Patents

Literature

258results about "Unpacking by expelling contents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

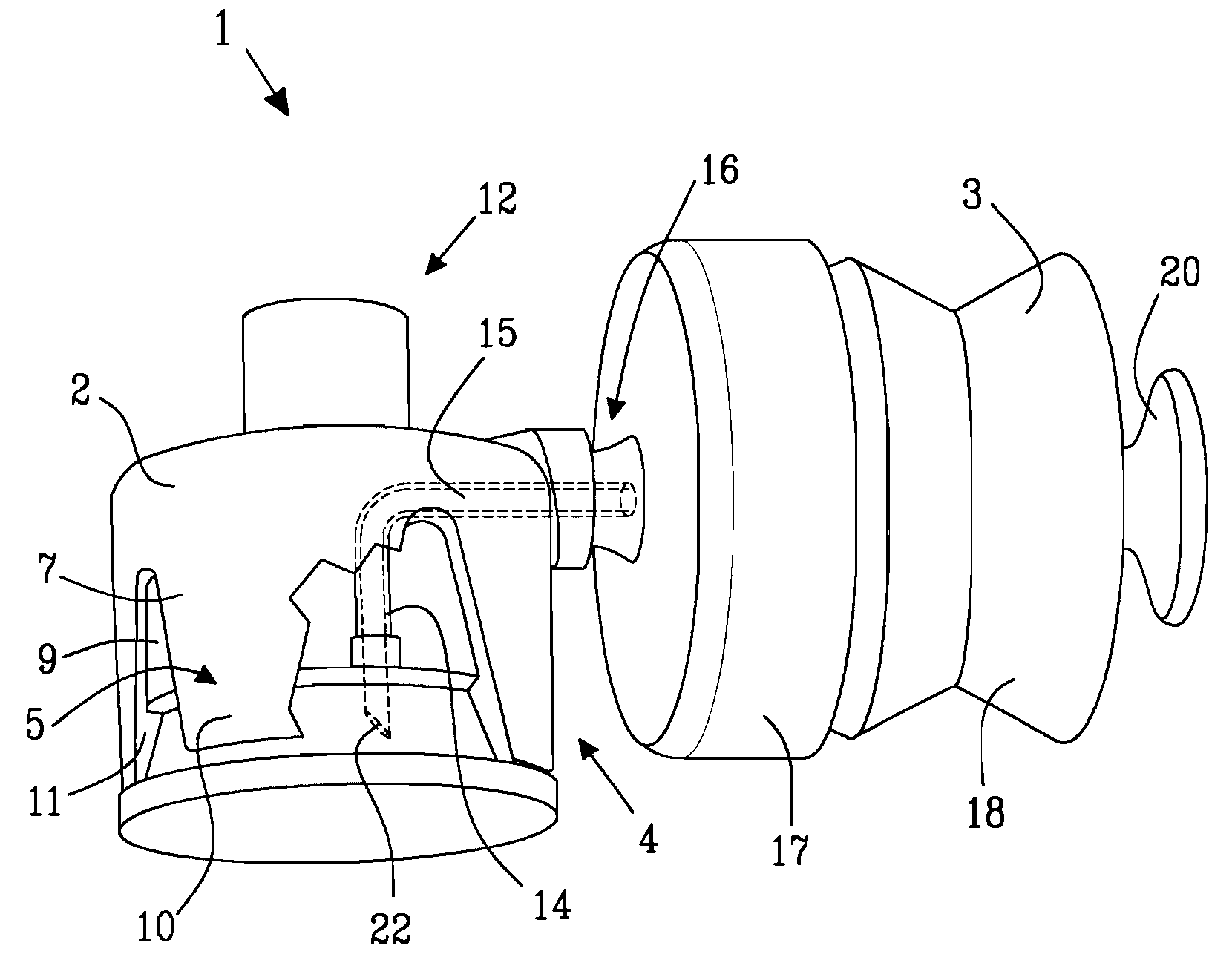

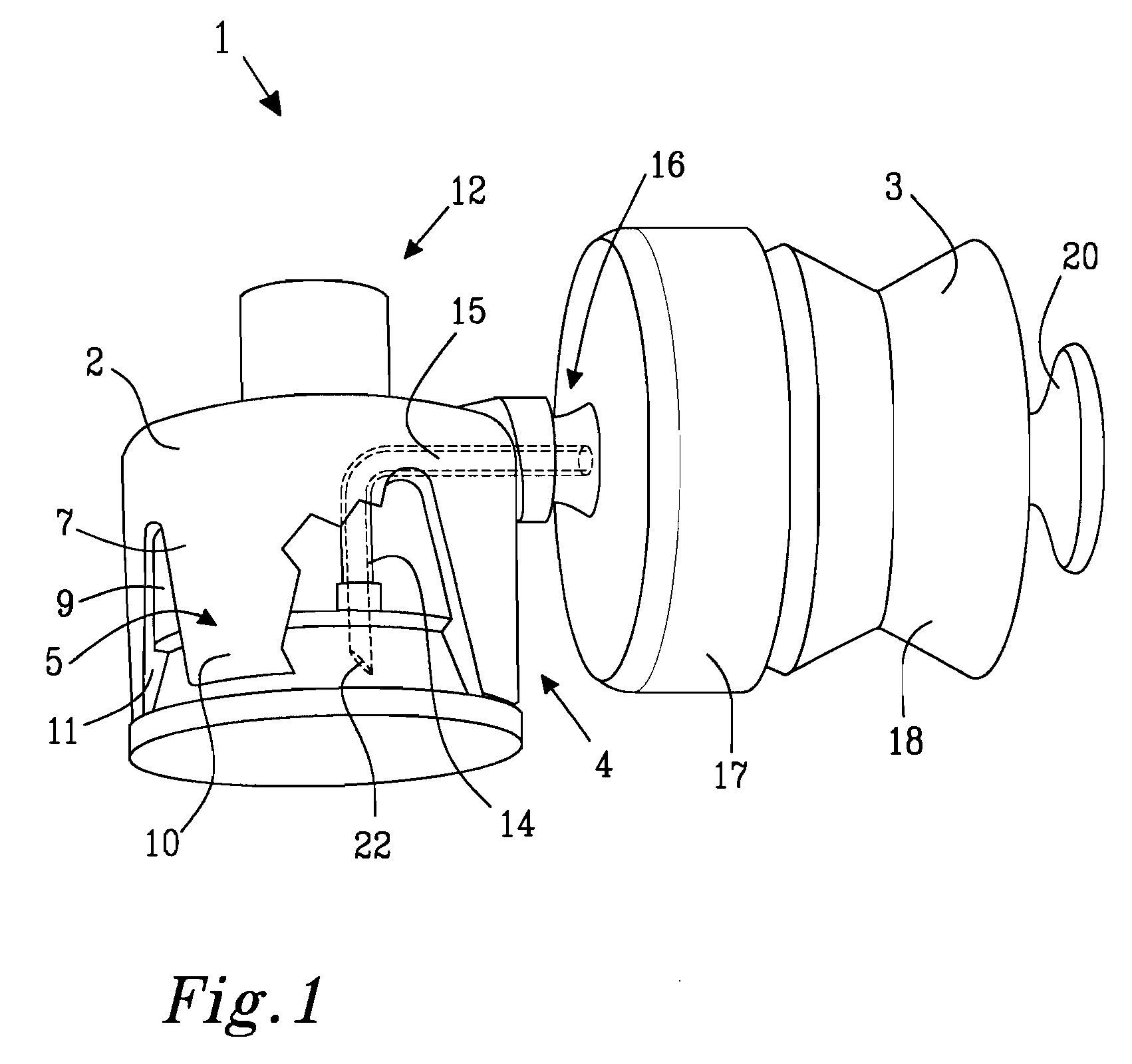

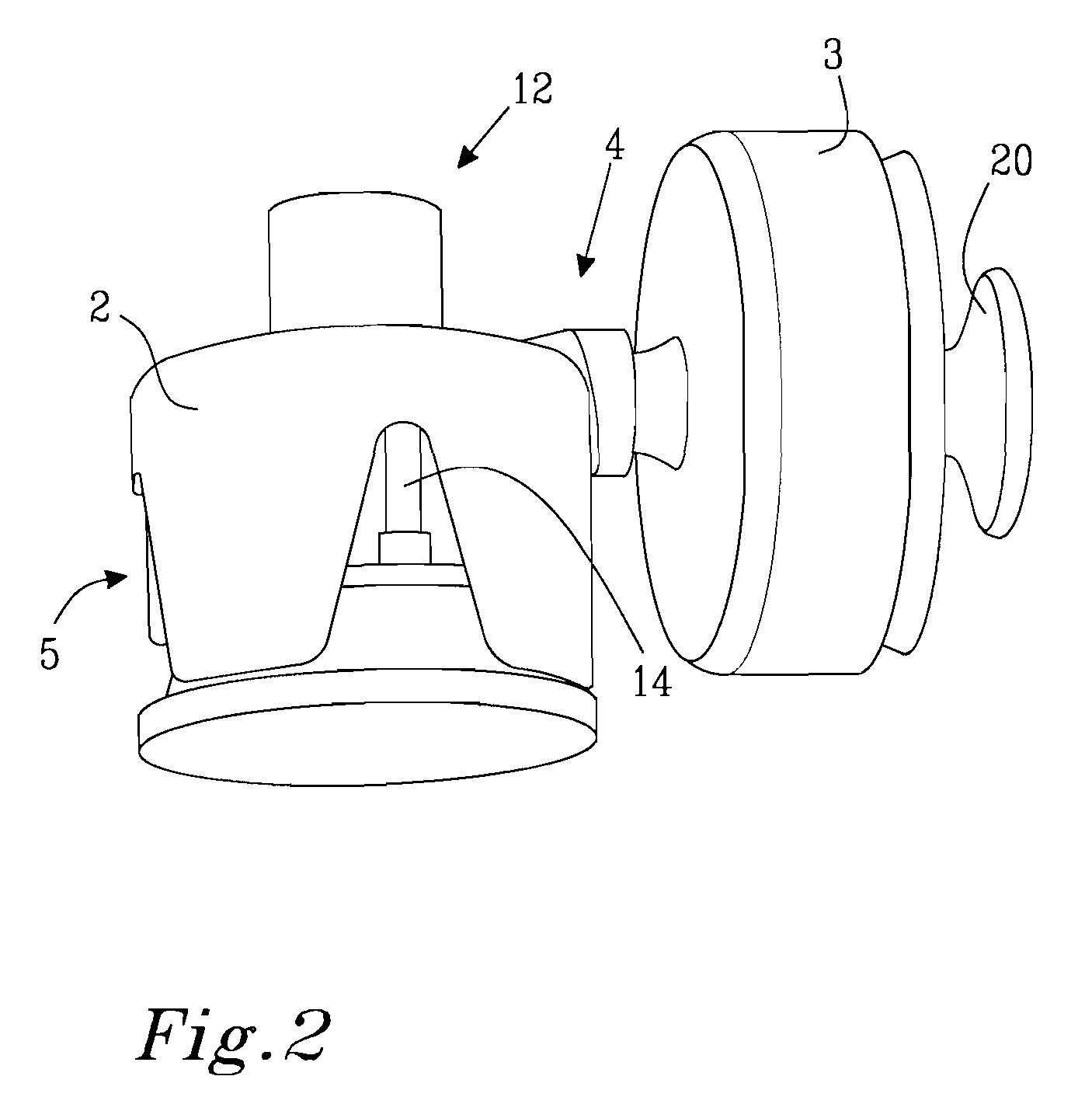

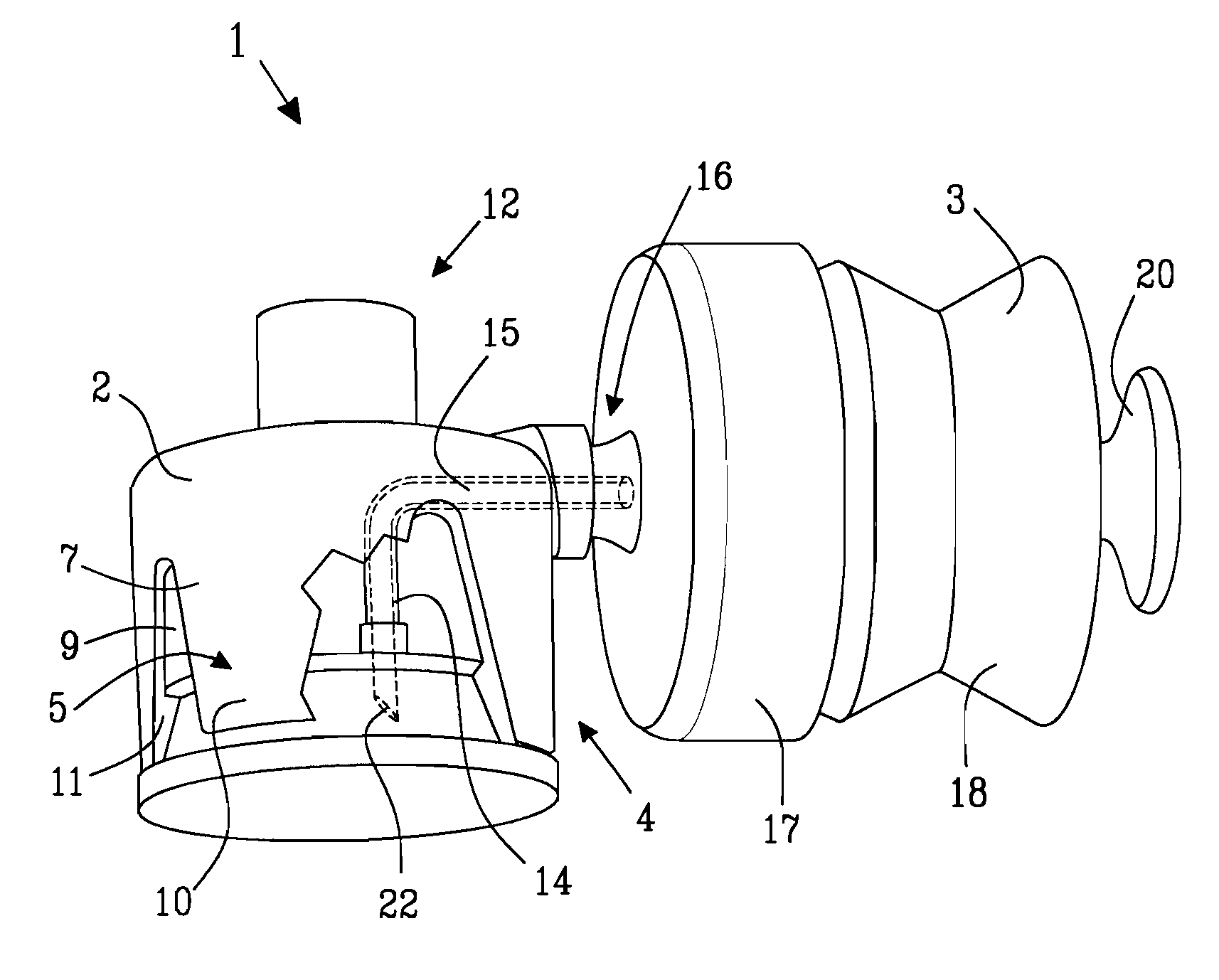

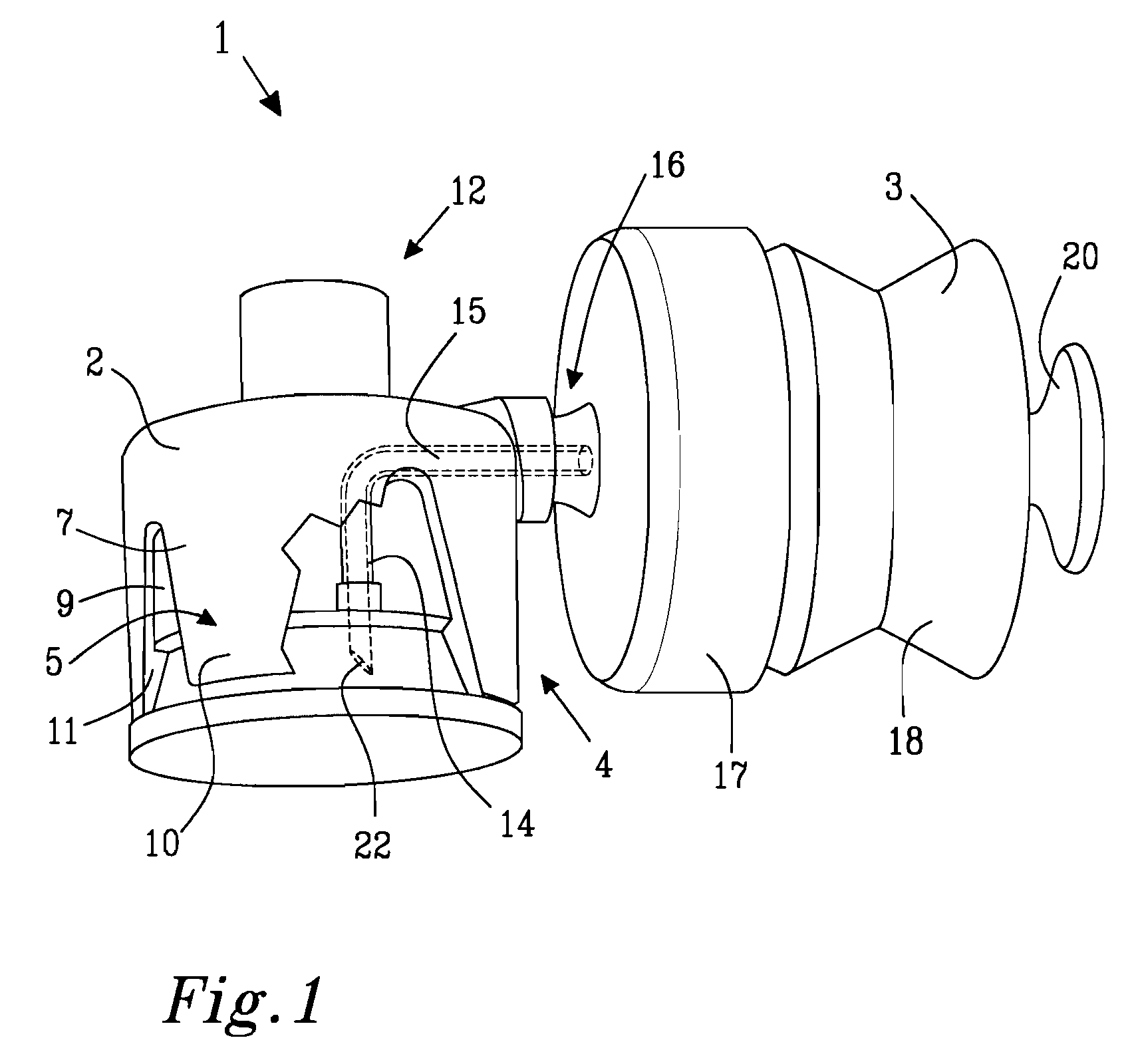

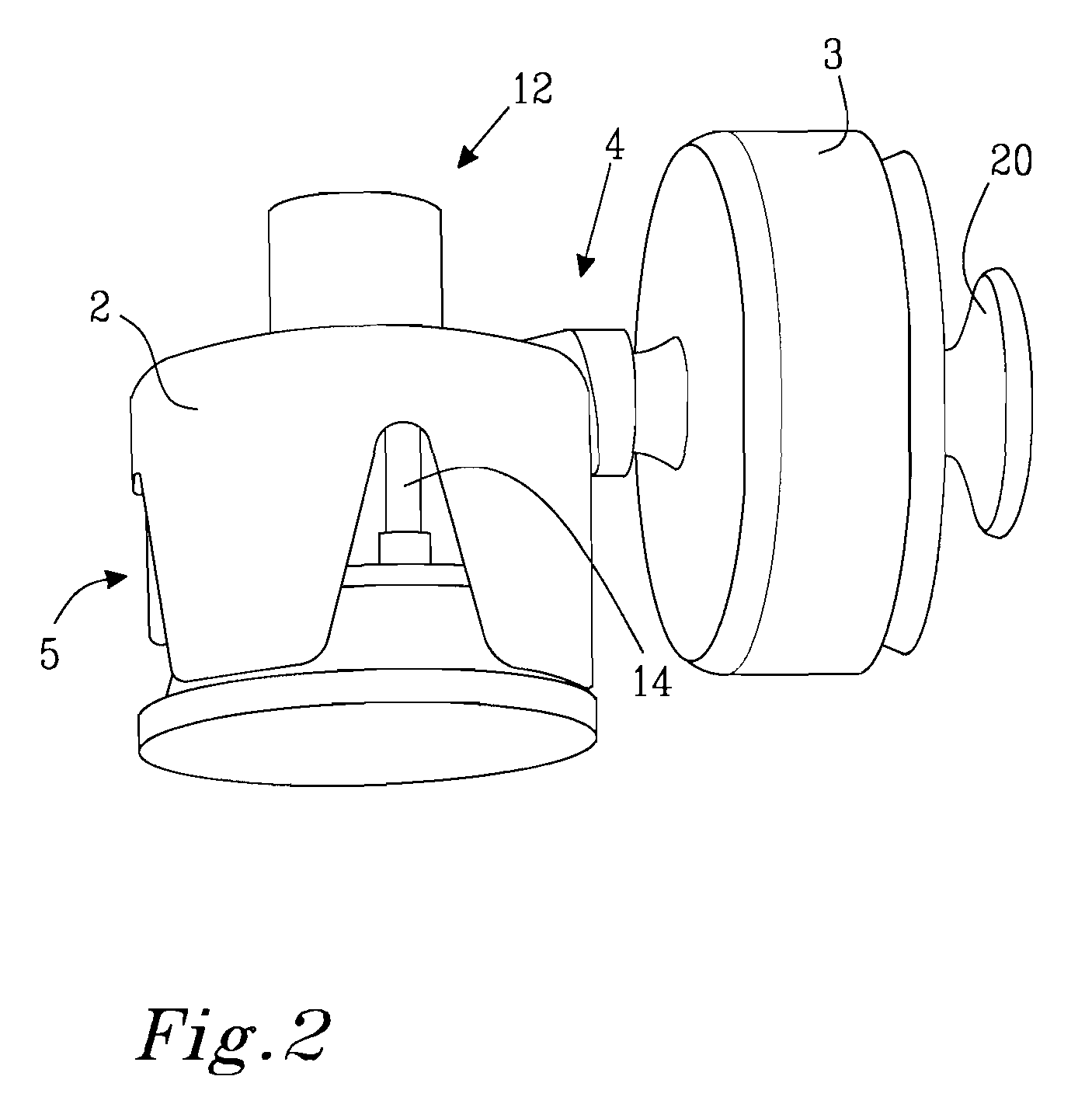

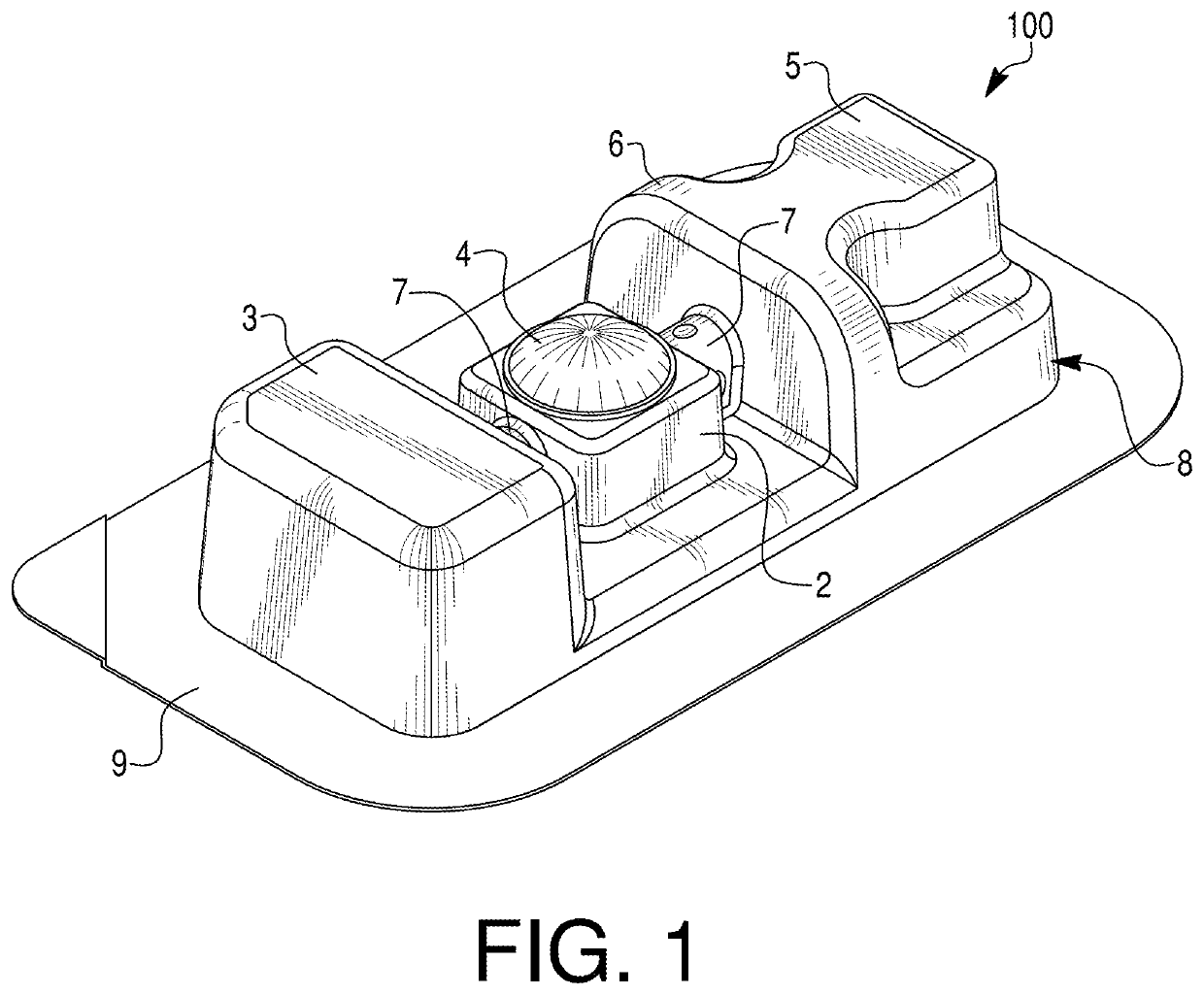

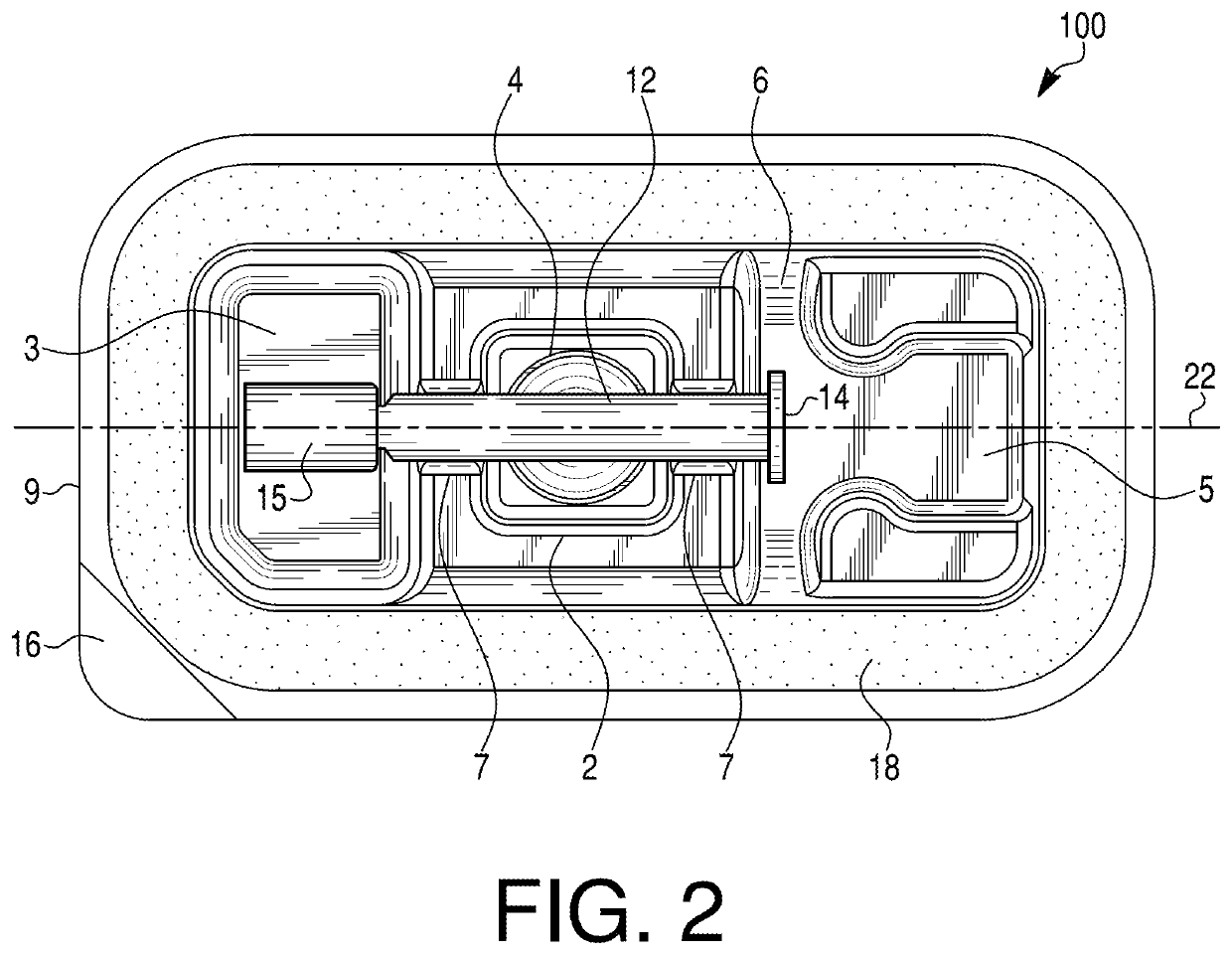

Device for providing fluid to a receptacle

ActiveUS20080312634A1Low costLower the volumeBacterial antigen ingredientsDiagnosticsEngineeringMechanical engineering

Owner:CARMEL PHARMA

Device for providing fluid to a receptacle

ActiveUS8657803B2Easy to operateBacterial antigen ingredientsDiagnosticsEngineeringBiomedical engineering

Owner:CARMEL PHARMA

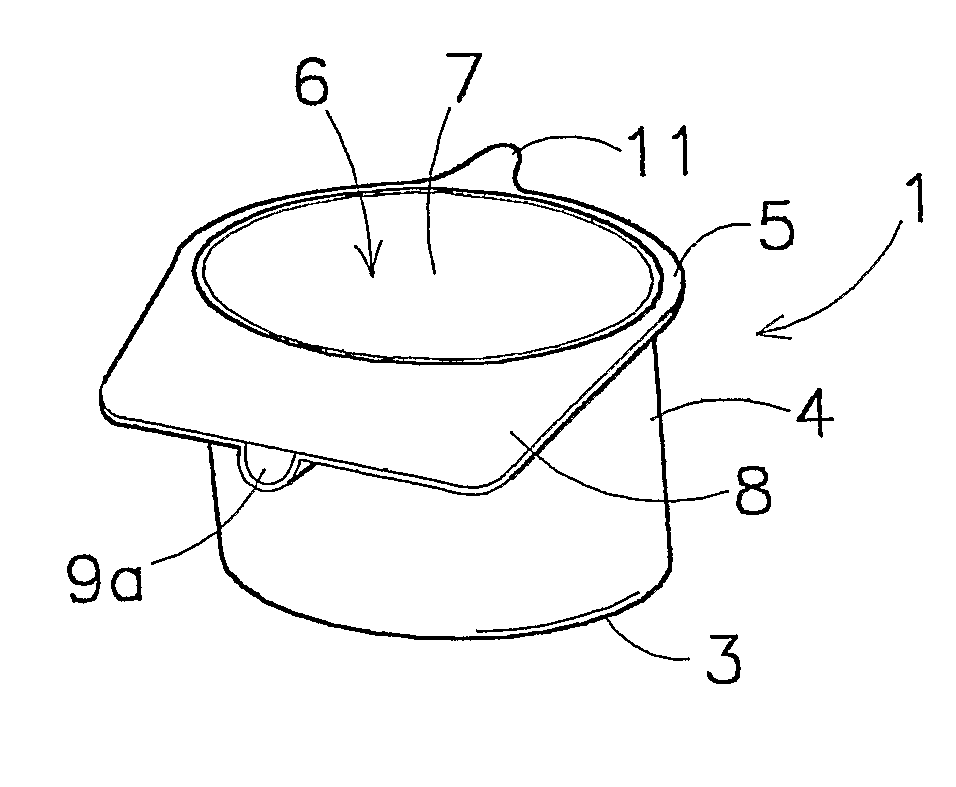

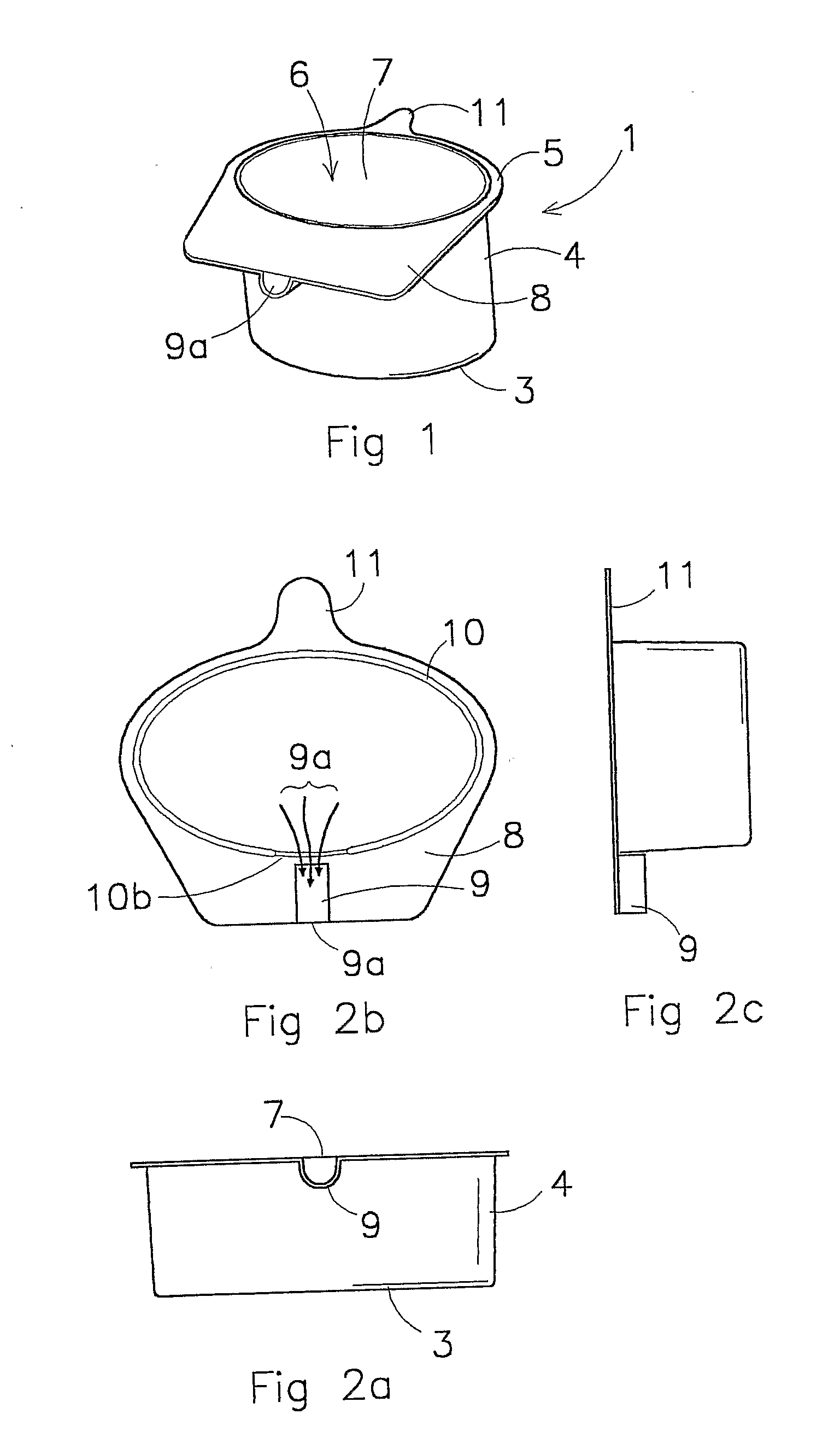

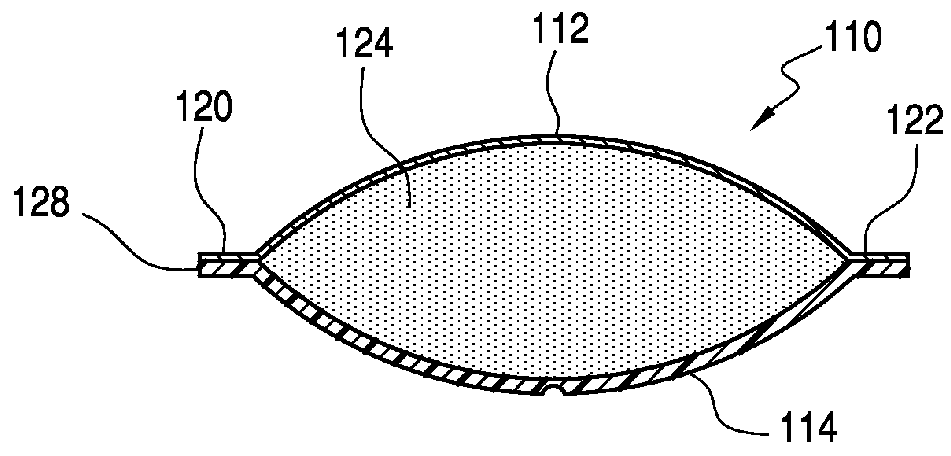

Dispensing of a substance

The invention proposes to dispense a substance from a container filled with a single portion of a substance. The container comprises a preformed deformable body, preferably made of sheet material, defining a filling cavity which body has an opening and an integral planar circumferential rim surrounding said opening, which opening is closed by a cover sheet which is sealed to the circumferential rim by means of a circumferential sealing seam. The container with the substance is opened by making use of the deformability of the cover sheet. A support surface supports the cover sheet except at the position of a recess. The recess is positioned at least over a part of the circumferential sealing seam. Upon compression of the container body the substance is pressurized and the cover sheet bulges out into the recess such that the sealing seam is broken at the location where the bulge is formed resulting in the container being open.

Owner:MDS GLOBAL HLDG

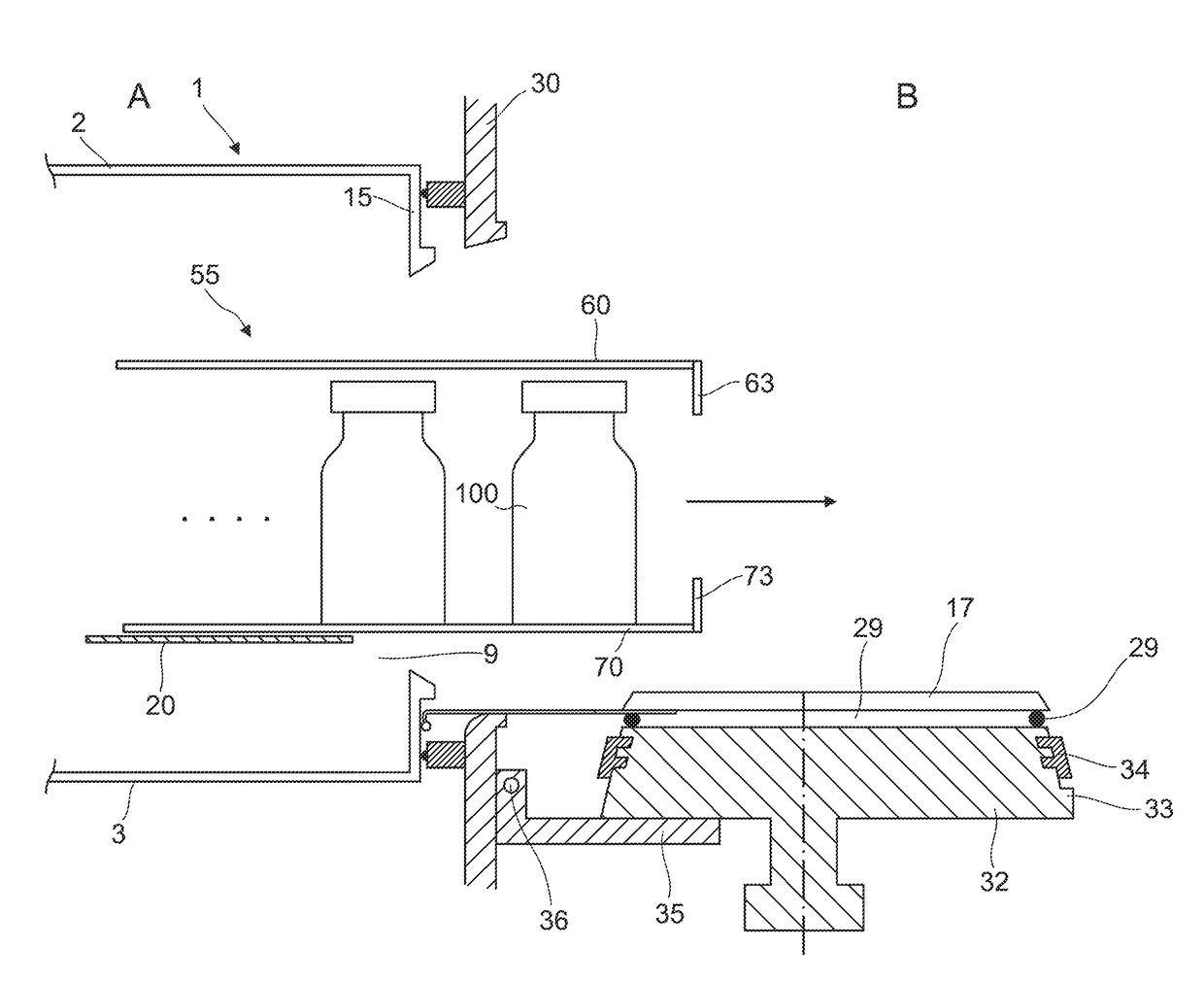

Method of transferring a plurality of containers and/or closures to a clean room, transport and packaging container and packaging structure therefore

ActiveUS20170247132A1Surgical furnitureAir-pressure/air-lock chambersEngineeringMechanical engineering

Owner:SCHOTT PHARMA AG & CO KGAA

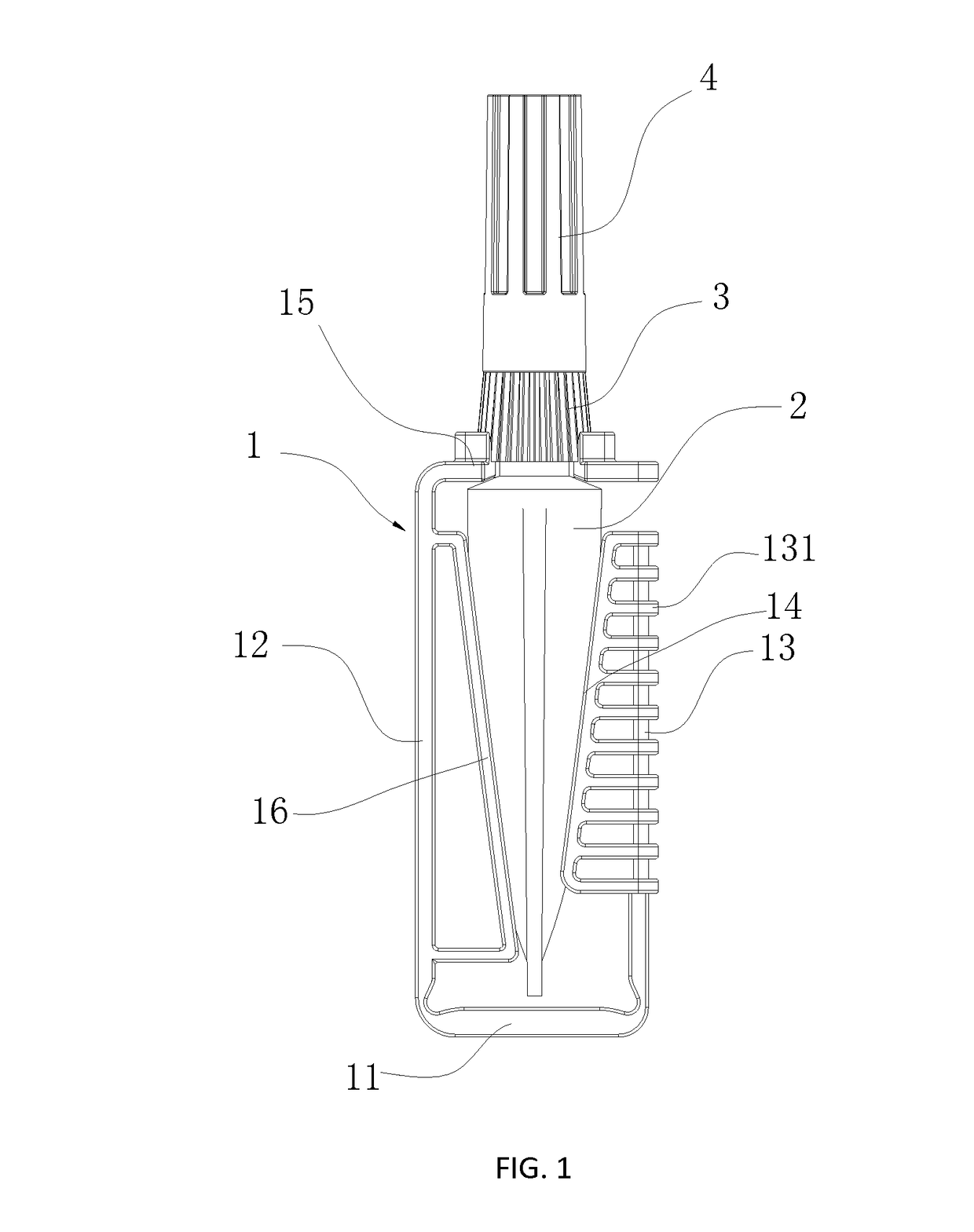

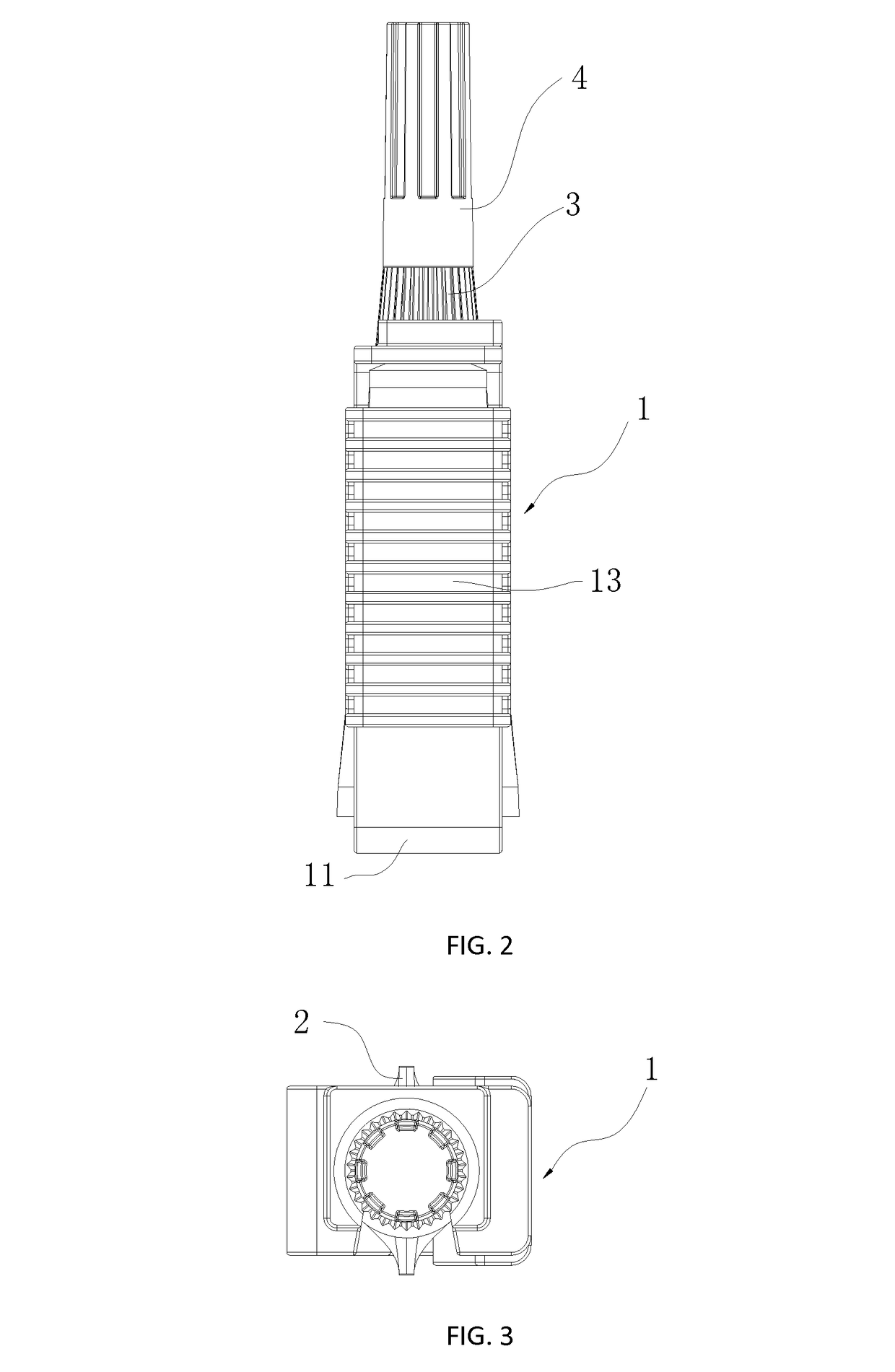

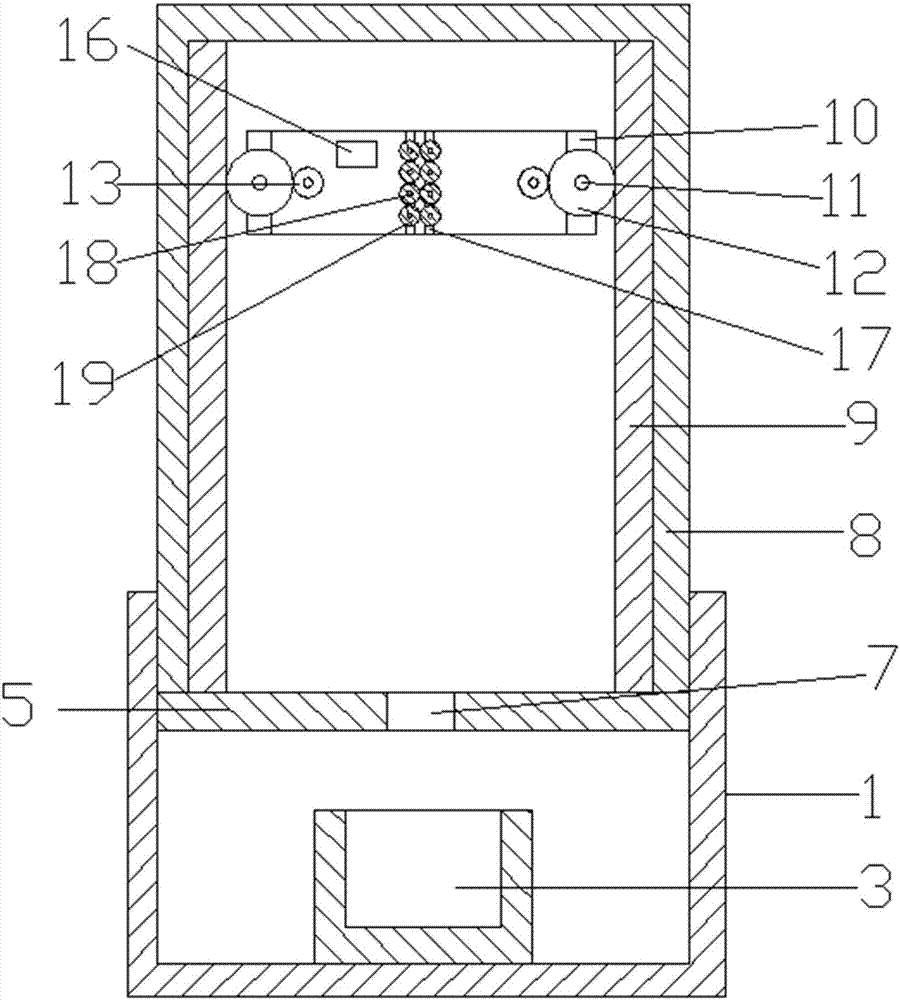

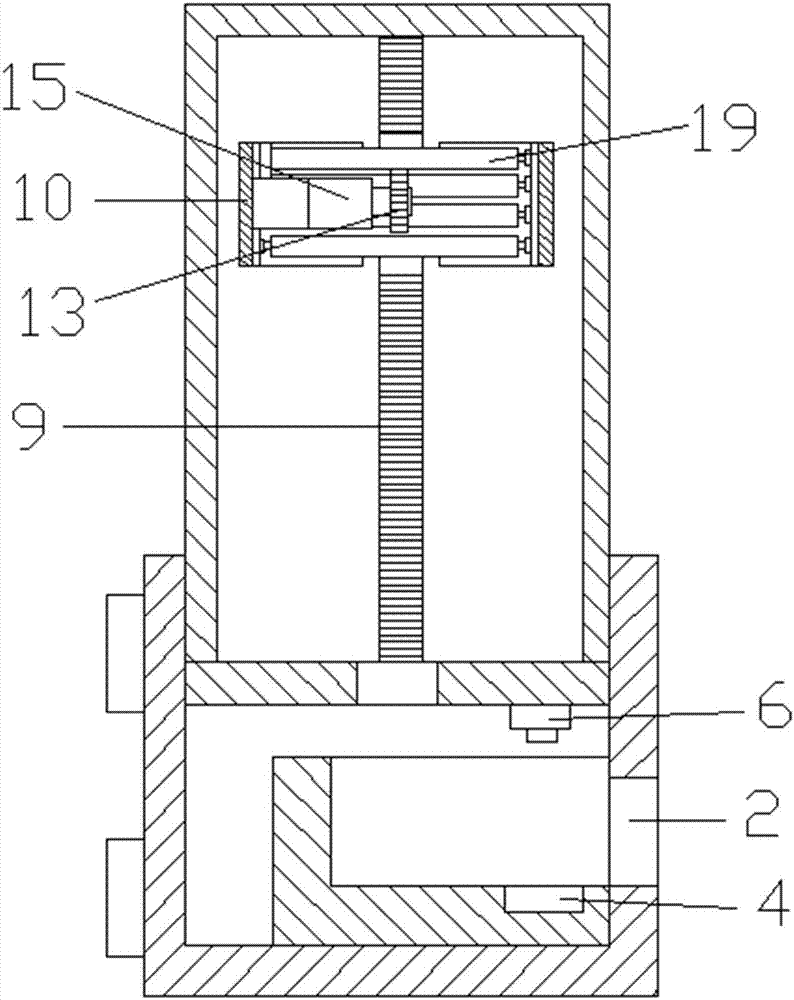

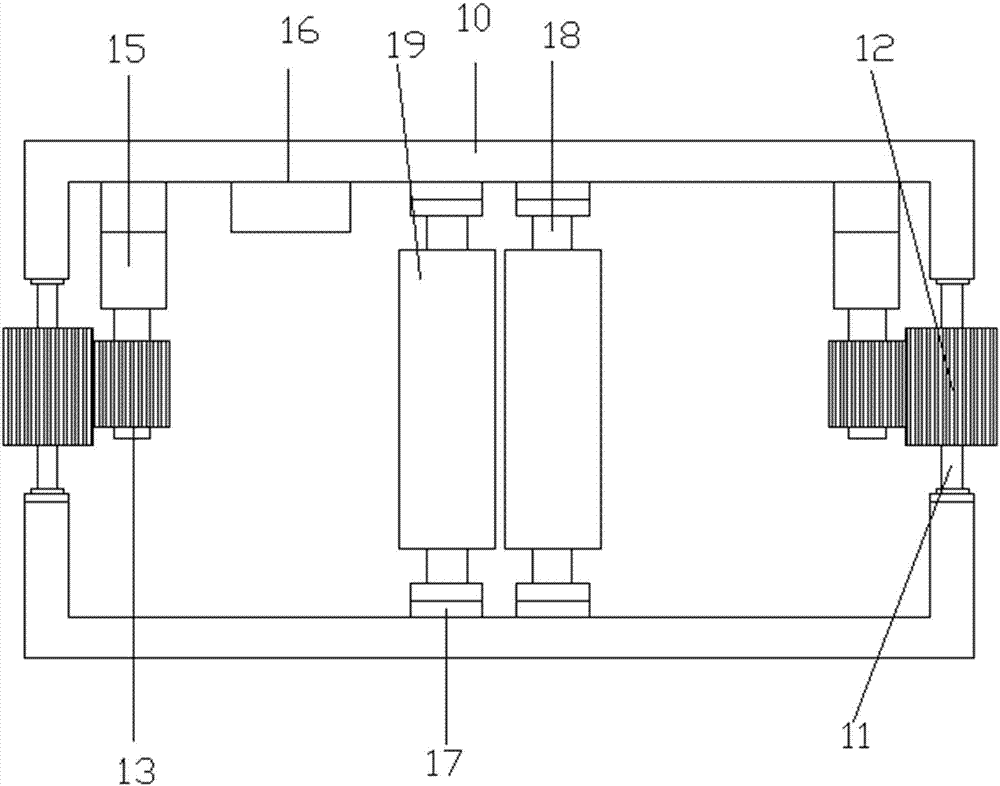

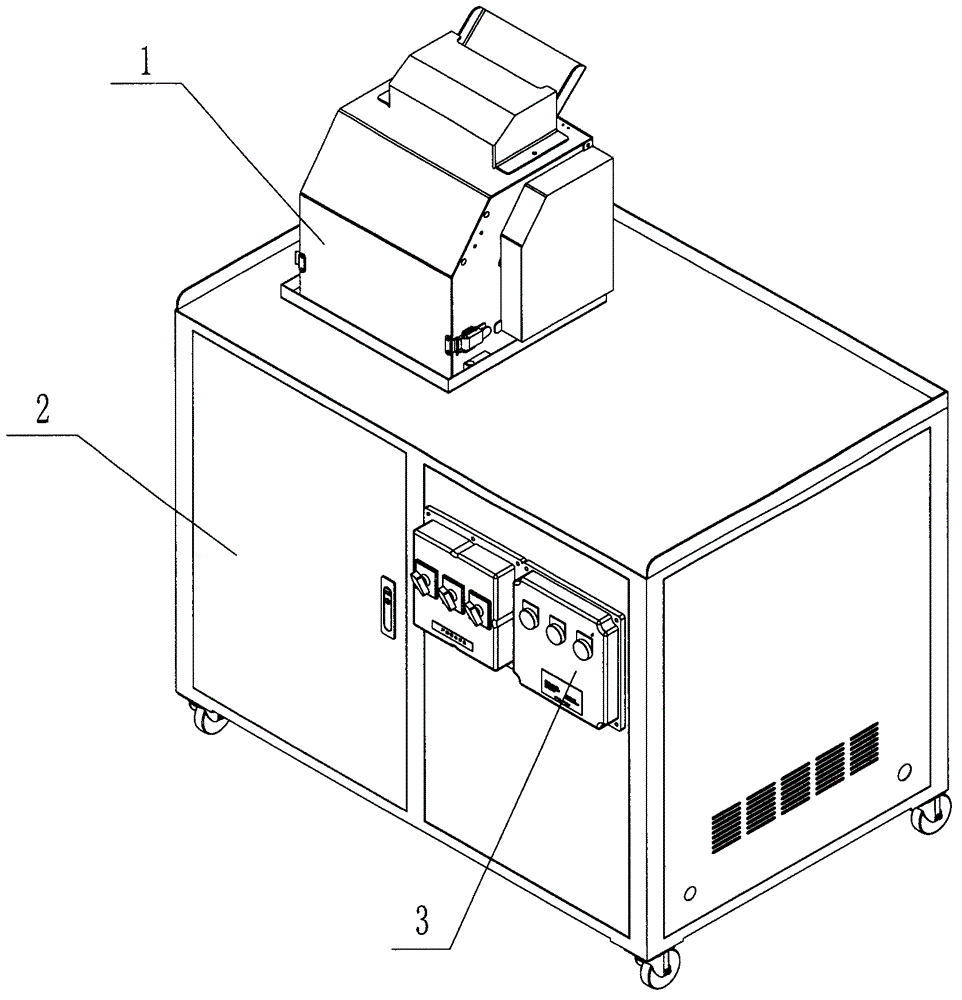

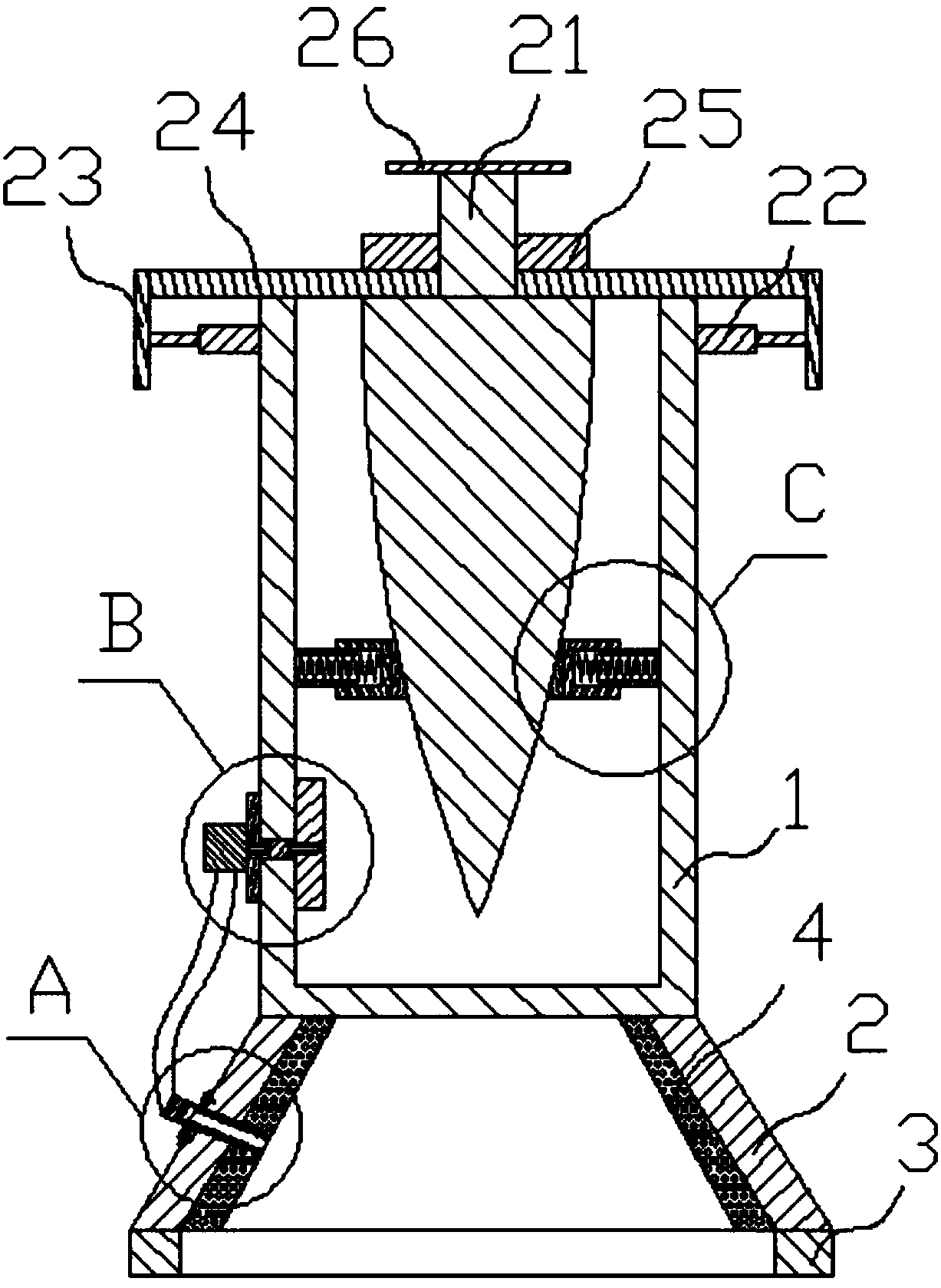

Toothpaste squeezing device with good safety performance

ActiveCN109124436AAvoid infectionImprove securityHolders and dispensersUnpacking by expelling contentsCouplingToothpaste

The invention belongs to the technical field of toiletries, especially the toothpaste squeezing device with good safety performance. In order to solve the problems of the inconvenience of operation ofthe toothpaste extruder used in hotels, and the problem that the health and safety of toothpaste in hotels cannot be guaranteed, the following scheme is proposed, including a main body and a connecting tube, the top inner wall of the main body is provided with a connecting rod, and the other side of the connecting rod is provided with a mounting plate, both sides of the top outer wall of the mounting plate are provided with reinforcing rods, and the other side of the reinforcing rod is fixed with the connecting rod by screws, the two ends of the top outer wall of the mounting plate are provided with a stepping motor, the output shaft of the stepping motor is connected with a first screw rod through a coupling, and the one side outer wall of the two first screw rods is connected with the same moving plate through screws. The invention can automatically squeeze toothpaste through two squeeze rollers, can effectively disinfect and sterilize the stored toothbrush, and greatly improves thehygiene safety of the toothbrush.

Owner:HANGZHOU YUJIN TECH CO LTD

Glue Extruding Device

ActiveUS20170267413A1Conveniently manufacturedLow costUnpacking by expelling contentsFlexible containersMechanical engineeringExtrusion

A glue extruding device for tube of glue is composed of a base, on which the device is placed vertically; two side plates, of which at least one is pressing plate with extrudable elastic connection to the base and a pressing surface on inner wall to contact outer surface of aluminum tube and facilitate glue extrusion; a retaining clip above the base, with one end to connect to the top of a side plate and a through-hole in the middle from which the mouth of tube can extend out. There is an accommodating cavity between the base, the two side plates and the retaining clip to place and position tube body.

Owner:NINGBO PASCO UNITED IND

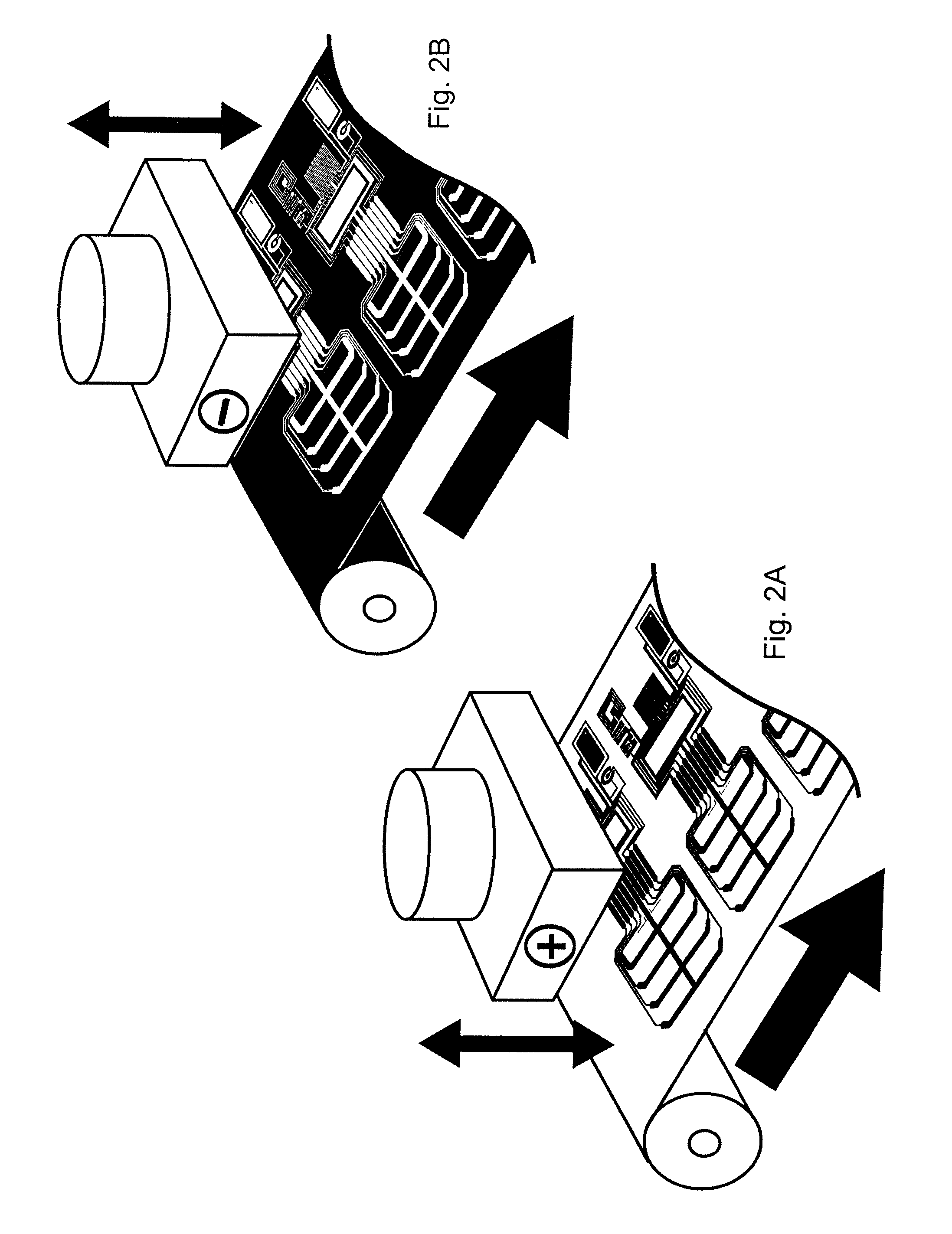

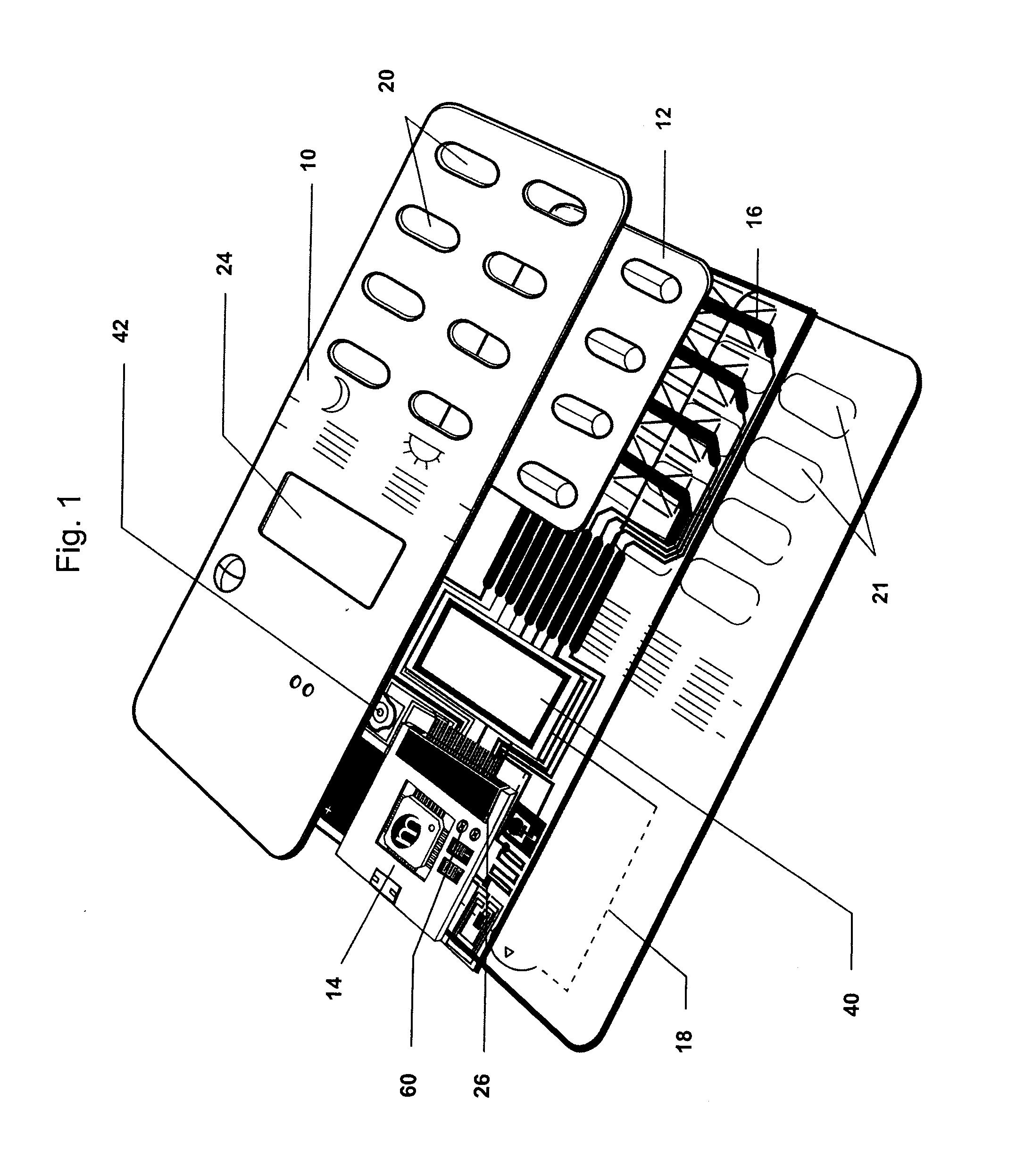

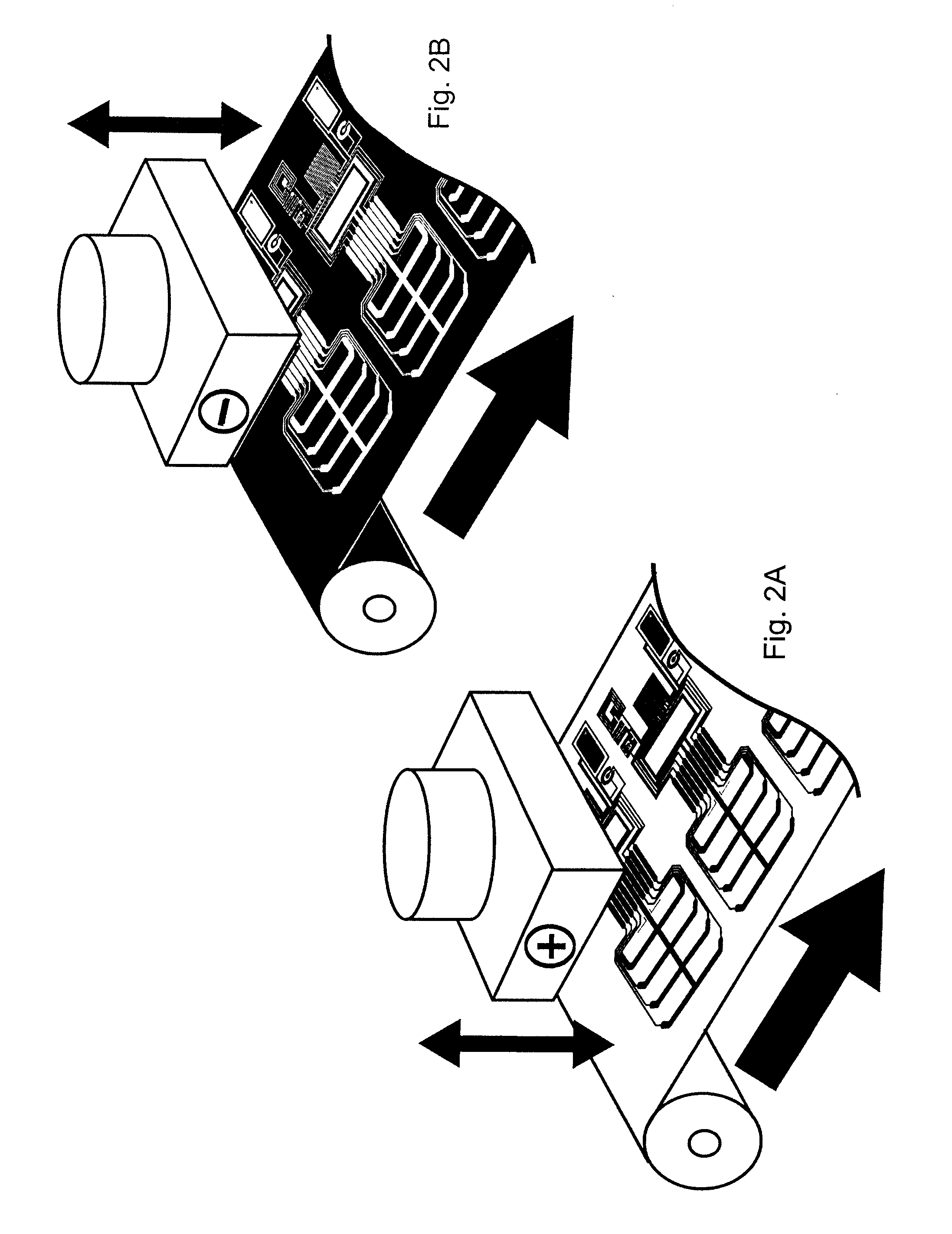

Medication dispenser

ActiveUS20150191268A1Coin-freed apparatus detailsPharmaceutical containersMedication DispenserRegimen

The present invention provides a medication dispenser enabling the controlled sequential delivery of a regimen of pills on an as-needed basis with a predetermined prescribed minimum time interval between delivery of each pill, from any flat multiple pill-containing pack of the blister package type having at least one column of pills to be dispensed, said dispenser comprising: a) an access portal sized to receive at least one any such blister pack and to guide said pack to at least one electromechanical blister pack advancing unit which in turn sequentially advances said pack to a stationary de-pilling station, said station comprising: i. pill detecting means; ii. a blister pack support having at least one pill receiving aperture, sized and positioned to receive pills of different sizes, shapes and spacing in said blister pack array; and, iii. an electromechanical depilling press means positioned, upon activation, to force at least one pill at a time from its respective blister through the backing of said blister via said aperture as said blister pack is advanced through said stationary

Owner:P C O A DEVICES LTD

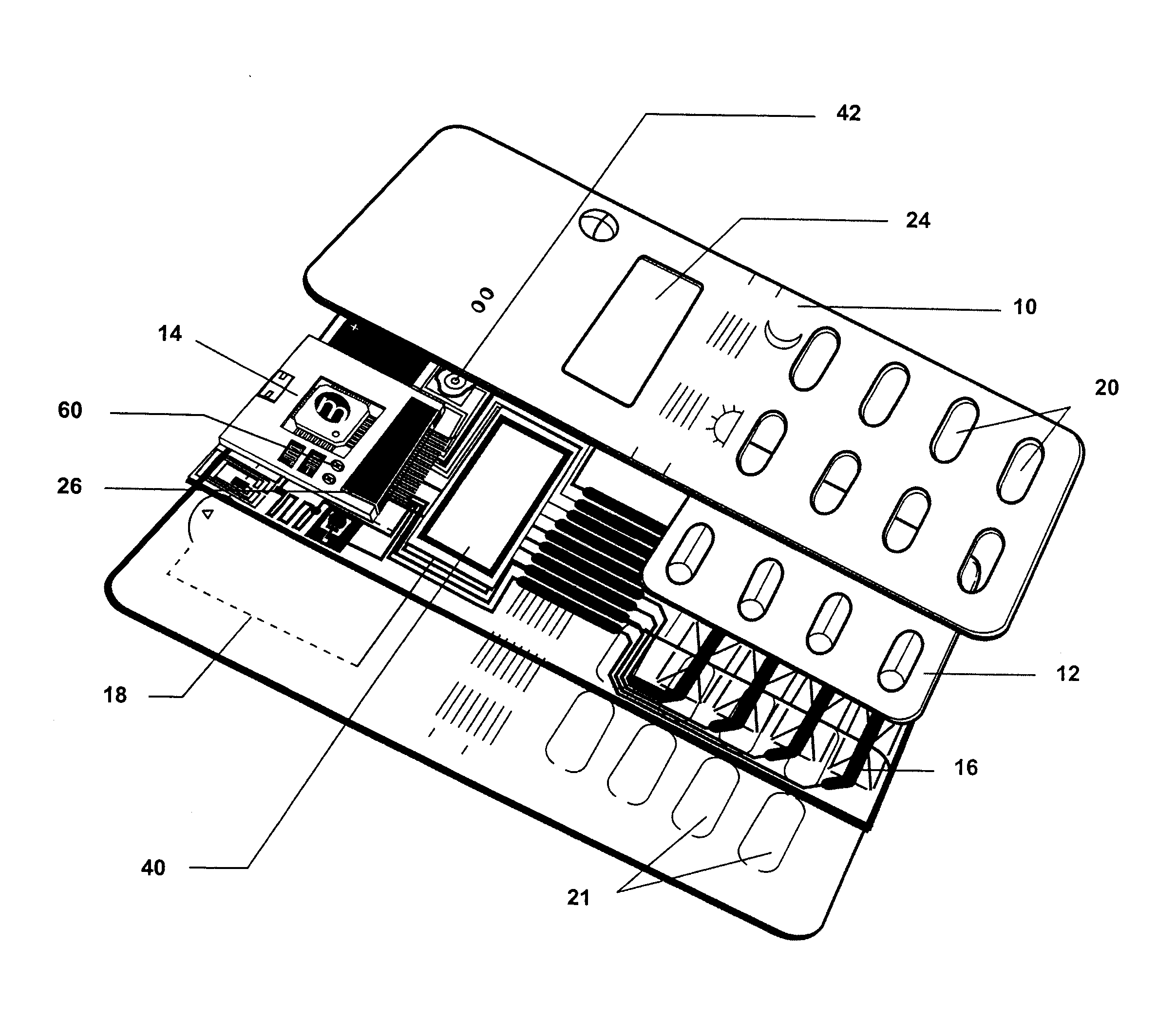

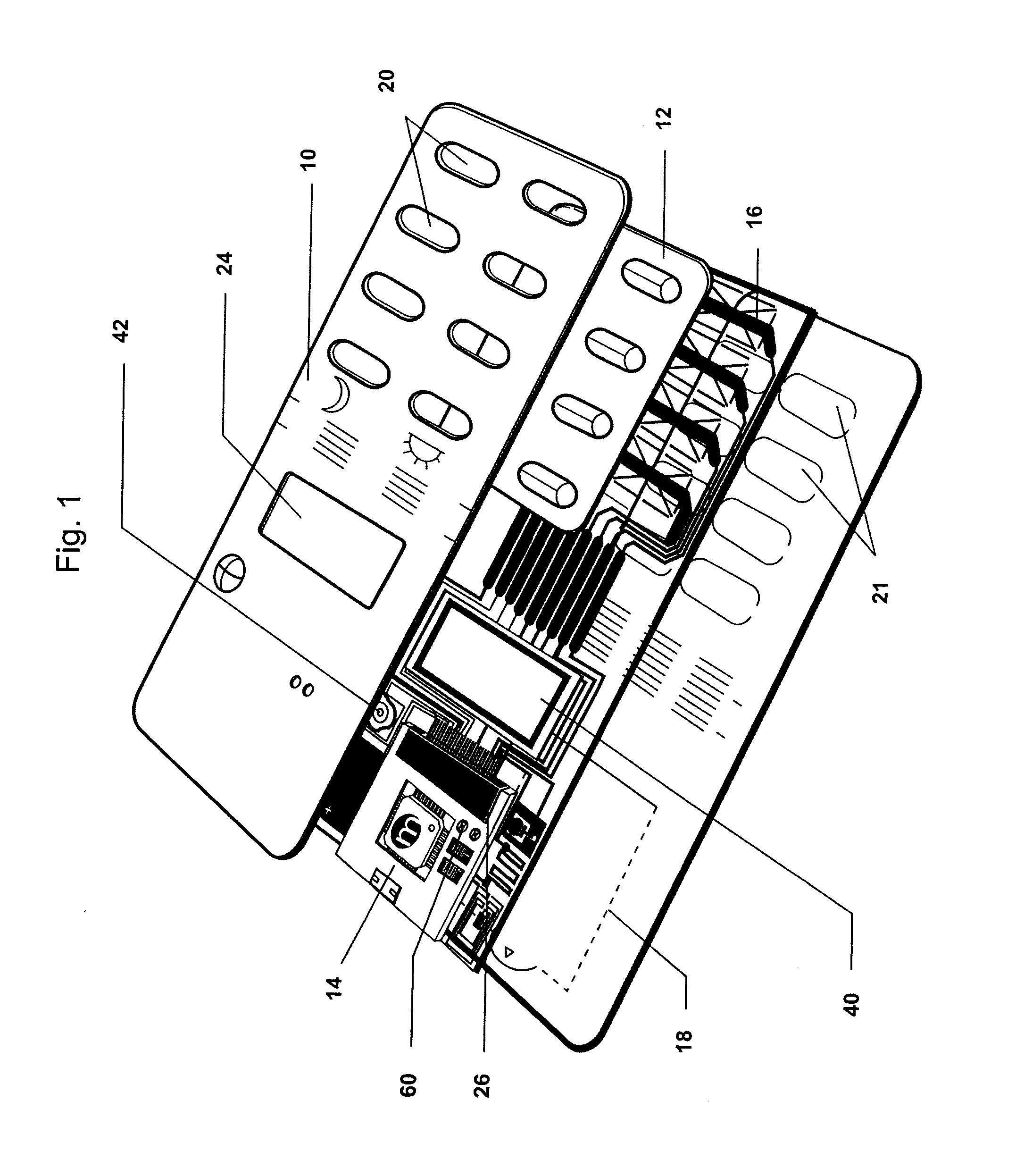

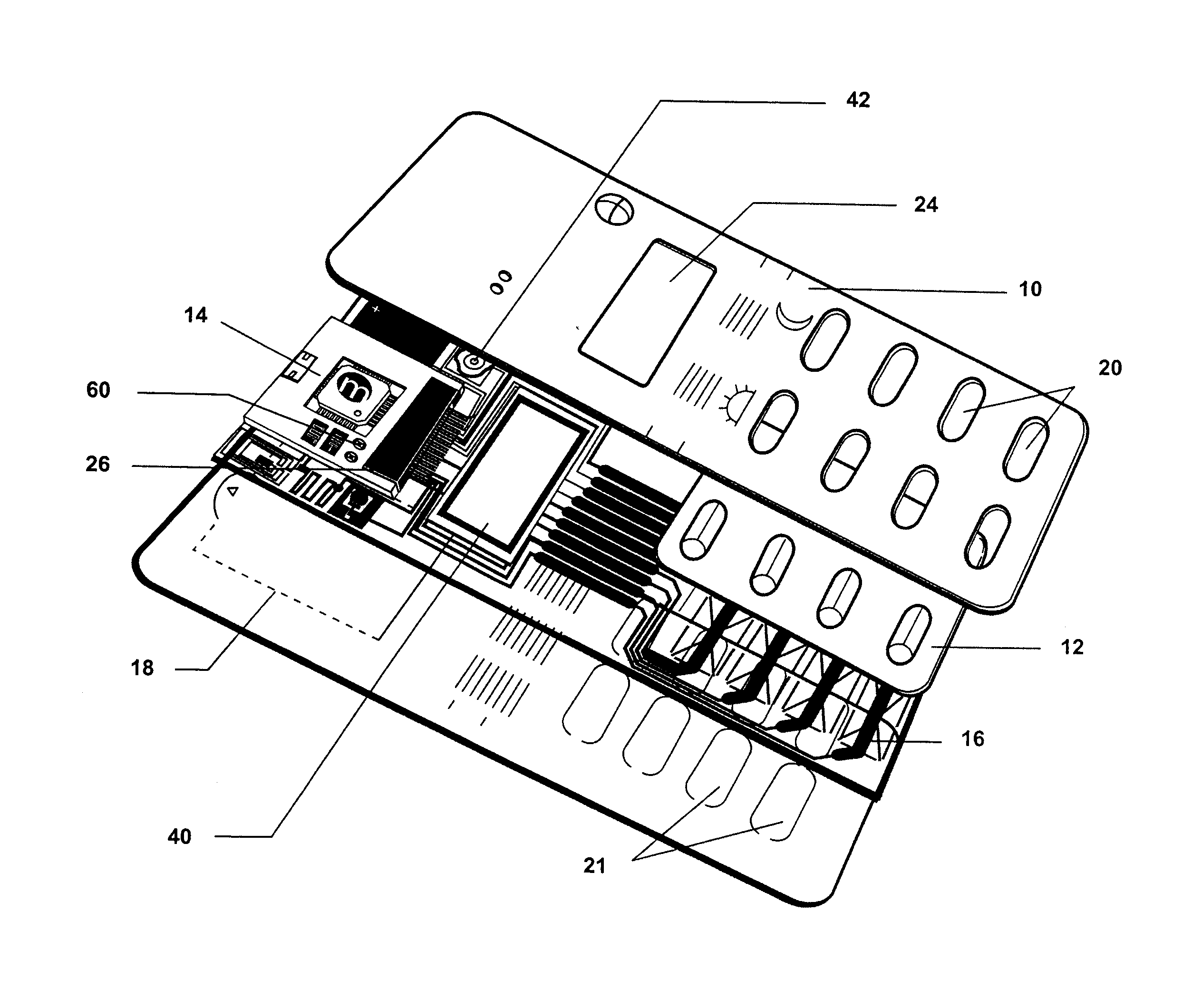

Disposable content use monitoring package with a removable re-usable electronic circuit board

Owner:INTELLIGENT DEVICES SEZC

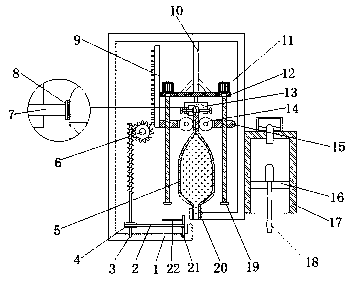

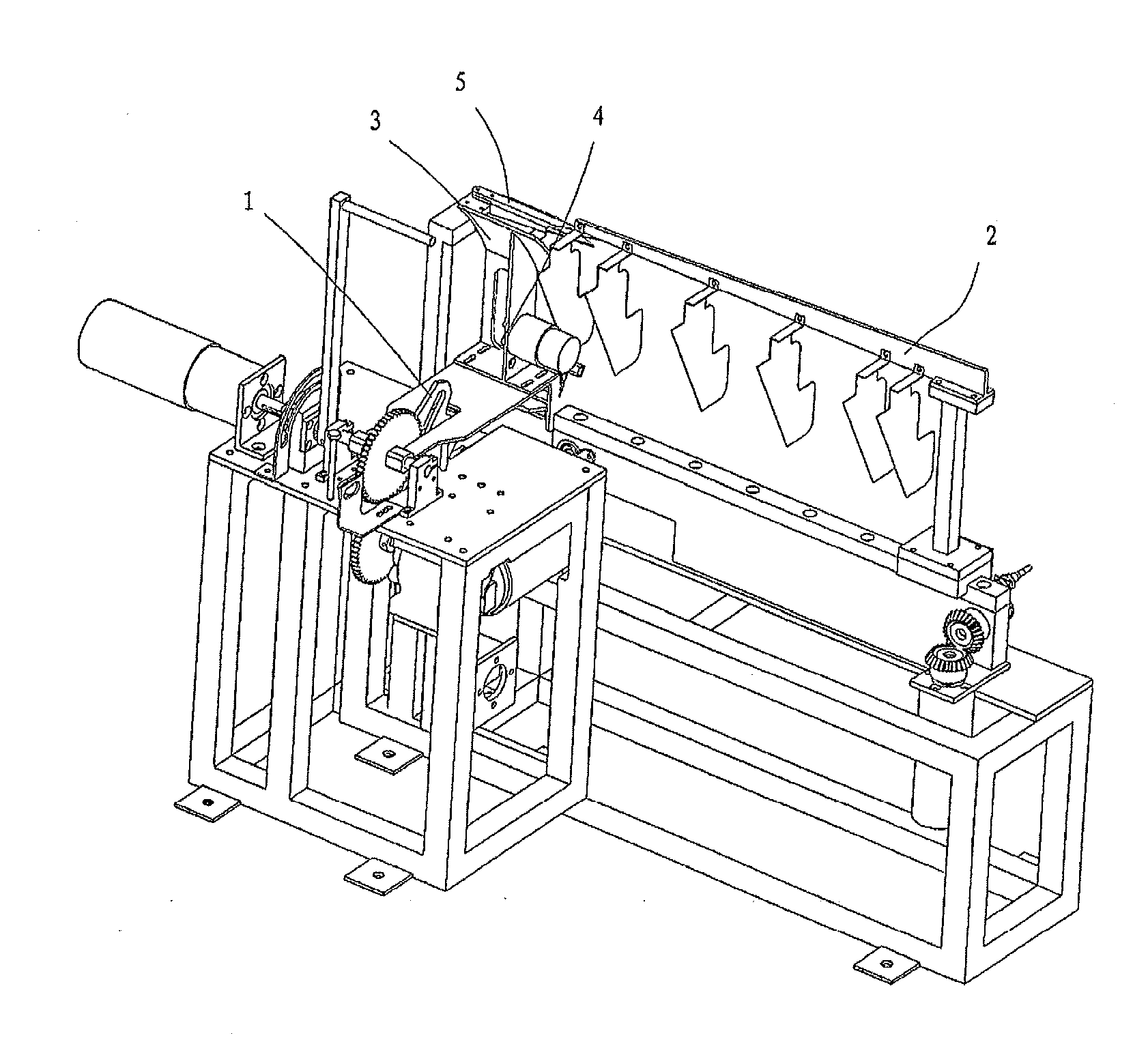

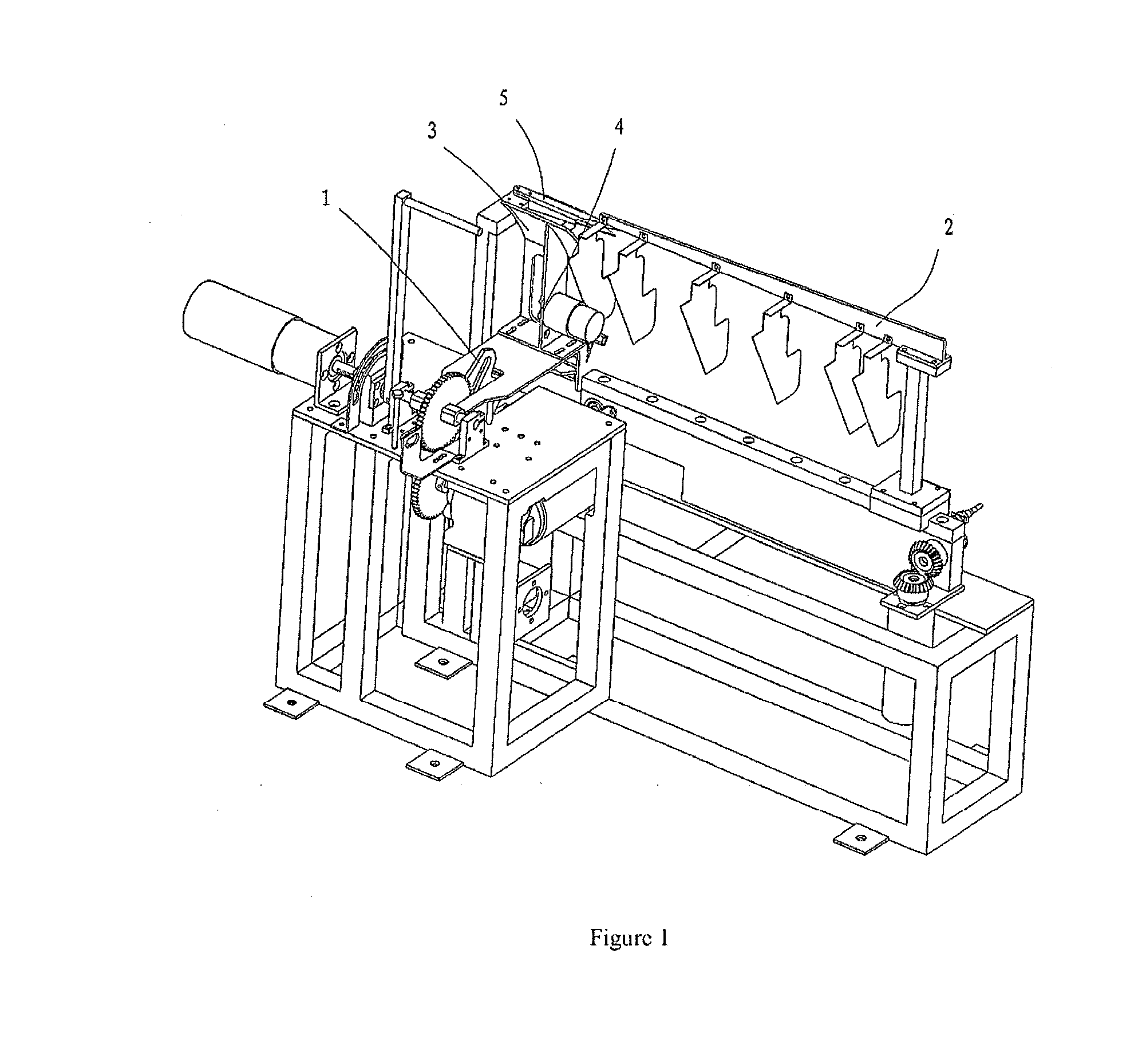

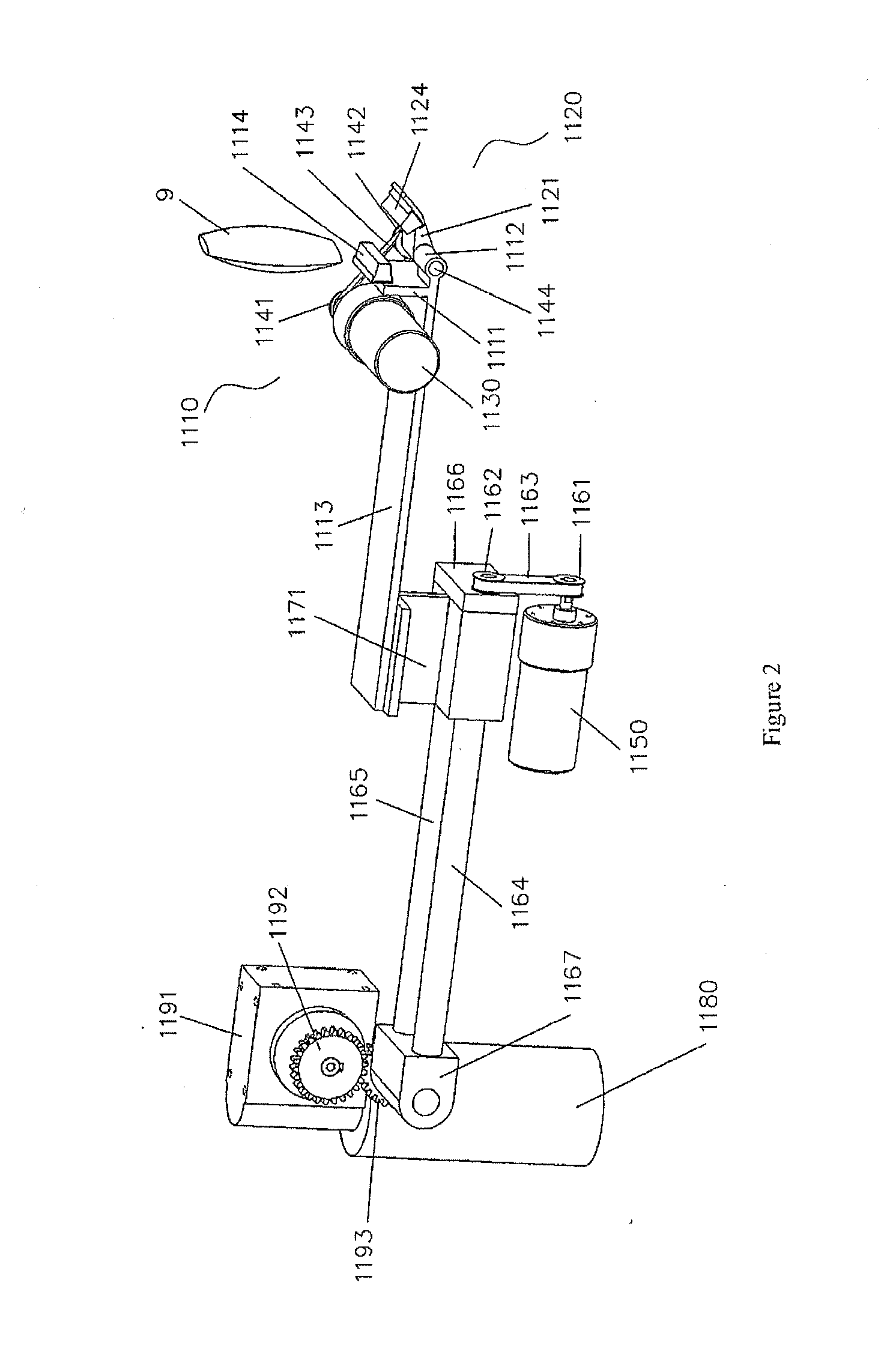

Cooking material dispensing method and dispensing system

ActiveUS20150128536A1Convenient and swift and simplified cooking processMove preciselyOpening closed containersBottle/container closureEngineeringCooking process

Disclosed are a cooking material dispensing system and dispensing method. The dispensing method comprises the following steps: setting a material bag (9) clamping station in a position near a cooking pot opening but outside the range of the pot opening, and clamping the material bag (9) containing a cooking material at the material bag (9) clamping station; confining the material bag (9), such that the material bag (9) is kept in a clamped state to control the deformation thereof during the dispensing procedure; flipping and / or tipping the material bag (9), and when in a position near the cooking pot opening, dispensing the cooking material in the material bag (9) into the cooking pot; and once the cooking material has been dispensed, shifting the material bag (9) from the range of the cooking pot opening and releasing the clamping of the material bag (9). The cooking material dispensing system comprises a dispensing device capable of clamping, confining, and transferring the material bag (9) and flipping the opened material bag and / or tipping the cooking material into the cooking pot. The dispensing system and dispensing method take a material packaged in the material bag (9) and can accurately move the material bag (9) into the dispensing position, making the cooking process convenient, fast and simple, and the entire process will not be contaminated.

Owner:LIU XINYU

Disposable content use monitoring package with a removable re-usable electronic circuit board

There is provided a content use monitoring package and method of making the same. The package includes a cover layer followed by a blister card layer. The third layer comprises an electronic sensor monitoring tag connected to a rupturable layer imprinted with a conductive grid. The grid is printed on a non-conductive, non paperboard rupturable substrate and is aligned with associated blisters in the blister card. To ensure precise and reliable electrical continuity between the tag and grid they are connected by a low or zero insertion force flat flex connector which connection is also reversible. The tag includes re-usable electronic circuitry and power source. The fourth and bottom layer is a backing which contains a mechanism to tear open the package and remove the tag by unplugging the flex circuit connector. The tag can then be reused and the battery replaced as required.

Owner:INTELLIGENT DEVICES SEZC

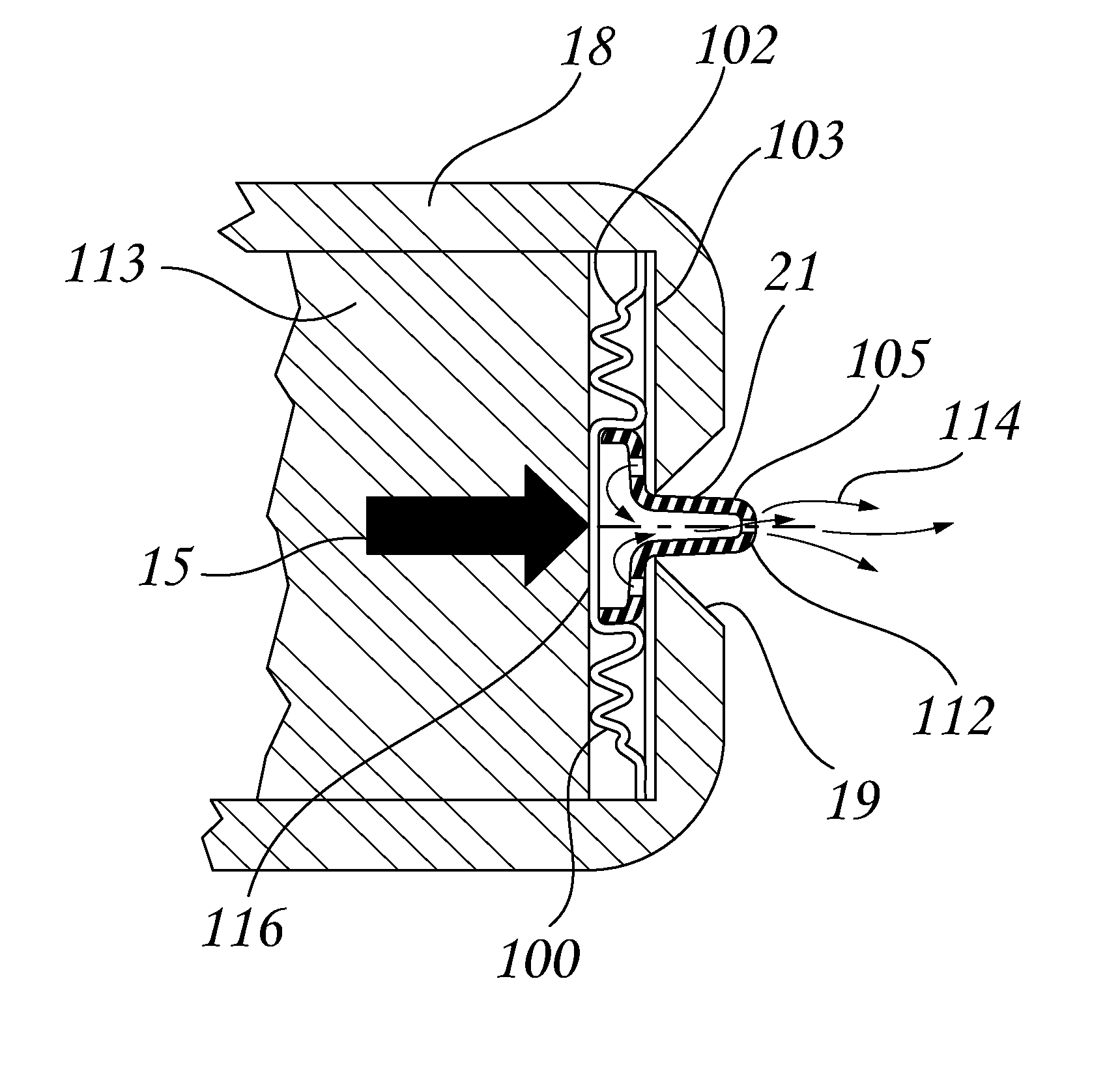

Devices and Methods for Packaging and Dispensing Unit Doses of Personal Care Products

InactiveUS20150274344A1Precise deliveryLittle wastedOpening closed containersBottle/container closureEngineeringPersonal Care Product

Packaging and delivery systems for personal care products and methods of providing samples or single units of use, include dispensing devices that produce a spray, mist, or stream delivery of measured amounts of personal care products packaged in internally pierced blister unit doses which protect the quality of the unused product and reduce the amount of product wasted in providing samples.

Owner:MYSTIC PHARMA INC

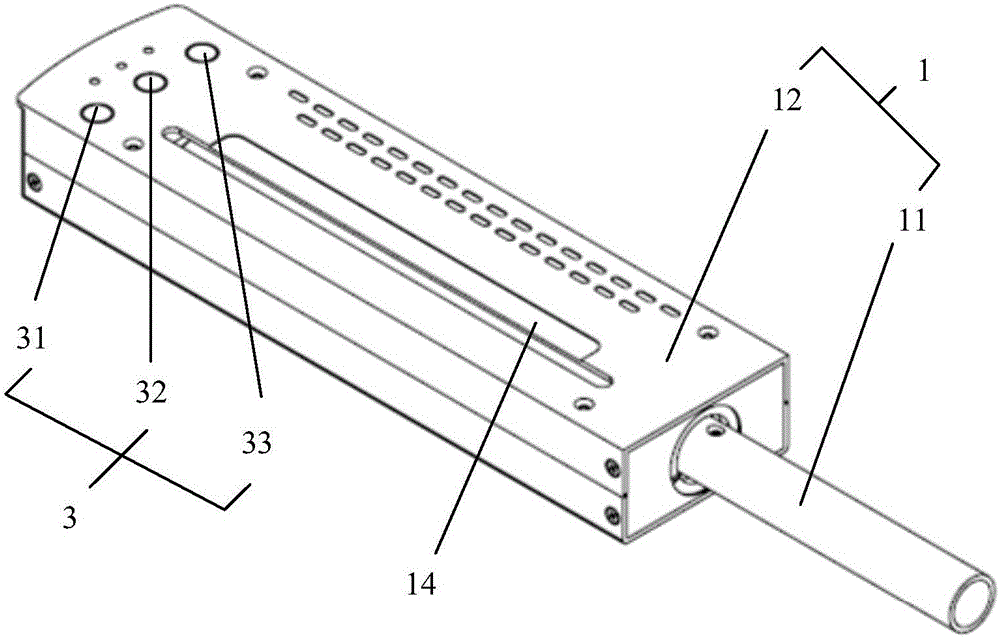

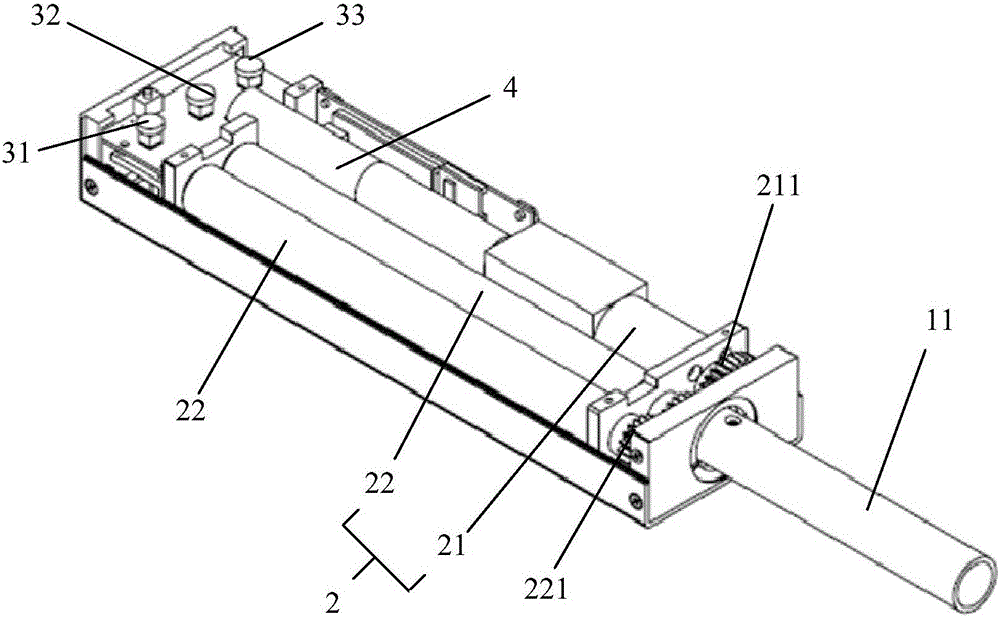

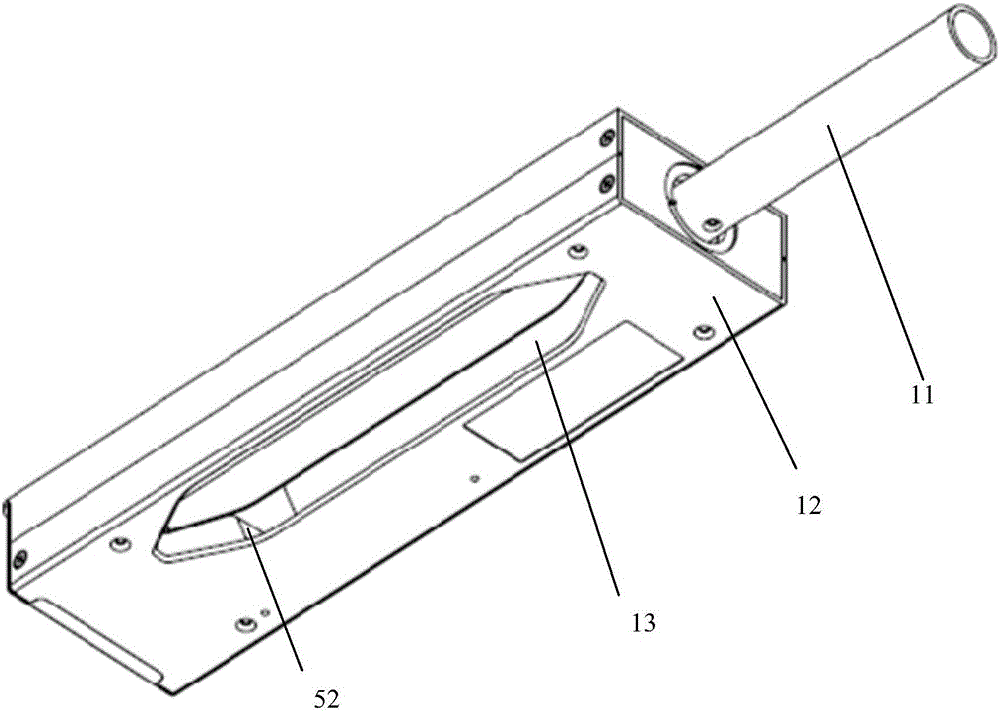

Handheld flexible packaging ink automatic extrusion device

InactiveCN105857796AAvoid contaminationMeet the use requirementsUnpacking by expelling contentsParallel compressionEngineering

The embodiment of the invention relates to a handheld flexible packaging ink automatic extrusion device used for extruding ink in an ink package. The automatic extrusion device comprises a device shell, a rolling device, a control circuit and a power source. The device shell comprises a handle and a shell body. The handle is arranged on one side of the shell body and fixedly connected with the shell body. The bottom face of the shell body is provided with a first opening. The top face of the shell body is provided with a second opening. The rolling device is arranged in the shell body and comprises a compression roller driving motor and two parallel compression rollers. One end of each compression roller is provided with a compression roller driving gear, and the two compression roller driving gears are synchronously meshed. The compression roller driving motor is provided with a motor gear meshed with one compression roller driving gear. The compression roller driving motor drives the corresponding compression roller driving gear to rotate so as to drive the two compression roller driving gears to rotate synchronously in opposite directions. The control circuit is arranged in the shell body and connected with the compression roller driving motor. The power source is arranged in the shell body and supplies power to the control circuit and the rolling device.

Owner:桑春龙 +6

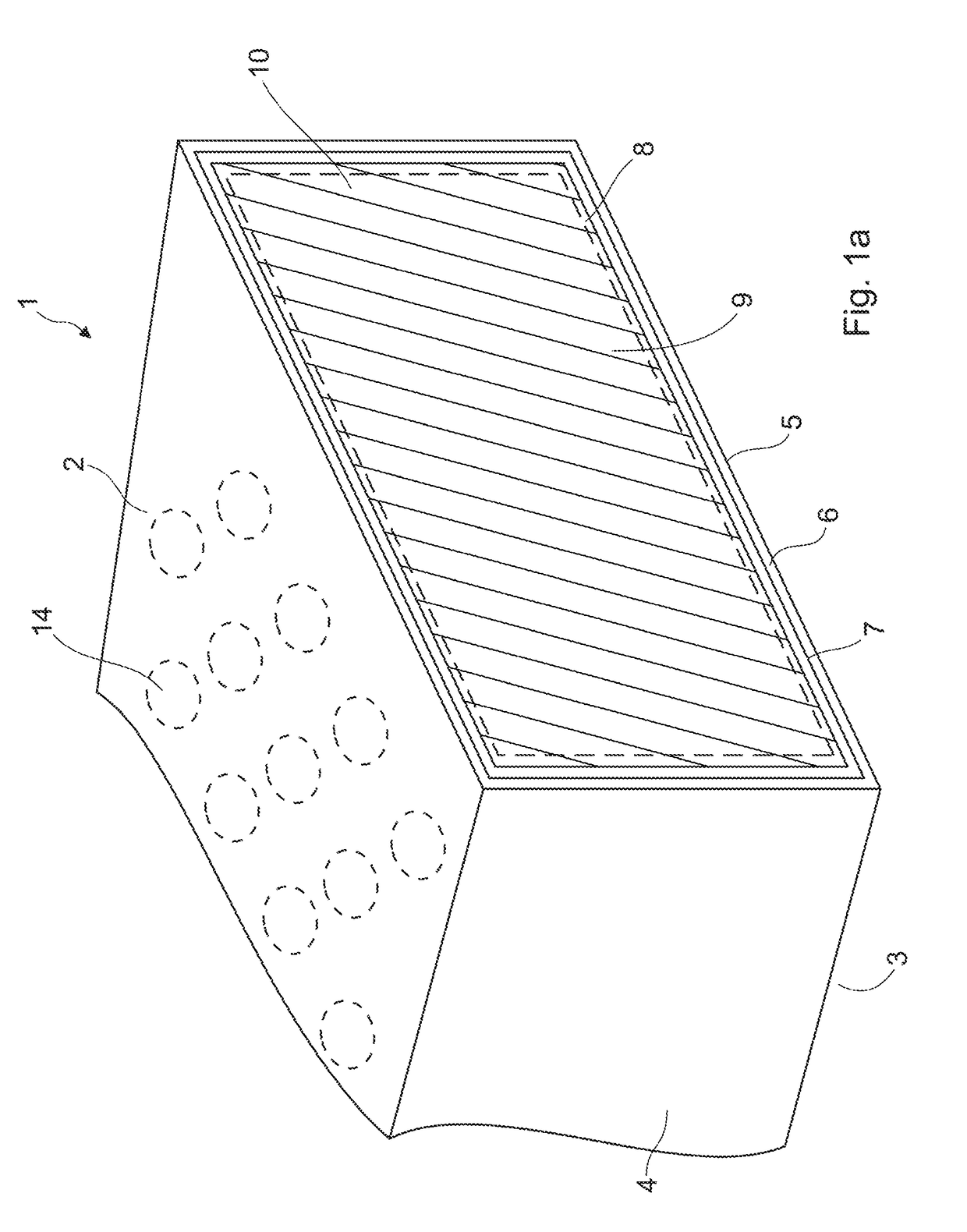

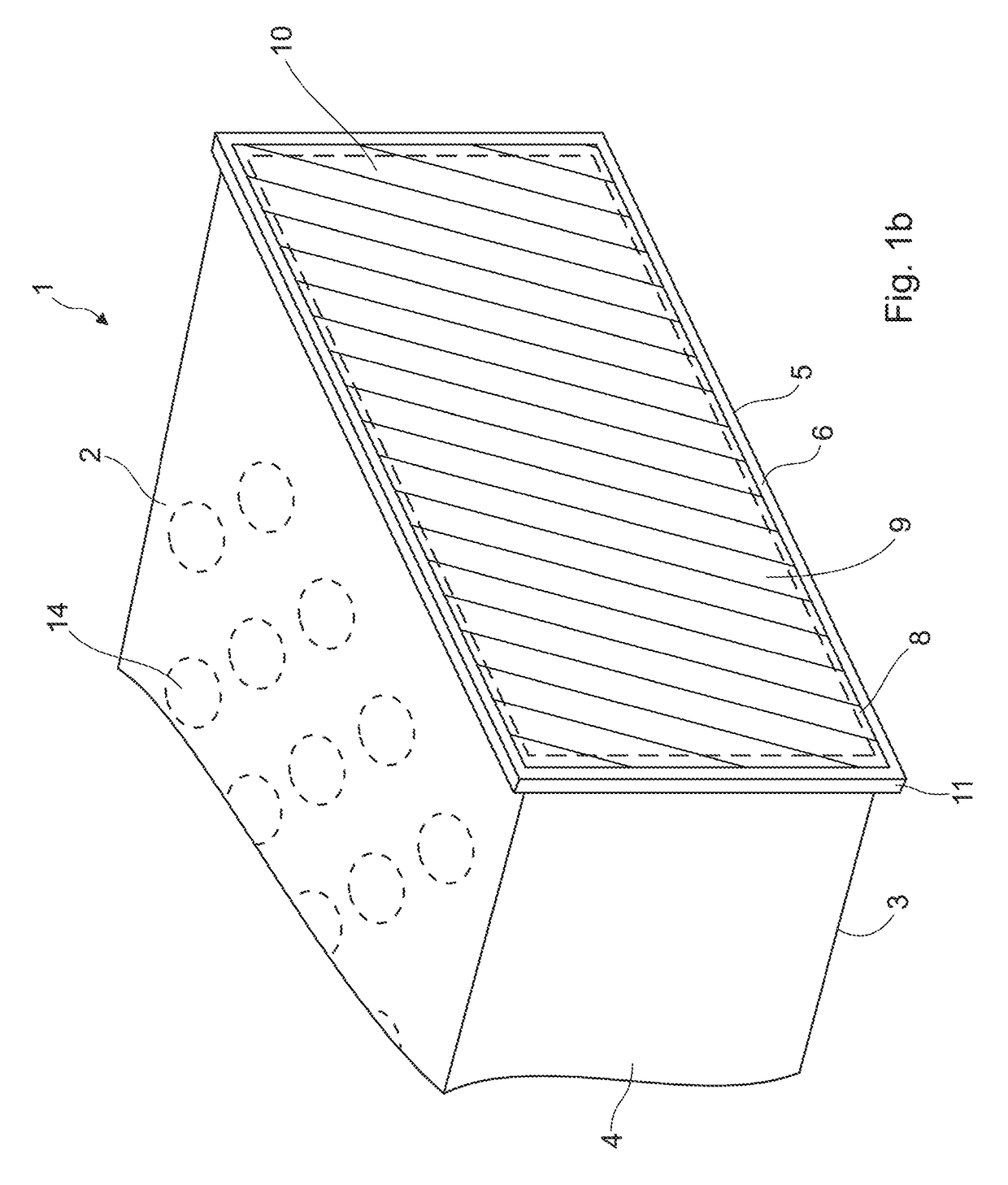

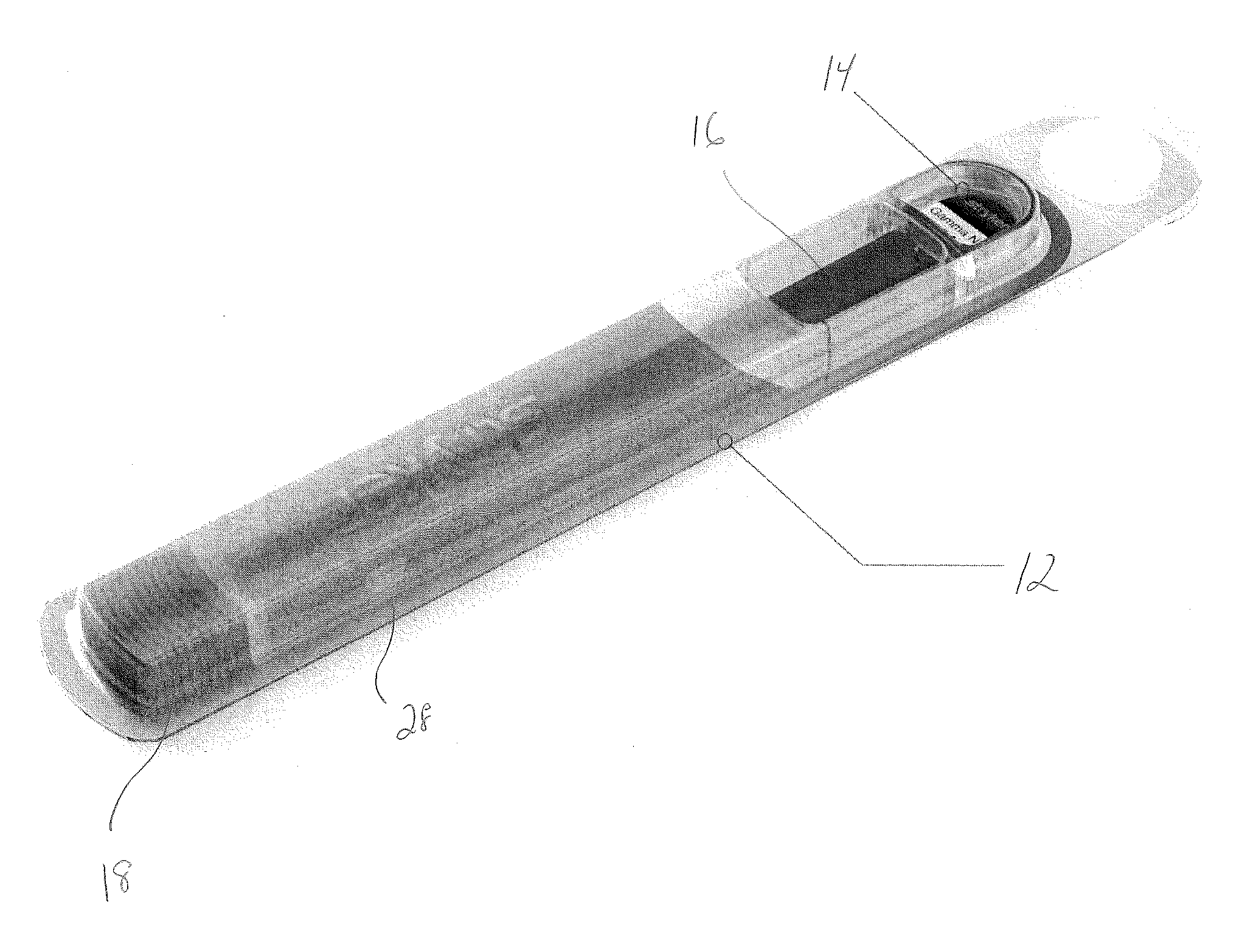

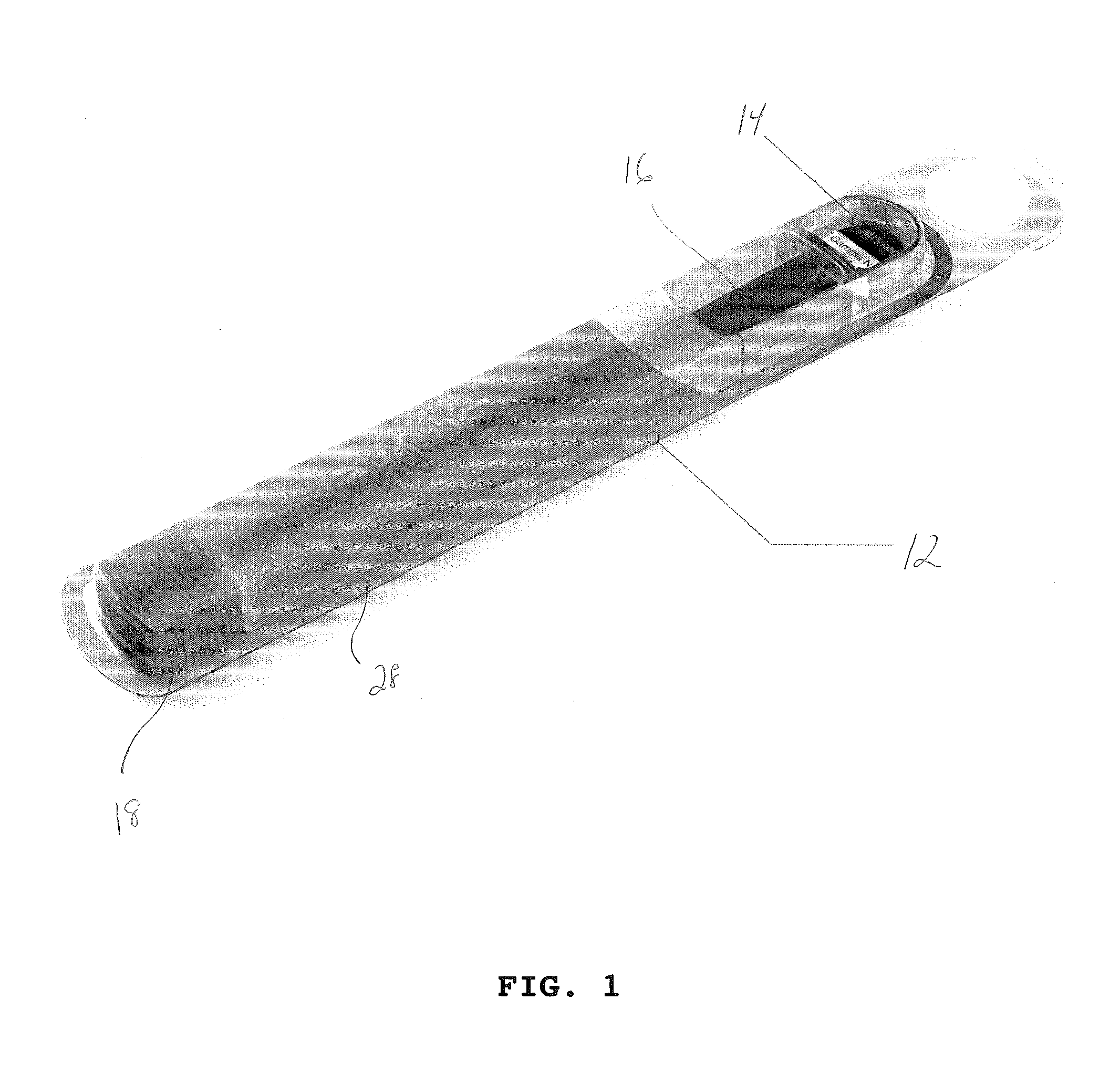

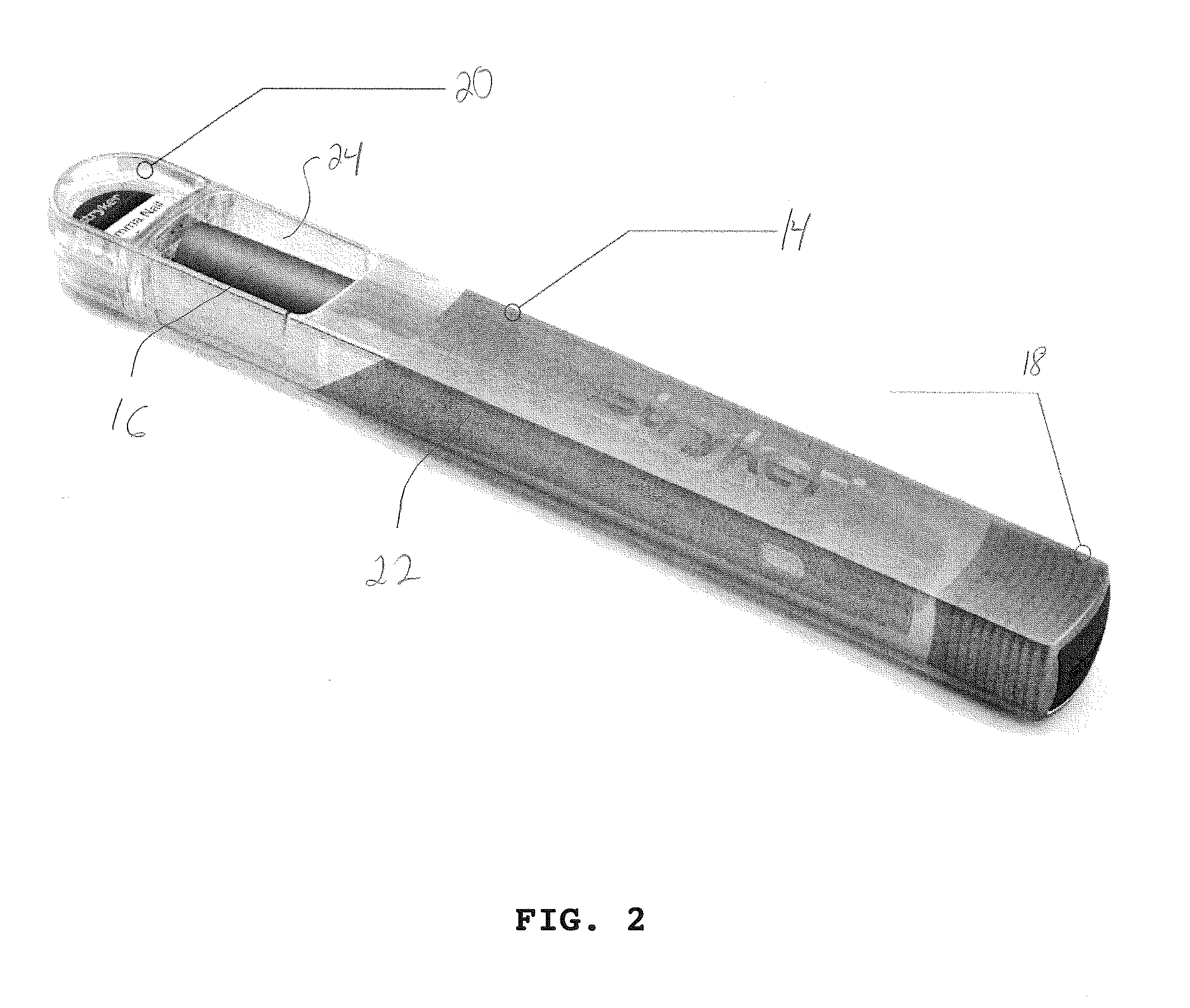

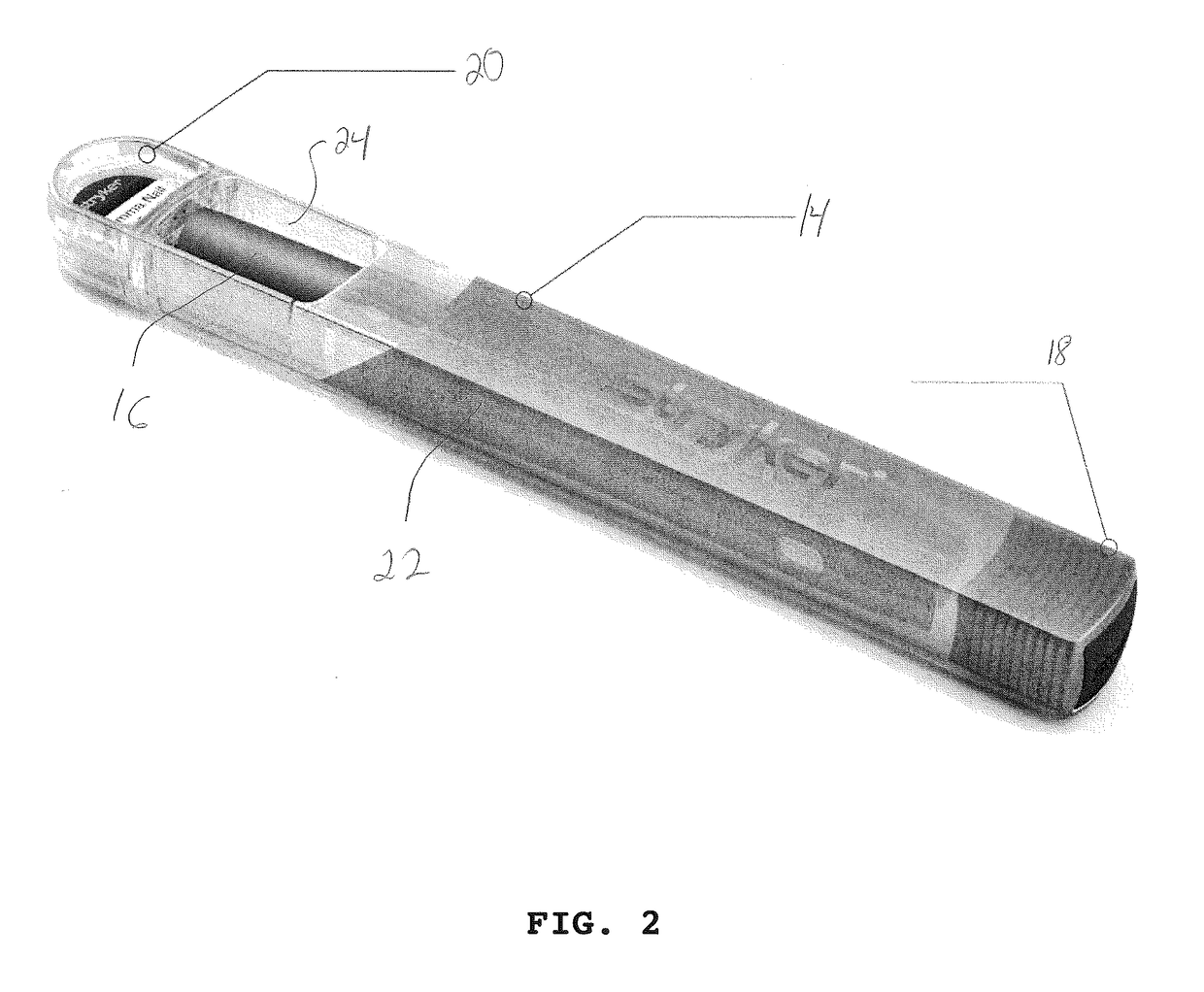

Orthopedic packaging

A package for an orthopedic device is disclosed. The package includes inner and outer packaging and preferably allows for accessibility of the orthopedic device without direct handling by hand. Methods of utilizing such packaging are also disclosed.

Owner:STRYKER EURO OPERATIONS HLDG LLC

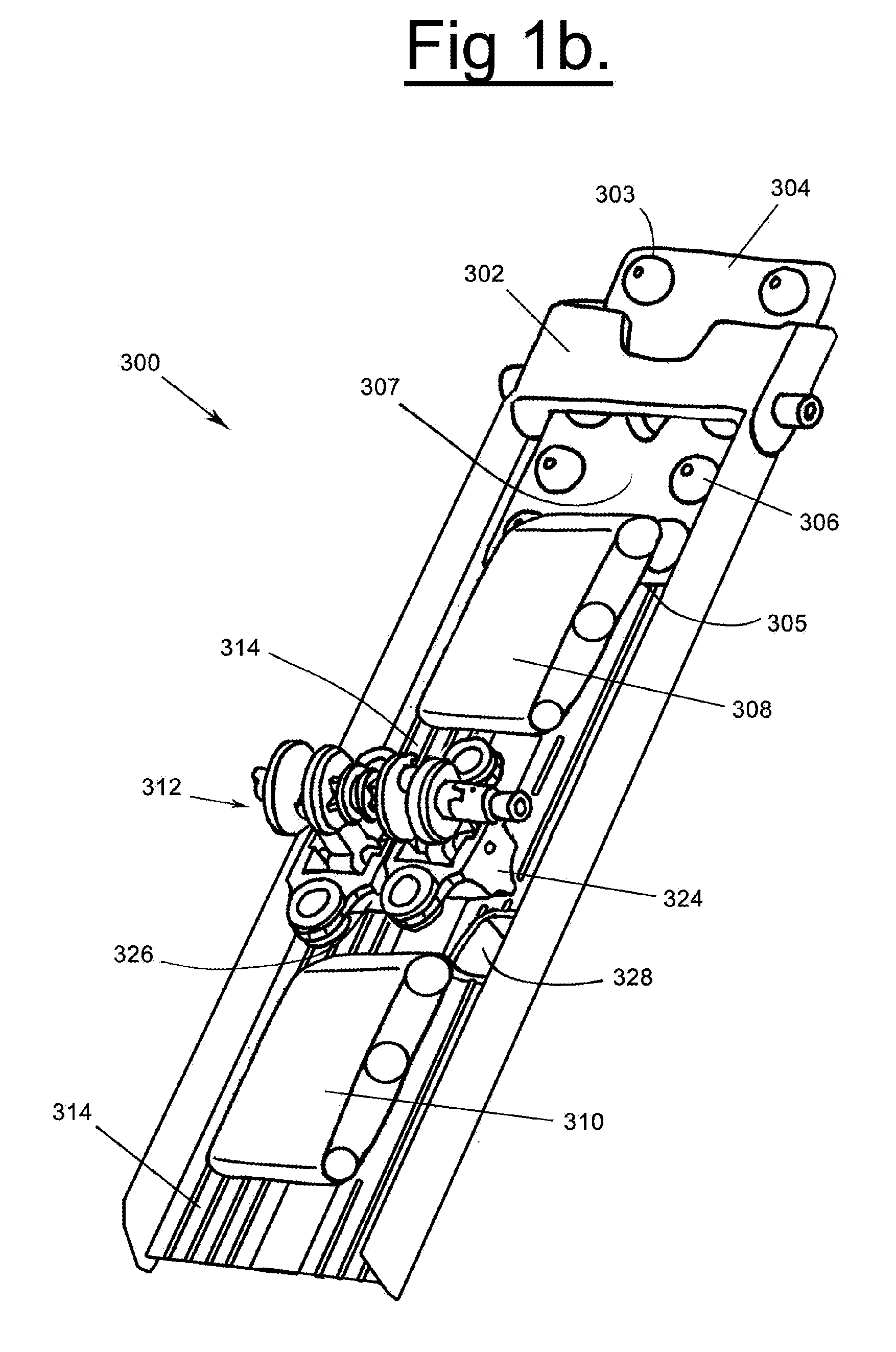

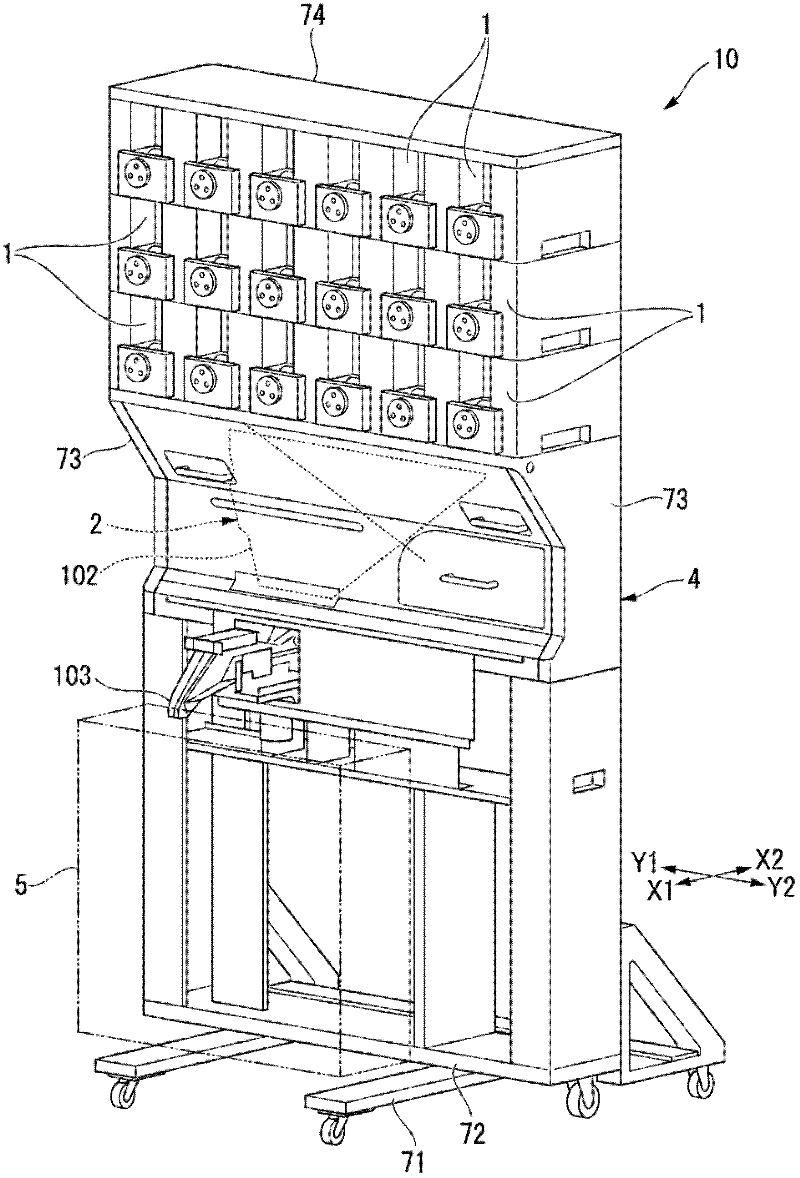

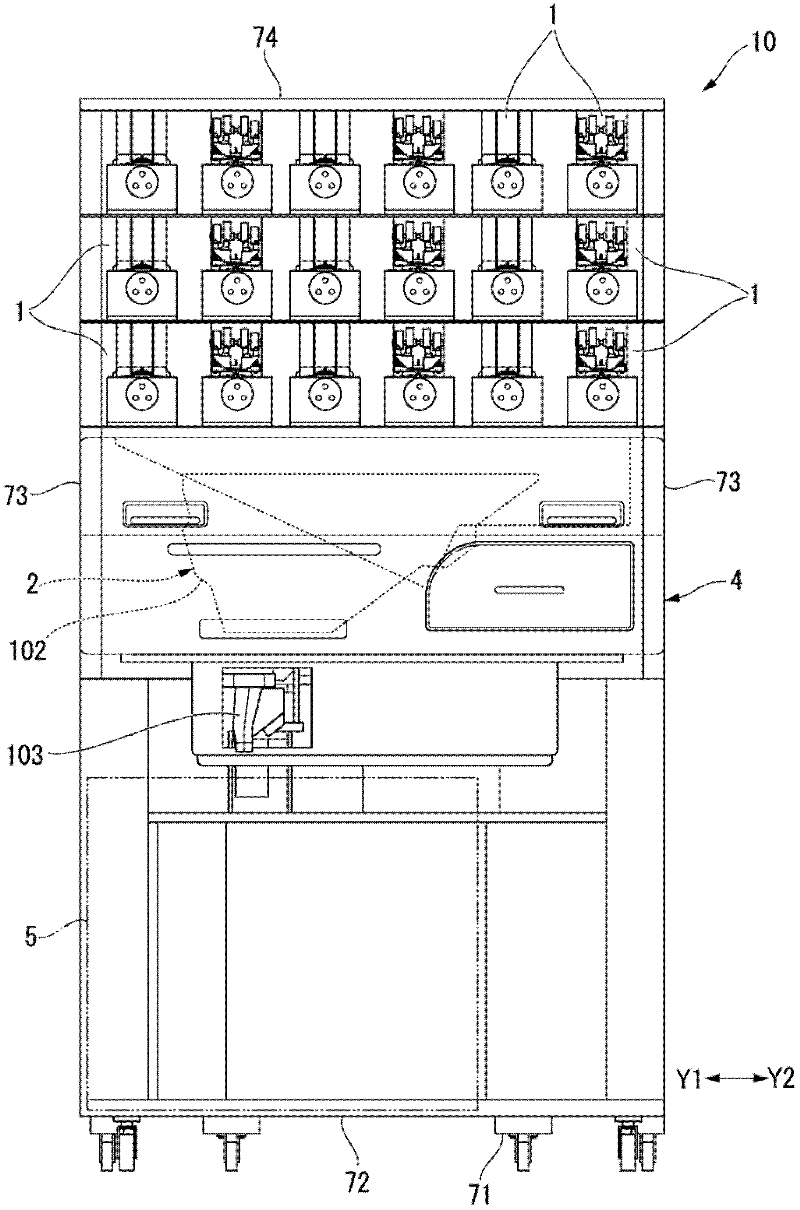

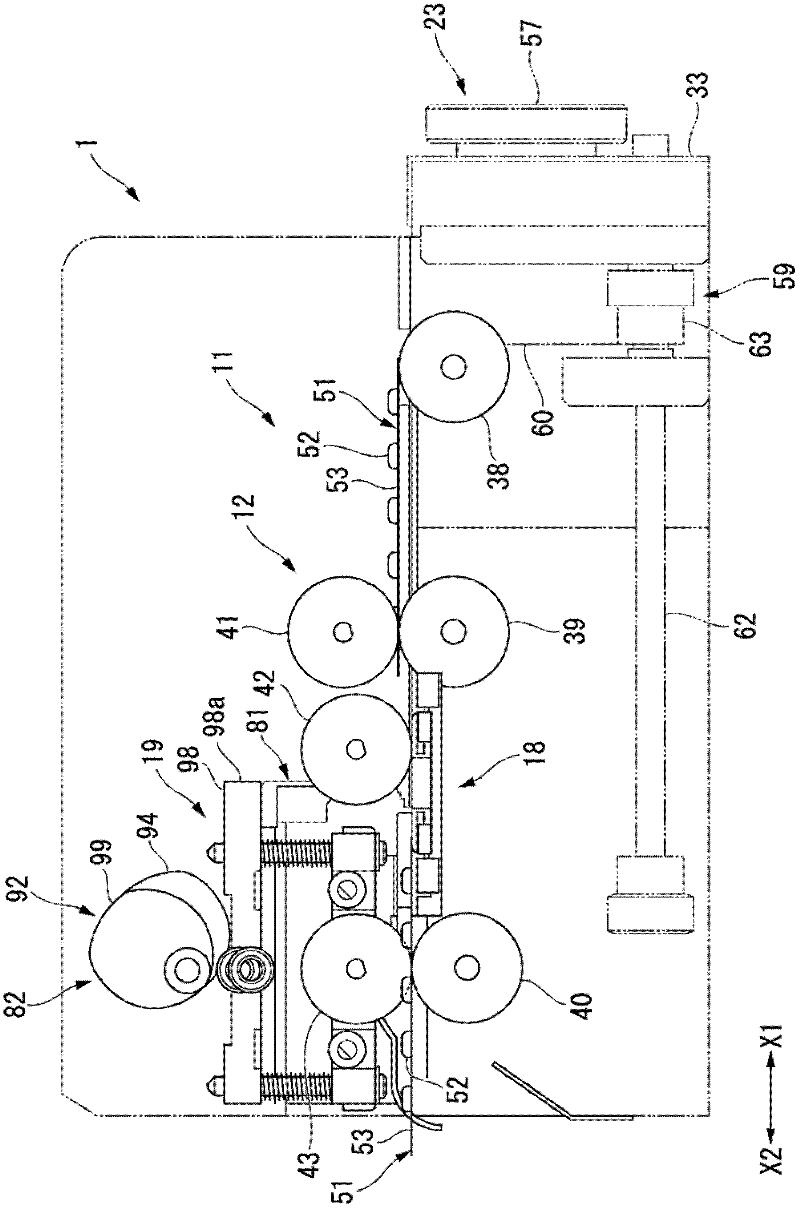

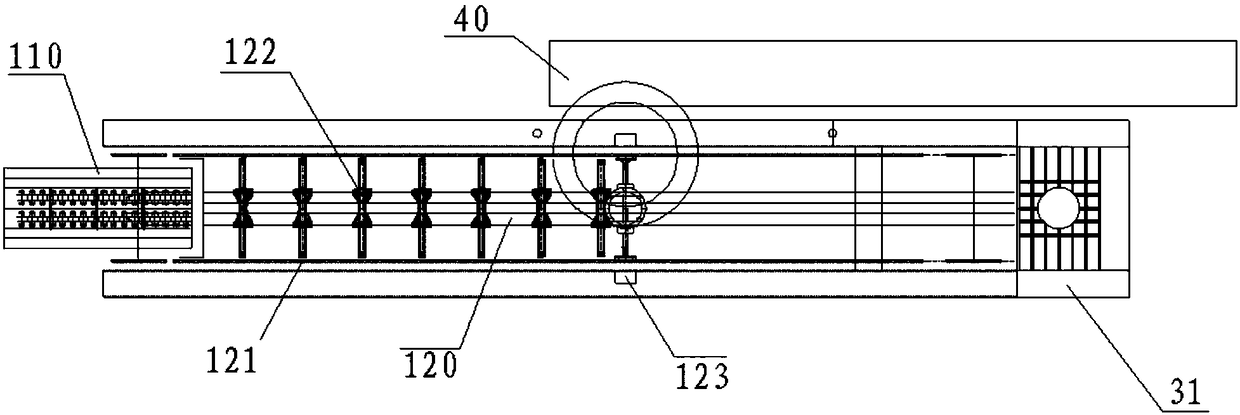

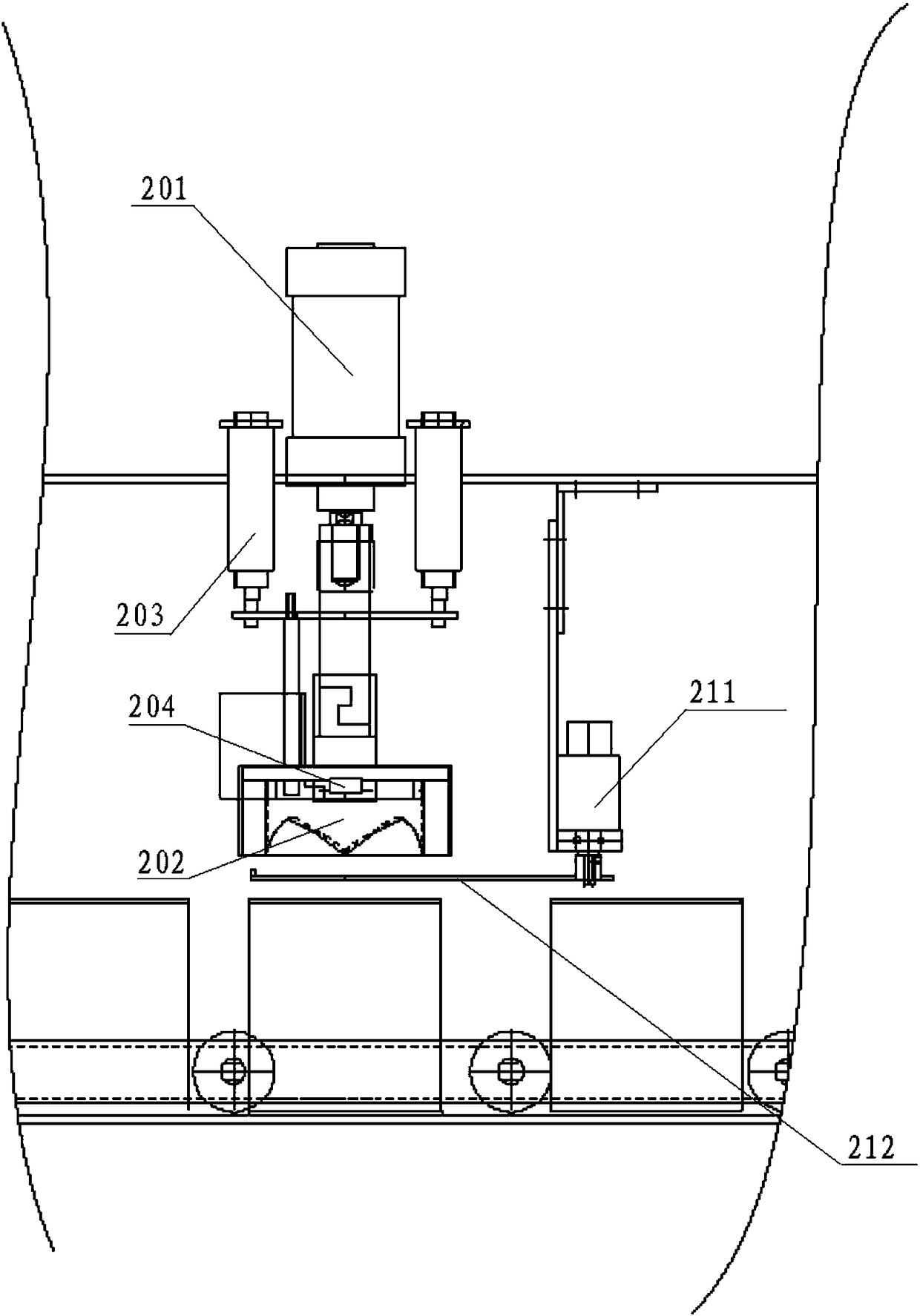

Tablet supplying apparatus and unwrapping system

ActiveCN102556418AEfficient supplyImprove work efficiencyIndividual articlesUnpacking by expelling contentsEngineering

The present invention provides a tablet supplying apparatus and an unwrapping system, wherein the tablet supplying apparatus takes out tablets form a tablet plate respectively sealing a plurality of tablets in a tablet receiving portion and supplies the tablets. The tablet supplying apparatus comprises one or more tablet taking-out unit and a supplying unit for supplying the tablets took out by the tablet taking-out unit. Additionally, the tablet taking-out unit is provided with a tablet plate receiving unit for receiving one or more tablet plates, a carrying mechanism for carrying the tablet plates, a loading table for loading the tablet plate carried by the carrying mechanism, and an extruding mechanism for pressing the tablet plate receiving unit of the tablet plate of the loading table and taking out the tablets. Additionally, the loading table is provided with a discharging hole for enabling the tablets took out by the extruding mechanism to fall into the supplying unit.

Owner:ELQUEST +2

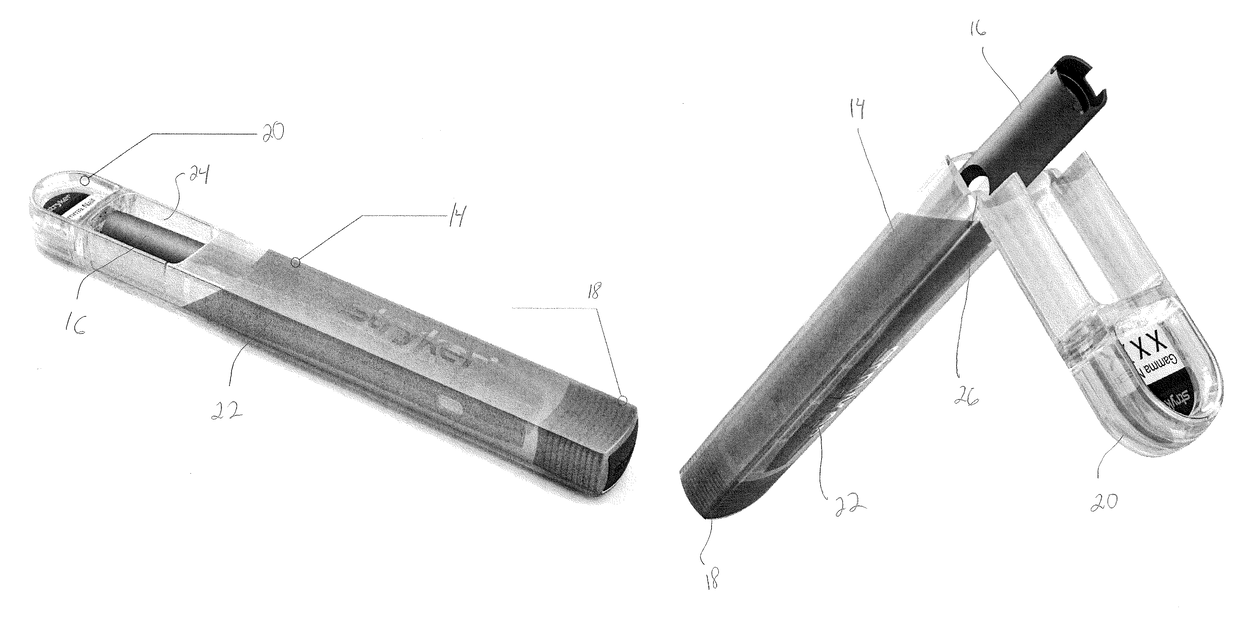

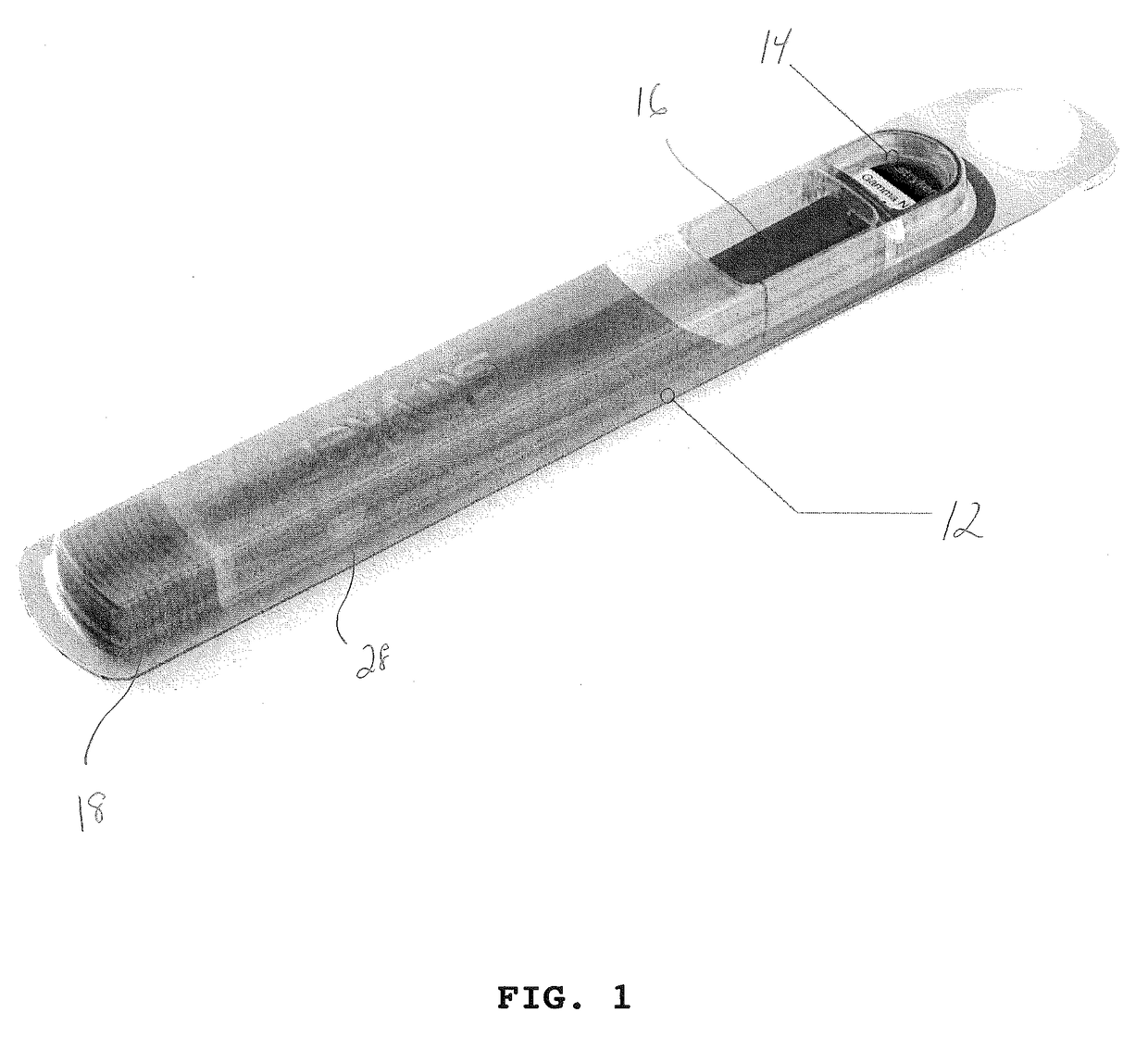

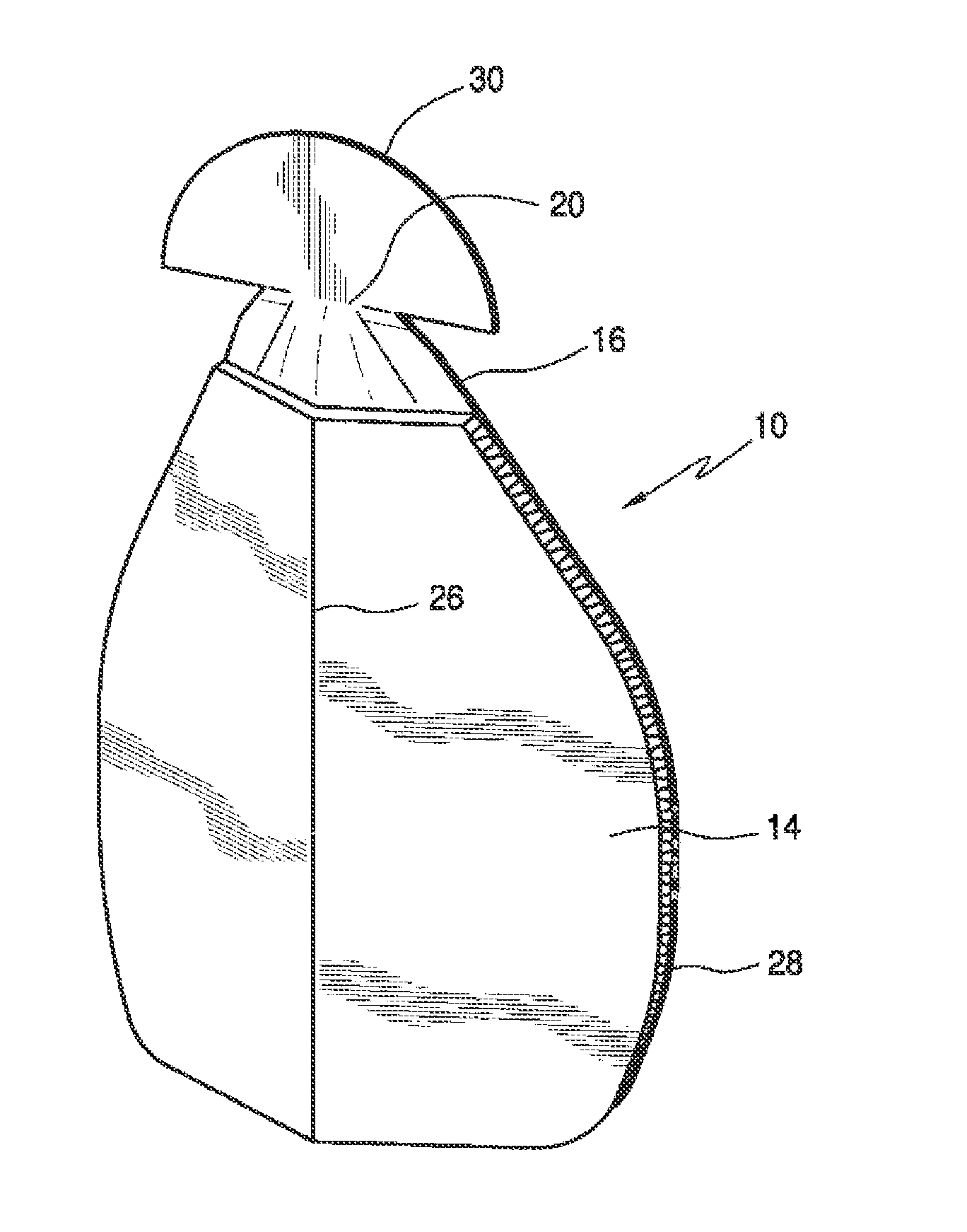

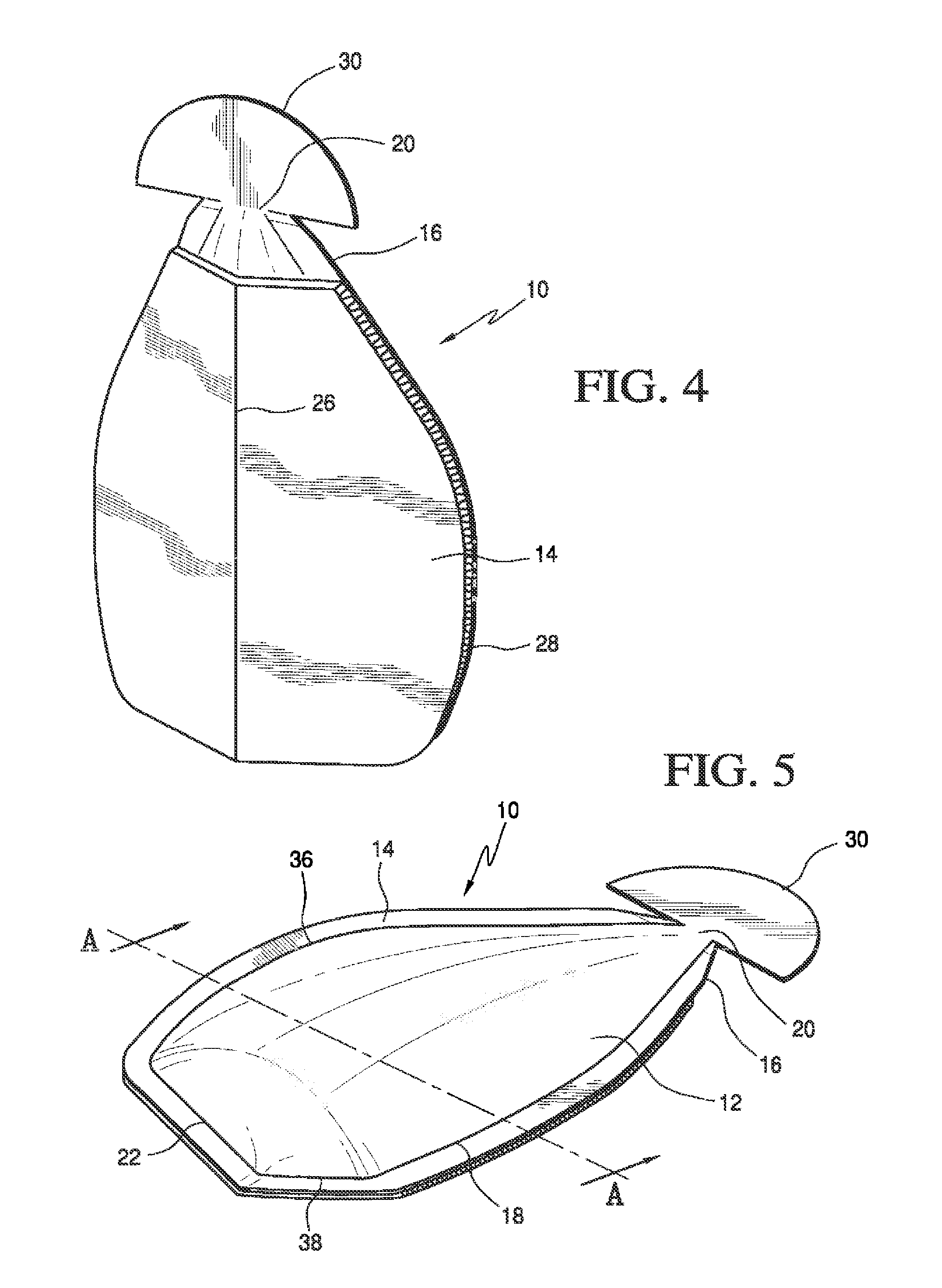

Orthopedic packaging

ActiveUS9872754B2Avoid pollutionSurgical furnitureUnpacking by expelling contentsEngineeringOverwrap

A package for an orthopedic device is disclosed. The package includes inner and outer packaging and preferably allows for accessibility of the orthopedic device without direct handling by hand. Methods of utilizing such packaging are also disclosed.

Owner:STRYKER EURO OPERATIONS HLDG LLC

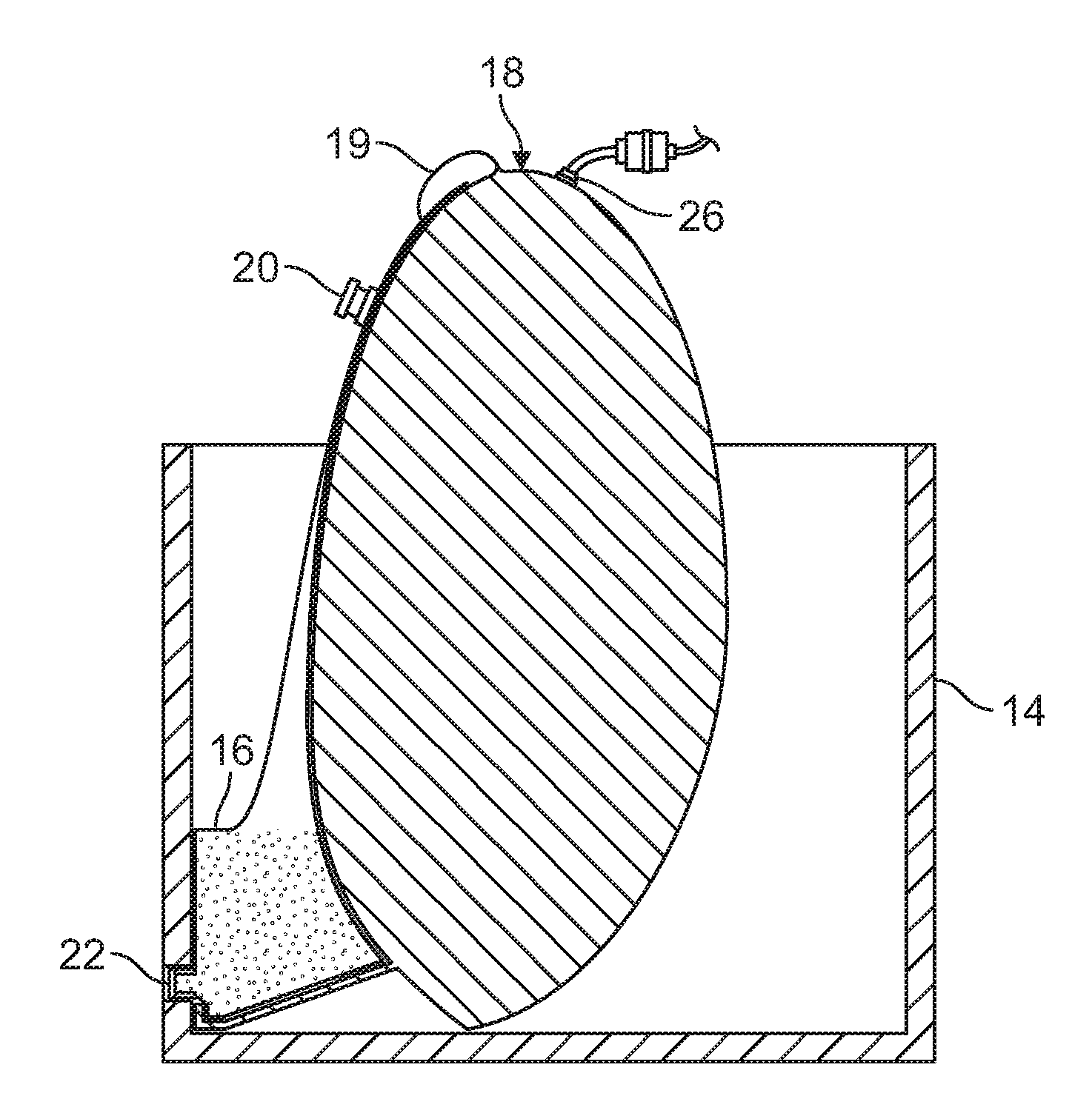

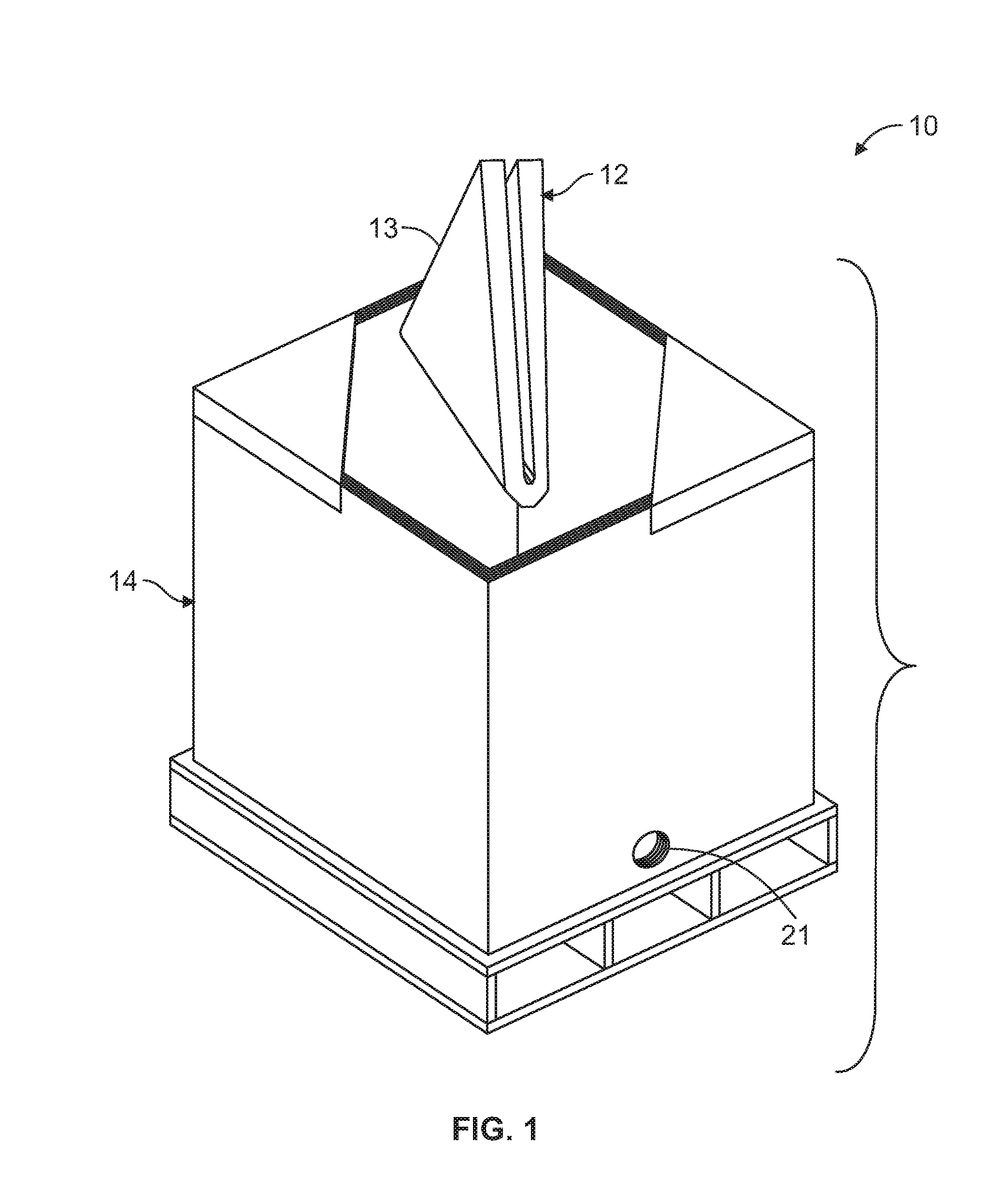

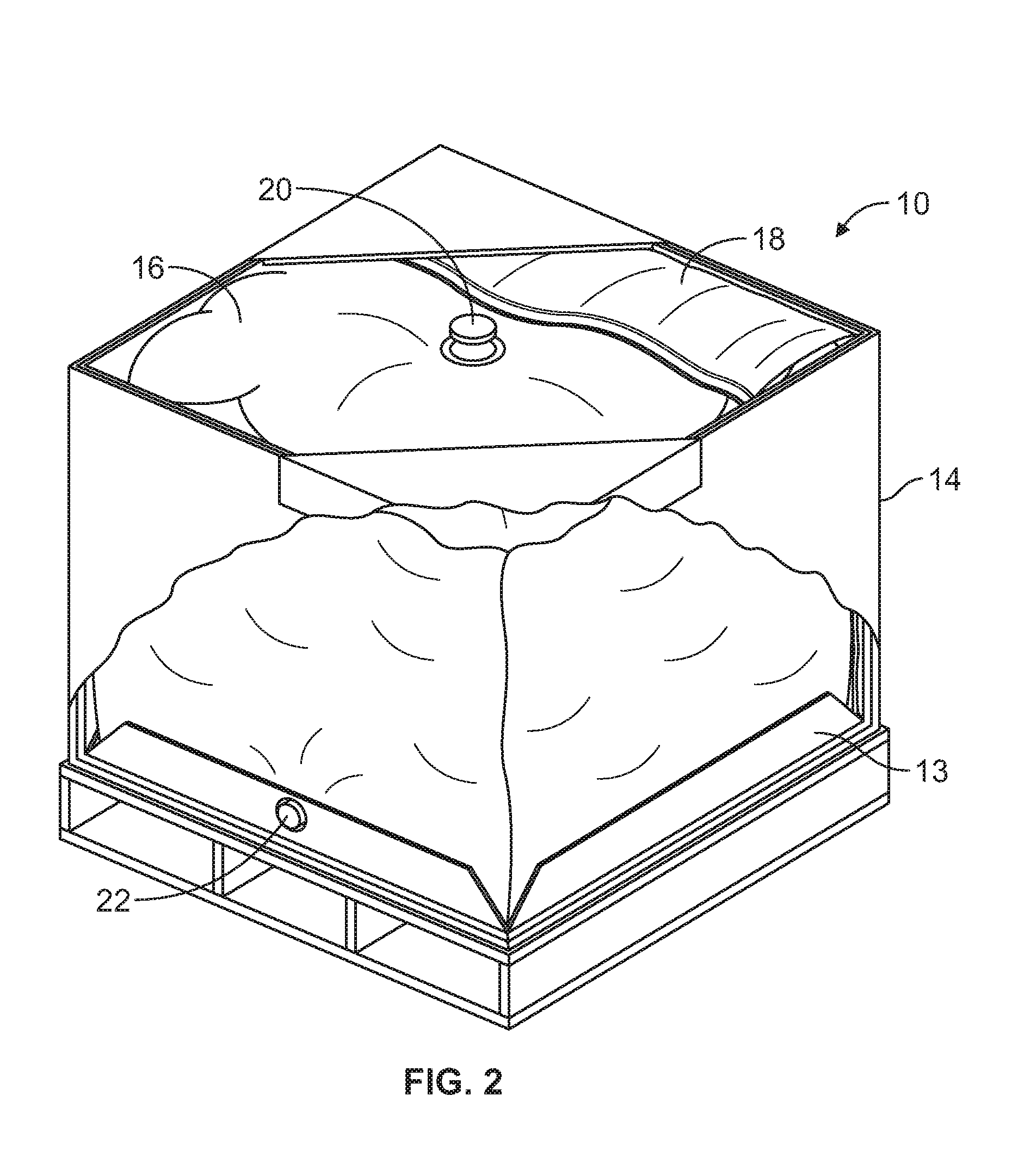

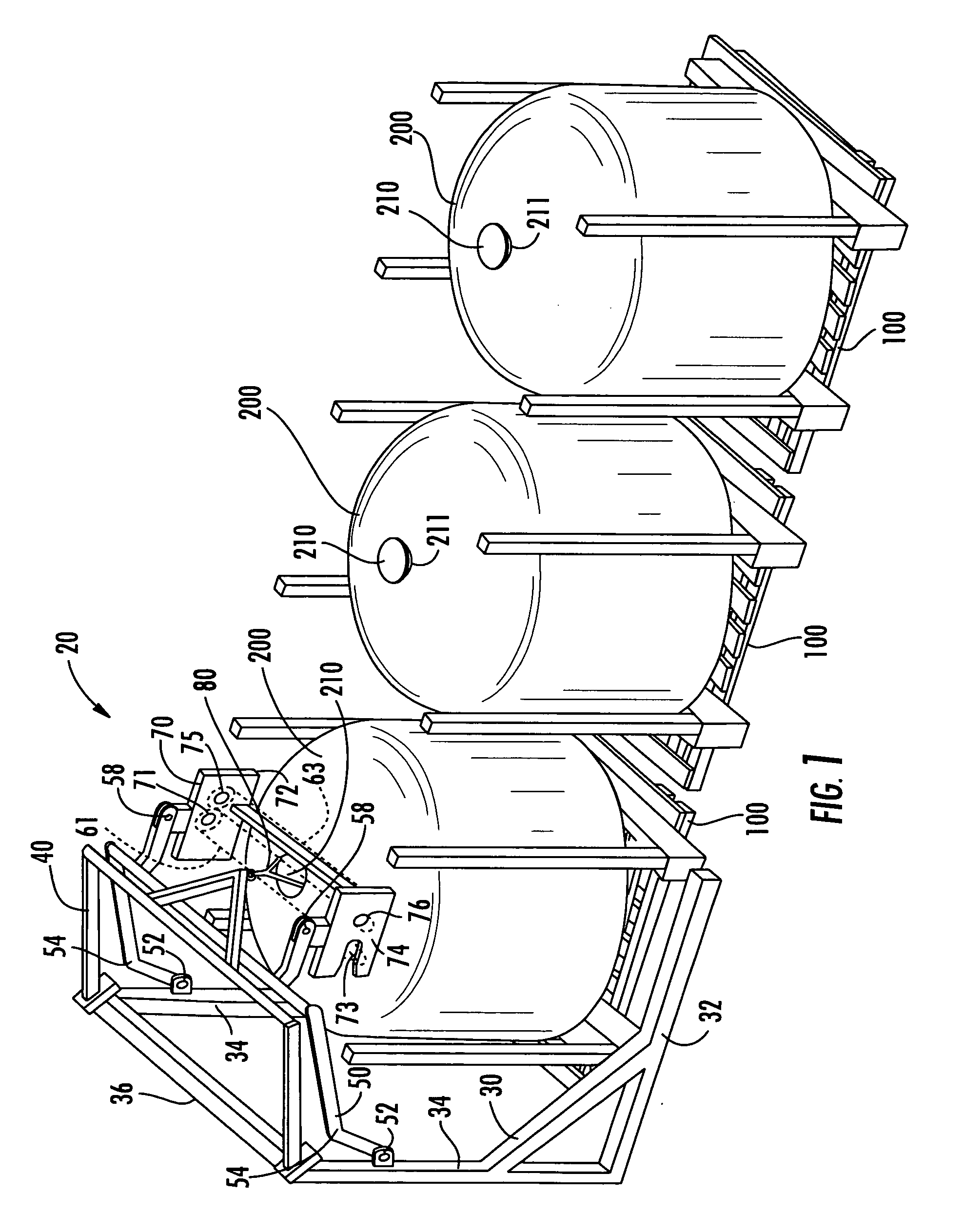

System for complete dispensing of flowable materials from a bulk shipping container

ActiveUS20170008697A1High quality plastic materialGood flexibilityLarge containersLiquid transferring devicesBulk boxEngineering

The present invention is directed to a system for fully dispensing liquid from a bulk shipping container. The system includes a bulk bin and a cassette disposed therein. The cassette includes a cassette board, a liquid bag having inlet and outlet ports and an air inflated bag that is attached to the liquid bag. The air bag includes an air inlet port formed at one end thereof and used for inflating the air bag from a source of pressurized air. The air bag further includes an obstruction region defined by a weld line that is formed on an opposite end from the air inlet port to redirect the pressurized air within the air bag when inflating the air bag reaches a level at which the pressurized air counteract the liquid pressure within the liquid bag so as to urge the liquid toward the outlet port of the liquid bag.

Owner:INT PAPER CO

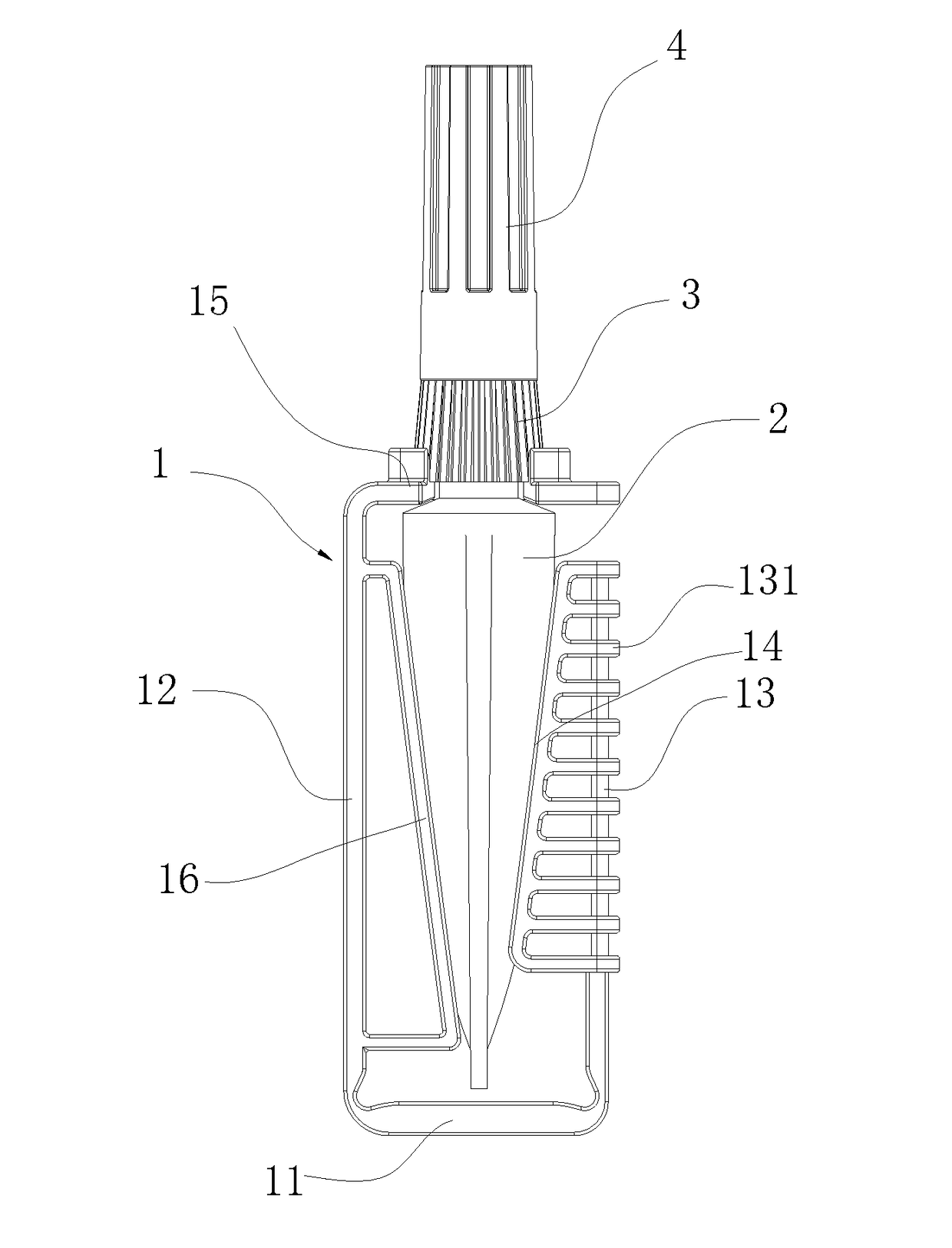

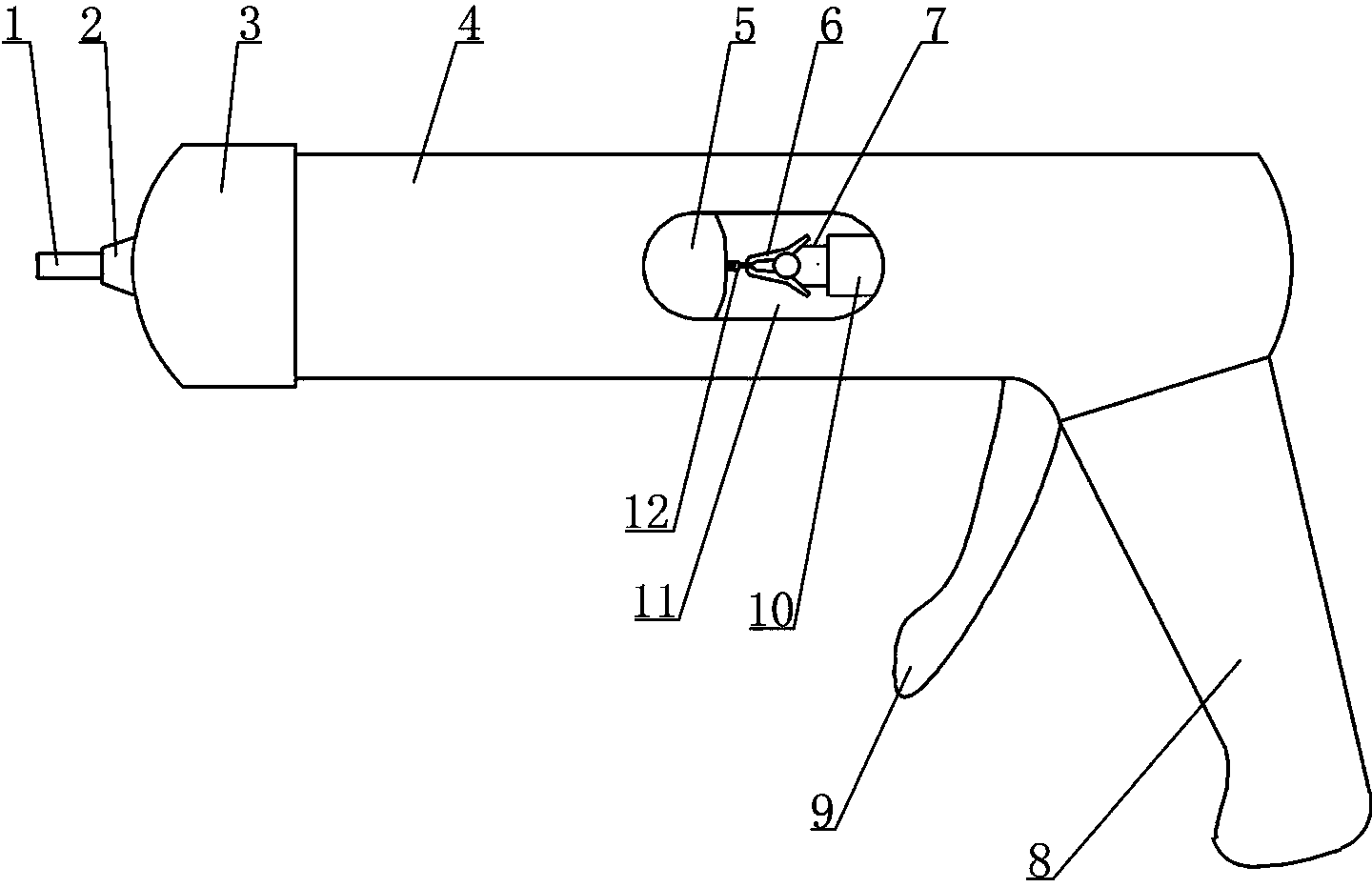

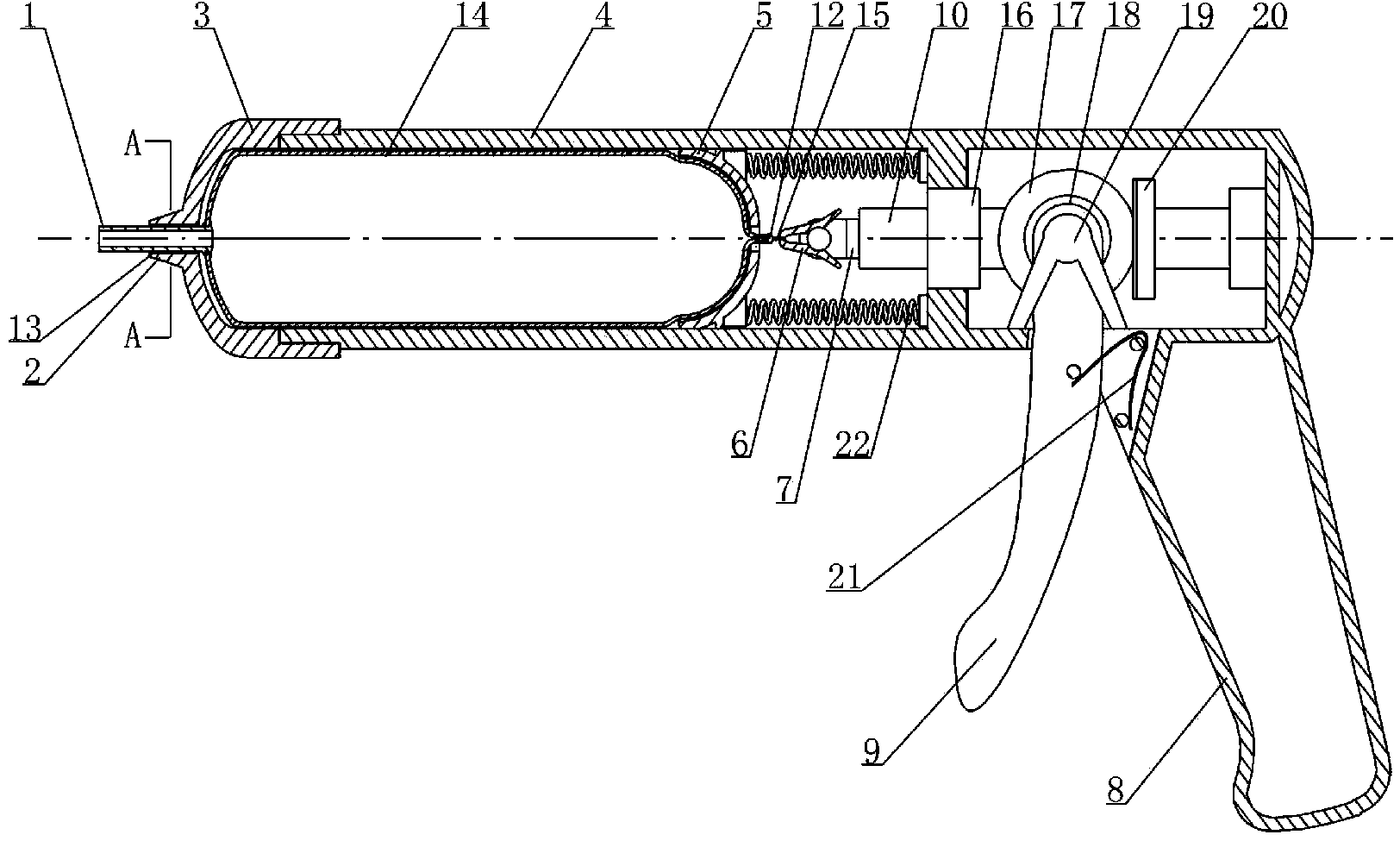

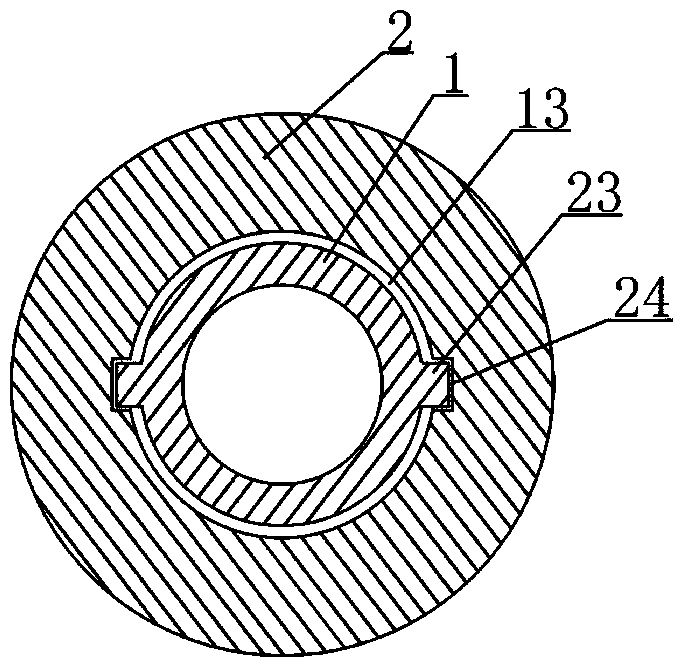

Viscous material injection device

ActiveCN104386327AAvoid large residuesAvoid residueUnpacking by expelling contentsColloidClinical care

The invention discloses a viscous material injection device. The device comprises a shell, a material bag, an ejection bowl, a spinning and extruding assembly and a handle driving assembly, wherein the shell consists of a cylinder, an end cap and a handle; the material bag takes the shape of a pipe barrel, and is put in the cylinder; a discharge nozzle is formed in the front end of the material bag; the bag wall at the back end of the material bag is gathered to be tightened by a hoop; a clamping piece is arranged at the back side of the hoop; the ejection bowl is buckled at the back side of the material bag; a center hole is formed in the bottom of the ejection bowl; the spinning and extruding assembly comprises a bushing and a telescopic shaft rod; a fixed clamp is arranged at the front end of the telescopic shaft rod; and the handle driving assembly consists of a handle, a shaft sleeve, a gear and a one-way transmission mechanism, and is used for driving the spinning and extruding assembly to rotate in one direction. The viscous material injection device is conveniently operated, is suitable for bulk materials to save the production cost, prevents direct contact between the materials and the cylinder to reduce the residue of the materials in the material bag, guarantees the service life thereof, and reduces the resource waste. In addition, the viscous material injection device is conveniently held, is small and compact in structure, can be used for injecting various colloids in such industries as industry, architectural engineering and decoration, and can be used for injecting various liquid diets in clinical care.

Owner:江苏开创检测技术有限公司

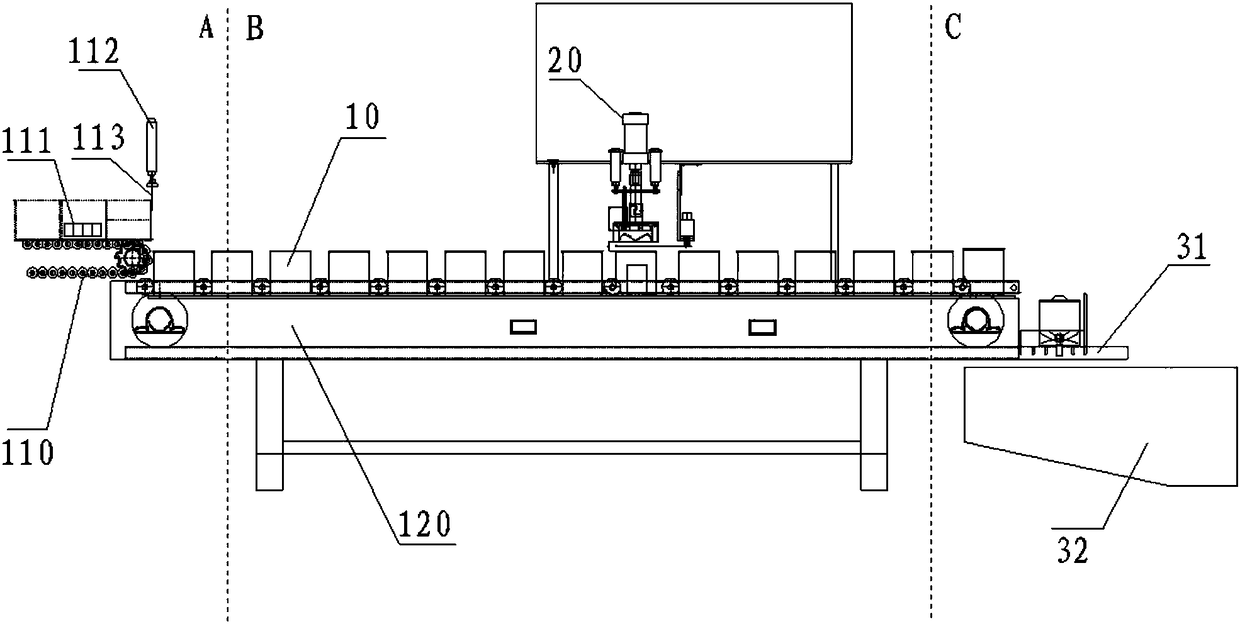

Automatic can opening device

ActiveCN108082629AFully automatedNo human intervention requiredUnpacking by expelling contentsEconomic benefitsEngineering

The invention provides an automatic can opening device. The automatic can opening device comprises a conveying module, a can opening module and a collecting module, wherein the conveying module penetrates through a feeding area, a can opening area and a discharging area in sequence; the can opening module is arranged in a can opening area, and the collecting module is arranged at the position, located at the tail end of the conveying module, in a discharging area; the conveying module is used for sequentially conveying cans to the can opening area to be opened, and conveying the canned cans tothe discharging area; the can opening module is used for opening the cans and separating the cans from can covers; and the collecting module is used for collecting the can contents. The can opening device has the beneficial effects that conveying, can opening, can content recycling, empty can and can cover sorting are integrated, so that automation of the whole production process is realized, manual intervention is not needed, the production efficiency is greatly improved, labor cost is saved, and the economic benefits of enterprises are greatly improved.

Owner:阳江喜之郎果冻制造有限公司

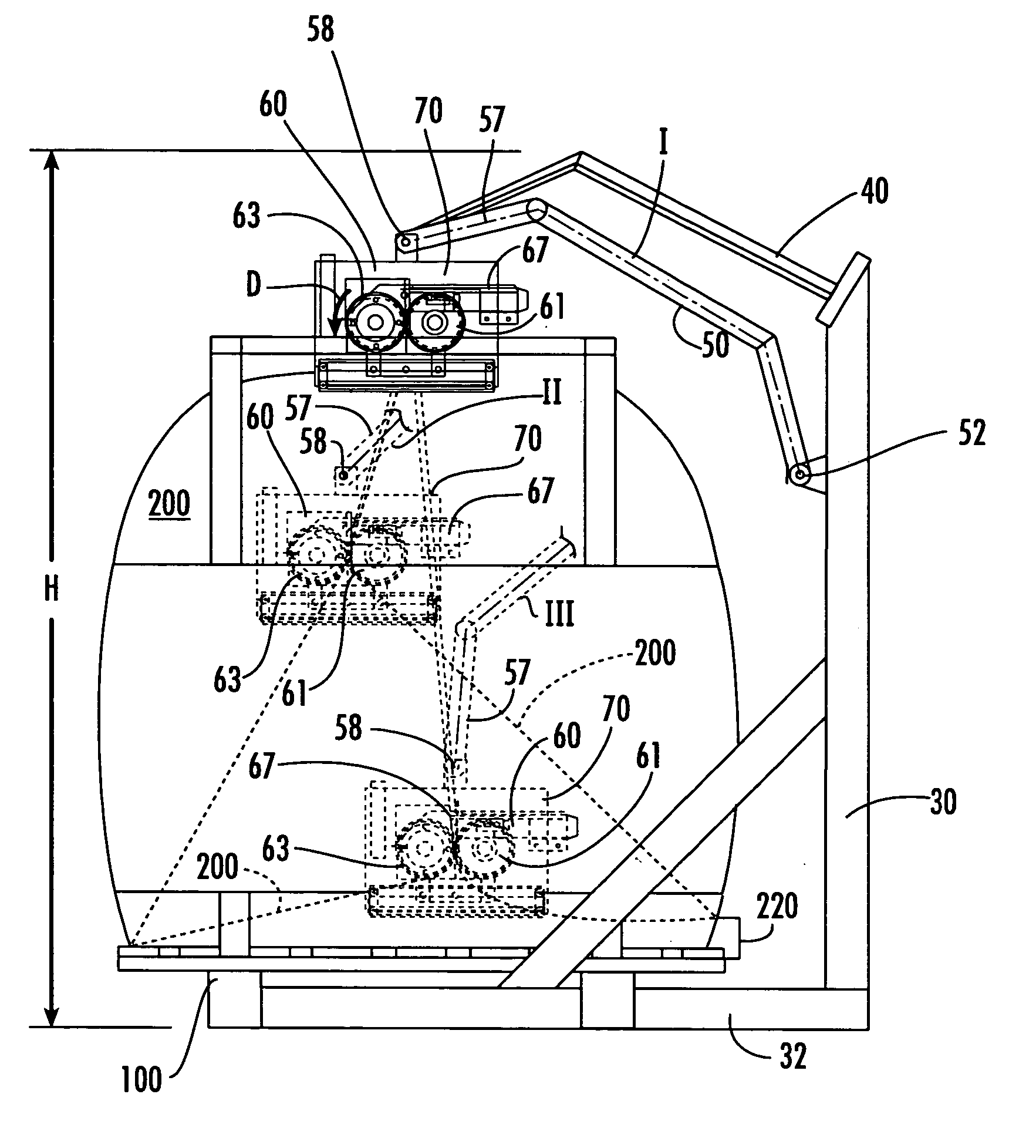

Bulk transfer dispensing device and method

ActiveUS20070080167A1Flexible bulk container emptying systemsLiquid flow controllersEngineeringMechanical engineering

Owner:PORTEC RAIL PRODS

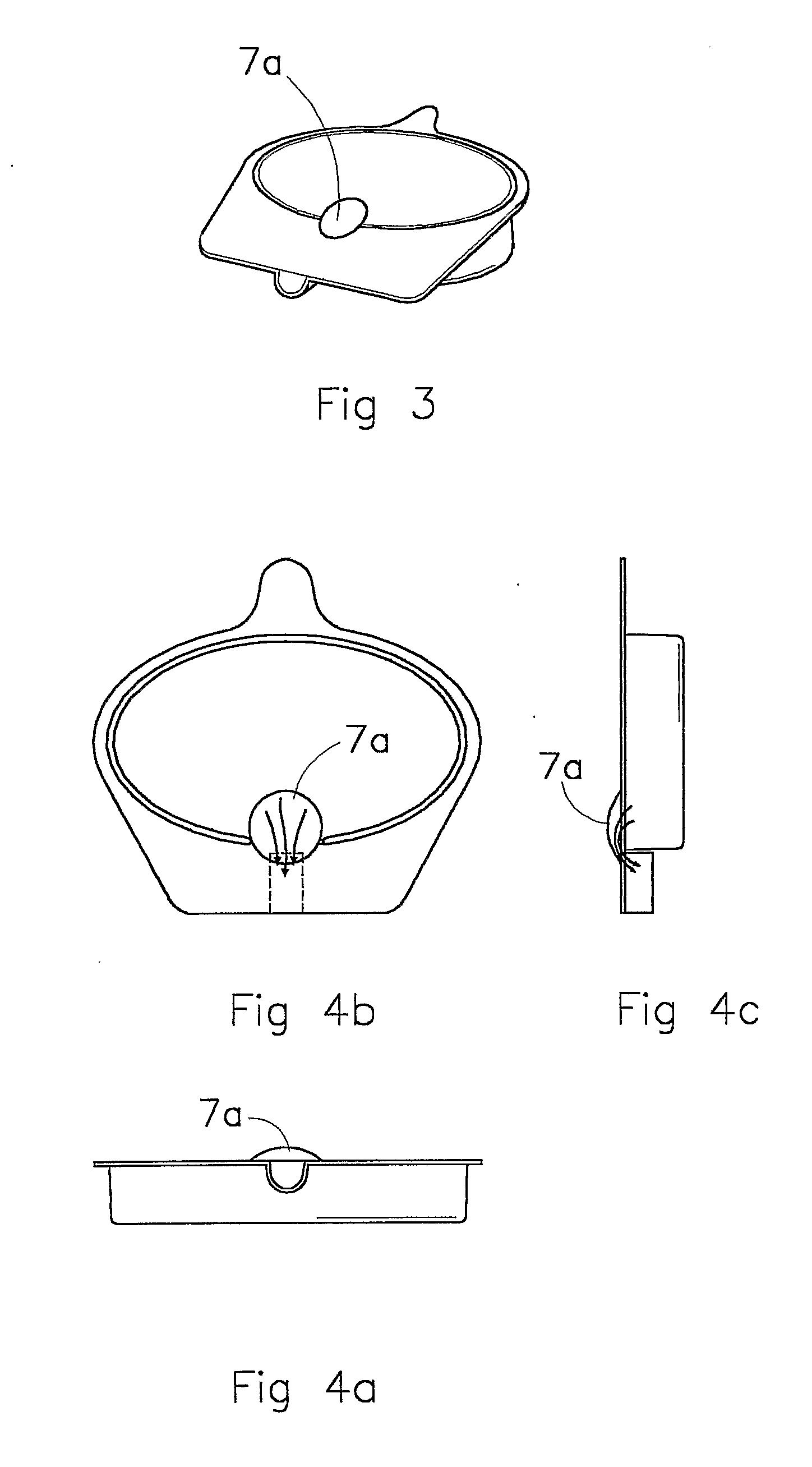

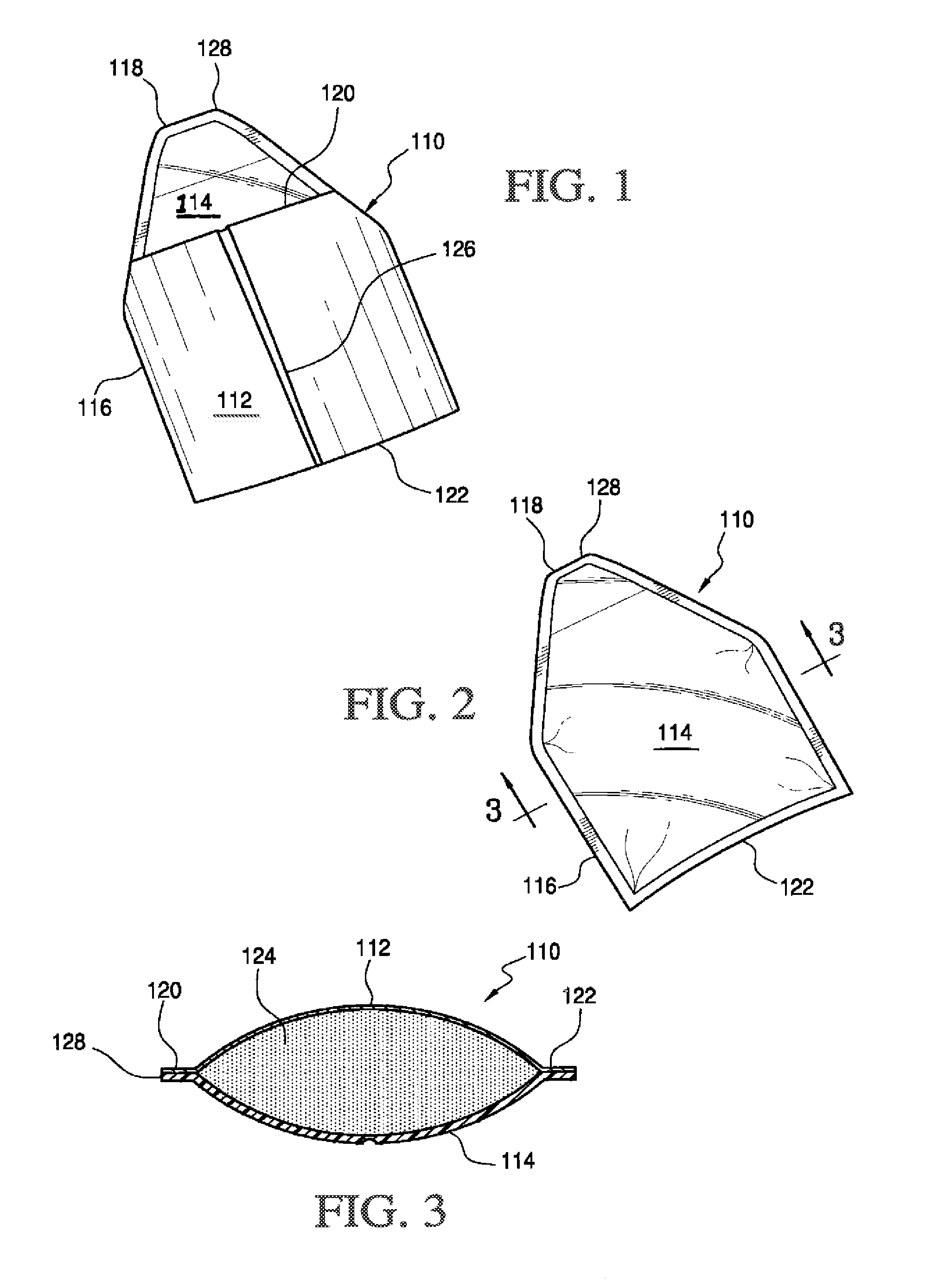

Medical device packaging and related methods

According to one aspect of the disclosure, packaging for a sterile syringe having a nominal size of less than 1 mL may include a flexible tray having a cavity for containing the syringe. The cavity may include an opening, one or more sidewalls, and a base. A lip may surround the opening, may extend radially outward from the cavity, and may define a periphery of the tray. A removable cover may have a periphery that is adhered to the lip, and the removable cover may be permeable to a gaseous sterilant, including one or more of vaporized hydrogen peroxide or ethylene oxide. A projection may be associated with the base of the cavity and may extend away from the base of the cavity in a direction opposite to the opening of the cavity.

Owner:REGENERON PHARM INC

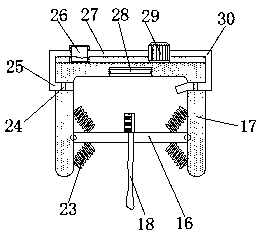

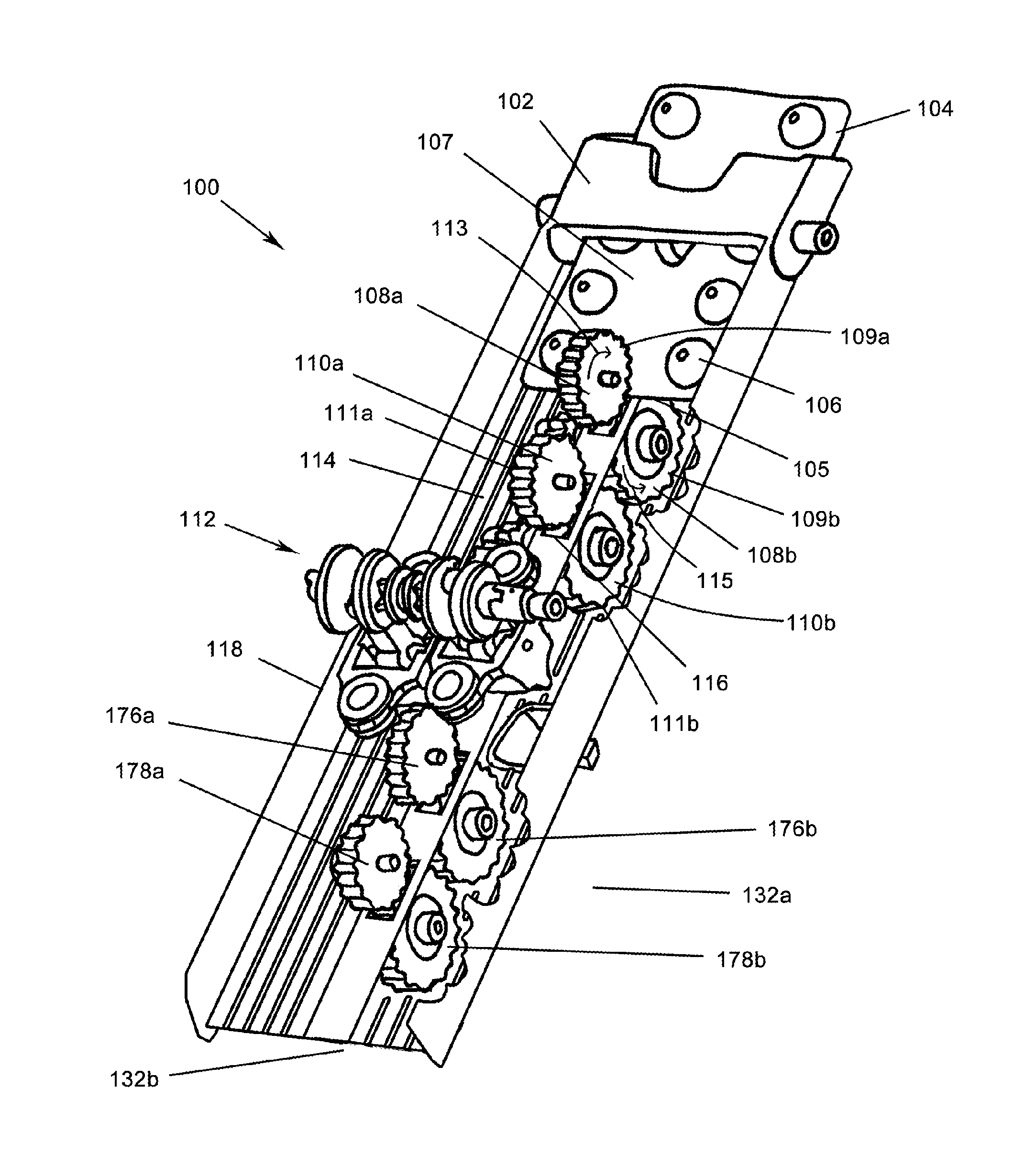

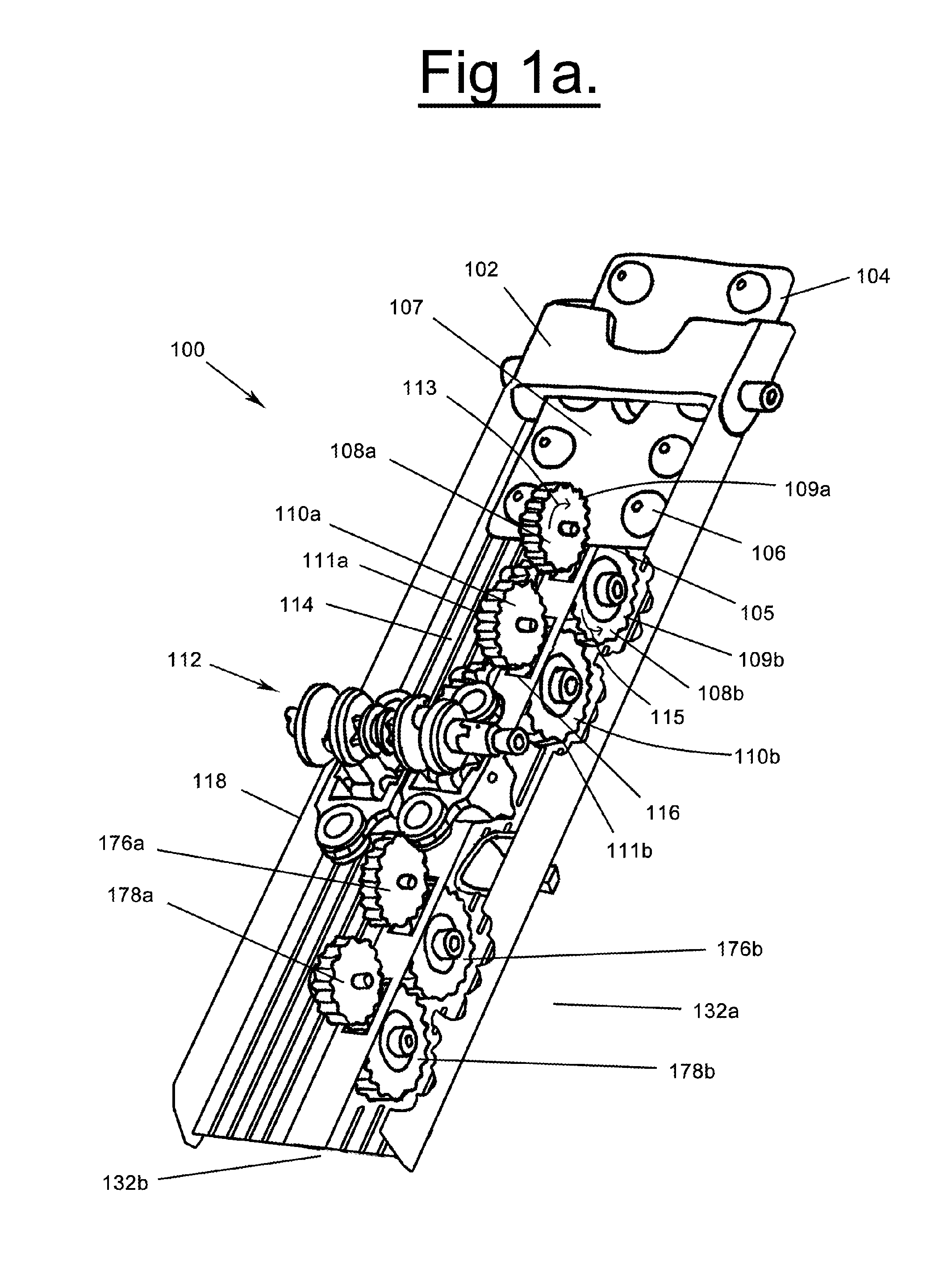

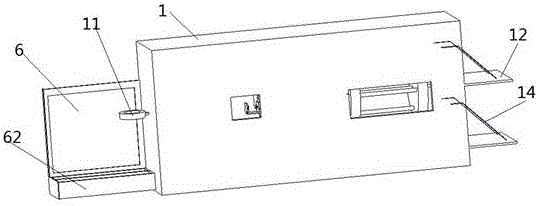

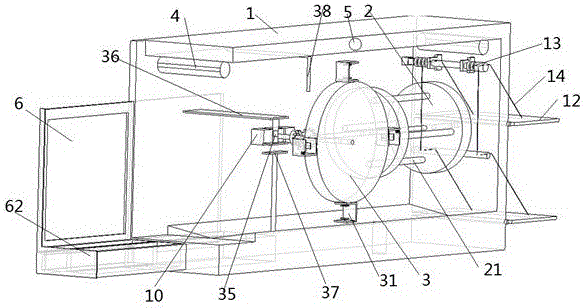

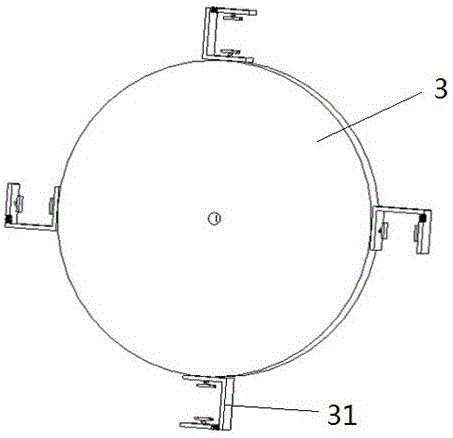

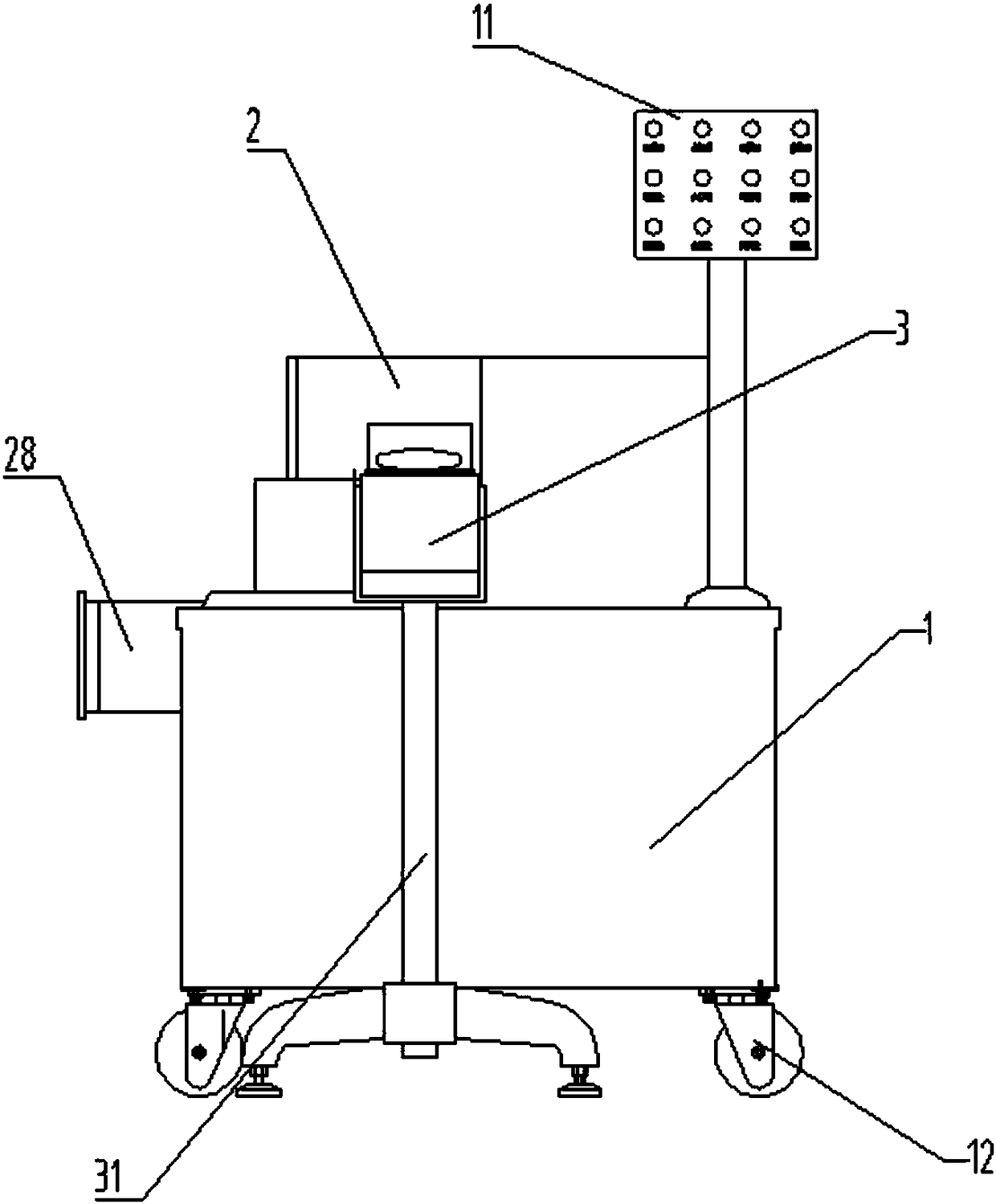

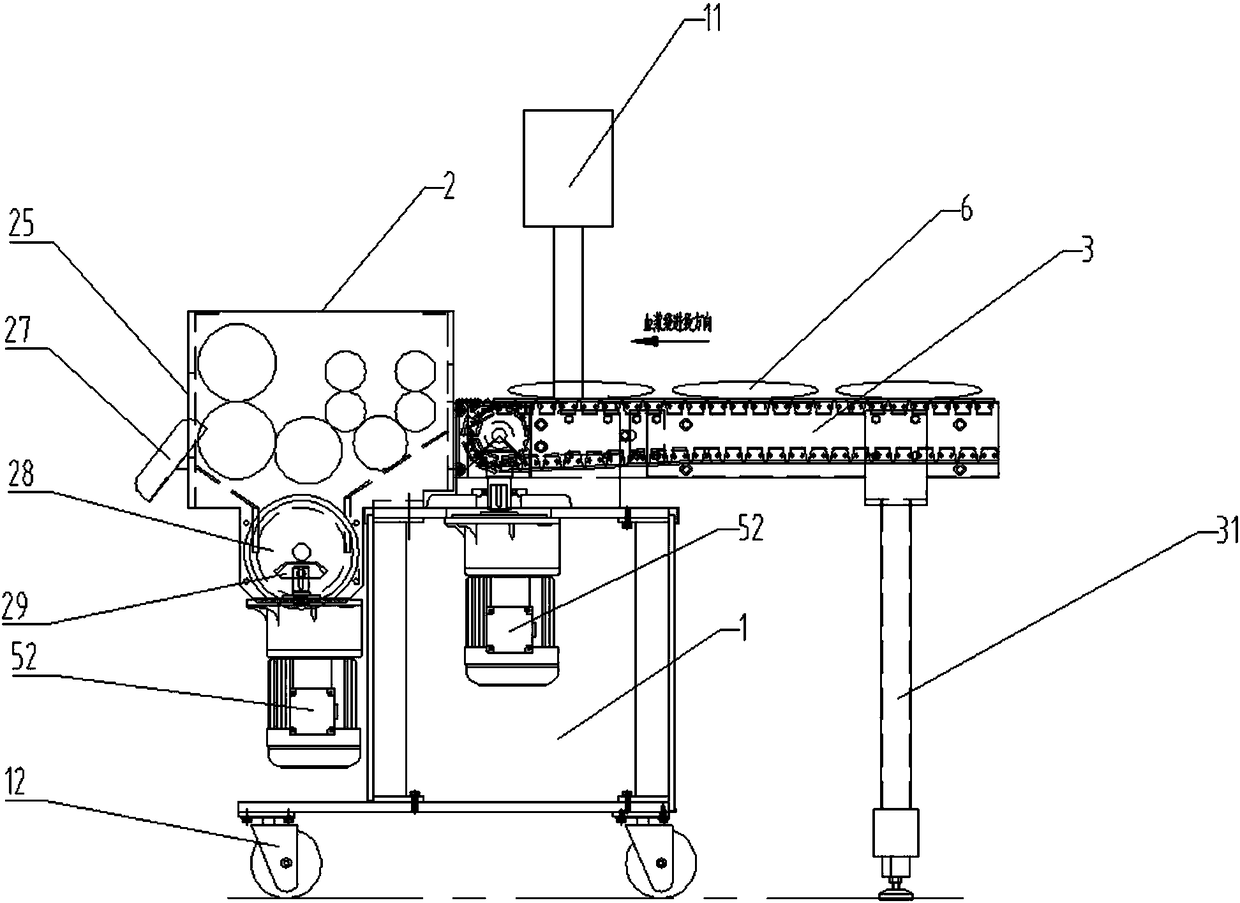

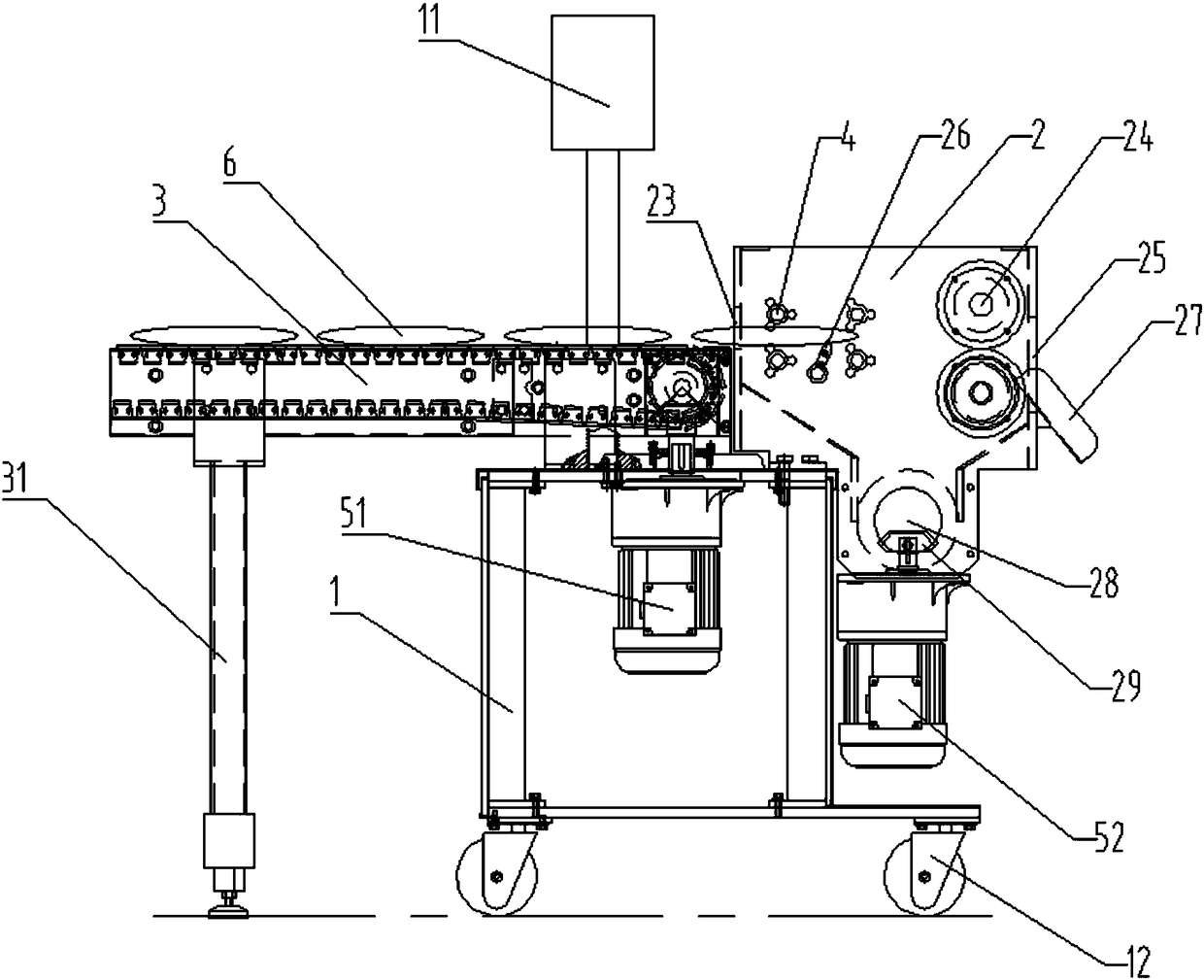

Automatic toothpaste squeezing equipment

InactiveCN107985700AReduce wasteEasy to useUnpacking by expelling contentsFlexible containersGear wheelElectric machinery

The invention discloses automatic toothpaste squeezing equipment. The automatic toothpaste squeezing equipment comprises a base; a toothbrush placement seat is disposed on the lower side of the base;an infrared receiver is disposed on the upper side of the front end of the toothbrush placement seat; a partition board is disposed at the upper end of the toothbrush placement seat; a toothpaste mounting hole is formed in the middle of the partition board; a connecting cover is disposed on the upper side of the base; gear racks are disposed at the left end and the right end of the interior of theconnecting cover; a connecting frame is disposed at the upper end of the interior of the connecting cover; connecting shafts are disposed at the left end and the right end of the connecting frame; connecting gears are disposed on the connecting shafts; driving gears are disposed on the inner sides of the connecting gears; small motors are disposed on the rear sides of the driving gears; a controller is disposed on the rear side of the interior of the connecting frame; connecting blocks are disposed at the left end and the right end of the middle of the connecting frame; a plurality of rotaryshafts are disposed between the connecting blocks; and squeezing rollers are disposed on the rotary shafts. By means of the automatic toothpaste squeezing equipment, automatic toothpaste squeezing canbe effectively achieved, and toothpaste in a toothpaste shell can be conveniently and totally squeezed.

Owner:ZHENGZHOU YOUAI NETWORK TECH CO LTD

Bag-breaking and liquid-taking machine for bagged product

InactiveCN104309875AEasy to cutReasonable structural designUnpacking by expelling contentsUnpacking by cuttingEngineeringDrive motor

The invention relates to a bag-breaking and liquid-taking machine for a bagged product. The bag-breaking and liquid-taking machine comprises a control cabinet and a liquid separating device, wherein the liquid separating device comprises a left wall plate and a right wall plate; a wall-plate fixing plate is arranged between the left wall plate and the right wall plate; a cutter group is arranged at the upper part between the left wall plate and the right wall plate; a feeding port is arranged above the cutter group; an extruding roll drum and a discharging roll drum are arranged under the cutter group; an extruding driving roll drum is arranged under the extruding roll drum and the discharging roll drum, and a liquid collecting hopper is arranged under the discharging roll drum; a liquid groove is arranged in the control cabinet under the liquid collecting hopper; the control cabinet is internally provided with a driving motor which is linked with a gear transmission box arranged on the right wall plate; the gear transmission box drives the cutter group, the extruding roll drum, the discharging roll drum and the extruding driving roll drum to rotate. The bag-breaking and liquid-taking machine has the advantages that by the cutter group in the liquid separating device, a bag can be easily cut, and manual tearing for the bag is not needed, so that the production efficiency is improved, the expenditure for labor cost is reduced and the recovery efficiency is improved.

Owner:KUSHAN LEIPUSEN AUTOMATION TECH CO LTD

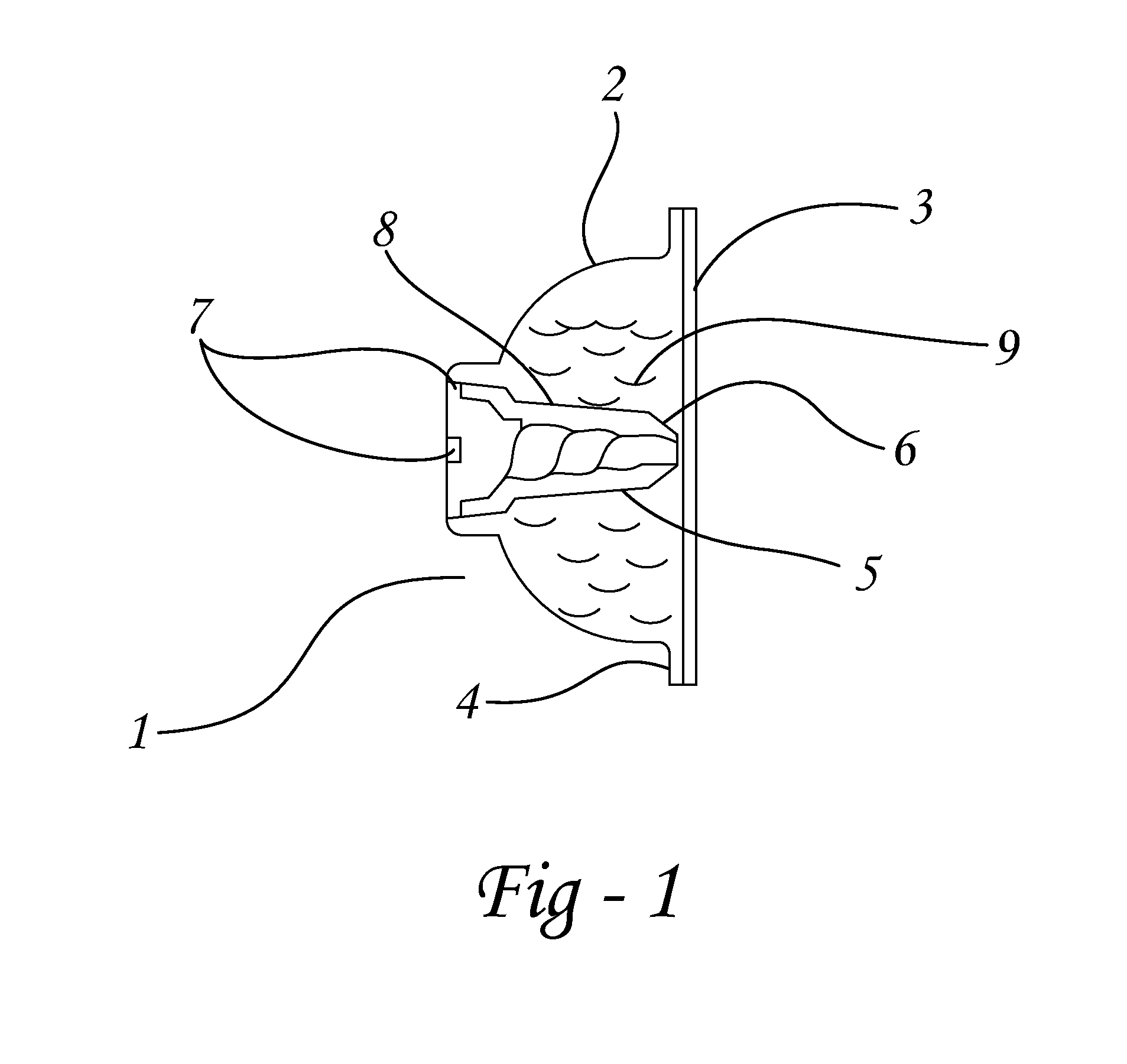

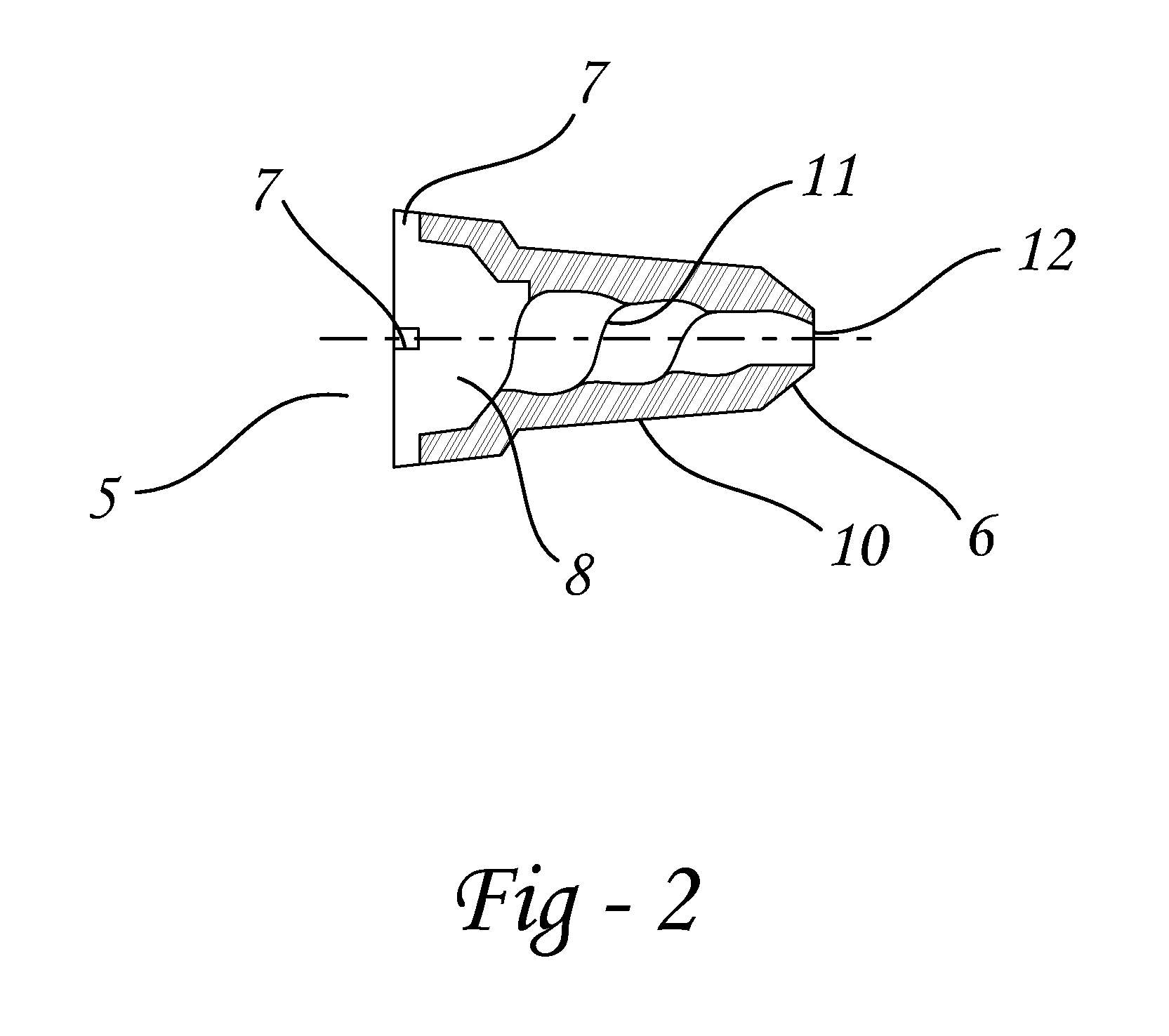

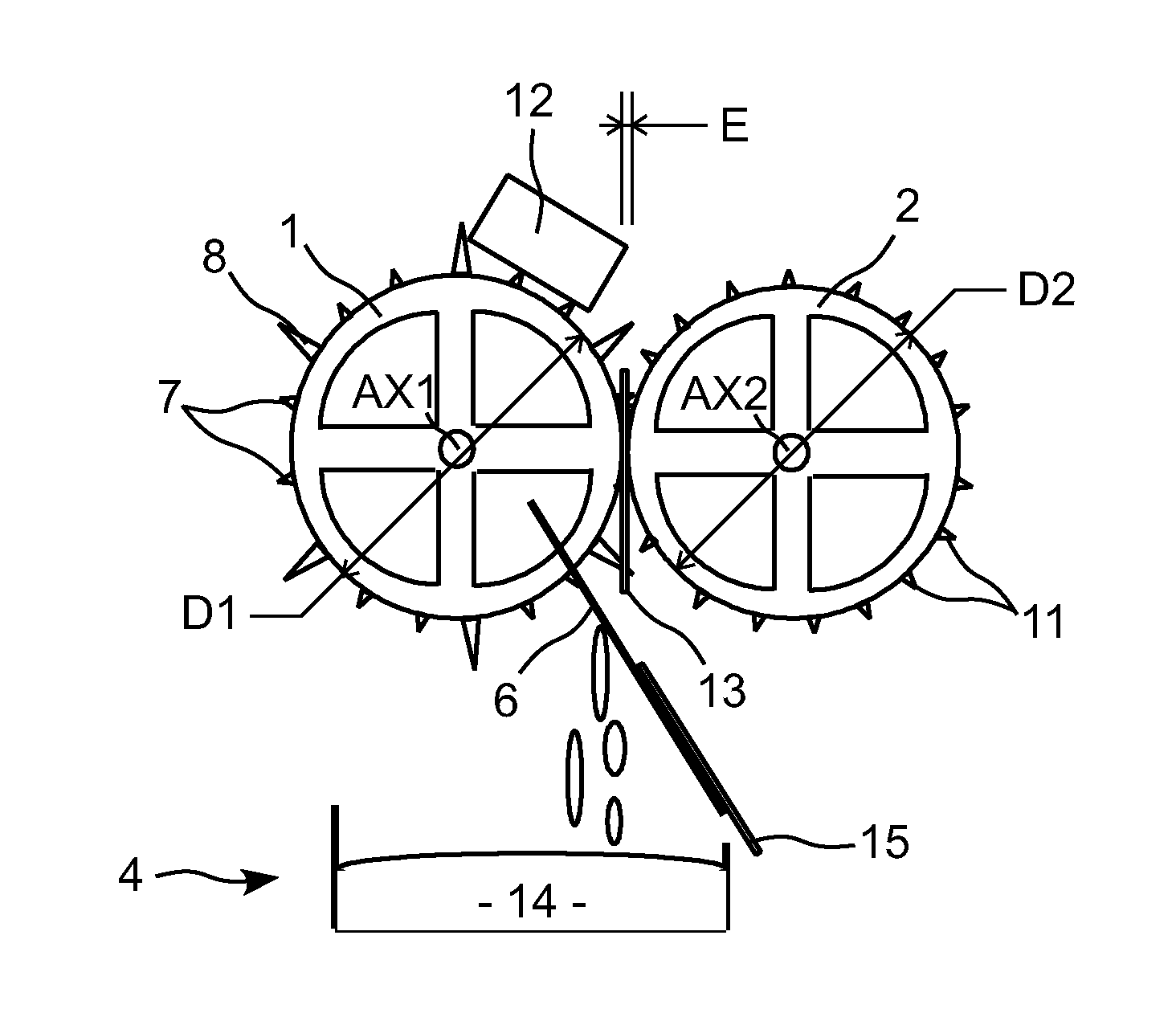

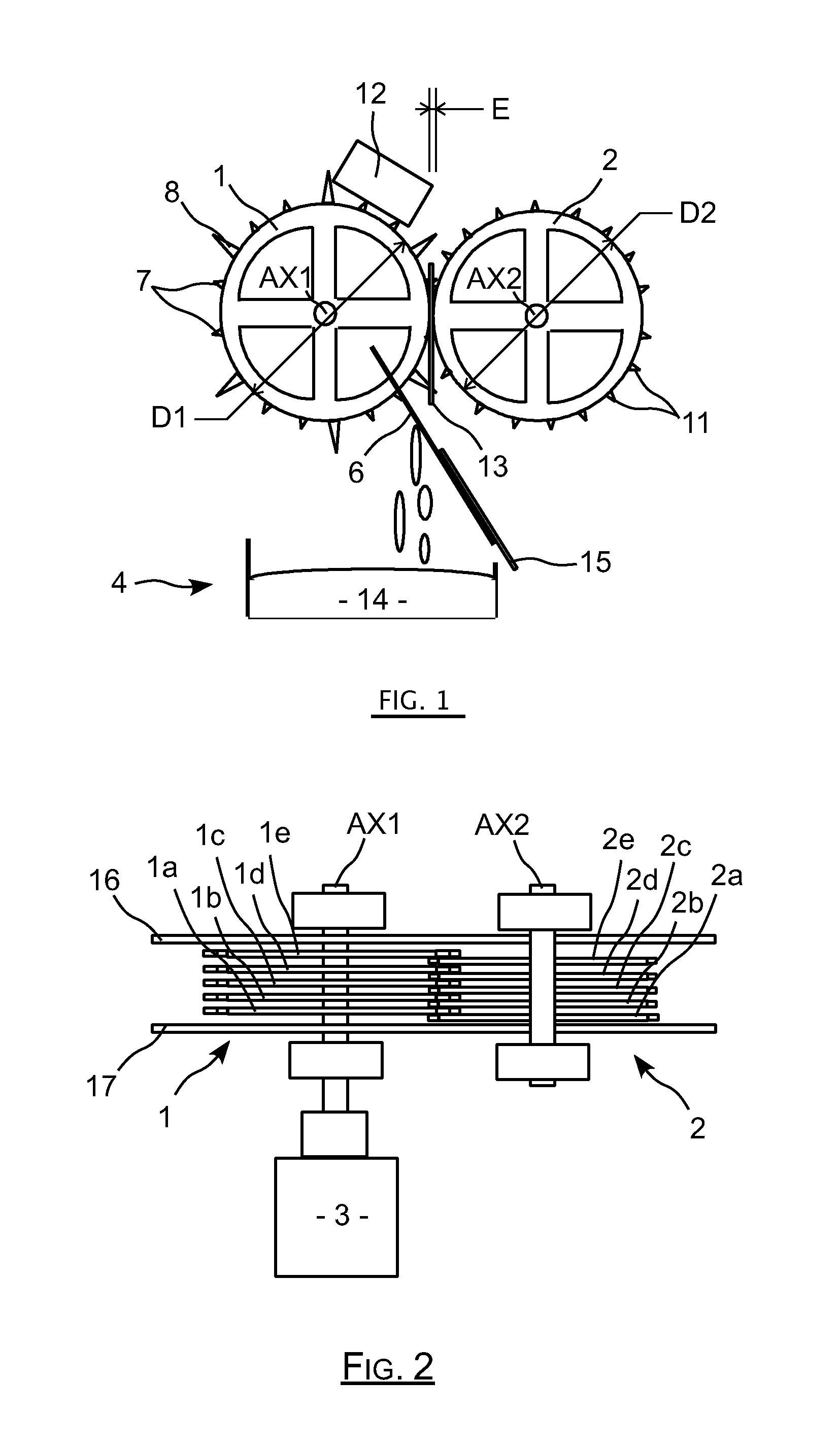

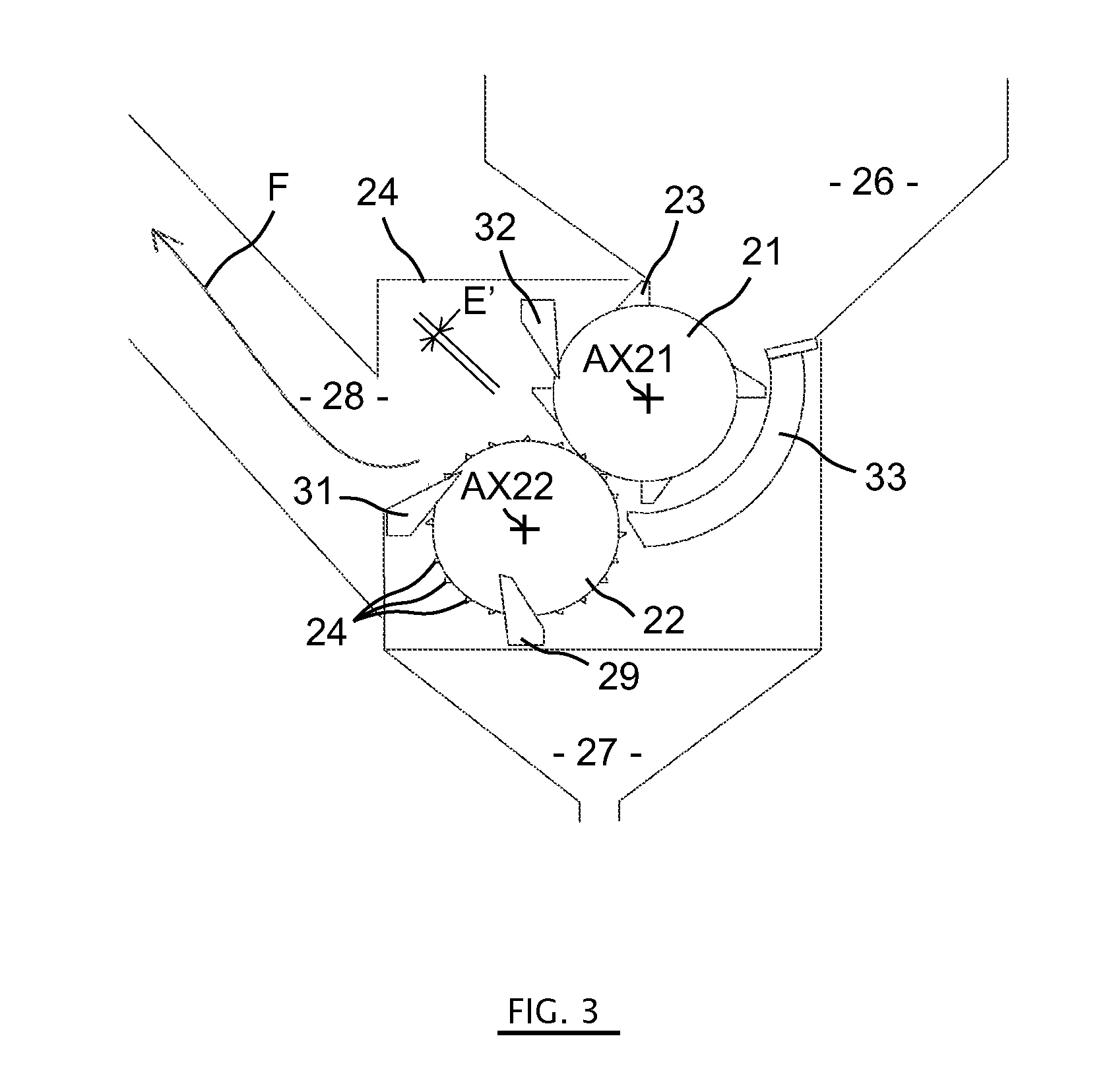

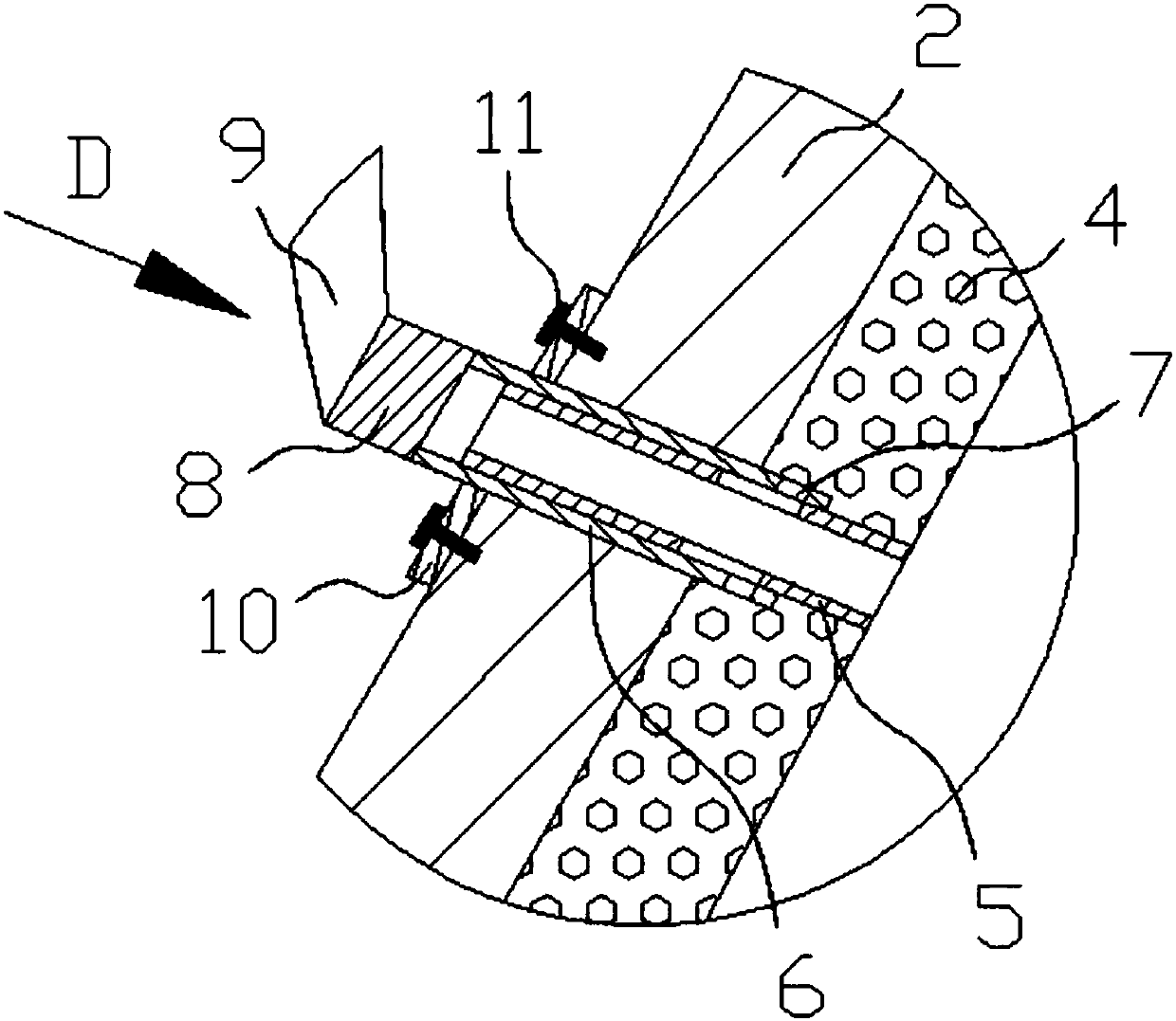

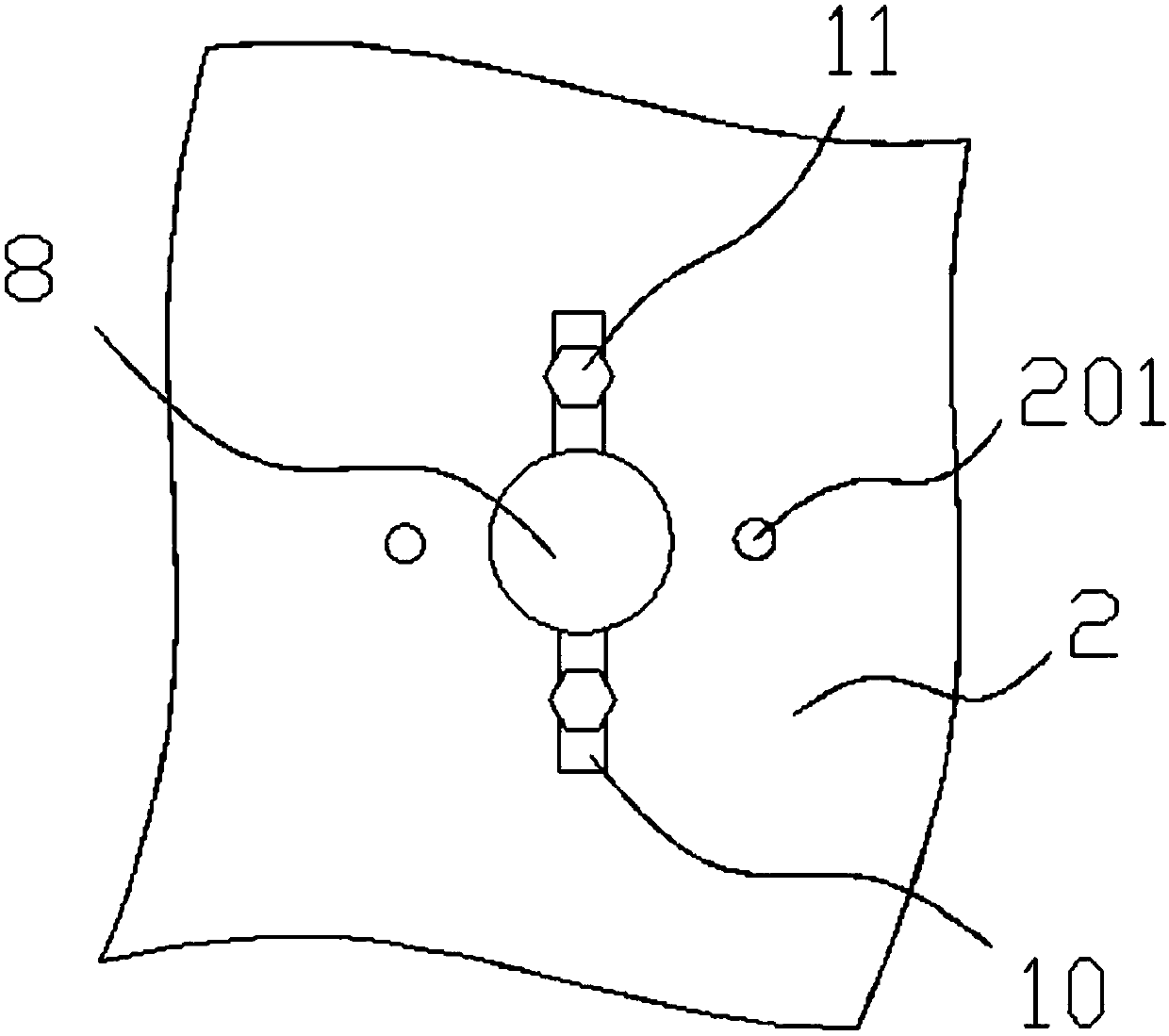

Device for extracting a liquid contained in containers made of an infrangible material

InactiveUS20120079930A1Efficient separationShearing machinesBags openingElectric machineryStructural engineering

The invention relates to a device for extracting a liquid (14) contained in a container (12, 13, 15) of non-brittle material such as a container containing a liquid or pasty cosmetic or food product. The device comprises two wheels (1, 2) rotating about parallel axes (AX1, AX2) and separated from each other by a gap (E), together with motor means (3) for driving the two wheels (1, 2) in rotation in opposite directions. At least one of the wheels (1, 2) includes spikes (7, 11) projecting radially from an outer base diameter of the wheel (D1, D2) and engaging in corresponding recesses in the other wheel (1, 2; 21). The device serves simultaneously to compress and to pierce the containers (12, 13, 15) when they pass through the gap (E) between the two wheels.

Owner:GREEN CREATIVE

Intelligent toilet article cabinet

InactiveCN105747962AAvoid breedingAvoid enteringPicture framesHolders and dispensersEngineeringMicrocomputer control

The invention discloses an intelligent toilet article cabinet which comprises a cabinet body. An airing drum device, a toilet article holding turnplate, a heating and drying device, an ultraviolet sterilizing lamp, a single chip microcomputer control unit, a Bluetooth module and a stepping motor. The intelligent toilet article cabinet can dry and sterilize toilet articles and can automatically prepare toilet articles for people by utilizing the Bluetooth module, so that space of a bathroom is saved greatly. The intelligent toilet article cabinet is reliable in performance, enabling people's life to be more intelligent, and is handy and time saving.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

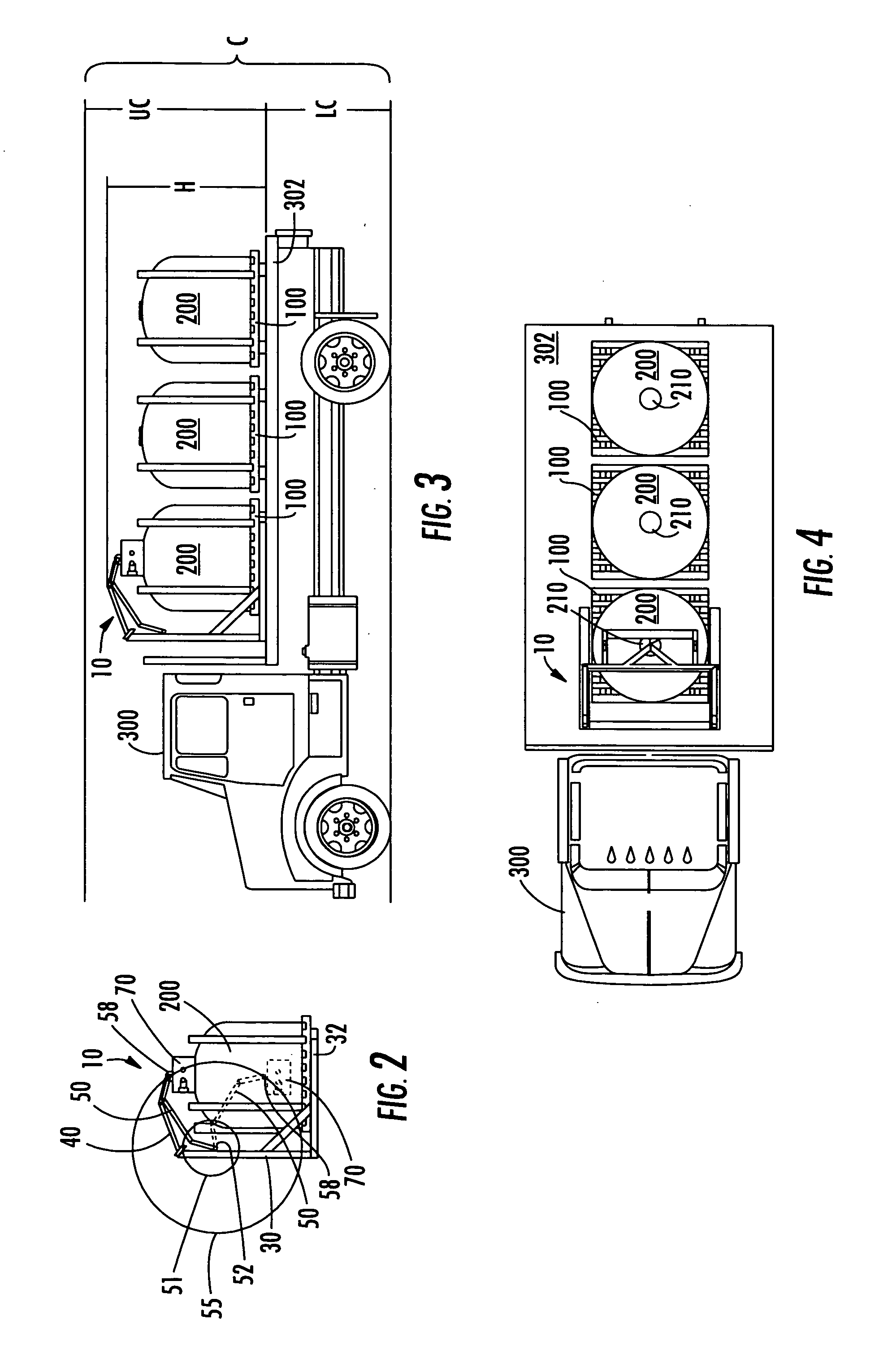

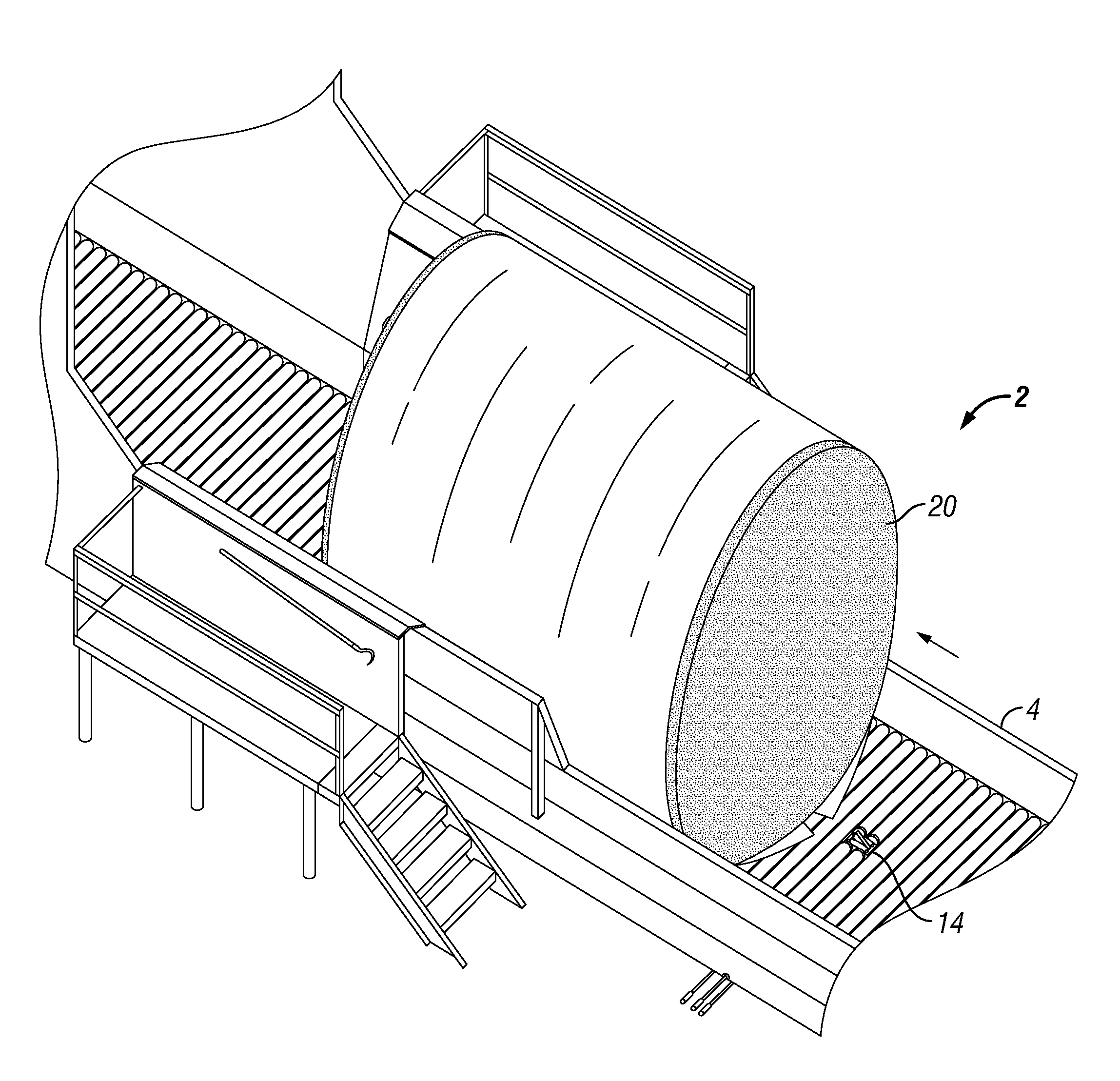

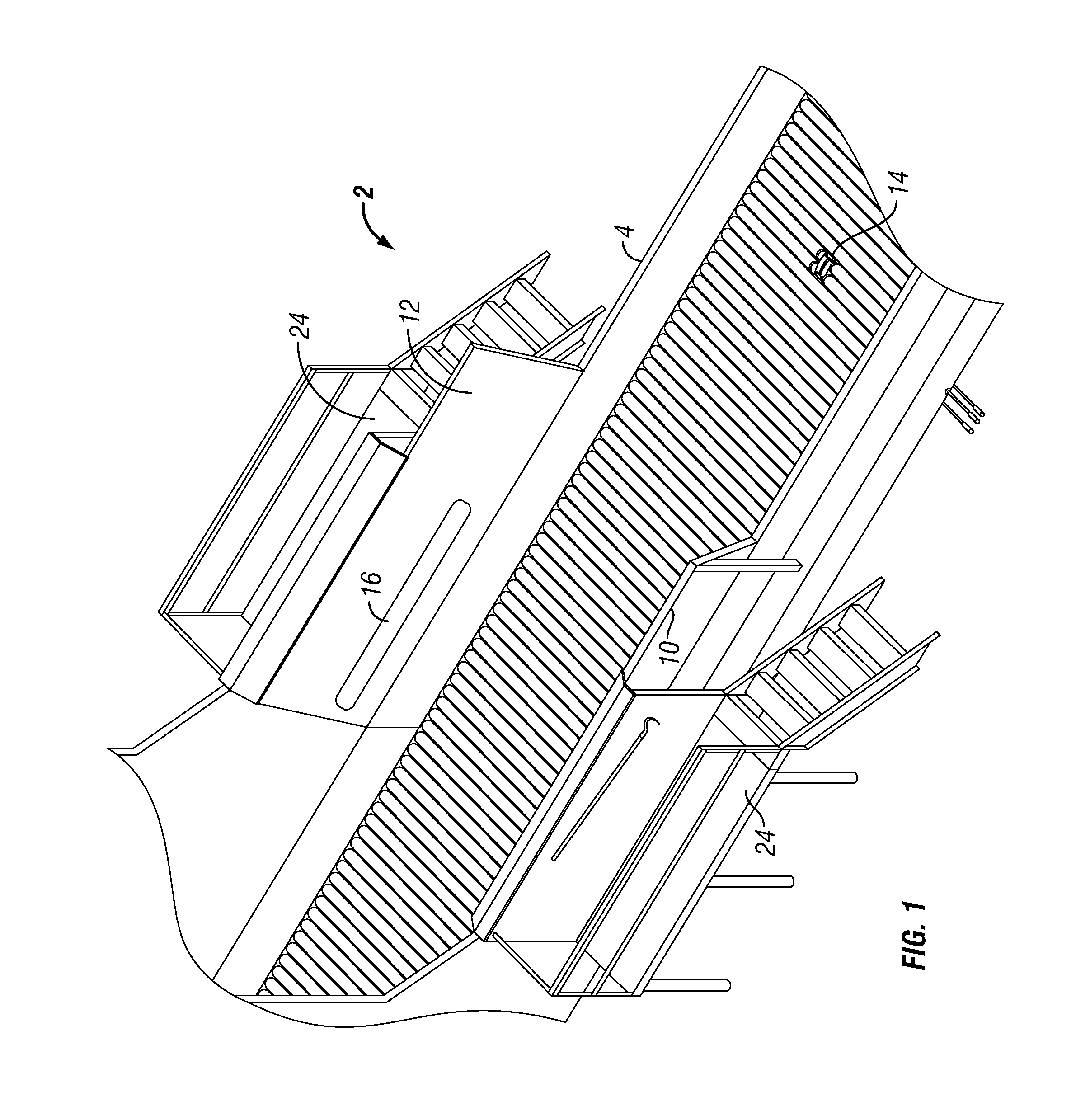

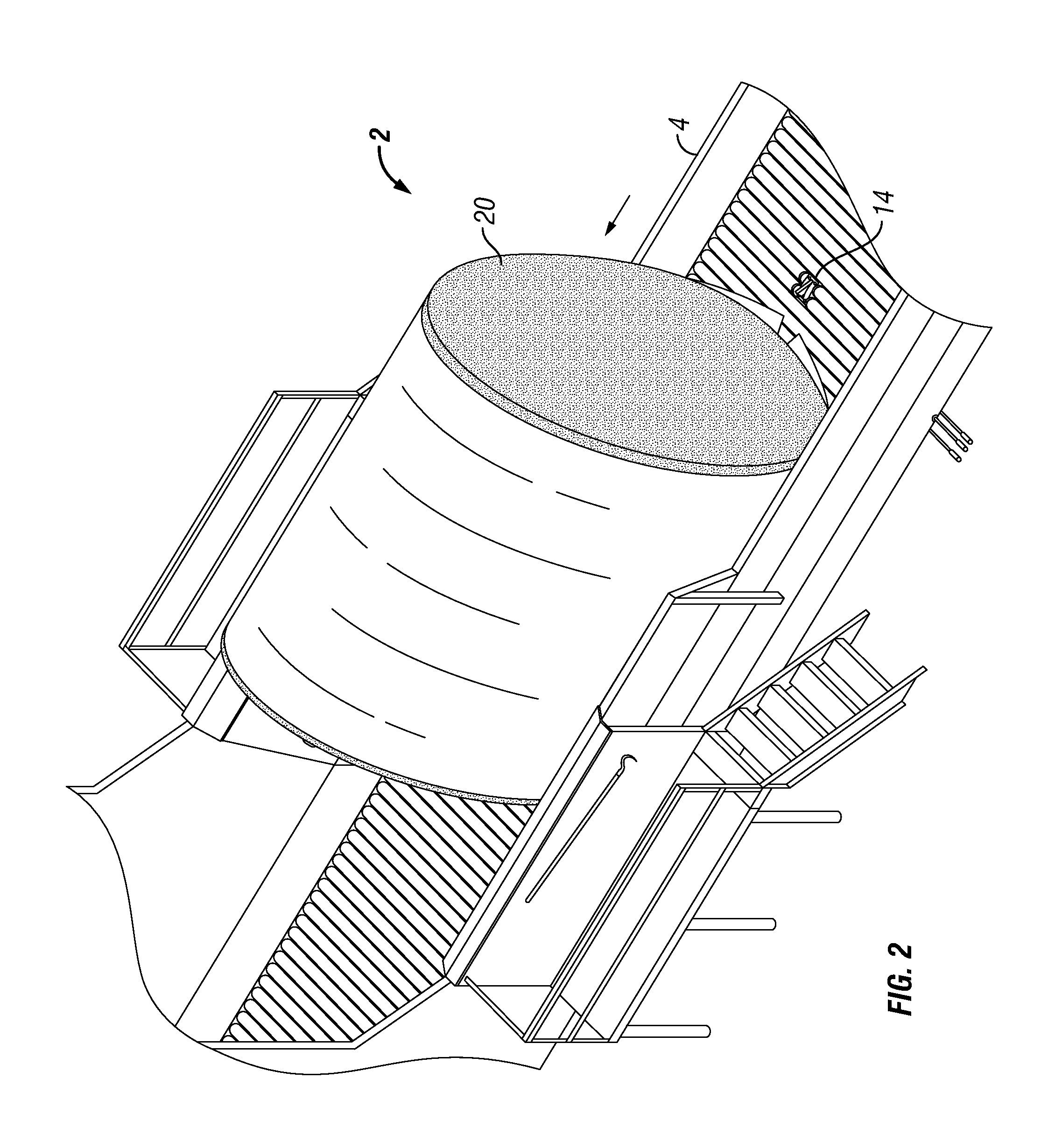

Module feeder system and method to use same

InactiveUS20130152345A1Opening closed containersBottle/container closureHydraulic cylinderEngineering

A module feeder system is disclosed. The module feeder system comprises a module feeder which has an unload bed, a feeder bed, a first side wall and a second side wall. A cutting device is attached to the feeder bed. At least one hydraulic cylinder is positioned on each of the first and second side walls. Each hydraulic cylinder is configured to project in a direction away from the sidewalls and over the feeder bed. A method used to unwrap a cotton module is also disclosed.

Owner:BROWN JOE GOODWIN

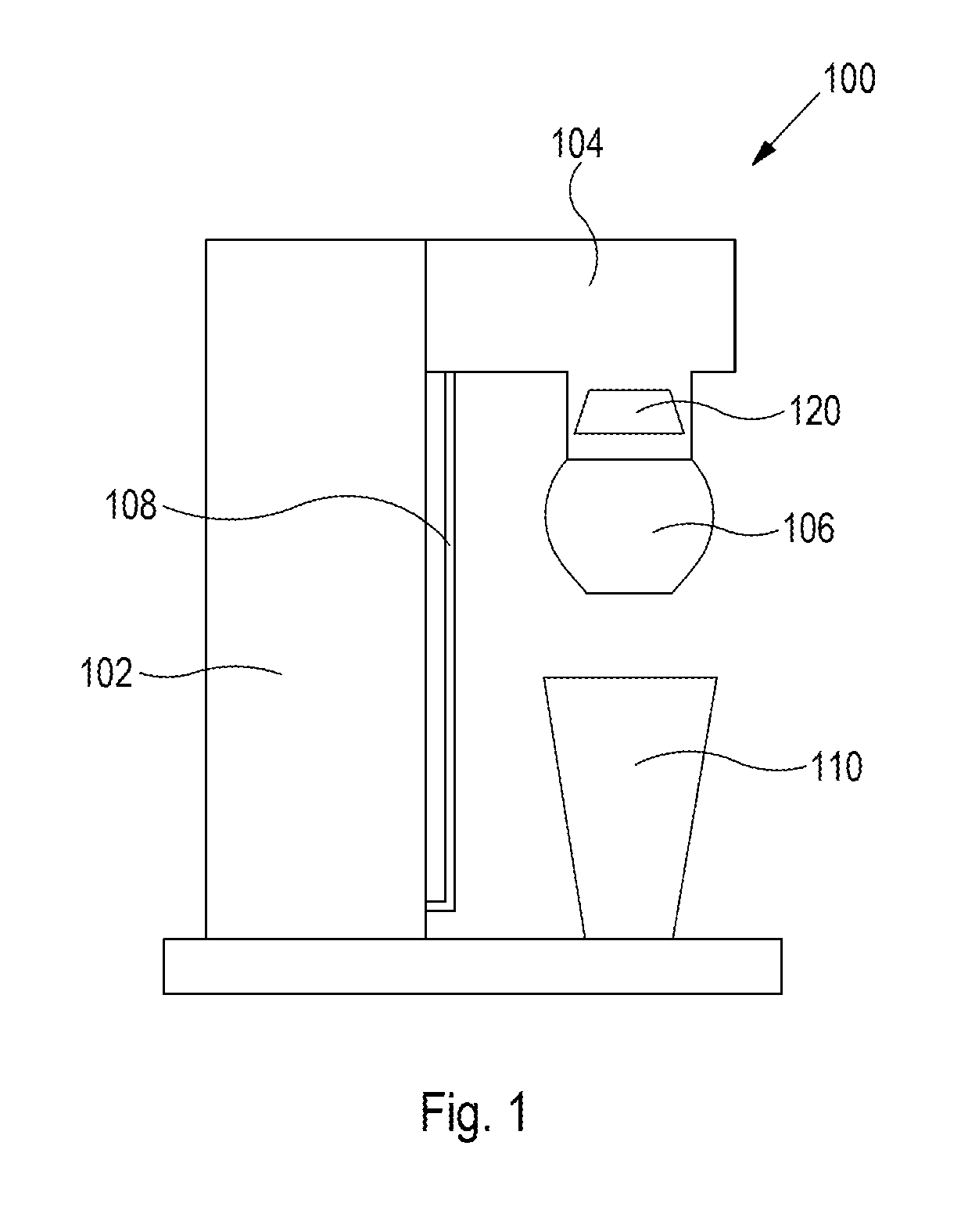

System for filtering liquid

InactiveUS20190231119A1Prevent overflowTreatment involving filtrationBeverage vesselsEngineeringLiquid storage

There is provided a system for filtering liquid. The system comprises a liquid storage reservoir and a liquid inlet reservoir. The system further comprises a filter receiving portion configured to receive a filter, such that, in use, a filter is provided between said liquid inlet reservoir and said liquid storage reservoir and is, in use, configured to filter liquid passing from the liquid inlet reservoir to the liquid storage reservoir along a first liquid flow path. The system further comprises second liquid flow path from the liquid inlet reservoir to the liquid storage reservoir which by-passes said filter.

Owner:NE INNOVATIONS LTD

Method for forming a pouch

InactiveUS20120102885A1Difficult to useLiquid surface applicatorsWrapper twisting/gatheringEngineeringMechanical engineering

Owner:SHARP PHILLIP NEAL +3

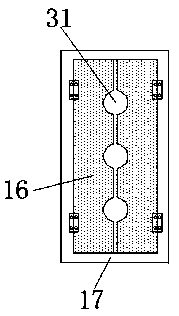

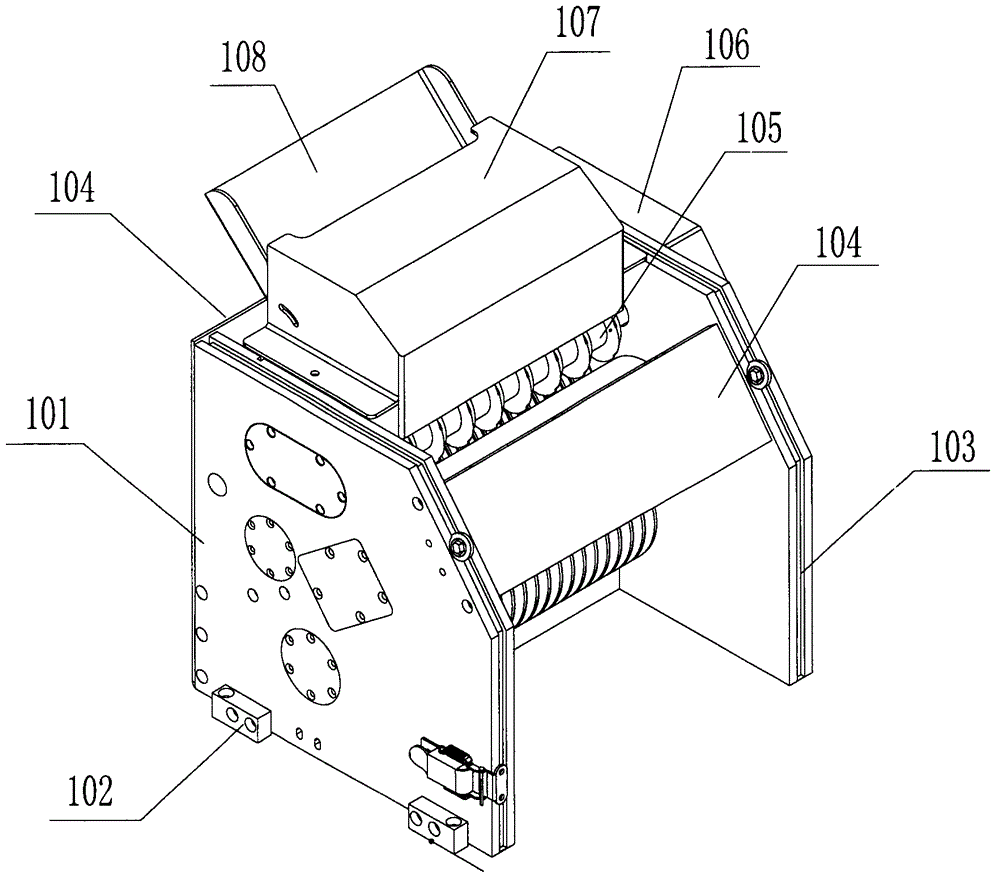

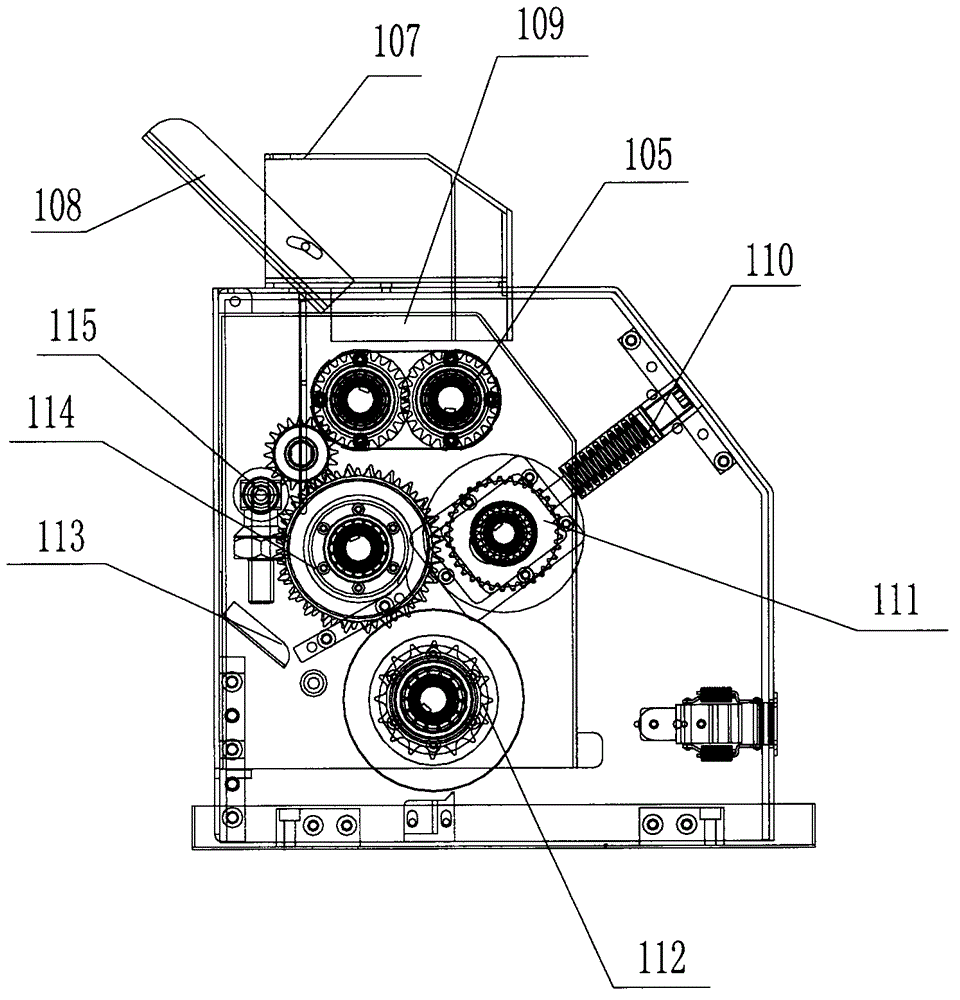

Automatic blood and bag separator

PendingCN109204983AReduced risk of contaminating plasmaEfficient fully automatic mechanical bag breakingBags openingUnpacking by expelling contentsGear wheelBlood plasma

The invention discloses an automatic blood and bag separator. The automatic blood and bag separator comprises a workbench, a driving mechanism, a machine box and a transmission mechanism, wherein thetransmission mechanism and the machine box are both located above the workbench, the machine box is located at the tail end of the transmission mechanism, and a feeding port, a conveying roller mechanism, an extrusion roller and a blood and bag discharge port are sequentially arranged in the machine box along the conveying direction; a bag breaking knife is located below the conveying roller mechanism, and a blood plasma discharging port is located at the bottom of the machine box; and a gear mechanism is further arranged on the side face of the machine box, and the transmission mechanism, theconveying roller mechanism and the extrusion roller are directly driven by the driving mechanism or indirectly driven by the gear mechanism. Due to the adoption of the technical scheme, compared withthe prior art, full-automatic completion from feeding to discharging is achieved, time and labor are saved, and the working efficiency is improved by one time or above; operating personnel in contactwith blood plasma are reduced to zero person from four persons, the risk that the operating personnel pollute the blood plasma in an operation process is greatly reduced, and meanwhile, the bag breaking cost is further reduced; and the plasma yield is increased to 99.4% or above now from the original 99%.

Owner:衡阳鑫山机械设备制造有限公司

Method for forming a pouch

Owner:HENKEL IP & HOLDING GMBH

Toothpaste extruding mechanism capable of facilitating decoration and mounting

InactiveCN107837021ARealize automatic extrusionEasy to useHolders and dispensersUnpacking by expelling contentsAir pumpToothpaste

The present invention relates to the field of daily life mechanical equipment, in particular to a toothpaste extruding mechanism that can be easily decorated and installed. The extrusion device, the lower part of the extrusion cylinder is connected with a square installation cone seat, the lower part of the installation cone seat is provided with an installation seal ring, and the installation cone seat is provided with a suction pipe passing through the wall of the cone seat, and the suction pipe passes through the installation ventilation hose The ventilation pump is connected, and the ventilation pump is installed on the extrusion cylinder through the ventilation pump installation block, and the extrusion device and the ventilation pump are connected to the controller; the present invention places the toothpaste in the extrusion cylinder, and cooperates with the extruding cylinder in the extrusion cylinder. The output device realizes the automatic extrusion of toothpaste. Through the installation part set at the lower part of the extrusion cylinder, the extrusion cylinder can be fixed on the washstand, which not only facilitates the use of toothpaste, but also can cooperate with the washstand to achieve a decorative and beautiful effect.

Owner:DONGGUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com