Method for forming a pouch

a technology of a pouch and a pouch body, which is applied in the field of forming a pouch, can solve the problems of cumbersome and difficult operation of the dispenser or gun, affecting the operation efficiency of the dispensing device, and requiring significant hand strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0038]Packet samples are evaluated to establish a design for dispensing a viscous material.

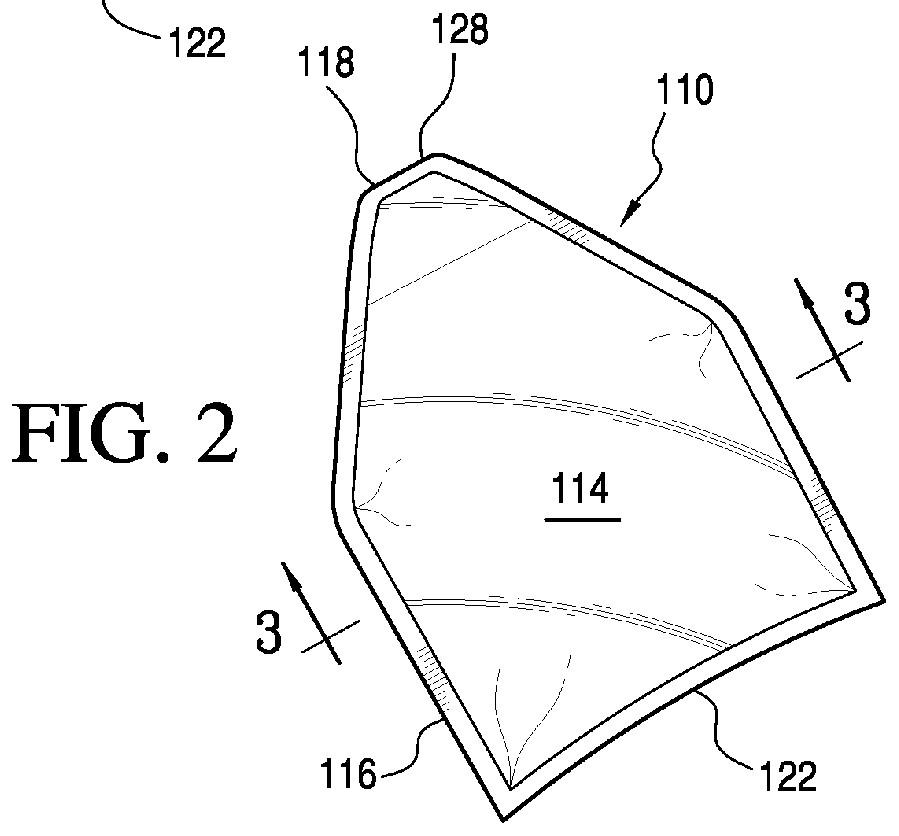

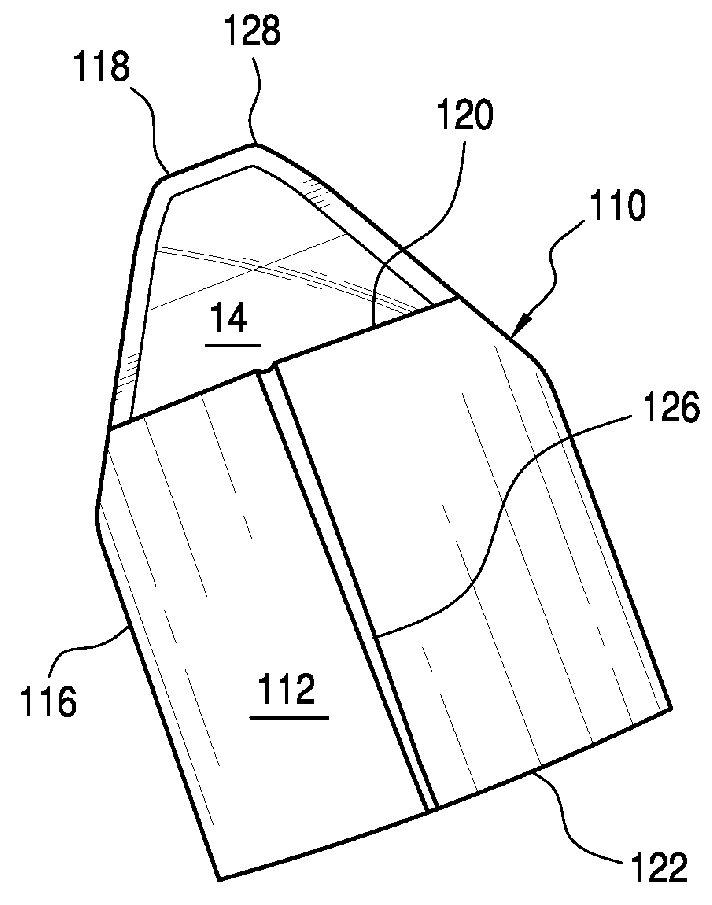

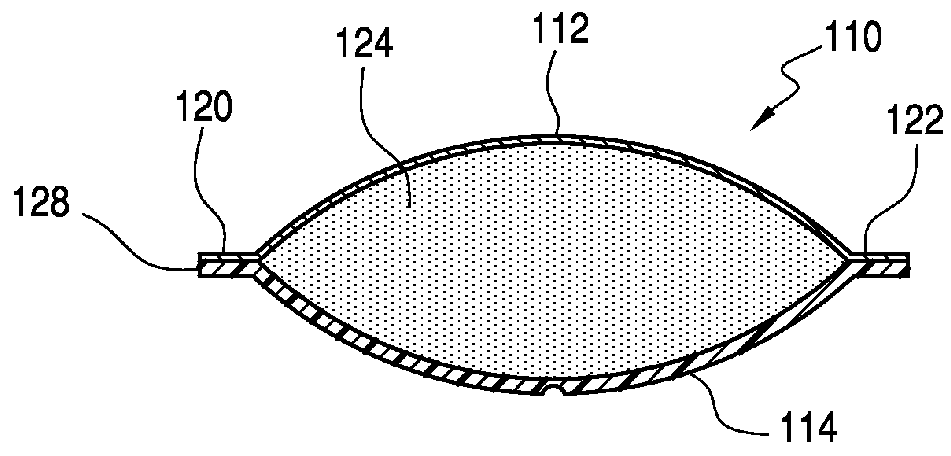

[0039]The samples are constructed from clear polypropylene Ziploc® packets, thin (<1 mm) black polypropylene and polyethylene sheet and acrylic thin film (<1 mm). The sheet materials are formed and heat sealed into packet shapes by first cutting oversized top and bottom rectangular shapes with triangular ends and heat sealing the pieces together with the triangular ends at one side to form a nozzle. Some of the packets are formed with gussets. The gussets are formed by folding the film at the packet sides and bottom.

[0040]Excess material is cut away from the packet after forming. Each packet is filled with material and then heat sealed to form an enclosure. The packets vary in length from about 4 cm to 20 cm, in width from about 2 cm to 15 cm and in thickness (filled with material) from about 0.5 cm to 2 cm. The packets are filled with acrylic caulk or silicone sealant.

[0041]A panel of evaluat...

example 2

[0046]A resulting design was functionally tested by others that represented a consumer panel. Ten packets of the design were distributed among 6 persons of the panel. Each person was instructed to express material from a packet according to a procedure of manually pressing the packet with one hand with an index finger along the crease to fold the packet longitudinally to express the sealant from the packet nozzle.

[0047]A jury of designers observed the expressing procedures and noted the panel's comments. The consumer panel responses were filmed to capture use of the packet and comments

[0048]The panel approved the proposed design. The following panel comments on the design were recorded: “This is really nice! I'm digging this.”“I think that's kind of amazing. I can only say good things about it.”“Super easy to use. I love the bead that it gave me. It feels like I have a lot of control.”“I like this already, and I'll tell you why. Because you can really manipulate the pressure. You ca...

example 3

[0050]This EXAMPLE describes a series of iterative evaluations of packet samples to determine a best more rigid material.

[0051]First, a range of materials including a paperboard, plastic sheet and corrugated fiberboard were evaluated for output performance. Sample paperboard thickness was varied from approximately 0.010″ to 0.100″; a high density polyethylene sheet (HDPE) was varied in thickness from approximately 0.005″ to 0.100″; and a corrugated fiberboard corrugation was varied from B flute to N flute.

[0052]User ratings determined that a paperboard with a thickness less than approximately 0.080″ did not have sufficient stiffness for acceptable dispensing and “ease of use.” A thicker paperboard gave improved performance results but was rated unacceptable because of bulky feel. Thinner HDPE samples below 0.040″ in thickness, were rated unacceptable because of insufficient stiffness. Thicker HDPE samples showed improved performance but increased cost.

[0053]Performance for corrugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com