Multi-ply collapsible bulk container

a multi-ply, bulk container technology, applied in the field of bulk containers, can solve the problems of affecting the appearance of the container at these folds, affecting and reducing the strength of the erected container, so as to maintain the structural integrity of the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] While this invention is susceptible of embodiments in many different forms, there are shown in the drawings and will herein be described in detail preferred embodiments of the invention with the understanding that the present disclosure is to be considered as an exemplification of the principles of the invention and is not intended to limit the broad aspect of the invention to the embodiments illustrated.

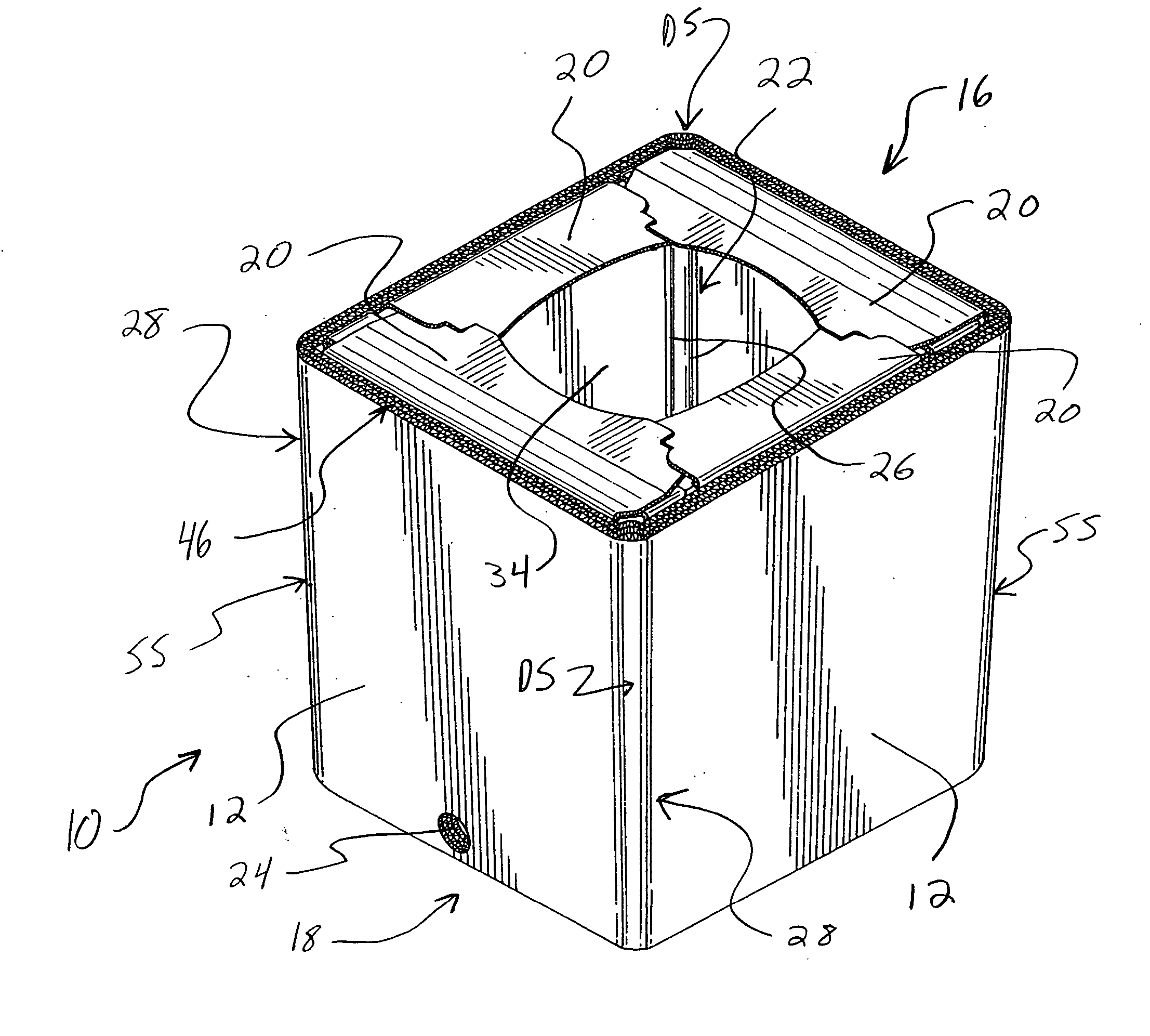

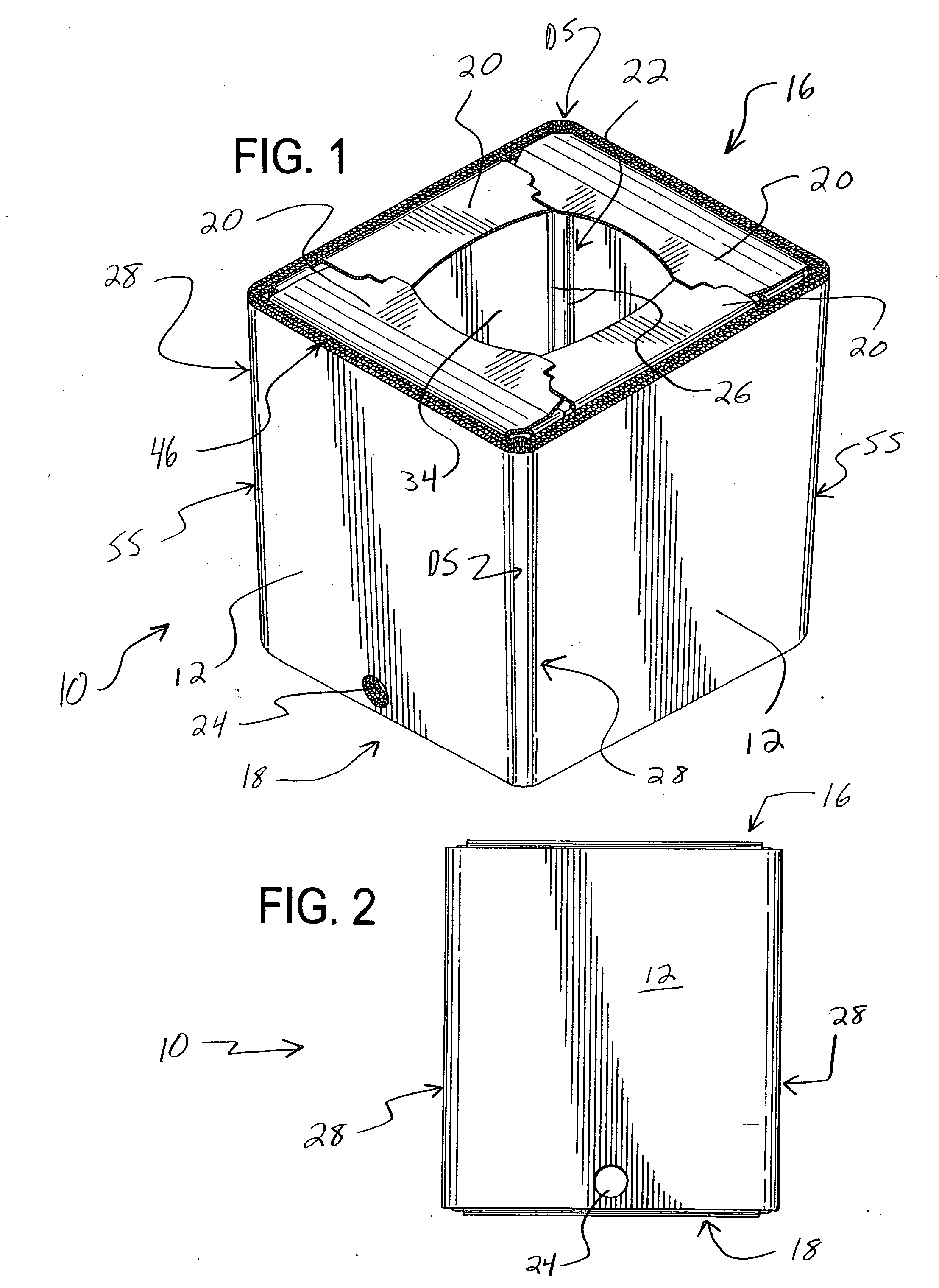

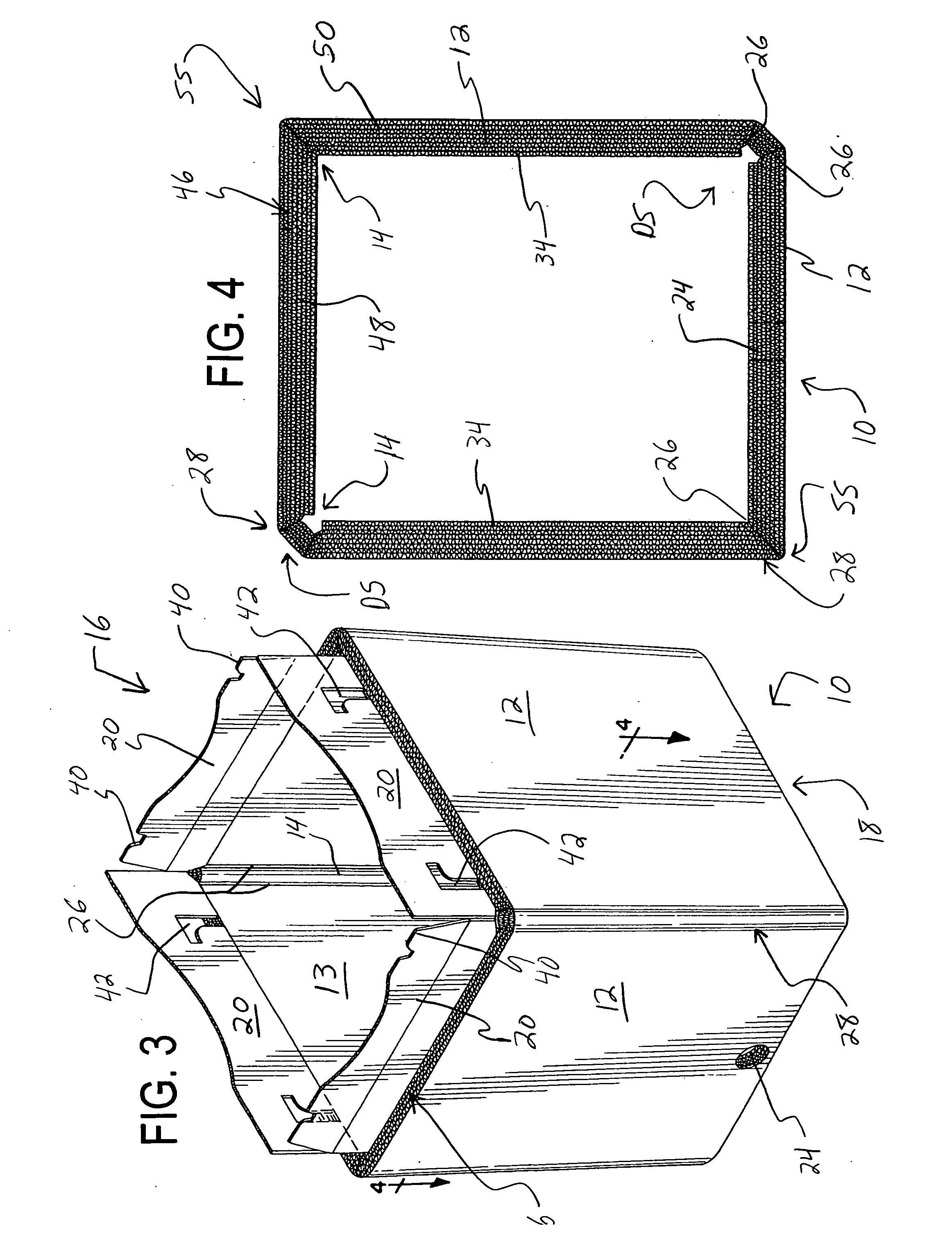

[0038] Referring now to FIGS. 1-21, and initially to FIGS. 1 and 14, there is shown a bulk container 10 having four substantially planar walls 12 and four corners 28, each corner 28 connecting two walls 12, a top 16 formed by four foldable flaps 20, and a bottom 18 formed by four foldable flaps 20. A preferred embodiment is depicted in FIGS. 1-13, and the most preferred embodiment is depicted in FIGS. 14-21. The walls 12 of the container 10 are formed of a sheet material, preferably cardboard. As shown in FIGS. 1 and 14, the container 10 is rectangular, having bi-lateral sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com