A low-stress boost inverter and its implementation method

An implementation method and inverter technology, applied in the direction of converting AC power input to DC power output, output power conversion device, electrical components, etc., can solve the problems of unbalanced capacitor voltage, lower output power, and using more devices. Achieve the effects of reducing harmonic distortion rate, increasing output level, and eliminating specific harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

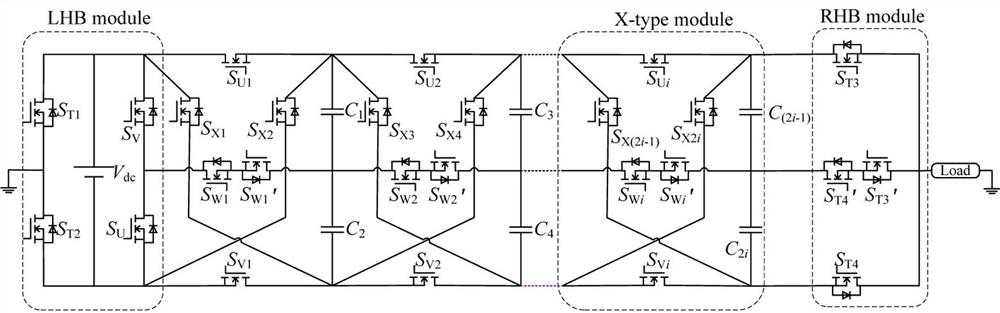

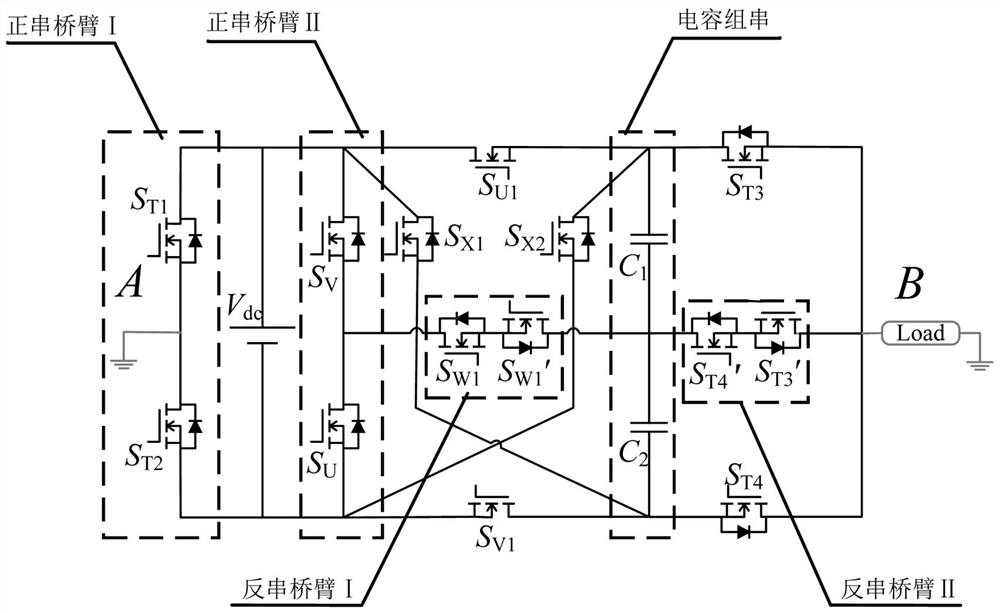

[0048] as attached figure 2 As shown, a setting where the DC power supply V dc A low-stress boost inverter between the load and the load, which includes a left half-bridge module, an X-type bipolar module and a right half-bridge module, and the left half-bridge module includes positive series bridge arm I and positive series bridge arm II, so The X-type bipolar module includes reverse-series bridge arm I, X-type bridge arm and capacitor string, and the right half-bridge module includes reverse-series bridge arm II and forward-series bridge arm III;

[0049] One end of the reverse series bridge arm I is connected to the midpoint of the forward series bridge arm II, and the other end of the reverse series bridge arm I is connected to the midpoint of the capacitor string and one end of the reverse series bridge arm II. The other end of the reverse series bridge arm II is connected to the midpoint of the forward series bridge arm III;

[0050] The midpoint of the positive serie...

Embodiment 2

[0062] On the basis of the low-stress boost inverter with one X-type bipolar module in Embodiment 1, this embodiment provides a specific implementation method of a low-stress boost inverter:

[0063] The low-stress boost inverter outputs 7 levels in one working cycle, including the switching of seven working modes:

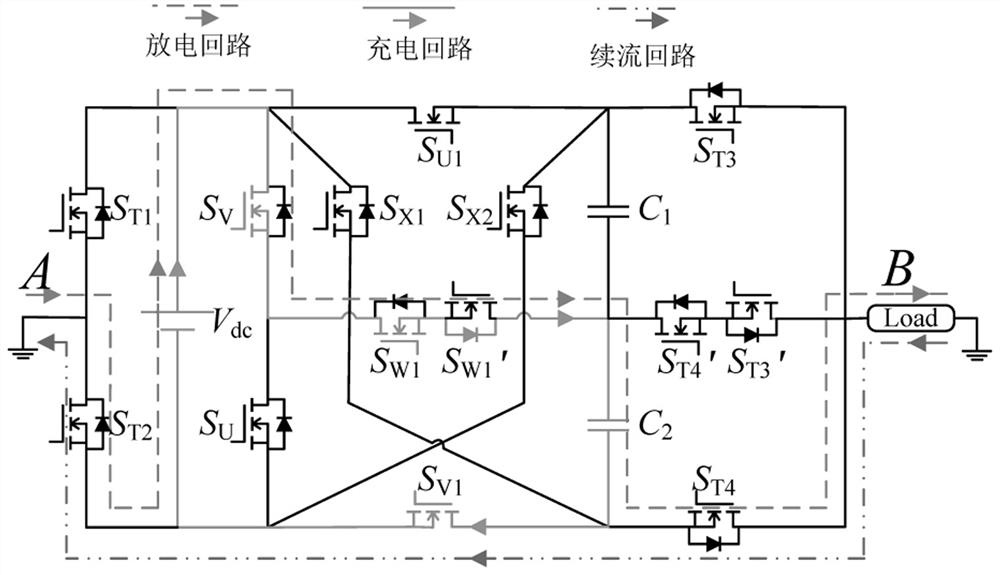

[0064] Working mode I, setting: the switching tube S of the positive series bridge arm I T2 , the switching tube S of the positive series bridge arm II V , the switching tube S of the X-shaped bridge arm V1 , the switching tube S of the anti-series bridge arm I W1 , the switching tube S of the positive series bridge arm III T4 and the switching tube S of the anti-series bridge arm II T3 'Turn on, the rest of the switch tubes are turned off, and the output level is 0;

[0065] as attached image 3 As shown, the electrolytic capacitor C of the capacitor string 2 with DC supply V dc charged in parallel to V dc , electrolytic capacitor C 1 constant;

[0066...

Embodiment 3

[0102] This embodiment provides a low-stress step-up inverter system, including an inverter and a controller, and the inverter is the above-mentioned low-stress step-up inverter.

[0103] This embodiment also provides another specific implementation of a low-stress boost inverter system, including an inverter and a controller. Steps of a method for realizing a voltage inverter.

[0104] This embodiment provides a specific implementation manner of a readable storage medium, on which instructions are stored, and when the instructions are executed by a processor, the steps of the method for implementing a low-stress boost inverter as described above are implemented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com