Hydraulic system of a transmission unit, comprising a main transmission pump and an auxiliary pump

A hydraulic system and transmission technology, applied in transmission control, transmission parts, transportation and packaging, etc., can solve problems such as unreachable, ISG clutch cannot be closed, internal combustion engine cannot start automatically, etc., and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

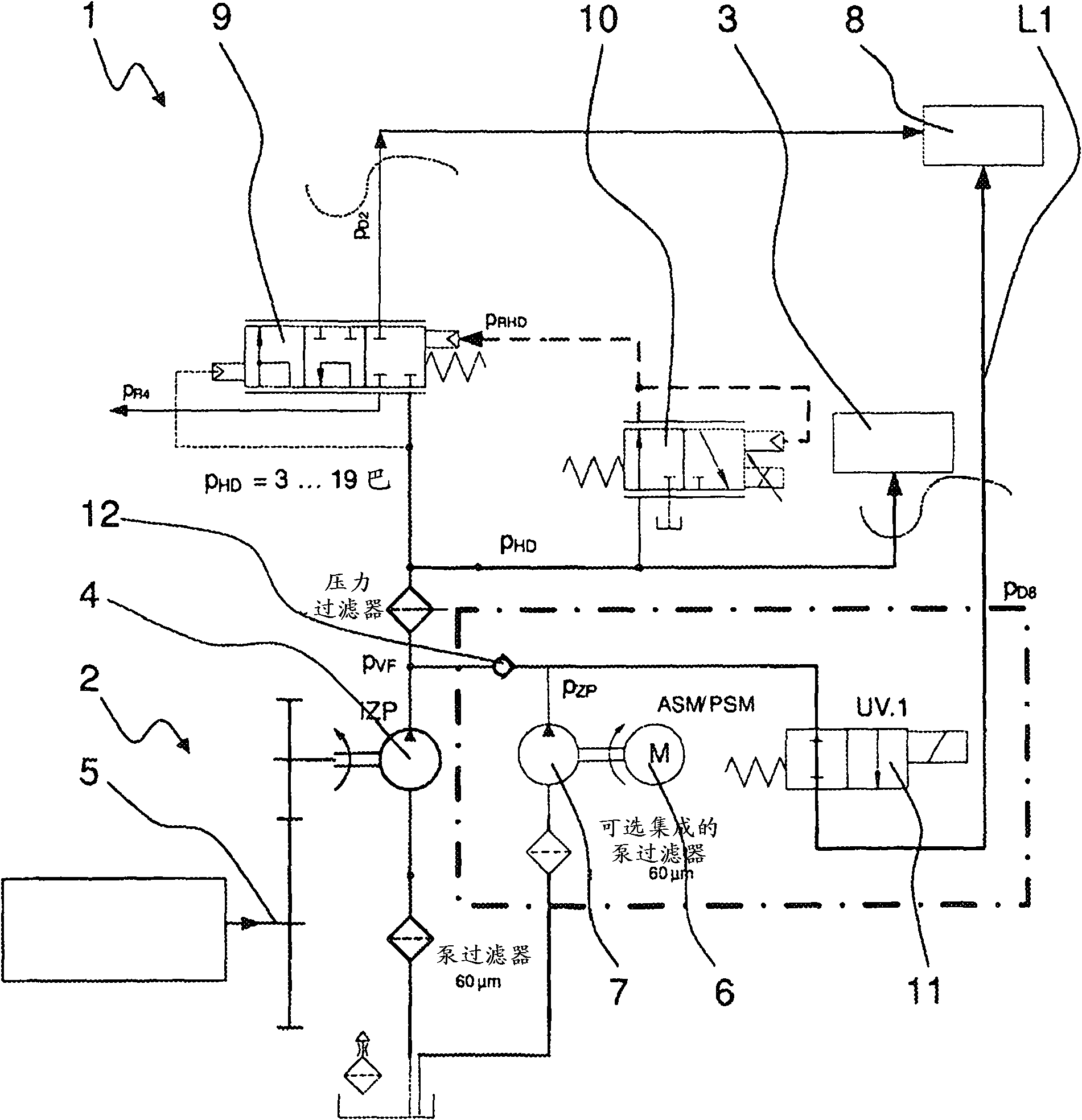

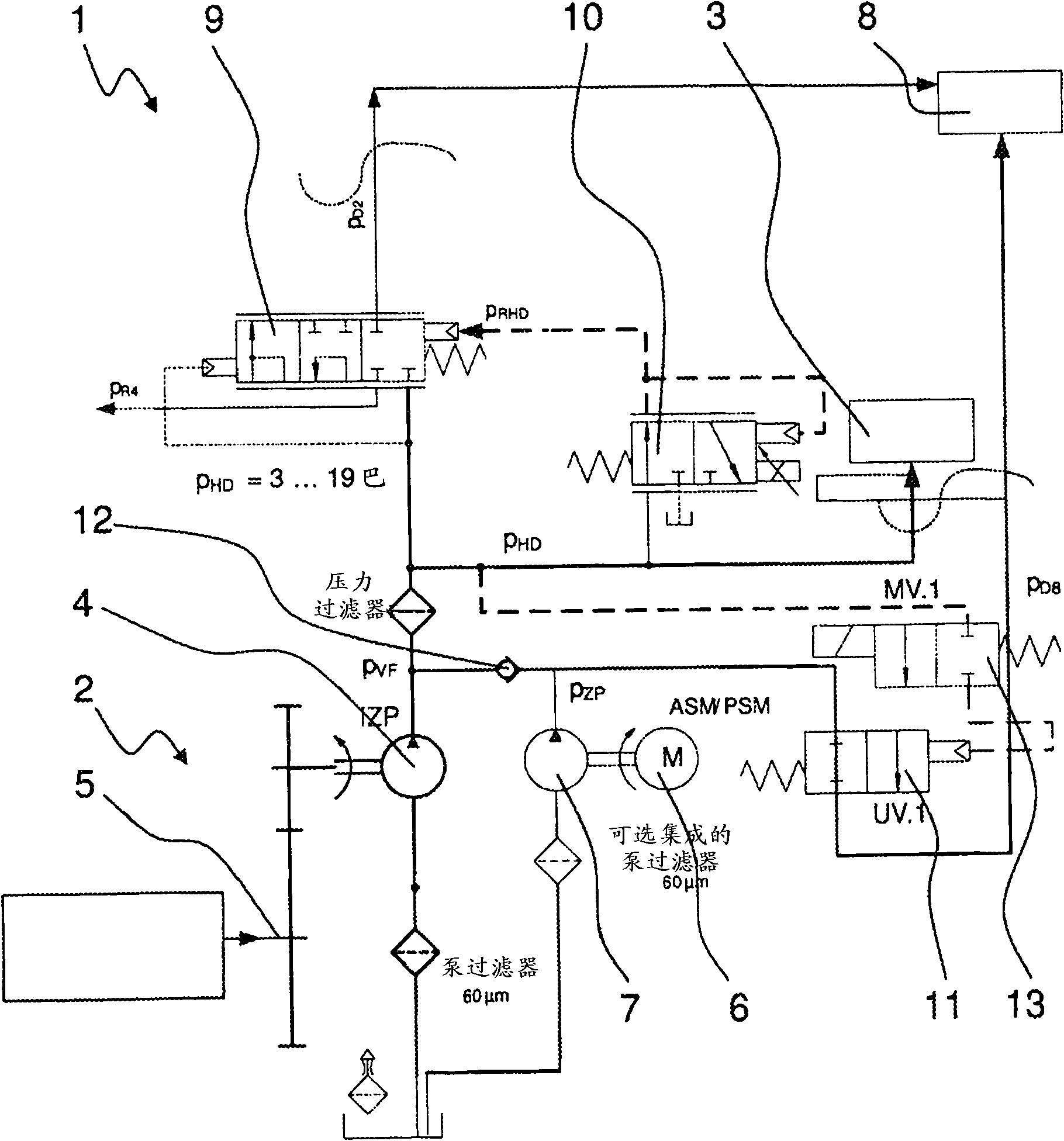

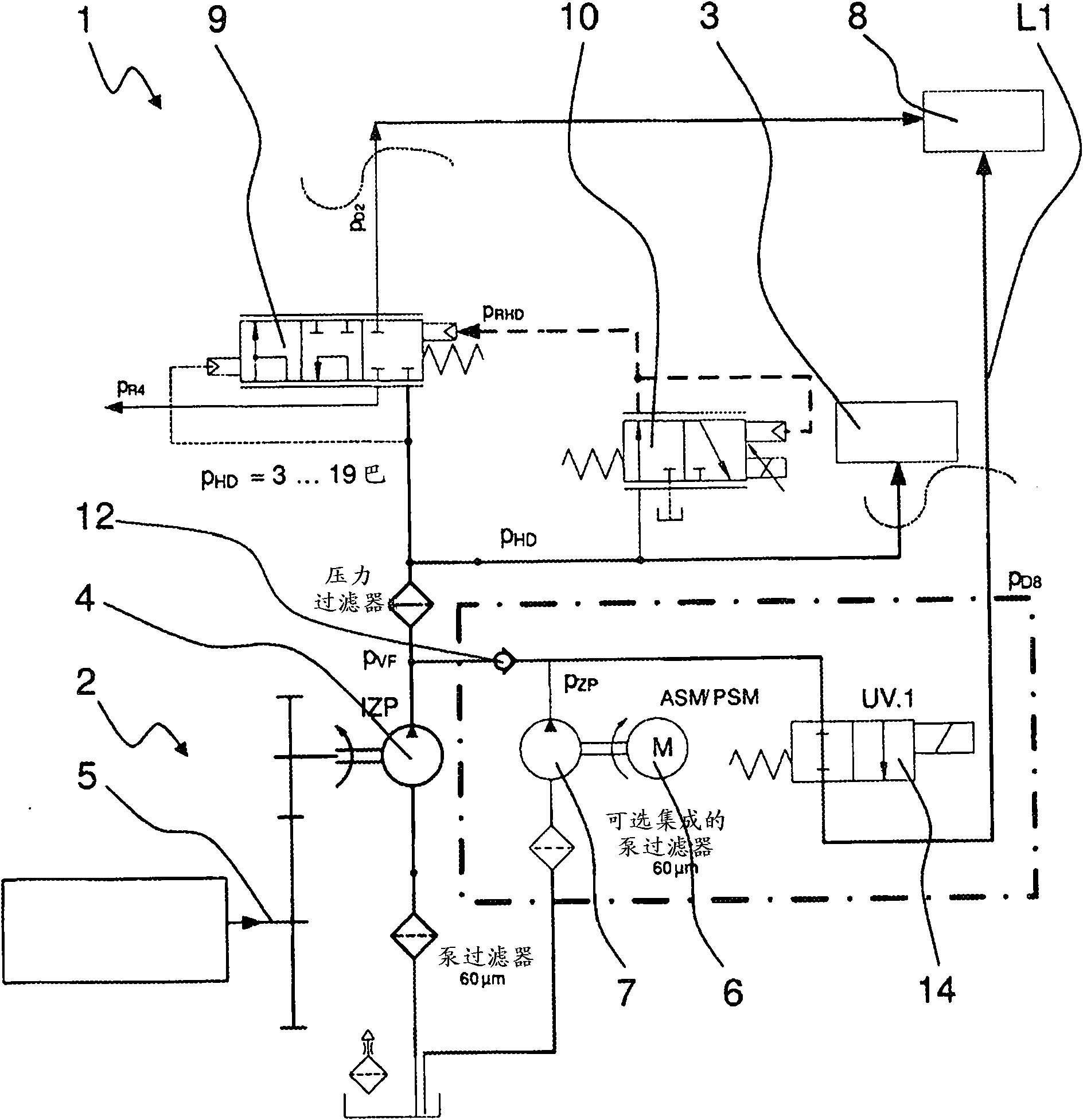

[0032] figure 1 A greatly simplified schematic diagram of the hydraulic system 1 of the transmission device of the vehicle or the powertrain of the vehicle is shown. The vehicle is provided with a hybrid drive device in a known manner. The hybrid drive device includes a power device configured as an internal combustion engine, an electric motor 6 and a transmission device 2. The transmission device 2 can in principle be any known automated manual transmission or automatic transmission in practice, which is provided with hydraulically controllable shift elements such as friction-locked shift clutches or disc brakes and can also be applied to commercial applications Vehicles such as public vehicles or similar vehicles.

[0033] In the transmission device 2, a plurality of shift elements that can be hydraulically controlled by the hydraulic system 1 can generate a force transmission chain, and the shift elements can be loaded with operating pressure through the primary pressure cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com