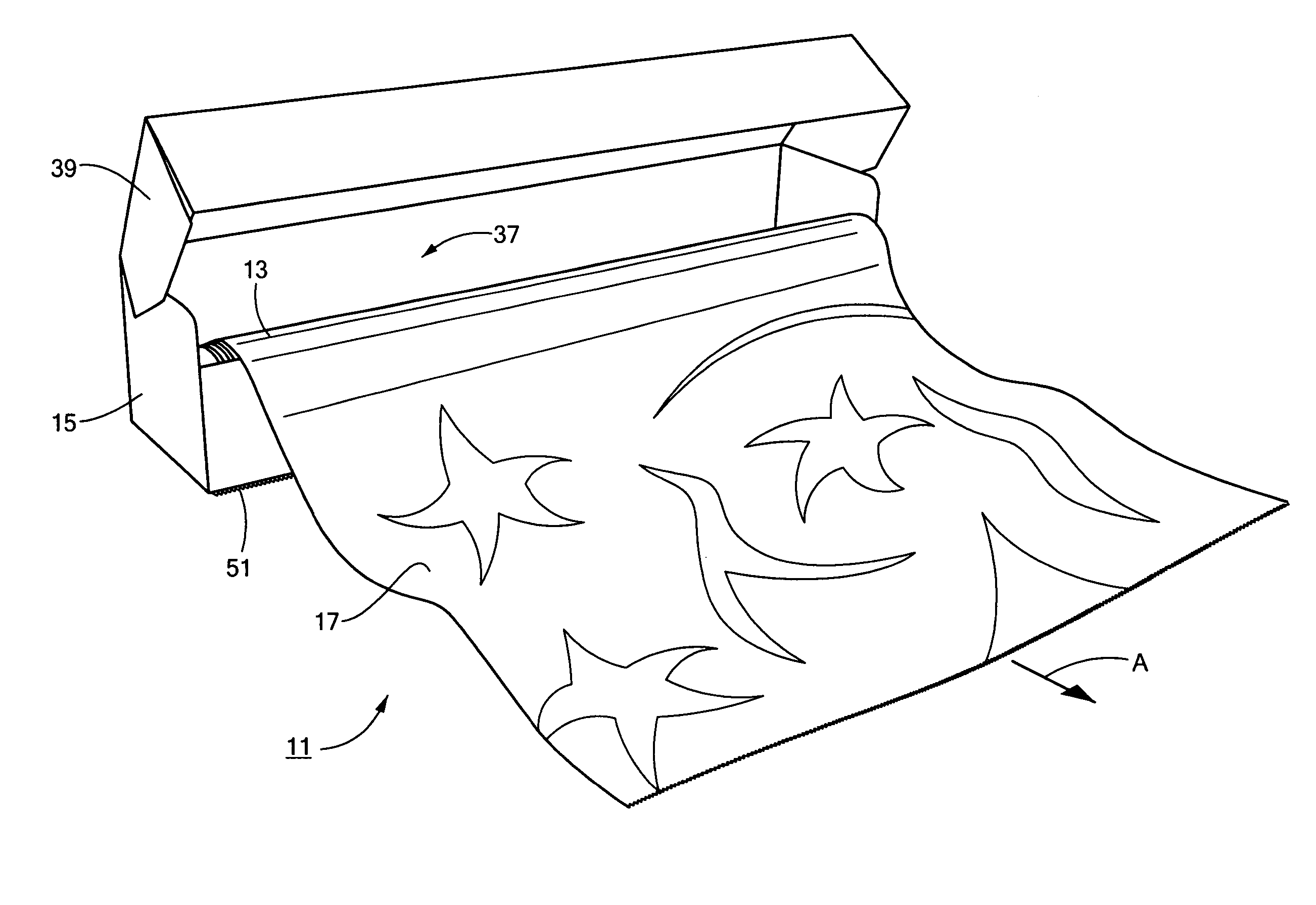

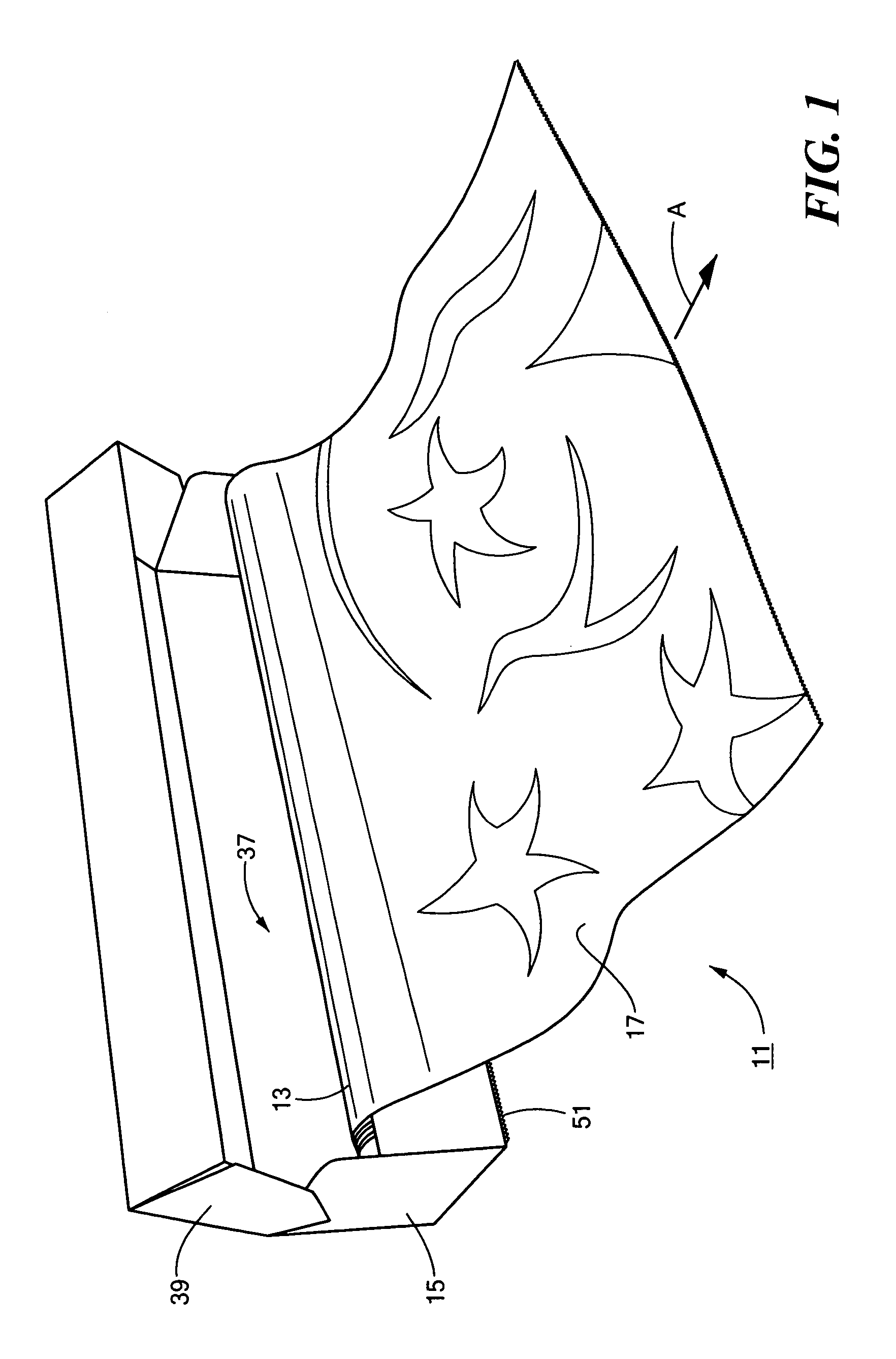

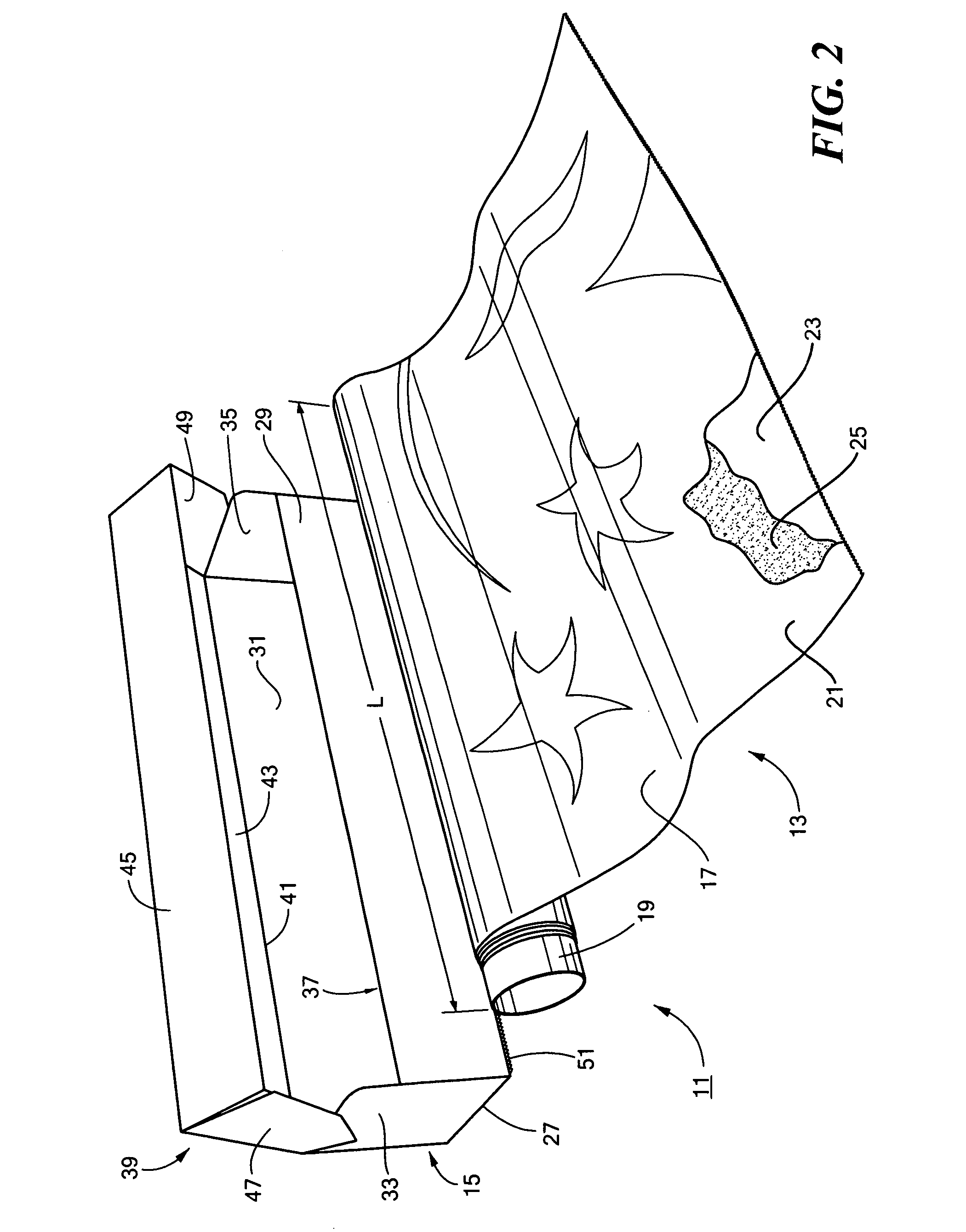

Gift wrap dispensing system

InactiveUS20070074986A1Small sizeEasy to carryContainers for annular articlesDispensing apparatusCardboardGift wrapping

A gift wrap dispensing system includes a roll of gift wrapping that is retained within an enclosable carton. The roll of gift wrapping is in the range of approximately 10-16 inches in length and includes a rigid cardboard tube on which a supply of wrapping paper is wound. The wrapping paper includes a decorative film, such as a holographic or metallized film, that is bonded onto a coated paper substrate using a layer of bonding material. The carton is preferably constructed from a unitary cardboard blank and includes a bottom panel, a front panel, a rear panel and a pair of side panels which together define a longitudinal cavity which is sized and shaped to receive the roll of gift wrapping. The carton additionally includes a lid that is pivotally coupled to the rear panel and that is designed to be pivoted between an open position and a closed position. In order to dispense a supply of wrapping paper, the lid of the carton is pivoted at least partially open. A user-defined section of the wrapping paper is extracted from the carton and is severed from the remainder of the roll of gift wrapping using an externally-accessible serrated cutting edge that is mounted on the carton. With the section of wrapping paper dispensed, the lid is pivoted closed to protect the remainder of the roll of gift wrapping pending further use.

Owner:KING MEDORA

Method for metallizing surface of microwave dielectric ceramic

InactiveCN106747675AEliminate pollutionStrong adhesionVacuum evaporation coatingSputtering coatingDielectricEnvironmental resistance

The invention discloses a method for metallizing the surface of a microwave dielectric ceramic. The method comprises (1) surface treatment: carrying out fine grinding on the surface of a microwave dielectric ceramic and carrying out ultrasonic cleaning and vacuum plasma cleaning, (2) depositing an underlying metal through a magnetron sputtering method under low magnetron sputtering atmospheric pressure of 0.1-0.2 pa, and (3) depositing a metallized film system through the magnetron sputtering method under conventional magnetron sputtering atmospheric pressure of 0.3-0.7 pa. Compared with the other microwave dielectric ceramic surface metallization methods, the method utilizes a two-step atmospheric pressure sputtering method to deposit a multiple-layer metallized film system, effectively improves the adhesion of a metallized film layer on the surface of a microwave dielectric ceramic, has a simple and reasonable process design, has industrial production feasibility, is environmentally friendly and does not produce pollution in production.

Owner:ZHEJIANG UNIV

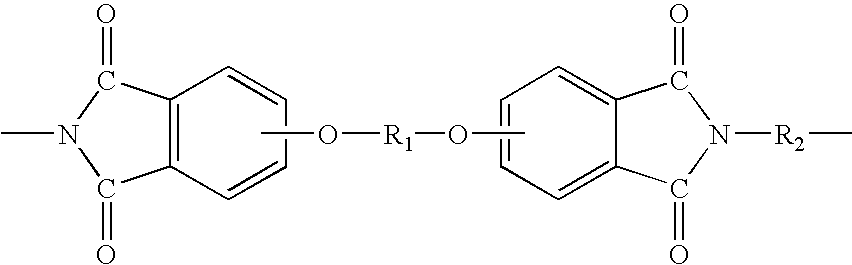

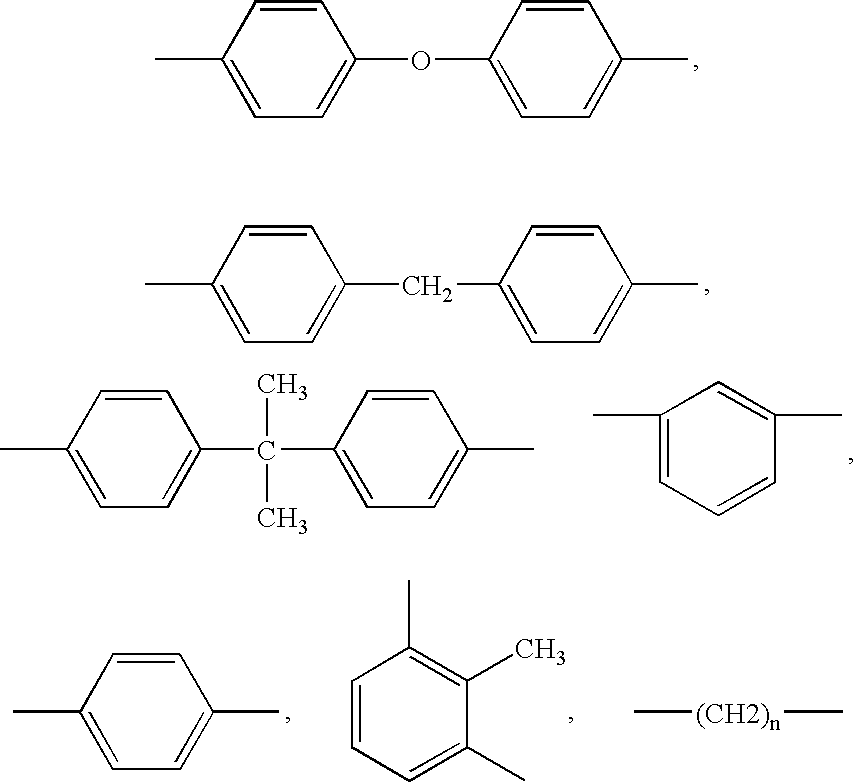

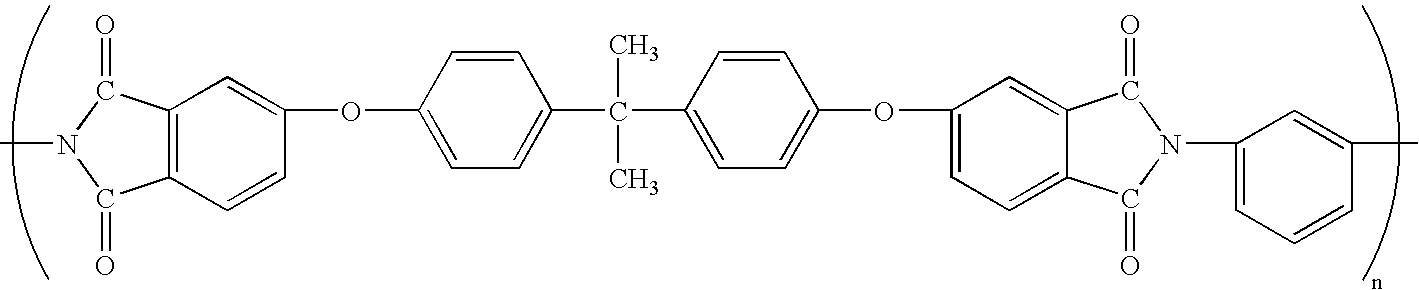

Polyester film for heat-resistant capacitor, metallized film thereof, and heat-resistant film capacitor containing the same

InactiveUS6974620B1Fixed capacitor dielectricSynthetic resin layered productsPolyesterPolymer science

A polyester film for use in a capacitor having high heat resistance, which consists of a biaxially oriented film containing a polyester (A) as a main component and a polyimide (B) and has a glass transition temperature of 105° C. to 145° C. and an elongation at break in the machine direction of 70% to 150%, offers a high glass transition temperature and excellent insulation volume resistance and insulation breakdown voltage at high ambient temperatures. This film can produce a metallized film for use in a capacitor having high heat resistance and also a film capacitor having high heat resistance.

Owner:TORAY IND INC

Composite container with RFID device and high-barrier liner

ActiveUS20050255261A1Improve barrier propertiesImprove uniformity and continuityEnvelopes/bags making machineryContainer decorationsGas phasePaperboard

A high-barrier liner for a composite container that is compatible with the use of RFID devices in the container includes a paper layer having an outer surface for attachment to an inner paperboard surface of a body wall of the container, and a metallized film attached to the inner surface of the paper layer, the metallized film comprising a polymer film substrate having a vapor-deposited layer of metal applied to one surface of the substrate. The liner also includes a heat seal layer disposed on an opposite side of the metallized film from the paper layer and forming an innermost surface of the liner. The metallized film can include a metallization-promoting material coated onto the substrate prior to metallization to improve the uniformity and continuity of the metal layer. The metal layer of the metallized film can have a protective coating applied over it.

Owner:SONOCO DEV INC

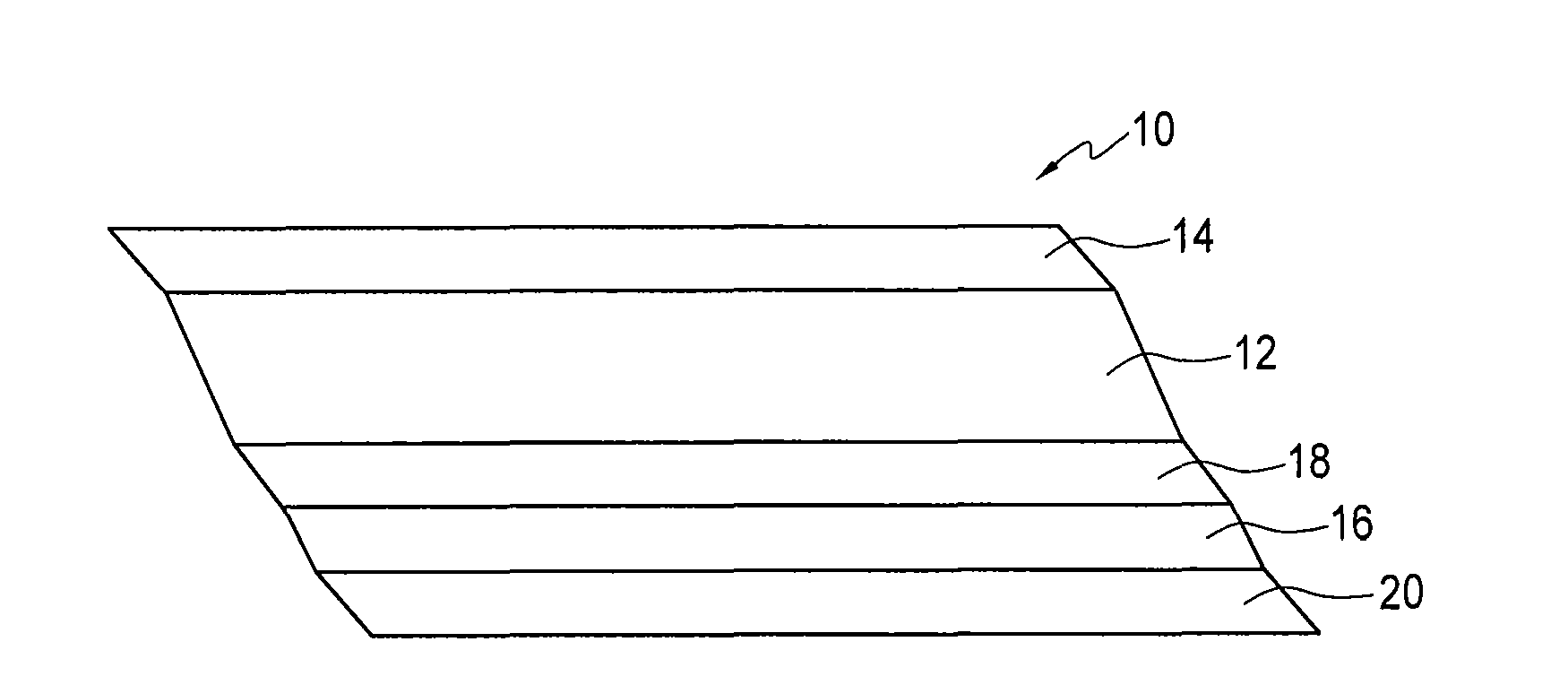

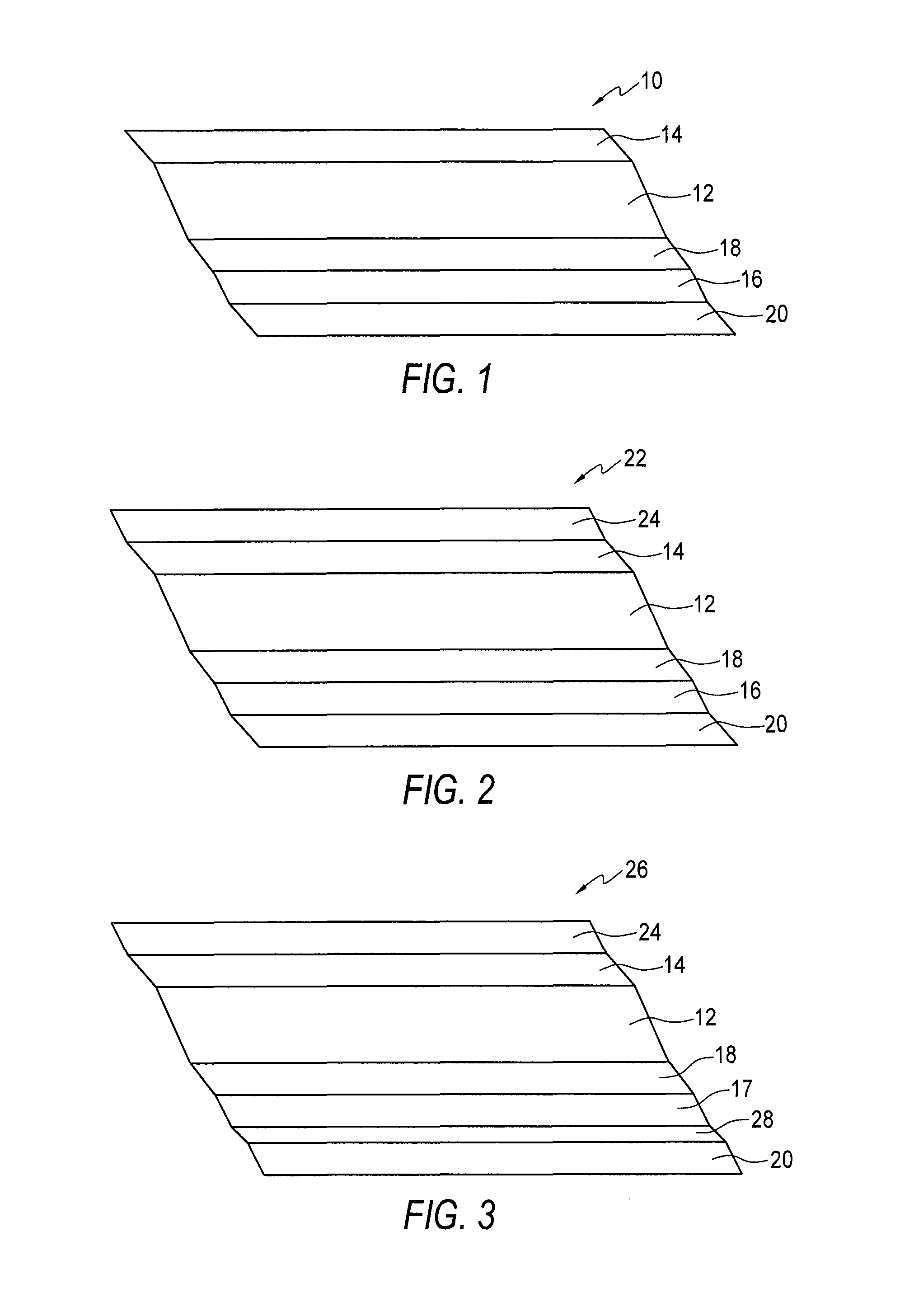

Substantially biodegradable and compostable high-barrier packaging material and methods for production

ActiveUS20100178523A1Easy to optimizeSynthetic resin layered productsCellulosic plastic layered productsEngineeringMetallised film

Bio-degradable, high-barrier packaging materials and methods for production are provided. The present high-barrier packaging materials include a substrate having a print side and a back side, a coating having nano pigments on the print side and a metalized film applied to the back side with a binding layer. Preferably, at least one of the metalized film and the binding layer includes polylactic acid. Moreover, the back side preferably also includes a polylactic acid heat seal layer.

Owner:PIXELLE ANDROSCOGGIN LLC

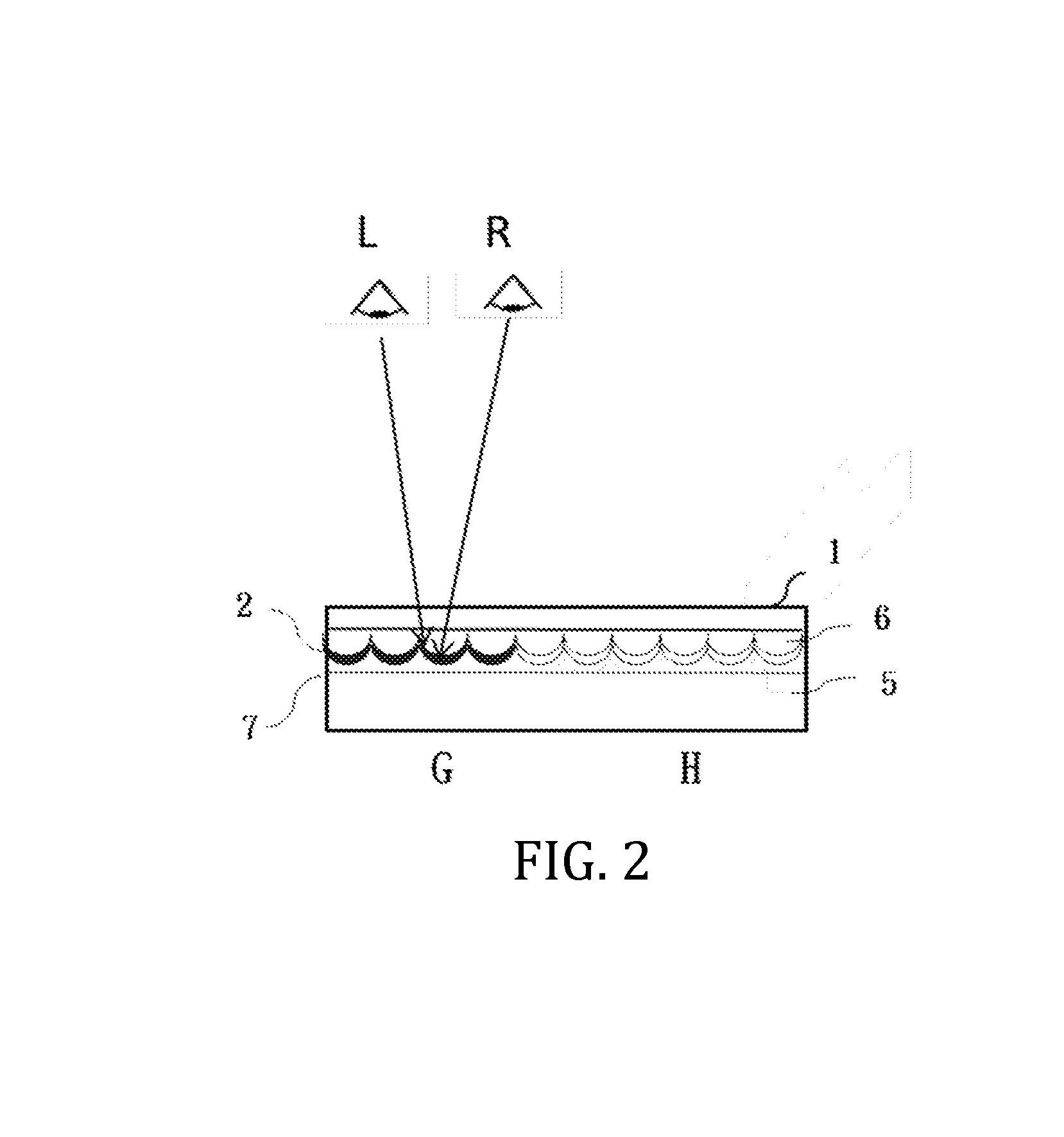

3D Printed Decorative Film And Products Made Thereof

InactiveUS20140205814A1Unique visual effectsDecorative surface effectsDuplicating/marking methodsConvex structureFresnel lens

A 3D printed decorative film includes a transparent substrate with one-sided or two-sided concave or convex structures and a printing layer. The transparent substrate is a thermoplastic film. The heat softening temperature of concave or convex structures is at least 50° C. higher than that of thermoplastic film. An additional reflective layer was applied on top or bottom of printed layer. The reflective layer can be reflective powder, metalized film or high reflective index materials. The concave or convex structure lens is prism, half sphere, half cylindrical, pyramidal, Fresnel lens structures or the combination of above.

Owner:HWANG YU CHEN

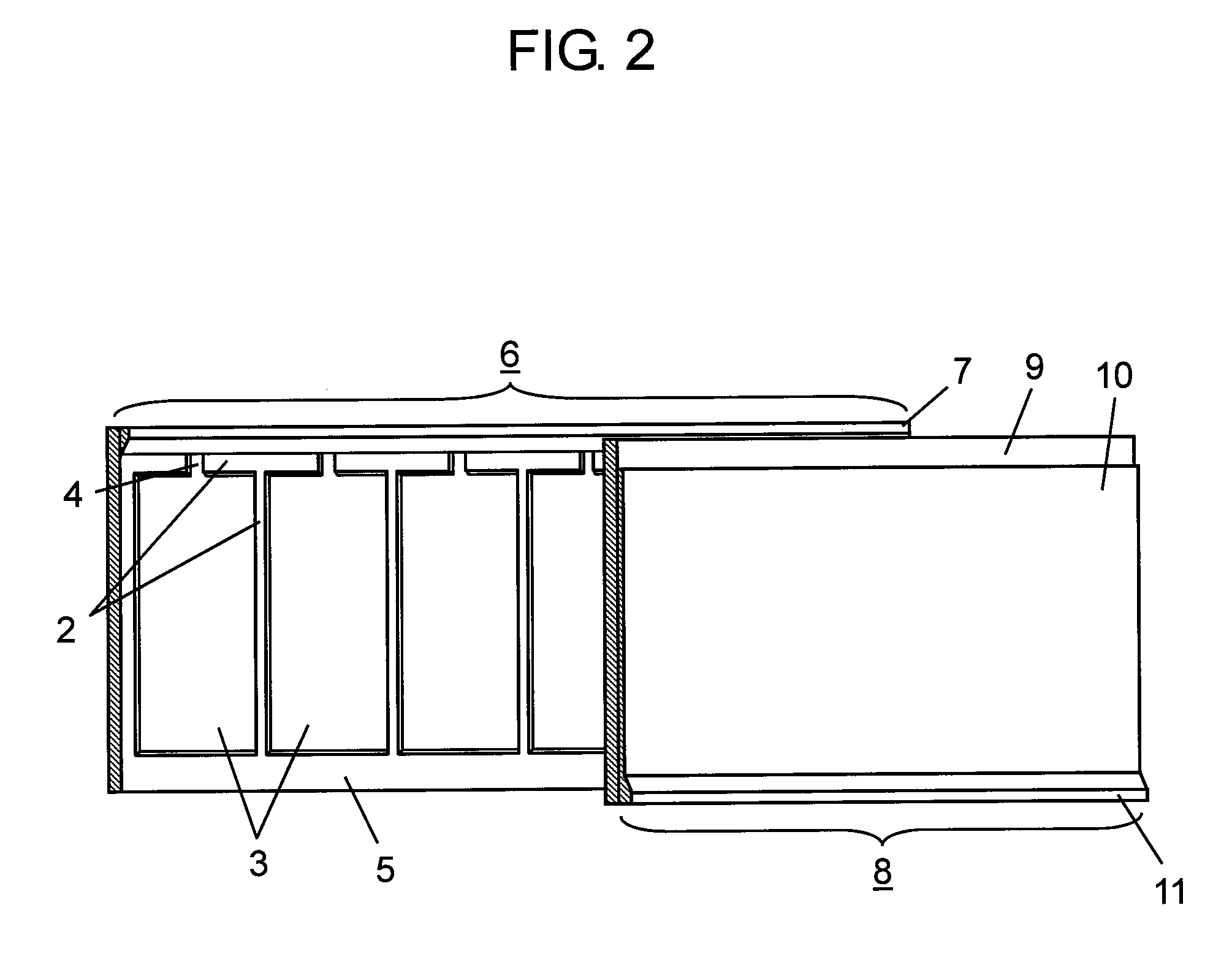

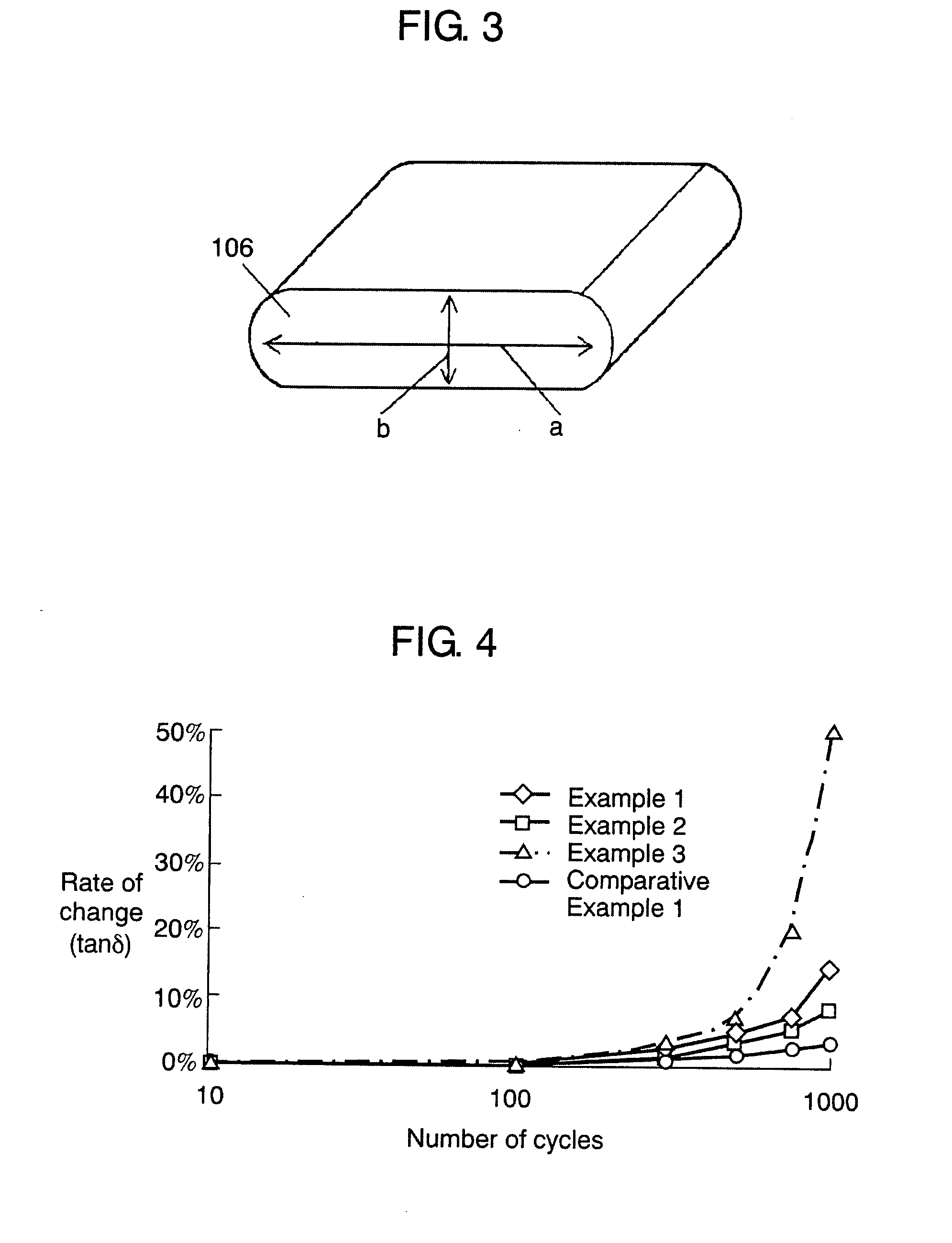

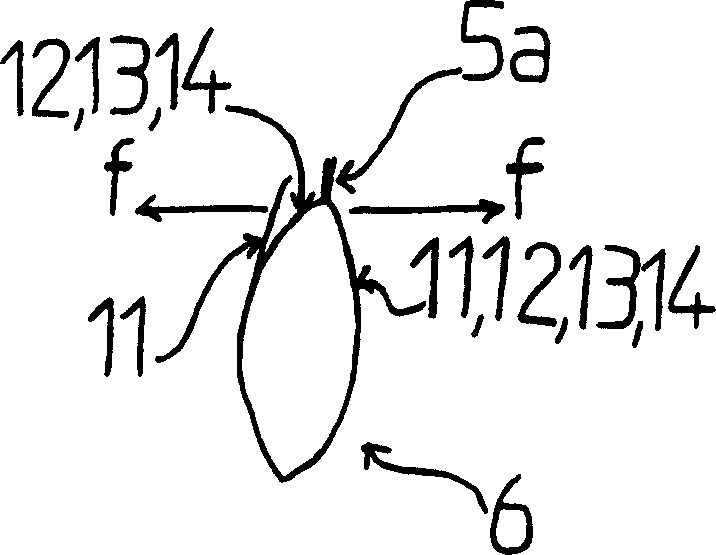

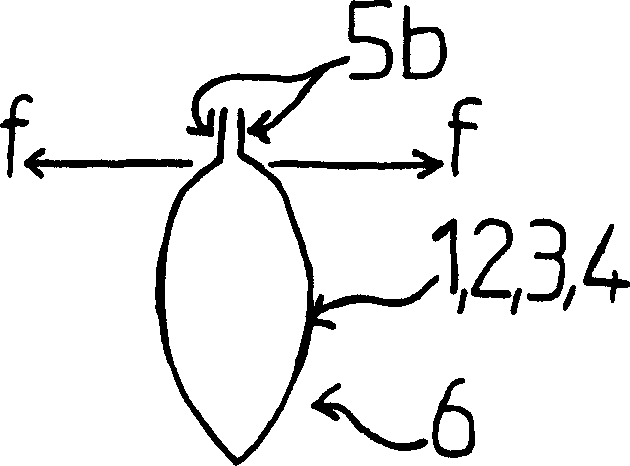

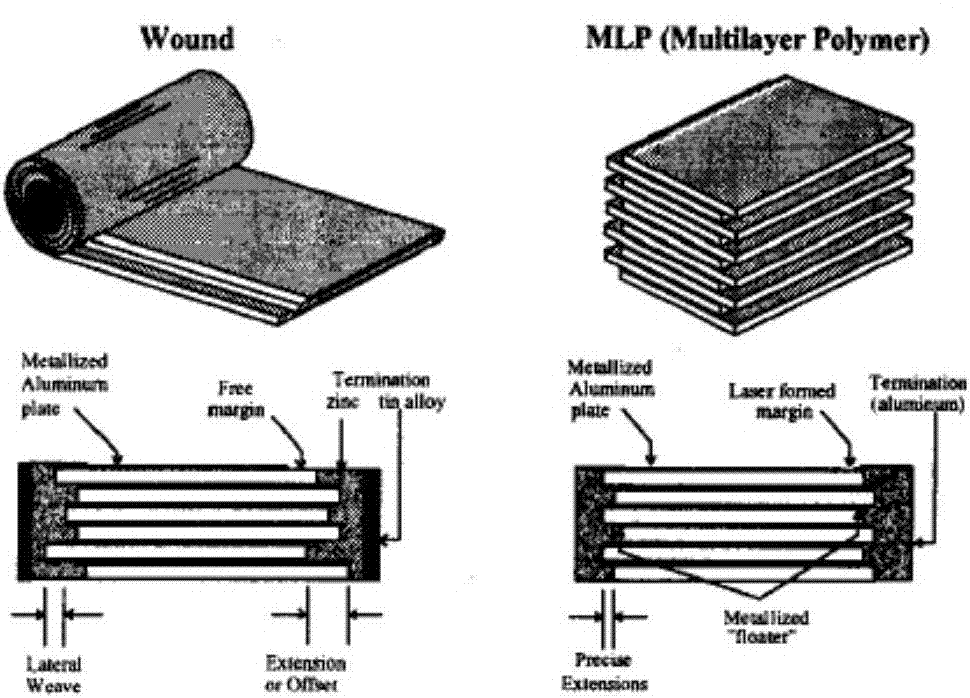

Metalized Film Capacitor, Case Mold Type Capacitor Using the Same, Inverter Circuit, and Vehicle Drive Motor Drive Circuit

ActiveUS20080310075A1Large capacitySmall and thin sizeFixed capacitor electrodesFixed capacitor dielectricDrive motorMetallised film

A metalized film capacitor capable of exhibiting stable performance in a wide temperature range is provided. The metalized film capacitor has an elliptical cross sectional shape having a major axis of 60 mm or above. In this capacitor, offset for shifting in the width direction of a pair of metalized film is set to 1.2 mm or above. Since the bonding state between metal vapor-deposited electrode and metal sprayed electrode formed on the end surface is stable, a stable contact between metal sprayed electrode and dielectric film is maintained, thereby preferably maintaining tan σ and exhibiting excellent performance even if the use temperature range is increased and the thermal stress is increased.

Owner:PANASONIC CORP

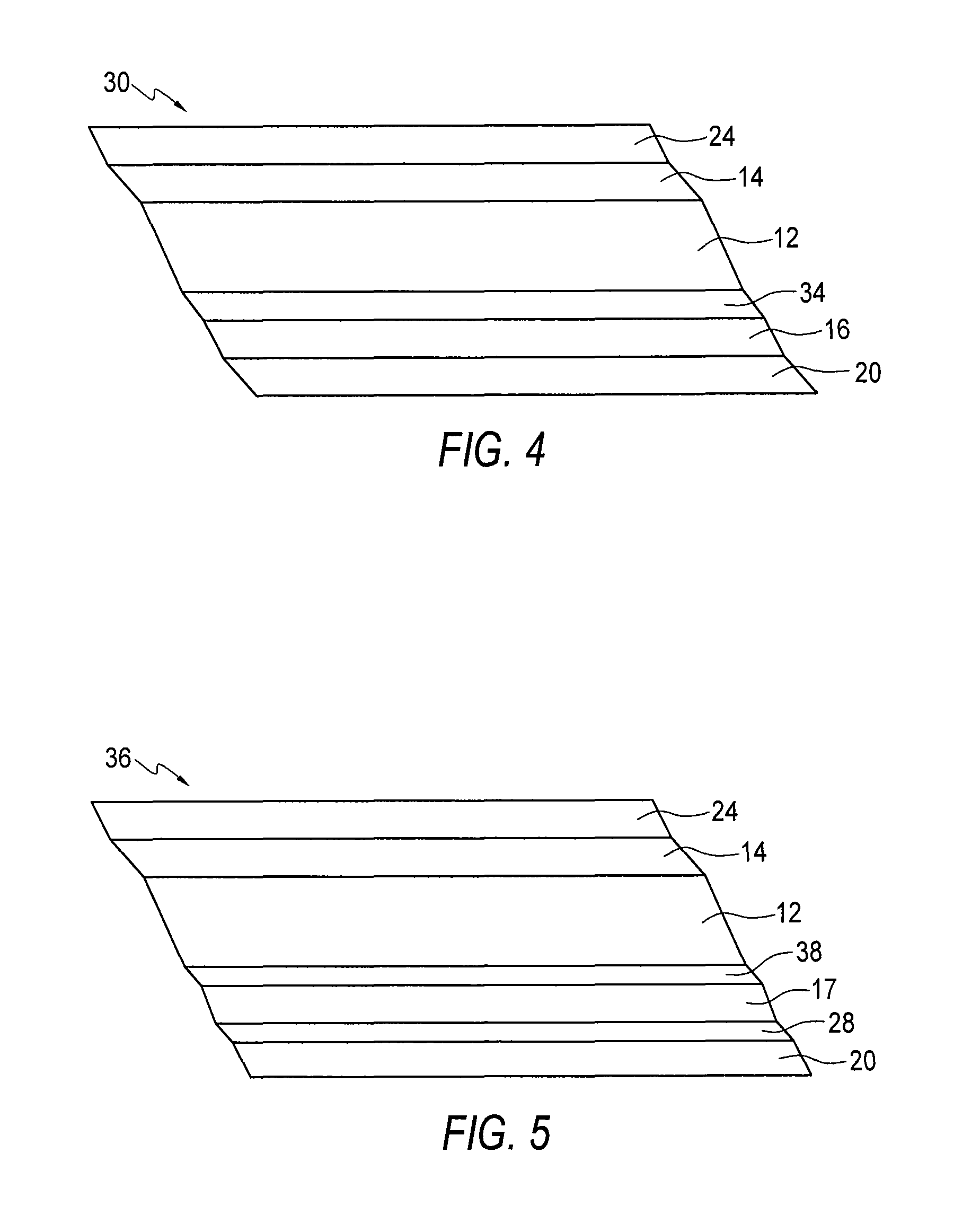

Structure comprising metallized film and ethylene copolymer

Disclosed are a multilayer structure, an article therewith, and a process therefor. The article includes packages such as pouch. The structure comprises a metallized film and an ethylene copolymer composition. The process is a lamination process or extrusion coating process with the ethylene copolymer composition providing adhesion of metallized film to a substrate.

Owner:EI DU PONT DE NEMOURS & CO

Metallized-film capacitor sealing agent

InactiveCN102367331AImprove electrical performanceImprove moisture resistanceOther chemical processesWaxPolymer science

The invention provides a metallized-film capacitor sealing agent composed of components of, by weight: 40 to 60 parts of petroleum wax, 10 to 15 parts of polyisobutylene, 20 to 30 parts of vaseline, 10 to 15 parts of mica powder, 10 to 15 parts of vermiculite powder, 10 to 15 parts of sulfur, 3 to 5 parts of straw ash, and 10 to 15 parts of attapulgite. The metallized-film capacitor sealing agentprovided by the invention has good toughness and plasticity, excellent electrical properties, and appropriate kinematical viscosity. With the sealing agent, gaps between metallized-film capacitors can be conveniently filled.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Coated Metallized Films and Their Method of Manufacture

InactiveUS20110236703A1Synthetic resin layered productsPretreated surfacesPolymer scienceWater vapor

Provided is a method of preparing a film including the steps of providing a polymer substrate, depositing a metal layer on the polymer substrate in a metallization chamber, removing the metallized film from the metallization chamber, and applying a topcoat to said metal layer within 1 week of depositing the metal layer on the polymer substrate. A film produced by such a method exhibits improved barrier properties, such as improved water-vapor transmission rates.

Owner:JINDAL FILMS AMERICAS LLC

Metallized multi layer coating

The invention relates to a metallised film, produced by means of a multilayer structure with a binder layer comprising 5 to 50 wt. % of a mixture (A) with: 5 to 100 % of a mixture of co-grafted polymers (C1) and (C2) comprising 90 to 20 wt. % of a polyethylene metallocene (C1) with a density of between 0.865 and 0.915, 10 to 80 wt. % of a polymer (C2) which is either a non-metallocene LLDPE or a homo- or co-polymerised polypropylene and 95 to 0 wt. % of a polyethylene (D) selected from the homo- or co-polymerised polyethylenes and the elastomers. The mixture (A) is such that the content of graft monomer grafted is between 30 and 10<5> ppm, the MFI or flow index in the molten state (standard ASTM D 1238, at 190 DEG C with 2.16kg) is between 0.1 and 30g / 10min and 50 to 95 wt. % of a polypropylene (B) homo- or co-polymer.

Owner:ATOFINA

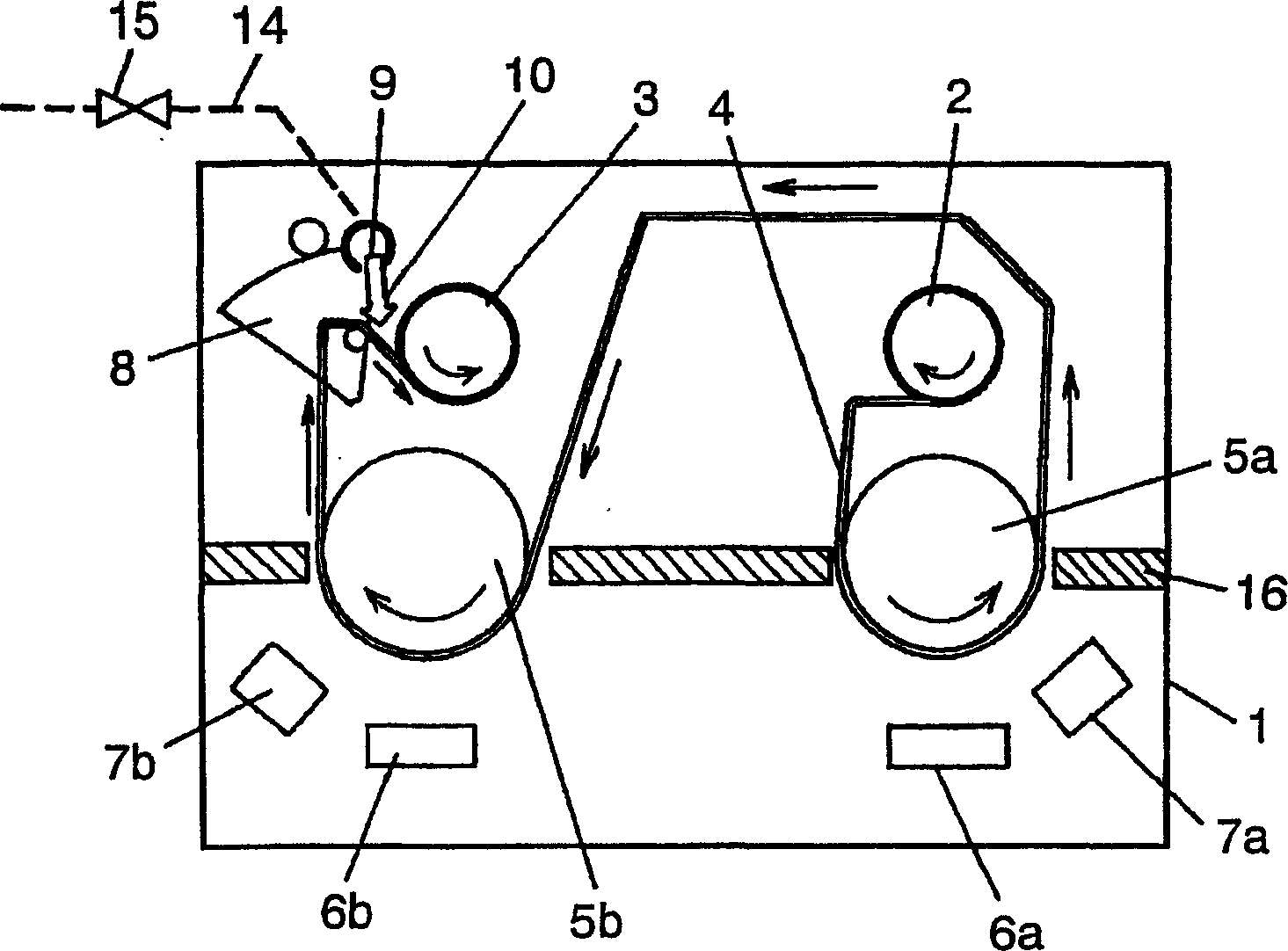

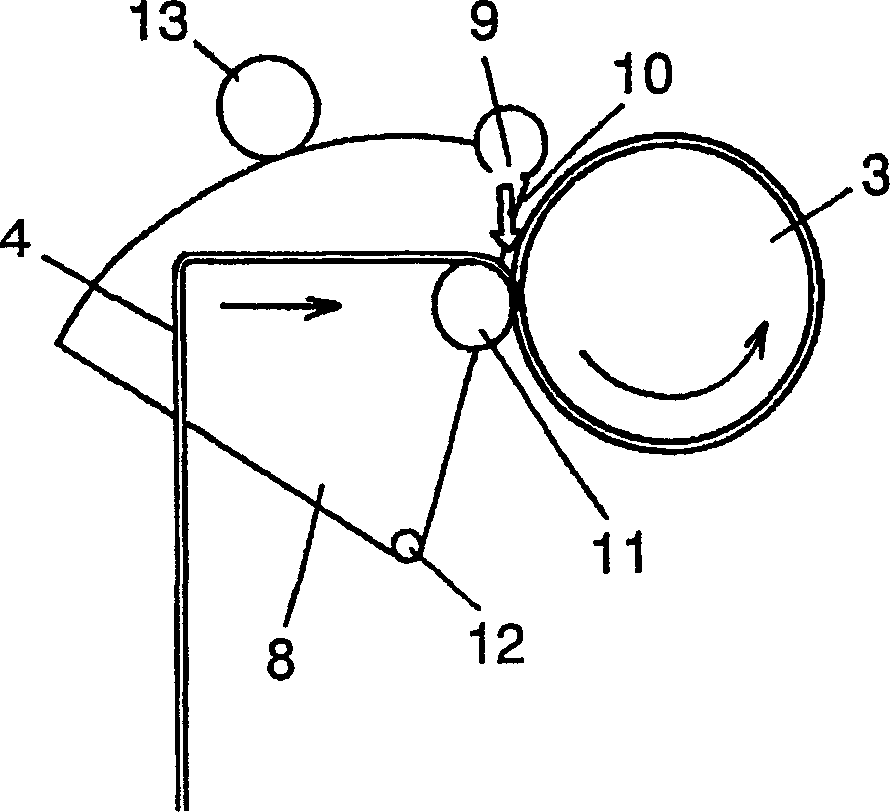

Mfg. method of double-sided metallization film and metallization film capacitor using same

InactiveCN1463450ALess laborNo increase in tanδFixed capacitor electrodesVacuum evaporation coatingPolymer scienceOxygen

Owner:PANASONIC CORP

High-temperature resistant ultrathin polypropylene metalized capacitor film for capacitor

ActiveCN102751091AHigh temperature resistantGood physical propertiesThin/thick film capacitorFixed capacitor dielectricCapacitancePolymer science

The invention discloses a high-temperature resistant ultrathin polypropylene metalized capacitor film for a capacitor. The high-temperature resistant ultrathin polypropylene metalized capacitor film is prepared by the following steps of: sucking polypropylene resin particles with the isotacticity of 96 percent in an extruder hopper through a vacuum suction machine, and dissolving the particles to form a viscous-state melt; filtering impurities and non-molten substances in the viscous-state melt by employing a candle filter; casting the melt on a die head to form a flaky melt; adhering the flaky melt to a cooling roller through an air knife, so that the surface layer of the polypropylene melt is cooled and solidified to form a sheet; transversely stretching the sheet to obtain a film; transversely stretching the film to obtain a thin film; cutting a side film which is not stretched, and performing corona treatment to obtain the metalized capacitor film; and dragging the metalized capacitor film of which the breadth accords with the specification into a coil. High-isotacticity polypropylene particles with the isotacticity of over 98 percent are replaced by the conventional polypropylene particles with the isotacticity of 96 percent to produce an ultrathin polypropylene film with the thickness of 3-4mu m, the polypropylene film has excellent physical properties and electrical properties and particularly has high-temperature resistance, when the operating temperature of the coiled capacitor reaches 100 to 115 DEG C, the polypropylene film has high mechanical strength, and the heat shrinkage and the inner haze are reduced.

Owner:江苏中立方实业有限公司

Composite container having an electromagnetic surveillance device

InactiveUS20050255262A1Improve barrier propertiesImprove uniformity and continuityContainer decorationsLevel indicationsMetal foilThin membrane

A composite container having an electromagnetic surveillance device such as an EAS or RFID device or the like, and an outer label and / or inner liner that does not contain a metal foil layer. The label in one embodiment comprises a lamination of a paper layer and at least one polymer film layer. The polymer film layer is either metallized with a vapor-deposited layer of metal, or has a metallic ink disposed thereon. The liner comprises a paper layer, a barrier-coated film attached to the inner surface of the paper layer, and a sealant layer disposed on an opposite side of the barrier-coated film from the paper layer and forming an innermost surface of the liner, the sealant layer comprising a heat seal material. The barrier-coated film can comprise a metallized film, an aluminum oxide-coated film, a silicon oxide-coated film, or the like.

Owner:SONOCO DEV INC

Ring ceramic dielectric capacitors

InactiveCN1731548ASuitable for high frequency occasionsLow costFixed capacitor electrodesFixed capacitor dielectricDielectric membraneCapacitor

The invention relates to a cyclic ceramic dielectric capacitor, which comprises two sets internal electrodes. Every set internal electrode is connected with a terminal electrode and comprises one or more layers conductive films, between the adjacent conductive films that belong to different internal electrodes is ceramic dielectric membrane lay that alternately lap on the internal electrode conductive film; the dielectric membrane and protective layer are laminated into homogeneous capacitor and both present as circularity, conductive films of the two sets internal electrodes are cyclic and the capacitor is cylinder with holes; the terminal electrode comprises outer-ring and inner-ring ones, wherein the metallized films of the inner-ring and outer-ring terminal electrode separately cover on the inner wall of the through-hole and the outer wall of the cylinder.

Owner:GUANGDONG FENGHUA BANGKE ELECTRONIC CO LTD

High-barrier liner for beaded composite can

InactiveUS20050252952A1Not perishableImprove barrier propertiesFlexible coversWrappersPaperboardSealant

A high-barrier liner for a composite container for products comprises a tubular body member comprising at least one paperboard body ply having an inner surface. The composite container further comprises a liner ply adhered to the inner surface of the tubular body member. The liner ply comprises a metallized film disposed between inner and outer sealant layers. The metallized film comprises a polymer film substrate and a vapor-deposited metal layer on one surface of the substrate. The metallized film is advantageously oriented such that the metal layer of the metallized film faces towards an interior of the composite container.

Owner:SONOCO DEV INC

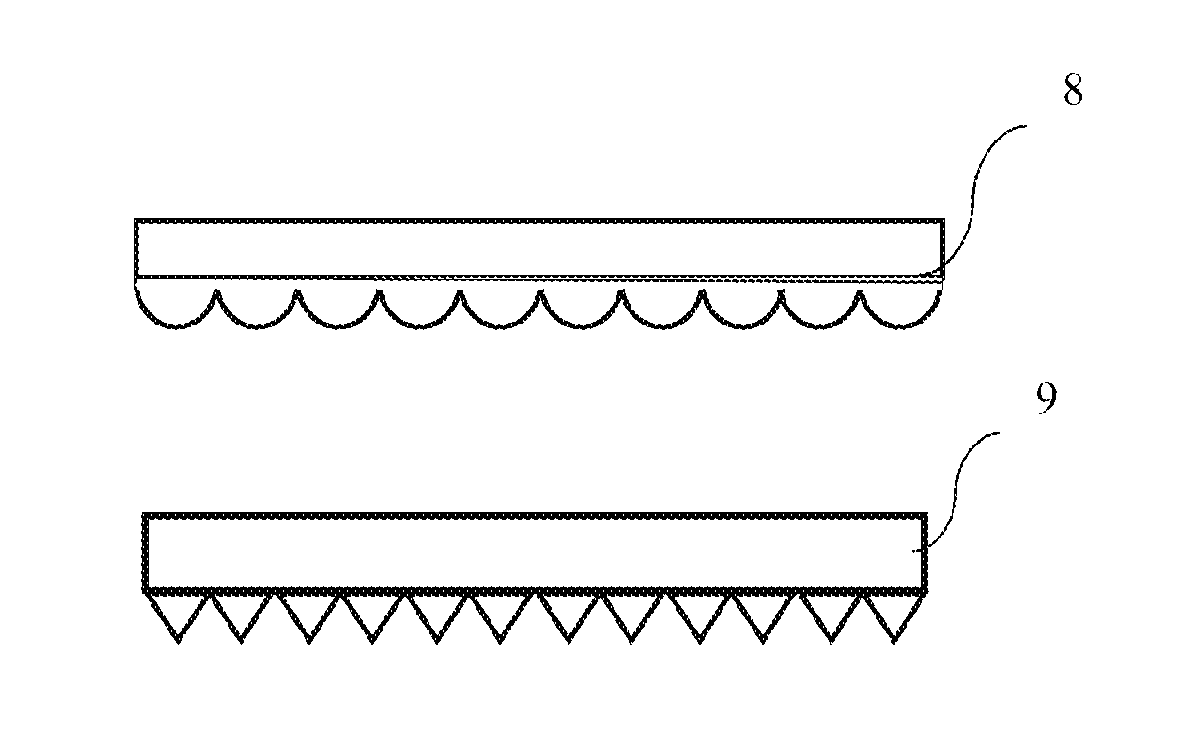

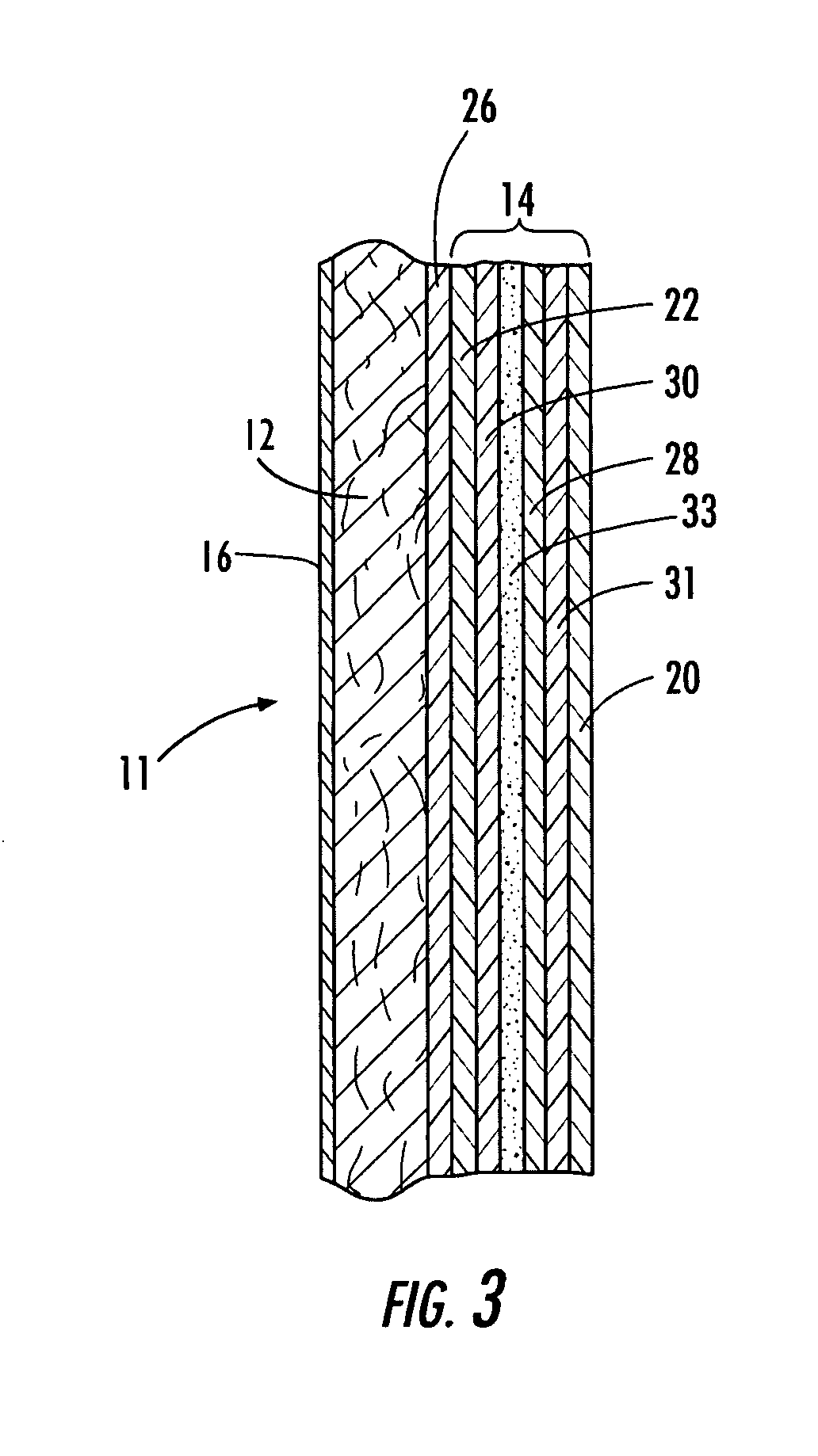

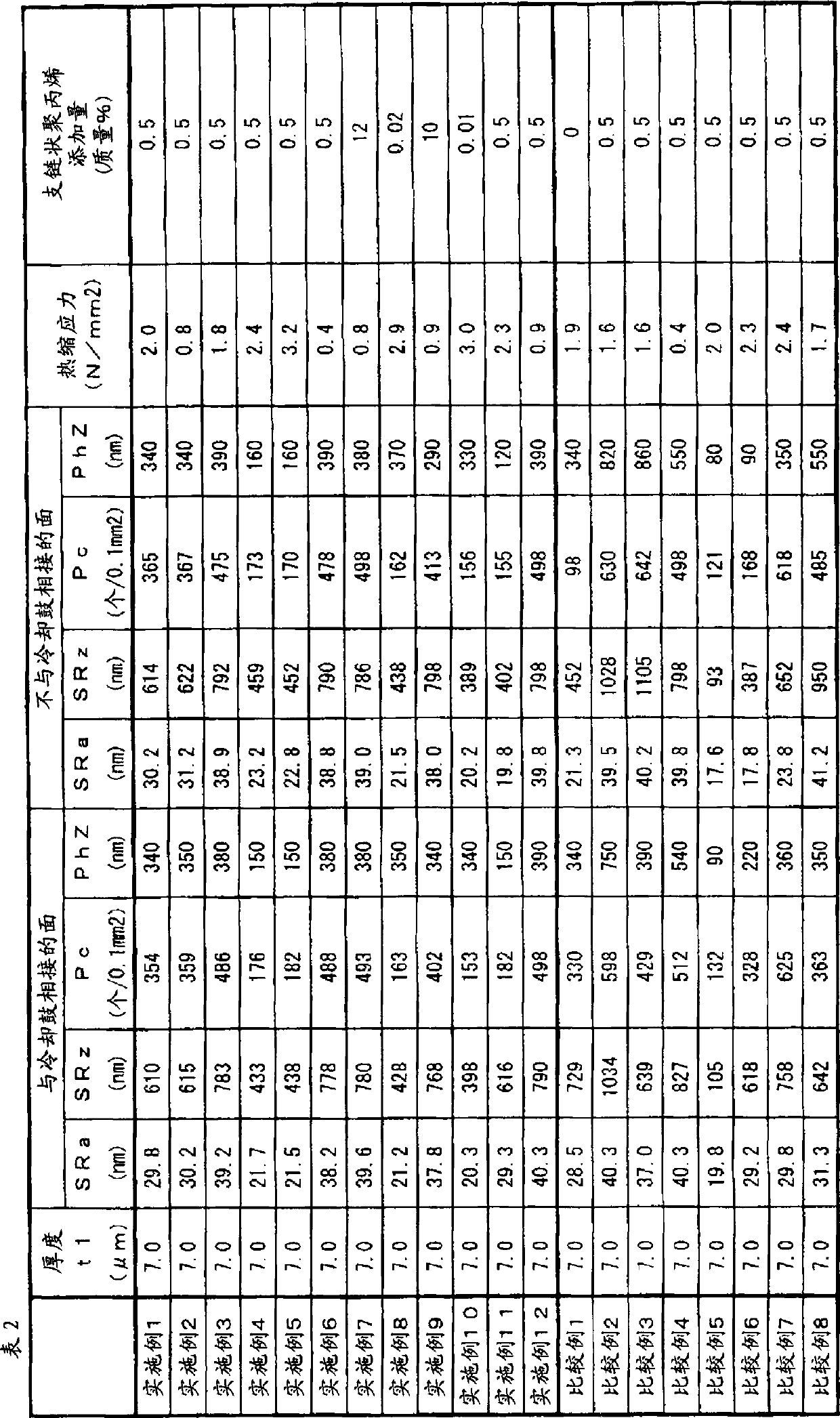

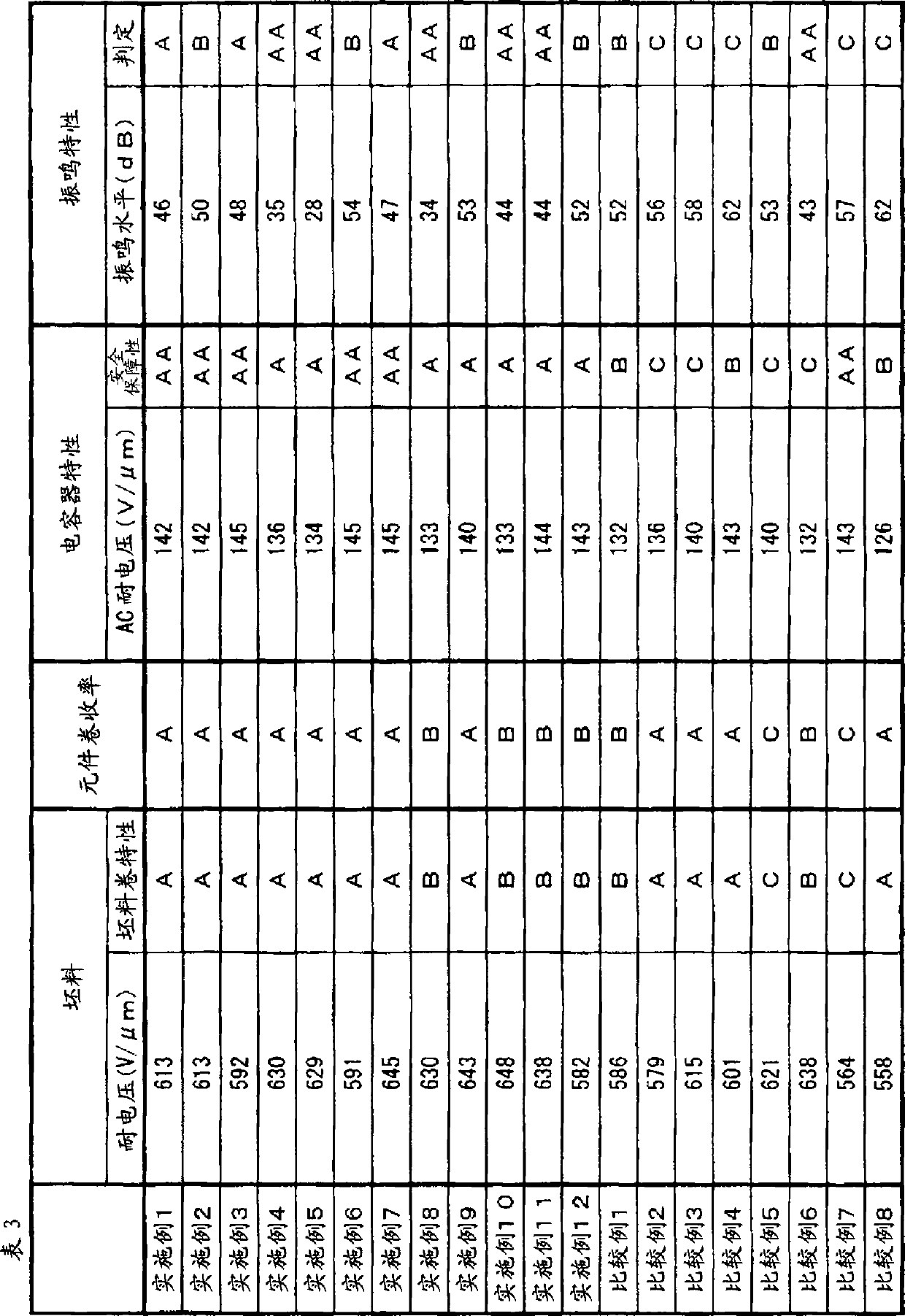

Biaxially oriented polypropylene film, metalized film, and film capacitor

ActiveCN102959656AImprove withstand voltage performanceSuitable component processabilityFixed capacitor dielectricThin material handlingEngineeringPolypropylene

Disclosed is a biaxially oriented polypropylene film which has projections on both surfaces of the film. The most common height (PhZ) of the projections among the projections on each surface is 100 nm or more but less than 400 nm on each surface, and the number of projections (Pc) per 0.1 mm2 of each surface is 150 projections or more but less than 500 projections on each surface. The biaxially oriented polypropylene film is easily processed into an element, and provides a capacitor that has high withstand voltage and excellent squealing characteristics when processed into a capacitor.

Owner:TORAY IND INC

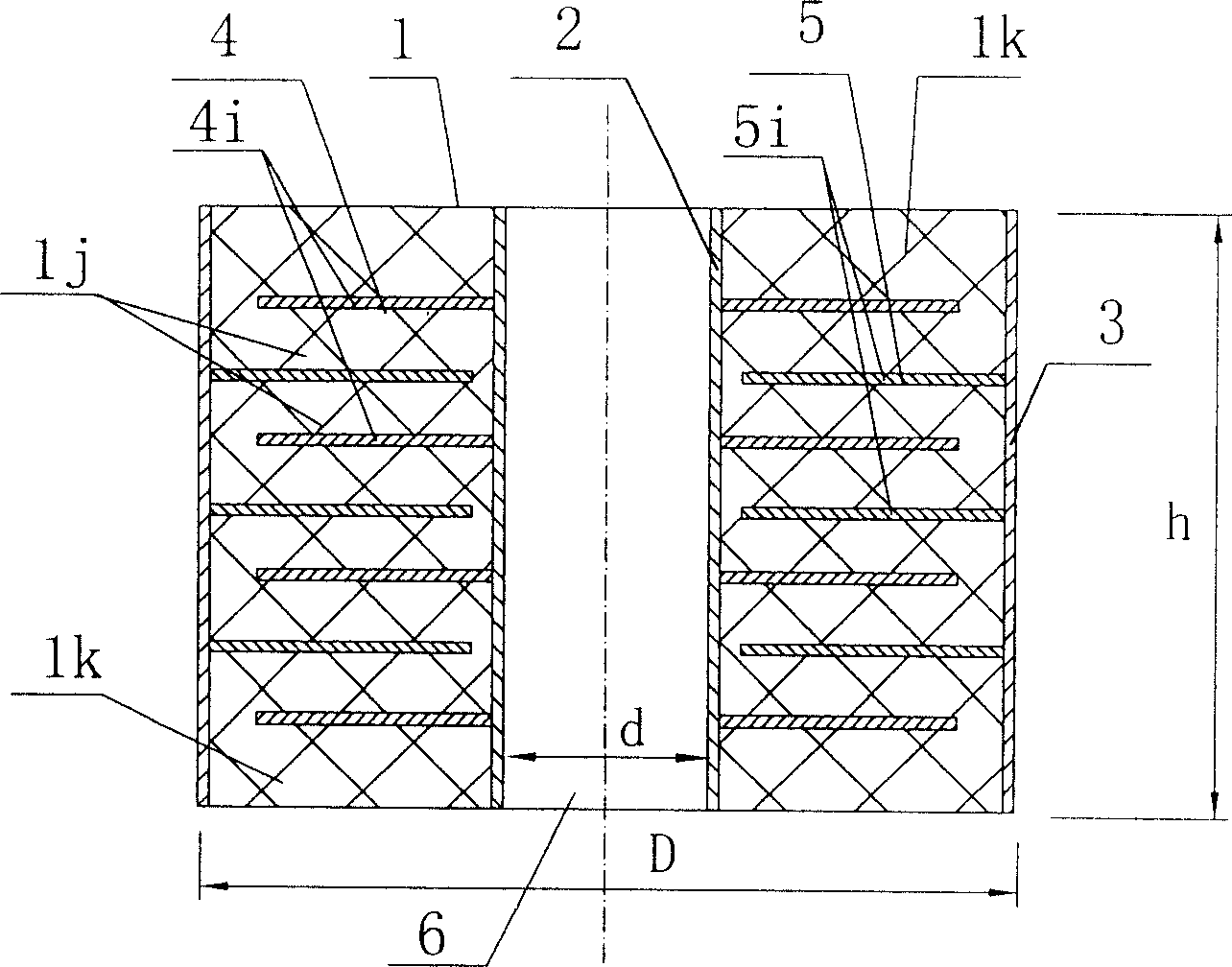

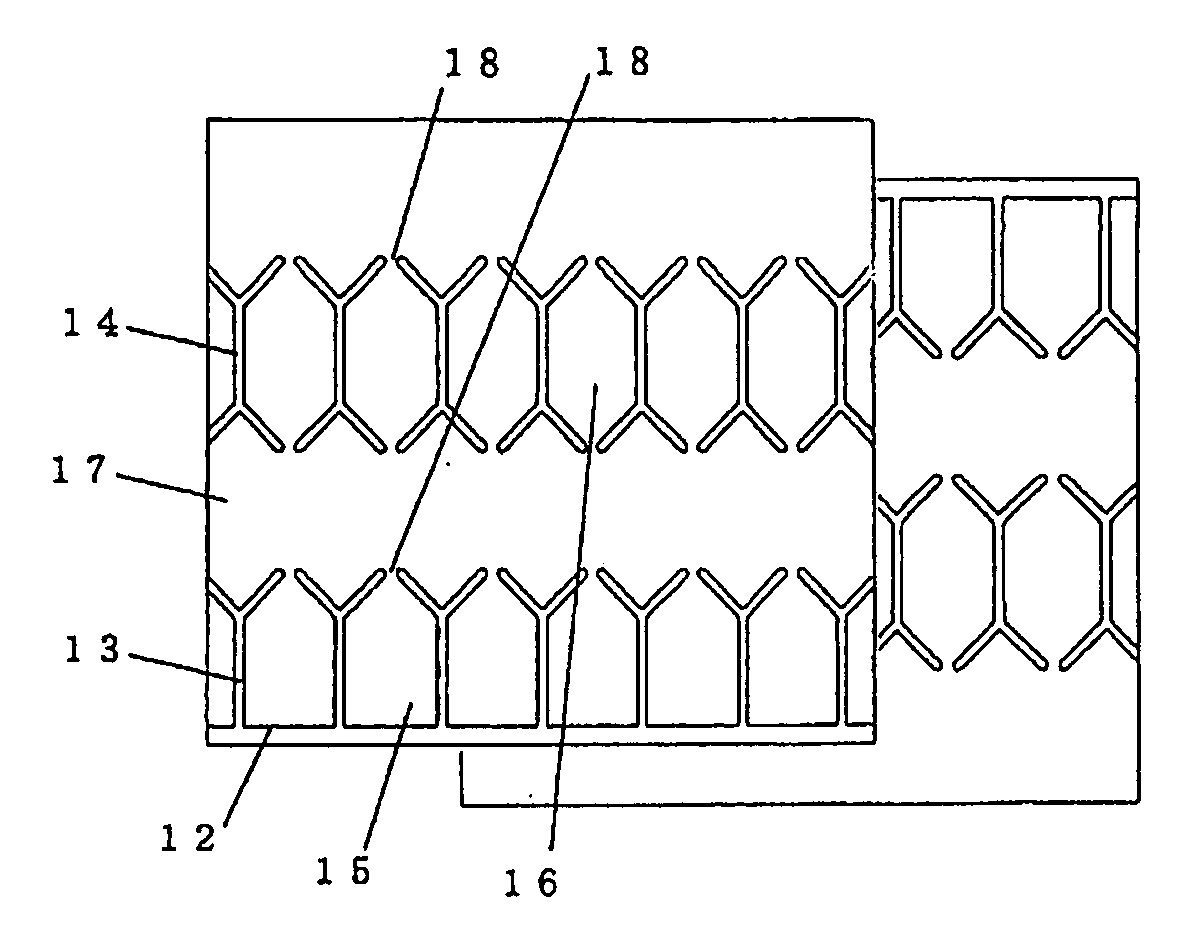

Metalized film capacitor

ActiveUS20120002346A1Guaranteed functionGood safety-keeping performanceMultiple fixed capacitorsFixed capacitor electrodesEngineeringMetallised film

Disclosed is a metalized film capacitor having excellent safety preservation ability and an excellent withstand voltage at high temperatures. This capacitor has a structure for which a split electrode section wherein a split electrode is formed by spliting a metalized film along the longitudinal direction by means of plural insulating slits, and a non-split electrode section for which a vapor-deposited electrode is continuous in the longitudinal direction, are arranged alternately in the film width direction of the metalized film, with each split electrode being connected to the non-split electrode section by a fuse formed between the ends of adjacent insulating slits; and has a structure for which three rows or more of split electrode sections, which are split by means of insulating slits that are aligned in the longitudinal direction of the film, are arranged in the width direction, with each split electrode that forms a split electrode section being connected to an adjacent split electrode by a fuse, and the area of a split electrode in the center of the film being smaller than the area of a split electrode arranged on the outer side.

Owner:NICHICON CORP

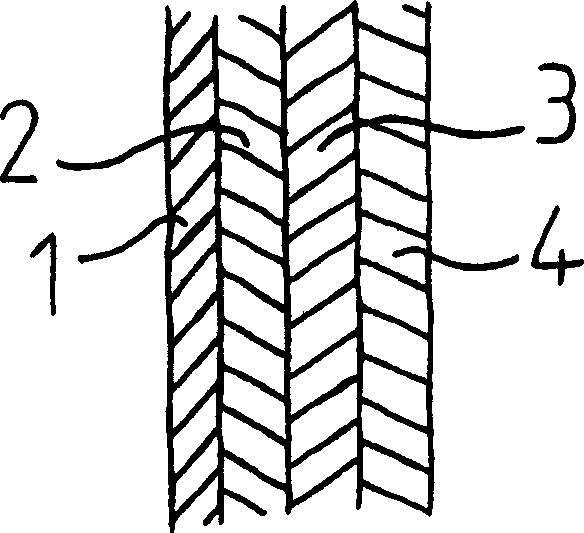

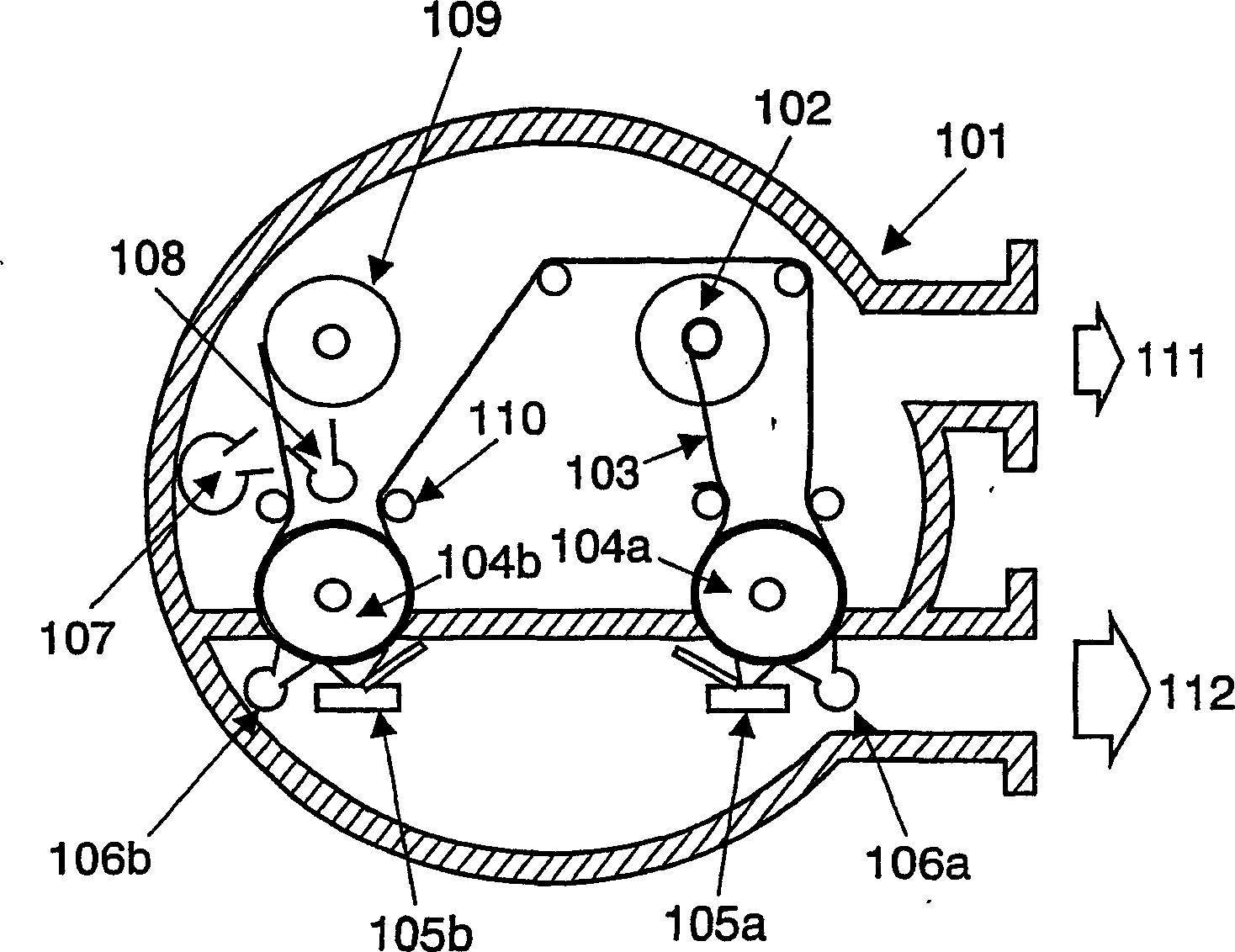

Folded thin film capacitor and fabrication method thereof

ActiveCN106935405AHigh energy storage densityInhibit sheddingThin/thick film capacitorStacked capacitorsPower flowInternal resistance

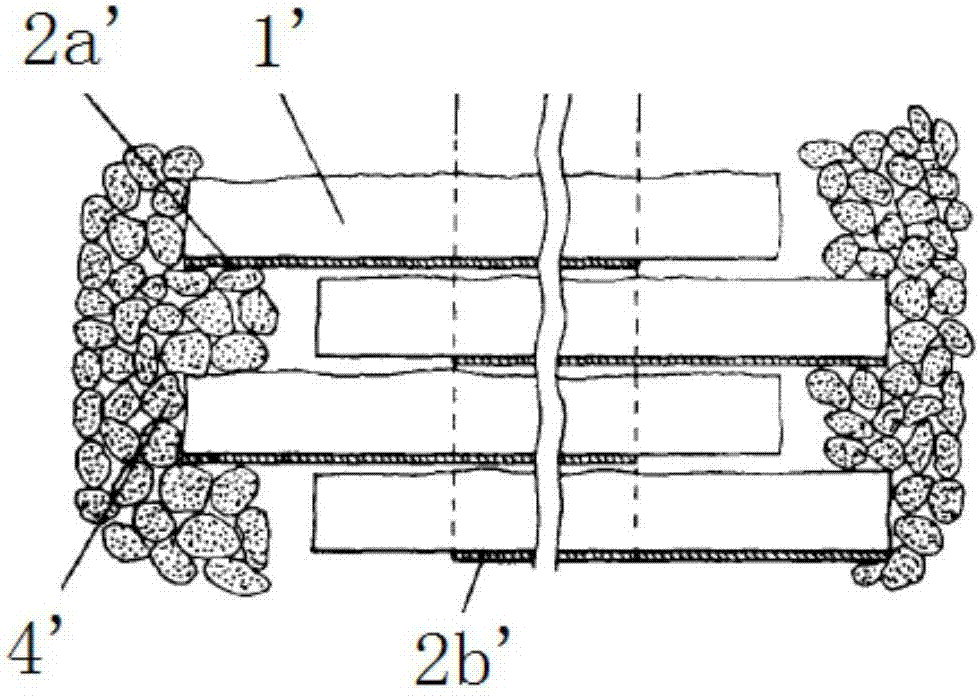

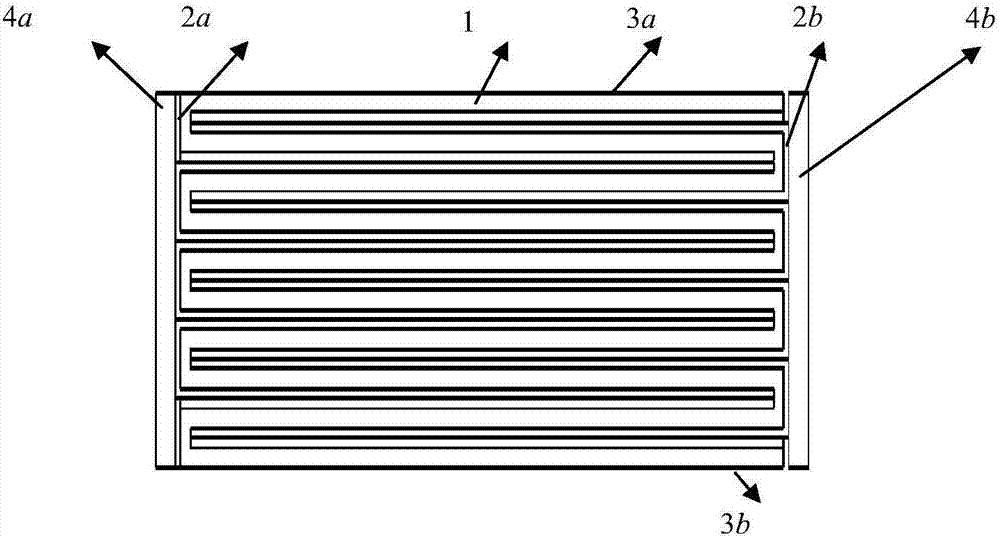

The invention provides a folded thin film capacitor and a fabrication method thereof. The folded thin film capacitor comprises a metal thin, two metal spraying layers (4a and 4b), two electrode terminals and a shell, wherein the two electrode terminals are respectively connected with the two metal spraying layers (4a and 4b), the folded thin film capacitor is characterized in that the metal film comprises a first metal evaporation film (2a), a second metal evaporation film (2b) and an electrical insulation polymer basic layer (1), the electrical insulation polymer basic layer (1) is sandwiched between the two metal evaporation films (2a and 2b), the metal film is repeatedly folded to form a cuboid block in a longitudinal direction, folded angles of the first metal evaporation film (2a) and the second metal evaporation film (2b) are superposed to respectively form a first side surface and a second side surface of the block, and the two metal spraying layers (4a and 4b) are respectively arranged on the first side surface and the second side surface. By the folded thin film capacitor and the fabrication method thereof, the problem that a metal spraying electrode at an end part of the thin film capacitor is seldom in contact with a metal film contact point is solved, heat generation of the end part of the capacitor is reduced, the internal inductance and the internal resistance of the capacitor are reduced, the lifetime of the capacitor is prolonged, and the folded thin film capacitor is particularly suitable for the field of large-current application.

Owner:SOUTHWEST JIAOTONG UNIV

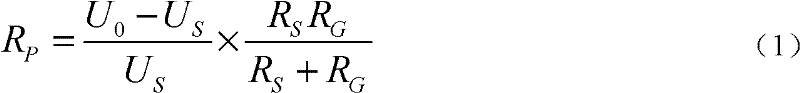

Method and device for measuring insulation resistance of metalized film capacitor under high field strength

ActiveCN102435852AAccurate measurementSolve the problem of inaccurate measurementResistance/reactance/impedenceCapacitanceEngineering

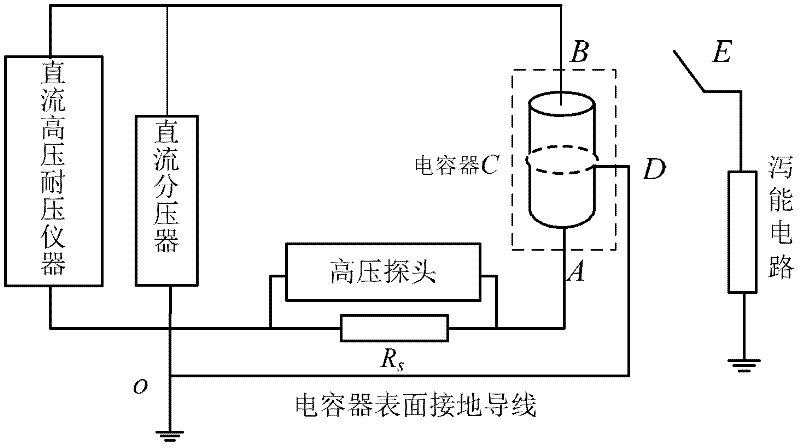

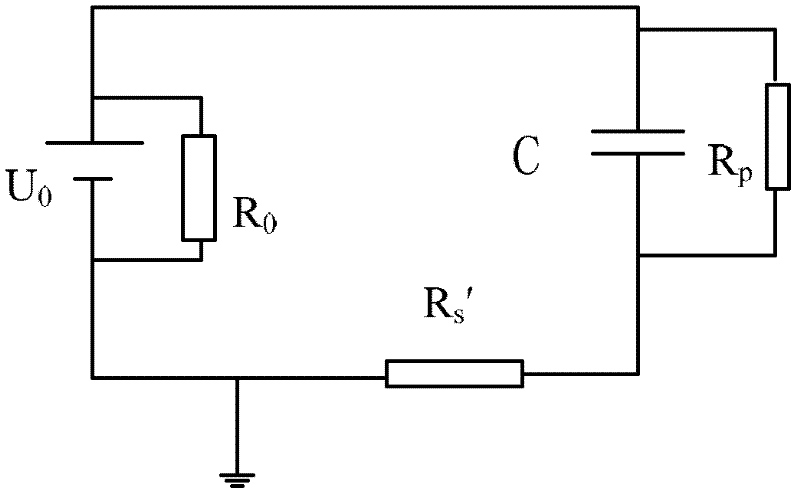

The invention discloses a method and a device for measuring insulation resistance of a metalized film capacitor. The method comprises the following steps: placing the capacitor in an environment with constant temperature and humidity; serially connecting a mega-ohm level sampling resistor RS with the capacitor; applying direct-current high voltage to the capacitor and the sampling resistor; and calculating the insulation resistance of the metalized film capacitor under high field strength according to an intrinsic standoff ratio of the sampling resistor and the capacitor under the direct-current high voltage. The invention also provides the device for realizing the method, which mainly comprises a constant temperature humidity chamber, a capacitance measuring meter, a direct current high voltage resistance meter, a mega-ohm level sampling resistor, a direct current high voltage bleeder and a high voltage probe. The device can be used for accurately measuring the insulation resistance of the metalized film capacitor under the high field strength. The defects of a conventional insulation resistance measuring meter that the size of output voltage is limited, a voltage-resistance time is insufficient, the measurement of the insulation resistance is unstable, and the like, are overcome.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com