Patents

Literature

408 results about "Cardboard box" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cardboard boxes are industrially prefabricated boxes, primarily used for packaging goods and materials and can also be recycled. Specialists in industry seldom use the term cardboard because it does not denote a specific material.

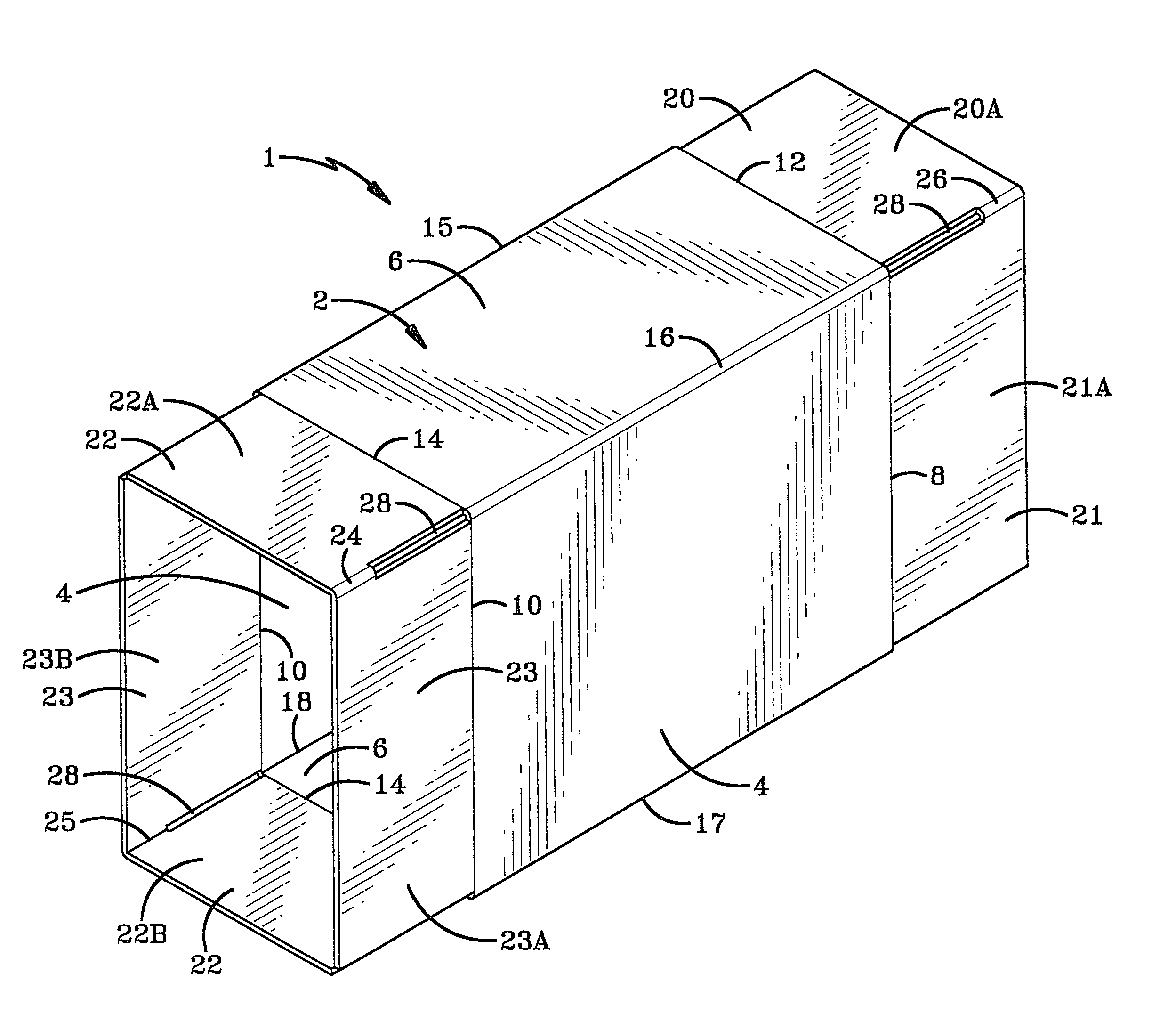

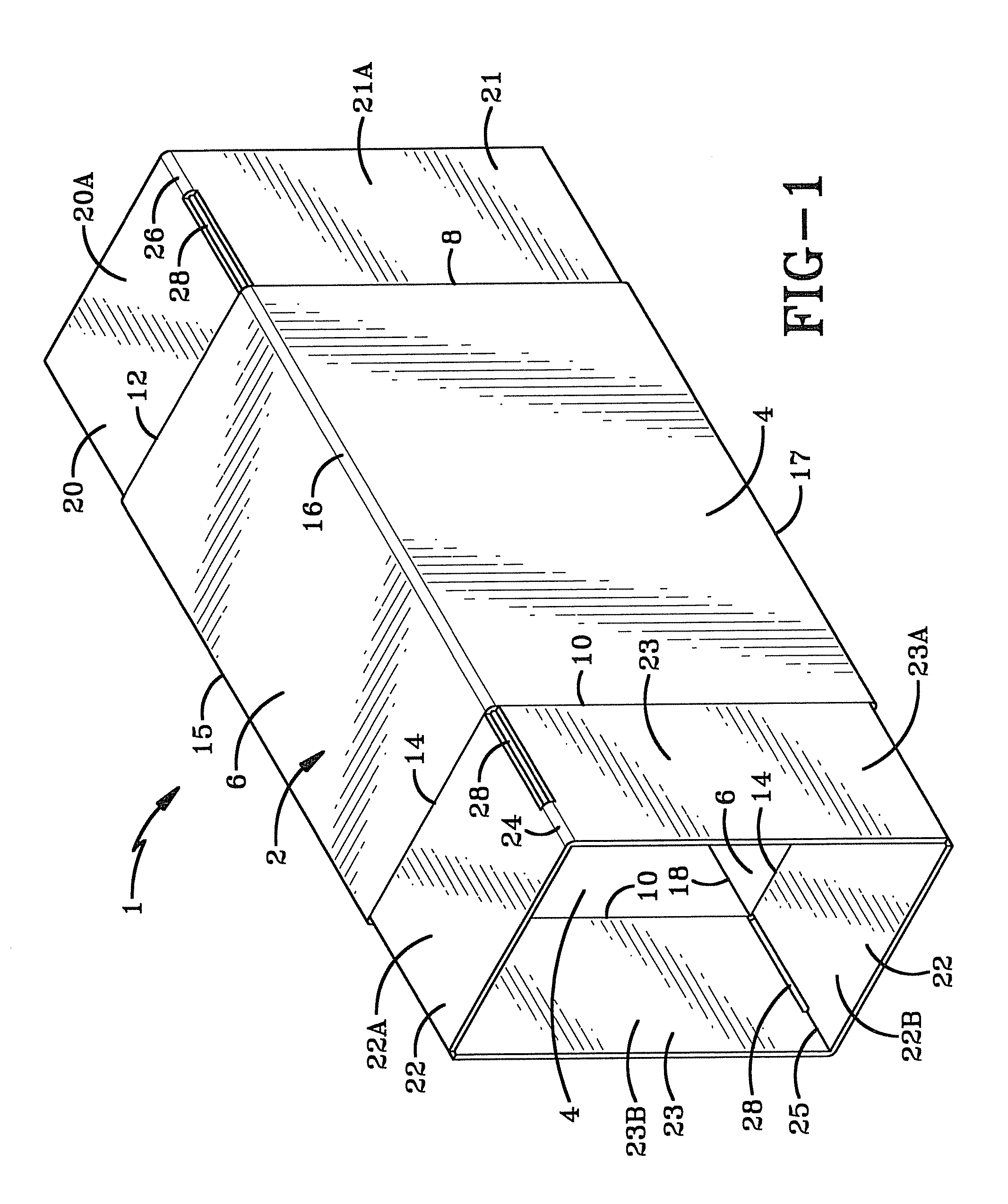

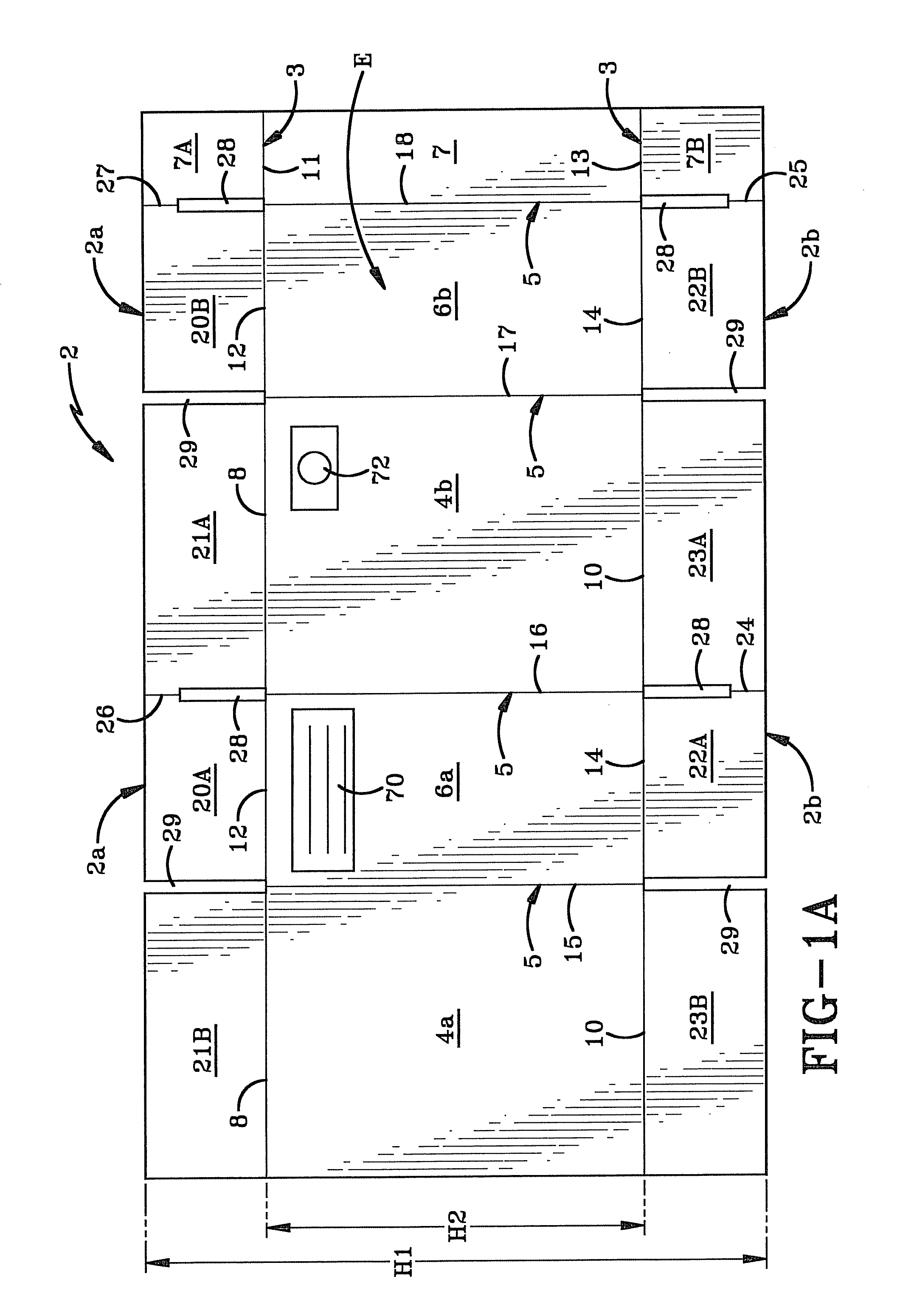

Method and apparatus for making, shipping and erecting boxes

InactiveUS20100001056A1Reduce the overall heightPaper-makingBox making operationsEngineeringFace sheet

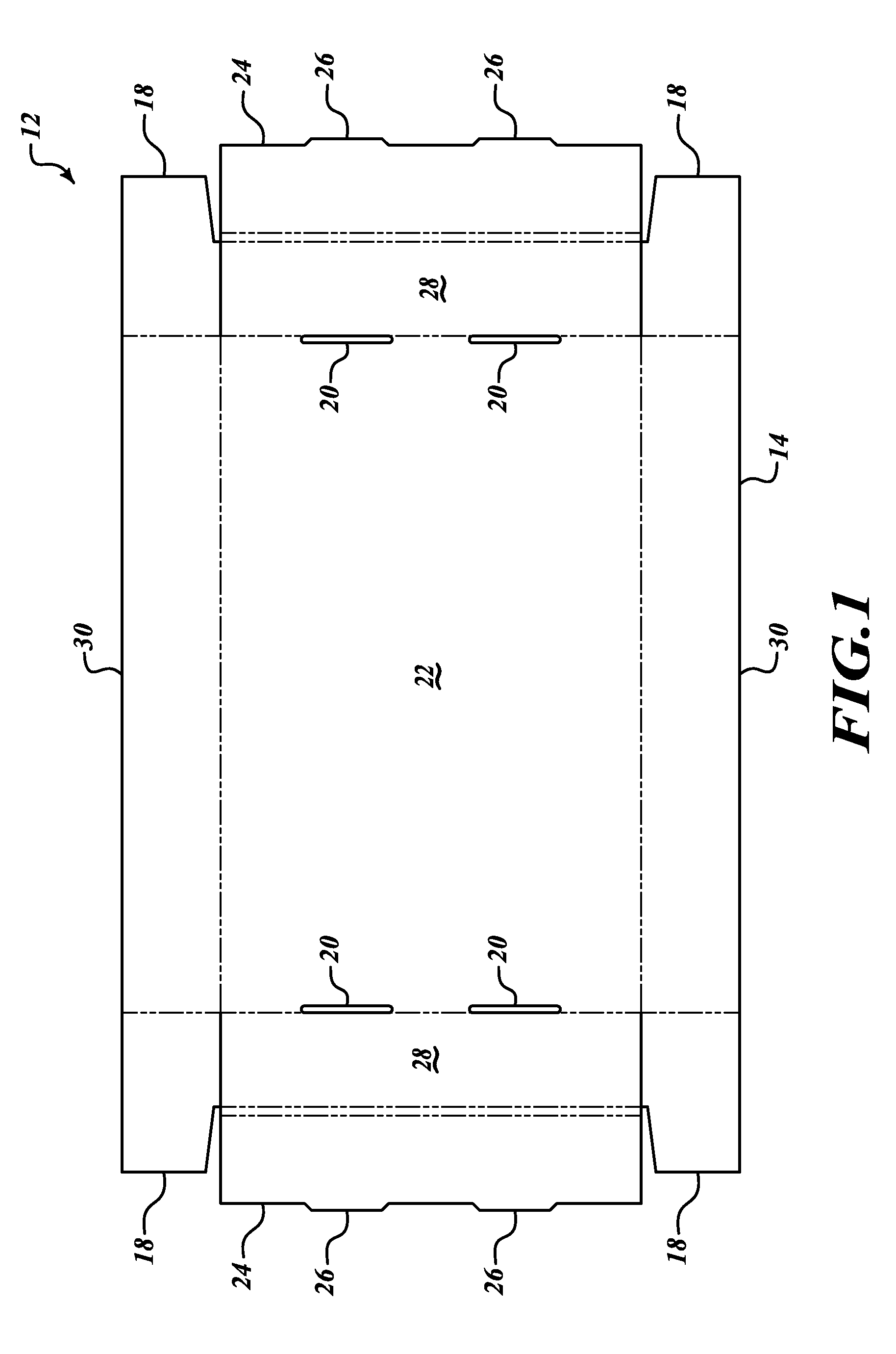

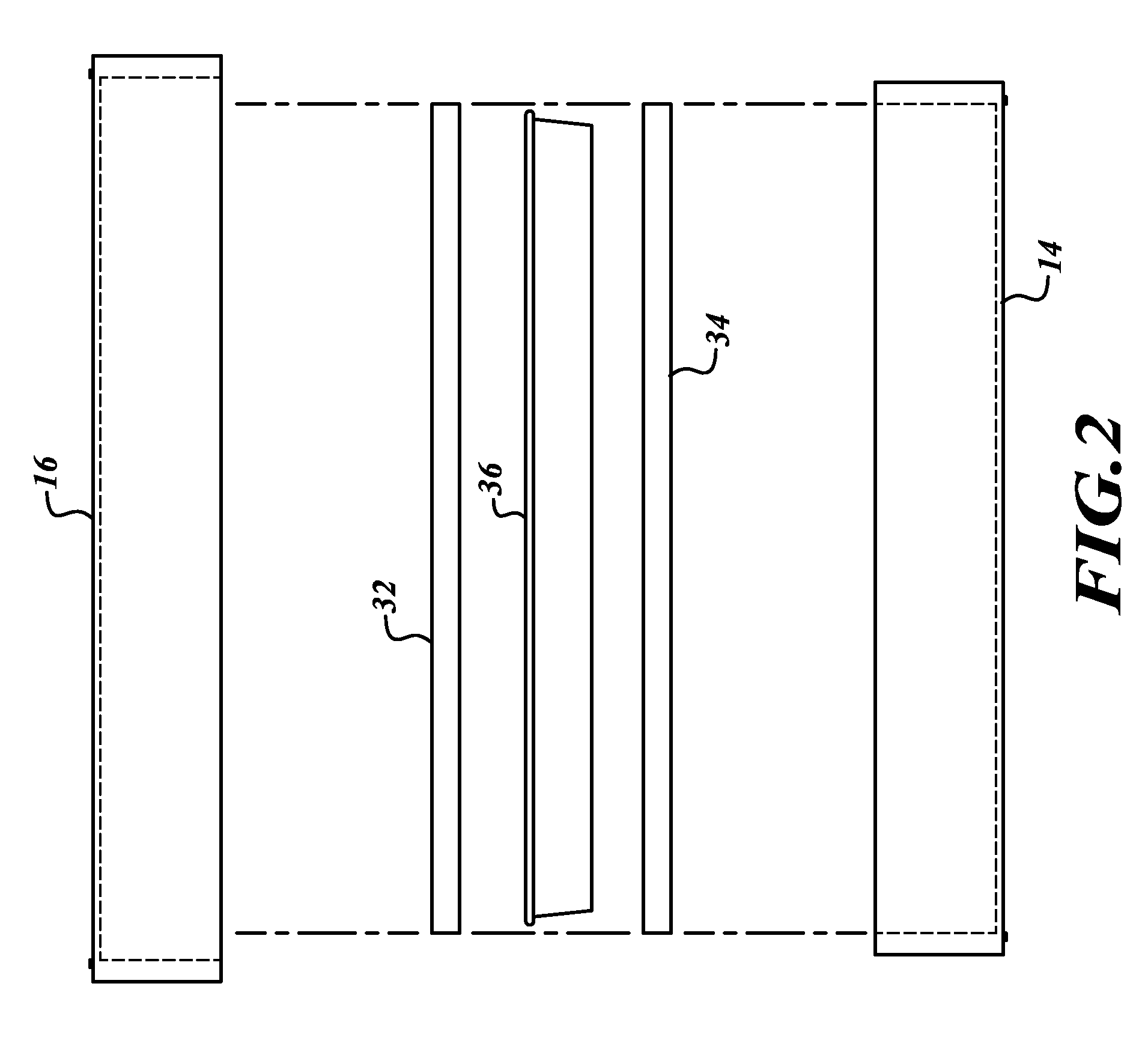

A cardboard box with four side panels, four bottom flaps and four top flaps. The box is made from a blank having a first height measured between the outermost edges of the top and bottom flaps. The flaps are rotated into abutting contact with the exterior surface of the panels thereby reducing the overall height of the box to the height of the panel. Adjacent pairs of top and bottom flaps are provided with living hinges that enable them to remain in this position when the box is collapsed. The collapsed box is shipped through the mail in this diminished size and then erected into a box of the same height as the panels.

Owner:KITARU INNOVATIONS

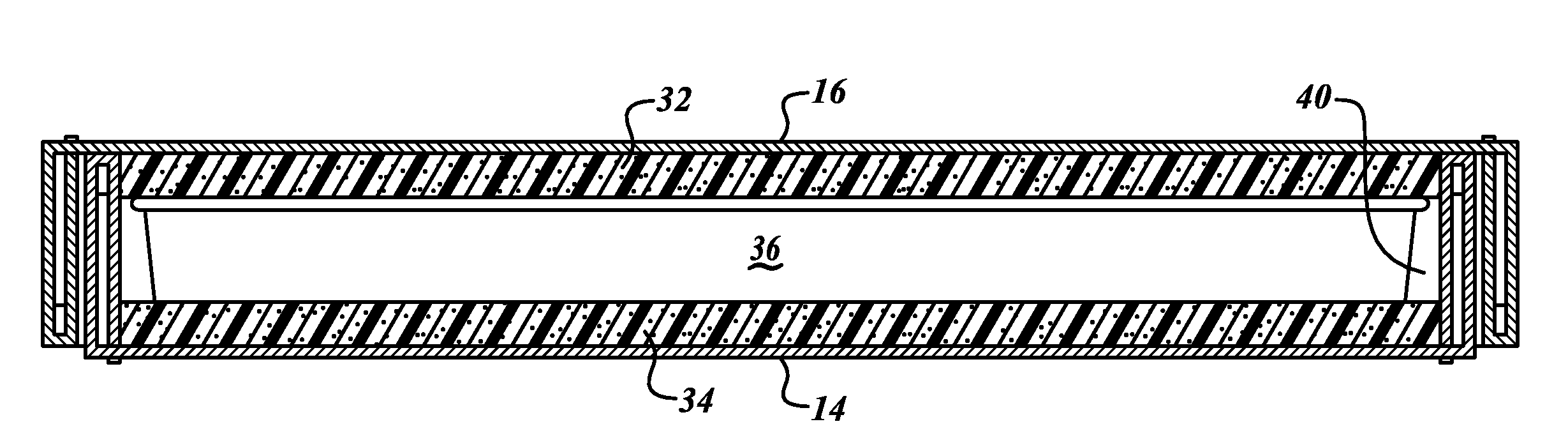

Insulated food crate

InactiveUS20080296356A1Easy to cleanThe process is simple and effectivePackage recyclingBoxes/cartons making machineryDouble wallEngineering

An insulated food crate comprises a generally rectangular, typically cardboard box having separable top and bottom portions with double walls providing insulative properties and also insulating inserts fitted into the top and bottom portions. The box may also have ventilation holes or slots and / or compartments for serving utensils and may be disposable. In alternate embodiments, the insulated food crate may be made from a heat-resistant composite material, such as a reinforced plastic or stainless steel, as a more permanent, durable, and reusable solution. This inexpensive, accessible catering box keeps hot foods hot and cold foods cold while allowing quick and easy access to the foods inside.

Owner:HATCHER JOHN AUGUST +1

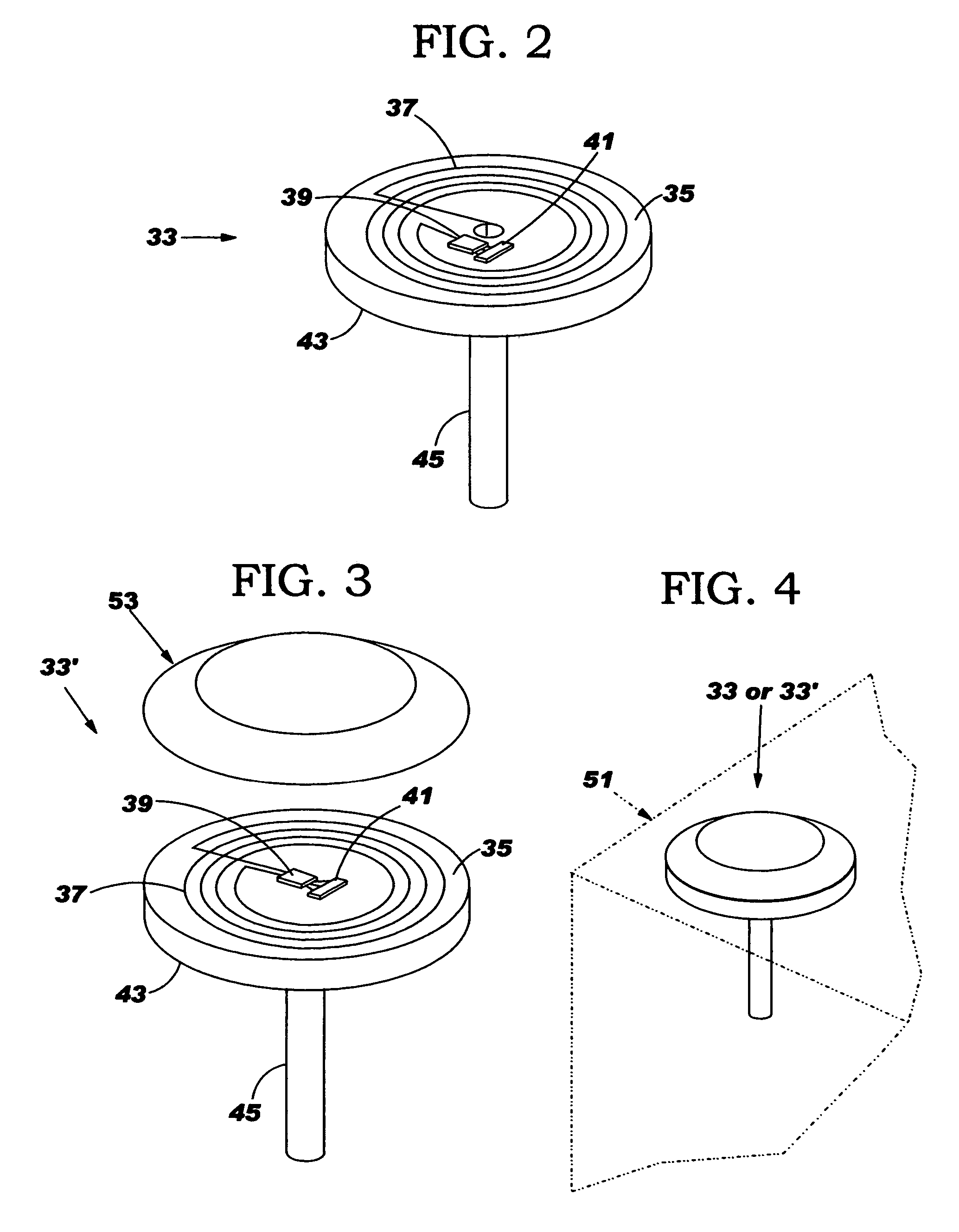

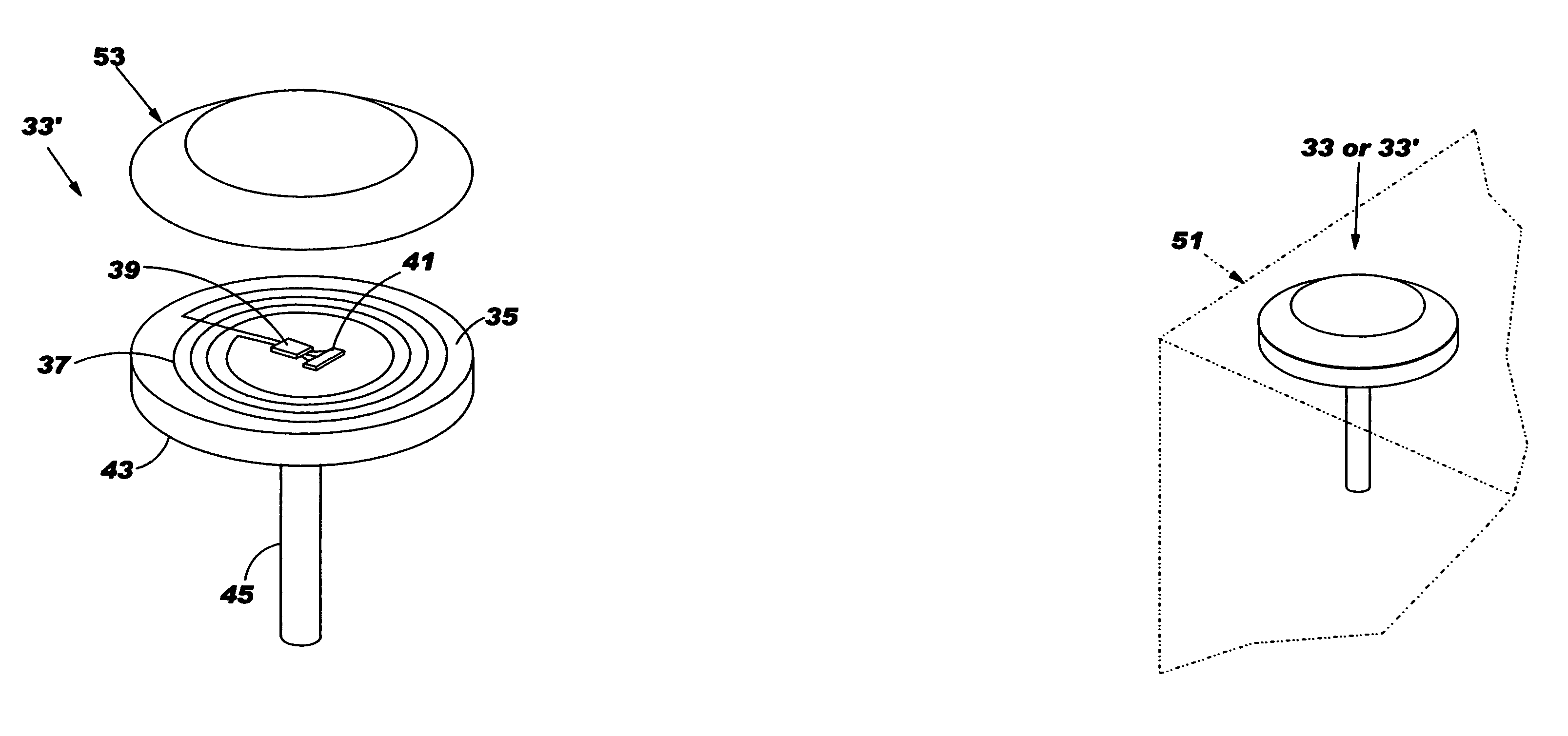

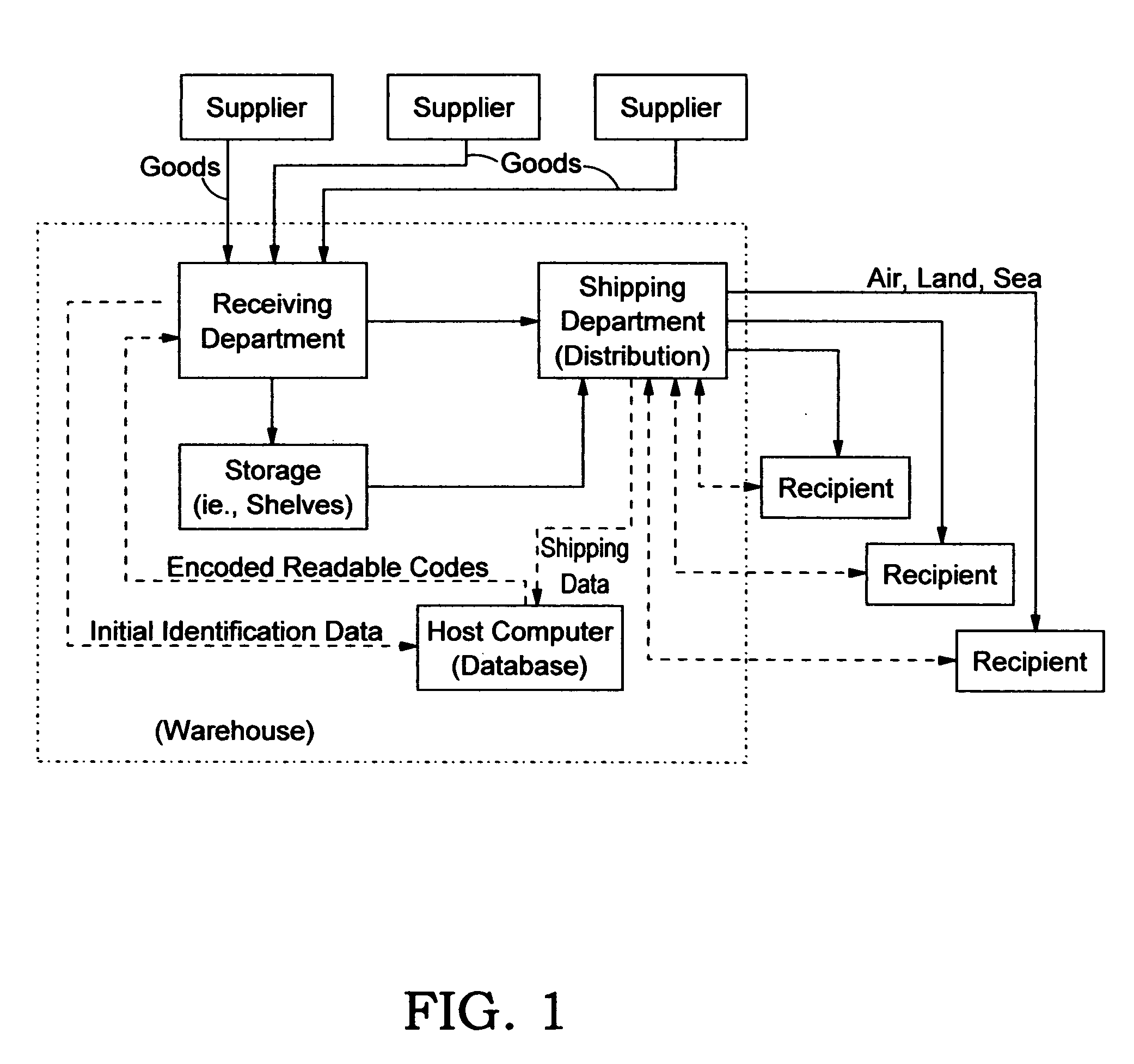

Radio frequency device for tracking goods

InactiveUS7142121B2Safe and efficient and fast trackingLow costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipRadio frequency

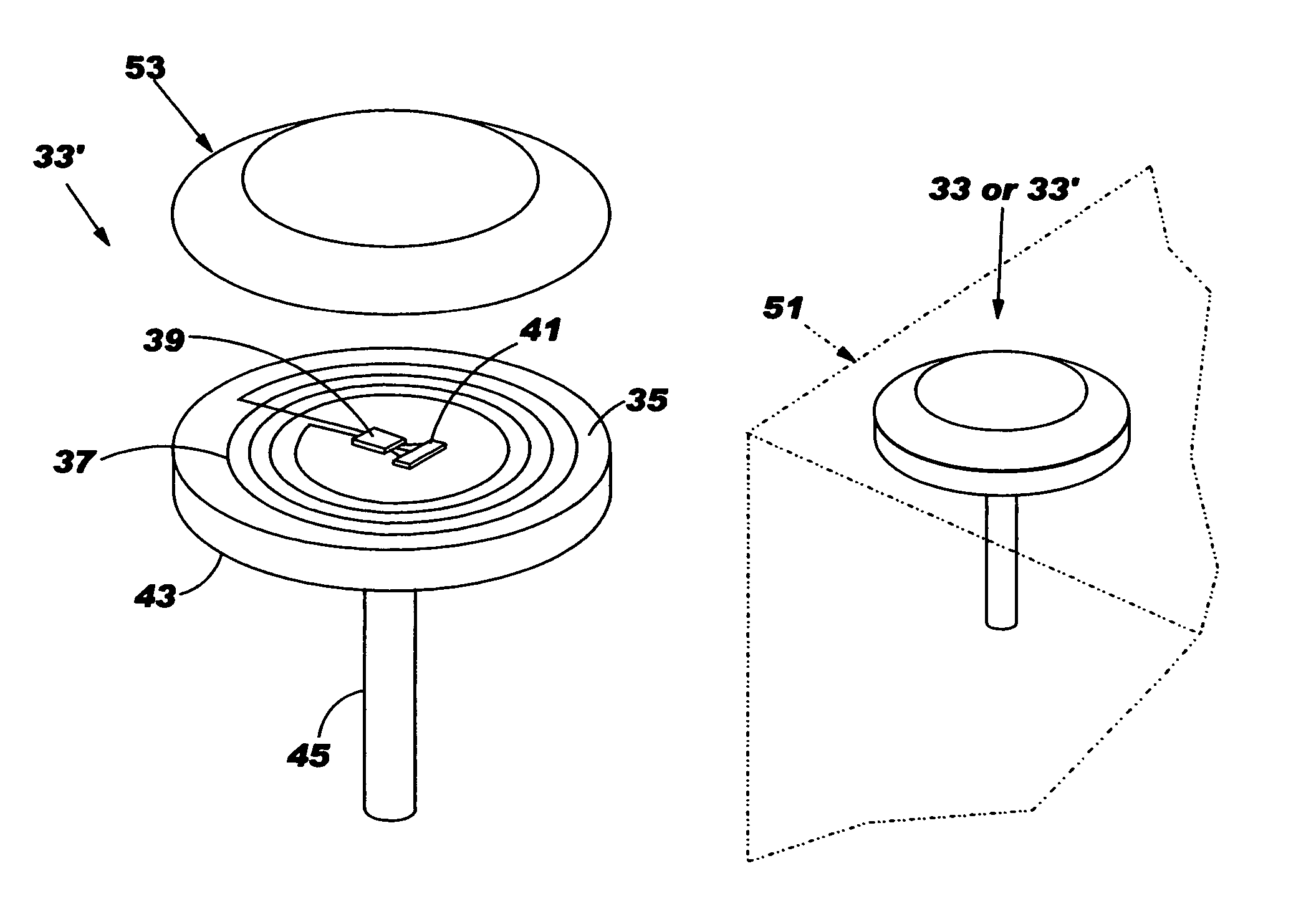

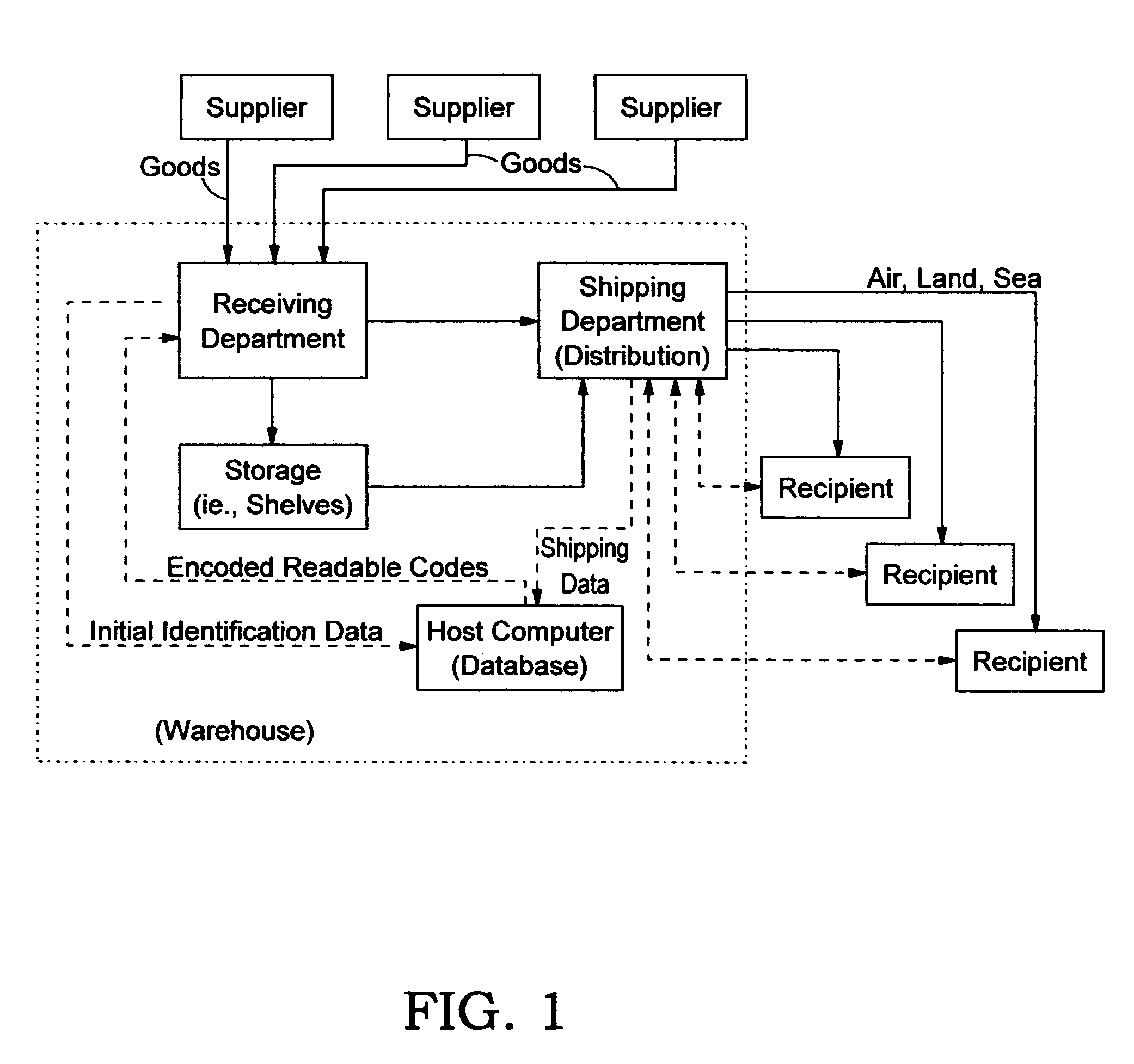

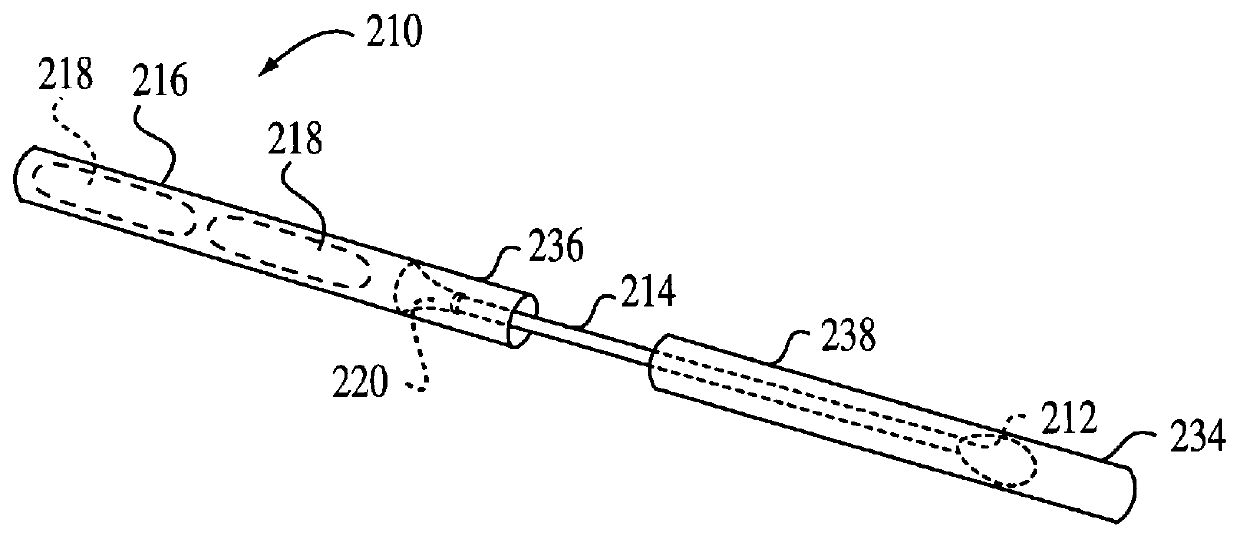

A radio frequency (RF) device (or “tag”) for containing specific information relating to a particular good being shipped from one location (e.g., warehouse) to another (e.g., customer). The device includes a circuitized substrate (e.g., a printed circuit board), a semiconductor chip, an antenna and a power regulator, and is designed in one embodiment to be partly inserted within a good (e.g., a cardboard box) containing one or more of the goods being shipped and tracked. Alternatively, the device may be attached by other means (e.g., adhesive). A shipper can simply track the goods containing such devices using wireless communication devices (e.g., satellites) to quickly and readily ascertain the specific location of the goods at any time as well as the appropriate desired information relating to such goods (e.g., quantity, weight, type, etc.).

Owner:WACHOVIA CAPITAL FINANCE NEW ENGLAND AS AGENT +2

Radio frequency device for tracking goods

InactiveUS20050270160A1Safe and efficient and fast trackingLow costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A radio frequency (RF) device (or “tag”) for containing specific information relating to a particular good being shipped from one location (e.g., warehouse) to another (e.g., customer). The device includes a circuitized substrate (e.g., a printed circuit board), a semiconductor chip, an antenna and a power regulator, and is designed in one embodiment to be partly inserted within a good (e.g., a cardboard box) containing one or more of the goods being shipped and tracked. Alternatively, the device may be attached by other means (e.g., adhesive). A shipper can simply track the goods containing such devices using wireless communication devices (e.g., satellites) to quickly and readily ascertain the specific location of the goods at any time as well as the appropriate desired information relating to such goods (e.g., quantity, weight, type, etc.).

Owner:WACHOVIA CAPITAL FINANCE NEW ENGLAND AS AGENT +2

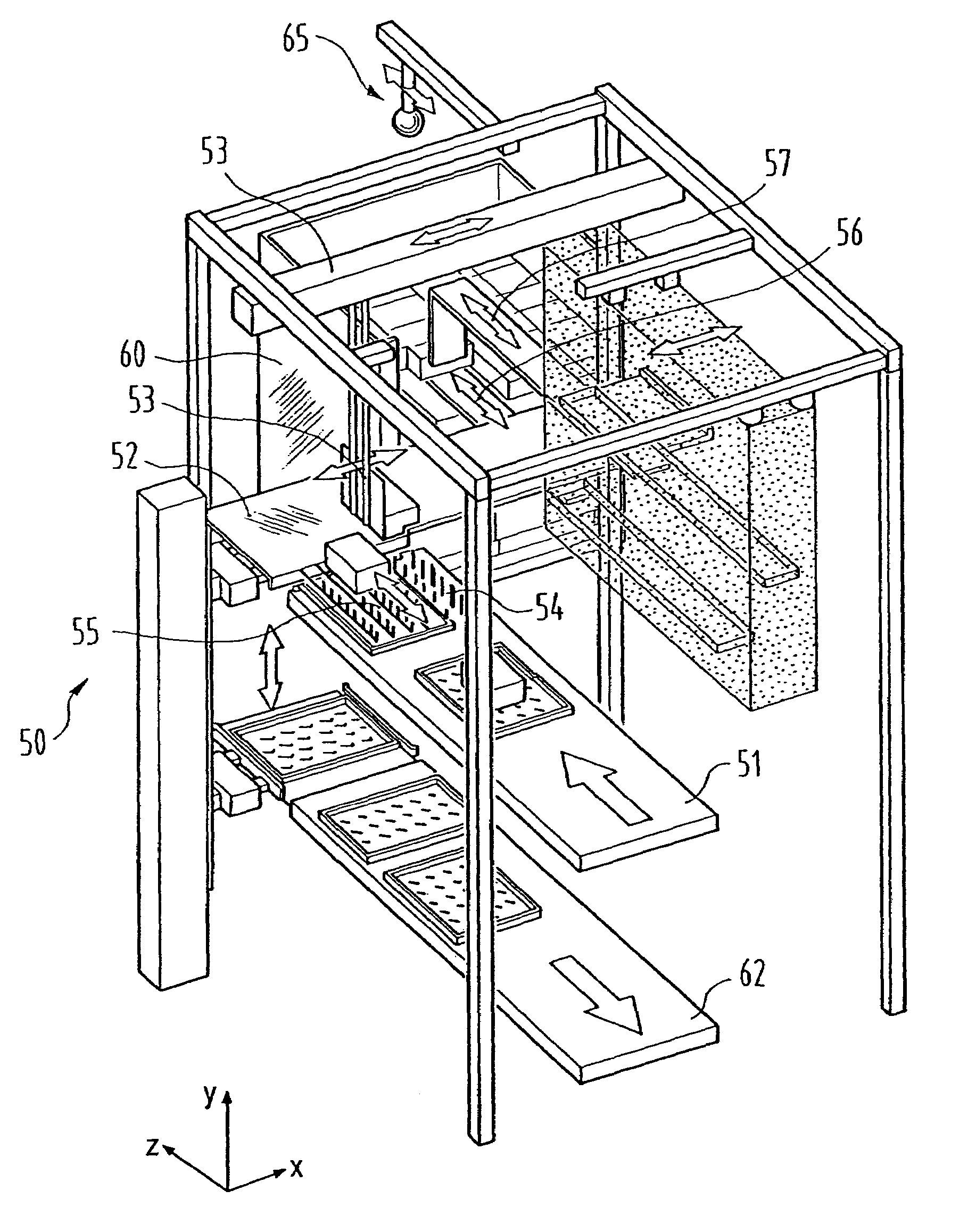

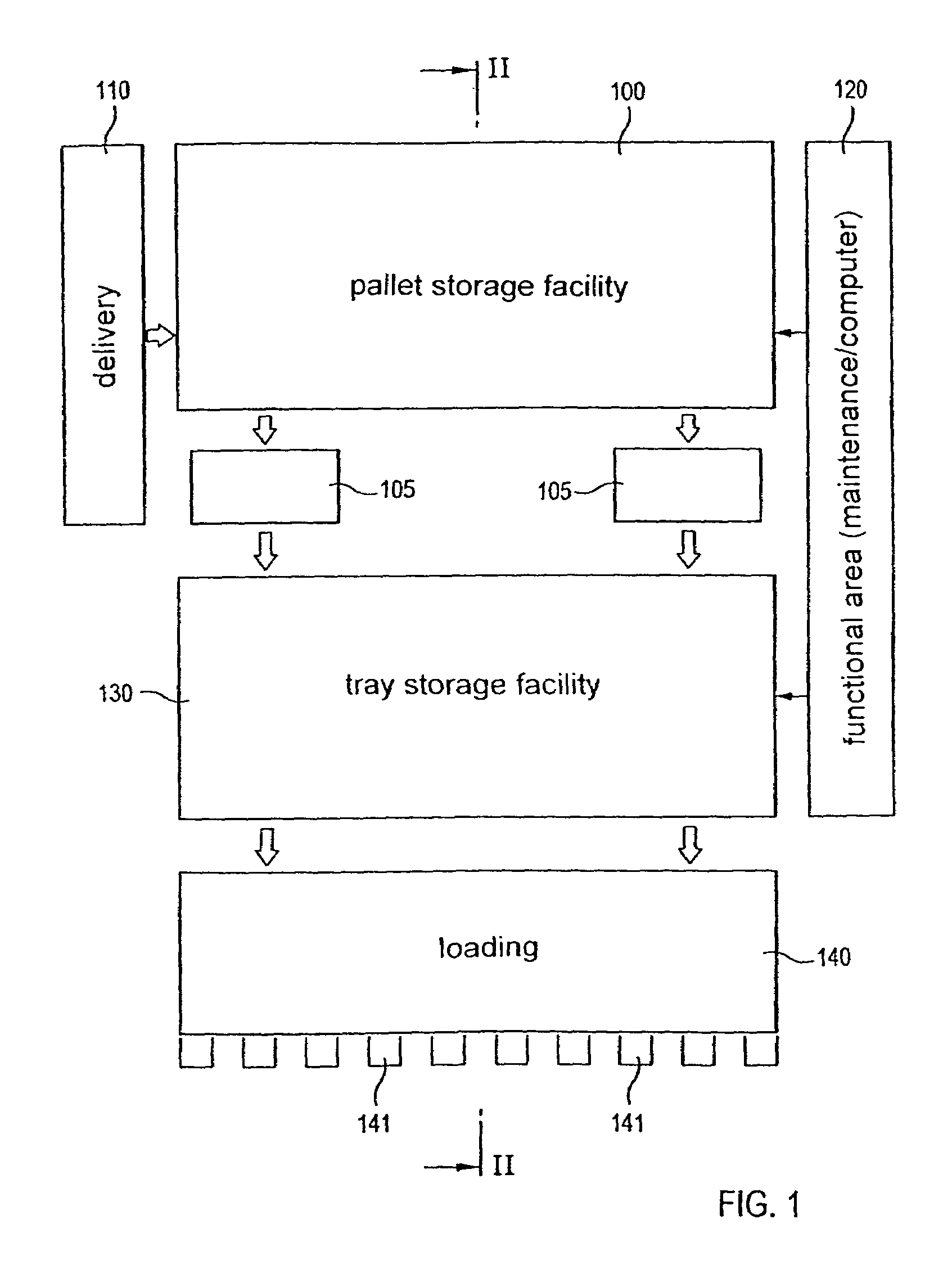

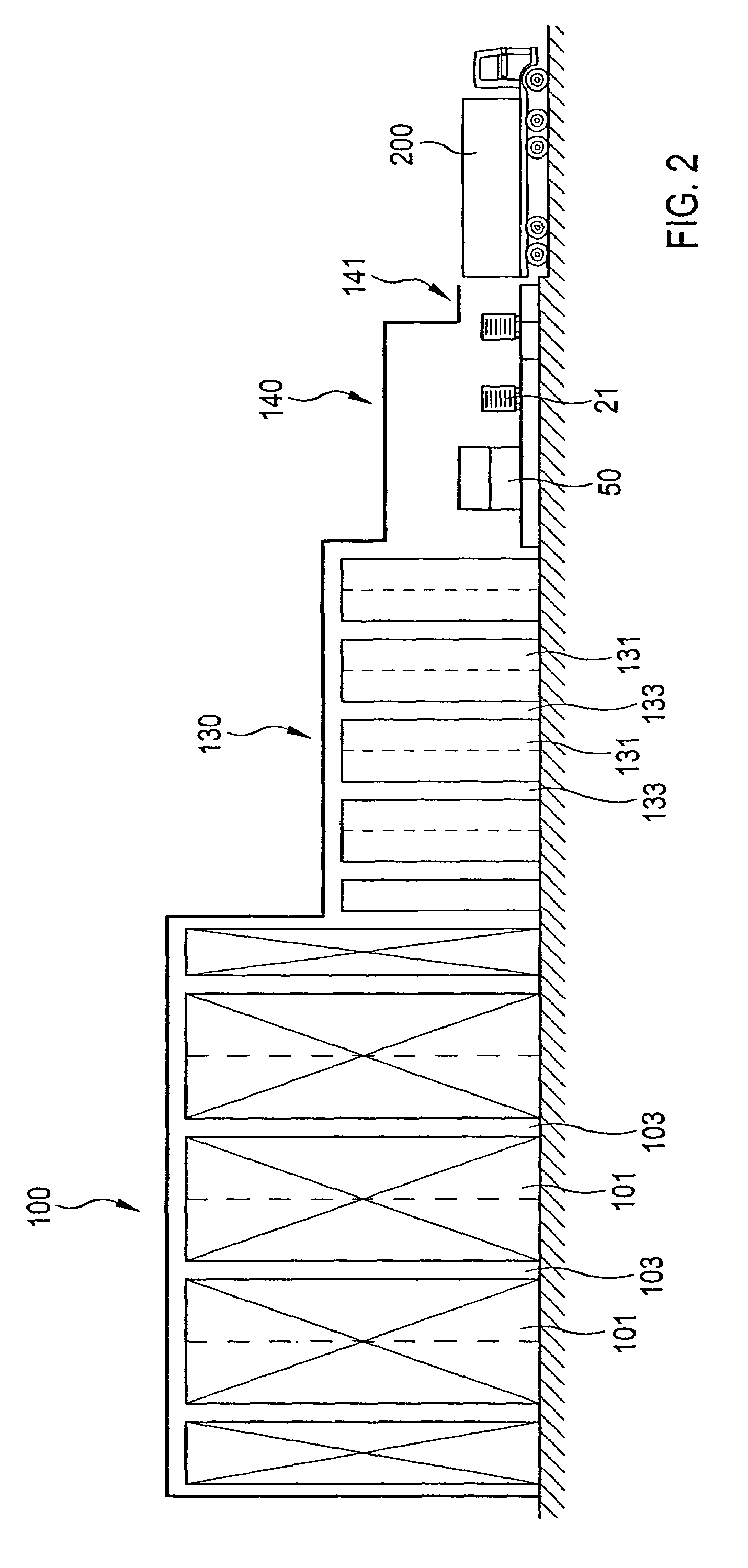

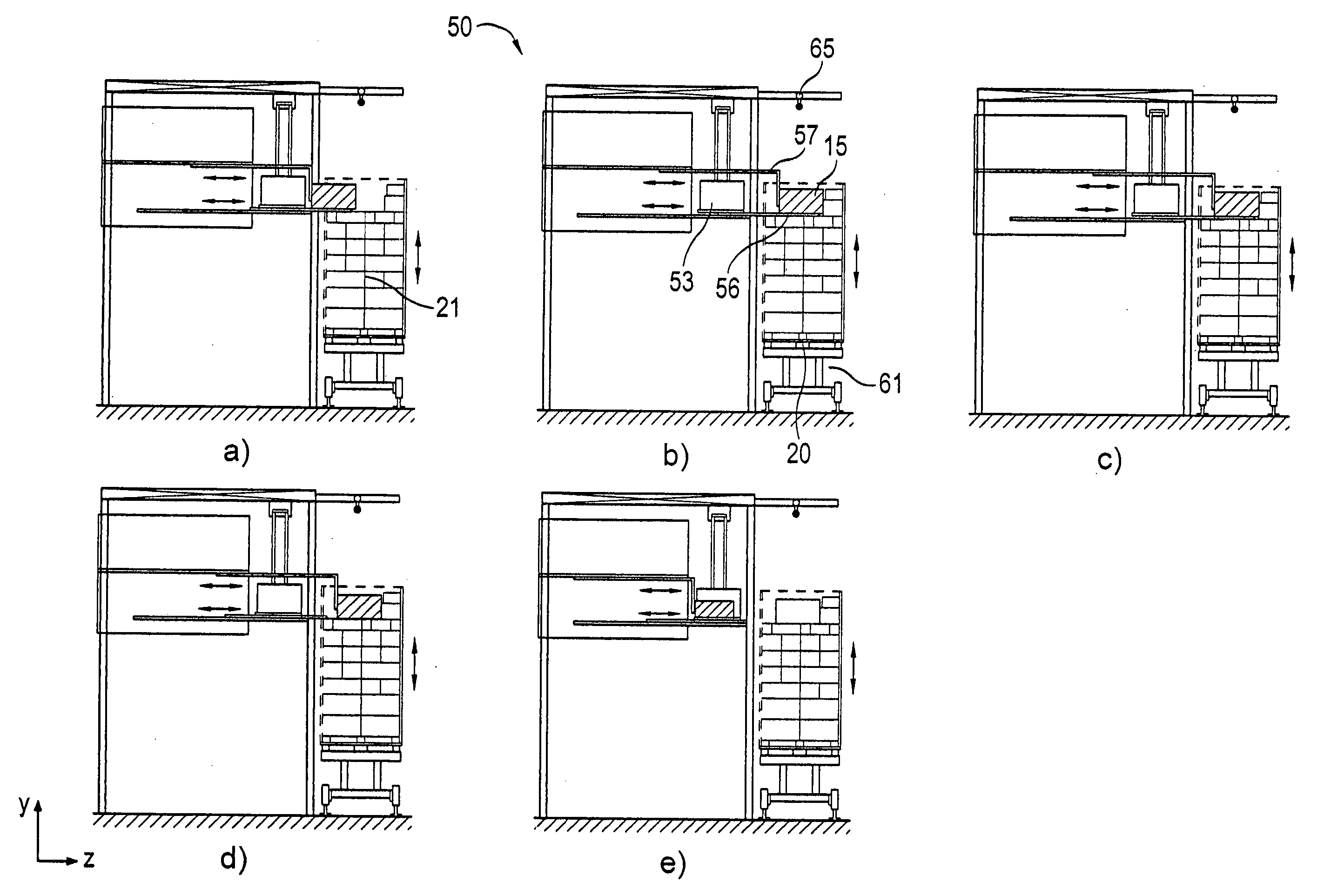

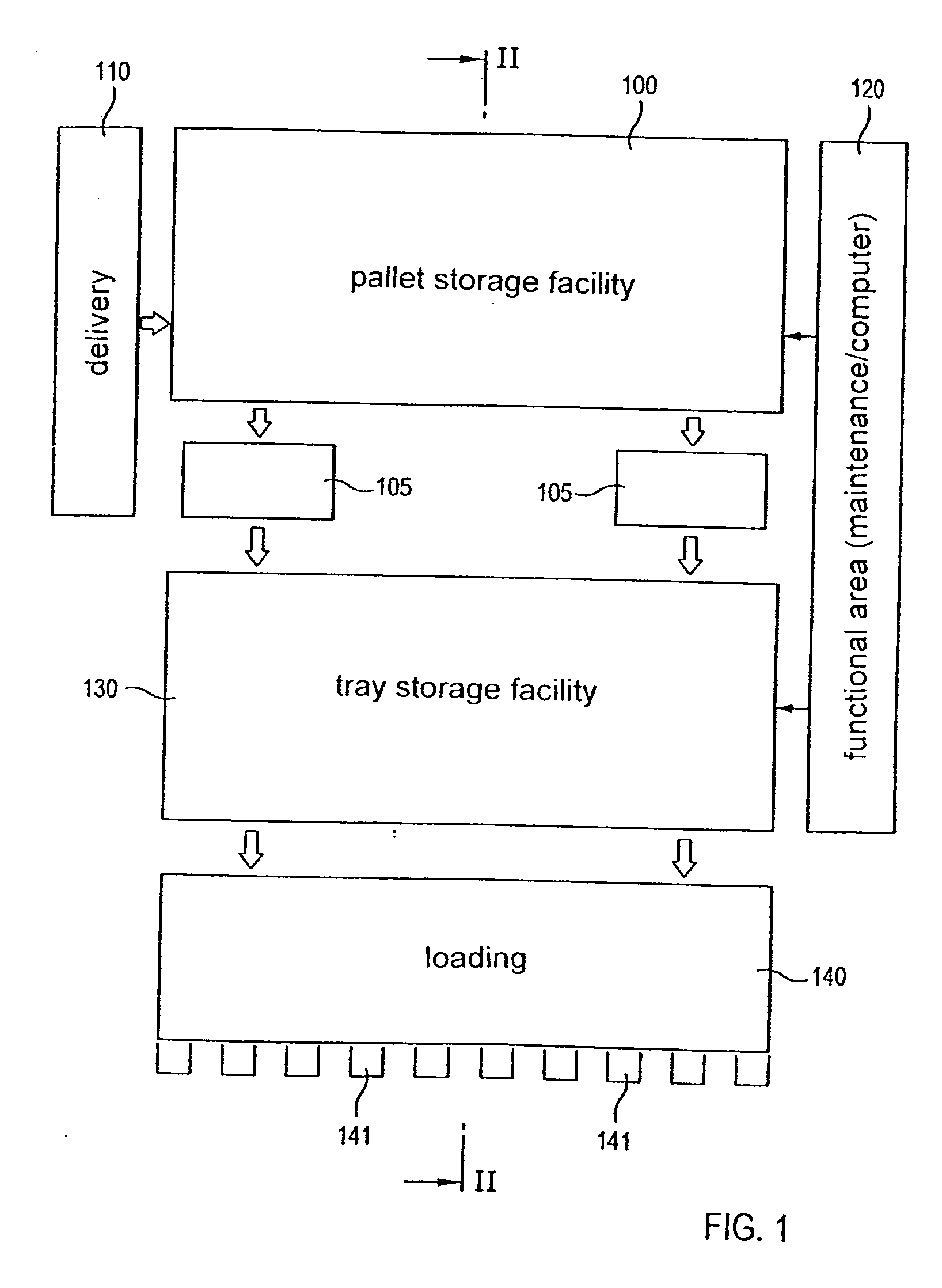

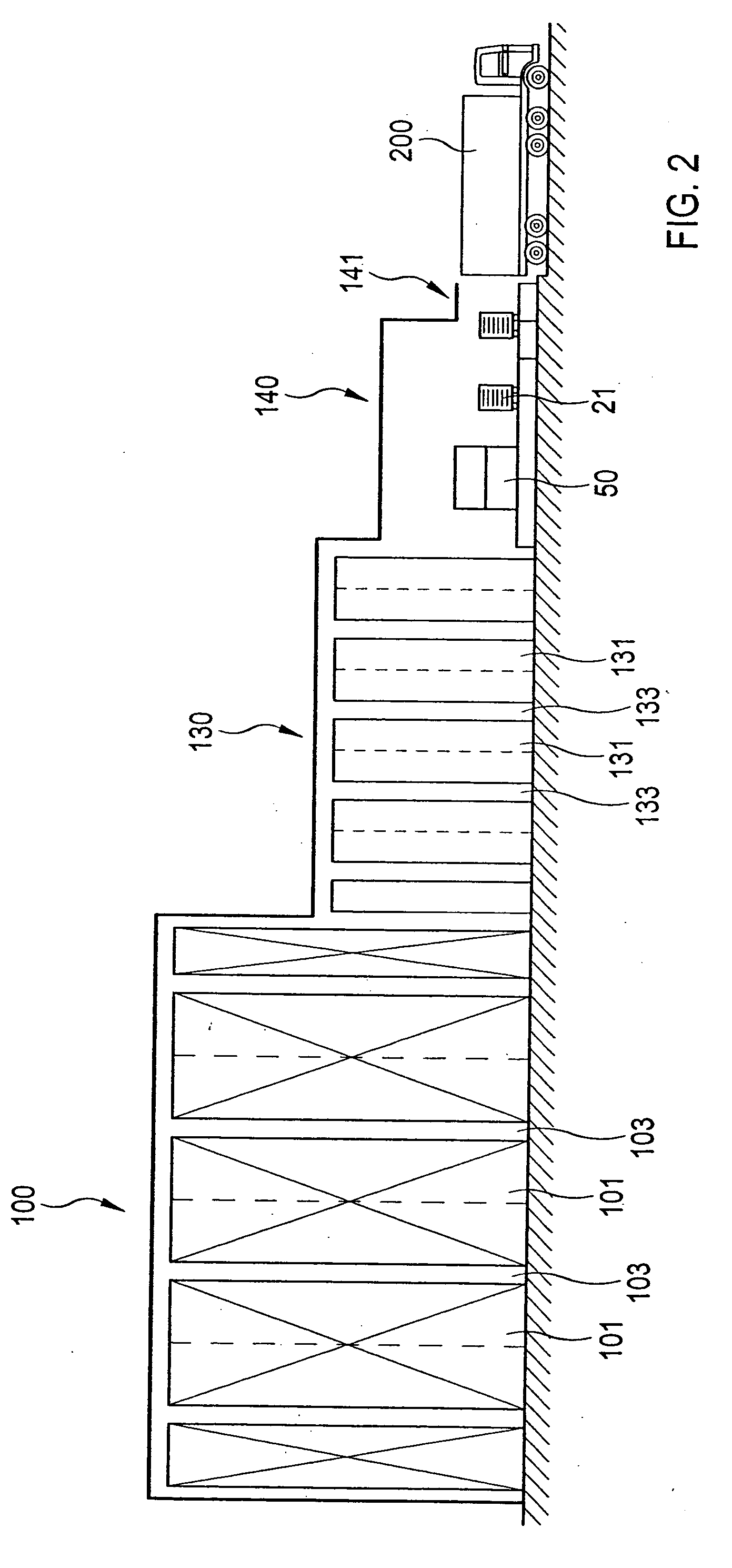

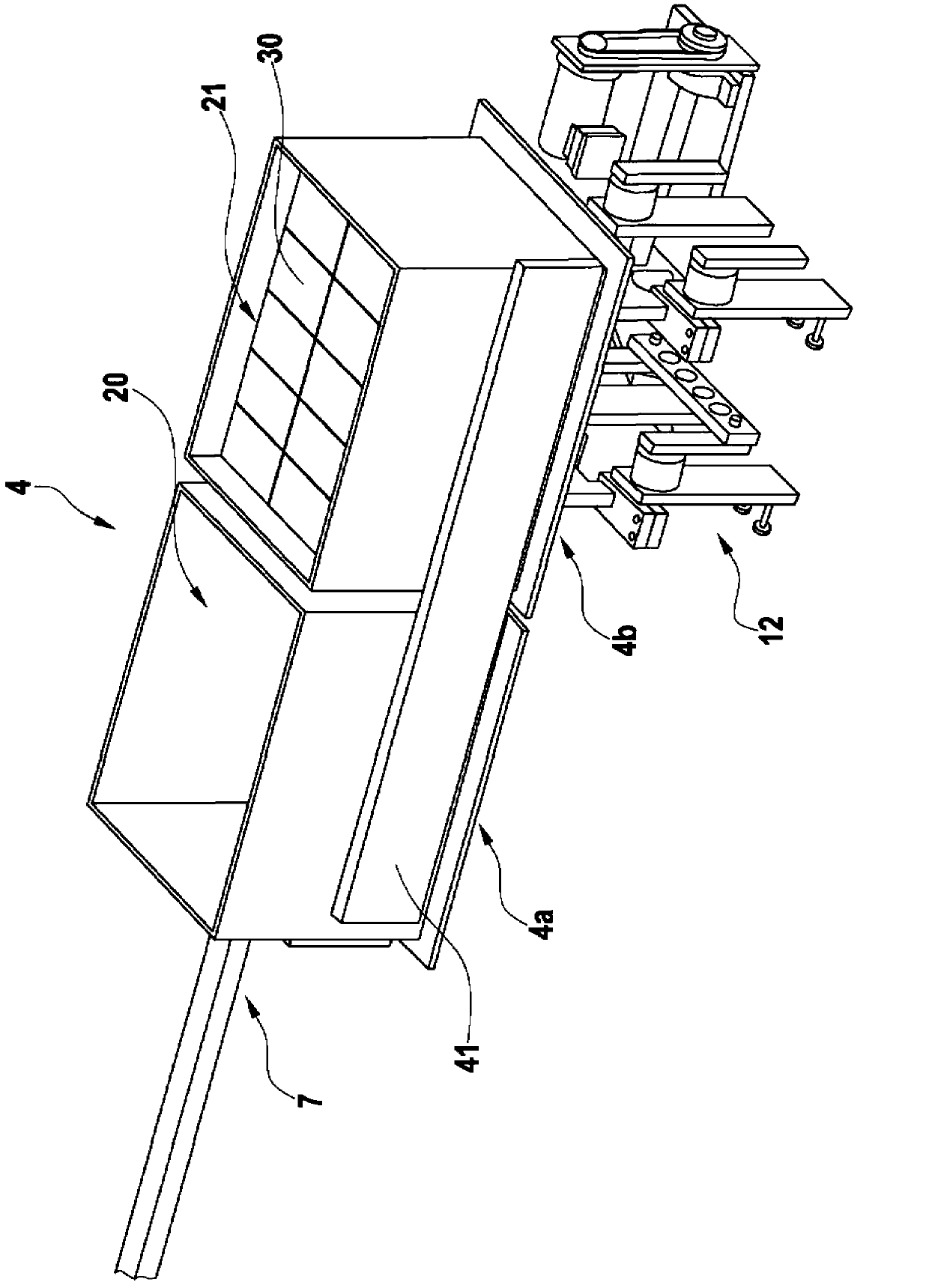

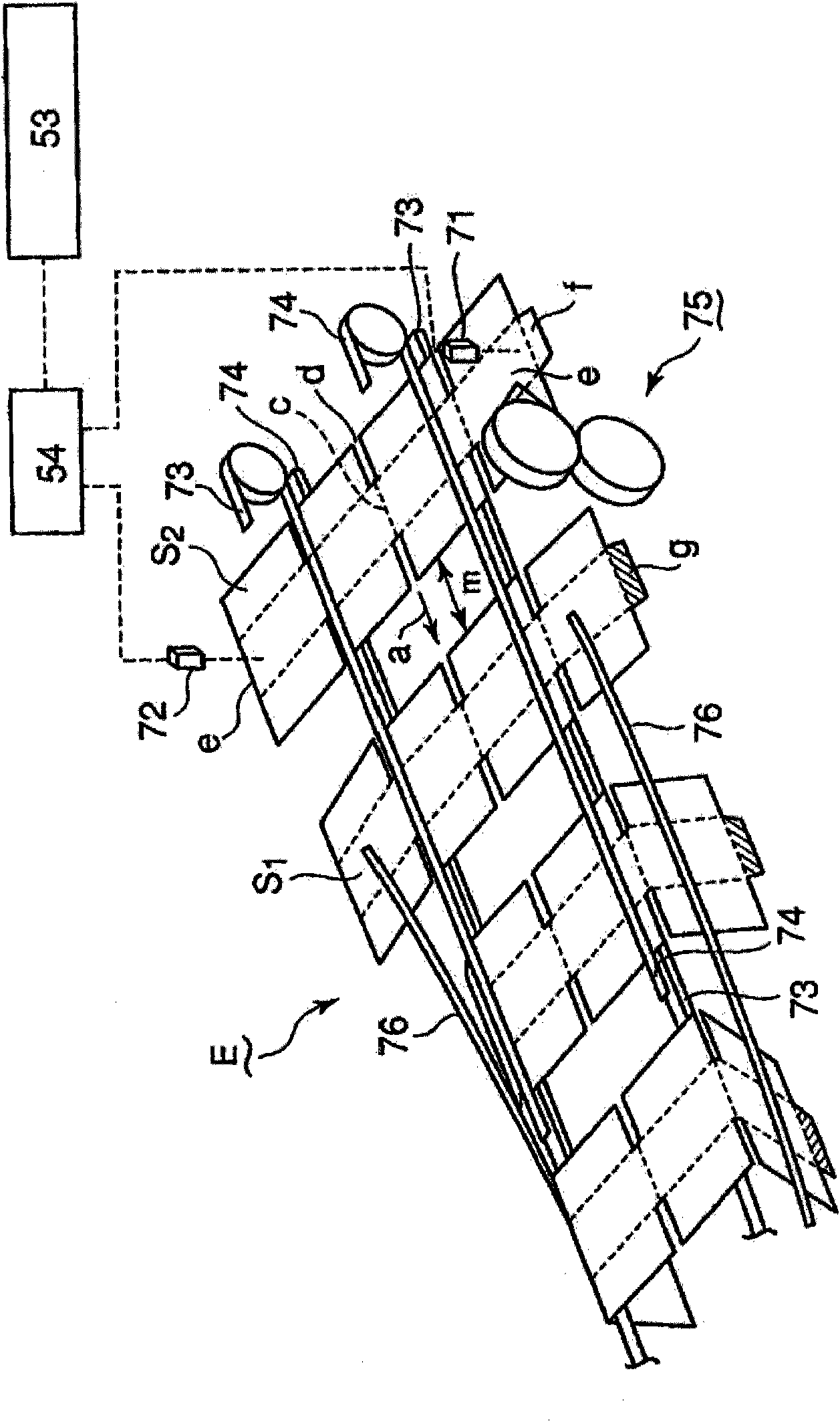

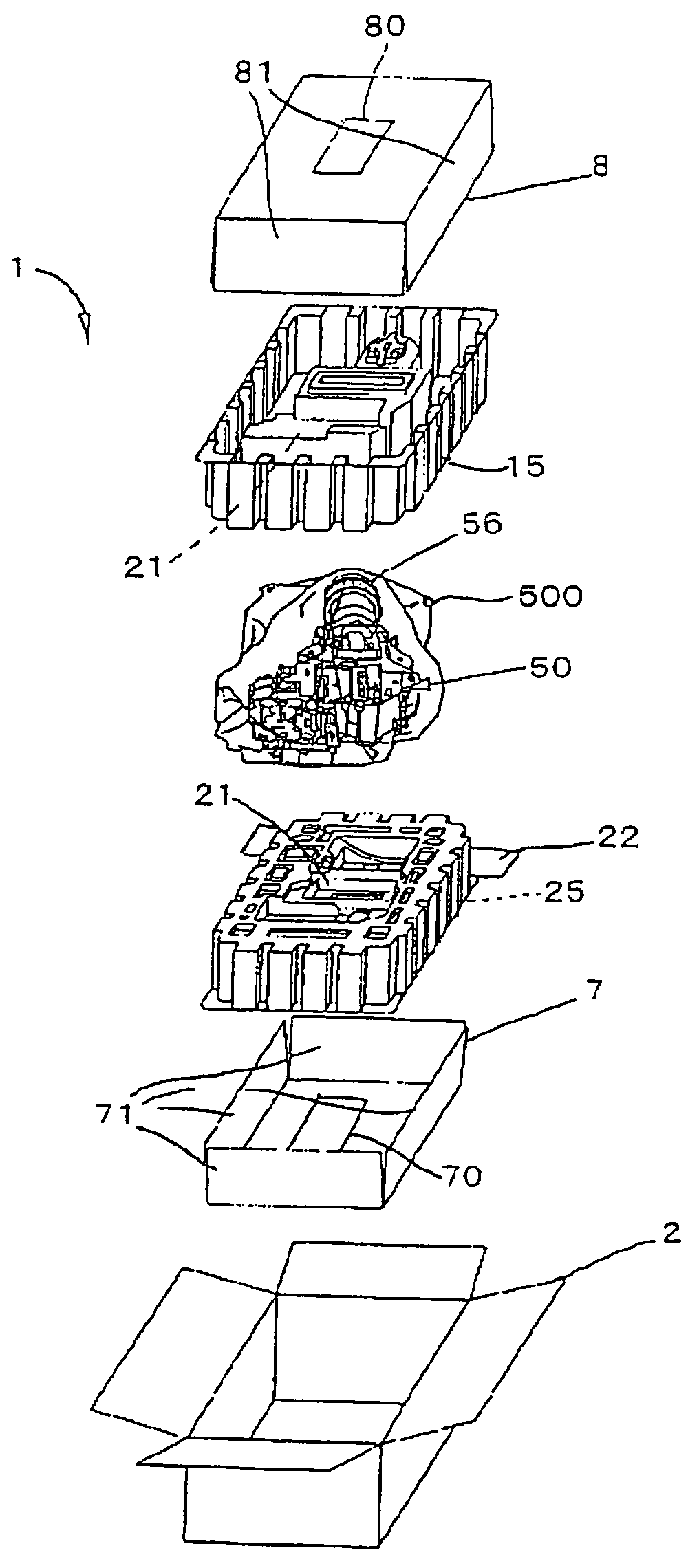

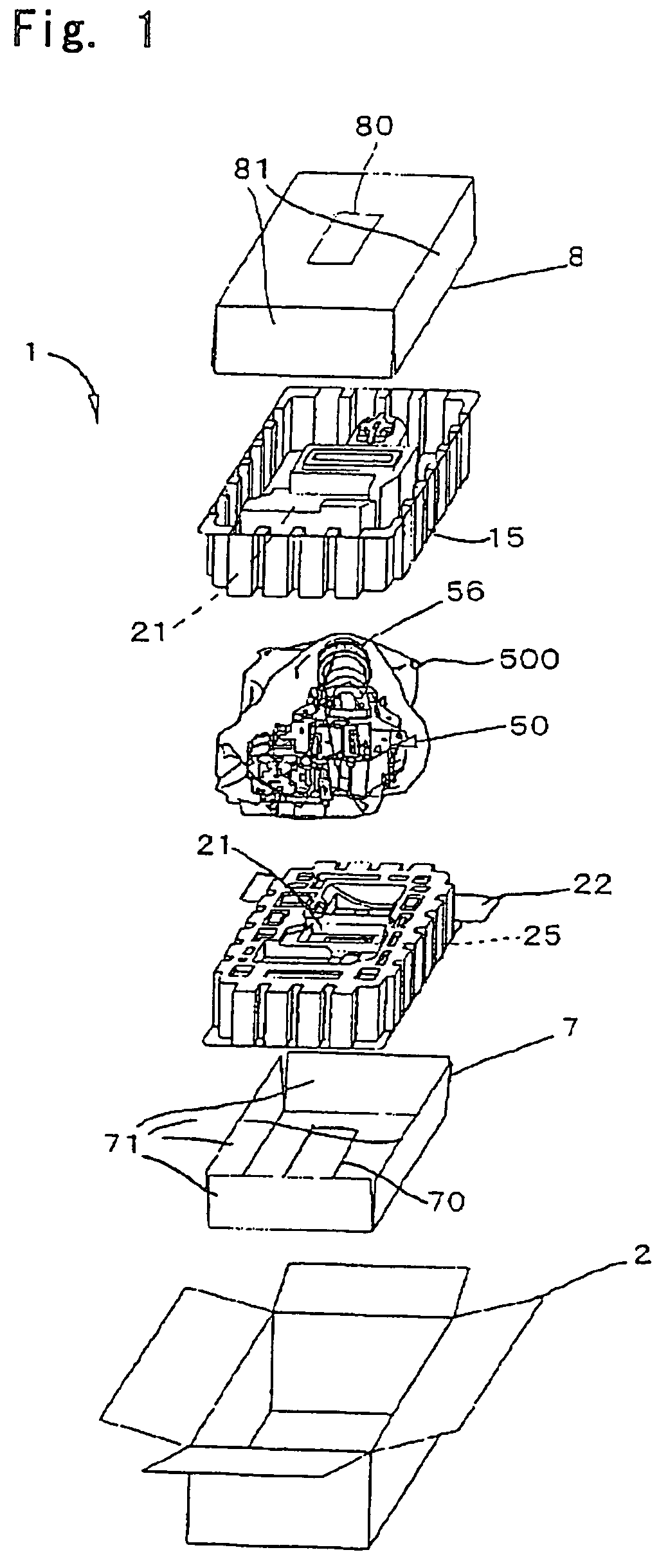

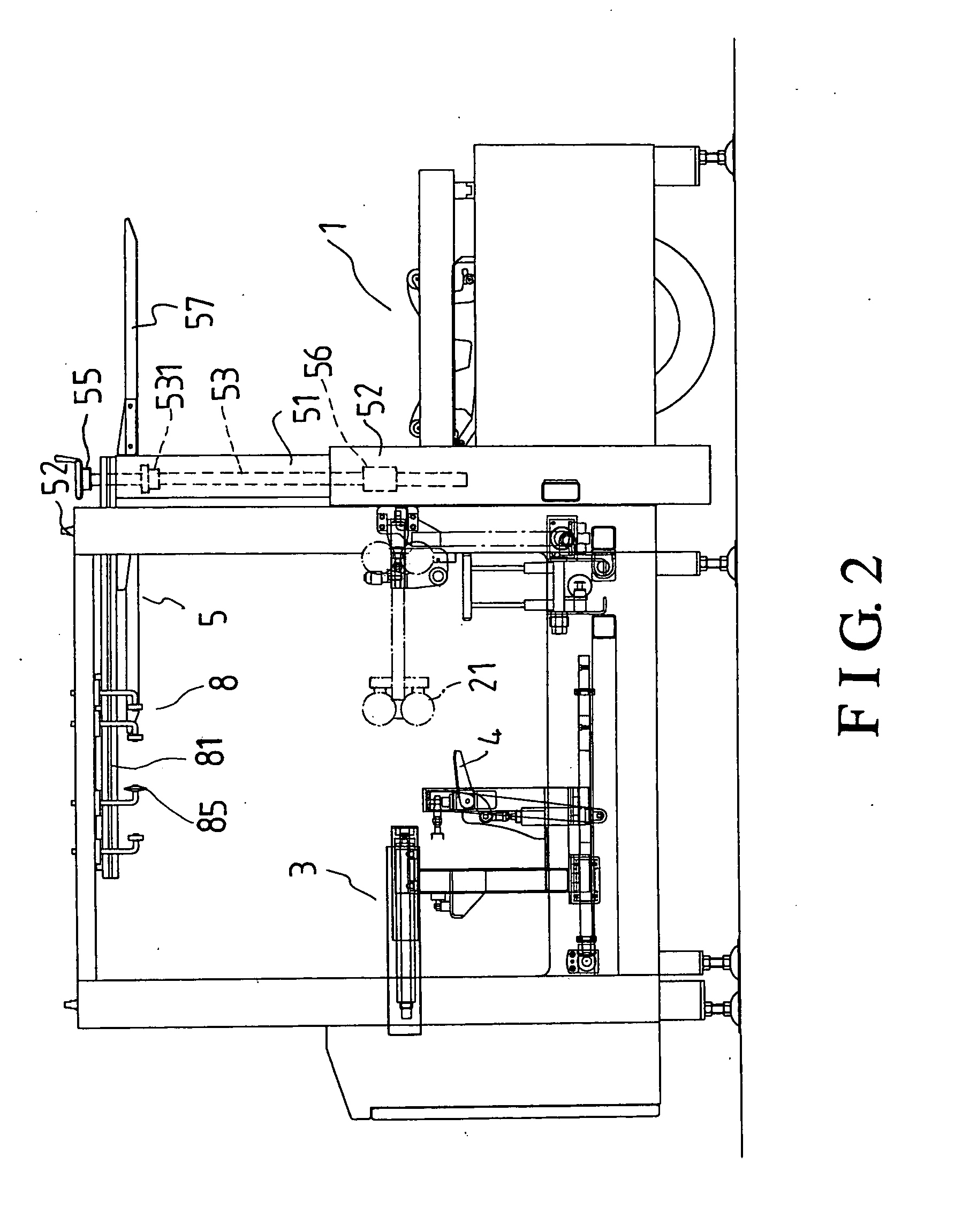

Apparatus for depositing a packing unit at a desired position on a load carrier

InactiveUS7047710B2Strong loadLoaded safely and reliablyWrappers shrinkageConveyorsEngineeringMaterial quality

A machine for loading a load carrier (20) such as a pallet with packing units (cardboard boxes, collis etc.), which form a load stack (21) on the load carrier, is presented. The machine includes handling and support mechanism (52–57), that allows a packing unit (15) to be loaded. The handling and support mechanism supports the load from below throughout the operation of loading from a feed device (51) onto the load stack. By virtue of the handling and support mechanism, the packing unit may be deposited at any selectable spatial position on the load stack. It is therefore possible to form an optimized load stack on the load carrier in which the packing units are always supported from below, with the result that the loading is not dependent upon the material quality of the packaging of the packing unit.

Owner:LOGISTIK INFORMATIK

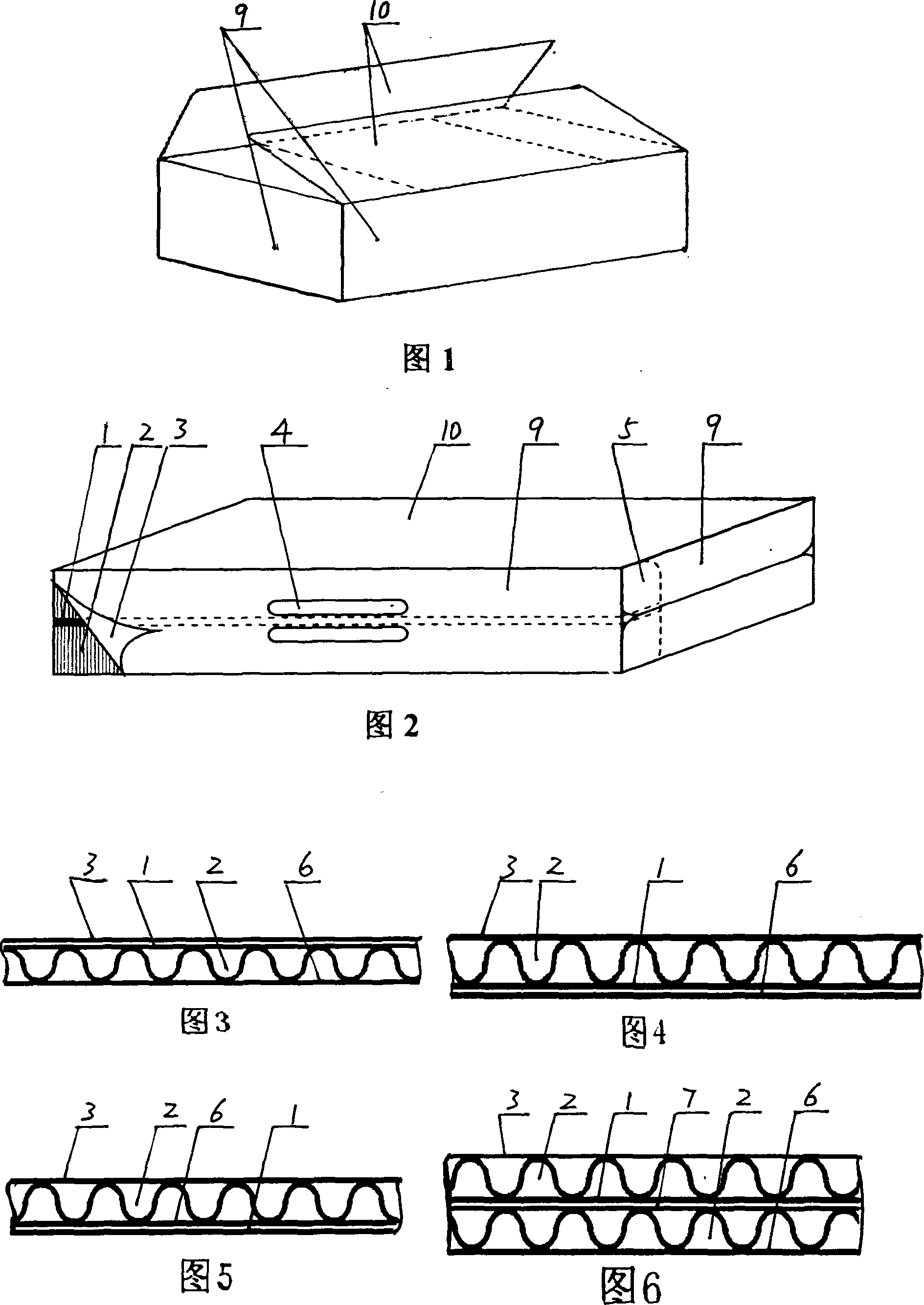

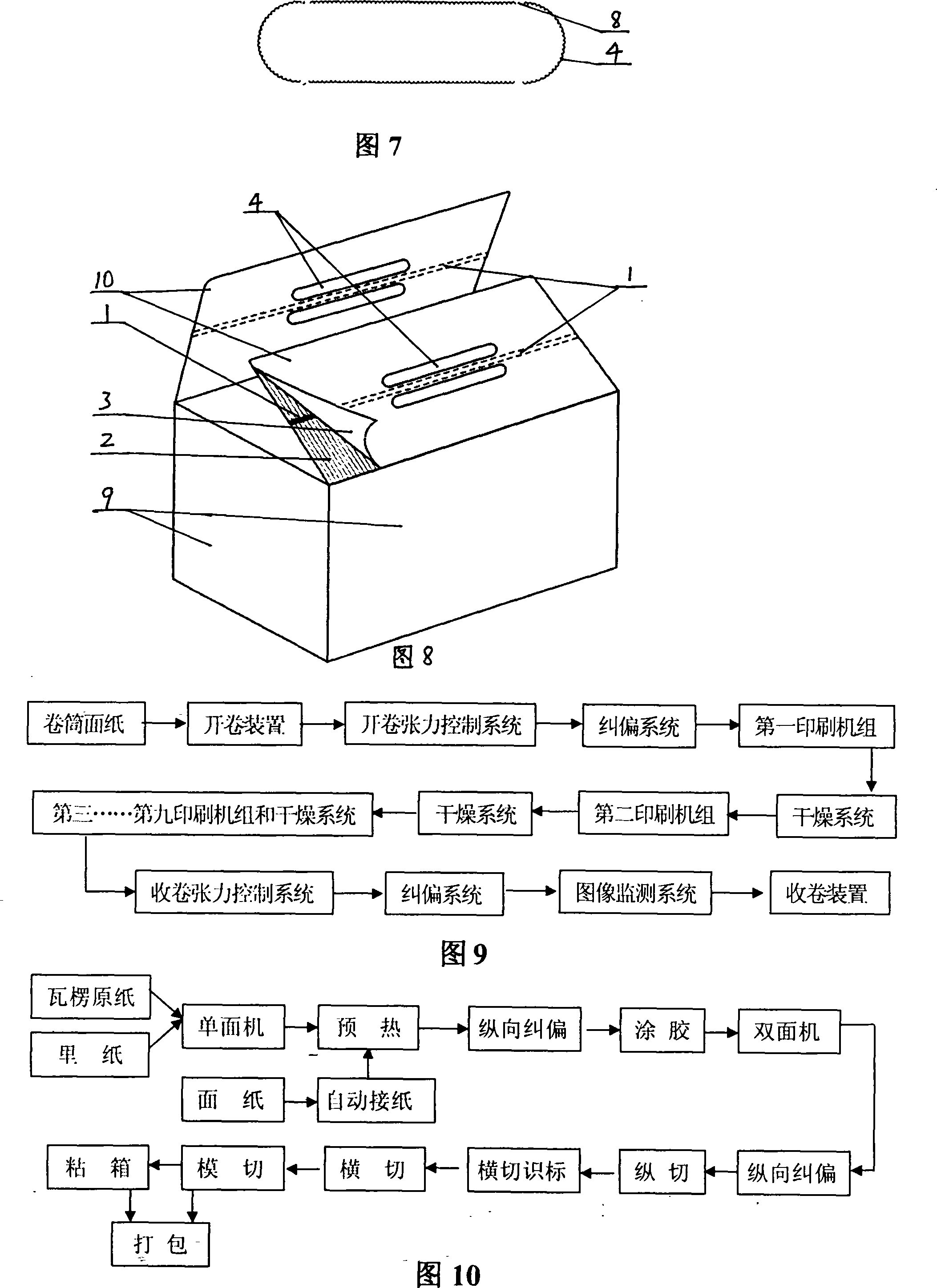

Flexible preprinting cardboard box, production method and production equipment thereof

The invention discloses a flexibly pre-printed paper box, a manufacture method and a manufacture equipment thereof; the paper box has a box body consisting of a printed sheet, corrugated paper, inner paper and in some cases core paper; color patterns on the printed sheet are flexibly printed on the printed sheet before the paper box is manufactured. The manufacture method consists of a manufacture method of flexibly printed paper sheet and a manufacture method of the paper box; firstly the color patterns are manufactured on the printed sheet with a rotary flexographic press; then bright oil is applied, and then the printed sheet, the corrugated paper and the inner paper are made into the paper box by adopting a corrugated paper manufacture device; some paper box also comprises the core paper. The manufacture device consists of the rotary flexoographic press, the corrugated paper manufacture equipment and a die-cutting machine. Adopting the method and the equipment of the invention, the manufactured paper box is green and environmental protective, nice in printed patterns, high in compressive strength, convenient in lifting and low in reject rate; compared with paper boxes which are printed with offset printing and directly with flexible plate of the same quality requirement, the paper box of the invention has lower cost.

Owner:保定中士达包装有限公司

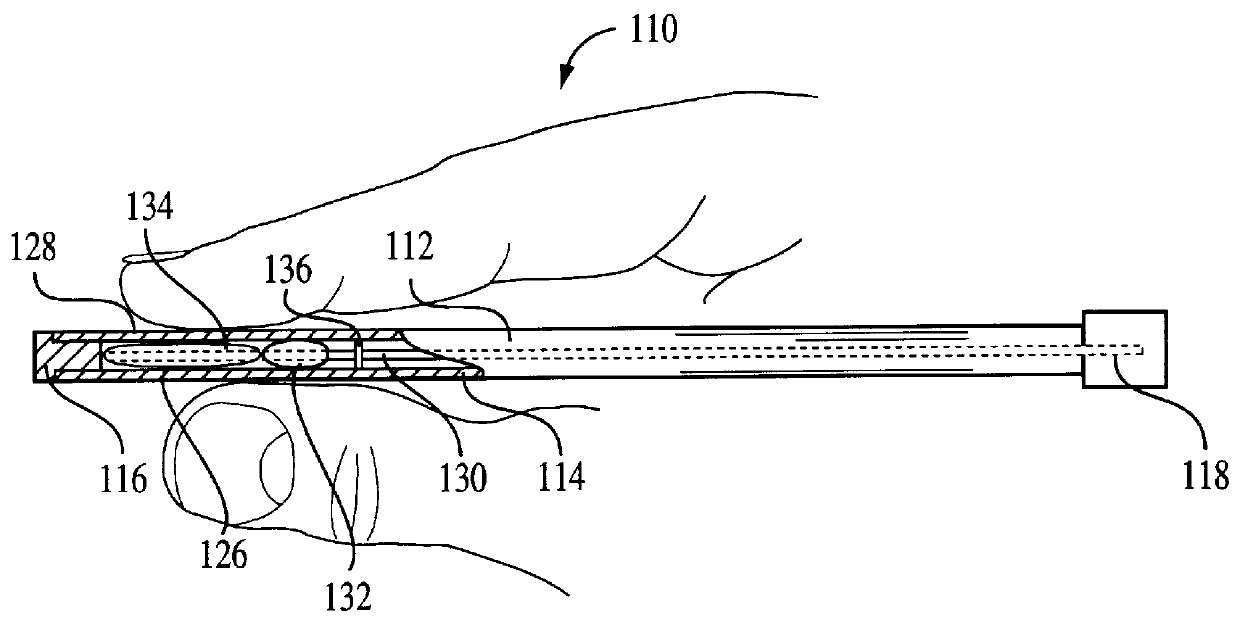

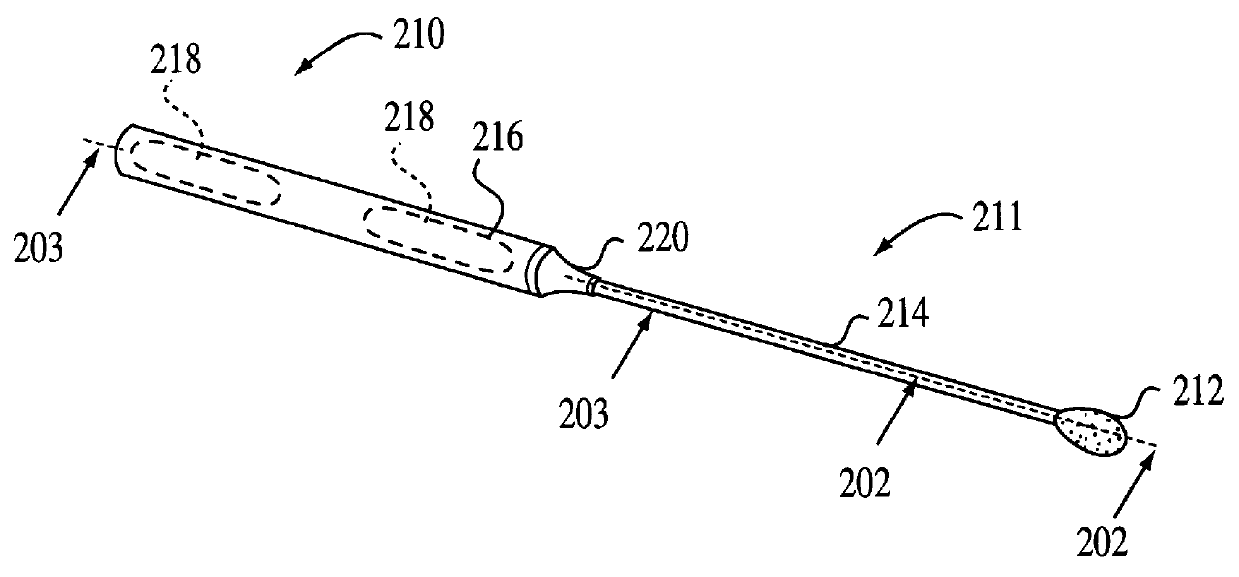

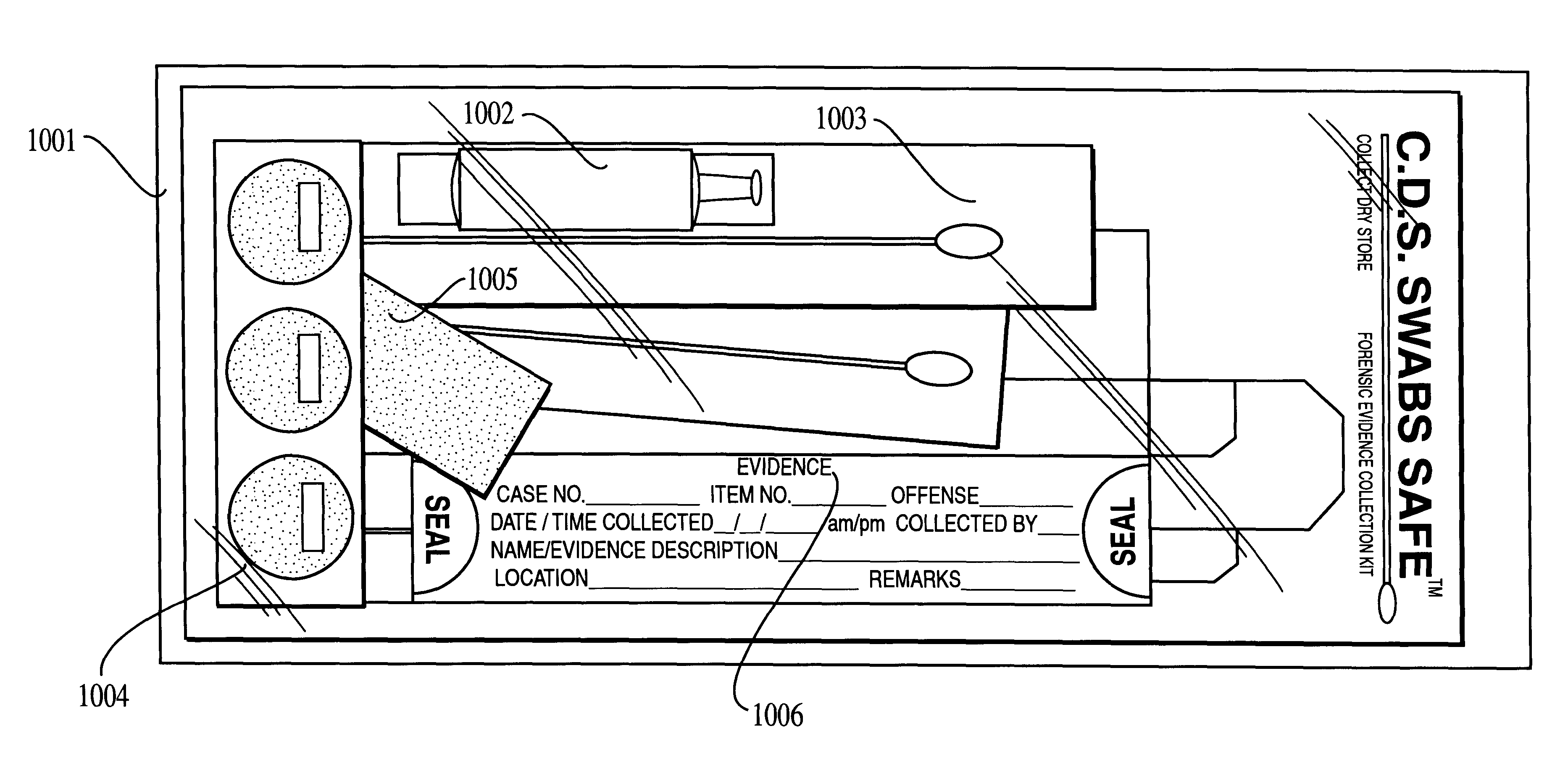

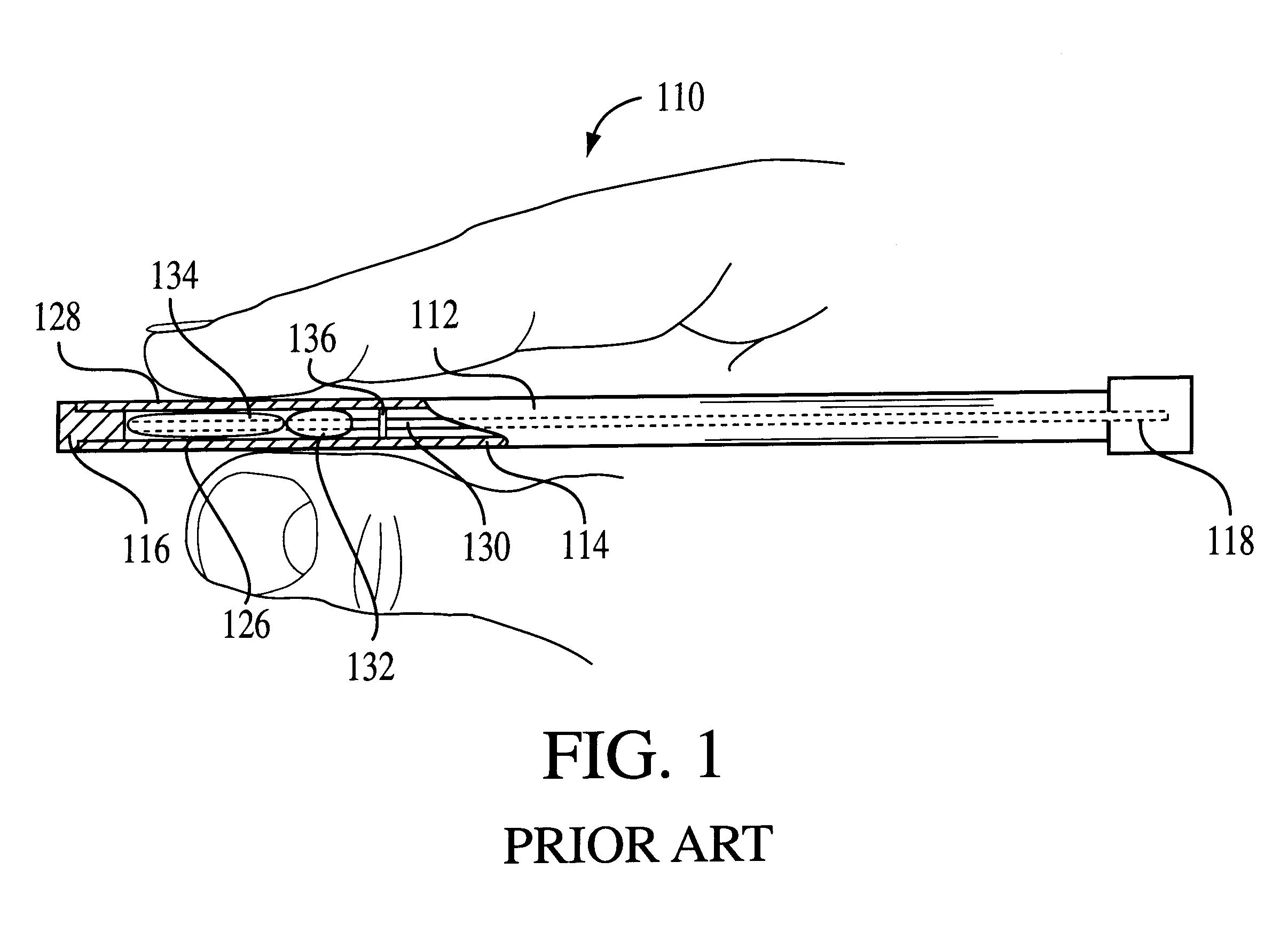

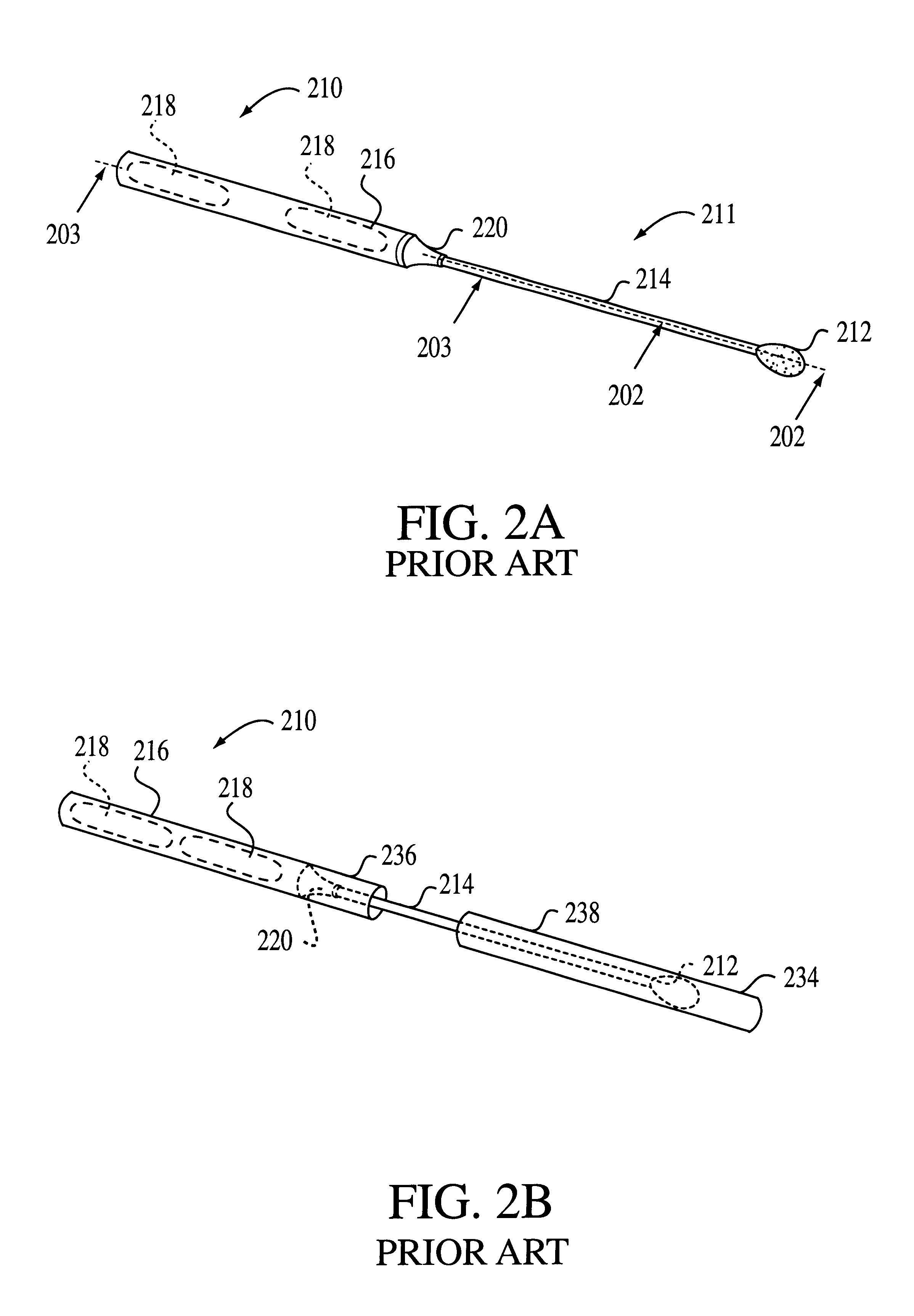

Foldable cardboard box for contact-free drying and long-term storage of biological evidence recovered on cotton swabs and forensic evidence collection kit including same

InactiveUS6085907APrevent tamperingDispensing apparatusVaccination/ovulation diagnosticsContact freeEngineering

A biological evidence collection apparatus provides contact-free drying, storage, identification, and protection against sample switch and contamination of collected biological samples. The apparatus may include the described forensic evidence collection kit which provides a set of tools for the collection and storage of biological evidence. The collection apparatus may also be used as part of a sexual assault evidence collection kit, or a kit for the collection of buccal swabs, and the like.

Owner:INST OF LEGAL MEDICINE OF THE UNIV OF BERNE

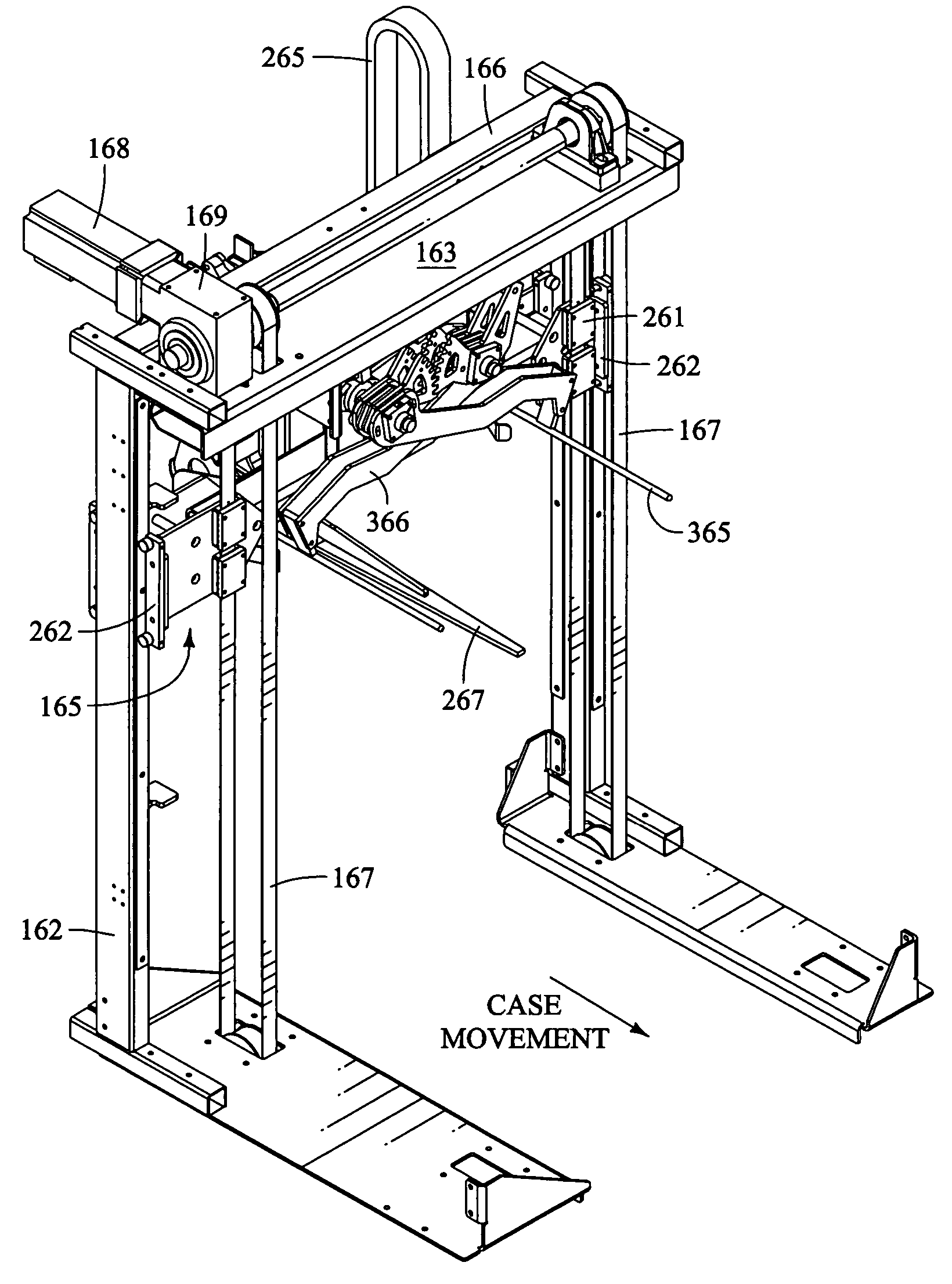

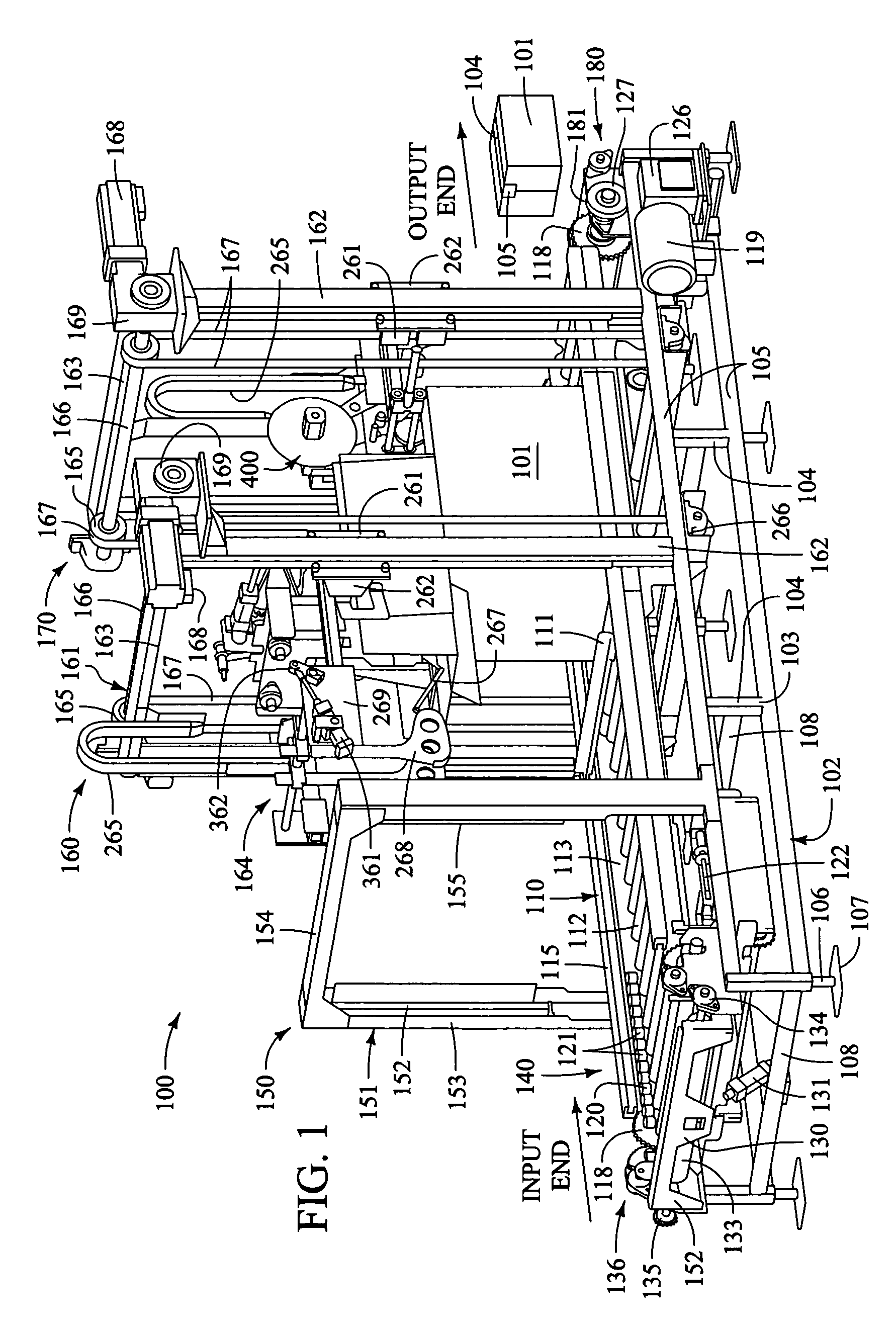

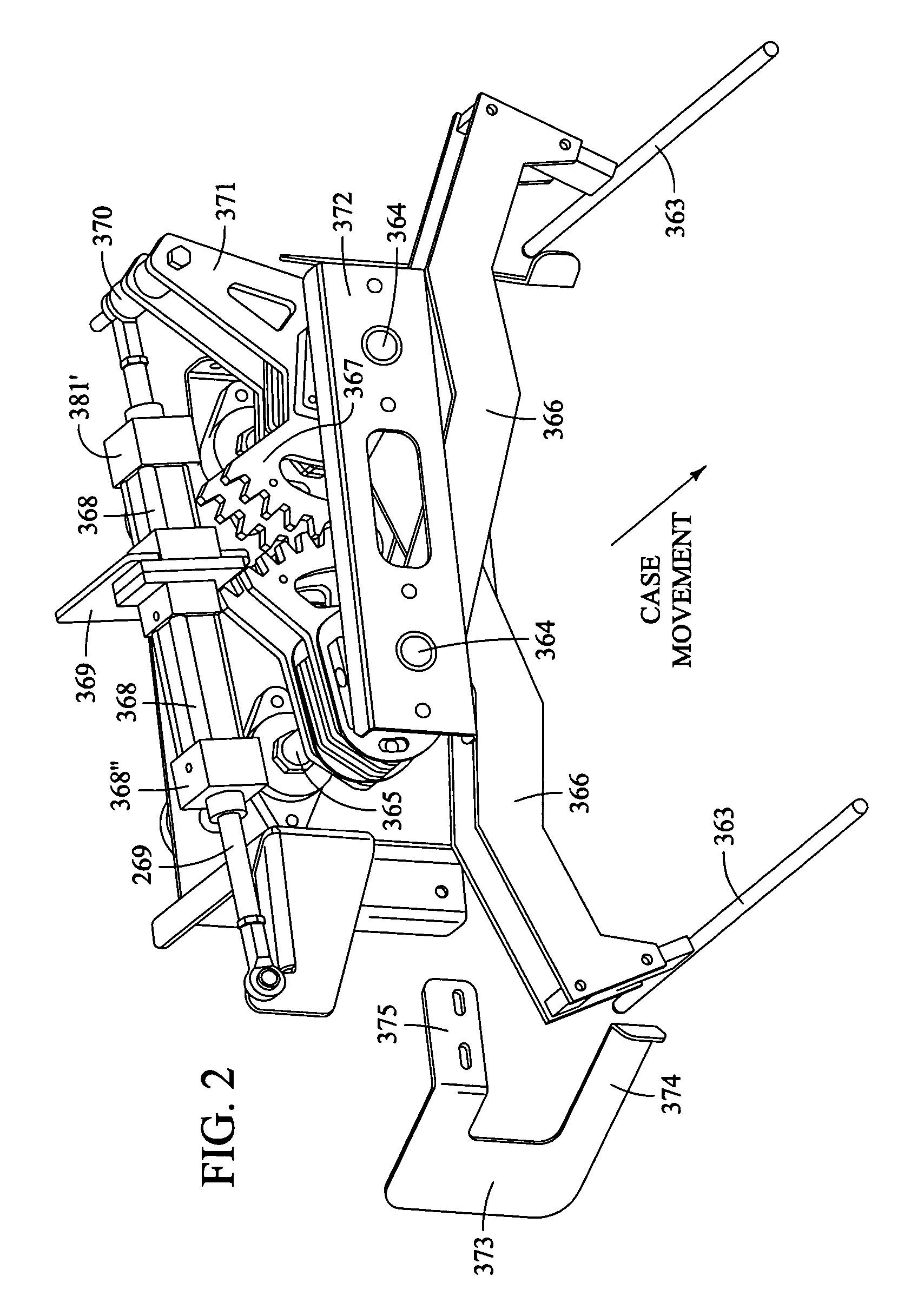

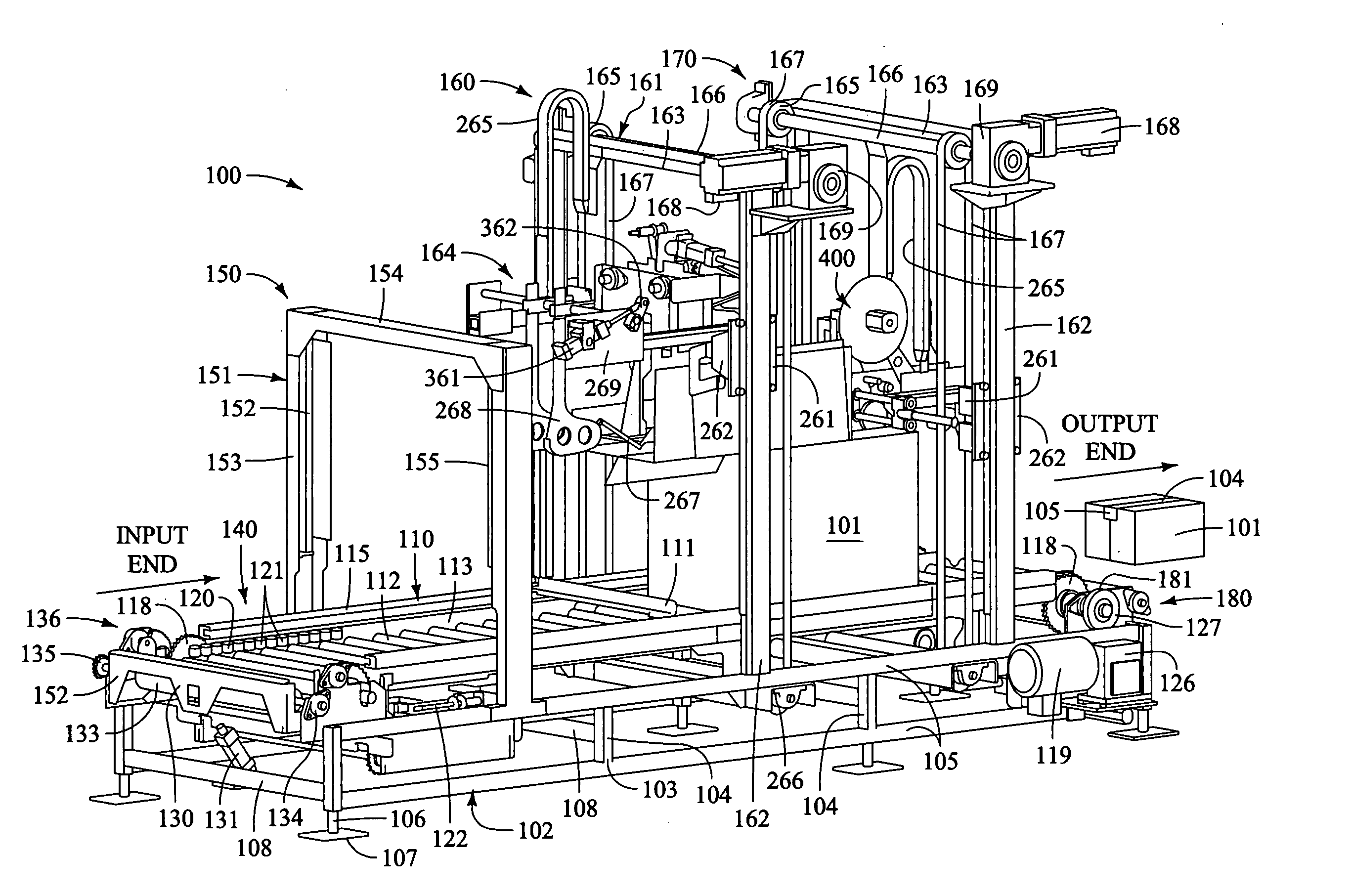

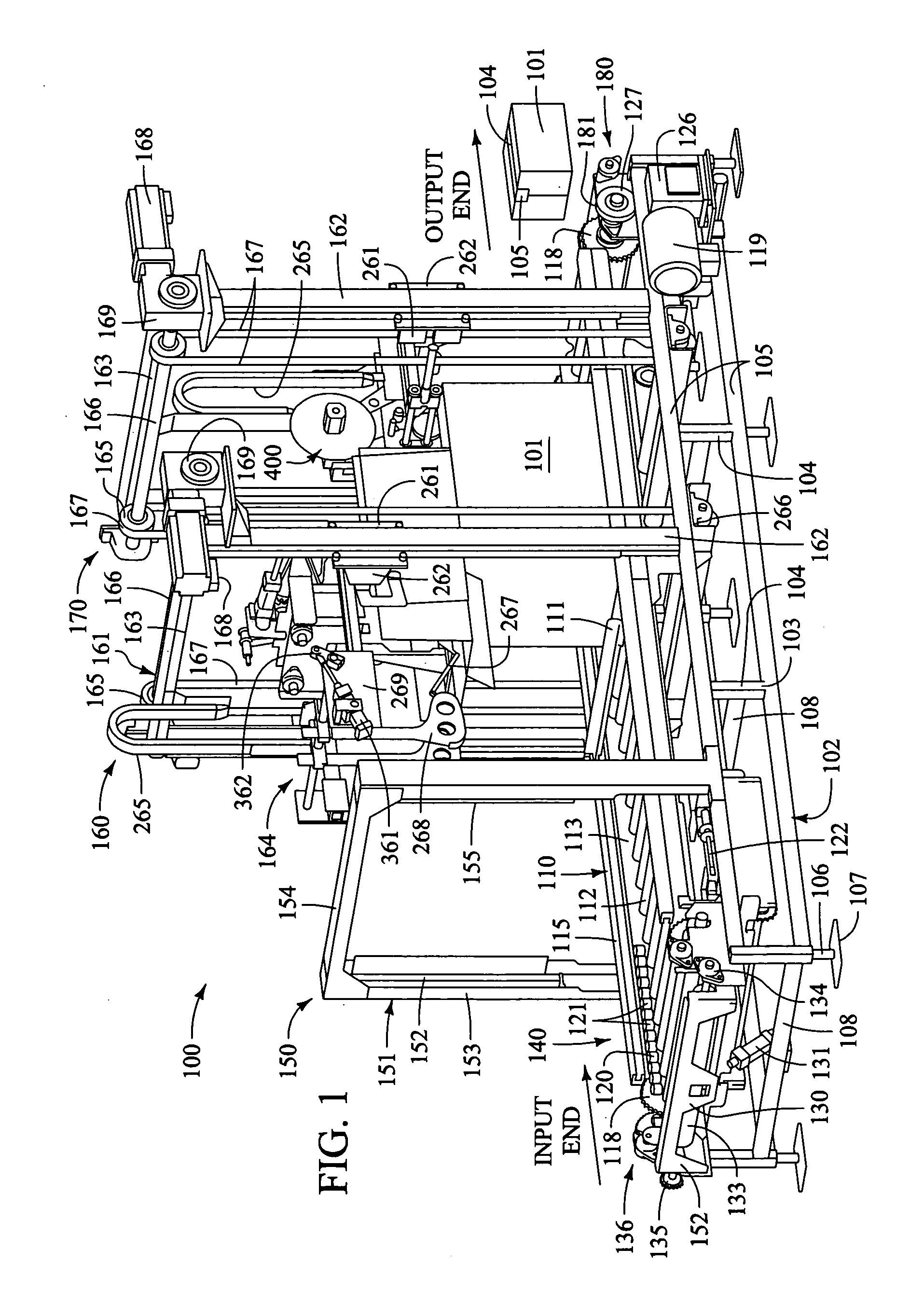

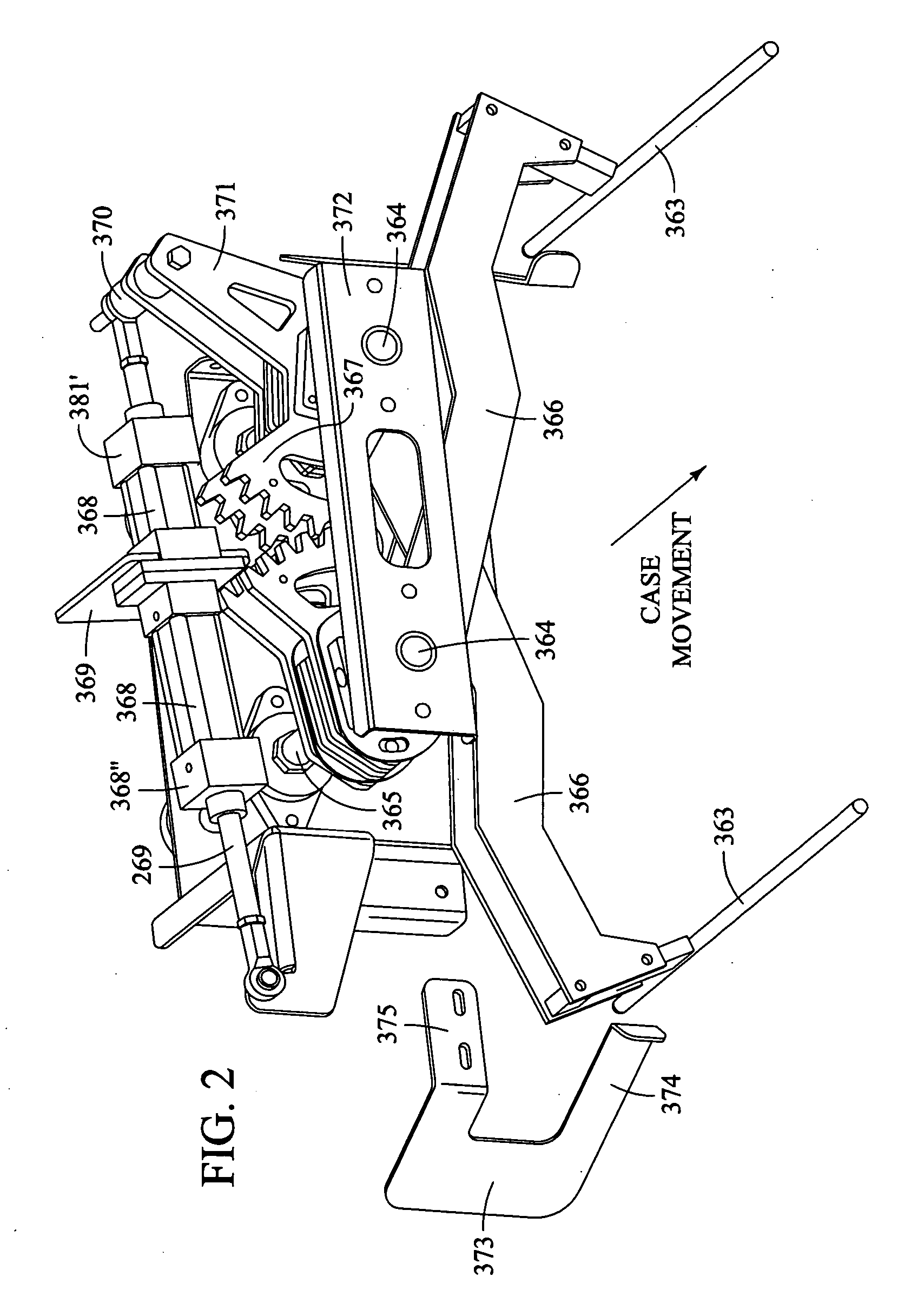

Packaging case closing and tape sealing machine and processes

A machine for closing and sealing cardboard boxes or other packaging cases with random sizes of cases presented. An input gate controls passage of cases onto at least one conveyor that moves the cases through the machine. An input positioning stage centers and squares the case. A measuring station performs a primary measurement of the width and height of the open case. A closing station and tape sealing station are adjusted to the primary case size measurement. The case closing station then closes the case. The side major flaps are closed using a major flap closer with crossed arms pivoted at separated pivot axes. The sealing station has a secondary or closed case measurement detector which more accurately adjusts the tape applicator height. Lateral support heads engage the sides of the case to prevent distortion while tape is applied.

Owner:R A PEARSON

Packaging device

InactiveUS20130283731A1Easy to convertEasy to adaptSolid materialLiquid materialEngineeringMechanical engineering

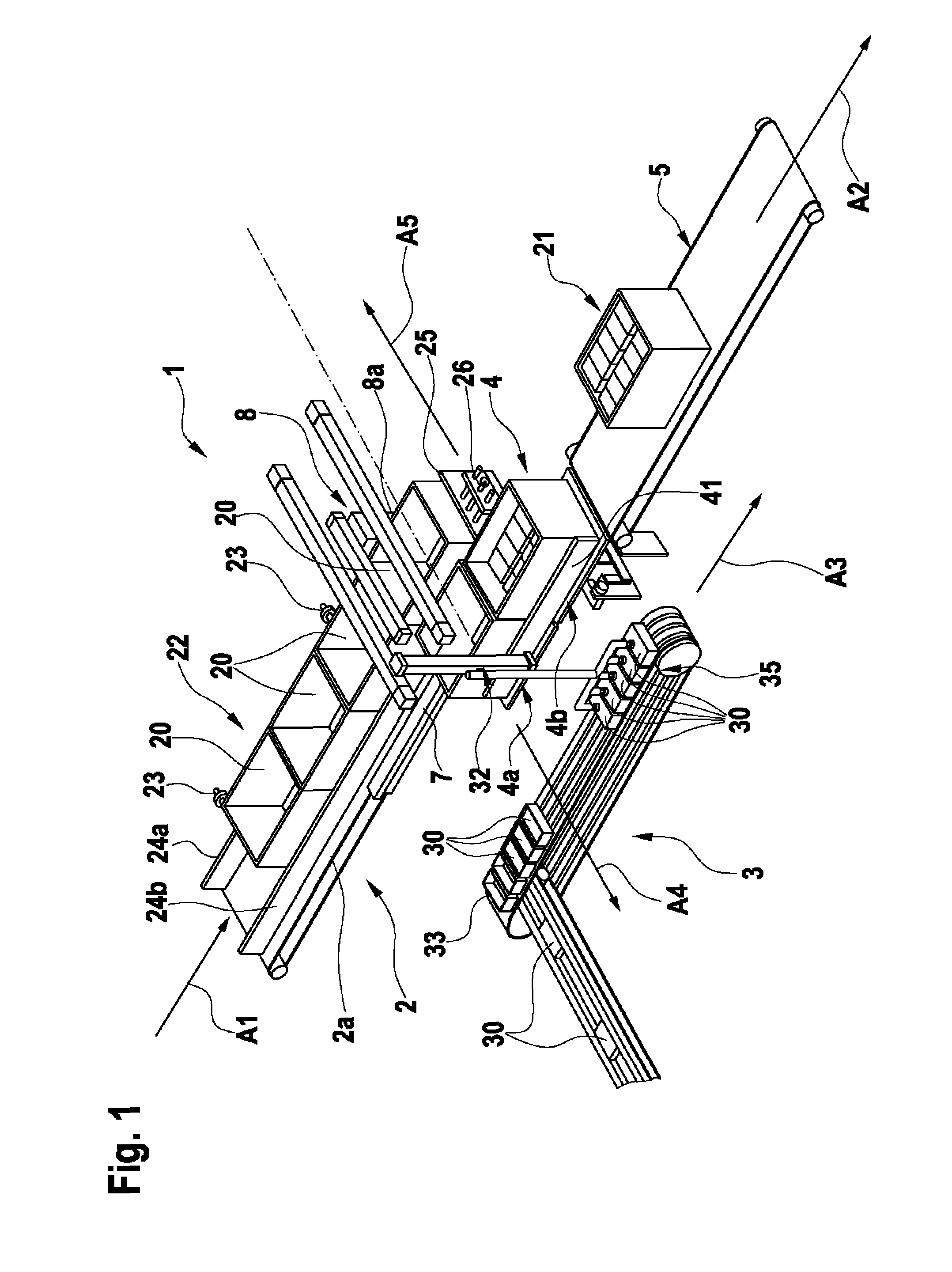

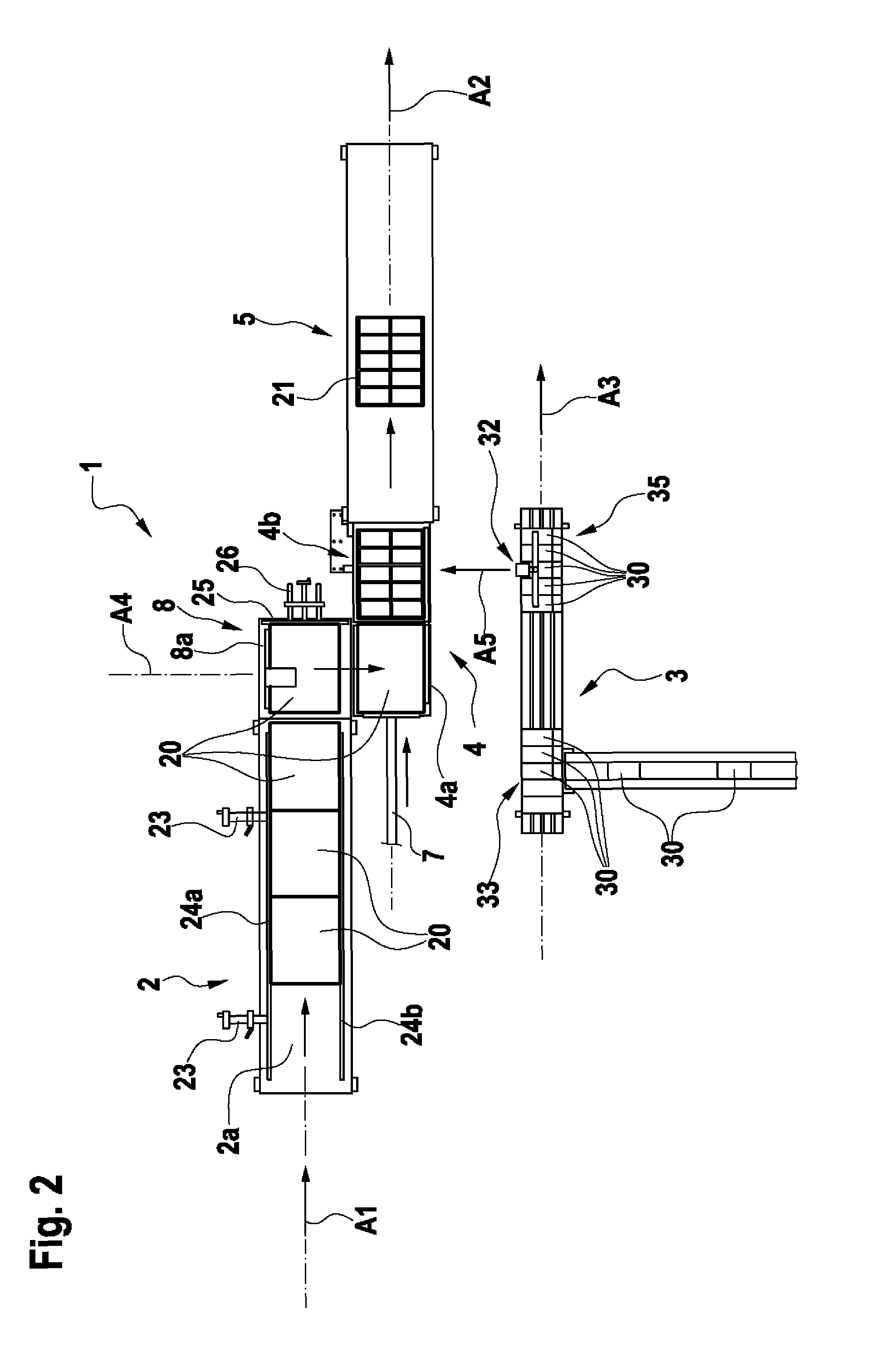

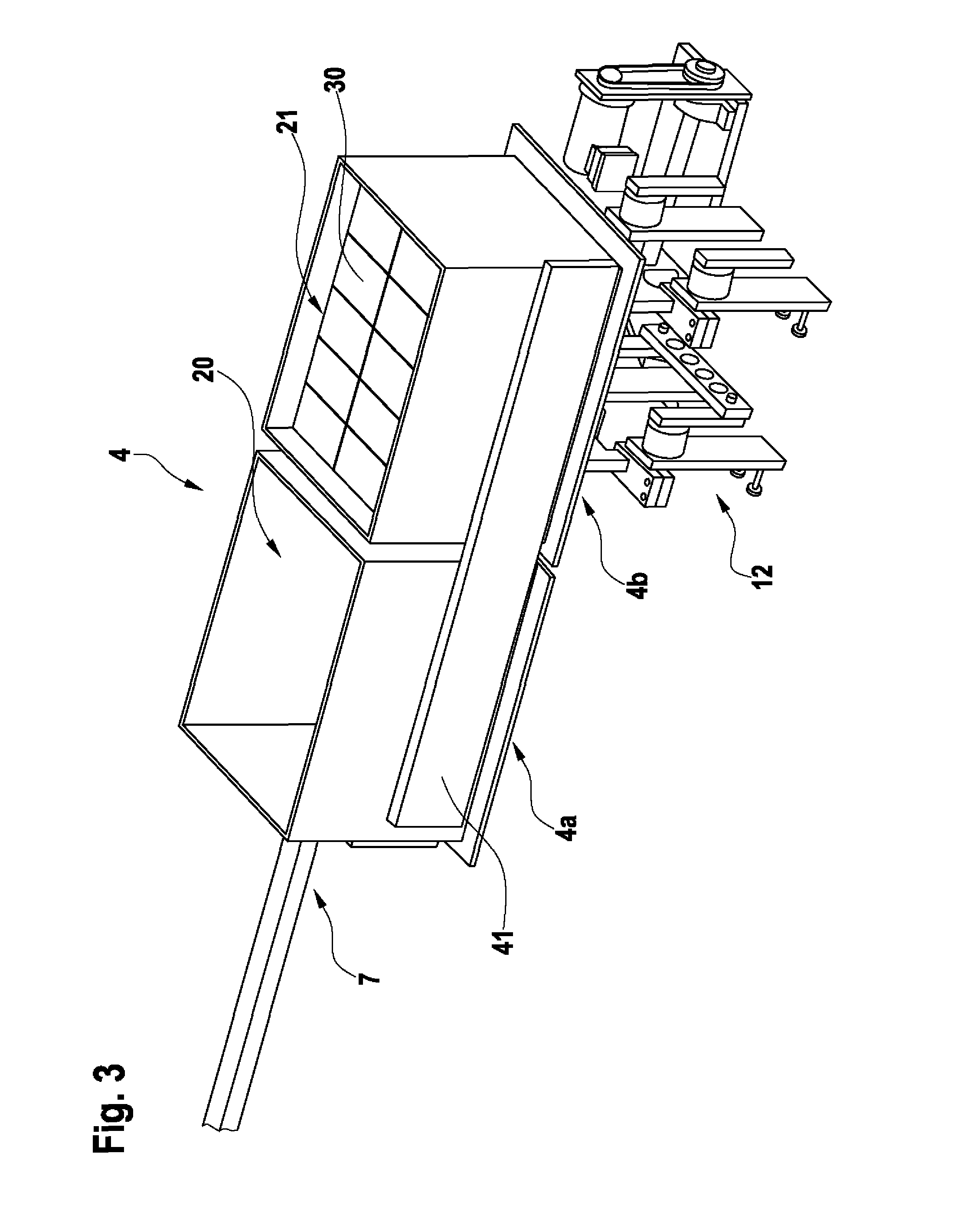

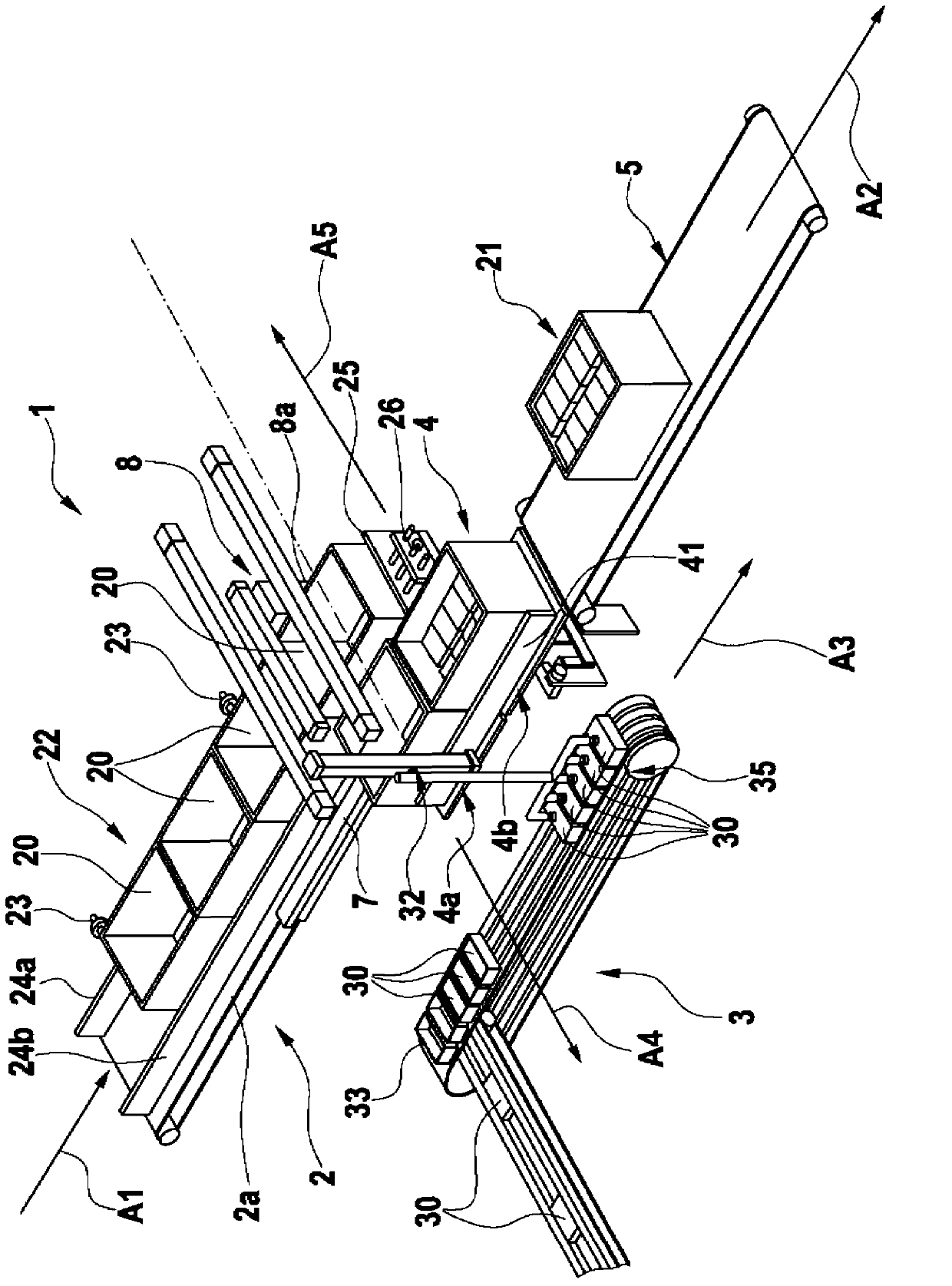

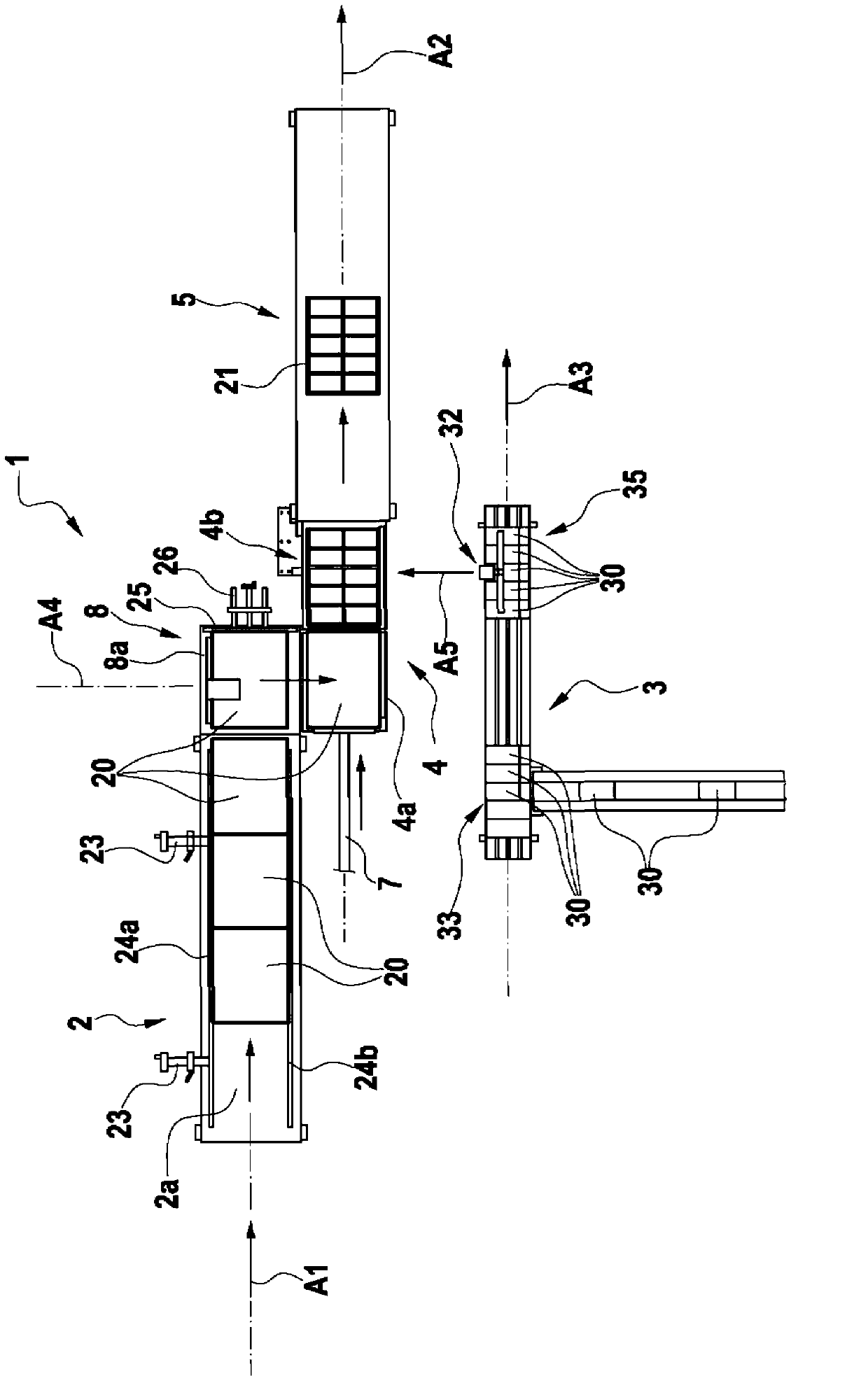

The invention relates to a modularly constructed packaging device, comprising: a package feed (2) for feeding empty packages (20), a product feed (3) for feeding products (30, 40), a loading station (4), in which the products are packed into the empty package in order to provide a packaging container (21), and a cardboard-box discharge (5), which leads away the packaging container.

Owner:ROBERT BOSCH GMBH

Foldable cardboard box for contact-free drying and long-term storage of biological evidence recovered on cotton swabs and forensic evidence collection kit including same

InactiveUS6171260B1Vaccination/ovulation diagnosticsDiagnostic recording/measuringContact freeEngineering

A biological evidence collection apparatus provides contact-free drying, storage, identification, and protection against sample switch and contamination of collected biological samples. The apparatus may include the described forensic evidence collection kit which provides a set of tools for the collection and storage of biological evidence. The collection apparatus may also be used as part of a sexual assault evidence collection kit, or a kit for the collection of buccal swabs, and the like.

Owner:INST OF LEGAL MEDICINE OF THE UNIV OF BERNE

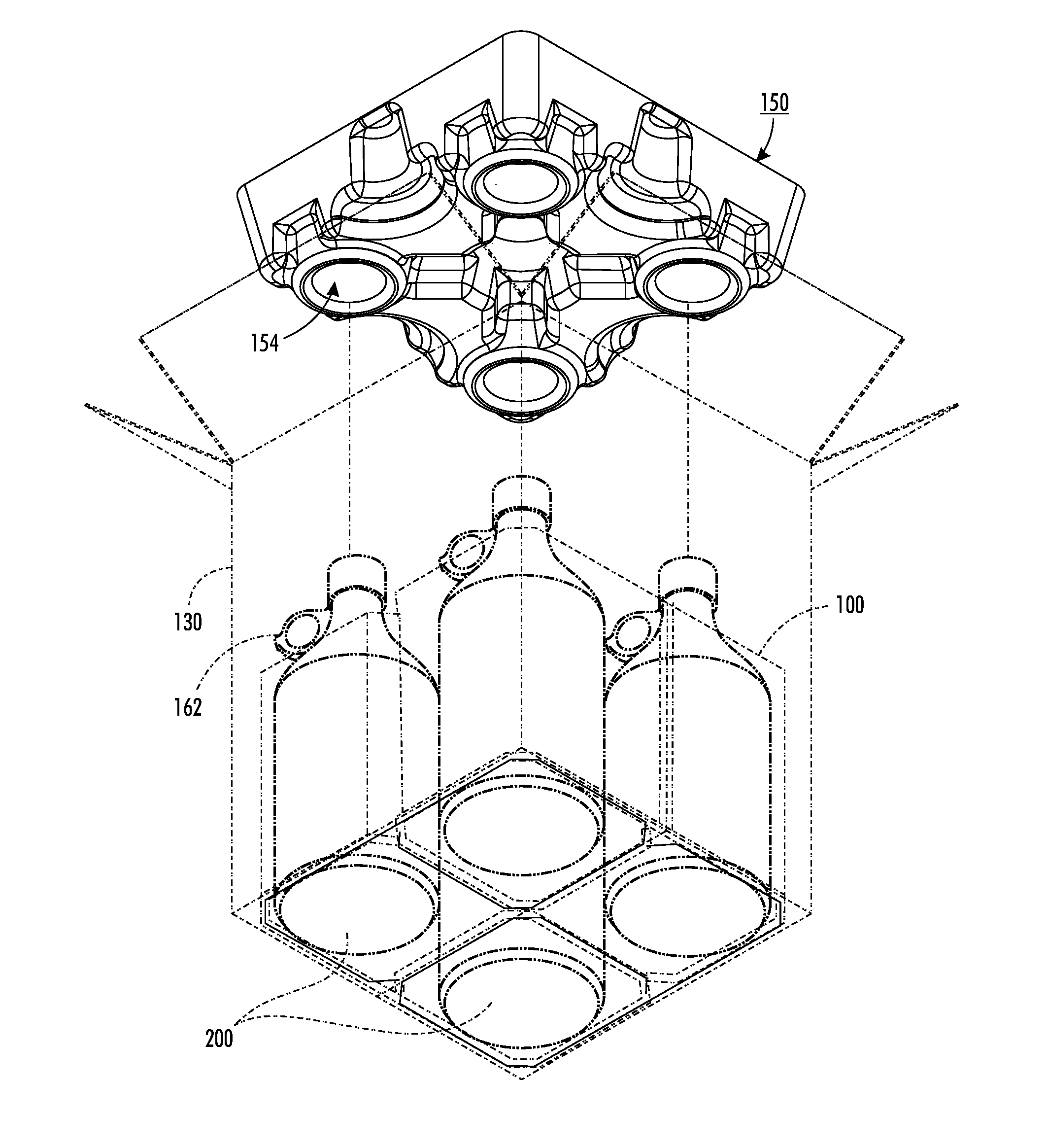

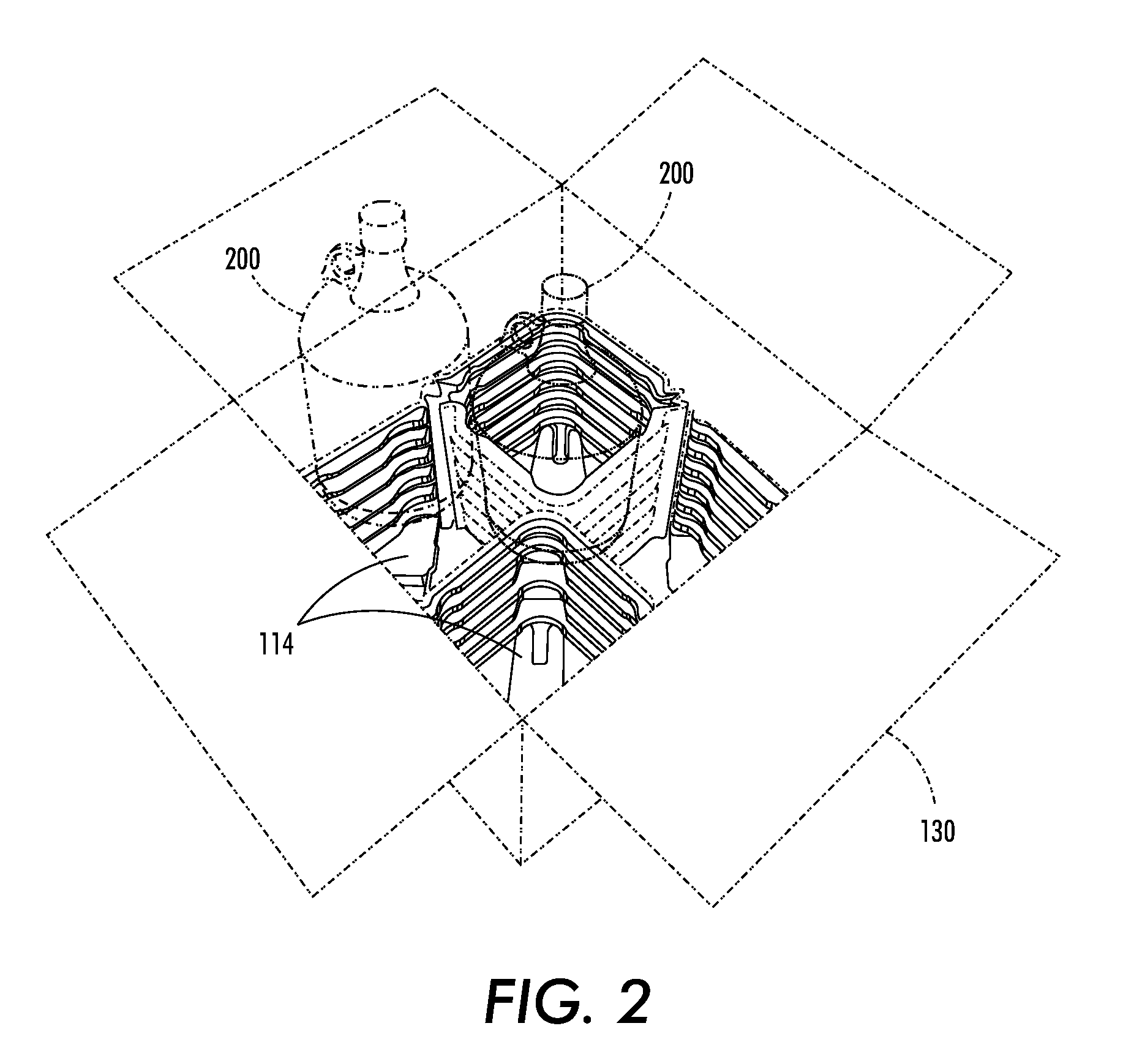

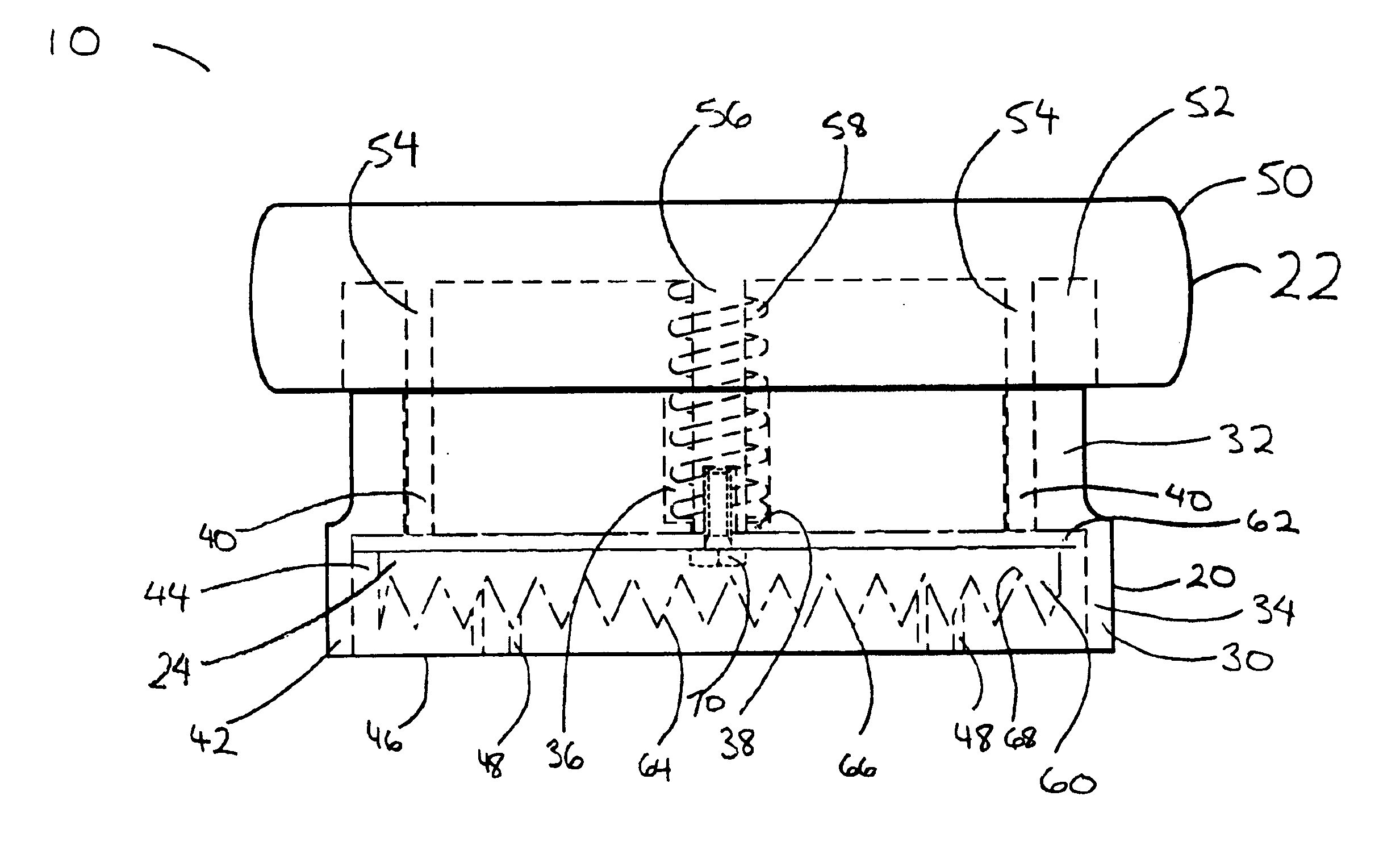

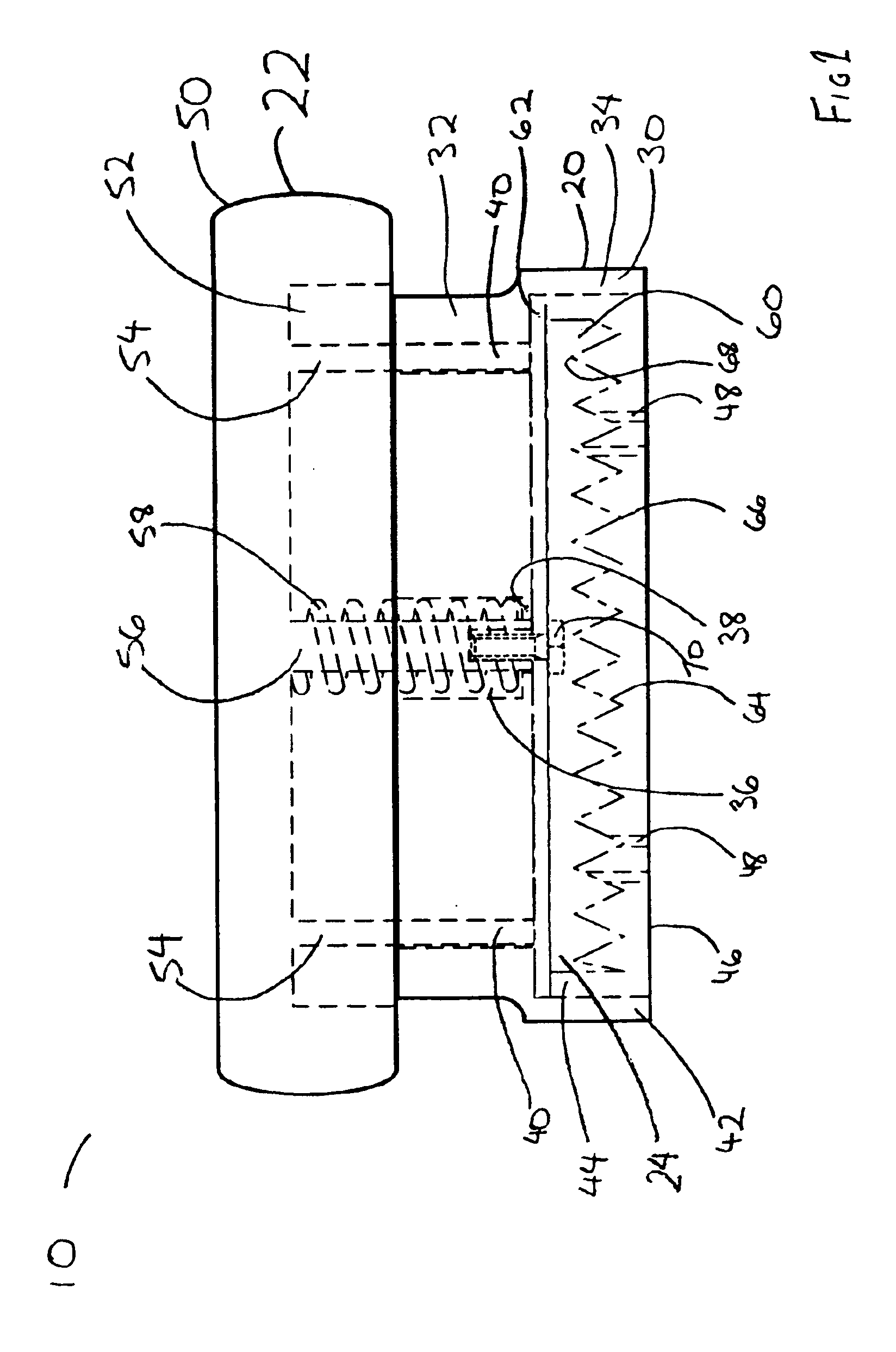

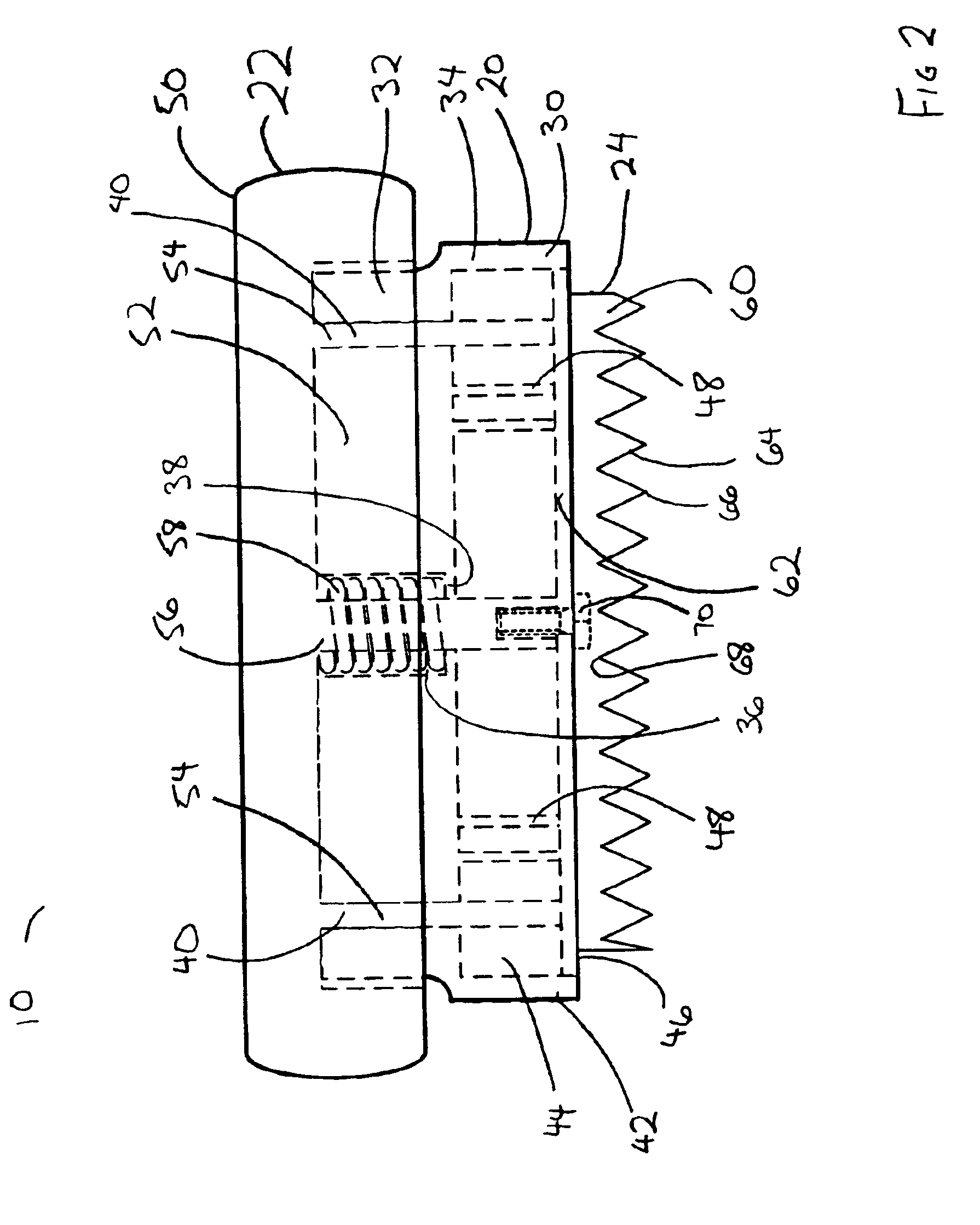

Bottle shipping system

Disclosed are systems and methods for an improved bottle packaging system and shipping container, and more particularly to a container wherein a plurality of inserts are employed to stabilize the bottle(s) and to provide impact resistant cushioning during shipment of liquids and the like. For a 4-bottle (quad) pack embodiment the improved insert design includes a folding bottle separator or insert to receive and secure a bottle bottom, along with a top insert to receive and restrain a bottle shoulder and neck region (bottle top). The inserts, in combination with a two-layer cardboard box may be used to provide a re-usable and recyclable shipping container or package for chemicals and the like.

Owner:FIBERCEL PACKAGING

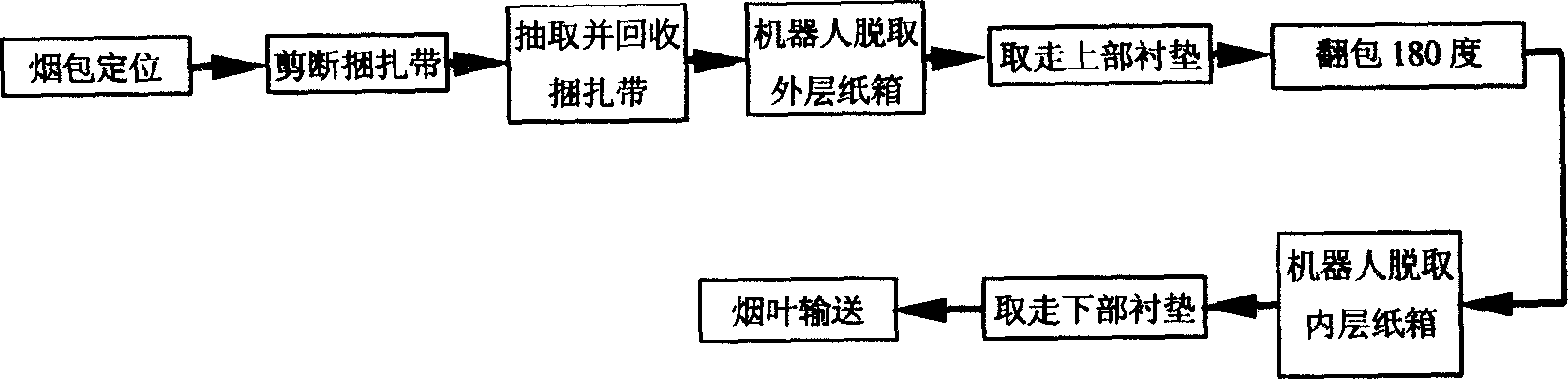

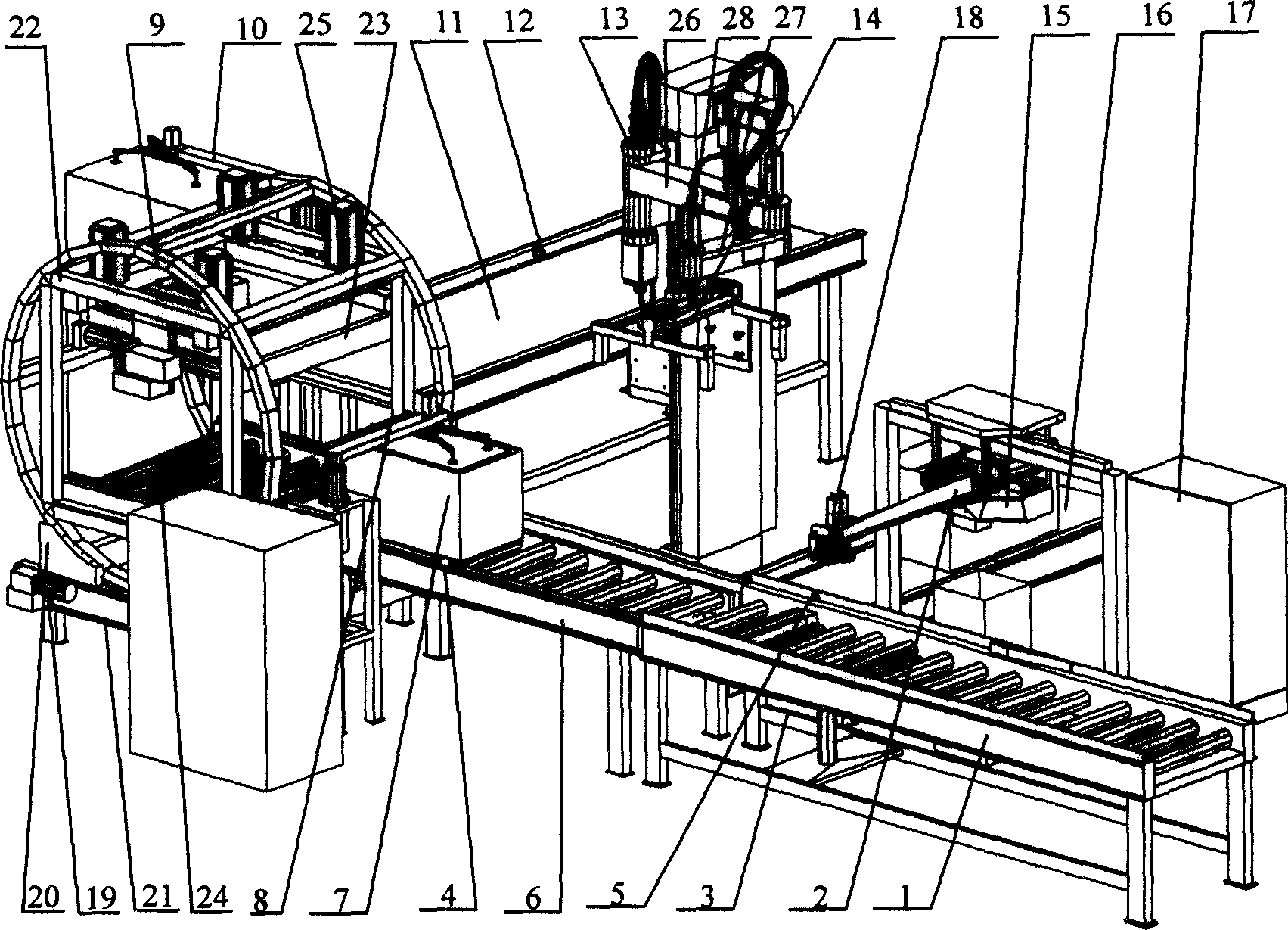

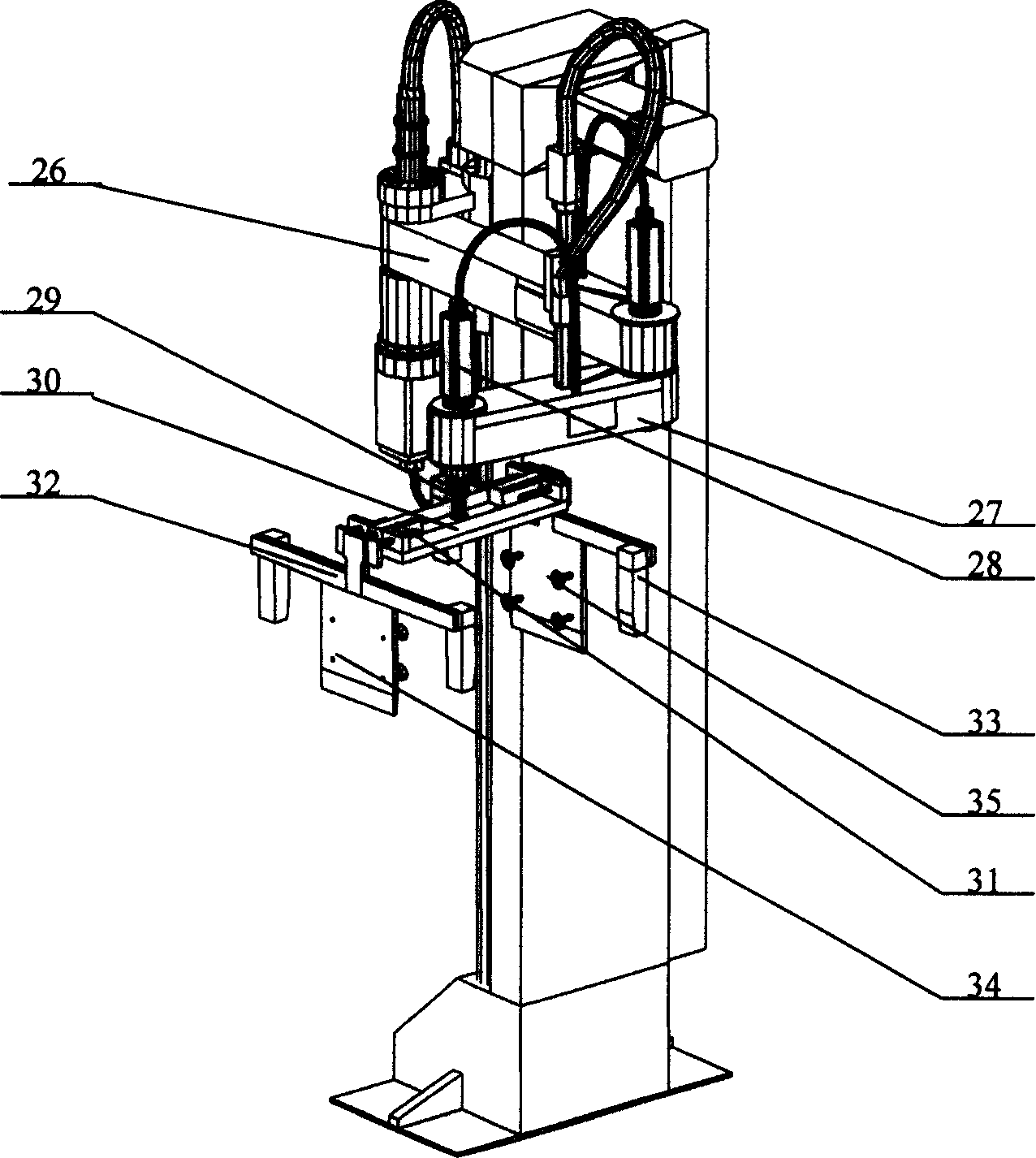

Process and apparatus for automatically opening cardboard box for cigarette

The invention relates to tobacco package carton automatic open technics and facility. The technics includes steps such as carton transferring and locating, package enlace belts testing, cutting, removing, and collecting, outer carton removing, upper interleaver removing, carton reversing, inner carton removing, lower interleaver removing, tobacco transferring. The facility are carton transferring machine(1) whose back is reversing machine(9), tobacco package transferring machine(11) and interleaver removing machine hand(10) by the side of reversing machine(9), porter robot(13) is between the carton transferring machine(1) and the tobacco package transferring machine(11). The invention has a proper process arrangement and a high efficiency by adopted with pipelining parallel processing method. It is highly automated and adapted to the opening of different sized carton, also to the deformed carton. It does no damage to the carton so to recycle the carton much better.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

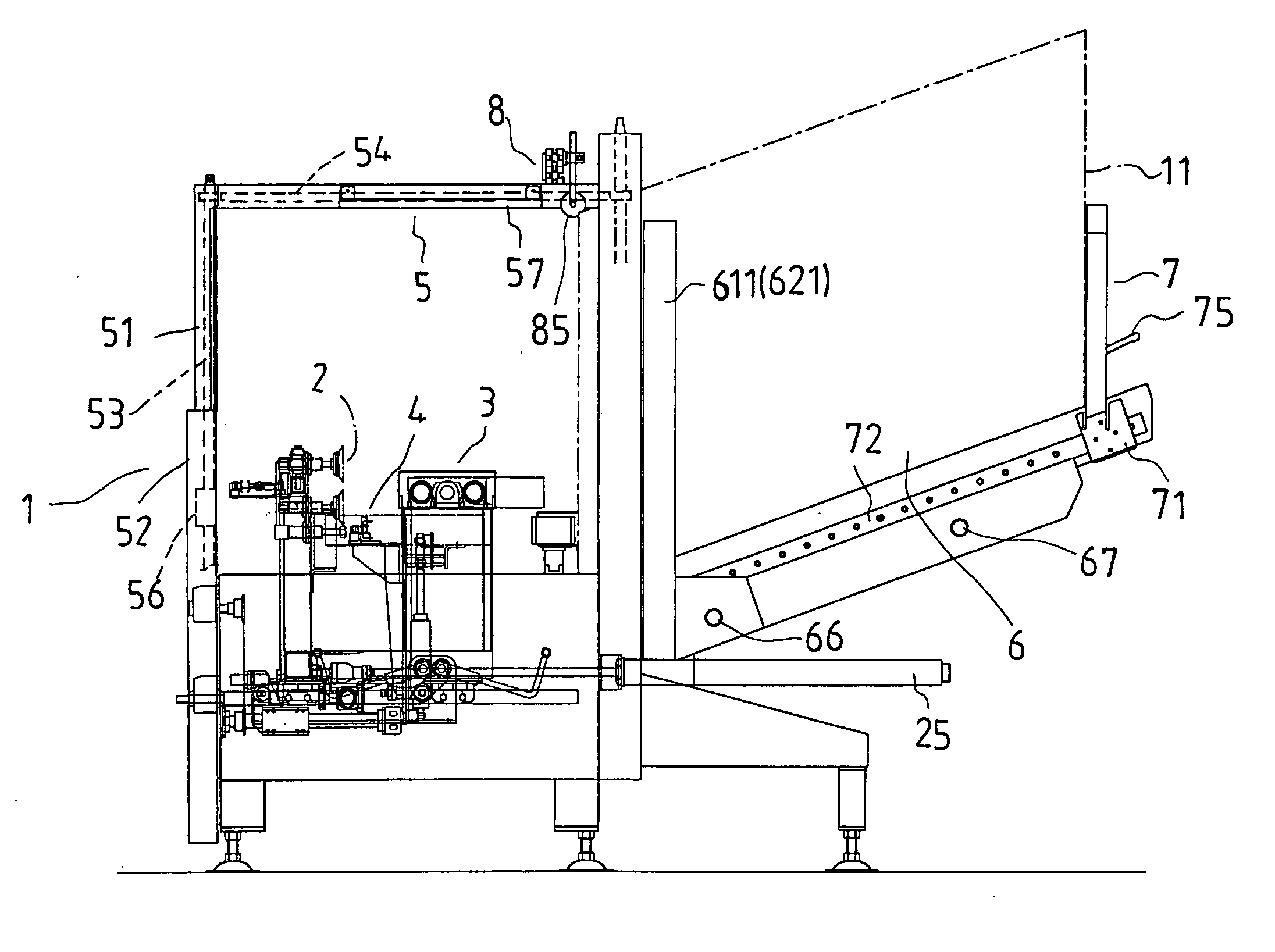

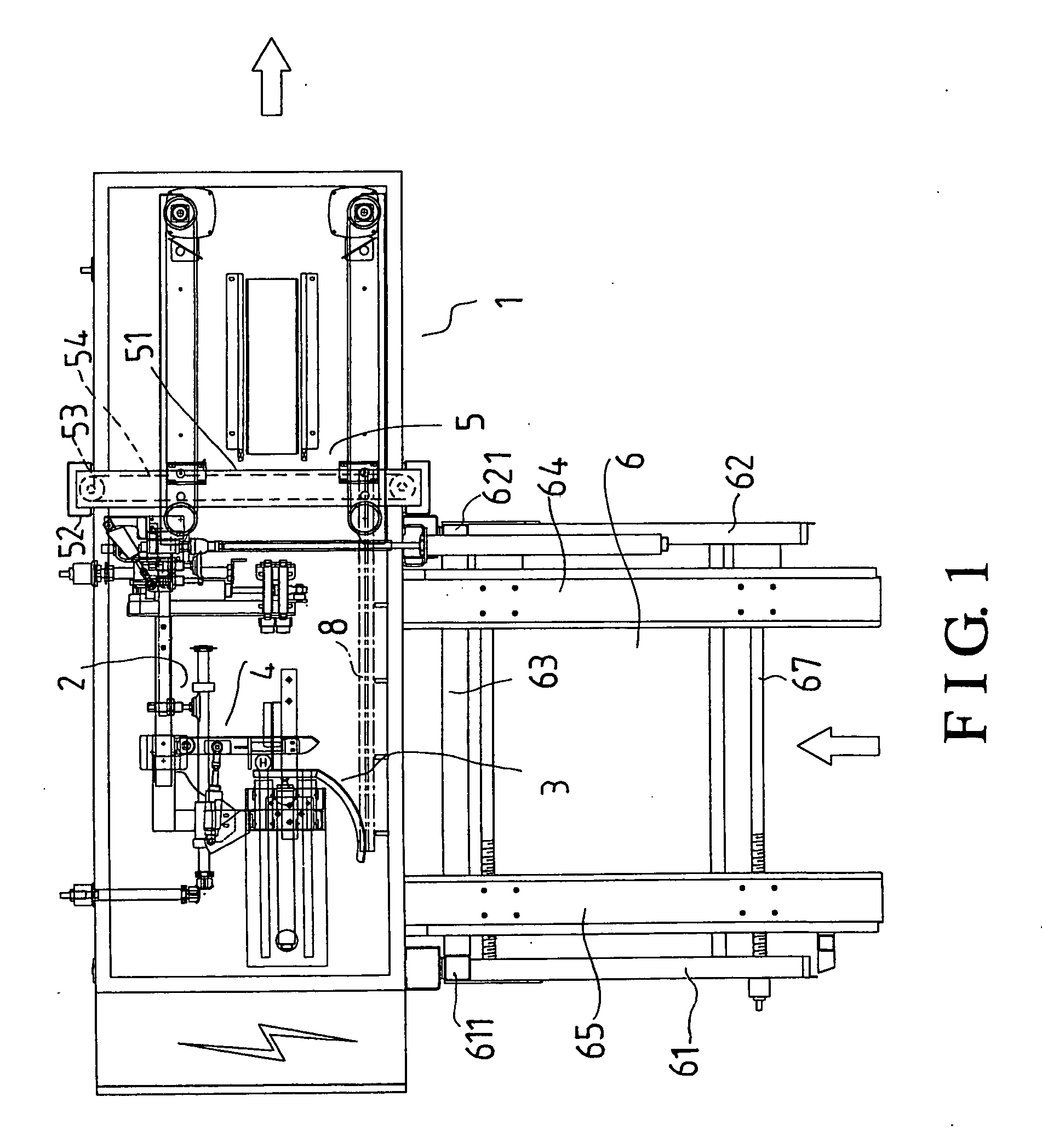

Load-carrier loading apparatus

ActiveUS20040191049A1Strong loadLoaded safely and reliablyWrappers shrinkageConveyorsMaterial qualityPallet

A machine for loading a load carrier (20) such as a pallet with packing units (cardboard boxes, collis etc.), which form a load stack (21) on the load carrier, comprises handling and support means (52-57), by means of which a packing unit (15) to be loaded is supported from below throughout the operation of loading from a feed device (51) onto the load stack. By virtue of the handling and support means the packing unit may be deposited at any selectable spatial position on the load stack. According to the invention it is therefore possible to form an optimized load stack on the load carrier, wherein the packing units are always supported from below, with the result that the loading is not dependent upon the material quality of the packaging of the packing unit.

Owner:LOGISTIK INFORMATIK

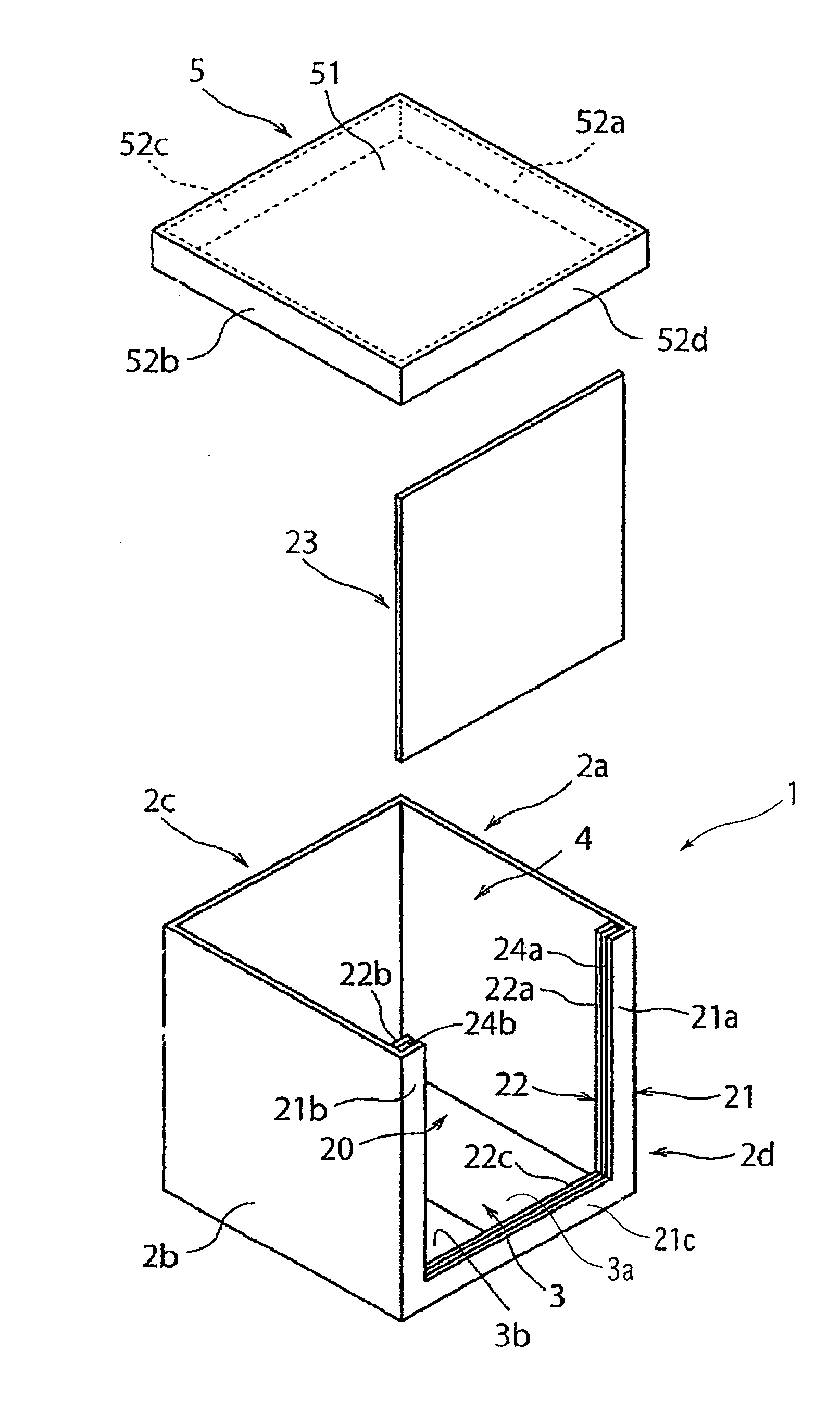

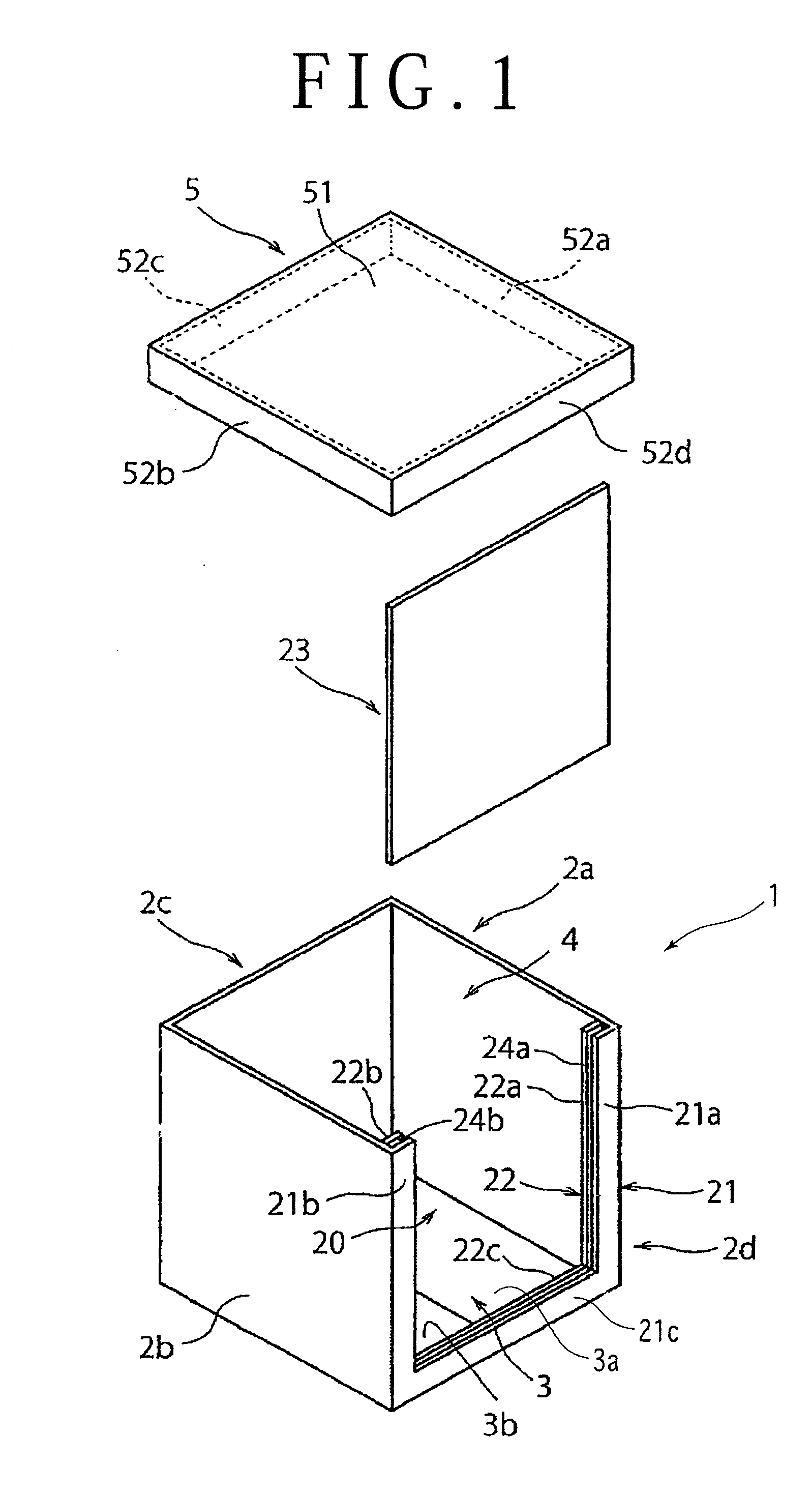

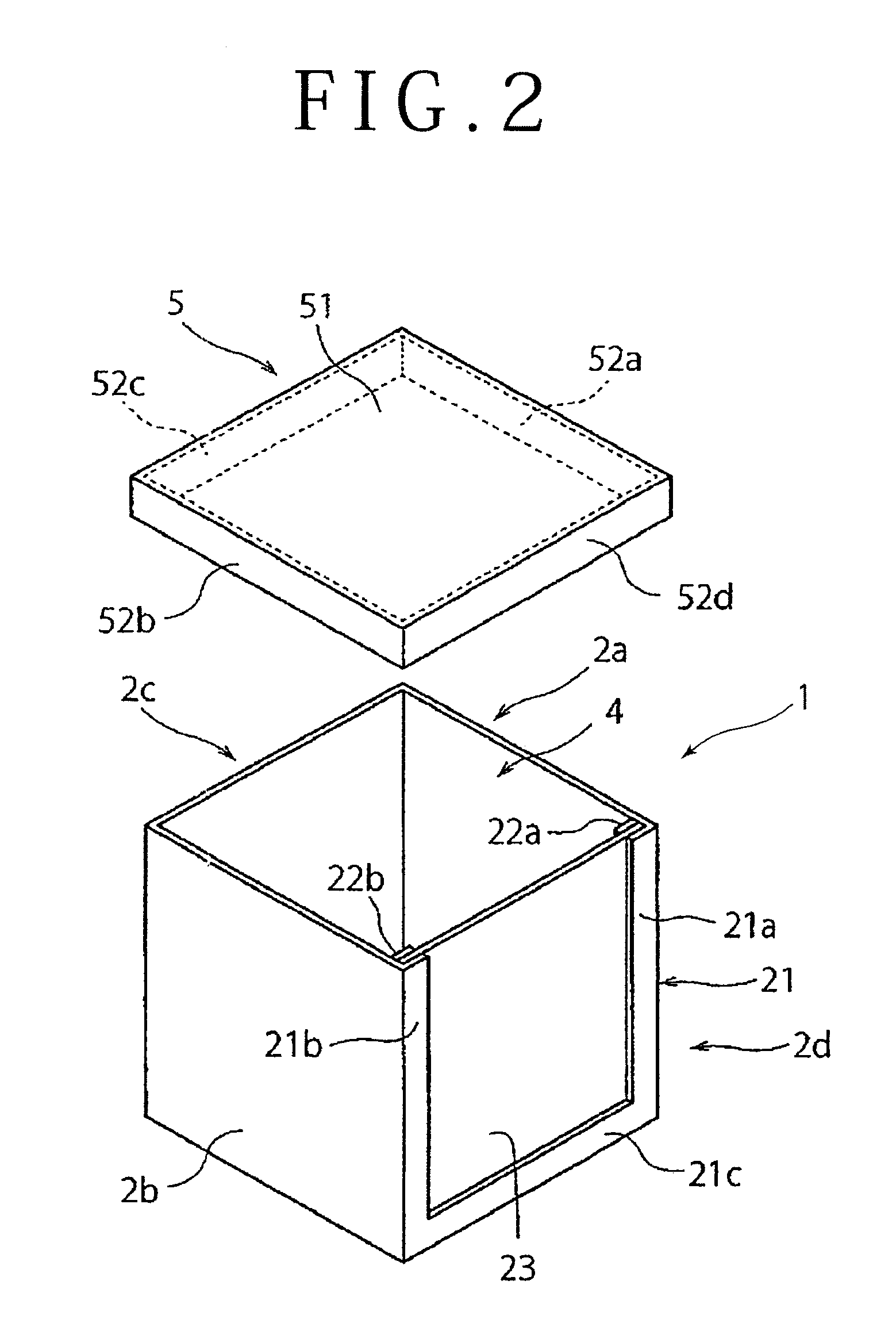

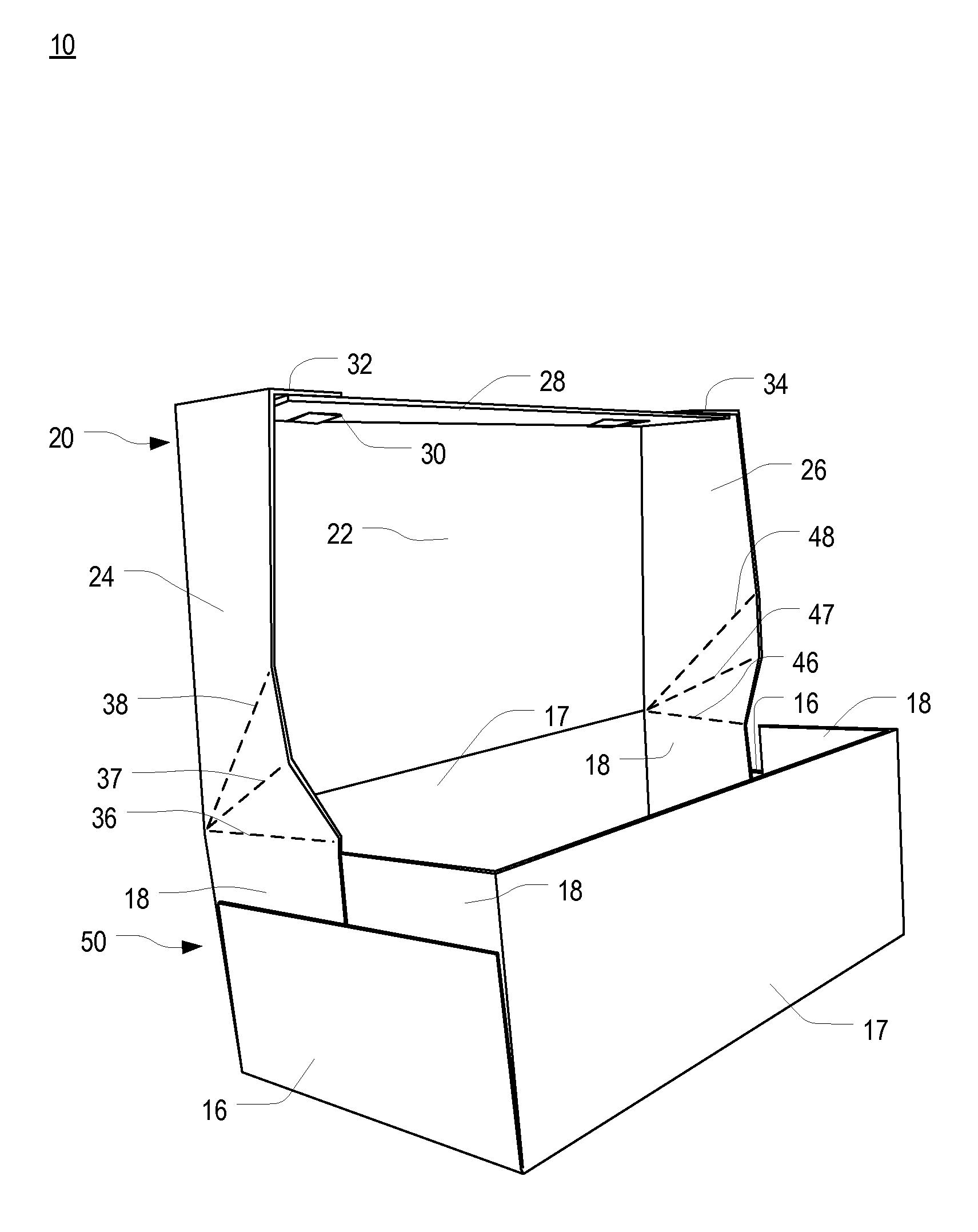

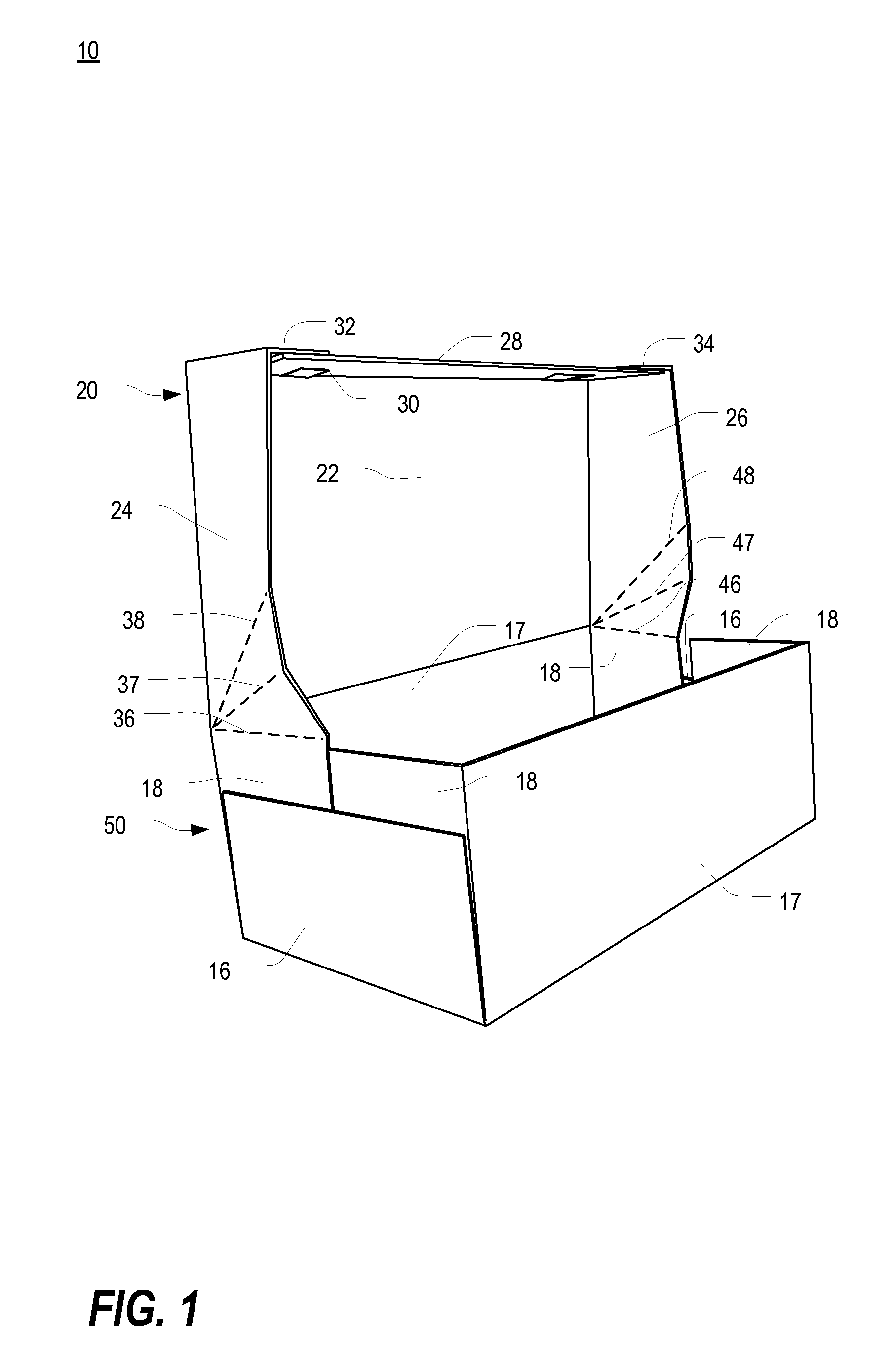

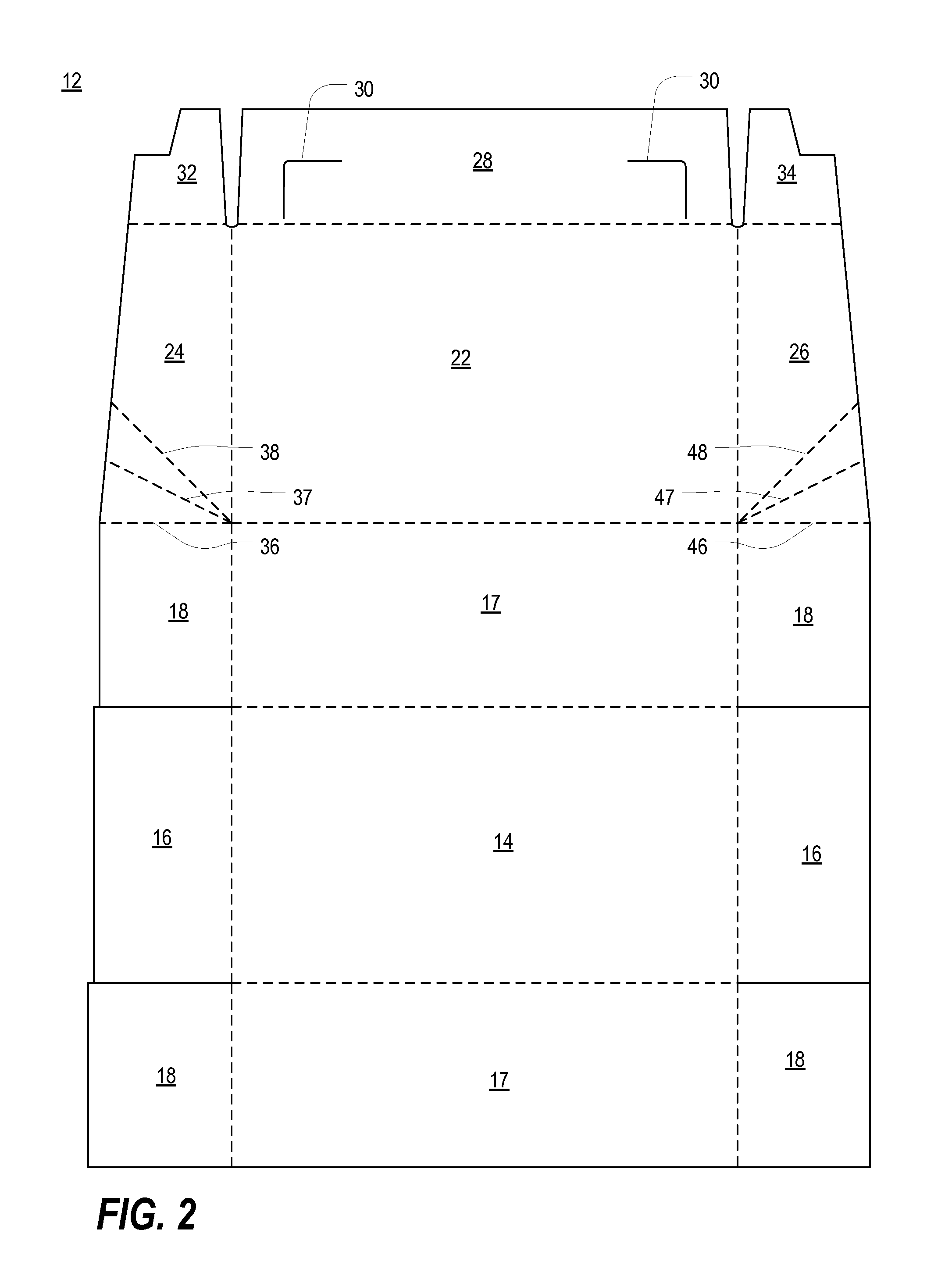

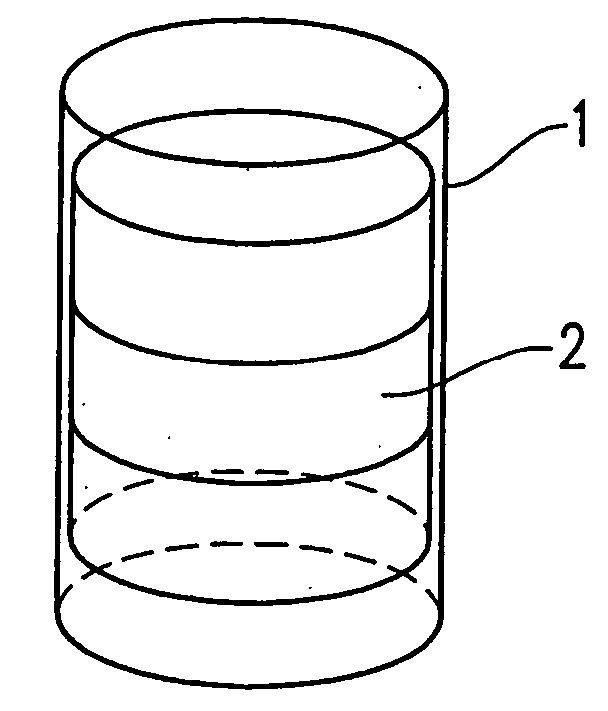

Cardboard box

A cardboard box includes: two pairs of opposed side walls; a bottom wall closing a region defined by the lower ends of the two pairs of side walls; and a lid covering an upper opening defined by the upper ends of the two pairs of side walls. At least one of the side walls can be opened and closed.

Owner:DISCO CORP

Packaging device

InactiveCN103298696AShort cycle timeContinuous packaging stepsIndividual articlesMechanical engineeringCardboard box

The invention relates to a modularly constructed packaging device, comprising: a package feed (2) for feeding empty packages (20), a product feed (3) for feeding products (30, 40), a loading station (4), in which the products are packed into the empty package in order to provide a packaging container (21), and a cardboard-box discharge (5), which leads away the packaging container.

Owner:ROBERT BOSCH GMBH

One-piece box with integrally connected lid

InactiveUS20120234904A1Boxes/cartons making machineryBox making operationsEngineeringMechanical engineering

A one-piece container includes a single sheet of corrugated material, including: four walls, a bottom, and a lid, the lid being hingedly and integrally connected to one of the four walls. The bottom and the four walls define a storage area for housing articles therein. The lid is configured to transition between an open position, an intermediate position, and a closed position. The one-piece container includes a mechanism for maintaining the lid in a closed position. In some embodiments, the mechanism biases the lid toward a closed position when in the closed position, an open position when in the open position, and an intermediate position when in the intermediate position. In other embodiments, the mechanism includes tabs and slots for retaining the lid in the closed position. Other embodiments include a combination of these features. The container may be a cardboard box.

Owner:THATBOX DESIGN

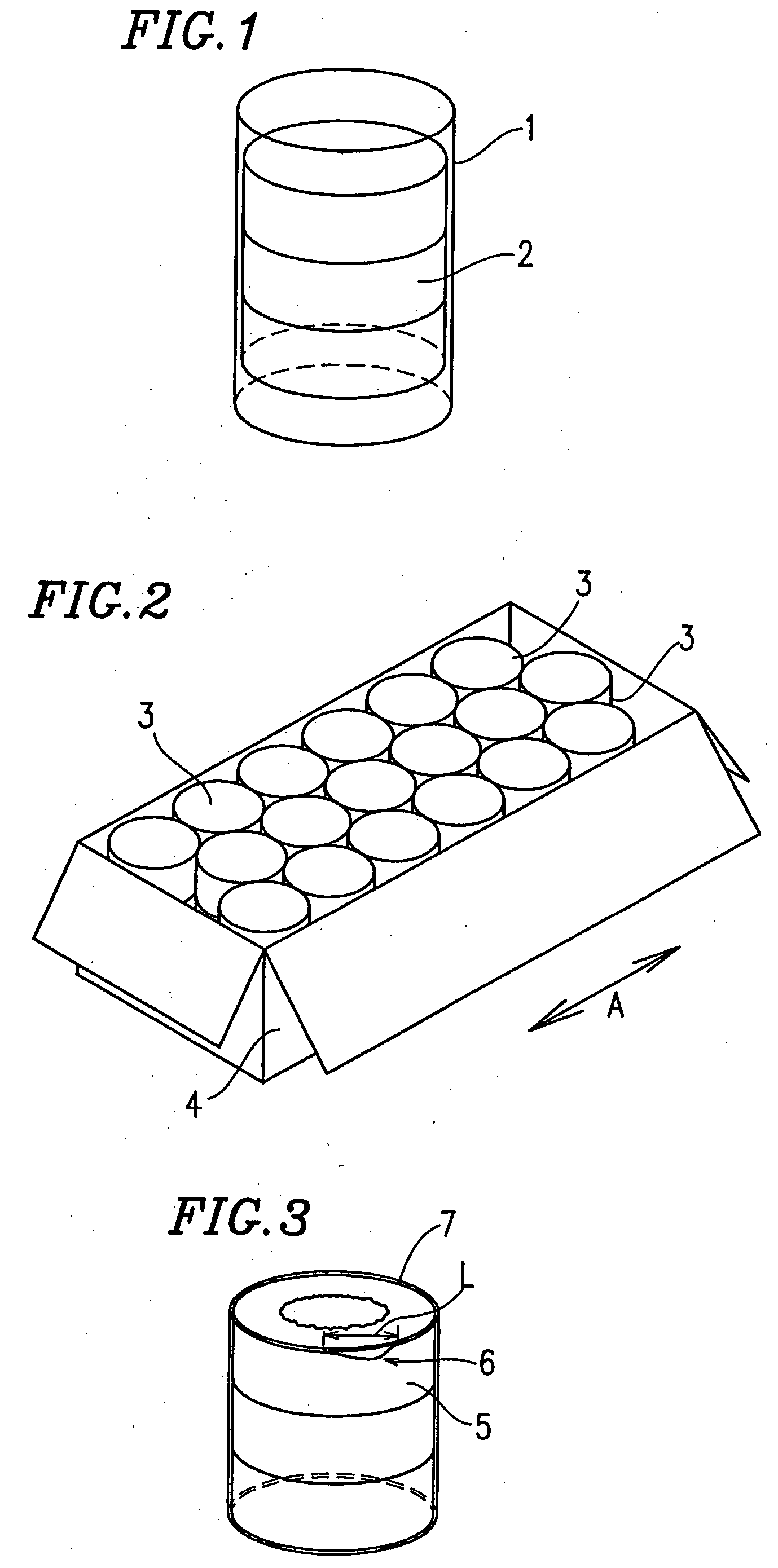

Heat shrinkable polyester film

InactiveUS20050196563A1Improve seismic performanceHigh adhesive retentionEnvelopes/bags making machineryLayered productsPolyesterPolymer science

A heat shrinkable polyester film of the present invention has a transverse tear defect percentage of about 20% or less as determined in the following vibration test: the film is rolled into a tubular shape, two of its opposite edges bonded together, and then the tubular film is placed around a vertical stack (total weight: 660 g) of three food container cans each having a diameter of 72 mm and a height of 55 mm; the can stack with the tubular film placed therearound is passed through a shrink tunnel to shrink the tubular film onto the can stack; a total of 18 packs of such can stacks are placed into a cardboard box having a length of 455 mm, a width of 230 mm and a height of 165 mm (6 packs in the length direction by 3 packs in the width direction), and the cardboard box is sealed; the cardboard box is vibrated along the width direction for 30 min by a stroke of 50 mm and at a vibration rate of 180 reciprocations / min, after which the transverse tearage of the tubular film is visually observed; and the transverse tear defect percentage (%) is determined based on the number of defective packs per 18 packs, wherein the defective pack is any pack having a tear flaw of 30 mm or longer along a can periphery. The heat shrinkable polyester film of the present invention has a good shock resistance during shipping especially under low temperatures, with a good finish after shrinkage and a sufficient solvent adhesiveness. Thus, the heat shrinkable polyester film of the present invention is suitable for use in a multi-packaging label for packaging, inter alia, a stack of cans.

Owner:ITO HIDEKI +4

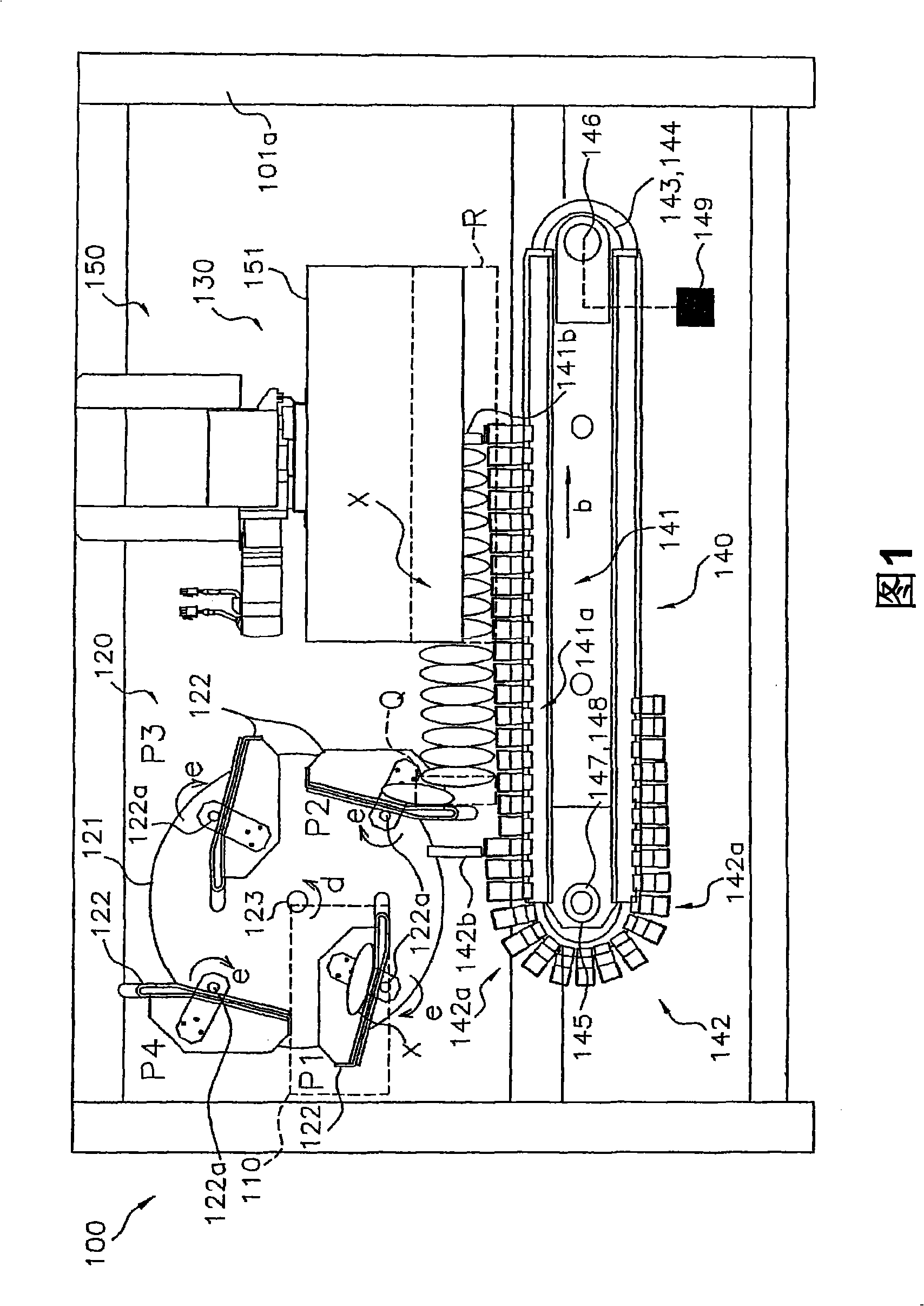

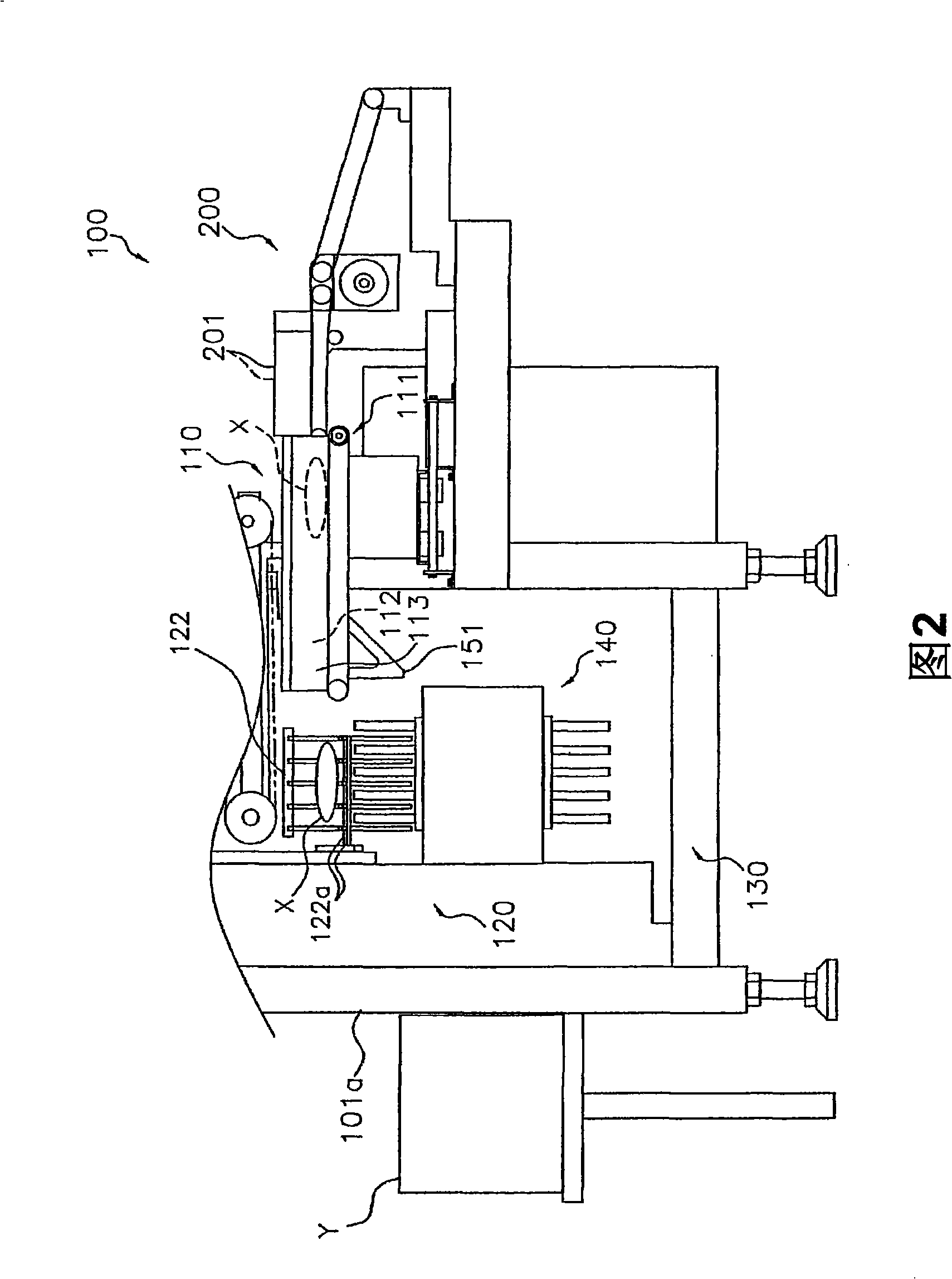

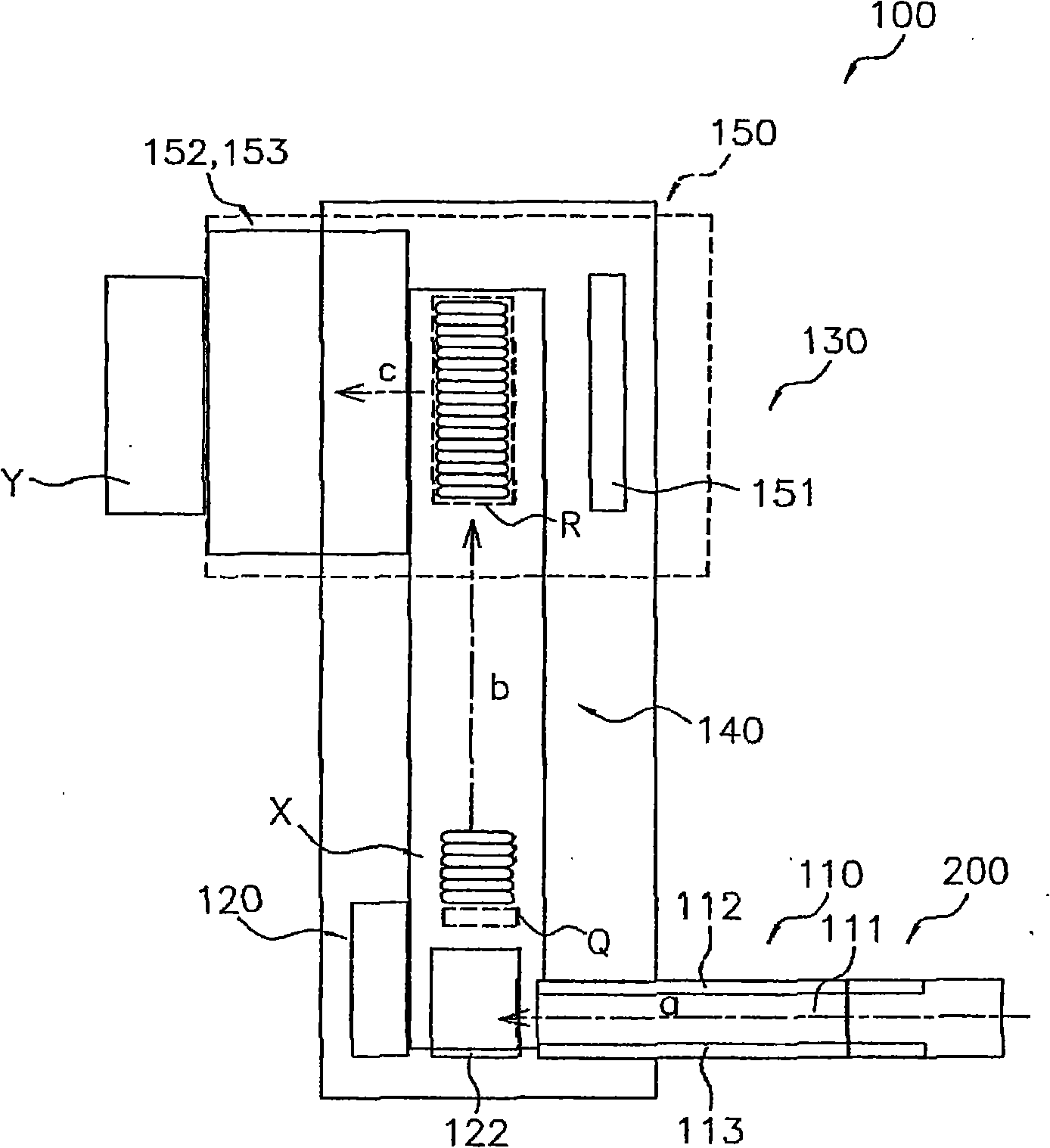

Conveyance device, and box packing device and box packing system with the same

InactiveCN101516734AThe queuing state is not easily disorderedQueuing disorderIndividual articlesConveyor partsCartonEngineering

The present invention provides a conveyance device capable of changing, relative to the opening of a corrugated cardboard box, the orientation of an article to be packed in the box. Depending on a desired accumulation condition [horizontal mode, oblique mode, and vertical mode], the box packing device (100) switches between delivery / reception intervals (CL) in delivery and reception of an article (X) between a paddle (122) and buckets (141, 142).

Owner:ISHIDA CO LTD

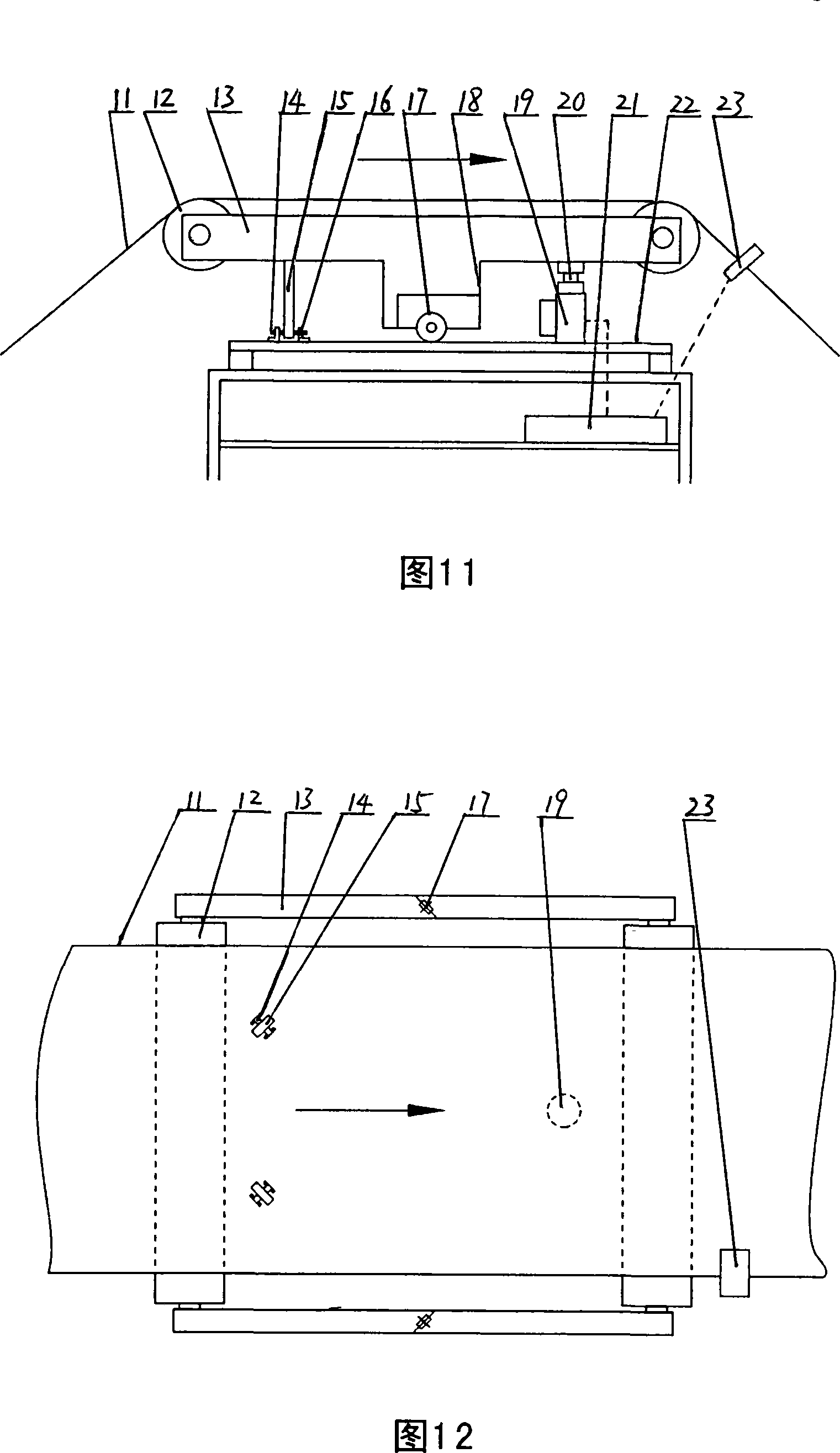

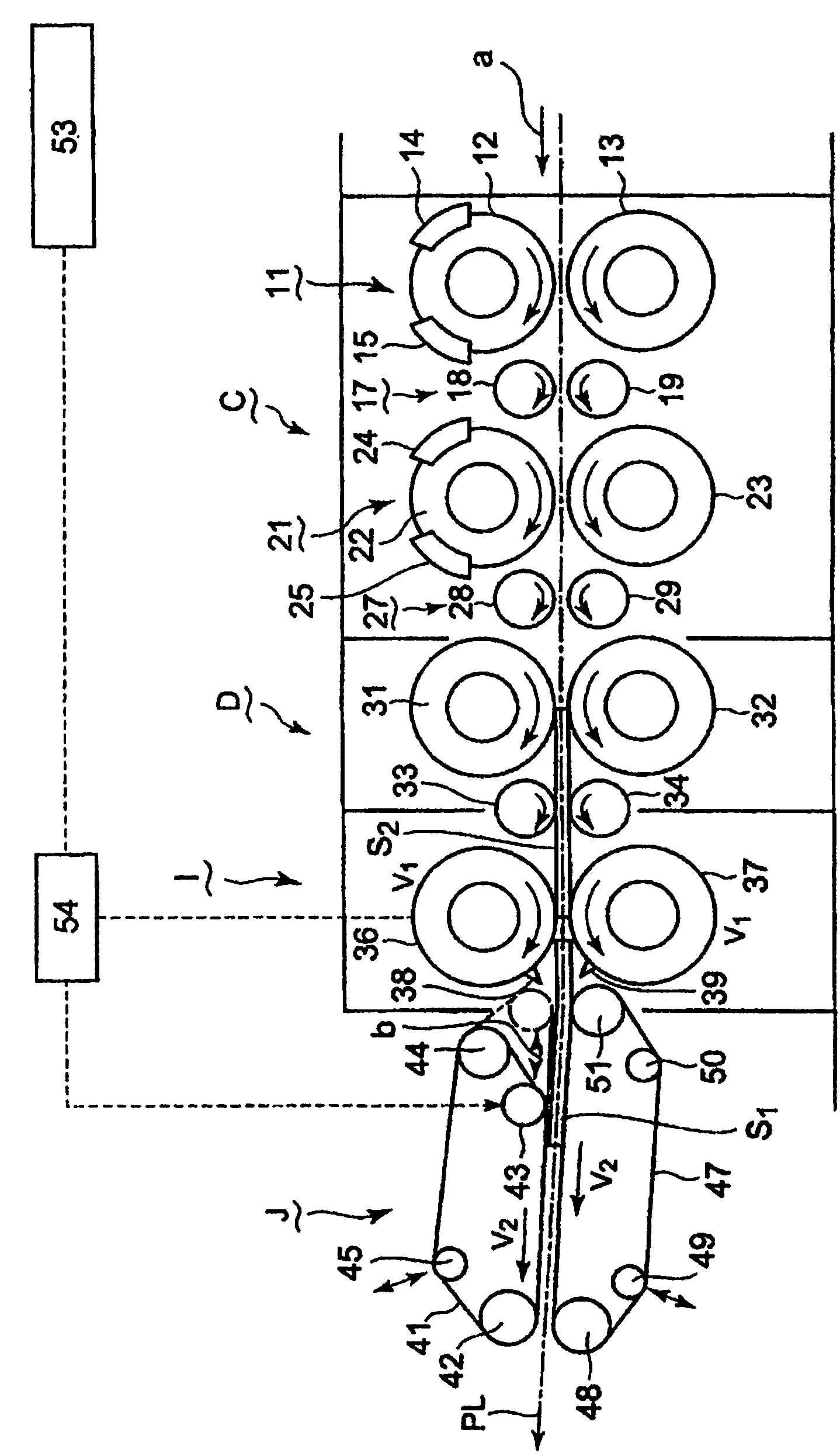

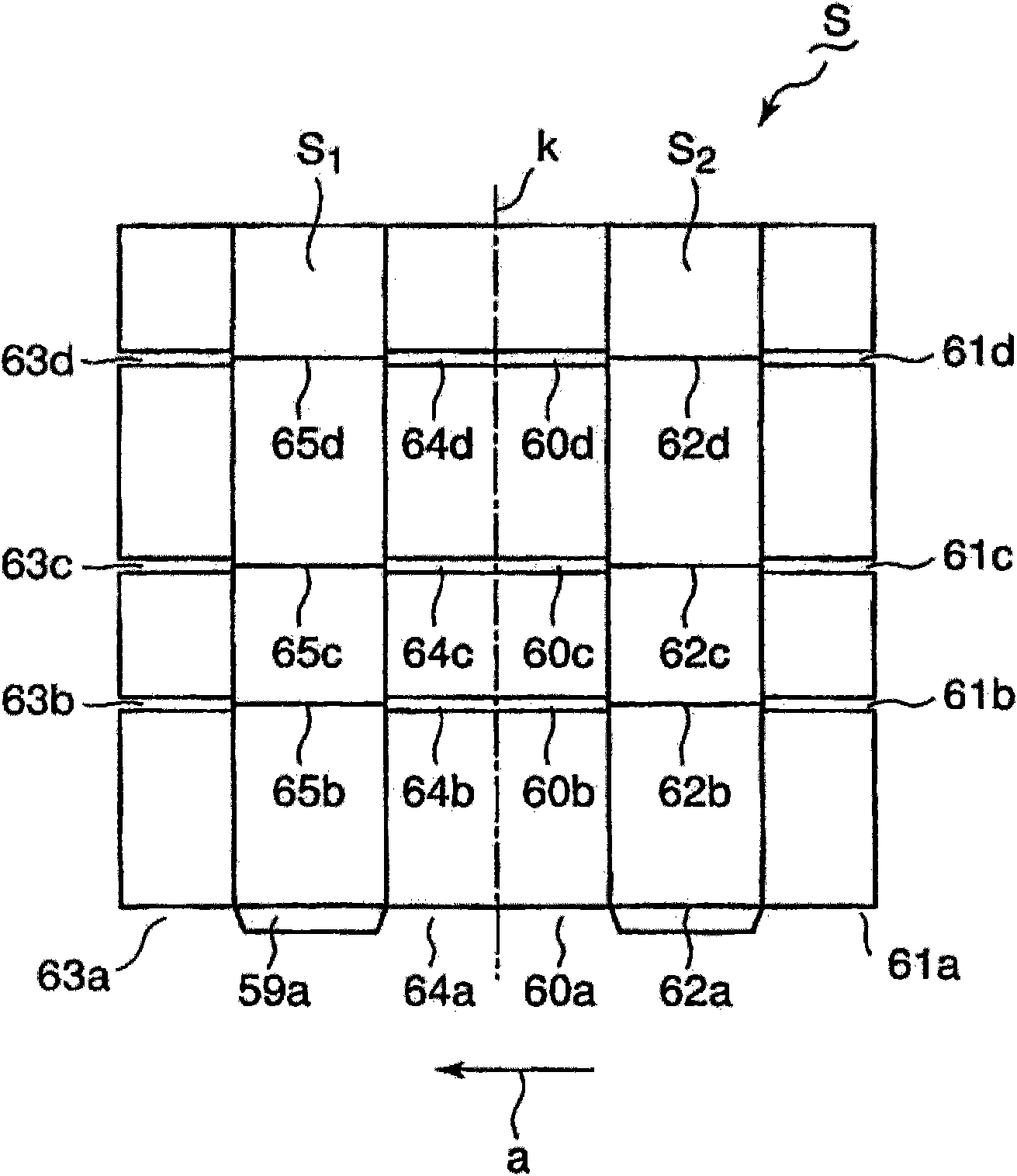

Method and device for making box of corrugated cardboard sheet

ActiveCN101873926ASmall spanEasy to handleBoxes/cartons making machineryPaper-makingCountermeasureCardboard box

Disclosed is a method for producing a cardboard box by performing a box-making process of a corrugated cardboard sheet which is formed to have dimensions of a plurality of cardboard boxes wherein the yield of the cardboard sheet and the production efficiency are enhanced and a countermeasure can be taken against paper powder. A method for making a box of a corrugated cardboard sheet by performinga box-making process of a cardboard sheet (S) which is formed to have dimensions of a plurality of cardboard boxes and then cutting the cardboard sheet (S) into dimensions of one cardboard box comprises a step (I) for cutting the cardboard sheet (S) into dimensions of one cardboard box by a cut line (k) in the direction intersecting the conveyance direction (a) along a box making line (PL) after a ruling and grooving step (C) and before a pasting and folding step (E), and a speed increase step (J) for spacing the cardboard sheets (S1) and (S2) thus cut by a set dimension following to the cutting step (I) by increasing the speed of the cardboard sheets (S1) and (S2) while conveying toward a subsequent step.

Owner:MITSUBISHI HEAVY IND MACHINERY SYST LTD

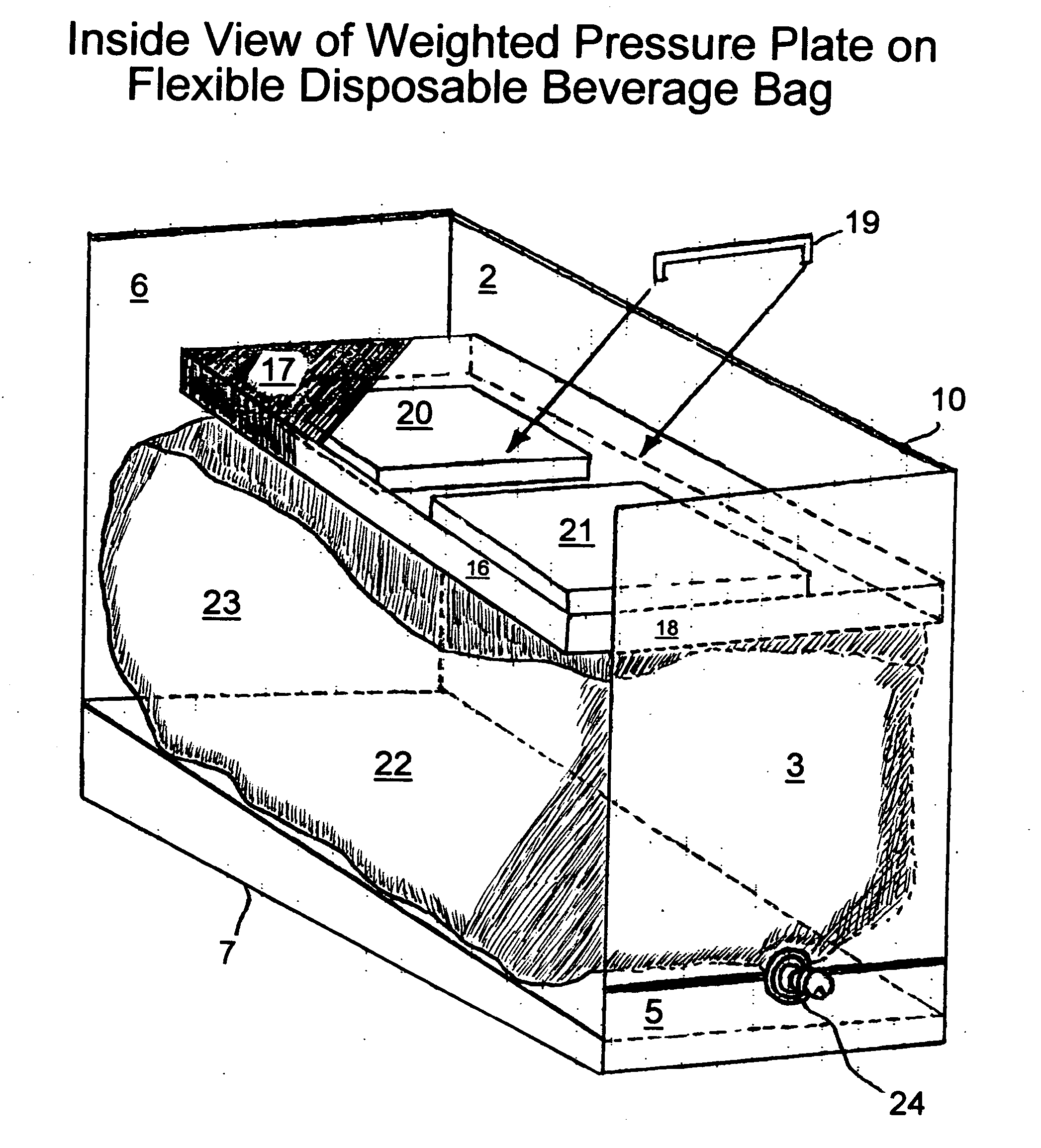

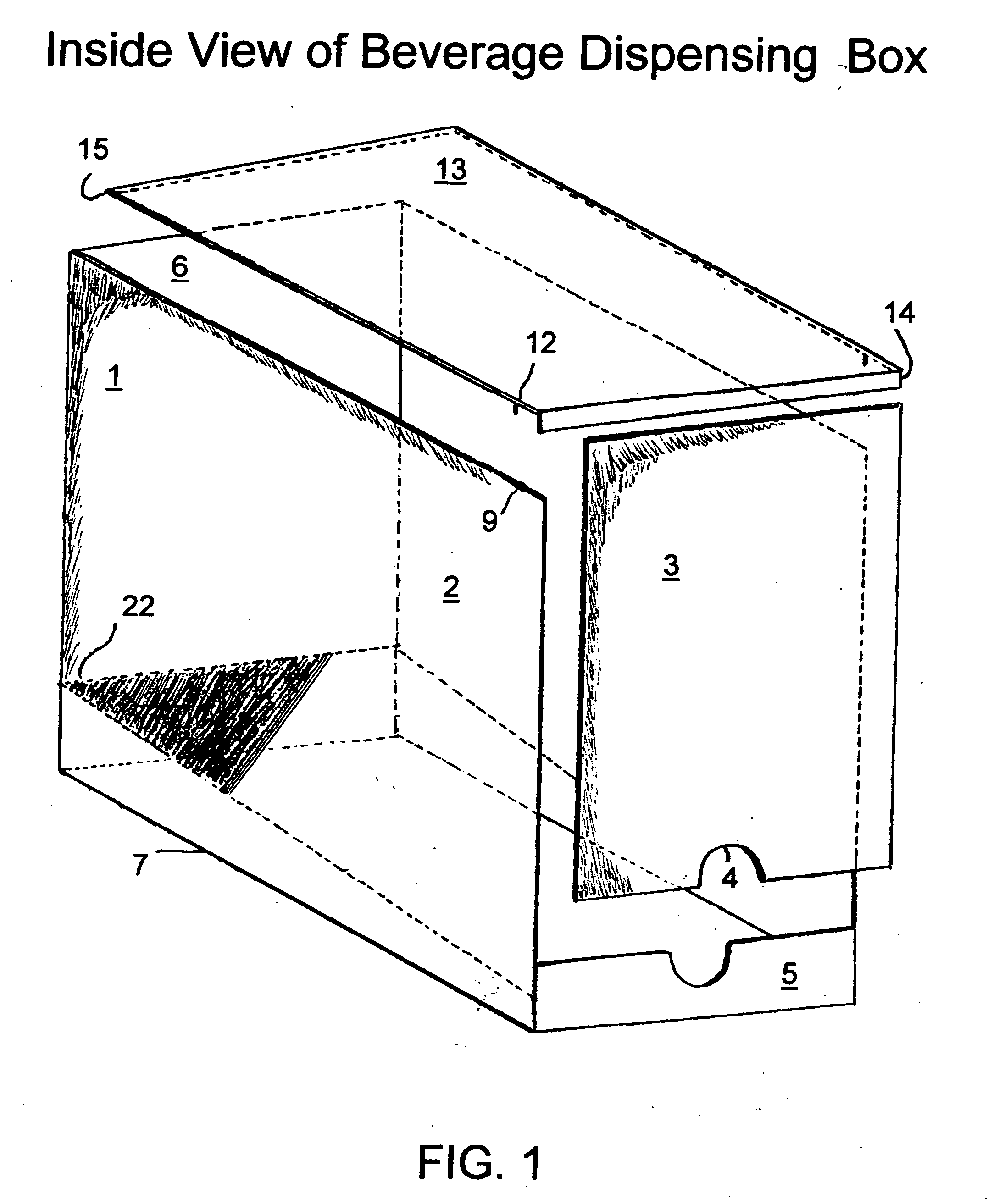

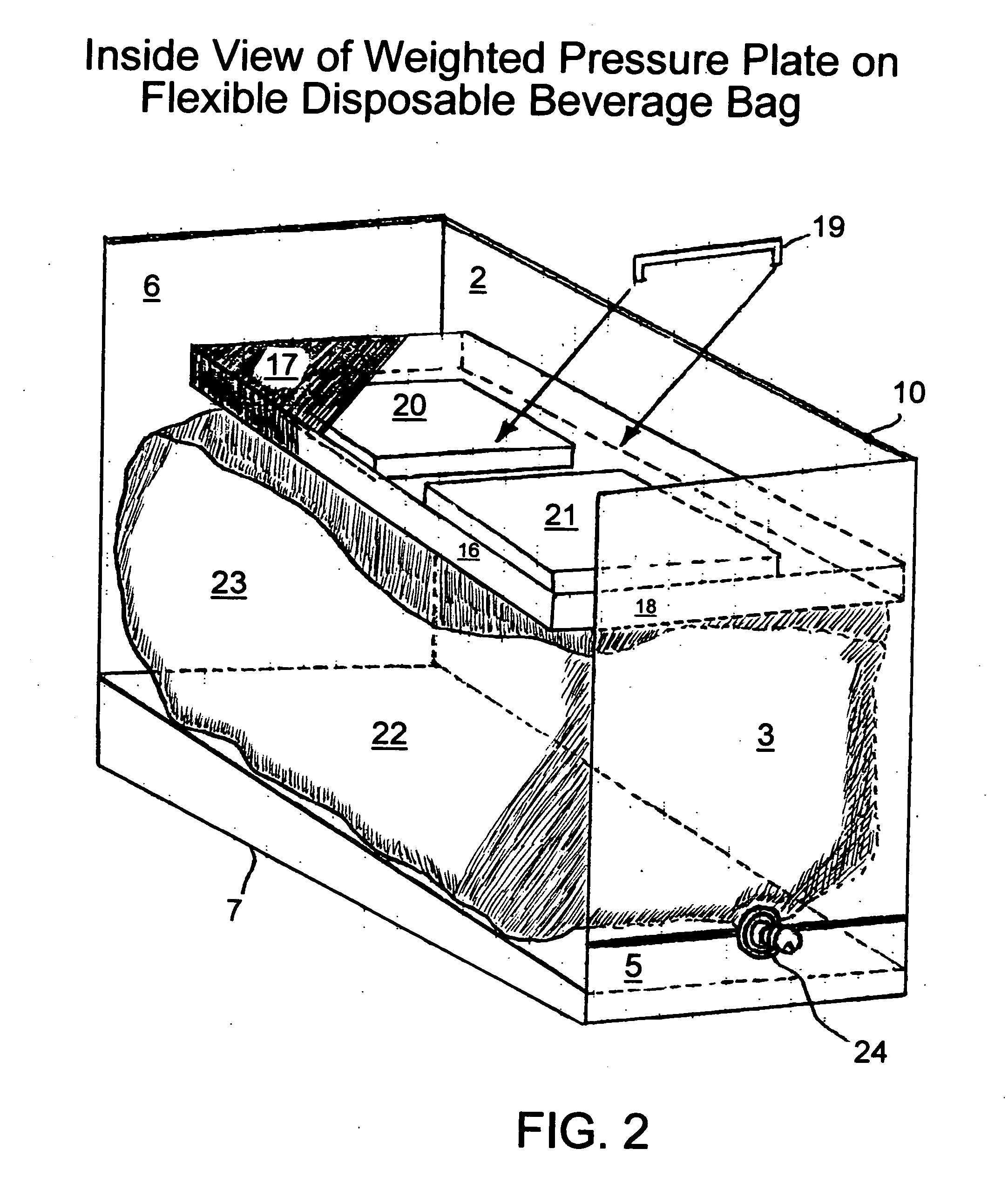

Beverage dispensing box for office and kitchen counters

The Beverage Dispensing Box for Office and Kitchen Counters is intended to hold a flexible disposable beverage bag filled with a potable liquid and dispense that liquid under pressure when the spigot is opened. The Beverage Dispensing Box is unique in that it employs the law of gravity. Through the use of a sloped container floor and a weighted pressure plate, a natural force (non-mechanical or electrical) is applied to the flexible disposable beverage bag, thus causing the potable liquid to flow from the bag under pressure at a greater gallon per minute (GPM) rate than that of a typical un-pressurized flexible disposable beverage bag—commonly found in corrugated cardboard boxes such as the Wine-in-a-Box container; and at a greater GPM rate than that of a typical 2.5 or 5 gallon bottled water dispensing apparatus. The Beverage Dispensing Box is designed to sit on office, kitchen or other countertops where no electricity is required for use. The Beverage Dispensing Box is a durable reusable container that will positively impact the environment because it will be manufactured from recycled plastic and metals; and will displace the need for disposable plastic bottles, such as bottled water.

Owner:MANION RANDOLPH THOMAS

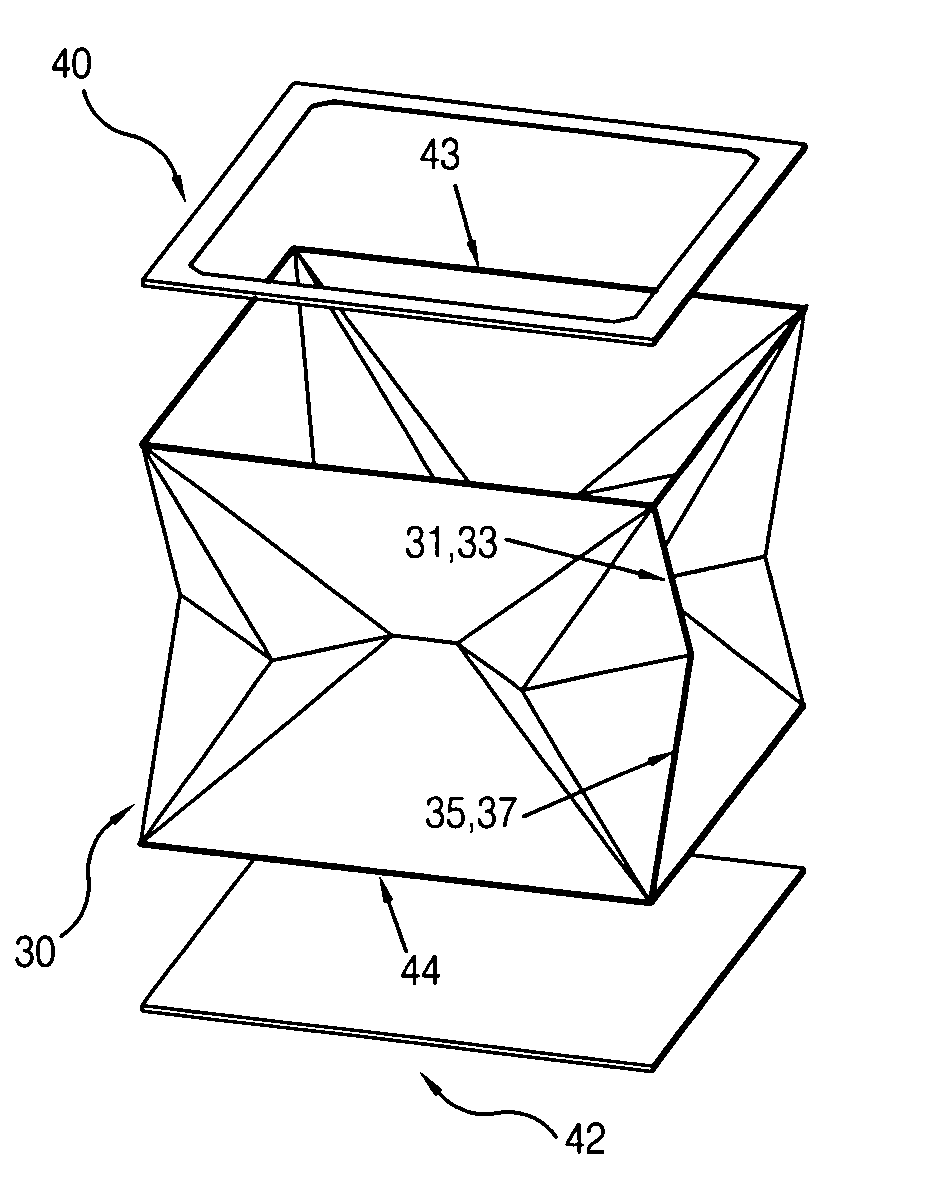

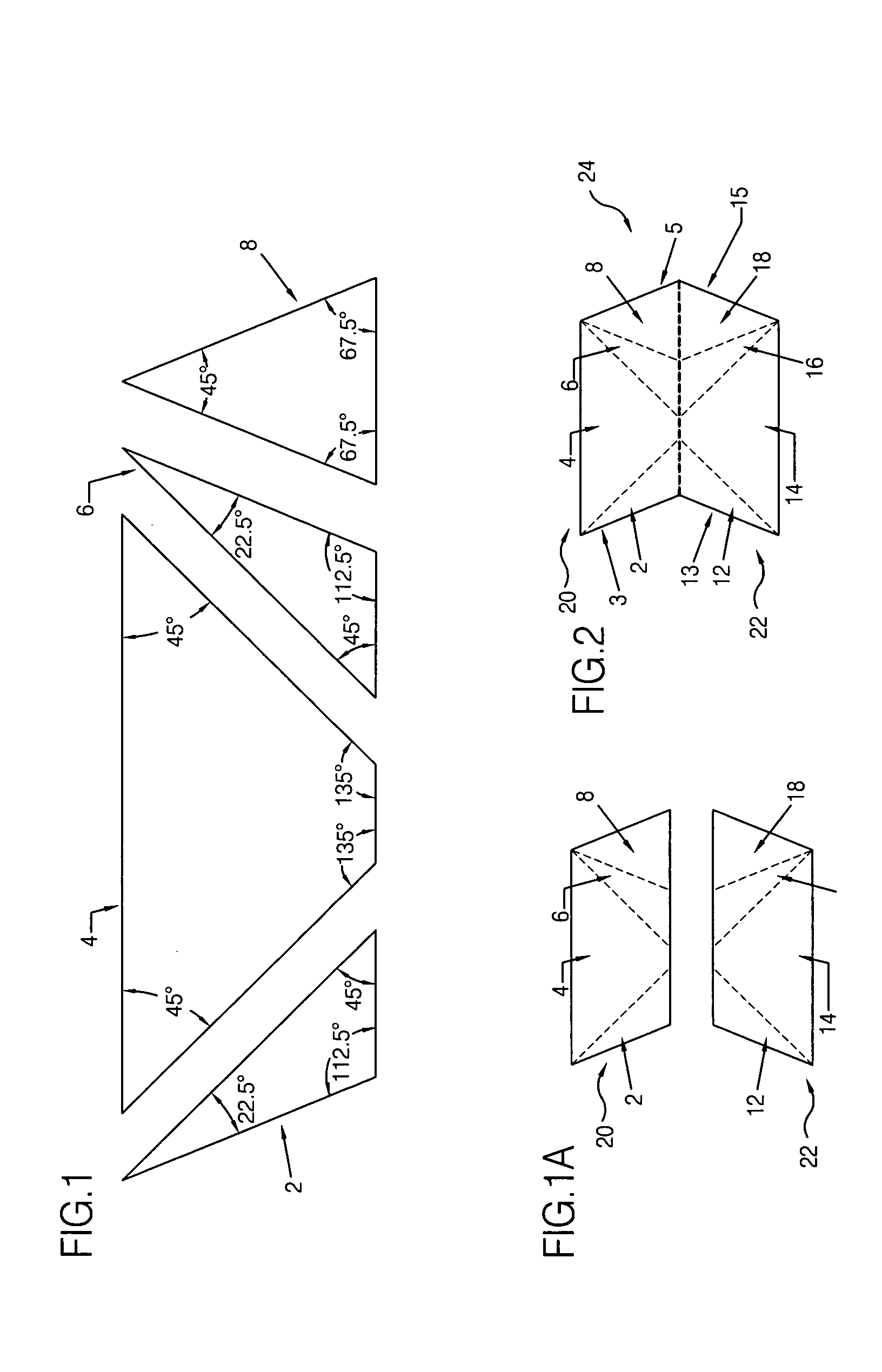

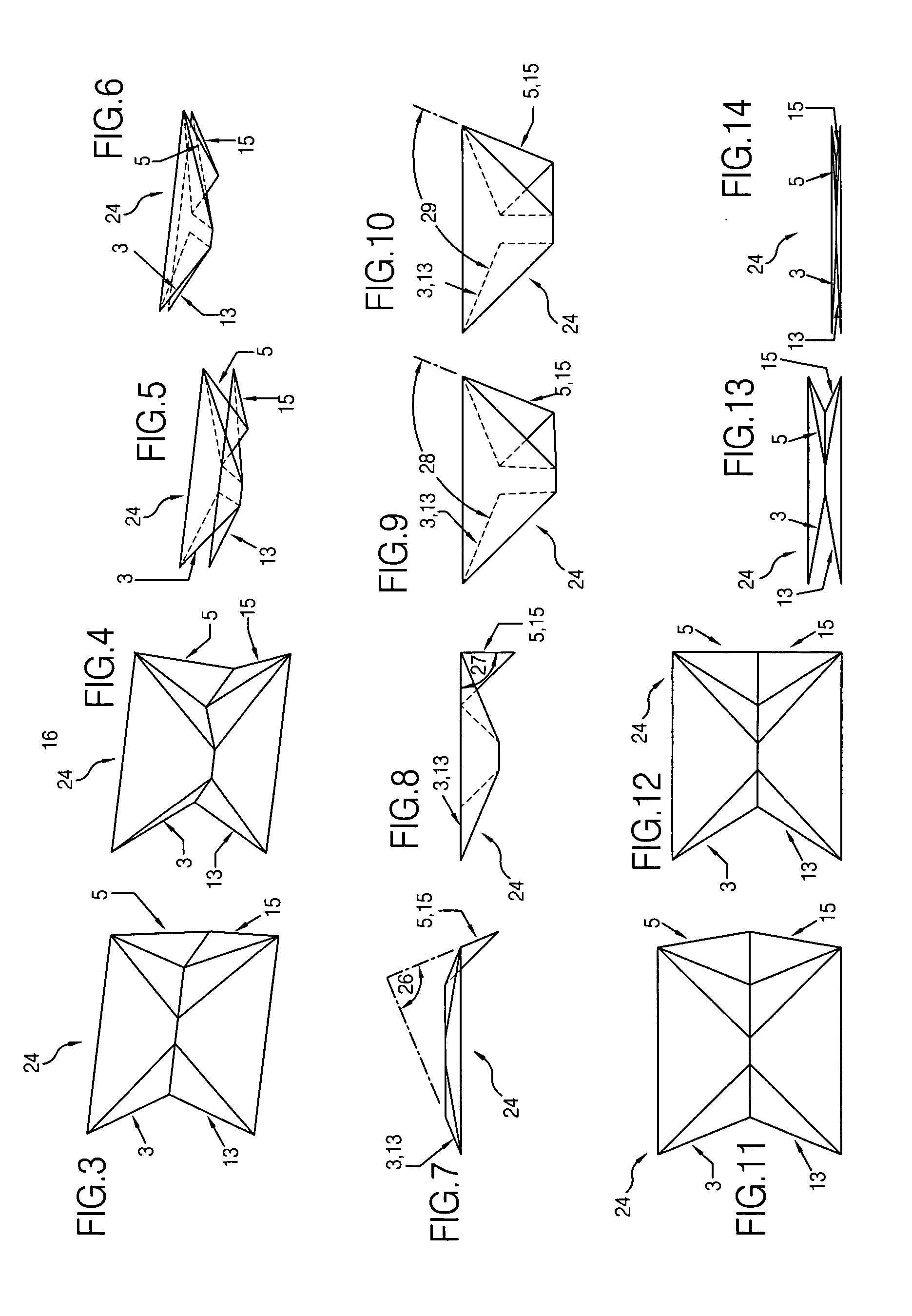

Collapsible containers

A system whereby a collapsible box may be formed in the same way that standard cardboard boxes are made by folding a single sheet of material is provided. Square and rectangular boxes may be constructed which may be collapsed down to compact size and easily popped open. Boxes so constructed remain fully assembled with all seams and edges attached even as they are repeatedly folded and unfolded. The box may be made of corrugated cardboard or plastic and easily folded to a fraction of their open volume. The box may open instantly, and when opened, it becomes structural—that is resistant to applied loads—by “popping” certain points outwards. An element or construction that is comprised of a sheet of material that has been provided with a network of hinges such that when the element is folded its edges maintain a right angle relationship is also provided.

Owner:HOBERMAN CHARLES

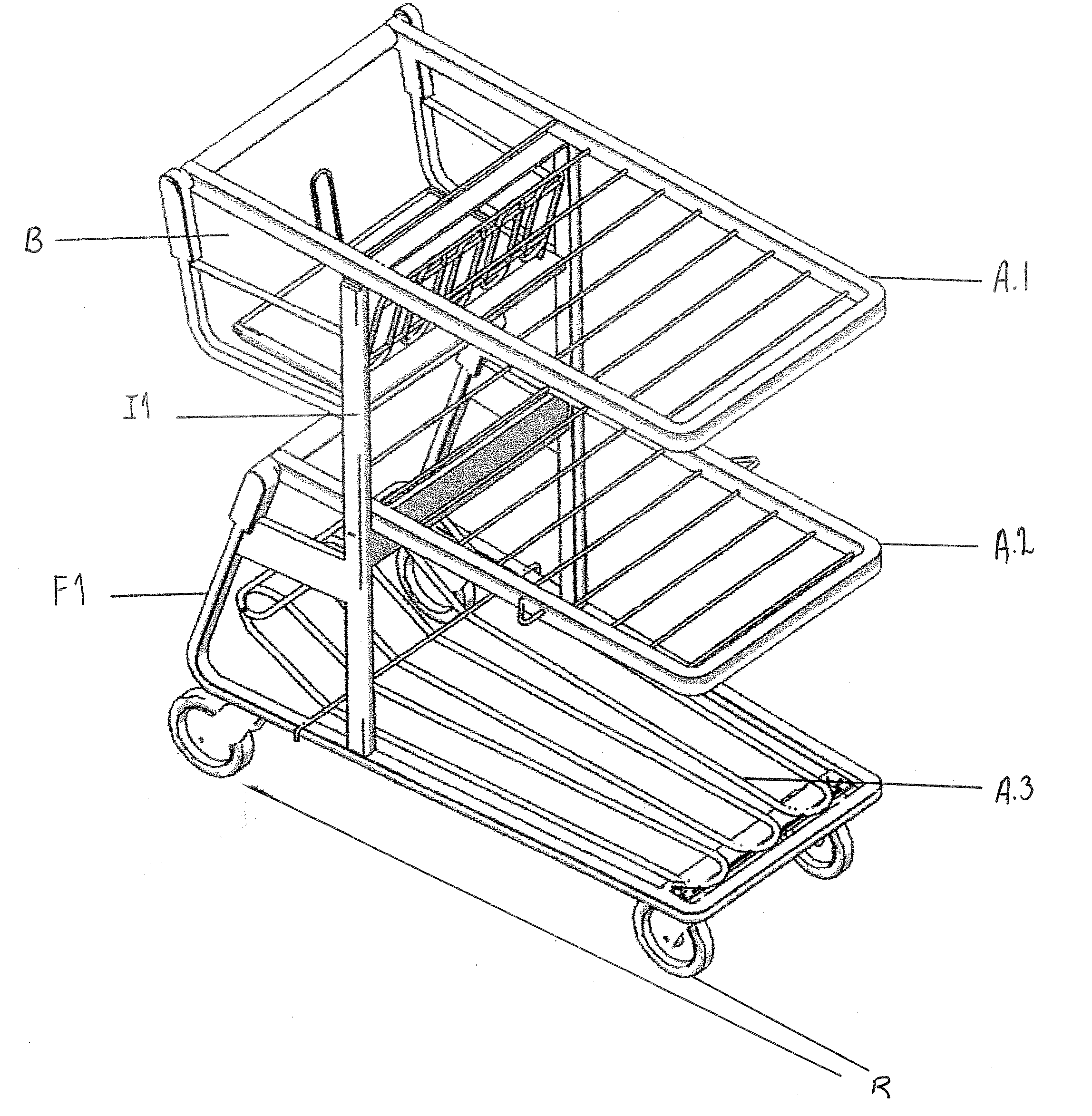

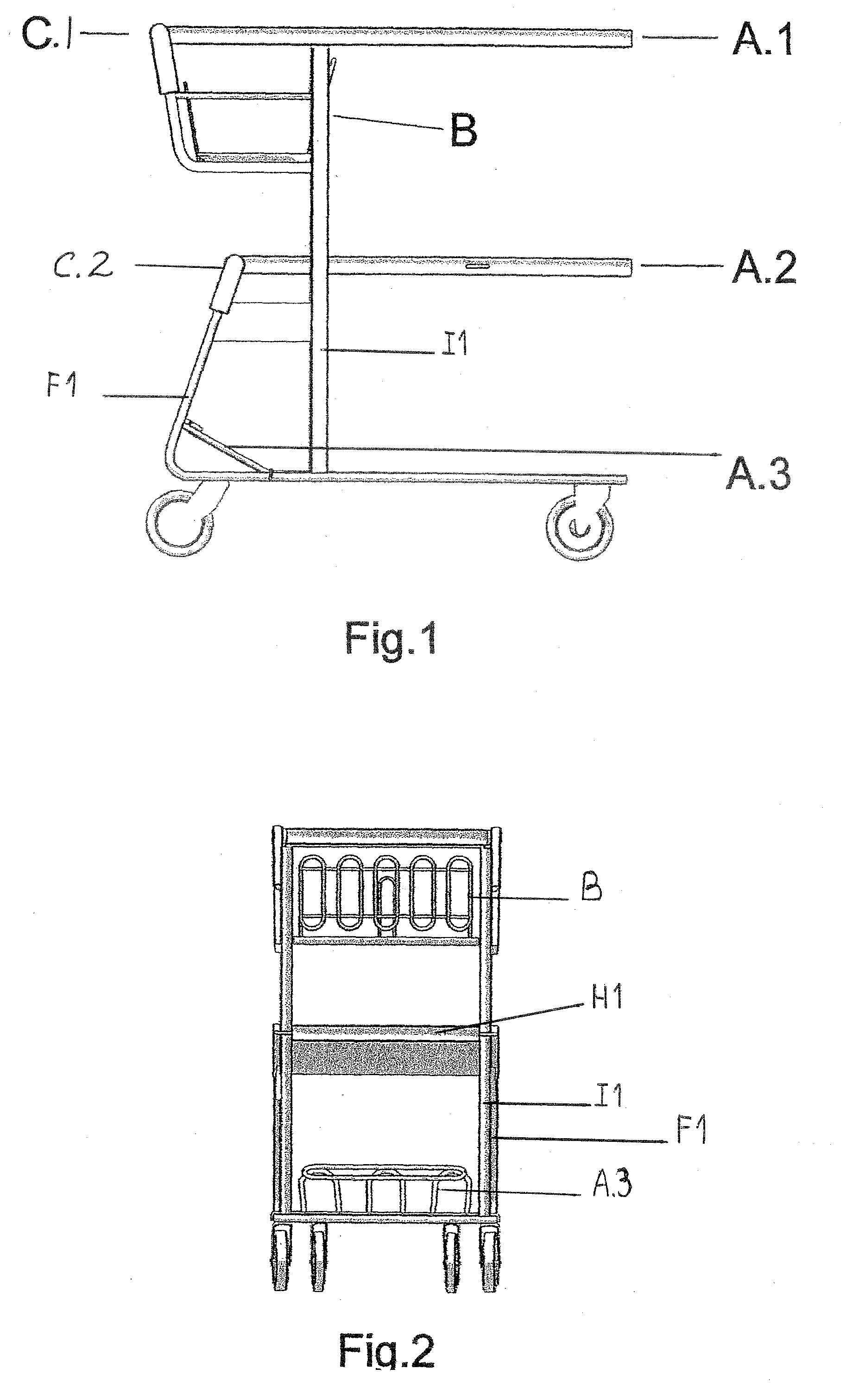

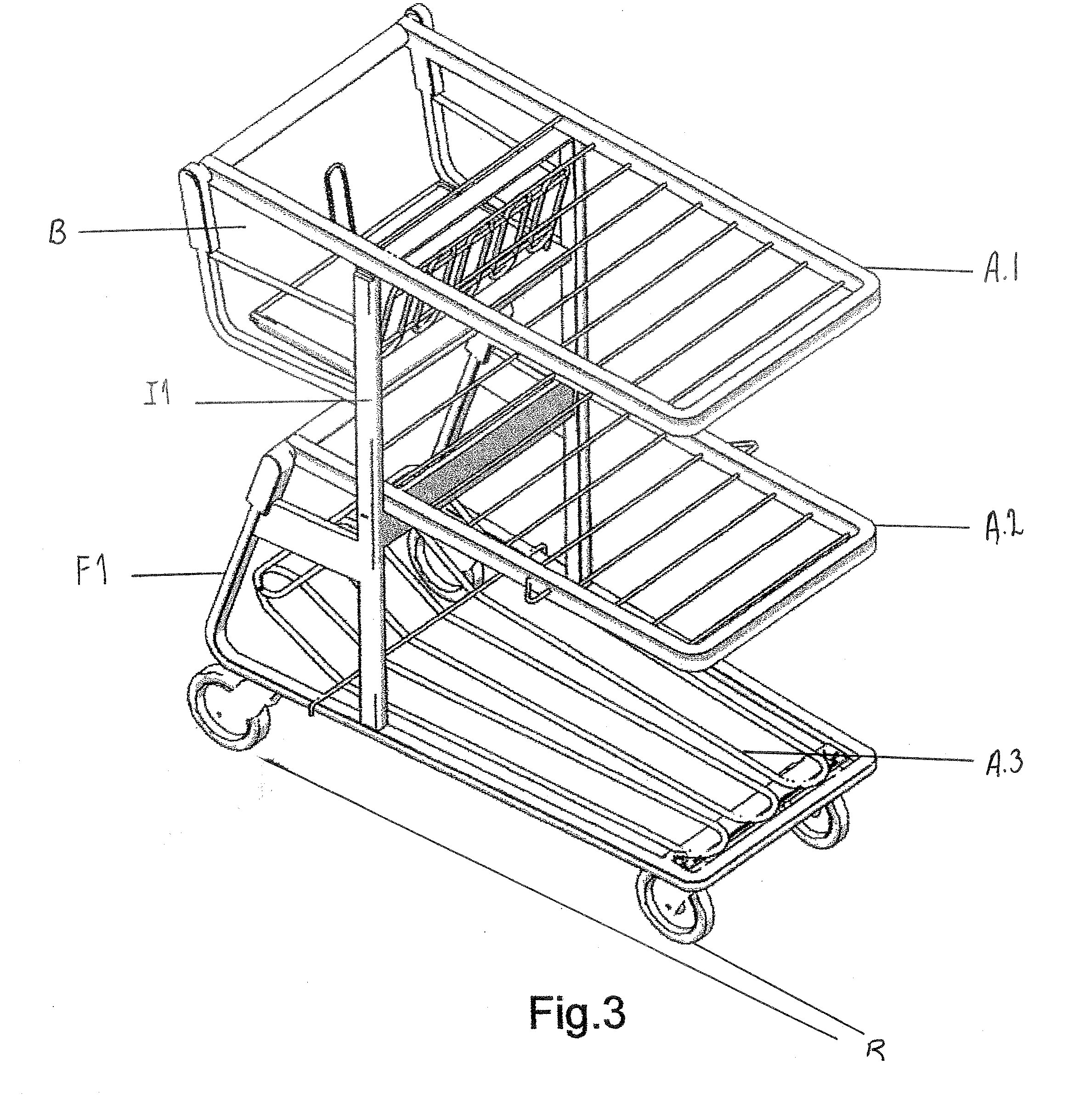

Transportation cart

InactiveUS20110115177A1Carriage/perambulator accessoriesHand carts with one axisTransport engineeringCardboard box

Owner:DE SOUSA ROGERIO LUIZ

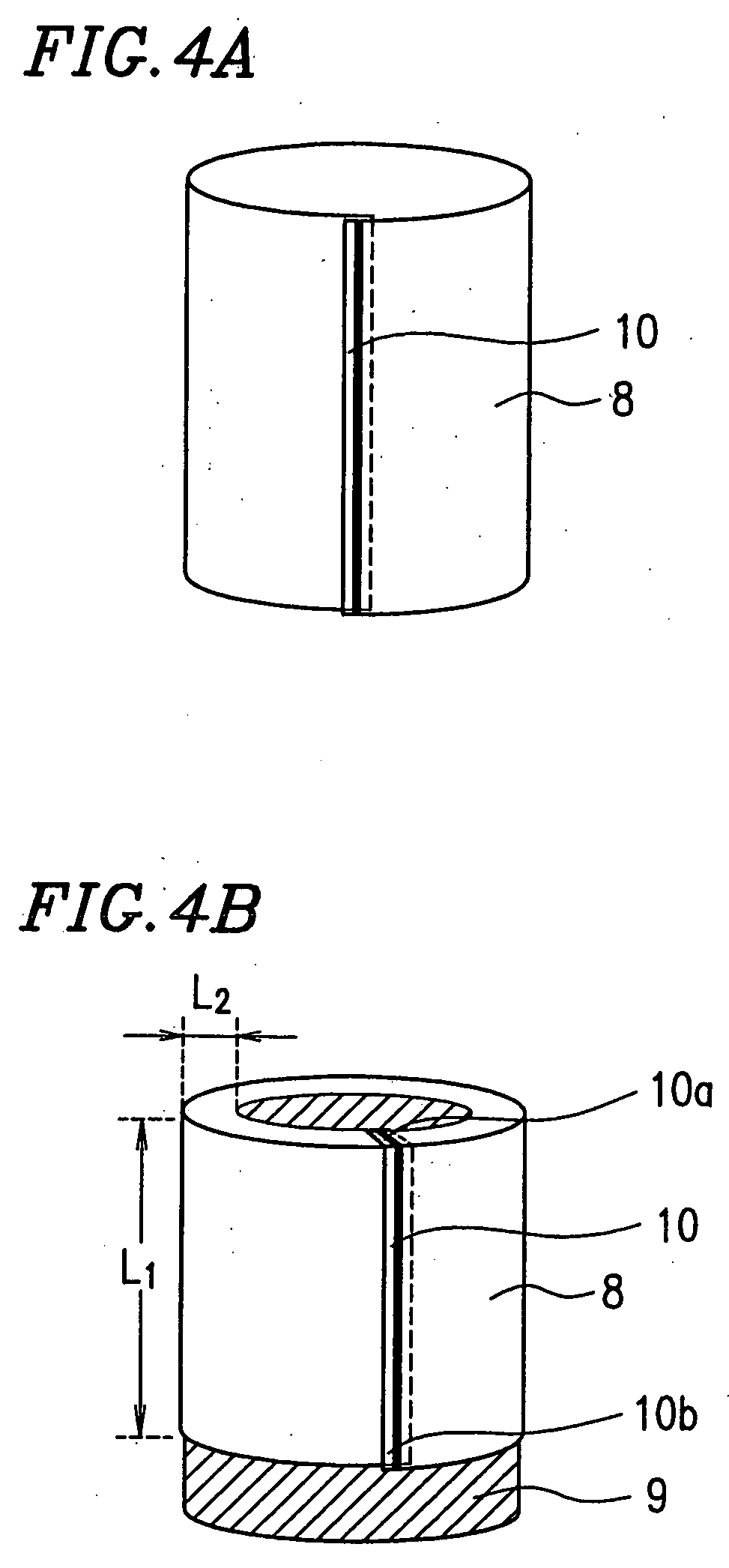

Packing of polycrystalline silicon

ActiveUS20130269295A1Solid materialPackaging under special atmospheric conditionsOptoelectronicsPolycrystalline silicon

A method for packing polycrystalline silicon in the form of fragments or round rods, wherein at least one film in each case is inserted into a cuboidal cardboard box matched to the dimensions of the polycrystalline silicon to be packed, the polycrystalline silicon is introduced into the at least one film, the at least one film of thickness 10 to 1000 μm subsequently being welded and enclosing the polycrystalline silicon, and this at least one film being surrounded by a further film having a reinforcing structure or by a shaping element.

Owner:WACKER CHEM GMBH

Delivery systems for mycotechnologies, mycofiltration and mycoremediation

InactiveUS20050176583A1Promote decompositionEnhancing habitat recoveryBiocideFungiBiospherePlanting seed

The present invention utilizes fungal spore mass or hyphal fragments in landscaping cloths, fiber substrates, paper products, hydroseeders and agricultural equipment. The fungi may include saprophytic fungi, including gourmet and medicinal mushrooms, mycorrhizal fungi, entomopathogenic fungi, parasitic fungi and fungi imperfecti. The fungi function as keystone species, delivering benefits to both the microsphere and biosphere. Such fungal delivery systems are useful for purposes including ecological rehabilitation and restoration, preservation and improvement of habitats, bioremediation of toxic wastes and polluted sites, filtration of agricultural, mine and urban runoff, improvement of agricultural yields and control of biological organisms. The invention allow for a variety of methods and products including the use of cardboard boxes as a delivery system for fungi with or without the combination with plant seeds for starting gardens, for controlling insects, or for the process of ecological recovery.

Owner:CISCO TECH INC +1

Packaging case closing and tape sealing machine and processes

Owner:R A PEARSON

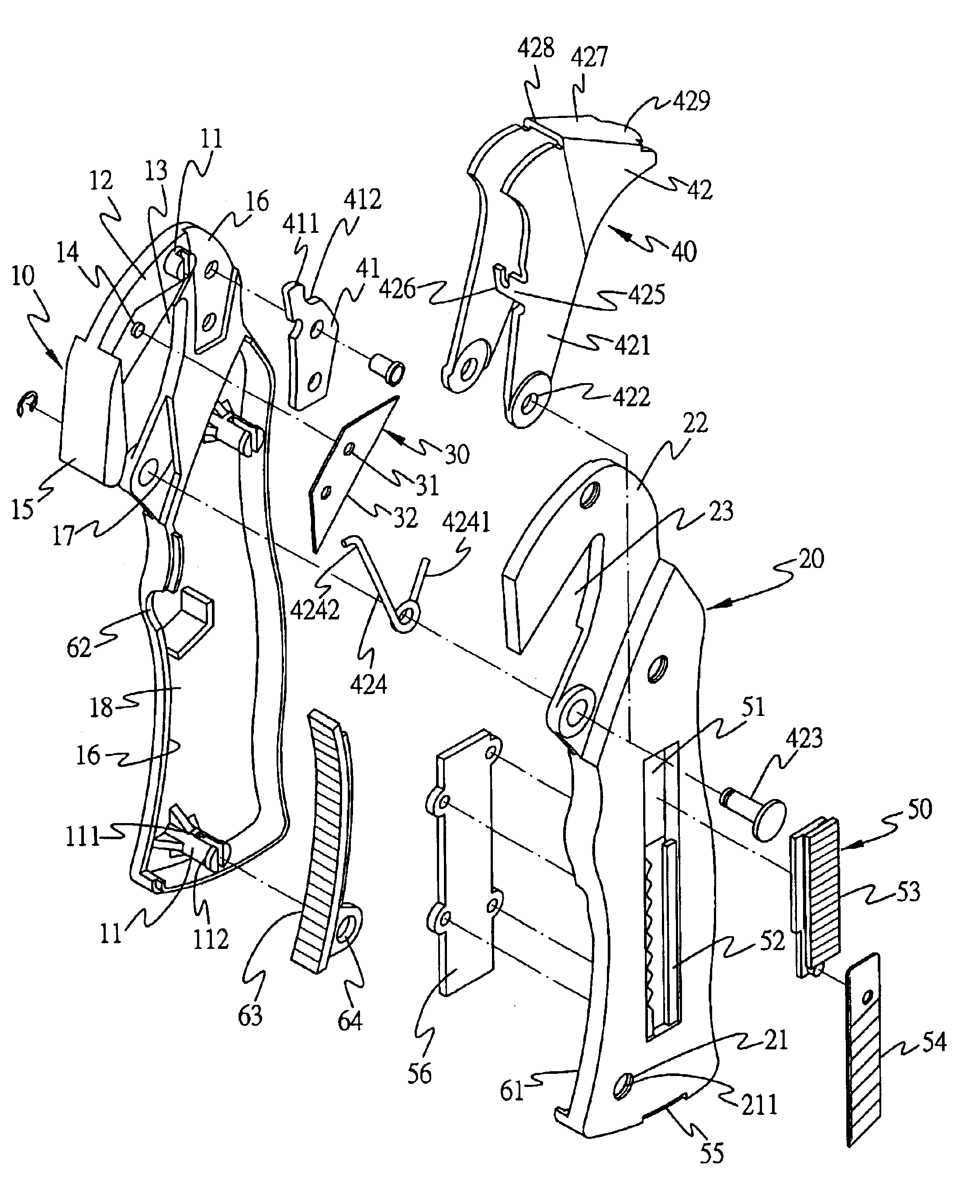

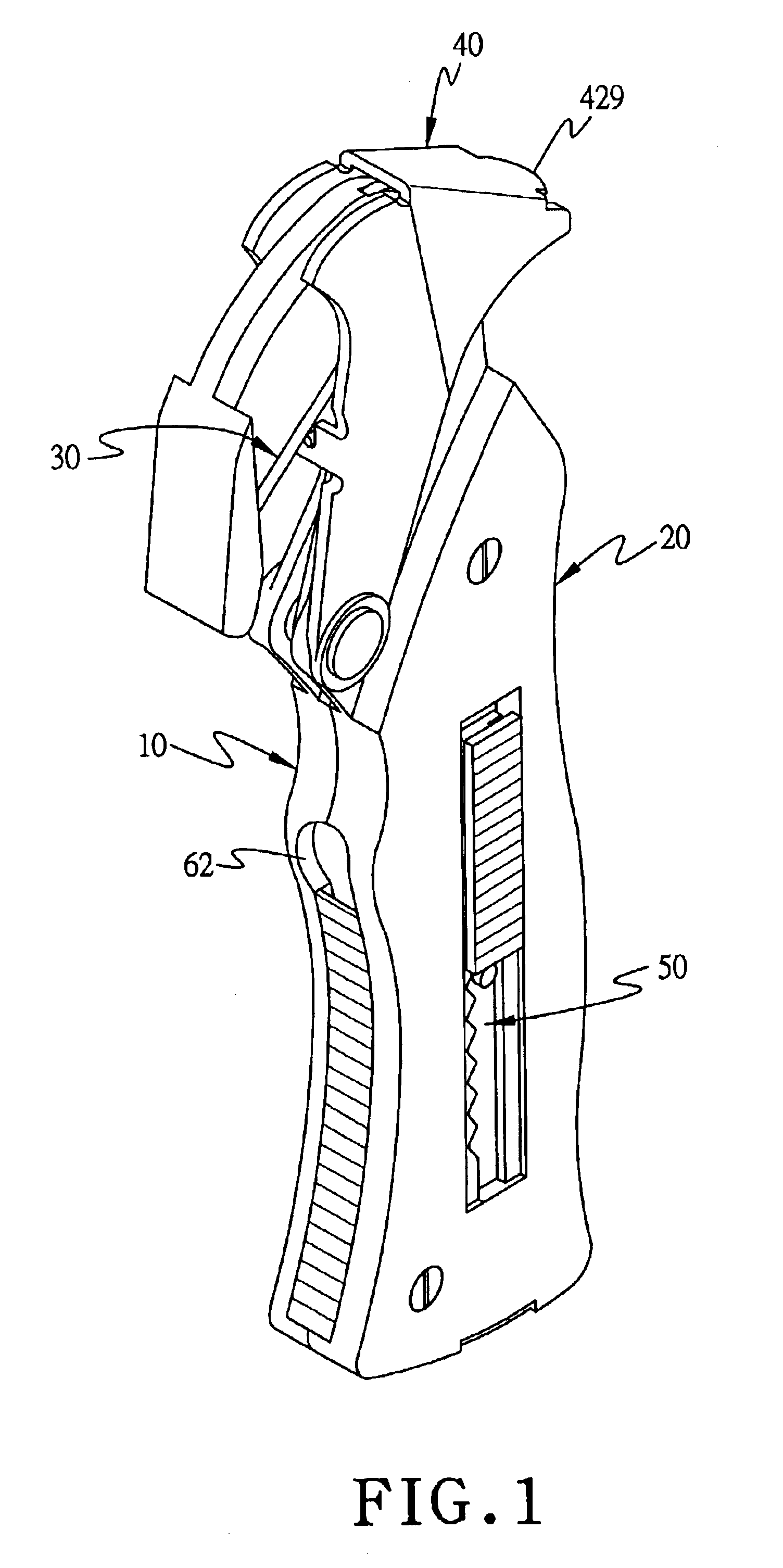

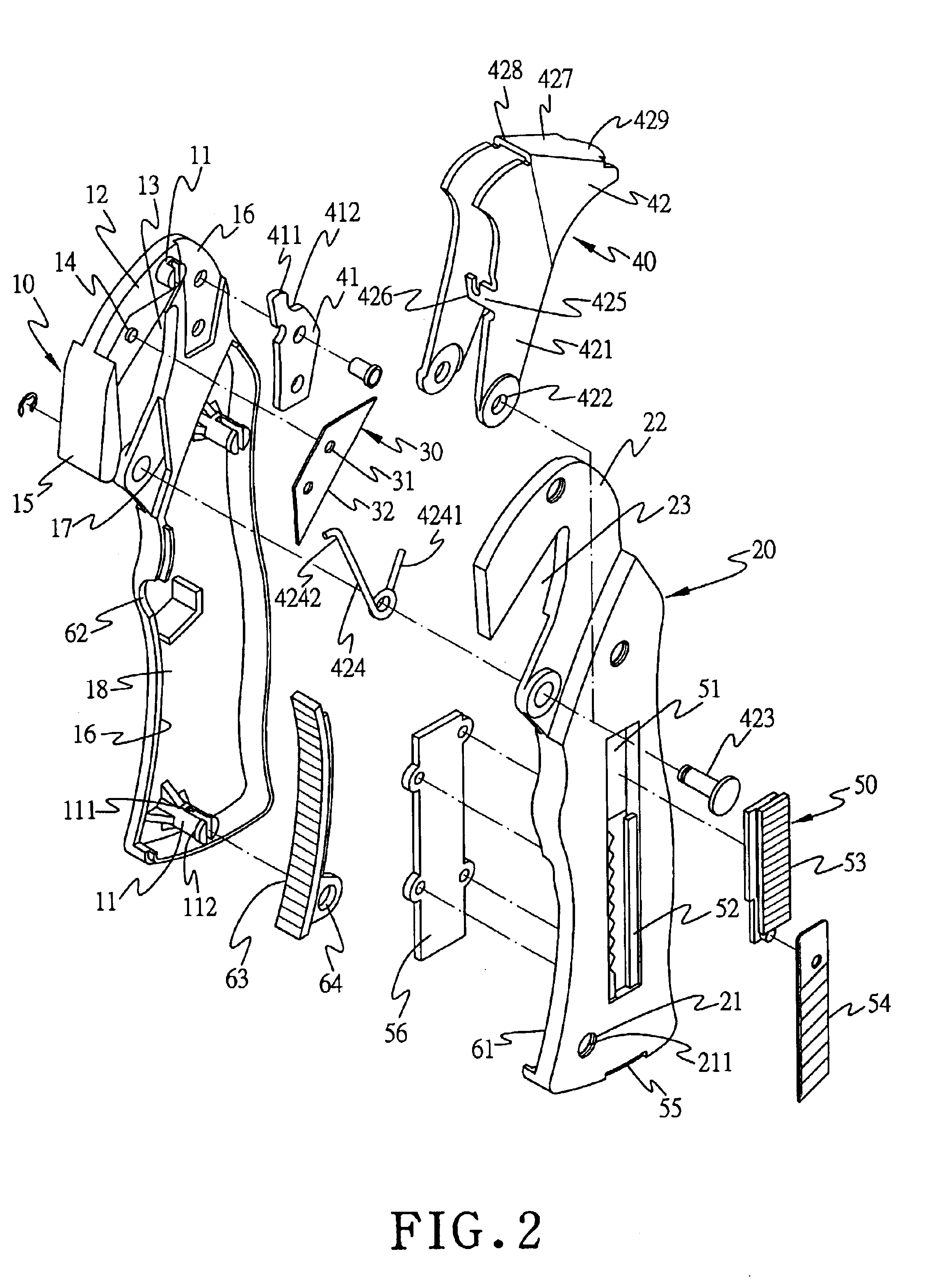

Cardboard box unpacking device

A cardboard box unpacking device has a blade positioned in a slanting blade groove fo a main body and a covering body for cutting off plastic packaging strap tensioned on a cardboard box, a staple removing device provided at the upper rear side of the main body for removing staples from the cardboard box and a telescopic blade device disposed at the lower portion of the covering body for culling off adhesive tape adhered to the cardboard box.

Owner:YU CHEN HSIU MAN

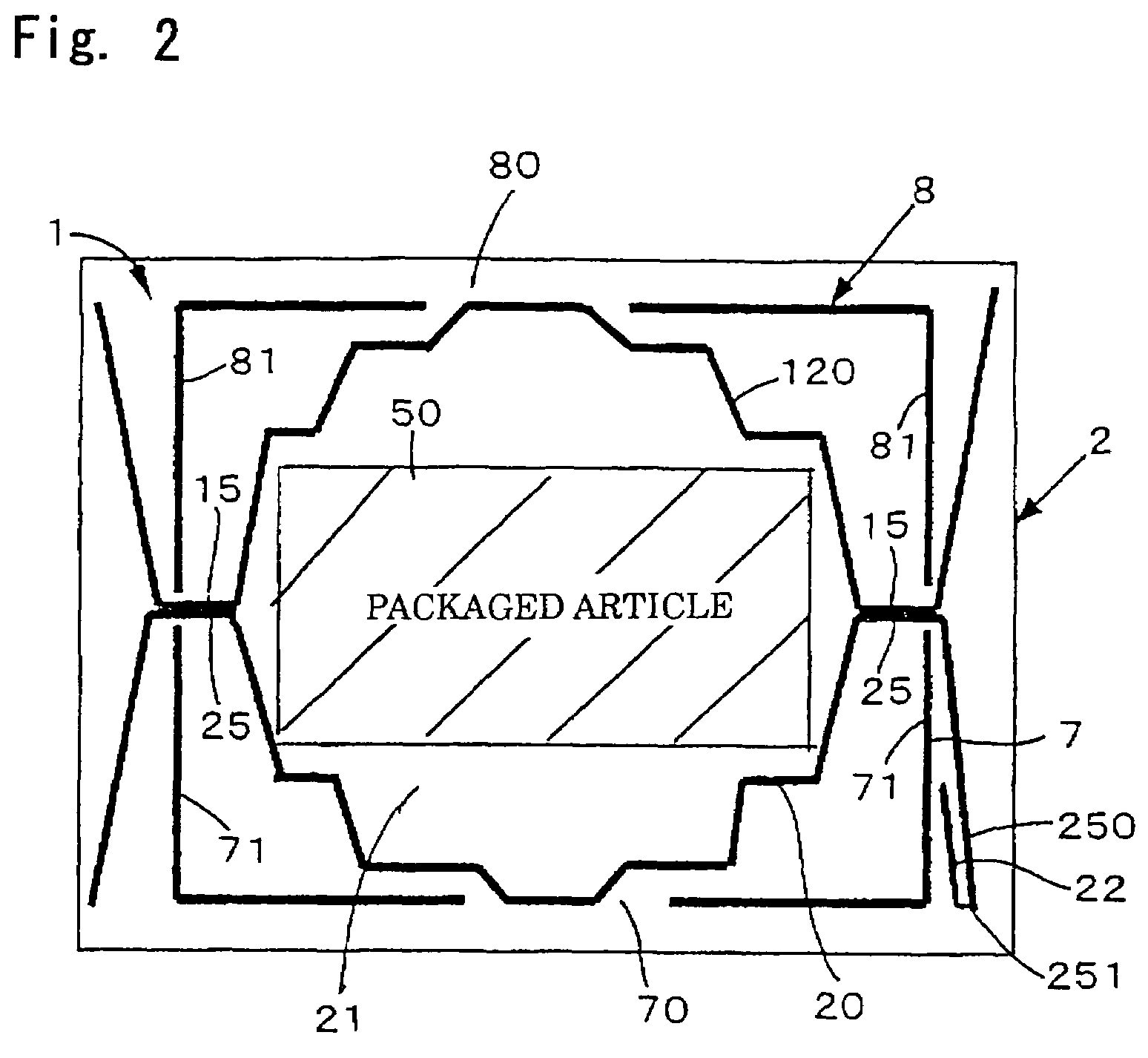

Cushioning material for packaging and packaging matter

InactiveUS7328800B2Improve protectionEasy to replaceContainers to prevent mechanical damageRigid containersCushioningAntistatic bag

The invention provides a cushioning material for packaging that is suitable for packaging an electronic apparatus, an optical apparatus or an electronic apparatus having an optical system mounted therein, and a package that uses the cushioning material for packaging. In the invention, a lower spacer formed of corrugated cardboard, a lower pad, a projector as an article to be packaged that is wrapped in an anti-static bag having electrical conductivity, an upper pad and an upper spacer formed of a corrugated cardboard can be stacked inside a corrugated cardboard box. The upper and lower pads are, respectively, provided with a plurality of upper pad side hollow convex portions and a plurality of lower pad side hollow convex portions protruding in such a fashion as to encompass an accommodation space for the projector. Upper and lower side reinforcing plate portions of the upper and lower spacers, respectively, enter deep into these convex portions.

Owner:SEIKO EPSON CORP

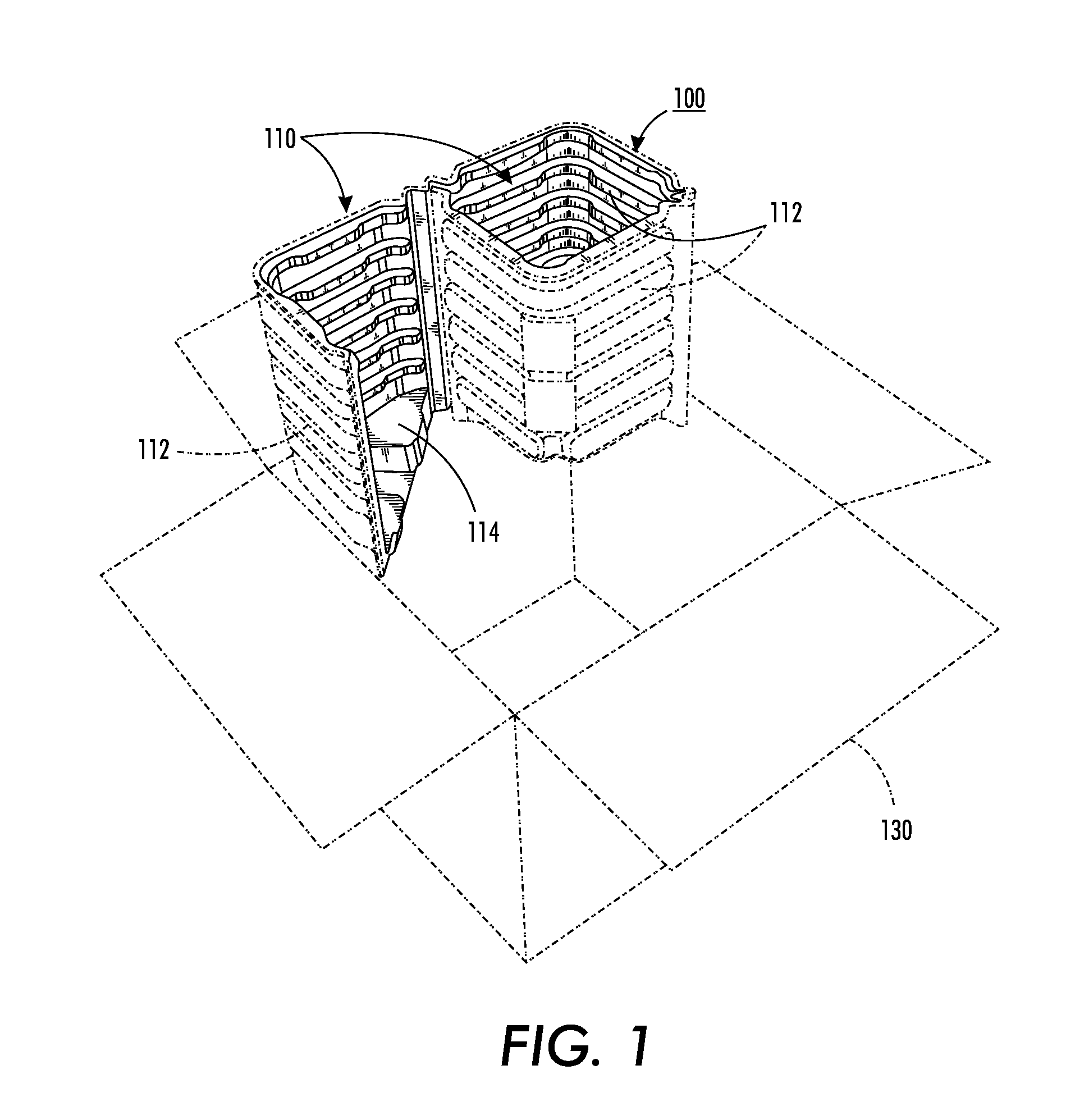

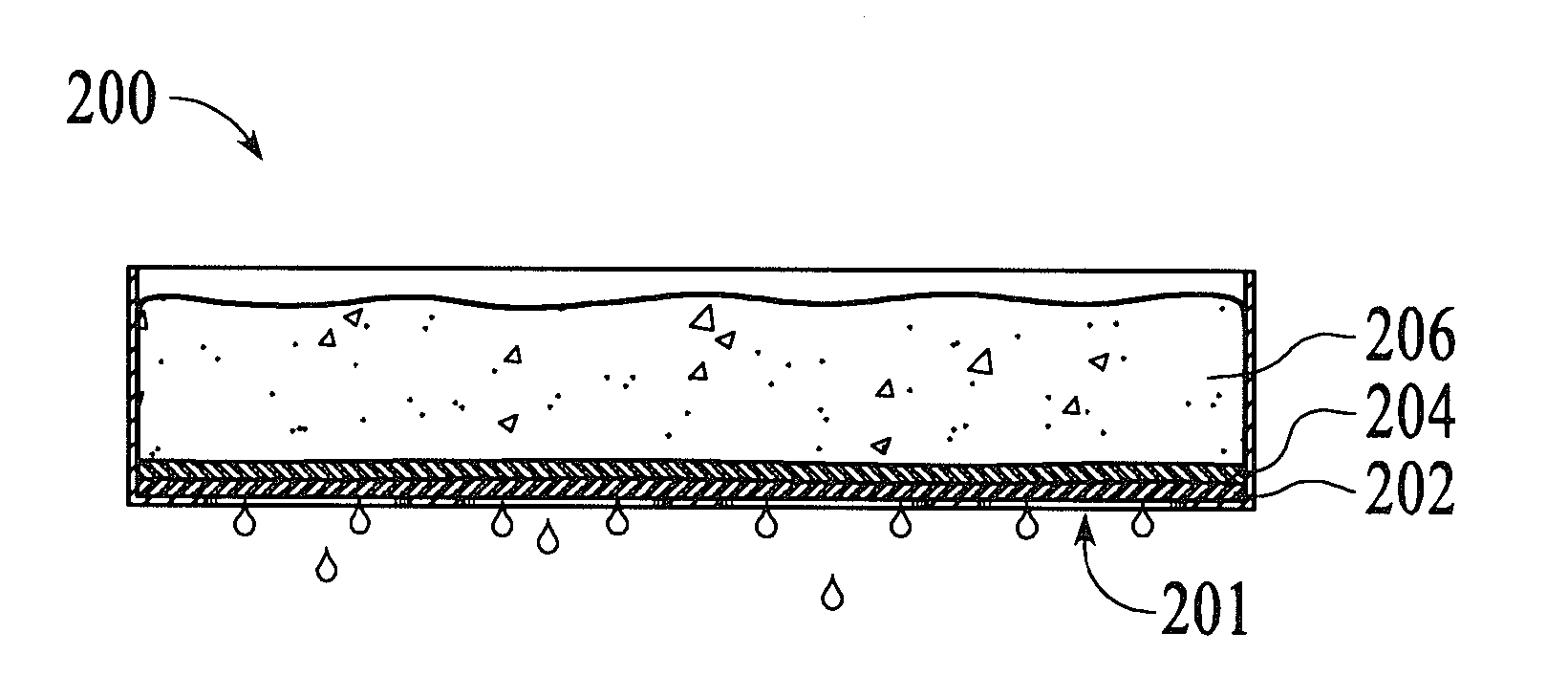

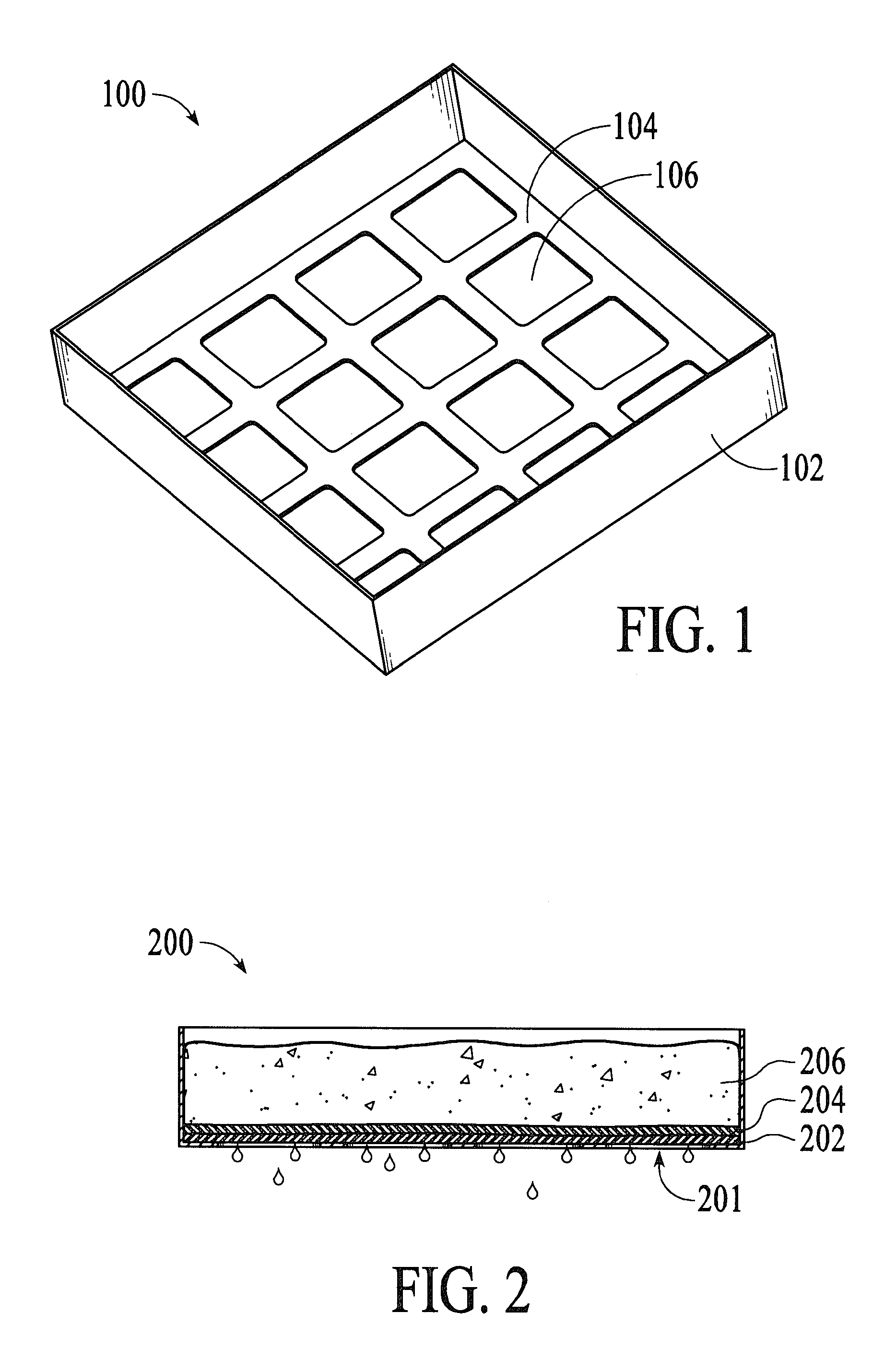

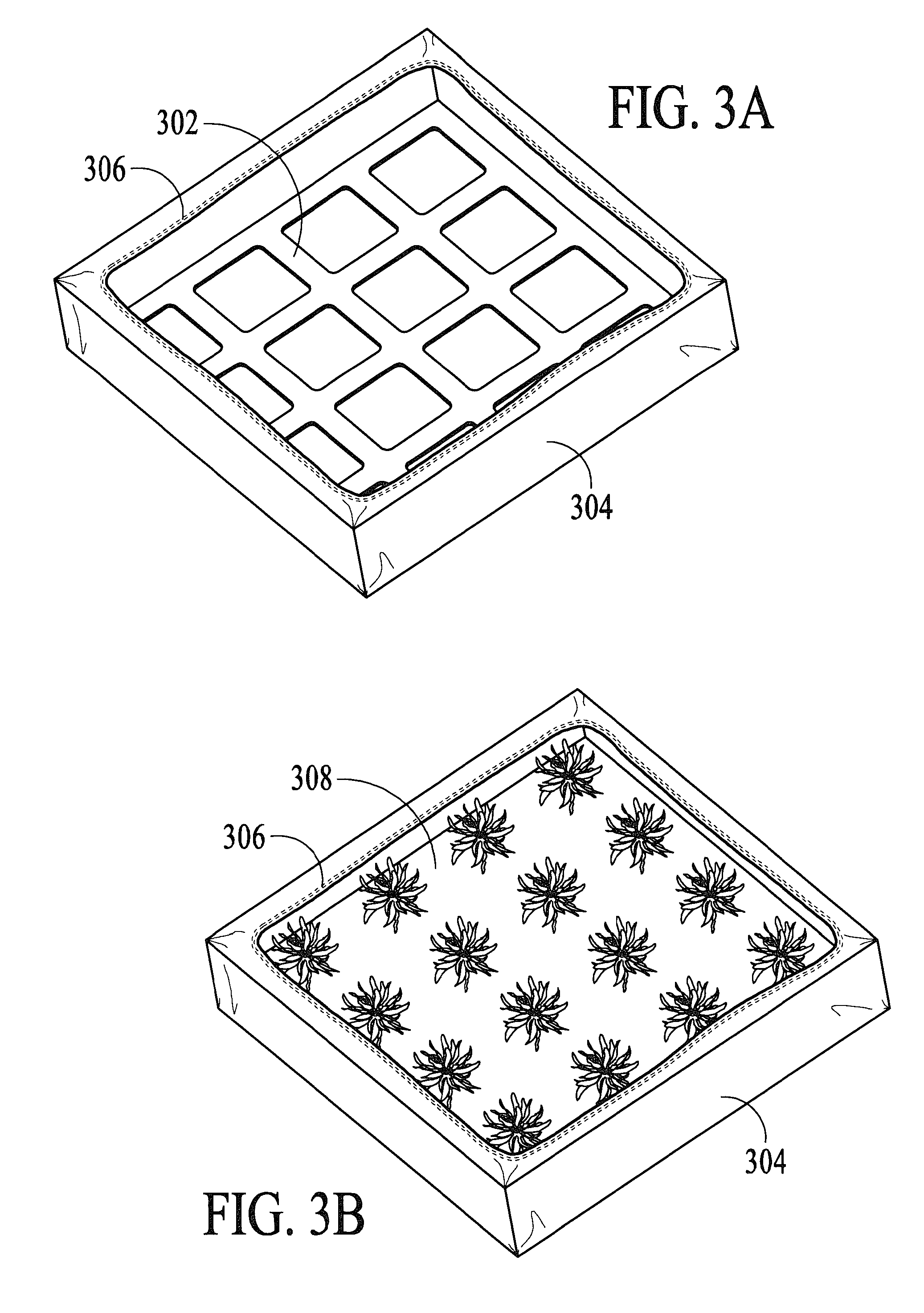

Modular, pre-vegetated recycled cardboard box system for green roof applications

InactiveUS20130031833A1Easy to transportFunction increaseTurf growingCultivating equipmentsVegetationEngineering

Embodiments are described for a cardboard box assembly for use in a modular green roof system. The box includes a drainage board, filter and pre-vegetated growing media. A lid assembly is placed over the box during transport and storage. The box / lid assembly is designed to be stackable for easy transport on pallets for placement in an interlocking array on a roof or similar surface. The box is made of biodegradable cardboard allows for the eventual breakdown of the container portion of the assembly and the formation of an integrated green roof of interlocking plants after a period of time after installation. The filter fabric sock wrapping the box bottom, sides and fitted top provides the enclosure that will hold the pre-vegetated modular components together when the cardboard box eventually biodegrades.

Owner:MACKINNON JANET L

Machine for spreading out cardboard boxes automatically

A machine is provided for spreading out cardboard boxes automatically, which is structured such that cardboards can be held in a holding mechanism upright and closely side by side, and fed to a main body one after another, and which have sucking disks for drawing the cardboards to spread out the same; the sucking disks can be adjusted in position as well as length of space between them; the machine further has a bending mechanism for bending bottom shutter portions of the cardboard boxes after the cardboard boxes are spread out; adhesive tapes are automatically applied onto the bottom of the boxes to seal the boxes after the bottom shutter portions of the boxes are bent.

Owner:TIEN HENG MACHINERY

Handle cutter assembly

A handle cutter assembly for making C-shaped handle cuts in cardboard boxed and the like. The cutter assembly has a body having an outer shell defining a blade cavity therein. The body has an upper end and a lower end. A lower aperture is positioned in the lower end. The body also has a blade slider mounted thereto and a grip portion is mounted to its upper end. A cutting blade is mounted within the blade cavity. The cutting blade is slidable by the blade slider between a retracted position substantially within the blade cavity and a cutting position. In the cutting position, the cutting blade extends below the lower end through the lower aperture. The cutting blade has a cutting edge extending away from the body which has a C-shaped cutting profile.

Owner:ROBITAILLE LIONEL L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com