Patents

Literature

206results about How to "Extrusion process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

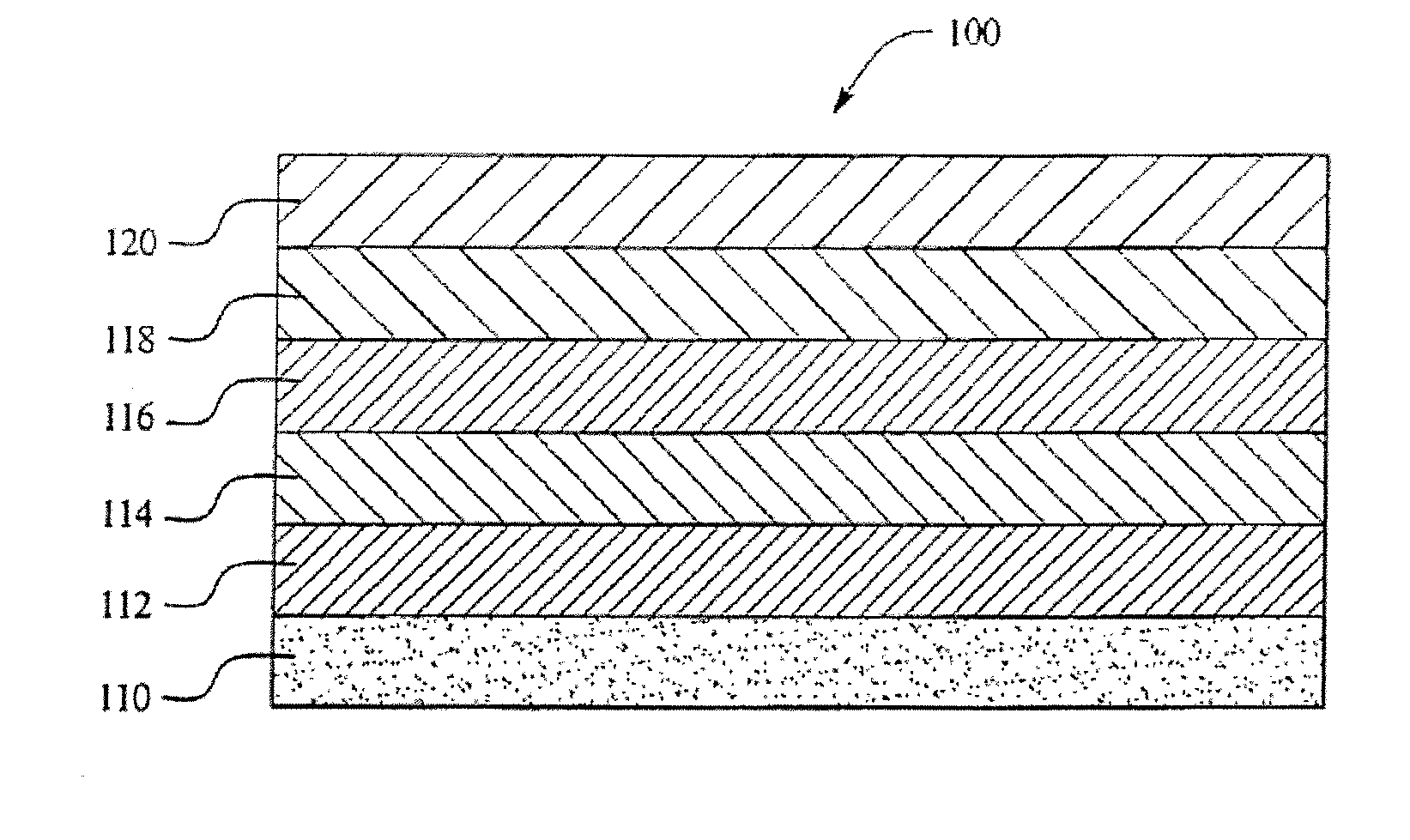

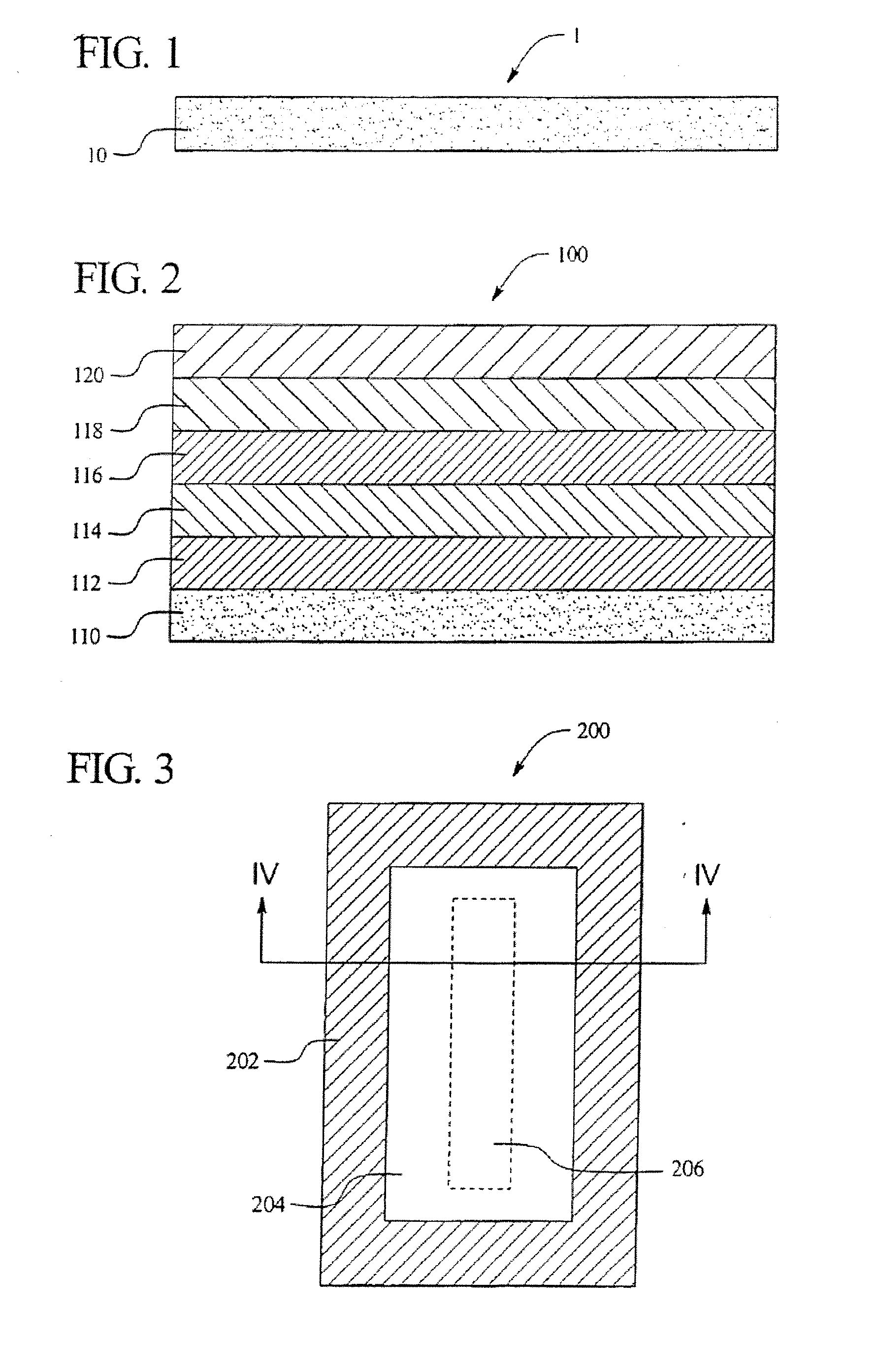

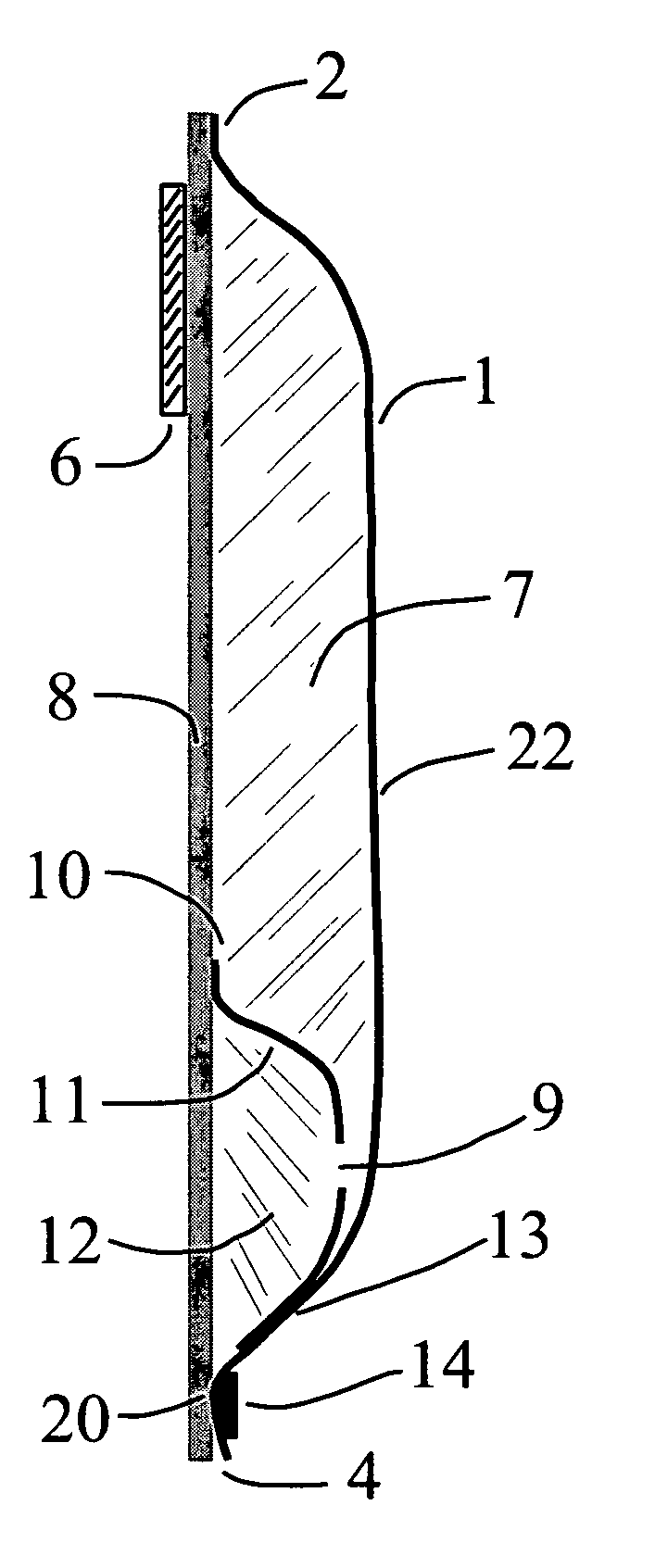

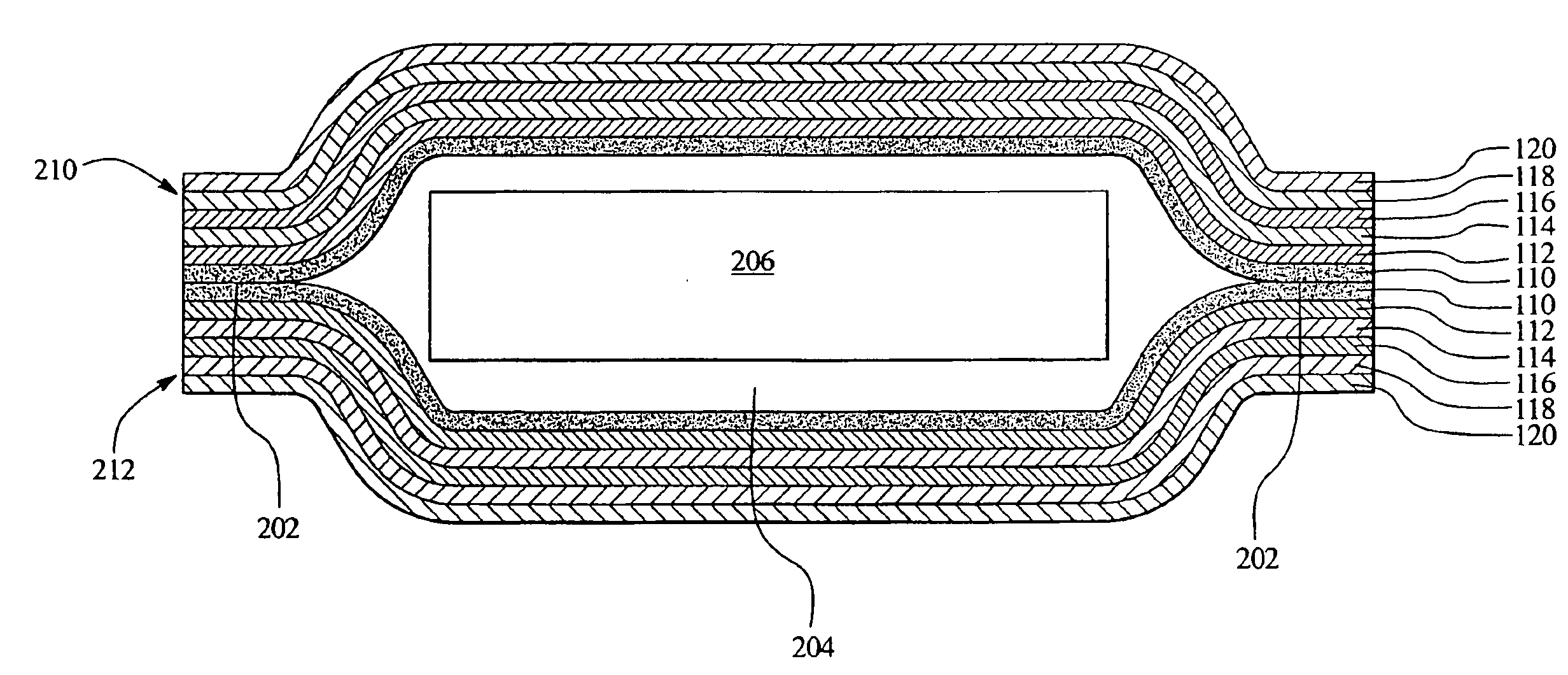

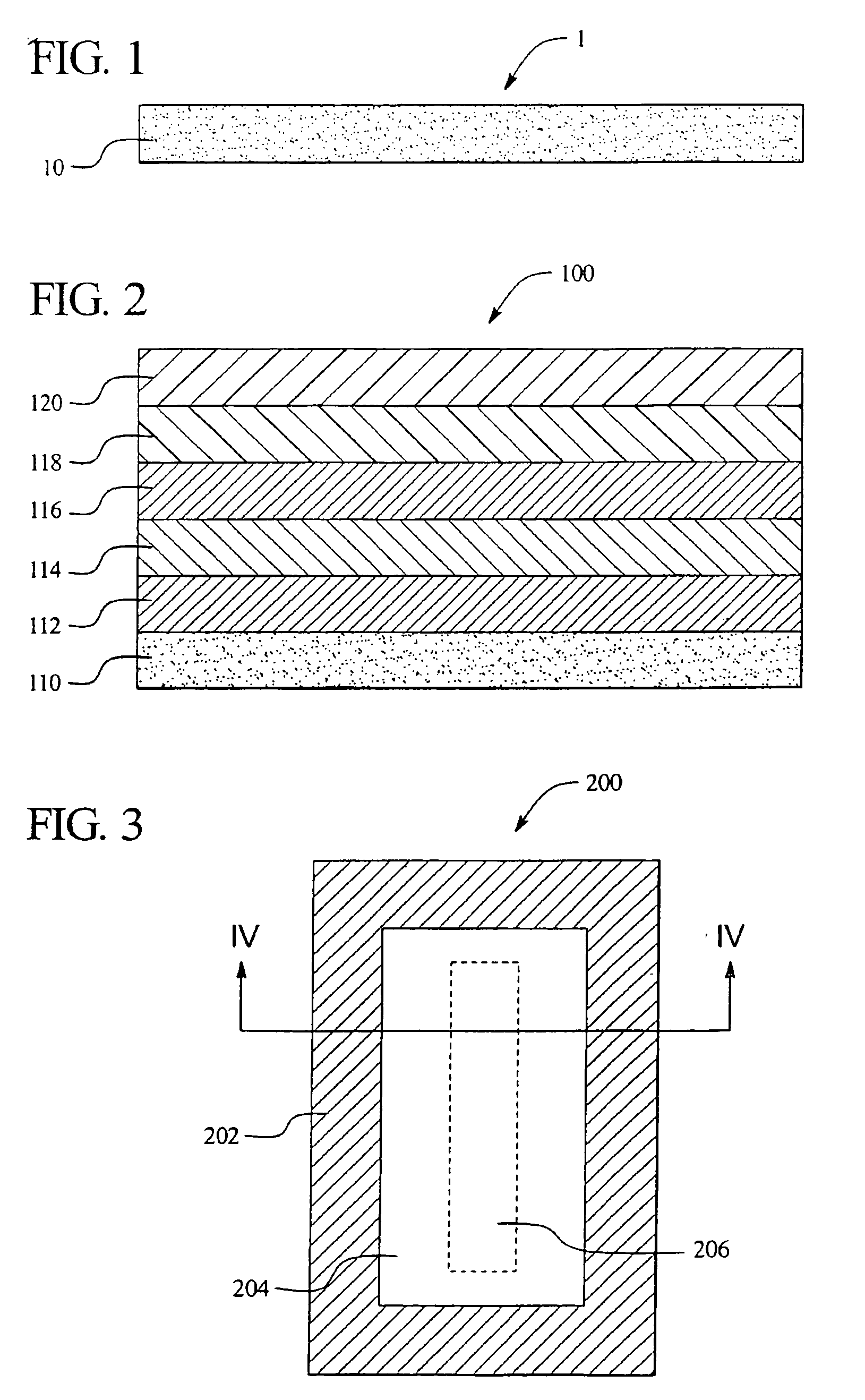

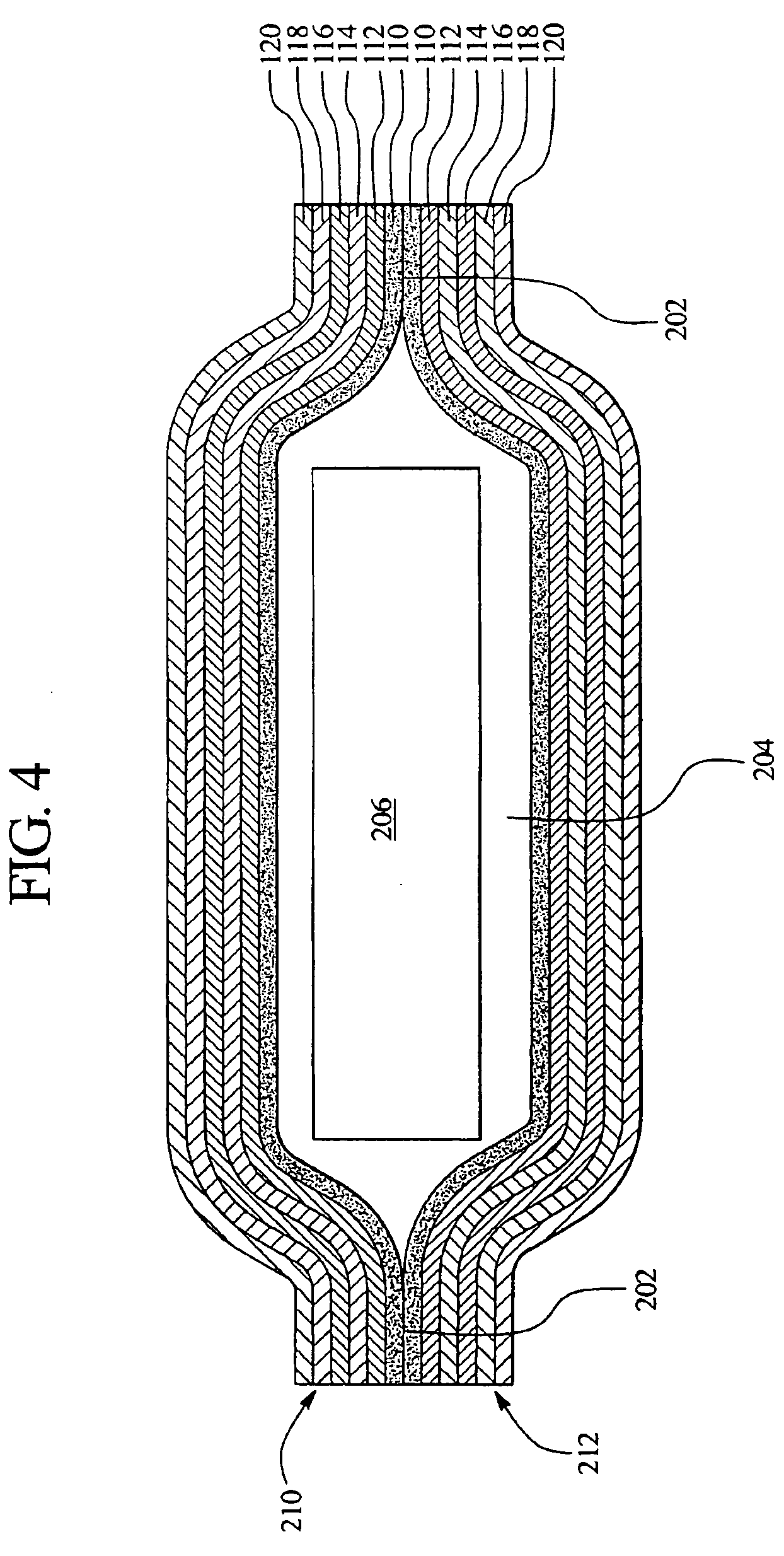

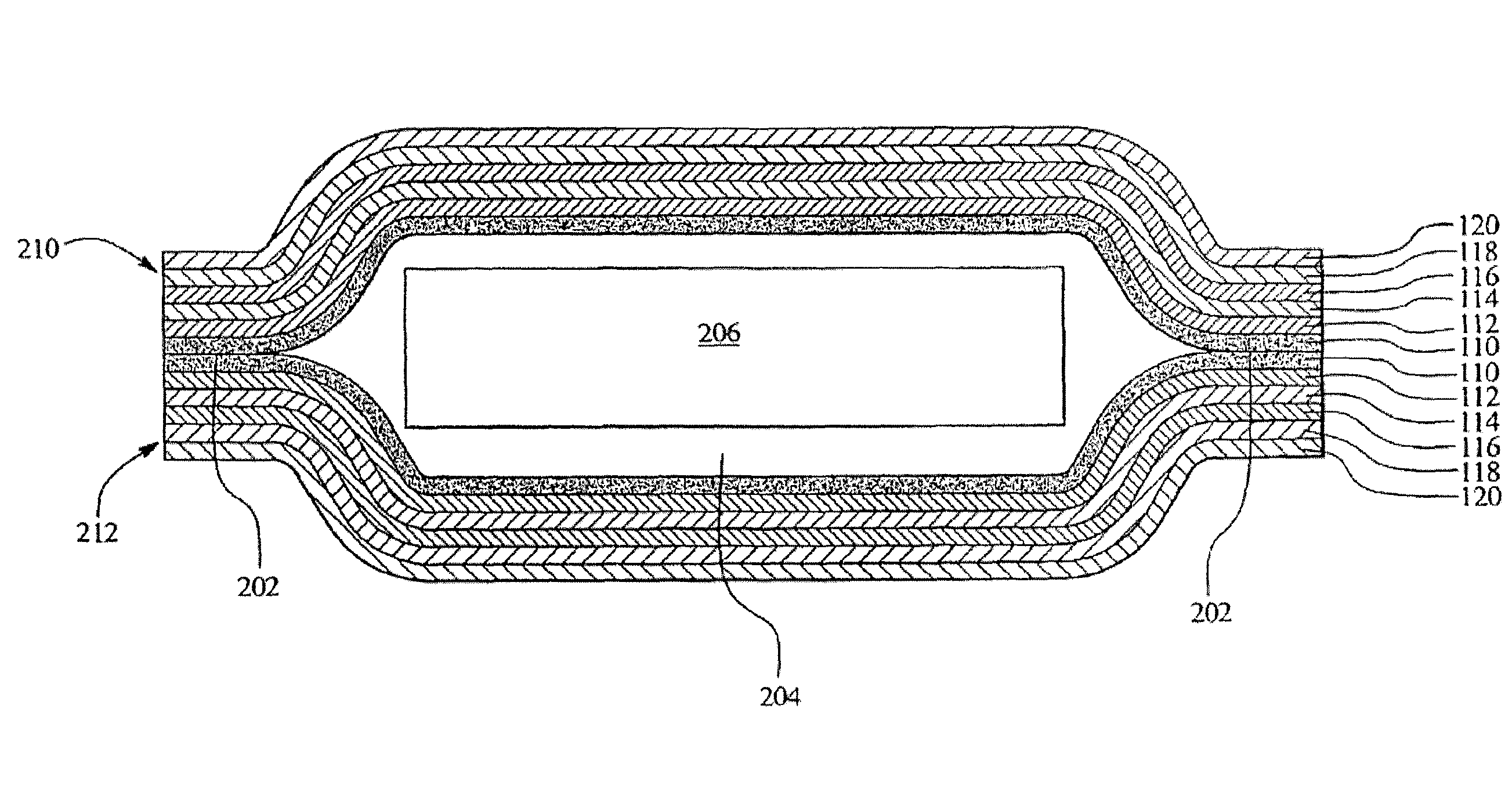

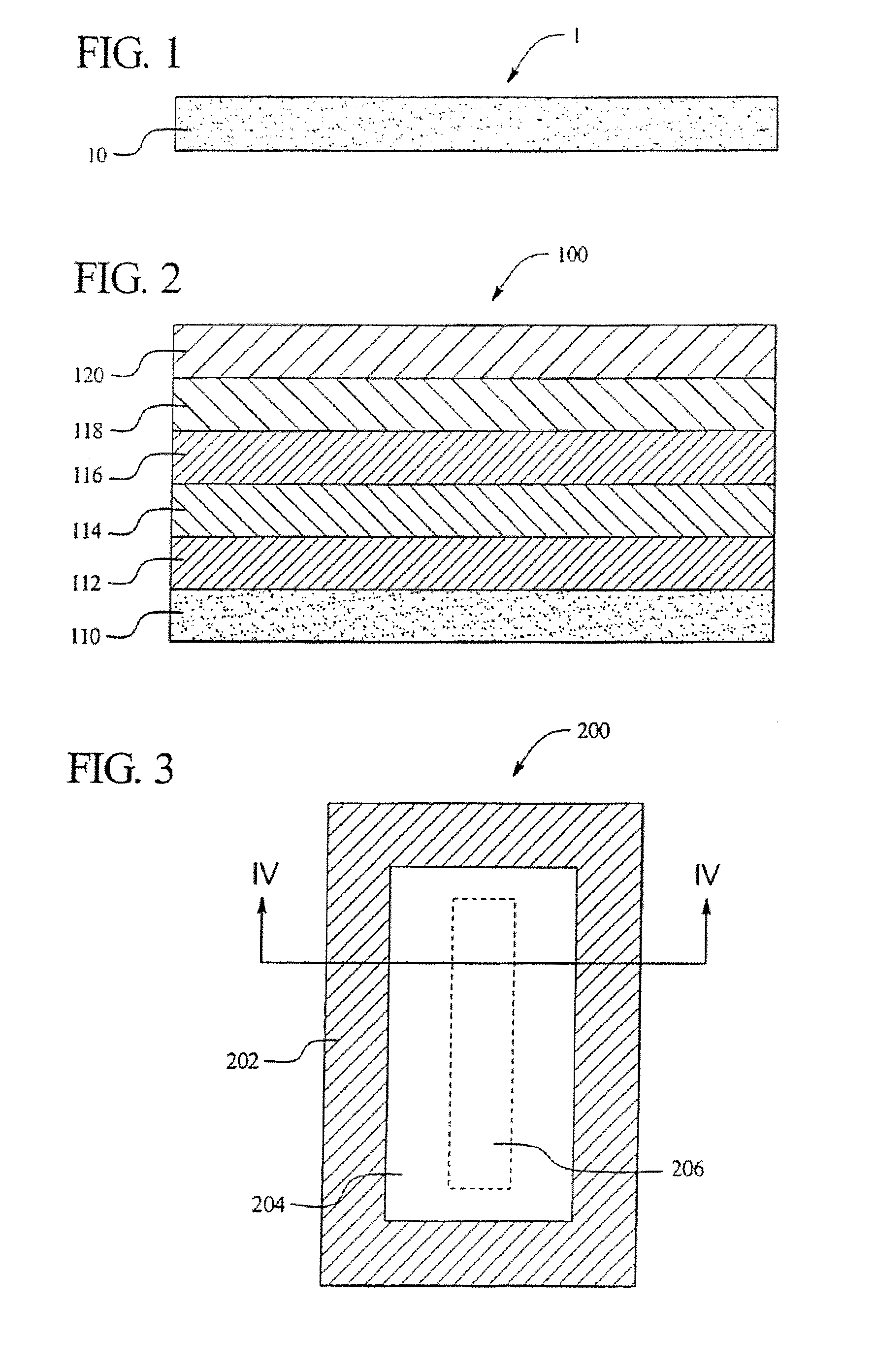

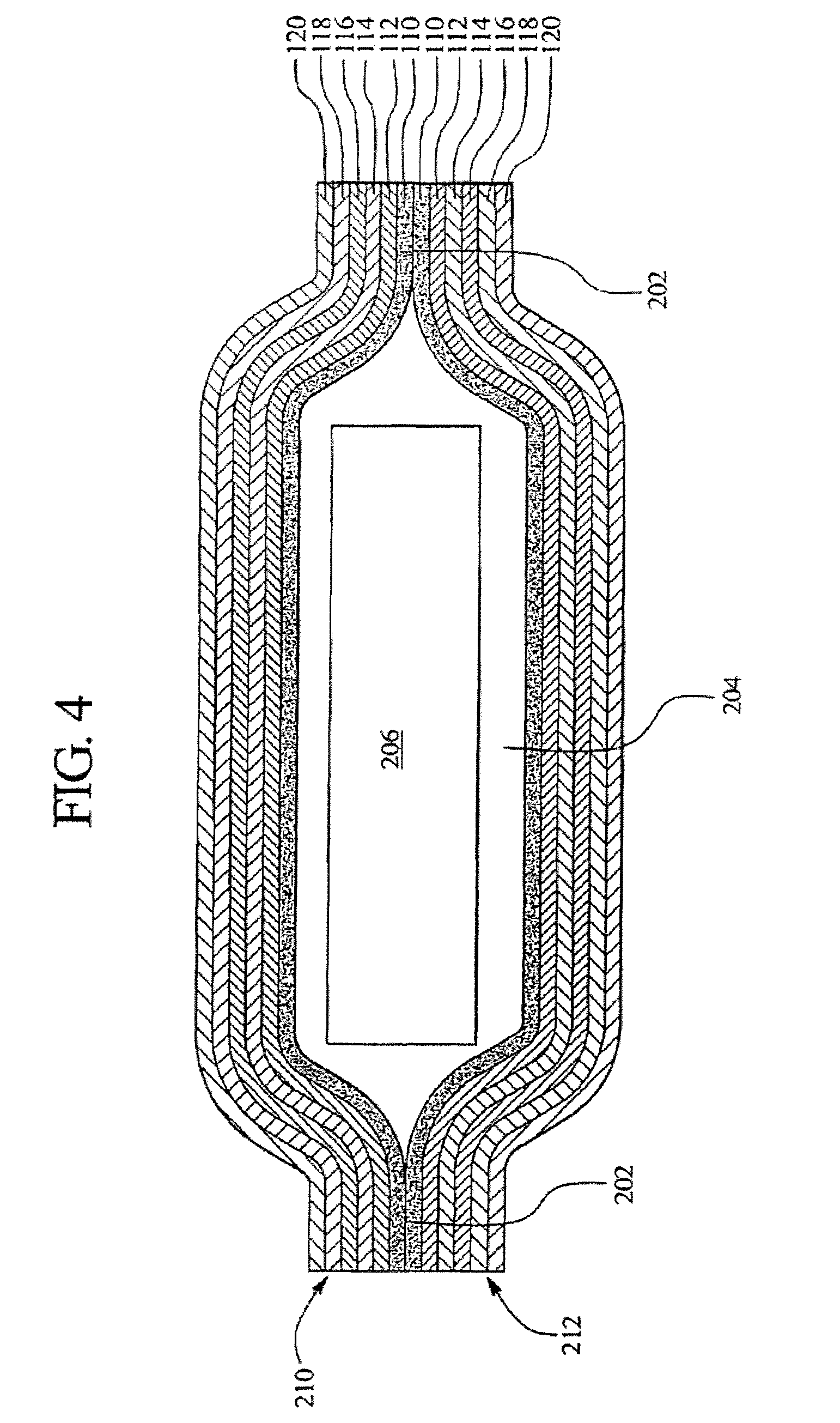

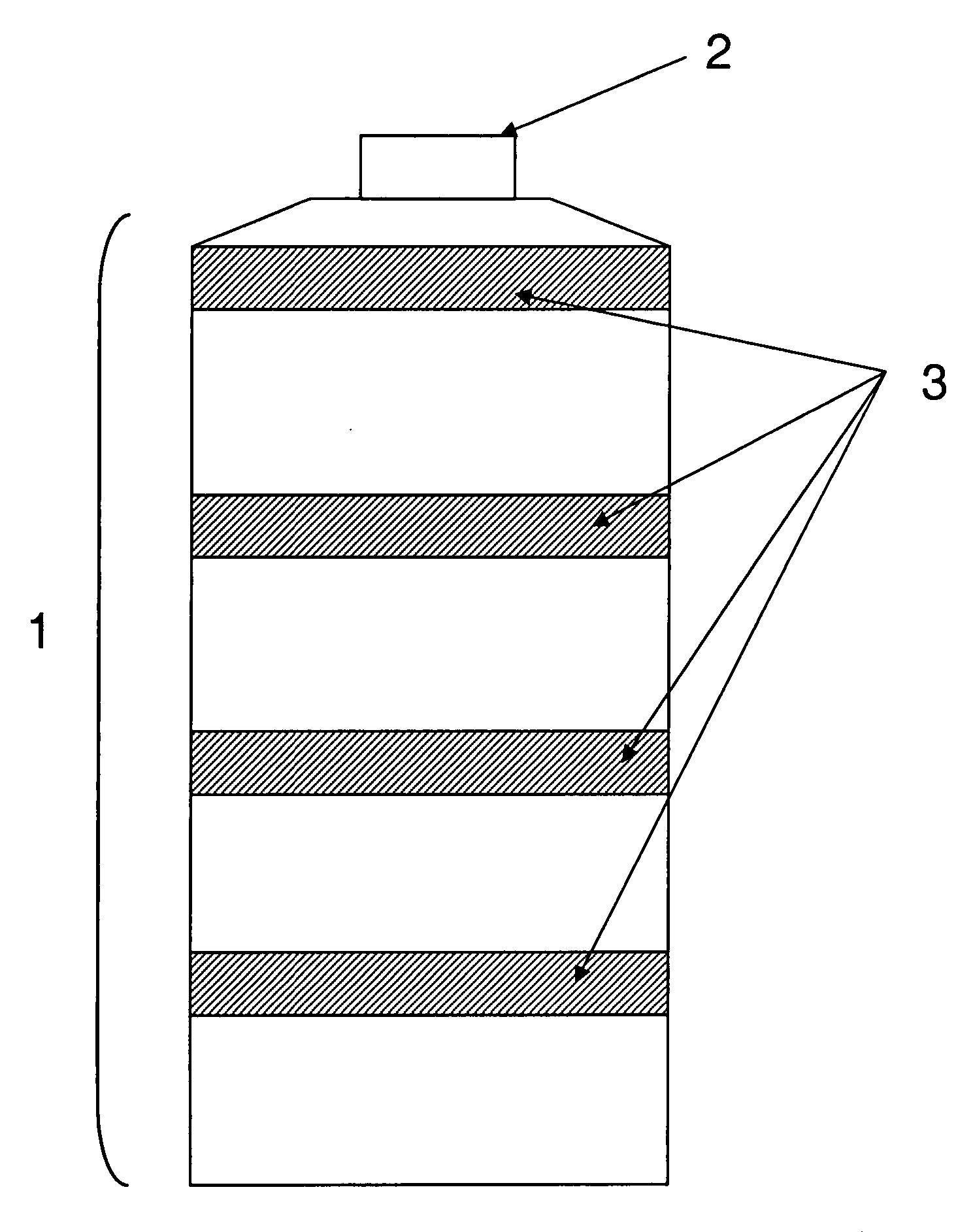

Films having a desiccant material incorporated therein and methods of use and manufacture

InactiveUS20070160789A1Improve efficacyExtended shelf lifeSurgical furnitureDiagnosticsDesiccantInsertion stent

Film structures, packages, films and methods of making the same are provided wherein the film structures have a desiccant material incorporated into at least one layer of the film structures and further wherein the film structures can comprise a material for making a peelable seal when the film structures are heat sealed to other film structures. The film structures are utilized for a package to hold a product that may be sensitive to the presence of moisture. The product may preferably be pharmaceutical products, nutraceutical products, or devices such as absorbable sutures or medical stents, although any moisture-sensitive product is contemplated by the present invention.

Owner:ALCAN PACKAGING FLEXIBLE FRANCE

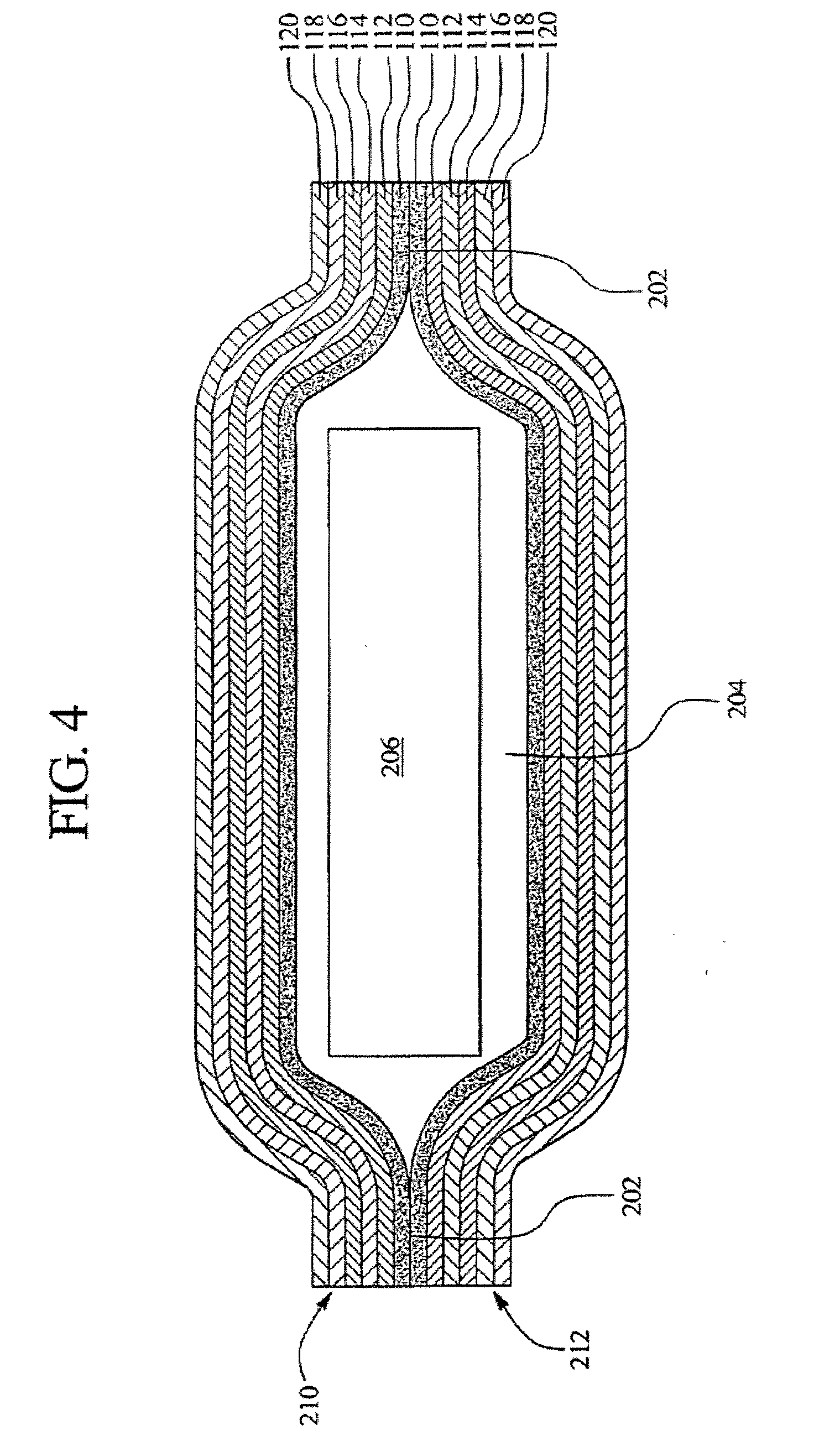

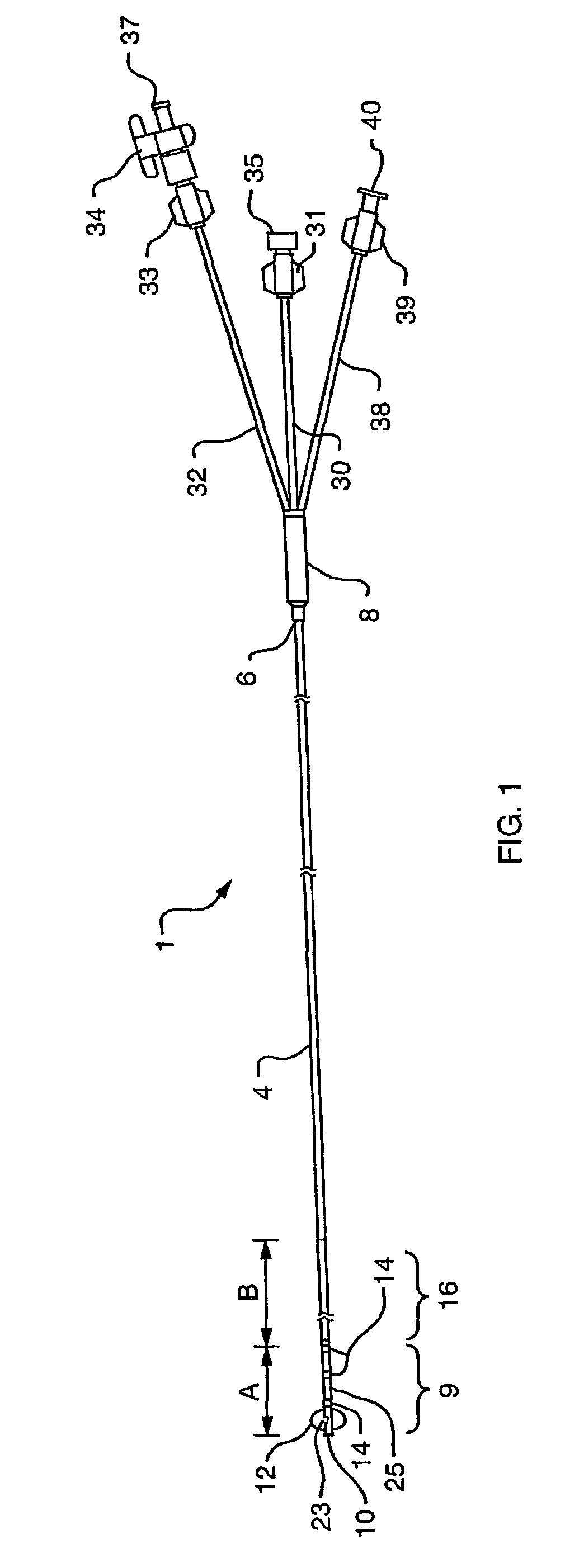

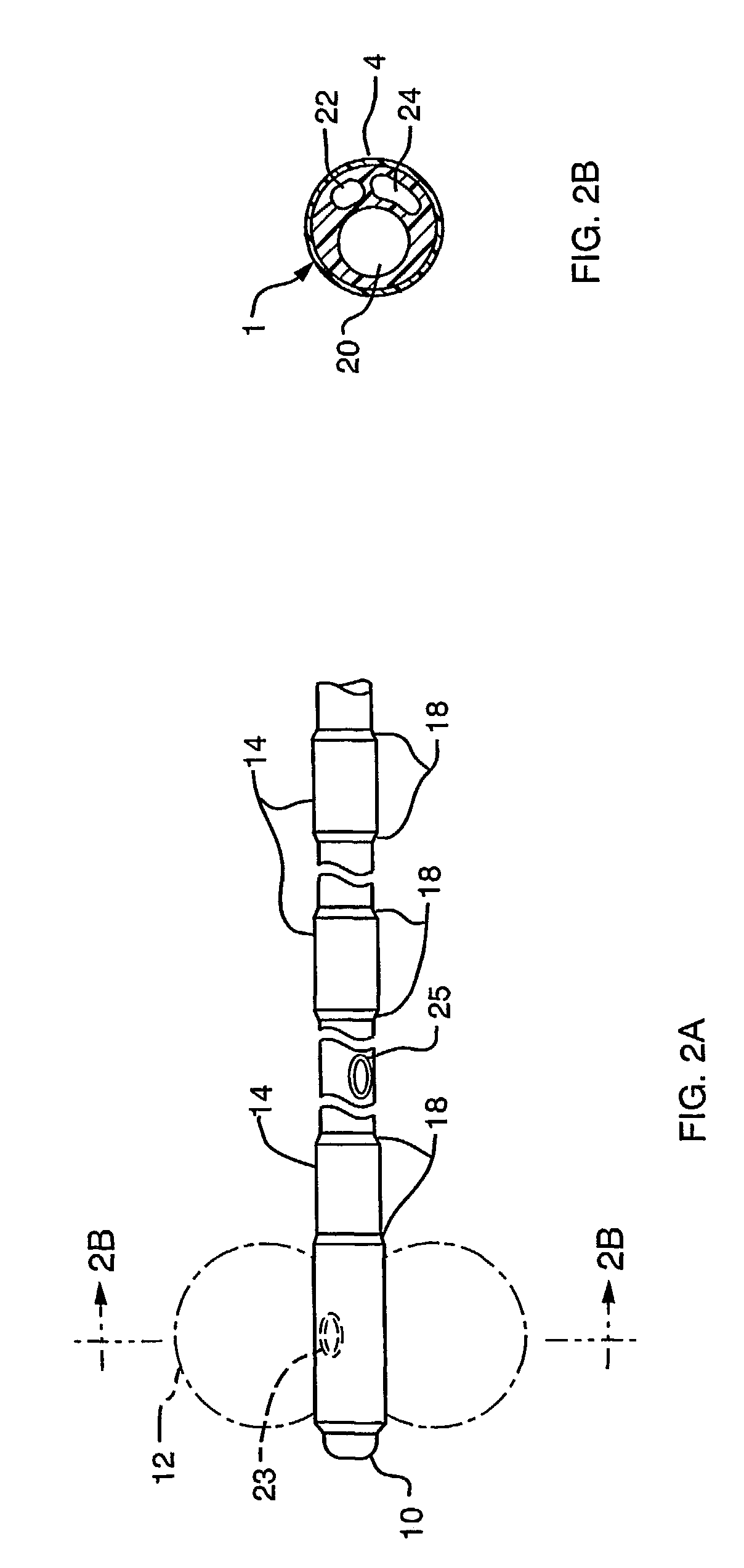

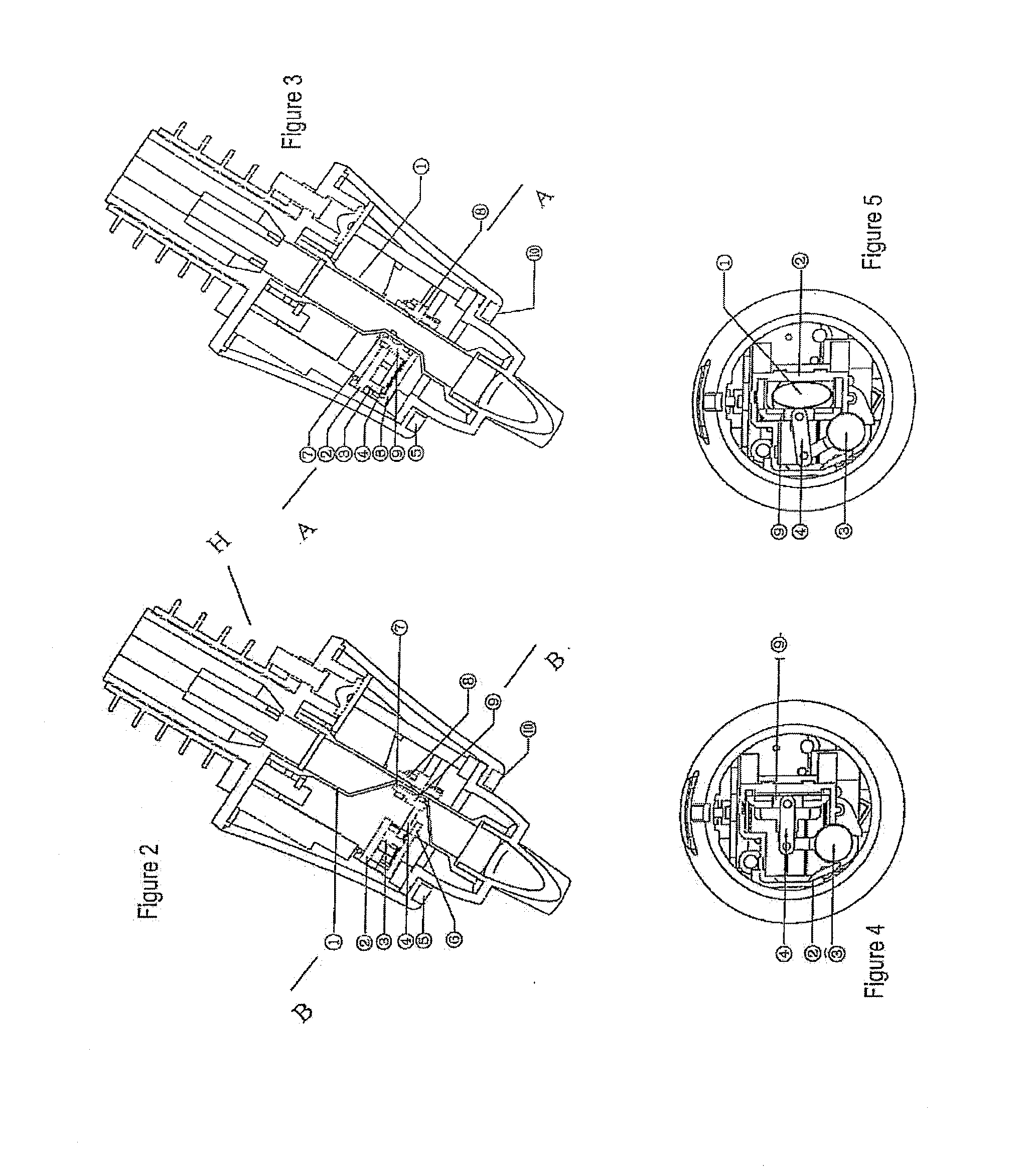

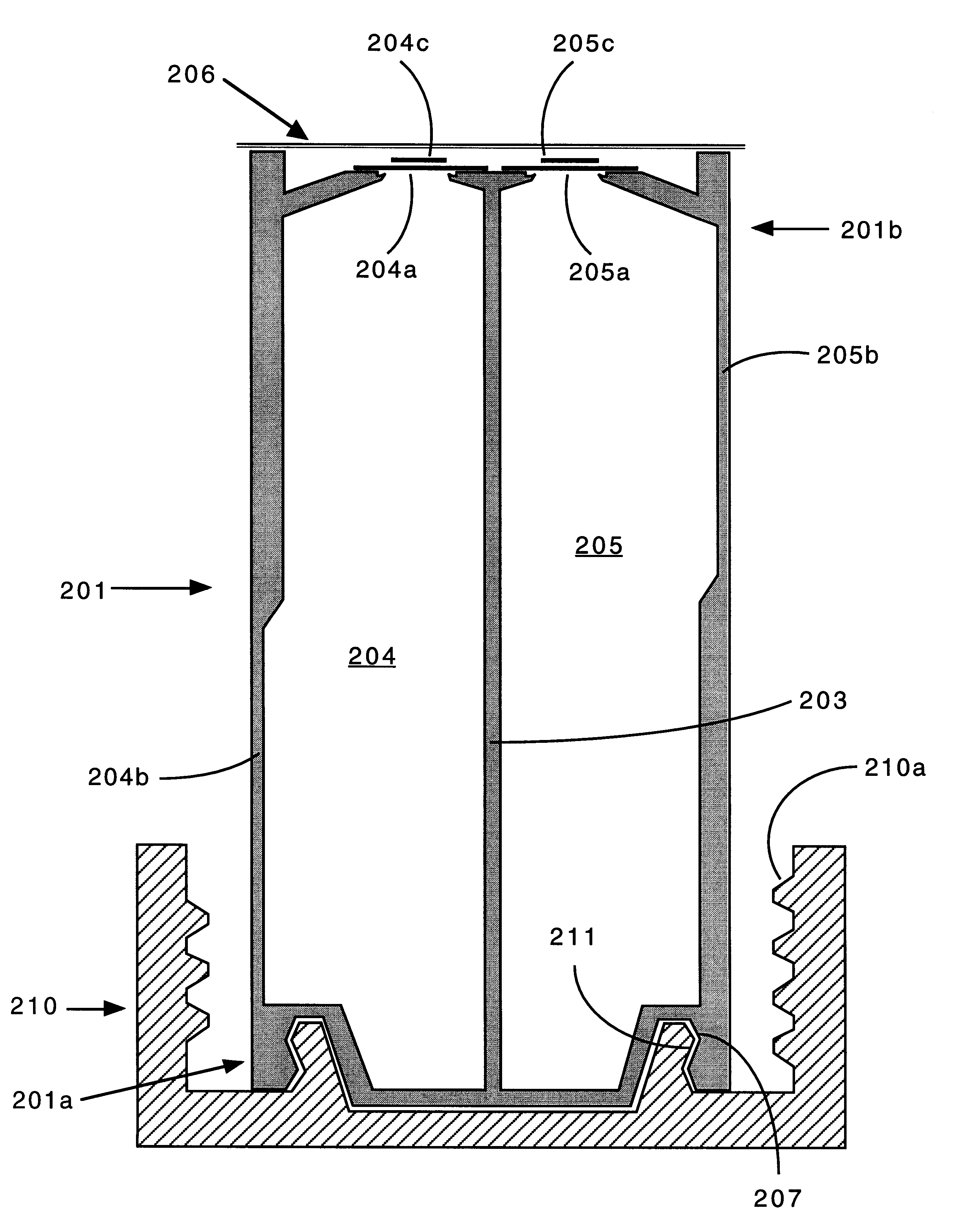

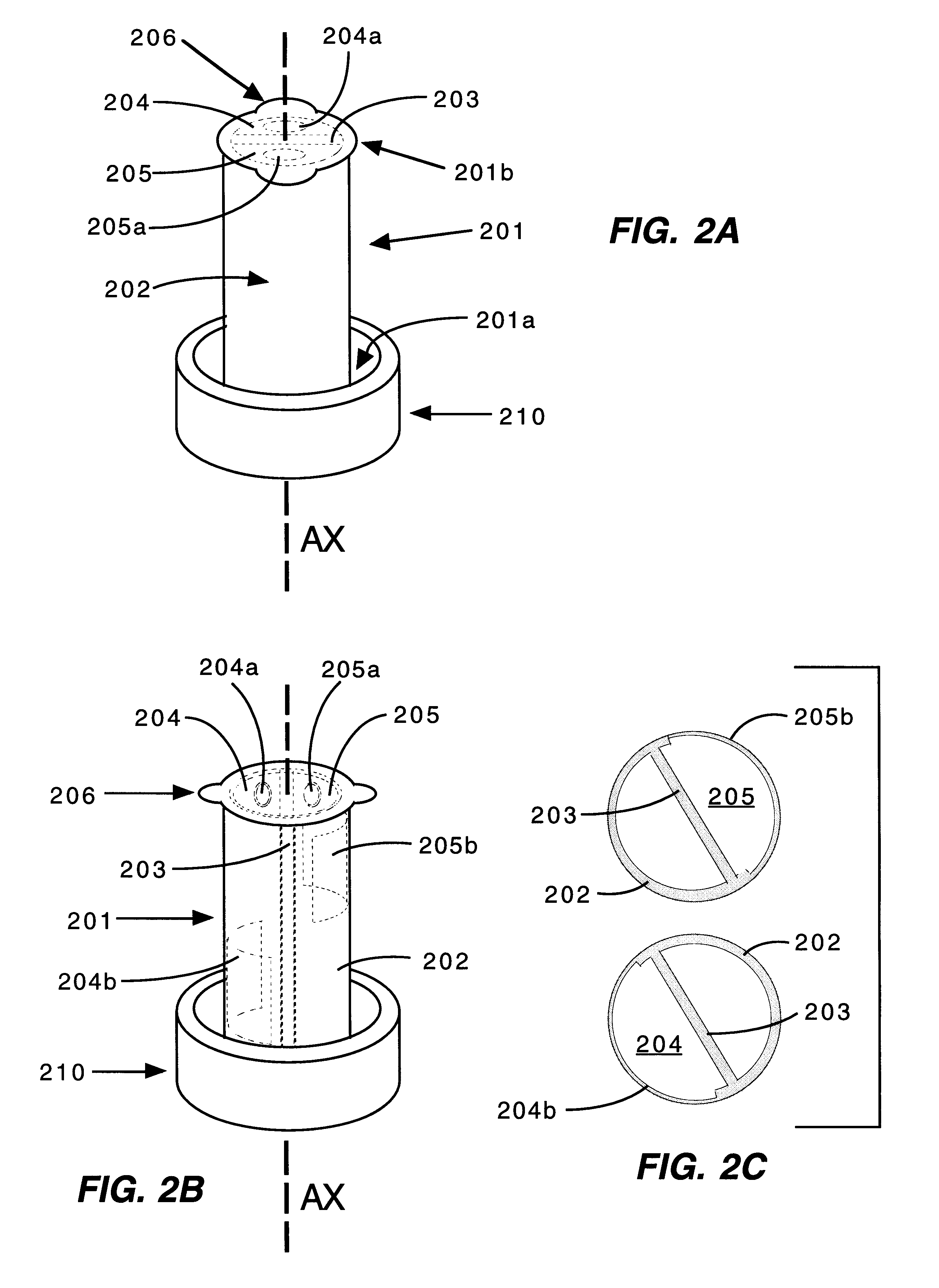

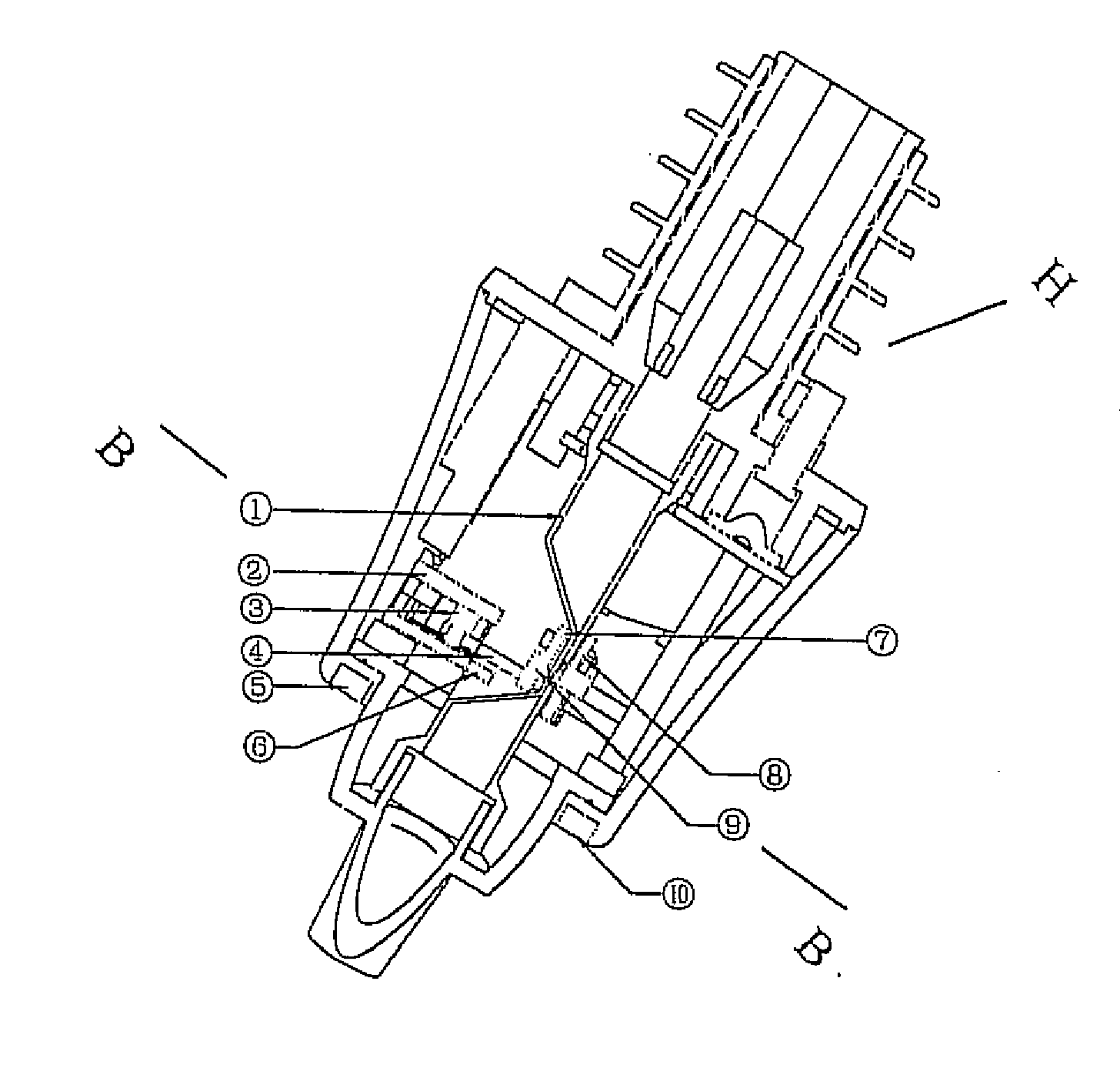

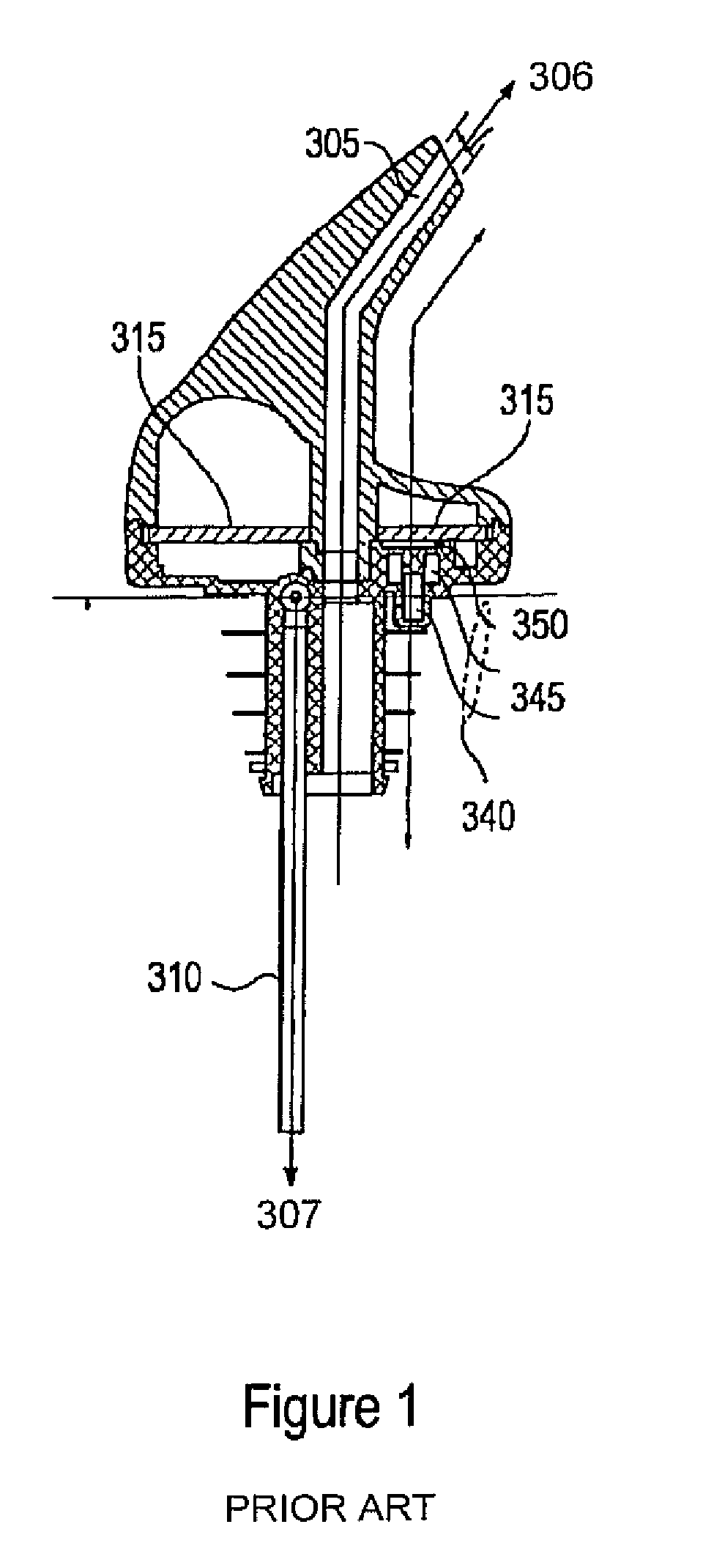

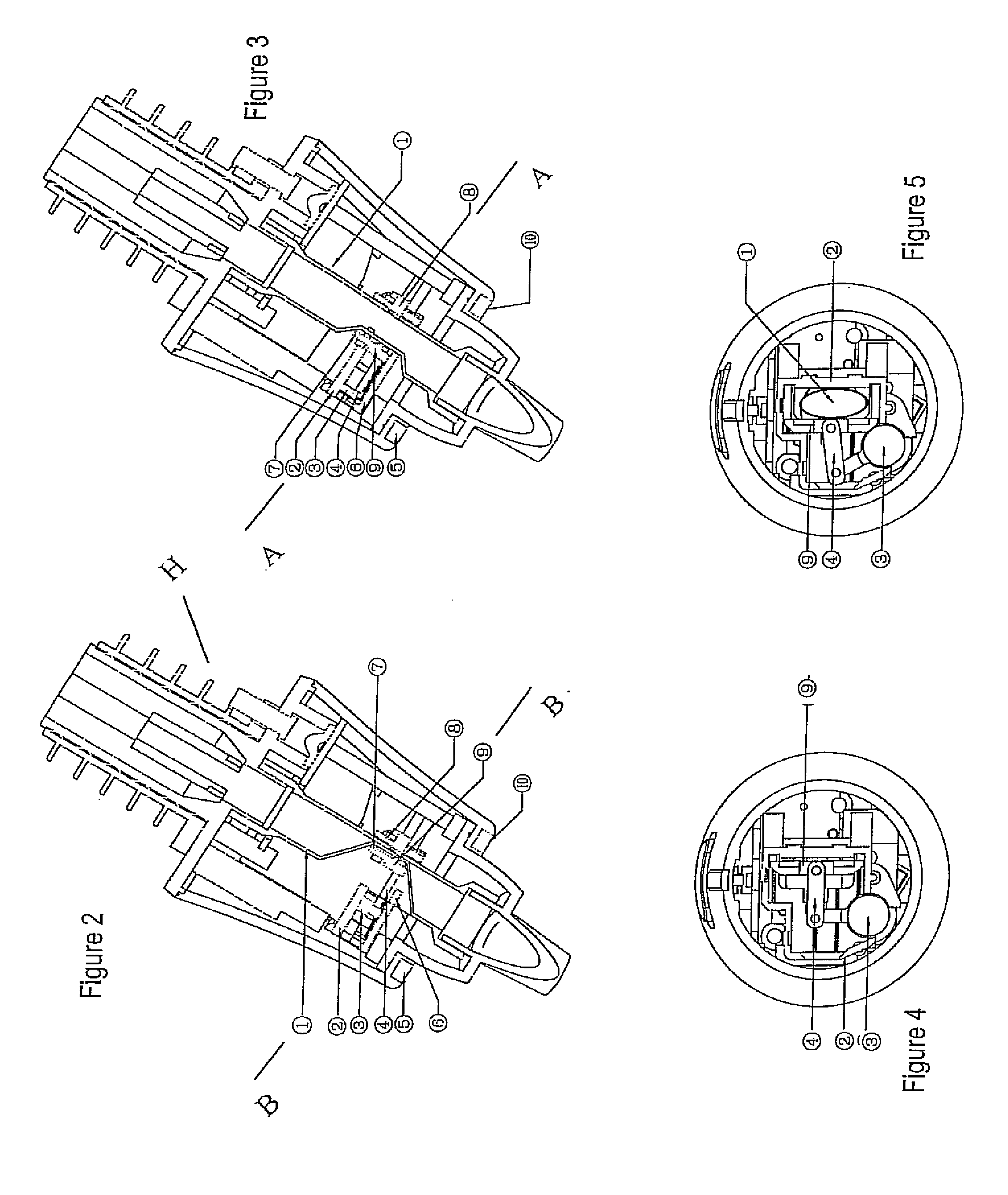

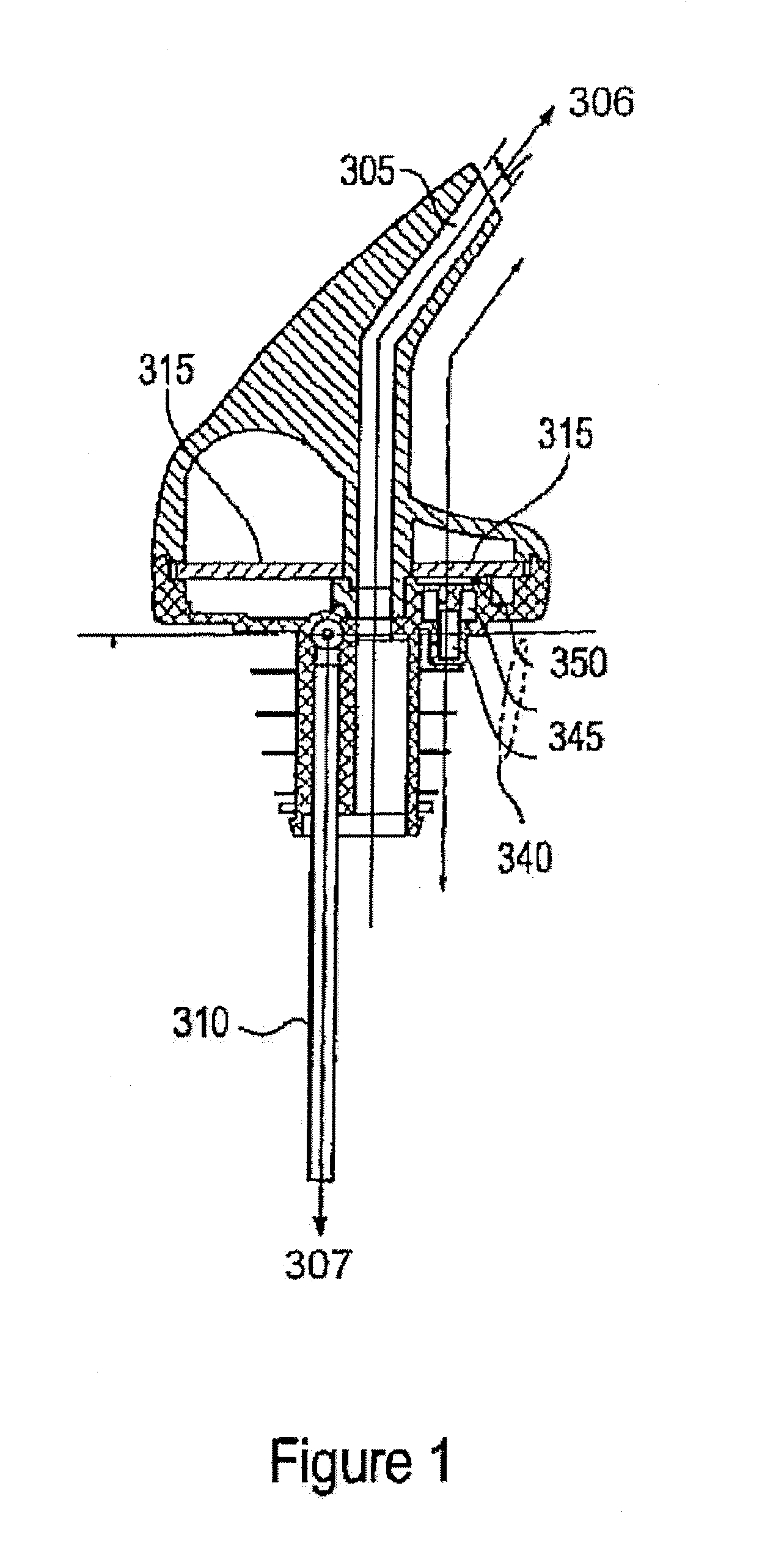

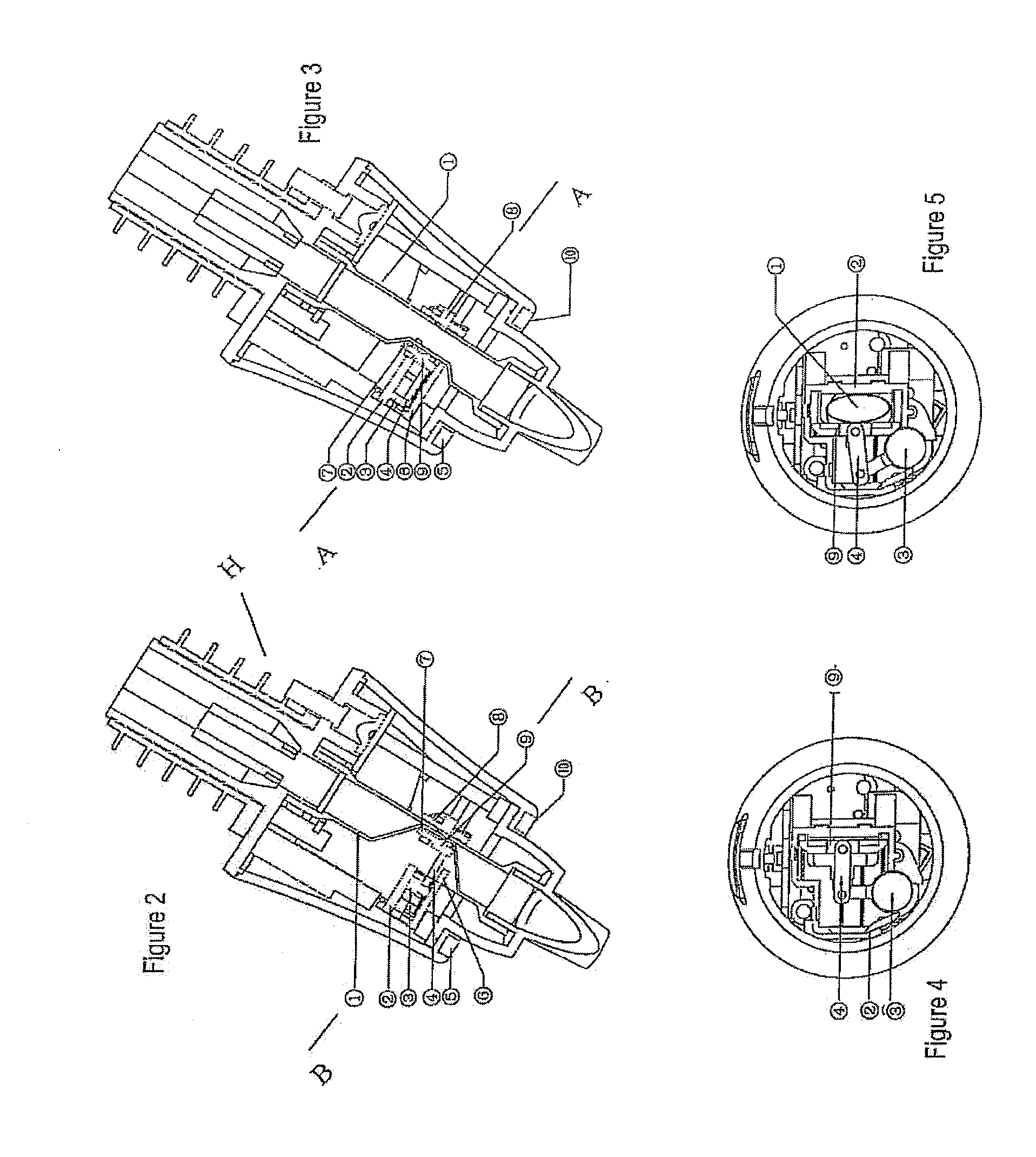

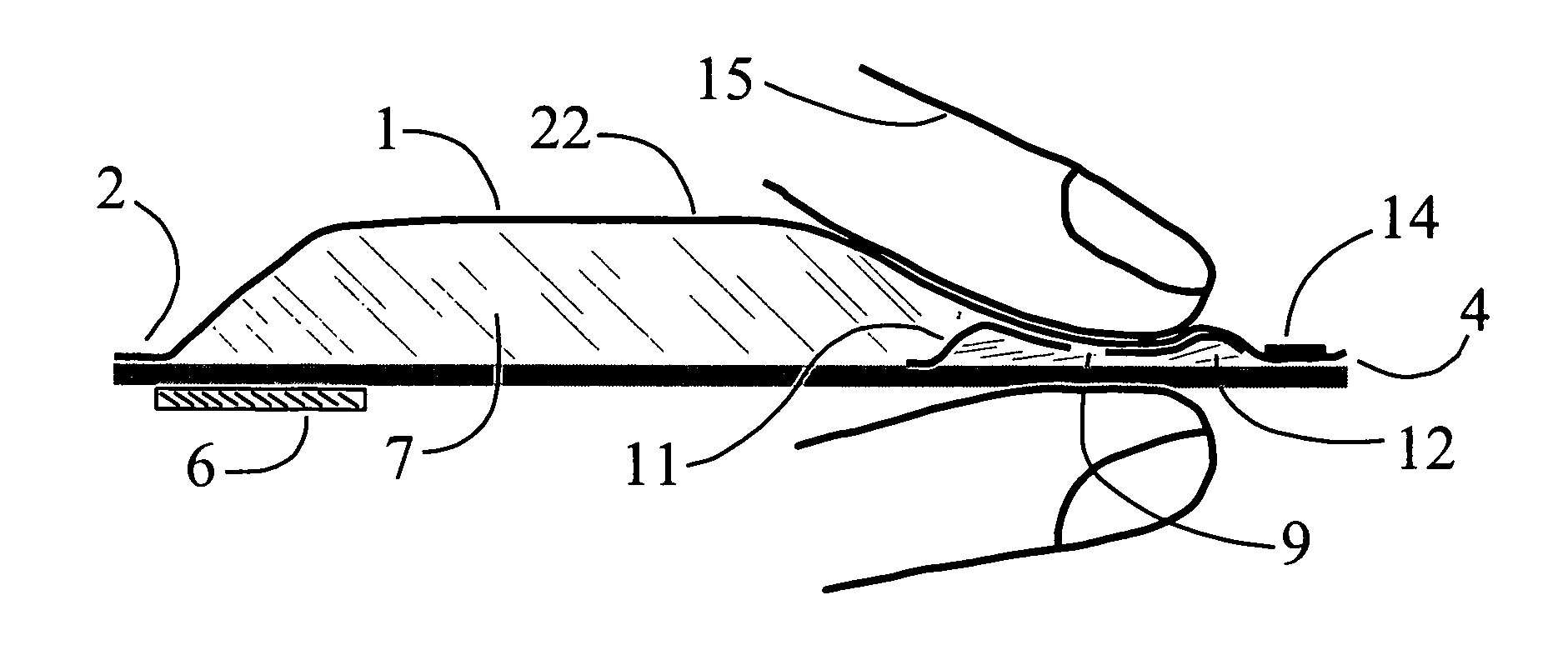

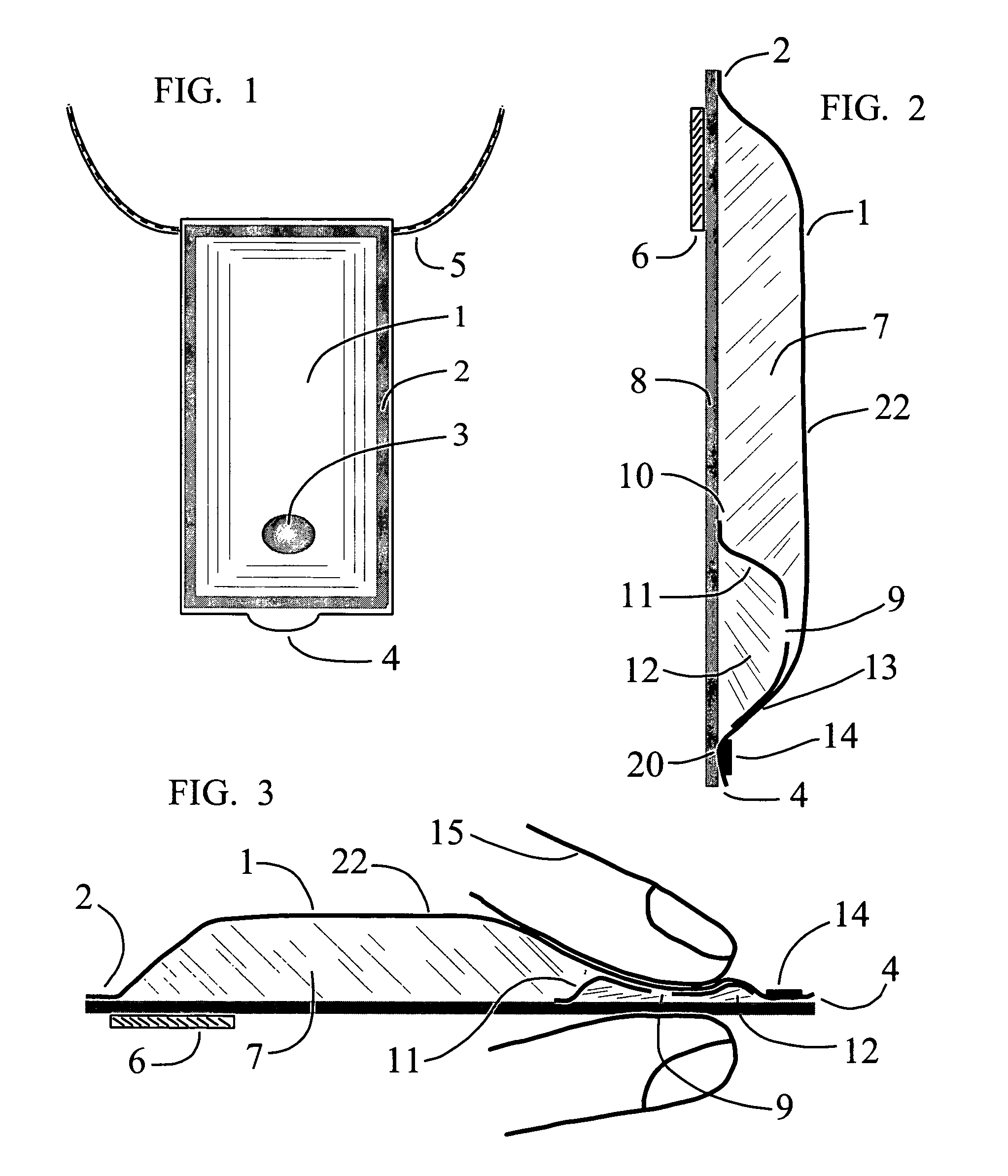

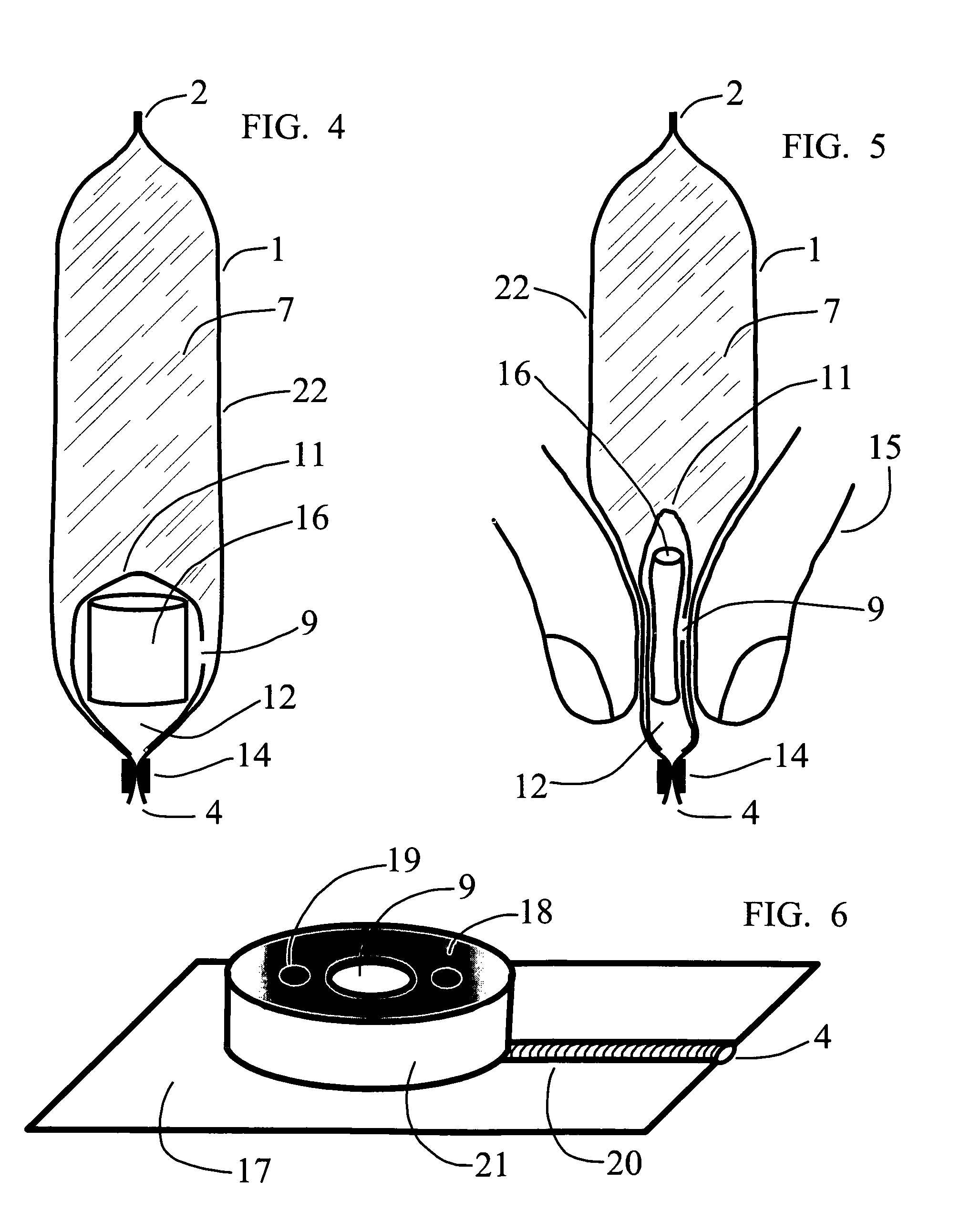

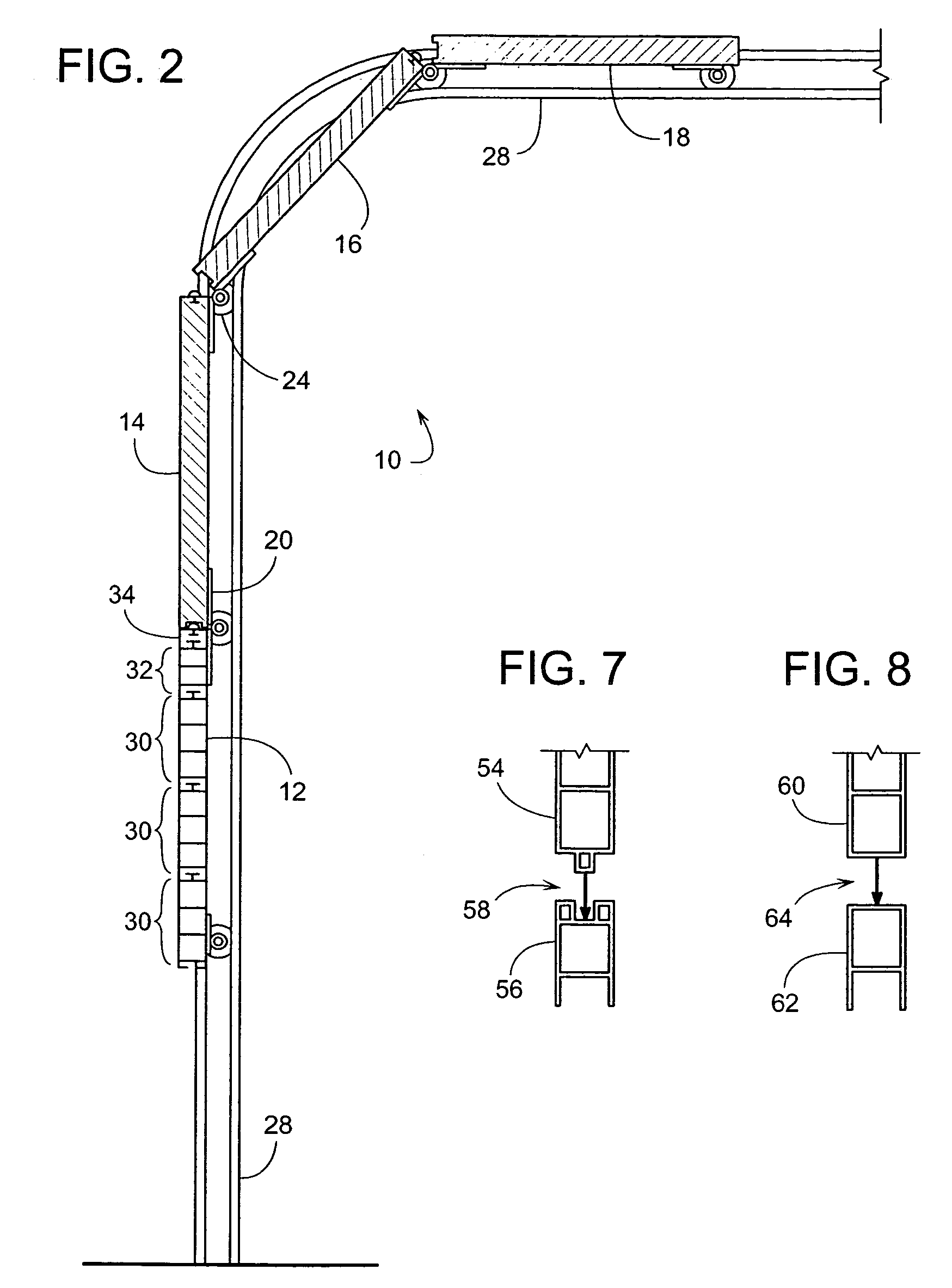

Triple lumen stone balloon catheter and method

InactiveUS7481800B2Acceptable inflationAcceptable deflation rateStentsBalloon catheterBalloon catheterKidney

A triple lumen stone balloon catheter (1) having a tapered distal end (9). A lumen (24) dedicated to transmitting contrast media is dimensioned and adapted to conform to the shape of a kidney in a main shaft of the catheter and conform to the shape of a crescent in a distal end of the catheter. The geometric shaping of the contrast media lumen (24) enables wall thickness to be maintained within acceptable ranges to sustain desirable mechanical characteristics while allowing for enhanced contrast media flow. A method for employing the balloon catheter (1) is also disclosed.

Owner:COMMAND ENDOSCOPIC TECH

Molding composition based on polyetheramides

ActiveUS20050014842A1Increase melt viscosityAdequate long-lasting flexibilityBiocideOrganic active ingredientsEtherDicarboxylic acid

A composition suitable for molding is provided having the following components: I. from 97 to 80 parts by weight of a polyetheramide, having units based on one or more linear aliphatic diamines having from 6 to 14 carbon atoms, one or more linear aliphatic or aromatic dicarboxylic acids having from 6 to 14 carbon atoms, and one or more polyetherdiamines having at least 3 carbon atoms per ether oxygen and having primary amino groups at the chain ends, II. from 3 to 20 parts by weight of a rubber containing one or more functional groups; and where the total of the parts by weight of I and II is 100; and moldings produced therefrom.

Owner:EVONIK OPERATIONS GMBH

Elastomeric laminate and elastomeric film

InactiveUS20110177735A1Improve heat resistanceImprove thermal stabilitySynthetic resin layered productsPaper/cardboard layered productsElastomerEngineering

An elastomeric laminate and an elastomeric film are provided. The elastomeric film can be a monolayer elastomeric film or a multilayer elastomeric film, wherein the monolayer elastomeric film includes an olefin-based elastomeric polymer and an effective polymer, and the multilayer elastomeric film when used as an alternative includes a first elastomeric member layer, and a second elastomeric member layer. The first elastomeric member layer includes at least one olefin-based elastomeric polymer, and at least one first draw down polymer. The second elastomeric member layer includes at least one elastomeric polymer and at least one second draw down polymer. The monolayer elastomeric film or the multilayer elastomeric film, and the elastic carrier are laminated together to form the elastomeric laminate.

Owner:CHENG KENNETH +1

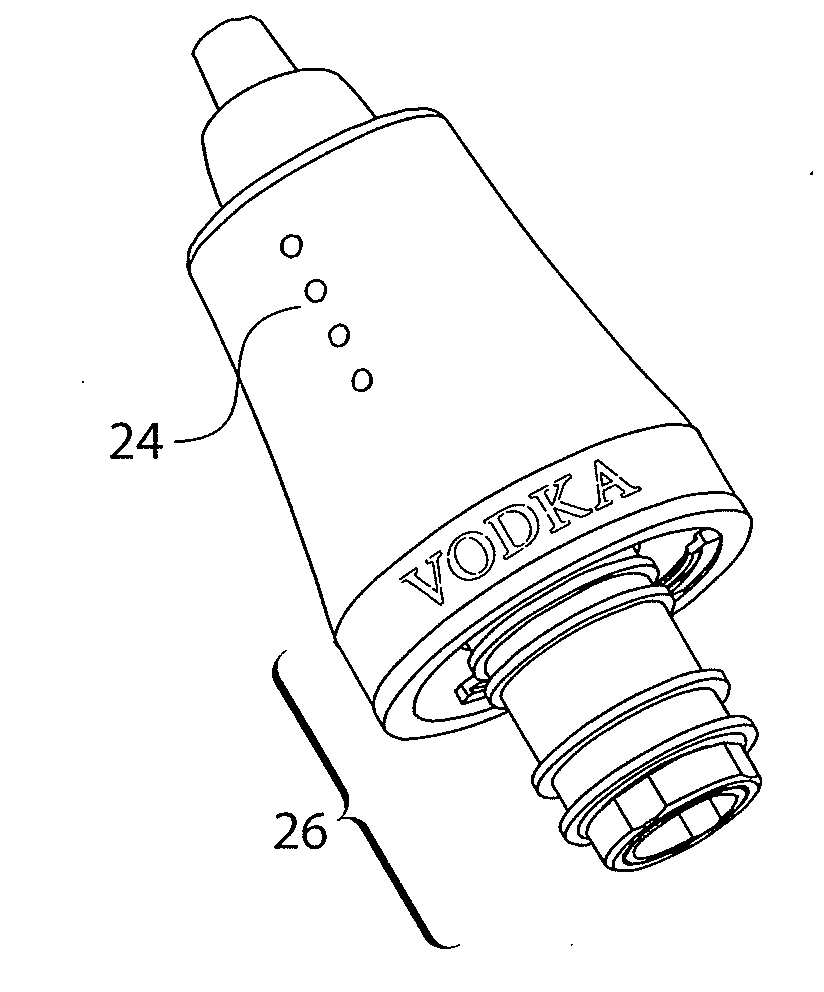

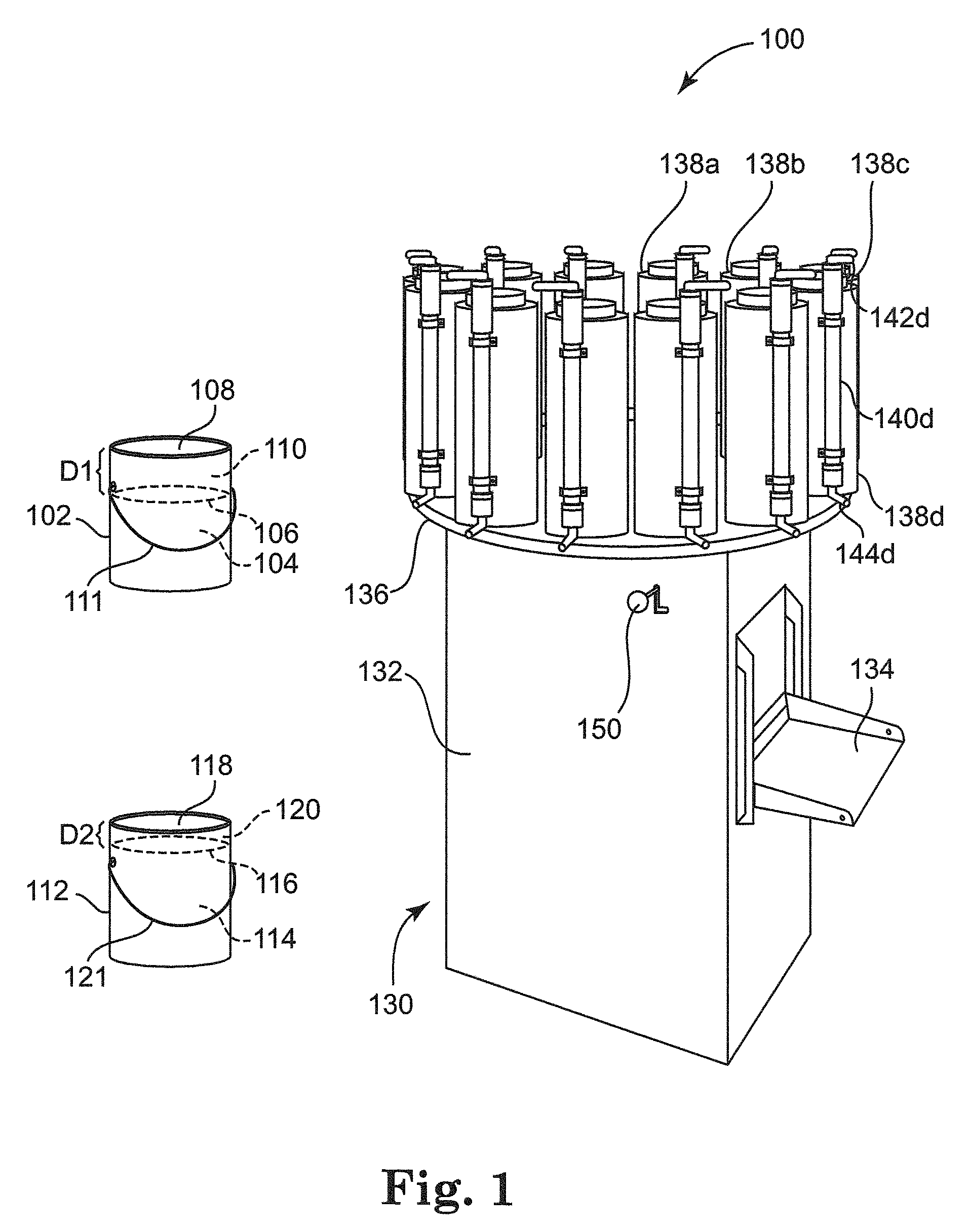

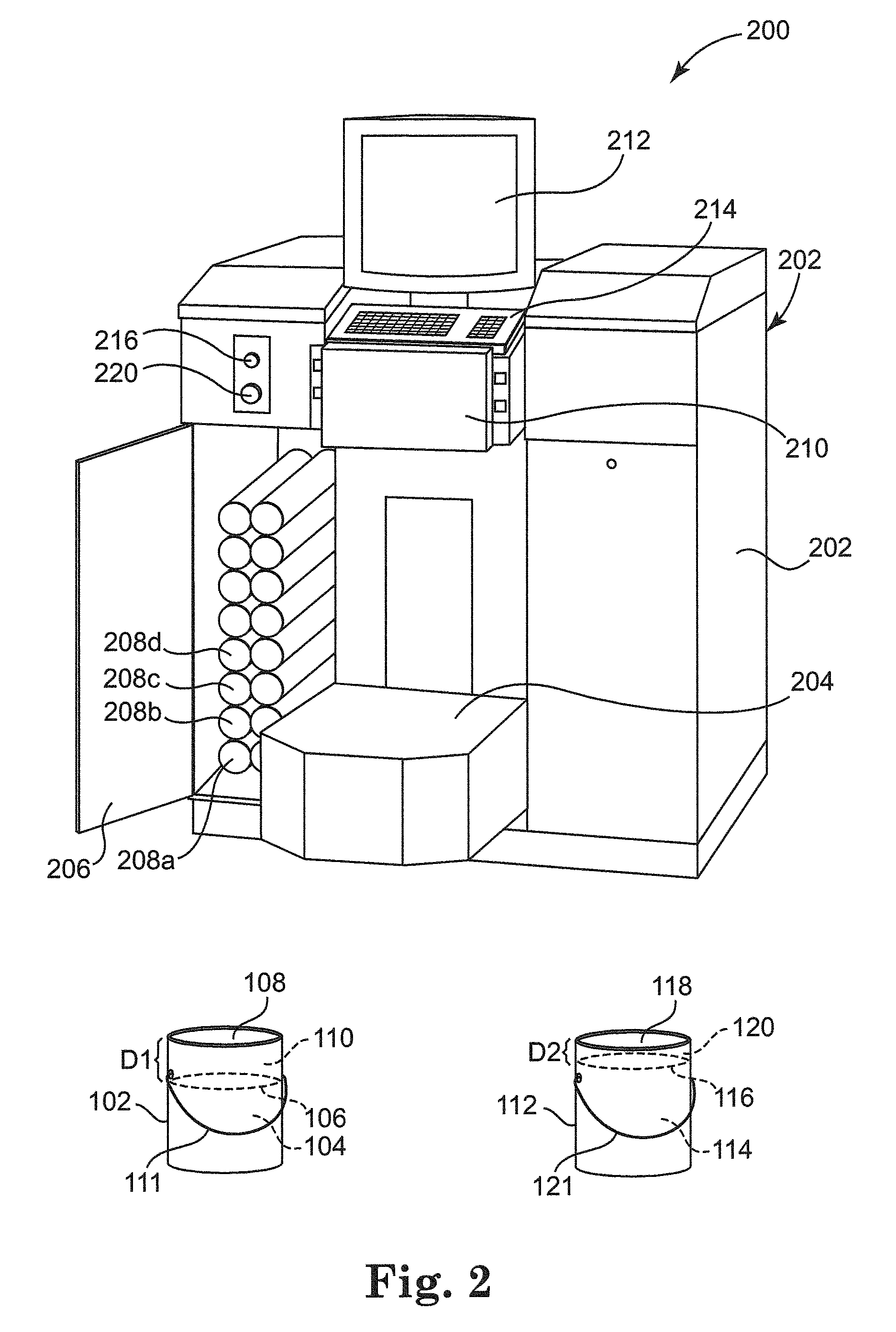

Wireless spout and system for dispensing

ActiveUS20120211516A1Quick and controlled flowExtrusion process is simpleVolume measurement and fluid deliveryLiquid flow controllersEngineeringColored light

Embodiments of the present invention provide a pouring device for a container for the dosing of liquid. The pouring device has various features intended to ease use, including an improved removal and attachment system and a system to identify and visually illustrate selected pour sizes. In a specific embodiment, the pouring device has a colored light or LED indicator system that allows the user to quickly and easily confirm the selected pour size. Embodiments may also include one or more features that ease attachment and removal of the pouring device to a liquid container, such as a replaceable cork system.

Owner:LAB2FAB LLC

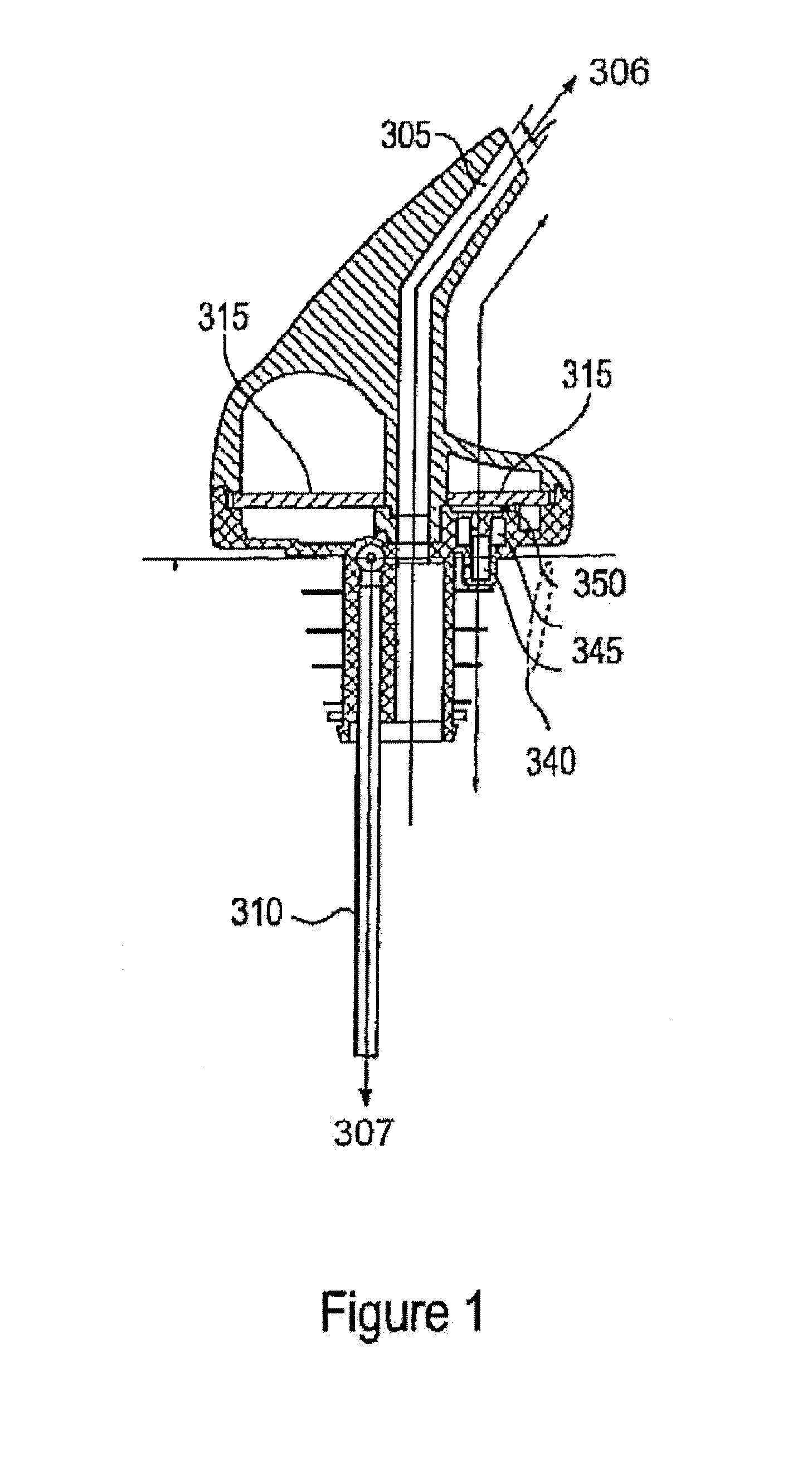

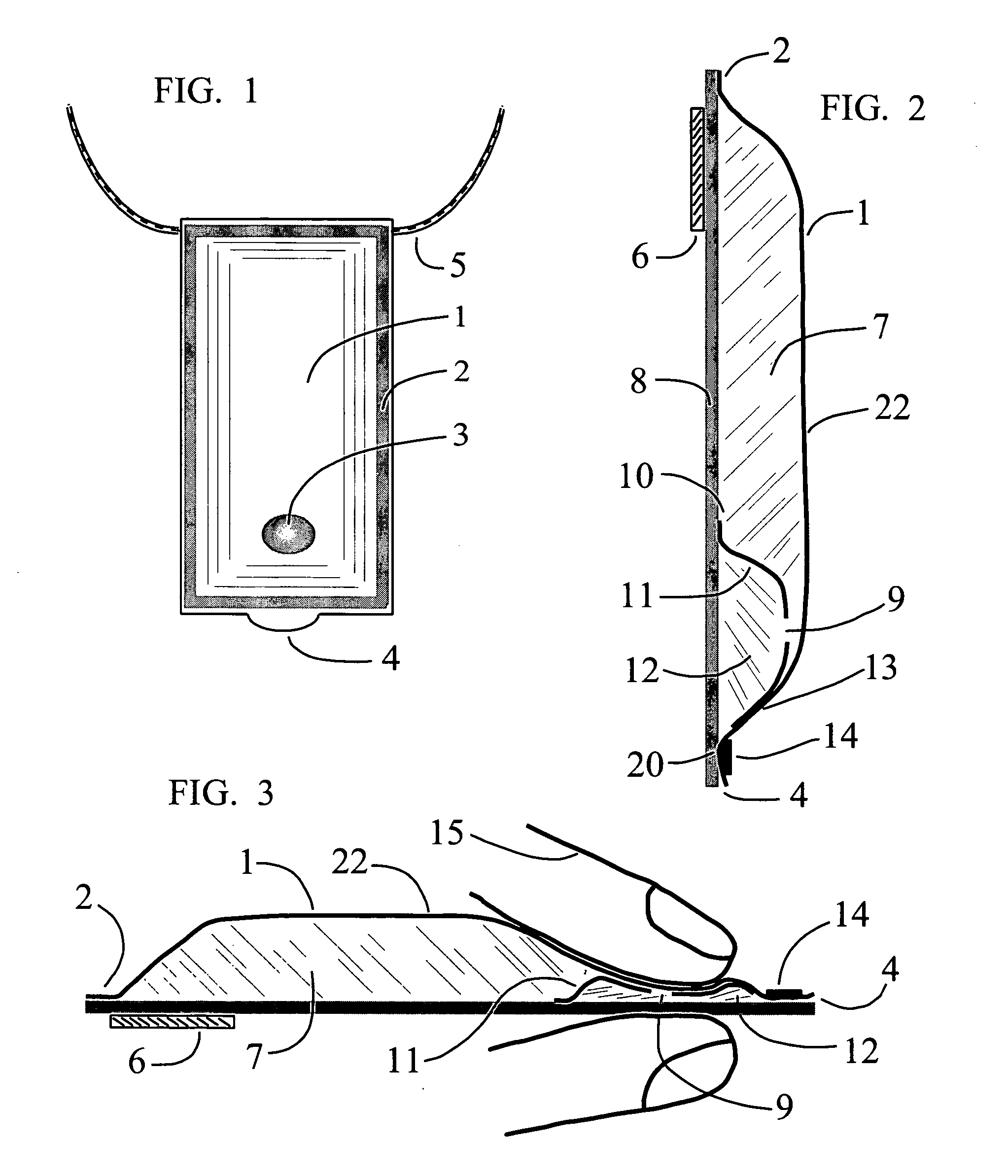

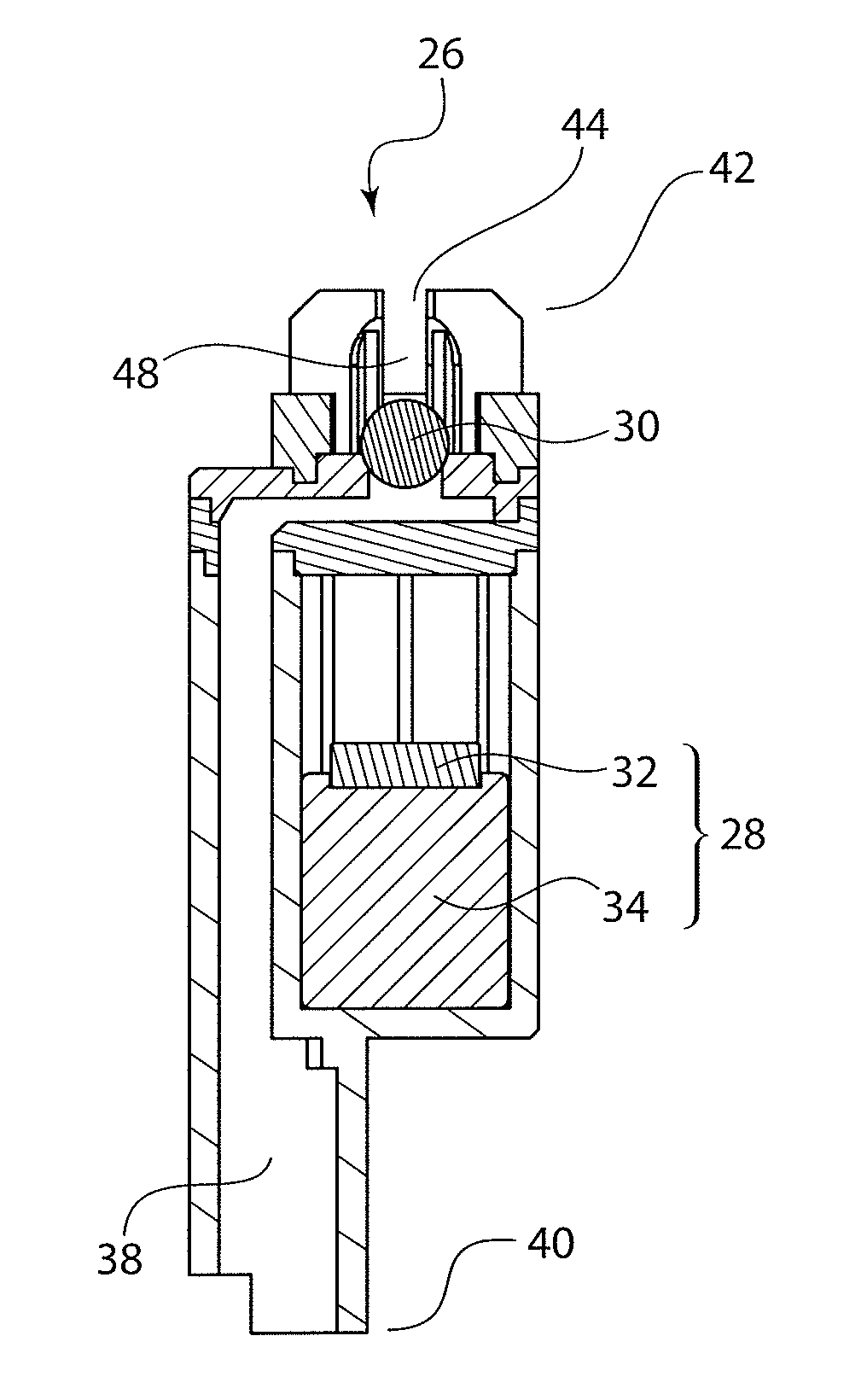

Fluid dispenser with internal pump

A hand operated fluid dispensers comprised of a sealed flexible reservoir chamber containing a fluid, a flexible pump chamber encased by and drawing fluid from the reservoir, and a pump cycled by external pressure applied through a reservoir wall. This class of simple, inexpensive, disposable dispensers is particularly useful in packaging cosmetics, foodstuffs, and healthcare products. As pocketable dispensers they are popular for dispensing small amounts of stored viscous liquids easily damaged when exposure to the atmosphere, a condition where sealed reservoirs coupled with airless pumps working together successfully prevent such product contamination and deterioration. A method of improved healthcare employing such pump dispensers containing a hand sanitizing fluid is also discussed.

Owner:PENNCREEK

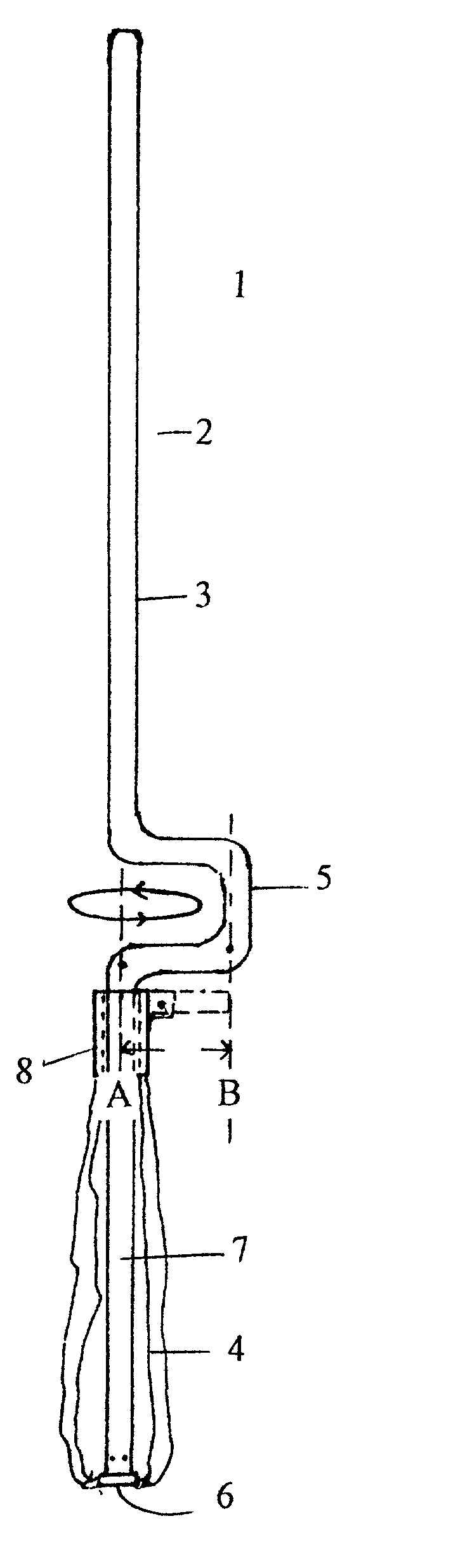

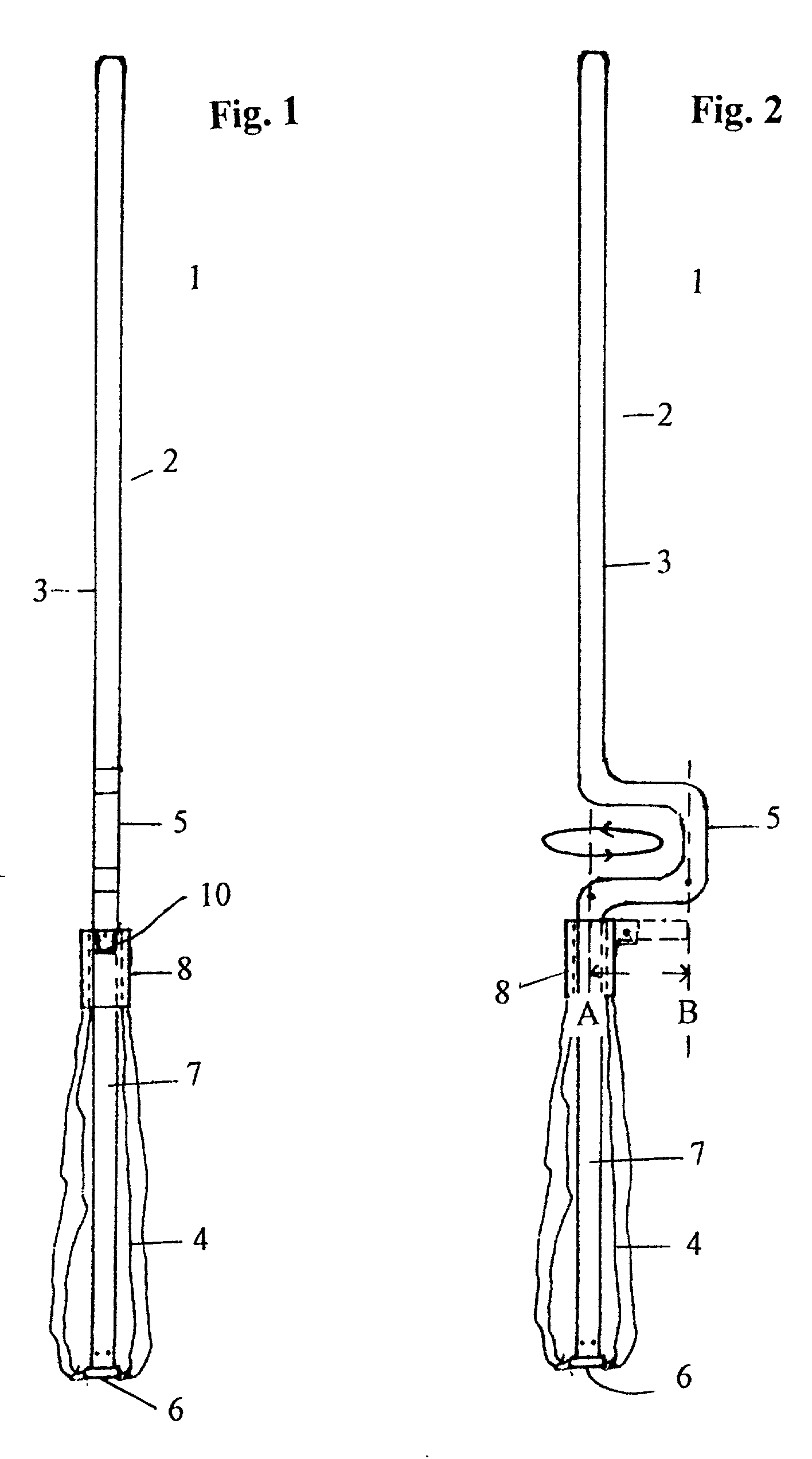

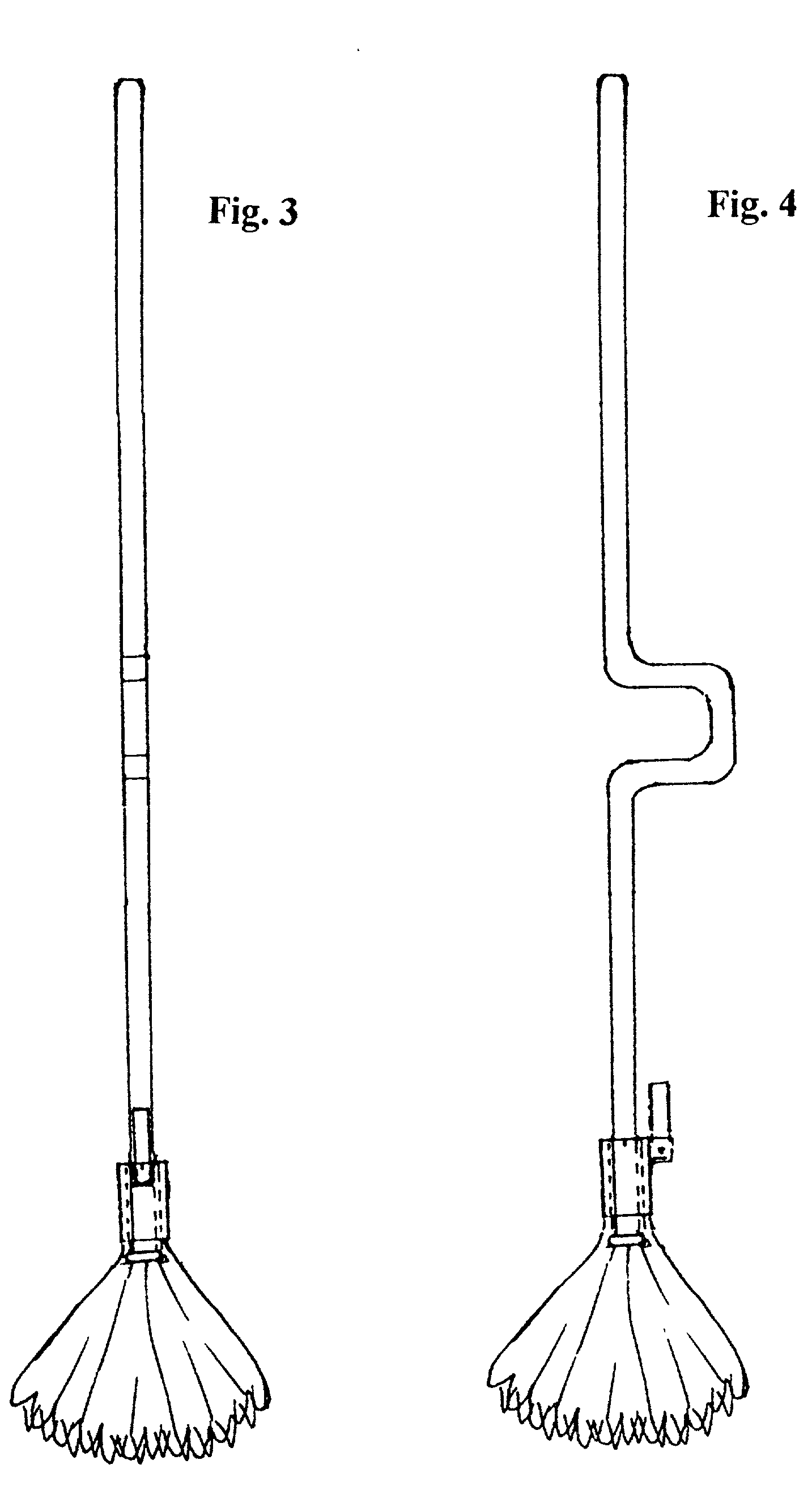

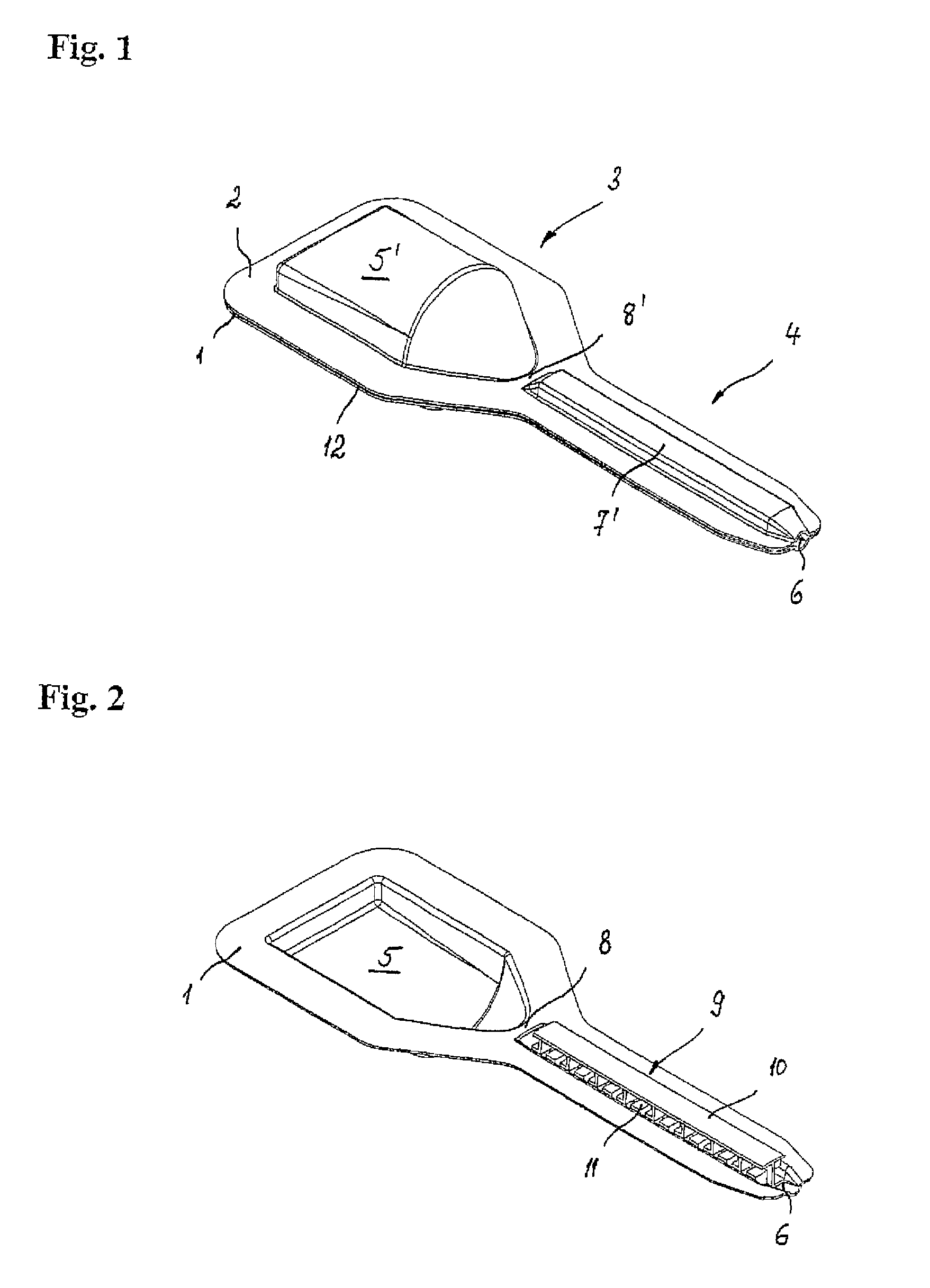

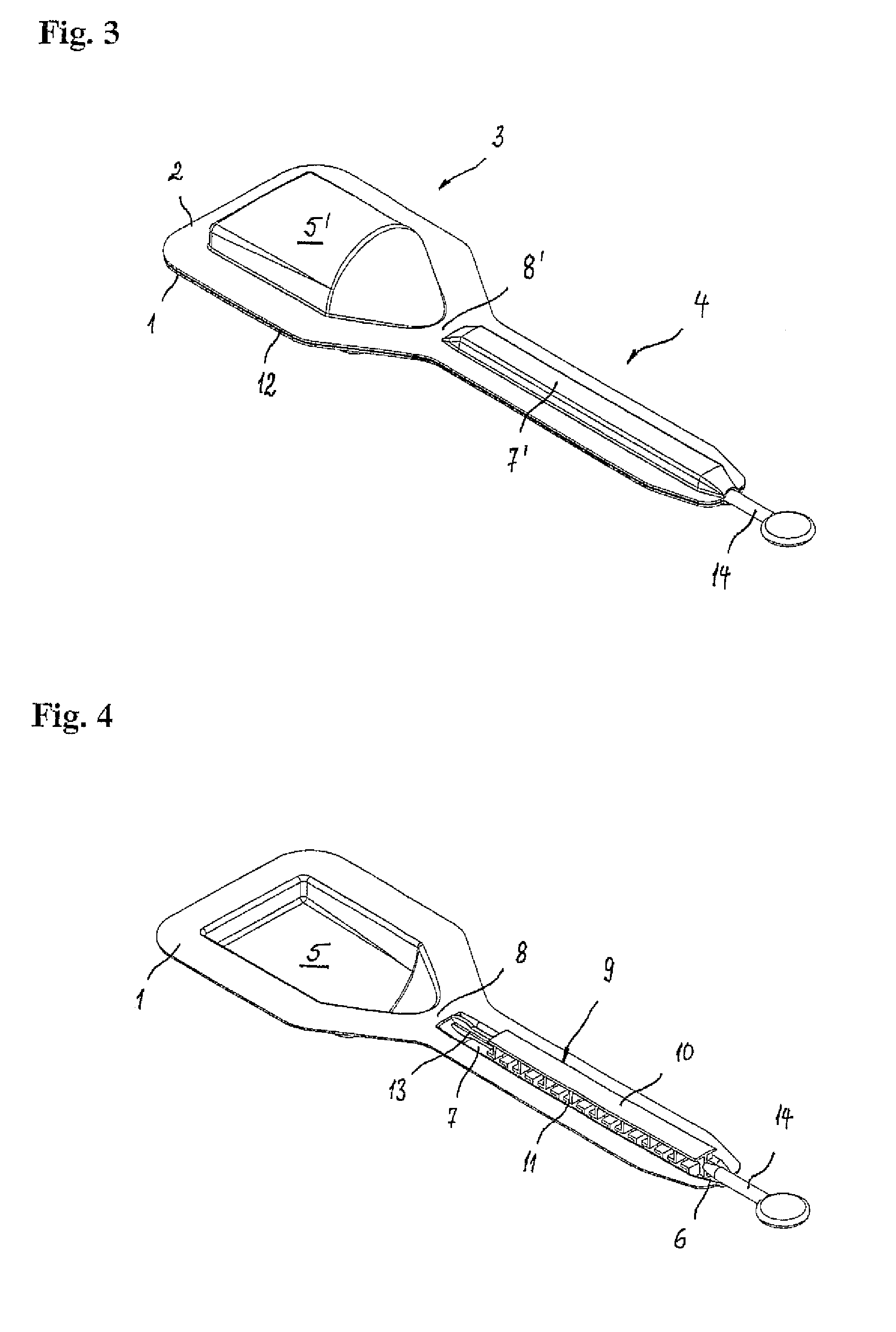

Easy mop

InactiveUS20030000036A1Extrusion process is simpleKeep dryCarpet cleanersFloor cleanersEngineeringHand held

A easy mop allows user to easily squeeze water out of it, meanwhile, saves user's power and keeps hands dry. The easy mop includes: a long handle with an extended arm of force either a bow portion or a handle, a mass of absorbent material, a sleeve with a twisting handle or a metal bar instead of the sleeve and twisting handle. While twisting the mop, one hand hole the twisting handle, another hand hold the bow or handle then turn around, the water being easily squeezed out of the mop.

Owner:FAN JIANHUA

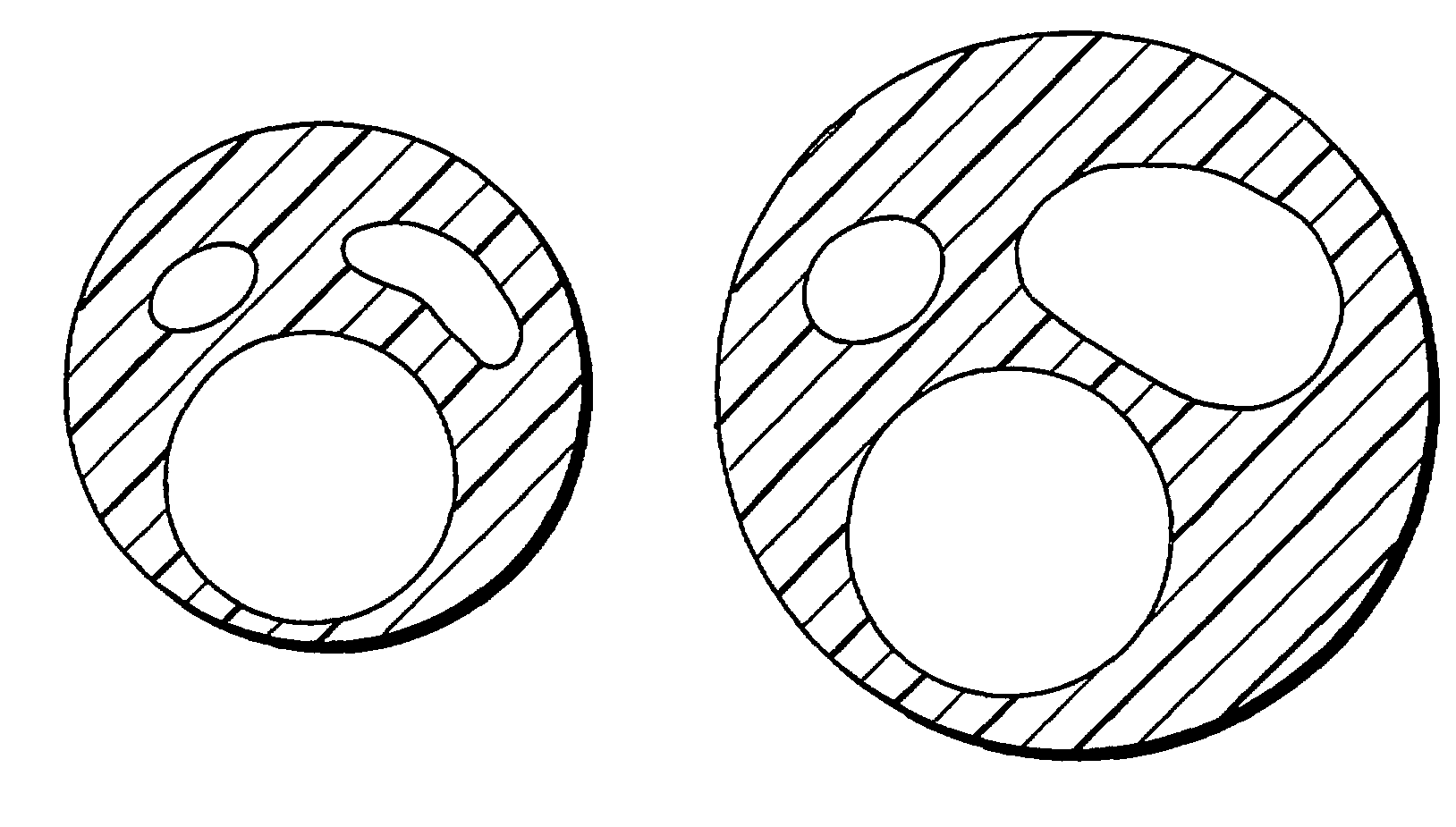

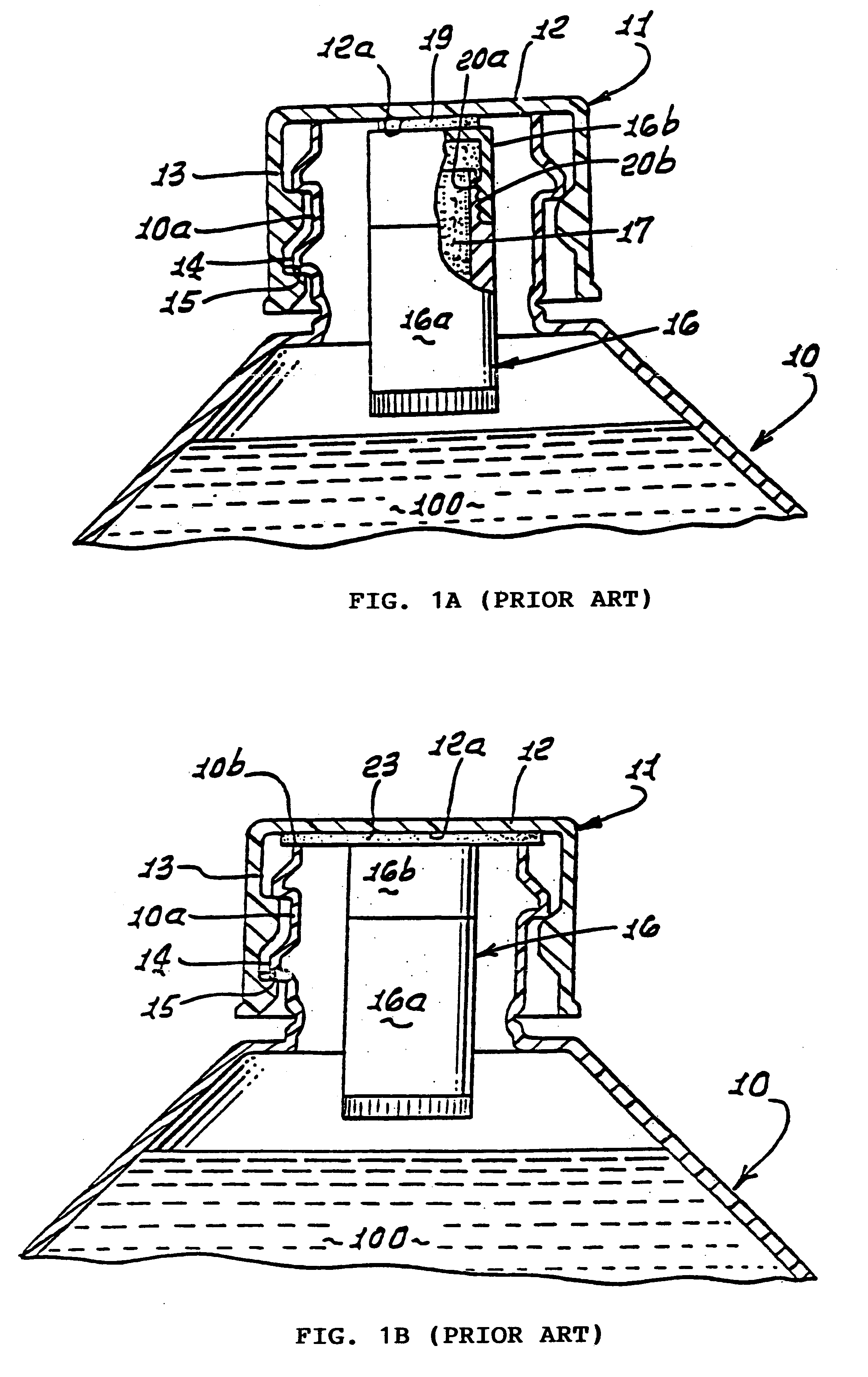

Device for maintaining separate ingredients in liquid food products

InactiveUS6250346B1Extrusion process is simpleSafe storageCapsLiquid fillingAdditive ingredientEngineering

A device for maintaining ingredients separately within a bottle container of the type having a removable container cap has a sub-container body formed with squeezable plastic outer walls and inner divider walls forming multiple compartments having respective orifices for dispensing the ingredients contained therein. Each compartment can be separately opened (by removing a sealing element) and its ingredient can be dispensed into the container by squeezing on corresponding portions of the outer walls. In different embodiments, the device may be formed with the sub-container body in a cylindrical shape, the divider wall aligned with the cylinder axis or transverse to the cylinder axis, and the cylinder body snap-fitted to the underside of the cap or fixed to a collar which is held on the container neck by the cap. In another approach, a device, for use with a can container having a fixed can top and pull tab, has a one or more sub-container vessels held in exterior well(s) recessed in the surface of the container top, and held in place by and protected by the pull tab. When the pull tab is removed and the tab opening is exposed, the sub-container vessel (s) can be removed from the exterior well(s) to dispense their separate ingredients into the container. These improved devices allow multiple ingredients to be safely stored separately from the carrier liquid and conveniently used and controllably metered to the user's tastes.

Owner:CASTILLO JAMES ANZAI

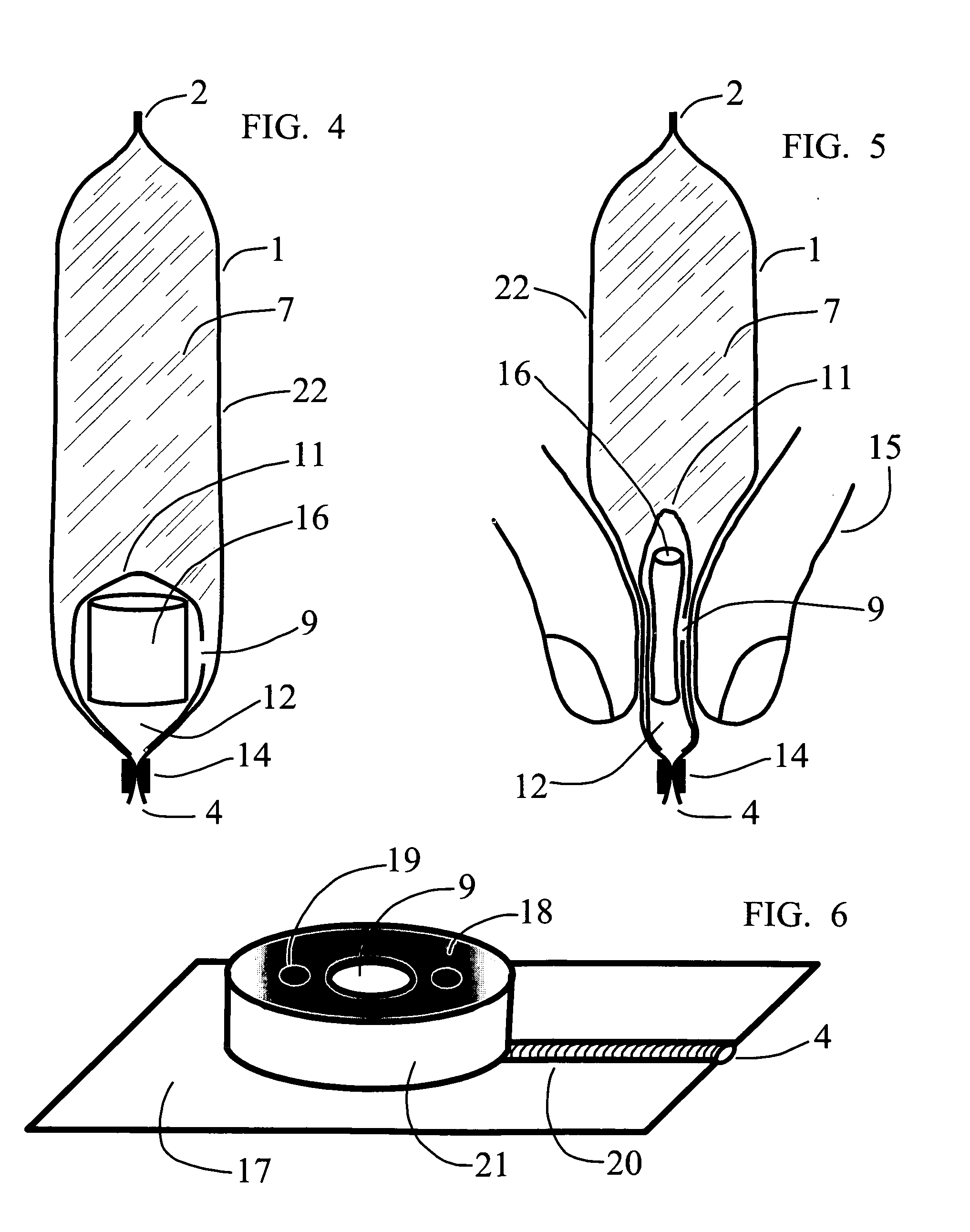

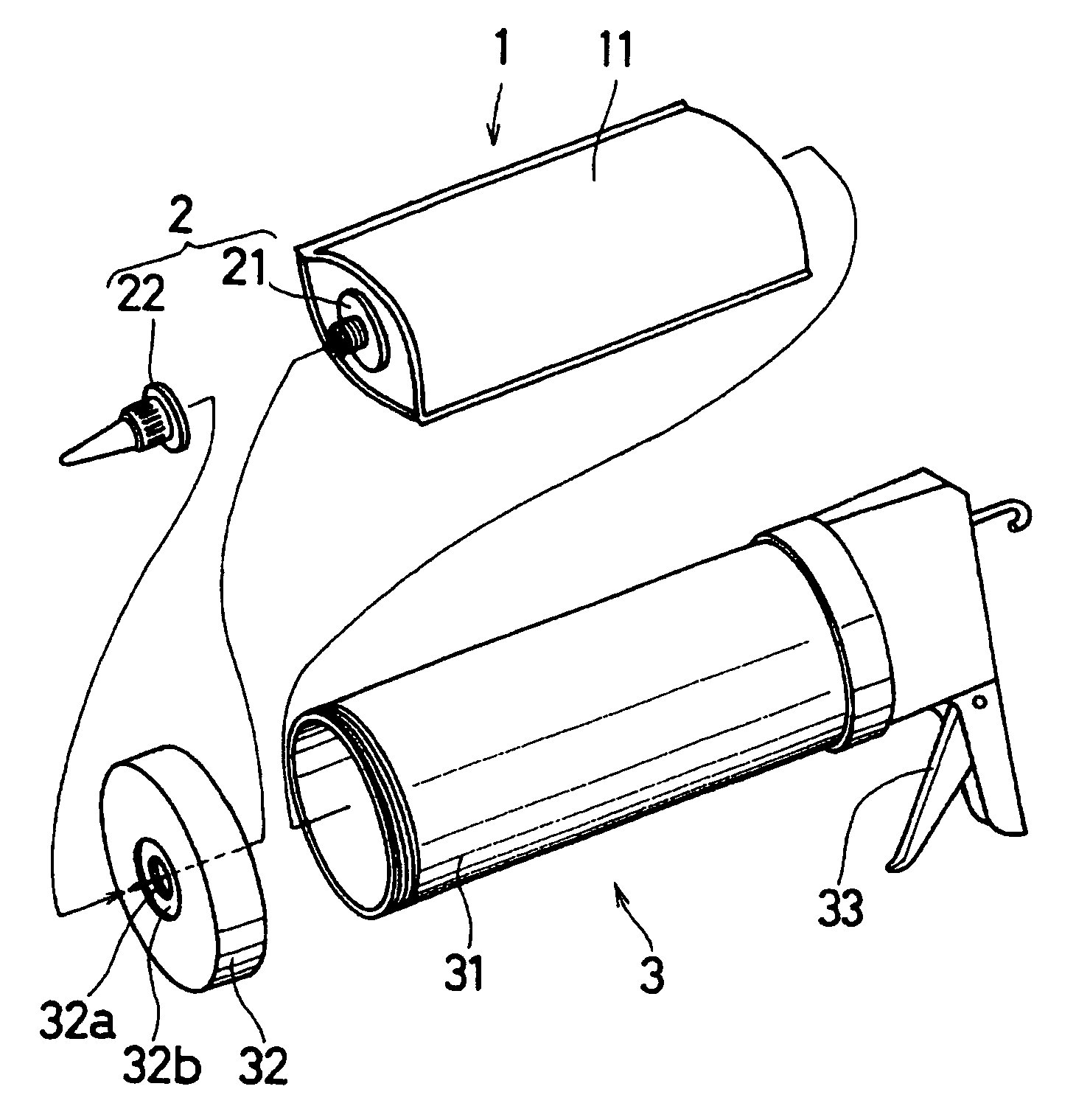

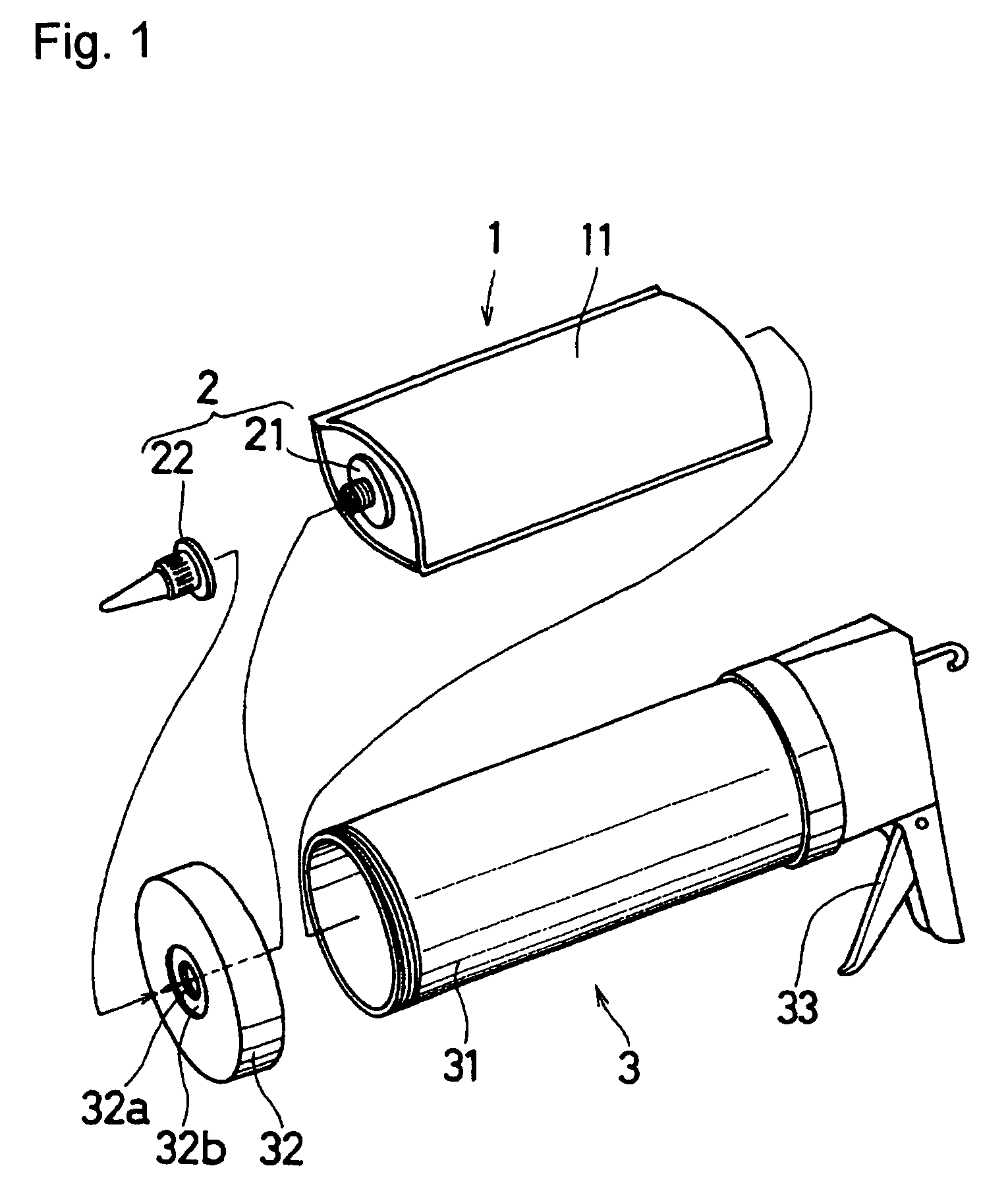

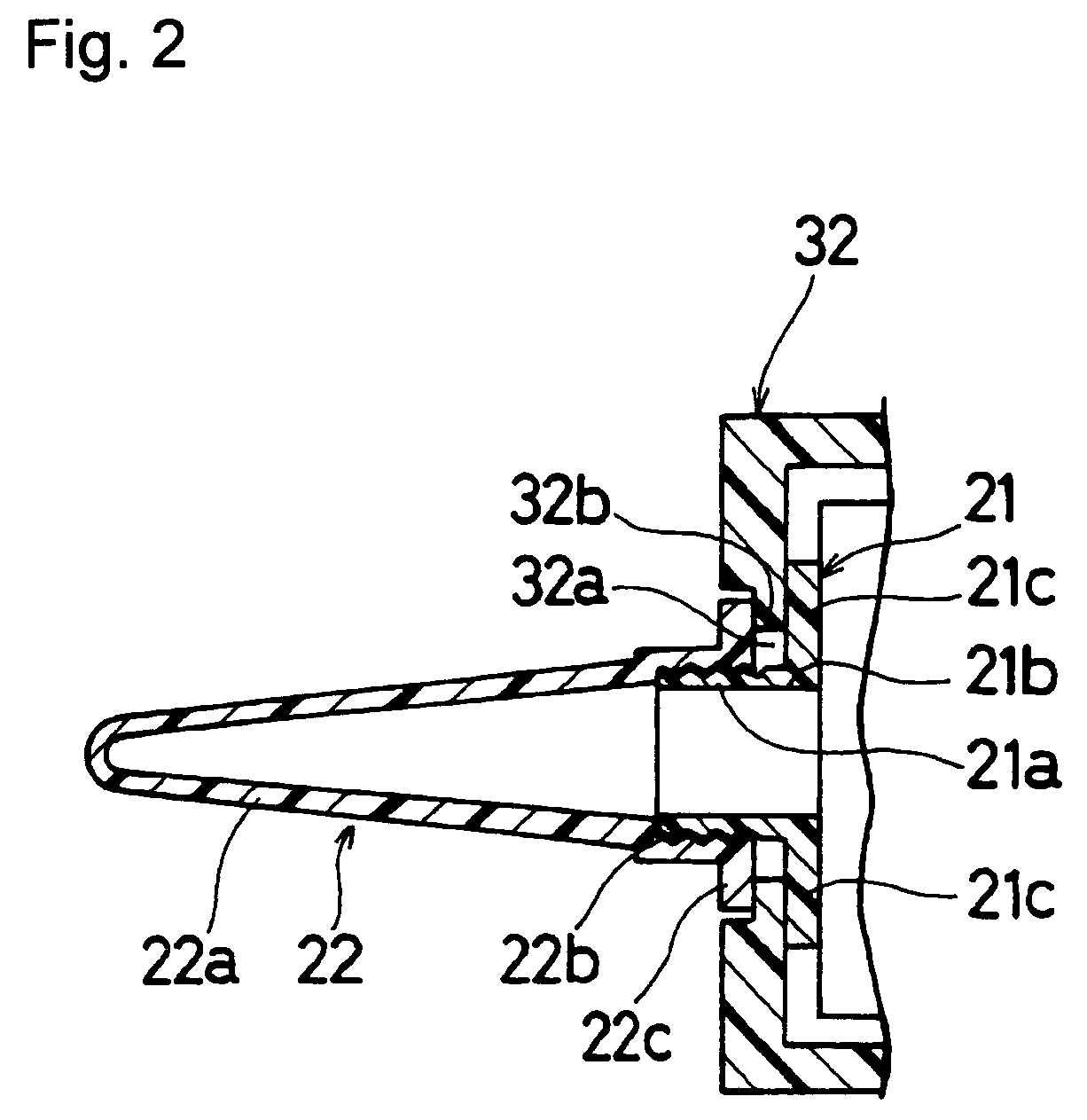

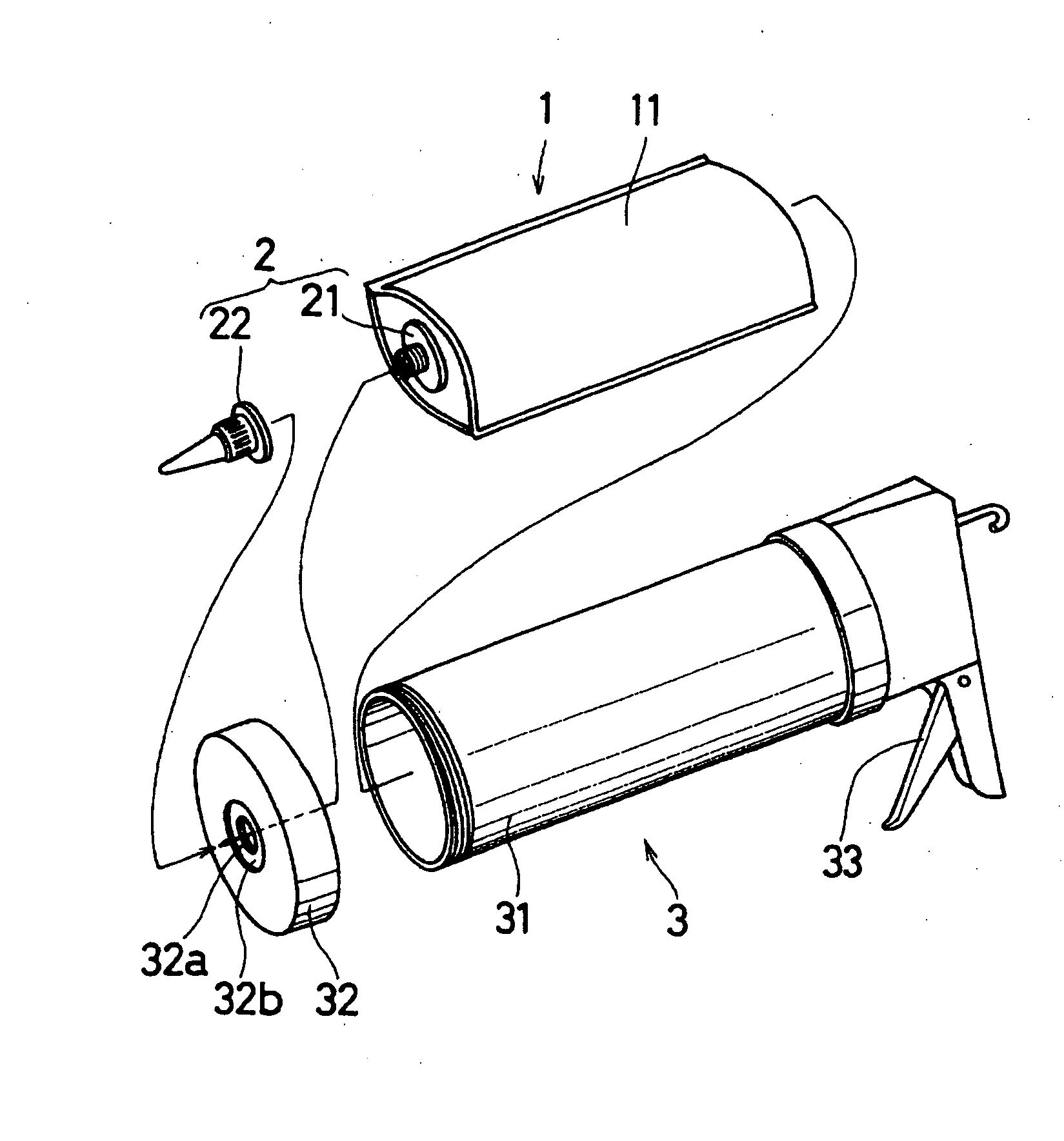

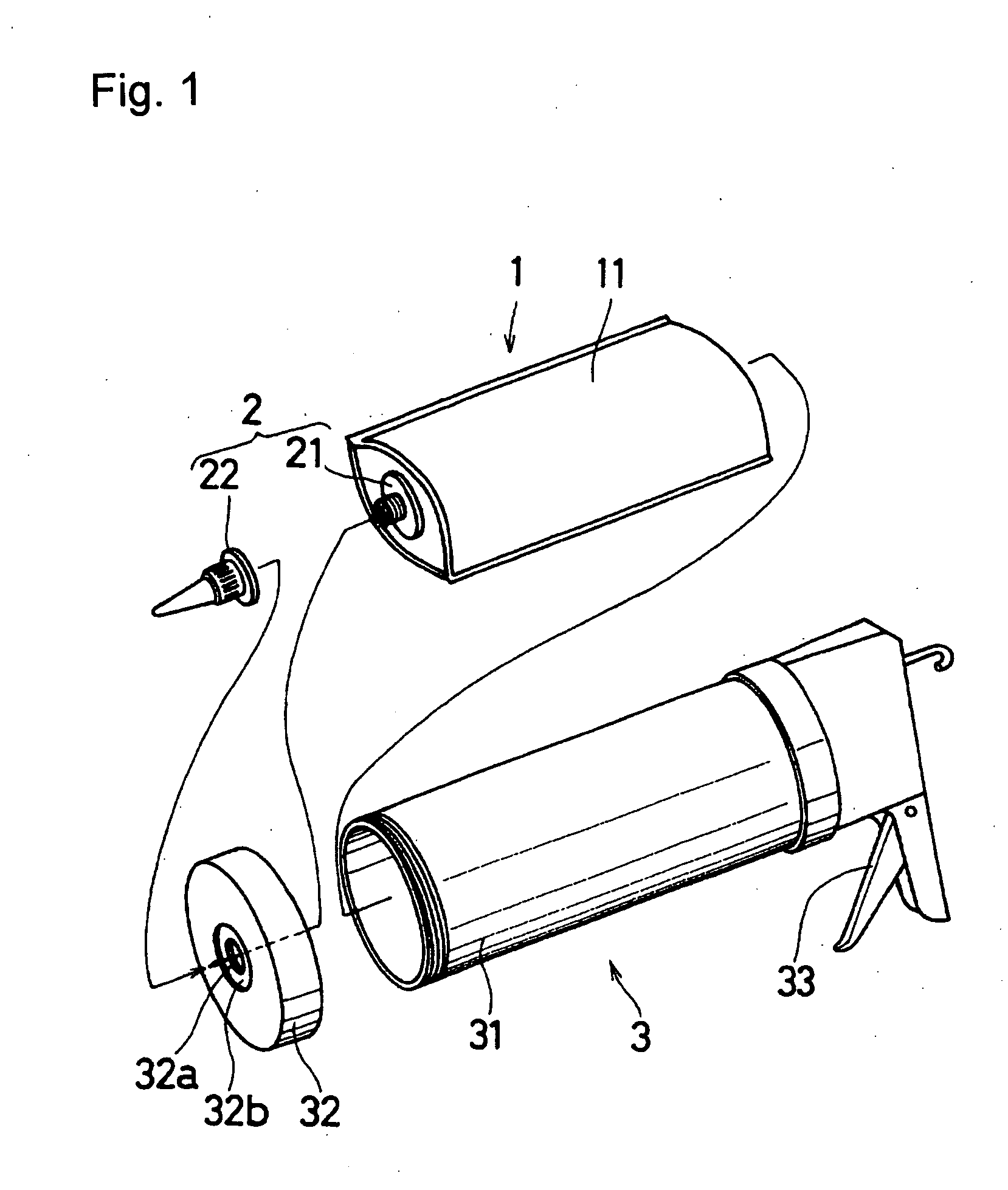

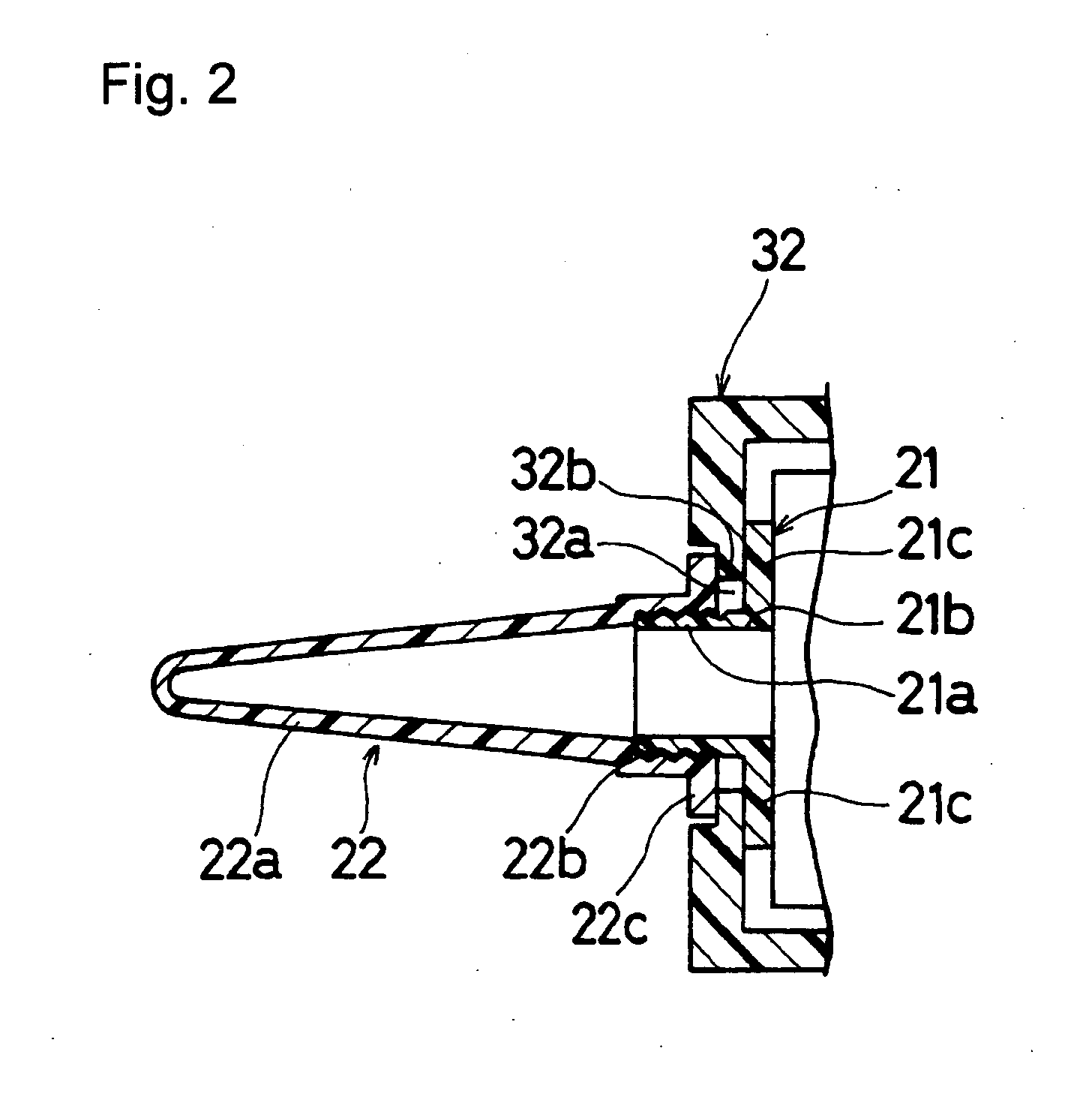

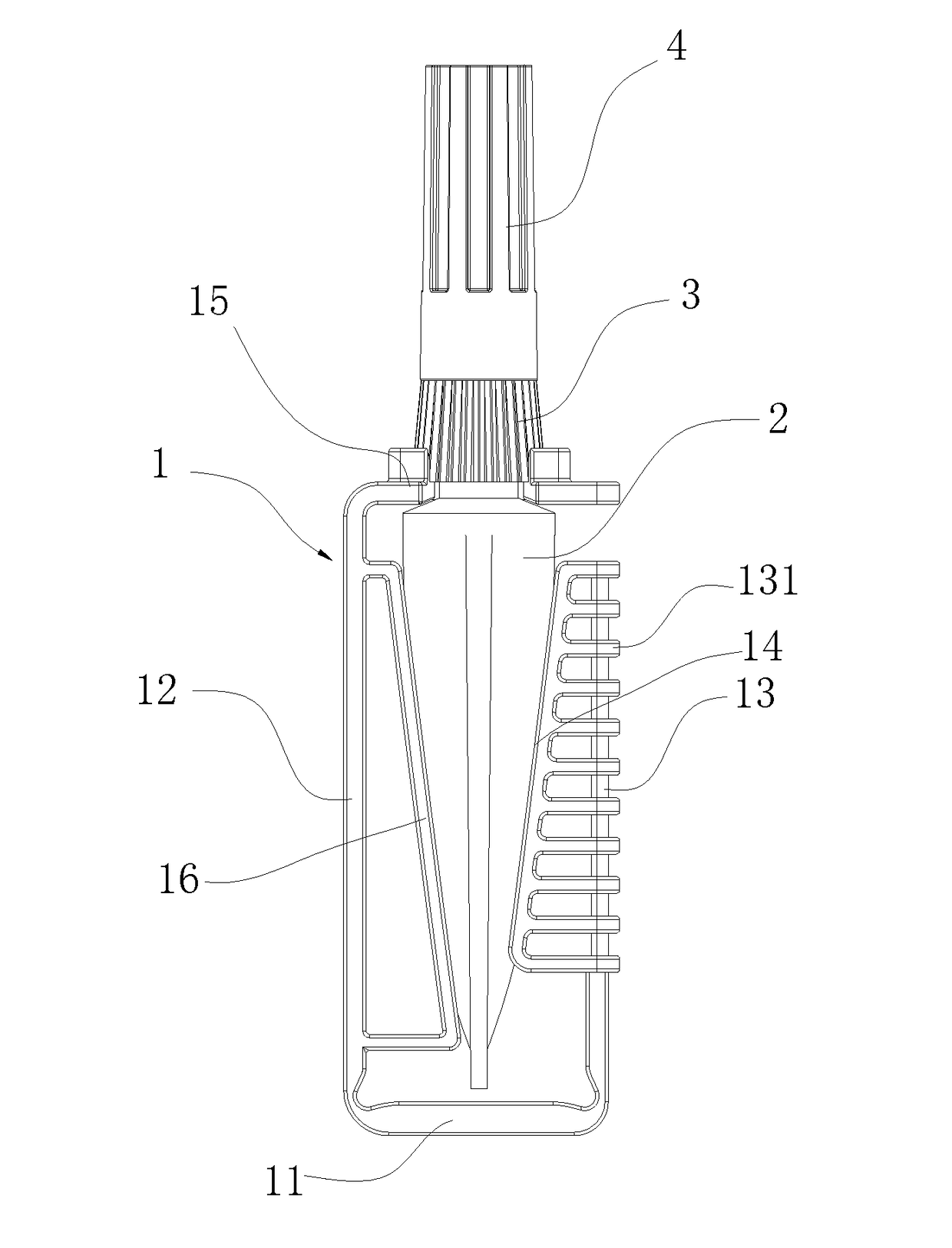

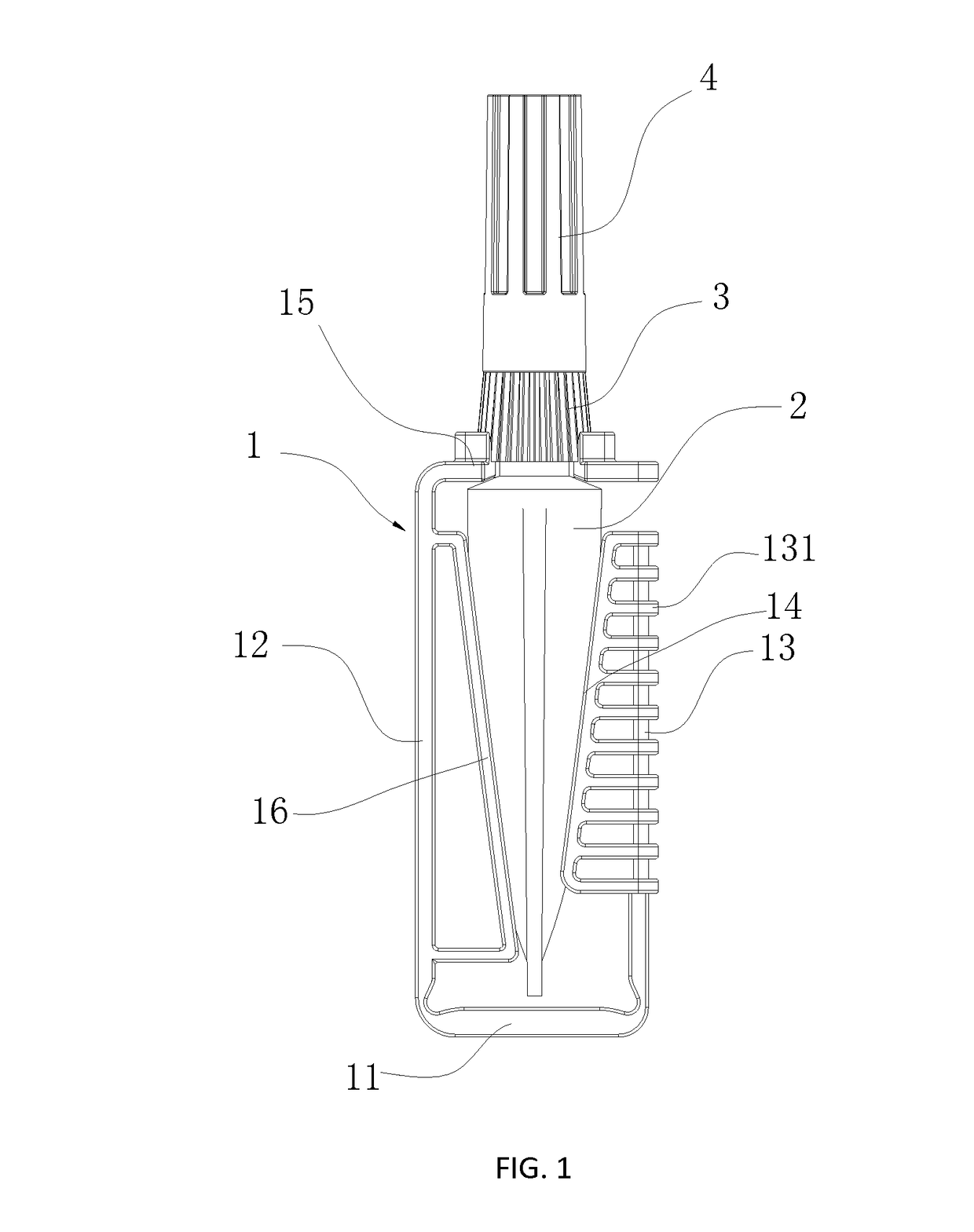

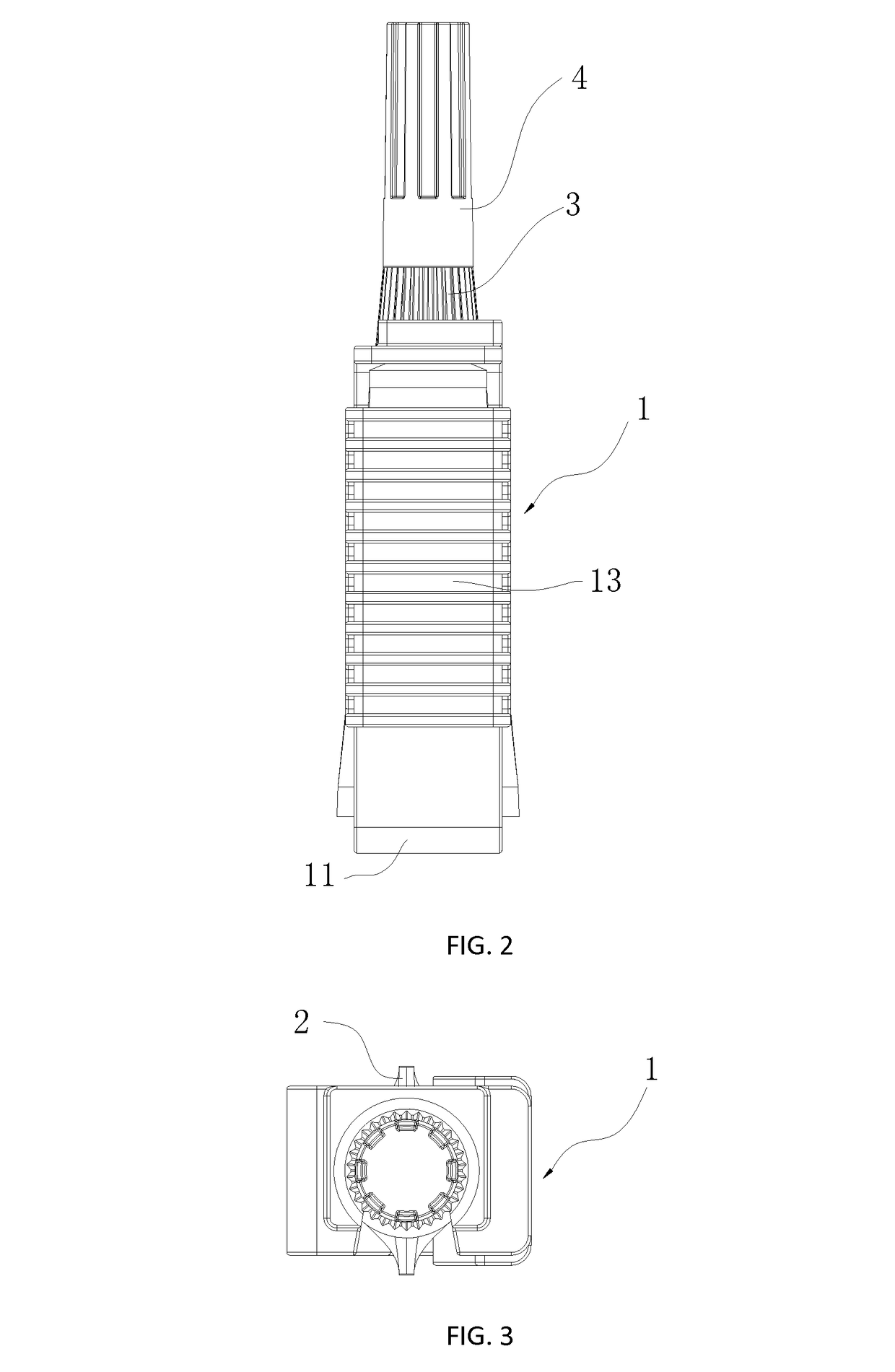

Container and pusiier

InactiveUS7445135B2Low costExtrusion process is simpleLiquid surface applicatorsBagsEngineeringSealant

A container, which houses a liquid such as a sealant in a flexible pouch 11 in a sealed state, is provided with a spout 2 that is constituted by an extrusion nozzle 22 and a spout base member 21 and formed on one end thereof so that the extrusion nozzle 22 is fixed by sandwiching the vicinity of a hole 32a formed on one end face of an extruder 3 by a flange portion 21c of the spout base member 21 and a flange portion 22c of the extrusion nozzle 22, and an extruder 3a is arranged so that an adjusting member 322b, which controls the tilt of the nozzle 22, is allowed to protrude outward from a hole 322a of the extruder 3a.

Owner:SHARP KAGAKU INDS

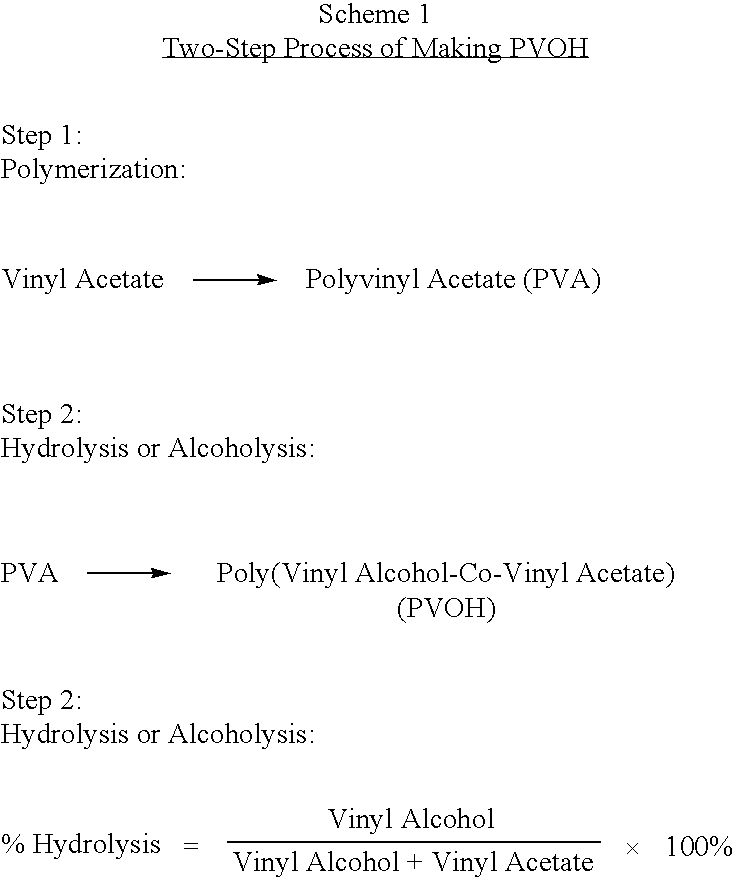

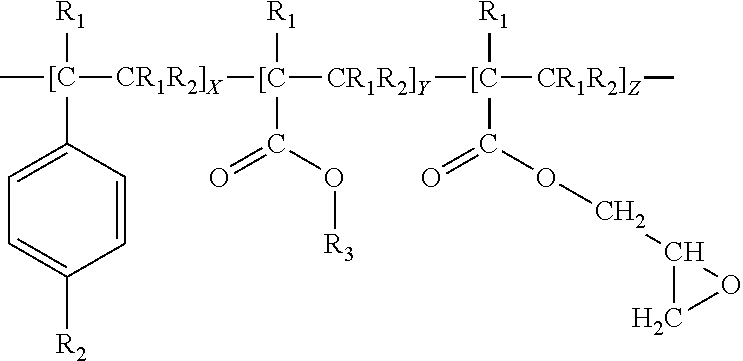

Blend compositions of an unmodified poly vinyl alcohol and a thermoplastic elastomer

InactiveUS7012116B1Good flexibilityImprove ductilityNon-fibrous pulp additionSynthetic resin layered productsPolyvinyl alcoholThermoplastic elastomer

This invention relates, in general, to blend compositions of an unmodified poly vinyl alcohol and a thermoplastic elastomer and thermoplastic film and fiber structures comprising these blend compositions. More specifically, this invention relates to substantially water-free films and fibers comprising unmodified polyvinyl alcohol and a thermoplastic elastomer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

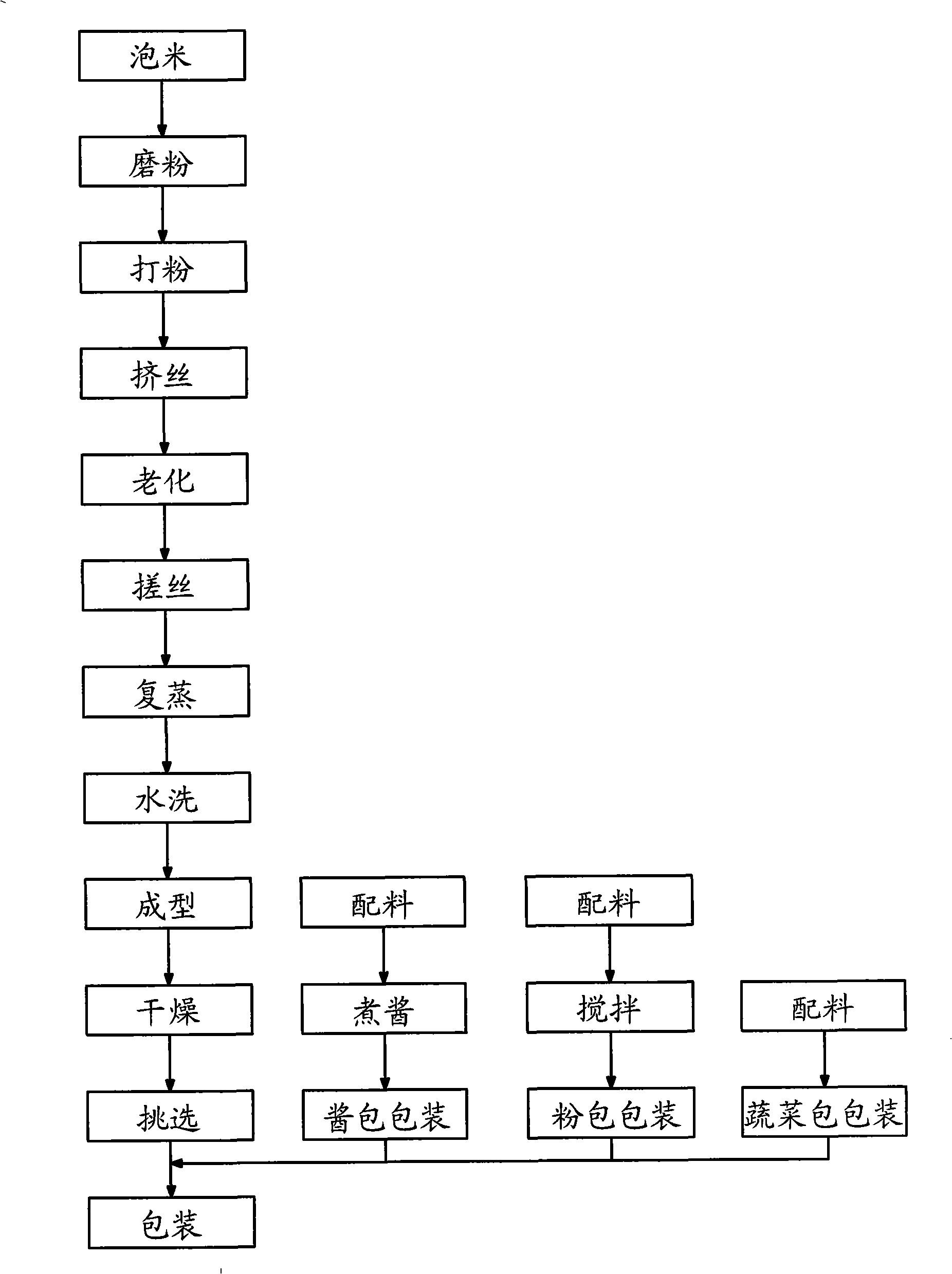

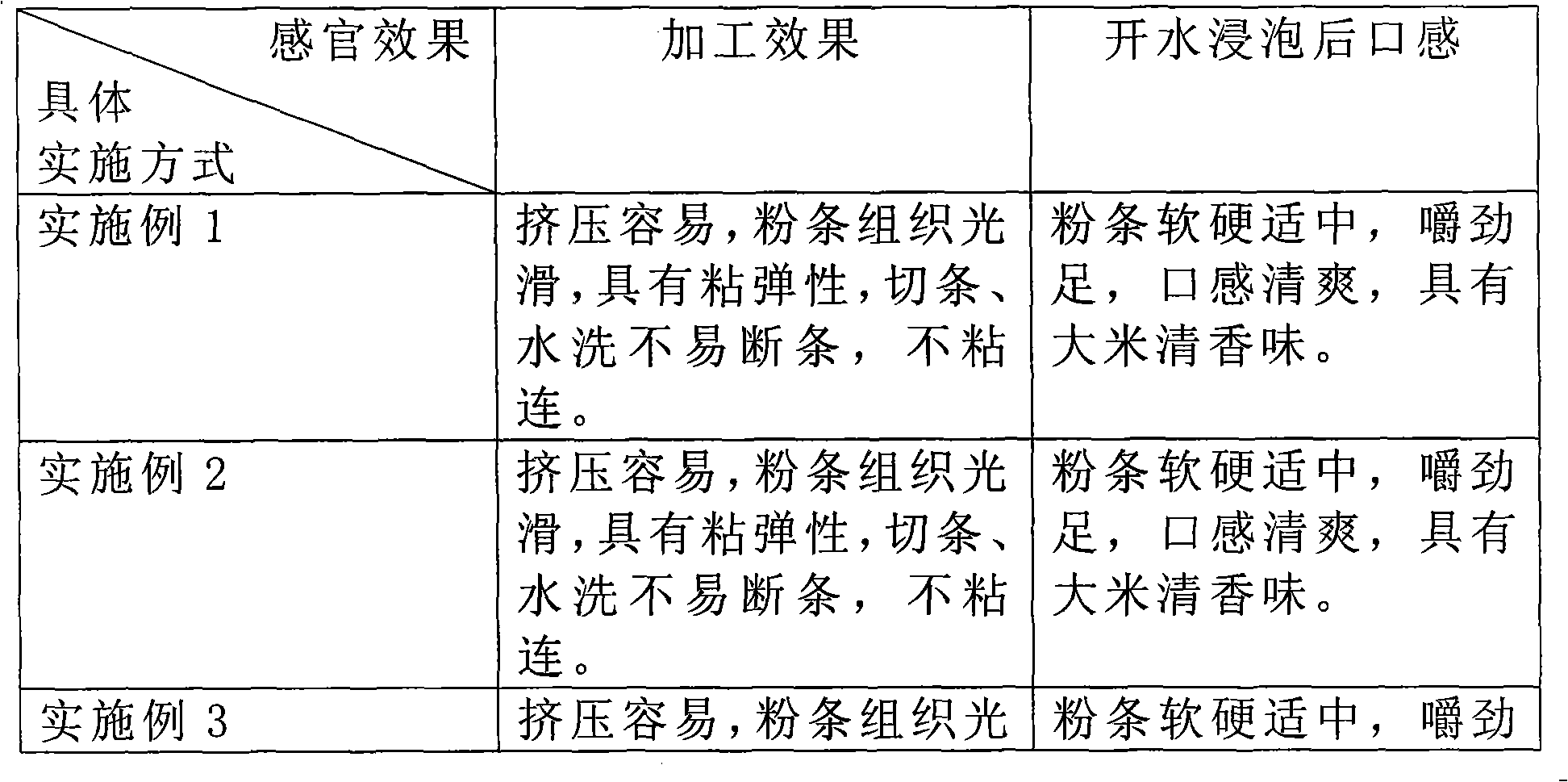

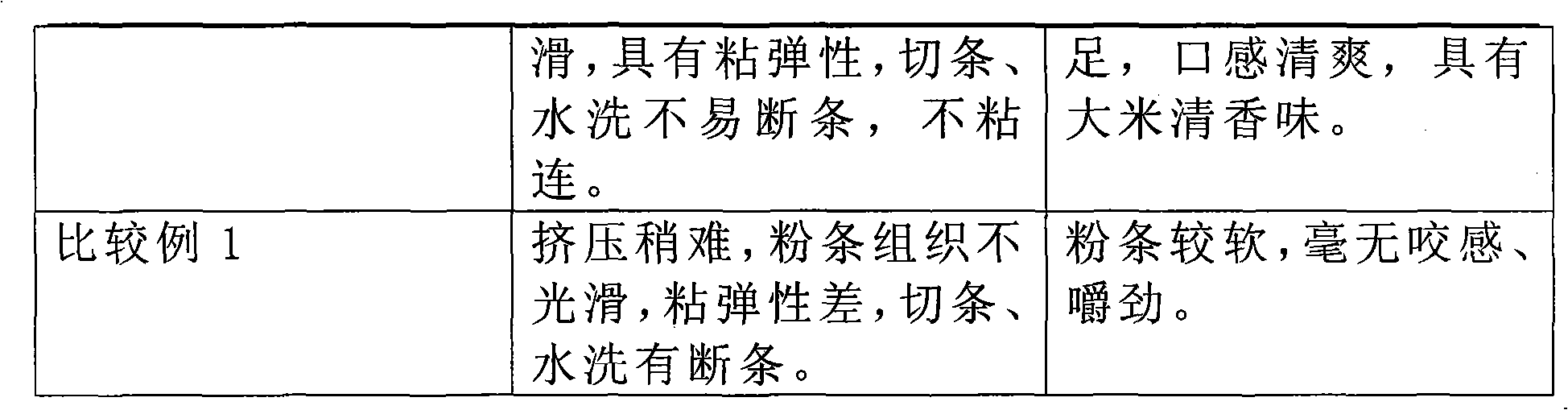

Preparation method for convenient rice noodle

InactiveCN101341945AExtrusion process is simpleTissue smoothFood preparationConvenience foodToughness

The invention provides a preparation method of rice noodles, which belongs to the technical field of instant food. The preparation method solves the problems that the preparation methods of the prior rice noodles need to be added with additive, soaked in boiling water or are easy to be conglobated when being cooked, etc. The preparation method of the instant rice noodles comprises the following steps: rice soaking and flour milling; long rice is selected to be soaked in water; the long rice is ground into rice flour after being soaked; powdering and thread extrusion; aging and thread rolling; the flour thread is put into a closed cavity to age; after aging, the glutinous thread is loosened by thread rolling; redistilling: the flour thread after being rolled is put into a steam box, and steam is fed in; washing, shaping and drying; the rolled thread is washed by water, so that the flour thread is fully loosened, put into a mould box to be shaped, dried, and the instant rice noodles are obtained. The rice noodles prepared by the preparation method of the instant rich noodles have the advantages of good taste, no paste, good toughness, sufficient biting performance, etc.

Owner:姚万胜

Container and pusiier

A container, which houses a liquid such as a sealant in a flexible pouch 11 in a sealed state, is provided with a spout 2 that is constituted by an extrusion nozzle 22 and a spout base member 21 and formed on one end thereof so that the extrusion nozzle 22 is fixed by sandwiching the vicinity of a hole 32a formed on one end face of an extruder 3 by a flange portion 21c of the spout base member 21 and a flange portion 22c of the extrusion nozzle 22, and an extruder 3a is arranged so that an adjusting member 322b, which controls the tilt of the nozzle 22, is allowed to protrude outward from a hole 322a of the extruder 3a.

Owner:SHARP KAGAKU INDS

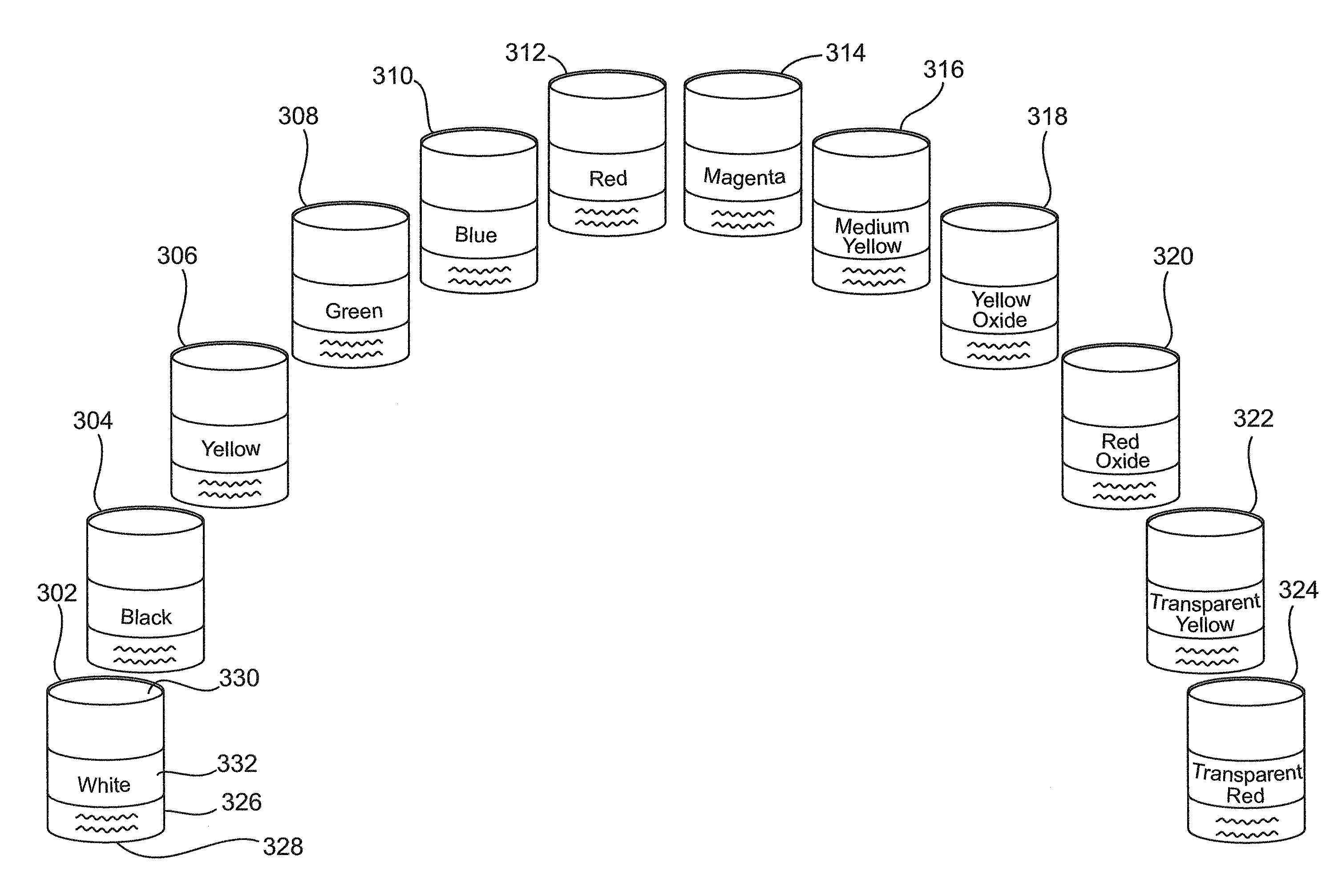

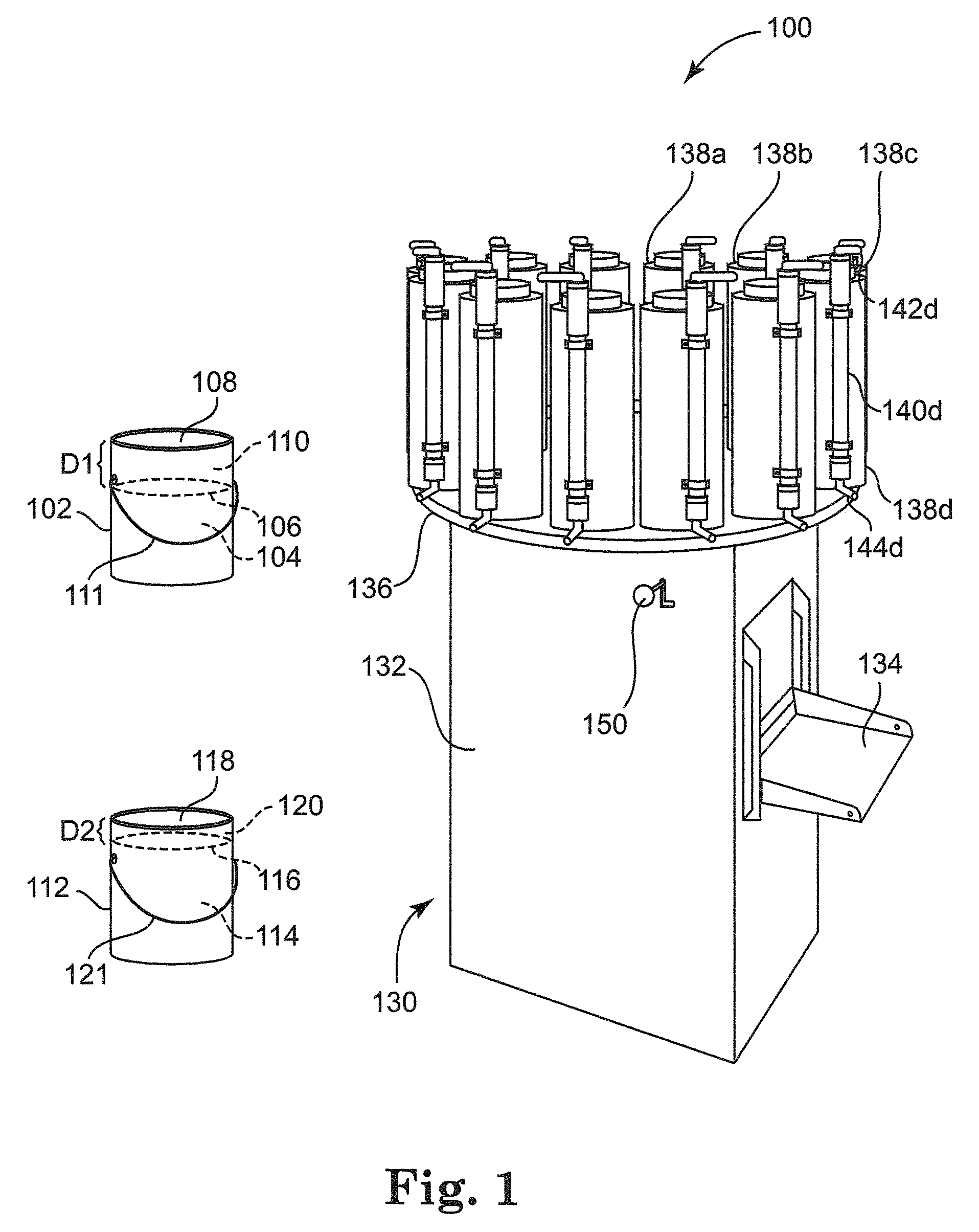

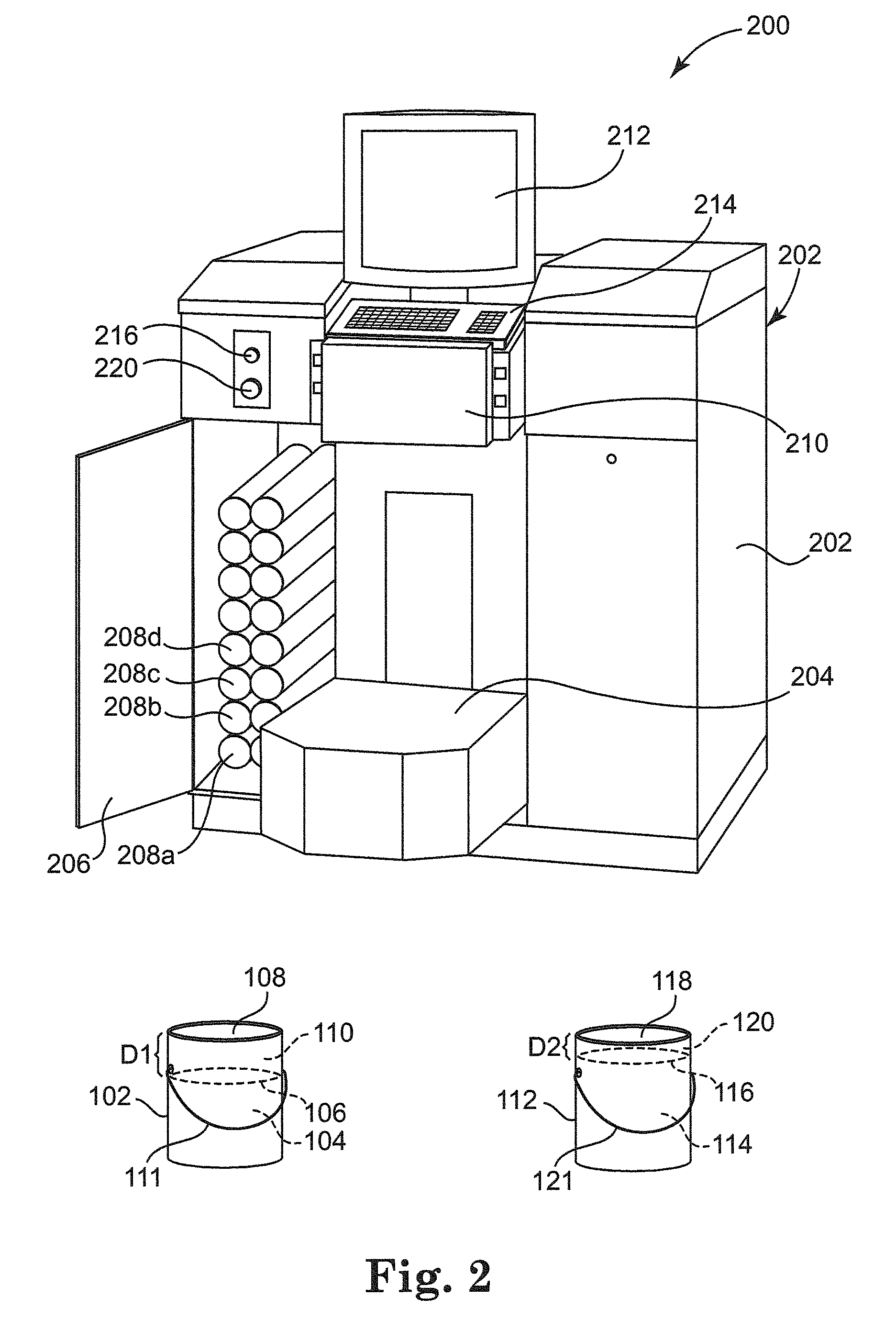

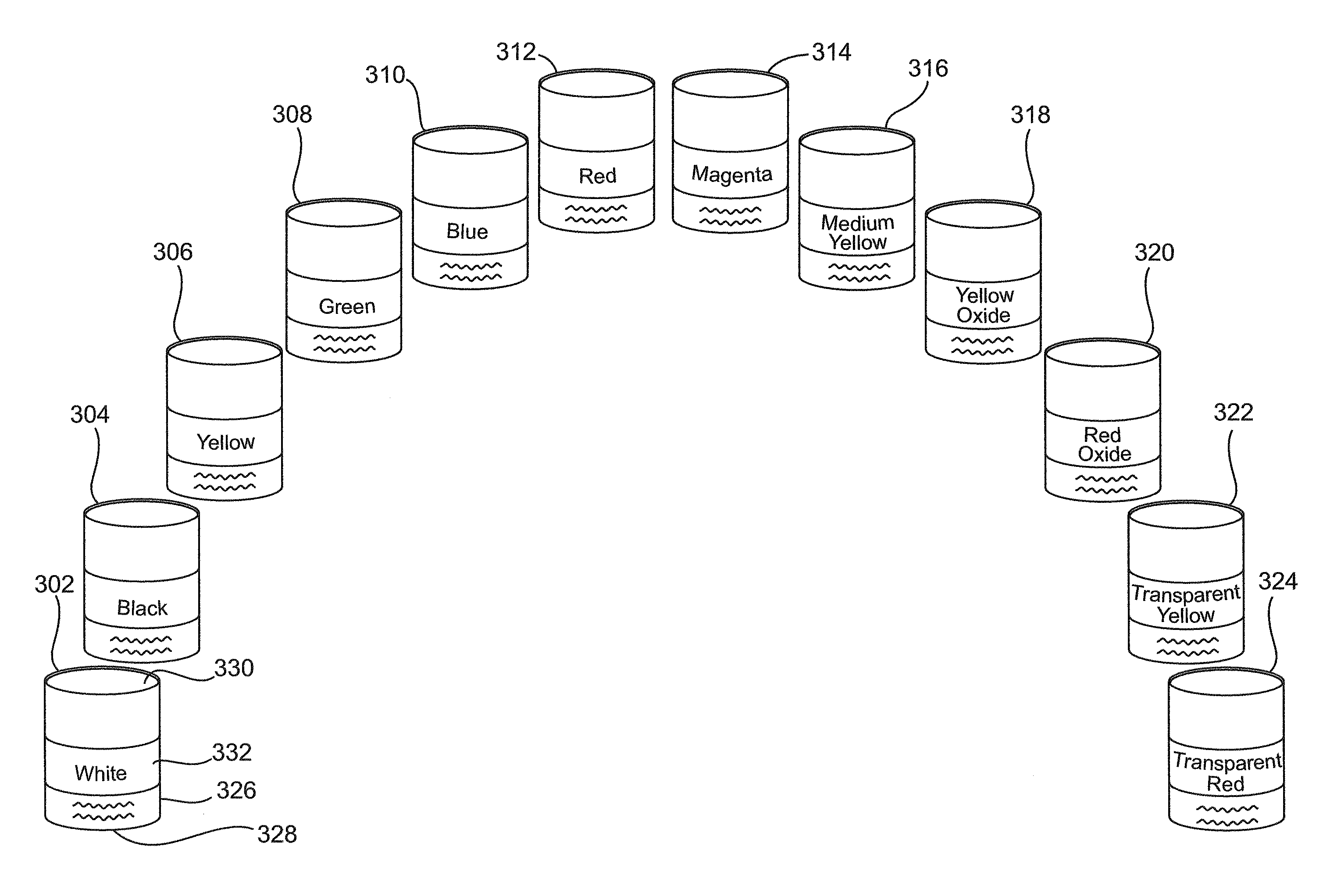

Architectural paint and stain tinting system with tip drying resistance

ActiveUS8822580B2Lower Level RequirementsImprove rheologyPigmenting treatmentFilm/foil adhesivesSURFACTANT BLENDStain

Custom-tinted paints and stains are made using an array of low VOC concentrated liquid colorants including at least at least white colorant; black colorant; and green-hued, blue-hued and red-hued primary colorants at least one of which primary colorants comprises polyalkylene glycol humectant, ethoxylated surfactant and extender pigment. For colorants in the array containing polyalkylene glycol humectant, the humectant and ethoxylated surfactant amounts are sufficiently high and extender pigment amount is sufficiently low so that the colorants will not problematically plug colorant dispenser orifices if left in the dispenser without an orifice cap for a full day. The polyalkylene glycol humectant is also present in an amount sufficiently low so that dried paint films made by mixing the colorants with a clear waterborne base paint will resist blocking.

Owner:SWIMC LLC

Wireless spout and system for free-and pre-measured dispensing

InactiveUS20090277931A1Extrusion process is simpleStop the flowVolume measurement and fluid deliveryLiquid flow controllersBottleAir bubble

The present invention is related to a pouring device for a container for the dosing of liquid, said pouring device comprising: a) a housing; b) a passage for the liquid within the housing; c) an electrical operated opening / closing mechanism for opening or closing the passage in order to dosing of a predetermined or registerable amount of liquid, characterized in that the passage comprising a silicone tube, and the opening / closing mechanism is to block the silicone tube by squeezing the silicone tube in order to close the passage. The silicone tube inside the spout is the only path for the liquid to go through from the bottle, meanwhile the rest components are protected from liquid. This guaranties a quick and controlled flow of the liquid and avoids any air bubbles to influence the pour precision.

Owner:AUTOMATIC BAR CONTROLS

Films having a desiccant material incorporated therein and methods of use and manufacture

InactiveUS20060269708A1High costReduce packaging costFlexible coversWrappersFilm structureEngineering

Film structures, packages, films and methods of making the same are provided wherein the film structures have a desiccant material incorporated into a layer of the film structures and further wherein the film structures can comprise a material for making a peelable seal when the film structures are heat sealed to other film structures. The film structures are utilized for a package to hold a product that may be sensitive to the presence of moisture. The product may preferably be pharmaceutical or nutraceutical products, although any moisture-sensitive product is contemplated by the present invention.

Owner:MERICAL RICK +2

Films having a desiccant material incorporated therein and methods of use and manufacture

InactiveUS8003179B2Improve efficacyProlong lifeSurgical furnitureDispensing apparatusDesiccantAbsorbable suture

Film structures, packages, films and methods of making the same are provided wherein the film structures have a desiccant material incorporated into at least one layer of the film structures and further wherein the film structures can comprise a material for making a peelable seal when the film structures are heat sealed to other film structures. The film structures are utilized for a package to hold a product that may be sensitive to the presence of moisture. The product may preferably be pharmaceutical products, nutraceutical products, or devices such as absorbable sutures or medical stents, although any moisture-sensitive product is contemplated by the present invention.

Owner:ALCAN PACKAGING FLEXIBLE FRANCE

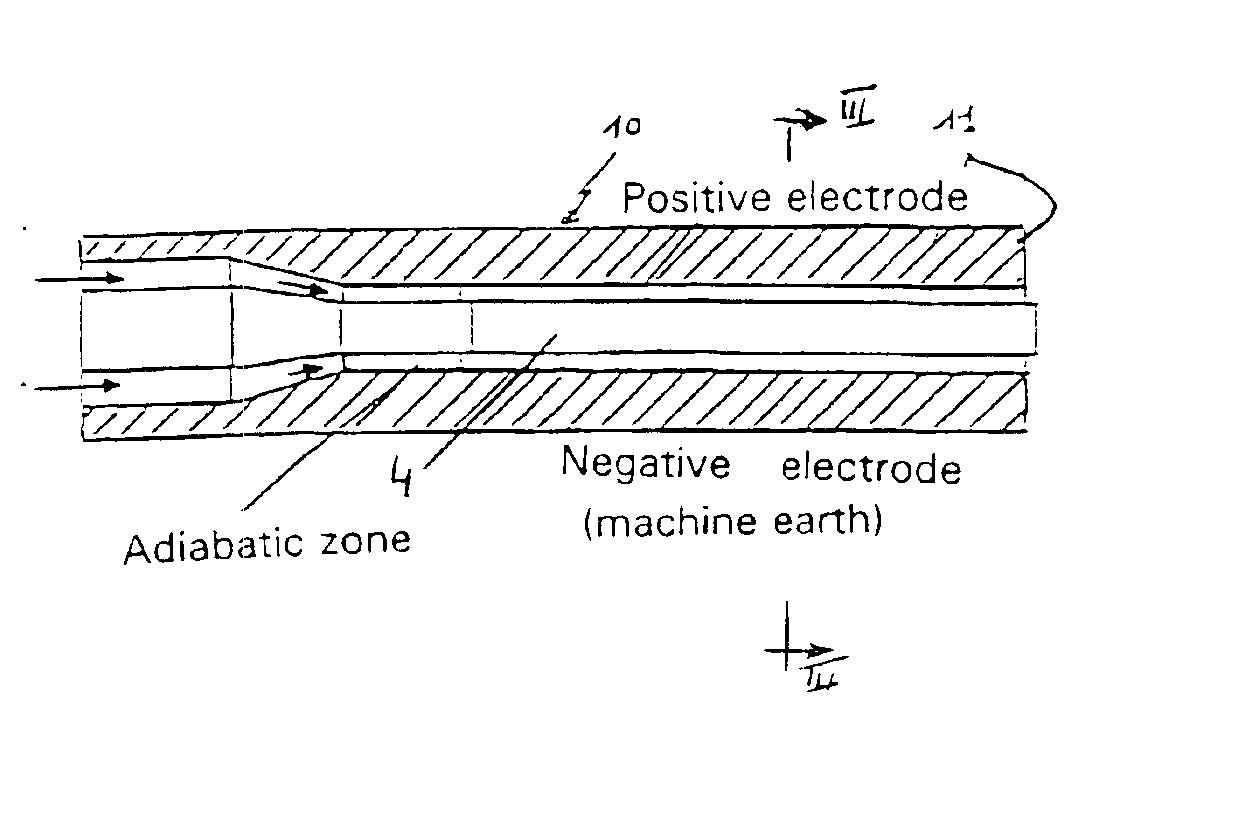

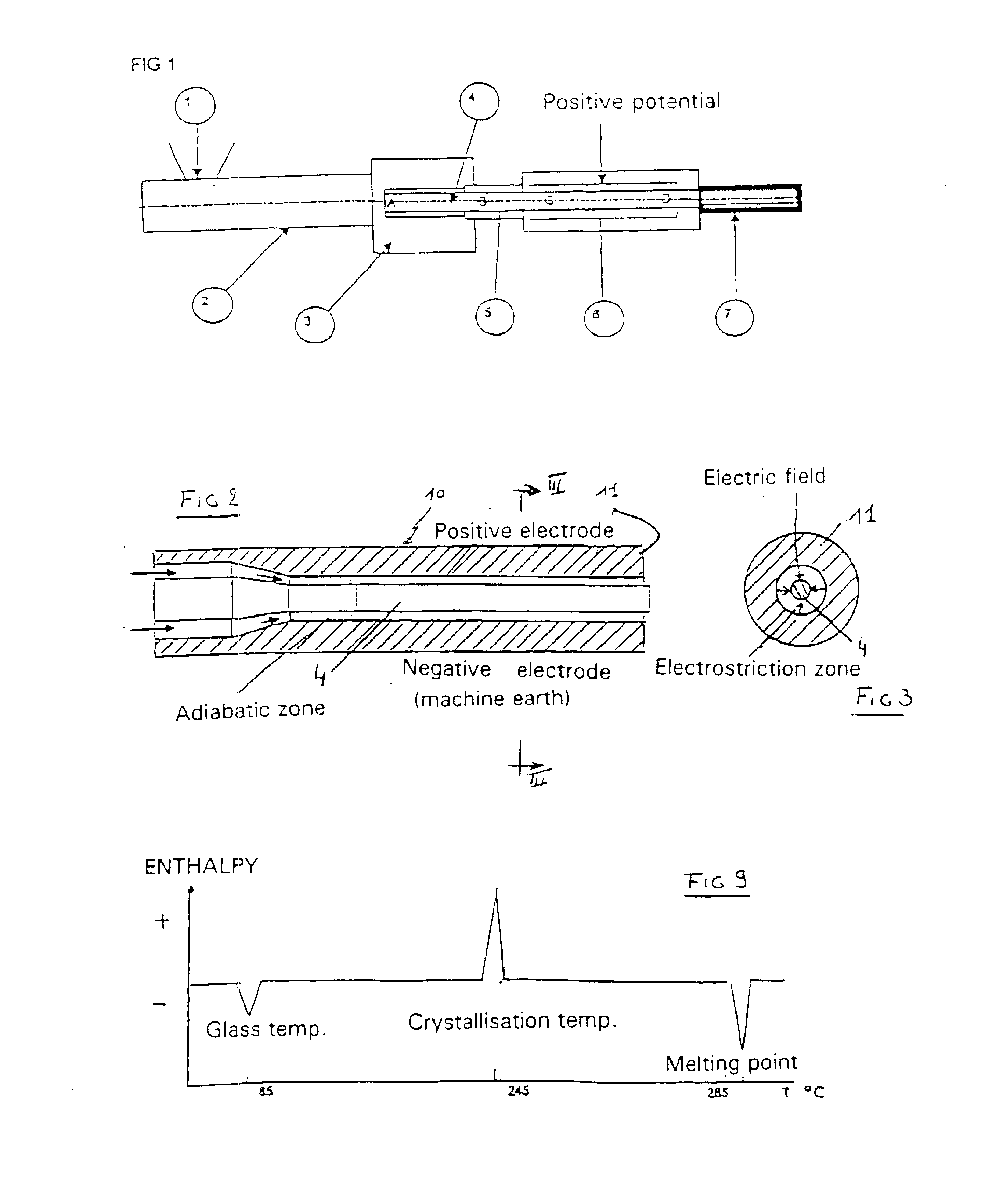

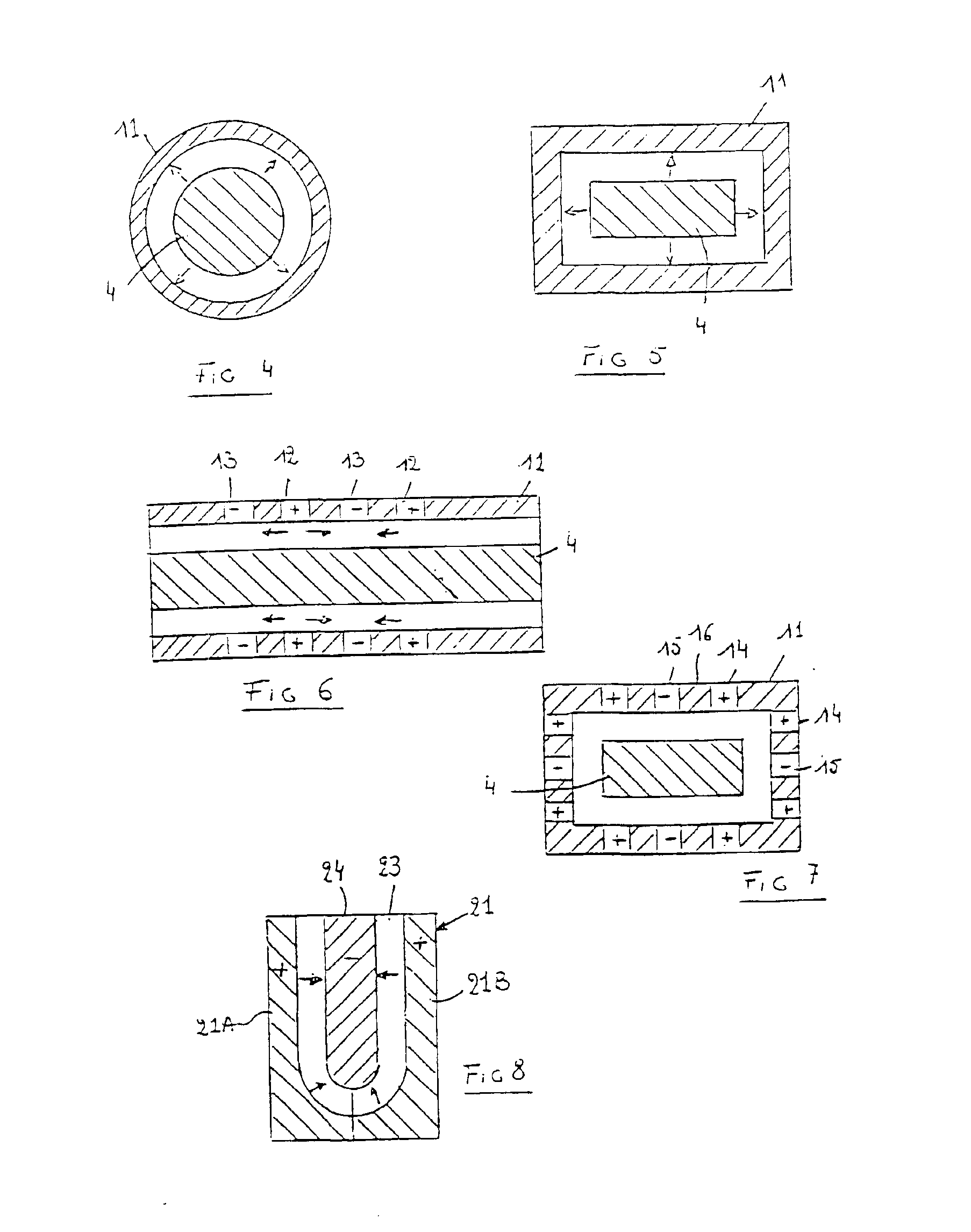

Method and device for transforming crystalline or semicrystalline polymers

InactiveUS6875394B2Extrusion process is simpleElectric discharge heatingArtificial filament physical treatmentEngineeringPolymer

A method for processing thermoplastics in a shaping device, whereby before and / or during its passage in the shaping device the thermoplastic is submitted to a static electrical field.

Owner:INT BRAIN SYST

Architectural paint and stain tinting system with tip drying resistance

ActiveUS20120316273A1Low in VOCsDesirable resistance to blockingPigmenting treatmentInksChemistryHumectant

Custom-tinted paints and stains are made using an array of low VOC concentrated liquid colorants including at least at least white colorant; black colorant; and green-hued, blue-hued and red-hued primary colorants at least one of which primary colorants comprises polyalkylene glycol humectant, ethoxylated surfactant and extender pigment. For colorants in the array containing polyalkylene glycol humectant, the humectant and ethoxylated surfactant amounts are sufficiently high and extender pigment amount is sufficiently low so that the colorants will not problematically plug colorant dispenser orifices if left in the dispenser without an orifice cap for a full day. The polyalkylene glycol humectant is also present in an amount sufficiently low so that dried paint films made by mixing the colorants with a clear waterborne base paint will resist blocking.

Owner:SWIMC LLC

Air valves for a wireless spout and system for dispensing

ActiveUS20130056502A1Extrusion process is simpleStop the flowClosuresLiquid flow controllersEngineeringNozzle

Embodiments of the present invention provide a pouring device for a container for the dosing of liquid. The pouring device has an improved air valve system that works via cooperation between a weighted magnetic component and a metal ball in order to control opening and closing of the air valve inlet.

Owner:LAB2FAB LLC

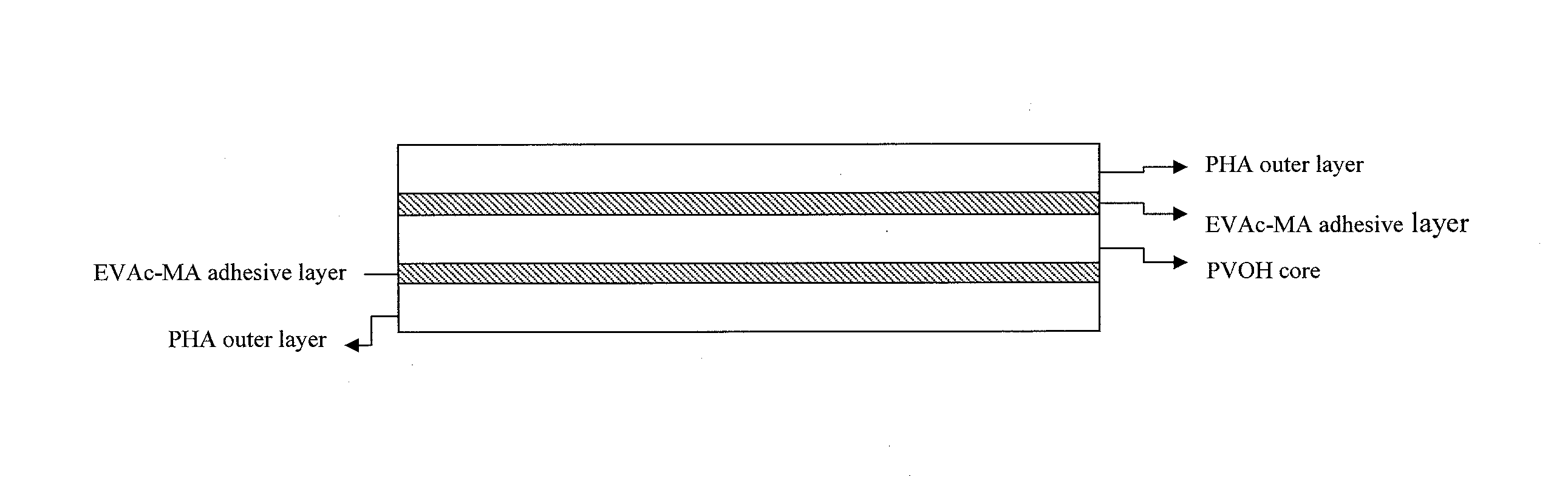

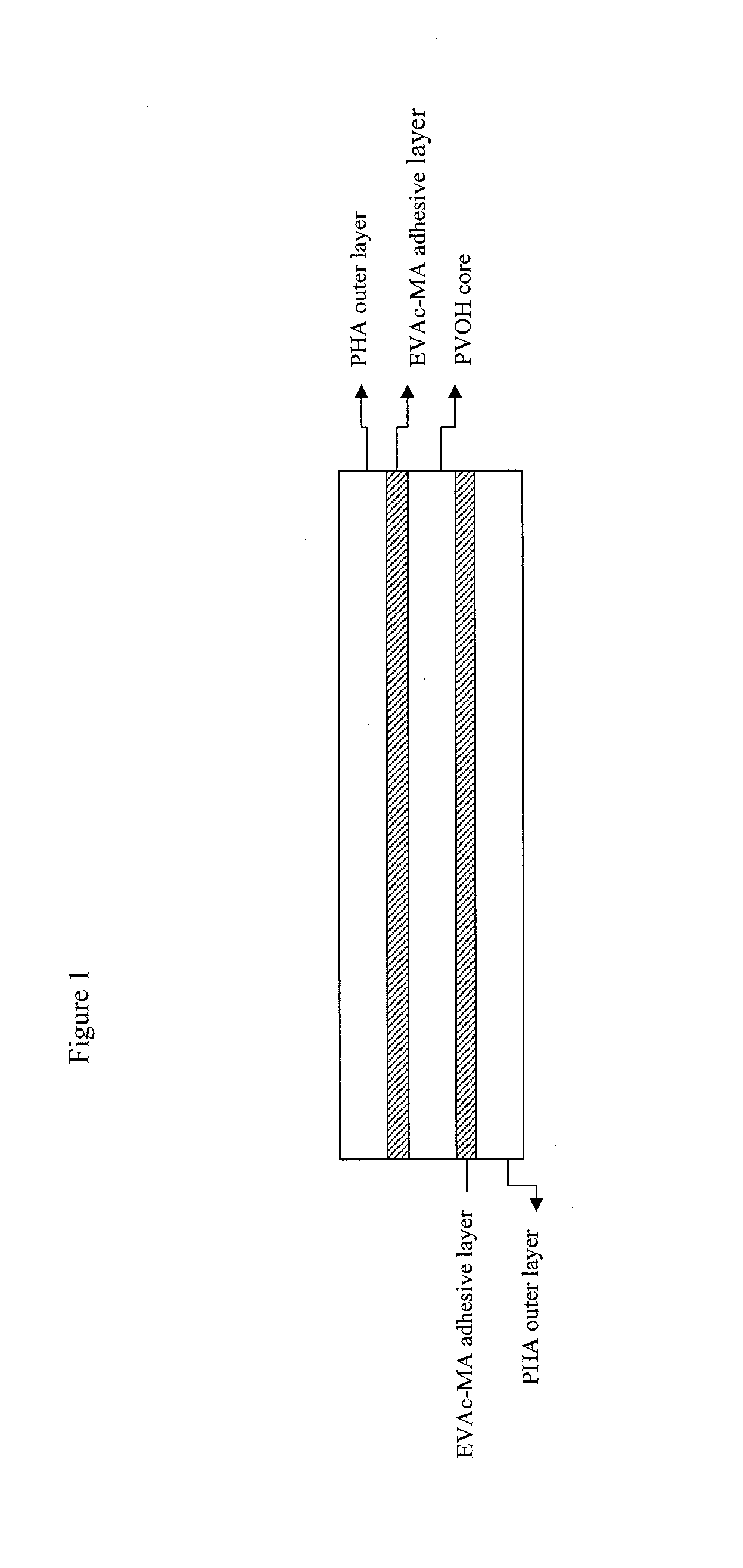

Biodegradable Coextruded Multilayer Films

InactiveUS20140030536A1Extrusion process is simpleImprove barrier propertiesSynthetic resin layered productsLaminationGas barrierChemistry

Described herein is a biobased, fully biodegradable multilayer film having gas barrier properties. Also included is a method of making such material.

Owner:METABOLIX

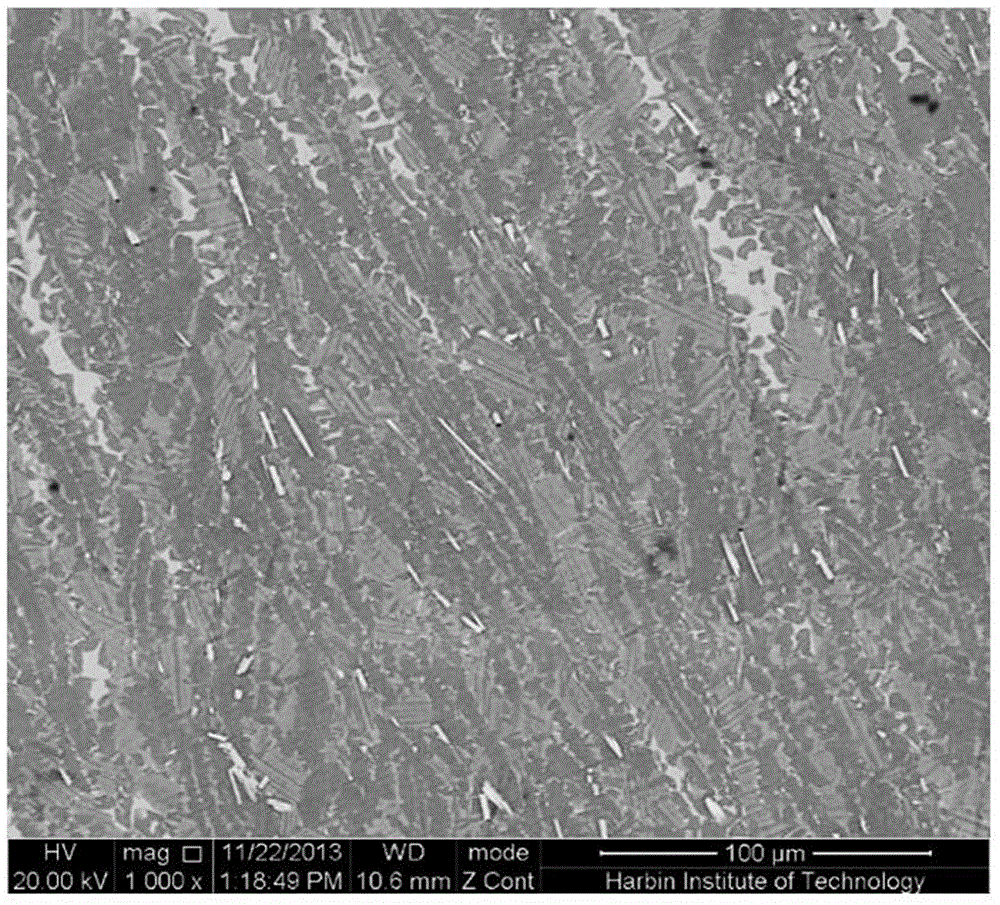

Zinc alloy bar extruding process designing and optimizing method

ActiveCN102463268AHigh degree of automationSolving Extrusion Cracking ProblemsConstitutive equationMicrostructure

The invention relates to a zinc alloy bar extruding process designing and optimizing method, which comprises the steps of: obtaining a true-stress and true-strain curve of a zinc alloy by adopting a high-temperature compression and high-temperature tension test; establishing a constitutive equation and an operation drawing of the zinc alloy, carrying out microstructure analysis, researching a thermal deformational behavior, selecting a deformation condition suitable for processing; carrying out finite element numerical simulation, establishing an extrusion forming limit drawing, optimizing an extrusion process window, carrying out thermal extrusion to obtain a zinc alloy bar; and establishing an extrusion test data base, and predicting a relationship between the extrusion process and surface cracking, quality and performance of the extrusion bar by adopting a neutral network. The invention can realize optimal matching of all parameters in a process of extruding the zinc alloy bar, accurate control on the extruding process, and integration of process design, optimization and performance control. The prepared zinc alloy bar has the characteristics of better surface quality, fine and uniform textures, high performance, high pass percent and high production efficiency, is suitable for massive production, and has remarkable economic and social benefits.

Owner:GRIMAT ENG INST CO LTD

Fluid dispenser with internal pump

A hand operated fluid dispensers comprised of a sealed flexible reservoir chamber containing a fluid, a flexible pump chamber encased by and drawing fluid from the reservoir, and a pump cycled by external pressure applied through a reservoir wall. This class of simple, inexpensive, disposable dispensers is particularly useful in packaging cosmetics, foodstuffs, and healthcare products. As pocketable dispensers they are popular for dispensing small amounts of stored viscous liquids easily damaged when exposure to the atmosphere, a condition where sealed reservoirs coupled with airless pumps working together successfully prevent such product contamination and deterioration. A method of improved healthcare employing such pump dispensers containing a hand sanitizing fluid is also discussed.

Owner:PENNCREEK

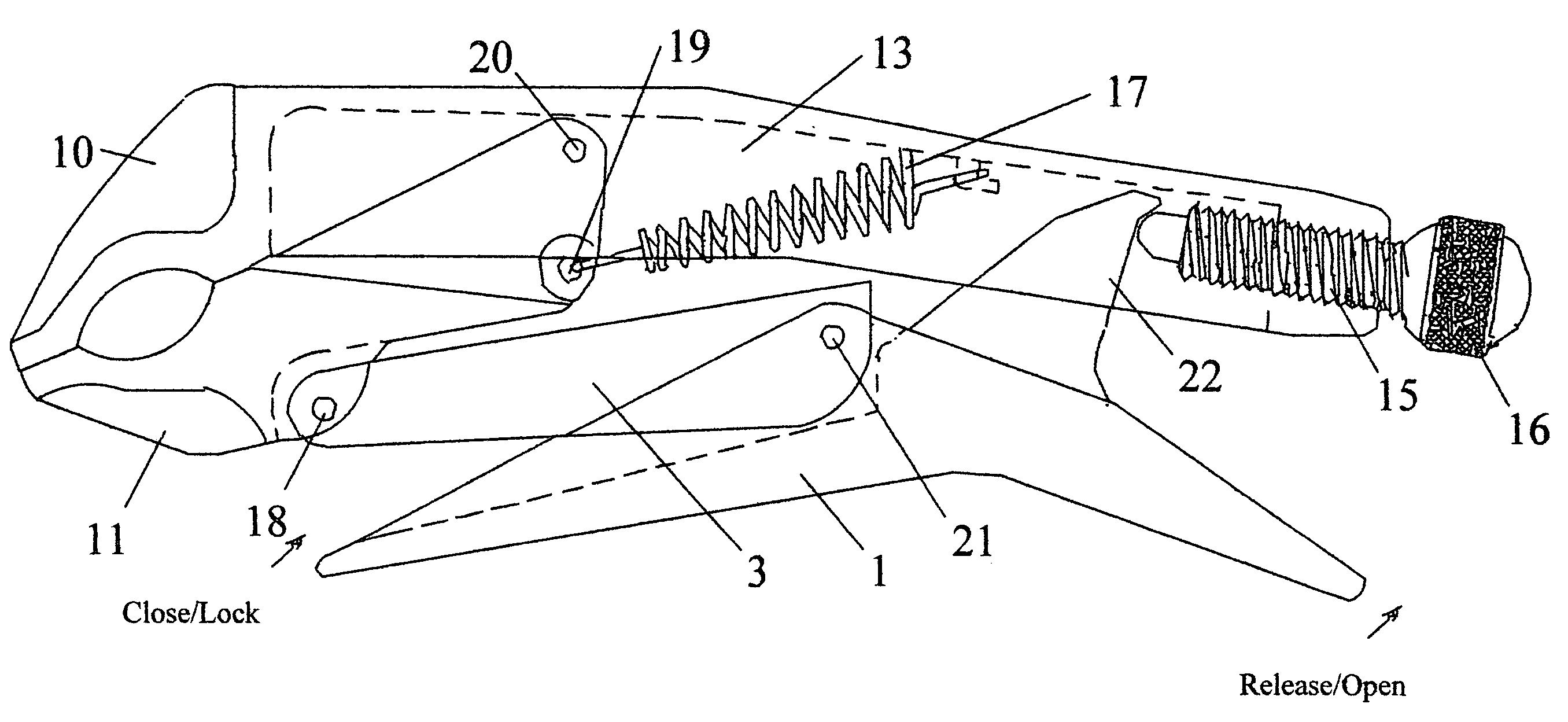

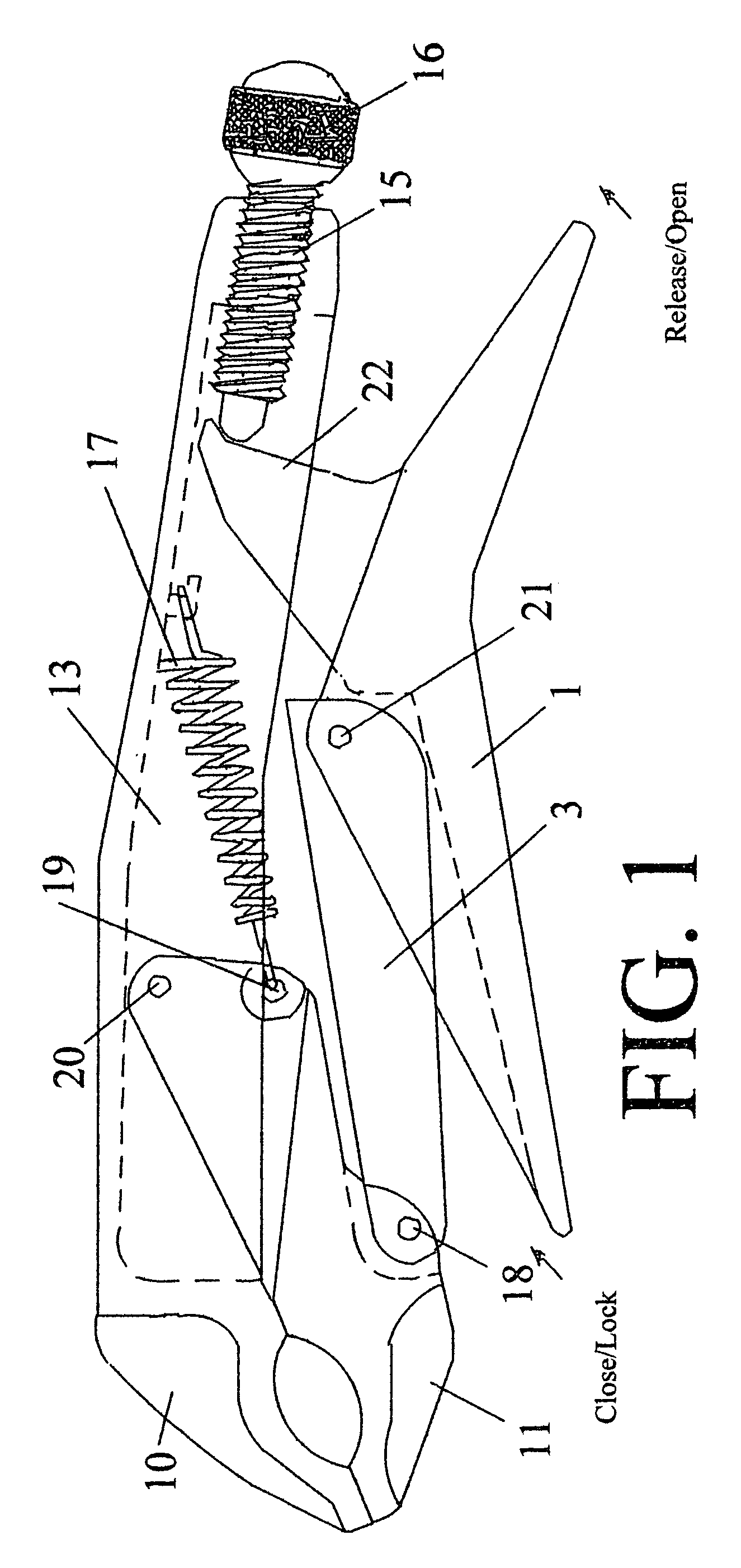

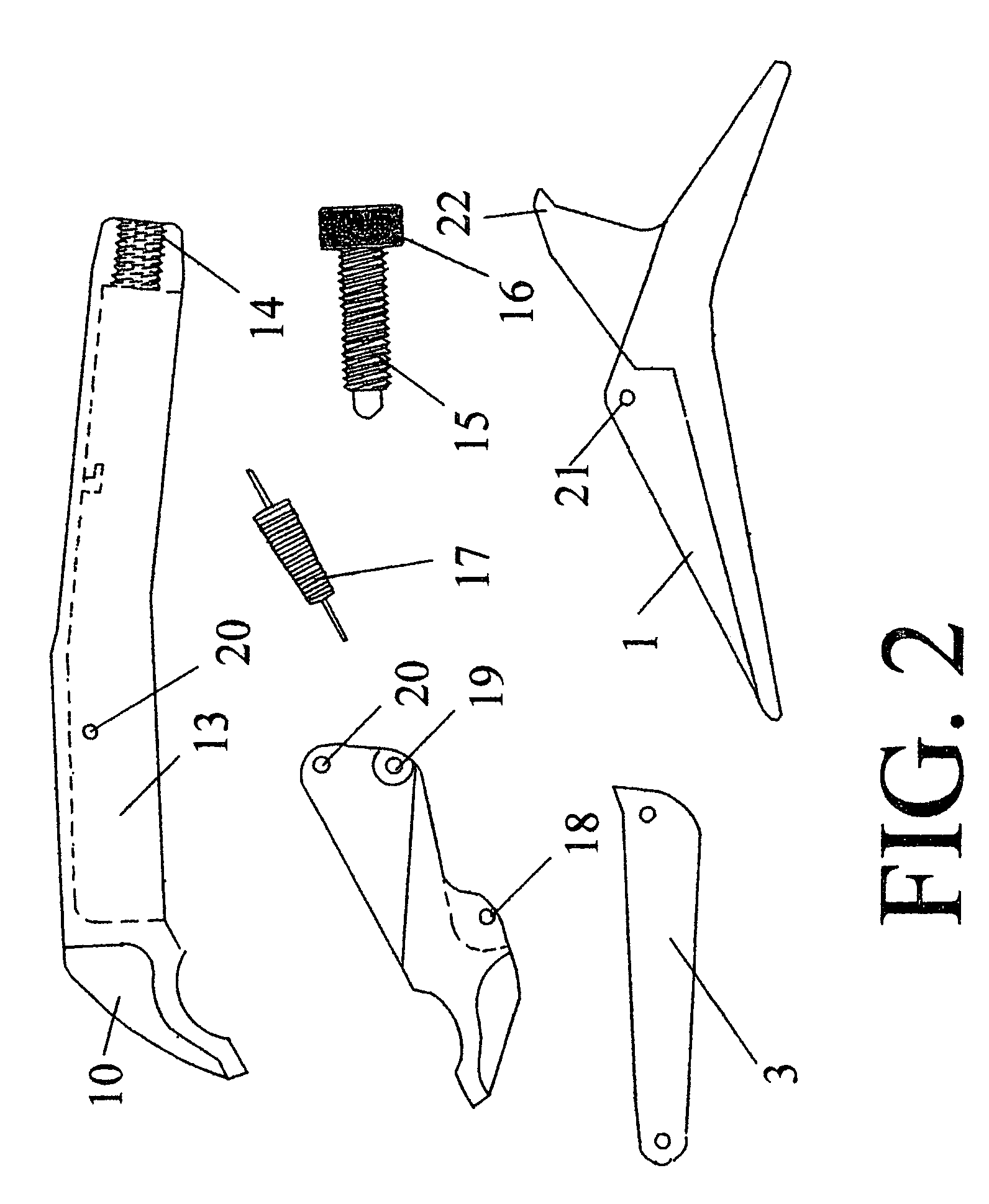

Dual action locking pliers

A locking pliers tool with an improved dual action driver handle comprising two intersecting handles and interacting jaws. When the user grips the handle forward the resultant force produces a locking action. Conversely, when a rearward gripping force is initiated, the tool releases its grip on the object. A limited amount of energy on the inventive handle produces free movement of the handle and gripping mechanism to lock or release. The system operates with a handle and stationary jaw in conjunction with a second pivotally secured jaw and internal adjustment bolt. A second lever handle rests against the adjustment bolt. An over center toggle link connects the second lever handle to the pivotally secured second jaw. A tension spring interconnects the first handle and the pivotally secured second jaw.

Owner:HEAGERTY MICHAEL

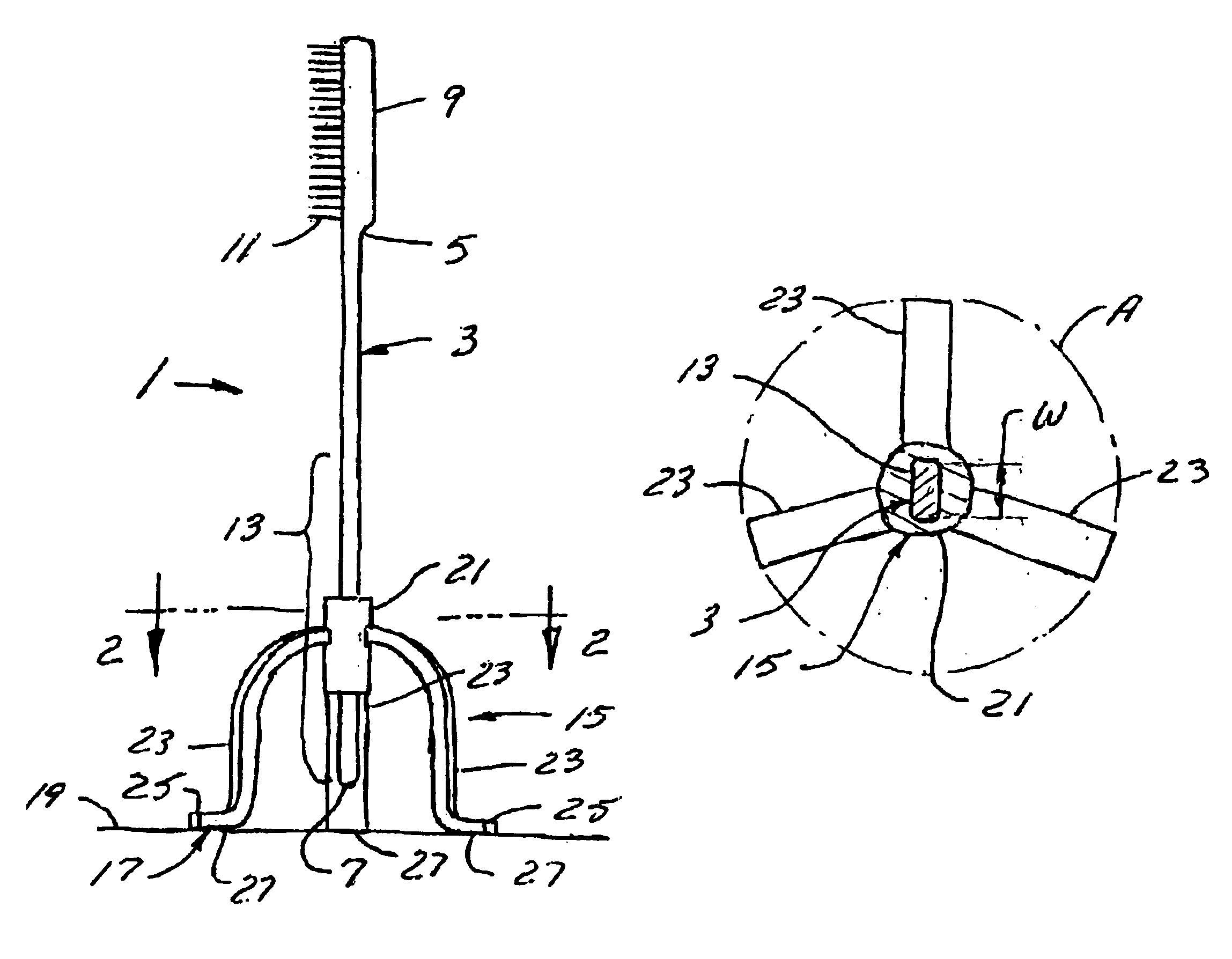

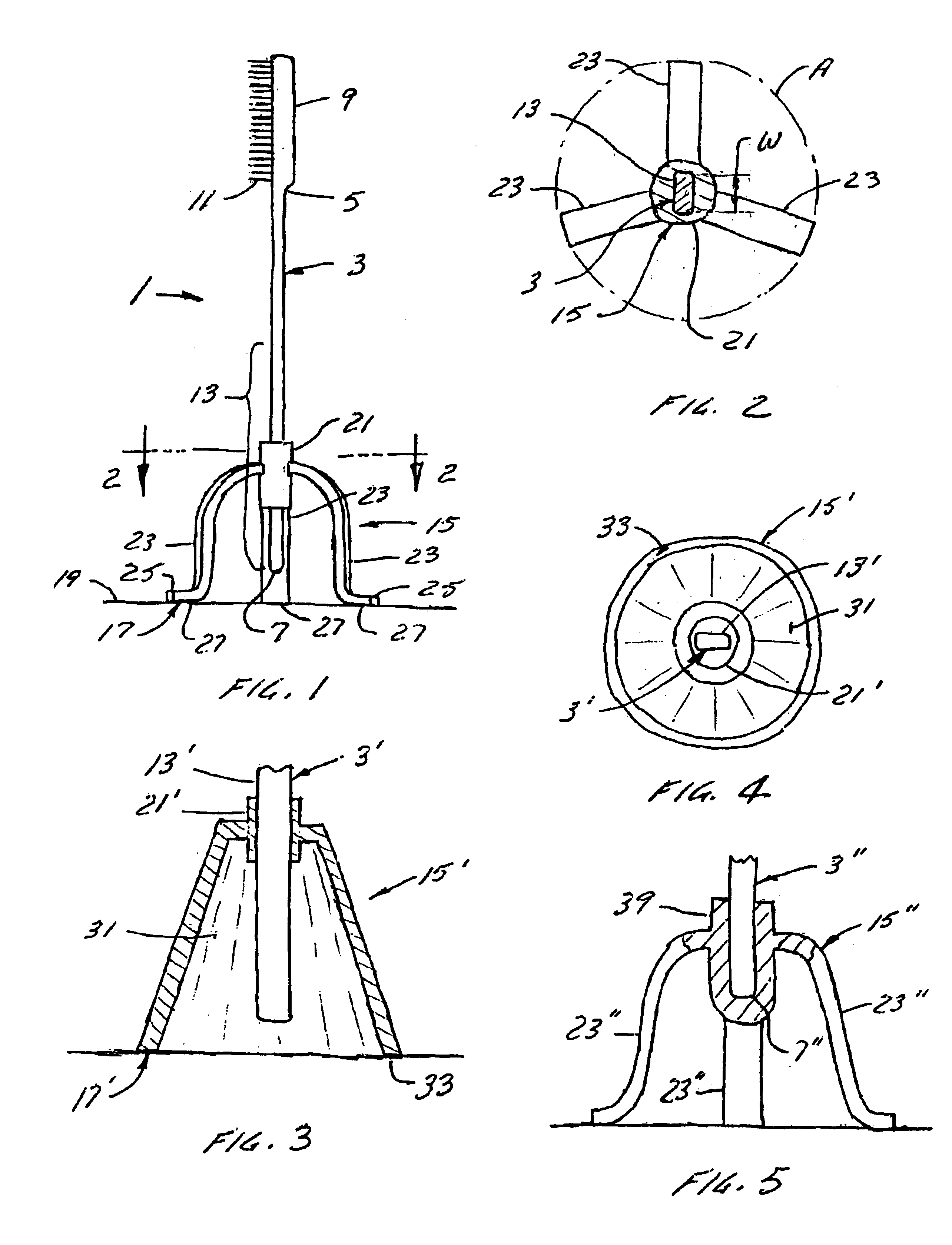

Toothbrush with stand

InactiveUS6907638B2Easy to storeExtrusion process is simpleWing handlesWriting connectorsEngineeringHand held

A stand-up toothbrush having an elongated handle with a head at one end, the head carrying bristles, and a hand holding portion at the other end, the hand holding portion long enough to be fully grasped by the hand of the user. A stand is provided on the hand holding portion of the handle at the other end, the stand extending past the other end of the handle and terminating in a support end. The support end extends transverse to the handle and is large enough to stably support the toothbrush in an upright storage position. The handle is made from relatively rigid material, and the stand is made from resilient, flexible material of the type allowing the stand to be moved against the hand holding portion of the handle when the user grasps the stand and the hand holding portion so as to interfere minimally with holding the toothbrush during use, and to return to its original position when the brush is released.

Owner:REVOLUTION ACOUSTICS

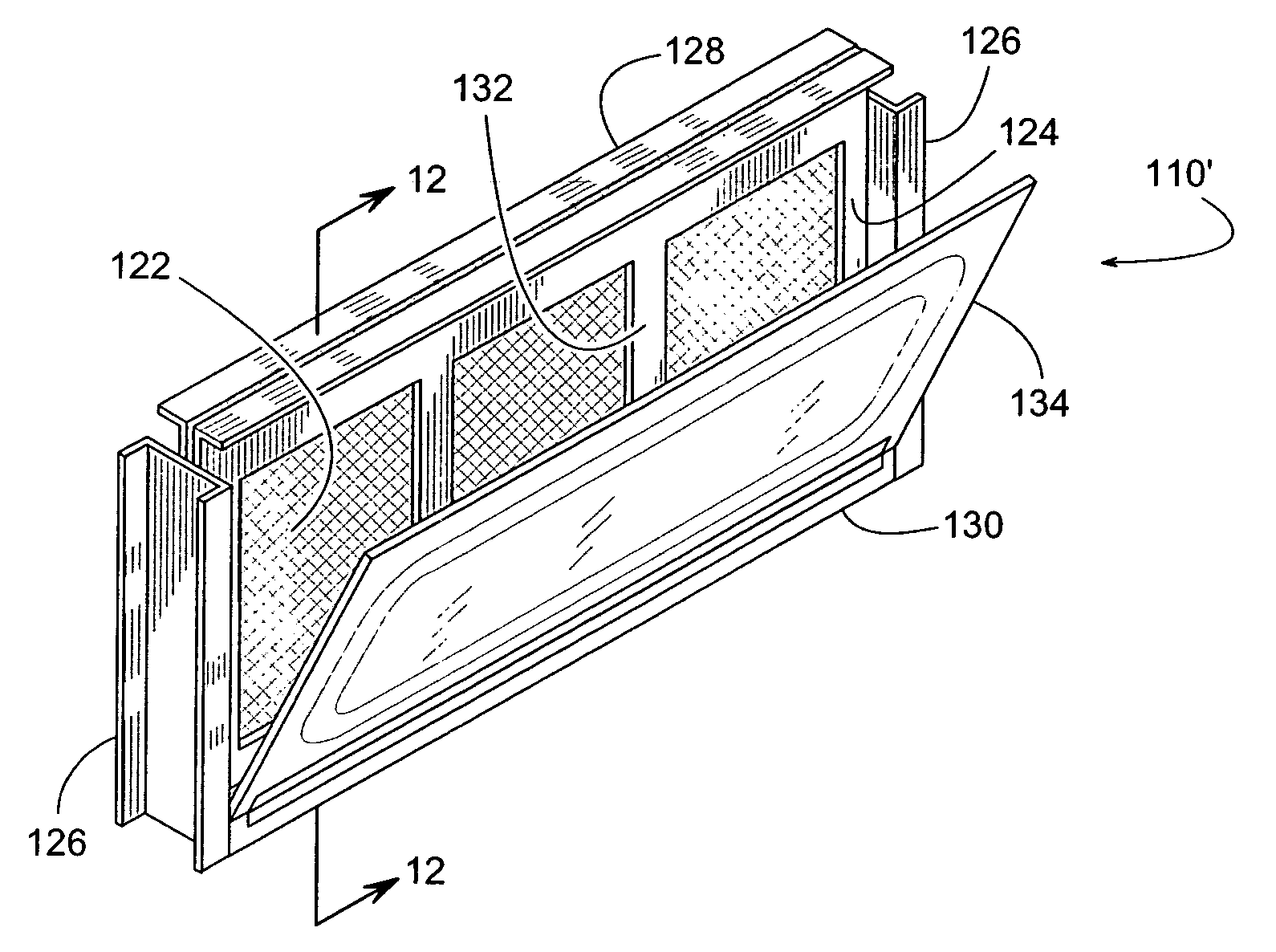

Extruded door panel members

InactiveUS7040373B2Extrusion process is simpleDoor/window protective devicesCurtain suspension devicesPhysical propertyElectrical and Electronics engineering

A door panel comprises several interlocking panel members. The panel members can be extrusions that are readily cut to length to create assembled door panels that match doorways of various widths. The ability to readily provide a door panel in various widths and lengths makes such a panel particularly useful as a replacement panel whose size needs to match that of existing door panels. In some embodiments, a physical property of the panel member's extruded material varies from one panel member to another and / or varies within a single panel member to provide a door panel with certain desirable characteristics.

Owner:RITE HITE HLDG CORP

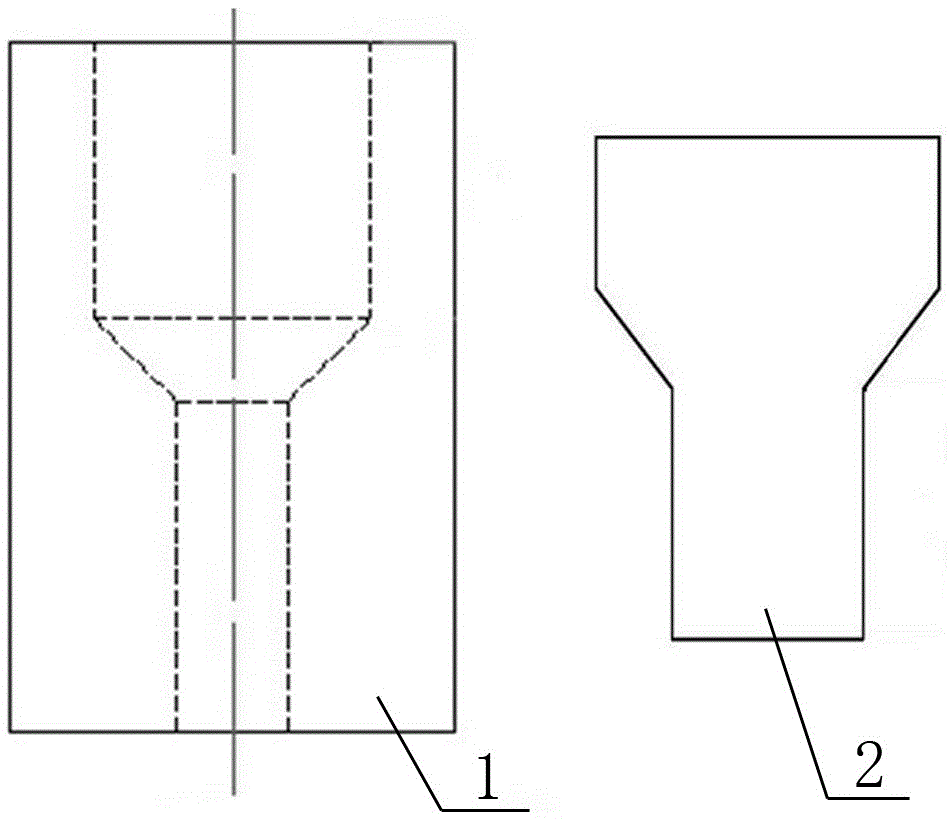

Preparation method for TiAl alloy bar

ActiveCN106636741ASolve the problem of severe segregationPrevent surface oxidationExtrusion diesIngotSkull

The invention discloses a preparation method for a TiAl alloy bar and relates to a preparation method for a bar. The preparation method for the TiAl alloy bar aims at solving the problems that according to a TiAl alloy bar prepared through an existing method, the preparation process is complex, the surface of the bar cracks, the diameter is nonuniform, the bar structure grain size is nonuniform, and TiAl alloy reacts with package materials and is molten when the extrusion temperature is too high. The preparation method for the TiAl alloy bar comprises the specific steps that 1, all raw material components are weighed; 2, a cast ingot is prepared through water cooling copper crucible induction skull melting; 3, pretreatment is conducted on an extrusion blank; and 4, bar extrusion is conducted, and thus the TiAl alloy bar can be obtained. The surface of the TiAl alloy bar obtained through the preparation method is free of cracking, the diameter is uniform, the bar structure grain size is uniform, and the process is simple.

Owner:山西中工重型锻压有限公司

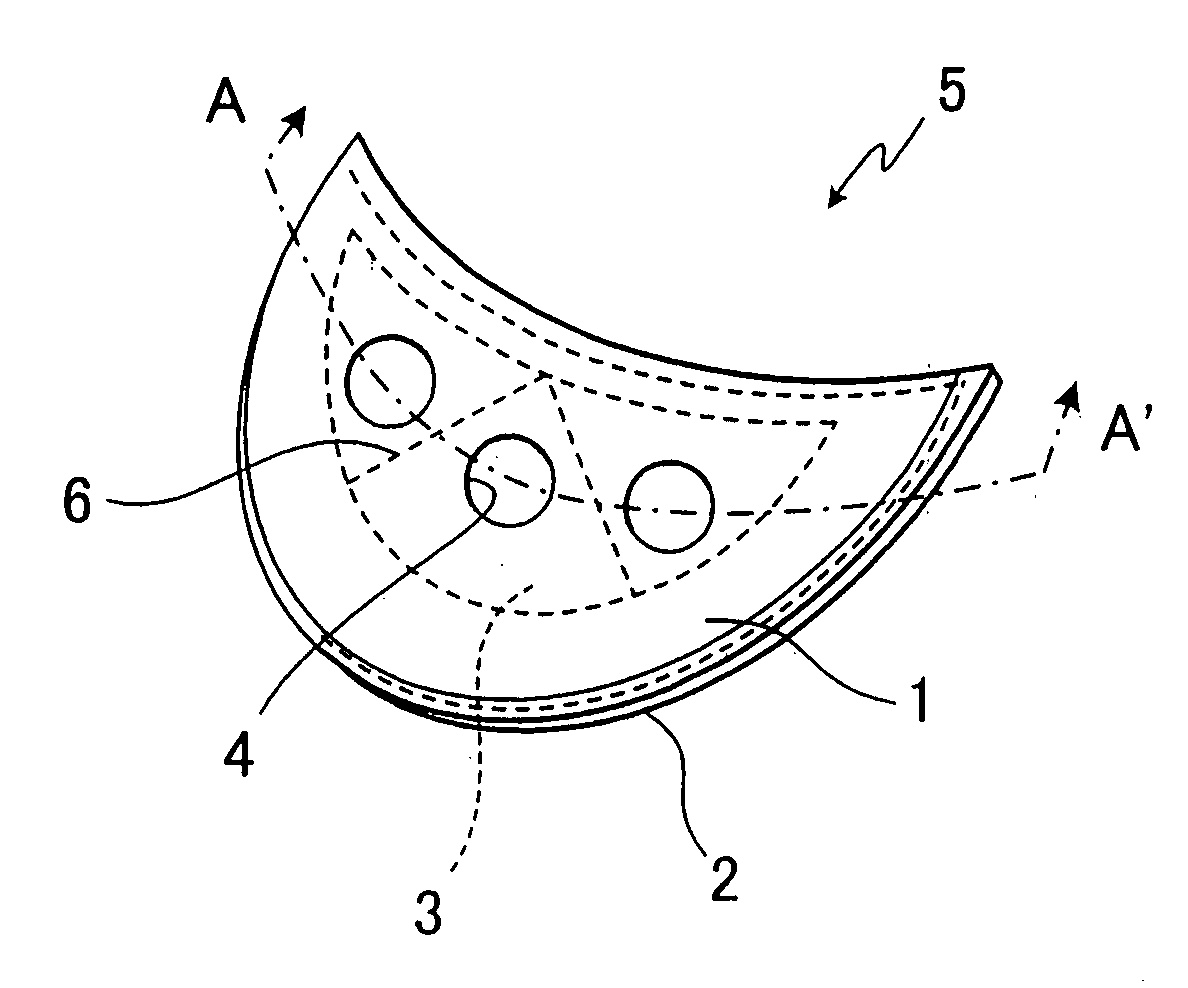

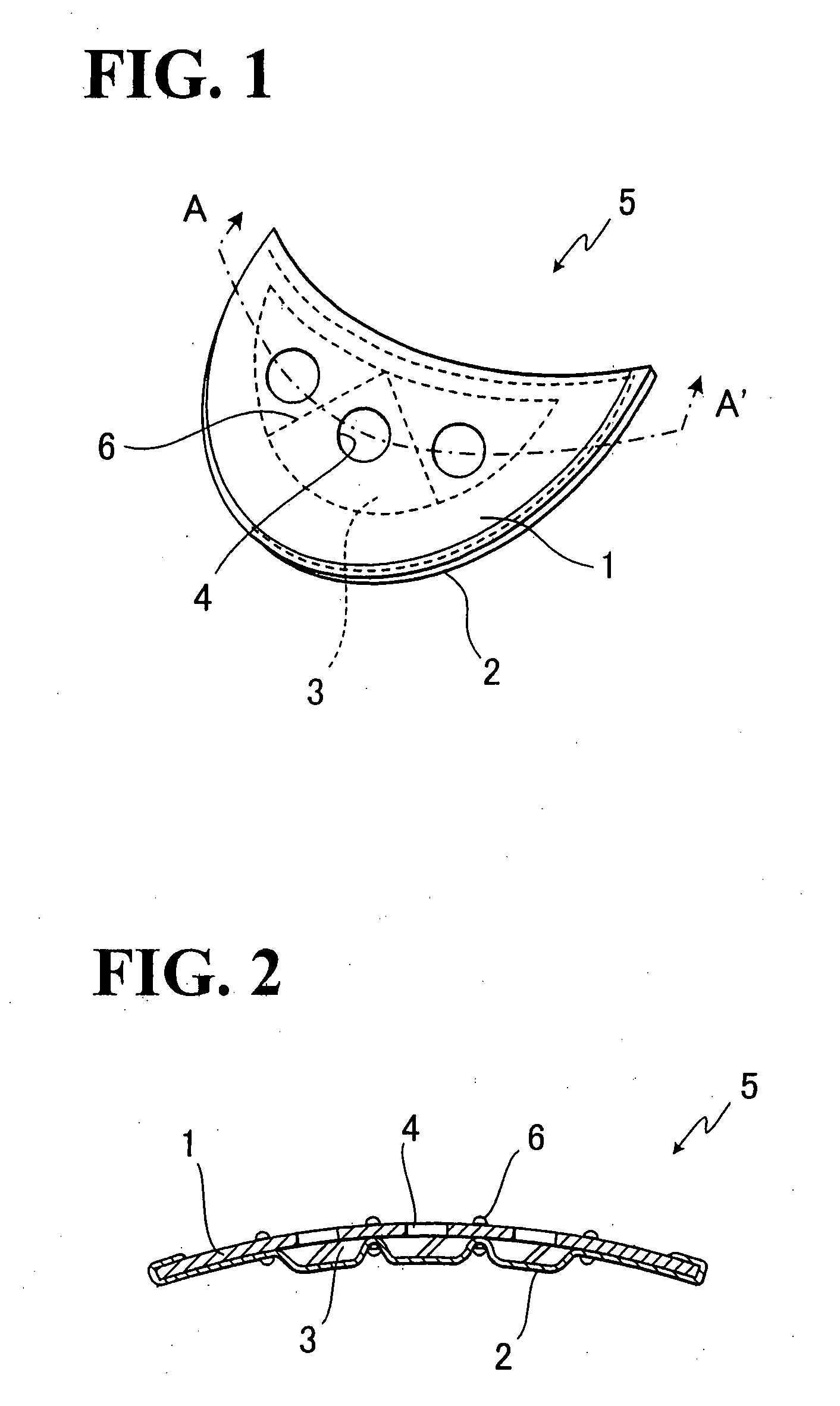

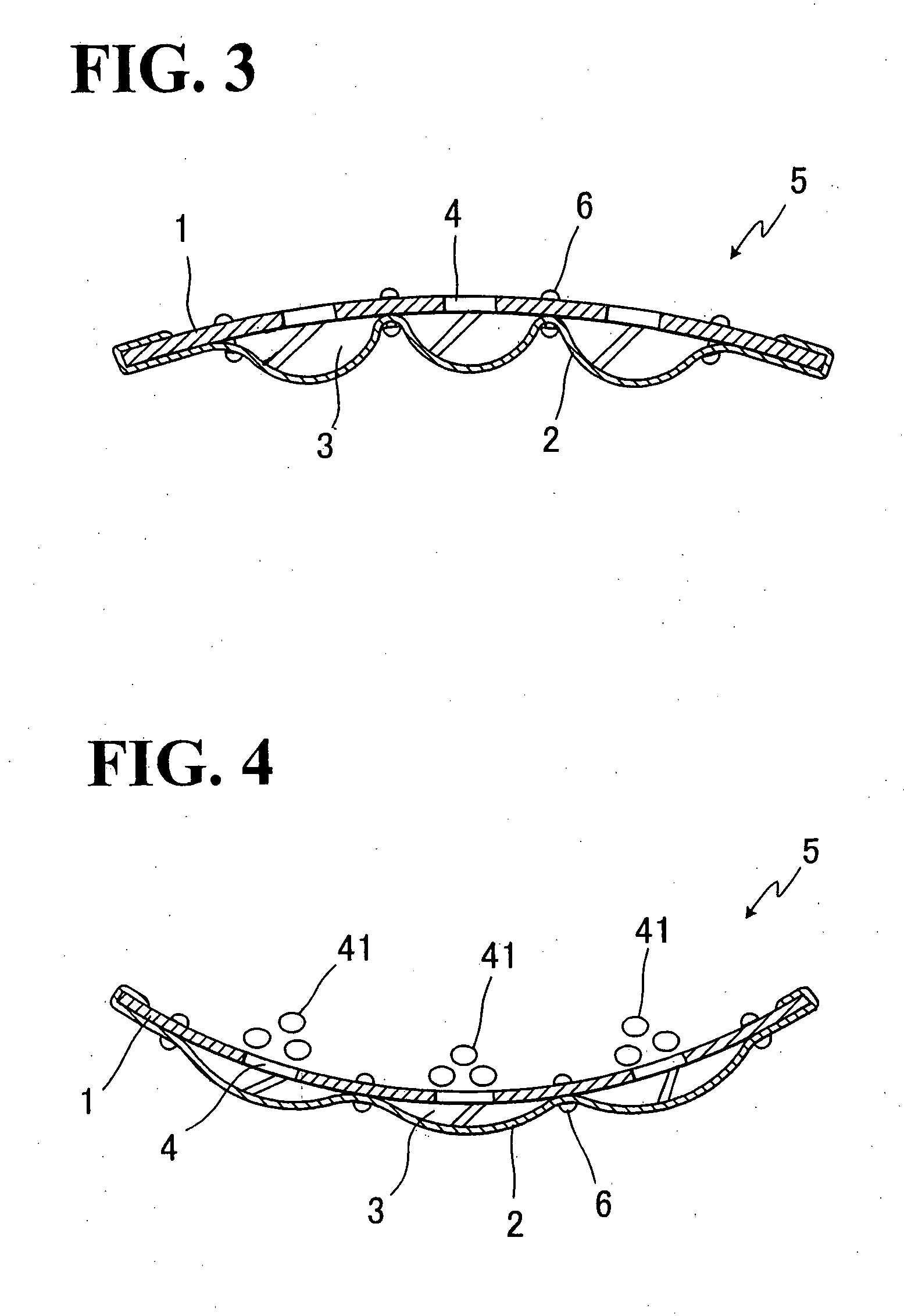

Cooling Member for Use in Hat, Sun Visor or the Like

InactiveUS20090049578A1The process is convenient and fastFeel coolLighting and heating apparatusEye-masksEvaporationHardness

This present invention is for cooling the forehead, face and armpit of a person or imparting cool feeling.The cooling member comprises a water-absorbing material sheet sandwiched between a flexible planar material provided with a ventilation means, having an adequate hardness, and capable of holding its shape, capable of being bent in a predetermined direction and in the reverse direction a plurality of times, and having a curvature in the predetermined direction and backing cloth having a similar area and a means for dividing the water-absorbing material sheet into parts each having an adequate area corresponding to a vent in such a way that water absorbed in the water absorbing material sheet does not flow out easily into adjacent parts and is used for cooling by allowing the water absorbing material sheet to absorb water and by using its heat of evaporation to cool the surroundings.The cooling member constitutes a brim portion of a hat, a sun visor or the like, or a pad portion for the forehead, face or armpit of the person and provides a means for imparting a cool feeling to each heat generating portion of the human body.As preparation for use, the cooling member is dipped into water and bent by applying a force reversely to the curvature in the predetermined direction. Consequently, excess water and water drops are squeezed out easily and uniformly with only the cooling member without wetting the hand of the person.

Owner:KOBAYASHI TOYOHIRO

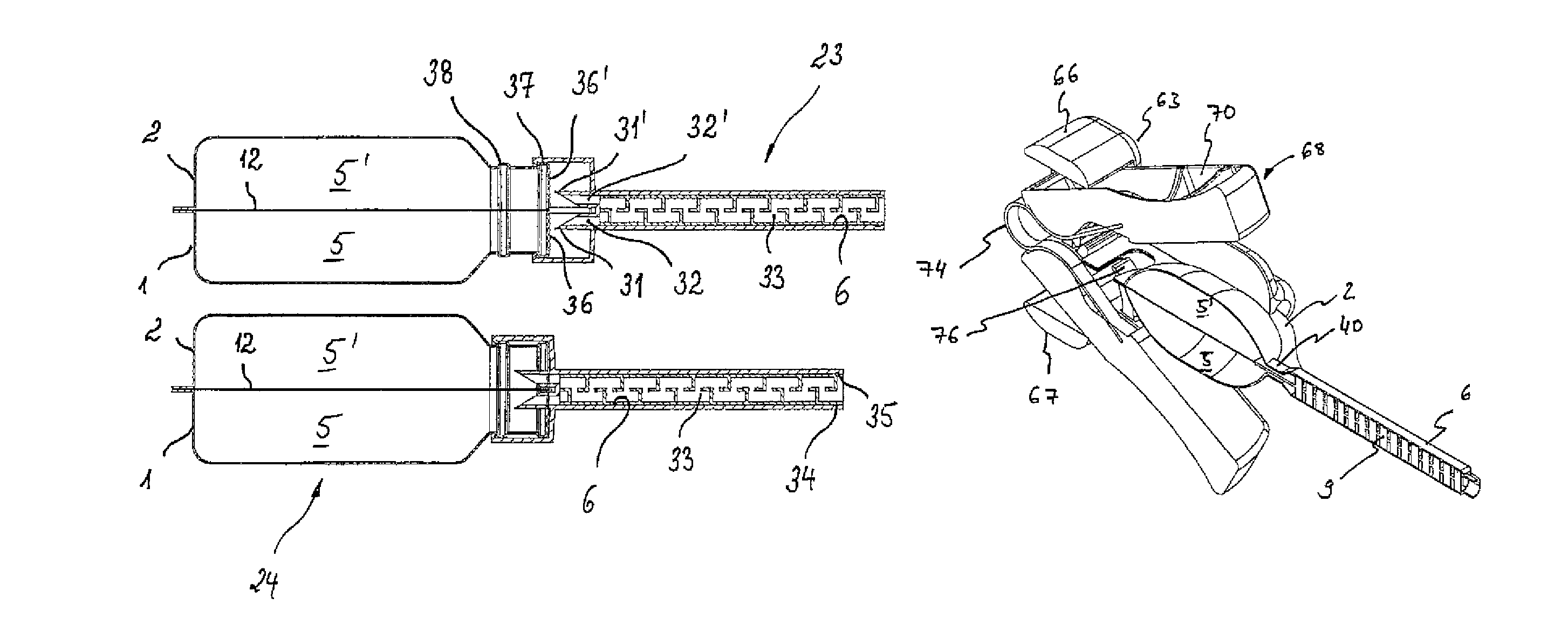

Multicomponent foil-type container

InactiveUS7934864B2Extrusion process is simpleEasy to adaptSmall article dispensingFlow mixersEngineeringMechanical engineering

Owner:SULZER MIXPAC AG

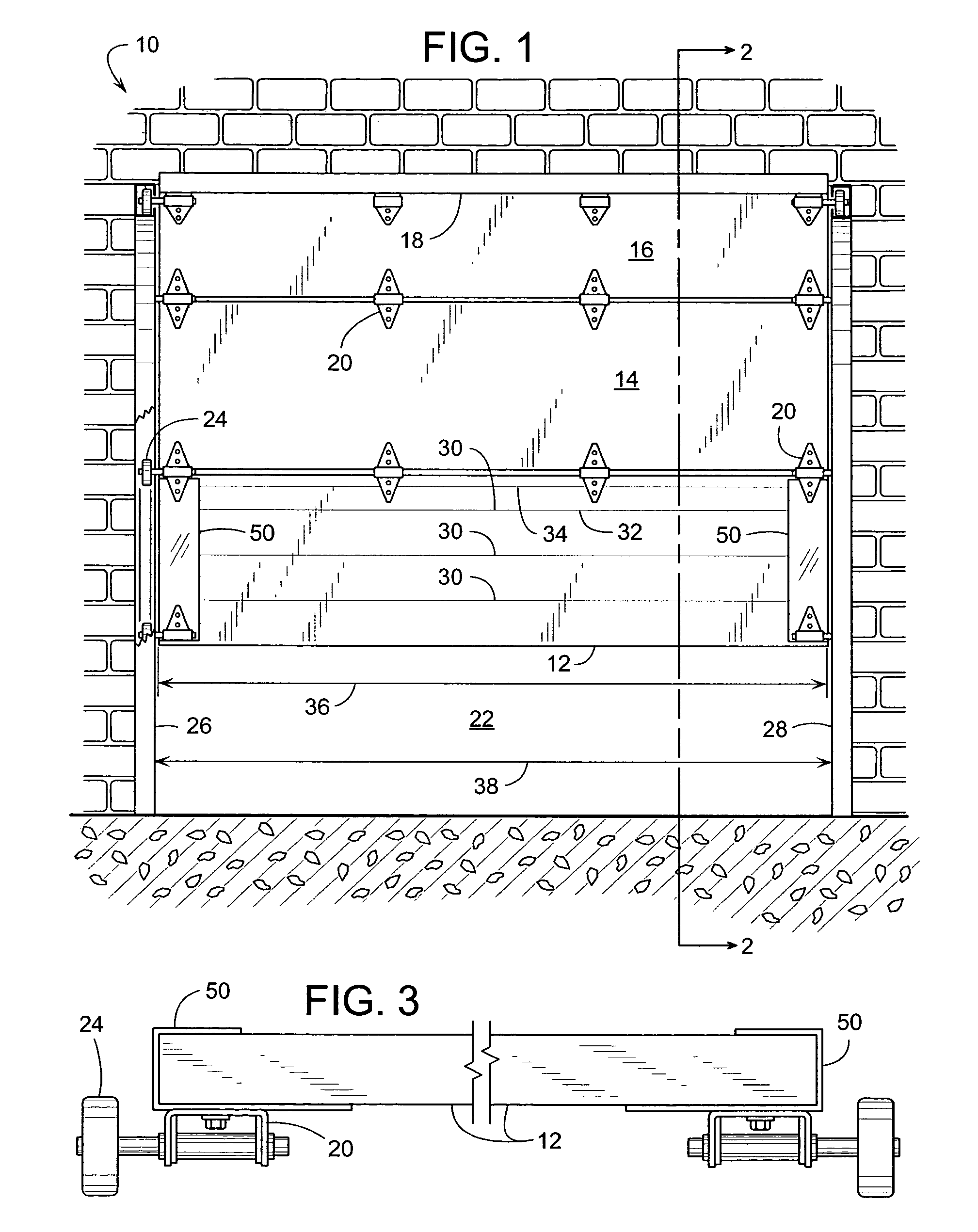

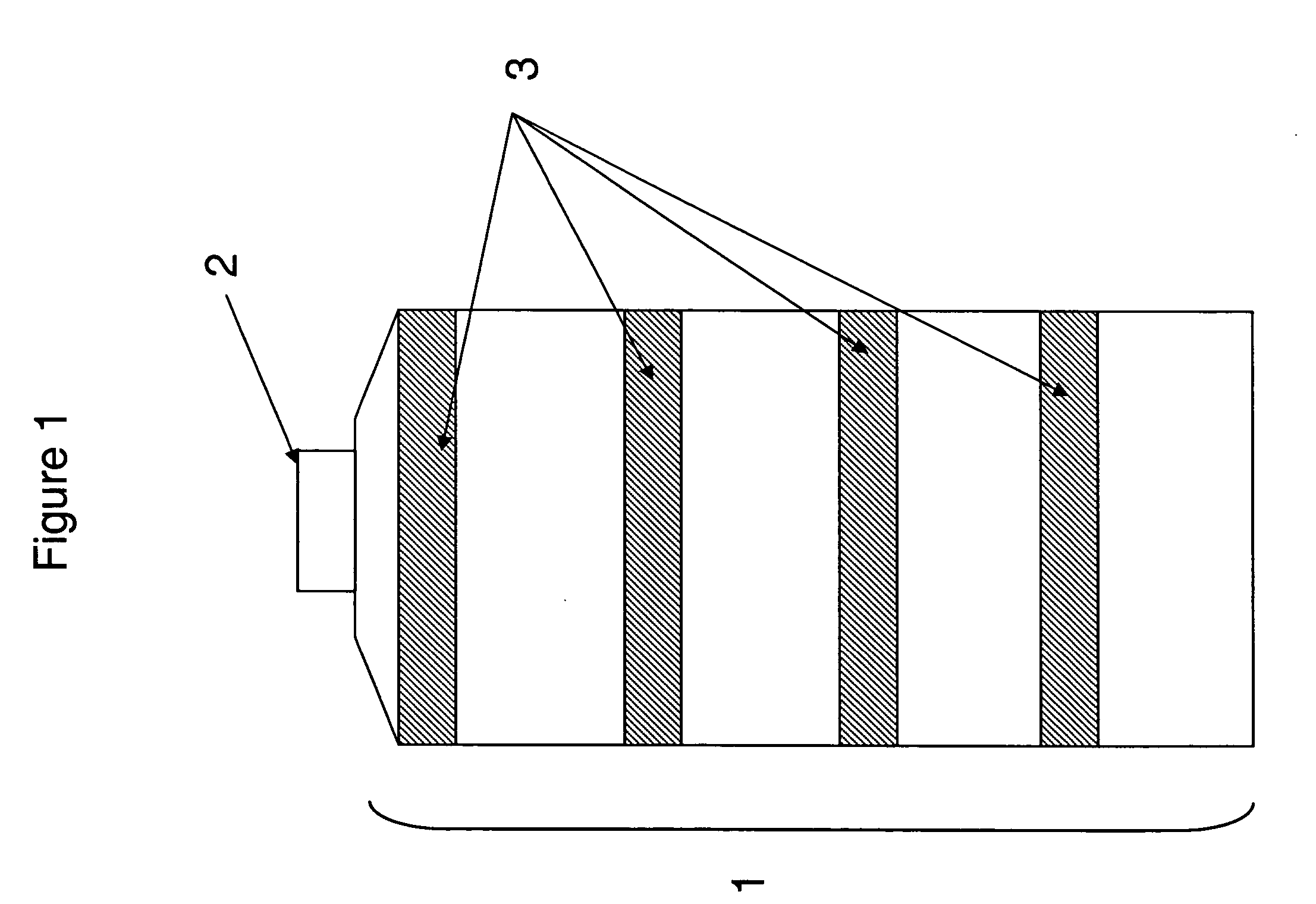

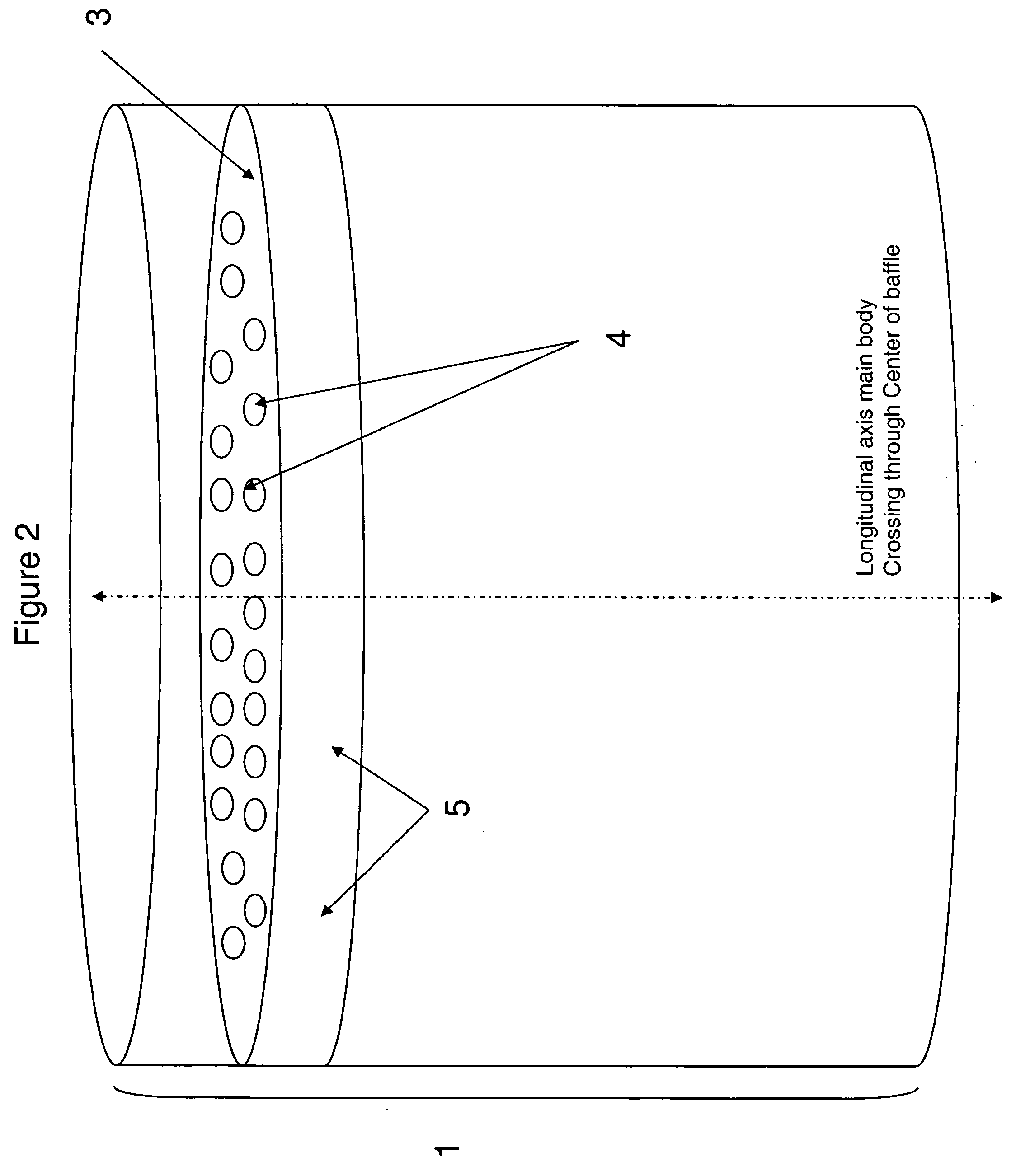

Baffled water bottle

InactiveUS20060027611A1Maintaining distance runner performanceMaintain healthTravelling sacksLiquid flow controllersLong distance runnersEngineering

The invention is a water bottle intended primarily for distance athletes such as long distance runners. Internal to the water bottle is a series of baffles whose main body surfaces are located perpendicular to the longitudal (long) axis of the water bottle. The baffles are attached to the inner walls of the water bottle. The baffles are sufficiently rigid to arrest fluid motion minimizing the noise of water sloshing and energy loss due to fluid motion. The baffles are structurally attached to the water bottle in a manner that requires no central connecting structure and in a sufficiently rigid manner to arrest fluid motion during high intensity athletic events. The design may also incorporate a longitudinal baffle connected at near right angles to the previously described baffles or connected to partial baffles. Finally, the design may incorporate baffles that are non-planar (cup shaped).

Owner:HOBBS WADE TRAVIS

Glue Extruding Device

ActiveUS20170267413A1Conveniently manufacturedLow costUnpacking by expelling contentsFlexible containersMechanical engineeringExtrusion

A glue extruding device for tube of glue is composed of a base, on which the device is placed vertically; two side plates, of which at least one is pressing plate with extrudable elastic connection to the base and a pressing surface on inner wall to contact outer surface of aluminum tube and facilitate glue extrusion; a retaining clip above the base, with one end to connect to the top of a side plate and a through-hole in the middle from which the mouth of tube can extend out. There is an accommodating cavity between the base, the two side plates and the retaining clip to place and position tube body.

Owner:NINGBO PASCO UNITED IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com