Ring ceramic dielectric capacitors

A ceramic dielectric and capacitor technology, applied in the field of capacitors, can solve problems such as the inability to meet the requirements of high-voltage and high-power filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

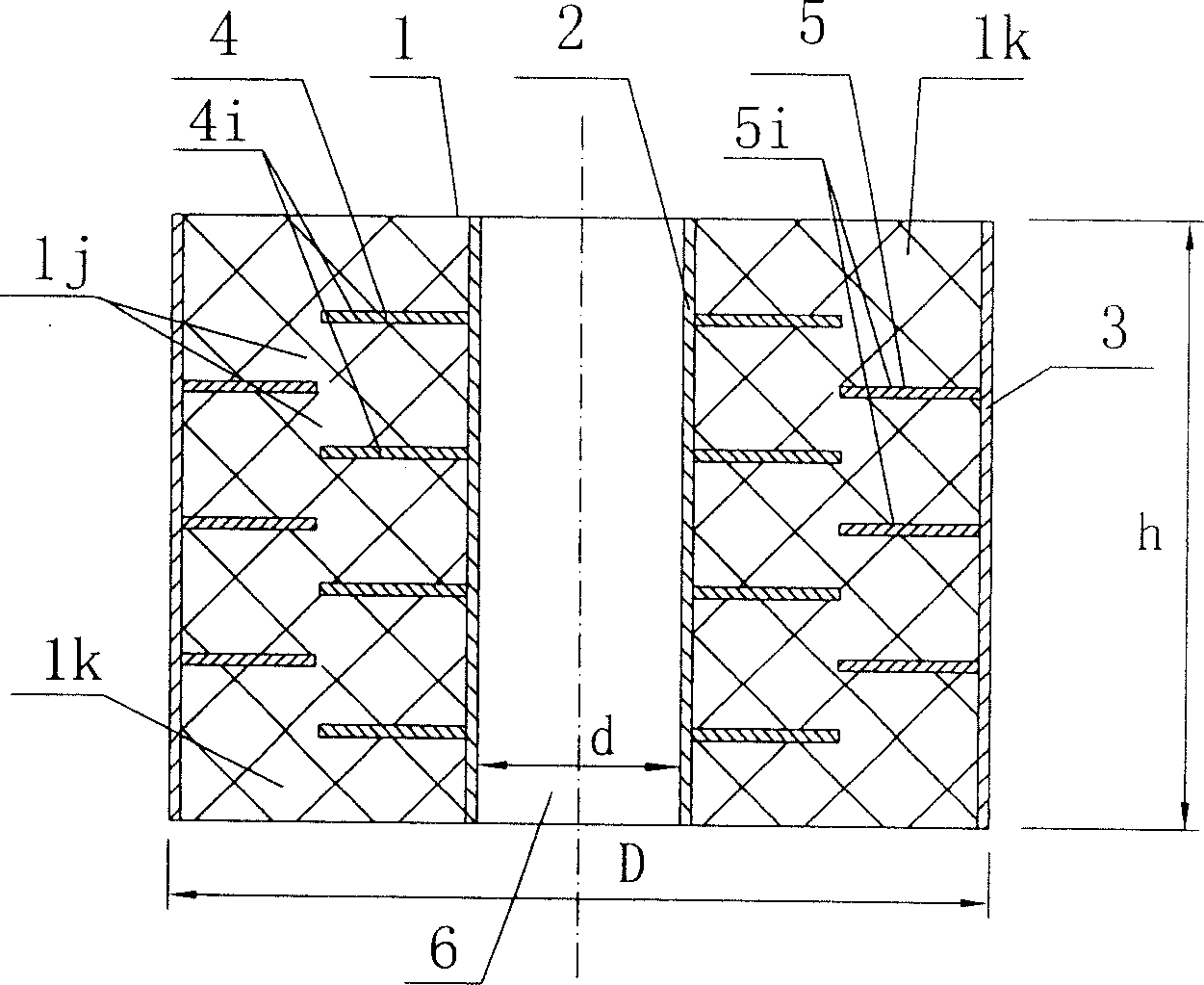

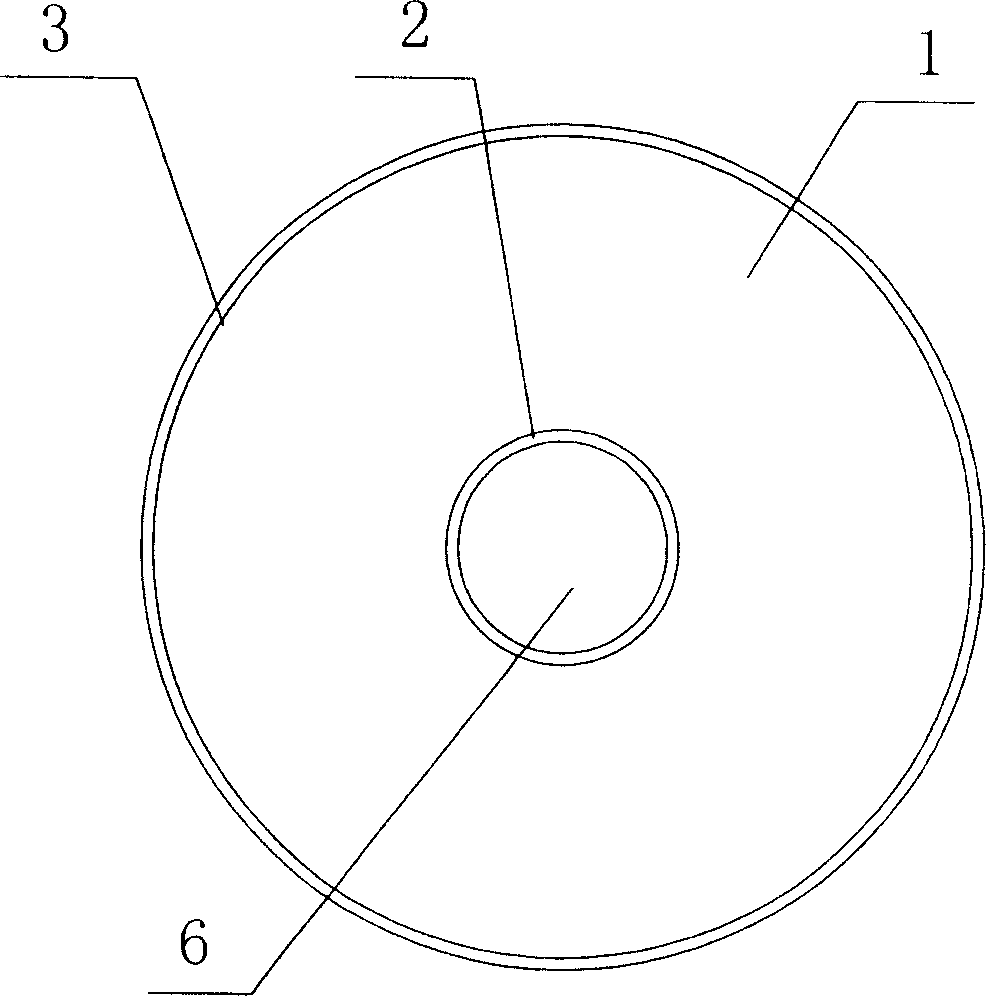

[0051] Such as figure 1 , 2 , shows an annular ceramic dielectric capacitor, the ceramic dielectric capacitor includes two sets of inner electrodes 4, 5, the inner electrode 4 is connected to the inner ring end electrode 2, and the inner electrode 5 is connected to the outer ring end electrode 3; each set The internal electrodes 4, 5 respectively include multi-layer conductive films 4i, 5i parallel to each other, and there is a ceramic dielectric film layer 1j between the adjacent conductive films 4i, 5i belonging to different internal electrodes, and the dielectric film layer 1j and the internal electrode 4 The conductive films of , 5 are stacked alternately; the top and bottom of the capacitor also include a ceramic dielectric protection layer 1k, and the dielectric film layer 1j is laminated together with the dielectric protection layer 1k to form a homogeneous capacitor body 1; and the dielectric protection layer 1k, The dielectric film layers 1j are all annular bodies, t...

Embodiment 2

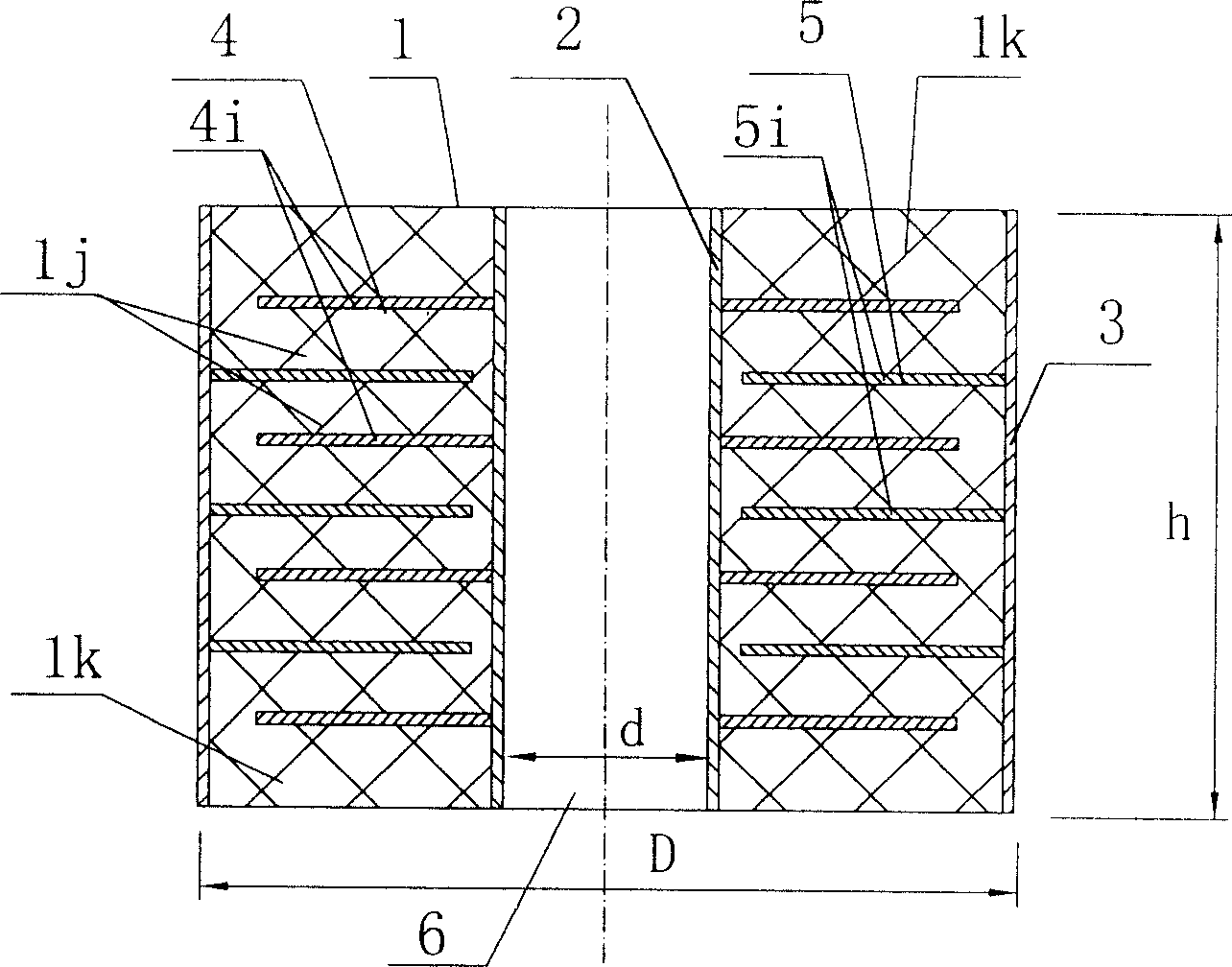

[0055] Such as figure 1 , 3 , shows an annular ceramic dielectric capacitor, the ceramic dielectric capacitor includes two sets of inner electrodes 4, 5, the inner electrode 4 is connected to the inner ring end electrode 2, and the inner electrode 5 is connected to the outer ring end electrode 3; each set The internal electrodes 4 and 5 respectively include multilayer conductive films 4i and 5i parallel to each other, and the adjacent conductive films 4i and 5i belonging to different internal electrodes are separated by a ceramic dielectric film layer 1j, the dielectric film layer 1j and the internal electrode conductive film 4i, 5i are stacked alternately; the top and bottom of the capacitor also include a ceramic dielectric protective layer 1k, and the dielectric film layer 1j is laminated with the dielectric protective layer 1k to form a homogeneous capacitor body 1; and the dielectric protective layer 1k, dielectric film layer 1j is a ring body, the conductive films 4i an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com