Production process of motor stator with high hardness, high heat dissipation efficiency and high insulation

A motor stator and production process technology, which is applied in the field of motor stator production process, can solve the problems of small size, uneven glue layer, and limited glue filling space, etc., and achieve the effects of improving the pass rate, improving safety, consistent appearance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

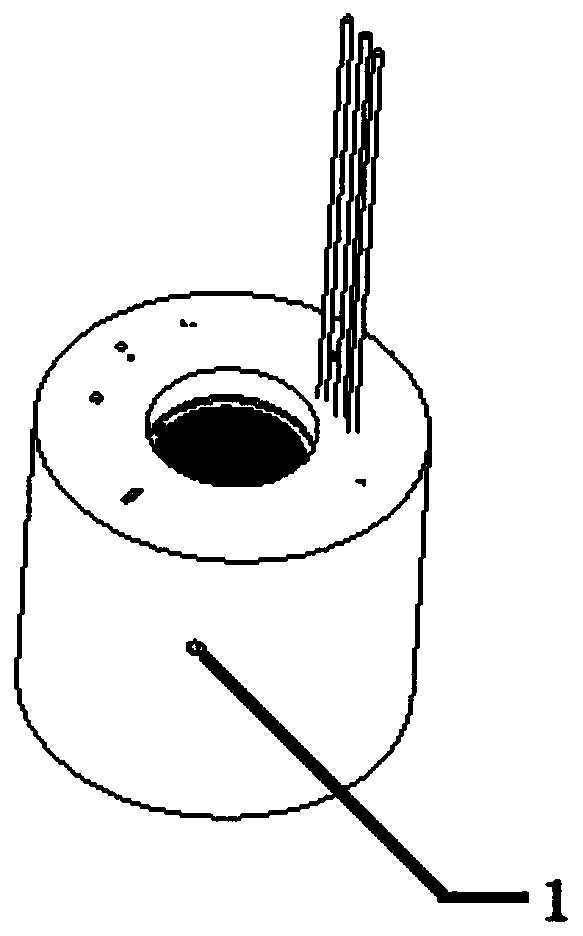

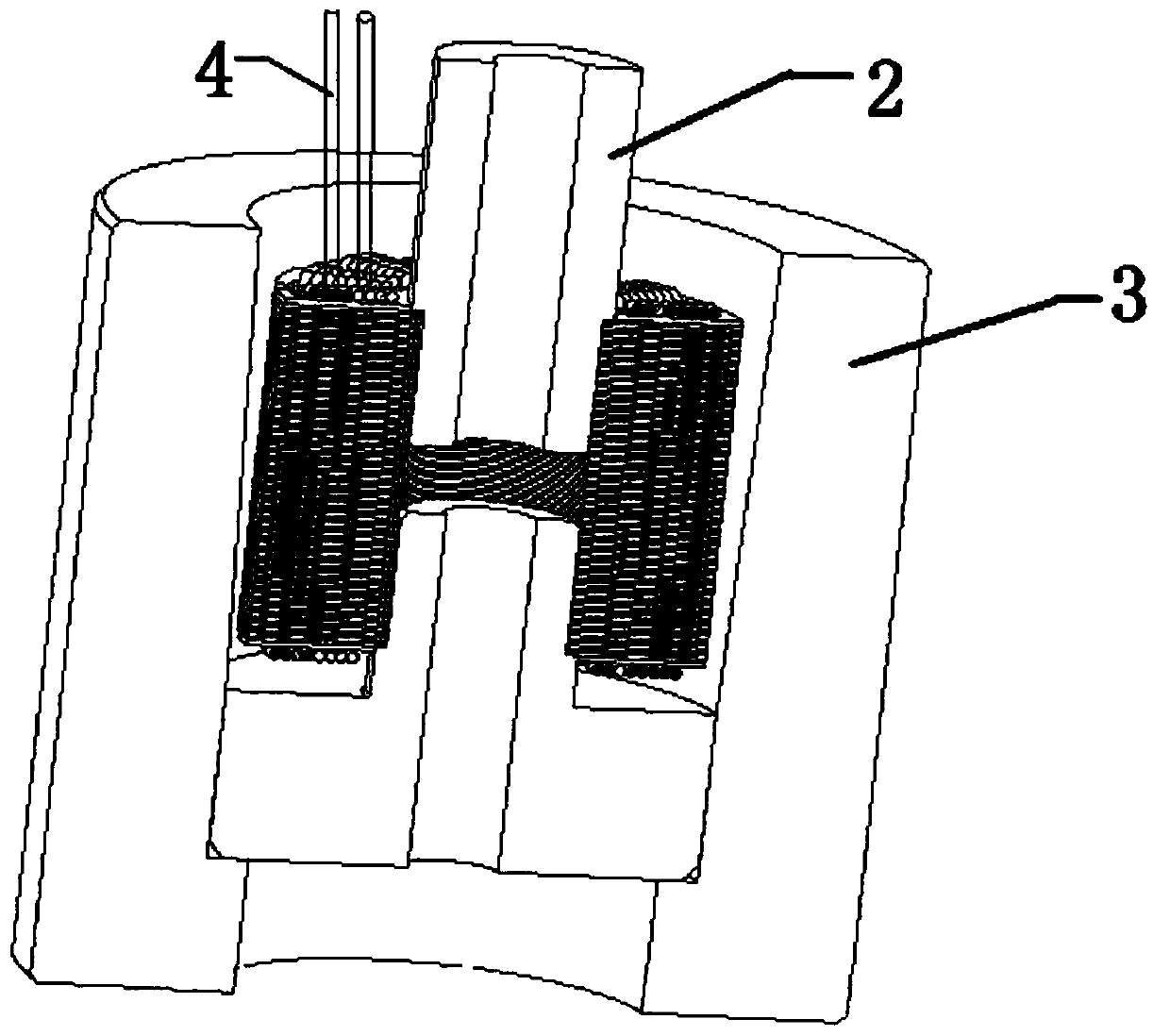

[0023] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

[0024] A high hardness, high heat dissipation efficiency, high insulation motor stator production process, the steps are as follows:

[0025] Step (1), choose epoxy potting glue with strong thermal conductivity and very high hardness and insulation;

[0026] Step (2), selecting a plastic mold with excellent adhesive layer forming performance and mold release performance;

[0027] Step (3), select automatic glue filling and glue filling equipment that accurately controls the amount of glue;

[0028] Step (4), injecting epoxy potting glue into the glue filling equipment, and pouring glue upwards from the bottom of the plastic mold through the glue filling equipment to obtain the plastic mold after glue filling;

[0029] Step (5), place the plastic mold filled with glue on a high-frequency vibration machine and vibrate for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com