Pressure circulation service life testing system and method

A cycle life, test system technology, applied in vibration testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of inability to directly use pressure pulsation simulation test, difficult to use directly, and achieve low assembly and maintenance costs , the effect of low static load and precise pressure pulsation

Active Publication Date: 2014-04-09

TIANJIN AEROSPACE RELIA TECH

View PDF8 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the precise displacement control provided by the shaking table cannot be directly applied to the pressure pulsation simulation test

At the same time, for most of the hydraulic fatigue test equipment, the pulsation amplitude can be realized by c

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

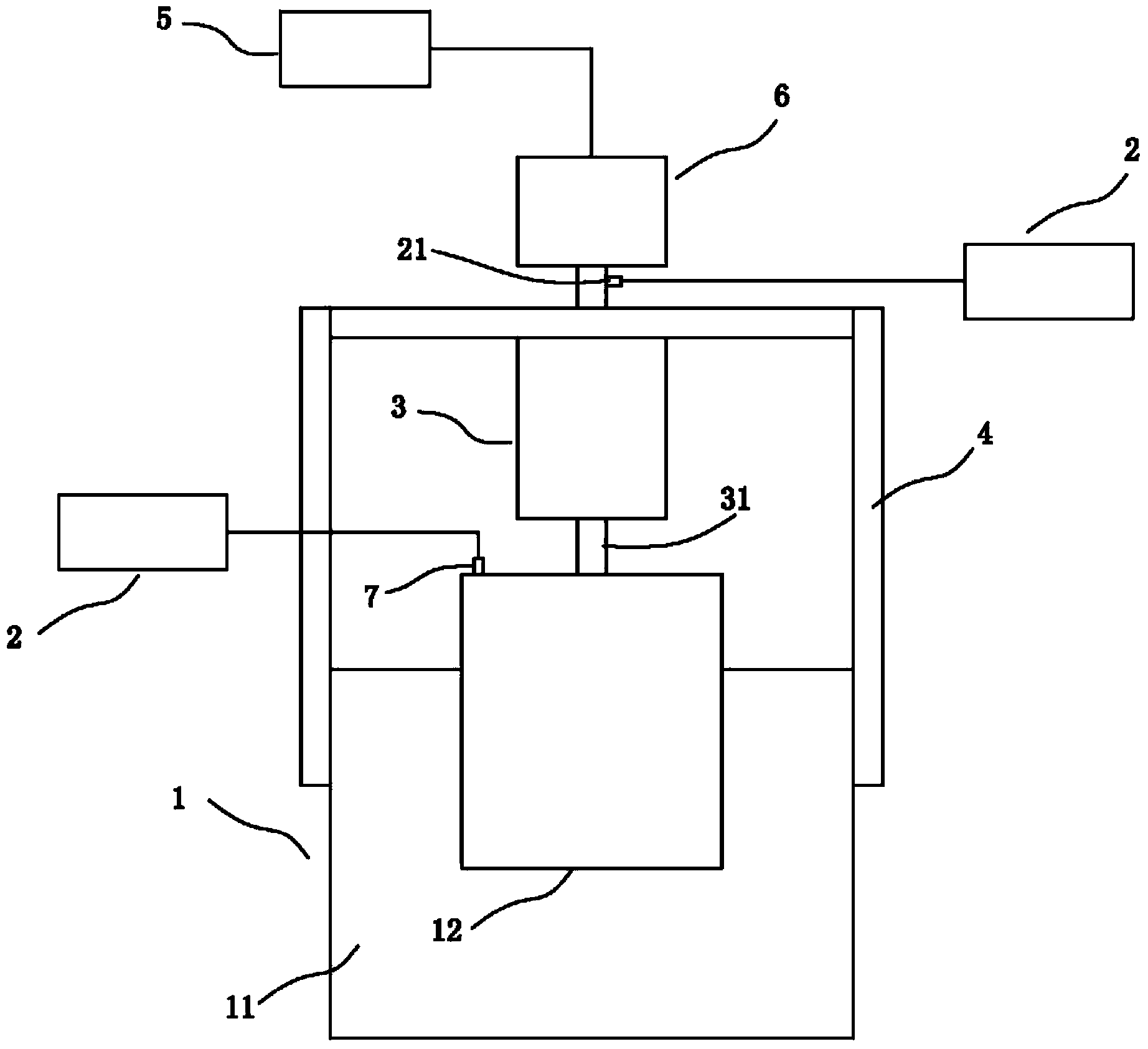

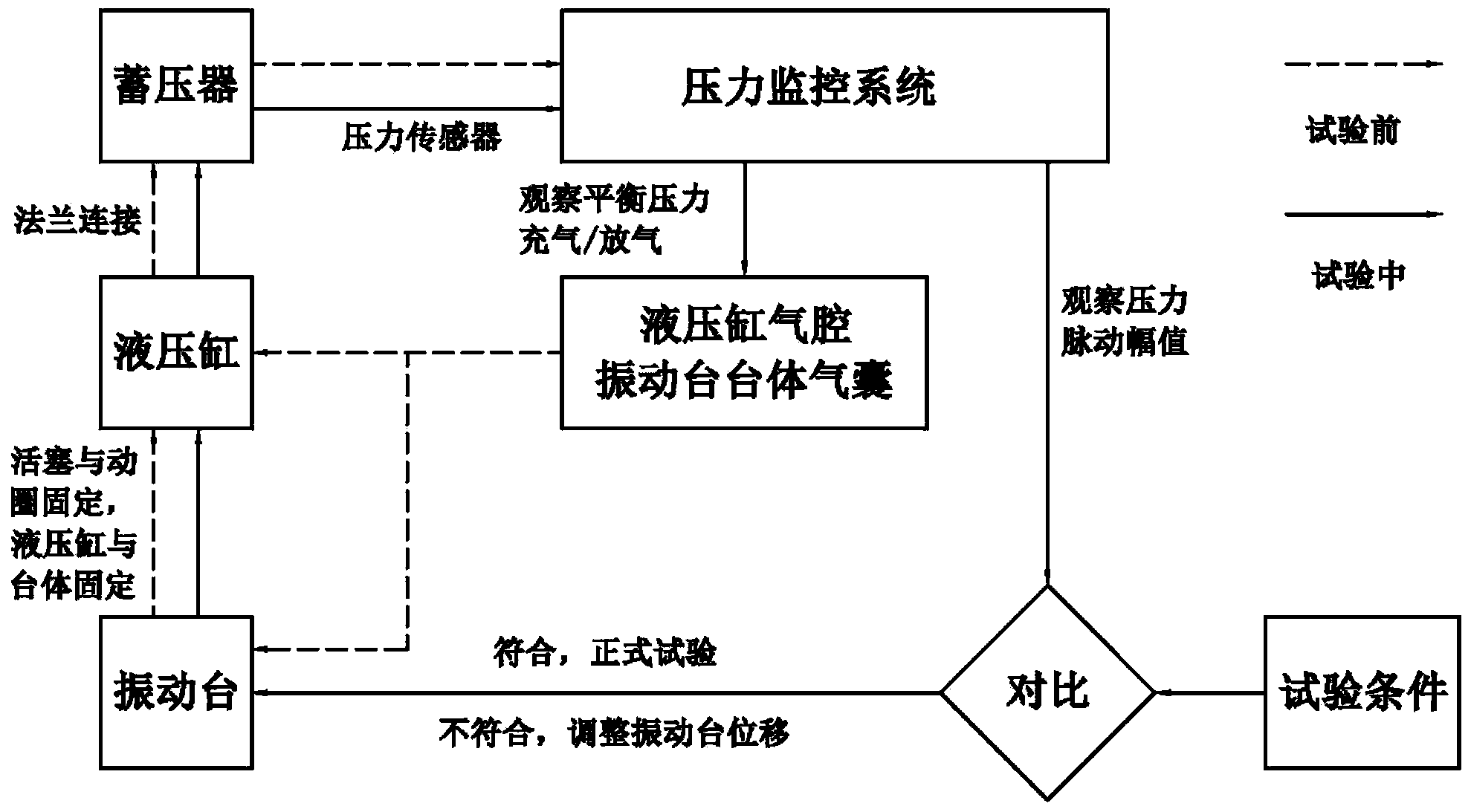

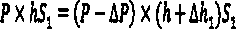

The invention discloses a pressure circulation service life testing system and method. According to the typical embodiment, a vibrating platform is provided as a power source, a hydraulic cylinder is provided as a transmission element, a piston is arranged in the hydraulic cylinder, the piston is in transmission connection with a moving component of the vibrating platform through a piston rod, air is filled into a hydraulic cylinder inner cavity located on one side, close to the vibrating platform, of the piston, a hydraulic cylinder inner cavity located on the other side of the piston is communicated with an accumulator liquid cavity, and water is filled into the hydraulic cylinder inner cavity located on the other side of the piston and into the accumulator liquid cavity. The vibrating platform is started, through motion of the moving component of the vibrating platform, water filled into the hydraulic cylinder and the accumulator liquid cavity is made to extrude an accumulator air cavity to form pressure fluctuation. The pressure circulation service life testing system can adapt to different pressure fluctuation amplitudes and frequencies conveniently by adjusting the output displacement and the frequency of the vibrating platform, so that high control precision of the pressure fluctuation is guaranteed, and the system is simple in structure, low in assembly and maintenance cost and easy to operate.

Description

technical field [0001] The invention particularly relates to a test device and method for simulating pressure fluctuations in a rocket fuel delivery pipeline for evaluating the fatigue performance of a pressure accumulator on the pipeline. Background technique [0002] The severity level of pressure pulsation in rocket fuel pipeline consists of pulsation amplitude, equilibrium pressure and pulsation frequency, and its simulated medium is usually water. At present, the electromagnetic vibrating table cooperates with the vibration controller, which can accurately realize the predetermined alternating frequency and displacement amplitude, and can also provide a large thrust. However, the precise displacement control provided by the shaking table cannot be directly applied to the pressure pulsation simulation test. At the same time, for most of the hydraulic fatigue test equipment, the pulsation amplitude can be realized by compressing the air cavity of the pressure accumulator...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00G01M7/02

Inventor 李杰徐海博

Owner TIANJIN AEROSPACE RELIA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com