Patents

Literature

153 results about "Pressure cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stimulating fluid production from unconsolidated formations

The present invention provides methods of stimulating fluid production from an unconsolidated formation penetrated by a wellbore while preventing the migration of formation sand with fluids produced from the formation. The methods basically comprise the steps of injecting a liquid composition into a portion of the formation surrounding the wellbore which converts into a gel-like substance and plugs the permeability of the injected portion of the formation, but allows the injected portion to remain flexible and resist breakdown due to pressure cycling therein, creating at least one fracture in the formation extending from the wellbore through the plugged portion of the formation into an unplugged portion thereof and depositing hardenable resin composition coated proppant in the fracture and causing the resin composition to harden and consolidate the proppant into a hard permeable mass.

Owner:HALLIBURTON ENERGY SERVICES INC

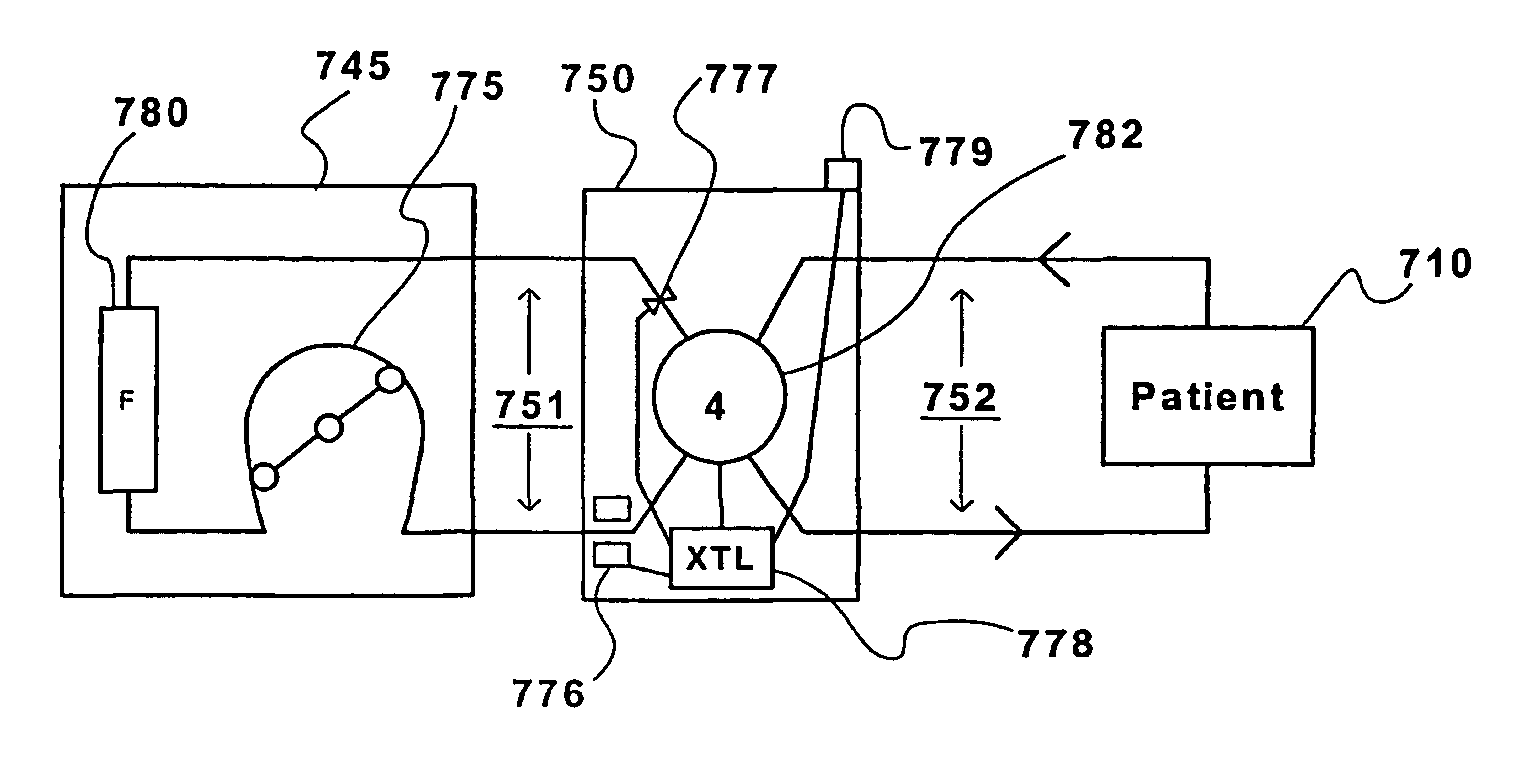

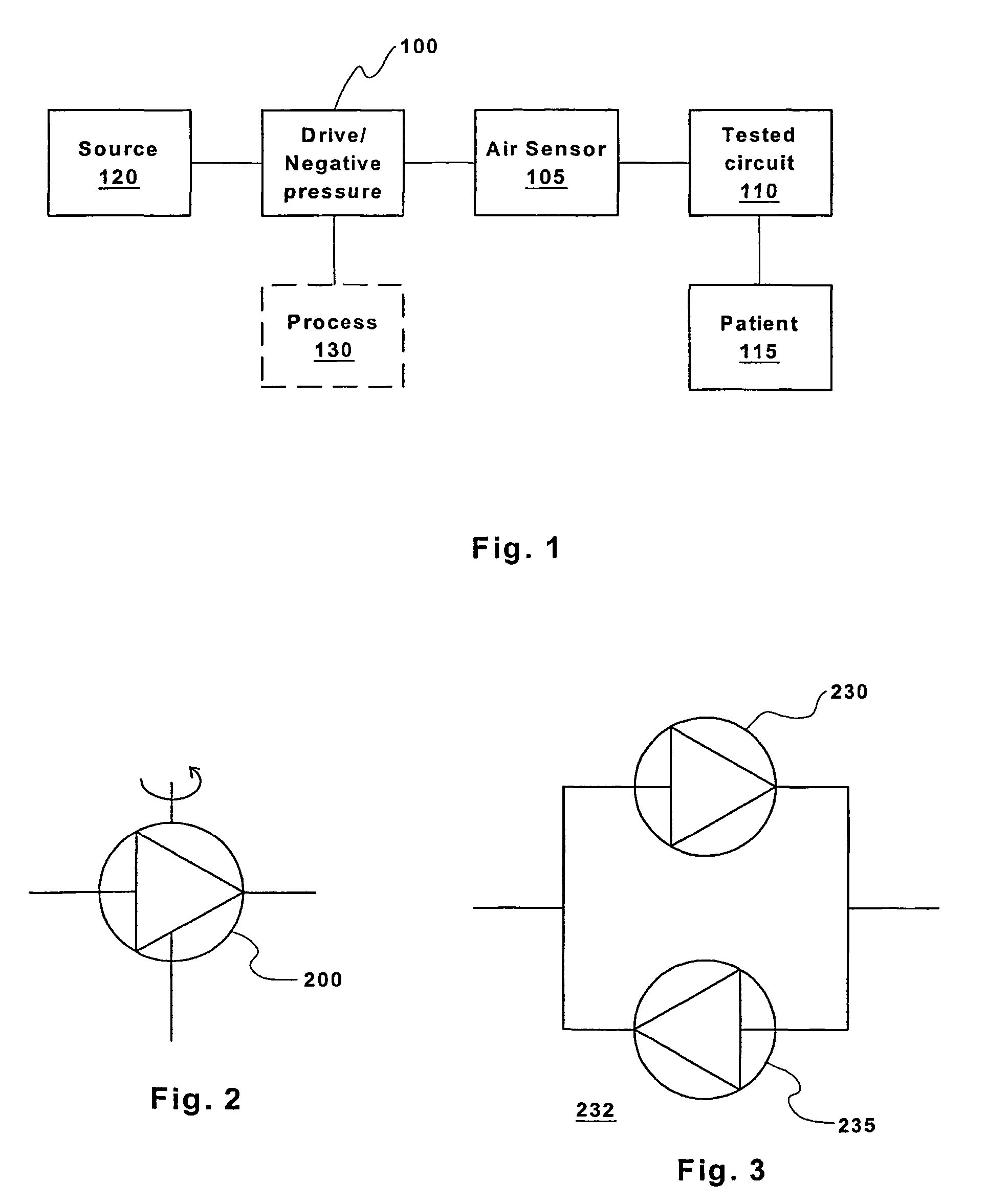

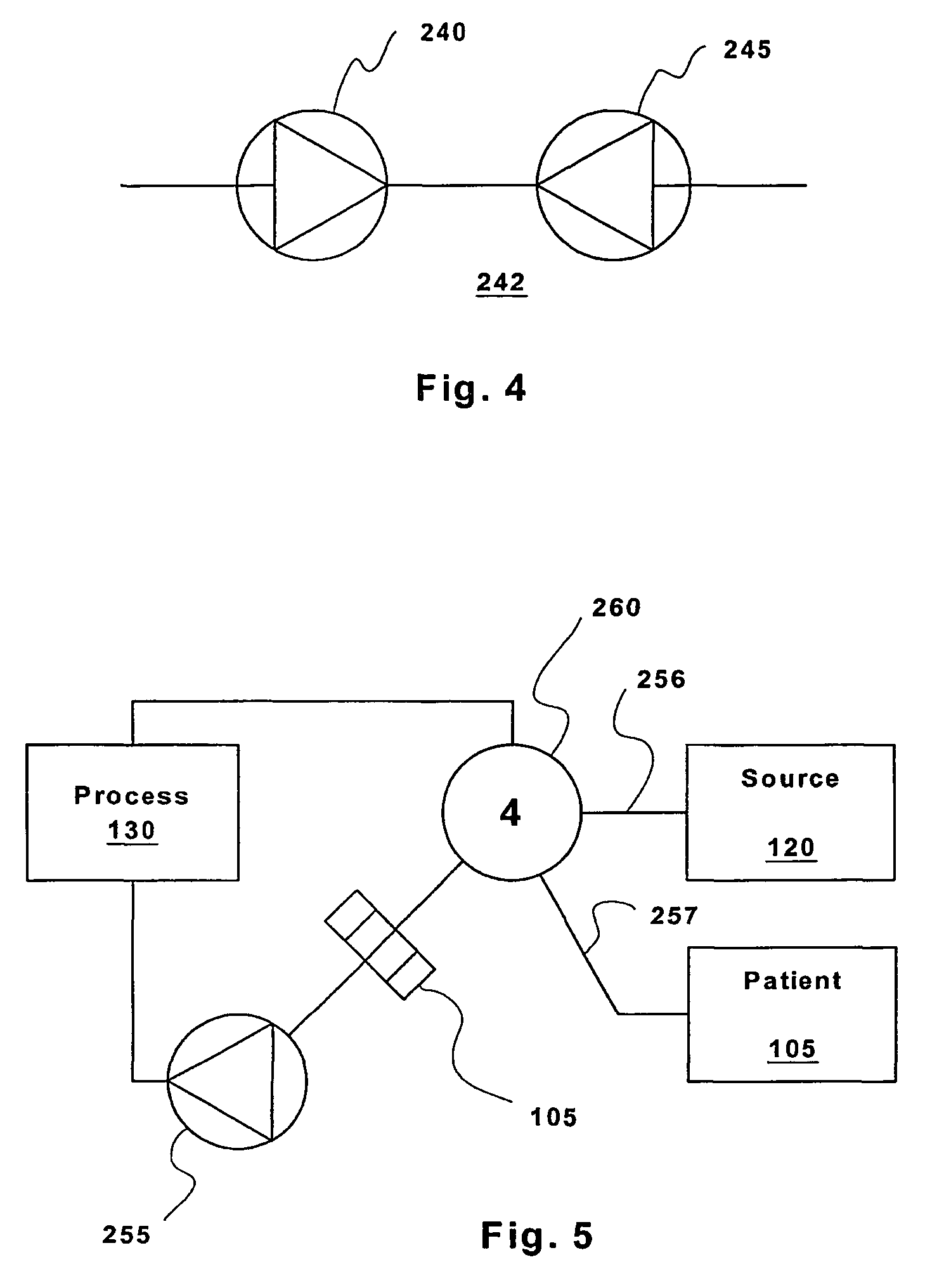

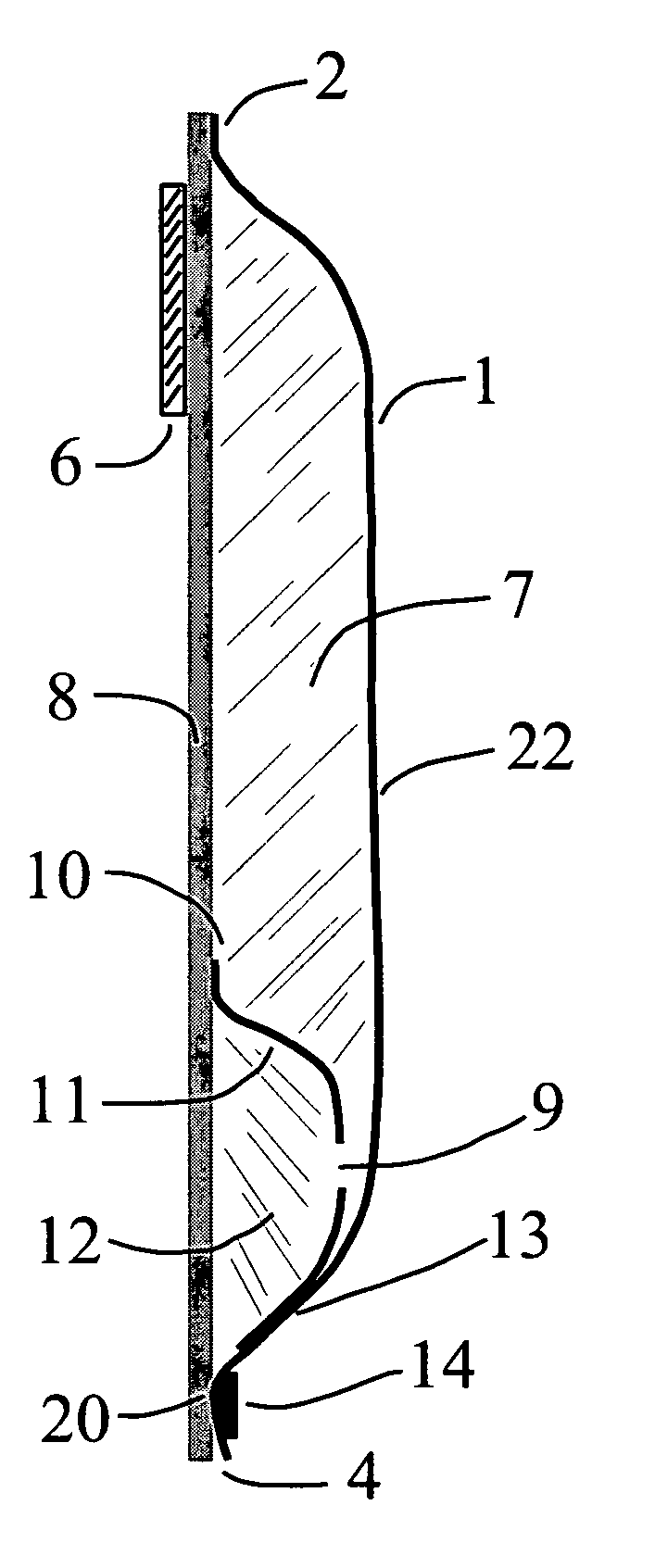

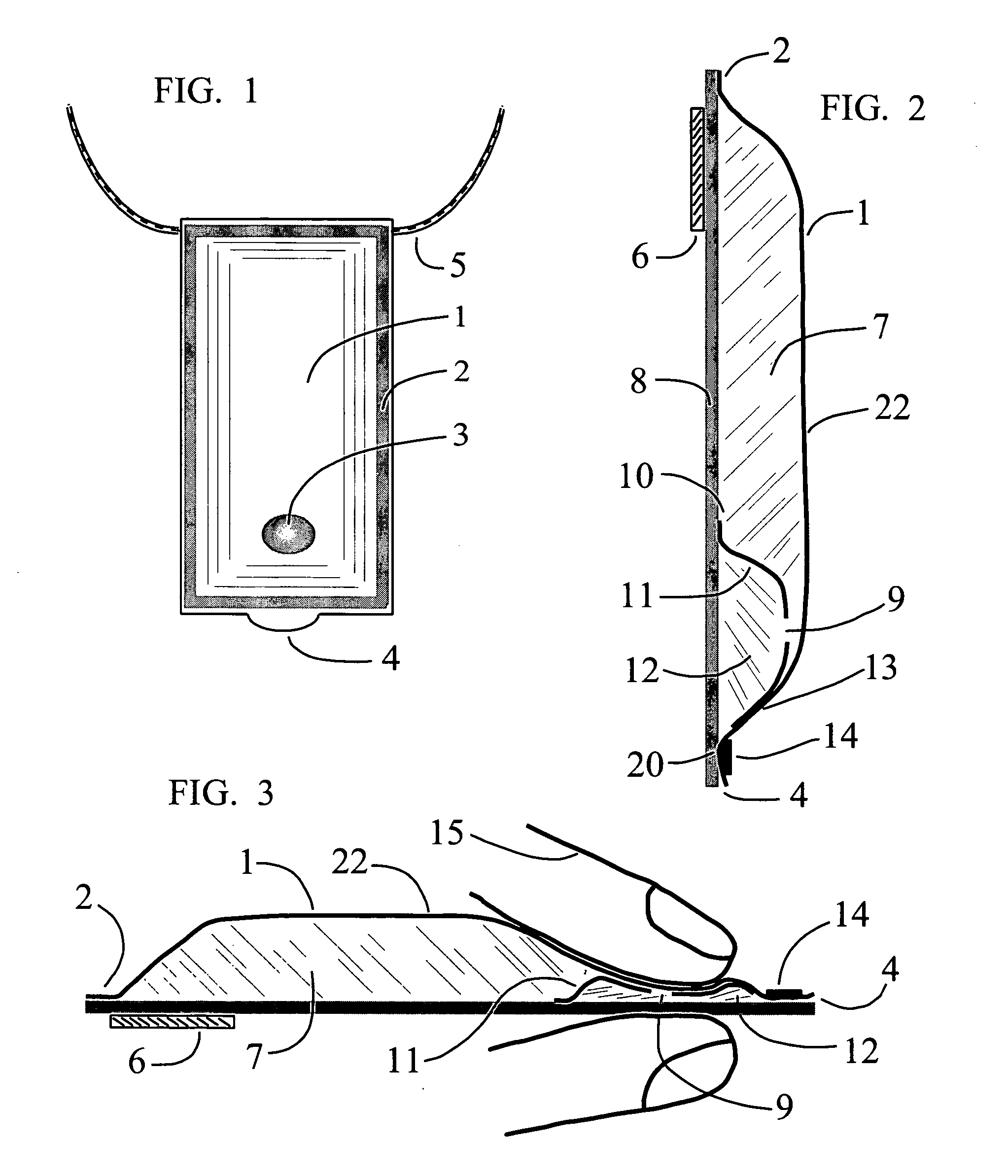

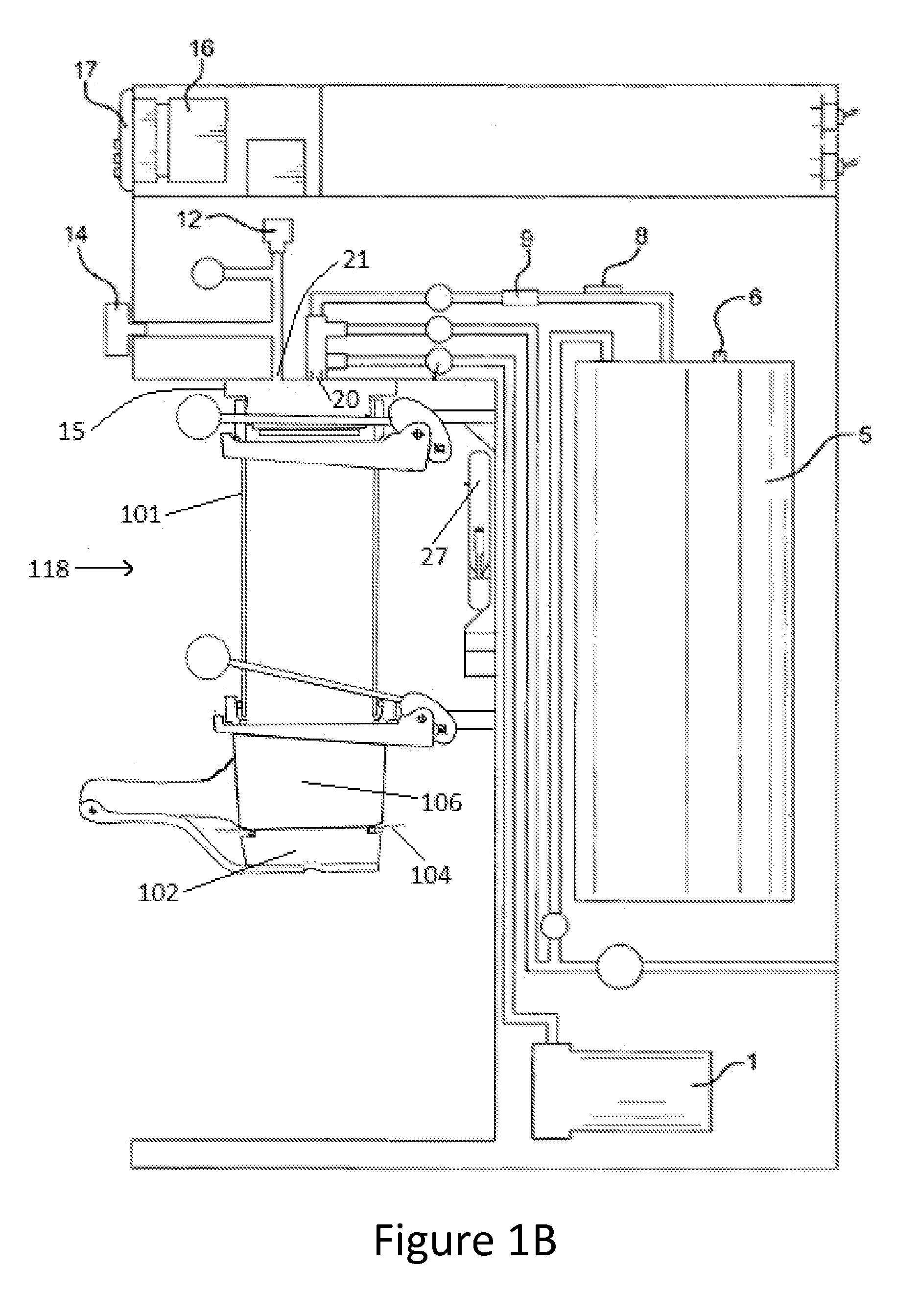

Method and apparatus for leak detection in a fluid line

One of the most significant safety concerns in the automation of extracorporeal blood treatments such as dialysis is the risk of blood leakage. Such systems draw blood at such a high rate that a loss of integrity in the blood circuit can be catastrophic. The most reliable leak detection method known is the detection of infiltrated air in the blood line, but this only works in blood lines under negative pressure. According to the invention, a leak detector for return lines is provided by periodically generating a negative pressure, which may be brief or at a 50% duty cycle, in the blood return line to draw air into it and thereby reveal the leaks using an air sensor. Although the return line is ordinarily under positive pressure, during the negative pressure cycle, the blood return line draws air through any leaks or disconnects. If air is detected, the system is shut down and an alarm generated.

Owner:NXSTAGE MEDICAL

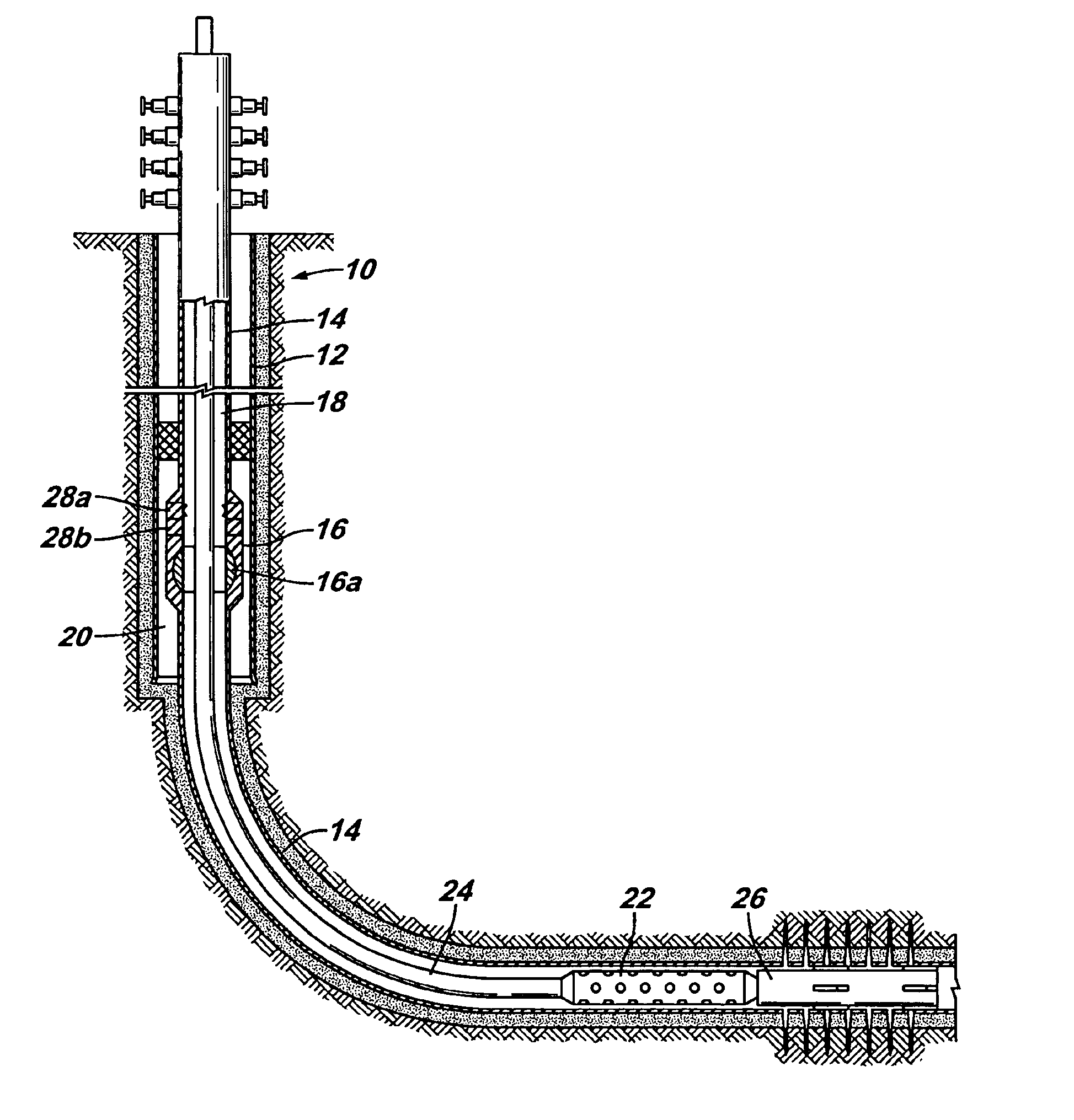

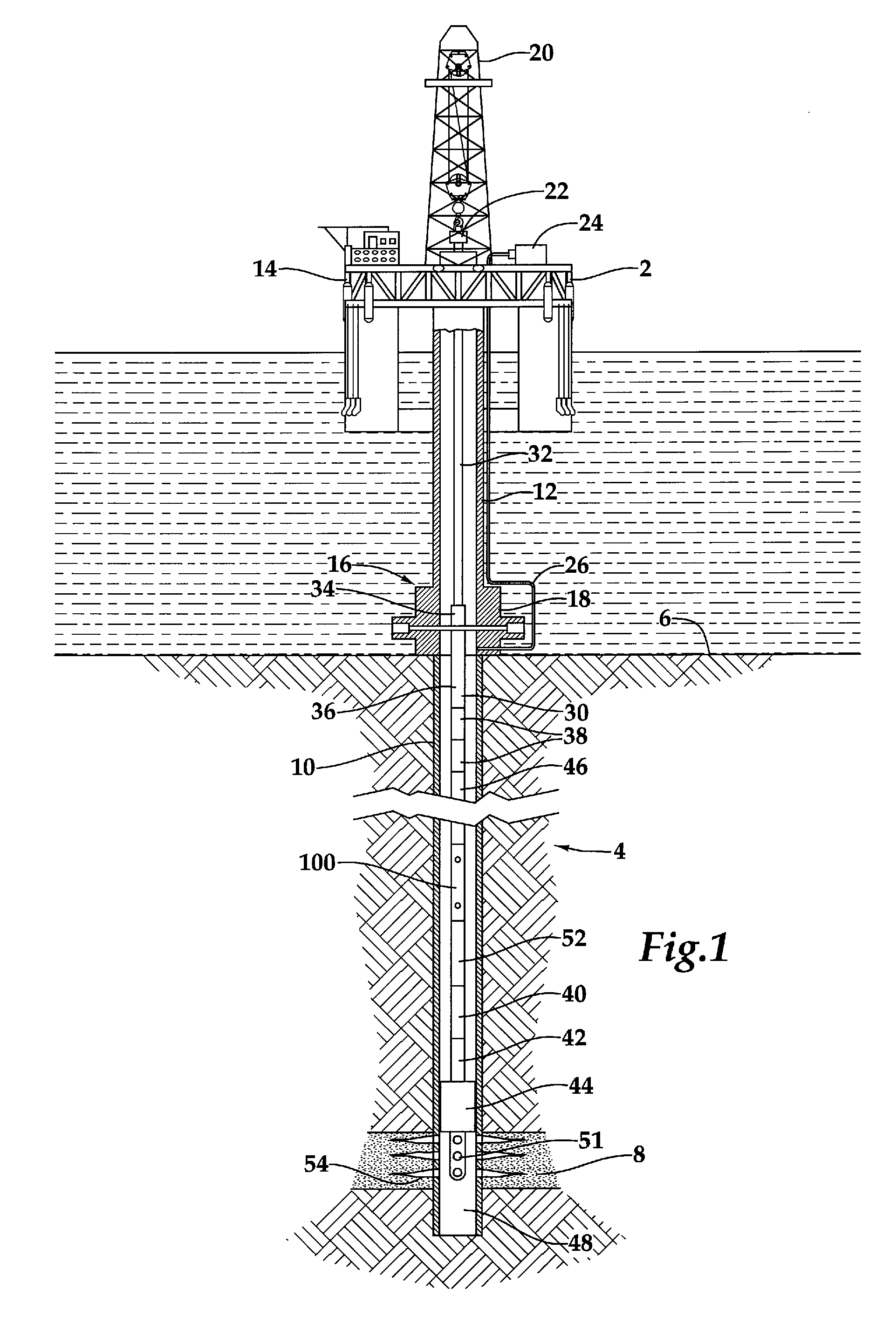

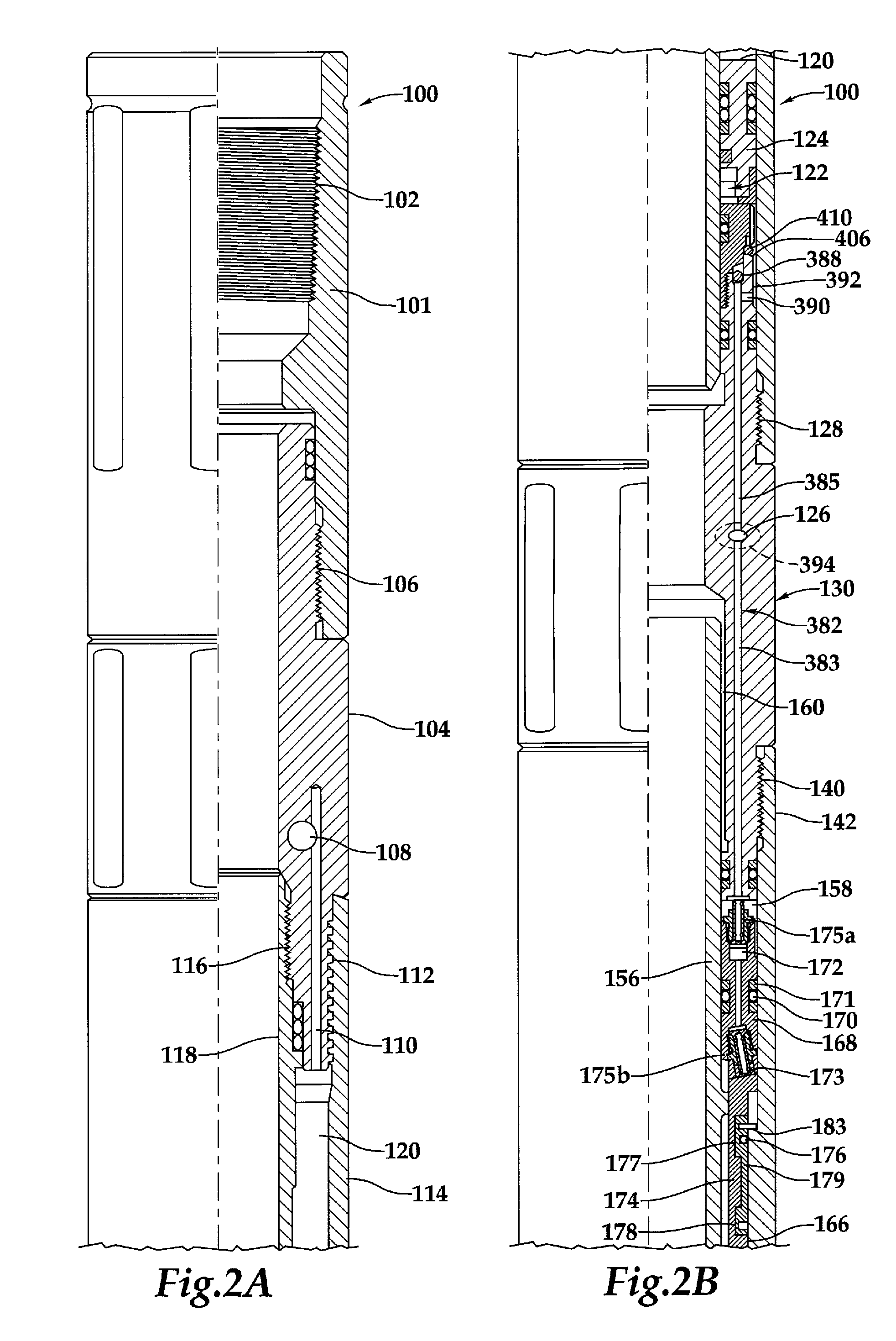

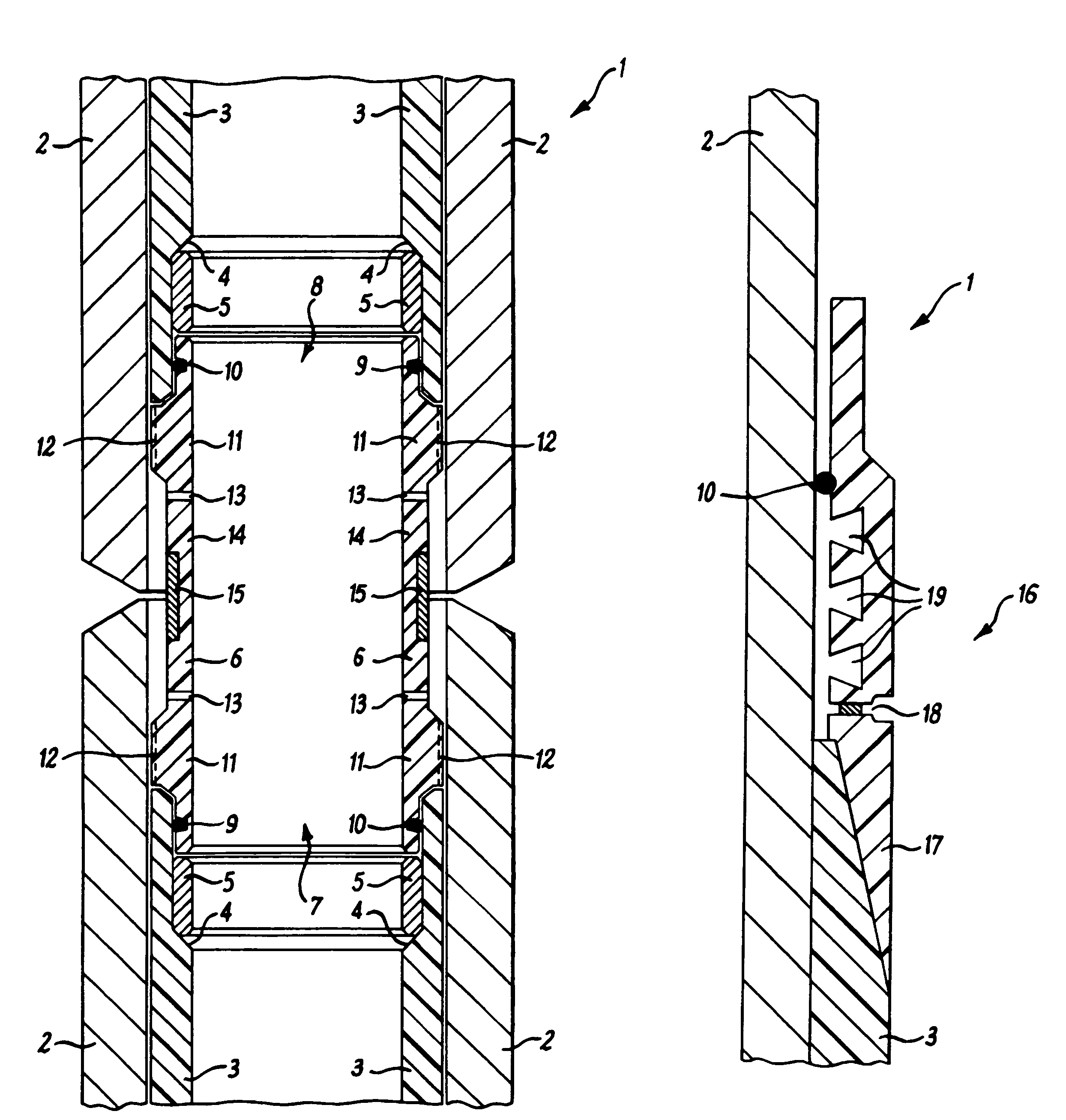

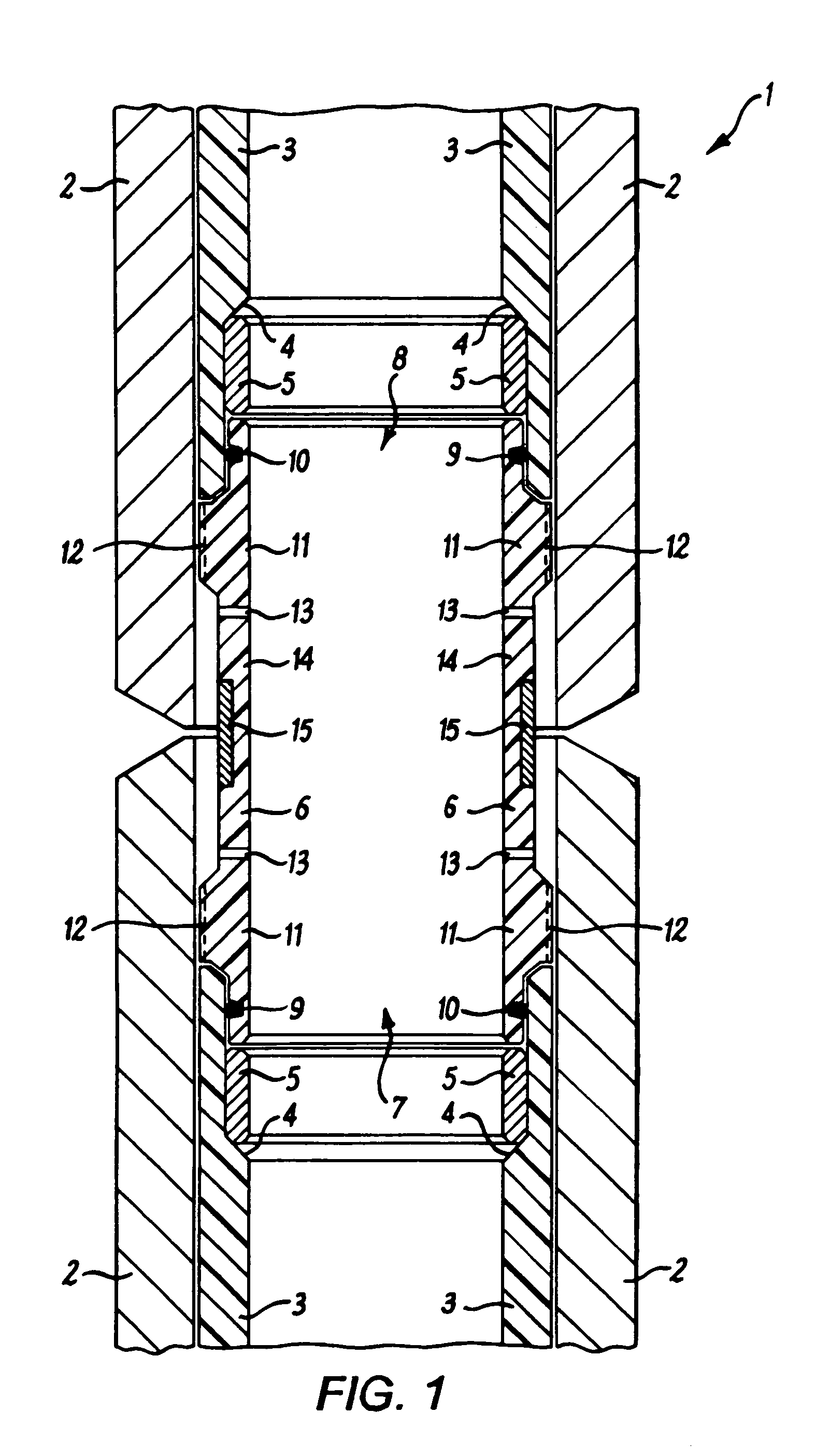

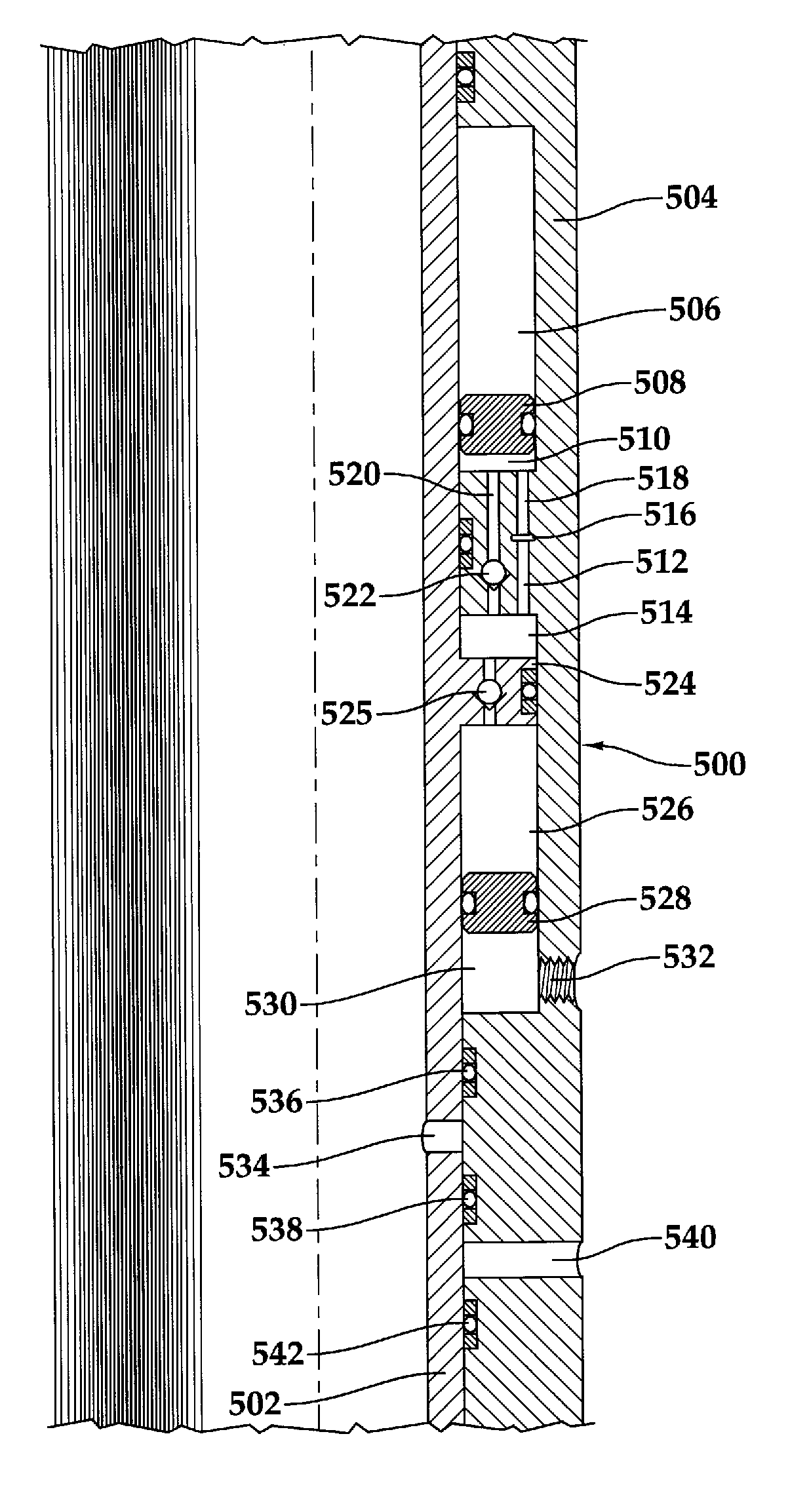

Multiple interventionless actuated downhole valve and method

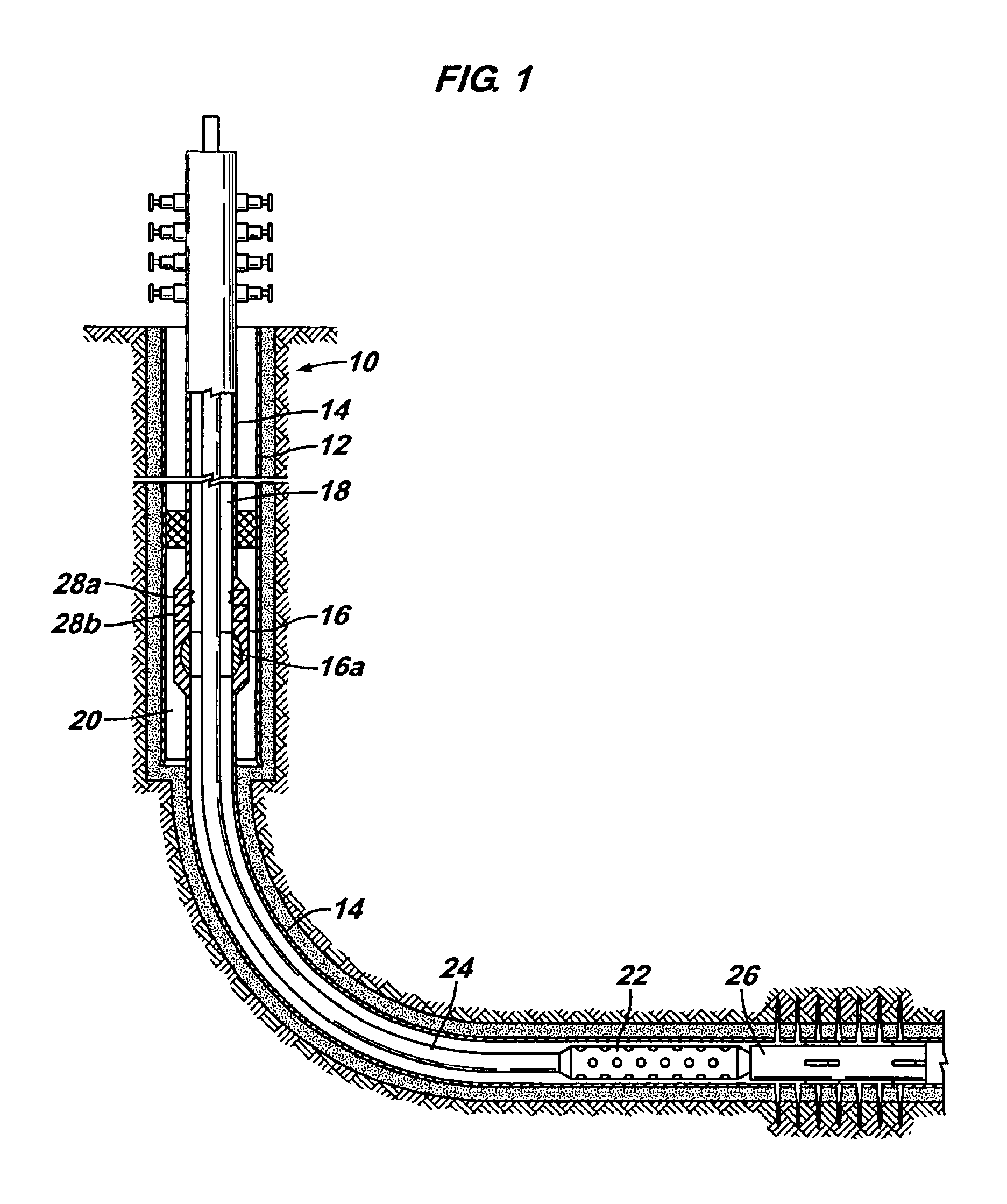

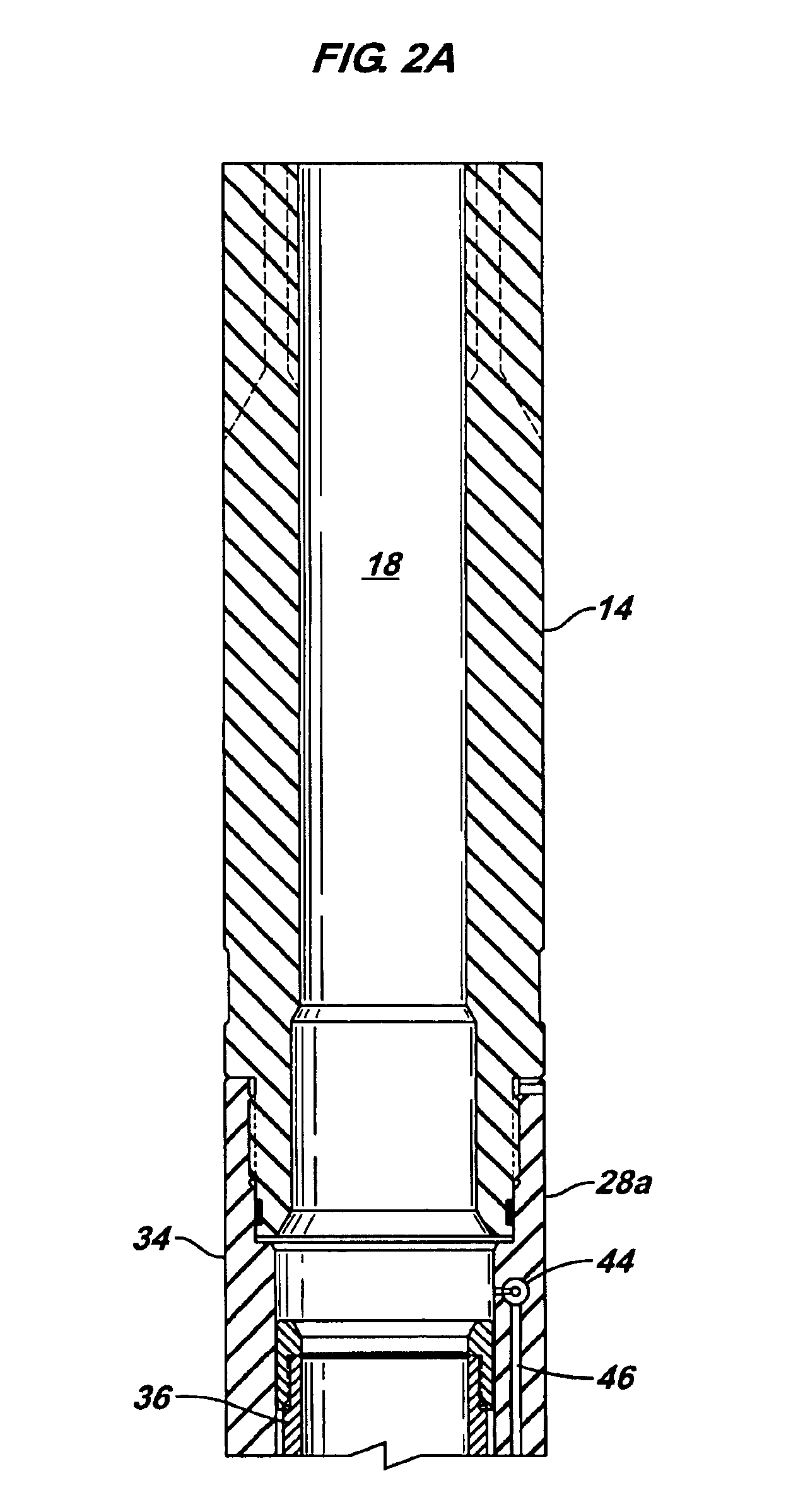

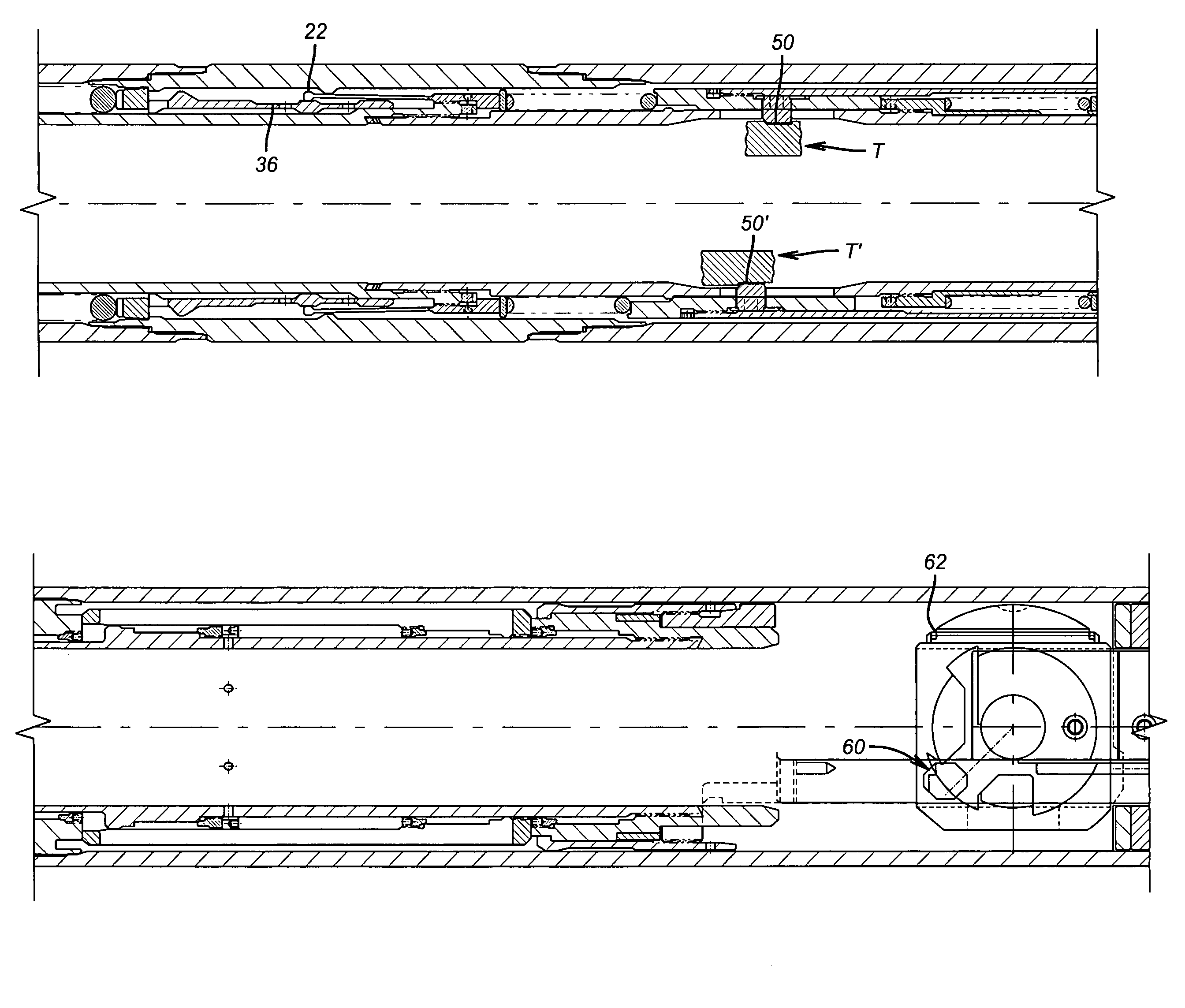

The multiple interventionless actuated downhole valve includes a valve movable between an open and a closed position to control communication between an annular region surrounding the valve and an internal bore and more specifically controlling communication between above and below the valve, and at least two remotely operated interventionless actuators in operational connection with the valve, wherein each of the interventionless actuators may be operated independently by absolute tubing pressure, absolute annulus pressure, differential pressure from the tubing to the annulus, differential pressure between the annulus and the tubing, tubing or annulus multiple pressure cycles, pressure pulses, acoustic telemetry, electromagnetic telemetry or other types of wireless telemetry to change the position of the valve and allowing the valve to be continually operated by mechanical apparatus.

Owner:SCHLUMBERGER TECH CORP

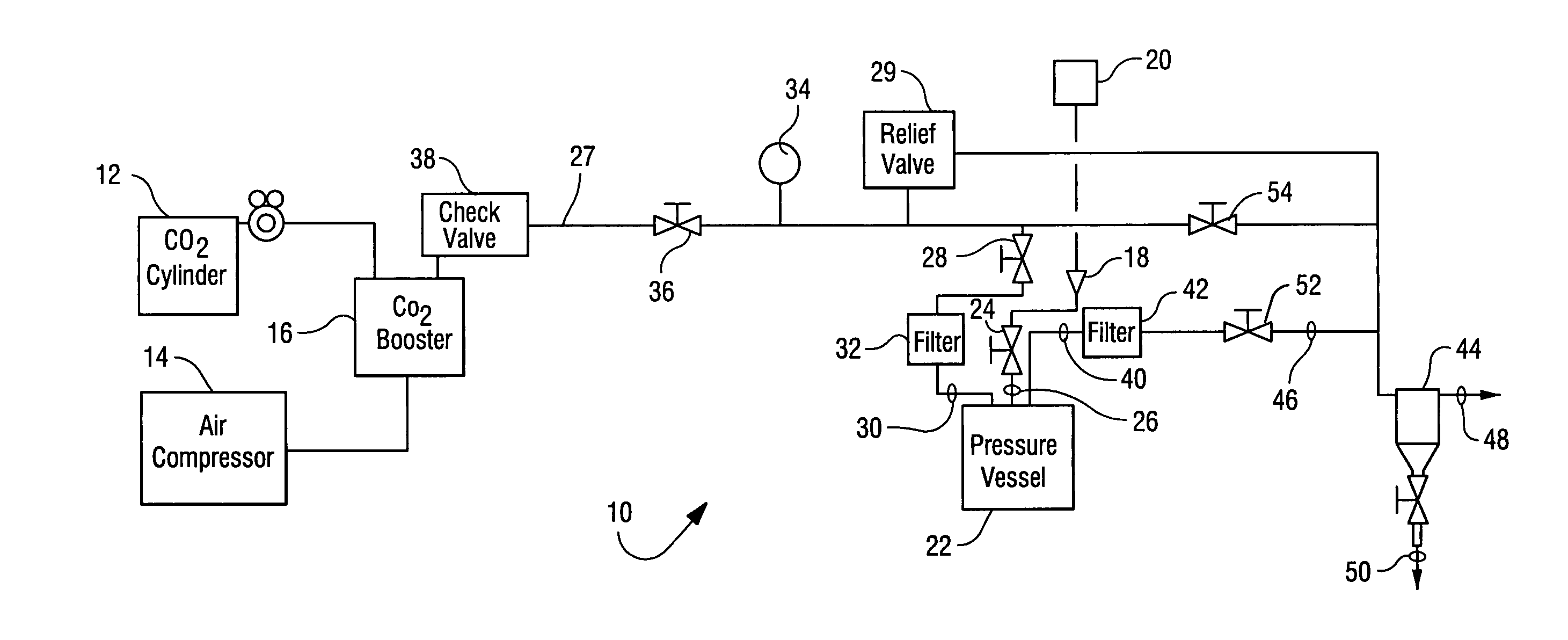

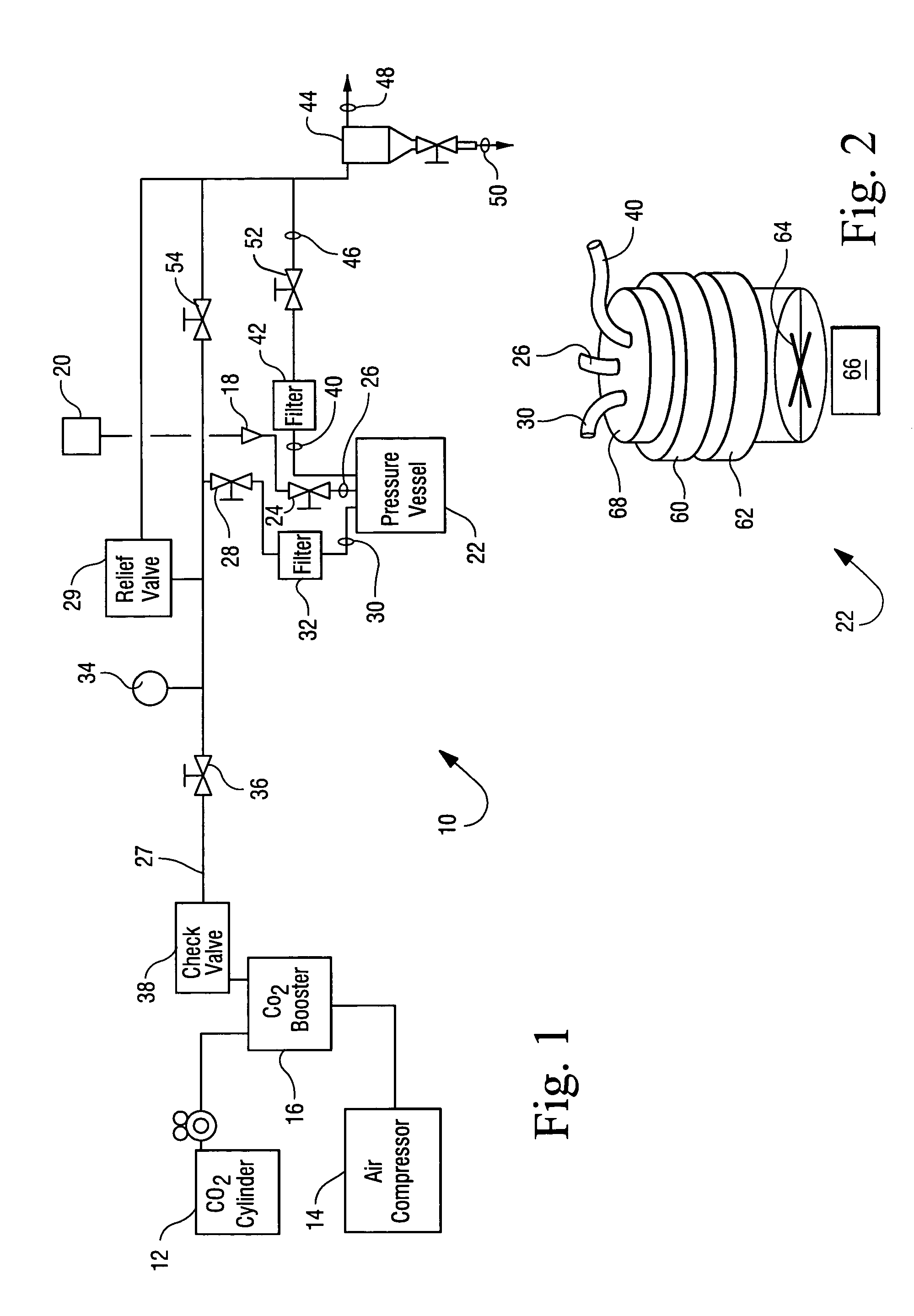

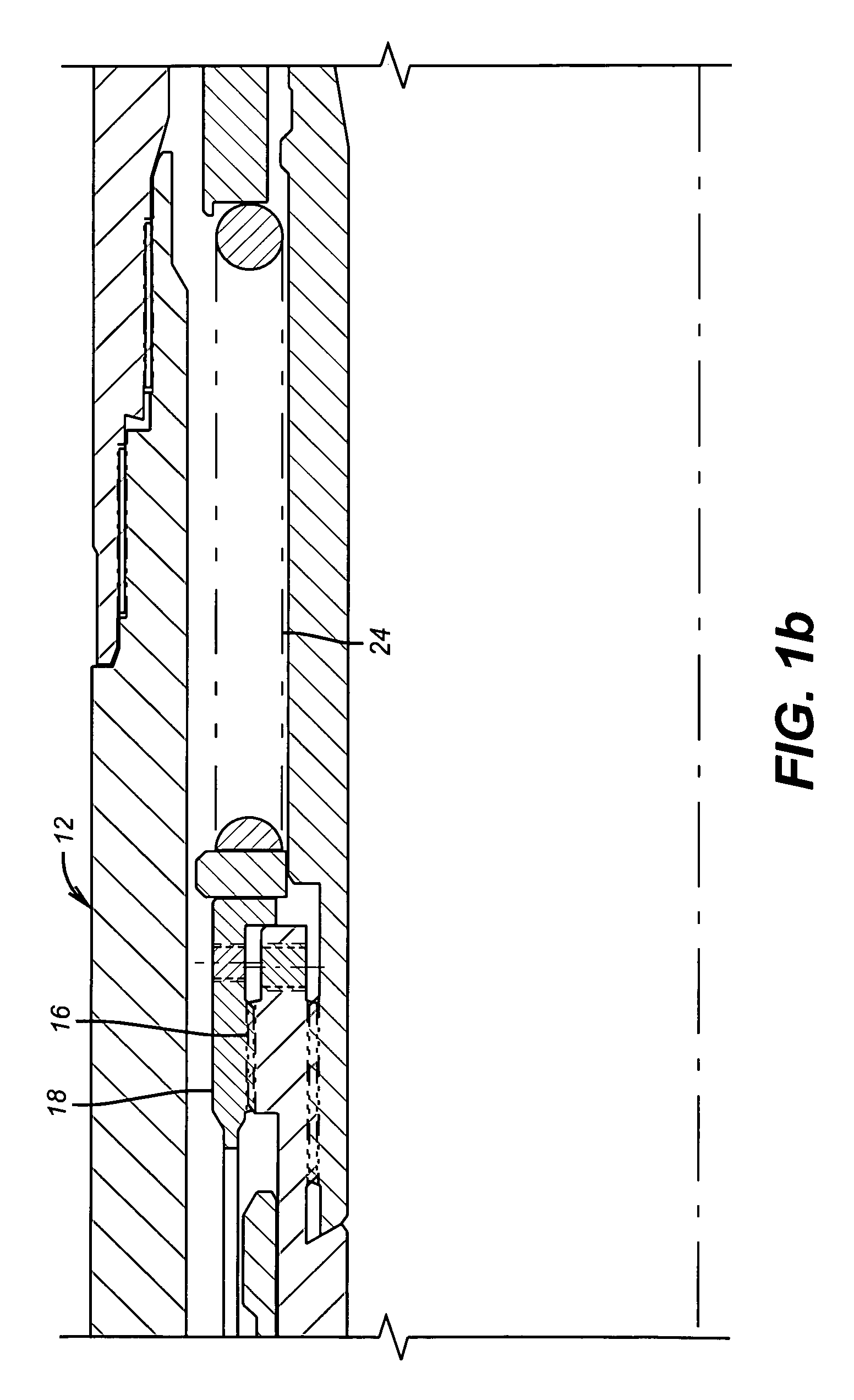

Sterialization methods and apparatus which employ additive-containing supercritical carbon dioxide sterilant

ActiveUS7108832B2Enhances mass transfer and sterilizationImprove sterilizationSamplingOther chemical processesSporePressure cycling

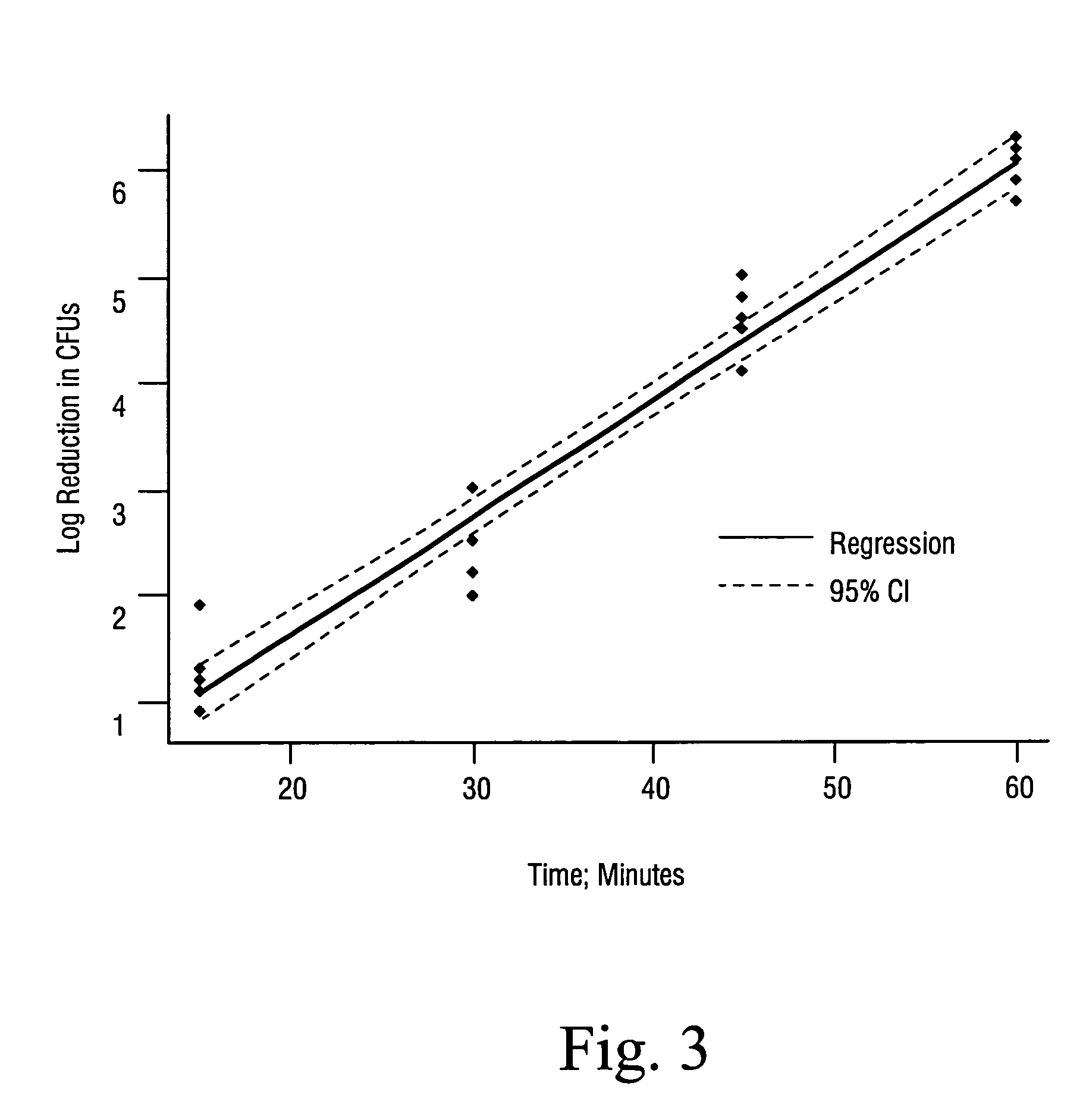

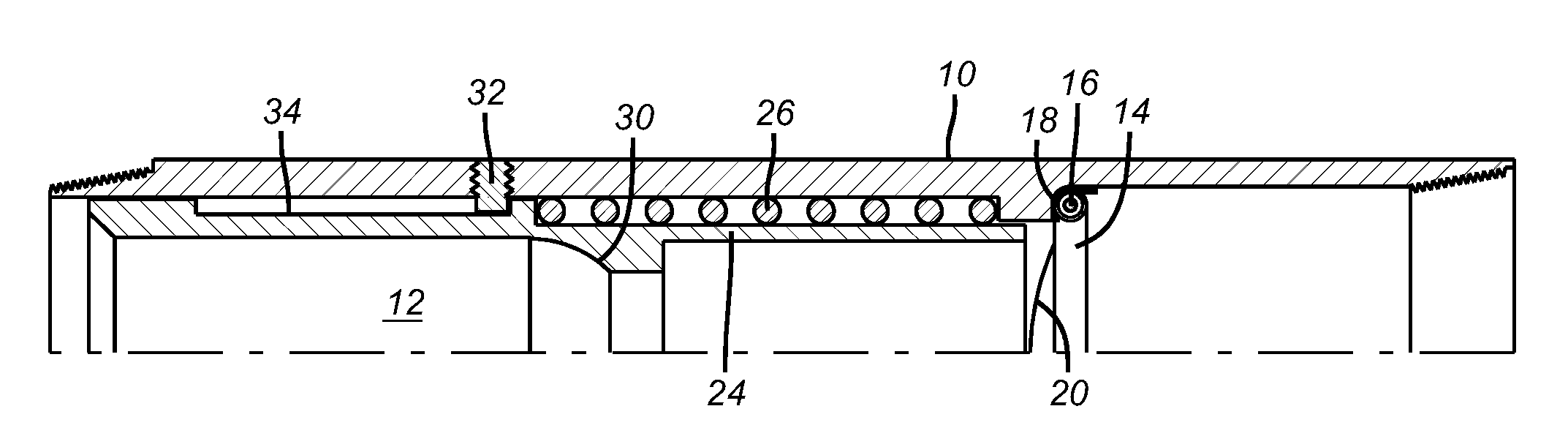

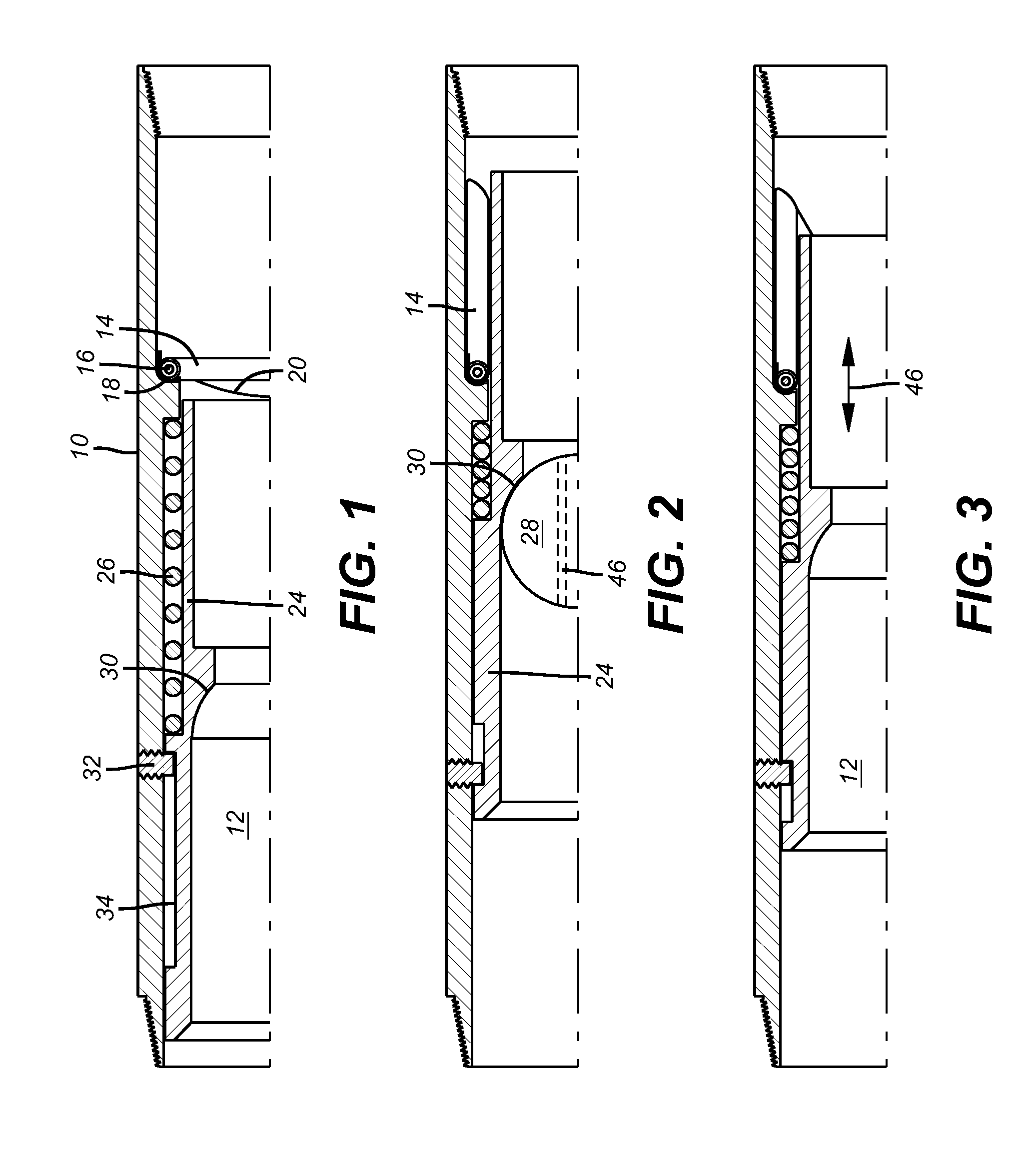

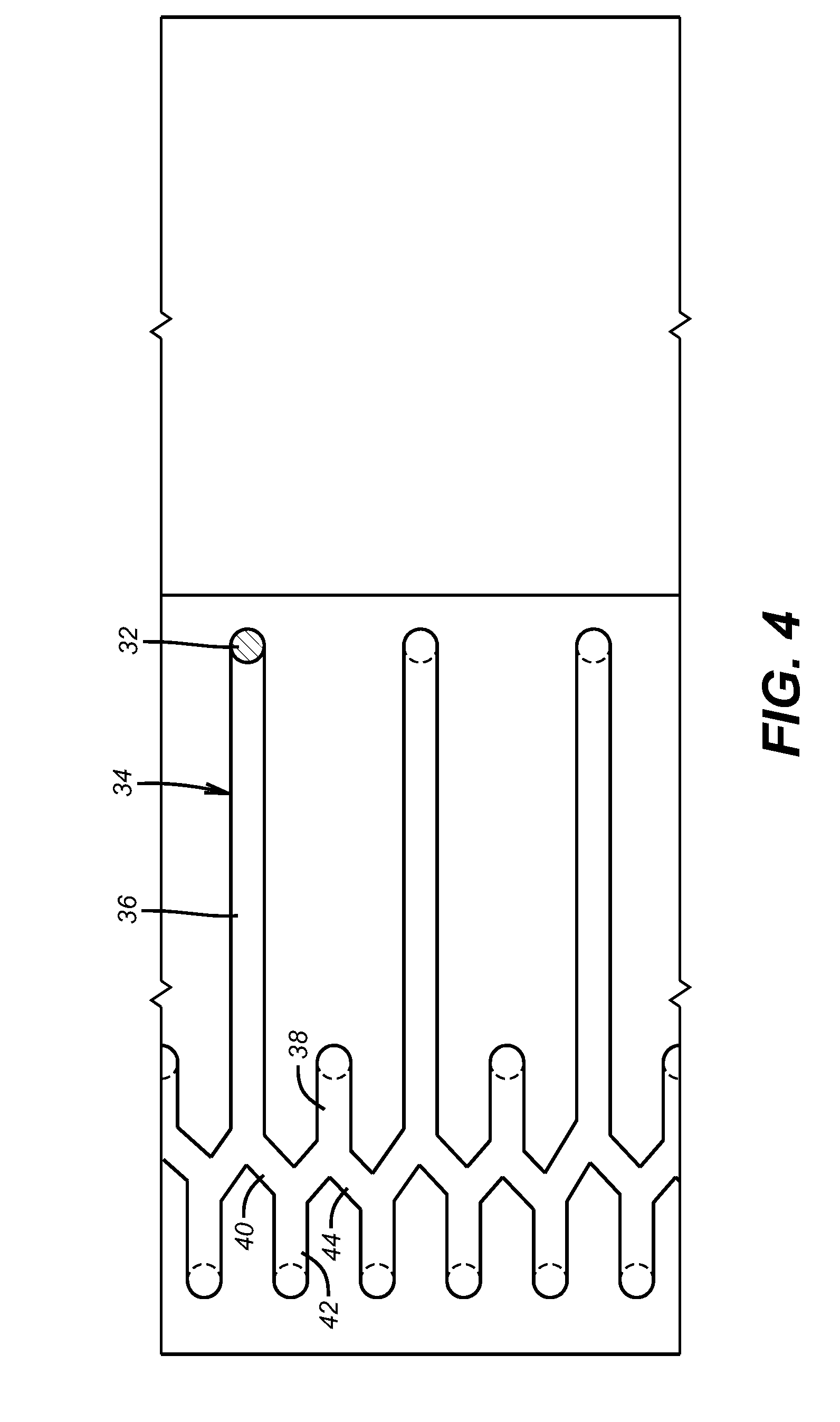

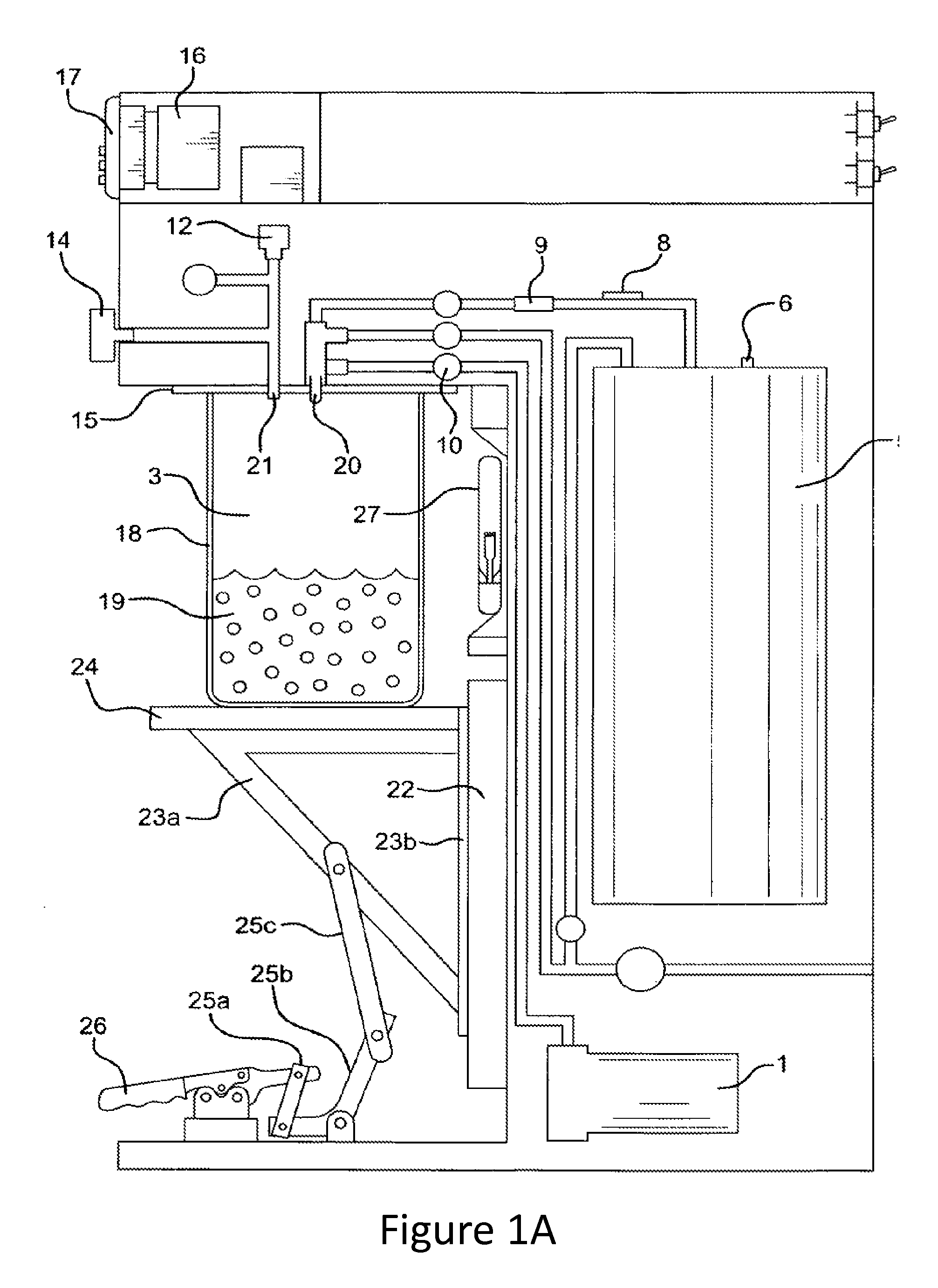

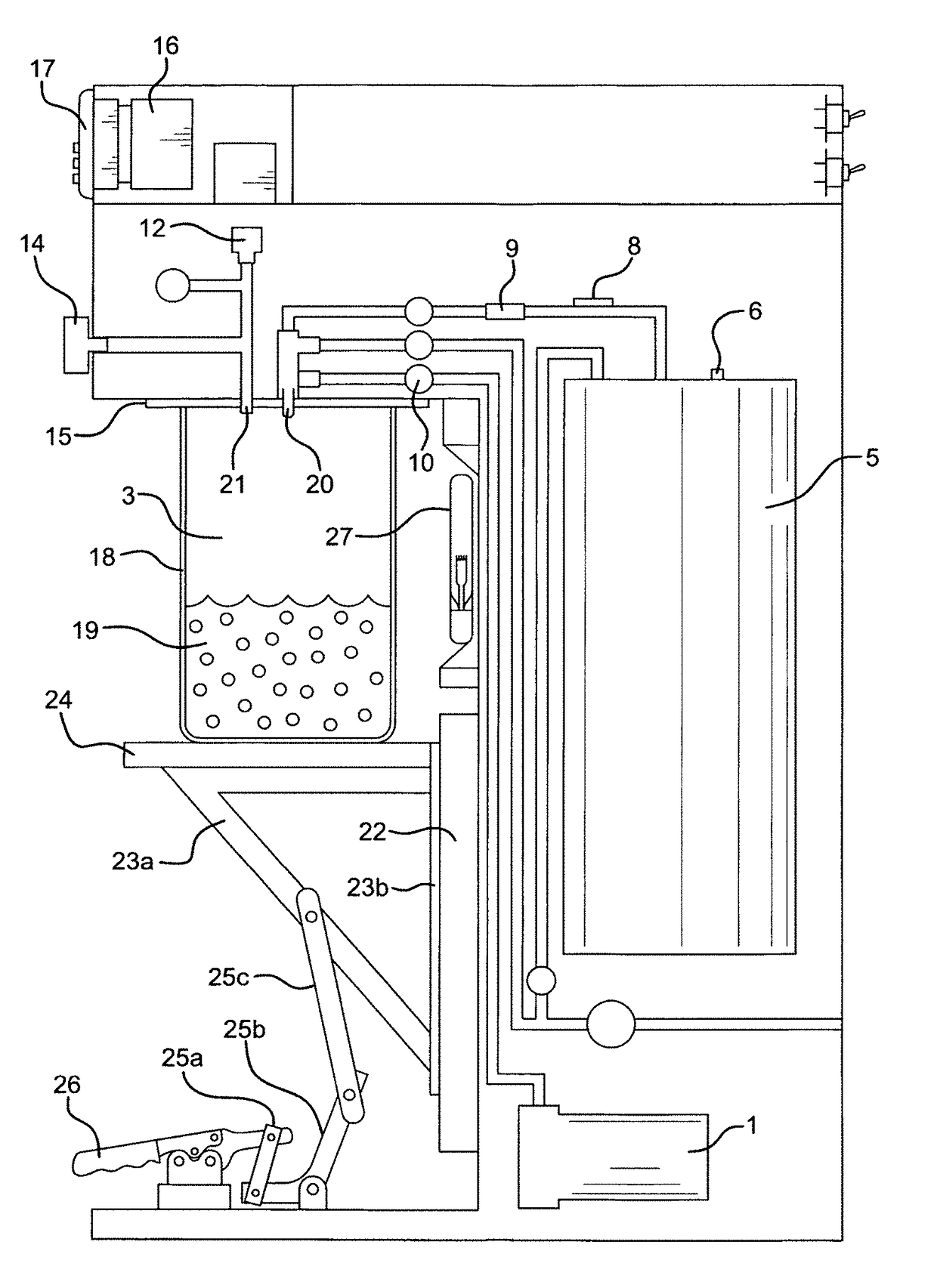

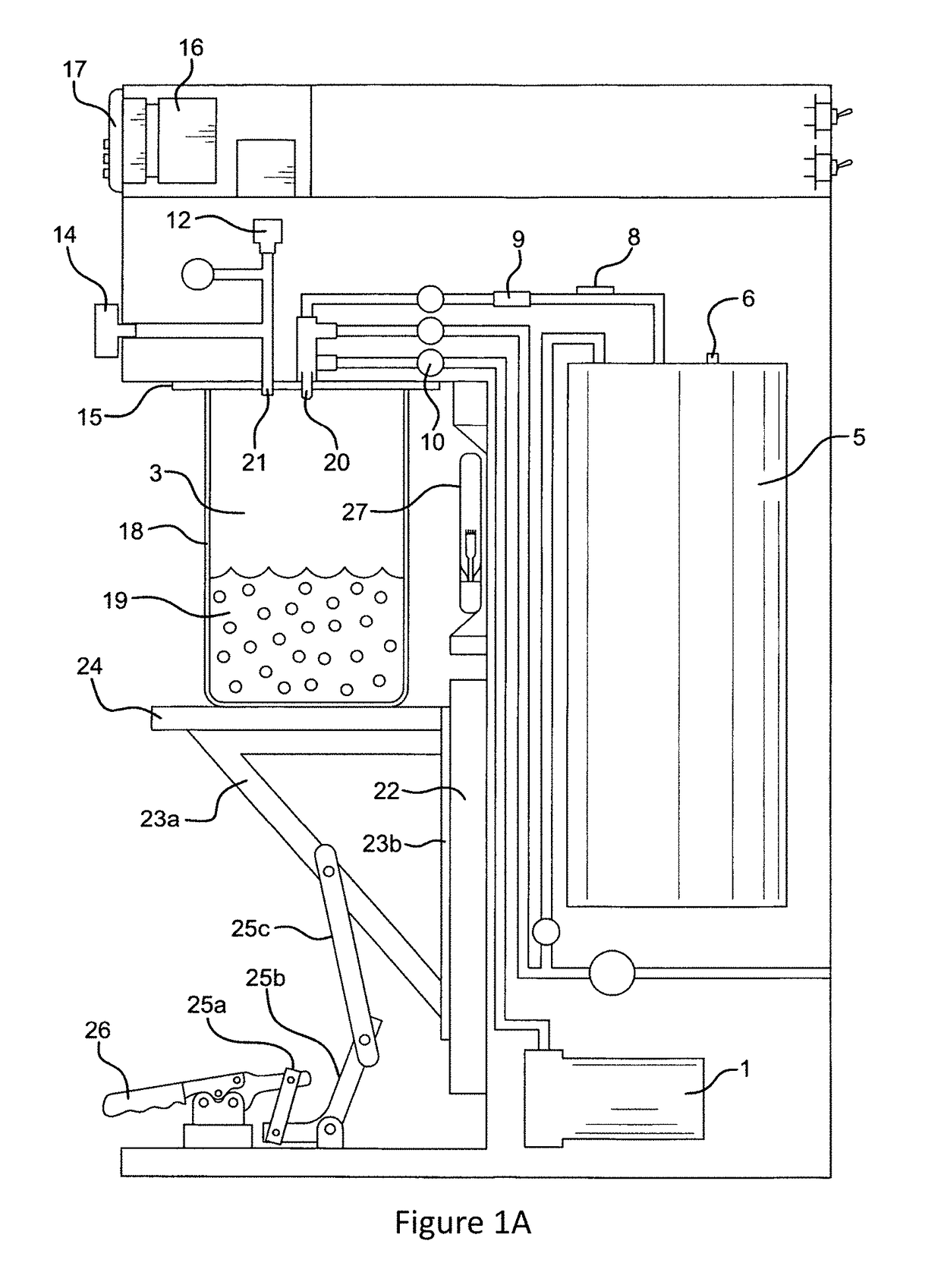

Sterilization methods and apparatus are effective to achieve a 6-log reduction in CFUs of industry standard bacteria and bacterial spores, i.e., B. stearothermophilus and B. subtilis spores, by subjecting sterilizable materials to a chemical additive-containing carbon dioxide sterilant fluid at or near its supercritical pressure and temperature conditions. Most preferably, the chemical additive-containing supercritical carbon dioxide sterilant fluid is agitated during sterilization, e.g., via mechanical agitation or via pressure cycling.

Owner:NOVASTERILIS

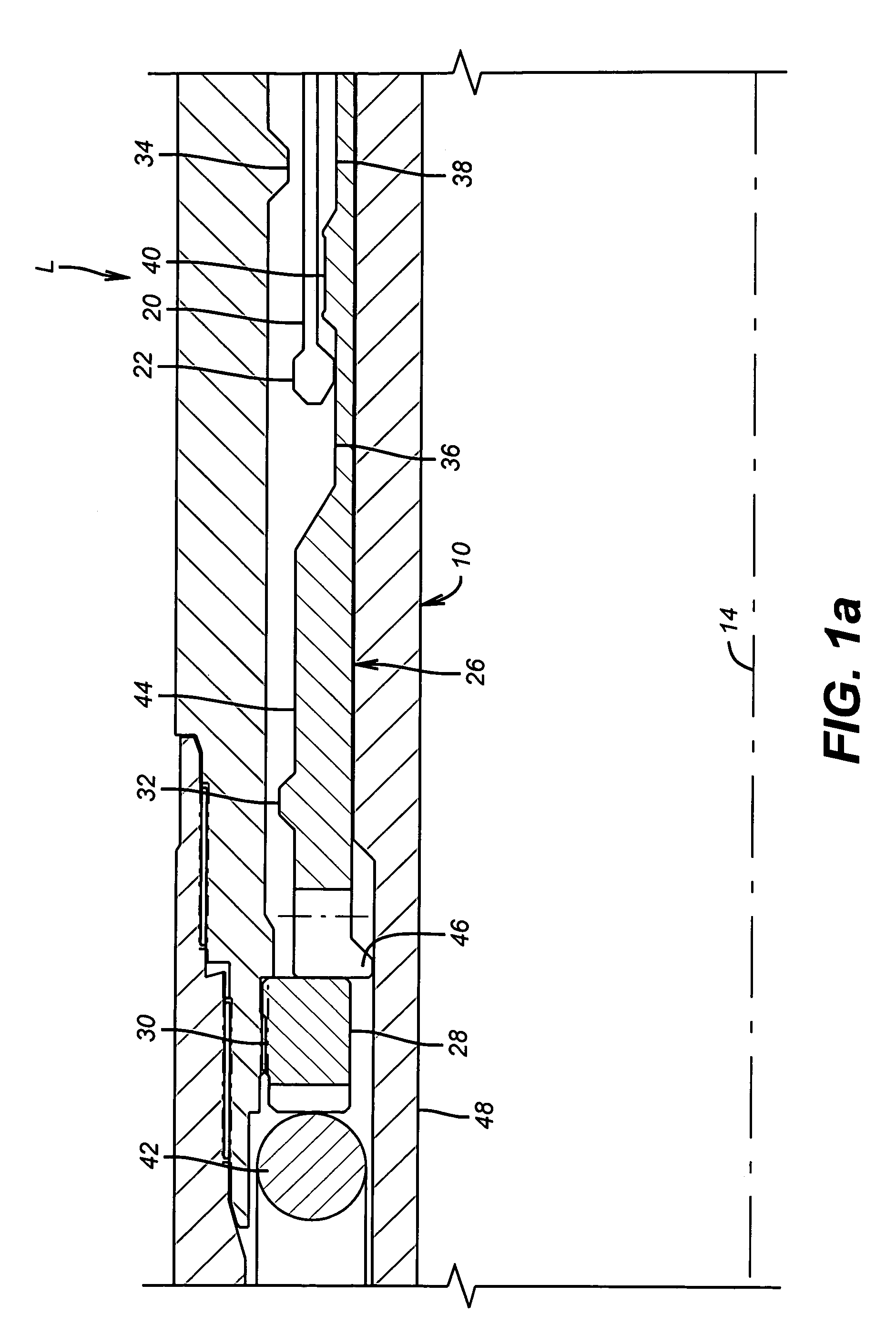

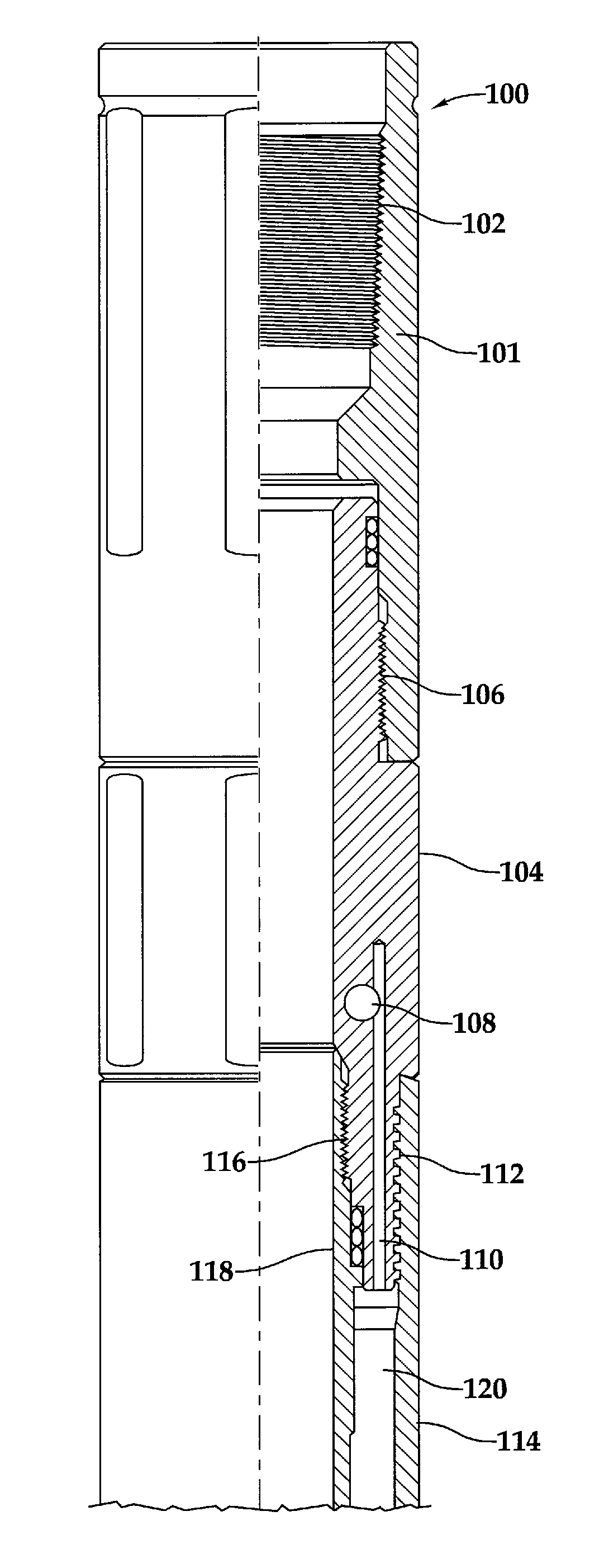

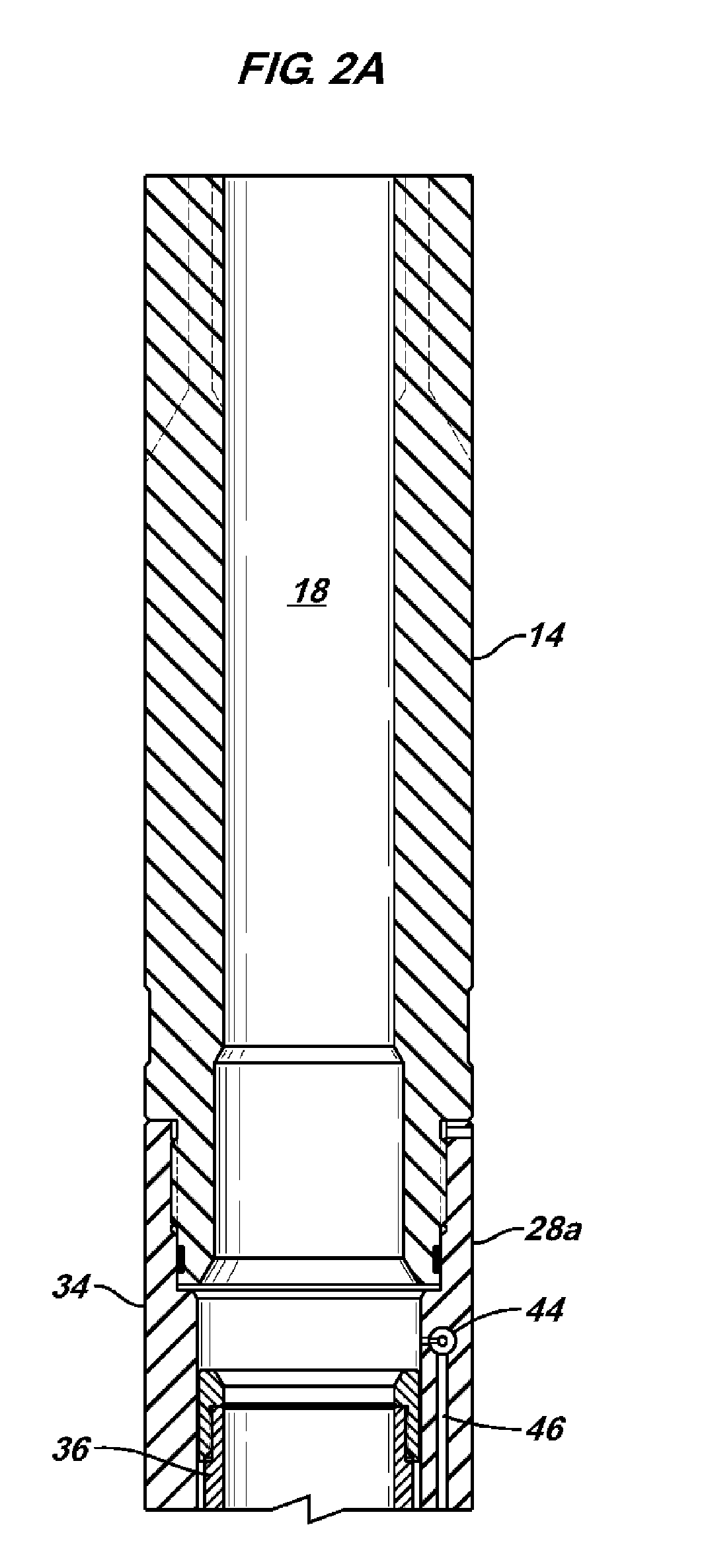

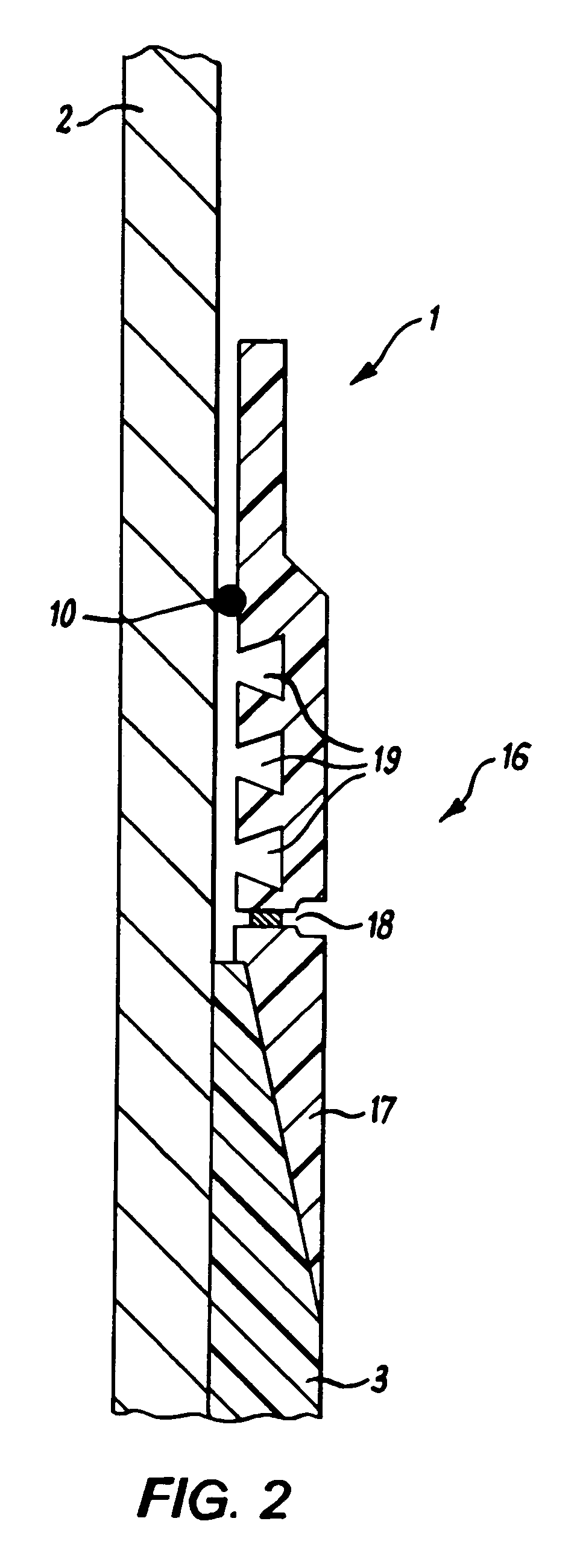

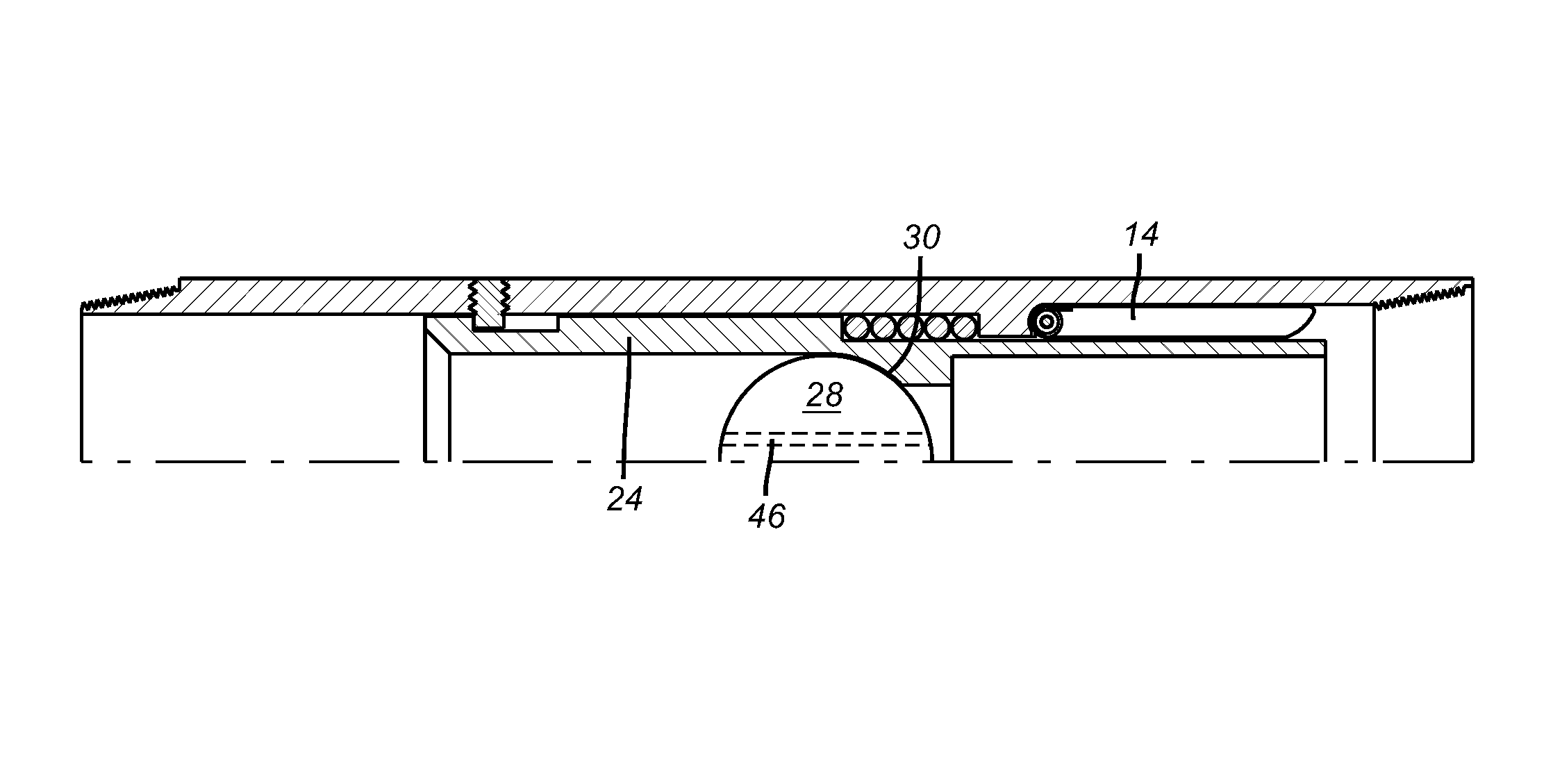

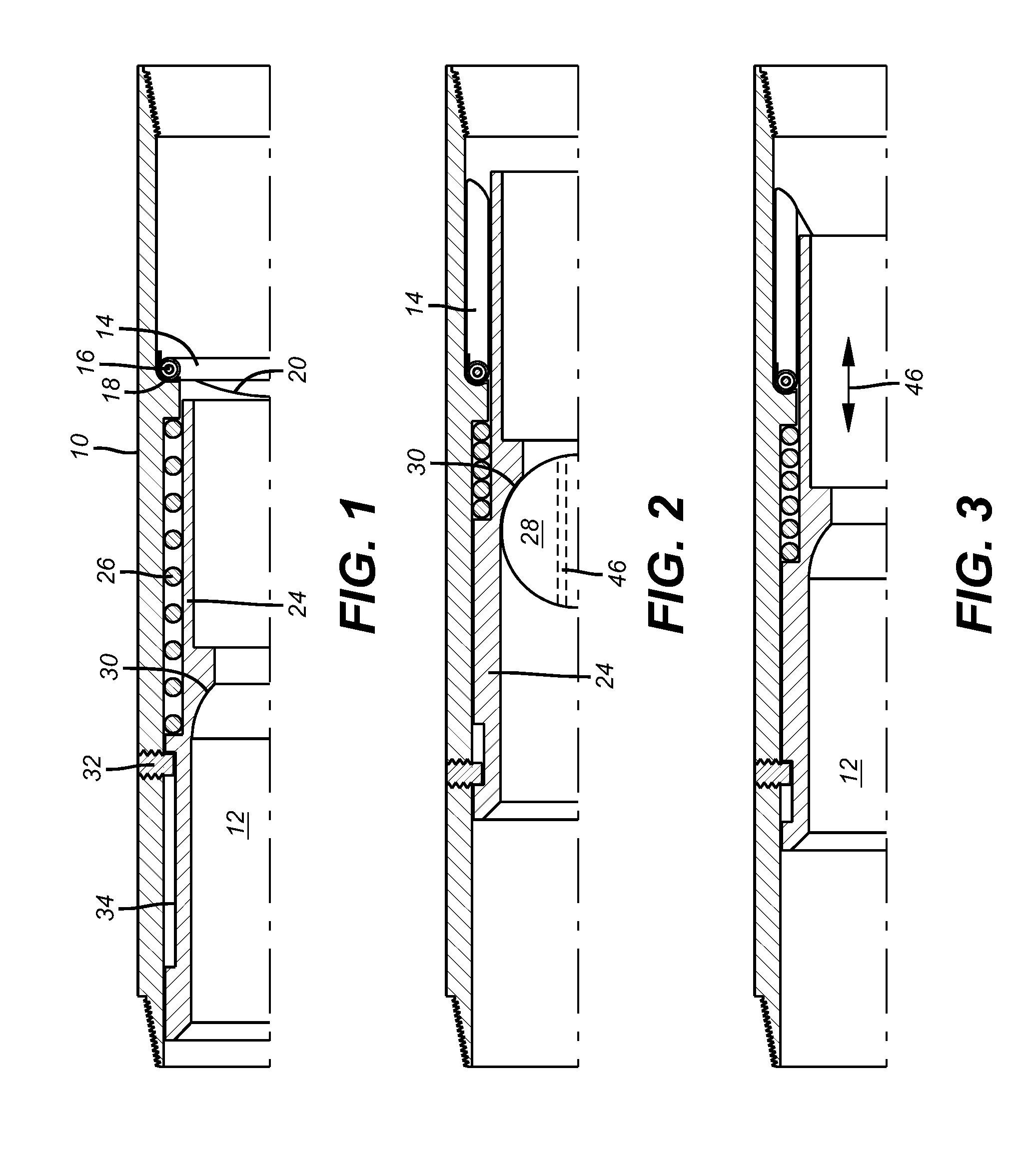

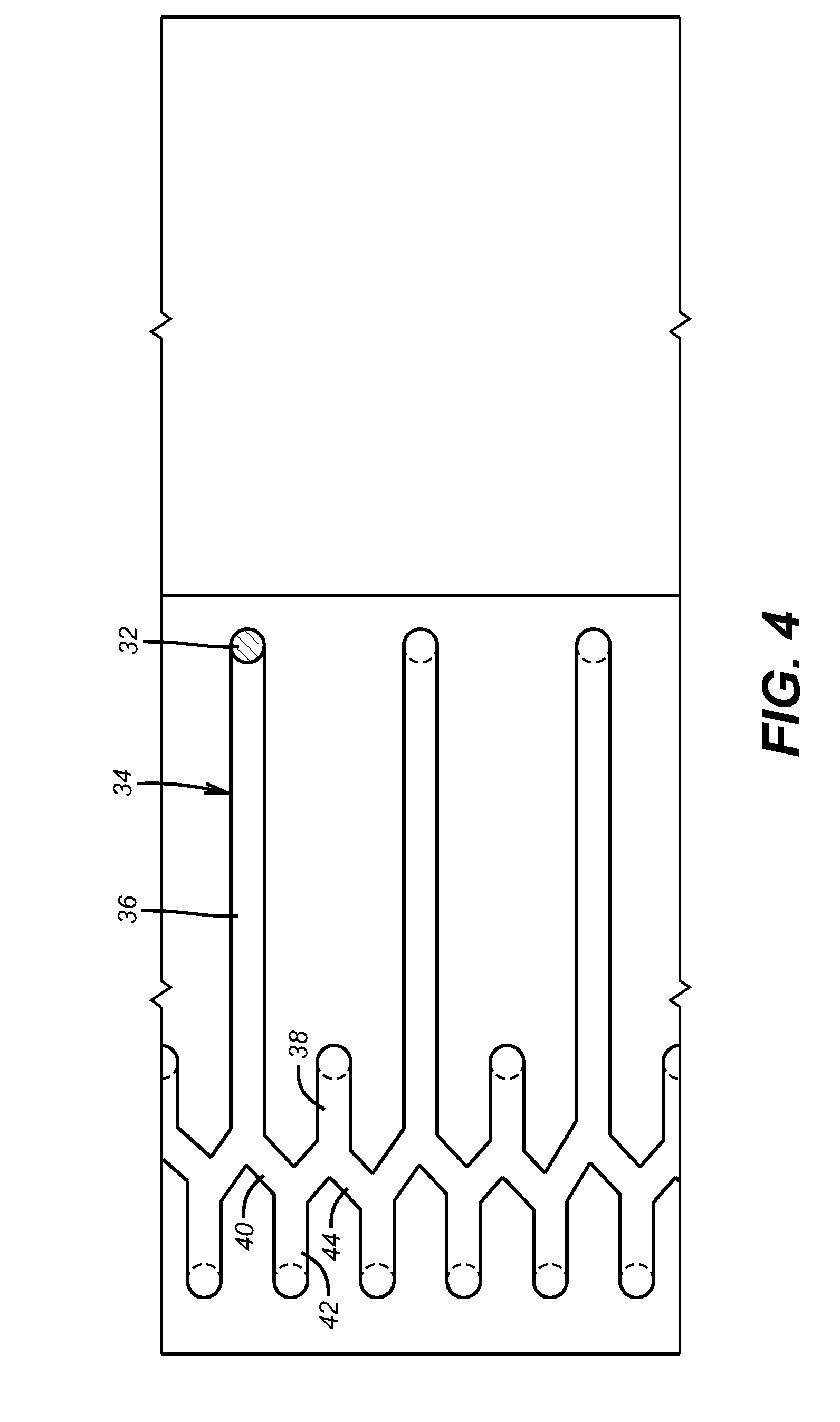

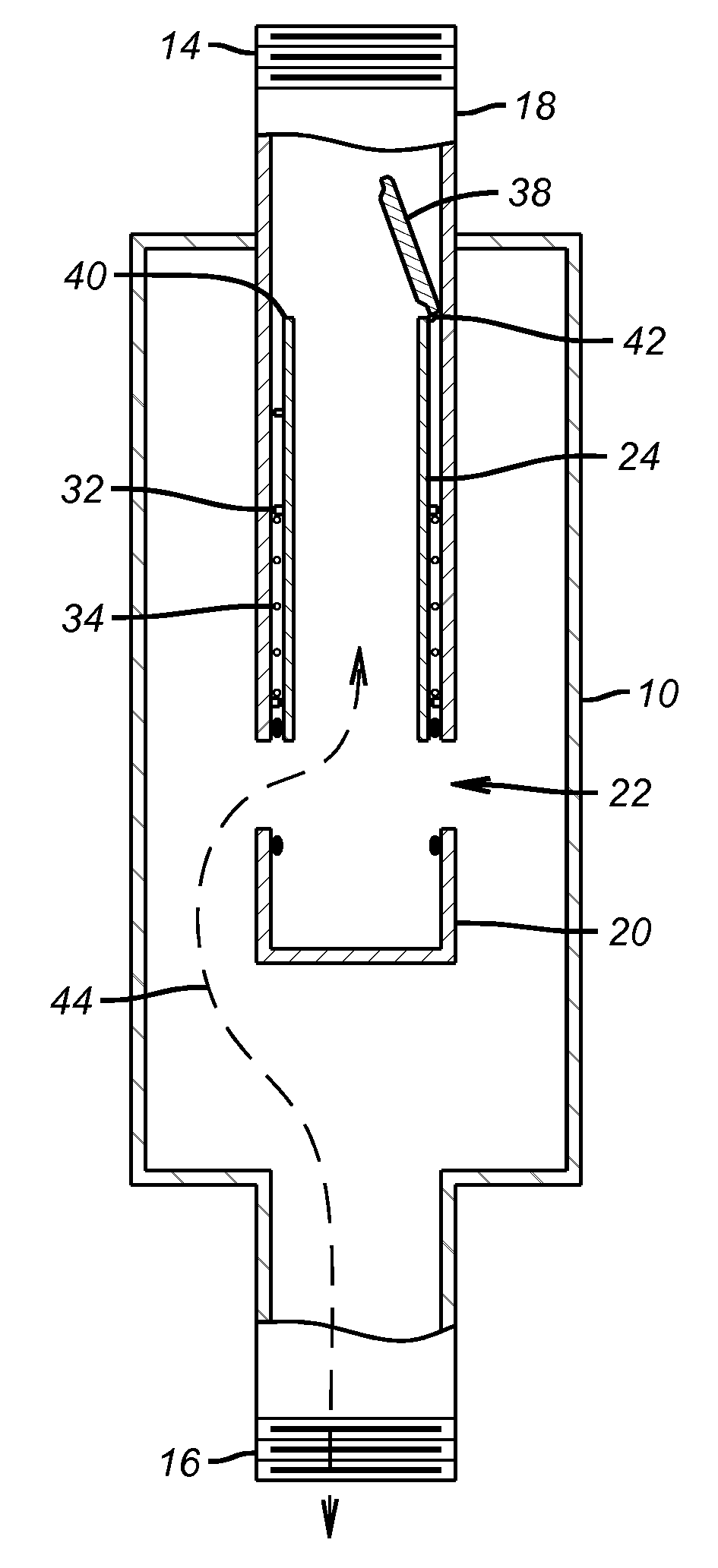

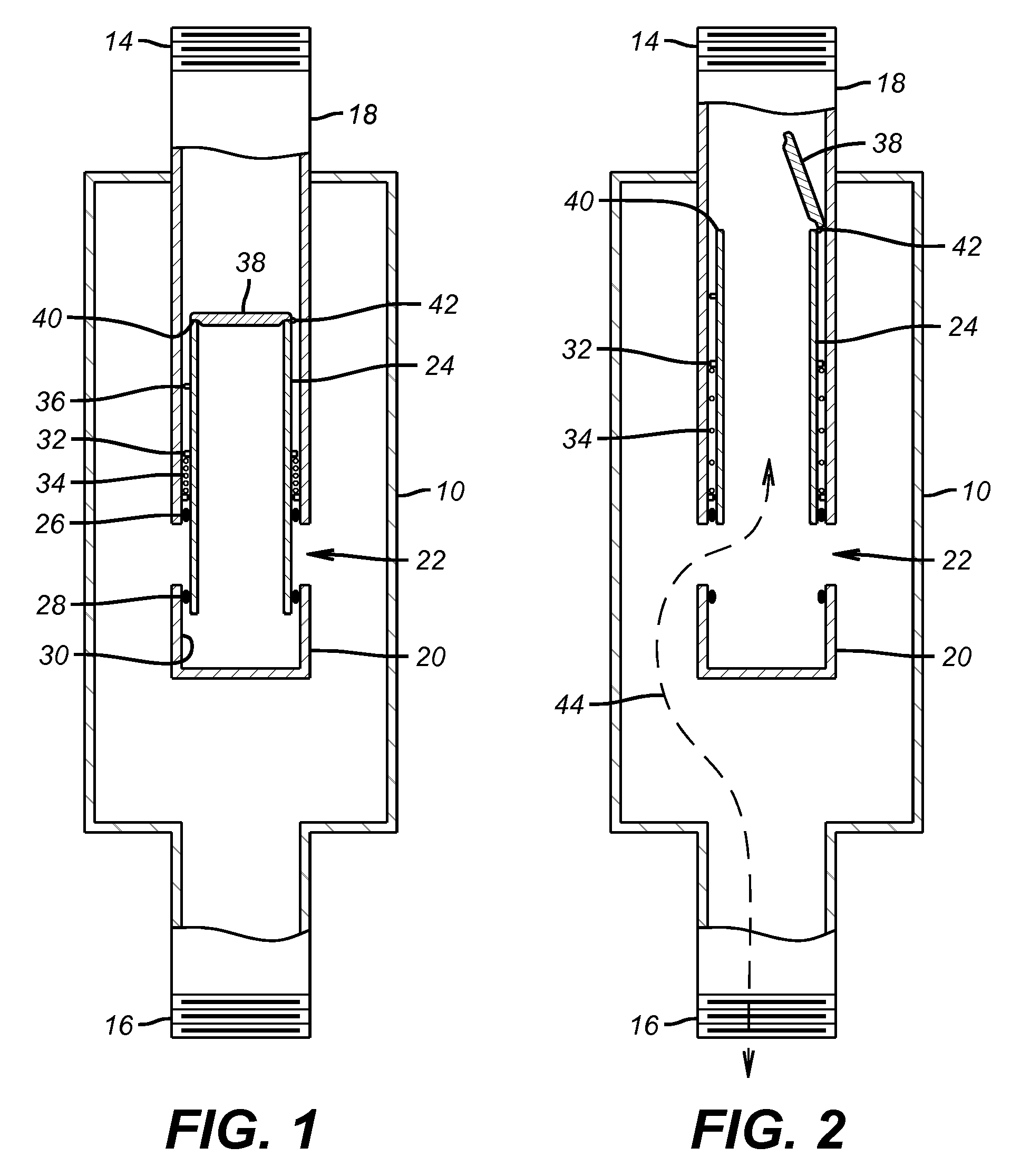

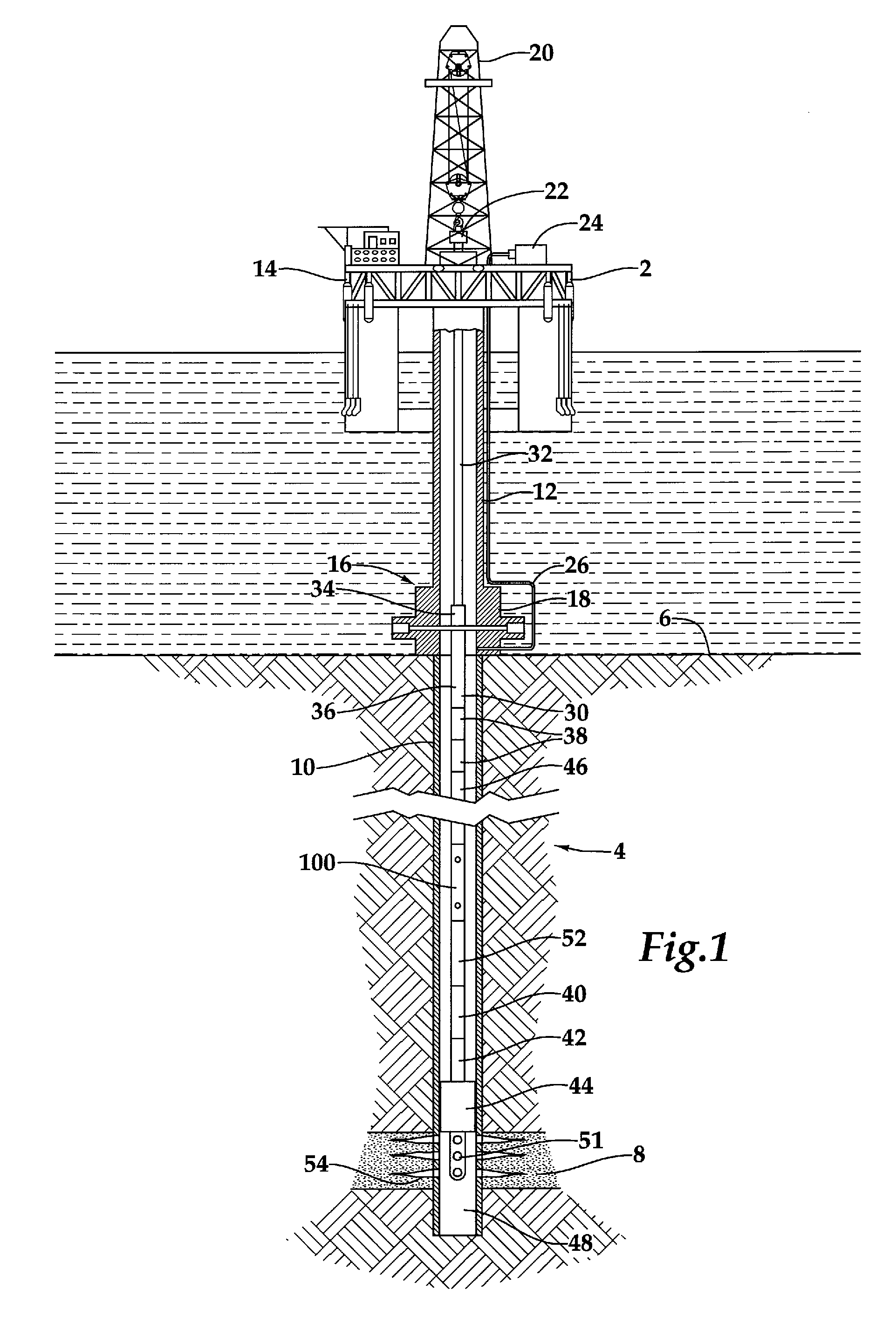

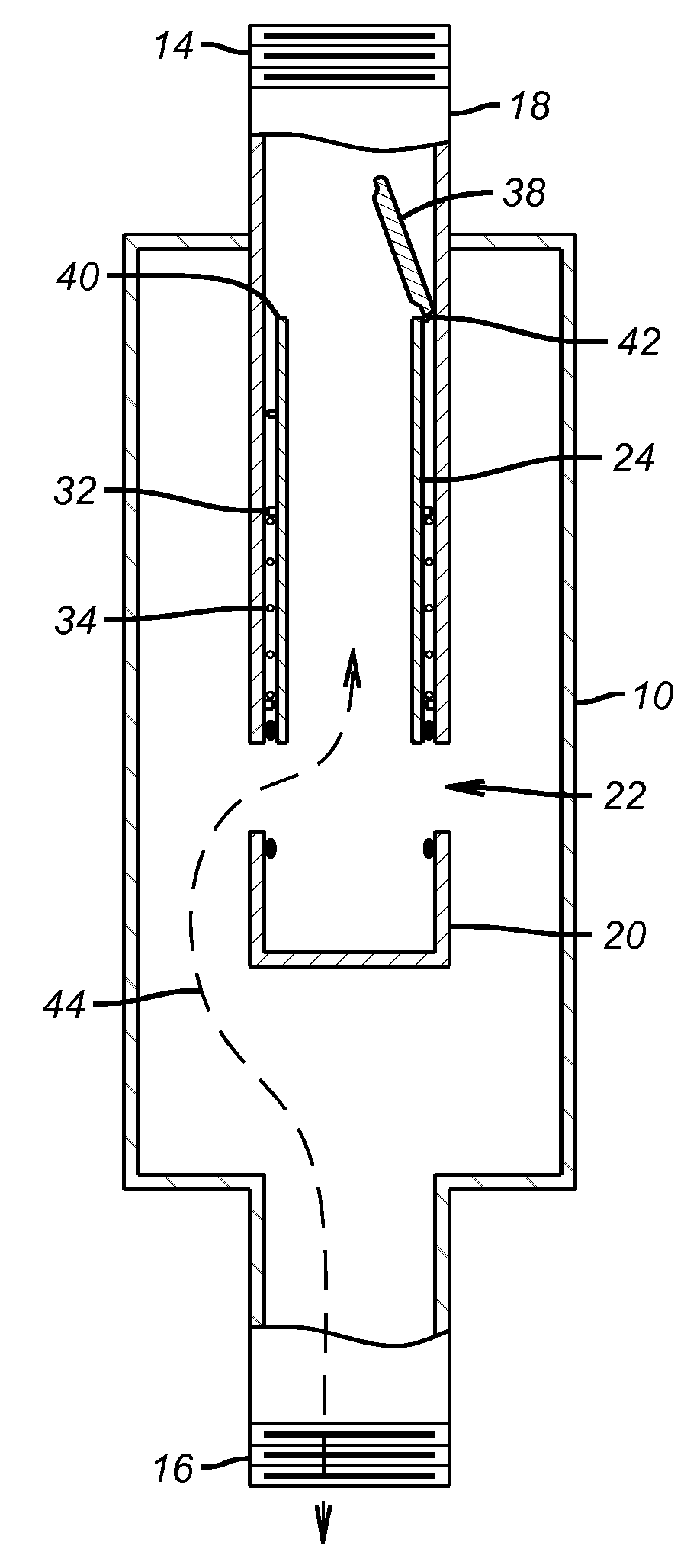

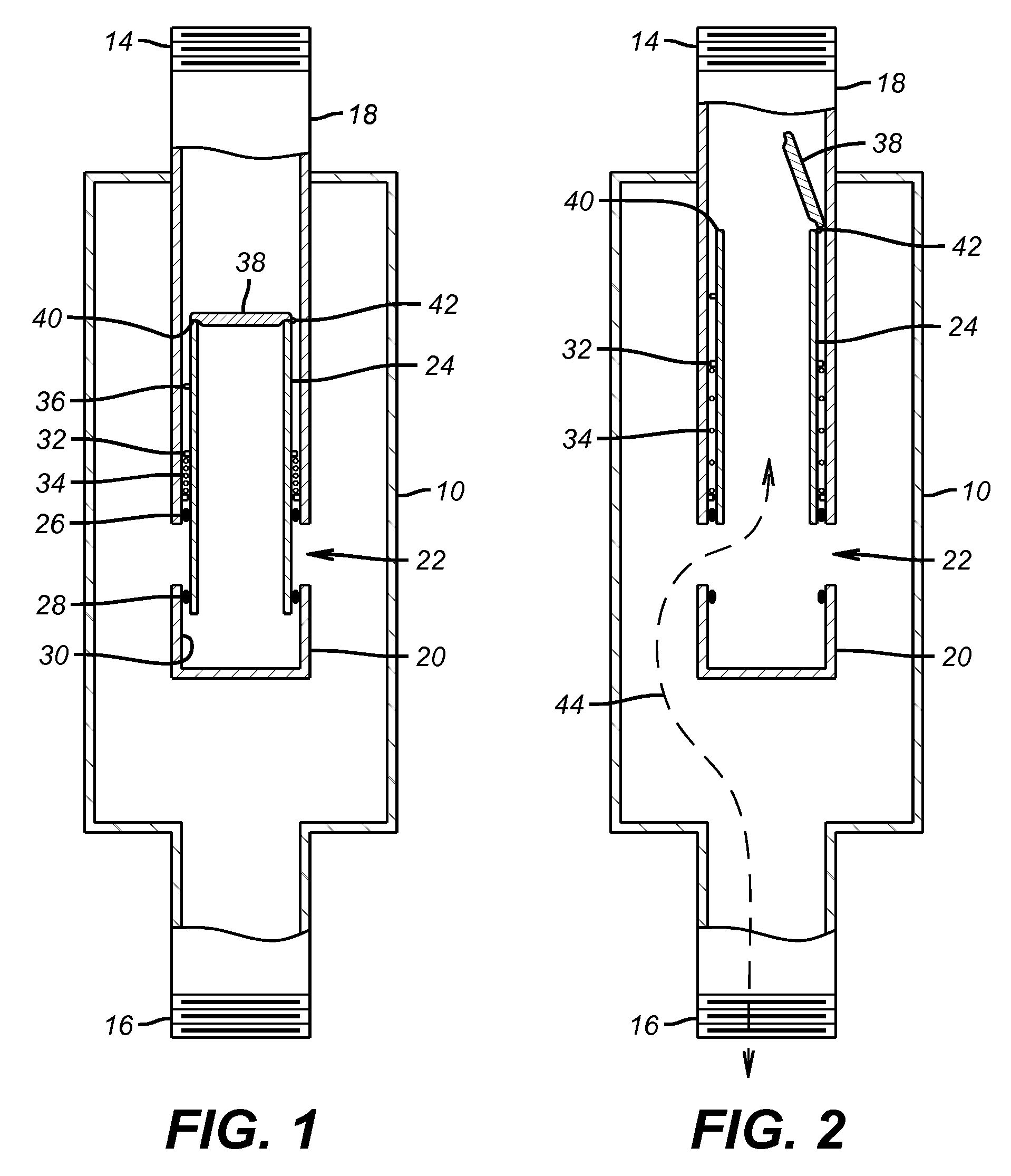

Injection Valve with Indexing Mechanism

A flapper valve preferably used in injection application in deep subterranean locations has an actuating sleeve with a seat to accept an object. A j-slot connects the actuation sleeve movement to the housing so that with an object on the seat and an applied pressure cycle the sleeve moves the flapper to the open position. The plug is dissolved and the injection begins. The plug can have an opening so as to allow continuous injection flow as the flapper is operated. Closing the flapper involves a second object on the same seat and a pressure cycle so that a spring can push the sleeve away from the flapper to allow a torsion spring on the flapper to close it.

Owner:BAKER HUGHES INC

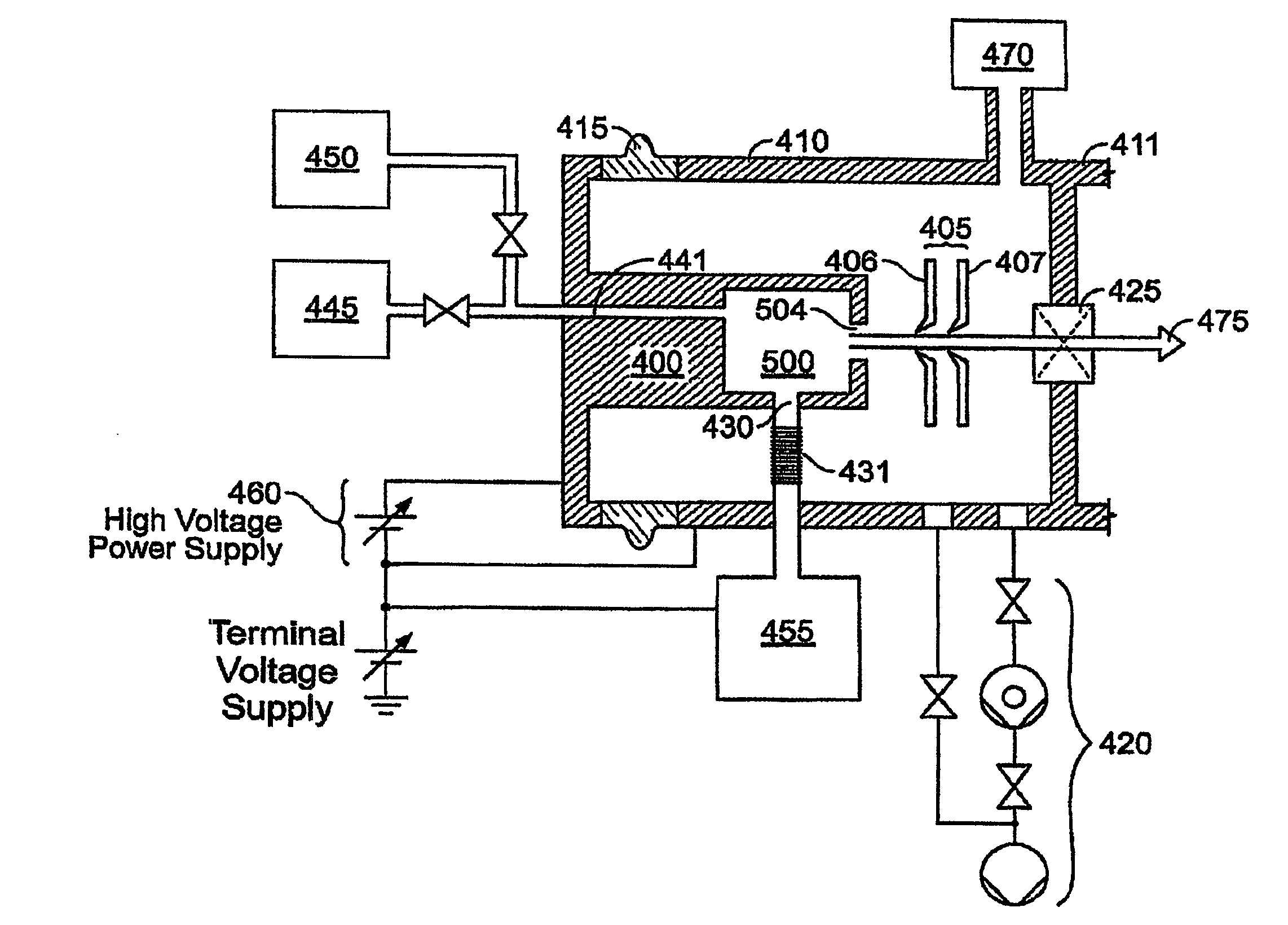

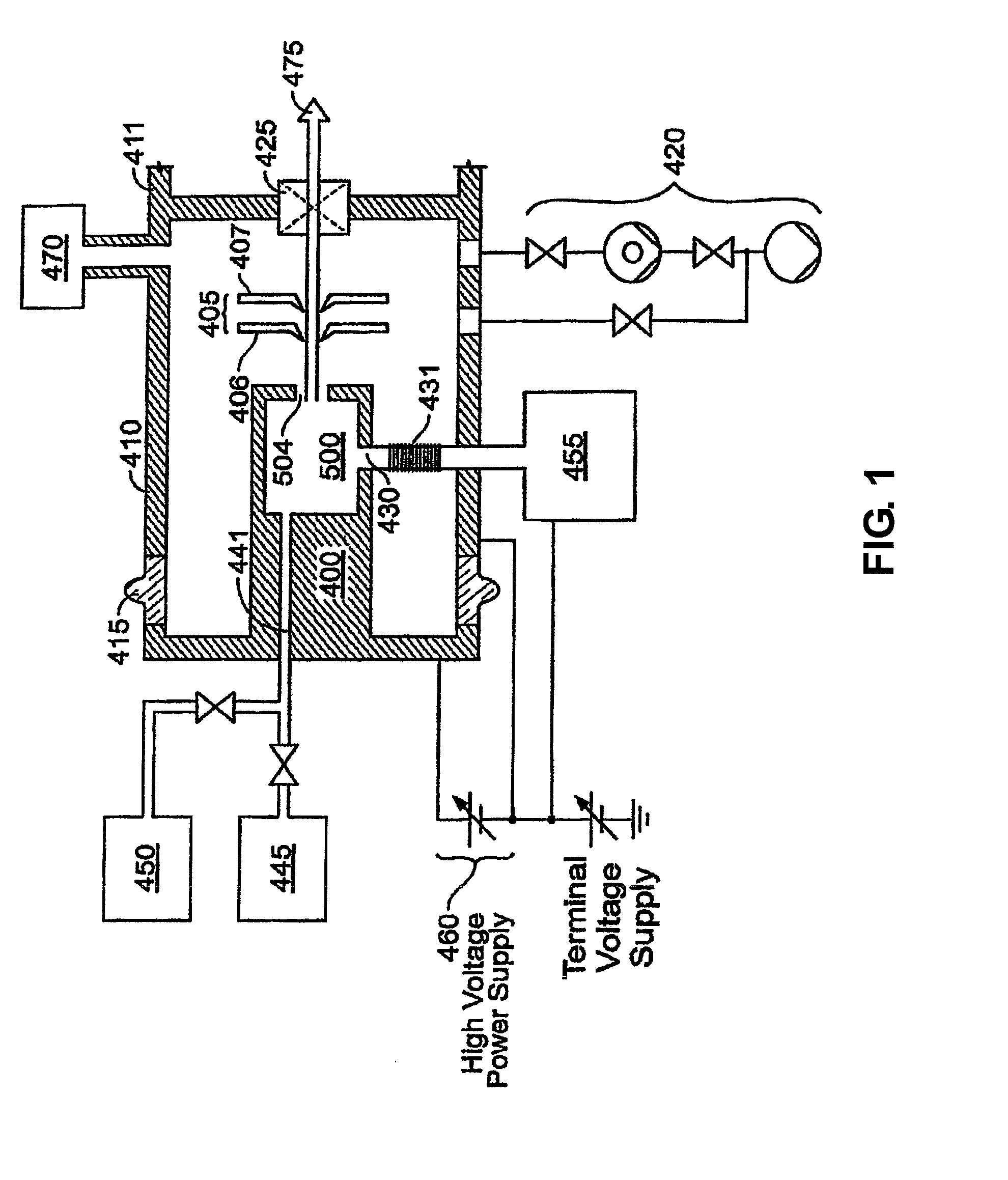

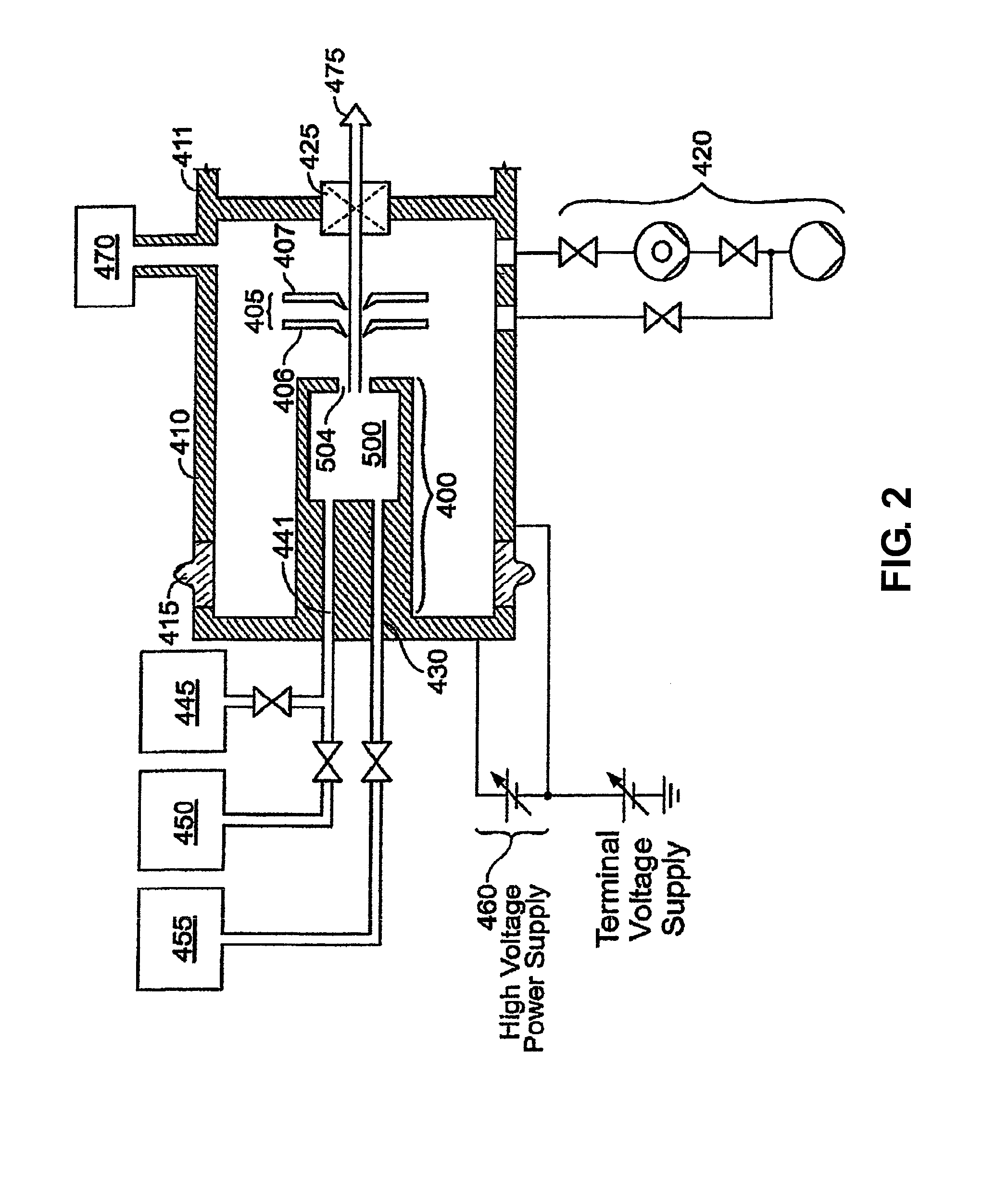

Method and apparatus for extending equipment uptime in ion implantation

InactiveUS20080223409A1Increasing effective reaction rateReduce pressureElectric discharge tubesHollow article cleaningPressure cycleReaction rate

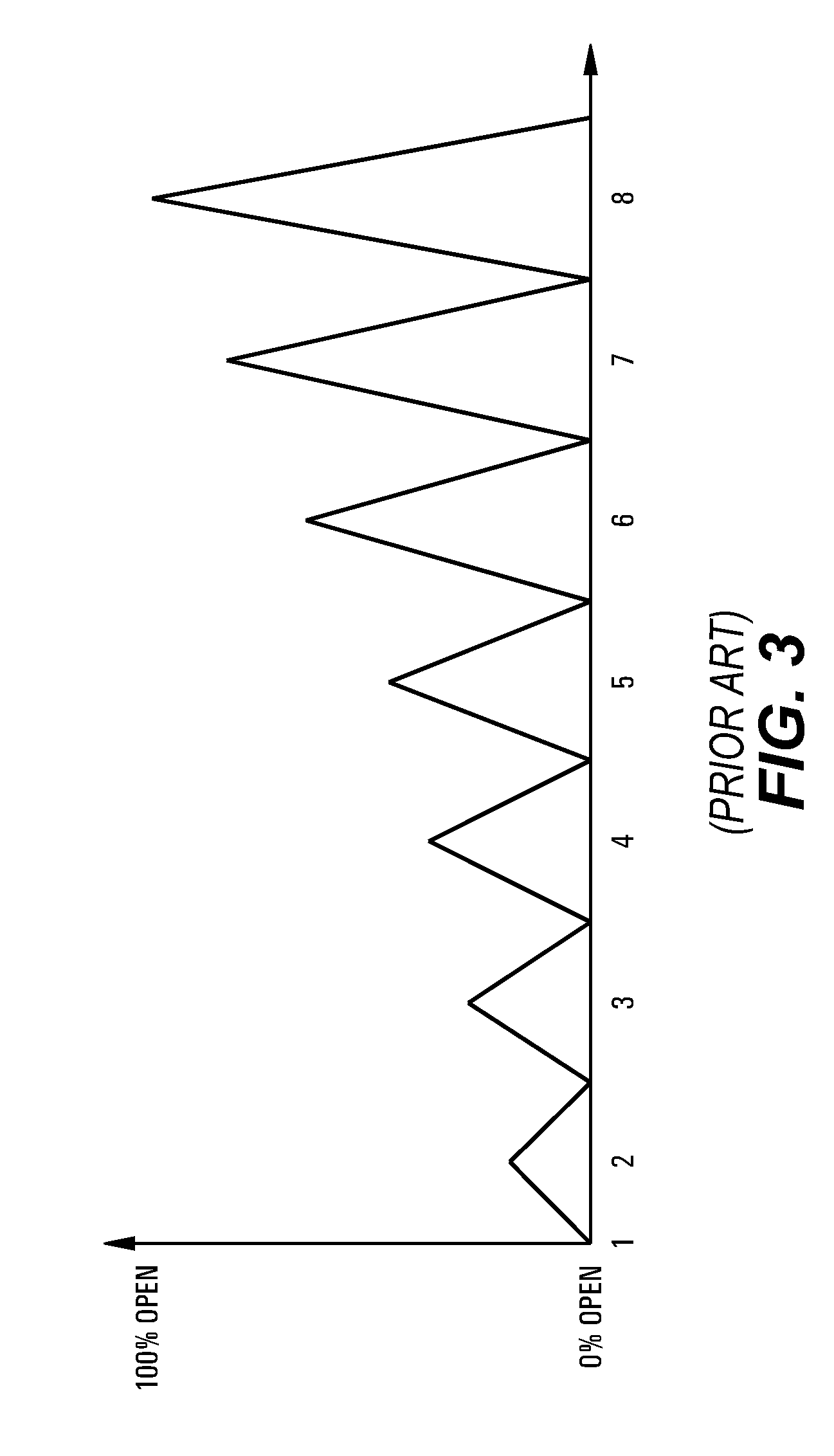

An in situ cleaning system is disclosed for use with semiconductor processing equipment. In accordance with an important aspect of the invention, the cleaning system provides for dynamic cleaning of the semiconductor processing system by varying the pressure of the cleaning gas over time during a cleaning cycle. In particular, the cleaning gas is applied to the semiconductor processing system in repeated pressure cycles. Each pressure cycle begins with the pressure of the cleaning gas at PMIN. The pressure of the cleaning gas is increased to a maximum pressure PMAX during a fill portion of the pressure cycle and maintained for a dwell time selected to allow the available reactants to generate the desired end products. The pressure in the chamber to be cleaned is then reduced during a vent portion of the pressure cycle to permit venting of the reaction products. As such, each time the chamber to be filled is vented and re-filled, reaction products are removed and new reactants are introduced into the chamber to be cleaned, increasing the effective reaction rate.

Owner:SEMEQUIP

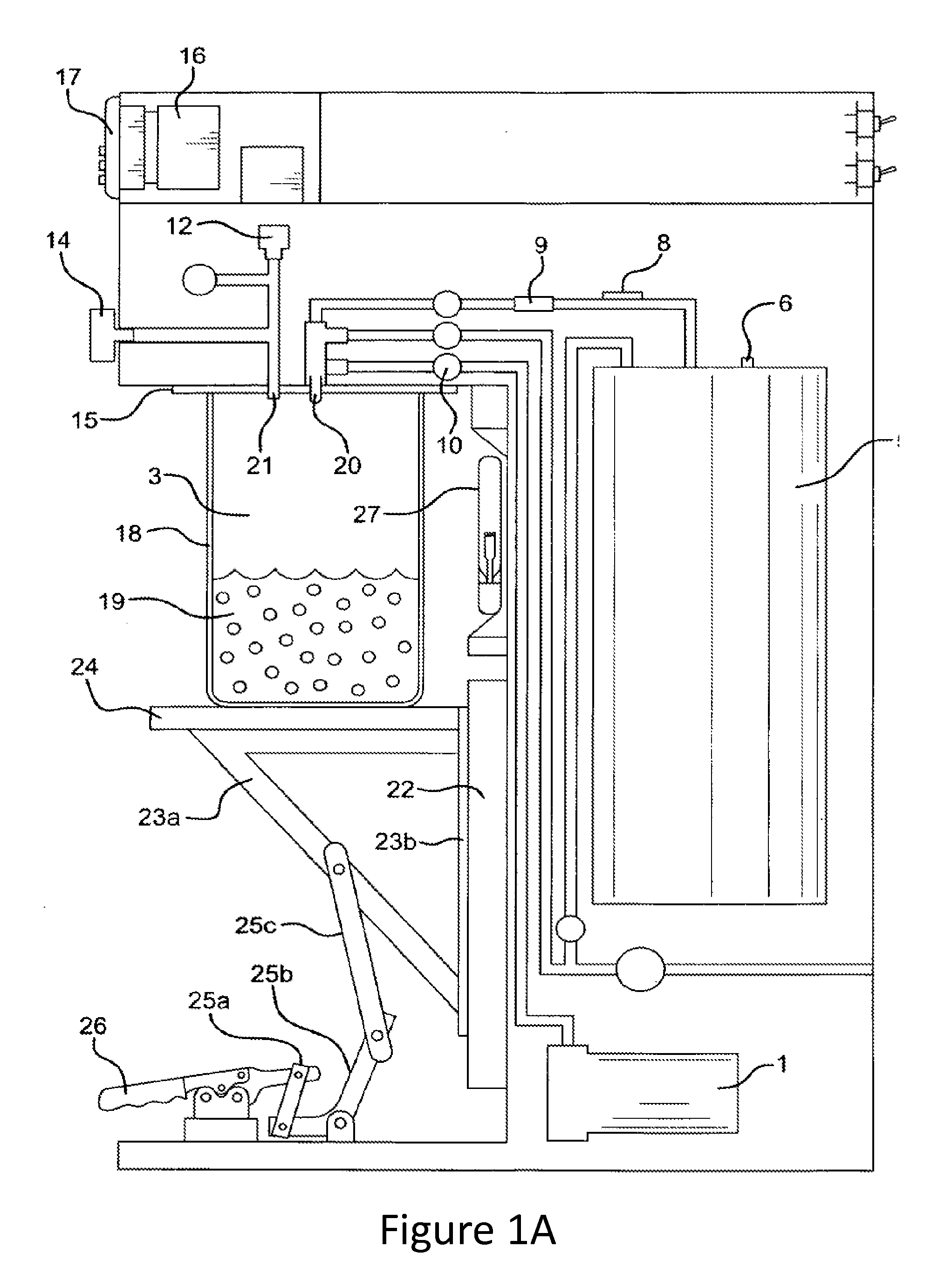

Liquid infusion process and method of brewing a beverage

ActiveUS8586117B2Enhance stirringIncrease ratingsTea extractionTea substituesPressure cycleEngineering

A liquid infusion and / or brewing process is described. The process includes the steps of placing a desired amount of an infusion material into a chamber at atmospheric pressure, placing a desired amount of liquid into said chamber, sealing said chamber from the surrounding atmosphere, and applying at least one reduced pressure cycle within said chamber, wherein said at least one cycle includes reducing pressure within said chamber to form at least a partial vacuum within said chamber and subsequently returning said chamber to about atmospheric pressure. Methods for separating the brewing media from the liquid after completion of the brewing process are also described.

Owner:BKON

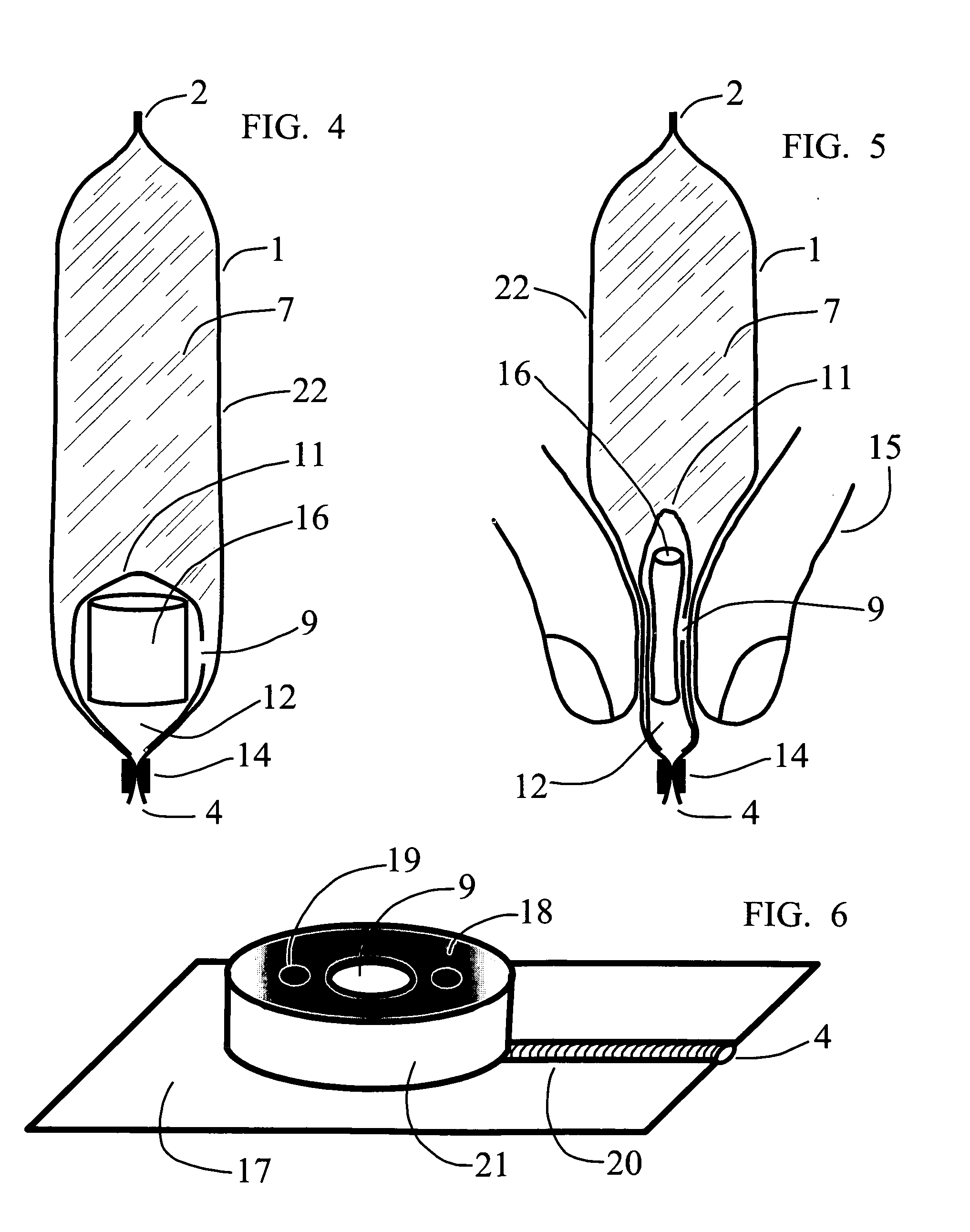

Fluid dispenser with internal pump

A hand operated fluid dispensers comprised of a sealed flexible reservoir chamber containing a fluid, a flexible pump chamber encased by and drawing fluid from the reservoir, and a pump cycled by external pressure applied through a reservoir wall. This class of simple, inexpensive, disposable dispensers is particularly useful in packaging cosmetics, foodstuffs, and healthcare products. As pocketable dispensers they are popular for dispensing small amounts of stored viscous liquids easily damaged when exposure to the atmosphere, a condition where sealed reservoirs coupled with airless pumps working together successfully prevent such product contamination and deterioration. A method of improved healthcare employing such pump dispensers containing a hand sanitizing fluid is also discussed.

Owner:PENNCREEK

Oxygen enrichment of indoor human environments

InactiveUS6866701B2Reduce concentrationIncrease alertness and productivity and comfort and overall wellDucting arrangementsMechanical apparatusWater useFiltration

This invention provides systems and methods of supplying oxygen-enriched air to an enclosed space or compartment. The systems and methods may distill oxygen from ambient air by a molecular sieve pressure cycle mechanism, such as a pressure swing absorption, may generate oxygen from water using electricity or may use oxygen enriched air produced by membrane filtration. The invention helps people improve their wellness, productivity and comfort, improve performance of mental and / or physical tasks, increase their alertness, quality of life and pleasure, reduce their drowsiness, and aid in curing and preventing disease by increasing the percentage of oxygen in the enclosed space to a beneficial and safe level.

Owner:ENVERID SYST

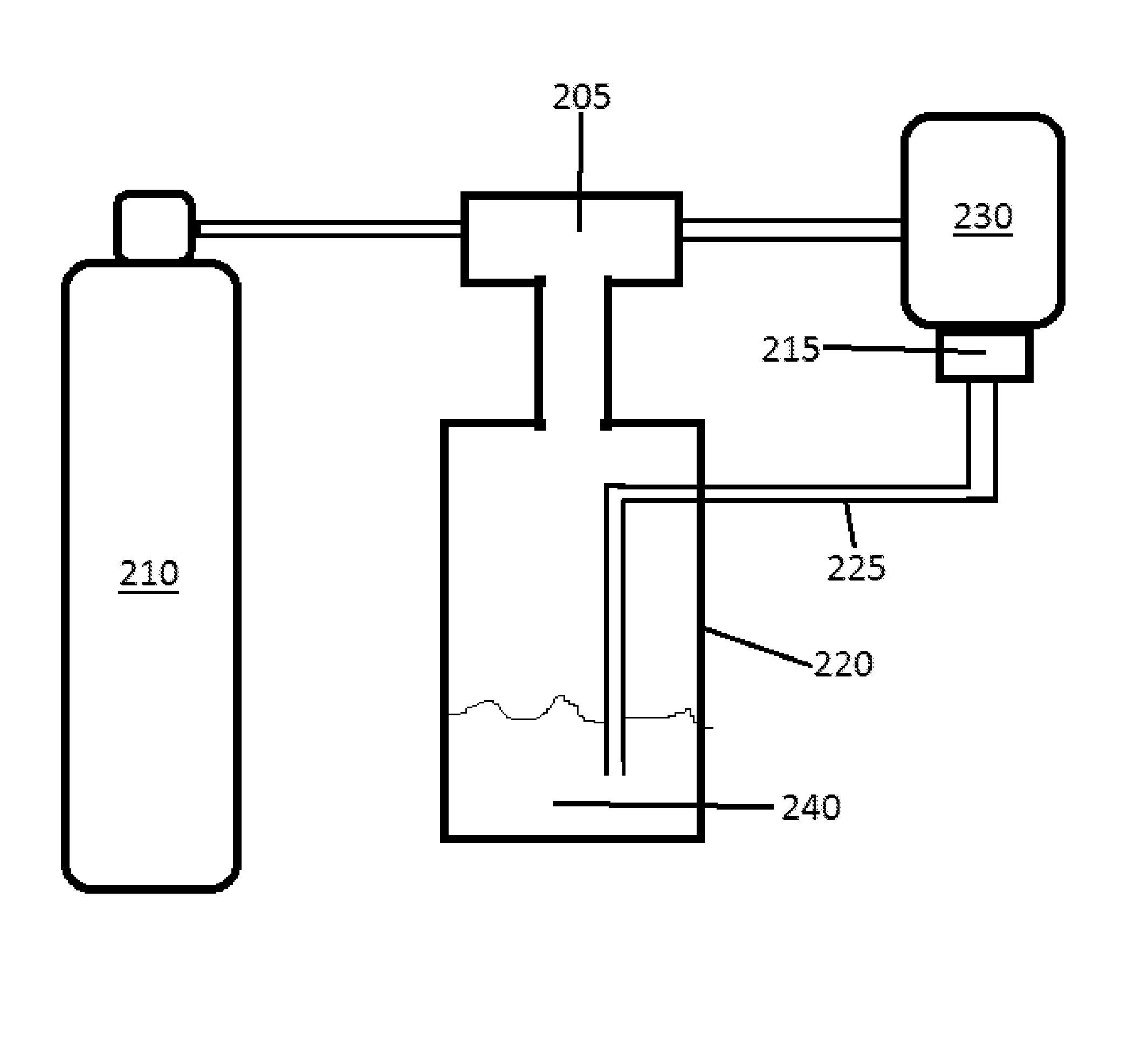

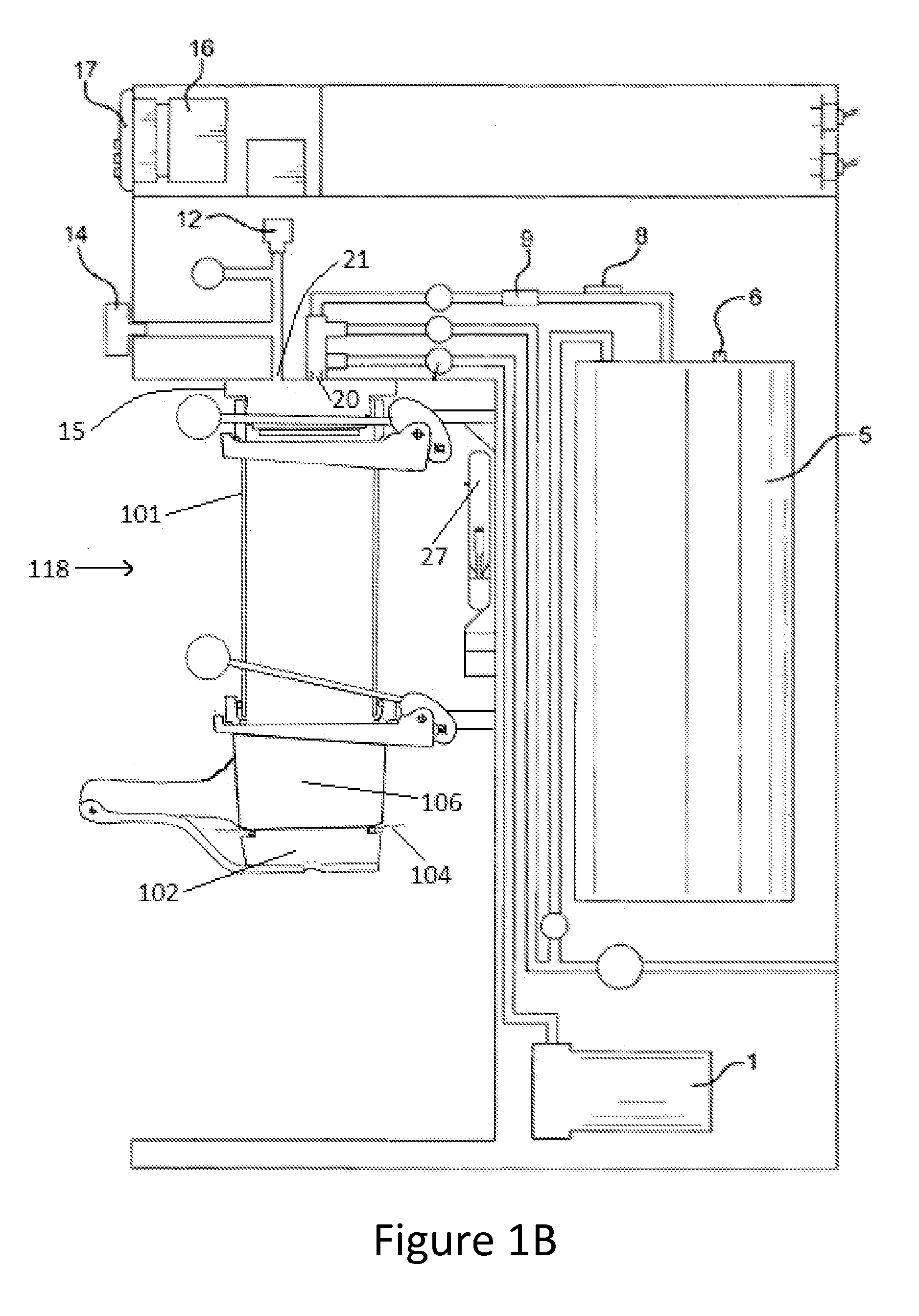

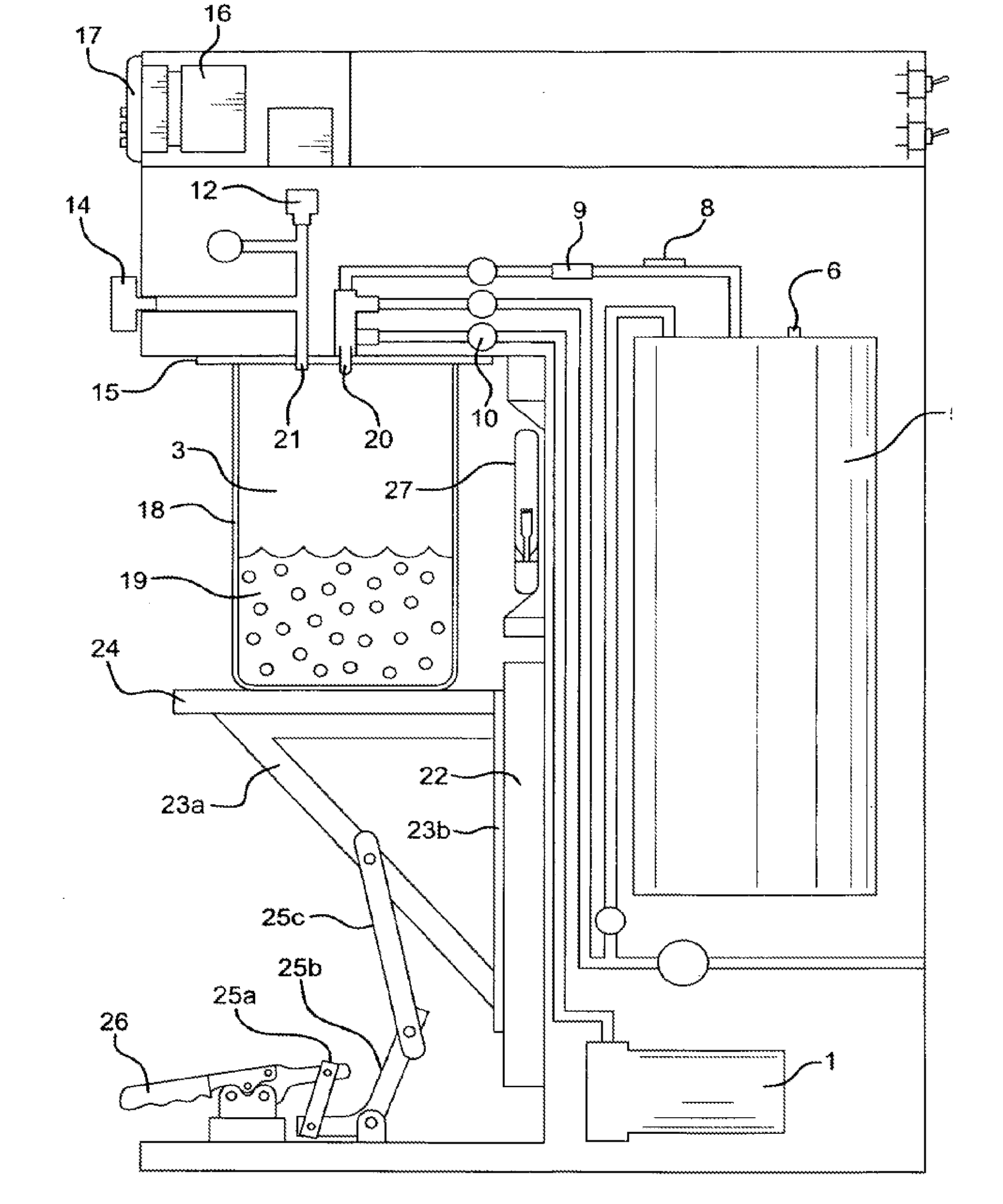

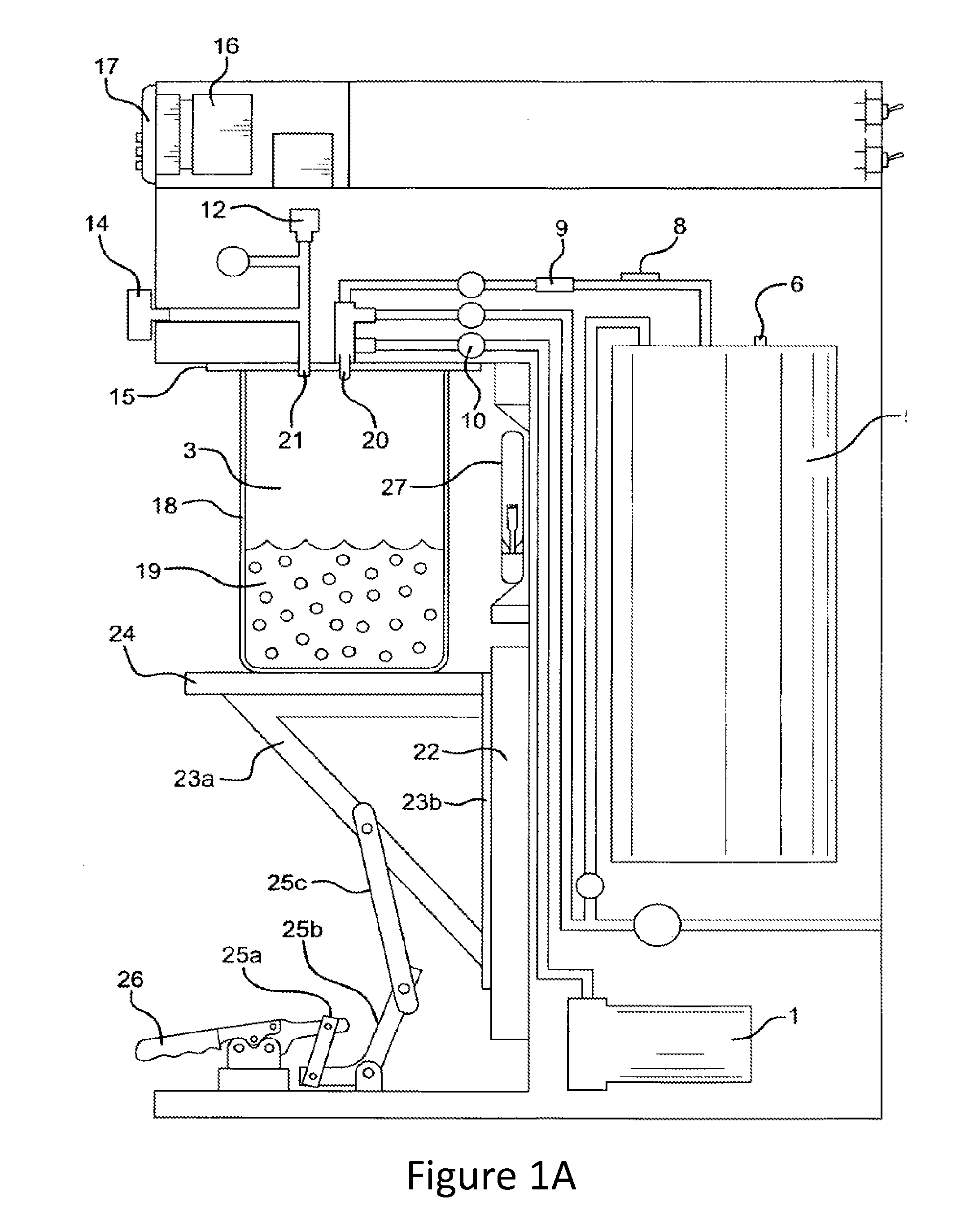

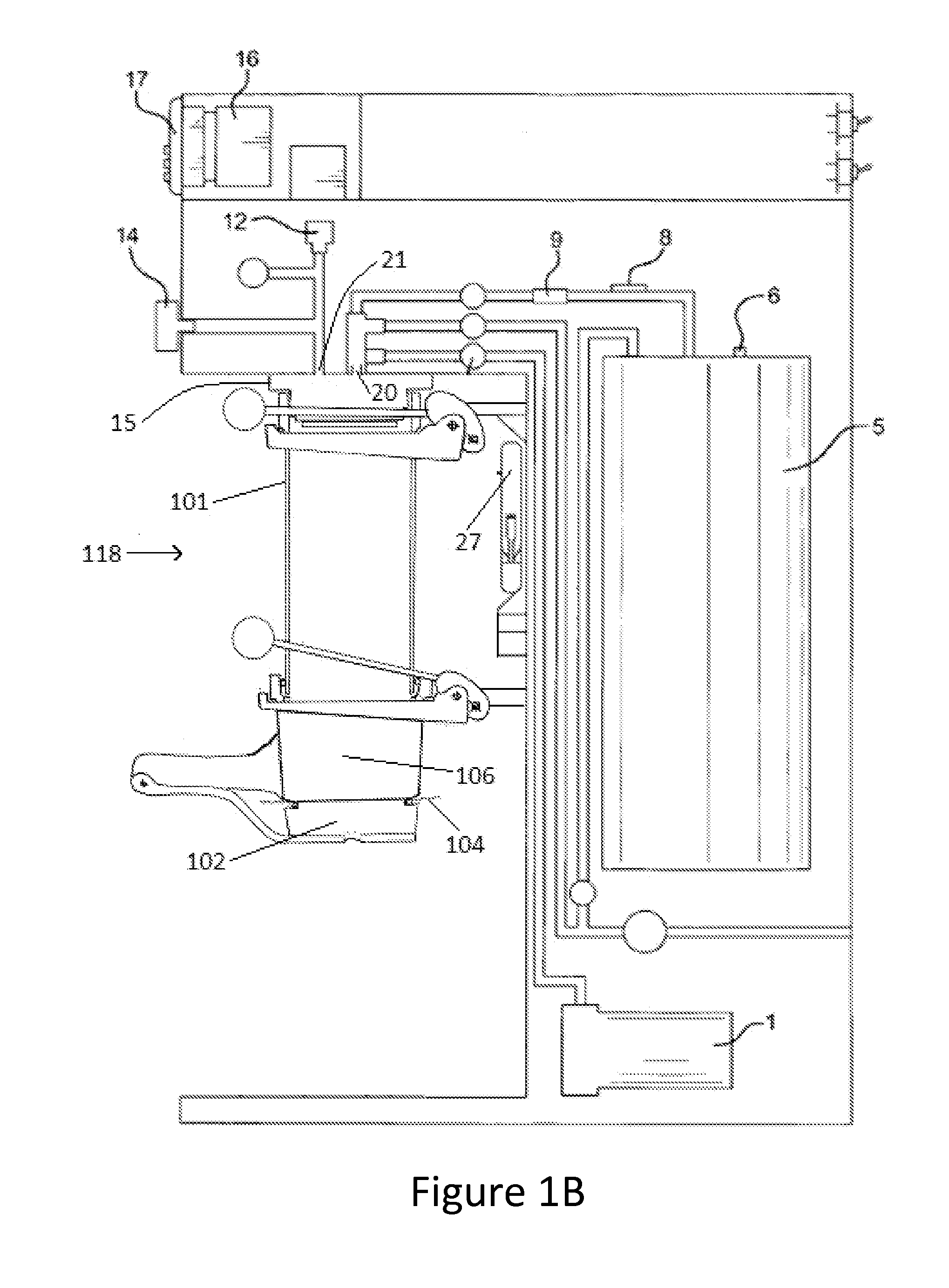

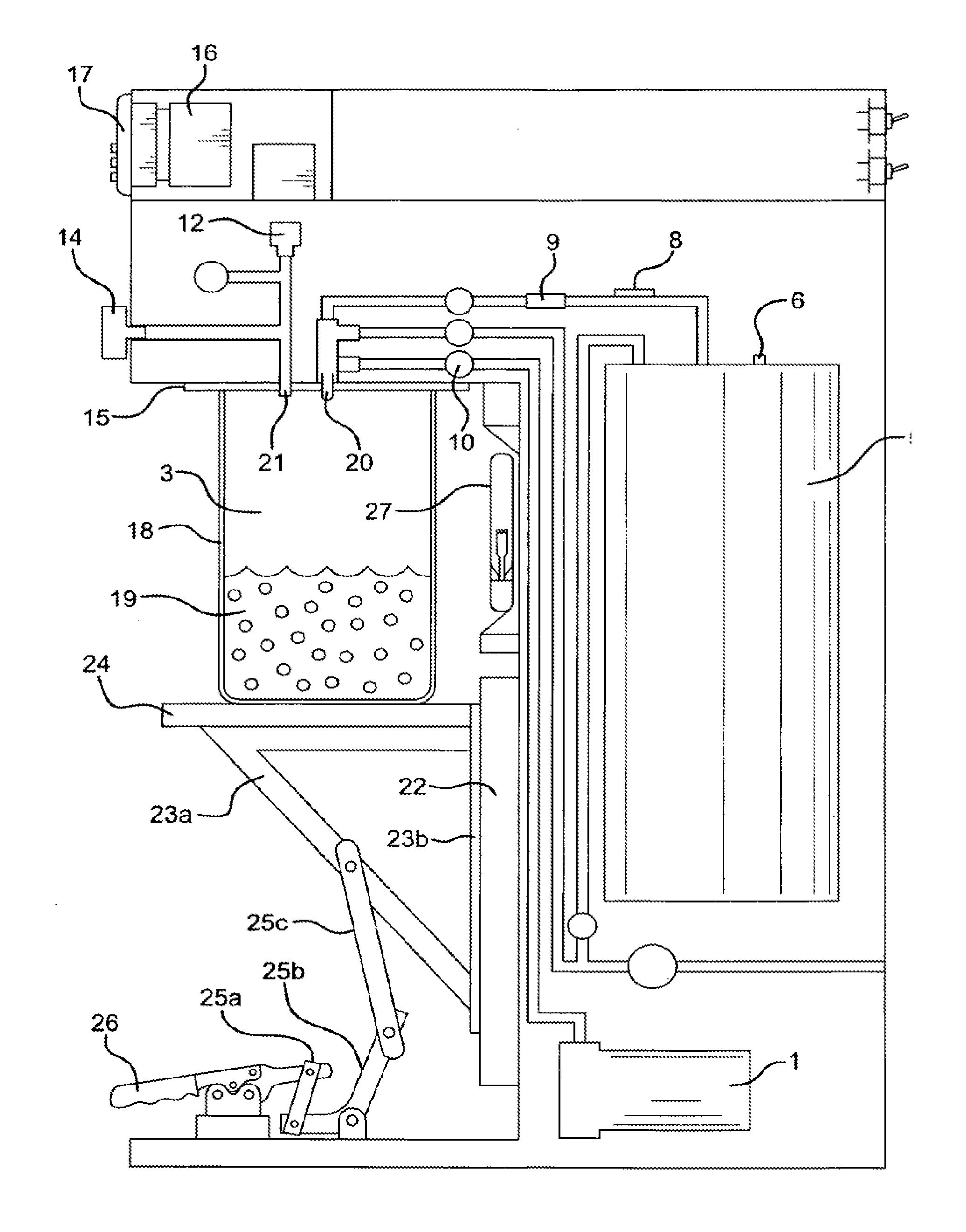

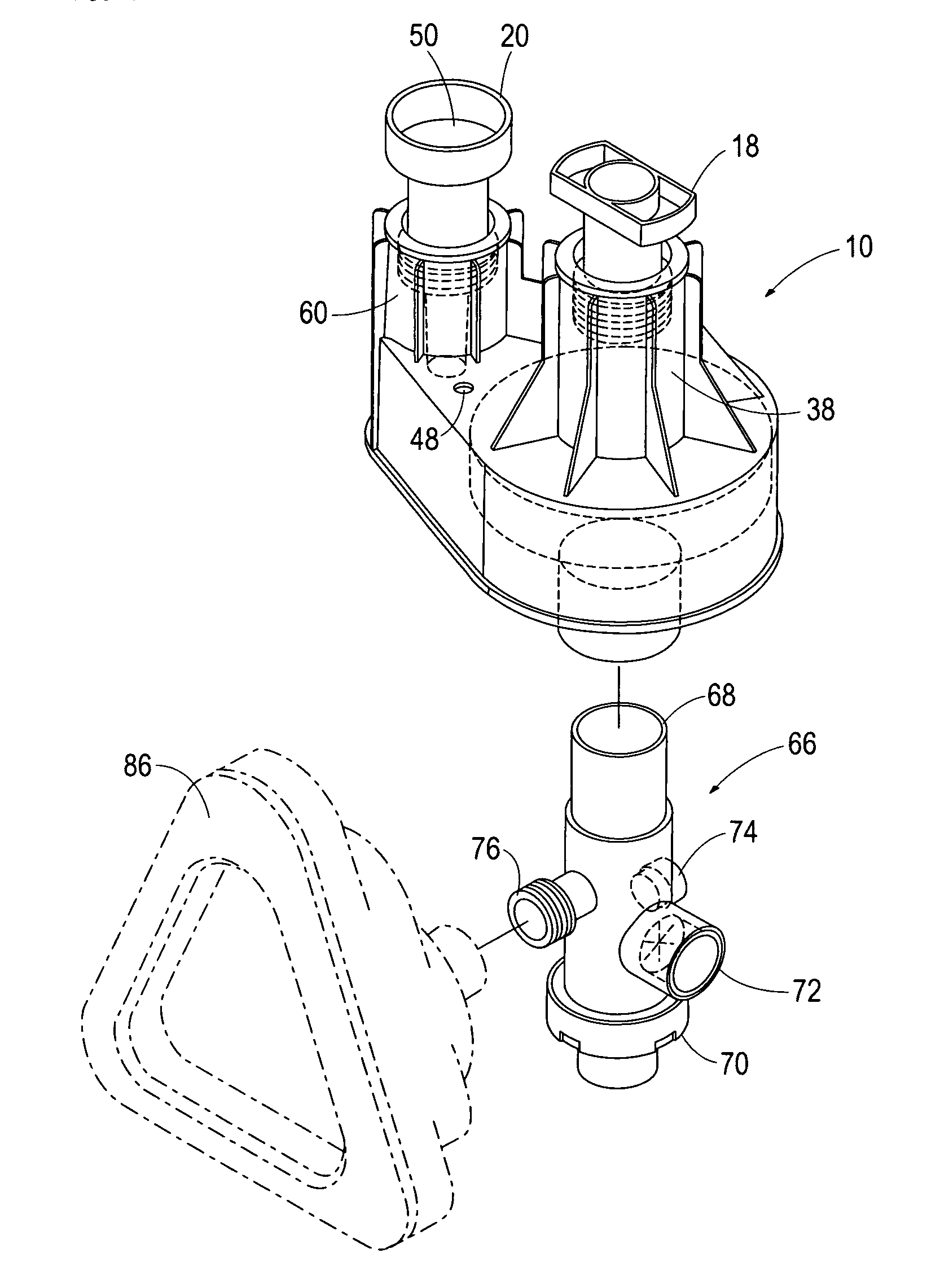

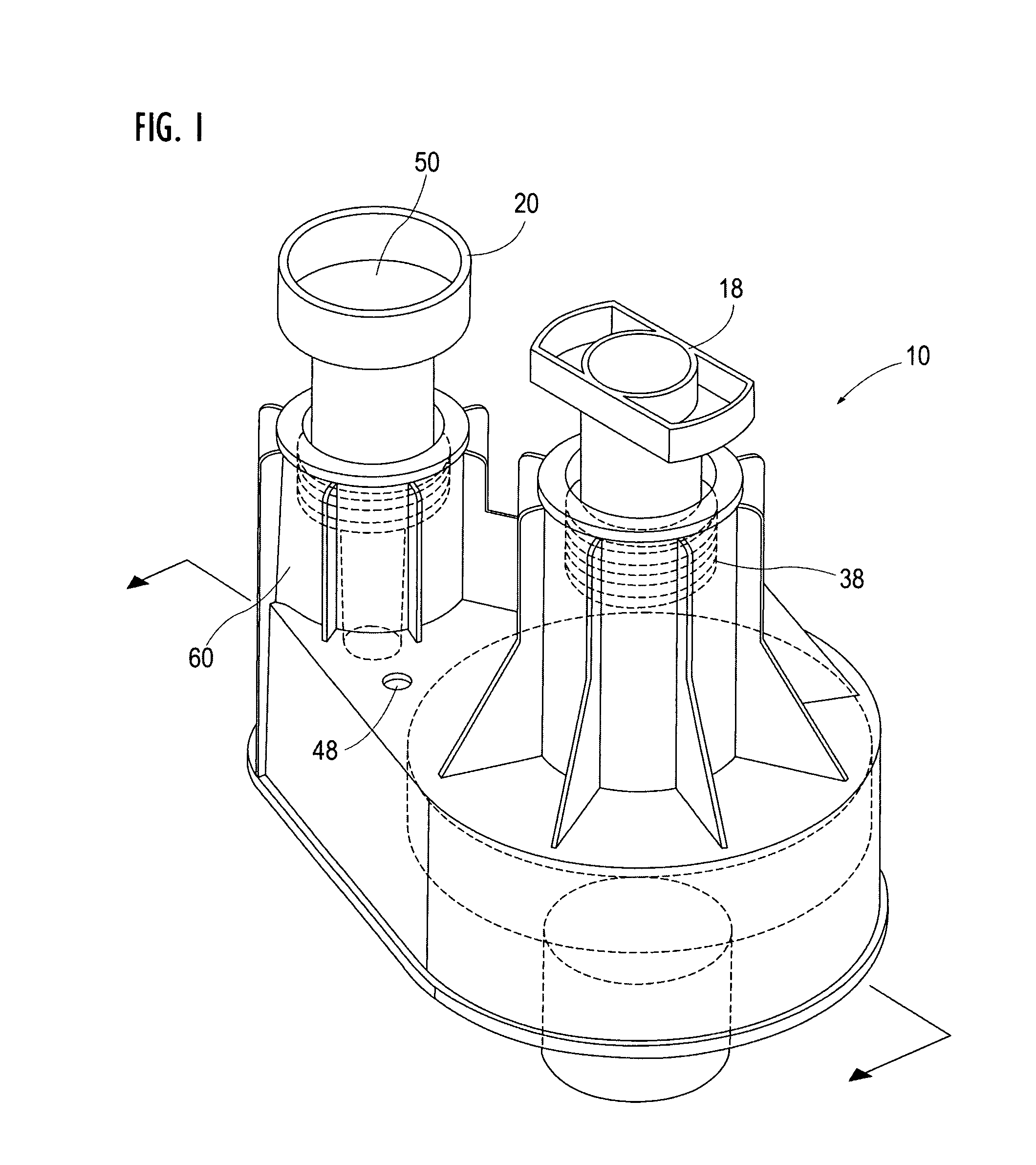

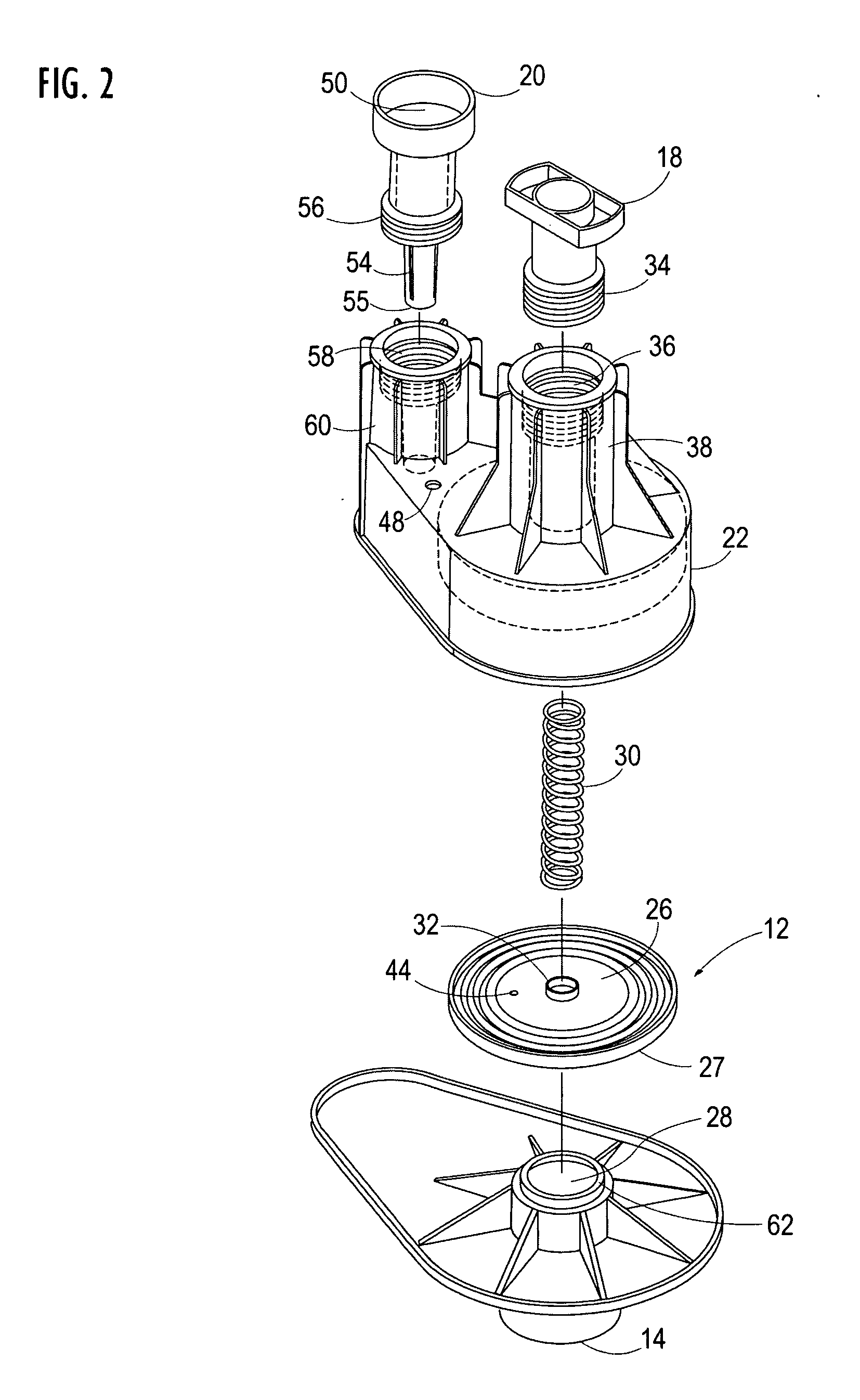

Vacuum Infusion Machine and Vacuum Infusion Method

ActiveUS20150017297A1Enhance stirringReduce pressureAlcoholic beverage preparationBeverage vesselsPressure cycleInfusion method

A process for infusing a consumable substance is described. The process includes the steps of placing a desired amount of an infusion material into a chamber at atmospheric pressure, placing a desired amount of consumable substance into said chamber, sealing said chamber from the surrounding atmosphere, and applying at least one reduced pressure cycle within said chamber. Methods for separating the infusion material from the consumable substance after completion of the infusion process are also described. In addition, devices for infusing liquids or consumable substances, and / or brewing beverages are described. The present invention relates to an apparatus for brewing beverages or infusing a consumable substance comprising a vessel, said vessel comprising a sealable chamber for holding a brewing or infusion material and a liquid or consumable substance, and a filter assembly connected to the sealable chamber; a liquid supply and conduit for introducing at least a portion of said liquid supply into said sealable chamber; and a vacuum source and conduit for reducing pressure in said sealable chamber.

Owner:BKON

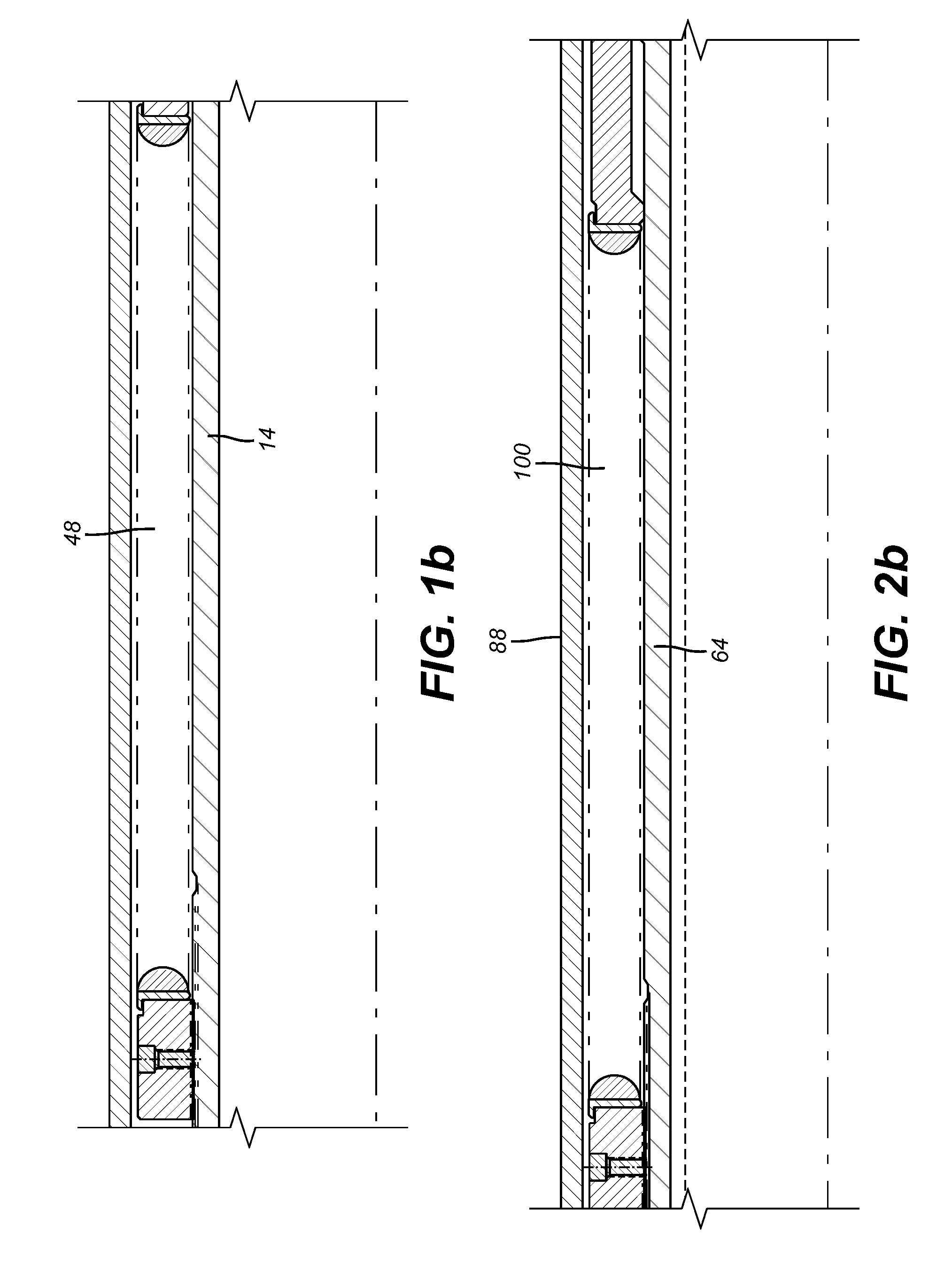

Lock for a downhole tool with a reset feature

The lock allows two members in a downhole tool to be temporarily held together. In an application where mandrel movement is dictated by pressure cycling in combination with a J-slot mechanism, such as in a downhole valve, the mandrel is releaseably retained to an adjacent connector against mechanical impacts. The mandrel features an extended collet that moves relatively to a floating sleeve during pressure cycles. At some point the collet heads rise to an elevated groove that causes them to contact a no-go shoulder for locking. The lock is defeated be removing the collet heads from the elevated groove for normal tool operation.

Owner:BAKER HUGHES INC

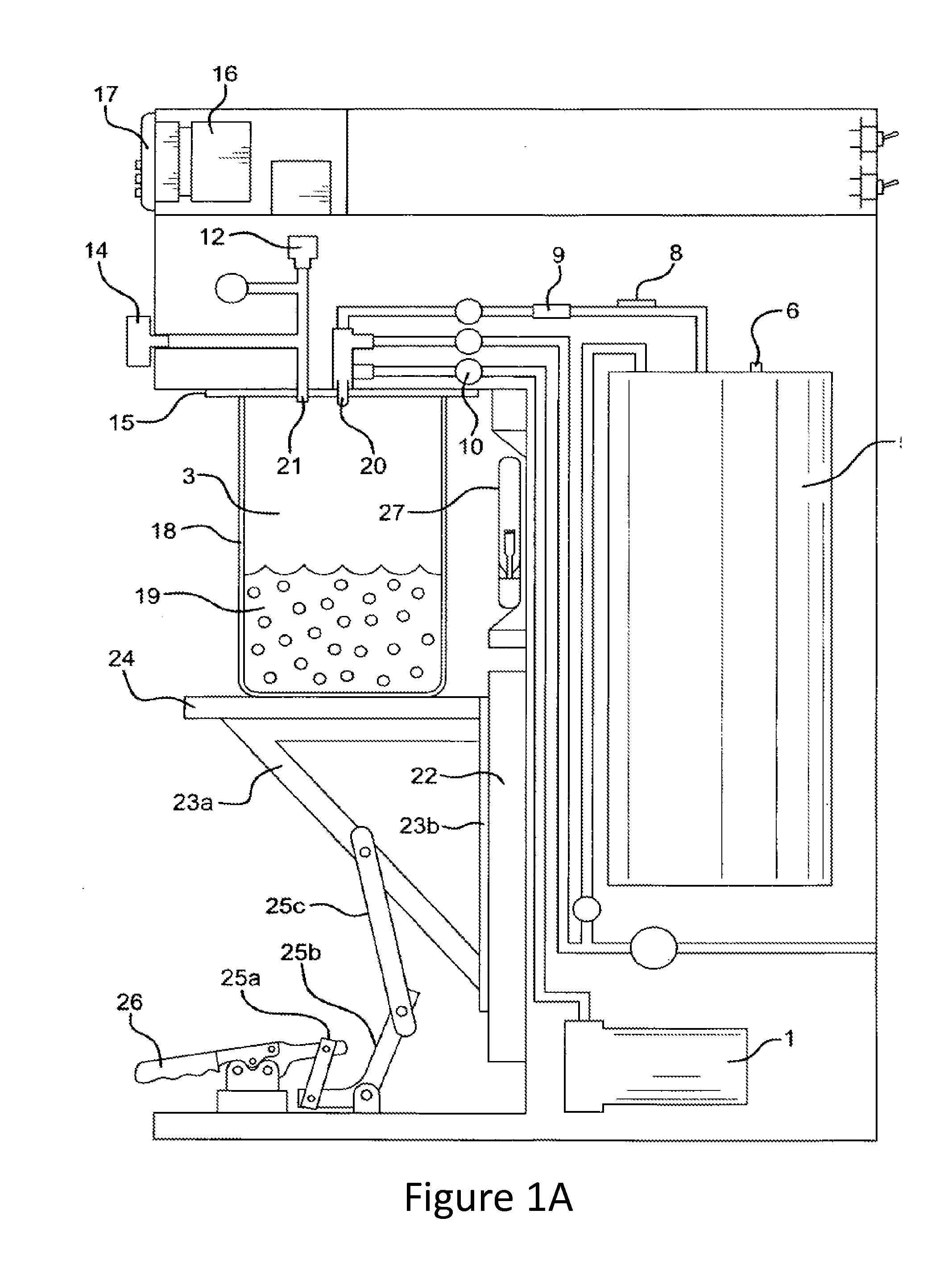

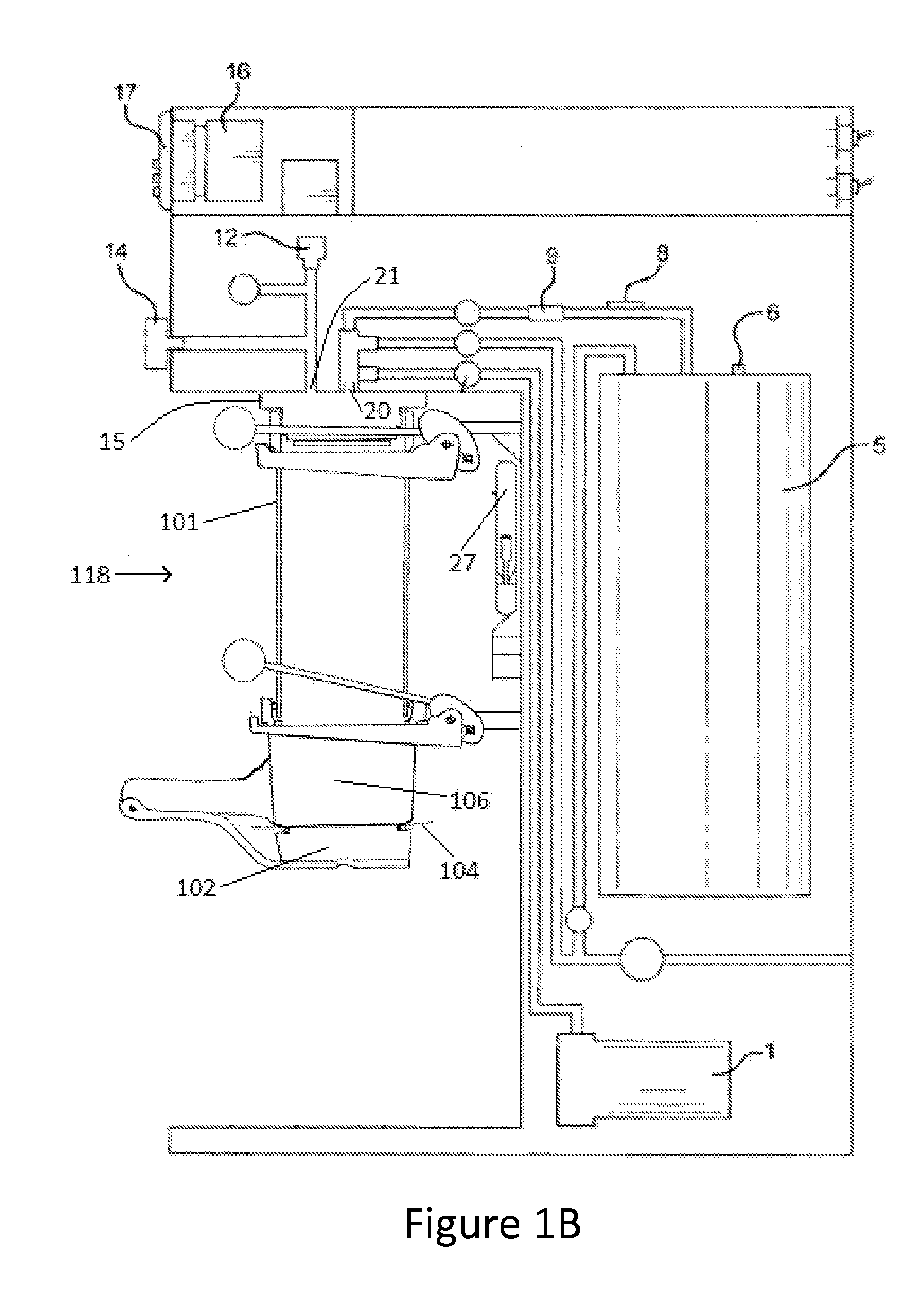

Vacuum Brewed Beverage Machine And Vacuum Brewing Method

ActiveUS20130136833A1Enhance stirringIncrease ratingsTea extractionTea substituesPressure cycleEngineering

A liquid infusion and / or brewing process is described. The process includes the steps of placing a desired amount of an infusion material into a chamber at atmospheric pressure, placing a desired amount of liquid into said chamber, sealing said chamber from the surrounding atmosphere, and applying at least one reduced pressure cycle within said chamber, wherein said at least one cycle comprises reducing pressure within said chamber to form at least a partial vacuum within said chamber and subsequently returning said chamber to about atmospheric pressure. Methods for separating the brewing media from the liquid after completion of the brewing process are also described.

Owner:BKON

Hydraulic Lockout Device for Pressure Controlled Well Tools

InactiveUS20100200245A1Increase the differential pressureAvoid communicationConstructionsFluid removalPressure cyclePressure transmission

Owner:HALLIBURTON ENERGY SERVICES INC

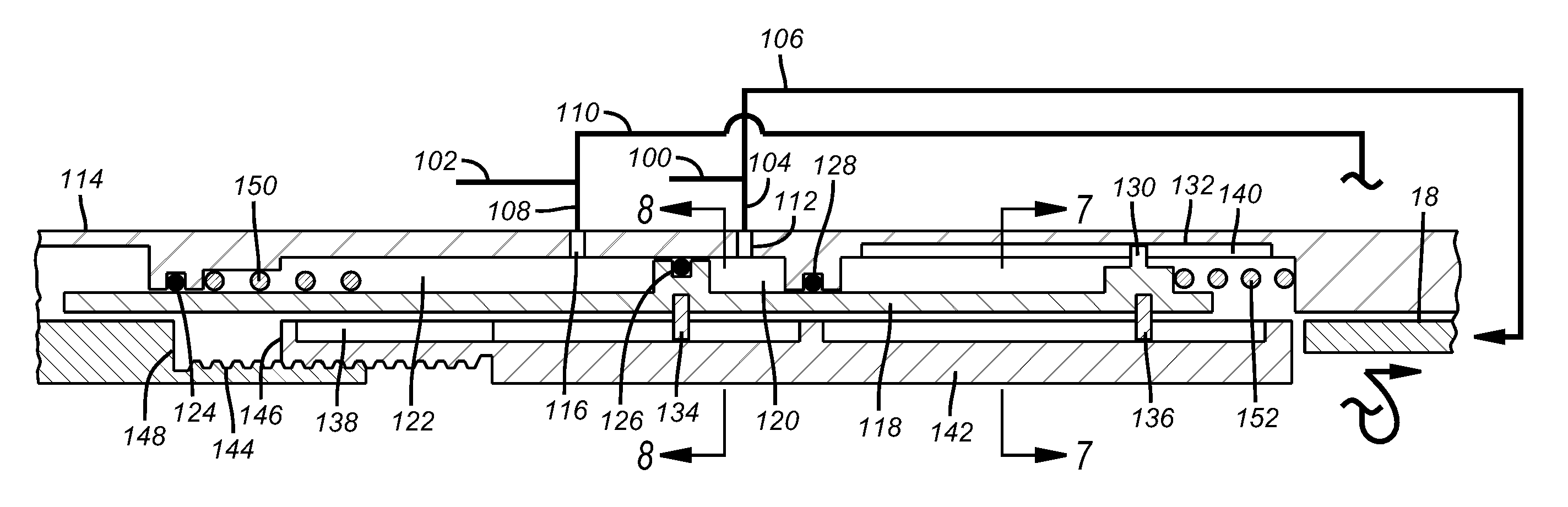

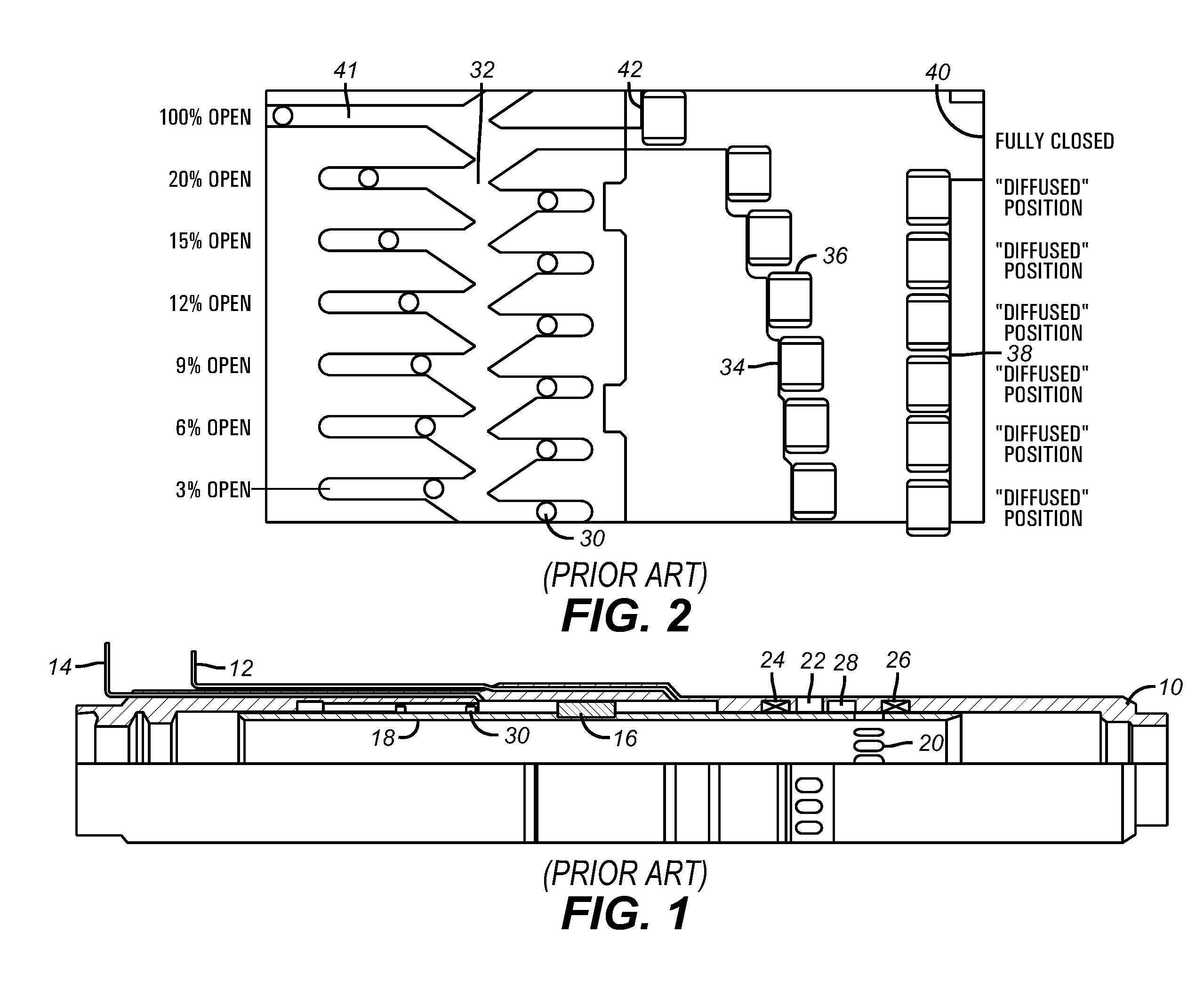

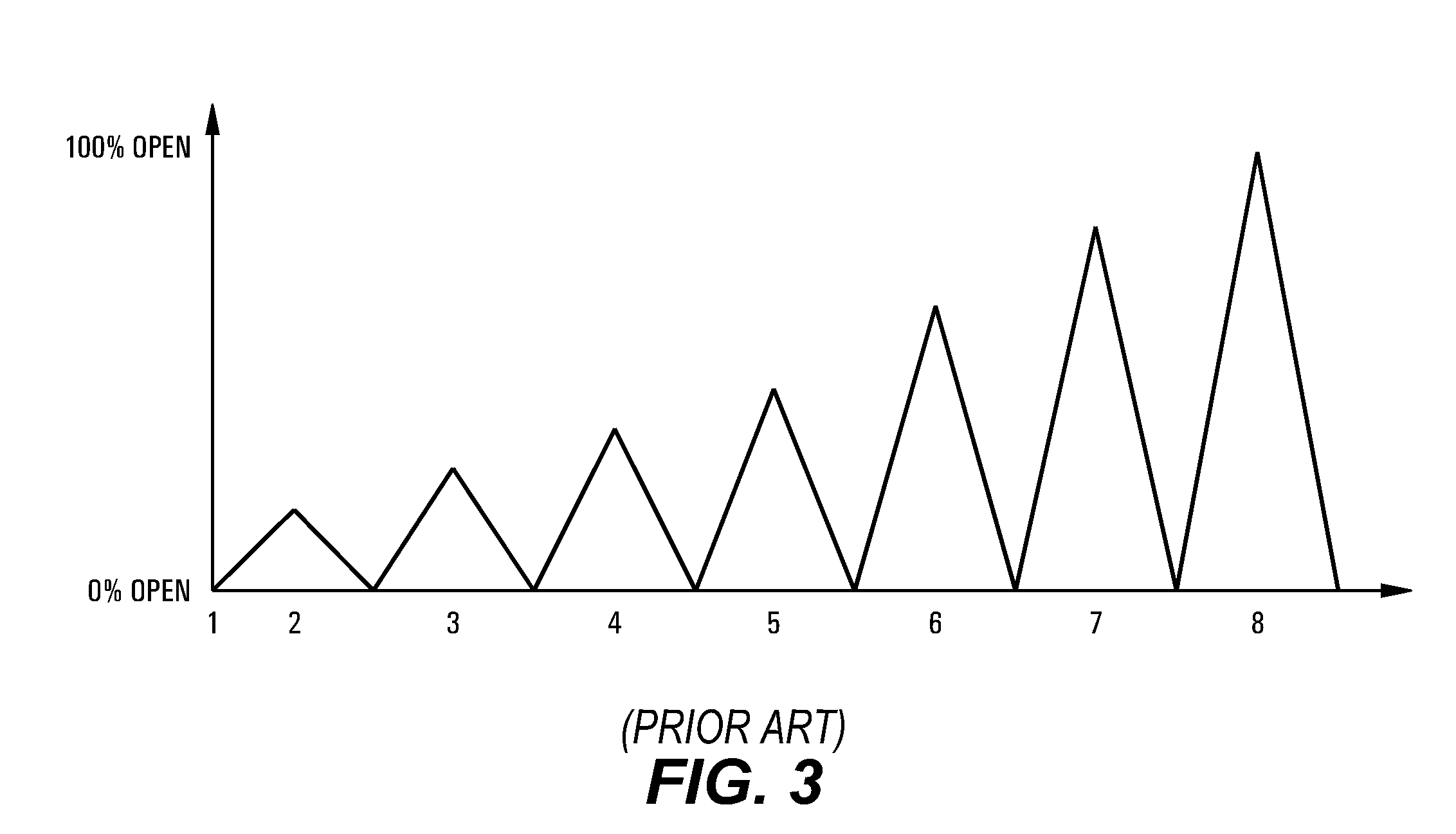

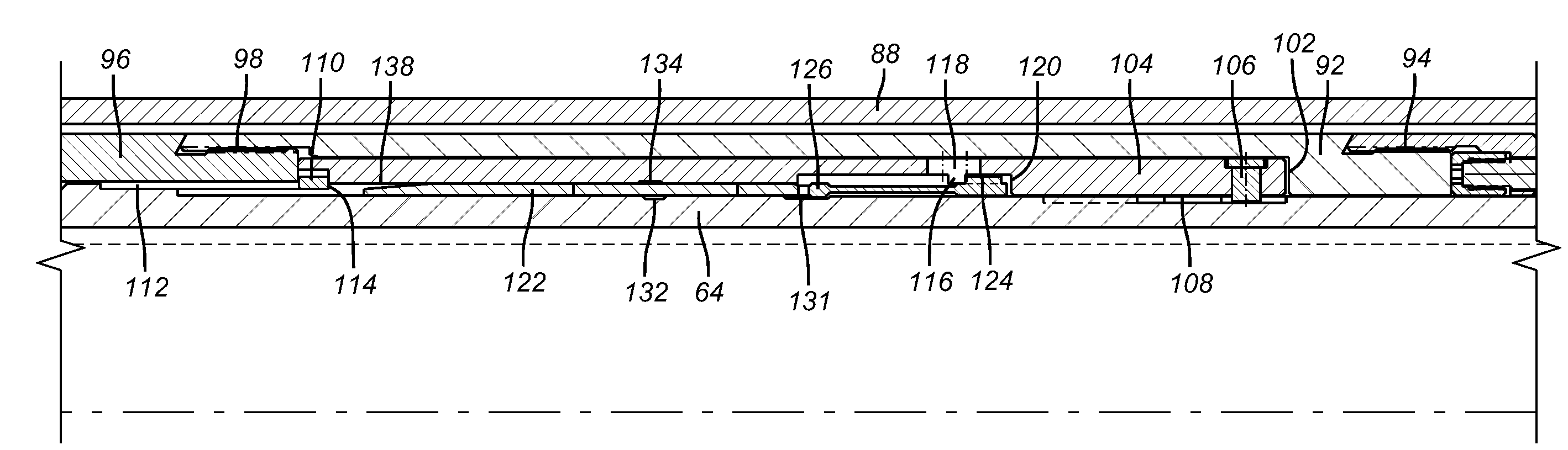

Controller for a Hydraulically Operated Downhole Tool

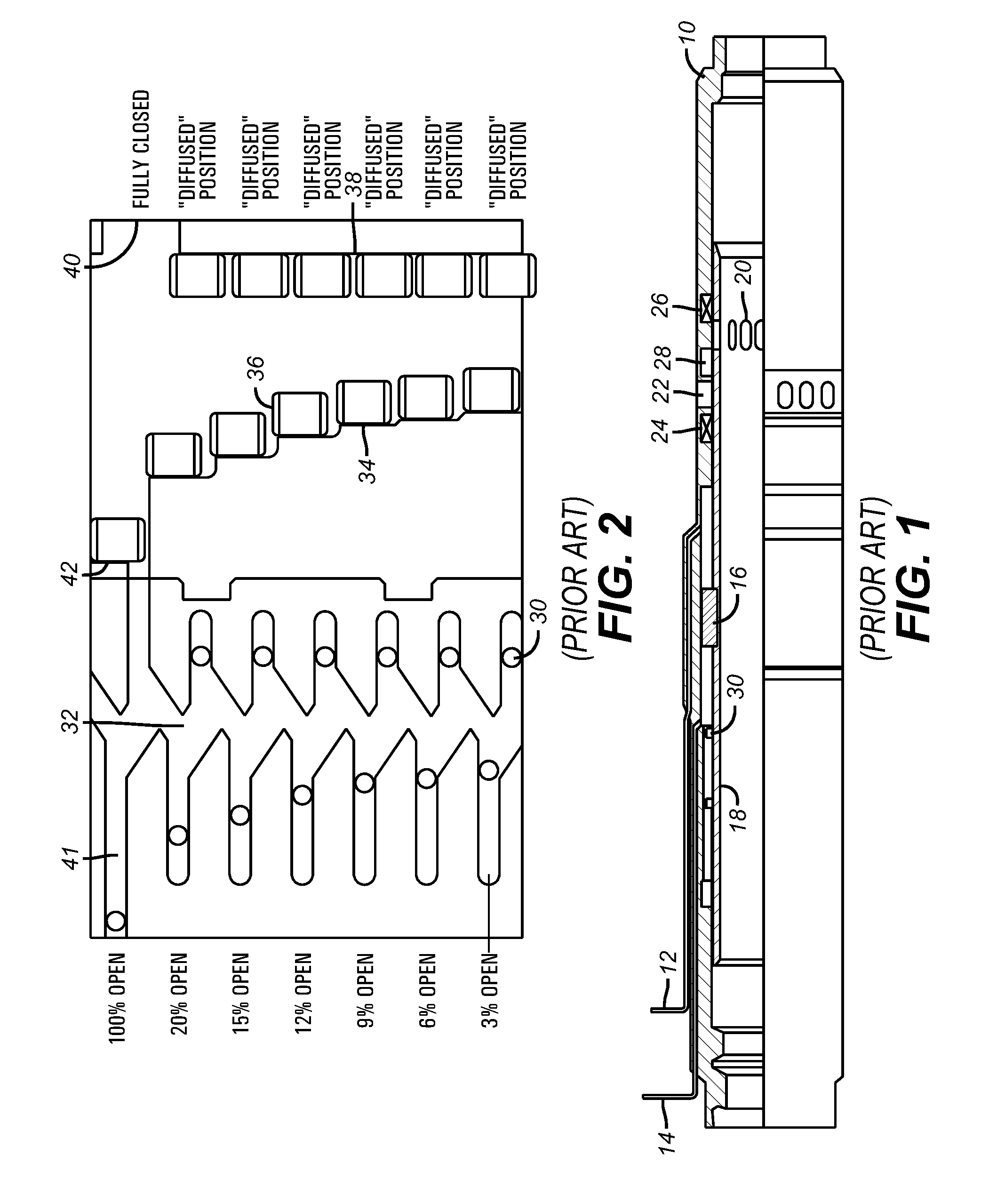

A hydraulic control system can be used on a downhole choke and has the feature of moving a travel stop for a sliding sleeve using discrete j-slot mechanisms for selectively moving the stop in either one of two opposed directions. The valve can be incrementally opened further with pressure cycling on an opening chamber. The valve can be immediately put to the closed position with pressure on a closing chamber. After closing, the valve can assume its former open position or other selected less open positions by reconfiguring the travel stop while the valve stays in the closed position In order to achieve a higher open percent after closing, one or more pressure cycles must be applied to the open chamber after the valve is reopened to the position it was in before it was closed.

Owner:BAKER HUGHES INC

Liquid Infusion Process and Method of Brewing a Beverage

ActiveUS20140079854A1Enhance stirringIncrease ratingsTea extractionAlcoholic beverage preparationPressure cycleEngineering

Owner:BKON

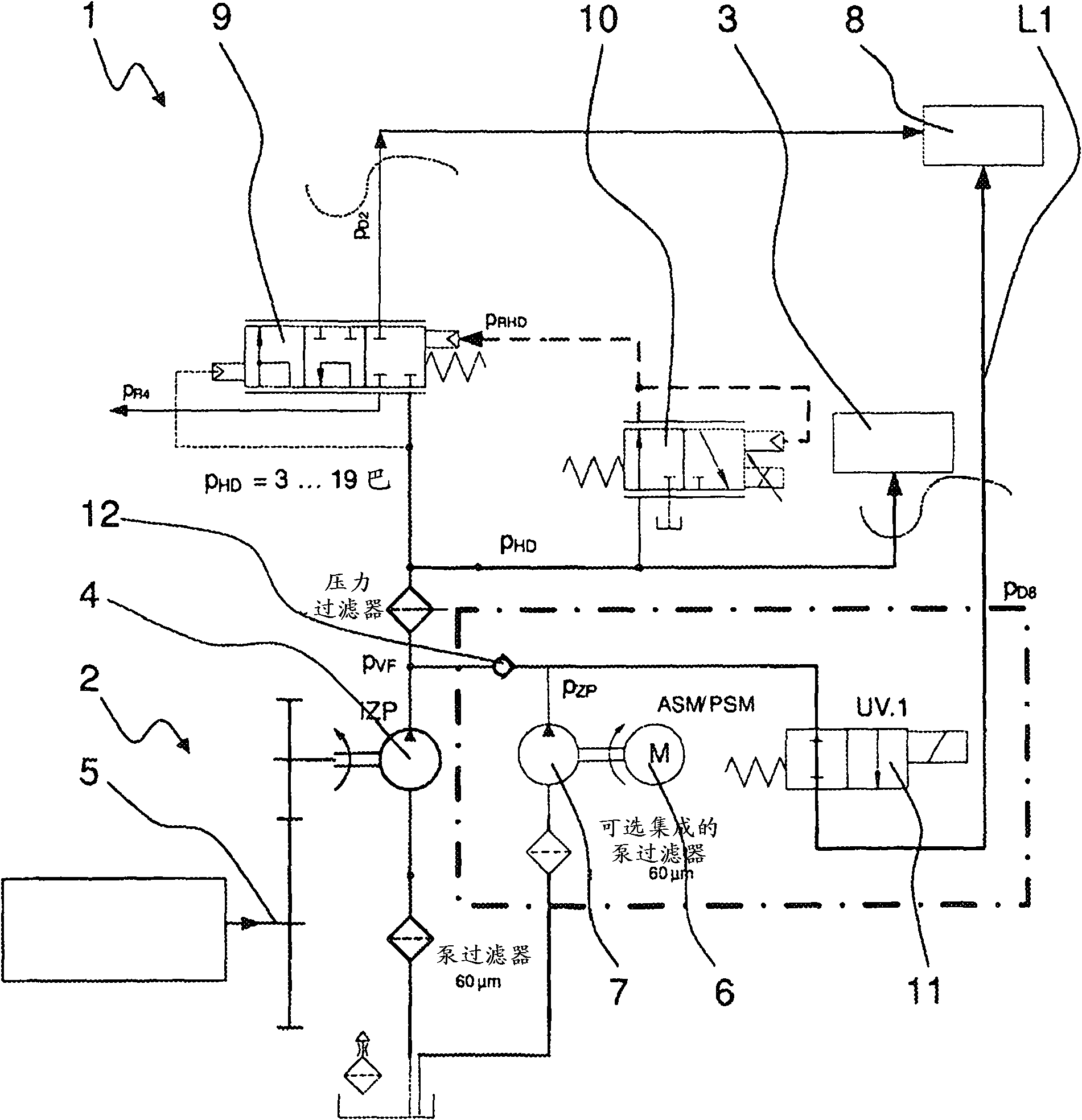

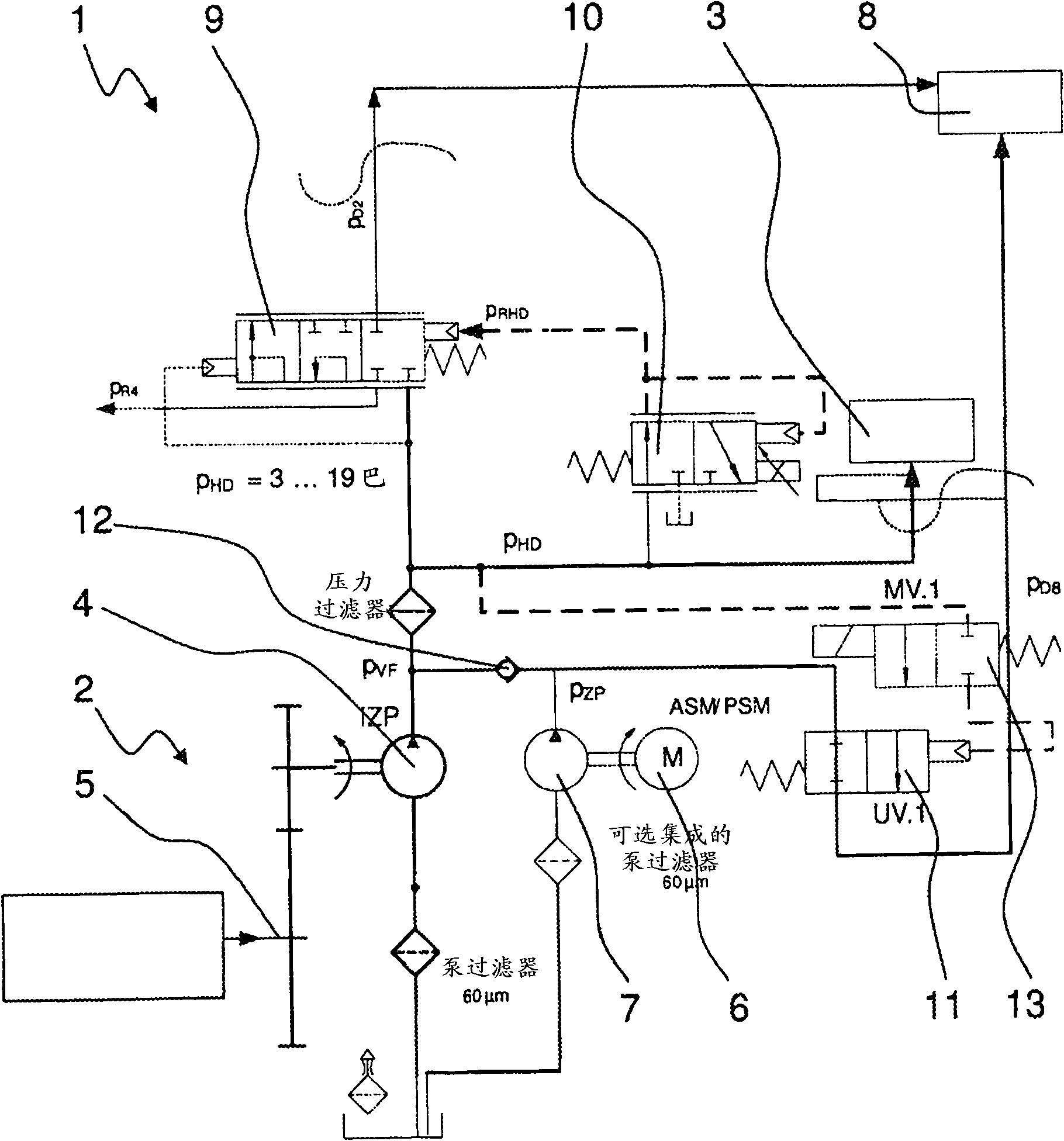

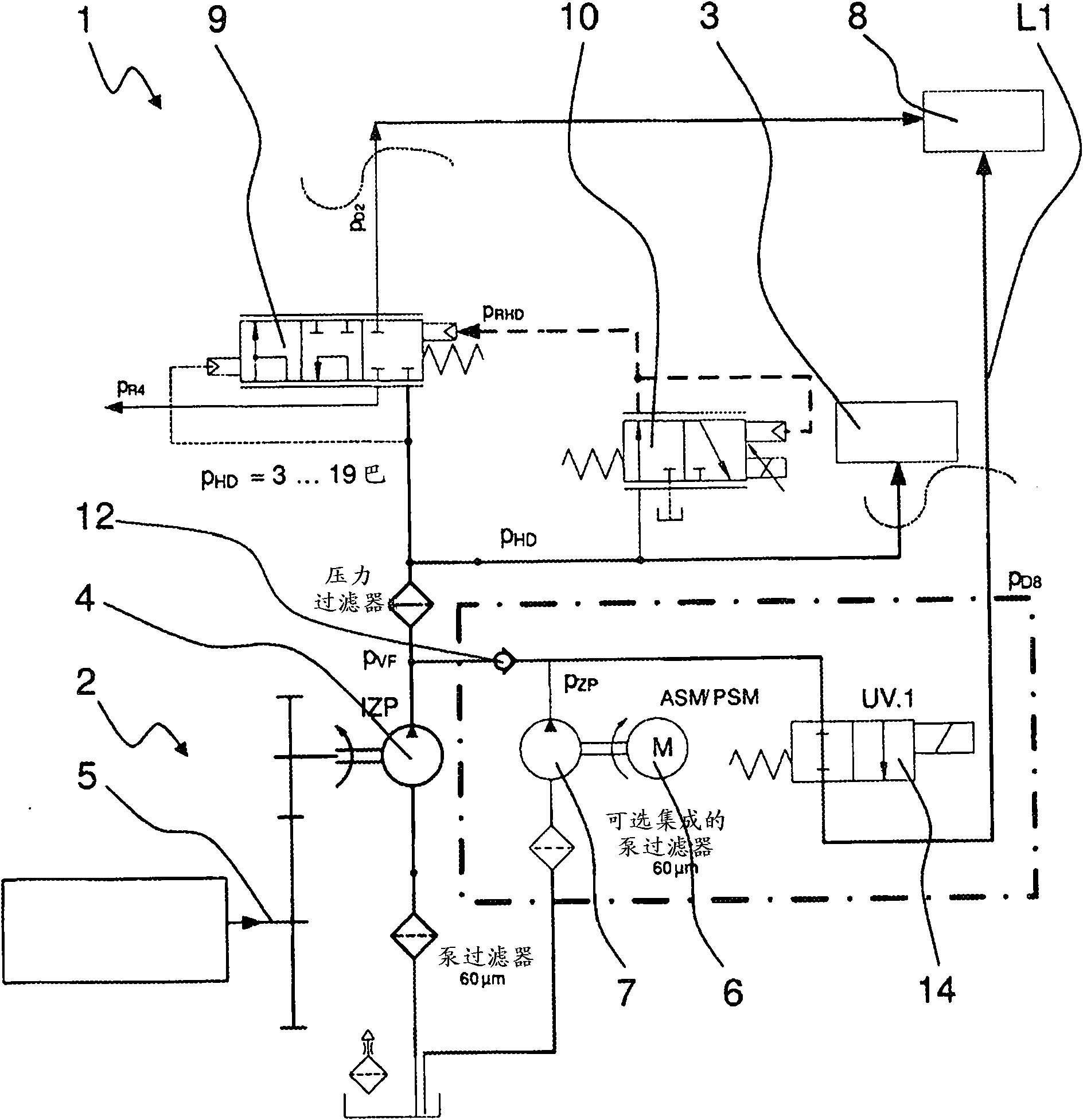

Hydraulic system of a transmission unit, comprising a main transmission pump and an auxiliary pump

InactiveCN102077000ALow powerLow costGear lubrication/coolingGearing controlPressure cycleElectric machine

The invention relates to a hydraulic system (1) of a transmission unit (2) comprising a main transmission pump which can be driven by a torque applied via the transmission unit and an auxiliary pump (7) which can be driven by an electrical machine (6), the two pumps supplying a primary pressure circuit (3) and a secondary pressure circuit (8) with hydraulic fluid depending on the operational state. A pressure side of the main transmission pump and a pressure side of the auxiliary pump (7) are connected to the primary pressure circuit (3) upstream of a pressure relief valve (9) which adjusts a main pressure (pHD) of the primary pressure circuit (3). The pressure relief valve (9) is arranged between the pressure sides of the main transmission pump (4) and the auxiliary pump (7) and the secondary pressure circuit (8). The pressure side of the auxiliary pump (7) can be actively connected to the secondary pressure circuit (8) via a hydraulic line (L1) which can be blocked in the direction of the primary pressure circuit (3) and the secondary pressure circuit (8) and which by-passes the pressure relief valve (8).

Owner:ZF FRIEDRICHSHAFEN AG

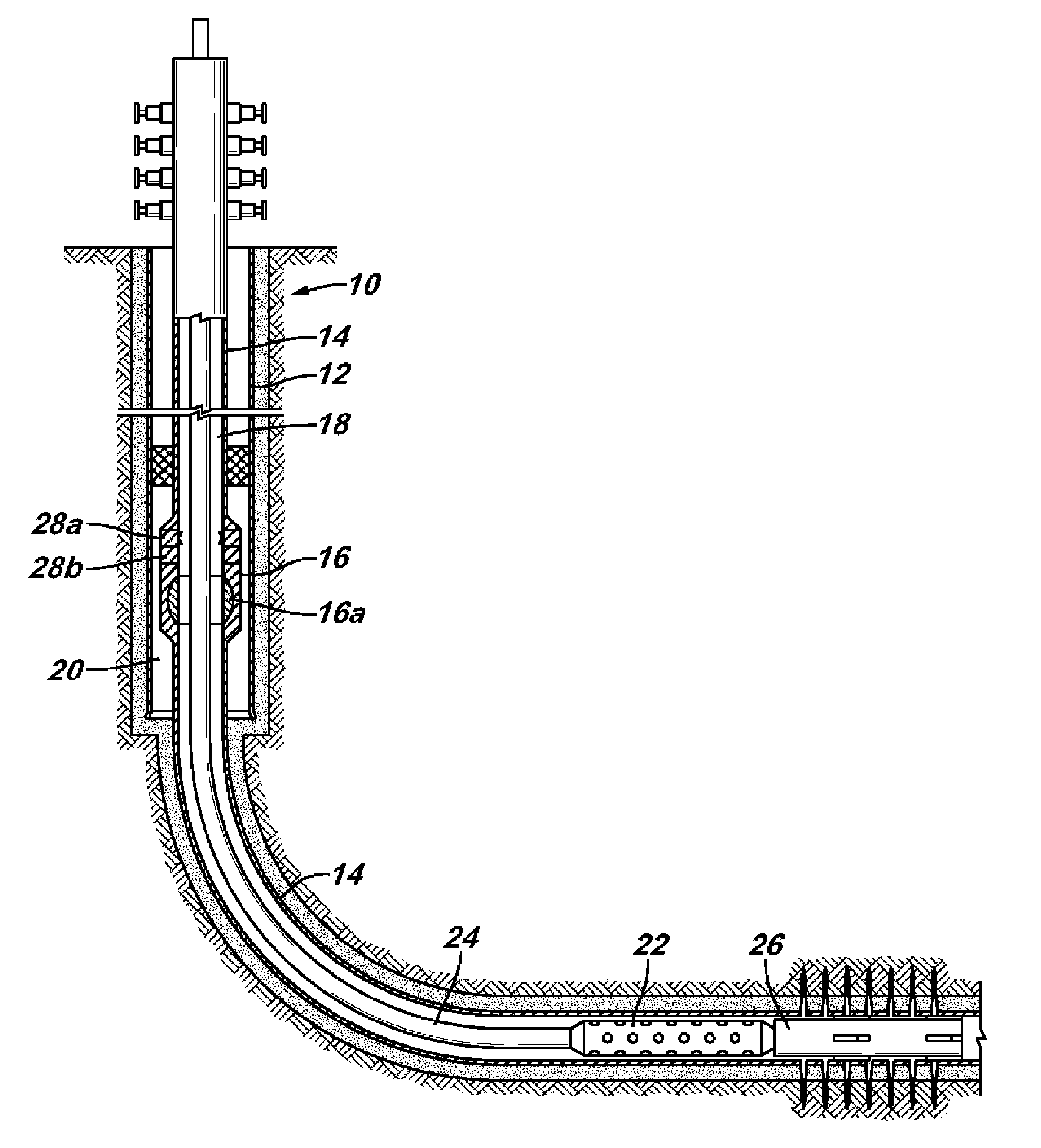

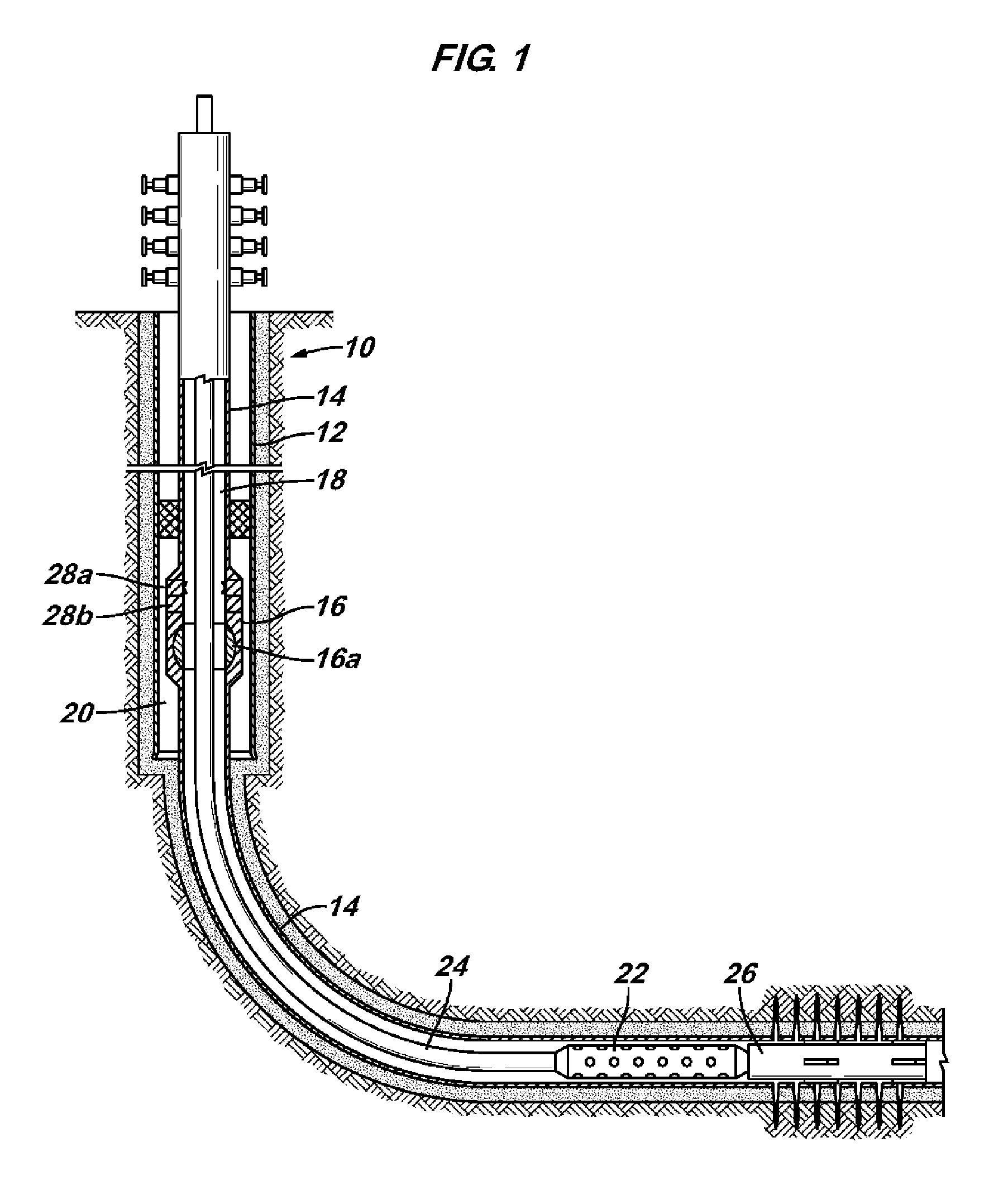

Multiple Interventionless Actuated Downhole Valve and Method

InactiveUS20050224235A1Fluid removalWell/borehole valve arrangementsPressure cycleDifferential pressure

The multiple interventionless actuated downhole valve includes a valve movable between an open and a closed position to control communication between an annular region surrounding the valve and an internal bore and more specifically controlling communication between above and below the valve, and at least two remotely operated interventionless actuators in operational connection with the valve, wherein each of the interventionless actuators may be operated independently by absolute tubing pressure, absolute annulus pressure, differential pressure from the tubing to the annulus, differential pressure between the annulus and the tubing, tubing or annulus multiple pressure cycles, pressure pulses, acoustic telemetry, electromagnetic telemetry or other types of wireless telemetry to change the position of the valve and allowing the valve to be continually operated by mechanical apparatus.

Owner:SCHLUMBERGER TECH CORP

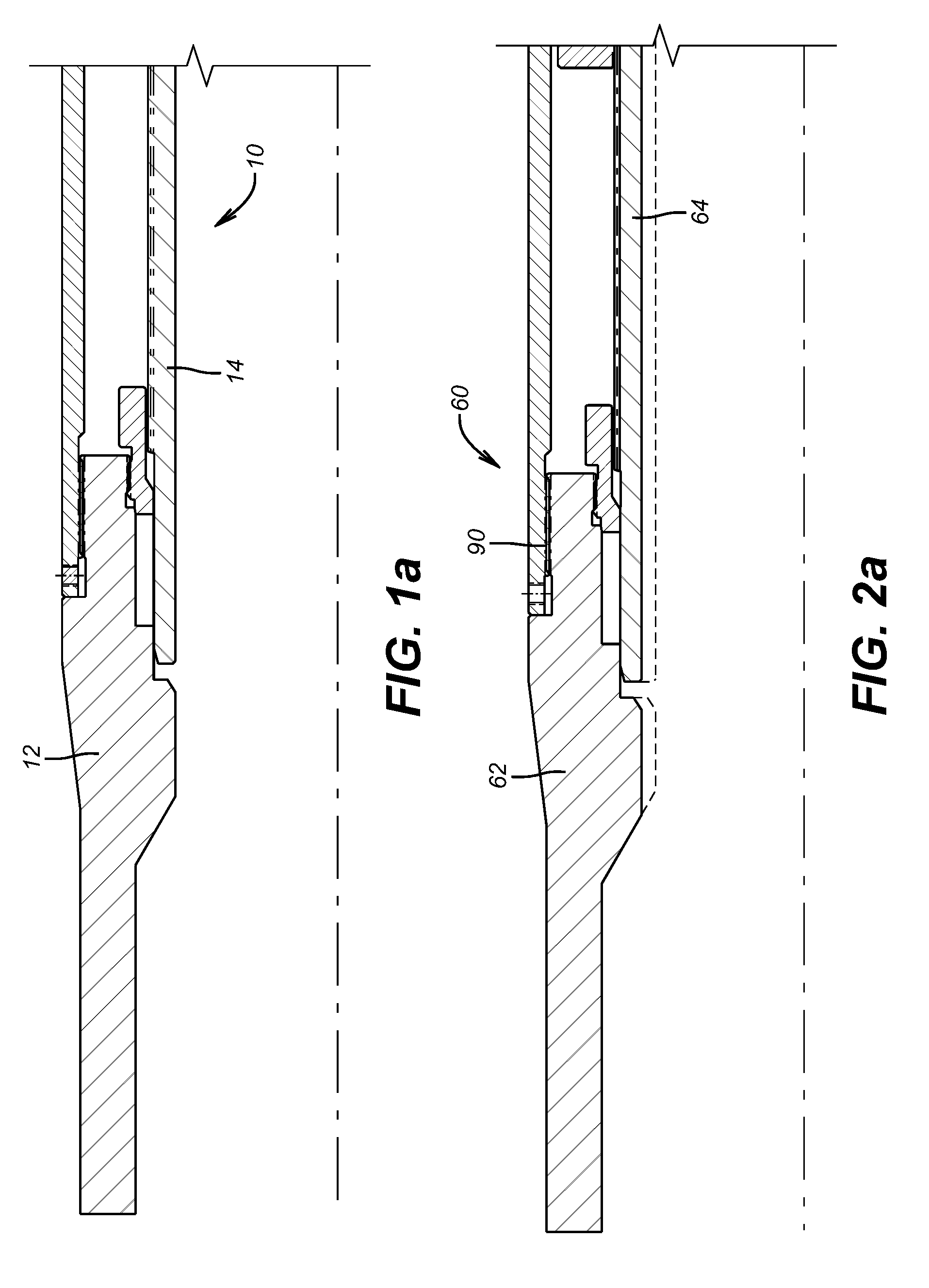

Modular hydraulic operator for a subterranean tool

A modular pressure operated actuator can be coupled with a downhole tool to selectively operate it at least once. In the preferred embodiment the module can be mounted adjacent an isolation valve and after a fixed number of on and off pressure cycles allow a spring to push an actuator to operate the valve to an open position. The actuator, in another embodiment, can be reset with a tool run into the module to move the actuator back against a power spring and hold that spring force until the pressure cycling begins again. The preferred application is for a formation isolation ball valve but other valves, such as sliding sleeves, or other types of downhole tools can be actuated with the module that permits a retrofit of a hydraulic operation to a heretofore purely mechanically actuated tool.

Owner:BAKER HUGHES INC

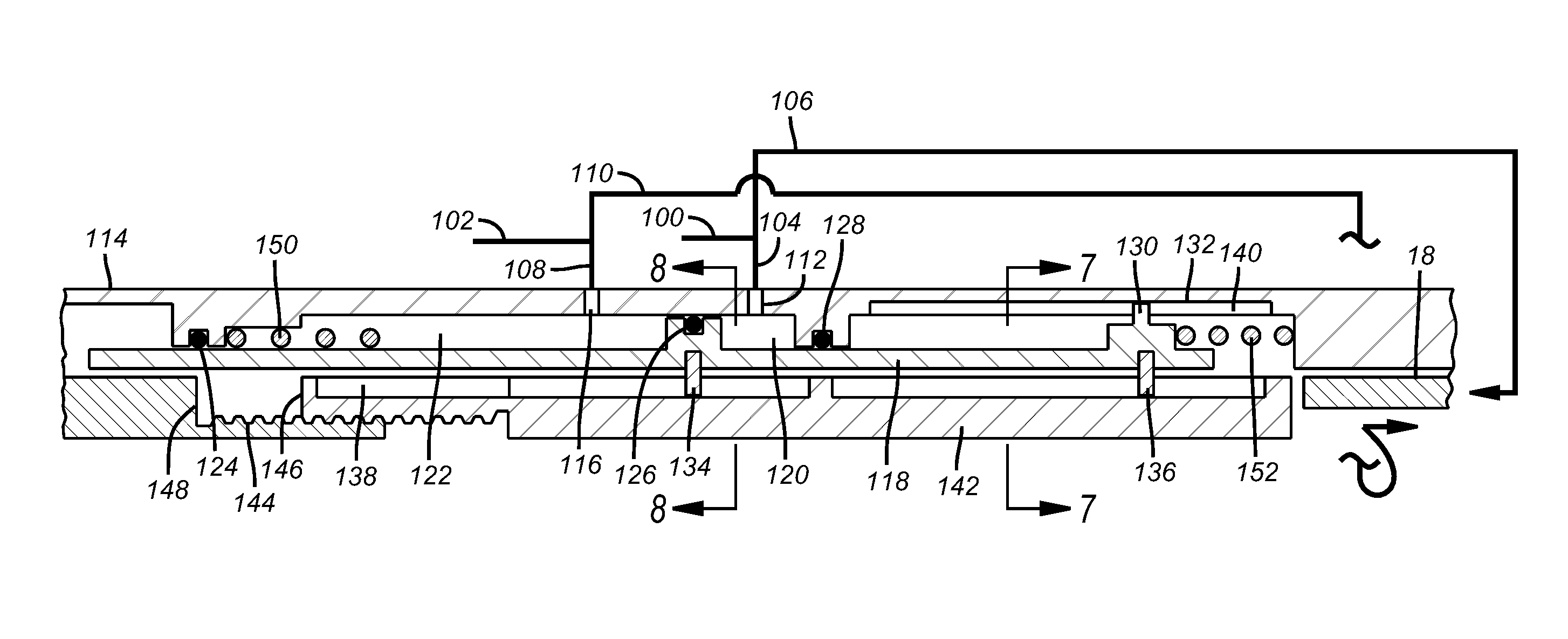

Enhanced manually actuated pressure controlled modulator technology

InactiveUS20110197892A1Easy to detectRespiratorsRespiratory apparatusOperation modeMedical treatment

A dual area pressure pulmonary modulator apparatus which provides constant flow, pressure cycled ventilatory support to patients that is additionally equipped with fluid conduits in the valve mechanism and body that allow the clinician or user to manually actuate inhalation by occluding a fluid path emanating from the modulator. Such feature is useful for when the device stops cycling due to physiological changes of the patient, for determining if the patient is cycling the device or if the device is automatically cycling by nature of its setting, coordinating medical procedures with the breathing of the patient, increasing the PEEP beyond the intrinsic design PEEP of the device for a given PIP setting, increasing inspiratory hold time, and providing an easy to use alternative mode of operation for users with less sophistication.

Owner:PIPER MEDICAL

Controller for a hydraulically operated downhole tool

Owner:BAKER HUGHES INC

Vacuum infusion method

ActiveUS9763461B2Enhance stirringIncrease ratingsTea extractionAlcoholic beverage preparationPressure cycleInfusion method

Owner:BKON

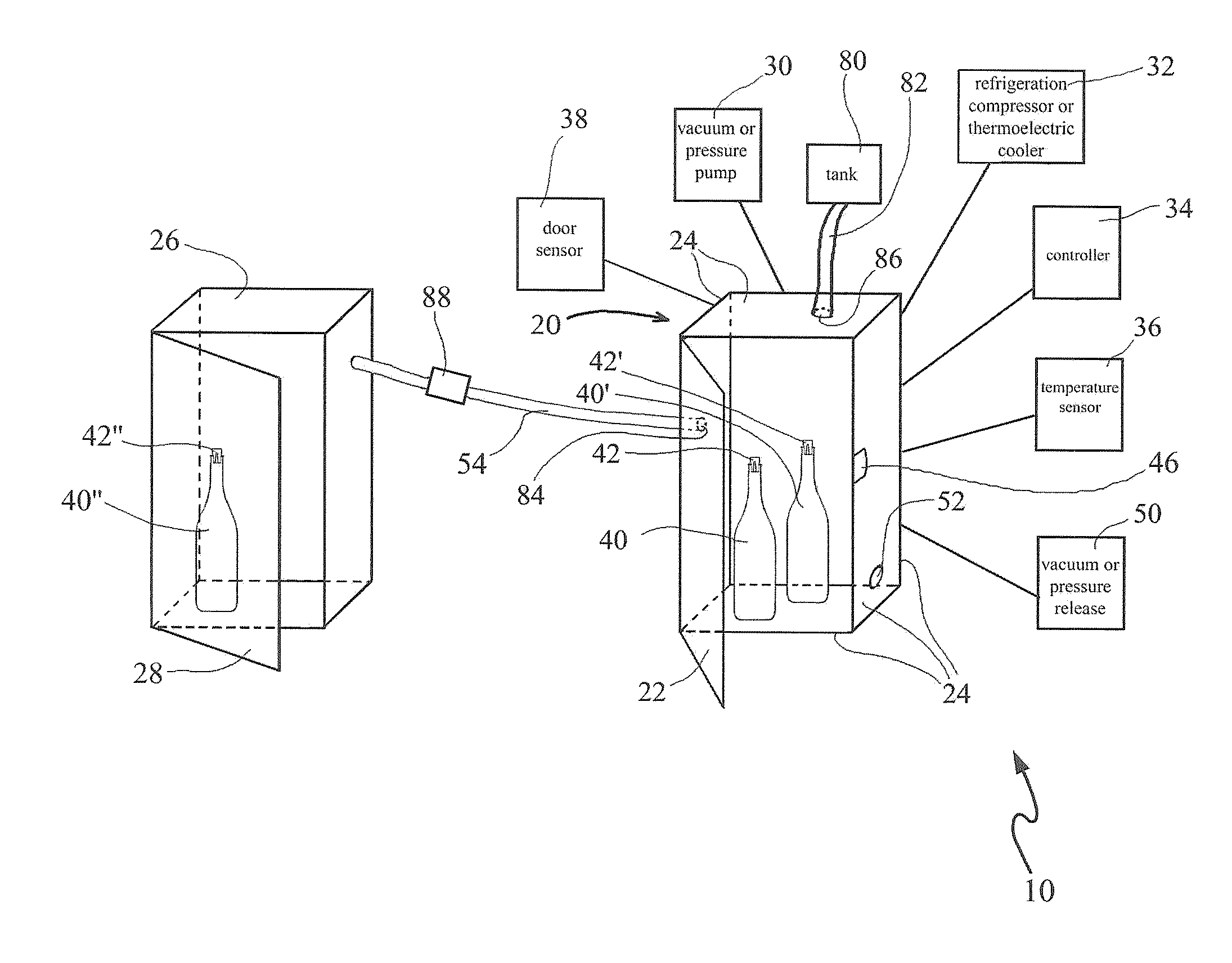

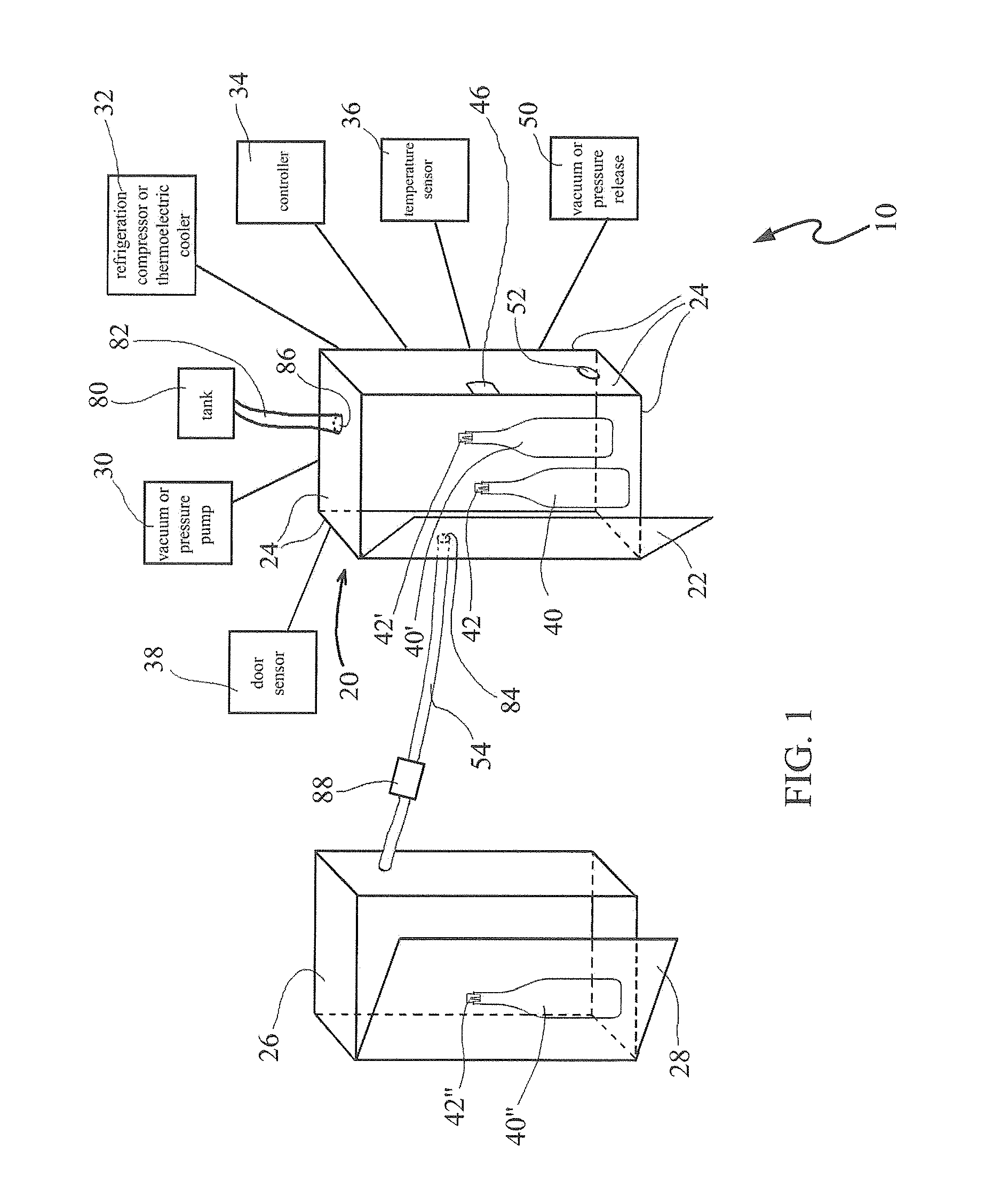

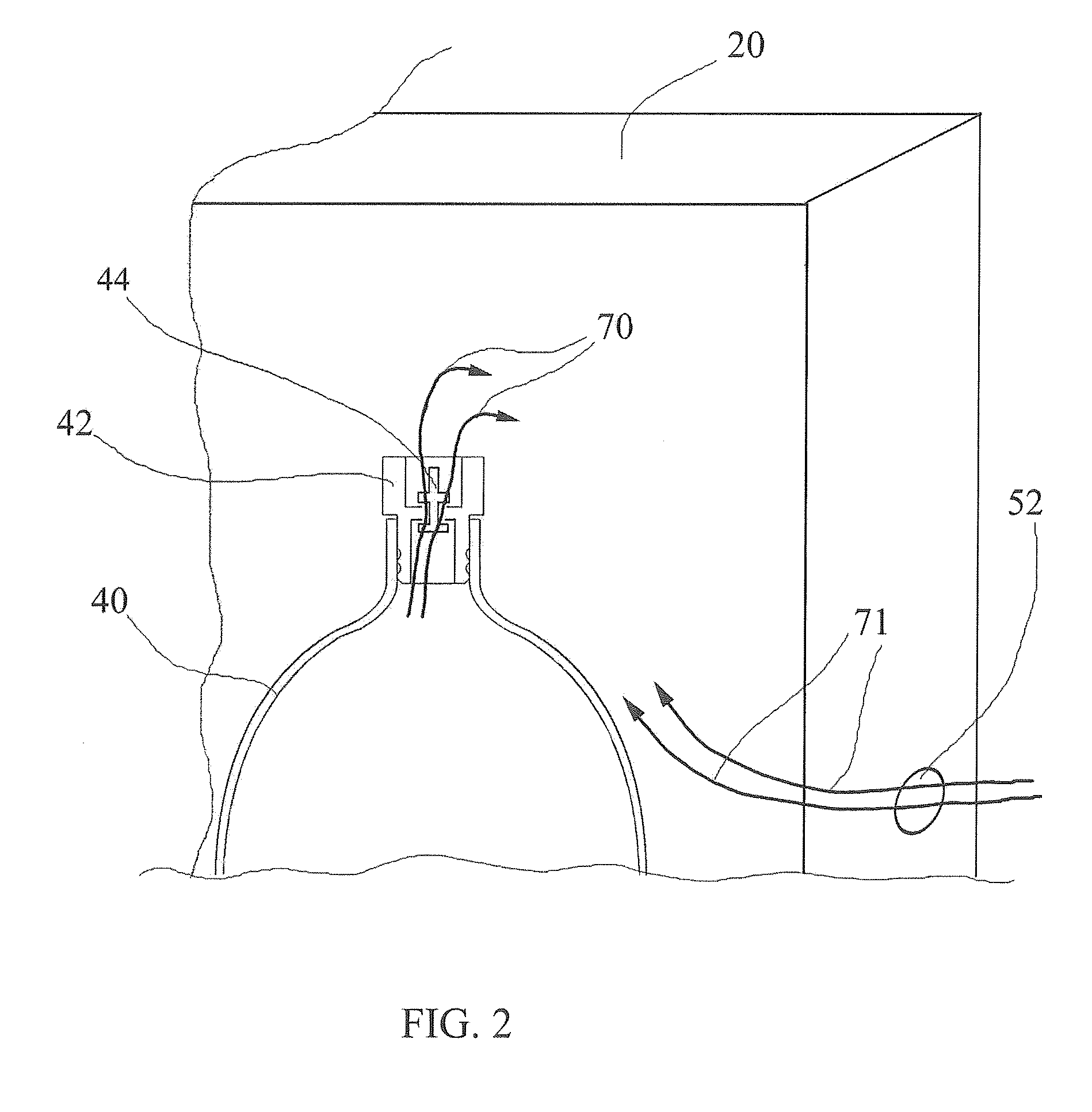

Vacuum or pressure storage system for food or beverage containers

InactiveUS20090211202A1Small sizeIncrease pressurePackage sterilisationPackaging by pressurising/gasifyingPressure cycleEngineering

A vacuum or pressure refrigerator for storing containers having one-way valves and maintaining contents thereof under vacuum or pressure within a specific temperature range. Upon receiving an input that the door is closed, a refrigerator controller is adapted to cease operation of the cooling device and initiate a vacuum or pressure cycle. The vacuum or pressure cycle includes evacuating at least a portion of or pressurizing the air inside the compartment, operating the pump until a desired degree of vacuum or pressure is attained and terminating pump operation. The one way valves then evacuate or pressurize the containers. The controller is also adapted to subsequently initiate a cooling cycle, the cooling cycle commencing when it is determined that the temperature is above an upper set point and to operate the cooling device until the temperature reaches a desired lower set point, at which time the cooling cycle is terminated.

Owner:LEMME ANTHONY R

Pipe liner connector

A pipe liner connector suitable for connecting pipe sections that comprise a liner is described. The pipe liner connector comprise vents and / or venting grooves which act to balance the pressure between the micro-annulus, formed between the liner and the pipe sections, and the pipe bore formed when the pipe sections are connected together. The inclusion of these features helps prevent the collapse or the uncontrolled distortion of the pipe liner connector during pressure cycles in operating pipelines.

Owner:PIONEER LINING TECH

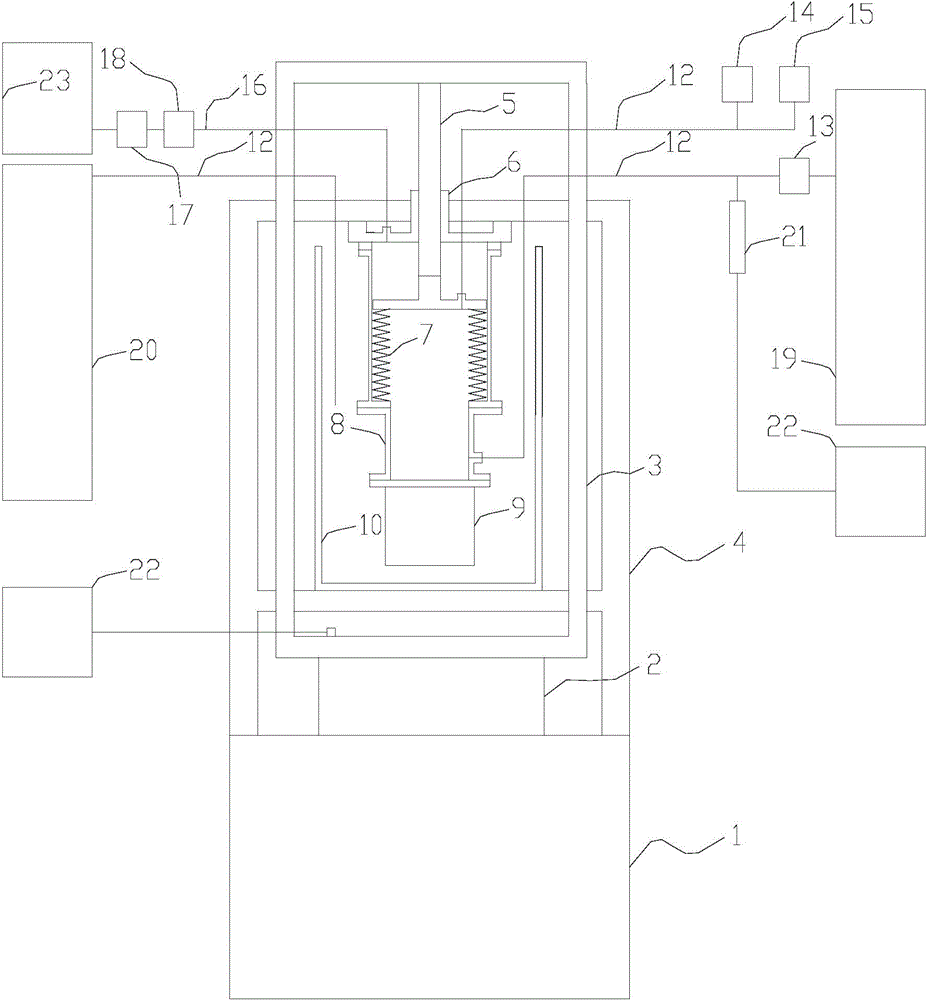

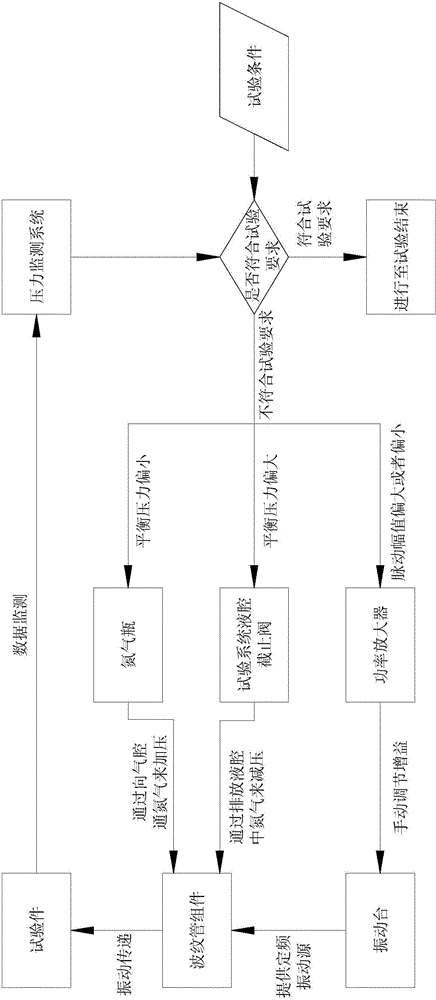

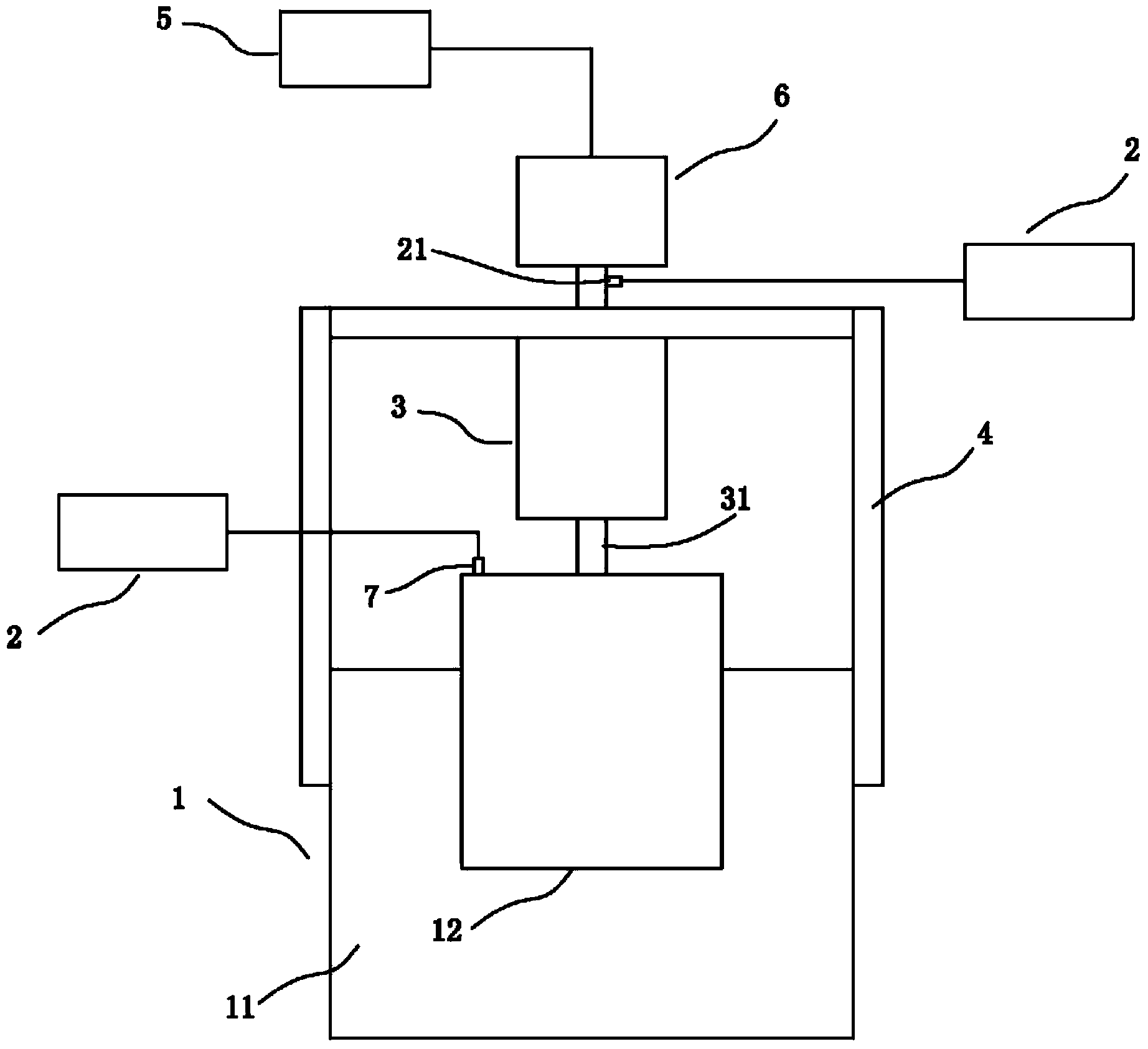

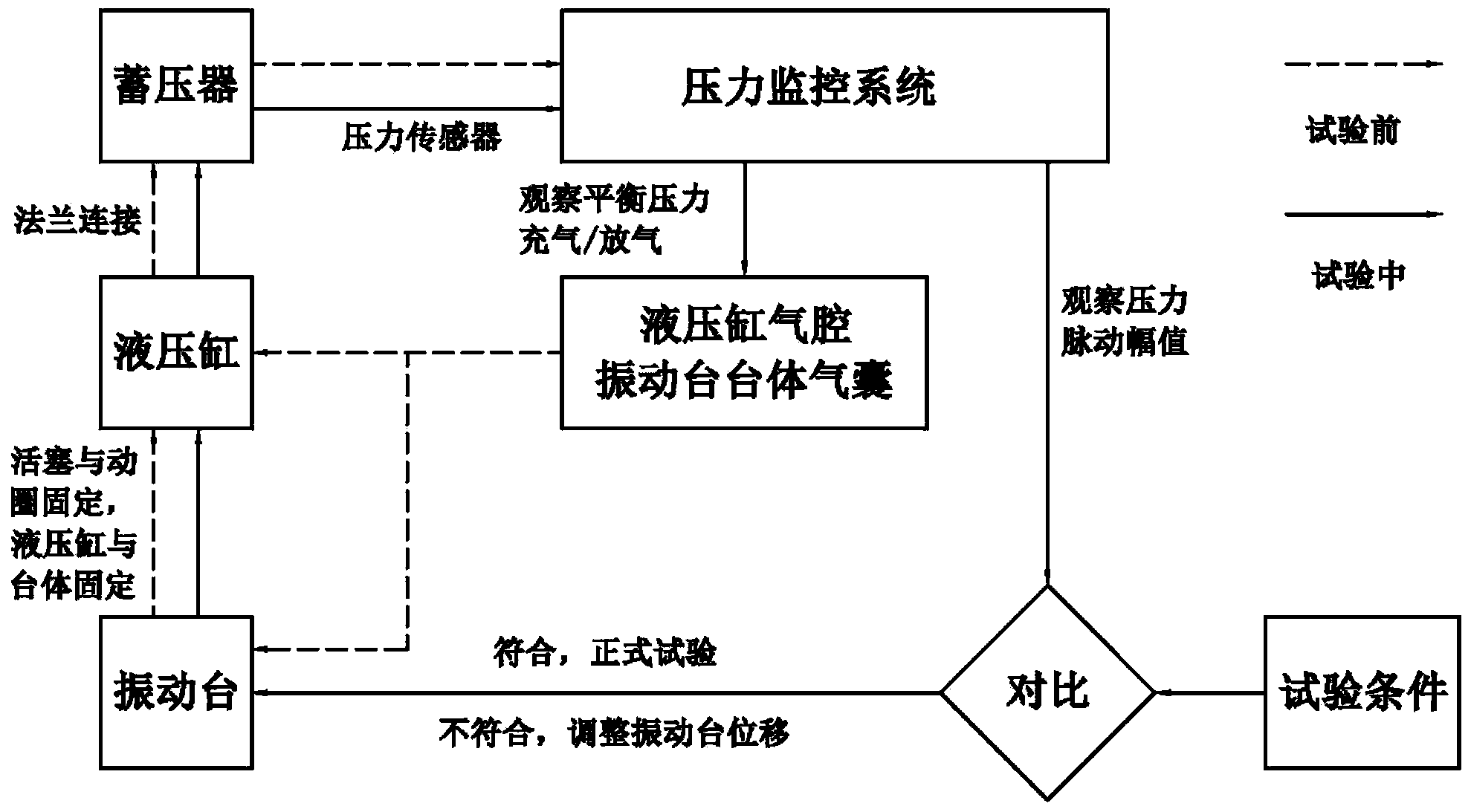

Low-temperature pressure cycle life testing method and system

ActiveCN104897493ARegulating pressureSmall static loadMaterial strength using repeated/pulsating forcesPressure cycleEngineering

The invention discloses a low-temperature pressure cycle life testing method and system. According to a typical embodiment in the invention, a vibration generator and a bellows assembly are respectively used as a power supply and a driving element; a driving part of the bellows assembly is connected with a moving part of the vibration generator through a driving assembly; an enclosed liquid chamber filled with an incompressible low temperature fluid medium and an enclosed gas chamber filled with a compressible low temperature fluid medium are formed by separate cooperation among the bellows assembly, a pressure testing joint pipe, a diaphragm capsule, etc.; and the driving part of the bellows assembly stretches out and draws back under the driving of movement of the moving part of the vibration generator, so a liquid in the liquid chamber extrudes the diaphragm capsule so as to form pressure fluctuation. The system provided by the invention has a simple structure, has low assembling and maintenance cost, is easy to operate and can conveniently adapt to different pressure fluctuation amplitudes and frequencies by adjusting the output displacement and frequency of a vibrating table, thereby guaranteeing high control precision of pressure fluctuation.

Owner:TIANJIN AEROSPACE RELIA TECH

Injection valve with indexing mechanism

A flapper valve preferably used in injection application in deep subterranean locations has an actuating sleeve with a seat to accept an object. A j-slot connects the actuation sleeve movement to the housing so that with an object on the seat and an applied pressure cycle the sleeve moves the flapper to the open position. The plug is dissolved and the injection begins. The plug can have an opening so as to allow continuous injection flow as the flapper is operated. Closing the flapper involves a second object on the same seat and a pressure cycle so that a spring can push the sleeve away from the flapper to allow a torsion spring on the flapper to close it.

Owner:BAKER HUGHES INC

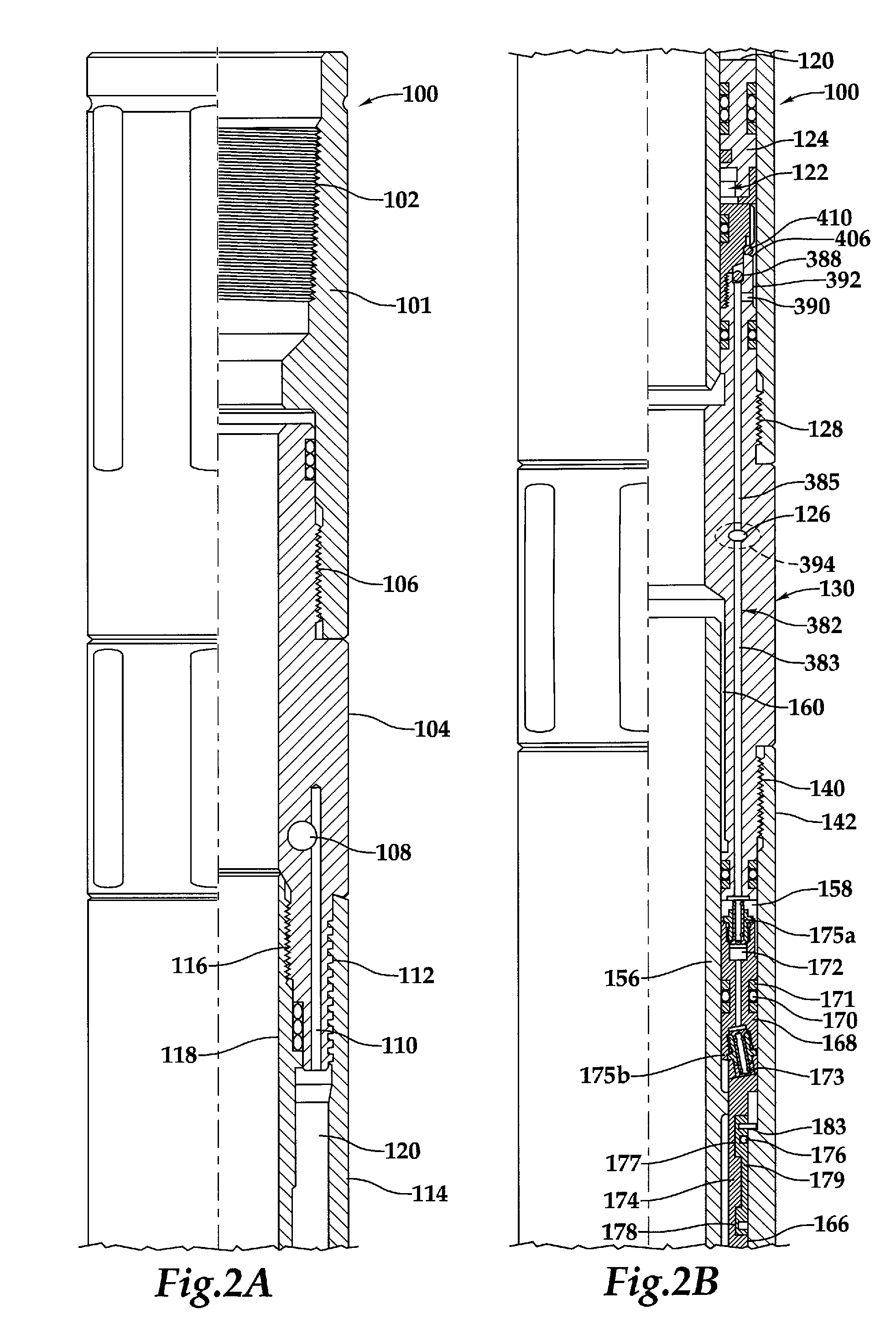

Multi-purpose pressure operated downhole valve

A downhole valve features a flow port that can be selectively obstructed by a pressure actuated sleeve that is movable in a pin and slot mechanism to rotate while being cycled up and down by application and removal of pressure in a cyclical manner. When the sleeve is cycled to the port closed position, a flapper mounted near its upper end can fall on a seat on the sleeve to allow pressure to be applied to the flapper and sleeve, causing the sleeve to move to a position that will prevent fluid loss from the tubular string into the formation. The Closed flapper allows pressure cycles of the sleeve. A double closure against fluid loss can be affected.

Owner:BAKER HUGHES INC

Pressure circulation service life testing system and method

ActiveCN103712787AEasy to adjust balance pressureLow static load requirementsMachine part testingVibration testingHydraulic cylinderPressure cycle

Owner:TIANJIN AEROSPACE RELIA TECH

Hydraulic lockout device for pressure controlled well tools

InactiveUS7926575B2Avoid communicationIncrease the differential pressureConstructionsFluid removalPressure transmissionPressure cycle

Owner:HALLIBURTON ENERGY SERVICES INC

Liquid injection and humidity method for lithium ion battery

InactiveCN101267033AWet evenlyMoisturize wellFinal product manufactureCell component detailsPressure cycleInternal resistance

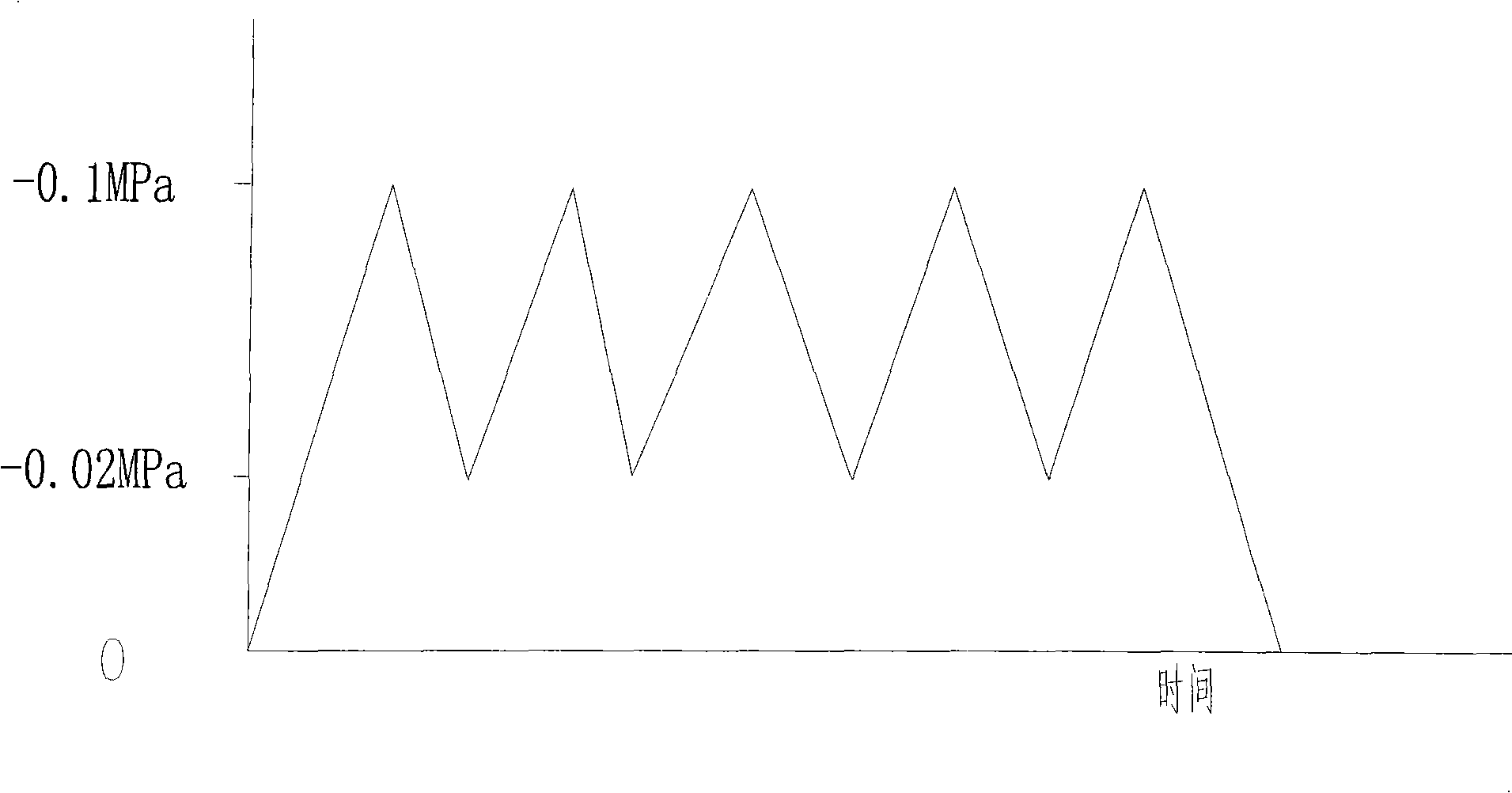

The invention relates to an improvement of wetting method of lithium-ion battery liquid injection, characterized in that negative pressure wetting is negative pressure cycle changed wetting in -0.1MPa to -0.02MPa vacuum. Electrical core absorbs electrolyte wetly, uniformly and quickly because of using cycle changed negative pressure, the battery reaches liquid injection requirement only 12 to 15 minutes when the flexible packaging is 2000 mA, the time of liquid injection wetting is saved about 1 / 2 compared with the time of original constant negative pressure wetting, and consistency of internal resistance and capacity of battery is improved greatly, the consistency can improve at least about 10 percent compared with the original technology wetting. In addition, the realizing way of changing negative pressure circularly is simple, and need not increase equipment investment basically, and has low use-cost, and is easy to implement.

Owner:JIANGSU DIO ENERGY SCI TECH

Multi-Purpose Pressure Operated Downhole Valve

A downhole valve features a flow port that can be selectively obstructed by a pressure actuated sleeve that is movable in a pin and slot mechanism to rotate while being cycled up and down by application and removal of pressure in a cyclical manner. When the sleeve is cycled to the port closed position, a flapper mounted near its upper end can fall on a seat on the sleeve to allow pressure to be applied to the flapper and sleeve, causing the sleeve to move to a position that will prevent fluid loss from the tubular string into the formation. The Closed flapper allows pressure cycles of the sleeve. A double closure against fluid loss can be affected.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com