Vacuum or pressure storage system for food or beverage containers

a vacuum or pressure storage and food or beverage technology, applied in the field of vacuum or pressure storage systems for food or beverage containers, can solve problems such as spoilage of beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

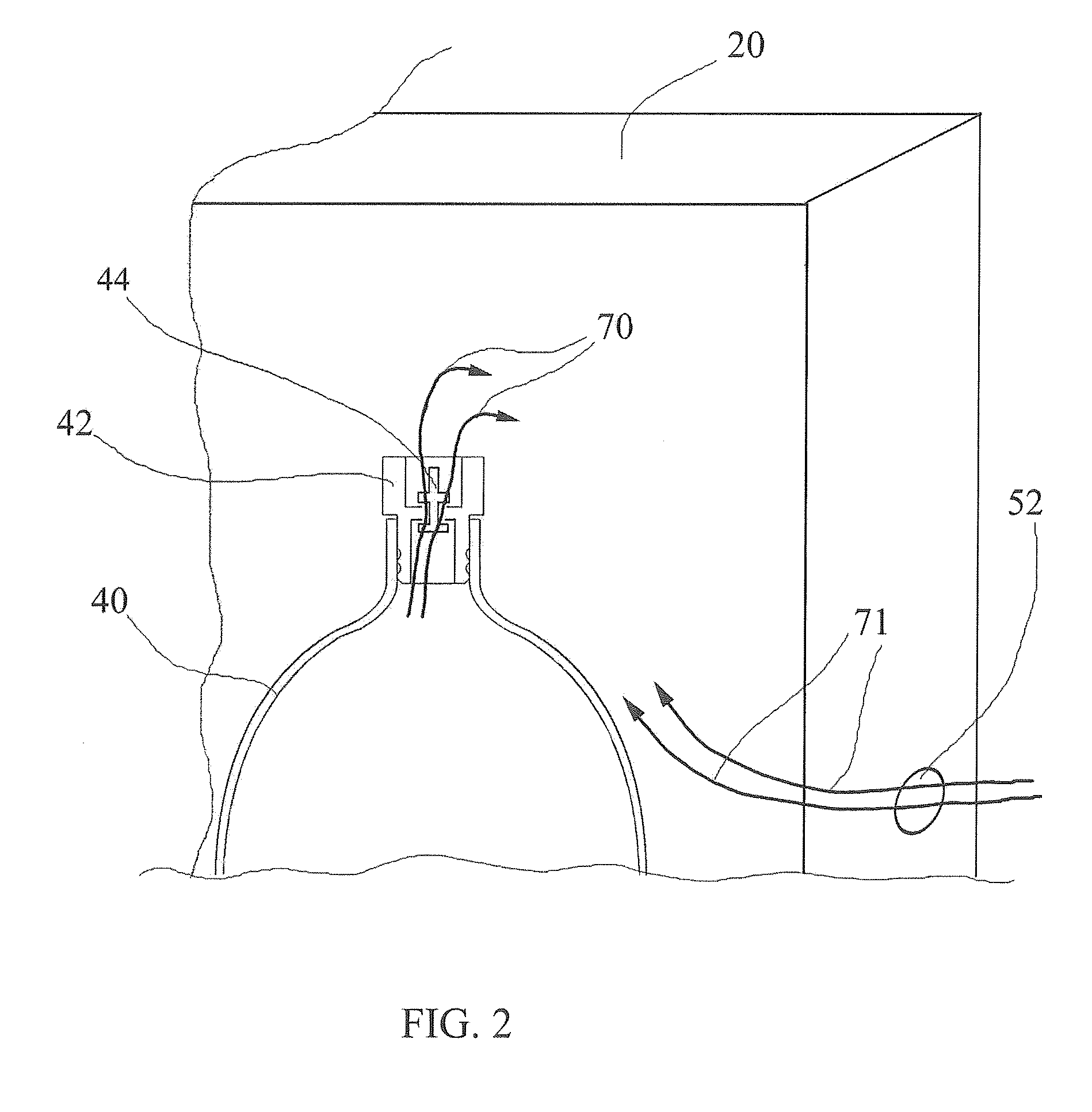

[0034]In describing the preferred embodiment of the present invention, reference will be made herein to FIGS. 1-5 of the drawings in which like numerals refer to like features of the invention.

[0035]The present invention describes uses of stoppers having one-way valves in a system for maintaining proper pressure and temperature, which stoppers are described in U.S. Pat. Nos. 5,031,785 and 7,198,074, the disclosures of which are hereby incorporated by reference.

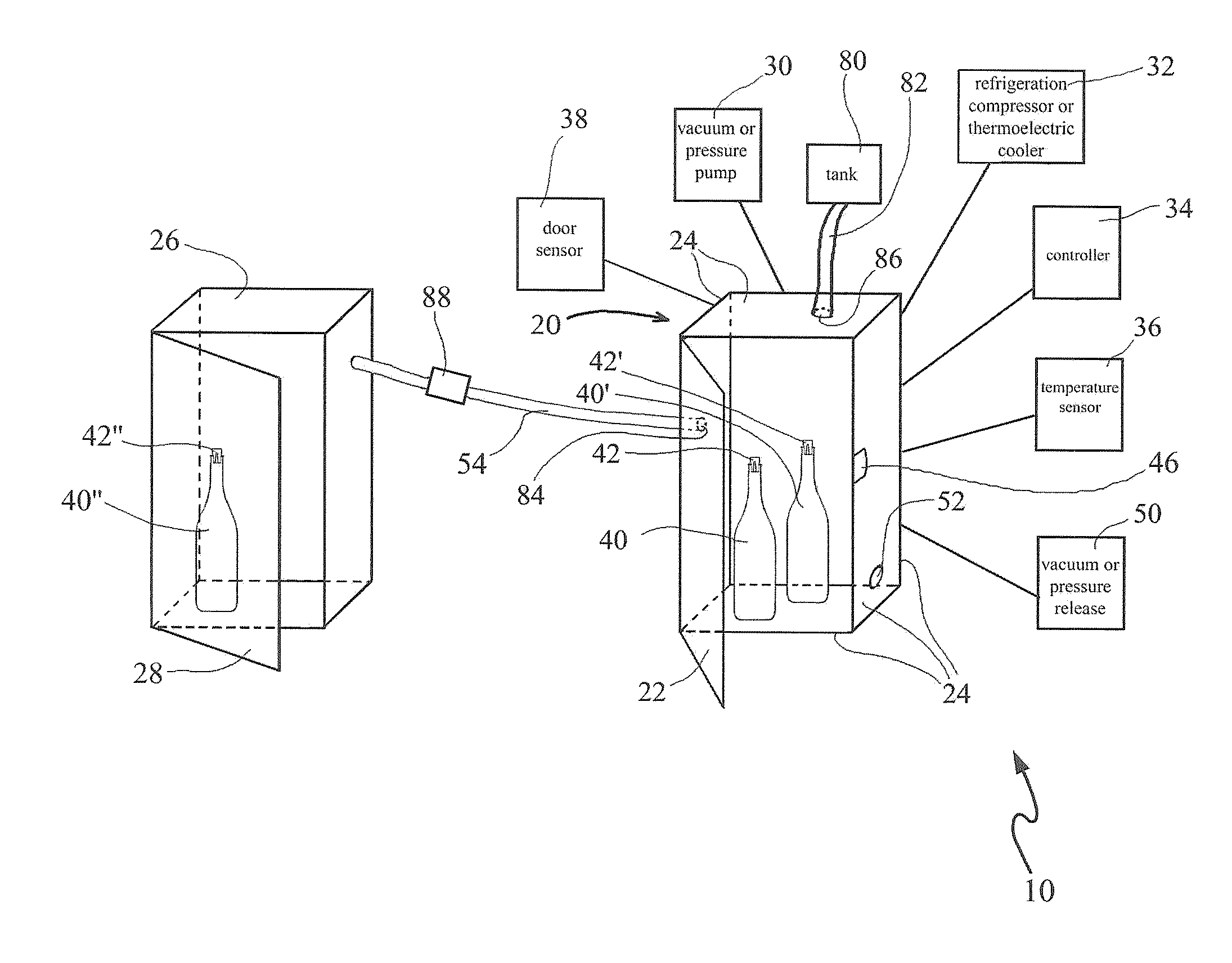

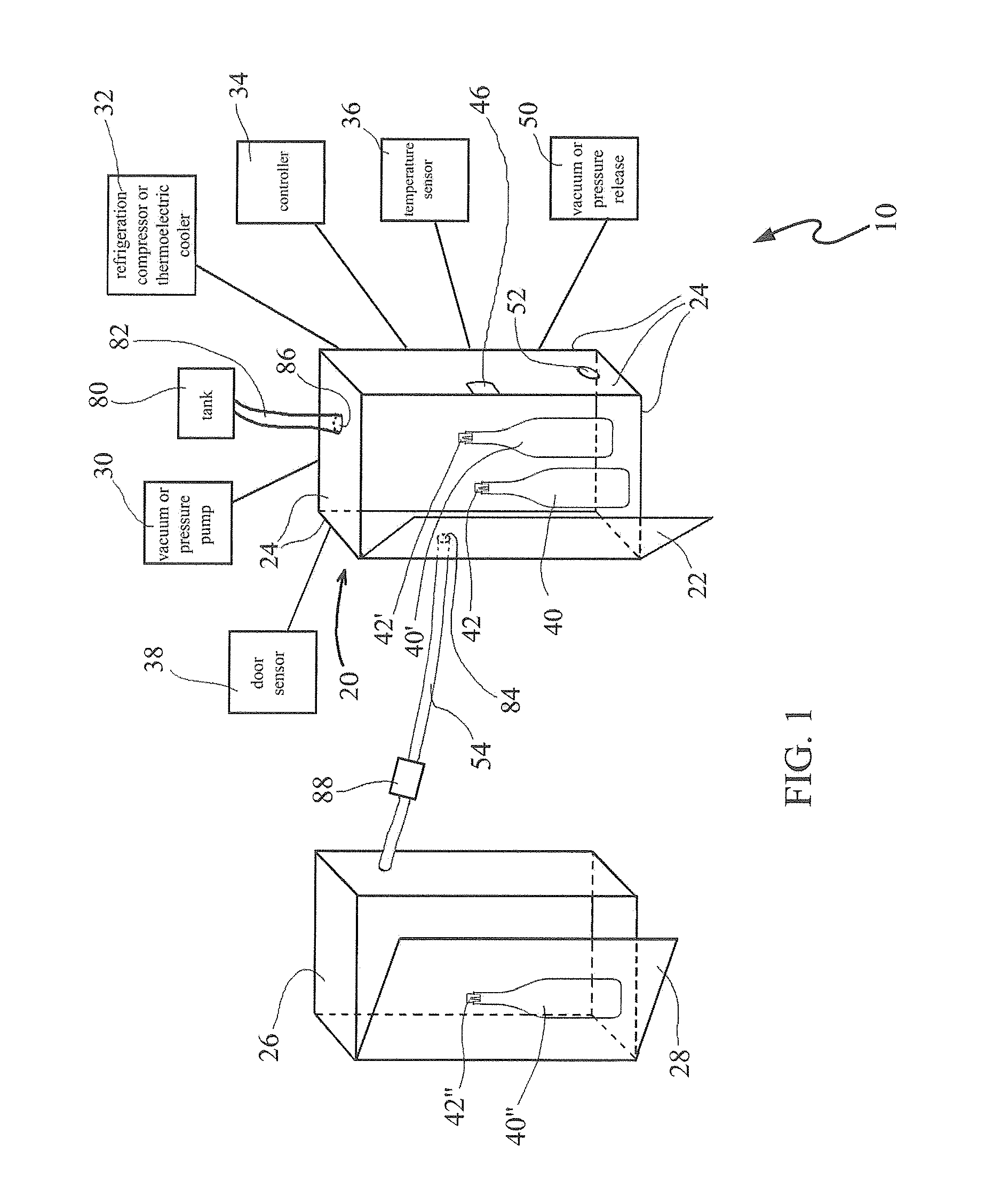

[0036]FIG. 1 shows a schematic of a combination refrigerator and air evacuation or pressurization system. A combined refrigerator and vacuum and / or pressure chamber 20 is provided with an otherwise conventional refrigeration compressor or thermoelectric cooler 32 to cool the interior compartment of the refrigerator and a vacuum or pressure pump 30 to remove air from or add air to the interior compartment of the refrigerator. While a combined vacuum / pressure pump may be employed, so that the system may be used in both vacuum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com