Patents

Literature

639 results about "Multilayer membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

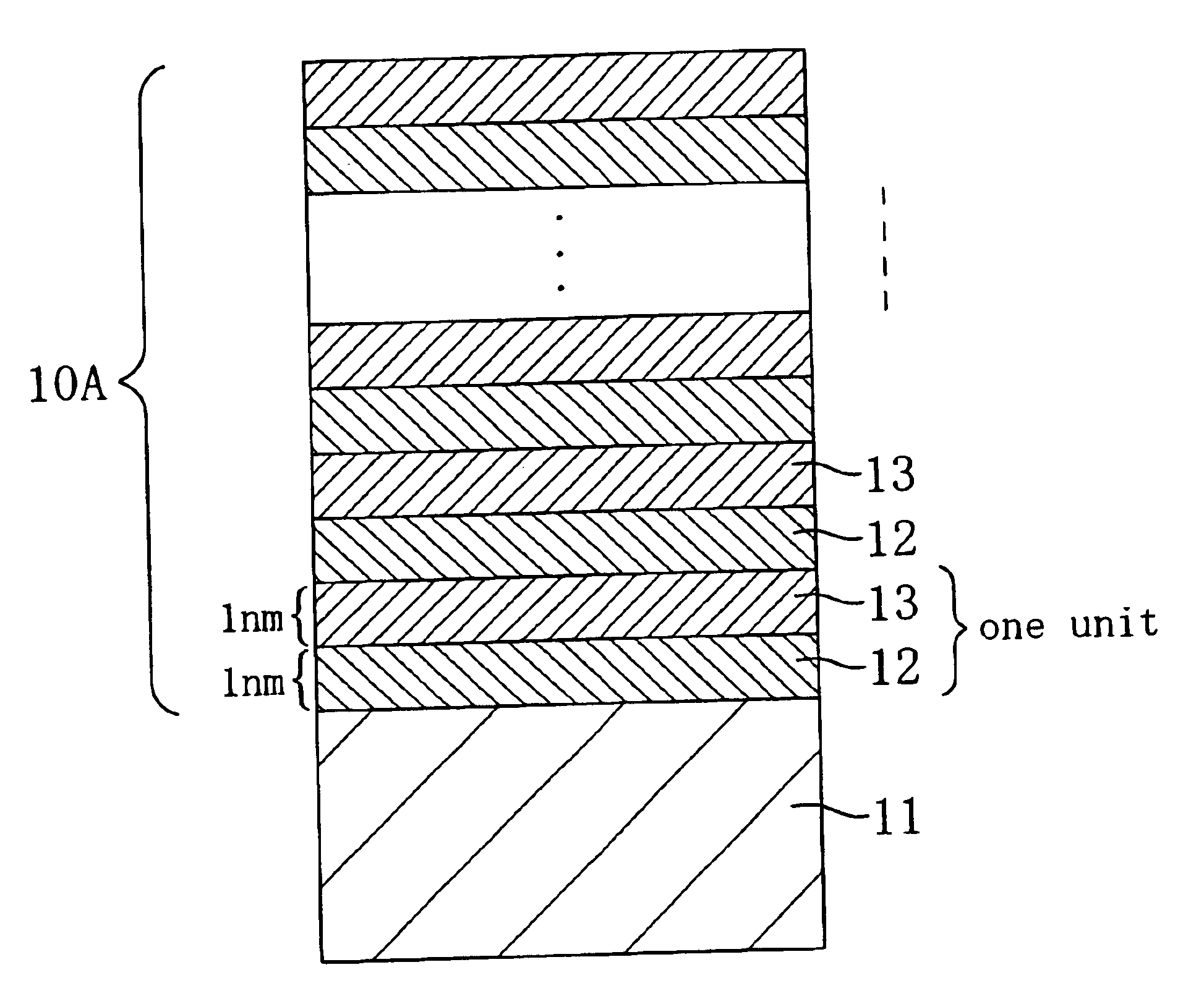

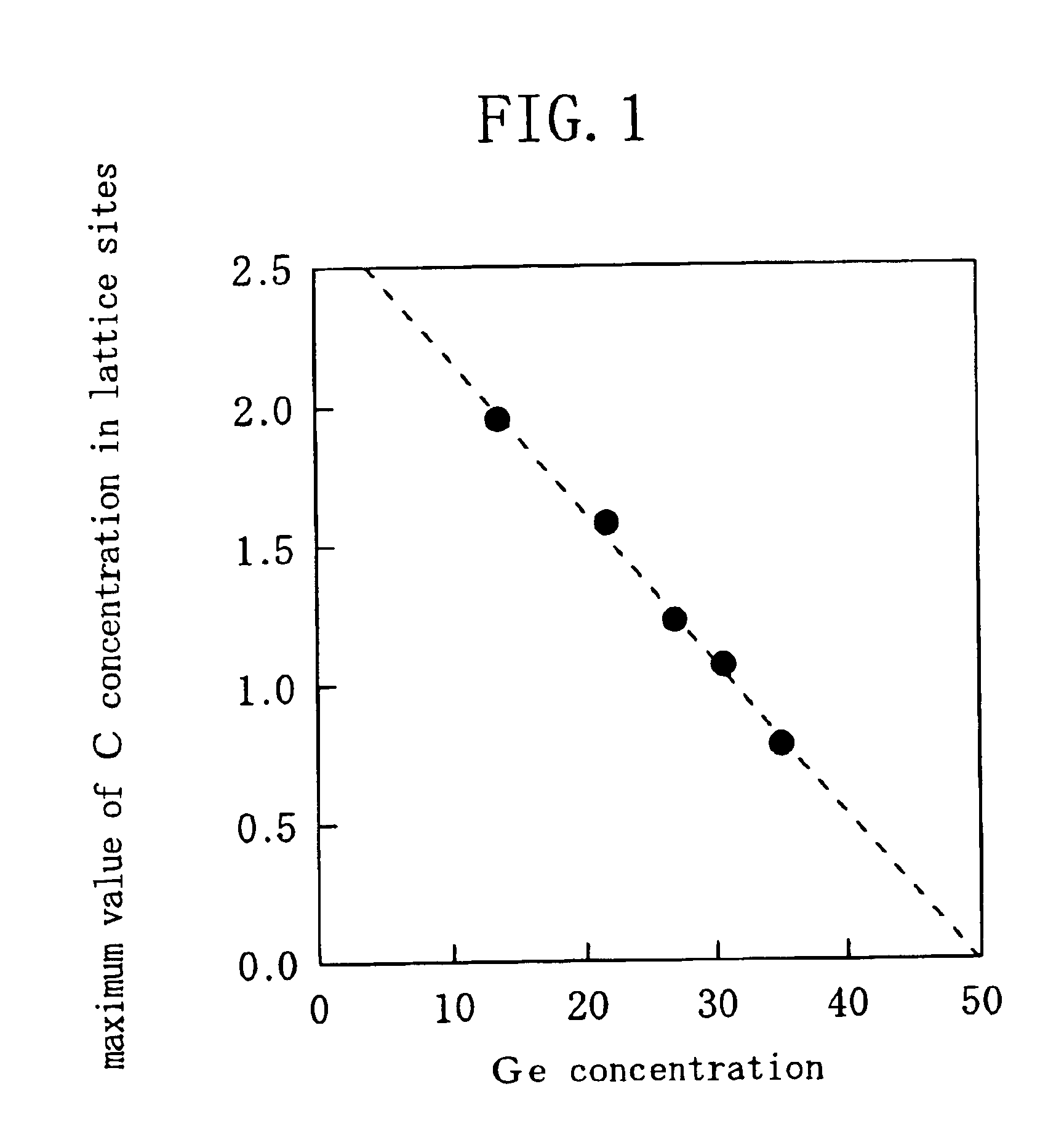

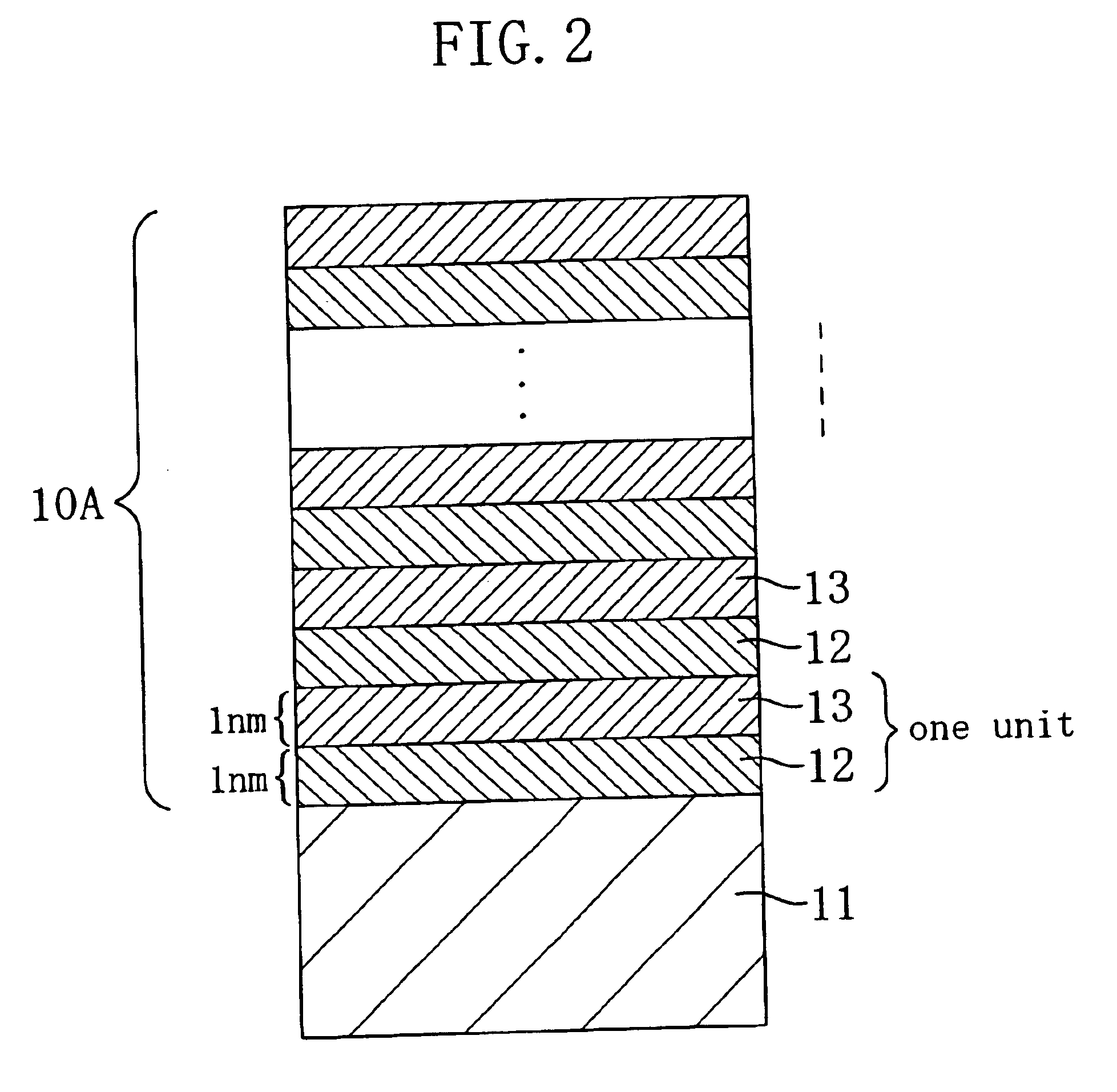

Semiconductor crystal film and method for preparation thereof

InactiveUS6852602B2Promote stratificationEasy to getTransistorSemiconductor/solid-state device manufacturingMultilayer membraneThin membrane

Owner:PANASONIC CORP

Process for detecting leaks in sealed packages

InactiveUS20060121613A1Chemiluminescene/bioluminescenceSynthetic resin layered productsLength waveChemistry

The present invention relates to a process for detecting a leak in a package. The process comprises preparing a package by covering at least a portion of an O2-sensitive product with a multilayer film comprising (i) a leak-indicator layer in which a O2-sensitive indicator is present throughout the leak-indicator layer; and (ii) an O2-barrier layer outward of the leak-indicator layer. A low O2-environment is provided within the package. The leak-indicator layer is then illuminated with light containing a wavelength absorbed by the O2-sensitive indicator, so that the O2-sensitive indicator produces an emission of radiation in an amount inversely proportional to a level of O2 present with the O2-sensitive indicator. Then the multilayer film is scanned while the O2-sensitive indicator is emitting radiation, the scanning being carried out by sensing and comparing the amount of radiation emitted from at least two different regions of the multilayer film.

Owner:CRYOVAC ILLC

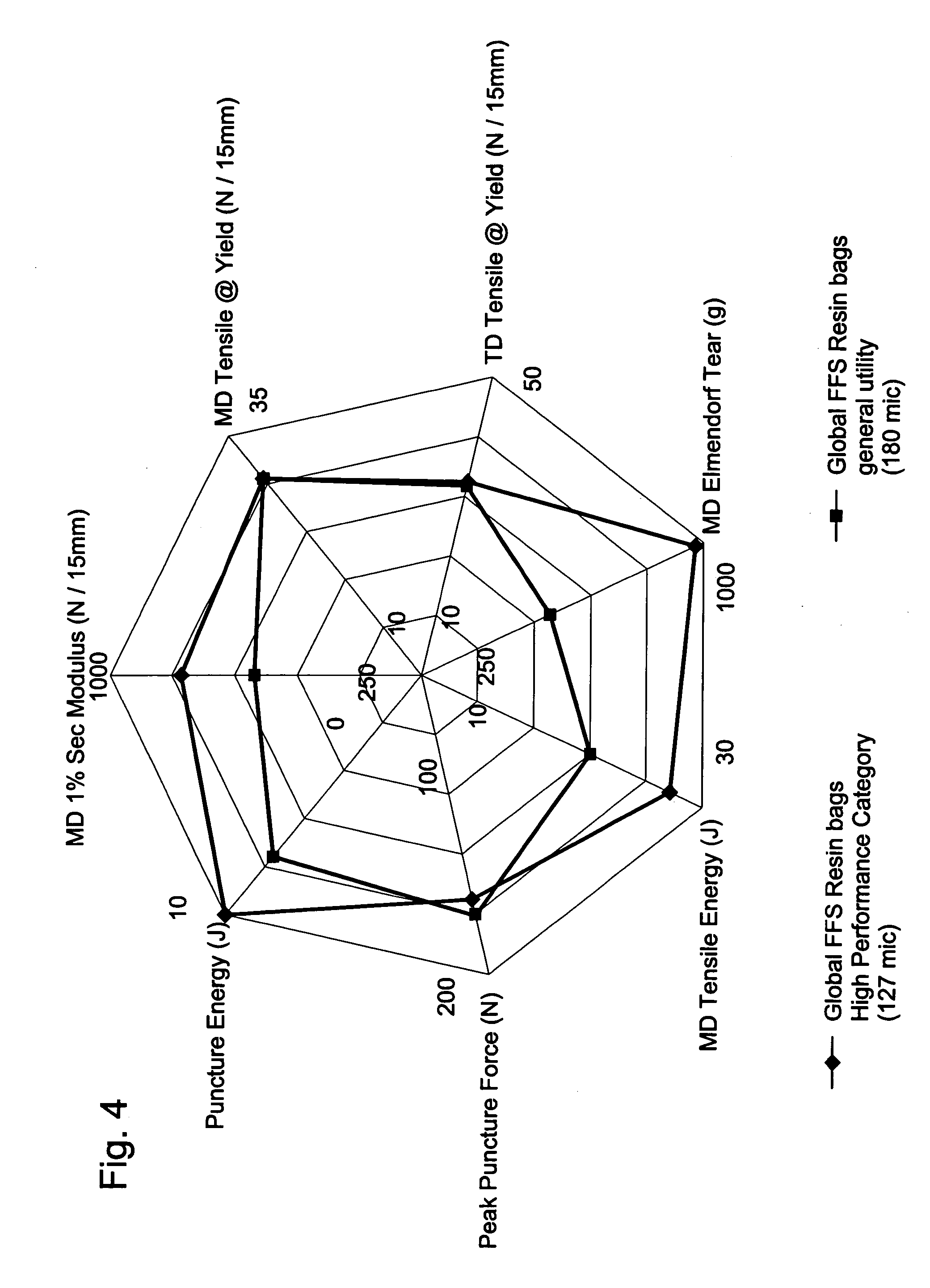

Multi-layer polyethylene films

InactiveUS20060188678A1Improve sealingResist impactSynthetic resin layered productsBagsEngineeringHeavy duty

An improved multi-layer film and packaging, including heavy duty sacks made therefrom having improved properties that permit processing on high speed bagging / Form Fill-Seal equipment are disclosed. The multi-layer films of the invention include a mLLDPE-containing skin layer and a core layer that includes both HDPE and mLLDPE.

Owner:EXXONMOBIL CHEM PAT INC

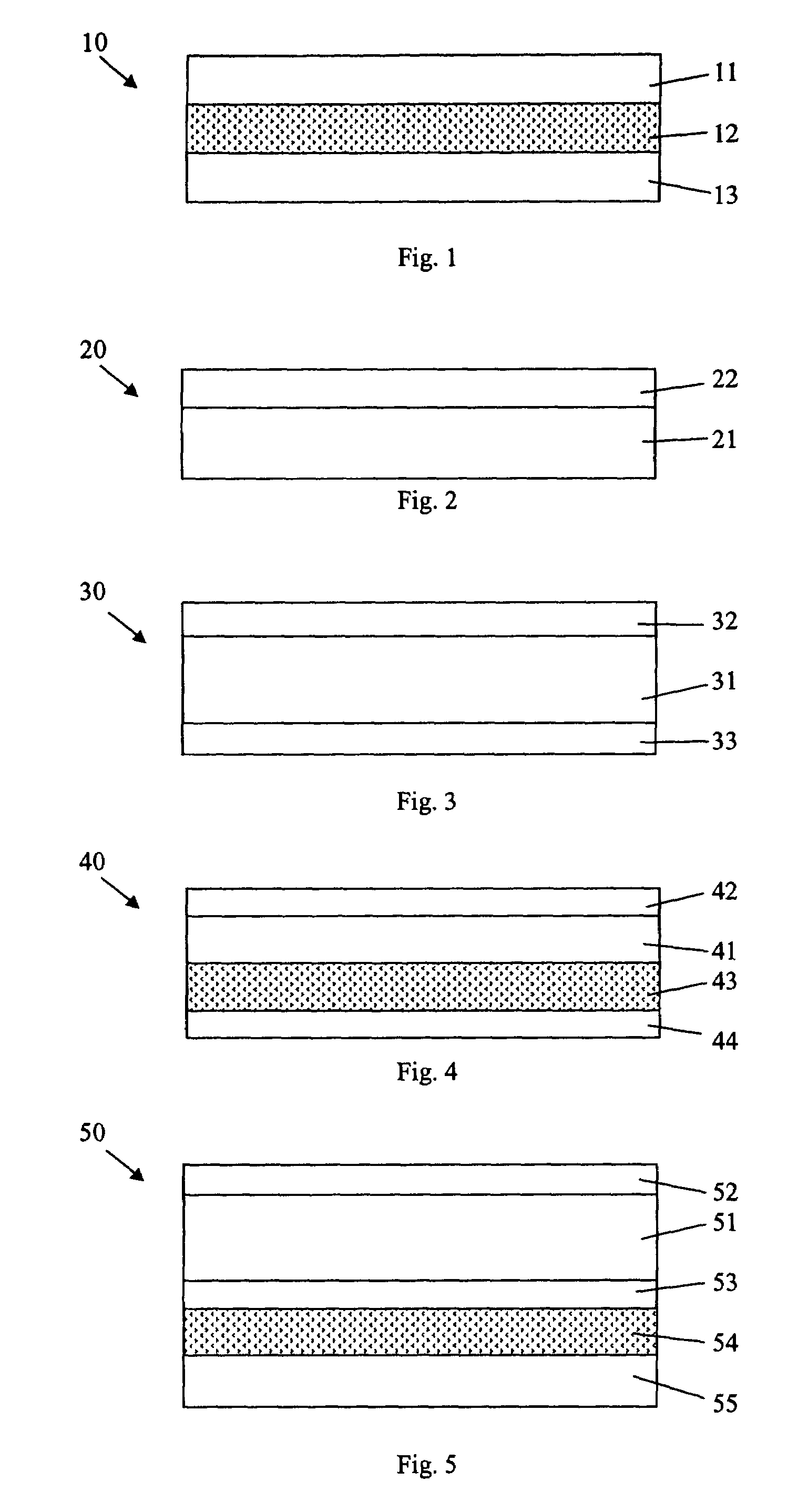

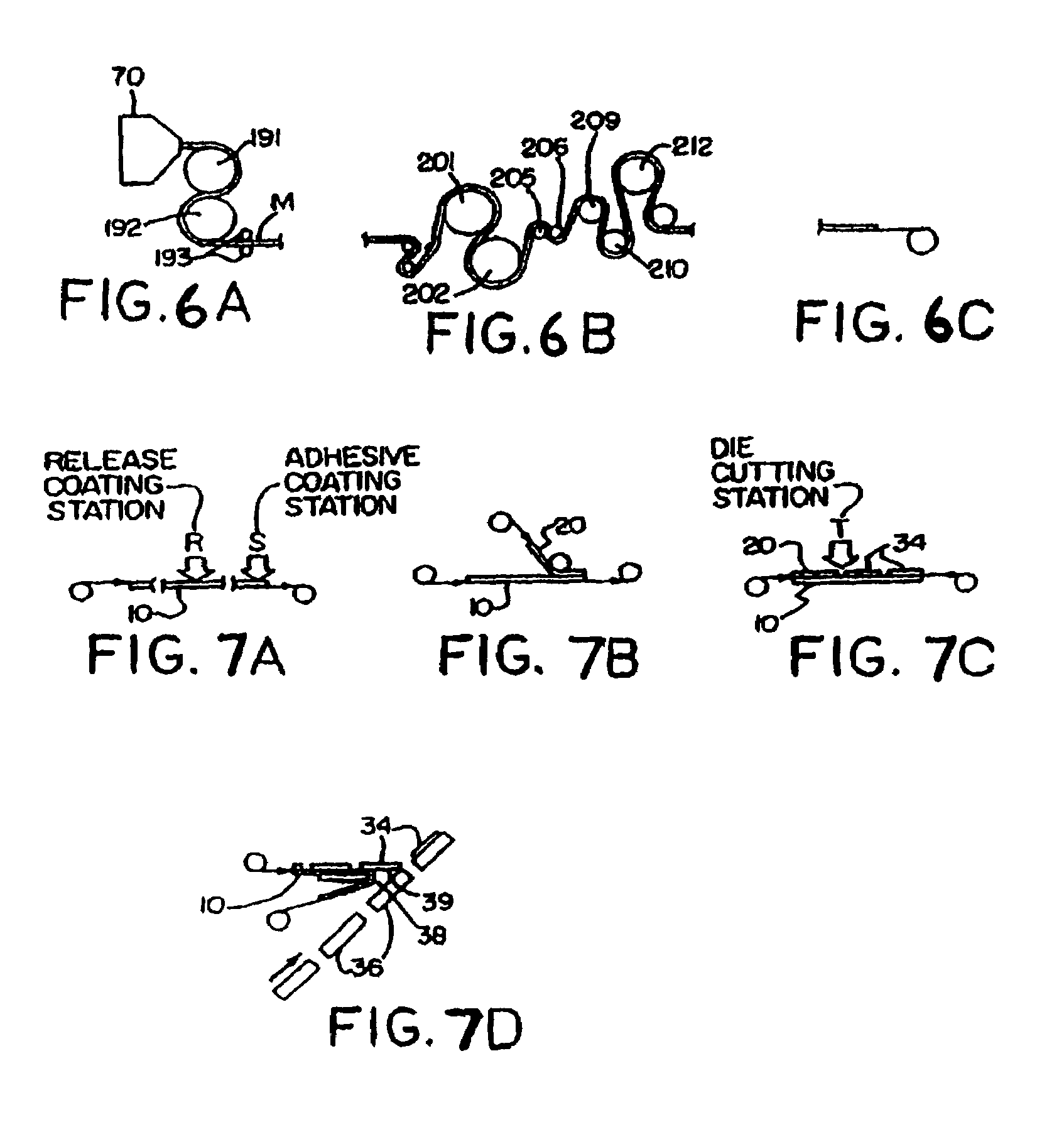

Machine direction oriented polymeric films and methods of making the same

InactiveUS7217463B2Increase stiffnessImprove clarityStampsFilm/foil adhesivesElastomerMultilayer membrane

This invention relates to a film comprising a machine direction oriented polymeric film prepared from (A) at least one propylene homopolymer or copolymer or lend of two or more thereof, wherein (A) has a melt flow rate from about 6 to about 30 and (B) an olefin elastomer having a melt flow rate of 0.5 to 10. In one embodiment, the film also contains a nucleating agent. In one embodiment, these films are clear. The films have good stiffness and clarity with low haze. These films are useful in preparing labels and may be used as a monolayer film or in a multilayer film. In one embodiment, the films are printable. Die-cut labels are also described which comprise a composite comprising the extruded, machine-direction oriented polypropylene copolymer films of the present invention in combination with an adhesive associated with said copolymer films for adhering said label to a substrate. Multilayer composites also are described which comprise a label facestock material comprising an extruded oriented multilayer film of the present invention, an adhesive layer associated with said facestock material, and a release-coated liner or carrier. Combinations of the labels of the present invention joined with layer of adhesive to a substrate such as glass bottles also are described.

Owner:AVERY DENNISON CORP

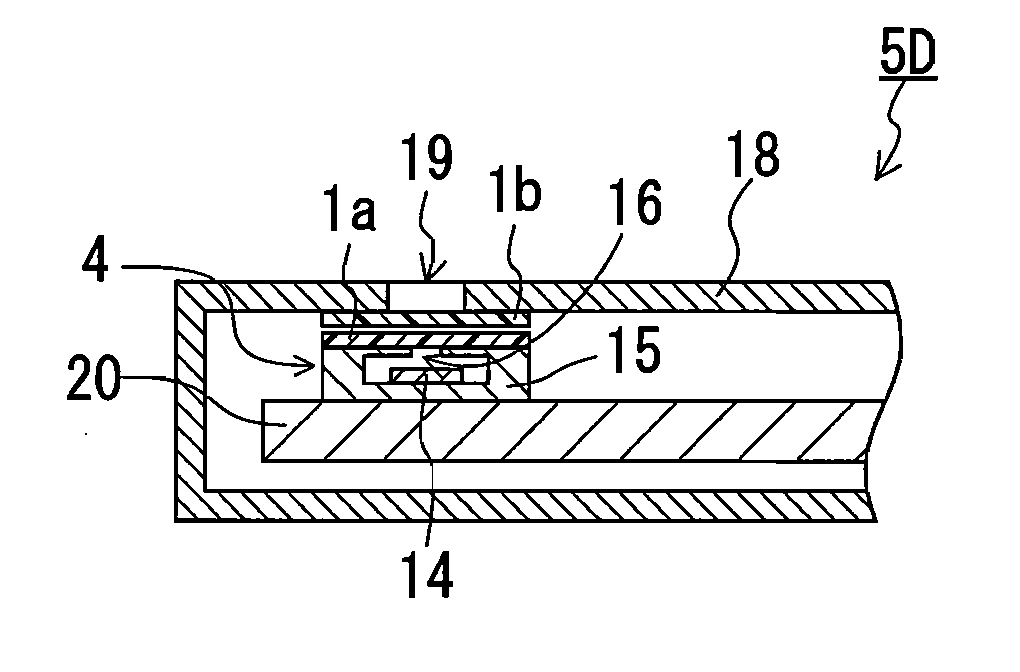

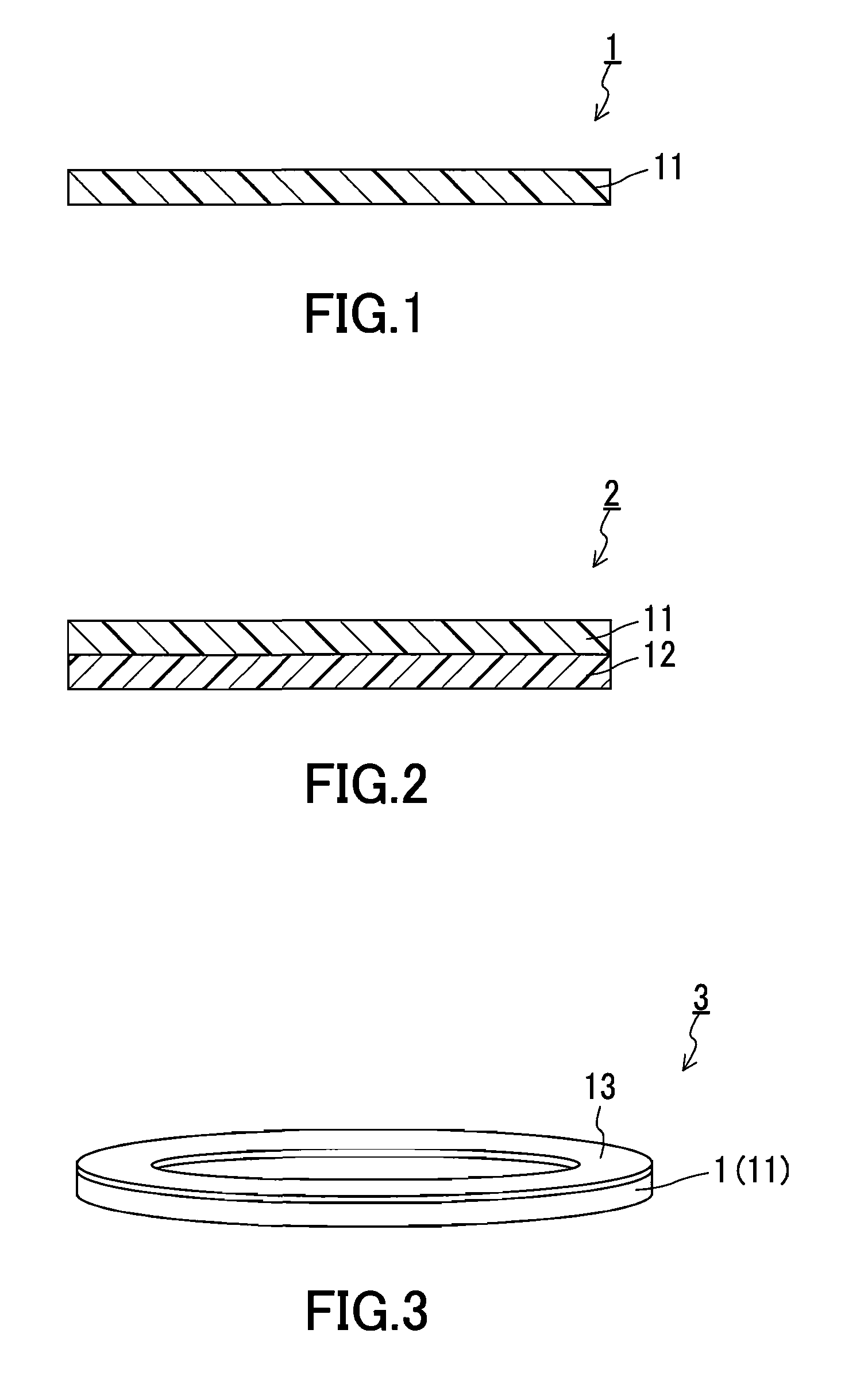

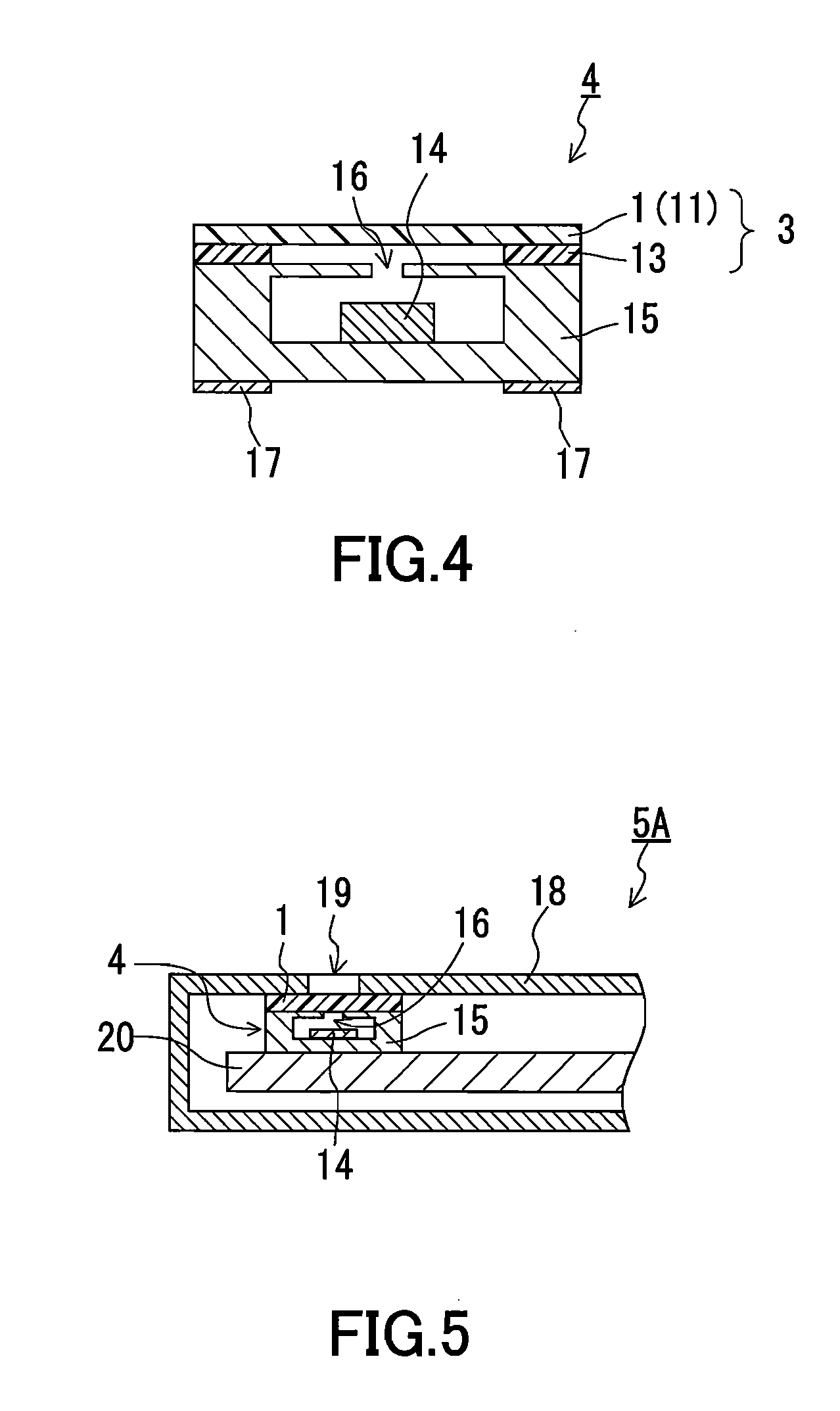

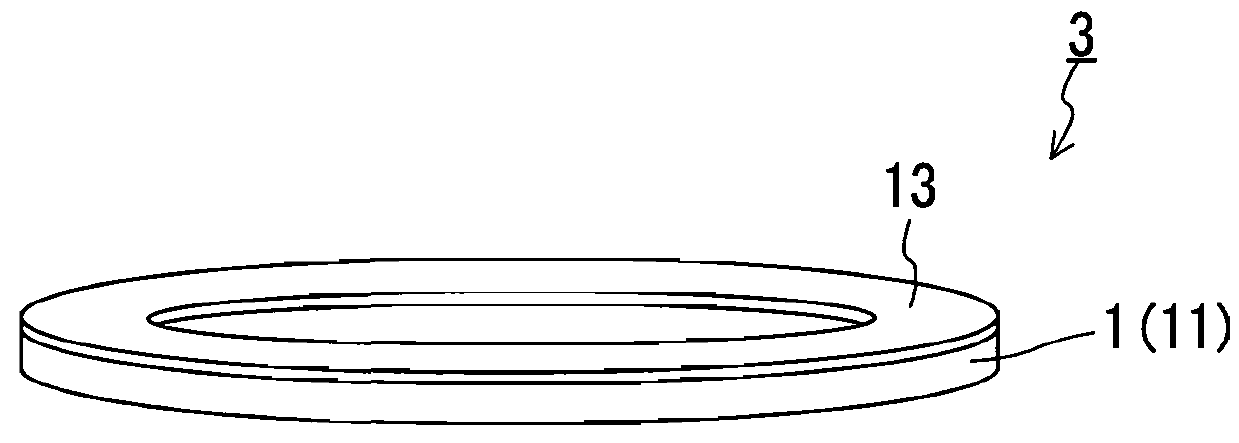

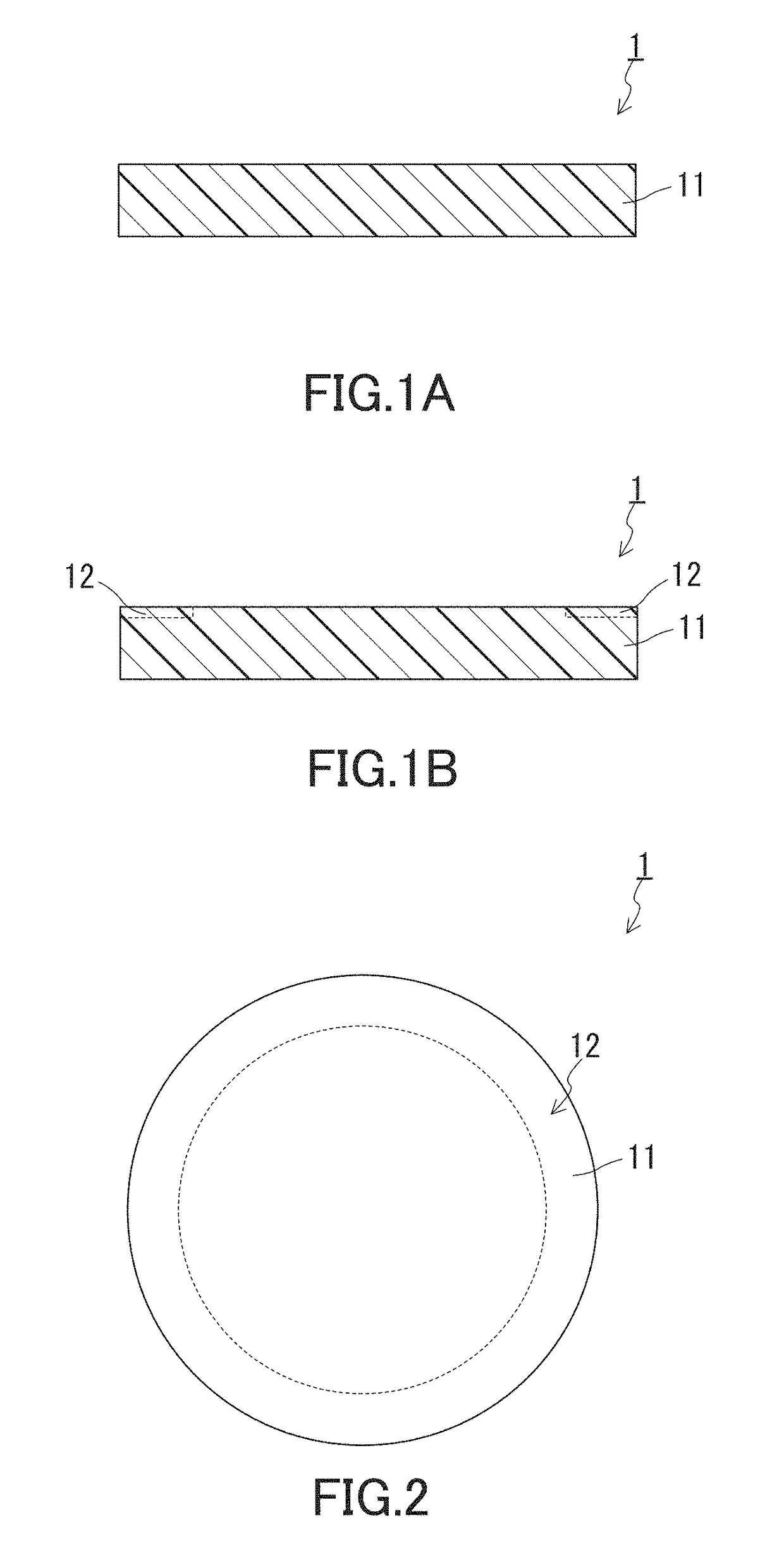

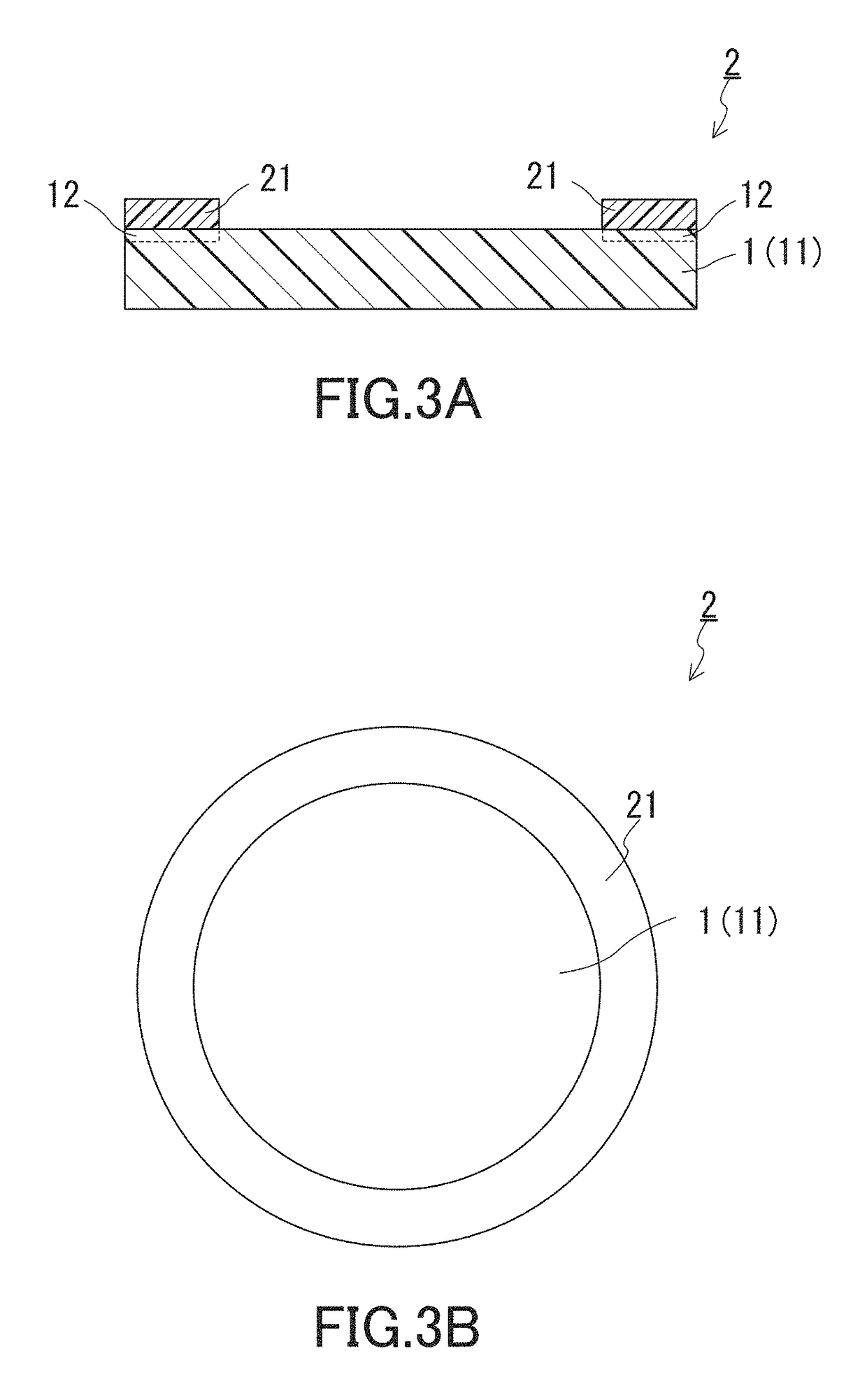

Sound-transmitting membrane for microphone, sound-transmitting membrane member for microphone provided with the membrane, microphone, and electronic device provided with microphone

ActiveUS20110255728A1Suppress water condensationEnsure microphone performancePiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesForeign matterAcoustic transmission

The present invention provides a sound-transmitting membrane for a microphone, to be disposed to a sound-collecting opening of the microphone so as to allow sound to transmit through the membrane while preventing a foreign matter from entering into the microphone through the opening. This membrane for a microphone prevents the entry of a foreign matter, such as fine dust and water vapor, that is difficult for conventional sound-transmitting membranes to block, and ensures the microphone performance. This membrane for a microphone is composed of a nonporous film or a multilayer membrane including a nonporous film, has a surface density of 30 g / m2 or less, and has a sound transmission loss of less than 3 dB in a frequency range of 300 to 4000 Hz.

Owner:NITTO DENKO CORP

Multilayer films comprising tie layer compositions, articles prepared therefrom, and method of making

InactiveUS20070231576A1Synthetic resin layered productsVehicle componentsPolymer sciencePolycarbonate

A multilayer film comprising a superstrate, and a tie layer comprising a tie layer composition comprising a polycarbonate and a poly(alkylene ester) is disclosed, wherein a substrate contacted to the tie layer opposite the superstrate has initiation peel strength between the tie layer and the substrate of about 20 to about 60 pounds per linear inch (about 3,500 to about 10,500 Newtons per meter), measured at a 90° peel angle and a peel rate of 12.7 cm / min. An article comprising the multilayer film is disclosed. Methods of forming the multilayer film and the article are also disclosed.

Owner:SABIC INNOVATIVE PLASTICS IP BV

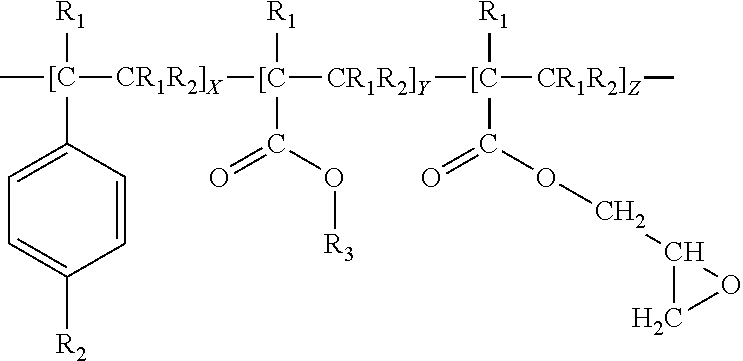

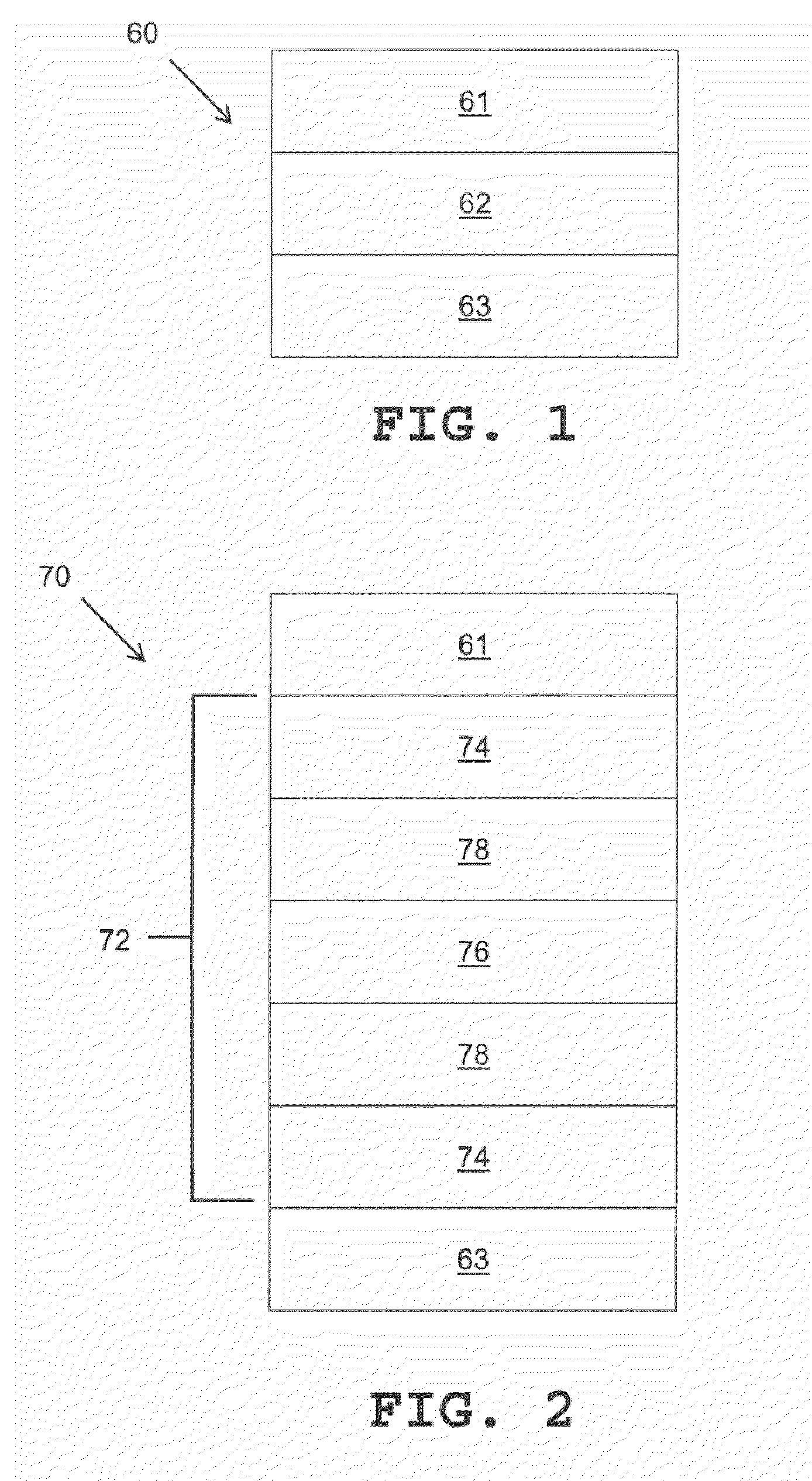

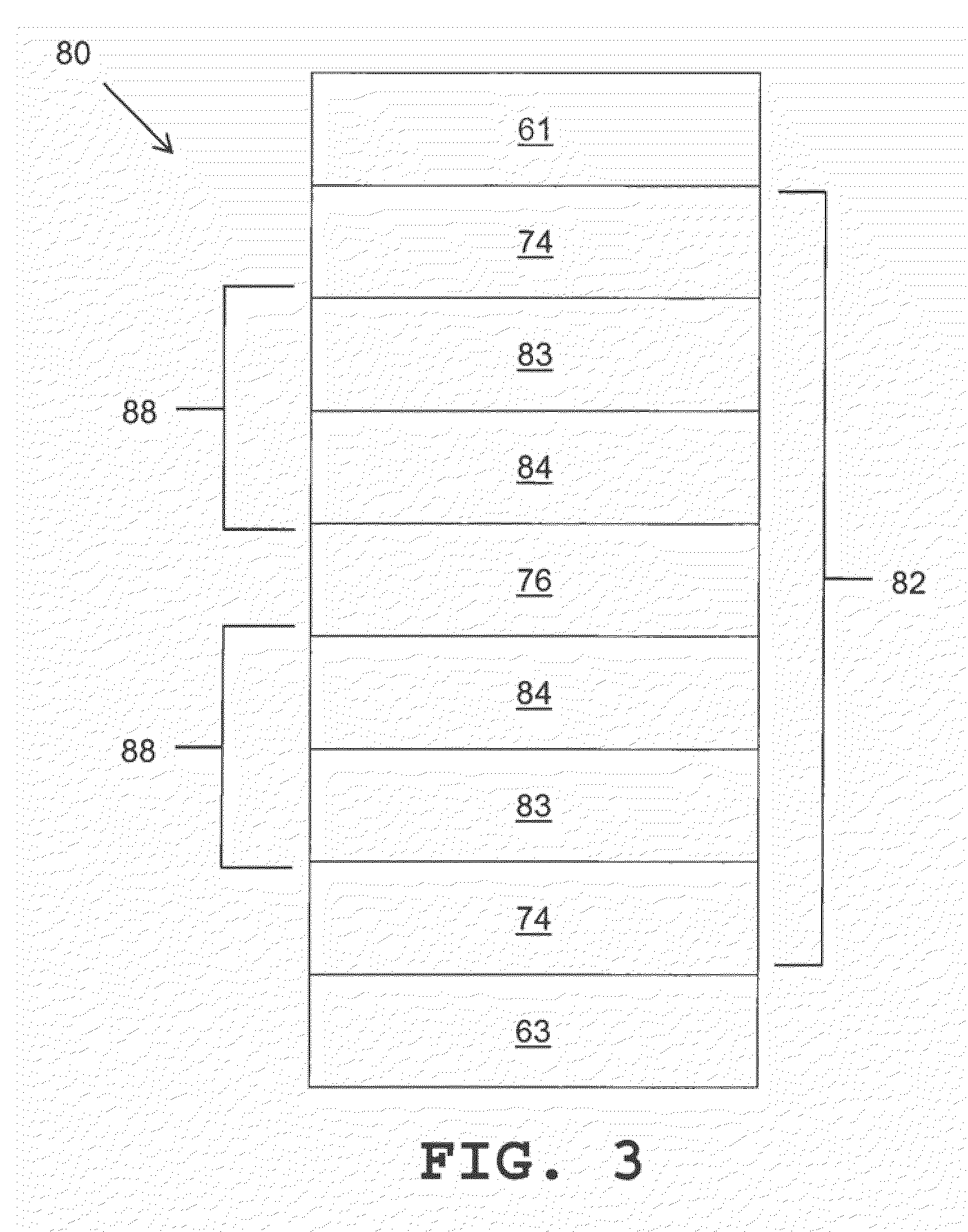

Compliant, nanoscale free-standing multilayer films

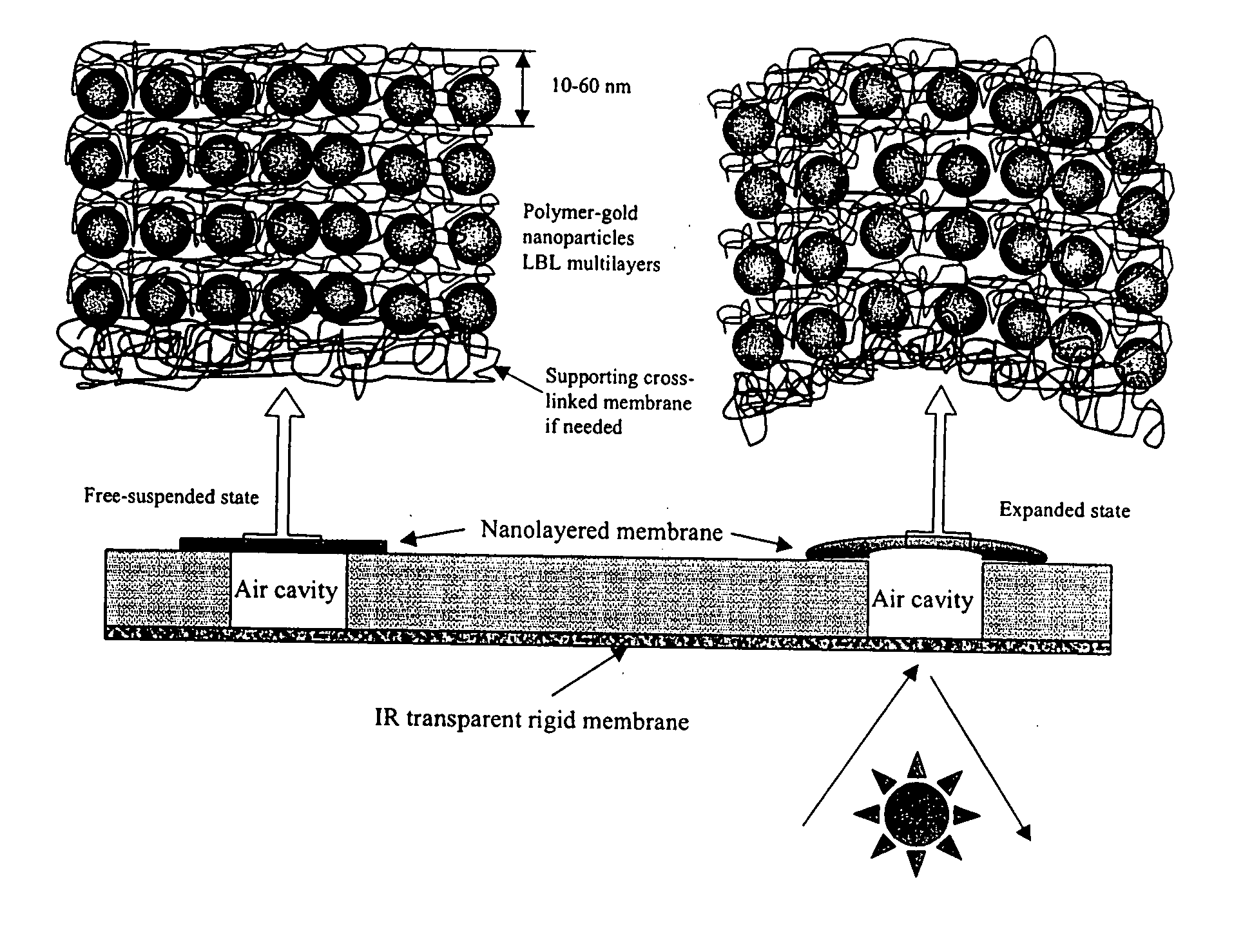

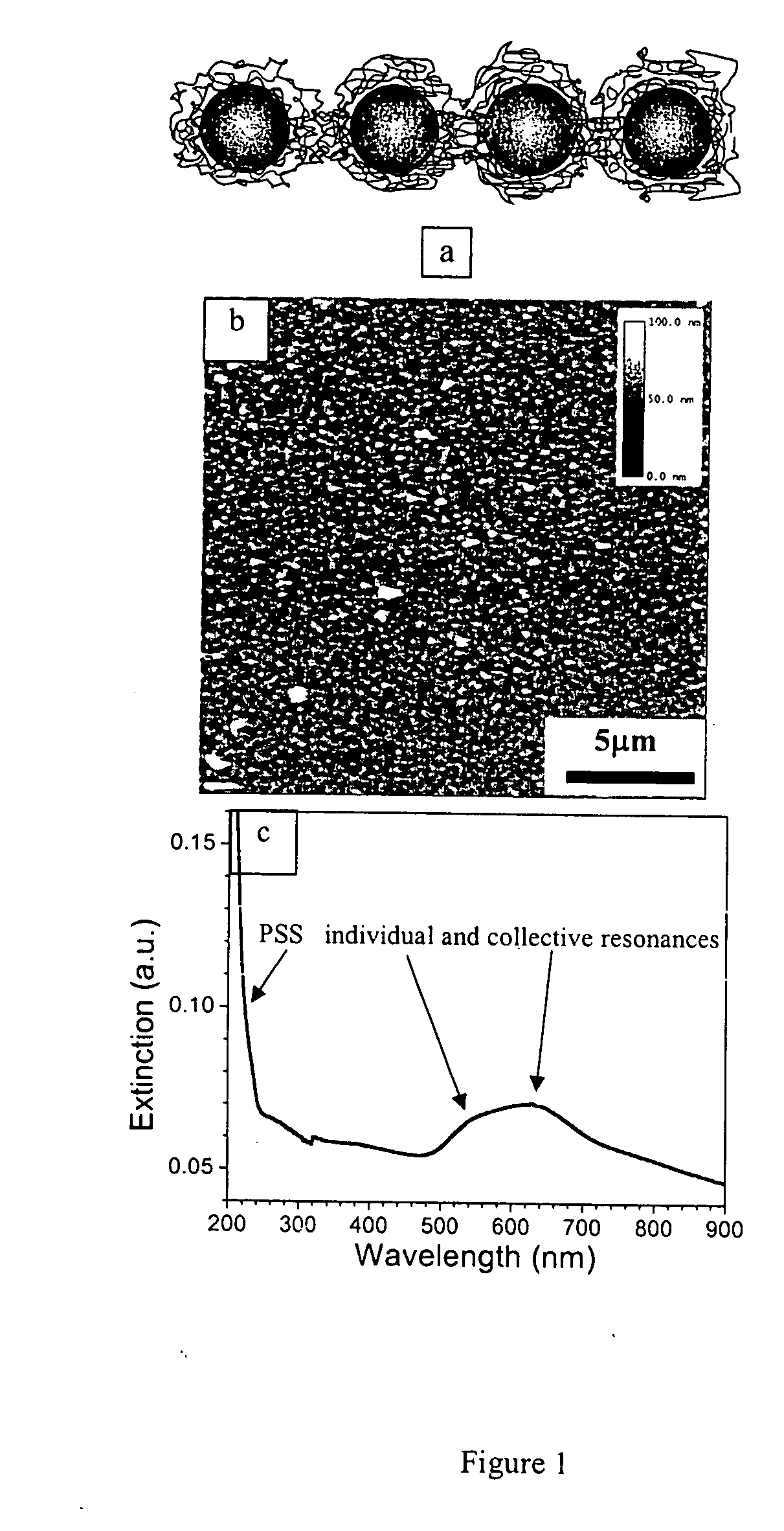

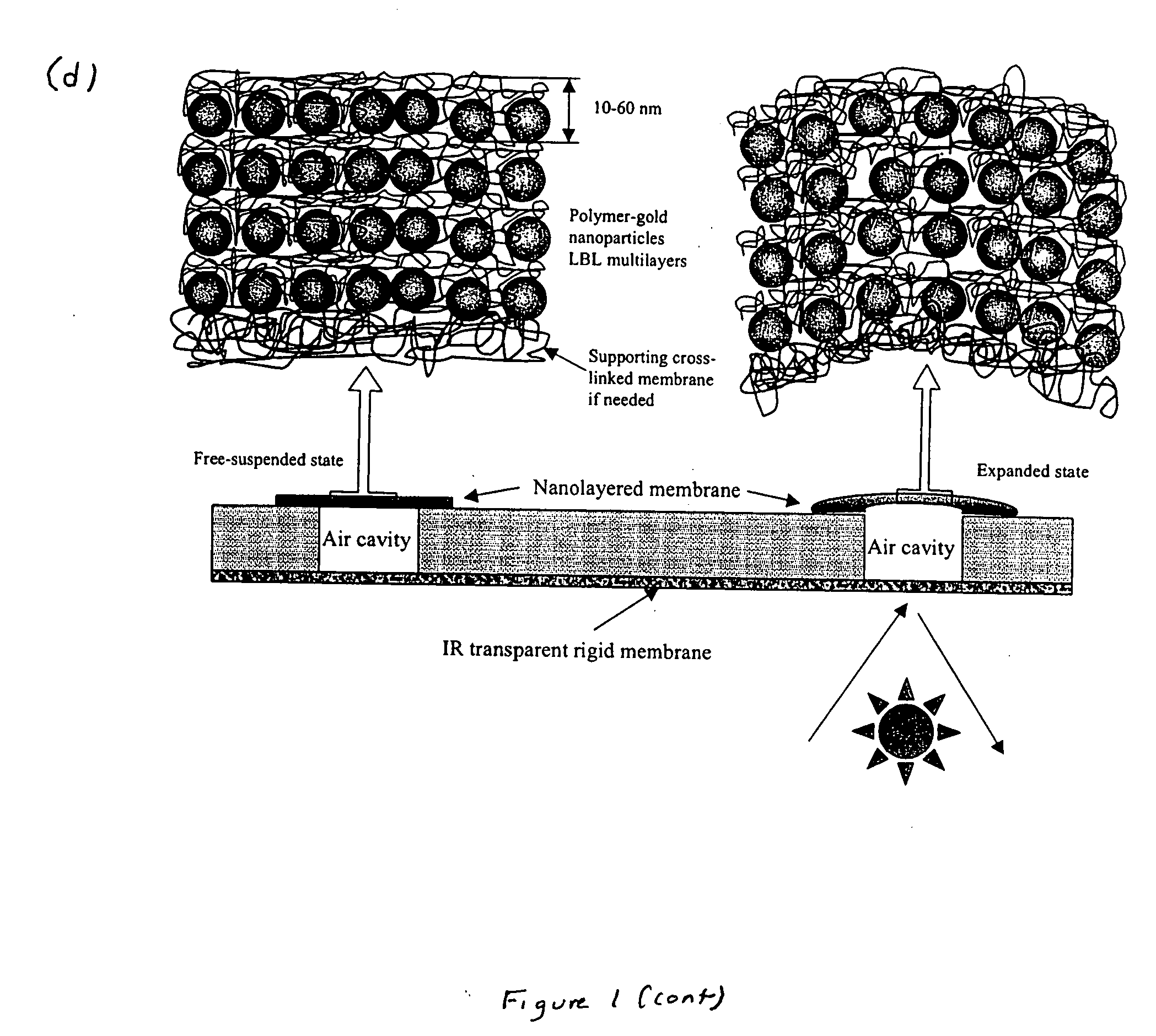

InactiveUS20050175507A1Improve featuresImprove responseMaterial nanotechnologySemi-permeable membranesMultilayer membraneAnionic polymers

A compliant free-standing multilayer membrane is provided of the cross-sectional formula:[(Pcat−Pan)nPcat / Met / (Pcat−Pan)nPcat]mwherein (Pcat31 Pan) represents a bilayer of an anionic polymer and a cationic polymer between at least one layer of Met; n is about 1-50, m is about 1-10; Met is an inert metal nanoparticle; Pcat is a cationic polymer and Pan is an anionic polymer, preferably prepared by a spin-assisted layer-by-layer assembly on a sacrificial substrate layer.

Owner:IOWA STATE UNIV RES FOUND

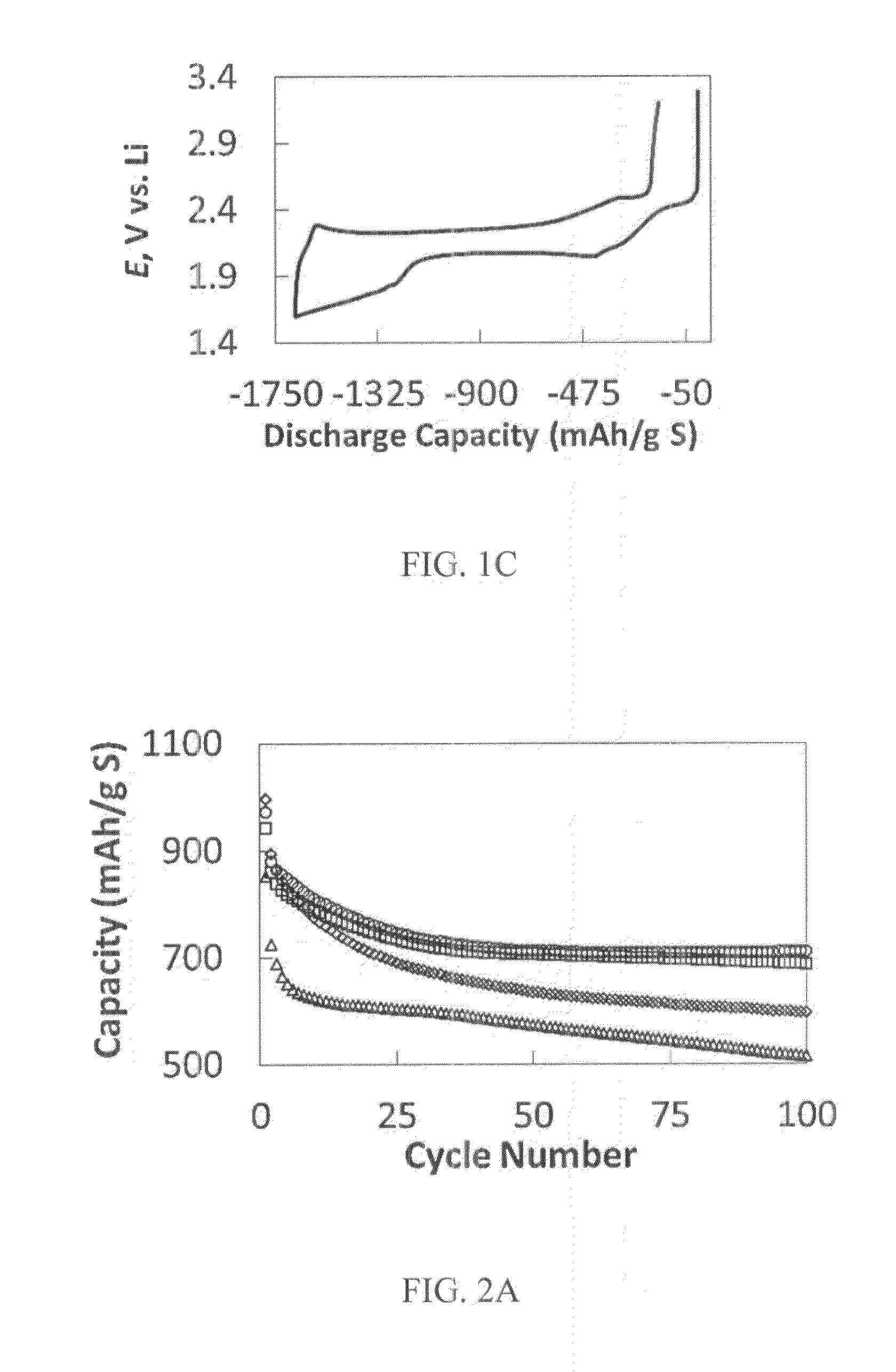

Carbon-sulfur composites encapsulated with polyelectrolyte multilayer membranes

InactiveUS20140234707A1Active material electrodesNon-aqueous electrolyte accumulator electrodesPolyelectrolyteMultilayer membrane

Owner:TOYOTA JIDOSHA KK

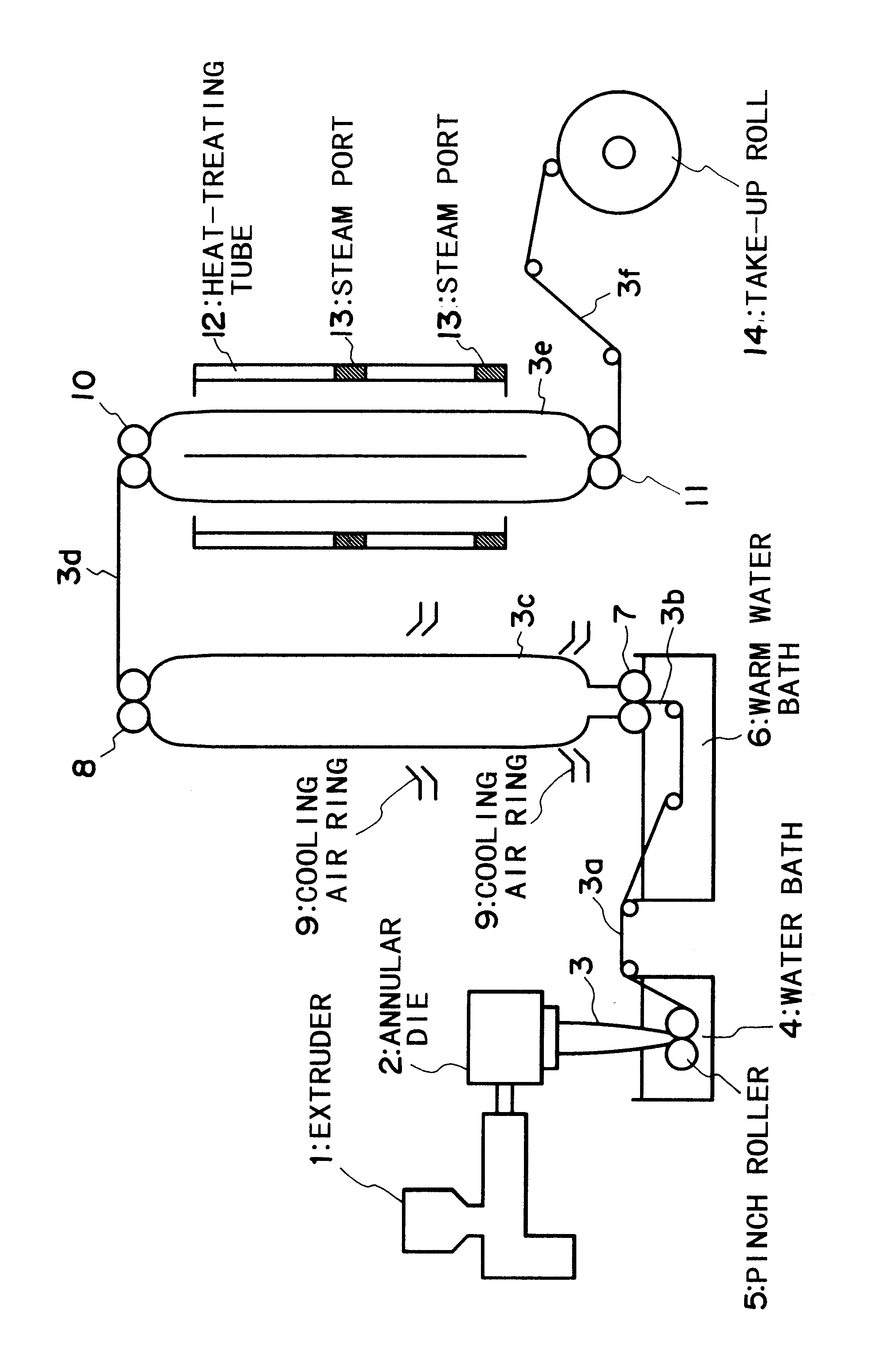

Heat-shrinkable multilayer film

A polyamide resin-based heat-shrinkable multilayer film is caused to satisfy various properties required of a packaging material, especially a food packaging material, at high levels, and particularly exhibit a highest level of heat-shrinkability. The multilayer film comprises at least three layers including an outer surface layer (a) which comprises a polyester resin or a polyolefin resin; an intermediate layer (b) which comprises a mixture of 85-60 wt. % of an aliphatic polyamide resin, and 15-40 wt. % of an aromatic copolyamide resin which is a copolymer of aliphatic diamine / isophthalic acid and aliphatic diamine / terephthalic acid, and an inner surface layer (c) which essentially comprises a copolymer of ethylene and alpha-olefin having a density below 0.915. The heat-shrinkable multilayer film has been biaxially stretched and then heat-treated to have hot-water shrinkabilities at 80° C. of at least 30% in each of longitudinal / transverse directions and at least 35% in at least one of longitudinal / transverse directions.

Owner:KUREHA KAGAKU KOGYO KK

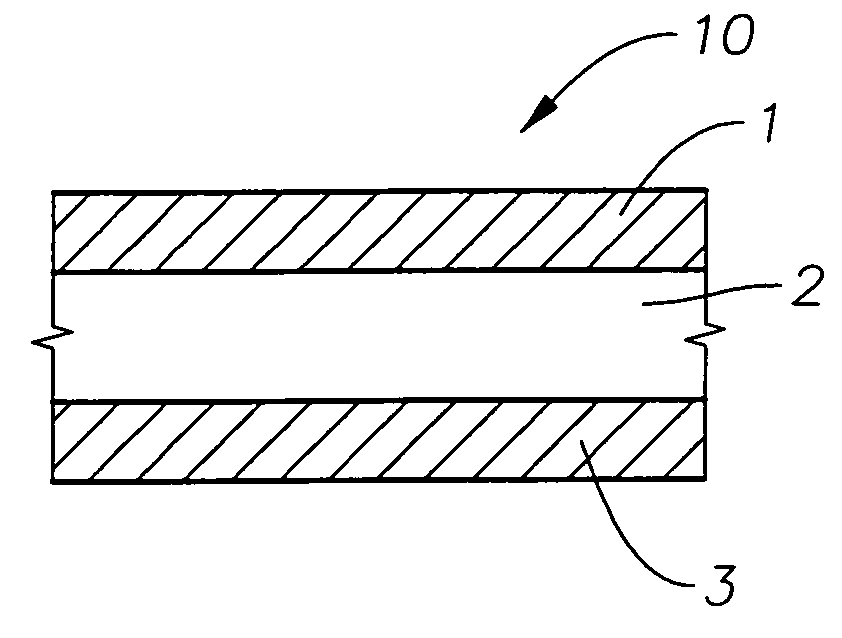

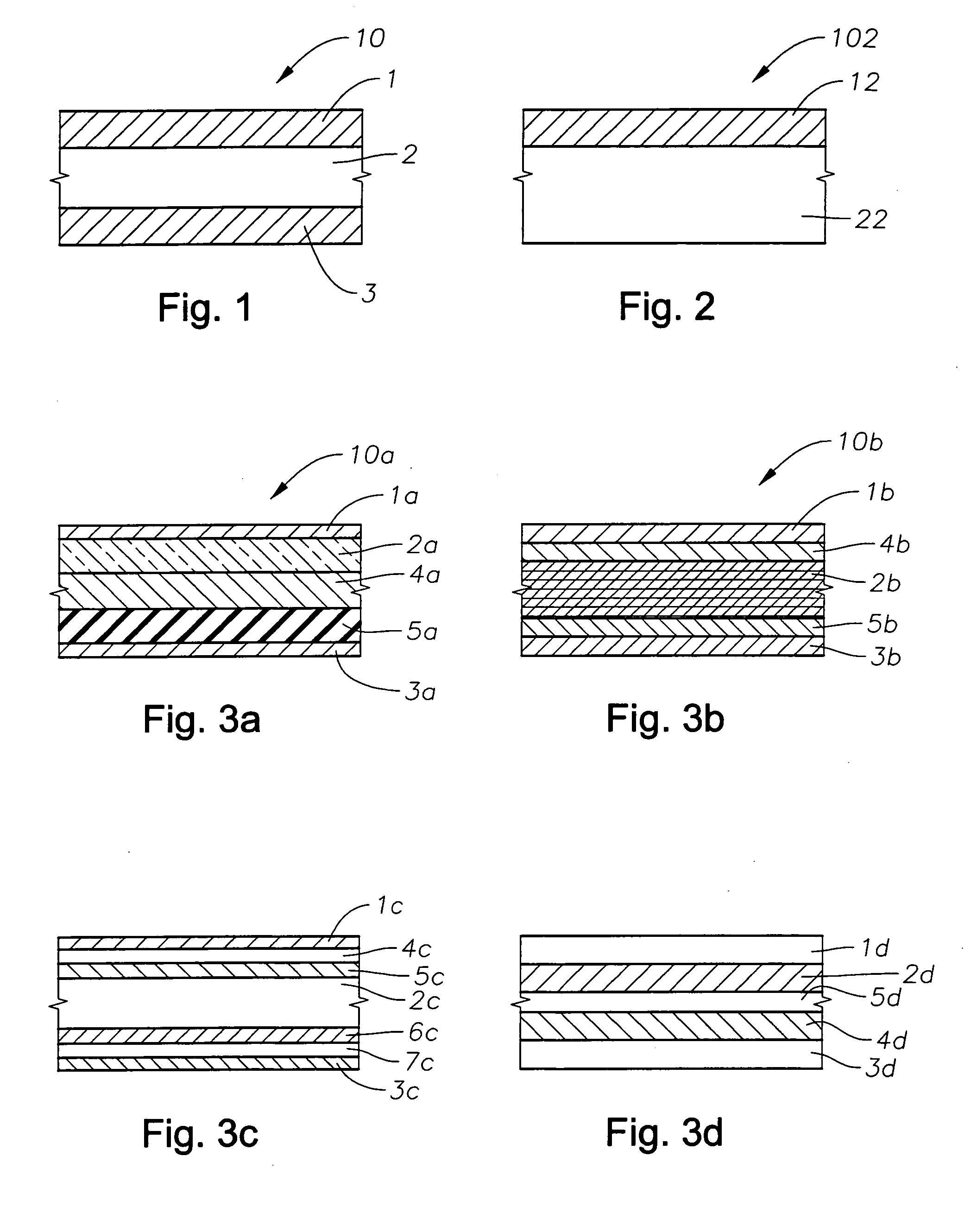

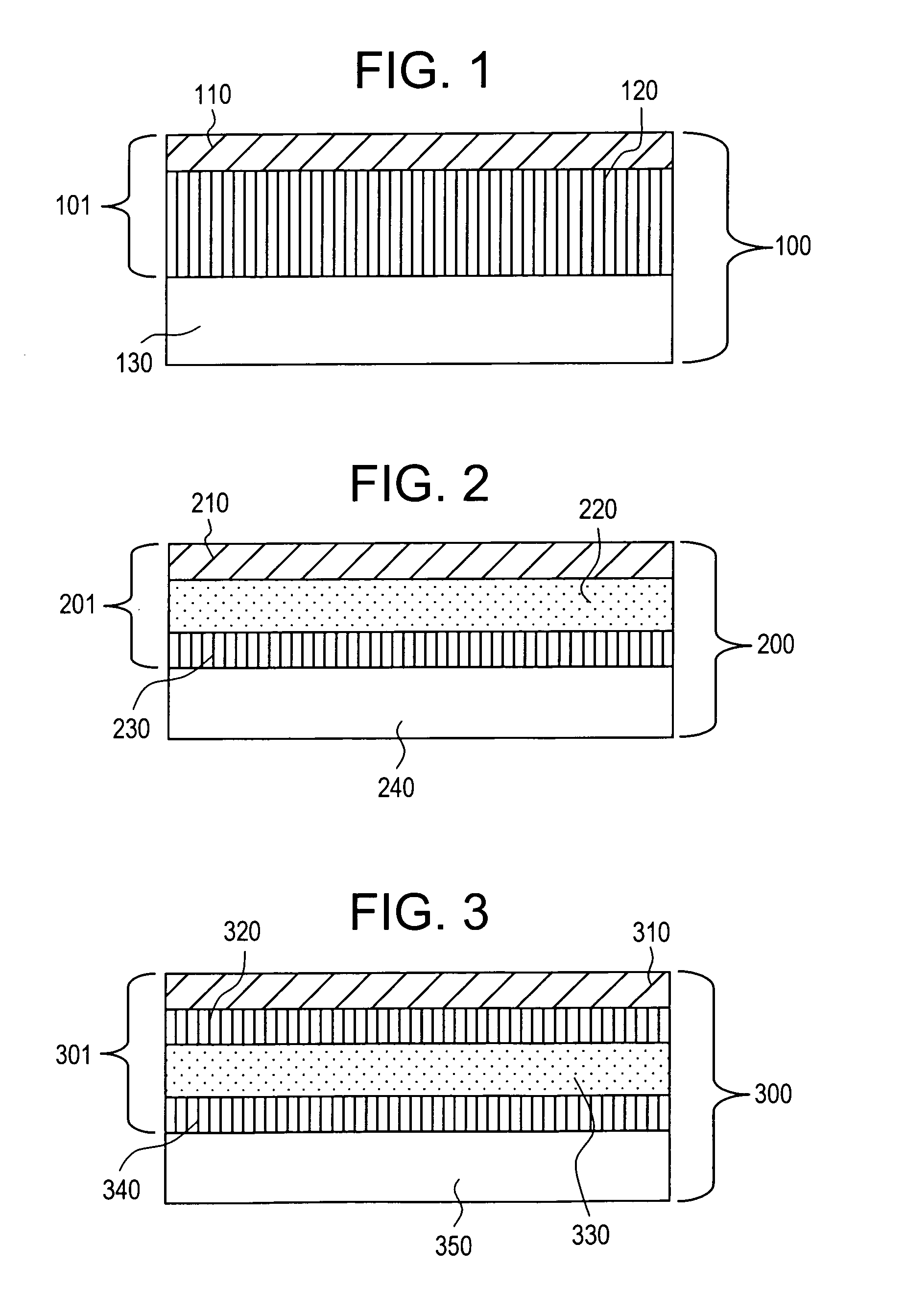

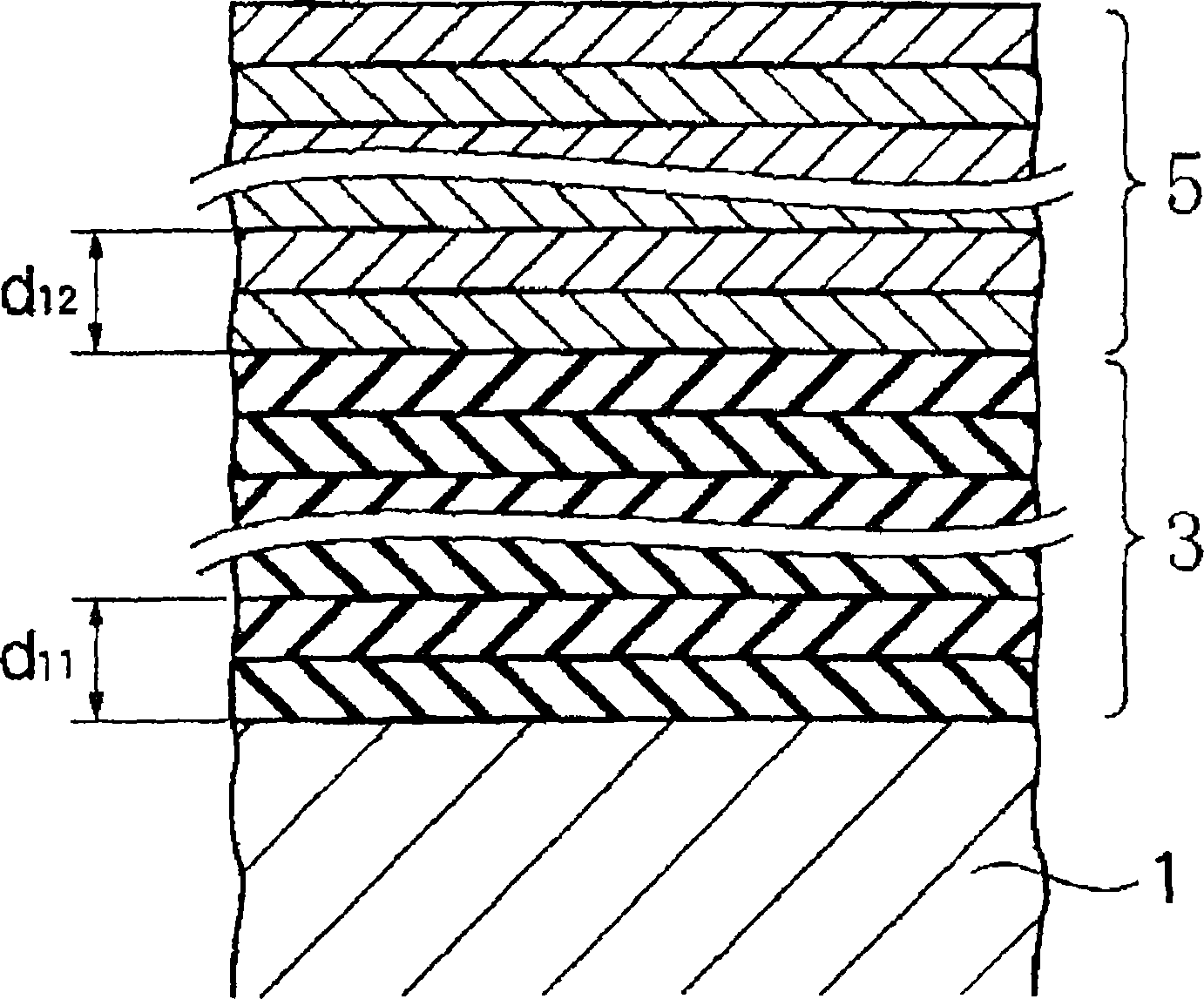

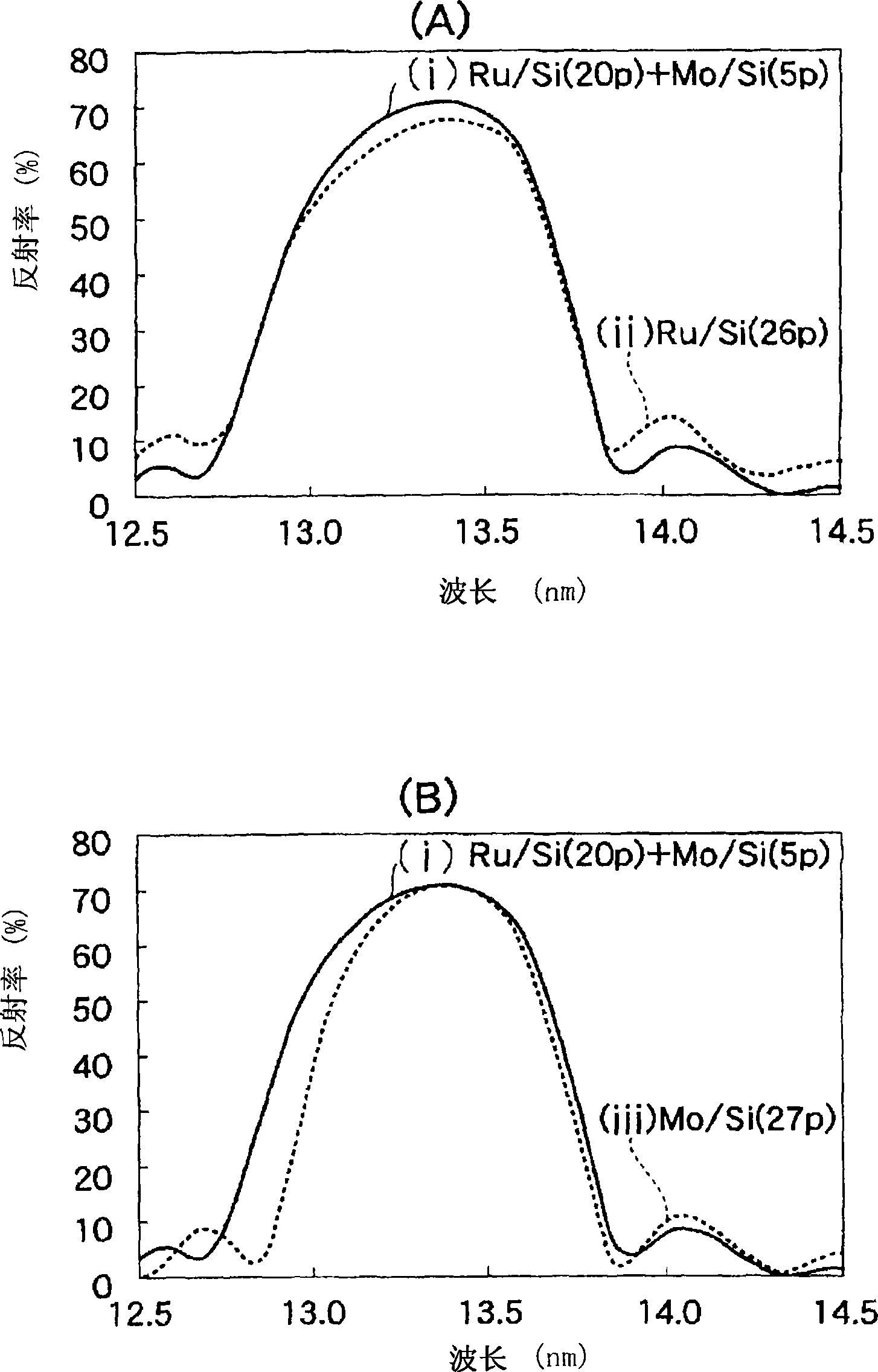

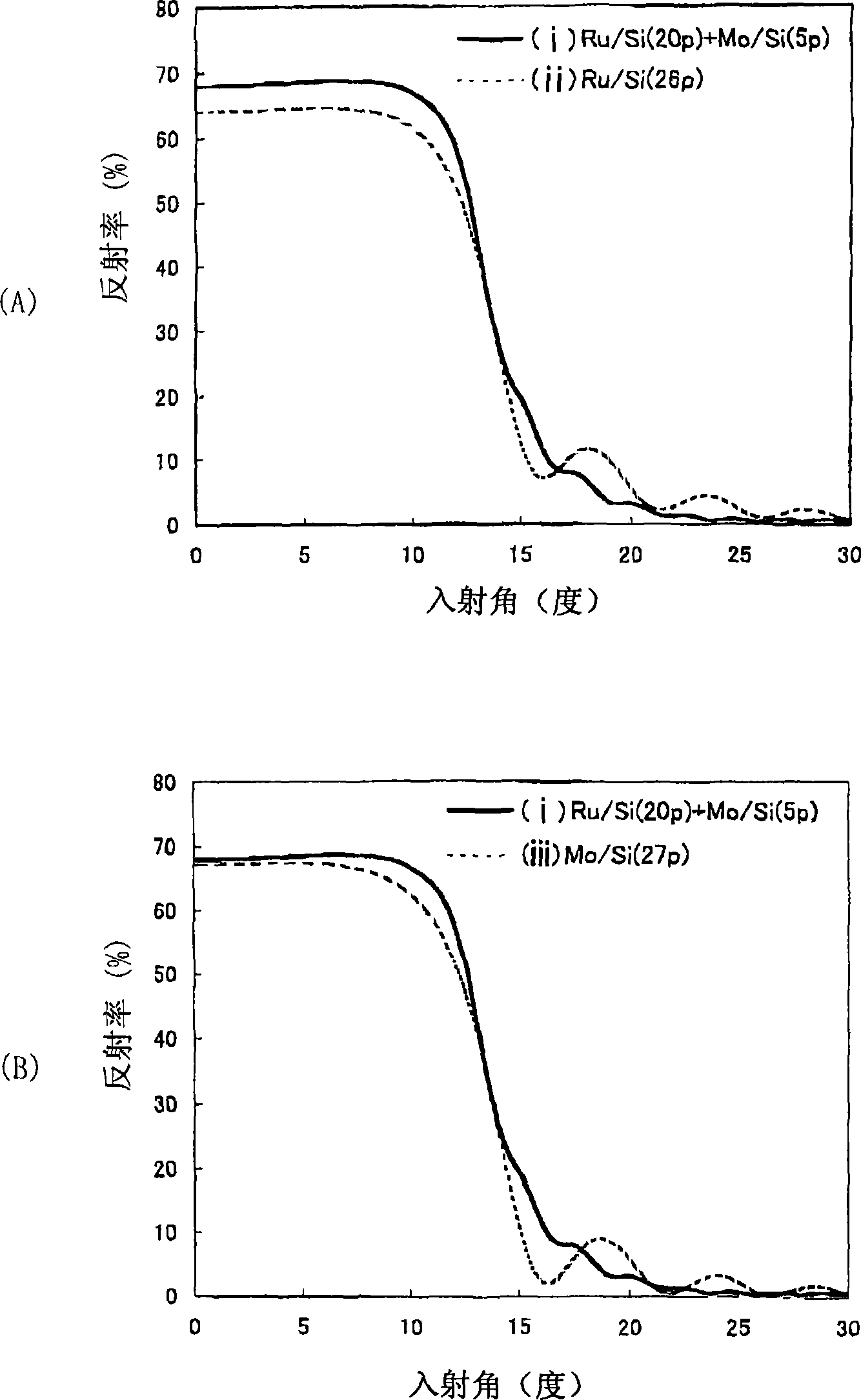

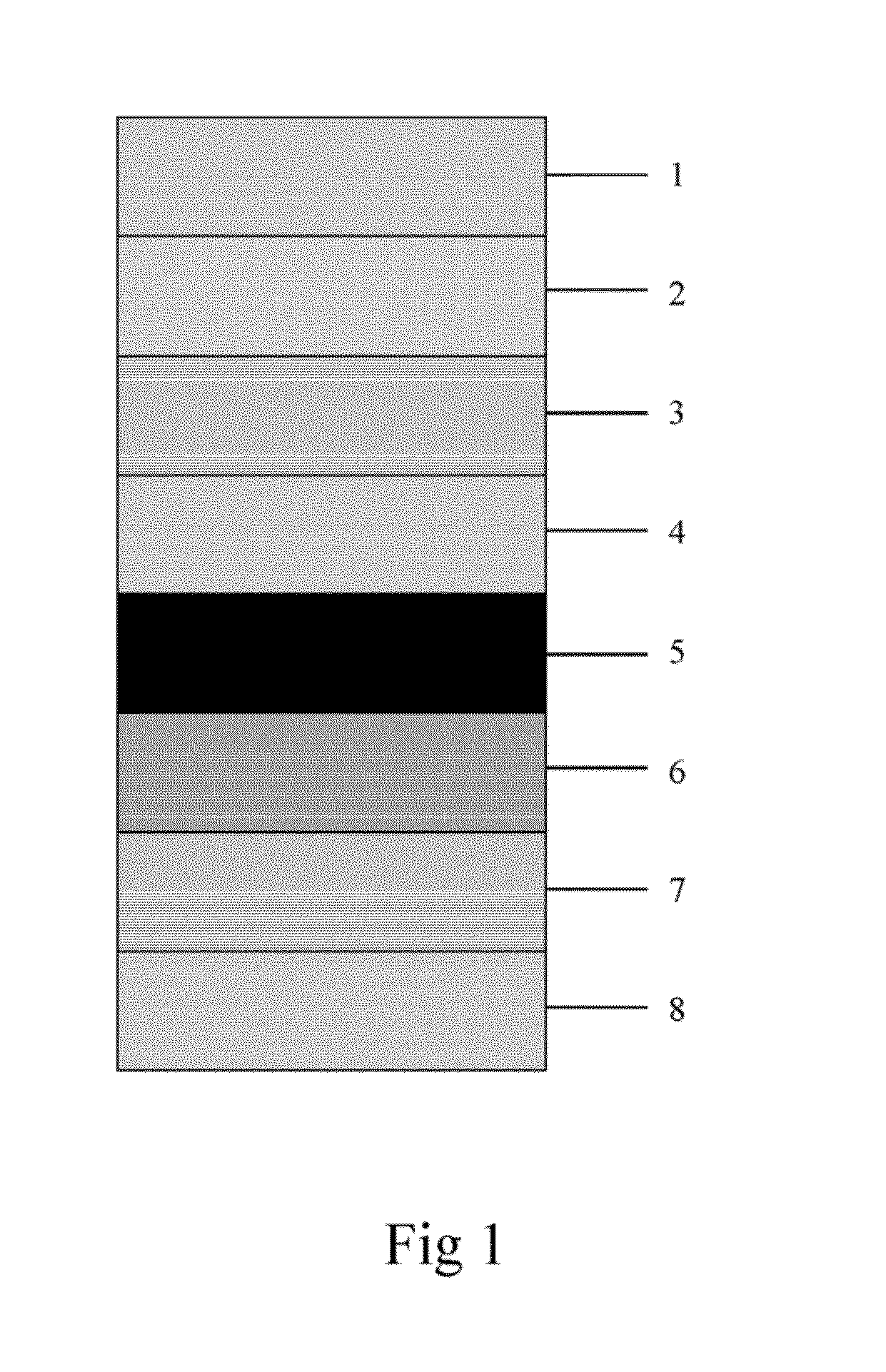

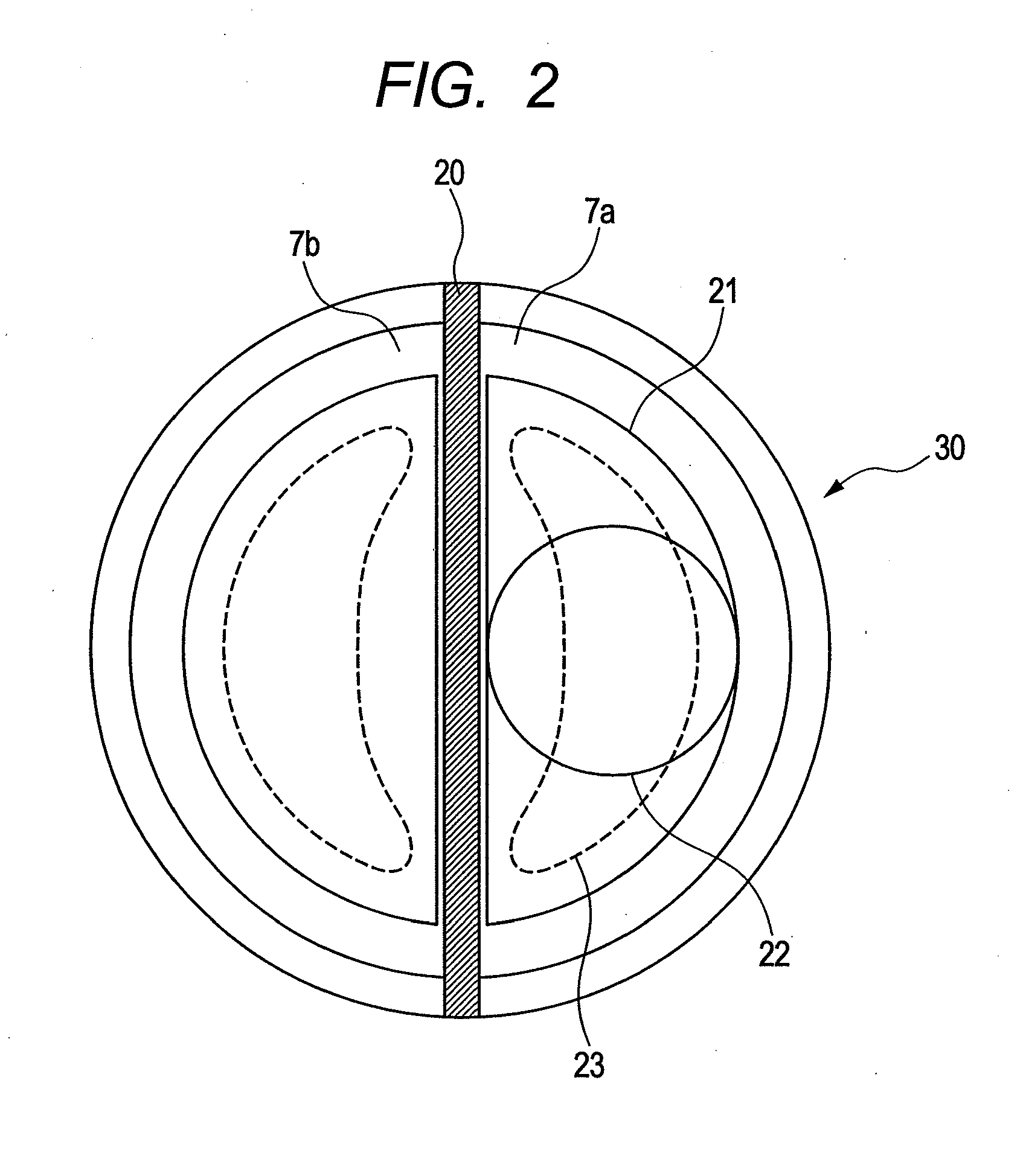

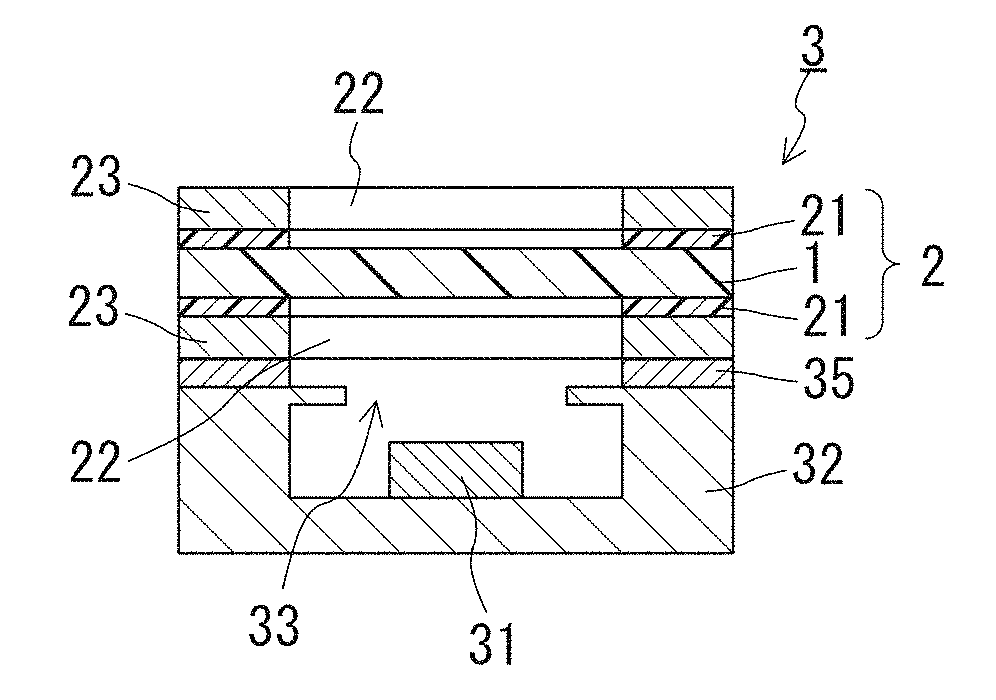

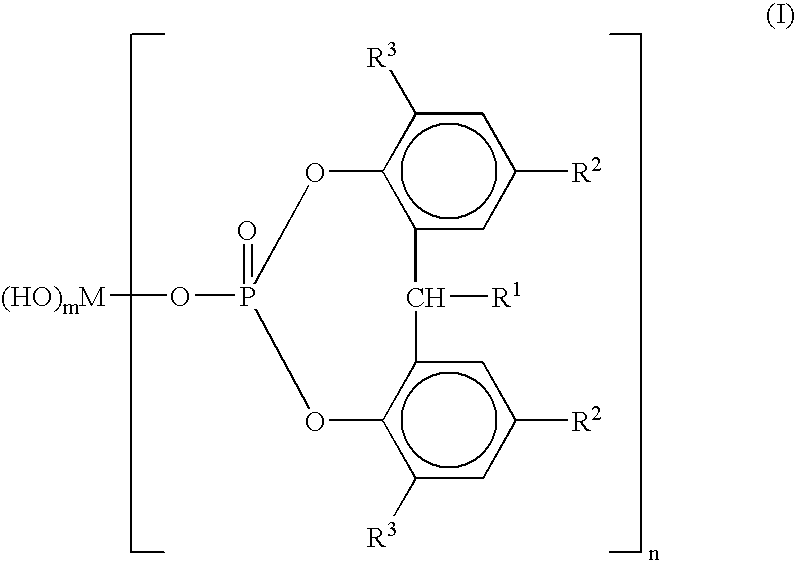

Multilayer mirror, method for manufacturing the same, and exposure equipment

InactiveCN1868033ALittle complianceImprove reflectivityMirrorsHandling using diffraction/refraction/reflectionOptoelectronicsThermal expansion

A multilayer film reflection mirror intended to reduce the dependency of reflectance on an incident angle. A substrate (1) is made of a low-thermal-expansion glass polished until its surface (top surface in the FIG.) has a roughness of up to 0.2 nmRMS. An Ru / Si multilayer film (3) having the large half width of peak reflectance is formed on the surface of the substrate (1), and an Mo / Si multilayer film (5) having a high peak reflectance is formed on this Ru / Si multilayer film (3). Accordingly, a reflectance peak having a higher reflectance than the case with of Ru / Si only and a larger half width than the case with of Mo / Si multilayer film (5) only is obtained. Since Ru provides a larger EUV beam absorption than Mo, a higher reflectance than with the case of a structure in which the Ru / Si multilayer film (3) is formed on the Mo / Si multilayer film (5) is obtained. Since a multilayer film having a larger half width at a spectral reflectance has a smaller dependency of reflectance on an angle, the invention can keep a high imaging performance in a projection optical system.

Owner:NIKON CORP

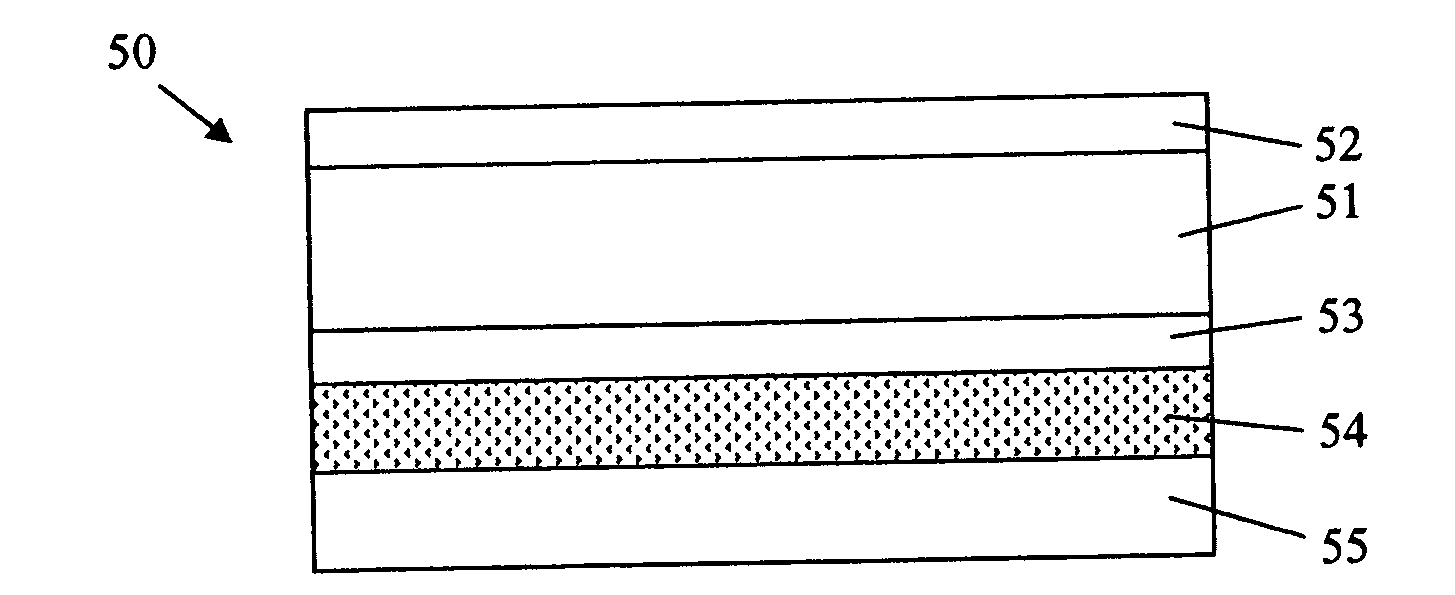

Anti-Scalping Transdermal Patch Packaging Film

A flexible, multilayer packaging film suitable for packaging an article for collecting or administering a physiologically active substance such as transdermal drug delivery patches, oral dissolvable thin strips, and disposable, microfluidic test cassettes having:(a) an article contact layer having at least 90 wt. % of a norbornene ethylene copolymer or derivative thereof and a glass transition temperature of from 65 to 110° C.;(b) a polyolefin bulk layer;(c) a first intermediate adhesive layer;(d) an oxygen barrier layer having an oxygen transmission rate of less than less than 0.01 cm3 / 100 inches2 / 24 hours at 1 atmosphere and 23° C.;(e) a second intermediate adhesive layer; and(f) an exterior protective layer comprising a polymer selected from the group consisting of amorphous polyester, polyamide, polyolefin, nylon, polypropylene, or copolymers, blends or derivatives thereof;wherein said multilayer film has the following properties:a WVTR of less than 0.01 g / 100 inches2 per 24 hours at Room Temperature (RT) (23° C.) and 1 atmosphere; and a thickness of 10 mil or less.

Owner:BEMIS COMPANY INC

High-obstruct multiple-layer film for packaging liquid and manufacturing method thereof

InactiveCN101081653AReduce consumptionReduce thicknessFlexible coversWrappersPolyesterPolymer science

The present invention discloses one kind of multilayer high blocking film for packing liquid material, the multilayer high blocking film includes polyethylene-based heat sealing layer(s), blocking polymer layer(s) preferably of ethylene-vinyl alcohol copolymer, PVA or polyvinylidene dichloride; and protecting layer(s) of polypropylene, polyester, etc. It has the total thickness below 80 micron, preferably of 55-65 micron. The present invention discloses also the making process of the multilayer high blocking film.

Owner:刘建林

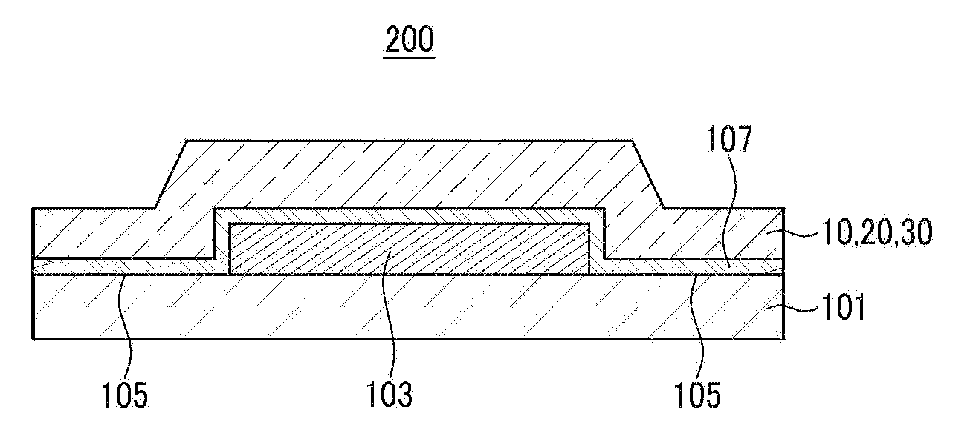

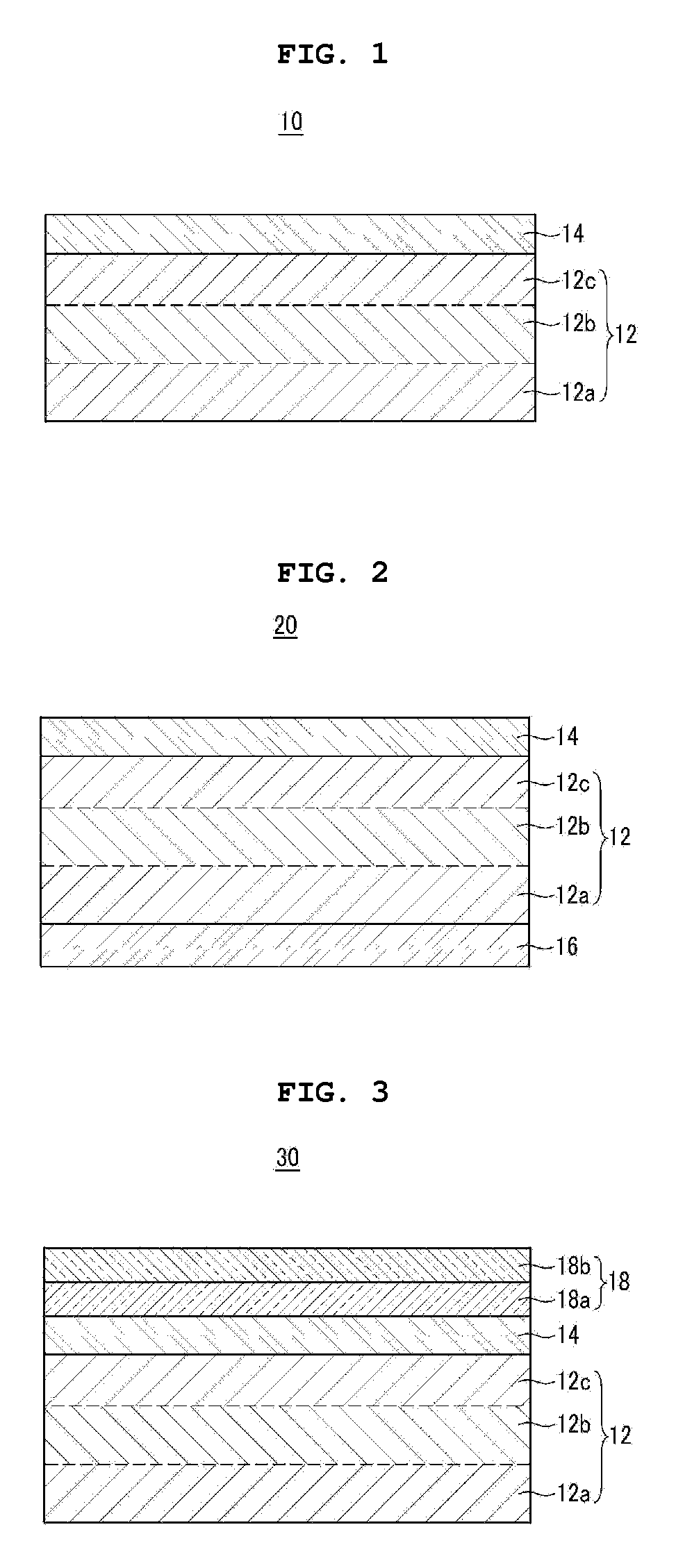

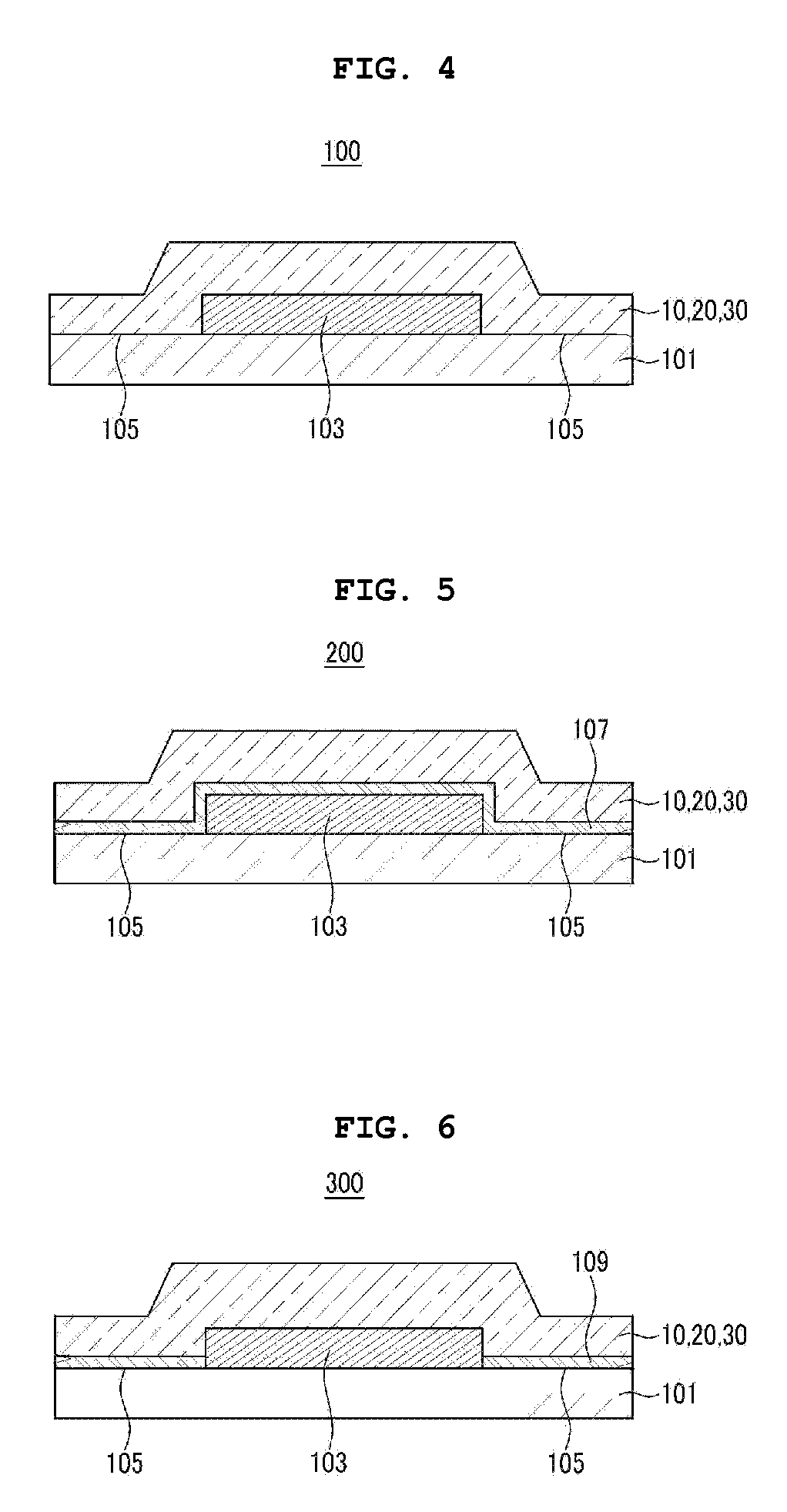

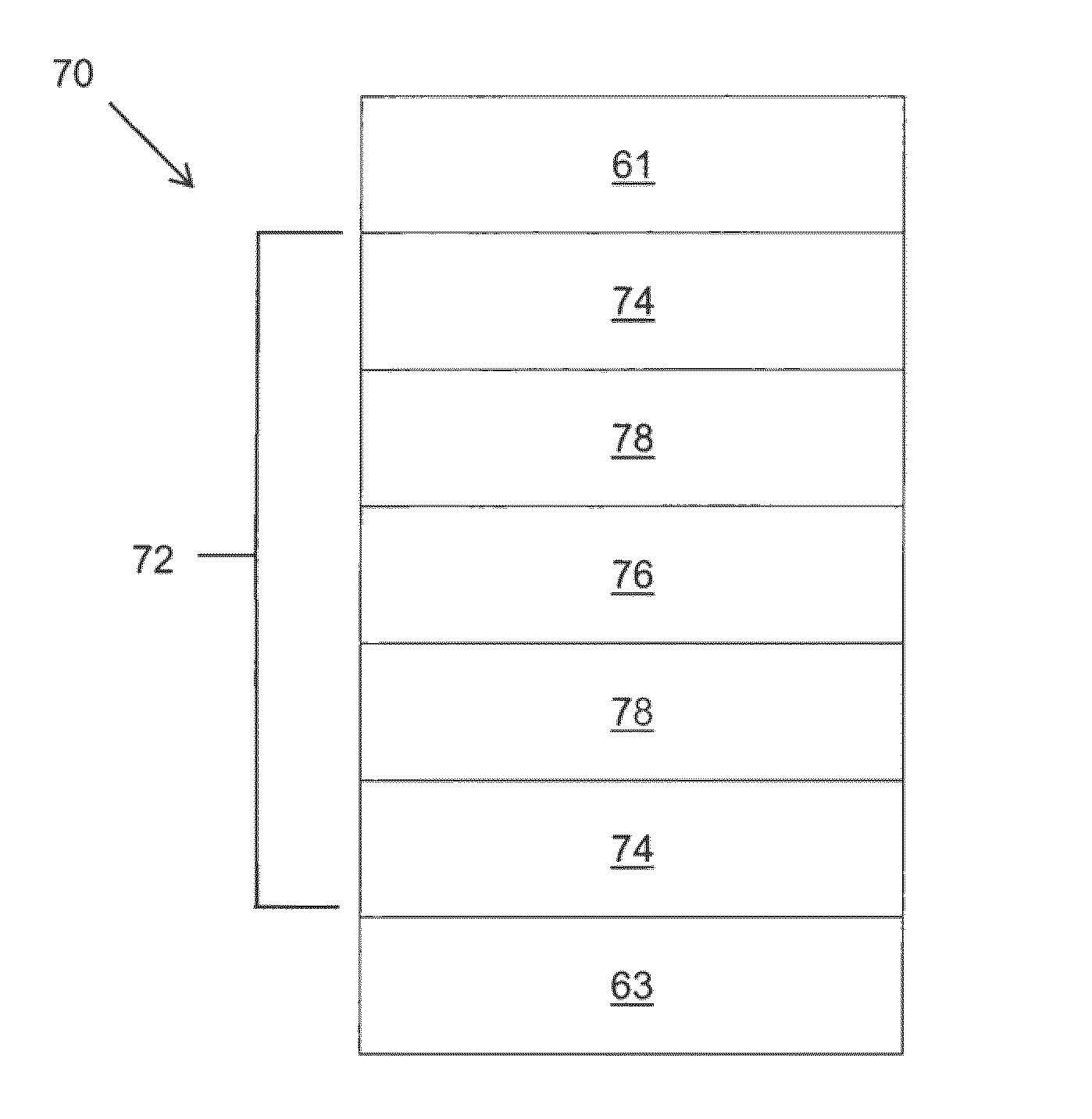

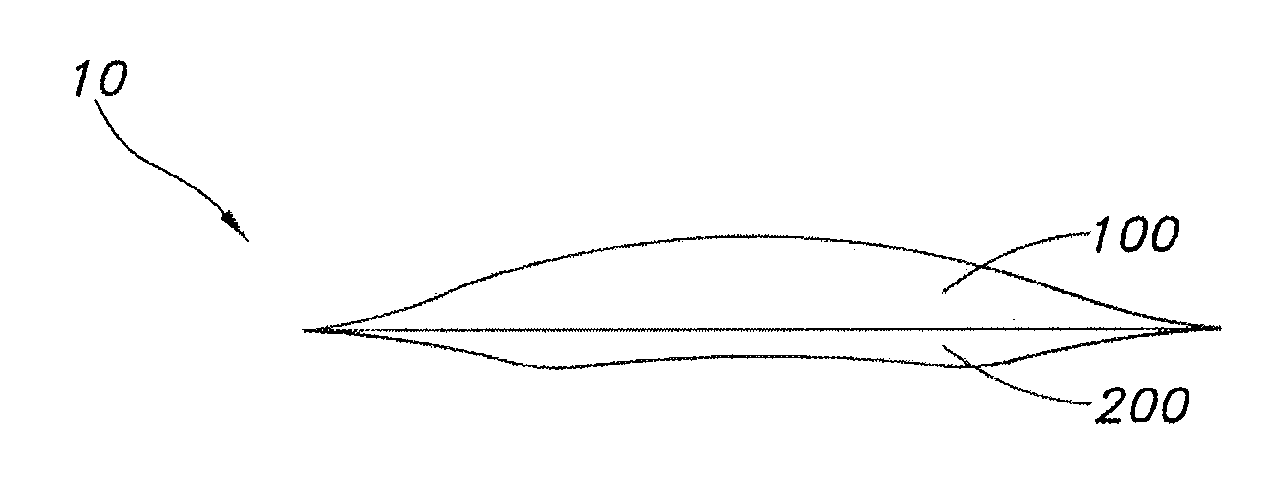

Multilayer film, method for manufacture thereof and articles including the same

A multilayer film is provided. The multilayer film includes a barrier layer and an adhesive layer underlying the barrier layer. The adhesive layer contains a block copolymer that can phase separate into two or more different domains. The multilayer film has good gas and moisture barrier properties and is highly flexible. Therefore, the multilayer film can be effectively used in manufacturing encapsulation structures for electronic devices. In addition, the multilayer film is suitable for use as a substrate for a device. Further provided are a method for producing the multilayer film and an encapsulation structure including the multilayer film.

Owner:SAMSUNG ELECTRONICS CO LTD

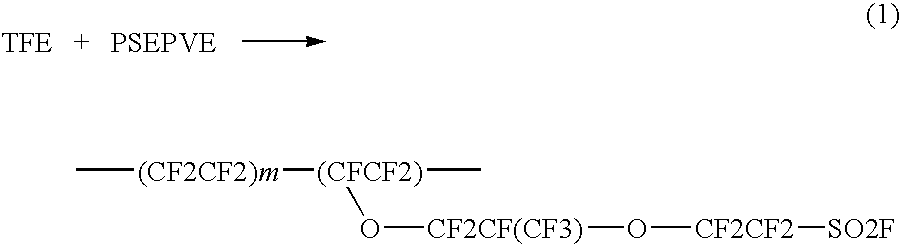

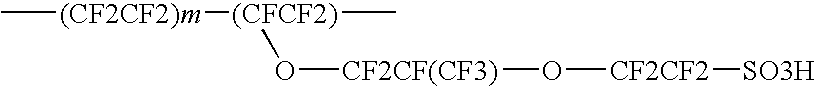

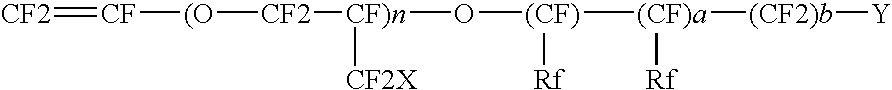

Fluorochloro Ionomers

This invention discloses novel fluorochloro ionomers and processes of making them. The first preferred body of invention is perfluorochloro ionomers having (1) equivalent weight between 600 and 1500, preferably between 800 and 1200, and most preferably between 900 and 1100; (2) chlorine content between 8% and 30% by weight. These ionomers are breathable and excellent barrier materials, capable of being processed into thin films or membranes and are well suited for low humidity or high temperature fuel cell applications and for chemical protective covering materials. The second preferred body of invention is partially fluorochloro ionomers having (1) moisture vapor permeability rate >3000 gram H2O / m2 / day (about ½ mil thick film); (2) chlorine content of between 10% and 39% by weight. These ionomers are breathable and excellent barrier materials that can also be processed into thin films or membranes and are suited for some fuel cell applications and more preferably for breathable protective covering applications. The membranes can be monolithic films or multi-layers films, or composite films, or bipolar membranes. These novel fluorochloro ionomers are made by radical copolymerization of at least one fluorochloro monomer and at least one comonomer consisting of at least ionic group or at least one precursor that can be converted to ionic groups such as acid groups or amines or quaternary amine groups. The said fluorochloro monomer containing at least one fluorine and at least one chlorine atom is free radical polymerizable including chlorotrifluoroethylene (CFCl═CF2) and dichlorodifluoroethylene (CFCl═CFCl).

Owner:ZHEJIANG HYPROOF TECH CO LTD

Sound-transmitting membrane for microphone, sound-transmitting membrane member for microphone provided with the membrane, microphone, and electronic device provided with microphone

ActiveUS9253297B2Condensation suppressionEnsure performancePiezoelectric/electrostrictive microphonesElectrostatic transducer microphonesAcoustic transmissionForeign matter

Owner:NITTO DENKO CORP

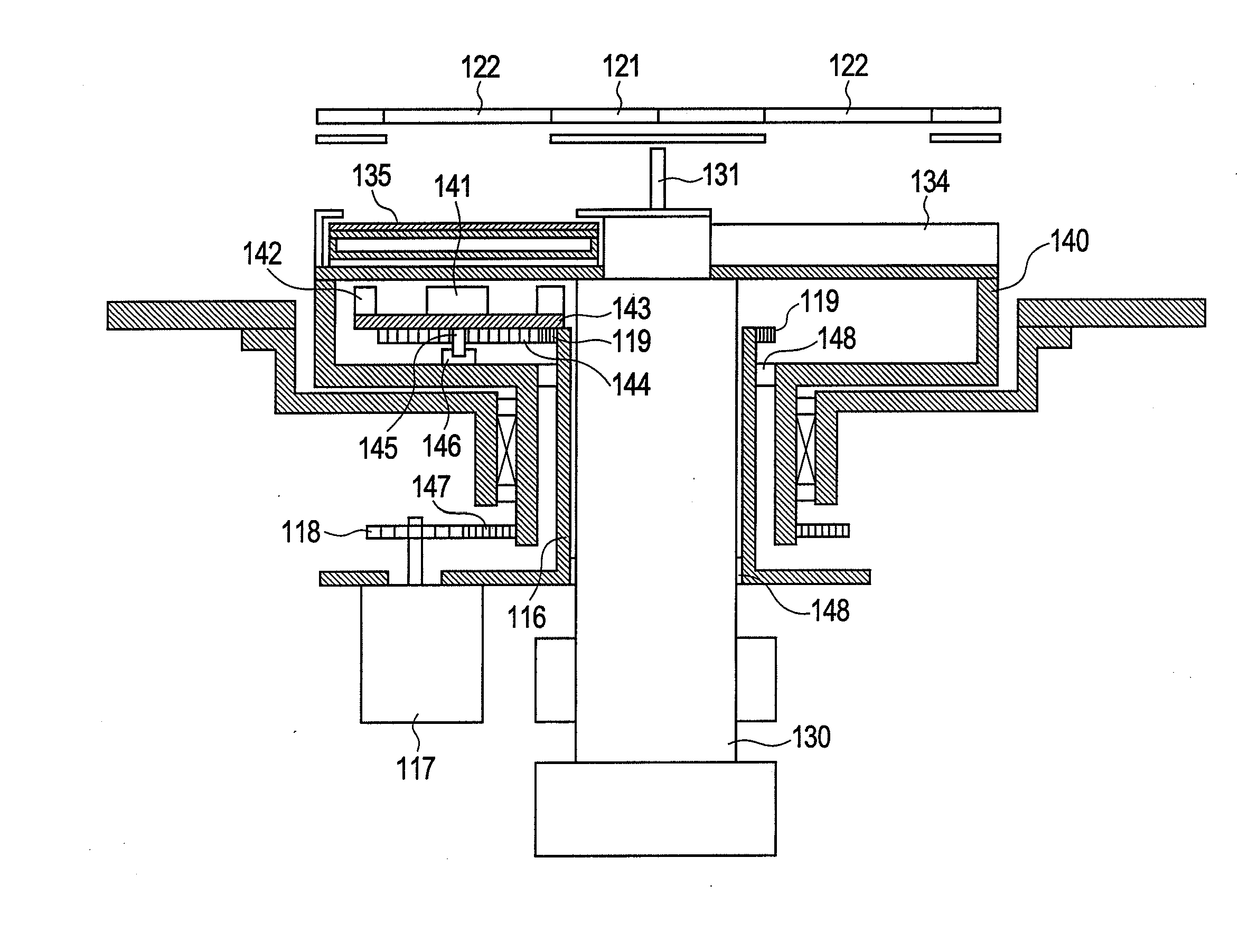

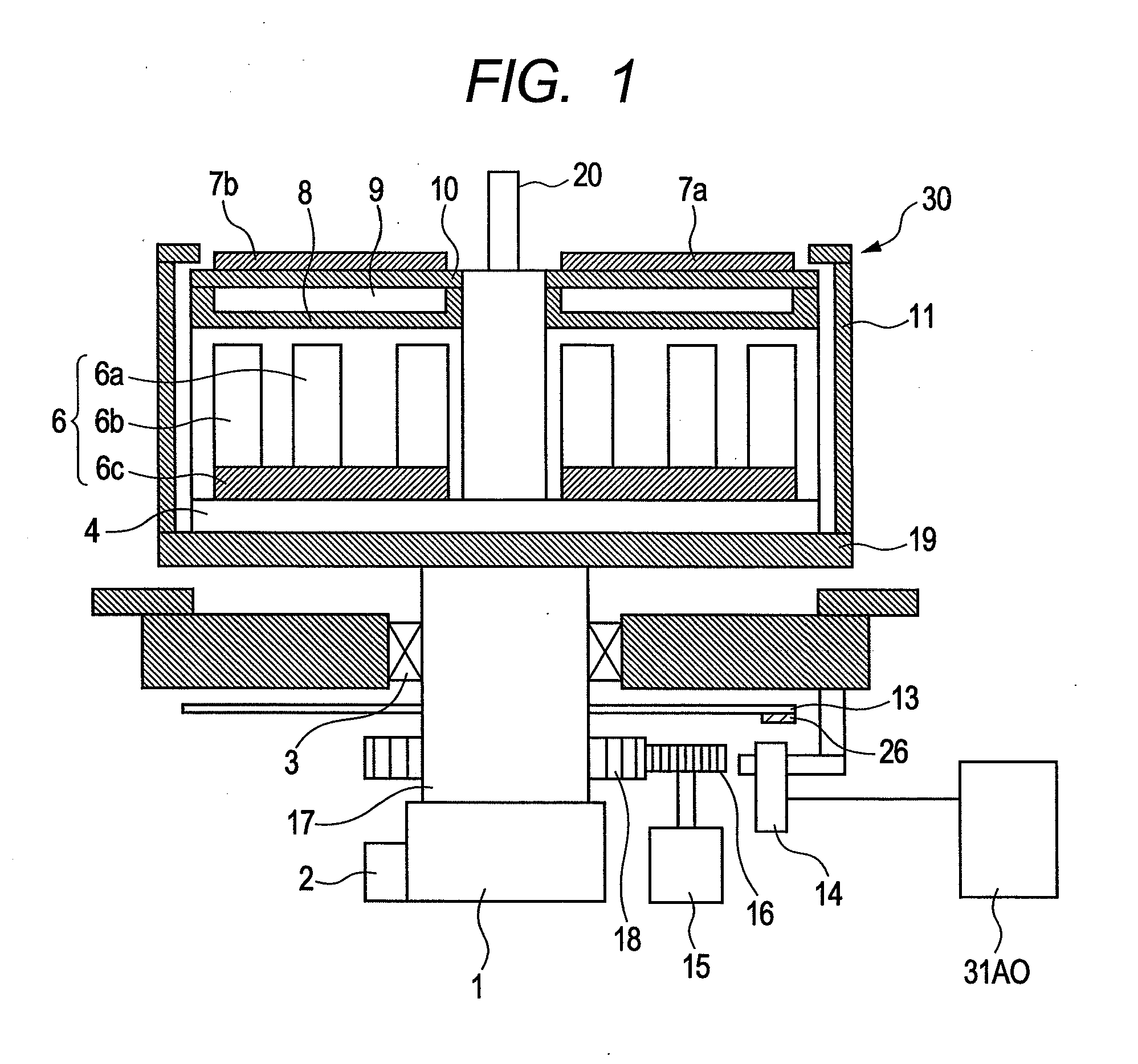

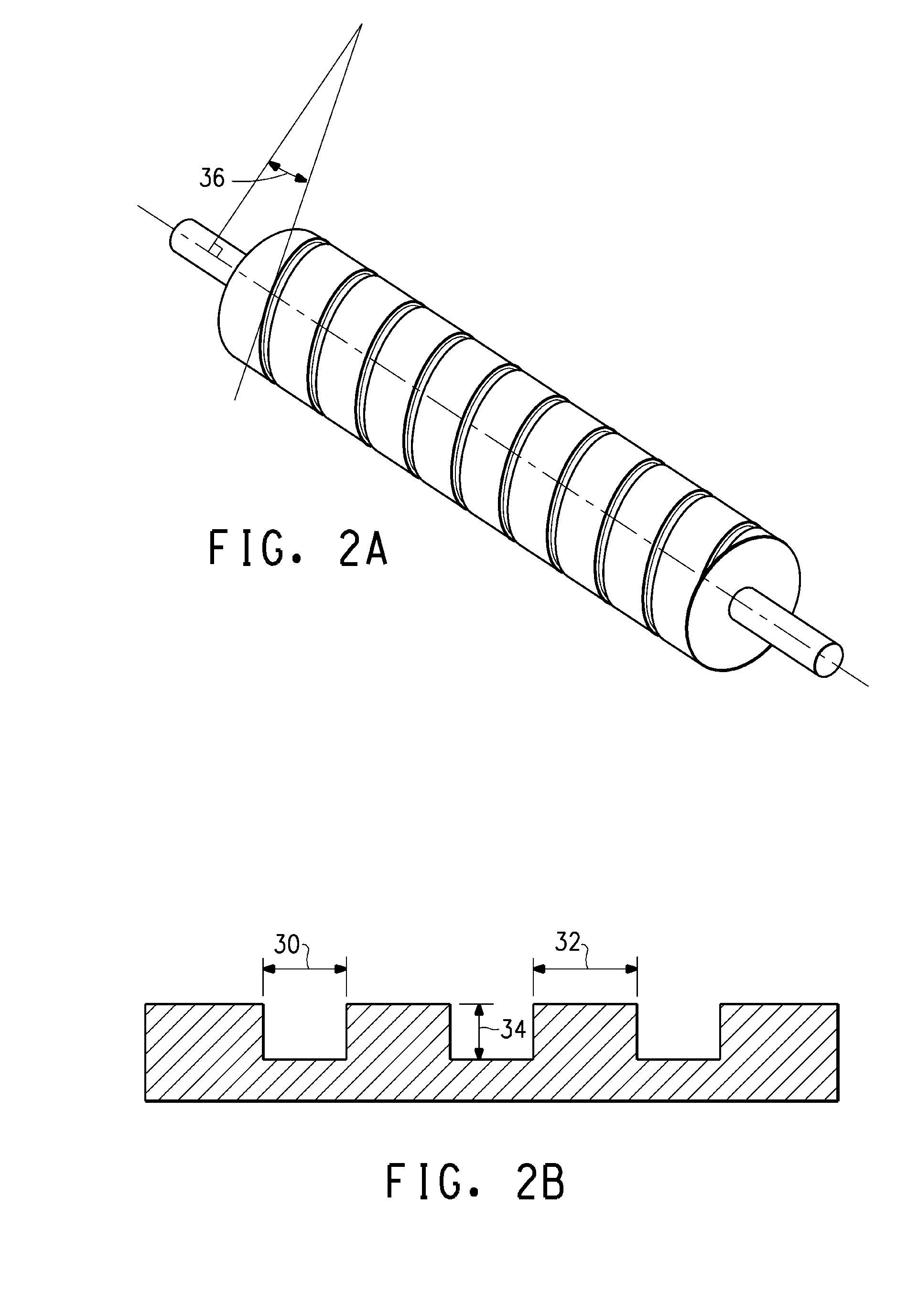

Multilayer-film sputtering apparatus and method of forming multilayer film

ActiveUS20110168545A1Improve efficiencyImprove productivityCellsElectric discharge tubesProduction rateSputtering

Provided is a sputtering apparatus which can form a multilayer film giving high productivity and with less spiral pattern by effective use of targets, and a method of forming multilayer film using the apparatus. An embodiment is a multilayer-film sputtering apparatus comprising: a rotatable cathode unit (30) having cathodes (7a and 7b) arranged on the same circumference with respect to the rotational center, and having a power-supply mechanism for supplying power to each cathode; a sensor (14) for detecting the position of cathode; and a rotation mechanism for rotating the cathode unit (30).

Owner:CANON ANELVA CORP

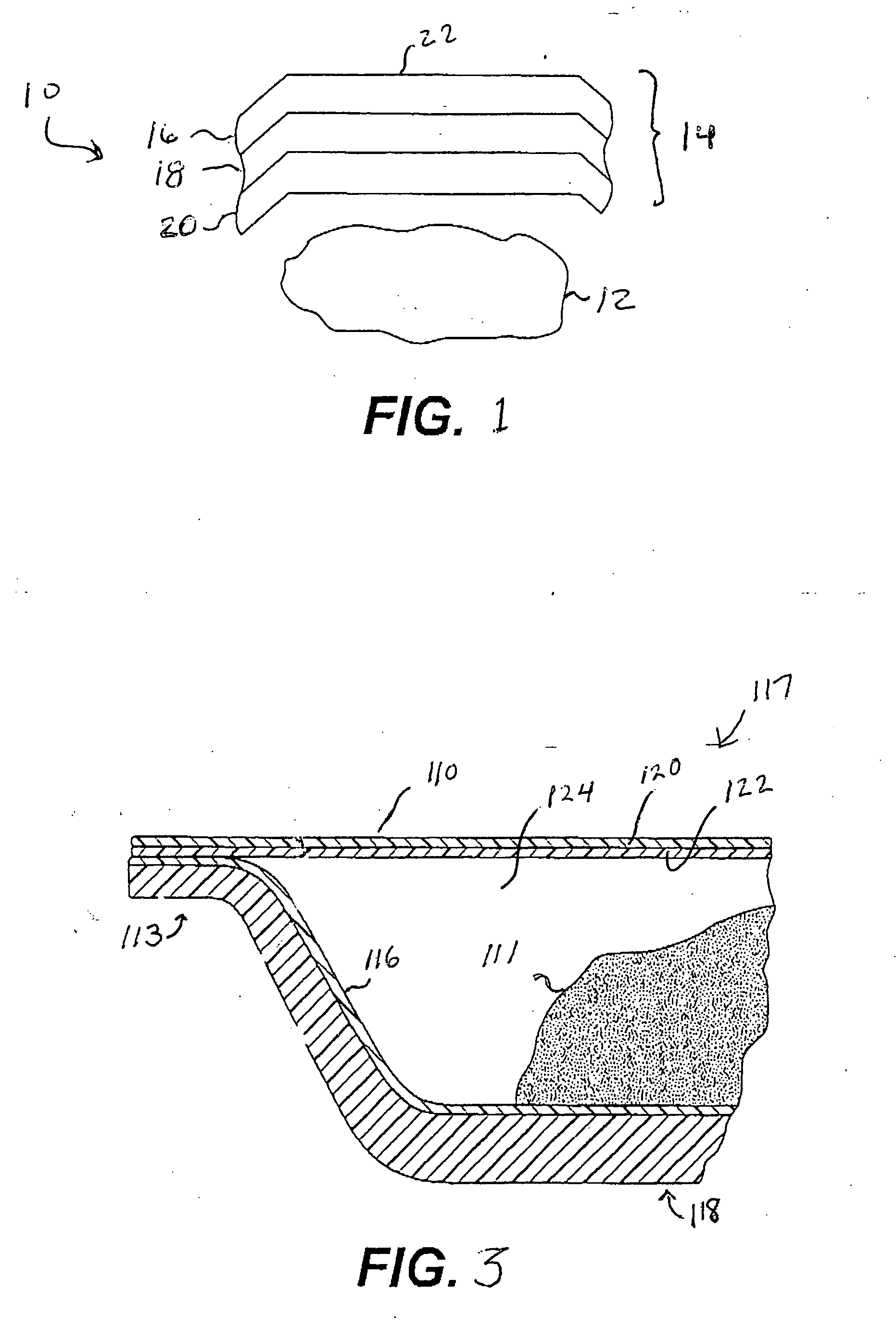

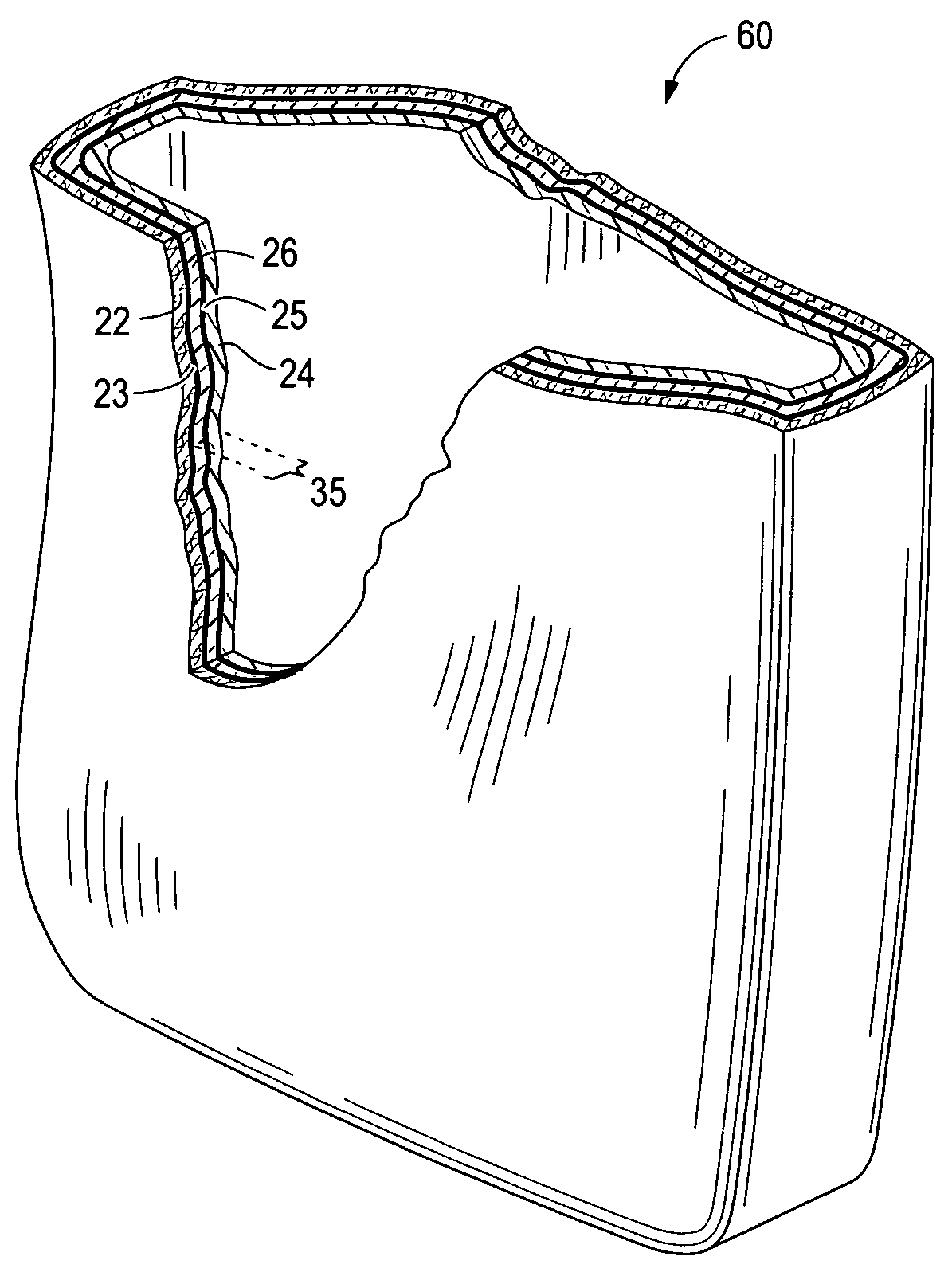

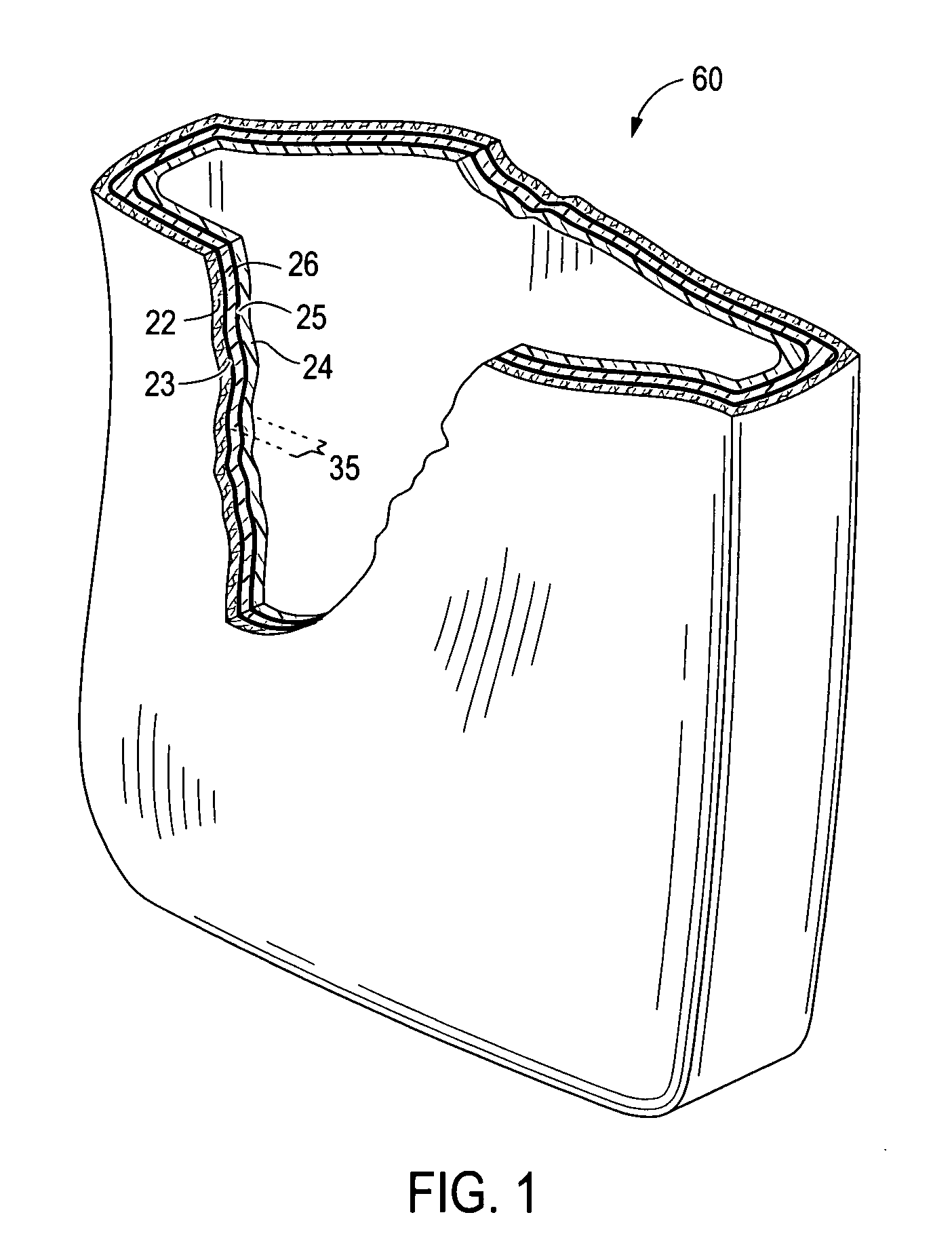

Tear resistant bag for consumables

The invention is a tear-resistant container or bag made with a multilayer film comprising a composite structure of relatively inexpensive polymers and paper. The multilayer composite structure generally consists of an oriented polymer film layer adhered to a reinforcing scrim layer via a thermal bonding layer, to form a backing structure, and at least one paper layer adhered to the backing structure.

Owner:DUPONT TEIJIN FILMS US LTD

Multilayer films

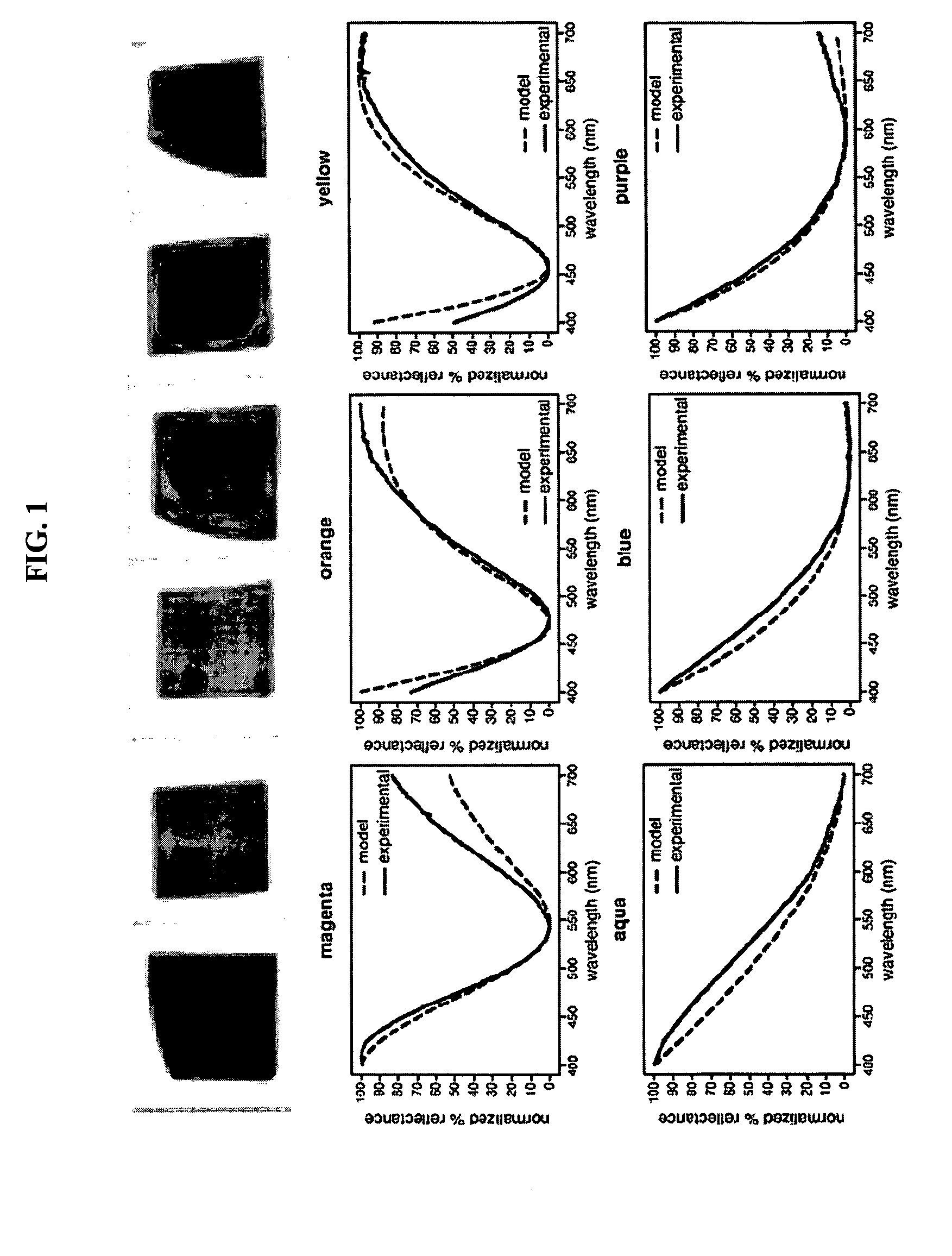

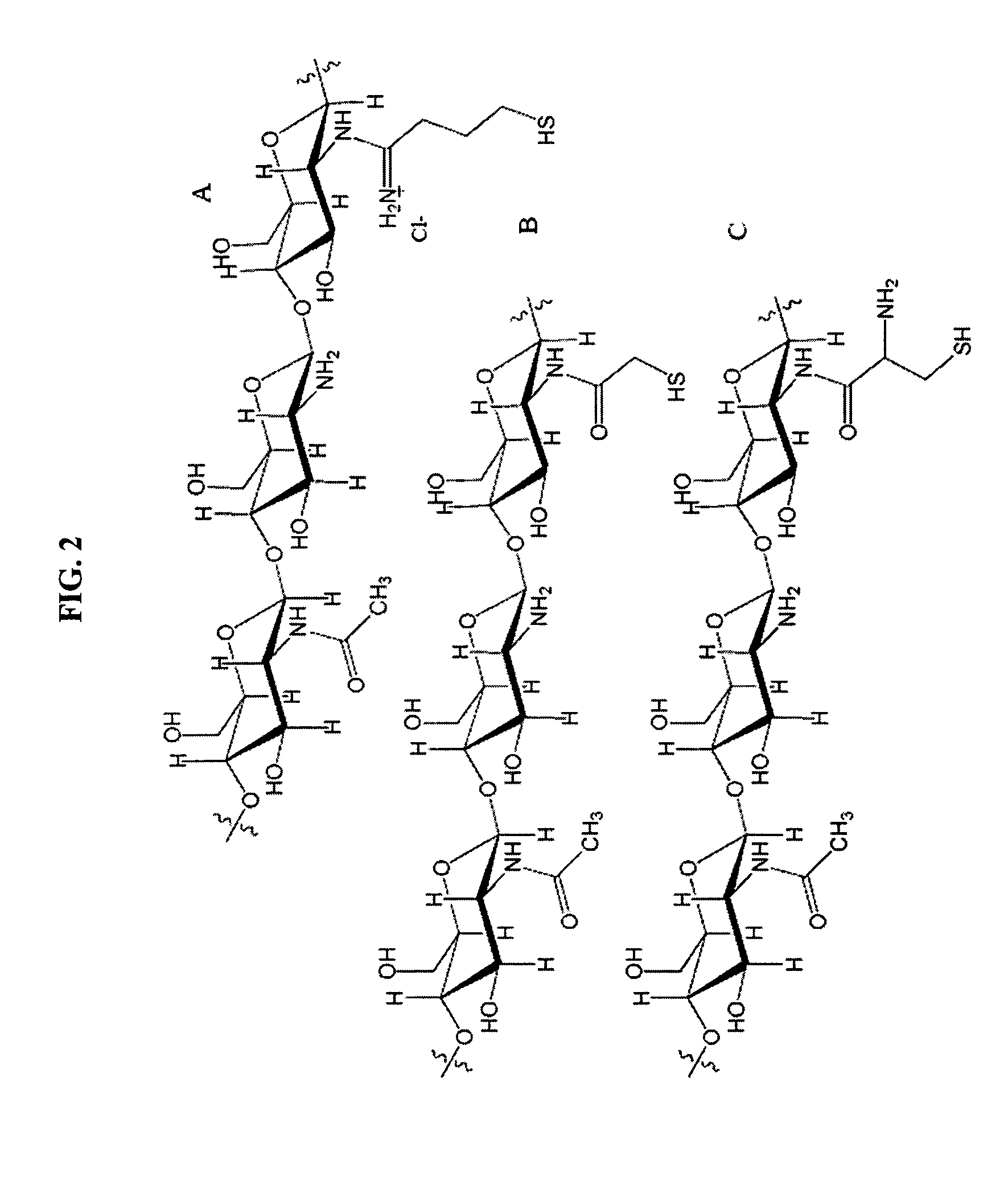

InactiveUS20100062232A1Cosmetic preparationsMaterial analysis by observing effect on chemical indicatorCrosslinked chitosanMultilayer membrane

The present invention concerns multilayer films comprising a plurality of layers, at least some of the layers comprise (i) cross-linked chitosan, alginate, chondroitin sulfate, or hyaluronic acid and (ii) particles or void spaces; wherein the layers are 20-260 nm in thickness. Also disclosed are multilayer films comprising at least two of: a layer comprising a first polymer; a layer comprising a second polymer; a layer comprising particles, wherein said particles comprise ceramic material, metallic species, or both; and, a layer comprising a combination of said first polymer and said particles; wherein said multilayer film is capable of displaying structural color. Also provided are methods for making and using the inventive multilayer films and compositions comprising the multilayer films.

Owner:DREXEL UNIV

Thermoplastic film with good interply adhesion

A multilayer film including an outer layer that includes a homo- or interpolymer of propylene and, directly adhered to the outer layer, a layer that includes a homogeneous ethylene / alpha-olefin interpolymer having a density of no more than about 0.91 g / cm3 exhibits good seal strength and good adhesion between the two layers, even in areas where the film is sealed, even after the film is oriented, even when the film is subjected to the elevated temperatures involved in cook-in procedures, and even where the film is subjected to, e.g., grease from fatty foods. The film also can include one or more, for example, bulk layers, O2-barrier layers, and / or abuse layers.

Owner:CRYOVAC ILLC

Multilayer film

ActiveUS20130260144A1Excellent gas barrier performanceHigh laminate strengthSynthetic resin layered productsRecord information storageAcrylic resinPeak intensity

The invention provides a multilayer film comprising a substrate film and a coating layer arranged on at least one surface of the substrate film, wherein the coating layer contains an oxazoline group and comprises an acrylic resin, the coating layer has a thickness (D) of 5-150 nm, and the ratio (P1 / P2) of the peak intensity (P1) of a peak that has an absorption maximum in a region of 1655±10 cm−1 to the peak intensity (P2) of a peak that has an absorption maximum in a range of 1580±10 cm−1 in the total reflection infrared absorption spectrum of the coating layer and the thickness (D) of the coating layer fulfill the relationship represented by the formula: 0.03≦(P1 / P2) / D≦0.15.

Owner:TOYO TOYOBO CO LTD

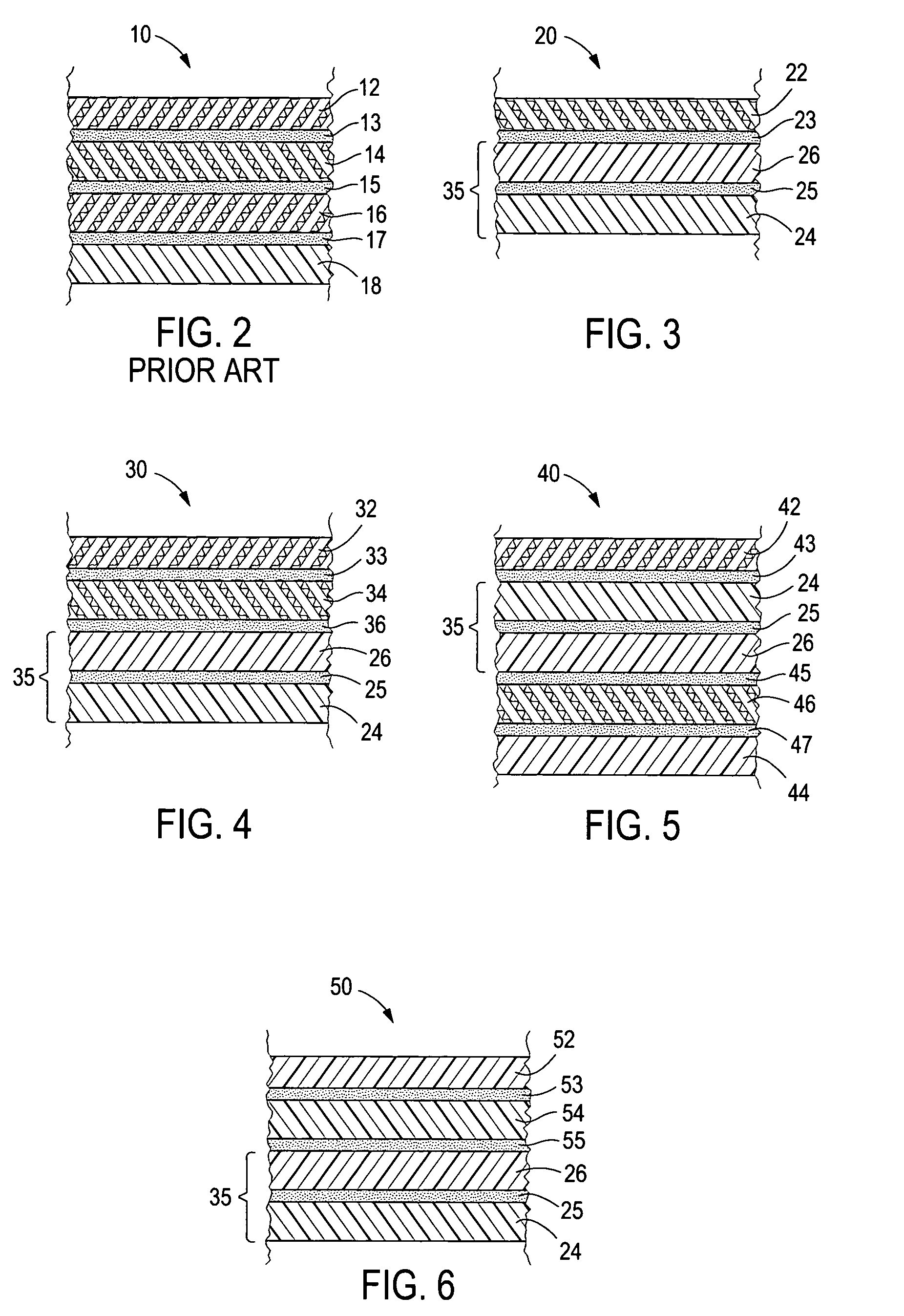

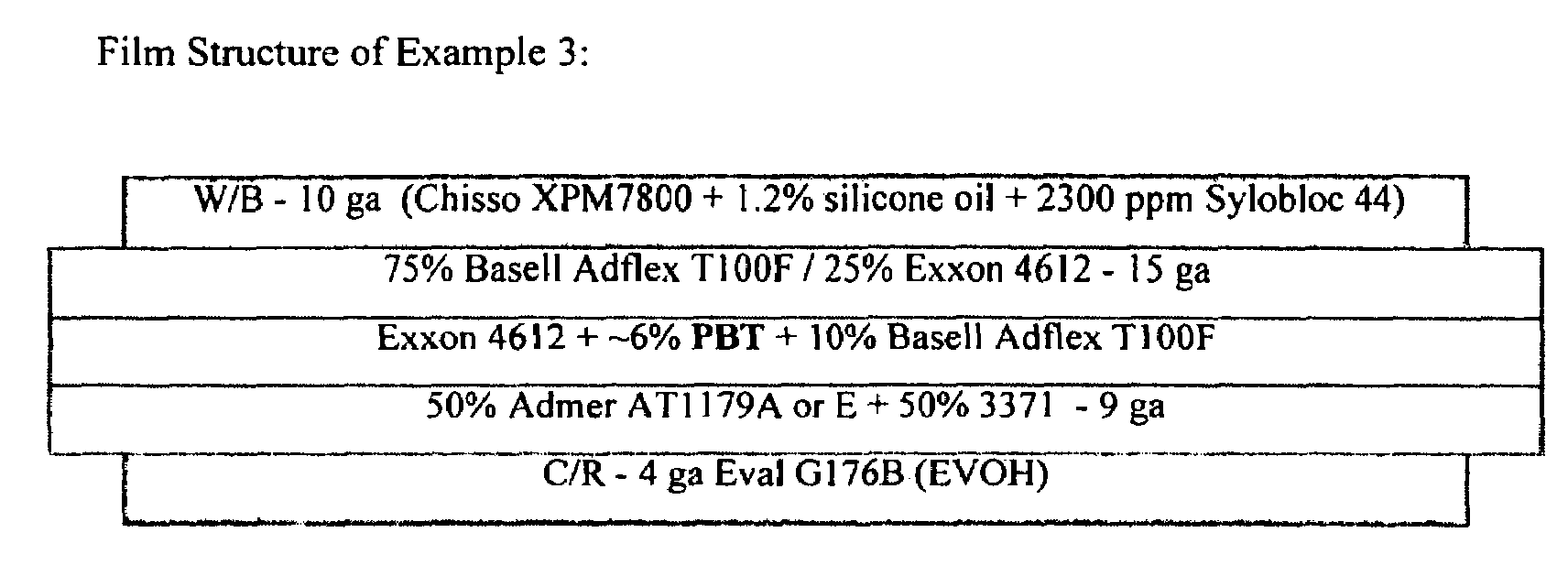

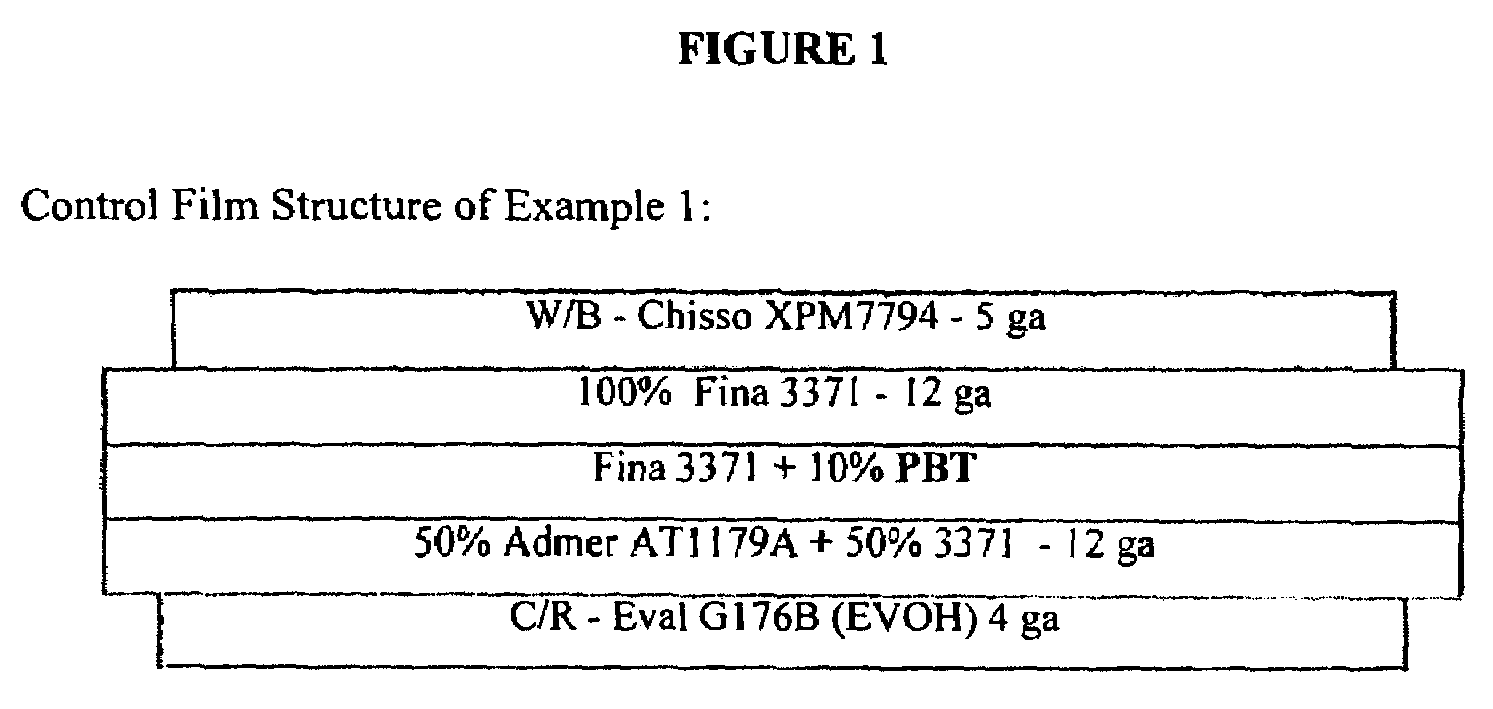

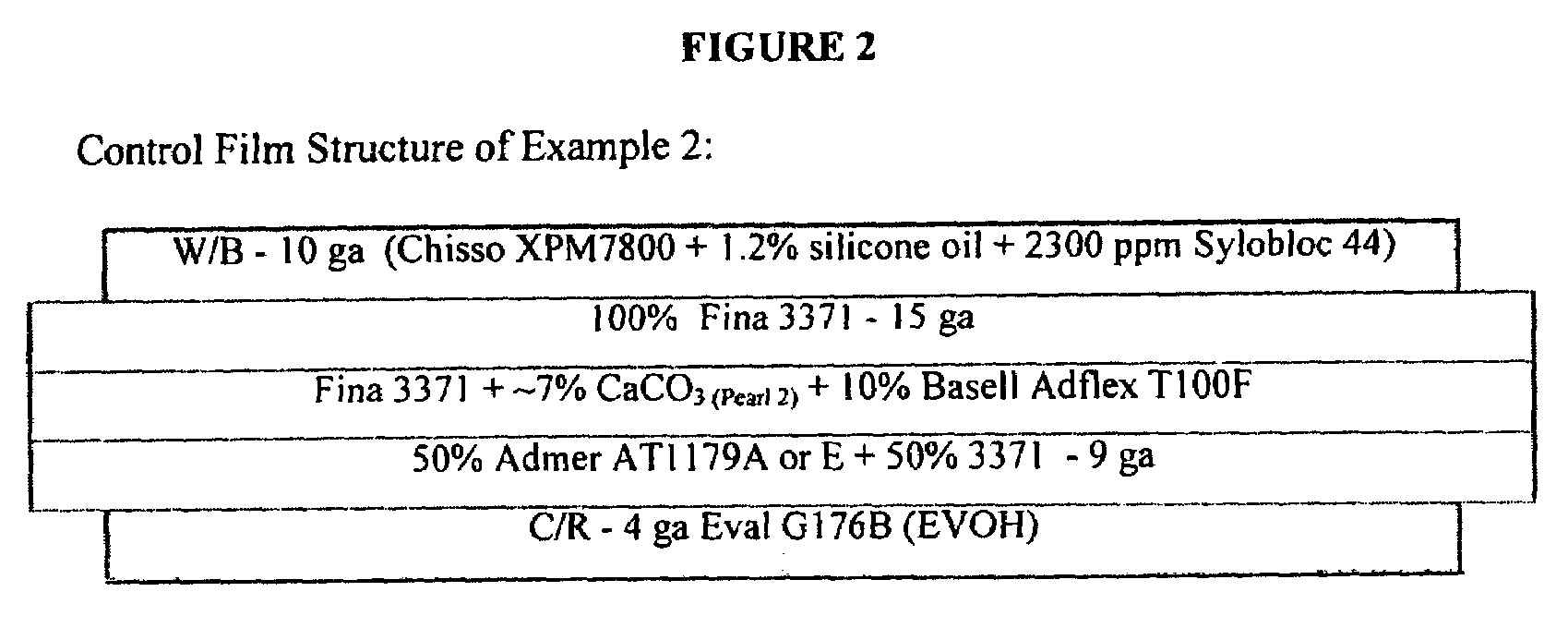

Multi-layer films having improved sealing properties

InactiveUS7537829B2Improving seal strength and impact strength and resilience and hermeticityReduced-temperature sealabilitySynthetic resin layered productsLaminationEngineeringPolymer

Multi-layer films that are suitable for packaging and having improved sealing properties are disclosed. Some embodiments may also provide a lower minimum sealing temperature. A soft polymer is blended in a core layer and a tie layer comprising the soft polymer and, optionally, another polymer. A sealable layer is provided on the side of the tie layer opposite the core layer. The multi-layer films may be transparent, contain a cavitating agent, or are pigmented to form an opaque film. Also, the multi-layer film may be metallized or coated with a barrier coating.

Owner:JINDAL FILMS AMERICAS LLC

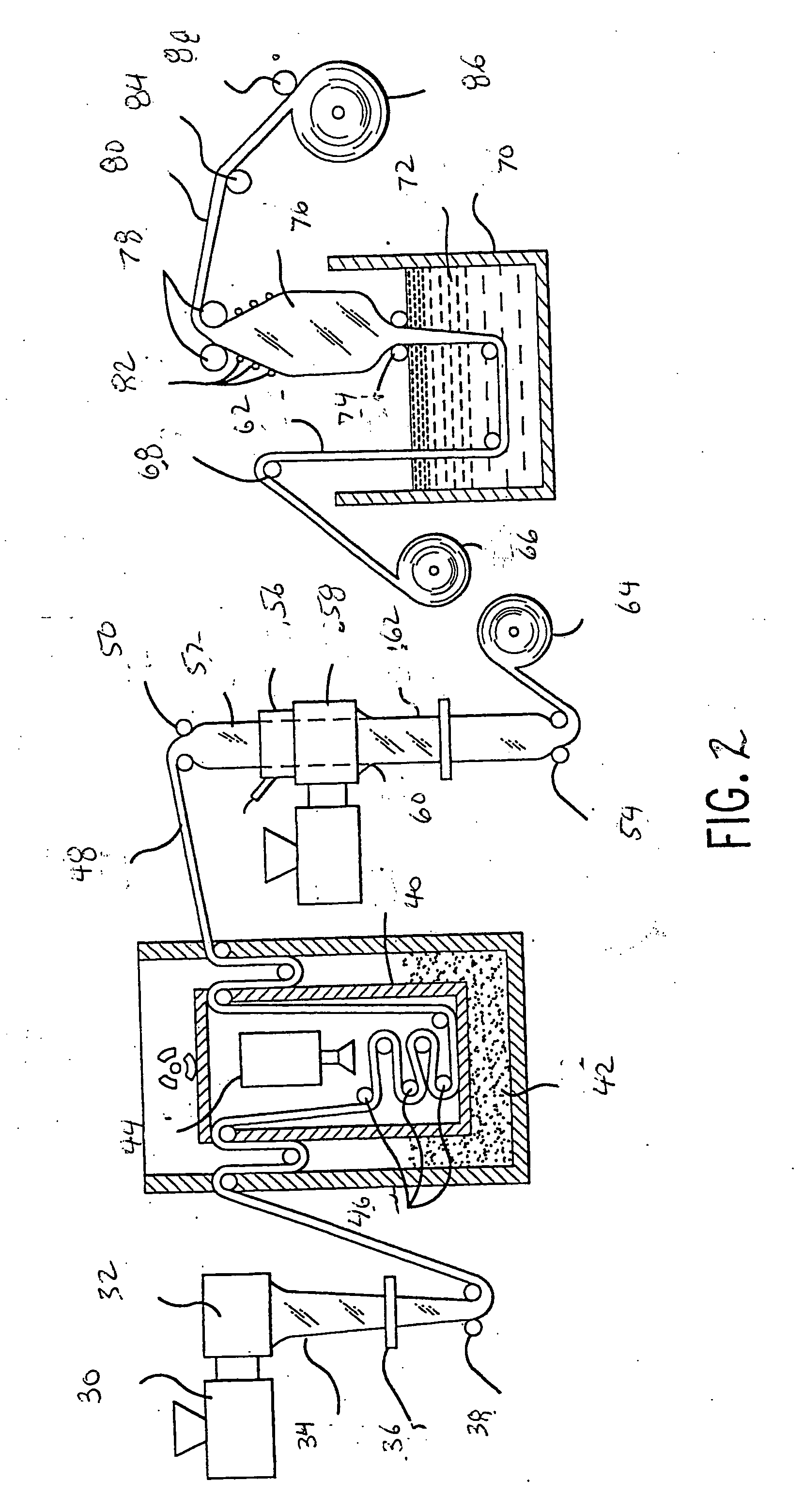

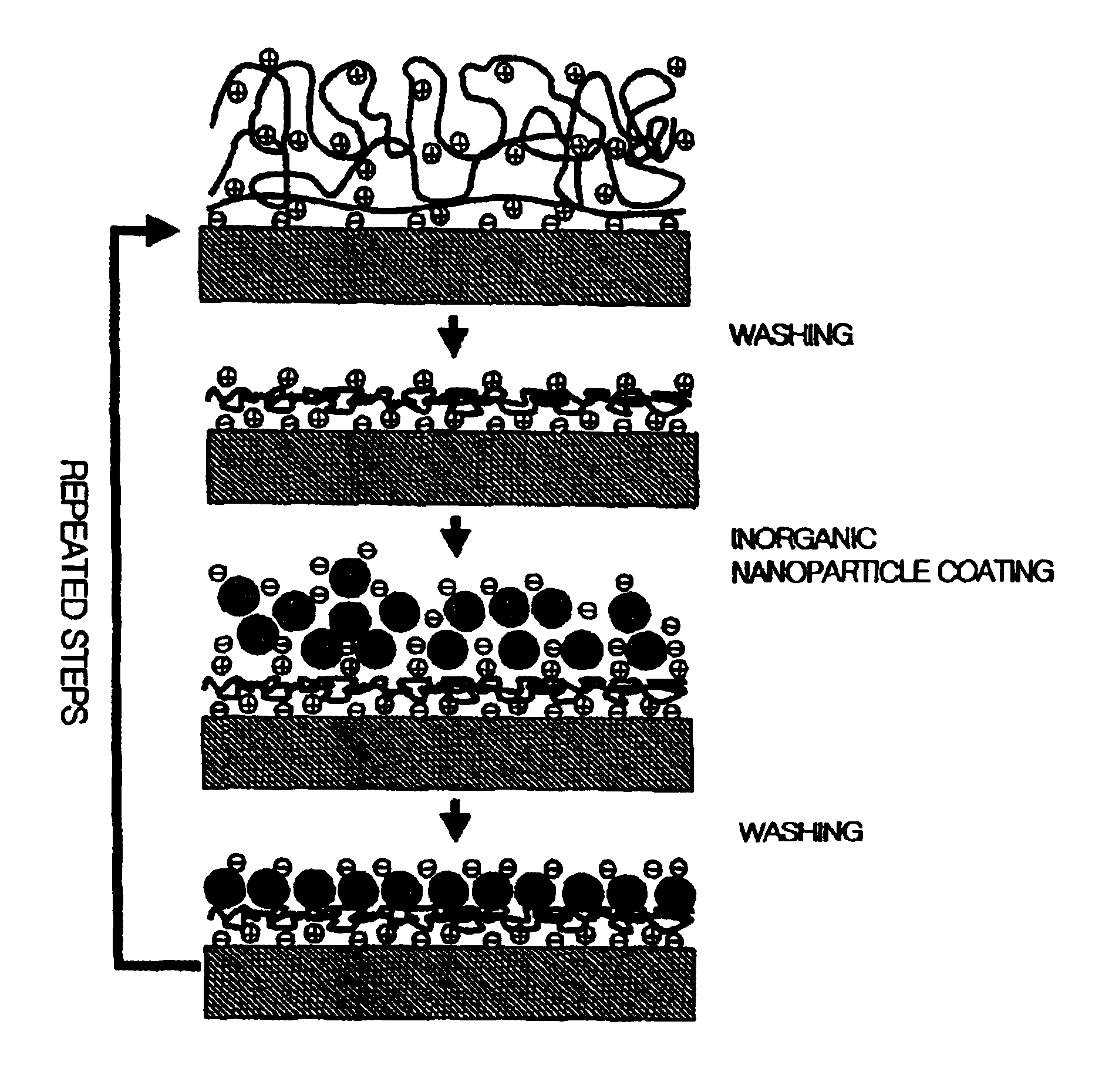

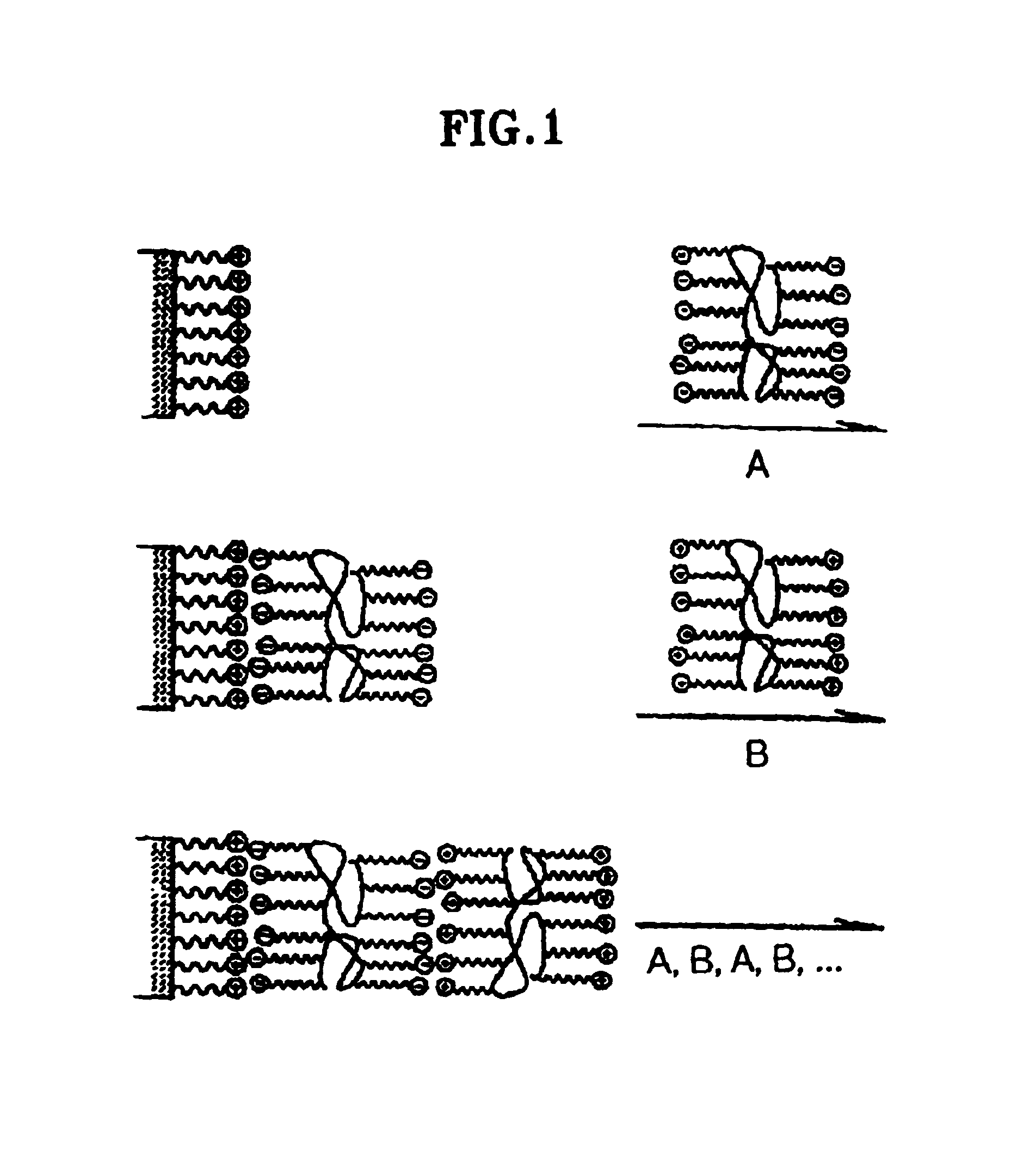

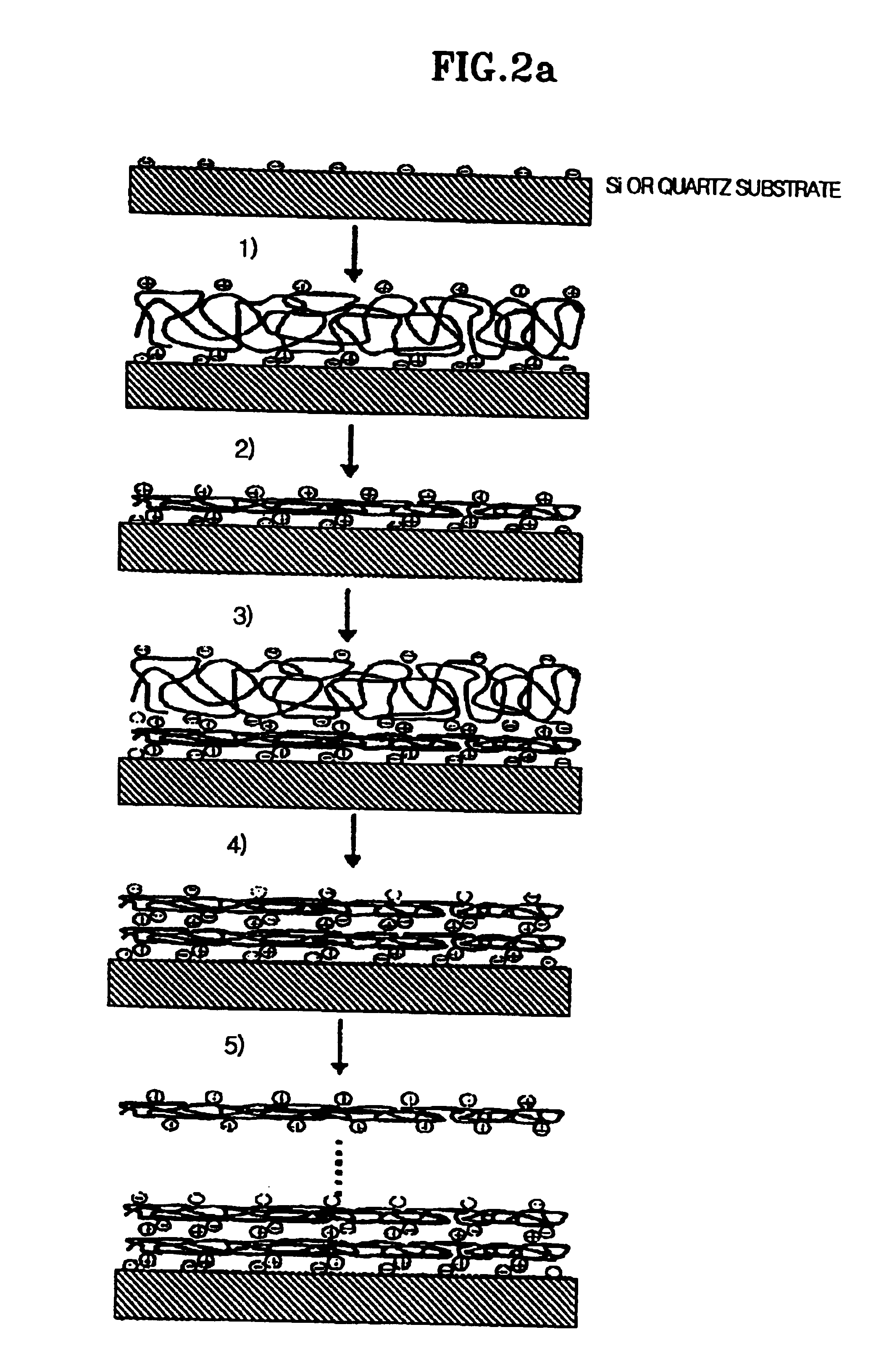

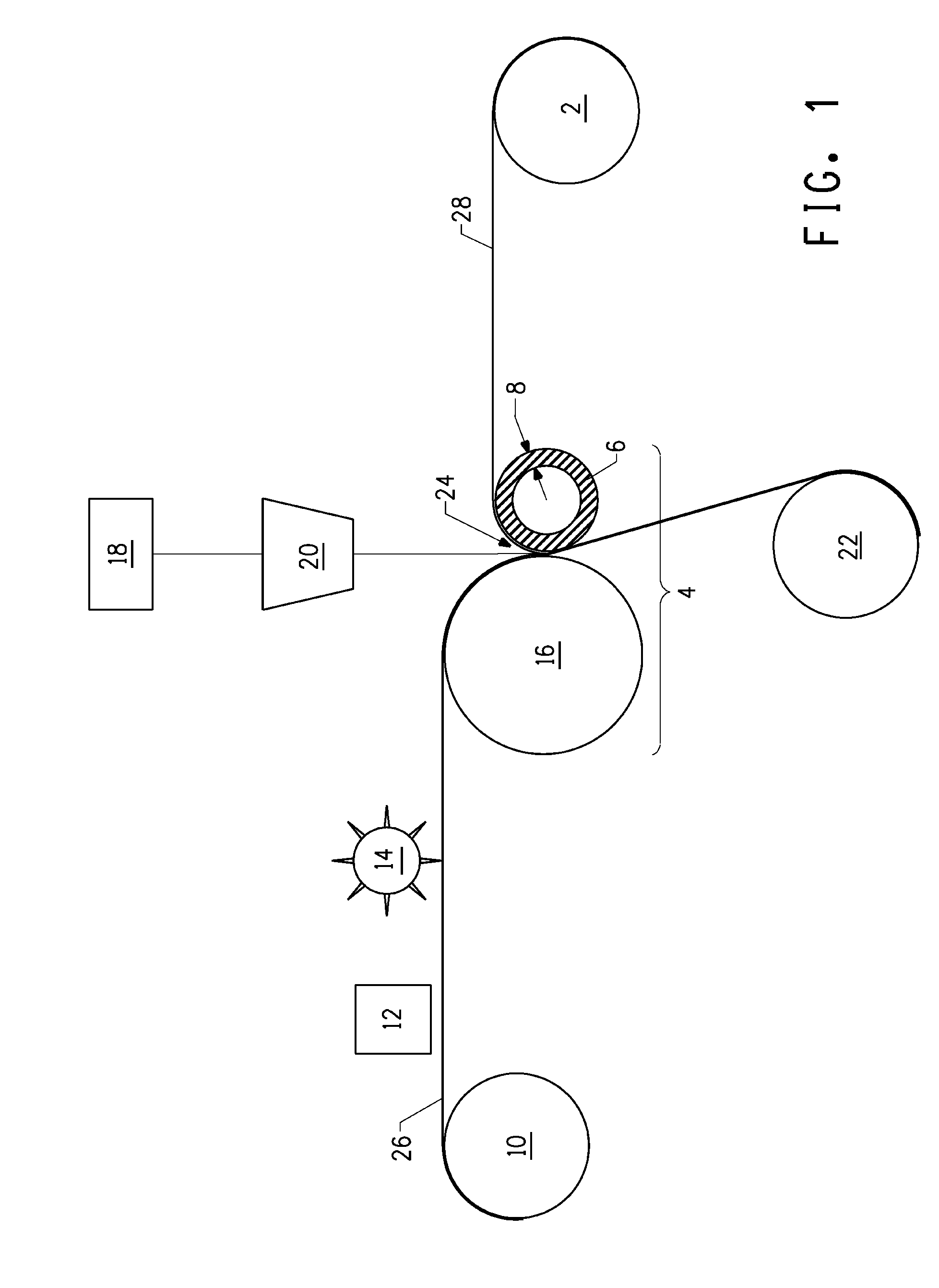

Process for fabricating monolayer/multilayer ultrathin films

InactiveUS6881444B2Improve film qualityShort processing timeLight-sensitive devicesSemiconductor/solid-state device manufacturingHydrogenMetallurgy

The present invention provides a process for fabricating ultrathin monolayers or ultrathin multilayer films, the process comprising the steps of: introducing positive or negative charge or a material capable of hydrogen-bonding to a substrate and placing the substrate on a spinner(pretreating step); introducing a material (A) bindable with the material deposited on the substrate, and spinning the substrate at 500 rpm to 30000 rpm for 4 to 200 seconds(first coating step); dropping washing solvent onto the substrate after completion of the first coating and spinning the substrate at 500 rpm to 30000 rpm for 4 to 200 sec to remove weakly-bound material (A) and form a thin film (A)(first washing step); introducing another material (B) bindable with the material (A) coated on the substrate and further coating it in the same condition as of the first coating(second coating step), dropping washing solvent onto the substrate after completion of the second coating and spinning the substrate at 500 rpm to 30000 rpm for 4 to 200 sec to remove the weakly-bound material (B) and form a thin film(B)(second washing step), wherein the entire above steps are more than once repeated.

Owner:HONG JONG DAL +2

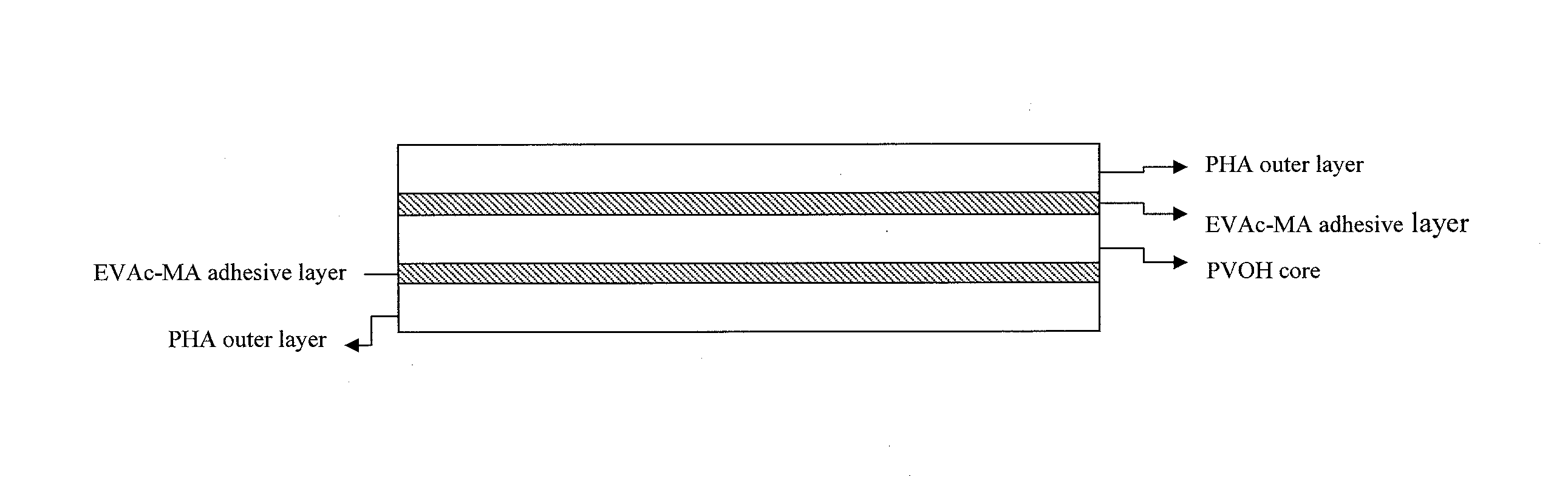

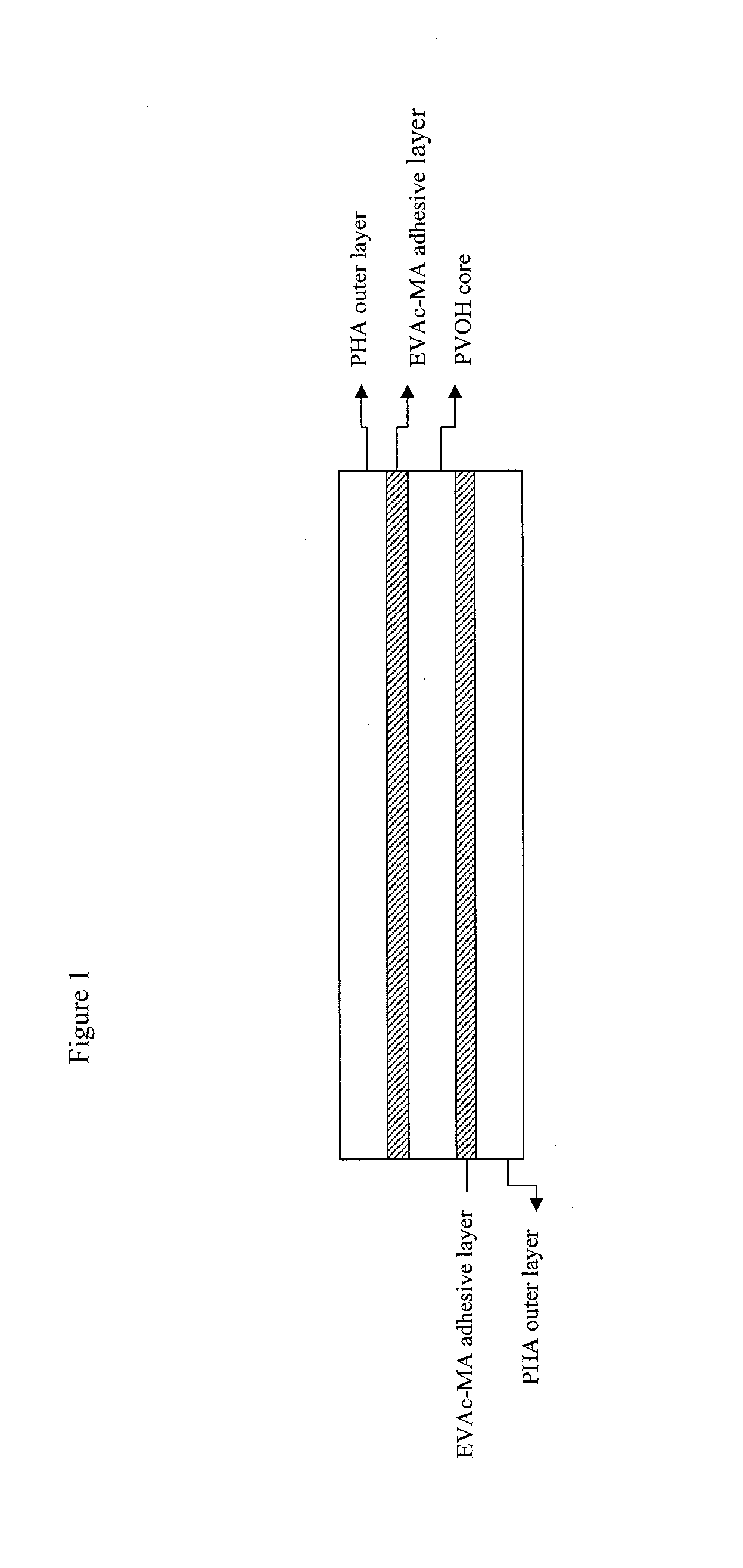

Biodegradable Coextruded Multilayer Films

InactiveUS20140030536A1Extrusion process is simpleImprove barrier propertiesSynthetic resin layered productsLaminationGas barrierChemistry

Described herein is a biobased, fully biodegradable multilayer film having gas barrier properties. Also included is a method of making such material.

Owner:METABOLIX

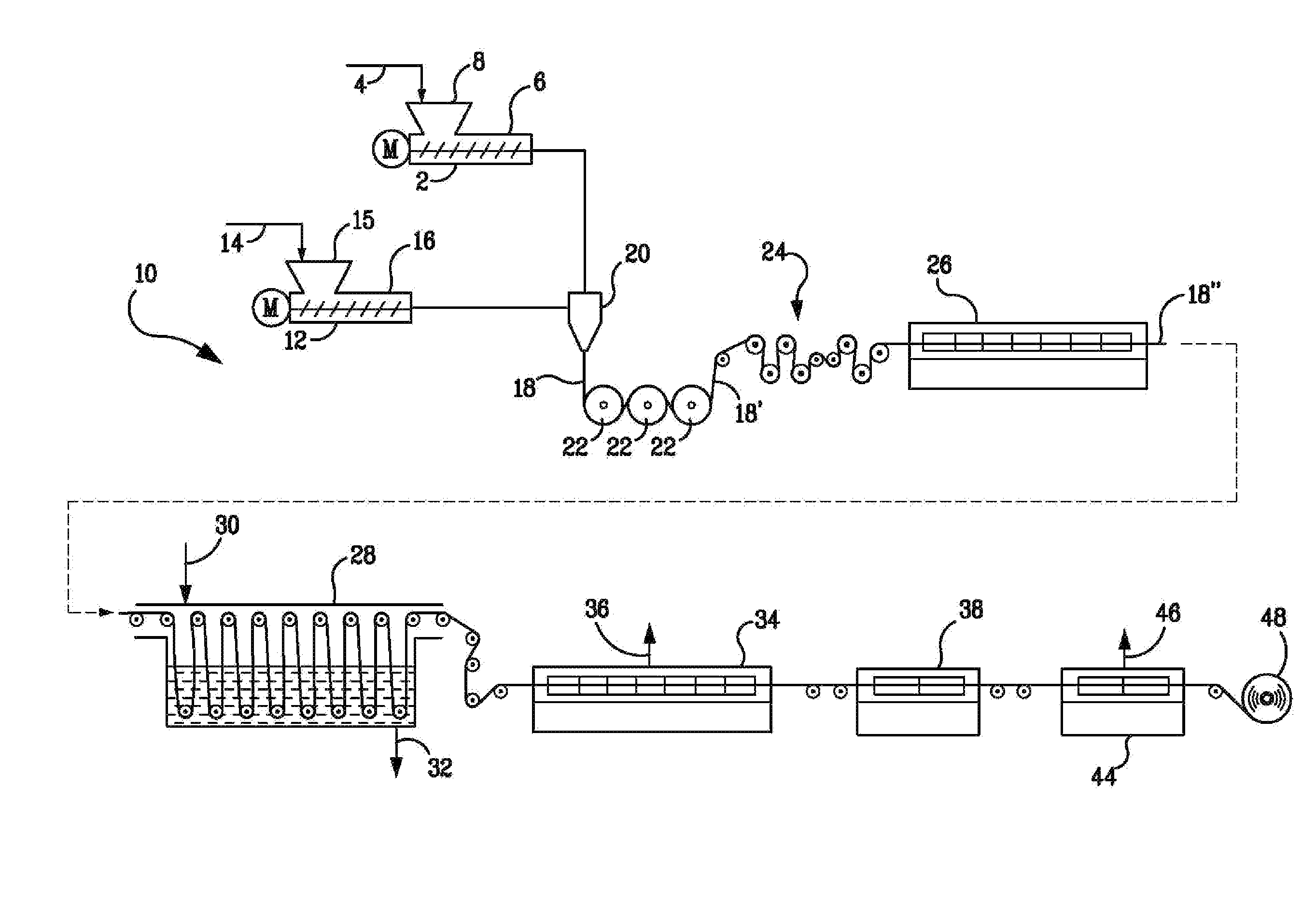

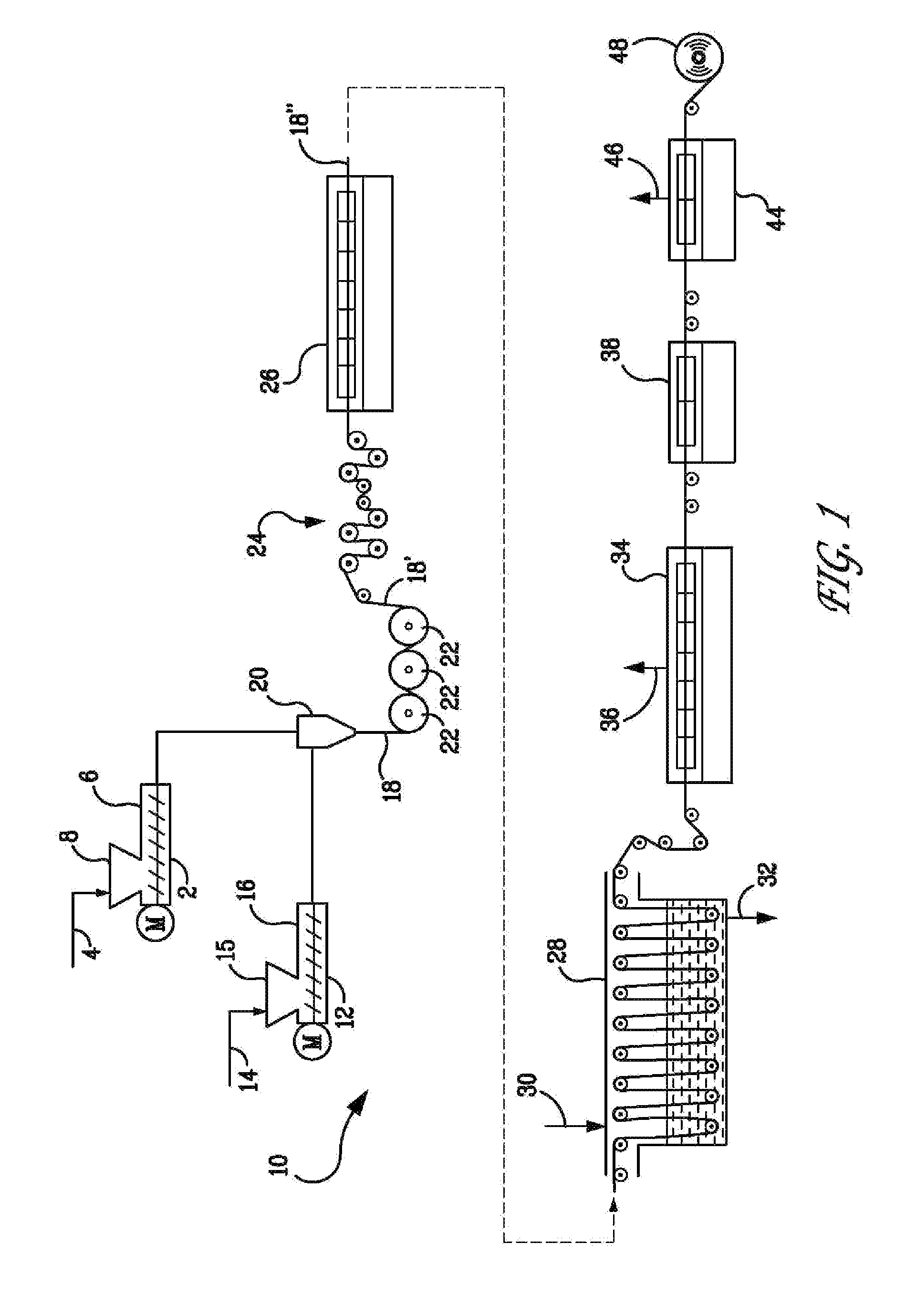

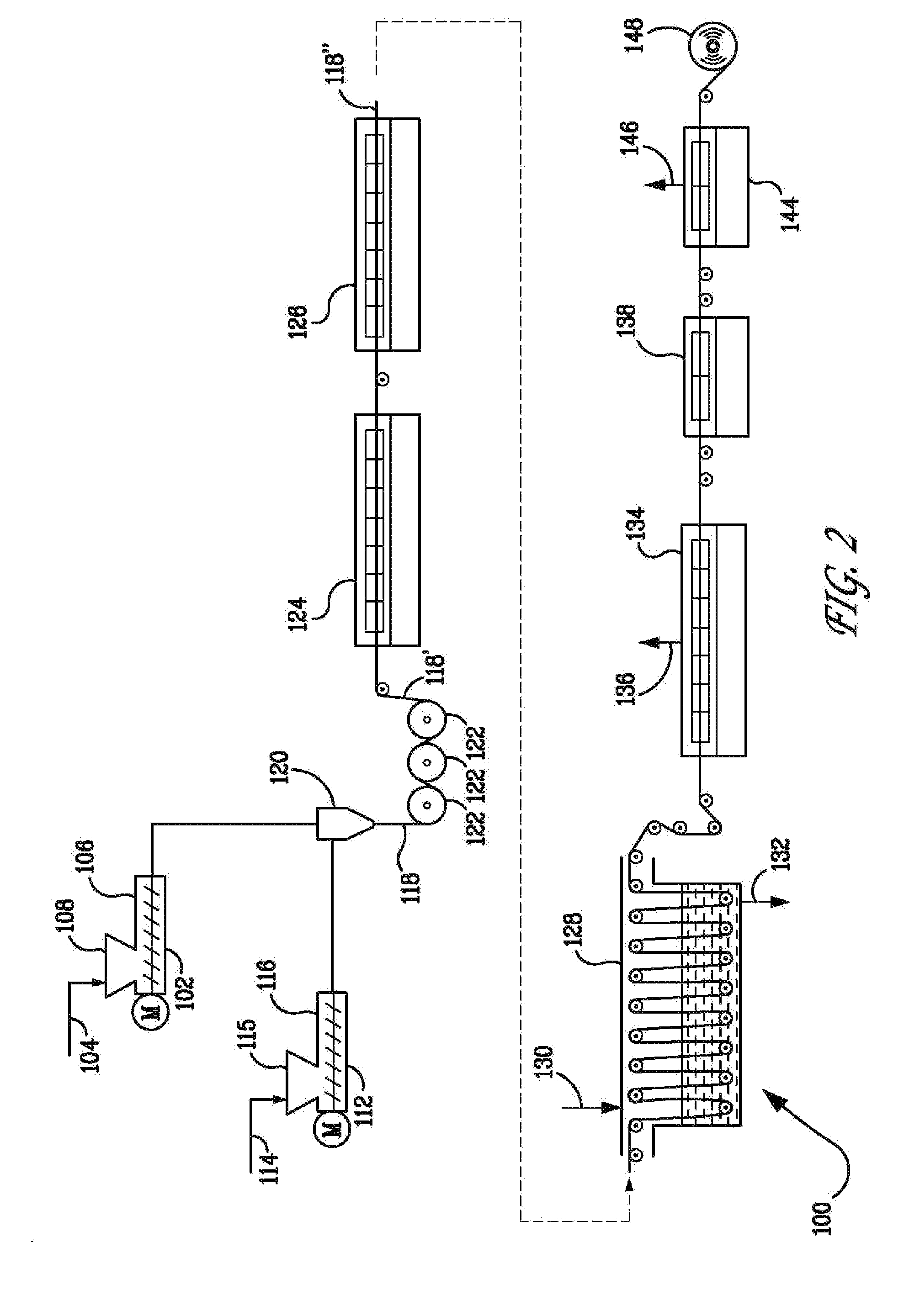

Microporous Multilayer Membrane, System And Process For Producing Such Membrane, And The Use Of Such Membrane

InactiveUS20100248002A1Raise the ratioIncrease temperatureSemi-permeable membranesSecondary cellsPolypropyleneMembrane configuration

The invention relates to a multilayer microporous membrane comprising polyethylene and polypropylene and having an improved balance of properties including improved thickness variation in at least one planar direction. The invention also relates to a system and method for producing such a membrane, the use of such a membrane as a battery separator film, and batteries containing such a membrane.

Owner:TORAY BATTERY SEPARATOR FILM

Multilayer coextrusion paper-like liquid packaging film

PendingCN101905776AGood dispersionGood compatibilityPackage recyclingFlexible coversMultilayer membraneFood packaging

The invention provides a multilayer coextrusion paper-like liquid packaging film. In resent years, people demand more dairy products, and the demand for the packaging films of various kinds of dairy products and liquid foods increases along with the continuous development of a UHT (Ultra Heat Treated) sterilization technology. According to incomplete statistics, only the consumption of milk packaging films reaches 7200 tons / year in 2009, and because liquid foods have self characteristics, liquid packaging films which are all made from 100% plastics are impossible to adopt a biodegradable packaging material to package the liquid foods so that gigantic pressure is brought to environmental protection, and a great amount of oil resources is consumed. Therefore, the field needs a material which can be used for packaging liquid, particularly a multi-layer liquid packaging film for packaging liquid dairy products and being capable of reducing the consumption of oil resources. According to one aspect of the invention, the invention provides the multilayer film is used for packaging liquid and can greatly reduce the consumption of plastic raw materials.

Owner:刘燕

Sound-permeable membrane, sound-permeable membrane member including same, microphone, and electronic device

ActiveUS20170245036A1Maintain good propertiesLoudspeaker screensMouthpiece/microphone attachmentsMultilayer membraneForeign matter

The sound-permeable membrane of the present invention is adapted, when placed over an opening for directing sound to or from a sound transducer, to prevent entry of foreign matters into the sound transducer through the opening while permitting passage of sound, the sound-permeable membrane including a non-porous film or a multilayer membrane including the non-porous film. The non-porous film is formed of oriented polytetrafluoroethylene. This sound-permeable membrane has an unconventional configuration and exhibits various excellent properties. At least one principal surface of the non-porous film may have a region subjected to a surface modification treatment.

Owner:NITTO DENKO CORP

Multi-layered film

InactiveUS20070082185A1Increase capacityHigh strengthLayered product treatmentSynthetic resin layered productsMultilayer membranePolymer science

To provide a multi-layered film as transparent as that produced by T-die or water-cooled inflation molding, even when produced by air-cooled inflation molding, and excellent in tearing strength, impact strength, heat-sealing capacity at low temperature and interlayer strength. The multi-layered film comprises a propylene-based resin layer composed of a propylene / α-olefin random copolymer as the major component, which has a melt flow rate (MFR, determined at 230° C.) of 1 to 30 g / 10 minutes, melting peak temperature (Tm) of 110 to 165° C. and Mw / Mn ratio of 1.5 to 3.5, and is produced in the presence of a metallocene catalyst, wherein the propylene-based resin layer is laminated, on each side, with a copolymer of ethylene and α-olefin of 3 to 12 carbon atoms, having an MFR (determined at 190° C.) of 0.1 to 20 g / 10 minutes and density: 0.860 to 0.925 g / cm3.

Owner:JAPAN POLYPROPYLENE CORP

Chlorine-Free Packaging Sheet with Tear-Resistance Properties

InactiveUS20110104342A1Lower the resistance valueEnvelopes/bags making machineryDomestic containersMultilayer membraneTear resistance

A chlorine-free packaging sheet having a first rigid component, a second rigid component and a multilayer film positioned between the first rigid component and the second rigid component, a package comprising such packaging sheet and a method of manufacturing such sheet. The packaging sheet has a normalized combined tear initiation and propagation resistance in both the machine direction and the transverse direction of less than about 0.115 in*lbf / mil energy to break and less than about 0.800% / mil elongation, and a normalized tear propagation resistance in both the machine direction and the transverse direction of less than about 0.300 in*lbf / mil energy to break and less than about 0.145 lbf / mil peak load.

Owner:BEMIS COMPANY INC

Multi-layer films having uniform content

InactiveUS20110200715A1Organic active ingredientsCosmetic preparationsPolyethylene oxideActive component

The present invention relates to edible multi-layer films that dissolve in water. In particular, the edible multi-layer films have a first water-soluble film layer and one or more additional water-soluble film layers in at least partial face-to-face engagement with the first film layer. The film layers include a polymer composition which contains polyethylene oxide alone or in combination with at least one water-soluble polymer. The edible multi-layer films may include pockets defined between the layers that house an active component. Upon addition of water, the multi-layer film dissolves, thereby releasing the active component into the water.

Owner:MONOSOL RX

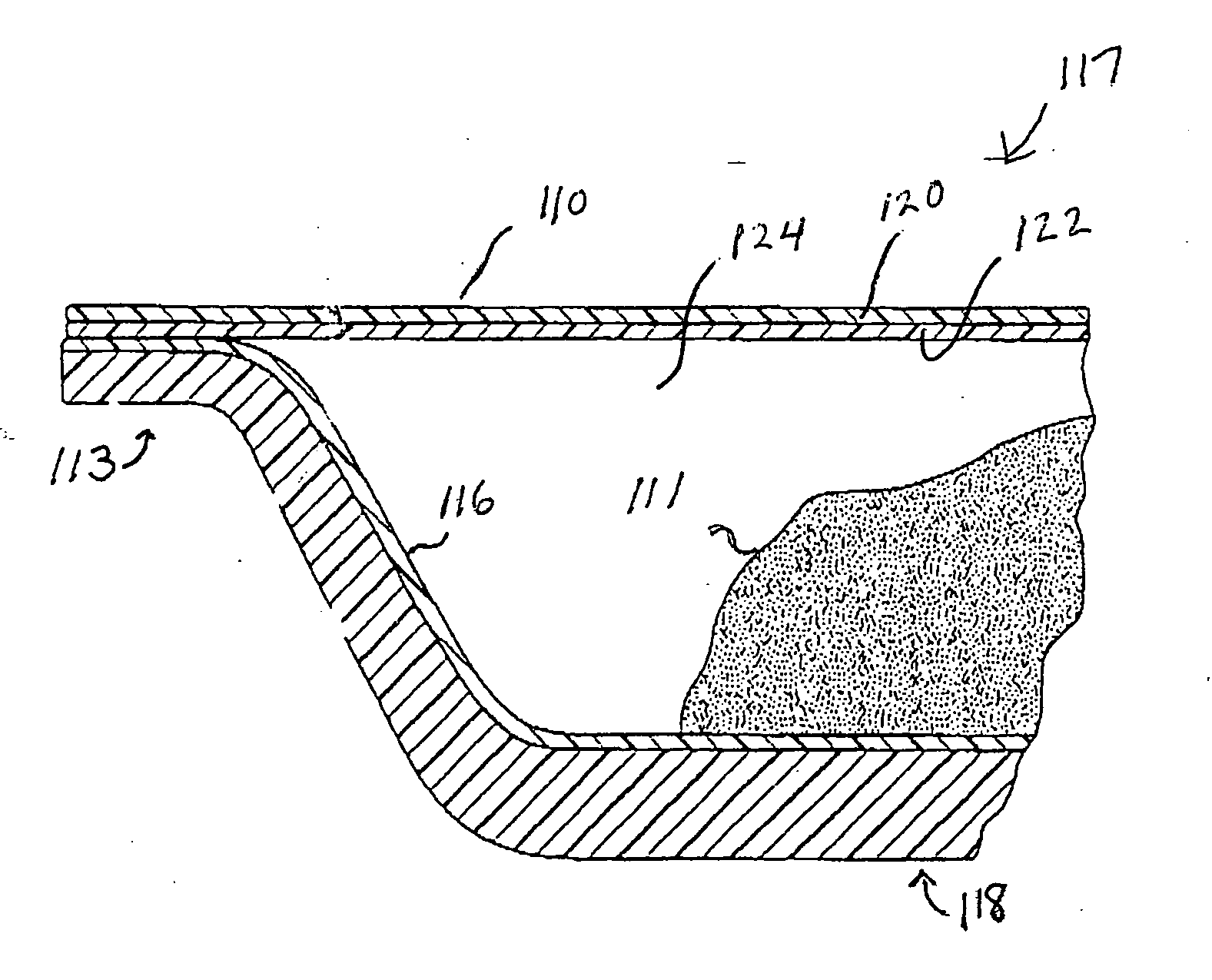

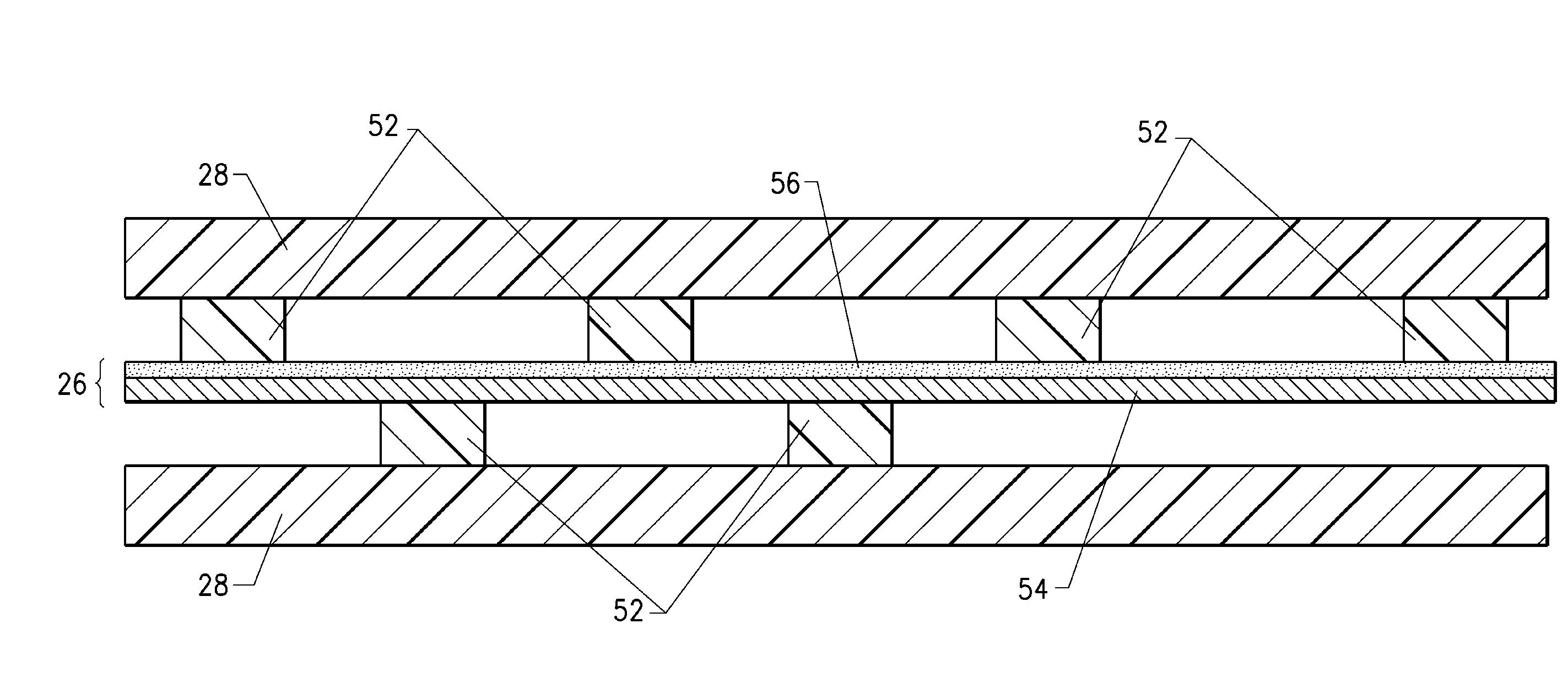

Multi-film structures for thermal insulation

InactiveUS20100028649A1Improve barrier propertiesImprove productivityLamination ancillary operationsLayered product treatmentIonomerThermal insulation

The present invention provides multi-film structures which are designed for applications where thermal insulation is needed. Disclosed multi-film structures comprise a) at least one flexible baffle film including at least one thermoplastic layer comprising one or more ethylene acid copolymers and / or ionomers thereof, the flexible baffle film further comprising a metal or metal oxide layer deposited onto the at least one thermoplastic layer, and b) at least one external layer, wherein the at least one baffle film and the at least one external layer are bonded together at predetermined and selective locations so to form cells within the multi-film structure.

Owner:COLDPACK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com