Patents

Literature

1575 results about "Corrugated fiberboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrugated fiberboard is a material consisting of a fluted corrugated sheet and one or two flat linerboards. It is made on "flute lamination machines" or "corrugators" and is used in the manufacture of shipping containers and corrugated boxes.

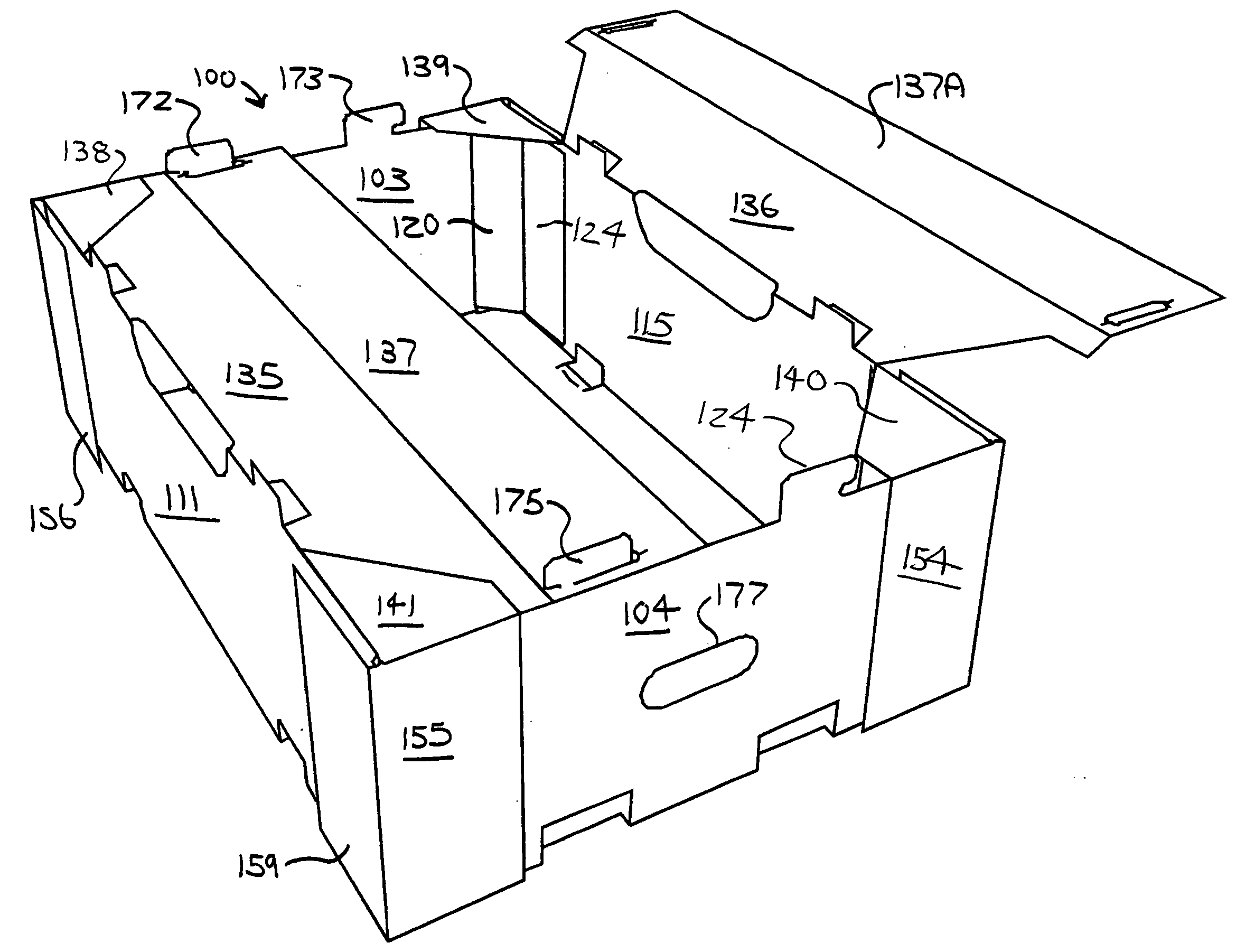

Insulated shipping container and method of making the same

InactiveUS6868982B2Domestic cooling apparatusLighting and heating apparatusEngineeringFoam polyurethanes

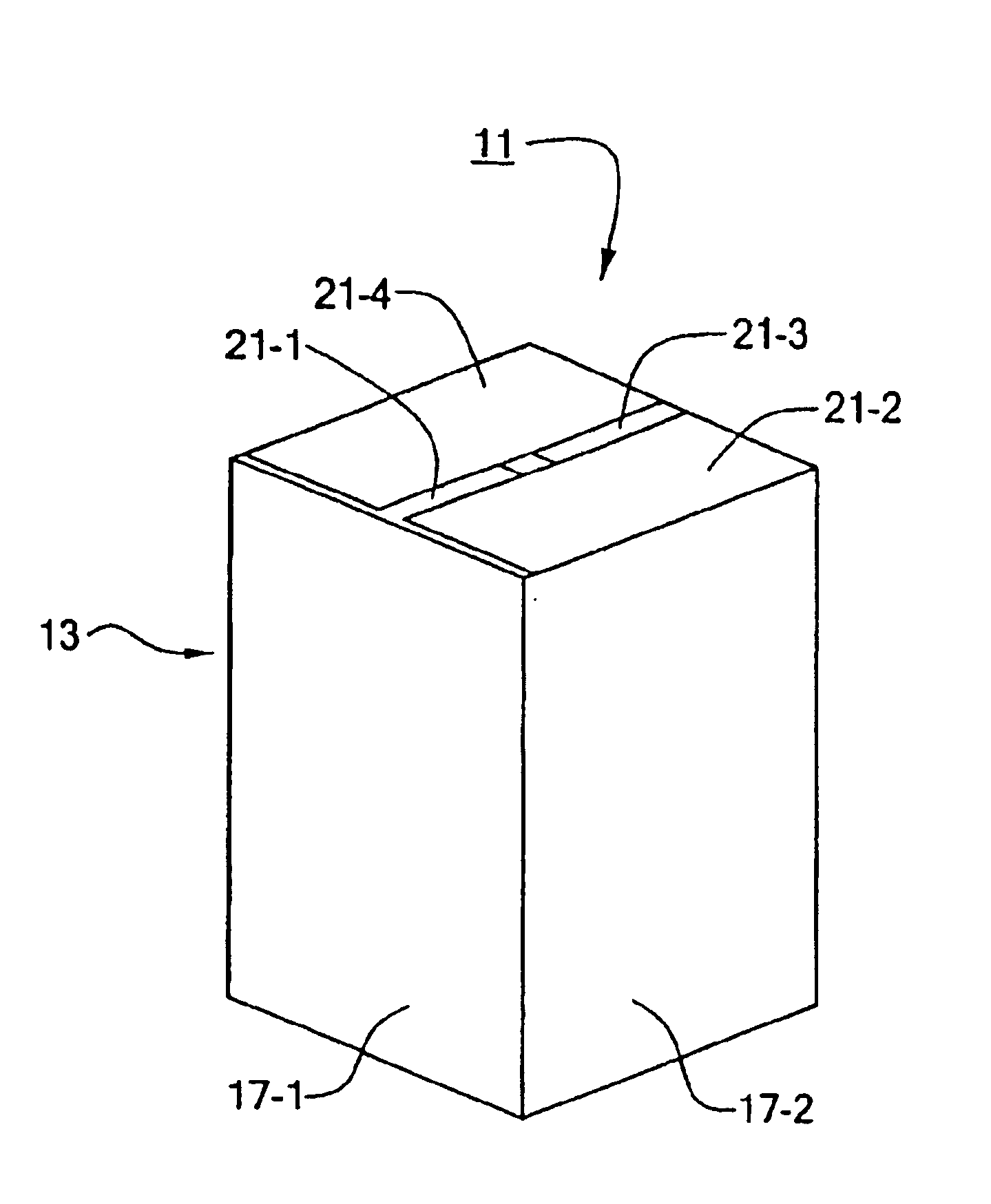

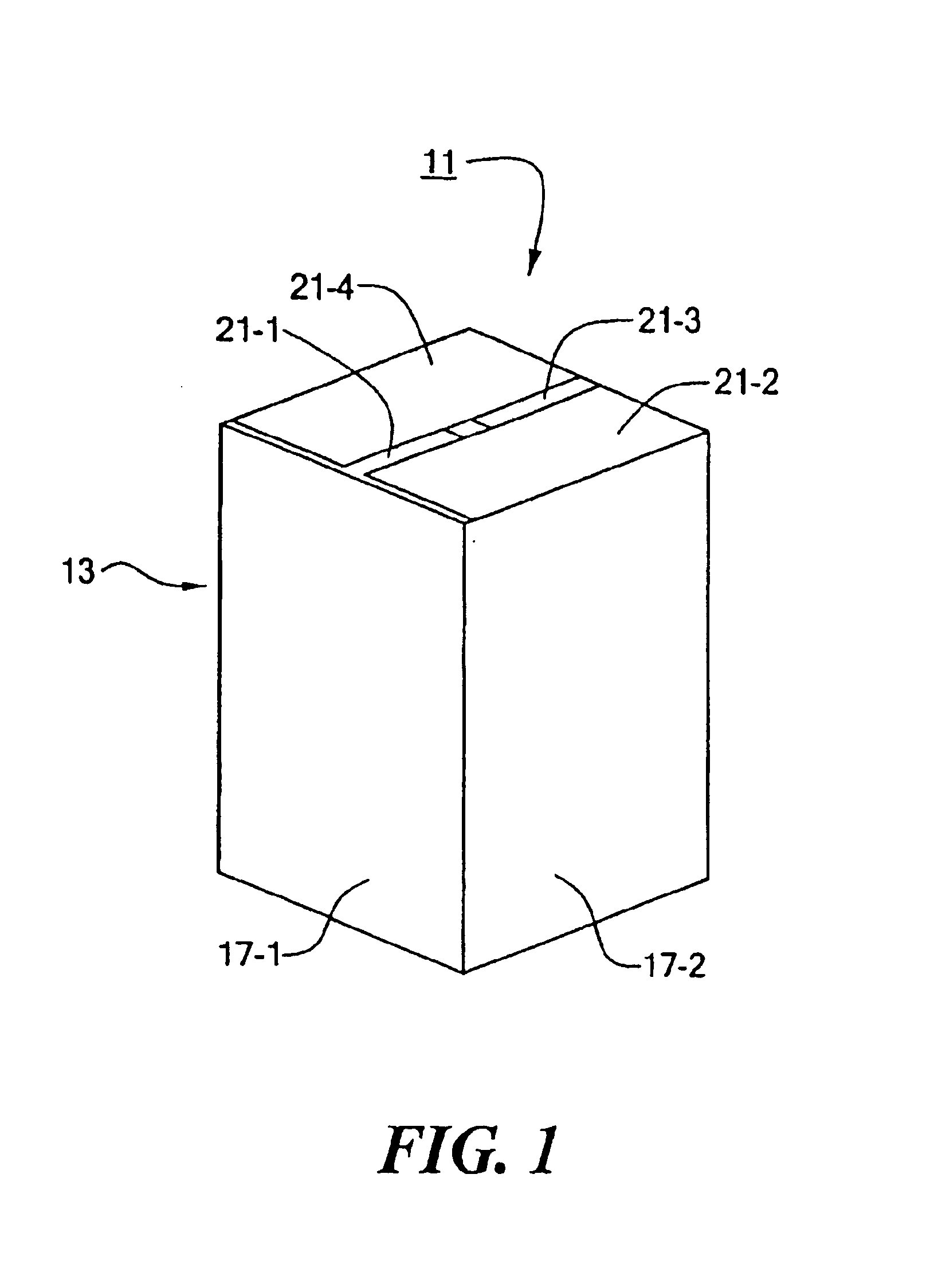

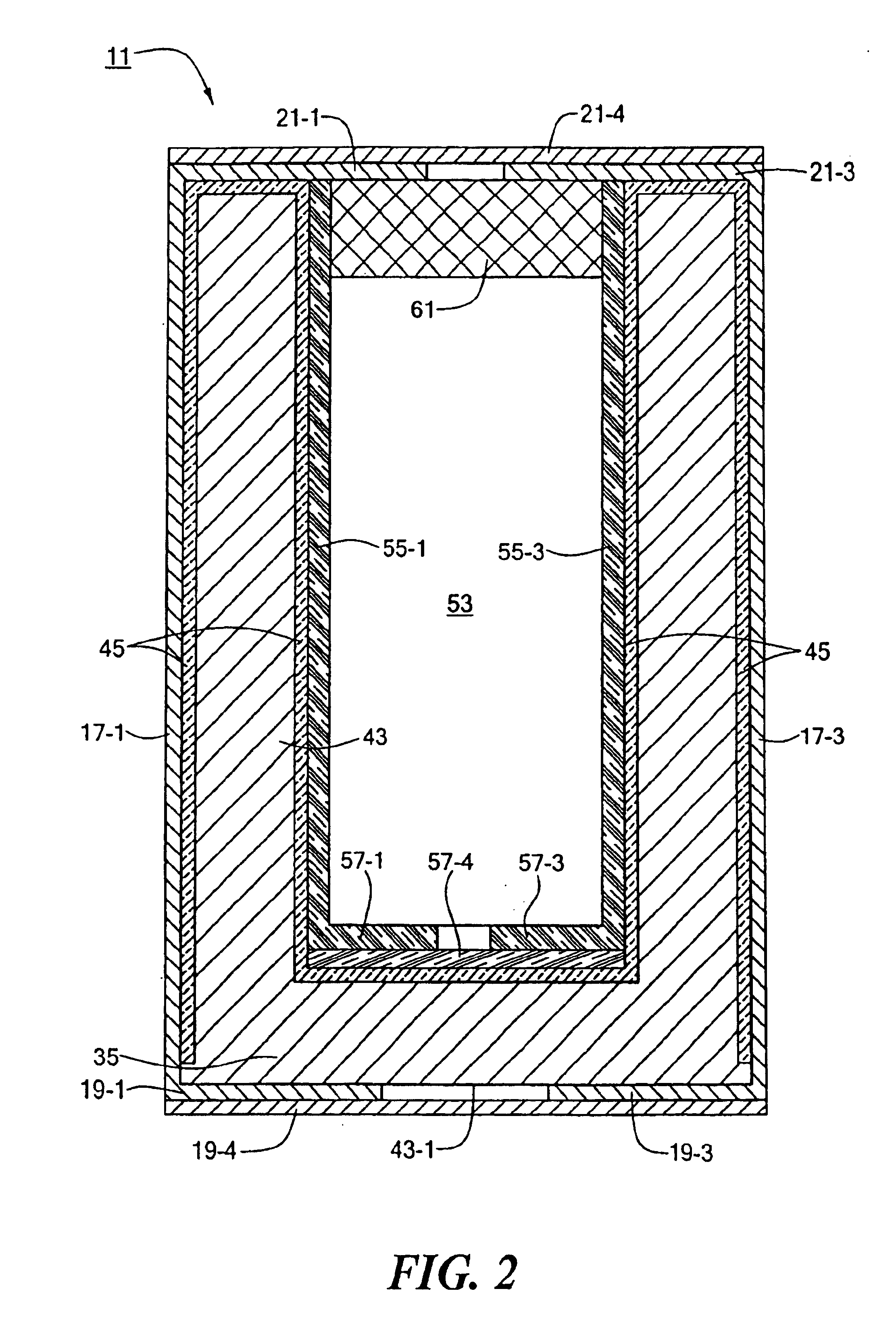

Insulated shipping container and method of making the same. In a preferred embodiment, the insulated shipping container comprises an outer box, an insulated insert, an inner box and a closure member. The outer box, which is preferably made of corrugated fiberboard, comprises a rectangular prismatic cavity bounded by a plurality of rectangular side walls, a closed bottom end, and top closure flaps. The insulated insert is snugly, but removably, disposed within the outer box and is shaped to define a rectangular prismatic cavity bounded by a bottom wall and a plurality of rectangular side walls, the insulated insert having an open top end. The insulated insert is made of a foamed polyurethane body to which on all sides, except its bottom, a thin, flexible, unfoamed polymer bag is integrally bonded. The bag is a unitary structure having a generally uniform rectangular shape, the bag being formed by sealing shut one end of a tubular member with a transverse seam and forming longitudinal creases extending from opposite ends of the seam. The inner box, which is snugly, but removably, disposed within the insert, is preferably made of corrugated fiberboard and is shaped to include a rectangular prismatic cavity bounded by a plurality of rectangular side walls and a closed bottom end, the top end thereof being open. The closure member is a thick piece of foam material snugly, but removably, disposed in the open end of the inner box.

Owner:COLD CHAIN TECH

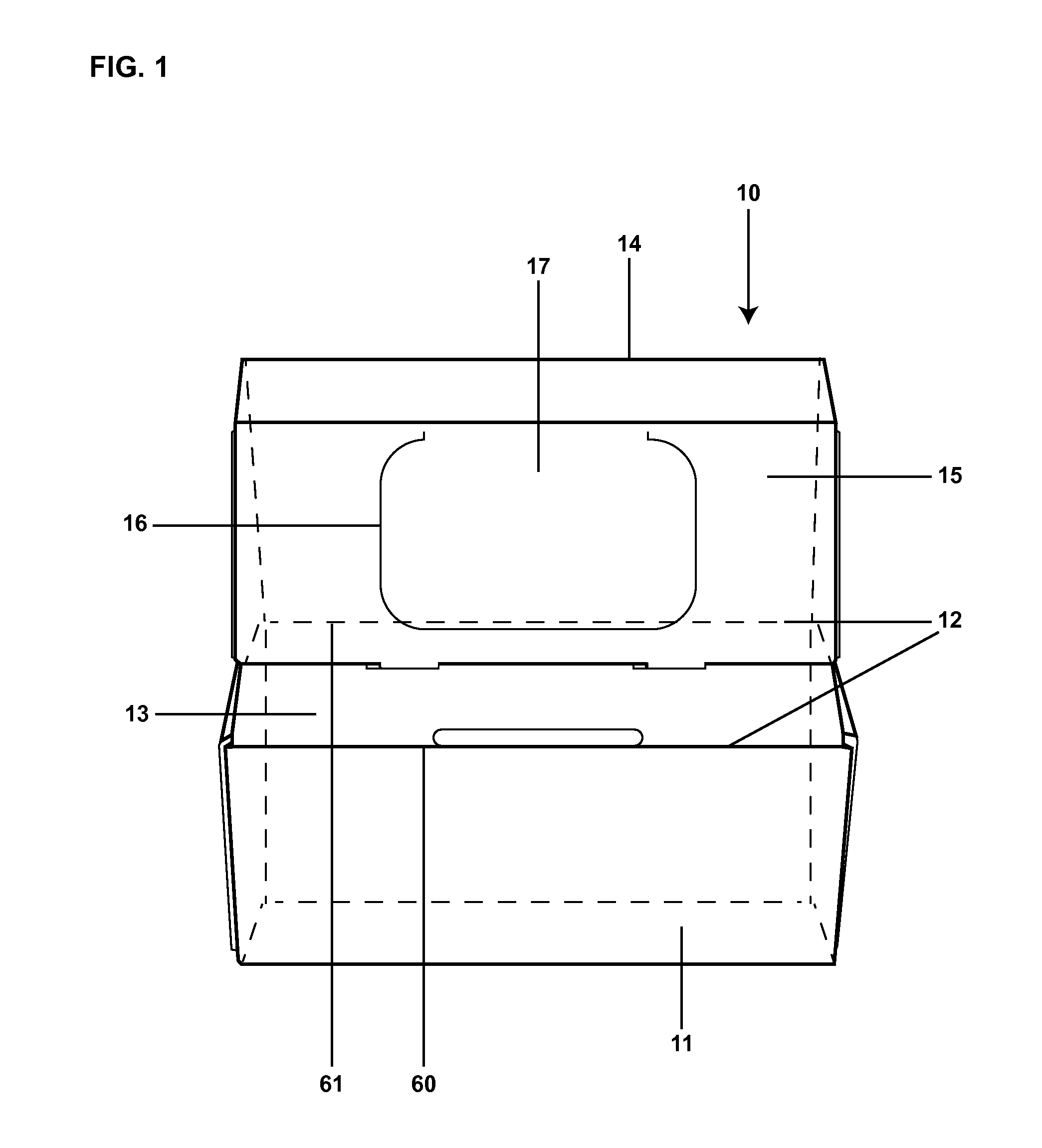

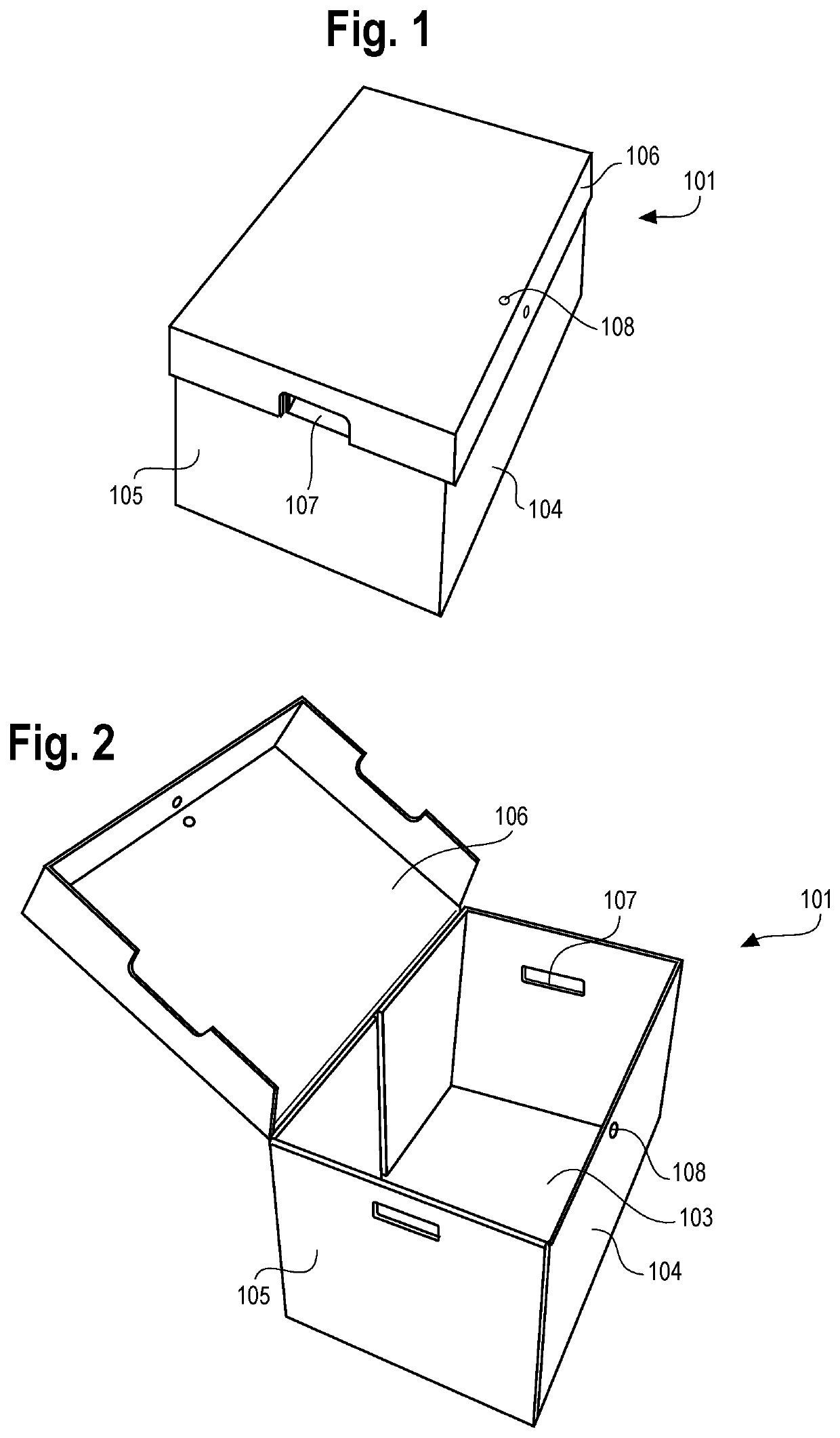

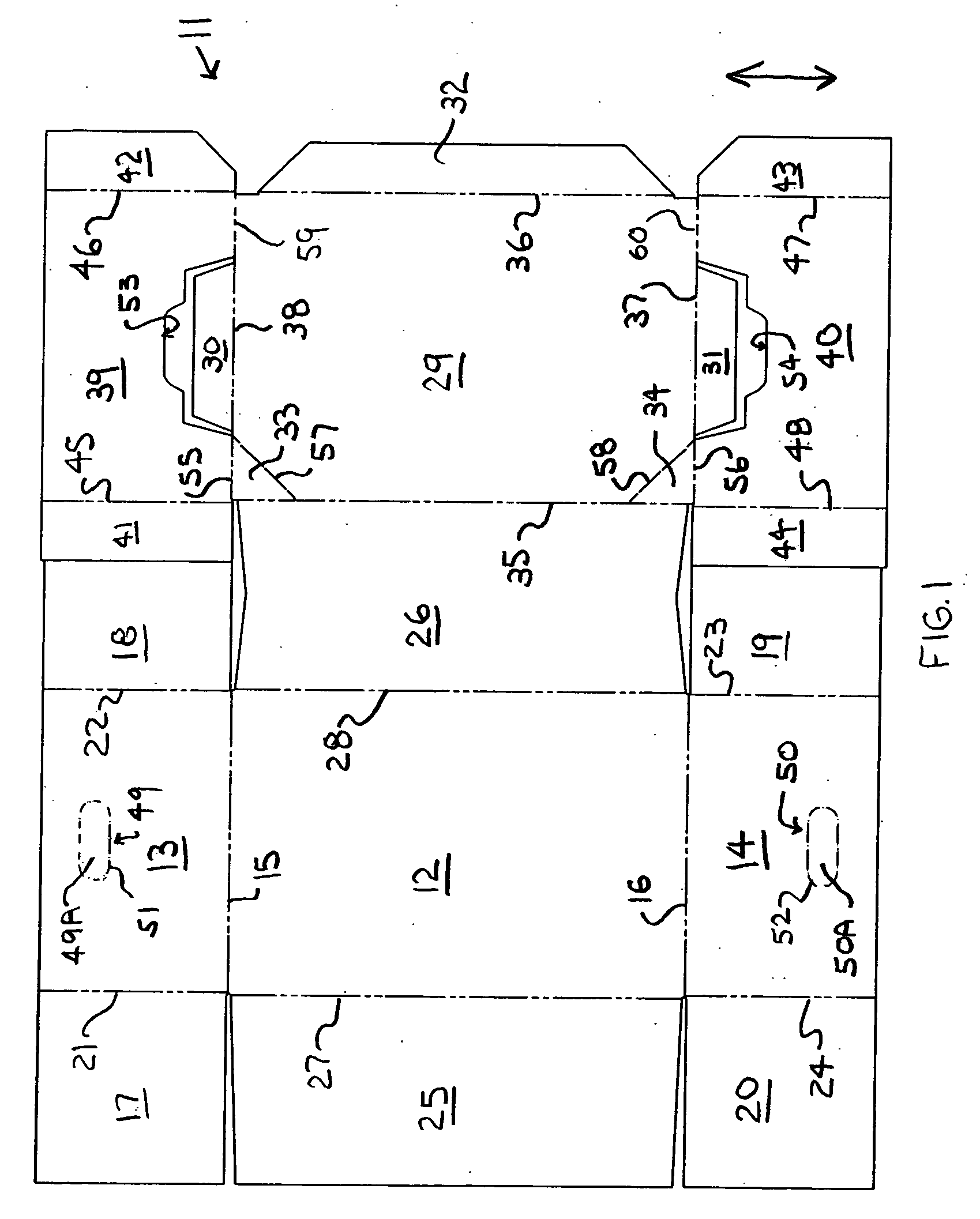

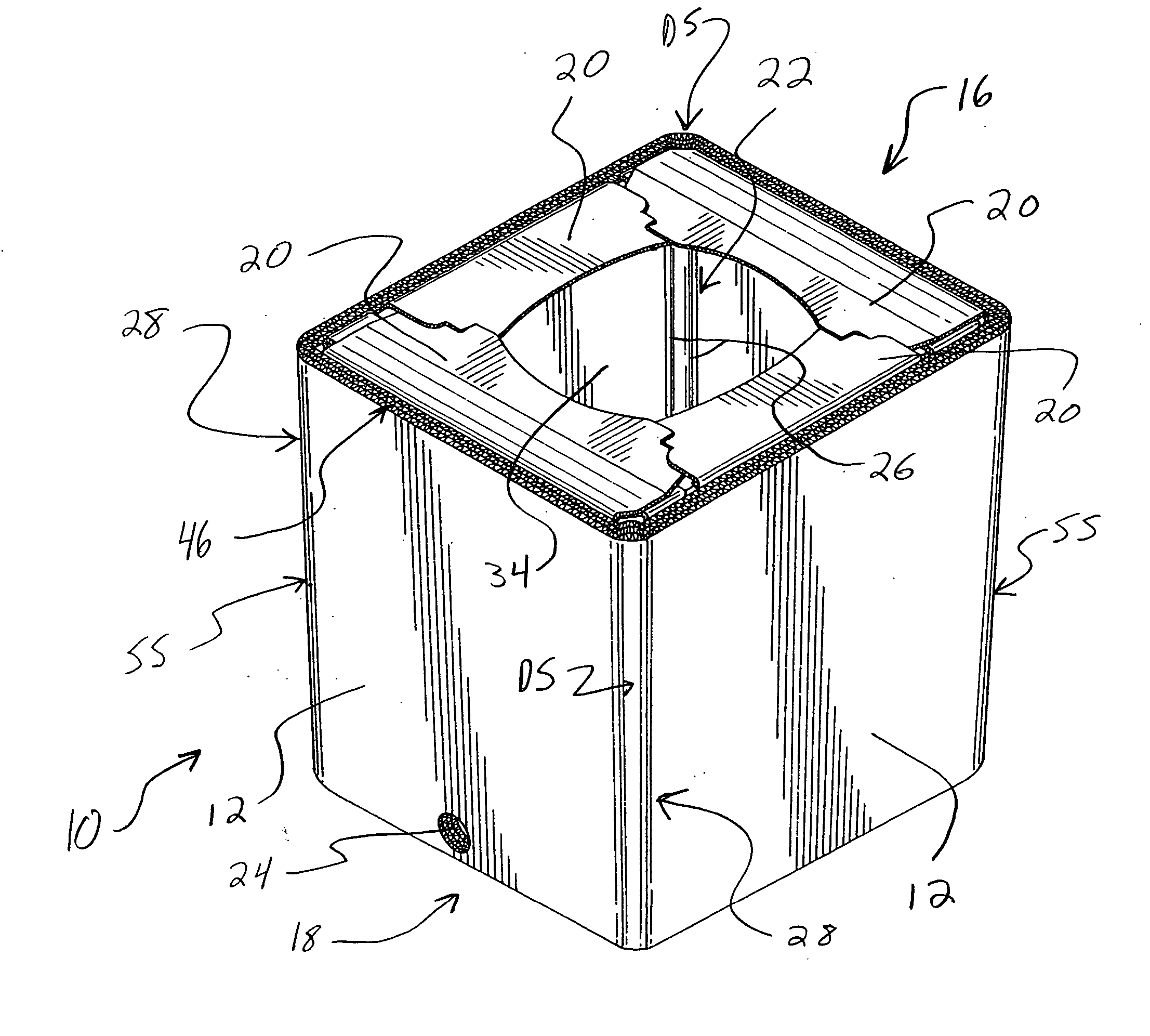

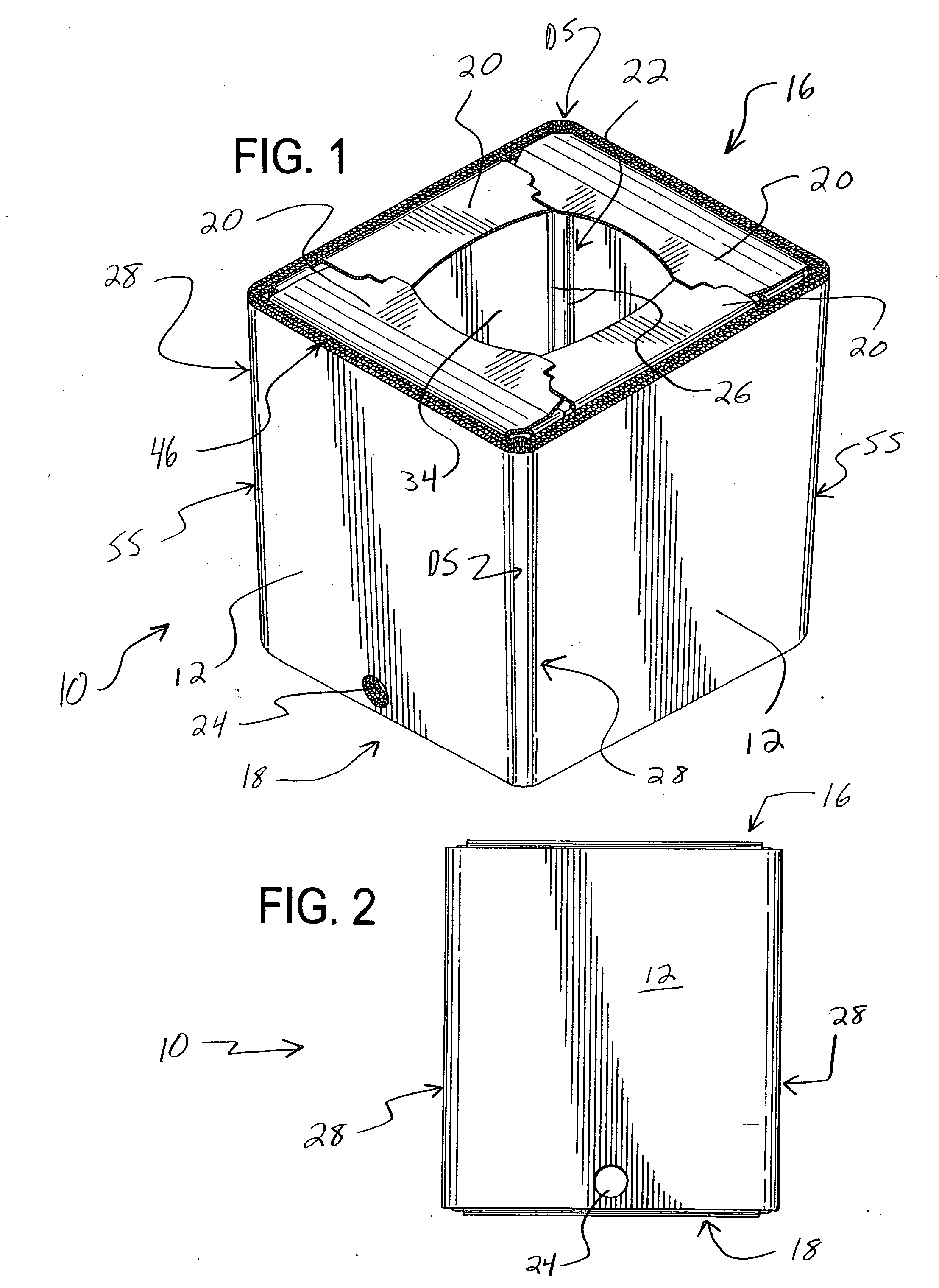

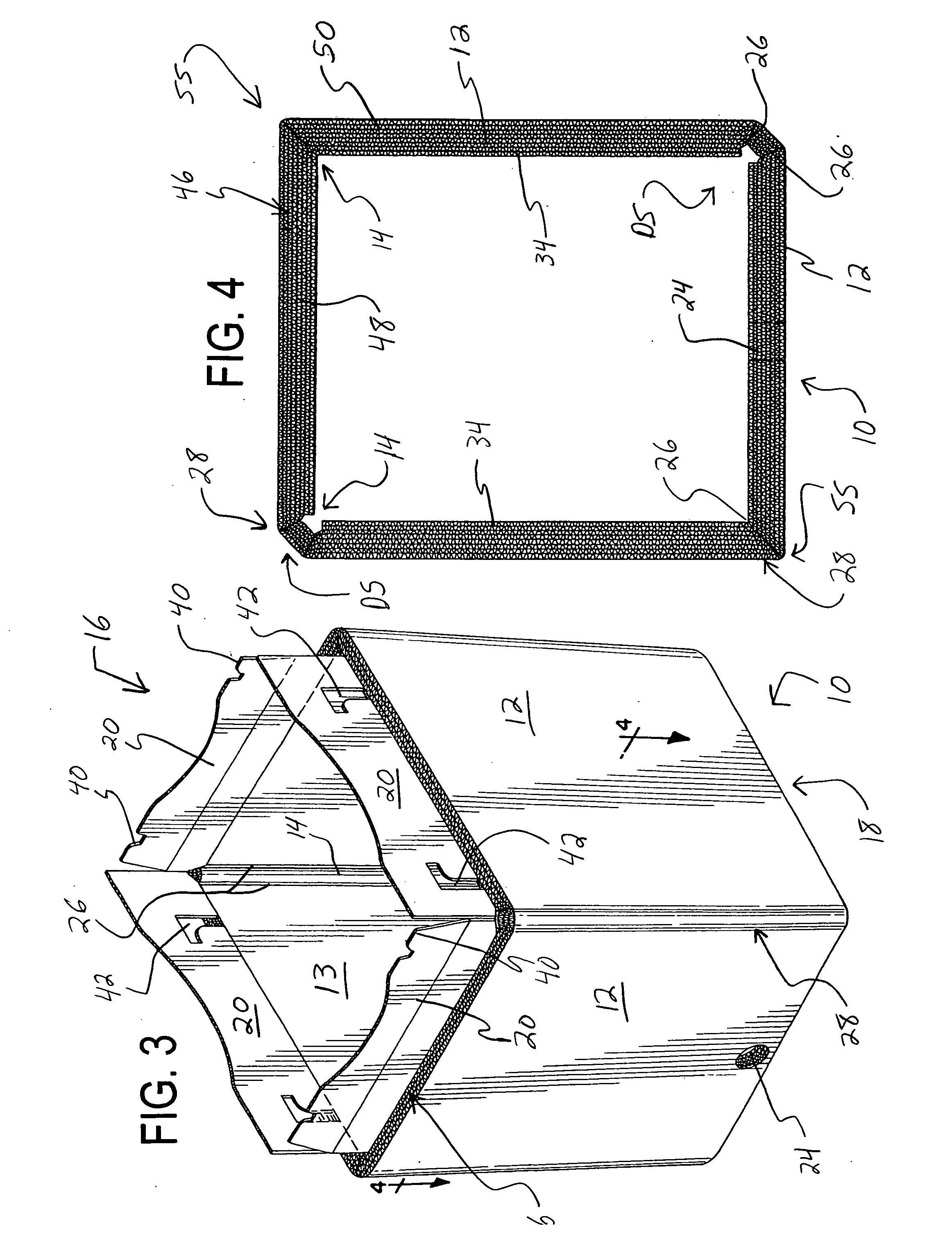

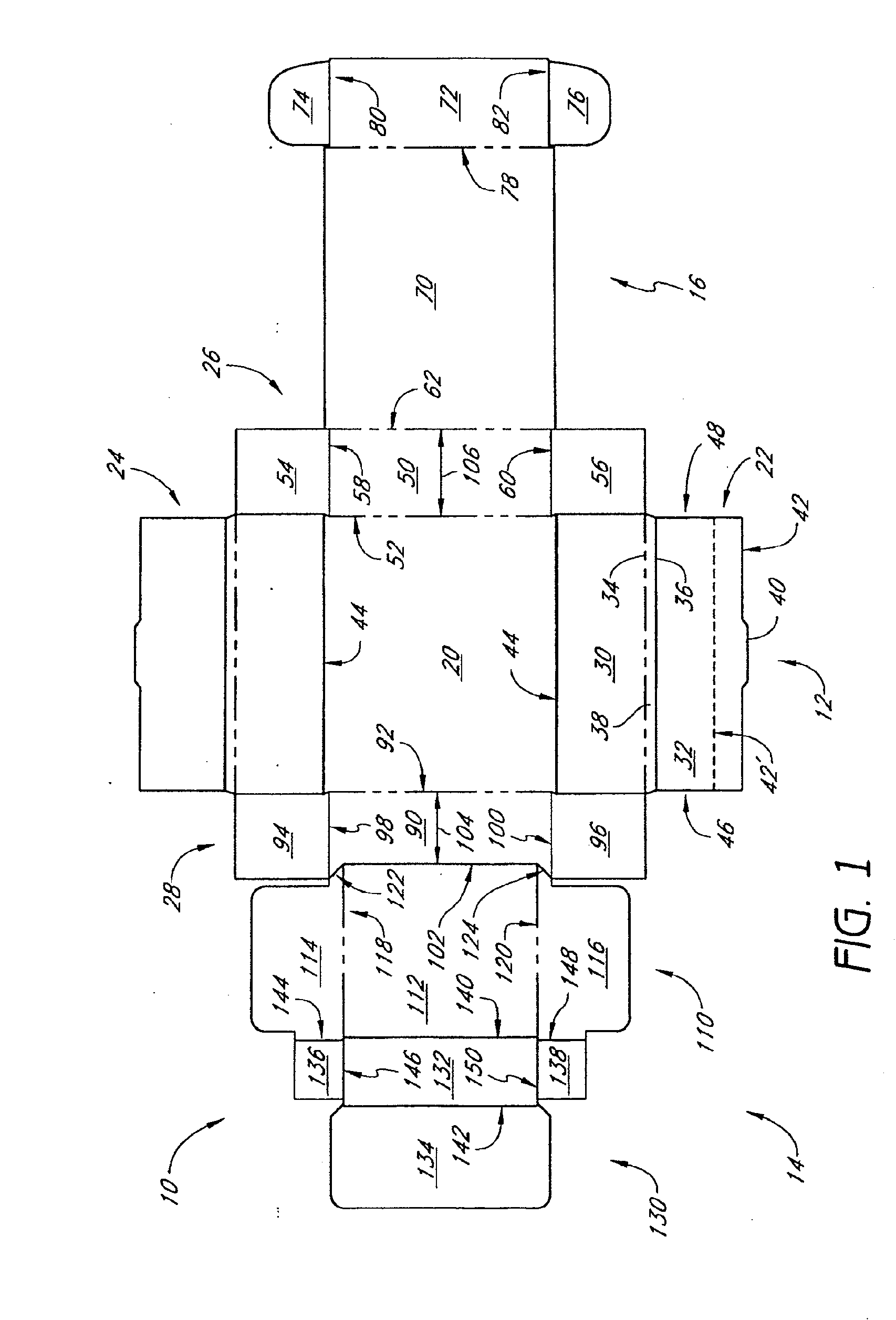

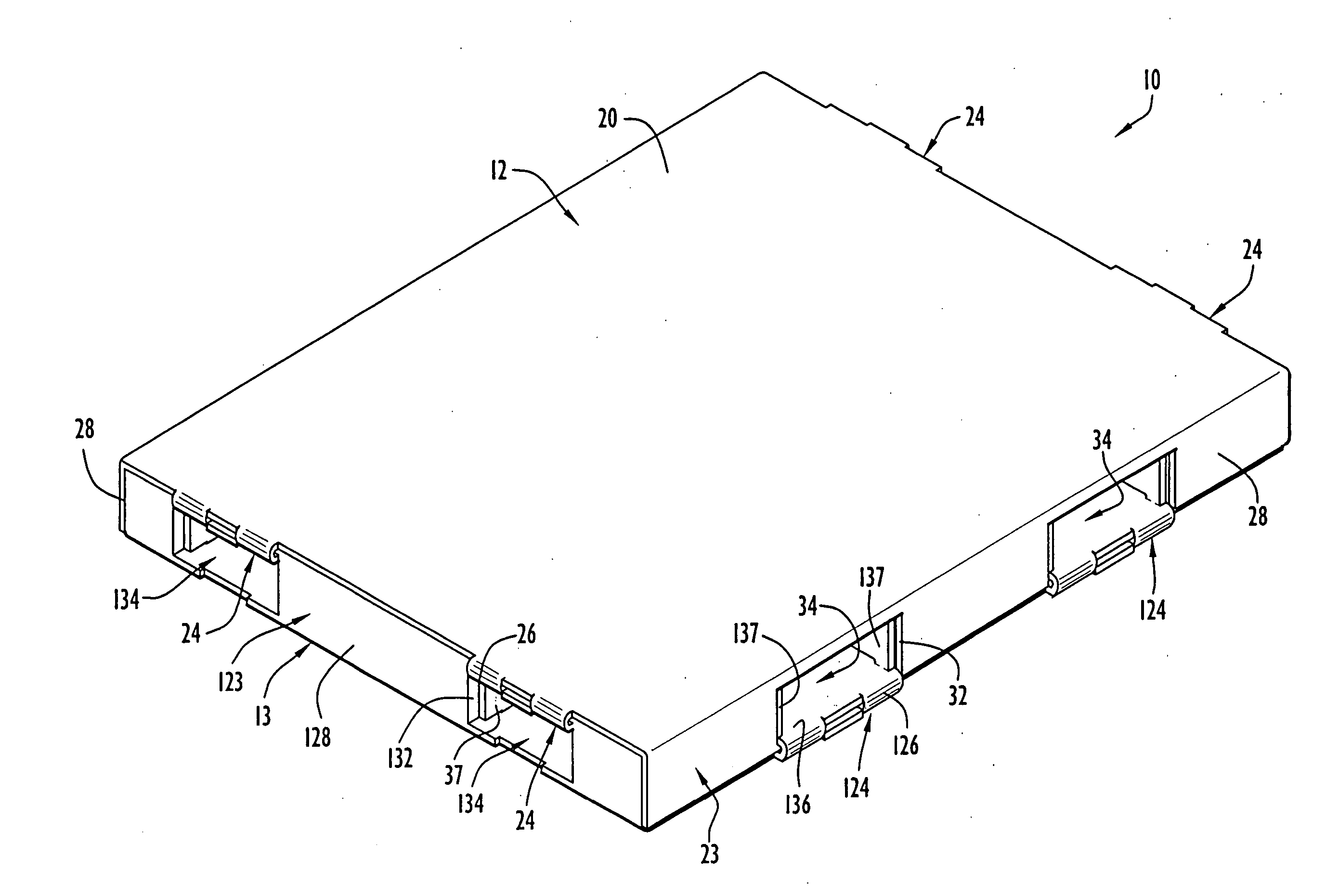

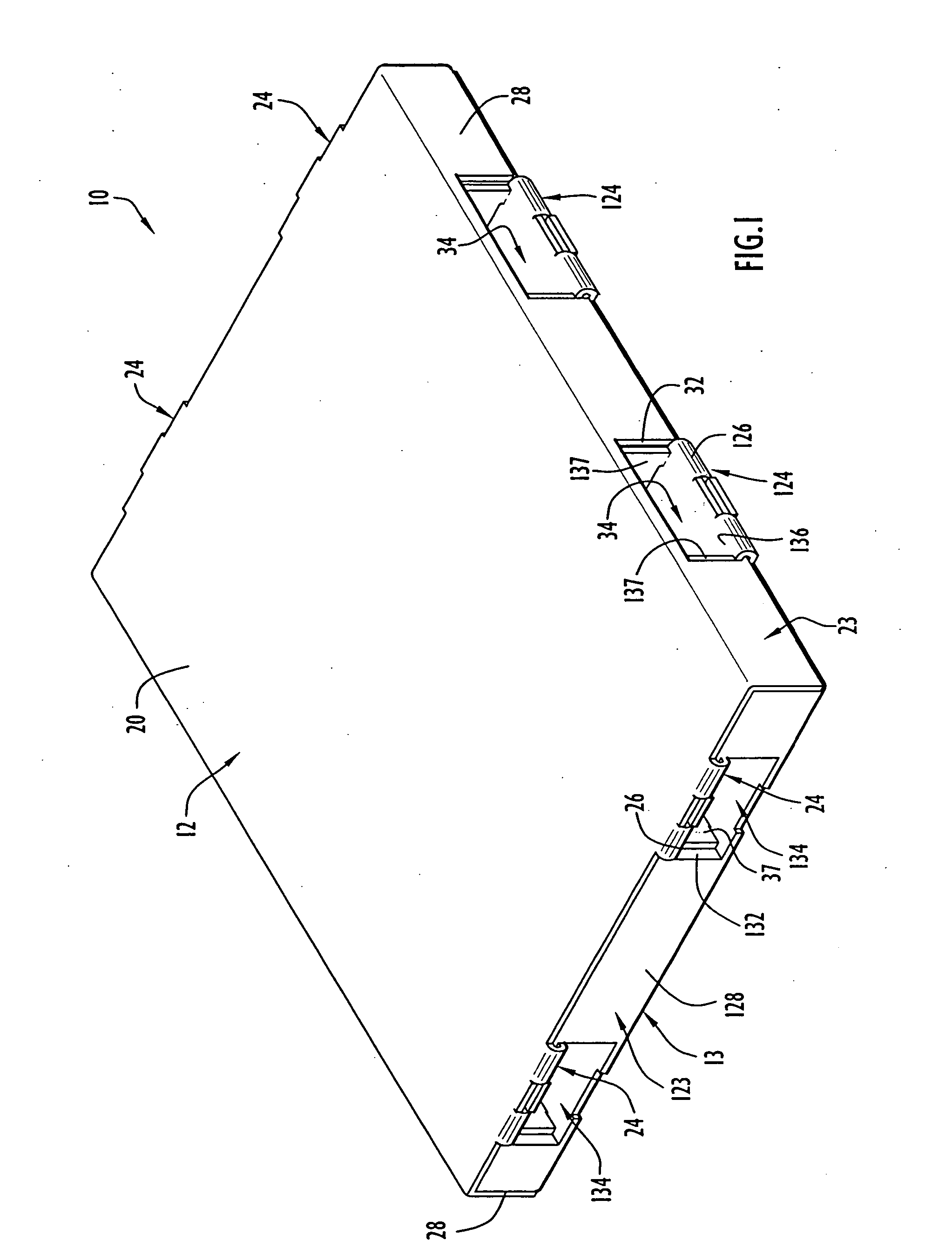

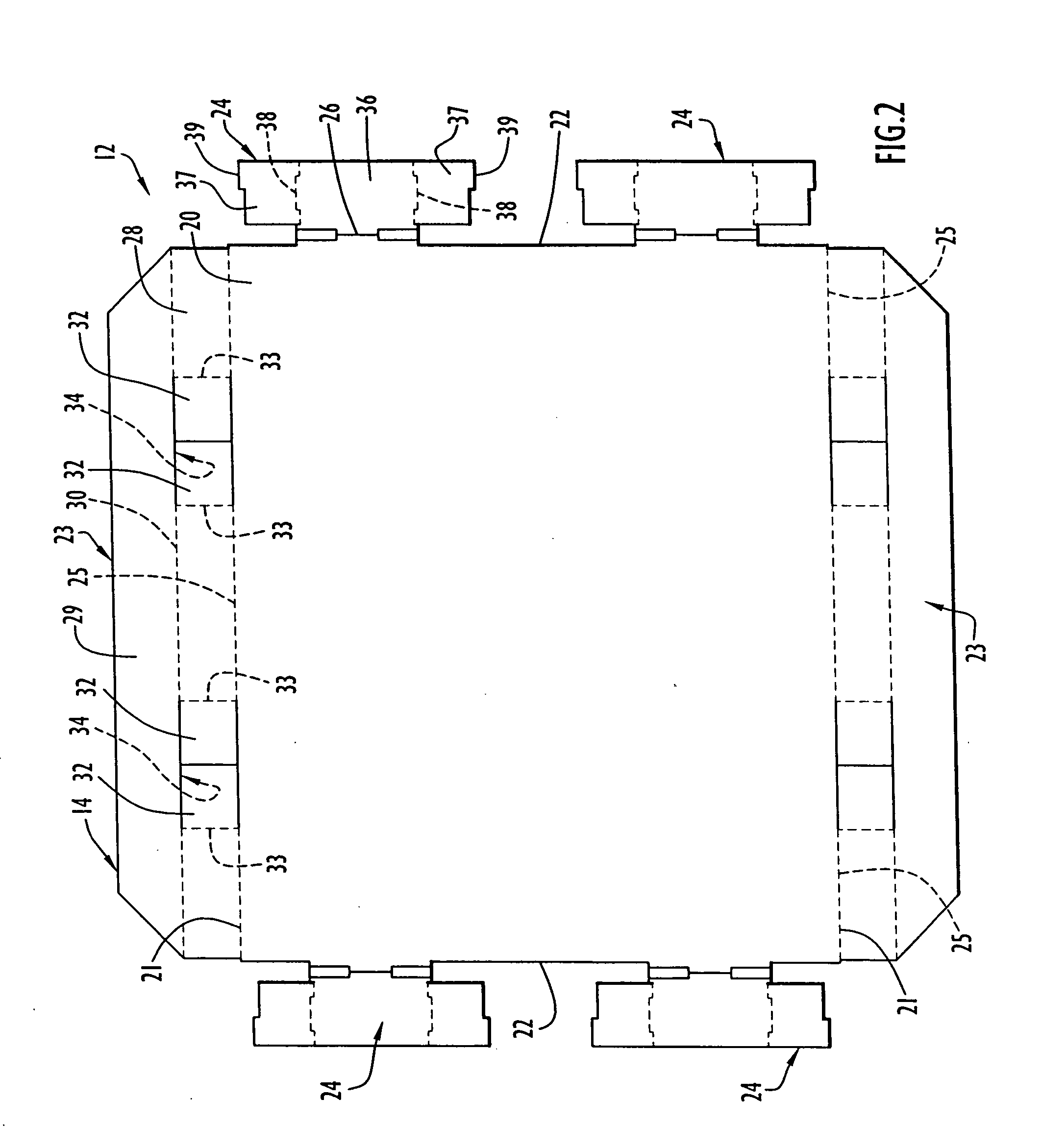

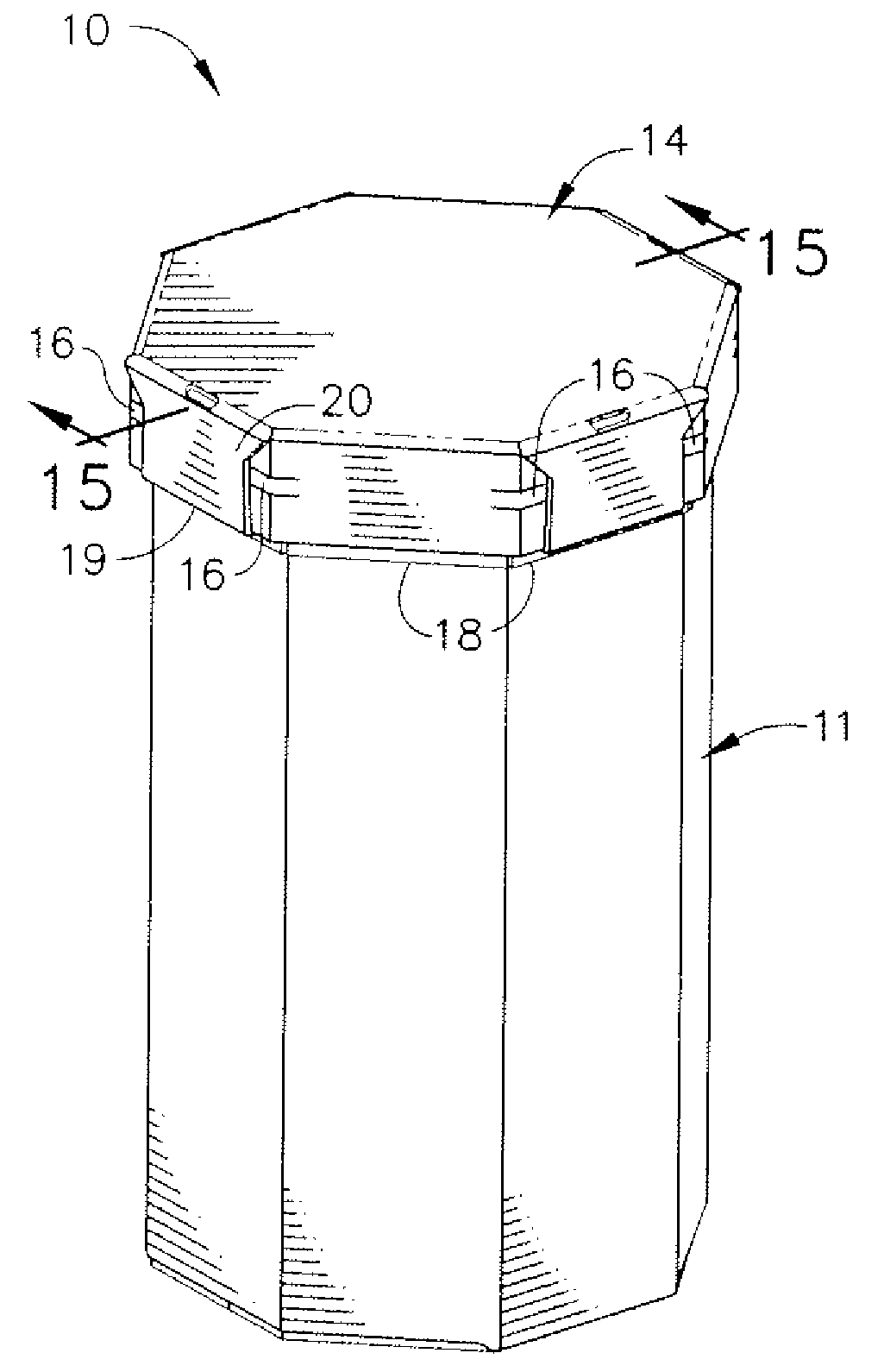

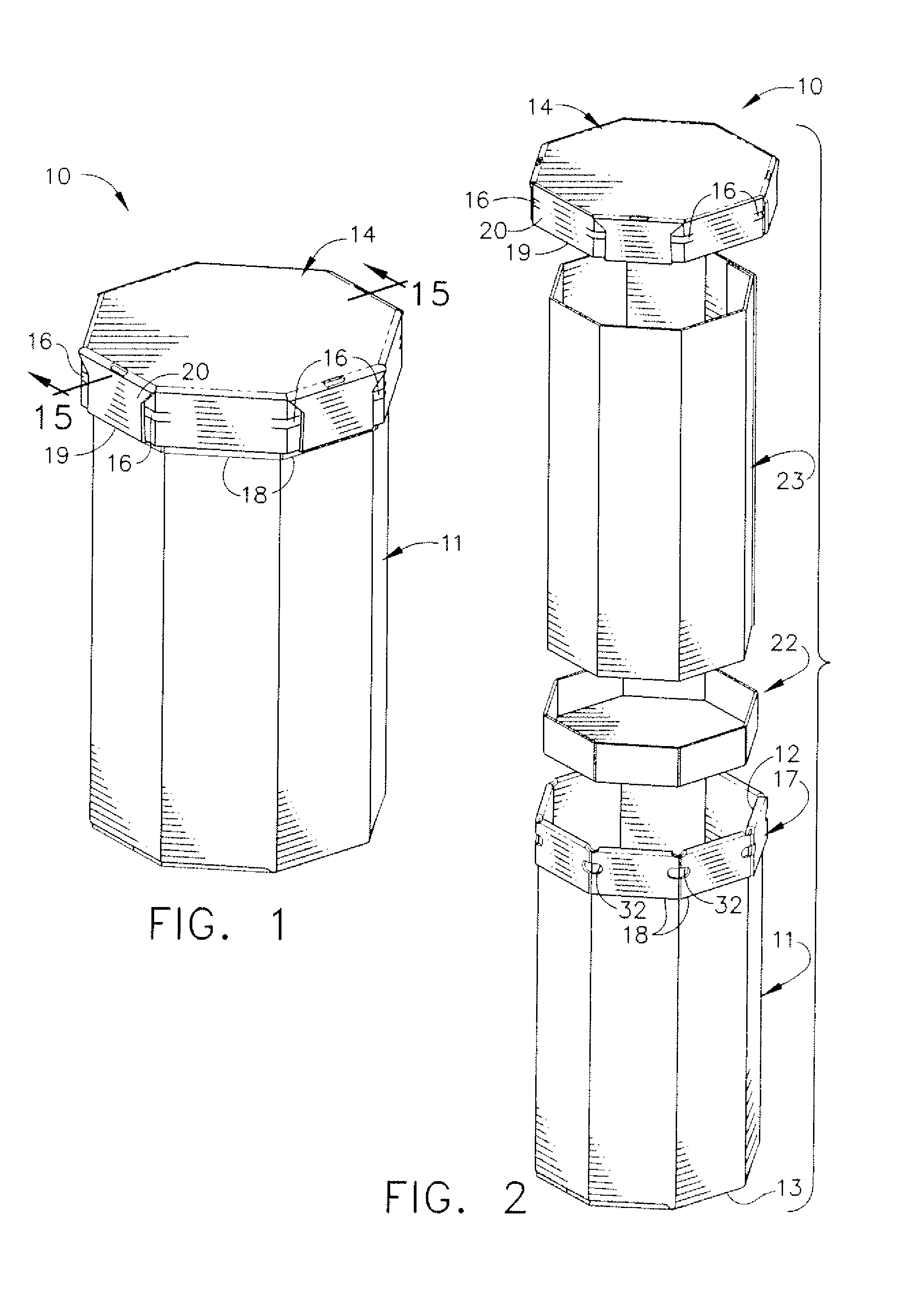

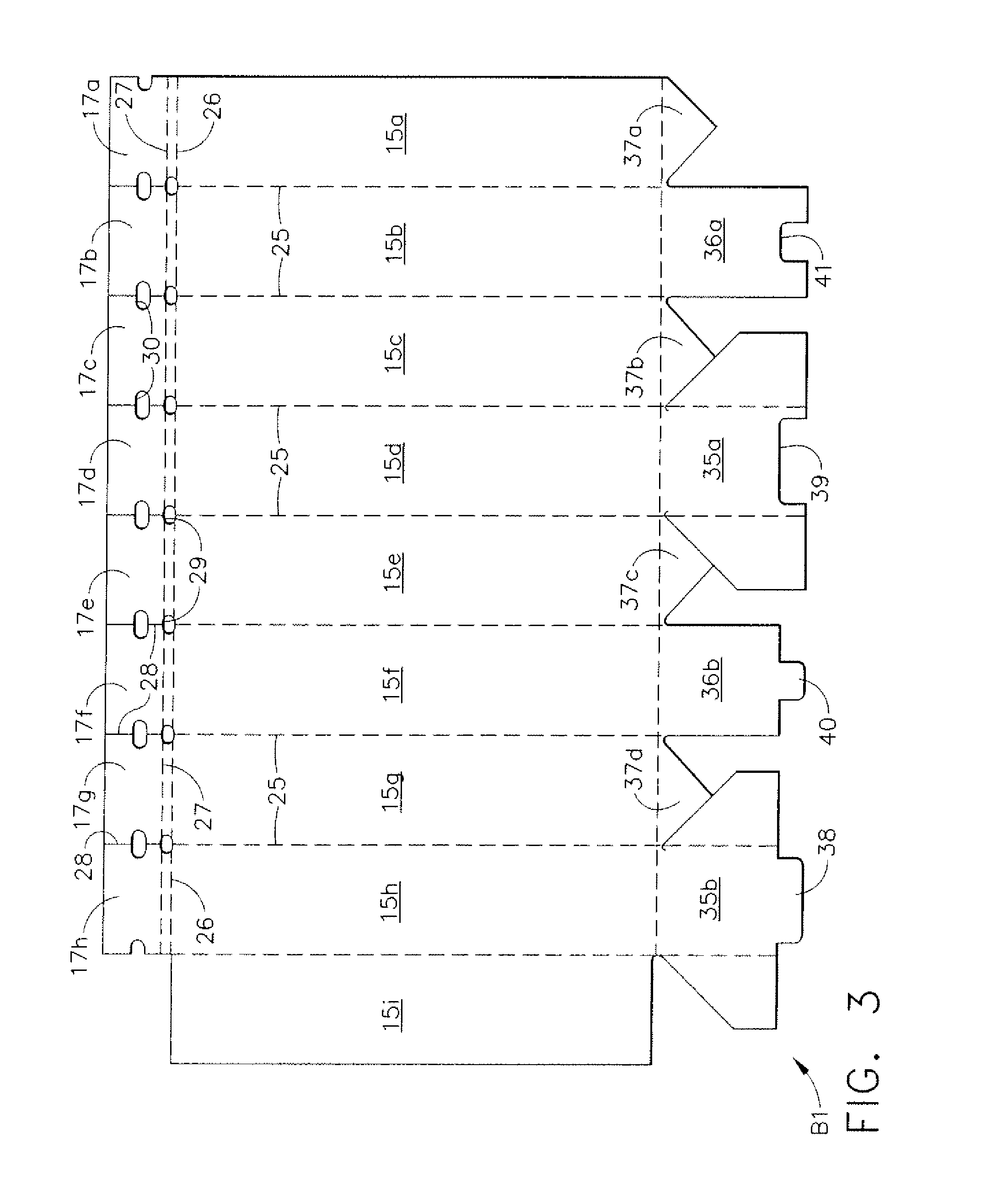

Lid assembly for shipping container

InactiveUS8579183B2Simplifies collection and shippingSimplify collectionUmbrellasPaper/cardboard articlesCardboardEngineering

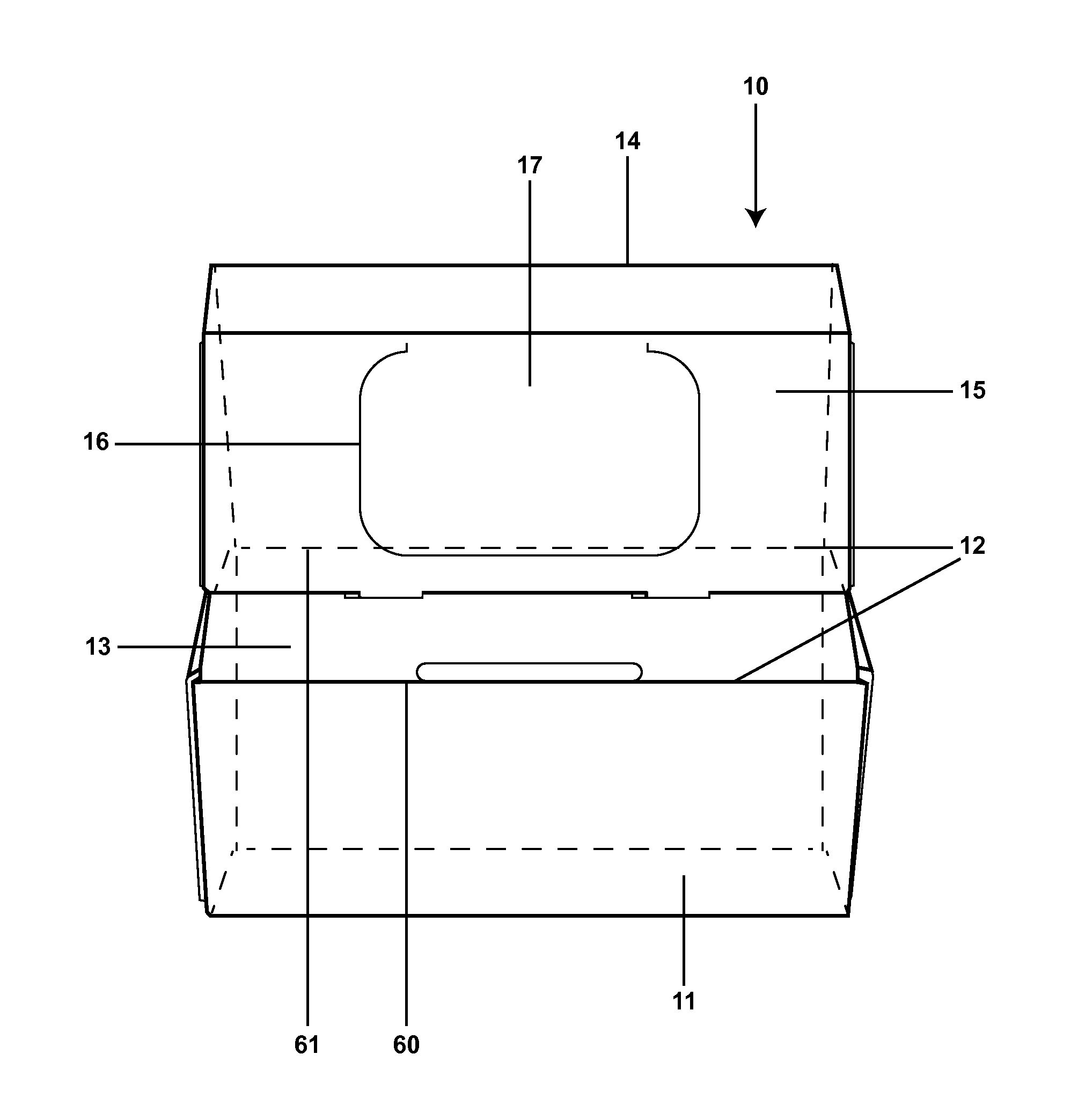

A container for storage and shipping of objects includes a lid assembly having two configurations and an open-top box. In the first configuration the container can be loaded with objects for storage or collection while limiting physical and visual access to the contents of the box and in the second configuration, the container is sealed for shipping. The lid assembly contains side flaps which may be used to stabilize the lid assembly in the first configuration, and in the second configuration, secure the lid assembly to the open-top box. Preferably, the container is formed from one contiguous blank. The blank is preferably made of corrugated cardboard but may be formed from any substantially rigid material.

Owner:CALL2RECYCLE

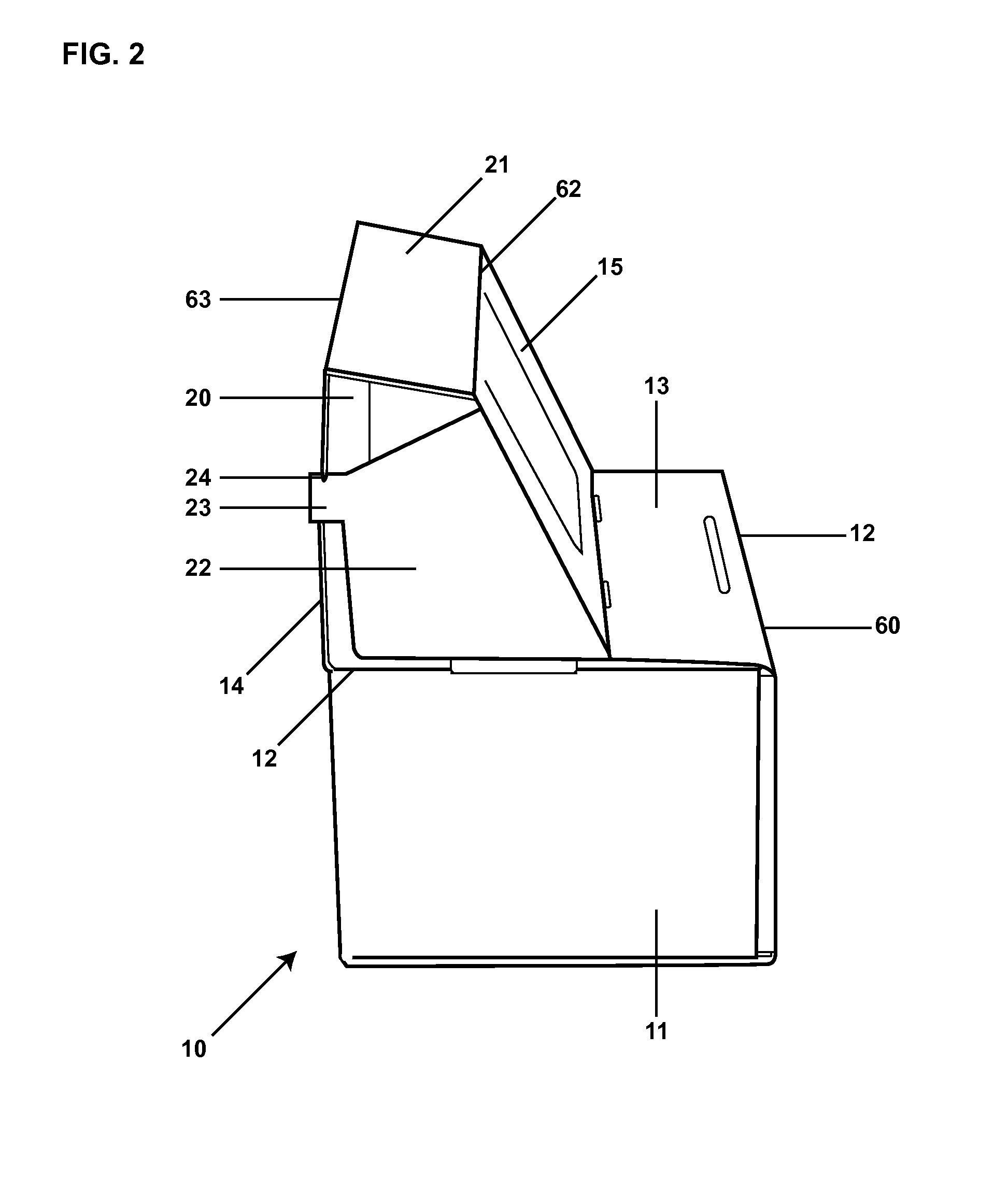

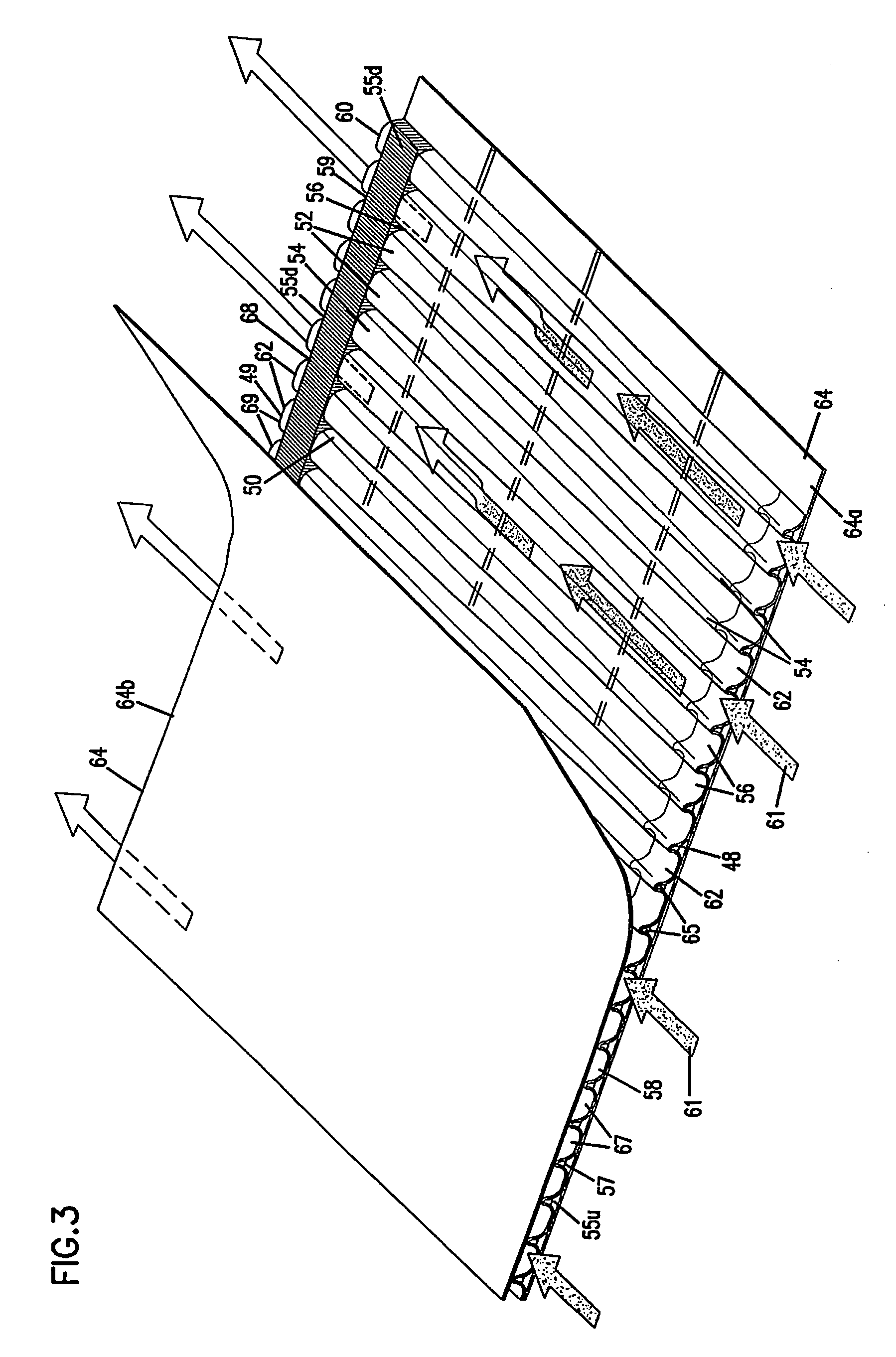

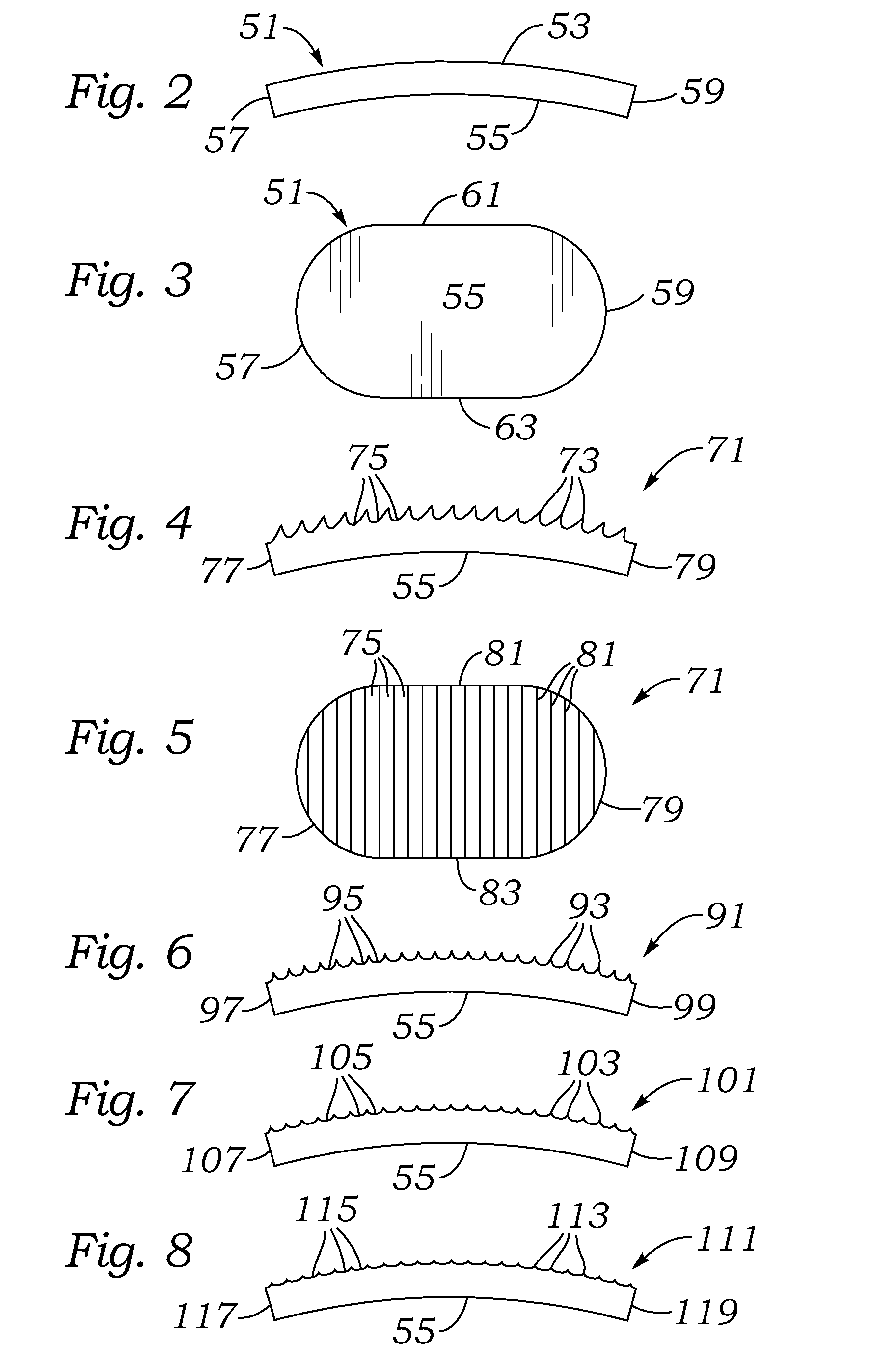

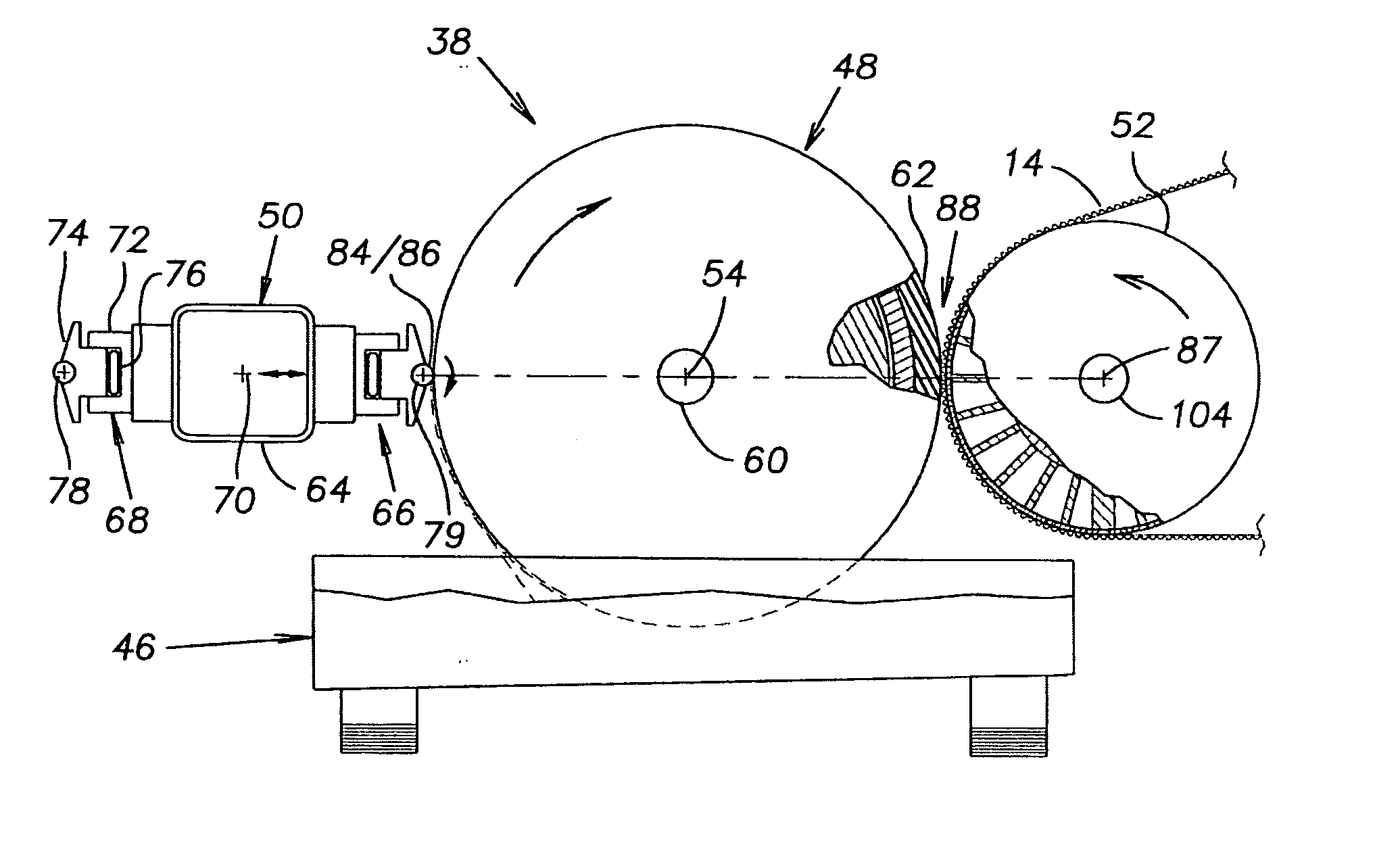

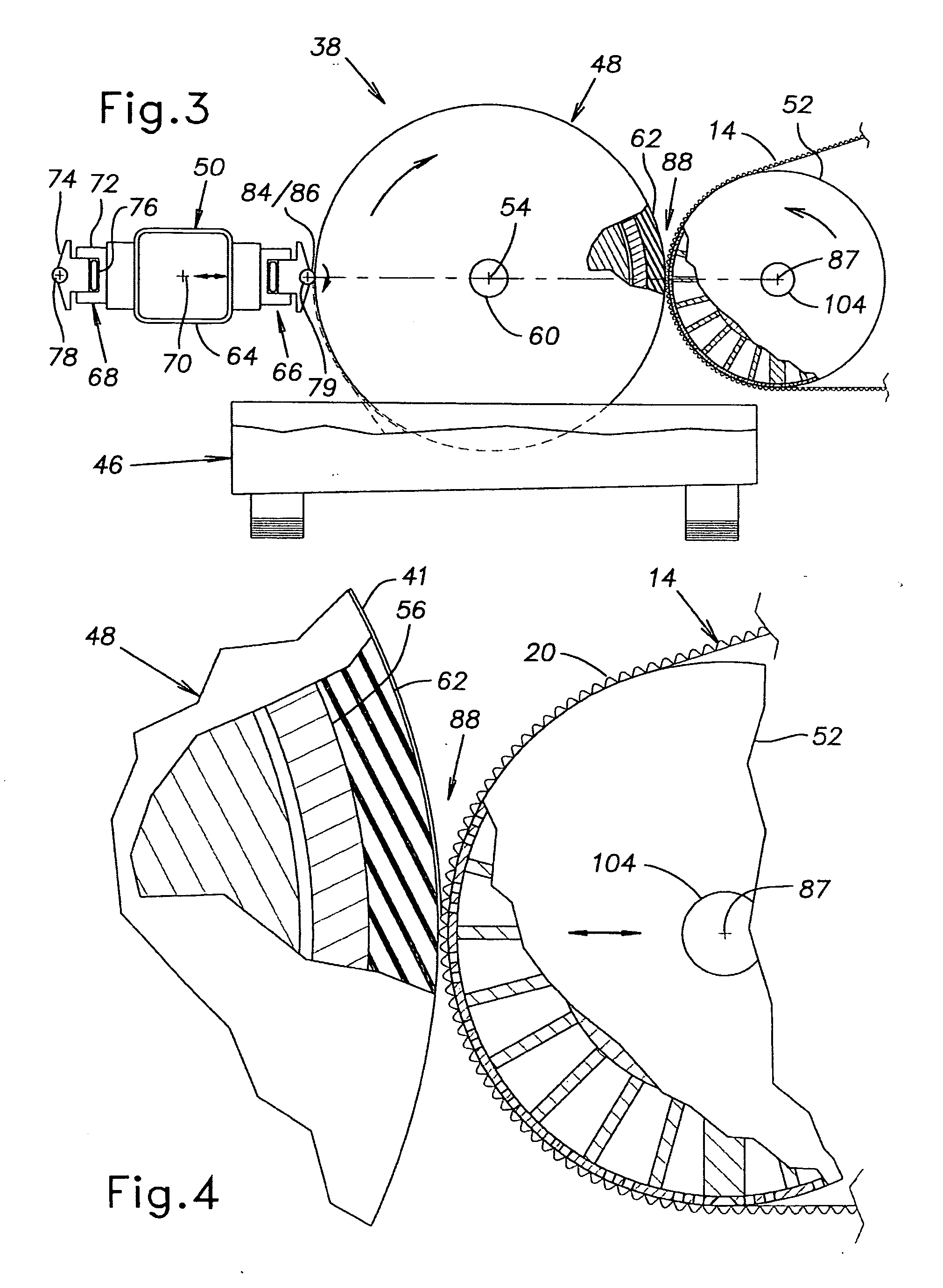

Filter element using corrugated media sheet

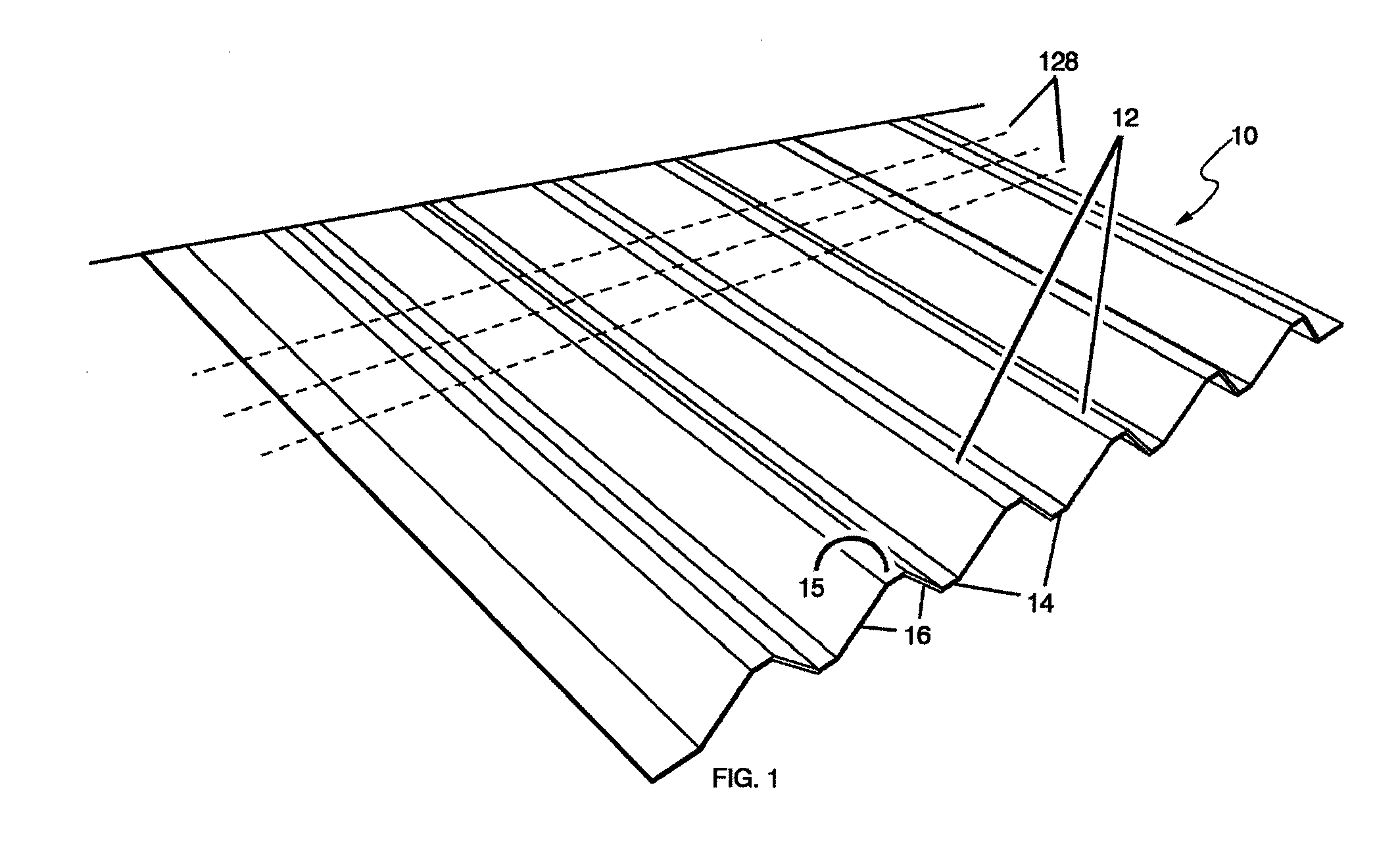

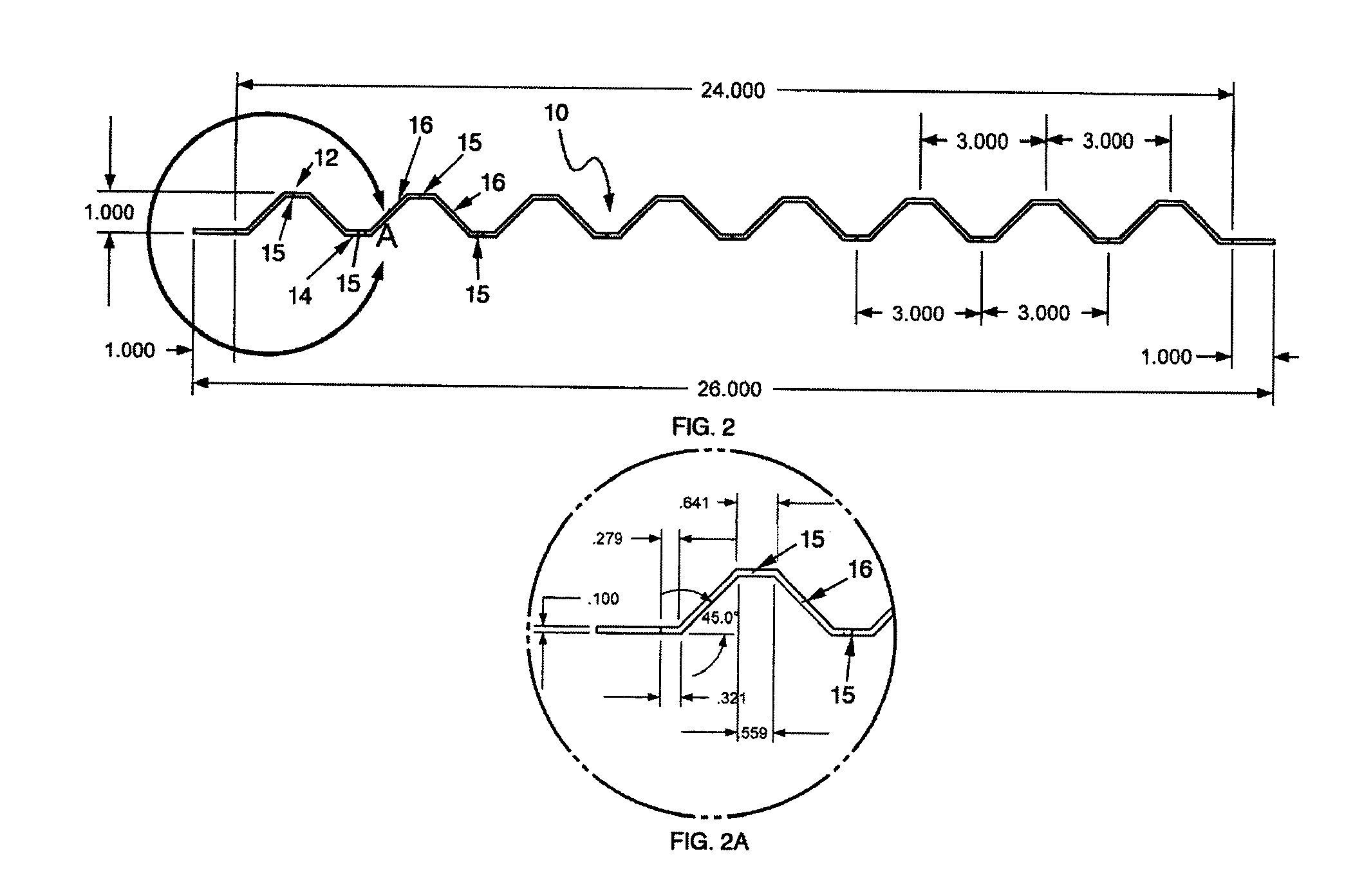

A corrugated web having tapered flutes is usable in straight-through flow filter elements. The corrugated web can be made by passage between a pair of corrugated rollers having tapered teeth. Methods of making usable corrugated rollers include methods for generating the tapered teeth at the end points and the extension between the end points. Corrugated webs may be made from a variety of media, including certain media that stretches in the machine direction. Methods of forming the corrugated web into filter elements (e.g., air filter elements) includes forming filter media by securing a flat sheet to the corrugated web. The filter media may then be wound into a filter element, including application of sealant during the winding process to close selected flutes.

Owner:DONALDSON CO INC

Repulpable container

A repulpable insulated container assembly having a container formed of paper such as corrugated cardboard or varying paper materials and defining an interior; and a repulpable insert placed within the interior of the container and formed of a first paper layer; and a paper fiber pad coupled to the first paper layer.

Owner:PRATT RETAIL SPECIALTIES LLC

Method for printing a pattern on a substrate

ActiveUS20090186308A1Photosensitive materialsSemiconductor/solid-state device manufacturingPaperboardEngineering

The invention provides a method for printing a pattern of ink on a substrate, such as corrugated paperboard, with a relief printing form made from a photosensitive element. The method includes forming an in-situ mask for the photosensitive element, exposing the element to actinic radiation through the in-situ mask in an environment having an inert gas and a concentration of oxygen between 190,000 and 100 ppm, and treating the exposed element to form the relief printing form having a pattern of printing areas. Printing is accomplished by securing the relief printing form to a print press, applying the ink to the printing areas on the printing form, and contacting the ink from the printing areas to the substrate to transfer the pattern of ink onto the substrate.

Owner:DUPONT ELECTRONICS INC

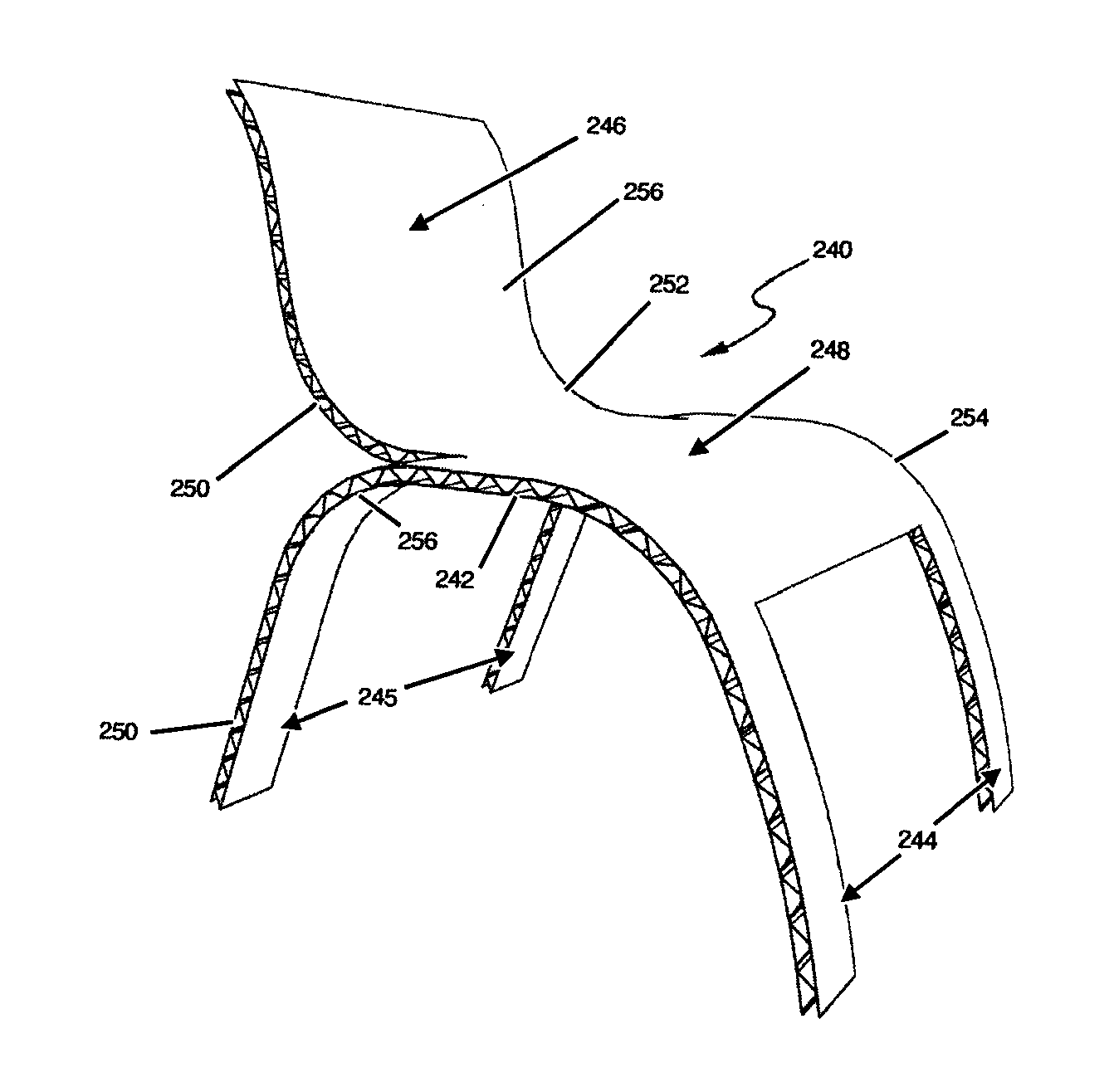

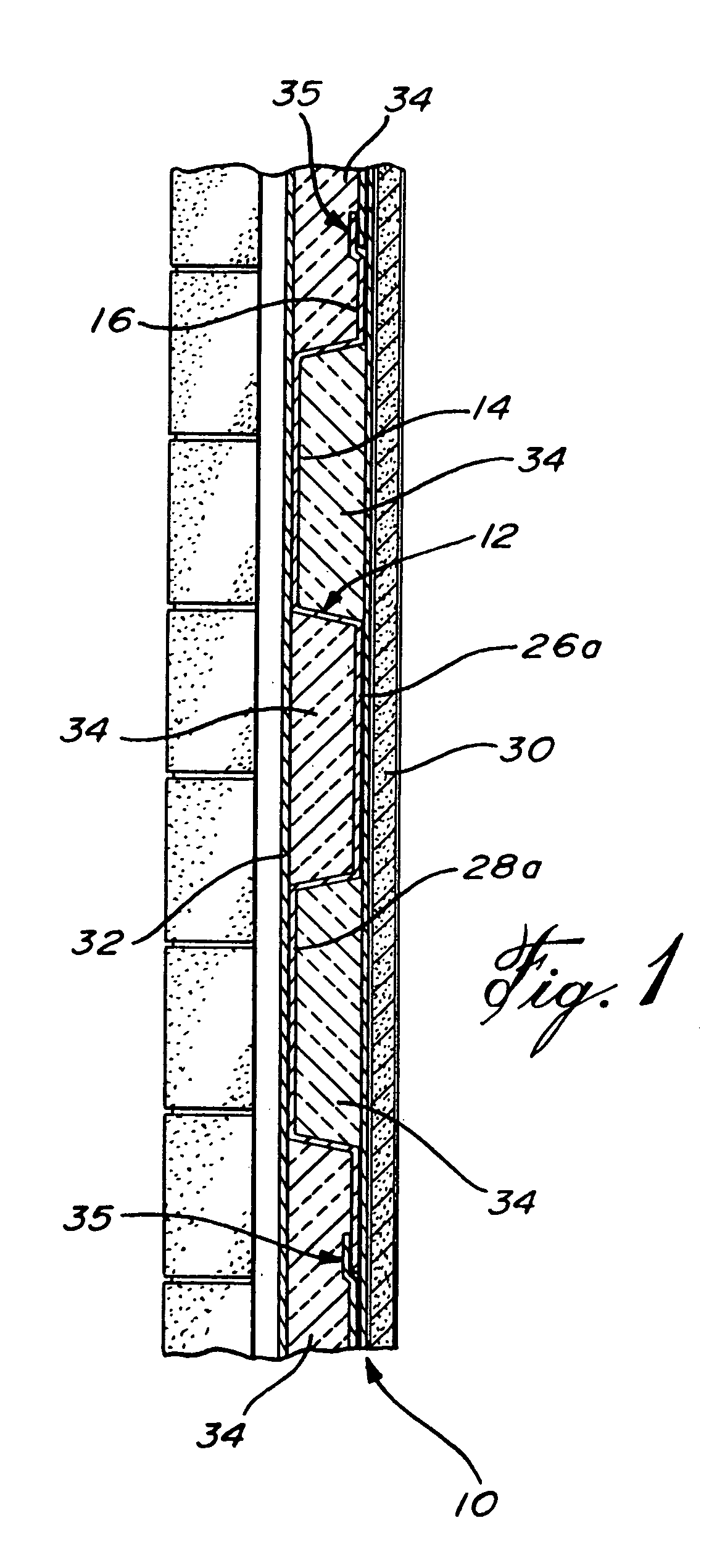

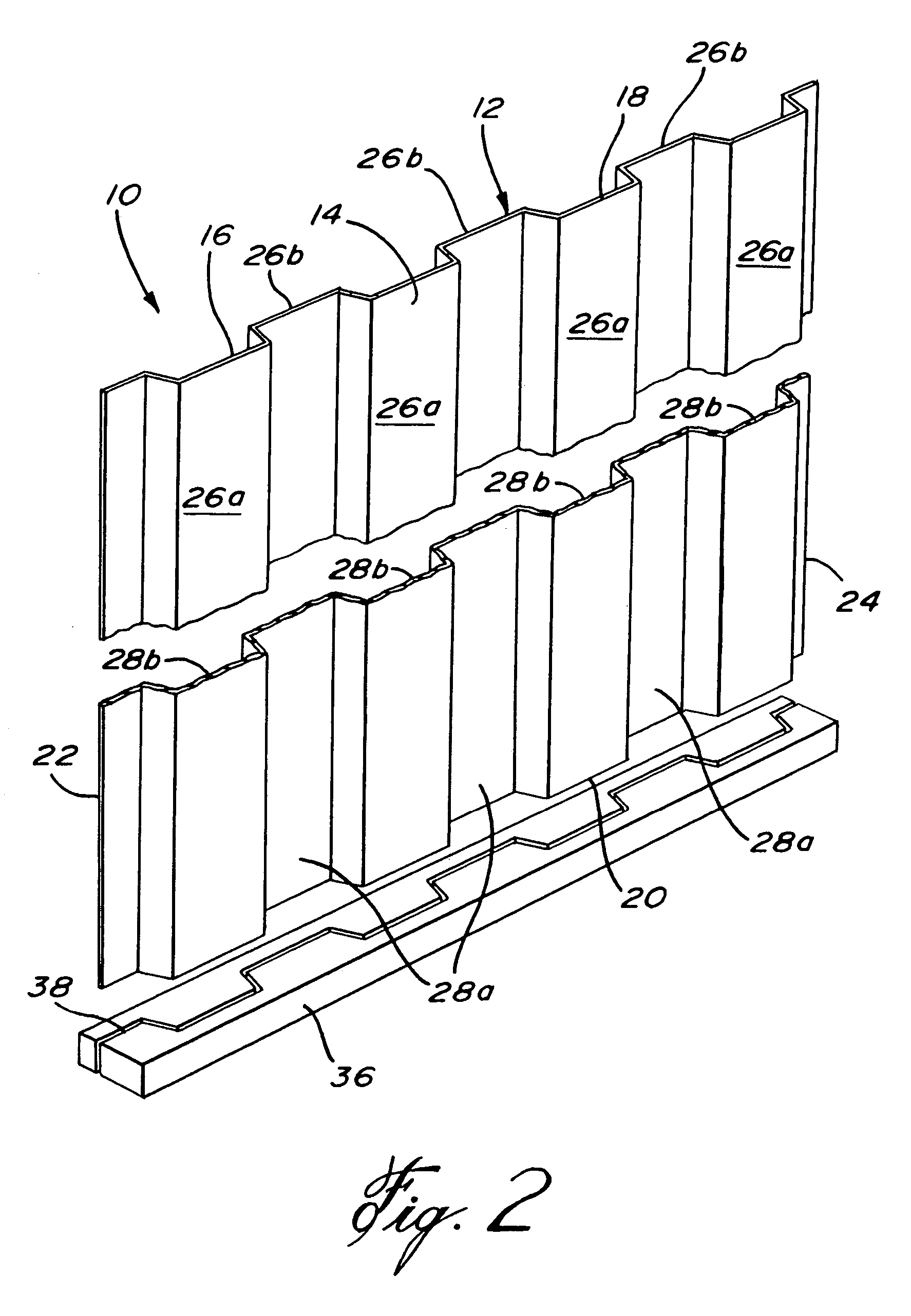

Engineered Molded Fiberboard Panels. Methods of Making the Panels, and Products Fabricated From the Panels

A honeycomb-shaped panel is formed from a plurality of generally sinusoidally shaped strips of molded fiberboard material each having spaced, oppositely directed flat peaks, the peaks of adjacent strips being secured together to form a plurality of hexagonally shaped cells extending perpendicular to the surfaces of the sheet. The strips may be cut from a single sheet of corrugated fiberboard sheet material and then secured together to form the honeycomb panel, or a plurality of such panels may be secured together face to face with their ribs aligned to form a stack, and selected cuts may be made through the secured, stacked panels to form a plurality of honeycomb panels of desired surface shape and height dimensions. The strips forming the cells are substantially rigid and resistant to collapse of the cells, and form a substantially rigid core when assembled between two flexible fiberboard skins, while the panel is bendable to adopt a desired panel curvature.

Owner:US SEC AGRI +1

Rotary die cutter insert

InactiveUS20120285306A1Control ejectionReduces instanceStock shearing machinesMetal working apparatusInstabilityEngineering

The provision of a hardened elevated surface within the a inside die cutting area of a cutting rule to limit and control the extent to which die cut scrap processed corrugated fiberboard sheet material can position itself within the area within the cutting rule before ejection limit the tendency for instability within the cutting rule after the die cut is achieved and to better control the ejection of the scrap processed corrugated fiberboard sheet material to better eliminate unwanted scrap downstream of the die cutting process. Eliminated scrap reduces malfunctions in further processing and helps to eliminate health and contamination hazards in the finished corrugated fiberboard sheet product.

Owner:WEIBELT BRUCE

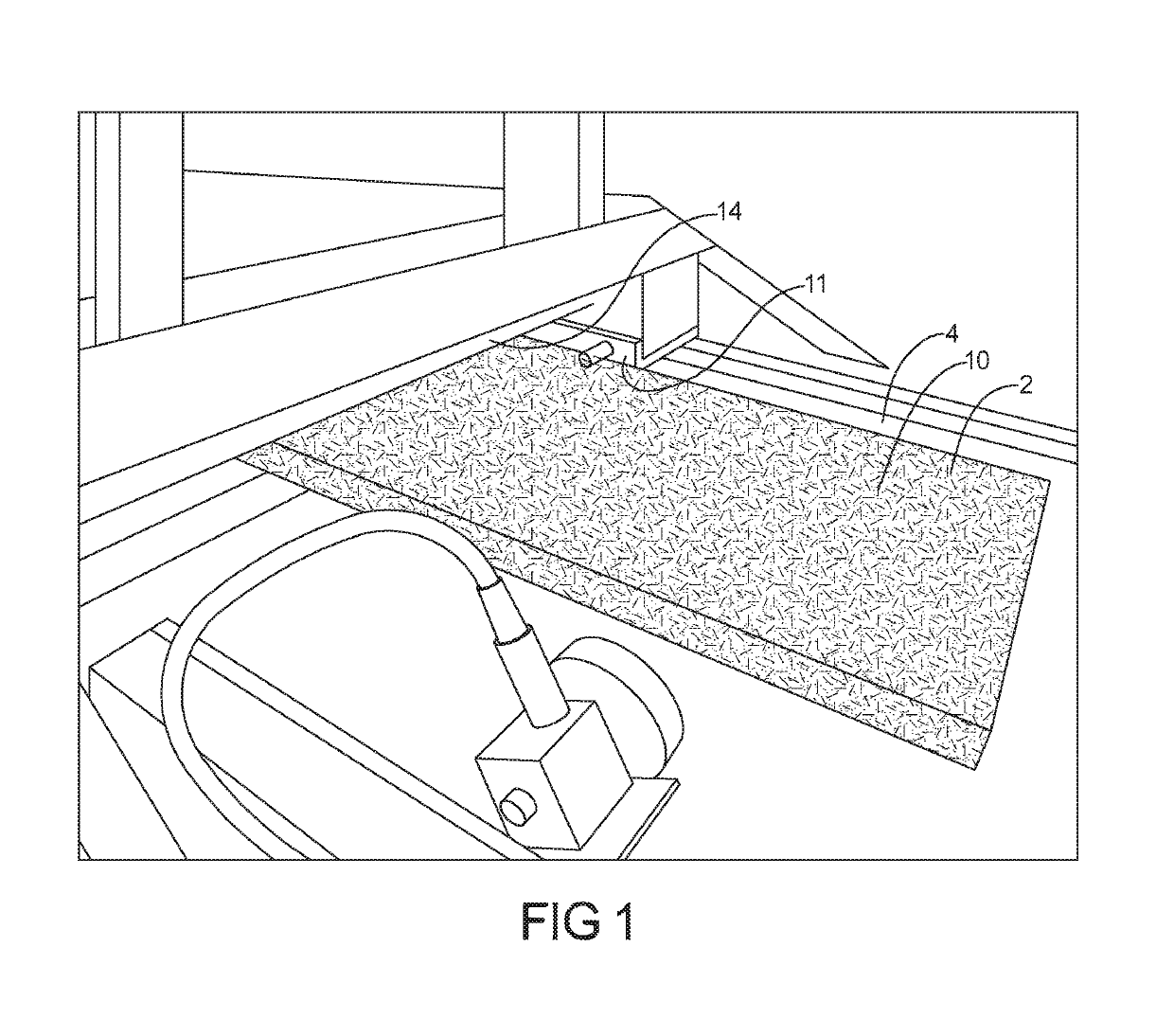

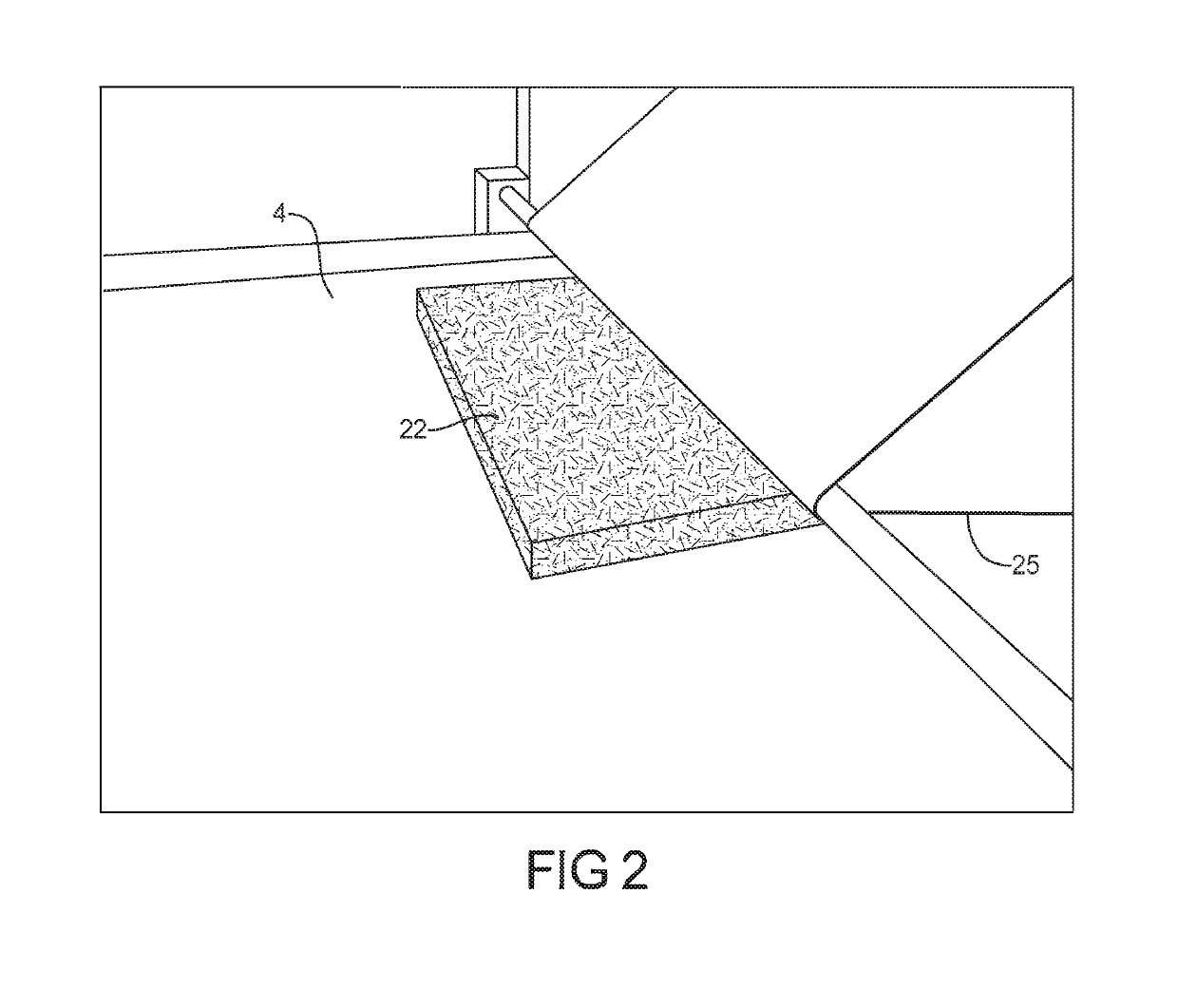

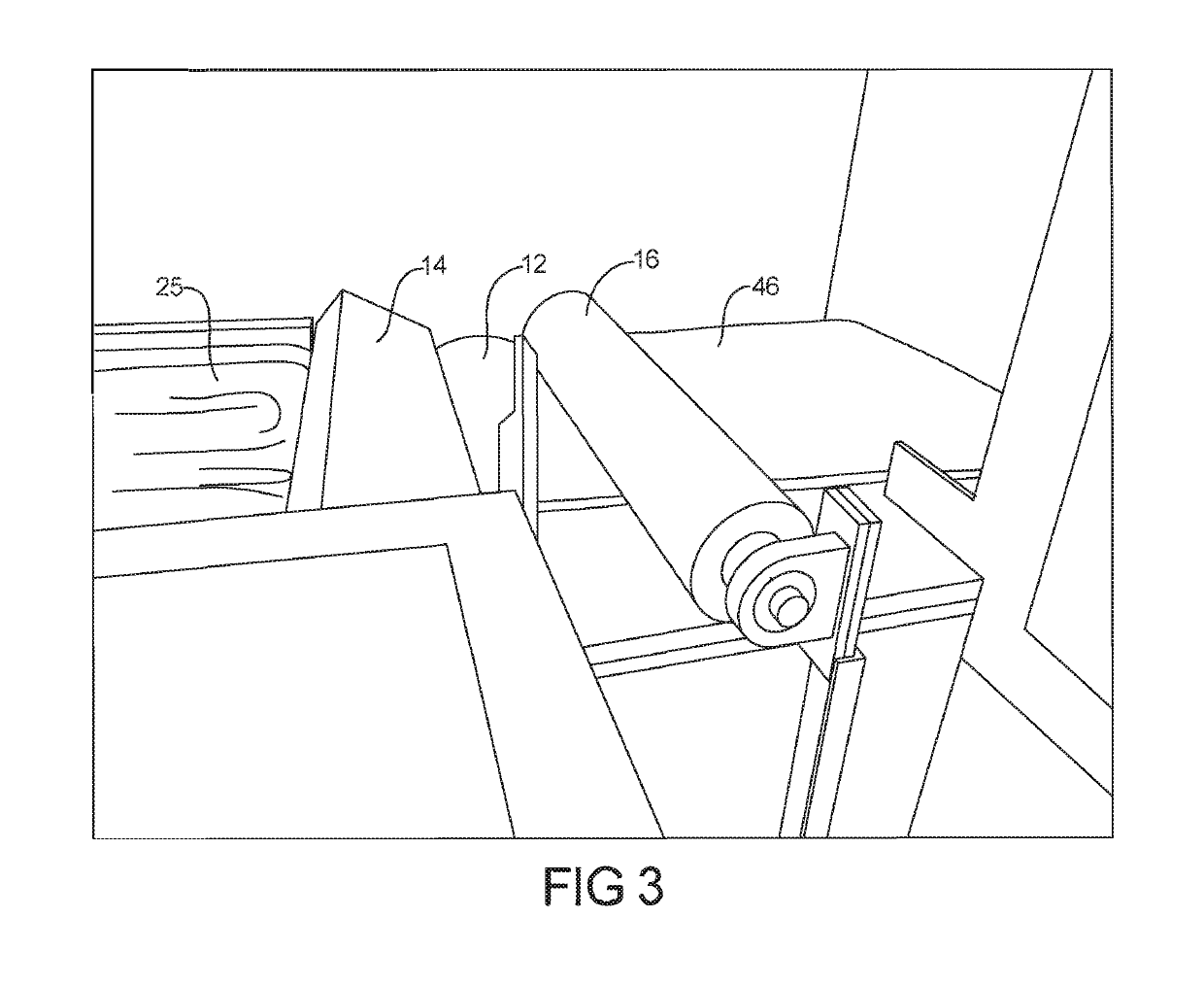

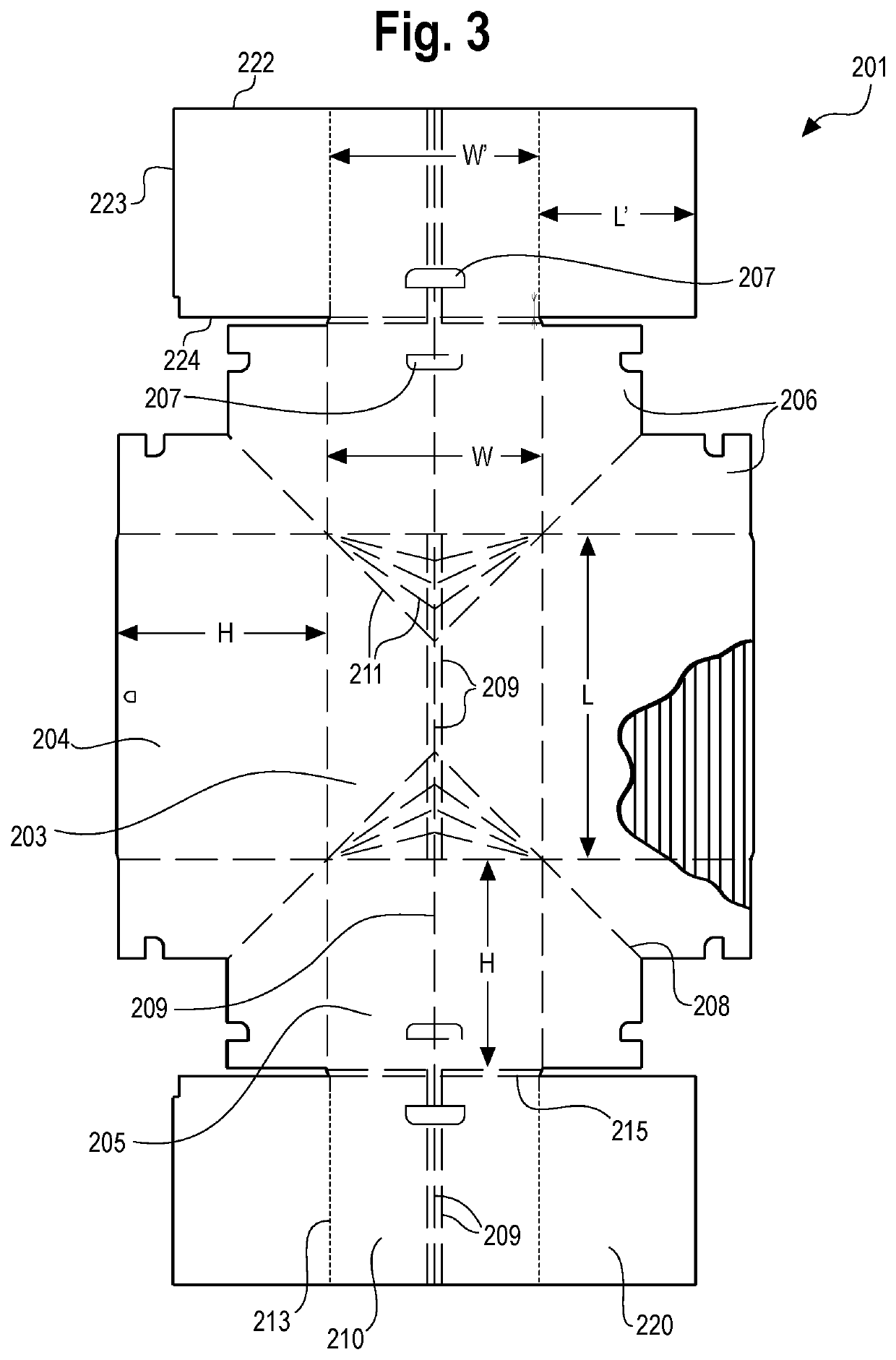

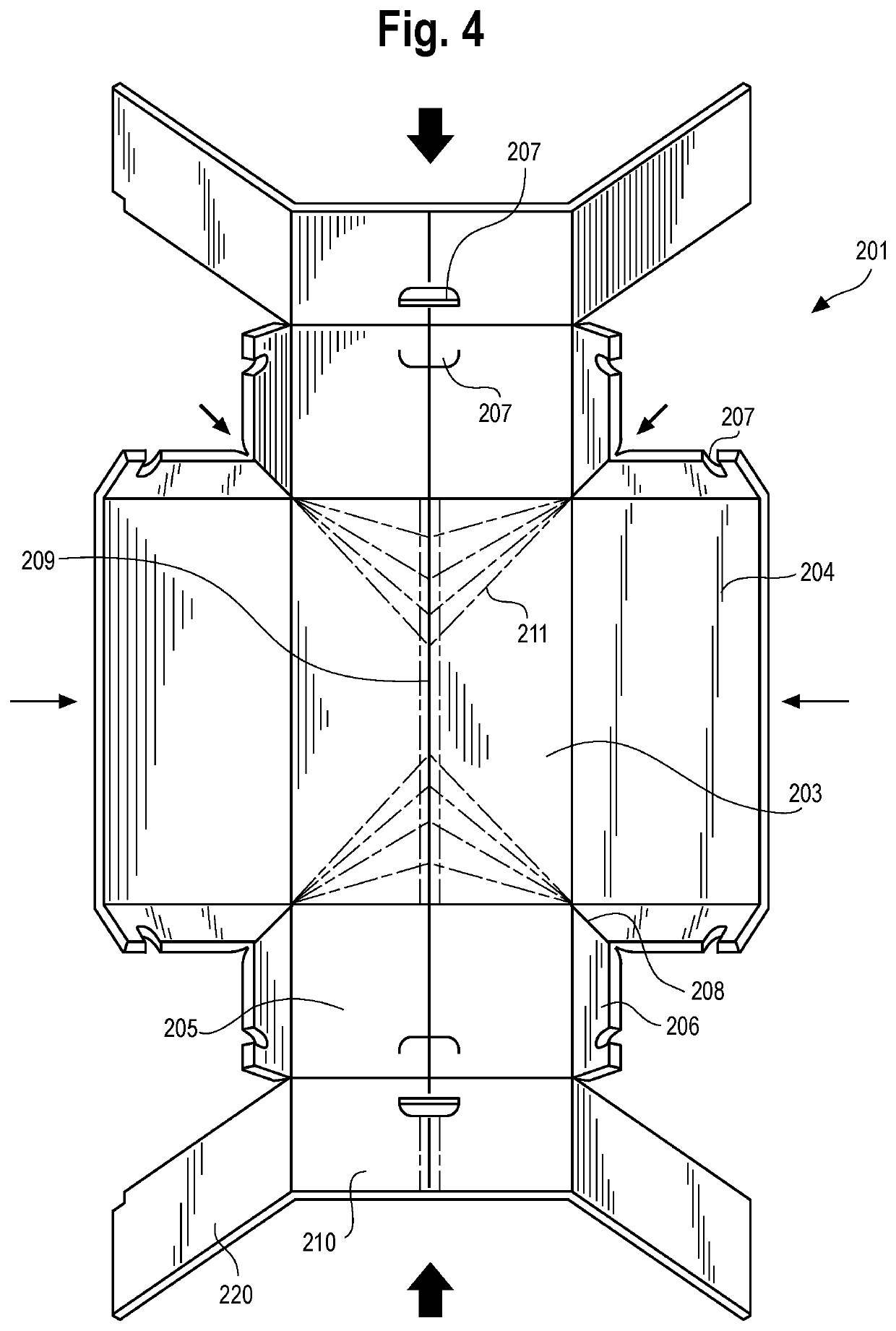

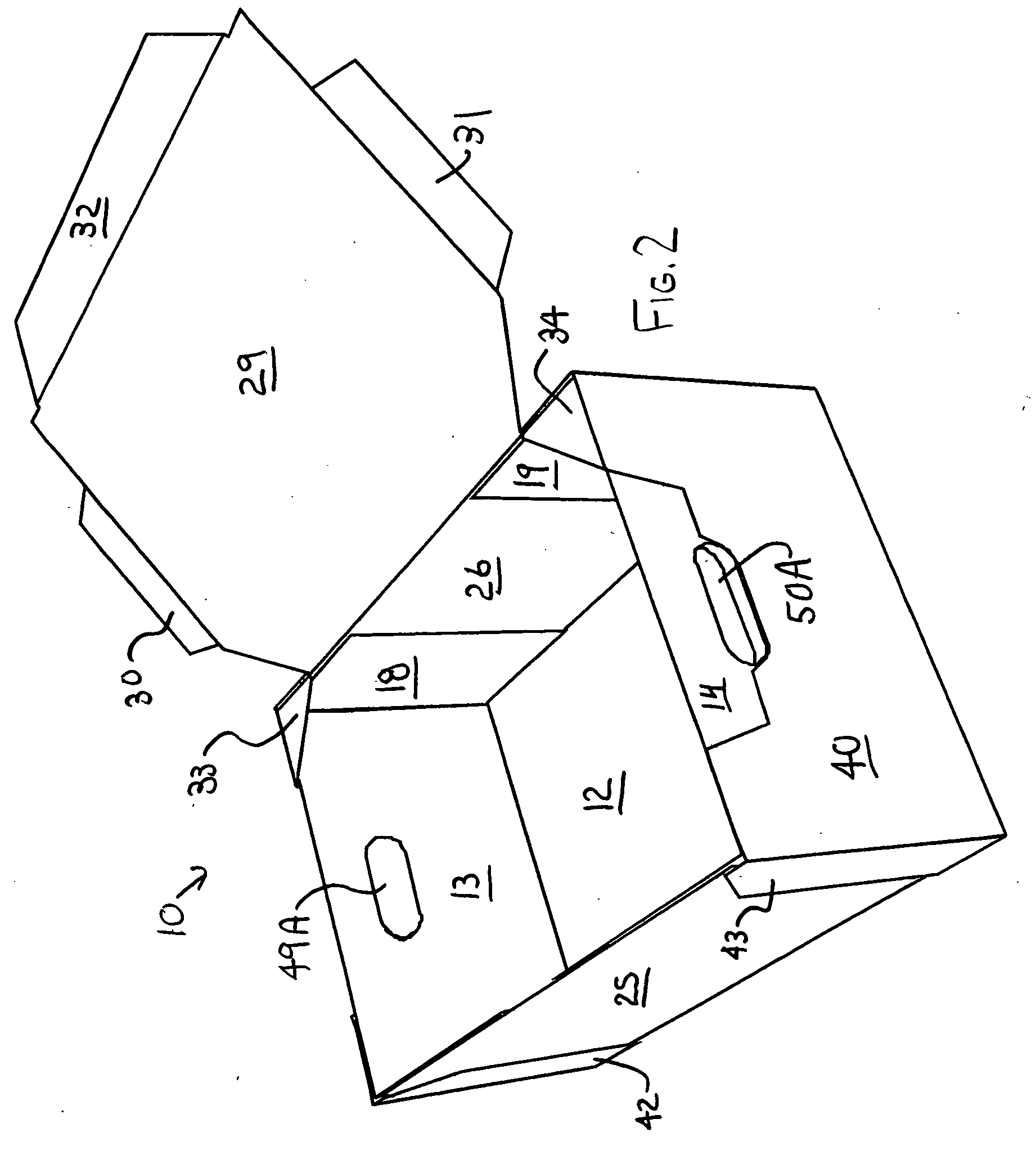

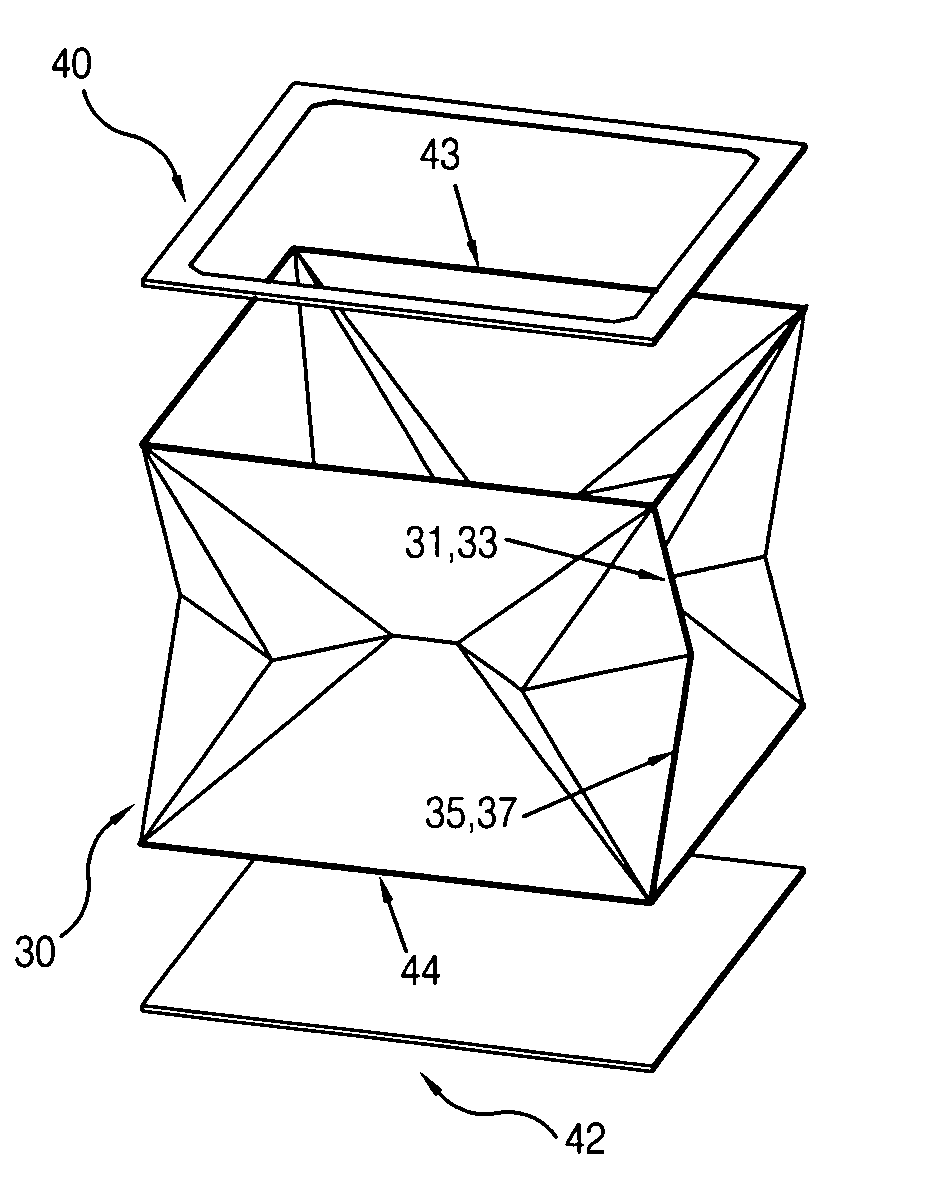

Suspension packaging system

InactiveUS20060138018A1Easy to storeSimplifying transportationContainers to prevent mechanical damageRigid containersCardboardEngineering

A suspension packaging system can include a foldable member configured to form a cavity as well as a suspension device for suspending an article to be packaged within the cavity. The suspension portion can include foldable portions configured to cooperate with a retention member having pockets. The foldable portions can fit into the pockets and then be folded so as to generate tension in the retention member. The entire device, with the exception of the retention member, can be made from a single piece of material, such as corrugated cardboard, which thus reduces waste and simplifies bulk distribution of such a suspension packaging system.

Owner:CLEARPAK

Corrugated pallet

InactiveUS20050247240A1Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces form an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

Container having improved compression strength

Owner:MEDLINE IND LP

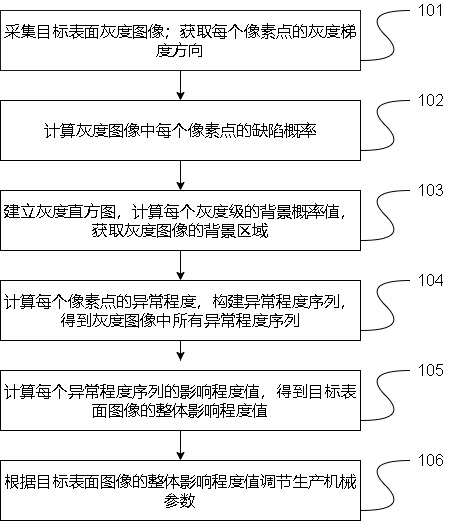

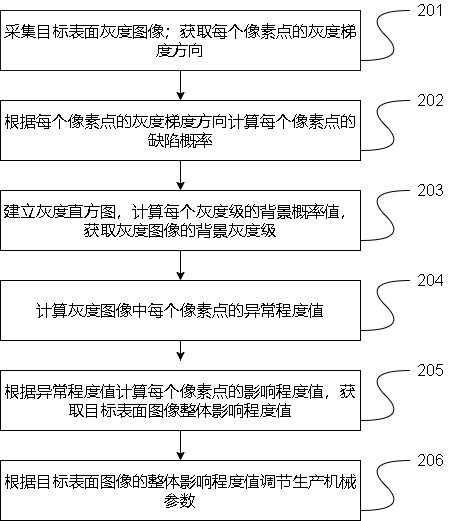

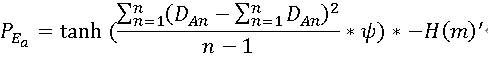

Corrugated board production quality regulation and control method based on machine vision

ActiveCN113934190APrecisely control the amount of glueImprove product qualityProgramme total factory controlTarget surfaceMachine vision

The invention discloses a corrugated board production quality regulation and control method based on machine vision, relates to the field of artificial intelligence, and is mainly used for mechanical parameter control of corrugated board production. The method comprises the steps of obtaining a target surface grayscale image; obtaining the gray gradient direction of each pixel point; calculating the defect probability of each pixel point; establishing a gray level histogram, calculating a background probability value of each gray level, and obtaining a background region of the gray level image; calculating the abnormal degree of each pixel point in the grayscale image, and constructing a sequence of all abnormal degrees in the grayscale image; calculating an influence degree value of each abnormal degree sequence to obtain an overall influence degree value of the target surface image; and adjusting production machinery parameters according to the overall influence degree value of the target image. According to the technical means provided by the invention, the influence degree of the defect is calculated through the target surface grayscale image, so that the mechanical parameters are adjusted, and the product quality and the production efficiency are improved.

Owner:武汉春田纸品包装有限公司

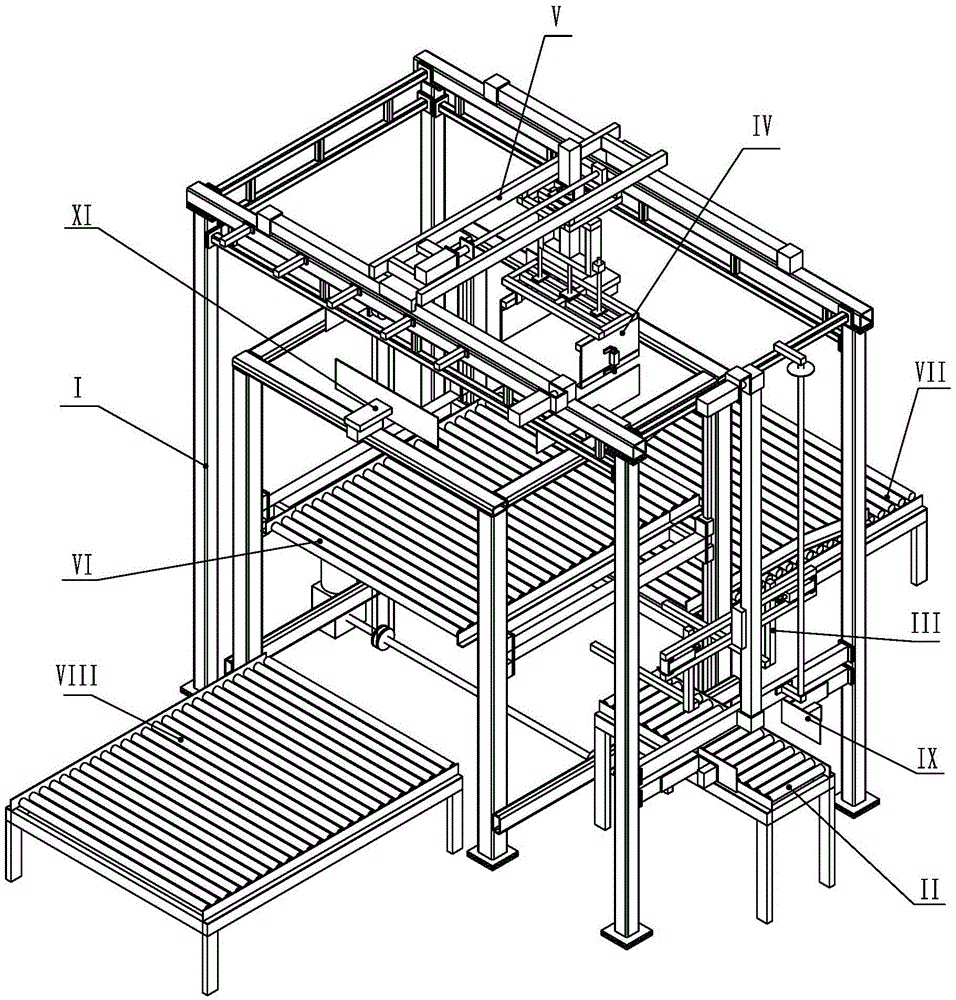

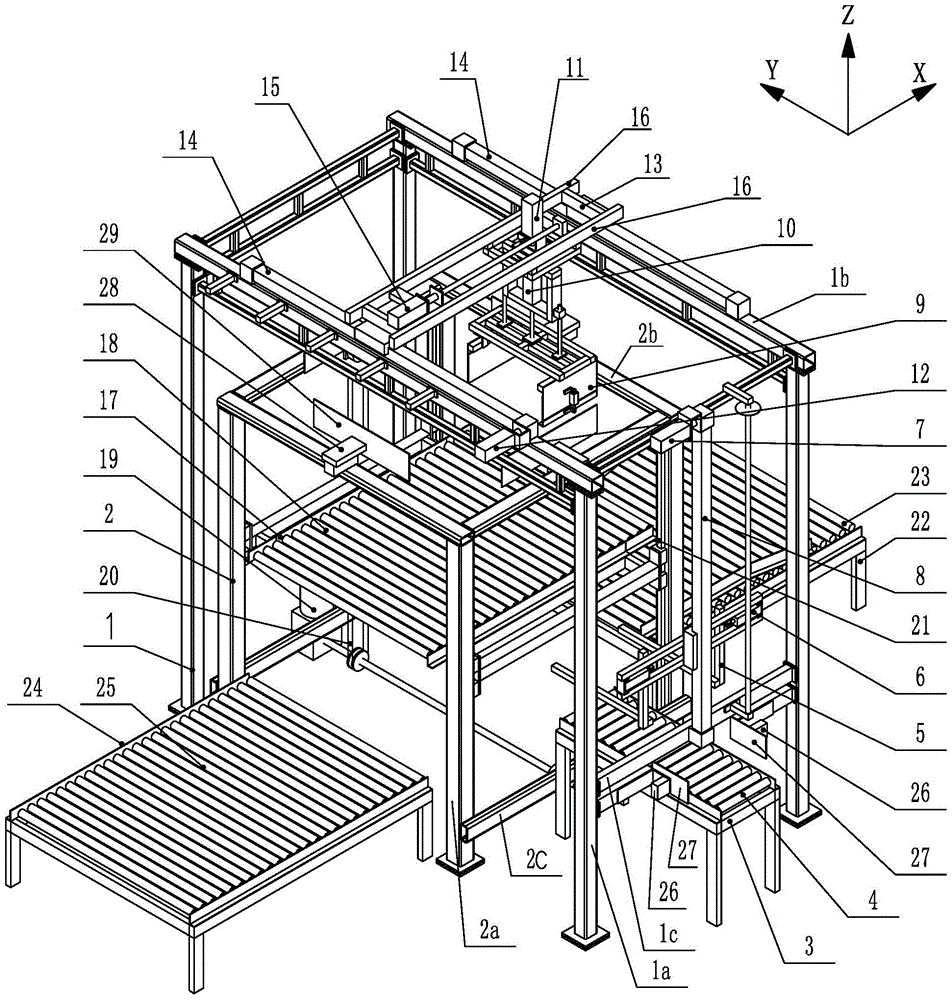

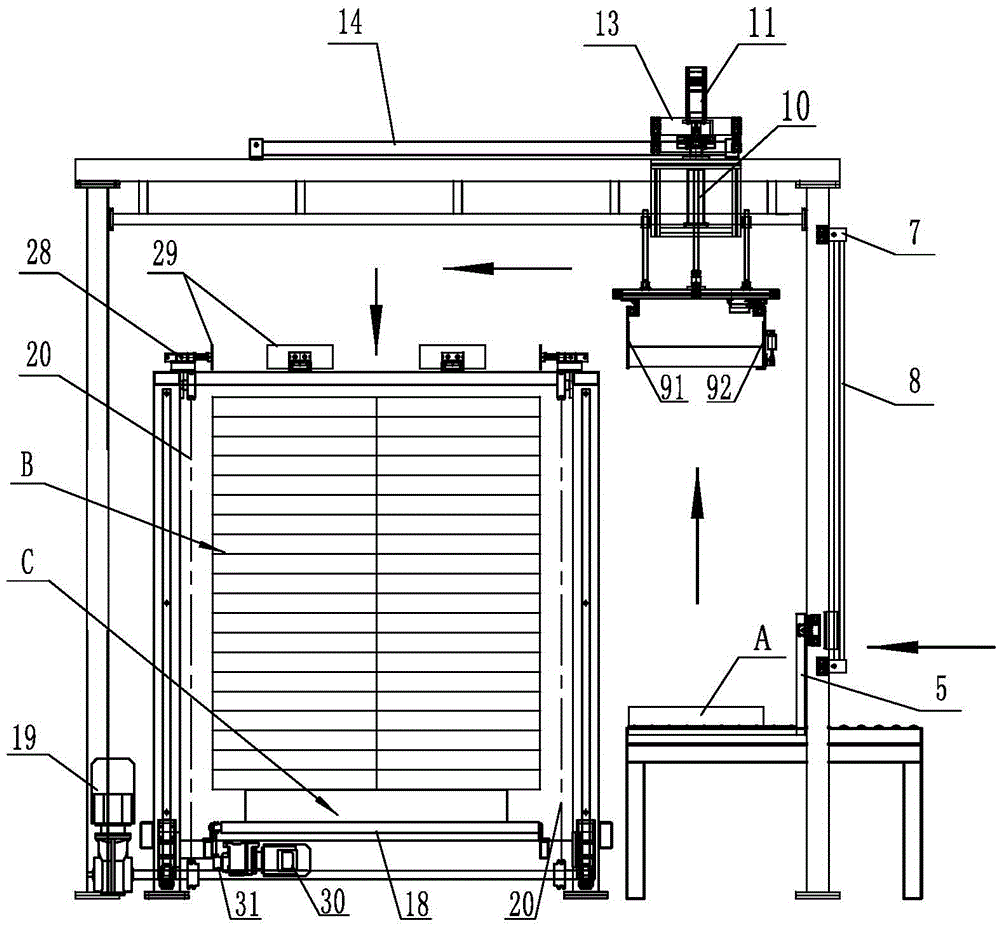

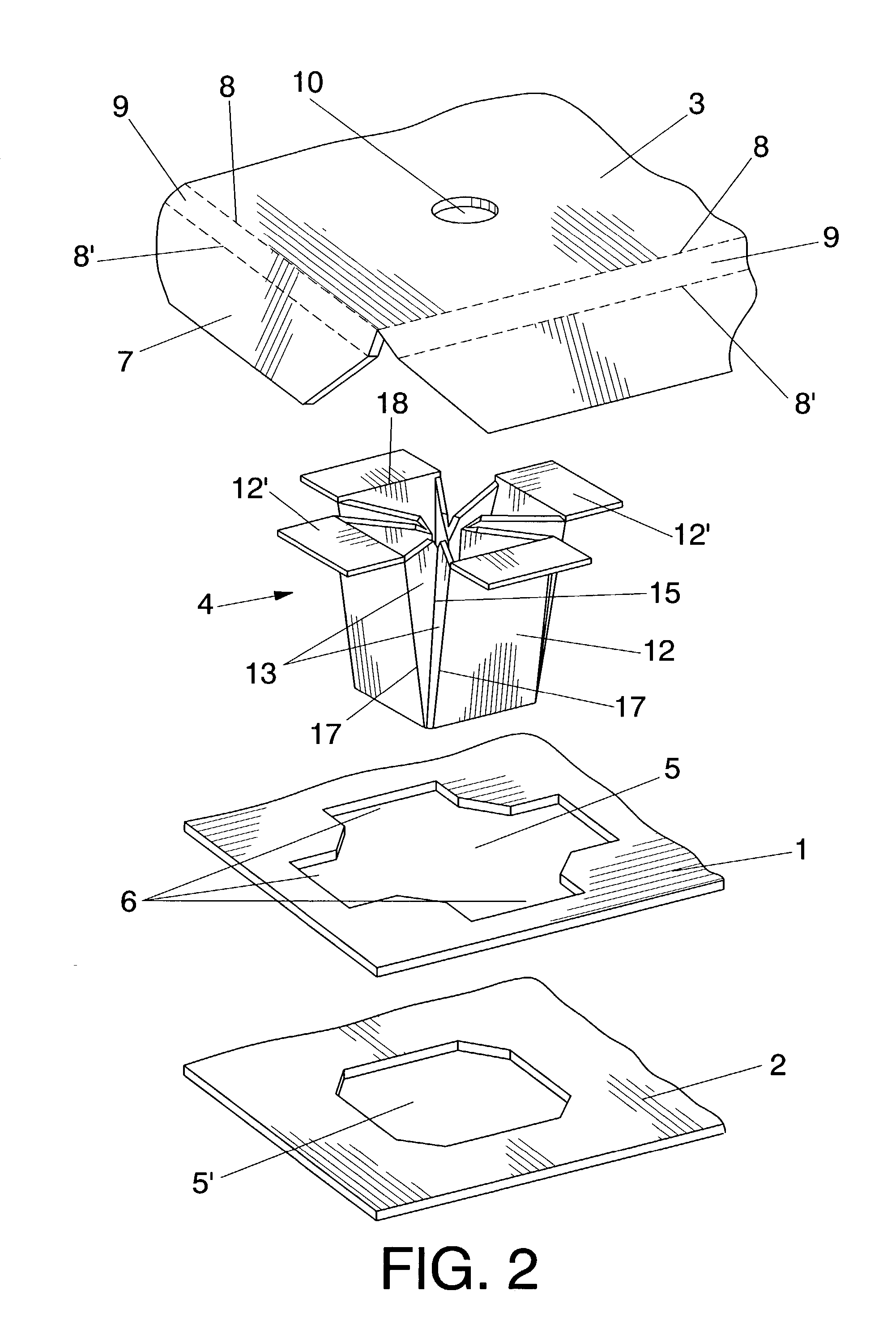

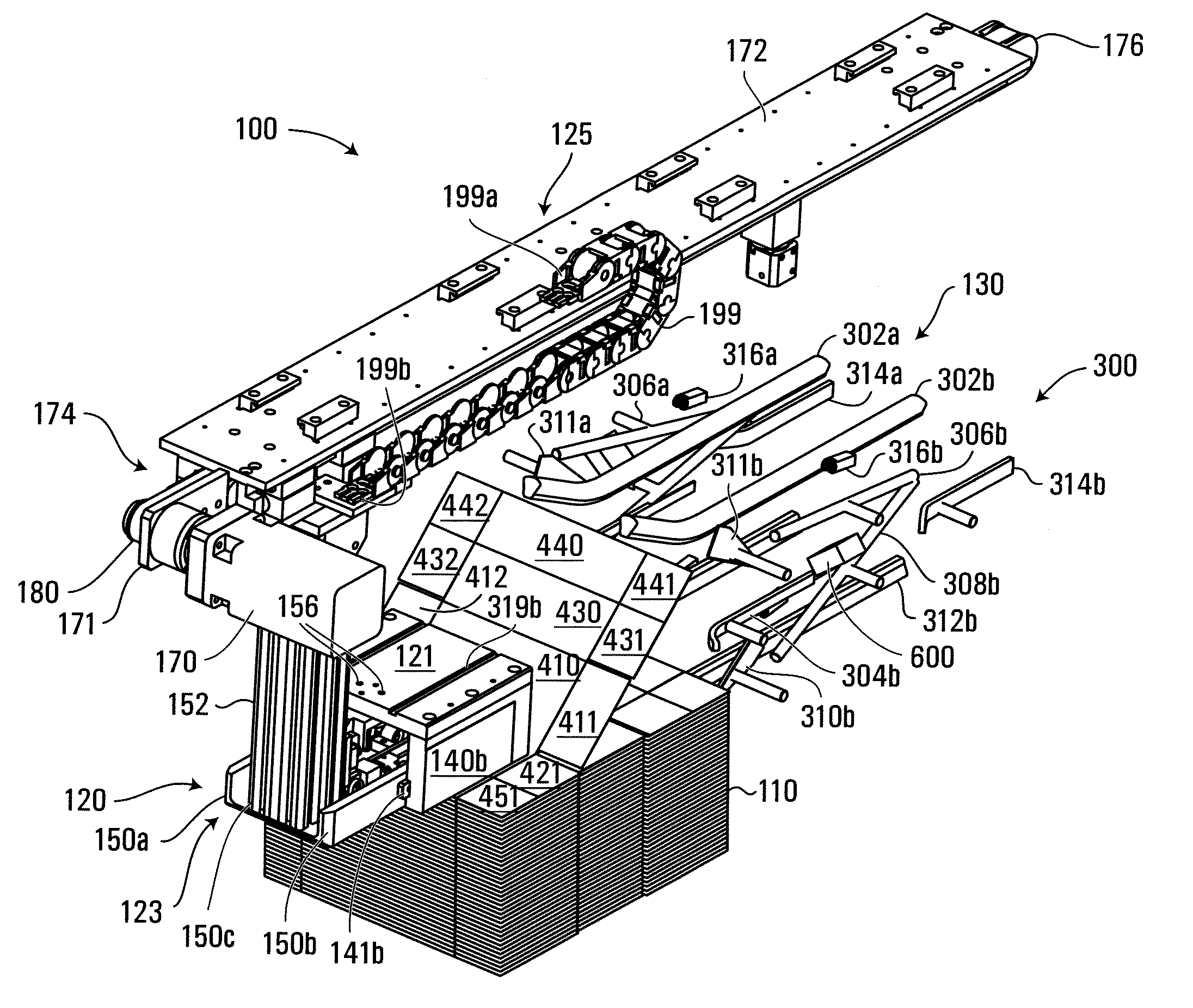

Paperboard stacking device and paperboard stacking machine

ActiveCN105565017ARealize automatic feedingAutomate operationPile receiversArticle feedersCardboardStack machine

The invention discloses a paperboard stacking machine and a paperboard stacking device. The paperboard stacking machine comprises a paperboard stacking device, a paperboard feeding mechanism, a tray feeding mechanism and a paperboard output mechanism; the paperboard stacking device comprises a main body frame; the main body frame comprises an outer frame and an inner frame; a paperboard lifting mechanism is arranged at one side of the outer frame; a gripper mechanism and a gripper translation mechanism are arranged on a top beam of the outer frame; a paper feeding normalizing mechanism is arranged on a stand column of the outer frame; a tray lifting output mechanism is arranged on the inner frame; and a stacking normalizing mechanism is arranged on a top beam of the inner frame. The paperboard stacking machine realizes automation of automatic feeding and paperboard feeding, paper feeding normalizing, lifting, grabbing, translation, rotating, releasing, stacking normalizing, paper stack descending and paper stack output of the tray, and can trimly stack packaged corrugated paperboards or cartons according to predetermined putting positions and rules, thus realizing automatic operation, being good in stacking quality and high in stacking speed, and saving manpower.

Owner:SHANDONG CENTURY MACHINERY

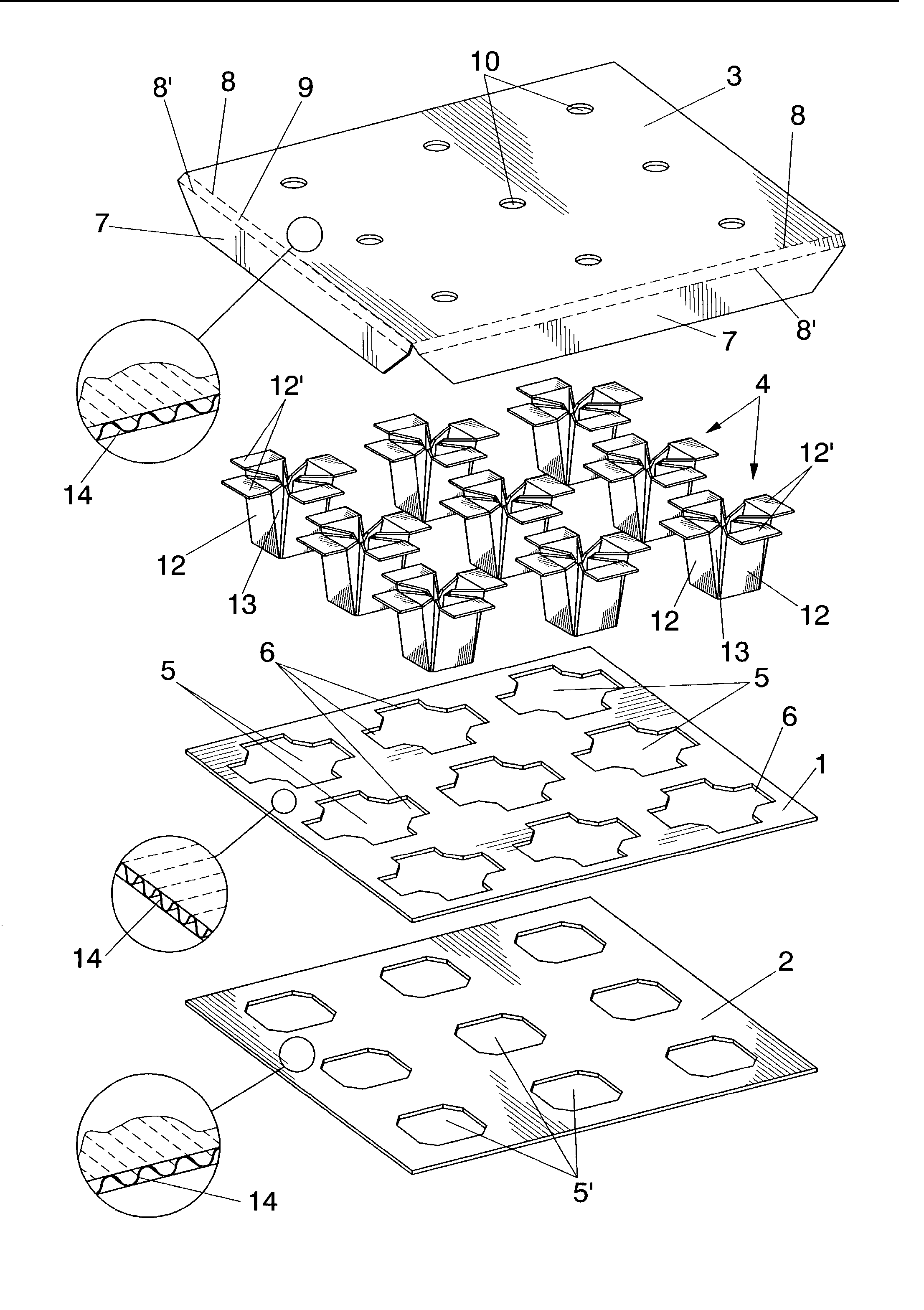

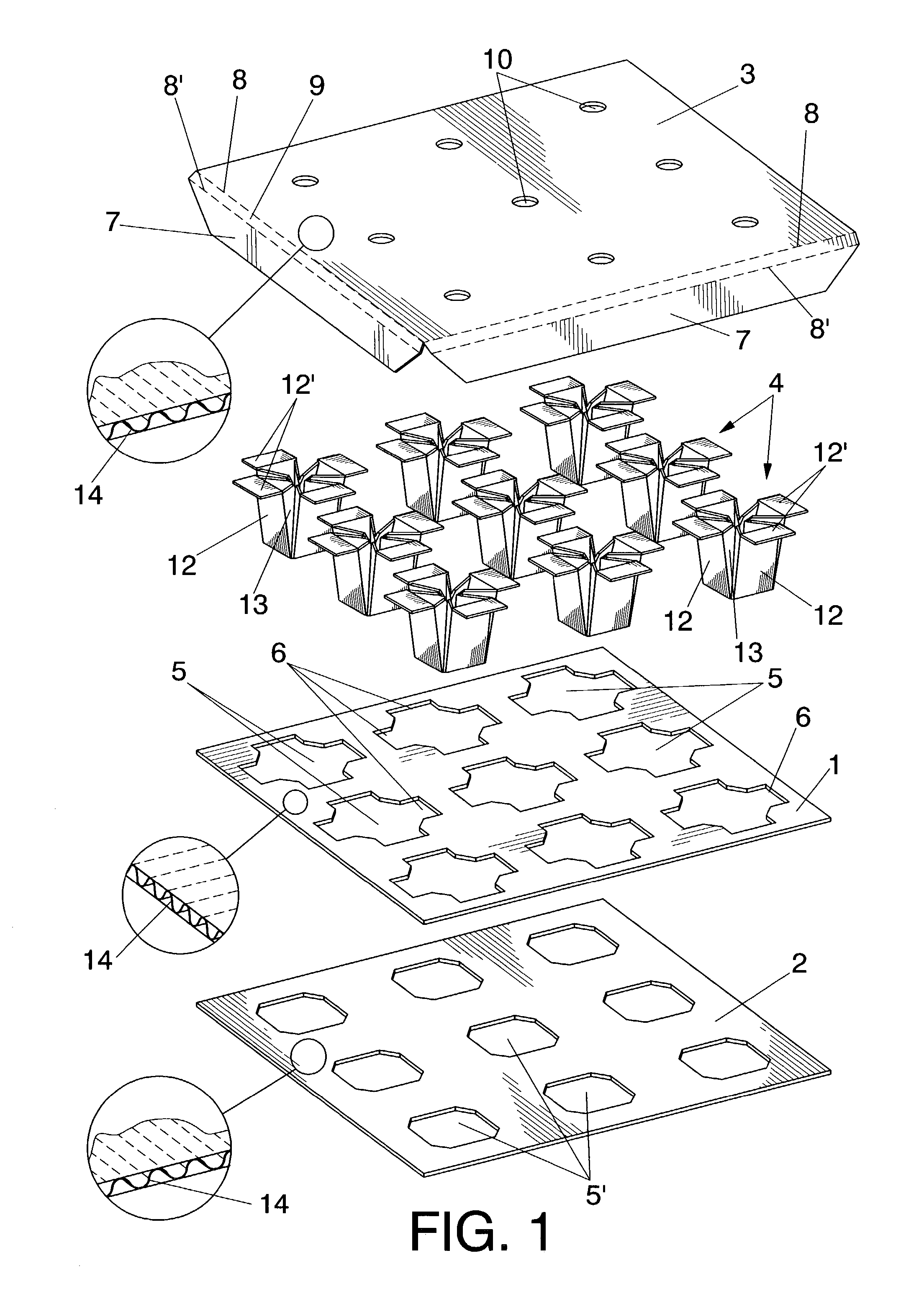

Cardboard pallet

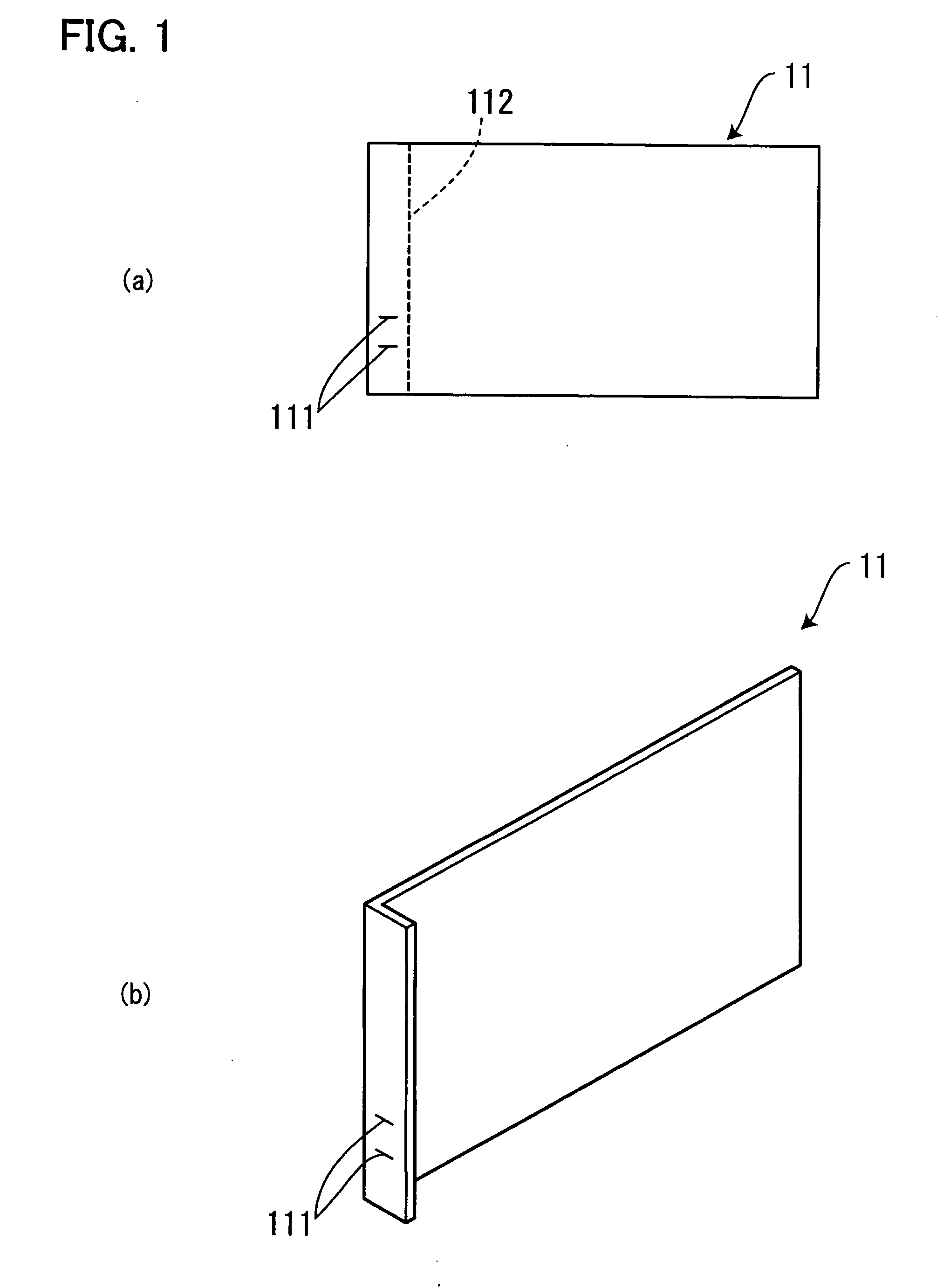

The pallet is formed from two sheets (1 and 2) superposed underneath, an upper sheet (3) acting as a cover, and a series of legs (4) of inverted trunco-pyramidal configuration that are fixed on polygonal apertures (5 and 5') established in the lower sheets. All the referred to elements are made of corrugated cardboard. The novelty of the pallet consists of the legs (4) being obtained starting from a development in a cross, with a central sector (112) constituting the lower support surface for the leg, certain rectangular sectors (12) and some double and triangular sectors (13) that are folded via their mid-line in the form of an accordion. The leg shaped by folding those sectors presents certain upper and side flaps (12') that are positioned in notches (6) in the apertures (5), with the leg being correctly located in its place, which is finally fixed by means of gluing of the sectors (134) and of the flaps (12'), these latter being retained between the lower sheet (2) and the cover (3).

Owner:SANVIPALET

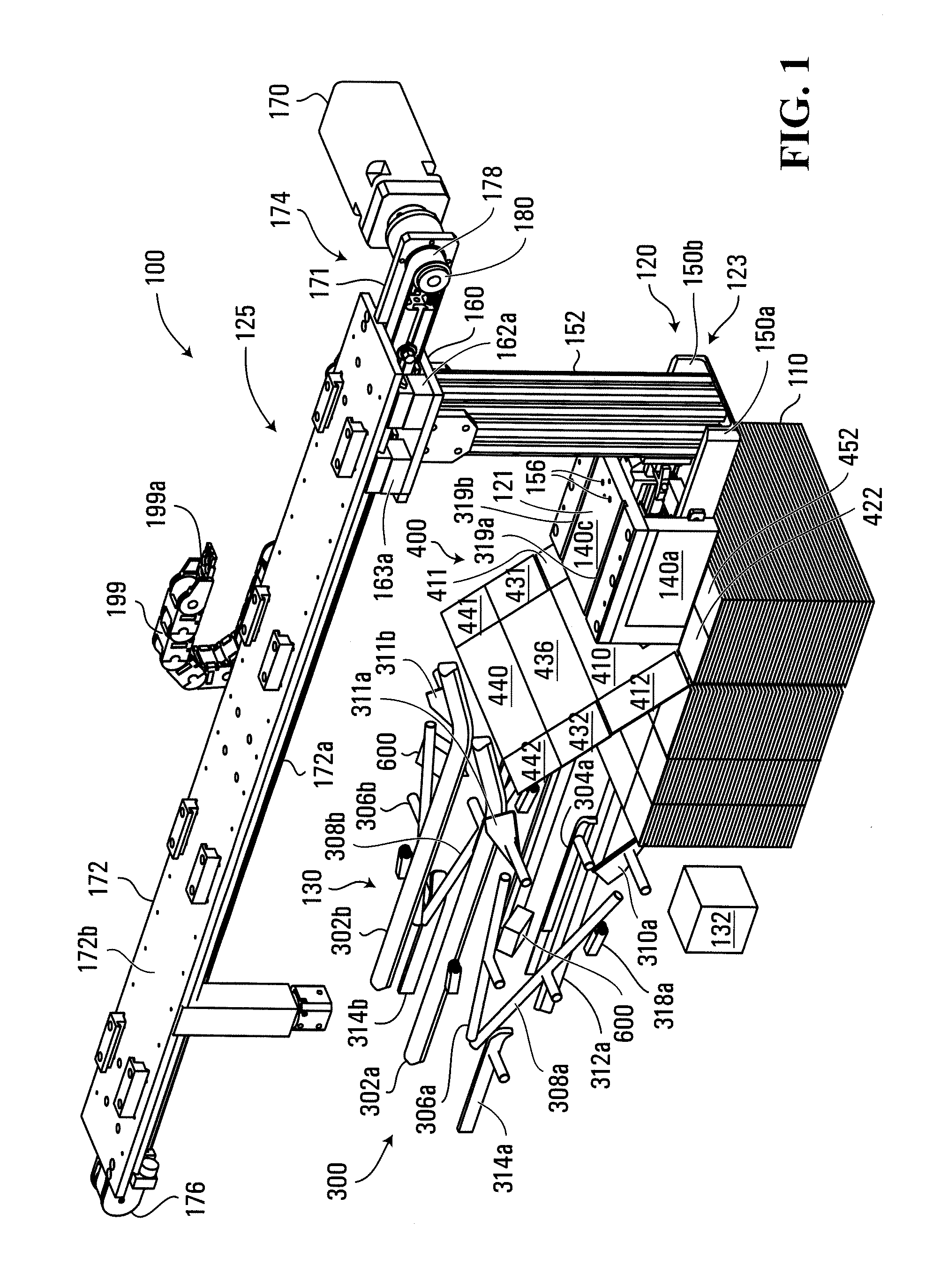

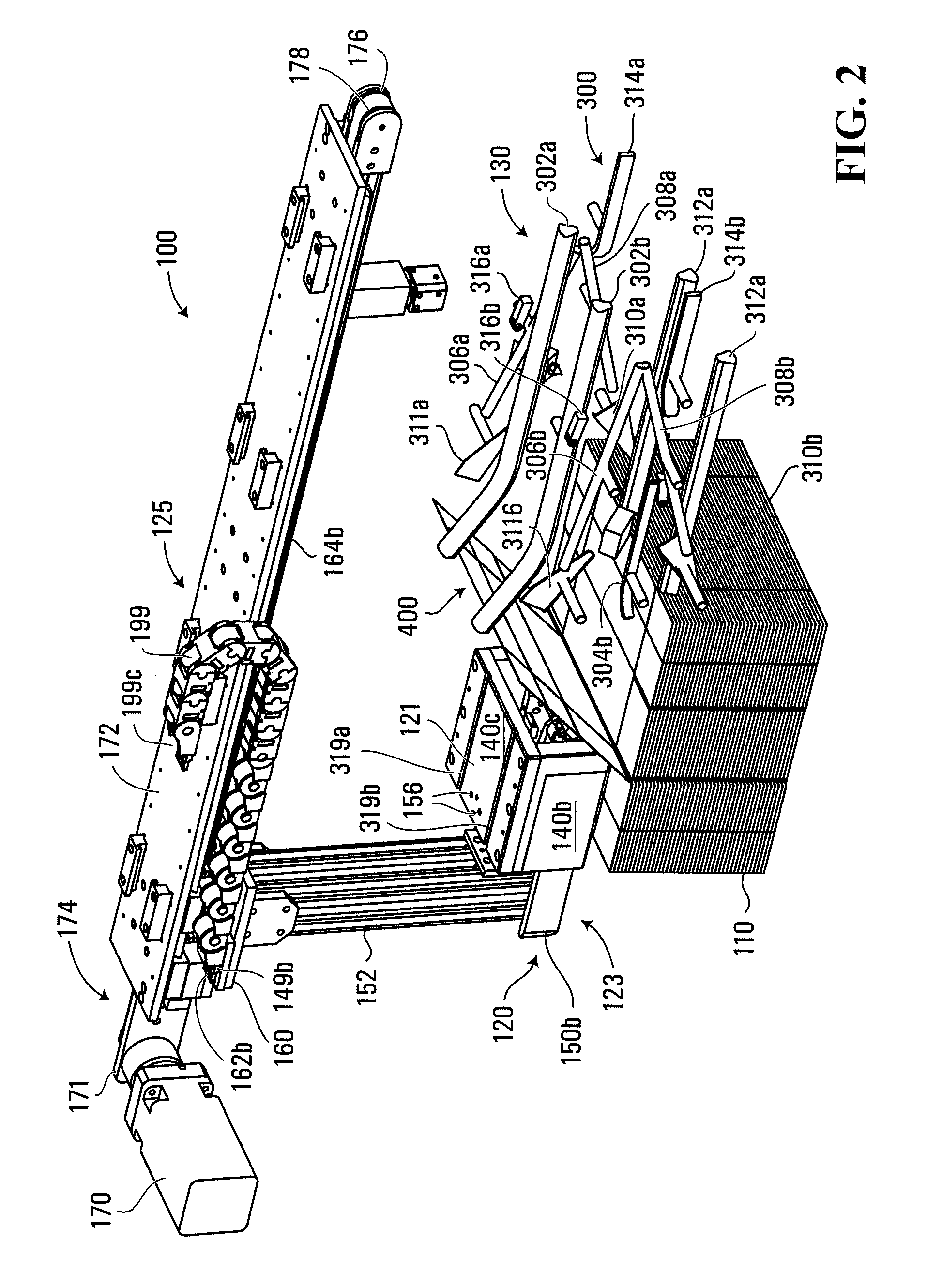

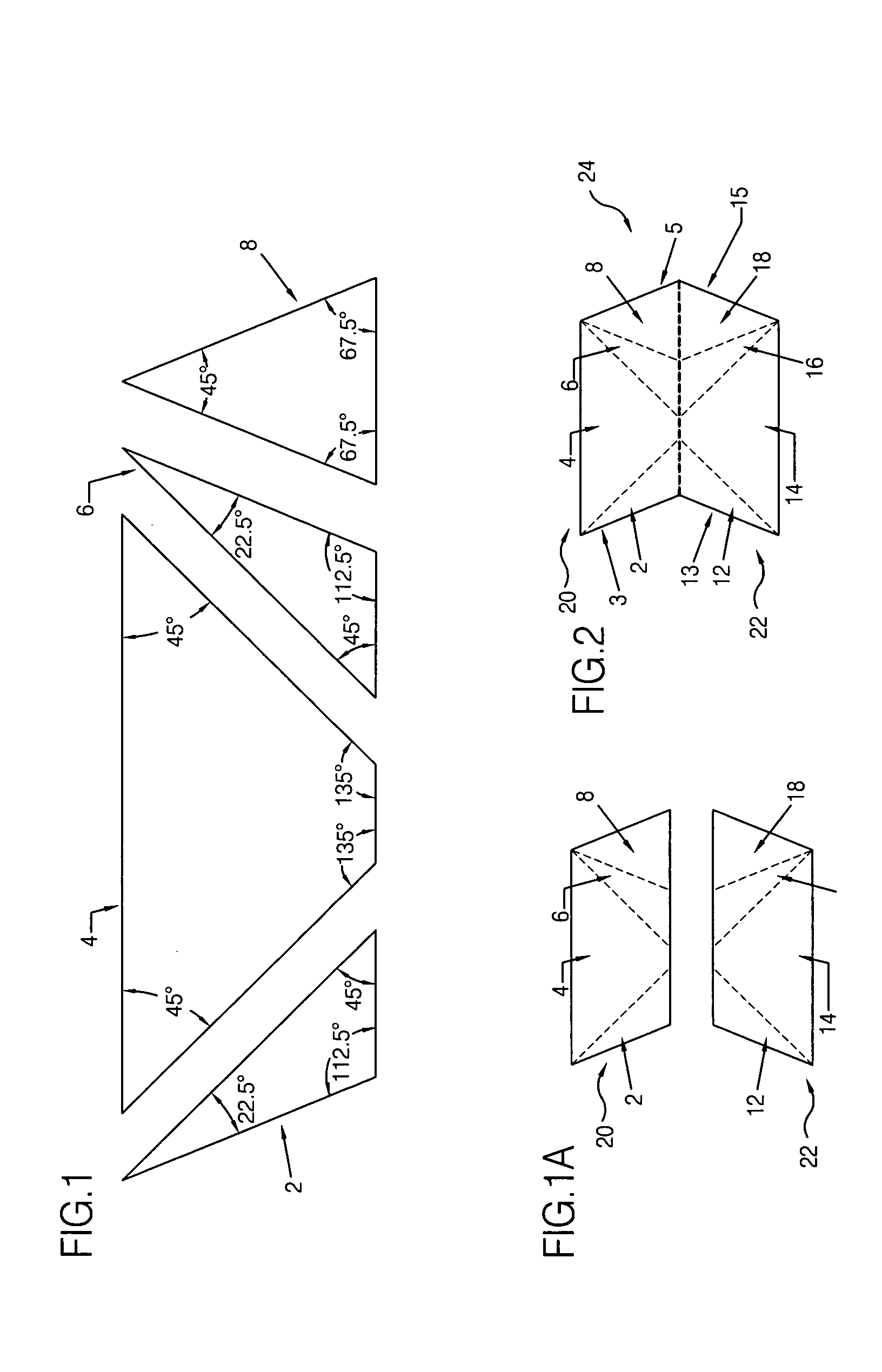

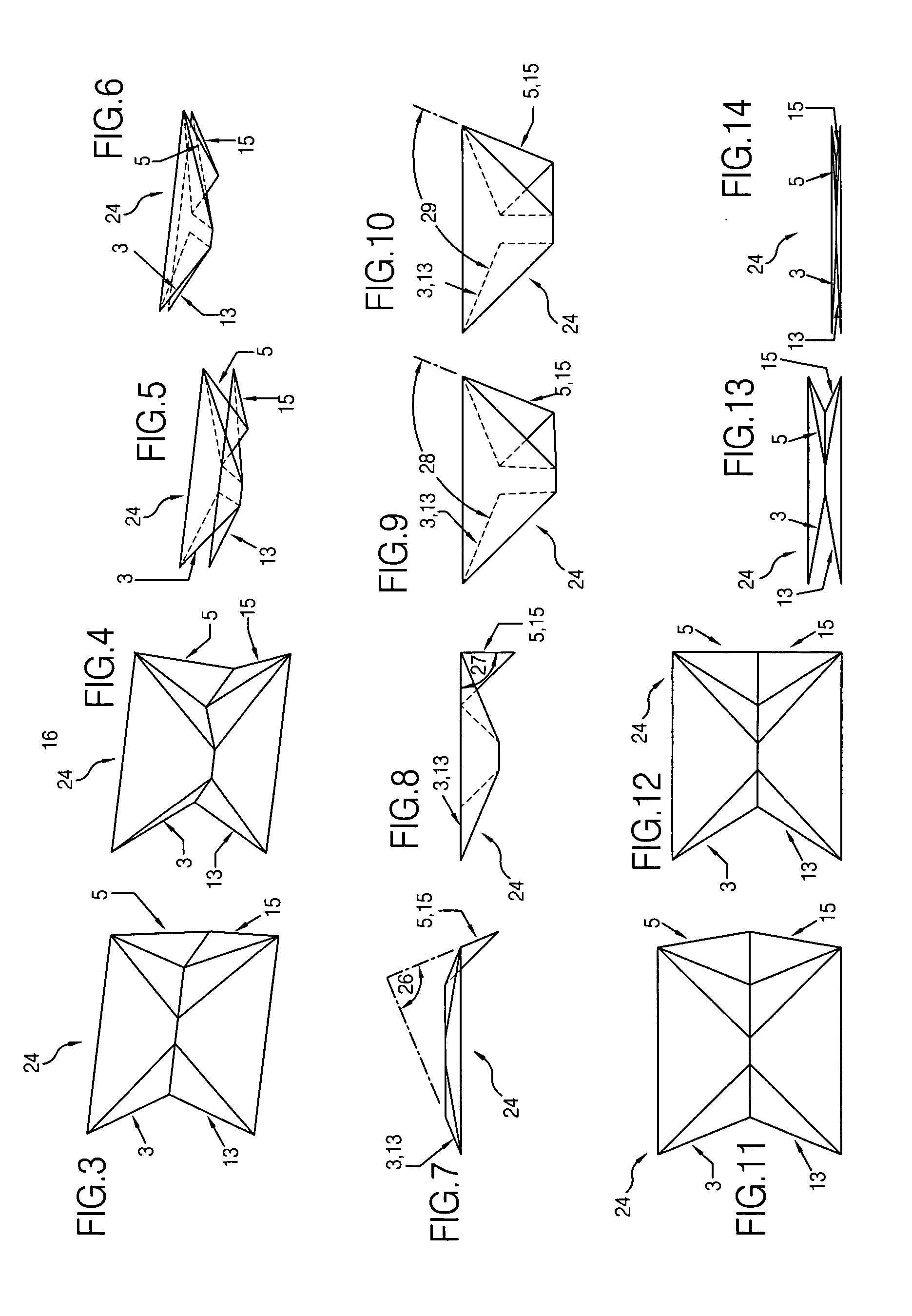

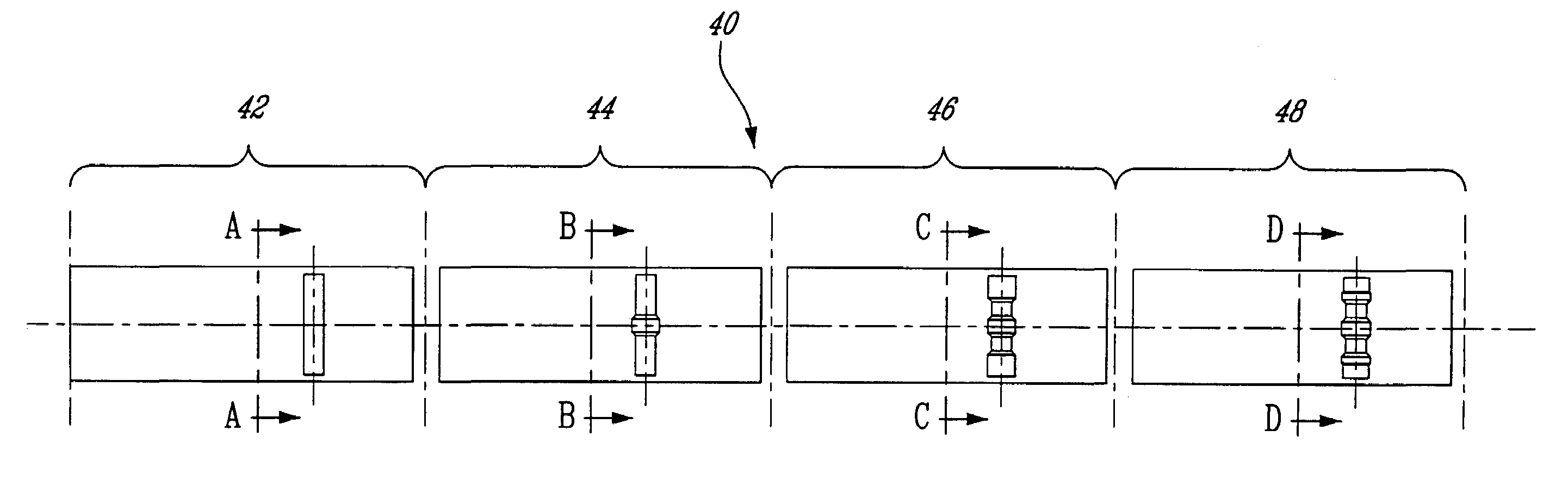

Method and apparatus for forming containers with corrugated material

ActiveUS20100263333A1Reduce manufacturing costEquivalent and good strengthMechanical working/deformationBoxes/cartons making machineryEngineeringCorrugated fiberboard

A case is disclosed that is made from a corrugated material and has a generally flat transversely extending base panel and first and second transversely extending, generally parallel, side wall panels upstanding from, and being oriented generally orthogonal to, the base panel. First and third end wall panels meet at a first vertically extending seam extending upwards from one end of the base panel and second and fourth end wall panels meet at a second vertically extending seam extending upwards from an opposite end of the base panel. A blank for forming such a case is also disclosed. A method comprises forming a sheet of corrugated fiberboard; operating a die cutting apparatus to form a generally flat case blank from the sheet of corrugated fiberboard at a first location; transporting the flat case blank to a second location; operating a case forming apparatus at the second location to fold the case blank to form the case; after the case has been formed by the case forming apparatus, operating a loading apparatus to load at least one item into the case; and sealing opposed top panels.

Owner:LANGEN H J PAUL

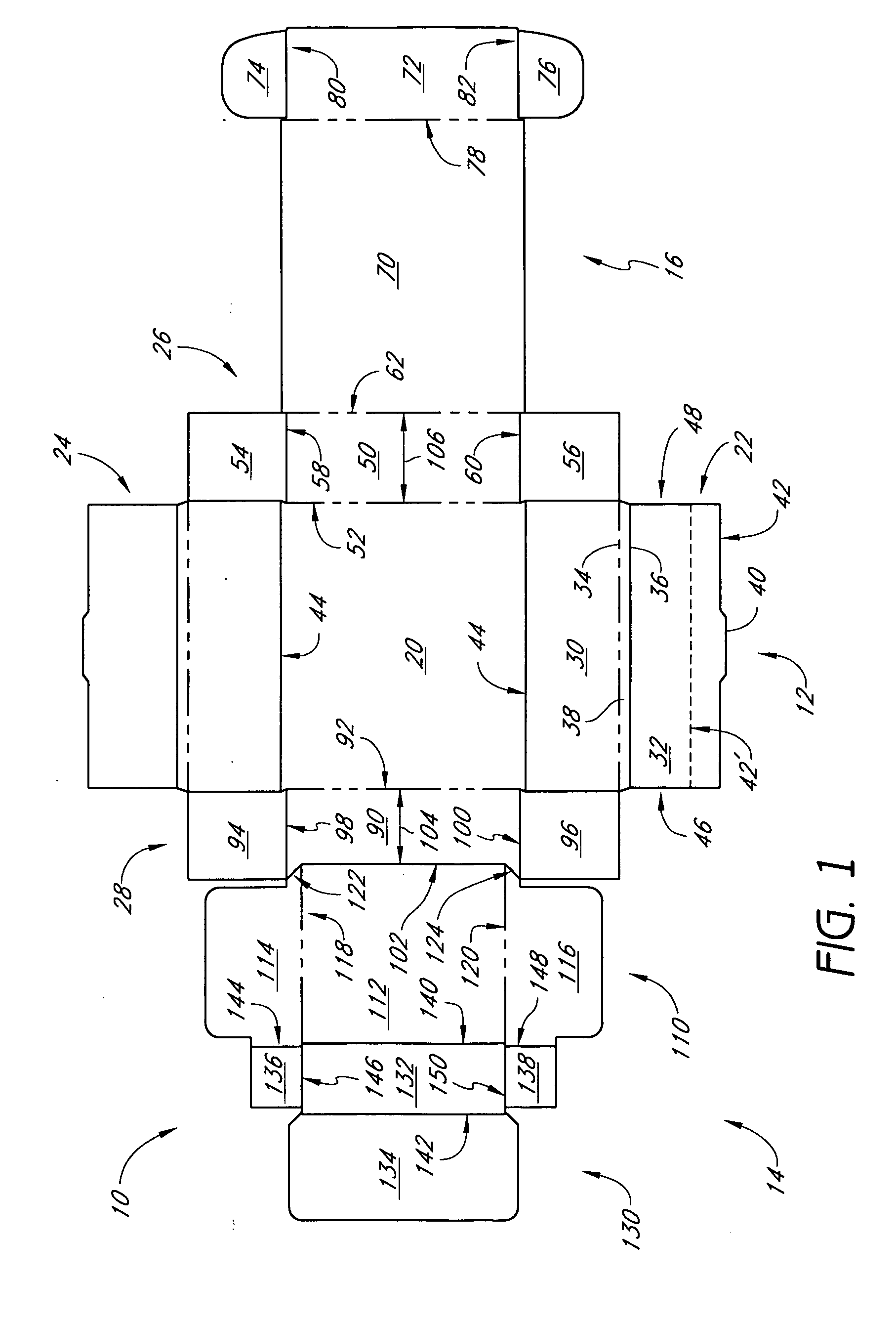

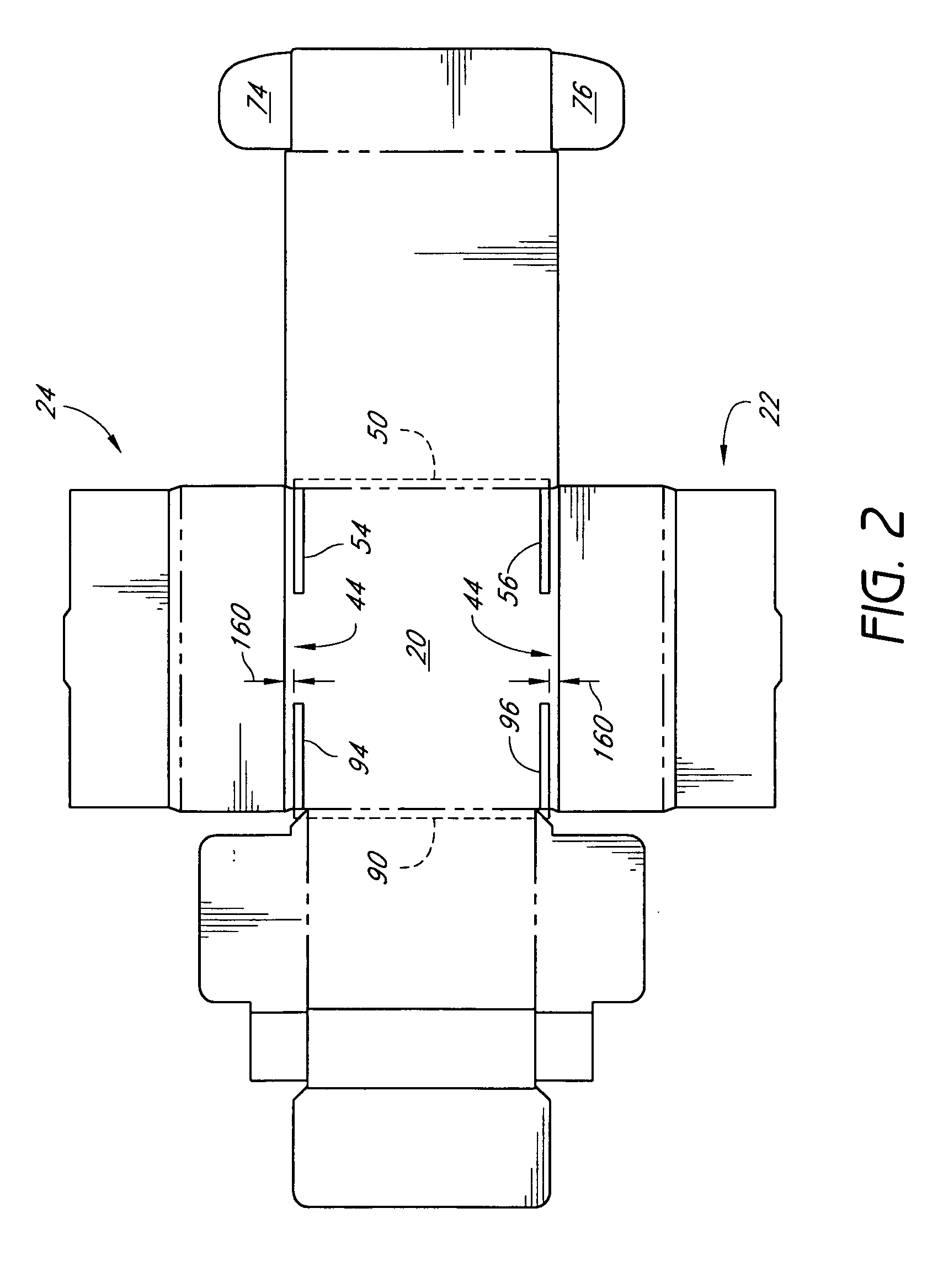

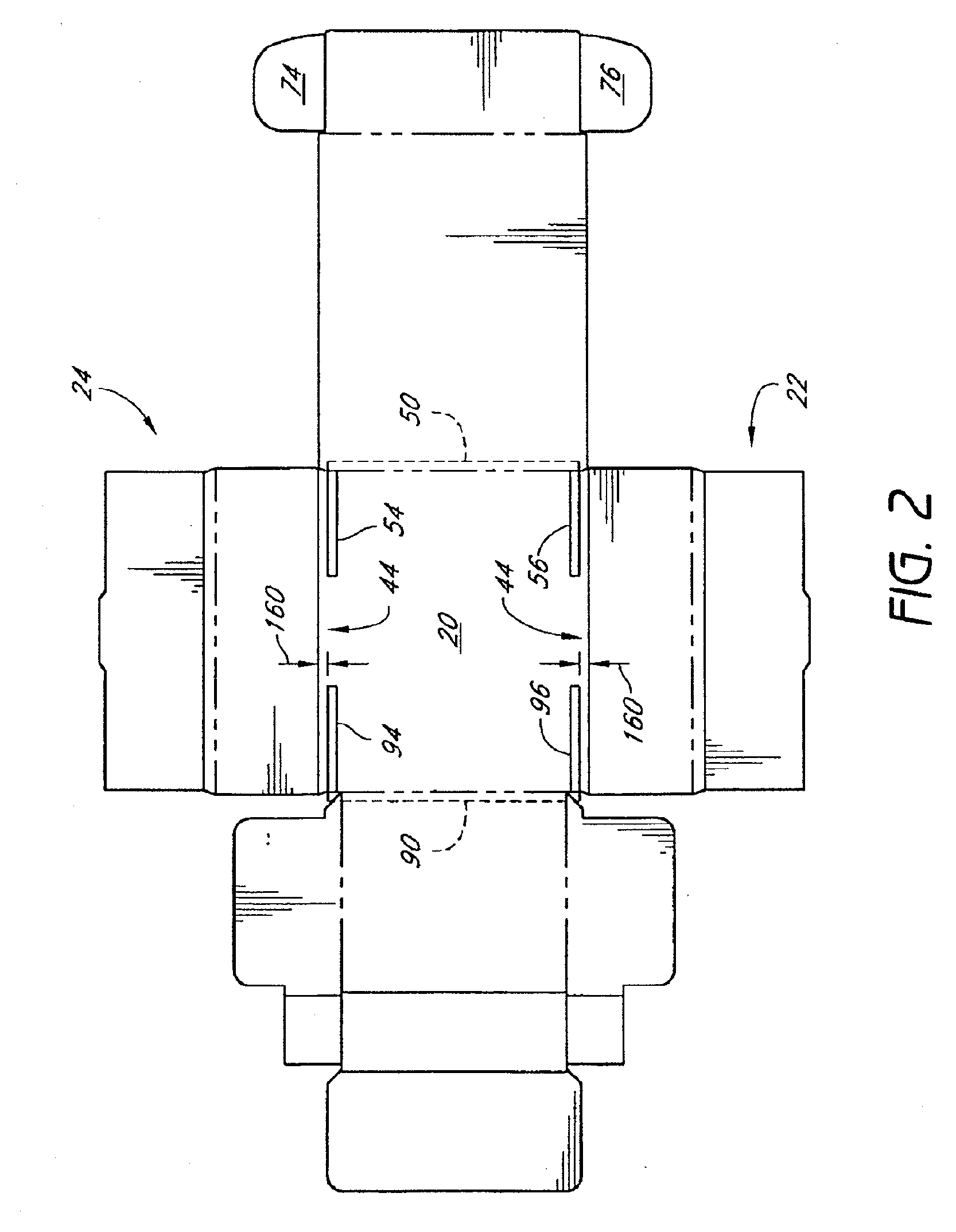

Integrated carton lid designs

Owner:WESTROCK SHARED SERVICES LLC

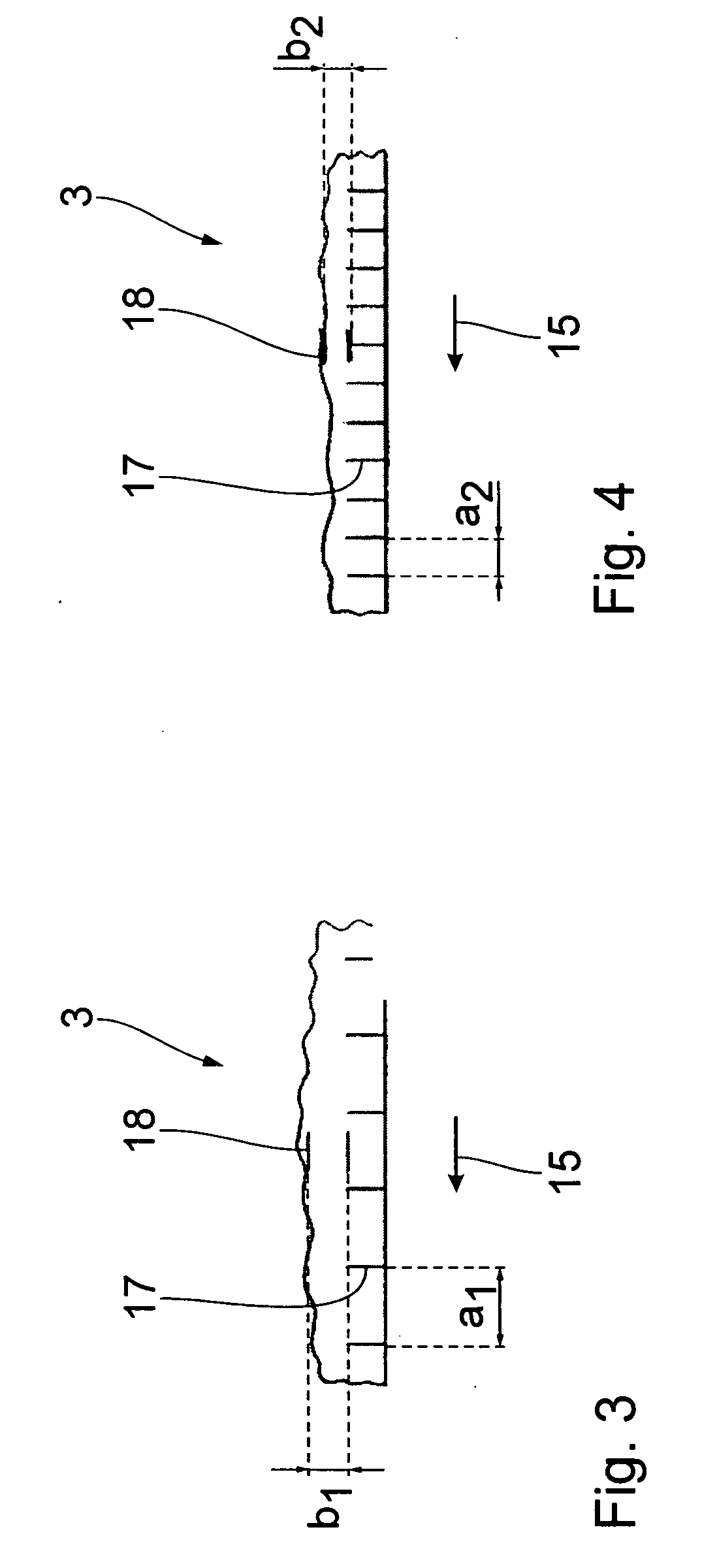

Method and adhesive applicator unit for continuous application of adhesive to webs

InactiveUS20040241328A1Accurate thicknessAccurate measurementMechanical working/deformationPretreated surfacesAdhesive cementEngineering

An adhesive applicator unit for a web of corrugated board comprises a frame which houses an adhesive applicator roll, and an adhesive pre-metering roll which is disposed underneath the applicator roll, and an adhesive re-metering roll which is disposed by the side of the applicator roll, each of which is rotatably drivably mounted. Formed between the adhesive pre-metering roll and the adhesive applicator roll is an adhesive pre-metering nip where pre-metering of the adhesive takes place. Between the adhesive applicator roll and the adhesive re-metering roll, provision is made for an adhesive re-metering nip where final re-metering and calibration of the adhesive film takes place.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

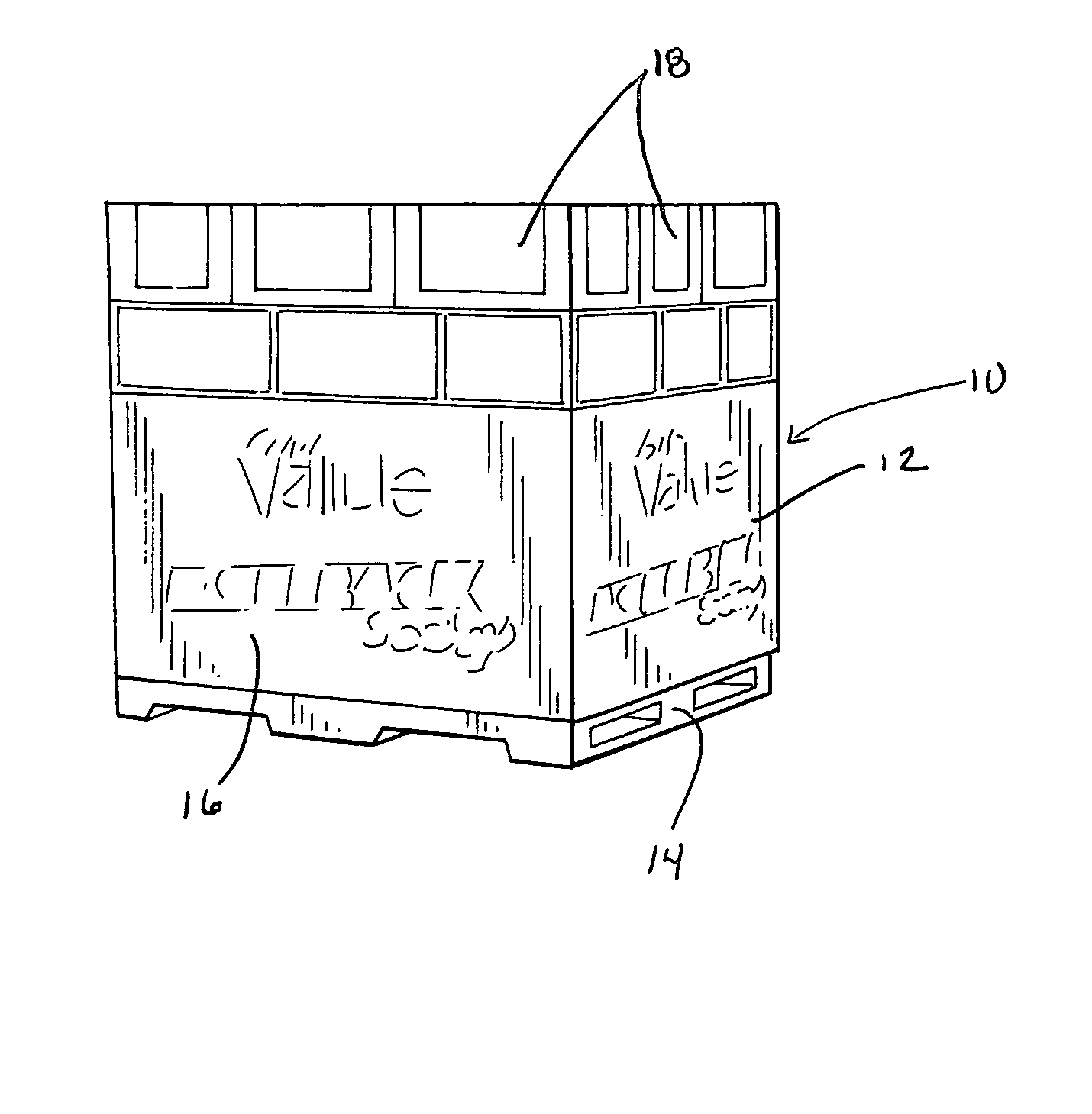

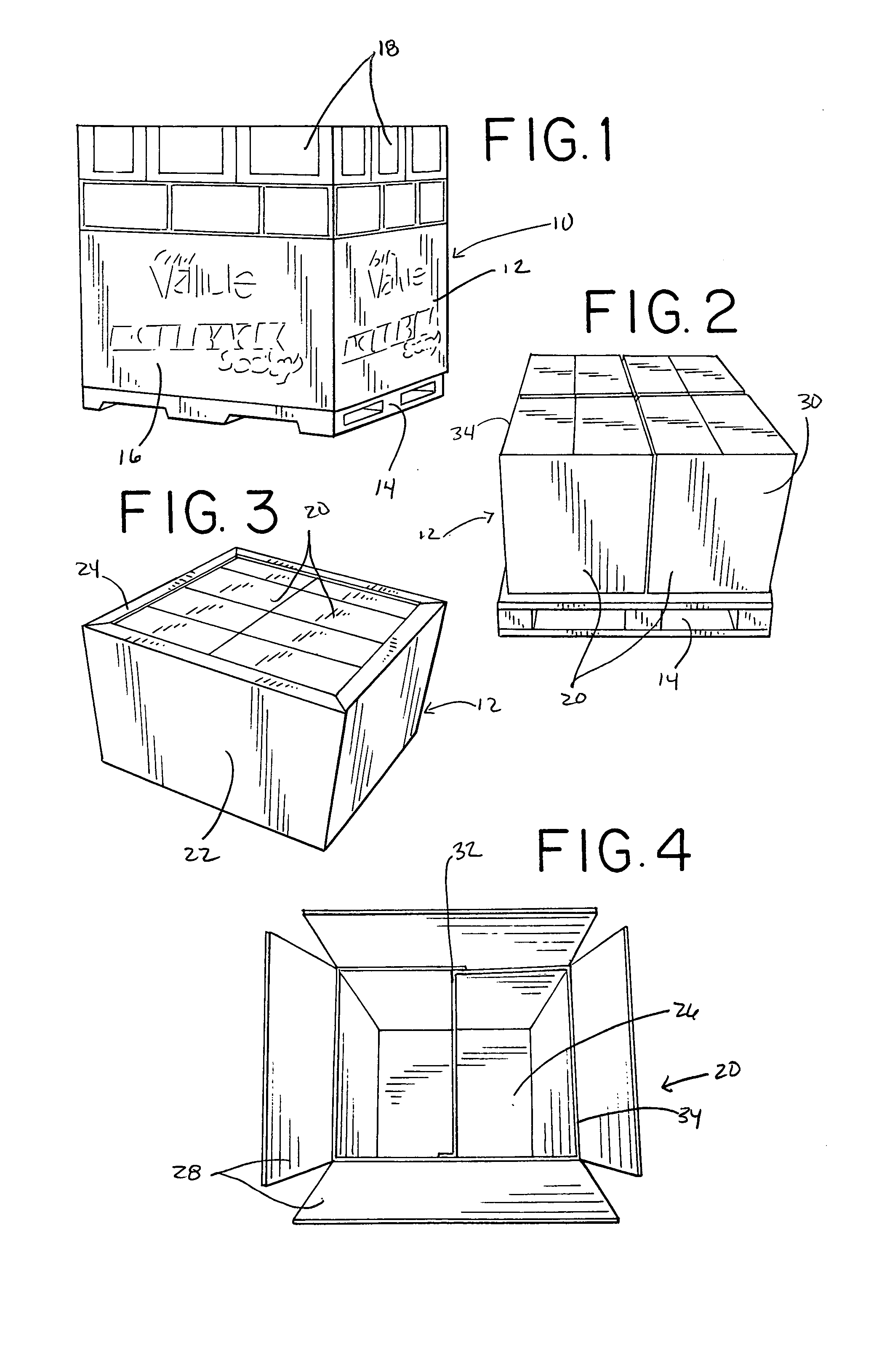

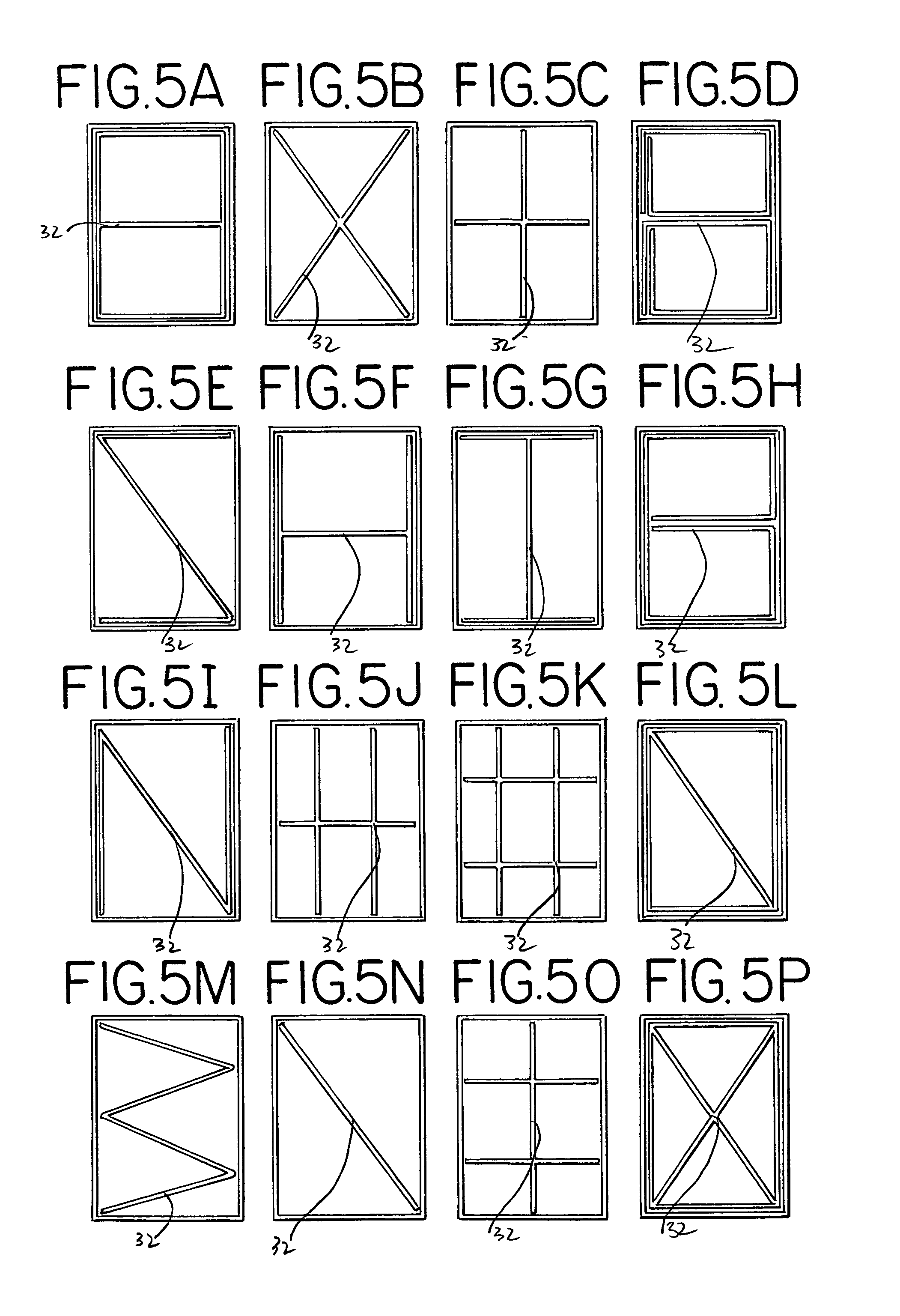

Shipping and display system

A light-weight, disposable and re-cycleable base for shipping and displaying multiple product packaging units, and which may be capable of supporting relatively heavy product loads. Several corrugated fiberboard support units having an internal brace element may be secured to each other to create a base. The base is placed upon a pallet and one or more layers of product cases containing the product to be shipped and displayed are placed on top of the base. Advertising graphics advertising the product to be displayed and sold may be placed on the exterior of the base or on a sleeve or wrap secured to the base for that purpose. The base and products may be secured together by for shipping. The entire system may be loaded by forklift into a standard trailer and a second unit may be loaded directly on top of the first unit. The units may be shipped to the end user, unloaded and placed directly on a sales floor display and sale of the products.

Owner:SCHREIBER FOODS ENG

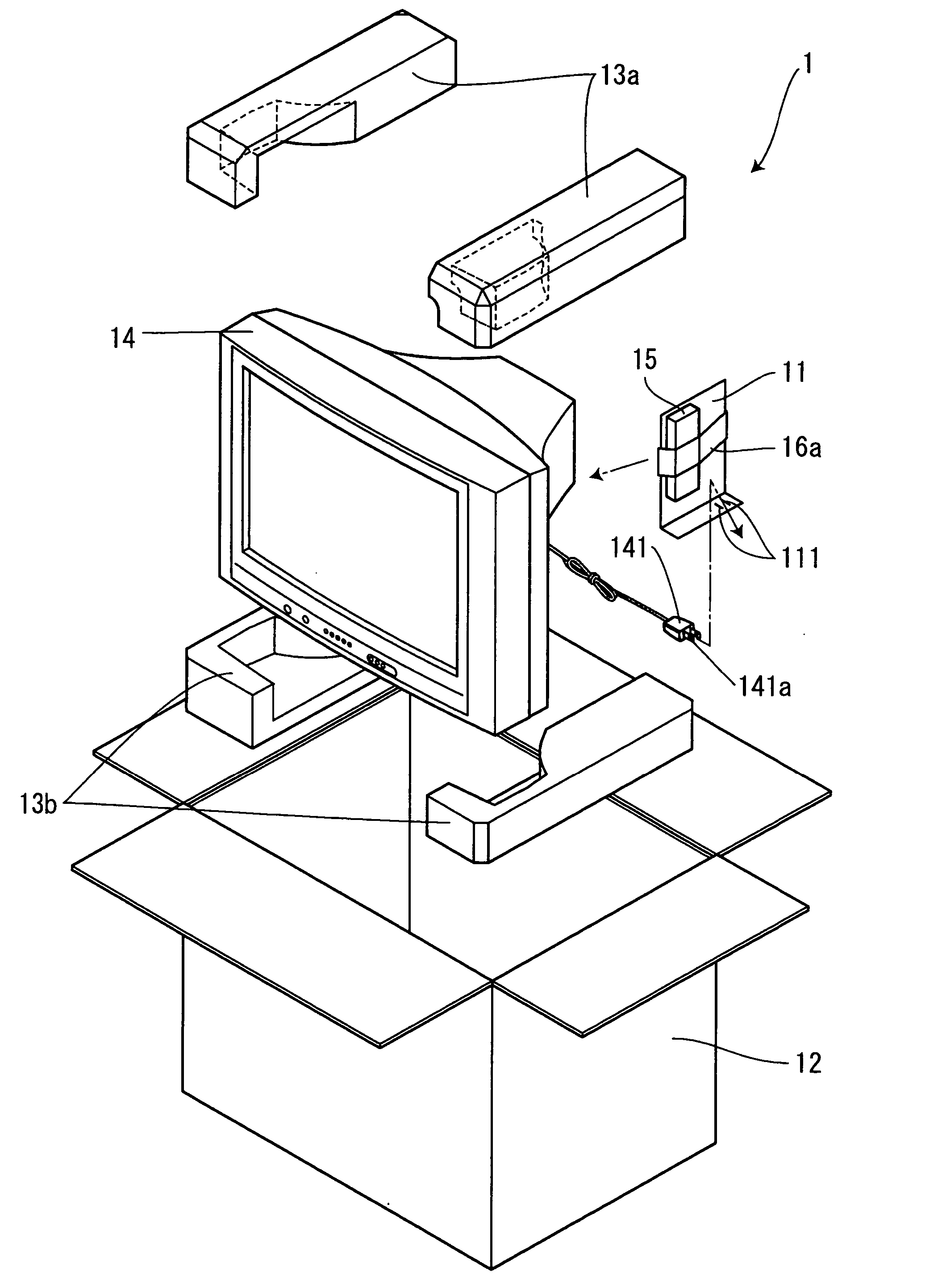

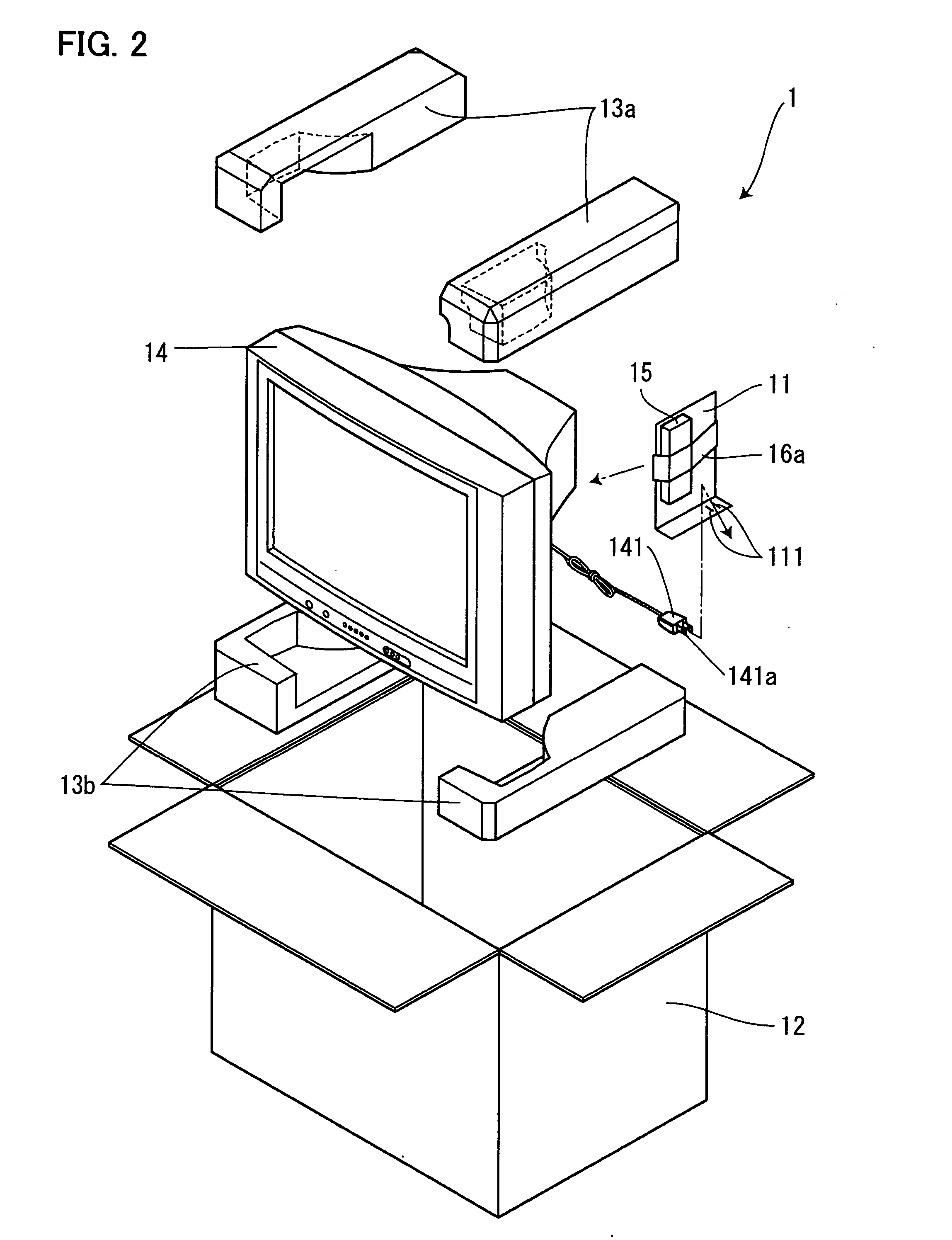

Package for electric apparatus

InactiveUS20060113214A1Efficiently housedAvoid contactOther accessoriesContainer/bottle contructionElectrical devicesEngineering

To provide a package for an electric apparatus which allows a power cord to be efficiently housed when an electric apparatus is packed and which enables the power supply cord to be appropriately held in a packaging box. A power supply plug holding member 50 is formed by creating a cut-in portion 52 through which a power supply plug 611 is inserted, in a foldable packaging material such as a corrugated fiberboard and then folding the packaging material into a general U shape. The power supply plug 611 of an electric apparatus 61 is locked in the cut-in portion 52 in the power supply plug holding member 50, which is then housed between a packaging box 62 and the electric apparatus 61.

Owner:ORION ELECTRIC CO LTD

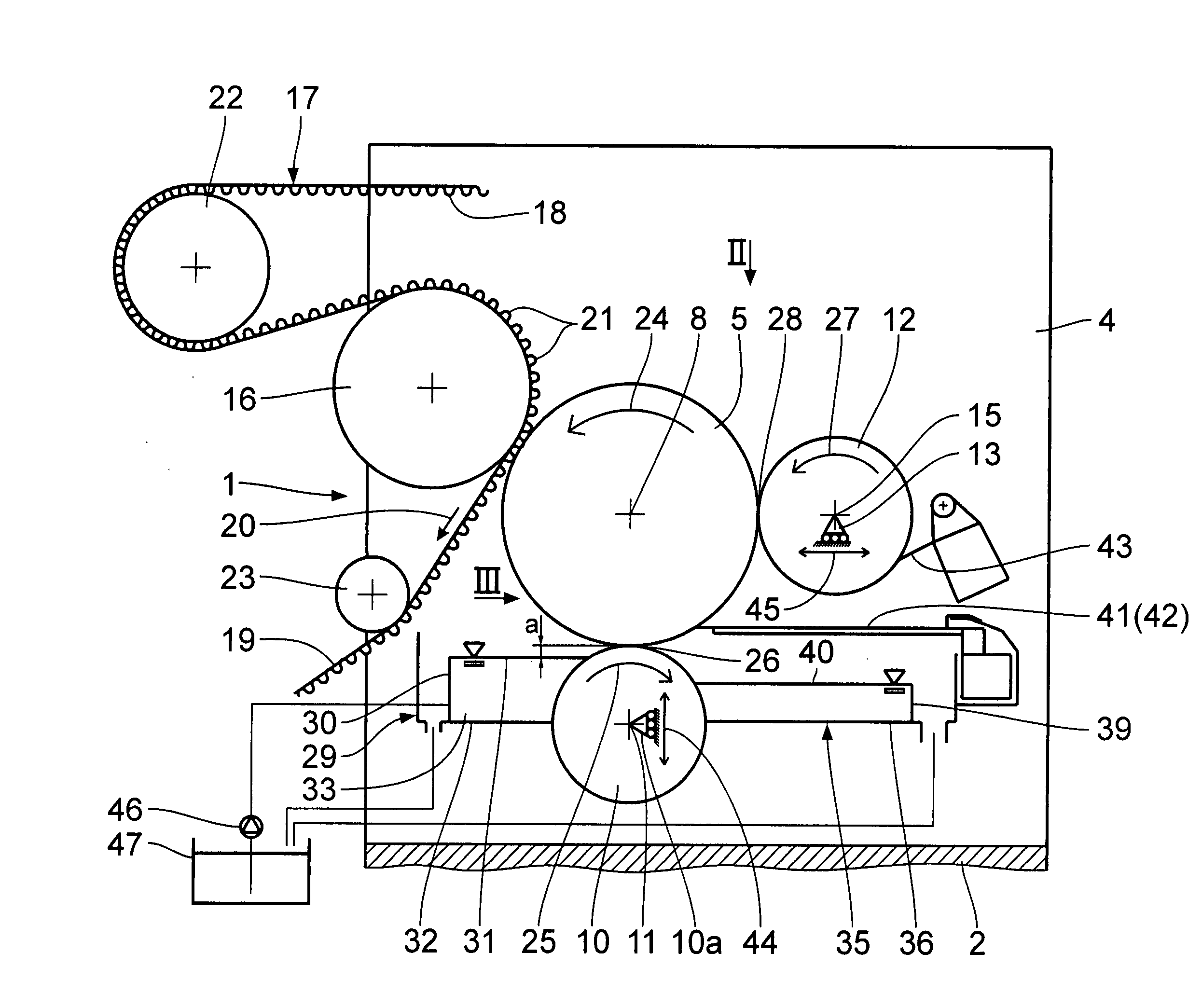

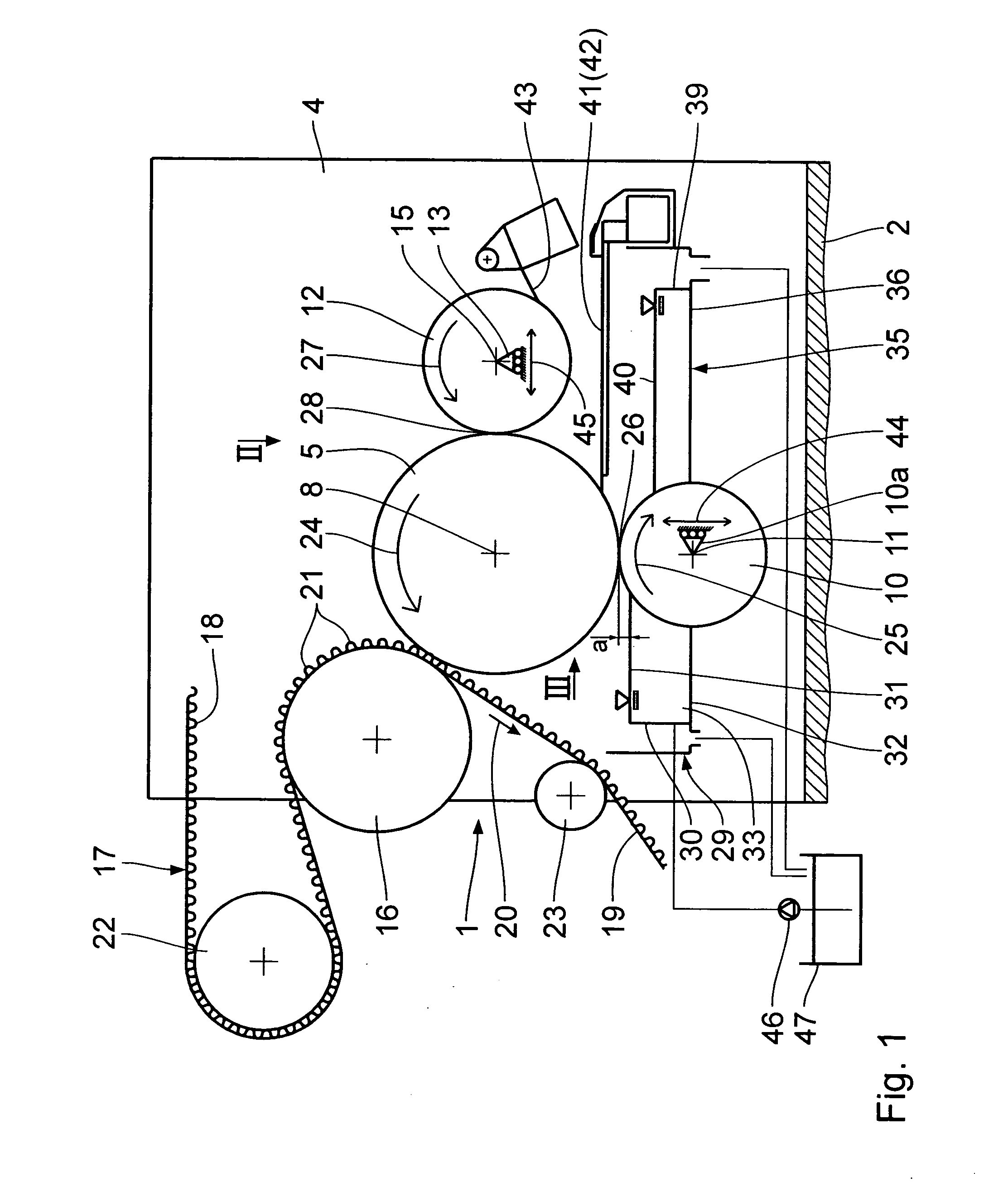

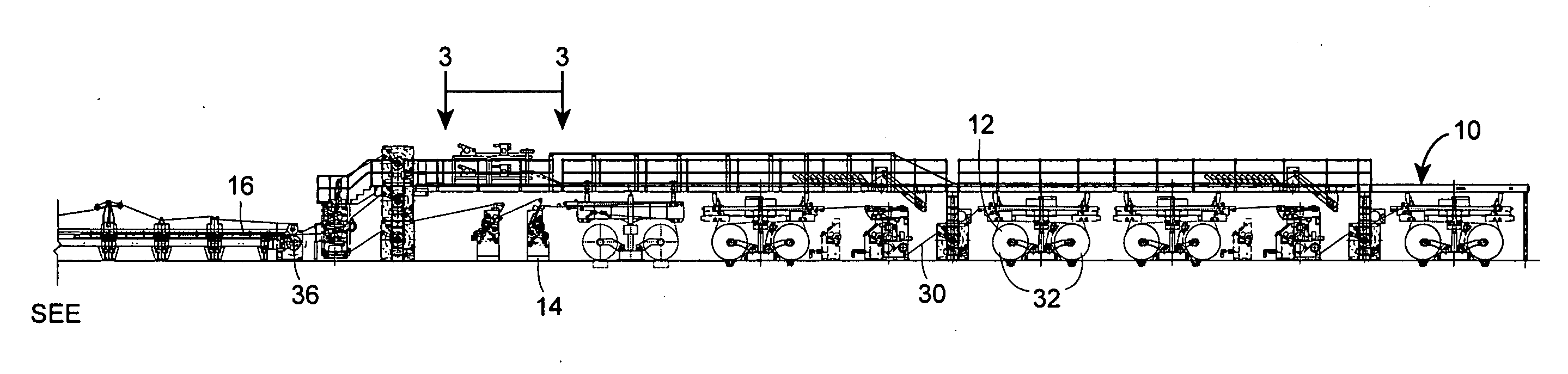

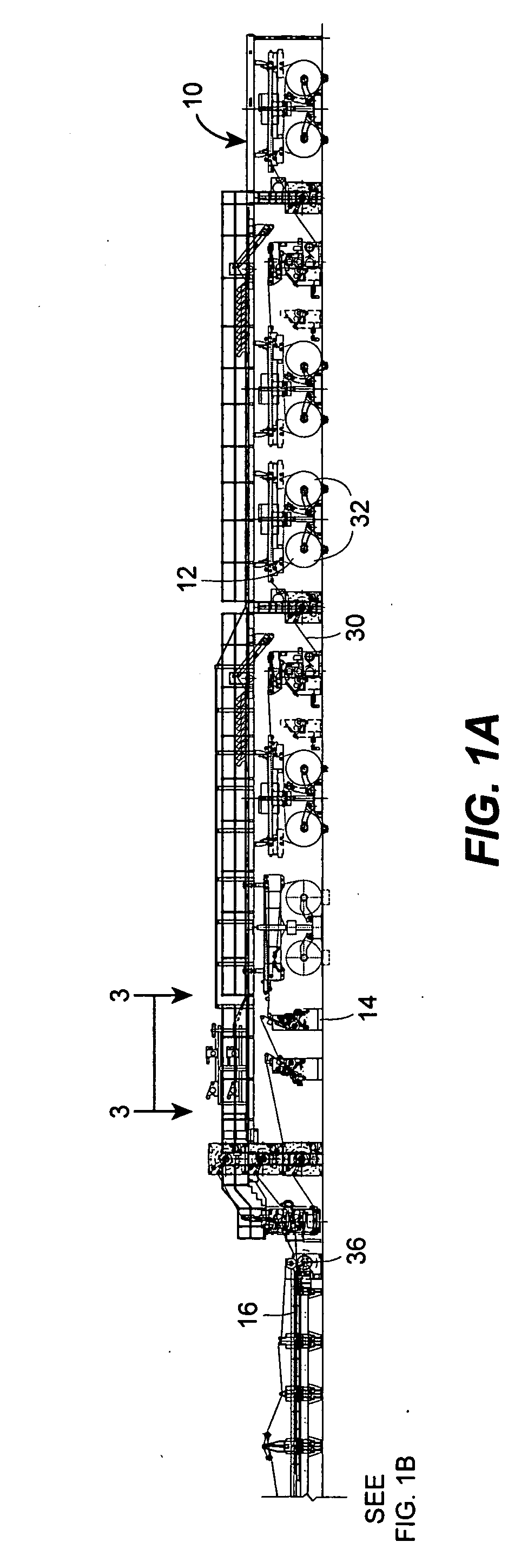

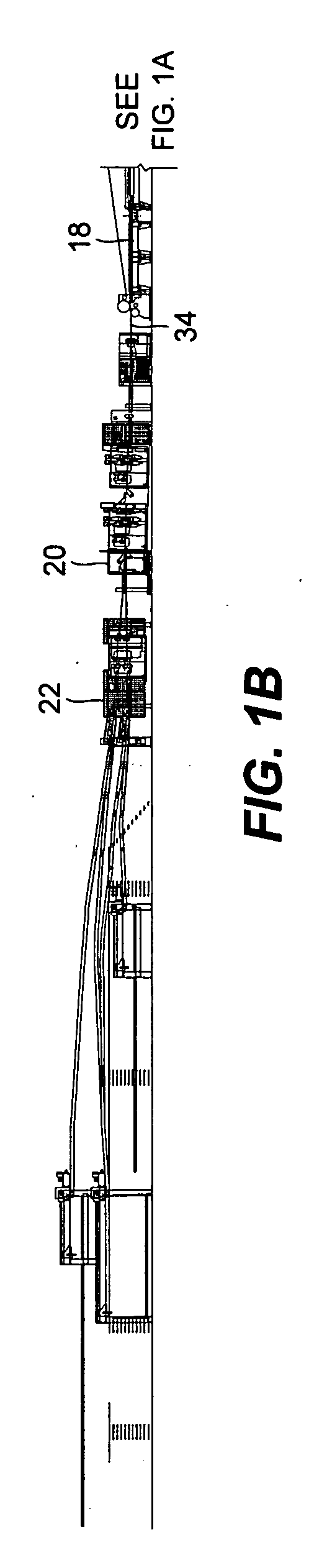

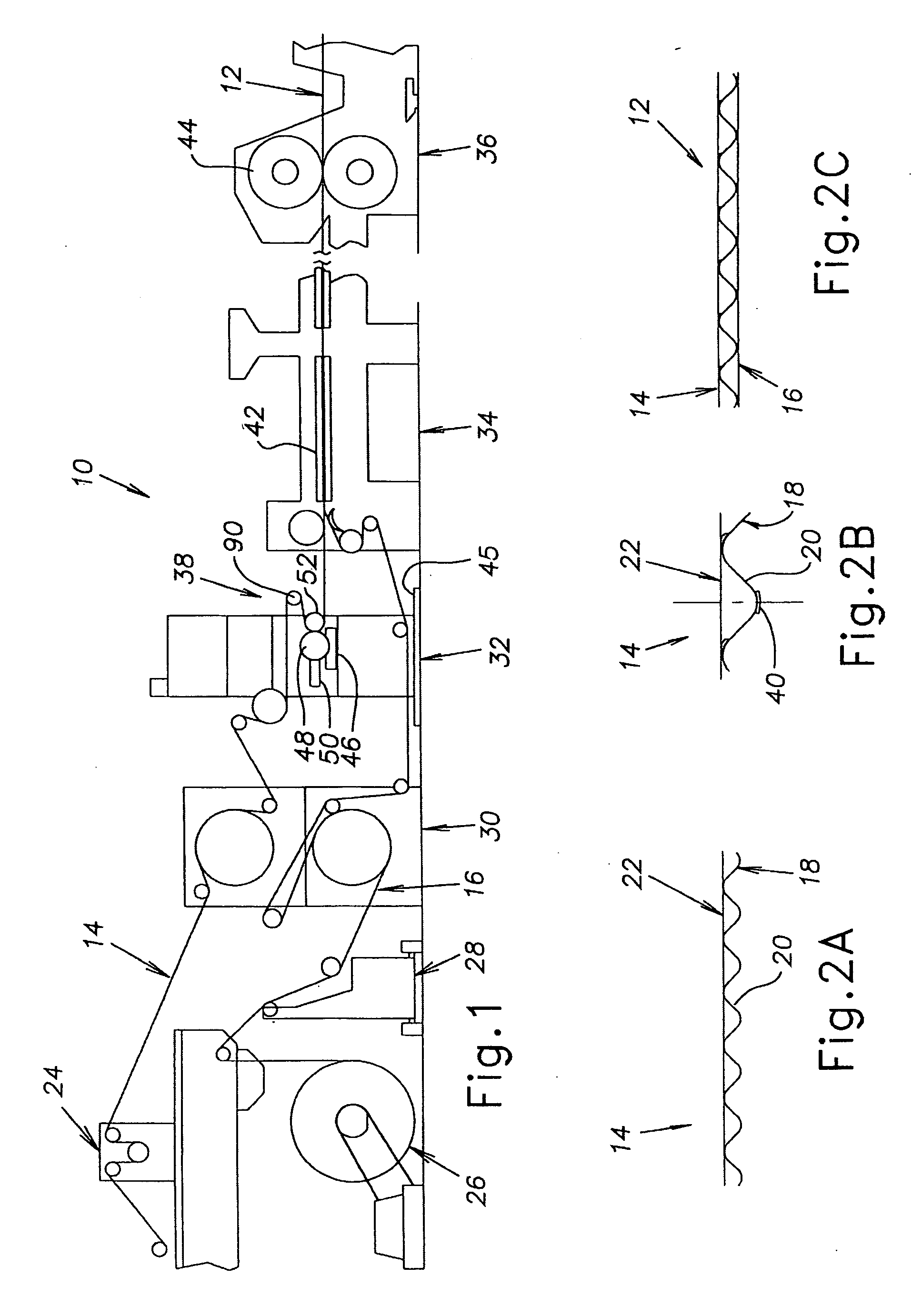

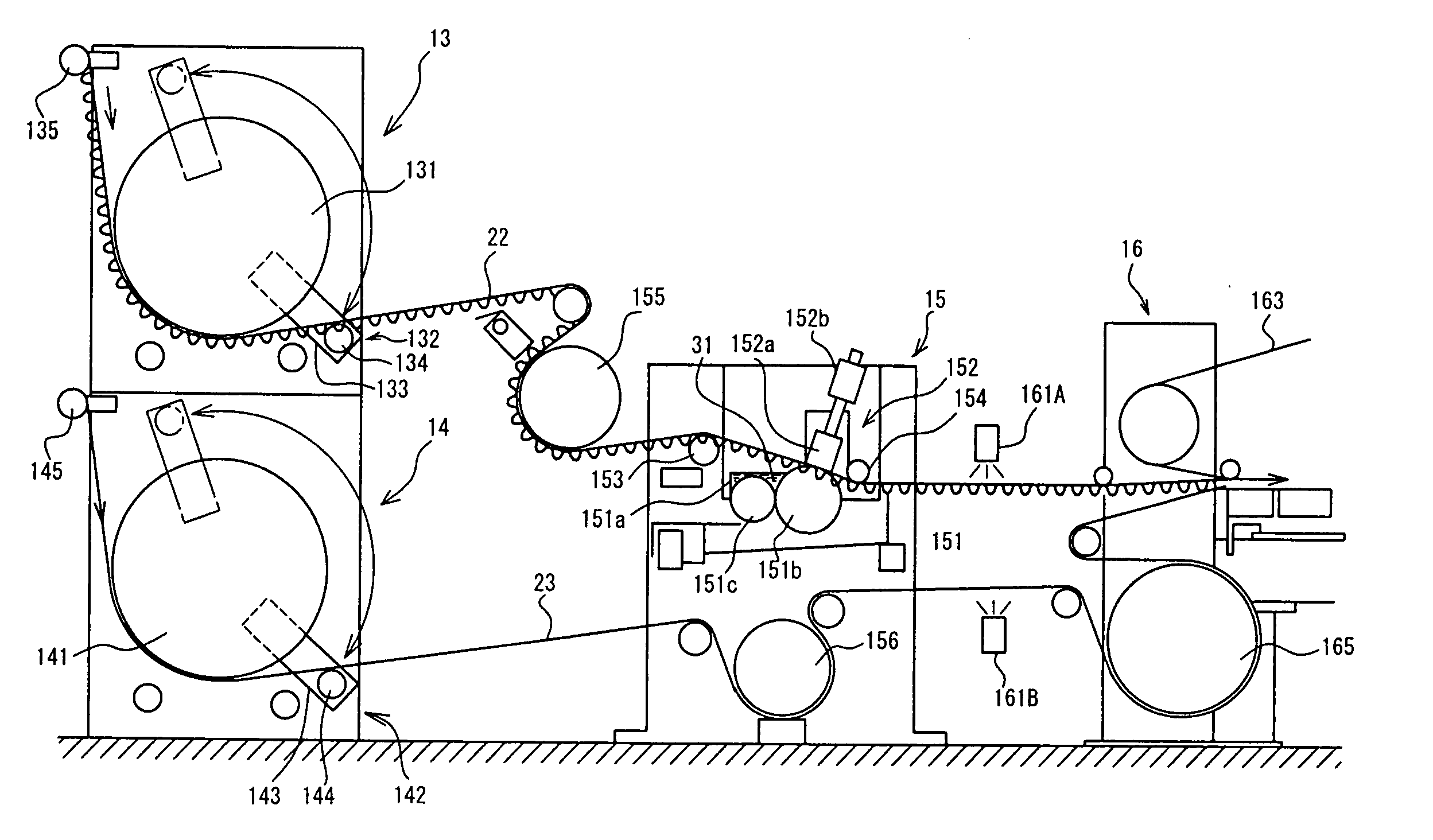

Manufacturing line for making corrugated cardboard

A manufacturing line for making corrugated paper has both a conventional feed stock location where stock is fed to the line and a gluing station where the stock is connected to the corrugated medium. The line includes multiple in-line printers that are positioned between the feed stock location and the gluing station. One printer can be used to print a first color or coating on a first portion of the stock, and another printer can be used to print a second color on a second portion of the stock. A center trim pickup can be used to divide the paper stock between the two portions.

Owner:CORRUGATED SUPPLIES CORP

Collapsible containers

A system whereby a collapsible box may be formed in the same way that standard cardboard boxes are made by folding a single sheet of material is provided. Square and rectangular boxes may be constructed which may be collapsed down to compact size and easily popped open. Boxes so constructed remain fully assembled with all seams and edges attached even as they are repeatedly folded and unfolded. The box may be made of corrugated cardboard or plastic and easily folded to a fraction of their open volume. The box may open instantly, and when opened, it becomes structural—that is resistant to applied loads—by “popping” certain points outwards. An element or construction that is comprised of a sheet of material that has been provided with a network of hinges such that when the element is folded its edges maintain a right angle relationship is also provided.

Owner:HOBERMAN CHARLES

Multi-ply collapsible bulk container

A bulk container is disclosed, having a plurality of substantially planar walls, a plurality of corners connecting the walls, and a top and a bottom both formed by a plurality of foldable flaps. A first corner and a second corner opposite the first corner each have two substantially parallel score lines on an inner side of each corner allowing the corners to fold at an angle of substantially 0° while maintaining the structural integrity of the container. The walls of the container are constructed from a multi-ply corrugated cardboard sleeve made up of two layers of multi-ply corrugated cardboard laminated to each other. Two corrugated cardboard inserts, each having foldable top and bottom flaps are laminated to the sleeve. Also disclosed is a method of manufacturing the container using a number of blanks and inserts.

Owner:MENASHA

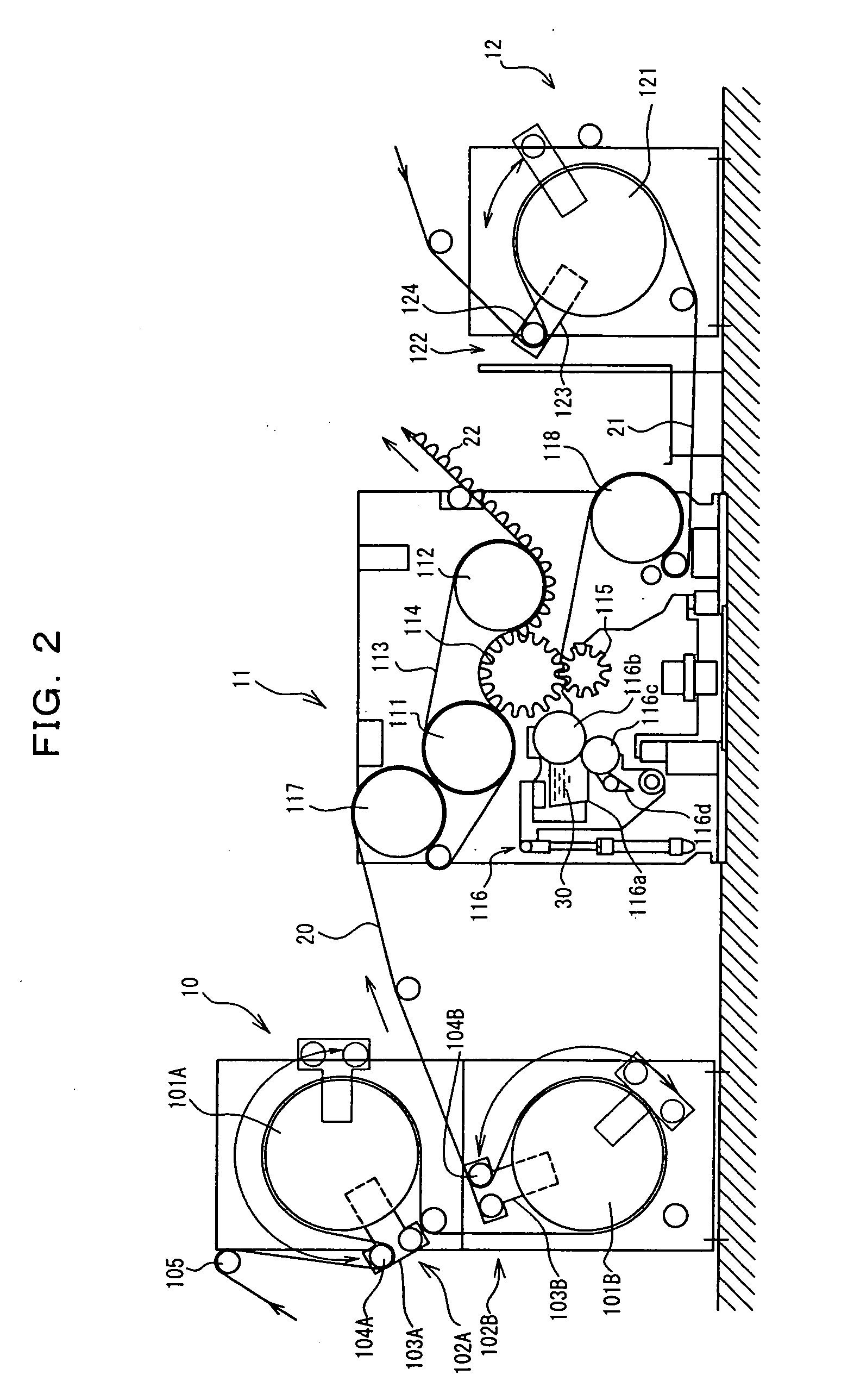

Single facer with angled medium feeding

The present invention relates to a single facer, which comprises a humidifying and heating unit placed on the upstream side of an air pressurization corrugating mechanism for humidifying and heating a corrugating medium and a feed mechanism for supplying the corrugating medium, processed by the humidifying and heating unit, to the air pressurization corrugating mechanism at a given speed. The corrugating medium is supplied at the given speed after the humidification and heating process for the corrugating medium, so that an air pressure to be taken at the corrugation is reducible and a predetermined flute configuration is maintainable. In addition, the spring back of the corrugating medium hardly occurs, which makes it possible to manufacture a corrugated fiberboard sheet with a high shock absorbing ability.

Owner:MITSUBISHI HEAVY IND LTD

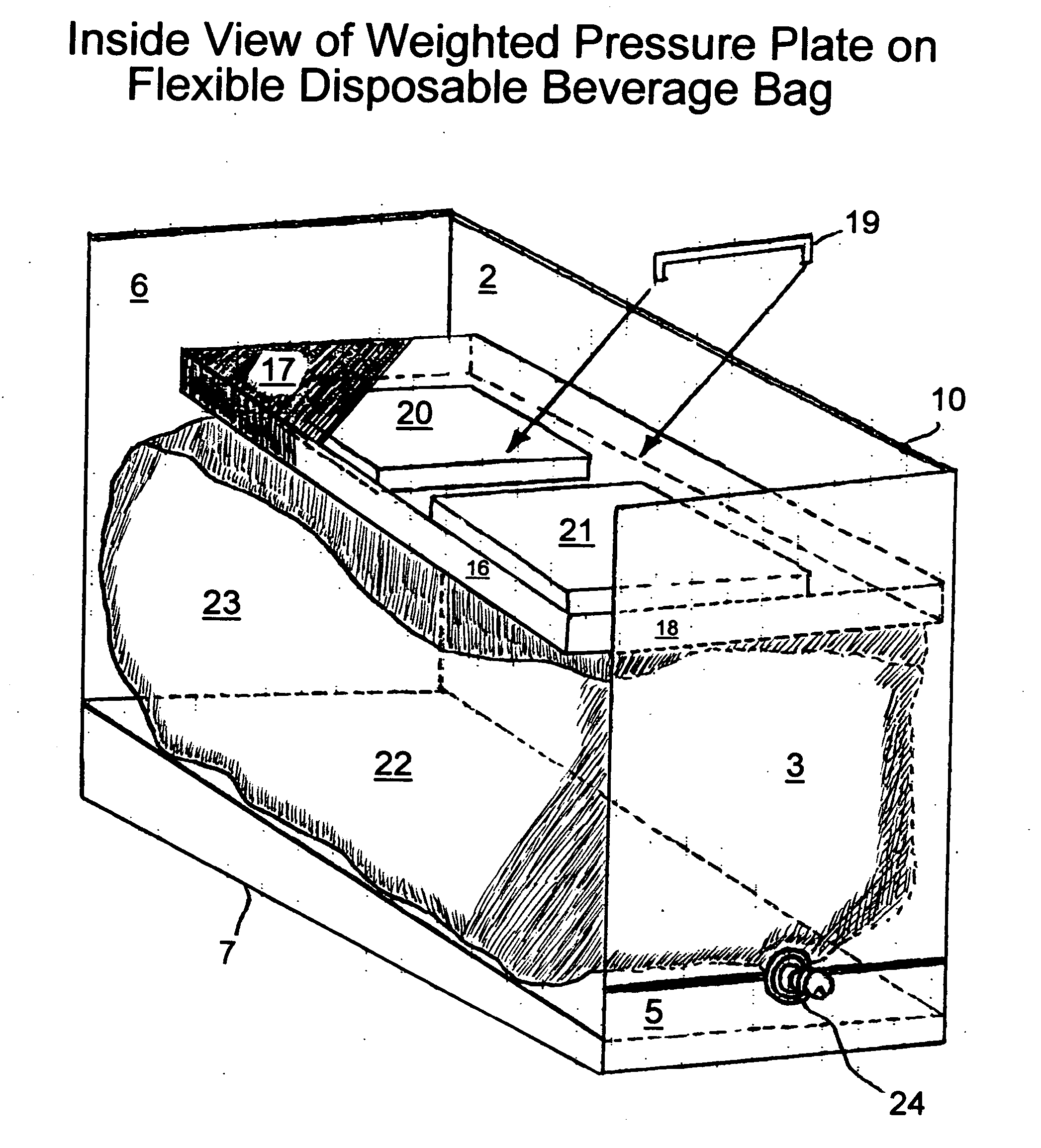

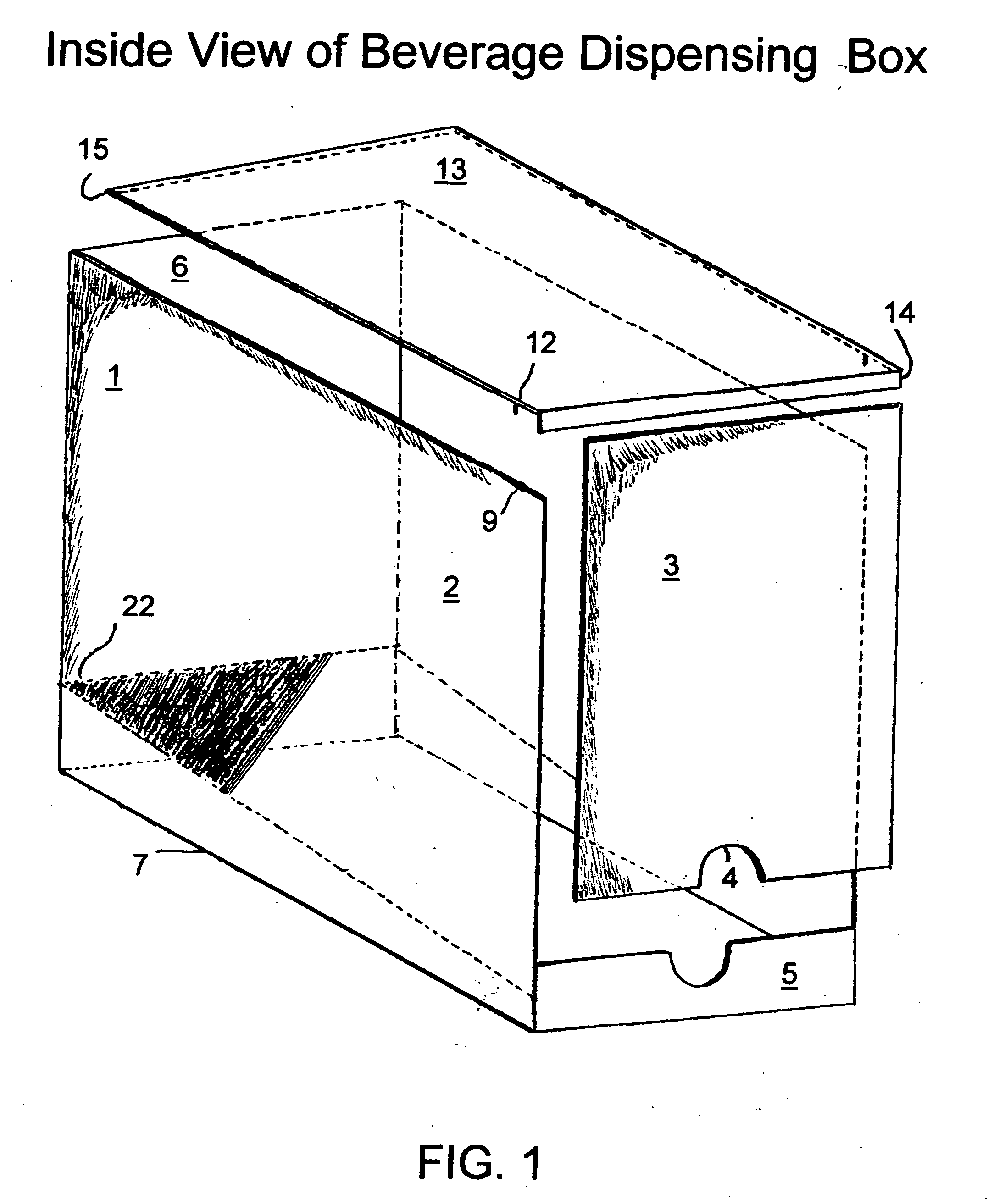

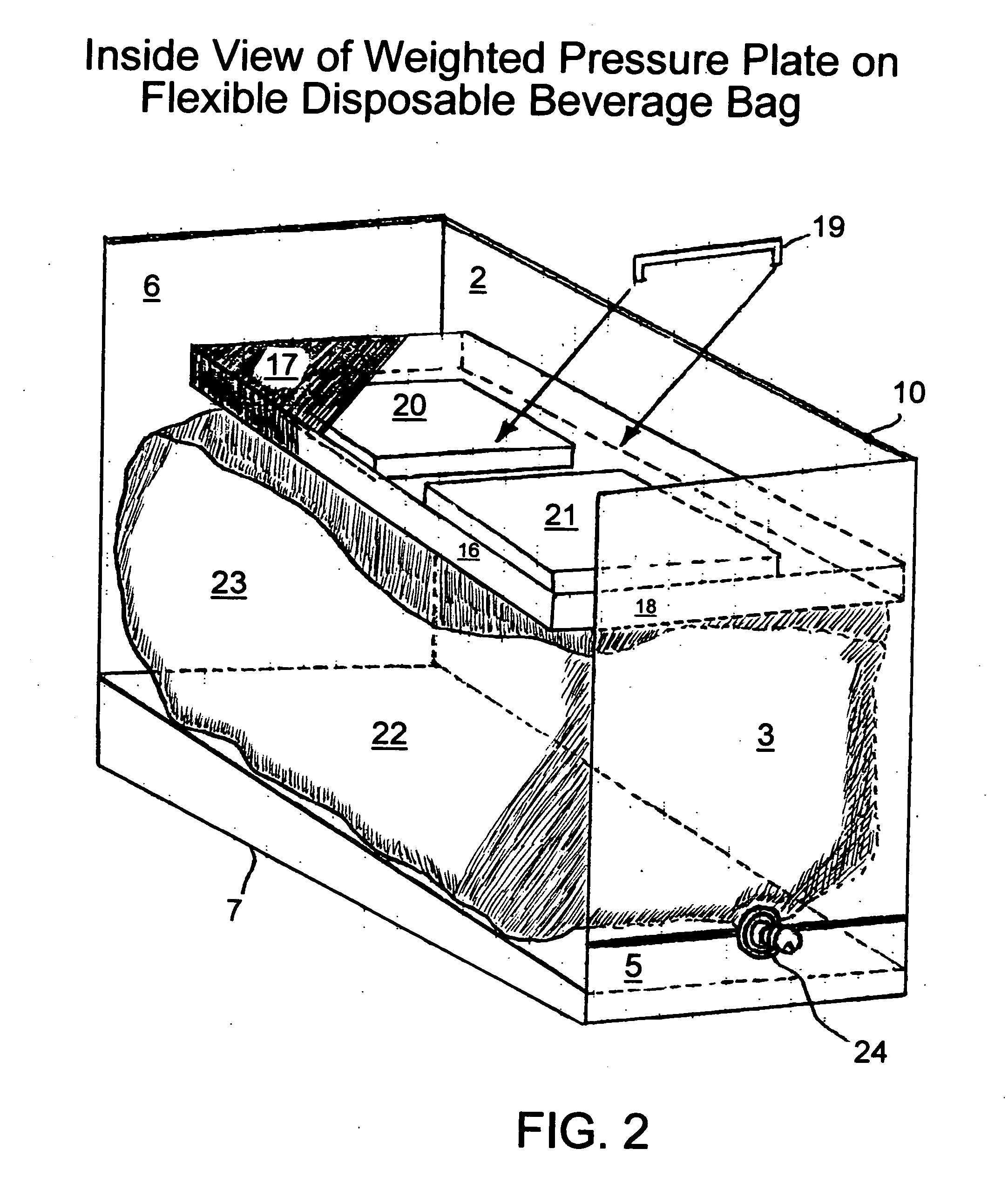

Beverage dispensing box for office and kitchen counters

The Beverage Dispensing Box for Office and Kitchen Counters is intended to hold a flexible disposable beverage bag filled with a potable liquid and dispense that liquid under pressure when the spigot is opened. The Beverage Dispensing Box is unique in that it employs the law of gravity. Through the use of a sloped container floor and a weighted pressure plate, a natural force (non-mechanical or electrical) is applied to the flexible disposable beverage bag, thus causing the potable liquid to flow from the bag under pressure at a greater gallon per minute (GPM) rate than that of a typical un-pressurized flexible disposable beverage bag—commonly found in corrugated cardboard boxes such as the Wine-in-a-Box container; and at a greater GPM rate than that of a typical 2.5 or 5 gallon bottled water dispensing apparatus. The Beverage Dispensing Box is designed to sit on office, kitchen or other countertops where no electricity is required for use. The Beverage Dispensing Box is a durable reusable container that will positively impact the environment because it will be manufactured from recycled plastic and metals; and will displace the need for disposable plastic bottles, such as bottled water.

Owner:MANION RANDOLPH THOMAS

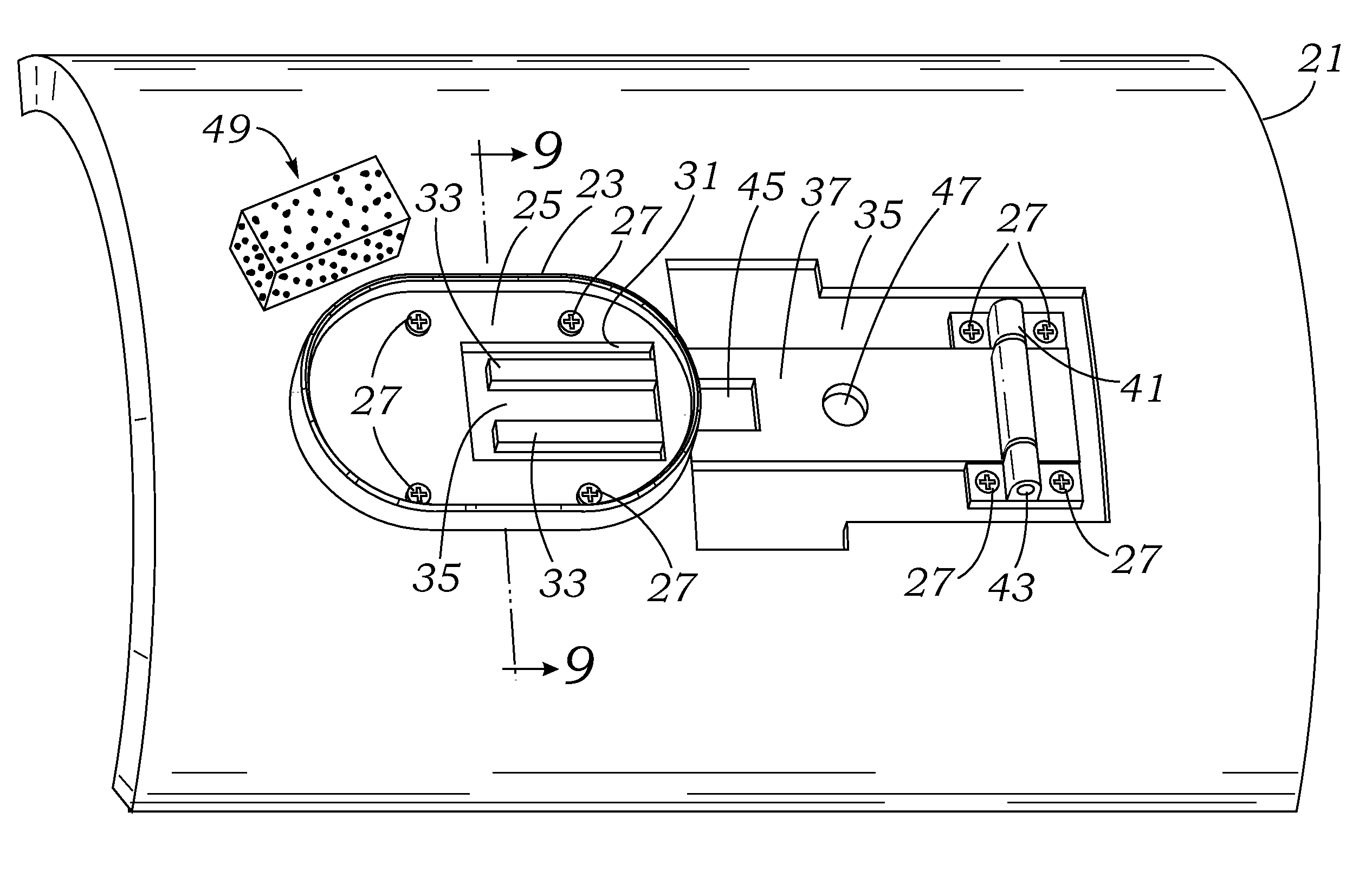

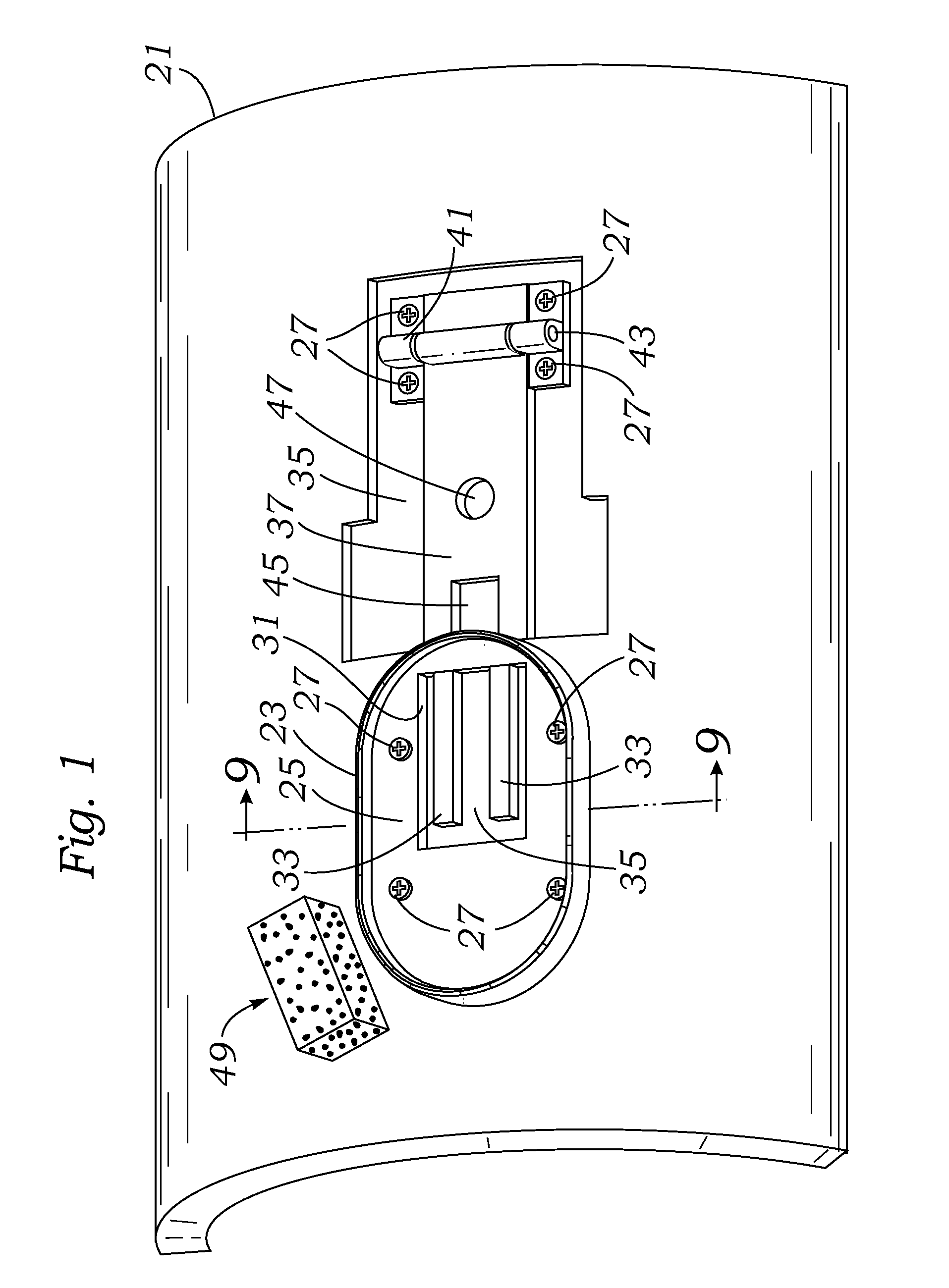

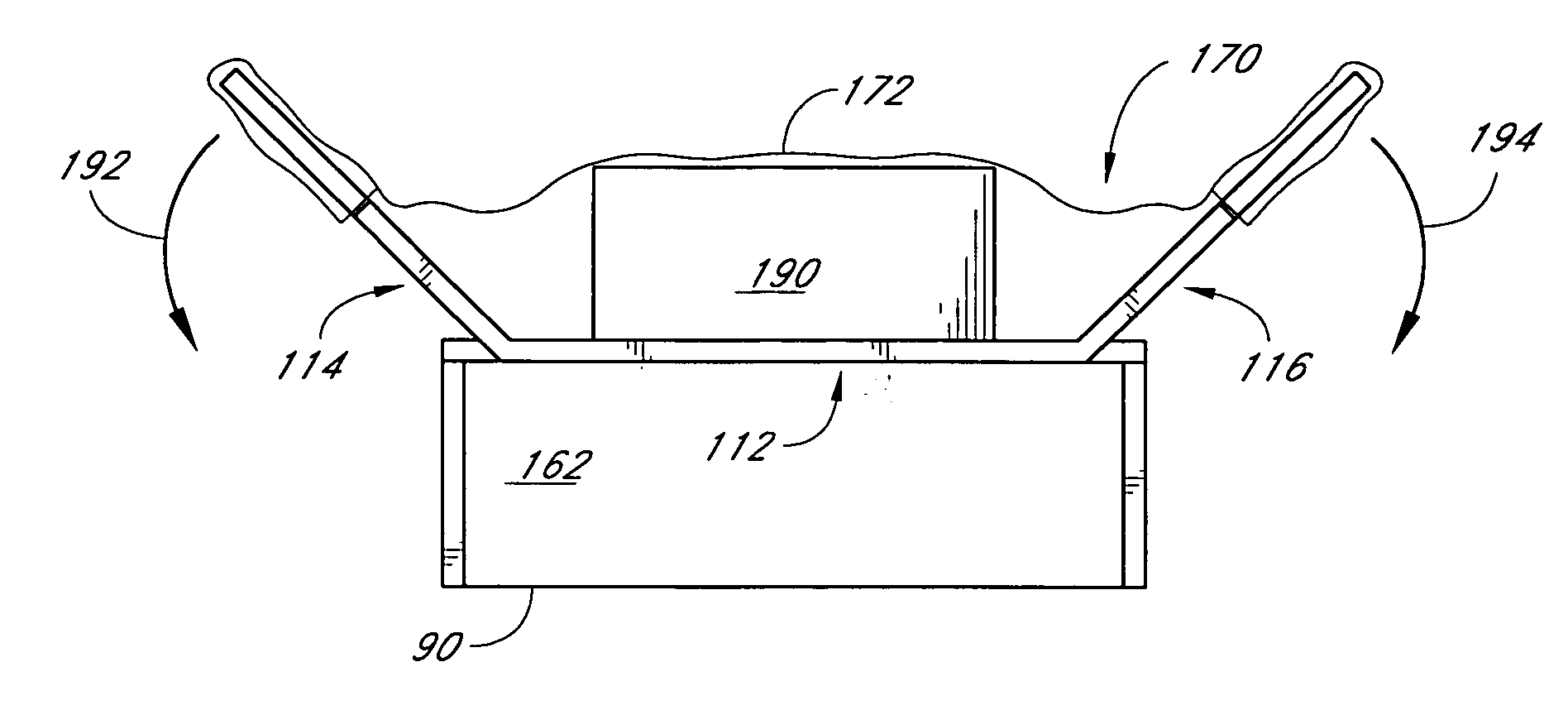

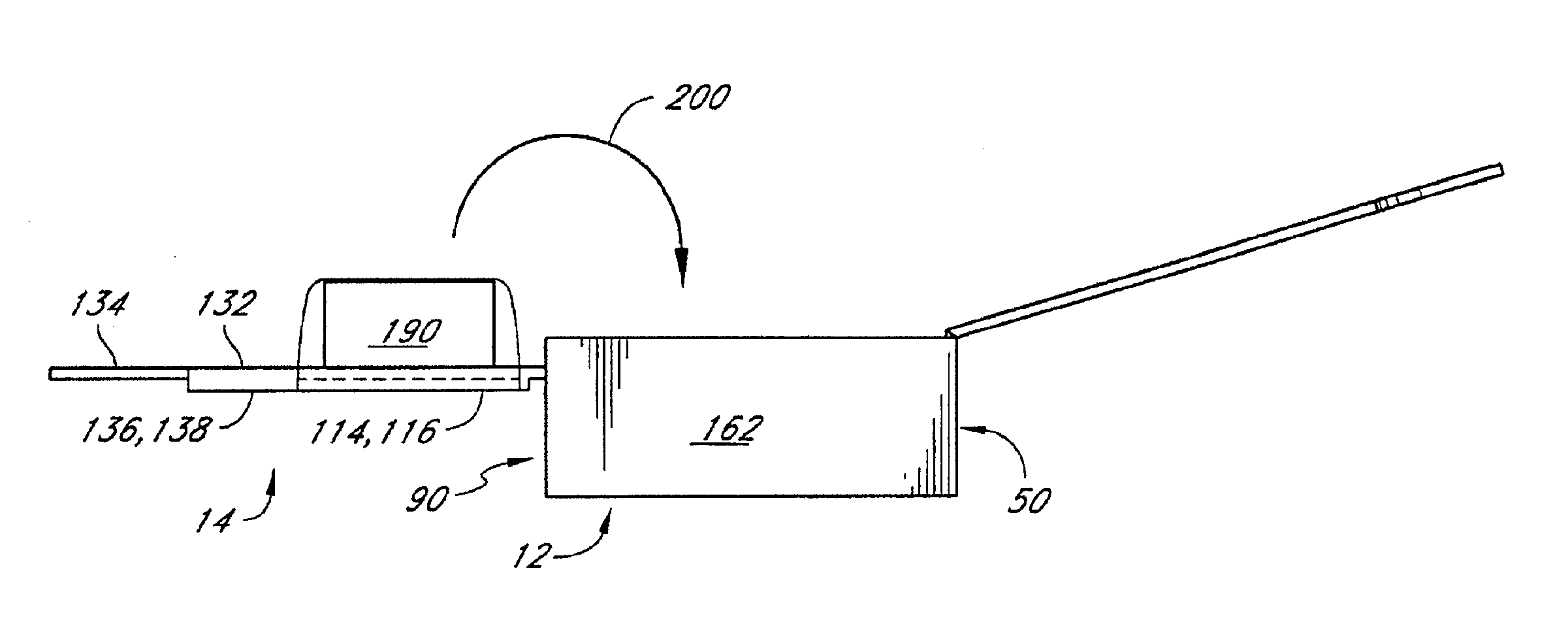

Suspension packaging system

InactiveUS20080067103A1Easy to storeSimplifying transportationContainers to prevent mechanical damageRigid containersCardboardBiomedical engineering

A suspension packaging system can include a foldable member configured to form a cavity as well as a suspension device for suspending an article to be packaged within the cavity. The suspension portion can include foldable portions configured to cooperate with a retention member having pockets. The foldable portions can fit into the pockets and then be folded so as to generate tension in the retention member. The entire device, with the exception of the retention member, can be made from a single piece of material, such as corrugated cardboard, which thus reduces waste and simplifies bulk distribution of such a suspension packaging system.

Owner:CLEARPAK

Method for producing corrugated cardboard

ActiveUS20070098887A1Uniformly and accurately applyingIncrease line speedMechanical working/deformationPretreated surfacesCardboardAdhesive

A method is provided for applying adhesive to the flutes of a corrugated sheet web. An applicator roll is provided with a uniform thin coating of adhesive by a metering rod. Exposed crests of the flutes are brought into contact with a coating of adhesive that has been applied to a surface of an applicator roll in order to provide a uniform bead of adhesive on the flute crests. The flutes are compressed against the applicator roll surface in a forward direction relative to the direction in which the web is moving adjacent the applicator roll surface. In one embodiment, the applicator roll has a surface linear velocity greater than the speed at which the web is traveling.

Owner:INTPRO LLC

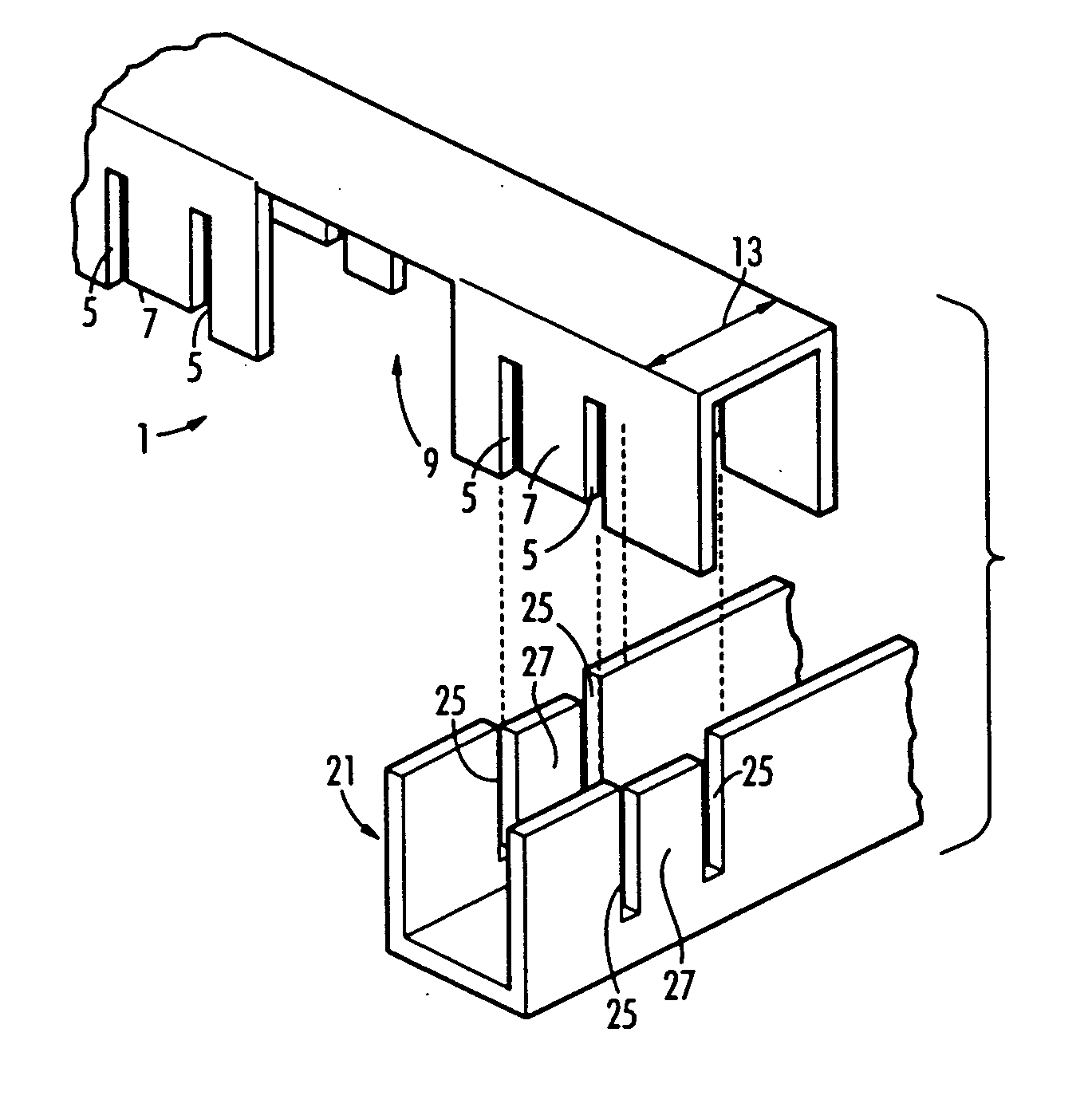

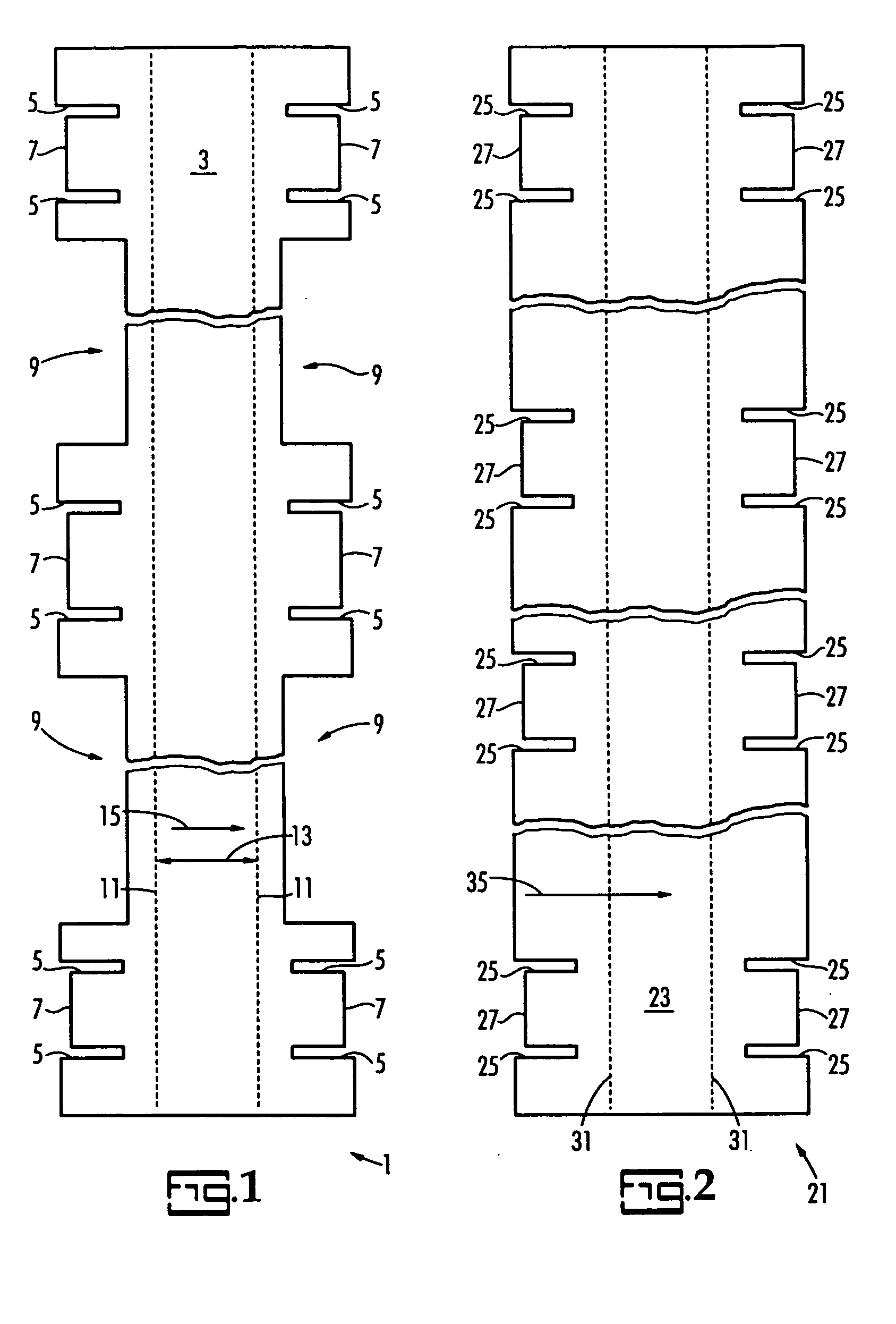

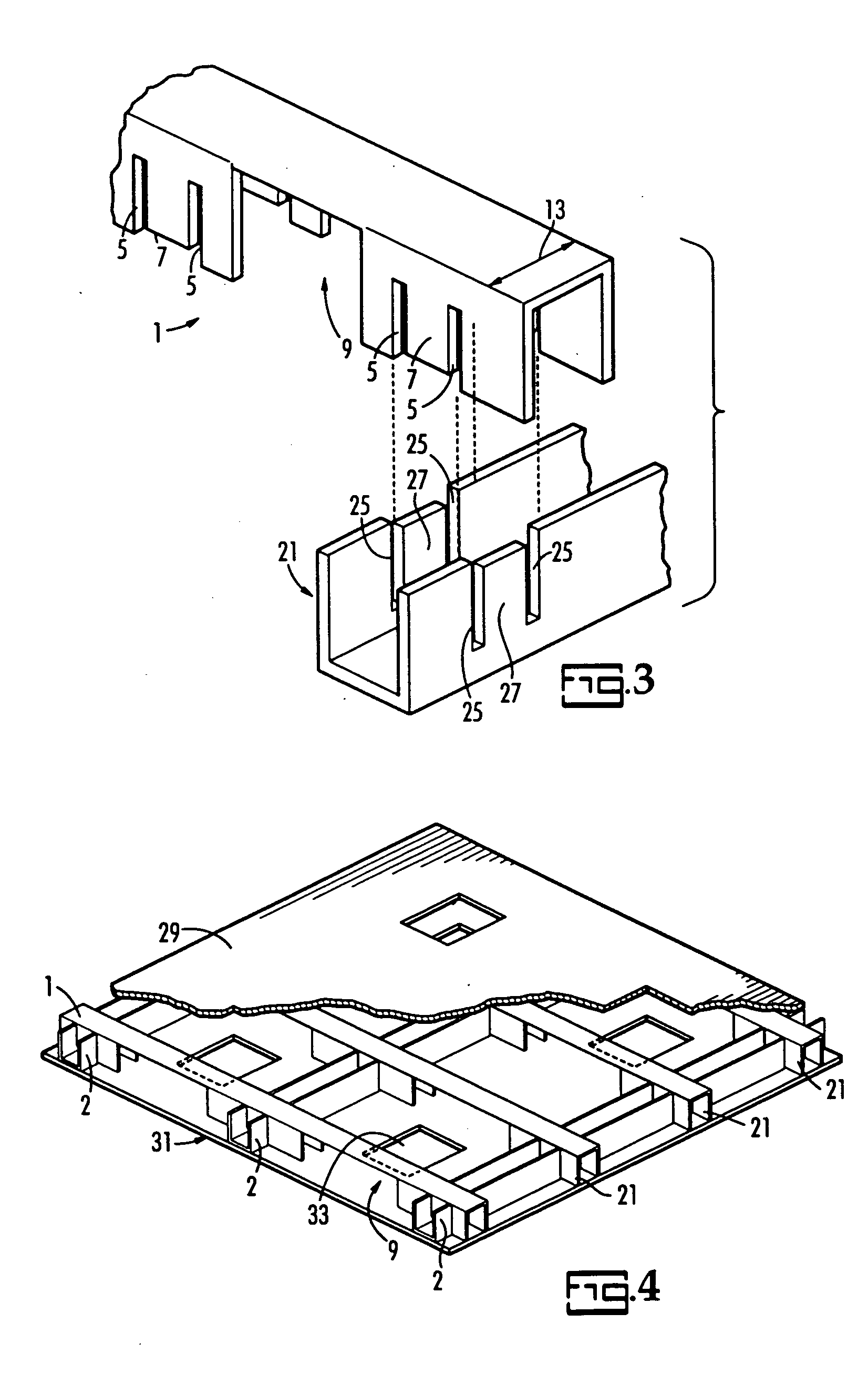

Foldably constructed force-resisting structures

A foldably constructed force-resisting structure comprises a top member and a bottom member foldably constructed and assembled from one or more blanks of sheet material, preferably corrugated paperboard, initially in a flat condition prior to folding. The bottom member includes a base panel and at least one interior support flap folded from the base panel to provide vertical support for a base panel of the top member disposed at least substantially parallel to the base panel of the bottom member. The top and bottom members may be interlockingly secured in various ways by interengagement of various portions of the one or more blanks themselves.

Owner:DESIGN PALLETS

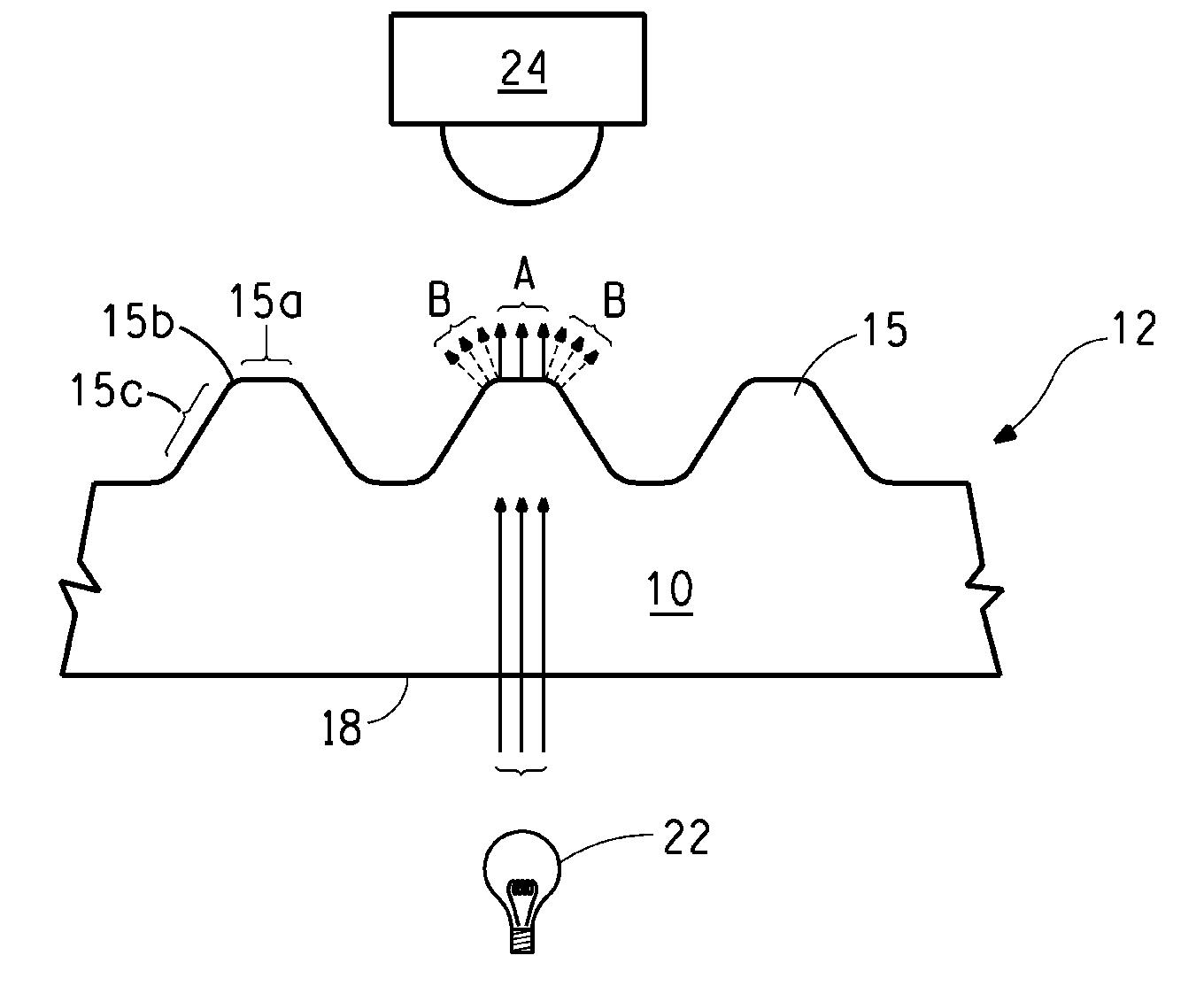

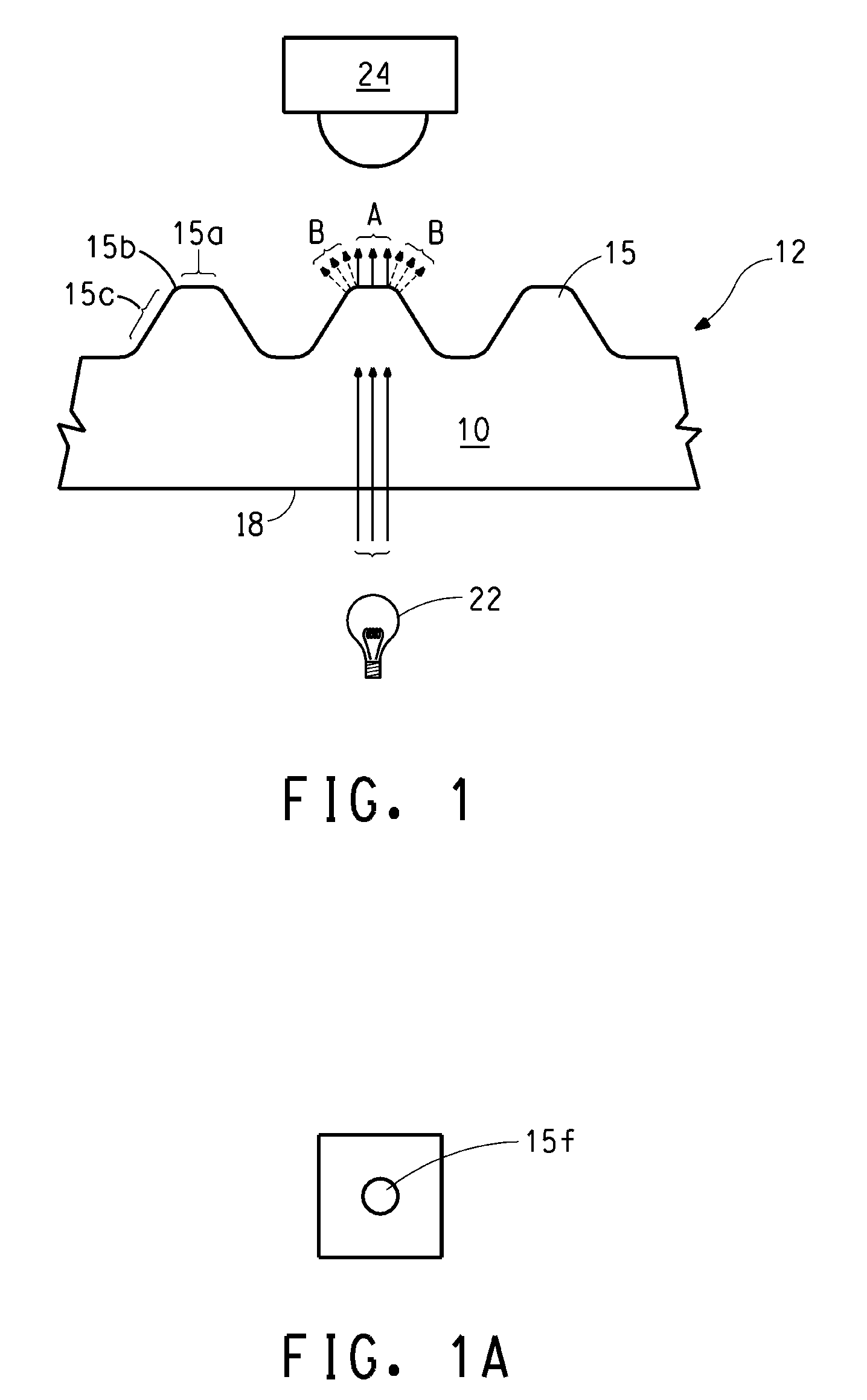

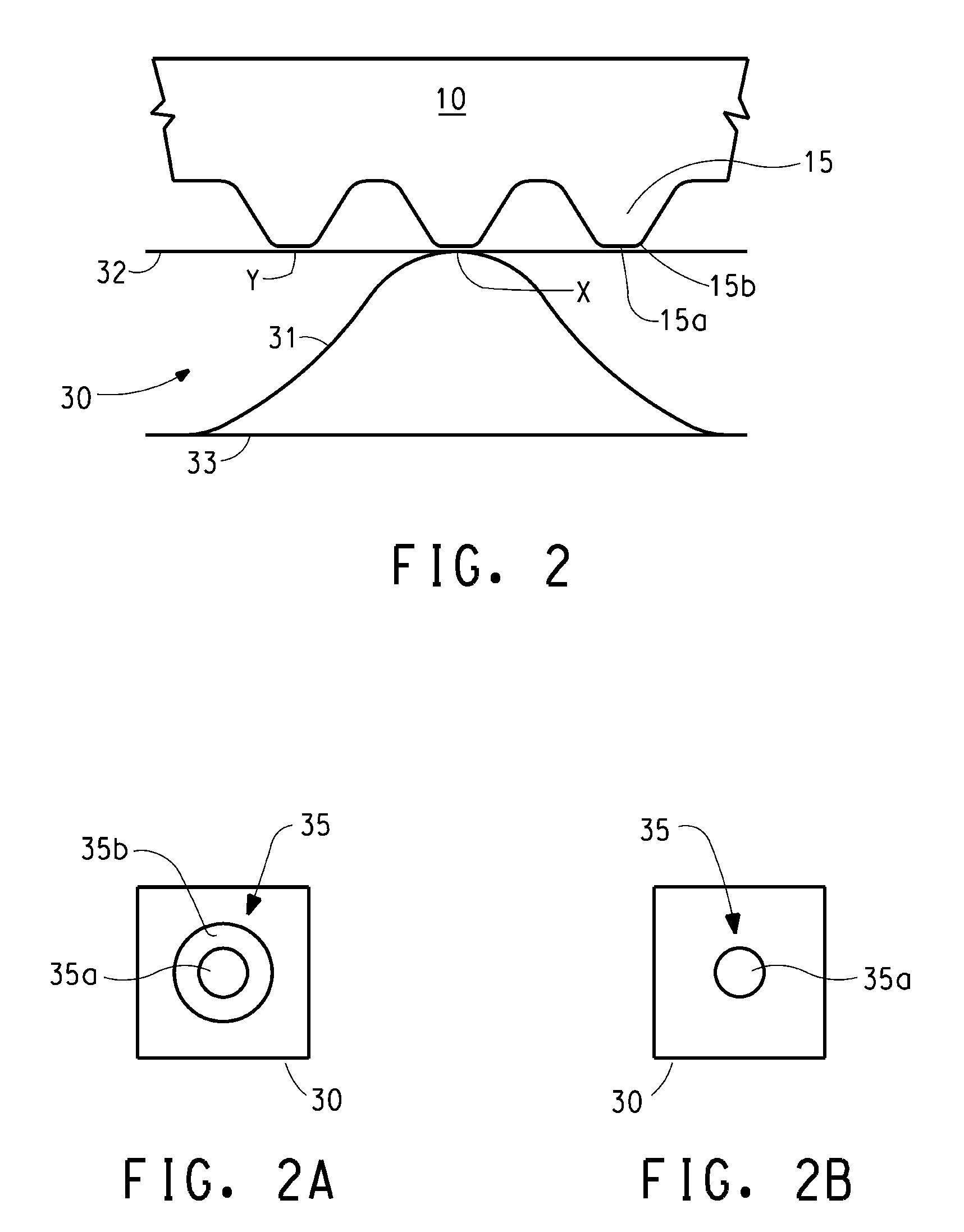

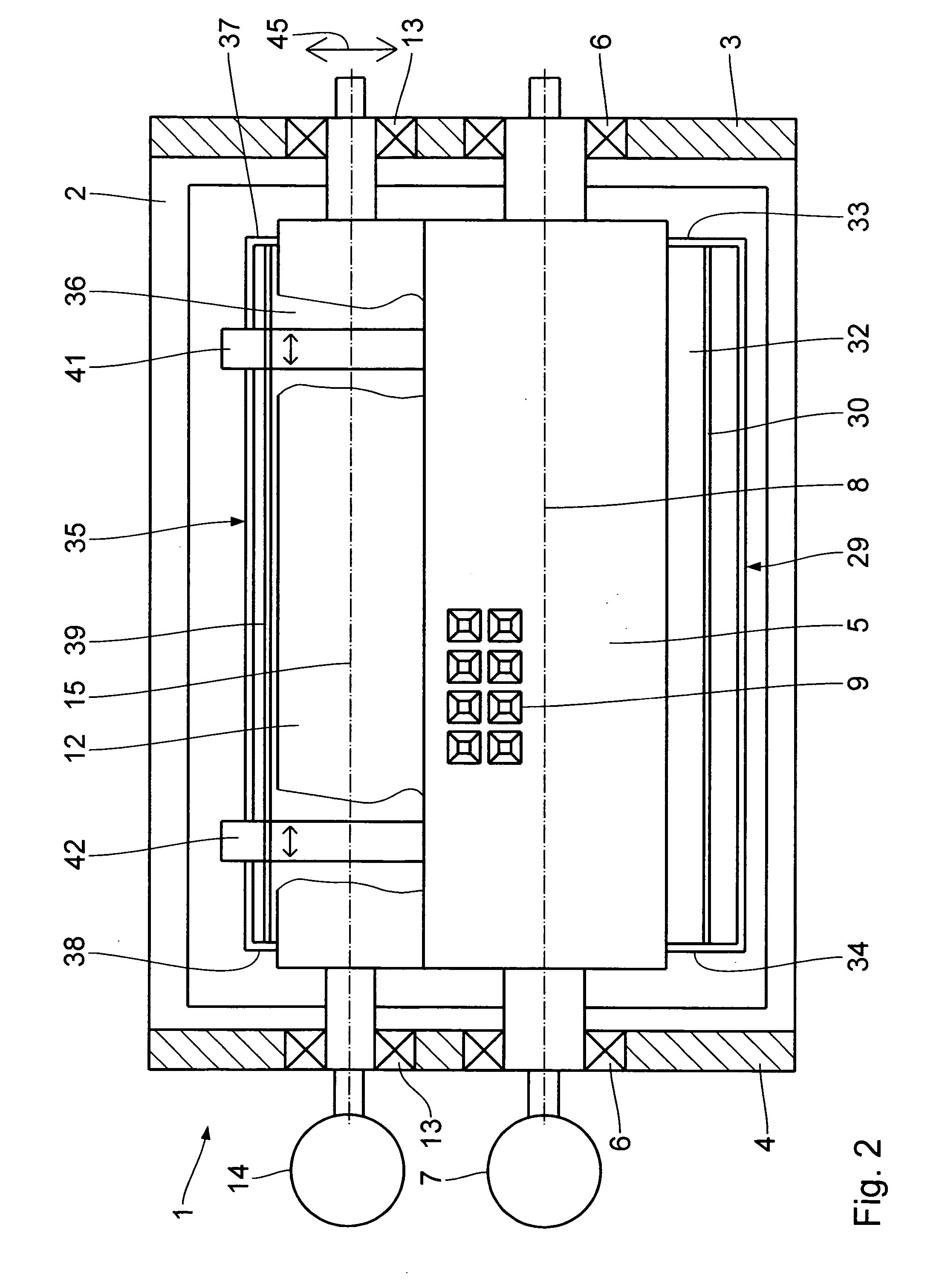

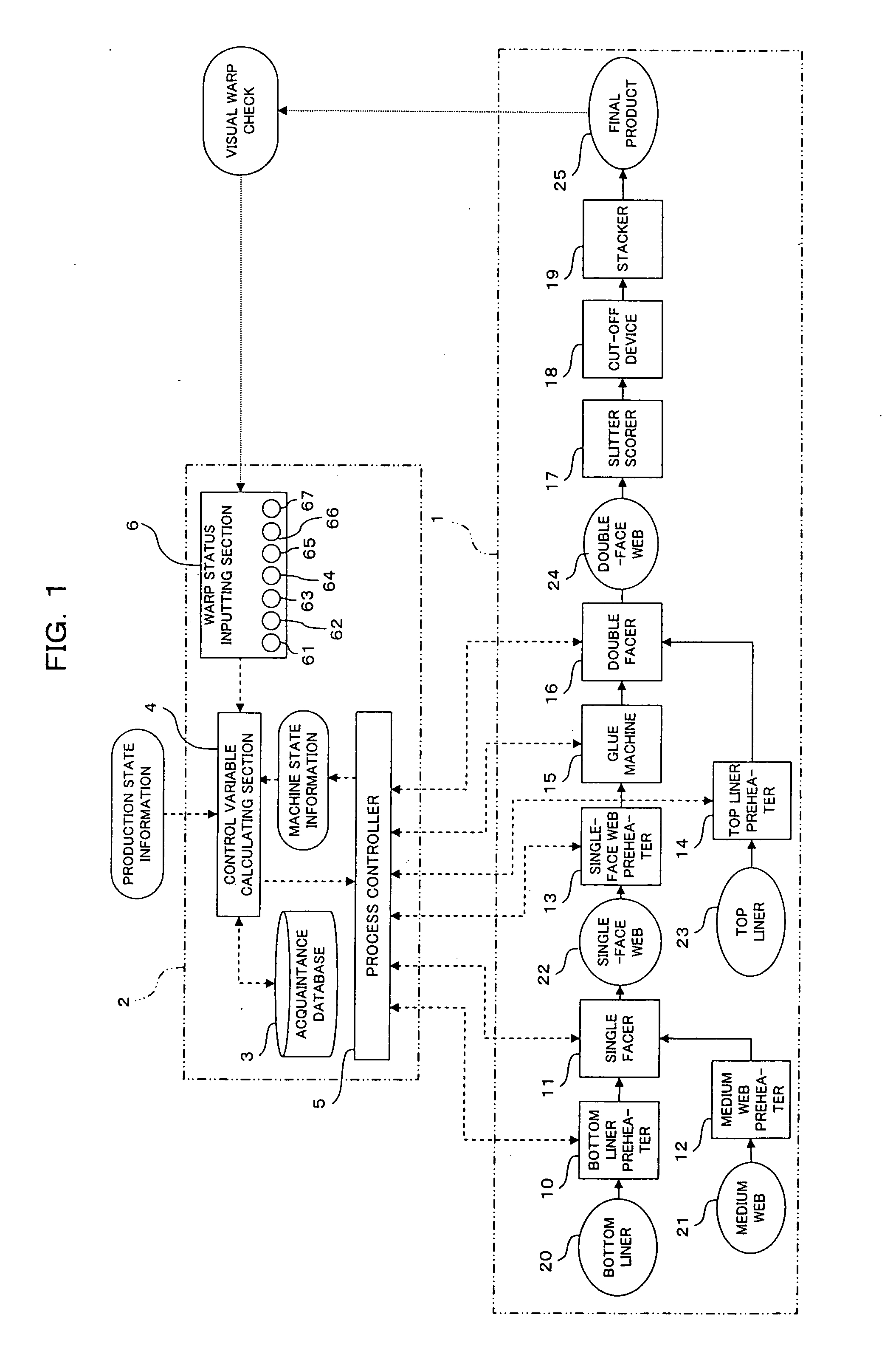

Production system for corrugated carboard sheet

InactiveUS20050284579A1Accurate correctionLamination plant layoutMechanical working/deformationCardboardEngineering

A system for fabricating a corrugated board sheet fabricated includes warp status information obtaining means (6, 6A-6H, 7, 7A, 7B, 8, 8A-8H, 240a, 240b, 241a, 241b) for obtaining warp status information concerning status of the warp of the corrugated board sheet fabricated by a corrugated-board fabrication machine (1); running-state information obtaining means (5, 5A-5H) for obtaining running state information concerning a running state of the corrugated-board fabrication machine (1); control variable calculating means (4, 4A-4H) for calculating a control variable of a particular control factor that affects the warp of the corrugated board sheet and that is one among control factors used to control the corrugated-board fabrication machine (1) based on the warp status information of the corrugated board sheet and the running state information of the corrugated-board fabrication machine (1); and control means (5, 5A-5H) for controlling the particular control factor using the control variable calculated by the control variable calculating means (4, 4A-4H).

Owner:MITSUBISHI HEAVY IND PRINTING & PACKAGING MACHINERY

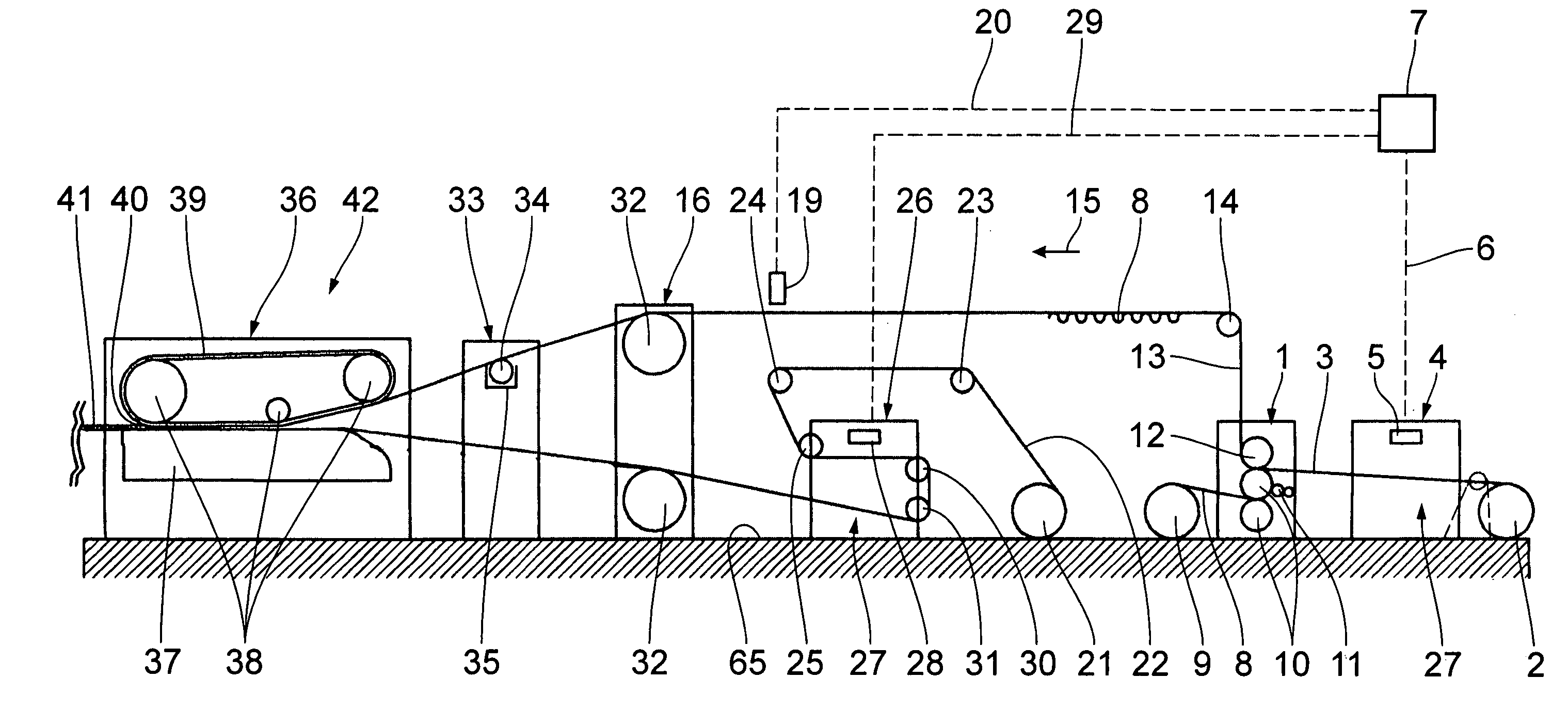

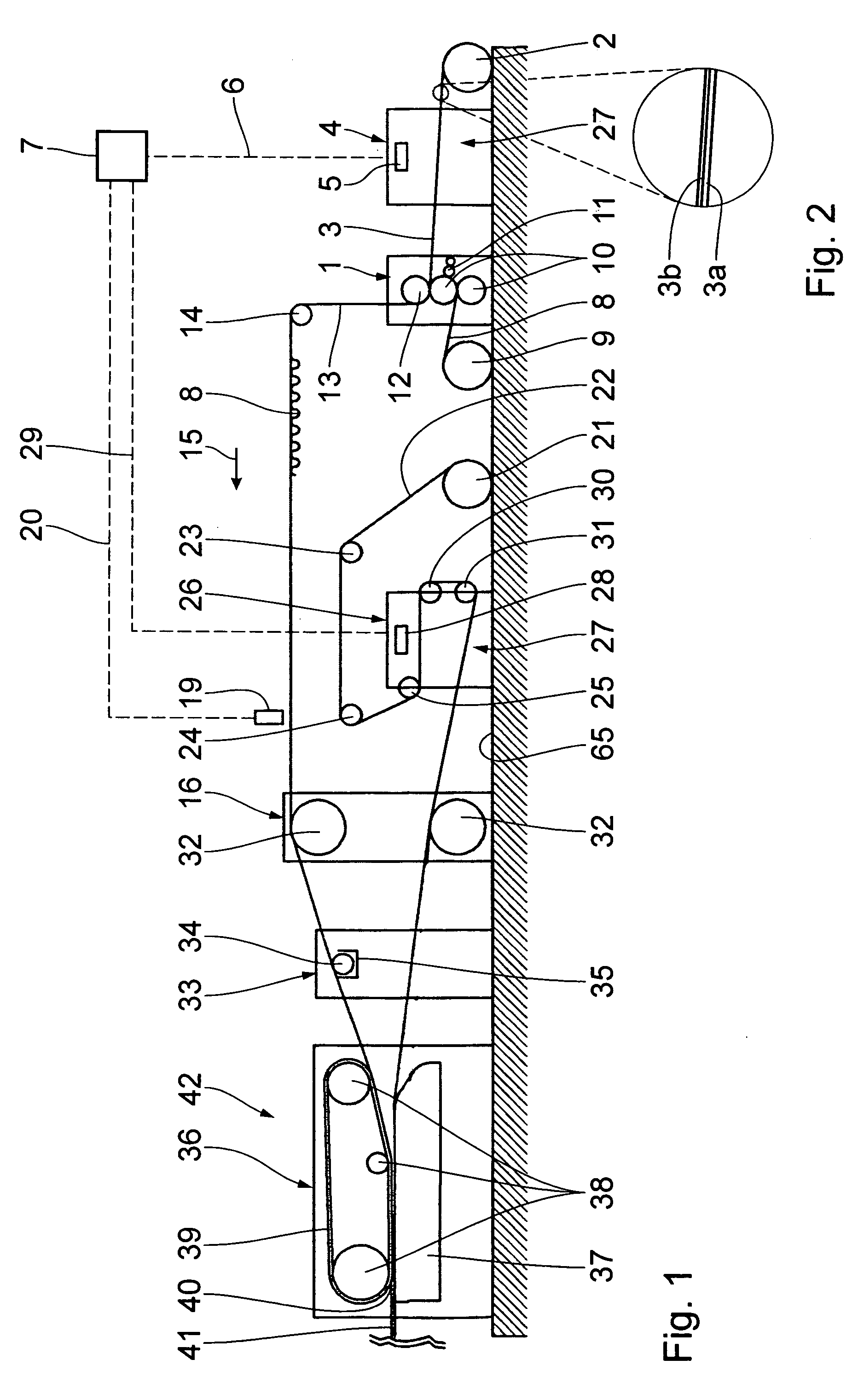

Method for the manufacture of corrugated board

InactiveUS20040182504A1Improve printing qualityImproves printing quality resultMechanical working/deformationLamination ancillary operationsEngineeringCorrugated fiberboard

A web of material serves for use in a corrugating machine for the manufacture of sheets of corrugated board. The corrugating machine comprises at least two unroll stands for unwinding webs of material. A fluting unit serves for the manufacture of at least one corrugated medium from one of the webs of material. A processing equipment serves for uniting the webs of material to form a web of corrugated board. The sheets of corrugated board are cut from the web of corrugated board by means of a cutting unit. A printing system is provided for printing at least one of the webs. The web of material has a coating for improved printing quality. A method for the manufacture of sheets of corrugated board is specified, using such a web of material. The results are sheets of corrugated board with improved imprint.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

Corrugated fiberboard panels for use in the construction of walls, ceilings and floors

InactiveUS7077988B2Low production costEasy to installFibreboardLamination ancillary operationsJoistFace sheet

A corrugated wooden fiberboard panel system provides a new structural member for use in the construction of building walls, ceilings, and floors as a substitute for conventional framing members, such as studs and joists.

Owner:JACQUES CARTIER TRAVAUX DE FER IRON WORK

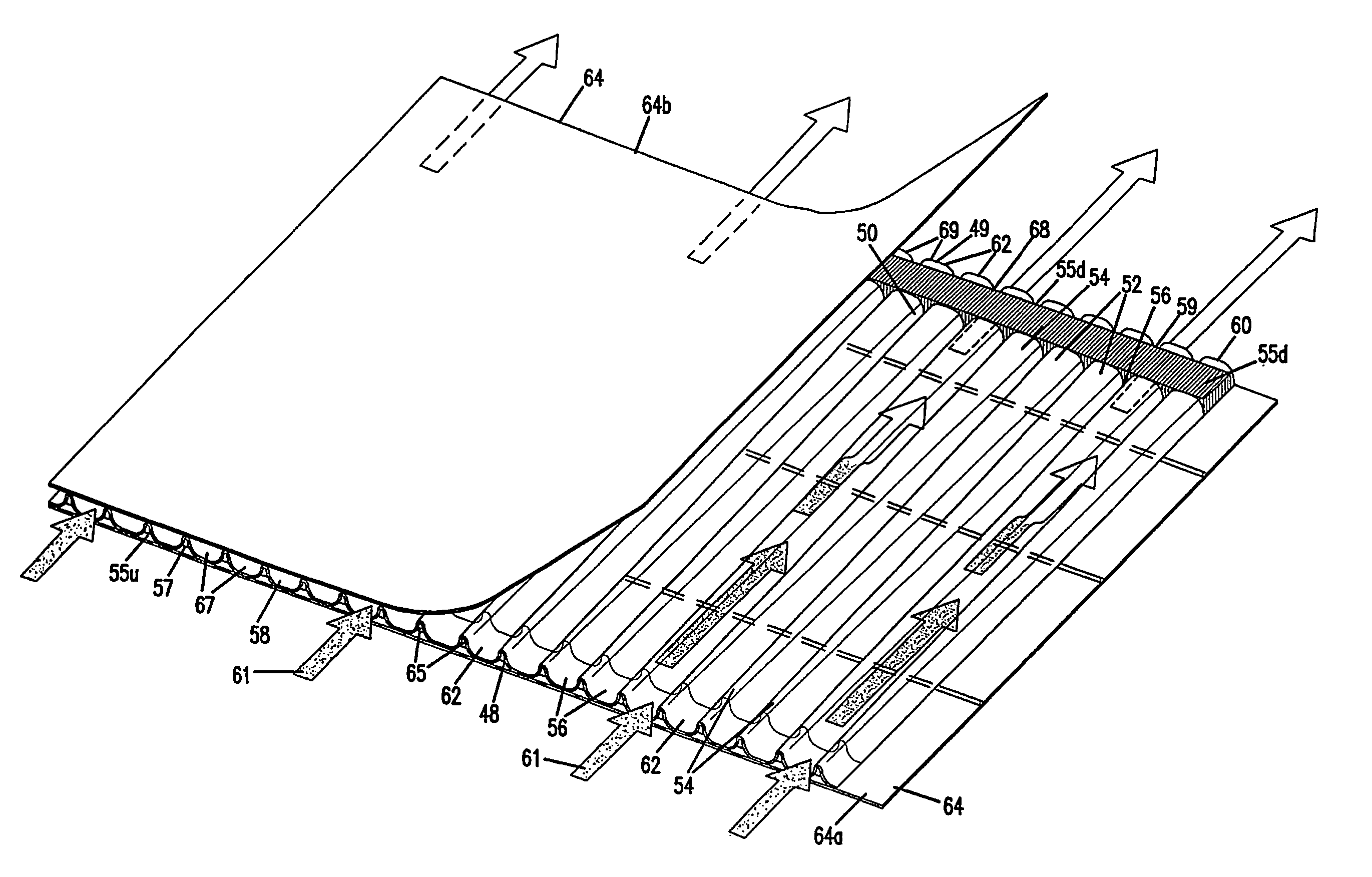

Bulk shipping container

ActiveUS20100301108A1High strengthEasily and fully recyclableRemovable lids/coversLidsEngineeringCorrugated fiberboard

A bulk shipping and storage container in the form of a drum is made of corrugated fiberboard and includes a bin with a sidewall, a closed bottom and an open top. The sidewall has a plurality of interconnected sidewall panels, and a rim is on an upper outer surface of the sidewall for engagement by the tines of a forklift to carry the container. The locking structure on the lid and bin enable the lid to be locked in place. The bottom of the container has adhesively attached overlapping panels that provide smooth interior and exterior surfaces. A preferred embodiment has a tray inserted in the bottom and a liner inserted in the tray and extending upwardly inside the sidewall. In another embodiment, a shock-absorbing pad is between the liner and the lid.

Owner:INT PAPER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com