Metallized multi layer coating

A metal layer, multi-layer structure technology, applied in the field of packaging, can solve problems such as not being able to be opened cleanly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described more specifically below. The packaging, the article of the invention - comprises a film made of metallized cast polypropylene (abbreviated MCPP). The film can be formed into the following structure type: BOPP or BOPET layer / ink layer / adhesive layer / MCPP film.

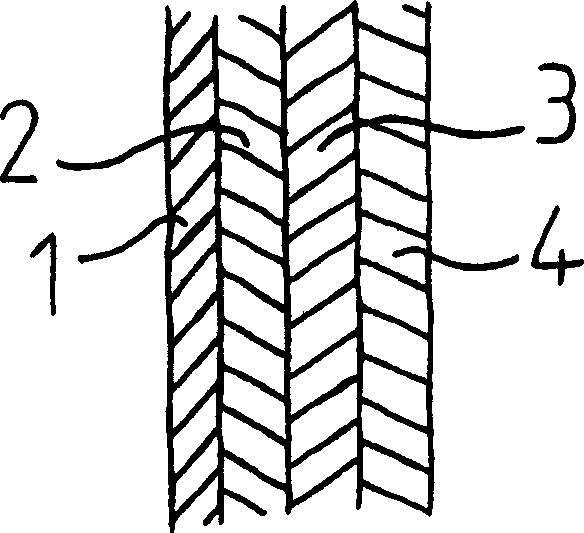

[0034] MCPP film has such as figure 1 The multilayer structure shown is in the following form: layer (1) / layer (2 / layer (3 / layer (4), the composition of which will be given below.

[0035] In the MCPP film, there are the following layers, which are arranged in the following order: BOPP or BOPET layer / ink layer / adhesive layer / layer (1) / layer (2) / layer (3) / layer (4).

[0036] Layer (1) is a metal layer applied on top of layer (2). For example, it may be a metal sheet or film, such as: aluminum, iron, copper, tin, nickel, silver, chromium, gold or an alloy mainly comprising at least one of the above metals.

[0037] Layer (3) is a polypropylene layer. The polypropylene of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com