Corrugated board production quality regulation and control method based on machine vision

A corrugated cardboard, production quality technology, applied in the field of artificial intelligence, to achieve the effect of reducing labor intensity, improving product quality, reducing defective and scrapped products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

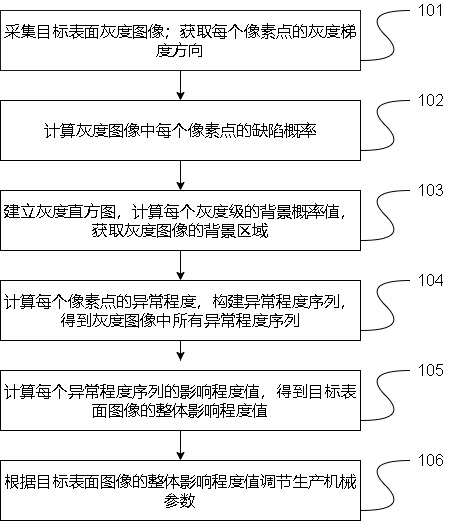

[0040] Such as figure 1 As shown, a schematic structural diagram of a method for controlling the production quality of corrugated cardboard based on machine vision according to an embodiment of the present invention is provided, including:

[0041] 101. Collect the target surface image and perform grayscale processing to obtain the target surface grayscale image; acquire the grayscale gradient direction of each pixel in the grayscale image.

[0042] The scenarios targeted by this embodiment are:

[0043] First, the corrugated cardboard is pressed by a high-temperature, high-humidity corrugated roller with gears to form a corrugated paper core with alternating concave and convex shapes. The corrugated paper core is in contact with the roller with glue and then bonded with the face paper. After drying at high temperature, the corrugated cardboard is formed. Acquisition of grayscale images of corrugated cardboard surfaces. The corrugated cardboard produced is sampled, and the g...

Embodiment 2

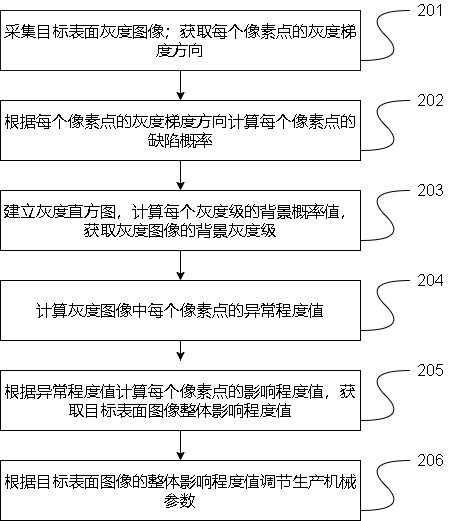

[0063] Such as figure 2 As shown, another method for controlling the production quality of corrugated cardboard based on machine vision in the embodiment of the present invention is provided, including:

[0064] 201. Collect the target surface image and perform grayscale processing to obtain the target surface grayscale image; acquire the grayscale gradient direction of each pixel in the grayscale image.

[0065] The scenarios targeted by this embodiment are:

[0066] First, the corrugated cardboard is pressed by a high-temperature, high-humidity corrugated roller with gears to form a corrugated paper core with alternating concave and convex shapes. The corrugated paper core is in contact with the roller with glue and then bonded with the face paper. After drying at high temperature, the corrugated cardboard is formed. Acquisition of grayscale images of corrugated cardboard surfaces.

[0067] Sampling the corrugated cardboard produced, analyzing the collected grayscale imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com